Clara Bucar Fit Construction LP 1666 Callowhill St Philadelphia, PA Master of Science in Construction Management Thomas Jefferson University MCM 901 Masters Project Summer 2018 Instructor: Professor Bennett Colesberry Advisor: Tony Maras Clara Bucar Fit Construction LP 1666 Callowhill St Philadelphia, PA Master of Science in Construction Management Thomas Jefferson University MCM 901 Masters Project Summer 2018 Instructor: Professor Bennett Colesberry Advisor: Tony Maras

For the 620 N 3rd St project, we are aiming to transform issues into opportunities for improvement. Two aspects were identified as this project’s major challenges: the site location and layout and the incomplete design. First, the building will occupy the entire lot, leaving no space for construction staging, while also being located in a very densely populated residential area with no possibility for storage close by. This scenario forces strong communication and coordination between team members, as well as efficiency in material delivery and handling, cutting back waste in the form of time, material and effort, an ideal situation for LEAN implementation.

Fit Construction will provide in this manual, information about itemized budget, detailed schedule, construction risk administration divided into risk management, environmental, quality and safety, the demonstration of the BIM model to be updated and utilized all throughout the project, explanations on our management means, methods and processes, our layout for site logistics, suggestions for LEED Silver certification and more. This manual allows for a deep understanding of how Fit Construction will, by using a continual learning strategy, successfully manage the 620 N 3rd St project into completion on time, on budget, safely while upholding the highest quality standards.

All of these factors allows us to do what we do best: planning. This manual represents the consolidation of years of documented information and analysis of past projects applied to the reality of the 620 N 3rd St project, with a hint of creativity to foresee and prepare for potential future challenges.

This manual concerns the full planning of the 620 N 3rd St project, a five story multifamily residential building to be constructed in the Northern Liberties neighborhood in Philadelphia, PA. Close to Center City, this area has become one of Philadelphia’s hottest spots for real estate developers and families looking forward to buying or renting a home. This project, estimated at $3,016,360, will encompass 28,536 square feet distributed in nine residential units and made up of high end finishes and materials. Two of these units will have private roof decks. The building also has nine parking spots, an elevator and a shared roof deck. The structure is basically composed of a concrete and steel structure basement and first floor, wood structure and framing from the second floor up to the roof. Our company, Fit Construction, feels strongly about technology, relationships and people. We invest on BIM, Lean and LEED as ways of improving the quality of the service we provide our clients. Our bonds are tight with our employees and subcontractors, the core of our business.

08/01/2018MCM 901 Page 1 of 224 Master Thesis: 620 N 3rd St Clara Bucar INTRODUCTION

Considering the scenario, Fit Construction, PRDC, and the Owner, decided on a form of light IPD with the maintenance of the traditional Design-Bid-Build contractual relationships. The delivery method counts on monthly revisions to the scope to foresee and plan for upcoming changes while keeping full cost transparency on a cost plus a fee basis with an incentives program. An audacious plan that could, in the future, guide the way for more efficient processes.

Second, the agile decision to move forward with the plan to accelerate the construction schedule to start in 2018, despite of the incompleteness and inaccuracy identified in the set of construction drawings, drives for a flexible delivery method that’s able to quickly accommodate changes.

08/01/2018MCM 901 Page 2 of 224 Master Thesis: 620 N 3rd St Clara Bucar SECTION ONE - Company Information 1.1. Company Overview - Page 12 1.2 Company Organizational Chart - Page 15 1.3. Interaction Between Home Office and Field - Page 16 SECTION TWO - Project Information 2.1. Project Overview - Page 18 2.2. Project Organizational Chart - Page 19 2.3. Project Management Team Responsibilities Matrix - Page 20 2.4. Project Delivery Method Analysis - Page 22 2.5. Construction Administration / Communication - Page 23 2.6 Construction Risk Administration - Page 24 SECTION THREE - BIM Model 3.1. Floor Plans - Page 26 3.2. Building and Wall Sections - Page 32 3.3. Elevations - Page 37 3.4. Aerial Perspectives - Page 40 3.5. Renderings - Page 42 3.6. Cross Sections - Page 43 SECTION FOUR - WBS, Estimates, Schedules, Cash Flow 4.1. Work Breakdown Structure - Page 47 4.2. Basis of the Estimate - Page 64 4.3. Estimate Summary - Page 65 4.4. Division 01 - General Requirements - Page 66 4.5. Detailed Estimate Backup - Page 68 4.6. Masonry Detailed Back-up (Self Performed) - Page 73 TABLE OF CONTENTS

08/01/2018MCM 901 Page 3 of 224 Master Thesis: 620 N 3rd St Clara Bucar 4.7. Estimate Summary - LEED Option - Page 74 4.8. Detailed Estimate Backup - LEED Option - Page 75 4.9. Design and Preconstruction Schedule - Page 81 4.10. Procurement and Buy Out Log - Page 84 4.11. Submittal Schedule - Page 87 4.12. Schedule Summary with Milestones - Page 88 4.13. Construction Schedule with Critical Path - Page 89 4.14 Cash Flow - Page 113 4.15. Cash Flow Graphics - Page 114 SECTION FIVE - Site Layout and Logistics Plan 5.1. The Project, the Surrounding Community and Local Street Access - Page 116 5.2. Access to the Site - Page 117 5.3. Typical Working Hours and Days - Page 117 5.4. Safety for Pedestrians and Traffic Management - Page 117 5.5. Construction Staging and Parking Areas - Page 117 5.6. Material Delivery and Storage - Page 119 5.7. Mobilization Phasing - Page 119 5.8. Pre-Shell Phasing - Page 120 5.9. Post-Shell Phasing - Page 121 5.10. Waste Management - Page 122 5.11. Construction Impact Control And Community Relationship - Page 122 5.12. Clean-Up, Final Clean And Closeout - Page 122 5.13. Snow Removal - Page 122 5.14. Illustrated Construction Sequence - Page 123 SECTION SIX - Management Means, Methods and Controls 6.1. Preconstruction - Page 126 6.1.1. Delivery Method, Constructability And Value Engineering - Page 126

08/01/2018MCM 901 Page 4 of 224 Master Thesis: 620 N 3rd St Clara Bucar 6.1.2. Incentives Program - Page 126 6.1.3. Procurement - Page 127 6.1.4. Bonds and Insurance - Page 127 6.1.5. Mobilization - Page 127 6.1.6. Project Organization - Page 127 6.2. Construction - Page 128 6.2.1. Work Hours - Page 128 6.2.2. On Site Supervision And Home Office Support - Page 128 6.2.3. Subcontractors And Vendors - Page 129 6.2.4. Payment - Page 129 6.2.5. Organization Of The Site - Page 129 6.2.6. Safety And Health - Page 129 6.2.6. Quality Assurance - Page 130 6.2.7. Equipment - Page 130 6.2.8. Masonry (Self-Performed) - Page 130 6.2.9. Change Orders - Page 130 6.3. Communications - Page 130 6.3.1. Documentation - Page 131 6.3.2. Rfp: Request For Proposal - Page 131 6.3.3. Rfc: Request For Clarification - Page 131 6.3.4. Rfi: Request For Information - Page 131 6.3.5. Submittals And Transmittals - Page 131 6.3.6. Weekly Progress Reports - Page 132 6.3.7. Meetings - Page 132 6.4. Closeout - Page 132 SECTION SEVEN - Project Risk Management Analysis 7.1. Site Specific Risk Breakdown Structure - Page 135 7.2. Risk Register - Page 136

08/01/2018MCM 901 Page 5 of 224 Master Thesis: 620 N 3rd St Clara Bucar 7.3. Project Team Risk Responsibility Matrix - Page 138 7.4. Management Plans for the ‘Top Five’ Risks 7.4.1. Material Delivery And Storage Difficulty - Impact To Schedule - Page 139 7.4.2. Need For Highly Efficient Coordination - Page 139 7.4.3. Incomplete/Inaccurate Construction Documents - Page 140 7.4.4. Scarcity Of Qualified Subcontractors Due To High Season - Page 140 7.4.5. Disputes Over Budget Due To Delivery System (IDP) - Page 141 SECTION EIGHT - Site Specific Safety Plan 8.1. Site Specific Safety Management System - Page 143 8.2. Site Specific Safety Hazard Analysis - Page 145 8.3. Management Plans for the ‘Top Five’ Safety Hazards 8.3.1. Falls - Page 147 8.3.2. Electrocution - Page 148 8.3.3. Impalement - Page 149 8.3.4. Structure Collapsing - Page 149 8.3.5. Toxic Fume Inhaling - Page 150 SECTION NINE - Site Specific Environmental Plan 9.1. Site Specific Environmental Management System - Page 153 9.2. Site Specific Environmental Impacts - Page 154 9.3. Management Plans for the ‘Top Five’ Environmental Aspects 9.3.1. Air Pollution - Page 155 9.3.2. Waste Pollution - Page 156 9.3.3. Noise Pollution And Vibration - Page 156 9.3.4.Traffic Issues - Page 157 9.3.5. Pedestrian Experience Risk - Page 158

08/01/2018MCM 901 Page 6 of 224 Master Thesis: 620 N 3rd St Clara Bucar SECTION TEN - Site Specific QA/QC Plan 10.1. Site Specific Quality Management System - Page 160 10.2. Contract Quality Requirements - Page 161 10.3. Management Plans for the ‘Top Five’ Quality Issues 10.3.1. Concrete - Page 163 10.3.2. Steel - Page 163 10.3.3. Wood Framing - Page 164 10.3.4. Plumbing - Page 164 10.3.5. Mechanical - Page 165 SECTION ELEVEN - LEED Silver Credentials 11.1. Minimum Program Requirements (MPRs) 11.1.1. Location and Transportation - Page 167 11.1.2. Sustainable Sites - Page 167 11.1.3. Water Efficiency - Page 167 11.1.4. Energy and Atmosphere - Page 168 11.1.5. Materials and Resources - Page 168 11.1.6. Indoor Environmental Quality - Page 169 11.1.7. Innovation - Page 169 11.2. LEED v4 Scorecard - Page 170 REFERENCES - Page 171 APPENDIX Table of Contents - Page 173 A. Original Drawings and Specifications - Page 175 B. Management Means and Methods Referenced Documents and Forms - Page 180 C. LEED v4 - Requirements and Specs - Page 186 D. Agreement and Contracts - Page 216

08/01/2018MCM 901 Page 7 of 224 Master Thesis: 620 N 3rd St Clara Bucar Section One: Company Information FIGURE 01: The beach house, 2012: Fortaleza, Brazil - Page 13 FIGURE 02: Fortaleza Art Museum, 2015: Fortaleza, Brazil - Page 13 FIGURE 03: Sapiranga Social Housing Complex, 2016: Fortaleza, Brazil - Page 14 FIGURE 04: United Nations New Canopies, 2016: New York City, NY - Page 14 FIGURE 05: Company Organizational Chart - Page 15 Section Two: Project Information FIGURE 06: Project Location - Page 118 FIGURE 07: Project Organizational Chart - Page 119 Section Three: BIM Model FIGURE 08: Floor Plan - Basement - Page 26 FIGURE 09: Floor Plan - 1st Floor - Page 27 FIGURE 10: Floor Plan - 2nd Floor - Page 28 FIGURE 11: Floor Plan - 3rd Floor - Page 29 FIGURE 12: Floor Plan - 4th Floor - Page 30 FIGURE 13: Floor Plan - Roof - Page 31 FIGURE 14: Section AA - Page 32 FIGURE 15: Section BB - Page 33 FIGURE 16: Section Cc - Page 33 FIGURE 17: Section Dd - Page 34 FIGURE 18: Section Ee - Page 35 FIGURE 19: Section Through Southeast Wall - Page 36 FIGURE 20: East Elevation - Page 37 FIGURE 21: West Elevation - Page 37 FIGURE 22: South Elevation - Page 38 FIGURE 23: North Elevation - Page 39 LIST OF FIGURES

