Head Office Unit 2, Stour Vale Road, Stourbridge, DY9 8PP 0121 501 3903 sales@rapidfast.co.uk www.rapidfast.co.uk Manufacturing Hub Unit 27, Lye Valley Industrial Estate Stourbridge, DY9 8HX • Volume stockist of standard fasteners & fixings • In House Bespoke Manufacturing • Exclusive Far East Manufacturing Capacity • Next day Nationwide Deliveries • Vendor Managed Systems ; JIT / Kan Ban • Assembly & Kitting • Full Certification ; 3.1,3.2 & ISIR’s • Contract & Schedule orders YOUR COMPLETE FASTENER SUPPLIER THINK FASTENERS THINK RAPID RAPID INDUSTRIAL FASTENERS LTD Issue 03 / June 2023

Publisher Jerry Ramsdale Jerry@torque-direct.com

Editor Hayley Everett Hayley@torque-direct.com

Deputy Editor

Rachel King Rachel@torque-direct.com

Contributing Editor

Jonathon Harker Jonathon@torque-direct.com

Sales Manager – UK

Claire Warman Claire@torque-direct.com

Sales Manager – International Harry Whyte Harry.whyte@torque-direct.com

Circulation

Tracy Howell Tracy@torque-direct.com

Head of Production Luke Wikner production@torque-direct.com

Designers

Dan Bennett production@torque-direct.com

Victoria Arellano production@torque-direct.com

Published

INSIDE THIS ISSUE EDITOR’S COMMENT

04 Product news

COVER PROFILE

08 Rapid Industrial Fasteners –Comb-ining distribution and manufacturing for a unique advantage in the UK fastener supply market

TECHNICAL INSIGHTS

12 Lightweighting – How is growing demand for lighter products affecting fastener materials and designs?

36 CPG – The basics of fire protection testing and certification

40 Bumax – The specialist fasteners being used to secure a new payload for the ISS

IN-DEPTH – RENEWABLE ENERGY

16 Analysis – What new opportunities beckon for the fastener industry?

18 Hague Fasteners – Demonstrating social and economic responsibility with sustainability

20 Nord-Lock – Eliminating costly repairs for wind turbine MRO

22 EJOT UK – Supporting greater PV adoption without compromising flat roof performance

24 Dörken – Enhancing the protection of bolted connections with zinc flake coatings

27 Fluke – User-friendly tools for solar power installation

28 Gala Precision Engineering –Protecting the integrity and durability of fasteners in wind energy

PRODUCT INNOVATIONS

30 Clips & clamping – Superior clamping technology for operational continuity

34 Torque tools – A round up of the latest innovations in torque tools

INDUSTRY EVENTS

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-direct.com

Web: www.torque-direct.com

Disclaimer Although

RENEWED HOPE

EVENTS of past year have exposed significant vulnerabilities in the supply and demand of electricity around the world. The ongoing conflict in Ukraine has demonstrated the need for greater energy independency amongst countries who do not wish to be held for ransom over their energy supply, while extreme weather events have shown just how easily current supply can be interrupted and jeopardised. As the climate crisis intensifies, the supply and demand of energy will be increasingly affected, prompting the need for action sooner rather than later.

However, with the International Energy Agency (IEA) recently forecasting that renewable energy will meet over a third of global power generation by 2025, the future for renewable energy at least looks bright. With this, comes new opportunities for the fastener, tool and coatings industries. In this issue’s InDepth focus, we look at the companies already innovating in the renewable energy space, from the construction of wind turbine towers and blades to the installation of solar panel arrays, and much more in between.

Also under the spotlight in this issue is the topic of lightweighting, specifically how increasing demand for lighter products is affecting fastener materials and design. The latest product innovations in clips and clamping technologies and torque tools are also in focus, alongside technical insights into fire protection testing and certification and the space-faring fasteners chosen to secure a new payload to the International Space Station (ISS). The upcoming international trade show for hardware and industrial supplies, +Industry, is also previewed.

As always, if you have news or insights to share from your corner of the fastener, tool, coating and adhesive industries, then get in touch.

32 +Industry – Showcasing the latest products across hardware & industrial supplies

To subscribe to Torque-Direct visit: torque-direct.com/subscribe or scan this QR code...

As part of our commitment to the environment, Torque Direct is fully recyclable.

Hayley Everett Editor Hayley@torque-direct.com

by Stag Publications Ltd 18 Alban Park Hatfield Road St Albans Herts AL4 0JJ

the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd. Copyright Entire contents copyright © 2023 Stag Publications. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 03

LATEST PRODUCTS FROM THE FASTENER & TOOL INDUSTRIES

NEW PLASTIC & RUBBER HARDWARE RANGE

TR Fastenings is expanding its product portfolio with the addition of 1,500 new part numbers to the existing Plastic & Rubber Hardware range, in response to product requests from across the automotive, health and home, and energy, tech and infrastructure sectors.

The new product ranges include Screw Rivets, which are ideal for applications where maintenance or servicing via a

removable panel is required, and Barbed Pushin Rivets, often used in automotive applications such as wheel arch bumpers, splash shields, bumper assemblies, internal upholstery and trim. Meanwhile, new Kwik Nuts that allow for tool free rapid installation are now available for automotive applications like vehicle acoustic engine liners and interior assemblies, as well as for air conditioning and ventilation equipment.

Also new to the range are Push Screws, a new product which combines the rapid installation of a Fir Tree Clip with the versatility of a conventional threaded screw. The part is designed to push fit and retain in a female thread, then be removed with a standard screwdriver to enable rapid tool free installation. Finally, the new additions are rounded off with Shockproof Snap Rivets, a new development and an improvement on the standard design of a conventional Snap Rivet. The design incorporates a locking mechanism under the head which resists pin movement when subject to mechanical shock or vibration, making them ideal for automotive interior applications, industrial lighting, pumps, heating and ventilation.

www.trfastenings.com

AUTOMATED SCREWDRIVING SOLUTION

DEPRAG and Micropsi Industries have announced a cooperation to jointly develop an automated screwdriving solution capable of handling different types of variance at production stations. Pitched as a solution that enables screw assemblies to be robustly automated for the first time, the screwdriving product will be suitable for the assembly of a wide range of products and components within household appliances, electronics, automotive parts, agricultural machines and more.

The cooperation will bring together DEPRAG’s screwdriving technology and Micropsi Industries’ MIRAI robot control system. By using artificial intelligence, MIRAIcontrolled robots can reliably manage complex production tasks which were previously either not possible or very complicated and unprofitable to automate.

The intelligent screwdriving solution will enable position and angle tolerances, as well as production tolerances, to be compensated on a component, while dynamic tasks on a moving belt can also be mastered.

www.deprag.com

///////////////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT NEWS ///////////

//////////////////////////////////////////////////////////////////////////// /////////////////////////////////////////////////////////////////////////////////////////////////// 04 torque-direct.com /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Tel: +44 (0)121 4397329 Fax: +44 (0)121 4397346 Unit 4, Alma Industrial Estate, Stafford Road, Wednesbury, WS10 8SX, United Kingdon The Insert Company (UK) Limited Specialists in Threaded Inserts for Wood, Plastic and Metal Zinc Alloy InsertsSteel Inserts Brass InsertsFurniture Connectors Headed Hex Drive Steel Knock-in Barbed ExpansionCountersunk Caps

