SUSTAINABILITY

75 Years!

Born in 1947 in The Netherlands, indispensable in Belgian sports construction since 55 years, German sports hall champion for 50 years and last but not least: 38 years of successful sports activities in Great Britain.

Sports facility construction is our passion. Collaborative, digital - and therefore time and cost efficient - project management is the focus of our overall process. We use LEAN planning methodology to set up your projects, always using the latest technology and BIM methods to optimise design and construction processes. We don’t just think about tomorrow, we focus on the distant future: We make our buildings sustainable, efficient and with a high well-being factor.

Editorial

DEAR IAKS MEMBERS AND “SB” READERS,

As people around the world struggle to come to terms with the impact of extreme weather pat terns, as well as trying to work out how to cope with the effect of huge rises in energy prices on their households, the issues around sustainabil ity and environmental design have taken on an even greater sense of urgency and significance.

The 2021 United Nations Climate Change Con ference in Glasgow (COP 26) had seen renewed efforts to move towards renewable energy and target urgent cuts in greenhouse gas emissions, with many countries committing to net carbon zero targets.

This issue of “sb” magazine takes a look at “sustainability” in a broader sense. More than ever, we are dedicated to going beyond just a discussion around design principles, to also in clude management and operation decisions in the reports.

Based on comprehensive data of around 100 sports and leisure buildings from six decades, architecture firm FaulknerBrowns developes values for embedding carbon reduction into the design process. Partner Michael Hall and Senior Associate Irina Korneychuk also under take a certified Whole Life Carbon assessment of the recently completed Ravelin Sports Centre in Portsmouth, UK. The findings are interesting but sometimes counterintuitive.

With reference to recent projects in Australia, such as the Ken Rosewall Arena, Queensland Country Bank Stadium, Sydney Football Sta dium, and Optus Stadium, their architects dis cuss design principles and the impact on a “net zero” facility.

The choice of material is also crucial to net carbon zero targets. The case study of the Eric Tweedale Stadium in Merrylands, Australia, high lights how timber construction can be a key element in delivering a highly sustainable devel opment that is low carbon, low waste, and highly energy efficient.

The Climate Pledge Arena in Seattle, USA, is poised to become the world’s first arena to earn a net zero carbon certification from the Interna tional Living Future Institute. It embraces sustain able design by employing numerous sustainable practice and operations – including being pow ered solely by renewable energy sources – and by retaining the existing roof and façade of the original building – significantly reducing the em bodied energy in construction.

Mercedes-Benz Stadium in Atlanta, USA, was the first professional sports stadium in the USA to achieve LEED Platinum, incorporating a range of sustainability measures that includes energy reduction, renewable energy, stormwater man agement, and the inclusion of an urban garden.

La Trobe Sports Stadium in Melbourne, Aus tralia, incorporates a high-performance building fabric that lowers energy use and greenhouse gas emissions, as well as incorporating rainwater harvesting for the outdoor parkland area.

CommBank Stadium in Sydney, Australia, is the first stadium in the world to achieve the new LEED v4 Gold certification for sustainability. The project achieved a 40 % reduction in global warming potential through measures like the integration of solar panels on the roof.

The energy-neutral Sports Hall in Zwolle, Netherlands, incorporates a series of energysaving measures that allow its overall building performance to deliver an energy-neutral status.

I hope that the examples of sustainability show cased in this issue of “sb” magazine will help to encourage you in your own efforts to promote sustainable design and operation in the sports and leisure sector.

Tom Jones Senior Principal, Populous IAKS Vice President

SUSTAINABILITY

PROJECTS

Mercedes-Benz Stadium in Atlanta

AMB Sports + Entertainment

On the path to “net zero” energy stadiums

Dr Matthias Irger and Russell Lee, COX architecture

Reducing the carbon footprint of sports and leisure centres

Michael Hall and Irina Korneychuk, FaulknerBrowns

The new age of timber

Ivana Simkovic, dwp – design worldwide partnership

Climate Pledge Arena in Seattle

La Trobe University Sports Stadium

Warren and Mahoney, MJMA

CommBank Stadium in Parramatta

The newly built WRZV halls in Zwolle

Pellikaan Bouwbedrijf

PROFESSIONALS & PROFILES

DENMARK LEADING THE WAY IN ACTIVE LIVING

IAKS CONFERENCE “INNOVATIVE OUTDOOR ACTIVITY AREAS” IN ODENSE

On 5 and 6 October, the “Lab for Innovation and Play” at SDU Southern Denmark University in Odense was packed with 50 experts from 11 countries for a day full of information, learnings, and discussions.

Internationally renowned researchers from SDU presented their findings about „Active Living“. Jens Troelsen, Jasper Schipperijn, Bjarne Ibsen, and Signe Højbjerre Larsen (all SDU Department of Sports Science and Clinical Biome chanics) shared their knowledge around the question “What does active living mean for developing cities and providing infrastructure?”

