Ahead of

curve.

• Directional Core Drilling (DCD) • Rotary Steerable System (RSS)

Both coring (DCD) and non-coring (RSS) DeviDrill systems fit directly to a standard drill string and are fully compatible with N-size wireline systems. With integrated survey instruments and no need for additional water pumps or drill strings, DeviDrill is the ultimate choice for saving time, meters and money, whilst reducing environmental impact, on your next drilling project. With or without core. www.imdexlimited.com

Drilling: More than 100 years of experience combined by David Bradley, Co-Owner at RJLL Drilling

20 Top mineral exploration drilling contractors for 2022: Statistics of diamond drilling meters by Coring Magazine’s team

24 Epiroc’s Explorac RC30 Smart A meeting of minds between Australia and Sweden

28 Marcotte’s commitment to reliability, innovation and automation by Mathieu Audet, Mechanical Engineer at Marcotte

32 Directional core drilling: San Miguel Infill Program: A uniquely challenging gold exploration project by Nils Ivar Iversen, Chief Executive Officer and Daniel Popescu, Office Manager at Aziwell, and David DuCote, Operations Manager at IDS de Mexico /EXPLORATION & MINING GEOLOGY

39 Q&A from the experts: In conversation with Nick Tate Specialist Consultant Mapper of Geology, Alteration and Mineralization Systems

46 The airborne geophysics power for mineral exploration: An Amazonian Craton case study by Bruna de Freitas, Independent Exploration Expert Geologist and MSc in Mineral Resources

50 Hydrothermal system models: A great tool for understanding challenging geology by Mark Lindsay, Former Chief Geologist at GBM Resources

54 A short explanation why optical petrography knowledge is the key to preliminary identify hydrothermal magmatic processes by Paula Montoya-Lopera, Postdoctoral Research Fellow in Economic Geology at CODES, University of Tasmania

Drilling services

Drilling equipment & accessories

equipment

Colin Rice Owner of Colin Rice Exploration Drilling Advisory

,

and Daniel Popescu, Office Manager at Aziwell and David DuCote, Operations Manager at IDS de Mexico

Bradley Co-Owner at RJLL Drilling

Mathieu Audet Mechanical Engineer at Marcotte

CORING MAGAZINE

November 2023

Cover photo Epiroc Issue 25

ISSN 2367-847X

Not for resale. Subscribe: coringmagazine.com/subscribe

Nick Tate Specialist Consultant Mapper of Geology, Alteration and Mineralization Systems

Bruna de Freitas Independent Exploration Expert Geologist and MSc in Mineral Resources

Contact Us

Coring Media Ltd.

119B D. Petkov Str., Sofia 1309, Bulgaria

Phone +359 87 811 5710

Email editorial@coringmagazine.com Website coringmagazine.com

Mark Lindsay Former Chief Geologist at GBM Resources

Paula Montoya-Lopera Postdoctoral Research Fellow in Economic Geology at CODES, University of Tasmania

Publisher Coring Media

Founder Grigor Topev

Executive Officer & Editor in Chief Martina Samarova

Editor Maksim M. Mayer

Section Editor – Exploration & Mining Geology Dr Brett Davis

Digital Marketing Manager Elena Dorfman

Graphic Design Cog Graphics

Coring Magazine is an international quarterly title covering the exploration core drilling industry. Published in print and digital formats, Coring has a rapidly growing readership that includes diamond drilling contractors, drilling manufacturers and suppliers, service companies, mineral exploration companies and departments, geologists, and many others involved in exploration core drilling.

Launched in late 2015, Coring aims to provide a fresh perspective on the sector by sourcing authentic, informed and quality commentary direct from those working in the field.

With regular interviews, insightful company profiles, detailed product reviews, field-practice tips and illustrated case studies of the world’s most unique diamond drilling and mineral exploration projects, Coring provides a platform for learning about the industry’s exciting developments.

Open the box and GO. The GoGyro is fully integrated and designed specifically for simple, easy everyday use.

Configure your GoGyro as you need it for your surveys without unnecessary extra running gear. Simply add the needed fitting to run as:

• Core retriever

• Wireline

• Centralizers

Minimize downtime & Maximize efficiency. Simply GO Survey!

Fully integrated with SurveySafe for fast, convenient and secure online survey data management.

Owner, Colin Rice

Exploration Drilling Advisory

Colin Rice is the Owner of Colin Rice

Exploration Drilling Advisory, a company that provides consulting and training services to the exploration drilling sector.

In the early years, Colin was one of the founding partners of SAMCHEM (Pty) Ltd; Professional Diamond Drilling Equipment (Pty) Ltd; and Borehole Survey (Pty) Ltd, which was the first company in sub-Saharan Africa to utilize advanced electronic survey tools successfully.

Grigor Topev: Colin, thank you for agreeing to this interview. Let’s start at the beginning. How did you decide to replace a career in teaching mathematics with drilling? Which aspects of the drilling industry did you get involved in?

He played a key role in establishing the National Diploma in Drilling Practice at Technikon SA and has been teaching drilling and exploration-related courses at various institutions and in several Southern African countries for the past three decades.

Colin launched the Drilling Industry Certification Authority of South Africa (DICASA) and is a past President of the Borehole Water Association of Southern Africa. Furthermore, Colin has been recognized as an Honorary Fellow of the Geological Society of South Africa. Recently, he contributed to the development of the newly registered QCTO Driller qualifications as a member of the working group.

In 2013, Colin launched DrillSafe as a mechanism to share safety information and to improve the ability of the industry to manage safety on drill sites.

Colin Rice: When I went to university, I went for the sole purpose of becoming a Mathematics teacher and so I majored in Mathematics and Chemistry. After I finished university, I taught senior school mathematics in Zimbabwe for eight years.

In 1984, my wife and I decided to emigrate to South Africa. We left Zimbabwe with our little daughter, who was two at the time. I didn’t want to go back into teaching, so I looked for a job elsewhere. The mid-1980s was an incredibly difficult time in South Africa, and finding a job was not easy. Eventually, I was offered a job as a development chemist for a company that manufactured drilling fluids. I knew nothing about drilling, I didn’t know what drilling mud was, but I was desperate for a job, and I grabbed the opportunity with both hands. So, I didn’t make a conscious decision to move into the drilling industry – it just happened.

As I look back over the past 35 years, I consider myself to be extremely lucky because the lessons that I learned in those early days have been foundational for my career going forward.

GT: What was drilling like in the 1980s and 1990s?

CR: South Africa hosts the deepest gold mines in the world and so, many boreholes were drilled to depths of up to 4000 m (13 123 ft).

Back in those days, the South African gold mining industry was dominated by four major gold mining companies and each of those companies had its own ‘in-house’ drilling company that did the bulk of its drilling. The in-house contractors got work whether they were good or bad, it didn’t really matter because they were part of the family.

In addition, each of the major mining companies also owned their own equipment manufacturing company and it was very difficult for independent contractors or suppliers to get work from the four dominant drilling companies.

I am sure that many people would disagree with me, but I believe that the development of the industry was inhibited because of the structure of the industry.

Once the downturn hit in the late 1980s, deep gold exploration work dried up and the big in-house companies had to bid for shallower work in other sectors of the industry. They simply could not compete with the smaller, more agile independents and they all eventually closed.

GT: You mentioned that South Africa hosts some extremely deep holes. Please elaborate on that and share some stories from the 80s and 90s. What is the deepest hole you know of in the region?

CR: One of the first deep holes I worked on as a young mud technician, was a 3800 m (12 467 ft) gold exploration borehole. The contractor was having a problem with an over-pressured shale band, and I was asked to help stop the caving. I decided that a small increase in mud density would solve the problem and so I set about mixing up the mud system.

In those days, B-size wireline drill rods couldn’t reach deeper than 1400 m (4593 ft), so the borehole was drilled conventionally with a 3 m (9.84 ft) single-tube core barrel. Typically, it would take 45 minutes to fill the barrel, then 13 hours to pull and another 12 hours to lower the drill string! I had to be on site when the bit was on bottom, so I drove to site, watched them drill for about an hour and then I drove back to my office for a day’s work while they pulled and lowered. These deep and ultra-deep boreholes were very costly to drill and always involved a great number of deflections. All deflections

were done using steel wedges and so many boreholes took several years to drill.

I was also lucky enough to have worked on some small oil rigs that were brought into South Africa to drill some ultra-deep boreholes. The boreholes had to be drilled very quickly and so they were piloted using tricones to approx. 3000 m (9843 ft) and then cored 4.8 in (12.19 cm) to the target depth.

As with any new technology, the first few months were not terribly productive.

‘I consider myself to be the luckiest guy in the drilling industry because I have had exposure to a number of aspects of our industry and that has pretty much shaped how my career has developed.’

