6 Exclusive interview: Harvey Tremblay, Chairman at Hy-Tech Drilling Ltd.

FOCUS

Rodren Drilling: Looking to the future by Kevin Norberg, President at Rodren Drilling Ltd.

20 Recon Drilling: Breaking records. Again. by Mark Scoles, General Manager LATAM at Recon Drilling SAC

22 HELM Diamond Drilling: Tackling the harsh northern terrain by Alan McPherson, Owner at HELM Diamond Drilling

26 How Fordia Powered by Epiroc and Major Drilling created a faster head assembly by Michelle White, Business Development and Key Account Manager at Fordia Powered by Epiroc

30 We welcome a new idea of the future by the Comacchio team

/EXPLORATION & MINING GEOLOGY

35 Q&A from the experts In conversation with Dr Richard Tosdal President at PicachoEx LLC

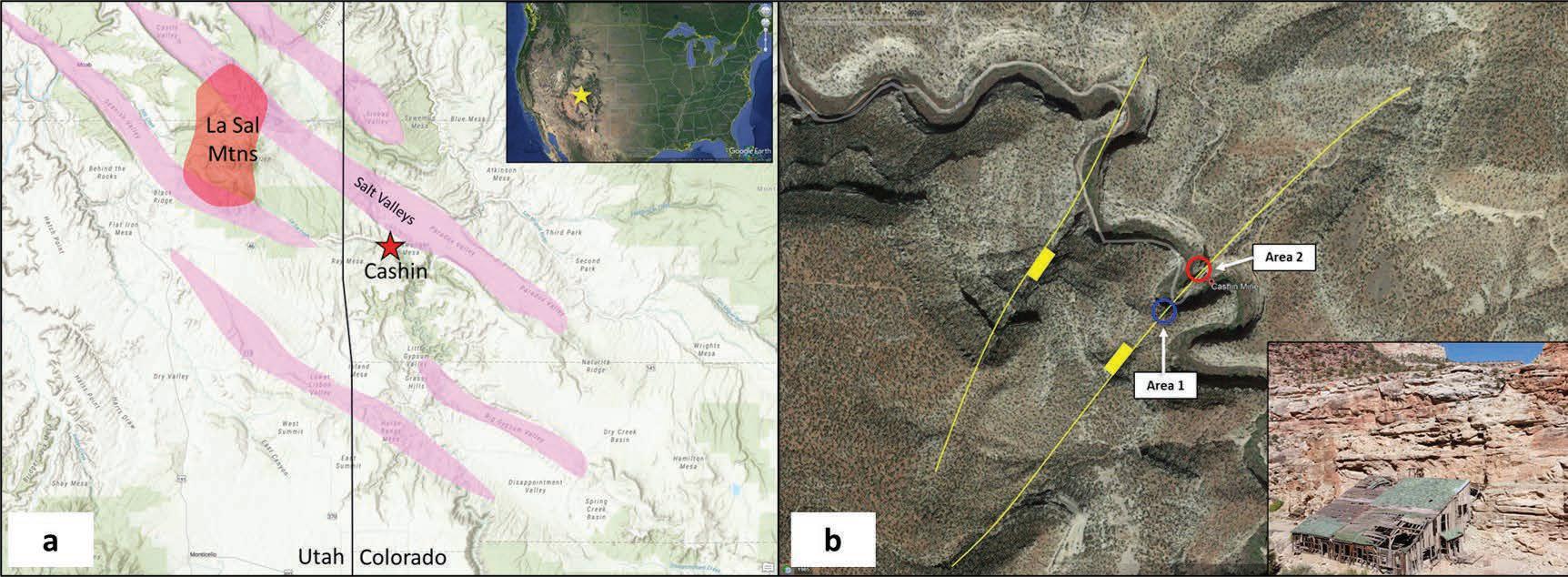

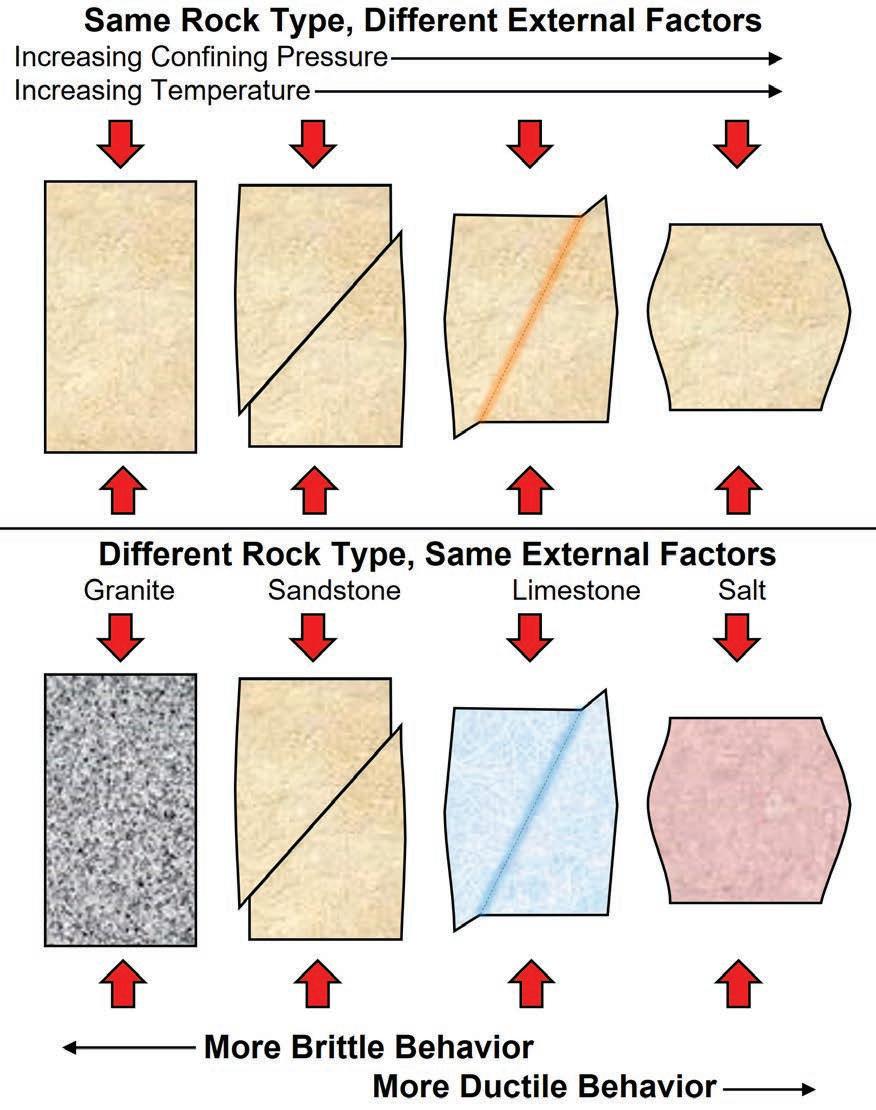

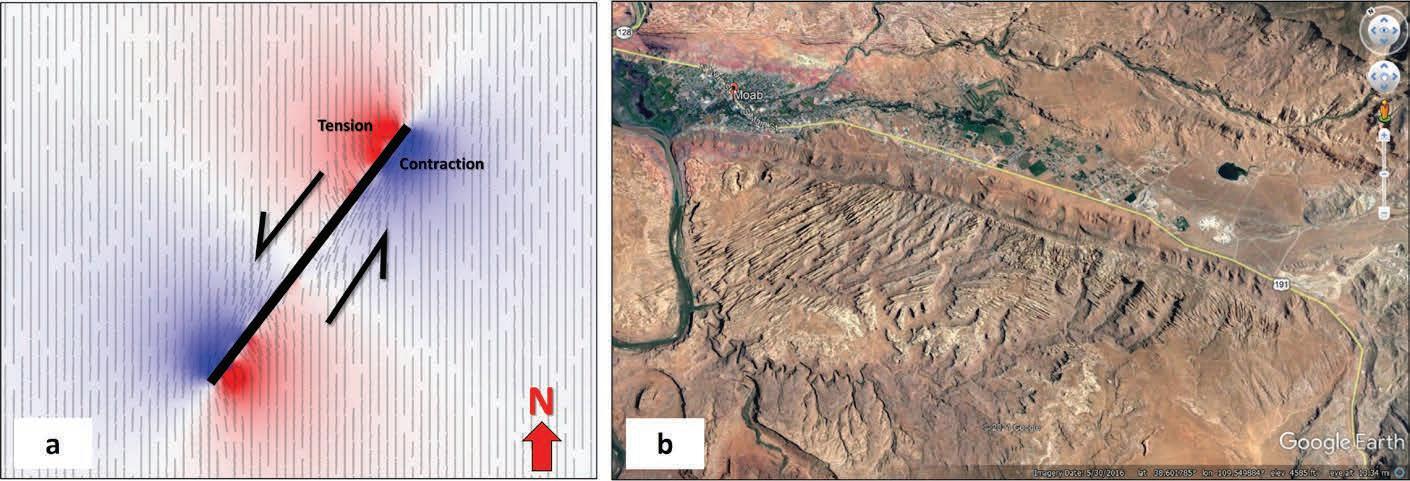

40 A few structural geology concepts for sediment-hosted Copper exploration

A case study from the Cashin Mine in the US by Dr Molly Turko, Structural Geology Expert & Dr Ali Jaffri, CEO at Applied Stratigraphix

46 Power to the people: How citizen development is driving a digital mining operations revolution by Udit Poddar, CEO and Vahishta Mistry, Content Lead at WorkOnGrid

50 What makes a geologist?

Thoughts on declining discovery rates, and other strange animals - a practising Ni-PGE-sulphide geologist’s (heretical) viewpoint by Richard A. Hornsey, Consulting Geologist, Ni-PGE Specialist at Richard Hornsey Consulting (Pty) Ltd

58 PDAC 2023: Back to the roots

Drilling services

Drilling equipment & accessories

Survey equipment

Miscellaneous

Harvey Tremblay Chairman at Hy-Tech Drilling Ltd.

