... we have everything covered JANUARY 2023 read online @ www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com 4th &5th October 2023 NEC, BIRMINGHAM www.surfaceworld.com

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House

2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2022 ISSN 1757-367X

1 JANUARY 2023 SURFACE WORLD 2023 Surface World 2023 - bringing over 20 years of service to your industry 2 INDUSTRY NEWS Gema UK & Ireland Team News. 6 QUALICOAT’s Third Party Accreditation. 8 AkzoNobel launches dedicated range of Resicoat powder coatings to help drive the electric vehicles of tomorrow. 14 Jim Kavanagh appointed as Managing Director of Industrial Coatings, AkzoNobel. 15 AkzoNobel recognized as a European Top Employer. 15 World Coatings Council Publishes First Global Sustainability Report. 18 Beckers announces sale of global Railways Coatings business to KANSAI HELIOS. 20 Corrodere Academy launch Coating Inspector courses with ICorr accreditation. 22 Inquiry launched to investigate urgent need to grow apprenticeships in engineering, manufacturing and technology. 26 ELECTROPLATING, ANODISING AND GALVANIZING On Demand Plating Live Technical Advice-Service. 28 Aluminium Anodizing. 30 PAINT & POWDER Quick Colour Change PVC Booths. 34 Simply the first choice for tinted HMG Paints. 36 Aluminum tubes for high-voltage equipment with high-quality coating. 40 Axalta’s 2022 Global Automotive Colour Popularity Report Marks 70th Year of Providing Industry Insights. 44 MASKING - TAPES, CAPS & PLUGS Suspension and masking technology for the surface finishing industry. 47 PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING Solvent vs Aqueous. 50 New Test Center for high-putiry cleaning applications. 54 Our 2023 Brochure now available. 58 Straaltechniek UK Ltd provide bespoke solutions & equipment. 60 Save on Elbow Grease with Kemet Mould Tool Cleaning Solutions. 62 WATER & EFFLUENT TREATMENT Cleantech Oxyle powers wastewater treatment as it raises CHF 2.8 million to scale growth. 64 Monitoring of the Coating Baths for Uniform Colouring. 67 MATERIAL & EQUIPMENT SUPPLIERS 69 TRADE FINISHERS 76

Specify

JANUARY 2023 VOLUME 30 NUMBER 1

QUALICOAT for all your architectural aluminium powder coating requirements qualicoatuki.org

Surface World 2023bringing over 20 years of service to your industry

Trade shows, exhibitions and other events can be an excellent way to showcase your products and services. They give you the opportunity to increase awareness of your business, launch new products and services, network with industry members, explore partnership opportunities, see what competitors are offering, generate new business leads, attract and convert customers.

What is a Trade Show?

A trade show is a platform where businesses (exhibitors), professionals and business representatives (visitors) come together under one roof to exchange knowledge and make connections with other like-minded professionals.

Exhibitors book a stand and use this space to connect and engage with visitors to the event. Ideally, the event is used to generate leads, network, promote products and services, and hopefully close a few sales in an organic setting that’s tailored to them and their audience.

How can you benefit from exhibiting at a Trade Show?

There are many reasons why you would choose to exhibit at a trade show, which include:

Make sales – the golden ticket to trade show success, hitting a quota or making direct sales is the ultimate definition of winning.

Capture leads – without leads salespeople have nobody to convert, so generating enough leads for your marketing funnel is a must.

Analysing the competition – what technology are they using, what marketing angle are they taking? It’s good to know what the competition is up to.

Engage with existing customers –existing customers are more likely to invest in new products and services, so you can keep building relations and offering them more benefits.

Introduce new products/ services – new and old customers could benefit from your new product.

Account-based marketing – go into a trade show with an idea of who you’d like to speak with, so you can create a strategy that’s more likely to convert them.

Gather feedback – feedback is how you improve services and sales and marketing; you could receive advice that revolutionises how you do things.

Spot trends – spotting trends is vital if you want to stay relevant or avoid something that’s a flash in the pan.

What should you look at when selecting a trade show?

The best success can be gained from participating at an event that has a well-established history. These events usually draw the best reward. The event organiser should have proven methods in place to market the event to the right audience. They will have a database they have accrued over many years of business. The venue should be easily accessed by road or public transport and have plenty of parking. A venue with excellent nearby facilities, hotels, restaurants, entertainment, can also be a bonus if the event is held over more than one day.

Can You Make Money at a Trade Show?

Keeping costs down is a benefit when deciding which trade show to exhibit at. Smaller shows tend to be cheaper, so choosing an event that is aimed at your target audience is the key to a successful outcome from exhibiting. Here are some ways you can get a healthy ROI from a trade show, including:

Only buy the space you need – the area you buy takes up a significant amount of your budget, so overdoing

2 JANUARY 2023

SURFACE WORLD 2023

it can waste money, which is going to eat into your sales.

Get an enticing exhibition stand – you can have a tiny space and still attract people if your stand is attractive, making your area presentable promotes credibility.

Organisation is key – there’s a temptation to blindly hand out literature and marketing collateral, putting it at the back of your space makes reps think about engaging first, which is more likely to generate a lead or a sale.

Use tech where it’s useful – the whole purpose of a trade show is to generate business through face-toface marketing, so don’t dehumanise the event by using too much technology.

Pick the right team – there’s no point in attending an event if you pick the wrong staff. Ideally, it would benefit you if you had people who understand and empathise with customer challenges, but also know when to close deals.

Work the aisles – do not limit yourself to the boundary of your stand, you can reach out to passers-by and engage in the aisle.

Tell people you’re exhibiting –use as many marketing techniques as you can to create a build-up to the event and get people excited. Utilise all marketing opportunities the event itself offer, these are generally targeted directly at your required audience.

What Do You Need for a Trade Show?

The last thing you want to do is under prepare. Get the following ticked off before you get to your event:

Event space – the first thing you

need is event space, you’ll have a shock if you turn up and there’s nowhere for you to pitch!

Stand with supporting collateral – your stand and marketing collateral are what attract people to your stand.

Travel plans – train, bus, plane, car? It would help if you had robust plans in place before you depart.

Accommodation – if you’re planning on staying over, which you may want to as events are long, tiring days, reserve in advance as hotels may get booked up prior to the event.

Marketing collateral – brochures, leaflets, business cards; get all the material you need and ensure you get plenty. You don’t want to run out.

Staff – ask your staff well before the event to ensure they are available to attend, cancelling holidays will not be seen as favourable to you! Remember your staff are the face of the business at the event, get them prepared.

Could You See Success at a Trade Show?

Trade shows aren’t an antiquated form of marketing and sales – they’re proven to generate targeted, high-quality leads and sales. Not every business can benefit from attending trade shows, but they’re certainly worth exploring. Just like trade shows give you the opportunity to better connect with prospective customers, exhibiting at a trade show also allows you to meet existing customers face-to-face.

While most of today’s business is conducted over email or

phone, face-to-face meetings are undeniably a fantastic way to do business.

The Wall Street Journal agrees. Citing a study by Oxford Economics, the well-known financial publication reports that face-to-face meetings are the most effective way to strengthen relationships with both prospective customers and current customers.

Trade shows help bring all the different aspects of an industry together –consumers, distributors, suppliers and manufacturers, all in one place. With such a broad audience together in one place, businesses are able to schedule meetings, negotiate orders and other opportunities and collaborate on other projects. Trade shows allow businesses to facilitate discussions with their suppliers and even with other businesses, as well as move projects to another level if the opportunity arises.

3 JANUARY 2023 SURFACE WORLD 2023

Bean at:

+44

Email: nigelbean1@aol.com

World 2023 is a well established trade event, with over 20 years of experience, specifically tailored to the Surface Finishing Industry.

If you are interested in exhibiting or visiting this event, please contact Nigel

Telephone:

(0) 1442 826826

Surface

PosiTector ® Inspection

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

DesignandFeatures

Customized Inspection Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs.

