Modular construction of customized machines – fairytale or reality? By Gerard Ramaker – Manager Sales Automotive at AWL Some years ago there were three major factors affecting the competitive positions of machine manufacturers: 1. Customization and differentiation to customer specifications 2. Short time-to-market 3. Innovative products We have noticed a shift in strategic prioritizations caused by rapid technological developments and the current dynamic market situation. Digital transformation and business innovation are now in first and second place. These priorities make it possible to respond better to customer-specific wishes and also to shorten time-to-market and manufacturing processes. There is no doubt that the current automotive market is making every effort to get through the crisis, with cost reductions being the first strategy.

Smart manufacturing

Flexible and economical construction

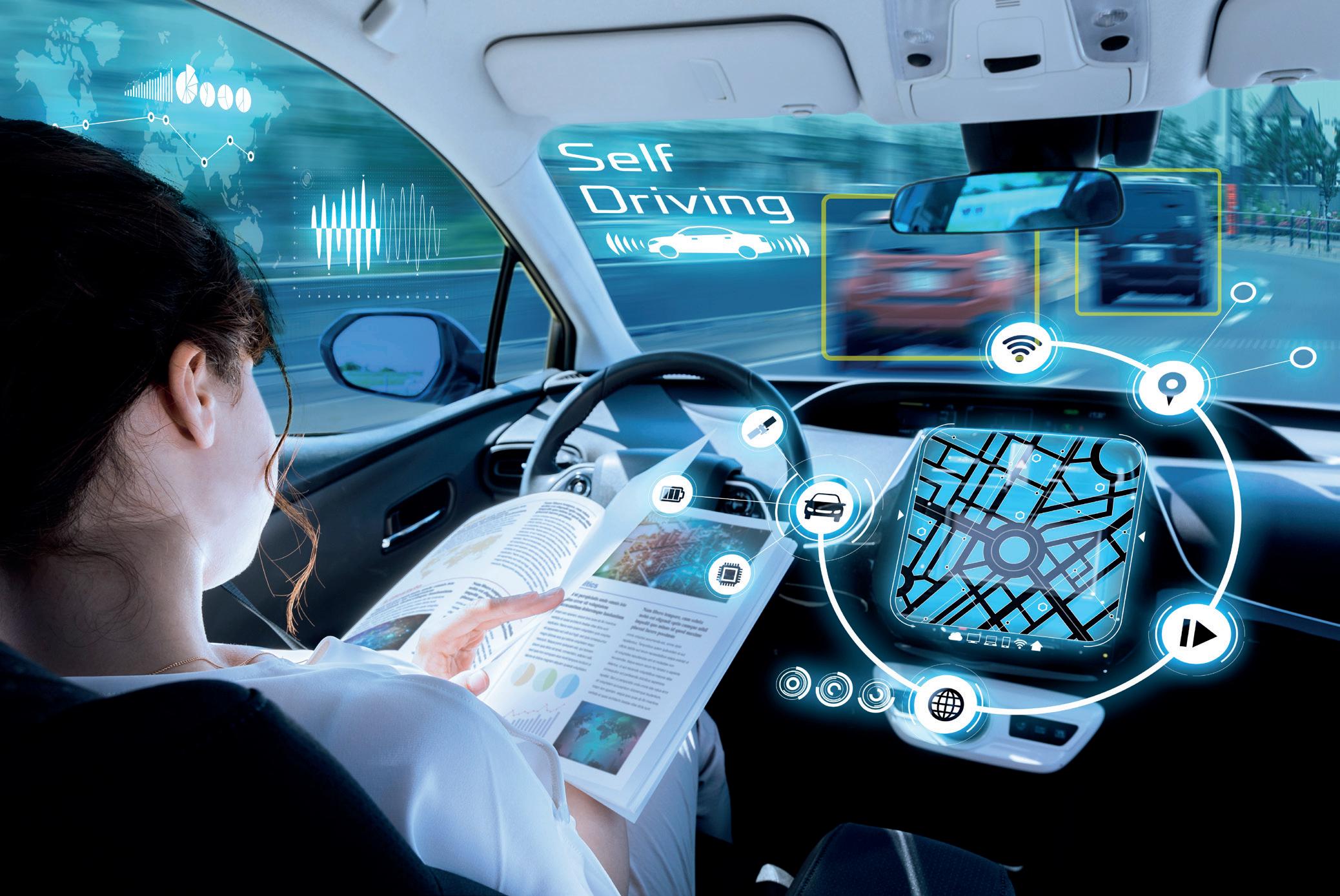

Thanks to technological developments, machines are becoming smarter. They are equipped with software that can be monitored and controlled remotely, taking data security into account. By providing insight into and anticipating machine data, new opportunities arise for machine-building companies such as AWL to create value for customers, including data-driven improvements in the production process. Better control over this process provides possibilities for cost reductions. Artificial Intelligence (AI) is increasingly playing a role in generating trends from data with predictive values for production forecast and machine maintenance.

AWL sees more and more companies making the transition to standardization and modularization. After proper coordination on customer specific standards and wishes, it is possible for AWL to develop modular and highlyautomated manufacturing machines. This involves smart customization: machine configuration that takes customer-specific requirements into account. And with that, modular building of customized machines is no longer a fairytale – it has become a reality! Because of the modular philosophy, multiple ‘machine lives’ are guaranteed and can quickly be scaled when production numbers go up or down. By offering different product options in the form of modules, this not only makes your production capacity more flexible, but it also reduces your costs.

Production processes are becoming smarter as well. Examples include advanced software for virtual prototyping and simulations that run parallel to the physical construction (digital twins). This makes it possible to start testing and preparing a new machine design at an earlier stage (virtual commissioning). This is important because both the timeto-market and the product lifecycle are becoming ever shorter.

Ordering custom machines from a configurator is no longer a fairytale!

What can AWL do for you? AWL wants to play an important role in this technological and digital transformation. With our developed modular platform, we are able to deliver your customized welding machines at shorter delivery times. Using our digital platform Lyla, customers can analyze data from their production process and visualize it in smart ways. We deliver machines that enable you to:

1. Bring your products to market faster 2. Increase your productivity (Overall Equipment Effectiveness) 3. Reduce the total cost over the machine lifecycle 4. Earn back the investment faster 5. Eliminate long and costly sourcing processes www.awl.nl/m-line

19