PROJECT

Autors

Paula Alfaro Arce

Ana Regina Salyano Vargas

Joseph Alexander Sánchez Mandujano

Instituto Tecnológico y de Estudios Superiores de Monterrey (ITESM)

Escuela de Arquitectura, Arte y Diseño (EAAD)

Participatory Architecture of Medium Complexity (Gpo 601 QRO 2411)

Semester February - July 2024

Professors

Miguel Anaya Díaz

Viviana Margarita Barquero Díaz Barriga

Roberto David Cevada González

MsC Urb MAR Diana García Cejudo

Pedro Mendoza Hernández

Rodrigo Pantoja Calderón

Andrea María Parga Vazquez

INDEX

PART ONE. INTRODUCTION

PART TWO. SITE ANALYSIS

PART THREE. MAIN PROJECT

PART FOUR. MAIN SYSTEMS

PART FIVE. ENERGY EFFICIENCY

Our biggest gratitude to not only our teachers and professors, but also to Kent State University for the continuos proudness and insights.

Your support and appreciation will be our guide to become better architects everyday, and your kindness as an unconditional way of loving architecture.

Paula, Joe and Ana Regina.

PART ONE. INTRODUCTION

Introduction

Vallejo is the city that contributes 4.7% of national manufacturing in Azcapotzalco, becoming the area that generates 46,000 jobs according to SEDECO. We recognize that urban infrastructure is a vital part of cities and is necessary for new developments and intelligent systems.

The energy transition enters joins into the topic within the production of this industrial city. It has been mentioned that “it is estimated that in the future, generating clean energy will not only be good for the environment, but that it will be accessible to all social classes and the investment in use will be appropriate” since most cities occupy only 2% of its territory to represent 76% of the energy demand in producing cities. Despite these figures, Vallejo does not have sustainable, open, and welcome spaces.

And it is NO exception for the number two most carbon-polluting industry in the world, after the oil industry, Zara, industry located

in Vallejo.

According to Greenpeace, the pollution generated by clothing production is approximately five hundred thousand (500,000) tons of microplastics per year that go directly into the oceans.

This are bad news, despite considering itself a company focused on caring for the environment and a sustainable production, in countries like Asia and Mexico, they cause devastating pollution in the air and water. What’s more, 85% of textiles end up in landfills and release hundreds and thousands of micro plastics into the ocean every year, since the corporation, now INDITEX, including Zara, Pull&Bear, Massimo Dutti, Bershka, Stradivarius, Oysho and Zara Home offer more than 24 collections a year, which means it produces two to three times more carbon in the production of cotton and polyester.

But let’s not only think about the environmental impact that this problem is causing, the conditions of the workers are the same, or worse, due to labor exploitation, and in Mexico it is no exception in establishments of this company that are not even factories or productions.

Group Manifesto

The group's manifesto highlights the disproportionate impact of climate change on the global south, which can be seen as a crisis of energy injustice. Countries like Mexico experience slower progress in decarbonization due to political constraints, low economic flexibility, insufficient energy infrastructure, or reduced access to innovation.

Cities consume 75% of global energy generation, so the question is how they can effectively follow the path to transition.

When properly addressed, this urgent effort can significantly impact social, political, economic, environmental, urban and energy sectors everywhere.

Industry, Stop Greediness

That invites the facilities to the forum of energy efficiency and business collaboration.

Unleash Earth’s Power

Talks about reducing dependencies on extreme energy sources and water consumption.

Power to the People

Which talks about promoting a community environment where people participate in sustainable energy projects.

Intervene and generate an area within an industry, generating 70% of sustainable energy that is lost in Vallejo because making changes is imperative if we want to advocate a sustainable energy paradigm, adopt not only an energy transition, but also adopt the SDGs of quality of life and product.

The answer lies in the energy transition. How much carbon dioxide can the operation of this intervened building save? How efficient can it be? We generate a scale from 5.6 tons of carbon dioxide per year to 3.7 tons per capita, being a friend of the climate according to the CLIMATE HERO CARBON FOOTPRINT scale. We also invite other industries to join the movement.

Main Goal

Recognizing our main objectives and areas of opportunity, a potential analysis was carried out in Vallejo and the next property was chosen, which is a ZARA INDITEX warehouse. The fashion industry produces around 10% of our annual carbon footprint.

INDITEX offers more than 24 collections a year.

32.8% of land use is allocated to parking lots and operational patios.

We generate a scale of 5.6 tons per year of carbon dioxide.

Where Can It Go?

Industries Analysis

ZARA INDITEX, currently a storage-only center within Vallejo, is no exception to these conditions. Receiving criticism for the state of its facilities, good quality of life but poor pay and nothing has been done to make the facilities a center of commitment and inspiration for other large companies, despite being well known.

- State of the facilities: The ZARA INDITEX facilities in Vallejo have received criticism for their state. There are issues with the physical condition of the facility, which could include issues such as cleanliness, maintenance, or infrastructure.

- Quality of life and salary: Although the quality of life in the facilities may be good, salaries are low. This indicates a disparity between working conditions and remuneration, which could be a source of dissatisfaction for employees.

- Lack of commitment and inspiration: Despite being a recognized company, nothing has been done to turn the facilities into a center of commitment and inspiration for other large companies. It demonstrates a high lack of initiatives to improve the image and impact of the company in the community and the environment.

- Environmental impact: Mexico City is one of the most polluted cities, and starting a change from there could improve the vision of other producers with high levels of carbon emissions. This suggests criticism towards the lack of action by ZARA INDITEX to address its environmental impact, especially considering its position as a globally recognized company.

Carbon Storage

Carbon Sequestration

Carbon

Storage

Carbon StorageReforestation of areas, planting and improving plant use practices to increase the absorption of CO2 by the soil.

Use of CO2

Conversion to fuels: The captured co2 is converted into synthetic fuel through processes such as electrolysis. Chemical Production: Using co2 as a raw material for the production of plastic, its use of co2 in cement and construction materials.

Clean Energy Production

Bioenergy, using biomass and through a system of burning and releasing the carbon previously absorbed by plants

Textile Reuse

Encourage the reuse of garments to reduce the need for new production, without demand, there is no supply.

Carbon Sequestration

Direct Capture DAC (Direct Air Capture) with biopanels and vegetation, it is extracted directly from the air. Store through dioxide sequestration technologies in underground geological formations

Life cycle design: Buy consciously with an approach to recyclability and reuse until the end of its useful life.

PART TWO.

