COBRE PANAMA OPERATE LIEBHERR T284 UNITS ON CLAYCRETE HAUL ROADS

· POTHOLES - One litre of CLAYCRETE will treat 5 cubic meters of Road Material.

· GRAIN STAGE – Whether it is open air or emergency storage having a proper floor CLAYCRETE allows you to keep more product and lose less. Claycrete is environmentally safe and will not contaminate the food product.

· STRUCTURAL FLOORS – CLAYCRETE will stabilize the ground that your founda�ons will o on. This leads to less issues around the founda�on s e�lingeducing foundada�onacking.

· AIR STRIPS & HELIPADS – CLAYCRETE drama� ally reduce dust and leave a smooth surface eradica�ng “Bown Outs”

· FLOCCULANT FOR TAILING PONDS – When CLAYCRETE bonds with free clay par�cles th y take on hydrophobic proper�es. These n w water repellent prroper�es helpo rapidly separate any water from the treated materials.

· DAMS, DIKES & LEVEES – Small leaks lead to big leaks and big leaks lead to failure. Stop leaks in the first place and keep water at bay with CLAYCRETE.

GeoGroup Cover www.geogroup.co.za

EDITOR

Goodwill Sibanda editor@africamininginsight.co.za

WRITER Kennedy Chamu writer@africamininginsight.co.za

SALES

Leon Jaure leon@africamininginsight.co.za

Cleopas Moyo cleopas@africamininginsight.co.za

Emmanuel Chipeta emmanuel@africamininginsight.co.za

Godrick Jere godrick@africamininginsight.co.za

Roslyne Mangena roslyne@africamininginsight.co.za

Design and Layout

Qhawe Maphosa design@africamininginsight.co.za

Subscrip�on

Thatho Ndlovu subscrip�on@ fricamininginsight.co.za

General info@africamininginsight.co.za sales@africamininginsight.co.za

Call: +27 11 0257 031

+27 67 7677 393 www.africamininginsight.co.za

There is absolutely no doubt that the growing applica�on of digital solu�ons is the right answer to many of the challenges facing the mining industry.

Advanced digital technologies, whether ar�ficial intelligence (AI), machine learning or robo�cs, can poten�ally disrupt conven�onal mining opera�ons in a posi�ve manner.

Mining is crucial to retrieving the ores and minerals that keep important industries running smoothly, but retrieving those products isn't always simple or straigh�orward. Mining innova�ons do more than increase efficiency; they also protect workers and ensure consistent yield that supports further mining explora�ons.

In a vola�le market, you need to ensure your mining opera�ons perform as efficiently as possible to be successful, you need a strategy that spans your global por�olio across the asset lifecycle. This means managing your assets in a safe and secure way, maximising produc�on and increasing profitability

Digital technology can help you unite, analyse, and manage your engineering data, processes, and supply chain in an intelligent and efficient way. It can also help you operate with the highest levels of corporate social responsibility

As important as on-site technologies are, entering mining efforts with a plan in hand minimizes issues and maximizes targe�ng for rich ore and lucra�ve veins. 3-D mapping helps the en�rety of the mining team - from administrators to miners - get on the same page instantly. By highligh�ng the most promising areas for excava�on before the machinery is ever powered up, resources are intelligently used to zero in on the best mining areas in the least amount of �me.

In this issue Radia�on Risk, Safety and Security in Wireline Logging, HVI cable fault loca�ng, Geogroup: sonic drilling service provider, Benefits of Clamp-on flow metering in Mining and Metallurgical Opera�ons, Drone magnetometry and geophysical methods for mining explora�on and much more.

Africa Mining Insight is an informa�ve source for C-suite, heads and managers of mine opera�ons, METS and support services from top enterprises around the globe to define the current and future mining landscape, including discovering the latest innova�ons and technologies that are spearheading mine produc�vity, efficiency and safety

Best regards

Goodwill Sibanda

Disclaimer: All material is strictly copyright. The magazine or any part thereof may not be reproduced or adapted without writen permission from the publisher: - Africa Mining Insight welcomes material submi�ed for publica�on but retains the right to edit copy. The views expressed in the publica�on are not considered those of the publisher, which accepts no liability of any nature arising out of or in connec�on with the contents of this magazine. While every effort has been taken in compiling this publica�on, the publisher does not give warranty as to the completeness or accuracy of its content. The publisher and the editor cannot accept responsibility for any loss inconvenience & damage that may occur there from.