Michelle White Business Development and Key Account Manager at Fordia Powered by Epiroc

Mark Scoles General Manager LATAM at Recon Drilling SAC

Alan McPherson Owner at HELM Diamond Drilling

Dr Richard Tosdal President at PicachoEx LLC

CORING MAGAZINE

February 2023

Cover photo

Rodren Drilling Issue 22

ISSN 2367-847X

Not for resale. Subscribe: www.coringmagazine.com/subscribe

Contact Us

Coring Media Ltd.

119B D. Petkov Str., Sofia 1309, Bulgaria

Phone +359 87 811 5710

Email editorial@coringmagazine.com

Website coringmagazine.com

Publisher

Coring Media

Editor in Chief

Grigor Topev

Executive Officer & Editor

Martina Samarova

Editor

Maksim M. Mayer

Section Editor –

Exploration & Mining Geology

Dr Brett Davis

Digital Marketing Manager

Elena Dorfman

Graphic Design

Cog Graphics

Coring Magazine is an international quarterly title covering the exploration core drilling industry. Published in print and digital formats, Coring has a rapidly growing readership that includes diamond drilling contractors, drilling manufacturers and suppliers, service companies, mineral exploration companies and departments, geologists, and many others involved in exploration core drilling.

Launched in late 2015, Coring aims to provide a fresh perspective on the sector by sourcing authentic, informed and quality commentary direct from those working in the field. With regular interviews, insightful company profiles, detailed product reviews, field-practice tips and illustrated case studies of the world’s most unique diamond drilling and mineral exploration projects, Coring provides a platform for learning about the industry’s exciting developments.

Open the box and GO. The GoGyro is fully integrated and designed specifically for simple, easy everyday use.

Configure your GoGyro as you need it for your surveys without unnecessary extra running gear. Simply add the needed fitting to run as:

• Core retriever

• Wireline

• Centralizers

Minimize downtime & Maximize efficiency. Simply GO Survey!

Chairman at Hy-Tech Drilling Ltd.

Harvey Tremblay started his career doing carpentry. He then climbed his way up from service work at drill sites, to exploration services, to working as both a driller and a foreman. He bought an off-theshelf JKS-300 drill rig from his old boss and launched Hy-Tech Drilling from his home in 1991. After a couple of small jobs, Harvey landed what turned out to be a nine-year contract. Over the next 30 years and countless completed projects, the company grew to a fleet of 75 drill rigs and 500 employees, operating throughout Canada, the US, Europe, and South America.

Nowadays, Harvey is the Chairman of Hy-Tech and in the past has served as Director of both the Canadian Diamond Drilling Association and the Association for Mineral Exploration in British Columbia.

Grigor Topev: Harvey, thank you for taking the time to answer our questions. Firstly, tell us your current business status and if there are any projects or initiatives you are working on. Harvey Tremblay: Hy-Tech Drilling has gone through an aggressive period of growth these last few years with projects across Canada, the US, South America and Europe. As we’ve grown, the company has effectively morphed into several companies – including a dedicated R&D arm to create new hardware and software for both surface and underground applications. It’s always been our goal to innovate and improve every aspect of what we do. Now we’re partnering with others who share the same vision, while looking at ways to open up and share many of these new technologies with the industry as a whole.

GT: You began your career in construction. Tell us the story of how you switched to drilling.

HT: I was doing carpentry work for a man named Henk van Alphen, who also happened to own an exploration services company. He asked me to help them build camps in some very remote areas, then one thing led to another. When you’re already out in the field, the jobs just keep coming because it’s too expensive to ship in somebody else. I was putting in the grid lines, setting up the power system, the water system, setting up radio antennas, taking soil samples, and staking new claims. At that time, I was also building drill pads by myself with a chainsaw – not a safe practice these days, but it was a huge learning experience.

Then Henk got his hands on a diamond drill, and everything changed. He’d hired a couple of drillers and I became one of the helpers. These guys wound up quitting as fast as they could be hired, so I was promoted very quickly until I became both the drilller/foreman and the

mechanic. I would work on the drill when the season was over, taking it apart, putting it back together, and learning a lot as I went. That’s how it all started.

When the industry went into a downturn, I made a deal with Henk to buy the drill. I only had enough money to pay for half, but another guy came on the scene to buy Henk’s dozer and after chatting for a bit, he offered to buy the other half with me. We went into business together for a few years, then I bought him out.

GT: So, I assume, this is the origin story of Hy-Tech Drilling, right? Where was your first project?

HT: Yes, indeed, the origin of Hy-Tech starts with my old partner Joe Nouch and the offthe-shelf JKS-300, which we’d bought fromHenk. We made a few modifications and ran the drill for two or three years on some small jobs, then Joe decided to get out of it and offered to have me buy him out.

Joe agreed to four payments over two years on a promissory note, so I had to work very hard in a short time. With a deal in place, I was able to get an operating line from the bank using the drill as collateral. It was ‘jump or walk away,’ and I decided to jump in with both feet.

The drill itself came with a small job that had already been booked with a company called Ore Quest, which gave us our start. Our next project was with Peter Holbeck from Homestake, and we were off to the races. These were pretty small jobs, but for one drill it was an ideal way to start. Having to do everything makes you into a very busy person – drilling all day, then going home at night to wrangle parts and supplies.

I had just paid off Joe and set out to build a better drill. At Homestake, a young Andrew Kaip was aware of my plans and called me with a project that required exactly the kind of drilling solution I had in mind. He asked me what I would need to tackle this job. I told him I’d need a CAD 50 000 advance, a contract in hand, and a month to get ready, which he agreed to. This allowed me to tackle a new design that would marry power with portability. Andrew’s project was proof of concept for our design, which then allowed us to land what turned out to be a nine-year job at Eskay – enabling us to build out much of the infrastructure that supports Hy-Tech to this day. When we built our shop, our largest competitor had just been sold and was in the process of shuttering theirs. We had a little corner of Northern BC to ourselves for a few years, along with a fly drill that could do

5000 ft (1524 m). The timing could not have been better.

GT: Please share with our readers the relative size of Hy-tech Drilling today.

HT: We have a fleet of 75 rigs, with no more than 50 turning at any given time. We currently sit at around 500 employees, drilling approximately 600 000 m (1 968 503 ft) on an average year. Hy-Tech Griffith is a recent partnership in South America, where we are operating another dozen rigs on some truly challenging terrain at very high altitudes.

come to life. This all comes back to our quality system to drive improvement. The other thing that stands out is our infrastructure. We pick an area to support, then we invest in it. If we had one drill in every country, it wouldn’t work out the same way. We focus on areas and support them fully.

From day one, innovation was a big part of our DNA. Designing and building our own rigs, shacks, support equipment – it’s again a driver for us to always be better and build better equipment, and we were effectively forced into it because other companies simply wouldn’t build drills the way we wanted them built. Going all the way back, our drill was designed around the specs of personnel-sized helicopters, versus ferrying in a medium sized one. This cut the bill from CAD 50 000 per move to CAD 1000, so it was a very big deal.

‘I think what people see more now is a reflection of the steps we took to manage quality. Adopting ISO 9001 helped us create a culture of constant improvement, where we’re always looking for new ways to add value and reduce any unknown variables.’

GT: What is your approach towards clients and partners and what do you think makes Hy-tech different from other companies? What were/are the key factors for success?

HT: What makes us different, I think, is that we’ve become quite proactive over the years. We have a talented group that used to pride themselves on their responsive firefighting abilities, and now we’ve become more focused on fire prevention. It’s not as ‘exciting,’ but we’ve always been very careful about maintaining quality and making sure that the things we say we’re going to do actually

GT: What is the most challenging drilling project your company has ever worked on?

HT: The one that really stretched us was called the ‘Sullivan Deeps.’ The Sullivan mine went for over 100 years, but when you looked at the ore body, it felt like only half of it had ever been realized. It was a common belief that half of it was still out there. The company we were working with was confident they had found it, but it also happened to be under the Kimberly Water Catchment Area.

There could be no roads to this site, and they needed us to drill 7000 ft (2134 m). We couldn’t guarantee 7000 ft, because at that point we’d only drilled 5500 ft (1676 m). We had to do a lot of modifications to the drill, but we ended up hitting the horizon of the ore body at 8856 ft (2699.3 m) in two holes, back-to-back. It was quite an unusual thing to tackle, where the best we could promise was to do our best.

Funny thing, we ended up trucking in this fly drill, because they got approvals to build a road at the last minute. So, the fly drill never saw any airtime, but it did the job anyway and showed what our little drill could do.

GT: Please share a particularly funny story from your drilling days.

HT: We had just bought the drill from Henk, we had our hands full with two little kids on a farm, we had a mortgage and all the bills that young couples have, and everything was on the line.

Late in that year, I was lucky enough to land a job to drill a project in the coastal mountains in some very challenging terrain.

I wanted to make sure the drill head was in good working order, but we didn’t have a shop to work in. So, I said to my wife, ‘I gotta bring this thing to the house.’ Much to her chagrin, I ended up doing all the work on our kitchen table!

Finally, we took it to work, and it did the job. It’s funny to think about servicing my first drill in our kitchen now, but I definitely wasn’t laughing back then. That’s what it looks like when you start a drilling company with no money. It forces you to be resourceful, because you must get the job done no matter what.

GT: Please share more about your mentors or the people that taught you drilling. What skills did you find useful?

HT: In the beginning, when Henk threw me in the deep end, I thought, ‘How am I going to keep up?’ No one was teaching me, so I figured I would do everything I could to teach myself. I ordered an old book from one of my suppliers called The Diamond Drill Handbook by James D. Cumming, and I studied it from cover to cover. It gave me a good understanding of how drilling had evolved over the years, a complete breakdown of all the tools, the case studies for different challenging projects, and the technical know-how to solve many different problems.

Out in the field, I had the pleasure of working with some old-time drillers – real rugged types who, in their day, would move drills around the bush with the hoisting cable of the drill. The frame of the drill was built like a toboggan, and they would winch themselves from tree to tree. The crazy lives these guys lived inspired me all on their own. It would take days to move from one spot to another, but they got it done. Once they got on a site, they’d make a tripod with three suitable trees and hang a pulley on it to pull rods. This was before hydraulics came into the picture. You had to use a wrench to tighten the jaws and they were all independent, so it was a challenge to keep them centered. This predated carbide inserts, so the steel jaws would get dull, and you’d have to tighten them like you would not believe.

