Surns

The Signature Series Premium prlmed Mouldings

. Ultra-Smooth Surface for an Elegant, professional Finish

Sharp Detail for Superior Shadow Lines

. Three Coat Finish - Eliminating Visible foints and Crain

Fingerjointed Pine - Lighter, Easier to Cut and lnstall than MDF May be Painted with any Cood Acrylic or Oil Based paint.

. Distinct Collections - Matching Bases, Casings & Crowns

For over two decades the Kelleher Corporation has led the way in sourcing, developing, and distributing pre-primed moulding products; such as early water and lacquer based primed MDF & LDF, prinred Redwood, primed treated, etc. With our latest innova_tion, Signature Series premium primed Mouldings, you can offer your customers an easy to use product that achieves professional results with less time and effort. Homeowners will appreciate the ease of use, and general contractors can achieve the results of a painting subcontractor.

The three coat finish gives the look of hardwood with no visible joints. The finish is also very thin resulting in sharp detail, crisp shadow lines and a rich effect.

Fingerjointed pine is easier to cut and lohree trtctorY naif and a Pine crown w!ll often appear to ttpplied,coatings "slraighten" out a slightly crooked wall. The 5ignature Series has three collections of nratching bases. casings ano crowns

lor customer convenience; the Monterey collection whlch has a more detailed look, the Beaded having a more contemporary feel, arrd a classic Crctftsmon.

'PREMIUM-PRIMED MOULDINGS B*#

Finqeriointpd Pine

Ask your sales representative about the new Siqnature Series and Premium Primed Mouldings, or visit our website at wwwkelleher.com.

Backed by 20 years of proven performance, and a lihtim limited wan:anty.

Looking for a treated wood product to sell and install with confidence? Choose Preserve pressure-treated wood, an environmentally advanced copper and quaternary (ACO'j) system that provides proven, long-term protection from decat/ and termites.

AWPA standardized wood preservative and ICC-ES building code approved

NAHB Research Center Green Approved Product

US EPA Presidential Green Chemistry Challenge Award

. Lifetime limited warrantv

Proven performance against decay and termites

Above Ground and Ground Contact applications

Approved for fresh water immersion and salt water splash zone

For decking, playgrounds, walkways, benches, chairs, fencing and gazebos

M I n G HAil I

Special Features

B Fmrunr Sronv

HrcH-ENo vs. Low-ENo Mrrrwonx

1 0 MnNrcrmrrr Trps

GBrrN YouR OprnRrroNs

'l 2 MnnncriurNr Trps

Stop "SLRCr-oFF SUMMER" SyNonorve

1 4 Co,r,rprnnvt I trtttLr-rcENcE

HoNrNc SocrRl Meorn Srtls

'l 6 lr.rousrnv Tnrnos

LuvaER PRrces HR,vUERED BY ENo or CReott, RtstNc l,raponrs

19 SprcnL Focus: NAWTA

16-Pncr Sprcrnr SecrroN Drvorro ro

46 Pnoro Rrcnp: IACN 2ruo GnowrH

Suv,vrn Mrrr ron 40-&-UNorn Cnoup 47

Lumnrn Oln-Trurns

ln Every lssue

Online

Ste.480, Newport Beach, Ca. 92660-1872 by Cutler Publishing, Inc. Periodicals Postage paid at Newport Beach, Ca., and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 westem states. Copyright@2010 by Cutler Publishing, Inc. Cover and enthe contents are fullv Drotected and must not be reproduced in any manner withodt r4/ritten permission. All Rights Reserved. lt reserves the right to accept or reject any editorial or adverlising matter, and assumes no liability for materials tumished to it.

Horizon* decking in lpe and sewood. Better than the real because our patent pending Tech* surface protects the Even under tropical sun.

atched in the industry at providing the ch multichromatic look of fine hardwoods. extension of elegance from inside the me to a relaxed backyard lifestyle.

Each deckboard is wrapped on all four sides, so it's protected from stains, scratches and fading with the industry's first stain and fade warranty, now extended to 20 years.

Non-organic surfaces eliminate a food source for mold, resulting in the ultimate in mold resistance. Sustainable product. Sustainable beauty. The endurance contest? lt's over.

Forever changed

f rHtNx MANv oF us BITsTNESS owNERS have been forever changed by the receslsion as to how we are running and will run our businesses in the future. A recent survey of small business owners suggested that two-thirds of us are thinking differently about how we operate.

As I wrote last month, we are in a highly interconnected global market where the slightest sneeze anywhere sends a panic signal around the world. Information is pushed out instantly, at the touch of a send button. Much of this information is without commentary, leaving plenty open to interpretation. Most of us have learned that nothing is predictable, and the business models we have used to great success may no longer be valid in today's revolution of change.

For those of us who are surviving, many are different from what we were three years ago when the recession kicked in. We have become leaner and meaner (and meaner maybe not in a good way), pragmatic, cynical, and yet still uncertain of what the future holds, particularly in our industry, which could well be among the last to recover from the effects of the recession.

I can well understand the temptation to hunker down and wait for the sun to shine again. Again, as I wrote earlier, at a time when the national and global psyche has changed due to factors out ofour individual control, it is difficult to invest in new business opportunities-or even to get capital. But when competition fades and distribution strategies change, one man's bust is another man's gain. As someone told me recently, the sooner we all realize and accept that everything has changed, the faster we will look at our opportunities in a different light and the faster we will recover.

So accepting that today is a new day and believing in the 80/20 rule (that 807o will not change enough), what do you do to make yourself one of the 20Vo who will? I remind that you can never be satisfied with what you have achieved one day after you have achieved it. Take a moment to enjoy your achievements, but rea|izethattomorrowisanotherday.Sittingstillshouldnotbeanoption.

Instilling that thinking throughout youi"ornpuny is not easy, especiallv ffircr many are burned out from the stresses of the past years and wary of charLge. As someone who has consulted for other businesses,I have learned that most ()ompanies lack a clear understanding of who they are, what they are, and where tltey are going. Business sort of just happens. When was the last time your compirny sat down and in a meaningful way rethought its vision and strategy for the future?

Each company must understand and restate why it exists. When your firm started, for example in 1982, there was a different reason for doing business than what exists today. Times change, as do the reasons you exist. What do you want to achieve-be a $50-million company, be the No. I in your region, or beat out XYZ Co.? Define how you will go about achieving those goals in clear, concise and actionable statements.

Next, what values do you expect throughout the organization? Yes, the old standards are still valid (integrity, respect, etc.), but you should also include ways to differentiate your service from everyone else.

Lastly, create or recreate your brand by also differentiating your company or products. A brand is not just a logo or ad campaign; it is about creating a platform from which all marketing, communications and actions emanate. Everything you do afterwards either enhances or dilutes the brand. Understand what your customers think of you (something I can guarantee most of us are clueless about) and take actions that strensthen the brand.

Identifying what makes us tick provides the ammo to push forward and take us to a better place. There has never been a better time to begin the analysis. Good luck!

Alan Oakes, Publisher aioakes@aol.comwww. bu ild n g-products. com

A publication of Cutler Publishing 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors Dwight Cunan, Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@buildi ng-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

WEST, MIDWEST, SOUTHEAST

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231

ccasey@building-products.com

NORTHEAST Paul Mummolo 404 Princeton Ave., Brick, N.J, 08724 Phone (732) 899-8102 Fax 732-899-2758 mummolop@comcast.net

ONLINE Alan Oakes www.building-products.com

Phone (949) 852-1 990 Fax 949-852-0231 ajoakes@aol.com

CLASSIFIED David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-producls.com

How to Subscribe

SUBSCRIPTI0NS Heather Kelly Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $22 Two years, $36 Three years, $50 FOREIGN (Per year, paid in advance in US funds):

Surface-Canada or Mexico, $48 Other countries, $60 Air rates also available.

SINGLE COPIES $4 + shipping BACK ISSUES $5 + shipping

High-end vs. low-end The millwork industry goes to extremes

upscale, Atlanta hotels that are looking to boost guests through an easy, elegant addition such as crown mouldings."

