February 2018 // Railway Track & Structures AUGUST 2023 | WWW.RTANDS.COM ALSO: BALLAST RAIL WELDING SPECIAL TRACKWORK RT&S EDITORIAL BOARD

DEVELOPMENTS IN

of Rail & Gauge Face

FRICTION MANAGEMENT CONSUMABLES

Top

Tamping Technology

The Plasser heavy-duty, high speed, continuous action switch and production track tamping machine 09-2X DYNACAT is capable of tamping one or two ties at a time with an integrated dynamic track stabilizer. Tamping and lifting units are mounted on a separate satellite frame attached to the main frame. While the satellite indexes two ties during the actual work process (lifting, lining, cross-leveling, and tamping), the machine’s main frame with stabilizer system moves smoothly and continuously. Equipped with AGGS, ATLAS, PLC CAN bus control system, and it‘s unique design and construction allows the 09-2X DYNACAT to achieve production rates of up to 4,200 feet per hour.

”Plasser & Theurer“, ”Plasser“ and ”P&T“ are internationally registered trademarks plasseramerican.com

HIGH

CAPACITY I PRECISION I RELIABILITY

August 2023 // Railway Track & Structures 1 rtands.com CONTENTS FEATURES Follow Us On Social Media @RTSMag 10 Rail Friction Management Consumables Top of Rail and Gauge Face 18 Vendor/Product Spotlight Special Track Work 20 Vendor/Product Spotlight Rail Welding 24 Vendor/Product Spotlight Ballast Maintenance August 2023 20 DEPARTMENTS COLUMNS MxV Rail R&D Thermal Effects of Engineered Polymer Composite Ties on Track Gauge AREMA Message from the President 4 30 Editor’s Notebook RT&S Editorial Board Special Report Meet the RT&S Editorial Board From the Dome What is the House GOP Thinking? 3 8 36 18 Cover: Rail Lubricant Being Applied to Track For story, see p. 10

GET A NEW LEASE ON BALLAST MAINTENANCE SURFACING SETS THAT KEEP YOU MOVING WHY LEASE? GET THE PARTS YOU NEED SCAN THE CODE •Flexible cash budgeting •Access to the latest technology •Asset-light model A job’s not done without tampers and regulators. That’s why we revitalized our surfacing eet to power yours with safety, reliability, and innovation.

KERSHAW

46-2

REBUILD ALSO AVAILABLE) HARSCO

HARSCO

MARK IV PRODUCTION TAMPER

REBUILD

(4600

3000 UTILITY/SPOT TAMPER

CONTACT US. LET’S TALK BUSINESS. 800.962.2902 quotes@RELAMinc.com RELAMinc.com RELAM, Inc. 7695 Bond Street Glenwillow, Ohio 44139

6700 PRODUCTION TAMPER (CALLISTO UPON REQUEST)

Vol. 119, No. 8

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121

Woodstock, GA 30189

Telephone (470) 865-0933

Website www.rtands.com

DAVID C. LESTER

Editor-in-Chief dlester@sbpub.com

JENNIFER M c LAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

David Clarke, University of Tennessee

Brad Kerchof, formerly Norfolk Southern William Riehl, Genesee & Wyoming/AREMA

Scott Sandoval, Genesee & Wyoming

Robert Tuzik, Talus Associates

Gary Wolf, Wolf Railway Consulting

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200

Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR.

President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS

Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ

Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp.

253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195

curt.ciesinski@parsintl.com

RT&S Editorial Board

For many years, Railway Track & Structures has bene ted from capable editorial leadership and outside contributors. Beginning with this issue, I am proud to announce that we have assembled an Editorial Board for RT&S to provide overall guidance and suggestions for improving the magazine, strengthening the editorial content, and helping all RT&S media outlets to be more useful to the railroad maintenance-of-way sector.

We are very fortunate to have a distinguished group of rail engineers and consultants who are pro led in the “Special Report” section that is found on page 8. Meanwhile, let me introduce the six individuals who comprise our Editorial Board.

• David Clarke, civil engineer, professor and former Director of the University of Tennessee Center for Transportation Research at the University of Tennessee, Knoxville.

• Brad Kerchof, retired Norfolk Southern civil engineer and writer/speaker.

• William Riehl III, Chief Engineer of Structures for Genesee & Wyoming and AREMA Senior Vice President for 2023-2024.

• Scott Sandoval, Director, Engineering Testing and Compliance at Genesee & Wyoming.

• Robert Tuzik, principal of Talus Associates.

• Gary Wolf, retired Norfolk Southern civil engineer, independent consultant.

Of course, as Managing Editor and Editorin-Chief, respectively, Jennifer McLawhorn and I will continue to make the editorial decisions for the magazine and electronic media. However, our e orts will be guided by, and much more fruitful with, the decades of experience represented by our new Editorial Board. Each member was invited to serve, and they all graciously accepted.

Membership on our Editorial Board is not an honorary position. Each board member is charged with providing regular feedback, advice, and suggestions for articles for both print and web. So, there will be continuous communication throughout the year. In addition, Jennifer and I will formally meet with the board twice each year, and each board member has been asked to prepare at least one original

article for the magazine each year.

is is a major milestone for RT&S. As best as I can tell, the magazine has never had an Editorial Board since publication began in 1905. Our sister magazine, Railway Age, has long had a series of contributing editors who, I suspect, provide more guidance to the editorial sta than simply contributing an article now and then.

You’ll note that William Riehl, with Genesee & Wyoming, is also the Senior Vice President of AREMA for the 2023-2024 year. You likely know that AREMA elects a new slate of o cers each year, including the SVP position. erefore, each year, the newly elected AREMA SVP will join our board and replace the outgoing SVP. erefore, not only will our Board possess long and superb experience in rail engineering, but we’ll also have a current connection with AREMA through the rotating SVP role. is will ensure that the magazine is connected to the latest thinking, research, and product development in the industry.

We are excited about our Editorial Board and look forward to their contributions. e rail industry, especially maintenance-of-way and infrastructure, is as dynamic as ever. Technology is almost developing faster than anyone can keep track of, and it’s being employed in the rail industry as it makes sense to do so, which is quite o en. Our Board will help us keep track of and report on the latest developments so readers can stay current on infrastructure technology.

We are grateful these six individuals agreed to serve, and appreciate AREMA’s show of support by allowing us to include the organization’s rotating SVP to be a member. As regular readers know, we feature AREMA content in the magazine each month, and each member of AREMA receives a subscription to RT&S. AREMA’s representation on our Board will further strengthen the relationship between our organizations. I believe you’ll see the impact of our new Board soon.

DAVID C. LESTER Editor-in-Chief

EDITOR’S NOTEBOOK August 2023 // Railway Track & Structures 3 Railway Track & Structures (Print ISSN 0033-9016, Digital ISSN 2160-2514), (USPS 860-560), (Canada Post Cust. #7204564; Agreement #40612608; IMEX P.O. Box 25542, London, ON N6C 6B2, Canada) is published monthly by Simmons-Boardman Publ. Corp, 1809 Capitol Avenue, Omaha, NE 68102. Printed in the U.S.A. Periodicals postage paid at Omaha, NE, and additional mailing offices. Pricing: Qualified individual and railroad employees may request a free subscription. Printed and/or digital version: 1 year Railroad Employees (US/Canada/Mexico) $16.00; all others $46.00; foreign $80.00; foreign, air mail $180.00. 2 years Railroad Employees US/Canada/Mexico $30.00; all others $85.00; foreign $140.00; foreign, air mail $340.00. Single Copies are $10.00 ea. Subscriptions must be paid for in U.S. funds only. COPYRIGHT © Simmons-Boardman Publishing Corporation 2023. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For subscriptions and address changes, Please call 847-559-7372, Fax +1 (847) 291-4816, e-mail rtands@omeda.com or write to: Railway Track & Structures, Simmons-Boardman Publ. Corp, PO Box 239, Lincolnshire IL 60069-0239 USA. POSTMASTER: Send address changes to Railway Track & Structures PO Box 239, Lincolnshire IL 60069-0239 USA.

Thermal E ects of Engineered Polymer Composite Ties on Track Gauge

Special Considerations for EPC Ties

Yin Gao, Principal Investigator I, MxV Rail

Since the early 2000s, MxV Rail has been evaluating the performance of engineered polymer composite (EPC) ties and working to improve design guidelines and recommendations as part of the Association of American Railroads (AAR) Strategic Research Initiatives (SRI) program. e EPC ties, which have been used at the Facility for Accelerated Service Testing (FAST) and in revenue service tracks for over two decades, are the most common type of composite ties, and they o er a potential alternative to solid sawn timber ties. e material used for EPC ties is especially attractive for use in regions where wood is susceptible to degradation by moisture and decay organisms.

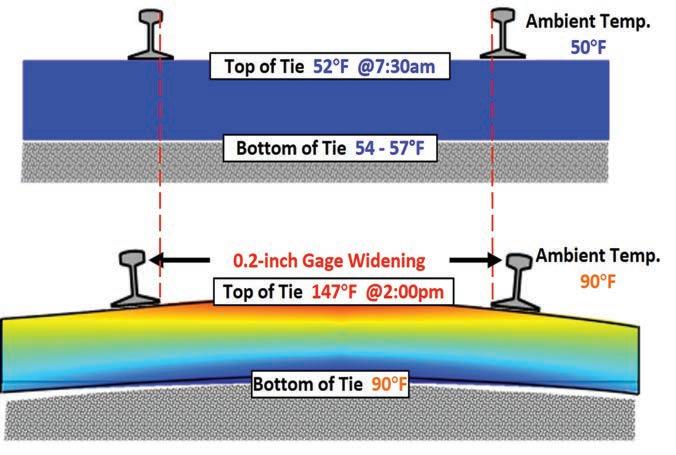

However, recent research performed at FAST in Pueblo, CO, under the AAR SRI Program showed that track supported by EPC ties experienced more gauge widening variations due to temperature changes than

track supported by wood ties. Speci cally, the track gauge for tracks with EPC ties was approximately 0.2 inch wider in the a ernoon than in the morning. Direct sunlight in the a ernoon can cause the top surface of the ties expand more than the other parts of the ties, thereby causing bending of the ties and widening of the track gauge. is article includes eld measurements that show the track gauge changes due to thermal in uence and presents the results of computer

simulations that illustrate how thermal properties a ect EPC tie performance.

Field Investigation

In the fall of 2016, track gauge measurements were taken at di erent times throughout a single day at FAST using a track geometry inspection vehicle. Unloaded gauge measurements were taken on three EPC tie zones and wood/concrete tie zones in the same curve and using the same inspection

4 Railway Track & Structures // August 2023 rtands.com MxV RAIL

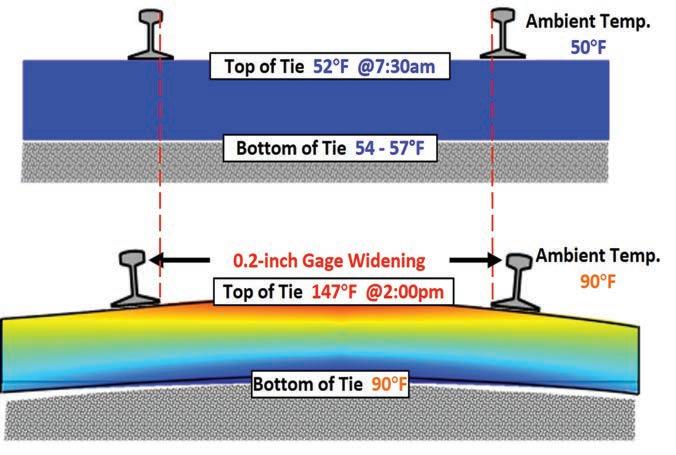

Figure 1. Temperature measurements and gauge widening at FAST

Figure 2. Simulation of direct sunlight on the track

vehicle. At the time of each test run, the tie temperatures were measured for one tie sample in each test zone. MxV Rail researchers measured tie temperatures at di erent locations on the ties’ tops and bottoms (measured from tie end and side). Ambient temperatures were recorded as well. e gauge measurement from the lowest tie temperature was recorded at 7:30 am, and the gauge measurement from the highest tie temperature was recorded at 2:00 pm.

