SUSTAINABILITY 2020 - 2021 REPORT

© The Bahrain Petroleum Company B.S.C. (Closed) 2022. All rights reserved.

© The Bahrain Petroleum Company B.S.C. (Closed) 2022. All rights reserved.

His Royal Highness Prince Salman bin Hamad Al Khalifa

Crown Prince, Deputy Supreme Commander, and Prime Minister of the Kingdom of Bahrain

His Majesty King Hamad bin Isa Al Khalifa

King of the Kingdom of Bahrain

Contents His Highness nogaholding Chairman 4 His Excellency Bapco Chairman 8 Executive Management 10 About Bapco 12 Timeline 14 Introduction 16 Bapco’s Commitment To Sustainability 18 Our Contribution 20 Who We Are Organisational Profile 26 Strategy and Governance 32 Stakeholders and Materiality 42 Our Business Governance and Ethics 58 Compliance with Customer Standards 60 Emergency Preparedness and Response 64 Asset Integrity 68 Our Environment Energy and Climate Change 80 Air Emissions 84 Water Withdrawal and Consumption 88 Effluent Management 90 Waste Management 94 Biodiversity 100 Our Community Community Impacts 110 Value Generation and Distribution 116 Local Content 120 Human Rights 122 Responsible Supply Chain Management 124 Our Employees Health, Safety and Wellbeing 137 Learning and Development 141 Equal Opportunities 145 Employee Relations 149 Appendices Glossary 153 GRI Content Index 155 Special Topics Senior Women Profiles 40 Company Profiles 48 Crisis and Emergency Response 66 Response to the COVID-19 Pandemic 70 Marine Assessment 92 Beautification Project 98 Green School Award 114 BMP Social and Environmental Projects 126 L&D and the Oil & Gas Academy 143

His Highness nogaholding Chairman

To achieve success we require individual self-discipline and perseverance in the face of volatility. The pandemic has taught us how each individual is responsible for the outcomes of our future, for the resilience of our economy, the continuity of businesses and the health of our families. Sustainability requires everyone to play their part in ensuring a safe and reliable future for the next generation to meet their economic, societal and environmental needs. The Kingdom emerges from the pandemic with bountiful experiences and lessons learned to build upon and progress towards a sustainable Bahrain for everyone.

The Kingdom of Bahrain’s Economic Vision 2030 is designed to balance the many conflicting needs of sustainability, fairness and competitiveness. At its heart is a shared goal of building a better life for every Bahraini. By achieving this vision, we have aligned the aspirations of our future generations with sustainable development. Bapco’s contribution to the Economic Vision is measured by alignment with the 17 Sustainable Development Goals (SDGs) issued by the United Nations in 2017, which encompass technological advancement, environmental stewardship, economic progress and societal welfare. Collectively, these goals are reflected in this report as “Bapco of Tomorrow”, highlighting the vision and strategy of Bapco that will support the Kingdom’s journey towards sustainability.

I am inspired by the youth of Bahrain as I see them overcome many challenges with optimism and energy. Our capability to respond to adversity is enhanced by access to the best education, affording the opportunity to invest in the strengths of the next generation. Giving back to the Kingdom with passion is a key to our success.

Bapco’s contribution to education is long-established, taking students from many educational establishments and training them for a career that benefits the Kingdom and helps with their professional development.

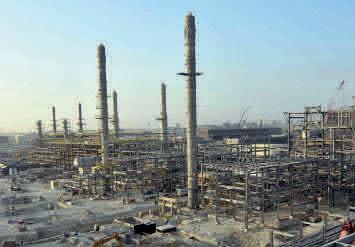

Throughout our Kingdom’s history there have been significant transformation opportunities that accelerate economic development and invest in our communities. The Bapco Modernisation Program (BMP) is one such opportunity. During my recent visit to BMP, I remarked on the contribution being made by both men and women to BMP that is driving the economic growth of the Kingdom. Bapco has continued to diversify its workforce, with several high-profile appointments of women to the Executive Management during 2020-21. The project’s economic legacy will be powerful, but perhaps more importantly BMP is building the capability of Bahrainis to operate world-class technologies.

Sustainability is, above all, a measure of hope and second chances for the youth of Bahrain who will shape the future of the Kingdom. We are bound through the fabric of our great nation to a common future, and it is everybody’s responsibility to give back to the Kingdom when success is achieved. Bapco is allowing the next generation to achieve their own successes and is therefore making a fundamentally important contribution to the sustainability of the Kingdom of Bahrain. This report highlights our stories that tell of a very positive future for us all.

His Highness Shaikh Nasser bin Hamad Al Khalifa nogaholding Chairman Kingdom of Bahrain

4 Bapco Sustainability Report 2020 - 2021

GRI 102-14: Statement from senior decision-makers

“ We are bound through the fabric of our country to a common future and it is everybody’s responsibility to give back to the Kingdom when success is achieved

5 Introduction

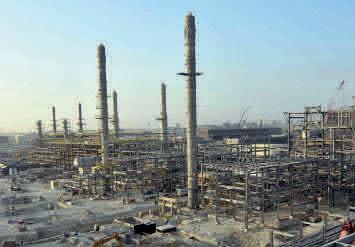

A birds-eye view of the construction activities at BMP Greenfield, driving the economic growth of the Kingdom