Open-holing the top sections through extremely hard rocks was difficult and slow and once the rigs got to coring, bit life was a huge problem. Eventually, they got things right and they did some amazing work.

I remember setting up the mud system on one of the last boreholes that the rigs drilled on the day they spudded. I was again on the rig 84 days later when the borehole was at 4048 m (13 280.84 ft)! 4048 m in 12 weeks –that has to be some sort of record.

GT: You managed a company called Professional Diamond Drilling Equipment (Pty). What products did you manufacture?

CR: After I left the mud business, I met up with an old friend, Graham Martin. We were both looking for something to do and we decided to purchase a company called Professional Diamond Drilling Equipment (Pty) Ltd (PDDE). PDDE was the Southern African agent for JKS Boyles, a very famous Canadian drilling equipment manufacturer. The products that JKS Boyles manufactured were a perfect fit for the Southern African exploration industry at that time and so the business grew very quickly. Graham was the most incredible business partner; we were business partners for 31 fantastic years.

In 2000, we saw an opportunity to purchase a diamond bit manufacturing company and that decision was probably one of the most significant decisions that we ever made. As a major manufacturer, we became a significant player in the Southern African industry, so much so that our company was acquired in 2003 by the Craelius Division of Atlas Copco.

GT: What are the main aspects of your current business - Colin Rice Exploration and Training?

RC: I consider myself to be the luckiest guy in the drilling industry because I have had exposure to a number of aspects of our industry and that has pretty much shaped how my career has developed. I guess my current business involves three main areas of activity:

• Consultancy: I do consulting work for a number of mining companies around drilling issues; I do a lot of development of tender specifications and evaluation of tender submissions. I have done a number of reviews of exploration projects, and I have developed a lot of cost models for a number of mining companies.

• Safety: I am involved in safety auditing for many different companies in several different countries.

• Training: The third aspect of my business probably developed because of my teaching background. Back in 1987, I started presenting training programs for geologists aimed at improving their understanding of basic drilling principles.

Over time the demand for courses on safety and drill site supervision increased and so I have developed and presented a fairly wide

range of training programs, for many mining companies, for industry organizations, for universities, and even for contractors.

As I have aged, my appetite for travel has diminished and so about six years ago, I migrated all of the programs onto an online platform. We now have people from all over the world involved in our programs.

Training is one of the most satisfying parts of my work – there is nothing more satisfying than seeing people being able to apply a skill or a piece of knowledge that you have taught them. I really love the training part of my business.

GT: Please share with our readers about DrillSafe Southern Africa. How did you start the initiative and what has been its impact? What’s its ultimate goal?

CR: DrillSafe was originally launched in 2013 as an attempt to improve safety performance in the industry. I have always believed that there is nothing proprietary about safety – if I know something that can save an arm or a life, it is my obligation to share that information.

Initially, we published technical articles with a safety focus, and we published safety information – incident and accident reports. Through a number of sources, I was given

incident and accident reports from many different places in the world. I would then ‘sterilize’ the report by removing all references to a person, a product, or a place. All I wanted were the learnings from the incident so that we could share the information on the website and hopefully prevent a repeat.

The website took off very quickly, but after a couple of years, some mining companies decided to no longer share incident and accident information across the industry and the initiative lost momentum.

By October 2017, I had been involved in a great number of safety audits and investigations and I became increasingly frustrated at seeing the same safety issues time and again at every project I visited. Large and small contractors alike had the same fundamental lack of understanding of basic safety principles and thus I decided to refocus and relaunch DrillSafe.

I believe that one of the biggest problems our industry currently faces is a lack of skills and contractors have people working on drill sites who have no, or very little experience or training. All training given to new entrants is focused on getting them onto site - little is focused on technical or safety issues. Every driller is expected to complete a pre-start check of his rig, but often the driller does not really know how to identify a defect. In many cases the driller has not been trained to identify defects in equipment or processes, and critical safety issues are not identified.

To help with this, I decided to create a series of ‘Drillers Resources’. These are a series of A3 posters that deal with specific safety aspects, such as how to inspect a flexible hose, how to inspect a steel wire rope, the risks associated with pressure relief valves and so on. These resources are available for free on DrillSafe.

Our overarching objective of the initiative is to encourage the sharing of knowledge and experiences, and we are fortunate to have the support of remarkable companies like Anglo American and Major Drilling who believe in the initiative. I am very proud of DrillSafe and I hope that more people in the industry use the resources on the website.

GT: How do you manage to adequately identify drill site hazards and associated risks when so many diamond drilling contractors refuse to reveal incidents, occurring at their drill sites?

CR: Despite what I said earlier, over the past few years there has been a dramatic shift in attitude among a number of mining companies and they now very openly share

information. I am part of a couple of ‘safety groups’ made up of safety leaders from all the major mining companies, Anglo American, Rio Tinto, Newcrest, First Quantum, Newmont to mention only a few. We meet on a monthly basis and have amazing discussions on safety issues, equipment and trends, and experiences and learnings are openly shared.

GT: What are the most common drill site injuries and how to avoid them?

CR: Instead of talking about common injuries, I would rather use this opportunity to talk about the significant risks on drill sites! I believe that drill site safety revolves around four key elements:

1. the equipment that is used, the drill rig, compressors, boosters, rod loaders, etc;

2. the people who interact with the equipment on a day-to-day basis;

3. the activities or procedures that take place on a routine and non-routine basis and,

4. the local environment that may alter the way that certain procedures are conducted.

All these elements are interrelated, and all affect one another, but very frequently mining companies and contractors focus only on equipment safety.

We must never forget that equipment doesn’t kill people, processes kill people. Very seldom do we hear of a catastrophic equipment failure in the industry, we only hear about failures in procedure that have caused an accident or a fatality. We have to rely on people, drillers and offsiders to conduct the procedures and everyone in the industry is acutely aware of the shortage of skills and experience in the industry.

Our greatest risk, I believe, is not the equipment that we use, it is the people that use and maintain it.

GT: Considering your extensive knowledge and experience, can you think of a drilling development that at one time was hailed as revolutionary, but turned out to be a fad lost to time?

CR: This is a difficult one, I don’t think I can identify one particular development that failed. Many lessons learned from an apparent failure have helped develop a new product or technique.

I have always tried to approach drilling issues from a technical perspective. Everything that happens on a drill site can be explained in terms of physical principles and

so, I am in full support of companies that innovate and try new processes or techniques. Unfortunately, many people often put more energy into explaining why something won’t work than they do trying to make it work - I find this attitude incredibly frustrating.

Back in the 1980s many of the old ‘conventional’ drillers said that wireline would never work – well it did!

GT: What is your experience with directional drilling?

CR: I got involved in directional drilling, not as a driller but as a supplier of technology to drilling contractors. Back in the early 1990s, all directional surveying was done with filmtype magnetic survey tools. There was only one major manufacturer and in South Africa, the sole distributor was very expensive, so we were asked by some of our customers if we could source the same equipment. It didn’t take much effort to source the same equipment at very much reduced costs and that was our entry into the surveying business. Eventually, we started a contract survey company, Borehole Survey, that used to survey very deep gold and platinum exploration boreholes using film-type multi-shot tools.

Surveying a 3500 m (11 483 ft) deep borehole using a film-type multi-shot tool was fraught with difficulty and in 1995, we decided to purchase two electronic multi-shot tools from Reflex, the Swedish manufacturer. These were the first electronic survey tools in sub-Saharan Africa and they totally revolutionized the deep hole surveying in Southern Africa.

satisfying projects that I have ever been involved in. This was a pivotal moment as directional drilling became a significant part of our business.

At that time, one of the large gold mining companies was drilling some very deep gold exploration boreholes in South Africa. On two of these holes, very long deflections were required to reach some hard to get to targets, so we got involved in running small diameter, 23/8-in, downhole motors at depths of 3000 m (9842 ft). Again, this was brand-new technology applied in very difficult conditions.

One of the boreholes was a remarkable success and the other was not so successful! In the second one, we got a bit ambitious with the build rate and we created a dogleg at very great depth that eventually caused the borehole to be abandoned.

Today, there are numerous successful directional drilling techniques that are widely applied in deep exploration boreholes. I think that the industry has developed a good understanding of what is and isn’t possible and I believe that directional drilling has a massive role to play in the exploration industry.

GT: What is the state of the drilling market in South Africa nowadays? Which are the main players, what are the biggest projects?

We became the local agent for Reflex and at one point our little business was responsible for selling 25% of Reflex’s production of electronic survey tools. This was how I started understanding the survey business.

One of our major customers was a large coal mining company that was attempting to develop a technique for drilling surface-to-inseam boreholes for dolerite detection. I believed that the steering technology that they were using was inefficient and I convinced them to change to a mud pulse telemetry system. This technology was well-established in the oil and gas industry but had never been used in a mining application before.