"Meanwhile," Duncan continues, "the d-i-y segment seems to be gaining momentum. Homeowners realize the economic situation remains to poor, but the initial shock is gone and people are gaining some confidence again. Many cannot afford to sell their homes, but they can undertake di-y and small remodeling projects to make their homes more comfortable or more competitive, should they decide to sell. Geographically, we have noticed a large upswing in Texas, specifically the Austin area, where the real estate market remains viable in these economic times."

fltelr ro A MoulDtruc and millwork company that's sur-

viving the recession-or one of the few that's thriving despite itl-and you'll probably hear one of two seemingly disparate tales: They'll admit that the housing slump has killed their sales of low-end products typically used in tract homes, but they're flourishing with high-end products for custom, luxury homes. Or they might say that tough economic times have made low-priced millwork more appealing to cash-strapped do-it-yourselfers, forced to stay in and fix up their old homes. So which is it?

Windsor Mill, Cotati, Ca., provides both high-end and low-end products, but growth has come from the formerbecause those are the customers who have survived.

"For the space that we're in, the quality craftsman and the quality builder have survived over the last five years because of the quality of the wood," says president Craig Flynn. "They're our core customer, and we haven't seen them switch."

On the other hand, notes Dwight Duncan, owner and president of Century Architectural Specialties, Marietta, Ga., "From my viewpoint in the millwork industry, the slump continues with high-end new construction, unless it is large scale project related. For instance, we have had some recent success with commercial installations in

Jim Russell, president and sales manager, Russell Manufacturing, Hubbard, Or., agrees: "During recessions, homeowners elect to do repairs themselves, which boosts the home center business. Door shops and distributors typically purchase material for new homes, which is off maybe 40-507o from previous years, so they're slow. Banks have tightened money to contractors so it's harder for them to finance a spec home. Starter homes and multi-family housing has been hit the hardest; a new homeowner finds it difficult to secure a mortgage."

Some high-end business remains-but it already was a small slice of the pie. "People who have luxury homes have the money anyway and see that this is the cheapest time to remodel, as everyone is looking for work, but only maybe 57o of production goes to high-end custom homes," Russell says.

Richard A Ungerbuehler Sr., president, Federal Millwork Corp., Fort Lauderdale, Fl., has seen a recent uptick in demand, but attributes it to the loss of competing custom manufacturers rather than an increase in constrution. "To be sure, in our south Florida marketplace, the construction industry continues to lose jobs every month," he says. "The overbuilding, coupled with mortgage abuses, foreclosures, the shifting population, business closures adding to the unemployment numbers, and the lack of land for development all add to the malaise in which we all have fallen victim."

He thinks, percentage-wise, high-end may be holding up better than low-end. "The construction we see in the residential market is at the upper end of the construction eco-

nomic scale," Ungerbuehler shares. "They seem willing to spend because of the stiff competition among builders fighting over contracts, lumberyards and manufacturers offering deep discounts, reduced land costs, and low interest rates."

He sees the trend, however, as dating back even before the recession. as "potential buyers (seemed) more discriminating when it came to profile, species and finish. The buying public was becoming more discerning in their taste for quality over quantity, highend instead of low-end products."

Yet, says Ungerbuehler, "there will always be a place for the low-end product offered to the public. Frankly, that is what the masses can afford. However. with the introduction of synthetics of all types, there seems to be a move to offer the appearance of high-end products at the low-end price. Flooring is a good example. Quality hardwood floors are being replaced with laminated products, both with wood and a form of plastic veneers. A quality hardwood floor will last the life of a home and can be refinished. The synthetics may last a generation, but offer no way to regenerate its appearance or functionality."

Moulding & Millwork, Ferndale, Wa., has been fortunate to have a healthy housing market in its backyard. "In Vancouver, B.C., housing prices have flourished," says Stuart Cuthbert, national sales manager. Construction "slowed down, there was a bit of a dip, but ever since housing values have shown a constantly upward graph. However, in the last 18 months, there's been significant pressure to be tight on cost. But that hasn't necessarily pushed people toward lower end profiles."

Although Dorris Lumber & Moulding Co., Sacramento, Ca., produces only premium solid pine mouldings, c.e.o. Joshua Tyler also sees cost as the key, no matter if one specializes in "high-value or low-value mouldings." Retailers who squeeze hardest on price are still buying. "I would say that if you sell into Home Depot or Lowe's, business is better than normal," Tyler explains.

Overall. both scenarios seem truemillwork companies are succeeding by focusing on low- and high-end. Everything's down, but sellers are improving their chances for serving the demand that remains by knowing their market and specializing in what it wants.

Downie I imber/Selkirk Specralty

Enyearl Cedar Products

Gilbert Smith Forest Froducts Ltd.

Haida Forest Products Ltd.

nte rfo r

Northwest Forest Products

North Enderby Timber Ltd

lrePac Bui lding Products

Premier Forest Products, lnc.

Pcwer Wood Corp.

0uadra Wood Products

Green your operations

ff,/Heu Ir coMES ro cREENING the workplace, LBM

Y Y dealers have a headstart advantage. Most dealers already sell common green building products-from compact fluorescent light bulbs (CFLs) and automatic light sensors, to enviro-friendlier caulking and insulation. Greening your own business can be as easy as installing and using products from your own inventory.

Going green also means being aware of every product being used in your business. Everything from the copy paper in the office to the toilet paper in the restrooms is available in a greener version. Get your employees involved and look for ways to recycle, reduce, and reuse.

Remember that waste isn't just bad for the environment-it's also bad for your bottom line.

Get a Plan

Overall, the greatest savings relate to energy efficiency-even simple, inexpensive changes can reap big benefits. Higher savings will require more effort, but the payoff can be impressive.

The first step is to develop a green-business plan that covers every aspect of your business: energy and water efficiency, waste reduction, transportation. computing, equipment efficiency, and building design. Then you can choose which options can be implemented now, and which can wait for later.

Light Wisely

Artificial lighting accounts for up to 4OVo of the energy consumed by businesses. Taking advantage of natural light lowers energy costs, boosts retail sales, and improves worker productivity and satisfaction.

When natural light is not adequate, install energy-efficient CFLs and LED desk lamps. An LED bulb can last 60,000 hours, while a CFL bulb provides 10,000 hours of light-significantly

more than the I,500 hours provided by most incandescent bulbs. Replace older 1.5" fluorescent tube lighting with newer 1" tubes and solid-state electronic ballasts.

Building Gheck Up

Plug all leaks in your building's outer shell with weatherstripping or caulking. Use expandable foam to fill any gaps. Workspace air quality is also crucial. Good ventilation and lowVOC paints and materials (such as furniture and carpet) will keep employees healthy.

If you're building a new commercial space or remodeling an old one, consider environmental and cost-savings options such as solar panels.

Save Water

Instead of personal-size water bottles, provide filtered drinking water to encourage employees and customers to fill their own reusable containers. Better yet, consider a reusable water bottle or coffee mug as a promotional giveaway. Both items tend to be kept and used regularly by recipients, so your company name and logo will get noticed longer.

Periodically inspect pipes to make sure there are no leaks, and quickly fix any leaks you do find. When it's time to spruce up the restrooms, install dual-flush toilets and automatic faucets. These two products can go a long way toward saving water and

lowering costs.

Recycle,Recycle, Recycle

Place recycling bins in accessible, high-traffic areas and provide clear information about what can and cannot be recycled. When you receive unwanted catalogs, newsletters, magazines, or junk

mail, request removal from the mailing list before you recythe item.

Recycle paper and refill computer ink cartridges rather than send them to the landfill.

When computers and printers stop working, make sure that they are taken to a place that can recycle the parts. Donate unused equipment to a school or nonprofit and qualify for a tax credit.

Energy-Efficient Gomputi ng

Computers and peripherals consume a surprising amount of power. During the day, set your computer to go to sleep automatically during short breaks to cut energy use by 707o. Remember, screen savers don't save energv -f

Make it a habit to turn off your system-and the power strip it's plugged into-when you leave at nisht or on weekends. Just check with your tech expert first, to make sure it doesn't need to be on for backups or other maintenance.

When it comes time to buy new equipment, invest in energy-saving computers, monitors, and printers, and make sure that old equipment is properly recycled. Consider laptops that consume up to 807o less energy than equivalent desktops. Inkjet printers use up to 75Vo percent less energy than laser printers.

Reduce Printing

Think before you print: could this be read or stored online instead? All kinds of documents-even employee manuals-can be stored online. rather than copying and filing them. Besides reducing costs for paper and ink, saving documents online makes them easier to retrieve and update.

