INTO HEAVY- DUTY CRUSHING

The need for technical skills in the local quarrying sector, and the extractive industry at large, cannot be stated enough. In the face of an ageing workforce and the massive brain drain, the industry needs to ‘grow its own timber’ to plug the broad skills gap. In recent years, local technical skills have been migrating faster than the local industry can retain them.

A key takeaway from my recent conversations with two industry executives is that the development of high-end technical skills is a critical factor for the advancement and sustainability of the industry. It plays a key role in improving safety and productivity, as well as providing opportunities for personal development, which in turn impacts economic growth.

One of the challenges hindering the development of skills is the fact that training is not cheap – it takes time and money. However, investing in skills development can save a lot of money in the long term. These words, which are so true, are often quoted, and have been attributed to several different people: “If you think training is expensive, try ignorance.”

The skills challenge is likely to increase in the coming years due to the advent of the Fourth Industrial Revolution – characterised by fastpaced technological progress, which will further transform the labour market.

breed the new skills the workforce requires. The Future of Jobs study highlights that skills demand will change significantly over the next five years, pointing at the importance of aligning education with skills needed in the labour force.

The same view is shared by Professor Brian Armstrong, BCX chair in digital business at Wits Business School, who is worried that a lot of skills development initiatives being pushed at this stage are about the transfer of specific knowledge. He reasons that what is more important now is helping people help themselves to learn. There is need to harness the ability to reinvent ourselves over and over, thereby staying relevant in this fast-changing world.

MUNESU SHOKO Publishing EditorEmail:

munesu@quarryingafrica.com

LinkedIn:

Munesu Shoko

Quarrying Africa

According to the World Economic Forum’s Future of Jobs Report 2023, the result could be a net loss of over five million jobs in 15 major developed and emerging economies –including South Africa. These patterns may even be more intensified in other African economies unless all key stakeholders start pulling together as a matter of urgency.

While government, business and labour are starting to collaborate in tackling skills shortages, there is also a need for a balance between honing attributes that have always been valued in the workplace and learning to

The skills development initiatives of the day seem to be bred with an industrial economy in mind, but we have since moved into an information economy, and it is definitely time for a change. It is difficult to predict whether, or when, these traditional skills will become obsolete, but I agree with Alvin Toffler’s viewpoint that the “illiterate of the 21st century will not be those who cannot read and write, but those who cannot learn, unlearn and relearn”. At the height of the current technological revolution, the skills world is changing rapidly; technical skill and content are no longer enough. Both schools and skills development focused initiatives should be able to develop individuals who are comfortable with complexity and not having the answers. The vast majority of what we now call knowledge work – routine, methodological and fact-based – will be done by computers, not primarily because they are cheaper, but because they are faster, make fewer mistakes and scale more quickly.

In a world where repetitive tasks are handled by technology and artificial intelligence, our skills development strategies should aim to develop creative thinkers, innovators, risk-takers and problem solvers. Emphasising these attributes will help create a skills pool that is less vulnerable to automation. a

EXPANDING SUPPORT FOOTPRINT

SCREENING ACROSS APPLICATIONS

THE ROLE OF SCREEN MEDIA IN AGGREGATES PRODUCTION

TOP TIPS FOR BUYING A WHEEL LOADER

TOWARDS ELECTRONIC BLASTING SYSTEMS

HIGHLIGHTING SAFE CONVEYOR EQUIPMENT DESIGN

DIAGNOSING SCREEN MEDIA PROBLEMS

Publishing Editor: Munesu Shoko

Sub Editor: Glynnis Koch

Business Development Manager: Elmarie Stonell

Admin: Linda T. Chisi

Design: Kudzo Mzire Maputire

Web Manager: Thina Bhebhe

Quarrying Africa is the information hub for the sub-Saharan African quarrying sector. It is a valued reference tool positioned as a must-read for the broader spectrum of the aggregates value chain, from quarry operators and aggregate retailers, to concrete and cement producers, mining contractors, aggregate haulage companies and the supply chain at large.

Quarrying Africa, published by DueNorth Media Africa, makes constant effort to ensure that content is accurate before publication. The views expressed in the articles reflect the source(s) opinions and are not necessarily the views of the publisher and editor.

The opinions, beliefs and viewpoints expressed by the various thought leaders and contributors do not necessarily reflect the opinions, beliefs and viewpoints of the Quarrying Africa team.

Quarrying Africa prides itself on the educational content published via www.quarryingafrica.com and in Quarrying Africa magazine in print. We believe knowledge is power, which is why we strive to cover topics that affect the quarrying value chain at large.

Printed by:

Contact Information

Email: munesu@quarryingafrica.com

Cell: +27 (0)73 052 4335

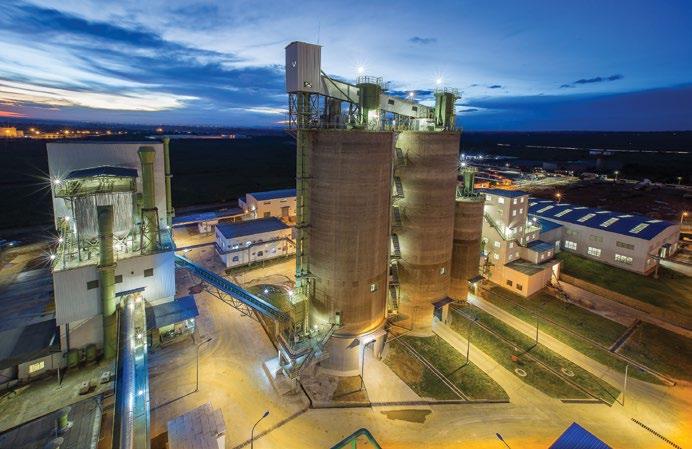

Cement & Concrete SA (CCSA), the consolidated body taking the lead on all matters relating to cement and concrete in South Africa and its members recognise that achieving the nationally determined commitments (NDC) in terms of the country climate change response would require both political will and investments supported by enabling government policies.

Furthermore, it is evident that the SD goals are all interrelated and hence will depend on a multidisciplinary approach. In terms of major country challenges, South Africa is a water scarce country, coal-based energy reliant, high unemployment rates and lagging behind waste management practices with regards to implementing the hierarchy of waste principles. However, everything from reducing the clinker factor, use of supplementary cementitious materials, to use of industrial wastes as fuels have been implemented by CCSA members to date in various degrees.

Both government and industry have recognised that policy certainty and regulatory / financial support is required to ensure economic growth, job creation and decarbonisation outcomes to further the objectives of a just transition towards a greener economy.

CCSA Industry Development executive Dr Dhiraj Rama will present about enhancing a just transition to a greener economy by increasing the utilisation of AFRs in the cement sector at the upcoming CarbonZero Global Conference and Exhibition (Lyon, France, October 26-27). He will outline some of the developments with regards to policy and law reform related to waste management to enable the cement sector to improve its uptake on alternate fuels and resources in the context of the circular economy.

Dr Rama is active in championing sustainable development

in the cement sector and plays a key role in informing climate change as well as environment policies and legislations related to the cement sector. He is a PhD graduate in Biochemistry from Wits University, Johannesburg. a

Leading construction material supplier, AfriSam, celebrated a significant milestone at the company’s Vanderbijlpark Slagment Operation when it achieved 1,75-million Lost Time Injury (LTI) Free hours earlier this year, demonstrating the high safety standards upheld at this plant.

As one of the leading players in the supply of aggregates, cement and concrete readymix, AfriSam is committed to safe operation at all its facilities. A strong commitment to ongoing training of its people as well as visible felt leadership underpins the company’s approach to safety and has clearly borne fruit at the Slagment Operation.

The origin of this operation, situated in the industrial area on the outskirts of Vanderbijlpark, dates back to the 1950s when Dr Niko Stutterheim thoroughly researched the suitability of South African slag for manufacturing cement and for use in concrete. His conclusion that the slag was eminently suitable led to the establishment of the company Building Binders Ltd, which was subsequently registered as Slagment Limited in 1960. Today, this operation still produces slagment and supplies the product to operations within AfriSam as well as to other customers for the manufacture of blended cementitious products.a

Leading mid-tier mining and materials company, Afrimat, has today announced the acquisition of Lafarge South Africa Holdings (Pty) Ltd (LSA), including all its subsidiaries (LSA Group), subject to the fulfilment of conditions precedent relating to the receipt of customary regulatory approvals.

LSA Group, a member of the Holcim Group, is a provider of construction materials in South Africa, offering an extensive range of products to the construction and infrastructure industry, including aggregates, concrete, cement, and fly-ash.

The acquisition will be housed in Afrimat’s Construction Materials division, which together with its subsidiaries (the Afrimat Group) supply a wide variety of aggregates and concrete-based products to the market, and the Afrimat Group, in response to

market and product development within this segment.