Eventually, they decided to switch to the new technology and the project really took off. The value of the information that the boreholes provided to the mining company was immense and I consider that particular project to be one of the most successful and

CR: South Africa is not enjoying its finest times in terms of exploration and mining, policy uncertainty and many other structural problems make investment in long-term projects unattractive. Most major mining companies have left the country and there is not as much greenfield exploration taking place as in other African countries. By far, the bulk of exploration work is ‘on mine’, essentially for ore body extension.

Drilling rates are extremely low compared to other countries and local contractors have had to become incredibly efficient to survive and make money. Companies like Rosond Exploration, Zaaiman Exploration, Hall Core Drilling and Master Drilling are among the largest local contractors.

GT: Building from the previous question, is there anything that the global industry can learn from the South African market?

CR: Wow, this is potentially a very dangerous question. From a technology point of view, the South African industry just does not have the critical mass that other countries have and so investment in technology has been far short of other countries. Having

Major Drilling is one of the world’s largest drilling services companies primarily serving the mining industry. We maintain field operations and offices in Canada, the United States, Mexico, South America, Asia, Africa and Australia.

said that, one South African contractor, Rosond, has undoubtedly led the way in terms of true, hands-free drilling technology. The company currently runs a massive fleet of state-of-the-art drill rigs involved in diamond core drilling, grade control and rotary percussion applications. To my knowledge, Rosond’s fleet is by far the largest of its kind in the world and that is something that they can be very proud of.

I would also add that in many respects standards of safety on some South African exploration projects are as good if not better than in many other countries. I think it is fair to say that South African contractors have embraced safety initiatives, therefore contractors are no longer part of the problem –they have become a part of the solution to improving safety standards.

GT: Various companies in our industry are releasing autonomous drill rigs and rod handlers. Please share your opinion on these developments… Do you think they can make the work of drillers truly safer?

CR: Mining companies and many manufacturers perceive drill string handling to be the most significant risk in an exploration drilling

operation, so ‘hands-free’ rod handling became the target. Unfortunately, mining companies did not define what hands-free means to them and many systems were released that were not at all hands-free. A great deal of time and money were expended for very little reduction in risk. In fact, many systems increased risk.

Designing a mechanical rod handling system for rotary percussion and RC drill pipe is relatively easy and many rod handlers have been developed that significantly reduce risk and make drilling safer. Mechanically handling wireline drill rods, however, presents several additional challenges – the requirement for accurate thread alignment, the requirement to clean and lubricate threads, and for correct compensation when making or breaking a connection are critical and unless these requirements are addressed, the consequential damage could easily outweigh any benefit. Some manufacturers have successfully managed these challenges and they will undoubtedly make the work of drillers safer.

I do not believe that drill string handling does in fact present the greatest risk in a wireline drilling operation. I think that wireline retrieval represents the greatest risk but

very little work has been done on mechanical inner-tube handlers. I have recently seen a couple of add-ons to existing drill rigs that assist in inner-tube handling, though I do not believe that they are the complete answer. The industry must be encouraged to look at solutions. I am absolutely convinced that some workable systems will begin to be introduced in the short term.

We must not forget that every piece of technology that we add to drill rigs brings with it its own set of risks and it is essential that these risks are fully assessed and mitigated. If we don’t, we will continue to hurt people in our industry.

GT: Teaching the new generation of drillers and mentorship are the cornerstones of our industry. How should companies approach teaching the ropes to newcomers? What can young drillers do to develop their skills and knowledge?

CR: I think that this question hits the nail on the head. Without a doubt, people represent the greatest risk in any drilling operation. While ‘human-free’ drills are the objective, we will still need human beings to interact with drilling equipment for the foreseeable future and the only way that we can manage

the associated risk is to ensure that people are correctly trained.

Based on many interactions with large and smaller contractors, training is focused on two objectives: getting the person approved to get onto site and teaching the person enough that they can produce meters. We need to do more than just this, we need to deepen drill crews’ understanding of basic drilling principles, the equipment, surface and downhole, that they use and how all systems in a drilling operation affect one another.

GT: What are the latest developments in drilling fluids and additives? Is there anything different today compared to when you first entered the industry?

CR: Bearing in mind that drillers used water instead of drilling fluids back when I started, I would say that there have been some significant changes in the drilling industry over the years.

One major shift is the increased emphasis on environmental considerations. Nowadays, drilling operations are much more environmentally conscious than in the past. In the old days, we didn’t pay as much attention to environmental impacts, but today, there’s a greater awareness of the need for responsible practices.

Another development is the improved understanding of fluid technologies. Drilling companies now grasp the benefits of using additives, both in terms of managing geological risks and enhancing drilling efficiency. This understanding has grown significantly since my early days in the industry.

While I don’t closely monitor the mud industry anymore, it appears that the industry has become quite competitive in recent times with some new companies making significant inroads, challenging the established players.

GT: What is the most important lesson that you have learned for yourself during your career?

CR: I guess there are three lessons that I would pass on to any young person entering the industry:

1. All business is based on relationships. relationships take many years to develop but they can be destroyed

in seconds. Build relationships and value them, don’t destroy them.

2. Trust is everything. If your customers trust you, your chances of getting work from them are very good. Always act with integrity, always under-promise and over-deliver.

3. Never stop learning. Use every experience, whether it is a good or a bad experience, as a way of deepening your understanding. Ask questions and then ask more and more, but do not believe everything that you hear on a drill site!

GT: You claim that in order to be good in the drilling business you have to know the process from the beginning until the end. What are the main things in your view?

CR: As I mentioned earlier, an exploration drilling operation is made up of a great number of systems that affect one another and the better our understanding of these systems and their relationships, the more effectively we can manage an exploration drilling project.

None of these systems are terribly complex, but often, I see cases where a driller does not understand the most fundamental aspect of the work.

I recently completed a review of a very large number of drill rigs and not one of the drillers could tell me what their pump output was – not one!

Consequently, none of them knew what their annular velocity was, and none had any real idea of what flow rates should be.

These are very simple concepts and so to answer your question, the main things that we need to understand are basic drilling principles.

GT: You’ve had several truly successful businesses in your career. What do you think is the most important personal quality to run a successful business in the industry?

CR: I am very flattered that you believe that I have run successful businesses. I am not sure how one measures success in business, but if I have been successful then I guess my appetite for work has been a major contributor.

I truly love what I do, and I have absolutely no problems getting up in the morning to face the day.

I must also add that no one runs a business or develops a career in isolation, many people have been pivotal in my career: my wife held my family together all the times that I was away on business; Andre Ferreira gave me my first job, the late Mario Paro gave me my first order for drilling fluids in 1985; Stu MacGregor asked me to audit an exploration project that he was managing and that opened up the world of safety auditing for me; Graham Martin has been my business partner for over 30 years, and my daughter Erin played a huge role in developing the training part of my business. Without these people, I would not be where I am now, and I am forever grateful for their influence and help.

GT: Where are you currently located?

CR: My wife and I moved to Melbourne in April because all my children and grandchildren have been here for eight years now. We have a very close family, and it is fantastic to be able to spend a great deal of time with them. We have a beautiful home here and over the next couple of years, I would like to wind down so I can spend even more time with my children and grandchildren.

GT: How is a normal working day for you nowadays?

CR: I am still working on several projects in South Africa and other African countries, so my day usually starts at about 3 p.m. and runs through until about 10 p.m.! The time difference between Melbourne and South African time takes some getting used to! I am not sure that I have adapted fully yet, but I am grateful that I have so much work.

GT: What are your interests outside of the drilling industry?

CR: My wife would tell you that I have no interests outside of the drilling industry! I am extremely lucky that I am kept very busy on projects for the wonderful companies that have supported me over the years and I learn something new from every project I do. I guess, maybe my wife is correct – the industry is my hobby! C

AVAILABLE NOW. WORK SMARTER NOT HARDER.

The updated Quick Descent™ Head retains roller latching for reliability and adds automatic latch retraction and improved valving for maximum speeds. Combined with easier maintenance, it is a step ahead of the industry standard Link Latch™.

• Sealed bearings and simplified maintenance

• System descends 32% faster than our previous head design

• Threaded connections and no assembly pins

More than 100 years of experience combined

by David Bradley, Co-Owner at RJLL Drilling

RJLL Drilling (RJLL) was founded in 2014 by Réal Lemoine and Jérôme Lefebvre. They both started working for Bradley Brothers at the age of 16, climbing the ladder from helpers to drill rig operators to supervisors. In the last years of Bradley Brothers, Réal was the Canadian Operations Manager and Jérôme was the Arctic Superintendent. They worked for Bradley Brothers for 36 years up until Major Drilling bought the company in 2011.