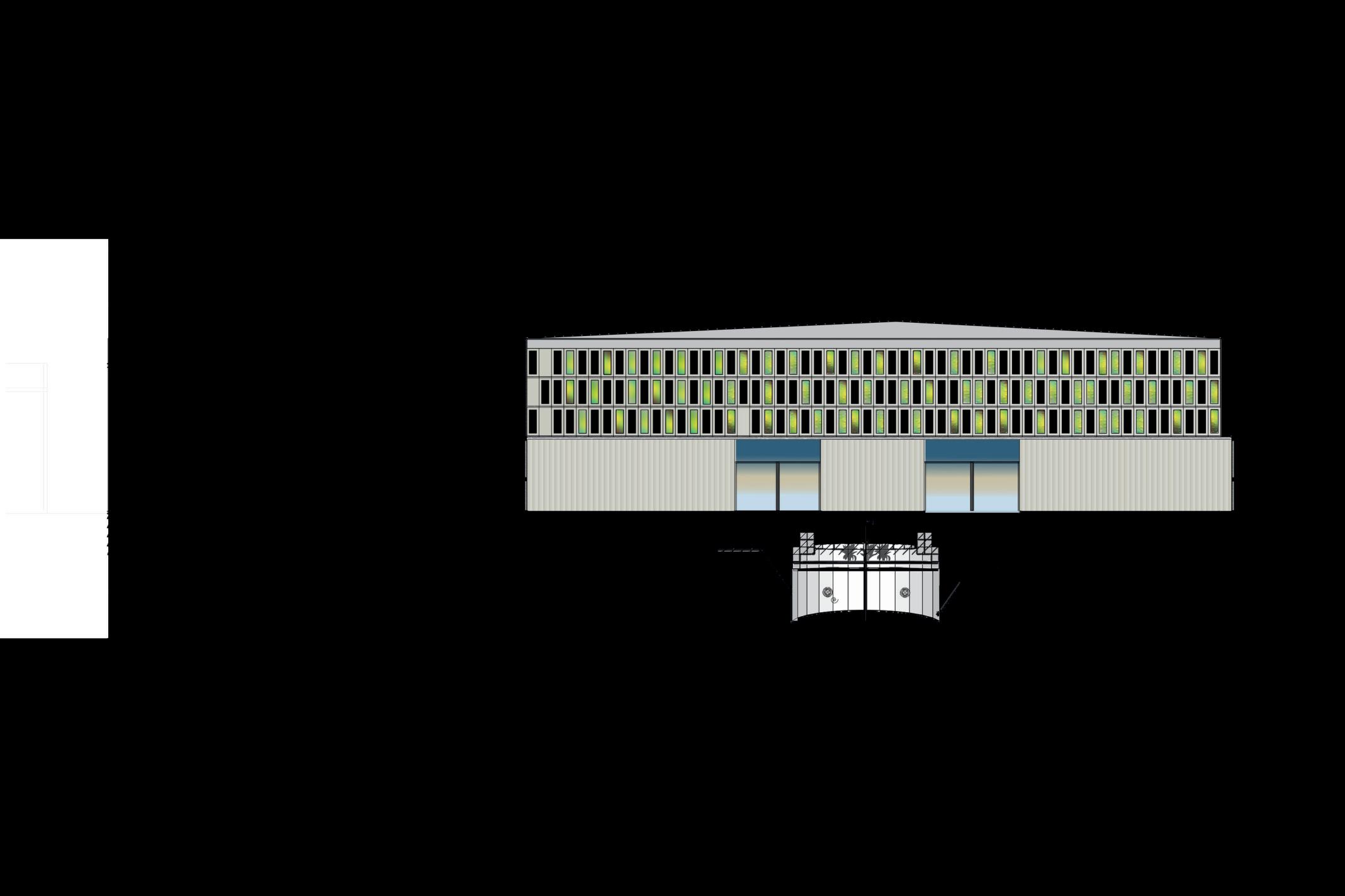

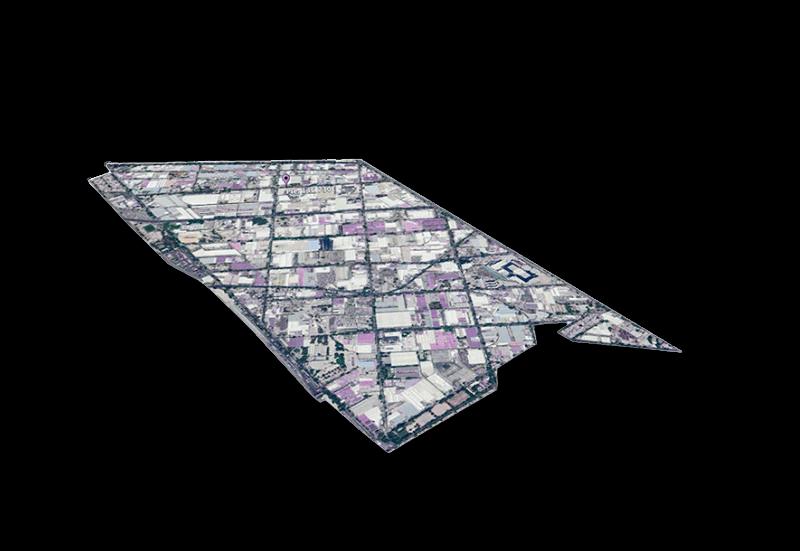

Our zone is located in the North of Vallejo, two streets lining the main street: Pte. 146 730, Industrial Vallejo, Azcapotzalco, 02300 Ciudad de México, CDMX. It completes with our objetives with the textile industry since it is actually the main one, while there is another but it’s only a store.

Front View

Front View

Right View

Right View

Site Analysis Before

We found opportunities with the movement of people, since it is a very busy area as it is a reference point for many jobs, residential houses in the north of our property, as well as challenges in eliminating noise and odors from the factory of flour and paper, in other words a reference point to invite people, not only workers.

Main External Circulation

Bioclimatic Facts

Sunshine from east to west, with more intense heat at 12am.

Temperatures of up to 33 degrees Celsius in the station closest to the study area.

Low porcentaje of green and in need of green zones.

Opportunities

Reducing the original heat that the zone phases by adding case studies in which an energy transition is explored:

BIG HOUSE

Splitterwerk and Arup

Hamburg, Germany

Real state development

Covered with microalgae that generates renewable energy in the process.

in Hillerød The New North Zealand Hospital (2014)

space that leds to the exploration of green areas.