Figure 1 shows both the ambient temperature and the temperatures recorded at various locations on a tie at the coolest and warmest times of the day. e plot also supports the general observation that the bottom of the tie tends to remain insulated by both the tie itself and the crib ballast. e insulation e ect creates a thermal gradient and generates center negative bending. Linear expansion of the tie coupled with center negative bending resulted in about 0.2 inch of gauge widening—a measurement that was consistent between all three EPC tie zones. No measurable gauge increase was observed in the adjacent wood or concrete tie zones throughout the day.

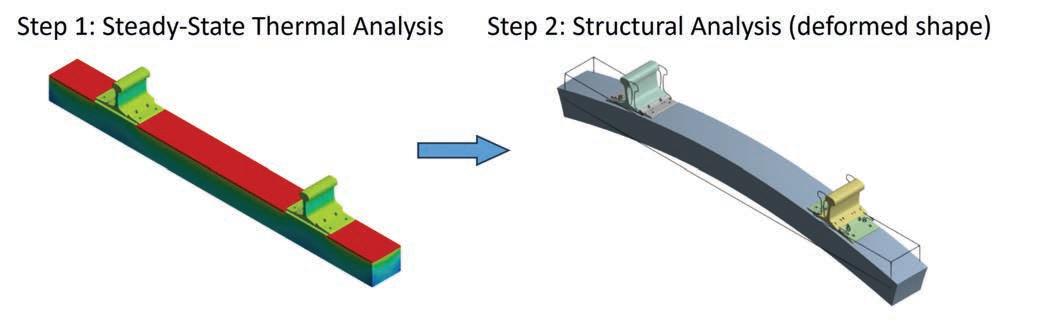

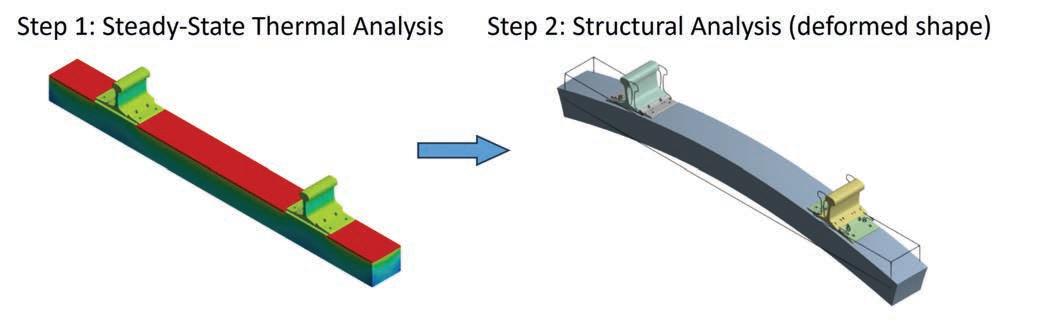

Model Description

In-track gauge measurements indicated that EPC ties can expand under heat and generate measurable gauge widening. A nite element model was established to further investigate the thermal e ect on EPC ties.

e model included 1) two short pieces of rail, 2) two American Railway Engineering and Maintenance-of-Way Association (AREMA) 14-inch tie plates, 3) one EPC tie, and 4) a supporting ballast layer. e steady-state thermal analysis was used to model the e ects of steady thermal loads on

the system and quantify the resultant gauge widening using structural analysis.

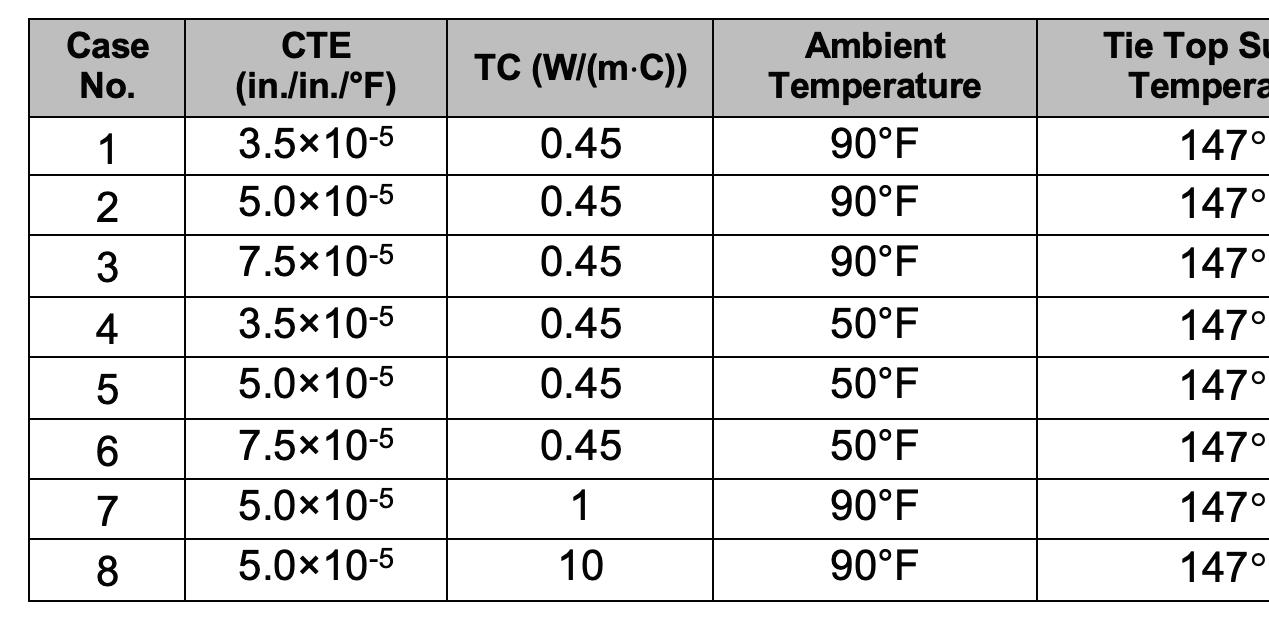

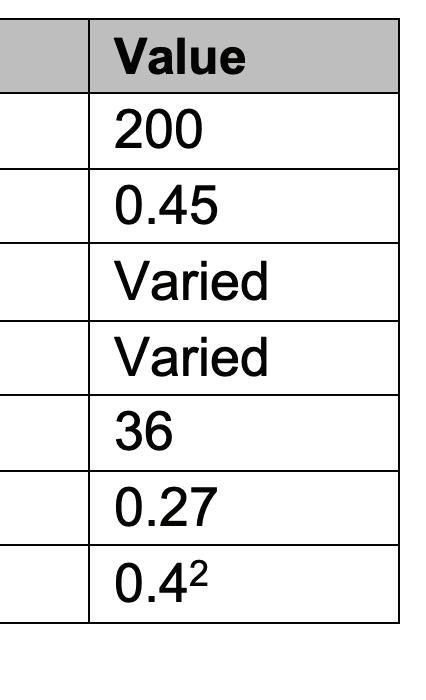

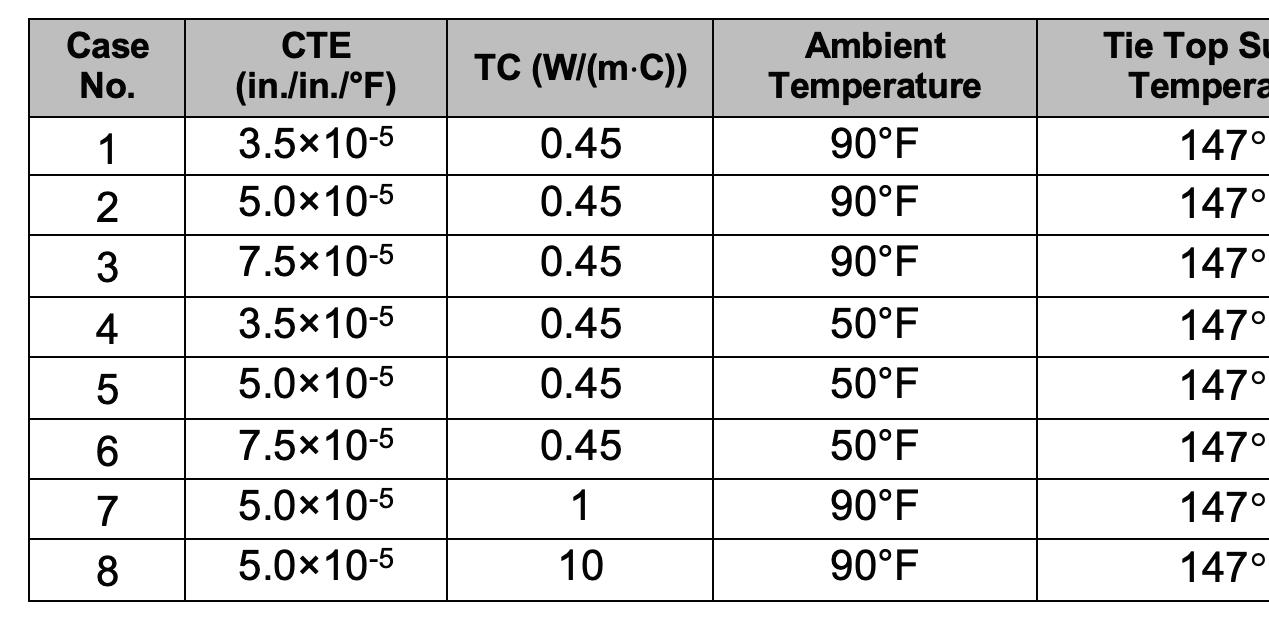

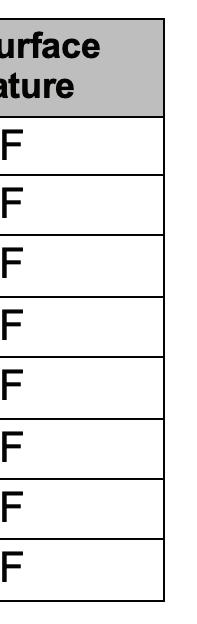

As shown in Figure 2, heat sources were applied both on the rails and on the top surface of the EPC tie (red area), excluding the tie plate area. e convection areas were all surfaces of all the components in the system. Because this was a preliminary study on the thermal e ect on the track gauge of EPC ties (not speci c to any type of tie), each model used the typical mechanical properties of each component, as listed in Table 1.