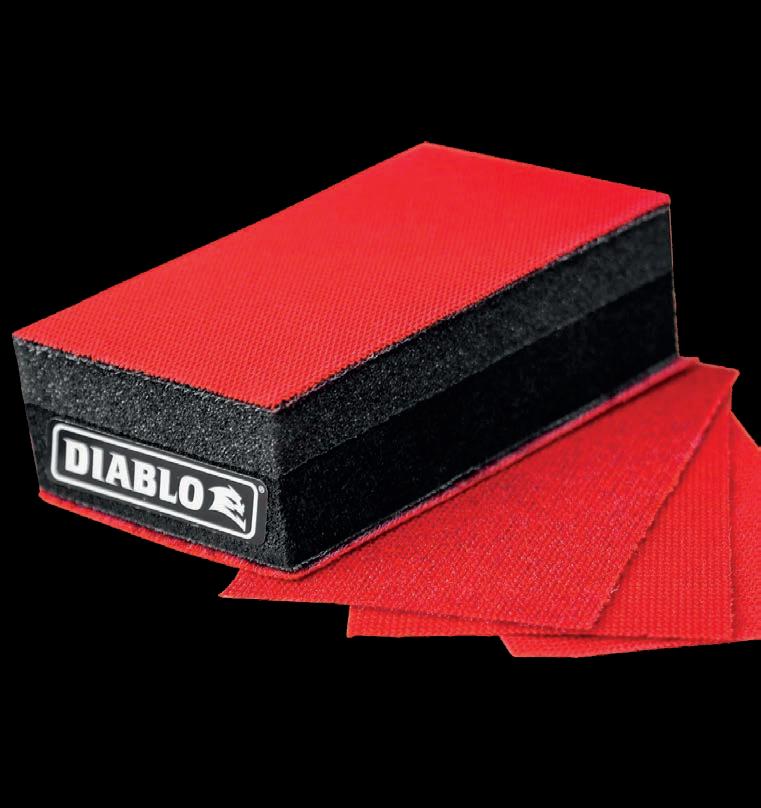

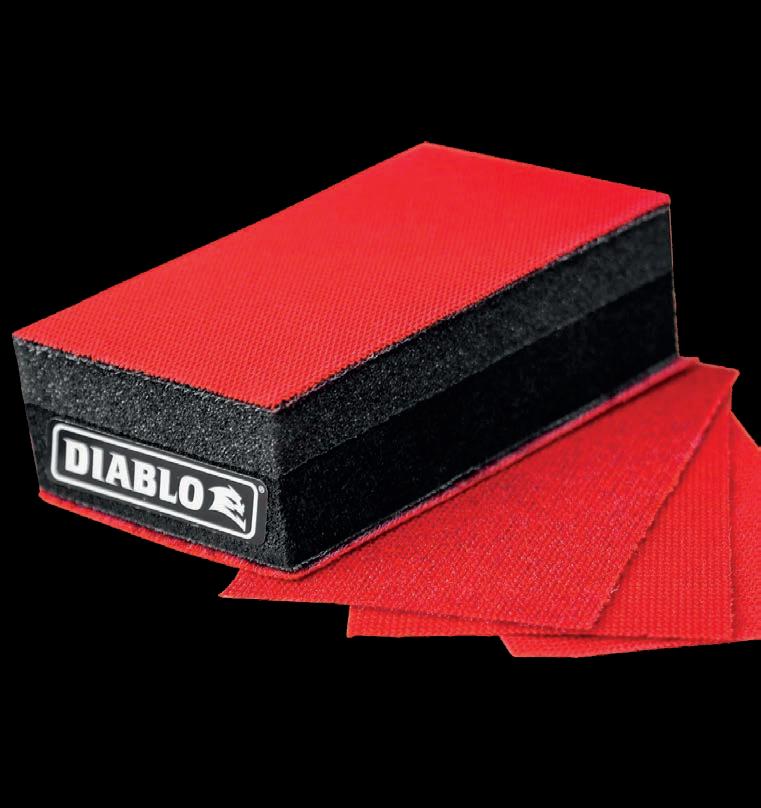

NEW REUSABLE SANDING BLOCK

Diablo Tools has introduced a new reusable angled handing sanding block that it pitches as truly being a ‘tool’. Going further than traditional foam sanding blocks that only provide a onedensity, single grit application, the new sanding block allows users to reuse it time and time again with a variety of sand ing grits thanks to Diablo’s SandNET sanding sheets.

With its advanced design, it can be used either dry or wet and features an exclusive twoin application that provides greater flexibility and increased productivity on the jobsite. The block also features a corner contact edge for consistent scratch patterns and ultrasmooth finishes when sanding precise edges and tight corners.

The angled sanding block allows professionals to sand hardtoreach areas on drywall, wood, paint, metal, fibreglass and plastics. The block is designed to work specifically with the reusable SandNET sanding sheets, which are reportedly the only reusable sanding sheets currently on the market.

www.diablotools.com

NEW GRINDING RANGE

FEIN has announced a new grinding product range that offers a whole host of safety and performance features. The portfolio includes the launch of the CG 15 compact angle grinder, which is the first of its class to feature a fully encapsulated, brushless FEIN PowerDrive motor. The tool’s 1,500W motor and powertoweight ratio allow the user to operate with improved efficiency and endurance, while also putting cost and longevity considerations at the forefront.

Requiring fewer wearing parts and offering longer service intervals, the tool is designed to incur lower maintenance costs throughout its life, while a variety of safety features help to ensure operator safety.

A total of 10 tools have been launched in the range, including FEIN’s Protago highsafety angle grinder which was created in collaboration to set new safety standards in the industry. Each of the tools are now available on the 18v AMPShare battery platform powered by Bosch, which allows users to power over 200 different tools from more than 30 brands with just one AMPShare battery.

www.fein.com

LATEST PRODUCTS FROM THE FASTENER & TOOL INDUSTRIES

06 torque-direct.com

////////////////////////////////////////////////////////////////////////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT NEWS ///////////

DISTRIBUTION AND MANUFACTURING: A COMPLETE SUPPLY SOLUTION FROM RAPID INDUSTRIAL FASTENERS

Rapid Industrial Fasteners on how its two sides of the business –distribution and manufacturing – combine to give it a relatively unique advantage in the UK fastener supply market…

Rapid Industrial Fasteners occupies a fairly unique position in the industry, offering a blend of services that few others are capable of in the UK in 2023. A longestablished distributor of fasteners, Rapid Industrial Fasteners was founded around 40 years ago, based in the heart of the UK’s fastener heartlands, the West Midlands. It’s decision to open a manufacturing floor and start producing fasteners inhouse in 2019 gave it an edge that few can also offer, but more of that later.

As you might expect with a name like Rapid, the business prides itself of speed of response and service to customers. When it comes to getting product fast to customers, stock availability is of course crucial, so Rapid is committed to high

volume stocking. MD Richard White tells Torque Direct: “We have regular import cycles of standard items from approved Far East manufacturers, and we have solid relationships with key wholesalers in the UK.”

That continued commitment to high level stocks and service has seen Rapid Industrial Fastener’s stock holding expand over the decades to the point where, last year, it had to relocate its warehouse. Its former facility was struggling to house its expanding stock holding, so the move, conveniently much closer to Rapid’s machine shop, was a sizeable 10,000ft² increase on the old unit, with around 970 pallet locations and approximately 18,000ft² for Rapid’s standard fastener stock lines.

/////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 08 torque-direct.com

COVER PROFILE

Rapid’s fasteners are supplied into an increasingly broad range of sectors and markets, not least infrastructure, so quality remains integral for the company, which has taken a comprehensive approach, as White explains: “We have tools for Positive Material Inspection (PMI), hardness testing and we routinely issue 3.1 and 3.2 material validation certificates, and our quality system is robust. We have ISO 9001 Quality Manage¬ment System certification, tested by SGS, a higher end reputable testing agency. We offer complete traceability and tighter controls on material handling in accordance with ISO standards.”

A complementary fastener manufacturing business

Rapid Industrial Fastener’s distribution business has grown over the years but by far the biggest milestone along the way was the decision to drastically expand its remit, by adding a machine shop to its business.

By including fastener manufacturing in its service mix, Rapid Industrial Fasteners was effectively becoming a fastener distributor and manufacturer which, as anyone in the industry will tell you, is a relatively unique set up for the UK. There are some typically smallscale fastener manufacturers in the nation and a good number of fastener wholesalers, importers and distributors, but rarely under one roof, so to speak.

2019 was the year that Rapid opened its machine shop.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 09

Rapid Industrial Fasteners’ new warehouse has circa 970 pallet locations

”WE HAVE TOOLS FOR POSITIVE MATERIAL INSPECTION (PMI), HARDNESS TESTING AND WE ROUTINELY ISSUE 3.1 AND 3.2 MATERIAL VALIDATION CERTIFICATES“

Starting from scratch, albeit with skilled personnel who boasted extensive fastener manufacturing experience, the manufacturing facility has grown substantially in a short space of time. With its foundation close to the white heat of the Covid lockdown, during which the machine shop picked up a lot of business, it’s been an intense period of hard work that started with a ‘blank slate’ of an empty unit with four walls and a roof, to a fullyfledged manufacturing facility.

The progress of the manufacturing side of the business has allowed Rapid to bring in more lead and key roles to handle the increasing workload. Led by Managing Director Richard White and Operations Director Jason Hayfield, new machines have been acquired, on a relatively regular basis, with further investments scheduled, including even more advanced machines that will boost efficiency by combining multiple processes.