Coating Thickness Surface Profile

Conditions

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

DFT Instruments UK LTD

DFT Instruments UK LTD

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

01442 879494

01442 879595

Proud

supplier of DeFelsko Inspection Instruments

16A

t:

f:

www.dftinstruments.co.uk e:

sales@dftinstruments.co.uk

Ultrasonic

Environmental

Wall Thickness HardnessSalt Contamination

NEW

Proud

DeFelsko

16A

t:

f:

www.dftinstruments.co.uk e:

n Low Frequency n Xtreme NEW

supplier of

Inspection Instruments

01442 879494

01442 879595

sales@dftinstruments.co.uk

DesignandFeatures

s EASY OPERATION . DOUBLE PRODUCTIVITY. SuperCenter EVO Powder preparation & supply center • Ideal for frequent & fast color changes • High degree of automation for optimum efficiency • Double-designed fresh powder station for increased productivity wagner-group.com Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

Gema UK & Ireland Team News

Gema is delighted to announce the appointment of two new team members in the UK. Neil Scragg and Josh Bowker have joined the business as part of our ambitious ‘fit for the future’ growth strategy and to add additional Technical & Sales support for our customers.

Neil joined the business in December as our UK Head of Sales and will be directly managing our distribution network and sales in the Northern Region. Neil has been in the Surface Finishing industry for 34 years and started his career as an Apprentice Mechanical Design Engineer and moved into Technical Support roles, Sales & Engineering Management and ran one of the UKs market leading Surface Preparation machine manufacturers before he joined GEMA. Neil has a wealth of experience and knowledge of applications, processes and systems which are complimentary to our powder coating expertise and looks forward to supporting our customers on the latest GEMA technologies and improvement opportunities.

Josh came on board in January as our Technical Sales Manager for the Midlands and South region. Josh started his career as an apprentice at General Electric in Stafford, gaining valuable experience in engineering as well as qualifications in mechanical and electrical engineering. Josh advanced into the manufacturing office as a Design & Production Engineer, implementing jigs, fixtures, tooling and CNC equipment as well as supporting the production team on the day to day running of the company. More recently Josh has worked as a Design Engineer, designing Industrial switchgear and Automatic transfer switches and supported the technical sales of EV charging infrastructure.

Leon Hogg, General Manager of GEMA UK & Ireland, has also reached a milestone of 15 years’ service with the business. General Manager of GEMA Europe, Richard Hawkins, is presenting Leon with his long service award.

Richard has been with the business for 37 years and has helped pioneer the adoption of GEMA powder coating systems into new markets and applications. Leon & Neil both served their engineering apprenticeships at the same business. Leon completed his electrical engineering apprenticeship and was heavily involved in the design and manufacture of control panels and systems. Leon progressed into equipment installation and commissioning and then into Technical Sales & Management.

Leon joined GEMA UK in January 2008 as the Sales Manager for the UK and progressed into the General Managers position in January 2016 and has since very successfully led the GEMA UK & Ireland team to become the market leading powder coating brand. Leon was also inducted into the GEMA management programme and achieved a prestigious MBA from Warwick Business School.

At GEMA, our team of professionals aim to be the best in our industry. We are the undisputed worldwide leader in our market. We have reached this position and maintained it for many years thanks to our strong investments in innovation, a real passion for high quality products and our service mentality that puts the customer at the centre of our initiatives.

The success of these strategies is largely based on our worldwide employees, who are the real driving force of our company. We invest in the best talent to bring a fresh perspective into our organization and become our tomorrow’s leaders.

For more information on Gema please visit: www.gemapowdercoating.com/en/

6 JANUARY 2023 INDUSTRY NEWS

Neil Scragg – UK Head of Sales

Josh Bowker – Technical Sales Manager

Richard Hawkins presenting Leon Hogg with his long service award

Scan & Spray

Dynamic Contour Detection

Programming-free coating of any shape! Gema

The second generation of Dynamic Contour Detection detects the object contour fully automatic and positions the guns individually even for thin objects and at high conveyor speeds. Due to the programming-free adaption of all relevant line settings the application range is significantly extended.

Europe Srl – UK Branch

gemapowdercoating.com

Tel: 0044 1202 763 942 Email: uk.sales@gema.eu.com

QUALICOAT’s Third Party Accreditation

By Angus Mackie -

QUALICOAT Chair

British Standards offer a respected specification are often used across the globe to recognise a ‘standard’ for manufacture or provide a service. By specification of a standard you are asking for a product or service that will fulfil its duty in use in any particular industry. However, as a specifier you rely on the credibility of the supplier to ensure that they maintain the consistency of the standard by checking and testing product and processes. The same can be said for many other national standards.

If a supplier fails to meet the level of specification within a given standard, often products can be replaced, but what happens when this cannot be achieved? Usually lengthy legal challenges take place costing time and money. Citing architectural powder coating as an example, it is not possible simply to remove the product and replace it as coated products are built into a building project. Often the final position for such failures of specification on installations is somewhat of a compromise. As we all know, it is better to get it right to start with, which is the holy grail for any specifier on behalf of their client.

Turning to third party accreditation, a process that protects both the specifier and the client, surely this

should be something that we should be insisting on? Often critical specifications are inspected by consultants, but is this really necessary, would it not be better for the supplier themselves to lay bare their processes so a third party can qualify the supplier against a standard for all production?

Simply put, third party accreditation invites an independent person or company the responsibility to undertake process and product checking to ensure the product or service meets the quoted standard. The result gives the client confidence that the product will fulfil their specified needs whilst the supplier is also qualified as a supplier of quality product.

The Association QUALICOAT has placed third party accreditation at the heart of their architectural powder coating specification. As a global specification, when used across the UK & Ireland, the specification is managed by ‘QUALICOAT UK & Ireland’ with offices based in the West Midlands.

So what is the QUALICOAT specification and how does it differ from the BS EN 12206 standard for powder coating?

First of all it is fair to say that the much smaller British Standard is largely covered by the much larger and more up to date QUALICOAT specification, simply because it is the correct way to powder coat architectural profiles. The difference is that the QUALICOAT specification is far more precise in giving details of process and process control parameters offering a far better consistency in quality output. So, who writes this more detailed QUALICOAT specification? Surprisingly the very members themselves acting in working groups consisting of members across the globe. Why? In order to offer the best possible quality of architectural powder coating for a long sustainable life expectancy. All updates to the specifications are a result of detailed research by dedicated working groups only made up of employees of member companies.

We have all said at sometime ‘put your money where your mouth is’, well this

8 JANUARY 2023

INDUSTRY NEWS

Powder coating of aluminium profile

Angus Mackie

elcometer.com Everything you need for fast and accurate coating inspection in one cost-effective, easy-to-use kit. climatic monitoring | surface profile | coating thickness INSPECTION KITS Elcometer3045 · FAST · REPEATABLE · ACCURATE · DURABLE COATING Surface World - December 2022.indd 2 19/12/2022 14:52:20

is exactly what QUALICOAT members do on a regular basis. They not only sign up to a more onerous QUALICOAT specification when they become members, but also agree to invite and pay for unannounced independent audits from a third party company. All current QUALICOAT licence holders can be checked on the main qualicoat.net website and on the UK & Ireland’s qualicoatuki.org website.

IFO from Germany are QUALICOAT UK & Ireland nominated independent test house who are regularly in the UK to undertake twice yearly unannounced inspection of coating members. Reports are issued to the Association and member noting any noncompliances against the QUALICOAT specification. Minor non-compliance issues, rare as they are, may be reinspected, unannounced, again in a short period, more critical non-compliance issues could mean that the coater will lose their licenced status and will not be able to use the QUALICOAT name in any of their business dealings.

Members meet four times a year to discuss progress of the working groups and to review updates to the specification which are often implemented as soon as they are released.

Each QUALICOAT member prides themselves on offering high quality coating, so any QUALICOAT licence holder coater not only signs up to offer the enhanced specification but also proudly carries the credibility of one of the worlds most wide reaching specification in building construction. But, it doesn’t stop there, to ensure vertical integration with quality powder producers and aluminium pretreatment systems providers, both these supply chain providers also have meet the QUALICOAT specification and follow a similar third party inspection regime. All major powder suppliers are QUALICOAT licenced as well as many of the chemical systems companies for pretreatment. Integrating these companies into working groups ensures that enhancements to the specification, which occur in real time, meet with the approval of the complete supply chain. So quality products supplied to quality powder coaters who then are able to offer possibly the best powder coating finish specifiable.

Finally, in the words of a very famous entrepreneur ‘one more thing’! In the Association‘s pursuit of the highest quality architectural powder coating, recently launched is QUALICOAT 3.0. Over the last decade as we use more recycled aluminium the Association has recognised that poor quality recycled content does affect the sustainability of the powder coating. A QUALICOAT 3.0 specification targets the aluminium processor to

ensure that their output of extrusion or sheet aluminium reaches strict tolerances for both process and contaminant content to ensure the longest possible surface coating life expectancy. This specification is now live and open to specifiers to use.