www.africamininginsight.co.za

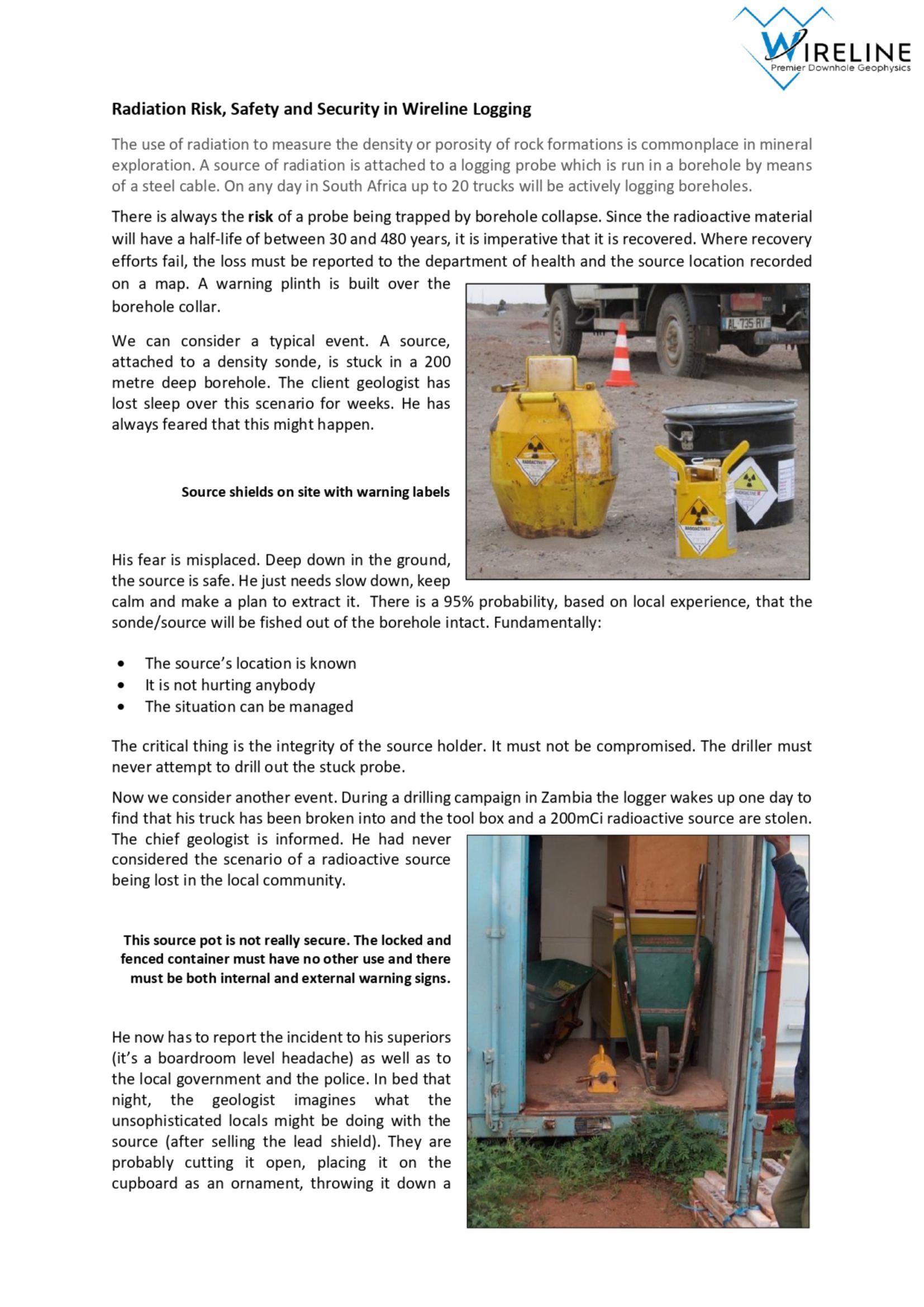

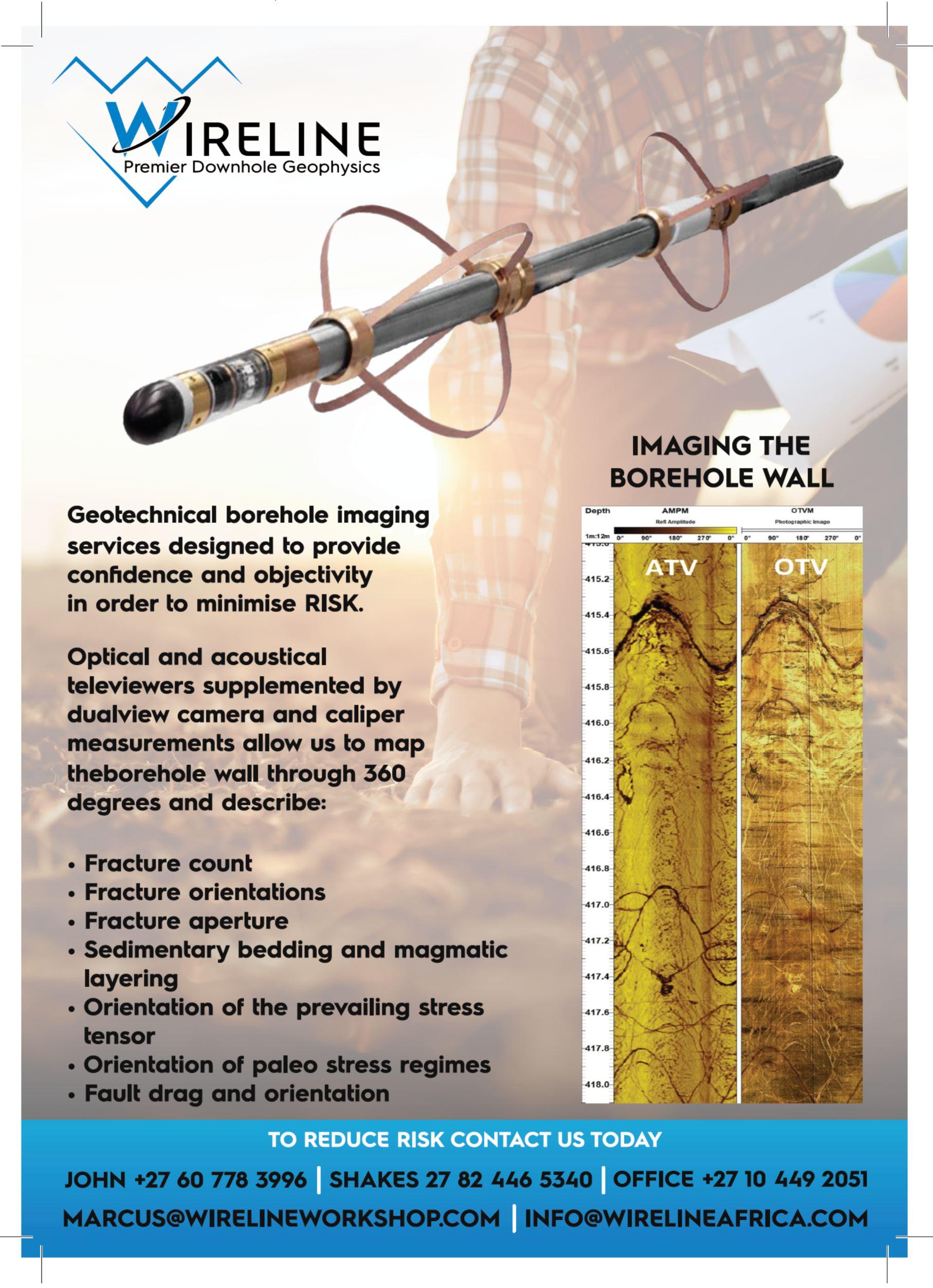

WIRELINE LOGGING

CABLE FAULT LOCATING ÇLEAN-IN-PLACE ELECTROWINNING

GEOSYNTHETICS IN MINING WORKS

DISTRIBUTOR FOR MINING PARTS

WATER-BASED LUBRICANTS

SONIC DRILLING SERVICE PROVIDER

BENEFITS OF CLAMP-ON FLOW METERING I

TAILINGS RECOVERY SYSTEM

NILFISK/WAP PRESSURE WASHERS

METHODS FOR MINING EXPLORATION

MINES AND MONEY CONNECT

MINING ENGINEERING

PAGE 06

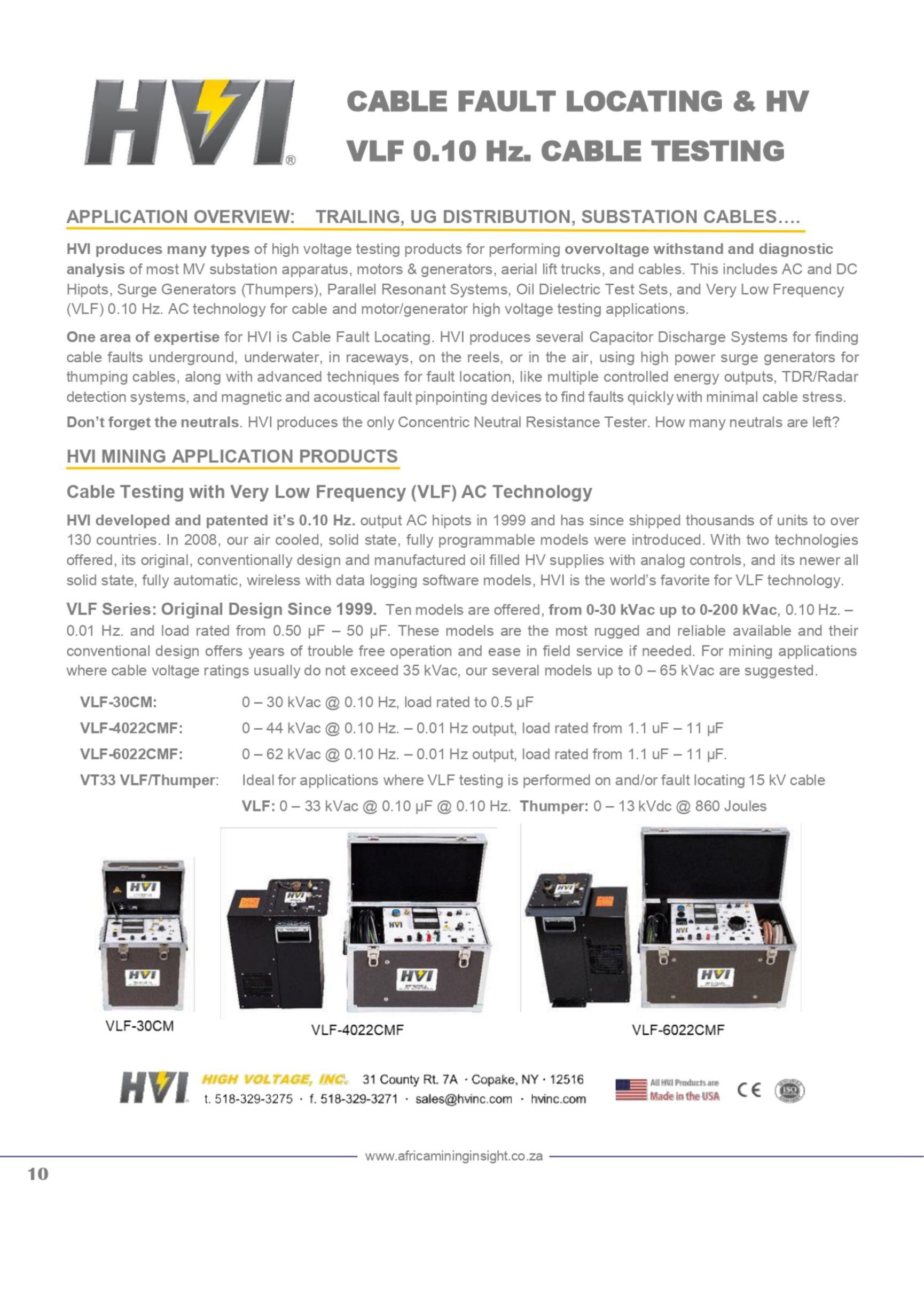

PAGE 10

PAGE 14

PAGE 16

PAGE 19

PAGE 22

PAGE 24

PAGE 26

PAGE 28

PAGE 30

PAGE 34

PAGE 36

PAGE 40

www.africamininginsight.co.za

www.trentyre.co.zw

Çlean-in-Place Electrowinning. It's a concept that when you see it in ac�on seems obvious. But for years the process used in ADR plant goldrooms in gold mines around the world, has involved the removal of individual cathodes from the electrowinning cell by means of overhead gantry to a dedicated wash-bay for recovery of gold sludges.

“It's �me consuming, ergonomically demanding on operators and fraught with the poten�al for gold sludges loses to the goldroom floor” says Sean Galvin, Engineering Manager at Cadia Systems – a Perth based mining equipment manufacturer.

Mr. Galvin was, for over a decade, formerly manager and designer at the Equipment Division of Como Engineers – another Perth based Engineering Consultancy and Equipment manufacturer. Having been responsible for design and commissioning of goldroom equipment and modular elu�on systems worldwide, he first hand experienced the short comings of cell cleaning - even on the electrowinning cell designs he had been responsible for

Issues common in goldroom cell cleaning ac�vi�es include dealing with heavy lids requiring either counter balances for winches to li� open, slow movement of overhead gantry cranes when reloca�ng cathodes or anodes, heavy cathodes which were o�en man handled in and out during cleaning processes, and problema�c connec�ons of

cathodes and anodes to the main busbars.