Control over specials manufacturing

To take greater control and improve customer service were among the reasons for Rapid taking the plunge and entering the world of fastener manufacturing: “We used to rely heavily on subcontractors to turn around orders for special parts, but we were frequently let down and timescales drifted. It meant we weren’t always able to get products to customers when we wanted to. It meant we couldn’t be as consistent as we aimed

to be. Now we are a UK manufacturer, so we have more control.”

With a name like Rapid, the business has prided itself on its responsiveness and reliability, and in that sense, the machine shop has simply been another element that allows Rapid to serve its customers to a high level.

While manufacturing and distribution are, on the face of vastly different types of businesses (For that reason, Rapid keeps its production and distribution arms in separate units, just a stone’s throw from each other), some principles remain core, including quality. Likewise, both facets of Rapid are committed to quality relationships; with customers, within the business itself, with customers and with suppliers. The firm is fully invested in the notion that “people buy from people”: “Our goal is to have happy customers that will keep coming back. We’re willing to make it happen for them, whatever they want.”

With common guiding principles like that and the advantageous and fairly unique combination of fastener distribution and manufacturing inhouse, Rapid Industrial Fasteners believes itself to be uniquely placed to serve end user customers.

“We offer a complete supply solution. We’re passionate about what we do, and we believe we are an asset for any end user business.”

www.rapidfast.co.uk

/////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 10 torque-direct.com COVER PROFILE

”THE PROGRESS OF THE MANUFACTURING SIDE OF THE BUSINESS HAS ALLOWED RAPID TO BRING IN MORE LEAD AND KEY ROLES TO HANDLE THE INCREASING WORKLOAD.“

YEARS 1948 2023

LEVEL UP WITH LIGHTWEIGHTING

How is the growing demand for lighter products affecting fastener materials and designs?

Lightweight materials and product design has long been an important consideration within many industries, from automotive and aviation to renewable energy and rail. In line with global trends towards reducing CO2 emissions and improving resource efficiency, the need for lighter and more efficient parts is becoming increasingly vital.

In light of this, the lightweighting of fastener designs is also evolving. Joining lightweight materials can present numerous challenges, from different panel thicknesses and retention requirements to corrosion and the need to reduce the complexity of fastening interfaces. As such, new fastener designs must meet the desired performance and reliability standards unique to each industry, prompting the need to develop more suitable mechanically and chemically compatible solutions.

Market demands

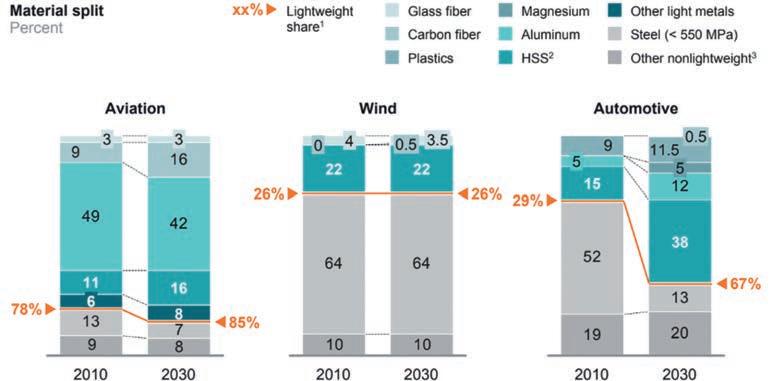

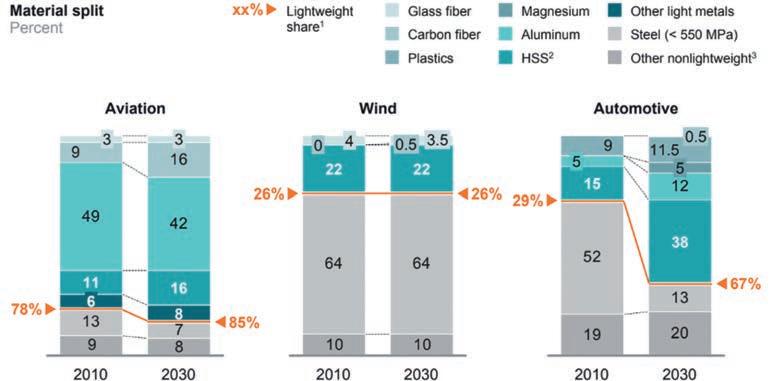

While an important factor for many industries, such as aerospace and electronics, lightweighting is particularly imperative for the automotive industry, as the weight of a part has a substantial impact on vehicle autonomy, fuel consumption and CO2 emissions. According to a recent report by McKinsey & Company, expected changes in materials use are likely to have the most significant impact on this sector with the rise of carbon fibre application and lighter metals such as aluminium and highstrength steel.

The rise of electric vehicles (EVs) is also accelerating the demand for lightweight fastening solutions. With added weight of batteries and associated electronics systems, the efficiency of these vehicles relies heavily on developing lighter parts.

Types of lightweighting

Lightweighting can be achieved through several different means. Direct lightweighting is where the fastener itself is made lighter than a traditional fastener might be. To accomplish this, manufacturers can opt to use a lighter weight material for the fastener, but must weigh this against the potential loss of other desirable mechanical properties like strength and resilience. Another way of achieving direct weight savings is

to develop lightweight designs, such as the ‘lightening holes’ drilled out in aerospace applications to reduce mass without compromising on structural integrity.

Other ways to achieve weight savings is to utilise fasteners that possess improved technology that provides better or equal performance than a traditional fastener. New and innovative technologies can often provide performance improvements over older, more traditional fastening technologies, or can act as an enabling technology for revolutionary fastener and component designs.

Material choice matters

When developing lightweight fasteners for any industry, structural integrity and durability are paramount. To ensure this, any new component design must include specific design and validation processes to ensure it performs as intended in any given application.

Material choice is a big part of this, as performance can vary hugely depending on the chosen application and surrounding environmental conditions, while cost can often be another factor. Currently, there is an ongoing trend in the fastener industry of moving away from heavier steel materials and towards lighter alternatives such as aluminium, carbon fibre, nylon, plastic, titanium and multimaterial assemblies. These types of materials are allowing engineers to shed weight from fasteners without compromising their strength, durability or reliability. Meanwhile, new advances in manufacturing technologies and processes are enabling more innovative multimaterial assembly solutions, which can help to not only reduce weight but also to lower production costs.

In short, fasteners play an important role in lightweighting for a myriad of applications across different industries. Engineers and designers are continually developing new ideas and technologies to make parts lighter, some of which cannot be realised until a new fastening technology or design is developed to complement it. As such, lighter and more optimised fasteners are an integral part of lightweighting efforts across industry as it looks to reduce CO2 emissions and optimise efficiency.

//////////////////////////////////////////////////////////////

TECHNICAL INSIGHTS LIGHTWEIGHTING /////////// 12 torque-direct.com

PERFORMANCE POLYMERS

HPP’s Project Coordinator, Megan Kitts explains how high performing polymer components fit into an ever-changing industry

High performance polymer fasteners are specialised plastics that have enhanced mechanical and thermal properties compared to standard polymers. One particular benefit offered by these fasteners is their lightweight properties. As polymerplastic fasteners are much lighter than metal fasteners, this makes them easy to handle and transport, while also reducing the weight of critical components in industries like aerospace and automotive for which weight reduction is vital.

One of the UK’s leading manufacturers and distributors of performance polymer fastening components, High Performance Polymer (HPP) stocks over one million polymer components used in multiple industries worldwide. These products play a key role in overcoming issues encountered with metallic or substandard polymer components, whether it be within the oil and gas, medical or automotive sectors.

One of the major issues that metallic screws can cause is galvanic corrosion, whereby when utilising two metals like aluminium and steel, one metal corrodes preferentially to another due to being exposed to a conductive solution such as water. Polymer components mitigate galvanic corrosion by insulating the metals while maintaining the performance necessary to keep up with the demand of the environment, whether this is high tensile or compressive strength, temperature or UV resistance.

As technology in industry advances, different characteristics are required within components to meet the project or product specification. Performance polymer components have a variety of favourable characteristics that ensure any project can continue as planned. One example of this is radio frequency (RF) transparency featured in PEEK. This characteristic has been proven to increase the range of remote electrical devices by reducing interference often found when using metal fasteners and componentry. HPP has provided a full PEEK solution for remote monitoring devices for oil pipelines that spanned large distances.

