From pre-feeding to palletizing, BOBST connects every step of the modern corrugated packaging process, to deliver more performance and value for you. Interested? Find your local BOBST representative at www.bobst.com/contact

The Asian Packaging Excellence Awards is the only regional Independent Packaging Print competition. Since 2001 we have been awarding Gold Silver and Bronze for packaging printers who have excelled in producing world class quality. The judges are non-supplier but are retired educators or production professionals and come from all over Asia/Europe/Australia.

* WE MUST have 5 consecutive samples for each job in ALL catergories

* ONLY 3 Jobs allowed for each catergory you enter

1. Narrow Web Flexo (up to 500mm width only)

1a Paper/Board

1.b Film

2. Mid Web Flexo (501mm to 914mm width only)

2a .Paper/Bpard

2b Film

3. Wide Web Flexo (915mm and over)

3a . Paper/Board

3b Film

4.Carton & Cups

5.Post Print for Corrugated

6.Pre Print for Corrugated

1. Flexo

2. Letterpress

3. Offset Labels

4. Gravure Labels

5. Combination Printing (Many different processes or embellishments)

6. Non Pressure Sensitive material

7.Digital Labels

7a. Up to 4 colours

7b. 4 to 5 colours

7c. 5 to 6 colours

7d. 7 Colours

1. Paper/Board

2. Metallised Paper/ Aluminium Foil Surface Print

3. Film

3a.. Surface Print

3b. Reversive Print

4.Speciality Gravure (Must provide written explanation)

OTHER

6 Mockup/Sample

7 Digital Packaging

8 Hybrid Printing

9 Offset Packaging

PLEASE READ: Asian Packaging Excellence Awards are open to all packaging compnaies across Asia. It is free to enter and winners will be presented Gold Silver Bronze awards live on stage in Bangkok 21st Sept 2023. If you do not attend we will not send awards to you. Job submitted must have been produced from November 2022 till September 2023. Judges decision is final and no other correspondance will be considered

SECTION A - This is seen by the Judges ONLY 3 JOBS PER CATERGORY PLEASE SELECT 5 FLEXO 5 LABELS 5 GRAVURE 5 MOCKUP

5 DIGITAL PACKAGING 5 HYBRID 5 OFFSET PACKAGING

Catergory Entered for this job (See catergories opposite page) _

Company Name_____________________________Contact Person________________________

Compnay Address________________________________________________________________

Country________________Contact Number _______________e-mail ______________________

Name of Entry_____________________________Printing Company_______________________

Your Name ________________________________Signature_____________________________

#

#

SECTION B - TAPE THIS TO THE BACK OF THE JOB ENRTY

Catergory Entered_____________Print Method_______________Number of colours__________

*Brand of Machine_________________________*Ink Supplier____________________________

*Plate Supplier__________________________*Tape Supplier____________________________

*Pre Press by_________________________________*Printed Quanity_____________________

*Paper/Board/Film/Label supplier____________________________________________________

*Web Width ___________________Other detials_______________________________________

If you would like to supply more information, please attach this to Section A above

Please send your entries to: Send your best work to:

ATT Asian Packaging Excellence Awards

c/o PRINT & MEDIA ASSOCIATION OF SINGAPORE

627A Aljunied Road, Biztech Centre, #04-07, Singapore, 389842

Telephone: +65 6336 4227

THE SHIFT 23 Conference will be held in Bangkok on the same day as the Asian Packaging Excellence Awards dinner presentation (September 21st) in Bangkok, during the Pack Print International and Corrutec Asia Exhibitions

The SHIFT 23 conference (now in its 21st year) is designed to give Packaging companies, no matter what area of production they are involved in, a view on the trends and technologies that effect business today.

Supported by the leading manufacturers and suppliers, the event offers you the chance to hear from world leading speakers on a whole range of industry topics. Also meet and network with other companies like yours at this intensive one-day event.

More detailed information will be available in the coming weeks so mark this date in your calendar, 21st September 2023, BITEC exhibition halls, Bangkok Thailand.

And if you enter the Asian Packaging Excellence Awards, we hope to see you on stage receiving your Awards for excellence in packaging.

PACKAGING EXCELLENCE AWARDS: 2023

Issue 5 - 23

Print - Packaging INNOVATION

Asia Magazine

Published by Asian Print Awards Management Pte Ltd 65 Chulia Street #46-23 OCBC Centre 049513 Singapore

Print Innovation Asia Labels and Packaging Innovation Asia Asian Print Awards Packageing Excellence Awards Label and Packaging Conferences

Publisher Paul Callaghan paul@printinnovationasia.com

Editorial Elizabeth Liew elizabeth@printinnovationasia.com

Packaging Sales Elizabeth Liew elizabeth@printinnovationasia.com

An MPS EF 430 next generation flexo press has been installed at Sungsin in Korea for the printing of multilayer adhesive labels. The machine sale and installation were led by MPS’ local partner Müller Korea and MPS Systems Asia.

Features of Sungsin’s new EF flexo press include the MPS inline laminator to easily laminate pre-printed webs; a laminator for cold foil; the MPS crossover unit to slit the web and place the separate layers on top of each other; the MPS rail system for easy

positioning of converting units on the press; E-sleeve technology providing predictable print results with increased speeds; and MPSConnect for realtime performance insights of the press through data collection and analysis.

Traditionally a letterpress printer, Sungsin specializes in pharmaceutical labels, multilayer labels, booklets, and agricultural labels. Müller Korea has a long-standing partnership with Sungsin since 2016 providing pharmaceutical printing solutions from H+H, Prati, and Smag Graphique.

“The MPS EF press is Sungsin’s first entry into flexo label printing,” said Nakyeon Cho, President & Owner Müller Korea. “They were impressed with the range of the EF’s innovative technology designed by MPS, especially the multiple options to facilitate multi-layer label production combined with the very stable web path and easy registration. The combination of local technical specialists from our team and MPS Systems Asia was also a key factor in the press investment.”

“In addition to owning a highly automated flexo machine, gaining the maximum from it is where our performance press feedback via MPSConnect comes in,” said Tim Klappe, Managing Director Asia Pacific at MPS. “Through ongoing data analysis collected from MPSConnect, report generation, goalsetting, and ongoing hands-on training, we can assist Sungsin with a reduction of waste and errors, and major gains in productivity and capacity to achieve the optimum benefits of flexo label printing.”

Sale and installation led by MPS’ local partner Müller Korea and MPS Systems Asia

Connect to Grow. That is your key to stay ahead in a demanding market. By connecting with MPSConnect, you ensure the best in reliability and productivity from your printing press. You will increase competitive advantages and maximize profits.

To improve productivity and profi tability, it’s critical to increase the understanding of your overall label print operation. With MPSConnect, you get real-time insights in the operator activities. You dive into the printing press and see exactly what’s happening.

With MPSConnect we see recurring annual cost savings of €50,000 - €100,000 and even more thanks to a more efficient workflow, time management and waste reduction.

mps-printing.com/connect-to-grow

The trend of recent months is continuing: average online print prices for flyers have also risen in the first quarter of 2023 and are once again reaching record levels for some suppliers.

This means that online print prices appear to be decoupling from graphic paper prices again for the first time - after all, these have slightly fallen recently. The ZOPI shopping cart is somewhat different: Here, prices are slightly below those of Q4 2022. All developments can be found in the current Zipcon Online Print Price Index.

With the start of the new year, three new suppliers have also been added to the ZOPI: druckdiscount24, PrimusPrint and Printkit. This gives the Zipcon Online Print Price Index an even broader data base and enables us to assess individual developments even better.

The overall economic situation

After the overall inflation rate of +8.7% in January and February of the year was still almost at the record level of November 2022, it fell slightly in March 2023 to +7.4% year-on-year. This is still an above-average value, but the peak seems to have been passed for the time being.

According to the Statistisches Bundesamt (Federal Statistical Office), prices for energy products also weakened. In March, these were 3.5% higher than in the same month a year earlier - in January this figure was -19.1% and in February -23.1%.

In March, however, a base effect due to the sharp rise in energy prices in the previous year took effect; in addition, the price brake for electricity, natural gas and district heating, which has applied retroactively since January 2023, is now also taking effect. However positive the slight decline may be, it should at best be seen as a "brief breather", as both the inflation rate and energy prices remain well above the levels of a year

Companies in the German printing and media industry also appear to have bottomed out: As the March economic telegram of the Bundesverband Druck und Medien (BVDM - German Printing and Media Industries Federation) showed, the business climate, business situation and business expectations were again assessed more positively overall in the first three months of the year than in the last two quarters of 2022. Even though the respective values varied in January, February and March and remained below the level of the first quarter of 2022, printing companies are again somewhat more positive about the future overall.

The fact that prices for graphic papers have been falling slightly for some time, as indicated by the Verband der Papierindustrie (German paper industry association) "Die Papierindustrie" and the Statistisches Bundesamt (German Federal Statistical Office), may also have contributed to this. However, and this is also part of the truth, production

and sales of graphic papers have also fallen by a good 30% year-on-year. Perhaps because there are fewer print shops? Because according to the BVDM, the printing industry started the new year with just under 6,900 companies - a decline of 3.1% overall, driven primarily by fewer production companies in the newspaper market, but also among traditional print shops.

Online print companies have coped better with the challenges of the last three years compared to many classic

print service providers and have recovered more quickly. In particular, the top 5 - Cewe, Flyeralarm, Cimpress, Onlineprinters and Celebrate - were able to significantly increase their sales last year and, according to estimates by zipcon consulting, their combined sales

How are prices developing in online printing?

But back to the first quarter of 2023: The Zipcon Online Print Price Index, or ZOPI for short, is a trend barometer that takes a close look at price developments in the online print market, thus providing a more detailed overview of the market. It is important to note that the index does not focus on the sales figures of the groups, but rather on the prices charged by the most important online print providers for various product clusters.

sourc-e. All of them were asked to print 10,000 flyers in DIN A5 format, printed in four colors on both sides and on 135 g glossy paper. The average price increase for this order had reached a provisional high of 28.77% in November 2022 - which would have climbed even higher in March, to +33.22% based on the previous nine suppliers. However, the addition of the three new companies pushes the average value down somewhat, as already described, to +25.43%.

Looking at the details, the picture is more mixed: While Unitedprint/print24 called up the largest recorded price increase to date for the 10,000 flyers in March with +65.50% compared to the index value from summer 2020 (December 2022: +58.12%), Vistaprint again marked the largest downward deviation from the index value with -5.43% (December 2022: -12.43%).

hBetween these two extremes, the other providers sort themselves out in March 2023 in descending order as follows: sourc-e with +50.59% (December 2022: +29.20%), Onlineprinters with +36.99% (December 2022: +31.70%), Saxoprint with +35.33% (December 2022: +34.00%), Redprintgroup

The newly considered companies (druckdiscount24, Primus-Print and Printkit) have an impact on the average values, which without the new providers would have reached a new high of +33.22% in March 2023, especially in the flyer product cluster, but even including the additional data are only a few percentage points lower at 25.43%. Here, the slightly lower paper and energy prices do not yet seem to have had a direct impact on the online print price.