Encourage communications by email, then read and store them online instead of printing. If you need to keep a copy for legal reasons, or for various other reasons, store it online. Reduce fax-related paper waste by using a fax cover sheet only when necessary. Better yet, send, receive, and store faxes online.

Many companies offer an electronic alternative to notifications traditionally sent out by mail, especially when it comes to invoicing. Request that all communications be sent via email rather than snail mail to reduce the paper sent to your business.

Print Smarter

The average U.S. office worker goes through 10,000 sheets of copy paper a year. Make it a habit to print on both sides of paper, or use the back of old documents for faxes, scrap paper, or drafts. Avoid color printing.

Buy chlorine-free paper with a higher percentage of post-consumer recycled content. Recycle toner and ink cartridges and buy remanufactured ones.

Gontrol Your Temperature

Comfort is a function of temperature, humidity, and air movement. Thermostat settings of 3o to 5' higher can feel

as comfortable with fans.

Install programmable thermostats to automate your HVAC system and save significant amounts ofenergy.

Gut Gosts for Transportation

If your business has company-owned cars or a fleet of vehicles, consider purchasing fuel-efficient or hybrid vehicles whenever possible-tax credits and special loan prosrams are available.

Develop a companywide policy to eliminate unnecessary idling of truck engines. Auxiliary power units can heat or cool the truck when stopped, aliowing the main engine to be shut down. Look for shippers who belong to the EPA's SmartWay Transport Partnership, which encourages energy efficiency that significantly reduces greenhouse gases and air pollution.

Greening your business is an ongoing affair. Once you see cost savings, you'll be motivated to do more.

Getting employees involved will also keep the momentum going, so consider organizing a Green Team to meet monthly and brainstorm new options. And don't forget to spread the word-let your customers know that going green is a real priority for your business.

Six ways to keep your company focused

f, H, sur,t',rER... THAT WoNDERFUL lLtime of year when everything slows down-including your business. Your clients, employees and vendors are on a seemingly constant rotation of vacation time. No one's ever in when you need them.

The easiest thing to do, then, is just accept this state of affairs. After all, there is a gentlemen's agreement in the business world that operations are supposed to slow down a little in the summer, and since your competition has slowed down, it's fine if you put on the brakes for a while, too. Right?

Wrong, says business strategy expert Tom Hall. ln fact. summer is the best possible time to really get focused on what makes your company tick-in large part precisely because your competition is taking it easy during these lazy,hazy, crazy days.

"It makes perfect sense," says Hall, co-author of Ruthless Focus: How to Use Key Core Strategies to Grow Your Business. "If everyone else is slowing down and losing their focus during the summer months and you do the opposite, then you will be way ahead of the competition when fall rolls around. Plus, losing your collective grip on what you're supposed to be doing-and why-for three months is just bad for business."

The ability to focus-ruthlessly-is what separates the companies that grow steadily and successfully from the ones that get distracted, trot down the wrong side path, and find themselves lost in the forest, says Hall.

"Focus requires complete concentration, which can be difficult to achieve when the joys of summer are distracting you and your employees," he says. "It's difficult but not impossible. Take the right steps and you can end the summer in a much better posi-

tion than when it began."

Step 1. Vow to make this the Summer of Strategy.

This summer, strive to make your core strategy (the main strategy that drives your business) the focus of everything: meetings, new projects, old projects, communications with clients and prospects-everything. You should be able to describe your core strategy in a couple of crisp sentences. And it should answer two key questions: (1) How are we going to beat the competition? and (2) How are we going to make money?

"Every action, every day, moves you and the business forward, especially in the summer," Hall says. "A clear strategy will help you stay focused and help you stay on track. If you get off track, use that same clear strategy to help you identify what happened and what needs to change. Keep the two key questions in the forefront of everything you do."

One great way to maintain focus during the summer and beyond is to create a stick-to-the-strategy group. Hall explains: "The group should include people from every department. Their main objective should be to make sure the organization as a whole isn't losing sight of the core strategy. They'll bring you and the rest of your employees suggestions on how to push forward and get back on track whenever necessary."

Step 2. Plan the work and work the plan.

Sometimes the best way to stay focused during the summer is to put everything you have to do right there in front of you. Create a to-do work list and encourage your employees to do so as well. Carefully manage the

master list so that you are regularly updating it with new tasks and crossing off those that you have already completed. Make sure your employees do the same with their individual lists. The constant focus on these work lists will keep people from slacking off just because it's summertime.

"You'll be surprised how gratifying it can feel to check a task off of your to-do list," says Hall. "When you do, it provides you with the encouragement you need to move on to the next task. Making a to-do list might seem like a simple idea, but, trust me, it will have a big payoff. The list will help you see the big picture, and having everything in front of you will be a great way to continuously remind yourself that there is a lot to accomplish this summer."

Step 3. Don't let people use their vacation as a get-out-of-workfree card.

Speaking of to-do lists, anyone getting ready to go on vacation should be paying close attention to his or hers. A pending vacation should not be an excuse for not getting work done. Rather, it should be a red flag that urges you to be mindful of deadlines, rearrange more flexible projects, and ask for help if you need it. This is the message leaders should be sending to employees: If you are going to be on vacation, know what your deliverables are-and then deliver!

"Have a meeting with employees a couple of weeks in advance of their vacations in order to go over their lists," suggests Hall. "Point out those tasks that absolutely must get done before they go. Obviously, it's important for everyone to get a break during the summer, but no one-not your employees, not you-should take

months off just because it's summer. Not only will ng your work done make for a more enjoyable vacation for you, but it will make things a lot easier on coworkers and employees while you are out. And it will make your return a lot easier, as well."

Step 4. Update clients once a week.

During the summer, you and your employees aren't the only ones who are traveling or just MIA. Clients likely will be, too. Knowing they aren't as available as usual, you might allow yourself to slip into less frequent communication with them. Don't.

"Make yourself provide your clients with an update on what's going on with their accounts at least once a week," says Hall. "Doing so is a great way to stay ruthlessly focused on providing them the best service and making sure you are on track to meet your clients' goals. Providing updates will push you to pay close attention to each of your clients. It forces you to keep the ball moving, constantly thinking about what step should come next, what goal should be reached next, and what you can do to improve your overall service."

Step 5. Leverage the freedom of summer to generate fresh ideas.

Summertime is just more fun than any other time of the year. It brings out people's "inner child" and sparks creative ideas. That's why summer is a great time to focus on developing fresh ideas at your organization. One way to get people's creative juices flowing is to hold an organizationwide contest.

"Ask everyone to submit their bright idea for the company and a plan for implementation," he advises. "To motivate them to give you their best effort, offer the winner an extra day of vacation or a Friday off. Another way to inspire is to hold a brainstorming lunch with your staff once a month or so. Ask them to each bring at least one idea, whether it be a way to help a client, a way to save money, or a way to improve the business as a whole.

"Finally, get outdoors from time to time," he adds. "Take everyone to the local park one day. Encourage them to use the time outside the office to brainstorm ways to improve the business or tackle a problem that has been giving them trouble. Not only will people get to spend some fun time together enjoying the weather, they'll have a chance to clear their heads and do great brainstorming."

Step 6. Look for ways to keep people refreshed.

Staying focused shouldn't be about drudgery. People need a bit of fun and levity to prevent boredom and burnout. That's why Hall suggests you look for ways to infuse the spirit of summer into your organization. Let your employees enjoy the things that make summer great without ever leaving the office. Provide fresh flowers for everyone's desks. Serve up a pitcher of ice-cold lemonade. Relax the dress code (at least one day a week). Pipe beach music throughout the office. The possibilities are endless.

"Do whatever you can to make work more summer-y," says Hall. "It will create a nice escape from the status quo that will refresh you and your employees and help everyone refocus on the work at hand while still getting to enjoy the spirit of summer."

"It may sound like a great idea to check out for the summer and just pick things back up in September," he says. "But in doing so, you leave a lot of great opportunities on the table."

Commodities

Honing your (social) media skills

Cicorr THolans oFFERS a word to the L)wise (and the not-so had better listen up all the harder). As marketing director of Parksite, a l0-location outfit based in Batavia. Il.. he's a believer in that grand marketing guru's pronouncement that "The media is the message."

Thus, according to Thomas, spending advertising dollars solely on newsprint ads, direct mail, TV and radio while ignoring faster, more expensive modern tools is living in the past. He's thinking digital these days.