6 Bapco Sustainability Report 2020 - 2021

7 Introduction

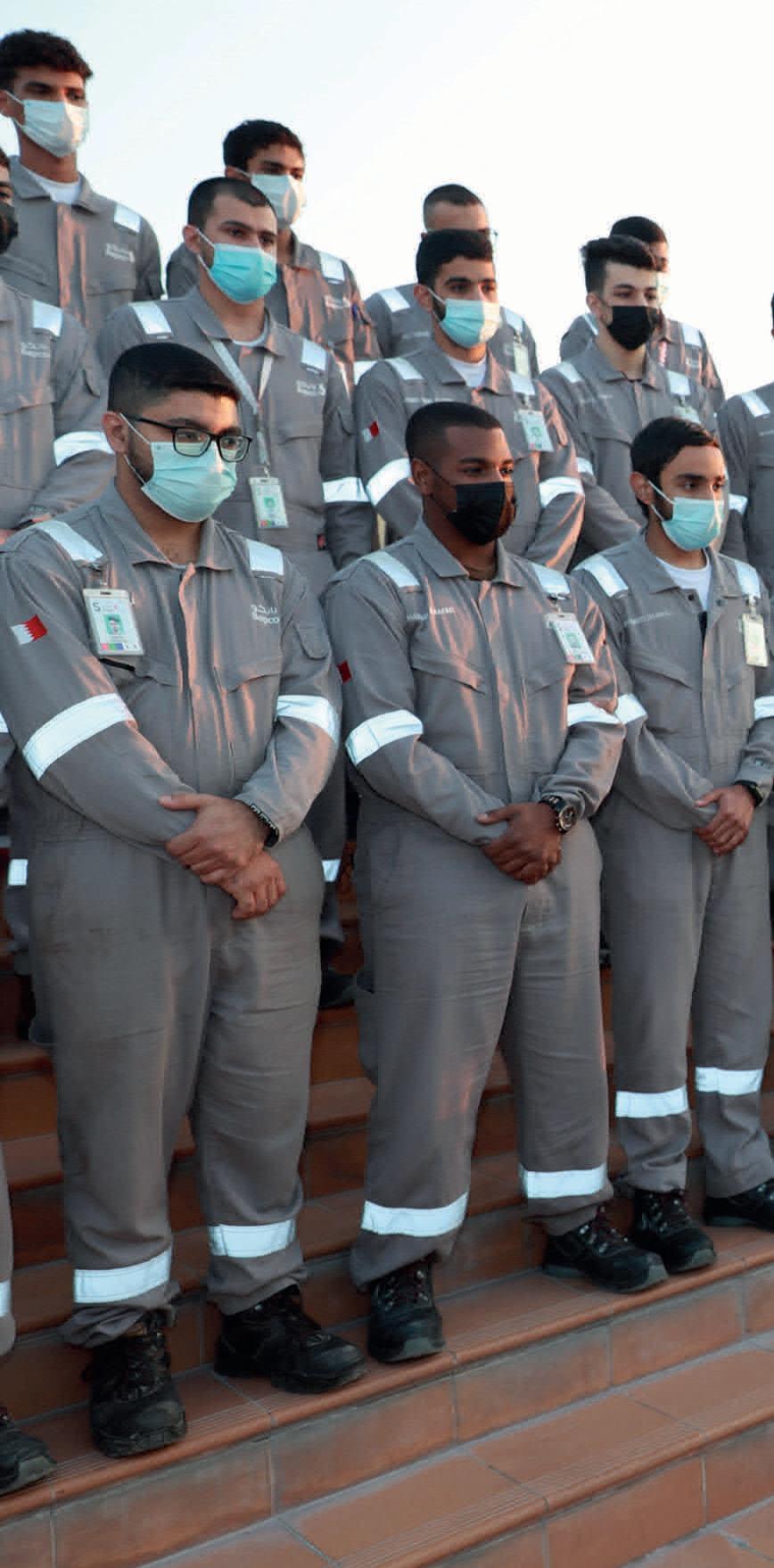

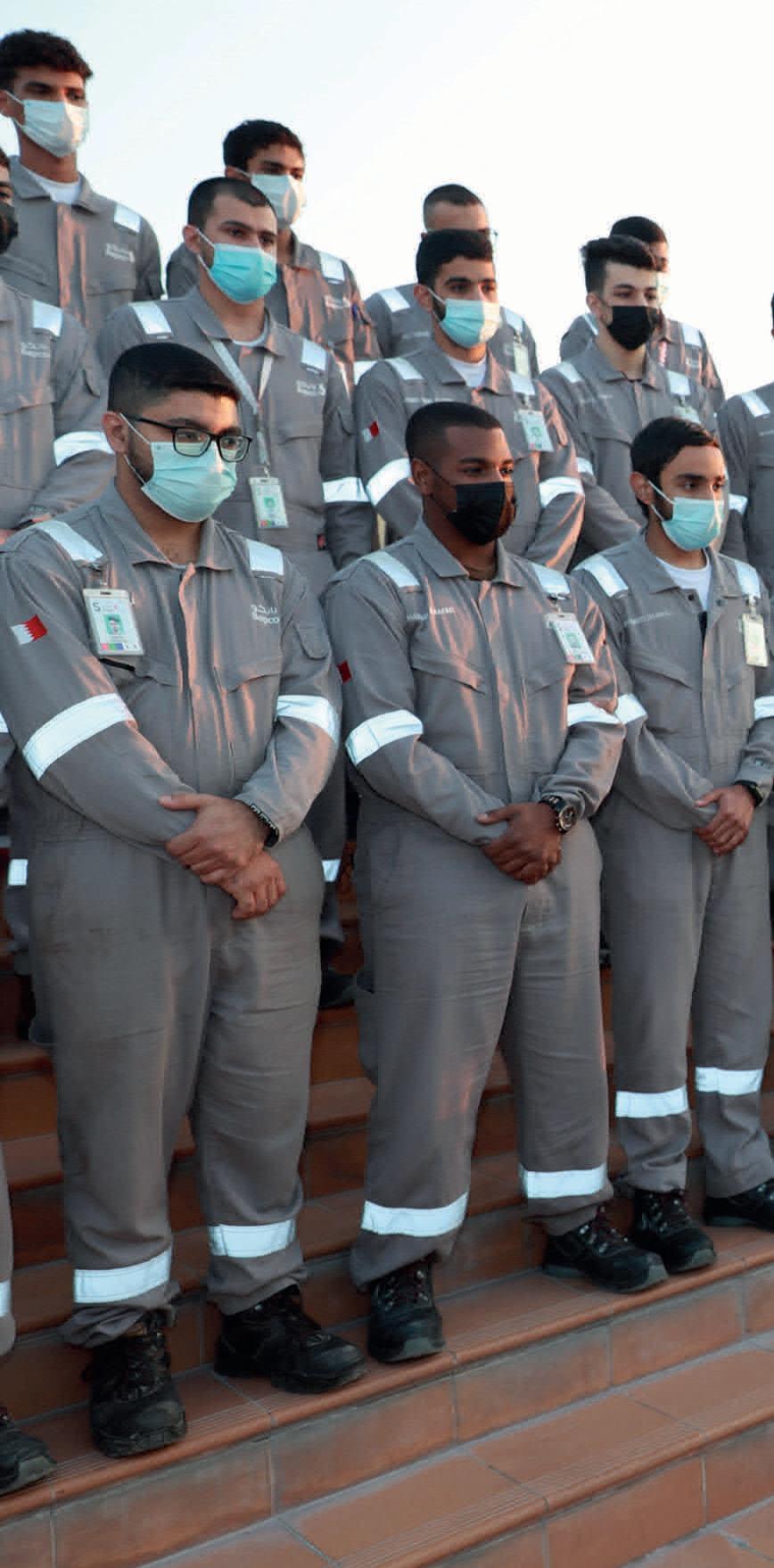

H.H. Shaikh Nasser bin Hamad Al Khalifa visiting the Refinery to talk to Bapco’s next generation of operators and engineers

His Excellency Chairman of the Bapco Board of Directors

GRI 102-14: Statement from senior decision-makers

I am honoured to be appointed as the Chairman of the Board of Directors for Bapco, and to provide our 2020-21 Sustainability Report foreword.

Bapco has a rich heritage from over 90 years as the Arabian Gulf’s oldest operator and is one of the largest employers in the Kingdom of Bahrain. We have always placed great emphasis on ensuring the wellbeing and safety of our employees and protection of the environment, whilst at the same time providing our employees with continuous education to create a highly skilled workforce. This human capital is a significant asset and competitive advantage to the Kingdom of Bahrain, and one in which Bapco continues to invest heavily.

Our pioneering multi-billion dollar BMP is the largest capital investment in our company’s history and our main priority is the safe, reliable and timely completion of the project to the benefit of the Kingdom of Bahrain. BMP is especially important as it further aligns the company with the Bahrain Economic Vision 2030 and the ongoing work of our shareholder nogaholding in defining the energy road map for the Kingdom of Bahrain. The variety of ongoing initiatives within Bapco are linked to the 17 United Nations Sustainable Development Goals focusing on technological advancement, environmental stewardship, economic progress and societal welfare. BMP provides significant new job opportunities to the youth of Bahrain, building our human capital.

BMP also establishes Bahrain as one of a handful of countries worldwide to be using the latest LC Fining Chevron Lummus Global (CLG) licensed technology, which reduces waste and energy consumption and increases the value generated from production.

The vision is to further develop Bapco as one of the leading world-class companies in the petroleum refining sector. This forms part of a wider national goal of sustainable value creation in the Kingdom’s oil and gas sector and to achieve the ambitions under the wise leadership of His Majesty King Hamad bin Isa Al Khalifa, and His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince, Deputy Supreme Commander, and Prime Minister.

This mandate has been given to us by His Highness Shaikh Nasser bin Hamad Al Khalifa, His Majesty the King’s Representative for Humanitarian Work and Youth Affairs and the Chairman of the Board of Directors of The Oil and Gas Holding Company (nogaholding), and one which I, my fellow Board Directors and Dr. Abdulrahman Jawahery, Chief Executive Officer of Bapco and the Executive Management, are committed to delivering.

With the full support of the Board of Directors, the management and employees I am confident that we will work together to realise this bold ambition, to improve our operating model and deliver breakthrough value built on the safe, reliable, timely and successful completion of BMP; integration of the Kingdom’s SDGs; and higher standards of ethics and integrity - all delivered with Bapco’s passion to excel and innovate.

His Excellency Abdulla Jehad Al Zain Bapco Chairman Kingdom of Bahrain

8 Bapco Sustainability Report 2020 - 2021

“ BMP establishes Bahrain as one of a handful of operators worldwide to be using advanced LC Fining technology

9 Introduction

Construction activities at BMP Greenfield, providing significant new job opportunities to the youth of Bahrain

Executive Management

GRI 102-14: Statement from senior decision-makers

Welcome to Bapco’s 2020-21 Sustainability Report, which is being published to the Global Reporting Initiative’s (GRI) Comprehensive Level, reflecting even greater coverage and transparency on what we are reporting to you.

The theme of this report is “Bapco of Tomorrow”, meaning Bapco’s transformation journey to be more competitive, profitable and environmentally friendly. The journey will enable Bapco to serve the industry’s demands and Bahrain Economic Vision 2030.

Achieving our transformation requires a clear mission and vision. Our mission is to create value for our shareholders, customers and employees, which we will achieve by operating as a dynamic and empowering national energy company that can compete globally. Our role as the Executive Management is to translate the vision of leadership and the mission of the Board, under the chairmanship of H.E. Mr Abdulla Jehad Al Zain, into a sustainable reality.

Our sustainability report draws attention to two very different and equally important facets of our business. Firstly, the technological; BMP construction is now well progressed and will deliver to the Kingdom world-class technologies only currently operated at a handful of locations across the world. Secondly, the human capital; Bapco is only able to operate these new technologies by recruiting and training the very best talent across the Kingdom. One facet cannot exist without the other.

Since our last sustainability report was published, great strides have been made on BMP, consolidating Bapco’s contribution to the Kingdom of Bahrain for the decades ahead. At the end of the 2020-21 reporting period BMP construction was 79% complete and we continue to have over 15,000 workers onsite involved in the construction activities. Bapco is rightly proud of its exemplary personal and process safety record for BMP with some remarkable statistics that demonstrate our commitment to environment, health and safety, for example working over 3 years on the BMP project without a Lost Time Injury (LTI) and accruing over 49 million safe project hours.

What is even more remarkable about BMP is that construction as well as operation of our base business continued throughout the COVID-19 pandemic. This difficult period represented one of the greatest challenges faced by Bapco in living memory. Whilst many organisations were able to shift their operations from office-based to remote work, we were faced with the daunting prospect of having to sustain 24-hour operation of our Refinery. For our staff in operational positions there was no option for work to be conducted remotely, shift work had to continue throughout the pandemic in a manner safe for Bapco personnel and sustainable for the company. Managing BMP construction schedules with its sizeable workforce was an additional complication. Numerous initiatives were implemented, and educational programmes were rolled out, to enable work at site to continue uninterrupted, whilst keeping all employees, contractors and workers safe. Innovative techniques were also implemented to carry out detailed engineering work in various

10 Bapco Sustainability Report 2020 - 2021

“ The theme of this report is “Bapco of Tomorrow”, meaning Bapco’s transformation journey to be more competitive, profitable and environmentally friendly

operating centres around the world, which redefined many engineering processes that may continue in the new world post-pandemic. The ability to innovate and respond in a timely manner has been a key component to our success.