The situation is different for the shopping cart: here, the average price in both cases - without the new providers (+25.98%) and with the new providers (+23.46%) - is below the peak value from November 2022 (+34.97%). However, a look at the individual online printers is more exciting.

In the Zipcon Onlineprint Price Index, twelve providers were thus considered for the first time for the first quarter of 2023: In addition to the three already mentioned, these are: Vistaprint, Wirmachen-Druck, Unitedprint/print24, Onlineprinters, Flyeralarm, Saxoprint, Onlinedrucken, Redprintgroup and

with +34.70% (December 2022: +21.13%), Wir-machen-Druck with +34.28% (December 2022: +39.10%), and Onlinedrucken with +27.84% (December 2022: +28.41%). The latter two have thus actually lowered their prices slightly compared with the end of last year.

Below the new average price in this product cluster were Flyeralarm with +19.20% (December 2022: +18.43%) and Vistaprint with -5.43% (December 2022: -12.43%). The three new providers were in the single digits - however, these values refer to a starting value from the summer of 2022. Accordingly, the changes in the prices for the 10,000 flyers were +5% for Primus-Print, +1.97% for druckdiscount24 as well as -0.79% for Printkit.

The biggest price jumps compared to December 2022 have occurred at sourc-e, Redprintgroup and Unitedprint/print24, while in the same period the prices at Wir-machenDruck, Onlinedrucken and Printkit have slightly decreased.

The prices for the shopping cart have developed differently than the prices for the order for the 10,000 flyers. Here, the average change compared to the first survey of this product category in November 2020 was +23.46%. However, it must also be remembered here that the addition of three new suppliers has pushed the figure down slightly. However, even without the "newcomers," the average change in price in March 2023 would have been +25.98%, lower than the December figure (+33.46%).

In addition to the 10,000 flyers in DIN A5 format, the shopping basket also includes brochures (32 pages, DIN A4, stitched, printed on both sides) and business cards (4/4 color, without finishing). Ten suppliers have been considered for this product cluster since the new year: In addition to the three "newcomers", these are: Wirmachen-druck, Unitedprint/print24, Onlineprinters, Flyeralarm, Saxoprint, Onlinedrucken and the Redprintgroup.

Best in class mix-job productivity for maximum business opportunities.

Automated workflows for maximum productivity gains

Versatile modular configuration catering to different requirements and needs.

The following picture emerges from the detailed analysis: Unitedprint/print24 also marks the largest upward deviation in percentage terms in the shopping cart, with +59.92%, 3.46 percentage points more than in December 2022 (+56.46%). At just +2.27%, Flyeralarm was charging almost the same prices again in March 2023 as it did at the start of the shopping cart ZOPI in November 2020. Flyeralarm is also one of two suppliers in the shopping cart analysis to have reduced its prices compared with the end of last yearand significantly so, in this case from +21.37% to now +2.27%. This is probably also one reason why the average value was lower this time.

The remaining suppliers that ZOPI regularly monitors for the shopping cart developed as follows in the first quarter of 2023: At +37.11%, Wirmachen-Druck called up the secondlargest change compared with the first survey in summer 2020. This value had still been +35.47% in December 2022.

This was followed by Onlineprinters with +35.70% (December 2022: +33.60%), Onlineprinters with +35.03% (December 2022: +24.50%), and Saxoprint with +34.87% (December 2022: +34.67%). The change compared to the index value was comparatively low for Redprintgroup: +10.92% (December 2022: +28.17%).

The online print brand of Druckhaus Mainfranken has significantly reduced its prices since February. This means

that Redprintgroup, together with Flyeralarm, forms the duo that is charging lower prices than in December.

After the feared recession in the German economy failed to materialize last year, the German Council of Economic Experts, in its economic forecast of March 2023, dares to take a still cautious but very cautiously positive view of the current year: it states that German GDP could rise by 0.2% in the current year, but by 1.3% in 2024. A stronger upswing is not to be expected, partly in view of the lower purchasing power due to inflation and the deterioration in financing conditions. However, inflation has peaked and energy supplies have stabilized for the time being.

Incidentally, in its spring projection just published, the German Federal Ministry of Economics and Climate Protection has raised its expected

economic output slightly and is now forecasting growth of 0.4% for the current year and 1.6% for 2024.

Nevertheless, it is of course important to be prepared for all eventualities. The fact that the markets have become volatile is something we have to learn to deal with - that has been clear since the pandemic at the latest. The fact that online print shops in particular can act flexibly against this backdrop and respond quickly to developments in the market is something we have impressively demonstrated to ourselves in recent months. So there is no reason to panic - online print shops in particular can and should look to the future with confidence. Because, as I said at the Online Print Symposium 2023: online print is the evolutionary reactor of the printing industry. The only thing is, we have to keep at it and keep developing to make sure it stays that way! So, we better roll up our sleeves!

Our Suprasetter set the benchmark in all format classes based on lessons learned from installing several thousand CtP systems. They are leading the way not just in the quality of their imaging, but also their reliability and availability. Their integration into the Prinect print shop workflow guarantees the correct delivery of all order-related data and enables our technicians to fix small faults remotely from a distance. This saves you precious time – and you will see a noticeable reduction in operating and maintenance costs. heidelberg.com/sg

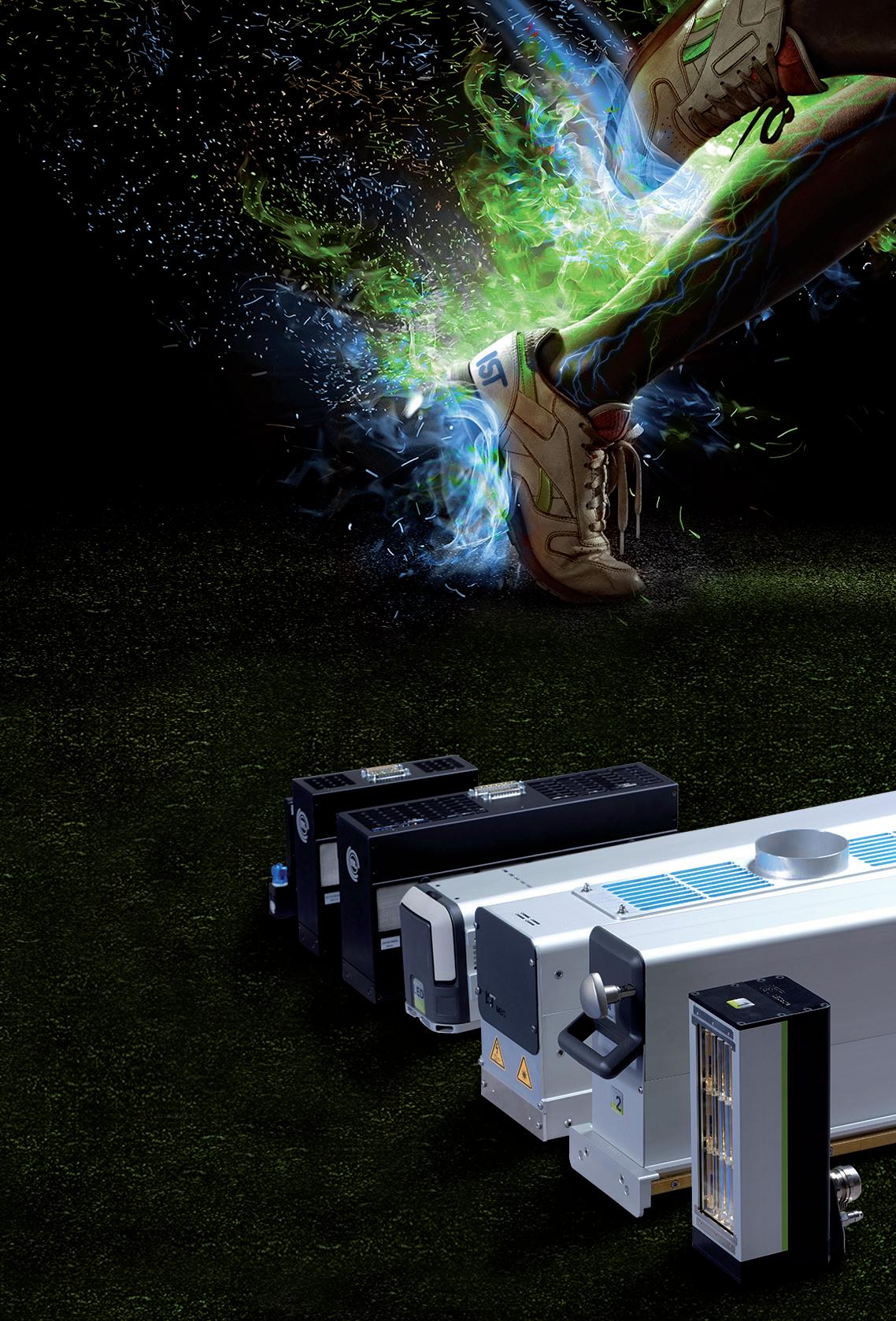

Recent study reflects adding an EFI Nozomi LED digital printer to the shop floor generates extra analog capacity, improves profitability and speeds time to market

An Electronics For Imaging, Inc. business case study examining data from a corrugated packaging plant demonstrates the overall productivity and opportunity advantages the EFI™ Nozomi 14000 LED digital singlepass printer can deliver in a real-life production environment. The study conducted at a North American EFI Nozomi printer user that also operates analog equipment for corrugated printing details how the addition of an EFI Nozomi 14000 LED single-pass inkjet industrial press increased analog capacity by 42%.

The study demonstrates that investing in digital technology adds capabilities and extra flexibility by:

• Allocating jobs to the equipment that produces high quality graphics most efficiently – based on the characteristics of each order

• Leveraging existing analog capacity without the need to invest in new flexo presses

• Maximizing overall equipment effectiveness (OEE) and overall plant profitability

• Delivering a rapid return on investment (ROI).

EFI conducted the study by analyzing data collected from two of the corrugator plant’s flexographic printers that, combined, produce 5.6 billion square feet of printed board per year.

By identifying jobs that were more appropriate for digital and moving them to the Nozomi single-pass digital inkjet production system, the company increased its analog capacity 42%, added 3.77 billion square feet of total capacity, and will realize a payback on their Nozomi digital press investment in less than 2 years.

In addition, adding the Nozomi singlepass digital press for corrugated enabled the company to take on work that would have been unprofitable to produce with analog technologies, including doublesided printed e-commerce boxes, versioned packaging for promotions, and fully customized boxes.

The EFI Nozomi 14000 LED press is a 55-inch-wide UV LED single-pass inkjet system that prints at speeds up to 328 linear feet per minute and offers outstanding high-graphic packaging production with superior color registration.

Designed to deliver high uptime and reliability in heavy industrial production environments, it gives corrugated packaging converters the ability to print high-quality graphics direct to board, on all flute types.

The press also drives greater sustainability in corrugated converting, printing exact quantities needed in

contrast to the overproduction and make-ready waste of analog processes. Plus, EFI Nozomi technology leads the corrugated market in digital print energy efficiency, based on data from print research organization Fogra, and its printed output is certified for repulpability and recyclability by the Western Michigan University Recycling, Paper and Coating Pilot Plant.