Maria Keinicke (KEINGART), Rachel Kenny (ARUP), and Mikkel Hjort (Transparent Design) presented exemplary projects and approaches for “temptations to move”, “walk able cities”, and “participative design”. Casper Lindemann (DIF) and Jens Øyås Møller (LOA Foundation) showed ex amples of successful trail centres for outdoor sports as well as for water sports.

Supported by

The SDU Sports Science Department and the prize-winning Athletics Exploratorium were the perfect setting for pre senting and discussing innovative ideas for facilitating active living. Some (provocative) conclusions were: Don’t build or upgrade any facility, unless you know what the community in the neighbourhood needs, and without knowing which institution, group or club will take the “own ership” of the facility to fill it with life and activities.

Hitting the nail on the head, Maria Keinicke summed up her five steps to meaningful innovation: 1) Base everything on knowledge from research; 2) Find local evidence by listen ing and learning; 3) Develop different scenarios; 4) Create a new synthesis by pushing boundaries; and 5) Evaluate and adjust to improve and learn.

IAKS AUSTRIA’S CONGRESS “BEWEGTES ÖSTERREICH” IN SALZBURG/RIF, 21 SEPTEMBER FOCUSED ON LOCAL SPORTS PROJECTS

The IAKS Congress “Bewegtes Österreich” brought togeth er participants from various fields on 21 September in Salz burg/Rif to discuss the future of Austria’s sports facilities. The focus was on local sports projects, reports on experience in Germany and the relevance of sports centres in Austria. Chaired by Marissa Jöbstl, eight speakers gave exciting insights into the current state and potential of Austria’s sports facilities.

Sports facilities and spaces for people

IAKS Germany President Prof. Dr Robin Kähler kicked off the event with an engaging keynote speech on the topic of

“Sports facilities and spaces for people”, in which he addressed the current challenges, the range of facilities currently available and ideas on sports facility architecture. Among other things, the 76-year-old from Mannheim presented his findings that “current sports spaces exclude certain groups (such as women, children and people with disabilities)” and, above all, that “school halls are outdated and their interiors were defined 100 years ago”. Ending with the words “architecture can do more than it does”, the first lecture set the tone for the rest of the IAKS Congress day.

(Report by: Nils Daiker)

IAKS UK AUTUMN EVENT

TOTTENHAM HOTSPUR STADIUM, 22 NOVEMBER 2022

IAKS UK is arranging a one-day seminar at Tottenham Hotspur Stadium in London on Tuesday 22 November. The day will consist of seminars looking at issues around venue operations and sustainability that are affecting sports and leisure facilities, as well as including a comprehensive tour of the stadium after lunch and a panel discussion to close the day. The stadium won a Gold Medal at the 2021 IOC IPC IAKS architecture prizes and showcases lots of design inno vation in its main concourse and hospitality spaces, as well as the innovative sliding pitch that moves under the south stand to reveal the artificial pitch for NFL matches.

2ND INTERNATIONAL IAKS POOL CONFERENCE

POOL CONFERENCE AND FACILITY TOUR TO NORWAY‘S FUTUREBUILT MODEL PROJECT IN NORWAY, 7 8 SEPTEMBER

More than 60 international experts from Austria, Canada, Denmark, Germany, Iceland, Norway, Switzer land and the UK converged for the 2nd IAKS Pool Conference which took place in Asker, Norway from 7-8 September. They discussed energy efficiency in pools, embodied carbon in pool buildings, the feasibility of a climate neutral pool, alternative air circulation concepts, and pool water quality.

The sustainability concepts of Holmen pool in Asker and the aquatic facility at Baerum Sports Park were presented at the conference, rounded up by the impressing facility tour of these two best practice examples. The delegates continued to exchange thoughts and ideas during the net working dinner.

How to reduce embodied carbon? Most experts agreed that in general, the aquatic facility industry is well on its way to apply all relevant technologies and methods for building and operating energy-efficient pools. They see a big po tential to operate more sustainably by increasing visitor numbers. The more people use a facility, the smaller the operational carbon emissions per person.

FaulknerBrowns Partner Michael Hall summed up the dif ferent stages of embodied carbon reduction: Retrofit first, build less, build lean, build to last, build for reuse. www.iaks.sport/events

View picture gallery!

This is what people said

„This was a great event to discuss holistic approaches to build and o perate future indoor swimming pool facilities.“

Prof. Dr-Ing. Wolfgang Uhl, Aquateam COWI, Norway

Jens Øyås Møller, Danish Foundation for Culture and Sports Facilities, Denmark

„Thank you for an interesting program and thanks to all for visiting our Norwegian pools!“

Elisabeth Kolrud Head of Sustainability, Asplan Viak, Norway

Supported by

Webnet for sports and fun

Rely on Webnet for sports and playground fencing. Our stainless steel net is virtually transparent and offers a durable, high-quality design. As a ball catch fence, Webnet is almost silent.

