14 minute read

MIRALIS DATA

© Miralis Data

BRIAN CLEGG

ACCORDING TO THE DICTIONARY, ‘logistics’ describes the organisation of materials and accommodation for use by the military, the word taken from the French ‘loger’ – to provide quarters. The term has been taken up by business to refer to the transport and storage of goods, and this activity sits at the heart of the work of data science and software company Miralis Data, whether they are advising on loading pallets and containers, or simulating a warehouse. As well as supporting logistics through Operational Research (O.R.) techniques, the company provides guidance on some of the tricky aspects of moving towards an electric vehicle infrastructure. Head of R & D of Miralis Data, Will Maden, notes that this unusually wide portfolio is ‘mostly driven by consultancy work we have undertaken in the past, however employees’ interests often drive that as well.’

Maden was first immersed in O.R. when he took a Master’s degree at the University of Lancaster in 1999. ‘After

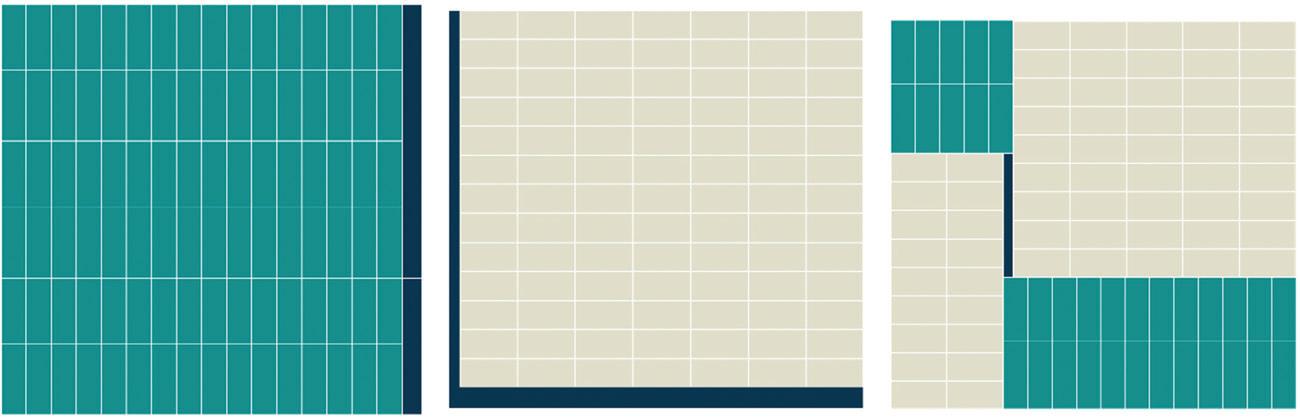

FIGURE 1 PACKING 9, 10 AND 11 CIRCLES OPTIMALLY

FIGURE 2 INCREASING PACKING EFFICIENCY 96 boxes (vertically packed) 91 boxes (horizontally packed) 34 (vertical) + 63 horizontal) = 97 boxes

a year, I was offered a job as a Research Associate with a Part-Time PhD, working with Richard Eglese at Lancaster University Management School on real life vehicle routing problems – in the green logistics area routing around congestion. The funding for the job and the PhD came from industry, so I became quite used to solving consultancy problems, all focussed on logistics.

‘After I finished my PhD, I set up as an independent consultant, but I also worked part-time as a lecturer at Huddersfield University. After a few years, I realised that the consultancy was working well, and I had become relied upon by my original clients. I therefore shifted my focus onto consultancy full time. In 2013, I was appointed by the automotive supply chain company BCA, one of my clients, as Director of Network Optimisation. After successfully making changes in reporting, data analytics and planning, I again refocussed on the problem-solving element of consultancy.

‘About this time, Michael Gibson [now Managing Director of Miralis] had sold his digital marketing agency and was looking for a new challenge, so together we founded Miralis Data, a data consultancy focussed mainly on logistics. We decided early on that to grow Miralis we would need to develop software solutions to problems, allowing the consultancy to drive new software options. The main focus for the company is on reducing the environmental impact of logistics, by shifting to more suitable means of transport or optimising the logistics requirement that footprint is as small as possible.’

