The Research Approach

As part of this thesis’s approach to deep dive into the use of wicker works in buildings and infrastructures, three methodology of research will be employed. Firstly, research will be carried out through the basic form of crafts - prototypes of rattan weave. Through the art of making, the nuances and intricacy will be expounded and displayed. Secondly, research by travelling to the heart of rattan industry to observe firsthand the craftmanship of experts and production. Currently, 85% of raw materials of rattan is produced in Indonesia (Jamaludin, 2006), hence making Indonesia the ideal research destination for this exploration of rattan. Thirdly, through the vast text and archives of information online I will put together a comprehensive understanding of the development and direction of the past, present and future of rattan.

10

11

Crafts woman weaving rattan, Cirebon, Indonesia, Yong Soon, 2023

12

Jakarta, Indonesia, Yong Soon, 2023

Context

Colonialism has historically been a catalyst for significant changes in the global trade of materials and the cultural exchange of design aesthetics. Among the many commodities affected by this historical phenomenon, rattan—a versatile material primarily used in furniture making—has seen notable shifts in importation, exportation, and stylistic interpretations. Traders from the Western world, particularly those influenced by Scandinavian design principles, have played a pivotal role in reshaping the perception and utilization of rattan in furniture production.

The Western traders introduced a distinct shift in the cultural interpretation of furniture styles, impacting the import and export dynamics of rattan. The Scandinavian design ethos, characterized by its emphasis on simplicity, functionality, and natural beauty, influenced the perception of what constituted desirable furniture. Jamaludin, Boyke, and Subkiman (2018) highlight how this influence altered the traditional approaches to rattan furniture, reshaping it with sharp lines, functional forms, and a focus on the material’s innate beauty.

The modernized style brought by Western traders emphasized craftsmanship, material selection, and geometric simplicity, which remains relevant in contemporary furniture design. O’Neill (2017) underscores the enduring relevance of these attributes, reflecting how the Scandinavian style, with its emphasis on form following function, continues to influence furniture design trends.

This transition in the interpretation and utilization of rattan as a material for furniture-making underscores the broader impact of colonialism on cultural exchange and trade. The imposition of Western design principles not only altered the aesthetics of rattan furniture but also transformed the markets for its import and export.

The Western preference for the Scandinavian style significantly affected the global trade of rattan-based furniture. Countries rich in rattan resources found new markets for their products, as the demand for furniture with clean lines and natural beauty surged in Western societies. Conversely, the traditional styles of rattan furniture, which might have been prevalent in the local markets of rattan-producing regions, began to witness a decline in demand due to the preference for the modernized Western style.

The legacy of this shift is still evident in the contemporary furniture industry. Rattan furniture, influenced by the Scandinavian design principles introduced during the colonial era, continues to be popular worldwide. The clean, minimalist lines and emphasis on the material’s natural attributes have transcended time, maintaining their allure in a globalized market.

However, it’s essential to acknowledge the complexities and nuances embedded in this narrative. While the Western influence undeniably transformed the perception and global trade of rattan, it’s also crucial to recognize the cultural heritage and diverse styles that existed and continue to exist within the regions where rattan is traditionally cultivated and used.

In conclusion, colonialism, particularly through the introduction of Scandinavian design principles by Western traders, has significantly impacted the importation, exportation, and cultural interpretation of rattan as a material for furniture. The enduring influence of this modernized style, with its emphasis on simplicity, functionality, and natural beauty, continues to shape the global furniture market, underscoring the profound and lasting impact of colonial legacies on trade and cultural exchange.

13

14

Exports

Indonesia remains as the largest exporter of rattan as it controls the supply of raw rattan being rich in natural resources - forest. It accounts for 70% of the world’s rattan furniture exports

In 2022, the value of exports to USA from indoensia was at 14.6 mil $USD and UK was at 3.8 mil USD$

15

16

Journey through the origin

This segment documents the journey taken to deepen the understanding of the craft. The importance of the skills and knowledge of materiality is crucial to the architecture that Indigenous vernacular architecture produces.

17

Travel itenary - Part I DATE 21 OCT 2023

Day 1

Flight from SIN to CGK (FLIGHT 3K 201) 0725

Check-in at Wonderloft Hostel 1030

Lunch 1200

Jaya Rattan Furniture 1300

Dinner Cafe Batavia 1700

Taman Fatahillah City Square 2000

Haryono Rotan Rattan Shop 1000

Lunch 1200

Tayo Rotan Rattan Shop 1330

Rattan Workshop 1430

Jaya Rattan Furniture Shop 1600

Dinner 1800

Train to Cirebon 15:55 - 18:05

Factory visit to Rattan Cirebon 0845

Factory visit to Martino Rattan 1000

Kampung Sabin 1130

Lunch at Bukit Bambu 1230

Train to Jakarta 1415

Flight from CGK to SIN (FLIGHT 3K 201) 2250

Day 2

Day 3

18

19

Drought impacted land, Cirebon, Indonesia, Yong Soon, 2023

20

Flat-lay of Travel Essentials, Yong Soon, 2023

Survival Kit

Essentials items brought along with me. With the digitalisation of documentation and travel, I found myself relying on my smart from to navigate, photograph and make payment.