Both Réal and Jérôme worked for Major Drilling for a few years, but the different culture between a private and public company was too difficult for them to bear, so they decided to start RJLL Drilling in 2014.

Réal and Jérôme’s objective at the time was to have a small but efficient drilling company that would surpass the industry standards. Since their sons were also drillers, they too saw the opportunity to build something with them and eventually pass the company down for generations.

In 2019, Réal and Jérôme asked David Bradley if he would like to join them on the adventure. Having worked together in Bradley Brothers for over 20 years, it was an easy decision for David to make. So, in January 2020, David officially joined as a shareholder. At the time RJLL had three surface drills in operation, one in Finland and two in Canada.

David had worked for his family business - Bradley Brothers for 23 years. He started working on drills as a summer job at the age of 13, then after college, he worked for six years as a helper and then as a drill rig operator.

At the age of 26, David started in the office as an assistant contract manager. A couple of years later, he became an operations manager for the Canadian operation and at the age of 30, David became VP of Operations and a co-owner of Bradley Brothers. When the family business was sold in 2011, David spent the next nine years as a co-owner of a management consulting firm until he joined RJLL.

In the fall of 2020, Marc-André Larouche joined the company as Financial Director and became a shareholder of RJLL in July 2021.

Powered by the Bradley Brothers culture, RJLL is committed to providing high-quality service and exceeding the expectations of our customers.

As of today, we cover mainly the provinces of Quebec and Ontario, the Canadian Arctic, and Finland. The main office is based in Rouyn-Noranda and we have a branch office in Timmins, Ontario. We do helicopter-supported drill jobs, shallow holes and deep hole drilling. We specialize in wedges, directional drilling, and complicated projects.

RJLL also has two important Joint Ventures. The first is RJLL/Nuvumiut with the Qaqqalik Land Holding Corporation out of Salluit, which covers the Québec Arctic. Another JV is with the Anishnabe Community of Lac Simon, which covers their territory in the Abitibi region.

We believe that our strength is our employees. RJLL has 145 employees as of today. We have great people in our administration and in the shop. Our in-field team is wonderful. Most of them have worked with Bradley Brothers and have many years of experience, and specialize in heli-portable work, deep hole, and directional drilling.

Everyone in the company is committed towards excellence. When a situation arises from a project, our approach is not to hide anything from our customers. We prefer to be honest and share with the client the information we gathered and then find and propose a solution that will make sense to all parties involved. We believe that the way management and employees react when facing an issue makes a big difference in customer satisfaction.

RJLL has 20 surface drills in operation. Our equipment consists mainly of drills made by Usinage Marcotte (learn more on p. 28), which are based in Val d’Or. We have 14 HTM 2500 rigs that can drill down to 2500 m (8202 ft) in N-size. We also have six Mancore 900H or equivalent that can do heli-portable and mobile drilling work with a depth capability of up to 900 m (2953 ft). All our drills come with the proper equipment that can move them to different hole locations. Our equipment of choice for such tasks are the Caterpillar D6-T tractors. Additionally, RJLL supplies the proper equipment to carry the crews to the drilling location. Our fleet consists of several Polaris 6x6 and Argo ATVs, and Prinoths and other snow machines in the winter. It is very important for us to have good and well-maintained equipment for the safety of our crews, particularly when working in the Arctic wilderness.

We believe that all drilling projects are important, yet we are extremely proud of the following:

We are presently working on a heli-supported job where we will have five drills. Considering that in the winter, we only have about eight hours of daylight to do drill moves with a helicopter, we are building tracked platforms, which will be able to carry the drills to new sites around the clock and maximize productivity. What makes this project special is that we have to be able to dismantle the platform into parts of no more than 2000 lb (907 kg), so we can sling them to the project site with the helicopter. Once there, our team will reassemble the platform and install the drill on top. The platform will be powered by the drill engine. This for us is adapting to our customer’s needs!

Going back in time over our many successful projects, the first one that stands out, in particular, is the Wasamac project with Yamana Gold in Rouyn-Noranda. We are truly proud that we solved the challenges we had on this specific project. All the drilling was being done in a residential area where houses were very close. One of the main challenges for this job was to work with Yamana in finding a way to minimize the sound of the drill to a point that had never been achieved before. Basically, the challenge was that the residents wouldn’t hear the drill at all!

When we started thinking of a solution to this challenge, there were two considerations: the first one was to eliminate the old-fashioned sound mitigation walls that were very heavy, therefore not safe to

manipulate, and build an effective sound mitigation system that was extremely efficient. We worked with a great supplier that had the sound mitigation expertise we needed. They helped us find the right solution for this specific project, while Yamana did all that could be done with the community; and they are having great success with project acceptability.

After a few months of planning and another month of testing, we surpassed our objectives. The system we developed was great because it was installed directly on the drill so there was no need for manipulation from the crews once set up, but if manipulation was needed, this system was extremely light. And the efficiency was excellent! At 10 m (32.8 ft) away from the drill, the noise was less than 60 decibels (for reference: roughly the level of a normal conversation). At 60 m (197 ft), you could barely hear the drill.

Another project we are very proud of is the O3 mining project in the Val d’Or area. When we began work on this project, we had to drill 2500 m (8202 ft) holes in soap stone. We were the first contractor to be able to get to the targeted depth.

To be able to go through this rock formation, our supervisors worked in close collaboration with mud suppliers to be able to find the right mixture that would allow to drill at depth without having the rock formation squeeze and stick our rods in the hole.

At the early stage of RJLL, we did a program for BHP Mining. Just qualifying to work for BHP made us proud because it meant that our organizational structure in safety and environment was excellent. To us this meant we could work for both major and junior mining companies.

Our next development phase is underground drilling. The objective is to have a total of 10 underground rigs in the Canadian market. Once we achieve this goal, we will be at our sweet size we had aimed for in January 2020 with 20 surface and 10 underground drills. In parallel, we are looking to develop in Scandinavia and other parts of the world. Outside of that, our main goals are to continue growing a great business with great values and to continue building good relationships with our Joint Ventures, customers, suppliers, and employees. This way we can become one of the leaders in the industry. We are not aiming to become the biggest drilling company, but we are aiming to provide exceptional quality!

Our dream would be to surround the next generation with great people and be able to pass it along! C

For more information

Visit: rjll.ca

Introducing CoreMatrix™, the new redesigned bit line-up from Di-Corp Drillers Edge.

The new CoreMatrix™ bits from Di-Corp are re-engineered for enhanced bit life and faster penetration rates across every ground condition.

With 21 matrices and a comprehensive matrix selection chart to guide you, it’s easier that ever to find the perfect CoreMatrix™ bit for your drilling conditions. Available with three waterway configurations and several specialty options for Abrasive conditions, Extended life, and Free-cutting matrices.

Drilling is tough. Get rugged to the core with new CoreMatrix™ bits by Di-Corp Drillers Edge.

by Coring Magazine’s team

Disclaimer

Coring Magazine is proud to present the new statistics of ‘Top mineral exploration drilling contractors for 2022’. Companies are classified by the number of meters achieved only through diamond drilling. These results were provided and confirmed by the companies themselves and have been rounded to whole numbers. The statistics present results for 2022, as at the time of publication (November 2023), complete data for 2023 was not available.

Other companies qualify but are not listed here for reasons beyond our control. We did our best to contact and include as many diamond drilling contractors as possible. However, many did not respond to our invitations; others were omitted per their request. Everyone is invited to get in touch and submit their numbers as long as their results equal or exceed 50 000 diamond drilling meters per annum.

Coring Magazine cannot be held liable for any errors or inconsistencies presented in this report.

In 2022, a wave of inflation washed across the world. The costs of labor, materials and fuel skyrocketed. Nonetheless, the interest in drilling services remained high.

2022 brought a slight contraction of over 5% in the meterage achieved by diamond drilling contractors in these statistics. We should stress that this contraction does not reflect an industry issue rather it may be a sign of increased drilling efficiency. This theory is supported by S&P Global data, as the approximate number of completed drillholes jumped to 70 008 in 2022 vs 69 000 drillholes in 2021. The number of drill projects globally climbed to 1751.

The economic conditions of 2022 have also reflected in the revenue reported. There is an increase in the range of 15-20% compared to 2021, possibly fueled by the increase of the cost per meter drilled globally. Reported profits, however, paint a complicated picture. Certainly, there are many companies with double-digit and even record-breaking increases, while others reported tame gains.

The number of drill rigs owned by the contractors in this list remains close to 2000, mostly unchanged from 2021. Most of the participating companies have augmented their fleets with new drill rigs, however. Rig utilization for the several companies that have reported it remained well over 75%.

Many companies also increased their staff in 2022, though some challenges to recruitment remain. Training and safety continue to be a focus for contractors, alongside ESG. Injuries remain low, and companies (including some that have chosen not to provide data) continued the zero-LTI streaks set in 2021.