Symbology

Green Zones

Zara INDITEX Vallejo

Temperature Maintenance

Copenhagen Green THE PLUS (2022) Magnor, Norway Furniture factoryPARKING LOT

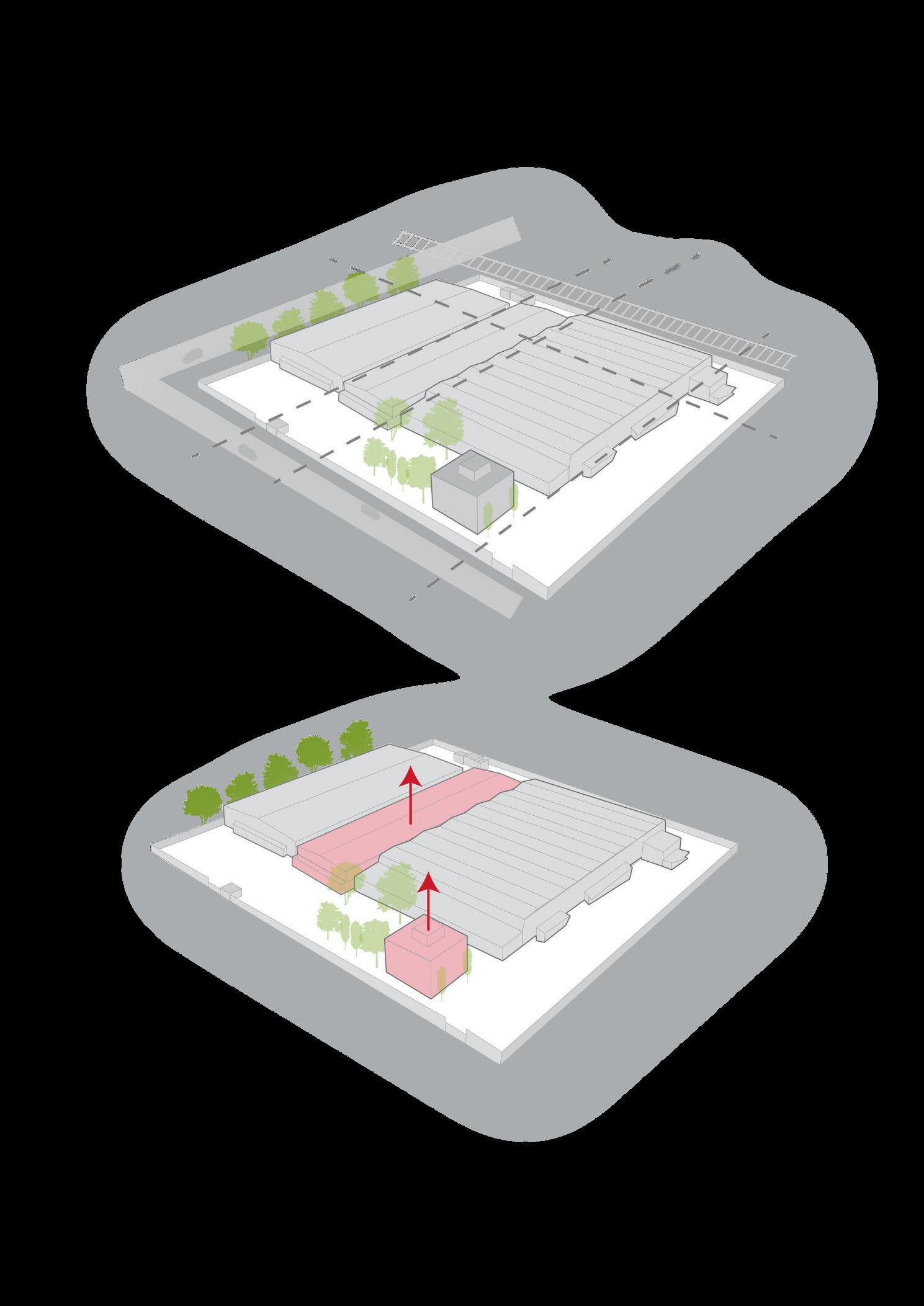

(ORIGINAL VOID)

WAREHOUSES

OFFICES

Our property has dimensions of 195 meters deep by 170 meters wide, it has the main void which is the parking lot for trucks and cars, three warehouses and some offices.

Symbology

Original VOID

Warehouses

Vehicles and Trees

Obligatory Circulation

External Circulation

Massing

Eliminate the offices and central warehouse for

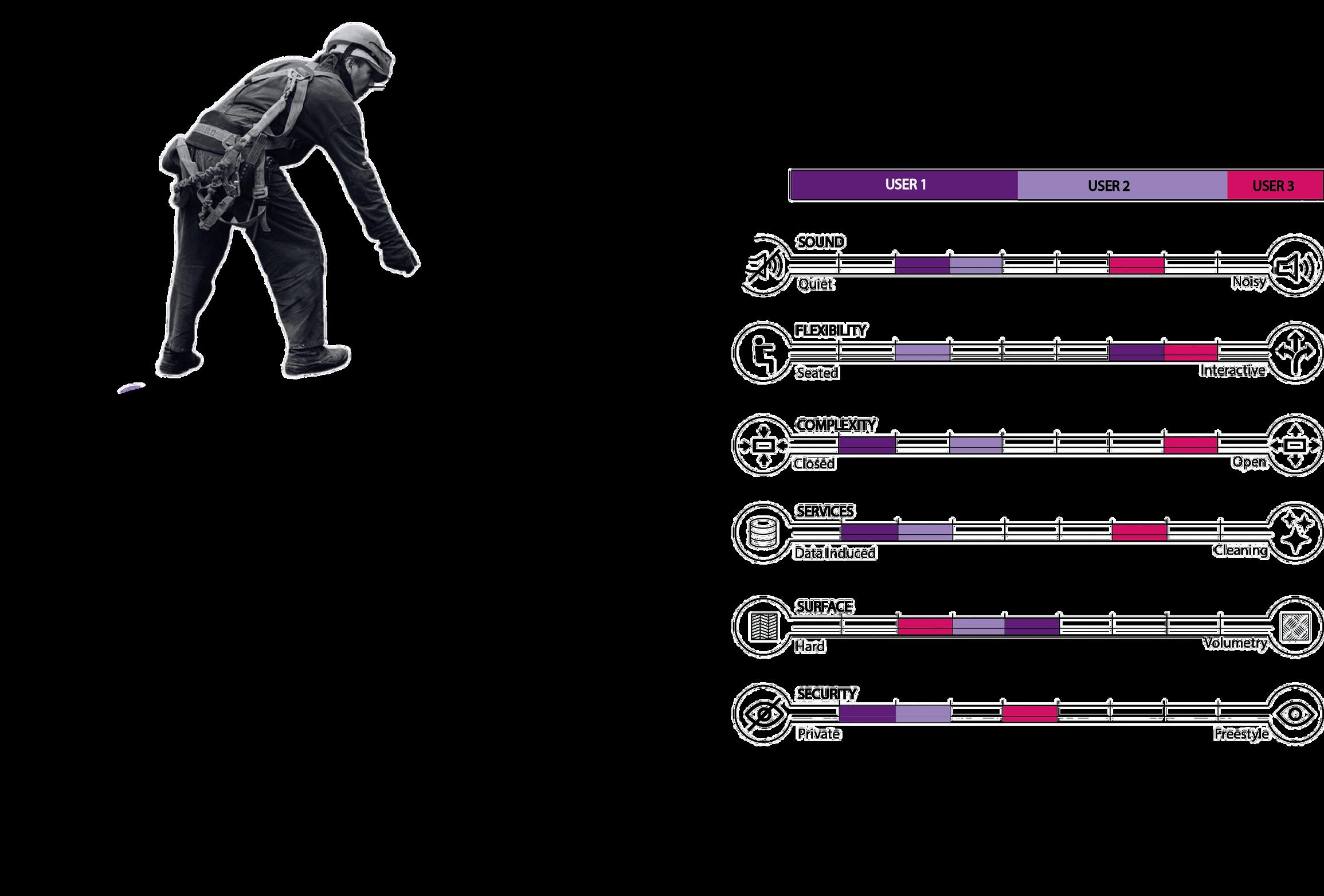

USER 2: AGENTS

Finance, operators and storage administrators of ZARA INDITEX, ages from 35 to 56 years old, limited working space.

USER 1: WORKERS

ZARA INDITEX Machinery

Operators, ages between 30 to 45 years, with working hours of 8.

USER 3: OUTSIDERS

Relatives of ZARA INDITEX workers, focused on sales and commerce of products, ages between 30 to 45 years old.