21

Travel itenary - Part II DATE 20 DEC 2023

Day 1

Flight from SIN to CGK (FLIGHT 3K 201) 0725

Brunch at Grand Indonesia Mall 1030

Train to Cirebon 1230

Check-in Cordela Hotel Cirebon 1300

Dinner Taichung Satay 1700

Alun-Alun Kejaksan Cirebon 2000

C.V Mutiara Rotan (Rattan Factory) 0900

Day 2

Perumahan Griya Plumbon (Rattan Production Houses) 1100

Domo Coffee and Resto (Lunch) 1330

Perumahan Griya Plumbon (Rattan Production Houses) 1430

Sunyaragi Cave Park 1600

Keraton Kasepuhan (Historical Site) 1800

Mie Colot Cirebon (Dinner) 2250

Day 3

Lezafani Ratan (Rattan Production House) 0900

Martino Rotan (Rattan Factory) 1045

Sumber Pedas (Lunch) 1200

Terasering Panyaweuan (Plantation Fields) 1130

Jiwan Coffee & Things Cirebon (Dinner) 1800

Alun-Alun Majalengka 1900

22

Day 4

Mantera Rattan (Rattan Factory) 0900

Mantera Coffee Corner (Lunch) 1100

Rattan Factory Houses 1230

Alun-Alun Cirebon 1500

Festum (Dinner) 1700

Train to Jakarta 2105

Wonderloft Hostel Check-in 0030

Cafe Batavia 1200

Alun-Alun Jakarta 1330

Grand Indonesia West Mall 1530

Dinner 1800

Flight from CGK to SIN (FLIGHT 3K 201) 2005

Day 5

23

Modes of transport

Travelling through the land took me on different modes of transport from plane to motorcycle

24

Sun-rise on the flight to the origin of rattan, Singapore, Yong Soon, 2023

25

Traffic on a motorcycle, Indonesia, Yong Soon, 2023

26

Line-up of Gojek riders, Indonesia, Yong Soon, 2023

Motorcycle parking, Jakarta Indonesia, Yong Soon, 2023

27

Travel by train, Indonesia, Yong Soon, 2023

Boarding and alighting of a train, Indonesia, Yong Soon, 2023

28

Sun-rise on a train, Indonesia, Yong Soon, 2023

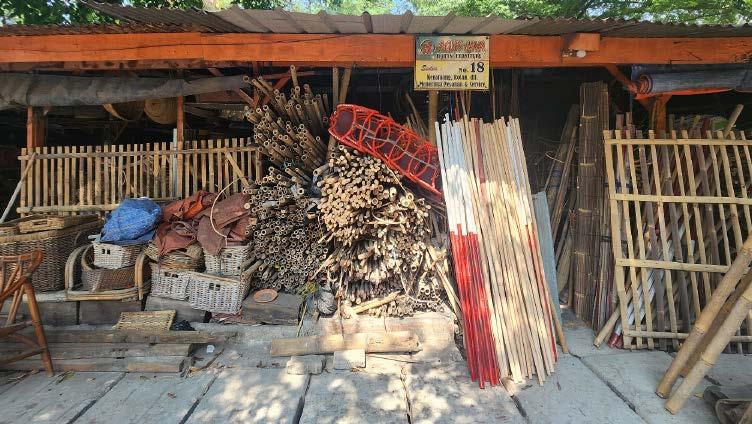

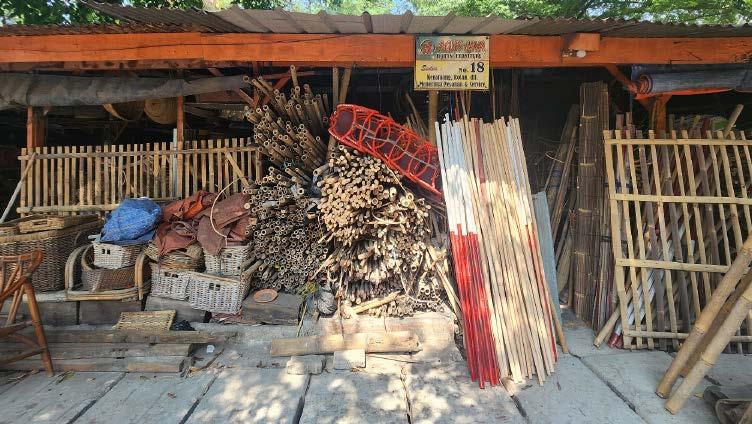

Rattan Shops

Journeying through the land of Indonesia, Jakarta found myself in the vast field of rattan shops situated in the outskirts of the city area. Most of the shops are roughly 15minutes away from the city centre

Most of the products sold are not made by the owners of the rattan shop, rather they are distributors, and the rattan products comes mainly from west Java, namely Cirebon, Bandung. (Achidiawan, Ramadhani, & Tarigan, 2022)

These rattan shops are often overcrowded with pile and piles of rattan furniture stocks. To the untrained person, one might not have imagined that the government had tried to ban the export of raw and unfinished product in 2004 to protect the domestic craft industry by restricting foreign access to the material. (Achidiawan, Ramadhani, & Tarigan, 2022)

What remains of the domestic rattan shops are craftsman struggling to keep up with the fast paced production of massed produced furniture. The shops often have to either innovate new products or compete by lowering prices.

29

30

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

31

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

32

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

33

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

Rattan Shop, Jakarta Indonesia, Yong Soon, 2023

Origins of Rattan

Rattan, a broad term that refers to the genus palm tree family of Palmea or Arecales. The family has a sprawling 600 different types of species in the world. As identified previously, the majority of the exports belongs to Indonesia. Trailing behind are equatorial countries such as the Philippines, Cambodia, Vietnam and Philippines. The rattan are often naturally found and grown in forest. Farmers will cut the canes on site before being processed partially to be exported as raw materials for crafts. (Pauline, 2021).

