25 Celebrating years of quality woodworking

MAY / JUNE 2024

Next Generation Mirka Tools Deliver 20% More Sanding Power

Rehau Extends Its Range In Edgebands & Surfaces At MAFS

Panelco Expands Portfolio Through New Strategic Partnership with Polyrey Euro Superabrasives Ltd Announce New Partnership

Materials & Finishes Show 2024

Long Life-Span Comes As Standard Fire Doors Made Easy

Kent Home Improvements Squares Up With HOMAG CABTEQ S-250

The OVVO Range Of Invisible Connectors Keeps Growing, Combilift Longevity And Sustainability - 101 Years Of Vincent Timber

AXYZ to Showcase Innovative Woodworking Solutions MAFS 2024

Blum Wows Visitors At Kbb 2024

Ostermann - Edgings Bring Fresh Spring Breeze To Indoor Furniture

Laminate Fabricator First To Invest In New Edgebanding Technology From Biesse

AJB Group - Celebrating 25 years of Woodworking Excellence

HOMAG UK Supplies Ar18 With New EDGETEQ S-500 & XES 200 Service Station

JJ Smith Unveils Innovative Product Range From Woodworking Robotics

SCM’s Smart&Human Evolution At Xylexpo

Extractly Cuts Costs For Doorco Manufacturing

Go Invisible With Lamello’s S-20

Mokko Ltd Starts Up With Joinerysoft

HOMAG’s STORETEQ F-100 + SAWTEQ S-200 Cell Increases Productivity

Cut Costs, Not Efficiencies With AL-KO

IronmongeryDirect Adds Depth To Its Range

Jacksons Fencing introduces Jaksun™ Solar Fence Panel

PUBLISHED BY:

TELEPHONE:

EMAIL:

WEBSITE:

PUBLISHER:

DESIGNER:

PRINTER:

EC Media 21 Cedric Road

Westgate on Sea Kent CT8 8NZ

0771 314 8831

clare@p-j-production.com

www.p-j-production.com

Clare Hollister

Russel Goldsmith TRACE Creative Agency www.tracecreative.co.uk

The Magazine Printing Company www.magprint.co.uk

Reproduction of articles: All material appearing in Panel & Joinery Production is strictly copyright, and all rights are reserved.

No part of the publication may be copied or transmitted in any form whatsoever, including photocopying without prior permission of the publishers.

Publishers note: The editorial opinions expressed in Panel & Joinery Production are not necessarily those of the publishers, who shall be under no liablity with respect to any article published herein.

2 4 6-7 8-9 10-11 12 14-15 16-17 19 20-21 22 24-25 26-27 28-30 32-33 36-37 40-41 46-48 50-51 52-53 54-55 56-57 58-59 60 62-63 1 Panel & Joinery Production - May / June 2024 CONTENTS FRONT COVER 58-59 22 32-33 24-25

EDITORS PICK

6-7

NEXT GENERATION MIRKA TOOLS DELIVER 20 PER CENT MORE SANDING POWER

Mirka is upgrading its DEROS and DEOS orbital sanders with a long-life electric motor that delivers 20 per cent more sanding power to make light work of demanding jobs and heavy applications.

The Mirka® DEROS II and DEOS II feature a new visible LED indicator that makes it even easier for the operator to adjust the sanding speed and there’s a new on/off button and lockable speed function.

For monitoring vibration levels, the smart, user-friendly tools are compatible with the myMirka app through Bluetooth® technology.

Operator comfort continues at a high standard, as the brushless electric motor is smooth-running with a low noise level, reducing stress when sanding for longer periods. The sander’s compact, ergonomic design makes it easy to use, and it is low maintenance.

www.mirka.com/en-gb/

As well as ergonomics and ease of use, the hallmark of the Mirka sander range is compatibility with dust-free sanding. Combine the DEROS II or DEOS II with a Mirka dust extractor and start sanding with dust-free abrasives for a safer and healthier working process thanks to efficient on-tool dust extraction.

Craig Daycock, managing director, Mirka UK, says, “We’re constantly reviewing how we can continue to improve our power tools and these next generation smart sanders will ensure operators can tackle a multitude of heavy tasks easily and comfortably, without putting pressure on their hands and arms.”