“I remember commissioning a system for Metso in Finland in 2011 on Christmas day” he states, “they were 800 sized cathodes with 40 cathodes over two split cell designs.”

“A�er moving the first few to the wash-bay using the overhead monorail I just gave up”

Mr Galvin instead proceeded manually hauling the cathodes out of the cell one by one and laying them on top of the remaining anodes and cathodes in the cell. “That was my version of clean-on-top of cell”, he laughs. Cadia Systems specialises in the development of innova�ve technologies for the gold processing industry. The business has a strong focus on cleanroom style technologies that bring safety improvements for operators. The equipment also has a clear design focus on improving recoveries and op�mising performance.

Their proprietary protected EC Clean-in-Place Electrowinning Cell was developed a year a�er Mr Galvin started Cadia Systems.

U�lising a novel automated li�ing mechanism, the cell li�s the anodes and cathodes away from the main connec�ng busbar connec�ons, allowing the anodes and cathodes to be slid one by one across the cell to provide access to the cathode face for insitu, in-cell washing.

An addi�onal clever addi�on to the cell designs include a near neutral-pivot, low

weight/high rigidity cell lid. The lid simply slides back with a minimal operator pressure to the front of the lid. For larger cells, which can be as large as 1200mm cathodes in size, the lids are also available with automated opening and closing.

The cells also have front mounted busbars that are located out of the vapour zone to minimise corrosion from ammonia fumes. The busbar contains stud connec�ons which provide �ght inter-busbar connec�on �ghtness to avoid hot-spot connec�ons. So no more losing those pesky nuts. A guard protects the busbars when in opera�on, but also forms part of an inbuilt keyed locking mechanism for security of the precious metals while in opera�on. Anodes are manufactured to provide longer design life�me, and cathodes can accommodate either mild steel or stainless mesh or more common pre-made pillows.

“The product has really been a great success with clients!” says Mr Galvin, “Goldroom operators love them and site management love the enhanced safety and recovery aspects”.

Cadia Systems has also entered a collabora�ve arrangement with Gekko Systems for the design and supply of modular elu�on systems using Cadia's equipment and design experience and Gekko's world-class engineering, manufacturing and support services.

The use of geosynthe�cs in mining opera�ons grows annually as mining companies focus on the technical and economic advantages of geosynthe�cs. In this regard, Naue can

· support the economic extrac�on of valuable resources in heap leaching,

· offer engineering solu�ons for mine waste and water management in tailings facili�es,

· provide sealing, drainage, filtra�on or separa�on materials for all kinds of ponds or mine remedia�on of old mining opera�ons,

· deliver reinforcement and stabilisa�on products and systems for embankments, haul and access roads or steep slopes and walls.

This means that our polymeric materials enable more efficient barriers, stronger access roads, space-saving and safety-enhancing retaining structures and much more. But mining projects are o�en sensi�ve to the environment and are located in remote areas. Therefore, our geosynthe�cs can not only offer cost and �me savings but also reduce the environmental impact (carbon footprint, energy consump�on) on most projects involving geotechnical work compared to conven�onal methods.

® Our HDPE geomembranes Naue Carbofol are extremely durable with a great cost-benefit ra�o. And in parallel, they are an important line of defence to protect the environment. The applica�on of our reinforcement and stabilisa�on ® ® products Naue Secugrid and Naue Combigrid results in a reduced need for quality engineered fill material for sub-base reinforcement. Our ® geosynthe�c clay liner Naue Bentofix or ® mul�component GCL Bentofix X can replace clay In both cases, the transport costs to the site will be

reduced, and the speed of construc�on will be increased. To sum up, the costs of construc�on materials such as aggregates or concrete, construc�on �me and environmental impact will be reduced significantly

You can use our geosynthe�cs individually or combined as an intelligent system solu�on. They are built to last for long-term usage when properly designed and installed. Naue can provide

· engineering, specifica�on and design support,

· so�ware tools (for base courses, slopes and walls or working pla�orms),

· tes�ng (e.g., shear box tes�ng, leachate tes�ng),

· training and supervision,

· installa�on.

Design and specifica�on of the solu�on should be carried out as early as possible within the scheme's development and guided by appropriate ground inves�ga�on.

For example, heap leaching. Without ques�on, heap leach has become an enormous driver of the growth of mining opera�ons wordwide. 25 years ago, only about 3% of copper and gold supplies were produced through heap leaching. Today, the volume surpasses 30% annually. Valuable chalcopyrite copper, previously not considered economical in heap leach development, is now heap leached, as is nickel laterite, uranium, and even rare earths. Heap leach stacks can be up to 200m, as opera�ons look to prove site yield more quickly. Heap leaching accomplishes this – but only with the containment support of geosynthe�cs.

Geomembranes and geosynthe�c clay liners (GCLs) are used in lining system solu�ons as heap leach pad liners, pregnant solu�on trench liners,

processing pits, onsite water storage, “raincoat” covers over ore stacks to shed stormwater – rather than dilute the leach heap solu�on – and onsite wastewater management. Geomembranes are not all that mining sites require. Nonwoven geotex�les provide long-term, robust protec�on of and fric�onal stability for geomembranes on difficult terrain and in tall ore stack scenarios.

The second example is TSF. When an ore's valuable deposit is extracted, what remains of the ore is waste. O�en, it is a high percentage of the ore handled at the mine. Poten�ally contaminated from the extrac�on process or containing environmentally harmful components, tailings must be isolated to prevent long-term environmental damage. As mine sites increase in size, the engineering needed to properly contain the volume of tailings has intensified. This scaling up of containment frequently requires not just lining systems but reinforcement and sealing systems for perimeter berms on tailings pond. Weaker, earthen-only berms are at risk of satura�on, erosion and failure.

