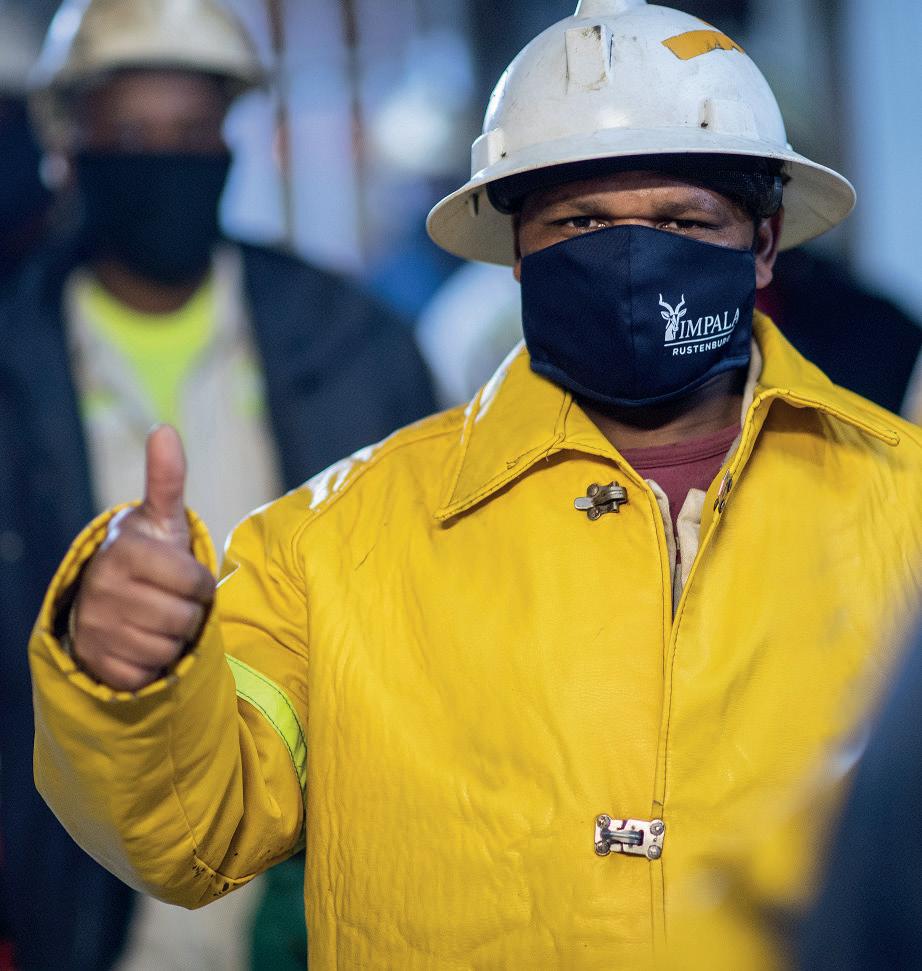

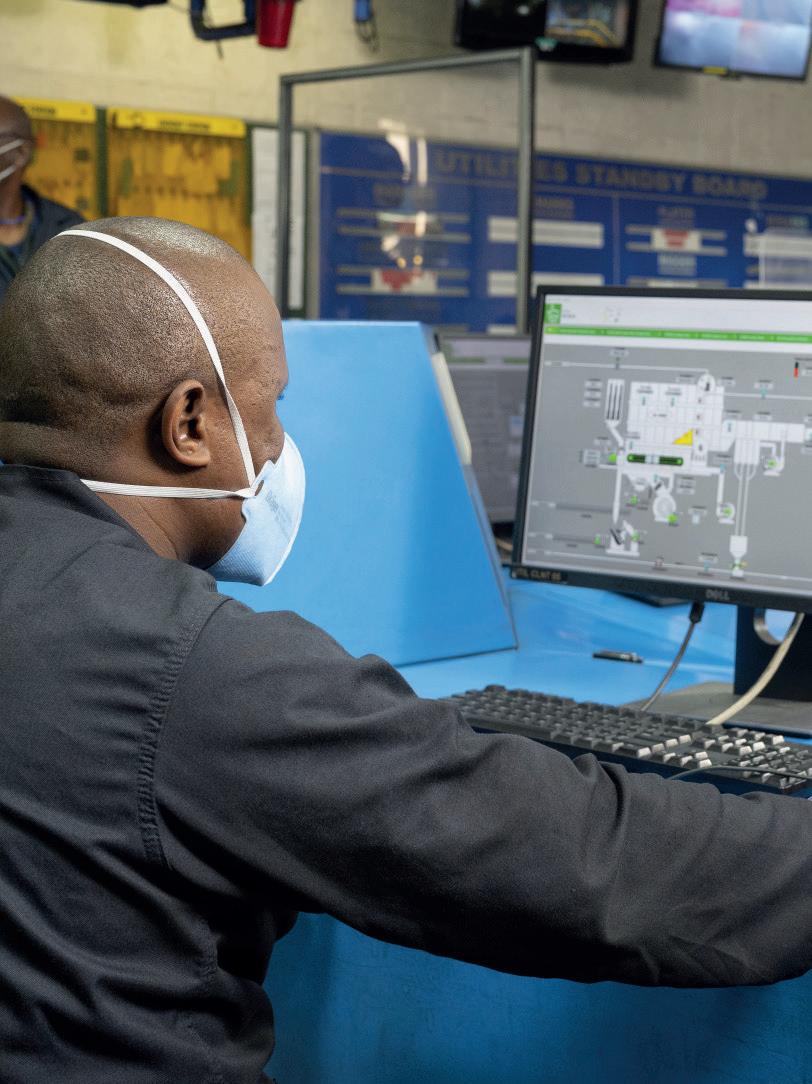

...through the metals we produce Creating a better future

Nolitha Fakude

President, Minerals Council South Africa

Honorary Vice Presidents

Gwede Mantashe

Minister of Mineral Resources and Energy, South Africa Ebrahim Patel

Minister of Trade, Industry and Competition, South Africa Blade Nzimande

Minister of Higher Education, Science and Technology, South Africa

President

Z. Botha

President Elect

W.C. Joughin

Senior Vice President E. Matinde

Junior Vice President G.R. Lane

Incoming Junior Vice President

T.M. Mmola

Immediate Past President

I.J. Geldenhuys

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk G. Njowa

Z. Fakhraei S.J. Ntsoelengoe

R.M.S. Falcon (by invitation) S.M. Rupprecht B. Genc M.H. Solomon

K.M. Letsoalo A.J.S. Spearing S.B. Madolo A.T. van Zyl

F.T. Manyanga E.J. Walls M.C. Munroe

Co-opted to Members

K. Mosebi

A.S. Nhleko

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

J.R. Dixon J.L. Porter

V.G. Duke M.H. Rogers

R.T. Jones D.A.J. Ross-Watt

A.S. Macfarlane G.L. Smith

M.I. Mthenjane W.H. van Niekerk

G.R. Lane–TPC Mining Chairperson

Z. Botha–TPC Metallurgy Chairperson

M.A. Mello–YPC Chairperson

K.W. Banda–YPC Vice Chairperson

Botswana Being established DRC Not active

Johannesburg N. Rampersad

Namibia Vacant Northern Cape I. Tlhapi

North

Pretoria

Zambia

Zimbabwe

Zululand

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

S.O.

R.D.

P. den

I.M.

R. Dimitrakopolous*

M. Dworzanowski*

Falcon

R.T.

W.C.

A.J. Kinghorn

D.E.P. Klenam

H.M. Lodewijks

D.F. Malan

R. Mitra* H. Möller

C. Musingwini

S. Ndlovu

P.N. Neingo

M. Nicol*

S.S. Nyoni

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

K.C. Sole

A.J.S. Spearing* T.R. Stacey E. Topal* D. Tudor*

F.D.L. Uahengo D. Vogt*

*International

Journal Comment: Mining papers revisit old issues

P. Pistorius

President’s Corner: Why do we need to have this conversation? Why is diversity so important?

Z. Botha

A discrete event simulation approach for mine development planning at Codelco’s New Mine Level

I. Soto, A. Anani, and E. Córdova

This paper presents a discrete event simulation (DES) model that individualizses each of the unit operations in the development cycle in new caving megaprojects. The results indicate an impracticality in that achieving the advance rates scheduled in the original plans is not practical if the unit operations use the status quo. A significant improvement can be achieved by applying instituting changes to the equipment maintenance strategy of the equipment, ore pass availability, and in the initial planning sequence. Recommendations are made.

Evaluation of pre-treatment methods for gold recovery from refractory calcine tailings by P. Mutimutema, G. Akdogan, and M. Tadie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In this study gold recovery from a refractory calcine tailings dam was investigated. Bulk mineralogy of the tailings indicated that gold was present in submicrometren and micrometren sizes, as free gold, and associated with arsenic, sulphur, and silicates. Gold recovery with direct cyanidation was low. Microwave roasting and assisted leaching did not achieve higher recoveries. The investigation confirmed that chemical treatment with NaOH is a powerful tool for gold extraction from refractory tailings.

to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal.

U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

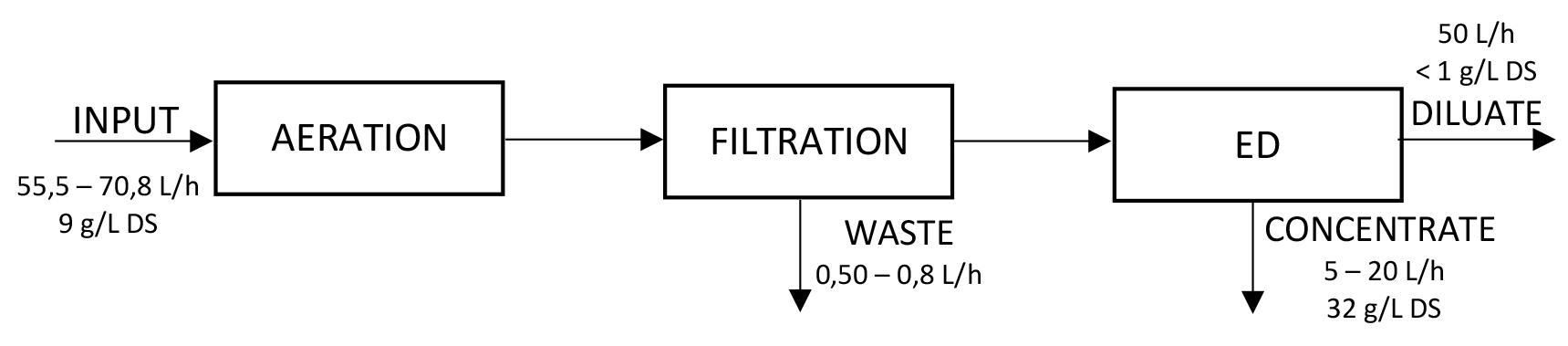

Water production as an option for utilizing closed underground mines by J. Dvořáček, P. Malíková, R. Sousedíková, S. Heviánková, P. Rys, and I. Osičková 571

The closure of a mine does not necessarily mark the tail-end of its life- cycle. Best practice references indicate that there are many viable options post-closure. The production of service water is one such option. Research has proved the practical feasibility of service or process water production. Good prospects for this additional resource can be assumed since with respect to requisite water pumping is required for safety reasons.

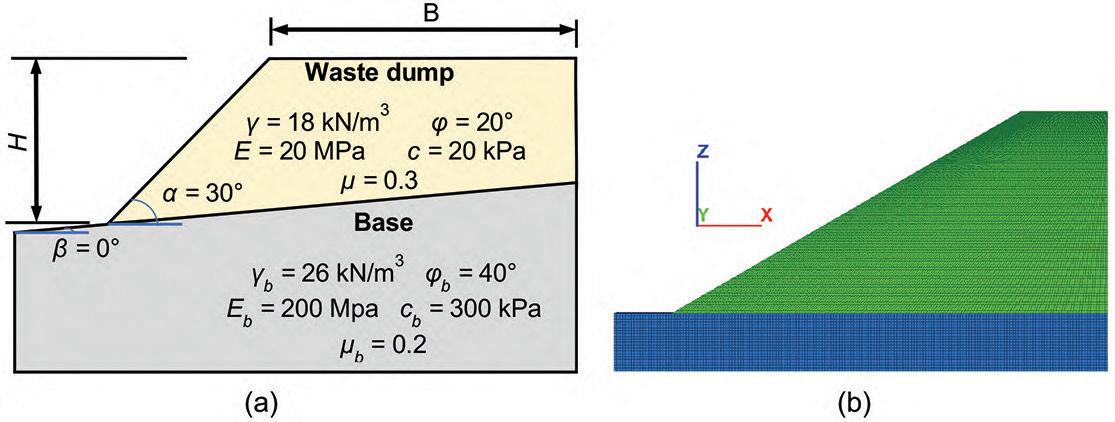

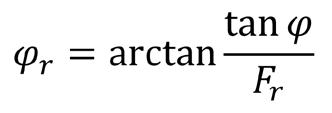

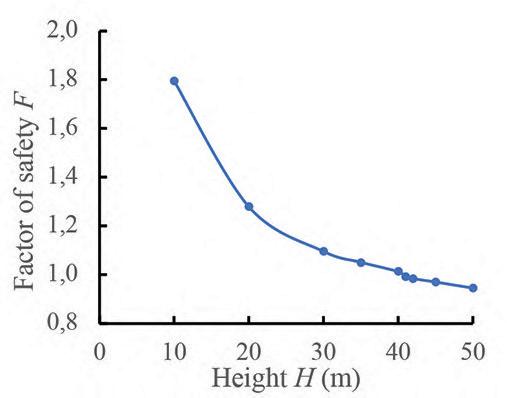

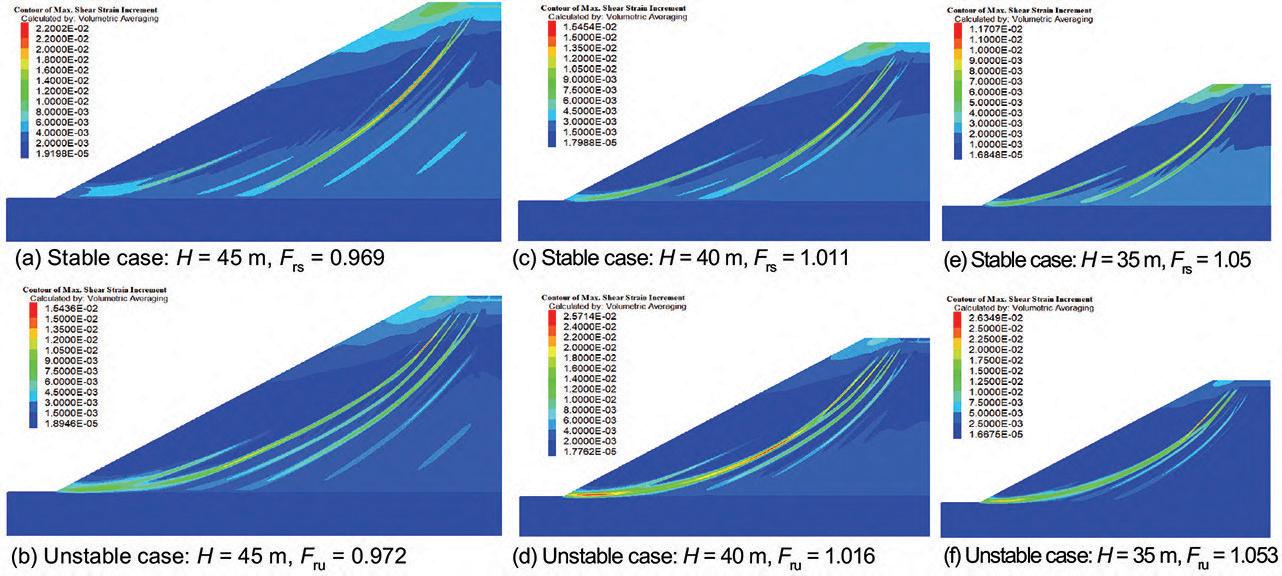

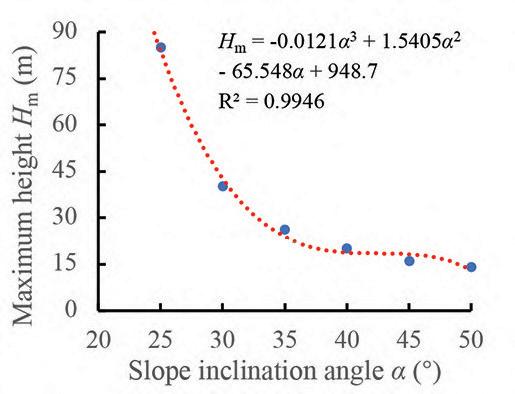

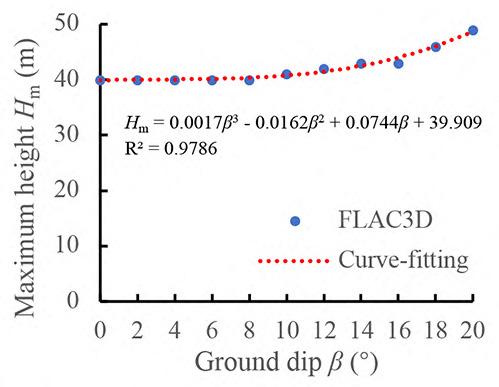

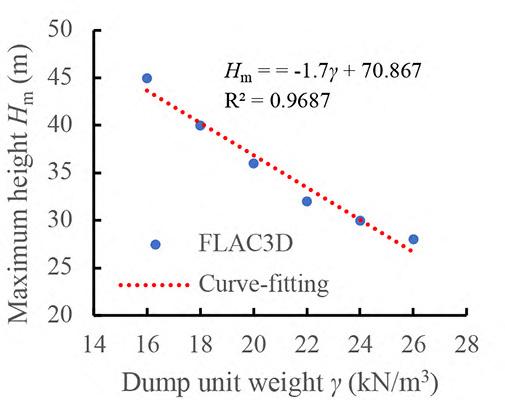

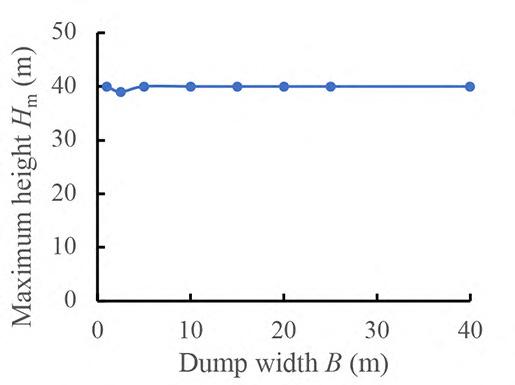

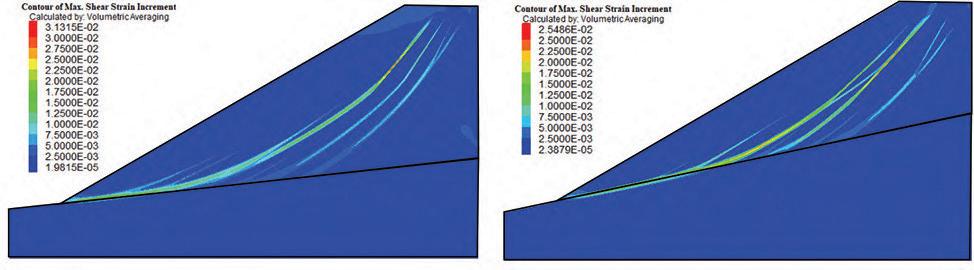

Maximum height estimation for mine waste dumps by S. Chai . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 579

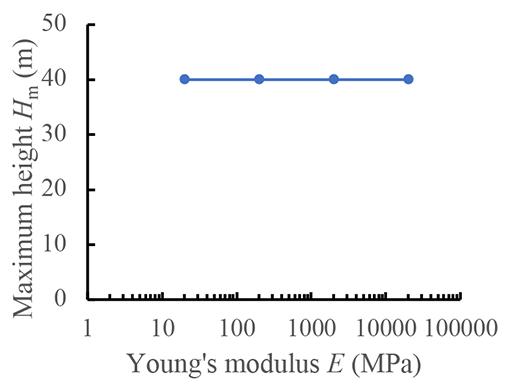

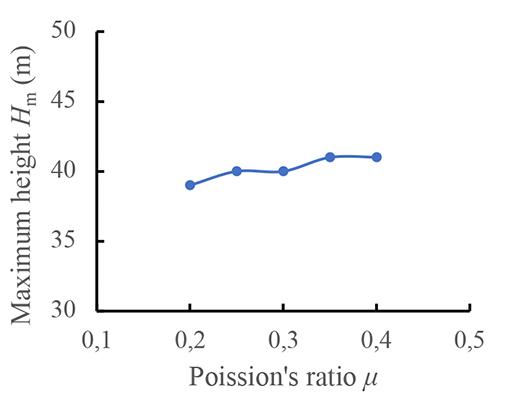

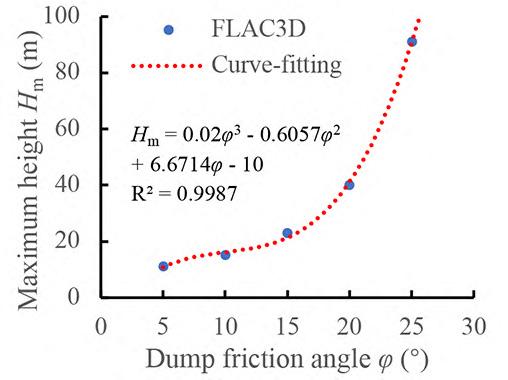

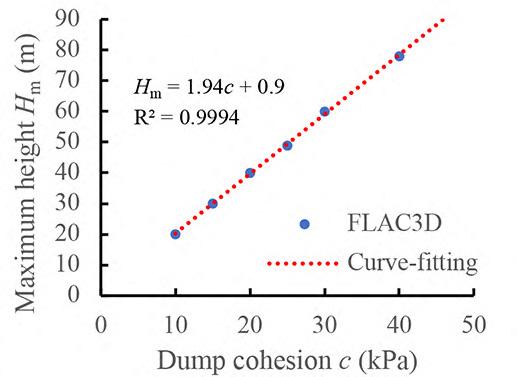

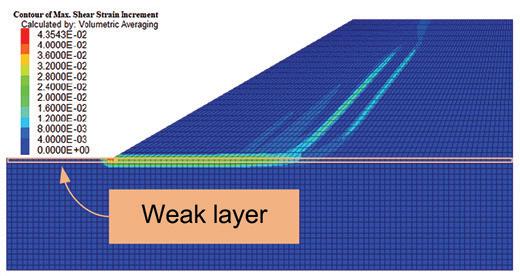

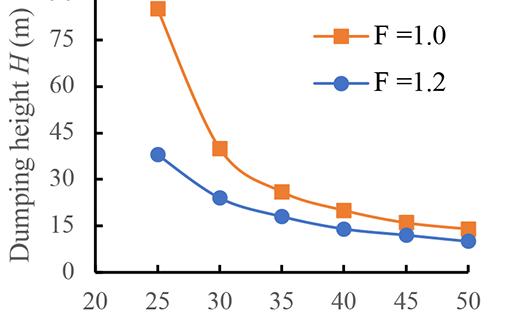

The dumping height of waste dumps will increase gradually, which may induce sliding failure once the dumping height exceeds a critical value. Estimation of the maximum dumping height is crucial to the life-cycle use of a waste dump. In this study, the maximum dumping height is estimated based on the strength -reduction technique by numerical simulations. Good agreements was obtained between numerical results available in the literature and those obtained in this study, suggest indicating the reliability of the results