Convinced that digital marketing is the wave of-never mind the future: the world of today-two years ago, he convinced company management of his plan to exploit its potential. Sure, the company already had a website (duh) and Internet messaging (ditto), but how about expanding to include

social

media-explicitly, blogs,

Twitter and Flickr?

The sweet part of obtaining the goahead was this: The campaigns would cost virtually nothing, beyond the expenditure of time on the part of the marketing staff, who were lJOVo behind the idea. The rest of the organization, not so much: "It's still an ongoing hurdle," Thomas concedes. "Many associates still struggle with how to incorporate these new marketing tools into their daily roles and don't spend time communicating these resources to their customers. But," he's convinced, "that will change. As things evolve, companies will realize that those 'kids with the iPads' and the always-online mentality will be tomorrow's customers. Additionally, as younger people come into the building material industry, they will

expect access to modern technology and encourage them to be part of a company's marketing scheme.

"The point is, today, vs. 15 years ago, consumers have access to information from a bunch of different sources, not just print and TV. What dealers and distributors have to understand is that a huge, huge percentage of homeowners do research online before even entering a store. They often know about products before we do, so we'd better join 'em: Get with it, or miss the boat," he says. "The world moves too fast to rely on wordof-mouth these days. You can't just wait for something to happen."

Thus, Parksite has embraced marketing efforts via email and social media, such as Twitter, via daily tweets, including product updates, links to helpful blog articles, industry news and trends, and more. On YouTube, it offers videos of, say, Dupont's Tyvek and Nichiha's fiber cement panel applications-all aimed, says Thomas, at "relaying information on our products."

But if a YouTube video plays in a forest and no one....? Okay, that's where email and Twitter come inways to alert and encourage potential viewers. Email also serves as an easy "and incredibly inexpensive" way to distribute the company's newsletters and press releases.

Here's how Thomas has learned to utilize those email alerts: "Our CRM database includes architects, developers, builders, remodelers, lawn & garden people, general contractors and lumberyards, and we use it to drive demand for a product and to support or drive customers."

Customizing a message for each demographic segment of the list is easy. Where the skill comes in is in

crafting the subject line-"the most important part of a message," he instructs: "That will determine if the email even gets opened."

For an industry segment with 10,000 email addresses, Thomas tries out three different subject lines for a press release, sending each to 1,000 people. "We can get instant feedback, so we know right away which one got opened the most. Then we use that subject line for the other 7,000 in our database. You could never achieve that with a newspaper or TV ad," he declares-"those media are a blind investment. With our CRM database, we reach thousands of people in minutes, and we can control the content and target the audience by industry, title or geography."

Digital content also has a lengthy shelf life. "Your digital information is constantly out there and doesn't disappear," Thomas contends. "In fact, it's picked up by search engines like Google, Yahoo and Bing, which helps your website search engine rankings."

Best yet, you can track hits to your blog, tweet or video in real time, "so your ROI comes in ASAP. By linking to tracking websites, you can tell the number of viewers that day, that month, whatever. For instance, links to YouTube that we embed in email communications can be tracked on bit.ly, which shows how often a specific link was opened." Bonus: "If a YouTube viewer tells his friends to watch it, too, he's doing your advertising for you, and for free."

Yet, don't get marketing director Thomas wrong. "Digital is just one component of our overall marketing scheme," he explains. "Still the most effective element I know is face-toface. That's how you build trust. Our salespeople-with an average tenure of over 15 years-are very good in communicating with their customers." They also play their roles as what Parksite calls its building products specialists, meeting with builders, contractors, architects, what have you, to help in ways that range from correct use of a product to designing custom P-O-P displays. Parksite also offers classes that deliver continuing-education credits to contractors and architects.

Okay, probably your salespeople are similarly adept at one-on-one customer service. To take that to the next step, it's time to supplement those efforts with (bite the bullet) the abovementioned digital tools. Thomas offers this advice for beginners: "Start with a website. Then, assemble a good email database, comprised of your customers and potential customers."

Step Three: look for an email marketing service (they're fairly inexpen-

sive) to help you with design and deliverability. To start reaching the up-and-coming generation, think about a presence on Facebook (your company has a page, certainly?) and Twitter. Finally, says Thomas, "I'm a big fan of two-or three-minute videos, your best marketing piece today. Remarkable! They're easy to get to and can reach millions of people. And once the message is out, people forward it and do the marketing for you."

Are there pitfalls to steer clear of, Scott? Well, sure. But the good news is, mistakes won't cost you money. Counsels Thomas, "Don't start it up and then not stick with it. You've got to get people in your company to understand that it's a team effort that they all need to participate in and promote. And you've got to have consistency of content."

Parting words of advice: "Anything worth doing is worth doing poorly," Thomas jokes. "It won't cost you anything. Just remember: Today's marketing is about being helpful, not intrusive, and putting constructive information in the places where people go to find it." And that translates to social media.

For inspiration, peek at Parksite's blog at www.parksite.com/blog, tweets at www. twitter.com/parksite, or view videos at www. flickr.com/parksite.

r INDUSTRY Trends

By Gary Zauner, Crow's Weekly Market Report/RlSlEnd of credit, rising imports hammer lumber prices

f, s r-uuneR PRICES retreat to la,lows for the year, calls for production to again conform to current demand levels are growing. This is reminiscent of 2008 and 2009, when the long slog to bring production and consumption into balance was occurring. Eventually, in the latter half of 2009, a balance was restored.

Now that the housing stimulus in the form of homebuyers tax credits ended April 30, demand is wavering. The pace of housing starts and permits has the appearance of slowing, builders are less confident about what the future holds, and the real estate industry is forecasting a two to three month period in which home sales will decline. Within the wood products industry, reports of a downturn in the business climate surfaced early in the second quarter.

As to whether the homebuilder tax credit worked, it would be hard to argue against its success in the short term. Home construction was stimulated, certainly more than what the industry expected. Due in large part to the stimulus, lumber consumption increased and so, too, did lumber prices, giving producers and the distribution chain a long-awaited dose of price volatility and profitability.

It is also within reason to argue that results from the tax credit, estimated at around $35 billion, fell short of the cost. For example, the National Association of Realtors estimates that out of the 4.4 million homes purchased during the stimulus period, only I million were purchased because of the stimulus. In other words, $27 billion was spent on sales that would have occuned without the stimulus.

It is widely believed that the tax credit helped limit inventories of unsold houses in the market, which helped stabilize home prices. A stabilization of home prices in turn limited the loss of equity in homes. Some estimates show the stimulus savine $2

trillion in homeowner equity, equating to an average of about $21,000 per homeowner.

As for home construction, it appears the market has stalled, despite affordability figures that are quite favorable. Future buying and construction was likely pushed forward by the tax credits, giving the appearance of a sustainable upward trend. For instance, new home sales in May totaled just 300,000 units on an annualized basis-32.7Vo below the April Census Bureau figure of 446,000.

Within the industry, signs of a troubled economy, even while housing starts increased, were evident in the western red cedar market. Even after significant cutbacks in production over the last couple of years, demand has lagged. Not as strongly tied to housing starts as other species. consumer spending on deck and other outdoor projects remains limited.

In southern pine treated lumber, sales have stagnated since May, a time when buying is usually in full swing. Treaters report that their sales in May and June were down lO-ZOVa compared to the same months last year. Disappointing treated wood sales played a large role in the steep and extended downturn in southern pine lumber prices. Even sales surrounding the Memorial Day holiday, typically a big weekend for big box store sales, were below expectations for treaters.

The slower pace of consumption is not the only factor driving down fram-

ing lumber prices. Traders are pointing to June's increase in Canadian lumber exports into the U.S. as a contributing factor. Their premise is not only are buyers seeing more imports ship into the states in June, they also expected in May that imports from Canada would multiply this month. Therefore, it is the well-founded stance of traders that even the perception of greater supplies available in June helped stifle demand in May.

Actually, a strong connection exists between two of the largest factors influencing lumber prices over the past few months: the U.S. government's housing stimulus and increased imports from Canada. Simply put, the homebuyer tax credit helped stimulate demand beyond production levels, pushing lumber prices higher. Elevated prices led to the elimination of duties on Canadian softwood lumber exports for June.

Canadian exporters, taking advantage of the suspension of export taxes, are now shipping at a pace of nearly 1.0 billion bd. ft. into the U.S. for the month, far exceeding the pace set in either April or May. Again, it is a widely held perception within the industry that those volumes entering the U.S. from Canada are now having a negative influence on pricing.