Boart Longyear takes the first spot with reported 2 516 765 m (8 257 103 ft) achieved through diamond drilling, a less than 0.1% increase from the results of 2021. According to the annual report, the drilling services division of Boart Longyear remains the bigger portion of the company’s business and achieved nearly 20% growth in revenue and over 25% in EBITDA for FY22 (ended in Feb. 2023).

Major Drilling achieved 2 381 663 m (7 813 855 ft) through diamond drilling in calendar 2022. This result represents an increase of ≈40 000 m (131 234 ft) from 2021. Drilled meters for RC in 2022 were 1 193 372 m (3 915 262 ft). The company has 600 drill rigs (450 diamond), almost unchanged from 2021. Revenue and profits for FY22 (ended in April 2022) have increased by over 50%, while both revenue and profit for FY23 have increased by over 10% from 2022.

DDH1 Limited has skyrocketed to the third spot, partly due to the completion of the industry-changing merger with Swick Mining Services. The new entity, also consisting of DDH1 Drilling, Strike Drilling and Ranger Drilling, has achieved 2 123 267 m (6 966 099 ft) in diamond drilling and 1 283 156 m (4 209 829 ft) through RC for 2022. The group has a total of 183 drill rigs (149 diamond). DDH1’s earnings for FY22 increased by 14%, while EBITDA gained 10% over FY21. In late 2023, DDH1 Limited announced that it will reshape the industry again by merging with Perenti.

Orbit Garant Drilling has operations in North and South America and Africa. In FY22, the company achieved 1 356 033 m (4 448 927 ft) from diamond drilling and another 457 970 m (1 502 526 ft) through RC. These results mark an increase of ≈10% from 2021. Orbit Garant Drilling’s fleet was 217 rigs with 199 dedicated to diamond drilling and 18 to RC. These numbers were smaller than in 2021, because of a fleet upgrade, where six older rigs were retired from the fleet, and three new ones were purchased. Revenue for FY22 (ended on June 30 2022) was a record CAD 195.5 million, signifying a 19.7% increase from FY21.

For 2022, Foraco International reported 1 017 485 m (3 3382 05 ft) achieved through diamond drilling and 393 348 m (1 290 512 ft) for RC. The result for diamond drilling represents ≈5% increase from 2021. The company fleet consists of 302 drill rigs. For FY22 (ended Dec. 31), Foraco reported a 23% increase in revenue and significantly higher profitability compared to FY21. The company’s operations have grown the most in South America, as demand for drilling services has increased tremendously in the region.

Explomin Perforaciones is among the largest companies in Latin America. In 2022, they achieved 604 194 m (1 982 264 ft) through diamond drilling. This result represents a decrease of less than 4% from 2021. The company’s fleet, however, has increased to 107 rigs (101 diamond). Explomin has reported working on 26 diamond and four RC drilling projects in 2022.

Hy-Tech Drilling achieved 594 422 m (1 950 203 ft) through diamond drilling in 2022; a decrease of less than 2% from the previous year. The company’s fleet has grown significantly to 69 diamond drill rigs from 46 in 2021. Furthermore, Hy-Tech Drilling’s number of projects has more than doubled to 35. Hy-Tech Drilling also reported excellent revenue of CAD 124.7 million for 2022.

For 2022, Canadian contractor Forages Rouillier Drilling reported a decrease in meters achieved through diamond drilling to 582 769 m (1 911 972 ft). While this is a double-digit decrease compared to the results from 2021, the company has increased the number of diamond drill rigs to 60 (50 in operation; 10 on standby).

Geodrill and their subsidiary in South America Recon Drilling reported 407 103 m (1 335 640 ft) achieved through diamond drilling in 2022. The results for RC drilling are 942 410 m (3 091 896 ft). Although the meterage for both diamond and RC is lower compared to 2021, Geodrill has a larger fleet – 76 drills (70 diamond/multipurpose and six RC), drastically more projects (48 vs 25), and has reported back-toback record fiscal years.

Capital Drilling achieved 368 958 m (1 210 492 ft) through diamond drilling in 2022. Of these, 190 591 m (625 299 ft) were through underground diamond drilling. The results represent a significant increase from 2021 driven by major contract renewals. Capital had 15 projects and 57 rigs. For FY2022 (ended March 2023), the drilling division contributed USD 209 million in revenue; a 21% growth from FY21.

This year, Team Drilling is celebrating its 15th anniversary and over 2960 days without a loss time injury. These achievements come on the back of a strong 2022 with 210 000 m (688 976 ft) achieved through diamond drilling, a fleet of over 40 rigs (24 diamond), and 13 diamond drilling projects across Canada.

One of the biggest Turkish contractors, Ortadoğu Drilling, reported 193 249.7 m (634 021 ft) achieved through diamond drilling for 2022. The company services the Eurasian region with its in-house-manufactured 35 drill rigs (29 diamond), and it is one of the few contractors that can produce everything required for a drilling operation. Ortadoğu Drilling had 23 diamond drilling projects last year.

Hall Core Drilling is the only contractor in this list with one project – the platinum mine in Limpopo, South Africa. In 2022, the company achieved 161 331.51 m (529 302 ft) through diamond drilling; a tremendous increase of nearly 60% from 2021, fueled by the expansion of drilling operations in Limpopo. As a result, Hall Core’s fleet more than doubled to 35 diamond drill rigs.

Brazilian contractor DrillGeo has achieved 124 629.25 m (408 889 ft) through diamond drilling and 9325.12 m (30 594 ft) by RC in 2022. The company is a new entry into Coring’s statistics, boasts a fleet of 36 rigs (34 for diamond drilling) and had 14 diamond drilling and one RC project. C

Helicopter Portable Diamond Drill

1400 Meter NWL Depth Capacity

Cummins Power Unit 160 or 260 HP

‘P’ Size Rotation Unit & Clamp

Safety Package: Full Guarding, Multiple E-Stops, Interlock Rod Guard & Power Lock-Out