08/01/2018MCM 901 Page 8 of 224 Master Thesis: 620 N 3rd St Clara Bucar FIGURE 24: Aerial Perspective - Page 40 FIGURE 25: Aerial Perspective - Page 41 FIGURE 26: Renderings - Page 42 FIGURE 27: Renderings - Page 42 FIGURE 28: Cross Section - Page 43 FIGURE 29: Cross Section - Page 44 FIGURE 30: Cross Section - Page 44 FIGURE 31: Cross Section - Page 45 Section Five: Site Layout and Logistics Plan FIGURE 32: Google Maps. North 3rd Street view - Page 115 FIGURE 33: Google Maps. North Galloway Street view - Page 116 FIGURE 34: Regional Plan - Page 118 FIGURE 35: Mobilization Logistics - Page 119 FIGURE 36: Pre-Shell Logistics - Page 120 FIGURE 37: Post Shell Logistics - Page 121 FIGURE 38: Illustrated Construction Sequence (1) - Page 123 FIGURE 39: Illustrated Construction Sequence (2) - Page 123 FIGURE 40: Illustrated Construction Sequence (3) - Page 123 FIGURE 41: Illustrated Construction Sequence (4) - Page 123 FIGURE 42: Illustrated Construction Sequence (5) - Page 124 FIGURE 43: Illustrated Construction Sequence (6) - Page 124 FIGURE 43: Illustrated Construction Sequence (7) - Page 124 Section Seven: Project Risk Management Analysis FIGURE 44: Site Specific Risk Breakdown Structure - Page 135

08/01/2018MCM 901 Page 9 of 224 Master Thesis: 620 N 3rd St Clara Bucar Section Two: Project Information TABLE 01: Project Management Team Responsibilities Matrix - Pages 20 to 21 Section Four: WBS, Estimates, Schedules and Cashflow TABLE 02: Estimate: Basis of the Estimate - Page 64 TABLE 03: Estimate Summary - Page 65 TABLE 04: Division 01 - General Requirements - Pages 66 to 67 TABLE 05: Detailed estimate back-up - Pages 68 to 72 TABLE 06: Masonry Detailed Back-up (Self Performed) - Page 73 TABLE 07: Estimate Summary - LEED - Page 74 TABLE 08: Detailed Estimate Backup - LEED - Pages 75 to 80 TABLE 09: Design and Preconstruction Schedule - Pages 81 to 83 TABLE 10: Procurement and Buy Out Log - Pages 84 to 86 TABLE 11: Submittal Calculator - Page 87 TABLE 12: Schedule Summary with Milestones - Page 88 TABLE 13: Construction Schedule with Critical Path - Pages 89 to 112 TABLE 14: Cash Flow - Page 113 TABLE 15: Cash Flow Graphics - Page 114 Section Seven: Project Risk Management Analysis TABLE 16: Risk Register - Pages 136 to 137 TABLE 17: Project Team Risk Responsibility Matrix - Page 138 Section Eight: Site Specific Safety Plan TABLE 18: Description - Page 144 TABLE 19: Hazard Matrix - Page 144 TABLE 20: Site Specific Safety Hazard Analysis - Pages 145 to 146 LIST OF TABLES

08/01/2018MCM 901 Page 10 of 224 Master Thesis: 620 N 3rd St Clara Bucar Section Nine: Site Specific Environmental Plan TABLE 21: Site Specific Environmental Impacts - Page 154 Section Ten: Site Specific QA/QC Plan TABLE 22: Contract Quality Requirements - Pages 161 to 162 Section Eleven: LEED TABLE 23: LEED v4 Scorecard - Page 170

Section One will describe Fit Construction, its trajectory, past projects, strengths, values and communications. For that, a company’s written description can be found, as well as images and legends of successful projects. A diagram displaying how the company is organized can provide valuable information as to its processes and hierarchy. Lastly, this section aims to inform how the staff at the construction site maintains efficient communications with the home office, given that the project management happens in both worlds at the same time.

SECTION ONE COMPANY INFORMATION

08/01/2018MCM 901 Page 11 of 224 Master Thesis: 620 N 3rd St Clara Bucar

Currently, Fit Construction has over two hundred direct employees and several hundred people working as subcontractors, having reached a revenue of $85mi in 2017. Please see some of our completed projects within the next pages.

We love construction and believe there is no such thing as a perfect project, there is always room for improvement. That is what we work for!

08/01/2018MCM 901 Page 12 of 224 Master Thesis: 620 N 3rd St Clara Bucar 1.2. Company overview and data sheets

Fit Construction was founded by Clara Bucar in 2012. Initially, the company worked with small commercial and residential fit outs, providing design and construction, often on a Design-Build delivery method basis. Since then, the company has grown to perform a variety of small and mid size new construction and fit outs, as well as providing specific consulting services, such as LEAN and TechnologyLEED.isafocus point for Fit Construction. We invest in technologies such as Procore and BIM to provide excellence in management and quality. We invest even higher in the continued education for our employees, looking forward to making them feel valued and invested on as a way of maintaining our talents. Our people are our greatest strength.

08/01/2018MCM 901 Page 13 of 224 Master Thesis: 620 N 3rd St Clara Bucar 01 02 Fortaleza Art Museum, 2015: Fortaleza, Brazil. Budget: $10mi. Design Build. The beach house, 2012: Build.$500,000.Brazil.Fortaleza,Budget:Design

08/01/2018MCM 901 Page 14 of 224 Master Thesis: 620 N 3rd St Clara Bucar03 Sapiranga Social Housing Complex, 2016: Fortaleza, Brazil. Budget: $25mi. Design Build. United Nations New Canopies, 2016: New York City, NY. Budget: $4mi. 03 North Canopy

08/01/2018MCM 901 Page 15 of 224 Master Thesis: 620 N 3rd St Clara Bucar Fit Construction Board of PresidentDirectors (VManagementicepresident of construction) (OperationsOperationsDirector) HR (HR Director) SuperintendantGeneralSuperintendant (EstimatingEstimatingDirector) Senior AssistantManagerManagerProjectProjectPM Field Engineer PersonnelInsuranceManagerOffice EstimatorEstimatorSenior (MarketingMarketingDirector)(ProcurementProcurementDirector) EngineerProject DevelopmentMarketingSpecialistBusinessMaterialsProcurementManagerandNecessities (FinancialFinancesDirector)AccountantControllerCostEngineer EnvironmentalManagerSafetyQualityManagerManager BIM(BIMDepartmentManager)BIMEngineer 1.2. Company Organizational Chart

Every week, the Project Manager, the Owner, the Designer and other relevant project participants do a walk through the site with the Site Superintendent and the Field Engineer to identify results and challenges. This is another important strategy to keep communications effective: making the subjects concrete, instead of just an abstract subject line on an email.

In addition, the Site Superintendent participates on biweekly meetings with the General Superintendent and other superintendents to discuss each project. These meetings are held at the office and are useful to share strategies and results all across Fit Construction’s projects.

08/01/2018MCM 901 Page 16 of 224 Master Thesis: 620 N 3rd St Clara Bucar 1.3. Interaction between home office and field

The interactions between home office and field happen in different ways. All projects participants, especially those from Fit Construction, are connected at all time through the construction software, Procore. With Procore, all project communications, including emails, occur through the software and are automatically documented on the cloud. One of the Field Engineer’s primary responsibilities is to compose a daily report of the construction. This daily report is submitted to the Project Manager and all other relevant project participants.

Lastly, Fit Construction, being based in Philadelphia, allows for a direct line of communication with our staff, the 620 N 3rd St and the owner. All project participants are welcome to reach out to us at our office with any questions or concerns.

08/01/2018MCM 901 Page 17 of 224 Master Thesis: 620 N 3rd St Clara Bucar

SECTION TWO PROJECT INFORMATION

Section Two will demonstrate project specific, variate pieces of information. It starts with a description of the project, it’s main components, structure and spaces. Then, a diagram showing the interactions between the project participants is displayed, providing useful information on the project’s hierarchy and communication dynamics, which can provide clarification on team communication. These same project participants are then listed under a responsibility matrix which describes their roles in each project task and phase. Another part of Section Two concerns the description of the delivery method approach. In the 620 N 3rd St project, an unconventional delivery method system was defined, composing an important part of the project. Lastly, this section provides information on how Fit Construction will handle construction communication, as well as a description of the risk administration method utilized to analyze and plan around management, safety, quality and environmental issues.

08/01/2018MCM 901 Page 18 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.1. Project Overview

A new basement, to host storage units and mechanical/electrical rooms, will be excavated and will occupy roughly half of the property. The first floor will have a garage with nine parking spaces, as well as access lobbies and a trash room. The second, third and fourth floor will each have three residential units, totaling nine apartments in the entire building. The roof will host a mechanical area, two separate private decks, as well as a shared deck and planters dividing the spaces. The structure of the building will be diversified. The basement and the on-grade portion of the first floor will be composed of concrete slabs and columns, in addition to structural steel columns and beams. The other portion of the first floor and the second floor are structural steel with metal decking and poured concrete. From the second floor “floor” and up, the structure is all wood, including the roof and the exterior walls, with few exceptions.

