Editor’s Choice Coatings Control & Automation

Drives, Motors & Gears

Electrical & Electronics

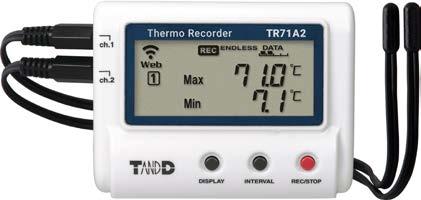

& Safety Machining & Machinery Measurement & Monitoring

AUDI

All models manufactured at the Neckarsulm site from 2025 will be net carbon-neutral

SMB BEARINGS

How bearings can improve safety and efficiency in cobots

CMB

Morley forges automotive role at leading European industrial association

WSCAD

WSCAD launches the first AI-Powered electrical CAD software

INMOCO

Does inertia matching still matter when designing a servo system?

PORTESCAP

Portescap to exhibit with the Power of One Regal Rexnord at SPS

Cover photo: Audi

UNIVERSAL ROBOTS

Universal Robots unveils its AI Accelerator, enabling a new wave of AI-powered cobot innovations

INN-COM TRAINING

£200,000 automation cell unveiled by In-Comm Training to boost advanced skills in the Marches

BURKERT

Tradition benefitting from technology

OPTIMAL

Elevating control strategies for fluidised bed drying to the next level

SPELSBERG

Spelsberg’s GEOS enclosure helps make tough decisions

BECKHOFF

How APC technologies drive consistency and efficiency in process industries

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 158,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Jake Page jake@pecm.co.uk Tel: 01227 937174

SALES MANAGER

Martin Richardson martin@pecm.co.uk Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

Please

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk Tel: 01304 806039

DIGITAL ASSISTANT

Stacey Goodwood Tel: 01227 936971

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk

All models manufactured at the Neckarsulm site from 2025 will be net carbon-neutral

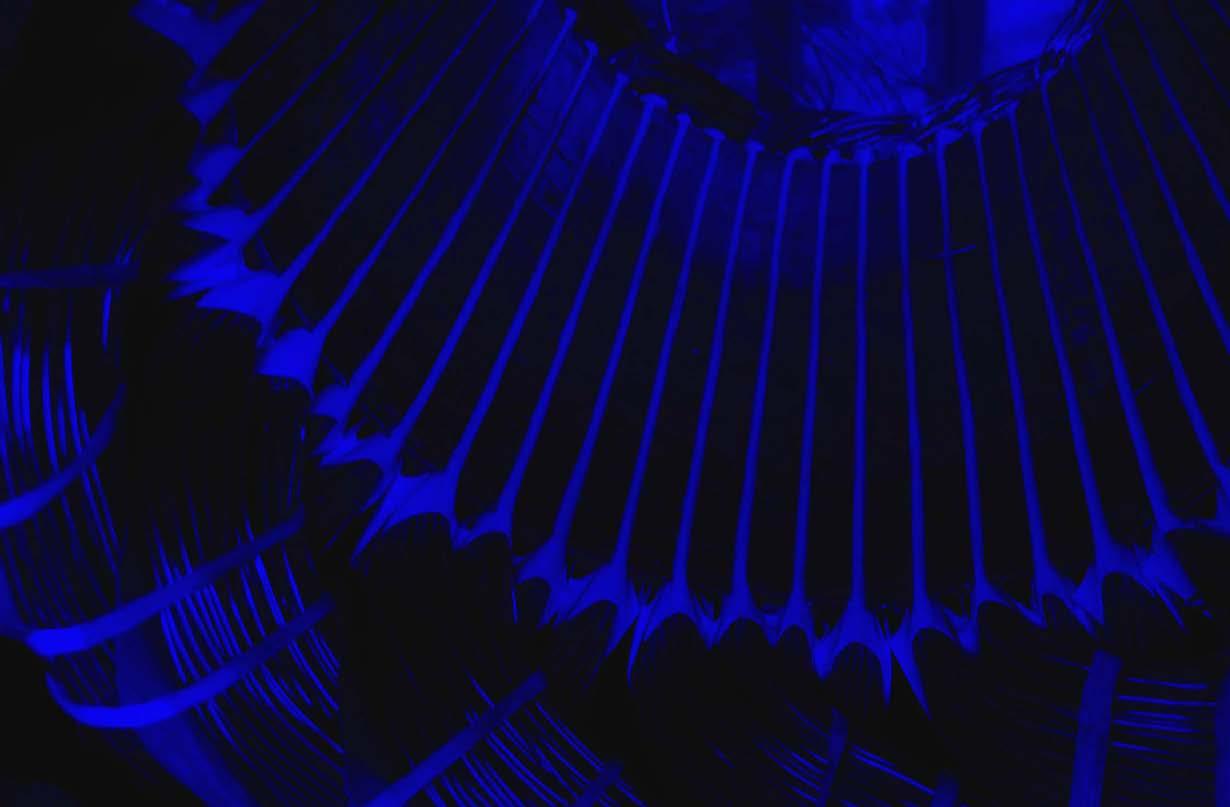

With the new Audi A5 family, the first models based on the Premium Platform Combustion (PPC) with partially electrified drive systems and new electronic architecture are rolling off the production line in Neckarsulm. The brand with the four rings is consistently gearing vehicle production towards sustainability. The goal: In line with the “360factory” production strategy, all models manufactured at the Neckarsulm site from 2025 will be net carbon-neutral. To achieve this, Audi is relying on more efficient production lines, a higher degree of automation, and innovative technologies. From 2025, the renovated paint shop will be one of the most modern in the automotive industry.

As production of the new Audi A5 in Neckarsulm commences, the largest start-up phase in the plant’s history has begun. “Thanks to many years of experience in the production of vehicles with combustion engines and expertise in complex ramp-ups, the Neckarsulm team has the ideal prerequisites,” says Board Member for Production Gerd Walker. Fred Schulze, Plant Manager of Audi Neckarsulm, adds: “For the new Audi A5 family, the Neckarsulm workforce has acquired further qualifications for new systems and automotive production technologies. At the same time, we have created a future-proof production plant infrastructure.” Rainer Schirmer, Chairman of the Works Council at Audi Neckarsulm, is also confident: “Neckarsulm employees can handle complexity and are flexible. With these skills, we will contribute to the success of the Audi A5 for our site and Audi.

The company is modernizing, digitalizing, and transforming its plants to manufacture sustainably.

The four Rings’ vision for the production of the future is thus continuing to take shape: The company is modernizing, digitalizing, and transforming its plants to manufacture sustainably. By 2025, Neckarsulm, like all Audi sites worldwide, is set to achieve CO2neutral production.

When it is completed in 2025, the renovated paint shop at the Neckarsulm site will be among the most modern in the automotive industry. Numerous processes have already been optimized, and environmentally friendly procedures have been introduced for the launch of the Audi A5. While sustainable water-based paints have long been standard at Audi, the latest models also undergo a new painting process. The filler is

replaced by a pre-zone paint that can be applied wet-on-wet. The previous separate drying of the filler is no longer necessary, allowing the four rings to reduce energy consumption significantly: Up to 140 kWh can be saved per vehicle.

In Neckarsulm, Audi relies on modern and effective methods to prevent corrosion. Cathodic dip painting, for example, includes dipping and rotating the body upside down in the tank using a rotation process. This is more spacesaving and thorough, as it avoids minimal air bubble formation and dirt deposits. A new, more energy-efficient process is also used for drying the cathodic dip coating. Instead of the previous external drying process, a so-called transverse drying process is now used. Air is blown into the interior, and the body is heated from the inside. In addition to being more energy efficient, the transverse dryer is better suited to future electric and hybrid vehicles and their strengthened floor assemblies.

Audi achieves a further energy saving of around 50 kWh per vehicle thanks to a new paint separation process. Previously, the paint mist was collected in water with 100 percent fresh air and disposed of. In the new dry separation process, it is captured by state-of-the-art filters instead. This process allows more than 90 percent of the filtered air to be reused, largely eliminating the need for energy-intensive fresh air conditioning. At the same time, in contrast to conventional wet separation, the use of fresh water and chemicals is eliminated.

