INTRODUCTION

“Therapidincreaseinpopulationovertheareaof thetropicspresentsitselftotheworldasaproblem oftheutmostgravity....”

MaxwellFryandJaneDrew

As the equatorial city’s relationship to climate, density, and carbon becomes a critical concern to the health of our planet, the studio will research the mediums ofHotAir,Density,CarbonForm,andLaboursituatedinHoChiMinhCity,adense and growing city on the equator. Students working in small groups will propose planet-positive additions to the city. As the equatorial city evolves from the granular, porous, and informal to a more formal, conditioned, and carbondependentmetropolis,theideaofthecarbon-neutralorplanet-positivecityseems increasingly challenging in the face of large-scale capital, global aspirations, and importedtechnologicalsystemsthatshapethecityinitscurrenttrajectory.Adding new buildings by demolishing old areas erases the historical legacies and active informal networks of neighborhoods. It also throws tremendous carbon into the atmosphere that was invested by earlier generations. How architects imagine a future of planet-positive action, decarbonization AND increased rural-urban migration, increased densities, and aspirations to have similar conveniences at the Global North will be questions that guide the design studio research.

Rapid population growth and increased urbanization about the equator have led to tighter building aggregations, closer building proximities, and enlarged plot coverages,eachofwhichprofoundlychangesthespatialqualityoftheequatorial city. This urbanization process also requires tremendous embodied carbon as cities go higher and increased operational carbon to ventilate and manage the interiorairenvironments.Withrespondingincreasesinbuildingheight,theclimatic primacy of a broad tropical landscape to shield the building from intense sun and heat has shifted from the necessity of the manicured jungle imagined in George Orwell’s “Burmese Days” to that of the elevation and sealed enclosure in mid and large-scaled urban densities. This process is visibly and dramatically evidenced in the case study of Ho Chi Minh City. Moreover, the externalities of carbon – the extractive processes (mining, melting, polluting) that produce this developmentalandverticallandscapehavebeenrenderedoutsideofarchitectural discourse.Andatthesametime,thelaborthatisembeddedintheurbanlandscape from the architect to the craftsperson is increasingly discounted as a valuable investment. It is within this dramatic context that the studio will be situated.

In Ho Chi Minh City, the collision of mounting densities, architecture, air, and carbon not only impact quantitative changes of increased solar insolation, urban wideheatgain,rainwaterrun-off,extremesofhumidity,anddecreasedventilation but implicate degraded material streams, excessive carbon consumptions and territorial scale effects that degrade the larger ecosystem in which the city is situated.

The design research will propose adaptive reuse of examples of robust and compelling mid-twentieth-century tropical buildings (from 1930-1980) selected by the student teams. The students will study the precedents through carbon, atmospheric, and material ecosystems and understand how these buildings are situated in the context of HCMC and the more prominent ecologies from which they are formed. Students will then propose adaptively reuse of the buildings, expanding their area and volume while making informed material choices consideringLifeCycleAnalysis,operationalandembodiedcarbonwithaminimum demandthattheproposalsarecarbonneutral.Theresearchoutcomeswillexpand students’ capability beyond the optic and iconic to the climatic and atmospheric in consideration of carbon and lifecycle concerns to make planet positive action on our planet.

Ho

Leave Carbon Symposium to Changi

Arrival at Tan Son Nhat International Airport + SIM card purchase

Dinner at 4Ps Pizza

Breakfast at Little Hanoi

Visit Saigon Central Post Office

Lunch at Pho 2000

Visit Case Study Buildings

Collection of Visa from Vietnam Embassy

Arrival at Tan Son Nhat International Airport

Architectural firm visit at Kientruc O w Dam Vu+Mel Shneck Dinner and sharing with Mel Shneck

Visit Case Study Buildings

Architectural firm visit at Aaaaaa w Triet Le

Lunch and Sharing w Triet Le Sharing with Archie at Red Door Cafe

Visit Case Study Buildings Free and Easy

Dinner w Erik at 4Ps Pizza (Restaurant of Shade, Nishizawa)

Fly back to Singapore

Visit Case Study Buidlings Free and Easy

ANALYZINGSOUTHERNVIETNAMESE MODERNISTARCHITECTURE

THE CARBON METRIC

EMBODIED CARBON OF BUILDING MATERIALS GEO SPECIFIC TO VIETNAM (KgCO2eq/Kg)