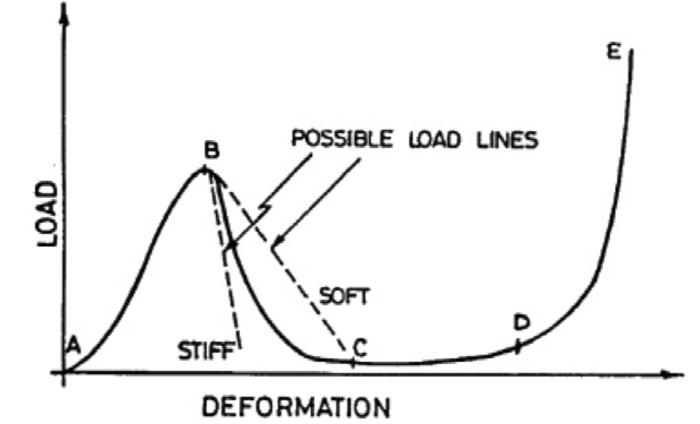

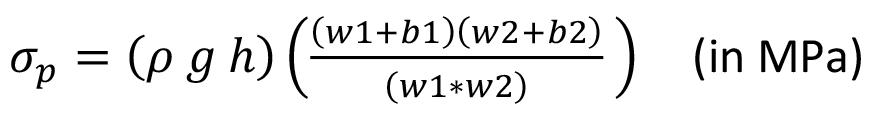

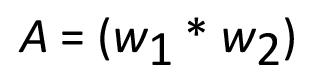

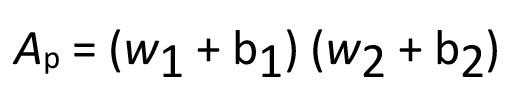

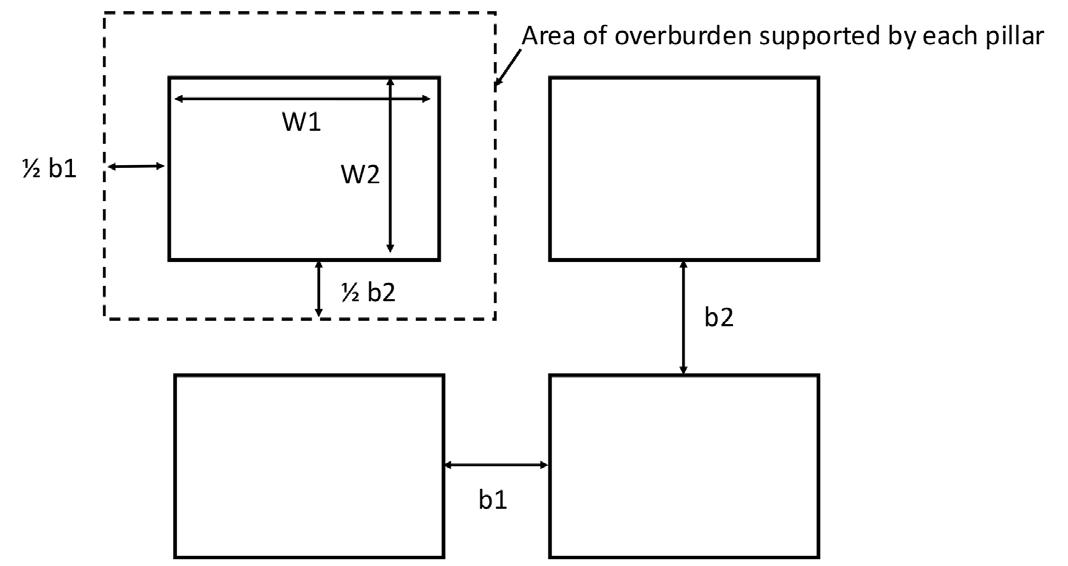

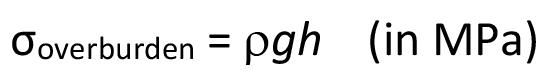

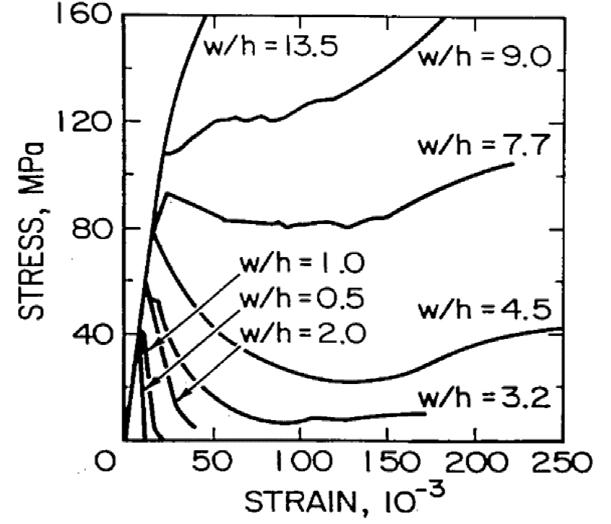

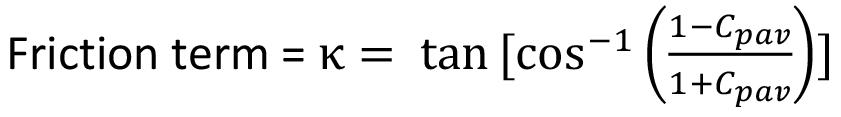

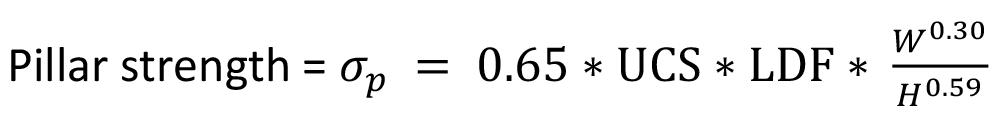

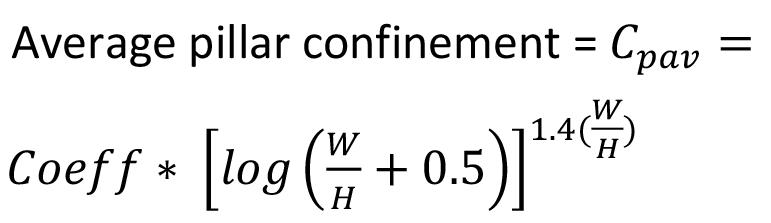

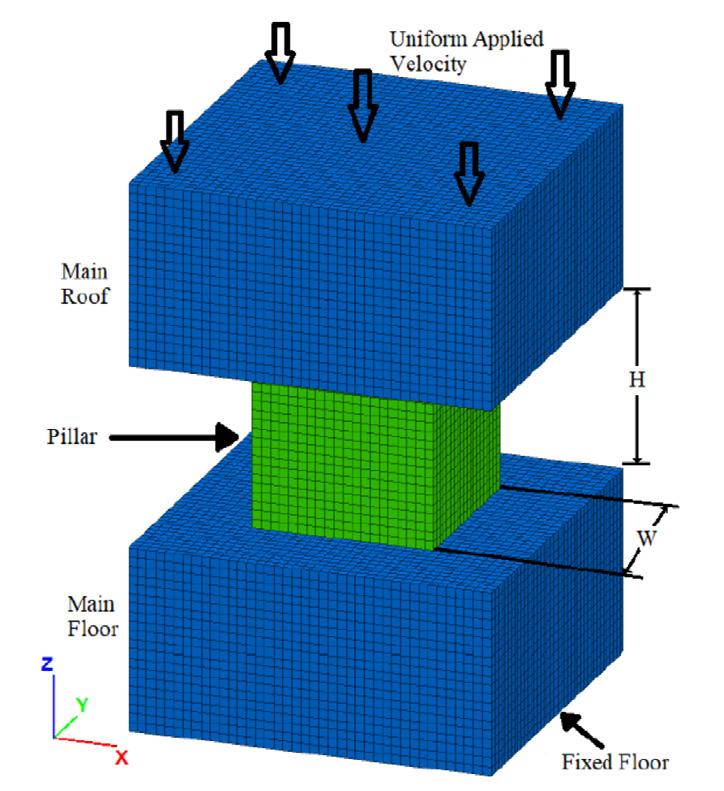

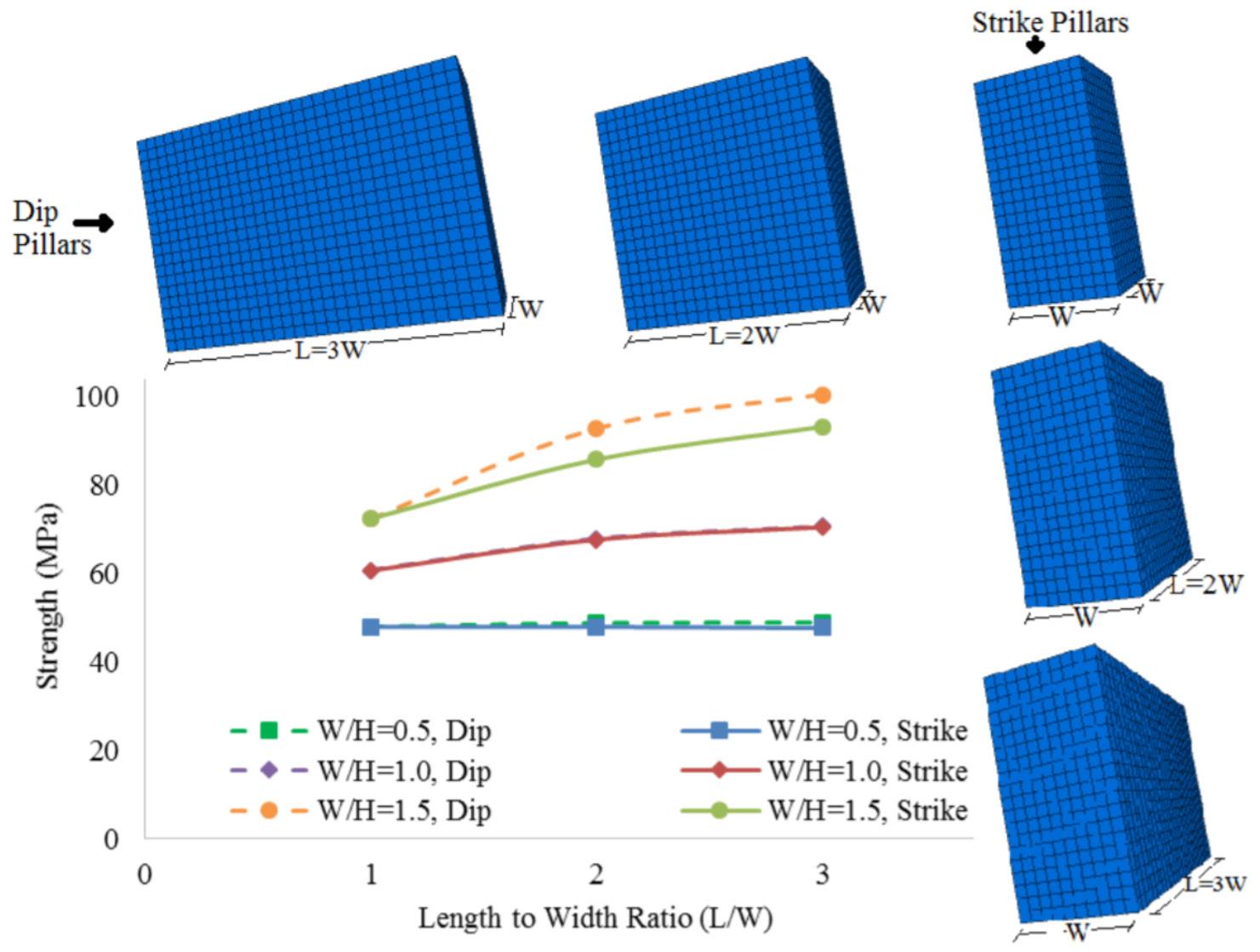

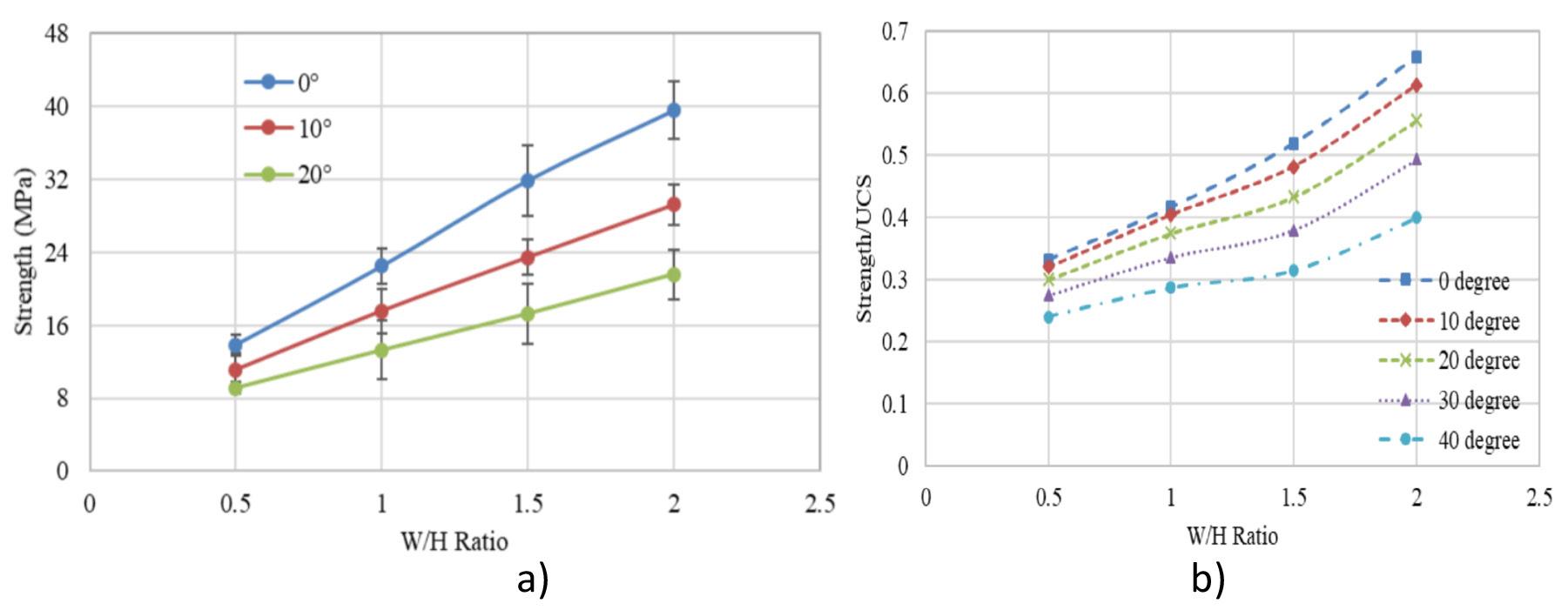

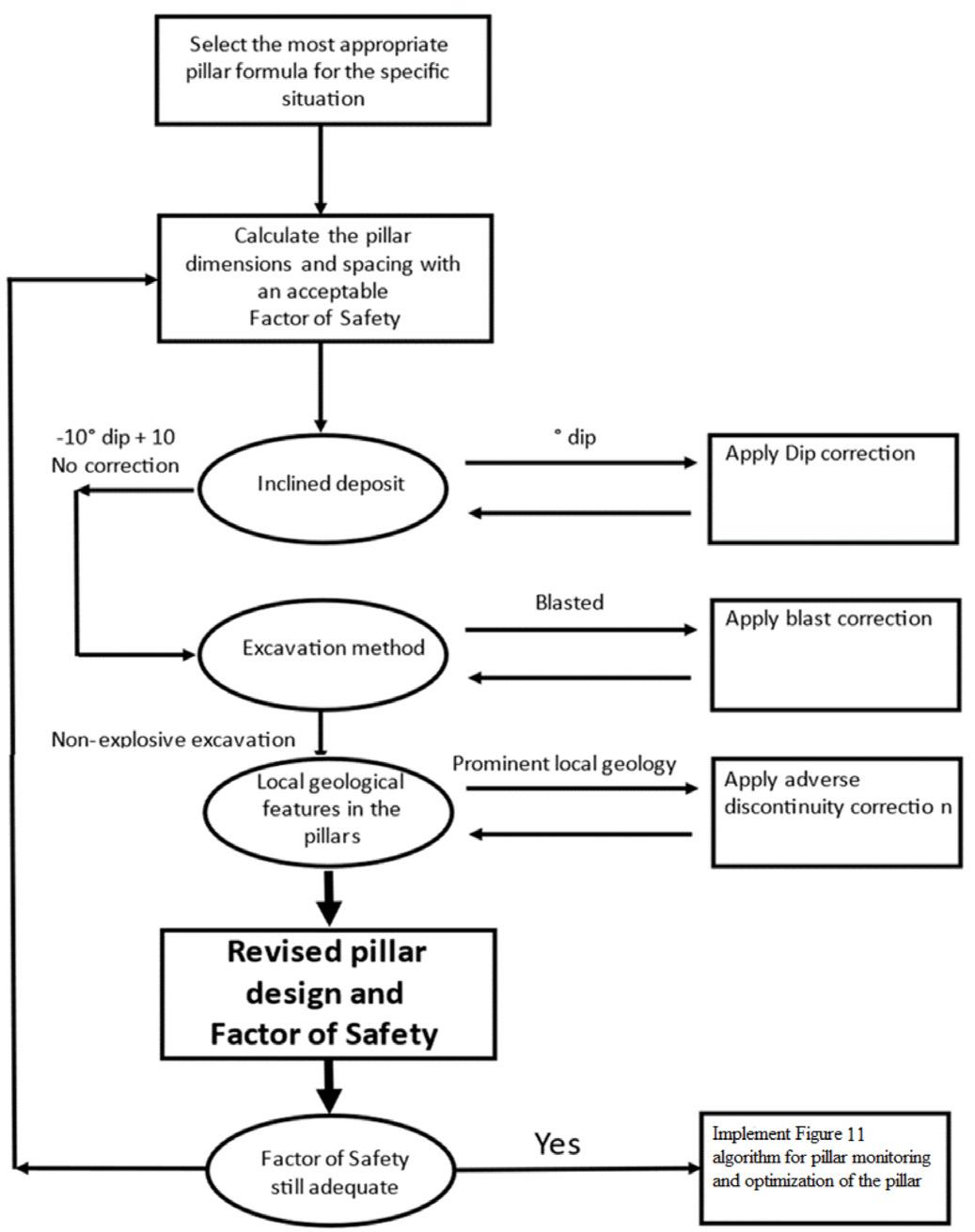

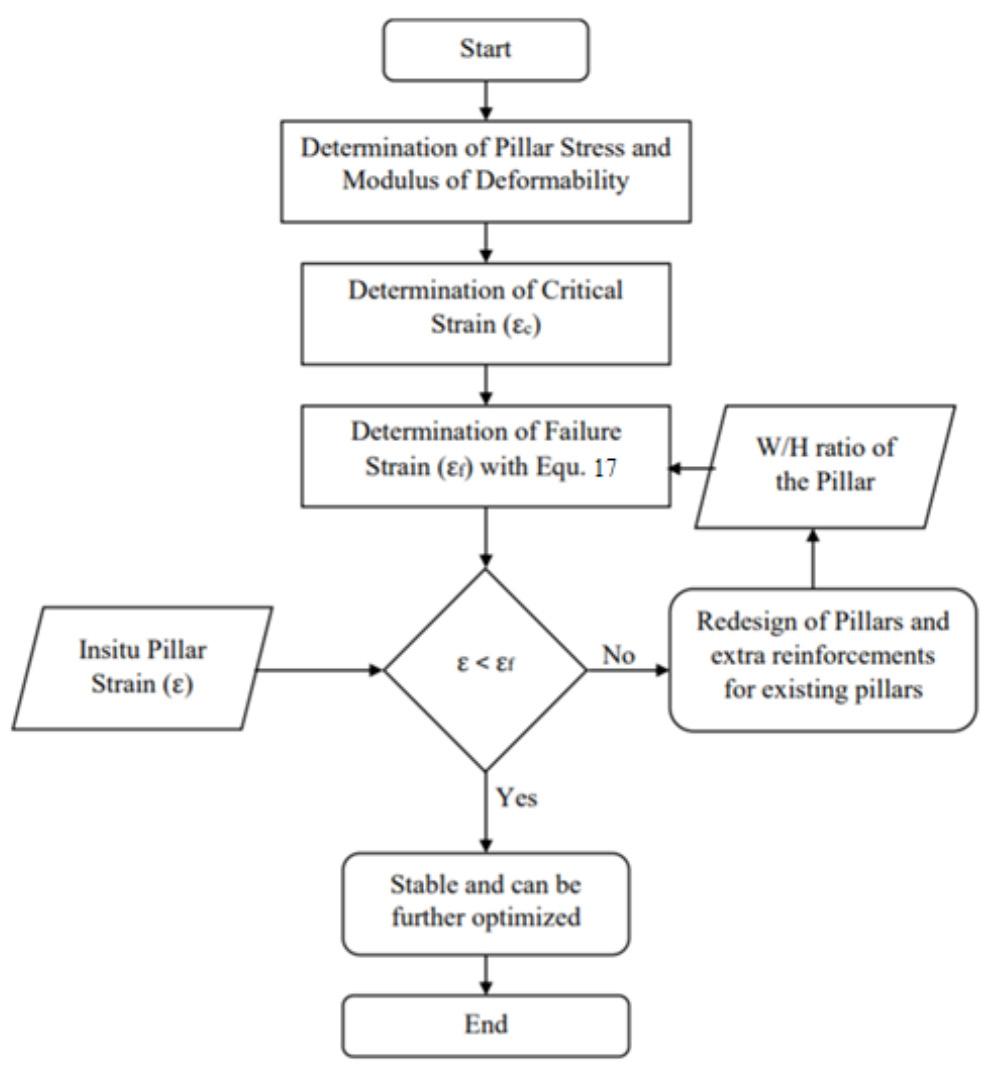

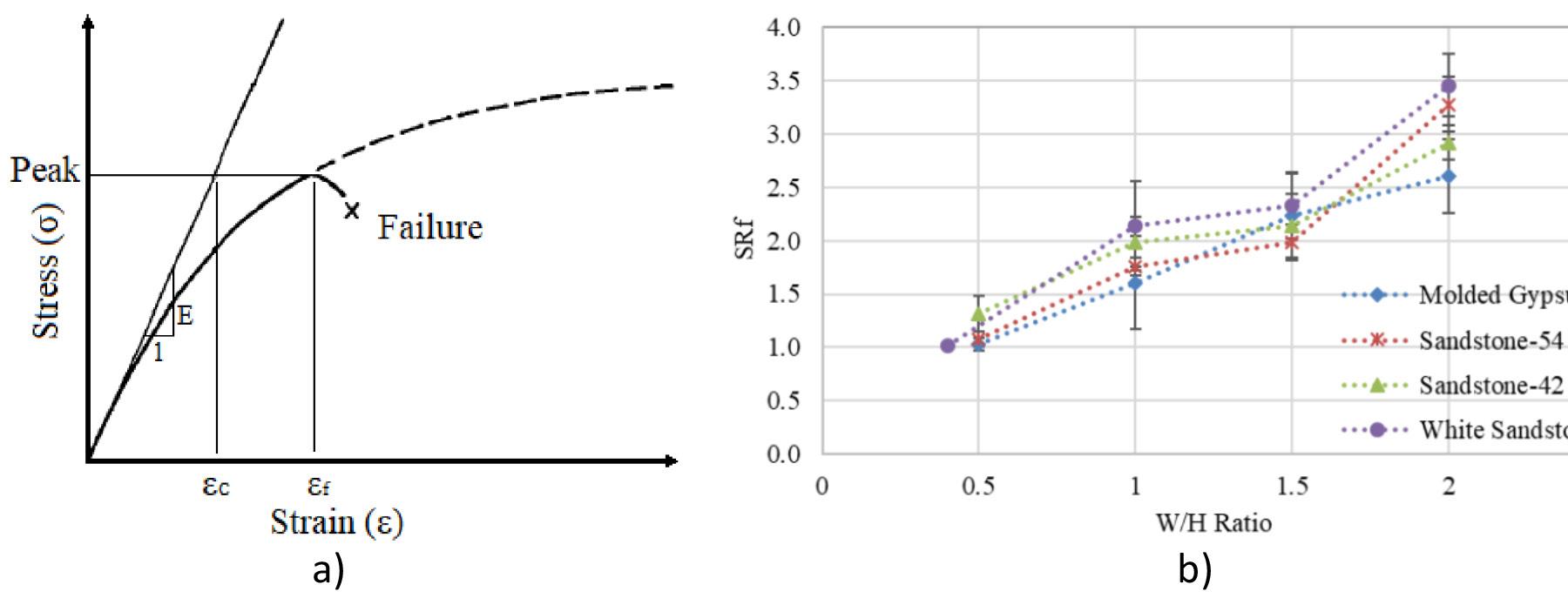

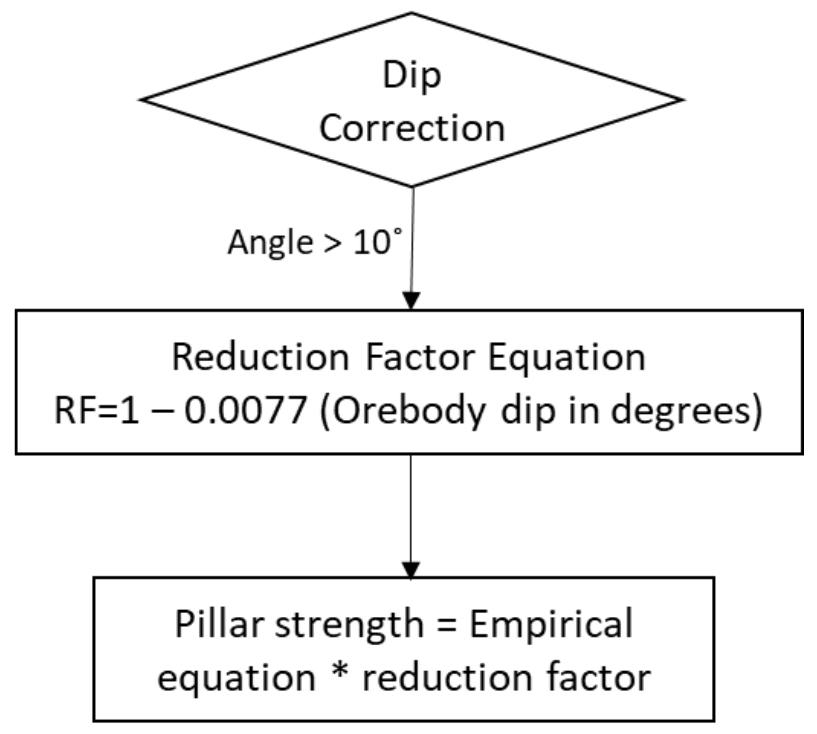

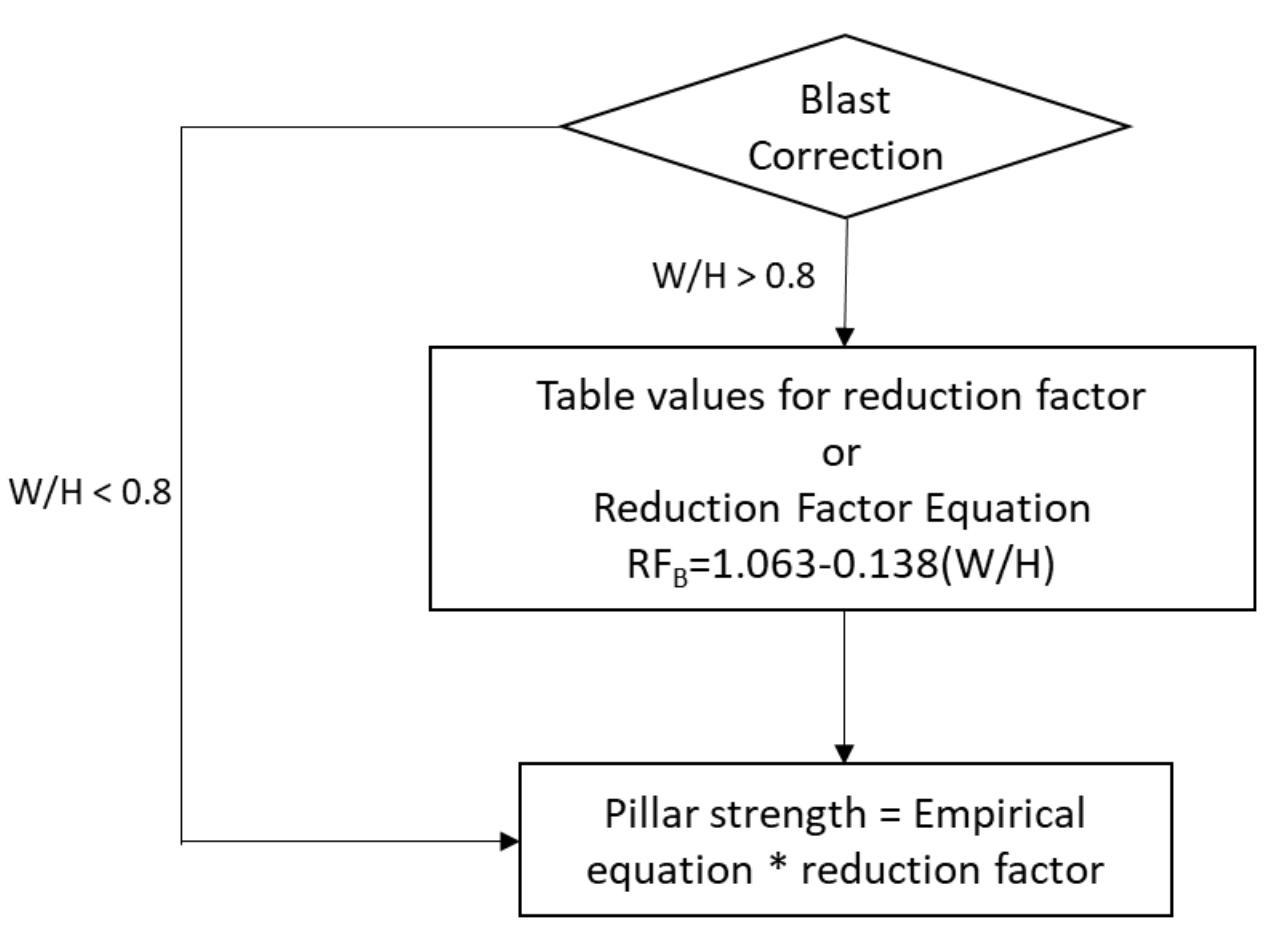

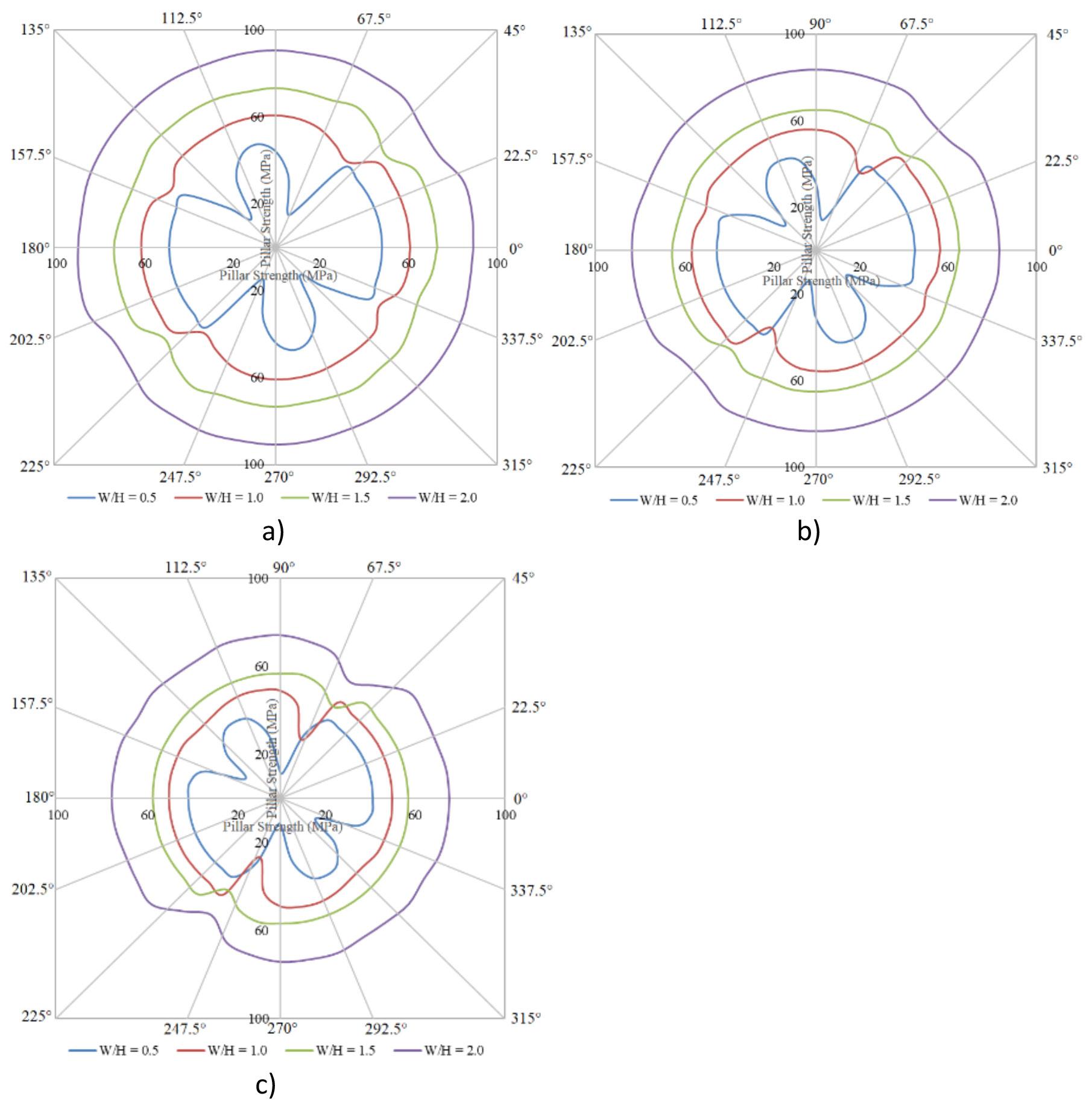

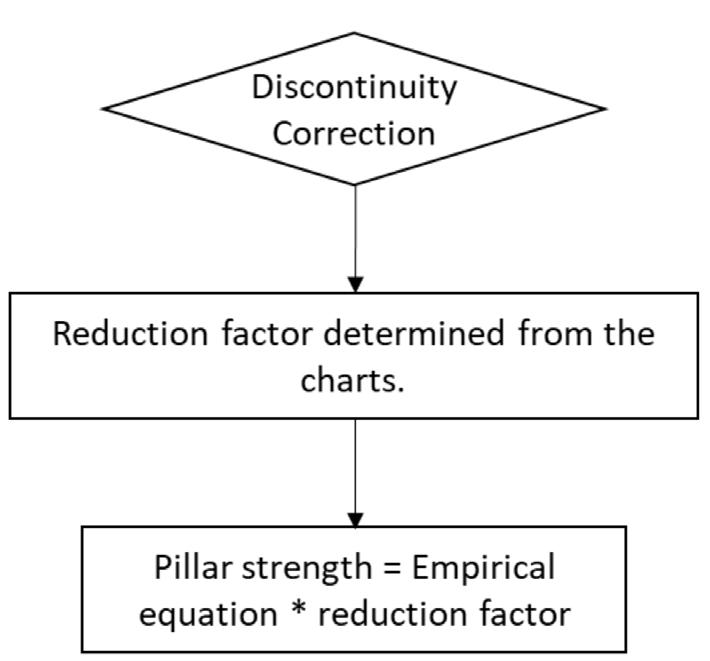

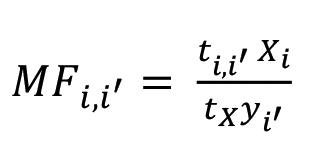

An improved pillar design methodology by K.V. Jessu, A.J.S. Spearing, and M. Sharifzadeh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 587

Empirical pillar design methods are commonly used in the mining industry. However, the parameters are frequently unknown to the user or ignored. This can result in potentially serious pillar design strength overestimates. Laboratory tests and numerical modelling were used to understand the effects of orientation of pillars, blasting, and presence of discontinuities on pillar strength. The pillar design approach outlined in this paper can better optimize the pillar mining method by considering other generally ignored but important parameters, thus improving safety, productivity, and economic aspects

