Hoffmann Report Truly Positive Return To Ligna

Sikkens Introduce New Topcoats & Stains

World-Class Glass For The Joinery Network Members

SCM’s New Entries Attracted Considerable Interest At Ligna 2023

Harmonious Lift System Composition From Blum / Blum: Committed To Sustainability

Leitz’s New E-Commerce Platform Proves To Be A Success With Customers

Alwood Edges Ahead With HOMAG EDGETEQ S-300 And XES Glue Station

Introducing The AXYX Woodworker CNC Router

Think CNC … Think Masterwood

Hranipex – Immerse Yourself in Luxury. Discover Riextrack

Combilift – Celebrating 25 Years Of Lifting Innovation

IDS Launches Contemporary Decorative Feature Wall Panelling Range Decorative

Panels Lamination And Fineflex Metallics - A Recycled PET Collection

Powering Production With Holz-Her

Ecogate® Ligna Debut “Outstanding”

Materials & Finishes Show Announce Hranipex as Relaunch Partner

Ranheat Engineering - “One Stop Shop” For Wood-Waste Burning Equipment?

TM Machinery - More efficiency. More performance. Less Space.

Chilfen Joinery Invests In HOMAG SANDTEQ W-200

Biesse - Master Of Materials, Since 1969

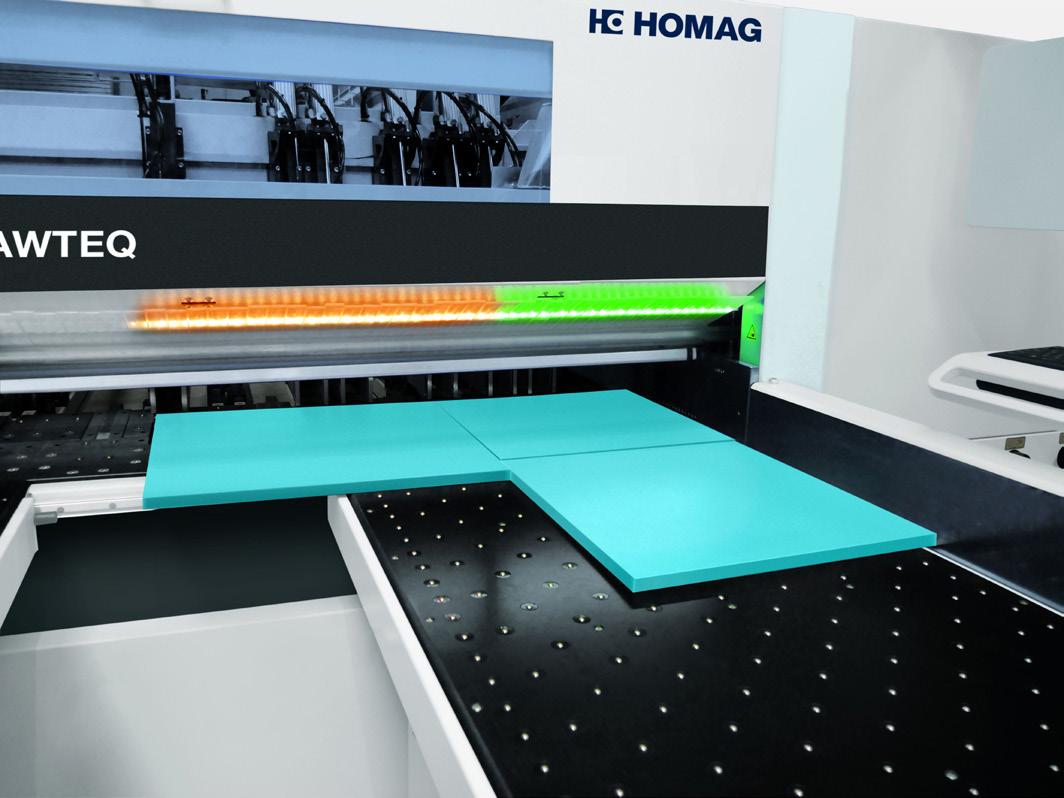

Homag’s Sawteq B-130 & B-200 Entry Level Beam Saws Punch Above Their Weight

Stakapal - Annual Racking Inspections - why are they needed?

PUBLISHED BY:

TELEPHONE:

EMAIL:

WEBSITE:

PUBLISHER:

DESIGNER:

PRINTER:

EC Media 21 Cedric Road Westgate on Sea Kent CT8 8NZ 0771 314 8831

ecmedia@btconnect.com

www.p-j-production.com

Clare Hollister

Russel Goldsmith

TRACE Creative Agency www.tracecreative.co.uk

The Magazine Printing Company www.magprint.co.uk

Reproduction of articles: All material appearing in Panel & Joinery Production is strictly copyright, and all rights are reserved.

No part of the publication may be copied or transmitted in any form whatsoever, including photocopying without prior permission of the publishers.

Publishers note: The editorial opinions expressed in Panel & Joinery Production are not necessarily those of the publishers, who shall be under no liablity with respect to any article published herein.

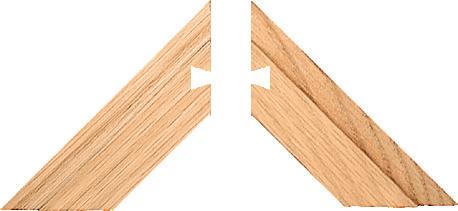

There were various machines on show at the event, ranging from the smaller bench top X-line 20 and MU-3, up to the free standing MS35- SF and PP2-NC. Also unveiled at the show was the new MU-S. Designed specifically for easy transport, use on site, and in limited space.

‘’Initially we weren’t sure what to expect prior to attending the show this year, but what you could really feel was that people were genuinely happy and excited to be visiting exhibitions again. It actually turned out to be very busy.

The beginning of the week was mainly international customers who had also visited the exhibition ‘Interzum’ in Cologne the week before. ‘’They were real quality buyers and decision makers, not only ‘’tourists’’. We had a busy stand from opening at 9am right through till closing at 6pm. We could not only meet end users and existing customers but also dealers, importers and especially our partners from Europe, the United States and more. This is very important to us because it’s very rare to be able to meet our partners face to face.’’

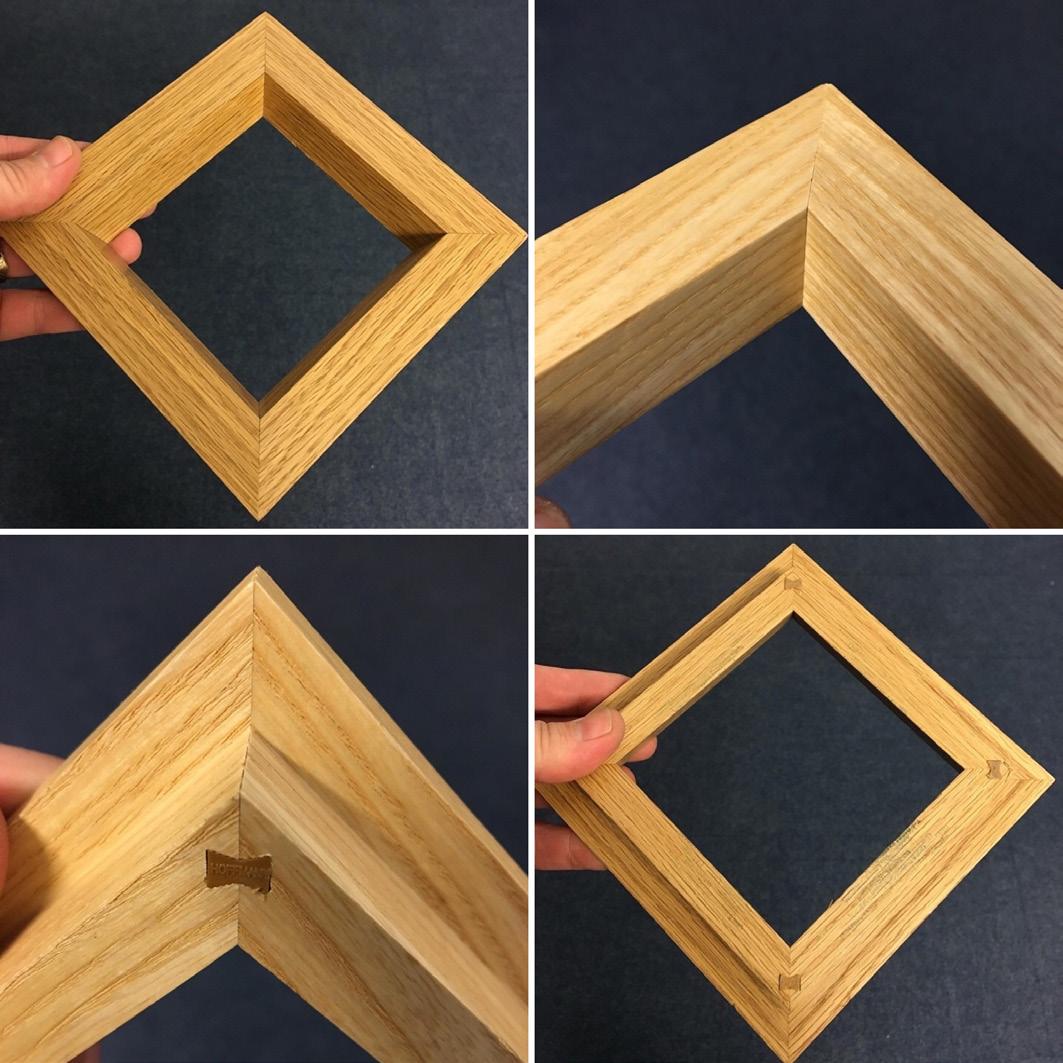

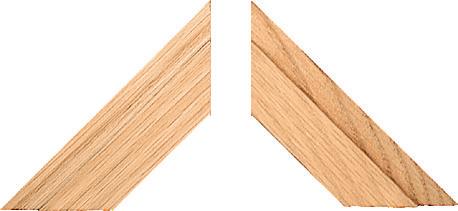

A wide range of machines were sold over the course of the show, from the smallest and newest MUS, right up to the MS35 SF double mitre saw. Many major Door-Set manufacturers were particularly interested in the Hoffmann MS35 SF to produce “Vision Panel Cassettes” and also “Architrave Sets”. The MS35 SF simplifies a time-consumingprocess and produces accurate joints in an essential area of door-set manufacture.”

All in all, it was a very satisfying show, and a very positive return after such a long pause. T:

MD. Thomas Hoffmann: -

Leading industrial wood coatings manufacturer adds fresh new products to its line-up of interior wood coatings stains and topcoats in EMEA.

Sikkens Wood Coatings shows that Colour is in its DNA with the recently introduced portfolio of interior coatings. As part of an eye-catching brand refresh, AkzoNobel has introduced a full range of stains and new topcoats to give customers even more design and creative flexibility.

