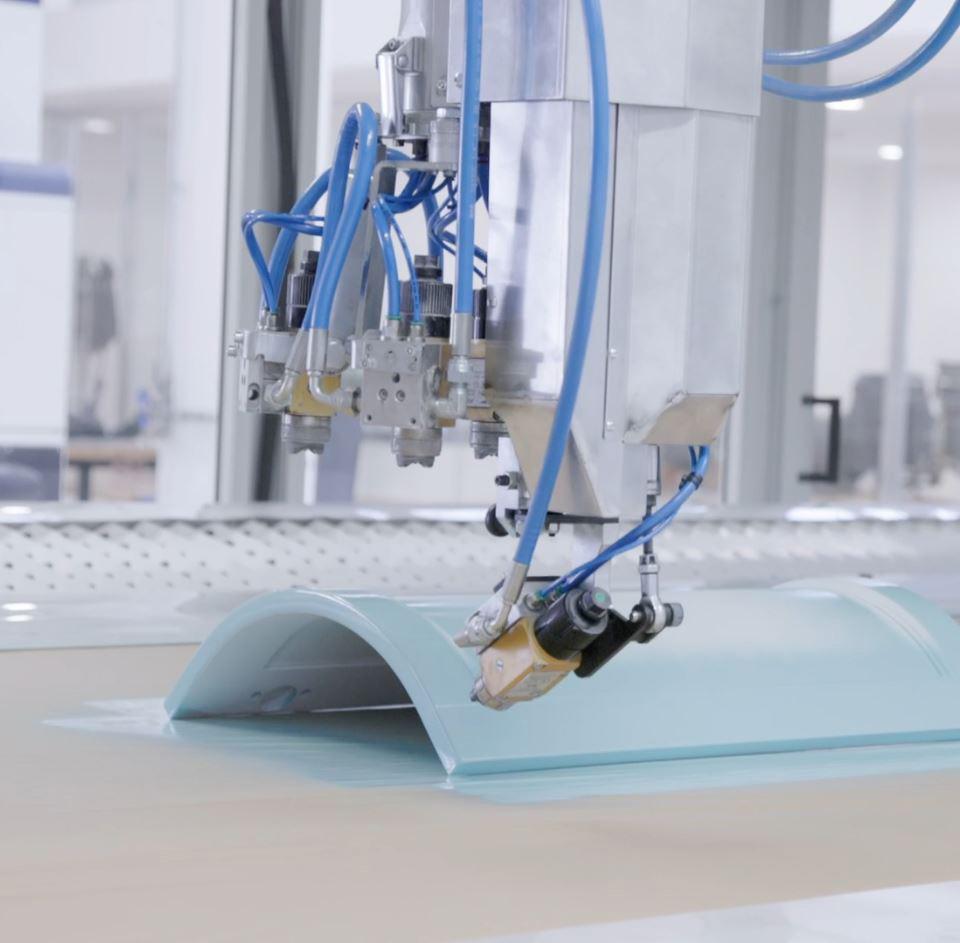

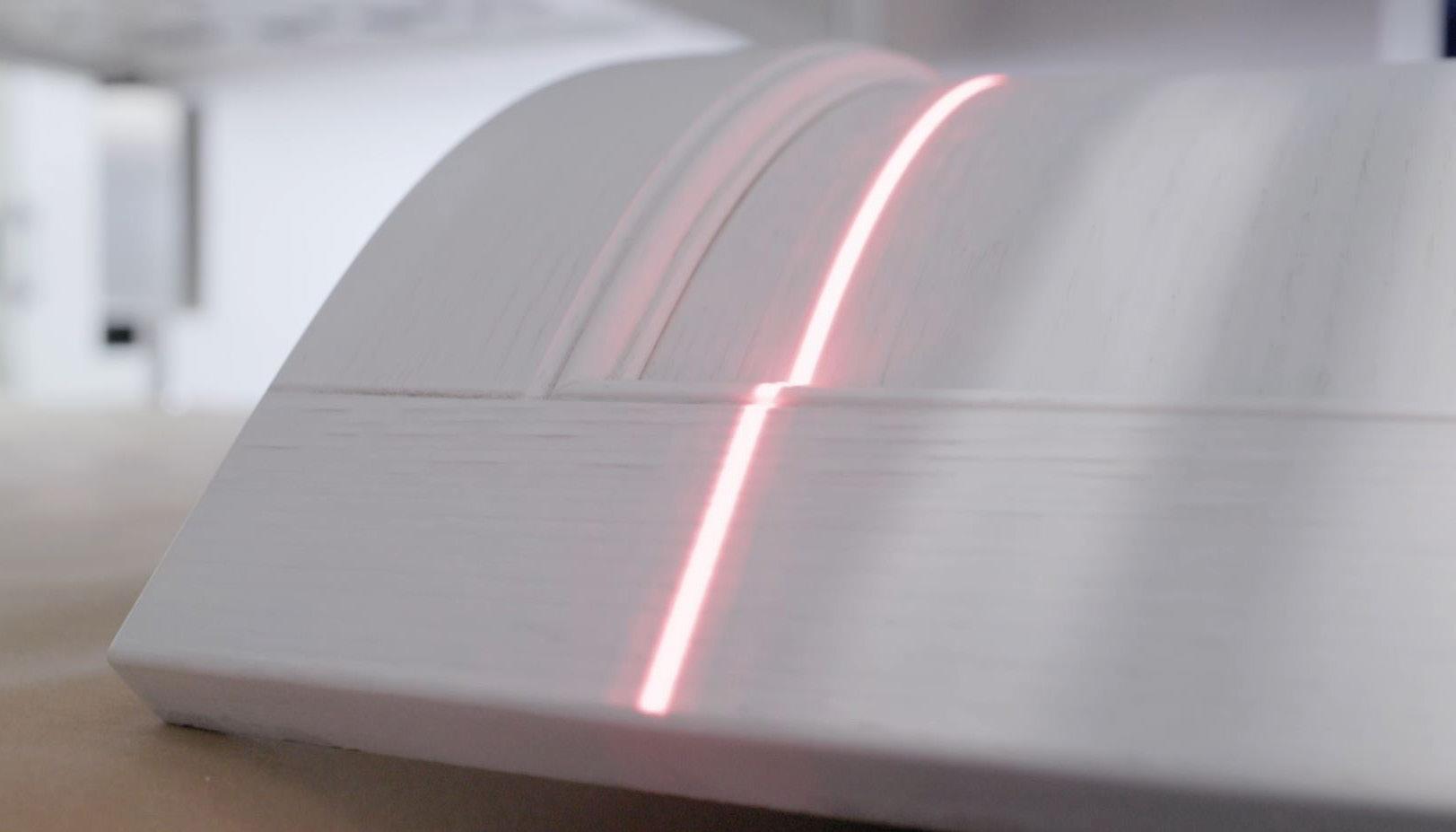

The original Superfici Valtorta Bravorobot is the perfect combination of precision and speed of application. This Cartesian robot guarantees spraying reliability and smoothness thanks to its 5-axis system that simulates the manual spraying typical of craftsmen. It is all enclosed within a pressurised cabin that ensures a clean and healthy working environment

The versatility of the application shines through with the possibility of tilting and positioning the robotic arm so that the guns can be adapted for edges and non-planar workpiece geometries. After taking an automatic reading of the workpiece it will be possible, via the simple and intuitive software, to calculate the best spraying trajectories. No spot, not even the most intricate, will be forgotten

SCM UK

Tel. +44(0)115 9770044 scmuk@scmgroup.com www.scmwood.com

PUBLISHED BY:

TELEPHONE:

EMAIL:

WEBSITE:

PUBLISHER:

DESIGNER:

PRINTER:

EC Media

21 Cedric Road

Westgate on Sea

Kent CT8 8NZ

0771 314 8831

clare@p-j-production.com

www.p-j-production.com

Clare Hollister

Russel Goldsmith

TRACE Creative Agency

www.tracecreative.co.uk

The Magazine Printing Company

www.magprint.co.uk

Reproduction of articles: All material appearing in Panel & Joinery Production is strictly copyright, and all rights are reserved.

No part of the publication may be copied or

in any form whatsoever, including photocopying without prior permission of the publishers.

Publishers note:

MARCH 2024

19-22 March

HOLZ-HANDWERK Nuremberg, German

APRIL 2024

16-21 April

SALONE DEL MOBILE – EUROCUCINA Milan Rho, Milan

16 Apr - 21 Apr

SALONE DEL MOBILE Milan, Italy

16 April – 18 April

NEY’S IN-HOUSE EVENT Coventry, UK

24-25 April

FURNITURE COMPONENT EXPO

Telford International Centre

MAY 2024

2 May - 4 May

PROPOSTE

Villa Erba Cernobbio Como, Italy

14 May – 16 May

HOLZ-HER UK

Connect Event – Fire Door Manufacturing Abingdon, UK

14-17 May

FIMMA + MADERALIA Valencia, Spain

19-22 May

MATERIALS & FINISHES SHOW NEC, Birmingham

21-24 May

XYLEXPO

Milan Rho, Italy

JUNE 2024

6-7 June

INTERZUM FORUM ITALY Bergamo, Italy

11 June – 13 June

WEINIG UK CONNECT Window & Door Production Abingdon, UK

JULY 2024

10-11 July

MANCHESTER FURNITURE SHOW Manchester Central

AUGUST 2024

6-9 August IWF

Atlanta, Georgia

SEPTEMBER 2024

17 Sept – 19 Sept

HOLZ-HER UK

Connect Event – Edgebanding Abingdon, UK

OCTOBER 2024

8 Oct – 10 Oct

WEINIG UK CONNECT EVENT Performing with Powermat Abingdon, UK

10 Oct – 11 Oct

MARKFIELD AUTUMN IN HOUSE SHOW Leicestershire, UK

The woodworking community has a milestone birthday coming up: LIGNA will be celebrating its 50th anniversary in 2025. LIGNA’s origins date back to 1950, when it was the first “Woodworking Machinery Group Show” at the “German Industrial Trade Fair in Hanover”.

The general conditions for LIGNA’s anniversary year 2025 are notably challenging. The industry is grappling with economic difficulties such as a decline in orders due to stagnation in the construction sector, diminishing sales, cost pressures, short-time work, a shortage of skilled workers, job cuts, and the implementation of new legal regulations for supply chains and the circular economy. Throughout history, LIGNA has been described as a steadfast anchor in tumultuous times, serving as an economic barometer. This resilience was evident in 1985 when, faced with a similar situation, the closing announcement included a quote that resonates with the current state of the industry: “Due to the innovations presented, LIGNA HANNOVER 1985 will have a lasting impact on the sales development of the timber industry in the coming weeks and months. It will become an important

pillar of the domestic industry economy, currently weakened by the slowdown in demand in the construction sector.”

“LIGNA is a truly unique trade fair. Throughout its five decades, it has consistently succeeded in bringing together all industry topics under one roof while still providing each with its distinct space. The collective enthusiasm of industry participants for innovation and performance is unparalleled. The shared commitment to shaping technological progress and, in turn, ensuring business growth, stability, and prosperity is what motivates everyone involved. As the organizer, being able to witness and contribute to this spirit fills us with pride to be part of such a remarkable community”, says Stephanie Wagner, Head of LIGNA at Deutsche Messe AG.

For a compact overview of the past five decades, you can find more information in the LIGNA history on www.ligna.de

The kbb Birmingham show attracted over 16,000 visitors this week showcasing over 320 exhibitors with over 20 countries represented.

kbb Birmingham is Europe’s largest dedicated kitchens, bedrooms and bathrooms exhibition with a comprehensive display of everything kbb - from surfaces, fixtures, fittings, furniture, flooring, decorative panels and much more –highlighting the latest trends from the entire product mix for retail and contract environments.

Exhibitors such as Blum, Mirka, Hettich, Titus, Hranipex, Hafele and many more chose this platform to showcase their latest products with style, innovation and clever space saving ideas.

The Innovation Awards, now in their sixth year and in partnership with Blum, had three categories for innovative products to be entered. The judges choice was Space-Plug Ltd who offer a space saving solution for the woodworking industry. Their invention of the Space-Plug adjustable spacer fixing saves material, times and provides more accuracy for fitters.