Speaking on the acquisition, Andries van Heerden, CEO of Afrimat says, “A key focus of Afrimat is our conscious operational efficiency initiatives, which are aimed at expanding volumes, reducing costs, and developing the required skill levels across all staffing categories. This exciting deal forms part of the Afrimat Group’s ongoing diversification strategy and will increase Afrimat’s offering in the construction industry, by expanding our quarry and readymix operations nationally and allowing for Afrimat to enter the cement value chain competitively.”

Afrimat is highly cash-generative and effectively debt free, allowing this acquisition to be financed largely in cash. “We are confident that this acquisition is a good use of our cash

the Afrimat Group’s balance sheet will remain healthy with debt levels well within our target range.”

Core assets acquired consist of aggregate quarries, readymix batching plants, an integrated cement plant, cement grinding plants, cement depots and highquality fly-ash sources. The lime and aggregate sources are long-life assets, well-designed and all with good-quality plants and infrastructure characterising the entire portfolio being acquired.

The purchase price for the acquisition of the equity in the LSA Group is USD6-million, with an additional amount of R900-million towards repayment by or on behalf of LSA of an amount owing by LSA to the Holcim Group. The effective date of the acquisition is 10 business days after all the conditions precedent have

The J6 is an exciting addition to our jaw crushing product range in the local market. By introducing this machine, we have answered our customers’ call for a heavyduty mining machine. It is a significant leap, in terms of size, compared with the J45.

17,96 m

Despite its large size, the J6 does not compromise on portability for transport purposes. With a transport length of 17,96 m, the machine has a transport height and width of just 3,9 m

• Optional extended warranty available

• Onboard side conveyor as standard

• 1 400 mm wide discharge belt

• Heavy duty bolted track frame

• Feeder removable for transport

• On-board rock breaker as standard

Kemach Equipment, recently acquired by Kanu Equipment, used a customer open day to introduce its latest offering, the McCloskey J6 jaw crusher – the largest in its stable to date

Attended by the local crushing and screening community, largely crushing contractors, the event was held at the company’s Jet Park, Gauteng headquarters on July 7

With a 1 200 mm x 864 mm jaw opening, the J6 accommodates large feed size of 700-800 mm

The new 75-t J6 jaw crusher gives Kemach Equipment a tool to compete at the heavy-duty end of the mobile crushing market

The J6 comes with a 1 400 mm-wide, angleadjustable main conveyor with a discharge height of 5,13 m

At the centre of Kemach Equipment’s aftermarket regime is a new 6 000 m² parts warehouse in Pomona, which carries millions of rands worth of OEM spare parts at any given time

While a side conveyor remains an option for many jaw crushers in its class, the J6’s folding conveyor is standard and has an 800 mm adjustable speed belt with a stockpile height of 3,99 m

Amid increased demand for larger mobile crushing units, Kemach Equipment has launched the McCloskey J6 jaw crusher, which closes a crucial gap in the company’s offering and thus gives it a much-needed footprint into the heavy-duty crushing market.

By Munesu Shoko.Kemach Equipment, recently acquired by Kanu Equipment, used a customer open day to introduce its latest offering, the McCloskey J6 jaw crusher – the largest in its stable to date. Attended by the local crushing and screening community, largely crushing contractors, the event was held at the company’s Jet Park, Gauteng headquarters on July 7.

At the time of writing, the first machine was due to be deployed at a customer site on a trial-to-purchase basis. Bradley Karolus, sales specialist at Kemach Equipment, says the new 75-tonne (t) machine gives the company a tool to compete at the heavy-duty end of the mobile crushing market.

Previously, the McCloskey J45, with a 250-300 tph production capacity, was Kemach’s largest jaw available for the local market. With a much larger capacity of 600-700 tph, the J6 is a massive upgrade from the J45.

With a 1 200 mm x 864 mm jaw opening, the J6 accommodates large feed size of 700-800 mm. In addition, the machine is said to deliver high tonnes per hour due to its innovative jaw chamber design and enhanced material flow.

The material path is enhanced with the adjustable 1 204 mm x 2 360 mm

double-deck grizzly pre-screen under the hopper that, along with the variable speed pan feeder, allows for better sizing of material with a variety of mesh options.

“The J6 is an exciting addition to our jaw crushing product range in the local market. By introducing this machine, we have answered our customers’ call for a heavy-duty mining machine. It is a significant leap, in terms of size, compared with the J45,” says Karolus.

With a minimum closed side setting of 70 mm, the J6 comes with a 1 400 mm-wide, angle-adjustable main conveyor with a discharge height of 5,13 m. According to Karolus, a quick release and ground-level access makes the belt easy to maintain and service, thus enhancing machine uptime. In fact, the whole machine is designed with service in mind, with ample space around all the key service points.

“In addition, while a side conveyor remains an option for many jaw crushers in its class, the J6’s folding conveyor is standard and has an 800 mm adjustable speed belt with a stockpile height of 3,99 m. We also offer the machine with an on-board rock breaker as standard,” says Karolus. “Another key talking point is that the J6 is equipped with wellknown hydraulic and electrical components such as Danfoss, Eaton and Kawasaki pumps.

Despite its large size, the J6 does not compromise on portability for transport purposes. With a transport length of 17,96 m, the machine has a transport height and width of just 3,9 m.

McCloskey, adds Karolus, placed technological advancements at the centre of the development of the J6. For example, the standard 12” control panel provides push button control of the jaw, track and feeder functions.

Furthermore, the new crusher is fitted with a telematics modem for the new 365SiteConnex, a connectivity solution for the monitoring of McCloskey products. 365SiteConnex is based on the latest leadingedge communication technologies to collect, analyse and deliver machine information which customers rely on to optimise production and increase efficiency.

Also contributing to the efficiency of the J6, particularly in remote locations, is the high-volume fuel tank, said to be sufficient to run the machine for approximately 20 hours.

As with all McCloskey equipment, safety is paramount, and the J6 is equipped with a number of features to ensure workplace and operator safety. For example, engine safety shutdown systems, start-up alarms, full safety guarding, external maintenance access and a tagout capability on the isolator, all contribute to the safe operation and maintenance of the machine. Ground level access also promotes safety, and allows for quick service and maintenance, reducing downtime for customers.

Based on interactions with customers during the open day, Karolus is confident that the J6 will find quick traction in the market, with several customers expressing interest in the new jaw crusher. “One of key competitive edges is that we are price-competitive, not only on the capital outlay, but also on our parts and the cost of service at large,” he says. “This is key to reducing the total cost of ownership for our customers.”

Stock availability, he says, is another key competitive edge. Under the ownership of Kanu Equipment, the company has invested significantly in its stock to eliminate waiting times for customers. To provide context, Kemach Equipment has 40 stock machines (McCloskey) on order.

“Following the takeover by Kanu Equipment, we have made significant investments in not only machine inventory, but also in our aftermarket support capabilities. At the centre of our aftermarket regime is a new 6 000 m² parts warehouse in Pomona, which carries millions of rands worth of OEM spare parts at any given time,” he says.

Karolus says the Kanu Equipment takeover has brought with it a positive change in the business. Under the leadership of GM Twan Bell and CEO Stephen Smithyman, the company has not only invested in expanded machine and parts inventory, but also in the right skills to ensure high levels of customer service.

“We have beefed up our McCloskey team with four highly-skilled individuals with a deep understanding of the crushing and screening business. This will be key to enhancing customer experience, in line with our ‘Experience the Support mantra,” concludes Karolus. a

Cloete Sand & Stone, South Africa’s leading aggregates reseller, has expanded its footprint with a new branch in Cape Town. This is the first time the company has operated outside its traditional Gauteng market, marking a significant growth trajectory in its 41-year history. In a one-on-one with Quarrying Africa, MD Wesley Cloete discusses the company’s blueprint for success in what is known to be a cut-throat and low-margin business environment. By Munesu Shoko.

From humble beginnings with a single lorry some 40 years ago, Cloete Sand & Stone has over the years transformed its business to become one of the premium aggregate resellers in South Africa. Founded by Brian Cloete in 1982, the company initially subcontracted transportation services to quarries, before moving into the aggregate reselling market, explains MD Wesley

Cloete, who joined the family business in 2008 and took over the reins in 2017.

The migration from basic transportation services to aggregate reselling was informed by the need for better service in the industry at the time, the business having been founded on this from its onset.

“My father started the business as a lorry owner/ driver, before he switched to aggregate reselling,”

The company has grown its fleet from 17 trucks in 2008 to 72 to date

Cloete Sand & Stone has expanded its footprint with a new branch in Cape Town

By injecting a new level of service excellence – going beyond customer expectations and delivering an industry-leading experience – Cloete Sand & Stone has grown its business significantly over the years

One of the key factors to this growth has been the focus on efficiency, which is instilled in all aspects of the business

As a fleet-driven business, the business places value on premium trucks, which are primarily its main tool of trade

says Cloete. “At the time, we were supplying dry sand to contractors who specialised in gunite pools. Their business was extremely time-sensitive – they needed the material at specific times – yet the demand for sand outstripped supply. However, service excellence was key to meeting these specific customer needs, and this was instrumental in the growth of the business.”