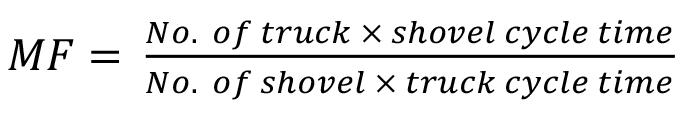

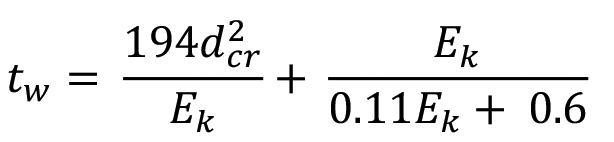

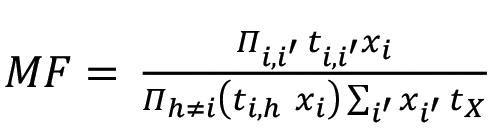

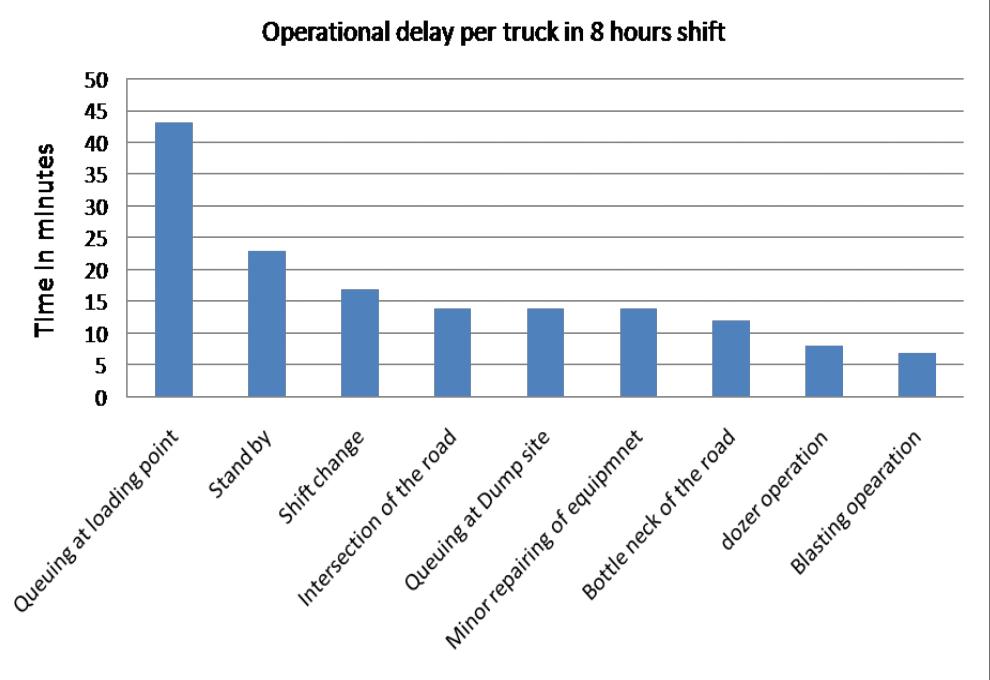

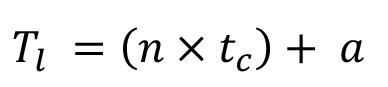

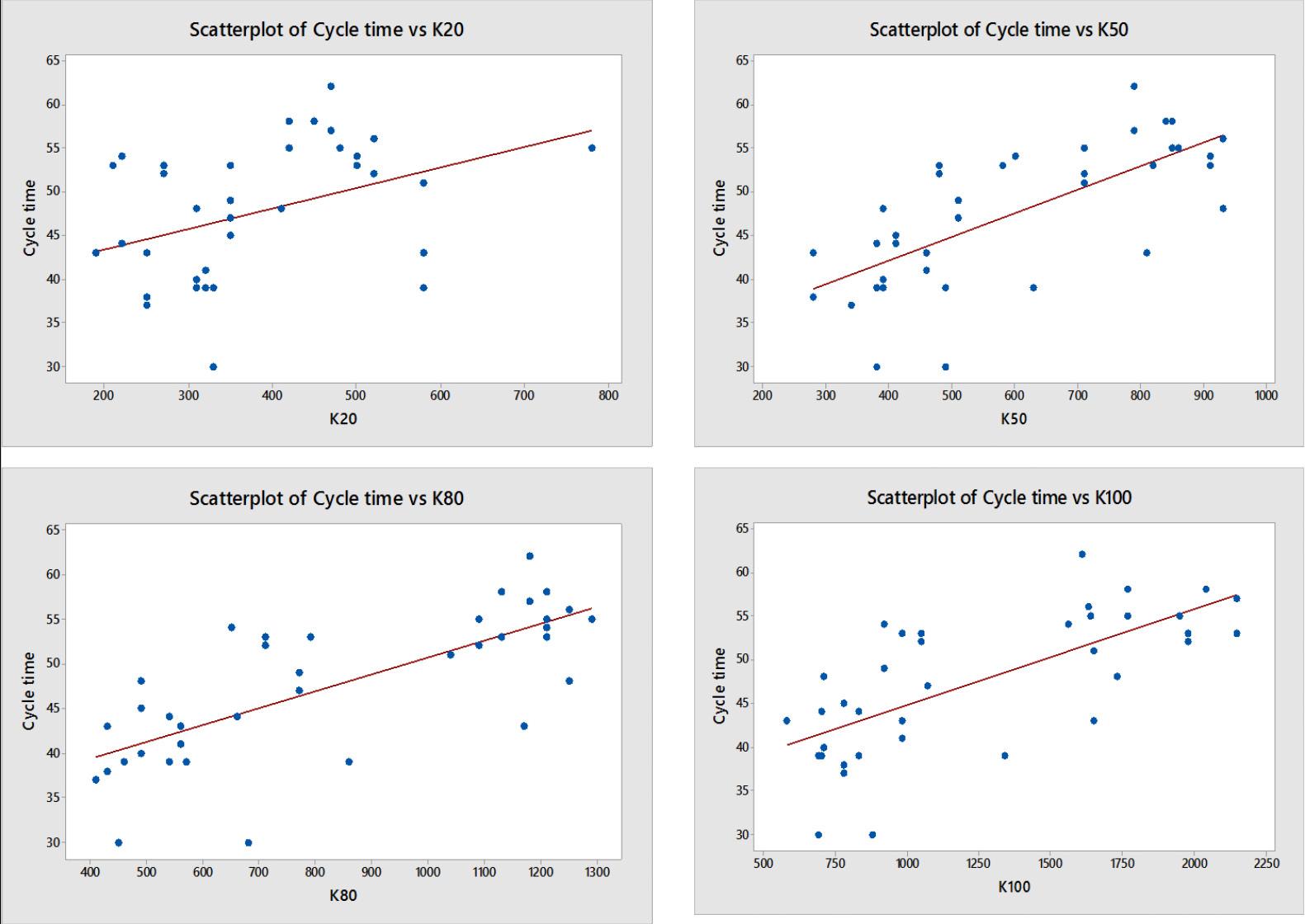

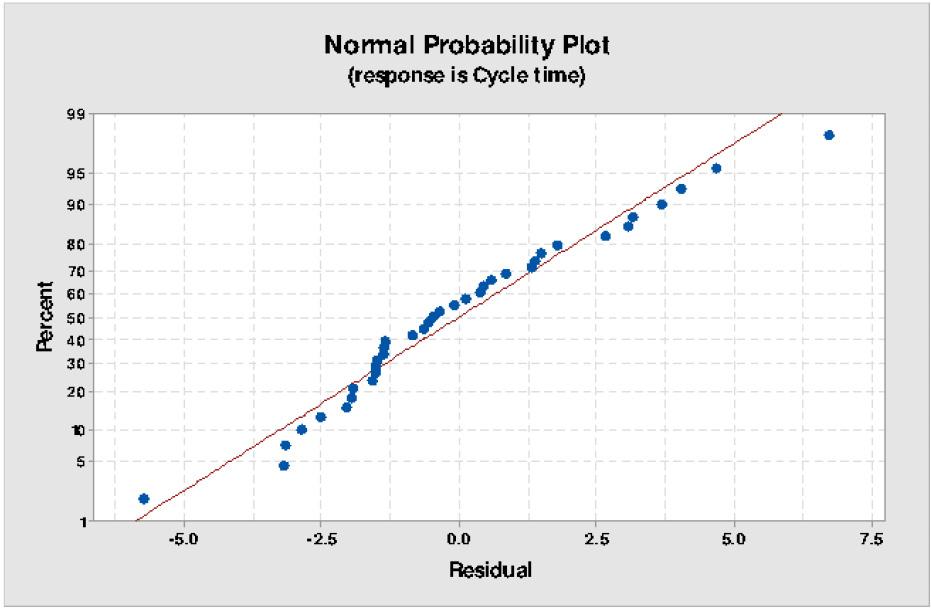

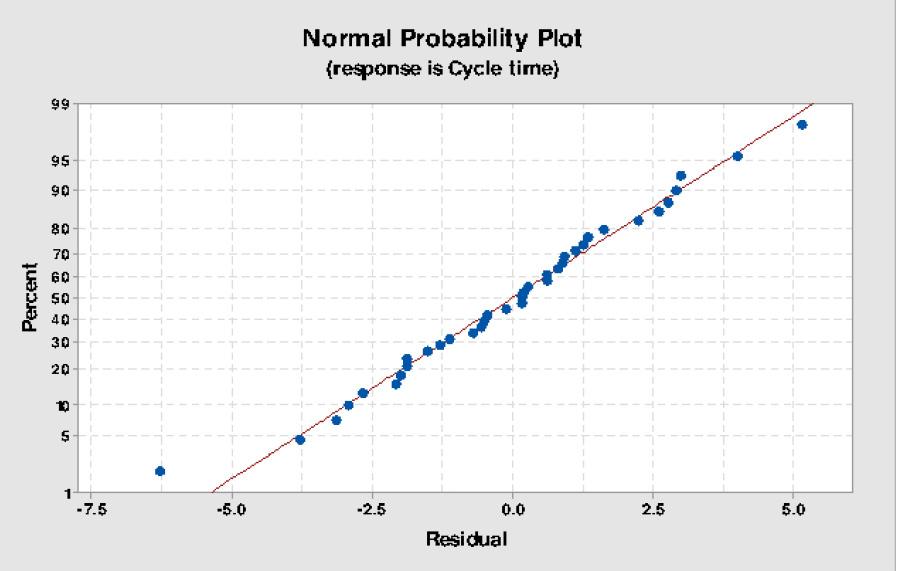

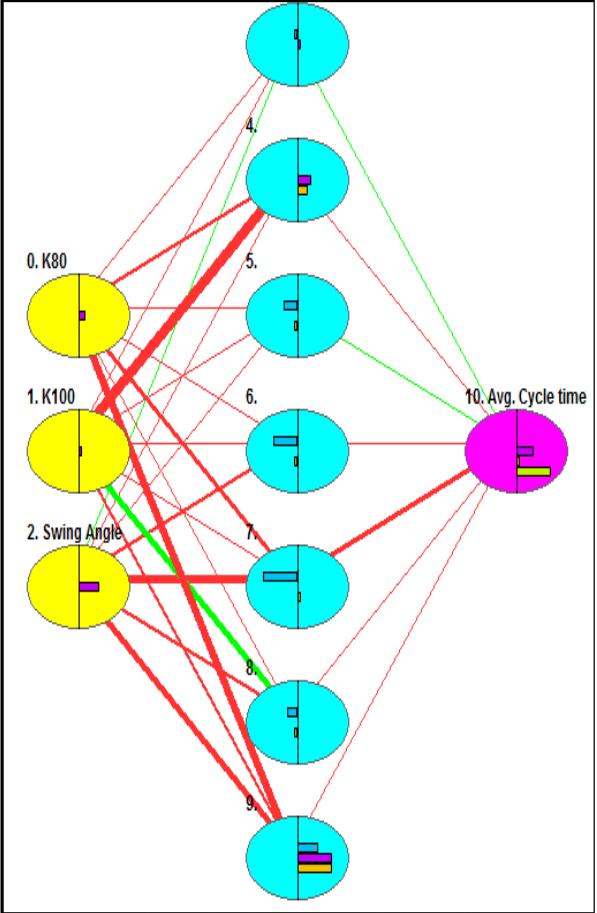

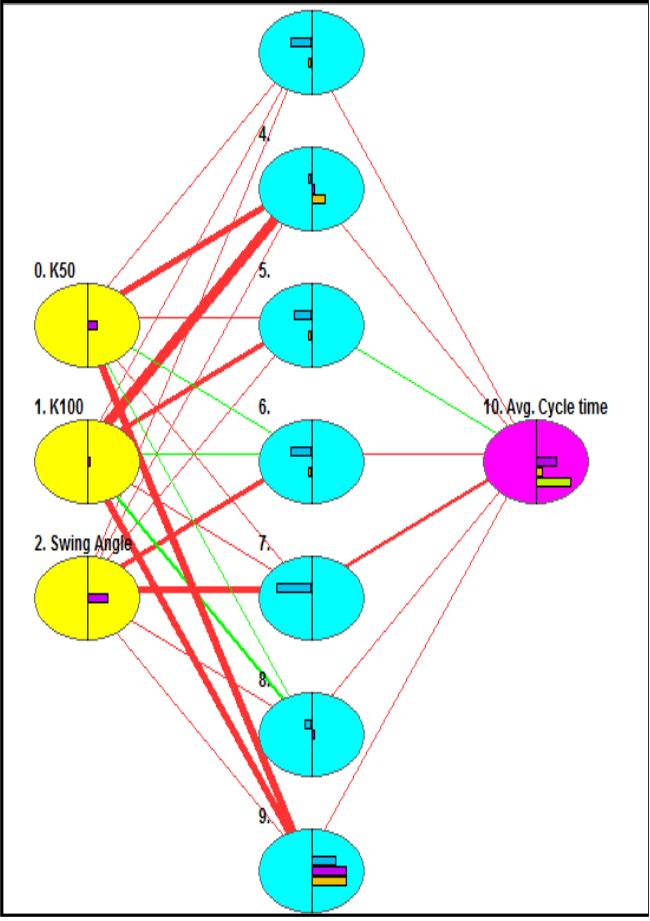

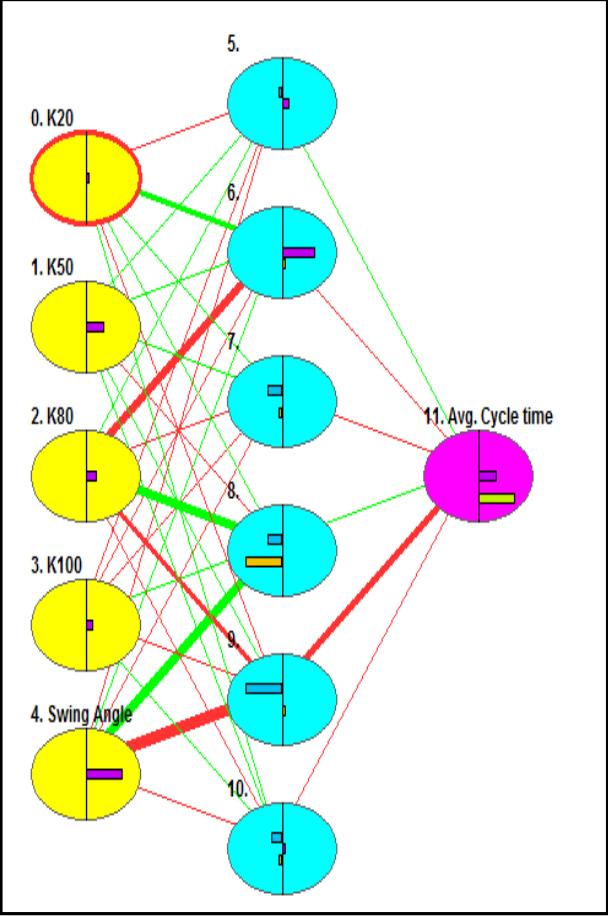

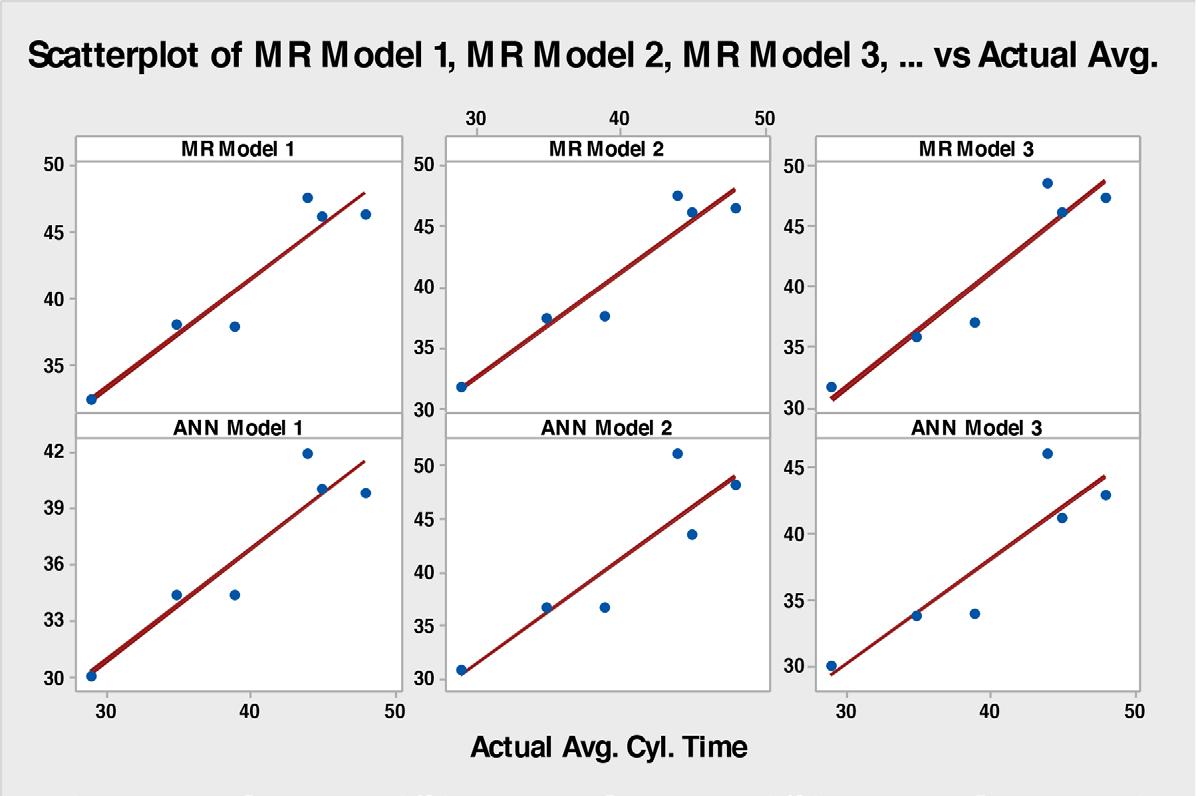

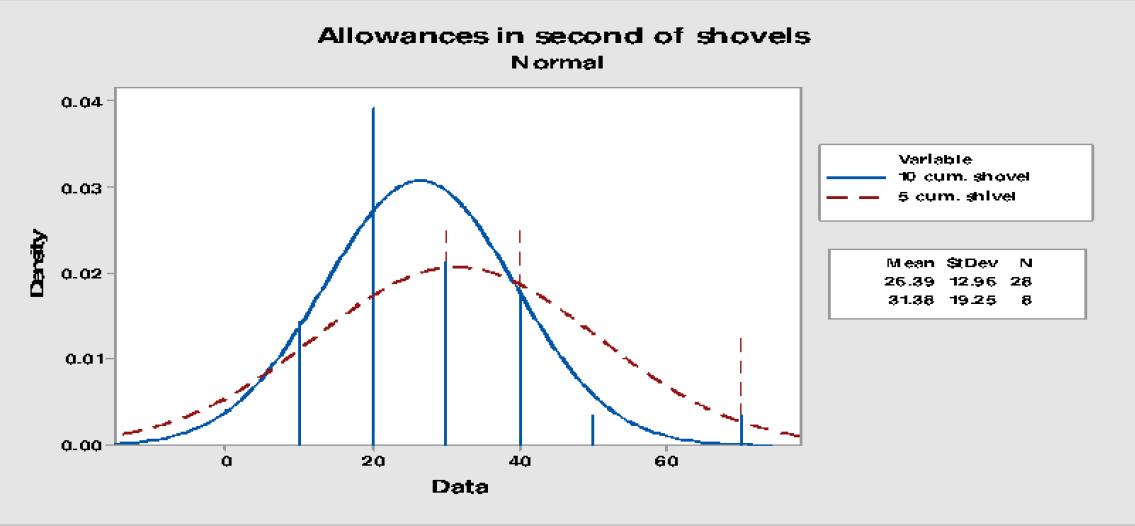

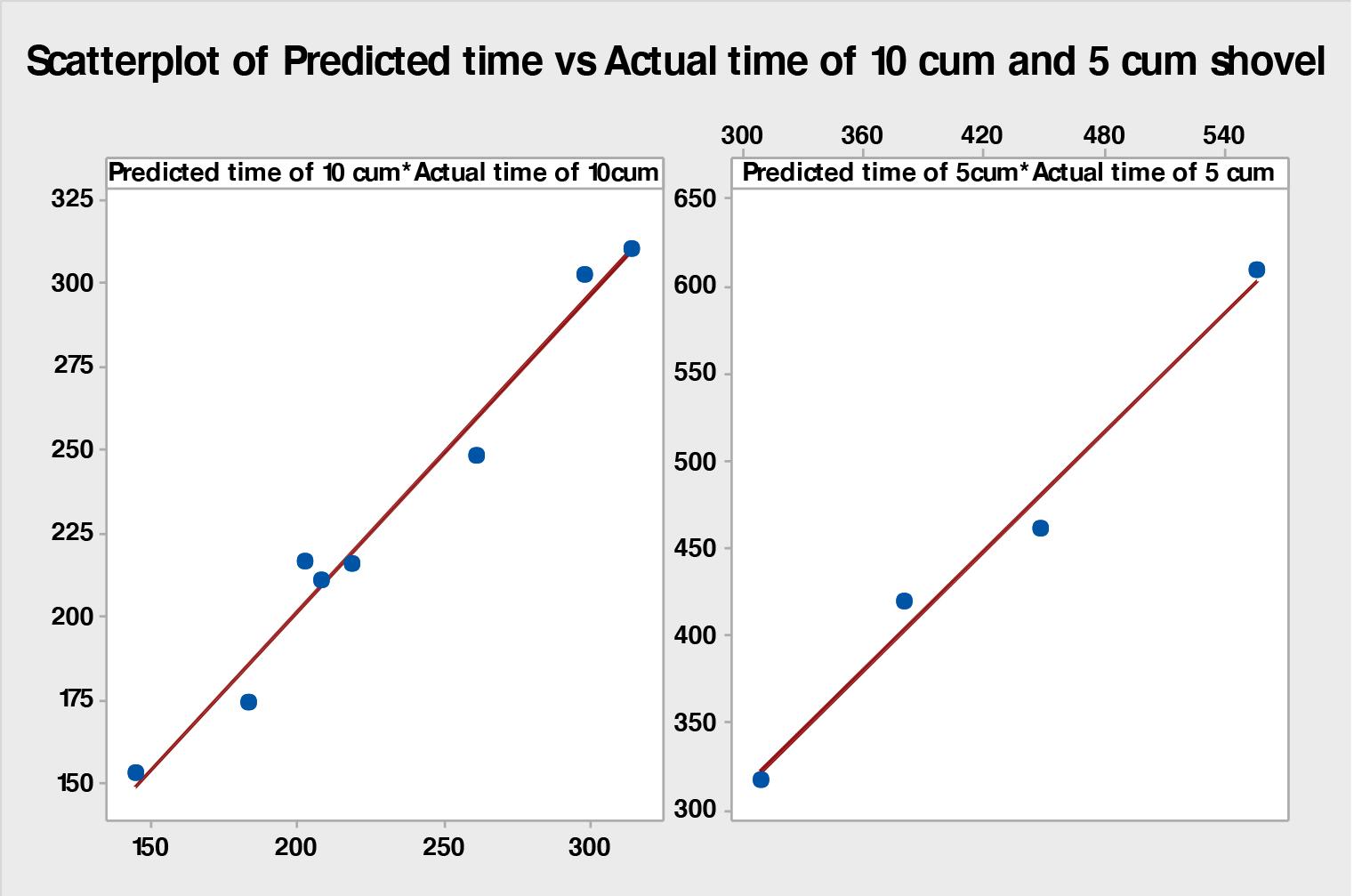

Application of MR and ANN in the prediction of the shovel cycle time, thereby improving the performance of the shovel-dumper operation – A case study by S. Dey, S.K. Mandal, and C. Bhar 597

Loading and hauling of ore and waste are the key operations of an open cast coal mine. The productivity of a mine can be increased by reducing the cycle time of loading equipment as well as utilizsing dumpers optimally. Developed models are validated by comparing the predicted data with actual field data. With the help of the best model for the prediction of shovel cycle time, the plausible fleet size is determined for optimal to utilise the shovel and dumper utilization optimally and to improve the performance of shovel–dumper operation.

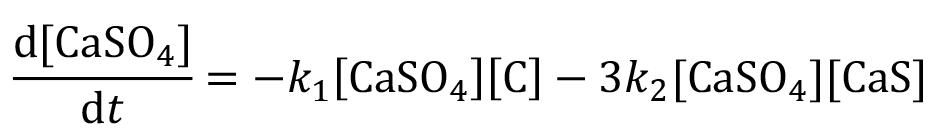

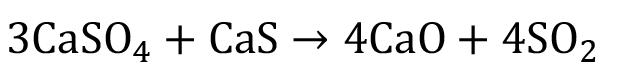

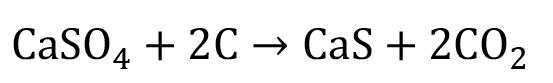

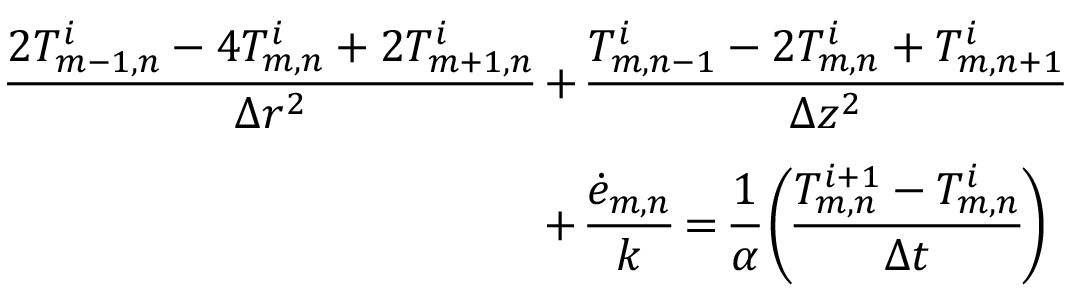

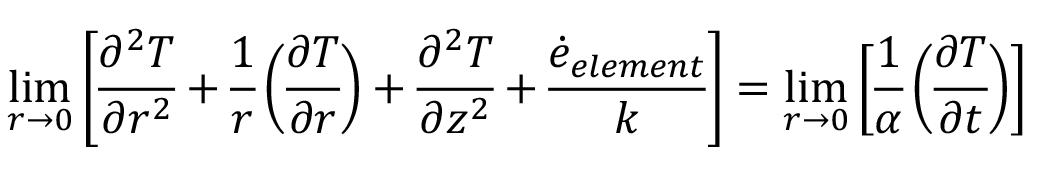

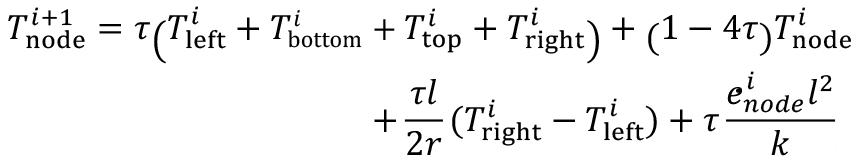

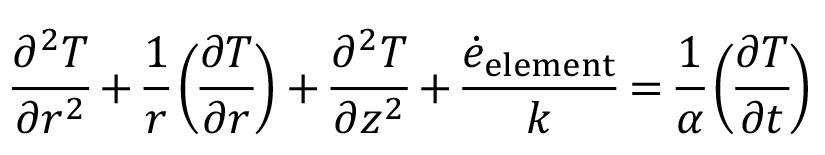

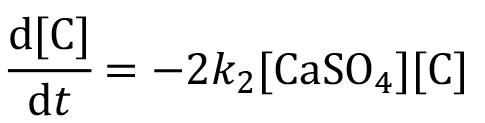

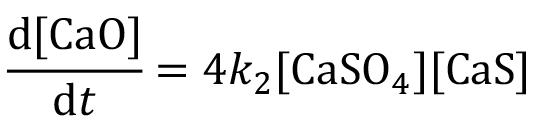

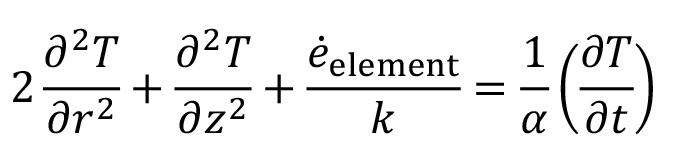

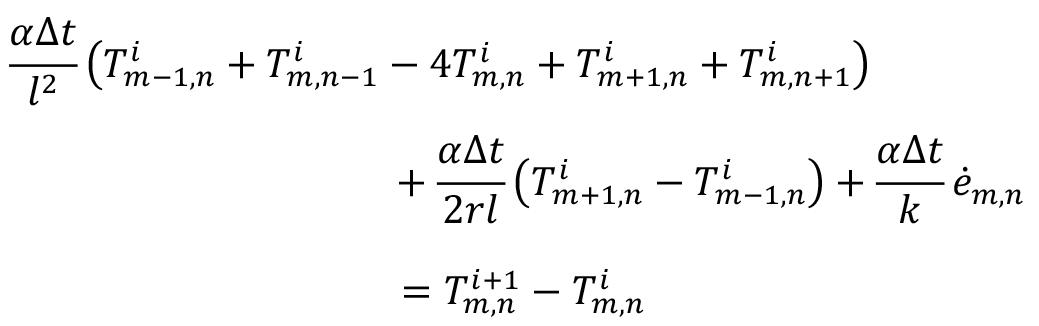

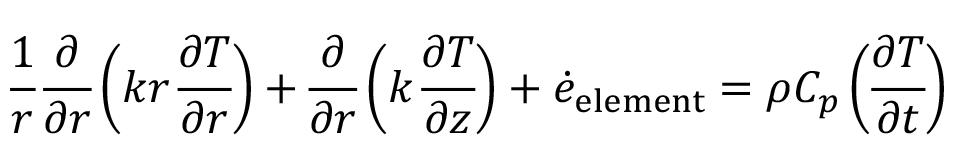

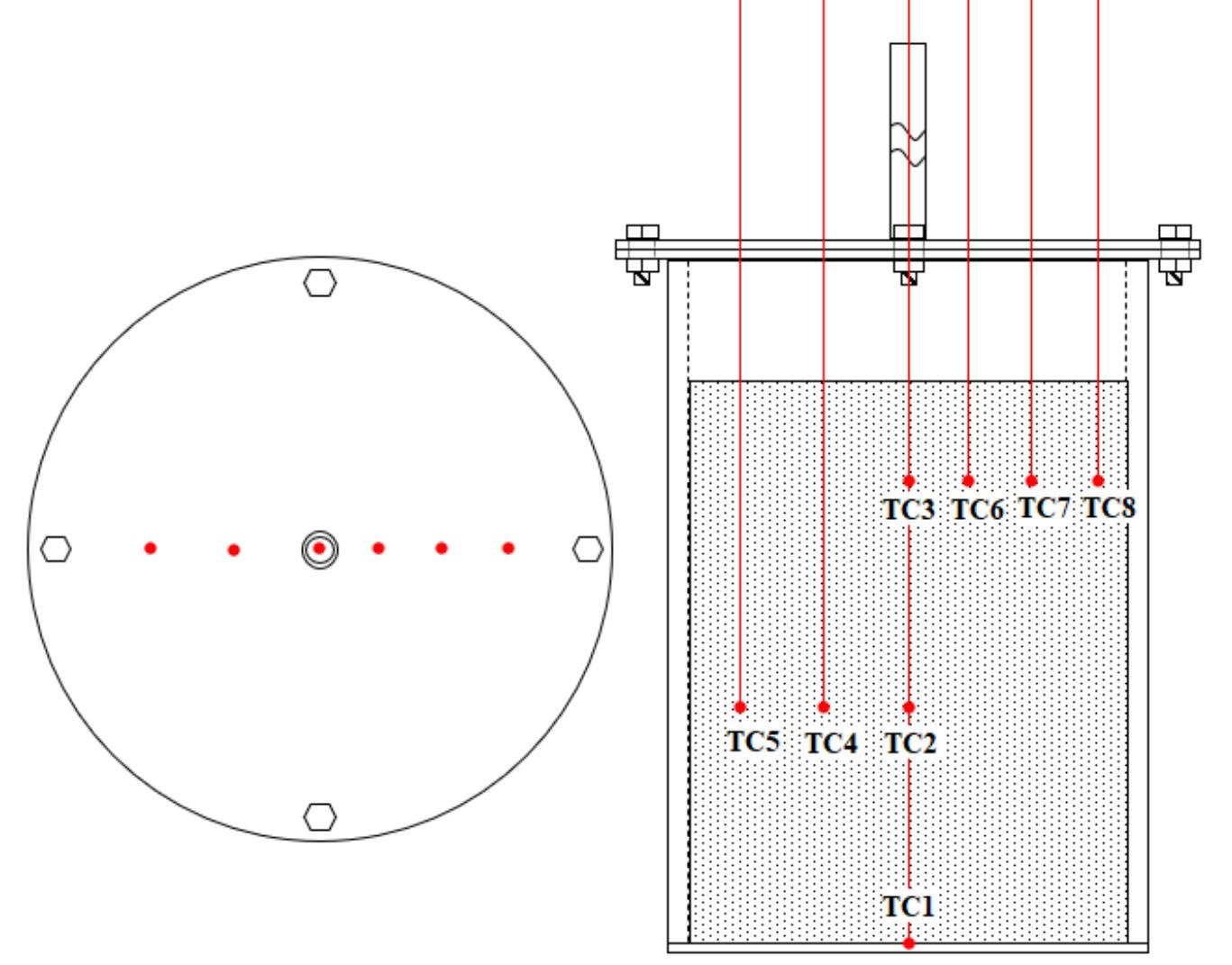

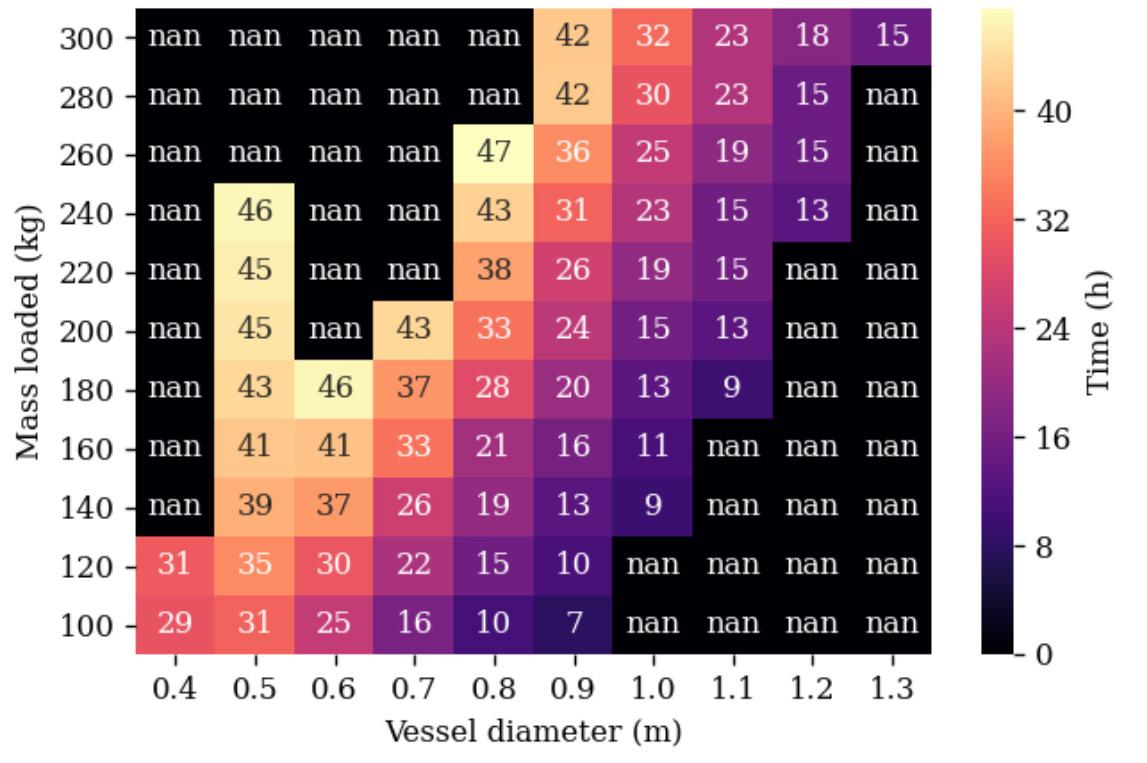

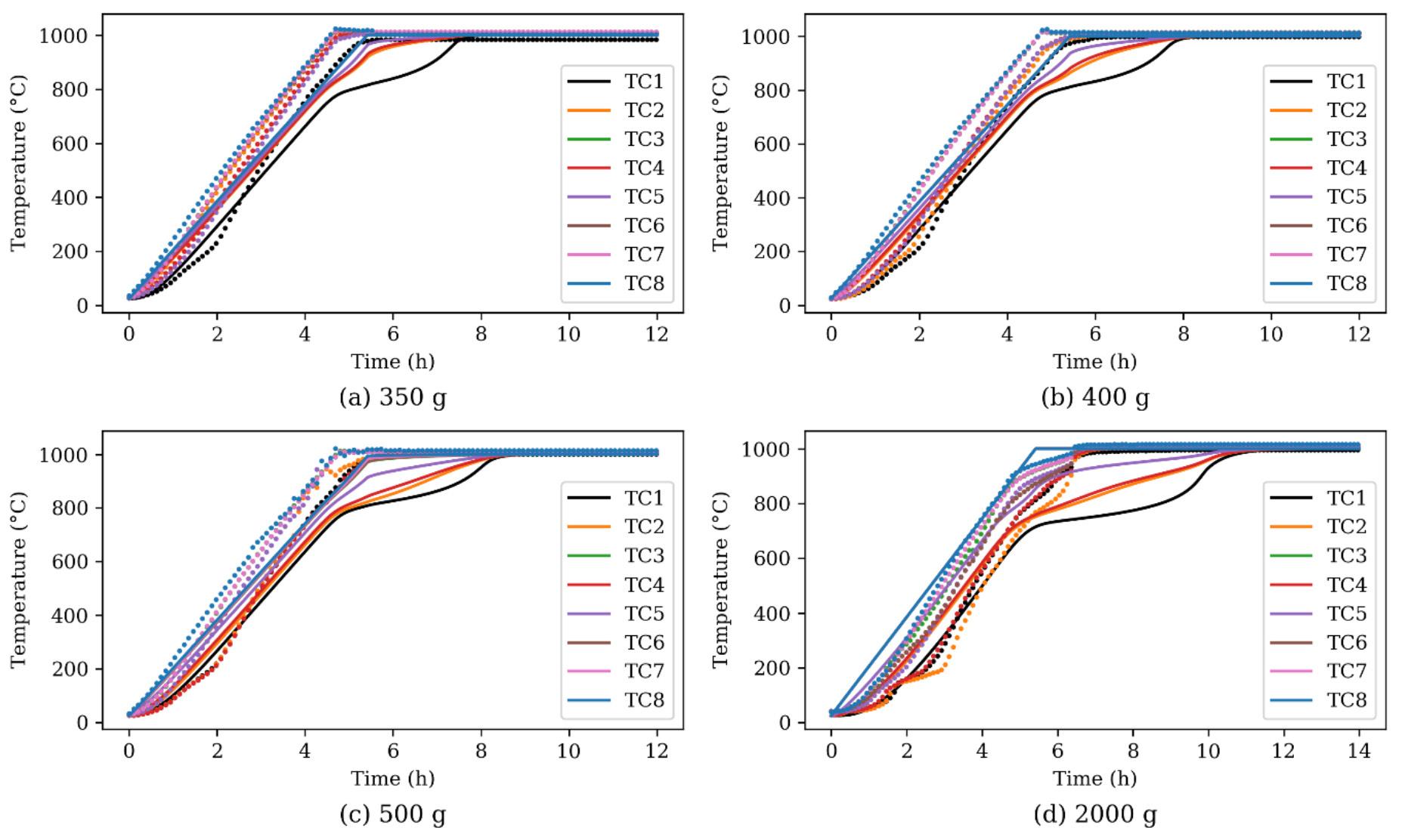

Heat-constrained modelling of calcium sulphate reduction by L.A. Jordan and D. van Vuuren 607