The fact that we not only continued operating throughout the pandemic but did so without significant business interruption to either the base business or BMP is a truly remarkable achievement. We are very proud to have such a dedicated and talented workforce who made many personal sacrifices to ensure business continuity.

Our transformation journey requires us to change how Bapco is organised and to recruit the best talent to lead the organisation. A range of transformation projects are currently being implemented from across the organization including finance, IT, human resources, procurement and others. All of these transformational initiatives are aligned to prepare the “Bapco of Tomorrow”, and ensure that our business is safe, reliable, sustainable and competitive for decades to come.

Bapco has always recognised the important role that women bring to the business. During 2020-21 there were several new appointments to the Executive Management as well as other senior roles across Bapco that were made to women. We have celebrated these appointments by including profiles of nine of the most senior women at Bapco in this report.

We have additionally provided other profiles from across our business to highlight the talent that can be found at all career stages across all Departments. The profiles include both male and female employees, the latter accepted within the cohorts of trainees by Bapco for some years. Several of the profiles are from those who joined through the Bapco International Scholarship programme, which support the students during their further education. Some of the profiles are also from those who have attained senior positions within their disciplines. Their experience is invaluable in assuring continuity of operations within the business. What is common across all the included profiles is the sense of belonging and pride of being part of the Bapco family.

Our links to the community remain as strong as ever, with many initiatives taken each year by Bapco employees for the benefit of the community. INJAZ Bahrain, a non-governmental organisation empowering the next generation of Bahrainis, continues to be a very popular programme with many volunteers across the company. BMP has additionally afforded Bapco the opportunity to undertake major social and environmental initiatives such as the rehabilitation of Eker Garden and sponsorship of Shaikh Ebrahim bin Mohammed Al Khalifa Centre for Culture and Research celebrating its 20th anniversary. Bapco also has a long-term aspiration to expand mangrove plantations around the Kingdom. We have a Mangrove Nursery within the Refinery and have now established several plantation sites across the Kingdom of Bahrain with the guidance of the Supreme Council for Environment (SCE). This will also contribute to the Bahrain National Target to combat Climate Change announced at the COP26 held in Glasgow, UK during October-November 2021.

Our commitment to sustainability across all facets of our business is further demonstrated by our membership of the UN Global Compact and commitment to the ten principles that underpin a sustainable approach to conducting business. Bapco anticipates building these principles into its various transformation programmes that will be completed in future years.

We are grateful for the continuous guidance and wise leadership of His Majesty King Hamad bin Isa Al Khalifa, and His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince, Deputy Supreme Commander, and Prime Minister. Coupled with the direction provided by the Chairman of nogaholding, His Highness Shaikh Nasser bin Hamad Al Khalifa, and guidance of the Chairman of the Bapco Board of Directors, H.E. Mr Abdulla Jehad Al Zain, we are confident that we are building a sustainable and competitive company for the future: “Bapco of Tomorrow”

Thank you for taking the time to read this report and we look forward to sharing our sustainability journey with you.

Executive Management

The Bahrain Petroleum Company Kingdom of Bahrain

11 Introduction

About Bapco

Wholly owned by the Government of the Kingdom of Bahrain, the Bahrain Petroleum Company B.S.C. (Closed), referred to in this report as Bapco, is primarily engaged in petroleum refining, storage, production and export of petroleum products.

Bapco was established in 1929 by the Standard Oil Company of California. In 1932, Bahrain was the first country to discover oil in the Arabian Peninsula. Bapco started exporting crude oil in 1934 and refining in 1936, with an initial capacity of 10,000 barrels of oil per day (BPD). Some 90 years later our refining capacity is 267,000 BPD. With the commissioning of Bapco Modernization Programme (BMP), our refining capacity will have increased 42% to 380,000 BPD.

The company continues to shape the modern Kingdom of Bahrain through its many economic, social, and environmental initiatives in line with our Vision, Mission and Purpose, some of which are described in this report. These initiatives directly support sustainable development as defined by the United Nations Sustainable Development Goals and the Ten Principles of the United Nations Global Compact.

The company’s core business is the production of high-quality refined petroleum products. The company owns a Refinery, storage facilities for 14 Million barrels (MMbbl) of crude oil and products, a Local Marketing Terminal and a Wharf for the export of petroleum products.

About one-sixth of our refined crude oil originates from the Bahrain Field, with the remainder being pumped from Saudi Arabia by pipeline. About 90% of Bapco’s refined products are exported. Our customers are regional, predominantly Gulf Cooperation Council (GCC) countries that account for almost half of export destinations, followed by the Far East, with the balance to Europe, Africa, South East Asia, and the Indian subcontinent.

12 Bapco Sustainability Report 2020 - 2021

13 Introduction

Our Hydrocracking Unit, part of our Low Sulphur Diesel Production Complex. Hydrocracking breaks down or ‘cracks’ heavy oil into more valuable petroleum products

BMP Timeline

Project sanctioned and feasibility study completed

Refinery Master Plan renamed to Bapco Modernisation Program

Project Front-End Engineering Design completed

Project Front-End Engineering Design commenced

Refinery Master Plan study completed

Technology selection process commenced

Environmental approval received from the Supreme Council for Environment

Environmental Screening (EA-2) Form submitted to Supreme Council for Environment

September2012 December 2016 August 2015 September2013 November 2010 September2014 April2016 September2009 14 Bapco Sustainability Report 2020 - 2021

Engineering, Procurement and Construction contract (EPC) signed with Joint venture consortium consisting of TechnipFMC (Italy/USA), Técnicas Reunidas (Spain) and Samsung Engineering (South Korea) - TTSJV

90% detailed engineering (major works) completed

Foundation stone laying ceremony

August 2020 March 2019 December 2021 May2019 February2018 15 Introduction

February2017

Commencement of site preparation works

Project financial

79%

January 2019

Ground Breaking Ceremony and start of civil piling works at the site

close completed

project completion achieved

Introduction

What is Sustainability Reporting ?

This report describes how we at Bapco are supporting the Kingdom of Bahrain’s sustainable development objectives, described in the Bahrain Economic Vision 2030. Our report has been prepared in accordance with the GRI Standards Comprehensive option

Sustainability means achieving an environmental, economic and social status quo that meets the needs of future generations without compromising the needs of current generations. The concept of sustainable development was originally proposed in 1987 by the United Nations World Commission on Environment and Development. Since then, the concept has expanded to encompass a range of economic, environmental, technical and social objectives that collectively represent sustainable development.

Sustainability reports are issued by all major global corporations, including the oil industry, to help others understand their commitment to sustainable development. A sustainability report transparently reports an organisation’s financial, social and environmental risks and obligations, and provides opportunities for others to understand these obligations.

Bapco makes a very substantial contribution to sustainable development through technological innovation, investment in our workforce education and training, and our economic productivity. We are delighted to be documenting some of these contributions in this latest sustainability report.

What are the Global Reporting Initiative (GRI) Standards?

The GRI Standards are internationally recognised as a leading framework for public sustainability reporting, allowing organisations to demonstrate how they contribute to national and international SDGs. The GRI standards are used by over 10,000 companies internationally as their framework for sustainability reporting.

The GRI Standards help companies identify material topics with the most significant impacts and influence on their stakeholders, in addition to reporting on general contextual information about the organisation, its reporting practices, and its approach to how material topics are being managed.

The GRI standards are regularly updated with the last major revision - the launch of the revised Universal Standards - occurring in 2021. This report uses GRI as its reporting basis and has been fully updated against the latest standards as of 2021.

GRI referencing

GRI Disclosure numbers are provided throughout the report in the format Disclosure number, Disclosure title. The icon is used to emphasise each Disclosure number. Where Disclosures are for a Management Approach then the title is given as the same. The same Management Approach may be applicable to several disclosures, in which case all applicable Disclosure numbers are listed. Refer to page 155 for the GRI Content Index and complete list of Disclosures, year and version.

16 Bapco Sustainability Report 2020 - 2021

17 Introduction

Views from the Oasis island inside our Refinery

“

Bapco makes a very substantial contribution to sustainable development through technological innovation, investment in our workforce and our economic productivity

Our Commitment To Sustainability

Our Commitment

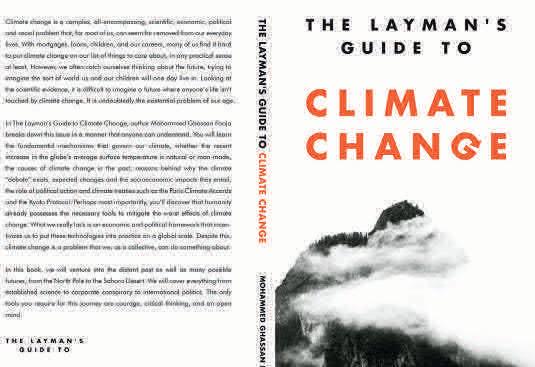

Bapco’s transformation journey has a common theme of sustainability. Speaking at the 26th United Nations Climate Change Conference of the Parties (COP26), His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince, Deputy Supreme Commander, and Prime Minister pledged to cut the Kingdom’s emissions by 30 per cent by 2035. The Kingdom further aims to reach Net Zero by 2060.