Rattan in Indonesia is located differently when locating its source of palm and source of processing plant. The plant is harvested mainly from Sumatra, Kalimantan and Sulawesi Island. Meanwhile, the industry that processes the harvest are located within west Java, particularly Cirebon where it has the largest export in the region of Indonesia. (Achidiawan, Ramadhani, & Tarigan, 2022)

34

35

36

Kampung Sabin, Cirebon Indonesia, Yong Soon, 2023

Types of rattan

Rattan can be classified generally into four types, cane, reed, manau and synthetic rattan. A typical craft can consist of more than one types that works harmoniously to create something beautiful. Each type has its specific uses and strength and weaknesses.

37

Cane rattan

Cane rattan is an extraction of the rattan plant’s outer protective sheath. This sheath act as its protective bark that has a smooth and reflective outer side and a raw unfinished inside. The outer sheath has a firm structure that is unbroken, allowing it to be segmented into elongated strands.

Given its binding ability as a rope, it is often used to tie elements forming the intermediary of connections between two parts. With its hydrophobic side, it is also a preferred choice when weaving over planes. (Navneet, 2022)

38

39

Raw Cane Rattan, Yong Soon, 2023

40

Raw Reed Rattan, Yong Soon, 2023

Reed Rattan

Like cane rattan, both are harvested from the stems the rattan plants. They are the core of the rattan vines. Often circular in shape, it comes in varying dimensions and thickness. With the larger reed rattan, it is often chosen as main structural elements in a furniture craft.

While thinner rattan stalks are much more flexible naturally, the thicker poles can be bent as well after an application of heat and steam. They can be manipulated into the different shapes and bent to the required form. When dried, it retains its given shape.

(Navneet, 2022)

41

Manau Rattan

Manau rattan is highly durable and thicker than other varieties. Manau rattan is often used as the core of the crafts for its stability and sturdiness. Its ability to hold its shape and weight allows it to be used in furniture like chairs.

42

43

Rattan storage, Jakarta Indonesia, Yong Soon, 2023

44

Synthetic rattan chair for children, Jakarta Indonesia, Yong Soon, 2023

Synthetic

Synthetic rattan is a manufactured material produced out of polyethylene and other polymers. Often used in children’s toy as it is resistant to moisture, making it a suitable material for outdoor furniture.

This is especially so in the tropics where we are constantly exposed to the hot and humid weather, where wood products are seen as an inferior product due to its ability to degrade when placed out in the elements.

45

46

Craftswoman weaving a chair, Cirebon Indonesia, Yong Soon, 2023

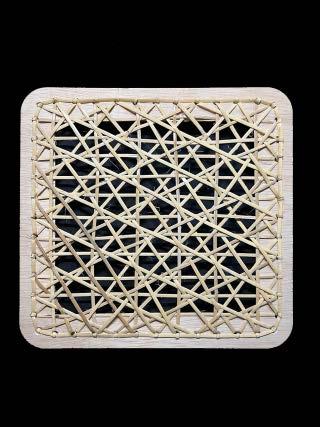

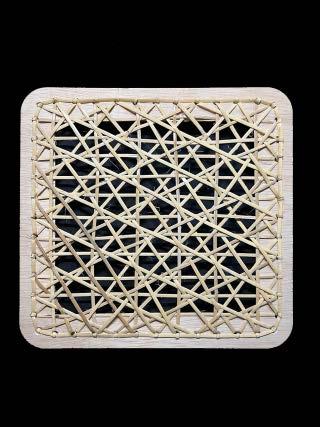

The process of making

The process of exploration takes place right in the hearts of my own house and comfort. As i experimented with working with rattan, It has been a laborious task with each individual weave needing to be individually weaved, strand by strand

47

48

Square Weave, Yong Soon, 2023

Double Square Weave, Yong Soon, 2023

49

Four way weave, Yong Soon, 2023

Five way weave, Yong Soon, 2023

50

Six way weave, Yong Soon, 2023

Single Victoria Weave, Yong Soon, 2023

51

Double Victoria Weave, Yong Soon, 2023

Double Double Victoria Weave, Yong Soon, 2023

52

Diamond Weave, Yong Soon, 2023

Snowflake Weave, Yong Soon, 2023

53

Daisy Chain Weave, Yong Soon, 2023

Spiderweb Weave, Yong Soon, 2023

Labour

The topic of labour always surrounds the making of rattan as it is a highly labour-intensive production. Such knowledge requires time and constant exposure to the material to hone its expertise.

From the transient interaction I had with the rattan shop keeper and factory craftsman, these are everyday objects made from rattan and the labour took communicated to me. Comparatively to mass manufactured injection moulded plastic chair which take less than 10minutes to be formed from pellets to chair, a hand-crafted chair would take 3 to 7 days depending on the complexity of the build. Could the amount of labour be further reduced to accommodate a faster production line?

As such, with every visit, I identified and selected objects of different complexity present in the shops of rattan shops around Jakarta.

The following depicts each craft with labour measured in terms of working days - the amount of time required and took to build the product from start to finish by the craftsman.

54

55

Rattan Lampshade, 2 days, Jakarta Indonesia, Yong Soon, 2023

56

Table decoration, 2 days, Jakarta Indonesia, Yong Soon, 2023

57

Rattan Baby’s cot, 3 days, Jakarta Indonesia, Yong Soon, 2023

58

Fruit basket, 3 days, Jakarta Indonesia, Yong Soon, 2023

59

Children’s rocking horse, 5 days, Jakarta Indonesia, Yong Soon, 2023

60

Bamboo and rattan storage, Cirebon Indonesia, Yong Soon, 2023

Bamboo and rattan storage, Cirebon Indonesia, Yong Soon, 2023

Rattan Production in Cirebon, Indonesia

The main aim of the visit to Indonesia was to have a deeper understanding on the production of rattan furniture. The visit to production plant yielded the following understanding with regards to production methodology.