There was a focus on sustainable solutions and the environment with companies focussing on what they can do to make their products more sustainable and

environmentally friendly to meet the demands of their consumers. Sustainable design, customisations capabilities and cutting edge technologies is a high priority across the sectors.

www.kbb.co.uk

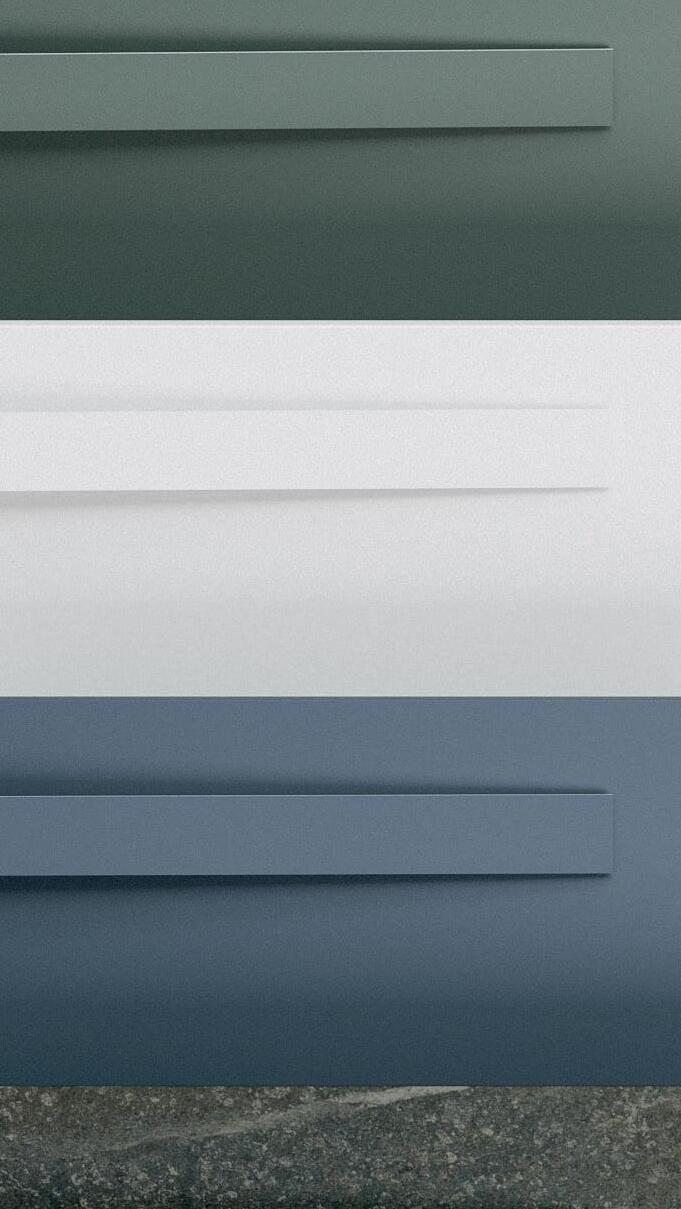

Ostermann supplies the carpenter/cabinet maker with all edgings for the new Egger Decorative 24+ collection within 24 hours

In time with the launch of the new Egger collection in February, Ostermann has all matching edgings ready for delivery. In any required width up to 100 mm and with their tried and tested quick delivery service.

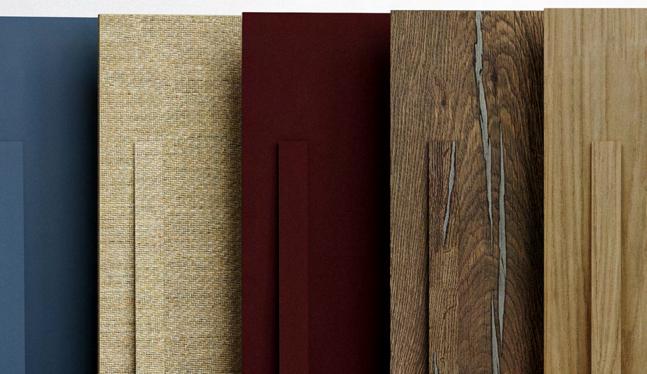

As always, the Ostermann experts have made themselves closely familiar with the boards from the Egger Decorative 24+ collection: the latter features elegant and restrained wood decors, matt and velvety plain colours as well as classic material reproductions that impress with their realistic embossings. A particular focus was put on sustainable use: all decors can be combined with each other and will thus fulfil changing requirements in the long term. Numerous PerfectSense lacquer boards with wood and plain decors are part of the collection. The boards are now commercially available - ready to be transformed into individual pieces of furniture by skilled carpenters/cabinet makers. Ostermann’s contribution to making this possible began early on by sampling and allocating all matching furniture edgings.

The company now presents edgings to all the colours and decors, available from stock in the standard dimensions 23, 33, 43 and 100 x 1 and / or 2 mm. They are dispatched from 1 metre. Every 100 mm wide ABS edging can also be cut to customised widths on request. Businesses that work with zero bondline technologies can also order the edgings for their laser, Airtec or Infratec units with TPU functional layer. All variants are also available with a hotmelt adhesive coating for processing with hot-air devices. If you want to see the new products immediately, you can find them under the search term “#Highlights02” at www.ostermann.eu

Egger collections have always been characterised by a large number of classic wood decors. A look at the types of wood shows that oak is still predominant, but with calmer patterns than before. The many dark decors are suited to create comfortable yet opulent interiors. The Feelwood surfaces are particularly worth mentioning. Their authentic

appearance is based on their lifelike feel. At Ostermann, you will find matching wood decors in coordinated patterns and embossings.

When it comes to plain colours, the variety of neutral colours from white to beige and grey to velvety black is striking.

The trend colour green also plays an important role in the spectrum. It is accompanied by numerous shades of blue which can be combined well with most wood decors thanks to their restrained colouring. The brighter colours are also rather matt and accentuate without being obtrusive. The Ostermann edgings are available in the same respective colours with matching surface finishes.

In relation to the number of wood and plain colours, the selection of textile, stone and metal decors is comparatively small. However, materials such as linen, iron or marble are covered by some timelessly modern designs. The stone decors have slightly metallic accents. When producing the matching edgings, Ostermann placed particular emphasis on the right feel of the edgings’ surfaces. This means that even in material reproductions, board and edging appear as if made from one piece.

One advantage with Ostermann is that you can order from a single source. All materials for a project can be ordered here in one fell swoop: from edgings, fittings and equipment items to workshop supplies. This saves valuable time, which is then available to advise customers.

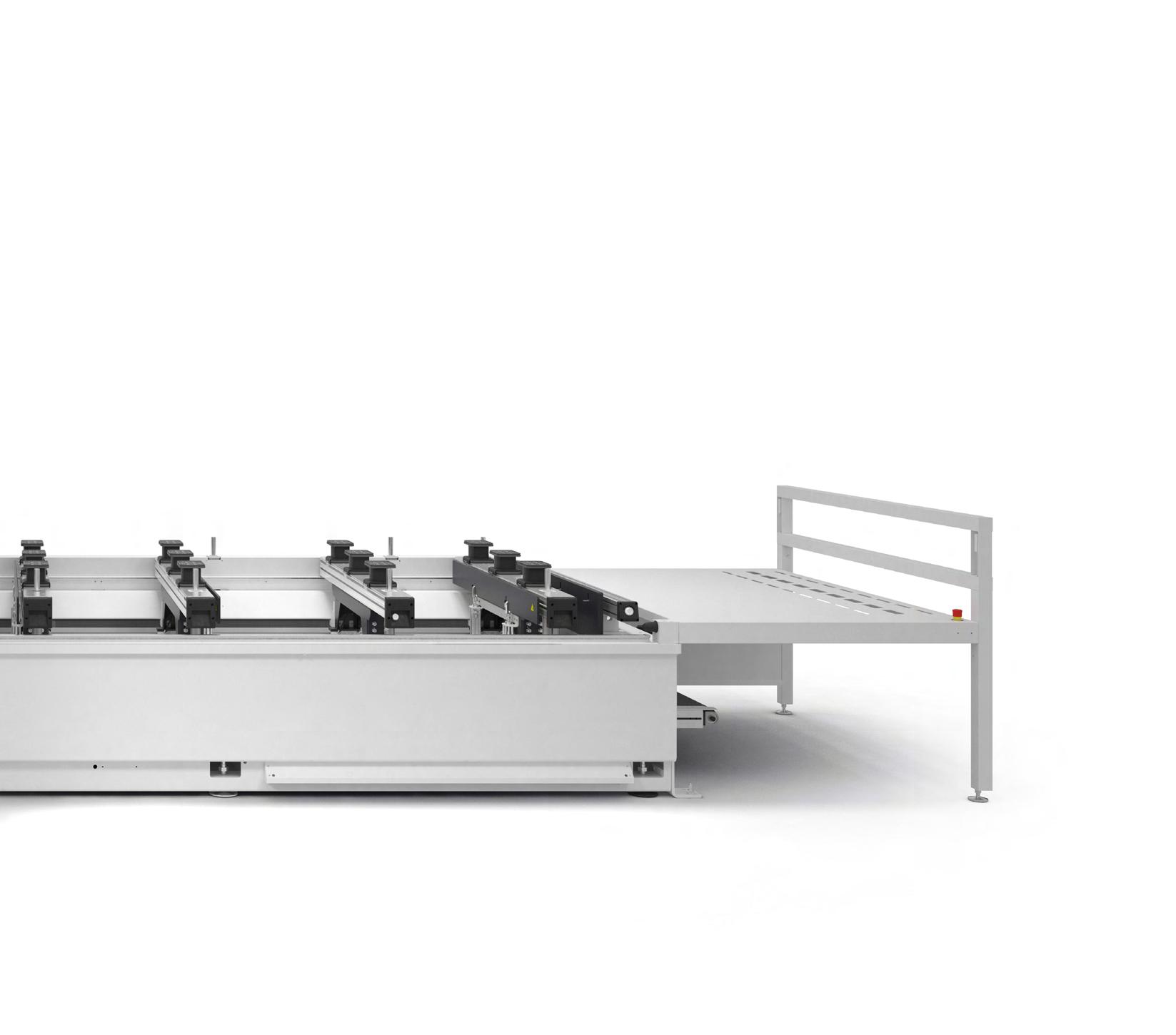

HOMAG offer a comprehensive range of panel saws to help process work with greater flexibility, speed and efficiency. Precision finish cutting solutions for both woodworking shops and industrial customers for every type of wood-based or plastic panel material.

The SAWTEQ S-100, is the smallest of the range. Competitively priced compared to a well-equipped table saw yet provides a much more precise, efficient and fast cutting process. Its compact footprint, sturdy design and proven technologies consistently deliver exceptional results.

With its power, precision and flexibility, the SAWTEQ S-200 offers everything a woodworking facility needs to cut panels horizontally. Two standard models can be enhanced with a wide range of technology options, customisable to any particular production requirements whilst remaining flexible for future growth needs.

High performance in a compact space is the strong point of the SAWTEQ S-300. This panel dividing saw is suitable for producing in batch size 1 as well as in smaller series and is ready for connection to automatic horizontal storage systems.

Tel. 01332 856500 | Email. info-uk@homag.com | www.homag.com

Three of the furniture manufacturing and joinery industries leading brands have announced that they will collaborate as part of the brand new Live Demo Zone at Materials & Finishes Show.

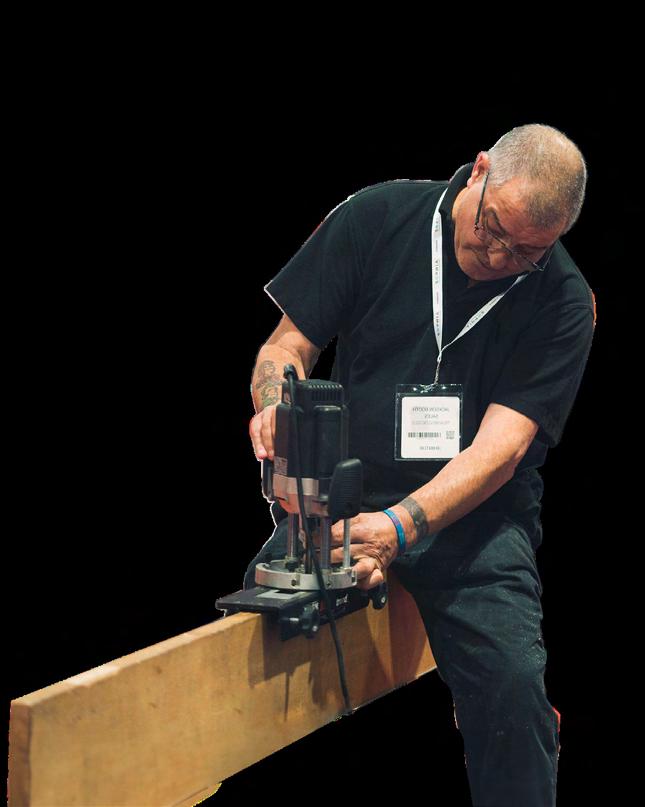

Leitz Tooling UK, Advance Machinery Services (AMS) and The Joinery Network will work together on the show floor to produce a full timber window manufacturing demonstration, with two live demos taking place on each day of the UK’s trade show for the furniture manufacturing and joinery industries.

Visitors will be able to see the end-to-end production of the timber window frame, which will be expertly crafted utilising AMS distributed Wadkin Bursgreen woodworking machine and Lignum tooling supplied by Leitz Tooling and The Joinery Network’s Owen Dare.

This is the first time that visitors to Materials & Finishes Show (formerly W Exhibition) will have seen brands collaborate in this way as part of the brand new demonstration feature within the exhibition.

AMS managing director, Steve McGloin commented: “We cannot wait to exhibit at Materials & Finishes Show this May and are excited to announce our collaboration with Leitz Tooling and The Joinery Network, who share our vision of providing hands-on advice and support for the industry. Our demonstration is not to be missed!”