The waterborne range of stains includes Wipe on Patinas, which provide an easy-to-apply option and countless design possibilities for pre-coated wood, while its Aqua Creative range offers pigmented stains with good hiding power and options for both opaque and transparent finishes.

The solventborne options include Universal Stains, offering a palette of very bright, colourful hues, to Antique Effect Patina and Vintage Patina Glaze for an entirely different look.

In addition, new topcoat products being introduced to the Sikkens Wood Coatings line-up include Aqualit Color T4401, a 1K opaque high-quality waterborne coating with great performance. Ideal for furniture, cabinets, and interior joinery, Aqualit Color T4401 is suitable for all types of wood and is available in a wide range of colour options, thanks to the Sikkens Wood Coatings waterborne tinting system.

Similarly, Aqualit Color T450-10 is a waterborne 1K or 2K topcoat offering consistent reduced gloss with good filling and hiding power, and great mechanical and chemical resistance. The lightfast properties of this new coating give it excellent resistance to fading.

Another key product in the expanded interior portfolio is the new Quantum T264-03 - the ultimate matt clear PU acrylic topcoat. Anti-fingerprint and resistance to scratches enable this solventborne 2K ultimate matt clear topcoat to provide a beautiful and lasting appearance every time.

“Our partners and end-users can now find a wide range of inspirational colour options with our new stains and topcoats for interior applications,” says Henri Bijsterbosch, Global Colour Marketing Manager, Industrial Coatings, AkzoNobel. “We offer countless hues according to NCS, RAL and Sikkens Wood Coatings 5051 collections, and provide associated colour fan decks and colour tools with real colour chips to help customers with their colour and design decisions,” he adds.

As part of AkzoNobel, a global leader in colour, Sikkens Wood Coatings is firmly committed to helping customers, not only with colour selection, but with colour quality and delivery. Its leading-edge colour technology tools, including a spectrophotometer colour measurement device, enable colour matching with ease and confidence. In addition, the Sikkens Wood Coatings colour software, available to distributors with selected fit-for-purpose tinting machine options, puts any imaginable colour at the fingertips of customers.

“Our creative thinking goes beyond the can,” says Bijsterbosch. “Our practical, end-to-end approach to colour adds real value to customers, giving them access to a wide range of versatile, high-performing coatings to suit every application and enable them to express their own creativity”.

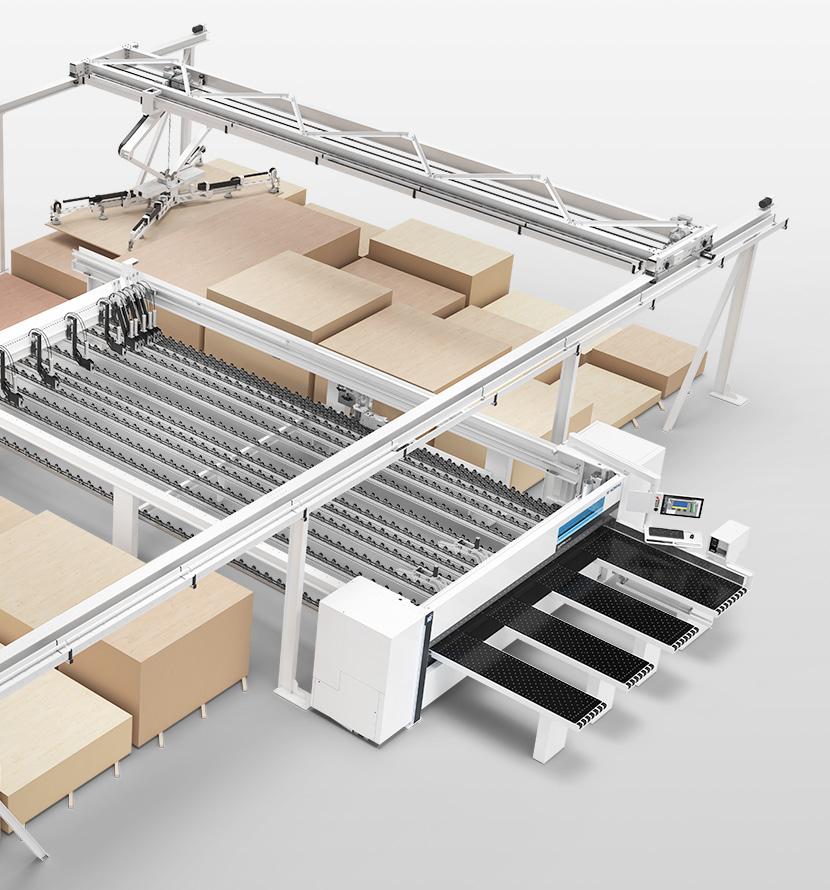

HOMAG offer a comprehensive range of panel saws to help process work with greater flexibility, speed and efficiency. Precision finish cutting solutions for both woodworking shops and industrial customers for every type of wood-based or plastic panel material.

The SAWTEQ S-100, is the smallest of the range. Competitively priced compared to a well-equipped table saw yet provides a much more precise, efficient and fast cutting process. Its compact footprint, sturdy design and proven technologies consistently deliver exceptional results.

With its power, precision and flexibility, the SAWTEQ S-200 offers everything a woodworking facility needs to cut panels horizontally. Two standard models can be enhanced with a wide range of technology options, customisable to any particular production requirements whilst remaining flexible for future growth needs.

High performance in a compact space is the strong point of the SAWTEQ S-300. This panel dividing saw is suitable for producing in batch size 1 as well as in smaller series and is ready for connection to automatic horizontal storage systems.

RegaLead is a member of an impressive affiliate company scheme as part of The Joinery Network’s extensive support for timber manufacturers. As a global leader in the supply of decorative products for the glass, windows and doors industries, RegaLead is the perfect partner. With over 30 years’ experience and a vast wealth of industry knowledge, RegaLead has created hundreds of designs for the fenestration market.

RegaLead is the exclusive supplier of decorative glass for the Lignum range of timber entrance doors. With 57 designs in both traditional and modern styles, and a stunning selection of decorative glass created by RegaLead, Lignum doors can be designed to suit every home. The Lignum door catalogue showcases the vast selection of sizes and designs available, including the classic-inspired glass designs, like the worker bee, which fits beautifully with the Bingen door style. RegaLead has also invested in supplying a huge range of design choices for joiners to offer customers, all on short lead times.

The Joinery Network Affiliate Programme brings specialist companies together to offer a range of services for businesses who manufacture and/or install timber windows and doors. It’s part of the added value that The Joinery Network brings alongside a fully tested window and door system.

Luke Piper, Director of The Joinery Network says: “There is higher demand from homeowners to use more sustainable products, but they have to perform from an energy efficiency perspective as well. RegaLead gives the Lignum door range a competitive advantage because it offers brilliance in both design and performance.”

The UK’s architecture demands huge choices from door manufacturers to suit the wide scope of properties. The Joinery Network offers 57 designs and RegaLead adds to these design options with a comprehensive range of decorative glass, both traditional and contemporary.

T: 033 33 44 98 95

https://thejoinerynetwork.co.uk

Outstanding success at the trade fair for SCM with visitors from more than 100 countries. Important contacts and negotiations in every strategic market starting with the DACH area and Northern Europe.

Considerable interest shown in the Group’s new automated and connected solutions, software and services for integrated digital processes and world previews from timber construction to laser sanding.

SCM recorded outstanding success at the 2023 edition of the Ligna Trade Fair. Thousands of customers and business visitors from more than 100 countries, crowded into the Group’s stand covering more than 3,000 m2 of exhibition space and more than fifty technological solutions between Hall 13 and Hall 16 (the latter being Superfici technologies for finishing).

There was an excellent return in terms of orders, negotiations and contacts on a vast range of product types and important opportunities arose in all the international markets, especially the DACH area, North and Eastern Europe, North and South America and South-East Asia. SCM presented innovations in all the application fields for secondary word processing, both physically at the trade fair as well as digitally and interactively. As well as the extensive demo programme organised at the SCM Live Show, at the heart of the stand, there was no lack of contributions to

Ligna. Recruiting and Ligna.Stage on the new trends for digital transformation and automation, timber construction and surface treatment.

Some of the new entries that elicited the greatest interest included automated and connected solutions developed for highly bespoke, versatile and sustainable production. The Smart&Human Factory system for the furniture industry presented new flexible cells with robot and integrated with unmanned AMR shuttles: gabbiani gt2 for beam saw, stefani cell E for edgebanding, morbidelli cx220 for drilling as well as a new cut c 200 right-size-box-making machine for cardboard packaging.

Also being presented for the first time at Hanover was a Smart&Human Factory model for joineries, an integrated cell for flexible and bespoke production from raw material to the finished piece of furniture, enhanced by its integration with an MES software.

Considerable interest at the fair for the latest integrated offer on software and services presented at the Digital Hub supporting each stage of the process: from planning and programming to after-sales assistance. These include the new functions on the Maestro cnc nest cutting optimiser, the Maestro optiwise optimiser for single-blade and angular panel saws, Maestro power TMS, optimiser to manage the tools inside the tool storages on the CNC machining

centres and Maestro 3drill for drilling. Some of the new HMI software presented includes Maestro active square for profiling, squaring and tenoning machines and Maestro active beam&saw for CNC machining centres for timber construction. Also attracting attention was the platform for Maestro connect digital services integrated into the “Woodworking made Izy” and the new Service Bundles, SCM service packages created to offer an integrated solution that helps the customer with any requirements.

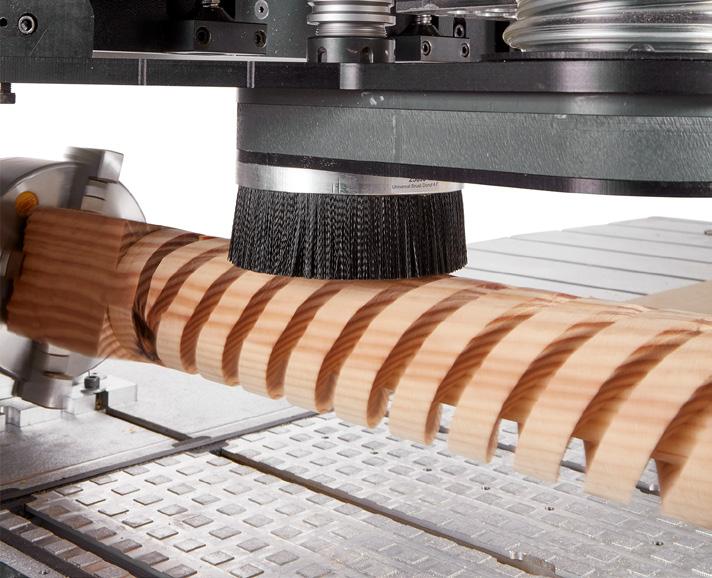

Some of the most popular machines include the new entries for timber construction and prefabricated houses, especially oikos xs, a cnc machining centre offering operating speed and high configuration levels, dedicated to the production of straight beams, prefabricated walls, trusses, roofs and blockhouses. A new entry that further extends SCM’s range of high-tech solutions for the sector together with dmc system xl to sand and calibrate X-lam/CLT panels and the other new entries on show at the Randek stand, an SCM partner specialising in advanced machining systems for prefabricated houses.