Factories here have identified that their raw rattan canes come mostly from Kalimantan or Sumatra Forest. Raw rattans are imported in for processing into rattan furniture which most of them will then be exported directly overseas and a small percentage of the products distributed to shops in major local cities such as Jakarta locally.

61

62

63

How to Start your own Rattan Factory Production

Indonesia is well-known for its low cost labourers, and it is no different in Cirebon, Indonesia where most of country rattan exportation takes place. To embark on the journey to start the factory, a capital of 800$USD to hire a skilled craftsman with knowledge for a month worth of work is required.

The village of plumbon is filled with craftsman working on different scale and different types of rattan products. Most of them works at the comfort of their own home.

64

65

Craftsman weaving basket in homes, Cirebon Indonesia, Yong Soon, 2023

66

Craftsman bending rattan in a village home factor, Cirebon Indonesia, Yong Soon, 2023

Tools Required

In setting up the workshop within the homes, the tools required are rudimentary and easily sourced. Complex machinery are not required and the most advanced technology used is the air-compressor where pneumatic tools is connected.

With the air-compressor being the most expensive tool in the arsenal, capital cost would simply set you back another 400$USD.

The following are the fundamental tools that the rattan home-factories uses.

67

68

Flat floor for building with floor chair, Cirebon Indonesia, Yong Soon, 2023

Wooden bender tool, Cirebon Indonesia, Yong Soon, 2023

69

Steamer boiler, Cirebon Indonesia, Yong Soon, 2023

Hand Saw, Cirebon Indonesia, Yong Soon, 2023

70

Propane Tank with torch attachment, Cirebon Indonesia, Yong Soon, 2023

Small Pool for Soaking Rattan, Cirebon Indonesia, Yong Soon, 2023

71

Aircompressor for Pneumatic Tools, Cirebon Indonesia, Yong Soon, 2023

72

Wood for frame making, Cirebon Indonesia, Yong Soon, 2023

Stockpile of Rattan, Cirebon Indonesia, Yong Soon, 2023

73

Pneumatic Nailer and tools easily reachable, Cirebon Indonesia, Yong Soon, 2023

74

Homes of villages with Rattan Products on the porch, Cirebon Indonesia, Yong Soon, 2023

How Rattan Furniture is Produced In Plumbon, Cirebon, Indonesia

While we might be familiar with production of furniture in factories, manufacturing in the town of plumbon within Cirebon has a slightly different manufacturing process and flow.

Rattan production does not begin with conventional factories settings, rather, it begins within the villages of plumbon, where most of the villagers are skilled rattan craftsman and craftswoman.

The only clue that a fully functional factory is operating within the garage of these village homes is the unassuming rattan products stacked up on the porches of the homes. The next tell-tale sign to confirm a rattan production taking place is the sound of pneumatic nail clicking in the backgound against a quiet countryside with the occasional motorbike engine sound zooming past.

75

1.Rattan preparation/cutting

First step in making rattan furniture is selecting the right materials from a wealth of materials available. Rattan itself comes in varying diameter, hardness, curvature, and finishes. Based on the requirement of the desired crafts, craftsmen would select and start cutting material according to the required dimensions with a handsaw. Because of the porous nature of rattan, cutting with a handsaw is relatively easy.

76

77

Stockpile of Rattan of different sizes in the garage, Cirebon Indonesia, Yong Soon, 2023

78

Steam oven in a factory, Cirebon Indonesia, Yong Soon, 2023

2.Softening

Most of the Rattan has been processed to straighten. Rattan exist as curvy and bending in nature as it is a vine. To achieve the desired shapes required, the Rattan is soften through a steam boiler which saturates the rattan with water and heat, making it malleable.

79

3.Bending

Rattan with the aid of heat and steam, can be easily manipulated through bending it with tools. The craftsman will then bend and shape the rattan according to the desired shape and curvature. This process is repetitive such that the craftsman will soften the rattan through steam and heat continuously while shaping it.

At the end of this process, the rattan would be tied with raffia strings to hold the shape of the rattan while it dries and fixates the curves for the next process.

80

81

Craftsman hand bending using table jig, Cirebon Indonesia, Yong Soon, 2023

82

Assembly Stations, Cirebon Indonesia, Yong Soon, 2023

4.Form Making

In the assembly station, workers gather the bent rattan and start assembling the frame of the furniture. To ensure consistency within each product, jigs is often used to match the exact length and sizes required. To remove excess material a handsaw makes its way through the reed rattan easily like butter in the hands of the craftsman.

83

5.Assembly

To attach different parts of the rattan together, pilots holes is often drilled and screws used to attach different elements of the product together. In the process of assembling, there would be jigs made to ensure it conforms to the dimension set out by the production line.

84

85

Craftsman measuring chair using a jig, Cirebon Indonesia, Yong Soon, 2023

86

Crafts woman reinforcing joins using rattan, Cirebon Indonesia, Yong Soon, 2023

6.Joinery Winding

With the exposed nails in the joints and screw holes, workers then start covering these details with rattan cane by winding around the joints. This process reinforces the joints at the same time as it is wound in different direction. When done skilfully, the screws and nails disappear into the windings and each component seems to be only held together by cane windings. .

87

7.Caning / Weaving

To add meshes to panels, seats, and span open spaces, braiding is done. This is the most tedious part of the assembly process as weaving requires individual weaves to be done by hand. Canes are soaked in water to soften and make it more pliable. Craftsman will individually weave and interlock the dampened rattan. This process brings out the pattern that most people are able to recognise as rattan patterns.