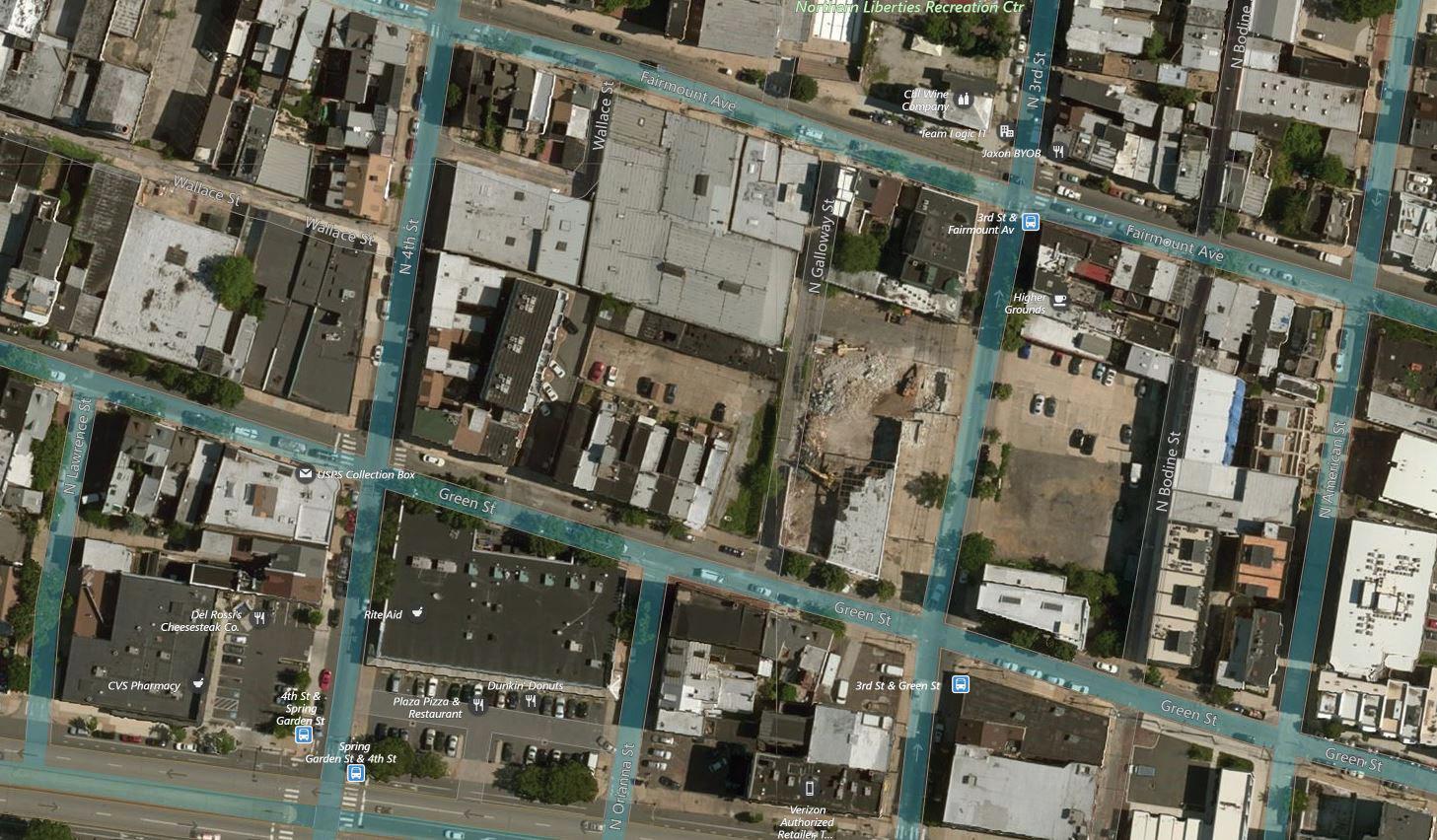

The 620 N 3rd St project consists of a residential, multifamily building located at 620 N 3rd St, Northern Liberties, Philadelphia - PA (highlighted on the map below). It’s composed of basement, ground level, 3 floors of residential units and a deck on the roof. The site, which can be accessed from both N 3rd St and N Galloway St, will be completely occupied with construction.

The vertical circulations are two stairs, one on each side of the building, and one elevator. The elevator shaft structure is masonry. Further details will be demonstrated throughout this manual. Floor plans, elevations and sections Image: Bing.

On the upper right side, the Fit Construction home office staff which work closely with the 620 N 3rd St project are listed. These employees work mainly from the office but may perform frequent visits to the site to assure that specific parts of the project are running accordingly, such as Quality, Safety, etc. Others are not required to visit the site, but still deal with the project on a daily basis, such as the Accounting Lastly,Department.onthe lower right quadrant the construction site based participants are showed. Its important to highlight that the masonry scope of the project will be self-performed. The foreman and the crew at the site are coordinated by the Site Superintendent. At the site, the Site Superintendent is the main authority and contact point to the subcontractors. The Project Manager is, overall, the main line of communication for the project, this person is the contact for the Designer and the Owner and has the responsibility of translating decisions to the subcontractors’ Project Managers and the Site Superintendent.

Construction (Field) EnvironmentalManagerSafetyQualityManagerManager Preconstruction DevelopmentBusinessEstimatorProcurementManager Field Engineer (Masonry)Labor Office support Operations Director Senior Project Manager Fit Construction Project Manager Accountant Owner Designer Accounts (Subcontractors/payableVendors) Superintendant Subcontractors/Vendors receivableAccounts(Owner) superintendantGeneral BIM Engineer

The Project Organizational Chart displayed in this manual is a diagram that shows the main interactions between the project participants. On the upper left quadrant, the contractual relationships are highlighted in yellow arrows, while the white arrow represents the close yet non-contractual relation between Fit Construction and the Designer.

On the lower left side, the main departments involved with preconstruction are listed. These departments work on attracting clients and providing the Project Manager with essential information for the bid and the client communications.

08/01/2018MCM 901 Page 19 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.2. Project Organizational Chart

08/01/2018MCM 901 Page 20 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.3. Project Management Team Responsibilities Matrix ResponsibilityResponsibilityDeliverableP-PrimaryA-Approval Authority S - Support or ConsultingI-Informed Owner ExecutiveProject ManagerProject EngineerField SuperintendentGeneral Superintendent Accounting SuperintendentCraft ManagerQuality ManagerEnvironmental/Safety EngineerBim Estimator managerProcurement ForemenCraft Architect ConsultantsArchitect's Subcontractors/Vendors Preconstruction DocumentsDesign/Construction A S S I I I I I I I I I I I P P I Permitting S S S I S S I S I I I I I I P P I Project Delivery System P P A I I I I I I I I I I I I I I Estimating I S S I S S I I I I S P S I I I I Contracts P A S I I I S I I I I I S I A I I Procurement / Buyout Qualifications based A P P I I I S I I I S S P I I I S Award A P P I I I S I I I S S A I I I S Preplanning Mobilization I S S P P P I P I I I I I I I I P Construction Management I P P S A A I S I I I I I I I I S Equipment I A A S A A I A I I I I I P I I P Labor I A A S A A I A I I I I I P I I P Material I A A S A A I A I I I I I P I I P Cost Control A A A S A A P S I I I I I S I S S Payments A A A I S S P S I I I I I S I I I Change Orders

08/01/2018MCM 901 Page 21 of 224 Master Thesis: 620 N 3rd St Clara Bucar ResponsibilityResponsibilityDeliverableP-PrimaryA-Approval Authority S - Support or ConsultingI-Informed Owner ExecutiveProject ManagerProject EngineerField SuperintendentGeneral Superintendent Accounting SuperintendentCraft ManagerQuality ManagerEnvironmental/Safety EngineerBim Estimator managerProcurement ForemenCraft Architect ConsultantsArchitect's Subcontractors/Vendors Risk Management Risk Management Plan S P P S S S I I I I I S S I I I I Risk ImplementationManagement S P P S A A I I I I I S S I I I I Safety & Environmental Safety Plan I S S A A S I A I P I I I I I I I Safety Implementation I I I A A S I A I P I I I I I I I Quality Quality Control I S S P S S I S P I S I I S A A S Quality Assurance I P P S S S I A P I S I I S I I S Communications Documentation A P P P P P P S P P P P P S S S S RFIs I A P S P P I S I I S S S S P P S Submittals A A P S P P I S S I S S S S P P S Weekly Progress Reports I A P S P P I S S S S I I S S S S Closeout closeoutPunchlist/Punchlist A A P S P P I S P I I I I I S S S Owner training P A A P P P I S S I I I I S S S S Warranties/O&M Manual P A A P P P I S S I I I I S S S S Financial resolution P P P I S S P S I I I I S I I I I Demobilization I A A P P P I P I S I I I P I I I Final payment P P P I S S P S I I I I I I I I I

An unconventional method was established for the 620 N 3rd Project due to the specific circumstances. First, the Owner, PRDC Properties, is a real estate development company, which implies the assumption that, in this case, the client has experience with construction. Second, the plot of land has already been purchased through an expected deal and the loan payback is scheduled to start in 2020. This scenario tells that, unless this project happens as scheduled, starting in 2018 and ending 2020, financial losses due to underutilized resources will start to incur. It’s important to note that, for higher efficiency during construction, the beginning of Spring and all of Summer is the ideal time to develop the work.

The Designers, due to the unexpected nature of the deal on the plot, were hired on an urgency basis to develop the project. Consequently, the incompleteness of the construction drawings was made evident during the bid, closed to pre-qualified contractors, including Fit Construction. Given the scenario, a complicated construction process could be foreseen with too many change orders, delays and relationship issues. To help solve this puzzle, Fit Construction came up with a strategy to help avoid these risks while transforming those into opportunities. The method is composed of two parts:

08/01/2018MCM 901 Page 22 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.4. Project Delivery Method Analysis

2) Preconstruction, construction and closeout: As stated previously, the incompleteness of the construction documents was made evident during the bid. Fit Construction and PRDC had previously worked with a multi residential building in Philadelphia and, therefore, had a pre-established relationship which influenced the contracting company selection. After winning the bid, Fit Construction approached PRDC to discuss the work. In that meeting, the complex variables were listed and the decision for an integrated project delivery was made. The contractual relationships were maintained as traditionally, between the Owner and Contractor, and Owner and Designer separately. Likewise, all the subcontractors are contractually obligated to Fit Construction, not PRDC. The lump sum number established during the bid was set as a baseline on a cost plus a fee basis but Fit and PRDC agreed that many project changes were inevitable, and that flexibility was essential. For that, a monthly meeting with Owner, Contractor, Designer and main subcontractors was established. In these meetings, the project team would bring issues regarding the following months’ worth of work and discuss what changes could provide value engineering to the work. These changes, once approved by all relevant project participants including the Owner, would then be incorporated to the project. To ease the weight of a changing budget, Fit Construction agreed to work with open books, on a cost plus a fee basis with PRDC, who would have full transparency and control over the project. Additionally, an Incentives Program was laid to stimulate results. Further details of the 620 N 3rd St delivery methods are explained under Section Six of this manual.

1) Bid and award: Before and during the bid process, a traditional Design-Bid-Build with a lump sum was utilized. Fit Construction received the set of construction documents, estimated the costs and submitted the bid to PRDC Properties, having won the job.

Naturally for an integrated delivery method project, communication is encouraged between all project participants as much as possible. From a process point of view, the Project Manager is in the center of the major communications. This person is the Owner’s main contact point, as well as the Designer’s. The Project Manager translates the information circulated between Owner and Designer and makes decisions regarding the subcontractors and the construction site. The Project Manager communicates these decisions to the Site Superintendent, who is then responsible for implementing these directions at the site. Conversely, the subcontractors and Site Superintendent gather questions and concerns at the construction site and inform the Project Manager, who is then assigned to discuss it with Owner and Designer. The project specific communications are further explained under Section Six of this manual.

The 620 N 3rd St project was studied and analyzed holistically by Fit Construction. Work packages were established with portions of the project, which were then awarded to prequalified subcontractors. A Master Schedule was established and weekly reports, including updates on the real progress of the schedule, are to be submitted. Fit Construction will bill PRDC monthly on the work performed. The subcontractors also bill Fit Construction monthly and agree to a paywhen-paid contract. The work is to be tracked utilizing a percentage completion strategy and communicated to the Owner every week.

08/01/2018MCM 901 Page 23 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.5. Construction Administration / Communication

08/01/2018MCM 901 Page 24 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.6.

Construction Risk Administration

Essentially, a risk is a potential occurrence with a possible negative effect. Considering the singularity and customization of each project, to understand risks and opportunities before they happen are challenges faced even by the most experienced managers. At the same time, the success of the project is highly dependent of the risk evaluation process during early stages of construction. That makes Risk Administration a pivotal component of the construction industry and a keyconcern of Fit Construction. In compliance with the ISO-9001 approach, Fit Construction adopts the cyclical process of Planning - Doing - Checking - Acting - Reviewing to gather and analyze project data. The mentioned strategy provides accurate data to be applied into future projects, contributing to its success rates and the growth of Fit Construction. It also offers the opportunity to allow a comprehensive yet realistic brainstorming of scenarios with tangible outcomes for potentially complex situations.