2 www.p-j-production.com

INDUSTRY

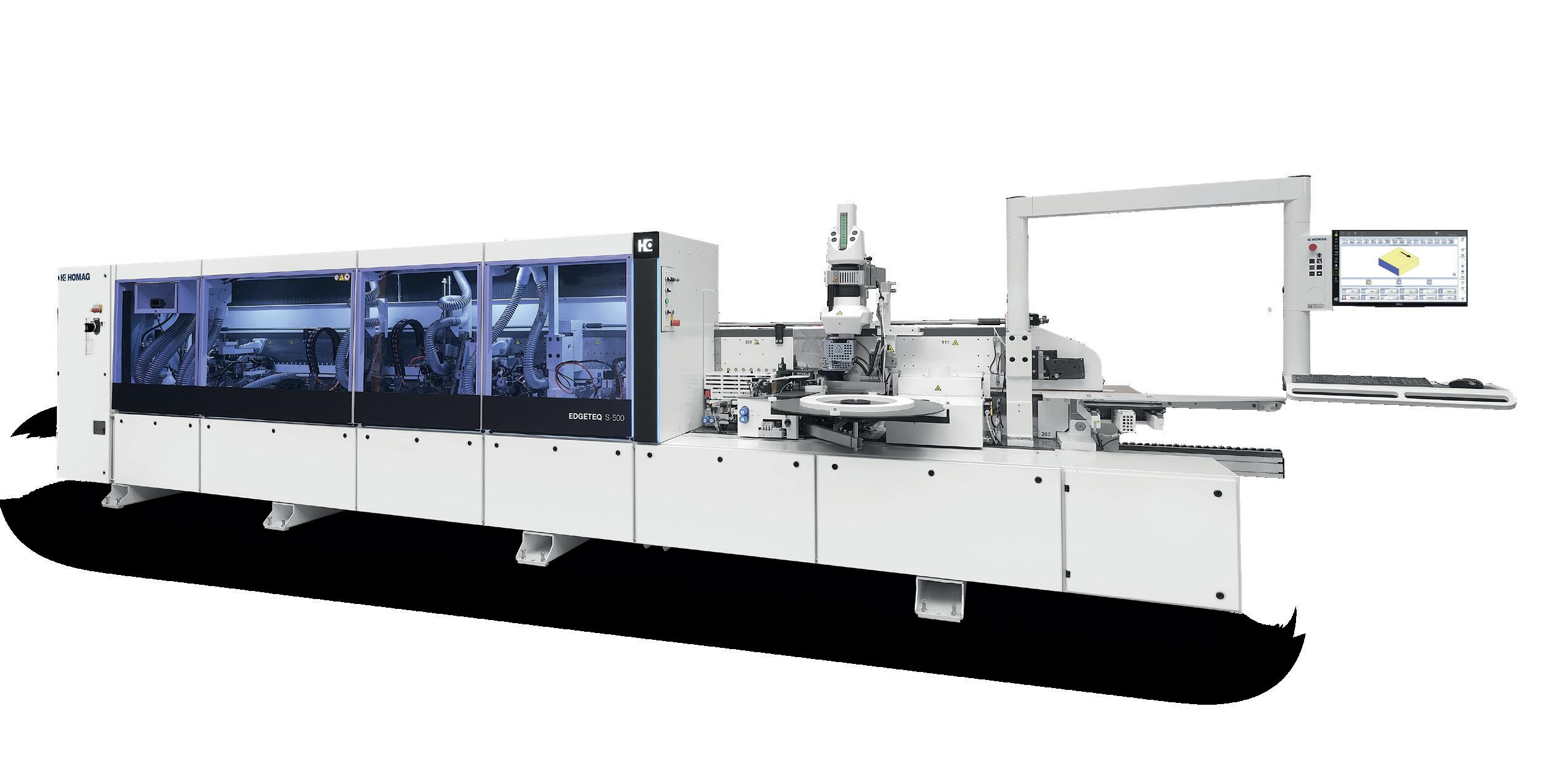

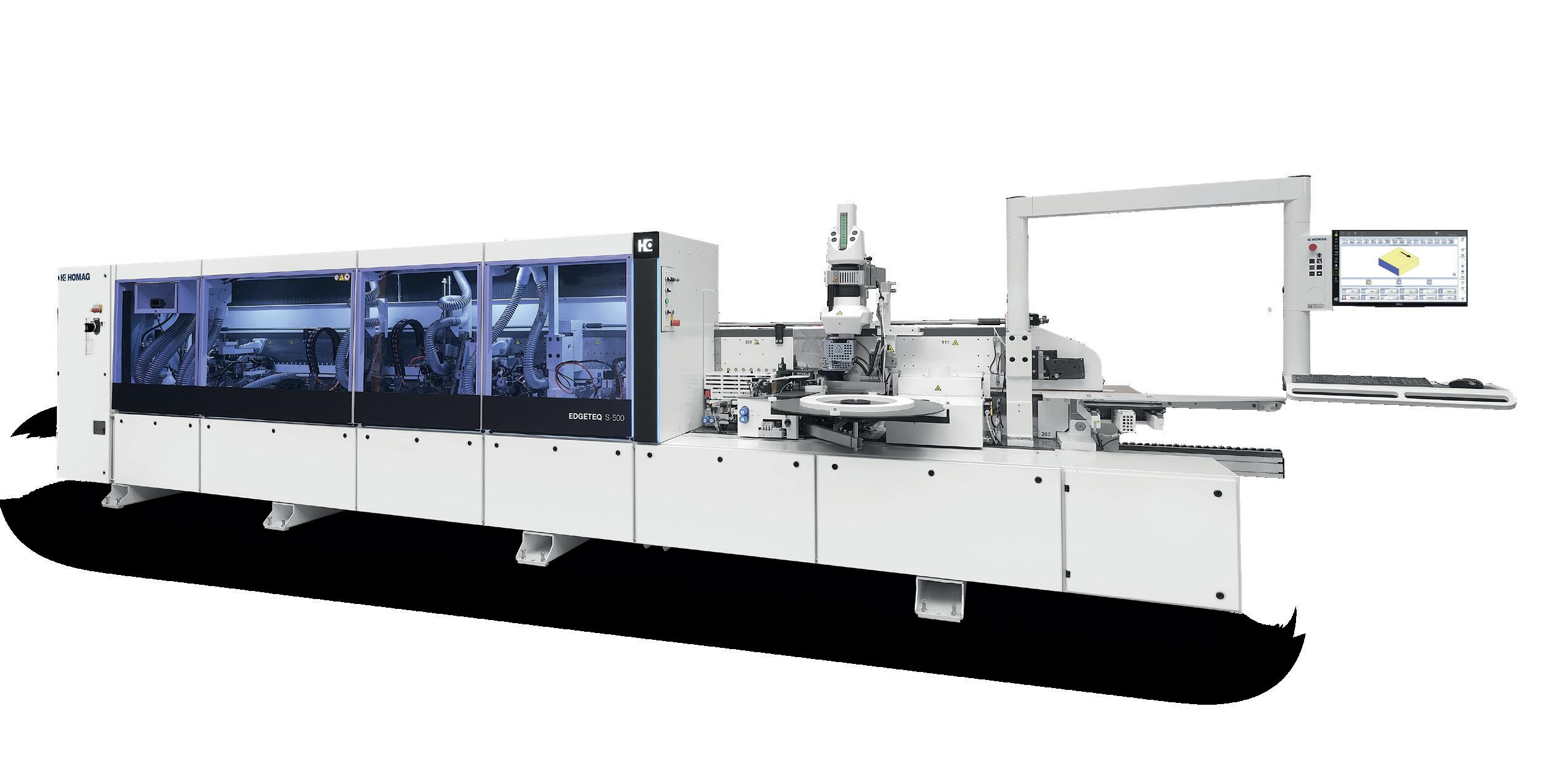

Efficient production for perfect edges

EDGETEQ S-500

The high performance EDGETEQ S-500 offers enormous flexibility for the ultimate edge quality. Designed to seamlessly process PUR, EVA and airTec zero joint technology, this model effortlessly handles the demands of industrial level manufacturing. With its energy-saving features and environmentally friendly benefits, this model is packed with impressive advancements to compliment any high quality production line.

Innovative and efficient technology

airTec for zero joint edge manufacturing

airTec is the optimum zero joint solution for the woodworking industry. It is a clean, cost-effective use of resources which results in perfectly crafted products, where joints are no longer visible. At the core of the airTec unit is a rotating fan heater, which, in addition to a high level of efficiency, provides a significantly reduced noise output.

Available across the full range of HOMAG edge banders means that businesses of any manufacturing size can benefit from ‘zero-joint’ technology.

HOMAG UK Tel. 01332 856500 | Email. info-uk@homag.com | www.homag.com YOUR SOLUTION SEE IN ACTION!

SCAN ME!

REHAU EXTENDS ITS RANGE IN EDGEBANDS AND SURFACES AT MATERIALS AND FINISHES SHOW 2024

REHAU Interior Solutions will be participating in the Materials & Finishes Show in May 2024. Here the company will be majoring on its expertise in edgebands and taking the opportunity to showcase exciting new ranges.

Products from the full range of edgebands and surfaces from one of the biggest players in the market will be on display. The company is especially excited to showcase, as part of its expertise in edgebands, new ranges coordinating with the major players in the surfaces market.

One range of particular interest this year, designed by Egger is the Egger Decorative 24+ collection, which addresses the current focus on natural materials and sustainability. As edgeband specialists, REHAU offers solutions for perfect coordination with all the market leading surface providers.

For example, RAUKANTEX Noble matt complements the panels from Egger’s Perfect Sense Matt range and the TM12 Perfect Sense Omnipore Matt. There are also matching edgebands for the new ST40 surface.

These edgebands are supplied with REHAU’s Scratch Protect lacquer, which as the name suggests is resistant to scratches but also fingerprints and can be processed without a protective film. The lacquer has an anti-sheen effect, which ensures that the edge does not shine even at a shallow angle.

Further new ranges provide matching edgebands for the new 2024 FALCO surfaces collection. REHAU edgebands can now be paired up with FALCO’s new and attractive selection of design panels, Swiss Krono. The new BE.SAFE board collection offers active triple protection against viruses/ bacteria/fungi.

Various edgeband designs have been included in the RAUKANTEX Express Collection 9 to match the collection, Fundermax - the Essential collection, which comprises a

total of 213 decorative designs – 74 of which are brand new – and 15 textures, focusing on maximum decor choice and efficiency.

REHAU has the perfect edgeband to match, with hundreds of Edgeband options available from stock in Manchester, with no minimum order quantity and available in standard dimensions and next day delivery. Find the perfect edgeband and order samples the online tool from REHAU: interior. rehau/edgebandsearch

“Visitors to our stand at the Show will see how we are ‘Enabling Exceptional Design’ for our customers,” says Scott Williams, REHAU Sales Manager. “We are proud that we are able to partner with the leading players in the market to enable our customers to develop their own exceptional designs for their projects.”

REHAU will also be promoting its impressive customer services at the Show, including the new Surface Select tool, which has been launched this year and which is designed to help customers find the perfect decor for their project.

Surface Select can be found at: interior.rehau.uk/surfaceselect

More information on products and services from REHAU Interior Solutions can be found on the company’s recentlylaunched website for the UK market. This is packed full of inspirational photography and ideas for the furniture industry and its customers, while presenting a modern and clean feel, maximising the use of video and leading edge online technologies. It can be found at: interior.rehau.uk REHAU looks forward to seeing all customers, new and old, at the Show!

UKenquiries@REHAU.com

4 www.p-j-production.com

INDUSTRY

Specialist

High-quality solutions for commercial & domestic environments, all KLÜG products come with a 10 year guarantee as standard for peace of mind.

door kits & hardware. Call or go online 0300 303 88 21 IronmongeryDirect.co.uk Scan me KLÜG Intelligent Solutions

products for specialist jobs

Sliding

PANELCO EXPANDS LAMINATE PORTFOLIO THROUGH NEW STRATEGIC PARTNERSHIP WITH POLYREY

Industry-leading decorative panel and sheet experts Panelco has announced a strategic brand partnership with specialist technical and decorative panel designer and manufacturer Polyrey to expand the range of high-pressure laminate (HPL) and compact laminate products it can offer its customers.

As a prominent stockist and manufacturer of innovative products, ranges and decorative designs, Panelco has grown over its two-decade history to become a byword for quality in the sector.

This new partnership sees the company work together with Polyrey, part of Wilsonart Egineered Surfaces, the global leader in engineered decorative surfaces.

Beginning in April, the two businesses will cooperate to offer an extensive collection of Polyrey products to Panelco’s customer base of design and architectural professionals. The collection will include Polyrey’s newly-launched Galerie range – the largest single collection of interior panels for commercial applications.

Galerie gives fabricators, manufacturers and specifiers the opportunity to choose from a collection of over 800 designs comprising a multitude of decors and finishes inspired by the most prominent design and societal trends driving the interiors market. With 90 new designs and a new Silk finish which brings Galerie’s total number of finish options to 18, Polyrey has fused premium technical performance with aesthetic impact.

The new partnership will see Panelco offer Polyrey’s Galerie Integral and Plus ranges, alongside the brand’s other specialist collections including Cubicle & Washroom, Durion and Doors. With over 60 years of manufacturing heritage, Polyrey are at the forefront of technical and decorative surfaces. Galerie Integral decors are available in high pressure laminate (HPL), melamine faced chipboard (MFC) and compact laminate. The Galerie Plus collection presents specifiers with an additional set of premium designs available in HPL and compact laminate.

“We are delighted to announce this new partnership with Polyrey and be able to offer their extensive product range, covering all applications associated with their HPL and Compact collections.” said Julie Dean, Group Marketing Manager at Panelco. “Polyrey is well-known for supplying innovative surface solutions to the design and architectural sectors; their exceptional designs, quality, service and availability will strengthen our wider decorative portfolio. We are truly excited to be part of this partnership and look forward to seeing how the start of this new chapter will benefit both businesses.”

Polyrey is a registered RIBA CPD provider in the UK, ensuring its team of engineered surfaces experts is on hand to support architects with their ongoing professional development. This expertise proved appealing to the Panelco team, who are looking forward to taking their next step as a company together with Polyrey.

6 www.p-j-production.com

FEATURE

7 Panel & Joinery Production - May / June 2024 FEATURE For more information on Panelco’s new offering, please visit panelco.com or contact sales@panelco.com Alternatively, to explore the new Galerie collection by Polyrey, visit wilsonart.co.uk/polyrey.

Some limitations on substrate materials due to thermal coefficient

EURO SUPERABRASIVES LTD ANNOUNCE NEW PARTNERSHIP FEATURE

Limit up to 750 ℃

Euro Superabrasives are delighted to announce that they are now a distributor for Pin Power - vacuum brazing machine technology.

Located in the Innovation Centre in Darlington, this facility is poised to revolutionize the way they showcase their vacuum brazing machine technology.

Only PCD and PCBN: low temperature

This is no ordinary demo centre - it’s a testament to Euro Superabrasives unwavering commitment to providing world class service and innovative solutions to their valued customers across Europe. The state-of-the-art facility is equipped with the latest technology and expertise to cater to the unique needs of the European market.

Max. 20pcs per hour reduces graphitization

But that’s not all - Euro Superabrasives Ltd is inviting interested parties to join them for FREE brazing trials! Experience the incredible benefits of their vacuum brazing solutions, specifically tailored for manufacturers of diamond tools. Whether you’re a seasoned professional or new to brazing, their dedicated team will be there to guide you through the process.

Manual process, quality depending on worker’s skill level

Euro Superabrasives Limited, believe in the power of handson learning. Their Demo Centre offers the opportunity to witness the cutting-edge technology and expertise behind their vacuum brazing machines.