Marcel Carrier was one of those guys who taught me a lot. He’d been all over, and just his stories while we were driving across Canada from North Bay and back – the questions I was asking and his can-do experiences from around the world – it all contributed to making me a better driller.

GT: By chance, I’ve visited a couple of HyTech drill sites. I was always impressed by how mobile, organized, and efficient

the working space was. How was that achieved?

HT: When we designed the drill, we made the footprint compact on purpose because we knew we’d be flying. What really shocked people was the fact that this small hydraulic fly drill could also reach 5000 ft (1524 m) in depth.

I think what people see more now is a reflection of the steps we took to manage quality. Adopting ISO 9001 helped us create a culture of constant improvement, where

GT: You have vast experience in the exploration drilling industry. How has it changed since you started?

HT: The beginning was a rough time. Hard hats weren’t even that common. Everyone smoked a lot, drank a lot, and it was rare to see ten fingers on any one person. It was not very disciplined at all. People just went in and did their best and worked very hard. Drilling depths in the thousands of feet versus hundreds of feet changed our industry immensely. Now, it’s bigger diameter and much deeper than it’s ever been. The equipment used to be all cable with a hoist, a basket, and winches. I called our business Hy-Tech Drilling because I wanted to go all hydraulic. I knew something had to change. I wanted to get out of the baskets and onto the deck. Our focus on hydraulics helped build our company.

‘ We’ve introduced some significant changes for drill performance , information tracking, water management, automation and most recently, new ideas around directional drilling for our customers. Faster, better, cheaper, safer - those are always good goals to have .’

we’re always looking for new ways to add value and reduce any unknown variables. Everything from the motor to the tools is standardized. Everything is brought to one standard, from the way we work to maintaining our drills. We figure out the best way, then we adopt it across the board. It’s saved us all a lot of time and trouble.

On every job, all the rigs are standardized. Europe sees these same rigs mounted on tracks, underground is an entirely different configuration, but it’s all the same components and quality standards at the end of the day.

GT: Is there a game-changer advancement or a new technology in diamond drilling that you wish existed nowadays?

HT: The advancement I wanted from DAY ONE was understanding what was going on at the bottom of the hole. When the bit was 8000 ft (2438 m) in the ground, and all you had was the sound of the exhaust and gear backlash to interpret, it was more art than science. Things have certainly improved, and we have more gauges that help us, but measurements are still from the surface. This is something that’s being actively worked on by a number of players, but I feel like we’re making real advances towards a solution. Truly, all our innovations center around better control and better information. We’ve introduced some significant changes for drill performance, information tracking, water management, automation and most recently, new ideas around directional drilling for our customers. Faster, better, cheaper, safer – those are always good goals to have.

GT: There is a well-known labor shortage within the industry, particularly in Canada. What do you think companies should do to solve it?

HT: I think it boils down to three things. The first would be automation to increase safety and reduce the physicality of the job, enabling a much larger workforce for us to tap into. The second would be to find ways to bring in more people from abroad. Lastly, I think the industry needs to do more to educate people around the life of a driller or driller’s helper. The job is kind of mysterious today, in that you have to hear about it

from another person who’s already working in it. We can do much more to increase the visibility of our industry, because let’s face it: you’ve really got to have a head in this business. Not everyone gets to be an astronaut. This is a job that’s heavily supported and requires the right kind of person to succeed.

GT: In your opinion what makes a good driller? What qualities should a driller possess in order to advance to foreman and even beyond?

HT: For us, the thing we look for is people that can get the job done, no matter what. It’s the ‘can do’ attitude we need, because there’s a million reasons why it can’t be done. Our people are our people because they can modify and change things up to keep it all moving forward. It’s an attitude.

You also have to be able to work with people. The wrong person in camp simply

won’t last. In the end, these people weed themselves out, because everyone has to depend on each other to be successful and safe. It’s all about the team. A healthy camp becomes a very close-knit group, with little tolerance for toxicity.

GT: What is your take on automated rod handlers? I have a feeling that Hy-Tech is not a huge fan of this technology…

HT: We have some rod handlers. We are huge fans of rod handlers. We just need to find a solution that’s practical. The early versions were as big as the drill itself, with too many moving parts.

I do wish we could eliminate the human element from rod handling because that’s where most of the safety and physicality issues happen. And we’re working to come up with a better solution for this – something the industry hasn’t explored enough yet.

If we could achieve this, we could open the industry to more diversity. We are putting in serious work to find a more elegant solution. The current solutions are just a bit too primitive. They cost a lot and take a lot of time. Long term, it’s our goal to create a solution that is cheaper, faster, better and above all, safer.

GT: Considering my background and involvement in directional drilling, I have to ask you: what does directional drilling lack and what would you like to see available?

HT: My view is that we need to find a better solution than the ones that are currently available. They are, for most clients, prohibitively expensive and time-consuming. It’s our goal to lower the cost and reduce

the time required for this type of work. Hitting the target every time would be nice to offer if the cost was reasonable.

GT: We are facing increased inflation (among many other difficulties). What are the changes you see in your business?

HT: Wages are far and away our largest cost, but the industry is still experiencing a shortage of workers. We’re always impacted by outside costs like steel because it affects so many of our own estimates. We need to think about these things when we’re bidding.

The cost to finance our growth is another consideration. On the one hand, we have an increase in work. On the other hand, the cost of borrowing is now much higher. The rising risk demands that we be more cautious about the companies we engage with. Do they rely on the market, or do they have their own source of revenue? Organic growth is great if it can be done without taking on significant long-term debt. It’s the small operators that rely on the junior market that are most vulnerable.

GT: Following up from the previous question, what is your advice for drilling company managers and leaders?

HT: Being financially conservative has certainly served us well over the years. The markets rarely go up at the same speed that they go

down – the rise is gradual, but the fall can be overnight. We’re in a big upcycle right now, but we all know it won’t stay that way. Being prepared for both success and failure puts you in a better spot.

GT: Harvey, a final question, looking into the next five to ten years… Do you think we will see an increase in diamond drilling activity?

HT: I would say it would be an increase in five, but the next ten are unknown. We may hit an apex before ten years. You can always bet on eventually hitting a saturation point. That would be my guess. I would expect things to ramp up to some level where we can keep up with demand. Today, it feels like there’s just not enough rigs to go around. But these things always get overbuilt, so there’s that. As always, there will be drillers that get checked out along the way. What I can say is there will always be room for big ideas and better solutions, regardless of where the market chooses to take us next. C

Trusted, proven, and precise. For generations, Boart Longyear has designed and manufactured some of the most advanced exploration products in the industry

Longyear diamond bits represent a long tradition of innovation and dedication to the drillers and geologists who rely on us every day. Find your local sales team online.

by Kevin Norberg, President at Rodren Drilling Ltd.

Rodren Drilling (Rodren) was founded by Rod Cyr on June 23, 1977, in Canada with one drill rig and one crew. The mission was to provide the best diamond drilling contractor service in North America.

Over the 45 years since, Rodren Drilling has continuously strived to upgrade their equipment, train their staff, work with a safety-first attitude, and grow responsibly in order to listen to, match and exceed the expectations of clients. The company built a fleet of 20 drills and 150 employees and countless successful projects throughout Canada and abroad.

The 45th anniversary of Rodren Drilling in 2022, was marked by a large event so that all suppliers, friends and industry people could celebrate at the Assiniboia Downs Racetrack in Winnipeg, Canada. Last year also marked another significant achievement: the completion of a 2610 m (8563 ft) deep hole.

With the company’s founder Rod Cyr retiring, Kevin Norberg was appointed president in order to create a vision for the next 45 years of business focusing on adding new services and strategic partners, new staff and reformed cultures, and expanding Rodren Drilling’s fleet with new drills, trucks, and support equipment and certainly new contracts.

With new leadership, growing team, vision, and culture, Rodren Drilling is ready to tackle anything the future has to offer!

Rodren Drilling is growing internally with both the addition of drill rigs as well as growth and diversity via strategic partnerships. The company has added many services to its menu via a very valuable partnership with Earth Drilling, based in Calgary, as well as Fasdrill Directional Services, a Calgary-based directional drilling firm. Rodren has supportive relationships with both companies allowing to offer nearly every drilling service available under its brand and it is currently negotiating other potential partnerships to expand its reach to better cover Canada’s Eastern regions.

Additionally, Rodren has strategic partners in all corners of the industry – fixed wing aircraft, bulk fuel, rotary aircraft, camps, logistics, land freight, drilling services, geotechnical drilling, directional drilling and supply chain management.

Rodren Drilling offers the following specialized services:

• Surface diamond drilling;

• Remote/arctic/permafrost/deep holes/deep overburden;

• Helicopter supported drilling;

• Ice-based drilling and construction;

• Underground drilling;

• Environmental and Geotechnical drilling;

• Barge drilling;

• Mud Motor Directional steering and drilling (GWD Drilling Technology).

Rodren Drilling enjoys a large number of clients and partners around the world and has provided the services needed with pristine quality. The new additions to the team at Rodren Drilling in 2022 bring a fresh outlook to a legendary and prosperous name in the diamond drilling industry.

The management team has diversified its client base and geographical footprint in the past twelve months and has added work in the US, based out of Nevada, Arizona and California. Rodren’s mission to work their home province of Manitoba has been successful. The company has mobilized their first underground rig and has increased their volume in the Canadian province to up to ten drills.

Rodren Drilling has completed various projects for its most valuable clients: Qulliq Energy Corp, Callinex, Hudbay, 1911 Gold, New Age Metals, International Lithium, CNRI, RESPEC, Q Gold, First Mining, Sinomine, Trillium Gold and many more to come in the future.

Rodren’s work in Baker Lake was completed for a client and involved a specific scope of work. The assignment was to mobilize an aircraft-portable diamond drill rig to Baker Lake from Winnipeg on short notice to drill a 600 m (1969 ft) permafrost borehole and install a specialized instrument to collect temperature data from the rock formation. The work was to be done in the summer originally, but due to permit delays, it was pushed to November.

This involved packing a complete drill package, trucking to Yellowknife and loading into a Lockheed L188 Electra aircraft and mobilize to Baker Lake in early November in absolutely terrible weather conditions. The crew was mobilized to move all of the gear to the pad where

they executed the plan. Drill the borehole, install the instrumentation and make it home before Christmas which they did as if it was easy.