Leitz Tooling UK marketing manager, Ben Mitchell said: “Materials & Finishes Show is set to re-establish itself as the main event in the UK calendar and we did not want to miss out the opportunity to connect with the UK furniture manufacturing and joinery industries when

the show returns this May. A leading global manufacturer of high-quality precision tools and tooling systems, we pride ourselves on providing expert tips and advice for the industry which is why it was a natural choice for us to participate in the new Live Demo Zone. We’re excited to showcase our collaboration at the event.”

Owen Dare, The Joinery Network founder added: “When I set up The Joinery Network it was with the ambition to connect leading industry suppliers with joiners, bringing practical support. Our collaboration at Materials & Finishes Show, and our involvement in the new Live Demo Zone, embodies everything that we stand for as an organisation. I’m looking forward to meeting with visitors at the event this May.”

Alongside the manufacturing of a timber window frame, visitors will also be able to participate in a range of ‘handson’ activities and demonstrations from other brands across the four days. The Live Demo Zone will complement the new seminar theatre feature which will include four packed days of CPD certified learning content, from panel discussions and keynotes through to seminars delivered by industry experts. Materials & Finishes Show event director, David Todd commented: “We’ve been excitedly waiting to announce the collaboration between Leitz Tooling UK, Advance Machinery Services (AMS) and The Joinery Network, following a successful trial run at the AMS customer showroom earlier this month. We know that visitors will be equally excited to see running machinery at the show, which is why we’ve developed the new live demonstration feature.

“Alongside the timber window construction from these three companies, visitors will also be able to see tooling, paint and finishing brands deliver hands-on, practical demonstrations, bringing new products, innovations and technology to life for

joiners and carpenters on the showfloor in a way like we’ve never done before at the event.

Materials & Finishes Show attracts buyers from every corner of the industry, from furniture and joinery manufacturers and designers right through to retailers, the KBB market, carpenters, joiners and worktop fabricators.

All areas of the material journey, from the initial stages of raw processing through to finishing and component supply for completed products, will be represented at Materials & Finishes Show.

Materials & Finishes Show will mark the first opportunity for the UK furniture manufacturing and joinery industries to come together since 2018. Visitor registration is now live.

Robin Clevett, the self-confessed carpentry, joinery and building fanatic, has been announced as an official ambassador for Materials & Finishes Show 2024.

As well as working closely with the event organising team in the run up to the UK’s trade show for the furniture manufacturing and joinery industries, Robin will also make a special appearance at the exhibition this May Robin, who boasts over 113,000 Youtube subscribers, more than 40,000 YouTube Followers and hosts The Carpentry Show in FIX Radio, will play a hands-on role as part of the brand new Materials & Finishes Show demonstration area, as well as compering a special panel on the main seminar stage.

Speaking about the collaboration, Robin said: “I was approached by the Materials & Finishes Show team last year and was instantly impressed with what the organisers have been doing to redevelop the show for the market. As a working chippy and active member of the wider carpentry and joinery community, I know that there’s a real appetite for this type of UK event for our community.”

Materials & Finishes Show event director, David Todd added: “We’re hugely excited to announce Robin’s involvement in Materials & Finishes Show this May. What better way to shape the content and features than collaborating with someone who is on the cold face of the industry and walking in the shoes of a large proportion of our visitors.

“We’ve been bowled over by Robin’s enthusiasm and this, combined with his expertise and knowledge can only make for a winning formula for our visitors from the joinery and carpentry communities. As organisers, we’re always looking at new and innovative ways to connect with our audiences - Robin’s involvement is the first of many new partnerships we’ll be announcing in the run up to the show.”

Registration is now live, register for a FREE ticket via Robin’s personal link

https://materials-finishes-show-2024.reg.buzz/robin

In recent years, we have seen the growing popularity of metallic design accents in interior and furniture design. Adding a touch of glamour and elegance, metallic details are a great way to liven up any space. Regardless of the style in which we decorate our interiors, decorative metal surfaces fit perfectly and add a unique touch.

Decorative Panels now offer a range of 6 brushed metal HPL designs from Kronospan - leading manufacturer of wood-based panels. These Metal HPL finishes are modern and sophisticated and include Brushed Aluminium, Brushed Titan, Brushed Inox, Brushed Gold, Brushed Copper and Brushed Bronze. These metal decors, made from highquality MDF substrate, are coated with real aluminium sheets, and covered with protection foil. They are suitable for vertical applications such as doors, as well as horizontal surfaces like home and retail countertops, offering a stylish and tactile experience in residential, business, or commercial spaces.

In an arrangement, where straight lines and neutral colours dominate, decorative metal surface additions are an interesting contrast and eye-catcher. We can use them, for example, in the form of a furniture fronts, which will provide unique focal points in the space. Nowadays, interior and furniture design are no longer limited to wall colours or the choice of furniture. The Group’s designers are looking more and more for original solutions to give rooms and furniture a unique character and elegance.

One such trend is the inclusion of metal accents in interiors and furniture, which add a touch of glamour and luxury. If metal accents in furniture are not enough for you, you can also opt for larger metal HPL surfaces, such as walls.

Decorative Metal HPL surfaces are particularly eye-catching, with the advantage that the metallic brilliance and elegance will always be visible and eye-catching, never fading into the background.

The shine and lustre of metallic decors adds elegance and luxury to any room. We can use Metal HPL surface on the walls as a decorative element. These types of surfaces go well with both modern and classic arrangements. This is just another way of incorporating sparkle into interior.

A striking metal HPL finish is highly resistant and durable. It is expressive and elegant in its unrivalled simplicity. Distinctive metal surfaces are an alternative to traditional decors. Metal decors are long-lasting, stylish, and fashionable. This makes a Metal HPL surface a winner over for example traditional wood chests of drawers. In addition to classic painted furniture, metal HPL decors are very effective. Metal HPL with the effect of brushed metal surface will certainly attract people who are bored with traditional solutions and love these raw, expressive accents.

Functional and almost indestructible Metal HPL surface in an interior bring an atmosphere of calm and order to the room. If you are one of those who appreciate subdued elegance and pure functionality in furniture, Metal HPL surface collection from dp-limitless range, is excellent for you. Brushed Copper, Brushed Gold and Brushed Bronze accents adding warmth and nobility to interiors and combining fantastically with most of the decorative surface materials. Metal HPL Brushed Inox, Brushed Aluminium and Brushed Titan on the other hand, takes us into a more industrial atmosphere. Metal provides a feast for both the eye and the sense of touch. Regardless of the style of the interior, metal finishing introduces intriguing material contrasts into the designed space.

Possibly one of the most evident characteristics of metal HPL surface is that it is a much more resistant material. Metal, in addition, compared to other materials, is not affected by excessive exposure to light and withstands from the lowest to the highest temperatures.

Resistance also gives them durability. Metal HPL material can last for many years with minimal care. In fact, the care they require is another of their advantages; cleaning is very easy and simple.

Metal HPL is extremely resistant both to weight and to possible damage caused by use, such as scratches. They do not present problems of breakage or peeling of edges. Thanks to its durability, in the long term it represents a saving, as they do not go out of fashion and are kept in perfect condition.

Beyond its strength, durability and quality, the use of Metal HPL has also become popular because of the variety of design possibilities it offers. Metal HPL’s have simple but unique brushed lines, and metallic effect integrates harmoniously into any decorative style. They are compatible and can be combined with furniture made of other materials.

Metal HPL’s surface is an ideal choice for the home. In fact, they are trendy, and not only in more industrial styles, as they combine perfectly with wooden furniture. They can be part of an eclectic decor with warm elements.

It is thought that because metal cools a room, it can be a difficult material to work with. However, with careful application, it can become the focal point of any interior design. For example, warmer tones can then be used to

surround the colder tone, producing a stunning effect of balance and statement.

Your furniture selection is a tangible representation of your inner world and the ideal way to communicate your ideas and sense of self. Along with modern Metal HPL designs, your furniture pieces will radiate its unique personality. Discover how to transform your interiors with Metal HPL accents and create unique, striking spaces that will delight everyone. Get ready to discover a new dimension in furniture design and join the ranks of trendsetters who know how to incorporate a touch of glamour into their home. Decorative Panels Lamination is here to give you endless possibilities from their dp-limitless range.

Available board sizes: 3050mm x 1310mm, available substrates: 15mm & 18mm MDF.

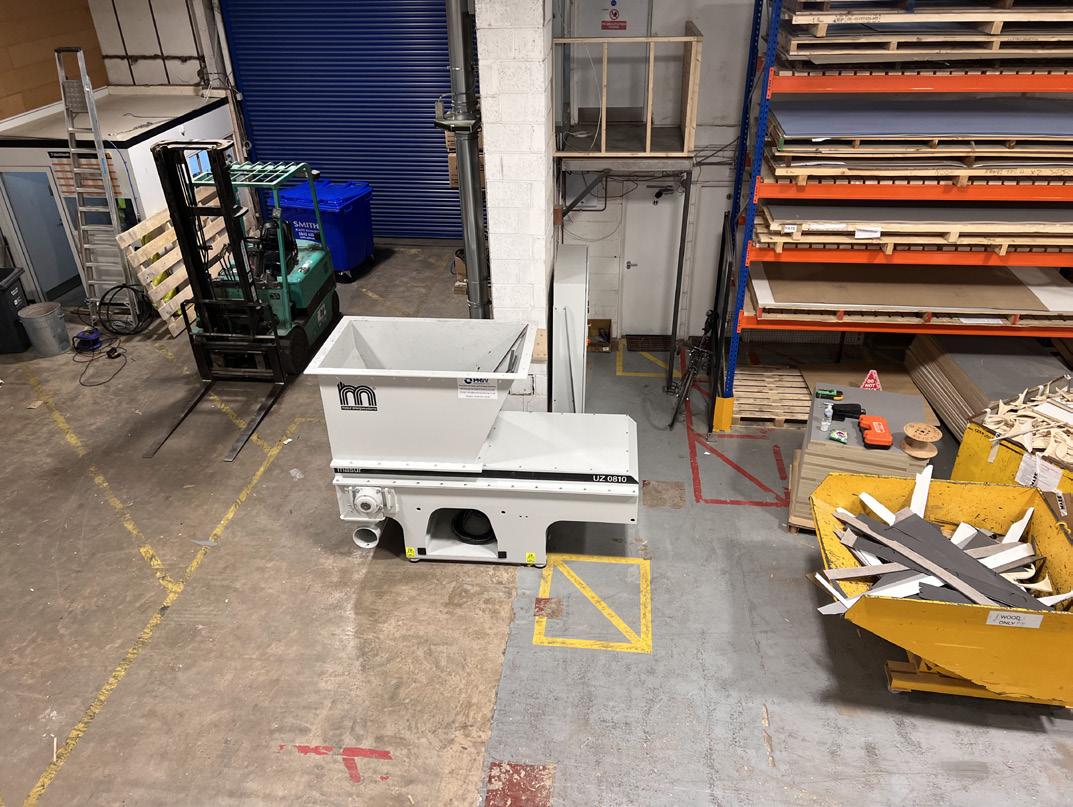

Chris Franklin MD at Ranheat Engineering Ltd. a leading UK manufacturer of wood combustion equipmentcontinues his series of articles for Panel and Joinery Production.

This issue he looks at the first year of operation of the plant installed in January 2023 at Paneltech, located close to the M5, south of Bristol.

The location of a wood fired industrial heating system is often dictated by the location of the dust extraction system. Generally, if installing an integrated dust extraction and industrial wood fired heating system you don’t want it at the front of your premises.

Often dust extraction systems are installed at the rear and sometimes access to this area is none-vehicular, particularly with a bag-based dust extraction system. Individual bags can be carried through standard doors and put into a skip. As companies expand and with the introduction of high speed CNC machines the changing of bags becomes a regular and messy operation. So, the solution to getting rid of the bags is to install the existing filter onto a new storage silo.

Ranheat modify the base of the filter and supply a new storage silo that the existing filter can sit on connected by a purpose made flanged upstand.

The silo is fitted with accredited burst panels on the dirty side of the filter. By using this method no expensive to run transfer fan is needed.

The automatically fed system was to replace an existing hand loaded system and Ranheat modified the existing 8 bag filter system.

Ross Larner, Operations Director of Paneltech, indicates below the differences the new system has made to the company and to the staff.

“Firstly the staff hated changing the bags on the old system and to change the bags meant that the extraction had to be turned off so no machines needing extraction could be used at this time. It was a dirty task and PPE was needed. Also the bags had to be carried through the building to be put in a skip at the front of the building.

The hand loaded heater it replaced meant we came in to a cold factory each morning. The loading of the hand loaded heater was labour intensive. To get the unit to operate smokeless meant the heater had to be loaded every 10-15 minutes so it was labour intensive. As part of the project, we also installed a woodchipper to deal with the off-cuts. Now all of our waste is automatically transferred to the storage silo both as chips and extracted dust. Not having to load the heater and change the dust extraction bags has eliminated two labour intensive jobs that were also unpopular with the workforce”.

The chosen wood-chipper was a 800 mm wide cutter with 22kW drive motor with an 18mm screen 40 cutters and a capacity up to 800kgs/hr. The extraction is fitted with a humpback magnet to collect any soft metal fixings that may be present.

C & S Interiors specialises in producing beautiful bespoke pieces of furniture and helping customers with electrical, plumbing and other building projects. With its modern 3,500 sq. ft. manufacturing facility in Harrow, C & S creates affordable, uniquely designed made-tomeasure quality furniture.

“At the start of 2023 we realised the need to automate and speed up our production if we were to meet the growth targets we’d set for the business,” explains Matt Rybak, director and founder of C & S Interiors. “Our existing manual edge bander was slow and produced inconsistent finish quality. To improve, we needed to invest in a new, automated edge bander that would be fast and produce panels with a first class finish every time.”

“HOMAG is the world’s leading woodworking machinery and software brand; it has an unmatched reputation for designing and manufacturing technically advanced, dependable and robust machinery. As a consequence, we

www.p-j-production.com

had been interested in investing in one of its machines for some time.

“Initially we looked at a couple of alternative manufacturers, but as soon as we saw the HOMAG edge bander in action, we knew it was the right machine for our business. The key factors that gave us confidence to invest in the EDGETEQ S-300 were the speed of throughput, the quality of the finished edges, and the ease of operation and control which is performed directly from the screen on the machine.

“Price was a big factor for us too, as was the comprehensive aftersales support. HOMAG has its own team of dedicated service engineers ready to help if needed. Should an issue arise, HOMAG’s hotline technicians can remotely dial into the edge bander and fix most issues very quickly. That’s a really big plus for us because it means any downtime is kept to an absolute minimum.

“Our HOMAG area sales manager, Ian Woodall, is another reason we chose to partner with HOMAG. We can rely on Ian

to provide unbiased advice that’s in our best interest. Ian’s input is invaluable, and he was instrumental in helping us decide which edge bander model was right for our particular needs.

“His knowledge, not only of HOMAG products, but also of joinery and furniture manufacturing, is impressive. We took his recommendation on which model was the best for our requirements – the HOMAG EDGETEQ S-300 – and it’s proved to be an excellent choice.”

“The installation of the EDGETEQ S-300 was extremely well-planned and the machine was quickly installed and commissioned. The HOMAG engineers then trained our people on site as to how to setup and operate the edge bander.

“Once our team had mastered the basics, they were able to familiarise themselves with the best procedures to maximise the throughput and performance of the machine.

In terms of getting the very best out of such a technically advanced piece of kit like the EDGETEQ S-300, it is very much a case of learning progressively as the operators gain more experience running it.

“The new HOMAG edge bander has been a game-changer for us. There is a world of difference compared to our old edge bander; the EDGETEQ S-300 is easy to control directly from the screen and we don’t have to do manual adjustments. Everything is automated, easy to set up and the speed of throughput is very impressive, as is the superb quality of the finished edges.”

“The S-300 has increased our production capacity, and there is no doubt it will pay for itself in under three to four years. It will also help us to increase our turnover well beyond the current £300,000 a year mark.

“For any company looking to take its business to the next level, I can highly recommend HOMAG and the EDGETEQ S-300 edge bander. As a partner, they are easy to deal with, responsive and thoroughly professional,” concludes Matt.

If you would like information or a demonstration of any HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

A bespoke-furniture cabinet making company has purchased a wood waste heater from Wood Waste Technology to save money on its operating costs.

Derek Barrett Design manufactures high-quality, individually designed hand-crafted furniture for homes, offices and commercial interiors. The company decided to purchase a wood waste heater to utilise the waste timber it generates daily, to reduce business expenditure on heating and waste disposal.

Director, Derek Barrett explains: “As the business has grown, we expanded into a neighbouring business unit. For the last 3-4 cold winters, we’ve been trying to heat the space with diesel heaters, but they were becoming more and more expensive to run. We’d seen wood waste heaters in use at other companies like ours, so decided to see how they might save our business money and make us more efficient.”

Derek researched the marketplace to try to find the best wood waste heater for the company’s needs. Having read favourable reviews about UK manufacturer Wood Waste Technology, the company requested more information.

Following a site survey and quote, a WT5 was installed at the company’s manufacturing office in Ford, Buckinghamshire by Wood Waste Technology’s experienced engineers. Derek says: “We’re delighted with our wood waste heater and would 100% recommend the heater, and Wood Waste Technology as a supplier. In terms of investment, it’s a no-brainer. You spend money up front, but it pays back quickly. For example, we’re saving around £600 each month now that we don’t need the two skips we used to have to hire. We also opted to have the heat dump fitted, so we can continue to burn our waste throughout the summer and send the heat to atmosphere.”

MD of Wood Waste Technology, Kurt Cockroft says: “The recent energy crisis has resulted in a lot of manufacturing companies reviewing their operating costs, and a wood waste heater is a great way to save money on the bottom line.”

Wood Waste Technology’s years of expertise in wood waste solutions have helped many companies reduce their waste disposal and heating costs. As well as offering site survey, design, manufacture, installation and on-going maintenance for new units, the company also services all types of wood waste heaters and supplies genuine spares up to 60% cheaper than other suppliers.

In addition, Wood Waste Technology is the UK official distributor for Gross Apparatebau GmbH, a German manufacturer of dependable, precision engineered shredders and briquetters, available in various size and specifications to suit all business applications.

T: 01785 250400

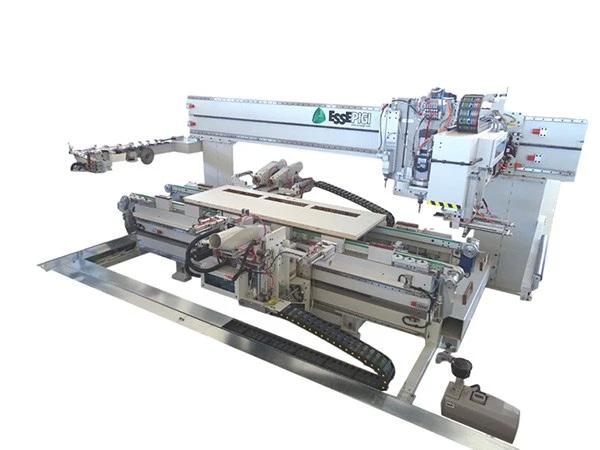

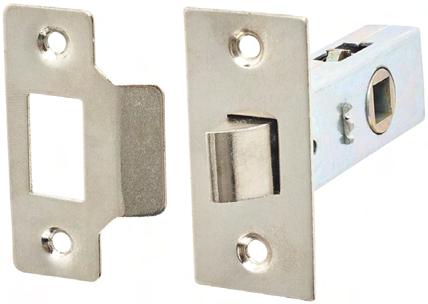

With over 150 machine installations throughout the UK and Ireland, JJ Smith can rightly boast they are the number one choice for customers looking for the latest door and frame machining solutions. From simple semiautomatic programmable standalone machines, through to fully CNC controlled working centres with automated infeed and outfeed handling systems, JJ Smith can provide a solution to suit customers’ individual production requirements.

Partnering with Europe’s leading manufactures to offer different levels of machining solutions, JJ Smith are able to recommend the best possible machine from both a budgetary and specification point of view.

Centauro - produce three different models of machine; the ALFA, ALFA Twin and ALFA Jamb. The hugely successful ALFA model is ideal for the customer looking for a costeffective solution for machining doors and frames. Simple to set up / program, it is ideal for hinge recessing, lock case slotting, 3-point locking systems and making handle holes and key slots. To date there are over 80 ALFAs installed in the UK and Ireland, 95% of which are working on doors and frames. The ALFA Twin is a through feed machine that can simultaneously machine both sides of a door in just two minutes. The ‘new’ ALFA Jamb is also equipped with an infeed loading and outfeed unloading system, maximising production output of frames / jambs.

Comec - offer a range of bespoke CNC machining solutions for the volume production of door frames. The multi head MD Jamb is designed for cutting, drilling on the end of frames and / or with the facility to drill and machine up to

six sides of the frame. These can be made from MDF, solid wood, chipboard and other similar materials. Optionally the MD Jamb can be equipped with a front vertical hopper feed loading system or a horizontal loader with through feed driven belt. It is possible to select for the processing of an assembled jamb or flat jamb either batch or series production. Programming is through dedicated 4WOOD software assisted by 3D working models and parametric functions. On request, anti-collision simulation can be specified along with bar or QR code reading. Additionally, Comec produce the FRT series of hopper fed double sided milling machine for trenching / notching of the frame head.

Essepigi - manufacture the Doormatic double sided through feed machines, including the top of the range ‘Evolution Bridge’. On this machine it is possible to carry out all the required machining operations of a door including sizing the blank, cutting apertures for vision panels or letter boxes, drilling for spy holes plus hinge and lock recessing. Thanks to the automatic linear tool changer it is possible to machine out grooves for the door seal and closer. As standard, the machine is equipped with an automatic door width sensor system to ensure all doors are within specified width tolerance. Optional equipment includes loading, unloading systems, vacuum lifting and automatic barrel turners to rotate the door through 360 degrees.

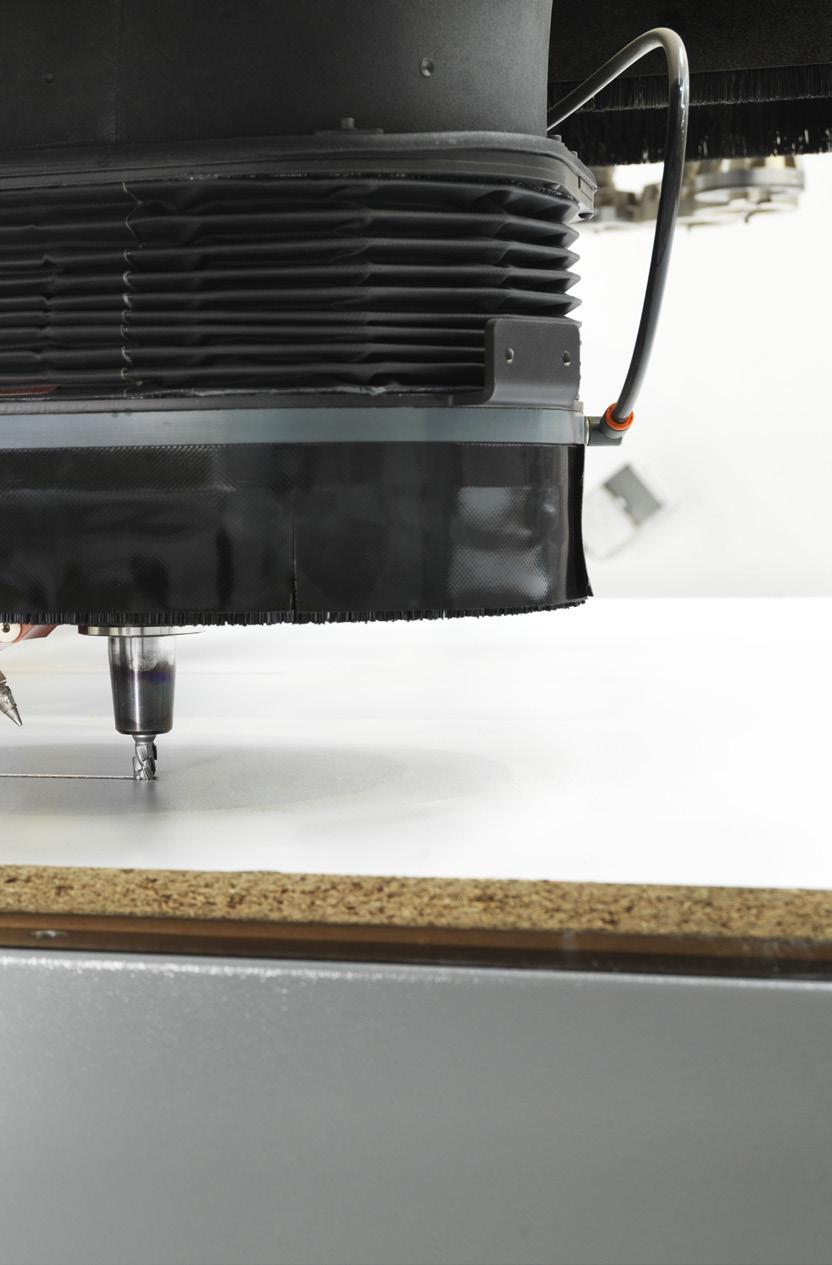

By cleaning the cut line as the dust is produced, Biesse’s awardwinning T-JET dust mitigation solution increases finishing quality, prolongs tool life and boosts process efficiency by accelerating job turnaround.

Dust is an unavoidable feature of any panel based machining application and has to be contained for obvious health & safety reasons. Once it is airborne, it becomes an occupational hazard, which is why it is best controlled at source. Machine protection is another reason for controlling dust during the CNC operation - if it contaminates electrical components or settles on vital mechanical parts, it can over time, without proper maintenance, cause costly damage. Then there is the all-important finish - if the tool has to plough through a layer of dust, it can affect the quality of the cut.

The usual approach to dust removal in CNC operations is to add a sweeping arm and an offloading table. The sweeping arm sits on the back of the machine and transfers the panel onto an adjoining table whilst at the same time cleaning the bed with an extraction manifold. Aside from occupying additional floor space, the downside of this arrangement is that the sweeping arm does not remove the dust from inside the channels or the sides of the panel. This means that after offloading the panels, the operator has to spend time vacuuming the machine bed and the panels. Over the course of a week, this cleaning time can add up to several hours.

A set of high pressured nozzles are mounted to the rotating C axis and, using the compressed air veins that an aggregate would use, follows the cut line, dislodging any dust that has settled in the cutting channel. As soon as it becomes airborne, the dust is removed by the extraction system that sits over the spindle so that channels are clean and free from dust and the side surfaces of the pieces are totally clean.

Cleaning whilst machining is a simple enough concept but designing a rotating air jet system that can keep up with the tool as it changes direction and turns corners is no mean engineering feat. In this respect, T-JET represents a

breakthrough solution - an achievement that was recognised in 2022 when Biesse received the IWF 2022 Challengers Award for T-JET.

Using the T-JET rather than a sweeping arm to clean the panel (and the table) not only saves on floor space by reducing the overall machine footprint, it also saves on time. With targeted dust collection at the point of production, no further cleaning of the flat bed is required. This can amount to considerable efficiency gains as the operator can simply offload the panels and start the next programme straight away, rather than having to clean the bed between programmes using a vacuum cleaner or sweeping arm. From a health & safety perspective, T-JET protects workers by limiting the amount of dust that enters the working environment.

There are also secondary advantages to using T-JET technology: the air flow keeps the tool cool, reducing the amount of stress on the spindle, which ultimately extends the life of the tool.

Unimpeded by dust, the saw blade is able to travel smoothly and perform a cleaner cut, with less likelihood of chipping. With effective suction guaranteed even at high feed speeds, this results in unprecedented finishing quality.

And, at a time when energy costs are a major concern, T-JET represents the most energy efficient method of removing and containing dust. There is no need for an additional compressed air supply as T-JET will work on the standard pressure available on the machine. The rotating action of T-JET is powered by an additional high-speed motor, but as the motor is very lightweight and servo-controlled it uses very little energy - far less than a sweeping arm. The T-JET and the tool rotate independently of one another, which means T-JET can be turned off to save energy when it is not required. T-JET is classed as an aggregate or deflector, so it can be removed from the machine altogether.

Kesslers London Limited is a business which puts manufacturing at its heart. Providing design and production services to the retail industry, it is able to draw upon a 130 years of heritage in its work for brands such as L’Oréal, M&S and Sainsbury’s. Recently bought out by the management team, the company has a strong three-year strategy which builds upon the solid foundations of 2023, when the company moved into a new, bespoke 40,000 sq. ft. manufacturing facility in East London.

Neil Mead, HSE facilities & compliance manager for Kesslers London takes up the story: “As a company, we have invested in HOMAG machinery for over 20 years and have always found it to be solid, reliable and technically advanced.

Consequently, when it came to looking for an innovative CNC machining centre for the new Kesslers London manufacturing facility we went straight to HOMAG UK.

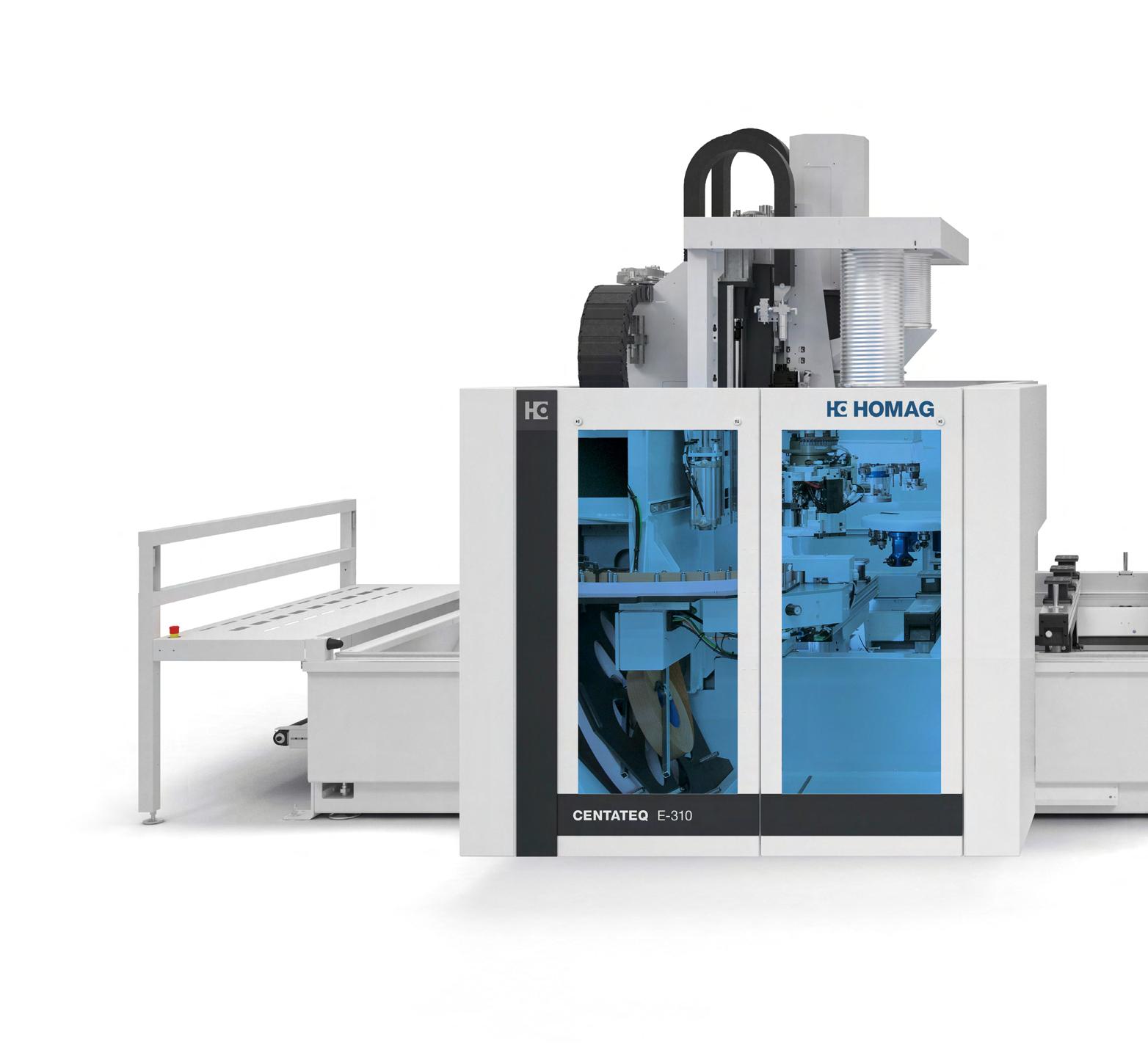

“Our production team worked closely with James Mason, HOMAG UK’s area sales manager, to select and specify the right machine for the business. Essentially, there were two potential HOMAG models that fitted the bill, but we eventually settled for the CENTATEQ E-310 CNC machining centre.”

“There were three key factors that steered us towards this model. The E-310 features the latest CNC technology at a competitive price; it will deliver (we believe) a return on investment within two years and it was available for delivery within the tight time frame we stipulated.

“HOMAG UK was able to introduce us to Deutsche Bank who provided a competitive finance package for the purchase of the machine. The installation of the CENTATEQ E-310 was relatively straightforward as it was installed in a largely empty facility. The complete installation and training process took less than three weeks, with all the essential training carried out onsite by the HOMAG engineers. In addition, some of our operators went on a programming course at HOMAG’s UK headquarters in Castle Donington.”

Attention has been focused on making the operation of the CENTATEQ E-310 as easy as possible. All of the essential functions are in view and mounted directly on the machine. As the CENTATEQ processes work, the large window means everything is always in view. To improve productivity, access to the table is unhindered, with no restrictive fences. Instead, fully implemented bumpers combine productivity, security and easy access to the machine.

The E-310 CNC features ‘dynamic alternating operation’ without fixed field subdivision. In simple terms, this means that even in the case of long parts being processed on one side of the table, short parts can still be placed on the other side.

To maximise the flexibility of the CENTATEQ E-310 an extensive range of options is available, from edge banding, sawing and drilling choices to clamping systems, table types and software solutions.

“The CENTATEQ E-310 has provided us with more options to produce different components for our retail and brand point of sale displays. It has also upped our game in terms of the finish quality of our products which was already to a high standard. We have no doubt that it will more than pay for itself over the coming months and years,” concludes Mead.

If you would like more information or a demonstration of any of the HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

The Danish design company, furnipart, was at the KBB Fair in Birmingham 2024. furnipart is known for launching several collections of handles every year and this year presented their News Collection 2024 which contains designs from Rikke Frost, Hans Sandgren Jakobsen, VE2, Meneghello Paolelli, Kamper Form and Steffensen & Würtz.

The range consists of no less than 13 new designs with distinctive features and exciting details. The details are what characterize good design and the reason why furnipart always collaborates with acclaimed designers.

The company are facing questions such as how they can not only enhance production but also create designs with a longer lifespan. How they can create something that can be passed down to the next generation and, at the same time, can be repaired or refreshed to give it new life? The News Collection 2024 is their response to these challenges as they strive to create products that are not only beautiful but also sustainable and environmentally friendly.

CEO, Rasmus Byriel, says:

“Our high quality is known throughout the industry, and we are therefore very conscious that each collection must live up to our high standard.

Nothing should be left to chance when designing objects that will be used multiple times every single day.”

furnipart produce handles for kitchens, bathrooms and furniture and our products are synonymous with top-quality handles. They have been designing and manufacturing handles since 1977, and work with internationally recognised designers in all our projects to develop new collections, which adorn drawers, cabinets and furniture in more than 60 countries.

www.furnipart.com

With two-hundred registrations for a total exhibition area of 20 thousand square meters, Xylexpo 2024 event is coming alive. Halls 1 and 3 at the Fieramilano Rho expo center will showcase present and future technologies, offering to thousands of Italian and international visitors the opportunity to update, compare different solutions and plan their investments.

“The preparations for the next edition –from 21 to 24 May 2024 – are going on in a season of great turmoil for an industry that, after a “happy” period for orders and revenues, is showing signs of concern, probably exaggerated, about short-to-medium-term perspectives”, said Dario Corbetta, exhibition director.

This statement is reflected by Italian market figures for the January-July period – the latest figures published by the Italian statistics institute Istat and processed by Acimall –showing that export has exceeded one billion euro, up by 9 percent from the positive result of 2022. The United States, Germany and France keep ensuring “sustained” demand, with a global trend that remains basically positive, also confirmed by the growth of Italian import (plus 3.6 percent, for a total value of 156 million euro).

“We believe that Xylexpo, despite the current period of transition, will be once again an opportunity not-to-bemissed for anyone seeking high visibility in the Italian and international market”, Corbetta concluded.

EGGER PARTNERS WITH JAMES LATHAM FOR A UK ROADSHOW, AND UNVEILS THE ‘EGGER 24+’ DÉCORS COLLECTION, COMPRISING OVER 230 NEW HIGH-DEFINITION FINISHES.

James Latham, one of the UK and Ireland’s leading distributors of decorative panel products, is supporting one of its most popular melamine, laminate, and edging brands, EGGER, with a specially-curated roadshow to promote the launch of its latest collection, EGGER 24+.

Running throughout March and April, it’s a nationwide tour which will showcase what makes EGGER one of the world’s most innovative, creative, and versatile building product manufacturers. Not only that, it will also present an opportunity to find out more about why James Latham, in its partnership with EGGER since 2002, remains a vital distribution partner for the brand, and how this benefits both current and potential customers.

Kicking off on 12 March 2024 at James Latham Ireland’s Belfast depot, the roadshow will visit 8 selected James Latham sites, from Scotland in the north to Fareham on the South Coast and multiple locations in-between, offering customers a unique opportunity to discover the exceptionally high-quality of these new finishes in person.

CHARTING NEW TERRITORIES

Particularly, visitors will be able to explore one of the largest catalogues of premium décors currently available on the UK specification market. Putting this in perspective, EGGER 24+ comprises over 230 decor combinations. This includes 201 matching-material Eurodekor decors, 82 Eurodekor decor combinations and 7 new textures.

Influenced by the latest design trends, these new finishes range from faithful interpretations of elegant timbers and natural stone to hyper-realistic reproductions of lustrous metals, soft textiles, solid colours, and more.

They will also get a unique insight into their manufacturing process; sustainably produced by EGGER in a lowcarbon facility, using the latest in cutting-edge decorative technology. Particular highlights of 24+ demonstrating this include TM12 – Omnipore Matt and ST20 Metal Brushed. TM12 – Omnipore Matt is a muted, sophisticated selection of finishes, with matt lacquered surfaces, and anti-fingerprint properties and reduced reflectivity, offering a powerful, yet natural, appearance, especially in a wood grain design. ST20 Metal Brushed is impressively realistic, with a deep-brushed metallic surface, bringing an industrial look to both furniture and interiors.

The tour features a showroom truck with specially-curated displays, samples, and opportunities to meet the EGGER team and try out their new digital design tools. The James Latham depot teams will also be on hand to discuss individual project requirements.

JAMES LATHAM AND EGGER – PERFECTLY MATCHED

The roadshow also presents the opportunity to showcase what makes James Latham’s partnership with EGGER so strong, and why the distributor has built a nationwide reputation for customer service excellence. Each depot team on the Roadshow will be able to showcase their unique understanding of EGGER 24+, answering questions, providing advice, and explaining how Lathams can help with specifications.

Ross Garrard, Group Business Development Manager, Melamine and Laminate, at James Latham shares his enthusiasm: “The EGGER 24+ Roadshow is a prime example of our dedication to supporting cutting-edge products. This event is not just a launch, it’s a celebration of creativity, design, and quality craftsmanship. We’re thrilled to collaborate with EGGER, and our depot teams across the UK, to bring these exceptional materials directly to our customers, showcasing what sets us apart as a best-in-class distributor.”

The EGGER 24+ Roadshow will stop at 8 James Latham depots over the course of the tour, a full list of dates follows:

Belfast: 12 March

Hemel Hempstead: 19 March

Scotland: 4 April

Leeds: 8 April

Thurrock: 10 April

Fareham: 16 April

Leicester: 17 April

Yate: 18 April

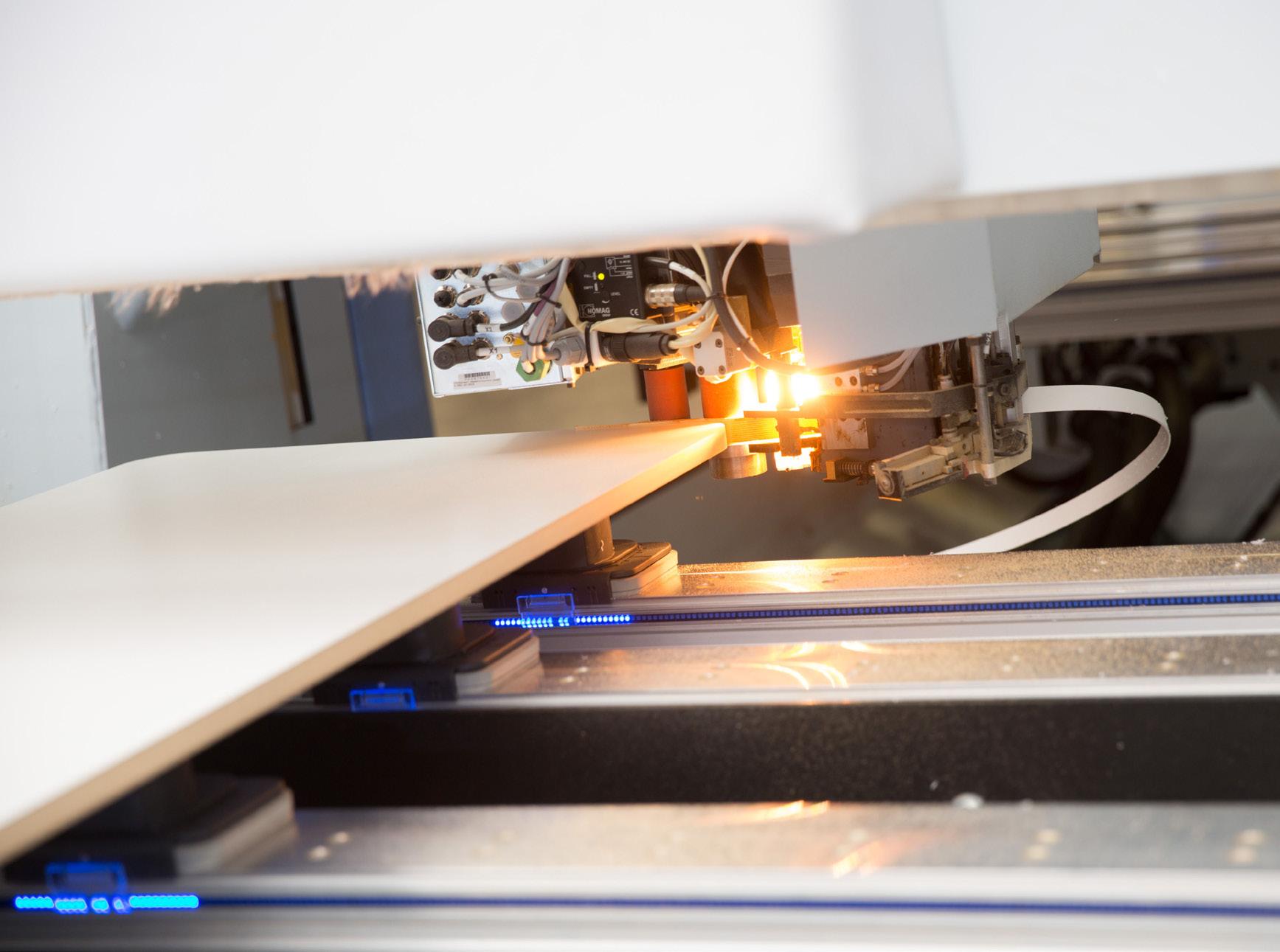

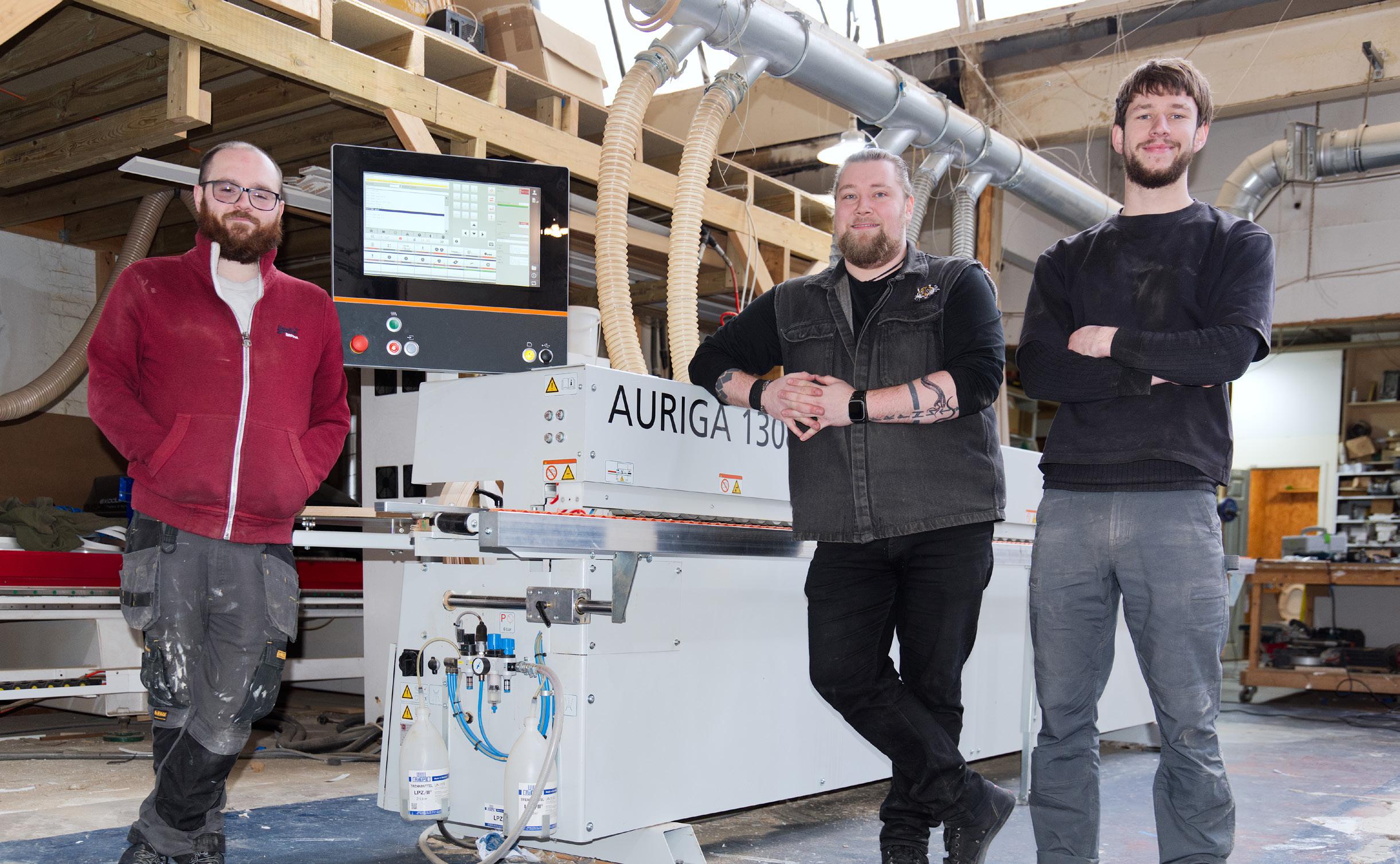

London-based bespoke furniture manufacturer, Hill & Hurl understands what it takes to create beautiful residential furniture. Offering a complete service – from design conception to installation – its manufacturing capabilities need to remain as fluid as their designs and investing in the right machinery to maintain its high standards is a must. That’s why, when the company’s old edgebander was no longer able to keep up, Hill & Hurl turned to Holz-Her UK to supply a brand-new Auriga 1308 XL edgebander.

“Our last edgebander was troublesome to say the least,” begins Alex Watson, Bench Joiner at Hill & Hurl. “To compensate for its shortfalls, we would spend inordinate amounts of time finishing every panel by hand. We’d use coloured glues to try and disguise the glue lines and we’d have to wax every panel to get the results we were happy with. I’ve lost track of how many Stanley blades we’d go through every month removing excess glue from boards and perfecting each edge. Then there were the painfully slow heat-up times to contend with, the inflexible and inconsistent machining and the lengthy clean-down process. We were fighting a losing battle.”

Hill & Hurl’s requirements were clear. “We needed an edgebander that could offer us quick and precise application on a wide range of material – from standard 18mm MDF and plywood to expensive veneers, textured boards and Valchromat – an eco-friendly MDF board. We also knew that we’d benefit from a higher degree of automation – especially when it came to machine set-up –and we needed a quicker solution for cleaning the glue pot. As soon as we saw the Auriga 1308 XL and its Glu Jet system in action, we knew it was exactly what we needed.”

The compact Auriga 1308 XL – which comes with three finishing systems and features a rotating 21.5” touchscreen control panel for simple operation - hasn’t disappointed and has helped the company make immediate savings on both production time and labour. “The heat-up time on

our old edgebander was crazy. We could be waiting up to 45 minutes for the glue to reach temperature – especially in the winter months. The Glu Jet’s heat-up time is phenomenal. Holz-Her says to expect a three minute heat up time but that’s really only on a super cold day. More often than not, it’s ready within two minutes which allows us to work much more efficiently.”

Alex continues, “Before we had the Auriga, we had zero production flexibility and programming was a very manual process. Our fitters could be waiting up to 90 minutes for a damaged panel to be re-edged before going back to site. Or worse, if we were using a different glue colour the day they came in, the panel wouldn’t be able to be re-edged until the glue pot had been cleaned out – meaning an overnight wait. It was painful.” This exposed the furniture manufacturer to potential delays and increased labour costs. Now, thanks to its three minute heat-up time and ability to switch between edging tapes and materials, a new or modified panel can be completed within minutes. Plus, its stored programmes and fast setting technology (fa.s.t.) make it possible to perform various operations simultaneously for streamlined machining.

For machinery operator Ben Samuels, the worst part was emptying the old edgebander’s glue pot. “We still get nightmares about it,” he laughs. “The manual told us to put sticks in the glue pot and solidify the glue around it. In theory, once the glue had dried overnight it should have come out in a big block but in reality, it came out more like chewing gum and it left a burnt, sticky residue on the bottom. We hated cleaning it and it took ages. Now, we no longer have to use such primitive techniques to keep our machine clean. We simple push a button and Holz-Her’s four minute automatic cleaning cycle starts.”

The Auriga can machine panel thickness from 8-60mm, edge thicknesses from 0.4-8mm and offer a feed rate of up to 10m/min, making it suitable for a wide range of applications. Alex says, “We’ve edged materials as thin an 9mm and as

thick as 54mm. I must admit, I’m surprised how versatile this machine has turned out to be. It’s definitely given us scope to grow our product offering.”

The team also has more confidence when working with challenging materials like textured board thanks to the edgebander’s IntelliSet intelligent tool correction – a feature that allows intuitive adjustment of all milling and scraper operations. “The old machine would ignore any texture and eat through veneer,” explains Alex. “It was impossible to edge a nice radius and it required us to hand finish each edge. However, the tracing shoe automatically adapts to the thickness of a panel and compensates for any tolerances.”

There were similar issues with matt board, too. “It is an extremely delicate material and comes with a 0.5mm plastic film on its edge to protect it from scratches and dirty marks. However, this does mean some variation in thickness is to be expected. To reduce the risk of damaged panels, we’d run multiple test pieces through the machine – wasting time and material - and more often than not, still having to hand finish each piece. Thankfully, we no longer need to do this. The Auriga handles the material much more gently and its finishing units are exceptional.”

It’s also eliminated the issue of visible glue lines. “We no longer need to stock coloured glues to combat a visible glue line as the Auriga edges each panel with a near invisible glue line. We use EVA from Jowat which works beautifully with the Augria. It only heats what is needed so it doesn’t affect the strength or colour of the glue and it applies the right amount of glue automatically. This alone has reduced postproduction times by at least 50% and has significantly reduced material waste.”

So, how simple is the Auriga to use? Owen Wilson, Hill & Hurl’s new Operations Manager has been using the Auriga for two weeks and can vouch for its simplicity. “It’s certainly not difficult to use and you don’t need a lot of experience to use it. After a week, I was pretty confident on the basics and I’ve been running different sized panels through the machine quite easily. The more intricate workings of the machine will follow but for now, the machine’s automatic set-up options and touch-screen PC make it intuitive to use. It just makes sense.”

Between them, the men in the workshop have used eight different edgebanders and without hesitation, have agreed that the Auriga was the best they’d come across. “It’s not only built to last but everything is in the right place and easy to get your head around,” says Alex. “It’s a straightforward piece of kit that, when you look at the amount of technology and innovation in its design, shouldn’t be straightforward at all. The technology works and because of that, we can now edge, wrap and clean in less than half the time .”

On a final note, Alex says, “Engineering aside, Holz-Her’s service needs a mention because they will always go the extra mile. We have a group chat with an edging specialist and if we come up against a problem or have a question, he will reply within a few hours with a full video walk through. No ticketing system, no annoying chat bots – an actual human who is willing to help. It’s the best kind of customer service you can get. Teamed with a pretty awesome machine, Holz-Her is a great package for companies looking to raise the bar in furniture design and we couldn’t be happier.”

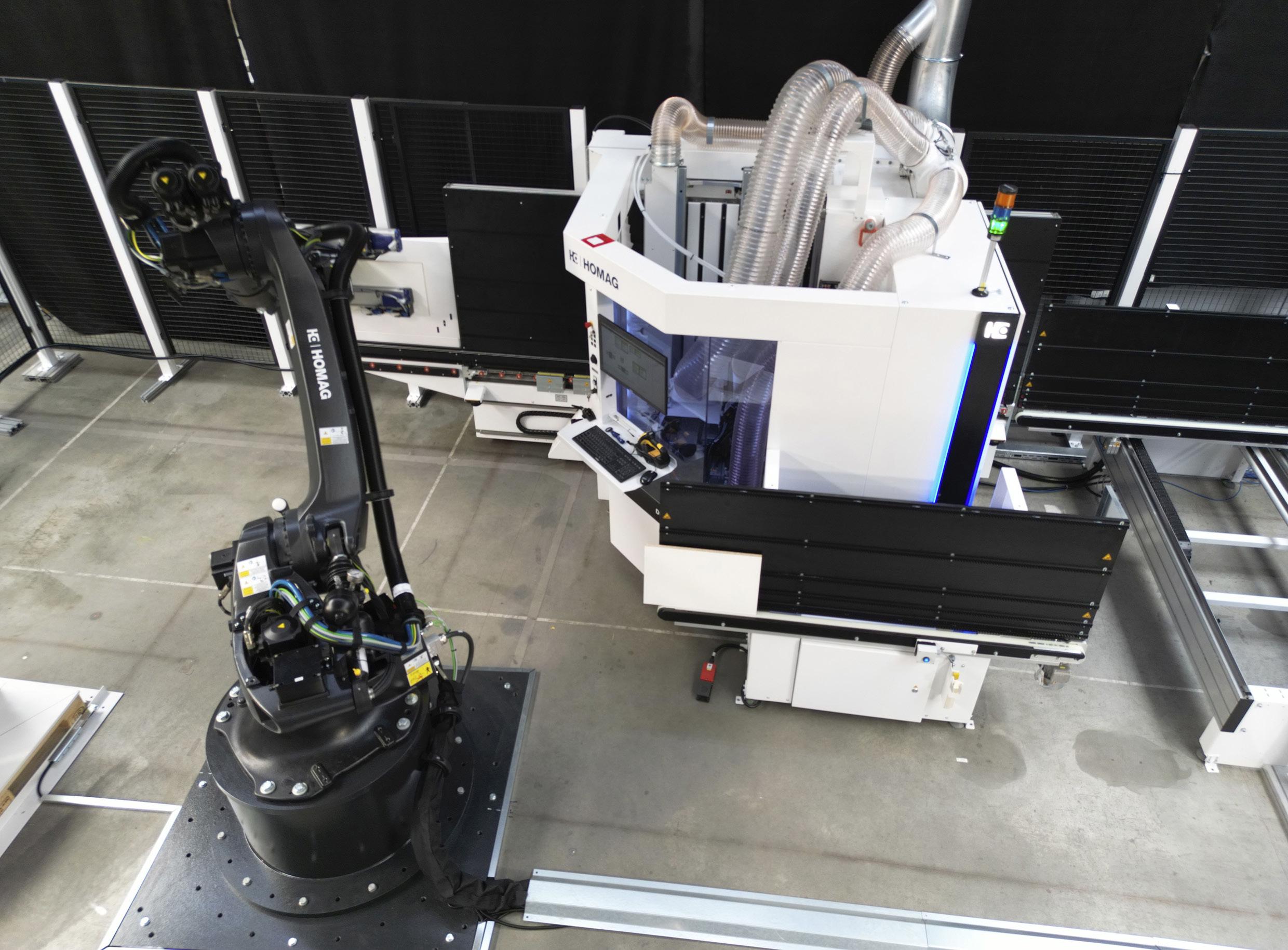

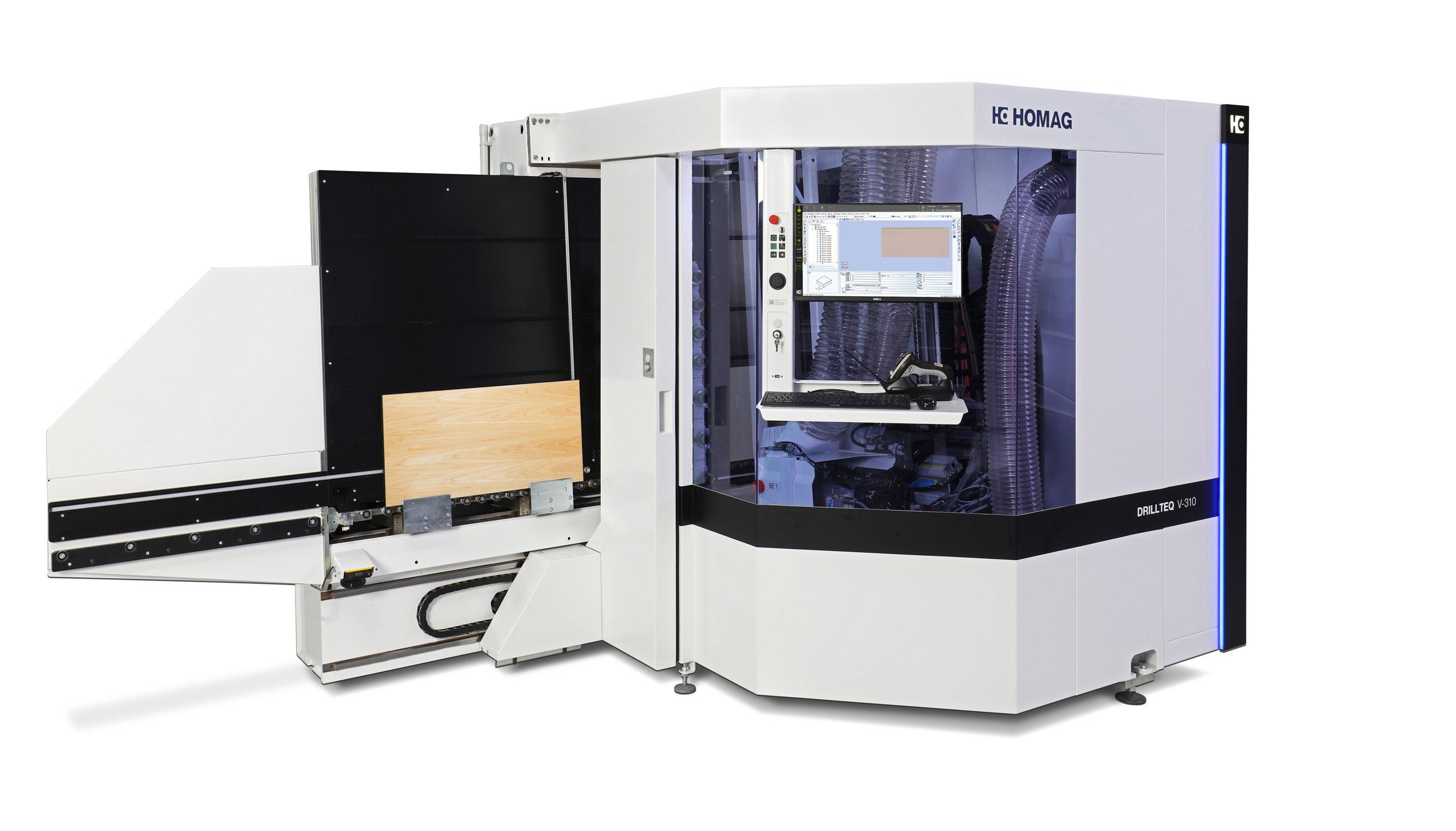

If space is a major issue in your production facility then the latest vertical CNC processing centre from HOMAG, the DRILLTEQ V-310, could be just what you’re looking for. The design brief for this advanced machine was to incorporate as much functionality as possible in as small a space as possible.

“The new DRILLTEQ V-310 vertical CNC really is a space miracle,” claims HOMAG UK managing director, Simon Brooks. “With a footprint of just 11 m2 it offers more drilling (up to 45 drilling spindles), more grooving (two groove saws), a dowel unit and more trimming than any other machine in its class. Despite the compact nature of the V-310, it can still handle panels up to 1,250 mm in width and 80 mm in thickness.

“Attention has also been focused on energy-efficient processing, with the vacuum-free clamping system not only saving energy, but also providing fast setup times.

“A number of ‘plug & play’ automation add-ons are available to extend machine running time, including the FEEDBOT D-310 robot feeder and a return conveyor. These additions virtually eliminate manual parts handling and reduce the need for more machine operators.”

A WIDE RANGE OF CONFIGURATIONS FOR ANY

The DRILLTEQ V-310 offers a great choice of drilling heads including a twin head configuration which can perform row hole drilling in half the time on certain panels. The machine can be specified for routing with automatic tool changing in the standard three axis format or additionally, it is possible to choose a four axis model to permit the use of aggregates for horizontal routing, sawing, corner notching and even traced surface routing. As a further option, it is possible to select an automatic dowel gluing and insertion unit to allow panels to be fully processed within one cycle.

HOMAG’s safeScan technology enables optimum interaction between operator and machine. At the infeed and outfeed there is a scanner which is triggered as soon as the machine operator approaches to within 900 mm of the loading or unloading area.

A highly efficient feature of the technology is the automatic continuation of production as soon as the operator leaves the area. No confirmation or restart of processing is required due to the Autoquit feature.

Controlling the DRILLTEQ V-310 is even faster and more intuitive with the latest control system powerTouch 2. The

new, modern design has a clear structure with an innovative touch operation.

Compared to the previous version, you can achieve a time saving of up to 30%. This is possible due to new features, such as automatic word completion, a pop-up keyboard that can be kept open and Windows-like functions, such as the selection of common actions directly via the start button.

Manage tools easily and quickly with the twinio web app With the twinio app tool management is easy and quick. Different functions in the app ensure an overview of the statuses and storage locations of the tools is always available. Important maintenance, such as tool sharpening is simple to schedule with just one click.

The app provides historical data in a graphical format of how tools have performed after previous sharpening cycles, presenting information to improve future performance.

Automating the material handling has many benefits including low maintenance operation, highly flexible production and the elimination of health and safety issues that come with manual handling.

With a sensitive floating crosshead to ensure gentle handling of parts, the FEEDBOT D-310 can handle large variances in workpiece size. It has a ‘plausibility check’ which compares data from the control to the actual part. Using woodFlex the setup of the complete cell (CNC and robot) can be handled automatically with visual confirmation on screen.

Utilised in a cell, the FEEDBOT increases overall productivity. It does not have to take a break, it can work around the clock and ensures consistently high quality results. It saves a lot of time, reducing the workload for production staff. This enables the workforce to be moved to more value-added activities in the manufacturing process.

In conclusion, Simon Brooks said: “The DRILLTEQ V-310 is a significant milestone in the design of small-footprint vertical CNCs. The number of functions incorporated in this compact model are amazing. When it was presented to the trade last year it caused a real buzz and no doubt there will be high demand for it in the UK market.”

For more information or a demonstration of the DRILLTEQ V-310 or any other HOMAG machinery and software, please contact Adele Hunt at HOMAG UK on 01332 856424.

Dust and fume extraction specialist, Extractly Ltd, has recently completed the installation of a new extraction system, incorporating Ecogate® energy-saving technology, at Planova UK’s manufacturing facility in Leeds, West Yorkshire.

Founded in Denmark, in 1964, Planova has grown to be a world-leading provider of specialist shop fitting solutions and shelving systems; transforming retail spaces and reinforcing market branding for a host of blue-chip clients. Today the business is delivering turnkey project solutions to customers across four continents and, in 2020, Planova (UK) Ltd amalgamated with Leeds-based Bartuf Ltd; making it a part of the global Planova group.

Production capabilities at Planova’s production centre in Leeds, formerly Bartuf’s headquarters, have been enhanced over recent months with the company’s investment in a fully-equipped timber processing department, and Ian Rayner, Extractly’s National Sales Manager, was invited to submit proposals for appropriate dust extraction equipment to meet the expected demand. “With only a few machines requiring extraction, and a clear, modern factory space to work with, system design was by no means over-complicated,” says Ian, “but, what was obvious to me straight away was the potential energy and cost-savings we could provide for Planova by incorporating Ecogate® ‘on-demand’ energy-saving extraction technology.” By their very nature, the diverse joinery commissions undertaken at Planova require bespoke machining, and this new dust extraction installation provides a perfect illustration of how Ecogate® technology can offer significant benefits to any woodworking operation; however large or small.

As Ian Rayner explained: “There were a couple of key factors we had to take into consideration with the installation at

Planova: The company was naturally keen to get underway with production as soon as possible, but not all of the new woodworking machines could be delivered on the same lead-times, and delays with provision of a new 415 volt 3-phase connection from the electricity grid, which was required to power the new 30kW main fan and associated electrical control gear, was also having a knock-on effect with a commissioning date for the new extraction system.

However, Extractly were able to offer Planova a temporary extraction solution: “Ian Rayner arranged for a multi-filter bagging unit to be made available to us, on loan for several months, until we had everything in place and ready for the new system to be installed”, said Jonathan Richards, Operational Director at Planova.

“Having the bagging unit in place allowed for machine utilisation, on a staggered basis, as the various pieces of equipment were installed and commissioned, and enabled us to commence production in the new workshop earlier than anticipated. Once we were in a position to give them the go-ahead, one of Extractly’s teams of installation engineers, along with the Ecogate technicians, had the new, permanent system up and running within a week.”

Planova’s workshop currently includes a Holzher beam saw and edgebander, along with a couple of CNC machines, and a second edgebander is due to be installed soon. With all five machines in operation at the same time, a filter unit capable of extracting around 20,000 cubic metres of dust-laden air per hour was going to be required. Extractly supplied and installed an LBR-B 2HJ SmartFilter unit; an advanced, modular, reverse air baghouse, externally-sited on a compact footprint of just 2.4m x 2.4m which, if additional capacity is ever required, can be easily extended by simply adding further modules. Contaminated air enters the filter

through an inlet where larger dust particles drop out of the airstream, and finer particles are captured by an array of highly efficient SUPERBAG filters which allow cleaned air to pass through and vent to atmosphere. As the captured dust accumulates on the filter bags, two 1.1kW regeneration fans blow air in the reverse direction to dislodge the dust; allowing it to drop into the lower hopper section from where it’s collected in steel dust bins located below the hopper.

“As this is a completely new extraction system, Planova have no previous electricity bills to compare and calculate the savings achieved with Ecogate® installed, but energy usage is continuously monitored, and data gathered by the Ecogate® greenBOX® Nxt controller automatically calculates the ongoing savings being made when compared to energy consumption with the fan running at full power, all day, every day”, added Ian Rayner. “In a traditional system, a 30kW fan, running continually at full power would typically consume around 60,000kW of electricity per year – with Ecogate® installed, we predict the effective payback period for Planova’s investment will be less than 3 years.”

Since Ecogate® technology, controls the extraction, the main fan will run ‘on-demand’, in real-time, at the exact speed necessary to maintain optimum extraction; for Planova, this also means that no excess energy will be consumed prior to installation of the second edgebander… but the system is ready to connect and deliver efficient extraction from day one.

In conclusion, Jonathan Richards had nothing but praise for the part Extractly played in getting the new department set up: “We couldn’t have got the joinery shop up and running as quickly as we did without the temporary extraction they provided and now, with everything working efficiently, I can definitely say that Ecogate® does exactly what it says on the tin!” T:

After months of preparations, the EGGER team is fully immersed in presenting its new, rolling collection concept for distributors, designers, architects and fabricators.

The EGGER Decorative Collection 24+ is packed with inspiring new introductions and a wide range of digital tools, all delivered via EGGER’s market leading customer services.

The collection has evolved from its last release in 2020, to expand its offer of adaptable interior design solutions that reflect increasingly changing design trends.

With the Decorative Collection 24+, EGGER presents a rolling collection for the first time. This means that it will be updated with new decor and texture combinations every two years, which will enhance the existing range.

EGGER presents the Decorative Collection 24+ under the motto ’Time for more’ offering customers more possibilities and solutions. Inspiring new introductions, new textures and decors, all with a range of digital services that complement the extensive collection folder.

The international Decorative Collection 24+ offers over 230 decor and texture combinations

This latest update includes 82 new decors and seven new textures. Among those are 25 developments in matt surface technology, including award-winning Perfect Sense Lacquered Chipboard in solid colour and woodgrain reproductions. Other new arrivals include 19 innovative material finishes that offer opulent surfaces in natural stones and luxurious metallic.

Now with 39 Worktop reproductions across two thickness and three formats, 12 Accent Edgings and a matching edging for every finish, completes EGGER UK’s expansive stock offer of more design possibilities for 2024 and beyond.

The concept is reflected in new decors. Colour evolves towards muted yet bold shades, and widens to include an elegant spectrum of natural greens and rich reds, as well as developments in the established blue-grey trend. Ever present, neutrals now take on a warmer, calmer appearance for heightened combination opportunities.

The evolution of woodgrain reproductions towards a redefined simplicity sees the rustic oak finish now evolving to a calm more adaptable variant.

Reproductions are no longer given authenticity through cracks and knots, but through texture, such as the new ST40 Feelwood Oakgrain. This latest generation of EGGER synchronised pore surfaces reflects the trend for reserved, matt wood effects, but still has the signature depth to touch.”

Material reproductions also offer simplicity. Instead of abstract designs, natural looking slate and marble are increasingly found in interior design schemes, commonly as the underpinning feature in frontals and furniture.

The texture development ST76 Mineral Rough Matt enhances new finishes, enabling timeless designs. The theme continues with metallic, with new UK texture ST20 Metal Brushed offering a stylishly matt and contemporary reproduction.

TIME FOR A GREENER FUTURE.

With the Decorative Collection 24+, EGGER leads the way towards an environmentally sustainable future.

Internationally, the publicised commitment to achieve NetZero by 2050 is complemented by the UK market’s pledge to plant a tree for every registration of the new Decorative Collection 24+ swatch.

BOOK YOUR VISIT – EGGER ON TOUR

EGGER is taking the Decorative Collection 24+ on a UK tour in March; join Panelco where we will be displaying the collection in full, supported by the Egger team a chance to discuss your projects and opportunities and see the development of the new collection.

Your chance to take away a NEW swatch collection with giveaways and prizes on the day.

To confirm your place RSVP below.

Panelco Scotland – 21ST March

South Shore Road

Grangemouth FK3 8TT

sales.scotland@panelco.com

Panelco South West – 11Th April

Meyer House

Vincients Road

Chippenham

SN14 6NQ

sales.southwest@panelco.com

Robust, precise and repeatable. Holz-Her’s patented Glu Jet system is your solution to flexible edgebanding.

• Perfectly near invisible joints with thin film technology

• Ready to run in 3 minutes

• 4 minutes change over from EVA to PUR

• Automatic cleaning at the touch of a button

• Touch nozzle for precise adhesive application

• Flexible application possibilities

• Cartridges or granules

• Simple colour change

• Laser equivalent at a fraction of the price

Watch the Glu Jet in action!

just scan the QR code...

www.holzher.co.uk

Egger, Formica, Polyrey and Resopal... Several European board suppliers are currently launching their new collections. As always, Ostermann is on the ball and delivers matching edgings as soon as the boards are available.

Whenever board suppliers bring out new collections, it is always worth taking a look at the Ostermann online shop, where carpenters/cabinet makers can rely on the proverbial Ostermann speed. With passion and dedication, the experts in edging at Ostermann do everything they can to provide a suitable solution for the board’s narrow surface as quickly as possible - from the moment the first boards are available on the market. At that point in time, all new Ostermann edgings are available from stock in standard dimensions of 23, 33, 43 and 100 x 1 or 2 mm. They are dispatched in small quantities from 1 metre. If you would like to see the latest edgings for the Egger, Formica, Polyrey, or Resopal collections, type the search term “#Highlights03” into the search field on www. ostermann.eu

PRESENTING: CURRENT TRENDS

In the collections mentioned, you can see many subtle plain boards, with increasingly matt colours. The wood decors are also becoming more matt, and they have more lifelike embossings, too. Stone decors still feature a lot of marble. The great number of new items in the Ostermann range ensures that you will definitely find the right edgings.

EGGER: DECORATIVE 24+

The Egger Group, headquartered in St. Johann (Austria), launched its Decorative Collection 24+ at the beginning of February. It consists of over 300 boards with more than 100 new colours and decors. The Decorative Collection 24+ includes elegant and understated wood decors, matt and velvety plain colours as well as classic material reproductions that impress with their realistic embossings. Numerous PerfectSense lacquer boards with wood and plain decors are part of the collection.

POLYREY: COLLECTION

The Collection 2024 from French manufacturer Polyrey also offers a wide selection with over 440 boards. There are more than 230 plain colours and 200 decors to choose from, among them more than 90 new products. According to

Speed is the name of the game: when board suppliers launch new collections onto the market, Ostermann quickly has matching furniture edgings in stock.

Polyrey, the collection features an “explosive” mix of current trends. These include Terrazzo and mosaique decors as well as material reproductions in OSB and cork look.

A new stock programme from Resopal has been available since mid-January. Here too, the collection has been expanded to include various neutral colours and another matt surface. In a total of 335 boards with 149 plain colours and 186 decors, 71 colours and decors are new. The Meran Oak surfaces, a modern yet rustic version of oak, and the new light-coloured Ventura Elm decor are particularly eyecatching.

The Formica group, which also includes Homapal, has its headquarters in the UK and operates worldwide. They will launch a new collection in mid-March. The Ostermann experts are expecting more than 40 new items and will be offering the right edgings in time for the start of the collection.

At Ostermann, carpenters/cabinet makers not only receive Europe’s largest immediately available range of edgings, but also the right materials to process these professionally: from the large selection of cleaners and hotmelt adhesives to items for edge processing and organisation. This means that many materials for furniture making can be ordered from a single source, saving time and ultimately money.

This May, Hoffmann Machine Company Ltd will be exhibiting at the world’s newest woodworking and wood processing trade fair, Materials and Finishes Show at the NEC, Birmingham.

Our team will be there on Stand G71 to show you our innovative machinery, and to answer any questions that you may have regarding how the Hoffmann Dovetail Jointing system could help you and your business.

The Hoffmann Dovetail Key, is an innovative jointing system developed in Germany over 30 yr.’s ago for furniture, door and façade fabricating as well as for the everyday projects in joinery workshops. The range includes key-way routing machines, double mitre saws and drilling and assembly systems.

We offer a wide range of machines with different processing steps for the efficient production and assembly of wooden components which need to be joined. This includes specialized machinery solutions that are tailored to specific production requirements and developed according to industry needs and standards. Such machines are increasingly in demand, because with equipment like CNC machining centers it is often the case that a special task can only be performed with additional time or making other compromises. This does not offer an efficient solution.

We will have various machines on show at the event, ranging from the bench top MU-3, up to the free standing MS35-SF. We will also have our new MU-S. Designed specifically for easy transport and use on site, and in limited space.

MU Range - Manual Dovetail Routing Machine

Transportable and adaptable bench-top machines, to rout a single dovetail slot with each machine cycle for Hoffmann Keys sizes W-0/-1/-2/-3

The Hoffmann CB-M is designed to produce an exact counterprofile on the ends of glazing bars when manufacturing Georgian style windows, door manufacturing and furniture.

Two clean precision mitre cuts to an exact length in one machine cycle. When both pieces are to be joined together or in a frame, then they can be prepared with one or two dovetail slots in precise positions in the cut faces for jointing with Hoffmann Keys. Suitable for work-piece sizes maximum 90 x 90 mm. Hoffmann Key sizes W-1/2/3. Ideal for cutting profiles for glazing beads, cornices, plinths etc. in wood, aluminium, or plastic at 45°. It can also be used solely as a Double Mitre Saw, to cut to length profiles such as glazing beads, cornices plinths etc. in wood, aluminium, and plastic. At 45° angles.

We look forward to welcoming all our existing and potential customers along to Stand G71.

Ask for a demonstration of the Hoffmann Dovetail system. It will only a few take seconds, but the impression could last forever.

dp-lamination leading the way in the production of laminated products. The largest and most diverse portfolio of decorative surfaces available in UK. Finish

www.decorativepanels.co.uk

Surface treatment plays an increasingly crucial role in raising the aesthetic and practical quality of a piece of furniture, a fixture, or a wooden floor... This is why SCM was the first to believe in the importance of expanding its extensive range of products and services for machining wood, even with exclusive solutions and skills in terms of Superfici finishing, a historical brand for designing, developing, and manufacturing complete machines and plants for painting.