S.p.A. Via Lago Vecchio 3/7 - 23801- Calolziocorte - Lecco - Italy Tel. +39 0341 630063 - Fax +39 0341 641165 - www.edilsider.com

AMES PARK is a patented modular system, designed to double the parking capacity of an existing area.

S.p.A. Via Lago Vecchio 3/7 - 23801- Calolziocorte - Lecco - Italy Tel. +39 0341 630063 - Fax +39 0341 641165 - www.edilsider.com

AMES PARK is a patented modular system, designed to double the parking capacity of an existing area.

It is a modular system, designed to double the parking capacity of an existing area. It consists of a structure made of prefabricated elements, which can be assembled in different numbers and arrangements depending on the type of the surface, without the need for of definitive and/or fixed foundations. The reliability and safety of the whole structure is guaranteed even in the event of earthquakes, in compliance with current regulations, thanks to the continuous R&D carried out by the company’s engineering department for the constant improvement of the individual structural elements.

The system can be:

Easy to disassemble and reassemble, with a single parking level in addition to the ground area; it is protected by industrial design patent no. 0001369877 , issued by the Ministry of Economic Development on 26thJanuary 2010.

With more than one parking level in addition to the ground area; these are usually heavy metal constructions.

The single-storey system, named AMES Park, makes possible to disassemble the structure completely and reassemble it in another place having a different floor plan, with the option to increase or decrease the number of modules and use all the available area in the best possible way.

The possibility to have a safe and durable parking system, which can also be disassembled and moved somewhere else, allows you to make changes in a specific area without making some definitive choices. With this peculiar features, the AMES Park system can be adapted, also for a few months, to areas that are usually intended for different purposes, such as tourist resorts that reach their peak in the summer months.

In addition, the main reason for using the AMES Park system is the lack of the technical and economic difficulties of typically arising from the creation of similar structures, built with traditional technologies (the need for excavation and foundation works, long construction time, expensive investments, delays in having the system produce income, working in inaccessible places, permanent structures that cannot be disassembled or moved elsewhere, etc.), .

EXTENSIBLE OVER TIME

LOW MAINTENANCE COST

10-YEAR GUARANTEE

LOW, QUANTIFIABLE COSTS

FAST IMPLEMENTATION TIMES

MODULAR SYSTEM

MOVABLE SYSTEM

MINIMAL FOUNDATION WORKS

In short, the most innovative features of the AMES PARK system are:

LOW, QUANTIFIABLE COSTS

FAST IMPLEMENTATION TIMES

Fast implementation times, 2 to 6 months on average, depending on the size of the parking lot and the number of floors.

MINIMAL FOUNDATION WORKS

No foundation works in case of single-storey systems (one storey above ground) and/or minimal foundation works for multi-storey structures.

AND DURATION

HIGH PERFORMANCE IN SEISMIC AREAS

VIRTUALLY NO MAINTENANCE REQUIRED

MODULAR CONSTRUCTION SYSTEM

Modular construction system that can be completely and easily disassembled and reassembled in different places, including in arrangements other than the original.

HIGHLY ADAPTABLE

Using a modular system, the construction can be easily adapted to different places; multi-storey structures can be adjusted in both width and height (by means of the ball joint at the base of the pillar, which ensures that the underlying plate is properly supported, including on uneven surfaces).

EXTENSIBLE AT A LATER TIME

The surface and number of storeys can be increased even at a later time.

FLEXIBLE OVER TIME

Increases the parking area (or storage area) of existing surfaces, whether they are easily accessible or not, even for limited periods of time;

EASY TO ASSEMBLE AND DISASSEMBLE

The structure can be disassembled and moved for temporary events, such as trade shows, congresses, sports events, which can attract a considerable number of visitors.

After selling the AMES Park system, the company’s technical department provides Customers full support to answer to any need for changes, variations or replacements. Even when you need to move the whole structure, our after-sales service will resolve any issues related to disassembling and reassembling the system.

It consists of composite modules, made up of a parking surface, placed at approx. 2.85m from the ground, and its vertical support elements and bracings. The area below the structure remains fully viable; indeed, it is even well protected from the elements. It is sized so that it can withstand any distributed or concentrated accidental loads, in addition to its own weight, as well as provided for parking lots (cars with a weight of up to 3 kN), Italian Min. Decree of 14 th January 2008 (“Technical Standards for Buildings” - published in the Official Journal of 4th February 2008. Thanks to the possible vertical and horizontal adjustments, the structure’s vertical supporting elements - that is, the base/pillar/joint complex - offset any level differences and slopes of the ground on which they stand, anyway ensuring that the parking surface above remains perfectly flat. The connection between vertical and horizontal elements, as well as with beams and between the latter and secondary beams, is achieved via bolted joints, to avoid any undesired stress. With this fixing system, the whole structure can be divided into smaller, lightweight elements, making it less expensive as to transport and easier and safer as to assembling. The structure is completed by vehicle ramps for the passage of cars, and stairs for the users of the parking areas.