Please contact your local QUALICOAT coater or head office in the West Midlands should you have any specification questions.

Powder coating of fabricated items

Powder coating of fabricated items

INDUSTRY NEWS 10 JANUARY 2023

Powder coated solar shading

FOR ALL YOUR VIBRATORY FINISHING EQUIPMENT AND MATERIALS

New and used vibratory finishing machines and systems from 2 litres to 4000 litres

Finishing media; Ceramic, Plastic, Wood, Steel and Maizorb

Liquid / powdered / paste compounds

Abrasive finishing wheels

Vibratory separators / sieving machines and re-meshing service

Repairs and relines

Effluent water treatment systems

Subcontracted finishing and industrial sieving services

Redundant machines purchased

Consultancy

Experienced Engineers After sales technical support Nationwide deliveries

Sharmic Engineering Ltd

+44 (0)1299 822135

878123/4/5 Email: info@sharmic.co.uk www.sharmic.co.uk SHARMIC FOR FAST, FRIENDLY SERVICE

Tel:

/

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

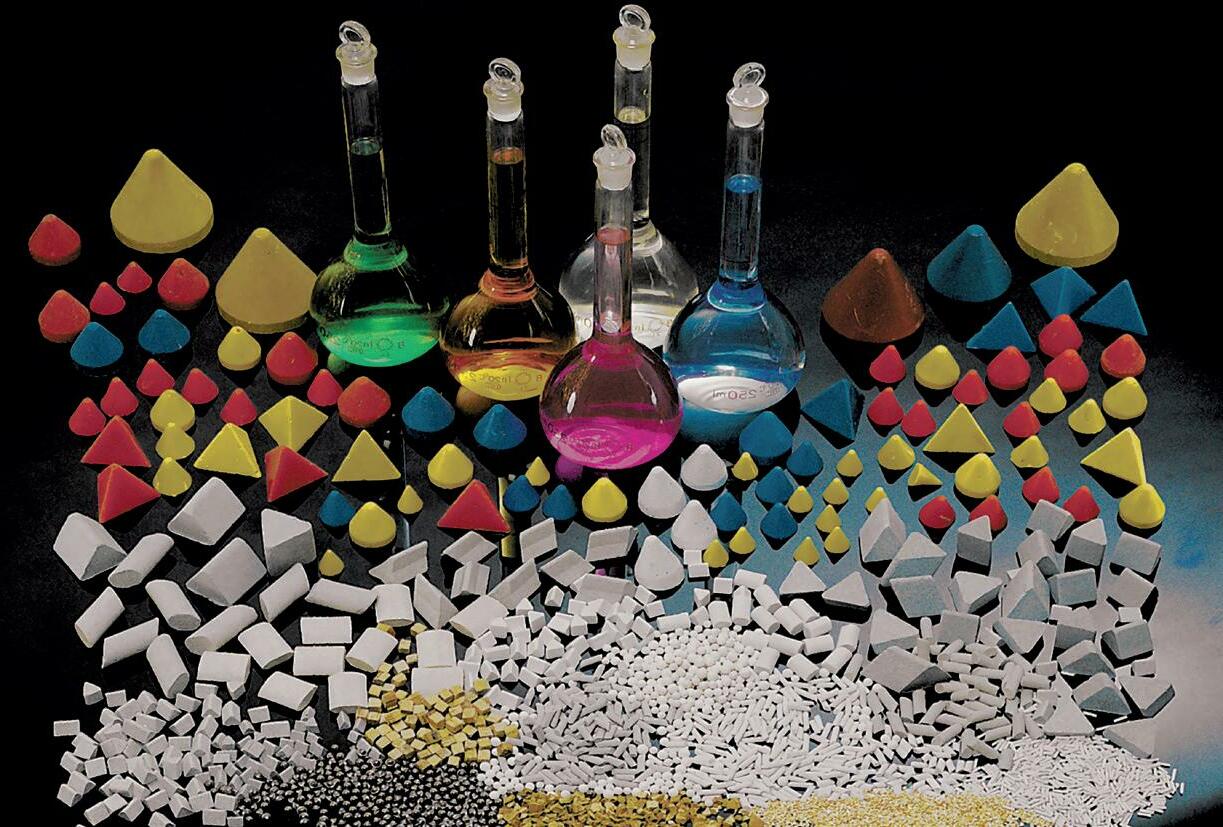

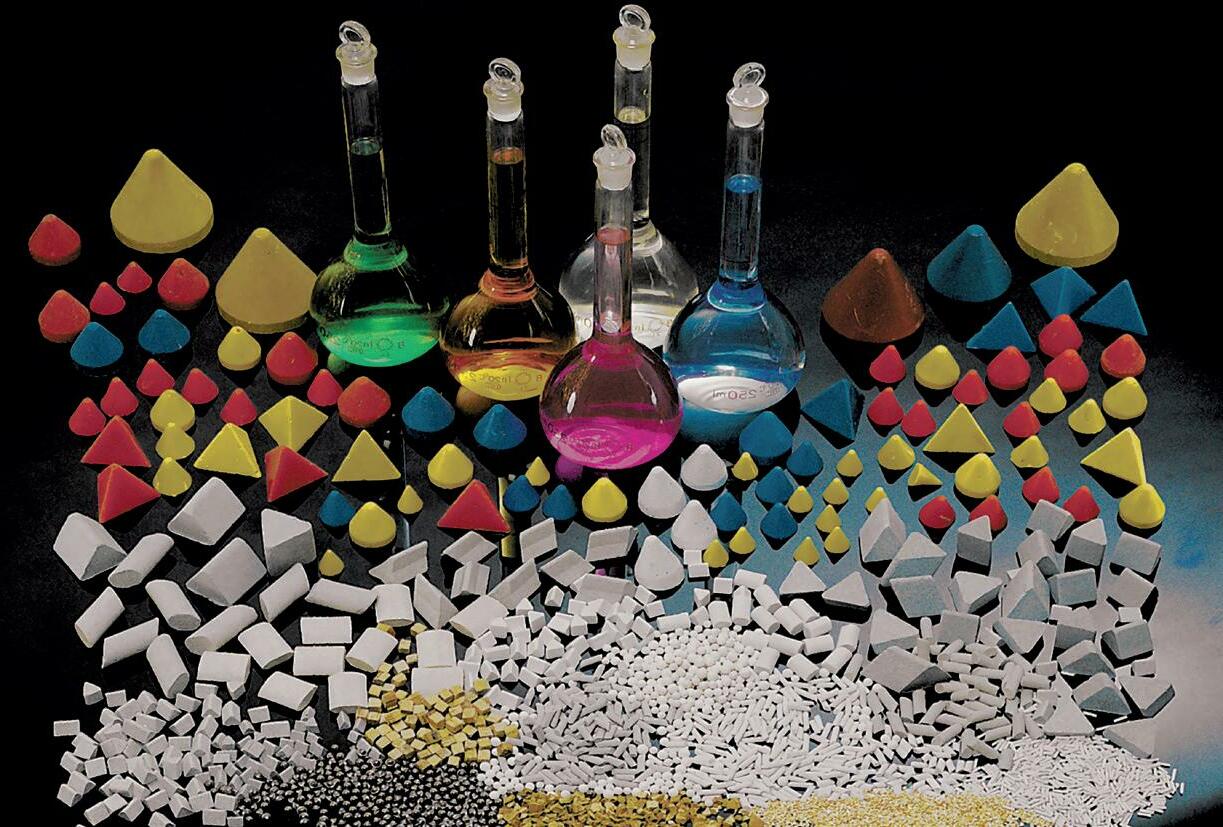

AkzoNobel launches dedicated range of Resicoat powder coatings to help drive the electric vehicles of tomorrow

The future success of EVs is dependent on the performance of the battery and associated systems. Battery performance, however, is highly impacted by its environment, which is why it needs protection to ensure the vehicle’s performance and the safety of the passengers. Powder coatings can improve the performance of the battery by providing insulation from electric current and protection against corrosion. This means manufacturers can extend battery life, and ensure the battery performs better for longer.

The range comprise Resicoat EVpack which delivers a range of protective properties for the battery pack or housing to insulate electrical systems; Resicoat EVcell which provides outstanding cell to cell electrical insulation for even the most intricate designs; and Resicoat EVcooling, designed to deliver superior performance in thermal conductivity, electrical insulation, edge coverage and consistent film building in cooling tube and cooling plate applications.