Under the umbrella of its parent company, nogaholding, Bapco will have a leading role to play in the aspirations of the Kingdom through the many projects already underway and those that have yet to start. For example, Bapco’s commitment to increase solar energy generation through the Bapco Distributed Solar Energy Pilot Project (BDSEPP) and enhance blue carbon sinks through the transplanting of mangroves in coastal areas, supporting the Kingdom of Bahrain’s objective to quadruple mangrove coverage.

All of Bapco’s sustainable development initiatives can be linked to the 17 SDGs, through the GRI. This section provides a list of GRI disclosures for each SDG and a short summary of some of Bapco’s initiatives that relate to the SDGs.

18 Bapco Sustainability Report 2020 - 2021

Princess Sabeeka Park, a facility managed by Bapco for the amenity of current and future generations

SDGs and UN Global Compact

Bapco supports the SDGs. Bapco’s sustainable development initiatives can be linked to the 17 SDGs through the GRI. The table overleaf provides a list of GRI disclosures for each SDG and a short summary of some of Bapco’s initiatives that relate to the SDGs. Refer to the content index at the back of the report to find the page number where each disclosure is reported.

Bapco commits to the United National Global Compact (UNGC) Bapco has written to the United Nations to give its commitment to adopt the Ten Principles of the United National Global Compact. The Principles provide a valuable framework that will guide the various transformation programmes described in this report and due for completion in future years.

19 Introduction

Our Contribution

The significant size of the BMP project provides both short and long term opportunities for the local labour market and local supply chain. BMP will create new skilled positions filled from positions advertised locally within the Kingdom.

Separately from the very significant contribution made by Bapco to the local economy, Bapco makes special provision for providing to the community during particular times of the year. During the holy month of Ramadan, Bapco provides all operators with meals during Iftar and arranges food distribution campaigns to the community.

All Bapco employees have access to the Refinery clinic and free treatment at Awali hospital. Bapco supports community wellbeing awareness via campaigns and events, for example the Family Day which was held in January 2020 at the Bahrain International Circuit and attended by more than 37,000 people. Each month a specific health campaign is run on various topics such as breast and prostate cancer awareness.

Bapco established the Oil and Gas Academy in 2017 which provides the company with the best skilled workforce necessary for the future. Along with the support provided to the employees and students, Bapco employees participate in the INJAZ programme, lecturing to students on science and engineering.

Bapco believes in equal opportunities irrespective of gender - refer to this report’s special topic on Senior Women. Bapco has many women holding senior appointments across Bapco including that of Acting Deputy Chief Executive - Corporate Support.

Bapco has invested in the latest technologies to minimise water abstraction required for refining. Bapco’s Waste Water Treatment Plant and Sewage Treatment Plant (STP) uses state-of-the art advanced Membrane Bioreactor Technology for water and effluent treatment.

Bapco has established an Energy Group and an Energy Committee that focus on energy conservation throughout the Refinery, leading to projects and initiatives focusing on energy reduction and efficiency improvement using the latest technologies and means of monitoring. Bapco additionally operates a 5 MWp solar energy facility.

20 Bapco Sustainability Report 2020 - 2021

SDG UNGC GRI Topic Specific Disclosures Bapco’s initiatives 1, 2, 3, 4, 5 and 6 207-01; 207-02; 207-03; 207-04; 202-01; 203-02; 413-02

Link between SDGs - UNGC Principles - GRI Standards - Bapco’s initiatives

1, 2, 7, 8 and 9 201-01; 203-01; 203-02; 411-01; 413-02

1, 2, 3, 4, 5, 6 and 10 401-02; 403-06; 403-10; 403-09; 403-10; 203-02; 305-01; 305-02; 305-03; 305-06; 305-07; 306-01; 306-02; 306-03; 306-04; 305-05; OG13

1 and 2 404-01

1, 2, 3, 4, 5 and 6 202-01; 401-01; 401-02; 401-03; 404-01; 404-03; 405-01; 405-02; 406-01; 408-01; 409-01; 414-01; 414-02; 203-01; 102-22; 102-24

1, 2, 7, 8 and 9 303-01; 303-02; 303-03; 303-04; 303-05; 306-01; 306-02; 306-03; 306-05; 304-01; 304-02; 304-03; 304-04; OG13

1, 2, 7, 8 and 9 302-01; 302-02; 302-03; 302-04; 302-05

Link between SDGs - UNGC Principles - GRI Standards - Bapco’s initiatives

Bapco continues to provide new opportunities through the BMP expansion, creating one of the most technologically advanced Refineries in the world. CLG, NAPCON, and Bapco have opened the LC-FINING Center of Excellence in Bapco’s Oil and Gas Academy. The Academy also plays a leading role in training for existing employees throughout their career at Bapco.

Bapco has a strong track record for technological innovation. Bapco has an Innovation Centre to nurture new ideas suggested by employees, using initiatives such as the ‘Seed’ programme to recognise employees for their innovative ideas. Bapco additionally participates in community initiatives designed to encourage innovation, such as the Green School Award Scheme launched in 2005, aimed at local secondary schools to identify and pilot green ideas.

Bapco has specific policies designed to tackle inequality, implemented by a dedicated team who work with contractors to monitor any potential breaches in Bapco policy. Bapco has for several years inducted both men and women trainees into engineering disciplines. Bapco’s merit-based International Scholarship Programme provides financial support for students of all backgrounds to study at some of the best institutions worldwide.

Bapco has undertaken many recent initiatives to improve social and environmental capital within the Kingdom of Bahrain. Several are described in this report - for example the rehabilitation of Eker garden for the community.

305-01; 305-02; 305-03; 305-06; 305-07; 306-01; 306-02; 306-03; 306-04; 306-05; 417-01

BMP will contribute to an important reduction of energy use through its new technology. Additional initiatives are being taken by Bapco, such as the use of innovative software to optimise steam and power generation and the replacement of heaters with the latest energy efficient technologies.

7, 8 and 9

201-02; 302-01; 302-02; 302-03; 302-04; 302-05; 305-01; 305-02; 305-03; 305-04; 305-05

Bapco is committed to support the Bahrain National Target to combat Climate Change announced at COP26. Bapco has been reporting its Greenhouse Gas (GHG) emissions since 2014 and has implemented several initiatives to reduce those emissions, such as the hydrogen plant CO2 recovery project that saves 40,000 tonnes of CO2 emitted per year, the solar benches installed across Bahrain, our BDSEPP and the maintenance of green spaces such as Princess Sabeeka Park.

21 Introduction

SDG UNGC GRI Topic Specific Disclosures Bapco’s initiatives 1, 2, 3, 4, 5 and 6 201-01; 203-02; 404-01; 404-02-03; 204-01; 302-01; 302-02-03; 302-04; 302-05; 306-02; 102-08; 102-41; 202-01-02; 401-01; 401-03; 405-01-02; 408-01; 409-01; 402-01; 403-01-04; 403-05; 403-09; 403-10; 406-01; 414-02; OG13

3, 4, 5, 6, 7, 8 and 9 201-01; 203-01

1, 2, 3, 4, 5, 6 and 10 102-08; 401-01; 404-03; 405-02; 207-01; 207-02; 207-03; 207-04

1, 2, 7, 8 and 9 203-01; 306-01; 306-02; 306-03; 306-04; 306-05; OG13

7, 8 and 9 302-01; 302-02; 302-03; 302-04; 302-05; 303-01;

Link between SDGs - UNGC Principles - GRI Standards - Bapco’s initiatives

Bapco has been conducting regular marine assessments since 1981 around the Bapco Refinery and Sitra operating facilities to monitor marine ecosystems. Results have shown a steady improvement due to Bapco initiatives such as biological effluent treatment plant. Bapco’s efforts to plant mangroves will stabilise near-shore sediments and encourage ecosystem diversity.

Bapco closely follows the guidance provided by SCE on enhancements to the natural and built environments. The Princess Sabeeka Park in Awali and the Oasis initiative inside the Refinery are two of the many environmental projects implemented.

Bapco is proud to follow all applicable national and international regulations for fair process. Bapco has an established code of ethics that describes the behaviours expected from all employees, contractors and other third parties who work for Bapco.

Bapco conducts comprehensive social impact assessments for our major projects in accordance with applicable laws and regulations, with stakeholder engagement to facilitate community consultation. Bapco is a long-standing partner of INJAZ, with wide participation in the programme by Bapco employees to volunteer time for the benefit of the community.

Bapco participates at COP26

H.H. Shaikh Khalifa Al Khalifa from Bapco’s BMP Health, Safety and Environment (HSE) function attended the 26th session of the Conference of the Parties (COP26) to the United Nations Framework Convention on Climate Change (UNFCCC). The two-week event held in October and November 2021 in Glasgow, United Kingdom, attracted over 30,000 visitors from 127 countries.

Bahrain’s delegation to the COP26 included representatives from the Oil and Gas Industry, nogaholding and SCE. The delegation participated in a number of sessions and meetings such as the Group 77 and China meetings, Arab Group meetings, the meetings on adaptation and mitigation of emissions and the discussions of Article 6 of the Paris Agreement on the integrity of carbon markets. The delegation also attended discussions on the future of hydrogen in the Middle East, and the benefits of nature-based solutions to achieve net-zero target.