Likewise, other project’s previously gathered and tested information was applied on the development of the 620 N 3rd St project as a part of its preconstruction process of risk assessment. In addition, Fit Construction workers’ experience is a key factor to look ahead and anticipate opportunities, empowering the project overall.

Construction Risk Administration will be divided into Risk Management, Safety, Environmental and Quality. For each of these, the process will encompass the following steps: 1) determining the project specific context; 2) recognizing risks; 3) examining probability and severity of registered ; 4) assessing and classifying the priority risks; 5) establishing strategies to approach the priority risks, 6) keeping track of the recognized outcomes of plans put in action; 7) assessment of the mentioned outcomes to provide continuity and 8) effective documentation to make information available for company members and future projects.

08/01/2018MCM 901 Page 25 of 224 Master Thesis: 620 N 3rd St Clara Bucar

Building Information Modeling (BIM) is a one of Fit Construction’s highest bets. The company strongly believes that technology can improve construction in different ways and provide efficiency. In Section Three, the BIM model built for the 620 N 3rd St project is demonstrated in floor plans, sections, elevations and rendered perspectives for a holistic understanding of the construction work. The referred BIM model is an important part of this project. It will be detailed weekly and utilized as a tool to provide deeper information on coordination issues, missing or faulty design, boundaries of each sub’s scope of work, precise take-offs for waste reduction and identification of construction issues before they happen. Section Three provides visual content on how the modeled information can be seen and analyzed.

SECTION THREE BIM MODEL

08/01/2018MCM 901 Page 26 of 224 Master Thesis: 620 N 3rd St Clara Bucar UP ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 Unit Storage 1 Pump Room 3 Peco Vault 4 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:03:216/10/201806 basementProject NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 3.1. Floor Plan - Basement

08/01/2018MCM 901 Page 27 of 224 Master Thesis: 620 N 3rd St Clara Bucar UP DN UP ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 Garage 5 Lobby 6 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:05:026/10/201801 1st fl Project NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 3.1. Floor Plan - 1st Floor

08/01/2018MCM 901 Page 28 of 224 Master Thesis: 620 N 3rd St Clara Bucar DNUP DN ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 Bedroom 7 UNIT #2C Living, Dining, Kitchen 8 Bedroom 9 Bedroom 10 Bedroom 11 Lobby 12 Bedroom 13 Bedroom 14 UNIT #2A Living, Dining, Kitchen 15 Bedroom 16 UNIT #2B Living, Dining, Kitchen 17 Shared Deck 19 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:12:086/10/201802 2nd floor Project NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 1" = 10'-0"1 2nd Fl 3.1. Floor Plan - 2nd Floor

08/01/2018MCM 901 Page 29 of 224 Master Thesis: 620 N 3rd St Clara Bucar DN ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 Bedroom 20 UNIT #3C Living, Dining, Kitchen 21 Bedroom 22 Bedroom 23 Bedroom 24 UNIT #3B Living, Dining, Kitchen 25 Lobby 26 Bedroom 27 Bedroom 28 UNIT #3A Living, Dining, Kitchen 29 Bedroom 30 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:14:106/10/201803 3rd fl Project NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 3.1. Floor Plan - 3rd Floor

08/01/2018MCM 901 Page 30 of 224 Master Thesis: 620 N 3rd St Clara Bucar UP ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 UNIT #4C Living, Dining, Kitchen 31 Bedroom 32 Bedroom 33 Bedroom 34 Lobby 35 UNIT #4B Living, Dining, Kitchen 36 Bedroom 37 UNIT #4A Living, Dining, Kitchen 38 Bedroom 39 Deck 40 Deck 41 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:17:566/10/201804 4th fl Project NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 3.1. Floor Plan - 4th Floor

08/01/2018 Master Thesis: 620 N 3rd St Clara Bucar ND NE NF NO E1E2E3E5E6 SF SE SD SC SB SA W1 W3 SG SH 071 091 101081 082 Scale Project number DrawnDate Checkedbybywww.autodesk.com/revit 1" = 10'-0" PM3:21:496/10/201805 roof plan Project NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 3.1. Floor Plan - Roof

08/01/2018MCM 901 Page 32 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.2. Section AA ND NE NF SNO G SH 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent - 9' - 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" ND NE NF SNO G SH 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent - 9' - 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20 4 1/2" 4th Fl 30 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50 2 1/2"

08/01/2018MCM 901 Page 33 of 224 Master Thesis: 620 N 3rd St Clara Bucar EE1E3 6 E5 E2 W 1 W 3 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' - 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' - 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" 3.2. Section BB 3.2. Section CC EE1E3 6 E5 E2 W 1 W 3 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' - 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' - 9 1/2" T.O. Flat Roof 41 2 1/2" T.O. Pilothous e Roof 50 2 1/2"

08/01/2018MCM 901 Page 34 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.2. Section DD 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20 4 1/2" 4th Fl 30 9 1/2" T.O. Flat Roof 41 2 1/2" T.O. Pilothous e Roof 50 2 1/2"

08/01/2018MCM 901 Master Thesis: 620 N 3rd St Clara Bucar 3.2. Section EE T.O. Flat Roof 41' - 2 1/2" T.O. Pilothouse Roof 50' - 2 1/2" 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2"

Master Thesis: 620 N 3rd St Clara Bucar 13' - 9" T.O. Flat Roof 41' - 2 1/2" T.O. Concrete Wall T.O. Flat Roof 41' - 2 1/2" 1st Fl Fin Flr Project number Drawn CheckedbybyUnnamed 3rd Fl 20' - 44th1/2"Fl30' - 9 1/2" B.O. -11'Footing1-10" T.O. Concrete13'Wall-9" ProjectOwner Name No. Description 1st Fl Fin Flr B.O.-2'Footing2-21/2" www.autodesk.com/revit ProjectOwner Name 1/2" = 1'-0"1 Section 1 1st Fl Fin Flr 0' - 0" B.O.-2'Footing2-21/2" Utility-9'Basement-111/2" 1st Fl Fin Flr B.O.-2'Footing2-21/2" UtilityB.O.-9'Basement-111/2"Footing1-11'-10" T.O. Concrete13'Wall-9"2ndFl 9' - 11 1/2" T.O. Concrete13'Wall-9"2ndFl 9' - 114th1/2"Fl30' - 9 Scale1/2"Project number DrawnDate Checkedbybywww.autodesk.com/revit 1/2" = 1'-0" PM8:56:357/7/201821 UnnamedProject NumberProjectOwner Name Issue CheckerAuthorDate No. Description Date 1/2" = 1'-0"1 Section 1 T.O. Concrete13'Wall-9"3rdFl20' - 44th1/2"Fl30' - 9 1/2" T.O. Flat Roof 41' - 2 1/2" www.autodesk.com/revit ProjectOwner Name A A B C B C D D E F E F

Master Thesis: 620 N 3rd St Clara Bucar W W1 3 9 11 B1/2 O Footing1 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' - 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2" W W1 3 E1 E3 EE6E5 2 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20 4 1/2" 4th Fl 30 9 1/2" T.O. Flat Roof 41 2 1/2" T.O. Pilothous e Roof 50 2 1/2" 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2"

Master Thesis: 620 N 3rd St Clara Bucar 3.3. South Elevation ND NE NF SNO G SH 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17' 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2"

Master Thesis: 620 N 3rd St Clara Bucar 3.3. North Elevation NNDNENF O SSG H 1st Fl Fin Flr 0' B0" .O. Footing2 2' 2 1/2" Utility Bas em ent 9' 11 B1/2" .O. Footing1 11' 10" B.O. Footing 17 1" T.O. Concrete W all 13' 9" 2nd Fl 9' 11 1/2" 3rd Fl 20' 4 1/2" 4th Fl 30' 9 1/2" T.O. Flat Roof 41' 2 1/2" T.O. Pilothous e Roof 50' 2 1/2"

08/01/2018MCM 901 Page 40 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.4. Aerial Perspective

08/01/2018MCM 901 Page 41 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.4. Aerial Perspective

08/01/2018MCM 901 Page 42 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.5. Renderings

08/01/2018MCM 901 Page 43 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.6. Cross Section

08/01/2018MCM 901 Page 44 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.6. Cross Section

MCM 901 Page 45 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3.6. Cross Section

08/01/2018MCM 901 Page 46 of 224 Master Thesis: 620 N 3rd St Clara Bucar SECTION FOUR WBS, ESTIMATES, SCHEDULES AND CASH FLOW

Section Four provides the must-see pieces of information for the 620 N 3rd St project: the detailed and summarized descriptions of the project’s baseline budget, schedule and cash flow. The general conditions subsection lists all the costs related to the project that are not subcontracted work related, but rather the conditions through which Fit Construction enables the subcontractors to perform the work packages. The work packages are each subcontractor’s specific contract pertaining their scope of work, this information can be found under the “Procurement and Buy-Out Log” subsection. As provided on Section Two under the “Project Delivery Method Analysis” subsection, the cash flow commits to show PRDC transparent cost information month by month.

Additionally, Fit Construction provides an alternative estimate for LEED Silver certification. PRDC has the opportunity to review the base and the alternate estimate and make an educated decision whether to pursue the certification or not.

The schedule is another critical portion of Section Four. A milestone report, the most important dates for the project, is provided under this section. Lastly, it contains the master scheduled with a detailed plan for the 620 N 3rd St project, as well as the critical path.

08/01/2018MCM 901 Page 47 of 224 Master Thesis: 620 N 3rd St Clara Bucar 0.1.ProjectPreconstruction1.1.Estimate 1.1.1.1.1.1.1.Take-offsSite work 1.1.1.2. Concrete 1.1.1.3. Steel 1.1.1.4. Framing 1.1.1.5. Masonry (self performed) 1.1.1.6. Interior finishes 1.1.1.7. Exterior finishes 1.1.1.8. Mechanical 1.1.1.9. Electrical 1.1.1.10. Plumbing 1.1.1.11. Elevator 1.1.1.12. Roofing 1.2. Schedule 1.3. Risk Management 1.4. Safety Plan 1.5. Environmental Plan 1.6. Subcontractor pre qualification 1.7. Bid and award 1.8. Site survey 1.9. Procurement 1.10. QA/QC Plan 1.11. Site logistics 1.12. Permits 1.13. Constructability Review 1.14. Notice to proceed 1.15. Mobilization 1.15.1. General conditions 1.15.1.1. Signage 1.15.1.2. Construction fence/Gates 1.15.1.3. Sheltered walkway protection 1.15.1.4. PECO aerial lines protection 1.15.1.5. Dumpsters 4.1. Work Breakdown Structure