Audi is committed to using valuable water resources responsibly across all its sites: The company aims to halve its ecologically weighted water consumption in production by 2035. To this end, the four Rings in Neckarsulm relies on a closed water cycle using the Unteres Sulmtal Wastewater Association’s wastewater treatment plant adjacent to the site. New pipes and plant technology ensure that no more process water will be taken from the nearby Neckar canal. This will save up to 70 percent of fresh water from 2025. Audi will further treat the water purified by the wastewater treatment plant with the help of filter systems and membranes. The process water then flows back into the treatment plant. Last year, Audi joined the Alliance for Water Stewardship (AWS), once again underlining its commitment to the economical and efficient use of water.

Neckarsulm is the first site in the Group to install all add-on parts in the body shop fully automatically. In this way, Audi improves the fitting accuracy of the add-on parts and minimizes external influences. Seven robots are used simultaneously for the highly complex fender attachment alone.

As part of Audi’s “360factory” production strategy, its supply chain relies on the smart, automated provision of materials. Automation roadmaps have been created for each location and are gradually becoming a reality. Neckarsulm was the first Audi site worldwide to put the freely navigating, driverless transport systems (DTS) into operation back in 2014. With the start of production of the new Audi A5, over 80 percent of the material volumes in the body shop are now provided automatically.

Virtually smokeless fixing is a world-first in car body construction. It involves attaching glued components, such as doors with small soldering points, to prevent the inner and outer parts from slipping. Previously, numerous soldered fixing points had to be cleaned, as smoke is corrosive. The new process almost eliminates residue build-up thanks to a rotating gas flow. Audi works more than twice as fast with the new method compared to previous techniques.

Quality control measurements in the body shop are mainly carried out inline, i.e., without removing a vehicle from the line. New measuring technology is used at two stations. Four robots at each station use measuring sensors to determine the components’ dimensional accuracy.

The measurement result is evaluated using software, visualized, and made available to the employees. With this new technology, every vehicle produced can be measured directly on the line. Consequently, Audi significantly increases the number of measurements and can react faster to any deviations. Continuous, interruption-free quality control is also possible thanks to the high degree of automation.

Employees use innovative technologies such as augmented reality (AR) to inspect car bodies. An AR app on commercially available tablets with an integrated camera shows the connection points to be checked in real time. This makes it possible to check and directly document whether, for example, weld seams or points are present and executed according to target specifications. The increase in efficiency through digitalization is enormous. For example, inspectors once had to go to great lengths to determine the specifications for a bonded seam. With the tablet, this work is now done in just a few seconds.

Audi defines balance sheet CO2 neutrality as a state in which, after exhausting other possible reduction measures with regard to CO2 emissions caused by Audi products or activities, CO2 emissions that are still present and/or currently unavoidable in the supply chain, production, and recycling of Audi vehicles are offset, at least in terms of quantity, by voluntary compensation projects carried out worldwide. CO2 emissions occurring during the use phase of a vehicle, i.e., from when a vehicle is handed over to the customer, are not taken into account here.

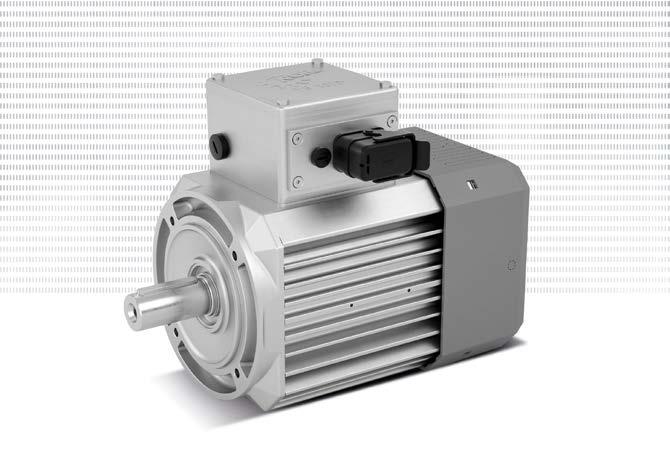

Menzel Elektromotoren has built a dust-explosion-protected motor in ignition protection type Ex tc (protection by housing) and provided it with the ATEX label II 3D Ex tc IIIB T125 °C Dc for use in zone 22 hazardous areas. The German motor manufacturer application-tailored the 1120kW squirrel cage motor for a leading Italian operator’s flour mill. Menzel used a machine from its extensive stock, upgraded it for converter operation, adapted the dimensions to the existing motor to enable a smooth replacement, and manufactured an oversized terminal box according to customer specifications. The mill motor with a nominal voltage of 690 V provides a nominal torque of 11575 Nm. It is suitable for operation in both directions of rotation and features protection class IP55 with IC 611 cooling (air-to-air heat exchanger CACA). Through its Italian subsidiary, Menzel has been the mill operator’s trusted motor supplier for many years. Thanks to its large motor warehouse, applicationspecific configurations and ATEX certification capability, Menzel can meet virtually any demand from a single source.

More about low, medium and high-voltage motors in ignition protection types Ex ec and Ex tc for zone 2 and zone 22 hazardous areas with a risk of gas or dust explosions can be found at the link at the bottom of the page.

Menzel has configured a squirrel cage motor from stock for use in zone 22 hazardous areas with potentially explosive dust atmospheres for converter operation, designing it for an efficient smooth replacement in the customer’s plant

Menzel Elektromotoren GmbH has manufactured and distributed electric motors since 1927. The company moved to a new, purpose built factory this year and specializes in large electric motors, including special models, within the shortest possible time.

Their range comprises high and low voltage motors, DC motors, transformers, and frequency inverters. Services include motor production and fast delivery of preengineered stock motors to specific requirements.

Thanks to its large motor warehouse, applicationspecific configurations and ATEX certification capability, Menzel can meet virtually any demand from a single source.

In order to ensure fast deliveries at all times, the company maintains an extensive inventory including more than 20,000 motors with a maximum performance of up to 15,000 kW. Qualified experienced engineers, and state-of-the-art production and testing facilities ensure Menzel, provide excellent reliability.

Menzel operates subsidiaries in the UK, France, Italy, Spain, and Sweden, and cooperates with numerous partners worldwide.

Scan to learn more:

• Leaner and faster production using cleverly designed modules which are standadized across different product categories.

• Modular and flexible design with a wide range of configuration options, optimizing response time to your specialized requirements.

• More agility, products can be ordered and manufactured faster than ever before with item prices and availability information easily accessible.

• The platform-base design enables faster conformity adjustments to ensure GEMÜ products are always optimized with the latest features.

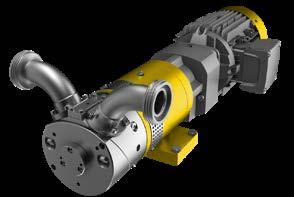

Today, we dispatched two brand new ATEX long-coupled centrifugal gas oil pumps to a client of ours.

They’re going to be used for highvolume marine diesel transfer from tankers to tanks and storage vessels.

What is gas oil?

It’s also known as red diesel, tractor diesel and agricultural diesel. It has no connection with what the Americans call ‘gas’, short for gasoline, or natural gas which comes from the North Sea.

Gas oil is a liquid fuel that’s made from crude oil. In fact, it’s exactly the same as ordinary diesel, also called white diesel, which you’ll find on the

forecourt at any UK petrol station. The only difference is it’s a low tax version.

So why is it called red diesel?

Even though red and white diesel are the same fuel, they’re taxed very differently. In the UK, white diesel is taxed at a standard rate of 52.95 pence per litre – the same as petrol. Whereas red diesel or gas oil has considerably less fuel duty added to it - just 10 per litre.

Driving fraudulently

Obviously, this means that some diesel vehicle owners and businesses using diesel might be tempted to fill up with it instead of normal dieseland make big savings.

However, it’s illegal to do this on British public roads which is why red dye was added to the fluid from the 1960s. It helps authorities and Customs & Excise to quickly identify if a vehicle was being run on gas oil.

How is gas oil produced?

Gas oil is made from crude oil that is pumped out of the ground. Depending on the way this is distilled, a range of fuels can be produced.