Environmental experts at COP26 recommended a variety of solutions to climate change mitigation and adaptation that the Kingdom of Bahrain can implement, such as water resource management, renewable energy use and financial solutions to enhance diversification towards a more sustainable and less polluting economy. As part of the Kingdom’s plans to reach Net Zero by 2060, Bapco has constructed a 5MWp photovoltaic

solar energy installation within the Refinery, Awali and the University of Bahrain (the BDSEPP). Bapco has also enhanced blue carbon sinks through the transplanting of mangroves in coastal areas around Bahrain, in addition to the construction of a new mangrove nursery in Ras Sanad.

The photo opposite was taken at the COP26 Action Zone, shortly after His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince, Deputy Supreme Commander, and Prime Minister had announced Bahrain’s commitments to reach Net Zero by 2060. The Action Zone is a dynamic events space that can host a variety of events such as talk-shows, special launch events, competition winners announcements, games, interactive activities and digital demonstrations - all of which focus on concrete climate action and provide a voice to the audience.

22 Bapco Sustainability Report 2020 - 2021

SDG UNGC GRI Topic Specific Disclosures Bapco’s initiatives 7, 8 and 9 304-01; 304-02; 304-03; 304-04; 305-01; 305-02; 305-03; 305-04; 305-05; 305-07

7, 8 and 9 304-01; 304-02; 304-03; 304-04; 306-03; 306-05; 305-01; 305-02; 305-03; 305-04; 305-05; 305-07

1, 2, 3, 4, 5, 6 and 10 403-4; 403-04; 403-09; 403-10; 410-01; 414-01; 414-02; 408-01; 102-16; 102-17; 102-21; 102-22; 102-23; 102-24; 102-25; 102-29; 102-37; 307-01; 416-02; 417-02; 417-03; 419-01; 205-01; 205-02; 205-03

1, 2, 3, 4, 5, 6, 7, 8, 9 and 10 207-01; 207-02; 207-03; 207-04; 203-02

23 Introduction

Bapco’s representative H.H. Shaikh Khalifa Al Khalifa (centre-left) and other Bahrain delegates attending COP26

“

Bahrain commits to reaching Net Zero by 2060, Bapco will be with the country on that journey

2,799 Employees

An increase from 2,521 - Page 27

74.6 MMBBL Products exported - Page 28

808 Suppliers

Majority local supply chain - Page 28

5 High priority topics

Materiality matrix - Page 45

24 Bapco Sustainability Report 2020 - 2021

Highlights

Who We Are

25 Who We Are

A view of the Low Sulphur Diesel Production Complex

Organisational Profile

Who we are, our markets and products, the associations that we hold to promote sustainable development and further information on how we report on our sustainability.

26 Bapco Sustainability Report 2020 - 2021

Installation of a BMP process unit

GRI 102-01: Name of the organisation

The Bahrain Petroleum Company B.S.C. (Closed), i.e. company shares are not offered to the public for investment.

GRI 102-02:

Activities, brands, products and services

Bapco is primarily a merchant export refinery, engaged in the refining of crude oil within the Kingdom of Bahrain. The company’s main products are Liquefied Petroleum Gas (LPG), naphtha, gasoline, kerosene, aviation turbine fuel, ultra-low sulphur diesel, heavy lube oil, fuel oil and asphalt.

GRI 102-03: Location of headquarters

Awali, Kingdom of Bahrain.

GRI 102-04:

Location of operations

Ma’ameer (Refinery complex) and Sitra (Local Marketing Terminal, Sitra Tank Farm and Wharf), Awali (Headquarters and other central functions), West Riffa (BMP project offices), all within the Kingdom of Bahrain.

GRI 102-05: Ownership and legal form

Bapco is wholly owned by the Government of the Kingdom of Bahrain under the Oil and Gas Holding Company B.S.C. (Closed) (“nogaholding”).

GRI 102-06: Markets served

90% of our production is exported. Our customers are regional, predominantly GCC countries that account for almost half of export destinations, followed by the Far East, with the balance to Europe, Africa, South East Asia, and the Indian subcontinent.

GRI 102-07: Scale of the organisation

During 2020-2021, the total number of employees within Bapco reached 2,799 divided between Operations, Awali Township support and the Awali hospital. During 2021, we exported a total of 74.6 MMBBL of our products and sold 1.65 MMBBL locally.

GRI

102-08:

Information on employees and other workers

The total number of employees has increased by around 11% since the 2018-19 reporting period, due to requirements related to BMP execution and post project operation. Refer to the table below. Bapco is committed to reaching 90% Bahrainisation within the next five years, post BMP.

GRI 102-10: Significant changes to the organisation and its supply chain

During the reporting period no significant changes occurred within Bapco’s supply chain.

GRI 102-41 Collective bargaining agreements

The number of employees who were members of a Trade Union in 2020 and 2021 was 904 (37.7%) and 1,058 (37.8%) respectively.

GRI

102-45: Entities included

in the consolidated financial statements

Bapco has a subsidiary and joint venture within its financial statements. Bapco holds 42.5% of the share capital of Bahrain Gasoline Blending W.L.L., a company involved in trading and blending of gasoline fuels. In addition, Bapco owns 27.4% of the share capital of Bahrain Lube Base Oil company B.S.C. (Closed), which is a manufacturer of high quality Group III lube base oil products.

27 Who We Are

Total number of employees by gender and region Type / Year 2018 2019 2020 2021 Male 2,054 (88%) 2,211 (88%) 2,416 (88%) 2,450 (88%) Female 286 (12%) 310 (12%) 331 (12%) 349 (12%) Total 2,340 2,521 2,747 2,799 Bahraini 1,680 (72%) 1,799 (71%) 1,896 (69%) 1,897 (68%) Expatriate 660 (28%) 722 (29%) 851 (31%) 902 (32%)

GRI 102-09: Supply chain

Bapco has integrated operations in production, refining and marketing. We operate a 267,000 BPD Refinery producing finished products for sale and distribution. Crude oil is imported from two sources. Locally produced crude oil from the Bahrain oil field is purchased from Tatweer Petroleum. Arab light crude oil is purchased from Saudi Aramco and transported to the Kingdom of Bahrain via the AB crude oil pipeline.

Raw material imports

The raw materials used by our Refinery are crude oil, natural gas and a smaller quantity of other semi-finished raw materials used in the manufacture of our products, e.g. additives required for diesel and petrol sold at fuel service stations. Other semi-finished raw materials, i.e. materials that have already undergone some processing elsewhere, are purchased according to demand and include fuel oil cutter stock (lighter petroleum fractions used to adjust finished product specifications) and vacuum gas oil. Natural Gas from the Khuff Gas Reservoir, used in the operation of the Refinery, is purchased from Tatweer Petroleum.

Product exports

In 2021, more than 74 MMBBL of products were exported, with middle distillates (kerosene plus diesel) accounting for about 56.9% of sales, followed by black oil products (fuel oil and asphalt) at 20.9%, naphtha at 19.1%, and base oil at 2.1%.

During the same period, Middle East countries (predominantly GCC) accounted for half of export destinations (53.1%), followed by the Far East (17.5%), with the balance to Africa (10.6%), Southeast Asia (5.9%), the Indian Subcontinent (4.9%), Europe (4.5%), South America (2.7%), and other countries (0.8%).

International diesel exports were all with an ultra-low sulphur content of 10 parts per million, consistent with the worldwide trend to promote environmental stewardship by adopting cleaner fuels. Bapco also sold diesel grades with more stringent distillation requirements at additional premiums.

Within the local market, the total volume of refined product sales amounted to 1.65 MMBBL in 2021, slightly up by approximately 5% year-on-year. Demand for most products were negatively affected by the ongoing pandemic, which resulted in a decrease in local consumption in all local sales except gasoline.

In 2021 the local market continued to favour the “fit for purpose” Jayyid gasoline grade (91 Research Octane Number - RON) over the higher octane Mumtaz (95 RON) gasoline. As a result, Jayyid gasoline accounted for almost half of the refined products sold domestically at 51.4% compared to 48.7% in 2020. Mumtaz gasoline accounted for 15.0% of the domestic sales versus 14.2% in 2020, while Super gasoline (98 RON), the premium gasoline grade, accounted for less than 1%. The remainder of local market sales were ultra-low sulphur diesel (22.5% in 2020 and 20.5% in 2021), LPG (8.1% in 2020 and 7.6% in 2021), kerosene (1.2% in 2020 and 1.0% in 2021), and Asphalt (2.7% in 2020 and 2.0% in 2021).

Local Suppliers

Bapco works with suppliers and contractors that share similar values. Our suppliers and contractors must pass a prequalification assessment to verify their commercial experience, organisation, financial stability and other management processes for quality, environment, and safety.

We strive to support an ethical and locally based supply chain that supports the Kingdom of Bahrain. During the reporting period there were a total of 808 active suppliers, of which 57% were local.

GRI 102-12: External initiatives

Bapco took the initiative in 2019 to produce its first sustainability report based on the GRI Standards. We have also recently written to the United Nations to give our commitment to adopt the Ten Principles of the United National Global Compact. The Principles provide a valuable framework that will guide the various transformation programmes described in this report and due for completion in future years (refer to our Introduction to this report).

Bapco is additionally certified and continues to maintain the certification to the following ISO standards:

• ISO 9001:2015 Quality Management, supporting our commitment to continuous improvement. (Certified since 1994);

• ISO 14001:2015 Environmental Management, supporting our commitment to environmental management (certified since 2008 to the previous version ISO14001:2004 and since 2017 to the current version);

• ISO 22301:2012 Business Continuity, ensuring our contingency planning and disaster recovery process follows recognised international best practice (certified since 2016); and

• ISO 45001:2018 Occupational Health and Safety, ensuring our occupational health and safety management is robust, and that it supports alignment with all other Bapco ISO standard certifications (certified since 2019). We have held equivalent OHSAS 18001 certification since 2003.