It also includes Resicoat EVbusbar to coat the busbars that carry and distribute electricity to improve heat dissipation and support a lower fire load with a longer lifetime during thermal impact.

Each of the five product ranges developed within the Resicoat EV range has been specifically innovated to enhance the safety and performance of the EVs of tomorrow. They have superior electrical insulating properties and enhanced thermal management to help protect the battery systems, motors, and electrical storage units.

To protect the electric motor, the Resicoat EVmotor range includes epoxy powder solutions that are specifically designed for the electrical insulation of hairpin stators.

Key solutions within the Resicoat EV range are tested and approved to UL 94 V-0 which enables vehicle systems to tolerate a certain amount

of exposure to a flame without igniting. They’re also tested and approved to UL746B and UL1446, ensuring they can resist thermal degradation and possible damage that can occur at elevated temperatures.

Sustainability is a significant driver in the popularity of EVs and similarly important to AkzoNobel. Crucially, the guaranteed durability of the Resicoat EV range in protecting essential components means those components last longer before needing to be replaced. Resicoat powder coatings have very minimum Volatile Organic Compounds (VOCs) and conform to the industry’s Restriction of Hazardous Substances (RoHS) Directive, to give coaters and customers ultimate peace of mind.

Jeff Jirak, Managing Director at AkzoNobel Powder Coatings, says innovation is the key to accelerating the future EVs: “For more than 60 years we have built the expertise and innovation inherent with our Resicoat brand to help resolve the challenge of electrical insulation. We understand how an exceptional powder coating with the right application technique will provide consistent electrical insulation for the life of the key components, such as the batteries in EVs,” he explains.

“It’s further proof of our commitment to supporting our customers through partnerships and product development to create, power and protect the designs of the future.”

For more information about Resicoat EV range, visit https://automotive. interpon.com/emobility/

14 JANUARY 2023 INDUSTRY NEWS

AkzoNobel has launched a new range of Resicoat EV powder coatings to protect the battery system and electrical components of a new generation of electric vehicles (EVs).

Jeff Jirak, Managing Director at AkzoNobel Powder Coatings, says innovation is the key to accelerating the future EVs

Jim Kavanagh appointed as Managing Director of Industrial Coatings, AkzoNobel

AkzoNobel has appointed Jim Kavanagh as its new Managing Director of Industrial Coatings.

Jim will lead the strategic direction across a diverse portfolio, including Coil and Extrusion Coatings, Packaging Coatings, Wood Finishes and Wood Adhesives. He joined AkzoNobel in 1990 as a development chemist in the Protective Coatings business. During his 32 years with the company, Jim has held various positions, including roles within product management and marketing. From 2000, he worked internationally as a General Manager and Commercial Director based in China, Africa and the UAE. Most recently, he was responsible for leading the Metal Coatings business in EMEA as Regional Commercial Director.

Commenting on his new role, Jim says: “I’m very proud to be leading a business with so many talented individuals and teams across such a diverse and impressive portfolio. I’m looking forward to further developing our capabilities and building on our leading global positions.”

AkzoNobel recognized again as a European Top Employer

AkzoNobel has launched a new range of Resicoat EV powder coatings to protect the battery system and electrical components of a new generation of electric vehicles (EVs).

AkzoNobel has been rated as a European Top Employer by the Top Employers Institute for the second consecutive year. In the latest benchmark review, the company has been recognized in eight countries – Brazil, China, France, Germany, the Netherlands, Sweden, the UK and the US – all of them repeat certifications. AkzoNobel qualifies as a European Top Employer because five of the certified countries are in Europe.

“In a year when many external developments impacted our focus, achieving eight certifications shows that we’re on the right track,” says Jöelle Boxus, AkzoNobel’s Chief Human Resources Officer. “It’s something to be proud of and we’re all keen to maintain this momentum going forward.” Each year, the Top Employers Institute certifies organizations who are focused on putting people first through their HR policies. The survey covers six HR domains consisting of 20 topics, including people strategy,

work environment, talent acquisition, learning, diversity and inclusion, and well-being.

“We ran several people-driven initiatives during 2022 designed to help our employees thrive and build their capabilities,” adds Boxus. “They focused on several key areas to ensure that we continue to create a diverse and inclusive environment which respects cultural differences and offers opportunities for personal development. With People. Planet. Paint. at the heart of everything we do, we’re committed to helping all our employees be the best they can be.”

The latest 2023 rating marks the second certification in a row for AkzoNobel in France, Germany and Sweden, the fourth for the Netherlands and the US, the seventh for Brazil, the tenth for China and the 11th for the UK.

To learn more about working for AkzoNobel, visit:

www.akzonobel.com/en/careers

15 JANUARY 2023 INDUSTRY NEWS

Bathing in non-reflective glory

When you are looking to push the boundaries of light, color and design, especially with an ultra matt surface, our Précis Ultra Matt range has the answers. With a finer mica effect that enables an ultra matt surface to change appearance depending on the way the light reflects on it, you can create a finish that not only looks amazing, but also offers stunning levels of superdurability.

With innovative solutions that push the boundaries of what’s possible, a vast range of sustainable products backed by industry leading certifications, and the best performing powder coatings on the market used and respected by architects around the world, your imagination starts with our finish.

architectural.interpon.com

Innovation in Thru-Process Automotive Paint Monitoring Safe ATEX Certified Temperature Profiling New Optic Video Profiling System Intrinsically Safe • 20 measurement channels • Paint & Powder coating • Includes Phoenix Factor cure index calculation During Production • Detect paint runs, drips and defects • Spot transport problems • Identify oven damage Phoenix Temperature Measurement T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com

World Coatings Council Publishes First Global Sustainability Report

The World Coatings Council is pleased to announce the publication of its inaugural report, Sustainability in the Global Paint & Coatings Industry. The report highlights the global industry’s ongoing sustainability efforts to advance technologies in coating science and manufacturing, while minimizing impacts on human health and the environment.

The report emphasizes the critical role coatings and the global industry play in contributing to the United Nations’ Sustainable Development Goals (SDGs), as framed by nine specific SDGs where industry can have the greatest impact:

(UN SDG #8); Industry, Innovation and Infrastructure (UN SDG #9); Sustainable Cities and Communities (UN SDG #11); Responsible Consumption and Climate Action (UN SDG #13); and Life Below Water (UN SDG #14). Featuring examples that support Sustainability charter, the global report underscores that coatings are essential to making products and our built infrastructure sustainable by providing resistance and durability; providing performance properties and healthy communities; and serving a critical role for applications in the health and food sectors, among many others. The report also highlights the industry’s efforts to achieve

resource efficiency in production processes, consideration of raw material consumption, and implementation of health and safety measures to ensure decent work and economic growth.

You can read or download the Sustainability in the Global Paint & Coatings Industry report by visiting www.worldcoatingscouncil.org.

About the World Coatings Council

The World Coatings Council is comprised of members representing associations from Australia, Brazil, Canada, China, EU, France, Germany, Japan, Malaysia, Mexico, New Zealand, South Africa, Spain, Turkey, United Kingdom, and the United States. The Secretariat position is currently conducted by the American Coatings Association.

The World Coatings Council provides a forum for information exchange and cooperation on the key issues and priorities facing the paint and printing ink industries worldwide.

For information about WCC and the activities it is involved in on behalf of the global paint and coatings industry, go to www. worldcoatingscouncil.org.

18 JANUARY 2023 INDUSTRY NEWS

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. ATEX certified • High quality alloy pumps Stainless steel construction • Wash cycle controlled by timer • Wash & rinse • Hot water wash • Inbuilt water recycling • Inbuilt solvent recycling Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: 6 K-type thermocouple ports High temperature stainless steel barrier box for long run times Download, view, and analyze data using PosiSoft Desktop Software or export to .CSV Oven Temperature Logger Measures and records oven temperature profiles 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Customizable PDF Reports Prices starting at: Oven Temperature Logger .......... £1895 Temperature Probes ............ £100 Wide variety of spring clamp and magnetic temperature probes available NEW

INDUSTRY NEWS

Beckers announces sale of global Railway Coatings business to KANSAI HELIOS

Beckers Group, a global purpose-led, innovationbased coatings company, today announces that it has reached an agreement to sell its Railway Coatings business to KANSAI HELIOS for an undisclosed sum. The asset purchase agreement for the sale of the railway coatings business of Beckers´ company Becker Industrie SAS, Montbrison (France) was signed on December 9th, 2022. After completion of closing conditions, KANSAI HELIOS will acquire all business assets of Becker Industrie SAS in the Railway Coatings segment.