First, the crude oil is pumped up from underground as a thick, black liquid. Then it’s heated in a distillation tower containing trays at different temperatures. After this it’s separated as the various components of the oil rise to different levels in the tower,

based on their boiling points. Next, the vapours of these substances condense on the trays and are collected. Gas oil is collected from near the bottom of the distillation tower, just above marine fuel oil.

So what’s the difference between gasoline or petrol, and gas oil?

Both diesel and gasoline are petroleum products refined from crude oil. However, gasoline or petrol is more refined than gas oil, which makes it thinner in density and more volatile. So petrol burns faster, which enables it to produce more power or horsepower, making it perfect for lighter vehicles that need less torque and more horsepower to go faster.

In contrast, gas oil is thicker, evaporates much more slowly and has a higher energy density. This means that it produces 20% more energy than petrol from the same amount of fluid. This is why diesel like gas oil is more suited to powering big machines because it can generate more energy at lower RPMs and provide more pulling power.

What did we specify for this project?

At North Ridge Pumps, we’re not limited to specifying just one type of pump.

As the UK’s largest pump supplier with over 25 years’ experience, we’re highly skilled at providing engineered pumps for a wide range of applications. We use this know-how to deliver a tailor-made solution for each client, not a standard product straight off the shelf.

Above all, we choose the best pump for every project – offering the lowest lifetime cost. For this specific job, we chose two of our XHLE longcoupled, end suction, single stage pumps. These are large, heavy duty horizontal centrifugal pumps with both high flow and high-pressure capabilities.

Both gas oil pumps will deliver around 180m³h (3000 L/min) at over 5 bar of pressure, and the client wanted this particular design

EN 733/DIN 24255, which means that the design is exactly the same size as many other pumps on the market.

Above all, we choose the best pump for every project – offering the lowest lifetime cost.

because it can operate at up to 80% efficiency. They’re also fitted with a brass coupling guard, ATEX motor and are long-coupled and aligned on a baseplate.

Our XHLE long-coupled, single stage pump is standardised to comply with

It can therefore replace most horizontal centrifugal pumps that are already installed, and indeed, is suitable for a wide range of applications in the industrial and marine sectors.

The XHLE long-coupled horizontal centrifugal pumps we supplied have ATEX motors which are mandatory for handling flammable fluids like gas oil.

If you have an application based around the bulk transfer of fuels or other liquids, speak to North Ridge Pumps today to see how we can help.

The vision of robots and humans working side by side is now a reality driven by the rise of collaborative robots — or cobots. Flippy, the world’s first autonomous robotic kitchen assistant, is one example. Debuting in 2017, Flippy flips burgers, fries sides, and works tirelessly in fast-food kitchens. Over the past decade, many cobots have emerged, but Flippy remains unique because of its pioneering role and continued advancements in kitchen automation. But what makes these cobots so effective? One crucial factor is industrial bearings. Here, Chris Johnson, managing director at bearing specialist SMB Bearings, explores how precision bearings are enhancing the performance and reliability of cobots.

Cobots, unlike traditional industrial robots, are designed to work in close proximity to humans. Achieving this necessitates levels of precision,

safety and reliability in cobots that are far higher than their industrial counterparts. Flippy, for instance, operates safely alongside human workers, showcasing the high standards required for such collaboration.

Bearings play a pivotal role in achieving these standards. Precision bearings, in particular, are essential for the smooth and accurate movement of cobots, allowing them to perform delicate tasks with the precision of a human hand.

The economic impact of cobots extends beyond individual businesses to the broader economy. By enabling companies to automate more processes and increase productivity, cobots can contribute to economic growth and competitiveness. For example, a report by McKinsey & Company estimates that automation technologies could help raise global productivity growth by 0.8 to 1.4 per cent annually.

According to Fortune Business Insights, the market for cobots is expected to grow at a compound annual growth rate (CAGR) of 42.7 per cent from 2020 to 2028. This growth is driven by several factors: the increasing need for automation and the push for improved workplace safety. Cobots are not replacing human labour but are instead enhancing it by performing repetitive and dangerous tasks, while

allowing humans to focus on more specialised tasks.

Manufacturers are particularly drawn to cobots for their flexibility and ease of integration. Unlike traditional robots, which often require extensive reprogramming and retooling, cobots can be quickly adapted to new tasks and environments. This makes them ideal for small and mediumsized enterprises (SMEs) that need to remain agile and responsive to market changes.

But why are industrial bearings so critical to the functionality of these machines? Bearings ensure these robots can move fluidly, reducing wear and tear and extending the life of the machinery.

In terms of efficiency, bearings reduce the friction between moving parts, which decreases energy consumption and increases the operational speed of cobots. This is particularly important in industries like electronics manufacturing, where speed and precision are essential. The ability to maintain high speeds without compromising on accuracy allows cobots to significantly boost manufacturers’ productivity.

Consider the automotive industry, where cobots are increasingly used for tasks like assembly, painting and welding. These applications demand high degrees of precision and reliability, as even minor errors can lead to significant defects.

Safety is a primary concern when integrating cobots into a human workspace. The bearings used in cobots are designed to provide accuracy and repeatability, ensuring that the robot’s movements remain

controlled and predictable. This predictability is crucial for preventing accidents and ensuring a safe working environment.

Bearings also contribute to the failsafe mechanisms in cobots. In the event of a malfunction, the robot can come to a controlled stop which helps avoid injury to human coworkers without the need for extensive safety barriers.

The food processing industry is another area where cobots are making significant inroads. Here, the precision and reliability of bearings are essential not only for the robots’ performance but also for maintaining hygiene and safety standards. Bearings used in food processing cobots are often made from stainless steel or other materials that resist corrosion and can withstand frequent cleaning and sterilisation.

Advancements in bearing technology are also driven by the development of new materials and coatings. For instance, ceramic bearings are gaining popularity due to their superior performance characteristics, including higher resistance to wear and corrosion compared to

In terms of efficiency, bearings reduce the friction between moving parts, which decreases energy consumption and increases the operational speed of cobots.

traditional steel bearings. These properties, and the ability to run unlubricated, make ceramic bearings a possibility for use in cobots, especially in environments that involve high temperatures, exposure to chemicals or where weight reduction is required.

What’s more, specialised coatings such as Teflon and graphite can be applied to bearings to further reduce friction and improve their durability. These advancements not only improve the performance and longevity of bearings but also contribute to the overall efficiency and reliability of cobots. By reducing the need for frequent maintenance

and replacements, these advanced bearings help manufacturers achieve higher levels of productivity and costeffectiveness.

SMB Bearings’ precision bearings for robotics are designed to meet the rigorous demands of modern automation, offering reliability and performance. By working closely with engineers and manufacturers it can provide tailored bearing solutions that enhance the safety and efficiency of cobots — whether that’s in automotive assembly lines, electronics manufacturing or food processing.

As cobots continue to evolve, the future of cobots is bright. With precision bearings at their core, cobots like Flippy are paving the way for a new era of collaboration between humans and robots. These bearings ensure smooth, reliable operation, enabling cobots to perform tasks with high precision and safety. The right components, like advanced bearings, are key to unlocking limitless possibilities for cobots and the industries they serve.

To learn more about SMB Bearings’ precision bearings for robotics, visit its website.

For further information, please visit www.smbbearings.com

A Stainless Steel fabricating company, who specialise in the design and manufacturer of equipment for the food processing equipment, contacted Castle Pumps looking for advice on a solution. A project they were commissioned to work on required a pump to be installed onto the equipment they were manufacturing for an ambient food manufacturer.

The pump was needed to transfer soup, which could contain both meat and vegetable pieces. It was highly important to the end client that the chunks are passed whole without damage. Due to the pump being used for handling food products, they of course need this to be a food grade pump and able to be cleaned in place to ensure the soup remains safe for human consumption at all times.

The requirement for a food grade pump was no problem for Castle Pumps; with the food and drink industry being one of their specialities, What was important to carefully consider was the gentle handling of the meat and vegetable chunks within the soup. Not only did the selected model need to be able to pump these solids without clogging, but also be able to keep them fully intact so that they weren’t crushed and turned to slurry within the soup.