Available in Heli-Portable, Skid Shack Mounted and Track Carrier

A meeting of minds between Australia and Sweden

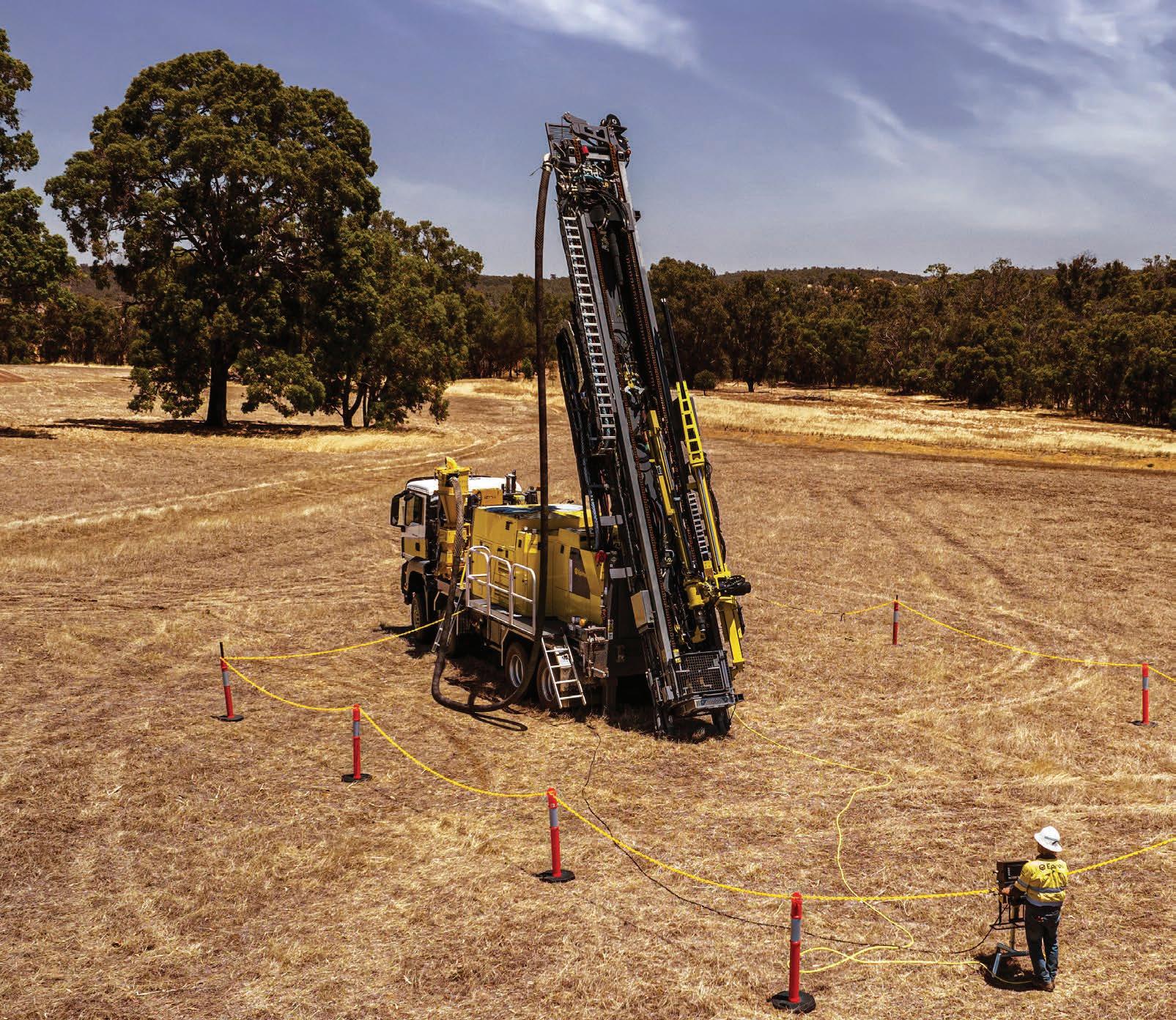

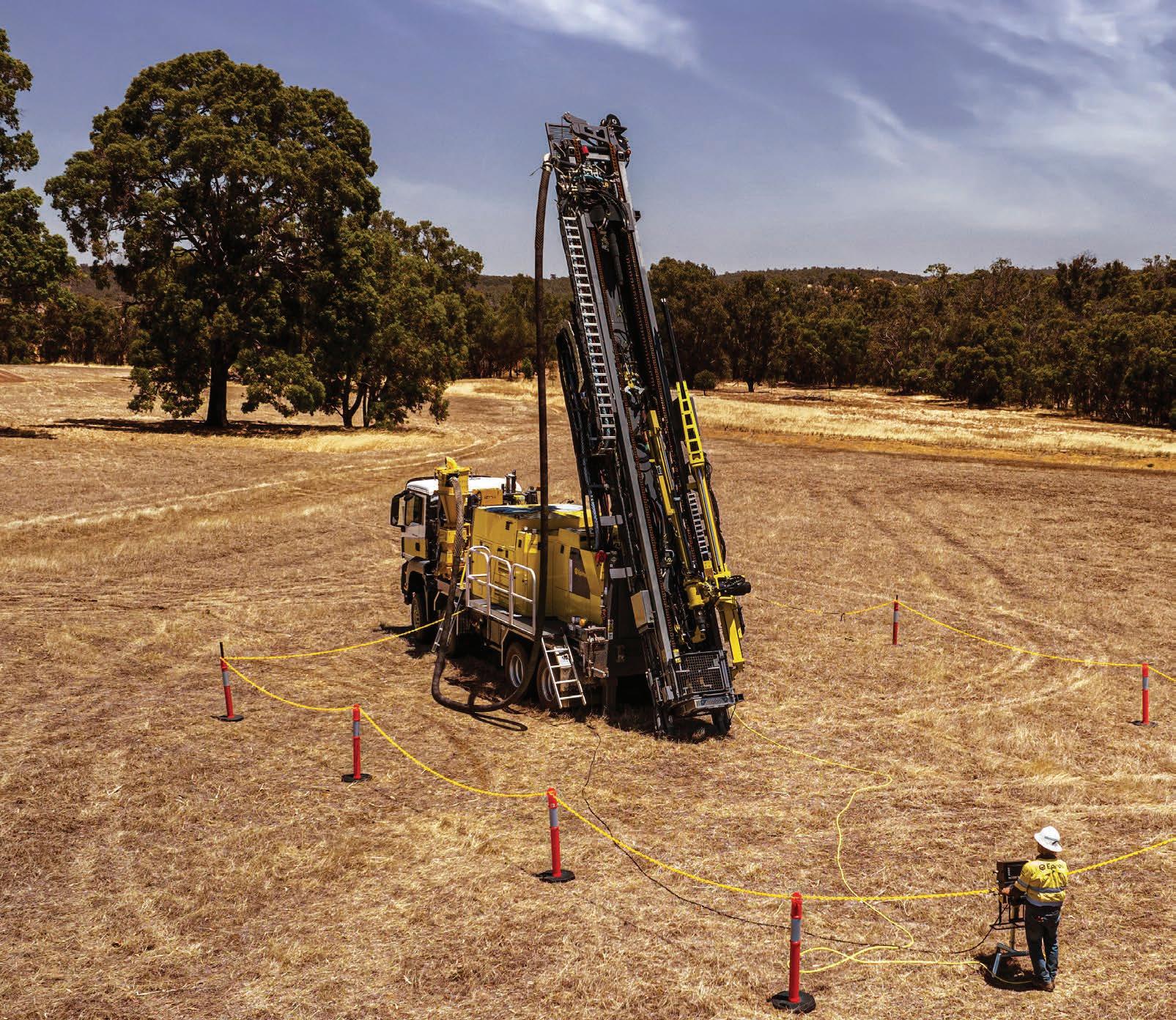

The story of Explorac RC30 Smart began in 2018 when contractor Ausdrill was faced with a strong demand from the exploration industry for automated drill rigs. They decided to partner with Swedish Epiroc, as they had worked closely in the past on the development of other rigs. The goals were lofty from the start: keep operators away from the danger zones, develop advanced interlocks and monitoring for both processes and safety, while still providing improvements to reliability and maintenance. All of this had to be done fast.

About five years later, Epiroc introduced to the world the Explorac RC30 Smart surface drill rig for Reverse Circulation. It promises to be a robust and reliable solution with highly automated functions, better capabilities both in terms of safety and productivity, and advanced rod handling functionality. All of this comes without any compromises to performance, as Explorac RC30 Smart provides 30 tonnes (67 442 lb) of pullback delivering sufficient capacity to take on deep work while not being excessive for shallower projects. It is available on a robust truck carrier which offers great mobility and gets you right where you need to be with the minimum of fuss.

Perhaps the first and most important innovation for Ausdrill could be summarized with the motto ‘Hands off steel’ or removing manual work from rod handling. For deep holes, rod handling is a complicated, dangerous, and tiresome process often requiring two people. There is the added challenge that automated rod running needs to be faster than manual work, otherwise drillers would continue doing it by hand to save time. The engineers at Epiroc obliged.

The Explorac RC30 Smart’s automated rod handling seamlessly combines automated sequences and embedded interlocks to execute the repetitive task of rod feeding. Not only does the automated rod handler improve safety but it also reduces fatigue and crews are freed up to perform other tasks. Wear and tear on consumables is also reduced, as the automated rod handler executes the task in exactly the same way every time, so uptime is increased and predictive maintenance is easier.

All of this happens with the push of a button on the Explorac RC30 Smart controls.

To remove drillers from dangerous situations also means smarter controls. Explorac RC30 Smart builds on the RCS platform, which has been tried and tested across the industry, by including radio remote control with multiple interlocks, a software-based safety system, and an emergency stop button, which protects both the rig and the operator during autonomous operation. Having the controls away from danger adds the benefit of reduced noise and vibrations, improving the work of drill crews.

Explorac RC30 Smart comes with a litany of other smart features, such as mast centralizers with variable grip force and an advanced breakout system with automatic application of thread grease. All of these help to optimize the life of drilling consumables and the need to go into the hazardous area is reduced.

Of course, it is sometimes necessary to approach the drill rig. Explorac RC30 Smart features high-visibility LED safety lights that indicate rig-status and whether it’s safe to be near the machine.

With the rapid development of new drilling technologies, scalability is an important part of Explorac RC30 Smart. The rig was designed to be scalable, meaning it can be expanded or upgraded with new automation features and functionalities over time. Epiroc’s excellent global after-sale support with both genuine parts and services safeguards the productivity of the rig. This ensures that contractors, such as Ausdrill, can easily support and upgrade their Explorac RC30 Smart rigs and get the highest possible returns on their investment.

Improvements to safety, smart and autonomous features and technological breakthroughs make a real change only when the rig has the performance to match and exceed the vast demands of exploration companies. With the 30 tonnes (67 442 lb) of pullback force, Explorac RC30 Smart offers the largest pullback capacity on any Epiroc exploration rig to date. This rig makes it possible to quickly and safely collect core samples down to a depth of 600 m (1968 ft).

The mast is 11.55 m (37.89 ft) long (including the jib) and can be angled between 45° and 90°. There is also a unique angle package with internal locking cylinder, meaning that setup can be performed quickly and safely from a distance.

‘We

have listened to the market and pushed to reach the high level of automation that drilling companies require. Drilling contracts today are more demanding than ever, both big and small contractors must meet a high safety level while maximizing the return on capital employed - automation simply makes sense. It removes personnel from dangerous environments, at the same time changing the game when it comes to operational efficiency and planning’, explained David Benton, Epiroc’s Global Product Manager for Exploration.’