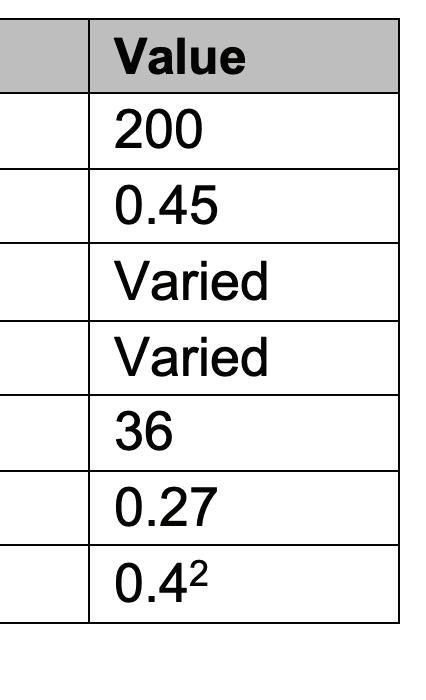

Modeling Results

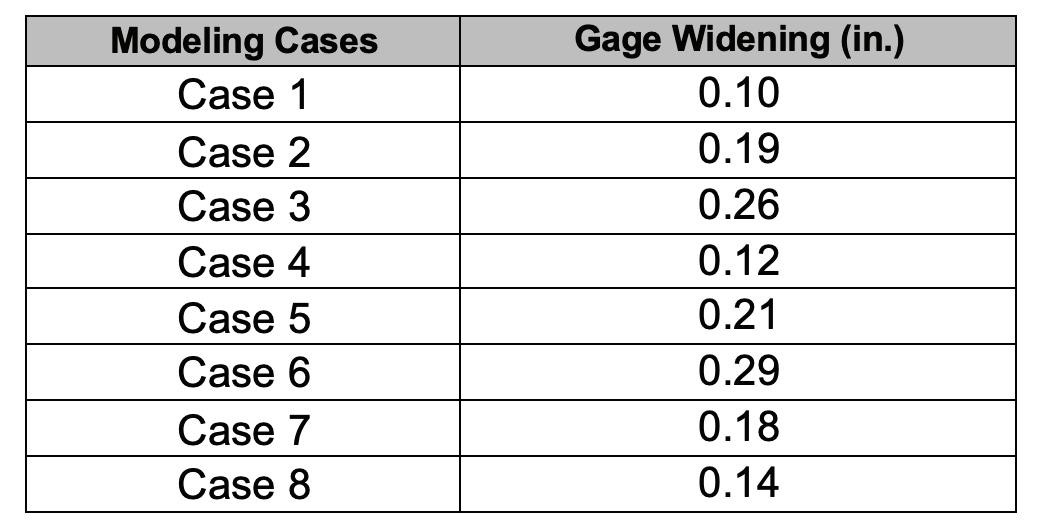

Gauge widening was calculated by changing three parameters in eight simulation cases— coe cient of thermal expansion (CTE), thermal conductivity (TC), and temperature condition— as listed in Table 2. e CTE of 3.5×10-5 in./in./°F is the lowest value of the three types of EPC ties on the FAST track;

the CTE of 5×10-5 in./in./°F is the average value of the three types of EPC ties on the FAST track; and the CTE of 7.5×10-5 in./ in./°F is the maximum allowable value in the AREMA Manual for Railway Engineering 4 e TC of 0.45 W/(m· C) is expected for high-density polyethylene,3 which is the typical EPC tie material; 1 and 10 W/(m· C) are considered high but reasonable TC values for polymer compounds.5

Table 2. Modeling parameters in simulation cases.

Cases 1, 2, and 3 were used to simulate the actual in-track temperature conditions in the FAST test for EPC ties with di erent CTEs. Cases 4, 5, and 6 represented extreme di erential temperatures between the top surface of a tie and the ambient temperature. Cases 7 and 8 increased the TC values using the parameters in Case 2 as a baseline. e in-track temperature and gauge widening measurements taken at FAST

August 2023 // Railway Track & Structures 5 rtands.com MxV RAIL

Table 1. Model parameters

Table 2. Modeling parameters in simulation cases

were used to verify the model. e CTE was assumed to be 5×10-5 in./in./ºF for all three types since each type showed a constant gage widening in the FAST test.

e modeling results show a 0.19-inchwide gauge (Figure 4) that was close to the in-track measured value of 0.20 inch. e resulting temperatures on the tie’s bottom (93 ºF) closely matched the actual measurements (90 ºF).

For each simulation case, track gauge was rst calculated using a low-temperature condition with the ambient temperature and all components at 50 F and then using a high temperature condition (simulated direct sunshine on the tie tops), which is listed in Table 2 for each case. e gauge widening value for each simulation case was the di erence between the two track gauge values calculated above (Table 3).

According to Federal Railroad Administration’s (FRA) Track Safety Standards, the allowable gauge widening for Class 4 and 5 tracks is 1 inch. Based on the results, the gauge widening caused by the thermal e ect on EPC ties did not

exceed the FRA standards. Track gauge widening can be the result of several superimposed causes, including 1) installation tolerances, 2) loading over time, 3) rail gauge face wear, 4) plate cutting/reverse rail cant, and 5) spike kill. If a Class 4 or 5 track is built at a 56.5-inch track gauge with EPC ties, the amount of classspeci c gauge widening may be reduced by at least 10 percent (Case 1) right a er construction and possibly more (29 percent in Case 6) for the tracks supported by EPC ties.

Comparing Case 1 to Case 6, two obvious and reasonable observations can be made:

• e track gauge widened more as the CTE of EPC ties increased.

• e track gauge widened more as the di erential temperature between the top surfaces of the ties and the ambient temperature increased.

Cases 2, 7, and 8 showed decreased gauge widening with increased TC values. In ties with a higher TC, the temperature eld was more uniform, making the ties bend less. erefore, a higher TC could reduce the thermal e ect on the gauge widening of EPC ties.

Conclusions

A eld investigation was performed to measure the track gage variations of EPC ties. In addition, a nite element model was built by researchers at MxV Rail to investigate the thermal e ect on the performance of EPC ties. e results from this work showed:

• Field measurements taken at FAST showed a 0.2-inch track gauge widening (consistent between all three EPC tie zones) due to the temperature swing in one day.

• Track gauge widening ranges from 0.10 to 0.29 inch in the simulation cases that had changes in temperature cases, the coe cient of thermal expansion, and the thermal conductivity of EPC ties.

• e extent of the gauge widening in the modeling did not exceed the FRA safety standards for any track class, but the thermal gauge widening could reduce the amount of gauge widening from other causes without altering the track class.

• e amount of gauge widening is predicted to be less when using EPC ties with a higher thermal conductivity.

Acknowledgement

MxV Rail gratefully acknowledges the support from the Association of American Railroads Strategic Research Initiatives Program – Tie and Fastener Systems.

References

1. McHenry, M., Y. Gao, and J. Baillargeon, 2018, “Implementing Improved Composite Tie Design and Testing Guidelines into the AREMA Manual for Railway Engineering,” Proceedings, 2018 Annual AREMA Conference.

2. Engineering ToolBox. ermal Conductivity of selected Materials and Gases. Available at: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html [Accessed January 28th, 2023].

3. Santa, G., F. Peron, A. Galgaro, M. Cultrera, D. Bertermann, J. Mueller, and A. Bernardi. 2017. “Laboratory Measurements of Gravel ermal Conductivity: An Update Methodological Approach.” Energy Procedia, Volume 125, Pages 671-677.

4. Manual for Railway Engineering, Chapter 30 – Ties, 2022

5. Grundler, M., T. Derieth and A. Heinzel, 2016, “Polymer Compounds with High ermal Conductivity.” 2016 AIP Conference Proceedings 1724, 020049.

6 Railway Track & Structures // August 2023 rtands.com MxV RAIL

Figure 4. Simulation of the in-track results for model verification

Table 3. Gauge widening in each case

LIGHT RAIL 2023

PRESENTED BY RAILWAY AGE AND RT&S

PLANNING, ENGINEERING AND OPERATIONS

Developed for planning, operations, civil engineering, signaling and vehicle engineering professionals, Light Rail 2023 o ers a comprehensive review of technical and operational issues associated with light and interurban railways.

Key Sessions

•Engineering for Operations

•Light Rail Engineering Standards

•Safety Certification

•Operations Planning and Modeling

•Battery and Hydrogen Fuel Cell Propulsion

•Signaling, Train Control and Street-Running Interfaces

•Leveraging Federal Funding

•PLUS Tour NJ Transit’s Hudson Bergen System

Keynote

Kevin S. Corbett President

and CEO

NJ Transit

Chalon

jchalon@sbpub.com

Regency

NOVEMBER 15 & 16 Hyatt

Jersey City on the Hudson Jersey City, NJ

LEARN MORE www.railwayage.com/lightrail SPONSORSHIPS & EXHIBITS

Jonathan

212.620.7224

Railway Track & Structures’ Editorial Board

Guiding RT&S Into a New Era

By David C. Lester, Editor-in-Chief

As I outlined in this month’s “Editor’s Notebook,” we are very pleased to announce the Railway Track & Structures’ Editorial Board. This distinguished group of engineers and consultants will provide overall guidance and counsel to improve the publication, strengthen the editorial content, and help all RT&S media outlets become more useful to the railroad maintenance-of-way and engineering sectors.

Membership on our Editorial Board is not simply an honorary position. Each member was invited to serve and is charged with providing regular feedback, advice, and suggestions for material in both print and digital form. There will be continuous communication throughout the year and our Managing Editor, Jennifer McLawhorn and I will formally meet with the Board twice each year. In addition, each member has been asked to prepare one original article for the magazine each year.

It is with great pleasure that I introduce our Editorial Board:

Dr. David B. Clarke is a civil engineer specializing in transportation, with a particular emphasis on railways. His career experience includes engineering, education, research, and management. David spent over 30 years in academia, with the final 12 years as Director of the University of Tennessee Center for Transportation Research. As Director Emeritus, he continues to teach railroad engineering and operations at the college level (undergraduate and graduate) and through workshops targeting working professionals. David’s rail research activities focused on line and terminal capacity, rail network performance, intermodal transportation, rail costing, railway safety, and track behavior. He served as the UT lead for the U.S. Department of Transportation funded National University Rail Center (NURail), a consortium of seven universities led by the University of Illinois at Urbana-Champaign.

During his time in academia, David, a licensed professional engineer, started

and maintained a part-time consulting practice that continues to the present. Through this work, he has gained extensive practical experience in railway operations and engineering. His work includes track design, track and bridge inspection, construction planning and management, and rehabilitation planning. David is a life member of the American Railway Engineering and Maintenance-of-Way Association (AREMA) and the American Society of Civil Engineers (ASCE). He is active in railroad committees in AREMA, ASCE, and the Transportation Research Board (TRB). He chaired TRB Committee AR040, “Rail Freight Transport” and the ASCE Rail Transportation Committee.

Brad Kerchof started his railroad career with Conrail in 1977. Significant assignments included division engineer in Indianapolis and Pittsburgh, as well as an 18-month tour at TTC, in Pueblo, Colo., as an industry exchange engineer. When CSX and Norfolk Southern split Conrail, in 1999, Brad transferred to NS and moved to Birmingham, Ala. as division engineer. His final position with NS was as Director – Research & Tests. Since retiring from NS in 2019, Brad has remained active in the industry, working for Advanced Rail Management, writing for Trains and RT&S and continuing as a regular presenter the Wheel-Rail Interface conference. Brad has a BSCE from the University of Virginia and is a registered Professional Engineer in Pennsylvania.

Bill Riehl is G&W’s Chief Engineer

Structures where he is responsible for overall structure safety management for the more than 10,000 track carrying structures and tunnels owned and operated by the G&W family of railroads in North America. A Structural Engineering graduate of the Pennsylvania State University in 1987, he worked several positions with railroad consultants, contractors, shortline and regional railroads including Florida East Coast Railway and RailAmerica. Along the way, he earned a Master of Science in

8 Railway Track & Structures // August 2023 rtands.com SPECIAL REPORT

Dr. David B. Clarke

Brad Kerchof

Bill Riehl

Industrial and Systems Engineering from the University of Florida in 2003.

Bill is a licensed professional engineer in Florida, Ohio and Wyoming. He currently is the AREMA Structures Functional Group Vice President and is a member of the Conference Operating Committee, Committee 7 – Timber Structures and Committee 24 –Education and Training, and is the incoming AREMA Senior Vice President. He is also a Fellow in the Society of American Military Engineers.

Scott Sandoval is the Director, Engineering Testing and Compliance. at G&W. Scott oversees G&W’s track testing programs with focus on rail flaw, geometry and tie grading for all 110+ short line and regional railroads. Scott began his railroad career with Norfolk Southern in 2012 as a Management Trainee and held various roles of increasing responsibility within the engineering department. In 2014, he joined G&W as a Manager of Track. Since joining G&W, Scott has continued his growth within the engineering department bringing him to his current role. He holds a bachelor’s degree in civil engineering from the University of Florida.

Bob Tuzik is principal of Talus Associates, railway marketing and consulting, and Executive Program Manager for Wheel-Rail Seminars, which produces the annual Wheel/Rail Interaction conference. He began his railway career in the Operating Department of the former Santa Fe Railway in Chicago, working in various positions from switchman to supervisor of operations over a dozen years.

He is the former editor of Railway Track and Structures and former engineering editor of Railway Age . He has also written for International Railway Journal, Trains, Mass Transit, and contributed to the Encyclopedia of North American Railroads . He currently publishes Interface , the Journal of Wheel/Rail Interaction, an online journal that provides in-depth coverage of issues and developments relating to vehi -

cle/track interaction.