Given the above point and the duty requirements at hand, Castle Pumps specified a food grade progressive cavity pump. The progressive cavity pump design is known for handling viscous, solid laden fluids without clogging thanks to its large cavities and absence of valves and

This fully stainless steel model is of complete sanitary design, free of dead zones, ideal for clean in place and fully compliant with FDA, EHEDG and 3A.

reciprocating parts. The smooth, gentle motion of its rotor also means the pump applies low shear to the fluid as it passes through, fulfilling the requirement of keeping the soup’s chunks whole.

With production of the soup relying on this pump, reliability for this customer’s application

was paramount. These models of progressive cavity pumps have a patented pin joint designed for 8000 hours before maintenance is required and consumes 20% less power than other models thanks to its long pitch rotor.

This fully stainless steel model is of complete sanitary design, free of dead zones, ideal for clean in place and fully compliant with FDA, EHEDG and 3A. The pump was supplied mounted on a Stainless Steel base plate for ease of integration into the wider system.

Getting the wrong pump for your process can result in inconsistency in the finished product, crushed solids, clogging, excessive wear, loss of productivity, waste of costly product or at worst, contamination. Always trust technical experts to specify the right pump for your application.

A pump may do the job, but only the right pump will save you excessive wear, process failures, product waste & operator time.

Get the RIGHT pump with our 15 years’ experience in:

✓ Solid-laden, viscous fluids without clogging/wear

✓ Safe handling of chemicals, fuels & flammables

✓ Highly accurate dosing of chemicals & ingredients

✓ Difficult to pump or delicate, shear sensitive fluids

✓ 99.98% barrel emptying to prevent product waste

Contact our technical sales engineers now!

The Huck® fastening system exemplifies innovation and excellence in the fastening industry; the diverse product range plays a crucial role in high-demand applications ensuring reliability, durability and efficiency.

In the ever-evolving landscape of industrial manufacturing, efficiency, reliability, and durability are paramount. The Huck® fastening range is a brand synonymous with innovation in the fastening industry. Renowned for LockBolt® and structural blind fastener technologies, Huck® fasteners provide solutions that enhance manufacturing processes across a multitude of industries where structural integrity is critical and where a strong, permanent, and tamper-resistant joint is required.

The Legacy of Huck® Fasteners

With over 80 years of fastener innovation, Huck® fasteners have consistently delivered performanceengineered solutions designed to withstand extreme conditions and demanding applications. This legacy of innovation and reliability has made Huck® fasteners a trusted name in the industry. The Huck® LockBolt, based on Lou Hucks’ original design, provides high stability and facilitates lightweight, stronger and more durable structures. Hucks’ ever evolving LockBolt and structural blind fastener capabilities continue to solve problems in in a wide variety of applications – no torque, easier evaluation, maintenance free and high corrosion standards are some of the benefits of using the Huck® fastener product range.

Speed of Installation: Huck® fasteners are designed for rapid installation. The installation process is often faster compared to traditional fasteners such as bolts and nuts, reducing assembly time.

Consistency and Reliability: The installation process of Huck® fasteners is consistent and reliable, reducing the likelihood of installation errors and rework, which saves time and resources. They benefit from rigorous testing, certifications, and quality management systems, ensuring consistent performance and building confidence in their use.

Cost Reduction

Reduced Labor Costs: Huck® fastener installation offers significant advantages in terms of efficiency and speed due to the straightforward process and visual inspection methods.

Reduced Material Costs and Weight reduction: Huck® fasteners are designed to create strong, durable joints, often requiring fewer fasteners compared to traditional fastening methods.

Maintenance and Longevity: Huck® fasteners typically have a long service life and require less maintenance, leading to cost savings over the product’s lifecycle.

Performance

Strength, Durability and Performance

Evaluation: Huck® fasteners provide high joint strength and are resistant to vibration and loosening; they are subjected to various tests to assess their performance under static and dynamic loads. Depending on the

fastener type, tests include tensile, shear, slip-load and creep testing as well as fatigue testing to emulate realworld conditions.

Aesthetic and Structural Integrity:

They can be installed without causing significant distortion or damage to thin sheet metal, preserving the material’s integrity and appearance.

Corrosion Resistance: Huck® fasteners are perfect for safety-critical applications; they are often subjected to harsh environmental conditions, including moisture, saltwater exposure, and chemical agents. Huck® fasteners are manufactured with coatings that resist corrosion, enhancing the longevity and performance of the final product. The coatings act as a barrier, shielding the fasteners from corrosive elements and preventing the onset of rust and degradation. By effectively sealing the surface of the fasteners, coatings significantly extend their lifespan, reducing maintenance requirements and replacement costs over time. This is particularly crucial in industries such as marine, offshore, and transportation, where corrosion can pose significant safety risks.

Advanced LockBolt Technology

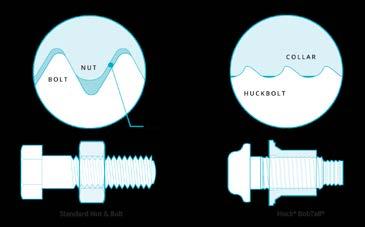

Huck® LockBolts are renowned for their strength and vibration resistance. Unlike traditional nuts and bolts, Huck® LockBolts form a permanent joint that resists loosening, even under extreme conditions. This makes them ideal for high-vibration environments.

Huck® LockBolts are installed using direct tension and swaging. The Huck® installation tool grips the pintail of a LockBolt and then pulls to close the gaps in the materials being joined.

One standout product is the Huck® BobTail®, which has been proven to increase manufacturing efficiency. The BobTail® LockBolt eliminates the need for torque and re-torque procedures, ensuring consistent and reliable installations while significantly reducing labour costs, and unlike traditional LockBolts® no pin-break is required, therefore leaving no corrosion-prone area of bare metal or spent mandrels to be collected.

Huck LockBolts

Positive Locking Mechanism: Threaded bolts rely solely on frictional forces, in contrast, LockBolts consist of a pin and a collar and are installed using direct tension and swagingthere are no gaps between collar and pin ‘threads’ – a common source of loosening in conventional nuts and bolts.

Huck® LockBolt brand names include, BobTail® Magna-Grip®, C6L®, C50L®, C120L® and Hucktainer® (also available in encapsulated Hucktainer which can be colour matched to customers’ requirements).

When accessibility is an issue, Huck® structural blind fasteners offer a robust solution. Designed for applications where only one side of the joint is accessible, these fasteners provide high-strength, reliable joints often replacing welding. A key benefit is their internal locking mechanism that retains the ‘pin’ after installation.

Huck® structural blind fastener brand names include, Auto-Bulb®, BOM®, FloorTight®, HuckLok®, MagnaBulb®, Magna-Lok®, Magna-Tite®, and Penta-Lok™

Standard Nut and Bolt Frictional Force compared with Huck LockBolt Direct Tension Swaging

Huck® LockBolts High and Consistent Clamp Force: The installation process ensures a precisely controlled clamp force. This high and consistent clamp force minimises any potential movement within the joint, further enhancing the resistance to vibration.

Star Fasteners are the UK’s largest distributor of the Huck® fastener product range and stock a wide range of sizes, head styles, materials, and plating’s; this versatility ensures a wide range of applications and industries are accommodated. As industries evolve, Star Fasteners remains committed to providing advanced fastening solutions that meet the rigorous demands of modern engineering and manufacturing.

Complementing their extensive range of fasteners, Star Fasteners offers a suite of installation tools designed for ease of use and efficiency – offering a versatile range of battery and air-powered

options that enhance productivity on the shop floor. These tools ensure that Huck® Fasteners are installed correctly and efficiently, further boosting the overall performance of the fastening system.

Star Fasteners prides itself on its customer-centric approach. Through detailed case studies and customer feedback, the company continuously improves its product range to meet realworld challenges. This commitment to excellence ensures that Huck® fasteners remain at the forefront of the fastening industry, providing solutions that drive success for their customers.

In conclusion, Huck® fasteners represent the pinnacle of fastening technology. Their innovative designs, superior performance, and proven customer satisfaction make them an invaluable asset in modern manufacturing. Whether it’s enhancing the efficiency of assembly lines, ensuring the reliability of components and safety critical products, or supporting the sustainability of green energy projects, Huck® fasteners deliver solutions that meet and exceed industry demands.

Morley forges automotive role at leading European industrial association

A leading UK manufacturing figure has been appointed as the Chair of the Automotive Group within Euroforge.

