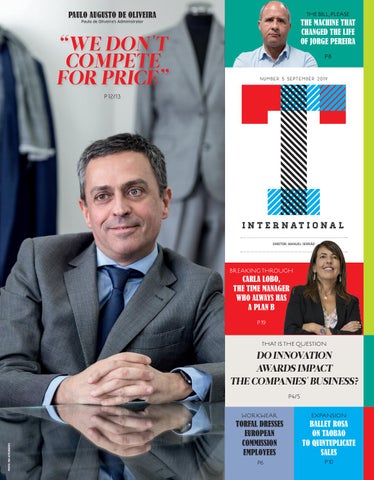

PAULO AUGUSTO DE OLIVEIRA

THE BILL, PLEASE

THE MACHINE THAT CHANGED THE LIFE OF JORGE PEREIRA

Paulo de Oliveira's Administrator

“WE DON'T COMPETE FOR PRICE”

P8

N U M B E R 5 S E PT E M B E R 2 01 9

P 12/13

I N T E R N AT I O N A L DIRETOR: MANUEL SERRÃO

BREAKING THROUGH

CARLA LOBO, THE TIME MANAGER WHO ALWAYS HAS A PLAN B P 19 THAT IS THE QUESTION

DO INNOVATION AWARDS IMPACT THE COMPANIES' BUSINESS?

PHOTO: RUI APOLINÁRIO

P4/5 WORKWEAR

EXPANSION

TORFAL DRESSES EUROPEAN COMMISSION EMPLOYEES

BALLET ROSA ON TAOBAO TO QUINTUPLICATE SALES

P6

P 10