88

89

Craftsman weaving a rattan sofa, Cirebon Indonesia, Yong Soon, 2023

7.Caning / Weaving

In some homes, craftsman and woman work alone in the confine of their smaller homes due to obligation of family whereby they have young children like the craftswoman in the photo on the right. She is weaving synthetic partition divider and factories would send materials needed to her house and a sample of the product to create. The factories provides the aircompressor, pneumatic nailer and caning required for job completion and these jobs are often lower in complexity whereby it is simply caning of the wood such as a divider. A tell tale sign of such homes are distinct by having a small footprint but with rattan furniture(Often caning products) overflowing onto the front porch.

90

91

Craftswoman weaving synthetic rattan in her house, Cirebon Indonesia, Yong Soon, 2023

92

Rattan products loaded from village homes on lorry, Cirebon Indonesia, Yong Soon, 2023

8.Transportation to Factories

The finished product is then stacked inside the homes and most of the times it would be too small and ends up at the front porch of the houses where it sits awaiting the transport to the finishing factories for exportation.

93

The craftsman in the village homes are paid according to the quantity of the product made and sold to the factories. A typical chair would yield the the home factory 8$USD paid by the exportation factories.

94

9. Unfinished Rattan

95

Small trucks transporting rattan products, Cirebon Indonesia, Yong Soon, 2023

Rattan products enroute to factories, Cirebon Indonesia, Yong Soon, 2023

The Middle Man

Most of the factories in Cirebon work on a split factory settings where production is split into two parts, the furniture assembling segment which is detailed previously, and the finishing and exportation segment which will be expounded on.

Factories like this would have english speaking sales associate that discuss and price the needs of buyers overseas from different parts of the world ranging from Russia, Switzerland, Mexico, Norway etc. The factories would typically have a mark up of about 1000% from the price they paid the villagers.

While foreigners are willing to pay a premium for hand-woven rattan, most of this is pocketed by the factories that act as a middle man and only a fraction of the cost ends up at rattan factories worker in the villages.

In the factories, it undergoes a finishing process which prepares them to be shipped out to the buyer.

96

97

C.V Martino Rotan Office Display, Cirebon Indonesia, Yong Soon, 2023

Entrance of C.V Martino Rotan Factory, Cirebon Indonesia, Yong Soon, 2023

98

Craftswoman sanding rattan chair, Cirebon Indonesia, Yong Soon, 2023

Knife is used to shave off stray rattan strands, Cirebon Indonesia, Yong Soon, 2023

1. Sanding / Refining

The rattan furniture that arrives in the factories are unfinished raw rattan with blemishes from the assembling process. The chair that arrives here undergoes a quality check process and rough and uneven are sanded and smoothed.

99

2. Spray finishing

Now that the rattan is smooth, it is ready for a final coat of varnish or colour depending on the specifications of the build required by the buyer. Craftsman will load the pneumatic spray gun with paint or varnish and add 2-3 coats letting it dry between coats.

100

101

Spray station in Rattan Factory, Cirebon Indonesia, Yong Soon, 2023

102

Craftsman inspecting chair for defects and rectifying it, Cirebon Indonesia, Yong Soon, 2023

3. Final Inspection

Before the chair is deemed as a finished product, ready for shipment, an experienced craftsman with a variety of tool such as nailer, sander, hammer, plier, knife and drill inspects and rectify and defects found

103

4. Packing and Padding

Most of the buyer originates from european countries which takes almost a month in shipment before arriving at its destination country. It is hence important to ensure that the handcrafted Rattan furniture is well protected and padded to endure the long journey that awaits it.

104

105

Packing and padding individual chairs with foam and paper, Cirebon Indonesia, Yong Soon, 2023

106

4 Storey high Rattan Chair, Cirebon Indonesia, Yong Soon, 2023

The Rattan Bridge

With globalisation assimilating into different culture and industry, it is at base level unfair and at worse criminatory that workers with a highly sought after skill set gets undercut by factories that takes advantage of their inability to communicate directly with buyers.

My architecture posits a bridge in the world of rattan production in cirebon whereby craftsman are duly paid for their artisan crafts. A governmental intermediary to provide a step towards closing the wealth divide of the uneducated and skilled labourers and the shrewd educated business minded aristocrats of indonesia.

107

Site Selection

The plot of land beside Cirebon, Alun Alun Plumbon was selected as this public square has great significance in indonesia’s cultural scene. Alun Alun has been known as a gathering place for people of different background regardless of socio-economical status. People would gather from all walks of live in the same village for dates, picnics, drinks and more. Situating my site beside this draws a statement that crafts should be made, enjoyed, and harvest enjoyed by the craftsman that contributed the most to its sales regardless of educational background.

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

first layer

Rattan construction support frame

125

Brick

Capstone

126

Rattan Weave Screen Reed Rattan Framing

127

128

The Intangibles

Having seen the amount of joy and camaraderie the villages craftsman had with one another and the hospitability, it has imbuned my view that craft itself does not stand only where its economical value ends.

In Cirebon plumbon, craft is a way of life and hence building ontop of the culture to create – kampung craft.

129

130

131 Appendix

Community of Practice

With the advent of technology in the new field of architecture, there is a transforming scene of dependency on new technology to propel primitive techniques and bring it back into fashion. Rattan explorers and architects such as Patrick Keane manages to incorporate built forms that is unconventional and non-rectilinear, pushing the boundaries of the materials limitation.

When it comes to labour as a form of resource, it still remains as a viable source of resources as it can be easily procured at a low cost in indonesia. While machinery proves to provide a partial solution with the ability to use a 5 axis machine to replace the manual weaving required (Wynne, 2019), it is not cost effective as machine itself cost over few years of the annual wages of the workers, making it a clear choice that manual labour is the cost effective method.