Need flux and extra cleaning

Need experienced labor

To schedule your visit and enjoy a complimentary brazing trial, contact Euro Superabrasives Limited. They are ready and waiting to welcome you to their Demo Centre and to share the excitement of brazing and diamond innovation.

HIGH SPEED VACUUM BRAZING MACHINE

Dangerous fumes

Our Vacuum brazing machine is excellent for brazing between super-hard materials, tungsten carbide, ceramics and all kinds of diamond types. Also, it is very easy to braze at rapid speed. It is effective on the following materials: natural diamond, synthetic diamonds such as PCD, PCBN, CVD, monocrystalline diamond etc. Typical substrate materials such as: tungsten carbide, steel, steel alloy, cermet, ceramic, etc.

The machine is fully automatic and once loaded, the brazing cycle time is approximately 30 minutes.

BENEFITS

High speed vacuum brazing technology results in a shorter cycle time, work place environment improvement, enhancement of braze joint strength due to degassing and reduction of distortion due to uniform heating and enhanced control. All levels of engineers can braze complex tools by using high speed vacuum brazing machine with a simple one touch operation.

ADVANTAGES

The advantages of this technology are:

• No diamond oxidation or graphitisation

• Enhancement of braze joint strength

• Reduction of tool distortion

• Easy temperature control

• Improvement to the work place environment

• Total cost efficiency

WHAT IS VACUUM BRAZING?

Vacuum brazing is a material joining technique that offers significant advantages over conventional induction or torch brazing: extremely clean, produces flux-free joints of high integrity and strength. The process can be precisely controlled as is performed inside a vacuum chamber. Temperature uniformity is maintained on the workpiece when heating in a vacuum, greatly reducing residual stresses due to controlled heating and cooling cycles. This, in turn, can significantly improve the thermal and mechanical properties of the material. As the name suggest, vacuum brazing is conducted in a vacuum chamber; and heat is transferred via radiation from the heating elements, this means that several different tool types can be made during one cycle and with the tools reaching the correct brazing temperature simultaneously..

Conventional Brazing

8 www.p-j-production.com

method realizes a shorter construction period, work improvement, enhancement of strength due to degassing distortion due to wholly heating. All levels of engineers tools by using high speed vacuum brazing machine touch.

9 Panel & Joinery Production - May / June 2024 FEATURE Euro Superabrasives look forward to seeing you at their UK Demonstration Centre. www.eurosuperabrasives.com

Easy

Work

improvement

temperature control

environment

YOUR GUIDE TO MATERIALS & FINISHES SHOW 2024 EVENTS

Materials & Finishes Show (formerly W Exhibition) takes place at the NEC Birmingham from Sunday 19 - Wednesday 22 May, 2024. It’s the UK’s trade show for the furniture manufacturing and joinery industries - and it’s not to be missed!

It is the primary platform for carpenters, joiners, machinists and installers to see running machinery, the latest materials, components, software, tools and innovations for the woodworking sector

Alongside networking with the entire industry under one roof, visitors will be able to see thousands of the latest products on the UK market and speak directly to leading manufacturers and suppliers for the woodworking sector.

Event director David Todd comments: “We’re so excited to bring the UK furniture manufacturing and joinery industries back together, under one roof, for the first time since 2018 at Materials & Finishes Show this month. We’ve been working hard behind the scenes to build on the legacy of W Exhibition and develop a platform that reflects the UK woodworking industry both now and in the future.

“The lineup includes over 160 exhibiting brands who will be showcasing thousands of the latest products. Whether you’re looking for the latest timber solutions, tools, fixtures, finishing products or machinery - Materials & Finishes Show really is your one-stop-shop.

“Nowhere else can you compare all of the very latest products, side by side, under one roof in the UK. As well as seeing the latest products, software and tools, take advantage of being able to speak first hand to the manufacturers and suppliers behind the brands who are lined up and ready to take your questions.

“Alongside the new brands, there are a raft of new features that you will not want to miss at this year’s show. Here’s our top five reasons you will not want to miss Materials & Finishes Show 2024…”

REASON ONE

100S OF BRANDS, 1,000S OF PRODUCTS P

Whether you’re looking for the latest timber solutions, tools, fixtures, finishing products or machineryMaterials & Finishes Show really is your one-stop-shop. No where else can you compare all of the very latest products, side by side, under one roof. As well as seeing the latest products, software and tools, you’ll be able to speak first hand to the manufacturers and suppliers behind the brands who will be lined up and ready to take your questions.

REASON TWO

BRAND NEW LIVE DEMO ZONE

Head over to our brand new Live Demo Zone where you’ll be able to see running machinery and demonstrations from brands including AMS, Leitz Tooling, The Joinery Network, Lamello, GreCon, Trend Tool Technology and Rubio Monocoat who will be showcasing their products across the four days of the show.

Alongside the construction of a timber window, visitors will also be able to see tooling, paint and finishing brands deliver hands-on, practical demonstrations, bringing new products, innovations and technology to life for joiners and carpenters on the showfloor in a way we’ve never done before at the event. All of the sessions are live on the website for you to start planning your visit today.

10 www.p-j-production.com

REASON THREE

CPD LEARNING PROGRAMME P

T: 07871544330

E: jess.hardisty@montgomerygroup.com

The brand-new CPD learning programme will deliver four packed days of CPD certified learning content, from panel discussions and keynotes through to seminars, all delivered by industry experts. The programme has been carefully crafted to arm you with the latest information, knowledge and inspiration to help you do better business once you leave the show.

Get ready for four days of sessions, from Navigating Compliance and Health and Safety Regulations, Social Media for Small Businesses, The Future of Factories through to Maximising efficiency and Minimising Cost: The Joinery Edition and Woodland to Workshop: Trees, Timber & Time. You can pre-book sessions via the Materials & Finishes Show website.

REASON FOUR

NETWORKING & CONNECT P

If you’re not able to take a full day out of the office, our Sunday opening and late night on Tuesday 21st May offer additional opportunities for you to maximise your workweek as well as visit Materials & Finishes Show. Our brand new Materials & Finishes Show Bar will provide an informal setting to meet clients and colleagues.

We’ll also be running a big social meetup on Monday 20th May where you will be able to meet online content creators including Robin Clevett, Tibby Singh, Alastiar Johnson and Derek Barrett who are part of our new campaign working with social media influencers to deliver the show to a wider audience online.

REASON FIVE

MISS IT, AND MISS OUT P

If you miss Materials & Finishes Show 2024, you’ll have to wait until the event returns in 2026. This is your main UK industry event platform to see every link in the supply chain under one roof, at the same time. Save time visiting multiple suppliers and distributors, cut out the need for more than one day to wrap everything up for the year ahead. Shop around, source, enquire, research, purchase, compare, network, learn - do all of this, under one roof, at Materials & Finishes Show.

And if you’ve still not got Materials & Finishes Show 2024 locked in your calendar, what are you waiting for? Register today at www.materialsandfinishesshow.com and you’ll receive regular updates in the run up to the event to make sure that your visit to Materials & Finishes Show is a successful one.

11 Panel & Joinery Production - May / June 2024

EVENTS

LONG LIFE-SPAN COMES AS STANDARD INDUSTRY

Chris Franklin MD at Ranheat Engineering Ltd. a leading UK manufacturer of wood combustion equipmentcontinues his series of articles for Panel and Joinery Production. This issue he looks at the long lifespan of Ranheat warm air heaters.

The renawable heat Incentive, (RHI) was a Government scheme that paid money to the operator of a Biomass burning plant for 20 years to encourage the use of renewable energy.

However it was only applicable to boilers and not to warm air heaters. As with many Government schemes this skewed the market with people choosing a more expensive water based heating system over a simple warm air system. Now the RHI has stopped for new applicants, more and more users are again choosing a warm air system. The government argued that a warm air system would not last the 20 years that the scheme was set to run. This is not the case. The design life of a boiler or heater is the same. What does affect the lifespan is what is used as a fuel.

Natural timber contains no ”nasties” however some wood based products once processed can contain compounds that can be corrosive to boilers and heaters. The main culpret is PVC. Some people still use PVC in their manufacturing process mainly in the form of PVC edgebanding. When PVC is burnt it combines with the water in the boards and produces hydrochloric acid, HCl.

So what about other conventional fuels? Coal was widly used but contained large amounts of Sulphur. Heating oil also cointains sulphur. Natural gas is less polluting but is a finite resource.

But what about Greenhouse gasses? By using wood as a fuel when trees grow they absorb Carbon Dioxide conventional fossil fuels do not have this ability.

Ranheats range of warm air heaters make an affordable soloution to even the smallest of joinery companies. To be able to control emmissions the plant needs to be automatically controlled. Hand loading of offcuts is time consuming and labour intensive far better to use a small granulator to process the offcuts and then mix with other extracted material fom woodworking machinery.

Most small sites have a bag based extraction system this can be a small 2, 3, 4, 5or 6 bag unit. To safely use this extracted material Ranheat invented the “bag-loader”

The Bag-loader consists of a central auger and two agitator arms driven by a simple low kW electric motor. The bagloader is for use with warm air heaters only and is not suitable for boilers. The reason is the Ranheat Warm Air heaters are fitted with a continuously running Induced Draught Fan or chimney fan. There are also two combustion air fans one for primary air and one for secondary air. The I/D fan and the secondary air fan run continuously with the primary air fan switching on and off with flue temperature. This control over the combustion process gives the smaller Ranheat Warm air heaters a high degree of control when

compared to a hand loaded heater which is more dependent on the operator and the frequency of loading. A lot of other makes of warm air heater do not have an I/D fan as they run at high flue temperatures (400oC) where a Ranheat Warm air heater has a multi-tube heat exchanger which ensures low flue temperatures Typically 160-180oC. This means more heat into the workspace and less heat up the chimney. Ranheat also make spares and service and repair other makes of woodburning boilers and heaters.

12 www.p-j-production.com

T: 01604 750005 E: sales@ranheat.com www.ranheat.com

Ranheat WA 150 industrial wood-waste heater, 150 kW output with Bag Loader, after 17 years of operation.

Ranheat “Bag-loader for feeding warm air heaters.