High performance polymer components have properties that far exceed the realms of what most people consider ‘plastic’ capable of. They can operate at high temperatures (360°C in some cases), have high tensile strength, are ultralow weight, have great insulting properties and chemical and corrosion resistance.

There are a multitude of polymer fasteners that specialise in meeting specific needs, so let’s look at some examples of HPP’s preferred polymer fastening components.

RENY

RENY is a high tensile strength Nylon. Its component property makeup is 50% glass fibre and 50% polyamide MXD6. When people think about a Nylon fastener, the first thing that comes to mind is a low strength, low quality and soft

////////////////////////////////////////////////////////////// torque-direct.com 13

TECHNICAL INSIGHTS LIGHTWEIGHTING ///////////////

material that is inadequate for most industrial applications. RENY, however, is the opposite with a high tensile strength (285MPa), high bend strength (380MPa), and low tensile elongation at 2.1%.

RENY fastening components are precisely manufactured to high tolerances and are particularly suited for applications that require high strength while encompassing the benefits of a polymer: insulating properties, chemical resistance, corrosion resistance and low thermal conductivity. Possible applications for RENY fasteners include flange bolting, robotics, automotive and aerospace applications.

Bespoke solutions

Offtheshelf polymer components are just one aspect of HPP’s operation; the company has vast experience in the engineering industry and offers bespoke component manufacture to a micron level of accuracy, which is particularly suited for life science and other niche applications. The firm also provides component and material consultancy to ensure the most appropriate material is used for a specific application.

This experience is embodied by the firm’s Director, Matthew HartleyJames, who worked as a mechanical engineer for a large scientific research facility for over seven years before launching HPP, often utilising PEEK and other performance polymer components for their radiation resistance, tensile strength and chemical compatibility.

As part of its offering, HPP ensures quality through a range of processes in line with its ISO 9001 certification. Raw material is traceable through to manufacture and all components are checked with high accuracy metrology equipment to ensure that they will meet the needs of any demanding environment.

While typical ‘plastic fasteners’ are thought of as an inferior and lowquality alternative, HPP’s polymer components are designed to meet the needs of the harshest environments and provide a dedicated solution to improving the reliability and functionality of products and devices used in industries worldwide.

PEEK and PEEK GF30

Polyether Ether Ketone (PEEK) is a more commonly known high performing polymer material. It is one of the most versatile materials available for extreme applications and is used extensively in various industries from defence to oil and gas. PEEK is known for its ability to withstand high temperatures, exposure to a variety of chemicals and provide phenomenal insulating properties.

HPP uses Victrex 450G exclusively in all its standard PEEK components, with batch traceability and certificates of conformance available. If the specifications of PEEK are suitable for a particular application, but the tensile strength is too low, HPP offers a GF30 option. PEEK GF30 has a makeup of 70% PEEK and 30% glass fibre, drastically improving tensile and compressive strength while maintaining high temperature resistance and chemical resistance.

www.highperformancepolymer.co.uk

////////////////////////////////////////////////////////////////////////////////////////////////////////// TECHNICAL INSIGHTS LIGHTWEIGHTING /////////// 14 torque-direct.com

”HIGH PERFORMANCE POLYMERS HAVE PROPERTIES THAT FAR EXCEED THE REALMS OF WHAT MOST PEOPLE CONSIDER ‘PLASTIC’ CAPABLE OF.“

Performance polymer components have a variety of favourable characteristics over their metal counterparts

EJOT’s Application Engineers have access to prognosis and forecasting software that has proved pivotal for designers and can impact positively on prototype and testing budgets.

Bringing it together.

No other fastener OEM knows e -vehicle assembly

EJOT.

EJOT’s pedigree as a fastening innovator goes hand in hand with automotive manufacturing’s own backstory - pretty well since day one.

And given that our fastening products and systems provide application-specific solutions for all modern engineering materials, their commonality supports modern engineering goals to build lighter, build stronger, build smarter.

No surprise then that EJOT has been working academically with design teams world-wide, to bring our fastening technology into electric vehicle assembly, and to all peripheral application developments, for some time.

If you’re involved with any area of EV design, at any stage, at any leveland you’d like a solutions-based conversation, then call or email our team:

T: +44 (0) 1977 387 040 E: industrial@ejot.co.uk

Build lighter. Build stronger. Build smarter.

inside and out, like

RENEWED AMBITION

The future of renewable energy is bright. With this, comes new opportunities for the fastener industry...

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 16 torque-direct.com /////////// IN-DEPTH RENEWABLE ENERGY > ANALYSIS

According to the International Energy Agency (IEA), renewable capacity will meet 35% of global power generation by 2025. In fact, the agency’s recent Electricity Market Report 2023 predicts that by this deadline renewable energy sources such as solar and wind power, together with nuclear, will on average meet more than 90% of the increase in global energy demand.

With the world’s electricity demand now expected to rise by 3% per year during this time, it is more crucial than ever that countries and governments look to reduce their reliance on fossil fuels in sectors like heating and transportation. As the share of coal and gasfired generation falls in line with renewables playing a larger role in the worldwide power generation mix, industrial CO2 emissions are also expected to plateau and then eventually decrease.

At present, though, both the supply and demand of electricity is becoming more and more affected by the climate crisis, throwing a stark light on the need for action sooner rather than later. The IEA warns: “The impact of weather events on electricity demand will intensify due to the increased electrification of heating, while the share of weatherdependent renewables will continue to grow in the generation mix. In such a world, increasing the flexibility of power systems while ensuring security of supply and resilience will be crucial.”

Turbulent weather conditions are not the only significant factor affecting global energy supply, with conflicts such as the recent war in Ukraine throwing the topic of national energy dependency into the spotlight. Going forwards, green technologies could play a significant role in helping nations to become more energy independent.

”INCREASING THE FLEXIBILITY OF POWER SYSTEMS WHILE ENSURING SECURITY OF SUPPLY AND RESILIENCE WILL BE CRUCIAL.“

Joining up renewable power

As outlined by Europa, renewable energy sources include wind power, solar power, hydro power, tidal power, geothermal energy, ambient heat captured by heat pumps, biofuels and the renewable part of waste. Fasteners play a key role in each of these technologies, from holding together huge wind turbine towers to securing solar panels to building roofs.

Naturally, these critical applications require specialty fasteners, materials and coatings to withstand the many issues the power generation industry faces, particularly regarding strength, temperature and corrosion. Wind turbines, for example, are continually getting larger, and as a result extra demands are being placed on the fasteners and materials needed to secure them.

Coatings, meanwhile, must ensure that the fasteners and fixings used in such applications are able to withstand the surrounding environmental conditions into which they are placed. With extreme weather becoming more common as a result of the climate crisis, the durability and corrosion resistance of such fasteners will be paramount.

Opportunities ahead

As the renewable energy sector continues to ramp up in terms of size and capacity, and in turn demand more from its equipment and machinery, there will be challenges in strength, quality control and fault detection for fasteners and fixings. With challenge comes opportunity, though, and for those that get their products right the potential in this growing market is huge. This indepth feature on renewable energy highlights some of the companies that are already innovating in this space, while offering insight into the vital fasteners and tools currently holding together the sector.

HEICO-LOCK®

Wedge Locking Systems

HEICO-TEC®

Tensioning Systems

Easy, fast and reliable assembly of large bolted joints

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 17

WWW.HEICO-GROUP.COM

The best value to secure and tighten bolted joints

The approved system for bolt securing Scan to fi nd out more

BIG ON BOLT S

Renewable energy is becoming an increasingly important aspect of the energy landscape as concerns over climate change and the depletion of nonrenewable resources grow. From solar and wind to geothermal and hydro, there are many types of renewable energy sources that are being developed and deployed around the world. As the demand for renewable energy increases, so too does the need for reliable, highquality equipment and infrastructure. Hague Fasteners’ expertise in the manufacturing of critical components in this infrastructure is crucial to the reliability and performance of the fasteners used in this exciting and developing industry. This article details the different types of renewable energy and the types of bolting that are required for each, all of which stipulate the highest quality and product certification which Hague Fasteners is known for.