132

Catalogue of Rattan traditional usage

Textile weaves has always been part of architecture. The rise of rattan as a commercialised furniture material has been cemented in the past century of growth and chaos. From Iconic chairs like the peacock chair to the unforgettable imprint that stains the skin when resting on a rattan chair. Given the short amount of time this thesis has allowed me to pursue the project, the catalog is meant not an exhuastive list but aims to depict and generalise the movement of how rattan has been used throughout the history.

133

134

Colonial masters chair2

Peacock Chair1

135

Rattan A frame chair4

Willis Curved Rattan Wingback chair3

136

Wicker egg chair6

Cocoon wicker woven chair5

137

Thonet Rattan Chair8

Bentwood Rocker Rattan Chair7

138

Paul Frankl Style Rattan Lounge1-

Marcel Breuer Cesca Chair9

139

Hans Wegner Wishbone Chair12

19th Century Rococo Revival Armchairs in Louis XV taste11

140

Poul Kjærholm PK15 Chair14

Borge Mogensen Spoke-back Chair13

141

Srigunting Chair 197316

Hans J Wegner Peacock Chair15

142

Kaare Klint Faaborg Chair 966218

Charlottenborg Chair17

143

Lipari Rattan Chair20

Mabrouka Rattan Chair19

144

Italian Tito Agnoli Rattan B4 armchaand pouf for Bonacina22

Giglio Rattan Chair21

145

Rattan armchair Rohe Noordwolde24

Veranda Rattan Armchair23

146

French Wicker and Bamboo Chaise Lounge26

Wicker loungechair25

147

Wicker Chaise lounge after Eames La Chaise28

Wicker Chaise lounge27

148

Wicker braided basket30

Wicker Suitcase29

149

Rattan and wicker shelves32

Wicker table31

150

Paul Frankl Bentwood Rattan Sofa34

Rattan Clothes Rack33

151

Rattan Cabinet36

Bernard Rattan Shoe Rack35

Rattan Contemporary Usage

Only recently has there been a rise in the usage of rattan in contemporary settings such as lighting fixture, facade treatment, sculptural elements and structural elements of a building. All of which seeks to defeat the stigma that rattan is rigid and traditional.

152

153

Yoga Sanctuary in Bangkok, Enter_projects

154

A museum installation by Japanese contemporary bamboo master Tanabe Chikuunsai

155

Yoga Sanctuary in Bangkok, Enter_projects

Yoga Sanctuary in Bangkok, Enter_projects

156

Billowing Rattan Columns, Designed by Enter Projects for Spice & Barley 2020

Chiang Mai Art Gallery in Chiang Mai, Thailand. 2022

157

Wicker Membranes / Andrea von Chrismar, 2010

Wicker Membranes / Andrea von Chrismar, 2010

158

coffee shop in jakarta with pivoting panels of rattan 2020

coffee shop in jakarta with pivoting panels of rattan 2020

159

Disclosure

I certify that except where due acknowledgment has been made, the work is that of the author alone; the work has not been submitted previously, in whole or in part, to qualify for any other academic award; the content of the project is the result of work which has been carried out since the official commencement date of the approved research program, any editorial work, paid or unpaid carried out by a third party is acknowledged, ethics procedures and guidelines have been followed.

Intellectual Property Rights are retained by Lee Yong Soon, who asserts moral rights and all other rights to be identified as the author of this work. I have acknowledged all copyright holders on the images and other references used.

160

Bibliography

American Heritage® Dictionary of the English Language, Fifth Edition. (2011). Wicker. Retrieved 11 november, 2023, from The free dictionary: https://www.thefreedictionary.com/wicker

Arora, V., Kumar Saran, R., Kumar, R., & Yadav, S. (2019). Separation and sequestration of CO2 in geological formations. Materials Science for Energy Technologies, 2(3), 647-656. doi:10.1016/j.mset.2019.08.006

Cambridge University Press. (11 November, 2023). Wicker. Retrieved from Cambridge Dictionary: https://dictionary. cambridge.org/dictionary/english/wicker

Jamaludin, Boyke, A., & Subkiman, A. (2018). The Influence of Scandinavian Furniture Design in the Development of Modern Rattan Furniture in Indonesia. Insitut Teknologi Nasional Bandung, 7(3), 19-26. doi:10.18533

Navneet, G. (18 August, 2022). Knowing Rattan Cane Wicker Bamboo and More. Retrieved 5 November, 2023, from trinity crafts: https://trinitycrafts.in/knowing-rattan-cane-wicker-bamboo-and-more/

O’Neill, M. (23 october, 2017). How Scandinavian Modern Design Took the World by Storm. Retrieved from architecturaldigest: https://www.architecturaldigest.com/story/how-scandinavian-modern-design-took-the-worldby-storm

Pauline. (2 november, 2021). Beyond baskets weaving a path into the future for rattan. Retrieved 5 october, 2023, from pluralartmag: https://pluralartmag.com/2021/11/02/beyond-baskets-weaving-a-path-into-the-future-for-rattan/

Peluso, N. L. (1992). Rich people, Poor forest: Resource Control and Resistance in Java (First ed.). California: University of California Press.

Raycheva, R., & Angelova, D. (2017). Woven Furniture Design: In Search of Form and Texture. PRO LIGNO, 455-465. Rudofsky, B. (1965). Architecture without Architects. New York: The Museum of Modern Art.

Semper, G. (1851). The Four Elements of Architecture.