The big question from here forward is whether the housing market can stand on its own two feet without the crutch of more government spending. Whether the tax credit was successful is certainly debatable, but it is clear that the underlying economy was not strong enough to gather much momentum from the stimulus.

- Gary Zauner is editor of Crow's Weekly Market Report, the longest-running source of prices in the North American lumber and panel industry. Reach him at gzauner@risi.com or sign up for a free trial subscription at wwtr. risiinfo.com/crows.

Piedmont Parts with LastYard

Piedmont Lumber auctioned off trucks, office equipment, and fittings at its closed yard in Pittsburg, Ca., and sold its last operational store, in Lakeport, Ca., to four-unit Mendo Mill & Lumber. Ukiah. Ca.

"As soon as possible, we'll reopen," said Mike Mayfield, Mendo's president and c.e.o. "Our goal is to retain as many staff as possible."

Just five months ago, Piedmont was operating five locations. Then on March 1, its lender, Umpqua Bank, filed judicial foreclosure actions against the company's properties. Less than two weeks later, a fire destroyed its yard in Walnut Creek, Ca. The blaze is still being investigated.

A week later, Piedmont sold its Oakland yard to Economy Lumber, Oakland. Its truss plant in Calpella, Ca., closed March 31, with its equipment auctioned off Aug. 12.

Piedmont retains its properties in Walnut Creek as well as in Pittsburg, which has been used as the company's headquarters since the yard was damaged by fire last summer. A Piedmont spokesperson said that former owner Bill Myer Jr., son of the founder, is in discussions with his insurance carrier and the city about rebuilding a home center in Walnut Creek.

UniversalTruss Pulling out of Southern California

Universal Forest Products is closing its Universal Truss plant in Fontana, Ca., and will no longer provide trusses to the Southern California market. The facility will be retained "for possible future business."

"Based on market and economic conditions in Southern California that we believe will prevail in that region for a while, we made the difficult decision to temporarily close our

Fontana operations," said Lynn Afendoulis, director of corporate communications. "Our intent is to close down by mid-September."

Universal acquired the plant from Gang-Nail Components in 2000. Some personnel are expected to transfer to UFPI's facility in Riverside, Ca.

UFPI will continue supplying trusses to Northern California from its facility in Riverbank, Ca.

Mid-Golumbia Goes Bigger

Mid-Columbia Lumber Products, Madras, Or., has acquired a former boat manufacturing plant in Culver, Or. After renovation, all production will move to the 200000-sq. ft. mill.

"We needed to look at all our options to most efficiently operate and provide value and logistical access to our customers," said Tim Stovall, president and general manager.

A $204,084 matching grant helPed fund improvements to its rail spur and siding to allow shipment of finished products.

Blaze Hits Utah Yard

Roof repair work at Colonial Building Supply, Centerville, Ut., sparked a July 26 fire that destroyed the main building and offices. Quick response from firefighters saved the warehouse, and no one was injured.

A passerby spotted the flames at approximately 6 p.m., called 911, and alerted two Colonial employees who were closing up the store. Within an hour, the store was roaring with flames and fire crews battled the blaze through the night.

By the next morning, employees were cleaning up the mess and handling orders from temporary offices in the parking lot.

Owner Fred Hale plans to rebuild as soon as possible.

Sutherland Lumber Co. is tiquidating its 38-year-old yard in Boulder, Co, The 5.6-acre site is site is located in an area being rezoned by the city to accommodate new office, retail and residential development, so the 14,000sq. ft. buiUing likely will be converted into office space.

Friedman's Home lmprovefl€llt tentatively agreed to build an 80,000-sq. ft. store with drive-thru lumberyard and 20,000-sq. ft. garden center in Petaluma, Ca.

lrvine Ace Hardwoto, lrvine, Ca,, is closing after 29 years, 18 at the current location.

Owner Scott Thoele has been offered a job at Woodward's Ace Hardware, Santa Ana, Ca.

Home Depot is stillwaiting for right-of-way and easement appraisals for a planned store in Grants Pass, Or.

Lowe's opened a new 103,000sq. ft. home center June 25 in NW Las Vegas, Nv.; hopes to complete a 117,000-sq. ft. store with 32,900-sq. ft. garden center in Oxnard, Ca., in 1st quarter 2012, and has begun building a 117,000-sq. ft. store in lwilei (Oahu), Hi., next to a Home Depot.

Lowe's is buying a site in Rohnert Park, Ca., to start construction in the spring; received the planning commission's blessing to build a 153,974-sq, ft. store on 16.65 acres in Carlsbad, Ca., and is still awaiiing approvalto build on old airport property in Clearlake, Ca, Pinal Lumber & Hardware, Globe, Az., was named Business of the Year by the local Chamber of Commerce.

Explosion Rips Alaska Mill

Icy Straits Lumber & Milling, Hoonah, Ak., is looking to rebuild on a smaller scale after a July 22 fire and explosion destroyed its primary milling operations.

Investigators linked the major damage to "dust explosions from sawdust material that had accumulated in the mill structural elements." They are unsure what caused the dust to ignite, but said an ember could have been smoldering undetected for up to two days before igniting.

Secondary manufacturing operations, including dry kilns, moulder and planer, were spared.

Codes Undo Green Supplier

Building code violations are forcing an environmental-minded building supplier to find a new home.

Over the past l2 years, Whole House Building Supply & Salvage, East Palo Alto. Ca.. has accumulated a diverse inventory of salvaged doors, cabinets, roofing, lighting, plywood, bathroom fixtures, slabs of granite, and more. There's also a compost pile, vegetable garden, and gallery of progressive political posters and fliers.

But owner Paul Gardner now has to pack them all up, blaming building and fire officials for cracking down on long-time code violations. He said it would cost $200,000 to $250,000 to make the required improvements, including installing seismic safety upgrades. fire prevention equipment. and a permanent bathroom.

"It's true that their job is to be concerned about the code," said Gardner.

"But it's a particularly bad time with the economy to demand that your local green business make these extremely costly upgrades. We certainly don't have the money to do it now."

Gardner has given his landlord notice that he will vacate by September and is negotiating to possibly lease a new site in Redwood City, Ca.

Oregon Bookkeeper Panched

A bookkeeper was sentenced to four years of prison followed by eight years of supervision for embezzling nearly $500,000 from Marine Lumber, Tualatin, Or., over a three-year period.

Faye Louise Clemens, 65, allegedly wrote company checks for cash and pocketed the money. During the trial, her attorney blamed her behavior on a gambling problem.

Labor Board Hits Lowe's DC National Labor Relations Board investigators have uncovered evidence suggesting that Lowe's DC in Perris, Ca., may have threatened and fired three employees in 2007 and 2008 because they were interested in joining the Teamsters union.

Lowe's is also accused of interrogating workers about their union activities and searching lockers and lunch pails for union-related materials. However, investigators found insufficient evidence of almost 20 other accusations of labor law violations.

Employees at the warehouse rejected union membership in 2006 by a vote of 450 to 325. Ot the company's 238,000 total employees, none are union members.

Quolity Western Cedqr Products

r SUPPLIER Briefs

Sierra Pacific Industries, Anderson, Ca., will reopen its main sawmill in Standard, Ca., in May 2011, reviving 130 jobs.

In July, SPI began converting the near-century-old plant, closed since last August, to handle small logs.

Boise Gascade's former mitt in Yakima, Wa., lost two buildings in a June 21 fire caused by exploding propane tanks.

Boise closed the facility in 2003 and two years later sold it to Melvin and Norman McDougal, timberland and mill owners in Eugene, Or. They leased it ro Yakima Resources.

BlueLinx Holdings is evatua! ing a proposed $49.6-million offer by Gerberus to buy all outstanding shares of its common stock. The private equity firm already owns 55.4% of the dishibutor.

Georgia-Pacific's Phitomath, Or., planer mill was briefly evacuated June 29 when smoke appeared in part of the plant.

A smallfire, likely caused by a piece of wood that became lodged in the planer, was quickly doused by automatic sprinklers and workers with hand-held extinguishers.

International Barrier Tech. nology, Watkins, Mn., has acquired from Pyrotite Corp., Seattte, Wa., all of Pyrotite's interest in its lntegrally Treated Oriented Strand Board technology used in creating fire-resistant OSB panels.