Steve Morley, the current president of the Confederation of British Metalforming (CBM), will take up the influential role at the association’s high-profile Autumn Summit in Milan on October 21st.

He will be responsible for developing a strategy to tackle some of the major issues impacting European automotive forgers, including the Carbon Border Adjustment Mechanism (CBAM), fluctuating energy prices and the availability of material across the supply chain.

The experienced auto specialist has also put together an industry-packed speaking line-up for the event from across Europe, featuring Matt Pearson (Partner at EY Pantheon), Philippa Oldham (Stakeholder Engagement Director at the Advanced Propulsion Centre) and Euclides Coimbra (Senior Partner and Managing Director of the Kaizen Institute).

Together, the trio will give Euroforge members a clear insight into the current industry landscape, as well as exploring access to funding of new technologies and how firms can maximise efficiencies through new process implementation.

The Autumn Summit is an important pre-cursor for conFAIR 2024 on the 22nd and 23rd October, which has a full house of exhibitors for the only European event specifically designed for the forging industry.

“I’m very honoured to have been appointed as the Chair of the Automotive Group, one of the most prestigious roles within an organisation that now represents more than 350 members across Europe,” explained Steve, who has more than 40 years’ experience working in manufacturing.

“We are at a very important time in the evolution of forging as an industry, especially when you consider the emergence of electric vehicles and the types of parts we can supply. One of my roles will be to take all the intel we’re getting on the ground and funnel them into a strategy that moves us forward as one collective.”

He continued: “Milan will be a great start to the position and I’m looking

forward to meeting everyone at the Autumn Summit.”

Steve has been President of the Confederation of British Metalforming since 2018, working with CEO Geraldine Bolton and its policy advisers to lobby UK government on key factors affecting the sector.

Some notable achievements secured in the last six years have included increasing steel safeguarded quotas domestically, lobbying on the escalation of rising energy costs and providing intelligence on CBAM to members ahead of its European introduction.

The former Group Engineering Director at Sertec Group has spent the majority of his 40-year career in and around the automotive sector, working at all tiers of the supply chain and running his own consultancy business.

“Steve has the experience, industry contacts and passion to make a really big difference as Chair of Euroforge’s Automotive Group,” added Geraldine Bolton, CEO of the Confederation of British Metalforming.

“Importantly, he will be able to factor in some of the issues facing CBM members, ensuring they are represented alongside their European peers. He will also be in an ideal position to see new technologies developing at the earliest possible opportunity, intelligence that will help accelerate the growth of our own domestic supply chain.”

For further information, please visit www.thecbm.co.uk or www.euroforge.org

ViSWIR Hyper APO Features:

• Capable of fully corrected focus shift in visible and SWIR range (400nm - 1700nm)

• Achieves spectral imaging with a single sensor camera by simply syncing the lighting

Floating design adjusts focus for different wavelengths 8mm, 12mm, 16mm, 25mm, 35mm* and 50mm* (*2023)

ViSWIR Lite Features:

• High transmittance at whole wavelength of 400nm - 1700nm by adopting hyper wideband AR coat

Outstanding cost-performance for single-wavelength lighting & narrow-band imaging

Compact design 5mm, 8mm, 12mm, 16mm, 25mm, 35mm, 50mm

Many manufacturers and engineers are finding their online presence increasing important in attracting and retaining clients.

Sarah West of leading B2B marketing agency, Full Mix Marketing, takes a look at some important areas of digital marketing.

Whatever you make or engineer, customers will often look you up online. Your website can be both the first and last impression you make. The litmus tests for a good website are:

• Is it immediately obvious what you deliver?

• Is it clear where someone needs to click for relevant information?

• Does your website explain how you can satisfy your customers’ needs?

• Is your website modern and up-todate?

Search Engine Optimisation (SEO) helps ensure your website appears higher up (Google) search results. First, it’s important to know if customers are looking online for what you do. In some sectors searches can be minimal.

The most influential element of SEO is content. You need to include text, images and video which directly address the needs of your target audience.

Backlinks from other websites show search engines your website is respected. An effective strategy is to share content with trade websites. Google assesses all websites ‘mobile first’, so it’s crucial your website is optimised for all devices.

Sharing content across your company’s social media and including it in your company email marketing are also powerful tactics.

Whilst waiting for SEO to improve your performance, PPC (Pay Per Click) advertising can help you appear higher up search results.

1. Conduct thorough research

Online tools can help you identify the search terms your target audience uses.

2. Create compelling ads

The most effective search ads highlight features and benefits. Use an active voice such as ‘get’ or ‘discover’ to encourage clicks.

3. Optimise landing pages Create or specify pages which relate closely to the keywords being targeted.

4. Set the right ad scheduling Concentrating your campaign on working hours can help attract businesses who are ready to buy.

Content can demonstrate your expertise, engaging with your clients and improve SEO. Fresh content on your website shows search engines you’re active. Sharing content helps build trust and demonstrate your

industry leadership. The attention span of busy professionals is short, so split articles into bite sized chunks and avoid being too salesy. Something genuinely newsworthy can become a press release. If trade websites publish it, it will help your SEO.

Sharing content across your company’s social media and including it in your company email marketing are also powerful tactics.

Around 50% of senior professionals are active on LinkedIn, making it effective for increasing awareness of your company and capabilities. The most successful posts typically report something new, such as a product, achievement or completed project.

To boost your reach:

1. Ask staff to regularly like and share your company posts

2. Request senior staff invite individuals in target organisations to connect with them

3. Once connected, they can invite contacts to follow your company page

There are many other areas of digital marketing, including those which are no longer regarded as purely digital, like email marketing.

Analytics are important too but it is best to take a wholistic approach rather than expect stats to inform every decision.

Suncombe stands at the forefront of industrial process cleaning technology with its innovative Mobile CIP (Clean-In-Place) systems. These state-of-the-art skids are transforming the way industries maintain cleanliness and hygiene, offering unparalleled flexibility and efficiency. Designed to cater to a wide array of sectors, including BioPharma, healthcare, cosmetics, and food processing, our Mobile CIP systems are a testament to Suncombe’s commitment to quality and innovation.

The Mobile CIP is a Total Loss cleaning system, designed to be mobile, allowing it to be easily transported to various points of use within a facility. This mobility is a game-changer, eliminating the need for fixed cleaning stations and enabling comprehensive sanitation of equipment such as tanks, vessels, mixers, and more. Whether operated manually or automatically, these systems ensure that every piece of equipment is thoroughly cleaned, adhering to the highest hygienic and sanitary standards, including ASME BPE.

One of the standout features of Suncombe’s Mobile CIP systems is their advanced design, which includes a CIP buffer vessel for efficient storage and delivery of cleaning fluids. Equipped with heating facilities, detergent dosing systems, and sophisticated instrumentation, these skids offer a user-friendly interface that simplifies the cleaning process. Operators can easily adjust parameters like temperature and cleaning agent

Our Mobile CIP systems are not only about efficiency but also about sustainability.

concentration, tailoring the process to meet specific requirements and ensuring optimal results every time.

Our Mobile CIP systems are not only about efficiency but also about sustainability. They are designed to optimise the use of resources, reducing water, energy, and cleaning agent consumption. This not only minimises waste but also lowers operating costs, aligning with environmental stewardship goals and promoting responsible manufacturing practices.

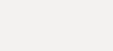

Safety is paramount in our design. Suncombe’s Mobile CIP systems incorporate safety features such as emergency stop buttons and safety interlocks, ensuring a secure working environment. Compliance with regulatory guidelines and quality standards further underscores our commitment to safety and reliability.

Suncombe’s Mobile CIP systems offer a flexible, efficient, and sustainable solution for industries requiring portable sanitation capabilities. By investing in our Mobile CIP systems, manufacturers can enhance operational efficiency, reduce downtime, and ensure product quality and safety. Experience the benefits of our cutting-edge cleaning technology and elevate your hygiene standards.

For more information or to discuss your specific CIP requirements, contact us at salesdept@suncombe. com. Let Suncombe help you achieve your industrial process cleaning goals.