08/01/2018MCM 901 Page 48 of 224 Master Thesis: 620 N 3rd St Clara Bucar 1.15.1.6. Trailer 1.15.1.7. Portable toilets 1.15.1.8. Parking passes 1.15.1.9. Temporary water 1.15.1.10. Temporary power 1.15.1.11. Security system - cameras 1.15.1.12. Osha posters 1.15.1.13. Walkie talkies 2. 2.1.ConstructionSiteWork 2.1.1. Excavation 2.1.2. Dirt storage for backfill 2.1.3. Dirt removal 2.1.4. Compaction 2.1.5. Backfill 2.1.6. Sidewalks: sidewalk topping and curbing 2.1.6.1. Sidewalk topping and curbing 2.1.6.2. Landscaping 2.2. Utilities 2.2.1. Water main lines 2.2.2. Sewage main lines 2.2.3. Stormwater main lines 2.2.4. Gas 2.2.5. Electric 2.3. 2.3.1.ConcreteUnderpinning 2.3.1.1. Excavation 2.3.1.2. Pour concrete 2.3.1.3. Tie backs 2.3.1.4. Dry pack with non-shrink grout 2.3.1.5. Backfill 2.3.2. Footings 2.3.2.1. Excavation 2.3.2.2. Compaction

08/01/2018MCM 901 Page 49 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.3.2.3. Formwork 2.3.2.4. Rebar 2.3.2.5. Pour concrete 2.3.2.6. Cure concrete 2.3.2.7. Remove formwork 2.3.3. Foundations 2.3.3.1. Excavation 2.3.3.2. Compaction 2.3.3.3. Formwork 2.3.3.4. Rebar 2.3.3.5. Pour concrete 2.3.3.6. Cure concrete 2.3.3.7. Remove formwork 2.3.4. Concrete walls - board form concrete 2.3.4.1. Board form 2.3.4.2. Rebar 2.3.4.3. Pour concrete 2.3.4.4. Cure concrete 2.3.4.5. Remove board form 2.3.5. F1: Slab on grade (new basement and portion of 1st floor) 2.3.5.1. Excavation 2.3.5.2. Removal of dirt 2.3.5.3. Compaction 2.3.5.4. Vapor barrier 2.3.5.5. 4” PADOT No. 2B stone 2.3.5.6. Formwork 2.3.5.7. Rebar 2.3.5.8. Pour concrete 2.3.5.9. Cure concrete 2.3.5.10. Remove formwork 2.3.6. Concrete piers 2.3.6.1. Formwork 2.3.6.2. Rebar 2.3.6.3. Pour concrete 2.3.6.4. Cure concrete 2.3.6.5. Remove formwork 2.3.7. Concrete slabs 2.3.7.1. FF3: Typical floor assembly - 2hr fire separation 2.3.7.1.1. 2” synthetic fiber traffic wear layer

08/01/2018MCM 901 Page 50 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.3.7.1.2. Control joint @ 4’ O.C. (parking) 2.3.7.1.3. ⅜” protect/drainage layer, miradrain 9000 (parking) 2.3.7.1.4. Liquid applied waterproofing membrane (parking) 2.3.7.1.5. 0”-4” lightweight concrete to achieve slope 2.3.7.1.6. 4” poured in place concrete slab on 1 ½” composite decking 2.3.7.1.6.1. 4” concrete 2.3.7.1.6.2. 1 ½” decking 2.3.7.1.7. Welded wire fabric 2.3.7.1.8. Closed cell sprayed-in-insulation R-30 2.3.7.2. FF3.B: Typical floor assembly - 2hr fire separation 2.3.7.2.1. 0”-4” lightweight concrete to achieve slope 2.3.7.2.2. 4” poured in place concrete slab on 1 ½” composite decking 2.3.7.2.2.1. 4” concrete 2.3.7.2.2.2. 1 ½” decking 2.3.7.2.3. Welded wire fabric 2.3.7.2.4. Closed cell sprayed-in-insulation R-30 2.3.7.3. FF4: Typical floor assembly - 3hr fire separation 2.3.7.3.1. 2” synthetic fiber traffic wear layer 2.3.7.3.2. Control joint @ 4’ O.C. (parking) 2.3.7.3.3. ⅜” protect/drainage layer, miradrain 9000 (parking) 2.3.7.3.4. Liquid applied waterproofing membrane (parking) 2.3.7.3.5. 4 ½” poured in place concrete slab on 2” composite decking 2.3.7.3.5.1. 4 ½” concrete 2.3.7.3.5.2. 2” decking 2.3.7.3.6. Insulation 2.3.7.3.7. (3) 1” mineral wool batts @ beams 2.3.7.3.8. 1” mineral wool batts @deck 2.4. 2.4.1.Steel Steel columns 2.4.2. Steel beams 2.4.3. Structural channel shaped steel joist 2.4.3.1. FF2: Typical floor assembly above parking 2.4.3.1.1. 1” poured floor underlayment - usg levelrock 2.4.3.1.2. ¼” sound reduction mat - usg levelrock srm-25 2.4.3.1.3. (2) Vapor barrier

08/01/2018MCM 901 Page 51 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.4.3.1.4. ¾” structural concrete floor panels 2.4.3.1.5. R-30 fiberglass batt insulation 2.4.3.1.6. Structural channel shaped steel joist @ 16” O. C. 2.4.3.1.7. Resilient channels @ 16” O.C. 2.4.3.1.8. ¾” fire rated exterior sheathing 2.4.3.1.9. Air barrier 2.4.3.1.10. Stucco finish 2.4.3.1.10.1. 3 coat stucco finish 2.4.3.1.10.2. Wire lath 2.4.3.2. R2: Typical floor assembly above parking 2.4.3.2.1. Wood deck on sleepers 2.4.3.2.2. Roofing membrane 2.4.3.2.3. ¾” T&G Plywood 2.4.3.2.4. Wood sleepers for slope 2.4.3.2.5. Pressure treated wood blocking 6”x6” 2.4.3.2.6. ¾” structural concrete floor panels 2.4.3.2.7. Rubber padding 2.4.3.2.8. R-30 fiberglass batt insulation 2.4.3.2.9. Vapor barrier 2.4.3.2.10. Structural channel shaped steel joist 2.4.3.2.11. Resilient channels 2.4.3.2.12. ¾” fire rated exterior sheathing 2.4.3.2.13. Stucco finish 2.4.3.2.13.1. 3 coat stucco finish 2.4.3.2.13.2. Wire lath 2.4.3.3. RD2: Balcony Typical 2.4.3.3.1. Wood joists beyond 2.4.3.3.2. Steel channel 2.4.3.3.3. Cont. metal drip 2.4.3.4. RD3: Balcony @ West 2.4.3.4.1. Wood deck on sleepers 2.4.3.4.2. Roofing membrane 2.4.3.4.3. ¾” T&G Plywood 2.4.3.4.4. Wood sleepers for slope 2.4.3.4.5. Steel channel 2.4.4. Walls and partitions 2.4.4.1. WF3.b: 2hr steel stud exterior wall 2.4.4.1.1. Brick ties 2.4.4.1.2. Brick veneer

08/01/2018MCM 901 Page 52 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.4.4.1.3. 1” air space 2.4.4.1.4. Weather barrier 2.4.4.1.5. ½” cement board 2.4.4.1.6. (3) ⅝” Gypsum board fire rated 2.4.4.1.7. R-19 fiberglass insulation 2.4.4.1.8. 6” steel studs @ 16: O. C. 2.4.4.1.9. Vapor barrier 2.4.5. Header 2.4.5.1.1. ⅗” stl 2.5. 2.5.1.MasonryMasonry walls 2.5.1.1. Lintel precast 2.5.1.1.1. Max span 4’-0” 2.5.1.1.2. Max span 6’-0” 2.5.1.2. WF6: 2HR rated interior concrete masonry wall 2.5.1.2.1.2.5.1.2.1.1.Material8” nominal concrete block wall 2.5.1.2.1.2. Reinforcing 2.5.1.2.1.3. 1 ½” furring channels 2.5.1.2.1.4. 1 ½” rigid insulation 2.5.1.2.1.5. ⅝” gypsum wall board 2.5.1.2.2. Labor 2.5.1.3. WF7: 1hr rated exterior wall at elevator shaft 2.5.1.3.1. 8” nominal concrete block wall 2.5.1.3.2. Reinforcing 2.5.1.3.3. 3” rigid insulation R-19 minimum 2.5.1.3.4. 2x4 wood studs @ 16 O. C. 2.5.1.3.5. ¾” exterior grade plywood sheathing 2.5.1.3.6. Weather barrier 2.5.1.3.7. 3 coat cement stucco finish (where there is no adjacent building) 2.5.1.4. Stone coping 2.6. Wood structure 2.6.1. Floor joists 2.6.1.1. FF1: Typical floor assembly B/T residential stories 2.6.1.1.1. 1” poured floor underlayment - usg levelrock 2.6.1.1.2. ¼” sound reduction mat - usg levelrock srm-25

08/01/2018MCM 901 Page 53 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.6.1.1.3. Vapor barrier: 0.010” 2.6.1.1.4. ¾” T&G Subfloor sheathing glued and screwed 2.6.1.1.5. 3 ½” batt insulation 2.6.1.1.6. Vapor barrier 2.6.1.1.7. Engineered wood joist 2.6.1.1.8. Resilient channels @ 16” O.C. 2.6.1.1.9. (2) ½” gypsum board fire rated 2.6.1.2. F2: Typical non-rated floor assembly 2.6.1.2.1. ¾” nailed down hardwood flooring 2.6.1.2.2. ¾” T&G plywood 2.6.1.2.3. Floor joists 2.6.1.2.4. Resilient channels 2.6.1.2.5. ⅝” gypsum board 2.6.1.3. F3: Typical floor @ bay 2.6.1.3.1. ¾” nailed down hardwood flooring 2.6.1.3.2. ¾” T&G plywood 2.6.1.3.3. Vapor barrier 2.6.1.3.4. R-30 batt insulation 2.6.1.3.5. ¾” exterior grade sheathing 2.6.1.3.6. Floor joists 2.6.1.3.7. Weather barier 2.6.1.3.8. Furring or shim 2.6.1.3.9. ⅝” architectural panel 2.6.1.3.9.1. Aluminum 2.6.1.3.9.2. Stone 2.6.1.3.9.3. Stucco finish 2.6.1.4. R1: Typical hot-roof assembly 2.6.1.4.1. Wood deck on sleepers 2.6.1.4.2. Roofing membrane 2.6.1.4.3. ¾” T&G plywood 2.6.1.4.4. Wood sleepers for slope 2.6.1.4.5. Pressure treated wood blocking 6”x6” 2.6.1.4.6. Rubber padding 2.6.1.4.7. Floor joists 2.6.1.4.8. Closed cell sprayed-in-insulation 2.6.1.4.9. (2) ½” fire rated gypsum board 2.6.1.4.10. River stone 2.6.1.4.11. Perforated stainless steel “L” angle 2.6.2. Walls and partitions