The business study and analysis mirror the consulting EFI performs with prospective EFI Nozomi press users and can be applied to any corrugated packaging operation. During the analysis process, EFI consultants identify the type of work a packaging company has and advise on how to can gain the greatest impact using EFI Nozomi technology.

“The data we have collected from corrugated packaging EFI Nozomi users across the globe indicate that EFI Nozomi C18000 Plus and EFI Nozomi 14000 LED presses have the greatest positive impact on converting operations that produce a significant amount of high-quality work requiring complex processes, such as flatbed diecutting, folder-gluer work, and other, more-complex manufacturing steps,” said Evandro Matteucci, vice president and general manager, Packaging and Building Materials, EFI.

THE

BEST MACHINE FOR SHORT RUNS, EVER

Onyx Go continues the long-lasting success story of Uteco’s Onyx flexo presses.

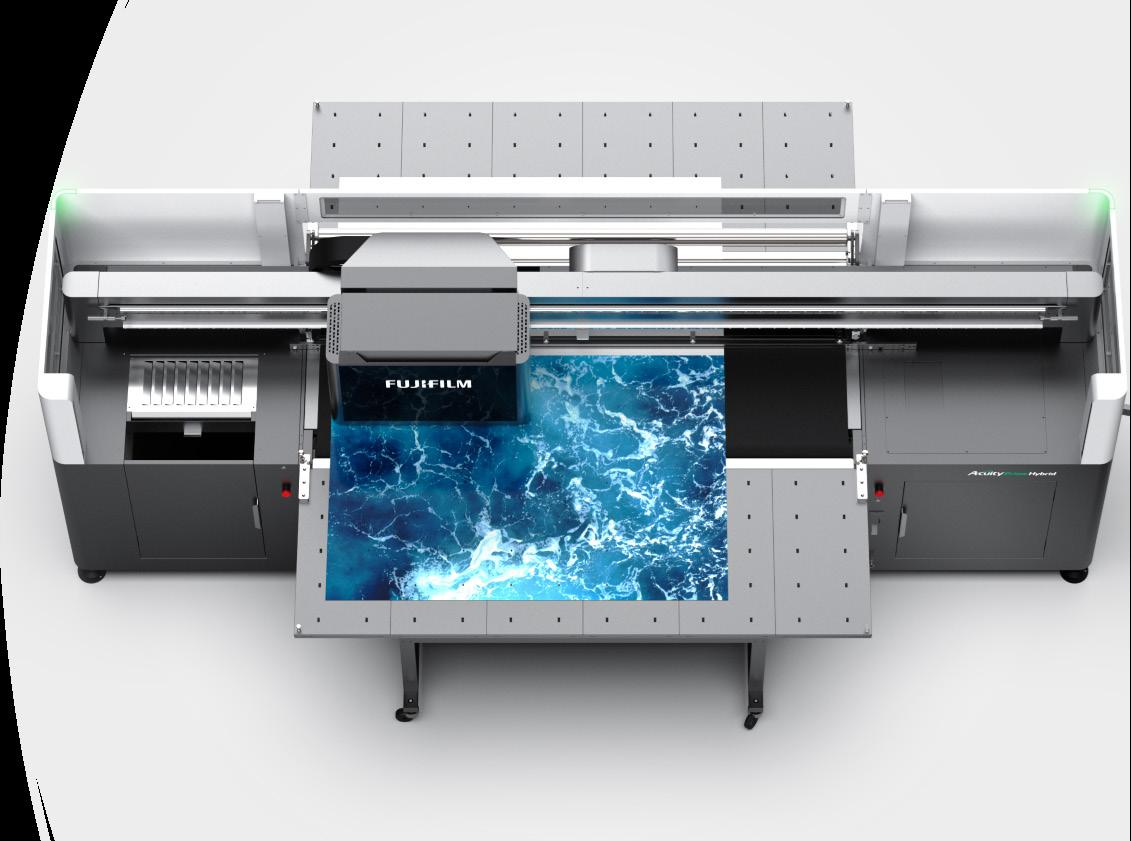

Spanish wide format specialist Oedim has once again partnered with Fujifilm to expand its fleet of Acuity wide format printers to increase productivity and support its growth.

The company, which already owns four Acuity Ultra printers, recently invested in a 5m ‘superwide’ Acuity Ultra R2.

The new printer, which has been installed at its 20,000 square metre site in Jaén, Spain, will predominantly be used to print wide format advertisements on canvases, as well as signage for events and building wraps.

Established in 1996, Oedim is a wide format print specialist that prioritises personalisation and efficiency, while delivering on versatility and value. Many of its customers operate in the marketing and advertising sectors, and require wide format prints on substrates including vinyl, cardboard, tarpaulin, textiles and more.

Oedim sought another Fujifilm wide format printer because it was pleased with the quality and reliability of its existing Acuity Ultra machines. It was also very happy with the service it had received from Fujifilm.

The Acuity Ultra R2, which is part of Fujifilm’s new range of wide format printers, is available in ‘superwide’ 5m and standard 3.2m configurations, and Mercury UV and LED UV configurations. Engineered from the ground up, with the operator in mind, it has won Red Dot, Good Design and iF awards for its impeccable design features.

Miguel Ángel Gómez Cano, Managing Director at Oedim, says: “At Oedim, wide format prints are our speciality. Many of our customers operate in the marketing and advertising sectors and require wide format prints – be it on textiles, vinyl, cardboard or tarpaulin. Our investment in an Acuity Ultra R2 has enabled us to prioritise personalisation and efficiency, while

delivering on versatility and value – all while achieving growth.”

“The machine is not only intuitive and easy to use, it is also reliable and offers exceptional quality. This is proven, as we use it predominantly to print on mesh and canvases and events canvases. ”

“Now, with an Acuity Ultra R2 included in our fleet of printers, we can offer our customers an even faster and more reliable service, particularly when delivering ‘superwide’ 5m prints.”

Speaking about working with Fujifilm, Cano says: “Our investment in yet another Fujifilm printer has enhanced our confidence in the company as a trusted and reliable partner.”

Joan Casas, Manager at Fujifilm Graphic Communications, Spain, comments: “We’re thrilled that the Acuity Ultra R2 is helping Oedim meet the needs of its customers and we thank them for being a loyal Fujifilm partner.”

Find out more Discover our latet innovation

function kicks starts business digital transformation

Versatile media handling expand new application opportunities

Seamless automation for maximum productivity and uncompromised quality.

Wallpaper has been around for a few centuries. But during the past twenty years, it has undergone an exciting reinvention.

Driven by the global hype of “everything can and will be customized”, so-called single-wall solutions have become an interior design must have. Putting up, and removing, wallpaper can be quite an effort prompting consumers to seek professional help. This, of course, increases the cost of the final product: a decorated wall.

Ahlstrom has overcome a lot of the challenges of applying and removing wallpaper with its a new range of self-adhesive nonwovens. In fact, wallpaper can now be easily swapped, enabling consumers to confidently fully customise and redecorate walls themselves.

Ahlstrom’s WallStar® Digital Peel & Up range makes decoration quick and effortless, even for a novice home decorator. No glue or special equipment is needed. It’s easy to reposition during installation and also straightforward to remove.

The user can simply peel away the wallpaper of the release liner and apply it to the wall. Trouble-free removability enables smooth repositioning or replacement with a different design. No adhesive is left on the wall after removal. The Peel & Up range includes 100% PVC-free satin and matt media.

WallStar® Digital Peel & Up is specifically designed to be printed using a Xeikon digital colour press. The Xeikon wall decoration solution, based on the Xeikon CX500 digital press, uses dry toner technology. The ability to print with five colours delivers design flexibility. Dry toner print technology stands for superior quality images and complies with all necessary regulations with regard to indoor emissions in the building industry.

Anna Brikh, Product Manager at Ahlstrom, comments,” As a substrate supplier we are literally in between the print and the consumer. The substrate has to bring those two worlds together, meeting market demands and ensuring the state-of-the-art quality of the end product.

With our range of nonwovens for wall decor, we have always been looking to provide printers and consumers with high-quality and easy-to-use materials. We believe that WallStar® Digital Peel & Up is an important step forward to meet the ongoing customisation trends in the decoration markets.”

“Digital print stands for printing whatever you need, whenever you need it”, says Dimitri Van Gaever, Xeikon’s director of segment marketing for the decoration markets, “We are delighted to be the partner of choice in this kind of development by leading industry players like Ahlstrom. We were very keen to test the Peel & Up range on our CX-series for wall deco as soon as possible. We believe it can become a game changer for the wall deco markets.”

time ensure premium print quality and highly stable and consistent colors, which meets Yonglin's demands for high quality and high capacity.

As one of the important production bases of packaging printing products at home and abroad, Guangzhou Yonglin Printing&Packaging Co., Ltd. partnered with Manroland introducing a brand new ROLAND 700 Evolution. The printing machine has been successfully installed and put into production by now.

Guangzhou Yonglin was founded in 1994. It is a large-scale comprehensive printing and packaging enterprise integrating design, printing, production, and sales of paper packaging with reputation, technology, quality and service as its market superiority. It specializes in packaging printing for food and perfume cosmetics, as well as the exquisite gift boxes of some worldrenowned companies (such as: Benz, SK-II, Coty, etc.) with Manroland, the world’s leading packaging printing equipment, and the strong strength in the color printing industry.

"As the saying goes, craftsmen must first sharpen their tools before they can do a good job. Since the establishment of the company, Yonglin has been using

leading packaging printing technology to ensure high quality printing and high productivity. Following the introduction of this ROLAND 700 Evolution, it is also equipped with fully automatic post-press hot stamping, paper laminating, die-cutting and boxmaking equipment.

“we plan to invest in more equipment in the next two or three years to continuously increase our production capacity and further improve customer satisfaction," Yonglin said proudly.

In addition, they believed that Manroland's century-old packaging printing brand name could not only help the packaging printers to significantly enhance their own brand images in the market, but also enhance customers' confidence in the packaging industry. The ROLAND 700 Evolution, equipped with many automation technologies, can provide Yonglin with unprecedented efficiency, productivity and quality.

With the printing speed of up to 18,200 sheets / hour, it can also at the same

The ROLAND 700 Evolution manufactured by Manroland Germany with the current top technology can meet the different production and printing process requirements of many customers in the market, such as the following technologies:

TripleFlow, With three different ink distributions at the push of a button, TripleFlow offers high color consistency during the whole print run and drastic savings in waste, which could further reduce the production costs.

Telepresence System, Through this system, the printing machine can be connected to the network of Manroland headquarters in Germany, and the related problems of the equipment can be solved online.

QuickChange Job, automatic job change sequences with pre-selectable content

Moreover, ROLAND 700 Evolution has a wide range of substrate thickness (0.04 – 1.0 mm), which provides more flexibility for Yonglin to better meet the requirements of different applications.

Finally, Guangzhou Yonglin thanked the Manroland team for their professional support especially during the COVID-19 pandemic. “They overcame many difficulties and completed the installation of the printing machine on time”, they added.