The transaction is an outcome of Beckers’ strategic review and part of the transformation of Beckers into a focused sustainable innovation-based leader. It allows Beckers to increase efficiency and reinvest into strategic core segments and new products. As a part of this transaction, KANSAI HELIOS will establish its first subsidiary in France, KANSAI HELIOS France SAS. With this acquisition KANSAI HELIOS will further strengthen its competitive position in the railway coatings sector in Europe and worldwide.

After closing the process, KANSAI HELIOS France SAS will take over the relevant employees of Becker Industrie SAS in the Railway Coatings business and add further resources in order to ensure continuity of the professional service that customers are used to. The transaction is expected to close in the first quarter of 2023. Beckers will continue to serve its Railway customers in India and China.

Christophe Sabas, CEO Beckers Group says: “This is a strategic deal for both parties. The Railway Coatings business will become an important part of KANSAI HELIOS’ growth strategy, while Beckers will be able to put more energy and resources behind our strategic businesses and new developments. We are very pleased to sell the Railway business to KANSAI HELIOS. Our committed Railway Coatings employees have been a much-appreciated part of Becker Industrie S.A.S. and I wish them the best of luck in the future. We know KANSAI HELIOS well and I am confident that joining the KANSAI HELIOS family will be good for those employees, customers and other stakeholders.

The Beckers Railway Coatings team is excellent and we are delighted that they have chosen the KANSAI HELIOS team to continue to serve their valued existing and new customers in France and around the world.

development and production has always been of great importance, and we have achieved a strong market position in recent years, being the largest producer of railway coatings in Europe with important brands such as Wefa, Rembrandtin and Helios. Beckers’ innovative industrial coatings designed to protect railway vehicles products guarantee the highest quality and environmental protection. The purchase rounds off our portfolio perfectly. This business acquisition is a further step of KANSAI HELIOS in the railway coatings segment, following our most recent asset acquisition and establishment of KANSAI HELIOS Wefa in Essen, Germany.”

Dietmar Jost adds: ”The Beckers Railway Coatings team is excellent and we are delighted that they have chosen the KANSAI HELIOS team to continue to serve their valued existing and new customers in France and around the world.”

Dietmar Jost, Executive Director KANSAI HELIOS Group states: “For KANSAI HELIOS the Railway Coatings

For more information visit: www.beckers-group.com www.kansai-helios.eu.

20 JANUARY 2023

Celebrating more than 70 years providing excellence in pumps and filtration

Pumps up to 250m³/h

Horizontal

Magnetic Sealless

Vertical Sealless

Filtration Systems up to 60m³/h

Cartridges

Bags

Papers

Microfibres

For all your product finishing requirements

High Quality German DC Switch Mode Rectifiers

DC Rectifiers

Pulse Rectifiers

High current rectifiers up to 10,000A

For all applications

Electroplating

Anodising

Hard Chrome

Reel-to-Reel Plating

E-Coat

UK Ltd | E : sales@hendo r-pe. c o .u k | W : w w w. H endo r-pe. c o.u k

Hendor-pe

Corrodere academy launch Coating Inspector courses with ICorr accreditation

Well established online training company, Corrodere Academy, are launching their popular Pipeline Coating Inspector and Insulation Inspector courses with ICorr accreditation.

Corrodere Academy offer globally recognised qualifications in the protective coatings industry including Train the painter, coating inspector and specialist courses. This is the first time ICorr accredited Pipeline and Insulation Inspector courses have been available online, offering flexibility and saving time and money when compared to classroom learning.

The importance of monitoring pipelines

Pipelines are energy lifelines, making almost every daily activity possible. They play a huge role in our everyday lives and are essential to the world’s industries. The world’s transportation would come to a complete stoppage without them as they carry everything from oil and gas to fresh water.

The course content includes an overview of the pipeline industry, pipeline corrosion, cathodic protection to pipeline and coatings, quality assurance and control, safety and pipeline inspector duties, recommended practices and international standards and environmental considerations.

This qualification opens extensive career opportunities in the oil and gas, subsea, fresh water, diesel and petrol and jet fuel industries.

The importance of monitoring insulation

One of the hottest topics in the protective coatings industry, insulation has been used for centuries to keep heat in and cold out or vice versa. The energy saving and environmental benefits that come from proper insulation are hugely significant. By making buildings and process systems more energy efficient, insulation helps reduce the amount of fossil fuel combustion needed to heat and cool homes, businesses and factories. That, in turn, decreases the amount of carbon dioxide emitted into the atmosphere.

The course content includes a history of insulation systems, corrosion under insulation, insulation design, standards and specification, quality assurance and control, safety and insulation inspector duties, insulation application and conducting coating surveys.

Why study with Corrodere Academy?

Convenience. Distance learning allows you to learn from home, work, and on the road.

Immediacy. Online training enables you to start the course when it is most convenient to you.

Affordability. Studying online means no accommodation or travel costs, saving an average of 50% compared to classroom learning.

Flexibility. Students decide when it is convenient to study and can make their own schedule to suit their job and lifestyle.

Adaptability. Online classes benefit different learning styles and allow you to work at your own pace.

Retention. Studies show that engaging, interactive, online training can increase learner retention by more than 70%, compared to classroom learning.

Relevance. All courses are regularly updated by well-respected industry experts, ensuring accuracy and relevancy.

Course structure

These online learning courses will each take 8-16 hours to complete with a final online monitored 90-minute multiple-choice exam. Training access is available for 12 months, and once completed, students will receive a Certificate of Achievement accredited by ICorr, which is valid for 5 years. The course material was created by industry experts including Brendan Fitzsimons and Trevor Parry who between them have 70+ years’ experience in protective coatings. If you’re interested and want to find out more visit corrodere.com/ coating-inspection-courses/ or contact the team on 01252 732233 or info@corrodere.com.

22 JANUARY 2023 INDUSTRY NEWS

Gwyn Watkins Sales & Logistics Director T: 01298 768 661 M: 07702 710188 Lhoist UK, Hindlow Buxton, Derbyshire gwyn.watkins@lhoist.com How big is your carbon footprint? World leading carbon neutral products At Lhoist we are: • Reducing our CO2 emissions • Increasing our process efficiency • Offsetting the remainder ...and offering customers a range of carbon neutral products today. Working with you towards carbon neutrality For further information scan this QR code

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

Detects holidays, pinholes, and other discontinuities using pulse DC High voltage Holiday Detector n Lightweight, ergonomic design reduces opera tor fa tigue n Regula ted pulse DC volta ge output ±5% accuracy n Industr y-standard connectors and ada ptors for compa tibility with nearly all existing electrodes n Volta ge calcula tor fea ture choose one of 11 interna tional standards and input the coa ting thickness to automa tically calcula te the required test volta ge n Removable lithium-ion ba tteries provide long-lasting po wer Ch f ide us m SPECIAL DISCOUNTED RATE PosiTest HHD Basic Kit (HHDKITB) £ 1 9 5 0 + VAT sa ve over £400 Limited time only In stock t: 01442 879494 www.dftinstruments.co.uk Proud supplier of DeFelsko Inspection Instruments t : 0 1 4 4 2 8 7 9 4 9 4 n w w w d f t i n s t r u m e n t s c o u k n e : s a l e s @ d f t i n s t r u m e n t s . c o . u k

Inquiry launched to investigate urgent need to grow apprenticeships in engineering, manufacturing and technology

As sector battles with acute skills shortage, inquiry seeks to explore concerning decline in apprenticeships uptake and find solutions to help with growing UK workforce

Employers, training providers and young people urged to take part in ‘call for evidence’

Former Labour and Conservative ministers Lord Knight and Lord Willetts, with support from charity EngineeringUK, are today launching an inquiry to uncover the reasons behind the worrying decline in engineering, manufacturing and technology apprenticeships starts seen over recent years in the UK.

Given the skills shortage and a growing demand for engineers and technicians, the inquiry will look to identify vital solutions which could help to increase the number and diversity of young people taking up apprenticeships in the sector. Employers, training providers, young people and those who work with them, are all being urged to get involved in the ‘call for evidence’ by submitting their views, evidence or ideas to improve this much-needed career pathway into the sector.