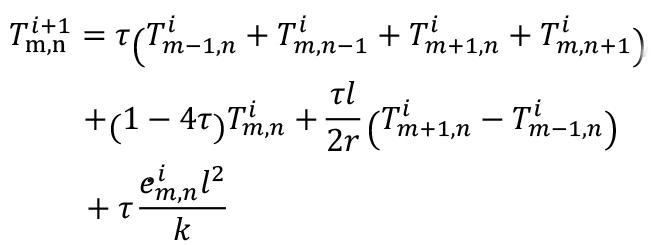

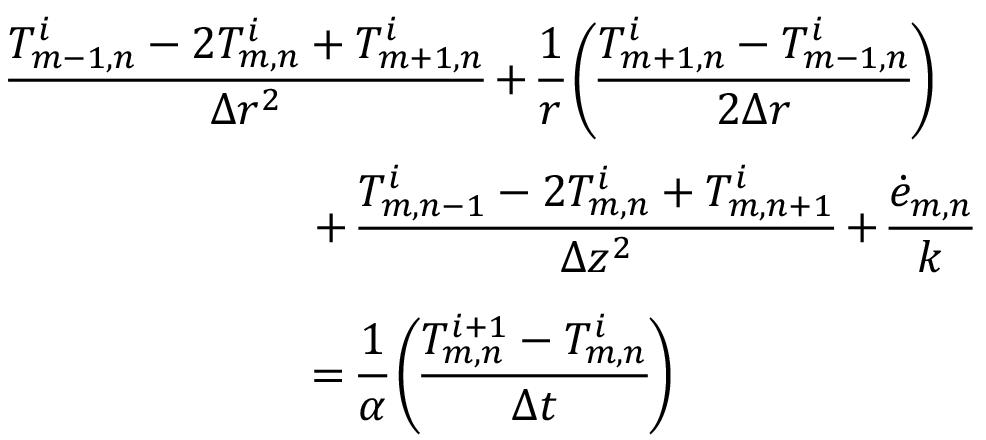

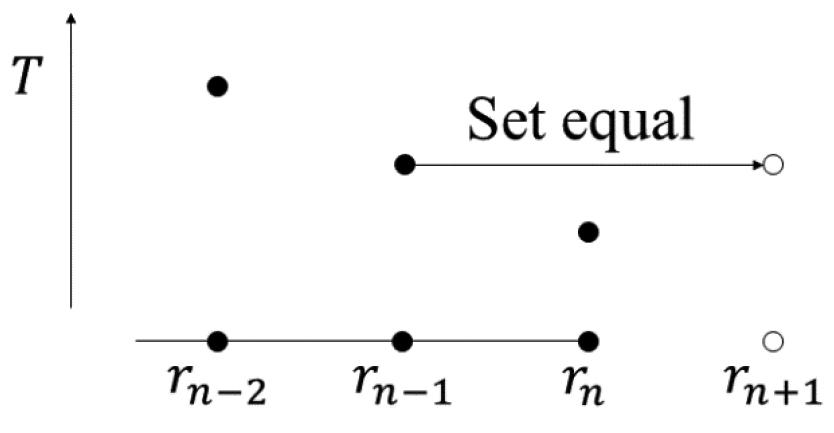

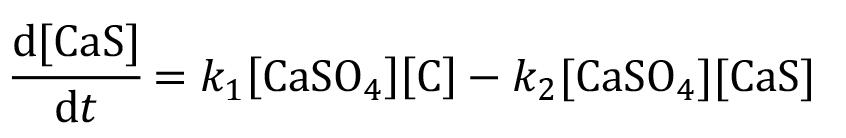

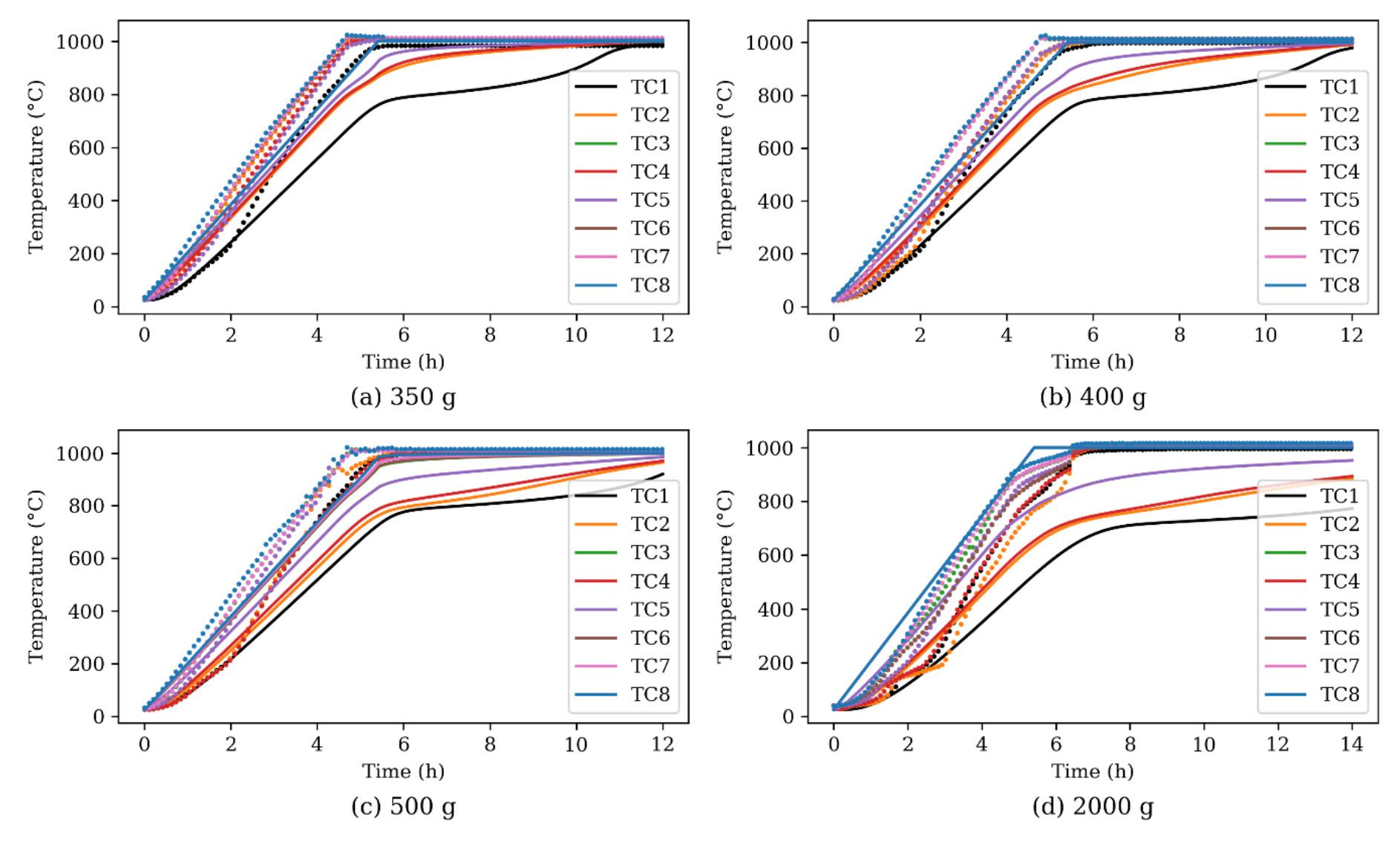

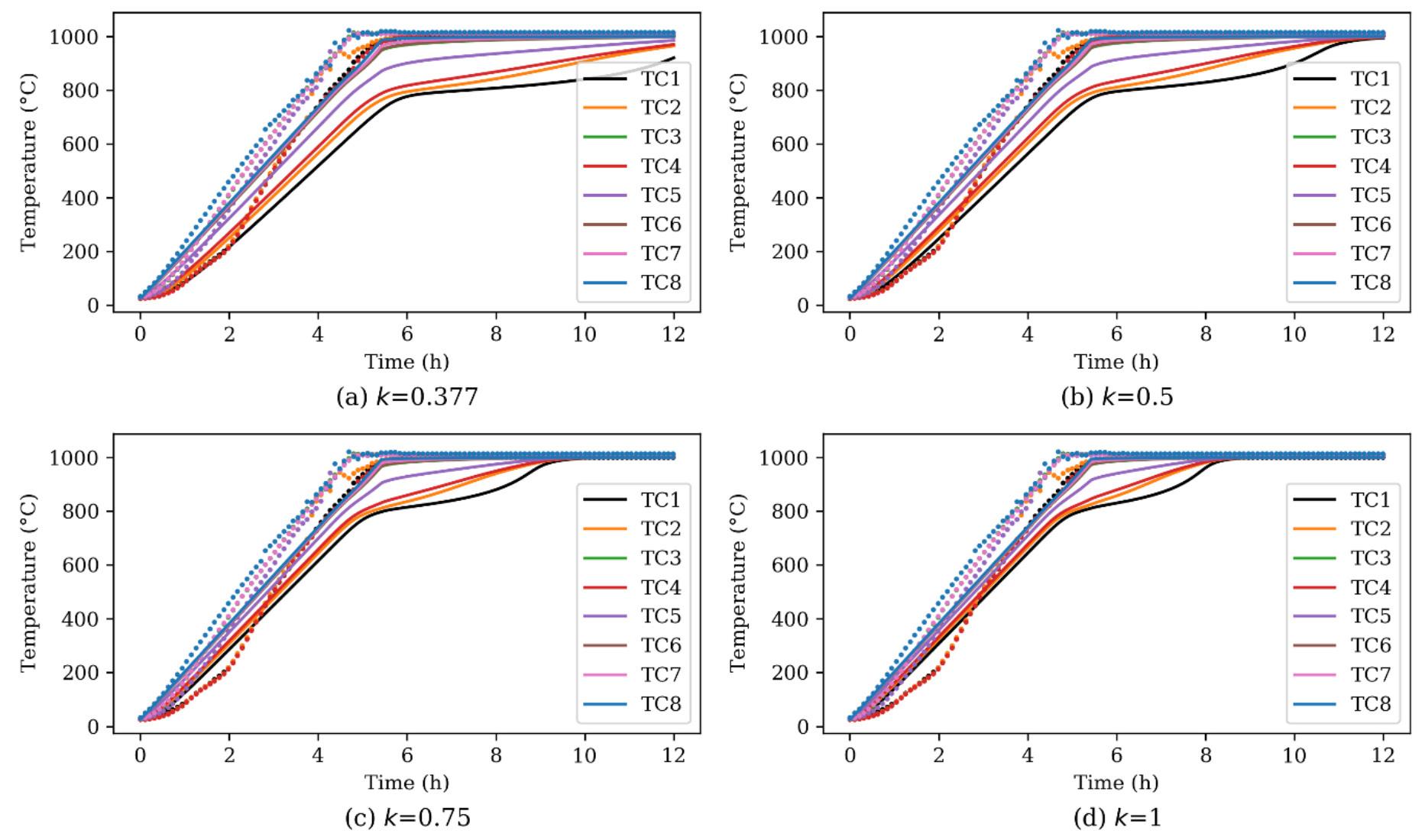

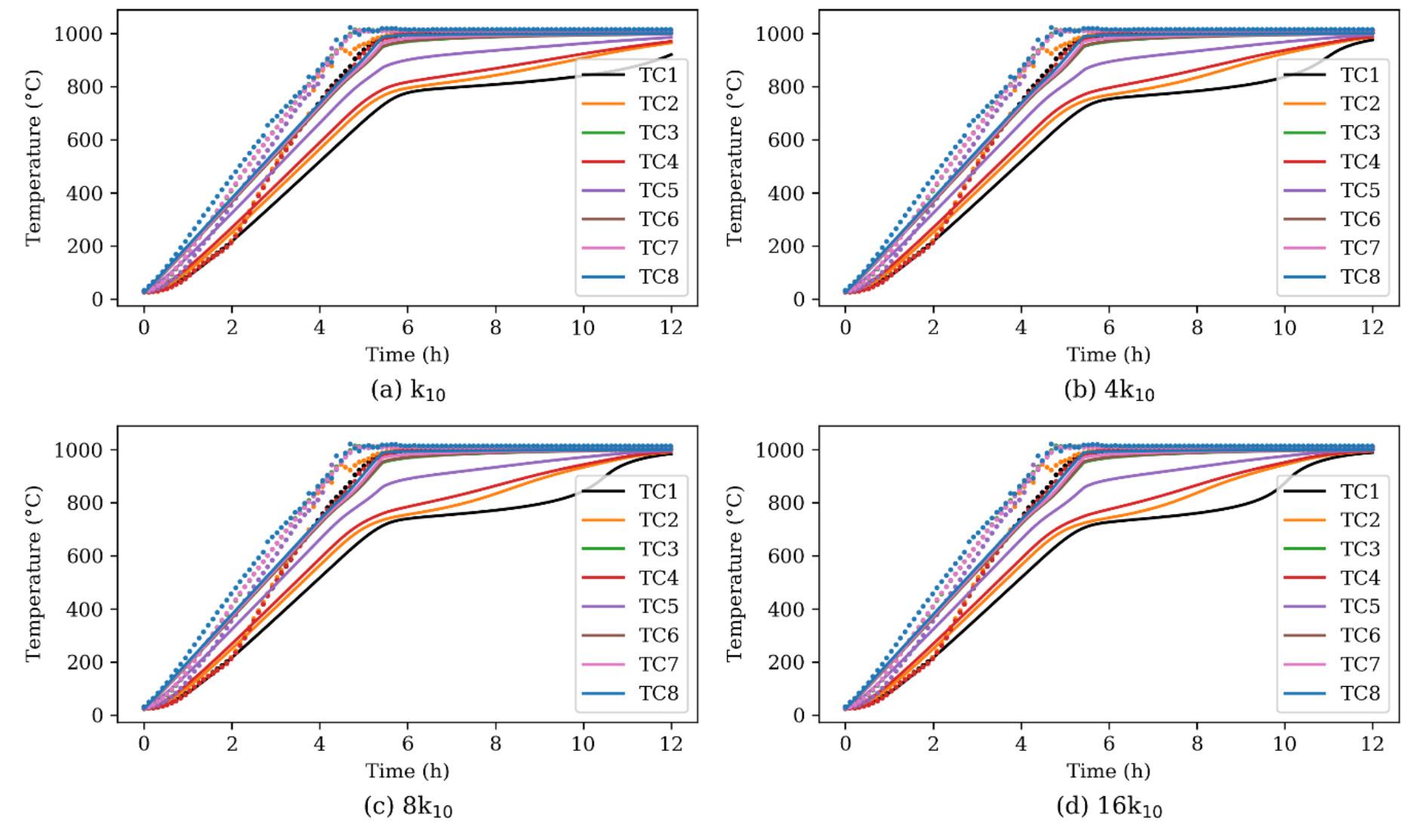

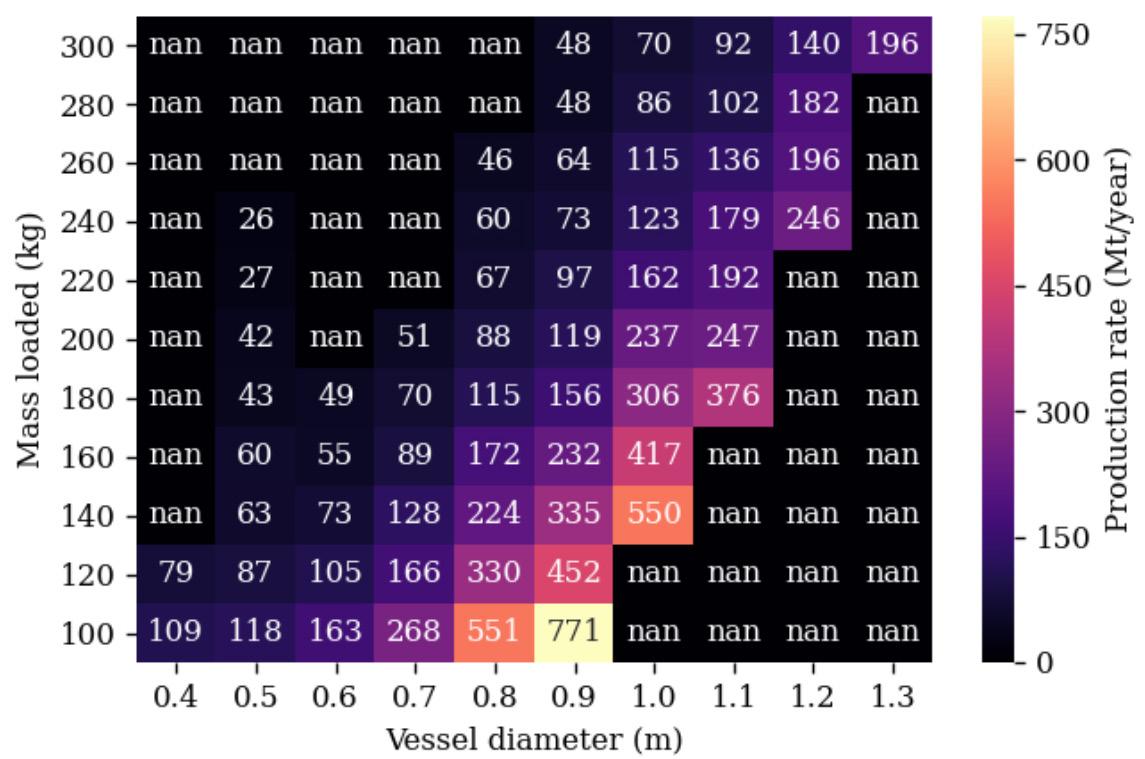

A two-dimensional finite difference model has been developed to describe the reduction of kilogram quantities of dehydrated phosphogypsum contained in a vessel. The model is validated against experimental data. A sensitivity analysis indicated that, at the envisaged process conditions, the behaviour of the system depends much more on the rate of heat transfer than on the rate of the chemical reaction. The model demonstrated a significant increase in accuracy when the thermal conductivity was modelled to increase linearly with temperature rather than compared to assuming a constant value.

Perdefinition, the Journal of the Southern African Institute of Mining and Metallurgy publishes papers related to mining and metallurgy. The Journal publishes about 140 papers every year, with an approximately equal number of contributions related to mining and metallurgy. This edition is somewhat atypical, in that two of the seven papers are related to metallurgy, and five are mining papers. The two metallurgy papers originated in South Africa, specifically, Stellenbosch University and the University of Pretoria. The mining papers were all written outside South Africa. A Czech paper in this edition explores the possibility of using a closed underground mine as a source of service water. Before I started school, in the sixties, my family lived in Potchefstroom. There were regular visits to my maternal grandmother in Pretoria. The national road network was developed only later, and our route took us past a water discharge point of what must have been one of the large West Rand gold mines. I remember my father from time to time remarking on the torrent of discharge water. It will be interesting to read a review on South African efforts to extract underground water to counteract the effects of decanting of mine water, an issue that was somewhat contentious some time ago. Possibly, some contributions from the online conference on Mine-Impacted Water, held middle October, will also find their way in the Journal. The route from Potchefstroom to Pretoria also took us past mine dumps. It is only on skimming a second mining paper, from China, considering factors determining the maximum height of a mine waste dump that I realized that there is (and was) a scientific basis for the proximity of these dumps to a public road.

P. Pistorius University of Pretoria‘Many conversations about diversity and inclusion do not happen in the boardroom

people are embarrassed at using unfamiliar words or afraid of saying the wrong thing — yet this is the very place we need to be talking about it. The business case speaks for itself — diverse teams are more innovative and successful in going after new markets.’

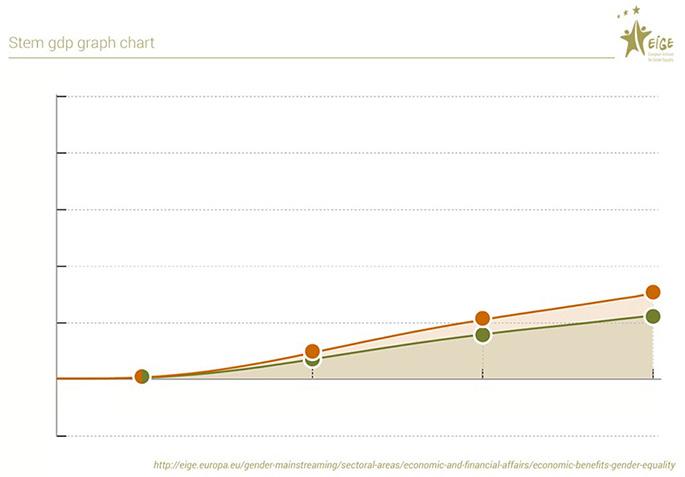

Inga Beale, former CEO of Lloyd’s of London

Simplyput, diversity is important because it leads to economic growth (European Institute for Gender Equality). Reducing the gender gap in STEM could help reduce skills gap, increase employment and productivity of women, and reduce occupational segregation, which will foster economic growth. Increasing the participation of women in STEM would contribute to an increase in EU GDP per capita by 2.2 to 3.0% in 2050. According to Christine Lagarde, head of the IMF, IMF research shows that adding one more woman to a company’s management will boost the return on assets by up to 13%. Another IMF report concluded that banks are more stable when they have more women on their boards.

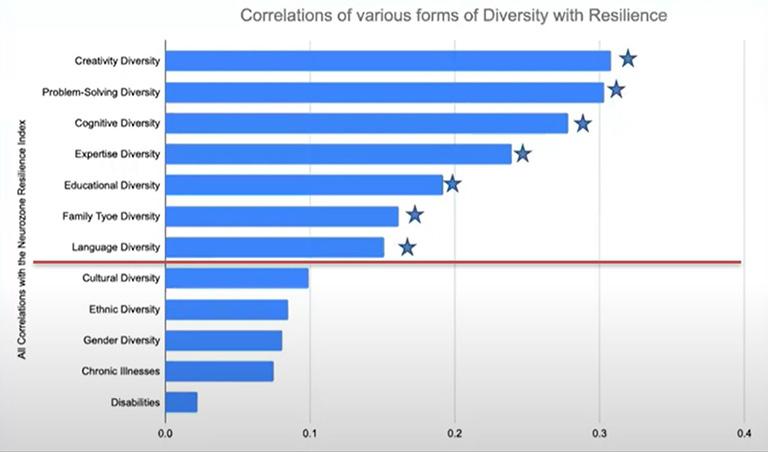

From a neuroscience perspective, there is a scientific need for diversity, so that we may increase our collective creativity and our collective knowledge (different knowledge). The MIT Center for Collective Intelligence found that equal gender brings empathy, innovative solutions, and more ways of doing one thing. They found that diversity and psychological safety equals the highest intelligence. The C Factor (collective intelligence) will always be higher in a diverse group than the intellect of any individual. Neuroscience work by Dr Etienne van der Walt has also shown that creativity, problem-solving, and cognitive diversity cannot be achieved without cultural, ethnic, and gender diversity. We need this diversity to build our own human resilience.

Therefore, the message is clear. It is advantageous to have a diverse work force and to have female leaders, as well as male leaders, in managing positions. This is a balance, a bridge, a collaboration. Barbara Annis, CEO of Gender Intelligence Group (GIG), advocates the value of gender unity. We need both female and male leadership styles to survive, and that is why collaboration is so important. But if diversity and inclusion are so important, why are we not reaching our targets?

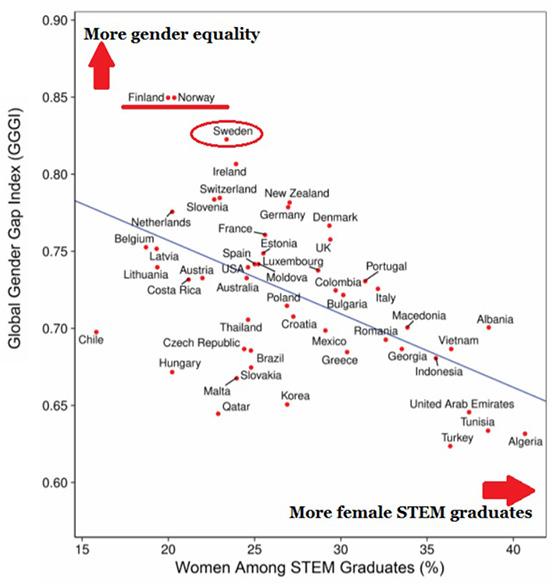

Why, in countries with equal education and opportunity, do women still choose not to enter STEM? This is known as the global ‘educational-gender-equality paradox’ (the more gender equality in a country, the fewer women in STEM). This paradox could have to do with the fact that women in countries with higher gender inequality are simply seeking the clearest possible path to financial freedom. And, often, that path leads through STEM professions. Experts do not have any clear answers; however, they did find that we should focus our efforts on those young, would-be STEM women and form programmes specifically aimed at creating positive environments for girls to interact with STEM ideas (Reinking, 2018).

We are all standing on a burning platform. Across the world, according to UNESCO, women with degrees in computer science represent only 40% of the total, and those with engineering degrees account for just 28%; cloud computing only 14%, and data and AI only 32%. It seems surreal, but women make up more than two-thirds of the world’s 796 million illiterate people (Facts & Figures | UN Women – Headquarters). When looking at South Africa, since 1996, when women were first allowed to work in underground mining, women have come to represent only 14% of the total mining workforce.

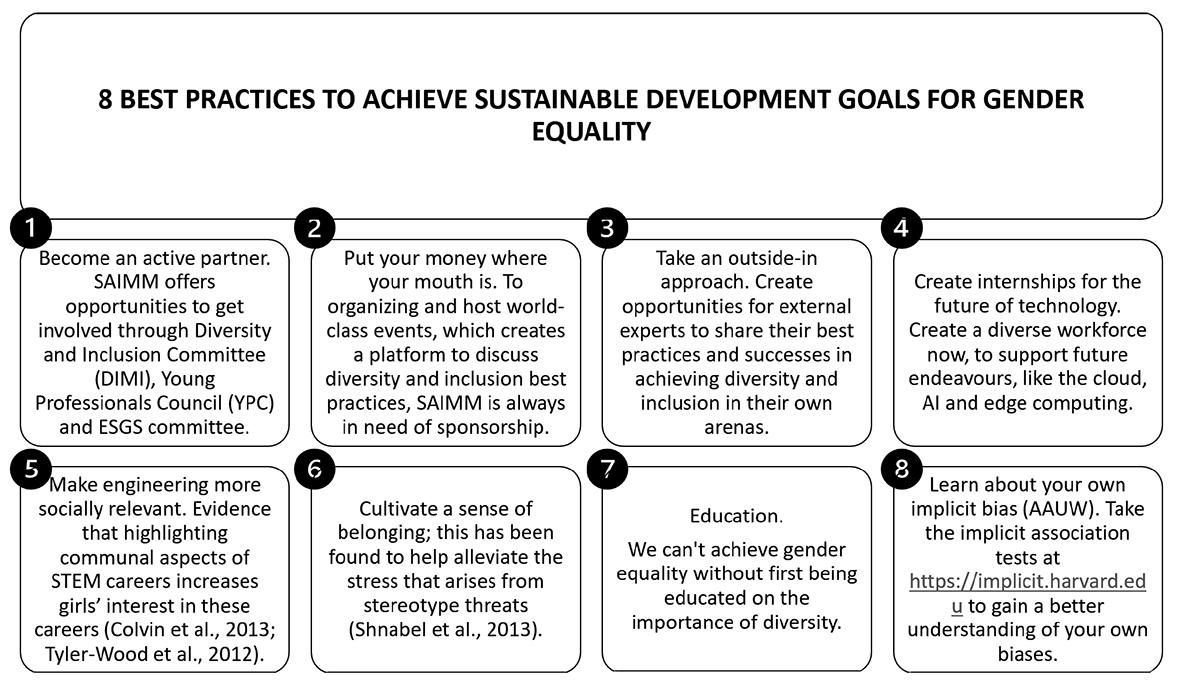

How do we go about positive change? Most literature shows eight key practices that everyone must commit to executing as part of their sustainable development goals for gender equality. The SAIMM already plays a role in each of these practices, by providing a platform for networking and dissemination of best practices in diversity and inclusion, by openly communicate drives for change, and by offering mentorship to young would-be STEM women.

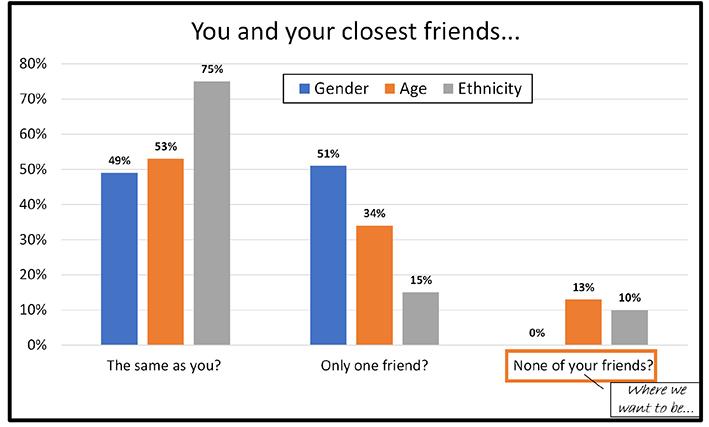

Let’s take our own, personal test. If you look at your two closest friends, your square squad, are they the same gender, age, or ethnicity as you? These questions were asked at the SAIMM AGM and although some delegates are seeking diversity in their own lives, most of us are still duplicating.

This month I want to challenge everyone to cultivate a sense of belonging for all and to work on courage enablers so that we can diversify in our own lives as well.

Z. Botha President, SAIMMFor leaders, the challenge is to draw out the expertise and insights that come from different perspectives.

Kelly McDonald, author ‘How to Work With and Lead People Not Like You’

Affiliation:

1Department of Mining Engineering, Pontificia Universidad Catolica de Chile, Santiago, Chile.

2Department of Mining and Geological Engineering, University of Arizona, Tucson, USA.

Correspondence to: A. Anani

Email: angelinaanani@arizona.edu

Dates:

Received: 8 Mar. 2022

Revised: 12 May 2022 Accepted: 14 Jun. 2022 Published: October 2022

How to cite:

Soto, I., Anani, A., and Córdova, E. 2022

A discrete event simulation approach for mine development planning at Codelco’s New Mine Level.

Journal of the Southern African Institute of Mining and Metallurgy, vol. 122, no. 10, pp. 549 560

DOI ID: http://dx.doi.org/10.17159/24119717/2045/2022

ORCID: A. Anani https://orcid.org/0000-00019125-6877

E. Córdova https://orcid.org/0000-00029187-4461

The new caving megaprojects that are planned to go into production in the next decade have scheduled horizontal developments at very high rates, which are difficult to achieve. Research has been conducted that seeks to model the construction times for underground developments to determine the feasibility of achieving the planned rates. However, these previous attempts do not consider all the operational aspects that make up the mine development cycle. Here, we present a discrete event simulation (DES) model that individualizes each unit operation of the development cycle to determine the construction rates that new projects will be able to attain. The developed model was applied to the New Mine Level (NML) of the El Teniente Division (DET). The results indicate that it would be impractical to achieve the advance rates scheduled in the original plans if the unit operations of the mine continue to be executed using the status quo. The metres developed after six years in the sections analysed can be significantly improved by changing the maintenance strategy for the equipment (457 metres increase), orepass availability (194 metres increase), and the initial planning sequence (1 598 metres increase). It is recommended that the mine implements a flexible maintenance strategy, defines a strategy to ensure and increase orepass availability to contractors, and makes use of current simulation tools for a more robust development sequence planning.

mine development, mine planning, caving, OR in natural resources, discrete event simulation.

The depletion of near-surface deposits has pushed the mining industry to transition to the extraction of deeper orebodies by underground mining methods. An essential part of underground mine planning is underground development to access the orebody, which is complex and capital intensive. The geotechnical uncertainties and capital investment requirements result in long development periods, delaying production ramp-up and minimizing the operational flexibility. The rate at which horizontal excavations are developed is an important factor for mine development, since it controls the accessibility of the deposit and the meeting of production goals. However, compared to surface mining, little technological advancement has been made to incorporate the uncertainties surrounding underground development and exploitation in mine planning (Musingwini, 2016).

Additionally, the new caving megaprojects or ‘supercaves’ that will soon commence production are very ambitious in terms of their production goals. These goals relate directly to the kilometres of tunnels that must be developed to achieve them. This is the case for the New Mine Level (NML) of Codelco’s El Teniente Division, a mine located 120 km south of Santiago, Chile, which is used as a case study in this paper. The mine must excavate more than 113 km of tunnels to extend the mine life for at least 50 more years (Díaz, Rojas, and Vargas., 2019). Therefore, important aspects of the production planning exercise should focus more on development planning than on production itself, since production is a result of the development rate (Rocher, Rubio, and Morales., 2011). In this paper, we present a disaggregated approach, using discrete event simulation that takes into account equipment and orepass availability and micro-activities in the drill and blast sequence that affect mine development goals. Based on current practices, we evaluate the feasibility of achieving the planned future development rate at the NML. The research also accounts for the impact of outsourcing mine development to contractors and their access to resources such as ore-passes on long-term development plans. Finally, a feasible medium- to long-term plan is developed using Datamine’s Studio UG with EPS tools, and recommendation made to facilitate achieving the development goals.