They consist of tubular and non-tubular profiles in S275JR steel, welded in the workshop and then hot-dip galvanised in a molten zinc bath. These elements are assembled on site using high strength bolts (8.8), which are also hot-dip galvanised. Clearly, because there are no foundations, it is required to use a specific structural support system able to expect and supporting the necessary tolerances - including any structural failures of the bearing surface, which may happen in a long time. This patented support system essentially consists of a base joint and a support plate, a height adjustment element and bracings.

Type A - It consists of prefabricated reinforced concrete slabs (predalles), measuring approx. 4.85x 2.5 and approx. 15 cm thick, featuring an industrial floor having a non-slip treatment. These predalles are lifted from the storage site by eyebolts and laid over the deck’s metal frame. On the long side, they feature a “saddle” profile which provides suitable coupling and, at the same time, creates an expansion joint absorbing temperature changes. This joint is completed, during the assembly, with an ethafoam (polyethylene foam) cord and waterproofing bituminous sealant. On the other sides (short sides), predalles are designed to include a rainwater runoff drain (storm drains) with steel grill. Brackets are used to complete the installation of predalles, they are placed on the reveal, and provide a suitable connection to the deck’s metal frame. Type B - It is made on site with cast concrete, reinforced with Ø12 bars and 8mm welded mesh (20x20 mesh), on 55/600 or 75/760 hi-bond sheet metal, with 2cm extruded polystyrene joints to form 10.00x2.50m slabs. The parking surface is finished with bituminous conglomerate flooring, after a coat of anchor primer and bituminous sheathing with -20°C cold flexibility. Adjusting the height of the base/pillar assembly gives the parking surface a slight slope, to facilitate the disposal of stormwater through storm drains, rain gutters, road grids and downspouts.

A traffic barrier (guardrail type, class N2) with handrail (sometimes even double, if required) is installed along the entire perimeter of the parking surface, including the sides of access ramps. As to external finish, according to the customer’s choice, there can be installed, on the deck’s perimeter: welded and pressed or expanded metal mesh cladding, a vibrated concrete parapet, wooden barriers, grids for vertical green, etc. All these additions are made in keeping with the urban context where the car park is installed.

The electrical system starts from the “shell-type” switchboard (complete with circuit breakers, contactors, release coil, digital time switch, twilight switch, etc.), RK piping with 20mm diameter for main distribution as well as rigid protective pipes and self-extinguishing PVC sheaths for secondary distribution, inside of which are flame-retardant FG7 power cables. The system is completed by junction boxes and terminal blocks, according to the plans to be draw up in accordance with local regulations. The lower floor is adequately lit (30 lux, 1 metre from the ground and 50 lux for manoeuvring lanes) with watertight ceiling lamps, with unbreakable, flame-retardant polycarbonate body and diffuser, with IP65 fire protection rating and 1x36W fluorescent or LED lamp. Some ceiling lights, placed above driving and manoeuvring lanes, include an inverter for emergency lighting. The latter is completed with “always-on” self-powered and self-illuminating exit signs, featuring an appropriate icon to indicate escape routes. At the customer’s request, single or double arm street light poles can be installed on the upper floor, arranged in such a way as to ensure the minimum illumination required according to roadworthiness standards on the upper floor (at least 20 lux, 1 metre from the ground); the lighting fixtures used are generally of the indirect light type (anti-glare).

A copper equipotential bonding is placed in a special watertight box, to be located near the switchboard, to which yellow/green protective conductors are connected (lighting system PE protective conductors; earthing system CT earth conductor; EQP equipotential bonding for mass connection). The earthing system consists of an adequate number of vertical galvanised steel rods, located in appropriate boxes, and of horizontal copper wire rods along the perimeter of the parking lot. Normally, the commercial offer does not include any excavation and restoration of the existing flooring, which will be the responsibility of the Customer.