VICTORYHOTEL

14 Võ Văn Tần, Phường 6, Quận 3 Thành phố Hồ Chí Minh, Vietnam Architect:Unknown Year:1960

Ashraff,LiuHeng

V.A.RBUILDING

9 Ho Tung Mau Street in Nguyen Thai Binh Ward, Disrtict 1, Ho Chi Minh, Vietnam

Le Van Lam

SAIGONUNIVERSITY

105 Ba Huyen Thanh Quan Street

District 3, Ho Chi Minh City, Vietnam

Architect:Unknown Year:1970s

PeiShan,XinYao

HOALUHOTEL

59 Nguyen Trai, Phung Pham Ngu Lao, Quan 1, Ho Chi Minh, Vietnam

1960

Chelsea,YongSoon

BACHIEUMARKET

Phường 1, Bình Thạnh, Thành phố Hồ Chí Minh Hö Chi Minh, Vietnam

Architect:Unknown Year:1942

Hazirah,Shawn

132TRANTUANKHAISTREET

Ashley,Hugo

ALTERNATIVELOW/ZEROCARBON MATERIALSRESEARCH

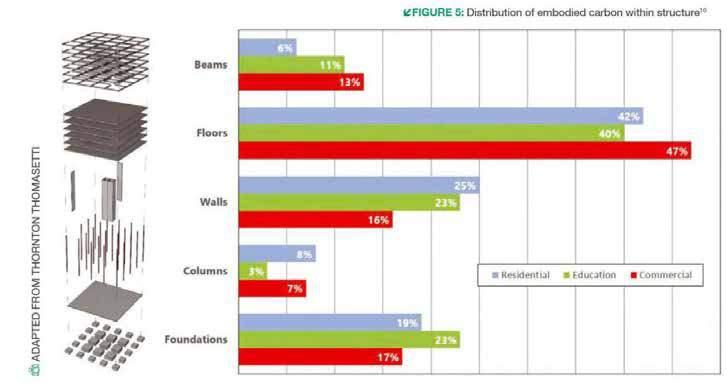

DISTRIBUTIONOFEMBODIEDCARBON WITHINSTRUCTURE

STRUCTURAL ENGINEERED BAMBOO

Structural | Engineered Bamboo

- Strongest MET on the market structurally

- 40% denser silica fiber, extremely fire resistant

- More stable in moisture and temperature changes on a cellular level

- Applications: Structural column and beam, roofs and facades, curtain walls, floor-to-ceiling frames

- Almost all engineered bamboo products are carbon negative

- 0.707KG of sequestered CO2 per 1KG of flattened bamboo in buildings

- One cubic metre of bamboo can reduce 249.92 CO2e from the atmosphere

- Bamboo already used in traditional Vietnamese architecture, growth is widespread locally

STRUCTURAL CORK BLOCKS

Structural | Cork blocks

- Expanded cork is a pure bio-material made with waste from cork forestry as it is too resinous to be used for wine corks

- By heating the granules they expand to fill a mould, and their natural resin is released, binding the granules into a solid block form.

- Negative embodied carbon, as high Co2 sequestration makes carbon footprint of material negative

- Trees are not cut down to produce it (only the bark is removed, which grows back every nine years).

- Suitable in hot and humid climates, resistant to mold

- Cork granules themselves are waterproof, when compressed to an extremely dense block, it is almost completely watertight

- Effective thermal insulation

STRUCTURAL MASS ENGINEERED TIMBER

Structural: Cross Laminated Timber Use

1. Cross Laminated Timber (CLT)– Layers of wood are alternating each layer at 90-degrees, its strength goes in two directions.It is predominantly used for walls, floors and roofs.

2. Glued Laminated Timber (Glulam)– Produced in a similar fashion but with the grain aligned in the same direction. This means all its strength goes in one direction, making it ideal for support structures such as trusses, columns and beams.

Structural: Cross Laminated Timber

Embodied Carbon Data

Embodied Carbon by Volume (CLT)= -608kgCO2e/m3*

Embodied Carbon by Volume (Glulam)= -570kgCO2e/m3*

Okuda, Shinya & Corpataux, Laurent & Muthukrishnan, Shravan & Kua, Harn. (2018). CROSS-LAMINATED TIMBER WITH RENEWABLE, FAST-GROWING TROPICAL SPECIES IN SOUTHEAST ASIA.

Okuda, Shinya & Corpataux, Laurent & Muthukrishnan, Shravan & Kua, Harn. (2018). CROSS-LAMINATED TIMBER WITH RENEWABLE, FAST-GROWING TROPICAL SPECIES IN SOUTHEAST ASIA.