Explorac RC30 Smart comes with a standard on-board 35-bar Atlas Copco two-stage compressor and cone splitter. The truck-mounted pipe rack for the automated rod handler can hold up to 15 pipes of 6 m (20 ft) in length (OD 4.5 in or 11.43 cm). The maximum rod holder clamping diameter is 124 mm (4.88 in). The power unit is a diesel CAT C18 Tier III ACERT ATAAC with a maximum torque of 2769 Nm at 1800 rpm (2042 lb) with an output of 522 kW (700 hp) at 18002100 rpm.

In total, Explorac RC30 Smart weighs 30 000 kg (66 139 lb) including a full rod rack, so it can be fitted on a variety of truck models.

Developing the breakthrough Explorac RC30 Smart required a great deal of effort from both Ausdrill and Epiroc, recounted Eric Gobbert, Senior Manager Business Development and Improvement of Ausdrill. He shares that in the first years of the collaboration, there were problems with parts wearing more quickly and the rig not staying in auto-drilling mode.

Finding solutions required open communication, innovative thinking, and a great deal of understanding of the specific requirements that make a great drill rig, especially with COVID-19 causing delays and wreaking havoc across the world. Despite all the challenges, the prototype Explorac RC30 Smart has now been delivered to Ausdrill. Early results show great promise but require some adaptation from drillers and technicians. One thing is clear, Explorac RC30 is merely the beginning, a strong foundation, for innovations towards the complete automation of the drilling process from start to finish. C

For more information Visit: epiroc.com

The Christensen CT20 is ready to take on core-drilling jobs in the toughest conditions. This safe, ergonomic, and versatile rig is available truck- or crawler mounted. The Christensen CT20 has all the power and capacity needed to ensure you get more core in the box. Find out more at epiroc.com United. Inspired.

by

Marcotte has been manufacturing drill components since 1992. Starting from a simple parts manufacturer, it reached the status of a complete drill manufacturer within a decade. From the notorious HTM-2500 to the versatile Mancore 900, Marcotte has since then developed a full array of robust and innovative drill rigs to answer the needs of its ever-growing customer base.

Be it for surface exploration, remote operations, underground operations and all the accessories that go with it, Marcotte has been committed from day one to ensure that its customers get the reliability of Canadian-built machinery every time they acquire equipment with its name on it.

temperatures while having everything it takes to deal with the harsh conditions known to Central and South America.

The STM-1500 was the first underground model designed by Marcotte and it allowed its users to drill deep holes thanks to its robust construction. The STM-1500 has made its place in the world of underground exploration as a reliable deep hole machine and is now one of Marcotte’s flagship products that benefit from a wide array of options. Its heavy construction gives this model the capacity to withstand a beating from high-hp power units in the hardest conditions an underground hole can get you. The STM-1500 can be found around the world in various configurations and equipped with power units ranging from 125 hp to 300 hp.

From this model were derived the STM-600 and STM-300, which were developed to work in much more limited space. These models benefit from many field-tested parts of its predecessor which make them a reliable and versatile choice for specific operations where high depths are not the main factor.

The HTM-2500 was the first popular model built for North American surface drilling. It is an unstoppable workhorse that will get the core samples out no matter the depth. With its 275 hp diesel prime mover, the base model can reach a pull capacity of over 66 000 lb (29 937 kg). Evolution has led it to incorporate many different key options. Its reputation opened the door for the arrival of the HTM-2500TA, which is a completely different model of very capable surface drill but built on top of a set of heavy-duty tracks. The TA was designed for drilling projects that require highly mobile equipment in milder

The Mancore 600 has been developed for remote projects that could only be accessed by foot or helicopter. Like most of the products in that category, it has a light modular design and Marcotte made sure that its configuration would allow intuitive assembling and dismantling while enabling its users to choose amongst multiple power unit options. Mostly found in southern parts of the world, this model has made its place with its simplicity and its robust mechanics.

The Mancore 600 paved the way for the development of its big brother the Mancore 900. However, this model has the capacity to access remote locations in northern parts of the world thanks to its modular configuration compatible with various shack options. The Mancore 900 also benefits from a single more powerful engine (instead of two or three separate ones) which enables it to reach higher depths. It possesses an impressive list of standard options:

heli-portable platform, skids, steel shack, composite shack, heavy-duty tarpaulin, rod handler, and a lot more which makes it the machine of choice when the job requires extra mobility all year long in challenging conditions.

Another sequel to the Mancore 600’s success is the Mancore 600TA. This model, running on a single diesel engine uses all the main components of the Mancore 600 to transform it into a heli-portable unit mounted on tracks and remotely controlled for the moves. Despite its modules being heavier, the heaviest one being the track frame weighing 1600 lb (726 kg), it allows faster moves between multiple distanced holes at remote locations while leaving the smallest possible footprint.

While continuously improving its most popular existing products with the help of its wide customer base, Marcotte also strives to supply the drilling market with new ideas. Improving mobility, reducing setup times, enhancing safety, achieving higher reliability, and incorporating automation are only a few of the many ways Marcotte sets new standards for the development and manufacture of its existing products and innovative projects.

The STM-600ME, a statement to Marcotte’s commitment to improving the core drilling industry in the underground world, is a unit that’s been developed for a very specific task in a very dynamic environment. The 600ME is a carrier-mounted, self-contained drill rig that allows super-fast mobilization and demobilization while providing a complete working platform (Canadian patent #2880877) to quickly

drill a hole and be ready to move to the next one within a single shift. This model carries all the equipment, tools, and consumables required for underground core drilling so it can move by itself from one drill site to the next without any need for extra machinery to get the work started. The carrier to which it is attached has two seats so that the helper can be with the driller when the machine arrives on site.

The latest innovation developed by Marcotte is the automated rod handler for surface drilling (Canadian patent #3021385). This unique accessory has been developed as an add-on to the HTM-2500TA model but has the still-untapped potential to be implemented on any other brand or model of surface drill. Achieving an impressive loading and unloading cycle below 1 minute per string of rods and having the capacity to manipulate strings of up to 9 m (29.5 ft), the current version of this equipment eliminates the need for human intervention when the time has come to change the bit. The Cyborg Rod Handler not only allows the workers to limit their exposure to repetitive heavy lifting but also helps management to forecast how much time it will take to proceed to a complete removal and re-insertion of a drill string in the ground.

Marcotte is committed to giving the best after-sales support in the industry to all its customers so that no drill stays out of service when it should not be. Backed by a professional and readily available team of technicians, Marcotte will answer every service call within an unmatched timeframe. Marcotte understands the value of an equipment that keeps on producing 24/7. So does its field support team. C

MARCOTTE is your key partner in mining exploration! Our passion for innovation is reflected in all our products, pushing back the boundaries to meet your exacting requirements.

Quality is at the heart of our approach. Robust and reliable, our products are specially designed to meet the challenges of mining exploration. For ultra-portable solutions, underground or surface work, join the professionals around the world who trust MARCOTTE and experience innovation, reliability and customer satisfaction at every stage of your project.

by

About 260 km (162 mi) southwest of Mexico City, on the southern bank of the Balsas River in Guerrero state, Torex Gold planned an intense infill drilling program at its Media Luna project.

Due to the site’s topography, environmental regulations, lack of hydrological resources, and highly variable geologic conditions, a conventional drilling program would have been almost impossible to execute with the desired accuracy and within budget.

Phase I of the program began in October 2018 and consisted of 117 targets divided into 16 blocks, reached from only nine drilling sites. Each collar comprised of one block with nine targets, designed on a 30- by 30-meter (98.4 x 98.4 ft) grid spacing, to upgrade the deposit to ‘measured’ status.

The authors would like to acknowledge and give a special thanks to Nicolas Landon, Exploration Manager at Torex Gold.

Media Luna is a skarn deposit located in the Morelos district, itself a part of the Guerrero Gold Belt. Its geological setting is dominated by limestone, siltstone, and other sedimentary formations cut by several intrusive bodies. The resulting contact metamorphism led to the formation of skarns, rich in gold, copper and silver.

The varying, thick sedimentary layers and the variety of intrusions create a unique set of circumstances that come with their own unique set of challenges for anyone attempting to drill through them.

One of the main issues encountered was the lack of hydrological resources. Considering drilling is dependent on having a reliable water supply, any planned program had to contend with the limitations of having to bring water to the project by tanker trucks.

Throughout its geological setup and structural deformation, the limestone in the area has been heavily affected by karst processes.

That presented another problem for the drilling program, where the underground caverns created could lead to a total loss of water in a drilling well, further exacerbating the previously mentioned issue.