CLIMATIC

ETHICAL AUTONOMY

ENERGETIC

FINANCING

CO2 reduction, fauna recovery, temperature regulation

clean technologies, green and cooperative uses of energy space for commerce and rest, citizen aid, space for culture self-sustainable, company identity

affordable, sustainable vision of zara

We are open to the exploration of different strategies, not only coming from the energy transition side, allowing our zone to be fresh, innovative and introduces a sense of autonomy for our workers, and the final payment of the project.

This allows other factories or companies to follow this new kind of productions for a space where work and clients collide as they compete with each others necessities. The strategies we introduce as also part of our group’s manifiesto.

PART THREE.

Description

A decarbonized district that meets different factors, the main one: reducing carbon dioxide without damaging Zara's profit by inviting Vallejo into a more social value focus, and is a new way of generating energy through the following strategies.

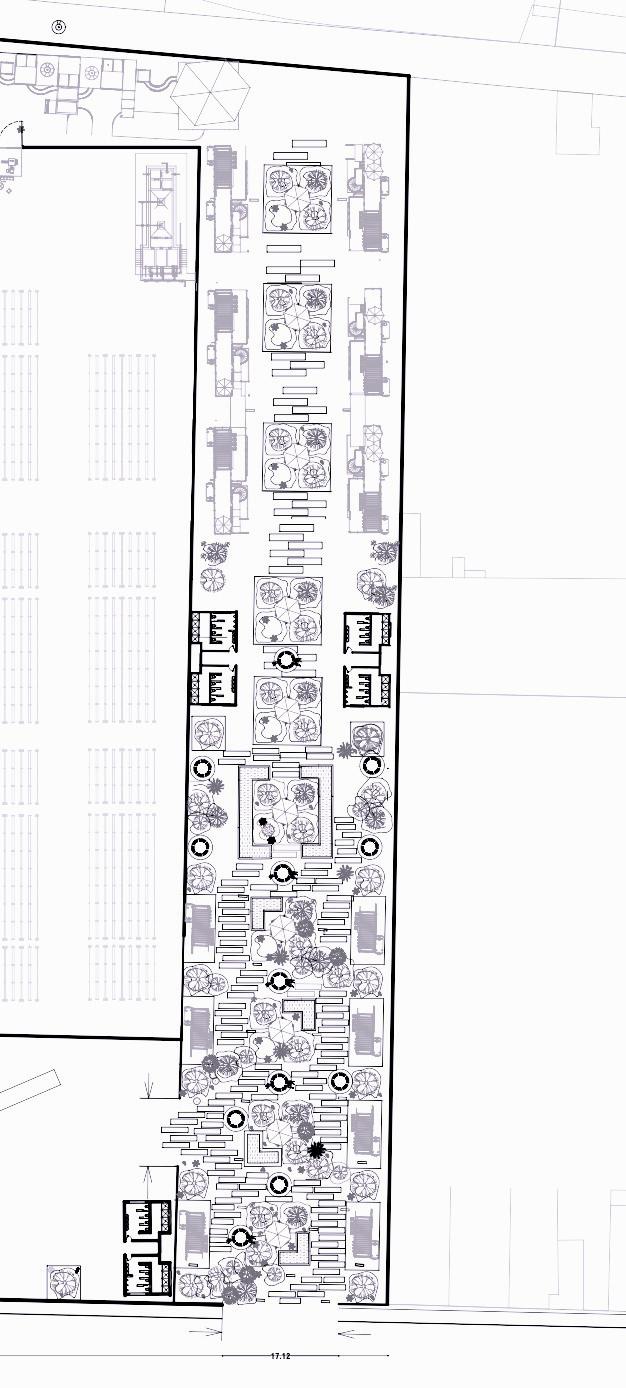

Measures: 32,009m2

ESC. 1.150

Locations Outside

Don’t get lost in our multiple zone warehouse intervention, the space is simple but has a lot to offer to people and ZARA INDITEX.

Circulations

Our zone is open to Vallejo’s citizens, ZARA INDITEX’S workers and informal salesman, as well as passengers that have the obligation to cross through ZARA INDITEX space.

Clean Energy Production

Carbon Cycle Carbon Storage

Carbon Sequestration

The concept of "carbon cycle efficiency" refers to the effectiveness with which the natural carbon cycle, comprising various reservoirs and processes, transfers and utilizes carbon among different components in our site:

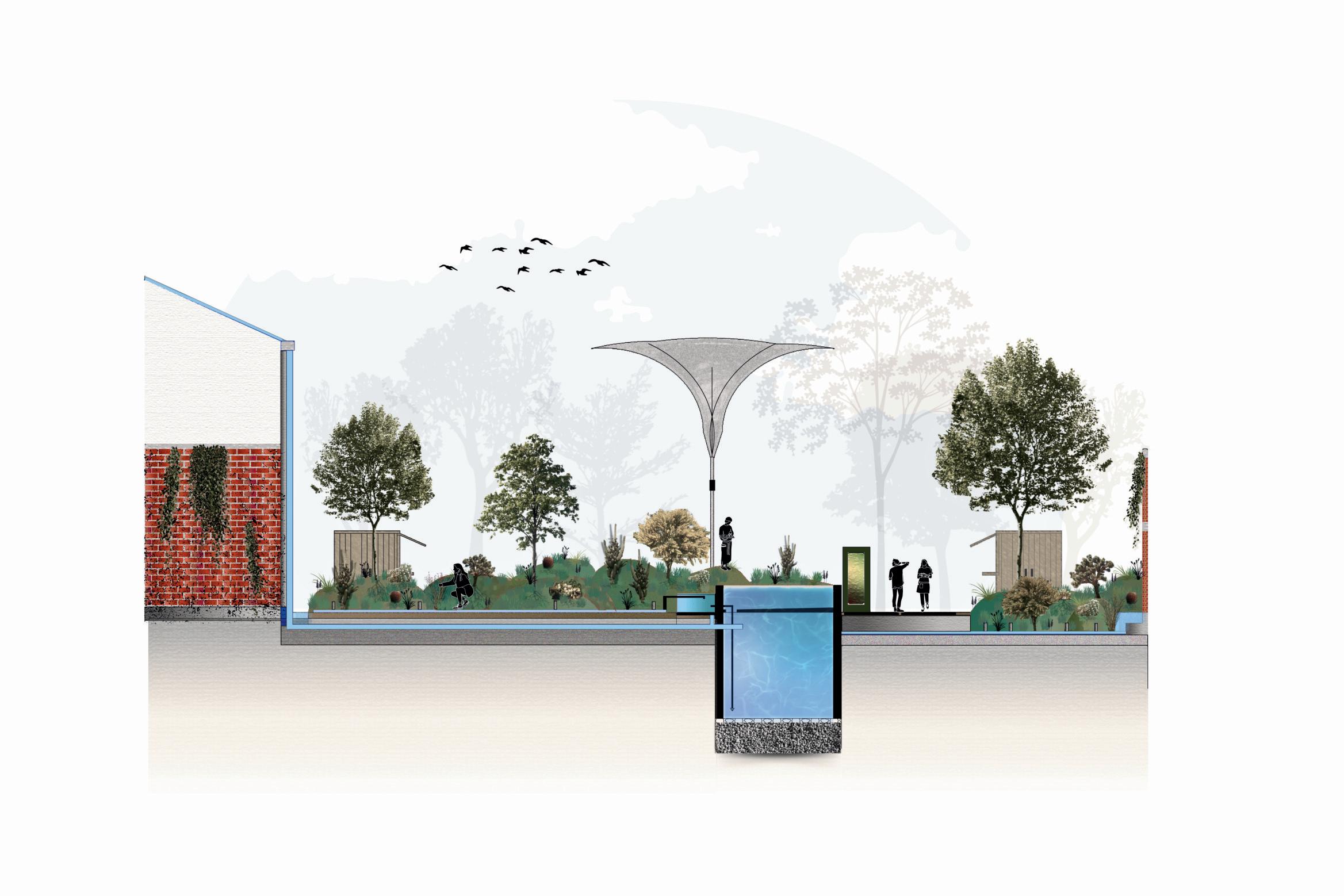

LA VAGONERA

Measurements: 280m x 30m

“Urban Green Areas contribute to improving the urban image, beneficially modifying microclimates, increasing vegetation cover with plants and trees, reducing pollutants in the atmosphere, in addition to minimizing the effects of climate change.”