„Very inspiring conference and facility tour!“

NEW TO THE IAKS NETWORK

KATASKEVES DAPEDON, THESSALONIKI (GREECE )

Kataskeves Dapedon Ltd. (KDF) is one of the most dynamic and export-oriented Greek companies (exporting to 70 countries on four continents), with production facilities and warehouses for both acrylics and polyurethanes sports flooring.

KDF has deep knowledge in sports flooring in Europe, pro viding complete acrylic or polyurethane-based solutions for indoor and outdoor sports courts and halls, as well as wet-pour playgrounds, running tracks and PU binder and glues. Operating under the requirement of ISO 9001/2015 gives particular attention to provide a fully upgraded range of products and services. The company provides certi fied systems by ITF, WORLD ATHLETICS, EU norms, LNE, LABOSPORT, ISASPORT and more.

www.kdf.gr

AQUATICUS DESIGN & CONSULTANCY, GREENSBOROUGH (AUSTRALIA)

Aquaticus Design & Consultancy (ADC) is a complete ly independent design and consultancy firm specializing in commercial swimming pool and aquatics projects. With over 25 years‘ experience in the building and construction industry, ADC provide complete, homogenous, and fully coordinated design packages including structures, water treatment, hydraulics, and finishes. This simplifies the ten dering process and avoids vital elements being omitted or forgotten about during the design or construction phases.

We pride ourselves on our commitment to provide a pro fessional and speedy service at all times, whilst maintaining the highest quality of work. ADC take on all types of com mercial aquatic projects, with all work all conducted to the highest standards. www.aquaticus.com.au

MUNICIPALITY OF BÜLACH (SWITZERLAND)

Founded in 1384, Bülach is a town with tradition and today the prosperous and growing centre of the Zürcher Unter land with a population of around 23,000. The sports centre features an indoor swimming pool with a wellness area, a covered artificial ice rink and one of the largest uncovered outdoor ice rinks in Switzerland. The facilities are comple mented by a mini-golf course, inline skating hall, tennis court, and a climbing and bouldering hall. The adjoining multifunctional sports hall rounds off the facilities. Also available are an outdoor swimming pool, various walking, biking and inline-skating trails, and football pitches. The municipality of Bülach assists clubs and athletes and oper ates the sports infrastructures.

www.buelach.chCO OP STUDIO, MELBOURNE (AUSTRALIA)

CO-OP Studio is a leading architecture firm with a clear focus on design of elite sport and community recrea tion facilities, with demonstrated capacity for delivery of complex, multi-faceted projects. The range of experience includes grass-roots level masterplans through to design, documentation and delivery of high performance facilities and venues. The studio champions an integrated, collabo rative approach and seeks to provide innovative, flexible and highly functional design outcomes. The practice is built around an ethos of client focused delivery and providing high quality design solutions that are responsive to the cli ent’s objectives and priorities.

www.co-opstudio.com.au

GEORGE DEVENISH, GISBORNE (AUSTRALIA)

As founder and Director of iDwala, George Devenish is a specialist consultant for the design and construction of out door sporting facilities.

Delivering innovative designs, technical expertise and advice on hundreds of sports facility projects, George has proven himself to be a highly sought-after consultant capable of offering his clients the benefit of in-depth con struction experience coupled with strong technical design skills.

Having contributed to the civil construction, mainte nance and sports surfacing industry for over 25 years, George’s innovative solutions are helping clients to meet the needs of Australia’s growing sports and active recrea tion community.

HARO Sports Flooring & Protective Walls:

Double experience

For more than half a century, Hamberger has been developing and producing one of the most important pieces of sports equipment: the flooring. HARO’s Protect Light, the new generation of area elastic protective walls, sets new benchmarks once again. All-in-one solutions for sports and multi-purpose halls that exceed all current standards, guarantee to comply with official regulations and also allow a fast and cost effective installation, are now possible. That’s for sure!

MATTHEW COHEN, PHUKET ( THAILAND)

As the Managing Director and founder of Trackmaster International, Matthew has been a true industry leader for the last 30+ years. Having worked in a staggering 80+ dif ferent countries throughout his career, Matthew has under taken 40 % of the world‘s Class-1 athletics track surveying and line marking, with a reference list boasting some of the world’s most prestigious and internationally acclaimed sta diums, Olympic venues and world class facilities.

NEW! PROTECT LIGHT 19 PRO

Fully compliant with current fire regulations! Available in almost every COLOR AND DESIGN!