28 Bapco Sustainability Report 2020 - 2021

Sales by product and region

0.6% 19.0% 21.8% 35.9% 2.0% 17.6% 2.5% 0.6% 0.3% 19.1% 15.9% 41.0% 2.1% 19.7% 1.2% 0.6% 0% 5% 10% 15% 20% 25% 30% 35% 40% 45% LPG NAPHTHA KERO/JET GASOIL LUBE FUEL OIL ASPHALT SULPHUR 2020 2021 46.0% 17.3% 6.1% 10.4% 0.0% 16.2% 1.7% 0.1% 0.4% 2% 53.1% 17.5% 4.5% 10.6% 0.1% 5.9% 4.9% 0.0% 0.6% 2.7% 0% 10% 20% 30% 40% 50% 60% MIDDLE EAST FAR EAST EUROPE AFRICA SOUTH ASIA SOUTH EAST ASIA INDIAN SUBCONTINENT AUSTRALIA U.S.A. SOUTH AMERICA 2020 2021 29 Who We Are

GRI 102-13: Membership of associations

Bapco is an active member of several local, regional and international associations that promote sustainable development. We are pleased to have an active role in the following associations:

• Bahrain Health & Safety Society

• British Safety Council

• Campbell Institute

• Centre for Chemical Process Safety

• Energy Institute

• GCC Health and Safety Committee for Oil Refineries & Joint Ventures for Refinery Operating Companies (JVROC)

• Founding Member of Gulf Downstream Association (GDA)

• Gulf Petrochemicals and Chemicals Association (GPCA)

• Industrial Environmental Networking Committee

• INJAZ

• Board Member of Oil Spill Response Ltd (OSRL)

• Regional Clean Sea Organisation (RECSO), for which Bapco currently holds the Chairmanship

• Supreme Safety and Health Committee, Ministry of Labour and Social Development

• U.S. National Safety Council

• United Nations Global Compact (UNGC)

Reporting practice

GRI 102-48: Restatements of information

Data reported under GRI 403-09 (Page 139) in the 2018-19 Sustainability Report have been revised in this report for consistency against the reported data for 2020-21.

GRI 102-49: Changes in reporting

The material topic “Diversity and Inclusion” listed in Bapco’s first sustainability report 2018-19 was changed to “Equal Opportunities” in this edition of the sustainability report, as it is more representative of the topic area. The topic-specific disclosures reported under the material topic “Contractor Management” were merged with “Human Rights”.

GRI 102-50: Reporting period

The reporting period is from January 2020 to December 2021.

GRI 102-51: Date of the most recent report

Bapco issued its previous sustainability report for the reporting period 2018-19.

30 Bapco Sustainability Report 2020 - 2021

GRI 102-52: Reporting cycle

The reporting cycle is currently planned to be biennial.

GRI 102-53: Contact point for questions regarding the report

Please send any comments or feedback on this report to:

Ahmed Khalil, Director HSE

Email: ahmed_khalil@bapco.net

Telephone: +973 1775 2970

GRI 102-54: Claims of reporting in accordance with the GRI Standards

This report has been prepared in accordance with the ‘Comprehensive’ reporting level as defined in the GRI Standards GRI 101 Foundation 2016.

GRI 102-55: GRI content index

Refer to the GRI Content Index at the back of this report for the year and version of General Disclosures and Topic Specific Disclosures used in this report.

GRI 102-56: External assurance

We have commissioned an independent third party to provide assurance that this report meets the requirements of the GRI Standards. The report has been overseen by our Decision Review Board (DRB), chaired by the Acting Deputy Chief Executive and BMP Project Director, and comprising selected Bapco General Managers. The DRB has met regularly during report development to approve report content and the selection of material topics.

31 Who We Are

Strategy and Governance

Our governance arrangements and highest governing bodies, our company strategy and how we set our strategy, and our approaches to the control of business risks.

32 Bapco Sustainability Report 2020 - 2021

Safe behaviours are ultimately dictated by strong organisational governance

GRI 102-18: Governance and Structure

Bapco is committed to the highest standards of corporate governance, which it believes are critical to maintaining stakeholder and shareholder confidence. Bapco applies high ethical standards to its operations to ensure that its governance structure complies with all laws and regulations that govern its business. Bapco’s corporate governance framework ensures that Bapco operates within the guidelines and practices of corporate governance as set out in the Corporate Governance Code 2018 and its Articles of Association.

nogaholding is Bapco’s sole shareholder. The oversight provided by nogaholding aims to create shareholder value through the successful management of governmental oil, gas and petrochemical assets. The Board of Directors comprises seven members, including the Chairman. The Board of Directors reports to the shareholder and sets the company’s vision and policies that shape organisational strategy.

In addition, there are three Board committees :

• The Bapco Board Audit and Risk Committee is responsible for oversight of the integrity and quality of financial reporting process, the effectiveness of Bapco’s risk management and internal controls, the review of Bapco’s legal and regulatory compliance and the performance and independence of Bapco’s auditors.

• The Bapco Board Executive Management is responsible for assisting the Board in its responsibilities for medium and long-term strategy, including any strategic initiatives.

• The Bapco Board Nomination, Remuneration and Governance Committee is responsible for assisting the Board on matters relating to nomination, compensation and remuneration of the Directors, senior executives, and general managers of Bapco, corporate governance matters and human resources (HR).

The listed Board Committees have been established as of 1 November 2021 following the appointment of the new Board of Directors, replacing the previous committees.

GRI 102-19: Delegating authority

Bapco’s delegated authority cascades from the Board of Directors to the Executive Management, who are responsible for implementing the company vision set by the Board of Directors. Bapco has two Acting Deputy Chief Executives for Technical and Corporate Support to whom other General Managers report. Department Managers hold functional accountability across Bapco, each with a team of Superintendents with management responsibility.

GRI 102-20: Executive-level responsibility for economic, environmental, and social topics

The expectation of nogaholding is that Bapco provides a leading contribution to the Kingdom of Bahrain’s Economic Vision 2030, for example through the technical innovation and value creation of BMP. The Executive Management is responsible for aligning Bapco’s initiatives with the principles of sustainable development. Items related to sustainability are directly reported to Dr. Abdulrahman Jawahery, the Bapco CEO, who takes overall accountability for Bapco’s contribution to sustainable development.

GRI 102-21: Consulting stakeholders on economic, environmental, and social topics

Bapco has an extensive programme of stakeholder engagement to support its major initiatives - refer to 102-43, page 45. Interested third parties may otherwise contact senior members of Bapco via methods that include email, committee meetings and public or town hall meetings.

GRI 102-22: Composition of the highest governance body and its committees

Refer to infographic on pages 34 and 36.

GRI 102-23: Chair of the highest governance body

The highest governance body for Bapco is the Board of Directors. The Board Chairman is not an Executive Officer for Bapco and the Board comprises non-executive Directors.

GRI 102-24: Nominating and selecting the highest governance body

nogaholding, Bapco’s sole shareholder, is the highest governing authority for Bapco. The Bapco Board of Directors is appointed by nogaholding. Board members are typically appointed for a period of three years, renewable for subsequent periods as per Article 12 of Bapco’s Articles of Association. The Board is composed of individuals who have the competence and independence to provide stewardship of Bapco’s affairs. The Board approves Bapco’s corporate governance statement, which is reviewed annually.

GRI 102-25: Conflicts of interest

The Bapco Code of Conduct applies to both Directors and employees of Bapco, and is therefore equally applicable to the Board of Directors. All are expected to be familiar with the Code of Conduct and to uphold to the highest standard. The Code of Conduct is designed to help all those who work with Bapco make informed ethical decisions, and provide mechanisms to report unethical conduct. Conflict of Interest is articulated in Section 2 of the Bapco Code of Conduct, emphasising the importance of bringing suspected conflicts to the attention of an appropriate higher authority.

33 Who We Are

Board of Directors

34 Bapco Sustainability Report 2020 - 2021

Mr. Mark Thomas Deputy Chairman

H.E. Abdulla Jehad Al Zain Chairman

Dr. Ashok KrishnaDirector

Mr Yusuf Abdulla Mohammed Taqi - Director

H.E. Yusuf Abdulla Ali Humood - Director

Mr. Saeed Husain Abdulrahman - Director

Mr Ahmed Yusuf Taleb Abdulghani - Director

Company Strategy

Purpose

Bringing energy to the world for the enduring prosperity of the Kingdom of Bahrain

Vision

To be recognised as a dynamic and empowering national energy company competing globally

Mission

To sustainably manage and operate an integrated energy business, leveraging best practices and creating value for shareholders, customers and employees

Enterprising

We are empowered and dynamic. This attitude and our business mentality enable us to innovate

Trusted

We are honest and respect others. By acting with integrity we garner trust internally and externally

Committed

We are determined and passionate. Personal accountability and teamwork produce the best results

35 Who We Are

Executive Management

36 Bapco Sustainability Report 2020 - 2021

Dr. Abdulrahman Jawahery Chief Executive Officer

Mrs. Afaf Zainalabedin Acting Deputy Chief Executive Corporate Support and Chief Financial Officer

Mr. Hafedh Al Qassab Acting Deputy Chief Executive Technical and BMP Project Director

Mr. Mahmood Mirza General Manager Engineering

Mr. Gaetano De Santis General Manager Reliability and Maintenance

Mr. Mahmood A Rahim Bucheery General Manager Refining

Mr. Michael Keough

General Manager HR and Administration

Mr. Khalid Ebrahim Buhazza General Manager Marketing

Mrs. Afshan Parveen Akhtar

Chief Legal Counsel

GRI 102-26: Role of highest governance body in setting purpose, values, and strategy

H.E. Abdulla Jehad Al Zain, Chairman of the Board of Directors, regularly leads a review of Bapco’s vision and strategy, supported by the Executive Management. Bapco has a medium and long-term strategy derived from elements that include but are not limited to: the Kingdom of Bahrain’s commitments to the concept of Net Zero; the Economic Vision 2030; medium and long-term forecast demand for petroleum products; and anticipated technical innovation in refining.