Steel for solar

Solar energy is the most popular form of renewable energy, with solar panels being installed on rooftops, fields, and even on the water. The installation of solar panels typically requires several types of fasteners, including bolts, nuts, washers, and screws. The bolts used to install solar panels are typically made from stainless steel or aluminium and must be able to withstand the elements, including wind, rain, and snow. Stainless steel is an excellent material for solar panel bolts because it is corrosionresistant and can withstand high temperatures.

Wind security

Wind turbines are another popular form of renewable energy, and they require a variety of bolts and fasteners to keep them secure. Bolts are used to connect the blades to the rotor, the rotor to the hub, and the hub to the tower. The bolts used in wind turbines must be able to withstand the forces generated by the rotation of the blades, which can reach speeds of up to 200 miles per hour. Highstrength bolts made from hardened alloy steel are commonly used in wind turbine applications often with specific designs and quality controls from specifications developed by specialist wind turbine engineers.

/////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH RENEWABLE ENERGY 18 torque-direct.com

Hague Fasteners’ wind energy bolts are fully identifiable and traceable

Jon Hague discusses the vital bolting requirements for the advancement of various renewable energy sectors

”A VARIED RANGE OF FASTENERS AND BOLTS ARE NEEDED TO SUPPORT NEW AND INNOVATIVE APPLICATIONS.“

The machining process for a turbine stud

Going geothermal

Geothermal energy involves tapping into the natural heat of the earth to produce electricity. Geothermal facilities require a wide range of bolts and fasteners, including those used in drilling and excavation, as well as those deployed in the construction of the power plant. The bolts used in geothermal applications must be able to withstand high temperatures and corrosive environments, as the fluids used in geothermal drilling can be highly acidic. Stainless steel, superalloys and highstrength alloys are commonly specified for these applications.

Harnessing hydro

Hydroelectric power plants generate electricity by harnessing the power of falling water. Hydro facilities require numerous types of bolts and fasteners, including those used in the construction of the dam, the penstock, and the turbines. The bolts used in hydro applications must be able to withstand the forces generated by the flow of water, as well as corrosion from the water itself. Design safety again is critical with specific attention to materials that are suitable for reliability in these highly corrosive environments.

Bolts for biomass

Biomass energy involves burning organic materials to produce electricity. A wide variety of bolts and fasteners are required for biomass facilities, such as those used in the construction of biomass boilers and turbines. The bolts used in biomass applications must be able to withstand high temperatures and corrosive environments, as the combustion process can produce acidic gases.

Meeting specifications

The evergrowing demand for special fasteners and precision engineered components for the different renewable energy industries means a varied range of fasteners and bolts are needed to support new and innovative applications in these areas. As such, products must be manufactured both to recognised international standards and to the custom specifications of specialist design engineers in order to support the infrastructure of these sectors.

From solar panels to wind turbines, geothermal plants to hydroelectric dams and biomass facilities, the fasteners used must be able to withstand the unique challenges posed by each type of renewable energy source. Products must be able to withstand the weather elements, high temperatures, and corrosive environments, and they must be able to provide a secure and reliable connection to ensure the safety and efficiency of the renewable energy facilities. As the renewable energy industry continues to grow, so too will the need for highquality, reliable fasteners and bolts to support it.

Having been at the forefront of supplying the renewable energy sectors for decades, Hague Fasteners is equipped with the expertise and experience to ensure the very highest quality components are used. The company manufactures fasteners in any size, shape, or material, and can also provide custom coatings or finishes to client’s specification and demands with full Certification Packages to release the finished parts. To this end, the firm offers a wide range of services, including technical support, quality control, and custom manufacturing.

www.haguefasteners.co.uk

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 19

A high-strength turbine stud used in wind energy applications

WINNING WITH WASHERS

The creation of an innovative wedge-locking washer kit is eliminating costly repair issues in the maintenance of wind turbine towers

Wind turbine towers, while built to be extremely strong and sturdy, are also designed to flex and bend in order to help dissipate the significant forces exerted upon them during operation. This flexing and bending, however, had been causing a major North American power company dangerous and expensivetorepair failures in the bolts that hold up the Yaw and Saddle decks inside its towers. Naturally, this was a major problem for the company which has some 6,000 towers of this design. On a wider scale, it is estimated there are up to 35,000 wind turbine towers of this type across the whole of North America. The wind turbine OEM attempted several inhouse fixes, such as putting stronger bolts in the Langle deck brackets. This was a complex and costly endeavour, involving maintenance crews working over shutdowns of more than 24 hours at a time, and still didn’t solve the problem.

After several years of struggling with this issue, one of the company’s engineers concluded that its was not the bolts that were the problem, but the bracket. After recognising that the answer most likely lay in the form of an articulating joint, he scanned the market for the right parts, but no suitable offtheshelf hardware was readily available. This led him to approach his local Fastenal store to search for possible equipment that could replace the OEM bracket.

Designing the fix

After discussions between the engineer and Fastenal’s technical experts, the partners came up with a simple solution based on an articulating joint secured with wedgelocking washers from bolting solutions manufacturer NordLock. The new bracket design was assembled and installed on two of the company’s wind towers to test their effectiveness.

NordLock’s original wedgelocking technology secures bolted joints, even when exposed to severe vibration and dynamic loads. Due to the wedge created underneath the bolt head and nut, it is impossible for products to loosen unintentionally under stress.

The washers were essential to the success of the design, preventing the bolts in the articulating joints from coming loose and holding the decks securely in place during operation – something that previous fixes had failed to do. The design allows the decks to move slightly in multiple directions when the tower deforms under wind forces.

The Deck Bracket Replacement Kit

After studying the condition of twenty of these test brackets installed for over a year in the Yaw and Saddle decks of the power company’s operating wind turbines, the partners confirmed no signs of wear. The positive results of these tests prompted the partners to create a simple Deck Bracket Replacement Kit for wind turbine towers of this design.

Developed to be available for shipment to wind turbine sites for replacement work, the kit consists of five articulating joints and the associated bolts, as well as the Nordlock wedgelocking washers. Besides offering a permanent solution to the repair and maintenance issue, the articulating joint is also much faster to install than previous solutions, taking between three and four hours.

The kit also provides wind tower OEMs with the additional benefits of revenue generation, improved safety of personnel, reduced maintenance costs and financial payback over the long run.

www.nord-lock.com

”DUE TO THE WEDGE CREATED UNDERNEATH THE BOLT HEAD AND NUT, IT IS IMPOSSIBLE FOR PRODUCTS TO LOOSEN UNINTENTIONALLY UNDER STRESS.“

/////////// /////////////////////////////////////////////////////////////////////////////// IN-DEPTH RENEWABLE

20 torque-direct.com

The Deck Bracket Replacement Kit could help reduce maintenance costs for up to 35,000 wind turbine towers across the US

ENERGY

SUPPORTING SOLAR PV ADOPTION

How one innovative mechanical fixing system is supporting greater photovoltaic adoption without compromising flat roof performance

As energy efficiency and decarbonisation becomes increasingly important for the built environment, solar photovoltaic (PV) panels have become a familiar sight on buildings across the world. Although technological development in PV has largely focused on maximising the performance of panels and their associated electrical infrastructure to ensure the return on investment is attractive, innovation in how PV arrays are attached to buildings – especially when retrofitting – has also been critical.

One particular focus for PV attachment systems has been on flat roofs, which of course are commonplace on industrial, commercial, public sector and multioccupancy residential buildings. With this kind of roof, panels usually need to be positioned at an angle, so any attachment system effectively turns the flat roof into a pitched roof.

But, in an effort to make the building more sustainable through the installation of a rooftop PV array, sustainability could in fact be taking a backward step. This is because the performance and lifespan of the flat roof may inadvertently be reduced as a result of the way the PV panels are attached to the roof. The use of

mechanical fixings can be problematic with flat roofing systems where a reinforced PVC membrane is incorporated to keep the building watertight and airtight. Inserting just one screw through this type of membrane can compromise its performance and invalidate the warranty.

As a result, we have seen the adoption of PV attachment systems which rely on ballast to hold them in place. But these are not without their drawbacks, especially the significant weight which they can add to the roof.

A combined fixing solution

One innovative mechanical fixing system from EJOT does, however, ensure the waterproof membrane remains complete, enabling the weight of the PV array to be spread across the roof area. Called EJObar, the product is a 2mm thick aluminium box section encapsulated in PVC which is hot air welded to the flat roof membrane to enable roofmounted elements to be mechanically fixed safely, unlike pointloaded alternative techniques.