The project was done within the timeline, the cost was completed within a few thousand of the budgetary estimates and the crew was able to pack up and make it home for Christmas.

Barge drilling enables drilling under a body of water by setting up a barge to support the rig on top of the water. The benefits of drilling on a barge are that it is more predictable than ice drilling, it is cost-effective, flexible and more time efficient, as the barge is simply moved to a new location without the hassle of preparing the site or using fly transport.

Rodren has always been known as the go-to contractor for specialized projects that involve barge and ice drilling for both exploration as well as geotechnical and specialized drilling assignments.

‘From pre-planning to demobilization, Rodren upheld a professional focus on safety, commitment to minimizing environmental impacts, while maximizing production of clean accurate core. 1911 Gold was extremely satisfied with Rodren's performance on our helicopter and land-based programs in 2022 and we look forward to new partnerships in the future,’

Devin Pickell, Chief Geologist, 1911 Gold Corporation.

↑ Rod Cyr and family on the 45th anniversary of Rodren Drilling

The company’s barge was mobilized to the drilling site, and a partner’s sonic drill was placed on to the platform. The drilling teams were able to achieve the clients’ goals while maintaining an ecofriendly and safe work environment.

In 2022, Rodren was brought into a project with its one-of-a-kind EF 100 rig to provide a drilling service that ended up evolving into an important specialized project requiring drilling down to depths well beyond 2500 m (8202 ft) with specialized environmental protocols to meet and exceed permit requirements. The crews were up to the challenge and acted in accordance with the required protocols with ease.

Rodren Drilling has made a commitment to overhaul its entire fleet in 2022 which was done in-house with the exception of one drill that was completed by Perfect Performance based in Cooks

‘What separates Rodren from others is their dedicated team that goes above and beyond in every measurable category to make our exploration campaigns a success. They have the necessary experience, work ethic, equipment and relationships to overcome any challenge that is inherent with executing in varying work conditions typical in exploration,’

Max

Porterfield, President & CEO, Callinex Mines Inc.

‘Rodren has been great to work with so far. Both the knowledgeable drillers and up-to-date management systems have made our work together seamless,’

Aaryn Hutchins, Project Geologist, Tantalum Mining Corporation of Canada Ltd.

↑ Rodren’s EF-100 drill nicknamed ‘Pinky’, which aims to raise awareness for cancer care

Creek Manitoba. Currently, Rodren’s fleet consists of over 20 drill rigs, which can tackle a range of depths, techniques, and terrains:

• DDM EF-50

• DDM EF-50 Fly

• DDM EF-75

• DDM EF-100

• EF-75 Track Mount

• Duralite 1800N Skid/Heli-portable

• MPP Discovery 1

• MPP Discovery 1.5

• MPP Discovery 2

• Epiroc U6 Deep Hole

• Gus Pech Truck mount Sonic

• Boart Longyear LS 600 Full size Sonic

• Boart Longyear LS 250

• Foremost DR24 Dual Rotary

• TerraSonic TSI 150 Crawler Sonic

• BBS Classics

In drilling, every team can be a high-performance team, yet very few actually are. At Rodren Drilling, one of the goals is to build such high-performance teams on every project and for every hole.

A high-performance team can be defined as a group of people with specific roles and complementary talents and skills, aligned with and committed to a common purpose, who consistently show high levels of collaboration and innovation, that produce superior results. The high-performance team is regarded as tight knit, focused on their goal and nothing else. Team members are so devoted to their purpose that they will surmount any barrier to achieving the team’s goals.

Within the high-performance team, people are highly-skilled and are able to interchange their roles. Also, leadership within the team is not vested in a single individual. Instead, the leadership role is taken up by various team members, according to the need at that moment in time. High-performance teams have robust methods of resolving conflict efficiently so that conflict does not become a roadblock to achieving the team’s goals. There is a sense of clear focus and intense energy within a high-performance team. Collectively, the team has its own consciousness, indicating shared norms and values within the team. It feels a strong sense of accountability for achieving their goals. Members display high levels of mutual trust toward each other.

To make this theory of a high-performance drilling team a reality, Rodren believes that people are the most important asset to the company and invests heavily in both physical and mental health.

Continuous training for all staff is another important aspect. Alongside the training and courses, company members have a mentor/leader to guide them toward their goals, personal and career growth, and upskilling.

Drillers Edge drill rods by Di-Corp are earning a global reputation for reliable, long-lasting performance under some of the most challenging conditions.

What makes Drillers Edge drill rods different? Our choice of premium quality steel. Our approach to stress relieving heat treatments, precision machining, intense quality controls, and the unique, specialty finishing process we use to harden our R™ Thread for unmatched pull-back strength.

All these differences help Drillers Edge to produce premium coring rods that deliver:

• More even pin and box wear.

• Better deviated drilling performance.

• Superior drill string life.

Di-Corp is a registered trade name of Diversity Technologies Corp.

The company has a well-rounded team from various backgrounds, bringing their unique knowledge and experience to every project. Team members come not only from drilling and mining but also from the sectors of oil and gas, heavy equipment, construction, engineering, and industrial procurement and industry sales. The wide diversity, paired with the training and mentorship, has brought multiple novel solutions to problems to each of Rodren Drilling’s projects.

In order to have high-performance drilling teams operate to the best of their abilities, the company believes that there should also be an allstar support team. To this end, Rodren Drilling has established an excellent support team of certified industrial mechanics, procurement specialists, welders, and hydraulic techs that can develop custom-tailored solutions for every project and do in-house R&D when needed. Furthermore, there are fully-fledged departments to deal with operations management, accounting, payroll, and accounts receivable, so drilling teams can focus on drilling and be absolutely certain that everything else has been taken care of.

Culture is the number one driver to the Rodren Drillings approach to ensuring reduced risk of accident or environmental impact during projects. The company’s approach and slogan are tied to all of its Visible Felt Leadership training (visits by management to workplaces, create a platform for both management and employees to discuss daily

1.800.661.2792

info@di-corp.com

www.di-corp.com

safety challenges of the tasks at hand); we all judge ourselves on what we do when nobody is watching.

Rodren Drilling strives to have a transparent culture where all employees hold each other accountable regardless of position or title. The company stands by its values and sets boundaries where needed, so drillers do not take any unnecessary risks on behalf of clients and their own colleagues.

An equally important approach is when beginning a project – the entire company looks at all variables that teams may encounter in the process of obtaining and delivering the core samples to clients. They also look at the amount of equipment needed, the terrain.

Throughout Rodren Drilling’s history, safety and environmental responsibility have been paramount. The company takes great measures to ensure that crews are well-trained, equipped, and protected for every job they undertake. The Safety, Environment and Quality program ensures that all standards, be it clients’ or regulators’, are met and exceeded.

Rodren Drilling is CORTM Certificated with the Canadian Federation of Construction Safety Associations, which is recognized throughout the world.

The company has properly and thoroughly insured its equipment and practices a culture of safe drilling and proper resource documentation to ensure consistency. Their employees are insured and protected with well-documented health and safety practices, which include a full Environmental Impairment Liability policy, Bodily Injury, Property Damage, and Completed Operations.

Rodren holds weekly, monthly and large yearly meetings to continue to grow and change its viewpoint on the industry. Supervisors learn about the business aspect of diamond drilling and why the numbers are so important to continue a sustainable, profitable and respectful relationship with all industry partners. The saying in business holds true – ‘If you’re not profitable – your future is predictable.’

Rodren Drilling believes that it is essential to give back to the community. Especially, since much of the company’s operations are conducted in close proximity to indigenous ancestral lands. The company has provided travelling and registration support for the following local athletes, sports teams and events: Haylee Welwood, Team Manitoba 16U Girls 2023, North American Indigenous Games in Halifax NS, Basketball.

Rodren Drilling also attracted a lot of looks with Pinky – their pink drill EF-100 drill, which aims to make the drilling industry aware of Cancer Care. The slogan of the campaign is Drilling for a Cure Rodren Drilling is also a large supporter of the Manitoba Women in Mining chapter as well as the Manitoba Prospectors Development Association and the mineral sector of Manitoba in general. Recently,

the company sponsored and provided instructors for training for indigenous workers looking to join the industry at the Manitoba Mineral Convention, and is also a sponsor of all association events, including the famous Reconciliation Gala, which allows guests to support promoting and advocating indigenous rights.

The company also holds several junior venture partnerships with the communities they operate in.

The future looks bright for the drilling industry, Rodren’s staff, and partners as they move into a new age of exploration. Looking for critical and industrial metals, continuing to search for precious metals and adapting to new technologies and opportunities as they arise.

The company’s greatest motivation is to grow its workforce from within, cross-train its people and grow their skillsets, continue to add strategic partnerships and grow a specialized workforce that can look for opportunities, should they wish, within the healthy and transparent group of companies.

Rodren Drilling aims to continue to support the drilling sector and secure its future and people for at least another 45 years. C

“Devico shall be world leading within directional core drilling, borehole surveying and belonging software.”

EST. 1988, Viktor Tokle

by Mark Scoles, General Manager LATAM at Recon Drilling SAC

Recon Drilling (Recon) recently expanded into the Chilean market and landed at Atex Resources’ flagship Copper-Gold Valeriano project. The Project is located approximately 125 km (78 mi) to the southeast of the city of Vallenar, Atacama Region, Chile and 27 km (17 mi) northeast of Barrick’s Veladero Mine. The clients requested a total of 10 000 m (32 808 ft) of deep hole directional drilling and a company that could provide this service entirely inhouse. Within weeks of choosing Recon, they were already setting up in Chile and were contacting vendors to get the ball rolling!

This was to be the first directional drilling program implemented by a junior company in Chile and dependent on the success of the initial drilling, the program could be extended with another 10 000 m (32 808 ft).

The location of the Valeriano project could also prove a challenge for a less-than-prepared company. Elevations vary from 3800 to 4400 m (12 467-14 436 ft) above sea level, meaning that we had to choose the right drill and equipment for the job.