INDUSTRY

FIRE DOORS MADE EASY

Holz-Her’s Sprint 1327 Door edgebander has been specifically designed for the UK fire door market. Created to simplify the processing of solid wood lipping application whilst meeting stringent fire safety regulations mandated by government and regulatory bodies, the intelligent edgebander comes equipped with heavy duty trimming motors suitable for use on larger timber sections and can apply solid lippings up to 15mm thick. Featuring a wealth of technology designed to de-skill the operation and increase efficiencies, the Sprint 1327 Door edgebander guarantees quick and simple set-up, flexible machining and repeatable accuracy demanded by medium to large-scale fire door manufacturers.

The Sprint 1327 Door specialises in solid wood processing, especially doors with solid wood lippings. It features the heavy duty MG705 edge feeder for the automatic and reliable transport of solid lippings.

With up to two flush milling units and an end trim unit incorporated into its design, the edgebander can process the hardest woods with ease, allowing for a high-feed rate Fire Doors Made Easy and consistent workflow.

Intelligent Tool Correction allows the operator to make fine adjustments to the profiling in relation to the edging by using the machine’s 18.5-inch touchscreen. Significantly de-skilling the operation, adjustments can be made between 0.1–0.01mm at the touch of a button.

fa.s.t technology has been integrated into the model to guarantee a continuous workflow. The clever technology enables you to run different machining processes at the same time, making it possible to switch between different programmes without the need for the piece to exit the machine first. An automatic locking roller also communicates with the process control to eliminate any risk of misfeeding the panel and to ensure minimal workpiece intervals for high productivity.

14 www.p-j-production.com

Eco mode puts all drives out of operation if not in use. If no workpiece enters the machine within six minutes, the heater on the glue application system automatically shuts down to stop energy being consumed.

Holz-Her’s Sprint 1327 Door comes with an intelligent iTronic and Glu Jet system. The fully-automatic functions of iTronic facilitate adaptive cutting, precise pressures to the pressing station and automatic glue quantity control. Teamed with the thin film technology of the Glu Jet system and heavy duty trimming units, it provides operators with a guaranteed, repeatable zero glue line on solid wood and a glue heat-up time of just three minutes.

The compact design of the Sprint 1327 Door provides the shortest possible open glue path, which has a significant effect on the strength of the glue joint. This ensures that each lipping is firmly bonded to the workpiece.

The exclusive Door model has been designed with heavy duty trimming motors in order to machine larger timber sections up to 15mm thick. It also offers an infinitely variable feed rate from 10-18m/min on workpieces ranging from 8-60mm thick and as short 160mm.

15 Panel & Joinery Production - May / June 2024 INDUSTRY HolzHer.co.uk

16 www.p-j-production.com CASE STUDY CABTEQ 1 S-250 case clamp

CASE STUDY

KENT HOME IMPROVEMENTS SQUARES UP WITH HOMAG CABTEQ S-250

Specialist kitchen furniture manufacturer, Kent Home Improvements, was set up in the 1970s. With a turnover of around £2½ million, the company has built a reputation for designing and producing high quality furniture components for the independent kitchen trade.

“Although the company is over 50 years old, it is only in the last six years that the business has grown exponentially,” enthuses Dan Endicott, general manager at Kent Home Improvements. He continues, “The expansion is down to the investment the new owners (who bought the business in 2017) have made in machinery and staff.

“The latest investment was for a HOMAG CABTEQ S-250 press. The company has been buying HOMAG machinery for over 40 years and has always found its equipment and software to be superb. We believe it is the best in the market and offers outstanding value for money.

“Our old carcass press was dying and we no longer needed such a big press. We wanted a robust, efficient and simple to operate carcass press to replace it and so we turned to HOMAG.”

A VISIT TO THE HOMAG SHOWROOM

“To ensure we invested in the right model, we attended one of HOMAG’s Open House days at its Castle Donington showroom. Seeing how easy to operate the CABTEQ presses are, and the perfectly square units they produce, gave us the confidence to place an order for the CABTEQ S-250 model. “As the last step in production before packaging and delivery, the assembly quality has a significant impact on the end customer‘s satisfaction with the product. So for us, when it comes to building kitchens, cleanly pressed cabinets are a key sign of quality in pre-assembled furniture.

“The HOMAG CABTEQ S-250 delivers on every front. It’s a reliable, high performance press that ensures all our cabinets are accurately and squarely aligned. Another bonus is you need no prior knowledge to operate the press; it’s simply a question of placing the cabinet in the press and pushing the start button.

“The plates move from their starting position to the pressing position at rapid speed. Then, just prior to connecting with the cabinet, the speed switches automatically to the slower pressing speed. This system minimises the time needed for the pressing process.”

VERSATILE, POWERFUL AND RELIABLE

The CABTEQ S-250 model can handle a diverse range of product sizes – from cabinets (l) 150 x (w) 250 x (h) 150 mm up to (l) 3000 x (w) 900 x (h)1400 mm. With a pressing pressure range from 12 –18 kN in both vertical and horizontal planes, the pressing force can be adjusted as required. This is simple to do on the control panel and ensures the pressure is distributed completely evenly on all sides of the cabinet.

Dan Endicott again, “Our new press from HOMAG has speeded up our production process as we no longer have to do any manual clamping. More importantly, perhaps, it has improved the quality of every finished product we manufacture – we can now be certain each cabinet will be perfectly square.

“Our long-standing relationship with HOMAG is based on trust and service. All the HOMAG people are friendly, professional and extremely knowledgeable; they are always there on the end of a phone if we need anything, and its machinery is reliable and delivers lifetime value for money,” concludes Endicott.

If you would like more information or a demonstration of any of the HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

T:01332 856500

17 Panel & Joinery Production - May / June 2024

E: info-uk@homag.com www.homag.com

Some things just go naturally together. The New EGGER 24+ Decorative Collection is a stunning range of on-trend decors, from classic woodgrains to contemporary textures, perfect for high-end furniture and interior design. Pair that with James Latham's service, support, and extensive stockholding across 12 nationwide depots, and your projects are in expert hands. Get the best of both worlds with James Latham and EGGER, and bring your creative ideas to life with the 24+ Decorative Collection — your vision deserves nothing less. Explore the EGGER Decorative Collection 24+ at James Latham.

Find out more about the EGGER Decorative Collection 24+ at: lathamtimber.co.uk/egger-24 or email

NOW AVAILABLE FROM JAMES LATHAM Choose Lathams for Nationwide depots Product knowledge Rapid delivery Great service Huge stockholding SHOWCASING: Light Natural Casella Oak | Natural Casella Oak | White Casella Oak

Perfectly matched.

THE OVVO RANGE OF INVISIBLE CONNECTORS KEEPS GROWING, NOW WITH THE ADDITION OF A GLUE-LESS 6MM DOWEL

OVVO continues to expand its range of wood joining connectors leading the way in furniture ‘Tools free’ assembly components, making life easier for consumers and end-users, and delivering a more profitable and efficient solution for manufacturers.

OVVO products are a range of cleverly engineered, awardwinning, invisible connectors that make joining wood simple. The connectors are installed during the manufacturing process so the end-user can simply click/push together cabinets, shop fit-out components, door frame assemblies or furniture without the need for tools, screws, or glues. The result is an accessible, sustainable product that saves time, money and effort for consumers and manufacturers alike. Manufacturers can also benefit from significantly reduced shipping costs, as items can be shipped flat-packed.

The latest addition to the OVVO product family of Dowels is the 6mm x 40mm version, namely the OD640 which is specifically designed to work in standard 6mm drill patterns. The OD640 is inserted into the panel without any glue to form a permanent joint in as thin as 12mm panels. These new connectors make it even easier for manufacturers to incorporate OVVO into their standard processes, saving time and money by eliminating glue and case clamping time. No additional equipment or capital needed to deliver tools free assembly products to the end customer.

This new self clamping, glueless, invisible OVVO Dowel (OD640) is designed for connecting cabinet parts and all types of furniture using standard drilled holes on both sides of the joint, thereby simplifying the panel processing operations while continuing to provide all of the benefits of OVVOs’ proven tools-free ‘Push-Click-Connect’ assembly methodology.

All OVVO connectors are designed for high-volume, automatic insertion, and ongoing partnerships with leading machine vendors such as Pro-Edge Technology and software providers Cabinet Vision, TopSolid, iFurn, Swood and Cabinet

Sense ensure that manufacturers can easily incorporate OVVO into their existing processes, and also into new product design and development. The PET CNC OVVO is the only machine in the industry with insertion capabilities for ALL OVVO connectors.

All OVVO connectors can be installed into a variety of materials ranging from high-quality hardwoods to low-grade particle board, and our recyclable plastic means any waste is put back into the production of our product. OVVO works best in boards >12mm thickness and is available in a range of sizes to perfectly match your requirements.

All connector sizes are available in both PERMANENT and RELEASABLE options, extending the range of materials and opportunities to inspire creative design and innovative development.

Consumer demands are shifting more and more towards convenience and sustainability. OVVO helps you meet those demands and give your products a competitive edge. Our team is on hand to support your switchover to OVVO and help you take the next step of innovation.

Furniture Assembly made simple – no need for tools, glue or screws. Simply push, click and connect.

VISIT US AT STAND N55 AT MATERIALS AND FINISHES SHOW.

19 Panel & Joinery Production - May / June 2024 FEATURE www.ovvotech.com

LONGEVITY AND SUSTAINABILITY 101 YEARS OF VINCENT TIMBER FEATURE

Established in 1923 in the Sparkbrook area of Birmingham, Vincent Timber is a prime example of how a fourth generation business with strong family values has also carved out a leading role in its sector – as a supplier of natural timber cladding, solar shading and decking for prestigious building projects across the country.

The range of options on offer such as Accoya® wood, Cape Cod cedar sourced from managed forests, and Sivalbp pre-coated timber cladding highlights the company’s commitment to sustainability. It was also at the forefront of the campaign to protect the environment as illustrated by the fact that it was only the 2nd company in the UK to be awarded Chain of Custody by BM Trada.