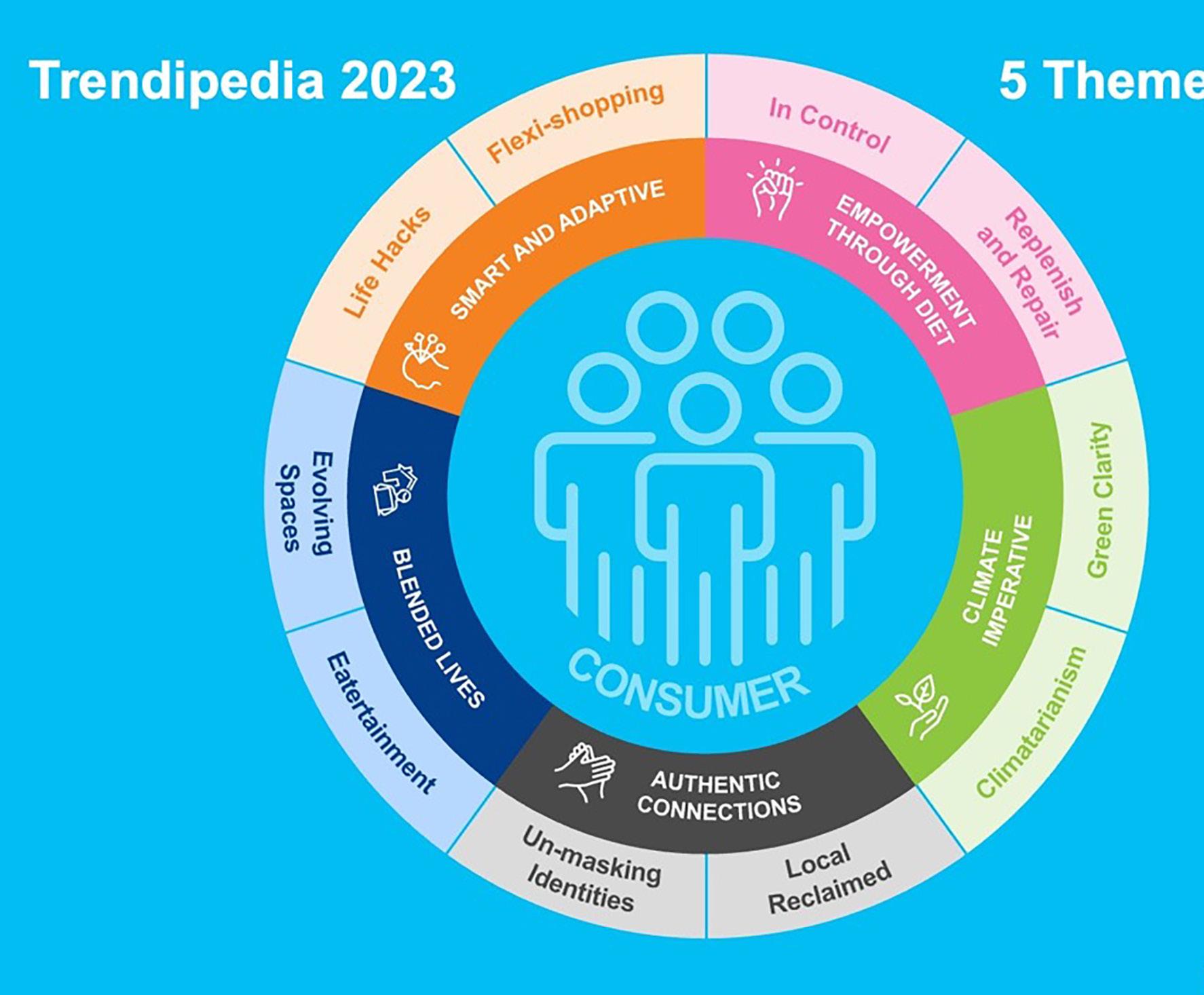

Tetra Pak, a world-leading processing and packaging solutions company, released key findings and insights from its full report, Trendipedia 2023.

The annual global report monitors changes in consumer behaviour, identifying and analysing interesting consumer trends and opportunities for businesses in the food and beverage industry to take advantage of.

“The world is always evolving, and we continue to be faced with emerging new trends. At Tetra Pak, we believe innovation is the answer, and through a collaborative approach, we gather customers, industry partners and experts, to tackle the most challenging issues in our industry.

We remain committed in playing our part to develop breakthrough solutions that will help shape a more sustainable tomorrow for people on our planet. The Trendipedia report holds many insights that can help our customers improve any dimension of their business and drive performance,” said John Jose, Marketing Director of Tetra Pak Malaysia, Singapore, Philippines, and Indonesia.

In the post-pandemic times, many have seen macro-level changes resulting in supply chain disruptions, pricing increases from inflation, and labor shortages that have caused businesses to scale back services. This has caused consumers to rethink and change their ways. “These days, consumers are setting new priorities and standards regarding where and when they use their money impacting their spending habits. As a result, companies need to be more creative in attracting consumers to choose their products today,” said Billie Ing, Global Head of Trends and Foresight at Ipsos Strategy3.

Simply consistent

Decrease waste and setup with predictable plates

Simply efficient

Increase on-press performance with a robust plate

Simply sustainable

Support sustainable inks and substrates all with the same plate

Simply better Address your most demanding brand and quality requirements

From prepress to on-press, deliver the efficiencies and productivity needed from your plates to maximize your bottom line.

According to the latest report, the main trends in Malaysia, Singapore, Philippines, and Indonesia are ‘Flexi-shopping’, ‘In Control’, and ‘Eatertainment’.

Flexi-shopping – This trend refers to consumers that are living with a flexible mindset, cutting back where needed

but treating themselves occasionally, especially where there are perceived additional benefits around health or sustainability.

“Despite rising inflation, Southeast Asian consumers say that health benefits and natural ingredients are more important factors than price, in determining if the food or beverage is of good value. Here, the ready-to-drink (RTD) category provides consumers with a convenient, accessible, and affordable way to drink beverages. This category continues to be popular due to its convenience and health-conscious varieties, supporting consumers with health-focused lifestyles,” said Jose.

In Control – This trend refers to how consumers are using the way they eat and drink to bring a feeling of control to their lives. The choice of whether to indulge or moderate their consumption can help people take their physical health into their own hands. In recent times, consumers have been embracing plant-based options in their diet to support a healthy living, and this trend shows no sign of slowing down. In fact, the global plant-based beverage category is predicted to experience a remarkable growth rate of 1.9% by 2024.

This increase is a strong indicator that consumers are seeking healthier and

sustainable options, and plant-based beverages are the answer.

Eatertainment – Whilst connecting with like-minded people, some are looking to be entertained as they dare to try new flavours, recipes, and trends from cyberspace. The food community is filled with Gen Zs, gamified, and creative consumers, empowered by social media. In Singapore, 54% of millennials and 53% of gen Z experienced virtual gaming and played immersive open-world video games .“To reach new segments of consumers, brands should consider exploring online and entertainment platforms that are growing in popularity. Social platforms such as TikTok have become a source of recipe inspiration for consumers to discover, experiment and share their food experiences. Moreover, social influencers and content creators play a key role in spreading information about the latest food trends,” added Jose.

Other major trends identified under the year’s five themes include ‘Life Hacks’, ‘Replenish and Repair’, ‘Climatarianism’, ‘Green Clarity’, ‘Unmasking Identities’, ‘Evolving Spaces’. The 2023 Trendipedia report will be shared with Tetra Pak’s customers to ensure they are onboard with the latest consumer shifts in consumer trends.

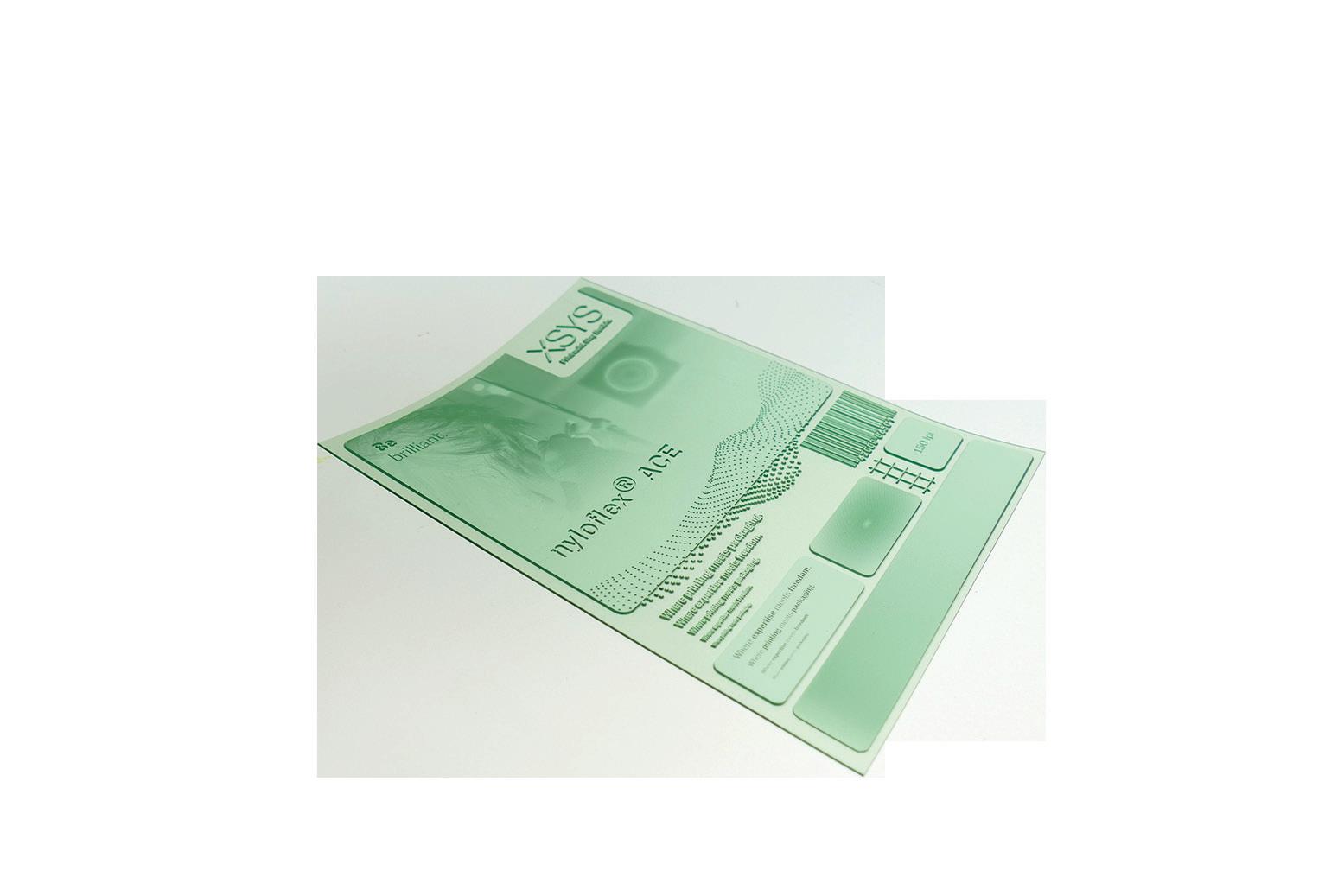

The Canadian flexible packaging specialist has improved the quality of its flexo printing and increased overall productivity by installing the first ThermoFlexX Catena-E 48 in North America.