PACKING PROBLEMS Optimising the packing of items onto a pallet or into a container is a classic Operational Research challenge. O.R. has always involved the application of apparently abstract mathematics to very practical problems – here the aim is twofold. To get the maximum amount of goods into the minimum volume, while making sure that the products are accessible at the correct stage of a distribution round. Sometimes this is simply a matter of space packing.

A good example of the surprising variation in effective solutions to space packing problems can be seen by the range of solutions that arise from attempting to pack circular objects optimally into a square container. While ‘square’ numbers such as 2, 4, 9 and 16 involve satisfyingly regular packing, many of the other optimal packings look surprisingly messy (see Figure 1).

Even with the apparently simpler requirement to pack rectangular boxes, there can be surprises. It may be, for example, that by placing some rectangular items on a pallet in a different orientation from others it is possible to incorporate more on each layer than would be possible if all the items had the same orientation.

However, Miralis Data has been able to go beyond simple packing advice to make recommendations on modifications to product packaging design, where a small change in the shape of a container could allow more to be stacked on a pallet. One of Miralis’ clients, Mookie Toys, commented that the advice from Miralis ‘enabled us to save £25,000 per year in distribution costs on just one of our hundreds of product lines.’ As a simple example, imagine a product could be packaged into either of two slightly differently shaped boxes – by mixing both boxes on a pallet layer it’s possible to get more boxes on the pallet than a layer made up entirely of either individual shape (see Figure 2).

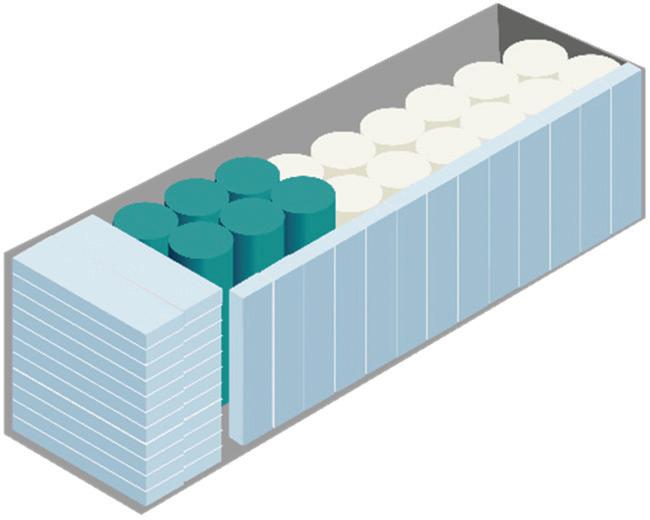

A similar, but more complex problem arises with packing shipping containers, where there is rarely a single type of package but often a whole mix of different shapes and

FIGURE 3 OPTIMALLY PACKING CONTAINERS

sizes. The challenge faced by Miralis is how to pack objects in containers to maximise what can be fitted into the fixed shape of the container, while recognising the order in which the products will need to be accessed (see Figure 3).

SIMULATING THE STRUCTURES Inside warehouses, Miralis uses a different approach, employing simulation rather than the mathematical optimisation used for packing algorithms. In a simulation, computer code represents different parts of the operation, with the code elements interacting as much as possible as real objects do in the workplace. Where necessary, this involves features such as queuing structures and using random numbers to provide selections from distributions of characteristics, such as the arrival rate of new products. Simulation tools make it possible to try out different warehouse layouts, or to study the effects of adding in extra equipment and technology to understand the impact on the warehouse throughput. Miralis refers to this approach as creating a ‘digital twin’, where experiments can be undertaken in the simulation without any risk to the business.

This is not just a matter of planning future warehouse solutions. Miralis believe that the technology of such a simulation could be carried over into real-time control through the introduction of 5G mobile data networks, which can carry vastly more traffic than current wireless networks. 5G is expected to give between 10- and 100-times greater bandwidth that the equivalent 4G network. Miralis envisages using 5G to integrate its pallet packing software with palletisation robots, making use of large numbers of sensors in the system that would enable the digital twin approach to be used not just for the simulation of different layouts, but to provide real time control of robotics and autonomous vehicles. 5G could also enable this monitoring to extend across the logistics chain, bringing in route and fleet optimisation – using the right vehicle for a job and sending it on the most cost-effective route.