08/01/2018MCM 901 Page 54 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.6.2.1. W1: Wood frame exterior wall with brick/stone veneer 2.6.2.1.1. 3 ¾” brick/stone veneer 2.6.2.1.2. Reinforcement 2.6.2.1.3. 1” air cavity 2.6.2.1.4. ¾” exterior grade plywood 2.6.2.1.5. R-19 fiberglass batt insulation 2.6.2.1.6. 2x6” wood studs @ 16” O.C. 2.6.2.1.7. Vapor barrier 2.6.2.1.8. ⅝” Gypsum board 2.6.2.2. W2: Wood framed exterior wall @ stucco and rainscreen 2.6.2.2.1.2.6.2.2.1.1.MaterialWeather barrier 2.6.2.2.1.2. ¾” exterior plywood sheathing 2.6.2.2.1.3. 2x6 wood studs @ 16” O. C. 2.6.2.2.1.4. R-19 fiberglass insulation 2.6.2.2.1.5. Vapor barrier 2.6.2.2.1.6. ⅝” Gypsum board 2.6.2.2.1.7. Exterior finish 2.6.2.2.1.7.1.2.6.2.2.1.7.1.1.Stucco 3 coat cement stucco 2.6.2.2.1.7.1.2. Wire lath 2.6.2.2.1.7.2. Architectural panels 2.6.2.2.1.7.2.1.2.6.2.2.1.7.2.1.1.Aluminum1”vented air layer 2.6.2.2.1.7.2.1.2. Aluminum rainscreen bearing system 2.6.2.2.1.7.2.2.2.6.2.2.1.7.2.2.1.Stone 1” vented air layer 2.6.2.2.1.7.2.2.2. Facade cladding panels 2.6.2.2.1.7.2.3. Wood slat rainscreen 2.6.2.2.1.7.2.3.1. 1” vented air layer 2.6.2.2.1.7.2.3.2. Heat treated poplar wood strips 2.6.2.2.1.7.2.3.3. Galvanized metal bar system 2.6.2.3. WF1: 1hr wood frame wall @ property line 2.6.2.3.1. Stucco finish (where there is no adjacent building) 2.6.2.3.1.1. 2 layers of stucco finish 2.6.2.3.1.2. Wire lath 2.6.2.3.2. Weather barrier

08/01/2018MCM 901 Page 55 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.6.2.3.3. ¾” exterior plywood sheathing 2.6.2.3.4. R-19 fiberglass insulation 2.6.2.3.5. 2x6 wood studs @ 16” 2.6.2.3.6. Vapor barrier 2.6.2.3.7. ⅝” Gypsum board fire rated 2.6.3. Posts 2.6.3.1. 2”x6” 2.6.3.2. 6”x6” 2.6.3.3. 5 ¼” x 5 ¼” PSL 2.6.4. Headers 2.6.4.1. 2”x8” 2.6.4.2. 2”x10” 2.6.4.3. 2”x12” 2.6.4.4. 1 ¾” x 11 ⅞” LVL 2.7. Interior partitions 2.7.1. Chain link partitions 8’ high (unit storage) 2.7.1.1. Partitions 2.7.1.2. Gates 3’ wide 2.7.2. P1: Typical interior partitions 2.7.2.1. Wood studs 2.7.2.1.1. 2x4 wood studs 2.7.2.1.2. 2x6 wood studs 2.7.2.2. Wood wall plates 2.7.2.2.1. 2x4 wall plates 2.7.2.2.2. 2x6 wall plates 2.7.2.3. Batt insulation 2.7.2.4. Nail heads 2.7.2.5. Wallboard joints covered with tape and joint compound 2.7.2.6.2.7.2.6.1.Wallboards ⅝” Gypsum board 2.7.2.6.2. ½” Dens-shield tile backer board (tile backer at tile and wet locations) 2.7.3. Perforations on fire rated walls 2.7.3.1. Seal sleeve with expanding concrete grout 2.7.3.2. Pipe sleeve schedule 40 galvanized 2.7.3.3. Seal: 3M wrapstrap firestop 2.7.4. WF2: 1h wood frame wall between units 2.7.4.1. (2) ⅝” fire rated gypsum wall board

08/01/2018MCM 901 Page 56 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.7.4.2. 2x6 wood studs @24” O.C. 2.7.4.3. 3” fiberglass batt insulation 2.7.4.4. Resilient furring channel 2.7.5. WF2.B: 1hr wood frame bearing wall 2.7.5.1. (2) ⅝” fire rated gypsum wall board 2.7.5.2. 2x6 wood studs @ 16” O.C. 2.7.5.3. R-19 fiberglass insulation 2.7.6. WF3: 2hr wood frame interior wall 2.7.6.1. (4) ⅝” fire rated gypsum wall board 2.7.6.2. 2x6 wood studs @16” O.C. 2.7.6.3. R-19 fiberglass insulation 2.7.6.4. Resilient furring channel 2.7.7. WF3.A: 2hr steel stud interior wall 2.7.7.1. (4) ⅝” fire rated gypsum wall board 2.7.7.2. 3 ⅝” steel studs @ 16” O. C. 2.7.7.3. 2” fiberglass batt insulation 2.7.8. WF8: 3hr shaft wall 2.7.8.1. (3) ⅝” fire rated gypsum wall board 2.7.8.2. 1” gypsum shaft liner 2.7.8.3. 2 ½” wide and 1 ½” deep C-H stud min 25 gauge steel @ 24” O.C. 2.7.9. WF5: Insulation and finish on concrete walls 2.7.9.1. WF5 with rigid insulation 2.7.9.1.1. ⅝” Gypsum board 2.7.9.1.2. 2” polyiso insulation 2.7.9.1.3. 2” Z-furring @ 16” O. C. 2.7.9.2. WF5 with batt insulation 2.7.9.2.1. Airgap 2.7.9.2.2. 2x4 wood studs @ 16” O.C. 2.7.9.2.3. R-19 batt insulation 2.7.9.2.4. ⅝” Gypsum board 2.8. Interior finishes 2.8.1. Walls 2.8.1.1. Gypsum board 2.8.1.1.1. Prime 2.8.1.1.2. Painting 2.8.1.2. Ceramic tiles - bathrooms 2.8.1.3. Ceramic tiles - kitchens 2.8.2. Ceiling

08/01/2018MCM 901 Page 57 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.8.2.1. Gypsum board 2.8.2.1.1. Paint 2.8.3. Floor 2.8.3.1. Concrete polishing 2.8.3.2. Baseboard 2.9. 2.9.1.OpeningsExterior openings 2.9.1.1.2.9.1.1.1.WindowsOperable windows 2.9.1.1.2. Fixed windows 2.9.1.1.3. Double panel operable and fixed 2.9.1.1.4. Circular glazing 2.9.1.2. Sliding doors 2.9.1.2.1. 2 panels 2.9.1.2.2. 3 panels 2.9.1.2.3. 4 panels 2.9.1.3. Entry doors 2.9.1.4. Garage doors 2.9.1.4.1. N 3rd St garage door 2.9.1.4.2. N Galloway St garage door 2.9.1.5. Peco access grating protection 2.9.2. Interior openings 2.9.2.1.2.9.2.1.1.Doors Insulated metal with aluminum frame 2.9.2.1.2. Wood core door 2.9.2.1.3. Interior solid wood door 2.9.2.1.4. Primed wood frame 2.10. Stairs 2.10.1. East staircase 2.10.2. West staircase 2.10.3. Exterior stairs - Unit 4C 2.11. Elevator 2.11.1. Structure 2.11.2. Elevator car

08/01/2018MCM 901 Page 58 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.12. Electric 2.12.1.2.12.1.1.Rough Wires 2.12.1.2. Receptacles 2.12.1.3. Junction boxes 2.12.1.4. Electrical panels 2.12.1.4.1. General panel (at basement) 2.12.1.4.2. Single panels (at floors, one per apartment) 2.12.2. Devices/Lighting 2.12.2.1. Light switches 2.12.2.2. Outlets 2.12.2.3. Interior lighting fixtures 2.12.2.4. Exterior lighting fixtures 2.12.2.5. Timers 2.12.2.6. Dimmers 2.12.2.7. Emergency exit signs 2.12.2.8. Motion detector 2.12.2.9. Owner appliances 2.12.2.9.1. Fridge 2.12.2.9.2. Stove 2.12.2.9.3. Oven 2.12.2.9.4. Microwave 2.12.2.9.5. Dishwasher 2.12.2.9.6. Washing machine 2.12.2.9.7. Dryer 2.12.3. Low voltage 2.12.3.1.2.12.3.1.1.Rough Automated shade wiring 2.12.3.1.2. Automated garage door wiring 2.12.3.1.3. Data wiring (CAT) 2.12.3.1.4. Tv Wiring 2.12.3.1.5. Intercom wiring 2.12.3.2.2.12.3.2.1.Final Shade motor power 2.12.3.2.2. Garage door opener 2.12.3.2.3. Data receptacles 2.12.3.2.4. Tv receptacles 2.12.3.2.5. Intercom 2.12.4. Security system

08/01/2018MCM 901 Page 59 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.12.4.1.2.12.4.1.1.Rough Wiring 2.12.4.2.2.12.4.2.1.Final Security cameras 2.12.4.2.2. Alarm keypad 2.12.5. Fire protection 2.12.5.1.2.12.5.1.1.Rough Wiring 2.12.5.2.2.12.5.2.1.Final Smoke detector 2.12.5.2.2. Fire alarm control panel 2.12.5.2.3. Duct smoke detector 2.12.5.2.4. Combo smoke and carbon monoxide detector 2.12.5.2.5. Photoelectric smoke detector 2.12.5.2.6. Manual pull station 2.12.5.2.7. Tamper switch 2.12.5.2.8. Water floor switch 2.12.5.2.9. Strobe only 2.12.5.2.10. Fire alarm horn/strobe 2.12.5.2.11. Photoelectric heat detector 2.12.5.2.12. Fire smoke damper 2.12.5.2.13. Auto dialer to locally approved central station 2.13. 2.13.1.PlumbingSanitary 2.13.1.1.2.13.1.1.1.Rough Sanitary sewer piping 2.13.1.1.1.1. 3” 2.13.1.1.2. Soil stack 2.13.1.1.3. Vent stack 2.13.1.1.4. Branch vent 2.13.1.1.5. Vent piping (cast iron) 2.13.1.2.2.13.1.2.1.Final Bathroom sink 2.13.1.2.2. Toilet 2.13.1.2.3. Shower drain 2.13.1.2.4. Kitchen sink 2.13.1.2.5. Sump pump 2.13.2. Cold and water supply

08/01/2018MCM 901 Page 60 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.13.2.1.2.13.2.1.1.Rough Cold water piping 2.13.2.1.2. Hot water piping 2.13.2.1.3. Tempered water piping 2.13.2.2.2.13.2.2.1.Final Bathroom faucet 2.13.2.2.2. Toilet 2.13.2.2.3. Kitchen faucet 2.13.2.2.4. Shower head 2.13.2.2.5. Hose bib 2.13.2.2.6. Valve 2.13.2.2.7. Owner appliances 2.13.2.2.7.1. Dishwasher 2.13.2.2.7.2. Washing machine 2.13.2.2.7.3. Dryer 2.13.3. Gas supply 2.13.3.1.2.13.3.1.1.Rough Gas piping 2.13.3.2.2.13.3.2.1.Final Devices connection valve 2.13.4. Storm water 2.13.4.1.2.13.4.1.1.Rough Storm water pipe 2.13.4.1.1.1. 6” 2.13.4.1.1.2. 5” 2.13.4.1.2. Roof downpipe 2.13.4.2.2.13.4.2.1.Final Roof drain 2.13.4.2.2. Floor drain 2.13.4.2.3. Spouts 2.13.5. Fire protection 2.13.5.1.2.13.5.1.1.Rough Piping 2.13.5.2.2.13.5.2.1.Final Hydrant 2.14. HVAC 2.14.1. Rough