In preparation, two specially-prepared Sandvik DE740 track-mounted drills were selected. With capacities of 800 m (2625 ft) in P-size, 1200 m (3937 ft) H-size and 1800 m (5906 ft) N-size, a small footprint and

9 m (29.5 ft) pull they were the perfect choice for this project. Recon’s Maintenance Team for the LATAM region, which includes experts from Chile, familiar with the difficulties of working at high altitude (air is less dense), prepared the drills, which were required to be fully disassembled and upgraded for power and set up in Recon’s Lima workshop. The team has come through yet again as has been proved by the rigs’ performance!

Recon also invested into all new lightweight drill pipes from Boart Longyear with stronger joints, making them the perfect rod for this type of project, especially through the directional portion. Additionally, Recon chose Oriented core, gyro-surveying equipment and downhole motors, provided by IMDEX Chile.

Recon’s team at start up included Australian General Manager Mark Scoles, who conducted the hole planning in-house allowing for complete control of the operation and avoiding the common challenges, together with international directional drilling specialists with Chilean drill crews and supervisors. Since directional drilling is a relatively new technique in Chile, and the region, the company invested heavily to ensure local crews receive continuous training.

Drilling began in October 2022 and having designed the holes, Mark Scoles was on site

to drill and complete Recon’s first Navi cut (NX) in the southern half of South America. Everything went as planned. That first hole was completed at 2130 m (6988 ft) in N-size. A 1275 m (4183 ft) daughter hole was also completed.

With a continuous cut of 63 m (207 ft) –between 870 to 933 m (2854–3061 ft) – the final target was reached at a depth of 1650 m (5413 ft) within 5 m (16.4 ft) of radius. The team conducted a whopping 717 m (2352 ft) of free drilling after the cut without any corrections by using drilling barrel configuration and drilling techniques to keep the hole tracking.

This daughter hole commenced from a vertical hole at approximately 850 m (2788 ft) with a casing wedge used to deflect out of the parent hole followed up with

in action at Valeriano

a directional drilling run to line the hole up with the target.

With the success of the initial holes Recon is validating the value of using directional drilling for efficient deep exploration with holes over 2000 m (6560 ft) in length.

Drilling on the Valeriano project is still ongoing with two drill rigs and two more deep holes on the way.

Established in 2020, Recon Drilling provides diamond core drilling services to major,

intermediate and junior mining companies in Peru and in the LATAM region. With a modern fleet of drills adapted for high altitudes, the company specializes in deep directional drilling using DHM (Down Hole Motor) and wedging methods. Recon Drilling is a subsidiary of Geodrill Limited, best known for its extensive footprint throughout Africa and its enviable reputation of providing safe, professional specialized drilling services to major, mid-tier and small exploration companies. C For more information Visit: www.recondrilling.com

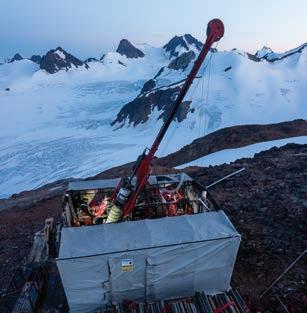

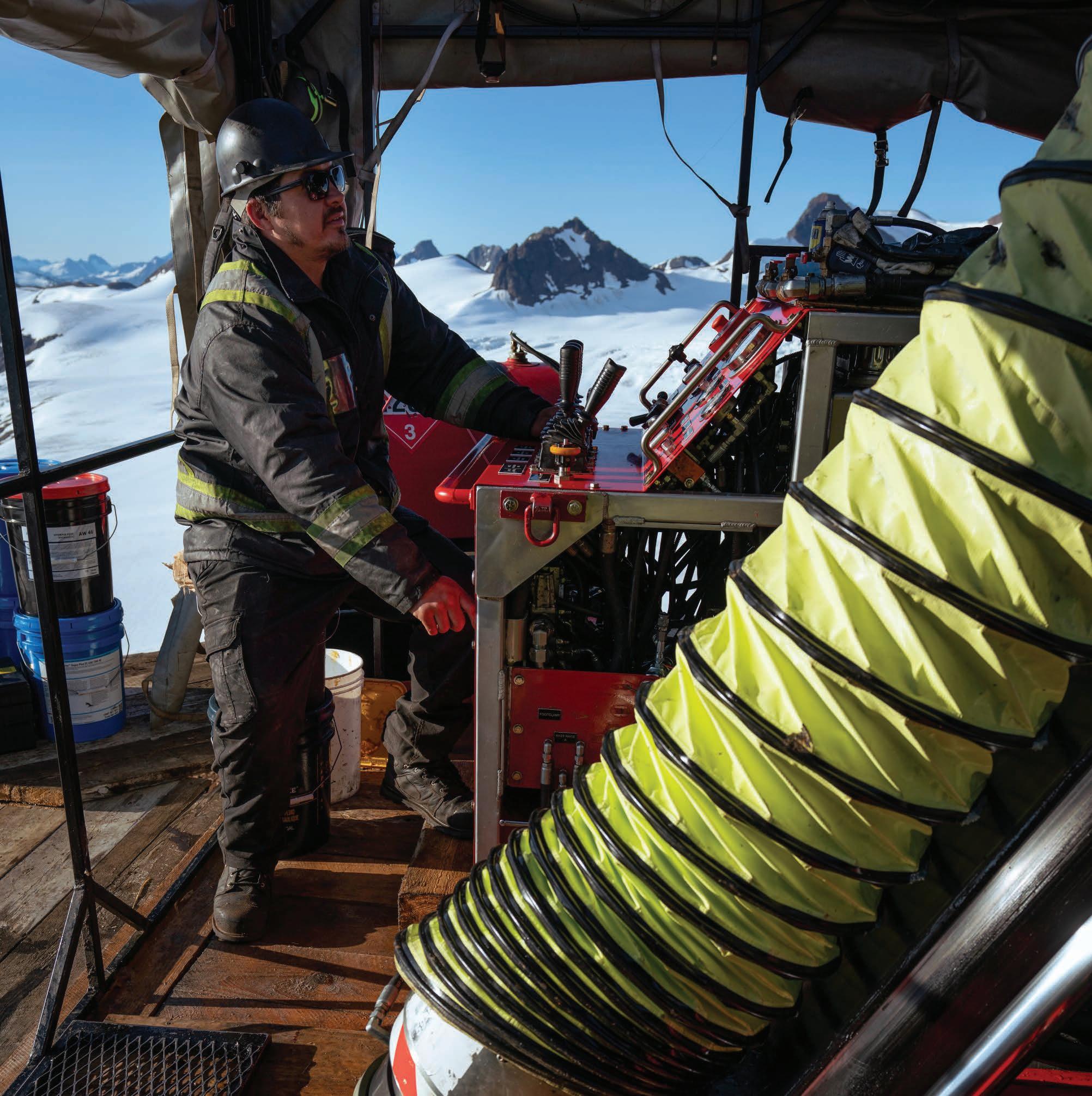

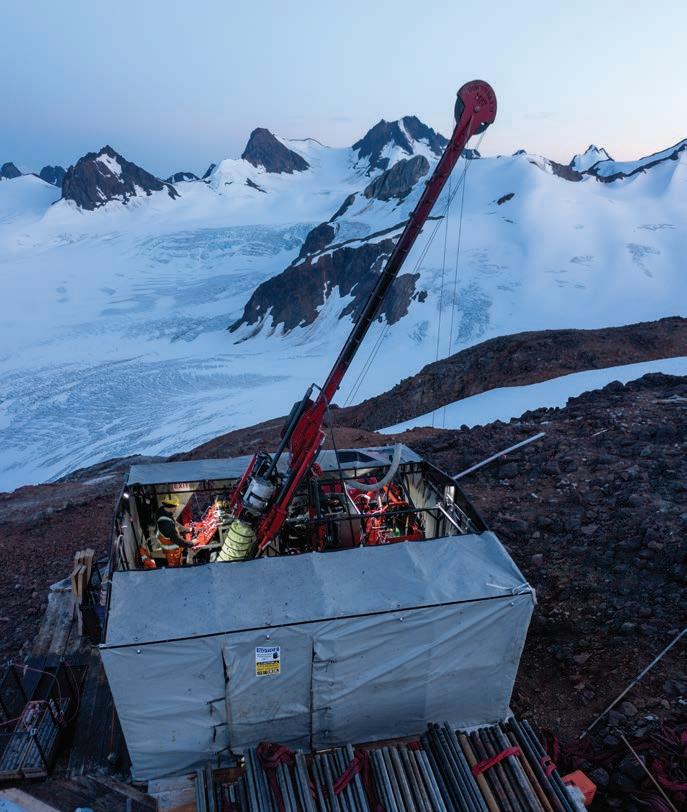

by Alan McPherson, Owner of HELM Diamond Drilling

HELM Diamond Drilling (HELM) is bringing highly skilled, new competition to one of Canada’s largest, and most competitive drilling sectors. This prospect would seem to be a difficult task for a new drilling company, but HELM is successfully doing exactly that.

Being a newcomer in a highly competitive drilling zone of Canada is no easy task. The number of competing companies in a single area generates some of the most challenging obstacles for a new diamond drilling company to face. The financial and production pressures that come with going up against bigger, more industry-established entities as a newcomer can be quite cumbersome for most, but the success that HELM has accomplished so far has greatly impacted the direction the company is going. HELM’s drive to accomplish some of the best results in this area came from a strategic forward-thinking mentality, a love for innovation, a keen focus on safety, and the proper investment into industry-leading equipment. These foundational pillars have led HELM to hold records in this area with the highest meterage recorded so far: 144 m (472 ft) in a single shift.

Among HELM’s active contracts is the exploration company Enduro Metals. Thanks to the relationship with the locals, the geological findings, and choosing the appropriate drilling company, this exploration team has one of the largest junior land positions in the famous Canadian region known as the ‘Golden Triangle’. It contains some of the most important gold deposits in the Canadian history. The name is derived from the abundance of gold, silver, and copper in the area and has played a major role in Canada’s mining industry for decades. This land position in the ‘Golden Triangle’ is located in northwestern British Columbia on the Tahltan First Nations territory. The property is known as ‘Newmont Lake’ and has at least four large mineralized systems: Burgundy, McLymont, Cuba, and Chachi.