The strategy is implemented by the Executive Management, who commission changes in strategic direction through organisational transformation programmes, each with defined objectives and identified accountable senior leader, and sets the Bapco mission statements. The alignment of Bapco’s mission, vision and values with this strategy are reviewed annually to confirm their adequacy to deliver company strategy. Dr. Abdulrahman Jawahery, the Bapco CEO, signs copies of mission, vision and values to indicate his approval for their communication to the wider Bapco workforce.

GRI 102-27: Collective knowledge of highest governance body

The Board of Directors are uniquely qualified in the functional areas of corporate finance, audit and risk management, refining technologies, major projects delivery, and human capital management. The Board of Directors additionally offers Bapco insights in business and risk management from their other non-executive oversight of organisations within the Kingdom of Bahrain. Mr. Mark Thomas, Deputy Chairman, is also Group CEO for nogaholding, Chairman of the Board of the Bahrain National Gas Company “Banagas” and Member of the Board of Tatweer Petroleum. Mr Yusuf Abdulla Mohammed Taqi is also a Member of the Board of Aluminium Bahrain (Alba).

GRI 102-28: Evaluating the highest governance body’s performance

Bapco’s three Board Committees report annually against their remit, in addition to their more regular reporting to the Board of Directors and their independent oversight of company governance arrangements. The performance of Dr. Abdulrahman Jawahery, the Bapco CEO, is reviewed annually by the Board of Directors.

GRI 102-32: Highest governance body’s role in sustainability reporting

Bapco has a DRB responsible for formal review of Bapco’s sustainability reporting. The DRB is chaired by Mr. Hafedh Al Qassab the Acting Deputy Chief Executive Technical and BMP Project Director and Chairman of the Environment, Health and Safety (EHS) Committee. The DRB seeks final approval from Dr. Abdulrahman Jawahery, the Bapco CEO. Bapco’s sustainability report includes performance statements from His Highness Shaikh Nasser bin Hamad Al Khalifa the nogaholding Chairman, H.E. Abdulla Jehad Al Zain, the Bapco Chairman and Bapco Executive Management.

GRI 102-16: Values, principles, standards and norms of behaviours

We have a Code of Conduct for all employees, whom we expect to work to the highest ethical standards. Our Code of Conduct applies as well to all workers at the BMP site, it is supplied through induction, written instructions and regular/refresher training which help workers to understand and respect the cultural norms in Kingdom of Bahrain.

Bapco’s guiding principles are expected to be followed by all employees and business partners, they go above and beyond compliance with all laws and regulations of the Kingdom of Bahrain and we expect all business partners to adhere to. Our Code of Conduct provides detailed guidance to all employees on avoiding potential conflicts of interest. This includes:

• Conflict of financial or other interests, such as personal interests in organisations with which we have an existing business relationship;

• Political conflicts of interest, which may conflict with activities related to work in Bapco;

• Solicitation or fundraising, which could be perceived as coercive or be potentially unlawful;

• Misuse of position, separating personal interests from work;

• Guidance on gifts and hospitality arrangements in line with applicable laws and regulations and reflecting current international standards of good practice; and

• Management of confidential information to respect employee privacy and protect our assets.

The Code of Conduct is published in Arabic and English as both e-copy and hard copy. Employees are required to sign that they have read and understood the Code of Conduct with records kept by HR.

GRI 102-17: Mechanisms for advice and concerns about ethics

Employees can consult with their supervisor or line manager for additional advise and clarification on ethical behaviours presented in our Code of Conduct. We highly encourage and advise employees, in case of any doubt of breaching one of the principles of the Code of Conduct, to report immediately any concerns to HR.

Risk control

Bapco’s internal control framework (the company’s business principles, policies, standards, guidelines and processes), has four objectives:

1. Ensure management, transactions and personal conduct comply with guidelines relating to corporate business conduct, as set out by the Bapco bodies responsible for corporate governance;

2. Ensure accounting, financial and management information provided to the bodies responsible for corporate governance in the company fairly reflects the financial position of Bapco;

3. Compliance with laws and regulations; and

4. Prevent or control business, legal and financial risks associated with company operation.

37 Who We Are

GRI 102-11: Precautionary principle or approach

A ‘precautionary principle’ refers to the strategy for managing potential harm in the absence of extensive scientific knowledge. This concept applies equally to recent areas of risk (safety, financial, business and environment) and is widely considered within our risk management strategies, the strength of which have been validated by their application throughout the COVID-19 pandemic.

For the purposes of sustainability reporting, The GRI Standards only consider environmental harm within the context of this section, as introduced by United Nations Principle 15 of the ‘The Rio Declaration on Environment and Development’

Application of the ‘precautionary principle’ within our business considers four areas:

• Risk management processes;

• Environmental monitoring programs;

• Adoption of international best available technologies; and

• Crisis and emergency response.

We have clearly defined risk management processes for key business risks. Each risk is assigned a score that is regularly reviewed by our Senior Management to understand the portfolio of risks managed by the organisation. Bapco’s corporate risk matrix includes environmental risks associated with major incidents involving oil spills, release of hydrocarbons and other losses of containment.

We have a comprehensive environmental monitoring programme to verify compliance with the local laws and regulations of the Kingdom of Bahrain, e.g. for our air emissions and effluent discharges. The emissions limits stipulated by law are ‘precautionary’, with statutory limits reflecting the level of uncertainty in cause and effect attributed to a given type of emission. We work in close coordination with SCE, the environmental authority within the Kingdom of Bahrain, whose representatives routinely inspect our emissions and effluent monitoring procedures. All new units comply with applicable local environmental regulations as well as international lender standards; including International Finance Corporation (IFC) standards and World Bank guidelines.

We have adopted some of the international best available technologies for BMP, which will significantly increase the energy efficiency index of our refining operations and allow us to produce higher-value products for supply to our domestic and international customers. There is growing evidence of the harm caused by global warming. A precautionary approach to GHG emissions is therefore considered international best practice. We are reducing CO2 emissions per barrel of crude oil processed and improving energy efficiency, and hence increasing energy conservation as part of our sustainability journey.

We help the Kingdom gather data on the potential impacts associated with GHG emissions by publishing our emissions data in accordance with relevant international reporting guidelines.

We have further offset our GHG emissions by investing in renewable energy production through our BDSEPP and initiatives such as the community solar bench project.

Our Crisis and Emergency Response Plan (CERP), which is based on the internationally recognised Incident Command System (ICS), includes a comprehensive precautionary oil spill response capability to safeguard the environment in the event of an incident.

GRI 102-15: Key impacts, risks, and opportunities

Bapco’s structured approach to its operations and processes facilitates rapid identification of internal and external emerging risks.

Bapco’s corporate risk management process is aligned to ISO 31000:2018 and certified to ISO 22301:2012. Bapco has an established framework for business resilience management implemented throughout the company. Significant risks with potential business impact are captured in Bapco’s Corporate Risk Register. As of the date of publication of this report there are 26 identified risks within four categories (strategic, operational, compliance and financial), comprising:

• One Strategic Risk;

• Twenty Operational Risks;

• Four Compliance Risks; and

• One Financial Risk.

The risks cover a wide category of internal and external risks representing aspects of Bapco’s activities that include safety, health and environment, reputation, cyber security, marketing, material availability, market volatility, human competency, and recruitment and retention. Bapco regularly evaluates these risks to ensure the effectiveness of the risk controls, to ensure effective reporting, and to ensure effective engagement in their control. Initial risk assessment is conducted with subject matter experts (SME) by workshop to identify each risk and its risk controls. Following the initial workshops there are three stages of verification and approval of the assessment. Initial review is by the General Manager of the respective area; then by the Business Resilience Management Committee; and finally by the Audit, Finance and Risk Committee. An annual review of the Corporate Risk Register is conducted to incorporate any updates.

The COVID-19 pandemic was an existential business risk during the reporting period. The potential impact of the pandemic on Bapco was effectively controlled by a Crisis Management Team (CMT). The CMT was multi-disciplinary and was therefore able to quickly build response strategies to emerging risks. Refer to the Special Topic on Bapco’s response to the COVID-19 pandemic on page 70.

38 Bapco Sustainability Report 2020 - 2021

An indirect consequence of the pandemic was the market volatility for petroleum products. Bapco was able to mitigate this impact through cost optimisation and, where necessary, temporarily reducing production output. The new technologies incorporated into BMP will provide Bapco with opportunities to sell an improved product slate with greater energy and production efficiency.