Vincent Timber has introduced certain measures in recent years to support its aim to be carbon neutral by 2030. These include installing LED lights with sensors throughout the premises, a biomass facility that uses waste products for heating, and substantial investment in a fleet of HGVs that are Euro 6 and ULEZ compliant, and which have reduced its carbon footprint by 50%.

It is no surprise therefore that the forklift fleet that it had operated for decades – “dirty red diesel trucks” - according to MD Darren Powell, has been retired, and replaced by something much more contemporary and in line with the company’s stance on environmental issues. Three Combilift electric powered C5000 SLE sideloader models are now in operation at the 2.5 acre site, following demos from various manufacturers for the team of drivers, who judged the Combilifts to be the best of the bunch. “Looking after our workforce is a major driver for our success,” said Darren, “and this applied to the choice of new handling equipment where operator feedback was decisive.”

Collaboration between materials handling suppliers Briggs Equipment, FTC Safety Solutions and the manufacturer Combilift resulted in a fleet of customised trucks that meet all operational requirements whilst reducing emissions and costs, as well as creating a quieter workplace. The Combilifts’ 5t capacity makes light work of handling products that can be up to 10m long and weigh in at 4t, whether they are being offloaded, loaded or put into the 5m high top racking in the undercover storage areas. Jake Vincent, Operations Director, commented:

20 www.p-j-production.com

Combilift trucks

“compared with the limited manoeuvrability of the old trucks the multidirectional capability is also particularly beneficial when moving product around tight spaces on the premises and between machinery on the factory floor.”

As a business that has the wellbeing of its 40+ strong workforce at the heart of its ethos, safety around equipment and in the warehouse is paramount. Vincent Timber therefore tasked FTC Safety Solutions to install its Pedestrian Detection Camera System onto the trucks, which uses AI and machine learning to help operators be more aware of pedestrians in their vicinity and to avoid collisions. The provision of real-time detection and alerts minimises the risk of injuries and damage.

“As well as celebrating the rich history of the company, we are also looking towards further growth, and have purchased some adjacent land from the council to facilitate this,” said Darren.

“Thanks to the expertise and first class service of all involved, our up to the minute fleet will allow efficient handling of an ever increasing volume of products across a more extensive area.”

http://www.vincenttimber.co.uk/ https://www.ftcsafetysolutions.com/ https://combilift.com/ https://www.briggsequipment.co.uk/

21 Panel & Joinery Production - May / June 2024 FEATURE

FTC in-cab screen

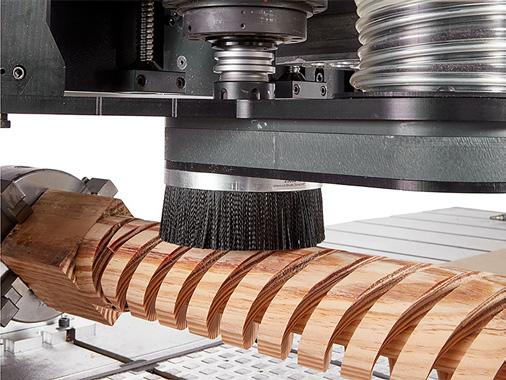

AXYZ TO SHOWCASE INNOVATIVE WOODWORKING SOLUTIONS AT MATERIALS AND FINISHES SHOW 2024 INDUSTRY

AXYZ, a leading provider of CNC router solutions, is pleased to announce its participation in the upcoming Materials and Finishes Show 2024, the UK’s primary platform for carpenters, joiners, machinists and installers to see running woodworking machinery, the latest materials, components, software, tools and innovations for the woodworking sector. Scheduled to take place from May 19th to 22nd, 2024 at the NEC Birmingham.

AXYZ will be showcasing one of its flagship products, the AXYZ WOODWORKER, at Stand K25. This cutting-edge CNC router is renowned for its precision, reliability and versatility, making it an indispensable tool for woodworking professionals across various industries.

The AXYZ WOODWORKER offers state-of-the-art features designed to streamline woodworking processes, enhance productivity and deliver exceptional results. With its advanced technology and user-friendly interface, it empowers users to bring their creative visions to life with ease.

KEY FEATURES OF THE AXYZ WOODWORKER CNC ROUTER INCLUDE:

VERSATILE PROCESS AREAS: the WOODWORKER boasts a wide variety of process areas that can accommodate all standard sheet sizes, with a remarkable 254mm (10”) high gantry clearance. This flexibility makes it easy to use with accessories such as vacuum pods or a rotary axis device, enhancing productivity and precision.

EXCEPTIONAL PERFORMANCE: equipped with powerful direct servo drives and helical racks, the WOODWORKER delivers outstanding performance, high-speed cutting, and impeccable finishes across a wide range of wood types. It excels even with phenolic-based products like High Pressure Laminate (HPL).

MULTIPLE SPINDLE CONFIGURATIONS: the WOODWORKER offers a choice of a single 5, 10 or 15HP HSD spindle, allowing users to tailor their setup to match specific production requirements. Additionally, a 9-position drill bank can be added to the multi-head configuration for faster and more productive operations.

EFFICIENT TOOL CHANGING: with a selection of 7, 10, 14 or 21 position automatic tool changers, the WOODWORKER ensures fast and efficient tool changes, minimising downtime and maximising productivity.

ADVANCED DUST COLLECTION: the router features a high-volume 4” dust collection system, complemented by an oversized dust boot, high-flow manifold, and hose management system. This comprehensive setup effectively collects both large chips and fine dust, maintaining a clean and safe working environment.

AUTOMATED LABEL PRINTING: the WOODWORKER offers an optional AXYZ Automated Label Printer (ALP), simplifying the identification of parts during the final assembly process. This integrated solution streamlines operations and enhanced overall efficiency.

Rotary Axis Equipment: for machining complex parts requiring 360° rotation, the WOODWORKER offers optional rotary axis equipment. This feature expands the router’s capabilities and enables the production of intricate and precise parts.

When it comes to furniture and cabinet making, the AXYZ WOODWORKER is the ultimate CNC solution. AXYZ has put extensive effort into developing a machine that seamlessly combines power, versatility, and precision to meet the unique needs of woodworking professionals.

In addition to the exhibition of the AXYZ WOODWORKER, AXYZ will have dedicated staff from CNCSHOP on-site to provide expert guidance, answer questions and offer insights into maximising the potential of CNC woodworking solutions.

AXYZ are delighted to participate in the Materials and Finishes Show 2024 and to showcase their cuttingedge woodworking solutions. The AXYZ WOODWORKER represents the pinnacle of CNC router technology and they look forward to demonstrating its capabilities to attendees at Stand K25.

The Materials and Finishes Show 2024 is a premier event for professionals in the materials and finishes industry, providing a platform for networking, knowledge-sharing and discovering the latest innovations. AXYZ’s participation underscores its commitment to delivering innovative solutions that meet the evolving needs of its customers.

Visit AXYZ at Stand K25 to experience first-hand the power and precision of the AXYZ WOODWORKER and learn more about how AXYZ and CNCSHOP can support your woodworking endeavours.

22 www.p-j-production.com T: 01952 291600 https://www.axyz.com/

Insert Connect Secure

Cabineo X

Cabinet connector and shelf support without edge drilling

– Time-saving unit connector for laying into position

– Any CNC machine can be used – Can be combined with screws or shelf supports

Visit us and experience our products! Material & Finishes Show, Birmingham 19 – 22 May 2024 // Hall 20 // Stand D20

INTERESTED?

LEARN MORE!

www.lamello.co.uk

BLUM WOWED VISITORS AT KBB 2024 WITH INNOVATIVE SOLUTIONS FOR FLEXIBLE AND COMPACT SPACES INDUSTRY

Held over four days at Birmingham’s NEC in March 2024, this year’s kbb show was the talk of the industry. With over 320 exhibitors, over 25 product categories and 15,000+ visitors, it was full of optimism and excitement with plenty to see, discuss and experience first-hand.

Leading components and fittings manufacturer Blum made a huge impact with its three adjacent stands, demonstrating why being a Blum partner opens up more opportunities for a business than simply buying a hinge or drawer runner and showing how customers can be inspired with innovative storage solutions for flexible and responsive living spaces. Embracing the trend for urban living, where compact houses and apartments in cities and built-up areas need intelligent and innovative solutions for one-space living, kitchen and dining, Blum was delighted to showcase its 22 square metre concept home. In such a small space, every millimetre matters and visitors were able to see how Blum’s storage solutions make life easier and more ergonomic at the same time. It showed how Blum fittings can be used not only in the kitchen, bedroom and bathroom but also in the hallway, home office and utility room, too.

With a hidden door to the bathroom, Blum’s 22 square metre home showed how space can be fully optimised at every level, with the new SPACE STEP providing access to top cupboards while also containing storage within, perfect for keeping a yoga mat, tennis rackets or rucksack for the gym safely and neatly tucked away until needed.

The Blum stand made headlines with its new REVEGO pocket system, a highly innovative solution that opens endless design possibilities, as demonstrated on the stand with a practical and stylish hidden kitchen and home office, both concealed behind REVEGO pocket doors. Perfect for studio apartments and city living, the kitchen can be completely hidden from view after cooking while home workers can close the door after their working day, free to relax during evenings and weekends.

REVEGO from Blum is a smart cabinet solution with fixed pocket widths that can be easily incorporated into plans featuring standard cabinets, making light work of assembly. Available as a single or double door application, it comes with a choice of plinth options and can be produced and preassembled by the manufacturer for delivery to the place of

24 www.p-j-production.com

The 22 square metre home

One of the three Blum stands

installation. Ideal for concealing kitchen units or even entire living areas, the large cabinet fronts of the new REVEGO pocket system are easy to plan, assemble and use, opening up brand new opportunities for designers, retailers and consumers alike.

REVEGO uses Blum’s TIP-ON motion technology so users can open doors with a single touch then slide them away into the pocket so they completely disappear from view while saving space at the same time. To conceal the kitchen, home office or laundry room once again, users just press the door to release it from the pocket then press again to elegantly conceal the entire area.