Also on show were SCM Surface Technologies products for integrated surface treatment, starting with the new dmc system tc automatic sanding-calibrating machine with laser unit and Never ending power sources, developed to create three-dimensional marking on parquet, wood elements, MDF panels to be ennobled, fibre cement panels and solid surfaces. Solutions capable of satisfying any processing demand for exclusive, sophisticated, fashionable finishing effects, as well as the Superfici new entries on display in Hall 16. They include the new compact xl sprayer, the uv led polymerisation system and the excimatt excimer technology for super matt finishing effects.

The CNC machining centres for panels and solid wood presented include morbidelli m100 with new FlexDrive worktable; morbidelli x200 with new in-cab labeller for nesting machining; accord 500 to manufacture doors, windows, stairs and solid wood elements.

The new olimpic 500 was presented for edgebanding to be used by artisan businesses looking for all the advantages of an edgebander in a compact space.

Some of the new entries presented digitally include the stefani sbx squaring-edgebanding machine for accurate squaring and top-quality machining, and windorflex, new automatic cell to produce complete windows and doors. Lastly, an extensive offer for artisan joinery where the new “Blade Off” safety system and the new starteck cn k 3-axis compact are highlighted.

The success of the five-day event was the crowning moment to an exceptional year for SCM and the entire Italian Group. As the Scm Group’s General Manager Luigi De Vito and the Product&Markets Director for the Wood Division, Pietro Gheller reminded us at the press conference, the Group’s turnover for the year ending 2022 was a record 850 million Euro (+14% on 2021) with orders of around 900 million Euro. The SCM Wood Division surpassed 600 million, again recording double-figure growth on the previous year and continues to gain global market shares in the woodworking industry: +1.5% from 2018 to 2021 with further advancement expected for 2022 while waiting for the final balance figures for the sector.

The fittings manufacturer demonstrated its sustainability credentials at interzum 2023

In a separate area of its trade fair stand and on the “Boulevard of Sustainability” at interzum in Cologne, Blum demonstrated the values of the family-run company and its commitment to sustainable business. The focus was on the challenge of precisely analysing the life cycle of the furniture in order to derive and implement appropriate measures. To preserve natural resources for future generations – a promise anchored in Blum’s fundamental orientation statement. The family business therefore largely focuses on the 17 Sustainable Development Goals, established by the United Nations, in their day-to-day activities. In order to demonstrate and substantiate these efforts, the Austrian fittings specialist showed its visitors at interzum 2023 concrete examples of sustainable action. Measures from areas such as energy and resources, transport and mobility as well as product sustainability were presented in a separate stand area on the North Boulevard of the trade fair centre, which this year was christened the “Boulevard of Sustainability”.

The company not only focuses on its own products, but also holistically on the entire life cycle of a piece of furniture –from the production of the raw materials, through all the manufacturing and assembly steps, until its usage and final disposal. This gives rise to questions such as: at which point in this life cycle are the most CO2 equivalents created? Where is the greatest potential for savings to protect the environment? What factors can Blum and its customers directly influence? At interzum, there were many points to discuss, such as the use of CO2-reduced materials or the correct storage of food and reduction of food waste.

For the first time, Blum presented a sustainability brochure for trade fair visitors, to illustrate the fittings manufacturer’s commitment and measures taken over the past business year. This 80-page comprehensive brochure is based on Global Reporting Initiative guidelines; in other words, it makes defined operational, ecological and social figures transparent and quickly comprehensible and comparable. It is available online at www.blum.com/sustainability

For the first time, Blum has compiled information about its own sustainability measures in a brochure

The compact design and integrated features of the AVENTOS top family are truly impressive.

Whether fold up, swing up and over, lift up or pivot up – lift systems for wall cabinets are practical and give total freedom of movement. Blum, the Austria-based manufacturer of fittings, offers compact AVENTOS HF top, HS top and HL top versions, as well as the existing AVENTOS HK top, to make dramatic solutions for the lift systems.

AVENTOS lift systems for wall cabinets are ergonomically advantageous and allow total freedom of movement, as well as best-possible access. Be it in the kitchen, the living room, the bathroom, or the hallway: Blum has different lift system types to provide the right solution for almost every installation situation to meet customers’ personal requirements – whether fold up, swing up and over, lift up or pivot up. The latest generation, the AVENTOS top family, has many impressive advantages in addition to the compact design: a set fixing position for the lift mechanism and the front fixing bracket for any cabinet height, adaptive BLUMOTION adjustment, and lift mechanism adjustment from the front, even when a cover cap is fitted. All this makes it easier to manufacture and assemble AVENTOS HF top, HS top and HL top, as well as the AVENTOS HK top stay lift that is already available on the market. Cross stabilisation is no longer necessary for AVENTOS HS top, and AVENTOS HF top can be implemented up to a cabinet height of 1200 mm for even more design freedom. AVENTOS HF top and AVENTOS HK top score points for their integrated opening angle stop.

There are two lift mechanism fixing methods available: an integrated positioning system or pre-mounted system screws, whichever best suits the respective production process. AVENTOS top hardly takes up any space at all, either in furniture or in the warehouse. The fittings are designed so that although manufacturers only need a few different components, they still have full control over the design. Because the lift mechanisms and levers are symmetrical in structure, they are suitable for several lift system sizes and can harmonise with all motion technologies. It is also possible to use the same cover cap for AVENTOS HF top, HS top and HL top, to ensure a consistent look with AVENTOS HK top. The minimalist design discreetly complements the furniture and has already won numerous awards.

AVENTOS HL top is suitable for creative applications, such as skilfully making the home office disappear

With AVENTOS HF top, it is possible to have a worktop mounted cabinet, where the removable top section easily reveals the contents, such as electrical appliances on a pull-out shelf as shown here.

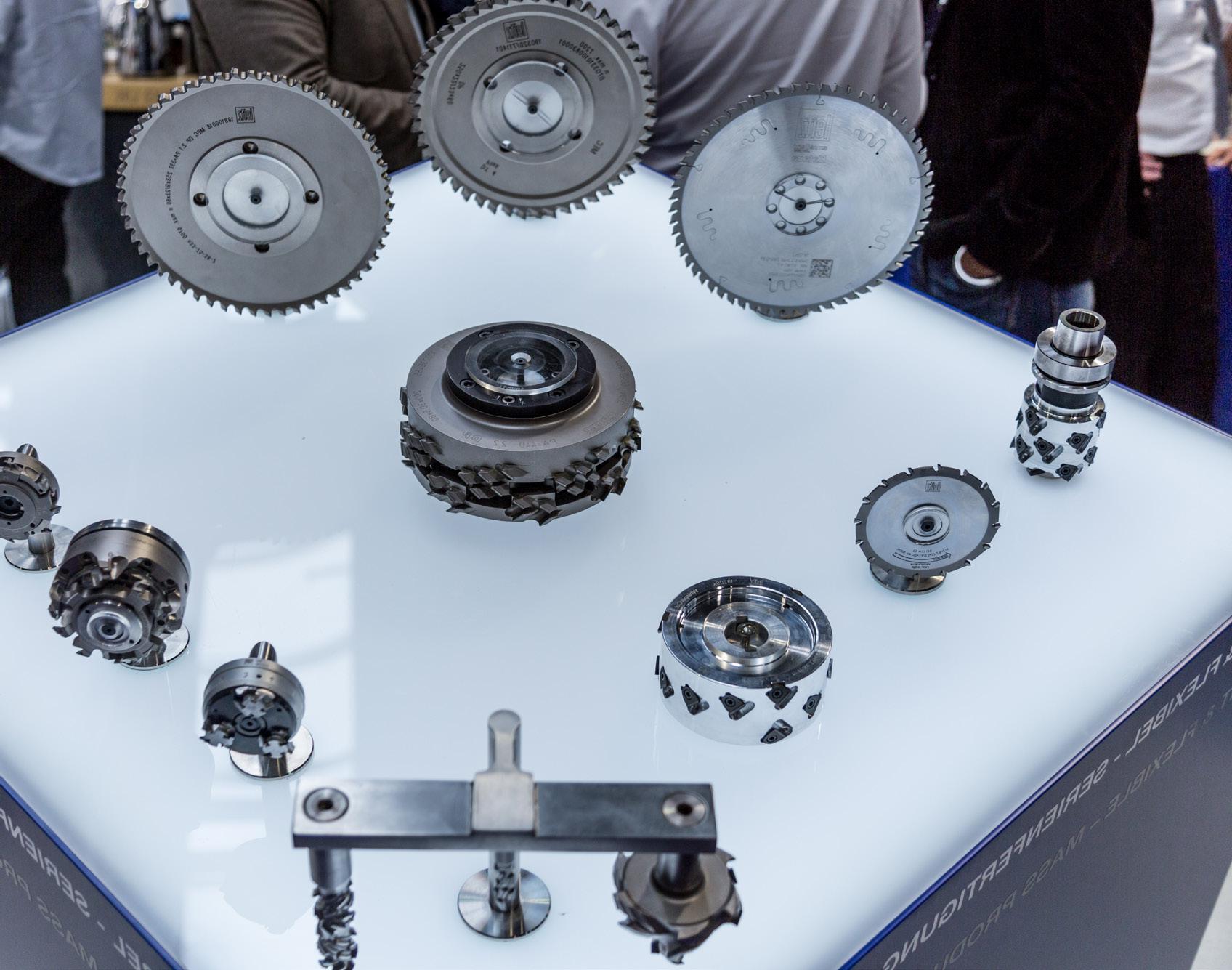

Leitz UK, the leading tooling solutions company, has been met with resoundingly positive feedback from its trade customers since the launch of its e-shop in February. The online store has streamlined the ordering process and transformed the customer experience –evidenced by its 4.7 Trustpilot rating and more than 30 5-star reviews.

The online store currently features over 400 of Leitz’s most popular tools, across six product categories – including its most popular consumables such as the ThermoGrip collect chuck, with more items being added daily.

In addition to the wide range of products available, customers now also have the added convenience of the service being available twenty-four hours a day, seven days a week. Simon Liddel, Managing Director for Leitz UK said,

“Our focus is to provide exceptional customer service and a comprehensive range of products; our new online service supports this by ensuring supplies are available to order any time customers need them, as all items are held on

a separate stock, and are sent via courier on a next day service, minimising downtime.”

“Our e-shop features a product finder to make it easier for customers to locate the correct parts and for larger businesses, support with the new option to deliver to multiple addresses, assisting the management of tooling needs for multi-site manufacturers.”