Beyond his railway and journalism experience, Bob has held senior management positions at track-related railway supply companies, service providers, track-maintenance software development, data collection and analysis providers, and as an independent consultant.

Bob’s perspective, gained as a railroader, supplier, consultant, program manager, railway-engineering writer, and editor, informs the projects in which he participates.

Gary Wolf began his career as an Industrial Engineer with Southern Railway in Atlanta in 1973. He moved into positions of increasing responsibility within the engineering department at Southern, then Norfolk Southern, until 1987, when he left the railroad to start TUV-RAIL Sciences in Atlanta, an independent consulting firm specializing in the application of advance analytical techniques for the solution of railway operational problems. In 2013, Wolf founded Wolf Railway Consulting, LLC, in Atlanta, an independent consulting firm specializing in train and vehicle dynamics, especially train accident and incident investigation. Wolf’s practice also includes teaching training seminars for derailment investigation, track maintenance and inspection (213), event recorder analysis, and mechanical inspections.

Gary holds a B.S. in Electrical Engineering from Ohio University in Athens, Ohio and an M.S. in Industrial Management from Georgia Tech in Atlanta. He serves as a regular presenter at the Wheel-Rail Interface conference, and is a member of the American Society of Mechanical Engineers (also serves on General Committee), American Railway Engineering and Maintenance Association (AREMA), the Air Brake Association, and the International Association of Railway Operating Officers, serving as a Regional Consultant and Vice President, and served a stint as President of the Organization, elected in 2006.

August 2023 // Railway Track & Structures 9 rtands.com SPECIAL REPORT

Scott Sandoval

Bob Tuzik

Gary Wolf

By Je Tuzik

DEVELOPMENTS IN TOP OF RAIL AND GAUGE FACE

FRICTION MANAGEMENT CONSUMABLES

Friction management works. Whether at the gauge face or top of rail, the bene ts are widely known and widely quanti ed. Friction management products facilitate reduced rail wheel wear, RCF mitigation, noise reduction, improved fuel e ciency, and many other systemic bene ts. Although these bene ts are considered settled science, advancements in friction management consumables continue to adjust the way these products are employed, and the value proposition they present.

Top of rail (TOR) friction modi cation (FM) products are designed to hit a target coe cient of friction usually in the 0.30 to

0.4 range – a balance between wear reduction/RCF mitigation and traction; “any lower than 0.30 would have a deleterious e ect on wheel traction and braking,” Louisa Stanlake, LB Foster Technologies’ Global Product Manager – Consumable products, told delegates at the 2022 Wheel/ Rail Interaction conference.

TOR consumables t into one of three broad categories based on their composition. ere are water, oil, and hybrid water/ oil products with di erent characteristics and applications. Water-based FM products di er from the other two types in that they evaporate, leaving a dry lm with an intermediate target-friction-level. Hybrid

and oil-based products are non-drying and tend to target lower friction levels. “Oil-based consumables can achieve an intermediate friction level, but it requires ne-tuning the application rate in order to avoid over-lubricating,” she said.

FM value/cost is determined by the total cost of ownership, which includes annual product consumption, product re- lling, seasonal product switch-out (winter vs summer), track access, product storage, and applicator maintenance. Advancements in all-season, higher-performance, and more environmentally friendly consumables have also a ected the total cost of ownership.

10 Railway Track & Structures // August 2023 rtands.com

RAIL FRICTION CONSUMABLES

Photo Credit: LB Foster

Traditional seasonal TOR and GF consumables are designed around and constrained by their operating temperatures which generally range from -40 to 122 degrees Fahrenheit (-40 to 50 C). And because seasonal consumables are specically designed around one extreme or the other, performance in the shoulder seasons can su er. ese modern all-season consumables are truly viable in all operating temperatures and have been proven in eld applications. Very low temperatures raise the viscosity of the consumable and can render applicator pumps unable to apply it adequately. High temperatures on the other hand lower viscosity and adhesion, o en causing the consumable to be over-applied, leading to signi cant waste. “Rail gets very hot in the summer, and if they’re hot enough that the consumable can’t adhere to the rail surface, it’s not going to provide any bene t,” Stanlake said. e current generation of all-season consumables have been engineered to be more consistent at a range of temperatures; they have increased carry-down and adhesion properties, more consistent application/output rate, and better stability in storage.

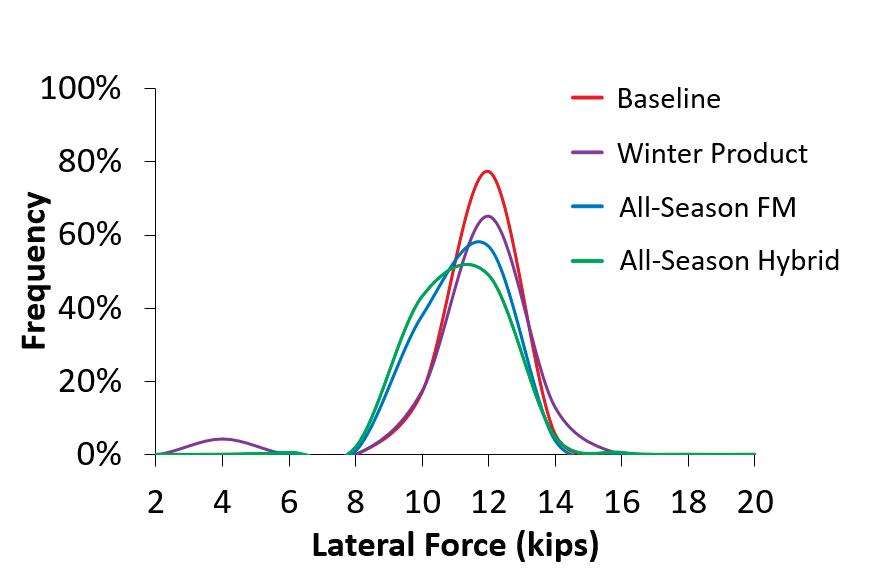

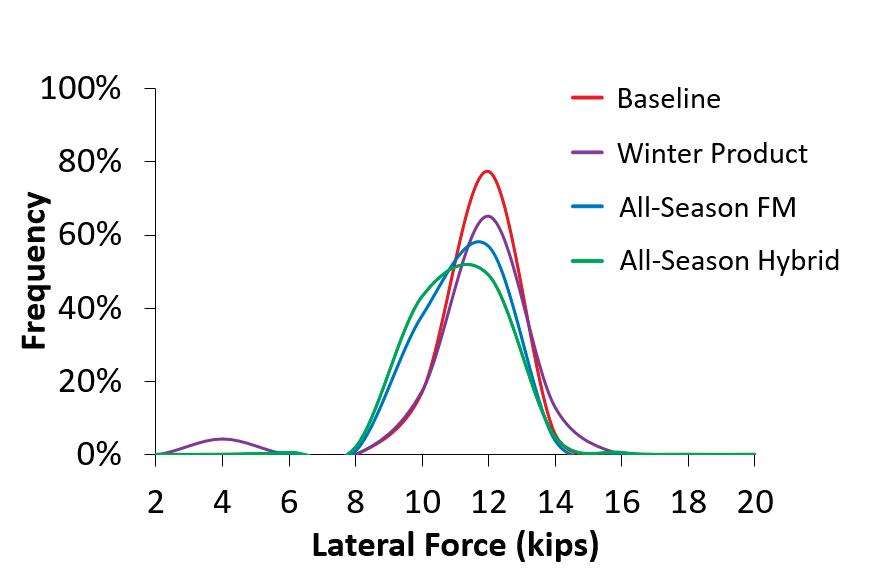

In order to ensure that consumables perform properly at a range of temperatures, manufacturers like L.B. Foster conduct various laboratory, scale, and eld tests. And while laboratory testing is a critical part of development, eld-testing is typically considered the gold-standard for demonstrating the real-world performance of the consumables. L.B. Foster conducted eld tests on three of their TOR products — an all-season waterbased, an all-season hybrid, and a coldweather water-based friction modi er — on an 8-degree curve with an ambient temperature range of 50 to -14 degrees Fahrenheit, with an average of 17 F degrees (10 to -25 degrees C, with an average of 8 degrees C) . e applicator unit was positioned at the beginning of the curve (before the spiral) in tangent track and a lateral/vertical (L/V) force measurement device was installed 3.5 miles down the track.

For the baseline (no TOR applied) measurement, the majority of the wheels passing through the L/V monitor measured between 10.5 to 14 kips (averaging about 12 kips). e results of the cold-weather TOR test were nearly identical (see gure 3). However, both all-season consumables showed substantial improvement, with L/V measurements averaging 11 kips. Despite being formulated for cold-weather operation, the cold-weather consumable’s higher

viscosity and lm durability meant that it’s carry-down rate couldn’t match that of the all-season formulations, Stanlake said.

All-season TOR FM has now been implemented in a number of locations with widely varying temperature ranges. Data collected over multiple years of use in these locations has validated L.B. Foster’s laboratory results indicating that allweather consumables are on average more e ective and e cient than their seasonal counterparts. “ e better carry-down rates of high-performance all-season [consumables] mean less product is consumed,

leading to an overall lower total cost of ownership,” she said.

As wayside consumables have evolved, so too have on-board friction management products. Wayside and on-board TOR FM are used to achieve the same, generally equivalent, result — lower L/V forces, reduced wear, and optimized adhesion. But due to the di erence in their application method, there are di erences in their formulation. Wayside TOR product is signi cantly more viscous than on-board FM. Where wayside applicators apply beads of product, on-board units produce

August 2023 // Railway Track & Structures 11 rtands.com

RAIL FRICTION CONSUMABLES

Figure 1: Factors a ecting the total cost of ownership of an FM consumable.

Figure 2: Relationship between temperature and viscosity of several FM products.

a ne, atomized spray, Stanlake said.

“On-board TOR consumables are [generally] water-based, so they’re sensitive to temperature, particularly low temperatures,” she said. As a result, on-board applicators typically require a signi cant amount of energy to heat not just the consumable, but also the hoses and nozzles of the applicator.

“ is introduces signi cant complexity (and cost) to the system, and signi cant unplanned maintenance,” she added. And even with properly functioning heating systems, there is still variability in the output rate of the consumable, depending on temperature.

In the case of on-board TOR, all-season consumables eliminate the necessity of the

heating system and enable a more consistent output rate across a wider range of temperatures, Stanlake said. In L.B. Foster’s twin-disc testing comparing their original, seasonal on-board product with their newlydeveloped all-season product, the latter achieved twice the retentivity or carry-down rate. “[ is] combination of reducing the complexity of the applicator and increasing the e ciency of the consumable nets a significant reduction to total cost of ownership.”

Gauge Face Lubrication

Gauge face (GF) lubricants (greases) aim to drive the coe cient of friction as low as possible, typically 0.25 or lower (0.30 for gauge corner); “any friction levels above 0.30 on the gauge corner and you begin to see metal lings due to gauge wear,” Stanlake said. Like TOR consumables GF grease is formulated in seasonal and all-season variants. And as with TOR, the aim is to achieve a consistent viscosity across the full range of operating temperatures.

Unlike TOR consumables, grease is always oil-based. Its viscosity is measured by penetration-testing (a cone is dropped into a volume of grease and its depth of penetration recorded) and graded on the NLGI (National Lubricating Grease Institute) scale. Summer-formulated greases,

12 Railway Track & Structures // August 2023 rtands.com

Figure 3: One of LB Foster’s test sites showing the e ect of di erent consumables on L/V values.

Figure 4: An on-board TOR FM spray (applied while vehicle is stationary in this case).

which are harder, are typically NLGI grade 2, while so er winter greases are grade 1. All-season greases tend between 1 and 1.5, she said. In addition to these metrics,

greases are graded by their biodegradability. Older petroleum-based greases rank poorly in this category, as their degradation can take years. e synthetic oils used

TheRailwayEducationalBureau

TrackSafetyStandards Subparts A-F

TrackSafetyStandards, containstheTrackSafety Standards,SubpartsA-F,forClassesoftrack1-5.The standardscovergeneralinformation,Roadbed,Track Geometry,TrackStructure,TrackAppliancesand Track-RelatedDevices,andInspection.IncludesDefectCodes.