Extreme magnetic anomalies were also present due to the iron-rich exoskarn. This prevented the reliable use of magnetic measurement instruments.

To save costs and reduce water consumption, the total number of meters drilled to intercept each target had to be cut drastically.

The only way to reduce meters while still reaching the same number of targets is to use directional drilling. In the simplest terms, it consists of producing an intentional and controlled deviation of a borehole to pre-determined target coordinates (Northing/Easting/Elevation). And of course, multiple deviations can be made from a single pilot hole.

The way to reduce water consumption is to use a directional core drilling tool. Directional drilling itself can be done with ‘full-face’ tools, or with ‘DCBs’ (Directional Core Barrels).

An advantage of the DCB is that it uses far less water compared to a full-face tool, such as a mud-motor, since it has no turbine that requires a higher flow volume. Furthermore, its ability to extract core increases the production rate compared to the alternative. As such, the AZIDRILL® NB DCB was chosen for the task. The AZIDRILL® cuts an N-sized hole and collects a B-sized core sample. In addition, the DLS (Dogleg Severity – a measure of the drill hole curvature), tool face (orientation), and borehole trajectory can be continuously monitored to make timely adjustments and maintain the planned course of the curve. In particular, DLS needs to be kept within ‘safe’ parameters, so as to not create an unacceptable amount of torque in the drill string which can then lead to a host of additional problems.

In every case, the mother hole was aligned to the center target and drilled to total depth before planning the daughter holes. This allowed the exploration team to select KOPs (Kick-off Points) in favorable zones, and eliminate the risk of setting wedges or beginning directional operations in unfavorable ground conditions. Each mother hole became the origin of eight additional daughter holes.

Due to the relatively shallow depth of the deposit of approximately 450-600 m (14761968 ft), every directional curve was designed to be completed with a length of about 40 m (131.2 ft) (on average). Although the AZIDRILL® collects a core sample during operation, extracting full-sized N core samples from the deposit was imperative, so the AZIDRILL® would have to be switched for the conventional core barrel after the curve was completed.

Mother holes began with collar alignment set to the central target based on the known natural deviation from the area. This was the only hole in the block where drill rig alignment was required. In all cases, holes were started with P-sized diameter for the collar and were advanced up to a depth of approximately 170-210 m (558–689 ft), where lithological and structural conditions demanded a reduction to H-size. The holes in which directional steering control was used were further reduced from H-size to N-size using conventional core barrels and casing wedges.

Upon the completion of the directional curve, the AZIDRILL® was pulled out of the

borehole and conventional drilling continued until the target was drilled and the borehole surpassed the limit of the skarn deposit.

In addition to drilling the curved sections, AZIDRILL® was also utilized to control conventional sections, such as mother hole corrections, where ground formations caused substantial natural deviation.

↑ Aziwell and Layne crew at the drill rig preparing directional drilling operations

After analyzing the core samples of each Mother hole, lithological and deviation information was considered to confirm the KOP, or if necessary, to propose an alternative KOP depth with better borehole conditions. Afterwards, anchors were installed as the base for the wedges.

For this project, two types of wedges were used: permanent bypass and P/H-size Casing, the latter of which is recoverable and reusable. Once on the hole bottom, the wedge was oriented with a tool face directed at the target. Subsequently, the wedge ramp was drilled off using a bull nose bitball bit, reducing the diameter from H to N-size. This methodology yielded three daughter holes per KOP (approximately 120° of separation between each tool face orientation).

In general, it is not necessary to extract the casing wedge upon completion of a daughter hole. Simply lift the drill string, rotate to the desired orientation, and set it down upon the

anchor again. This is a very effective method for eliminating the amount of time involved in setting permanent wedges.

To monitor the trajectory of each borehole and create an accurate model of the deposit, it is necessary to collect frequent deviation measurements as the drilling advances. Due to substantial magnetic interference in the area, all deviation surveys were collected via a North-seeking gyroscope. These instruments are unaffected by magnetism. Additionally, these gyroscopes were utilized to validate the survey data collected by the AZIDRILL® during the curves.

Due to the success of Phase I, the infill program grew subsequently throughout Phase II and III. At its peak of operation, eight di-

amond core rigs (CT14 /CS1500/CS4000), two AZIDRILL® systems, and two gyroscope survey crews operated around the clock.

With this methodology, the accuracy of target interception was significantly improved while dramatically decreasing the need for additional drilling. As a result, not only were funds and water saved by drilling less, but much fewer rig moves were required, leading also to less need for further pad creation and environmental permitting.

To date, there have been more than 1000 targets hit and 30 000 m (98 425 ft) of directional drilling. The joint venture efforts between AZIWELL, International Directional Services de Mexico, and Layne de Mexico have saved the projects millions of dollars and years of drilling while putting more than 4 Moz of gold equivalent in the ‘proven’ category.

The team is unaware of any other infill programs globally that have reached the same number of targets in such a short amount of time! C

In this Issue:

Q&A from the experts

In conversation with Nick Tate Specialist Consultant Mapper of Geology, Alteration and Mineralization Systems

The airborne geophysics power for mineral exploration: An Amazonian Craton case study by Bruna de Freitas, Independent Exploration Expert Geologist and MSc in Mineral Resources

Hydrothermal system models: A great tool for understanding challenging geology by Mark Lindsay, Former Chief Geologist at GBM Resources

A short explanation why optical petrography knowledge is the key to preliminary identify hydrothermal magmatic processes by Paula Montoya-Lopera, Postdoctoral Research Fellow in Economic Geology at CODES, University of Tasmania

Nick

Tate Specialist Consultant Mapper of Geology, Alteration and Mineralization Systems

Brett Davis: Firstly, thanks for giving Coring the opportunity to interview you, Nick. Very few people have a geological profile as well-respected, or as well-known, as you. So, it’s a real pleasure to sit down and chat with you. Can we start off by telling us what interested you in a career in geology?

Nick Tate: My father was an organic chemist at the Waite Institute (now part of the University of Adelaide) for most of his career. We went to a barbeque with one of his students at the house of her boyfriend, who was a paleontologist. I was about 5 years old at the time. The story goes that I spent the entire evening looking at shelves full of fossils that he had collected. Apparently, I was determined to be a paleontologist when I grew up until I was informed that there was no money in that career, but there was money in geology! Shortly after that, someone taught me how to pan gold and I would regularly borrow Mum’s cooking utensils to prospect for gold in the backyard.

Mum loved being outdoors. She designed and built her own sailing boat and rode dirt bikes so that fostered my love of being outside. Dad was only interested in the out-

Nick Tate graduated with a BSc in Geology from James Cook University. In the 40 years since, he has worked on dozens of contracts worldwide, becoming a specialist consultant mapper of geology, alteration, and mineralization systems.

His expertise has led to multiple notable discoveries in Laos, Mongolia, and Argentina, as well as an excellent reputation in the industry.

Nowadays, Nick runs his successful YouTube channel GeologyUpSkill and a series of courses providing young geologists with the necessary skills for fieldwork.

doors if it involved fishing. He used to say that it was the only time that he didn’t think about chemistry, but I think he was lying. It was really the time when his mind was undisturbed by the clutter of the chemistry lab, and he would sometimes scribble furiously some new formula that had come to mind when we got home. I find I do the same thing now on long traverses between outcrops. Mum also loved photography and she taught me how to shoot film, process it and make prints in a home darkroom. That skill set would have a fundamental influence on my career many decades later.

At high school, I had a friend who lived on a farm next door to an old alluvial goldfield, so we used to go there on weekends to dig dirt out of the shafts and pan real gold. I still have that gold! From then on, there was no question about my future career.

I remember being quite shocked when I arrived at university and most of my compatriots were still trying to decide what career they would like!

I was a serial underperformer at primary school because I was hopeless at rote learning and numbers didn’t excite me. I went to an ‘alternative’ school for grades 4 and 5 where I had lots of fun digging in the gar-

den and making model airplanes, but I didn’t learn much of the 3Rs. Grades 6 and 7 back at ‘normal’ school were a real struggle to catch up, but thanks to my parents and two very helpful teachers, I recovered lost ground. I found high school much easier, but I couldn’t study geology even though it was an available subject because it conflicted with the prerequisite science and mathematics subjects required for university entry.

I was kind of a nerd at high school, and I was too short to play any of the team sports with kids the same age so, along with a couple of similar friends, we set up a darkroom and made an unofficial photography club. I entered a print of my girlfriend at the time in a competition run by the local paper. It won first prize and that created a problem for us because the prize involved a camera for the winner and some equipment for the club, so we had to hastily make the club ‘official’ to accept the prize. That camera became a fundamental tool for my future geology work because I understood that a picture was worth a thousand words, and I hated writing! When I went to Flinders University in South Australia, I found studying easy because I could learn the underlying theory for a process and apply it to whatever problem was