Furthermore, the increasing depth of tailings storage ponds requires a stronger containment engineering design. With the environmental security of the site relying on these environmental protec�on systems, the geosynthe�cs selected must be trusted. Here, geosynthe�c solu�ons ® include our HDPE geomembrane Carbofol , our GCLs Bentofix and Bentofix X, our nonwoven ® geotex�le Secutex and our reinforcing geogrids ® ® Secugrid and Combigrid

Naue has more than 50 years of experience in geosynthe�cs development, produc�on and installa�on. We can be your single point of contact to find a proper solu�on for your geotechnical challenges in your mining projects.

Carima is a leading company on the European market in the produc�on and formula�on of water-based lubricants, for the installa�on of op�cal fibers and electrical cables.

Carima is a chemical company located in Gessate, near Milan (Italy), which has always tried to sa�sfy its customers with innova�ve products and short delivery �mes, in a con�nuous process of quality assessment and improvement.

We support our customers by producing various types of lubricants that meet the working methods of each installer. For example, if a technician has always worked with a gel lubricant, Carima will make sure to provide him with the most correct gel for his needs. We don't want to change the habits of technical installers, on the contrary we want to help them in their daily ac�vi�es. We can offer an op�mal solu�on for every request. All our products are Made in Italy and, through a qualified industrial process, they are a guarantee of op�mal performances in all sectors: industrial, civil and construc�on. S�ll with regard to our awareness of the environment that surrounds us, we take all the energy we need from the sun; numerous photovoltaic panels have been installed on our roofs in order to give energy to our daily work.

We also care a lot about the environment: that's why all our products are water-based and do not contain petroleum deriva�ves. Furthermore, all the electricity that CARIMA needs comes from the sun. For transparency,

the produc�on data of our photovoltaic system is updated in real �me every 15 minutes on our website at the link h�p://fv.carima.biz.

Carima produces and sells different products: Slips and lubricants

Specific slips and lubricants for laying electric cables and op�cal fibers such as GLISS® F, GLISS® GEL, GLISS® W, or S LUB 20, S LUB 100XL, etc. They allow to reduce the fric�on generated during installa�on opera�ons of cables and fibers in pipelines

Mono and bi-component products for electrical insula�on, such as SOFT SIL GEL 32, SOFT GUM, etc.

Solvents and detergents for removing plugging grease (jelly) from cables and for cleaning the fibers before splicing, such as FO Cleaner, Biosol 19

Technical spray products and water-based marking paints for usual work opera�ons, such as IDRO SPRAY, etc.

Various accessories for a be�er and simpler use and applica�on of our products, such as Duct Cleaner, ICE Mel�ng, Mass effect etc…

Chemical products developed, produced and sold by us for special needs, Green Glass, solar and photovoltaic panel cleaner, silicone and PAG-based greases, etc.

Why so many products?

Why do you need so many different types of slips and lubricants to solve a seemingly simple problem?

The answer is simple and precise Carima is able to offer the best solu�ons for every need. To do this, it supports the customer by producing various types of products to sa�sfy the "modus operandi" of each installer

So if a technician has always worked with a gel product, Carima will certainly have the right gel product in its wide range for him. Carima does not want to change the installa�on technician's work habits, but to help him in his daily ac�vi�es.

The produc�on lines are able to package the various products from the 100ml tube, up to the 1000kg IBC, passing through 500ml and 1lt bo�les, 5, 10, 20 and 25 liter tanks and buckets also including 50 liter drums, 100 and 200lt.

Special packaging requested by customers is possible.

Carima

Over the years, sonic drilling has con�nued to evolve, with improvements in vibra�on frequency, power output, and drill bit design. Today, sonic drilling is a widely used technique for a range of drilling applica�ons, from mineral explora�on and geotechnical surveys to environmental monitoring and geothermal energy produc�on Its advantages over conven�onal drilling methods include faster drilling rates, reduced waste material, and be�ercorerecoveryrates.

Sonic drilling is par�cularly effec�ve in so�er materials such as clay and sand, which can be difficult to drill using tradi�onal rotary core drilling methods. The sonic drill head allows the soil sample to enter the single tube core barrel by liquefying the ground on the sidewall ofthesampleenteringthecorebarrel,without disturbing the sample, thus providing very good core recoveries in the so�er more friable ground in which is tradi�onally more difficult to provide good core samples Sample

recoveries using sonic technology are usually over95%.

To date, the GeoGroup is a preferred supplier of sonic drilling services to the African con�nent.Outofthe3Sonicrigsintheirfleet,2 of these rigs are equipped with dual head masts able to switch between sonic and rotary core drilling. This eliminates the need to have mul�ple rigs on site as the mast head can quickly transi�on between Sonic and Rotary core.

The GeoGroup recently introduced the Secon Compact Sonic Crawler 190kN to their por�olio which can be operated remotely by two drill operators with wireless controllers. Using a wireless control system to operate a drill has several advantages over tradi�onal wired controls. Here are some reasons why wirelesscontrolmaybepreferred:

1

Mobility and flexibility:With a wireless control system, the operator can move around the drilling site more freely, without being tetheredtoacontrolpanelorconsole.Thiscan be par�cularly useful in drilling projects where the operator needs to move around the rig to access different drilling loca�ons or perform othertasks.

2

Increased safety: By elimina�ng the need for cables and wires, wireless control systems can reduce the risk of accidents and injuries caused by tripping over cablesorge�ngtangledinwires.Thiscan be especially important in drilling projectswheresafetyisatoppriority.

3 .

Improved efficiency: With a wireless control system, the operator can control

Geogroup: sonic drilling service provider

the drill from a distance, which can be more efficient and faster than manually adjus�ng controls at the drill site. Addi�onally, some wireless control systems offer advanced features such as automa�on and remote monitoring, which can further improve efficiency and produc�vity

Overall, sonic drilling is a versa�le drilling methodthatcanbeusedinawiderangeofsoil and rock forma�ons. Its efficiency makes it a popularchoiceformanydrillingprojects.

The Geogroup has 10 years of extensive experience in sonic drilling for various esteemed clients in the mining and geotechnical industries since our first sonic waspurchasedin2013.