FROM CASUAL PLAY TO SPORTING EXCELLENCE

BURNABY LAKE AQUATIC & ARENA FACILITY IN BURNABY, BC, CANADAThe Burnaby Lake Aquatic & Arena Facility will be a destination recreation facility with a widely stretched program from the NHL-sized ice rink, and spectator seating, to the 25-m pool, 50-m pool, leisure pool, hot pools, universal change rooms and washrooms, shared social spaces, reception, and café.

Connecting seamlessly to an existing competition-focused ice arena with extensive spectator seating, this facility re places an existing ice rink and indoor pool facility that have both reached the end of their useable lives.

The design is influenced by the history of Burnaby Lake to the west of the site, formerly a wetland and Indigenous fish ing place that was infilled over time as a result of settler ac tivities. Its potential for recreational uses resulted in repeat ed dredging to reclaim the lake in a rectilinear form de signed to permit rowing.

Over time, the natural habitat has been allowed to return, changing the area back to a seasonal marshland, with salmon now returning to the area. The facility, inspired by the tension between man-made forms and natural recla mation seen in the adjacent wetlands, is designed as a series of man-made forms placed within the landscape, separated and sculpted over time.

Natural organic forms

A series of large, sculpted volumes contains the large formal programmatic elements, such as the ice arena, the 50-m pool, 25-m pools, and the leisure pool. These formal volumes are sensitively located to allow for the “natural” spaces in-between, that contain informal program elements such as hot pools, universal changerooms, wellness

features and shared social spaces. Large glazing and natu ral organic forms within these spaces enhance a connection to the surrounding landscape, offering expansive views across Burnaby Lake Park.

Environmental performance

Respecting its role as a responsible custodian of the land, the facility is designed with highly efficient envelope, water management and building systems. Furthermore, the building will rely on electricity as a daily energy source; a gas connection is available for generators in emergency scenarios. These measures will considerably reduce the building greenhouse gas emissions to approximately 9 kg CO2 /m²/y, making this facility the lowest carbon emitter for its building typology in Canada.

Rainwater will be used for pool tops, extensive bioswales will manage storm water, and retention tanks will reduce year-round potable water for irrigation by 20 %. The gen erous social spaces, universal changerooms / washrooms, and accessible design features will create a welcoming place for all, inspiring positive change and connection within communities and the unique local environment.

The completion is estimated for 2025.

MANAGING “SUSTAINABILITY” AND CLIMATE ADAPTATION IN FACILITIES

A MATTER OF SURVIVAL

More than just a buzzword, “sustainability” captures exactly what is needed at this moment: an economy which co-exists with the environment. Far too often, “sustainability” only implies an understanding of how sport impacts the environment. However, sport has a bidirectional relationship with the environment: envi ronment is also impacting sport. The author advocates for adjusting our thinking to consider both directions in addressing environment and climate.

Management’s approach to sustainability Based on my own research into the perspectives that facility managers have on sustainability, there is a recognition of the importance of the topic and the need to address it. But many are prevented from adopting environmentally sustain able practices for a variety of reasons: budget, time between events, physical infrastructure capacity, person power, and lack of knowledge on the topic.

Some of these are easy to understand: new technologies can be expensive, too many events leave little time to make wholesale changes, and older buildings were not designed to accommodate current infrastructure needs. Each build ing also comes with its own challenges depending upon the sports and leisure activities it accommodates.

Management might recognize the need for sustainability but lacks the first-hand knowledge to do something with it –especially if people in charge have been in the industry since before sustainability was a concern. In response, often one of these two actions is undertaken: create a sustainability team or assign sustainability to one individual.

Sustainability teams have varying degrees of success but are highly dependent upon their power to make change versus recommend change. Recommendations are easy to dismiss, but we are often afraid to assign an ad hoc team (or commit tee) any real power. It can be difficult to strike a balance be tween upper-level decision-makers, lower-level employees who are responsible for carrying out these tasks, and other organisational and community members you might wish to include.

You see variations in success for individuals who get assigned sustainability too. Often sustainability becomes the respon sibility of people in operations or finance. Some hire an indi vidual whose full-time responsibility is managing sustainabil ity, but their success depends upon their level in the hierar chy and how their work is received by others. Sometimes a single passionate individual champions sustainability, but this momentum is lost when that individual leaves or retires.

Rethinking the whole organisation and beyond

Sustainability is not some task that can be compartmentalized and managed by a single unit. It requires buy-in from everyone: top to bottom, laterally, inside and outside of the organisation. Stakeholders from teams, tour operators, events, governments, suppliers, environmental organisations and the community should all be involved in the process.

Adding climate to the mix

Now, to address the other direction in this bidirectional relation ship, you should be asking yourself the question: “Is my facility ready to cope with climate change?”

This needs to be part of your facility’s sustainability manage ment strategy. Will you have access to the resources you need, or do you need to change your patterns of work? Will the space your facility occupies be viable for this purpose long-term?