(Secretaría del Medio Ambiente y Desarrollo Sostenible, 2023)

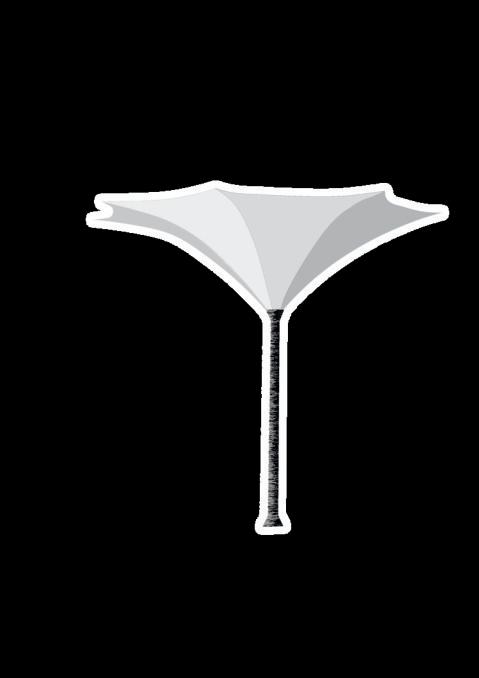

The heart of our project: The Vagonera, where we introduce not only workers, but outsiders, tourists, passengers and informal workers into a space where different technologies collide to a new experience, where you can buy, sell and relax while you help the environment.

Topsoil Mound

Sprinklers Located in the south of our property, we implemented a new way of generating oxygen without eliminating the pavement, turning it into a source of energy, oxygen and water collection while the user interacts with the technologies. Bathrooms

CaptaAguas: It works to collect and purify rainwater during the monsoon to provide drinking water and solar energy during the rest of the year. It can occupy an area of no more than 1 square foot and provides almost 360 square feet of catchment.

[1 - 4 horsepower per pump for constant pressure irrigation siren

The pump consumes at least 60 or 70 kW on average, to pump between 200 and 250 m³/hr, depending on the working pressure

Solar accessory with slope

Physical Filtration 20 microns

UV & Activated Carbon Filteration

Physical Filtration 20 microns

Ground socket

Horizontal drainage

ABS Plastic Pipes Steel

UV & Activated Carbon Filteration

Physical Filtration 20 microns

Ground socket

Horizontal drainage

ABS Plastic Pipes Steel

Topsoil Mound: The earth mounds are designed to prevent contamination of existing ZARA INDITEX concrete and encourage the natural circulation of serophilous roots and plants. It allows visitors and workers to move around as well as a unique space to relax.

Yucca brevifolia

Natural Soil Filling

Tree’s Roots

Pavement (Concrete)

Cimentation

Mixture of Soils

Natural Soil Filling & Natural slope stabilizer

Original Pavement made of Concrete

Black Soil1.

Chinese Stone4. Steel Grill

Waterproof vapor membrane

Yucca brevifolia

Natural Soil Filling

Tree’s Roots

Pavement (Concrete)

Cimentation

Mixture of Soils

Natural Soil Filling & Natural slope stabilizer

Original Pavement made of Concrete

Black Soil1.