08/01/2018MCM 901 Page 61 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.14.1.1.2.14.1.1.1.Ductwork6” diameter duct 2.14.1.1.2. 8” diameter duct 2.14.1.1.3. 12”x10” duct 2.14.1.1.4. 10”x10” duct 2.14.1.1.5. 8”x10” duct 2.14.1.1.6. 8”x8” duct 2.14.1.1.7. 12”x4” duct 2.14.1.1.8. 12”x6” duct 2.14.1.1.9. 24”x8” duct 2.14.1.1.10. 24”x10” duct 2.14.1.1.11. 20”x12” duct 2.14.1.1.12. 22”x16” duct 2.14.1.1.13. 14”x10” duct 2.14.1.1.14. 18”x10” duct 2.14.2. Final 2.14.2.1. Exhaust fans (bathrooms ceiling) 2.14.2.2. AHU (ceiling cassette heat pump units for lobbies) 2.14.2.2.1. Vibration isolation pad for roof 2.14.2.3. Gas furnace/Air conditioning units (one for each apartment) 2.14.2.3.1. AC unit (inside each apartment) 2.14.2.3.2. Filter 2.14.2.3.3. Flex connection 2.14.2.3.4. Vibration isolation pad for roof 2.14.2.3.5. Vibration isolation pad for each apartment’s mech. closet 2.14.2.4. Ceiling hung electric heaters 2.14.2.5. Baseboard electric heater 2.14.2.6.2.14.2.6.1.Grilles Surface mounted, 4 way square diffuser w/ adjustable discharge louvers 14”x14” 2.14.2.6.2. Aluminum surface mounted, 4 way square diffuser with adjustable discharge louvers 8”x8” 2.14.2.6.3. Aluminum, exhaust air grille 6”x6” 2.14.2.6.4. Steel, sidewall return grille 2.14.2.6.5. Steel, transfer air grille 2.14.2.7. Dryer boost fan 2.14.2.8. Roof caps 2.14.2.9. Duct cap 2.14.2.10. 10” Kitchen hood exhaust duct

08/01/2018MCM 901 Page 62 of 224 Master Thesis: 620 N 3rd St Clara Bucar 2.14.2.11. Thermostat 2.15. Landscaping 2.15.1. GD2: Planter at grade 2.15.1.1. Stone coping 2.15.1.2. Flashing 2.15.1.3. Geo filter fabric 2.15.1.4. ¾ x 2 x 4 treated blkg 2.15.1.5. ½” drain hole 2.15.1.6. Stainless steel spaces (provide weep holes) 2.15.1.7. Dirt 2.15.1.8. Plants 2.15.2. Planters at roof 2.15.2.1. Structure 2.15.2.2. Dirt 2.15.2.3. Plants 2.15.3. River stone 2.16. Specialties 2.16.1.2.16.1.2.2.16.1.1.MillworkKitchenCommon areas 2.16.2. Curtains 2.16.3. Cage for utilities in basement 2.16.4. Railing for balconies 2.16.5. Kitchen accessories 2.16.5.1. Kitchen counters 2.16.6. Bathrooms accessories 2.16.6.1. Toilet paper holders 2.16.6.2. Towel holders 2.16.6.3. Medicine cabinets 2.16.6.4. Shower base 2.16.7. Mailboxes 2.16.8. Stripe painting in garage 2.16.9. Garage bumper precast 2.16.10.2.16.10.1.SignageFront facade number 2.16.10.2. Leasing office reference 2.16.10.3. Trash room

08/01/2018MCM 901 Page 63 of 224 Master Thesis: 620 N 3rd St Clara Bucar 3. Close out 3.1. Punchlist 3.2. RFI closeout 3.3. Change order closeout 3.4. CO Inspection 3.5. Substantial completion 3.6. Commissioning 3.6.1. T&B 3.7. Financial resolution 3.8. Turnover

08/01/2018MCM 901 Page 64 of 224 Master Thesis: 620 N 3rd St Clara Bucar 4.2. Estimate: Basis of the Estimate Basis of the Estimate 7/7/2018 Project: 620 N 3rd St Building Type: Residential Location: 620 N 3rd St, Philadelphia PA Brief Description: 4 stories + basement and roof deck, 9 units total residential Below Grade Levels: Area SF Type / Description 1 2117 2117 Basement (storage and MEP) 2 Total Below Grade 2117 Ground Floor: Area SF 1 4527 4527 Parking and lobby 2 Total Ground Floor 4527 Supported Levels: Area SF 21 4105 4105 3 residential units 3 4105 4105 3 residential units 4 4105 4105 3 residential units 5 2933 Deck 6 Total Floor Area 21892 Gross Floor Area 28536 Net Finished Area 13860.6 Roof Area SF Total Area: 479.75 Walls LF / Height SF Foundations: 4664.5 Interior: 29762 Exterior: 15171 Site Work Area SF Total Site Area: 0 Parking: 0 Access Roads: 0 Sidewalk: 797 Landscaping: 381

08/01/2018MCM 901 Page 65 of 224 Master Thesis: 620 N 3rd St Clara Bucar Estimate Summary Company: Fit Construction Company Project: 620 N 3rd St Gross SF 28536 Date: August 1st 2018 WBS/CSI # Description Amount $ / S.F. % of Total 01 GENERAL REQUIREMENTS ($ 384,458) ($ 13.47) 12.7% 03 CONCRETE ($ 232,859) ($ 8.16) 7.7% 04 MASONRY ($ 33,947) ($ 1.19) 1.1% 05 METALS ($ 142,111) ($ 4.98) 4.7% 06 WOOD, PLASTICS, AND COMPOSITES ($ 228,915) ($ 8.02) 7.6% 07 THERMAL AND MOISTURE PROTECTION ($ 120,084) ($ 4.21) 4.0% 08 OPENINGS ($ 128,961) ($ 4.52) 4.3% 09 FINISHES ($ 432,638) ($ 15.16) 14.3% 10 SPECIALITIES ($ 137,096) ($ 4.80) 4.5% 14 CONVEYING SYSTEMS ($ 150,000) ($ 5.26) 5.0% 21 FIRE SUPPRESSION ($ 76,600) ($ 2.68) 2.5% 22 PLUMBING ($ 217,604) ($ 7.63) 7.2% 23 HVAC ($ 123,772) ($ 4.34) 4.1% 25 INTEGRATED AUTOMATION ($ 10,000) ($ 0.35) 0.3% 26 ELECTRICAL ($ 118,489) ($ 4.15) 3.9% 27 COMMUNICATIONS ($ 45,000) ($ 1.58) 1.5% 28 ELECTRONIC SAFETY AND SECURITY ($ 20,000) ($ 0.70) 0.7% 31 EARTHWORK ($ 13,865) ($ 0.49) 0.5% 32 EXTERIOR IMPROVEMENTS ($ 10,579) ($ 0.37) 0.4% 33 UTILITIES ($ 30,000) ($ 1.05) 1.0% TOTAL DIRECT COSTS ($ 2,656,977) 93.11 88.1% Subtotal ($ 2,656,977) 93.11 88.1% GENERAL OVERHEAD 6.0% ($ 159,419) 5.59 5.3% Subtotal ($ 2,816,396) 98.70 93.4% CM FEE/PROFIT 5.0% ($ 140,820) 4.93 4.7% SUBTOTAL A ($ 2,957,215) 103.63 98.0% BONDS 1.0% ($ 29,572) 1.04 1.0% Subtotal ($ 2,986,787) 104.67 99.0% INSURANCE 1.0% ($ 29,572) 1.04 1.0% Subtotal ($ 3,016,360) 105.70 100.0% CONTINGENCY 10.0% ($ 295,722) 10.36 9.8% TOTAL ($ 3,016,360) 105.70 100.0% 4.3 Estimate Summary

08/01/2018MCM 901 Page 66 of 224 Master Thesis: 620 N 3rd St Clara Bucar ITEM Unit Cost Unit Q'ty Total ON-SITE SUPERVISION & ADMIN. $194,300 Project Manager $1,000 Month 3 $3,000 Project Engineer $5,000 Month 3 $15,000 Project Superintendent (On site) $7,000 Month 12 $84,000 Field Engineer (On site) $4,500 Month 12 $54,000 BIM Engineer $4,500 Month 3 $13,500 Project Estimator $8,000 Month 0.25 $2,000 Safety Engineer $6,500 Month 2.4 $15,600 Health Insurance-Salary Staff $300 Mon Per Person 24 $7,200 ENGINEERING & SURVEY $33,800 2 way radios $150) Each 4 $600 Print bid packages $300) Each 2 $600 Print drawings for staff $500) Set 2 $1,000 Construction drawing print/copy $3,000) Lump sum 1 $3,000 As-built printing $750) Set 2 $1,500 O&M manuals $500) Each 2 $1,000 Outside Consultants $5,000) Lump sum 1 $5,000 PERMITTING $6,100 Zoning permit $500) Lump sum 1 $500 Building permit $2,000) Lump sum 1 $2,000 Permit to block sidewalk $300) Each 6 $1,800 Permit to block roads $300) Each 6 $1,800 SAFETY $5,110 Safety Incentives $500) Each 6 $3,000 Employee training $1,500) Lump sum 1 $1,500 First aid supplies $250) Lump sum 1 $250 Fire extinguishers (1 per 5,000 SF) $60) Each 6 $360 4.4. Division 01 - General Requirements

08/01/2018MCM 901 Page 67 of 224 Master Thesis: 620 N 3rd St Clara Bucar ITEM Unit Cost Unit Q'ty Total TEMPORARY FACILITIES $64,589 Office trailer 24x60 $2,000) Month 10.5 $21,000 Setup & remove trailer $1,000) Each 2 $2,000 Janitorial service for trailers $225) Month 10.5 $2,363 Temp toilets $125) Each per Month 24 $3,000 Wash stations (1 station for each 2 toilets) $95) Each per Month 12 $1,140 Preconstruction photo survey $1,500) Lump sum 1 $1,500 Bulletin boards $500) Each 2 $1,000 Project Signage $1,000) Each 2 $2,000 Office supplies $200) Month 12 $2,400 Computers $300) Each 2 $600 Printers $500) Each 1 $500 Network/Wireless (wiring & data lines) $120) Month 12 $1,440 Office software $2,500) Lump sum 1 $2,500 Postage & shipping $450) Month 12 $5,400 Cell phone $75) Month / phone 24 $1,800 Temp Fencing $8) Linear Foot 87 $696 Drinking water/Coffee $200) Month 12 $2,400 Temp water usage $300) Month 12 $3,600 Temp power – Office usage $350) Month 3 $1,050 Street sweeper $650) Month 12 $7,800 Snow removal $100) Month 4 $400 BUILDING SERVICES $77,660 Sheltered walkway $3,000) Month 6 $18,000 Temporary pulley $300) Month 6 $1,800 Temporary trash chute $300) Month 6 $1,800 Weekly cleanup (2mandays/week) $120) Man Day 117 $14,040 Dumpster rental - 40 CUYD $450) Pull 58.5 $26,325 Final building cleaning (int & ext) $0.55) SF 28536 $15,695 TRANSPORTATION $9,000 Pickup $450) Month 12 $5,400 Vehicle Fuel $215) Month / Vehicle 12 $2,580 Vehicle Maintenance $85) Month / Vehicle 12 $1,020 TOTAL $384,458