Globally, sport is already having to adjust to warmer tempera tures. FIFA has imposed water-break rules. Ski resorts are reliant upon artificial snow to stay open. Facilities are part of these ef forts since they are where sport takes place: from the commu nity level to the Olympic Games.

Concluding thoughts

Managing these bidirectional environmental relationships with sport and leisure facilities is essential to the discussion of sustain ability in facilities today. Know that it is a complex topic requiring complex solutions. My hope is that we can build more resilient venues that not only address the climate challenges of today but are better prepared to meet those needs of the future.

About the author

Dr Walker J. Ross is a lecturer in sport management and digital marketing in the Moray House School of Education and Sport at the University of Edinburgh. His main research interests are focused on sport ecology and sustainability in sport – particularly in venue management and mega-events.

FOR THE GREEN SPORTS INDUSTRY

Home to the NFL’s Atlanta Falcons, Atlanta United of MLS and many of the world’s top sports and entertainment events, Mercedes-Benz Stadium (MBS) was the first professional sports stadium in the world in November 2017 to achieve LEED Platinum Certification and by that time had gathered more points than any other sports facility in the world with a total of 88. The 158,804 m² stadium’s unique sustainability solutions for water, lighting, and energy conservation, as well as community programs and stewardship, have been a key part of the building’s story of innovation from day one.

Mercedes-Benz Stadium has become a trail blazer for green building in sports with its approach to building with low-/zero-toxicity materials. It was the first sports facility to pur sue LEED v4 credits, specifically in the materials and resources suite. A life-cycle analysis was performed on the buildings’ structure and building envelope materials, helping the de sign and construction team to identify and select materials that demonstrated an at

least 10 percent reduction in global warm ing p otential. Sustainability initiatives are projected to save 29 percent in energy usage versus a typical stadium design.

Flexibility Designed to be scalable to host some of the world’s top sports and entertainment events, the stadium is easily reconfigured to accom modate games for the Falcons, matches for

Atlanta United, the city’s Major League Soccer franchise, and for world-class events such as Super Bowl, FIFA World Cup matches and major concerts and performances. Retract able seats surrounding the field bring soccer fans closer to the pitch. A 30-meter high mega-column is wrapped with a 3- dimensional video board that encases more than 75 per cent of the column, designed to maximize additional unique programming space. The mega-column required more than 142 video boards.

Zero-waste efforts

In June 2022 Mercedes-Benz Stadium became the first sta dium in professional sports to be awarded Total Resource Use and Efficiency (TRUE) precertification for its zero-waste efforts. Administered by Green Business Certification Inc. (GBCI), TRUE precertification recognizes buildings and pro jects that have implemented the foundational programs and policies needed to effectively pursue zero-waste and have demonstrated a commitment to achieving official TRUE certification.

Through innovative strategies and strong community part nerships, the Mercedes-Benz Stadium has developed its en vironmental awareness and continuously pursued its sustain ability goals. Key drivers are:

Water treatment

Mercedes-Benz Stadium sits atop of the Proctor Creek Water shed, historically known for flooding during large rain events. The collective goal of the ownership, design and construction team was to positively impact the approach to water for the project. As a result, the project was the first sports stadium to receive all water credits due to these aspects: water conserva tion; rainwater recapture/reuse in a 3-million-liter cistern for the cooling tower and in landscaping irrigation; 5-million-lit er cooling tower; partnership with Trees Atlanta (to plant and maintain trees in the urban core) to share captured rainwa ter for tree and urban garden irrigation; and waterless urinals throughout the building. The highly advanced stormwater management system captures and slowly releases storm water to help to prevent flooding and storm surges in the

neighboring community. The stadium includes water-efficient fixtures that in aggregate use 47 percent less water than base line building standards (EPAct 1992).

Energy optimization

4,000 photovoltaic (PV) panels are installed on the stadium site and the campus with the goal of generating approxi mately 1.6 million kilowatt hours per year of renewable ener gy. This is enough to power a) roughly ten percent of the sta dium’s energy consumption (the equivalent of approximate ly 160 households in Atlanta) or b) more than nine Atlanta Falcons home games or 13 Atlanta United home matches.

Ten electric-vehicle-charging stations are installed in various parking areas on the campus with capacity to charge up to 48 vehicles simultaneously. Monitoring equipment helps to track energy consumption including lighting, heating and cooling use to ensure maximum efficiency.

The advanced stadium-wide LED lighting system lasts ten times longer than standard lights and reduces energy usage

by as much as 60 percent. The abundant natural light that enters the concourses and inner bowl through high-tech, en ergy-efficient, floor-to-roof glass and ETFE fabric reduces the need for additional lighting use.

Alternative transportation

The stadium provides excellent transit access for patron use with three convenient rail line stations. The layout of the property encourages the use of bicycle and alternative-fuel vehicle usage through direct connection to the Atlanta Bike Trail network and the availability of electric-vehicle-charg ing stations. A bike valet program is provided for fans who want to ride their bikes to the game and securely store bikes during the event. Pedestrian-friendly walking paths allow for easy connectivity between the communities.