Registered account holders benefit from additional e-shop features to help support their stock management. These customers have instant access to price visibility and can take advantage of Leitz’s express checkout option by saving their favourite products to their profile. Repeat ordering has been made easier with customers now able to save order lists or upload previous invoices to help manage prior orders and quotes.

County Armagh based Alfred Briggs (Alwood) Limited is the oldest and most innovative kitchen manufacturer in Ireland. With its rich history of designing and manufacturing award winning bespoke kitchens and bedroom solutions, it serves the retail and developer markets.

Quality is the cornerstone of every product it manufactures which is why the company favours HOMAG woodworking machinery, as development manager Alfie Briggs explains: “We’ve been making kitchen and bedroom furniture since 1933 when my grandfather, Alfred Briggs, started the business. From the early days, our philosophy has always been to invest in the best machinery we could find.

“We were the first company in Ireland to purchase a CNC machine and have always found HOMAG equipment to be amongst the very best on the market. The machine build quality and consistency of finished workpieces that you get with HOMAG is without match, particularly when it comes to its edge banding machines.

“Most people have no idea as to the complexity of an edge bander. There are so many processes that go on under the skin of the machine including a joint trimming unit, a glue station, a snipping unit, a trimmer, a radius scraper, a glue joint scraper and a buffing unit. Each has to work perfectly in order to produce first-class joints between the edge tape and the panel.”

“Our investment in the new HOMAG EDGETEQ S-300 with XES 200 glue station came about because the previous edge bander had reached the end of its productive life and we wanted to upgrade to a better quality model.

“With the new edge bander we wanted to be able to use water resistant PUR glue as well as the standard EVA glue. PUR glue offers increased resistance to moisture and heat. Consequently, it is ideal for use in manufacturing items that will be exposed to damp such as our kitchen furniture.

“Because we focus on small run, bespoke solutions, we don’t put high volumes through the edge bander. One drawback of this is that it can cause issues with PUR glue, particularly if there are extended interruptions to work such as overnight or over the weekend, when the PUR glue can go off.

“For this reason we also invested in a HOMAG XES 200 glue station. This clever piece of kit eliminates these issues. It is a really compact unit with a footprint of less than 1m2, and it enables easy, efficient switching between different colours and glue types.”

The station stores the glue application units in a vacuum; this delays the bonding time so that the PUR glue does not harden during an interruption to production. It then preheats the glue application unit to minimise downtime before use. Also, cleaning or glue change can be done automatically without interrupting production on the edge banding machine.

Alfie Briggs again, “The majority of the machines in our workshop are from HOMAG UK. When it came to choosing a replacement for our old edge bander, however, it was important we did our due diligence thoroughly to ensure we found the best solution for our needs.

“A couple of our engineers had a good look at the alternative machines in the marketplace. They carried out research both online and at exhibitions to see what different manufacturers had to offer. Whilst HOMAG is often our first port of call, it was by no means a done deal that they would get the order.

“At the end of the due diligence process we were convinced that overall the EDGETEQ S-300 with the XES glue station was the best fit for our requirements. Our production engineer worked closely with HOMAG to specify the machine to make sure it was fit for purpose.”

“Once the EDGETEQ was installed and commissioned, the HOMAG engineers trained our staff on site. The process was well planned and it meant we were up and running in about four days.

“We can now produce much higher quality products which we are confident will stand up against any of our competition. The PUR glue option gives us more flexibility and enables us to manufacture in smaller batches for bespoke solutions.

“The peace of mind we get from partnering with HOMAG means we can get on with designing and manufacturing the very best kitchen and bedroom furniture solutions. We don’t have to think about the quality of finish or the backup service; we just know it’s going to be first-class,” concludes Briggs.

AXYZ, a leading provider of CNC routing solutions, is excited to unveil the all-new AXYZ WOODWORKER CNC Router. Designed to revolutionise the woodworking industry, this powerful all-in-one solution is engineered for fast and effortless high-volume cabinetry and furniture production. With its customised machine configuration and a range of specially developed options, the WOODWORKER offers furniture and cabinet makers a clean and efficient manufacturing process.

KEY FEATURES OF THE AXYZ WOODWORKER

CNC ROUTER INCLUDE:

Versatile Process Areas: The WOODWORKER boasts a wide variety of process areas that can accommodate all standard sheet sizes, with a remarkable 10” high gantry clearance. This flexibility makes it easy to use with accessories such as vacuum pods or a rotary axis device, enhancing productivity and precision.

Exceptional Performance: Equipped with powerful direct servo drives and helical racks, the WOODWORKER delivers outstanding performance, high-speed cutting, and impeccable finishes across a wide range of wood types. It excels even with phenolic-based products like High Pressure Laminate (HPL).

Multiple Spindle Configurations: The WOODWORKER offers a choice of a single 5, 10, or 15HP HSD spindle, allowing users to tailor their setup to match specific production requirements. Additionally, a 9-position drill bank can be added to the multi-head configuration for faster and more productive operations.

Efficient Tool Changing: With a selection of 7, 10, 14, or 21 position automatic tool changers, the WOODWORKER ensures fast and efficient tool changes, minimising downtime and maximising productivity.

Advanced Dust Collection: The router features a high-volume 4” dust collection system, complemented by an oversized dust boot, high-flow manifold, and hose management system. This comprehensive setup effectively collects both large chips and fine dust, maintaining a clean and safe working environment.

Automated Label Printing: The WOODWORKER offers an optional AXYZ Automated Label Printer (ALP), simplifying the identification of parts during the final assembly process. This integrated solution streamlines operations and enhanced overall efficiency.

Rotary Axis Equipment: For machining complex parts requiring 360° rotation, the WOODWORKER offers optional rotary axis equipment. This feature expands the router’s capabilities and enables the production of intricate and precise parts.

When it comes to furniture and cabinet making, the AXYZ WOODWORKER is the ultimate CNC solution, AXYZ has put extensive effort into developing a machine that seamlessly combines power, versatility, and precision to meet the unique needs of woodworking professionals. AXYZ is confident that the WOODWORKER will revolutionise the industry by delivering exceptional performance and transforming production processes.

Discover the future of CNC woodworking technology with the all-new WOODWORKER from AXYZ. To learn more about this groundbreaking solution and how it can be customised to your exact needs, visit our website.

AXYZ is a leading global manufacturer of CNC routing and engraving solutions. With over 30 years of industry expertise, the company offers an extensive range of high-quality routers and ancillary equipment that cater to the diverse needs of various industries, including woodworking, signage, plastics, and metal fabrication. AXYZ is committed to delivering innovative, reliable and efficient solutions that empower businesses to achieve exceptional results.

Since the merger with KDT Machinery, Masterwood has introduced further machines for use in the panel industry. Over the past few years, our range has expanded to include high-speed drilling/routering CNC’s, Beam Saws, Panel Saws, and now - a selection of Edge-Banders. These new additions are built by KDT in China, before being sent to the Masterwood factory in Rimini, Italy, where they are upgraded to meet CE regulations, and are now being sold around Europe under the Masterwood name.

BEAM SAWS: With sheet cutting sizes from 3200mm x 3180mm up to 4300mm x 4280mm; these are a solid build, fast working machines, and can also be supplied with automatic rear loading systems to maximise space and production.

PANEL SAWS: Having already proven a success with sales and good reviews across Europe, the first Panel Saws from Masterwood are now available in the UK with the first one installed in June 2023. These High specification machines are fully computer controlled for stop, fence and saw positioning.

HIGH-SPEED DRILLING: The TF600 range can work on all six faces of a panel in one sequence, plus drill and router panels from above and below simultaneously. The TF600 KT model with a five-position tool changer is proving very popular for its working speed and accuracy.

EDGE-BANDERS: The most recent developments from the Masterwood/KDT partnership are the single sided automatic edge banders. Solidly built to reduce vibration and increase the quality of the final product, the machines are available in three models, from entry to high production.

The Matrix bed collection starts with the entry 2500mm x 1250mm bed, working up through a large range of sheet sizes, to beds of 7500mm in length. These machines are built with a solid frame bed, with the gantries driven on both sides of the matrix bed for added accuracy and long-lasting reliability.

These can be supplied with infeed and outfeed systems to automate production, or as stand-alone machines for smaller scale production. Barcode and label printing systems can also be added.

All of these machines can be manually fed or supplied with a mixture of automatic loading and unloading equipment, including Robotics.

All our machines are supplied with the tried and tested MasterWorks Cad/Cam; an easy to use, but powerful package for most CNC work. This software has had regular upgrades to keep up with current advances and includes options for macros to allow simple setting for items like Lamello jointing systems.

A new edition, known as the Winner HP, has recently been introduced. This special matrix bed is equipped with a highefficient vacuum system which allows an MDF baseboard to be fitted and ensures even small components are held firmly in place, while also allowing positioning of vacuum pods anywhere on the baseboard.

Starting with an entry level Project 250, moving through the larger 300 and 400 Project series to the top end Project 500 range, these CNC machines can be supplied in all formats for solid timbers, panels, composites, and other materials. This includes long or short beds, cantilever or gantry designs, manual or automatic beds, in 3, 4, or 5 axis formats.

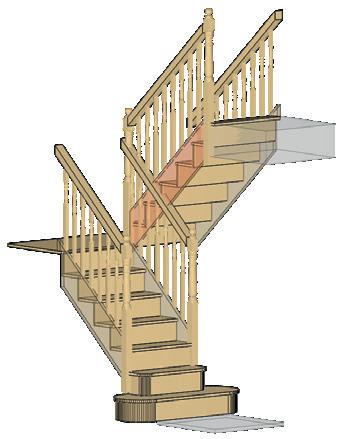

Keeping with tradition, Masterwood continues to develop bespoke and dedicated solutions for the solid timber industry. A recent introduction of the Teknoline, a CNC for high levels of door frame production, bolsters the innovative machining options Masterwood offers. Other dedicated machines Masterwood can provide include the 4WIN - for windows, Project Door - for full size doors, DoorLine -for door locks and hinges, and Teknomat - for window and frame components.

In addition, there are dedicated packages to cover Staircases, Windows, Door Sets (timber frame & solid core), Traditional Box Windows, Cabinets, Furniture, Louvres, and the latest 3D software for 3, 4, and 5-axis work. Any of these packages can be added to a customer’s machine at any time, giving them the ability to change direction or production methods, if required. All Masterwood software packages come with full on-site installation, and training to meet the customer’s manufacturing needs.

At Masterwood GB, the UK and Ireland representative for Masterwood Spa, we take great pride in our after-sales customer service. Not just for the immediate future after the purchase of the machine, but for many years to come. We understand that for first time buyers, CNC is likely to be the biggest investment a company makes, so it’s important that they see the results in their production as soon as possible and feel comfortable with the direction they have taken. We have a team of experienced technicians to cover installation and training for new and old machines, software support, servicing, and repairs.

This cutting-edge double wall slide kit exclusively from Hranipex brings a modern option to elevate your furniture manufacturing.