As stated, technological advancement in underground mining still lags that in surface mining, including the application of discrete event simulation (DES). Many parameters in a mining operation, such as commodity prices, are characterized by high uncertainty (Singer and Kouda, 1999; Dehghani, and Ataeepour, 2012; Haque, Topel, and Lilford, 2014). Simulation has been used in short-term mine planning to better manage the risks of uncertainty (Paravarzar, Pourrahimian, and AskariNasab 2021). DES is a method that models systems through a sequence of well-defined events, which has proven to be a very useful tool in decision support for the mining industry (Basu and Baafi, 1999; Vagenas,1999; Ahmed, Scoble, and Dunbar, 2014; Greberg et al., 2016; Dindarloo, Osanloo, and Frimpong, 2015) for both existing and future mines. Skawina et al., (2014) compared the use of mechanical excavation and drilling and blasting for underground tunnel development using DES. Similar to our study, their research proves that tunnel development using multiple development faces simultaneously increases performance significantly. The focus of their work, however, involved the comparison of tunnel excavation methods and lacked important factors of mine development planning such as resource availability. Manríquez, Pérez, and Morales (2020) developed a combined mixed-integer linear programming model and DES model to generate optimal short-term production schedules for a bench and fill mine. They conclude that a better mine plan is obtained by accounting for uncertainty using simulation. Musingwini (2016) explored the application of optimization algorithms in underground mine planning. He noted the difficulty in the use of exact methods to solve complex underground planning problems optimally. To overcome challenges in optimizing underground mine planning, he recommends the integration of stochastic optimization in development layout, as demonstrated in this research.

The most common application of DES in underground mines is the selection of equipment to maximize productivity (Runciman, Vagenas, and Baiden, 1999; Salama, Greberg, and Schunnesson, 2014; Park, Choi, and Park, 2016). Salama, Greberg, and Schunnesson, (2014) evaluated the impact of the combinations of trucks and LHDs and equipment sizes on mine productivity using DES. Park, Choi, and Park, (2016) used DES to optimize the number of trucks dispatched to three loading points in a truck-loader haulage system that maximizes productivity.

Greberg et al., (2016) used DES to compare the use of orepasses and trucks for the transport of ore in deep underground mines. Their results indicated that trucks could be economically viable at levels where the costs of managing an orepass become too high. Anani and Awuah-Offei (2017) also used DES to match shuttle-car haulage equipment to the continuous miner (CM) in different sections of a coal panel based on the CM cycle time. They determined that in sections of the coal panel, fewer shuttle cars can be used to extract the coal to achieve the same level of productivity. Anani et al., (2019) applied DES to optimize the extraction parameters in a bord and pillar coal mine. They maximized productivity by optimizing the cut-out distance, fleet size, and panel dimensions of the production system.

Skawina et al., (2018) used DES to evaluate the effects of orepass loss due to failure on loading, hauling, and dumping operations and productivity. The authors also determined the minimum number of orepasses needed to maintain production rates. Similar to our study, they conclude that orepass availability

has a significant impact on the production rate. Although their work does not focus on mine development, the impact of orepass availability on production rate is relevant. Salama et al., (2017) used DES combined with mixed-integer programming to evaluate the net present value (NPV) of an underground operation based on the copper price and increased costs as the mining rate increases. The authors conclude that at greater depth, it is beneficial to increase the mining rate during times of high copper prices, even with an increase in operational cost.

Few works can be found that apply simulation to horizontal tunnel development in small-scale underground mines (Leiva, 2015; Navarro 2012). They do not consider key factors such as the ability to work on multiple faces with a work crew and critical cycle operations such as roof support in the drifts. Previous research does not evaluate the impact of changes in critical operations management on the key performance indicators in mine development. Therefore, we develop a DES model that allows the identification and understanding of the critical operations in the horizontal development cycle in large underground mines. We consider all the unit operations of the cycle and the possibility of working multiple faces with a work crew. We also compare the impact of the original equipment manufacturer (OEM) and a flexible load-haul-dump (LHD) equipment maintenance strategy on the development rate. Lastly, we investigate the effect of orepass availability on the development rate and propose a new development plan that the mine can realistically achieve.

In the following sections, the proposed simulation model is detailed and subsequently applied to a case study of mining sections in El Teniente’s New Mine Level (NML). The results obtained from the simulation are validated with historical data from sections currently in operation at DET, and critical unit operations of the development cycle are identified. Experimental analysis is performed that incorporates changes in the management of critical unit operations and the results compared to existing and planned development rates. Finally, the conclusions and recommendations for future work are presented.

The case study pertains to the El Teniente Division (DET), an orebody exploiyed by a set of different underground projects through caving methods producing around 160 kt/d and a small open-pit operation (20 kt/d) on the surface. The orebody caves naturally after undercutting its base, and the caved material is recovered using drawpoints (Laubscher, 1994). El Teniente mine has been operating since 1904 and produces both copper anodes and copper cathodes. The mine is positioned as the most productive division of Codelco, reaching a production of 459 744 of fine copper in 2018 (Codelco, 2020). This production also positions it as the third most productive mine in Chile, surpassed only by Escondida and Collahuasi (Cochilco, 2019).

Production in Esmeralda, Dacita, Recursos Norte, and Diablo Regimiento, the current underground mines of DET, cannot be maintained through the ensuing decades due to depletion of the reserves. As a result, Codelco has developed a structural megaproject called New Mine Level (NLM), which aims at developing new productive levels at a greater depth than those currently exploited. By doing so, it will increase DET’s copper reserves by more than 2 Gt and thereby extend the life of mine by more than 50 years. This megaproject consists of four productive sections: Andes Norte (North Andes), Pacífico Sur (South Pacific),

A discrete event simulation approach for mine development planning at Codelco’s New Mine

Andes Sur (South Andes), and Pacífico Norte (North Pacific). These sections are expected to enter production in the years 2023, 2030, 2034, and 2038 respectively.

To make production from the NML sections viable, each section must have an undercut level, intermediate transport level, drainage level, ventilation level, and production level. The latter constitutes the largest number of developments. Therefore, the focus of this paper will be on planned developments at the production level. Figure 1 shows an example of an undercut level, where the drilling and loading equipment will undercut the ore deposit; production level, where the LHDs will load the ore from the drawpoints and dump it into the orepasses; and finally the intermediate haulage level where the trucks will circulate to collect the material from the production level and dump it into the orepasses. The orepasses are connected to the conveyor belt of the main haulage system. All these levels belong to the Pacífico Norte (hereon referred to as North Pacific) section of the NML.

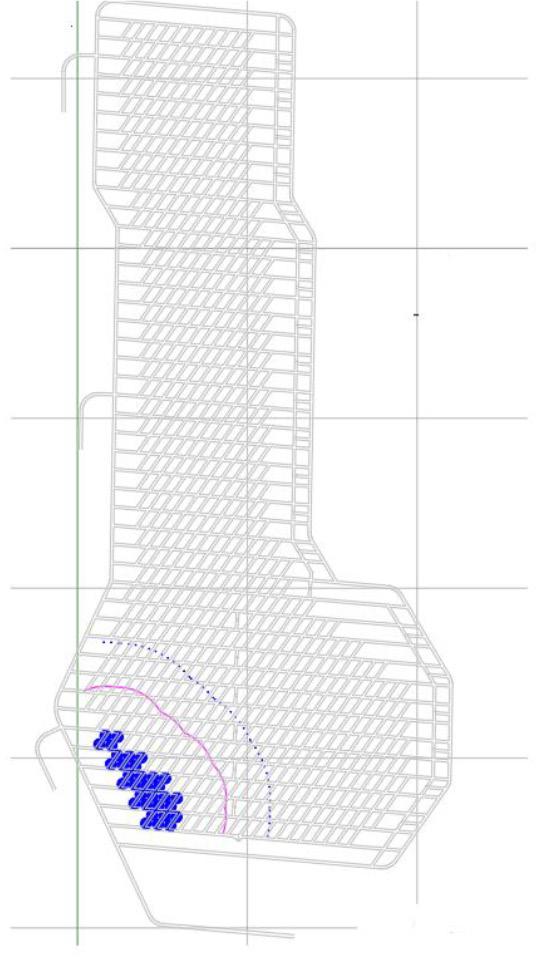

El Teniente mine has within its safety policies provisions to minimize the exposure of equipment and people in the so-called transition zone (TZ), which is defined as ‘That area where the state of the stress is increasing and is under continuous changes, and which generates stress conditions considerably greater than the in-situ condition’ (Lobiano, 2016). This area of increased stress due to mining and developing caves is the abutment stress zone, which moves through the footprint ahead and follows the undercut face. The stresses in this area can be 1.5 to 2 times greater than the main in-situ stress, which in the case of the NML is estimated at around 50 MPa (Hormazabal et al., 2014). DET established a rule to ensure that the development is always ahead of the TZ and leaves a margin of safety. This rule must be respected for each year of mine production. The rule states that ‘Between the transition zone (TZ) and twice the area that it encompasses (2TZ), all tunnels must be developed.’ Therefore, to generate the transition zone, the most external production points of each year must be taken to generate a circumference with a radius equal to the TZ, which for the North Pacific section is 80 m. The process must be repeated, this time taking circles with a radius of 160 m. Figure 2 shows the boundaries of the TZ and 2TZ

for the year 2038. In order to comply with the rule set by DET, all tunnels below the dotted blue line must be developed by the end of the year 2038. The main idea of the TZ is to have the minimum number of workers in the ‘increased stress’ zone; therefore, the developments must be advanced as much as possible before the influence of the abutment stress from the undercutting face reaches these areas.

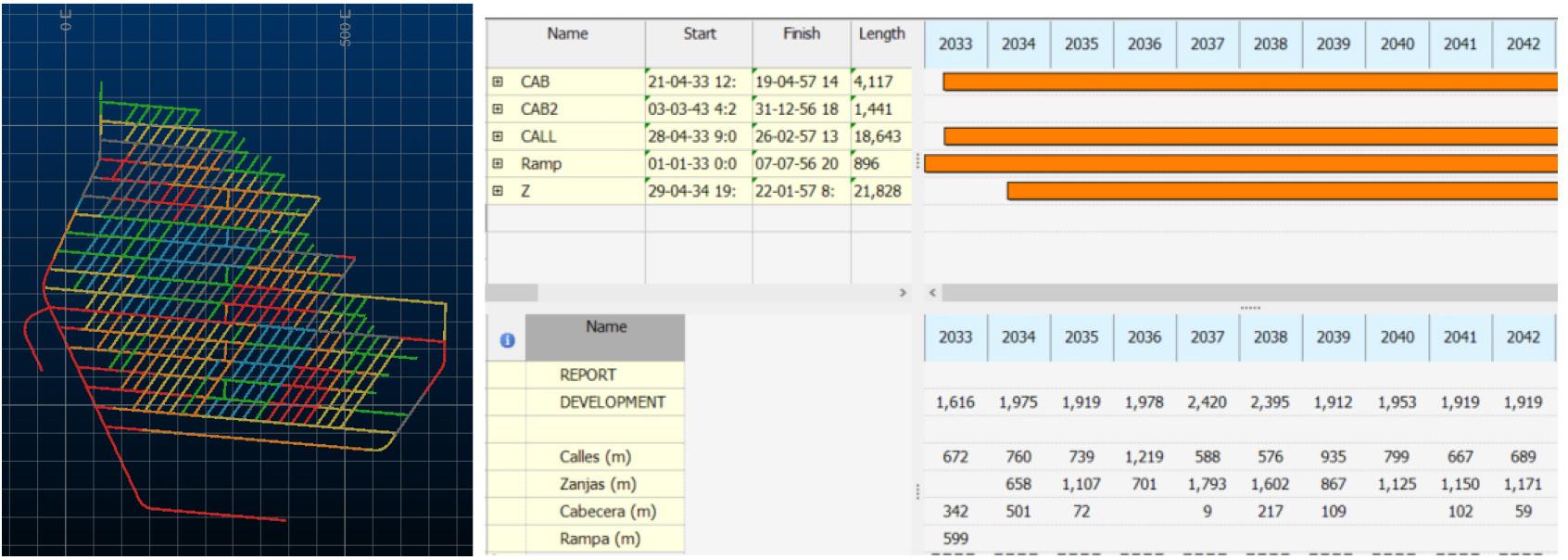

Mine design or AutoCAD software is used by the mine, taking as input the advance plans of the TZ and 2TZ of each section to obtain the sequence of the horizontal developments. Each segment drawn on the AutoCAD plans corresponds to a horizontal drift at scale. The use of this software is justified since it helps to document changes in construction scheduling (Memon, Majid, and Mustaffar, 2006) and communicates the planning to be carried out very effectively. The plans can be used by workgroups from other areas that do not have knowledge of specific software.

However, AutoCAD has limitations; for example, once the planning process is finished, there will be only one scenario to be evaluated (Ramírez, 2020). That scenario is not necessarily optimal since it is based only on the planner’s own criteria. Therefore, the use of specialized software such as Datamine Studio UG and EPS tools is recommended. Although none of these tools generates optimal plans, they do allow the simulation and evaluation of multiple scenarios quickly and reliably, and therefore are better for choosing a more robust scenario than the initial case. The scenarios consider different precedence rules for plannable activities (MacNeil and Dimitrakopoulos, 2017), on which the simulation model detailed in the following section can be run.

The North Pacific section planning is developed under the assumption that construction starts in 2033 with an open development face, three active faces in the year 2034 and between the years 2039 and 2060, and finally, five active faces between the years 2035 and 2038. An average advance of 45 m per month per face is planned based on these assumptions. In Figure 3, the red coloured segment corresponds to the first development to

be carried out in 2033 in the production level of the North Pacific section. From the figure, the restriction imposed on the 2TZ is satisfied since the development of all the tasks that are below the blue segmented line is planned.

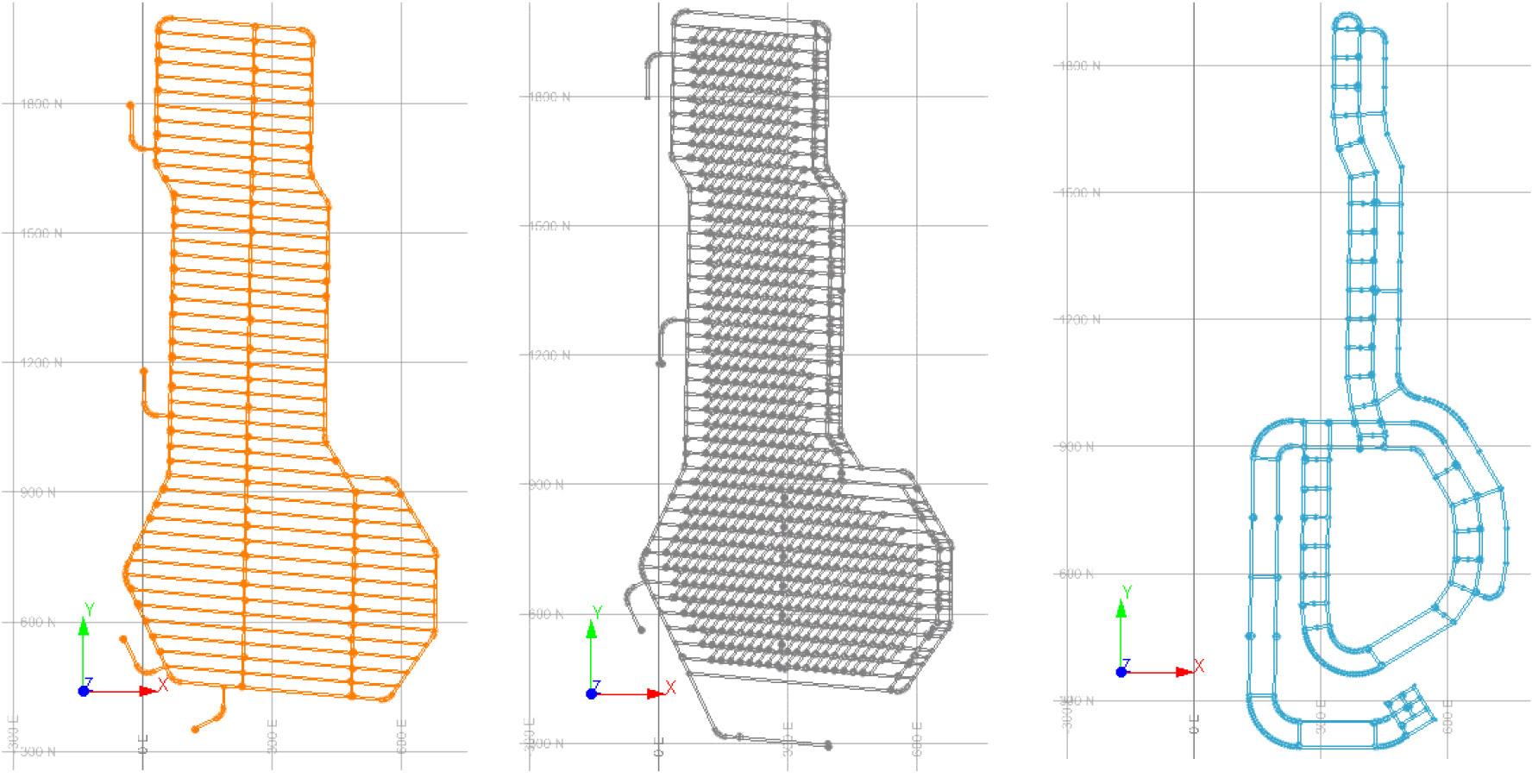

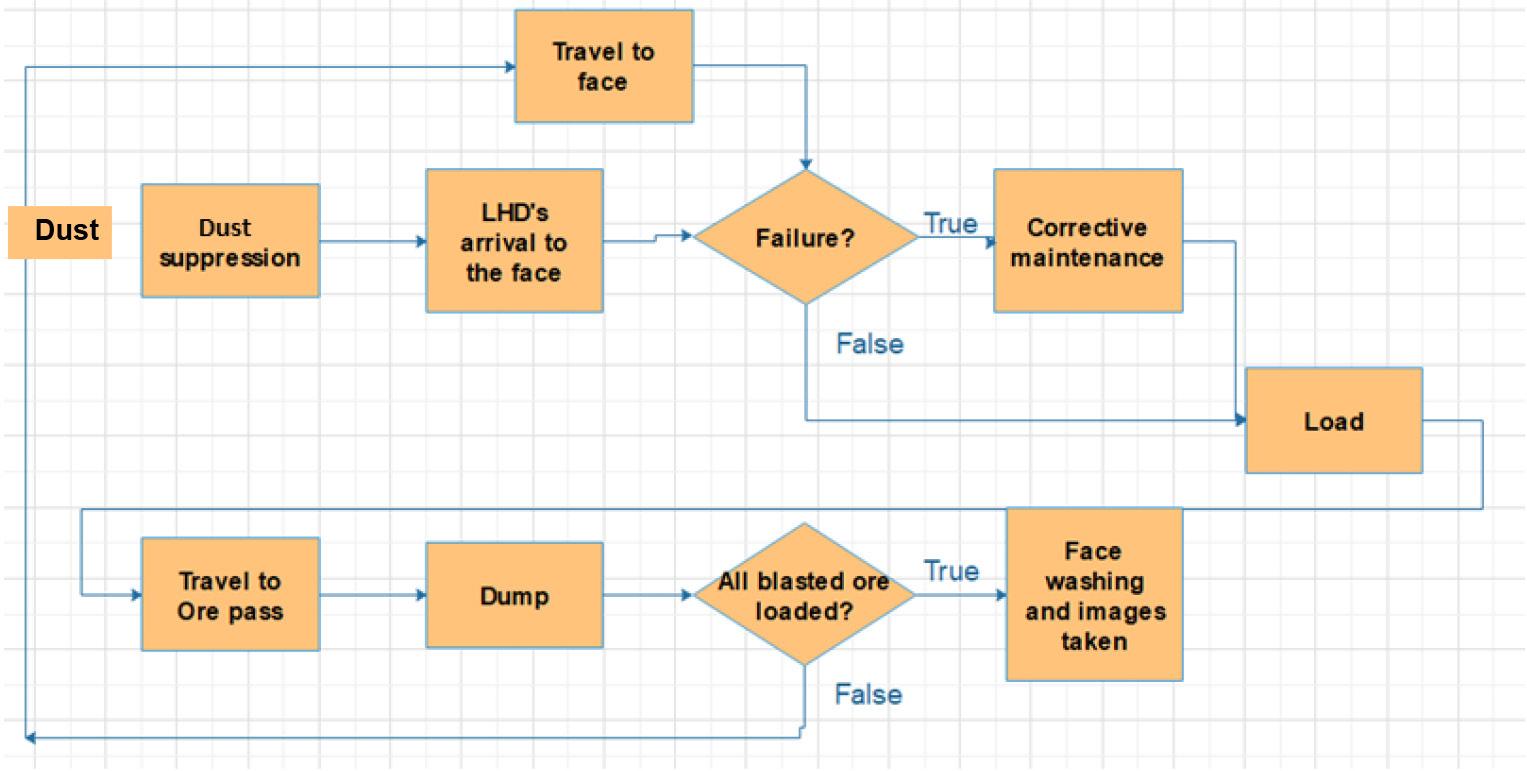

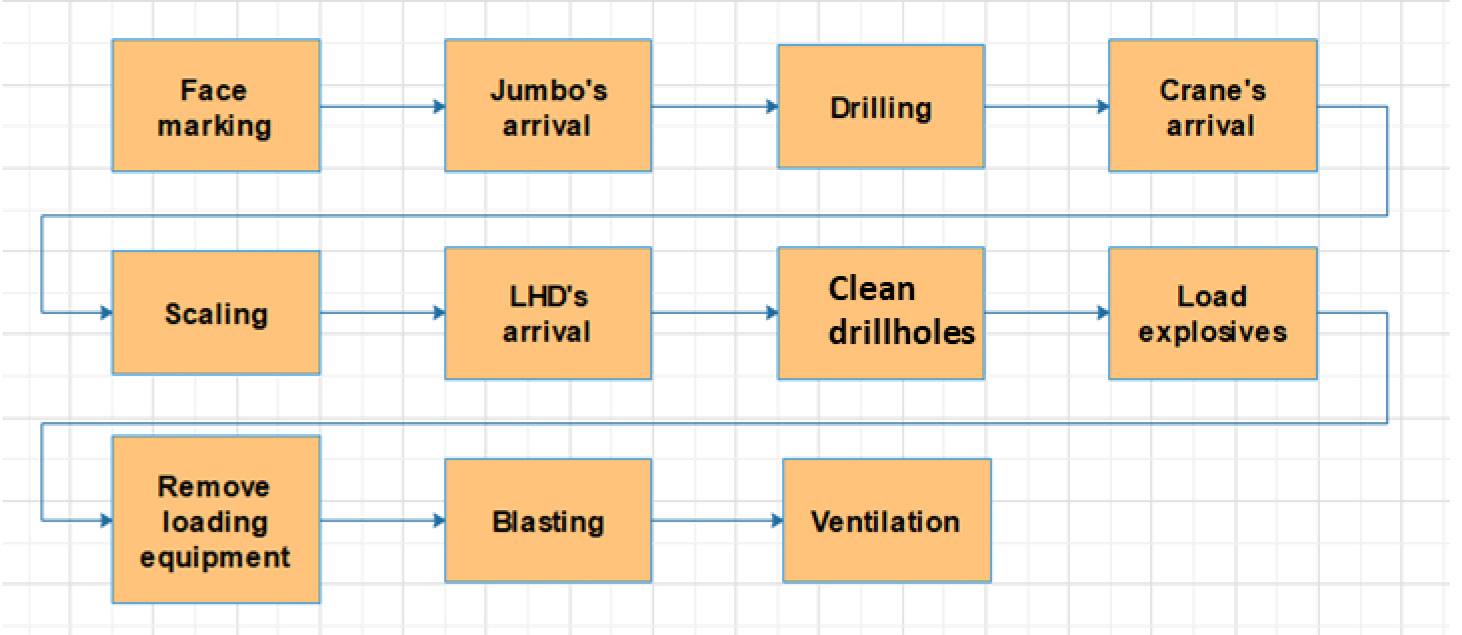

The system to be modelled corresponds to a classic drilling and blasting cycle. The complete development cycle consists of many stages, which can be grouped mainly into muck extraction, ground support, drilling of blast-holes, loading of explosives, blasting, ventilation, and scaling. Muck extraction (Figure 4) corresponds to all the activities necessary to transfer the recently blasted material from the face to an orepass or dumping point. An LHD of 9 cubic yards is used for this task. It is important to note that the availability of the LHD may vary due to failure resulting from hard use and lack of proper maintenance. This will directly affect the equipment performance and consequently the overall cycle (Balaraju, Govinda, and Murthy 2018a).

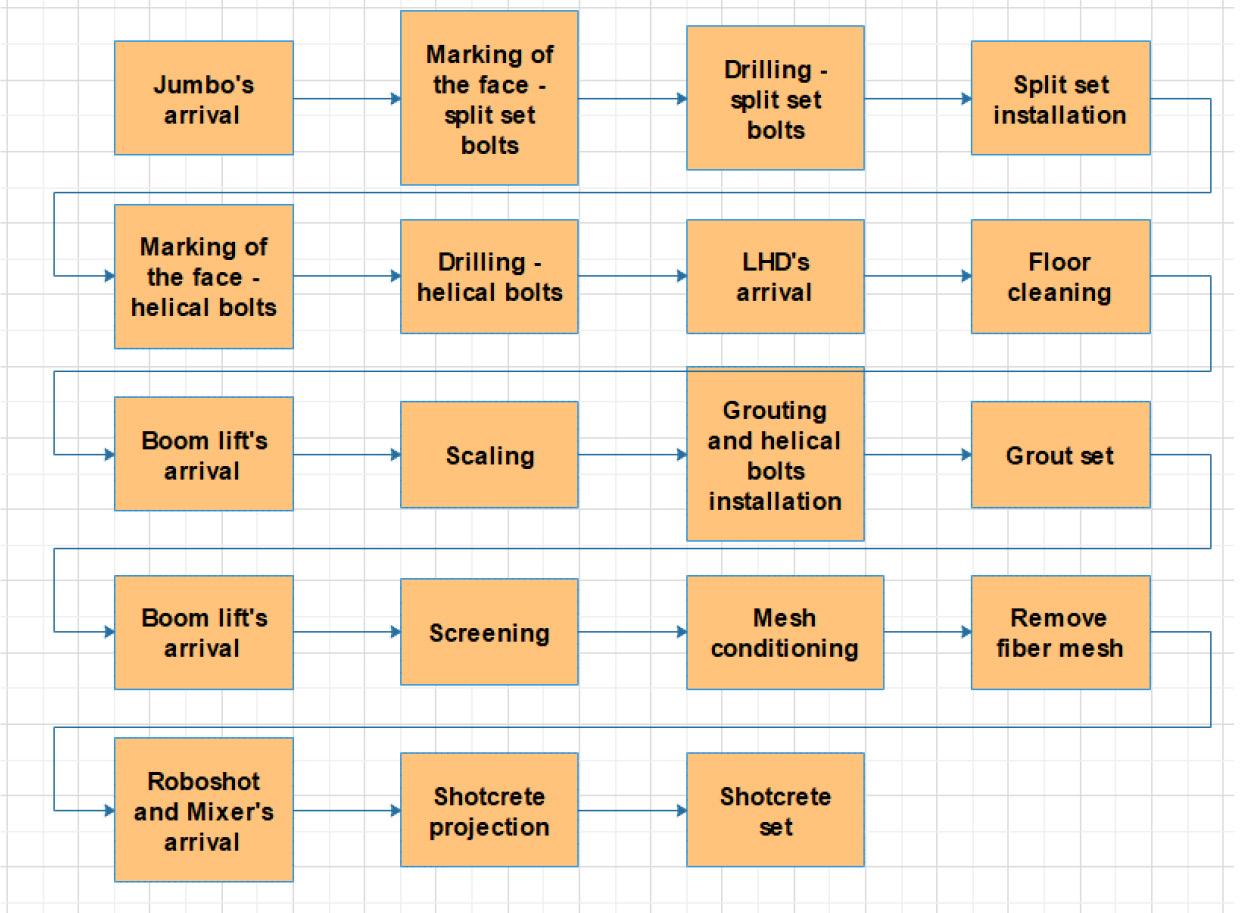

Ground support includes all the activities required to provide support and stability to the developed tunnels and thus minimize the risk of damage to equipment and injuries caused by rockfalls. The resources required for these activities are a crane, jumbo, LHD, roboshot, and mixer. Support of the face begins with the marking of support holes. The jumbo drills the support holes for the installation of the helical bolts and split-set bolts. The crane then enters the face to grout the bolts with a mixture of water, cement, and additives. Once the bolts have set, the crane with a boom lift enters the face for conditioning and installation of the support mesh. The last step in ground supportis the projection of shotcrete using the roboshot equipment. The sum of all these activities constitutes the longest time in the mining development cycle. Figure 5 shows all the necessary support activities.

Blast-hole drilling is carried out by a twin-arm jumbo, which is responsible for drilling the face according to the previously designed blast pattern. For the case study, each blast-hole will have a length of 3.2 m. The loading of explosives requires the use of the lifting crane to load each of the previously drilled holes with the corresponding explosive according to the defined blast pattern. Once each hole is loaded and connected, the shift manager acquires authorization to perform the blasting. Scaling is performed to remove loose rocks from the roof and the face. Unlike other activities, scaling will be necessary whenever loose rock is found. Therefore, it is carried out throughout the development cycle. This activity is considered to be always

performed after muck extraction, bolt drilling, blast-hole drilling, and blasting (Figure 6). The blast face is typically accessed 30 minutes after a blast due to ventilation regulations.

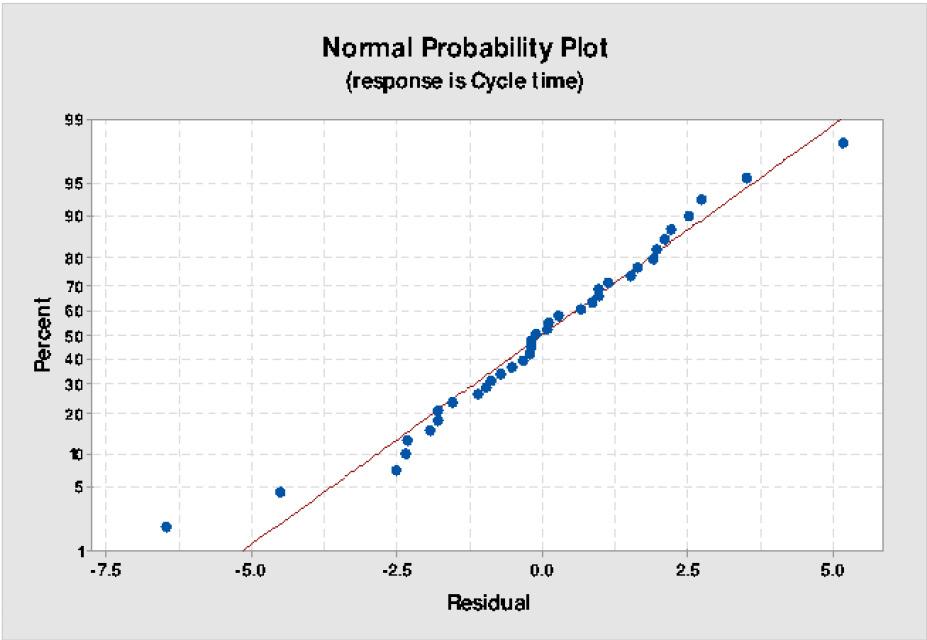

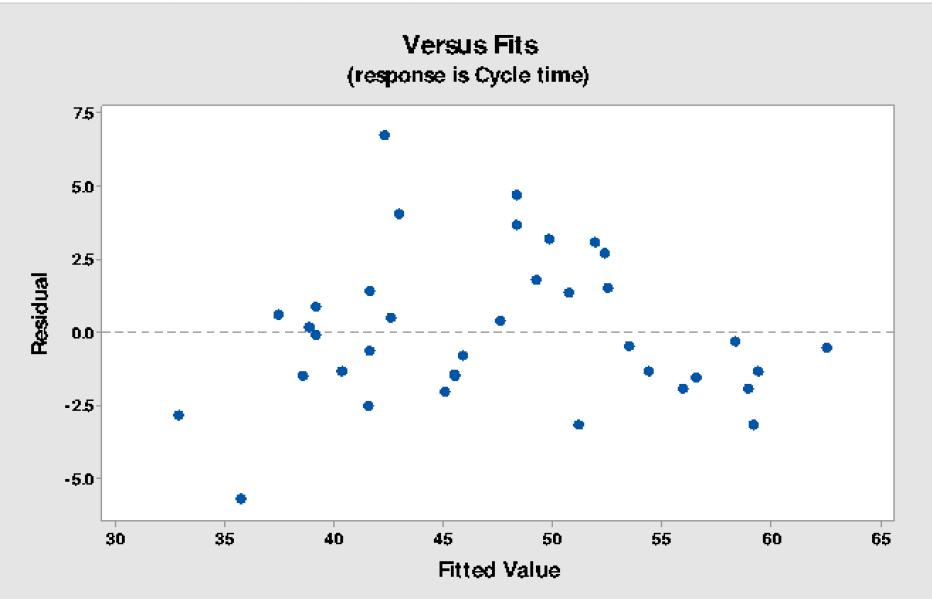

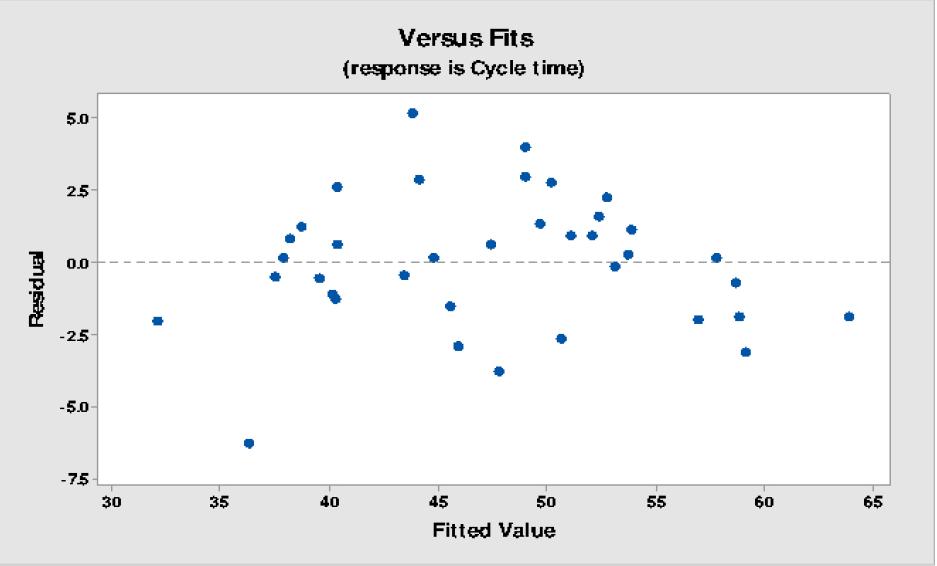

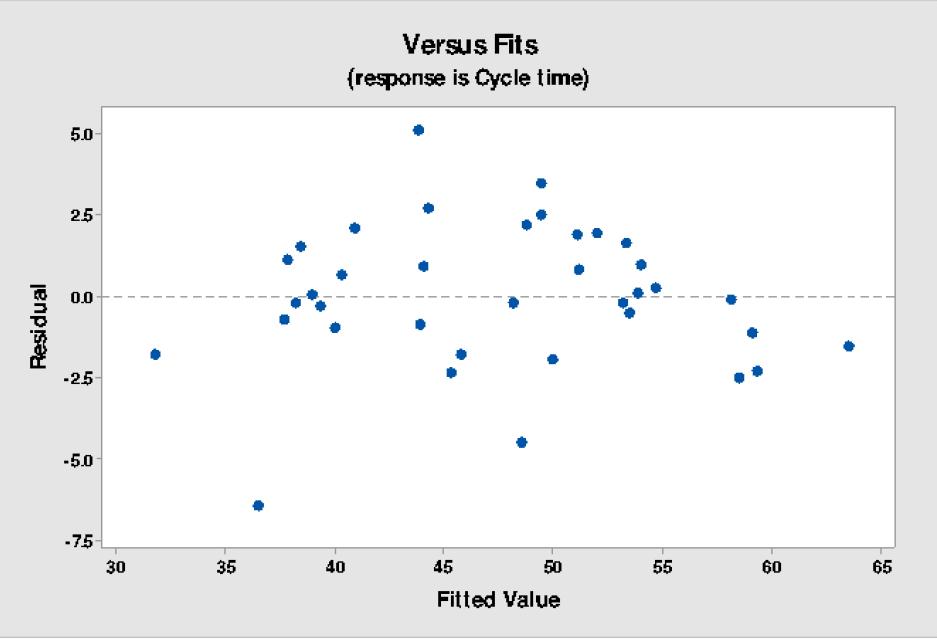

Data was collected for five days in a section currently in production at El Teniente to fit the execution times of each of the unit operations with a probability distribution. Raw data from similar studies in productive sections of DET (Ccatamayo, 2017; Chami, 2012) was used for validation during distribution fitting to select the appropriate distributions. It should be noted that mine production parameters such as productivity (normally distributed) typically follow known probability distributions.