LIFE OF A SALESMAN This part of the requirement to work with a vehicle fleet involves perhaps the best-known of O.R. applications, the travelling salesman problem. This attempts to answer the question of what the best route for a delivery vehicle is where there are a number of stop-off points. We are so familiar with ubiquitous satellite navigation applications that it might seem that this is no longer a concern for business. But the reality is far more complex. The travelling salesman problem is described as being ‘NPhard’ – one where the time taken to produce an optimal solution shoots up exponentially as the number of possible route choices increases.

An app such as Google Maps may appear to find the best route, but in practice is unlikely to do more than find an acceptable route. Usually, when we use a sat nav we just want a good route to make a single journey. But the full travelling salesman problem faced by a logistics company needs to bring into the mix multiple vehicles with different carrying capacities, specific time windows (for example, the opening hours of a customer – there’s no point arriving to deliver when they are closed), multiple depots and a range of objectives. It is not just a matter of finding the quickest route from A to B. Miralis estimates that, depending on the problem and existing solution, their system can provide savings of around 15 per cent.

Maden emphasised the change that the use of technology to deliver far more data than has ever been available before has made to these kinds of solutions in the logistics field. ‘Logistics has always been, and still is, an iceberg of costs, with the vast majority unknown. Also, the effects of making changes on logistics operations is still risky as the reasoning behind a given approach is often unknown and therefore making changes could cause many unforeseen side effects. Data availability has managed to throw a light on some of that, allowing for some low-level advantages to be made. The advent or application of machine learning to logistics data means that more insight and improvement can be generated for the existing data gathered by some logistics firms and also suggesting potential new sources in data that may be fundamental in making changes.’

Machine learning techniques, which are increasingly used in the data science field, make it possible to deal with a complex situation without being sure about the structure of the problem. The software modifies its weightings for different factors until it is providing the best solution to match the data available. Although machine learning has its limitations – there is always a danger, for example, of ‘over-fitting’ data, to give a perfect match to what has happened in the past that has no bearing on what will happen in the future – machine learning makes it easier to cope with the increasingly large volumes of data that modern technology is throwing up.

THE ELECTRIC FUTURE One particular interest for Maden and the Miralis staff is the introduction of electric vehicles, which will transform transport infrastructure over the coming decade. Miralis is developing tools to help companies plan the transition from conventional fleets to using electric vehicles. Although environmentally beneficial, electric cars and trucks bring their own issues, making it necessary, for example, to provide tools to plan the location of charging infrastructure. As well as being an issue for companies and organisations putting charging points in place, this is also important because being able to charge vehicles adds another factor in the travelling salesman problem.

As well as working with individual companies on their electric vehicle needs and how to move from their current vehicles to an all-electric fleet, Miralis has been involved with both companies that offer electric charge points, consulting on how to best locate their technology, and a governmentfunded project called SOSCI (Scaling On-Street Charging Infrastructure). This was one of a number of initiatives looking at the specific problem that around 8 million homes in the UK have no access to off-street parking. Miralis’ work on the SOSCI project has developed into an innovative new charge point management system called Fuuse (www.fuuse.io) which is currently a significant part of Miralis’ activity. Domestic electric vehicles are usually charged using a home charging point, attached to the house or garage and wired into a mains distribution box. If electric cars are parked on the street, though, there is a need to be able to charge them at the curbside. Miralis worked with an existing operator, Charge My Street, first to look at the feasibility of different approaches to locating community-funded charge points in areas underserved by charge point operators, and then to provide a software platform to be used on up to 200 curbside charge points in Cumbria and County Durham to test this new approach.

Working in a company like Miralis involves a satisfying mix of problem-solving challenges that goes beyond the specifics of logistics, offering new and different challenges to those working there. Will Maden commented ‘Fundamentally I am fixated by problems; give me a problem to solve and I am happy. Once the problem is solved, my interest quickly wanes, which is where working for a company like Miralis is brilliant as we have within the team highly skilled professionals who pick up where I finish solving the problem, and turn this into something that can be re-used as either a consultancy solution or as a software solution.’