By 2008, the business was operating five tipper trucks and 12 concrete mixers. The same year, Wesley Cloete joined and together with Brian Cloete mapped a new growth trajectory in a rapidly changing business environment. By injecting a new level of service excellence – going beyond customer expectations and delivering an industry-leading experience – Cloete has grown the business significantly over the years.

Key to the growth has also been his insatiable appetite for new technologies to drive higher levels of efficiency. This, he says, is important, especially given the rate at which technology is evolving and also the fact that aggregate reselling is a high-volume, lowmargin business.

“We have managed to grow the business from 17 trucks in 2008 to 72 to date,” he says. “We have also managed to expand our footprint with a new branch in Cape Town this year. The expansion was largely driven by some of our Gauteng customers who have opened new operations in Cape Town. We determined that there was a need for us to set up a base in Cape Town in order to provide them with the service to which they

have become accustomed. Our business is built on service and bending backwards for our customers.”

One of the key factors to this growth has been the focus on efficiency, which is instilled in all aspects of the business. As a fleet-driven business, the company places value on premium trucks, which are primarily its main tool of trade. Therefore, says Cloete, the company does not leave anything to chance when it comes to procurement time.

Cloete Sand & Stone runs a multi-brand fleet of tried and tested offerings – Volvo Trucks, Scania and Mercedes-Benz. “Leveraging our 40 years’ experience, we believe that these are the best products on the market for our line of work,” says Cloete. “By investing in new technologies, these OEMs continue to set the bar high in terms of fuel efficiency, reliability and productivity.”

To drive efficiencies within its business, the company investigates new trends in the market to inform some of its procurement decisions. For example, Cloete tells Quarrying Africa that, in direct contrast with some of the local norms where the 440 to 460 hp trucks are the standard in this line of business, the company places value on highhorsepower vehicles in the 520 to 560 hp range for its larger tippers. The same approach is applicable to its smaller rigid trucks, which are generally highhorsepower units in the 310 to 360 hp region.

“We are always on the lookout for new ideas. The reason behind our preference for high-horsepower vehicles is that these tools do not work as hard as smaller horsepower vehicles, which impacts on our operational efficiency. If driven correctly, they actually offer better fuel savings,” he says. “The capital outlay is obviously a lot higher, but our calculations tell us that there are major savings in terms of total cost of ownership over the lifetime of the asset.”

For its truck fleet, Cloete Sand & Stone maintains a 50% gearing ratio, which means 50% of the assets are at any given time paid off, while the other 50% consists of fairly new units still on vehicle finance. This move is informed by the need for balance in terms of reliability and economics. The older, paid off fleet, says Cloete, helps pay for the newer trucks, which in turn guarantee high levels of efficiency and reliability.

“In a perfect world, it would be ideal to run a completely new fleet, but the low-margin nature of the business cannot sustain it. A newer fleet keeps service costs down because the older the fleet gets, the higher the cost of maintenance. However, given the cyclical nature of the business, we cannot afford it, hence the need to maintain a balance between paid-off and newer trucks.”

Given the experience of running its preferred brands, the company has qualified mechanics to look after its older, out-of-warranty trucks. With its new vehicles, the company generally takes a five-year maintenance contract with the OEM, which provides peace of mind

that the assets are maintained according to OEM specifications with “no surprise costs”.

To further drive efficiencies, Cloete Sand & Stone has put several other initiatives in place. One of the key areas of focus is time management. “One of the critical parameters we monitor is standing time, whether at the loading point or at the point of delivery,” he says.

“To improve time management, we also ensure effective route planning using truck telematics and other freely available digital applications. We would rather choose to take a longer route to save time. Therefore, route planning for us is critical to achieving efficiencies.”

To further improve its operational efficiencies, the company insists on reducing what Cloete terms “dead leg” – trips where trucks travel empty. This is achieved by mapping and locating various quarries where material can be sourced within the delivery network to limit unladen travel.

That the local quarrying value chain has traditionally been stubborn in its reluctance to adopt new technologies is no overstatement. Against this background, Cloete Sand & Stone has over time quietly gone about its digital transformation to become a modern-day business.

A big proponent of new technology, Cloete says this approach has allowed for new, more flexible ways of carrying out the job. To work out the best technologies for the business, the company assessed its existing needs against its requirements, carefully considering the right technologies to drive efficiencies.

“My interest in new technologies – be it the vehicles we purchase or the systems we use internally – has paid dividends for the business,” he says. “One of our earliest technologies in our digital transformation journey was the adoption of a software system called

BiBi, a centralised digital system that enabled us to do quotations, delivery notes and invoices more efficiently than our conventional hand-written and typed documentation.”

However, the downside to this system was the need to have to continue to print out documents. During those days, Cloete recalls that he would work until 8 or 9 pm, printing out and despatching delivery notes for the day. This necessitated a significant capital investment in a paperless system called StratoPod, an ultimate delivery documentation solution.

“We worked together with the Strato IT Group to develop a solution that spoke directly to our needs, replacing all the manual processes and tasks associated with paper workflows. With the new system we can now, for example, assign and change loads on the fly without any need to phone drivers. It has also empowered us to endorse delivery documentation electronically at customer sites accurately, efficiently and safely. StratoPod has definitely been a game changer for us,” he says.

As a family business, Cloete Sand & Stone places value on its family culture, which has always been cultivated across the business, resulting in employee loyalty –an extent to which employees are committed and involved with the business. To provide context, some of the current staff have been with the business for 30 to 32 years, helping the business build and keep an effective workforce that has allowed it to develop, grow and perform efficiently.

“Without our loyal staff who, in fact, have become family, we would not be where we are today. I am grateful for their loyalty and dedication to the business. Speaking of loyalty, our success as a company also hinges on our loyal customers who value our work ethic and service as a business. These customers have identified with our brand as a representation of themselves and trust our abilities to meet their material needs above all others,” concludes Cloete. a

Through a multi-faceted approach, surface mining association, ASPASA, has put the advancement of women firmly on the agenda. Speaking exclusively to Quarrying Africa, ASPASA director Letisha van den Berg says the future of mining hinges on its commitment to build an industry that is truly inclusive and draws on the talents of women. By Munesu Shoko.

The representation of women in the global mining sector remains low. According to a recent report by the World Bank, women make up only 15% of the global mining workforce, with even lower representation in specific regions and subsectors. Additionally, this underrepresentation extends to leadership and management positions,

where women hold just 16,9% of board seats in the top 500 mining companies globally.

“Women are underrepresented in all levels of the mining sector, but mostly so in senior management positions. We need to promote individuals based on skill and not just on gender – there are highly skilled women out there,” says Van den Berg. “Lower levels are understandable,

15%

A

A commitment to furthering the involvement of women in all aspects of the mining sector should take priority.

because generally mining is a harsh environment to work in and not all women want to be exposed to such conditions. One either falls in love with the environment immediately or totally hates it.”

A commitment to furthering the involvement of women in all aspects of the sector is thus something that should be ‘front and centre’ for all stakeholders concerned. Setting up platforms to address gender issues, says Van den Berg, should be regarded as a positive step towards improving the workplace.

16,9% The

The representation of women in the global mining sector remains low

Women are underrepresented in all levels of the mining sector, but mostly so in senior management positions

Setting up platforms to address gender issues should be regarded as a positive step towards improving the workplace

Through a multi-faceted approach, surface mining association, ASPASA, has put the advancement of women firmly on the agenda

well represented in the regional women in mining forums. Most of our members are committee members of the regional women in mining forums. By just opening these platforms to women, it assists with advancement because they see the progress of other women,” says Van den Berg.

To track the progress made, ASPASA will look at the Minerals Council system and suggest a way its members can report on the Minerals Council South Africa platform. The association’s members all have their programmes in place to make a difference.

“Some of our members have excellent programmes which we will share after we have set up all our leading practices,” she says.

72 000

Surface mining industry association, ASPASA, drives the agenda through the Mining Charter processes, the Gender Justice Committee and its recent memorandum of understanding with Women in Mining Business (WimBiz) to advance women in mining supply chain opportunities.

“ASPASA supports the Minerals Council South Africa and The Mine Health and Safety Council programmes for women in mining as well. ASPASA members are

Van den Berg notes that there are already 72 000 women in the South African mining sector and the number will continue to rise as several industry initiatives come to the fore.

“We have come a long way and one must not forget the successes gained in the years gone by. The mining industry was never really ready for women, but there are now many guidelines and learnings available.