Despite a modest uptick in numbers last year, engineering-related apprenticeship starts in England are still 9% lower than in 2014/15. What’s more, the uptake varies by subject with a worrying 34% decline for engineering and manufacturing technologies.

Lord Willetts, Inquiry co-chair and former Conservative Minister for Universities and Science, comments, “Apprenticeships, especially in engineering and technology, enjoy enormous political and media support and are a crucial route into work for many people. Meanwhile the number

of young people actually doing these apprenticeships is falling.

“Our inquiry will draw on expert evidence to understand why this is happening and what can be done about it, so that we can grow and sustain the opportunities that apprenticeships offer to young people. I am delighted to be co-chairing this inquiry not least because my father ran the apprenticeship programme for a Midlands engineering firm.”

Lord Knight, Inquiry co-chair and former Labour Education and Employment Minister, comments, “Britain must transition towards a more sustainable and productive economy. The skills shortage is a dragging anchor on that transition, particularly in key areas such as engineering. The fall in young people taking up engineering and technology apprenticeships is an urgent problem, and I am delighted to be working with David Willetts and EngineeringUK to fully investigate where the problems lie and what can be done to fix them.”

The call for evidence, which is open until 27 February 2023, is seeking views and ideas from the sector on 4 key areas:

Opportunities

1. What part do apprenticeships play in helping to meet the UK’s skills needs in engineering and technology?

State of play

2. What are the reasons behind the

overall decline in engineering apprenticeship starts in recent years? We are particularly interested in understanding more about supply and demand.

Barriers

3. What are the barriers for businesses taking on young people as apprentices and what are the barriers for young people in accessing them?

Solutions

4. What do you think needs to change to help increase the number and diversity of young people taking up and completing engineering and technology apprenticeships?

Hilary Leevers, Chief Executive of EngineeringUK comments, “Given the pressing need for more engineers and technicians in the UK, now and into the future, we urgently need more young people to start and complete apprenticeships in the sector.

“We therefore urge the sector, as well youth training providers and organisations, to show their support for this important inquiry by sharing their experiences and suggestions for how to make engineering-related apprenticeships more available and accessible to young people. We hope the inquiry will open up conversations about how to break down barriers, inform effective policy making and widen opportunities for young people in engineering and technology careers.”

The inquiry - ‘Fit for the future: growing and sustaining engineering and technology apprenticeships for young people’ has opened its call for evidence until the 27 February 2023. For more information and to respond visit: www.engineeringuk. com/fitforthefuture

26 JANUARY 2023

INDUSTRY NEWS

100 Armoury Road Birmingham 811 2RH WASHING SYSTEMS EFFICIENT - ROBUST - RELIABLE INNOVATION FOR ALL YOUR WASHING NEEDS • SMALL BATCH WASHING TO CONVEYORISED SYSTEMS • SPRAY, SOAK , ULTRASONIC OR COMBINATION MACHINES. • FULL AFTER SALES SUPPORT • IN HOUSE TEST FACILITY • EUROPEAN WIDE CUSTOMER BASE • STANDARD AND BESPOKE SYSTEMS AVAILABLE • COMPLIMENTARY CHEMICAL RANGE AVAILABLE Call 01543 675800 or visit our website www.unitechwashers.uk.com

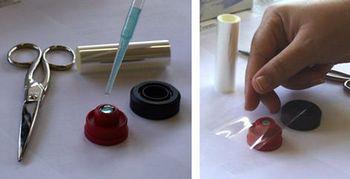

On Demand Plating Line Technical Advice-Service

Following another successful and rewarding year helping client’s realise a number of significant projects we look forward to this trend continuing through 2023 as we commence the eight year of assistance since our advice service was launched. Therefore Plating-LineAdvice had no hesitation in booking again for the next Surface World show once more being held at the NEC in October 2023.

One of the aspects of our offer that was again very well received at the 2022 show was our range of bespoke technical advice Service and Support Plans, reports Will Green.

Whilst similar advice services exist specifically for the chemical processes used in surface treatment, we find generally there is a lack of provision in the industry of independent technical support on the engineering design aspect of specialised plating equipment.

We think this lack of provision may be due to perhaps a perceived intermittent need for engineering advice of this type due to plant upgrades or capital expenditure only happening periodically whereas the chemical process is in continuous use.

For the same reason many processing companies will have full time in house chemical support but cannot justify

The engineering support that does exist in the industry is often supplier oriented in support of increasing sales of a particular product so cannot always be considered fully independent.

The Service and Support Plans offered by Plating Line Advice give the benefit of on demand access to specialist independent technical advice at a fraction of the cost of a permanent in house alternative. Costs are known and agreed in advance and divided into equal monthly instalments over the period of the service and support agreement. The support however is drawn down on demand as required by the particular project timescale and complexity of requirements. This arrangement makes budgeting simple as the costs are the same each month and relatively low.

In addition to the on-demand aspect regular periodic site inspections are built in to increase confidence and maintain operational efficiency.

Annual Service and Support Plan Examples Gold

40 days of onsite plus remote telephone and internet support. Suitable for organisations planning major capital investment or those who have multiple process line installations.

Silver

20 days of onsite plus remote telephone and internet support.

Suitable for

organisations planning both capital investment or upgrades to existing facilities.

Bronze

10 days of onsite plus remote telephone and internet support. Suitable for organisations planning some capital investment or upgrades to existing facilities.

The above are indicative examples and support plans are tailored to meet the needs of each individual organisation both in agreement duration and number of days required.

Feedback from our clients on previous projects:

“We couldn’t have done it without you”

- Project Manager

“That is the best technical specification we have ever sent out”- Works Engineer

“You should have charged more”Divisional Manager

“We need Will to be involved in this project” – Plant Manager

All projects are carried out subject to complete confidentiality.

We have offices in both the West Midlands and the South West “Peace of Mind through Confidence”

Contact: Will Green FIMF

E: will@plating-line-advice.com

T: +44(0)7481 322263

www.plating-line-advice.com

Visit us on Stand E18 at Surface World 4th & 5th-October 2023

NEC Birmingham UK

28 JANUARY 2023

ELECTROPLATING, ANODISING & GALVANISING

ELECTROPLATING, ANODISING & GALVANISING

Aluminium Anodizing

Additives from Chemetall

Temperature factor

Chemetall’s Anodizing Technology

Nowadays, it is possible to work with modern additives to the sulphuric acid in the anodizing bath. To this effect, the Surface Treatment global business unit of BASF’s Coatings division, operating under the Chemetall brand, offers innovative additives from its Gardobond range.

worthwhile at first glance. In fact, however, a closer examination and evaluation of the individual process steps reveals possibilities which not only reduce costs but also boost productivity. Chemetall’s anodizing technology demonstrates how this can be achieved.

As a further development of the well-known oxalic acid, it reduces the redissolution rate in the anodizing process and increases the tolerance to dissolved aluminum. This allows for anodizing at a higher temperature, a higher aluminum content and a higher current density at unchanged voltage and/or at a reduced anodizing voltage with the same current density.

The anodizing technology

Chemetall offers a new generation of highly efficient additives. Added to the anodizing bath, they afford a very consistent surface and reduce the aluminum and temperature sensitivity of the anodizing process.

A higher treatment temperature means voltage can be reduced to achieve a density (e.g., for 1.5 A/dm² the following a reference lab test: 19°C - 18 V, 25°C This already provides a possibility for savings. Moreover, basically the same energy will be needed. Thus, the use anodizing additive will allow for energy

From architecture to construction to packaging to automotive – there are almost no limits to the possible industrial applications of aluminum. The processing of this light metal also leaves room for new ideas. Due to the growing competitive pressure, companies are looking for cutting-edge ways to stay ahead of their global competitors with innovative and cost-saving technologies. The solutions to this are closer than you may think: “standard technologies” offer opportunities for saving on costs without compromising on high quality.

Finding potential for improvement in established and proven technologies and processes may not seem

Anodizing is much more than just an optical enhancement of aluminum. The anodized layer that forms using standard technologies reaches at about two thirds into the treated aluminum part and grows at about one third on its surface, thereby affording an attractive, smooth surface and longterm corrosion protection. In addition to these excellent properties, it is also easy to process, making anodized aluminum extremely versatile and suitable for a wide range of applications.

good alternatives in practice. This paper presents ideas for optimizing the anodizing process. Experiences and case studies from customer applications around the world have demonstrated the successful implementation of these new solutions in practice. However, it should be decided on a case-by-case basis which technologies are best suited for the respective application, as the applicability should be evaluated individually for each application.