The Arena® Input Analyser software was used to fit the data to different statistical distributions. Input Analyser considers the distribution with the least squared error as the best fit. The Kolmogorov–Smirnov test, goodness of fit test, and visual analysis were used to evaluate the quality of fit. The distributions and the parameters obtained for the unit operations are presented in Table I, and those for the LHD cycle in Table II. The distributions were selected based on data type, the number of data-points, and suitability to the variable type (Rockwell Automation, 2019).

Among the theoretical distributions (Weibull, lognormal, and exponential distributions) used to model equipment failure, the Weibull distribution is the most versatile and better represents the life-cycle of the LHD equipment (Balaraju, Govinda and

Variable studied Distribution Parameters

Ventilation Beta 100 + 44 * BETA (0.501, 0.601)

Gas suppression Beta 15 + 26 * BETA (0.526, 0.501)

Missed hole checking Beta 15.2 + 6.78 * BETA (0.793, 0.636)

LHD arrival Erlang 8 + ERLA (0.968, 2)

Face washing and images taken Triangular TRIA (21,30,38.33)

Jumbo arrival Expo 17 + EXPO (0.69)

Marking of the face - split set Triangular TRIA (6.38,13.6,14.75)

Drilling - split set Triangular TRIA (22.18,26,28.48)

Split set installation Triangular TRIA (14.4,17.35,19.63)

Marking of the face - helical bolts Triangular TRIA (10.45,.18.63,19.95)

Drilling - helical bolts Weibull 107 + WEIB (34.8, 0.794)

Floor cleaning Triangular TRIA (13.73,15.52,20.53)

Boom lift arrival Normal NORM (11.1, 1.37)

Scaling Triangular TRIA (21.83,25.28,40.67)

Grouting and helical bolt installation Gamma 90 + GAMM (35.9, 0.475)

Screening Expo 100 + EXPO (14.8)

Mesh conditioning Triangular TRIA (77, 83.22, 89.98)

Remove fibre mesh Triangular TRIA (6.45,8.5,9.48)

Roboshot and mixer arrival Triangular TRIA (14.22,14.97,15.53)

Shotcrete projection Beta 22 + 16 * BETA (0.543, 0.783)

Shotcrete set 120

Face marking Triangular TRIA (14.23,15.06,21.35)

Shot drilling Normal NORM (147, 10.5)

Crane arrival Normal NORM (9.23, 1.79)

Lifters cleaning Triangular TRIA (13.8,14.88,17.67)

Loading explosives Expo 72+EXPO (10.2)

Remove loading equipment Triangular TRIA (9.22,10.17,11.72)

Blasting Triangular TRIA (5.47,6.18,7)

Variable studied

LHD loading time

LHD dumping time

Distribution Parameter (s)

Normal NORM (58.5, 9.3) (s)

Gamma 8.5 + GAMM (1.44, 6.18) (s)

Travel speed loaded Weibull 0.71 + WEIB (0.782, 2.4) (m/s)

Travel speed unloaded Weibull 1.15 + WEIB (1, 2.45) (m/s)

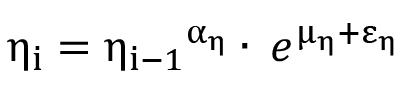

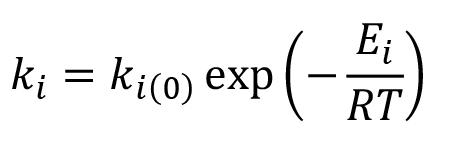

Murthy, 2018b). Historical data from an LHD of 7 cubic yards and an LHD of 10 cubic yards was taken and adjusted to a Weibull distribution to model the equipment failure rate to simulate the LHD failure. The failure parameter is defined as the number of failures per unit time that can be anticipated (Balaraju, Govinda and Murthy, 2018b). The equipment failure rate fitted with the Weibull distribution to historical data follows Equation [1].

where ß = 3.264 is the shape parameter, t is the hours of use of the LHD, and ηi is the characteristic life of the LHD, which depends on the number of overhauls i, following Equation [2]:

[2]

where aη = 0.371 and μη = 2.875 are drift parameters, and e η is Gaussian noise with mean zero and standard deviation s η = 0.095.

[1]

The failure of the LHD with hours of use in an interval dt occurs when the condition indicated in Equation [3] is met:

After every maintenance overhaul, t returns to zero, reducing the probability of failure compared to that before maintenance was performed. An LHD with i + 1 overhauls and t hours of use will have a higher probability of failure than an LHD with i overhauls and the same t hours of use, since

is more likely.

The Arena simulation software (using discrete event simulation) presents a flexible modelling framework with a hierarchical structure to analyse the impact of changes to a system. A valid model can be used to conduct simulation experiments and predict the performance of the system based on key performance metrics (Rockwell Automation, 2019).

The objective of the simulation is to develop a model capable of predicting real development rates obtained in the current production sections of DET. Arena’s high-level modelling modules were used to simulate the mining system following the operational logic in Figures 4, 5, and 6. The main equipment used in the mining cycle, such as the crane, roboshot, mixer and jumbos, and the orepasses, were modelled as resources. The progress throughout the mining cycle was modelled as an entity, and the LHDs for muck extraction were modelled as transporters. The input data for this model corresponds to the distributions listed in Table I in the previous section. The shift system was modelled for 10 hours, with two shifts per day.

One thousand simulations were run to simulate development at the production level for the first six years. A trial-and-error process based on the stability of the half-width was used to determine the optimum number of simulation runs. Using 100 simulations, the half-width obtained was 1.35% of the mean value. Since the computational cost to simulate this model was only a few minutes, it was decided to use 1000 simulations, obtaining a half-width of 0.46% over the mean value. The simulated time in each simulation was six years, as this is the planned time it takes to incorporate the first drawbell. Therefore, it can be assumed that during these first six years of construction, there are no operational interferences with Codelco’s production LHDs. There are only interferences with Codelco’s development crew, which is reflected in the availability of the orepass.

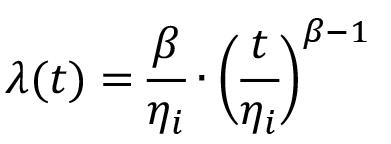

The system modelled was of the production level of the Dacita project in El Teniente, and the model was validated with the data collected from this area. The advances in this section were 3.1 m with a tunnel section of 4.1 x 3.9 m². The average distance between the draw-points and orepasses was 325 m. The simulation results (Figure 7) showed that the model predicted the construction of

1,088.11 m in a single year, 2.31% less than the 1 113.86 m developed in the same period. Given that the difference is less than 3%, we determine that the model is valid for further experimentation. Figure 7 shows the distribution of results (metres developed) obtained from the simulation.

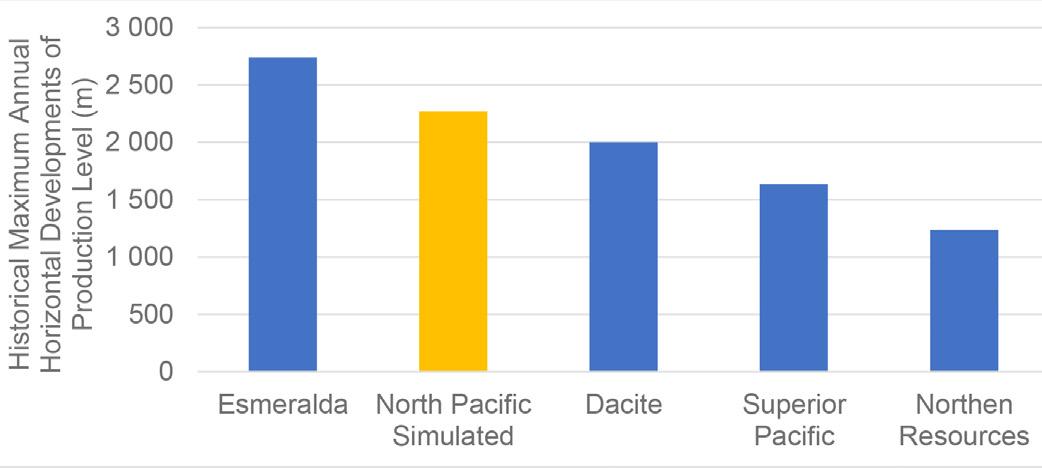

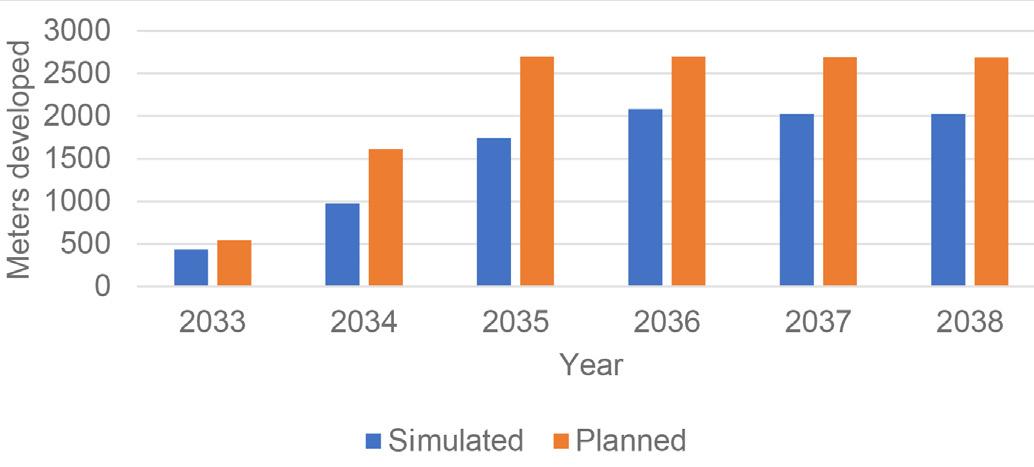

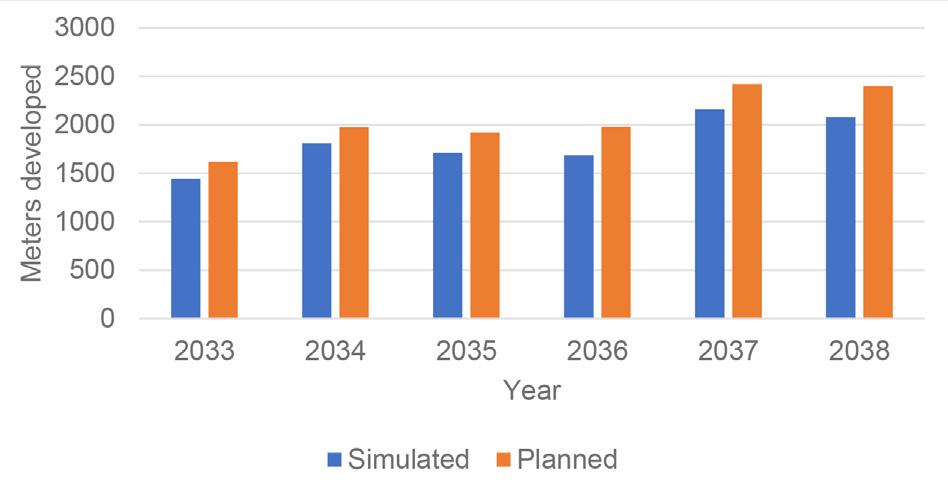

The results of the simulation are compared to the mine development plan for the North Pacific (planned) section (Figure 8) and to the sections of DET (existing) currently in production (Figure 9). From Figure 8, it can be seen that the simulated result is less than the planned development rate as the years pass for North Pacific (future development). This is because the simulation model considers an increase in equipment failure rate due to the accumulated hours of use, while the mine’s long-term plan did not consider this aspect. Figure 8 shows the maximum performance achieved by the simulation, which occurs in 2038 with 2085 m and is compared with the maximum annual performance achieved in each of the most relevant mine sections in DET. Based on current development rates, only one section (Esmeralda) of DET has a higher development rate (in metres per year) than that planned for the North Pacific project (Figure 9). This was only possible because the Esmeralda project had already been in production for several years, and therefore much of the section was already developed, which enabled working with multiple fronts and crews.

According to Ccatamayo (2017), one of the most inefficient operations in the development cycle of El Teniente mine projects is muck extraction. Since much of the time used to carry out this work is non-productive time, it does not contribute to the advancement of the face. As a result, three scenarios are proposed for the experimental analysis, which seeks to reduce non-contributory and non-productive times. In so doing, muck extraction becomes more efficient, thereby improving the development cycle time.

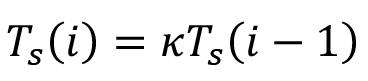

The first experimental scenario involves studying the effect that a change in the maintenance strategy for the LHD equipment has on the development rate. Currently, the strategy is to carry out preventive maintenance on the equipment every 250 hours, following the OEM’s recommendations, and to carry out all necessary corrective maintenance whenever the equipment fails while in operation. The alternative strategy to be evaluated seeks to decrease the interval between preventive maintenance, to take advantage of the fact that once maintained, the equipment is in better condition than before, even if not as good as it was originally (Balaraj, Govinda, and Murthy, 2018a, 2018b; Soto and Pascual, 2018). In this case, the preventive maintenance interval for LHD equipment will be reduced to a constant rate κ, following Equation [4].

where i is an index that indicates the number of overhauls that the equipment has undergone and T s is the recommended interval between preventive maintenance overhauls. Different scenarios were generated for κ values of 90%, 80%, and 70% in the simulation. The remaining input data stayed the same.

In DET, the horizontal development is not carried out by Codelco, but is outsourced to contractors. This is to focus Codelco’s efforts only on the production of ore and not on the preparation of the mine. The parallel work of Codelco and the contractors at the production level generates operational interferences since both tasks must share accesses, routes, and orepasses. Following the line of prioritizing production, the production level orepasses are mostly destined for mineral production, and only a few orepasses are assigned to the contractor to remove the muck. The purpose of this experiment is to study the effect of orepass availability to the contractors for muck removal on the development rate.

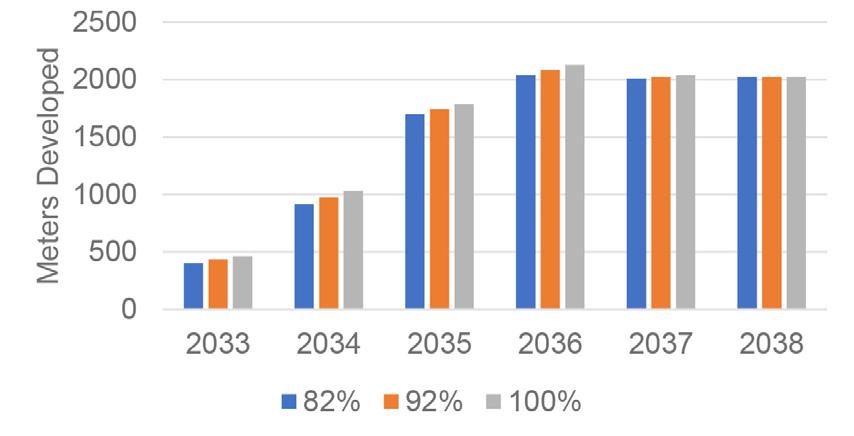

The input data used in the model is the same as for the base case, changing only the probability of available orepasses from 92%, which is the average value calculated in the current productive sections of DET, to 83% and 100%. These values correspond to the minimum and maximum values of orepass availability in the same section, respectively. Table III shows the average distance between the drawpoint and the dumping point when the assigned orepass is available and when it is not. It is expected that as the distance between the alternate route and the original route increases, there will be a greater impact on the developed metres as the availability of the orepass varies.

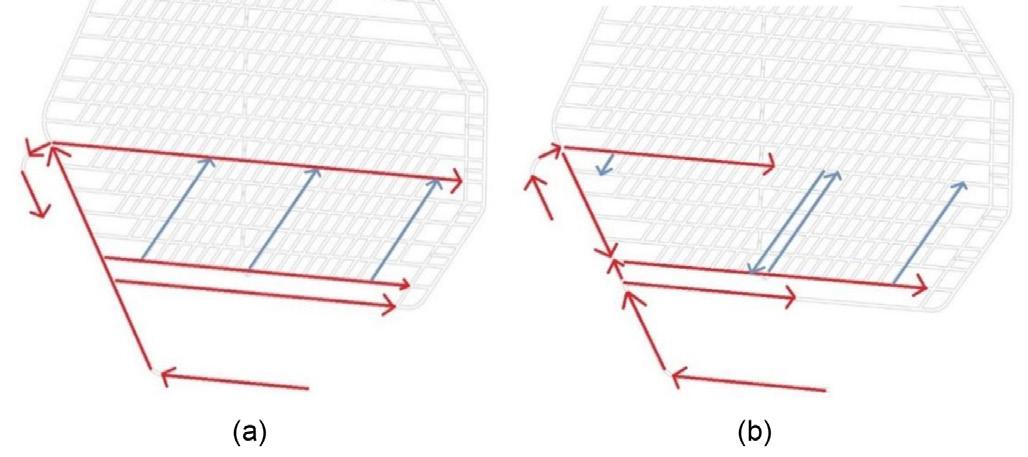

This experiment aims to study the effect of using a newly optimized development sequence on the annual development rate. Datamine Studio UG and EPS software were used to design and generate this sequence, which allows simulating and evaluating multiple developments and construction sequences quickly and easily. This new sequence considers starting the developments in the year 2033 by entering through two different accesses, and then between the years 2034 to 2036, the ability to open and work in three faces simultaneously. In 2037 and 2038, the number of faces that can be opened and worked will increase to five. Between the years 2039 to 2056, four active faces can be maintained, eventually decreasing to a single face from 2057 to the end of the development. This sequence is considered optimum since it

Figure 10—(a) Comparison of base case development sequence vs (b) optimized sequence

Year Distance when orepass is available (m) Distance when orepass is unavailable (m)

2033 700 700 2034 502 1100 2035 333 1036 2036 488 1003 2037 466 1003 2038 1076 1200

reduces the average transport distance between the drawpoint and the orepasses while meeting operational requirements. It also allows the LHD equipment to work in a range of distances where it is more efficient. Furthermore, it allows multi-face work to be started from the first year of development, increasing the efficiency and effectiveness of the work. Therefore, it is expected that implementing the new sequence will increase the metres developed annually compared to the planned design. In Figure 10, the red arrows indicate the development direction of the main accesses, and the light blue arrows the development direction of the extraction drives.

The Gantt chart (Figure 11) details the new sequence planned for the next ten years. The figure shows that in the year 2033, the optimized sequence is able to develop more than 600 m of extraction drive, which gives more flexibility in subsequent years by providing better routes that shorten the average hauling distance. Table IV shows the difference between the year-toyear mean distance for the planned sequence and the optimized sequence.

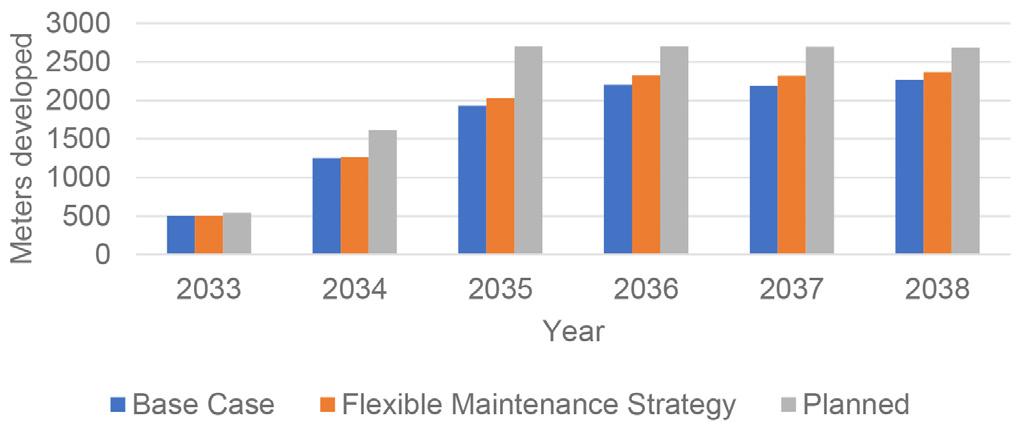

Table V shows the number of preventive and corrective maintenance actions and the corresponding downtime, derived from the simulation according to the parameter κ used. Using the proposed maintenance strategy with a parameter of κ = 80% gives the best results. Figure 12 compares the linear metres built between the OEM and the flexible maintenance strategy. It is noteworthy that after six years, the alternative strategy (κ = 80%) has developed 457 m more than the base case, which corresponds to an increase of 4.42%. This reduces the difference between the simulated and the planned development rate from 20% to 16%. Figure 12, illustrates the benefit of the flexible strategy in the later

A discrete event simulation approach for mine development planning at Codelco’s New Mine

Average

Year

2034

2035

2036

2037

2038

years. In later years, the characteristic life of the LHD is shorter, which causes it to fail more frequently, therefore more frequent preventive maintenance helps reduce the failure rate.

The simulation results indicate that as the availability of orepasses for muck extraction increases, the duration of the global muck extraction cycle decreases by an average of 13 minutes per cycle, while the duration of the complete development cycle decreases by 5 hours. Figure 13 compares the linear metres achieved year-byyear between the base case and the scenarios with 83% and 100% orepass availability. After six years, by increasing the availability of the orepass to 100%, it is possible to advance 194 more metres. Although this result can be considered of little significance, it should be noted that less orepass availability will mean longer mucking times. This will negatively affect the development

Figure 12—Simulation results

data),

Figure

this material will have to be transported to further dumping points. The benefit of 100% orepass availability has already been seen in the mines currently in production at El Teniente. This, however, has required a greater planning effort by the Codelco. Figure 13 shows the probability density function for the three scenarios. It can be seen that the greater the orepass availability,

the lower the variability presented since it decreases the probability that the LHD will have to travel greater distances to take an alternative route.

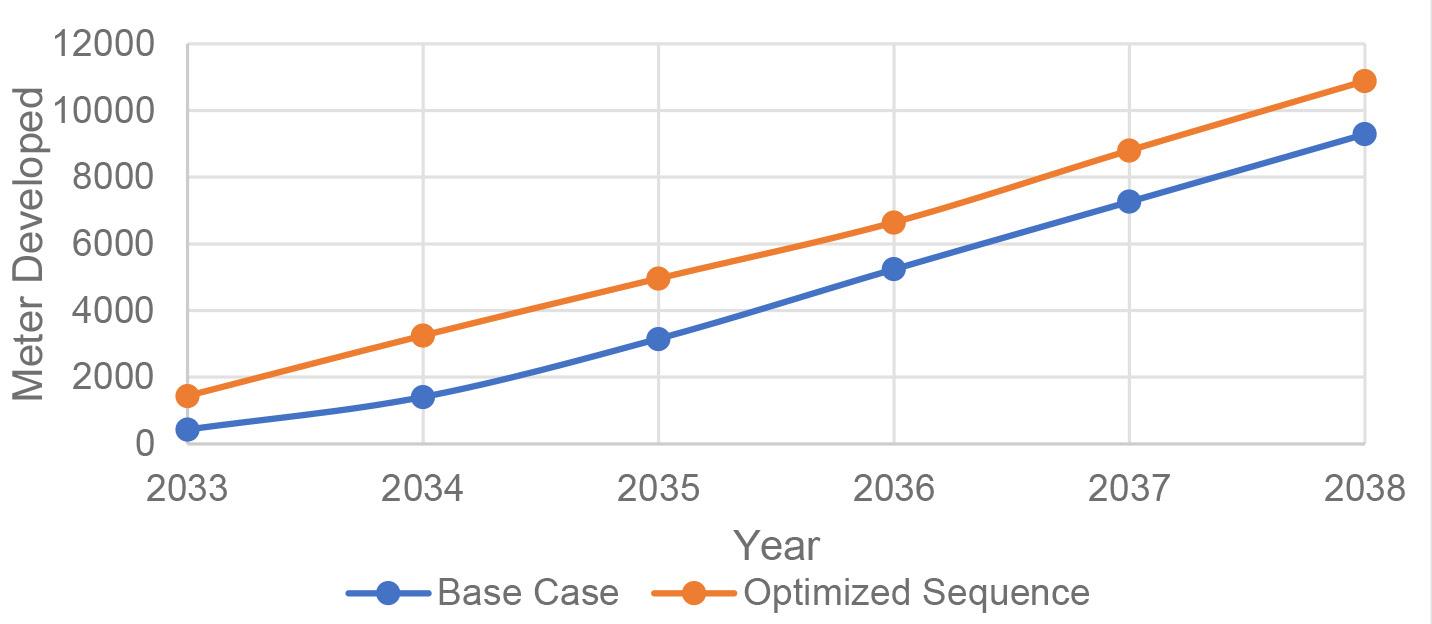

Figure 14 compares the linear metres achieved year-by-year between the base case (currently planned sequence) and the newly generated planning sequence. After six years, the new sequence enables the construction of 10 886 metres of tunnels, which is 1 598 metres more than the base case. This benefit is mainly obtained in the first year because the optimized sequence manages to work on an additional face. In the latter years, the optimized sequence performs better even when it works with the same number of faces as the base case, which is explained by the shorter distance between the drawpoint and orepass that is obtained each year. The new sequence is less demanding with the metres required for the first six years of development and better manages the use of work crews. Therefore, compliance with the planned development is more probable (Figure 14).

Estimating the optimal time to perform preventive maintenance depends on striking a balance between production loss due to downtime and unavailability of the equipment during maintenance. This is reflected in the simulation results obtained at a κ value of 80% outperformed that at 70%. Although using a flexible maintenance strategy increased the orepass availability, and the optimized development sequence increased the development and the probability of achieving the planned development rate at the Pacific North section, it is important for the mine to perform a cost-benefit analysis prior to implementing the research findings. Based on the study of the mine, the authors, however, believe that the mine has the resources to carry out the recommended plans, especially since the existing planned development would require more resources to achieve it. The use of a more advanced tool such as Datamine Studio UG and EPS allows for quick changes in the optimal development sequence and would enable as a fast decision-making tool in the case of unwanted incidents such as collapses and temporary loss of access to productive areas.

A simulation model of the development cycle for the El Teniente New Mine Level was presented. The model considers the uncertainty in the execution times of each unit operation of the cycle and allows the evaluation of the development rate through multiple faces. The New Mine Level is a megaproject of DET, the world’s largest underground copper mine. The operation aims to keep the Division’s copper production at 137 000 t/d through deeper mining of the orebody A DES model was developed and validated with historical data from current sections in operation. Three experimental scenarios were analysed using the validated model in the production level of the future North Pacific section of the New Mine Level to evaluate the feasibility of obtaining the planned development target. The results from the simulation experiment are compared with historical data from existing sections. The following observations were made:

➤ The metres developed in the base case simulation using historical data are less than the metres planned for the Pacific North section. This is because operational uncertainties included in the model, such as LHD failure and orepass availability, were not considered in the initial planning sequence, resulting in an overestimation of the development rate.

➤ The metres developed in the base case simulation for the North Pacific section is at the upper limit of the ranges reached by the Division’s current operating mines.

➤ A flexible maintenance strategy for LHDs increases the metres developed by 457 metres after six years.

➤ A 100% orepass availability allows the metres developed after six years to be increased by 194 metres.

➤ By using the proposed optimum development sequence, an increase of 1,598 meters can be achieved after six years as compared to the base case.

This work presents an initial base for evaluating the impact that the improvement of critical unit operations can have on the horizontal development cycle of an underground mine. Past research has not yet studied the relationship between underground mine development and unit operations in a disaggregated way. Reliability analysis of other equipment such as the jumbo and/or the impact of using different blast designs can be evaluated as part of future work. Future work should also include revaluation of the development rate in the New Mine Level sections using the developed model once operation commences. It is also recommended that more data be collected for future analysis.

The authors would like to thank Codelco – El Teniente Division for allowing us to work with them to obtain data from the development cycle and Datamine Software for giving us the software used in this paper.

The authors declare that they have no conflict of interest.

The authors received no financial support for the research, authorship, and/or publication of this article.

A discrete event simulation approach for mine development planning at Codelco’s New Mine

Ahmed, H.M., Scoble, M.J., and Dunbar, W.S. 2016. A comparison between Offset Herringbone and El Teniente underground cave mining extraction layouts using a discrete event simulation technique. International Journal of Mining, Reclamation and Environment, vol. 30, no. 2. pp. 71–91.

Anani, A. and Awuah-Offei, K.,2017. Incorporating changing duty cycles in CM-shuttle car matching using discrete event simulation: A case study. International Journal of Mining and Mineral Engineering, vol. 8, no. 2. pp. 96–112.

Anani, A., Nyaaba, W., Hekmat, A., and Córdova, E.A . 2019. Optimizing cut-out distance for maximum coal productivity. SIMULATION, vol. 95, no. 6. pp. 545–559.

Balaraju, J., Govinda Raj, M., and Murthy, C.H.S.N. 2018a. Estimation of reliability-based maintenance time intervals of Load-Haul-Dumper in an underground coal mine. Journal of Mining and Environment, vol. 9, no. 3. pp. 761–770.

Balaraju, J., Govinda, M., and Murthy, C. 2018b. Reliability analysis and failure rate evaluation of load haul dump machines using Weibull distribution analysis. Mathematical Modelling, vol. 5, no. 2. pp. 116–122.

Basu, A.J. and Baafi, E.Y. 1999. Discrete event simulation of mining systems: current practice in Australia. International Journal of Surface Mining, Reclamation and Environment, vol. 13, no. 2. pp. 79–84.

Ccatamayo Barrios, J.H. 2017. Aplicación de filosofía Lean en la preparación minera, mina El Teniente Codelco Chile. Application of lean philosophy in mining preparation, El Teniente Codelco Chile mine. Master’s thesis, Universidad de Chile, Santiago, Chile. http://repositorio.uchile.cl/ handle/2250/147376

Chami, J. 2012. Optimización de los procesos de Desarrollo y Construcción en minería de block caving caso estudio mina El Teniente Codelco Chile Optimization of Development and Construction processes in block caving mining, case study El Teniente Mine Codelco Chile. Master’s thesis, Universidad de Chile, Santiago, Chile. http://repositorio.uchile.cl/ handle/2250/114467

Cochilco. 2019. Anuario de estadísticas del cobre y otros minerales: 1999-2018 [Yearbook of Copper and Other Minerals Statistics: 1999-2018]. Santiago. Codelco. 2020. Memoria Anual 2019 [Annul report 2019]. Santiago. Dehghani, H. and Ataee-Pour, M. 2012. Determination of the effect of operating cost uncertainty on mining project evaluation. Resources Policy, vol. 37, no. 1. pp. 109–117.

Díaz, M., Rojas, P. and Vargas, M. 2019. Construction of mining projects in El Teniente. Campos, and Morales. The proceedings of the 6th International Conference on Geology and Mine Planning. Santiago, 7–9 August. Geomin, Santiago.