EJObar was originally developed by EJOT’s UK R&D team alongside an OEM to provide a simple carrier

/////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH RENEWABLE

ENERGY

22 torque-direct.com

EJOBar was originally developed for M&E application

EJObar Cross-section

system for flat roofs that eliminated workaround ‘rooftop’ solutions. Until it entered the market, it was not uncommon to see installers risk compromising the membrane integrity and safety in a variety of ‘makedo’ practices using everything from planks of wood to breeze blocks in an attempt to support rooftop ancillaries.

The hot air welding process is quick and delivers a secure fix with strong adhesion, making EJObar suitable for use with new and existing reinforced PVC single ply membrane roofs. It is approved for use by leading membrane manufacturers including Renolit, Soprema and Fatra, and 100% recyclable at the end of its long service life – another key factor in making the built environment more sustainable.

EJObar is designed to facilitate the use of mechanical fixings, in particular a class leading fastener from EJOT, the EJOFAST JF3 selfdrilling screw. This has a unique thread geometry that utilises displaced metal by driving it forward into the joint, with the added benefit of a piercepoint drill point which virtually eliminates the risk of ‘skating’. This reduces risk of an accidental tear to the membrane encapsulating EJObar.

The EJObar and EJOFAST JF3 combination ensures PV arrays can be attached to flat roofs with a system that is high strength and fast to install, with a quality end result easily achievable and virtually no swarf to clear. It offers assured structural integrity and a reliable design life, providing it has been correctly installed, which is important given the high wind loads the PV arrays can be subjected to.

Unlocking new rooftop design potential

Such is the simplicity and versatility of EJObar that its application potential is growing continuously and globally, with most EJOT subsidiaries now selling the product to their local markets. From its M&E origins, the system is unlocking new potential to effectively address specific design challenges, including aesthetics as illustrated by one project in central London.

EJObar was specified by the architect redeveloping a building near Leicester Square to create a curved zinc façade for a penthouse apartment. A zinc strip system was fitted over a PVC singleply membrane, spanning two roof levels, arriving at the lower roof via a broad curve, providing durable protection from the elements with the benefit of concealed fixings.

Here, 3m EJObars were heat welded to the Bauder waterproofing membrane to create a fixing base for the concealed metal fixsystem, without penetrating the actual roofing membrane. Its uniformity, coupled with its strengthofweld attributes, contributed greatly to the maintained visual arc that flows from one roof level to the next.

Ultimately, wherever EJObar is used, it is extremely effective at expanding the weight distribution of rooftop elements, with simplicity, compatibility and cost effectiveness at the heart of the concept.

www.ejot.co.uk

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 23

EJOBar solar panel installation on a commercial flat roof building

”THE EJOBAR AND EJOFAST JF3 COMBINATION ENSURES PV ARRAYS CAN BE ATTACHED TO FLAT ROOFS WITH A SYSTEM THAT IS HIGH STRENGTH AND FAST TO INSTALL.“

Neat and tidy installation

Testing the EJObar system at the Applitec centre

IMPROVING BOLT CONNECTIONS

In wind energy units, bridges, and steel construction, bolted joints are an indispensable component. In addition to the material and the tool, different climatic conditions also have a great impact on the coefficients of friction and, therefore, on the entire bolt connection.

A unitless dimension that describes the relationship between tension and torque, the coefficient of friction is an important element for a secure bolt connection. It is determined by two factors: thread friction and head friction. Thread friction describes the characteristics that arise when bolt and nut threads meet. In contrast, head friction occurs where the lower side of the head of the bolt meets the surface of the joint. The load pressure that affects the surfaces is the tension, which is also responsible for the elongation of the bolt and the corresponding spring effect. Torque, on the other hand, affects

How can zinc flake coatings enhance the protection of bolted connections in the wind energy industry?

the surface of the thread and the contact area. It is divided into three partial torques: thread torque, head friction and the part translated directly into tension. This means that the tension ultimately achieved with prescribed torque is dependent on the coefficient of friction.

The challenges for bolted joints

Different factors such as material pairing, surface, lubrication and wear all effect a bolt connection. In addition, there are external influences such as the ambient temperature, humidity or rain, which can lead to elastic deformations. In the worstcase scenario, bolts can break or the required pretensioning force cannot be achieved. This results in construction site stoppages with high costs as well as time delays due to repairs or the replacement of bolt sets.

/////////// /////////////////////////////////////////////////////////////////////////////// IN-DEPTH RENEWABLE ENERGY 24 torque-direct.com

”A UNITLESS DIMENSION THAT DESCRIBES THE RELATIONSHIP BETWEEN TENSION AND TORQUE, THE COEFFICIENT OF FRICTION IS AN IMPORTANT ELEMENT FOR A SECURE BOLT CONNECTION.“

The hot-dip galvanised bolt set with zince flake topcoat

FASTENING SOLUTIONS

SERVICING YOUR GLOBAL NEEDS WIDE STOCK AVAILABLE

ENGINEERING SUPPORT DELIVERED ON TIME

BRALO

EXPERTISE IN YOUR INDUSTRY ISO 9001 | IATF 16949 | ISO 14001

RENEWABLE ENERGY

Coatings manufacturer Dörken is taking up this challenge in a joint project with Peiner Umformtechnik, a manufacturer of bolt sets for the wind industry. The firm’s bolt sets – which consist of a bolt, a washer and a nut – must withstand extreme weather conditions during daily use. After months of intensive cooperation, the two companies have found a way to solve this challenge.

basecoat is applied directly to the component and determines the corrosion protection properties of the coating. The topcoat increases the corrosion protection and ensures that corrosive media such as water or salt are kept away from the surface. The topcoat is also responsible for resistance to mechanical and chemical stresses as well as abrasion. When coating bolts, a defined coefficient of friction can also be set.

Such a topcoat now also improves the bolt sets from Peiner Umformtechnik. After numerous trials and extensive tests, a product was defined that perfectly complements the company’s hotdip galvanised bolt sets. The hotdip galvanisation provides protection against corrosion, while the Dörken’s zinc flake topcoat, which is applied on top of it, is responsible for a secure bolt connection of the nut due to adjusted coefficients of friction. This is done without removing any of the hotdip galvanised layer. Thanks to this coating, the coefficients of friction are kept stable regardless of weather conditions. The combination of hotdip galvanising and topcoat achieves precisely those properties that are required in the wind energy industry.

Zinc flake coatings

For decades, Dörken’s zinc flake coatings have been deployed for a wide variety of applications in different industries. Such a system usually consists of a basecoat and a topcoat. The

The solution has not only proven to be a success under laboratory conditions, with various test series also being carried out in the field. In the meantime, millions of sets have been delivered and installed, with excellent process reliability on construction sites.

www.doerken.com

26 torque-direct.com /////////// /////////////////////////////////////////////////////////////////////////////// IN-DEPTH

”THE COMBINATION OF HOT-DIP GALVANISING AND TOPCOAT ACHIEVES PRECISELY THOSE PROPERTIES THAT ARE REQUIRED IN THE WIND ENERGY INDUSTRY. “

Dörken’s zinc flake coatings have proved themselves in various industries for decades

RENEWABLE ENERGY – FLUKE

SOLAR POWER TESTING

Growth targets for solar power demand increased knowledge in an expertise-constrained market. These user-friendly tools are enabling installation and maintenance professionals to reap the rewards

As nations around the world push ahead with protecting the planet and minimising the use of fossil fuels, installations of solarpowered energy systems are increasing. In order to be as productive and efficient as possible, technicians need access to the most userfriendly tools which will keep them safe while saving time and money.

The energy generation capacities of photovoltaic (PV) solar systems are predicted to quadruple between 2022 and 2026, which will increase the requirement for greater numbers of installation and maintenance technicians with various levels of experience and expertise. To ensure these operators will be able to work safely and efficiently – while complying with the IEC/EN 624461 standard – is by using tools in the field that simplify the process of carrying out tests while delivering data that is accurate, reliable and easy to transfer and analyse.

In the coming years, there will need to be many new recruits to the solar power sector, including electricians, project managers, technicians and others, and the tools they use will need to offer them optimal usability and functionality.

User experience and multi-functionality

The first requirement for testing tools is for them to be intuitive in their use in order to protect operators from the kind of issues that can arise when having to interface with complex instruments and processes. At the same time, solar power testing tools need to be capable of carrying out multiple tasks.