RiexTrack (F000183) presents a contemporary and efficient solution for drawer organisation, thanks to its 13mm slim metal slides. These sides not only enhance the overall drawer capacity but also provide a tangible and valuable benefit that consumers truly appreciate. Despite their slim profile, these double-wall side panels offer exceptional strength and stability. Designed to withstand daily usage, making them suitable for both residential and commercial applications.

Hranipex expert discusses RiexTrack capabilities

Adam Stevenitt, Hranipex business development manager confirms ‘‘The resounding success of RiexTrack in the market due to its sleek and contemporary appearance, coupled with its impressive load capacity of 40kg, means that even at maximum load, the drawer maintains excellent durability and reliability for many years without compromising its structural integrity.’’ Adam adds ‘’One of the standout features of this drawer assembly kit is its simplicity of assembly. The process involves minimal cutting for the drawer base, back panel, and front panel, eliminating the need for complex carpentry work. This user-friendly approach ensures that anyone, regardless of their skill level, can successfully assemble the drawers in a short amount of time.’’

railing offers two mounting options: a 10mm dowel or a screw mount. This versatile design allows you to choose the method that best suits your needs and preferences (Both included in the kits). Whether you prefer the convenience of a dowel or the added stability of a screw mount, the RiexTrack railings provide the flexibility to accommodate your specific requirements.’’

The range also includes inner division accessories (F000618), a profile divider for the internal space of RiexTrack drawers. This tangible asset allows the profile and the connecting plastic elements to create smaller compartments for bottles and other smaller items. Longitudinally, the profile is shortened by 40mm compared to the nominal drawer length (NL). Width wise it shortens by 52mm compared to the internal width of the cabinet (LW).

To experience maximum organisation with RiexTrack the range includes cutlery trays with side panels and dividers. (F000696). Available in a variety of compositions to suit your customer’s needs.

As a standard feature, the range is equipped with softclosing slides, adding a touch of elegance and practicality to your storage solution. The soft-closing mechanism allows for gentle and quiet closing, eliminating any slamming. This feature not only guarantees adaptability to various settings such as living spaces, offices, or educational institutions but also extends the lifespan of the drawer by reducing wear and tear.

Additionally, the RiexTrack set of 2 Square Railings (F000651) is specifically crafted to strengthen the raised sides of your drawers. Designed with durability and flexibility in mind, these railings provide added support while allowing for customisable adjustments. Adam Stevenitt confirms ‘’The front of the railing offers two mounting options: a 10mm dowel or a screw mount. This versatile design allows you to choose the method that best suits your needs and preferences (Both included in the kits). Whether you prefer the convenience of a dowel or the added stability of a screw mount, the RiexTrack railings provide the flexibility to accommodate your specific requirements.’’

For more information on RiexTrack visit Hranipex UK at hranipex.co.uk or call

F000183 F000651 F000696

When Combilift was established in 1998 it had a handful of employees working from a small manufacturing facility in a village near Monaghan Town. Since the company designed and launched the C4000 - the world’s first engine powered, all-wheel drive multidirectional forklift, it has been globally acknowledged as an unparalleled success story in the materials handling sector. It now exports to more than 85 countries and employs a workforce of over 700 people at its 46,500 m² HQ and factory – just a few miles from its original site. The first half of Combilift’s anniversary year has been quite eventful, with new products being launched at major trade fairs and the roll-out of truck number 75,000 from the production lines.

The timber, panel and joinery sectors were the first industries to recognise and appreciate the groundbreaking qualities of the multidirectional C4000 as well as the many other innovative models that have followed over the past quarter century, and they continue to be very important markets. Combilift is still headed up by the two founders, MD Martin McVicar and Technical Director Robert Moffett, whose combined engineering expertise and a strategy of substantial investment in R&D (7% of annual revenue) has enabled the company to always keep one step ahead of other manufacturers when it comes to introducing new models and concepts onto the market.

To mark this milestone, Combilift is launching no fewer than five new models throughout the year, the first of which was unveiled at the LogiMAT logistics trade fair in Stuttgart in April. The Combi-CUBE is an electric model which incorporates a host of technological and design features that enhance handling procedures and offer a high level of driver comfort. The driver’s position in the centre of the cab offers generous room and excellent all-round visibility. The angle of the telescopic steering column can be adjusted and the Grammer MSG65 seat, combined with hydraulic cabin mounts, guarantees a comfortable ride. An adjustable arm rest is mounted to the seat suspension which incorporates a multi-function joystick and an LCD colour touch screen. The optional unique Dynamic 360 Steering enables seamless directional change, making this model the most manoeuvrable counterbalance forklift on the market. At the Ligna trade fair in Hanover just a few weeks later, it

was the turn of the Combi-CB70E to take centre stage. This has been designed for sectors such as the timber industry in mind: it boasts the distinction of being the shortest 7t capacity counterbalance truck on the market whilst also benefitting from multidirectional ability, enabling the versatile space saving handling of both long and bulky loads such as packs of timber, even in very confined spaces. It also features the optional newly developed Auto Swivel Seat, which automatically engages and swivels the seat and armrest 15° to the right or left to accord with the direction of travel selected by the operator - reducing driver strain, particularly when travelling in reverse.

When the 75,000th Combilift - an Aisle Master articulated forklift – rolled off the production lines earlier in the year, Combilift’s management had already taken the decision to donate this truck to a charity. Convoy of Hope, a US based non-profit humanitarian and disaster relief organization which works with communities volunteers around the globe, was already using a number of Aisle Masters at its World Distribution Center in Springfield, Missouri, and these trucks have enabled quicker movement of loads, the best possible storage density and very efficient operation. Erik Meier, Senior Vice President – Supply Chain said: “We are so grateful to Combilift for donating this valuable piece of equipment – this is going to help people for years and ensure that every day someone in the world receives aid, and that brings hope.”

Martin McVicar, Combilift’s CEO points to yet more new products for the second half of the year. These will be further additions to the company’s ever growing range of electric models which offer powerful performance, extensive battery life and unrivalled ergonomics which at the same time help companies to achieve their aims for more sustainable operations. “We are looking forward to more events and opportunities to mark this milestone with our customers, dealers, sales personnel, representatives from the international press and of course our workforce. Their loyalty and support has been pivotal in enabling us to achieve the amazing level of growth and success that we have experienced during the last 25 years. We’re not going to rest on our laurels though – you can expect more innovation from us in the next few decades to come!”

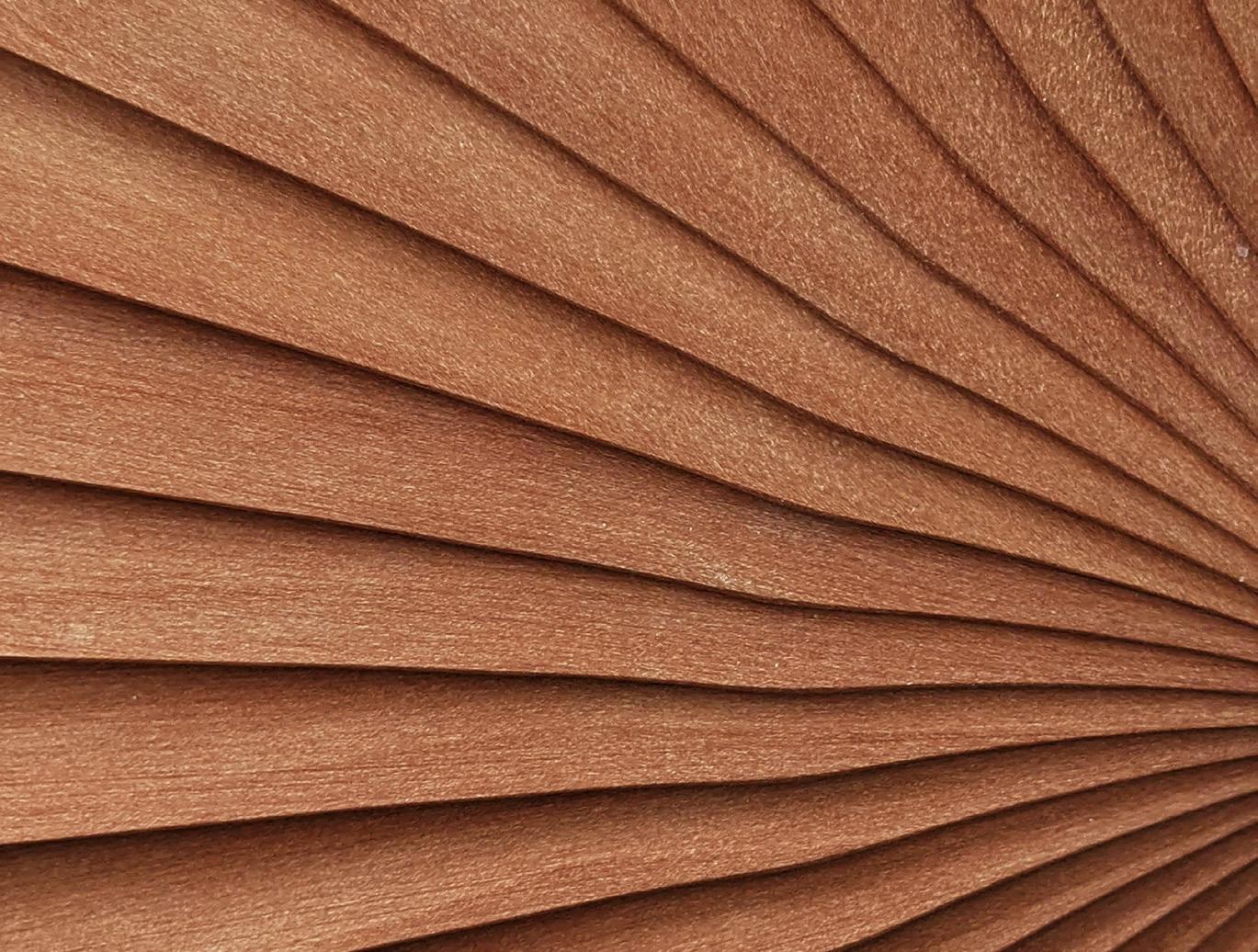

Specialist surface materials distributor IDS has expanded its wall panelling portfolio with Feature Wall, a new range of contemporary decorative panels.

Launched in response to the growing demand for stylish, slatted wood walls, Feature Wall panels are lightweight, easy to cut and simple to install. They are available in two sizes of 2400 x 600 x 22mm and 3000 x 600 x 22mm with concealed joins between each panel for a seamless finish.

Embracing the interior trend for contemporary, fluted finishes, Feature Wall panels add warmth and texture and provide homeowners, designers and installers with a striking and versatile design solution. Available in three real wood veneers, Feature Wall panels can help consumers transform walls in most rooms in the house: from kitchens, living rooms and bedrooms to hallways and home offices.