Our commercial offer includes the design and construction of a fire system in accordance with the provisions of the competent local Fire Department. This fire protection system will have at least one UNI 70 connection for the firefighters’ fire pump and UNI 45 standard boxes with hose and playpipe nozzle (one every 50 cars on the lower floor and one every 100 cars on the upper floor) as well as an adequate number of portable extinguishers. The system is completed with a water ring, made of galvanised steel pipes in compliance with current regulations, equipped with meter, full-flow ball valve and check valves. In the event that the local water supply operator cannot provide the water pressure and flow required for the firefighting system to operate smoothly, the Customer will have to add a water collection system (water tank) with the related pressure unit (these are usually not supplied by us). To prevent fires, there is also a manual fire detection system equipped with a control unit, powered by buffer battery, connected to break glass buttons and visible and audible alarm devices, as well as an external siren (also visible and audible). The commercial offer includes an economic assessment of the structure’s fire protection system according to applicable regulations and according to the requirements of the competent local Fire Department.

We install vertical and horizontal signs. Vertical signs consist of standard aluminium or pre-painted metal sheet road signs on a tubular support or fixed to structural elements with metal ties. Horizontal signs, on the other hand, are made of reflective traffic paint based on pure acrylic resins, titanium dioxide, selected charges, highly reflective glass beads. As regards traditional paint, acrylic traffic paint is characterized by higher abrasion resistance, increased adhesion, and higher resistance to degradation caused by traffic and changing pollution levels; whiteness and yellowing resistance are markedly greater. Refractive paint must comply with the directives of the Ministry of Public Works of 24/10/2000 published on the Official Journal No. 301 of 28/12/2000, transposing European legislation UNI EN 1436:1998.

PLAN

KEY

1 - B450C steel cross reinforcement

2 - Threaded rod with sleeve for hoisting the predalle

3 - Welded mesh

4 - Concrete

5 - Predalle with non-slip concrete floor

6 - Storm drain with galvanised steel grill and galvanised sheet metal channel

SECONDARY BEAM PREDALLE

CEILING LIGHT

DELLA PREDALLE

VERTICAL BRACE TURNBUCKLE HORIZONTAL BRACE

LOWER ROD

SECTION (EXAMPLE)

SECTION (EXAMPLE)

MODULAR HOUSING

TRAFFIC BARRIER UPRIGHT DOUBLE HANDRAIL

CLADDING

MAIN BEAM

PILLAR

CARTER

ADJUSTMENT PIN CASING

GROUTED THREADED RODS

EXISTING ROAD SECTION

PLAN

KEY

1 - HI BOND galvanised sheet metal

2 - Concrete casting

3 - Welded mesh

4 - Concrete casting configuration with 1% slope towards storm drains

5 - Polymer bituminous membrane

6 - 3cm hot-laid bituminous paving

7 - Storm drain with galvanised steel grill and press-formed galvanised sheet metal channel

BOND CEMENTIZIO (GETTO IN OPERA)

GETTO IN CALCESTRUZZO CON PENDENZA 1% BITUMINOSA ELASTOPLASTOMERICA

STESO A CALDO 3 CM ELETTROFORGIATO CON CANALE PRESSOPIEGATO IN

3CM BITUMINOUS PAVING

BITUMINOUS MEMBRANE

CONCRETE CASTING

WELDED MESH

HI BOND GALVANISED SHEET METAL

CEILING LIGHT

SECONDARY BEAM

MAIN BEAM

PILLAR

CARTER

ADJUSTMENT PIN CASING

GROUTED THREADED RODS

SECTION (EXAMPLE)

SECTION (EXAMPLE)

MODULAR HOUSING

DOUBLE HANDRAIL

TRAFFIC BARRIER UPRIGHT

CLADDING

PATENT

ITALIAN MINISTRY OF ECONOMIC DEVELOPMENT

THE AMES PARK SYSTEM IS PROTECTED BY INDUSTRIAL DESIGN PATENT

EN-ISO CERTIFICATIONS

BUREAU VERITAS - CERTIFICATIONS

MANAGEMENT SYSTEM

ACCORDING TO EN 1090, ISO 9001 AND ISO 14001 STANDARDS

LOCATION Rho Fiera

PROJECT Car park for 862 cars

DATE 2022

LOCATION

Guglielmo Marconi Airport

PROJECT

Single-storey car park for 333 cars

DATE 2020

LOCATION

Capodichino International Airport - Gesac

PROJECT

Single-storey

DATE

LOCATION

Auchan Shopping Center

PROJECT

Single-storey car park for 984 cars + 18 motorcycles

DATE 2018 Taranto

LOCATION

Piazza Mercato

Single-storey

Prospect North/West

Prospect North/West

Prospect North/West

PROSPECTS

SINGLE-STOREY

PROSPECTS

PROSPECTS

Prospect South/West

Prospect South/West

Prospect South/East

Prospect South/East SINGLE-STOREY

LOCATION

Caserma Ra.Lo.Ce. - Via Castro Pretorio

PROJECT

Single-storey car park for 172 cars

DATE

LOCATION

Stazione della Metropolitana M3 - Via Comasina

PROJECT

Single-storey car park for 269 cars

DATE 2014

LOCATION

Policlinico di Tor Vergata

PROJECT

Single-storey car park for 331 cars

Caorle (Ve)