Multifunctionality is essential if technicians are to avoid carrying several different pieces of equipment into the field and having to switch between them during the testing process. For example, technicians working on PV systems need to measure irradiance energy and take electrical readings, with checks including Watts per square metre of solar irradiation and temperature, as well as cardinal direction and inclination.

Integrated for electrical testing

The benefits are obvious of having a single solution that can measure IV curve tracing, protective resistance to earth, open circuit voltage (Voc), short circuit current (Isc), insulation

resistance, polarity and inverter efficiency while also testing diode and surge protection devices. By using a solar multifunction tester in conjunction with an irradiance metre – with both instruments connected via Bluetooth – a technician can boost efficiency as data is collected and logged in realtime in the field.

Another key requirement of any PV system testing tool, especially when working on large or complex projects, is to be able to import measurement data directly from the testing instrument to a PC, making it easier to manage all the certification and documentation involved in solar asset management. Consistent and easily understandable reports are essential for those involved in commissioning, installing and maintaining solarpowered energy systems.

Keeping safety in mind

Finally, tools such as solar clamp metres for current testing need to be as compact as possible since technicians often have to work in cramped environments and with small combiner boxes where space is limited. Safety and efficiency are improved by using measurement tools fitted with thin, durable jaws and a probe that can fit into extremely tight spaces.

“We always have the technician’s safety in mind, as well as their productivity and time, when we develop our tools,” says Mark Bakker, Field Application Engineer at Fluke. “That is why Fluke’s SMFT1000 Multifunction PV Tester for solar installations operating up to 1000V DC has been designed to offer an allinone, easytouse solution. Likewise, efficiency and userfriendliness have driven the design of our IRR1SOL Solar Irradiance Metre, 1587 FC Insulation Multimeter and 393 FC CAT III 1500 V Truerms Clamp Metre (the only 1500 CAT III, IP54 rated, thin jaw clamp metre).

“The world is changing as we move away from fossil fuel dependency, and it is vital that those working in the solar power sector are given the best opportunities possible to turn the dream of worldwide renewable energy into reality.”

www.fluke.com

///////////////// /////////////////////////////////////////////////////////////////////////////// torque-direct.com 27 IN-DEPTH

”MULTI-FUNCTIONALITY IS ESSENTIAL IF TECHNICIANS ARE TO AVOID CARRYING SEVERAL DIFFERENT PIECES OF EQUIPMENT INTO THE FIELD.“

The energy generation capacity of PV solar systems is predicted to quadruple between 2022-2026

PRECISION ENGINEERING FOR SUSTAINABILITY

How Gala Precision Engineering is protecting the integrity and durability of fasteners in the wind energy sector

The renewable energy sector depends on the seamless running of large machinery, such as wind turbines, solar panel arrays, and hydroelectric equipment. Naturally, these types of machinery require very specialist styles and sizes of fasteners to meet their performance and maintenance requirements, as well as to enable them to withstand all kinds of weather conditions and environments.

Renwable energy is a rapidly growing sector, with wind energy being one of the most significant contributors to renewable energy production worldwide. According to the International Energy Agency (IEA), wind energy is set to grow fourfold by 2030, with the potential to generate over 4,000GW of electricity by 2050. With such significant growth, the demand for highquality precision engineering products is only set to increase.

/////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH RENEWABLE ENERGY 28 torque-direct.com

Gallock Washers are used in the towers for onshore and offshore wind towers

Having identified sustainability and renewable energy as its strategic focus, Gala Precision Engineering’s expertise in this area has made it a trusted supplier of critical components for renewable energy applications, in particular for wind turbines. One of the most critical components the company supplies for this application is its Gallock wedge lock washer, which protects the integrity of the fasteners in various components within a wind turbine.

Gallock washers are used in blade connections, in nacelle, and within the towers for onshore and offshore applications, protecting the critical fasteners that keep a wind turbine erect and supporting them in producing maximum energy throughout the turbine’s lifetime. The most important wind energy applications for the wedgelock washers is for blade studs and nacelle fasteners.

Reducing costs

By using Gallock wedge lock washers, OEMs save on a large portion of their costs due to fewer maintenance cycles associated with the fasteners. Alongside the Gallock washers, Gala’s product range for wind turbine applications also includes heavyduty fasteners such as high tensile studs and bolts, anchor foundation bolts, blade studs, tower connections, nacelle fasteners and crossbones. According to Gala, it is one of the few companies that provides inhouse manufacturing of these types of critical components.

Having intently studied the requirements of wind turbine OEMs and the surrounding environments that the fasteners

are exposed to, Gala has developed a variety of coating solutions, such as zinc flake coatings and hot dip galvanising, to meet its customer’s specific needs. These coatings provide a salt spray life of up to 1,200 hours and beyond, which is essential for reducing the maintenance of wind turbinebased fastening solutions.

Investing in India

To further expand its product range and provide comprehensive solutions to the wind energy market, Gala is setting up a new plant in Chennai, India, which is the wind capital for manufacturing in India. At the plant, Gala will manufacture high tensile bolts and other critical fasteners with the aim of becoming a onestopshop for its clients. The new plant will expand Gala’s already strong presence in various regions of India and complement its existing plant locations.

The new plant will bring Gala closer to its customers in the region, including leading wind turbine manufacturers Vestas, Nordex and Enercon which are currently expanding their operations in South India. The plant will also enable Gala to invest in a new product line of in Hexagonal High tensile Bolts for applications in wind towers and nacelles as well as inhouse inspection and coating facilities that are widely used in the wind industry, such as automated spraybased zinc flake coatings.

The company’s focus on precision engineering for renewable energy is in line with the Indian government’s push for greater alternative energy production. The Indian government has set a target of achieving 450GW of renewable energy by 2030, with wind energy contributing significantly to this target. The country’s wind energy potential is estimated to be around 302GW, and the government is taking several initiatives to realise this potential.

While Gala aims to become a major player in the renewable energy sector, the company’s precision engineering capabilities are not just limited to wind turbines. The company also has diversified clientele in the industrial, railway and automotive industries, delivering critical fasteners and springs to OEMs and distributors across the globe.

www.galagroup.com

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 29

Gallock wedge lock washers protect the integrity of fasteners used in wind turbine components

”RENWABLE ENERGY IS A RAPIDLY GROWING SECTOR, WITH WIND ENERGY BEING ONE OF THE MOST SIGNIFICANT CONTRIBUTORS TO RENEWABLE ENERGY PRODUCTION WORLDWIDE.“

CORROSION RESISTANT CLAMPING

How

Under ordinary conditions, the connections between components are among the most vulnerable elements of any system. But in extreme environments, these vulnerabilities can be dramatically amplified. In the following case study, the application of superior clamping technology makes all the difference between operational continuity and the potential for expensive and timeconsuming disruption.

The challenge

The clean, icy waters of the Norwegian North Sea offer an optimal environment for offshore fish farming. But its attractive conditions also impose considerable operational challenges. Saltwater can compromise the integrity of structures, cables and connections by creating opportunities for pitting, crevice corrosion, and stress corrosion. Worse, the stormy North Sea makes maintenance difficult and expensive. Rough seas and powerful currents create fluctuations along cable lines that can undermine connections, sabotaging entire systems.

For an offshore fish farm 40km from Tromsø, Norway, successful operation means maintaining electricity and fibre optic systems without interruption; its undersea cables must withstand Arctic conditions at a minimal expense of time and labour.

The solution

Uninterrupted electrical and fibre optic service depends on reliable undersea cabling; these are most vulnerable where they bend. To protect the cables, installers deploy bend restrictor systems to prevent cable kinking.

For more than 25 years, NORMA has provided its client – a Norwegian maintenance and operations contractor to the oil and fishing industries – with suitable connectors for harsh undersea environments. Together, the client and NORMA’s DS Nordic sales team developed a bend restrictor system, based

on ‘failproof’ clamps, that could withstand Arctic weather conditions without regular maintenance.