Local food production

Edible landscaping on site, including blueberry bushes and trees carrying apples and figs contribute to the natural eco system. The MBS Urban Garden, featuring eight beds with

a variety of produce and flowers, grows spices and pro duce used in the stadium’s concession menus and serves as an educational resource for both staff and students of the culinary jobs training program, giving lessons on healthy eating, growing food and buying locally.

Recycling and compost

Since March of 2022, MBS has diverted over 90 percent of accumulated waste from landfill at all major events. MBS em ploys a variety of green practices and programs that allow the stadium to achieve zero-waste on event day and in the building’s administrative offices including:

• Using supply chain items made from recyclable and com postable materials

• Leveraging a 540 square-meter resource recovery room to reclaim, sort and divert materials from landfill

• Sustainability education and engagement programs for fans, associates and the stadium’s food and beverage partners

• Recycling and compost bins added to every stadium suite

• Compostable paper soda cups and lids used at all conces sion stands

• Compost and recycling bins clearly marked throughout the building so that fans can actively participate in the build ing’s sustainable efforts.

Community engagement

Atlanta’s Westside has been one of the most disinvested, marginalized and challenged neighborhoods in the city. In the decade prior to the stadium vision becoming a reality, many projects started to make a positive, meaningful differ ence on the Westside. Here are a couple of examples:

The Arthur M. Blank Family Foundation (AMBFF) provid ed more than USD 9 million in philanthropic investments in education, greenspace, health and other related issues.

AMBFF sees its primary role on the Westside as being a catalyst for positive neighborhood transformation. The foundation accomplishes this by: 1) making smart, strategic

funding investments; 2) leveraging additional resources to the Westside; 3) building community and political will to address systemic issues of poverty and disinvestment; 4) ensuring that neighborhood transformation benefits all, especially long-time residents; and 5) supporting, where appropriate, and leading, when necessary. The foundation is committed for the long-term.

In 2018, a new synthetic turf field was installed at the Salva tion Army Boys and Girls Clubs of Greater Atlanta – Bellwood Club, thanks in part to a USD 250,000 grant from the At lanta Falcons through the National Football League Foun dation Grassroots Program. They teamed up with the Local Initiatives Support Corporation (LISC). LISC identifies local, non-profit, community-based agencies that have an inter est in building or refurbishing football fields in schools and neighborhood parks. Through the program, local agencies are provided with the necessary financing and technical as sistance to improve the quality and safety of fields in their communities.

In May of 2019, a new counselling center in the historic West side community of Atlanta was opened with the help of CHRIS 180, an Atlanta-based non-profit organization dedicated to healing children and families with holistic health services and trauma-informed care.

With the Second Helpings Atlanta program, more than 30,528 kg of food (translating to 56,250 meals) were diverted from landfill and delivered via 19 partner agencies to the un derserved in the community.

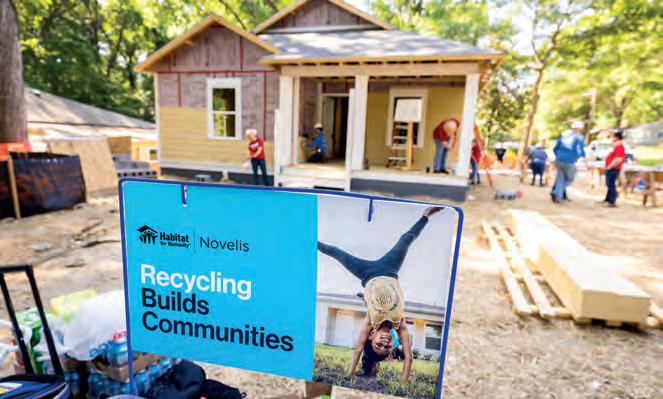

Recycle for Good, launched in partnership with AMBSE in 2017, turns aluminum cans and bottles collected from events into funds to support a Habitat for Humanity home build. For every three million bottles and cans collected and recy cled, one home is built on the Westside. To date, more than nine million aluminum bottles and cans have been collected and recycled from the Georgia Dome, former home of the Atlanta Falcons, and Mercedes-Benz Stadium, allowing the construction of the program’s third home.

ON THE PATH TO “NET ZERO” ENERGY STADIUMS

BEST PRACTICE EXAMPLES FROM AUSTRALIA

The challenge to achieve the goals of the Paris Climate Change Agreement to limit global temperature increases to avoid catastrophic impacts requires action by all sectors, including sport and leisure. With about 40 % of carbon emissions attributable to buildings and cities, transforming the way we design our built environment is fundamental to combatting the climate emergency. With reference to recent projects in Australia, such as the Ken Rosewall Arena, Queensland Country Bank Stadium, Sydney Football Stadium, and Optus Stadium, the authors discuss design principles and their impact on a “net zero” facility.