Further potential effects can also be achieved to the speed of the anodizing process. applies for the growth of the layer thickness anodizing with standard parameters, for architectural anodizing: the thicker its growth until it stops growing because acid attack have come to equilibrium.

In this context, a particular focus is placed on the possibilities of saving energy or increasing productivity by reducing the time of the anodizing process and also in the final sealing step.

Gardobond® Additive H 7526 thus yields coatings of perfect quality with a high aluminum content (max. 30 g/l), at higher temperatures (max. 30°C) while at the same time requiring a lower sulphuric acid concentration.

A reevaluation of the anodizing process and of the technologies commonly used in the industry is worth the effort since modified processes have proven to be very

The empirical formula to calculate this thickness (µm) = 0.3 x current density (minutes)

Efficiency improvements and costs

For the standard 1.5 A/dm², practical produced the following approximate values: 10 µm anodizing layer = approx. 20 20 µm anodizing layer = approx. 40

Over the years, almost any anodizer has tried to enhance his productivity by increasing the total number of workpieces to be anodized per day. Frequently, batches are simply increased in size without adjusting other important factors such as cooling. However, an increase of the batch size in many cases also means a drop in current density, which is crucial for surface quality.

This calculation formula clearly shows current density can have on productivity (due to shorter treating time).

Yet, the process temperature, current density and anodizing voltage have a great impact on quality, productivity and costs. As a general rule, higher temperatures result in a larger pore diameter, which in turn leads to less aluminum oxide and thus a softer anodic coating. The same effect can usually be observed at lower current density or (too) high acid concentrations. Coatings with larger pores are generally easier to dye, but in many cases show poorer sealing and corrosion resistance and are generally less durable because the anodic coating may become too soft. Conversely, lower temperatures and/or higher current density usually result in smaller pores that are more durable and thus of better quality.

30 JANUARY 2023

Aluminium Anodizing with Chemetall’s Technology. www.chemetall.com

ELECTROPLATING, ANODISING & GALVANISING

renewals. By increasing the maximum tolerance value for aluminum in the anodizing bath, bath renewals need to be conducted less frequently, thereby reducing the volume of acidic effluents and the volume of fresh water required for new bath make-up.

So how can efficiency be improved while at the same time reducing the direct costs of anodizing? Is there a way to speed up the anodizing process to increase productivity, but without compromising the structure and quality of the anodic coating?

Theoretically, it is easy to raise productivity by increasing the current density provided that sufficient rectifier capacity is available. An (excessively) high current density and/or the higher anodizing voltage needed to this effect, would generate a lot of heat that can lead to soft coatings and burns. Additional cooling would thus be necessary.

Additives from Chemetall

Nowadays, it is possible to work with modern additives to the sulphuric acid in the anodizing bath. To this effect, the Surface Treatment global business unit of BASF’s Coatings division, operating under the Chemetall brand, offers innovative additives from its Gardobond range.

As a further development of the well-known oxalic acid, it reduces the redissolution rate in the anodizing process and increases the tolerance to dissolved aluminum. This allows for anodizing at a higher temperature, a higher aluminum content and a higher current density at unchanged voltage and/or at a reduced anodizing voltage with the same current density.

Chemetall offers a new generation of highly efficient additives. Added to the anodizing bath, they afford a very consistent surface and reduce the aluminum and temperature sensitivity of the anodizing process.

Gardobond® Additive H 7526 thus yields coatings of perfect quality with a high aluminum content (max. 30 g/l), at higher temperatures (max. 30°C) while at the same time requiring a lower sulphuric acid concentration.

Temperature factor

A higher treatment temperature means that the anodizing voltage can be reduced to achieve a specific current density (e.g., for 1.5 A/dm2 the following was observed in a reference lab test: 19°C - 18 V, 25°C - 15,5 V, 30°C - 14 V). This already provides a possibility for significant energy savings. Moreover, basically the same

amount of cooling energy will be needed. Thus, the use of an adequate anodizing additive will allow for energy savings of ca. 40%.

Furthermore, a reduced consumption of sulphuric acid is possible, also combined with a reduction of the waste water flow due to reduced acid carryover into the rinsing baths.

Furthermore, a reduced consumption of sulphuric acid is possible, also combined with a reduction of the waste water flow due to reduced acid carryover into the rinsing baths.

Further potential effects can also be achieved with regard to the speed of the anodizing process. The following applies for the growth of the layer thickness during anodizing with standard parameters, for example those for architectural anodizing: the thicker the layer, the slower its growth until it stops growing because layer growth and acid attack have come to equilibrium.

The empirical formula to calculate this is:

The most important technical effect of the modified anodizing process, however, lies in the significant improvement of the surface and sealing quality. Higher anodizing temperatures also mean higher layer dissolution caused by acid attack, leading to an increase in anodic pore diameter while the oxide content in the layer decreases which causes the overall surface quality to drop considerably.

The most important technical effect of the modified anodizing process, however, lies in the significant improvement of the surface and sealing quality. Higher anodizing temperatures also mean higher layer dissolution caused by acid attack, leading to an increase in anodic pore diameter while the oxide content in the layer decreases which causes the overall surface quality to drop considerably.

thickness (μm) = 0.3 x current density (A/dm2) x time (minutes)

For the standard 1.5 A/dm2, practical experience has produced the following approximate values:

This in turn affects the sealing quality as well as the abrasion and corrosion resistance. The effect can be countered by using the appropriate additive.

This in turn affects the sealing quality as well as the abrasion and corrosion resistance. The effect can be countered by using the appropriate additive.

10 μm anodizing layer = approx. 20 - 22 minutes,

20 μm anodizing layer = approx. 40 - 44 minutes.

The pictures show the surface structure at different temperatures and aluminum contents: with Gardobond® Additive H 7526, the same pore sizes can be achieved at 25°C as in a bath at 19°C without any additive.

The pictures show the surface structure at different temperatures and aluminum contents: with Gardobond® Additive H 7526, the same pore sizes can be achieved at 25°C as in a bath at 19°C without any additive.

This calculation formula clearly shows the effect a higher current density can have on productivity enhancement (due to shorter treating time).

Gardobond® Additive H 7526

Positive side benefits

Another possible “side benefit” are less frequent bath renewals. By increasing the maximum tolerance value for aluminum in the anodizing bath, bath renewals need to be conducted less frequently, thereby reducing the volume of acidic effluents and the volume of fresh water required for new bath make-up.

Gardobond® Additive H 7526 can thus significantly improve the surface quality. The chart on the next page shows the options for improving the surface quality taking the example of the loss of mass as per ISO 3210 in an anodizing process with and without additive:

Possible benefits with Gardobond® Additive H 7526:

Lower overall process costs for energy (power and cooling)

Filter cake disposal: less sulphuric acid in the effluent

Productivity: reduced anodizing times

32 JANUARY 2023

improve the the options the example anodizing

Possible Lower (power Filter cake Productivity: Anodization does not the characteristics As a tried develops anodization Loss of mass measurement [mg/dm²] 120 100 80 60 40 5 g/l 18 °C Gardobond 20 0

19°C without additive25°C without additive 25°C with Gardobond ® Additive H 7526

WEDGE GROUP GALVANIZING Your Galvanizing Partner

Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products. With 14 plants across the UK, Wedge Group

Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m structural beams.

Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ ISO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944

bath value renewals need reducing the fresh water

Gardobond® Additive H 7526 can thus significantly improve the surface quality. The chart below shows the options for improving the surface quality taking the example of the loss of mass as per ISO 3210 in an anodizing process with and without additive:

ELECTROPLATING, ANODISING & GALVANISING

sulphuric acid the waste rinsing modified layer increase in surface the can be different Gardobond® achieved at

Possible benefits with Gardobond® Additive H 7526:

Anodization with the technology developed by Chemetall does not only improve the treatment processes, but also the characteristics and benefits of the aluminum proper. As a tried and tested technology supplier, Chemetall develops and optimizes customized technologies for all anodization applications – worldwide.

Contact and further

information:

Gary Mothersole

UK Sales Manager Aluminium Finishing

Telephone: 07825 319214

Email: gary.mothersole@basf.com

Visit: www.chemetall.com

Gardobond ® 7526

PAINT & POWDER

Lower overall process costs for energy (power and cooling)

Filter cake disposal: less sulphuric acid in the effluent

Productivity: reduced anodizing times

Quick Colour Change PVC Booths

ColorX series powder coating booths are produced from antistatic pvc material. Thanks to its smooth and slippery surface, it offers faster and comprehensive cleaning.