This year, kbb also saw Blum showcasing its AMPEROS concept, a safe and systematic solution that enables the easy electrification of furniture. Users can power or charge their devices directly in their Blum drawers, create ambience with atmospheric lighting or have easy access to kitchen appliances with AMPEROS, which is easy to retrofit with no electrical skills required.

Whether used to charge or power mobiles and tablets, hair dryers or hair straighteners, AMPEROS allows for the safe supply of power to Blum drawers or pull-out shelves without any free-hanging or visible cables and as AMPEROS doesn’t require a drawer back, it’s perfect for coffee machines, food processors, printers or other small appliances that can be placed on Blum’s pull-out shelf that locks into place and can hold 40-70kg of weight depending on the runner selected.

REVEGO pocket doors slide effortlessly into the custom-built carcass revealing the hidden kitchen

Blum also showcased their services and support highlighting their Technical Services during the show, demonstrating a Fitters Box for installers and specialist machinery for manufacturers that makes their role so much simpler and time effective. Also introducing their Customer Engagement team who were expertly demonstrating the 22 sq meter apartment but are also responsible for Blum’s excellent experience centre.

25 Panel & Joinery Production - May / June 2024 INDUSTRY T: 01908 285700 www.blum.com

The Home Office solution hidden by REVEGO doors when not in use

AMPEROS charging concept keeping cables tidy and un-tangled

EDGINGS BRING FRESH SPRING BREEZE TO INDOOR FURNITURE

As the days get longer and the sun’s rays warmer, we all long for bright, fresh colours. Interior design is an excellent place to start integrating these into our surroundings. A wide collection of new edgings from Ostermann offers solutions for every style and taste.

In spring we feel fresh, positive energy. We can use this energy and put it into a targeted selection of current colours and surface finishes when planning and designing new interiors. Pastel plain colours play a key role here. Together with light-coloured wood or stone decors in sandy tones, they create friendly interiors with an inviting atmosphere. To inspire carpenters/cabinet makers for upcoming projects, the Ostermann experts have put together a selection of coordinated furniture edgings in spring colours at www. ostermann.eu. To take a peek, simply enter the search term “#highlights04” in the search field on the starting page and you will be taken straight to the right page.

COLOURS AND DECORS FOR FEEL-GOOD ROOMS

Rooms in spring colours simply put you in a good mood! Light, easily combinable pastel colours such as the delicate

yellow of the Ostermann Pale Gold edging or the violet of Mauve Poudré, slightly offset with grey, serve as subtle dashes of colour. If you prefer more common colours, the calming light blue of the super matt Surf Blue edging or the friendly green of the Delicate green edging might be the right choice. The plain colours unfold their fresh effect best in combination with neutral and restrained colours as you can find, for example, in the Cashmere grey Stone finish edging. Its embossed surface gives this edging an original look. Alternatively, the plain colours mentioned can also be combined with subtle material reproductions such as the natural wood decor Portland Ash light or the understated stone decor Cream Tessina Ceramic.

ALL EDGINGS IN SMALL QUANTITIES FROM STOCK

Carpenters/cabinet makers who want to include the current spring colours in their projects can find matching edgings in Europe’s largest immediately available range of edgings by Ostermann. The edgings are available from stock and can be delivered within a very short time, also with a functional layer for zero bondline technologies on request. For an accentuating use of the pastel plain colours on individual

26 www.p-j-production.com

INDUSTRY

fronts, shelves or furniture elements, you can order just small quantities of these edgings, avoiding unnecessary remnants. For unusual ideas with curves or special board thicknesses, the company also offers numerous edging services, such as the application of a T-bar or slitting of a 100 mm wide edging to any desired width.

TIP: DON’T FORGET ADHESIVES AND CLEANERS

Along with the edgings, you can also order the appropriate adhesives and cleaners for the edgebanding machine from Ostermann. Here too, the company not only offers a wide range of products, but also many services, such as expert advice and practical accessories.

27 Panel & Joinery Production - May / June 2024 INDUSTRY T: 01905 793550 E: s.parsons@ostermann.eu www.ostermann.ue

CASE STUDY

LAMINATE FABRICATOR FIRST TO INVEST IN NEW EDGEBANDING TECHNOLOGY FROM BIESSE

Duncan Reeds’ investment in a Rover A pod & rail machine and a Stream A edgebander from Biesse has had a dramatic impact on efficiency at its Billingshurst site. The laminate fabricator’s CNC operation has become 25% more efficient as a result of reduced set-up time and downtime, whilst the edgebander is pushing performance boundaries thanks to the innovative AR70 high speed corner rounding unit.

Duncan Reeds’ first dealings with Biesse UK date back 30 years - when both businesses were in their infancy and compact laminates didn’t even exist. In Daventry, Biesse UK was in the early stages of establishing itself as a subsidiary of its Italian parent company - a leader in machining technology for wood, stone, glass and advanced materials. Meanwhile, from a modest unit in West Sussex, Duncan Reeds was building a business producing and sizing laminated boards.

As its business started to take off, Duncan Reeds decided to replace its table saws with a beam saw and opted for Biesse’s Selco brand. This marked the start of an ongoing investment policy that has continued to the present day.

“We started with simple table saws and an 8ft press. When we could afford it, we bought a 10ft press and a beam saw, adding to that as capacity increased,” recalls Andy Bilton (Director), who has been at Duncan Reeds since it was founded in 1989 by his brother-in-law and father-in-law. Andy says that Biesse’s support was invaluable to Duncan

Reeds during those early days. Fast forward to 2023 and once again, Biesse is supporting Duncan Reeds during another formative period - its transition to a highly flexible operation that can cater for batch one scenarios through digitalisation of certain processes.

30 YEARS ON…

In the interim both companies have grown considerably. Biesse UK, which celebrates its 30th birthday this year, now boasts a turnover of £30m+ and employs 100 members of staff. Duncan Reeds has grown its turnover progressively year on year and evolved into a dynamic operation with three sites across the UK. It has built up a reputation as a leading fabricator of bespoke laminated products for a diverse range of applications and industries.

“One day we might get an enquiry for 50 panels drilled with inserts for a furniture job and the next day we might be profiling the edges of a compact laminate or producing acrylic hygiene screens,” says Dean Harkess-Cowlyn (Director), illustrating the variety of jobs that make up the company’s workflow.

He adds: “Whether we are dealing with washroom companies, shop fitters, laboratory fitters or joinery companies, we need machines that are versatile enough to accommodate any profile, any material, any size and any tool.”

28 www.p-j-production.com

Regular contact by Biesse’s sales team meant that Duncan Reeds was aware of the progress the machine manufacturer had made in terms of adapting to flexible, batch one production. Therefore, when it came to replacing a 20 yearold edgebander, Biesse was the first (and only) port of call.

A UK FIRST: THE AR70

In January 2023, Duncan Reeds became the first UK company to take delivery of a Stream A edgebander with Biesse’s innovative new AR70 high speed corner rounding unit.

This NC controlled unit enables users to switch quickly between different radii (3mm, 2mm, 1.5mm and 1mm) or a chamfer finish for the corners of the panel, plus it rounds the top and bottom corners in one unit. This means that rather than having to change the tooling to accommodate different tape thicknesses or round off the corners, the machine does this automatically, reducing job changeover time.

Andy says the flexibility afforded by the AR70 was a key factor in the decision to invest in the Stream A edgebander.

“One minute we will be applying 2mm ABS edging, then will need to switch to 12mm trims on solid fire doors the next. Before, it was a case of making manual adjustments and running test pieces. Now, with the AR70, because the machine is numerically controlled, our operators just call up the preset programme and the machine recalibrates. Switching from one job to another can be done in a matter of minutes, seamlessly with no set up time hindering manufacturing.”

CASE STUDY

WORKING WITH WIDER PANELS

He adds that the Stream A’s flexibility will support the growing demand the company is seeing for floor to ceiling high end cubicles with 44mm solid floors and 15mm door rebates.

“Our previous machine could only accommodate timber of up to 19mm in width. Once we had put the timber on, dressed it, sized it and put a 15mm rebate on, there wasn’t a lot of margin - it was very tight. The Stream A can work with 22mm wide timber which gives us a lot more flexibility.”

Whilst the machine was being built, Duncan Reeds sent a pallet of samples to Biesse’s HQ in Italy. The load contained a diverse range of panels and edging materials - everything from ABS to timber lipping, laminate lipping, real wood edging, veneer panels, plain chipboards and laminated MDF.

This gave Duncan Reeds confidence that the machine they had ordered was going to be able to cope with any job that was thrown at it.

“It was sent back to us, we checked it all and it looked absolutely fine,” says Andy.

STREAM A SOLVES STICKY SITUATIONS

Two glue management features on the Stream A are also contributing to the efficiency gains Duncan Reeds is seeing. Firstly, the application of glue is numerically controlled, which means it is optimised for each preset programme.

29 Panel & Joinery Production - May / June 2024

Continued on page 30 >>>

CASE STUDY

“This makes life much easier for our operators. It makes for much more efficient use of adhesive enabling the exact amount to be used which eliminates unnecessary cleaning,” says Andy.

Secondly, an inbuilt CIP (Clean In Place) system within the glue head eliminates the need to remove the head from the machine for cleaning after using PUR.

“Previously, we shut down the system on a Friday afternoon and when we came back in on Monday, unless the glue head had been stored in a sealed nitrogen tank, we needed a new one,” recalls Andy.

ROVER A STREAMLINES CNC OPERATION

A month after the delivery of the Stream A, Biesse installed a Rover A pod & rail machine with a five-axis head.

“The Rover A was a direct replacement for a competitor’s machine which proved hugely problematic even after only three years,” says Andy.

“Biesse has been a breath of fresh air. The support we have received so far has been excellent,” he adds.

Biesse’s B_SOLID software, incorporated as a standard feature with the Rover A, has revolutionised the way that Duncan Reeds operates, thanks to its digital twin simulation and CAD drawing manipulation capabilities.

B_SOLID gives users a unique view into their CNC machine by creating a digital twin - that is a virtual replica of their real-world machine. Working on the machine’s control panel or on a remote PC, the user can use B_SOLID to design a machining programme for a particular project. They can then run a rapid and realistic 3D simulation of that programme - de-risking the project by verifying the feasibility of the intended tool path, machining speed and tool selection, and giving an accurate estimate of job completion time.