Chinese Stone4. Steel Grill

Waterproof vapor membrane

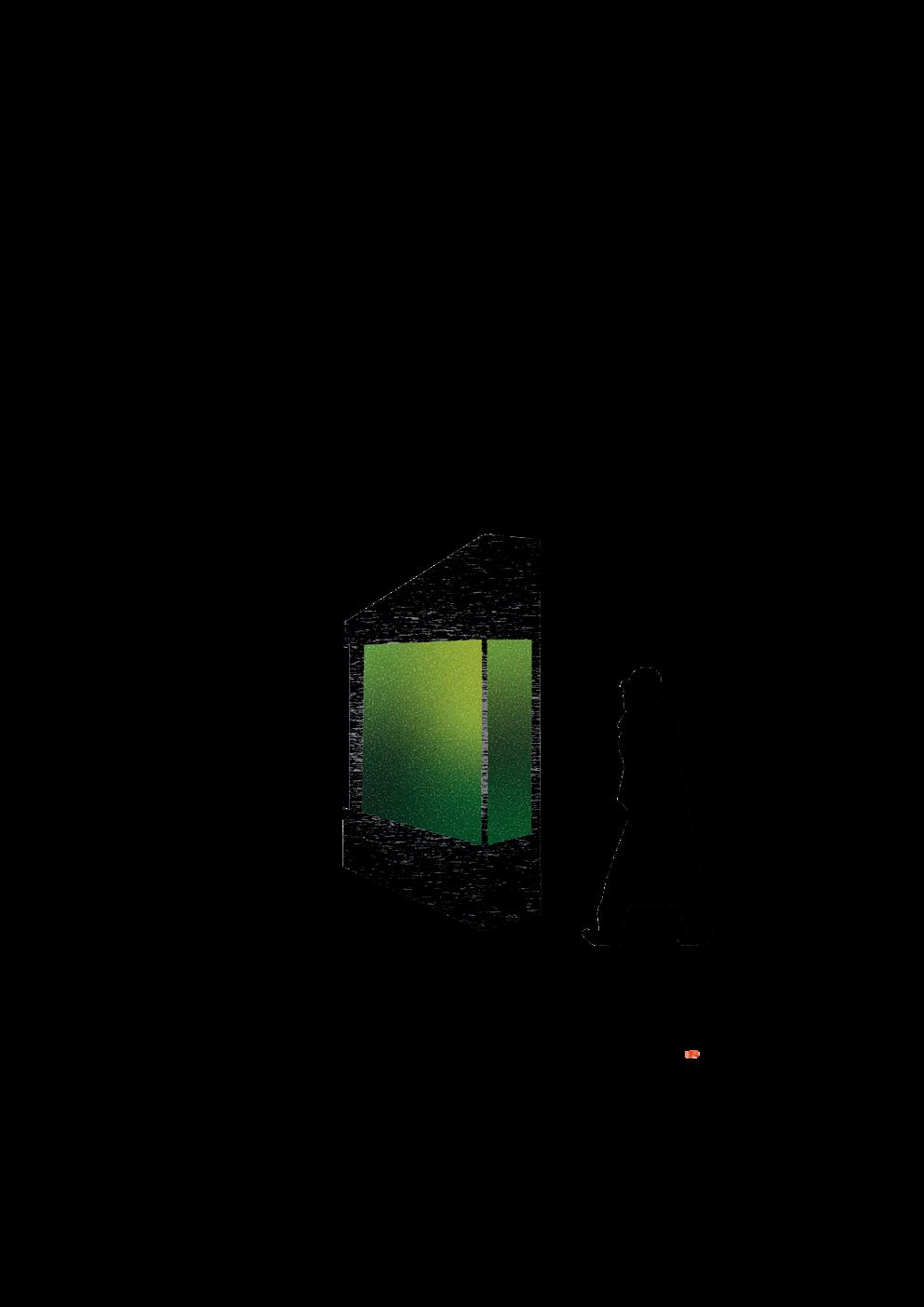

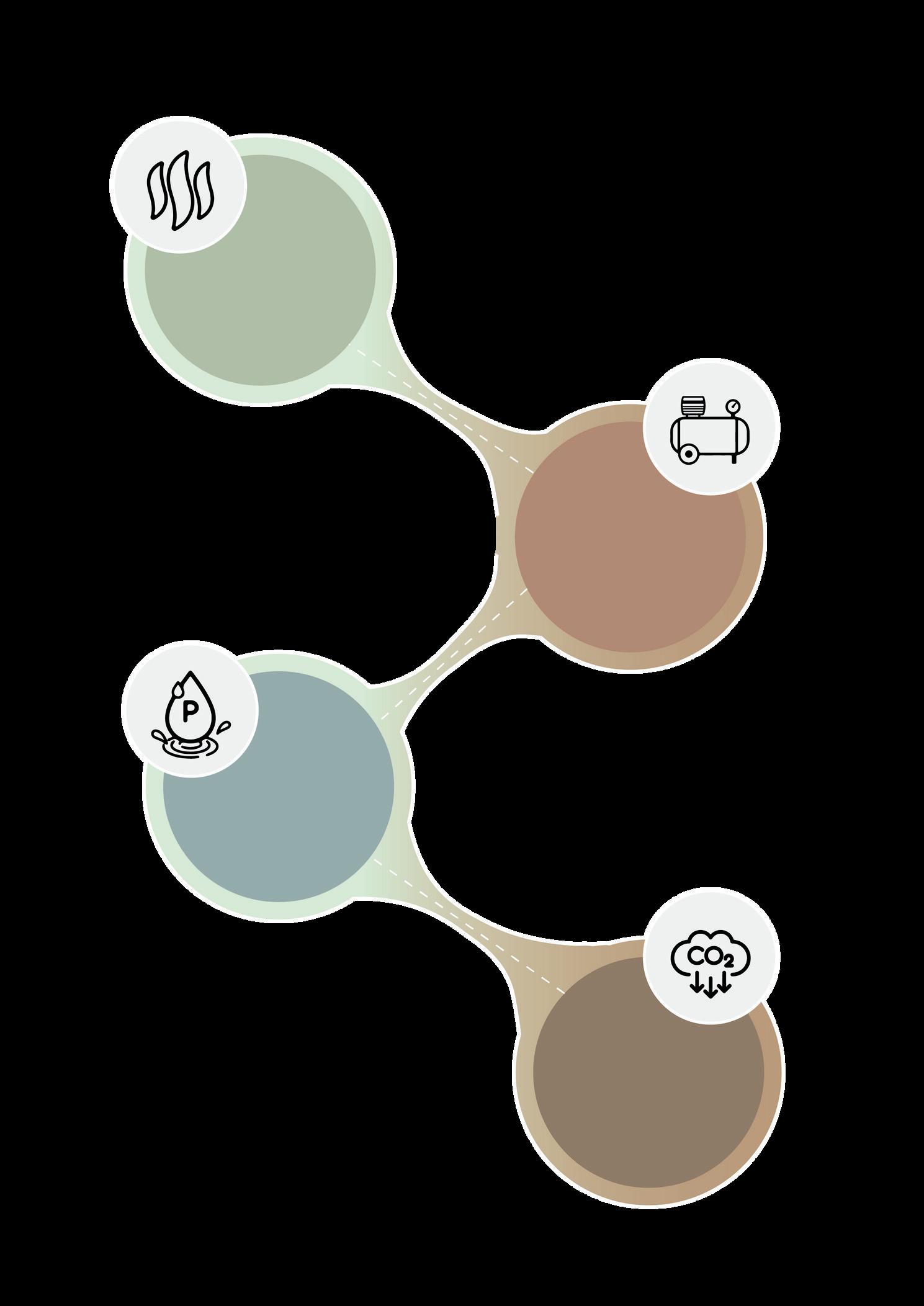

Algae Bio-Panels: A liquid tree is the solution to purify the air in large cities that cannot plant a large number of trees.

It is presented as an 'urban photo-bioreactor' that basically consists of a tank that houses a massive population of microalgae, diluted in 600 liters of water that acquires their characteristic green color.

Along with oxygen, the photosynthesis of microalgae leaves a certain amount of biomass as waste that can also be used as fertilizer.

biomass is extracted when carrying out maintenance and cleaning of the tank, something that can be done once a month.

Microalgae capture CO2 present in the nearby air and, through photosynthesis, produce clean oxygen that they return to the environment. Sunlight, the other major component of the process, comes directly through the glass walls that make up the tank.

Algae & Heat Exchanger

compressed Air (Nitrogen)

Phosphorus and Water

Building protocol:

Carbon Dioxide

Aluminium Unibody Box (25m x 0.7m)

Carbon Dioxide

Aluminium Unibody Box (25m x 0.7m)

Why algae bio-panels and not a tree?

The establishment of zero- or even surplus-energy buildings and technology represents an ambitious and forward-thinking objective within the realm of sustainable architecture.

It underscores a commitment to reduce energy consumption and to create buildings that generate more energy than they use, thereby contributing positively to the environment.

Our goal: to exploit the storage advantages of biomass to further this sustainable vision.

Biomass, particularly when derived from sources such as microalgae, offers a promising avenue for energy storage and generation.

One of the significant advantages of utilizing microalgae lies in their simple, unicellular structure, which facilitates rapid biomass production. Unlike larger plants, where only a fraction of the cells are actively engaged in photosynthesis, microalgae's single-cell configuration allows every cell to participate in the process of converting light into chemical energy.

When algae reproduce, they give off heat, which means that on a sunny day the water in the bioreactor can reach 100 degrees.

The air is compressed under the panel so that the algae can breathe and continue with its photosynthesis.

The food supply comes from the tube that escapes from a generator on the ground floor

The water is designed so that it is always generating heat and that the algae does not die.

Algae & Heat Exchanger Compressed air Phosphorus and Water Carbon Dioxide

Sale Containers: Our site warmly welcomes the commerce and sale activities conducted by external vendors, creating a vibrant marketplace atmosphere. This inclusion enriches the variety of offerings available to our visitors and supports local businesses and artisans.

Additionally, we designed our space to include a serene dining area, where guests can indulge in delicious meals and refreshments. This tranquil setting enhances the overall experience, providing a perfect backdrop for relaxation and enjoyment as visitors spend time inside the vagonera. Whether shopping, dining, or simply unwinding, our site offers a harmonious blend of activities and ambiance for everyone.