To achieve our targets, it is important that we do not isolate men from the women in mining forums. I also urge the media and all other platforms supporting women to engage with men to see how they experience women in the workplace. The challenge is not just one-sided,” she concludes. a

To execute a complex stockpile recycling project at an old iron ore mine, Gravmax Africa has deployed a bespoke two-stage crushing and screening plant supplied by Weir Minerals Africa. Leveraging combined experience in applications engineering, process engineering and mechanical design, Weir Minerals’ Comminution team delivered on the client’s need for a technically sound and cost-effective plant that meets site-specific requirements on all fronts.

By Munesu Shoko

By Munesu Shoko

ecovering saleable material from legacy mining dumps is one of the emerging paradigms across various commodity areas in the South African mining industry. Central to this growing trend is the availability of methods and technologies which offer better recoveries than in the past, allowing for the recovery of valuable material from previously discarded waste.

A case in point is a stockpile recovery project at the old Thabazimbi Iron Ore Mine in Limpopo, South Africa. Owned by a leading steel producer, the project is contracted to United States-based Phoenix Global on a build-ownoperate-transfer (BOOT) basis. Phoenix’s strong materials handling skills, its ability to finance and a joint track record and relationship built on trust with Gravmax Africa, made this project possible.

Gravmax Africa, a specialist in minerals processing and metal recovery plant design, construction and operating services, was subcontracted by Phoenix Global to design,

5 mm

The crushing and screening plant is deployed to liberate iron ore from gangue material by crushing it all down to smaller than 5 mm, before processing it through the dense media separation process

7,5 – 36 m

The different components of the two-stage crushing and screening plant are interconnected by means of a modular Trio conveyor system, with widths ranging from 600 mm to 900 mm wide and lengths from 7,5 m to 36 m

Gravmax Africa recently opted for a bespoke twostage crushing and screening plant supplied by Weir Minerals Africa

This direct feed configuration was one of the key factors in the company’s buying decision

Due to the fast-tracking requirement of this project, Gravmax Africa preferred to deal with a ‘one-stop’ supplier that could provide all the equipment in a modular format

The plant is unique in the sense that it crushes the ore down to a -5 mm size using a dry process

Our comminution team combined its experience in applications engineering, process engineering and mechanical design into one packaged offer to ensure that we ticked all the boxes for the client on a technical level – and that put us in the running as a legitimate contender for the project.

build and operate the process plant for this particular project. The project comprised a two-stage crushing and screening plant supplied by Weir Minerals Africa, as well as a separate dense media separation (DMS) plant.

Dieter Nebbe, plant manager at Gravmax Africa, explains that the Weir Minerals plant is the first step in the beneficiation process – liberating the desired iron ore from the unwanted gangue minerals. This project is focused on the production of fine, saleable iron ore from a banded iron stone formation. The hematite occurs in thin layers in between layers of gangue minerals.

Nebbe explains that the Weir Minerals crushing and screening plant is deployed to liberate the iron ore from the gangue material by crushing it all down to

smaller than 5 mm, before processing it through the dense media separation process, where the liberated hematite and gangue minerals are separated to produce a high quality, fine iron ore product.

Key to the decision to opt for the two-stage crushing plant from Weir Minerals Africa was the configuration, explains Corné Boshoff, director at Gravmax Africa. The Comminution team was able to present a solution that met Gravmax Africa’s needs, particularly with regards to effective choke feeding conditions for the cone crushers.

Karabo Moalamedi, advanced comminution specialist at Weir Minerals Africa, explains that the two cone crushers in the plant are coupled with a surge bin tower and a Trio EF pan feeder to guarantee enough surge capacity right in front of the cone crusher to ensure adequate choke feeding conditions at all times. This also protects the crusher from intermittent feeding which reduces equipment reliability.

“This direct feed configuration was one of the key factors in our buying decision,” explains Boshoff. “Having a surge bin directly before each crusher, coupled with a pan feeder that feeds material out of the bin straight into the crusher, means that there is no delay time, and it is easy to control the level of material in the crusher. This ensures good interparticle crushing due to the choke feed conditions, which in turn results in preferential breaking at the grain boundaries, which ultimately allows for better grades and iron recovery.”

Due to the fast-tracking requirement of this project, Gravmax Africa preferred to deal with a ‘one-stop’ supplier that could provide all the equipment in a modular format. Renowned for its Trio jaw and cone crushers, Trio feeders and Enduron screens, Weir Minerals Africa was in a position to put all these together in a complete plant within a short lead time.

According to Boshoff, Gravmax Africa also wanted a

dry process that could crush down to the required -5 mm fine size. Through simulation, Weir Minerals was able to prove the ability to produce this required very fine specification using its two-stage crushing and screening plant.

“The plant is unique in the sense that we crush the ore down to a -5 mm, using a dry process. Due to the liberation characteristics of this iron ore, we needed to crush it that fine to be able to upgrade it to saleable quality,” says Boshoff.

Phoenix is responsible for all materials handling on the plant, which includes in-field mobile primary crushing and screening to supply a pre-crushed and screened ore stockpile. Ore is fed into a 15 m³ live volume capacity feed bin using front-end loaders. The bin was supplied with a static grizzly with a fixed 130 mm aperture. Ore is extracted from the bin at a controlled rate by means of a Trio EF3606 pan feeder.

From here, material is fed into an Enduron DHG24/48 double deck horizontal secondary screen with 20 mm top deck and 7 mm bottom deck apertures. The undersize product is taken directly to the final product radial stockpile.

The oversize material from the screen is redirected to the secondary crushing station, consisting of a Trio TC51 live-shaft cone crusher fed by a 16 m³ surge bin tower coupled with a Trio EF3606 pan feeder. Crusher product recirculates back to the DHG 24/48 screen to form the first closed loop of the crushing circuit.

Mid-size material from the DHG 24/48 screen (-20 mm +7 mm) is sent to the tertiary screen, an Enduron DHG21/54 double deck horizontal screen. This screen has 20 mm aperture on the top deck and 7 mm on the bottom deck. The oversize and mid-size materials are mixed and sent to the tertiary crushing station, another 16 m³ surge bin tower feeding a Trio TP350 pedestal (or fixed-shaft) crusher by means of an EF3606 pan feeder. The undersize product is again

sent to the final product radial stockpile.

Product from the tertiary crusher is recirculated back to the DHG 21/54 tertiary screen, the second closed loop of the circuit. Final product is loaded to the radial stockpile by means of a 24 m Trio radial stockpile conveyor.

The different components of the two-stage crushing and screening plant are interconnected by means of a modular Trio conveyor system, with widths ranging from 600 to 900 mm wide and lengths from 7,5 to 36 m.

Commenting on why the various pieces of equipment, in particular, were chosen, Moalamedi says for the secondary crushing, the team went for a Trio TC51 cone crusher which is based on a reliable proven design and ideally suited for demanding applications. This is a low maintenance unit which helps ensure operating costs are kept low, a key parameter in the client’s buying decision.

“On the tertiary crusher, we needed a machine that would produce a high fraction of fine material (-5 mm) for feed to the next stage of the process. The crusher would also need to cope with a high recirculating load. The chosen TP350 cone crusher offers just that as it is a high-speed machine with a high pivot point and larger throw which translates into high capacity crushing and a high reduction ratio,” explains Moalamedi.

The vibrating screens offered are heavy duty and are designed for material with a high bulk density. These also produce a high acceleration (G force), which ensures maximum efficiency even at high load conditions.

While the plant has met all the operational expectations, the design was not without its challenges. Jaco Kotzé, senior engineer – team leader Comminution Design at Weir Minerals Africa, explains that the plant is located on the side of the mountain, which posed some limitations on the plant layout area.

On the tertiary crusher, we needed a machine that would produce a high fraction of fine material (-5 mm) for feed to the next stage of the process. The crusher would also need to cope with a high recirculating load.

“Gravmax Africa also requested that we optimise the layout to make the most efficient use of the natural slope of the ground in order to minimise the amount of filling and earthworks required. We achieved this by having the two closed crushing loops in a counter flow layout, and by positioning the crushers outside of the layout to allow for easy maintenance access by means of a mobile crane for liner changes and general

Gravmax Africa required a solution that made use of the natural slope of the ground to minimise filling and earthworks.

maintenance,” explains Kotzé.

The ore at the Thabazimbi mine is very abrasive and very difficult to handle due to the high moisture content as a result of the naturally weathered state of the dumps. Weir Minerals used a combination of material-on-material ledged chutes for the oversized screened material transfers as well as specialised low friction liners in chutes/underpans for handling the sticky fines and to prevent any unwanted fines buildup in these areas.

“The high efficiency and G force of the Enduron screens allowed us to keep this a completely dry processing plant, which significantly reduces the operational cost and complexity compared with a wet processing option,” says Kotzé.