To access the drilling location, HELM drill crews boarded a flight at a regional airport located in Terrace, British Columbia. A shuttle then transported the crew north on highway BC-37N for roughly six hours, passing three junctions before reaching a radio controlled dirt mining road. Once on this controlled road, the shuttle continued an additional hour into the valleys of the surrounding mountains to arrive at the designated camp location (Truffle). Once ready for shift, drill crews drive an additional kilometer and a half to a staging location before being airlifted by a helicopter to the drilling sites.

When drilling on top of the approximate 1900 m (6234 ft) above sea level zones, the task of dealing with a sufficient water supply becomes one of the more technical challenges posed. Due to the remote, elevated location, it is extremely difficult if not impossible at times to find a local water source that produces enough flow and pressure to

enable drilling at the depths required by the contract. This becomes even more challenging if drilling is continued past the 600 m (1969 ft) target depth. Drill crews have the laborious task of running high-pressurized hose lines across kilometers of undeveloped terrain which is largely traveled by foot.

Many challenges need to be faced when remote drilling, but there is one that cannot always be predicted; the weather. When working at such high elevations the weather sometimes does not coincide with the weather at the staging location where crew changes commence. With drill site locations being in such early stages of development, the focus of leaving minimal environmental impact is also of extreme importance and high priority. Due to this approach, there is often not enough space for the amenities the average person is familiar with when facing the changing meteorological conditions. When the weather fluctuates to either side of the spectrum, the drillers have to rely on strategically selected items previously delivered and assembled at the drilling sites. The weather can sometimes also affect crew changes if the pilot deems it to be unsafe for flying. Thankfully, HELM is always prepared for circumstances like these and takes the necessary precautions to be proactive as much as possible.

Before drilling can commence the team needs to fly in, via helicopter - at roughly 816 kg (1800 lb) a load - all the drilling equipment and water supply gear, along with all the safety equipment to accommodate for unforeseen circumstances. This safety equipment includes a survival shack, heating and sleeping gear, generators, and sustenance in case crews get stuck for long durations of time. This needs to be

↑ HELM’s crews are no strangers to drilling on the side of a mountain. Luckily, Multi-Power’s Discovery II makes the move as easy as possible.

methodically approached so the safety of the crews is the main priority while drilling takes a back seat until the conditions improve and are deemed safe. Once this is accomplished the drilling equipment is given the crews’ full attention, and loads are transported up piece by piece.

The choice of machinery was decided with safety, reliability, performance, elevation, and transportation in mind. In order to accomplish the required drill targets, the design choice of Multi-Power’s Discovery II drill was made. These drills have the capability and convenience of being transfigured for both ‘Skid’ and ‘Track’ mounted drilling, allowing for HELM to eliminate boundaries when considering a contract. The Discovery II has the power to drill up to 1285 m (4216 ft) with N-size bits and 875 m (2871 ft) using H-size with possibilities for expansion if needed.

Choosing this drill set up allows the entire drill rig to be broken into 10 pieces for fly transportation. These include the drill shack, stinger, drill head, control panel, engine, mud tank, rod rack, helper’s stand, toolbox, and frame. Having a system like this generates some of the most efficient drill moves attainable in this location with record timing, allowing the crew to safely continue drilling as soon as possible. With the mentality for constant improvement this will only get more efficient as HELM continues to grow.

The heart of HELM Diamond Drilling has a deeply rooted aboriginal connection, consisting of two owner/operators who are official indigenous members of Canada, making HELM 100% indigenous-owned.

Alan McPherson belongs to the Tahltan Nation located in the northern parts of British Columbia (and southern Yukon) while Devlin Luck is a member of the Binche First Nations group located in the Fort St. James area of central British Columbia. With over 30 years of combined drilling experience throughout Canada and connections to two highly economically active indigenous mining territories, HELM Diamond Drilling not only offers a leading approach in safety and innovative drilling, but also provides personal relations with each respective indigenous Band.

Incorporated on September 7th of 2020, specializing in mineral exploration, and beginning operations in December of the same year. HELM first spun rods at Gold Mountain Mining Corp’s ‘Elk Gold Project’, HELM has been building its name and expanding its capacity to numerous projects across BC. With the HELM headquarters situated on the Binche First Nations territory, the company respects the rich history of the indigenous peoples of Canada and actively seeks to follow aboriginal beliefs while safely integrating modern economic growth.

HELM Diamond Drilling looks forward to continuing its expansion and creative approaches to resolve any issues that may arise, no matter the complexity of the environment in which operations take place, while adhering to its number one concern; safety. This also includes actively seeking ways to properly train and introduce more indigenous members of all backgrounds into this industry with hopes to provide life changing careers and further build the capacity within aboriginal communities. C

For more information Visit: www.helmdiamonddrilling.ca

Helicopter Portable Diamond Drill

1400 Meter NWL Depth Capacity

Cummins Power Unit 160 or 260 HP

‘P’ Size Rotation Unit & Clamp

Safety Package: Full Guarding, Multiple E-Stops, Interlock Rod Guard & Power Lock-Out

Available in Heli-Portable, Skid Shack Mounted and Track Carrier

by Michelle White, Business Development and Key Account Manager

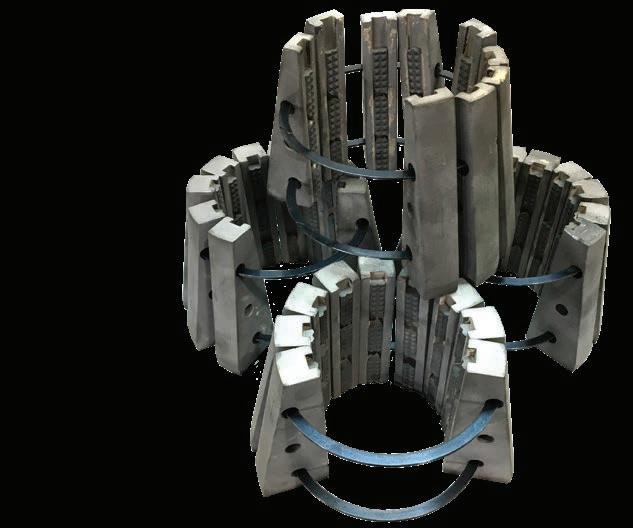

↑ The DiscovOre Prime is introduced to new sites in complete cases that ensure there is never a missing piece and that the first runs always go as smooth as possible

Early beginnings: safer, faster and better productivity with DiscovOre

Improving drilling performance has always been a priority on mineral exploration sites, so manufacturers have been focusing on ways to do that while still maintaining the safety of drillers. ↑ The DiscovOre Prime design is very similar to the regular DiscovOre, but those small changes make a huge impact on productivity (H-size shown above)

In 2016, Epiroc achieved that goal with the launch of the DiscovOre and Arrow 3S core barrel system, an innovation in drilling equipment that addressed both productivity and safety. After years of development, the Epiroc team, namely Patrick Salvador, applied their decades of in-depth diamond core drilling knowledge, along with extensive input from drillers in the field, to develop the most innovative coring system on the market in at least a quarter of a century. Some of the highlights include an automatic locking overshot that descends the back end faster, no roll pins and robust, leveraged latches that result in fewer stuck inner tubes and ultimately increase productivity. To this day, the DiscovOre has been vastly adopted across the globe.

‘When Ian Wilson, Innovation Manager at Major Drilling, was shown the DiscovOre, he was impressed,’ recalls Brent Kubish, Account Manager for Midwest Canada, at Fordia Powered by Epiroc. Yet, he felt that there was still more that could be done. Ian said, ‘Major Drilling is a leader in the industry for providing specialized drilling solutions. We have continual demand to meet expectations with the best solutions possible. That’s a big reason we were happy with this meaningful collaboration.’ Ian saw the potential for an even greater performance increase.

Working at one of the largest drilling contractors in the world, he knew that to sell this new concept in the field there would need to be a significant increase in speed.

As Innovation Manager, Ian and his team had been working on ways to improve drilling performance, always looking to be at the forefront of new solutions. The innovation team had recently developed a fast latch head assembly that focused on improving speed and he felt his team would be the perfect partner to collaborate with Fordia Powered by Epiroc to take the benefits of the DiscovOre even further. Both companies saw the synergy that was possible, and so a collaboration was born that resulted in the DiscovOre Prime, a premium, fast-descent head assembly.

The DiscovOre Prime was developed in partnership with drillers to be the safest and fastest core tube on the market. When the original DiscovOre was launched in 2018, it focused on mitigating the risk of injuries related to the roll pin and spearhead. It eliminated the failures associated with the spearhead design by using automatically locking lifting dogs and eliminating the roll pin altogether. What made the DiscovOre exciting was that these extra safety measures were automatic. With the DiscovOre and Arrow 3S, the built-in safety features are automatically engaged and did not require additional, manual steps. What’s more, the features did not add time to the coring cycle, so productivity was maintained.

Better speed was achieved with the Arrow 3S overshot which had a design that made it more efficient in terms of descent time. It was designed to be centralized in the drill string

for smoother, faster descent speeds. All in all, the DiscovOre system is still faster than any traditional head assembly, but with the work that Ian and his team had done, Ian thought that some of the team’s ideas for faster descent could be incorporated into this new product resulting in a significant performance increase.

Fordia has been manufacturing drilling equipment for mineral exploration since 1977 with a focus on exceeding customers’ expectations regarding both product quality and customer service. With offices across the globe, Fordia had been expanding successfully until 2019, when it was acquired by Epiroc, a global productivity partner for mining and infrastructure, creating Fordia Powered by Epiroc. The two companies combined their expertise to bring more to the world of mineral exploration.

Major Drilling International Inc. is one of the world's largest drilling and mine service companies primarily serving the mining industry. A global company with field operations and offices in Canada, the USA, Mexico, South America, Africa and Australasia, it provides a complete suite of drilling services for both surface and underground projects.

Major Drilling had been a customer of both Fordia and Epiroc and the collaboration on the DiscovOre Prime had started shortly before Epiroc acquired Fordia. Despite the timing, teams from all the parties worked together seamlessly to ensure the project would be a success.

The collaboration began in 2018 and within the year, the DiscovOre Prime was developed and ready to be tested. Both Fordia Powered by Epiroc and Major Drilling had set aggressive targets for speed and both are proud to say that the DiscovOre Prime exceeded those targets.

In addition to function, there was more focus on fluid dynamics in the design of the Prime. More emphasis on how the water runs through the assembly, providing more room for water flow, and the speed at which it moved through the equipment were a few

of the major differences between the DiscovOre and the new Prime version.