Concrete Sheet

Reinforced Steel

Aluminium

Unibody

Concrete Sheet

Reinforced Steel

Aluminium

Unibody

Reducing the original heat that the zone phases by studies in which an energy transition is explored:

Second Floor Dining Room

Algae Panels

Commerce

Site Existent Wall

Topsoil Mound

Concrete Existent

Algae Panels

Commerce

Site Existent Wall

Topsoil Mound

Concrete Existent

TEXTILE CENTER & PARKING LOT

Measurements: 80.26m2 x 56.18m2

“We consider chemical dissolving to be the most significant future method of circulating textile raw material.”

(Lindström Group, 2024)

Initial area of our property, inviting outsiders to a unique experience by reusing their textile products as a form of new energy.

Textile CenterAlgae Panels

Located in the north of our property, our main focus is the reuse of clothing and accessories by inviting others to join the textile center in a more colorful and safe path.

Anaerobic Digestor

Anaerobic Digestor

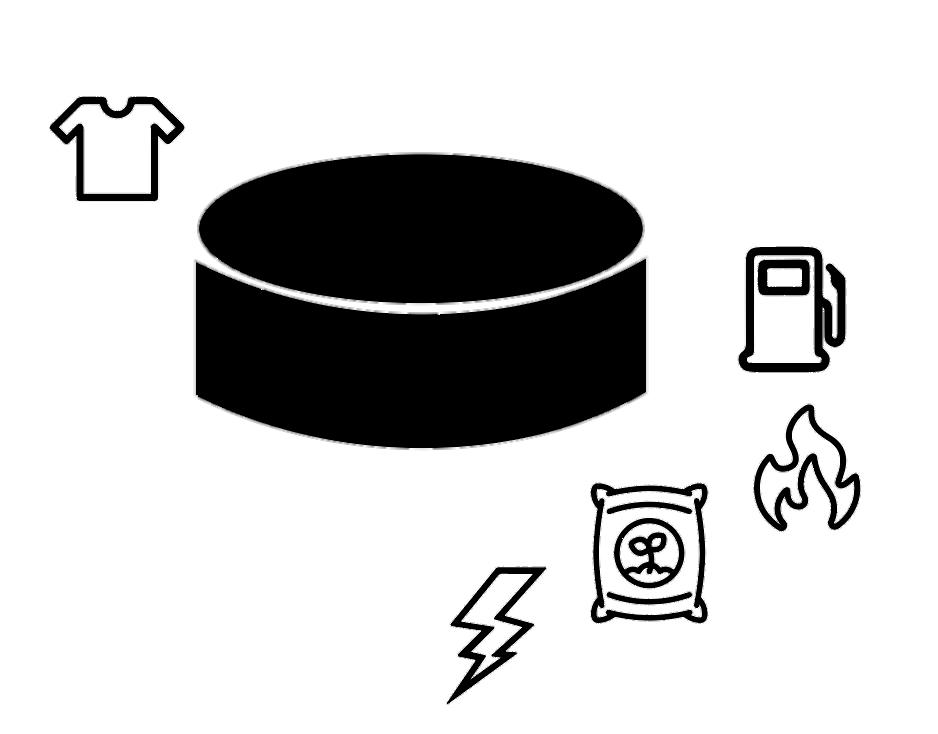

Anaerobic Digester: Works as a closed system designed to decompose organic matter in the absence of oxygen through the action of anaerobic microorganisms. This process generates biogas, a mixture of methane and carbon dioxide, and a digested residue that can be used as fertilizer.

In the context of the textile industry, waste natural fibers such as cotton, linen and wool can be processed in anaerobic digesters to generate biogas used for:

Energy for vehicles

Heat

Fertilizer

And mainly, it can be used to generate energy within the textile plant itself, reducing dependence on non-renewable energy sources and reducing operating costs.

By converting organic waste into biogas and fertilizer, the environmental impact of the textile industry is reduced, promoting sustainability and the circular economy.

The anaerobic digester is strategically located under the concrete of the property, taking advantage of the natural slope and design of the land. This location allows gravity to play a crucial role in transporting the waste to the digester, eliminating the need to install and maintain an additional electrical system for this purpose.

Thanks to this configuration, waste flows efficiently and continuously into the digester without requiring mechanical intervention, significantly reducing operating costs and energy consumption.

Original Pavement made of Concrete

Base Platform

Mixing System

Feeding System

Biogas Collection

Liquid Treatment

Digestion Tank Heating System

ABS Plastic Pipes Steel

Original Pavement made of Concrete

Base Platform

Mixing System

Feeding System

Biogas Collection

Liquid Treatment

Digestion Tank Heating System

ABS Plastic Pipes Steel

Biogas system

Discontinued textiles, which can include clothing, fabrics and other similar products, are collected and prepared for treatment..

Preparation of materials

Microorganisms break down textile macromolecules into molecules and convert them into fatty volatile acids.

The remaining material, known as digested, is a mixture of partially digested substances that can be additionally treated or used as organic soil mixture, depending on its composition and level of toxicity. Digestive Management

This is where specialised microorganisms transform intermediate products (acid, carbon dioxide and hydrogen) into metanoic acid (CH₄) and carbon dioxide (CO₂). This turns out to be the main component of biogas, which is a source of renewable energy.

Propane gas hose x 30m 200 gallon tankAlgae Panels in Textile Center & Offices: These panels, made of green fabric from the biomass contained in their interior, have various functions. They capture a carbon dioxide current which would otherwise be an emission source, and make bubbles through impregnated water with selected seaweed bowls. The algae absorb CO2 and solar light, photointensifying it, increasing its mass and generating fresh oxygen. The more solar light is available, the algae will grow more quickly, capturing approximately two amounts of carbon dioxide per amount of algae.

These panels also retain heat in their water. Firstly, when installed outside, the building is overshadowed by the reduction in energy consumption of conditioned air in the summer. Second, the heat can be detected, just like the biomass. The biomass generated is periodically filtered as pulp, which is then transferred and processed into biocombustible material, which is then transferred to the building and used in the boiler to replace the hot water system. Thanks to the biomass combustible material and the heat captured from the water in the panels, the building can sustainably cover almost any of its energy needs for water heating.

WAREHOUSES & PARKING LOT

Measurements: 130m2 x 72.84m2

“In the rapidly evolving world of logistics and supply chain management, sustainability has emerged as a key driver of innovation and efficiency. With the increasing awareness of environmental impacts and the growing demand for greener practices, the focus on sustainability in warehouse operations has never been more critical.” (Jakob Josten, 2023.)

We reuse the existent warehouses and make them a more efficient, energysolving system that allows new technologies, workers and future for ZARA INDITEX.

Storage Shelves

Energy regulation machines

Inside the Warehouse

This storage facility consists of robots or machines for handling and controlling the stock and its functionality is carried out through the use of specialized software.

Reception area

1.100

How is the warehouse built and why do we maintain its form?

The construction sector produces massive adverse impacts, both directly and indirectly, on the environment.

This industry, vital for the development and growth of companies, is likely to contribute significantly to the environmental degradation due to its practices and processes. The impacts of construction are varied and affect different aspects of the natural environment.

Among the most notable effects is the contamination of air, soil and water. These activities can release toxic particles and substances that deteriorate the quality of the air, increase soil contamination with soiling materials and chemical contaminants, and change water bodies to sediment and liquid residues.