A trailblazer in sustainability, Tempo chose the UV LED exposure unit from XSYS due to the advanced automation, reduced energy consumption, and higher operational speed.

Willstaett, Germany. 02 May 2023

– First established in 1970 as a poly bag manufacturer, Tempo Flexible Packaging Inc. has spent the past two years implementing a large-scale investment plan. Over 10,000 square feet have been added to the sizeable facility in Innisfil, north of Toronto, Ontario, along with the installation of new equipment, including a new CI flexo press from Germany.

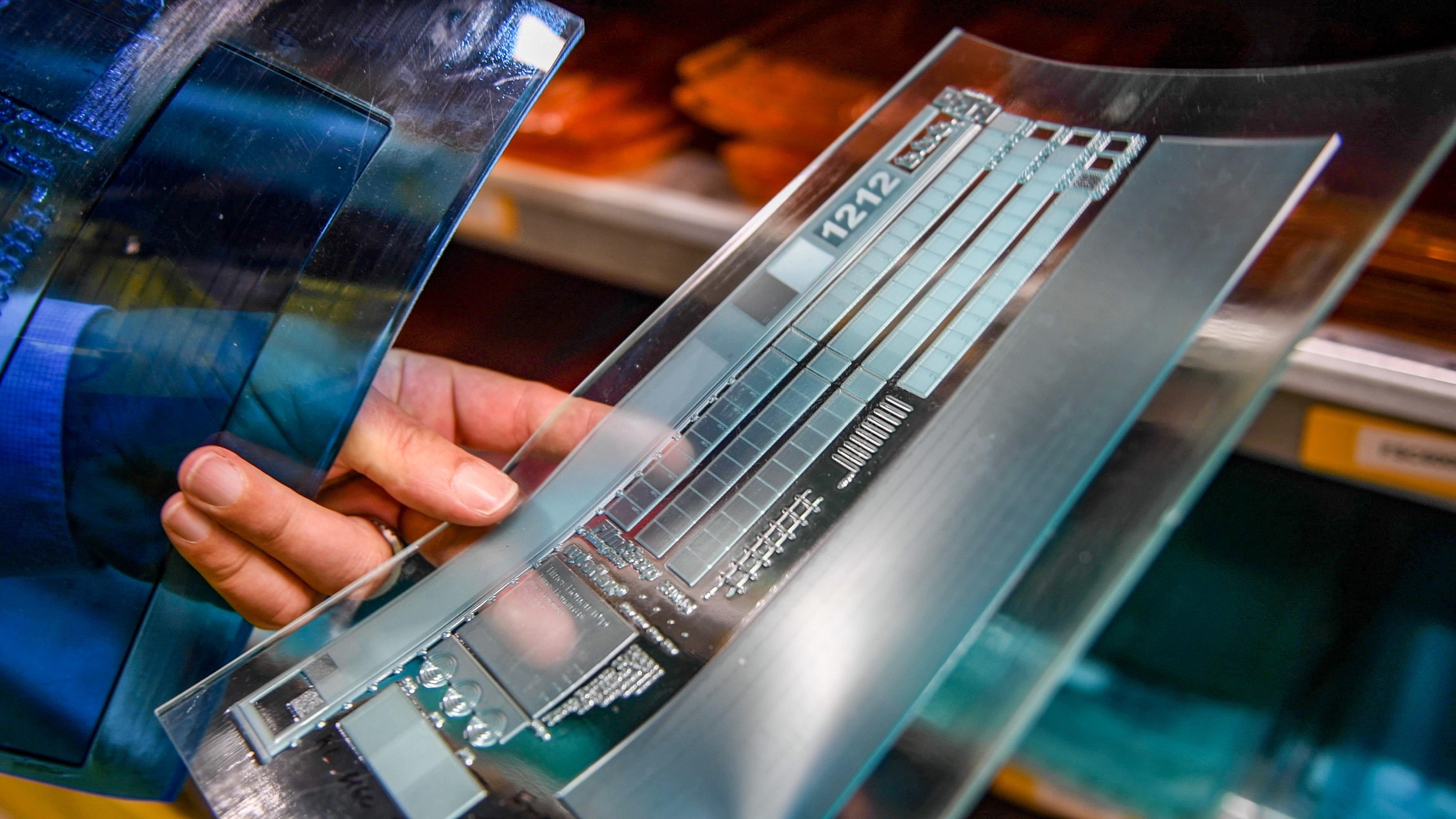

The ambitious project also involved upgrading the plate room, which already contained a ThermoFlexX 48 imager and Xpress Thermal processor, before the new Catena-E 48 exposure unit from XSYS was introduced late last summer.

The family-run company is the largest employer in the area with over 170 employees and supplies a wide variety of flexible pouches, as well as roll stock and bags, to the food, pet food, and lawn and garden industries across North America. As a vertically integrated manufacturing facility, Tempo is certified to FSSC 22000 v 5.1 standards, with all processes contained within the business, from extrusion, coating, printing, laminating and slitting to final bag- and pouchmaking. At the helm sit the children of co-founder Joseph Giglio; LeeAnne Giglio is the company’s COO, while her brother Leonardo Giglio is the OPTIMIST & CEO.

Sustainability is the core focus for Tempo, and it is reflected in its drive for product innovation and commitment to environmentallyfriendly production methods. “Our company vision is to be the preferred partner of sustainable and socially responsible flexible packaging solutions in North America,” states Lee-Anne. “And we always choose our partners, technologies and equipment with that vision in mind.”

The winning contender

Always striving to deliver exceptional packaging solutions for every client, Tempo Flexible Packaging continues to improve every aspect of its flexo printing operation. When it comes to choosing new equipment, the evaluation process is rigorous as technology from different manufacturers is subjected to close scrutiny before the final purchasing decision is made.

Craig Labossier is the Print Technical Services Manager at Tempo. He explained, “We had a pre-existing relationship with XSYS since we purchased the ThermoFlexX imager and Xpress processor in 2020, but we still did due diligence to ensure we got the best machine. Ultimately, we were down to two contenders, and it quickly became clear that the Catena-E technology had a strong advantage.”

The Catena-E 48 thermal system can image plates in sizes up to 900 x 1200mm (35 x 48”), enabling precise image reproduction and fine relief elements at faster speeds, perfect

for the type of flexible packaging applications that Tempo specializes in. And in terms of sustainability, not only do the LEDs use less energy than conventional lamps, more savings are achieved when exposing smaller plates as only the LEDs directly below the plate are active.

The Catena-E 48 LED exposure unit replaced an older conventional bank exposure unit that was causing quality issues for Tempo. “Even though we are already an award winning printer, we were never really that satisfied with the old unit and had been aiming towards switching to LED exposure for a while, knowing that it would give us the quality push we needed,” said Craig.

Set up to work seamlessly with the ThermoFlexX 48 imager and Xpress processor, the Catena did not disappoint and immediately made its presence known. “Right away, the new unit solved our problems, and there was a dramatic improvement in the print quality,” Craig said with satisfaction. “With the Catena-E 48, we can hold much smaller minimum dots, and they stay clean throughout the print run, so we can print for longer, which improves productivity and reduces waste. Our customers are also noticing the much cleaner print they’re getting.”

Further improving the results and the sustainability, Tempo is applying ThermoFlexX Woodpecker Sharp surface screening to their plates, which helps control the ink flow to deliver a smoother laydown, with less ink used and faster press speeds enabled. The pattern is not embedded in the job files, but applied directly during imaging, making the workflow less complex.

After witnessing a big difference in the productivity of the plate room, as well as the final print results, the team at Tempo was convinced that the Catena-E 48 from XSYS was the right choice. In addition, the ease of use and high level of automation provided by the unit made the transition process to the new LED technology quick and straightforward.

“The installation of the Catena-E 48 was very smooth; it simply slotted into the existing setup with the imager and thermal processor. It took less than a day to get the machine up and running, including the print trials on the press,” commented Craig. He concluded, “We now have the best possible workflow in our plate room and can run our presses faster for longer. With higher productivity, better quality and increased sustainability, we have truly taken our flexo production to the next level.”

As brands seek more sustainable packaging options, new coating technologies for fibre-based packaging are unlocking the full potential of paper. At Interpack 2023, Henkel and UPM Specialty Papers presented two recyclable paper solutions created through a joint development between the two companies that push the performance of barrier papers to an unsurpassed level of grease resistance – offering a heat-sealable alternative to conventional plastic packaging. By combining Henkel coatings with UPM packaging papers, the innovative combined solutions provide fully recyclable alternatives for both food and non-food packaging applications.

At a dedicated Happy Hour at UPM Specialty Papers’ Interpack stand, experts from Henkel and UPM presented a solution delivering heat sealability using Henkel’s Loctite Liofol

HS 2809-22 RE with UPM AsendoTM

90 g/m2 paper and a solution that combined barrier coating Aquence

EPIX BC 6134 and UPM AsendoTM

Pro 90 g/m2 paper to deliver barrier properties against grease alongside heat sealability. The jointly developed innovations ensure that these vital characteristics for packaging food and non-food items can be provided using paper. Henkel’s paper coatings can be used on a variety of substrates and enable easy recycling and recovery of fibres to support a circular economy.

“At UPM Specialty Papers, we are working closely with innovative partners to create transformative solutions that reimagine the future of sustainable packaging,” commented Mika Uusikartano, Senior Manager, Product Portfolio Management at UPM Specialty Papers. “Working alongside Henkel with a shared focus on creating sustainable alternatives, we have co-created a recyclable, heatsealable packaging material that is compatible with existing packaging lines. By combining our respective expertise, we are jointly creating barrier

paper structures and pushing their performance to an unsurpassed level of grease resistance, while providing converters with a tried and tested concept.”

“As the packaging industry and wider society work to take on urgent environmental challenges, it is essential that we collaborate across the value chain to rapidly deliver solutions. The solutions created with UPM –and successfully presented together at Interpack – embody this spirit of collaboration,” explains Christin Noack, Market Strategy Manager Europe at Henkel. “The creation of packaging and processes to effectively combine paper with barrier and heat seal coatings, required close collaboration with our partners at UPM over a lengthy joint development process to identify and optimize the right fibre-based substrate and coatings combination. Together, we are enabling paper to achieve unmatched barrier performance while meeting the demand for more sustainable packaging. These

paper innovations provide packaging manufacturers with turn-key solutions to significantly reduce their own development time when bringing new products to market and we were delighted to see this solution so well received by visitors to Interpack.”

LOCTITE® and AQUENCE® are registered trademark of Henkel and/or its affiliates in the USA, Germany and elsewhere.

At UPM Specialty Papers, we create transformative materials for packaging based on paper. Our 2,000 passionate experts are ready to help you co-create the right packaging solutions for your needs and meet your sustainability goals. Best of all, our papers are produced with renewable, responsibly sourced wood fibres. And with our mills in Finland, China, and Germany, you can trust us to deliver quality and consistency wherever you are in the world.