Updated January6,2023

BKTSSAF TrackSafetyStandards,SubpartsA-F $11.95 Only$10.75forordersof50ormore!

BridgeSafetyStandards

FRAPart237establishesFederalsafetyrequirements forrailroadbridges.Thisrulerequirestrackownersto implementbridgemanagementprograms,whichinclude annualinspectionsofrailroadbridges,andtoauditthe programs. Part237 alsorequirestrackownerstoknow thesafeloadcapacityofbridgesandtoconductspecialinspectionsif theweatherorotherconditionswarrantsuchinspections. Updated January6,2023

BKBRIDGE BridgeSafetyStandards $8.95 Only$8.00forordersof50ormore!

in newer all-season greases rank better here, degrading signi cantly faster and more completely.

To function properly, GF grease must meet a number of performance criteria in extreme temperatures in order to function properly:

• Adherence to hot or cold wheels and rail

• Low propensity for applicator bar clogging

• High pumpability

• Consistent output

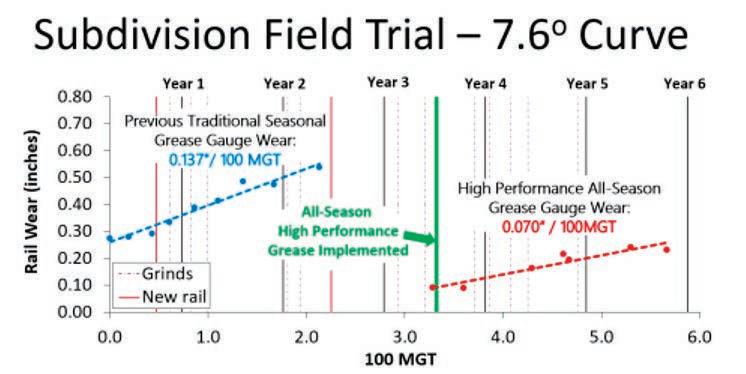

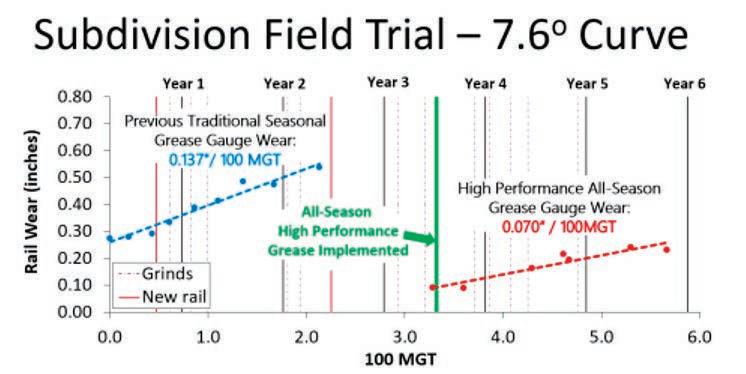

• Low oil separation

In order to assess the performance metrics of their all-season GF grease, L.B. Foster conducted a multi-year field test on a subdivision that was historically treated with seasonal GF grease. The site featured 20 curves and 25 wayside applicators. Based on prior twin-disc tests that indicated the all-season grease had significantly better carry-down than the seasonal variants, L.B. Foster deployed the all-season grease at a 50% reduced volume for the test, Stanlake said.

FederalRegulations

WorkplaceSafety

ThisreprintincludestheFRA's RailroadWorkplaceSafety Standards addressingroadwayworkersandtheirwork environments.Theselawscoversuchthingsas:personal protectiveequipment,fallprotection,andscaffoldingfor bridgeworkers;andtrainingissues.Alsoincludessafetystandardsfor on-trackroadwayvehicles. UpdatedJanuary6,2023

BKWRK RailroadWorkplaceSafety $11.50 Only$10.35forordersof50ormore!

TrackCalculator

The TrackSafetyStandardsCalculator isamustfor anyonewhoworksontrack.Thisslideruletype calculatorcontainsmanyofthedetailsforClassesof track1-5.Deviationfromuniformprofileandfromzero crosslevel.Differenceincrosslevel.Compliantwithpart213.

BKTCAL TrackCalculator $11.50 Only$10.75forordersof50ormore!

UpdatesfromtheFederalRegistermaybesuppliedin supplementform.

14 Railway Track & Structures // August 2023 rtands.com RAIL FRICTION CONSUMABLES

Figure 5: A gauge face grease applicator applying an all-season product.

TheRailwayEducationalBureau 1809CapitolAve.,OmahaNE,68102 www.RailwayEducationalBureau.com 800-228-9670 www.transalert.com AddShipping&Handlingifyour merchandisesubtotalis: Orders over$75, callfor shipping

UPTO$10.00 $6.10 $11.00 10.01-25.00 10.5018.25 25.01-50.00 14.3023.85 50.01-75.00 16.0529.75 U.S.A.CAN

e test compared roughly two years of historical gauge-face wear data to a similar time-frame a er the introduction of the all-season grease. Under the previous grease regime, one 7.6-degree curve experienced 0.137 in. per 100 MGT gaugeface wear. at same curve, treated with the all-season grease (at a 50% application rate) experience 0.070 in. per 100 MGT gaugeface wear. While there may be other variables at play, such as ongoing rail grinding during the course of the study, they were kept consistent as possible throughout the trial. Regardless, the performance of the all-season grease appears to be self-evident. “ e combination of less wear, less product consumption and reduced track accesses will drive a lower [total cost of ownership] over time,” Stanlake said.

Whether at the top of rail or gauge face, the shi away from seasonal consumables appears to be a quanti able bene t. And if these modern, all-season consumables can be applied at a reduced rate and still increase performance, as the data seems to indicate, the cost/bene t should be straight-forward.

As more properties implement all-season consumables, it will be interesting to see how their experience compares to the results of studies like these.

Je Tuzik is Managing Editor of Interface Journal. is article is based on a presentation made at Wheel/Rail Seminars’ 2022 Wheel/Rail Interaction conference.

August 2023 // Railway Track & Structures 15 rtands.com RAIL FRICTION CONSUMABLES

Figure 6: A comparison of the e ect on rail wear of two GF greases on the same curve.

Efficient

RAIL DRILL Two Speed 866-245-3745 www.trak-star.com Hydraulic & Gas Rail Drills • Hydraulic & Gas Rail Saws • Twister Bits ™ • Gas Impacts • Rail Accessories • Compact size • Two speed gear box • Honda 4-Stroke motor • Quill feed arbor • Carbide or HSS Twister Bits™ • Pressurized coolant • 10 point clamping • High torque gearing • Weighs only 49 lbs Hou-758 RTS.indd 1 1/17/23 8:37 AM

Fast

Holes

W OMEN IN RAIL

NOVEMBER 2, 2023 Chicago, IL

CONNECT. INSPIRE. INNOVATE.

Network and collaborate with a diverse group of women and allies who are making a difference in the rail industry. Learn how railroaders can maintain the momentum of inclusion, build strong support networks, and take advantage of ever-broadening career opportunities.

WHY ATTEND:

•Discover career advancement and development opportunities

• Learn about the career paths of women leaders and how today’s railways are supporting them

•Explore DEI (Diversity, Equity and Inclusion) initiatives

• Learn about mentorship best practices—from finding a mentor, to serving as one

•Discover how ERGs (Employee Resource Groups) are established for community building and support

•Connect with your peers—both upcoming talents and accomplished women in rail

SUPPORTING ORGANIZATIONS

AILWAY GE

SPEAKERS INCLUDE REGISTER: www.railwayage.com/womeninrail SPONSORSHIPS: Jonathan Chalon | jchalon@sbpub.com | 212.620.7224 Judy K. Carter SVP & Chief HR Officer BNSF Robert Grasty EVP & Chief HR Officer Amtrak Ed Quinn President & CEO R. J. Corman Railroad Group Janet Drysdale SVP & Chief Stakeholder Relations CN Rachael Peterson EVP & Chief People Officer Watco CleLeatha Shaw Mgr. - Crew Dispatching Metra Peter A. Gilbertson President & CEO Anacostia Rail Holdings Co. Don Itzkoff Chief Policy Officer Patriot Rail Company Kari Gonzales President & CEO MxV Rail

RUNNING KEEP IT

In August, we take a closer look at special trackwork and the maintenance technology that it requires to allow freight and passenger trains to operate without incident. Special trackwork, meaning turnouts, sidings, and crossovers, among others, are feats of engineering that make it possible for trains to move in the right direction. And the type of special trackwork needed is dependent on several factors. For example, the needs of a speci c railroad and the surrounding topography dictate where sidings can be built.

Sidings are tracks that split from the main line to allow trains to serve industries, access yards or move entire trains to a “passing siding” to allow a higher priority train to pass. Crossovers are a series of switches that allow trains to move from one parallel main line track to the other. Simply put, the purpose of special

trackwork is to allow a train to change direction and take a di erent route onto another track. e switch and the frog are two important parts of a turnout. While the switch is what allows a train to move from one track to another in a turnout, the frog is what guides the ange of the wheel through the crossing.

A turnout starts with stock rails, which are the rails that lay straight when the switch rails are in a closed position. Inside of the stock rails are the switch rails, or sometimes called point blades, and these are the movable rails in a turnout. ese switch rails, controlled by a switching rod, guide the wheels to stay on the current route or to turn onto another track. A shorter switch track section in a turnout allows for repairs and replacement of the switch track without having to replace the entire turnout.

e switch rails move at the switch point by way of the switching rod. Early versions of the switching rod were controlled by manual labor via a point person. Today, there are vendors who have developed point machines to handle this job. A track point machine has the ability to function remotely.

A vendor that has o ers a switch machine and works to develop a system approach to special trackwork is voestalpine Railway Systems Nortrak LLC. Tahira Dhanji, Senior Vice President of Strategy & Corporate Development told RT&S that “the bene ts of the systems approach go beyond reduced wheel impact loads and reduced noise – increasing service life, availability, and reliability, while reducing maintenance.”

Combined with more than four hundred years of railway design experience, Nortrak’s design expertise in concrete,

18 Railway Track & Structures // August 2023 rtands.com

SPECIAL TRACKWORK

Photo Credit: Nortrak (top left and right)

By Jennifer McLawhorn, Managing Editor

hydraulics, plastics, metallurgy, asset monitoring, and electrical systems deliver a “multi-disciplinary approach to railroading.” By integrating concrete crossties and turnout ties, switch drives, fastening systems, special trackwork performance, and asset performance, Nortrak has an extensive system for rail operations which includes a variety of freight and passenger operations.

In its o ering for a switch machine, Nortrak has developed its UNISTAR HR switch machine. It provides an array of bene ts, some of which include complete control of the switch points at a turnout and the ability to monitor each throw, alerting operators of deviations in trends that indicate maintenance requirements to prevent a failure.

In addition, the UNISTAR HR switch machine is easy to install due to its weight

of 165 pounds. It also has a smaller footprint that provides versatility to mount outside of gauge, on concrete, wood, or hollow steel ties, in gauge, or on tunnel walls.

ere are no additional modi cations to the signal system, and the same UNISTAR HR switch machine can control the movement and locking of Nortrak’s thick web moveable point frog (MPF) on turnouts as large as a #24. is system approach from Nortrak can reduce installation costs as well as the upgrading of a turnout to a thick web MPF. Once a switch machine such as Nortrak’s o ering has changed the direction of the ow of tra c, a passing train can continue to run smoothly through the rest of the turnout.

Along the rest of the turnout, the switch rails meet and form a small gap. e gap exists between the switch rails and the vee section to allow for a train to cross the

junction without hitting another track. e switch rails extend into wing rails past the frog, and the wing rails support the wheels through the frog as the train moves onto the diverting track. Check rails, or guard rails, exist on the inside of the stock rails to help guide the wheels onto the correct track. While the switch rails are the only moving components of a turnout, if a guard rail does not function exactly as intended, the wheel of a passing train can hit the frog and derail.