The heart of the bend restrictor solution are hose clamps capable of securing the seal and preventing cable kinks. NORMA designed the bend restrictors around its ABA Original SMO hose clamps made of SMO 254 austenitic stainless steel. Manufactured by the industryleading Swedish brand ABA for challenging environments, the ABA Original SMO is a premium hose clamp. Designed to perform where ordinary stainless steel

CLIPS & CLAMPING /////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT INNOVATIONS ///////////

”SUPERIOR CLAMPING TECHNOLOGY MAKES ALL THE DIFFERENCE BETWEEN OPERATIONAL CONTINUITY AND TIME-CONSUMING DISRUPTION.“

30 torque-direct.com

ABA Original SMO Hose Clamps are enabling worry-free fish farming in the unforgiving Norwegian North Sea

The ABA Original SMO clamps in action

and acidproof materials are insufficient, the clamp’s SMO 254 steel has proven its value in highpressure applications exposed to corrosive materials such as sea salt and chlorine, proving popular in many seawater, chemical, shipbuilding, and foodprocessing applications. As part of the bend restrictor solution, the ABA Original SMO wormdrive hose clamp was a novel innovation for reliable connections under extreme conditions.

The result

40km from land, the Norwegian fish farm could ill afford sudden interruptions. Worse, making repairs deep under water would be exceptionally complicated and expensive. By using ABA Original SMO clamps that resist corrosion in uncompromising conditions, NORMA’s client ensured uninterrupted electrical and fibre optic service for the next 20 years.

www.normagroup.com

”BY USING ABA ORIGINAL SMO CLAMPS THAT RESIST CORROSION IN UNCOMPROMISING CONDITIONS, NORMA’S CLIENT ENSURED UNINTERRUPTED ELECTRICAL AND FIBRE OPTIC SERVICE FOR THE NEXT 20 YEARS.“

The

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 31

ABA Original SMO hose clamp made of SMO 254 austenitic stainless steel

The clamp is designed to perform where ordinary materials are insufficient

ON THE PLUS SIDE

Industrial supplies and hardware will be on show at the third edition of +Industry

+Industry, the trade show for industrial supplies and hardware, will return to the Bilbao Exhibition Centre (BEC) between 68 June, 2023. During this time, the BEC will be turned into one of Spain’s biggest meeting points for advanced manufacturing with the colocated shows Addit3D, bedigital, Maintenance, Pumps & Valves and Subcontracting.

The 2019 edition of the show saw almost 20,000 visitors from 72 countries walk the halls of the BEC, where 1,300 exhibiting firms showcased the latest products from across the hardware and industrial supplies industry.

Sector synergies

+Industry will give suppliers the platform to display the latest products, innovations and technologies across industrial supplies, fixings, industrial hardware, electricity and industrial lighting, hand tools, power tools, services and locksmith industries.

Visitors from across all levels of the supply chain will be in attendance, including industry representatives in aeronautics, automotive, electronics, energy, railway, and the metal, iron and steel sectors. Meanwhile, distributors within industrial supplies, hardware cooperatives and purchasing groups, hard

/////////// /////////////////////////////////////////////////////////////////////////////////////// INDUSTRY EVENTS > SHOW PREVIEW 32 torque-direct.com

+INDUSTRY

Some 20,000 visitors attended +Industry in 2019

ware stores, large hardware retail and sectoral associations will also be in attendance. Additionally, professional users from the following professions will also be represented: locksmith, plumbing and heating, shipbuilding, electricity and woodwork.

Connecting dynamically

The third edition of +Industry will create dynamic spaces where visitors can interact and discover the latest products and innovations in a variety of ways. The exhibition area will be complemented by keynote speeches, live demonstrations, innovation workshops, prearranged B2B meetings and other complementary tools.

The joint holding of all the exhibitions will provide participants with a large industrial space in which they can make direct contact with other companies and potential clients. Technology and innovation will be at the heart of the trade

show, enabling attendees and exhibitors alike to connect, share experiences and knowledge, and boost their businesses.

The conference aspect of the trade show will cover the latest development strategies across additive manufacturing, digitisation, process automation, data sharing, industrial cybersecurity, sustainability, digital twins, robotics, and more. In

addition for this year, the celebration of the XX European Meeting of Industrial Subcontracting will provide one of the largest forums for arranged B2B interviews in the country. Nearly 100 international buyers and some 400 Spanish subcontracting companies across a myriad of sectors will take part, active across railways, defence, energy, steel, household appliances, automotive and petrochemicals, to name but a few. In fact, close to a thousand meetings are expected to take place across the threeday event.

As a result, +Industry is positioning itself as the largest platform in the country dedicated to smart manufacturing and Industry 4.0, helping companies across the industry to stay at the forefront of innovation.

www.plusindustry.eu

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 33

”+INDUSTRY WILL CREATE DYNAMIC SPACES WHERE VISITORS CAN INTERACT AND DISCOVER THE LATEST PRODUCTS AND INNOVATIONS .“

+Industry will bring together the advanced manufacturing sector at the BEC

Attendees can take advantage of pre-arranged B2B meetings

LET’S TALK

A round up of the latest innovations in torque tools

NEW IMPACT WRENCH SERIES

SATA has introduced a new series of four Air Impact Wrenches, extending its hand tool portfolio into the world of pneumatic power tools. Focused on durability and flexibility, the new series comprises four products, ranging from the lightweight 625Nm ½inch drive Air Impact Wrench to the 4,000Nm 1 inch Drive HeavyDuty Air Impact Wrench.

Three of the new standard duty ½inch wrenches f hardhitting, twinhammer design, while the ergonomic design of the heavyduty fastener makes it 10% lighter than compa rable tools in the market. In each of the models, a variable speed trigger enables precise torque control, while the lightweight and ergonomic, yet robust, nylon and fiberglass housing design significantly reduces user fatigue during continuous operation. Additionally, the handle exhaust at the bottom cable directs dust and debris away from the machine and operator for additional operator safety.

and precise to adjust.

The NovaTork range includes digital assembly wrenches which are digitally adjustable by torque and angular rotation to ensure the bolted connection is tightened correctly. The range also includes preset assembly wrenches set to a predetermined torque, and click torque wrenches designed for torque application when assembling bolts. These wrenches are equipped with a fixed ratchet head or as an insert spanner for optimum flexibility, and are also available in a screwdriver version.

With a maximum torque of 625 to 1050NM, the SATA ½inch drive Air Impact Wrenches easily master all fastening applications in professional settings as well as in the industrial sector. Meanwhile, a maximum torque of 4,000Nm makes the new SATA 1inch drive HeavyDuty Air Impact Wrench the most powerful air impact wrench on the European market, excelling within highly demanding applications in automobile repair, major construction projects, heavy equipment maintenance and product assembly.

www.satatools.eu

Additionally, dial torque wrenches are designed to indicate how much torque a bolt is mounted with, and the range includes a variety of insert tools, such as those with a square drive open end, in angle, or with rectangular shank head torque ranges.

www.rami-yokota.com

”A MAXIMUM TORQUE OF 4,000NM MAKES THE NEW SATA 1-INCH DRIVE HEAVY-DUTY AIR IMPACT WRENCH THE MOST POWERFUL AIR IMPACT WRENCH ON THE EUROPEAN MARKET.“

TORQUE TOOLS /////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT INNOVATIONS ///////////

”NOVATORK DEVELOPS AND PRODUCES A WIDE RANGE OF PRODUCTS TO HELP USERS ENSURE PRODUCTIVITY AND QUALITY WHILE BEING EASY AND PRECISE TO ADJUST.“

34 torque-direct.com

APPROVAL FOR ASSEMBLY

Global tower crane manufacturer Liebherr has approved Radial Torque’s battery operated MBRAD series torque wrenches for tower crane assembly. This opens up new technical possibilities for assembly companies to quickly and safely assemble the bolted connections.

After extensive machine capability analysis and EMC tests of the torque wrenches in the torque range of 1407,000Nm, Liebherr now includes the MBRAD series in its standard ‘Technical Information’ – a crucial move as the use of nonapproved torque wrenches for tower crane assembly is not permitted.

PRECISE SCREW TIGHTENING

The right tightening torque is essential when changing wheels on motor and commercial vehicles. Professionals in the workshop therefore need a torque wrench to tighten screw connections that also ensures precise tightening permanently and under considerable loads.

Gedore’s fivepiece TORCOFLEX UK Set 3550UKLS4 is designed to meet these requirements. The adjustable torque wrench offers controlled tightening over a range from 40

200Nm and is an ideal drive tool for socket inserts with a ½inch square holder. Due to its integrated reversible function, the tool is suited to highly efficient working. Precise clockwise tightening with a high repeat accuracy guarantees a safe screw connection, while a DIN ISO 6789:20172 test certificate confirms the wrench’s accuracy. Meanwhile, the tool’s three colourcoded protective sleeves help to protect delicate surfaces such as aluminium or chromeplated rims.

www.gedore.com