Anodization with the technology developed by Chemetall does not only improve the treatment processes, but also the characteristics and benefits of the aluminum proper. As a tried and tested technology supplier, Chemetall develops and optimizes customized technologies for all anodization applications – worldwide.

It allows you to save in terms of time and paint. It is suitable for manual and automatic applications. Its compact design allows operators to easily control the booths.

It is the best solution for continuous production. Feeding powder to the guns is done by powder coating centers.

E-Booth ColorX can be used with powder coating centers PM120 or PM130 with 20 or 30 injector modules, where adjustments and cleaning are done manually.

Also for automated systems, it can be used with powder coating centers PM220 or PM230 with 20 or 30 injector modules, or with pumped type powder coating center PM324P.

Our powder coating centers used for automated processes have fast colour change and automatic cleaning features. The part detection system we

offer as an option can detect gaps, height and width.

It is programmed to provide the best savings and the best paint quality according to the shape of each product to be painted.

It is designed in accordance with the 2014/34/EU Explosive Atmosphere Directive with reference to the EN16985: 2018 Standard. Optionally, Mobile Control Panel and Fire Suppression System

Contact: serkan.inci@electron.com.tr

Phone:+90 531 930 37 03

Visit: www.electron.com.tr

34 JANUARY 2023

Loss of mass measurement [mg/dm²] 120 100 80 60 40 25 g/l / 30 °C 25 g/l / 25 °C 25 g/l / 18 °C 15 g/l / 30 °C 15 g/l / 25 °C 15 g/l / 18 °C 5 g/l / 30 °C 5 g/l / 25 °C 5 g/l / 18 °C AI content / temperature Gardobond® Additivewithout additive 20 0

Detergents for Industrial Parts Cleaning Borer Chemie AG Gewerbestrasse 13 4528 Zuchwil / Switzerland www.borer.ch Bühler Ltd. Unit 8/9 Mercury Park, Mercury Way, M41 7LY Urmston, Manchester / United Kingdom Tel. +44 161 866 2800, Fax +44 161 866 2801 www.buhlergroup.com

Companies in Bedfordshire and beyond now have a simple choice when it comes to purchasing tinted HMG Paints products. As Barton Le Clay based Simply Coatings have completed the installation of a brand-new UNIT Tinting scheme.

The UNIT Tinting scheme allows Simply Coatings to mix a vast array of colours including BS, RAL, Agricultural and more for their customers. Furthermore, the scheme allows Simply Coatings to mix larger volumes of HMG Paints products and offer faster turnarounds for customers. Products that can be colour matched and tinted include 1K & 2K topcoats, undercoats and primers, as well as a variety of sheen levels.

Darren Hardiman, Managing Director of Simply coatings remarked “We are delighted to be working with some of the best in the industry here at Simply Coatings and for our new investment it was an obvious choice to partner the Corob equipment with HMG Paints as we continue to grow the business in 2023 and beyond.”

DTM, PVC, Wood Coatings and more

Like many of HMG Paints distributors Simply Coatings are an independent family business and supplier & distributor of Paint & Protective coatings. Simply Coatings pride themselves in offering a range of products and full support from the moment customers get in touch until long after they have received their order. Along with the HMG Paints range which includes Direct to Metal Coatings (DTM), PVC coatings and wood finishes they offer a range of systems from various manufacturers.

“The installation of the UNIT Tinting machine takes the offering from Simply Coatings to a whole new level, and will allow their customers faster turnaround across a wide range of HMG products.” added Roger Blinco, HMG Key Account Manager.

“Darren and the Simply Coatings team have built a great business and the installation of the new HMG

Mixing schemes shows their commitment to the customers on providing exactly the right product, in the right colour when they require it.”

A wide selection of colours

The new UNIT scheme installation is also backed up by the HMG

36 JANUARY 2023

PAINT & POWDER

C M Y CM MY CY CMY K

Simply the first choice for tinted HMG paints

URBAN FURNITURE APPLIANCES

GENERAL INDUSTRIAL FUNCTIONAL COATINGS

Markets:

AGRICULTURE & CONSTRUCTION EQUIPMENT (ACE)

ARCHITECTURAL TRANSPORTATION

FURNITURE

TAILOR-MADE SOLUTIONS

PRODUCT INNOVATION

EXPERT TECHNICAL SUPPORT

“OVER 100 NEW ENQUIRIES FROM SURFACE WORLD LIVE 2022” - WE’VE GOT YOU COVERED!

ColourBase Colour Box, which contains over 2400 colour chips, displayed in chromatic order within 20 fan decks. The box allows distributors and customers alike to choose the perfect colour from a number of ranges including RAL, British Standard, Commercial Vehicle Fleet Colours, Agricultural, Afnor and more. Every colour in the box can be then produced across a number of 1K and 2K HMG products. Across the whole of the UNIT mixing scheme HMG offer over 70,000 colour formulations ensuring that customers can always find the correct colour for their project. Uniquely HMG Paints actually manufacture their own range of colourants which in formulations to create exact colour matches. Being a colourant manufacturer means HMG can ensure each colourants uses the best pigments on the market ensuring the perfect colours every time.

As an independent paint manufacturer HMG Paints Ltd rely on a loyal, countrywide distribution network to supply and service customers. All of

HMG’s paints are Made in Britain accredited and supplied across a number of industries including, industrial, commercial vehicle, decorative, defence, wood finish and arts & craft. Distributors are selected based upon their reputation and the

Simply Coatings package of product and local knowledge makes them a perfect partner. Visit www. simplycoatings.co.uk to see the whole range of products available.

www.hmgpaint.com

PAINT & POWDER SPECIAL SYSTEMS ACIDPURE | Acid recycling EASYPURE | Fluid recycling IONPURE | Ionic filtration ACIDVAC | Acid draining vacuum EDUCTORS | Bath agitation [...] PUMPS & FILTERS L SERIES | Medium flow rate filter P SERIES | Ultra-high flow rate filter A SERIES | Mechanical seals pump M SERIES | Magnetic drive pump T SERIES | Vertical pump [...] We solve our customers filtration, chemical transfer and treatment needs. Contact us SIEBEC UK Ltd, Stafford +44 (0) 1785 227700 sales@siebec.co.uk www.siebec.co.uk FILTER MEDIA L-TECH | Pleated cartridge BAGTECH | Filtration bag QUALITHERM | Extruded cartridge QUALIBOB | Wound cartridge ANODTECH | Anode bag [...]

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Handling Solutions

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehensive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Monorail Chain Conveyors

Unit loads up to 300kg

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

Power & Free Conveyors

Unit loads up to 7000kg

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection

Part of the

Floor Conveyors

Unit loads up to 500kg

Gill Conveyors Ltd

3&4 Brook Business Park Brookhampton Lane Kineton, Warwickshire CV35 0JA, United Kingdom Tel: +44 (0)1926 641424 info@stewart-gill.co.uk www.stewart-gill.co.uk

Stewart

Unit

Aluminum tubes for high-voltage equipment with high-quality coating

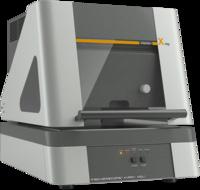

Hitachi Energy Brno, a manufacturer of high-voltage equipment, is now coating with Nordson’s HDLV technology, improving surface quality and doubling its production capacity.

The Challenge

Hitachi Energy is one of the world’s leading manufacturers of high-voltage equipment and produces some of the components required for this in Brno. In the Czech Republic’s second largest city, the company coats aluminum tubes up to 12 m long, which have different geometries inside and a diameter of up to 0.80 m, using the environmentally friendly powder coating process. A capacity doubling was needed while still ensuring that the coating of the workpieces met high safety and quality standards due to the high-risk area of application: An increase in output with the automatic guns of the existing old plant was not possible to the requested scope. In

addition, the company also wanted to make the coating process more economical and achieve powder savings in order to meet its high environmental requirements. Based on this, the decision was made to invest in a new, robot-guided powder plant.

The Solution

As part of their research, Hitachi Energy executives researched HDLV dense phase technology and conducted some preliminary testing at an HVAC manufacturer’s facility.

“Although we did not have 3D models of the workpieces for this robotic coating and therefore could not program the robots accurately, our customer was impressed with the