‘This thing will go as fast as you can feed it’

The feedback from drillers has been impressive and highlighted that as drillers become more experienced with the system, they are able to push it further, increasing speed while not reducing the proven reliability of the system. A faster head assembly means that a drilling company uses less water and fuel - and drills more meters.

‘This is not just another head assembly,’ explained Ian Wilson. ‘This is a system that was designed by drillers for drillers to help them get more core in the box. The result is a substantial increase in productivity - an experienced driller can double production at depth,’ he added. Results show that at a depth of 1000 m (3280 ft), up to 60+ m (197 ft) of core per shift is drilled as opposed to the usual 36-39 m (118-128 ft) of core. The Prime is also lighter, smaller, and easier to handle. The design also made sure that it’s easier to change latches and replace parts. As one driller said about the Arrow 3S overshot, ‘This thing will go as fast as you can feed it.’

Both Major Drilling and Fordia Powered by Epiroc are pleased with the results of their collaboration. Innovation has been a cornerstone of our operations. We are really pleased with how Major Drilling and our company have come together to develop solutions that benefit both customers and employees. These co-development opportunities help drillers outsmart drilling challenges which is one of our priorities.

The DiscovOre Prime is ideally suited for drilling companies that are focused on performance. Its higher price point is easily justified when you calculate the cost per meter drilled and payback can be as fast as a few shifts. Now the DiscovOre Prime and Arrow 3S overshot are available to all drilling companies worldwide. The system will be revealed to the drilling community at large at the upcoming PDAC, scheduled to take place on March 5-8, 2023, in Toronto. C

↑ A DiscovOre Prime head assembly being used by Major Drilling

↑ Drillers appreciate the DiscovOre Prime for its lightweight and impressive speed

What do you get when you take one of the most respected underground core drilling rigs on the market and fuse it with a wellproven and mobile carrier? You get the Diamec Smart 6M.

Find out more at epiroc.com United. Inspired.

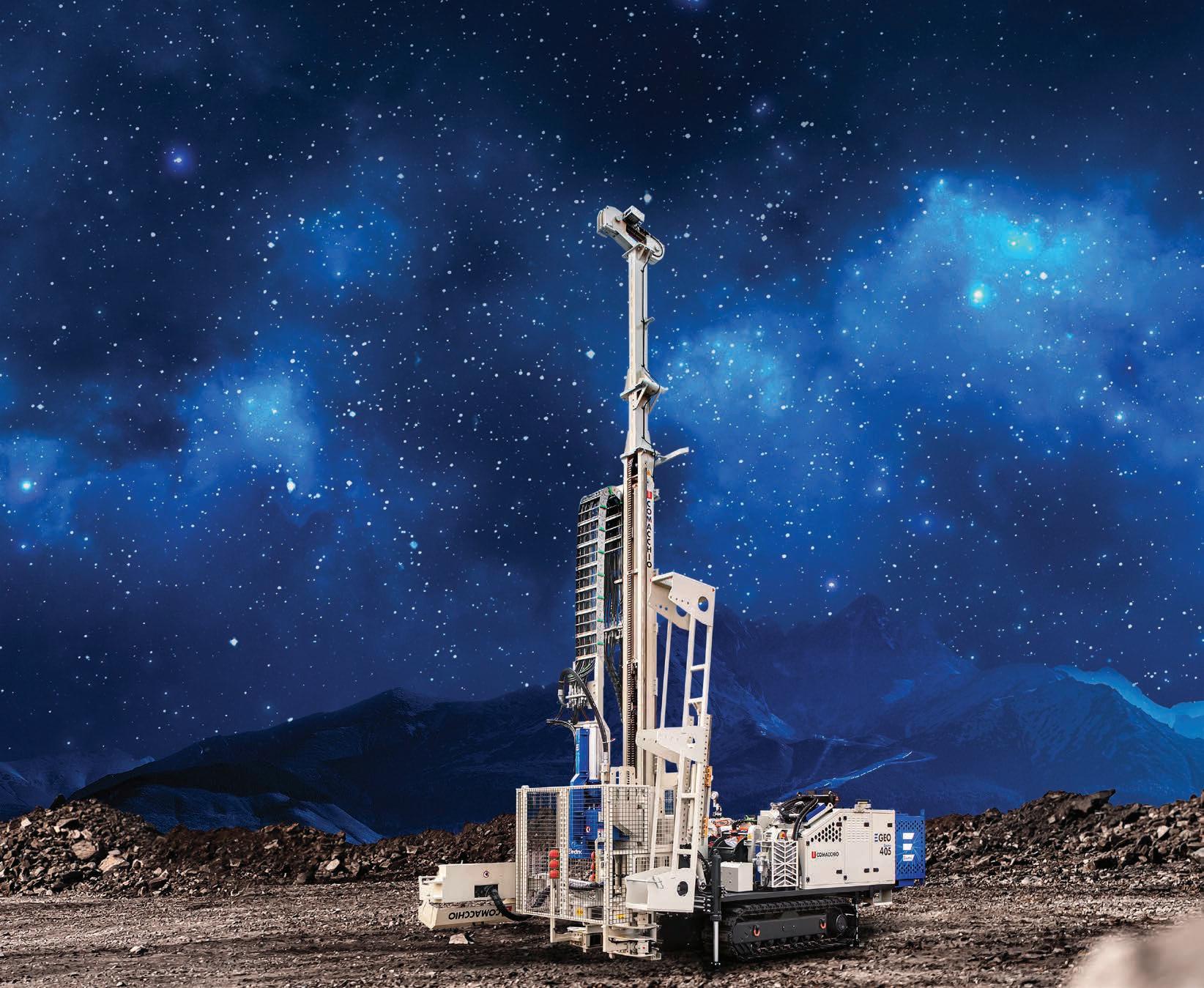

by the Comacchio team

As the world faces a climate crisis, creating a sustainable future for mining is rapidly becoming a priority for the industry. As part of their strategy for sustainable mining, top miners across the global market including Anglo American, Rio Tinto and BHP have enacted change towards carbon neutrality across all operations and have committed to net zero in direct and indirect emissions by 2050 or sooner. To reach such ambitious targets, companies are reviewing the equipment they use, trying to offset the adverse effects of pollution and reduced energy efficiency connected to the use of diesel-powered machines.

On the path towards a cleaner and smarter future for mining, Comacchio is taking a major step by introducing the first battery-powered drill rig for mining exploration operations.

Building upon its extensive experience with the CX range, Comacchio introduced eGEO 405 – a fully-electric exploration drill rig using lithium-ion rechargeable batteries. The rig was first presented during the Bauma show in Munich in October 2022. It can be considered a milestone in the journey towards zero-emission drilling in exploration drilling programs around the world, explained Emanuele Comacchio, technical and sales manager at the company.

The ‘heart’ of the eGEO 405 drill is the battery pack, consisting of a modular battery system, delivering a total energy content of 52 kWh and reaching a nominal voltage of 350V. The battery system uses multiple subpacks in series, it is characterized by a high energy density, scalability and extensive safety features. The solution is said to be robust against harsh conditions and to score especially well in applications that require high peak power, fast charging and a large number of charging cycles. The estimated lifespan is 2000 cycles. The battery system has a compact size and is placed on the rear part of the machine in a separate and exchangeable box, designed to be easily handled using a forklift, telehandler or other ancillary lifting equipment. The battery system should allow a runtime of up to eight hours, depending on soil

conditions. To ensure continuous operations even under ‘extreme load’ conditions, the rig is supplied with two swappable ‘power boxes’. Switching out a depleted battery with a fully charged one requires just a few minutes. The depleted batteries can be recharged on site using the mains supply or taken to a charging point and recharged there. Recharging to 80% can take as little as 30 minutes, depending on the starting level and the power supply capacity of the grid.

‘We have updated the battery system to include an on-board charging device (OBC). It is compatible with the single-phase and three-phase input voltage and it is designed to manage the flow of current from the charging station to the battery regulating the input current according to customer’s needs. This will allow the drillers to recharge the batteries while continuing working in plug-in mode,’ continues Mr Comacchio.

The low-voltage DC (direct current) power provided by the battery pack is changed into conventional AC (alternating current) by power inverters located on the sides of the rig, protected from vibration and heat and easily accessible for repair and maintenance operations. The inverters allow precise control of the flow of power to any of the rig’s AC motor loads that provide motive power for the rotary head, pumps and winches equipping the eGEO 405.

Unlike most of the competition, Comacchio has chosen to electrify all main loads of the drill rig through the use of permanent magnet synchronous machine (PMSM) technology. The electric PMSM motors offer smaller dimensions, lighter weight and higher efficiency as compared to conventional technology such as induction machines. The use of several motors (rather than one) brings the power supply directly to the point where it is needed, thus eliminating the losses due to energy dissipation and ensuring maximum efficiency of the system as a whole.

‘The biggest challenge in electrifying a drilling rig is integrating the batteries into a piece of equipment designed to accommodate a thermal powertrain. We developed the battery system and the power management from the ground up, including designing and implementing a software solution to effectively and safely manage power and energy between the batteries, the inverters and the electric motors powering the main loads of the rig. The power supply of the machine is controlled by a vehicle control unit (VCU) using CANBUS technology, allowing all the components to communicate with each other and managing the current flow from the battery according to the actual operating needs. The operating parameters of the machine can be viewed on a display located on the control panel,’ elaborates Mr Comacchio.