For more informa�on about GeoGroup, visit www geogroup.co.za.

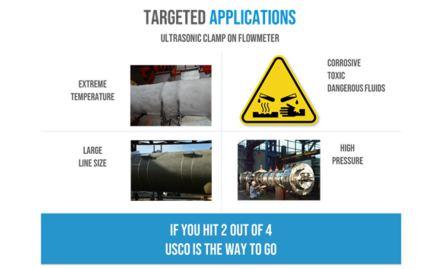

Clamp-on flow measurement using the ultrasonic transit �me technique has matured and is now a preferable technology for control and monitoring in many metallurgical and mining applica�ons. In general, if any two of the following are present then Ultrasonic Clamp On (USCO) should be considered or even preferred.

We at Flexim, as the leader in this field has seen an increase in requests par�cularly in the following areas:

Water monitoring and stewardship

Mines and minerals use water in various ways, from high pressure hydro power lines

in underground mines to drive drilling equipment, to a solvent in hydrometallurgical opera�ons to dust suppression, the common denominator is a requirement to responsibly and efficiently use and account for the water to do the least harm to the environment and nearby communi�es. Flexim's rugged portable meters are ideal for audits and repor�ng while the fixed meters are in many cases be�er suited than the tradi�onal mag meter

SO Abatement 2

Sulphuric acid produc�on as a method to reduce SO emissions is increasingly 2

becoming a preferred route to reduce this pollutant. The benefits are no addi�onal waste streams, a saleable product and, depending on the technology, low addi�onal water and other input requirements. A unique feature of metallurgical SO fed 2 Sulphuric acid plants is the fluctua�on of the feed SO concentra�ons and the resul�ng 2 affect it has on the stable opera�on of the plant. Flexim meters are an ideal solu�on as they can be retrofi�ed with no shutdown (no fines or risk to equipment during start up) give both flow and concentra�on measurement and work on both metal and GRP pipes. “We have recently installed meters on plants in Zambia, the DRC, South

Africa and Namibia”, says Mark Middelhoven the Africa Sales Manager, and all our customers have seen improvement in their plant performance.

SX circuits both water and hydrocarbon mediums and USCO is a good measurement technique as it can measure both phases. Typically these are installed on the organic side, recently Flexim has been involved in a project to provide metering on SX cells as part of an automa�on project. Previously this had been done by manually adjus�ng the valves, but as the trend to more automa�on

and reduced personnel con�nues the need to automa�on and the benefits of be�er control and efficiency the scope and usefulness of USCO is a key enabler

As the world moves towards a Net Zero future mining is key both in reducing its carbon emissions but also providing the raw materials for ba�eries, electrical infrastructure and catalysts for hydrogen produc�on. It is not surprise then the mines are inves�ng in improving their energy efficiency. Flexim again can help whether it is measuring steam in the processing plants or

compressed air, addi�onal metering points can be safely added hassle free.

One aspect holding back the adop�on of Clamp-on is previous bad experience, either through cheap portables or incorrect specifica�on. Since the meters are able to be installed outside the pipe, with no interrup�on, it is easy to de-risk the decision through a trial or demonstra�on. At Flexim we are happy to stand behind our product and a try before you buy approach is usually enough to convince scep�cal stakeholders. The technology has matured and should be the first choice of technology in many instances.

The Tailings Recovery System (TRS) is a technology developed specifically for recovering tailings from mine tailings pond deposits, to facilitate tailings pond reclaim opera�ons and management of tailings storage facili�es within an opera�ng mine site. TRS can also be u�lized for the remedia�on of legacy tailings ponds, and reprocessing mine tailings to extract valuable minerals.

TRS has been developed by Technika Engineering Ltd., a company based in Calgary, AB, Canada.

TRS effec�vely addresses the opera�ng limita�ons of the technologies tradi�onally u�lized for mine tailings reclaim opera�ons, including CSD dredges and submersible pumps. The limita�ons of these technologies include inconsistent tailings supply density and the need for frequent reloca�on on the pond. Dredging causes high turbidity of the pond surface water, which is o�en reclaimed

for the process requirements. Dredges and pumps are suscep�ble to plugging by various debris that is commonly found in tailings deposits.

Dredging is a crewed opera�on requiring people to be deployed on the pond, and may also be affected by seasonal weather condi�ons.

TRS technology is an unmanned, remotely controlled opera�on. Its control can be effec�vely integrated into the overall control system of the tailings treatment facili�es, which enables the supply of tailings at a density and flow rate that is op�mum for the performance of the tailings treatment processes.

TRS can operate from a single loca�on for an extended period of �me without a need to relocate.

TRS opera�on is based on a balance of parameters that include its geometry, tailings rheology and recovery rate. The opera�on of the technology is based on the principles of the hydraulic pressure balance within the tailings pond deposits and the TRS caisson structure. The opera�ng interface between TRS and tailings deposits effec�vely mobilizes the tailings within the pond deposits crea�ng the tailings draw zone. The mobilized tailings are brought to the surface within the TRS caisson envelope.

The tailings of the required density are

accessible from the surface for collec�ng and transport to the shore-based facili�es.

The TRS caisson typically comprises two telescoping shells that allow easy adjustment of the pumping depth. The telescoping shells can be elevated to facilitate the system's launching, deployment, and reloca�on.

The TRS assembly is of a modular design. The modules, which are designed to fit shipping envelopes, facilitate transporta�on and minimize �me to assemble the system onsite. This also enables easy reloca�ons between different tailings ponds or the mine sites.

An ini�al set of TRS units was developed by the Technika Engineering team and successfully deployed in large-scale tailings recovery opera�ons in the Canadian oil sands industry

The Company is now looking for opportuni�es to expand into other mining areas where the TRS technology can provide a valuable contribu�on to mine tailings reclaim and tailings management opera�ons.