Seemingly a simple design, special trackwork such as crossovers and sidings require a great deal of maintenance. Each component must be designed and aligned correctly to function as it should. Even with the addition of remote-controlled point machines such as Nortrak’s o ering, maintaining special trackwork is a technical and serious undertaking.

August 2023 // Railway Track & Structures 19 rtands.com

SPECIAL TRACKWORK

Turnouts enable freight and passenger trains to keep moving in the right direction.

Nortrak Moveable Point Frog (MPF) on concrete

Nortrak #10 Double Crossover on Direct Fixation Fasteners

IN ALIGNMENT

While track maintenance has more than its fair share of challenges, it could perhaps be argued that rail welding is among the most challenging. Welders must work to maintain the accuracy of the track geometry throughout. As rail ends are welded together, be it by electric ash-butt welding or thermite welding, it is imperative that rail ends are perfectly aligned. In order to do so, Class 1 and Short Line railroads alike both need high-quality materials to perform such tasks. What follows is a line-up of rail welding products and services currently o ered that allow railroad track maintenance departments to

rise to the challenge.

Holland has continued to provide highquality welds to its customers across North America and Australia for over y years. O ering its Intelliweld® Control System, it gives its operators and weld quality lab the ability to see real-time weld monitoring, control, and diagnostics for each weld performed. By doing so, the system enables a Weld Quality Conformance of 99.9%.

e newest addition to Holland’s welding portfolio is Short Plug Repair Welding. e ash-butt welding process allows for better quality and cost-e ective defect remediation in comparison to traditional methods whilst necessitating less equipment and

labor. In its’ short plug repair welding gang, 5’ plugs are used with two pieces of equipment and four (railroad and Holland) employees. Repairs can take up to an hour or more, and a single four-person crew can equal the e ciency of three thermite crews.

Holland told RT&S of its Automated Manganese Refurbishment, or HAMR™, and how it “provides robotically controlled welding procedures to build back the damaged areas on rail frogs and crossing diamonds, along with ash-butt welding services.” Holland reiterates its bene ts which include a higher quality with lower porosity than other, more traditional methods as well as two to three times faster

20 Railway Track & Structures // August 2023 rtands.com

Photo Credit: Holland

RAIL WELDING

A demand for perfect rail symmetry equals a demand for high-quality rail welding products

By Jennifer McLawhorn, Managing Editor

than the manual process. Regarding safety, operators are not required to work within range of the fumes for long periods of time since the robot can continue welding while trains go by on nearby tracks.

Holland provides a full refurbishment service with its HAMR™ weld warranty. Samantha Kozak from Holland told RT&S that within the last ve years, Holland has “repaired over 350 frogs on multiple Class 1 and Short Line Railroads.” And just last year, “15 frogs that surpassed two to three years of tra c were noted during inspections which exceeded expectations!”

A leader in North American Thermit® welding, Orgo-Thermit manufactures

both of its molds and Thermit® in a New Jersey facility. Michael Madden, President of North American Operations, tells RT&S that because of this, it makes OrgoThermit “fully compliant with all Buy America requirements.”

Orgo- ermit’s welding line includes their Safe Start Crucible, a patented product that eliminates the need for ignitors.

According to Orgo- ermit, this not only makes the welding process safer, but it also reduces costs of Hazmat transportation.

Its ermit® 2.0 portion is the only one that has been developed to work with head hardened rail with a hardness of 370B. Moreover, it has an AREMA static slow

bend test result of 0.8”, exceeding the test requirement of 0.6”. Madden also told RT&S that “with testing completed at TTCI on FAST,” Orgo- ermit “demonstrated more than double the life of an Intermediate Hardness weld with 355MGT vs 171MGT.”

Along with PortaCo tools, Orgo- ermit is able to o er a full range of tools to perform a ermit® weld, and this also enables the company to provide support to its customers in every part of its application. Orgo- ermit is able to meet all of its clients’ ermit® welding needs with technical sales and service representatives across North America and a combined 120+ years of ermit® welding experience.

August 2023 // Railway Track & Structures 21 rtands.com

Holland’s HAMR with Engine

YourGuidetoRailwaySignals isanexcellentguidefor trainingsignalpersonnelespeciallyrailwaycross-function managers,supervisors,andsupportpersonnel.High-quality graphicsanddiagramshavebeenusedthroughout. Complieswithallstandardsandcommonlyusedpractices.

RailwayGeotechnics

RailwayGeotechnics coverstrack,tracksubstructure,load environment,materials,mechanics,design,construction, measurements,andmanagement.Itiswrittenprimarilyfor professionalsandgraduatestudents. BKGEOTECH

TheTrackDataHandbook

Reprintedbypopulardemand,thisbookisavaluablereference forroadmasters,tracksupervisors,trackforeman,surveyors andothersinvolvedintheplanningandexecution oftrackmaintenanceandconstructionwork.

Fold-outdiagrams.Softcover.301pages.

With a focus on safety, Pandrol maintains its development of new products to address its customers’ needs. Among its recent developments of ATW products and services are its Battery Powered Pre-Heating System and Weld Shear, an Adjustable Mold, and a state-of-the-art lab in Memphis.

Pandrol’s High Flow Preheating System “provides a uniform preheat between the head and bottom of the rail which reduces stress in the weld,” according to Allen Go , Senior Director of sales for Pandrol. e High Flow Preheating System, or HFPS, is complete in that it can replace some preexisting preheating equipment.

While preheating processes now use a mix of oxygen and propane, Pandrol’s HFPS uses pure propane. is cuts the cost of oxygen needed and improves the experience of the welder because of its lower weight and smaller canister. Ignition, timing, and stop associated with the preheating process of the HFP are fully automated, and therefore, it eliminates the need for manual interference or ame adjustment.

Additionally, Pandrol o ers a

FundamentalsofRailway TrackEngineering

Gainadeeperunderstandingoftheevolutionoftrack technology.Thisbookpresentstheknowledgeneededfor rationaldesignandmaintenanceofpassenger,freight,and transittrack.

DictionaryofRailway TrackTerms

Themostcomprehensivecollectionofdefinitionsrelatingto track.Over1500termsfromantiquatedforgottenslangto today'sjargon.Clearlyillustratedlineartenhancesthetext.

TheRailroad Whatitis,Whatitdoes

Thefiftheditionof TheRailroad:WhatItIs,WhatitDoes is evenmorevaluablethanbefore.Insideyou’llfinda comprehensivelookathowtoday’srailroadsfunction—from equipmenttoproceduresandmarketingtomaintenance.

22 Railway Track & Structures // August 2023 rtands.com RAIL WELDING

Pandrol’s Lightweight Battery-Operated Weld Shear

Photo Credit: Pandrol

TheRailwayEducationalBureau 1809CapitolAve.,OmahaNE,68102 www.RailwayEducationalBureau.com 800-228-9670 www.transalert.com AddShipping&Handlingifyourmerchandisesubtotalis: TheRailwayEducationalBureau TrackResources 25.01-50.0014.3023.85 50.01-75.0016.0529.75 75.01-100.0019.1038.85 100.01-150.0021.7550.50 150.01-200.0025.4567.45 200.01-300.0030.9083.65 Ordersover$300,callforshipping U.S.A.CAN U.S.A.CAN

BKRRNN

WhatitisWhatitdoes $49.95

BKRTT

DictionaryofRailwayTrackTerms $38.00

RailwayGeotechnics $200.00*

BKFRTE

FundamentalsofRailwayTrackEngineering $150.00

BKTDH

TrackDataHandbook $53.50

BKYGRS

YourGuidetoRailwaySignals $109.95 YourGuidetoRailwaySignals

Light-Weight Battery-Operated Weld Shear. It works to achieve zero emission shearing and deliver quality shearing results that are both consistent and timely.

Among Pandrol’s rail welding offerings is an Adjustable Mold. A singular mold, it can be used for field weld applications that range from 132# worn to 141# rail profiles with a mismatch allowance of up to 1/8”. The advantage of a rail welding product like this one is that the customer only needs to stock one kit at the warehouse, and a welding crew only needs to carry one size on their truck. With a state-of-the-art welding lab in Memphis, Pandrol is also able to provide timely and detailed evaluations that complement its ATW product line.

With the number of eyes focused on the rail industry’s safety practices and

August 2023 // Railway Track & Structures 23 rtands.com RAIL WELDING

Photo Credit: Pandrol

TRUCKS AND EQUIPMENT FOR ALL YOUR RAIL & TRANSIT NEEDS. R ENTA L SYSTEM S, INC. PHILADELPHIA 800.969.6200 DENVER 800.713.2677 DANELL A.CO M/RE NTALS

A Topic We Discuss Often

By David C. Lester, Editor-in-Chief

BALLAST

Ballast is indeed a topic we discuss o en, and so does just about everyone who is involved in railroad maintenance-of-way. Without proper ballast maintenance, the railroad would be a mess. Ballast is the only sector of maintenanceof-way to which Railway Track & Structures devotes two Vendor/Product spotlights each year. While the others are certainly critical, we only focus on those once per year. Here is what the ballast maintenance vendors that chose to participate are up to now.

Mitchell Rail Gear

Recently delivered two John Deere 210G track Excavators to Northeast Illinois Regional Commuter Railroad Corporation D/B/A METRA, specially con gured for

track ballast maintenance. Mitchell installed their cab controlled Hydraulic Rail Gear for high-speed track travel. Mitchell’s hydraulic rail gear includes ride control with dual cobra rail brakes on each of its hardened forged rail wheels. Mitchell installed Tiltrotator’s on the excavators that quick attached a series of attachments that were con gured as plug and play attachments. Each attachment, such as the 12 . undercutter, plugs directly into the Tiltrotator without the operator having to perform any special machine monitor programing. e same goes for all the other attachments that include digging buckets, ditching buckets, clam buckets, brush cutters, buckets with thumbs, cold air blowers and magnets. Special machine tracks were installed that retained the full

width of the machine for stability and allow the machine to straddle the track so it can sit on the railroad ties when situations required additional stability. e John Deere Excavators were con gured with high- ow and medium- ow hydraulic circuits with an additional dedicated return line to handle any attachment for track maintenance. e machine joysticks were programmed for easy operation with safety buttons to prevent accidental attachment operation. With the variety of buckets provided the machine operator can quickly prepare the ballast for undercutting and then return the ballast to its normal con guration for train travel. Included with the machines were 3000 hours of lubricants and lters for easy maintenance. e magnet attachment can pick up

24 Railway Track & Structures // August 2023 rtands.com

BALLAST MAINTENANCE

Mitchell Rail Gear

C M Y CM MY CY CMY K

OTR along the right-a-way and extend the machine’s boom full reach for cutting and trimming trees. A multi-purpose machine such as this John Deere Excavator can easily switch attachments to perform jobs that were once only done with single purpose machines or easily add attachments in the future as the need arises.

Loram

In 2023 Loram started pairing the productivity of their Badger Ditcher with the versatility of their slot trains. is provides customers an equipment solution capable of managing any ditching and excavating needs with a single piece of equipment. is selfpowered machine is capable of track travel at speeds up to 45 miles per hour, excavating material from ditches at a rate of 1,000 tons per hour, and storing up to 250 tons of material on machine when necessary.

Loram o ers a full line of material

handling products to support delivering product where and when our customers need it. When industry leading material delivery is required, Loram’s DumpTrains can deliver 1,500 tons of material to washout locations, work sites, or stockpiles and unload a full consist in under an hour. O oading is done up to 45 feet from track centerline. e DumpTrain for Curves® o ers all the same features as the traditional DumpTrain and can operate while in curves or tangent track.

e DumpTrain and DumpTrain for Curves® are the only belt trains in the market today that can deliver sub-ballast as well as ballast.

e SlotMachine® eet continues to experience strong demand from customers that utilize the exibility of these machines to support almost any material handling demand. e SlotMachine® consists of overlapping gondola cars carrying an excavator that can traverse the full 378-foot length. is arrangement allows for quick and e cient

loading & o oading of ties, ballast, rip rap, spoils, and almost anything in the right-ofway that is within reach of the excavator. e Self-Powered Slot (SPS) has the same features as the traditional SlotMachine® while also including a traction car so the entire consist is self-propelled to and from the worksite.

e MHC60 material handling car continues to excel at storing spoils of excavating equipment and extending work windows in areas where discharging adjacent to the track is not an option. With bestin-class o oad rates and casting distances the MHC60 is a strong complement to undercutting, shoulder ballast cleaning, and vacuum excavation equipment.