Dindarloo, S.R., Osanloo, M., and Frimpong, S. 2015. A stochastic simulation framework for truck and shovel selection and sizing in open pit mines. Journal of the Southern African Institute of Mining and Metallurgy, vol. 115, no. 3. pp. 209–219.

Greberg, J., Salama, A., Gustafson, A., and Skawina, B. 2016. Alternative process flow for underground mining operations: analysis of conceptual transport methods using discrete event simulation. Minerals, vol. 6, no. 3. p. 65.

Haque, M.A., Topal, E., and Lilford, E. 2014. A numerical study for a mining project using real options valuation under commodity price uncertainty. Resources Policy, vol. 39. pp. 115–123.

Hormazabal, E., Pereira, J., Barindelli, G., and Alvarez, R . 2014. Geomechanical evaluation of large excavations at the new level mine—El Teniente. 3rd International Symposium on Block and Sublevel Caving, Universidad de Chile. pp. 486–500.

Laubscher, D.H. 1994. Cave mining-the state of the art. Journal of the Southern African Institute of Mining and Metallurgy, vol. 94, no. 10. pp. 279–293.

Leiva, F. 2015. Desarrollo de una metodología para la obtención de la major configuración de turnos para la construcción de un túnel horizontal, Minera San Pedro [Development of a methodology to obtain the best configuration of shifts for the construction of a horizontal tunnel, Minera San Pedro]. Thesis, Universidad de Santiago de Chile, Santiago, Chile.

Lobiano Correa, C.H. 2016. Inclusión de interferencias operacionales de origen geotécnico en planificación minera de Panel Caving. [Inclusion of

geotechnical operational interferences in panel caving mine planning], Master’s thesis, Universidad de Chile, Santiago, Chile. http://repositorio. uchile.cl/handle/2250/139851

MacNeil, J.A. and Dimitrakopoulos, R.G. 2017. A stochastic optimization formulation for the transition from open pit to underground mining. Optimization and Engineering, vol. 18, no. 3. pp. 793–813.

Manríquez, F., Pérez, J., and Morales, N. 2020. A simulation–optimization framework for short-term underground mine production scheduling. Optimization and Engineering, vol. 21, no. 3. pp. 939–971.

Memon, Z.A., Majid, M.Z.A ., and Mustaffar, M. 2006. A systematic approach for monitoring and evaluating the construction project progress. Journal of Industrial Engineering, vol. 67, no. 3. pp. 26–32.

Musingwini, C. 2016. Optimization in underground mine planning – developments and opportunities. Journal of the Southern African Institute of Mining and Metallurgy, vol. 116, no. 9. pp. 809–820.

Navarro, C. 2012. Simulación de ciclos de construcción de labores subterráneas mediante el método de Montecarlo, Proyecto Olivo Minera San Pedro. Simulation of underground work construction cycles using the Montecarlo method, Olivo Project Minera San Pedro. thesis, Universidad de Santiago de Chile, Santiago, Chile.

Paravarzar, S., Pourrahimian, Y., and Askari-Nasab, H. 2018. Short-term underground mine planning: A review. Mining Optimization Laboratory, University of Alberta, vol. 780, no. 1. p. 305.

Park, S., Choi, Y., and Park, H.S. 2016. Optimization of truck-loader haulage systems in an underground mine using simulation methods. Geosystem Engineering, vol. 19, no. 5. pp. 222–231.

Ramírez, I.J.S. 2020. Simulación como herramienta para identificar y comprender las operaciones críticas en el ciclo de desarrollos horizontales [Simulation as a tool to identify and understand critical operations in the horizontal development cycle], Master’s thesis, Pontificia Universidad Catolica de Chile, Chile.

Rocher, W., Rubio, E., and Morales, N. 2011. Eight-dimensional planning: construction of an integrated model for the mine planning involving constructability. Proceedings of the 35th International Symposium on Application of Computers in the Minerals Industry Wollongong, Australia. Australian Institute of Mining and Metallurgy, Melbourne. pp. 393 406.

Rockwell Automation. 2019. Arena: User’s guide. Milwaukee, WI.

Runciman, N., Vagenas, N., and Baiden, G. 1999. Evaluation of underground development mining systems using discrete-event simulation. Simulation, vol. 72, no. 1. pp. 4–11.

Salama, A., Greberg, J., and Schunnesson, H. 2014. The use of discrete event simulation for underground haulage mining equipment selection. International Journal of Mining and Mineral Engineering, vol. 5, no. 3. pp. 256–271.

Salama, A., Nehring, M., and Greberg, J. 2017. Financial analysis of the impact of increasing mining rate in underground mining, using simulation and mixed integer programming. Journal of the Southern African Institute of Mining and Metallurgy, vol. 117, no. 4. pp. 365–372.

Singer, D.A. and Kouda, R. 1999. Examining risk in mineral exploration. Natural Resources Research, vol. 8, no. 2. pp. 111–122.

Skawina, B., Greberg, J., Salama, A ., and Gustafson, A. 2018. The effects of orepass loss on loading, hauling, and dumping operations and production rates in a sublevel caving mine. Journal of the Southern African Institute of Mining and Metallurgy, vol. 118, no. 4. pp. 409–418.

Skawina, B., Greberg, J., Salama, A., and Schunnesson, H. 2014. Mechanical excavation and drilling and blasting–A comparison using discrete event simulation. Proceedings of Mine Planning and Equipment Selection, Springer, Cham. pp. 367–377.

Soto, I. and Pascual, R. Using maintenance options to minimise the expected total cost of mining haulage fleets. Proceedings of the 3rd International Seminar on Operational Excellence in Mining, Santiago, 21–23 March 2018. Gecamin, Santiago.

Vagenas, N. 1999. Applications of discrete-event simulation in Canadian mining operations in the nineties. International Journal of Surface Mining, Reclamation and Environment, vol. 13, no. 2. pp. 77–78. u

Affiliation: 1Department of Process Engineering, Stellenbosch University, South Africa.

Correspondence to: M. Tadie

Email: mtadie@sun.ac.za

Dates: Received: 30 Mar. 2022

Revised: 27 Jun. 2022

Accepted: 5 Jun. 2022

Published: October 2022

How to cite: Mutimutema, P., Akdogan, G., and Tadie, M. 2022

Evaluation of pre-treatment methods for gold recovery from refractory calcine tailings. Journal of the Southern African Institute of Mining and Metallurgy, vol. 122, no. 10, pp. 561 570

DOI ID: http://dx.doi.org/10.17159/24119717/2070/2022

ORCID: M. Tadie https://orcid.org/0000-00033111-5188

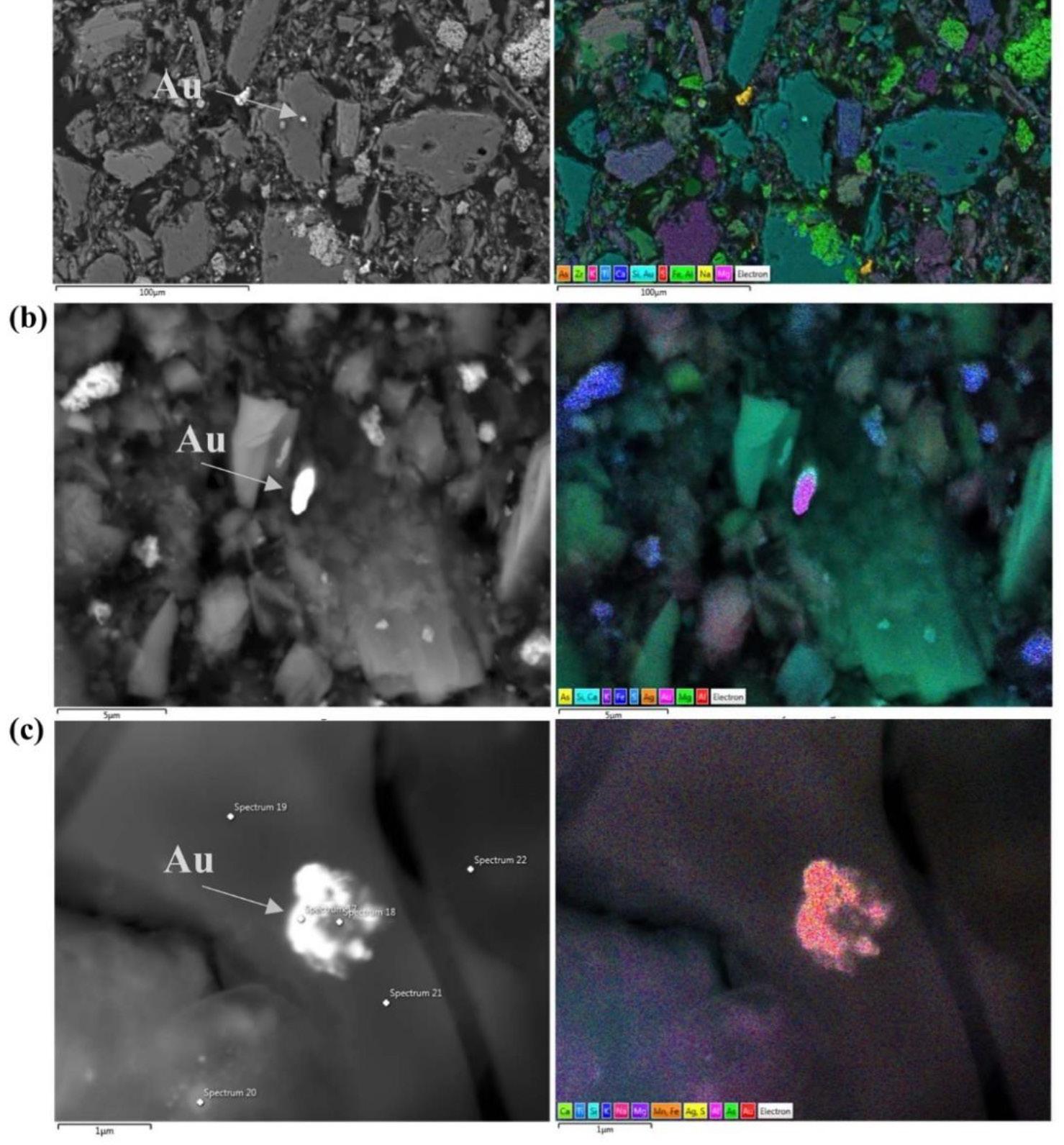

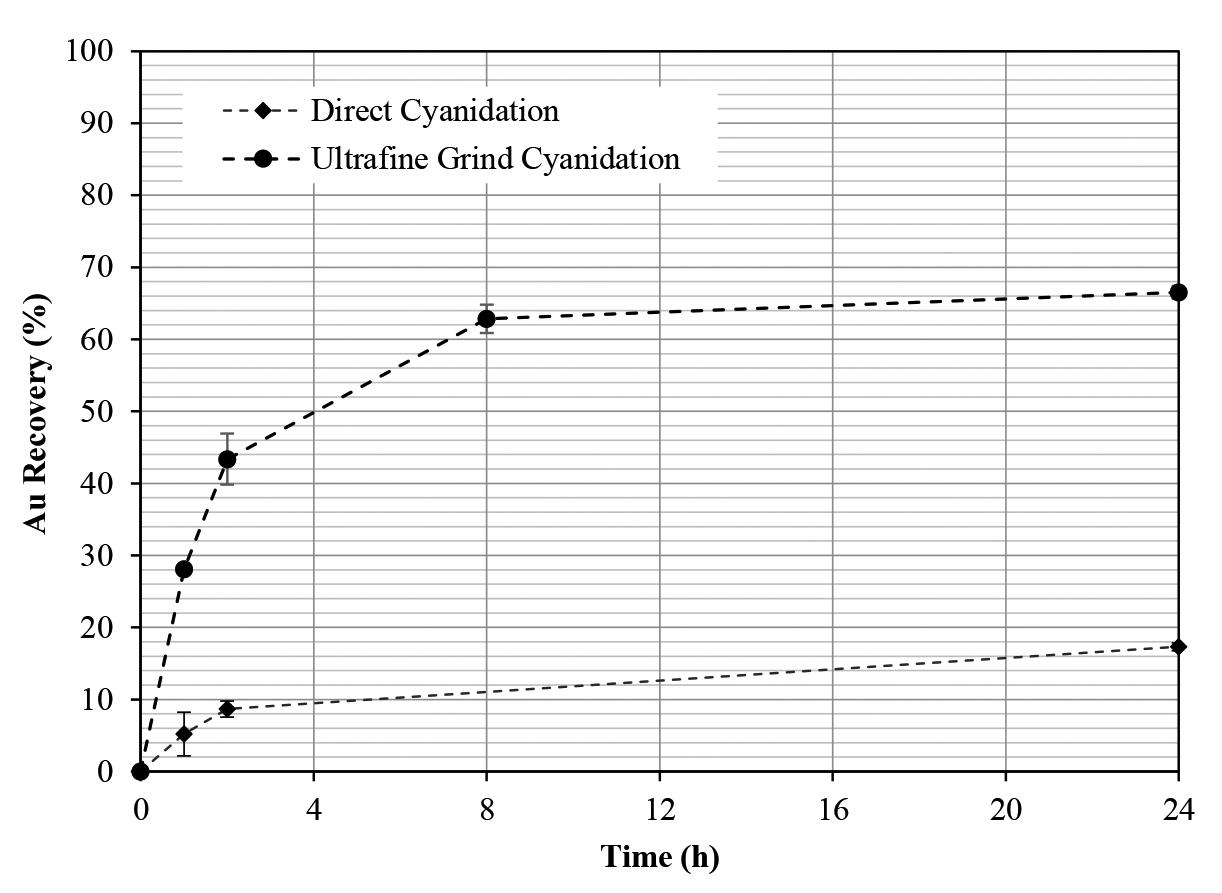

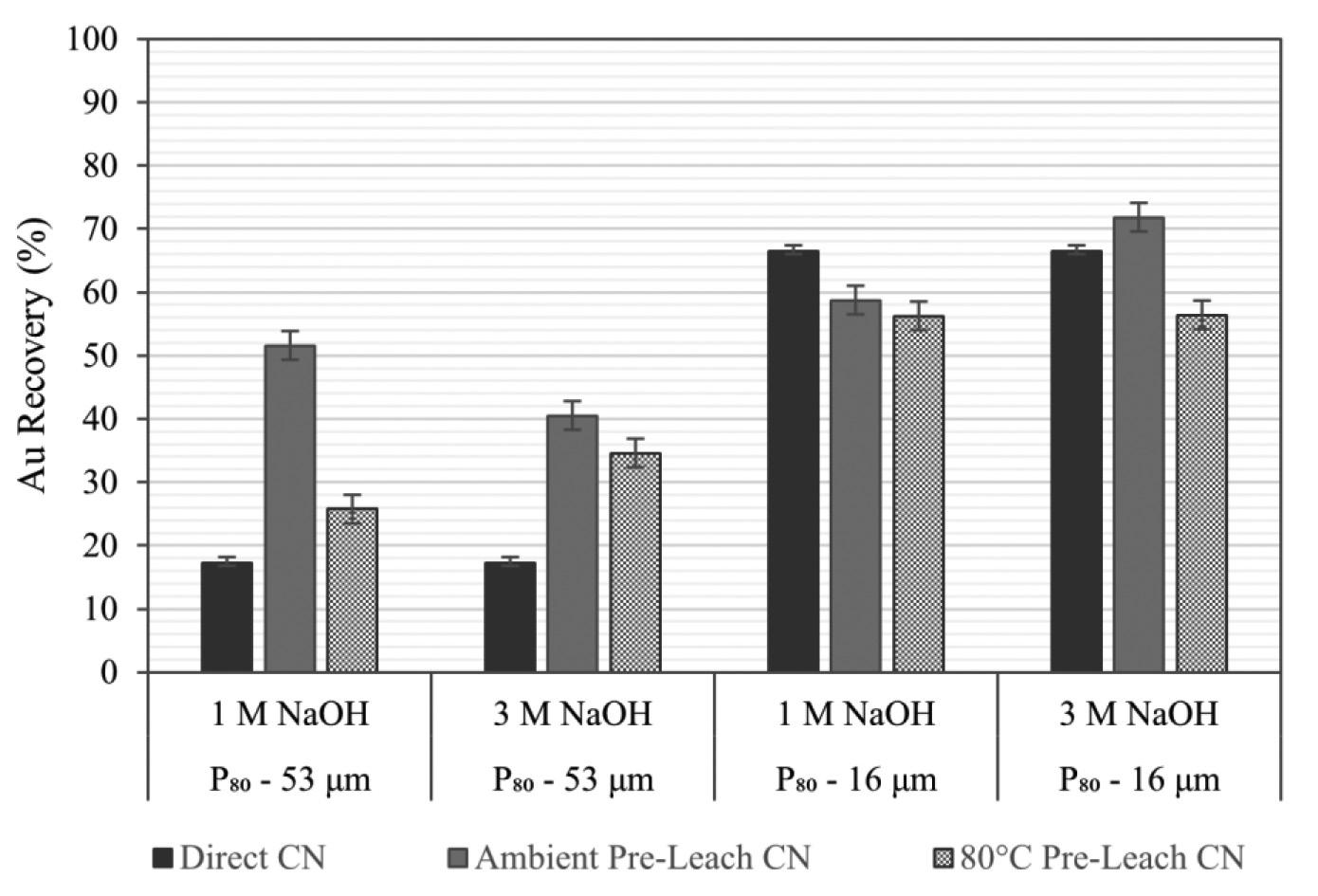

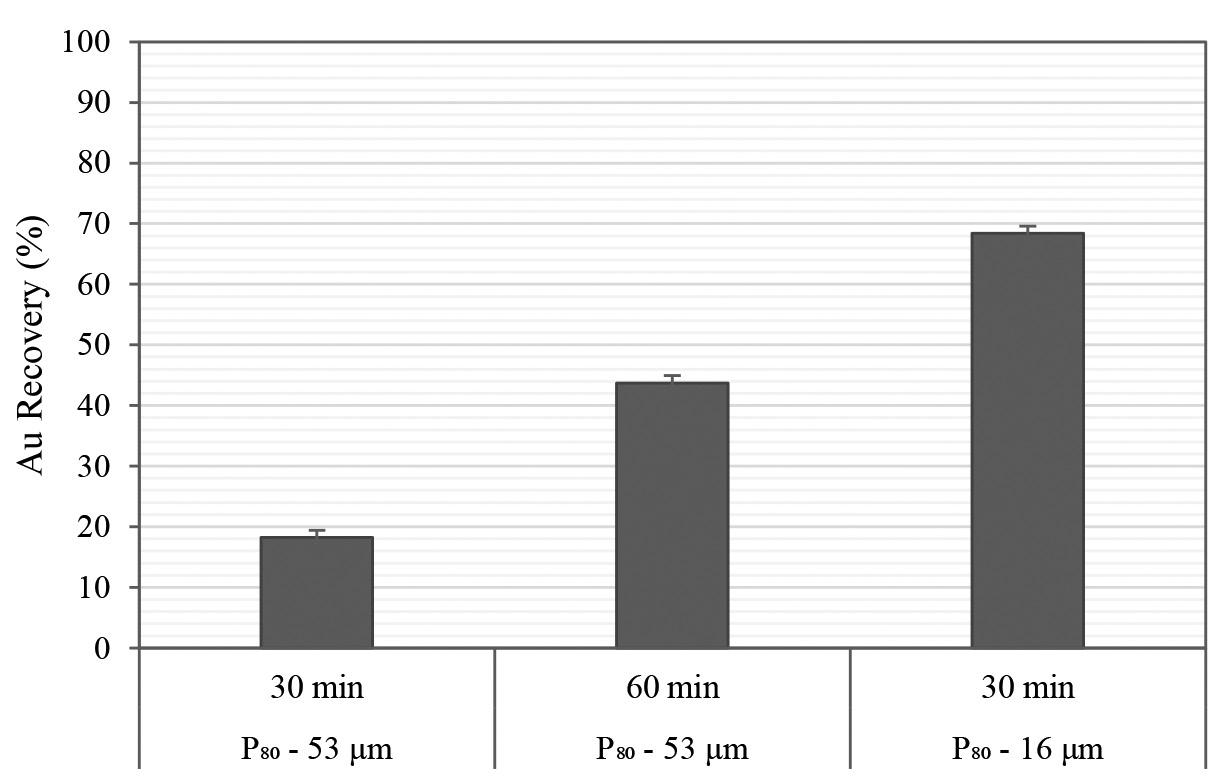

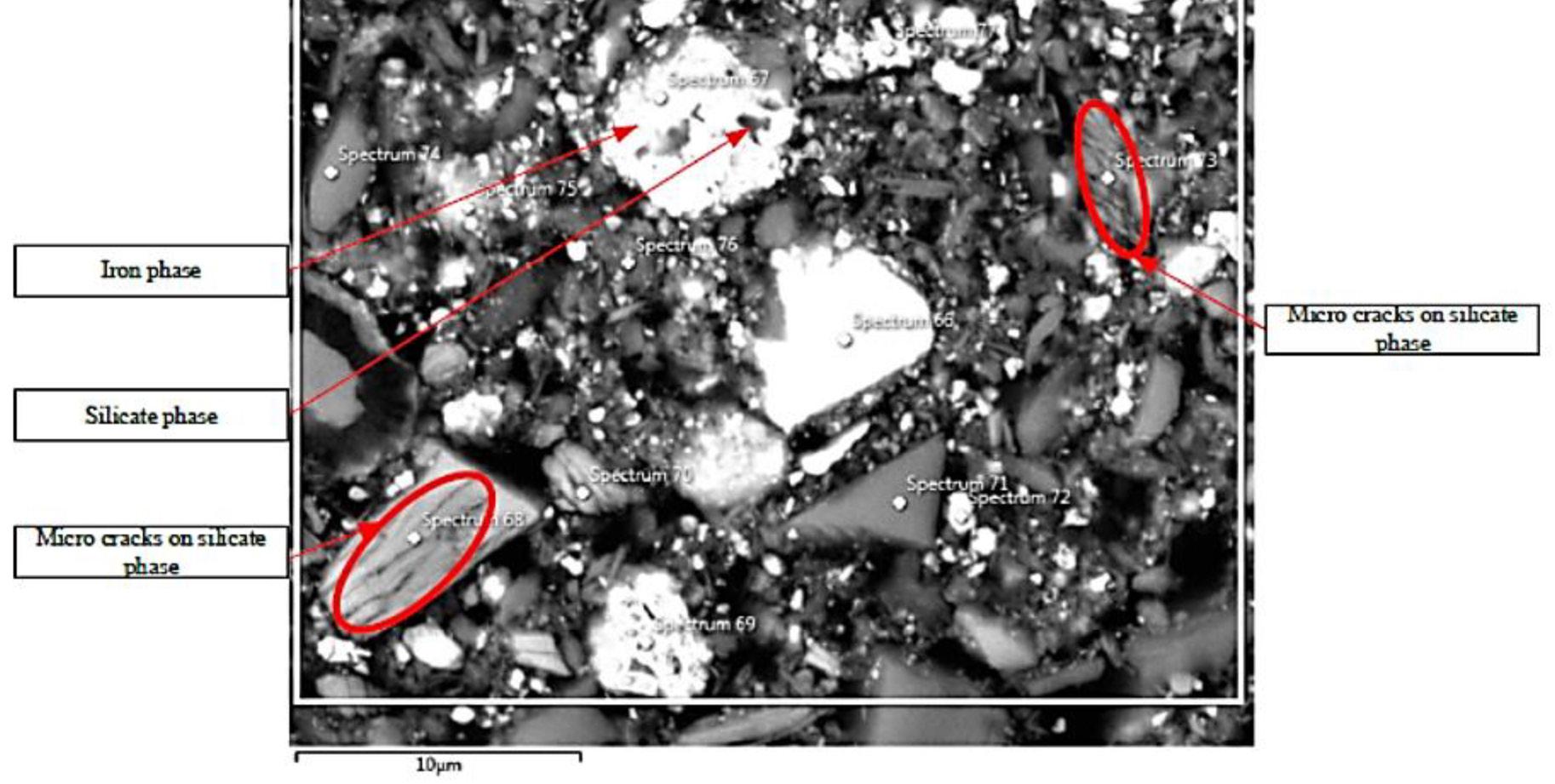

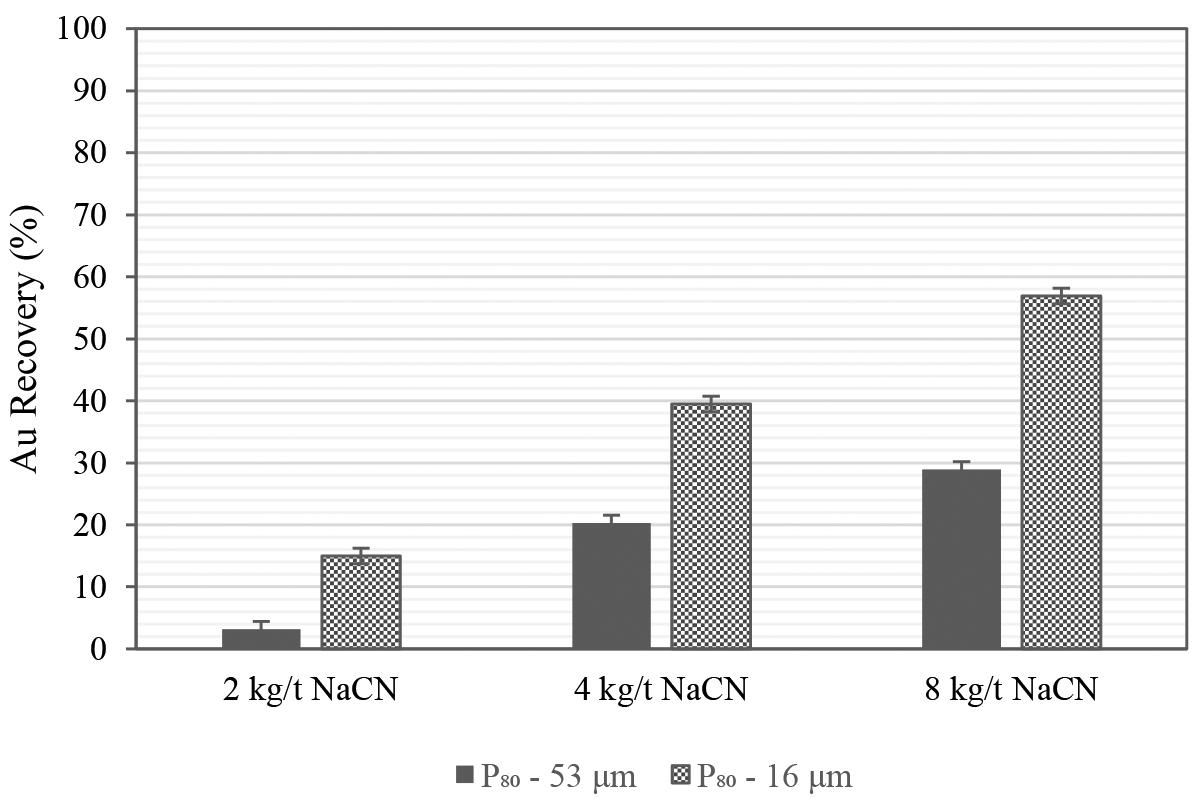

The South African gold mining industry has a legacy of abundant tailings dams, which have attracted the attention of investors because of their potential as a cheaper secondary gold resource. In this we investigate study gold recovery from a refractory calcine tailings dam. Bulk mineralogy of the tailings indicated silicates and iron oxides to be the most abundant phases. Scanning Electron Microscopy (SEM) showed gold to exist in submicrometre and micrometre sizes, as free gold, and associated with arsenic, sulphur, and silicates e.g quartz and talc. Gold recovery by direct cyanidation was low at 17.3%. Mechanical (ultra fine grinding P80 -16μm) and chemical (alkaline, NaOH) pre-treatment and microwave roasting and microwave-assisted cyanide leaching were investigated to increase gold recoveries. Ultrafine grinding was the most effective, producing recoveries of 66.5%. NaOH pre-leaching of ultrafine milled material increased recovery to 71.5%. Alkaline pre-leaching overall increased recoveries for non-pretreated material, making this process the most preferred because it is less costly than ultrafine grinding. Microwave roasting and microwave-assisted leaching did not achieve higher recoveries than alkaline pre-treatment or fine grinding. The investigation highlights and confirms that chemical treatment with NaOH is a powerful tool for gold extraction from refractory tailings.

gold recovery, refractory calcine tailings, ultrafine grinding, alkaline pre-treatment, microwave.

South Africa has over 500 gold tailings dumps, several of which have the potential to be profitably reprocessed (Janse van Rensburg, 2016). Gold lost to the dumps is attributed to inherent process inefficiencies. Historically and up to 1993, gold lost annually to tailings in South African mines was considered to equate to R8.5 billion, indicating a significant amount of value present in tailings (Metzner, 1993).

The reprocessing of tailings presents an opportunity, via modern technologies, for low-cost recovery of gold. Such activities can be used to supplement revenue for existing operations. Reprocessing tailings for gold recovery can be complex and is dependent on the mineralogy of the dump, which is in turn related to the original orebody characteristics or prior processing. Prior processing of tailings adds to the complexity of the mineralogy, which is either refractory and non-refractory. Typical refractory ores have a high sulphide content, such as those found in the Barberton greenstone belt. High-sulphide ores have been processed in the past by methods such as roasting and calcination. These processes oxidize sulphur species at high temperatures, liberating gold from cyanide-consuming sulphur matrices. High energy costs and SO2 emissions associated with these processes have led to their discontinuation.

Research is ongoing for pre-treatment methods that can be applied to aid gold recovery by cyanidation. Roasting, pressure oxidation (acidic and alkaline), biological oxidation, chlorination, microwaves, and ultrafine grinding have been applied to process refractory ores (Fraser, Walton, and Wells, 1991). Table I shows several pre-treatment methods for gold ores or concentrates. Flotation, biological oxidation, gravity separation, pressure oxidation, ultrafine milling, and sodium hydroxide pre-leach are applied commercially in metallurgical plants (Anderson and Twidwell, 2008; Anderson and McDonald, 2016; Das and Sarkar, 2018). Microwaves are being investigated at the pilot plant level by the University of Nottingham’s microwave process engineering department (Buttress et al., 2017). The use of ultrasound is also being considered (Wang, and Zhang, 2019).

In this research we investigated through gold recovery an analysis of the tailings mineralogy and application of different pre-treatment methods. The aim was to unlock gold from the complex mineralogy and formulate relationships between the prior treatment of the tailings and the gold

Pre-treatment methods for ores, or concentrates

Pre-treatment method

Flotation

Phases in gold-bearing ore or concentrate Reference

Sulphides, silicates, carbonate Allan and Woodcock (2001), Yalcin and Kelebek (2011)

Biological oxidation Silicates, sulphates, sulphides, oxides Asamoah, Skinner, and Addai-Mensah(2018)

Gravity separation and flotation

Sulphides, silicates, carbonate Wang et al. (2019)

Pressure oxidation Sulphides, silicates Koslides and Ciminelli (1992)

Flotation and ultrafine milling or roasting

Sodium hydroxide

Sulphides, silicates Ellis and Gao (2003)

Sulphides, silicates, oxides Mesa Espitia and Lapidus (2015), Snyders et al. (2018)

Microwave roasting Sulphides, silicates, oxides Nanthakumar, Pickles, and Kelebek (2007), Amankwah and Ofori-Sarpong (2011)

Conventional roasting Sulphides, silicates Dunn and Chamberlain (1997), Fernánde, Collins, and Marczak (2010)

Ultrasound

Sulphides, silicates Zhang et al. (2016), Guo, Wang, and Zhang (2019)

extraction behavior. Several potentially viable pre-treatment methods were considered as options, i.e. ultrafine milling as a mechanical technique, sodium hydroxide pre-leach as a chemical technique, and microwave technology (González-Anaya, NavaAlonso, and Pecina-Trevi˜no, 2011; Nanthakumar, Piddes, an Kelebode, 2007; Snyders et al., 2018). These pre-treatment methods were factored in as a mechanism to circumvent any challenges encountered due to the previous roasting and the associated refractory nature of the calcine tailings. Heating using microwave energy was explored to demonstrate the energy requirements to unlock gold by the lixiviant at normal operating conditions.

Material

100 kg of calcine tailings was obtained from a tailings dump in South Africa. The tailings were blended and divided into representative aliquots through cone and quartering, followed by riffle splitting, and finally rotary splitting to obtain 500 g samples.