The TRS technology is patented and proprietary to Technika Engineering Ltd. For addi�onal informa�on, please visit h�ps://wwwtechnikaeng.com/technology/tailings-recoverysystem-trs.html

contact@technika-eng.com

At Nilfisk, we have a clear mission that drives our dedica�on in what we do: we enable sustainable cleaning worldwide to improve quality of life. For more than a 100 years, we have been commi�ed to making the world a cleaner place. Nilfisk South Africa markets a wide range of pressure washers for a number of applica�ons.

Pressure washers are the most effec�ve way to clean outdoors and are extremely easy to use: connect the device to the water supply and power outlet, turn on the tap, switch on the pressure washer and let the cleaning begin! With added accessories, the devices are transformed into real all-rounders, the applica�on possibili�es are virtually unlimited. Typical areas of usage for the machines include cleaning applica�ons in the agricultural, construc�on, earth moving field, mining and heavy engineering industries. Nilfisk boast the most comprehensive range of pressure washers, namely the MC range, the MH range and the WAP range. The local range consists of the Novastar, Powerstar, Jetstar, Topstar, Centra, Electra and HPU which are medium and heavy duty pressure washers. Outside of this range we also manufacture purpose built units specific to applica�on. Although many applica�ons

require portable units, we also produce sta�onary units for wash bay and other similar applica�ons.

The WAP range both mobile and sta�onary have their components mounted on a sturdy steel base frame, protected by a steel impact protec�on cage. The high pressure pump is directly coupled to a standard speed electric motor. The machines have a sturdy steel chassis with roll cage for maximum component protec�on, as well as easy loading and off-loading. Opera�on of all the machines is controlled from a “trigger” type safety spray lance.

The Nilfisk MH series takes mid-range hot water high pressure washers to a new level. As the powerful engines provide pump pressures of up to 220 Bar, and the improved EcoPower boiler system offers high efficiency whilst saving both the environment and fuel costs - leaving our customers with an improved total cost of ownership. These high pressure washers are developed for our customers within agriculture, automo�ve, light industry, trade and building and construc�on. These businesses, with many daily cleaning tasks, will benefit from the highly improved and best-in-class mobile design enabling them to transport and move

the machines around their facili�es and giving them the mobility to work anywhere. From light industrial cleaning tasks to slightly heavier cleaning applica�ons in rough environments, ba�ling anything from mud, animal manure to road dirt, oils and greases. The Nilfisk MC range of compact cold water high pressure washers offers customers the benefits of reduced running costs, greater cleaning efficiency and easier overall handling for general everyday cleaning tasks. They offer superior cleaning results, saved �me and lower costs.

With the MC range, Nilfisk is introducing three major improvements to the high pressure cold water range: Detergents are now supplied more effec�vely through a new separate foam sprayer system. At the same �me, a new patented spray gun holder adds convenience together with a new turnable cable hook. They are the ideal choice for small building companies, light agriculture such as small crop and milk farms. The choice of “the correct” pressure washer unit is always determined by the applica�on, availability of power and water, as well as frequency of cleaning required.

Wendy.mcdermo�@nilfisk.com

When we talk about magnetometry with drones, we must consider the challenges presented by the applica�on of this geophysical method. When moun�ng a magnetometer on a drone, either total range or fluxgate, we find electrical components, magne�c materials, even the movement of the drone motors, which generate magne�c ac�vity that can easily cause altera�ons in the acquisi�on of data, preven�ng accurate and useful results for the regional characteriza�on of mineral resources.

The search for minerals with high magne�te content such as iron or nickel, are the ideal scenario for this type of applica�ons, however, the search for high value nonmagne�c minerals such as gold and silver, find great benefits through the applica�on of geophysical methods such as magnetometry with drones.

Therefore, our applica�on for the mining sector focuses on the regional characteriza�on of magne�c ac�vity, this means that we generate maps of magne�c ac�vity of large extensions, adap�ng to the topography of the terrain and allowing its correct measurement despite topographic changes, at mid-en high al�tudes flights, and obtaining more accurate readings for its interpreta�on; a ma�er in which most of the magnetometers that currently exist in the market are more limited. In this way we generate informa�on that allows us to make a punctual explora�on planning, in a short period of �me and with completely accessible costs.

Currently, we can inspect up to 600 hectares per day with a single opera�on team and its processing and interpreta�on, in addi�on, with our data cleaning so�ware we can deliver results in a ma�er of days. To date, AV3 AEROVISUAL has taken this solu�on to different parts of Mexico and La�n America, having generated maps of magne�c ac�vity over surfaces of thousands of hectares in

· Dronesandcustomizedfluxgatemagnetometersforaerialdataacquisi�on.

· Aerialinspec�onwithdronesforlargeextensionsoflandanddifficultaccessareas.

· Reliableresults,inless�meandatahighlycompe��vecost.

extension.

Magnetometry survey with drones is a disrup�ve solu�on with great economic benefits for the mining sector since, once the area of interest has been determined, it is possible to densify the data grids to collect magnetometric informa�on with more

www.africamininginsight.co.za

defini�on to further delimit the explora�on area or even, to apply other complementary geophysical methods such as AMT (audio magneto-telluric) soundings and gravimetry, to obtain greater certainty of the viable zones for explora�on and extrac�on of resources, besides giving the possibility of genera�ng

robust and reliable models for the planning and defini�on of zones of interest.

To solve the challenges posed by the applica�on of this geophysical method, since 2014 in AV3 AEROVISUAL the design and manufacture of the equipment we use today was carried out through the Na�onal Autonomous University of Mexico and the "Laboratory for Electromagne�c Innova�ons" of Ukraine, specialized in the manufacture of magnetometers and electronics for satellites. Currently, we have developed two versions of fluxgate magnetometers with the capacity to perform independent measurements in the 3 components (X, Y and Z) in addi�on to measuring their geoposi�oning, date, �me, inclina�on and other essen�al measurements for a correct interpreta�on of data. Likewise, these equipment have a design that eliminates the magne�c interference that the drone generates on them. To ensure the inclina�on and posi�on of the magnetometer during the flight, a non-magne�c stabilizer was designed and implemented that allows us to move the magnetometer up to 3 meters away from the drone; this stabilizer allows us to keep the sensor ver�cal with respect to the ground, in this way the wind trac�on and drag by the movement of the drone during the flight, does not generate loss or need to remove data not useful for interpreta�on, resul�ng in reliable informa�on of great value for decision making.