SIMULATION SOFTWARE ASSISTS JOB COSTING

Duncan Reeds is finding this simulation capability particularly useful for informing pricing; if they know how much time will be needed to carry out the required machining operations, this can be used as the basis for costings.

Dean noted: “We know exactly how much it costs to run a job, so if we are quoting for a project that is price-sensitive we can go in with a very accurate costing that will give us a greater chance of winning the work.”

B_SOLID has also sped up the process of translating customer drawings into CNC programmes at Duncan Reeds by enabling operators to import drawings directly into the machine’s software.

“Previously we had to redraw the drawing. Now, as soon as anyone in our team receives a drawing, it is emailed immediately to a dedicated email address so that an operator can get on and create the programme. This has streamlined the process, dramatically reduced programming and set-up time and made us really appreciate the advances in what technology can do. And we have managed to do that because of the training and support that Biesse has provided,” says Dean.

He continues: “Where in the past we used to see the CNC machine sitting idle while the operator was setting up the programme, now we are getting jobs done far more quickly because we are spending less time setting them up. I would estimate that we have increased efficiency by 25%.”

CONFIDENCE IN MACHINE CARE

And after its experience of frequent breakdowns with its last machine, Duncan Reeds is taking no chances on the warranty front. It has taken out Biesse’s industry-leading five-year Total Care warranty programme to protect its investment.

“I have every confidence that when the Rover A is five years old, we will be looking at replacing it with another Biesse machine with Total Care. We see continual investment in new technology as essential to remaining competitive in the marketplace and our confidence in Biesse is high owing to the success we have had with these two machines,” says Dean.

30 www.p-j-production.com

Edgebanders

CNCs,

Biesse on 01327 300366,

info@biesse.co.uk

visit biesse.com/uk

To find out more about

and

contact

email

or

Century House, Premier Way, Lowfields Business Park, Elland, West Yorkshire, HX5 9HF T: +44 (0) 1484 658341 E: info@decorativepanels.co.uk www.decorativepanels.co.uk Contact us for more information. Fantasy living A range of finishes that nature cannot provide, fantasy brings textures and colours that create unique outcomes.

Finish shown: Concrete Oxide

AJB GROUP - CELEBRATING 25 YEARS OF WOODWORKING EXCELLENCE FRONT COVER FEATURE

AMARJIT

BINJI

TALKS

TO CLARE

HOLLISTER AT PJP

ABOUT

HIS 25 YEAR JOURNEY IN THE INDUSTRY.

Amarjit Binji is a trained carpenter, joiner with a love and passion for the woodworking industry and a desire to have a workshop which showcased how the industry could look to the outside world by having clean, tidy and pristine workshops while delivering high class products. In 1991, frustrated with what he perceived to be a staid industry which lacked the ambition to move with the times he decided to fulfil that vision and start his own business. Thus AJB Group was born.

Fired by youthful enthusiasm and perhaps some naivety, he visited a mothballed pine furniture unit in Leicester and approached the landlord who saw something in Amarjit and allowed him to take the machinery and space for 3 months to see if he could fulfil the vision and make something of the space. The foreman of the unit, John Besse together with Mark Lord, who had been Amarjit’s mentor during his apprenticeship, joined the company and things began to fall into place. For four years the order book was full but it was a challenge to make the furniture and then jump in the van to deliver it all at the weekends.

Alongside this, door and window work was starting to come in so a change of mindset was needed.

In the summer of 2000 Amarjit closed the factory for 2 weeks. He made the decision to buy £50,000 worth of machinery and to revamp the workshop in order to get ready for the change of focus. Enlisting the help of his 13 year old brother, Mandeep, they cleaned, painted and moved everything around so by the time the staff arrived back from their break Amarjit had the pristine workshop of his dreams. Mark Lord, his foreman, took one look at it and pointed out that he had a workshop which looked like it had never seen any work, no forward bookings and a lot of expensive unused machinery.

A week of sleepless nights ensued but fate intervened when a man walked into the workshop one afternoon and asked if they made windows. Amarjit thought nothing of it and referred him to John but then asked how many windows? 110 was the response. So began the relationship with Mr Chaggar who put in his order based on the look of the workshop and the ambition he saw in Amarjit. He became their largest single customer and AJB fulfilled all the woodworking requirements for his 15,000 square feet house build. Mr Chaggar became a friend and business mentor, influencing and advising on business decisions with his cheerful ‘skies the limit’ attitude.

Amarjit says: “He was the first successful businessman I’d ever known. He was inspirational and generous with his time. He had faith and belief in me and I believe his influence is still with me.”

In 2000 during routine Sunday cleaning, a man called Bob Jones arrived and asked to look around the premises and liked what he saw. A week later a fax arrived inviting Amarjit to a meeting at Shadbolts in London and to quote on 9 cherry wood door frames. Arriving at Shadbolts and sensing the history of this 100 year old established veneer company with a slick reception area and board room Amarjit felt that things were about to change.

Bob introduced him to his colleagues and announced it was his last day and disappeared from the scene. So started a relationship which remains to this day. Shadbolts orders meant that the furniture side was no longer viable so in 2004 reluctantly Amarjit closed that side of the business. He installed an extraction unit, employed more staff and with the help of his sister registered for ISO9001.

By 2014 the 13.5K sq feet of space was bursting at the seams and the decision was made to move to bigger premises. With nothing affordable or suitable the search widened and the premises in Corby was found. After an exhausting and frustrating search for funding Royal Bank of Scotland agreed to fund the plan and the move was made with most key staff transferring over to Corby.

2015 saw Shadbolts orders ramp up from 100 to 850 in the space of 3 weeks. The staff all rose to the challenge, the orders were fulfilled and the client was very happy. New clients were found and things were looking up.

Then a series of challenges hit in the form of Brexit, then just as things started to improve the pandemic hit and although the factory carried on functioning, work diminished. Then as things started to look better there was a fire in the factory which could have been so much worse than it was but the fact the workshop was clean, tidy and free of sawdust and rubbish it was contained. However, the machine was a write off. Amarjit gives a big shout out to Biesse who provided a replacement machine within days and staff who worked tirelessly to get the unit cleaned and fit for purpose.

2022 and 2023 were tough years with the energy crisis and general industry turndown.

But despite all of these challenges the outlook for the AJB Group in 2024, their 25th year, is rosy. There are opportunities on the horizon which could change their future and the order book is strong.

Amarjit Binji remains determined to fulfil his vision with the help of his immediate family and his workforce who he regards as his extended family.

PJP looks forward to following their progress and updating our readers on their progress and news.

32 www.p-j-production.com

FRONT COVER FEATURE

I’m celebrating my 25 years with AJB this year and I feel like I’m under the family wing if help is needed. Collectively we can achieve anything.

There are exciting times ahead & I’m looking forward to evolving and changing

Darren Moore Factory Manager

I’ve been friends with Amarjit since we were 18! I’ve worked with him for 14 years.

This is a fantastic place to work –communication is key and we’ve seen some tough times but have weathered the storm.

I’m looking forward to what comes next!

This is a brilliant family business we all feel part of the family. Communication is everything. The future looks good and having started as an apprentice and moved up the ranks I see my future here and I have aspirations to one day join the management team

Lewis Elverstone Machine Shop Coordinator

I’ve watched the business growth from a young age. We are an inclusive and communicative business.

We strive to be the best and recognised as such in the business Progression happens through looking at bigger clients and different businesses

Mandeep Binji Operations Director

Hitts Maisuria Project manager

I’d love to see company grow with more staff and a full and varied order book.. I’m looking forward to growing with the business and perhaps meeting challenges in new roles in the future.

Kully Binji Company Secretary & HR Manager

33 Panel & Joinery Production - May / June 2024

T: 01536 267 139 www.ajb-group.co.uk

The Mirka® DEROS II and Mirka® DEOS II are not just power tools; they are game changers. It’s precision and power like never seen before, featuring new brushless electric motors with as much as a 20% increase in power, providing better efficiency in performing tasks. For further information or to arrange a demonstration, please contact Customer Services on 01908 866100.

NEW

Mirka® DEOS II - Where craftsmanship meets technology. Mirka® DEOS II Learn more at www.mirka.co.uk

The next generation.

Crafted for your business, to do business. We’ve started something new.

part

show

together

furniture

joinery

latest

Materials & Finishes Show was formerly known as W Exhibition. REGISTER FOR YOUR FREE TICKET AT materialsandfinishesshow.com/visit The UK’s trade show for the furniture manufacturing & joinery industries

Be

of the trade

that will bring

every corner of the

manufacturing and

industries. Hundreds of brands, thousands of the

products and innovations, all under one roof, across four days.

HOMAG UK SUPPLIES AR18 WITH NEW EDGETEQ S-500 AND XES 200 SERVICE STATION CASE STUDY

Founded in 2003 and based in Uxbridge, ar18 Limited is one of the UK’s leading names in retail furniture, bespoke joinery, CNC routing and sheet metalwork. From its impressive workshops near London Heathrow, it increasingly works in every corner of industry – from point of sale, signage and modular furniture to displays, innovative structures and other bespoke projects including reception desks, feature walls and cladding panels. It also provides a full service offering to small joinery companies and sign makers without in-house CNC facilities.

“From humble beginnings, our business has grown exponentially” enthuses Mark Smith, Head of Operations at ar18 Limited. He continues, “Over the last 20 years, one common thread has been our philosophy of always investing in the best machinery available. On the joinery side of the business, HOMAG has established itself as our partner of choice.

“Our plant list of HOMAG equipment includes two CNCs, an automated storage and retrieval system with the woodStore storage management system, a sander and a small edge bander. Consequently, when we made the decision to invest in a larger, more powerful edge bander we looked no further than HOMAG.

“The advancements in edge banding technology over recent years have been considerable, particularly when it comes to speed and quality of the finished workpieces. As a business, we were experiencing a slight directional change, taking on more and more modular furniture projects which required added high quality edging.”