Plasser American

Plasser American o ers a eet of machines that work together to improve track conditions and heighten e ciency during both regular operation and while performing regular maintenance. Ballast bed cleaning, ballast distribution, shoulder cleaning, stabilization, and tamping all work in concert to get track to its best performance.

Ballast cleaning machines with di erent performances ful ll the individual requirements in North America. Smaller Ballast Cleaning Machines, such as the RM80, are designed for plain track and turnouts with one excavating chain and one screening unit. e RM80’s 50 mph travel speed and short set-up and knock-down times allow maximum utilization of available track time.

e RM802, biggest undercutter in the U.S., is a high-production Ballast Undercutting/ Cleaning Machine especially designed to work on track with pre-dumped ballast. Production rates of up to 2,000 feet per hour are achievable. Shoulder Cleaning Machines like the FRM85F and FRM802 complement the portfolio, keep ballast shoulder free from

26 Railway Track & Structures // August 2023 rtands.com BALLAST MAINTENANCE

Plasser American

Loram

ballast breakdown, ensure drainage, and stretched maintenance cycles. Both shoulder and ballast cleaning machines are equipped with one of two self-leveling shaker boxes that can recover a high amount of ballast in tough conditions.

e BDS100/200 Ballast Distribution System is the ideal machine to accompany high-speed surfacing gangs or used alone to reposition existing ballast. e machines are equipped with a hopper unit for ballast storage, conveyors to distribute ballast and a fully adjustable x-type ballast plow, and unique shoulder plows to pro le the ballast.

e BDS100/200 opens new possibilities to distribute the existing ballast in the network and saves money and important resources.

e Plasser 09-2X DYNACAT is a heavyduty, high-speed, and continuous action switch and production track-tamping machine with an integrated dynamic track stabilizer. While the satellite tamps and indexes two ties at a time during the actual work process, the machine’s main frame, with stabilizer system, moves smoothly and continuously at a speed determined by the operator. is ensures a consistent quality throughout the whole tamping section.

Knox Kershaw Inc.

Knox Kershaw Inc. will introduce the HBR 2300, a hybrid model of its’ well known KBR925 Ballast Regulator, in the early months of 2024. It will have all the advantages of the standard KBR 925 Ballast Regulator with the added bene ts of hybrid technology, including fuel savings, battery powered operations to reduce emissions, improved engine e ciency, decreased demand on engine and pump components, and the use of environmentally friendly renewable energy.

From their recent experience converting straddle li cranes to hybrid technology,

KKI sees the immense advantages this innovation can have on current and future MOW equipment.

Benefits of the new Hybrid Ballast Regulator Model KHR 2300:

Engine Package: 3.8 L, 74 HP vs. 6.7 L, 260 HP:

• 7-9 gallon/per hour fuel savings

• NO DEF is required.

• Smaller engine package for increased visibility

• Lower Noise Emissions

Battery Capacity and Pump Power Unit:

• Fuel savings by using batteries to power operations such as the A/C and motors

• Electric HVAC for operator comfort

• Increased engine air lter life due to reduction in engine use

• Increased engine life (only runs when charging is needed)

• Less wear-and-tear on pumps

• Lower Noise Emissions (when engine is not running)

KKI is focused on product line expansion, especially in the eld of renewable energy. e company continues to improve upon

existing models of its machines to make them safer, more e cient, and easier to operate. We could not do this without the guidance and support of our customers. rough them we learn how to make our products better with each model.

Knox Kershaw Inc. is a top manufacturer of ballast regulator machines. With 5 di erent models to choose from, each one customizable with a variety of options, there is a Knox Kershaw Inc. Ballast Regulator to suit every job, large or small.

Rhomberg Sersa North America

Rhomberg Sersa North America (RNSA) provides ballast maintenance solutions and technologies o ering public and private railroads new and innovative approaches to ballast and trackbed management.

As part of its ballast management strategy and end-to-end service o ering, RSNA has recently added a Material Handling and Distribution Train (MHDT) which consists of MFS Cars and Power Wagons that collectively enable ballast to be loaded, stored, transported, and unloaded and distributed at site.

e MHDT is designed to operate with the

August 2023 // Railway Track & Structures 27 rtands.com BALLAST MAINTENANCE

Rhomberg Sersa North America

company’s eet of RM80 high output ballast undercutters to provide the ability to collect track spoil in areas where casting of material from the undercutter is either impractical, environmentally unacceptable, or both.

e MHDT con guration is highly adaptable and can also serve as a ballast feeder to the ballast cleaner during the undercutting process, optimizing production and reducing overall ballast maintenance cost.

With each MFS car having its own internal conveyor system that connects to each adjacent car, single line ballast cleaning is possible and removes the need and costly expense of taking adjacent track out of service to accommodate support equipment.

e recent introduction of our new material handling train in North America o ers an environmentally friendly method for the delivery and distribution of ballast and handling of track spoil material.

e system allows maintenance to be performed in challenging but highly critical infrastructure which includes highly

populated areas, environmentally sensitive locations, and “traditionally di cult” locations such as tunnels.