Europe's premier mining investment event, connec�ng miners with money and investors with opportunity

Long Event Descrip�on:

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest. See who is exhibi�ng here

The 70+ speakers will talk in various formats from in�mate fireside chats, to project spotlights, mining pitch ba�les and panel sessions. Expect to take away ac�onable insights you can deliver to your team to help deliver your business objec�ves. The key topics covered throughout the two-day program include what's next for the energy transi�on, government policy on cri�cal minerals and implica�ons for the mining field, new thinking in ECG, and sustainability and metal prices in 2023. View the program speakers here and .

Across two days, there are thousands of opportuni�es to network, brainstorm, and share knowledge, providing the perfect pla�orm to obtain invaluable new business contacts, connect with the industry's leading figureheads and explore new ideas.

Mee�ngs are at the heart of what we do. To ensure your �me is maximised onsite, there is an AI-driven mee�ng planner, allowing you to pre-schedule all of your mee�ngs, depending on your needs. Find out more here

There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at to connect@minesandmoney.com discuss your par�cipa�on or register for your pass here

For more informa�on on the event, visit the event website here or contact connect@minesandmoney.com

Quick reference links and informa�on

Dates: 25 – 26 April 2023

Loca�on: County Hall, London, SE1

Website: Minesandmoney.com/connect

Ticket Link:

h�ps://minesandmoney.com/connect/register

Email: connect@minesandmoney.com

LinkedIn: h�ps://www.linkedin.com/company/mines-andmoney/

Twi�er: h�ps://twi�er.com/minesandmoney

YouTube: h�ps://wwwyoutube.com/c/minesandmoney

Facebook: h�ps://wwwfacebook.com/minesandmoney/

Short Event Descrip�on:

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest. See who is exhibi�ng here There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at to connect@minesandmoney.com discuss your par�cipa�on or register for your pass here

Mines and Money Connect returns to London for the second year running a�er high demand, providing a space for global mining leaders to connect with ac�ve investors, solu�on providers and innovators.

From 25 - 26 April 2023, the event will bring together 700+ a�endees, including 80+ mining companies, and 400+ investors, for two days of unparalleled networking, high-class content and deal-making.

This event aims to shape the investment landscape in mining for 2023 and beyond. CEOs from junior mining corporates will join investors in face-to-face mee�ngs to share their latest projects, highligh�ng key reasons to invest.

The 70+ speakers will talk in various formats from in�mate fireside chats to project spotlights, mining pitch ba�les and panel sessions. Expect to take away ac�onable insights you can deliver to your team to help deliver your business objec�ves. The key topics covered throughout the two-day program include what's next for the energy transi�on, government policy on cri�cal minerals and implica�ons for the mining field, new thinking in ECG, and sustainability and metal prices in 2023. Across two days, there are thousands of opportuni�es to network, brainstorm, and share knowledge, providing the perfect pla�orm to obtain invaluable new business contacts, connect with the industry's leading figureheads and explore new ideas.

Mee�ngs are at the heart of what we do. To ensure your �me is maximised onsite, there is an AI-driven mee�ng planner, allowing you to pre-schedule all of your mee�ngs, depending on your needs.

There are a number of ways to get involved with Mines and Money Connect. Contact a member of the team at connect@minesandmoney.com to discuss your par�cipa�on.

www.africamininginsight.co.za

Mining engineers design safe and efficient mines for removing coal and metals. Mining engineers op�mize mines for removing resources in the most efficient manner possible. They ensure that the as much of the resource as possible is extracted.

Mining engineers o�en specialize in a par�cular mineral or metal, such as iron or coal. Some collaborate with geologists to find and evaluate new ore deposits. Others develop or improve mining equipment, or manage processing opera�ons that separate and refine minerals. Mining safety engineers implement best prac�ces, conduct mine and equipment inspec�ons, monitor air quality, and ensure compliance with all safety regula�ons to keep workers safe.

With the process of mineral extrac�on, some amount of waste and uneconomic material are generated which are the primary source of pollu�on in the vicinity of mines. Mining ac�vi�es by their nature cause a disturbance of the natural environment in and around which the minerals are located. Mining engineers must therefore be concerned not only with the produc�on and processing of mineral commodi�es, but also with the mi�ga�on of damage to the environment

both during and a�er mining as a result of the change in the mining area.

Mining engineers plan and direct the various engineering aspects of extrac�ng minerals from the earth. They prepare ini�al plans for the type, size, loca�on and construc�on of open pit or underground mines

Mining Engineer - Open Pit .

Mining Engineers working in open pits are involved with both long and short term open pit mine planning, mine design scheduling and budge�ng, strategic planning, supervision of technical and opera�ng staff, mine management. They are also involved with feasibility studies, drilling and blas�ng supervision, opera�on of mining systems, evalua�on of open pit mining equipment, mining contract development.

Mining Engineer - Underground

Underground Mining Engineers can be involved with coordina�ng mining ac�vi�es, maintenance scheduling for all equipment, short/ long term mine planning, scheduling and design. They supervise staff and are involved with feasibility studies, mining

contract development, design opera�on and maintenance of underground mining equipment.

Mining Engineer – Coal

Coal mines can be open pit or underground and tend to use different mining methods. Coal mines can be prone to gas and fire problems. Coal Mining Engineers can be involved with coordina�ng mining ac�vi�es, maintenance scheduling for all equipment, short/long term mine planning, scheduling and design. They supervise staff and are involved with feasibility studies, mining contract development, design opera�on and maintenance of mining equipment.

Mining Engineer - Consul�ng Mining

Engineers who work as consultants are o�en involved in a wide variety of projects, mining methods and different technical areas. They use computer programs to model the mining process and design and can work on both open pit and underground developments. Consul�ng mining engineers will typically be based in coastal ci�es and fly out to projects and mines as required.