LOCATION

Viale dei Tropici - Zona darsena dell’Orologio

PROJECT

Multi-storied car park (2 floors) for 500 cars

DATE 2010

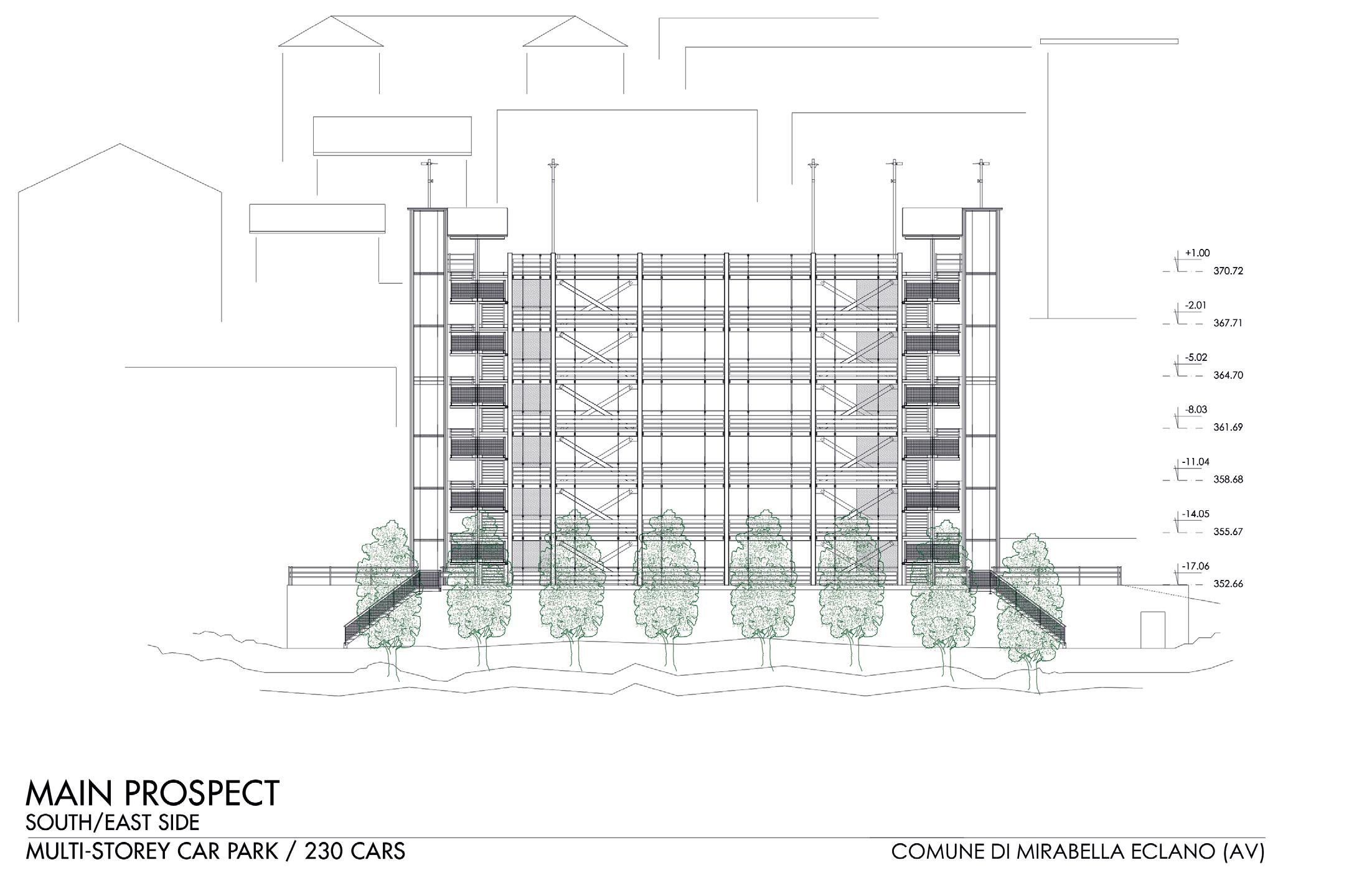

Eclano (Av)

LOCATION Via Municipio

PROJECT

Multi-storied car park (2 floors) for 230 cars

DATE 2009