Commenting on some of the key talking points of the plant, Kotzé highlights the Weir Minerals modular plant design, which allows for easy interfacing of the various modular stations. Each station is designed as a completely stand-alone system and design verification is done accordingly.

All equipment is mounted on self-contained skid structures, which require only basic civil raft foundations, instead of traditional individual plinths. This reduces the cost of civil works for the client and allows for more flexibility during installation.

“The Weir Minerals modular conveyor system is designed with minimal foundation requirements – standard conveyors only have three low ground pressure support footings; this drastically reduces the civil costs and allows for a very clean plant with easy access into the plant area,” says Kotzé.

The conveyors are modular, allowing for walkways on either side and for different standard installation angles without having to change the standard design. In addition, the conveyors head ends are self-supporting and do not need to be supported by the equipment skid structure which the conveyor is feeding, thus allowing completely modular interfacing between the different stations. By having the conveyors decoupled from the structures,

Tiisetso Masekwameng, GM – Comminution Equipment at Weir Minerals Africa, says the Gravmax project speaks volumes about Weir Minerals’ value proposition.

The concept of order qualifiers and order winners explains best how the comminution team works, she says. Order qualifiers are necessary attributes that a product must possess for it to be considered in the running for a client purchase, while order winners are the ‘winning’ attributes that lead to customers buying a product.

“Our comminution team combined their experience in applications engineering, process engineering and mechanical design into one packaged offer to ensure that we ticked all the boxes for the client on a technical level – and that put us in the running as a legitimate contender for the project,” says Masekwameng.

Weir Minerals, however, set itself apart through an iterative listening process with the clients’ team, being quick and nimble in its responses to meet their needs while using its experience to ensure the delivered solution was going to be efficient and technically sound. This is particularly evident in the conveyor designs, for example, which were a direct output of combined efforts between Weir Minerals and the Gravmax team. The client was strict about access – and Weir Minerals responded by allowing for walkways on either side, while maintaining its design nuances such as conveyors that are decoupled from structures to avoid vibration transfer.

“At the end of the day, Phoenix Global, through Gravmax Africa, had clearly articulated needs and we simply listened and worked tirelessly to deliver. They did not want an off-the-shelf solution; we provided a bespoke crushing and screening solution by using our modular plant design while mitigating the various project design constraints of the project. We aimed to provide and succeeded in providing, a safe, easy-tooperate and cost-effective plant to satisfy our client’s specific project needs,” concludes Masekwameng. a

To meet high-production requirements for one of its strategic mining contracts in Steelpoort, Limpopo, Zizwe Opencast Mining has deployed a train of Metso mobiles with remarkable success. The leading mining contractor has been particularly impressed by its newly acquired Lokotrack LT200HPS which is essentially a cone crusher and a screen on one tracked chassis, thus reducing double handling on site. By Munesu Shoko.

With productivity high on the agenda, Zizwe Opencast Mining does not leave anything to chance when it comes to the selection of its equipment for its mining projects. It is for this reason that the company has opted to deploy a fleet of three Metso mobile machines supplied by Pilot Crushtec International at one of its chrome processing contracts in Steelpoort. The train comprises a Lokotrack LT120 jaw crusher, a Nordtrack S2.11 scalping screen and a Lokotrack LT200HPS cone crusher.

As part of the production process, -450 mm run of mine (ROM) material is fed into the Lokotrack LT120 jaw crusher, which crushes it down to a -80 mm, which is in turn fed into the Nordtrack S2.11 scalping screen for further processing. At the scalping screen, the production team takes out sellable -15 mm product.

Any oversize material from the scalping screen is

fed into the Lokotrack LT200HPS cone crusher, which crushes it down to the desired -15 mm product. Anything above the -15 mm spec is passed onto the LT200HPS’s on-board return conveyor, which recirculates it back to the crushing chamber for a second or even third crush.

With the high production nature of the Metso machines, coupled with their reliability and ultimately high availability, Zizwe is meeting its production target of 200 tonnes per hour (tph), confirms Rayno Combrick, crushing and screening foreman at Zizwe. “We are very happy with the performance of the Metso machines we have deployed on this particular project,” says Combrick.

While all the three machines have proven their mettle, Joe de Beer, crushing and screening plant manager at Zizwe, is particularly impressed by the newly acquired LT200HPS cone crusher. By featuring

9

Zizwe currently has a total of nine Metso units in its fleet – six jaw crushers, two cone crushers and one scalping screen

30 000

Zizwe’s first Metso machine, a Lokotrack LT105 jaw crusher purchased in 2012, has clocked over 30 000 hours and counting

Zizwe Opencast Mining has deployed a fleet of three Metso mobile machines supplied by Pilot Crushtec International at one of its chrome processing contracts in Steelpoort

The train comprises a Lokotrack LT120 jaw crusher, a Nordtrack S2.11 scalping screen and a Lokotrack LT200HPS cone crusher

Zizwe is particularly impressed by the newly acquired LT200HPS cone crusher, which features a detachable screen and return conveyor on one tracked chassis

The fact that the LT200HPS does the job for two machines was central to Zizwe’s purchasing decision

The fact that the LT200HPS does the job for two machines was central to our purchasing decision. It features a detachable screen and return conveyor which guides screened oversize material back to the cone crusher. It is essentially a cone crusher, a screen and a conveyor on one tracked chassis.

a detachable screen and return conveyor on one tracked chassis, he says, the LT200HPS is basically two machines in one, which eliminates double handling on site.

“The fact that the LT200HPS does the job for two machines was central to our purchasing decision. It features a detachable screen and return conveyor which guides screened oversize material back to the cone crusher. It is essentially a cone crusher, a screen and a conveyor on one tracked chassis,” says De Beer.

Francois Marais, sales and marketing director at Pilot Crushtec, tells Quarrying Africa that this is the first ever LT200HPS with an overhanging screen to be supplied in the local market by Pilot Crushtec. In fact, the Lokotrack LT200HP now comes in three different configurations, depending on individual customer needs. Apart from the standard cone crusher configuration, he explains, it is also available with a pre-screen called the HPX, which is placed just before the crushing chamber, or alternatively with an overhanging screen called the HPS, located post the crushing chamber.

“In traditional operations, you would need two machines – a cone crusher and a screen – to do the same job done by this machine on its own. In addition, you would probably have to deploy a minimum of two or three conveyor belts to recirculate oversize

material from the screen back to the cone crusher,” says Marais.

Yeshen Achary, sales engineer at Pilot Crushtec, explains that Zizwe was looking for a single machine that could do the job of two machines. “Traditionally, we have always supplied the LT200HP in a standard configuration. Because cone crushers by their nature are not 100% efficient, the added benefit of having a screen post the crushing chamber is that it allows for recirculation of any oversize material back to the cone crusher,” he says.

This, explains Achary, eliminates the need for another machine to work in closed circuit with the cone crusher. Having a single machine doing the job of two machines offers significant cost benefits for the customer. Apart from the obvious capital cost benefit, having the cone and screen on one single chassis means that the machine is powered by a single engine, thus one less machine to maintain. Having a closed loop on a single chassis also makes it easy to transport the machine to site.

Zizwe currently boasts a mobile fleet of 24 crushers and 15 screens, comprising various brands. Of the 35 machines, nine are Metso units – six jaw crushers, two cone crushers and one scalping screen. The

company generally replaces its crushing equipment at 15 000 hours. In future, confirms De Beer, Zizwe is looking at standardising its whole fleet with Metso equipment.

Why Metso? Several factors, he says, are central to the decision, but more importantly it is the proven reliability of Metso machines. To provide context, Zizwe’s first Metso machine, a Lokotrack LT105 jaw crusher purchased in 2012, has clocked over 30 000 hours and is still going strong at one of the company’s crushing sites.

“The main reason behind our preference for Metso is the durability and performance of the machines,” says De Beer. “Added to that is the unparalleled aftermarket support we get from Pilot Crushtec. Worth mentioning is the parts availability, which is key to our machine uptime. Downtime is the enemy of success in our line of business. We therefore value a partner that we can trust for the long haul, while offering the best deal possible.”

De Beer makes special mention of Pilot Crushtec’s SupportLink service offering, which provides equipped, qualified and experienced personnel to professionally service and repair all the equipment supplied by Pilot Crushtec.

According to Marais, Pilot Crushtec has, over many years, reiterated its commitment to customer service by investing heavily and continuously in service infrastructure, spares and wear parts as well as in the continuous training of its people.

“We train, develop and retain the skills necessary to keep customers’ equipment up and running – to avoid costly downtime that could threaten their contracts and reputations,” says Marais. “This includes our 15 full-time service technicians, who travel over a million kilometres a year to see customers and deliver quality support.”