Fiberon is expanding manufacturing capacity at its facilities in Meridian, ld., and New London, N.C., due to growing demand for its Horizon Decking. Production capacity has already grown by 300% since January.

Roseburg, Roseburg, Or., is now exclusive supplier of Duramine thermally fused,melamine panels for California Closets' Lago cottection for the West Coast.

ilevel by Weyerhaeuser is now distributino Versatex PVC trim products trom Wolfpac Techno. logies, Pittsburgh, Pd. Dealers can now order smaller quantities of Versatex trimboard in one skid and still receive a bulk discount.

lx4 B0ARDS in 4, 5 ond 6'lengths

2x4 Ml6 in 8-10'both rough ond surfoced

Cedor 4x4 P0SIS in 4,5,6,7,8,9 ond l0'lengths

lx4 B0ARDS in 4, 5 ond 6'lengths

2x4 Ml6 in 8-10'both rough ond surfoced

Cedor 4x4 P0SIS in 4,5,6,7,8,9 ond l0'lengths

New networks and training help reposition wholesalers

A wELL-KNowN sAYTNG that -fil,became popular during the recent recession is that "A crisis is a terrible thing to waste." What that economist meant, among other things, was that during a time of uncertainty and change, companies have the opportunity and leeway to reposition in a way they wouldn't during good times.

Over the last two years, markets have shrunk or disappeared, production has decreased, and the industry has consolidated. The companies that have made it through are in a unique position to redefine themselves through better networks, workforce development, and crucial industry information. Companies can take advantage of the many programs offered by the North American Wholesale Lumber Association to assist them.

Expanded Networks

Companies have joined NAWLA for decades for the networking opportunities membership provides. These opportunities exist on a national and regional level, for both networking and education.

The NAWLA Traders Market was started in 1996 with the primary purpose of connecting the producer to the wholesale distributor. In those 15 years, the show has grown to average over the last few years 570 wholesale buyer attendees, 510 manufacturing representatives, and 260 exhibiting companies. With a program geared towards creating network events, it is known as a work-focused tradeshow.

"Traders Market is a unique tradeshow because it focuses almost entirely on the sale and distribution of lumber products. Because the exhibitors are primarily manufacturers and the attendees are primarily BnildltlgrRodudsom

wholesale buyers, Traders Market provides a very business focused atmosphere," says Gary Vitale, president of NAWLA. "As companies continue to reposition themselves and search for new customers during the economic recovery, no other venue can provide this affordability and value."

While some companies need to constantly address their national networks to thrive, some only need to focus on regional networks to expand their customer base. Lumber wholesalers whose procurement and distribution networks are located near to their business have the chance to be more active in regional meetings conducted by NAWLA.

Each NAWLA regional meeting is customized for that area. Some are morning seminars with an industry expert speaking on a timely topic

while others are evening receptions with panel discussions. With attendance ranging from 40 to 120, they can be a productive and manageable networking and educational tool.

Workforce Training

Almost every company has had to cut back on its workforce lately. With employees being asked to perform more duties while also being more productive, companies have looked at developing the workforce they have. They also have to ensure that any new hires learn the ropes in less time than previously.

The Wood Basics Course provides a comprehensive overview of the forest products industry, covering everything from seed to tree and from production to sales. Companies looking to train their employees and invest in their future have the option of sending

The NAWLATraders Market is the premier tradeshow devoted to the sale and distribution of lumber and related products, both softwoods and hardwoods.

The Traders Market Advantage: Exceptional Value and Affordabi lity Unlimited Networking Opportunities

Excellent Access to the Entire Supply Chain

New this year: New Product Showcase

. Enhanced global programming

Keynote Speaker Jim"The Rookie"Morris

SalesTraining by David Kahle

Com plete information and registration available at www.nawlatradersma rket.com

800-527 -8258 i nfo@nawla.org

new or veteran employees to the course.

Since 1981, almost 1,500 people have attended. For many in the industry, the class establishes their initial industry networks. "These new friendships have the potential to benefit our company far into the future", says Mark Kasper, president and c.e.o. of Amerhart Ltd., Green Bay, Wi. "It shows our staff that we are making a real commitment to their education and advancement in their careers."

The next Wood Basics Course will be held Sept. 13-16 in Corvallis, Or. In addition, NAWLA is considering holding a course in the Southeast in spring 201 l.

As the economy continues to recover, the ability to make the sale will become increasingly important. Companies will specifically need to train their sales force to differentiate itself from its competitors. Here again, NAWLA provides a special sales training class during the 2010 Traders Market.

David Kahle, of the DaCo Corp., will present his Top Gun Survival School during Traders Market. Companies have the chance to send their mid-level professionals to learn how to prioritize markets, create new customers, and make the close.

With so many companies cutting travel budgets, however, some are looking for online training. Technology now allows workforce training to be delivered directly to the office. NAWLA has hosted more than 40 webinars since the first in2004.

Webinars enable companies to invest in their workforce with little commitment. Multiple employees can attend without leaving the facility. Usually lasting a little over an hour, they cover topics ranging from chain of custody certification to marketing green products. NAWLA will host a webinar on Sept. 16 on credit management presented by credit managers from various wood products companies.

Companies today must work harder to make sure they have a competitive edge over other businesses. The industry and the market have changed dramatically since the recession begun and possibly no other industry has been more affected. Companies looking for the advantage of more networks, a better trained workforce, and timely information should consider the various benefits of NAWLA's programs.

- More detailed information on the services and programs offered by the North American Wholesale Lumber Association, including membership possibilities, can be found ar www.nawla.orp.

Nolionwide Disfribution -'Products Where You Need Them

When deolers reduce their rrumber of suppliers ond rely on the knowledge ond experience of Roseburg ond its supply choin portrrers, they corr sirlplify their business ond intprove their bottonr line. Roseburg's products crre ovcriloble oi over 2500 of Norih Arnerico's lorgesl ond rnost respecled wholesole ond pro yord disiribulion locotions.

TF800-245-llls

RlSl economists: Housins stock and vacancy

By Bob Berg, RISItTt"r

rMrNG oF THE HousrNG recovery hinges on two crit- I ical factors: the size of the inventory of vacant homes and the pace at which households are being formed. If we know these data, then we could develop so'iid estimates of how long it will take to absorb the excess inventorv of vacant homes

In past cycles, the market was not saddled with the level of vacant homes we currently have at the beginning of this recovery. In addition, solid recovery in the economy prevented household formations from straying far from the trend levels. Consequently, demand for new homes (additions to the housing stock) was quickly realized as the recovery unfolded.

In the current market, after more than a decade of excess production, we are saddled with a sisnificant volume of vacant homes and the slow pace -of economic recovery (which is in part due to the absence of a rebound in housing) is stifling job creation and putting downward pressure on household formations.

Focusing here on the vacancy issue, our inability to generate a solid estimate for vacancies arises from the inherent errors in the reported data and the difficulty in differentiating between total housing stock and economically viable housing stock. Errors in the reported data are due to the facts that the data are only updated once every 10 years during the Census and that in the interim years they are based on estimates that at the time seem quite confusing.

As a stock concept, housing stock at the end of a year is equal to housing stock at the end of the previous year plus additions (housing completions and mobile homes) minus subtractions (demolitions) during the year.