STRUCTURAL BAMBOO REINFORCED CONCRETE

Structural: Bamboo Reinforced Concrete

Use

Sustainable alternative as reinforcement for structural concrete beams, given that steel is currently the main reinforcement material and large amounts of energy is required in its production.

Made of:

1. Bamboo Fibers

2. Epoxy-Resin Matrix

hot-pressed in a mold along the fiber direction has high tensile capacity, similar to that of steel

Sustainable source(?) for epoxy system

Structural: Bamboo Reinforced Concrete

Embodied Carbon Data Archila,

1.Greater amount of concrete needed to meet load carrying requirement of RC

2.Steel is still needed in the RC composite (shear reinforcements)

Density of Bamboo Culms = 540 to 780 kg/m3

Volume of Bamboo used in example = 182/780= 0.233m3

Embodied Carbon Data= 15.7kgCO2e

Embodied Carbon by Volume= 15.7/0.233 = 67.3 kgCO2e/m3

STRUCTURAL GREEN CONCRETE

LOW

CARBON ALTERNATIVE MATERIAL (STRUCTURAL) - GREEN CONCRETE

HISTORY

“Green concrete” is a revolutionary topic in the history of concrete industry. This was first invented in Denmark in the year 1998 by Dr.WG

DEFINITION

Green concrete is defined as a concrete which uses waste material as at least one of its components, or its production process does not lead to environmental destruction, or it has high performance and life cycle sustainability.

EMBODIED CARBON

The CO 2 produced for the manufacture of structural concrete (using ~14% cement) is estimated at 410 kg/m3 (~180 kg/tonne @ density of 2.3 g/cm3).

Green Concrete reduces this carbon production by up to 50%.

OTHER ENVIRONMENTAL BENEFITS

-Reduction of the concrete industry’s CO2-emission by 30 %.

-Increased concrete industry’s use of waste products by 20%.

-NO environmental pollution and sustainable development.

LOW

CARBON ALTERNATIVE MATERIAL (STRUCTURAL) - GREEN CONCRETE

CHARACTERISTIC

->20% of the concrete shall be residual products used as aggregate

-has greater strength and durability than normal concrete

-the technology can be developed, which can reduce the CO2 emission related to concrete production

-requires less maintenance and repairs

- has better workability than conventional concrete

-good thermal resistant and fire resistant

-compressive strength behaviour of ceracrete with water cement ratio is similar to conventional concrete.

COST

For large projects, the cost of this green concrete is offset by the reduced volume of cement needed, making it no more expensive than conventional concrete.

STRUCTURAL FOSSIL-FREE STEEL

LOW CARBON ALTERNATIVE MATERIAL (STRUCTURAL) - FOSSIL-FREE STEEL

HISTORY

Steel is produced from iron ore through blast furnaces for the past 1,000 years, this traditional process uses coal and coke, which become carbon dioxide.

DEFINITION

Fossil-free steel is made without creating CO2 emissions and by using fossil-free energy sources.

EMBODIED CARBON

The CO 2 produced for the manufacture of Steel 1.85 tonnes CO2 per tonne of steel produced

With the manufacturing of Fossil-free steel, 10% fewer carbon dioxide emission will be produce in Sweden

OTHER ENVIRONMENTAL BENEFITS

-These effort will see it reduce emissions by 8 million tonnes a year compared with current levels.

-The primary advantage of fossil-free steel is that it is a material that has created zero CO2 emissions from fossil-fuels

LOW CARBON ALTERNATIVE MATERIAL (STRUCTURAL) - FOSSIL-FREE STEEL

CHARACTERISTIC

-High yield strength

-High tensile strength

-Hardness, resistance to localized deformation

-Resistance to damage such as dents and abrasion

-Achieve greater spans without additional supports

-Weldability, wear resistance, corrosion resistance

COST

Fossil-free steel is a premium product with a higher price than regular fossil-based steel products. The main cost-drivers for fossil-free steel are the investments in production and infrastructure, to switch from coal to fossil-free electricity and hydrogen, from natural gas to biogas, and from iron ore pellets to HYBRIT sponge iron..

STRUCTURAL GEOPOLYMER CEMENT

Structure material

02

Process

Geopolymer cement

Portland cement

02

Structure material

Geopolymer cement

Appropriateness

High carbon footprint

ibaotu.com

Our cements make it possible to obtain a low-carbon concrete, thanks to the absence of clinker

Alkali-activated binders

These innovative processes do not involve firing, but cold chemical reactions between materials by means of activators.