With their neutral tones, Natural Oak and Silver Oak are ideal for minimalist schemes or for those looking to bring modern Scandi style to the home. The darker Charcoal Oak will inject a touch of drama and is the ultimate choice for a luxurious, maximalist interior scheme.

Perfect for commercial as well as residential settings, Feature Wall panels are noise absorbing thanks to the density of their black felt backing. They are easy to install vertically or horizontally and can be adhered or screwed directly to the wall. To create a clean and uncluttered aesthetic, the panels can also be attached to battens to allow space to neatly conceal cables from view.

Feature Wall panels are made from black FSC® certified fire resistant MDF and come with a one-year warranty.

Feature Wall is available for 24-48 hour delivery from all IDS branches nationwide.

Feature Wall is a new range of contemporary decorative wall panels from IDS. The panels are lightweight, easy to cut and simple to install either vertically or horizontally. Panels are available in sizes of 2400 x 600 x 22mm and 3000 x 600 x 22mm in three real wood veneers: Natural Oak, Silver Oak and Charcoal Oak. Ideal for commercial and residential settings; Feature Wall panels are noise absorbing and can be adhered or screwed directly to the wall or attached to battens to allow space to neatly conceal cables from view. Pictured is Silver Oak. Feature Wall is available for 24-48 hour delivery from all IDS branches nationwide.

T: 0845 7 298 298

E: info@feature-wall.co.uk

www.idsurfaces.co.uk

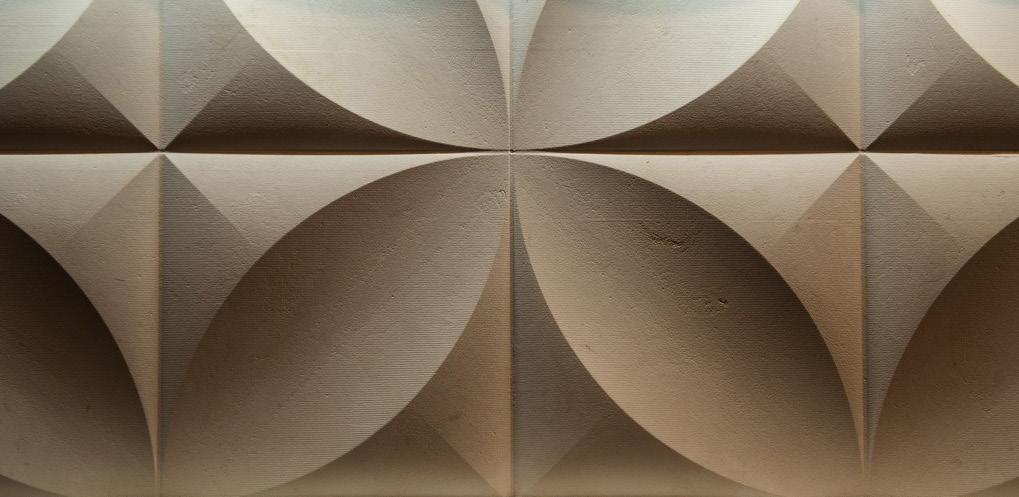

Decorative Panels Lamination have introduced to their already extensive dp-specialist range, a collection of Fineflex Metallic designs. The PET surface is made with a percentage of recycled PET and the iridescent shimmer is visible throughout the pigment creating a luxurious finish to both the eye and the touch.

With the merge of two premium surfacing brands; Fine Decor and Schattdecor, years of design expertise in the field of solid colours and decor printing have come together, along with pioneering technology to produce sustainable lacquer laminate surfaces. The two companies are united in their first joint product – Fineflex. A quality surface made with a percentage of recycled PET.

Through a patented lacquering process, a surface with a unique feel and anti-fingerprint technology has been achieved. Fineflex is particularly easy to clean and conforms to 6250 and 6222 standards. Thanks to its moisture resistance, the surface is not only ideal for furniture surfaces, but is also particularly suitable for use in humid areas such as kitchens and bathrooms. With outstanding processing properties, Fineflex is an environmentally conscious alternative for 2D lamination, as a thermoforming film for three-dimensional surfaces and wrapping or postforming.

With growing awareness and an increased drive to provide sustainable options for the market, Decorative Panels Lamination are certain the addition of 6 FineFlex metallics will be welcomed by their customers. Metallics have been coming into trend for some time now, but it has always been difficult to achieve consistency within the colour. Fineflex metallic surfaces do just that, their iridescent shimmer is visible throughout the pigment creating a luxurious finish to both the eye and the touch. The super matt finish is distinguished by the 6 warm and subtle earthy tones perfectly suited to create focal points and feature panels throughout the home.

Schattdecor and Fine Decor have a unique process to recycle the manufacturing scrap from their own production cycle into new raw material, thus bringing it full circle back into the production process. Decorative Panels Lamination are now part of the solution offering the perfect combination of firstclass design and surface quality with increased sustainability.

Available on 1220mm wide laminated on MDF and dp-lite Hollowcore board in a range of thicknesses.

To find out more about the Fineflex Metallic Collection and Decorative Panels Lamination’s wide range of decorative surfaces:

T: 01484 658341

www.decorativepanels.co.uk

Not only do we stock Reactive HotMelt Adhesive for Prole Wrapping and Edge Banding Applications.

We also stock Nordson compatible spare parts for EB 60V Slot Nozzles , Heated Hoses , Platen Seal for BM 200 and BM 20 Systems and generally anything to do with Prole Wrapping!

We also supply Slitting Blades, Moulder Wheels, Heat Guns, Elements and Brushes for Heat Guns

We have one of the largest stocks of Wrapping Wheels in the UK ! Stocking 30 different types and 8 different shore hardness! So literally thousands on stock at all times!!

Powerful performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range - the new COMBi-CB70E electric multidirectional forklift is the most compact 7,000kg counterbalance truck on the market. Its ability to handle long and bulky loads maximises the safety, storage & efficiency of your logistics.

Features incorporated in the Combi-CB70E that greatly enhance operator comfort include excellent all-round visibility, a spacious gas-strut suspension cab, independent electric traction and our newly developed Auto Swivel Seat which intelligently swivels 15°in the direction of travel.

To find out how Combilift can help you unlock every inch of your storage space.

2 5 combilift.com

Introducing the new Power-Pin from Holz-Her. Launched at LIGNA 2023, this state-of-the-art drilling and dowel insertion machine is the perfect complement to nesting. With a horizontal drilling aggregate and a dowel insertion unit as standard, it eliminates the need for manual dowel insertion after CNC machining – presenting huge cost and time-saving benefits.

Suitable for use with workpieces from 60mm2600mm in length, widths of 150mm for both horizontal and vertical machining and thickness of 12mm-60mm, the Power-Pin offers adaptable workpiece sizing.

Designed to incorporate all aggregates and storage tanks in the machine, the Power-Pin has a footprint of just 4m³ and an overall height of just 1755 mm (2095mm with the machine lid open). The space on the lid has also been cleverly designed to offers storage space for workpieces and depending on material flow, the Power-Pin can stand freely in a room or be placed against the wall.

The Power-Pin can drive in both pre-coated dowels and standard wooden dowels measuring 30mm, 35mm and 40mm in length. For Standard wooden dowels, glue is injected into the holes prior to insertion. With the optional second step conveyor, the change from 6mm to 8mm dowels is done in minutes.

For simple machining on the Power-Pin Dynamic, automatic program selection measures the width of the workpiece via a light barrier. When a preprogrammed workpiece width is detected, the appropriate program is automatically loaded. Additional VISE LED position indicators also simply operation further. On the Classic, the drilling depths and height can be set manually with two pre-defied drilling depths.

Holz-Her’s Campus NC-HOPS software comes as standard on every Power-Pin. With simple operation at the forefront of its design, the software allows the user to programme individual components and adapt them quickly using simple macros. It’s EasySnaps parametrically programmable feature also guarantees the upmost precision, whilst the complete machining operation is displayed in a 3D format on a 21.5” touch screen display for ease of use.

For short machining cycles, the dowelling unit can be variably off-set in 32mm increments up to 192mm, with the software automatically calculating whether simultaneous dowelling and drilling is possible. Depending on the number of holes and dowels, this can result in a 20% reduction in time.

Eco Mode offers a time controlled shutdown to save energy and reduce running costs.

The large-area support table enables multi-area loading of up to four components at one time. The intuitive clamping concept - which automatically adjusts depending on the material being processed - ensures that longer components up to 2600m can be loaded and uploaded quickly and safely. It also makes for simple operation when running large batch and recurring component sizes.

The 3-fold drilling unit allows for a variable speed of 2750mm – 4000 min and individually pre-settable drilling spindles in a 32 mm grid - ideal for carcass construction.

Paul Nightingale, National Sales Manager, Holz-Her UK: “The new Power-Pin offers vast time savings as the horizontal drilling and dowelling can be done by the nesting CNC operator whilst the next sheet is being nested. Thanks to machine’s low machine height, the operator can easily oversee the nesting process whilst drilling and dowelling in masked time – essentially completing this step without adding any time whatsoever to production.”

For more information please visit holzher.co.uk

Ecogate Ltd made its inaugural appearance at the longawaited Ligna exhibition and, by all accounts, the sales and technical team couldn’t help but woo visitors from all sectors of the woodworking industry with the latest energy-saving technology for dust and fume extraction.

Sales director, Jake Oldfield, admitted that they were “hardpushed to cope with the level of visitor interest, which was nothing short of outstanding, but I think we did manage to speak with everyone who approached us for information and advice.”

“The Ecogate® system has been around for well over a decade now, and over that time the concept has been well received by the UK market,” says sales manager Ian Rayner, “but electricity price hikes over the last 12 months have really hit home with manufacturers both at home and in Europe. Halving the cost of running your dust extraction system is an opportunity no factory owner wants to ignore, and the fact that the system can often pay for itself within 2 years, and then continue to reap savings, makes it a nobrainer.”

Here in the UK, Ecogate have a sole distribution agreement with Extractly Ltd and, with interest in the energy-saving technology burgeoning, the company is now actively seeking to establish further dealerships both here and in Europe. “The potential for take up of Ecogate technology in the current economic climate is significant,” says Jake Oldfield, “and the levels of enthusiasm we saw at Ligna – from both manufacturers and possible sales partners – was very encouraging.”

As with so many good ideas the concept is basically very simple, and the theory behind Ecogate’s on- demand energysaving technology is based on age-old laws of physics, but the system’s efficiency relies more on today’s computer processing power to achieve the energy savings. Realising the reduction in fan speeds is where Ecogate’s patented technology comes to the fore – reacting automatically, in real-time, to changes in demand for extraction.

Effectively, a small reduction in extraction fan speed results in a disproportionately large reduction in the amount of electricity consumed by the fan’s motor. In fact, as a rule-ofthumb guide, reducing fan speeds by just 20% will reduce electricity consumption by 50%... which means energy bills are typically halved.