08/01/2018MCM 901 Page 68 of 224 Master Thesis: 620 N 3rd St Clara Bucar Detailed Estimate WBS/ CSI Code Description Material and Labor Allowance SubcontractorQuote Total $/GSFQty Unit Unit Cost 02250 Concrete: Underpinning 0.00 0 ($ 15,000.00) ($ - ) ($ 15,000.00) ($ 1.08) 03310 Concrete: Footings 45.69 CY 305 ($ - ) ($ - ) ($ 13,935.34) ($ 1.01) 03310 Concrete: Foundations 284.07 CY 495 ($ - ) ($ - ) ($ 140,613.37) ($ 10.14) 03310 Concrete: Piers 1.29 CY 495 ($ - ) ($ - ) ($ 636.53) ($ 0.05) 033313 Concrete: Walls - board form concrete 365.00 CY 50 ($ - ) ($ - ) ($ 18,250.00) ($ 1.32) 033113 Concrete: Slab on grade 52.11 CY 228 ($ - ) ($ - ) ($ 11,881.33) ($ 0.86) 033116 Concrete: Lightweight Concrete 13.90 CY 200 ($ - ) ($ - ) ($ 2,779.26) ($ 0.20) 033113 Concrete: Slab poured in place 7.95 CY 210 ($ - ) ($ - ) ($ 1,669.31) ($ 0.12) 035113 Concrete: 3/4" Structural Concrete Floor Panels 4092.00 SF 2 ($ - ) ($ - ) ($ 8,184.00) ($ 0.59) 035116 Concrete: 1" poured underlayment 3620.00 SF 5.5 ($ - ) ($ - ) ($ 19,910.00) ($ 1.44) 051223 Metal: W-Wide flange steel beams 12.63 TON 4500 ($ - ) ($ - ) ($ 56,837.39) ($ 4.10) 051223 Metal: LL-Double Angle: 2L3-1/2X3X5/16LLBB 0.09 TON 4500 ($ - ) ($ - ) ($ 414.00) ($ 0.03) 051223 Metal: L-Angle: L3-1/2X3-1/2X5/16 0.22 TON 4500 ($ - ) ($ - ) ($ 1,000.80) ($ 0.07) 051223 Metal: C-Channel C8X11.5 0.15 TON 4500 ($ - ) ($ - ) ($ 654.64) ($ 0.05) 051223 Metal: W8X10 0.04 TON 4500 ($ - ) ($ - ) ($ 184.50) ($ 0.01) 051223 Metal: HSS Columns 2.01 TON $4,500.00 ($ - ) ($ - ) ($ 9,051.61) ($ 0.65) 052100 Metal: Structured channel shaped steel joist 6.35 TON $4,500.00 ($ - ) ($ - ) ($ 28,579.02) ($ 2.06) 053600 Metal: Composite decking 0.00 SF $0.00 ($ - ) ($ 13,489.00) ($ 13,489.00) ($ 0.97) 051223 Metal: Headers 8.92 LF $15.00 ($ - ) ($ - ) ($ 133.86) ($ 0.01) 051223 Metal: Lintel 0.00 LF $0.00 ($ - ) ($ 471.40) ($ 471.40) ($ 0.03) 054100 Metal: Framing 0.00 LF $0.00 ($ - ) ($ 13,052.88) ($ 13,052.88) ($ 0.94) 055000 Metal: Welded wire fabric 1862.00 SF $0.50 ($ - ) ($ - ) ($ 931.00) ($ 0.07) 055001 Metal: Resilient channels 3799.00 SF $1.50 ($ - ) ($ - ) ($ 5,698.50) ($ 0.41) 055002 Metal: Railing balconies 42" high 165.30 LF $40.00 ($ - ) ($ - ) ($ 6,612.00) ($ 0.48) 055003 Metal: Elevator ladder 0.00 EA $0.00 ($ 2,000.00) ($ - ) ($ 2,000.00) ($ 0.14) 055004 Metal: PECO grate 0.00 EA $0.00 ($ 3,000.00) ($ - ) ($ 3,000.00) ($ 0.22) 061733 Wood: Structual Wood Floor Joists 0.00 LF $0.00 ($ - ) ($ 57,685.76) ($ 57,685.76) ($ 4.16) 061000 Wood: Girders 0.00 LF $0.00 ($ - ) ($ 18,014.75) ($ 18,014.75) ($ 1.30) 061000 Wood: Posts 0.00 LF $0.00 ($ - ) ($ 15,448.44) ($ 15,448.44) ($ 1.11) 061000 Wood: Headers 0.00 LF $0.00 ($ - ) ($ 5,411.73) ($ 5,411.73) ($ 0.39) 061100 Wood: Framing 0.00 SF $0.00 ($ - ) ($ 52,339.20) ($ 52,339.20) ($ 3.78) 061200 Wood: Interior Stairs Wood Framing and Handrails 0.00 EA $0.00 ($ - ) ($ 8,000.00) ($ 8,000.00) ($ 0.58) 061600 Wood: Wood 3/4" subfloor sheathing 6969.00 SF $2.50 ($ - ) ($ - ) ($ 17,422.50) ($ 1.26) 061600 Wood: Exterior Plywood 0.00 SF $0.00 ($ - ) ($ 41,243.95) ($ 41,243.95) ($ 2.98) 06160 Wood: 3/4" fire rated exterior sheathing 0.00 SF $0.00 ($ - ) ($ 10,230.00) ($ 10,230.00) ($ 0.74) 061600 Wood: Sheer wall nailing 0.00 SF $0.00 ($ - ) ($ 3,118.92) ($ 3,118.92) ($ 0.23) 071800 Thermal and moisture: 3/8" protection layer 1477.00 SF $0.75 ($ - ) ($ - ) ($ 1,107.75) ($ 0.08) 4.5. Detailed estimate back-up

08/01/2018MCM 901 Page 69 of 224 Master Thesis: 620 N 3rd St Clara Bucar Detailed Estimate WBS/ CSI Code Description Material and Labor Allowance SubcontractorQuote Total $/GSFQty Unit Unit Cost 071801 Thermal and moisture: 2" Synthethic fiber traffic wear layer 1477.00 SF $2.00 ($ - ) ($ - ) ($ 2,954.00) ($ 0.21) 071400 Thermal and moisture: Liquid applied waterproofing membrane 1477.00 SF $0.75 ($ - ) ($ - ) ($ 1,107.75) ($ 0.08) 072100 Thermal and moisture: Closed cell sprayed-in insulation R-30 4098.00 SF $2.00 ($ - ) ($ - ) ($ 8,196.00) ($ 0.59) 070000 Thermal and moisture: 1/4" sound reduction mat 10589.00 SF $0.50 ($ - ) ($ - ) ($ 5,294.50) ($ 0.38) 072500 Thermal and moisture: Vapor barrier 26631.00 SF $0.25 ($ - ) ($ - ) ($ 6,657.75) ($ 0.48) 072100 Thermal and moisture: R-30 fiberglass batt insulation 4092.00 SF $1.00 ($ - ) ($ - ) ($ 4,092.00) ($ 0.30) 072100 Thermal and moisture: Batt insulation, 3 1/2" 6969.00 SF $1.25 ($ - ) ($ - ) ($ 8,711.25) ($ 0.63) 072100 Thermal and moisture: 1" mineral wool batts 546.00 SF $0.75 ($ - ) ($ - ) ($ 409.50) ($ 0.03) 072500 Thermal and moisture: 6 mil puncture resistant vapor barrier 4220.00 SF $0.50 ($ - ) ($ - ) ($ 2,110.00) ($ 0.15) 075000 Thermal and moisture: Roofing membrane 4561.00 SF $7.00 ($ - ) ($ - ) ($ 31,927.00) ($ 2.30) 072100 Thermal and moisture: Batt insulation (interior partitions) 4310.00 SF $0.25 ($ - ) ($ - ) ($ 1,077.50) ($ 0.08) 072100 Thermal and moisture: 1 1/2" rigid insulation 1230.00 SF $1.50 ($ - ) ($ - ) ($ 1,845.00) ($ 0.13) 072100 Thermal and moisture: Min 3" fiberglass batt 3799.00 SF $0.75 ($ - ) ($ - ) ($ 2,849.25) ($ 0.21) 072500 Thermal and moisture: Weather barrier 9545.00 SF $0.25 ($ - ) ($ - ) ($ 2,386.25) ($ 0.17) 072100 Thermal and moisture: R-19 Batt Insulation 16899.00 SF $0.75 ($ - ) ($ - ) ($ 12,674.25) ($ 0.91) 072100 Thermal and moisture: 2" min fiber glass Batt insulations 391.00 SF $0.50 ($ - ) ($ - ) ($ 195.50) ($ 0.01) 072100 Thermal and moisture: 1/2" cement board 2063.00 SF $0.75 ($ - ) ($ - ) ($ 1,547.25) ($ 0.11) 072100 Thermal and moisture: 2" polyiso insulation 147.00 SF $5.00 ($ - ) ($ - ) ($ 735.00) ($ 0.05) 072100 Thermal and moisture: 1" gypsum shaft liner 162.00 SF $3.00 ($ - ) ($ - ) ($ 486.00) ($ 0.04) 076000 Thermal and moisture: Metal flashing 465.00 SF $8.00 ($ - ) ($ - ) ($ 3,720.00) ($ 0.27) 078400 Thermal and moisture: Coating for metal fireproofing 0.00 $0.00 ($ 20,000.00) ($ - ) ($ 20,000.00) ($ 1.44) 085000 Openings: Exterior aluminum frame and glazing 1873.00 SF $37.00 ($ - ) ($ - ) ($ 69,301.00) ($ 5.00) 085001 Openings: Miscellaneous glazing 9.00 SF $250.00 ($ - ) ($ - ) ($ 2,250.00) ($ 0.16) 083000 Openings: Louvers for trash room 1.00 EA $1,500.00 ($ - ) ($ - ) ($ 1,500.00) ($ 0.11) 083001 Openings: Overhead garage door 2.00 EA $5,000.00 ($ - ) ($ - ) ($ 10,000.00) ($ 0.72) 083002 Openings: Interior Woods Doors 0.00 EA $0.00 ($ - ) ($ 21,110.00) ($ 21,110.00) ($ 1.52) 081001 Openings: Specialty Doors 0.00 EA $0.00 ($ - ) ($ 24,800.00) ($ 24,800.00) ($ 1.79) 093013 Finishes: Ceramic for walls 5782.15 SF $5.50 ($ - ) ($ - ) ($ 31,801.81) ($ 2.29) 099123 Finishes: Gypsum board walls - Prime and paint 44285.87 SF $0.50 ($ - ) ($ - ) ($ 22,142.93) ($ 1.60) 096400 Finishes: Baseboard trims 4254.17 LF $4.00 ($ - ) ($ - ) ($ 17,016.66) ($ 1.23) 092900 Finishes: 5/8" gypsum board for walls 29857.00 SF $1.00 ($ - ) ($ - ) ($ 29,857.00) ($ 2.15) 092900 Finishes: 5/8" fire rated gypsum board for walls 19534.00 SF $1.25 ($ - ) ($ - ) ($ 24,417.50) ($ 1.76) 093013 Finishes: Ceramic for floor 872.17 SF $10.00 ($ - ) ($ - ) ($ 8,721.70) ($ 0.63) 096400 Finishes: Hardwood flooring 8307.00 SF $10.00 ($ - ) ($ - ) ($ 83,070.00) ($ 5.99) 092900 Finishes: 5/8" gypsum board for ceiling 15705.00 SF $1.00 ($ - ) ($ - ) ($ 15,705.00) ($ 1.13) 092900 Finishes: 1/2" fire rated gypsum board for ceiling 8307.00 SF $1.50 ($ - ) ($ - ) ($ 12,460.50) ($ 0.90)