Many sports organisations around the world have now joined the UN Sports for Climate Action Initiative, which aims to “act, educate, measure and promote” the need to reduce carbon footprint. Sports facilities inherently provide a formidable challenge to achieve net zero carbon emis sions due to their large energy consumption on game days and material used in construction and operation, as well as their significant water use and waste.

The need to extend roof coverage to protect spectators from rising heat, rain and wind exacerbates the challenge of reducing embodied carbon in stadia: how do you pro tect from “more” but achieve this protection by using “less”?

These concerns are particularly acute in Australia where life is more affected by rising temperatures and extreme weather that has the potential to cancel events and put the wellbeing and enjoyment of both athletes and spectators at risk.

Three core principles for approach to sustainability As a signatory to Architects Declare, COX acknowledges the global climate and biodiversity emergency, and we un derstand the importance of protecting and regenerating the natural environment. By 2030, COX aims for all our new projects to be carbon neutral in our operations and achieve a 50 % reduction in embodied carbon emission. Addition ally, COX is pursuing broader environmental goals such as achieving net zero water and zero waste amid a circular economy, increasing climate resilience and enhancing na tive biodiversity.

COX’s approach to sustainability follows three core prin ciples – firstly the fundamentals of good passive design should be achieved to the degree possible on any given site, secondly the amount of embodied energy within the proposed fabric of a design minimised, and thirdly any ac tive systems appropriate to the site and the brief are fully explored before pen is put to paper.

Passive design

When applied to stadia, passive design remains one of COX’s key design considerations including solar manage ment with adequate sun protection for spectators and glass facades, natural ventilation, access to daylight and the use of light coloured, reflective materials for the building envelope.

Just as in any other building typology, facilitating natural ventilation in sport buildings can significantly reduce the reliance for HVAC systems, systems that can be expen sive to run and can quickly have trickle down impact on ticket costs as energy costs continue to rise. Furthermore, the COVID pandemic and the primacy of public health has made access to fresh air even more important, especially in high-density venues which are often cited by media as potential “super spreader” events.

Upgrading Ken Rosewall Arena

The redevelopment of Ken Rosewall Arena at Sydney Olympic Park allowed us to optimise the roof shape and operable facade to improve airflow inside the stadium and thus the thermal comfort of users as far as possible without the use of energy-consuming active conditioning. It was a combination of budgetary restraint and our “resilience” approach to design that also allowed us to upgrade this facility rather than advocate for its replacement. This is not always possible, or the most cost-effective outcome in the medium and long-terms, but it is always a starting point for our design and is usually a way to minimise the carbon footprint of our work.

Queensland Country Bank Stadium

Another example is Queensland Country Bank Stadium in Townsville, located in Australia’s tropical northeast. The stadium is rotated approximately 25 degrees east of North to align with the prevailing afternoon winds, the most fre quently used timeslot for both sporting and entertainment events. The stadium takes advantage of the local natural

breezes in two key ways – the open-ended horseshoe de sign allows the breeze to enter the bowl and the bowl is orientated toward the breeze to cool spectators, athletes, and employees. It’s almost a “back to the future” design, but one that is very modern in its form and realisation.

“The fundamentals of good passive design should be achieved to the degree possible on any given site.“

Apart from maximum temperatures and rainfall, wind speed is a significant climatic influencer on the design of Queens land Country Bank Stadium. Townsville is within a cyclonic region and has wind loads that are about 50 % higher than Queensland’s capital Brisbane, and 100 % higher than Syd ney, for instance. Therefore, the weight of steel required in response to these conditions is proportionate to these increased loads. However, the architectural and engineer ing teams have worked hard to design a roof structure that responds efficiently to the wind but also minimises material used. The roof is a combination of membrane to the truss forms and metal deck to the infill panels. The membrane produces the same visual shading as a solid roof panel whilst significantly reducing the weight of the roof, creating a sense of openness and an overarchingly light and mini mal expression. This expression, created for efficiency but crafted for elegance, has already become a unique identity element for the stadium. This minimal, ultra-efficient form also enables it to stand out from other global venues, so much it has been commented in the media that the sta dium evokes the leaf forms of the Pandanas tree, endemic to eastern Australia.

Embodied carbon

The most efficient way to reduce the embodied carbon footprint of new stadia is the adaptive reuse of existing structures and avoid complete demolition of outdated venues where possible.

As most of the carbon is usually embedded in the con crete bowl and foundations, retaining those would yield the largest carbon saving, while roofs are generally easier to dismantle and recycle.