Low-carbon concrete

Vietnam concrete market size is forecast to reach US$5.8 billion by 2027 after growing at a CAGR of 7.9% during 2022-2027.

STRUCTURAL BFRP REBAR

Structure material

02

Process

BFRP Rebar

Basalt Fibre volume fraction: 80%

Resin Matrix volume fraction: 20%

Sand Layer improve adhesion

Characteristics

Corrosion resistance

Rebar weight

You can ship seven times more product for the same cost and workers can assemble BFRP rebar mats easily, and then safely lift them into final position.

02

envelope material

BFRP Rebar

Characteristic and Data

Global warming potential of 6 mm BFRP bars, measured as kg CO2 eq, excluding transport, is 74% lower than that of steel, 22% lower than steel with 100% recycled content, 49% lower than galvanised steel, 88% lower than stainless steel and 44% lower than GFRP.

Reinforcement steel (rebar), generic, 0% recycled content (only virgin materials), A615 =22724.24 kg CO2e / m3

Estimated BFRP Rebar =5908.30 kg CO2e / m3

Facade | K-Briq

- 90% recycled building material (high quality, recycled sands and gravels, gypsum from waste plasterboard, and recycled pigments)

- Process: demolition/ construction waste -> compression & mixing

- Provisional calculation of embodied carbon: average 72.5 grams of CO2 per brick, or 13% of the embodied carbon of a traditional clay-fired brick (570g based on figures from the Brick Development Association)

- Exterior/ facing brick applications

- No need to fire & shorter production time

- Variety of colours

- Better insulation, keeps building cool in warm climate & bricks are traditionally used in HCMC

Facade | Rice Husk Polypropylene + (Other Rice Husk Applications)

- Rice husk (RH) is a waste product from rice cultivation; RH takes very long to decompose in manure/compost, hence it is often thrown in rivers or burned, leading to environmental consequences

- Used locally in small low-cost housing and apt in disaster relief buildings due to fast construction

- Main building products currently: Building Blocks & Roof Tiles

- Resistant to fire, provides heat/sound insulation

- Better insulation

- Water-resistant and lightweight

- Can be manufactured sustainably due to its composites of waste products

- Low CO2 emissions in manufacture process

- Can be manufactured close to site, low transport costs

ENVELOPE GLASS FIBRE REINFORCED CONCRETE (GFRC) PANEL

LOW CARBON ALTERNATIVE MATERIAL (ENVELOPE) - GFRC(GLASS FIBRE REINFORCED CONCRETE PANEL)

HISTORY

GFRC was first used and originally develop in Russia but it wasn’t until the 1970s that saw its transform to its current state.

DEFINITION

Glass Fibre Reinforced Concrete is a composite of cement, glass fibre, aggregates and polymers. It is concrete that use glass fiber for reinforcement instead of steel. With the things, hollow construction of GFRC products, they can weight a fraction of the weight of traditional precast concrete.

OTHER ENVIRONMENTAL BENEFITS

-GFRC has a much lower environmental impact by a factor of as high as 60% comparing to traditional precast concrete

-GFRC qualifies as sustainable as it used less cement than equivalent concrete

-Lightweight panel use 80% less material than precast

-Lightweight panel reduces fuel and costs of transportation

LOW CARBON ALTERNATIVE MATERIAL (ENVELOPE) - GFRC(GLASS FIBRE REINFORCED CONCRETE PANEL)

CHARACTERISTIC

-Lightweight, ease of handling,reduced siteworks and transport cost including transportation of raw materials to the factory and finished products to sites.

-High compressive strength

-Durable, expected to last as long as Precast Concrete

-Adaptable to high salt and moisture content

-Achieve greater spans without additional supports

-Easier fabrication

GFRC as a material, however, is much more expensive than conventional concrete on a pound-for-pound basis. But since the cross sections can be so much thinner, that cost is overcome in most decorative elements.

ENVELOPE CLAY BRICK WALL

LOW CARBON ALTERNATIVE MATERIAL (ENVELOPE) - CLAY BRICK WALL

HISTORY

Bricks date back to 7000 BC, which makes them one of the oldest known building materials. (Mud Bricks)

Brick made from clay fired over 1000 degree celcius

DEFINITION

Clay brick wall is produced simply by mixing clay and water

OTHER ENVIRONMENTAL BENEFITS

-Brick manufacturers strive to conserve energy in the firing process, using less than 50% of the energy required to produce brick in 2004 compared to 1981. Further fuel reduction efforts since 2004 have totaled approximately 10%.