When all machine stopping and starting is monitored throughout an average working day in a joinery shop or furniture manufacturing facility, the extraction system is typically only required to operate for around 80% of the time; and it’s the 20% of ‘downtime’ that an Ecogate system capitalises on – any time a machine comes online, the dust extraction adjusts automatically to accommodate the new extraction volume requirement. Similarly, when a machine ceases operations, the fan speed is reduced and energy consumption decreases.

Traditional extraction systems operate continuously throughout the working day, with the fan motor running constantly, at full power. With Ecogate installed, fan speed is continuously varied to exactly match extraction demand and optimise energy usage.

At Ligna, this principle was demonstrated very effectively with an interactive working display which also featured Ecogate’s latest development – the new “greenBOX Nxt” controller. Visitors to the stand were invited to mimic the action of a machine starting up by pressing a large ‘gameshow-like’ button. This change in demand for ‘extraction’ was acknowledged by the greenBOX Nxt, which in turn operated one of the display’s automatic dampers, which lit up like a Christmas tree to show it was opening! Simultaneously, an extractor fan started-up, and the ‘system’ status could then be monitored on the Nxt’s colour touchscreen. Pressing a second button opened another damper and the fan speed increased accordingly. Pressing one of the buttons again then closed a damper, the fan slowed down, and the actual power saving being made was displayed on the screen.

Ecogate’s new greenBOX Nxt controller is highly intelligent. As well as controlling the extraction system, real-time performance data shows how much electricity the fan motor is consuming, it checks filter pressure, air volume and air velocity at dampers, branches, as well as across the entire system, and also monitors machine utilisation across the factory. The greenBOX Nxt is able to stop and start the extraction system automatically at both ends of the working day; system performance is checked at start-up and confirmed by text or email, and at the end of the day, greenBOX Nxt will message again to confirm successful system shutdown.

Ecogate’s technical director, Will Kenyon, commented: “Since Ecogate was first introduced to the UK back in 2010, the concept and the potential for energy savings have been appreciated across the industry, and many manufacturers have implemented the technology into their factories over those years. For some, however, it was possibly just one more capital investment that had to go on the back burner but now, with the economics of the system making more sense than ever before, this is an investment that could ensure a future for some businesses.”

Hranipex, one of the leading European manufacturers and suppliers of products and expert consulting for the furniture industry, has been announced as an official partner for the relaunch of Materials & Finishes Show 2024 (formerly W Exhibition.)

The group, which is headquartered in the Czech Republic, will exhibit at Materials & Finishes Show when the UK’s leading trade show for the machinery, manufacturers, processors and installers of wood and associated materials returns to the NEC from 19 - 22 May 2024.

With a global presence in over 60 countries, Hranipex have established themselves as a key player in the furniture industry. The extensive product portfolio encompasses a diverse range of offerings, including furniture fittings, edge banding, adhesives, cleaners, and various components essential for furniture production. This wide array of highquality products showcases Hranipex commitment to delivering comprehensive solutions to meet the needs of furniture manufacturers worldwide.

Hranipex Marketing Specialist, Emma Avery said ‘’Hranipex are thrilled to witness the rebranding of the Materials & Finishes Show, as it presents an exciting opportunity to showcase our innovative range of furniture fittings.’’ This comprehensive collection encompasses a wide array of fittings designed for kitchens, offices, and diverse commercial and domestic spaces. In addition to locks, handles, lights, and electrical equipment, Hranipex takes pride in offering a diverse selection of top-quality products that cater to a broad range of needs.

Materials & Finishes Show event director, David Todd added: “We’re excited to announce Hranipex as a relaunch partner for Materials & Finishes Show. To have secured the support of such a forward thinking and ambitious elements company as a relaunch partner is a real coup for the show and will perfectly complement the machinery and materials brands who are already part of the exhibitor lineup.”

All areas of the material journey, from the initial stages of raw processing through to finishing and component supply for completed products, will be represented at Materials & Finishes Show.

Visitors will have the opportunity to see running machinery together with components, materials, technology and services for the manufacturing and processing phases of materials, alongside the latest products and developments for finishes.

Materials & Finishes Show will attract buyers from every corner of the industry, from furniture and joinery manufacturers and designers right through retailers, the KBB market, carpenters, joiners, worktop fabricators and stone masons.

The event, formerly W Exhibition, has over 50 years of heritage and will return to the NEC in its new and reinvigorated format from May 19 - 22, 2024.

Most purchasers of modern wood-waste burning equipment want one supplier to provide a “turn- key” solution. For Ranheat they even supply the mortice lock and key to the plant room. (as well as making the plant room)

Chris Franklin MD at Ranheat Engineering Ltd., a leading UK manufacturer of wood combustion equipment, continues his series of exclusive articles for Panel and Joinery Production. This issue he looks at the complete range of products made “in-house” by Ranheat.

“Many customers want us to undertake the complete project, from getting planning consent for the chimney, chimney height approval and local authority permits. We even make the buildings to house the equipment complete with ventilation panels and access doors.”. Ranheat started designing and manufacturing its own range of buildings over 40 years ago. Originally called “transcons” pre-wired and pre-plumbed, made of steel rather than the customer making a wooden “shed” building that is a fire risk and often not a cheap solution.

Ranheat have used standard shipping containers, but they need a metal floor and often are not big enough to get the equipment in. As well as all of the building and mechanicals Ranheat also make all of their control panels in their purpose-built electrical department. Most electrical problems that occur with any system are in the control panel. Because the panels are made in-house the Ranheat electricians know every wire they have installed and more importantly labelled. Adequate room is left for access, and they even have a light fitted to make working on the panel easier, once installed.

As well as the control panel Ranheat also undertake the complete mechanical and electrical installation on site.

Ranheat use flanged and welded pipework that is fabricated off site at the factory in Northampton. This avoids the need for any “hot work” on site. Heaters are delivered mounted on a frame and prewired and pre-plumbed and generally attached to the steel portal frame. The buildings are surveyed often using a 3-D optical scanner that produces an accurate 3-D drawing of the factory to avoid clashes with other services such as extraction ducting, lighting, and compressed air.

Ranheat also make the boilers and warm air heaters in-house. Each installation is unique but also similar to the ones before. This gives flexibility to the designers and the project engineers but helps simplify matters for the manufacturing team. Similar but not the same.

Ranheat also make the heat exchangers, combustion systems and flue gas filtration systems needed to meet the stringent emission regulations that now prevail.

Larger boilers are made in Denmark by Danstoker A/S. Ranheat still make all of the ancillary equipment for the larger systems at its factory in Northampton.

Ranheat also make spares and service and repair other makes of woodburning boilers and heaters.

For further information on all types and sizes of Industrial Woodburning equipment from 150 kW upwards contact Ranheat.

Calling all smaller workshops. If you’re looking for a centralised dust extraction system that offers high vacuum dust extraction on up to 12 handheld machines, AL-KO’s new Clean Vac needs your attention.

Launched at LIGNA 2023 and available exclusively in the UK from TM Machinery, the new AL-KO Clean Vac has been designed with the smaller workshop in mind. Available with a 8.5kw or 12.5kw motor and featuring effective pressurised filter cleaning, the system offers much needed flexibility and performance combined.

Connected to a centralised ducting system, the new dust extraction system can be connected to up to 12 handheld machines thanks to its high suction power of up to 25,000 Pa. This not only eradicates the need for individual vacuum cleaners to be connected to each handheld machine but also reduces ongoing maintenance and repair costs on multiple machines and ensures clean air in the workplace. It’s adaptable design also means it can work effectively with smaller woodworking machines like spindle moulders and compact edgebanders, too.

It’s operation and maintenance couldn’t be simpler either. Controlled by a simple wallmounted control panel, the workings of the unit are controlled automatically. The operator simply needs to empty a singular dust collection bin attached to the unit. As an optional extra, it even reminds you if it hasn’t been emptied and shuts down completely if it reaches its maximum capacity to avoid any damage to the system.

Short on space? The AL-KO Clean Vac has that covered too. Measuring 1,956 x1,038 x 2,430mm, it is designed to be installed inside or out, it has the ability to free up floorspace where you need it the most.

Matthias Schalast, Area Sales Manager for AL-KO Extraction Technology says: “Smaller manufacturing companies often find themselves having to balance performance and space but with the new AL-KO Clean Vac, you no longer need to. Specifically designed for the extraction of handheld machines - which require a significantly higher vacuum than standard woodworking machines –users can incorporate a highly efficient dust extraction system into their workshop that requires very little space and ensures a healthy workplace environment. The high vacuum of 25,000 Pa (250mbar) is achieved by an integrated side channel compressor. This allows for up to 12 handheld machines to be extracted simultaneously. This makes it a fantastic option for joinery workshops, woodworking classrooms in schools and colleges and larger outfits that require multiple handheld machines to be running alongside its woodworking machinery.”

For more information please visit tmmachinery.co.uk

The British Woodworking Federation (BWF) has joined forces with the Glass and Glazing Federation (GGF) and Community Wood Recycling to support timber window frame recycling across the construction industry.

Open to all BWF members, the recycling scheme will collect any waste wood for recycling – including timber frames and off-cuts –where a designated volume has been accumulated. Through Community Wood Recycling, 100% of the wood supplied is reused or recycled, meaning none of the waste collected will end up in landfill.

Not only does this make timber a more sustainable construction material than ever, the scheme also creates jobs, training, and volunteering opportunities for disadvantaged people.

Helen Hewitt, CEO of the British Woodworking Federation, said: “We know that our members do everything they can to make the most efficient use of their raw material, but we wanted to help them go even further. That’s why we’re delighted to be working with the GGF and Community Wood Recycling over this important initiative. “Timber is already recognised as a sustainable building material, and this partnership helps make it even more so. By joining the scheme, we’re helping our sector reduce waste and contribute more towards a circular economy. The scheme will allow our members to make a conscious effort to reduce the amount of wood ending up in landfill, while at the same time helping provide local training and employment opportunities.”

Chris Beedel, Head of Advocacy & Stakeholder Relations at the GGF, commented: “We have already seen huge success with our PVC-U and aluminium recycling schemes and are now pleased to be able to offer a similar solution for installers of timber frames.

“We aim to make all our recycling schemes as user-friendly as possible. And with that in mind, waste timber materials can have fixtures and fittings attached and be left in a designated area on site. Waste is collected when 12yd3 of timber has accumulated, meaning companies save on expensive skip costs. Community Wood Recycling can also provide a certificate of recycling for additional peace of mind for installers and the end customer.

The UK creates 4.5 million tonnes of waste wood each year. Last year, Community Wood Recycling retrieved nearly 24,000 tonnes of wood, a figure the scheme’s partners aim to increase through this initiative.

Leading specialist trade suppliers, IronmongeryDirect and ElectricalDirect have announced the appointment of Marcus Allen as their new Financial Director. With over 20 years’ experience in senior finance roles at both regional and Group level, Marcus brings a wealth of knowledge and expertise to the company.