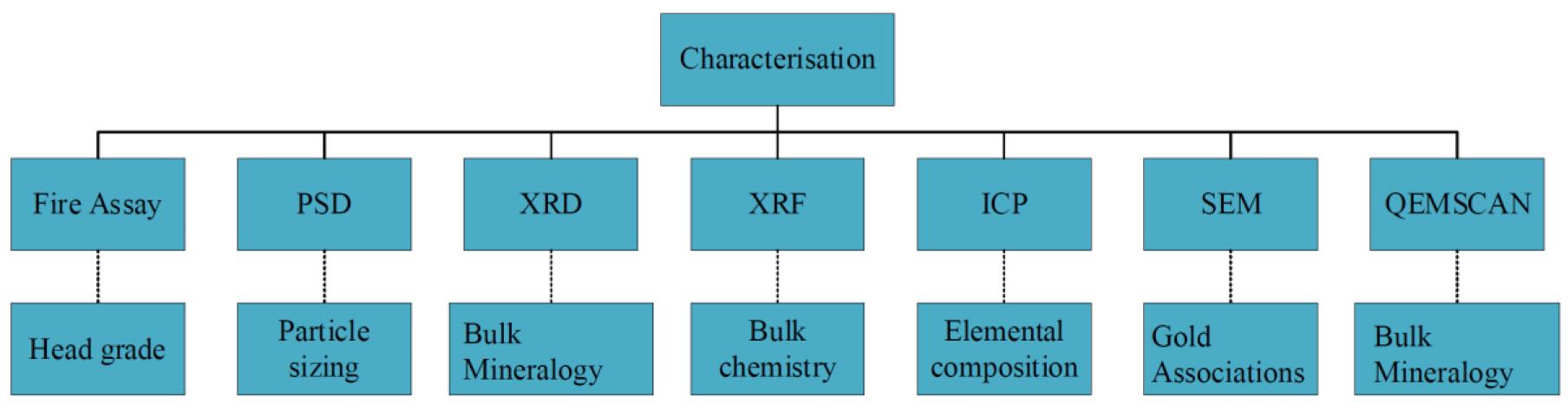

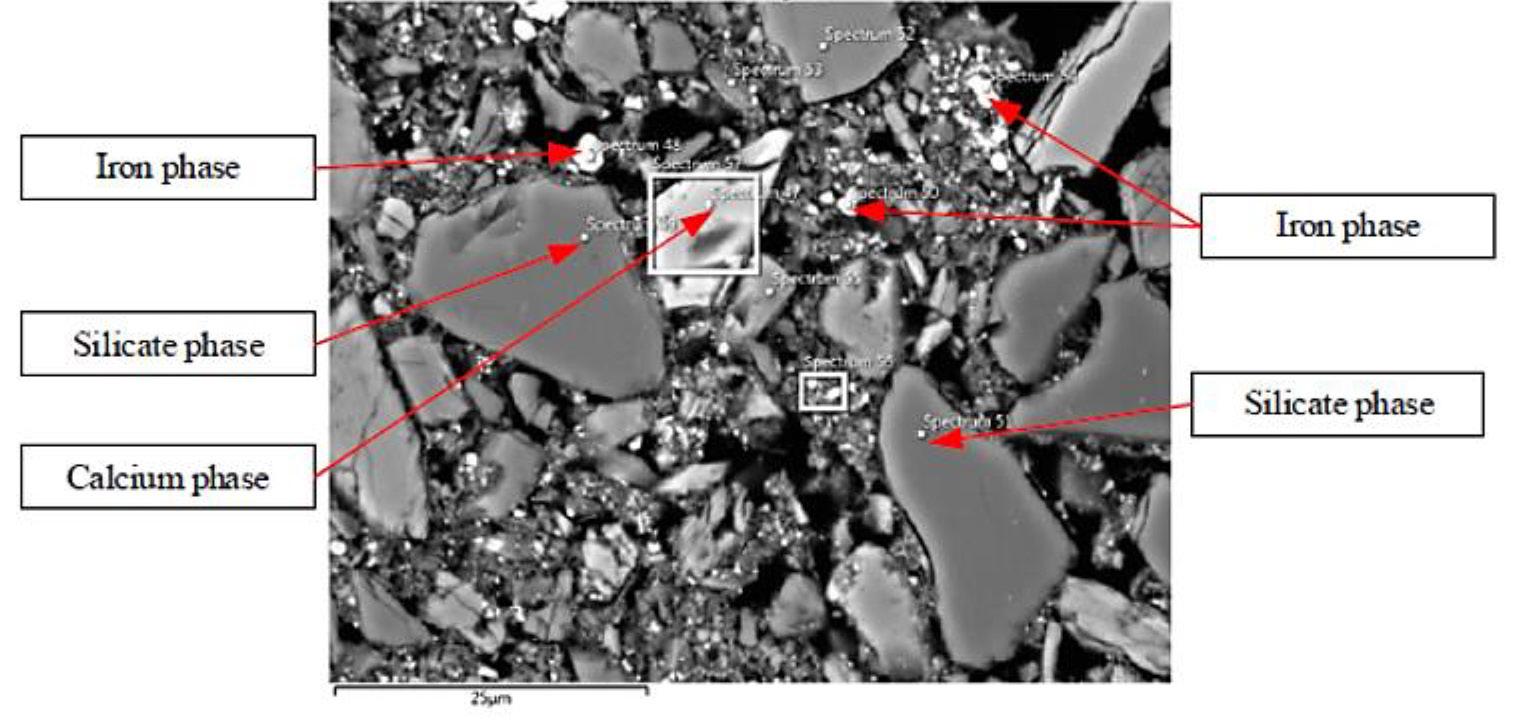

The tailings were characterized using multiple techniques to determine bulk mineralogy gold content and associations, as well as trace element chemistry. Figure 1 summarizes the different techniques applied to sample characterization and the nature of the information obtained.

Nine 100 g samples were analysed by fire assay to determine the head grade. Fire assay results showed an average head grade of 2.96 ± 0.26 g/t, a high grade relative to some run-of-mine operations. The tailings had a P80 of 56 μm, determined using a Micromeritics Saturn Digisizer 5200 laser diffraction particle size analyser.

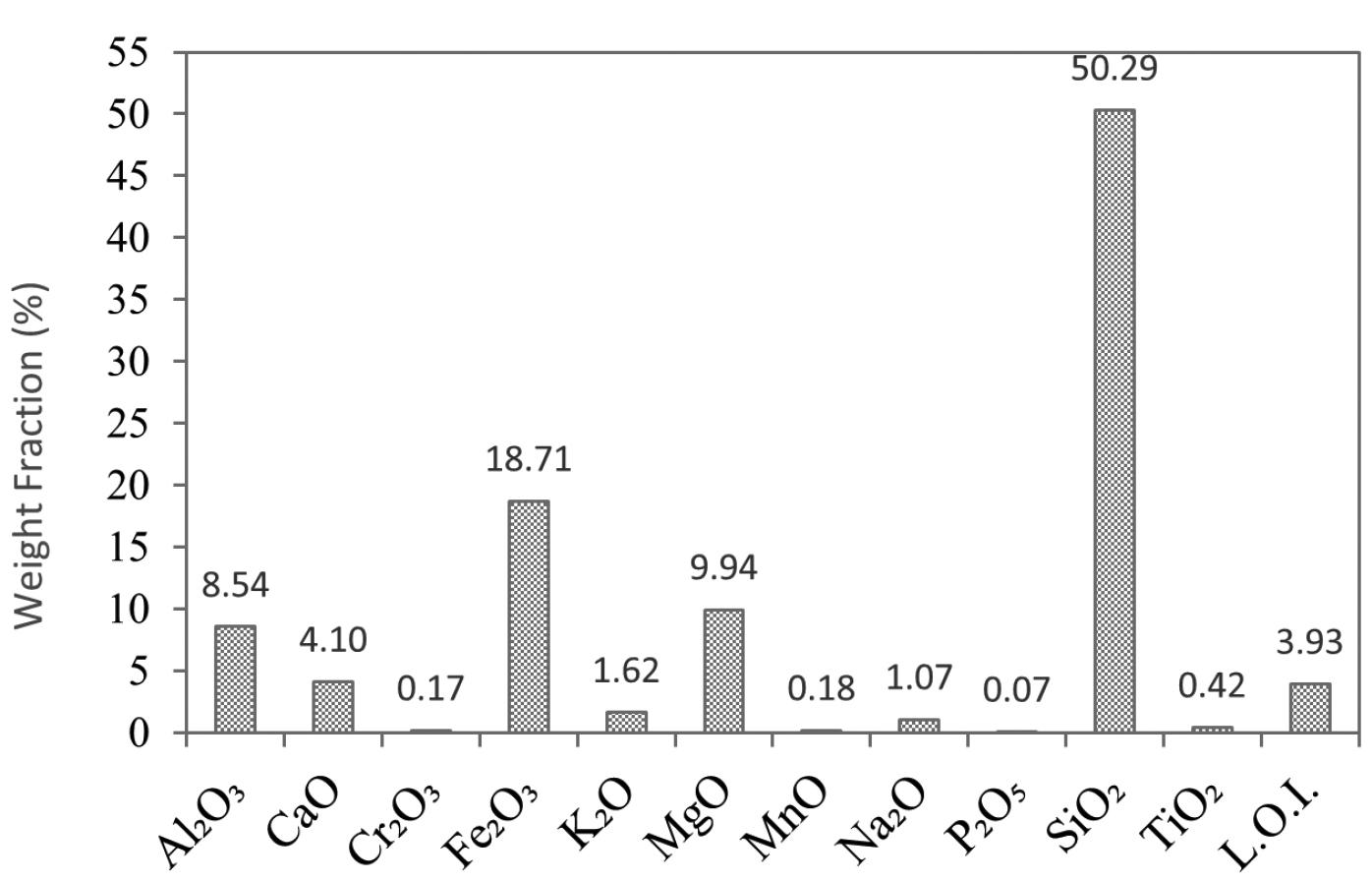

X-ray fluorescence spectroscopy (XRF) was conducted using a PANalytical Axios wavelength-dispersive spectrometer for chemical analysis. Silicon and iron were the major elements in the sample (Figure 2). Significant amounts of sodium, magnesium, potassium, and aluminium were detected. Loss on ignition (LOI) represents the elements (sulphur, arsenic, etc.) that were volatized during analysis.

Trace element analysis was conducted on three composite samples. Samples were digested using six parts nitric acid to one part hydrogen peroxide in a MARS microwave digester. The solutions were analysed using an Agilent 7900 inductively coupled plasma mass spectrometry (ICP-MS) instrument and a Thermo ICap 6200 inductively coupled plasma optical emission spectrometry (ICP-OES) instrument. Results shown in Table II indicate arsenic and sulphur in appreciable quantities, 4 106 ± 246 mg/kg and 5 173 ± 620 mg/kg respectively.

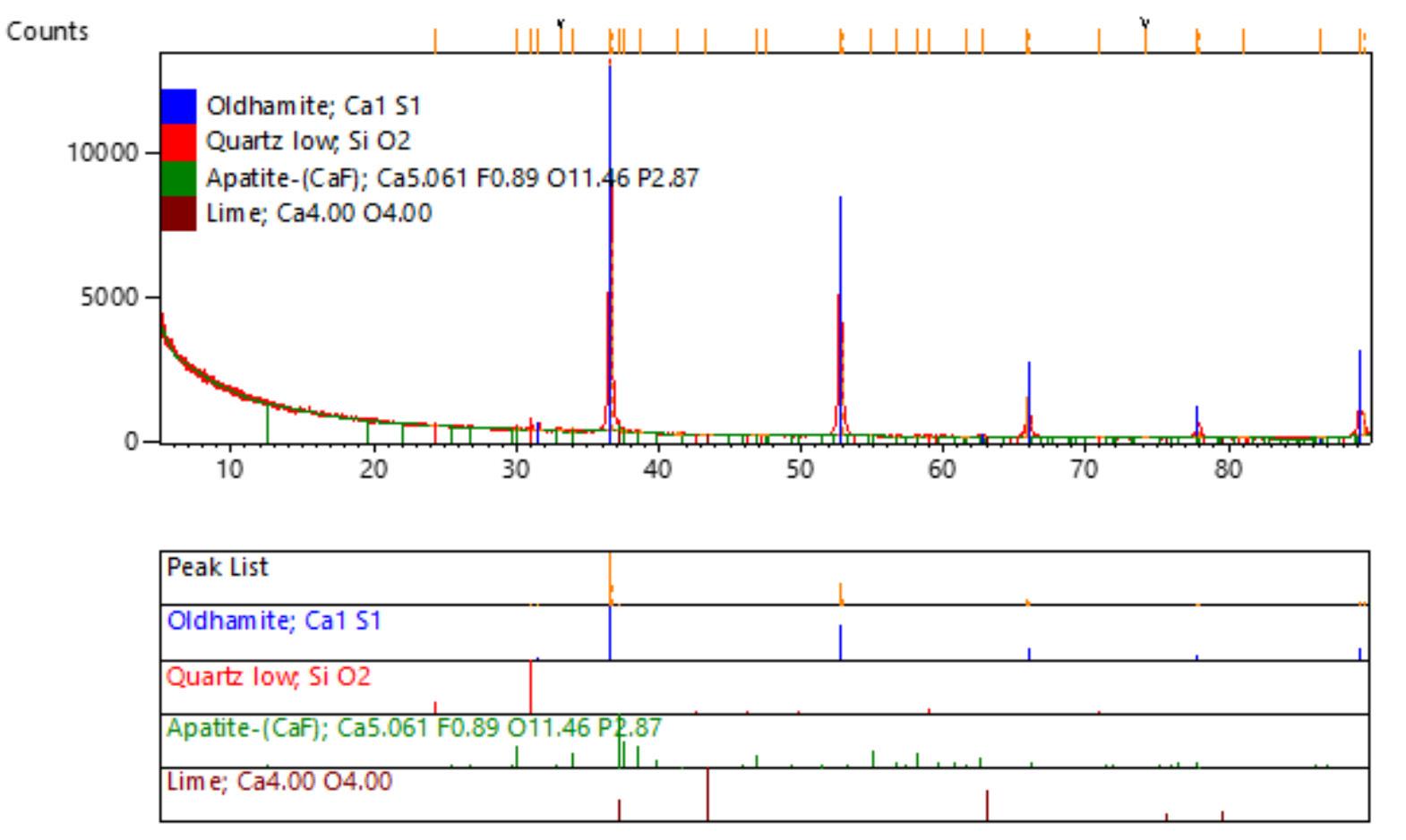

Quantitative X-ray diffraction (QXRD) was performed to determine bulk mineralogy. The sample was analysed with a PANalytical Aeris diffractometer with a pixcel detector and fixed slits with Fe-filtered Co-Kα radiation. Phases were identified using X’Pert Highscore plus software.

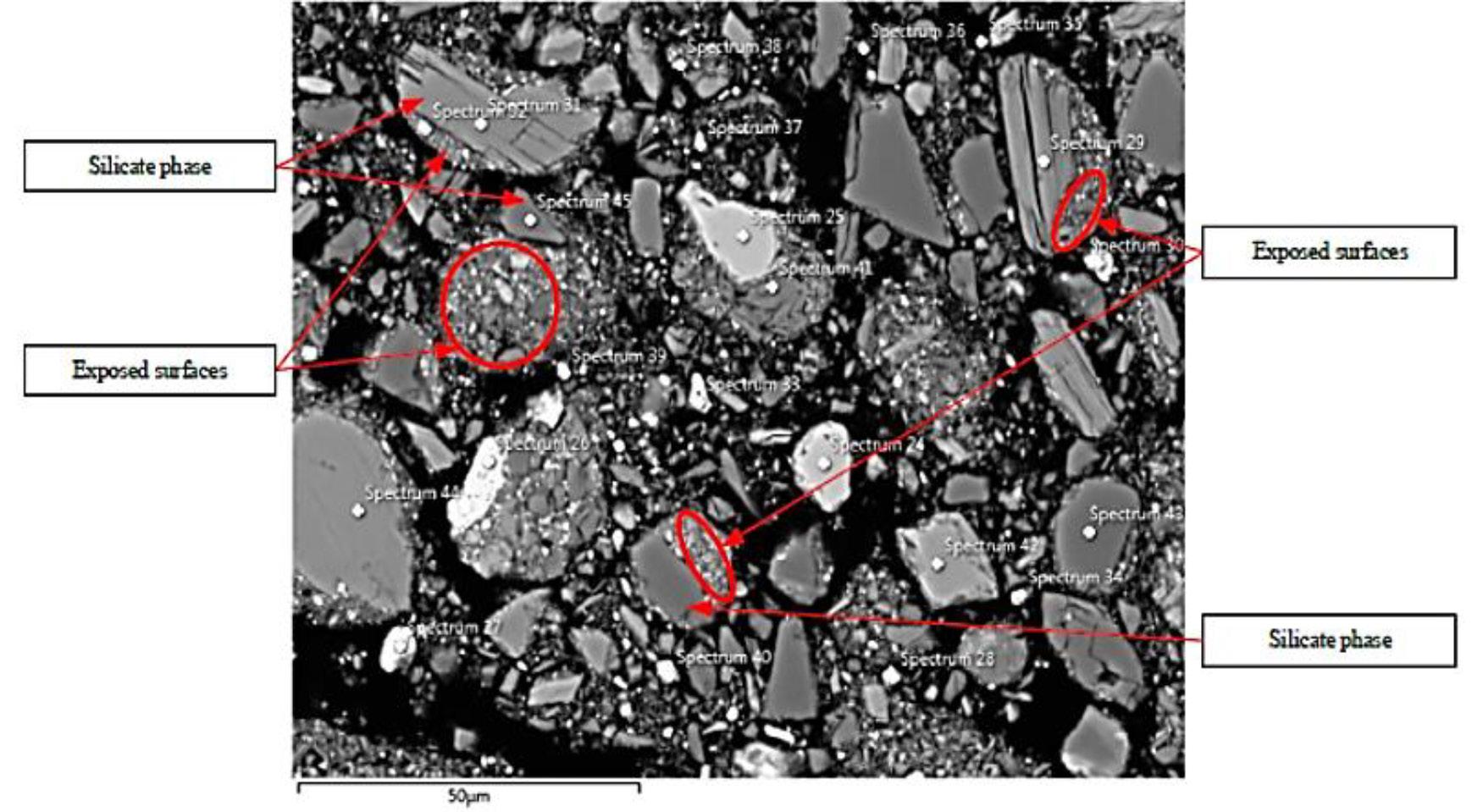

Gold particle size and associations were investigated using scanning electron microscopy (SEM)using a Zeiss MERLIN field emission scanning electron microscope. A Zeiss 5-diode back-scattered electron (BSE) detector (Zeiss NTS BSD) and Zeiss SmartSEM software generated BSE images. An Oxford Instruments X-Max 20 mm2 detector attached to the SEM and Oxford Aztec software were used to chemically quantify the samples by semi-quantitative energy dispersive X-ray spectrometry (EDS) and generation of corresponding EDS maps.

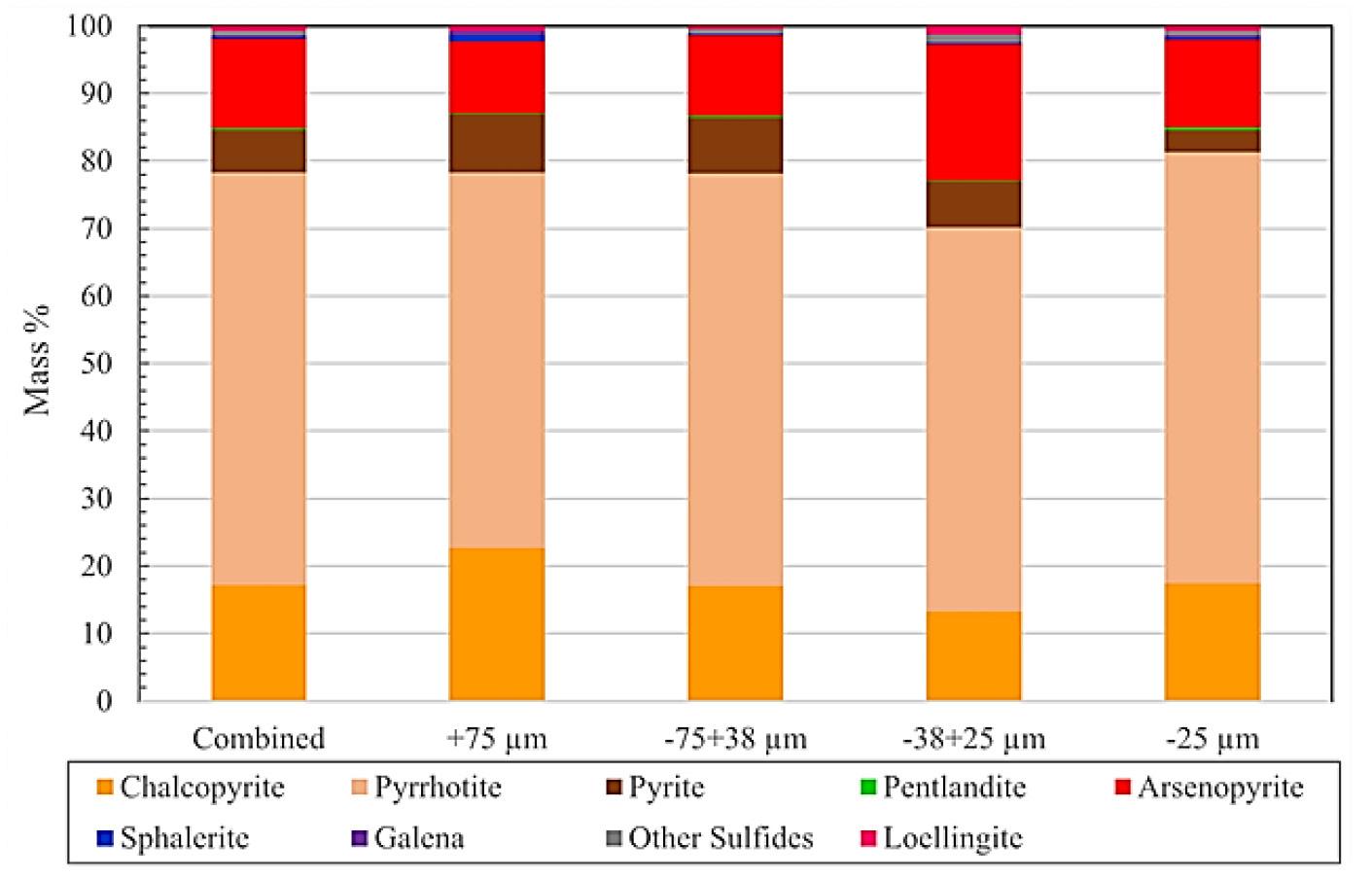

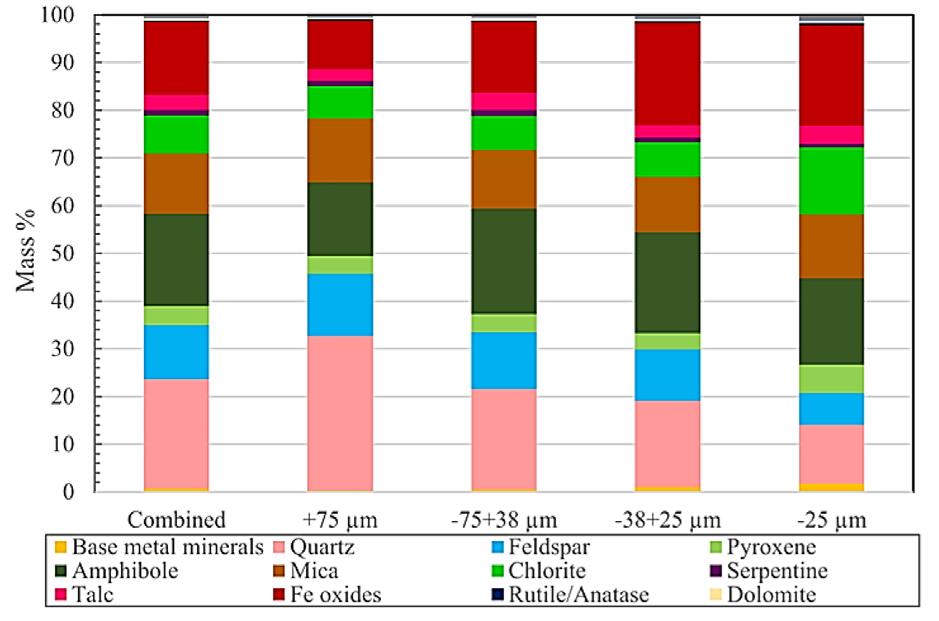

Finally, quantitative scanning electron microscopy (QEMSCAN) analysis was performed on the calcine sample. 500 g of the sample was screened into four particle size ranges; +75 μm, -75+38 μm, -38+25 μm, and -25 μm. Two polished sections were prepared for each size fraction. The sections were analysed by a QEMSCAN 650F with two Bruker EDS detectors. Bulk mineral analysis and trace minerals were measured in each section.

Leaching tests were conducted using a 24-hour bottle roll with

sodium cyanide as lixiviant. Unless otherwise stated, the cyanide addition was 2 kg/t. A solids density of 30% solids was used for the leaching tests. Lime was added to adjust the pH 10.5. Liquid samples were collected at 1-hour, 2-hour, and 24-hour intervals and analysed for gold using ICP-OES. The bottle roll tails were water-washed and filtered before oven drying at 50ºC. Dry tailings samples were sent for fire assay.

Ultrafine milling was performed using a pulverizer. A 100 g sample was pulverized for 120 seconds to achieve a P80 of 16 μm.

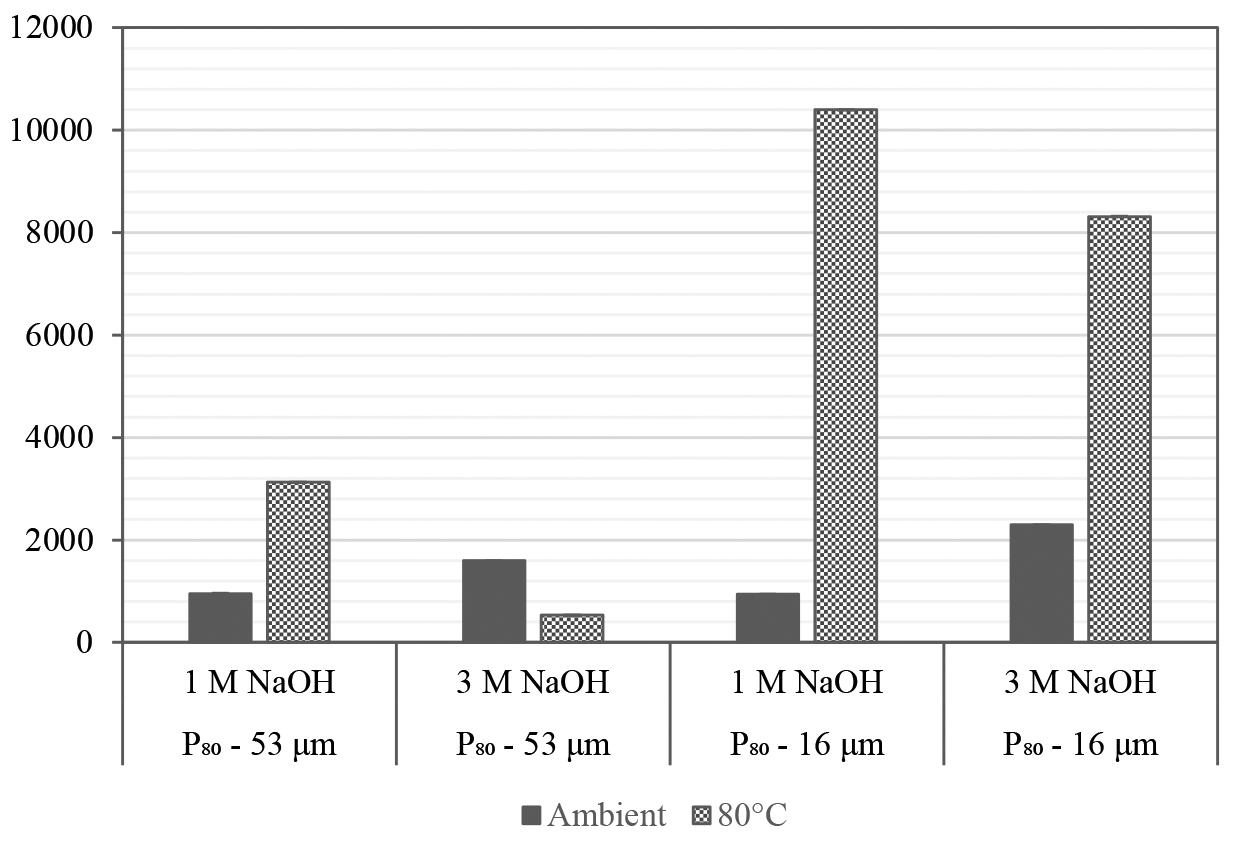

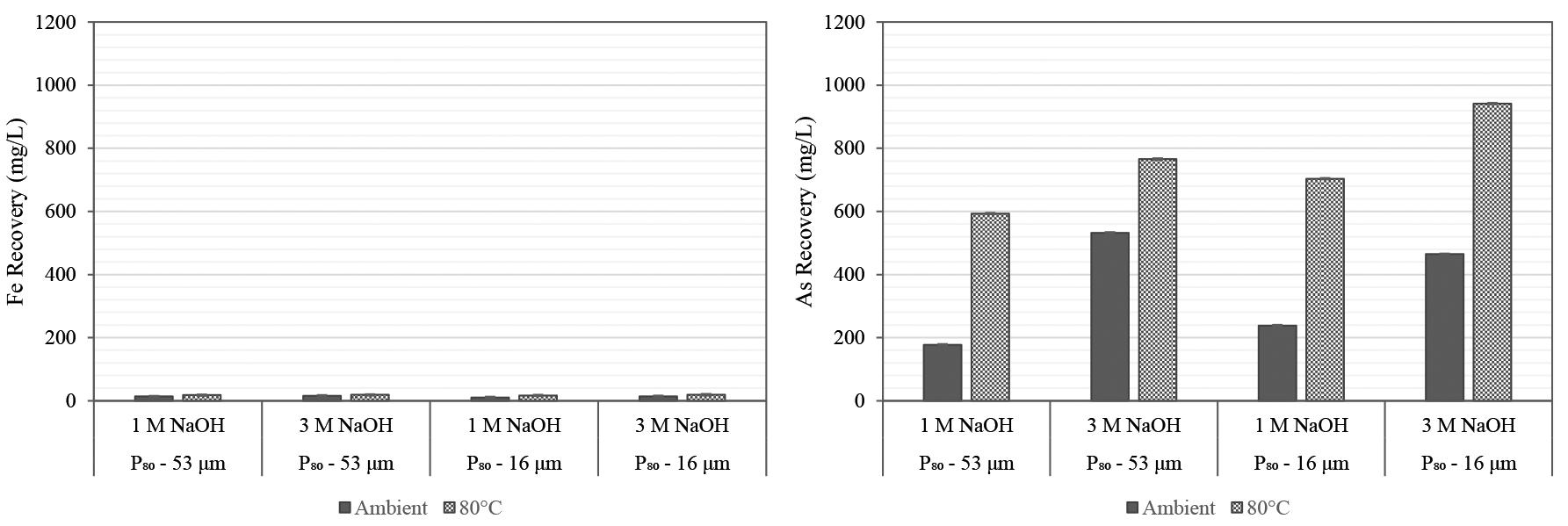

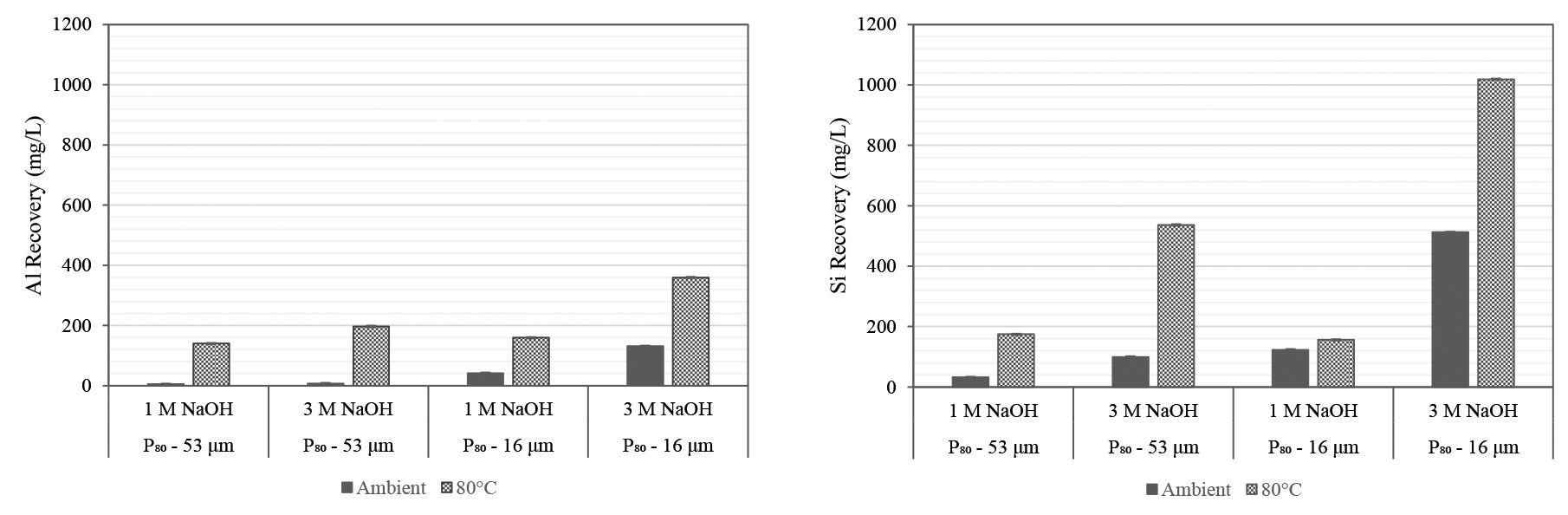

Analytical-grade sodium hydroxide was used for chemical pre-treatment. The pre-leach was conducted at 25% solids concentration (González-Anaya, Nava-Alonso, and Pecina-Trevi˜no, 2011) for 4 hours. Pre-leaching was conducted in a top-driven stirred glass vessel with temperature-controlled heater at the base of the vessel. Solution samples were collected after 4 hours and analysed for Au, As, Al, Fe, S, Si, and Zn using ICP-MS. Solid tails were washed with deionized water, filtered, and dried in an oven at 50oC before preparation for cyanidation tests. Cyanidation tests were conducted using the methodology described later. A full factorial design was conducted at two levels to investigate the effects of temperature, [NaOH], and particle size. Table III shows the levels and conditions investigated.

Microwave energy was used to facilitate the breakdown of refractory mineral matrices to liberate gold before and during leaching experiments. Microwaves were used as an energy source

ability to apply a high energy density over a short period of

The experiments are a demonstration of the

thermodynamic thresholds to be broken, in