Wynne, A. (2019, June 4). Robot-built pavilion launches V&A Engineering season. New Civil Engineer. https:// www.newcivilengineer.com/archive/robot-built-pavilion-launches-va-engineering-season-18-05-2016/

161

[1] 1 seater Sofa chair: Loft home furniture: Buy furniture online in SG. Loft Home Furniture. (n.d.). https://www.lofthome.com/1-seater-sofa

[2] Dutch colonial Indonesian cane and Wood Plantation Chair with extending arms. For Sale at 1stDibs | dutch chair. (n.d.). https://www.1stdibs.com/furniture/seating/lounge-chairs/dutch-colonial-indonesian-cane-wood-plantation-chair-extending-arms/id-f_34025762/

[3] Izabellahsimmons@gmail.com. (n.d.). Settle-in Rattan Lounger and ottoman. Gardenista. https://www.gardenista. com/products/settle-in-rattan-lounger-and-ottoman/

[4] 2016/2023, O. W. D. (n.d.). Eichholtz Aristide Dining Chair in Brown Classic Finish. One Word Deco presents the Eichholtz brand. https://www.interiors-and-styles.com/en/boutique/fiche/eichholtz-aristide-dining-chair-in-brownclassic-finish-126268.html

[5] Road, G. (n.d.). Grandin Road Mason Cocoon Outdoor Seating set - coastal - other - by Grandin Road. Houzz. https:// www.houzz.com.sg/photos/grandin-road-mason-cocoon-outdoor-seating-set-phvw-vp~89374633

[6] Daijia china rattan egg shape chair. Daijia China Rattan Egg Shape Chair. (n.d.). https://www.alibaba.com/product-detail/Daijia-China-Rattan-Egg-Shape-Chair_1600470929160.html

[7] No. 1 rocking chair by Michael Thonet for thonet, 1920s. #92425. (n.d.). https://www.vntg.com/92425/no-1-rocking-chair-by-michael-thonet-for-thonet-1920s/

[8] Vintage no31 chair by Kohn, 1885s. Design Market. (n.d.). https://www.design-mkt.com/en/260071-vintage-no31chair-by-kohn-1885s.html?redirected=true

[9] Original design: The cesca chair. Knoll. (2021, April 9). https://www.knoll.com/story/shop/original-design-the-cesca-chair

[10] Restored six-strand square pretzel rattan lounge chair with Ottoman. For Sale at 1stDibs. (n.d.). https://www.1stdibs.com/furniture/seating/lounge-chairs/restored-six-strand-square-pretzel-rattan-lounge-chair-ottoman/idf_35063502/

[11] Regence Fauteuil with cane - 4 for sale on 1stdibs. 4 For Sale on 1stDibs | fauteuil cane. (n.d.). https://www.1stdibs.com/buy/regence-fauteuil-with-cane/

[12] Grant solid wood chair imported beech for dining, writing study. Teak. (n.d.). https://teak-furniture-singapore. com/products/grant-solid-wood-chair-imported-beech-for-dining-writing-study

[13] Børge Mogensen, an oak “Tremme” easy chair, Fritz Hansen, second half of the 20th century. Bukowskis. (n.d.). https://www.bukowskis.com/en/lots/1386205-borge-mogensen-an-oak-tremme-easy-chair-fritz-hansen-second-halfof-the-20th-century

[14] Poul Kjaerholm PK15 chair. Danish Design Store. (n.d.). https://www.danishdesignstore.com/products/poul-kjaerholm-pk15-chair-fritz-hansen

[15] PP550 Peacock Chair. Chanintr. (n.d.). https://www.chanintr.com/products/pp550-peacock-chair

[16] Srigunting Chair, 1973. The Most Favourite Chair in Exhibiton and ... (n.d.). https://www.researchgate.net/figure/ Srigunting-chair-1973-The-most-favourite-chair-in-exhibiton-and-became-the-milestones_fig2_324814981

[17] Charlottenborg Chair. Domo Collections. (2023, November 7). https://www.domo.com.au/product/charlottenborg-chair/

[18] The faaborg chair 9662 & Designer Furniture: Architonic. Products We keep you informed with our News. (n.d.). https://www.architonic.com/en/product/carl-hansen-son-the-faaborg-chair-9662/1056150

[19] Nicholas Haslam. (2023b, November 8). Mabrouka Rattan Chair - Paolo Moschino. Paolo Moschino. https://www. paolomoschino.com/shop/seating/dining-chairs/mabrouka-chair/

[20] Nicholas Haslam. (2023, November 8). Lipari Rattan Chair - Paolo Moschino. Paolo Moschino. https://www.paolomoschino.com/shop/seating/dining-chairs/lipari-chair/

[21] Italian large mid-century bamboo chair, 1970s. For Sale at 1stDibs | sem vaccaro sedie. (n.d.). https://www.1stdibs.com/furniture/seating/chairs/italian-large-mid-century-bamboo-chair-1970s/id-f_36037532/

[22] Tito Agnoli | Armchair | MutualArt. (2021, September 14). Tito Agnoli | Armchair | MutualArt. https://www.mutualart.com/Artwork/Armchair/28B3B7F9FDAB8B15

[23] Riveria Chair - Noormandiri Furniture. (2018, April 23). Noormandiri Furniture. https://noormandiri.com/product/ riveria-chair

162

[24] Vintage Dutch Rotan armchair, 1960. (n.d.). pamono.eu. https://www.pamono.eu/vintage-dutch-rotan-armchair-1960-1

[25] Vintage Dutch Rotan armchair, 1960. (n.d.-b). pamono.eu. https://www.pamono.eu/vintage-dutch-rotan-armchair-1960-1

[26] Art Deco Rattan Chairs - 135 for sale on 1stdibs. 135 For Sale on 1stDibs | art deco wicker furniture, art deco rattan furniture, art deco wicker chair. (n.d.). https://www.1stdibs.com/buy/art-deco-rattan-chairs/