Designed to cater to a wide array of sectors, including BioPharma, healthcare, cosmetics, and food processing, our Mobile CIP systems are a testament to Suncombe’s commitment to quality and innovation

The Mobile CIP is a Total Loss cleaning system, designed to be mobile, allowing it to be easily transported to various points of use within a facility. This mobility is a game-changer, eliminating the need for fixed cleaning stations and enabling comprehensive sanitation of equipment such as tanks, vessels, mixers, and more. Whether operated manually or automatically, these systems ensure that every piece of equipment is thoroughly cleaned, adhering to the highest hygienic and sanitary standards, including ASME BPE.

Bergkirchen, Germany. In today’s fast-paced tech landscape, AI is now redefining electrical engineering design. WSCAD introduces ELECTRIX AI, the world’s first AIpowered Electrical CAD solution, eliminating tedious manual steps and completing tasks in mere seconds – slashing design time by up to 99%. With smart error-checking, intuitive guidance, and the power to tackle complex tasks with simple commands, ELECTRIX AI is a gamechanger for electrical engineers. Novices boost productivity faster, while seasoned pros free up time for more critical challenges, helping companies meet tight deadlines and bridge the skilled labor gap. “ELECTRIX AI is revolutionizing how electrical design is done,” says Axel Zein, CEO of WSCAD GmbH. “We’ve seen massive time savings, and the streamlined process unlocks major productivity gains.”

At the core of this breakthrough technology is the AI Copilot. With just a click on the button marked by three asterisks, a chat window pops up, ready to assist users in their daily tasks. The AI Copilot reviews designs, find errors, and adapts to the user’s needs on the fly. “Instead of manually searching for components or designing from scratch, you just ask the AI Copilot and hand over the tasks,” says Axel Zein.

From material lists to macros and components, everything is generated and positioned in record time. When using other electrical CAD software it can take over 20 clicks to create a BOM (bill of materials). In WSCAD

24V DC, 64A” delivers the perfect wire with a 16mm² cross-section right to your cursor.

The AI Copilot reviews designs, find errors, and adapts to the user’s needs on the fly.

it now happens in seconds with a simple “Create the bill of materials” command. Placing macros? A breeze – Ai Copilot takes 15 seconds to place four macros on a new page, down from the traditional five minutes. Need to check your design for errors? Just ask, “Find the errors in this project,” and ELECTRIX AI will scan your schematics in seconds, pinpointing open connections, missing assignments, or misplaced components. Even technical inquiries like wire gauges are resolved instantly. A quick request like “Give me a copper wire, blue,

ELECTRIX AI – The Solution to Time Pressure and Workforce

Beyond massive time savings, the real game-changer is how easy it is to use. ELECTRIX AI delivers specialized Electrical CAD expertise while continuously learning from user inputs, making it more efficient with each task. Novice users can now tackle jobs that were once for experts, while seasoned designers can focus on complex projects with significantly reduced time investment. “This new division of labor supercharges productivity, enabling companies to handle growing demands more efficiently,” says Axel Zein. “By integrating AI into our Electrical CAD software, we unlock new possibilities and pave the way for enhanced productivity.”

For further information, please visit www.wscad.com

ViSWIR Hyper APO Features:

• Capable of fully corrected focus shift in visible and SWIR range (400nm - 1700nm)

• Achieves spectral imaging with a single sensor camera by simply syncing the lighting Floating design adjusts focus for different wavelengths

• 8mm, 12mm, 16mm, 25mm, 35mm* and 50mm* (*2023)

ViSWIR Lite Features:

High transmittance at whole wavelength of 400nm - 1700nm by adopting hyper wideband AR coat

Outstanding cost-performance for single-wavelength lighting & narrow-band imaging

Compact design 5mm, 8mm, 12mm, 16mm, 25mm, 35mm, 50mm

With today’s technology, inertia matching isn’t the requirement it once was to design a servo-based machine. However, when tuning a system to minimise the inertia mismatch, wider requirements remain in order optimise an application’s motion control performance. From motor sizing through to minimising mechanical compliance, a comprehensive approach to motion design will enhance system stability and precision.

Gerard Bush, motion engineer at Intelligent Motion Control (INMOCO), explains.

To size a servo system, previously, it was always considered essential to match the inertia of the motor with the load. Matching the inertia, that is the resistance to changes in rotational motion, ensures the necessary torque to achieve the required acceleration and deceleration. It also enables the right dynamism and stability, and optimises efficient power transfer.

These rules remain true, yet the problem of aiming for a 1:1 inertia match ratio would often result in a much larger motor than might otherwise be required, or it would require a gearbox. Either approach would create a more expensive, and less efficient outcome. Instead, today’s technologies involving faster processors and advanced control algorithms enables correction of the inertia mismatch.

Thanks to a closed loop servo system, which continuously monitors and adjusts based on feedback, the control and stability of position, velocity, and current/ torque loops are enhanced. The

An extended look at the detail of interaction across a mechanical system is also important to address compliance.

servo drive tunes the control loops to operate with the required bandwidth, determining how fast the servo can adjust in response to commands. The servo drive also impacts the level of stiffness, optimising precision and control of the system by managing the response to deformation or displacement when force is applied. As a result of these improvements, the development of the servo drive significantly reduced the need for inertia matching.

The introduction of brushless motor technology and low mass, torquedense NeFeB magnets, reduced motor inertia further still, however this extended the inertia mismatch. In response, the development of increased processing power, as well as higher resolution feedback devices, allowed the servo controller to create accurate mathematical modelling and simulation of system responses. Today, these tools enable motion engineers and machine designers to create interactive analytics by showing the precise detail of the mechanical system. Crucially, this data indicates how to address performance limitations.

An extended look at the detail of interaction across a mechanical system is also important to address compliance. This challenge represents the natural springiness of the mechanisms between the driven load

and the motor that creates delayed response times, leading to reduced system bandwidth.

When a large inertia mismatch is introduced to the system, such as a small, high torque motor connected to an exceptionally large load via a coupling device, the compliance problem is magnified. When the motor quickly applies torque, the large load hesitates to respond due to its high inertia; the delay is a result of coupling compliance between the motor and load that introduces windup before the load begins to move. As the load finally synchronises with the motor, the large inertia causes overshoot of the target speed, resulting in the motor adjusting to slow down. When the system adjusts the overspeed of the inertia, the target speed is again passed, triggering the motor to adjust once more. This causes a continued cycle of repeated adjustment that creates resonance and an unstable system.

Most mechanical systems can be mathematically modelled and

simulated using various excitation frequencies to identify the response point where resonance occurs. However, the bandwidth of a system can never exceed the initial antiresonance point. In fact, the higher the compliance, the lower the frequency of the initial resonance point, that reduces bandwidth accordingly. When the driven load is directly coupled to the motor to minimise compliance, the mismatch is mitigated, increasing the initial resonance frequency and creating a higher bandwidth system.

Mathematical models show that the ultimate solution for a higher bandwidth and cost-effective system is to increase the mechanical stiffness and reduce total system inertia. Consider a direct drive solution where the load is directly coupled to the motor with near zero compliance; in cases like this, precisely controlling the system with high bandwidth can be achieved with inertia mismatches as high as 30:1. As direct drive solutions are not suited to all applications, compliant links will

inevitably be introduced. However, advanced analytical tools, such as the bode plot, can readily identify the compliant elements that reduce system performance.

Applications often characterised by a high inertia mismatch can include printing and labelling, as well as various robot designs. Although inertia mismatch is no longer the main challenge, resolving the imbalance requires careful specification across a range of aspects, from motor sizing, through to tuning and analytics of the control algorithms, and mechanical architecture.

Assistance in specifying a system is particularly useful for machines with an inherent inertia mismatch. With comprehensive application sizing and best practices in designing a stiff mechanism, this can achieve a high-performance motion system capable of higher bandwidths, improved move and settle times, and robust dynamic control.

For further information, please visit www.inmoco.co.uk

Andrew

Jones, the Technical Director at Axair Fans explains the deeper why behind their latest innovative and disruptive campaign –We’re Revolting

You’ve hopefully seen our revolting advertising out in the wild – and if not, or simply as a reminder, it features a few candid shots of me and our team in compromising situations; picking noses, ears, smelling armpits, or showing their lunch still inbetween their teeth. Revolting!