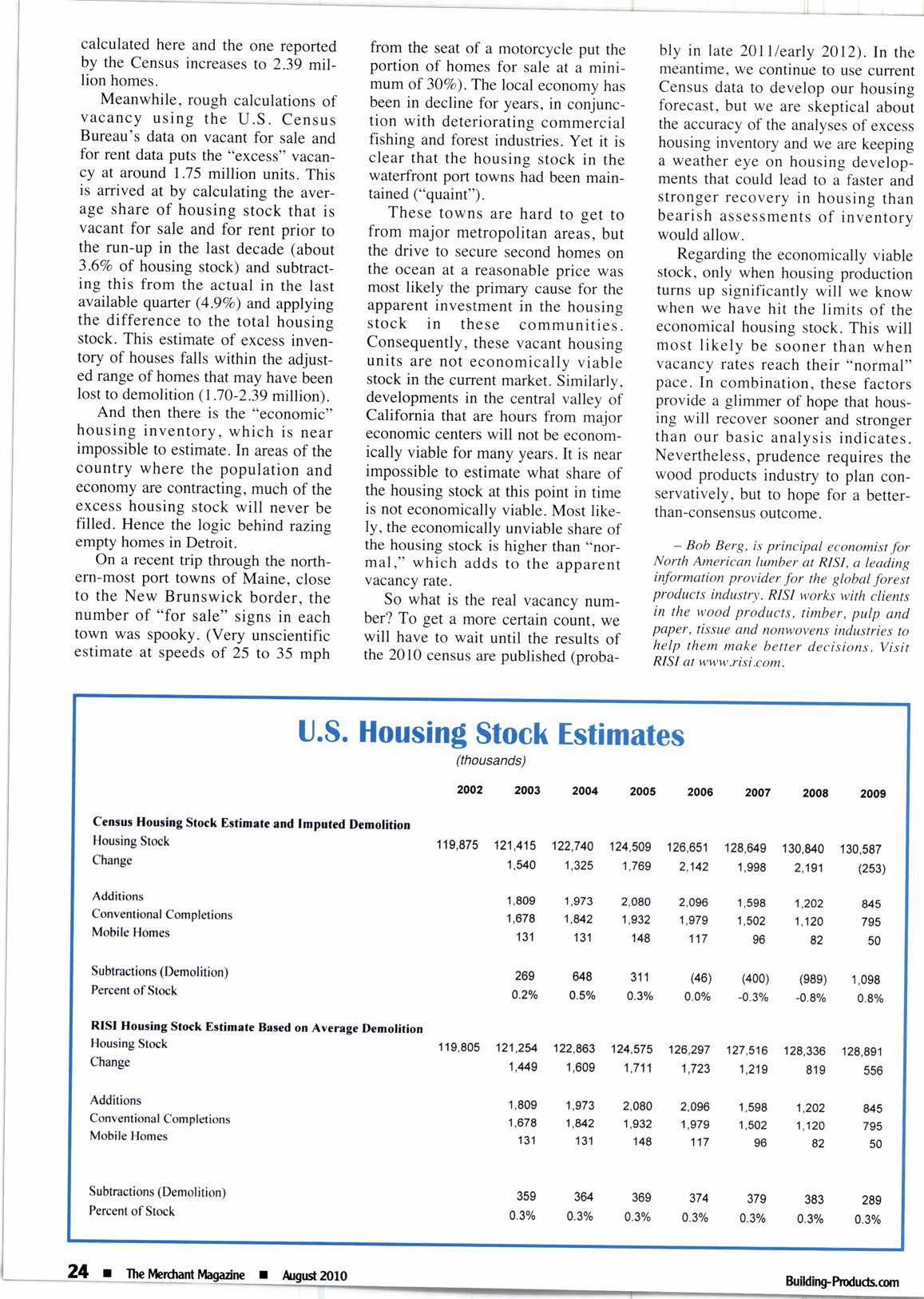

The table on page 26 contains the U.S. Census housing stock estimate from 2002 (when the data was last updated with the results of the 2000 census) through 2009 along with the housing completions (reported by the U.S. Census) and mobile home production (reported by The Institute for Building Technology & Safety). Given the housing stock and additions data (completions and mobile homes), one can calculate the demolitions used in developing the housing stock data. These demolition data are presented at the top of the table.

The confusing part of these data is the fact that the demolitions are negative in 2006-2008. Over this period, in effect, 1.44 million housing units were added to the inventory as a result of "demolition." During the very strong peak demand years in the 1970s, we experienced this same phenomenon as alternative buildings (i.e., old factories) were converted into housing faster than the rate at which houses were lost to natural and intentional demolition.

However, during the period 2006-2008, demand turned lower and it became increasingly evident that excess housing inventory was built. Consequently, one has to question whether the apparent net additions (rather than removals) reported under the demolitions category actually occurred. Then in 2O09, apparent demolitions shot up to just over 1 .0 million units, which was almost three times the average demolition pace in 2002-2005. The average demolition rate in2006-2009 was0.0l%o of the housing stock, which compares to a rate of 0 .3Vo per year in previous years.

The table also contains the housing stock estimated by holding the demolition rate at 0.3Vo for the entire period, the observed average in 2000-2005. Using this demolition assumption, the housing stock at the end of 2009 would be fully 1.70 million units fewer than reported by the U.S. Census. The analysis gets even more interesting because there are reports of increased intentional demolition (i.e., Detroit and some of the central valley homes in southern California). If you boost the demolition rate to just 0.52o in 2008 and 2009, the difference between the inventory level

RAW MATERIALS

$wanson operates under some of the most stringent forest harvesting practices on the planet. For verification, our SFI Certi' fication ensures that our timber resour@s are managed for sustainability and environmental rcsponsibility, protecting species, habitat, and water resources'

RENEWABLE ENERGY COMMITMENT

Three of Swanson's five mills are wod<ing with Pacific Powe/s Blue Sky program to purchase energy from renewable sources. Over the course of a year, this commitment by Swanson avoids putting 1,108 tons of carbon dioxide into the atmosphere.

CULTURE OF GREEN

We are focusing on the ftrture by creating a sustrainable culture that permeates the entire company. Swanson is located in a very green part of the world. we plan to keep it that way. After all, its our way of life'

calculated here and the one reported by the Census increases to 2.39 mlllion homes.

Meanwhile, rough calculations of vacancy using the U.S. Census Bureau's data on vacant for sale and for rent data puts the "excess" vacancy at around 1.75 million units. This is arrived at by calculating the average share of housing stock that is vacant for sale and for rent prior to the run-up in the last decade (about 3.6Vo of housing stock) and subtracting this from the actual in the last available quarter (4.9Vo) and applying the difference to the total housins stock. This estimate of excess invenl tory of houses falls within the adjusted range of homes that may have been lost to demolition (l 30-239 million).

And then there is the "economic" housing inventory, which is near impossible to estimate. In areas of the country where the population and economy are contracting, much of the excess housing stock will never be filled. Hence the logic behind razing empty homes in Detroit.

On a recent trip through the northern-most port towns of Maine, close to the New Brunswick border. the number of "for sale" signs in each town was spooky. (Very unscientific estimate at speeds of 25 to 35 mph

from the seat of a motorcycle put the portion of homes for sale at a minimum of 3}Vo).The local economy has been in decline for years, in conjunction with deteriorating commercial fishing and forest industries. Yet it is clear that the housing stock in the waterfront port towns had been maintained ("quaint").

These towns are hard to set to from major metropolitan area-s, but the drive to secure second homes on the ocean at a reasonable price was most likely the primary cause for the apparent investment in the housing stockin these communities. Consequently, these vacant housing units are not economically viable stock in the current market. Similarlv. developments in the central valley of California that are hours from major economic centers will not be economically viable for many years. It is near impossible to estimate what share of the housing stock at this point in time is not economically viable. Most likely, the economically unviable share of the housing stock is higher than "normal ," which adds to the apparent vacancy rate.

So what is the real vacancy number? To get a more certain count, we will have to wait until the results of the 2010 census are published (proba-

bly in late 2}lllearly 2Ol2). tn the meantime, we continue to use current Census data to develop our housing forecast, but we are skeptical about the accuracy of the analyses of excess housing inventory and we are keeping a weather eye on housing developments that could lead to a faster and stronger recovery in housing than bearish assessments of inventory would allow.

Regarding the economically viable stock, only when housing production turns up significantly will we know when we have hit the limits of the economical housing stock. This will most likely be sooner than when vacancy rates reach their "normal" pace. In combination, these factors provide a glimmer of hope that housing will recover sooner and stronger than our basic analysis indicates. Nevertheless, prudence requires the wood products industry to plan conservatively, but to hope for a betterthan-consensus outcome.

- Bob Berg, is principal economist for North American lumber at RISI, a leading information provider for the global forest products industry. RISI works with clients in the wood products, timber, pulp and paper, tissue and nonwovens industries to help them make better decisions. Visit RISI at www.risi.com.

U.S. Housing Stock Estimates

High Quality

Beautiful Color

. premrum quailry, starned cedar fencrnr;

r # 1 & BIr.2face

. no nole, no wane

. no downfall

. kiln-dried {or stability

.lrghtweight & easy to work with

dog-eared & square top

beautiful natural redwood heart water based stain

r factory applred custom stain, increased color stability

. end sealant reduces water ingress

. better lonq terrn weatlrering

The value of a wholesaler

tTtse sUPPLY cHntN for lumber and |- buitdinn materials can be long and complex, *Ith -uny variables.