The rig is equipped with a 6500 daN (14 600 lb) pull mast with 3500 mm (11.5 ft) stroke, featuring a hands-free clamping/breakout system with a clamping range of 45–325 mm (1.77 to 12.8 in). The high-performance rotary head can reach 850 daNm peak torque and a speed of 650 rpm. It can be operated in slow and fast gear, and the adjustment of torque and rpm according to the actual operating conditions can be carried out in an extremely precise manner. The machine on display at the Bauma industry event in Munich was equipped with a mud/water pump (with max flow rate 200 l/min and max pressure 45 bar), a 2000 kg (4500 lb) service winch, and a 600 kg (1320 lb) wireline winch. The eGEO 405 also features a rod rack holding up to twenty-eight 76 mm (3 in) rods with a max length of 3 m (9.84 ft) and can be thus transported with a total of 84 m (276 ft) of rods on board. The overall dimensions of the eGEO 405 are very similar to the diesel-engine equivalent, keeping the machine as compact as possible to facilitate transport. The transport weight ranges between 8500 and

↑ The Comacchio eGEO 405 features a modular battery system delivering a total energy content of 52 kWh and reaching a nominal voltage of 350V

9500 kg (18 750 and 20 950 lb), depending on accessories, including one battery pack.

cmyk - 100 / 69 / 0 / 0

cmyk - 75 / 64 / 60 / 78

Comacchio claims that the eGEO 405 is designed to perform as well if not better than the diesel-powered equivalent GEO 405. It can offer the same functionality and provide the maximum required power, regardless of drilling method, covering the full spectrum of applications connected with mineral exploration. Specifically, the eGEO 405 allows to carry out conventional and wireline coring using B-size, N-size, H-size and P-size rods at up to 350 m (1150 ft) depth. The machine can also be configured for RC drilling using DTH hammer, reaching 80–100 m (262-328 ft) depth. The multipurpose design of the rotary head allows to perform multiple drilling types with minor changes on the machine. This operational flexibility results in reduced unproductive time and lower total cost of ownership.

The safety features of the machine include protection against moving parts, such as interlocking guard meeting the European requirements of EN 16228. Furthermore, the eGEO 405 can be equipped with data logging system including ComNect, a remote monitoring software developed by Comacchio providing data that can be used for a variety of machine diagnostics and operational condition analyses.

The sustainability benefits are enormous and are expected to be a driving factor in the adoption of this kind of rigs. The use of eGEO 405 is to save up to 372 kg of CO₂, up to 0.62 g of particulate matter related emissions and is estimated to save up to 130 l of diesel over an eighthour workday. Ideally, if the batteries are charged from green energy sources, the drill generates complete zero emissions.

‘Thanks to the electric motor, the adjustment of torque and rpm according to the actual operating conditions can be carried out in an extremely precise manner.’

1. Higher energy efficiency. Diesel-run hydraulic drill rigs are estimated to lose 60% of energy due to the engine and another 30% due to the hydraulic system. Electric engines deliver 90% of energy at the output shaft and are therefore considered the most efficient option. Moreover, the use of electric motors eliminates energy losses and fuel consumption connected to idling times of both hydraulic pumps and diesel engines. With an electric drill rig, the current output from the battery is provided according to the actual load, accumulating operating hours only when truly in operation.

2. Low noise. Noise pollution is an underestimated threat to health and safety. eGEO O405 will help remove noise distraction, enhancing both productivity and safety on site.

3. Reduced maintenance required with electric drives compared to conventional combustion engines. Electric drill rigs have far fewer parts than their diesel alternatives. This means less breakdowns, longer service intervals and less maintenance. Over the course of their lives, the total cost of ownership for an electric drill rig is cut considerably in comparison to diesel-run variations. Additionally, the lifetime of an electric motor is much longer.

4. Optimal operational precision. High-performance motor control characterizing the electric PMSM motors equipping the rotary head and the main components of the rig provide accurate speed and torque control, offer smooth rotation over the entire speed range and have the advantage of sustaining full torque at zero speed, and fast acceleration and deceleration. This enables greater control of drilling parameters resulting in faster and better holes.

‘While creating the eGEO 405 we have chosen the most proven electrification technology available on the market, in order to provide reliable operation in harsh operating conditions associated with exploration projects,’ concludes Mr Comacchio. ‘We are approaching companies that are willing to become early adopters of new technologies. Carbon reductions will become a more important differentiator as many mining companies publicly commit to ambitious net zero targets and want to score well on key Environment, Sustainability and Governance (ESG) performance indicators, which is increasingly important to investors. Such ambitions will likely accelerate in the next years and Comacchio is committed to exploring new solutions including not only purely battery-electric drives, but also hydrogen-powered motors. The eGEO 405 was designed with a view to future developments that include the use of fuel cells powered by hydrogen instead of drawing electricity from the battery. This is the first step of a long path towards a new idea of the future of mining exploration’.

Comacchio is a world-renowned designer and manufacturer of drill rigs for a vast range of applications. Born in 1986, Comacchio is a family-run company, operating from its headquarters in Riese Pio X (Italy). The company’s ability to assimilate ideas, insights and specific requirements coming from the market has allowed creating an innovative and differentiated range of products, offering a range of features, options and enhanced automation solutions designed for optimal safety, reliability and performance. C

↑ The multipurpose design of the rotary head equipping the eGEO 405 allows to perform multiple drilling types with minor changes on the machine

↑ The battery system powering the eGEO 405 is placed on the rear part of the machine in a separate box designed to be easily exchangeable using a forklift or telehandler

For more information Visit: www.comacchio.com/en/

Safety is the challenge, CX Line is the answer. Compact design, hands-free rod handling system for fully automated and remote controlled operations: the future of exploration drilling is already here. Are you ready to join in?

In this Issue:

Q&A from the experts

In conversation with Dr Richard Tosdal, President at PicachoEx LLC

A few structural geology concepts for sediment-hosted Copper exploration

A case study from the Cashin Mine in the US by Dr Molly Turko, Structural Geology Expert & Dr Ali Jaffri, CEO at Applied Stratigraphix

Power to the people:

How citizen development is driving a digital mining operations revolution by Udit Poddar, CEO and Vahishta Mistry, Content Lead at WorkOnGrid

What makes a geologist?

Thoughts on declining discovery rates, and other strange animals - a practising Ni-PGEsulphide geologist’s (heretical) viewpoint by Richard A. Hornsey, Consulting Geologist, Ni-PGE Specialist at Richard Hornsey Consulting (Pty) Ltd

Dr Richard Tosdal President at PicachoEx LLC

Richard M. Tosdal received a bachelor’s degree from the University of California at Santa Barbara (USCB) in 1974, an MSc from Queen’s University (1978) and a PhD from the USCB (1988). He has been a Research Scientist at the U.S. Geological Survey or USGS (1978-1999), and the Director of the internationally recognized Mineral Deposit Research Unit (MDRU) at the University of British Columbia (1999-2008). He serves on technical advisory boards to junior companies and consults the minerals industry on aspects regarding the metallogenic evolution of plate margins, the structural controls on ore deposition, and the evolution of porphyry Cu, sedimentary rock-hosted Au, and epithermal deposits.

Dr Brett Davis: You have worked with an enormous number of people over the years. Apart from me, who has inspired you in the field of geology?

Dr Richard Tosdal: I would rather think about this question not from inspiration, but in terms of who has helped or facilitated or opened doors for me over the years. Two people are important in this context.

I want to start with my first undergraduate advisor at UCSB, Robert Webb, who took a youngster who picked geology as a major without having the first clue what it entailed, and then transferred universities. The main thought in selecting the major was that I could surf my life away. Dr Webb showed me how I could graduate by the end of the normal four years and was always available to manipulate the accessory course requirements such that I graduated on time. Without him, I am not sure I would have discovered the desire and ability to make geologic maps as a profession.

Second is Gordon Haxel at the U.S. Geological Survey who hired me off the streets on contract and ran interference through the bureaucracy that eventually led to a full-time position, he also supported me through my PhD at the time.

These two perhaps unbeknownst to themselves were important at a critical time early in my career.

BD: You’ve worked for the United States Geological Survey, and you’ve run the Mineral Deposit Research Unit at the University of British Columbia. What were your most rewarding moments in these roles?

RT: Working for the Geological Survey provided me with the opportunity to be exposed to the full range of geosciences, thereby introducing

a young geoscientist to world-class scientists who readily shared knowledge. Although each of us at the USGS had an assigned project requiring a product mandated by the funding agency, each geoscientist was expected and given the opportunity to go beyond what was required and encouraged to publish the results in international journals. It was expected if one wished to advance in their career.

At the University of British Columbia, I ran the Mineral Deposit Research Unit (MDRU). This is a self-funded joint venture group between the mineral industry and the university. There was a funding mechanism for the administrative group, but all research projects undertaken to provide opportunities for graduate students and post-doctoral fellows required securing time-limited outside funding. This led to the development of some excellent applied projects found upon fundamental basic science principles that I suggest had a lasting impact on our exploration concepts. These are the rewarding scientific moments.

On a personal side, seeing graduate students move on to successful careers is somewhat akin to watching your children grow up. One cares about their success, but only wishes they would keep in touch. Yet, I suspect they were just as happy to not see ink on the thesis drafts, to finally finish, and move on as I was to quit reading their thesis.

BD: Given your success in the research space, including your publication record and the postgraduate geology students you supervised, what made you move into a consulting role in the industry?

RT: Running a research consultancy business is similar in minor respects to running a company, but in this case, the product is well-trained geoscientists. Maintaining a high level of productivity in a self-funded group is possible over the years, and I could

have continued. However, self-funded entities, such as MDRU, require reinvigoration on a regular basis as their direction and productivity directly reflect their staffing. Without staff turnover, research groups eventually fall into a rut of continually doing the same sort of projects. Only by changing senior staff can the internal excitement be sustained. So, it was my time to move on. Besides, it was my wife’s turn to dictate where we live as she is in the biotech industry, has more degrees than I do, and was essentially under-employed while living in Vancouver.

BD: I feel I’m giving you too many compliments. However, they are well-deserved, and I’ll state here that you are one of the rare breeds of people who genuinely understand structural geology in the context of intrusion-related mineral systems. Can you convey your perspective on the importance of understanding structural geology at all scales in terms of mineral systems?

RT: Too many geoscientists (including structural geologists) view structure as divorced from other aspects of geology, such as mineralogy, geochemistry, petrology, etc. This is simply not the case, as most would admit, I am confident. However, when you read structure reports or manuscripts, there is a tendency to ignore or minimize the interaction of structural fabrics with all the other aspects of geology that together make an orebody.

BD: Leading on from the previous question, what fundamental geological puzzles do you think remain unanswered in the mineral system space?

RT: Is anybody correct in their basic assumptions? But being a bit of a cynic, I think we have been playing in the mineral system space for hundreds of years. There is now a set of words to describe what we have been doing. Or is it just a portion of the mineral deposit community that has been thinking this way?

BD: Are you undertaking any active research at the moment?