Are you still looking for multi-talent that meets all your requirement? There are no challenges in commercial, label, and packaging printing that a Speedmaster CX 75 cannot handle, and no customer requirements it cannot meet.

heidelberg.com/sg

The company, which mainly provides commercial and packaging printing for the domestic market, was founded 32 years ago with three shareholders, three employees and one Heidelberg SORD press. Today, the company has expanded with more machines in the pre-press, press and post-press sectors and employs 40 people. In 2016, the company also established a branch office in Singapore.

Today, the market is becoming increasingly competitive, with shorter delivery times, low and competitive prices, shorter run length and high quality being the norm. There are many printing companies in the area surrounding Bukit Serdang, with hundreds within a five-kilometre radius. In order to compete against the competitors, the issues of higher quality, lower prices and a shortage of skilled labour/resources need to be addressed. As part of this, the Speedmaster CX 75-4, which offers a high level of automation, has been installed to improve production efficiency, while ISO certification has helped to ensure that high quality is maintained consistently.

Significant improvement in both quality and productivity with the latest technologies.

“The performance, reliability, and quality in the solution from Heidelberg are undoubted. It is an undisputed fact that Heidelberg is the first choice of the printing industry. We are pleased to be able to serve our customers better with the latest technology in the Speedmaster CX 75-4, which offers high quality and significantly improved production efficiency.”

Make ready time, which previously took 30 minutes, have been significantly reduced to 15 minutes, while at the same time waste sheet has been cut by more than half. Production and output speeds have also increased by more than 50%, from 7,000 sheets to 11,000 sheets per hour, and a 20k job can be completed in less than two hours, including make ready. This has never been achieved before.

Reprinting is also no longer an issue anymore compared to the previous machine, which could not reproduce the same colours. With the Heidelberg solution, this problem no longer occurs.

For example, a commercial B5 size job used to have to be printed on a CD 102, but the CX 75 we have installed is F-format and larger, so we can now process more jobs, including this type of job in B5 size. Today, 70-80% of all jobs are printed on the CX 75. Operators love the press with modern technologies because it is easy to operate. Colours are also sharper and crisper. Print quality have consistency as it complies with ISO 12647-2.

Process automation provides advantages in production.

To achieve further improvements in productivity, the company also invested in the Heidelberg workflow, Prinect Production Manager and CtP Suprasetter, which are connected to the new CX 75. Workflow integration of the presses is one of the key elements in automated production. "A stand-alone press only fulfils what the machine is capable of, but when integrated with a Heidelberg solution, it becomes much more than a press, it comes to life. Operators are in love with the high level of automation and it certainly reduces the burden and stress in print production."

The workflow is kept up to date with the latest software versions through

subscription. The company is very satisfied with the latest technology solutions from Heidelberg and, most importantly, all its customers are extremely satisfied with the print quality of the CX 75.

“We want to expand from the existing commercial market to also include packaging solutions for our customers. We are also looking to invest in new equipment to strengthen our packaging business sector in the future. We are ISO 12647-2 certified, which gives our customers the peace of mind that they can rely on us to get the job done. There are very few printers in the Serdang area that can print to the ISO 12647-2 standard and we are proud to be one of them, offering our customers the highest international

Prepack Thailand uses Enable™ performance polyethylene to help enhance stiffness and maintain attractiveness in frozen food packaging with sustainability benefits

Challenge: Address the market need for sturdy, recyclable* frozen food packing solutions

Started in 1973, Prepack Thailand Co., Ltd is one of the leading flexible packaging companies in Thailand. Prepack offers an extensive range of products to help meet growing needs. Their quality films are used in

applications ranging from personal care and hygiene products to food products including frozen food, packaged food, snacks and rice to chemical, industrial and consumer products. An R&D center located at their manufacturing plant and headquarters also underscores their commitment to innovation as well as their continued focus on recyclable alternatives and solutions.

Prepack had been looking for a high performing mono-material laminated solution to replace their current solutions, which incorporate multimaterial laminates. While multi-material structures can provide excellent shelf appeal and machineability, they are typically more challenging to recycle.

At the same time, Prepack had commissioned a new 5L machine direction-oriented (MDO) line from Windmoller & Holscher (W&H) to enable them to penetrate the market for PE MDO substrate films. They experienced peeling and uneven stretching of the film (delamination) when they tested various MDO solutions in the market on this new line. It was crucial for Prepack to solve the inter-layer delamination issues, as they could adversely impact the integrity of the end-use application. .

Finally, Prepack was dissatisfied with the quality of optics derived from current market solutions.

Solution:

Utilize Enable™ performance polyethylene to create full PE frozen food packaging with sustainability benefits

Collaborating with Prepack and W&H, ExxonMobil recommended a formulation incorporating Enable performance polyethylene, which can:

• Solve the inter-layer delamination issues

• Offer excellent optical properties and high stiffness in full PE mono-material packaging

• Result in low gel occurrence

The ExxonMobil solution, together with advanced MDO technology and strong in-country technical support from W&H, helped to deliver excellent film quality.

“We were happy to supply our first MDO line in Thailand to an established flexible packaging manufacturer like Prepack,“ shared Henrik Schnellenberg, W&H Regional Manager Technical Sales, adding “And we are happy to have contributed to an MDO film solution for Prepack together with ExxonMobil. We look forward to more such collaborations in the future.”

“Prepack is one of our most valued customers so we are pleased to be able to provide a solution that helps to solve the inter-layer delamination issue, and meets their low gel and good optics requirements as well. Enable™ performance PE also helps boost bubble stability and helps provide ease of processing for trouble-free operations,” added Yeo Wei Jian, South Asia market development manager for ExxonMobil.

Results:

The new full PE MDO solution enabled Prepack to break into the MDO film market mainly in frozen food packaging, fabric and home care applications. Brand owners provided positive feedback, especially pertaining to advanced optics and increased visual appeal.

Karan Tejasen, Chief Operating Officer of SCG Packaging PLC, the

parent company of Prepack said, “We appreciate the good support from ExxonMobil in supporting our MDO PE/PE development, providing a proven MDO PE solution, leading the trials and helping to solve technical challenges during the process.”

He shared that Prepack is looking to extend the use of the full PE MDO solution into other primary packaging applications.

Hard photopolymer flexo plate with inherent flat top dots LED optimized plate formulation

Developed for the high end flexible packaging market Smooth plate surface is able to hold all customized surface screening patterns (e.g. Pixel+ and Woodpecker

+ Highest ink transfer and excellent highlights out of the box

+ Robust and consistent on press, simple to process, already includes flat top dots and a surface screening pattern

+ Optimal for short (quick to color) and long clean print runs (anti ink-filling)

+ Known in the market as THE digital plate for high quality Flexible Packaging Print

+ Excellent print results even under challenging printing conditions

+ Very good for long clean print jobs (anti-ink filling)

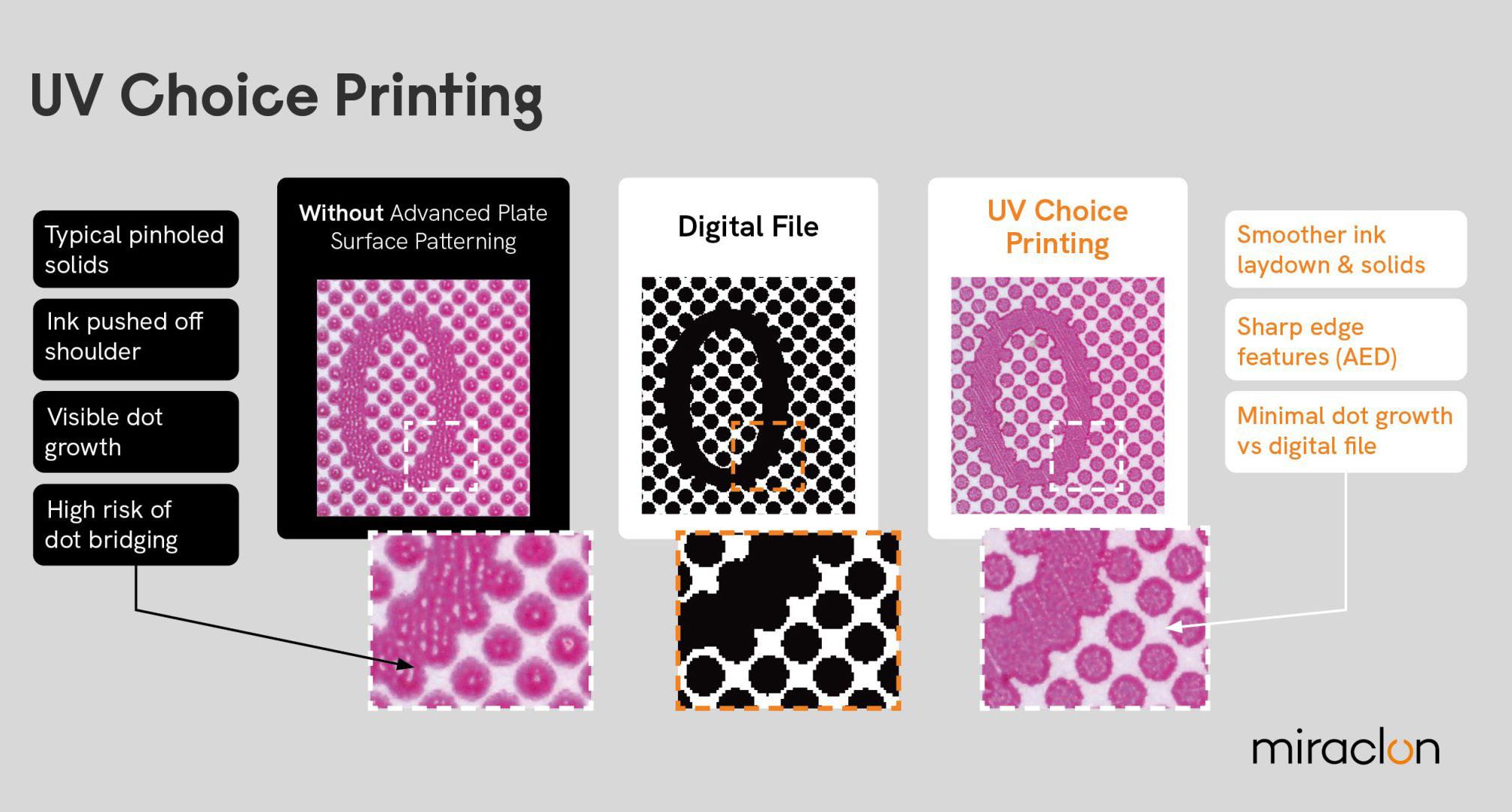

Miraclon today announces the launch of UV Choice Printing, enabled by advanced plate surface patterning technology and specifically tailored to increase printing performance for label and other UV flexo printed narrow web applications.

Available to KODAK FLEXCEL NX Technology users, UV Choice Printing offers both narrow web printers and trade shops the opportunity to:

Increase print performance and stability across a wider range of printing conditions.