Think about it. The production process alone includes timber, lumber production, transportation, secondary manufacturing, distribution, retail, and installation. That doesn't even include the supporting services such as credit, inventory, taxes, regulatory compliance, and marketing. Making sure a product finds a market can be daunting. Wholesale lumber distributors

play a vital role providing suppliers and users the value everyone needs to succeed.

As the central link of the supply chain, wholesale distributors have a part in supply meeting demand. In today's fast-moving economy, wholesalers can help lower procurement costs, broaden product selection, and add value to products.

The last few decades have seen a significant shift to just-in-time delivery of products becoming the industry

standard. Each company has to run lean to even consider making a profit. Wholesale distributors offer this ability in quantities ranging from multiple rail cars down to individual pieces. By working with a wholesaler, a buyer can have faster inventory turnover to lower costs and free up much needed cash for further investment.

A major benefit of wholesale distribution is the wide product selection that a buyer would otherwise have to receive from multiple sources. Instead,

it can be done with one-stoP shoPping. Because wholesalers are buying from many different producers, buyers can tailor their Products and species to the needs of their clients at a much lower cost.

In addition to offering a wide range of products, wholesalers can also provide unique value-added services, such as packaging, remanufacturing, and treatments. BuYers can often receive innovative product training and services to help sell products.

Wholesalers don't just bring value to the buyer; they also can help a producer succeed. Manufacturers often have to spend years establishing new distribution networks or adapting existins ones. Wholesalers have a

long history of knowing buYers and the markets. By working with a wholesale distributor, a producer can focus on its core business model.

As niche markets increase in importance and profitability, producers and suppliers need expertise and exoerience to create customization. brinding, and marketing for products. Wholesalers can often remanufacture a product in resPonse to market changes and also have experience in creating promotional camPaigns.

Wholesalers function as a crucial link between the manufacturer and the retailer, adding value along the supply chain. They can help ensure that the right product meets the right market at the risht time.

Technology helps LBM businesses weather economic storm

I unorNc MATERTAL business leadI-lers have been forced to make some tough decisions in the current recession. Although a natural instinct is to cut spending across all depart-

By Jim Hassenstab, DMSi ments,it's not always the best one. Technology investments can actually help your business weather through the current economic storm.

Increase productivity while reducing costs

Information systems streamline business operations and help you do more with less. By investing in new technologies and automating business processes, you can run your business more efficiently. It may even be a good time to consider moving your systems "into the clouds."

Cloud computing, also known as Software as a Service (SaaS), is the future of technology. It's a viable option for many companies to reduce costs and eliminate many of the issues that can accompany traditional software models. With a minimal investment, customers can access software over the Internet and never have to worry about investing in new infrastructure, training new personnel, or licensing new software.

LUMBER WHOLESALERS are cutting costs by employing the latest logistics technology, such as Appian Logistics'Direct Route, whiciicreatesihe most elonomical deh.very rourei giv6il lJyoue1. times, multiple day time-windows, Dor drive time regulations, and other factois. - - - "

Crow's Market & Price Service

The most comprehensive market & price service covering the North American lumber and panel market.

As a subscriber to crow's Market & Price service you'll get the following great features:

, Crou's Weekly Marhet Report, the longest-running & most respected lumber & panel price reporting publications in North America.

' crous's Price watch - an online service that allows you to analyze price trends and instantly see which prices are up and down and by how much.

' Crow'a Lurnber & Panel News Seruice - a comprehensive & reliable daily news service covering the latest lumber news & wood products industry developments

. AIS/'6 Lumber & Panel Outlooh a weekly analysis of wood products markets by RISI's economists - the most trusted source of forecastins in the North American industrl'.

"I first saw software hosted throush the Internet at a NAWLA tradeshJw and its potential was obvious to me," says David Zappone, general manager of Timber Trading Group, Worcester,

Crow's Gonstnrction ttdorials

Co$lndq - {6SC0

Ct/l?t is a weekfi ufrated indexhat s_hows the inpad of changing prices for a real world ap$batkn usd in residential singb family hone construction. hMuds used in the index are fro* tlwrnaterials list tu an actual hone plan.

Ma. "The SaaS program allows everyone in our office to be more mobile, more productive, and offer customers realtime answers when out of the office."

Gain competitive advantage and customer loyalty

With both businesses and consumers strictly evaluating their budgets and spending, it is more important than ever to differentiate yourself from the competition. While your competitors are cutting their technology budgets, you have the opportunity to expand market share. By leveraging technology, you can create innovative products and services or implement a new business approach to increase customer loyalty.

Optimizing the transportation process is one of the most impactful ways to reduce overhead. A centralized dispatch solution can significantly cut transportation costs and maximize profitability of sales. In addition, these solutions improve customer service by reducing wait time and eliminating backorders.

"We feel that our ODT (order delivery tracking) software gives us the real-time information we need to make sound financial and customer service decisions that are so critical to our business, especially in the cunent economic environment," says Alan Harwood, c.f.o. of Epperson Specialty Woods, Statesville, N.C. "ODT has become a critical component within our daily operation, as well as a contributor to the long-term profitability of our business."

Know your business

In the modern business world, knowledge is the single most important factor that can make or break a company. A good business intelligence system will help monitor various data, such as sales, profits, amounts lost in small transaction fees, and amounts paid originally. By pinpointing exactly where costs need to be cut or new systems put in place, your company is poised to increase profitability.

Viewing and interacting with data is now easier than ever before when using business intelligence applications. Information that used to take hours to compile is now just a few clicks away, allowing business owners to make key decisions quickly. Business intelligence applications allow users to interactively zero in on answers to business performance questions, instantly detect trends, and respond to the ever-changing events occurring in distribution.

"Before, if someone called asking for information, I ran to the cabinet to pull their file," says Mike Finn, vice president of SEEMAC Inc., Carmel, In. "A report was only upto-date the day it was printed. Today,I tap into the computer to retrieve real-time information. If everyone is doing their job, the information is always current."

Invest in the future

The economy will rebound eventually, and you need to be ready to hit the ground running when it does. While business has slowed and workloads have decreased, it is a perfect time to plan and implement IT infrastructure improvements. This way, when business does pick up, you will be better prepared and able to respond to growth.

In business, as in nature, the strong survive. Rather than trying to coast through the down economy, building material companies should consider ways to strengthen, improve. and grow business. This will better your chances of "survival" and enhance the future ofyour company.

- Jim Hassenstab is c.e.o. of Distribution Management Systems Inc., Omaha, Ne. He can be reached at (800) 347-6720 or jhassenstab@ dmsi.com.

Stop the bleeding!

Why an uneducated sales force is

the biggest single drain on corporate profits

tTt"t FoLLowrNG sceNnnto plays

I over and over again in every one of your sales territories every day. And it costs you hundreds of thousands of dollars annually.

I was working with one of my client's salespeople. The client was an HVAC commercial contractor. The salesman had an appointment with a prospect who had called and requested a visit. As we introduced ourselves, the prospect said, "We added on office space to our building a couple years ago, but we never expanded the air conditioning capacity. We'd like to get an idea of what it would cost to do so now."

The salesman asked to see the space. There, he took out a tape measure and note pad, dutifully measured the space, and outlined it in the notebook. Then he asked to see the existing unit. The prospect took us up into the attic and pointed out the unit, resting on a platform off to one corner.

By Dave Kahle, DaCo Corp.The salesman gingerly worked his way over to it, inspected it carefully, took some more notes, and slowly worked his way back to where we stood. "I have everything I need," he said. "Can I fax you a detailed quote in the next 24 hours?"

"Sure," said the prospect. The salesperson prepared to leave, intent on going back to the office, working out the detailed quote, and then faxing it to the prospect.

I felt the need to intervene. "Can I ask a question?"

"Sure," said the prospect.

"If you like the quote, what is the prospect of you placing an order in the next few weeks?"

"Oh. none at all." he said. "The boss just wants to get an estimate. If it's within reason, he'll put it on the budget and do it sometime next year."

"So," I said, "you really don't need a detailed proposal at this point, do you?"

"Not really. I just need a ballpark to give to the boss."

I turned to the salesman. "What's a ballpark price?"

"$3,500," he said.

The prospect thanked us, and we were on our way.