Underpinning these levels of service – which are available 24/7, 365 days a year – is the company’s parts and aftermarket infrastructure, which is similarly always open for business. This starts with a large stockholding of around 93 000 individual items, including about 2 500 wear parts alone. There are 20 dedicated parts personnel to efficiently manage this valuable resource, dispatching on average about 6 800 parts every month.

Zizwe also places value on the industry first, standard 5-year/ 10 000-hour EPS warranty offered on all Metso crushers and screens. De Beer says the extended warranty is a true reflection of Metso’s confidence in its product and Pilot Crushtec’s service commitment to the brand.

“Warranty is a valuable component of any capital equipment purchase, especially mission-critical equipment such as crushers and screens. A long product warranty gives us some extra coverage for our big-ticket assets, along with a little more peace of mind,” concludes De Beer. a

We are very happy with the performance of the Metso machines we have deployed on this particular project.

Traditionally, we have always supplied the LT200HP in a standard configuration. Because cone crushers by their nature are not 100% efficient, the added benefit of having a screen post the crushing chamber is that it allows for recirculation of any oversize material back to the cone crusher.”

In an environment where the dearth of technical skills continues to pose a huge challenge for the industry, leading construction materials supplier, AfriSam, continues to take the lead in skills development. Over the years, AfriSam has continuously invested in training programmes that have not only benefitted the company, but the industry at large.

By Munesu Shoko.

By Munesu Shoko.

Technical skills are in high demand in the quarrying industry as companies seek to maintain their competitive advantage and develop a track record of success through innovation. Given the dynamics, Glenn Johnson, GM Construction Materials at AfriSam, stresses that it is vital for companies to commit to the development of their people.

“I am a firm believer that our industry needs strong technical skills at the core

of our operational excellence – that is fundamental,” Johnson emphasises.

AfriSam’s ongoing commitment to skills development hinges on two main elements. Firstly, the company understands that it has a duty to the country to develop people. Johnson believes that there is a strong correlation between a skilled society and a country’s sustainable economic growth, and the absence of the former inhibits the possibilities of the latter.

“The second element, and probably the most important one, is that as

83

Out of the 113 development positions since 2012, a total of 83 artisans – both 18.1 and 18.2 learners – came through the Artisan Learnership programme

30

Of the 113 development positions created since 2012, 30 were Engineers-in-Training and internships

““Despite the recent challenges brought about by the Covid-19 pandemic and the continued downturn in the construction sector, which have put pressure on our development programmes, we continue to show the resolve to develop people. I also urge other industry players to play their part in developing skills the industry needs, now and well into the future.”

a business we ought to have better traction with the people that we develop ourselves,” he says. “By investing in our own talent pool, we are, from the onset, able to better equip our people to deal with the nuances of the organisation.”

Johnson stresses that discipline and standards are critical in the mining environment, and these are key focal points in AfriSam’s people development processes. Those who come through AfriSam’s skills development programmes have demonstrated a strong understanding of what it means to be part of the company – the value system, performance criteria and expectations of operational excellence. This helps employees to perform their roles more effectively and efficiently, leading to improved job performance and ultimately the success of the organisation.

As part of its skills development portfolio, AfriSam offers several internal training programmes for its aggregates business. These include Trainee Works Manager programmes, Engineer-In-Training, Artisan Learnerships and general operational training. This

As part of its skills development portfolio, AfriSam offers several internal training programmes for its aggregates business

The Engineer-in-Training is a structured training programme for young graduates who have come through AfriSam’s bursary pipeline

The Trainee Works Manager programme exposes candidates to all the critical aspects of works management on aggregate operations

The Trainee Operations Manager programme follows pretty much the same pattern, but with a specific focus on readymix concrete production, including technical specifications, product application and customer interface

has recently been expanded with the introduction of the Trainee Operational Managers programme for the readymix business unit.

The Engineer-In-Training is a structured training programme for young graduates who have come through AfriSam’s bursary pipeline. Selected individuals – those who have shown the best aptitude for the aggregates and readymix businesses – are integrated into the programme. The programme seeks to develop a strong pipeline of electrical, mechanical, civil and mining engineers.

“Engineers in training have to undergo a structured training programme with the aim of, first of all, getting them to attain their professional status. I am of the firm opinion that one only becomes an engineer once one has been registered as a professional engineer. We therefore encourage our young engineering graduates to formalise their education by acquiring their professional status. This opens new doors for them as they can be professionally recognised in their chosen engineering discipline,” he says.

Very often, notes Johnson, candidates who go through a trainee programme of this nature get lost along the way because they do not feel significant. Fundamentally, AfriSam affords its engineers in training a sense of significance by assigning them to drive projects that have a significant impact on a quarry operation or the AfriSam business at large.

“At the end of the day, it fulfils two purposes – it makes trainees feel significant because they have contributed to a meaningful cause, but more importantly it gives them the correct exposure in their journey to become professional engineers,” explains Johnson.

As part of their development, trainees are afforded the opportunity to tap into a network of engineers within the AfriSam environment and also contacts that the company has made externally, for example, providers of engineering solutions to AfriSam.

AfriSam has a two-pronged approach to further developing its Engineer-In-Training graduates. They are either afforded the opportunity to move into line management or to stay in their chosen technical discipline, be it mechanical or electrical engineering, or a multifunction of the two disciplines.

“Candidates for our Trainee Works Manager and Trainee Operational Manager structured programmes are chosen from our Engineer-In-Training pool. They can further their career by going into works management at our aggregates operations or become operational managers on our readymix plants. It generally takes up two years for candidates to complete these programmes,” says Johnson.

The Trainee Works Manager programme exposes candidates to all the critical aspects of works management on aggregate operations, including legal training, blasting certificates, financial management and, more importantly, people management, amongst others.

The Trainee Operations Manager programme follows pretty much the same pattern, but with a specific focus on readymix concrete production, including technical specifications, product application and customer interface, amongst others. Candidates are also exposed to the financial and operational aspects of the readymix business.

For AfriSam’s Artisan Learnership Programme, prospective candidates are generally people who have completed their National Qualification Framework (NQF) courses, be it internal employees (18.1 learners) or external candidates (18.2 learners).

According to Johnson, AfriSam plays an active role in the development of artisans because the company believes it is an important skills-set that has been lost in the country. A functional economy, he says, must have a sufficient number of artisans if it is to fulfil its

potential. The same goes for a technical industry such as quarrying – artisans are the lifeblood of a functional industry and “are the tool that keeps operations going”, says Johnson.

“In my view, it is a bit challenging to train artisans at the moment, largely because the quality of trade schools has deteriorated alarmingly compared to the years gone by. The quality of artisans today is not what it used to be decades ago when we still had functional trade schools. We need that same passion back in the country and therefore encourage young people to be tradesmen,” he says.

With that said, AfriSam has recorded massive success with its Artisan Learnership programme over the years. Several young people have qualified through this programme. To provide context, out of the 113 development positions since 2012, a total of 83 artisans – both 18.1 and 18.2 learners – came through the system.

Over the years, AfriSam has also achieved enormous success with its Engineer-in-Training and Trainee Works Manager programmes. For example, of the 113 development positions created since 2012, 30 were engineers in training and internships.

Flagship milestones attained over the years are also testimony to the success of these development programmes. For example, Isaac Mabalane, who now works for a different organisation, was the first black certified (GCC) engineer to come through AfriSam’s engineering graduate programme. Gao Sebego, the first black female works manager at AfriSam, is also a product of the Trainee Works Manager programme.

Several other works managers have also come through the programme. For example, every single works manager at all AfriSam aggregates operations in Gauteng has come through the company’s training programme. Some of the names that come

to mind include Louis Sterley (Rooikraal and Sub Nigel), Mohammed Docrat (Jukskei), Chris Yedwa Mgxekwa (Eikenhof) and Moses Nkuna (Ferro). In KwaZulu-Natal, Ernest Sebeelo (Petermaritzburg Quarry) and Llyod Maringa (Coedmore Quarry) are also products of AfriSam’s various development programmes.

High up the ladder, several line managers in the business have also gone through the training programmes. For example, Zielas du Preez, regional manager, Construction Materials Gauteng and Cape Operations, and Theolan Govender, former engineering manager and now regional manager, Construction Materials KZN, are products of the company’s training programme. Other high-profile executives who have their roots firmly rooted in these development programmes include Avi Bhoora, construction materials executive at AfriSam, and Glenn Johnson, General Manager Construction Materials. AfriSam’s investment in skills development has not only paid dividends for the company, but the industry at large. A case in point is the large number of ex-AfriSam employees in high-profile positions at competitor organisations and industry bodies. Letisha van den Berg, the now director of industry association, ASPASA, is one of the flagship names that springs to mind. Having started out her stellar 17-year AfriSam career as an admin clerk at the AfriSam Newcastle Quarry in KwaZulu Natal, she rose through the ranks to become Construction Materials Health and Safety Manager in 2015.