Supporting a range of substrates including foils, uncoated and coated labels, UV Choice Printing optimizes UV ink transfer and increases ink density by up to 15%, minimizing the need for troubleshooting quality issues on press, and delivering better reproduction of solids, fine lines, crisp bar codes and text at lower ink volumes.

Decrease press set-up times by 5-20%. UV Choice Printing simplifies and decreases press set-up times by up to 20%. It enables presses to come up to color faster, while delivering results in a wider variety of press conditions thanks to the increased latitude offered with lower volume anilox. It also maximizes print productivity and quality when using older equipment or less experienced press operators.

Reduce plate imaging time by up to 50%. In pre-press, UV Choice Printing maximizes efficiency by cutting imaging times thanks to optimizing the surface area to be imaged (compared to imaging without advanced plate surface patterning), enabling pre-press operators to cut imaging time in half.

“FLEXCEL NX Technology is specifically designed to address inherent flexo complexities and costs, from pre-press to on-press, to achieve the efficiencies, print performance and productivity users need,” comments Reid Chesterfield, Chief Technology and Innovation Officer, Miraclon.

“This flexible approach allows our customers to continue using the flexo plate technology they trust and benefit from, without the need for new hardware to take advantage of our newest innovations while offering forward and backward compatibility.”

“UV Choice Printing is the simple choice to enhance label and other narrow-web application printing. It addresses the key concerns and challenges our customers are telling us they’re facing, allowing them to continue pursuing better productivity and efficiency across a wider range of print conditions and applications to maximize their savings.”

Accessible through KODAK FLEXCEL NX Print Suite for Narrow-Web

Narrow-web printers and trade shops utilizing FLEXCEL NX Technology can subscribe to UV Choice Printing through FLEXCEL NX Print Suite for Narrow-Web, a fully integrated platform to optimize print performance features for the FLEXCEL NX System.

Subscribers benefit from immediate access to new features and innovations for narrow-web applications as they

become available, and Miraclon’s field applications team can provide expert implementation assistance and training, platemaking audits and tools that help maximize the benefits.

Also included: PureFlexo™ Printing – now available for water-based ink applications

Building on the widespread success customers have experienced with PureFlexo Printing since its introduction in 2021, FLEXCEL NX Print Suite for Narrow-Web subscribers will also gain access to the latest advancement of multi awardwinning PureFlexo Printing to control unwanted ink spread in printing of water-based ink applications. Already proven in solvent ink on film applications, it utilizes Miraclon’s advanced plate surface patterning technology to reduce press stoppages for cleaning, and now enables better print quality for water-based ink used in paperboard and paper applications such as tags, labels, folding cartons and disposables. PureFlexo Printing brings a wider operational window regardless of line screen, with compound savings from fewer unscheduled press stops each day, reduced downtime and delays, and faster color setups.

Organised by the Hong Kong Trade Development Council (HKTDC), the Hong Kong Gifts & Premium Fair; Home InStyle; the Hong Kong International Home Textiles and Furnishings Fair; Fashion InStyle; the Hong Kong International Printing & Packaging Fair as well as the Hong Kong International Licensing Show successfully attracted close to 56,000 buyers from over 130 countries and regions.

About 60% buyers were non-local coming from mainly Mainland China, Association of Southeast Asian Nations (ASEAN), Taiwan, the United States, Japan and Korea. The concurrent Asian Licensing Conference also invited about 30 global industrial giants and insiders to share insights. Exhibitors and buyers responding to surveys commissioned by the HKTDC said they expected business and sales to return to pre-pandemic levels within 6 to 18 months.

Sophia Chong, Deputy Executive Director of the HKTDC, said: “The development

of the creative and knowledge-based economy has become a major driving force for global economic growth. For the first time in April, the HKTDC held seven major lifestyle and licensing events concurrently. The Hong Kong Houseware Fair and the Hong Kong Fashion Week were rebranded as Home InStyle and Fashion InStyle respectively, offering more diverse creative products to international buyers; while the Licensing Show was repositioned to cover multiple lifestyle categories, bringing greater synergies and opening up more collaboration possibilities across industries. We are happy to see that many exhibitors were able to secure on-site orders, which is very encouraging.”

She added that Hong Kong was an important hub for promoting creativity and intellectual property trade in the region, with the advantage of being close to the mainland while connected to the world. Given the success of these events, the HKTDC hopes to seize more opportunities from the Regional Comprehensive Economic Partnership

(RCEP) and ASEAN markets, as well as the global market, by organising more large-scale international exhibitions, including CENTRESTAGE and the Hong Kong Watch & Clock Fair in September, further strengthening Hong Kong’s role as a global sourcing hub.

The six exhibitions, the physical editions of which have just concluded, attracted more than 4,100 exhibitors from 23 countries and regions. Under HKTDC’s EXHIBITION+ hybrid model, exhibitors and traders can connect online for another week beyond the physical fair days until 29 April via the Click2Match smart business matching platform. So far over 2,600 meetings between exhibitors and buyers have been scheduled.

Over 50% exhibitors and buyers are optimistic on growth prospects Commissioned by the HKTDC, an independent research agency interviewed around 850 exhibitors and buyers during the events. Over half of the respondents (52%) expected the relaxed quarantine measures and restoration of business travel worldwide would have a positive impact on business and sales, while nearly 70% expected business and sales would be back to pre-pandemic levels within 6 to 18 months. Most buyers also said Hong Kong (85%) and the mainland (60%) were their top choices for trade-fair participation.

The respondents also believed that the Northern & Western Europe (21%) and ASEAN countries (15%) would be their new target markets in the next two years, and they were optimistic about the growth prospects.

Regarding product trends, respondents at Home InStyle predicted sleek and simple design (41%) will be in high demand, while respondents at the Gifts Fair foresee

and Korea and identified six potential mainland suppliers during his Home InStyle visit. “We are very interested in their water bottles, glassware, food jars and storage boxes. We have asked them to send us samples and quotations and will place trial orders worth US$100,000-US$200,000 with the right suppliers.” he said.

sustainable products (61%) to be market trend. Products with the greatest growth potential are gardening, camping & outdoor products (24%), eco-friendly products (20%), health & wellness products (18%) and kitchenware & tableware (18%); while for gifts, prospects are best for sustainable gifts (26%), advertising gifts & premium (25%) and tech gifts (23%).

The Hong Kong Gifts & Premium Fair and Home InStyle launched a brand-new Cultural & Creative Corner, featuring more than 80 exhibitors. The Chairman of first-time participant Beijing Enamel Factory, Xie Yanhua, said: “The Cultural & Creative Corner has attracted the attention of buyers who are looking for unique products with cultural characteristics. We have connected with buyers from Hong Kong and Mainland China. We hope to develop long-term cooperation with them.”

This year’s Hong Kong International Licensing Show also featured more than 550 diverse licensing projects and brands including art, culture, entertainment and design. Many licensees expressed satisfaction with the exhibition’s traffic and successfully signed cooperation agreements.

Innovative technology is bringing revolutionary changes to various

industries. A Hong Kong exhibitor at Fashion InStyle's InnoFashion and Trade Services, Guy Shirazi, Director of Product of Stratasys said: “This is our debut exhibition in Hong Kong to increase the exposure of our PolyJet 3D printing technology. Buyers from Hong Kong, India and Mainland China approached us and showed strong interest in our 3D printers that enable direct-to-textile printing on garments, footwear and luxury accessories like hats and bags. We are positive about the business prospect. This exhibition is a great platform to drive our expansion in Asia.”

Visitors flock to joint exhibitions with onsite orders

Italian company TVS spa has exhibited at the HKTDC houseware fair since 2005. Their export area manager Theo Tassias said: “Two years ago, we launched a new collection called eco-ok induction which is made from recycled aluminium and comes with a recycled plastic handle. The physical Home InStyle held after the pandemic provides a good timing for us to introduce this eco-friendly collection to global buyers and new distributors. We have established connections with a lot of new buyers from many countries and regions such as Ecuador, India, Kazakhstan, Malaysia, Russia, Singapore, the United States and Vietnam.”

Buyer from Poland Pawel Kulig met new suppliers from the mainland, Taiwan, India

The six major exhibitions held under one roof for the first time provided buyers with a one-stop sourcing platform. Italian buyer Enrico Bassani said: “I am happy to be back in Hong Kong visiting Fashion InStyle to source some fashion accessories. I am liaising with four new suppliers from Hong Kong and Mainland China for jewellery watches. I’ve also met five packaging suppliers at Hong Kong International Printing & Packaging Fair. In total, I expect to spend about Euro 300,000 [US$333,000] this time for various kinds of watches and packaging items.” United Kingdom buyer Zahoor A Qurashi also visited the Printing and Packaging Fair. He identified 10 mainland exhibitors and expected to buy various types of food boxes from them with an estimated value of US$250,000.

The HKTDC organised a series of exhibitions and conferences this spring, covering various lifestyle sectors. The seven events ran concurrently for the first time, from 19 to 22 April at the Hong Kong Convention and Exhibition Centre. The events included the Hong Kong Gifts & Premium Fair; Home InStyle (formerly the Hong Kong Houseware Fair); the Hong Kong International Home Textiles and Furnishings Fair; Fashion InStyle (formerly the Hong Kong Fashion Week); the Hong Kong International Printing & Packaging Fair as well as the Hong Kong International Licensing Show and Asian Licensing Conference which ended on 21 April.

Sealed Air Corporation and Koenig & Bauer AG announced they have signed a non-binding letter of intent to expand their strategic partnership for digital printing machines.

The partnership aims to significantly improve packaging design capabilities by developing state-of-the art digital printing technology, equipment, and services. Solutions developed by SEE and Koenig & Bauer will scale and deliver digitally printed materials dramatically faster, enabling brand owners to promote products by connecting with consumers through a digitally enhanced package.

The Koenig & Bauer RotaJET-series of digital printing presses will feature SEE’s prismiq™ intellectual property, software and hardware. By accelerating the digitalisation of printing platforms, both companies will drive expansion of their portfolio of solutions. The partnership will expand market opportunities for both companies and result in co-branded digital printing presses.

Launched last year, SEE’s prismiq™ solutions empower brand owners to increase speed to market with higher quality and more cost-effective designs. These solutions also power business performance, improve operational efficiency, and reach consumers through digital content connected to packaging.

“SEE is pleased to partner with Koenig & Bauer to enhance both of our digital transformations,” said Ted Doheny, SEE President and CEO. “SEE’s prismiq™ technology will help Koenig & Bauer convert their printing platforms from analog to digital while Koenig & Bauer will help accelerate and improve the robustness and effectiveness of SEE’s digital solutions.”

"We are proud to intensify our established partnership with SEE. It is a strong and effective catalyst for the further development of our digital printing strategy and digital product initiatives and enhances the strong position of our RotaJET-series of printers for further industrial success,” said Dr. Andreas Pleßke, CEO of Koenig & Bauer AG.

“To strengthen our broad product portfolio of presses and software solutions for the printing and packaging markets, we have relied on successful cooperation agreements for many years. This unique collaboration with SEE will enable us to create enormous potential for technological progress and business development for both partners."