The visual is eye catching yes, but the messaging is powerful when you really get to grips with what we’re saying. If you’ve read my previous contributions on complacency in the fan industry, the importance of adding value to customer interactions, or the way we’re helping to bridge the skills gap in the industry, then you’ll understand that we’re leading a dramatic change from the front. A revolution if you will, and to lead a successful revolution, you need an initial revolt.

A revolution implies a successful revolt occurred which resulted in that major change, something we’re doing by making waves in changing the behavioural norms, advocating for a change in the way customer response times are reduced, how feedback on technical support is given within a set time, communication is paramount, and the same pre-sales support is delivered regardless of the value of the potential opportunity. Quite simply we’re waving the flag for what the customer deserves.

We’re revolting!

If you’re an advocate for changing fan supplier behaviour, then I encourage you to give yourself a nudge and examine the behaviours within your business.

We’ve not anchored our revolt on assumptions either, we’ve delivered and shared meaningful actions taken from research feedback, including customers not getting attention from the industry giants unless they’re a 6-figure customer, the average wait time on technical responses being 6 weeks or beyond, and the sheer amount of product fails with no final diagnosis or resolution.

We realised that what we offer is unique, we’re focused on customer outcome. It deserves to be shouted about, because it’s the basics of what the customer experience should be about but quite simply isn’t in the industry. Complacency and fear are leading the way right now.

So, the next time you see a post with one of our team’s uncomfortable poses disrupting

your social feeds, landing in your inbox or printed in an industry publication, give a thought to your current situation. Are you an advocate for change and how are you going about this?

The way customers go about sharing their advocated behaviours is now more important than ever, word of mouth for example in the digital intense era we’re in, spreads incrementally through online channels, very different to 20 years ago. Increasingly people make their decisions based on the influence of peers and people like them, to decide who to put their trust into.

LinkedIn is a prime channel with clear examples of grouped consensus, support and hyping each other up in this industry, specifically within the commercial kitchen sector. If you’re an advocate for changing fan supplier behaviour, then I encourage you to give yourself a nudge and examine the behaviours within your business.

Maybe it’s reviewing your supplier list to see if they truly add value, looking at product variations outside of your comfort zone, or demanding greater collaborative efforts from your component suppliers. As always, we’re here to support our customers outcomes and goals, that revolutionary change is right here in this text, as they say in Stoke, Viva la Revolution.

Portescap will be exhibiting at SPS 2024, Europe’s premier spotlight on the automation industry. Portescap’s range of miniature DC motors are designed with precision in mind, making them the perfect partner for robotics and smart manufacturing. This year the company is joined by sister brands, Stromag and Warner Electric, to showcase a full system approach for the end user.

Portescap and other Regal Rexnord Brands can be found at Booth 122 (Hall 3) at the Nürnberg Messe in Nuremberg, Germany from the 12th to the 14th November, 2024.

Portescap’s miniature motion solutions offer an extensive range of BLDC, brush DC, and stepper motors, complemented by motion accessories like gearheads, encoders, and controllers. Recent product highlights include frameless motors, which forego traditional

Portescap’s miniature motion solutions offer an extensive range of BLDC, brush DC, and stepper motors, complemented by motion accessories like gearheads, encoders, and controllers.

frame and bearings in favor of direct integration into mechanical assemblies; and slotted flat BLDC motors, whose flat architecture is ideal for applications where space is limited and performance demands are high. Working with our team of engineers, customers benefit from

maximum motor performance and efficiency, all within the smallest and lightest envelopes.

This year, the Portescap brand will be showcased with Stromag and Warner Electric brands, all part of Regal Rexnord. These sister brands offer electromagnetic brakes, limit switches, and servo motor brakes, which are perfectly suited for demanding automation applications. The show will highlight the capabilities of Regal Rexnord, showcasing support for customers as a single system provider for the most challenging industrial applications.

The Portescap team will be available throughout the show to demonstrate a range of products and to discuss specific customisation questions that visitors might have. To schedule an apportionment prior to the show, please email us at portescap. marcomrequest@regalrexnord.com.

Benefits of Keronite / PEO Applications?

• Extreme hardness

• Corrosion resistance

• High strain tolerance

• Uniformly applied coatings

• Wear resistance

• Environmentally friendly

• High fatigue performance

• High dielectric resistance (for electrical component applications)

• Plasma resistant coatings

its

enabling a

Universal Robots, the Danish collaborative robot (cobot) company, has presented for the first time the UR AI Accelerator – a ready-to-use hardware and software toolkit created to further enable the development of AI-powered cobot applications.

Designed for commercial and research applications, the UR AI Accelerator provides developers with an extensible platform to build applications, accelerate research and reduce time to market of AI products.

The toolkit brings AI acceleration to Universal Robots’ (UR) nextgeneration software platform PolyScope X and is powered by

NVIDIA Isaac™ accelerated libraries and AI models, running on the NVIDIA Jetson AGX Orin™ systemon-module. Specifically, NVIDIA Isaac Manipulator gives developers the ability to bring accelerated performance and state-of-the-art AI technologies to their robotics solutions. The toolkit also includes the high-quality, newly developed Orbbec Gemini 335Lg 3D camera.

With everything seamlessly integrated, the toolkit offers developers full go-to-market architecture and is ready to use straight out of the box.

Through in-built demo programs, the AI Accelerator leverages UR’s platform to enable features like

pose estimation, tracking, object detection, path planning, image classification, quality inspection, state detection and more. Enabled by PolyScope X, the UR AI Accelerator also gives developers the freedom to choose exactly what toolsets, programming languages and libraries they want to use and the flexibility to create their own programs.

“With the UR AI Accelerator, we provide our partners with everything they need to develop and deploy new, innovative AI solutions,” says Kim Povlsen, CEO and President of Universal Robots. “We are already a leading platform for taking AI cobot applications to market and now we are pushing the boundaries

even further. The most exciting part will be seeing the impact of these new capabilities for our partners and end customers.”

James Davidson, Chief AI Officer, Teradyne Robotics, elaborates:

“UR’s AI Accelerator is built for where AI will really make a difference - if you’re building solutions on our platform, it will decrease your time to deployment while also de-risking the development of AI-based solutions. With our objective to take physical AI to an entirely new level, AI Accelerator is just the first to market of a series of AI-powered products and capabilities in UR’s pipeline, all with the focused goal of making robotics more accessible than ever before.”

Unveiled the same week that sees hundreds of robot software developers gathering for ROSCon 2024 in UR’s hometown of Odense,

With everything seamlessly integrated, the toolkit offers developers full go-tomarket architecture and is ready to use straight out of the box.

Denmark, a demo of the UR AI Accelerator with a CNC machine tending application will be displayed at the ROSCon exhibition.

The PolyScope X platform is globally available and can be used for all cobot automation applications across industries. Its advanced flexibility and extensibility will be showcased at the PolyScope X Festival in November, presenting a range of the solutions already

developed with this new platform, including AI solutions. With a small hardware upgrade, the software is compatible with UR’s e-Series cobots and the new-generation cobots UR20 and UR30.

For more information, please visit www.universal-robots.com

automation cell unveiled by

A £200,000 state-of-the-art automation cell was unveiled at InComm Training’s Telford Technical Academy last week in a major boost to the Marches’ advanced engineering capability.

The independent training provider has extended its commitment to employer-led provision by developing a 6-axis ABB industrial robot and bespoke conveyor system, recreating a real-world manufacturing line that gives learners access to component nesting and sensing, robotic operation, PLC programming and interfacing systems.

Funded through the Local Skills Improvement Framework and the Marches Education Partnership, the new facility was demonstrated for the first time in front of more than 45 industry leaders from Collins Aerospace, HS Marston, Magna Cosma Casting, Autoneum, CEL Sheet Metal and VA Technology.

It is anticipated that hundreds of learners will be trained on it every year in four courses ranging from oneday Level 3 Cell Operator and 4-day Level 3 Robotic Programming, to an extensive EAL-accredited Industrial Robotic Technology qualification and a BTEC Level 4 in Automation, Robotics and Programmable Logic Controllers.