-Fuel savings since 2004 have also resulted in a reduction of approximately 145,075 tons of carbon dioxide. Air emissions are minimized with controls such as scrubbers installed on kiln exhausts.

-Brick manufacturing facilities are usually located near their source of raw materials.

LOW CARBON ALTERNATIVE MATERIAL (ENVELOPE) - CLAY BRICK WALL

CHARACTERISTIC

-Low maintenance, permanent, durable building material that won’t rot, rust, burn, corrode, decay, or encourage mold growth.

-Exterior brick walls are designed with a drainage component, or drainage cavity.

-designed to direct moisture that permeates through building materials or leaks via deficiencies in windows and other penetrations, back to the exterior.

GFRC as a material, however, is much more expensive than conventional concrete on a pound-for-pound basis. But since the cross sections can be so much thinner, that cost is overcome in most decorative elements.

Envelope: BIPV

Envelope: BIPV Curtain Wall

The International Energy Association (IEA, 2015), estimate that the average yield of PV in the UK at optimal angle in urban areas is 920 kWh per kWp, which they state is before an annual degradation of electricity generated of 0.7%. However, to remain conservative we will apply a 0.5% degradation factor. This is the annual electricity generation that we will use for the purpose of this article. This means that each year the output of the PV system drops by 0.5%.

Each year the PV system will generate electricity, thereby reducing the load on the national electricity network. This saves carbon emissions each year over the operational lifetime of the system, which is generally taken to be 25-30 years.

ENVELOPE

3D PRINTED RECYCLED PLASTIC

Envelope: 3D Printed Recycled Plastic Use

Berlin, Germany. 16th Sep, 2019. A new type of façade cladding was mounted on a wall in the inner courtyard of the Federal Centre of Competence for Culture and Creative Industries. BigRep, leading manufacturer of 3D printers, presented the world's first fully 3D printed environmental habitat for green plants and insects. It was made entirely from recycled plastic materials from PET bottles. Credit: Tom Weller/dpa/Alamy Live News

Envelope: 3D Printed Recycled Plastic Embodied Carbon Data

Potential Carbon Savings from using recycled PET

1.Support enhanced recycling and reuse of existing materials—for example, plastic waste can be used as an ingredient to make “green” concrete.

2.recycled plastics can substitute for high-emissions materials such as brick or steel.

Potential Carbon Savings from 3D Printing

1.The process produces a fraction of the waste of traditional construction manufacturing

2.Only requires a small factory with minimal space for storage materials

3. 3D printing does not require energy to move the same parts from one step to the next, unlike a traditional production line

Embodied Carbon for recycled PET = 0.45 kgCO2e/kg

Embodied Carbon for Virgin PET = 2.15 kgCO2e/kg

rPET reduces CO2 emissions and conserves fossil fuels

The result of the study exceeds previous assumptions. The rPET produced by PET Recycling Team GmbH in Wöllersdorf has a carbon footprint of 0.45 kg CO2 equivalent per kilogram of rPET. Virgin PET, or new material, accounts for a CO2 equivalent of 2.15 kg per kilogram. This corresponds to a CO2 equivalent of 1.7 kg or 79 per cent lower greenhouse gas emissions for rPET. Plant manager Peter Fröschel explains: ‘The savings for a single kilogram of rPET are enough to power a 13-watt bulb continuously for twenty days in the Austrian power mix.’

Characteristics

1 bagasse

2 wheat hush

Appropriateness

3.agricultural byproducts and mushroom mycelium

01 envelope material

COOL-LITE®XTREMEORAÉ®

PROCESS

Use recycled cullet and clean energy to produce glass.

The new ORAÉ® substrate has an estimated carbon footprint of only 7 kg CO2 eq/m2 (for a 4mm substrate), bringing a reduction of the carbon footprint around 40% compared to our European standard product PLANICLEAR®. Coated, processed and assembled in insulated glazing unit, the reduction is then around 25% to 30%.

Characteristic

The excellent energy performances of the COOL-LITE® XTREME coatings, which already drastically reduce carbon emissions generated by energy consumption, when using the building thanks to its high performance in terms of daylight intake, solar control and thermal insulation.

01 envelope material

COOL-LITE®XTREMEORAÉ®

Appropriateness

The country has updated its prohibitions on the import of certain waste materials.

Among the waste products to escape censure are cast iron, steel and tinned iron; and certain types of plastics, including those derived from polyethylene, polystyrene, and polyvinyl chloride (PVC). Cullet and other forms of glass waste have also been deemed acceptable.

CRITS

CRITS

AFTERCRITS