In addition, construction activities can damage or damage the properties and perils of local residents, causing a series of inconveniences and material losses.

Another critical aspect is the creation of safe working conditions, since the accumulation of waste and the handling of hazardous materials can increase the amount of work accidents.

To mitigate this contamination and its negative effects, it has been decided to implement specific measures in the actual storage. These measures include the incorporation of cleaning and sustainable technologies that improve energy efficiency. The aim is to reduce pollutant emissions as much as possible and optimize the use of energy resources, thus promoting greener and more responsible construction. The design of the storage also includes measures for water conservation, such as rain water collection and the installation of water saving devices.

In this context, the storage unit has been designed and constructed in the following manner:

Water collection channel

Aluminium unibody box

Vessel glass

Insulating padding

Drywall perimeter

N&P Feeders

CO2 Feeders

Soldering Tips

Biogas transport channel

1/4 x 1" Self Drilling Screw

22 caliber

Garden masonry and blacksmithing Constructive Details

LOSACERO 25 ternium sheet

LOSACERO 25 ternium sheet

CARBON SINK (OFFICES)

Measurements: 130.37m2 x 41.73m2

“A carbon sink is anything that absorbs more carbon from the atmosphere than it releases – for example, plants, the ocean and soil. In contrast, a carbon source is anything that releases more carbon into the atmosphere than it absorbs – for example, the burning of fossil fuels or volcanic eruptions.” (ClientEarth, 2008)

Our main oxygen producer, allowing a fresh introduction to the offices and brings out plants that grow no matter the temperature. It’s also a new visual experience inside your work place.

Reusing the original existing structure to prevent contamination

Existing Structure

AgaveNopal Cactus

BiznagaYucaSábila

PitaCactus SaguaroCactus Barrel

DandelionRat’s TailCactusQueenNight’s

EchinocactusRabbit’s EarHigo Chumbo

Star CactusWorm CactusCactus Feróz

AgaveNopal Cactus

BiznagaYucaSábila

PitaCactus SaguaroCactus Barrel

DandelionRat’s TailCactusQueenNight’s

EchinocactusRabbit’s EarHigo Chumbo

Star CactusWorm CactusCactus Feróz

Yucca brevifolia Gorrion

Paloma

YucaSaguaro

Cactus

Oruga

Cactus

Oreja de conejo

(Paloma, gorrion, ratones, lagarto, dientes de león, ocotilio, higo chumbo)

(Bees, caterpillars, mice, owls, saguaro, lizards, cacti)

Yucca brevifolia Gorrion

Paloma

YucaSaguaro

Cactus

Oruga

Cactus

Oreja de conejo

(Paloma, gorrion, ratones, lagarto, dientes de león, ocotilio, higo chumbo)

(Bees, caterpillars, mice, owls, saguaro, lizards, cacti)

Algae Panels The offices, located in the floresta passage, allows the reuse of the warehouses’ sheets and builds the opportunity of a fresh space for workers.

ALGAE FLORESTA

Measurements: 122m2 x 20m2

“[Did you know that] algae reproduce very quickly and need only sunlight or another form of energy, like sugar, water, carbon dioxide and a few inorganic nutrients to grow?” (Siloux City Journal, Bob Cast, s.f)

The algae floresta is the heart of our technologies, it seeks to provide oxygen, carbon sequestration, biomass creation, clean energy and air filtration. It is located in the middle of the pedestrian corridor to strategically provide water and electricity to the two front naves that the district has. Algae Floresta is a clean engineering space that coexists with users and offers experience.

Allowing a deserved rest to the workers and everyone around, the algae floresta allows the connection to the carbon sink, main vagonera and the algae that leads the light at night.

PART FOUR. MAIN SYSTEMS

Ecosystemic Value

Benefits and impacts that the project has on the surrounding natural environment and broader ecological systems.

Maintenance systems

749 Workers distributed in maintenance and care areas

Types of Users

Workers (749)

55 in security areas

235 in maintenance

(irrigation in green areas)

120 in maintenance (monitoring of energy generators)

300 in maquila

39 in offices (inventory management)

ESC. 1.150

Hydraulic System (Rainy Seasons)

Water flow in rainy seasons

Symbology

Water Supply

Hydraulic Installation

Sanitary Installation

Rainwater

Physical filters

Main tanks

Secondary tanks

Anaerobic digester

Drain to strainer

ESC. 1.150

Hydraulic System (Drought Seasons)

Water flow in drought seasons

Symbology

Water Supply

Hydraulic Installation

Sanitary Installation

Treated Water Installation

Physical filters

Main tanks

Secondary tanks

Anaerobic digester

Drain to strainer

Oxygen Production Maintenance

Most cactus absorb from 8 - 11kg CO2 while trees absorb 12 - 15kg CO2

Palma

Palma

PART FIVE. ENERGY EFFICIENCY

Consumption and Production

In terms of energy efficiency, production and consumption in an architectural construction refers to the way in which the building generates, uses and manages energy throughout its life cycle. The project consumes the total number of:

Based on the previous numbers, it is essential to evaluate the environmental impact in terms of carbon dioxide (CO2) emissions that IN-VZ is producing. This assessment not only helps to understand the contribution of IN-VZ to the Vallejo area but also provides insights into how the construction itself is being supported sustainably.

KgCO2 Used for: Energy, Light, Warehouse Efficiency

371,900 KgCO2

Total: 700 Lts of 6.72tons 67,200 KWh

Efficiency

Before:

Two Ficus Trees

In terms of efficiency, it is crucial to understand how the total serofilous vegetation, including trees and plants, within the construction project, is contributing to the production and consumption of CO2. This assessment provides valuable insights into the ecological benefits and the overall environmental impact of incorporating such vegetation.

C02 200,540 kg

Serophilous Vegetation

Adding the amount of energy technologies that we have implemented together with the vegetation that we have added to mitigate the CO2 consumption produced during construction in the area, and also considering the energy that is produced through these technologies, we obtain a significant total of positive environmental impact:

Energy Efficiency:

Energy: 64,521 KWh

Total

Total

Replicability

The replicability of technological projects is essential to ensure an efficient, effective and sustainable energy transition, facilitating the global adoption of renewable energies and clean technologies, and accelerating the path towards a low-carbon future. We are looking to replicate the algae bio-panels and the anaerobic digester, since they create more numbers than our other technologies in terms of energy.

Main Zone

Algae Bio-Panels

Anaerobic Textile Digestor

Type of Technology

ZD Logística y Negocios

Confilogistica

Sanhoo Home Textil

ZARA Springfield

Enlight Logística

Main Zone

Algae Bio-Panels

Anaerobic Textile Digestor

Type of Technology

ZD Logística y Negocios

Confilogistica

Sanhoo Home Textil

ZARA Springfield

Enlight Logística

References

Suárez Pastor, A,G. & Huerta Solorio, D. (2023) Cities Of Care. ProjectsForTheFutureCity. From: https://issuu.com/projectsforthefuturecity/docs/cities_of_care

Acosta, N. & Guerrero, M. (2022) UPCYCLING CITY. The (Future) City Project at EAAD Tec de Monterrey QRO. From: https://issuu.com/thecityproject/docs/upcycling_city