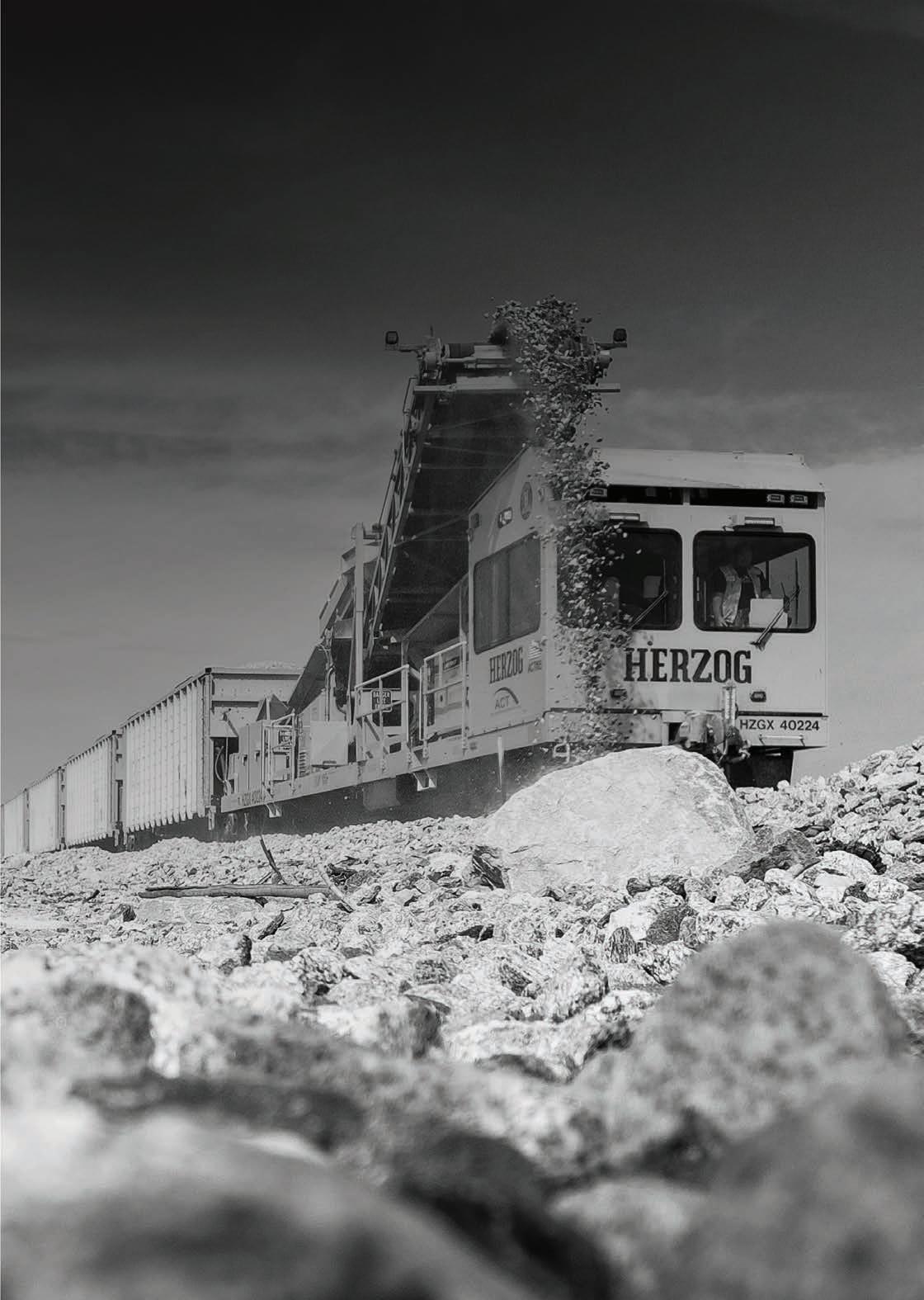

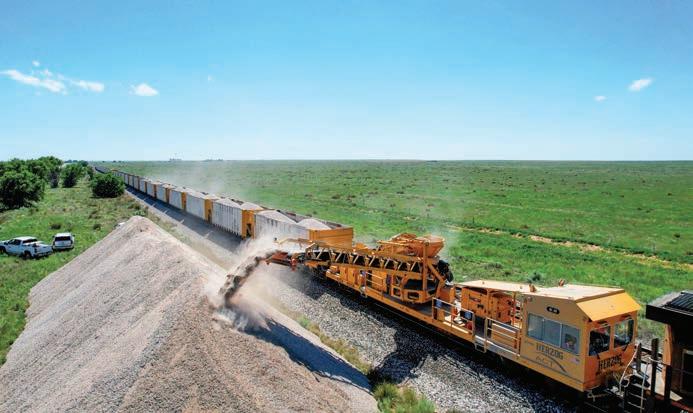

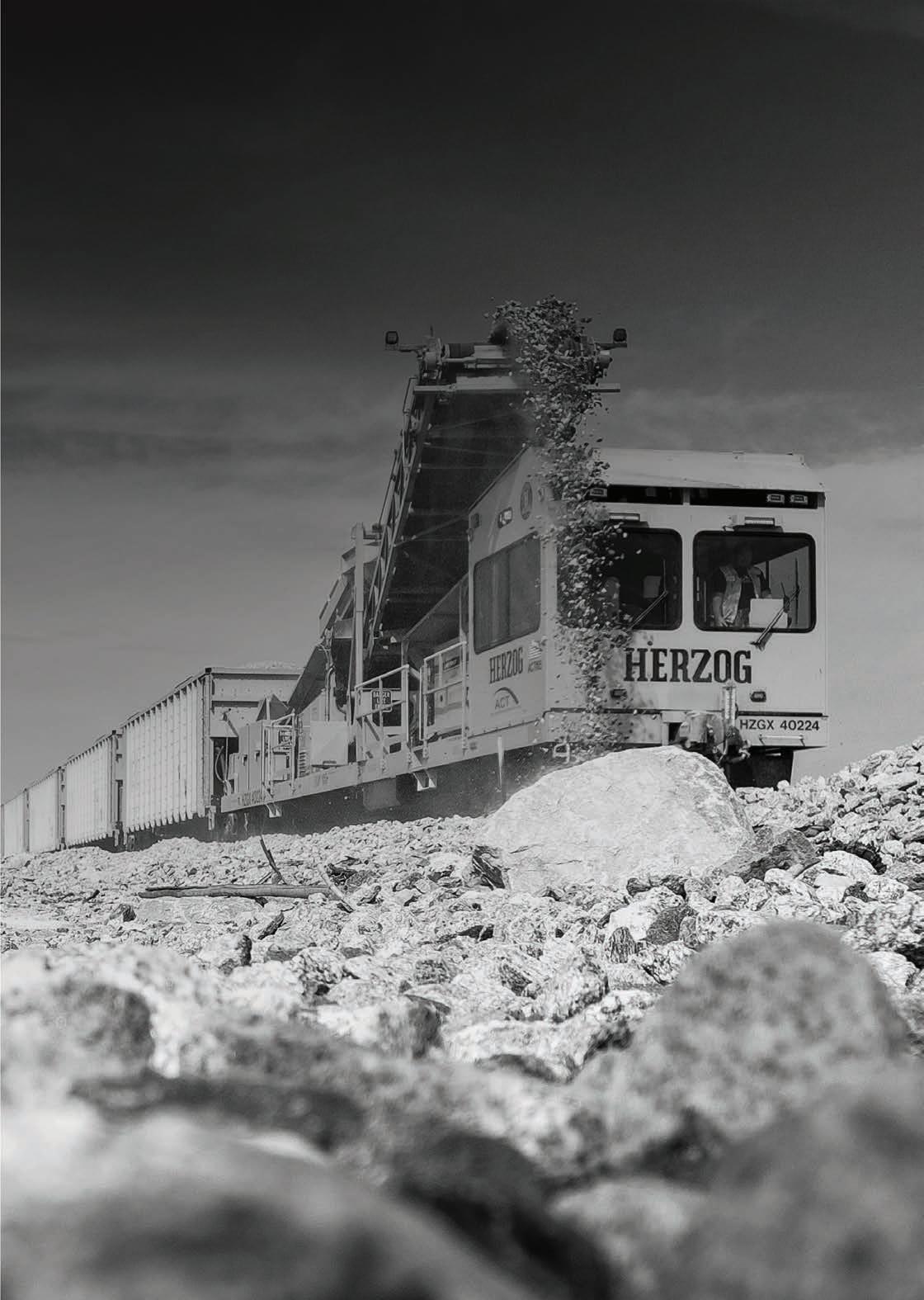

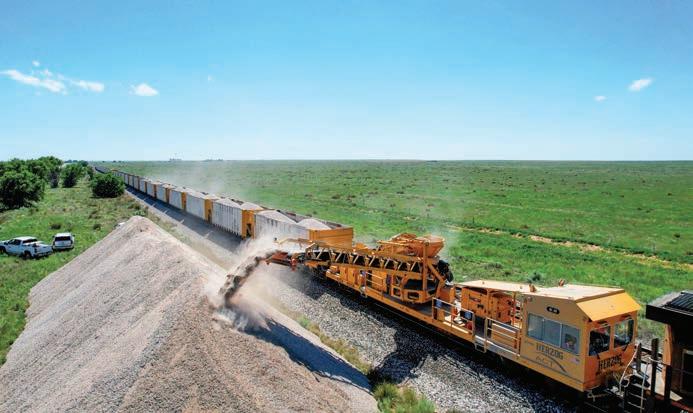

Herzog

Herzog just raised the bar again on the newest model of its Automated Conveyor TrainSM (ACT), designed and manufactured by Herzog railroad maintenanceof-way equipment experts. “Herzog has a culture of continuous improvement. We want each new product to be better than the last,” says Jake Herzog, Vice President of Engineering, Research, and Development. A er a re-design of the equipment’s gate system, the ACT now provides an increased production ow rate of 28% and further addresses railroad customers’ needs for versatile material unloading. e newest model can handle cohesive materials, such as base rock, that typically would not unload from a hopper of this type. “ e increased ow rate allows for less track time and more production,” says Ryan

Crawford, Vice President of Ballast Operations and Railcar Leasing. Its performance is evident as it can unload a 30-car consist of 2,900+ tons using just one generator car and one discharge car. Other enhancements include wireless tablet control from outside of the cab, simpli ed controls architecture, and an increased generator size for future consist expansion.

e ACT’s conveyor belt system excels at safely and e ciently distributing ballast, even in curves and S-curves with angles of up to 13 degrees. It unloads material 50 feet from the track center, 15 feet directly in front of the cab, and is accompanied by an automated plow to strike ballast away from the center of the track. e ACT signicantly improves delivery e ciency to the right-of-way and eliminates the need for additional truck transport.

e machine o ers numerous advantages, starting with its one-person operation from a climate-controlled cab, eliminating the need for ground personnel and ensuring operator safety by avoiding exposure to silica dust and adverse weather conditions. e locking mechanism on its 35’ conveyor arm enables safe working conditions on the eld side while train movement occurs on an adjacent track. Moreover, the ACT provides around-theclock support, with 24/7 unloading availability and eld support.

Custom Truck One Source

Custom Truck One Source’s rotary dump body proves a reliable solution for the transportation of ballast and other materials, up and down the rail.

e Load King 14 , 12-14 cu. yd. elliptical dump body has proportional hydraulics, joystick control, hinged drop ladder (street side), as well as rail dogs.

28 Railway Track & Structures // August 2023 rtands.com BALLAST MAINTENANCE

Eliminate Scrap with Short-Plug Flash-Butt Welding Get higher quality and more cost-e ective defect remediation versus traditional methods, with less equipment, rail and labor.

Herzog’s newest model of its Automated Conveyor TrainSM unloads base rock near Dalhart, Texas.

Rail gear included in this build includes hydraulic actuation, front brakes, front rail sweeps, slotted rear links, a heavyduty rear bracket and manual rear pins. Each unit is track-tested and includes FRA annual rail gear inspection. Custom Truck One Source’s railroad division has a full catalog from hi-rail pickups to tandem axle material handlers.

Ballast Tools Equipment (BTE)

Ballast Tools Equipment (BTE) has developed a new attachment for clearing fouled cribs between ties. e BTE Cribber was developed by the engineers at Ballast Tools Equipment, to make quick work of clearing ballast and debris that traditionally called for the use of a Cribbing Bucket. is new attachment, when teamed with a BTE Hi-Rail Excavator, makes short work of clearing out a run of ties.

According to BTE Sales Engineer Matt Weyand, “the BTE Cribber is an extremely powerful trencher-style undercutter for spot maintenance and cleaning out the cribs between the ties. Its continuous action allows for a faster, more e cient clean-out of debris

compared to using a traditional cribbing bucket.” He went on to say, “We understand that durability is crucial in demanding work environments. at’s why the BTE Cribber is built to withstand even the toughest conditions. Its robust construction ensures longlasting performance, reducing downtime and maintenance costs.”

Utilizing additional chain guarding, the BTE Cribber can protect against damage to the rails and ties while in use. e proprietary Tungsten Carbide protected cutter chain can withstand extreme wear during operation. is is the most e ective crib cleaning system on the market today. For more information go to https://BTEquip.com

August 2023 // Railway Track & Structures 29 rtands.com BALLAST MAINTENANCE

Ballast Tools Equipment (BTE)

Message From The President

PROFESSIONAL DEVELOPMENT

Get PDHS At Your Own Pace With Arema’s On Demand Education

Access to important professional development content is just a few clicks away with AREMA Education. Our On Demand content spans many disciplines of PDH accredited courses that allow you to get your PDHs by learning from experts online without leaving your office.

BENEFITS OF LEARNING ONLINE

1. LEARN MORE

Studies show that participants learn more while taking On Demand courses as you can skim through the material you understand and take more time in the more challenging areas.

2. GET INSTANT ACCESS

With AREMA On Demand courses, you don’t have to wait to learn and get your PDH’s as they’re available instantly after purchase.

3. CONVENIENT AND FLEXIBLE

Above all things, On Demand education is meant to take at your own pace and on your time. Study from anywhere in the world, whether from your office or the convenience of your sofa.

4. COURSE VARIETY

AREMA On Demand education offers a wide variety of topics for all studies of the railway engineering community.

Register and Start Learning today at www.arema.org.

BECOME A MEMBER AND SAVE

Not an AREMA member? Join today at www.arema.org and get discounts on all AREMA Educational Offerings, from Virtual Conferences to our Webinars.

My term as AREMA’s President concludes at the end of the AREMA 2023 Annual Conference which will be held in conjunction with Railway Interchange, October 1-4 at the Indiana Convention Center. is will be my last message. I have enjoyed sharing some of my thoughts and a few of AREMA’s endeavors with you over the past year. “Far and away the best prize that life o ers is the chance to work hard at work worth doing” – eodore Roosevelt.

I am honored to have been given the privilege to lead this distinguished association. I hope I am leaving it is just a little bit better than upon my arrival.

Early in my term I set up a Strategic Planning Committee which includes Ray Verrelle, Jr., Senior Vice President and four Past Presidents – Jim Kessler, Ed Sparks, Vic Babin, and Mike Freeman, and AREMA’s CEO and Executive Director, Beth Caruso.

e primary objective of this Committee is to update the AREMA Strategic Plan to progress our mission more e ectively in the coming years. ere are several additional objectives set before the committee, 1) revision of the AREMA Technical Committee Regulations and Procedures, which was successfully approved by the Functional Group Board of Directors (BOD) in June (thank you Past President Jim Kessler for all your work on this in the past few years!),

2) evaluate the bench strength for future leaders of the association - those who qualify for nomination to the BOD and Senior Vice President positions, and 3) propose modications to the AREMA Bylaws that may be necessary with our future direction. With

the help of an association organizational expert, the committee will be meeting numerous times this fall and winter to work on the Strategic Plan. Our schedule calls to have a new dra Strategic Plan in the rst quarter of 2024 that will be ready for review/ approval by the Board of Governors.

Several major initiatives will continue. Managing the health of the Manual for Railway Engineering and the Communications and Signal Manual has been an e ort underway for several years and is core to our mission. I am glad to report that we have made good progress to ensure the manuals remain healthy. ank you to all the committee leaders and members who have done all the hard work in reviewing and updating their respective manual chapters.

As the rail industry continues to evolve, AREMA will also evolve and respond to the needs of the times. I introduced AREMA’s Sustainability and Resilience Position Paper in my July message. Sustainability and Resilience are essential for the viability of our future – leveraging our inherent eciencies and nding solutions to become more sustainable will be a long-term journey for the industry and AREMA.

I am pleased to announce that AREMA will be hosting a Sustainability and Resiliency Symposium this coming February in Tampa, Florida. Look for details coming soon. For those of you that are already working in this space I invite you to share your knowledge. If this is new to you, I hope you will consider attending. Come to learn more about how you can be part of the solution in helping the industry become more sustainable and resilient. I would like to thank the R&S Symposium Committee (lead by Ashley Pate, Leo orbecke and Ned Bagniewski and Committee 13 (chaired by Kari Harris) for all the work they are doing to making this symposium successful for our membership.

As we continue to prepare for the Annual Conference, held in conjunction with Railway Interchange, I would like to thank the AREMA Program Committee for their e orts. anks to Ray Verrelle, Jr. and the Functional Group leaders for your dedication during the presentation selection and review process. anks also to Stacy Spaulding, Senior Director Executive & Board Operations for supporting this Committee and working closely with those

30 Railway Track & Structures // August 2023 rtands.com

TRENT M. HUDAK AREMA President 2022-23

presenters selected to present. ere will be an excellent line-up of presentations that you will not want to miss. ank you to all the sponsors who help make the event successful with your nancial support.

With regret, this will be the last Railway Interchange that AREMA will participate in for the foreseeable future. Although we recognize the value to the industry to have many associations collectively participate, it has not been nancially sustainable for AREMA. We are hopeful that someday in the future we can participate again. Looking ahead, plan to join us in Louisville, KY on September 15-18 for the AREMA 2024 Annual Conference & Expo.

I wish to thank the dedicated sta at AREMA headquarters that works tirelessly to provide value to our members and the railway industry. With the turnover and hiring of several sta positions, you have all stepped in to help with the transition and maintained the support to which we

2023 MEETINGS

SEPTEMBER 30 - OCTOBER 1

Committee 24 - Education & Training

OCTOBER 1

Committee 12 - Rail Transit