Paul Hodgetts, Business Development Manager at In-Comm Training, commented: “Our approach has always been to listen to what companies want and we’ve been hearing for a long time that they need flexible and modular courses that can

From left; Paul Aston, Jane Pottinger (both In-Comm Training), Steffan Willetts and John D’Angelillo (both Bauromat) and Paul Hodgetts (InComm Training)

deliver automation skills that have a real impact on the shopfloor.

“We held an industry meeting earlier this year and, due to further feedback we received, we tailored the cell and its operations even more. With the help of the Marches Education Partnership, we now have an unrivalled six-axis robotic automation line that you would only normally find in industry-leading businesses.”

He continued: “Located at our Telford Technical Academy, this will be available to SMEs, large business and OEMs in the Marches and West Midlands Combined Authority area, who need support in upskilling or training new staff in some of the latest robotic and automation skills. There was so much interest, we actually took several bookings for the courses on the day.”

Installation of the robotic and automation cell has been completed by Telford-based Bauromat, who has worked with In-Comm Training to ensure the line represents what

learners will be working on now and in the future.

The latest addition to the T54 facility will help existing engineers upskill or reskill in a new engineering discipline, providing companies with a more agile workforce and one that is prepared for the move to more automation and digital transformation.

Training will be focused on delivering Level 3 and Level 4 courses, with engineers learning how to interact with PLCs, perform essential maintenance and automate production lines.

Paul went on to add: “Thanks to existing partnerships with WMCA and Telford Council, we can offer funding for some of the courses but for a limited time only – the message is to act fast.

“Last week’s launch event highlighted the end of Phase 1 with the automation cell now ready and operational for learning. It will soon be followed by a further £75,000 private investment from In-Comm Training that will create a dedicated fluid power training suite, which will strengthen our ability to deliver advanced competences around fluid power, hydraulics and pneumatics.

He concluded: “The Marches has some world class companies and some fantastic industry disruptors, but these wonderful manufacturers need access to advanced automation, robotic and hydraulic skills required to release their full potential. We’ve giving them access to these competences right on their doorstep.”

Cordless tools have revolutionised industry; the convenience of being able to carry out tasks unencumbered by the need to find power and plug in, or to leave trailing leads around as trip hazards has resulted in almost all personal tools now being cordless.

In the World of vacuum cleaners, however, cordless options have been restricted to smaller machines with limited power and performance. This is because for anything other than the lightest applications, efficient vacuum cleaning requires a minimum of 1-1.5kW of power; something that is not easily achievable for useable durations with small batteries.

The new BVC IV60 eGX breaks the mould and has revolutionised the ability to provide cordless industrial vacuum cleaning power wherever and whenever it is required. This has been achieved through the unique combination of the proven BVC YP3 multistage vacuum turbine and the new Honda eGX electric engine with swappable battery power.

The Honda eGX is an engine that provides power in the 2hp class, powered by an on-board 750Wh lithium battery. When fitted to the BVC IV60 eGX industrial vacuum cleaner this power unit delivers around 1.5kW of power with a ½ hour run time, and around 1 hour of run time on a very useful half power setting. With a fast charger, and swappable battery continuous operation is achievable.

Since it’s introduction, the BVC IV60

eGX is finding diverse applications in several different markets. Examples include warehouse spillage cleaning in areas not serviced with power outlets, highbay cleaning with high-reach kits, use in areas for wet recovery and cleaning; in fact, many applications where the lack of available power outlets is the motivation to look for cordless alternatives.

Apart from the elimination of the need to find local power outlets for industrial vacuum cleaning, the other significant benefit the BVC IV60 eGX offers is the elimination of trailing leads. In an operational processing area, e.g. if there is a need to clean up spillages without interrupting the process or causing a hazard with trailing leads, BVC IV60 eGX can be simply pushed to the location and turned on for efficient cleaning.

Like all BVC Industrial Vacuum Cleaners, BVC IV60 eGX is available in different versions and with a wide range of hoses and tools. The first two versions available are the dry tank and wet tank versions. The dry tank version can

be optionally fitted with HEPA filtration and offered in M-Class and H-Class configurations. The wet tank version, can be fitted with a sludge separator bucket, and has a tipping tank and drain hose for easy emptying.

Both versions are provided with 51mm (2”) inlets allowing the use of the full range of BVC 51mm and 38mm hoses and tools available from Quirepace. The range of tools includes various crevice tools, bench and brush tools, and robust floor tools. BVC IV60 eGX is also suitable for use with carbonfibre high-reach cleaning tools for cleaning at high level whilst the operator stays at ground level, avoiding the need to “work at height”.

The BVC IV60 eGX is manufactured by Quirepace at the factory in Fareham, Hampshire, alongside the rest of the BVC Industrial Vacuum range of heavy-duty machines. UK manufacture means a UK source of spare parts and after sales services. In addition, BVC IV60 eGX has been validated by Honda as an officially approved product meaning that the warranty and any service requirements on the Honda eGX motor itself is available through any Honda service centre.

Quirepace have a specialist sales team covering the UK, so if you have a potential application, a member of the team can visit site with a demonstration unit for an on-site trial.

To find out more, contact Quirepace today.

The food and beverage industry is continually evolving, driven by the need for enhanced efficiency, quality, and safety. Central to these advancements is fluid process control, a crucial component in manufacturing processes such as mixing, fermentation, and pasteurisation. Recent innovations in this area have focused on precision, automation, and sustainability, significantly improving production practices.

Kieran Bennett, Industry Account Manager, Food & Beverage, for Bürkert, looks at the recent innovations in process control and the benefits they bring to the industry.

The brewery industry exemplifies the positive impact of recent developments in fluid process control. Modern breweries employ advanced process control systems to manage every stage of beer production, from mash preparation to fermentation and packaging. Automated systems monitor and adjust the flow of ingredients, ensuring consistency in flavour and quality. Precision sensors control the fermentation temperature and pressure, crucial for producing different types of beer.

As one of the simplest and most common examples, it only takes a deviation of a couple of degrees

during mashing or fermentation to have a noticeable impact on the flavour of the beer, which affects product quality. Process automation has numerous benefits, especially in terms of repeatability and accuracy. Modern process control valves can deliver this as well as achieving a long service life in a hygienic environment that is exposed to regular washdowns and humidity.

Aside from a clean and polished aesthetic, process valves can offer highly visible cues using multicoloured LEDs to indicate proper operation or process faults, enabling any issues to be resolved quickly with minimal interruptions to production. This status indication is supported by more advanced,

Bürkert’s FLOWave offers excellent accuracy, even with challenging fluids

fieldbus technology, which enables process components to be integrated, commissioned and operated more easily.

For smaller installations, modern communication technologies offer a greater freedom to experiment with new recipes while retaining the consistency and repeatability associated with the brand. Furthermore, the ability to monitor operations remotely with notifications of alarms and outof-tolerance conditions, enable operators to focus on core tasks and even spend time away from the brewery.

Beyond control valves, sensors also play a vital role in establishing the data points required for a consistent production facility and while many have remained unchanged for years, new technologies can improve process performance. Flowmeters are just one example. The challenges

The brewery industry exemplifies the positive impact of recent developments in fluid process control.

of accurately measuring the flow of fluids containing entrained gases have more recently been overcome using surface acoustic wave (SAW) technology.

Bürkert’s solutions for the brewery sector include the Element series of pneumatic control valves, which are well-suited to many applications, from small scale craft processes to much larger industrial-scale enterprises. The FLOWave offers excellent accuracy, even with challenging fluids, while

retaining the flow and hygienic characteristics of normal process pipework.

Recent advances in fluid process control are transforming the food and beverage industry, driving improvements in precision, automation, safety, quality, and sustainability. These innovations not only enhance the efficiency and reliability of production processes but also support the industry’s commitment to producing safe, high-quality products while minimising environmental impact. As technology continues to evolve, fluid process control will remain a key area of focus, shaping the future of food and beverage manufacturing.

Modern process control valves can deliver numerous benefits in terms of repeatability and accuracy

For further information, please visit www.burkert.com

Automated Water & Effluent Ltd

We at Automated Water & Effluent believe that accurate measurement and precision control is the key to process control, water and effluent treatment.

That’s why everything in our equipment range for measuring pH, Redox, Conductivity, Dissolved Oxygen, Turbidity and Liquid Level are of the highest quality for precision measurement.

We offer a wide range of products and services including: