News

Complex Connections Made Easy With Lamello

HOMAG SAWTEQ B-300 On Cue For Heywood Pool & Snooker Co

Hranipex – Meeting The Needs Of The Office Environment

AJB Group Ltd – An Introduction

SCM New Drilling Solutions

Hoffmann Partners with AJB Group

The OVVO Range Of Award-Winning Connectors Keeps Growing

HOMAG Turns Up The Heat With Makor Drying Technologies

Panelco – Front Cover Feature

So Simple! So Sustainable! So, Space-Plug

Markfield Announced As New Holz-Her Dealer

Ranheat – The Leaky Finders

Swallow GB Ltd A Happy Customer of Wood Waste Technology

Launch of the Combi-CUBE

The Latest CNC Innovations From AXYZ At FESPA 2023

HOMAG Is The Brand Of Choice For Woodcraft World

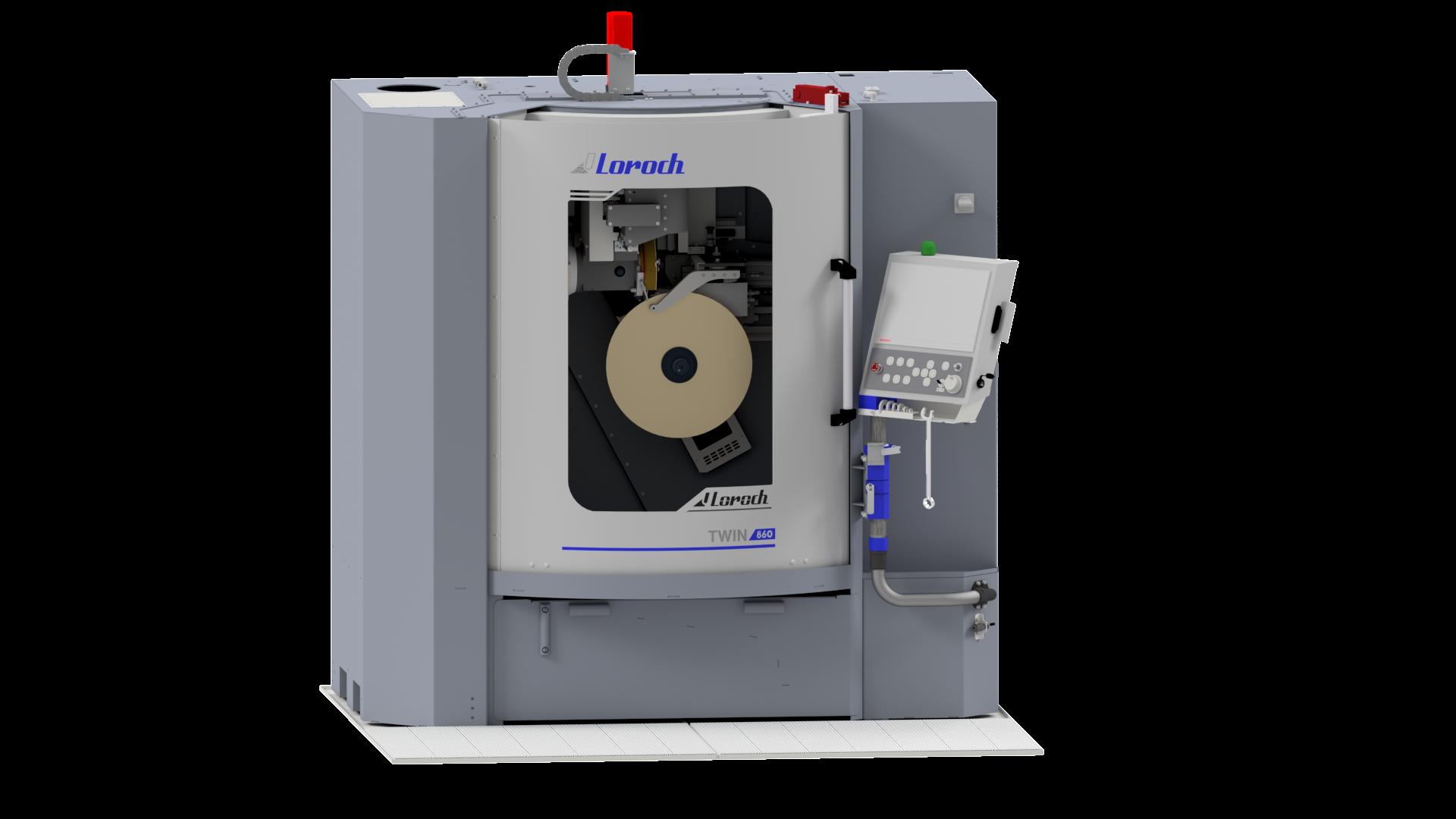

VOLLMER Doubles Benefits With New Loroch TWIN

- 17 Years Of Headlines

PUBLISHED BY:

TELEPHONE:

EMAIL:

WEBSITE:

PUBLISHER:

DESIGNER:

PRINTER:

EC Media 21 Cedric Road Westgate on Sea Kent CT8 8NZ 0771 314 8831

ecmedia@btconnect.com

www.p-j-production.com

Clare Hollister

Russel Goldsmith

TRACE Creative Agency www.tracecreative.co.uk

The Magazine Printing Company www.magprint.co.uk

Reproduction of articles: All material appearing in Panel & Joinery Production is strictly copyright, and all rights are reserved.

No part of the publication may be copied or transmitted in any form whatsoever, including photocopying without prior permission of the publishers.

Publishers note: The editorial opinions expressed in Panel & Joinery Production are not necessarily those of the publishers, who shall be under no liablity with respect to any article published herein.

Sikkens Wood Coatings celebrates a new look and an expanded product portfolio

Leading wood coatings brand in EMEA launches brand refresh and adds interior wood coatings to its product line-up.

Sikkens Wood Coatings, part of AkzoNobel, is celebrating 2023 in style with a refreshed image and an expanded portfolio of interior wood coatings products.

The brand, which was founded in 1792, is being given a more modern, dynamic look, in tune with today’s wood coatings market, while its portfolio of wood coatings solutions is expanding to include interior products, in addition to its well-established exterior assortment. As a result, Sikkens Wood Coatings will be able to offer a one-stop-shop solution to distributor partners and end-customers alike, with a fit-for-purpose portfolio to satisfy most industrial wood coatings requirements.

“This investment marks a significant and momentous occasion in our brand’s history. We look forward to launching the products and refreshed brand to our customers and continue to provide strong support moving forward,” said Alan Hall, Regional Commercial Director, Wood Coatings, EMEA, AkzoNobel.

The interior assortment includes products from the AkzoNobel Wood Coatings range of interior products, re-branded as Sikkens Wood Coatings for customers sourcing their products from distributors, so customers may already be familiar with some of the product names in the range, making the transition easy.

“Our customers can now find the wood coatings solutions they need -- both exterior and interior -- all in one place under the trusted Sikkens Wood Coatings brand. To complete the package, we’ve also launched an exciting, refreshed website, distributor portal, brand videos, a comprehensive catalogue featuring the full interior category and many other tools, all carrying our sharp, revived brand look and feel. These items have been

With the new VLaser 370, VOLLMER have extended the range of solutions for your tool manufacturing operation. In addition to the VOLLMER portfolio of grinding and erosion machines, VOLLMER now has a further technology for machining ultra-hard materials such as PCD, CVD-D and MCD. Highest flexibility, best quality and surface finish. New solutions combined with reliable precision: Simply VOLLMER.

IDS, the UK’s largest distributor of decorative surfaces, has updated its Solutions Guide for 2023. Bigger than ever before, this new bumper brochure spans 80 pages and provides retailers, manufacturers and contractors with an insight into the depth of IDS’s unrivalled portfolio, which includes flooring, wall panelling, worktops, solid surface, laminate, decorative panel products and composite decking.

This must-have guide gives professionals a detailed introduction to the 50 leading surface material brands that IDS represents and distributes throughout the UK. Imageled, the A4-sized book is packed with product information to support customers in their day-to-day business. For ease of reference, brands are split into dedicated categories with each featured across a full page where USPs are highlighted alongside inspirational lifestyle photography. Information on IDS’s multi-channel service, which includes 24/7 online ordering, is provided along with contact details for each of the company’s regional branches.

The guide can be viewed online through IDS’s website and hard copies are also available by emailing or calling IDS directly.

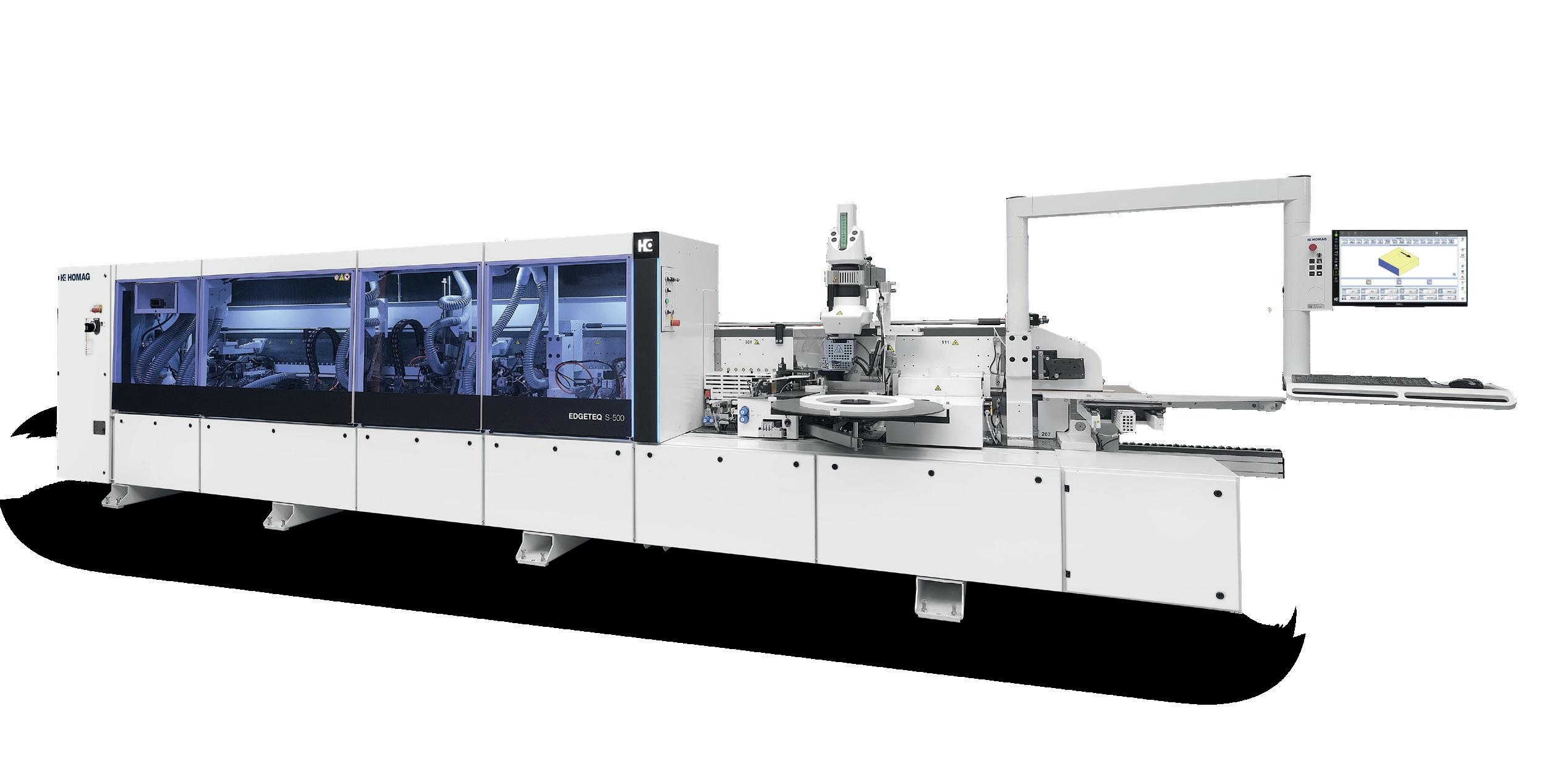

The high performance EDGETEQ S-500 offers enormous flexibility for the ultimate edge quality. Designed to seamlessly process PUR, EVA and airTec zero joint technology, this model effortlessly handles the demands of industrial level manufacturing. With its energy-saving features and environmentally friendly benefits, this model is packed with impressive advancements to compliment any high quality production line.

airTec is the optimum zero joint solution for the woodworking industry. It is a clean, cost-effective use of resources which results in perfectly crafted products, where joints are no longer visible. At the core of the airTec unit is a rotating fan heater, which, in addition to a high level of efficiency, provides a significantly reduced noise output.

Available across the full range of HOMAG edge banders means that businesses of any manufacturing size can benefit from ‘zero-joint’ technology.

SCAN ME!

If you’re looking to join complex components with ease, it’s time you put Lamello’s award-winning P-System to the test.

Recently, a Lamello Zeta P2 user asked for a quick and easy solution for inserting angled shelves into an entertainment unit after it had been lacquered. Traditionally, the process would have involved the gluing and lacquering of the complete unit but with multiple components and narrow angles incorporated into the design, it would have been a slow and laborious process.

For a P-System user, the solution is much simpler. By building a carcass using Lamello’s Tenso fixings – a selfclamping gluing aid – a furniture manufacturer can assemble the unit independently of its shelves and, once painted, the shelves can be fitted using the Clamex P-14 Flexus.

So, how does it work? Thanks to its flexible positioning pins, the Clamex P-14 Flexus offers an adaptable assembly sequence. The pins are bevelled and moveable, enabling workpieces to be tilted in both directions for ease of use and, with no limitations on the sequence of assembly, its ideal for the joining of corner connections, dividing panel joints and angles.

It’s also fully detachable, offers considerably stronger results than traditional joining techniques and because it can go into thinner materials, it’s suitable for use on mitres from 22.5-180 degrees on surfaces, corners and dividing panel connections.

Heywood Pool & Snooker Co. Ltd is a privately owned family business renowned for producing premium quality coin-operated pool tables for the pub and hospitality markets. Established in 1985 and with an annual turnover of around £3 million, the 15-strong team operates out of a 35,000 sq. ft. production facility in Heywood Lancashire.

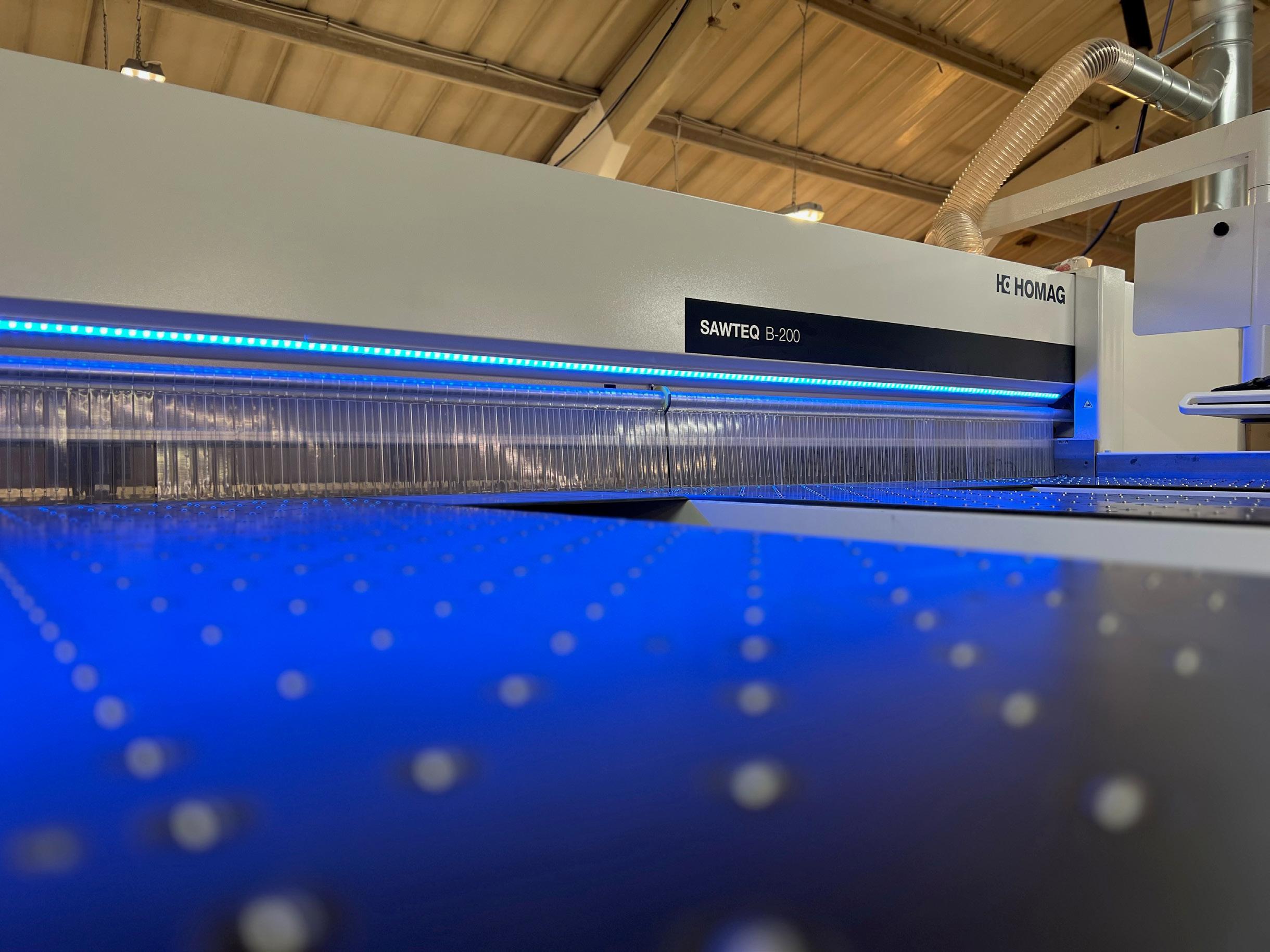

The business was having issues with its existing beam saw and concluded it was the right time to invest in a more state-of-the-art replacement. Heywood’s managing director, Dave Hallworth takes up the story: “Our old saw had broken down due to a software problem which took three weeks to fix. I worked out that the downtime had cost the business upwards of £30,000, and decided that enough was enough.” He continues, “We already had two HOMAG CNC machining centres in the workshop and they had worked tirelessly for many years. Consequently, when it came to selecting a new saw, we had no hesitation in contacting HOMAG first. Their

“We sat down with the HOMAG area sales manager and discussed our requirements. He recommended the SAWTEQ B-300 because it gave us the option of having the operating screen on the left or the right of the saw. Because of the layout of our production facility, it was important for us to have the screen on the left and the smaller saws didn’t give us this option.”

The installation of the saw went exactly to plan. Once Heywood had dismantled its old saw, the HOMAG machine was delivered and fitted within six working days. The engineers who completed the install also trained Haywood’s operators on site.

“The HOMAG engineers were fantastic,” explains machine shop manager, Steve Guidon. They were extremely thorough and accommodating, making sure we understood how to get the best out of the saw from day one. The SAWTEQ B-300

“It is easy to operate, extremely fast and delivers excellent quality. The cuts are squarer and more precise; we get consistent quality cuts no matter what size of panel we are processing.”

The CADmatic 5 control system for the HOMAG SAWTEQ B-300 features a new assistance graphic that clearly shows machine operators what they have to do next. This results in more efficient processing and consistent output. The powerTouch 2 user interface has simple tapping and swiping functions on its 24” full-HD monitor with multitouch display in widescreen format.

The optional intelliGuide system features a coloured LED strip at the cutting line. This enables intuitive operation and a quicker, safer way of working, as the machine operators can immediately see if a part has been fully processed, needs to be cut again or can be disposed of as waste.

In conclusion managing director Dave Hallworth says, “We are absolutely delighted with our new HOMAG SAWTEQ B-300. Not only is the machine superbly made, fast, efficient and easy to use, but also the backup service from HOMAG UK is fantastic. It gives us real peace of mind that we have partnered with such a professional company. Why would I buy from any other machine supplier?”.

If you would like a demonstration or further information regarding HOMAG beam saws or other woodworking machinery and software, please contact Adele Hunt at HOMAG

As the modern office evolves, the need for functional and aesthetically pleasing furniture continues to grow. With this in mind, over the past year Hranipex has evolved and adapted with the ever-growing industry and are proud to be a supplier of furniture fittings and components, that can offer solutions when manufacturing office furniture.

Hranipex extensive range of products caters to the needs of the modern office and ensures that furniture is equipped with the necessary features to support the work environment.

One of the most critical aspects of office furniture is its functionality. Furniture must be designed to meet the power needs of the office, and Hranipex supplies a range of power sockets that do just that. Our F004870 - Riex ED14 Electrical socket UK is an excellent example of this. This socket comes with four outlets and a 2-meter power cable with plug, making it perfect for office use. It is designed to meet UK electrical standards and has a sleek black body and modules that complements modern office interiors.

Cable management is another essential consideration when it comes to office furniture. Hranipex provides a range of cable management solutions that help to organise and conceal cables. The ASA Plastic Exit Dual 2.0 Aluminium cable outlet is an excellent product in this category. The outlet is designed to be mounted on a desk or workstation, providing easy access to cables while keeping them organised. Available in a sleek black (F005559) or white (F005558) finish and the top is made of solid aluminium that can withstand daily wear and tear.

Security is also a crucial consideration when it comes to office furniture. Hranipex offers an array of locks and accessories that can be used to secure furniture. An outstanding illustration of this can be seen in the F002104 - Riex EP64 Espagnolette bar lock. The lock is nickel-plated

Clare Hollister from PJP visited AJB Group Ltd in Corby recently for a fascinating chat with its CEO, Amarjit Binji.

AJB Group Ltd is situated on an unremarkable industrial estate in Corby but once inside it is anything but unremarkable. The reception is an interior design dream and feels more like the reception of a specialist high end car outfit than a woodworking machinery company. This is exactly the image which CEO, Amarjit Binji, wants to project and he has achieved the same clean, slick, process driven feel throughout the business from his board room to the business end of the factory.

Amarjit makes no excuse for having the ambition to be the ‘most famous face in woodworking’ (his words not ours) he wants to prove that the industry can be clean, bright, uncluttered and process driven, more in keeping with other industries.

As a 13 year old who had little interest in schooling apart from woodworking and sports, Amarjit got a weekend job with a local builder, Henry, who instilled in him a strong work ethic and passion for all things wood. He secured himself an apprenticeship with a woodworking company

and whilst he loved what he was doing he was frustrated by what he perceived as the chaos and untidy work place where your tea and sandwiches tasted of sawdust. He believed that every woodworking factory could be as clean and slick as a Mercedes Benz showroom; so with a loan from his father in 1999 he formed AJB Woodworking Ltd and moved into a rundown workshop in Leicester with the aim to have style, order, process and cleanliness at the heart of the business, somewhere that people wanted to work and that would attract young people into the trade and to provide a legacy for the future of the business and the area. The company specialises in the design and manufacture of high quality Internal Joinery, External Doorsets, Windows, Composite Doors and Mouldings for residential, commercial renovations and new-build developments of all sizes.

Having a hands on approach to the business worked for the first 24 years. Working with members of his family and close friends the business has gone from strength to strength and Amarjit moved the company to Corby and currently employs 40 staff. However, last year he realised that his talents were no longer best served on the shop floor. He has people in place who can do that and do it very well with the processes and design well established and ‘Gloria’ (so named by

Amarjit’s children) their super-efficient dust extraction and wood waste heating system fully functional. So, with some trepidation Amarjit Binji took on the role of CEO of the AJB Group Ltd and set about promoting AJB in order to improve the sales and marketing side of the business.

AJB works for many larger companies meaning the AJB brand is often not associated with the work produced so Amarjit decided to put his head above the parapet and introduce himself to the world of woodworking using PR and marketing and applying for various awards - they won 4 out of 5 that he applied for Entrepreneur of the Year – Midlands Business Awards 2022 / Entrepreneur of the Year – The Nachural Entrepreneurship Awards 2022 / Business Person of the Year - Signature Awards (London) 2022 / Joinery Manufacturer of the Year – Furniture & Joinery Conference Awards 2022. This has resulted in increased sales and a higher profile within the business.

His work ethic and desire to engage with his community comes from his strong Sikh faith – something that is subtly evident through the workplace – and is a reminder of his Grandmother who brought him up and instilled in him the responsibility of each individual to do the best they can

for themselves but also for others. There are quotes and thoughts on display throughout the offices and factory which serve to inspire and remind everyone who works at AJB that Amarjit’s door is always open and that the company supports its staff at every level.

By raising the profile of the company Amarjit wants not just to attract customers but also young people into the business. Growing a business is always about sales but also about legacy

“We want young people to understand that they are part of a growing, thriving business. We understand that they may want to spread their wings and look further afield but in truth we want them to stay with us progressing within AJB and building a strong inhouse trained workforce who understand the AJB Group culture and continue to build the legacy of the company.”

PJP looks forward to keeping readers up to date with the AJB journey.

www.ajb-group.co.uk

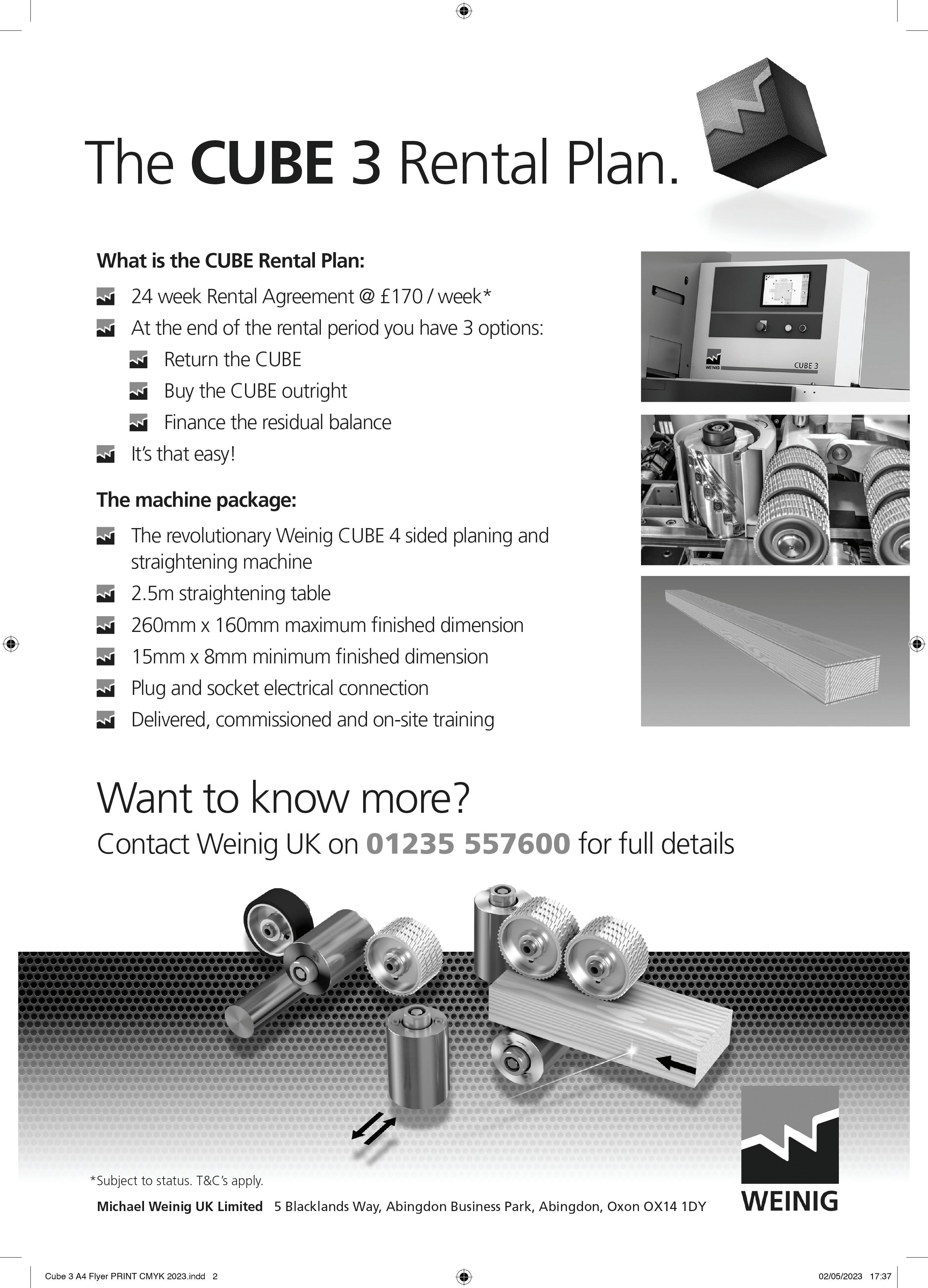

The brand new Cube 3 compact four-sided planer is more affordable than ever thanks to Weinig’s exclusive CUBE Rental Plan.

The low cost, risk free route to owning a Weinig CUBE 3

YOURS FROM £170 PER WEEK*

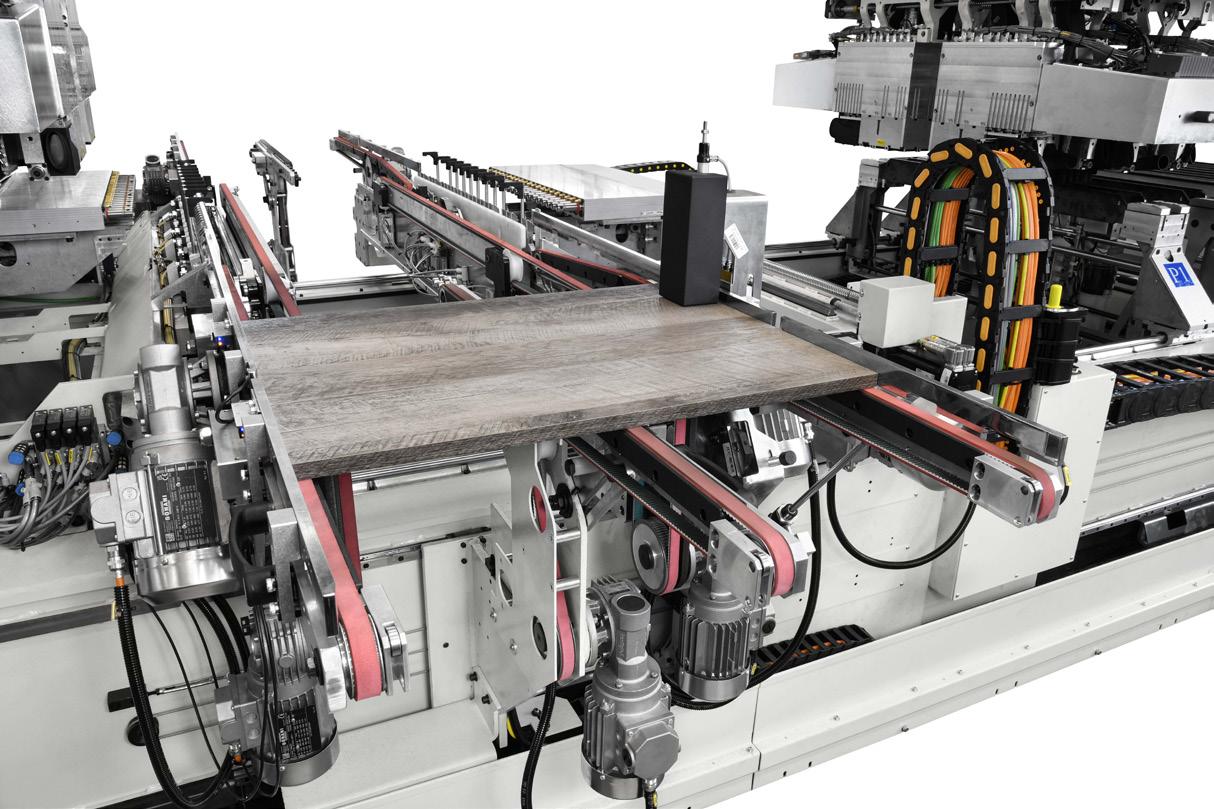

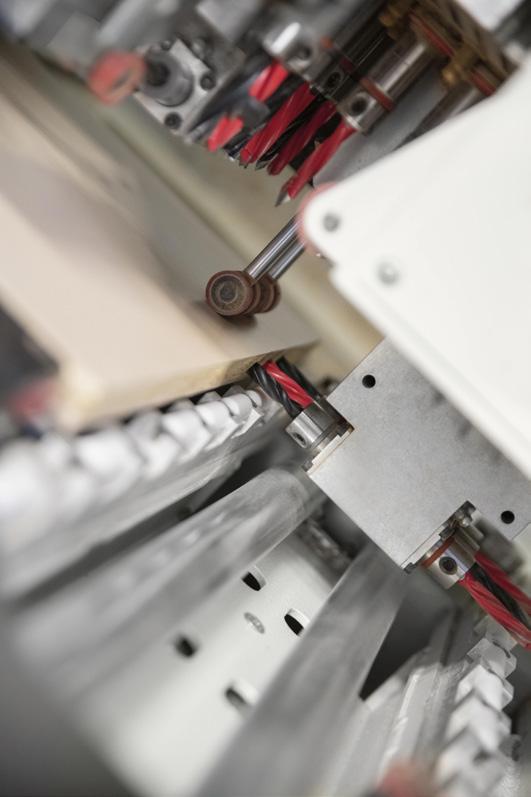

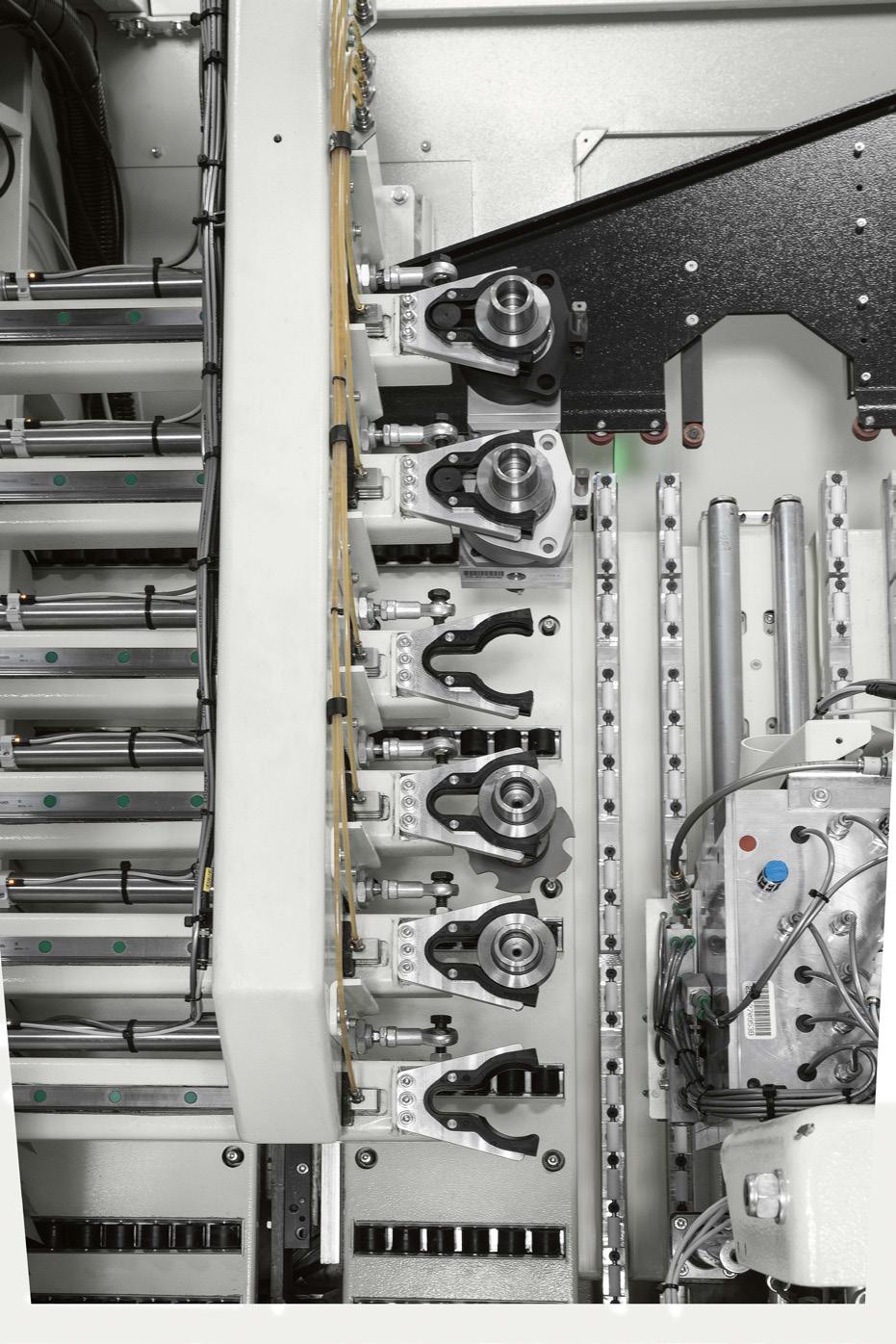

The two new solutions for drilling are to be found at either end of the Italian Group’s wide range of products for this machining: morbidelli pwx500 for very high production standards per shift on medium-large batches and morbidelli cx110 for extremely flexible batch 1 machining.

Dreams drill happen: the dreams of furnishing and furniture component manufacturers are about to come true with a new generation of versatile drilling machines, offering high productivity, extreme precision and the possibility of integration into automated systems.

SCM presents morbidelli cx110 and morbidelli pwx500, expanding its drilling solutions to offer an innovative and highly specialised response to the needs of both craft businesses and the large furniture industry. The two new solutions are to be found at either end of the vast range of morbidelli drilling machines: the cx110 model is mainly dedicated to companies that, regardless of their size and productivity volumes, desire a compact solution that is versatile, efficient and capable of solving all the critical issues of flexible machining; morbidelli pwx500, on the other hand, is for large furniture manufacturers and contractors looking for high-speed, connected and integrated drilling solutions without sacrificing the quality of the finishing and precision.

As Bruno Di Napoli, SCM Business Unit Manager for machining centres and drilling solutions says: “Market demands waver between two extremes: high production standards per shift and extremely flexible batch 1 machining work. SCM’s new morbidelli drilling machines were created to interpret the client’s expectations by developing the ‘best machine’ without compromises for both the artisan and large furniture manufacturers. Nowadays, we can say with even more certainty that we have a product range to suit every company requirement with new solutions which in both cases offer top performance at highly competitive prices”.

The morbidelli cx110 drilling machine offers maximum flexibility in performing any kind of vertical and horizontal drilling in less than 8 square metres.

The shaped clamp makes machining much easier because it drastically reduces the cases in which it is necessary to reposition the clamp, reducing the cycle times. Another advantage is represented by RO.AX spindles fitted on the drilling heads, with a rotation speed that can reach 8,000 rpm, maintaining a very high finishing quality.

The operator can efficiently and easily manage batch 1 drilling operations while having all the necessary tools always on board and benefitting from the advantages of an automatic 6-position tool changer.

The accessibility and ease of loading and handling the pieces is another distinctive plus: the machine is also ideal for those who need to machine lacquered and delicate panels because the new worktable has been designed to avoid any kind of friction.

Drilling is done with extreme precision and the guarantee of always having the correct corresponding piece while the machine is operating, without the risk of slipping or bending. This happens thanks to a four-sensor 3D PROBE decimal probing system and a presser that ensure maximum workpiece stability during machining. This stability is guaranteed irrespective of the repositioning of the clamp and also in the most unusual and elaborate machining: the slide bearings act as a continuous guide, providing considerable help to the operator and reducing possible errors with piece linearity.

This new drilling machine is extremely versatile: available in several configurations, it can also be fitted with a new unit to create “Clamex” joints.

The new morbidelli pwx500 is the ideal drilling solution for connected and integrated production and to achieve highly competitive production standards per shift on medium and large batches.

Production ability has increased by 10% compared to market standards. In fact, the drilling machine is able to work intensively over several shifts and is designed to significantly reduce tooling changes and other operations that cause unproductive time.

High productivity is guaranteed even by the automatic repositioning system, which is completed in under 45 seconds, including dowelling.

Reliability is another significant advantage: the system has been designed to have fewer moving components compared to standard ones, so fewer risks of damage over time.

This new drilling machine is also synonymous of high efficiency: indeed, it is the only one on the market to offer up to 5 rows of spindles on the right and left in order to reach the extremities of the panel to make structural holes according to different production needs.

Efficiency and high productivity combine with a considerable machining simplicity thanks to the optimiser software that controls the entire machine’s set up, the drilling steps and the integration of production lines consisting of several machines.

The new morbidelli pwx500 is also extremely adaptable: the panel drilling occurs with a FLEX transport and

positioning system that automatically adapts to the piece’s specifications, with the possibility of positioning the panel in one or more positions along Y axis.

Effectiveness is another key word: the panel is machined with 10 drilling units rapidly completing any furniture installation diagram thanks to the M-type heads and electrospindle with tool changer.

Lastly, the model can be highly customised: over 450 drilling tools can be fitted, 6+6 separate dowel insertion units, two workstations and different servo system levels.

The best tool position on the heads, depending on the client’s production batches, is identified by a powerful and innovative optimiser: Maestro powerset. This software satisfies a specific demand: facilitating and speeding up the set-up operation of the bits on the machine and providing the plant with flexibility.

As well as two new machines, SCM has integrated a new drilling software, Maestro 3Drill, to also apply the main advantages of morbidelli numerically controlled programming software to drilling machines.

Some of the main advantages include the possibility of directly importing three-dimensional solids with automatic recognition of the holes to be performed. This speeds up and simplifies the user’s programming experience.

www.scmwood.com

AJB Group specialises in the design and manufacture of high-quality Internal Joinery, External Doorsets, Windows, Composite Doors and Mouldings. Established in 1999 and providing an excellent service for residential, commercial renovations and new-build developments of all sizes.

AJB’s talented youthful workforce are like a breath of fresh air bringing life into their product range and they believe this is “where timber meets perfection”. They continue to strive forward with modern methods of manufacturing combined with advance technology which creates the hub to their success.

In the woodworking industry the mitred corner has always been recognised as a sign of high value and quality, especially in door production. The joints, when finished using the Hoffmann Key offer strength, durability and stability whilst the process of production offers simplicity and speed. AJB found all of these attributes in both the Hoffmann MS40 SF Double Mitre Saw and the Hoffmann PP2-H-DB Pneumatic Dovetail Routing and Dowel Boring Machine. The perfect combination in the fabrication of their doorframes.

The Hoffmann MS40 SF double mitre saw is designed to simultaneously cut one left and one right hand mitre with each machining cycle. Accurate, repeatable mitre cuts are achieved in a variety of materials, including hard and softwoods, wood related materials (MDF, plywood, particleboard), plastics and non-ferrous metals such as

aluminium. The heavy-duty design of the saw heads and precision machined components as well as the use of industrial quality carbide tipped saw blades assures perfect cuts with no burrs or tear out. The ideal double mitre saw for small and large shops when accurate and efficient mitre cutting is required.

The Hoffmann PP2-H-DB Pneumatic Dovetail Routing and Dowel Boring Machine is a free-standing version specifically designed for mitred corner production. The machine cycle begins by pressing the foot pedal. The work piece is clamped pneumatically and the unit’s router the dovetail slots and drill the dowel holes. The work piece is then released. The joint is completed using Dowels and Hoffmann Keys W1/2/3/4.

Extensive development has been AJB’s footprint to becoming a manufacturer of the highest quality in modern and traditional joinery. They have designed a product range that not only satisfies the performance and technical criteria of today’s industry but exceeds all expectations.

“We focus our attention on engineering timber and timber like products to the highest possible degree and then take it one step further. We take a raw material and engineer out all of its natural defects to provide our client with the very best in carpentry and joinery. With intelligent in-house designs, accurate estimating, a state-of-the-art production facility, we can deliver success without any hesitation.” –

Amarjit Binji – CEO- AJB Group

OVVO continues to expand its range of wood joining connectors leading the way in furniture ‘Tools free’ assembly components, making life easier for consumers and end-users, and delivering a more profitable and efficient solution for manufacturers.

OVVO products are a range of cleverly engineered, awardwinning, invisible connectors that make joining wood simple. The connectors are installed during the manufacturing process so the end-user can simply click/push together cabinets, shop fit-out components, door frame assemblies or furniture without the need for tools, screws, or glues.

The result is an accessible, sustainable product that saves time, money and effort for consumers and manufacturers alike. Manufacturers can also benefit from significantly reduced shipping costs, as items can be shipped flat-packed. The latest addition to the OVVO product family is the incredible OVVO DOWEL (OD30) which is specifically designed to work in standard drill patterns. The OD30 is inserted into the panel without any glue to form a permanent joint in 15mm panels and above. These new connectors make it even easier for manufacturers to incorporate OVVO into their standard processes, saving time and money by eliminating glue and case clamping time. No additional equipment or capital needed to deliver tools free assembly products to the end customer.

This new self-clamping, glueless, invisible OVVO Dowel (OD30) is designed for connecting cabinet parts and all types of furniture using standard drilled holes on BOTH sides of the joint, thereby simplifying the panel processing operations while continuing to provide all of the benefits of OVVOs’ proven tools-free assembly methodology.

Established in Ireland in 2014, the OVVO brand has gone from strength to strength, picking up numerous highly regarded industry awards along the way. Most recently awarded “Outstanding Furniture Accessories” award at Interzum-Guangzhou in April 2023 for the innovative connection system, the relentless quest to make life easier for people ensures that simplicity is at the heart of every new product: with each new product developed, the OVVO range has become more accessible to manufacturers, with the ability to be integrated into existing production processes, and suitable for a wide range of production capabilities.

All OVVO connectors are designed for high-volume, automatic insertion, and ongoing partnerships with leading software providers Cabinet Vision, TopSolid, iFurn, Swood and Cabinet Sense ensure that manufacturers can easily incorporate OVVO into their existing processes, and also into new product design and development.

All OVVO connectors can be installed into a variety of materials ranging from high-quality hardwoods to low-grade particle board, and our recyclable plastic means any waste is put back into the production of our product. OVVO works best in boards >12mm thickness and is available in a range of sizes to perfectly match your requirements.

All connector sizes are available in both PERMANENT and RELEASABLE options, extending the range of materials and opportunities to inspire creative design and innovative development.

Consumer demands are shifting more and more towards convenience and sustainability. OVVO helps you meet those demands and give your products a competitive edge. Our team is on hand to support your switchover to OVVO and help you take the next step of innovation.

Furniture Assembly made simple – no need for tools, glue or screws. Simply push, click and connect.

Immediate response, both on site and in “digital mode”, efficiency and professionalism are the three pillars at the base of our business strategy: from technical assistance to the supply of original spare parts, to training activities even remotely, overcoming the barrier of distance while maintaining efficiency and professionalism.

This is made possible by our network of over 500 technicians around the world and the latest generation of smart digital technologies and services that allow us to transform distance in an opportunity to always meet, with no more space-time limits.

“We’ll go the extra mile for you”: this is the spirit that sets the SCM Service team apart from the rest, today more than ever.

Makor is a world leader in coating and finishing technologies. Its partnership with HOMAG UK has enabled it to broaden the reach of the Makor brand. For the woodworking industry, Makor offers a number of advanced and efficient technologies for the drying and polymerisation of all kinds of paint finishes on panels, profiles and windows. From its Flexi Oven, created to dry water or solvent based coatings when longer permanence is required, to its Linear Dry Oven, ideal for drying waterborne paint when shorter drying times are needed, Makor’s drying solutions have been designed to meet the demands of each specific drying task.

FAST, EFFICIENT DRYING OF PANELS

The latest addition to the Makor range of panel drying ovens is the vertical Flexi Oven. Developed to offer maximum flexibility both for drying and storing, different drying times and panel dimensions can be set for tray. The Flexi Oven has a load speed of up to 8m/min and a cycle time of 40 seconds.

Being a modular design, the Flexi Oven can be specified with

The Makor Fastdry Linear Tunnel is ideal for the flash off and drying of varnished panels that require short-medium permanence time. The panel is exposed to a hot air flow moved by fans within a recirculating loop. This causes rapid evaporation, which enables quick drying of heat-sensitive materials without product degradation.

Designed to be versatile, The Fastdry Linear Tunnel is modular in construction with length options ranging from three to 30 metres. Numerous drying modules are available including laminar air (slow-speed air movement for initial flash-off, high-velocity air nozzles with hot or cooled air), TL (luminescent tubes), IR (infrared), NIR (near infrared) and UV (ultraviolet) lamps.

The Makor Multilevel Compact Drying Oven is perfect for small or fully automatic lines. Technically advanced ventilation systems enable short drying times for fast reticulation paints, flashing off paints before UV curing or drying glues to subsequently veneer panels. The oven has six overlapped belted trays housed in a highly insulated

The Multidry 90 Vertical Oven is Makor’s high performance model. It is designed to dry water or solvent based coatings that require medium to long drying times. Particular attention has been made to the structural design of bartrays; this ensures maximum load capacity, thus optimising the oven’s performance in terms of durability and stability. Its modular design allows for working widths of 1300 mm or 1600mm, with bar trays (3600 – 5500 mm) or belt trays (5500 – 7000 mm).

The Ultradry 1+2 is a UV-drying oven for ultra-fast drying. It instantly dries mono and bi-component UV paints, clear and pigmented, matt or gloss. This modular oven can be specified with one to three lamps.

Commenting on the latest drying technologies from Makor, Simon Brooks, managing director of HOMAG UK stated: “Makor has been designing and manufacturing drying ovens and systems for painting lines for more than 50 years. “The company’s latest technologies demonstrate Makor’s commitment to providing customers with some of the most advanced and efficient coating and finishing solutions on the market.

“Whether you need to dry coatings on panels or profiles, Makor has the answer. Its drying solutions can be standalone ovens or complete automated finishing cells that include sanding, spray finishing or painting and drying.”

For a demonstration or more information on the Makor range of drying technologies for panels or profiles, please contact Adele Hunt at HOMAG UK on 01332 856424.

T: +44 (0)1332 856500

E: info-uk@homag.com www.homag.com

Serica, the silky super matt premium surface, encompasses both anti-fingerprint and thermal healing properties. In the case of minor scratches the surface can be repaired using heat to renovate. This ultra modern collection is available as an 18mm double sided foil MDF panel, which makes this product a perfect choice for many applications. Designed for use in all types of furniture for the home, office and retail.

Panelco have updated their current range with an additional six new modern colours to their collection. Caramel the golden warm amber colour that permeates warmth throughout, this soft tone is perfect as a contrast to darker schemes to portray a contemporary look. A natural earthy Sage green, a simple natural fresh tone; this will surely enhance interiors to create a warm atmosphere.

The new Rusty Red décor is a subdued reddish orange hue, displaying warm tones yet a bold and rich hue. The sophisticated Scandi style is still very popular Alby Blue does not disappoint fresh and contemporary a modern design choice. Reed Green a calming warm green effect, classic and luxurious that can easily mix with interiors that require warmth yet still a neutral choice. Black is a design classic that never goes away an achromatic solid colour with modern style that will add statements in any scheme.

In addition to the new colours the many benefits of the Serica range prove invaluable to designers that are looking for something a little different for their creations yet with durable qualities. Silky Touch, Anti-fingerprint, High scratch resistance, Super matt, Easy Repair and Thermoformable surfaces to name a few this is a truly incredible product. An extremely robust product with no compromise on colour

choice, the range of Serica colours available from Panelco now totals 16 decors to choose from, ranging from stark whites, soft natural tones to dark modern tones.

In addition to the Serica collection Panelco carry a choice of 18 Senoplast high gloss designs. Scratch resistant properties and high UV resistance makes this a premium product.

Expect to see your classic solid colours alongside metallic decors and softer tones the choice really is yours. A full range of 34 decors confirms the ever growing partnership between Panelco and Decorative Panels who they have worked closely with for many years. “Part of my role is to develop product ranges with our suppliers and promote them in the best way possible” says Julie Dean, Group Marketing Manager. Since the installation of our design studios we encourage our customers to use the space in any way they like, it can be a design led meeting with the team or private meetings with their own customers. Having such a great space to display all of our ranges is a huge advantage when it comes to promotion. We plan to add in the new designs from Serica shortly and to display further new products in our Innovation areas, we love inviting customers to share this experience with us, we actively ask for their help in choosing decors and this is working well so far.

All six new designs are now available ex stock, contact our sales team to order your new updated swatch collection or A4 samples of any of the colours or find out more

www.panelco.com

Sustainability, Intelligent Design, Manufacturing Innovation, Production Economics, Customer Experience. All of these are addressed when a manufacturer embraces “Space-Plug Evolution”

The last 10 years has seen Space-Plug become the brand synonymous with fast effective fittings for kitchen base units and tying back all manner of KBB furniture. With the launch of their new system, “Evolution”, manufacturers will now be, “More Sustainable” whilst, “Saving Money” and including brand new, “Fast-Fit” technology.

It’s a simple idea. The cabinet is made with shorter side panels that no longer have to reach the wall. This strip of material is now saved in manufacture and replaced with the addition of their, “Datum Pegs” - 4 Grams can replace 1000 and puts the unit back to its original datum depth without wood in the way! This simple, handy measuring stick replaces all that excess material manufacturers have included unnecessarily for decades!

Manufacturers now save this material which more than covers the cost of a set of Evolution components and so Space-Plug guarantees to save money overall and offer much more to their fitters and more importantly, their customers!

The reason? These strips of board are in the way for fitting a kitchen. “The industry thinks installers want them” said Cliff Petit, Inventor and MD at Space-Plug. “Installers currently

think that, because manufacturers provide them and they are needed to create the service void. But both the manufacturers and the installers haven’t seen Evolution cabinets … Yet!”

Fitters time is wasted and customers cabinets’ edgebanding is sacrificed as these machined edges don’t marry to meandering walls, let alone around surface mounted services.

Fitters have to scribe round these pipes or cut away large sections to get the unit in place. Modifying the units onsite, causing more work, more dust and more risk … often contrary to the manufacturer’s warranties! This results in brand new cabinet material in the skip, wasted and customers board edges now exposedcompromising the new unit’s integrity.

“All of this is negated by Evolution” states James Marchant their Director of Marketing, “Not forgetting that all of these benefits are accompanied complete with a Space-Plug Adjustable Spacer Fixing. The five star, fast and purposeful professional fixing… basically Free of Charge”.

The system is already in manufacture in the UK and taking orders. With sustainability and customer experience at the forefront of its benefits, Evolution is set to eclipse the 7 million adjustable spacers Space-Plug has already sold.

Woodworking machinery distributor, Markfield Woodworking Machinery Ltd, has been announced as the new Midlands dealer for Holz-Her UK. The partnership will see the established Leicester-based company have exclusivity of Holz-Her’s complete range of panel processing machinery across the central strip of the UK from April 2023.

As well as offering over 40 years of experience in buying and selling woodworking machinery and accessories, Markfield’s aim to supply premium woodworking machinery brands to its customers works in parallel with Holz-Her’s ethos. Already the exclusive importer for England and Wales for Martin, the company understands the importance of customer satisfaction and is committed to providing a first-class service throughout the buying process.

This has seen the second-generation business invest in a purpose-built, 8,000sqft showroom. Currently home to over 40 machines from a wide range of well-known woodworking brands, the two-story showroom will be updated to include a dedicated Holz-Her machinery demonstration area.

The space, which is due for completion later this year, will include several Holz-Her machines, including a 6015 Linea Beam Saw, Streamer XL C edgebander, Artea 1030 edgebander and 1254 Sector vertical panel saw. In addition to this, customers will also be able to visit Holz-Her’s headquarters in Abingdon to view different models and specifications.

Paul Nightingale, National Sales Manager for Holz-Her UK says: “For over four decades, Markfield has built on its solid reputation as a trusted and reliable machinery supplier and in the process, has become a go-to company for start-up businesses and small workshops looking to mechanise their production processes. To build on this solid foundation, the Leicestershire-based company is committed to expanding its portfolio and working with premium brands that can

help and support new and existing customers looking to take their next step to growth. Holz-Her’s range fits this model perfectly.”

Gavin Cooper, Managing Director of Markfield Woodworking Machinery Ltd adds: “Our business is about providing long-term solutions to our customers and to do this, we need to work with the very best brands in the market. Holz-Her offers a much sought-after, premium range that fits seamlessly into our existing portfolio. Whilst it is not always suitable for the price-driven shopper, Holz-Her’s customers get the very best in panel processing technology at their fingertips and this is backed by a knowledgeable and experienced sales team and a dedicated service department. This gives us and our customers the upmost confidence in Holz-Her’s range and the level of quality they offer. We’re excited to be taking on the Holz-Her agency in the Midlands and look forward to welcoming new and existing faces to our Leicestershire-based showroom very soon.”

Malcolm Cuthbertson, Managing Director of Weinig UK concludes: “With the addition of Markfield, we now have a backbone of Holz-Her showrooms across the UK. This makes our panel processing machinery offering more accessible than ever. Working closely with our existing dealers - Lancashire-based Calderbrook and Hampshirebased Grovewood Machines – Markfield is ideally located in the centre of the UK and will offer midlands-based businesses an opportunity to see our machinery range on their doorstep. We are confident this move will benefit our customers going forward and we look forward to working closely with Markfield Woodworking Machinery Ltd.”

Mirka’s innovative Galaxy abrasive combines effectiveness with long life, thanks to a new self-sharpening ceramic grain, a clog resistant coating and the new Multifit™ hole configuration.

For further information or to arrange a demonstration, please contact Customer Services on 01908 866100.

In many manufacturing facilities, extraction fans operate continuously, at full power, throughout the working day.

Even when some machines are not in use, and often during factory breaks, the powerful, energy-consuming fans continue to run at full speed – wasting valuable energy... and money!

With ECOGATE, the extraction system responds in real-time to variations in machine use. When a production machine is switched on, the greenBOX Controller opens a motorised damper to provide extraction for that particular machine.

With ECOGATE technology installed, an extraction fan will consume the minimum power required to provide optimum extraction – reducing electricity bills by 68% on average. www.ecogate.co.uk sales@ecogate.co.uk 01924 520462

Chris Franklin, Managing Director of Ranheat Engineering Ltd. One of the UK’s leading manufacturers of wood-waste burning equipment, continues his series of articles exclusively for Panel and Joinery Production. The Renewable Heat Incentive (RHI) finally closed its doors to new applicants at the end of March this year, but it was a 20-year scheme.

As such, once accredited, payments can be made for up to 20 years, the problem is that a considerable number of makes of boilers will not last 20 years. Also, in the wood working industry a certain amount of PVC is used by some wood working companies as part of the material they use, often this cannot be separated from the feedstock. This can attack and corrode boilers.

Replacement boilers can be used under the scheme (RHI) but OFGEM (who administer the scheme on behalf of the Government) have applied rules and regulations that require a replacement boiler to meet the stricter emission regulations imposed at the closure of the scheme. Rather than the limits imposed at the time of applying. Sometimes this is not achievable due to cost or space limitations.

The answer is to repair the existing boiler by re-tubing the boiler and the tube nest plates. Repairs do not have to meet the stricter emission regulations.

Chris Franklin, of Ranheat Engineering Ltd, explains:

“I started my engineering career being trained in the NHS and attending Portsmouth University, to become a hospital engineer. (I studied Mechanical Engineering and Naval Architecture). Hospital engineers historically came from either the Royal or Merchant Navy. When a ship (or hospital boiler) started leaking you didn’t replace it, you re-tubed it. So I learnt very early in my career how to repair a water tube boiler. Ships and hospital boilers were so large you would have to dismantle the ship to take out the boiler.”

Most steel shell multi-tube boilers can be retubed several times in their life. So Ranheat are offering their services to re-tube boilers made by other manufacturers of boilers who no longer exist, or don’t have the facilities in the UK to undertake this work.

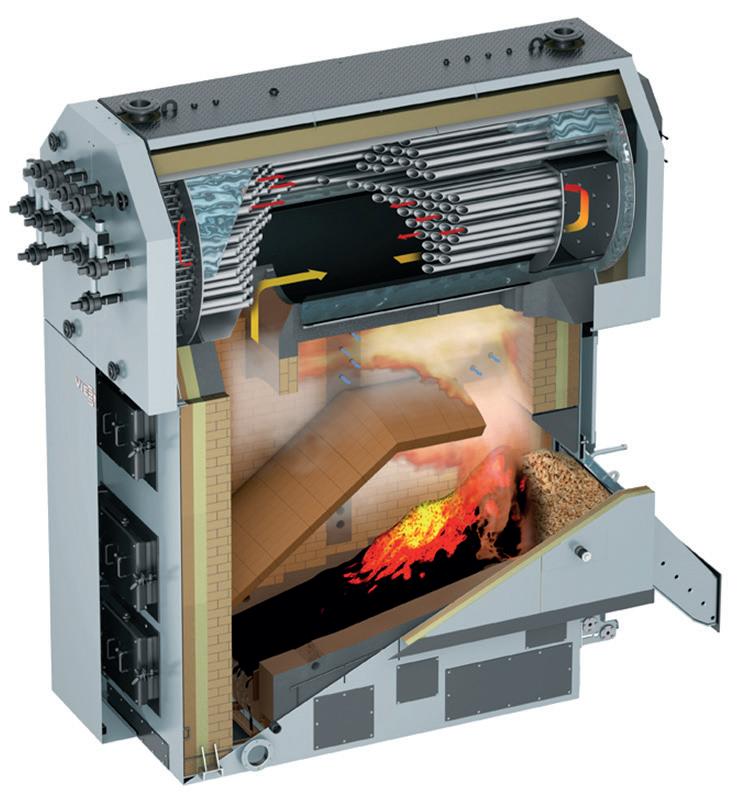

The following photo shows a steel shell boiler having new tubes welded into a new tube plate. Invariably Ranheat use thicker walled tubes than many other manufacturers, particularly European manufacturers.

Not only do we stock Reactive HotMelt Adhesive for Prole Wrapping and Edge Banding Applications.

We also stock Nordson compatible spare parts for EB 60V Slot Nozzles , Heated Hoses , Platen Seal for BM 200 and BM 20 Systems and generally anything to do with Prole Wrapping!

We also supply Slitting Blades, Moulder Wheels, Heat Guns, Elements and Brushes for Heat Guns

We have one of the largest stocks of Wrapping Wheels in the UK ! Stocking 30 different types and 8 different shore hardness! So literally thousands on stock at all times!!

A Yorkshire garden building company has purchased a second wood waste heater from Wood Waste Technology to save money on its operating costs.

Swallow GB Ltd supplies a range of products and services including the manufacture and installation of quality timber greenhouses. The business purchased a wood waste heater a couple of years ago to utilise the waste wood generated daily, to reduce expenditure on heating and waste disposal, and have recently purchased a second one.

Managing Director, Michael Bainbridge explains: “We were looking at purchasing a wood waste heater for a while, as we ended up with timber off-cuts as part of our manufacturing process which we had to pay to have removed. We realised that if we purchased a wood waste heater we could burn the waste wood to heat the factory, especially our spray booth, and save money on waste removal and heating costs at the same time.”

The team at Swallow GB was recommended to speak to Wood Waste Technology by another local company, and following a site survey and quote, purchased a WT15.

Michael continues: “We’re delighted with our purchase and glad we bought the model we did from Wood Waste Technology. We’re now saving around £13-£14,000 a year on electric and waste disposal costs, so the first heater paid for itself in less than 12 months! It’s easy and convenient to use, in fact, it’s now just part of our daily routine and makes the factory a more comfortable place to work. Purchasing the wood waste heater is one of the best things our business has done – which is why we bought a second one. “

Wood Waste Technology’s years of expertise in wood waste solutions have helped many companies reduce their waste disposal and heating costs. As well as offering site survey, design, manufacture, installation and on-going maintenance for new units, the company also services all types of wood waste heaters and supplies genuine spares up to 60% cheaper than other suppliers.

In addition, Wood Waste Technology is the UK official distributor for Gross Apparatebau GmbH, a German manufacturer of dependable, precision engineered shredders and briquetters, available in various size and specifications to suit all business applications.

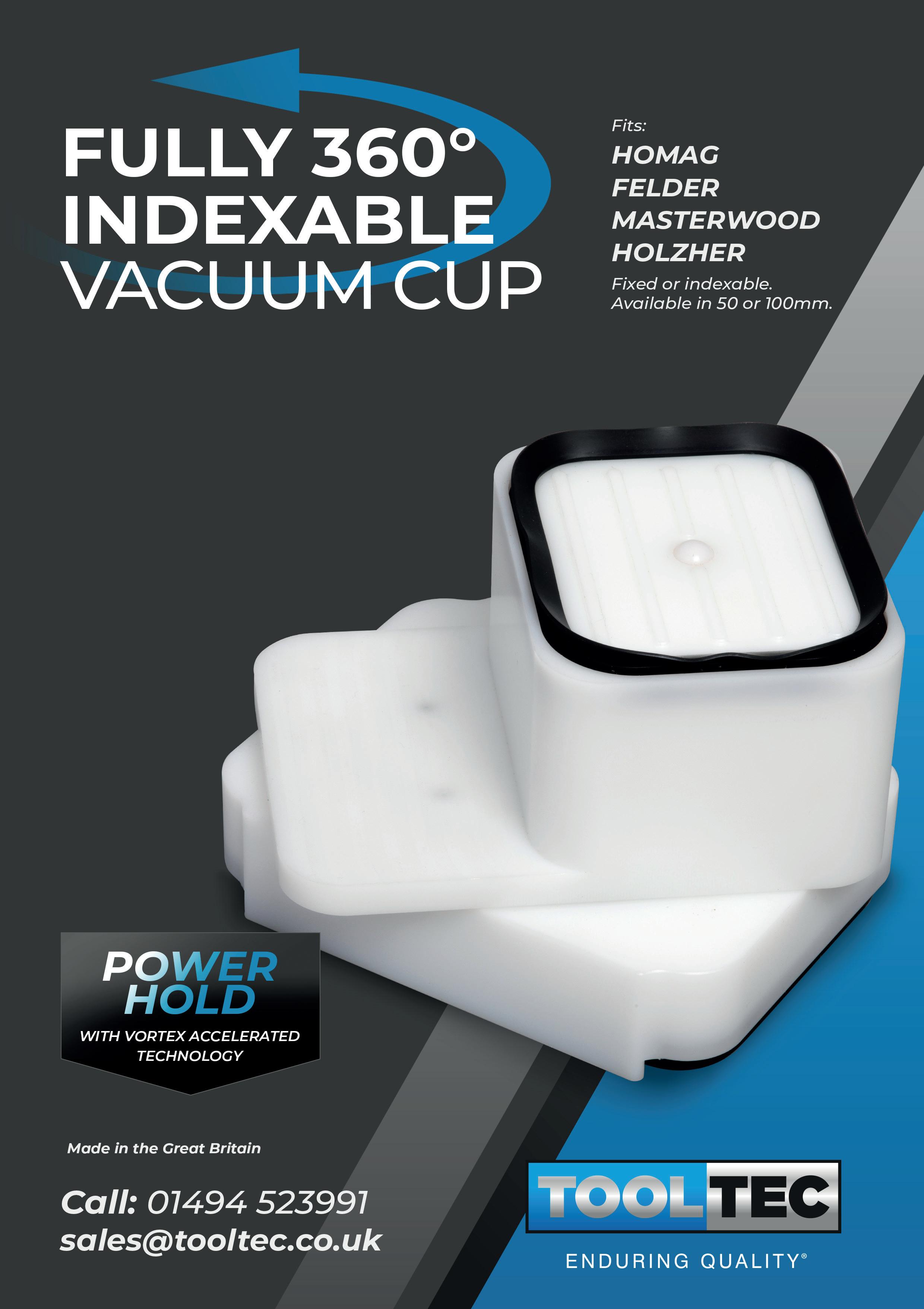

Our flexible fully 360° indexable vacuum cups are the most powerful upgrade available for your CNC machine. Rotate to fit the shape of your work piece easily.

Tooltec vacuum cups feature the unrivalled powerful vortex acceleration technology. Available in full half and quarter.

MAWERA UK LTD

PO Box 5581

Lichfield, Staffordshire WS14 4FS

Tel: O1543 258844

Email: info@mawera.co.uk

www.mawera.co.uk

As Combilift celebrates 25 years of innovation, the company plans to ensure that 2023 will be a year to remember, by launching multiple products across various exhibitions on a global scale. The first of these products - the COMBi-CUBE was launched at the LogiMAT International Intralogistics show in Stuttgart in April.

This new electric model incorporates a host of technological and design features that not only enhance handling procedures but also offer a high level of driver comfort. The driver’s position in the centre of the cab offers generous room and excellent all-round visibility. The angle of the telescopic steering column can be adjusted and the Grammer MSG65 seat, combined with hydraulic cabin mounts guarantees a comfortable ride. An adjustable arm rest is mounted to the seat suspension which incorporates a multi-function joystick and an LCD colour touch screen.

The new vibrant colour is also an eye catcher - this Combigreen shade will contribute to improved safety as the trucks will be easily visible in their operational environment.

Combilift’s unique dynamic 360 steering that enables seamless directional change while on the move can be integrated into the Combi-CUBE as an optional extra, making it the most manoeuvrable counterbalance forklift on the market.

Further notable features are the large rear wheel and rubber tyres on all three wheels. This means that, unlike certain other brands of electric multidirectional trucks, this model is not restricted to super flat floors and is eminently suitable for working indoors and out, ensuring that semirough terrain is no impediment to reliable operation. And for quicker battery changeover during heavy shifts, two new easy-change roll-out batteries are provided (Overall Design Copyright 015019216-0001)

Combilift CEO and Co-Founder Martin McVicar said: “Our engineers and R&D department have been tirelessly preparing for a year of new launches, and the Combi-CUBE is proof of our continued commitment to provide the best and most innovative handling solutions for our worldwide customers.”

INTERESTED?

Are you looking for the latest CNC innovations? AXYZ is proud to be exhibiting at FESPA Global Expo 2023 in Munich.

Our team of Technical Specialists will be on hand to answer any questions you may have about our most popular CNC machines – the AXYZ TRIDENT, INFINITE, and INNOVATOR Routers. These machines are designed to meet the needs of sign makers and businesses of all sizes, providing the flexibility and performance required to stay ahead of the competition.

Live demonstrations will be taking place on site of the AXYZ TRIDENT 6010 a combined routing machine that is revolutionising the sign-making industry. This innovative machine offers a router-knife hybrid system that allows for the processing of a wide variety of materials, including aluminium, acrylic, foam, and wood. With its advanced technology and precision cutting capabilities, this machine can handle even the most demanding projects with ease. At AXYZ, we are committed to providing our customers with the highest quality products and unparalleled service. We understand that each business has unique needs, which is why we offer customised solutions to help you achieve your goals. Our team of experts is dedicated to helping you find the best CNC machine for your business.

The TRIDENT 6010’s dual-purpose cutting head provides the versatility and precision necessary for creating high-quality signage. The machine can be configured with multiple routing and knife tools, allowing for a wide range of cutting styles and techniques. This feature is particularly useful for businesses that need to produce a variety of sign types, such as letters, logos, and graphics. We are proud to offer the TRIDENT 6010 as part of our comprehensive line of CNC machines.

For those looking for a customisable solution, the AXYZ INFINITE Router is available in a range of lengths and widths, allowing you to tailor the machine to your specific business needs. This machine is perfect for businesses that require flexibility and scalability as they grow.

Finally, our INNOVATOR Router offers standard Option Ready Installation Packages, allowing you to expand the capabilities of your machine as your business grows. With its advanced technology and cutting-edge features, this machine is the ultimate choice for businesses looking to take their operations to the next level.

For more information contact AXYZ : T: 01952 291600

E: enquiries@axyz.com

https://www.axyz.com

Starting a brand new business venture is never easy. Anyone embarking on a start-up company in the last 12 months or so, however, has had to face the added challenges of supply chain issues, the aftermath of COVID and Brexit restrictions.

“It’s certainly been an interesting process,” says Brett Manchett, factory manager of the fledgling Woodcraft World joinery business based in Kettering, Northamptonshire. He continues, “We began trading in early 2022 and to go from zero to where we are now in less than a year is amazing. “Once our directors, Kevin Baker and Andy Hubbard, had made the decision to set up a new joinery business it was a question of how quickly could we get all our ducks in a row ready for launch.

“As a company, we believe the most important piece of the jigsaw is investing in the best machinery available. I’ve been involved in the woodworking industry for over 15 years and during that time I have gained experience of working with a number of the leading machinery brands.

“From the outset we made the decision to buy what we consider to be the best equipment on the market. Without doubt, HOMAG machinery is head and shoulders above the competition. Not only are the machines exceptionally well built, but they are also technically the most advanced and reliable machines money can buy.

“If you want to consistently produce top quality products you need to invest in the best machinery and with HOMAG, that’s exactly what we have done.”

“To create our high performance workshop we wanted a beam saw, an edge bander, a CNC drilling centre and a cabinet press. To achieve this meant working closely with HOMAG to make sure we could get the equipment delivered when we wanted it and all at the same time. This was no easy task, but HOMAG bent over backwards to help.

“They had a SAWTEQ B-200 at a show in Barcelona and were able to secure that for us along with an EDGETEQ S-240 edge bander and CABTEQ S-200 that were available from stock. “The extremely popular HOMAG BHX 050 drilling CNC proved a harder nut to crack; the lead time for a new model from HOMAG didn’t fit with our schedule. After a bit of searching, however, we were able to source an excellent second hand machine which could be delivered at the same time as the new HOMAG kit.”

“I must give a big shout out to the HOMAG engineers who installed the equipment and trained our team. They were absolutely brilliant. Nothing was too much trouble; engineers Ian, Carl and Colin made sure we were totally happy with the machines before they left.

“On the training front they were extremely thorough, running through everything with our four operators,

including parts ordering and machine maintenance. They were so helpful and left no stone unturned which meant we were able to go fully operational almost immediately.

“One of the benefits of the HOMAG equipment is the quality of the software that controls the machines. Whether its woodWOP, CADmatic 5 or other control systems, they are all intuitive and easy to learn. The simple touch screen operation is quick and instinctive to use so our operators can move from one machine to another with ease.”

“Each HOMAG machine has performed superbly; the SAWTEQ B-200 is extremely fast and precise, consistently cutting panels to very high accuracy. Although the edge bander is an entry level machine, the quality of the edge finishing is exceptional and we consistently achieve a really clean finish.

“All this good work can be wasted if the cabinets we make from the panels are not glued and pressed absolutely square. This is where the CABTEQ S-200 comes into its own. It is easy to operate, precise and fast; it enables us to produce finished cabinets which are always true.

“What we’ve achieved as a business in our first year we couldn’t have done without the help of the HOMAG team. To a person, they have a positive attitude and get things done. If issues occur, most are sorted out online. If an engineer has to come out, however, they are usually with us inside 24 hours. We couldn’t be with a better partner,” concludes Manchett.

If you would like a demonstration or further information about HOMAG woodworking machinery and software, please contact Adele Hunt at HOMAG UK

Following the astounding success of two new circular saw blade grinding machines launched by VOLLMER last year, the saw blade sharpening experts are delighted to now present the new Loroch TWIN 860.

The revolutionary new Loroch TWIN 860 is a space-saving concept with a compact 2000 by 1250 by 1980mm footprint that introduces two different grinding processes in a single machine tool. This gives the end user a machine that can process both carbide tipped (TCT) saw blades for the wood, sawmill and metal cutting industries, as well as HSS, saw blades primarily used in the metal cutting sectors.

With the introduction of a fifth axis, a vast selection of TCT blades can be processed in addition to the common metal cutting circular saw blades. As with all Loroch machines, the new TWIN 860 machine grinds with the saw blade rotating. In each case, the grinding process consists of a precise, controlled movement of the grinding head and rotation of the saw blade with both axes controlled simultaneously in complete synchronicity.

HSS circular saw blades from 60 to 860mm can be sharpened and re-cut on the new TWIN 860 machine and automated chamfering is possible from diameters of 75mm and above. With HSS saws, the rake and clearance angles can be freely selected and this grinding process also permits the processing of solid carbide saw blades, friction saws and TK or TA saw blades such as carbide or cermet tipped thin kerf blades with chip guiding notches. This flexibility provides a remarkable range of opportunities for end users.

For the sharpening of TCT saw blades from 145 to 700mm diameter, the TWIN 860 has a secondary grinding process

whereby the tooth to be ground will remain in a stationary position with grinding performed exclusively by the grinding head. The feeding of each tooth is undertaken by the ultra-precise centre drive that intuitively identifies any pitch differences in the saw blade and automatically processes any irregular pitch patterns in the saw blades. In both grinding processes, complete machining is performed with only one DIA or CBN peripheral grinding wheel (14F1) in each case.

The benefits of the new TWIN 860 go far beyond the ability to undertake both fixed position and rotary processing of the HSS and TCT saw blades through its five servo-driven axes and the ability to detect and process different saw blade pitches. The flexibility of the TWIN 860 enables end users to process everything from straight back teeth, peg teeth, friction teeth, curved back teeth with chamfer, solid carbide teeth as well as TK saw blades and tooth shapes that include 301, 302/303, 304, 311 and many others. The multi-purpose machine also has an exceptionally high angular precision level, which is a benefit of the ultra-stiff machine base that minimises vibration and the extremely powerful blade clamping system – both attributes that enhance surface finishes and edge quality.

From a user-friendliness perspective, programming is fast and effortless with the touchscreen control that provides easily understandable symbols that intuitively direct the operator through the process. To further simplify operation, the TWIN 860 automatically suggests favourable machining data to guide the user. Furthermore, grinding wheel mounting is automated to minimise setup times. Possible operating errors are reduced to a minimum. For the machining of HSS circular saws, it is possible to

pre-programme saw blades to separate the machine programmer from the operator. The operator only has to clamp the respective saw blade, close the door and press start – another feature that minimises operator errors.

From a saw blade perspective, the TWIN 860 offers a chamfering angle of 75° for HSS saws and 145mm for TK and TCT saws with a tooth pitch of 1 to 40mm on HSS and TK saws and 6 to 60mm for TCT blades. The machine is capable of processing chamfer/bevel angles up to 45° and can grind blades with a maximum blade width of 8mm.

Joinerysoft’s ever evolving software has made life easier and more profitable for over 1100 customers - the choice for software in any company is simple. Don’t take our word for it - why not take our customers words for it - check out our full archive of articles on our website. Just a few of the articles available on our website: JMS 3D Pro enabling JCK Joinery/Unity Group to grow after 150 years in business

Serving the industry for over 150 years, JCK Joinery, now part of the Unity Group, decided to upgrade their in-house systems and JMS 3D Pro was the answer they were looking for. Wignall’s Fire Door expansion aided by Joinerysoft’s Commercial Door Software Trading since 1998, Wignalls is a family run business with a strong focus on quality. Their wide product range includes bespoke joinery as well as cubicles, and more recently fire doors. Wignalls bought into our JMS 3D Pro software to help take their new fire door manufacturing business to the next level. On the cutting edge: JMS now controls five-axis pod & rail CNC James Tanner, a relatively small joinery company, invested heavily in technology to take their business to the next level with a SCM Accord 25 fx five-axis pod and rail CNC machine and to power that, they bought our JMS Pro software. Our 3D Pro software controls all aspects of the machine allowing James to go swiftly from quoting to manufacturing without having to leave the software. Software proves essential for small Dorset joinery business.

If you’ve ever struggled to justify the cost of software for your joinery business, then read about James Selby who runs a small joinery business in Blandford Forum, Dorset. After two years using Joinerysoft’s Joinery Management Software (JMS), James says, “to be honest, I don’t think I’d want to run a joinery business without JMS now!” JMS saves 75% of time when quoting at M B Joinery.

As a small joinery manufacturer, Martin Birt of MB Joinery, found the initial outlay to purchase quoting and production software hard to justify. One year, after he took the plunge and purchased Joinerysoft’s Joinery Management Software (JMS), he’s found that the business is busier than ever, with time savings and professional quotes by JMS helping him win more work and enabling him to spend more time in the workshop and less in the office. Joinerysoft software streamlines paperwork at Churchview Joinery - swamped with paperwork and working all hours is a common dilemma for many joinery manufacturers. Churchview Joinery decided there had to be a better way and explain how software has given them more time to move their business forward. Joinerysoft software complements traditional valuesTomlinson Parbans has a long history with Tomlinsons which was established in 1850. Nearly fifty years ago it combined an established timber yard with a workshop for bespoke joinery to become Tomlinson Parbans. The company expanded very quickly and the workshop has been built on traditional values which has a reputation for high quality craftsmanship in the Cheshire area. You can read about how our JMS 2D software helped them take their business forwards and all the aforementioned articles and many more covering our 17 year journey on our website www.joinerysoft.com/news/

Do you have Joinery & CAD experience? Why not join the Joinerysoft team and help companies grow with the help of software. We’re currently looking for someone with joinery and CAD experience to join our team - it is a very exciting, diverse and dynamic role that involves configuring and training on our JMS systems. Fancy a challenge and think this could be you? Check out our vacancies page on our website

www.joinerysoft.com/vacancies/