“Despite the recent challenges brought about by the Covid-19 pandemic and the continued downturn in the construction sector, which have put pressure on our development programmes, we continue to show the resolve to develop people. I also urge other industry players to play their part in developing skills the industry needs, now and well into the future,” concludes Johnson. a

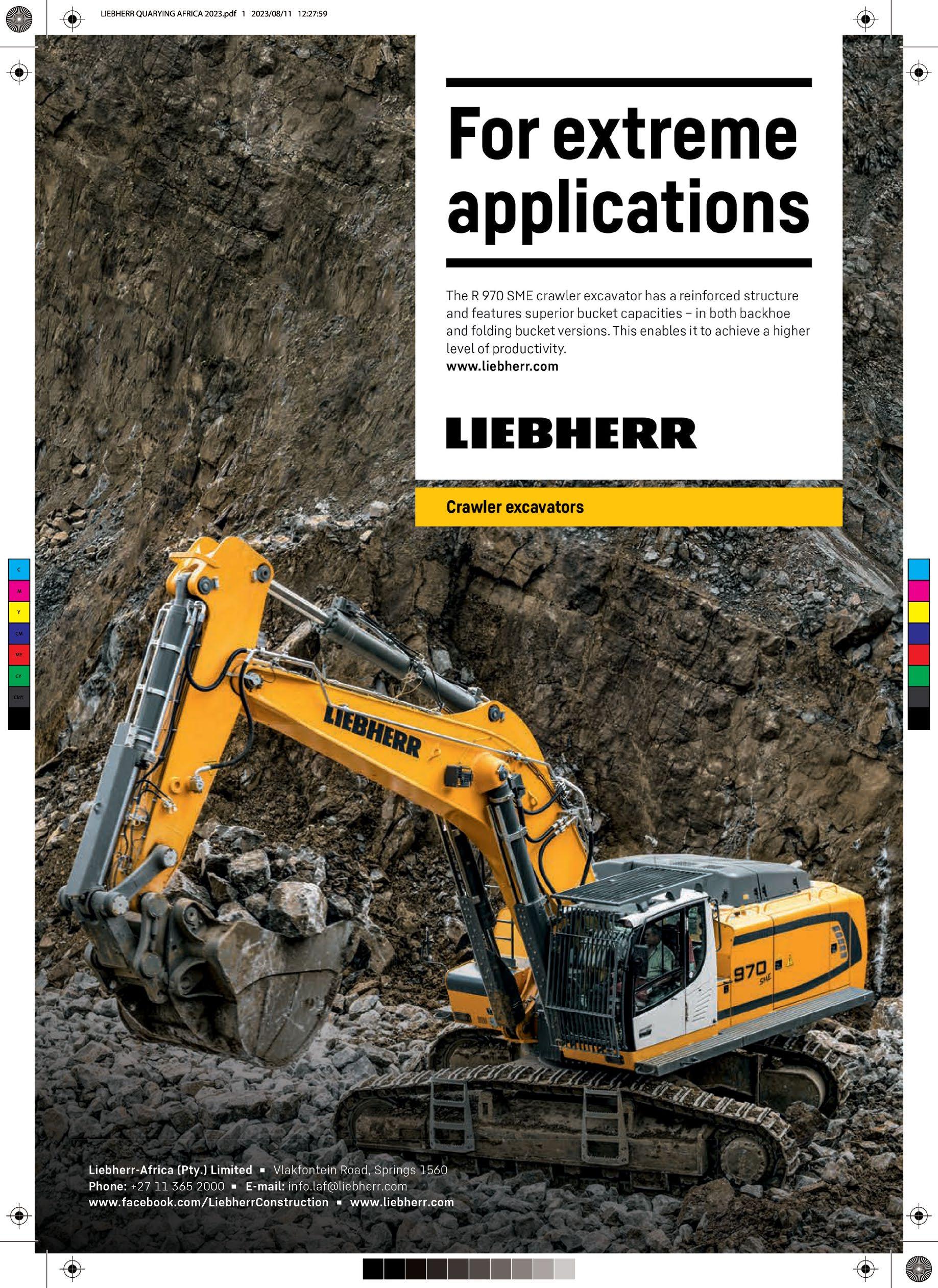

Ideal for high-production quarries, Liebherr’s 80-tonne (t) R 970 SME crawler excavator places value on increased safety, productivity and efficiency. As the industry grapples with long lead times due to global supply chain issues, LiebherrAfrica has enough inventory to eliminate waiting times for customers in southern Africa. By

Munesu Shoko.

Munesu Shoko.

14,5 t

A 14,5-t counterweight further increases the stability of the machine, allowing it to be equipped with a 5,2 m HD backhoe bucket

80 t

With an 80-t operating weight, the machine is ideally suited for loading 40-t dump trucks

With that in mind, Liebherr’s R 970 SME (Super Mass Excavation) crawler excavator has a special design focus on both productivity and efficiency – the key parameters for every quarry owner

Special hydraulic cylinders give the machine outstanding digging and breakout forces in arduous mining and quarrying applications

With efficiency in mind, the machine benefits from a complete range of Liebherr components, all the way from the engine to hydraulic pumps and electric systems

Maintenance work is also made easier by the large maintenance access with the easy-to-open engine hood, thus maximising both safety and machine uptime

7 m

The machine’s boom has a length of 7 m, with a 2,6-m-long stick

600 mm

The machine comes with a heavy D9G undercarriage equipped with 600 mm wide, two-bar track pads of the next size up machine, the 90-t R976 model, for greater rigidity and the much-needed machine stability to carry a larger bucket

The importance of an efficient load and haul system in achieving quarry productivity cannot be emphasised enough. Increasing productivity is one of the key drivers to counter diminishing profit margins as it effectively reduces operating costs. With that in mind, Liebherr’s R 970 SME (Super Mass Excavation) crawler excavator has a special design focus on both productivity and efficiency – the key parameters for every quarry owner.

In an environment characterised by long lead times for new machines, Tendayi Kudumba, GM –Earthmoving Technology at Liebherr-Africa, says local customers can take advantage of Liebherr-Africa’s readily available stock for the R 970 SME crawler excavator.

The R 970 SME is equipped with an array of features that speak directly to increased productivity. Central to this feat is the heavy D9G undercarriage equipped with 600 mm wide, two-bar track pads of the next size up machine, the 90-t R976 model, for greater rigidity and the much-needed machine stability to carry a larger bucket. The boom has a length of 7 m, with a 2,6-m-long stick. A 14,5-t counterweight further increases the stability of the machine, allowing it to be equipped with a 5,2 m HD backhoe bucket. “Some larger competitor offerings in the 90-t class actually come with 4,5 m³ buckets,” says Kudumba. “The Liebherr R 970 SME therefore punches well above its weight with a larger bucket, allowing customers to improve their productivity.”

With an 80-t operating weight, the machine is ideally suited for loading 40-t dump trucks. Traditionally, a key parameter in achieving the optimal match factor is the number of scoops a loading tool takes to fill the truck. The rule of thumb, says Kudumba, is four to five scoops for a high production site where quicker cycle times are required. The R 970 SME fills a 40-t truck with four scoops.

Lavell Ruthman, head of sales – Earthmoving Technology at Liebherr-Africa, adds that special hydraulic cylinders give the machine outstanding digging and breakout forces in arduous mining and quarrying applications. In fact, digging and breakout forces have been increased to over 15% higher than the predecessor model. All-in-all, these measures ensure good performance and economy of the excavator.

The cast sprocket wheel with double tooth segment for longer life is another talking point, comments Kudumba, who says most competitor offerings in this range come with single tooth sprockets, resulting in high wear and ultimately reduced life of the component. Available for Liebherr’s 50-t and larger machines, the double tooth sprocket means that the machine is able to withstand higher operational forces, even in arduous mining and quarrying applications.

With efficiency in mind, the machine benefits from a complete range of Liebherr components, all the way from the engine to hydraulic pumps and electric systems. This is in line with Liebherr’s international strategy to install in-house

components in its own equipment.

“Critically, we use our own components which are purpose- built for the machine. These components are made in house by Liebherr and are carefully designed to match each other to maximise machine performance and efficiency,” says Kudumba. Effectively, this one-stop shop approach means that the complete machine – from bucket to counterweight – carries Liebherr components, giving the customer the assurance of the Liebherr quality across the whole machine.

New features added to the uppercarriage of the R 970 SME increase safety for the excavator operator and also make it easier to service the machine. Platforms with galvanised surface protection located on both sides of the uppercarriage make the environment safer for the operator when cleaning and servicing the machine. Maintenance work is also made easier by the large maintenance access with the easy-to-open engine hood, thus maximising both safety and machine uptime.