SELECTING THE HOMAG EDGETEQ S-500 WITH XES 200 SERVICE STATION

“In terms of selecting the right model for our business, we first looked through all the information on HOMAG edge banders on the company’s website. Once we had a rough idea of the machine that would best meet our needs we asked our HOMAG area sales manager, Ian Woodall, to fine tune our choice of machine.

“Since Ian has been our main point of contact at HOMAG UK our relationship has gone from strength to strength. Ian is not only very knowledgeable regarding HOMAG’s portfolio, but he also has an excellent understanding of our business and we value his candid advice.

36 www.p-j-production.com

Edgeteq S-500

“Ian recommended the EDGETEQ S-500 along with the XES service station. To give us peace of mind, Ian arranged for us to visit another manufacturer that was already operating an S-500 edge bander. Seeing the machine in a real-life manufacturing situation was extremely beneficial; we pretty much sat down for coffee afterwards and ordered the EDGETEQ S-500 and XES 200.”

QUALITY, SPEED AND VERSATILITY

“As you’d expect from HOMAG, the delivery and installation of the equipment was planned and executed exactly to schedule. One of the installation engineers also trained our staff on the new equipment so they were able to hit the ground running.

“The quality of the finished workpieces, along with the speed of throughput, is massively impressive. We are also benefitting from having the choice of two different glue types – EVA and PU. The XES 200 glue service station is a big benefit too, as it prevents glue from going off when the machine is not in use and rapidly heats the glue when we’re ready to run again. In addition, it gives us the ability to switch quickly from EVA to PU and vice versa.”

FIRST CLASS AFTERCARE

“Apart from the robust, technically advanced, and reliable machinery and software, there’s another reason we keep going back to HOMAG. The company’s customer service is excellent; they’re always responsive and not only do they listen to feedback, but they also act on it.

“This level of support is vital for our business; we can’t afford for machinery to be out of action. The backup service we get from HOMAG gives us real peace of mind and allows us to keep our customers happy and satisfied at all times,” concludes Smith.

If you would like more information or a demonstration of any of the HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

T:01332 856500

E: info-uk@homag.com www.homag.com

37 Panel & Joinery Production - May / June 2024

CASE STUDY

XES-200 Service Station

Choose the right products for your projects Compact Laminate

High Pressure Laminate Door Laminate

sales@panelco.com

www.panelco.com The Perfect Partnership NOW IN STOCK Extensive HPL & Compact Collection

|

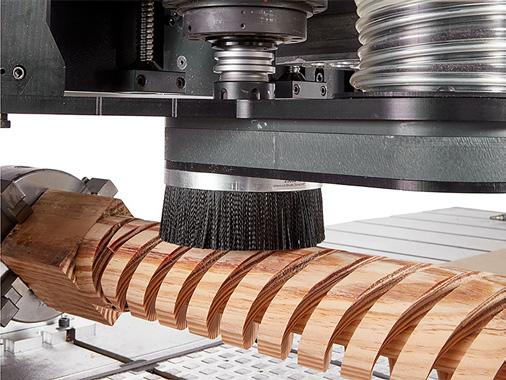

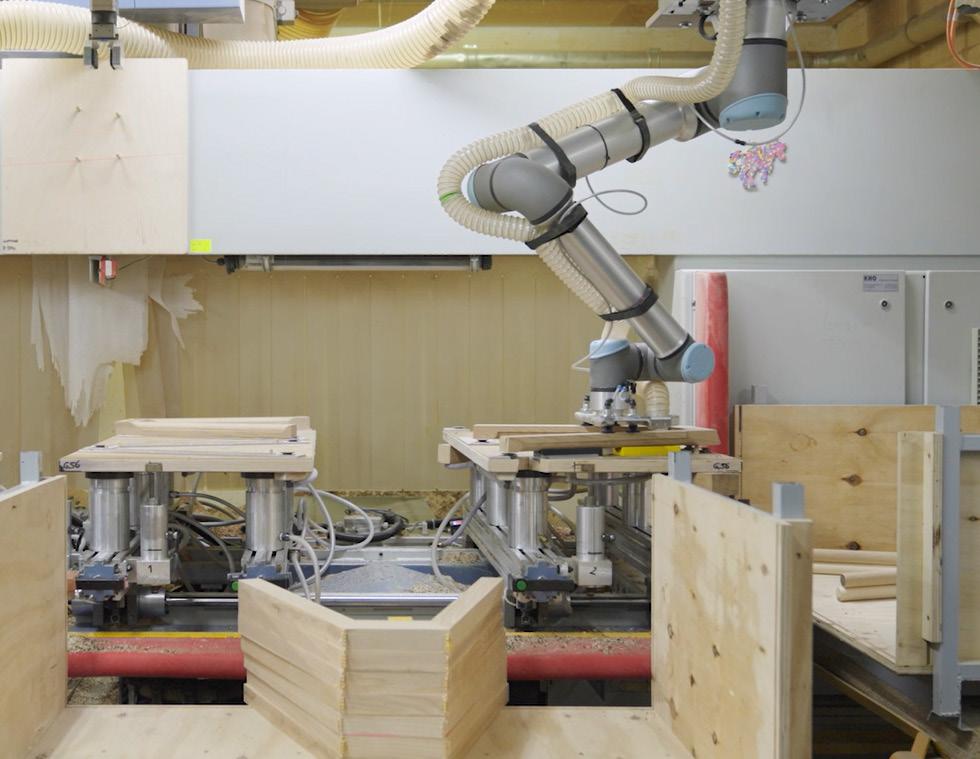

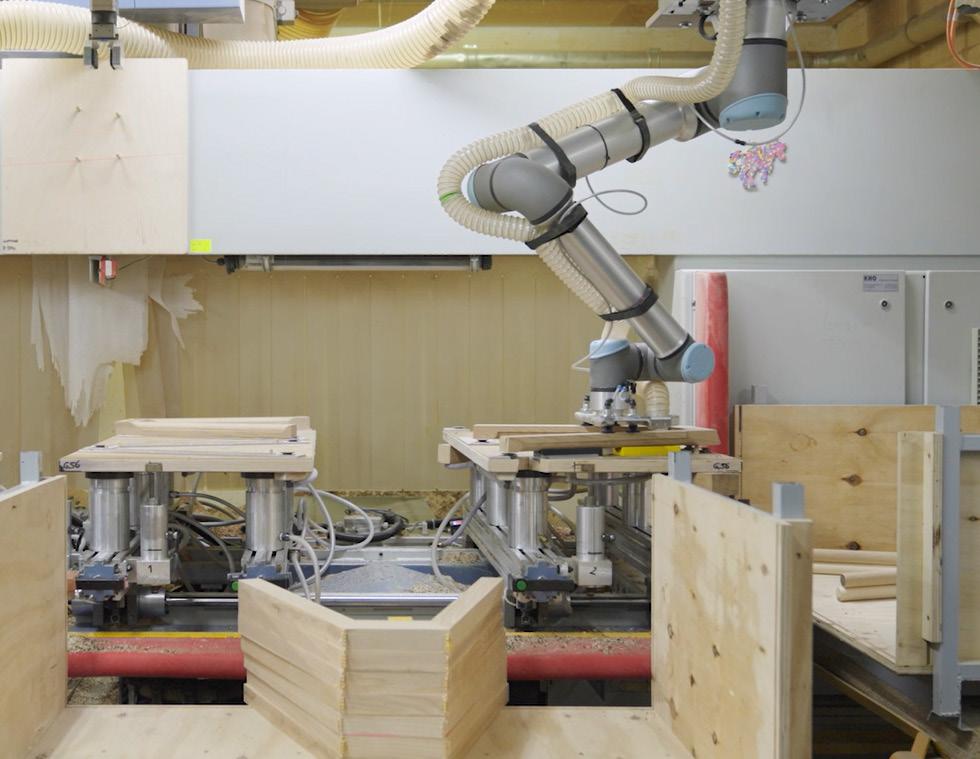

JJ SMITH UNVEILS INNOVATIVE PRODUCT RANGE FROM WOODWORKING ROBOTICS

Innovation and efficiency are the cornerstones of progress, and in the realm of woodworking, JJ Smith is at the forefront of transformation by introducing their latest innovative product range from Woodworking Robotics. Partnering with leading robotics manufacturers, they can offer cutting edge automation solutions to the woodworking industry aimed at simplifying manufacturing processes.

The aim of Woodworking Robotics is not to replace humans, but to enhance their capabilities. By delegating the ‘3 Ds’ of manufacturing – Dirty, Dangerous and Dull tasks – to collaborative robots, operators can redirect their focus to higher value tasks, boosting productivity and minimising risks.

ROBOTIC ASSEMBLY SYSTEMS

Whether the goal is to scale up output or streamline operations, these systems can automate fastening, dispensing and taping processes for wood-based products such as sheds, pallets, garden furniture, beehives, kitchen carcasses and bed frames.

ROBOTIC BANDSAW

Enhancing safety and accuracy, this automated solution facilitates the cutting of small wooden parts with customisable hoppers, maximising productivity with minimal human intervention.

ROBOT CONVEYOR LOADING / UNLOADING

Integrating seamlessly with existing conveyor systems, robots work collaboratively to optimise workflow by automating loading and unloading functions simultaneously. For added convenience, robots can be mounted on mobile bases so they can be easily redeployed to adapt to changing production demands.

ROBOTIC SANDING

By integrating with traditional sanding machines, this innovation eliminates the need for manual sanding of furniture parts and panels, freeing up valuable manpower and reducing the risk of repetitive strain injuries.

40 www.p-j-production.com

FEATURE

Robotic Assembling Systems

ROBOTIC MACHINE TENDING

Compatible with any woodworking machine, collaborative robots can automate machine tending tasks to help achieve production goals. A personalised assessment will be offered to understand the best way to optimise production with automation.

ROBOTIC SCREWDRIVING

Featuring automatic screw insertion with precision and accuracy, this system minimises the risk of repetitive strain injuries commonly associated with manual power tool work.

Loading and Unloading

ROBOTIC T-NUT INSERTION