[27] Rattan “Karlskrona” chaise longue by Karl Malmvell for IKEA, 1998. Chaise longue ikea rattan. (n.d.). https:// www.1stdibs.com/furniture/seating/chaise-longues/rattan-karlskrona-chaise-longue-karl-malmvell-ikea-1998/idf_35973922/

[28] Rattan Fainting Sofa Chaise lounge. Contour chaise on. (n.d.). LiveAuctioneers. https://www.liveauctioneers.com/ price-result/rattan-fainting-sofa-chaise-lounge-contour-chaise-on/

[29] Suitcase Rattan Storage Box Basket Woven. (n.d.). aliexpress.com. https://www.aliexpress.com/ item/1005002711709450.html

[30] Mark D. Sikes Signature Basket - french country | Mainly Baskets Home. (n.d.). Mainly Baskets Home. https:// mainlybaskets.com/categories/434141/french-country/products/mb5282/mark-d_dot_-sikes-signature-basket

[31] Merak Table - Noormandiri Furniture. (2018, April 23). Noormandiri Furniture. https://noormandiri.com/product/ merak-table

[32] Vintage Wicker Shelving Unit Retro 1980s Three Tier + Open Shelving + | Retrospect Vintage | Philadelphia, PA. (n.d.). ATTIC DC. https://attic.city/item/oH8O/vintage-wicker-shelving-unit-retro-1980s-three-tier-open-shelving-peacock-design-bohemian-furniture-plant-stand-home-decor-by-retrospectvintage215/retrospect-vintage

[33] Rattan Rainbow Clothes Rack. (n.d.). Jourès Canada. https://joures.com/products/rainbow-clothes-rack [35] Bernard Rattan Shoe Rack. (n.d.). En Decor Furniture. https://endecor.sg/bernard-rattan-shoe-rack/

[34] Paul Frankl mid century modern bamboo sofa. Lot 2158. (n.d.). https://www.invaluable.com/auction-lot/paulfrankl-mid-century-modern-bamboo-sofa-2158-c-914425fa8a

[36] Lap & Dado. (2022, October 4). Wells Rattan Bar Cabinet - Lap & dado. https://www.lapanddado.com/product/ wells-rattan-bar-cabinet/

[37] Rare Vintage Anglo-Indian Rattan & Wicker Pith Helmet Intricately Woven Hat | eBay. (n.d.). eBay. https://www. ebay.com.sg/itm/125079544445

[38] Shop Joie True. (n.d.). Chinese South East Asian bamboo rattan cone shape. https://www.etsy.com/listing/1487969110/chinese-south-east-asian-bamboo-rattan

[39] Authentic Vintage Chinese rattan Bamboo handcrafted rickshaw sun hat Antique. (n.d.). eBay. https://www.ebay. co.uk/itm/185973053790

[40] Poppy’s Vintage Clothing. (n.d.). Vintage 1940s Kepi Straw Hat Genuine Milan Cap w Visor Made in Italy Mens Size 7 - Poppy’s Vintage Clothing. Poppy’s Vintage Clothing. https://www.poppysvintageclothing.com/products/vintage1940s-kepi-straw-hat-genuine-milan-cap-w-visor-made-in-italy-mens-size-7

[41] TAO Vintage Rattan Partition. (n.d.). Urban Mood. https://urbanmood.sg/products/tao-vintage-rattan-partition

[42] BALI divider, rattan/weaving - natural. (n.d.). nordal.com. https://nordal.com/products/bali-divider-rattan-weaving-natural

[43] LaFloria Home Décor. (n.d.). Takibi separator duo. https://www.lafloriahomedecor.com/products/takibi-separator-duo

[44] Vintage wicker sunburst room divider - etsy. (n.d.-b). https://www.etsy.com/listing/911410594/vintage-wicker-sunburst-room

[45] The Architecture Computation Technology Lab. (2022, September 9). The Architecture Computation Technology Lab Explores the Intersection of the Architectural Practice. Retrieved November 13, 2023, from https://www.facebook. com/photo/?fbid=634874091399114&set=pb.100046295865933.-2207520000

[46] Parametric. (2021, January 16). Weaving enclosure. Parametric House. https://parametrichouse.com/weaving-enclosure-2/

[47] Gallery of Educating designers on computational design and robotics Can Make architecture and construction More sustainable - 6. (n.d.). ArchDaily. https://www.archdaily.com/929744/educating-designers-to-computational-de-

163

sign-and-robotics-can-make-architecture-and-construction-more-sustainable/5de91a493312fdbc3500010a-educating-designers-to-computational-design-and-robotics-can-make-architecture-and-construction-more-sustainable-image

[48] Material Balance Research | Woven mycelium. (2021, May 21). https://www.materialbalance.polimi. it/2021/05/21/woven-mycelium/

[49] The Bamboo and Rattan Pavilion of the 10th China Flower Expo - The Institution of Structural Engineers. (2022, September 8). https://www.istructe.org/structural-awards/projects/2022/the-bamboo-and-rattan-pavilion-of-the10th-china-f/

[50] Da Zzan, C. C. C. a. X. (2023, June 15). Mua Lau Lounge chair. A’ Design Award. https://competition.adesignaward. com/design.php?ID=149920

[51] Ebert, G. (2022, November 3). Built From Rattan, A Sinuous Structure Houses a Yoga Sanctuary in Bangkok. Colossal. https://www.thisiscolossal.com/2020/09/enter-projects-asia-rattan/

[52] Skopenko, A., Team, F., & Skopenko, A. (2022, July 22). Rattan made new - architectural deep dive. Figment. https://www.figment.live/journal/study-material-series-modern-rattan-part-i/

164

165

166

167