GRI 102-29: Identifying and managing economic, environmental, and social impacts

Bapco maintains a Corporate Risk Register that documents all significant business risks to which Bapco is exposed. The risks represent those encountered across economic, environmental and social domains both within the Kingdom of Bahrain and within the wider economic region. The types of risk included on the Corporate Risk Register align with Bapco’s potential high-level economic, environmental and social impacts on sustainable development. Successful management of Bapco’s business risks therefore also positively impacts on Bapco’s contribution to sustainable development.

The Board of Directors is ultimately accountable for Bapco’s enterprise risk, business continuity and other control frameworks established for Bapco. Management of Bapco’s Corporate Risk Register is delegated to the Executive Management. Bapco has independent Committees at both Board and Executive Management level designed to strengthen governance processes.

GRI 102-30: Effectiveness of risk management processes

Bapco’s Corporate Risk Register is a key input for Bapco’s strategy. Whilst the Executive Management has responsibility for management of business risks, it is the Board who holds ultimate accountability for oversight of Bapco’s risk management processes. Each of Bapco’s three Board Committees has a specific input to risk oversight dependent on their charter and each Board member provides functional advice relevant to their domain expertise.

GRI 102-31: Review of economic, environmental, and social topics

Topic review occurred regularly throughout the reporting period (with meetings conducted remotely via web conferencing when necessary). Bapco’s Board of Directors typically meets four times a year. The various Board Committees meet more regularly. Bapco holds Annual General Meetings and invites the Ministry of Industry and Commerce to attend. Topics of importance relevant to economic, environmental and social topics include Bapco’s response to COVID-19, changes in global demand for petroleum products, and workforce training for the anticipated commissioning of BMP.

GRI 102-33: Communicating critical concerns

Bapco has three independent formal means of reporting critical concerns to its government shareholder. Firstly, the Executive Management is responsible for communicating critical concerns to Bapco’s Board of Directors. Secondly, Bapco has strong independent governance processes that provide assurance of Bapco’s activities (refer to 102-18) and that may independently raise and communicate critical concerns to the Board of Directors. Thirdly, Bapco conducts external audits where there is a statutory requirement. The external auditors report their audit opinion to the shareholders independently of the Executive Management and Board Committees.

GRI

102-34:

Nature and total number of critical concerns

As a Closed company, the exact nature and total number of Bapco’s critical concerns are not published. However, Dr. Abdulrahman Jawahery, the Bapco CEO and former Chief Executives have presented on several critical concerns to the Bapco workforce during the reporting period. These include Bapco’s response to pandemic and changes in market conditions encountered during the reporting period.

GRI 102-35: Remuneration policies

As a Closed company, Bapco does not report on its remuneration policies for its highest governance body. Refer to 102-18 for details of how Bapco assures remuneration.

GRI 102-36:

Process for determining remuneration

All new graduates joining the company are assigned an Individual Development Plan (IDP) with performance metrics as part of their training programme. Annual performance appraisals evaluate individual performance and are used to guidance changes to remuneration. The HR business processes used to set remuneration are as expected fully aligned with the Kingdom of Bahrain’s labour laws.

GRI 102-37: Stakeholders’ involvement in remuneration

Bapco’s Board of Directors sets the company strategy that is used by the Executive Management to determine employee compensation. Dr. Abdulrahman Jawahery, the Bapco CEO has actively sought to make appointments reflective of Bapco’s sustainability strategy - for example the continued appointment of women to senior positions within Bapco described in this report.

GRI 102-38: Annual total compensation ratio

As a Closed company, Bapco does not report on its compensation ratios.

GRI 102-39: Percentage increase in annual total compensation ratio

As a Closed company, Bapco does not report on its compensation ratios.

39 Who We Are

Senior Women Profiles

Introducing the Initiative

Diversity and Inclusion is an important component of sustainable development, with the expectation that a sustainable society is one in which the contribution made by all genders is valued equally.

Bapco is proud of its track record in providing equal opportunities for all, employing the best talent irrespective of gender. The company makes great efforts to increase the number of women it employs, and has undertaken steps to leverage the critical role of women and increase their visibility within its organisation. The current reporting period is no exception, with several senior appointments made to women, including to the Executive. Refer to the separate section on Equal Opportunities to understand more about our demographics and the diversity of our workforce.

Profiles of senior women working in Bapco have been included throughout this report to celebrate Bapco’s commitment to the important role of women. The women selected are qualified in a variety of disciplines including engineering, HR, law and finance. All represent the high calibre of our employees.

Bapco celebrates Bahrain Women’s Day on the 1st of December of each year. Under the wise leadership of Her Royal Highness Princess Sabeeka bint Ibrahim Al Khalifa, the themes in 2020 and 2021 were Bahraini Women in the Diplomatic Field and Bahraini Women in National Development respectively.

We are very pleased to be able to include these profiles in our sustainability report and hope that you enjoy finding out more about some of those who work for Bapco.

40 Bapco Sustainability Report 2020 - 2021

Main picture and inset: Dr. Abdulrahman Jawahery, the Bapco CEO, meets with Bapco women employees on the occasion of the 2021 Women’s Day

41 Who We Are

52

Afaf Zainalabedin Acting Deputy Chief Executive - Corporate Support & CFO

Page

Afshan Parveen Akhtar Chief Legal Counsel

Sherifa Al Doseri Manager, CEO Office

Huda Yusuf Manager, Internal Audit

Ahlam Ebrahim Mohammed Acting Manager, Corporate Communications Department

Dana Bukhammas Manager, Human Resources

Haifa Almarzooq Acting Manager Operational Excellence

Abelin Ferrer Manager, Corporate Strategy

Jenan Al Askari Head of Employee Engagement

Page 54

Page 56

Page 76

Page 78

Page 106

Page 109

Page 133

Page 135

Stakeholders and Materiality

How we assure report quality, how we identify our stakeholders and the material topics important to them, and the changes in our material topics that have occurred since our last report was published.

42 Bapco Sustainability Report 2020 - 2021

Foliage at Princess Sabeeka Park

GRI 102-46: Defining report content and topic boundaries

Topic Boundaries

Topic boundaries describe how far an organisation is responsible for its impacts. ‘Impact’ can be defined as a change or effect attributed to, and caused by, the company’s operations. There may be both positive and negative dimensions to an impact.

Each material topic included in this report includes a description of:

• Where the impacts occur;

• Organisational involvement with the impacts, e.g. whether we have caused or contributed to the impacts or are directly linked to those impacts through our activities; and

• Any specific limitations concerning the topic boundary, e.g. procurement decisions that may restrict supply chains.

Recognised international good practice is used to define boundaries where appropriate, e.g. the calculation of GHG emissions in accordance with relevant international guidelines from the Intergovernmental Panel on Climate Change (IPCC).

Reporting Principles: Report Quality

GRI101 describes five principles governing report quality, which collectively ensure that the information provided is both reasonable and appropriate. These principles have been achieved through the involvement of SMEs providing information from across the organisation, and rigorous review by the DRB. Each report quality principle is considered in more detail below.

Report accuracy has been achieved by describing how data have been calculated. Raw (measured) data have been used wherever possible and in the majority of disclosures; where an estimate is used this is indicated in the supporting description. If there is a margin of error in the data provided, then this is also described.

Report balance has been achieved by presenting information factually and without unreasonable exclusion. Trends comparing data with the previous sustainability report have been included where relevant.

Report clarity has been achieved through clear descriptions of technical terms used in the report supported by a glossary. The report complies with corporate branding guidelines, which are designed for clear communication of information to stakeholders and other third parties.

Report comparability has been achieved by carefully following GRI guidelines on how data should be presented within each disclosure.

Report reliability has been achieved by careful independent review of the information presented. Much of the information reported here is already made available to third parties who may have undertaken separate verification of that information.

Report timeliness has been achieved by retrieving the latest available data and, where this is not available, providing a full explanation within the disclosure.

Reporting Principles: Report Content

Bapco has identified its stakeholders and key sustainability concerns. Bapco scored the identified sustainability topics for their potential stakeholder impact (as determined from documented stakeholder opinion) and impact on Bapco. The materiality matrix generated for our previous sustainability report was reviewed against the new scores and updated to reflect changes in impact.

The revised matrix was presented to the DRB, who provided further feedback on the relative positions of each sustainability topic presented in the matrix. On approval of the materiality matrix, a table of reportable disclosures was developed, considering the reporting level and the availability of data.

Stakeholder inclusiveness was ensured throughout this process by early involvement of stakeholders, who provided insight into known stakeholder concerns. Extensive stakeholder engagement conducted for BMP has provided a clear picture of the opinions of a wide range of stakeholders on sustainability issues. Additionally, stakeholder groups internal to Bapco were identified and open invitations were issued to those groups. The stakeholders were invited to bring other Bapco personnel to the workshops to avoid unconscious bias within the initially identified issues. Stakeholder workshops were held, and topic scores were modified according to the feedback.

Sustainability context was ensured by review of key regional sustainability concerns. Topics have been reviewed to confirm that the context for each item is understood and can be related to the topic-specific disclosures required by GRI. The relevance of each topic area to sustainability is further described in each section within this report to communicate its importance to the reader.

Topic materiality was determined from the ranked topic areas and development of the materiality matrix. Internal stakeholder workshops were convened to verify the relative positions and importance of each topic area.