Based on Liebherr’s understanding that a safe and comfortable operator is a productive one, the machine places value on ergonomics. According to Ruthman, the R 970 SME has the largest and quietest cab in this class size. “The cab has impact-resistant glass in the windscreen and skylight, which offers a much safer environment in which to work during quarrying,” concludes Ruthman. a

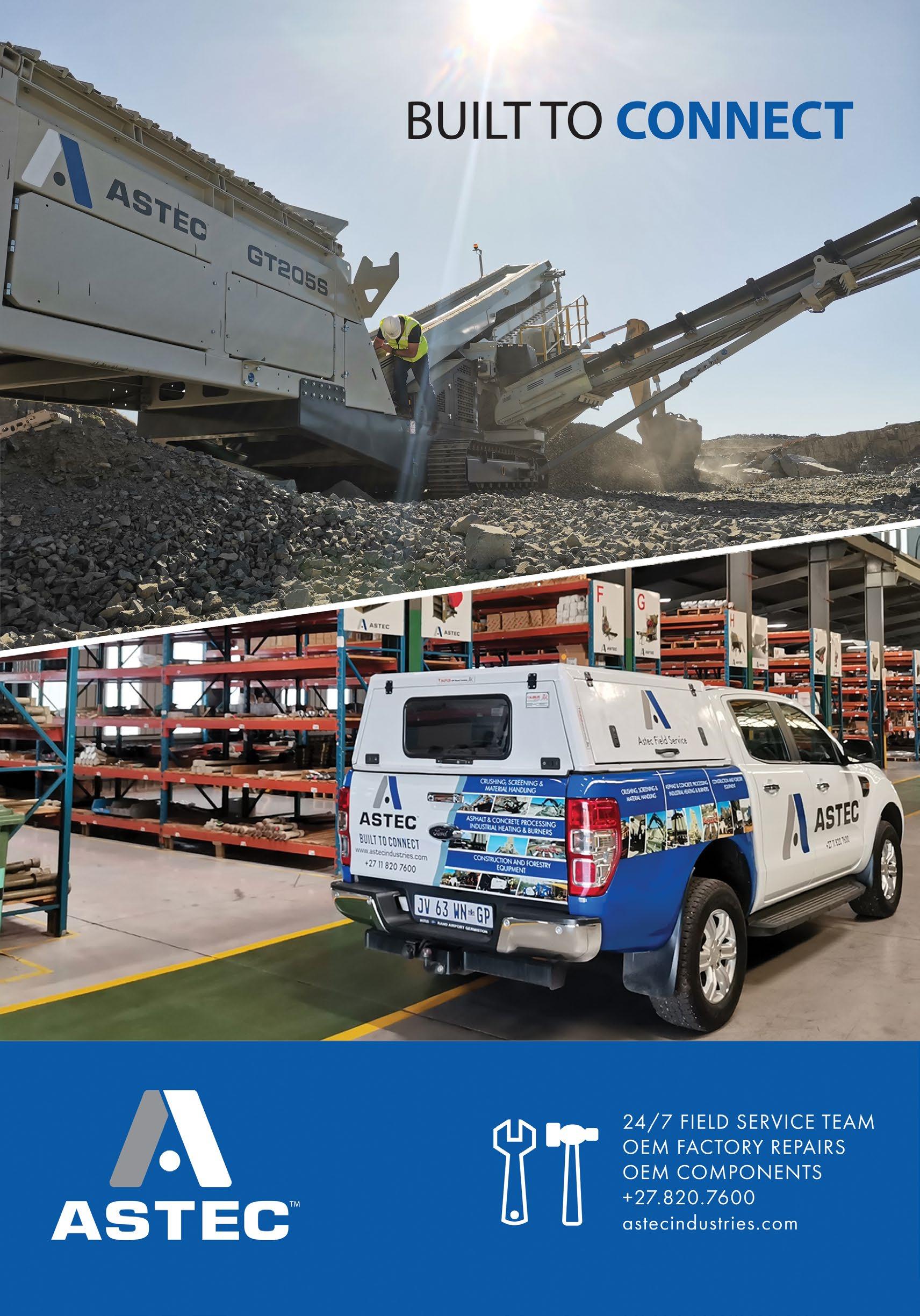

As part of its aftermarket support expansion strategy, SANY Southern Africa has invested in a new branch in Rustenburg, North West Province, South Africa. Officially opened on June 29, the new branch is aimed at supporting the growing installed base of machines in the mining area. By Munesu Shoko.

100

R300-million

o support the growing complement of its machines operating in the mining area of Rustenburg, SANY Southern Africa has officially commissioned a fully fledged branch that will provide field service and parts support to customers operating in the area.

98%

With

The new branch forms part of SANY’s newly adopted strategy to go to market directly, confirms Thabile Dube, key accounts executive at SANY South Africa. The opening of the Rustenburg facility follows hard on the heels of the commissioning of the Middleburg branch late last year.

Samuel Zhang, GM of SANY Southern Africa, tells Quarrying Africa that the decision to invest in a new branch in Rustenburg was necessitated by the growing

population of SANY machines in the area. “Rustenburg is such a strategic market for us with close to 100 SANY machines actively operating in the area. The new branch allows us to respond to service requirements timeously,” says Zhang.

As part of its strategy to further grow its aftermarket capacity, SANY will open branches in all major cities across South Africa. Dube confirms that the company has a target to open two more branches, in Richards Bay and Durban, in a year’s time. In total, SANY envisages a network of nine branches in South Africa within the next few years.

Apart from branches, SANY has committed a big investment in a new 12 000 m² parts warehouse. Strategically located along the R21 highway in Boksburg, the new worldclass facility will triple SANY’s current parts stockholding.

“We currently hold R90-million worth of spare parts in our existing facility. With the new warehouse, our target is to expand the value of our spare parts stockholding to about R300-million within a year,” says Dube.

“We understand the importance of parts availability for our customers, which is why we are committing to this big investment,” says Zhang. “With this new facility, we will be able to achieve a 98% local parts availability.”

In addition, SANY has committed a further R300million to the development of its new regional headquarters in Boksburg. Construction will start in the third quarter of this year, with completion expected by the end of 2024.

“These investments are informed by our drive for customer satisfaction and to advance the reputation of the brand in southern Africa, which is important for us. The huge capital investments also exhibit our long-term commitment to the local market,” says Zhang.

Over the years, SANY has become a force to be reckoned with in the global construction and mining equipment market. To provide context,

To support the growing complement of its machines operating in the mining area of Rustenburg, SANY Southern Africa has officially commissioned a fullyfledged branch that will provide field service and parts support to customers operating in the area

As part of its strategy to further grow its aftermarket capacity, SANY will open branches in all major cities across South Africa

the company ranks among the top five largest construction equipment manufacturers in the world, according to KHL Group’s Yellow Table 2023. In addition, the company held a sizeable 16% of the global excavator market in 2020/21.

A distinct focus on quality improvement has over the years yielded massive growth for the brand in southern Africa. To support the growing number of machines in the market, the company continues to invest in its aftermarket support.

“Over the years, we have focused our efforts on the quality of the product, which has improved immensely. In order to compete with other established names, we see the need to provide comparable service and support, and that starts with investments in branch and parts infrastructure,” says Zhang.

Zhang says that service ahead of product is not a new concept, but as the industry continues to develop and customers become more sophisticated, aftermarket support is gaining more focus and importance.

Zhang adds that the support for mission-critical equipment has never been more important as

customers seek to maximise availability and ultimately productivity. Efficiency, he says, is of paramount importance, and this requires the right support at the right time and with a realistic value.

“SANY’s continued investments in aftermarket support are informed by our understanding that customers place so much emphasis on speed of service and machine uptime. A short reaction time for service support is key to minimising downtime. It is important to have the correct parts or components available to ensure machine repairs are executed timeously,” says Zhang.

A machine sale, says Dube, is one thing, and being able to provide support after the sale, is quite another. Based on this understanding, Dube says SANY does not leave anything to chance as far as its aftermarket capabilities are concerned.

“To be able to execute a proper aftermarket strategy, a fundamental pre-requisite is to have the infrastructure that allows us to respond to any service needs timeously, hence our focus on new branches and the new parts warehouse,” concludes Dube. a

®

Amid a growing uptake of scalping screens, Wirtgen Group South Africa recently launched its new generation Kleemann MSS 802 EVO scalping screen in southern Africa. The machine impresses with its ability to be deployed in coarse and fine screening applications. By Munesu Shoko.

Having traditionally partnered another manufacturer for its screening range, Kleemann commenced the production of its in-house designed and built range of screens some four years ago. The first screens to roll off the company’s production line as part of this strategy were the MOBISCREEN MSC 702 and 703 EVO, as well as the MOBISCREEN MSC 952 and 953 EVO classifying screens.

The next natural step, explains Waylon Kukard, sales manager at Wirtgen Group South Africa, was the development of scalping screens, which resulted in the global launch of the Kleemann MSS 802 EVO some two years ago, before the local introduction early this year.