• Interpack 2023: New flexographic web printing system for high-volume folding carton production addresses key challenges of packaging producers

• Brand corporations increasingly using more sustainable option of folding cartons

• Heidelberg underlines leading role in packaging market

• First systems already installed at sites of large packaging customers

Heidelberg has unveiled a world premiere for the growth segment of high-volume folding carton printing with the completely new Heidelberg Boardmaster . This flexographic web printing system with a machine availability of up to 90 percent and a maximum printing speed of 600 meters per minute delivers double the productivity and thus dramatically reduces the total cost of ownership in industrial packaging production. As the global demand for packaged goods continues to grow, packaging and label printing is experiencing structural growth, making it an important core segment for Heidelberg.

“With the world premiere of our Heidelberg Boardmaster, we are responding to key customer challenges in the packaging market – cost pressure, the skills shortage, and the need to optimize productivity and sustainability,” says Heidelberg CEO Dr. Ludwin Monz.

Heidelberg has unveiled the Boardmaster at Interpack 2023, which runs from May 4-10 in the German city of Düsseldorf and is one of the world’s leading trade shows for the packaging segment.

Flexographic printing is now the number one technology in the packaging market and is continuing to benefit from the globally stable and significant growth of packaging and labels. It is already being used to produce some 15 percent of the total folding carton volume and this proportion is continuing to increase, with flexo folding carton printing volume exhibiting above-average growth of 2,4 percent in packaging printing.

setting

Brand corporations increasingly using more sustainable option of folding cartons

International brand corporations in particular are looking to combine printing quality with ever greater sustainability and recyclability across their entire packaging portfolio, and they are increasingly moving away from plastic. In the food sector, plastic is still the dominant packaging material by some margin. According to a recent study by Smithers, however, the proportion of fiber-based packaging made from materials such as board and paper will overtake plastic in the medium term and assume the top spot with a proportion of over 40 percent.

The new Heidelberg Boardmaster is especially suited to the food and beverage sector’s folding carton applications, which are becoming increasingly popular worldwide due to a growing global demand for packaged products.

The printing speed is up to 600 meters per minute, which corresponds to around 38,000 print sheets in format 6 (sheet width 148 centimeters) per hour.

Substrates with grammages of between 70 and 800 grams per square meter can be processed.

Depending on the postpress concept (reel to reel, reel to sheeter, or reel to die cutter), it is possible to avoid losing any time during production.

the new

Heidelberg Boardmaster reduces total cost of ownership in high-volume folding carton production

“The Heidelberg Boardmaster enables industrial packaging producers to significantly reduce their operating costs. With its numerous benefits for customers, the Boardmaster also provides an attractive alternative for many users who have so far opted for VLF – very large format –sheetfed offset printing,” says Christian Steinmassl, who is in charge of the Packaging segment at Heidelberg.

The Boardmaster was developed completely from scratch at the Heidelberg competence center for high-volume flexo folding carton printing at the company’s Weiden site in Bavaria.

Development work was carried out in close collaboration with international packaging customers and factored in their key challenges – cost pressure, the skills shortage, and the need to optimize productivity and sustainability. The first systems have already been installed.

The solution is designed to dramatically reduce industrial packaging customers’ total cost of ownership.

Each print deck has two print units. While one unit is busy with production, the second one is being readied for the next print job. Depending on the configuration, a machine availability of up to 90 percent is possible in production.

The Heidelberg Intellimatch prepress scanner safeguards printing quality, also ensuring the print decks are adjusted correctly and fully automatically.

Conserving resources is a key focal point: Less than ten meters of paper waste per job change

Far higher energy efficiency as a function of productivity than in offset printing Recovery of warm air that is generated Using water-based inks improves the material’s recyclability

High investment security is ensured, as the system’s modular design means users are able to grow in line with market requirements and adapt the relevant machine configuration to changed market conditions.

Higher productivity, lower costs – the Heidelberg Boardmaster is also an alternative for many packaging customers using very large format (VLF) offset printing in their production operations

The new Heidelberg Boardmaster dramatically cuts the total cost of ownership of packaging producers involved in high-volume folding carton printing.

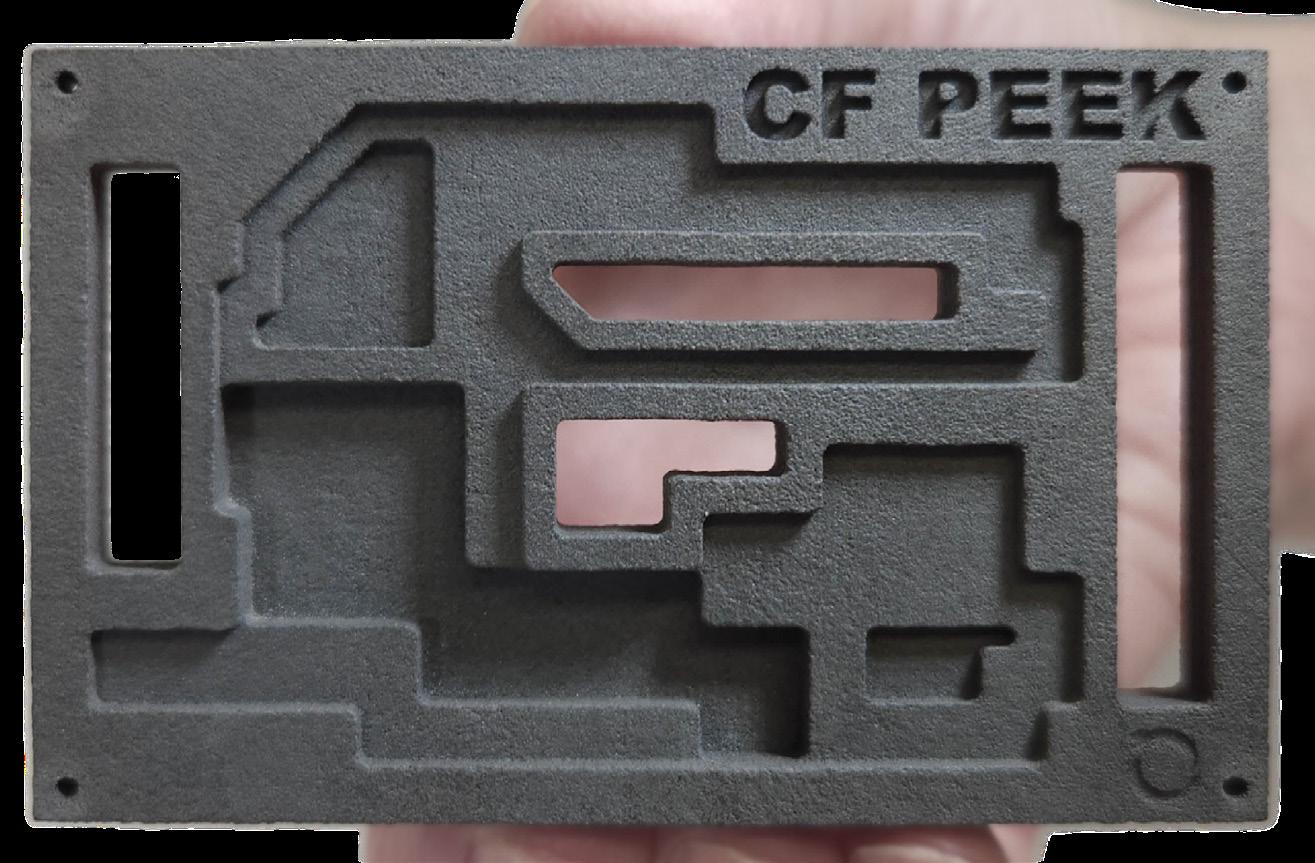

New 3D printer prints parts fifteen times faster than the nearest competitor

Impossible Objects, takes its revolutionary CBAM composite 3D printing process to the next level with the announcement of the CBAM 25 machine, which will be unveiled at the RAPID +TCT tradeshow in Chicago next month. Printing fifteen times faster than the fastest competition, the CBAM 25 brings 3D printing into mass production.

Commercially available in early 2024, the CBAM 25 will bring 3D printing to volume manufacturing, breaking the 3D printing speed barrier while using advanced materials for superior mechanical properties and tolerances.

“The world is made out of things and with the CBAM 25 we are changing the way they are made,” says Robert Swartz, Founder and Chairman of the Board at Impossible Objects. “The CBAM 25 is the world’s fastest

material options at the speed of true mass production. This is a Moore’s law moment for 3D printing, and this is just the first step.”

The CBAM 25 high-performance composite materials enable engineers to design stronger, lighter and more durable parts. Most notably, the Carbon Fiber PEEK material set achieves very high chemical and temperature resistance, and mechanical properties superior to most engineering plastics. Carbon Fiber PEEK parts are a suitable alternative for aluminum, tooling, spares, repairs and end-use parts. Impossible Objects is currently producing and selling parts in untapped 3D markets such as electronic tooling and for a broad range of applications, including aerospace, defense, and transportation industries. It is also replacing CNC machining with greater geometric freedom.

Impossible Objects’ CEO, Steve Hoover, emphasizes the importance of production speed with the new

CBAM 25: “With a fifteen times speed improvement over existing 3D printers our new CBAM 25 completes the transition of 3D printing from its roots in prototyping to the heartland of manufacturing. It’s hard to actually imagine what fifteen times faster means. For a comparison, this is also the speed difference between the fastest human running the mile and a Formula race car in a straight away. That’s the same difference that our new CBAM 25 has versus prior technologies. We believe that this is a huge-step forward not only for our company, but also our industry, as it moves 3D printing into volume manufacturing.”

Embellishment options at the lowest cost per sheet for decorating SRA3 to B1 sheet prints.

Scodix, the leading provider of digital embellishment solutions for the graphic arts industry today announces that premier online printer, Printed Easy, has installed the Scodix B1 Ultra 6000 Smart High Definition (SHD) system. The commercial printing company chose the Scodix Ultra 6000 Press, powered by SHD capabilities, to achieve the highest of quality embellishment options at the lowest cost per sheet for decorating SRA3 to B1 sheet prints.

Based in Letchworth Garden City, UK, Printed Easy offers printing services for a broad selection of general commercial products, including bound documents and brochures, roll labels and a host of other products. When Jon Lancaster took over Printed Easy as Managing Director in 2005, he pushed the family-owned business to expand into online printing whilst driving a raft of production efficiencies through its in-house software development. Since making the decision, the company has experienced a staggering 50-fold plus increase in sales.

According to Lancaster, the company started to pay attention to the Scodix Ultra 6000 Press when the team saw the format and quality: “The B1 format and new polymers allow low cost-per-sheet which competes with conventional UV on a flat finish, whilst SHD brings us breakthrough

quality in terms of sharpness and detail.”

Printed Easy intends to use the Scodix Ultra 6000 by adding both raised and flat UV and foil to every general commercial product, both bound and unbound, in its range, with many complex options currently being designed. The integration of the Scodix Ultra 6000 Press into Printed Easy’s automated production is the logical step to continue its mantra of bringing offline print to the Web2Print market. The software automation and the automatic registration system that Scodix offers was a significant attraction for Printed Easy.