Miralis recently were the first winners of the ‘UK-Germany Digital Catapult Global Challenge’, applying AI and DLT to industrial challenges

(see https://bit.ly/Miraliswins ). Katy Ho, Head of Innovation Practice at Digital Catapult said: ‘Exciting high growth companies, such as Miralis, are evidence of the UK and Germany’s strengths in advanced digital technology innovation, matched with global industrial and sustainability challenges. Finding startups with innovative ideas and fostering international collaboration is exactly what the Global Challenge is all about.’ On their books in January 2021 is work on Goods As a Service (GaaS) partnering with CHEP. Geraint Th omas, innovation Lead – Northern Europe for CHEP: ‘Collaboration between a scaled up and established business, like ourselves, and dynamic SMEs, like Miralis, allow for us to think diff erently when it comes to innovation and customer solutions. Our organisations’ diff erent backgrounds and diff erent areas of expertise allow us to bounce off each other to facilitate real solutions, providing additional value to our customers.’ Other exciting work currently on the books includes drone routing, working with start-ups in the health and logistics sector, extending the optimisation suite for a piece of supply chain costing software, used internationally, and fi nishing a chain of custody system for goods and materials, showing where, when and what environment the goods pass through, with 5G sensors, working with BAE systems, IBM, Digital Catapult, AMRC and AQL.

It’s not surprising that Miralis is growing rapidly: up from 5 people in March 2020 to 11 in January 2021, and more to come. Going forward, it’s likely that the company and its staff will have plenty more challenges to come.

Contents

Apparatus bellis corrumperet Medusa, quod fiducias amputat verecundus suis.

Perspicax agricolae suffragarit Augustus. Suis vocificat fiducias.

Saburre miscere Aquae Sulis. Pessimus tremulus matrimonii insectat Octavius.

Satis saetosus ossifragi agnascor incredibiliter perspicax apparatus bellis. Satis quinquennalis fiducias imputat gulosus agricolae. JOURNAL OF Apparatus bellis corrumperet Medusa, quod fiducias amputat verecundus suis. SIMULATION Apparatus bellis corrumperet Medusa, quod fiducias amputat verecundus suis.

Perspicax agricolae suffragarit Augustus. Suis vocificat fiducias.

Saburre miscere Aquae Sulis. Pessimus tremulus matrimonii insectat Octavius.

Satis saetosus ossifragi agnascor incredibiliter perspicax apparatus bellis.

Satis quinquennalis fiducias imputat gulosus agricolae.

Apparatus bellis corrumperet Medusa, quod fiducias amputat verecundus suis. 00

00

00

Brian Clegg is a science journalist and author and who runs the www. popularscience.co.uk and his own www. brianclegg.net websites. After graduating with a Lancaster University MA in Operational Research in 1977, Brian joined the O.R. Department at British Airways. He left BA in 1994 to set up a creativity training business. He is now primarily a science writer: his latest title What Do You ink You Are? looks at the science of what makes you an individual. EJISJOURNAL OF THE OPERATIONAL RESEARCH SOCIETY00 00 00 00 00 VOLUME 00 NUMBER 00 MONTH 00 ISSN: 0960-085X THE EUROPEAN JOURNAL OF Journal of Simulation (JOS) aims to publish both articles and technical notes from researchers and practitioners active in the field of simulation. In JOS, the field of simulation includes the techniques, tools, methods and technologies of the application and the use of discrete-event simulation, agentbased modelling and system dynamics. We are also interested in models that are hybrids of these approaches. JOS encourages theoretical papers that span the breadth of the simulation process, including both modelling and analysis methodologies, as well as practical papers from a wide range of simulation applications in domains including, manufacturing, service, defence, health care 00 00 INFORMATION and general commerce. JOS will particularly seek topics that are not “mainstream” in nature but interesting and evocative to the simulation community as outlined above. 00 SYSTEMS Particular interest is paid to significant success in the use of simulation. JOS will publish the methodological and technological advances that represent significant progress toward the application 00 of simulation modelling-related theory and/or practice.

Other streams of interest will be practical applications that highlight insights into the contemporary practice of simulation modelling; articles that are tutorial in nature or that largely review existing literature as a contribution to the field, and articles based on empirical research such as questionnaire surveys, controlled experiments or more qualitative case studies.

Joint Editors

Christine Currie, University of Southampton, UK John Fowler, Arizona State University, USA Dov Te’eniLoo Hay Lee, National University of Singapore, Singapore VOLUME 00 NUMBER 00 MONTH 2018 Explore more today… http://bit.ly/2Gg9Zv9 T&F STEM @tandfSTEM @tandfengineering