A qualified accountant who trained with PwC, Marcus Allen has a proven track record of working with local management teams to improve profitably and grow businesses. He has held senior finance roles across a number of businesses including Navitas, Avnet and Hewlett Packard, and most recently, at Harman. Here, he led the EMEA region through a significant change project before taking on the leadership of the international finance teams of a $1bn business that included the JBL brand.

Commenting on his appointment, Marcus said: “I’m excited to be joining IronmongeryDirect and ElectricalDirect at a time when the company is going from strength to strength. I look forward to working with the team to help drive continued growth and success.”

Outside of work, Marcus is a proud father of three grown children and enjoys both football and cooking.

The IronmongeryDirect and ElectricalDirect teams are delighted to welcome Marcus to the company and look forward to working closely with him to achieve their strategic goals.

IronmongeryDirect has been supplying architectural ironmongery to tradespeople for over 50 years and has the UK’s widest range with over 18,000 products in stock. ElectricalDirect has over 12,000 electrical products available, including everything from sockets and wiring to lighting and consumer units.

For more information or to view the products available, visit www.IronmongeryDirect.co.uk and www.ElectricalDirect.co.uk.

Based in Letchworth Garden City, Hertfordshire, Chilfen Joinery is part of the Chilfen Group of companies. With a heritage stretching back to 1960 the joinery division delivers bespoke joinery solutions to the commercial, high end residential, office, education and retail sectors.

“The company’s philosophy has always been to combine traditional workmanship with the latest technology,” explains Chilfen Joinery’s sales director, Simon Brown. He continues, “This approach has enabled us to remain at the forefront of the industry working closely with main contractors, architects, interior fit-out companies, contract office furniture suppliers and designers for retail brands.

“Our relationship with HOMAG began about eight years ago when we invested in an automated storage and retrieval system with a HOMAG beam saw. Since then we have added a new edge bander and a DRILLTEQ V-500 vertical CNC machine. The latest addition to our plant list is the HOMAG SANDTEQ W-200.

“The old sander was coming to the end of its lifecycle. So, in line with our policy of continuous investment, the time was right to upgrade to a machine that would complement and improve the production equipment we already have.”

“Given the relationship we’ve developed with HOMAG UK over the last eight years, naturally they were our first port of call when it came to discussing a replacement for the sander. Whilst we looked at what else was out there in the market, our experience of working with HOMAG, coupled with the positive feedback we gained from a site visit where the sander was already operational, gave us the confidence we needed to place the order for the SANDTEQ W-200. We were particularly impressed by the first-class finish the W-200 achieved.

”The SANDTEQ W-200 is far more efficient than the machine it replaced and that is largely down to the more advanced technology that is incorporated into the W-200. Although we have only had the machine a few months, we believe it will pay for itself in under three years. It is clear that not only is it more efficient, but it will also save us man hours and provide a superior finish to our products.

“As you’d expect from the world’s leading woodworking machinery brand, HOMAG planned the installation of the sander in great detail. It arrived on time and the installation went smoothly so there was little or no impact on our day-today operations.

“The SANDTEQ was fully operational inside a few days, with the HOMAG installation engineer training our operators on site. It really couldn’t have been more straightforward.”

“Working with a partner such as HOMAG is incredibly important for us. Not only have we benefitted from the build quality and technical superiority of all their machines, but we also profit from the trust, credibility, service, support and response times they deliver.

“As a second generation family run business it is qualities like these that we hold dear to our hearts. We would certainly recommend any joinery business looking to develop a true partnership with a machinery manufacturer to talk to HOMAG first,” concludes Brown.

“At Ligna we shared how our work can unleash the potential of any material through an immersive installation that showcased creativity and technology,” says Raphaël Prati, Chief Marketing & Communications Officer. “Our customers create products that are increasingly multi- material and Biesse provides access to a vast range of skills through a single company and a single brand”. The installation used physical and video elements to stimulate the visitor’s imagination and present multi- materiality. On one side, five stations presented the processes that allow the material to be transformed while, on the other, multimedia elements showed the result of the transformation, emphasising the potential of the processed materials themselves.

The itinerary ended with a display featuring four finished products made from the different materials to showcase the theme chosen for this installation at Ligna 2023, the seat.

“Among the novelties, part of the stand was dedicated to previews, concepts and trends and presented an ever-growing selection of glimpses into the future. We wanted to prime visitors to envision their own factory of tomorrow. Our showcases at Ligna 2023 included an edgebanding line with the new corporate colours and nomenclature and the Hydrogen Force System (HFS) hydrogen gluing system, a novelty in the field of edgebanding, designed with sustainable production in mind, that combines technological innovation and environmental performance”, commented Alberto Tuberti, Product Management Director Wood.

Turning to the machines and integrated lines available in the catalogue, the focus is on integrated automated solutions: specific machines shown in action are the Rover B FT HD machining centre, served by a robot, and the Rover A machining centre, integrated with Synchro and featuring a new, even more efficient and user-friendly configuration, guaranteeing limitless creativity. The Rover B FT HD nesting machining centre is in operation with the new “Dynamic Vacuum System”, which enables more efficient work by reducing electricity consumption and CO2emissions. “Ligna was an opportunity to confirm our partnership with Imos, a point of reference in the development and distribution of software for the furniture and woodworking industry.

Thanks to a technological partner like Imos, we have raised the technological and digital level of our solutions, offering software specifically created for the design and construction of cabinets”, says Ettore Vichi, Chief Regional Officer EMEA and APAC.

biesse.com

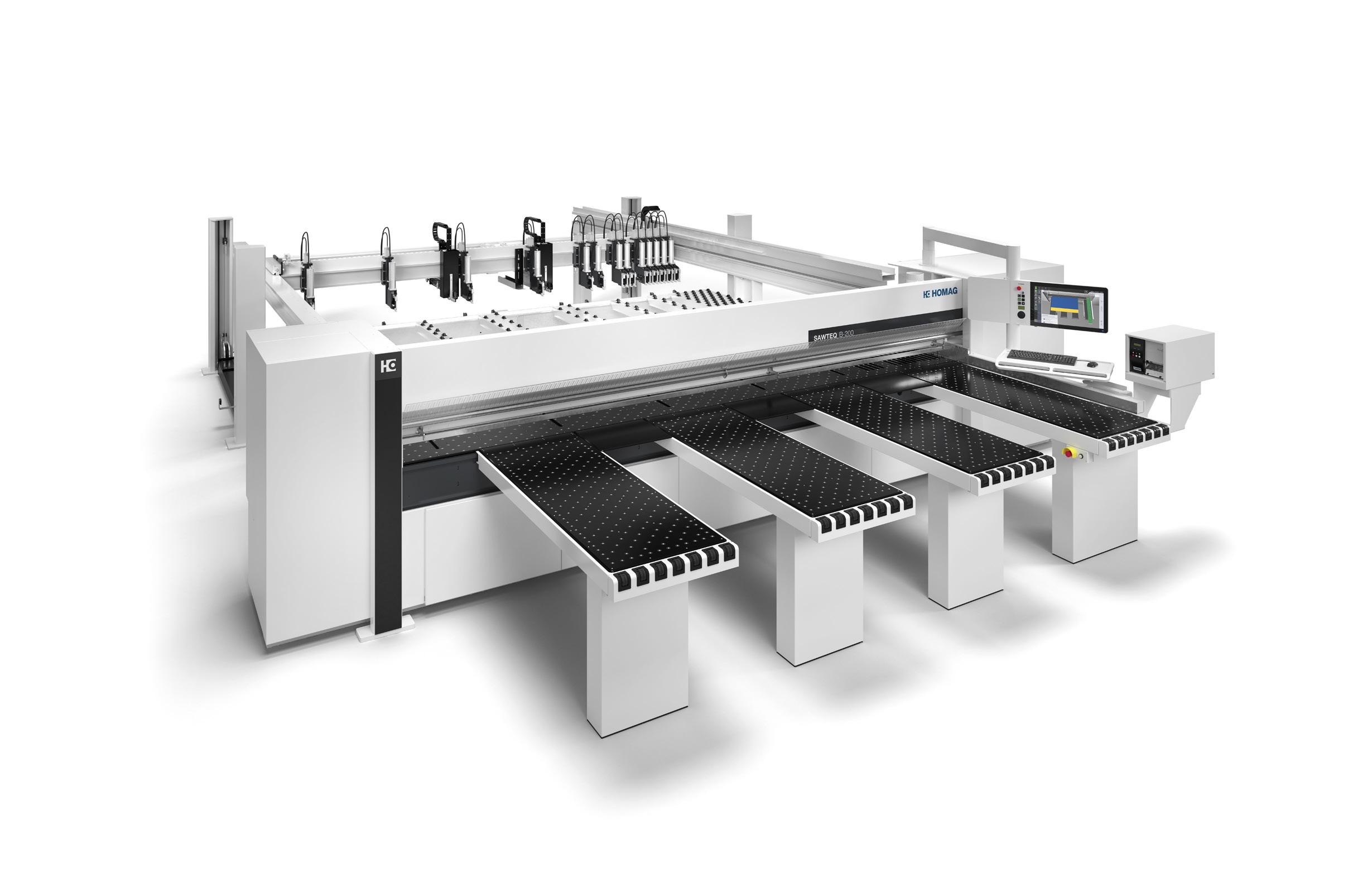

The HOMAG Group, the world’s leading provider of integrated production solutions for the woodworking industry, offers a comprehensive range of panel dividing beam saws. Panel saws help to process work with greater flexibility, speed and efficiency. The company’s selection of beam saws offers both woodworking shops and industrial customers precision finish cuts for every type of wood-based or plastic panel material.

The smallest HOMAG panel dividing saw, the SAWTEQ B-130, is competitively priced compared to a well-equipped table saw. The B-130, however, provides a much more precise, efficient and fast cutting process. Its compact footprint, sturdy design and proven technologies consistently deliver exceptional results.

Speed, quality and precision during the cutting process can only be achieved if panel materials are moved quickly, gently and with a high level of accuracy. The SAWTEQ B-130 includes technologies that smoothly interact with one another, from the program fence and pressure beam to the clamps and patented side pressure device.

The innovative Power Concept Classic is available on both the SAWTEQ B-130 and SAWTEQ B-200. At the heart of this technology is a clamp on the program fence that can be moved separately; It also moves in front of the program fence if necessary. The clamp enables two strips with different cross cut divisions to be cut to length simultaneously.

This feature significantly increases output and makes it easy to handle peaks in production. In addition, an algorithm adapted to the Power Concept Classic automatically sorts the strips directly at the saw blade.

Both the SAWTEQ B-130 and B-200 utilise HOMAG’s CADmatic 5 high performance saw control system. With a wide range of functions, CADmatic 5 is an intuitive operating concept with clear administrative functions. What’s more, it is open for communication with other machines and software solutions thus enabling manufacturing cells to be created.