The lighter the roof, the less materials are used As demonstrated by the redevelopment of Ken Rosewall Arena, it is possible to reuse much of the existing bowl su perstructure, substructure, and piling. It was found that the existing structure could support the new lightweight PTFE fabric roof. The circular form used creates a very efficient self-resolved tension structure. Again, by working together with our engineering partners we were also able to real ise a form that evokes a sense of lightness and elegance in its form and representation. This strategy minimised the use of resources relative to the protection afforded by the extended roof cover.

The lighter the roof, the less materials are used and the lighter the building, which in turn reduces the amount of concrete required for foundations. It sounds easy and obvi ous. But in a project and complex as a 40,000-seat stadium the opportunities to complicate and “add in” arrive daily in the design process so that it’s easy to see where projects can become unnecessarily “heavy”.

Our experience with lightweight structures has allowed us to design our lightest roof yet in close collaboration with

structural engineers Schlaich, Bergermann and Partner – the roof of the new Sydney Football Stadium (Allianz Stadium) and it is now reported to be the lightest stadium roof in the Southern Hemisphere. And again, this lightness is achieved without sacrificing coverage and guest comfort. This is exemplified by the fact that 100 % of the 42,500 seats are within the drip line of the roof.

“The most efficient way to reduce the embodied carbon footprint of new stadia is the adaptive reuse of existing structures [...].”

Business cases may demand for new built Unlike Ken Rosewall Arena, the legacy of Sydney Football Stadium was deemed unsuitable for an upgrade, based on an extensive series of studies and business cases. The cen tral requirement to extend the utilisation of the stadium and enhance patron amenity was beyond what any eco nomic “upgrade” could deliver.

The new stadium does boast some impressive statistics from recycling approximately 87 % of construction and demolition waste, to exceeding energy and water efficiency benchmarks by 20 %. The stadium’s lightweight roof struc ture uses 40 % less steel than a typical venue of the same size, and the building hosts integrated solar panels and water harvesting solutions.

Where concrete is unavoidable, we specify concrete with a high degree of ash or slack and recycled aggregate to mini mize its embodied carbon. Replacing concrete and steel with timber is the next frontier in the journey to carbon neutral stadia.

Energy

Whether designing a new stadium or redeveloping an exist ing one, minimizing operational energy use is paramount. Apart from reducing running costs by saving electricity, it also reduces the need to offset emissions for stakeholders who seek to entertain carbon neutral events.

Reducing lighting energy

Artificial lighting is generally the greatest contributor to electricity use in stadia. By allowing daylight to penetrate deep into the building, the translucent PTFE roofs of Ken Rosewall Arena, the new Sydney Football Stadium and Perth’s Optus stadium have proven an excellent strategy to reduce the need for artificial lighting, while providing shade and rain protection. It is an elegant solution that becomes a feature of a venue and an enhancer of experience rather than feeling like an omission; capturing the golden light of dusk in one of the concourse bars at Queensland Country Bank Stadium has already become a noteworthy experi ence for patrons for example.

The emergence of new technology is an important factor in continuously decreasing the operational energy in our sta dia designs over time. All COX projects incorporate efficient LEDs for interior and external lighting.

On-site energy generation

All our contemporary stadia designs include considerations for on-site renewable energy generation and incorporate solar PVs and provisions for future installation where fea sible. While the large roof area lends itself to the installa tion of PVs, they can also be installed to shade car parks and pedestrian walkways. The arrival of solar PV films will further support their integration in the next generation of ultra-lightweight structures.

Anaerobic digesters using organic waste to produce elec tricity out of biogas is another technology perfectly suit ed for stadia. Sports and entertainment venues produce a large amount of organic waste from food leftovers and grass clippings, which can either be locally composted or transformed to energy. A commitment to a plastic-free en vironment in combination with on-site organic waste treat ment significantly reduces the amount of waste sent to land fill and diminishes fossil fuel emissions from garbage trucks.

While surplus energy can be fed into the grid and power nearby buildings and precincts, on-site renewable energy generation is most efficient when supported by batteries as they help to manage disparities between energy demand and generation and stabilize the electricity grid.

Water collection and use

Conversing potable water is another important considera tion, particularly in Australia with its great rainfall variability and regular droughts, which are also predicted to wors en due to climate change. While stadia have a substantial

Sydney Football Stadium – Photo: Venues NSW – Gregg Porteousdemand for water on game days and pitch irrigation, a typically large roof area provides a great opportunity for rainwater harvesting and reuse to flush toilets and irrigate.

The new roof at Ken Rosewall Arena for example was de signed to enable the collection of rainwater from at least 90 % of the enlarged roof surface with a projected plan area of approximately 8,000 m². The fall and guttering of the roof can collect rainwater which can then be fed into a future tank in the next stage of the development, with the aim of water reuse for non-potable uses. In a predominantly dry and warm Sydney climate the on-site capture, storage and re-use of all water types is essential in enhancing landscape, maintaining amenity, and reduc ing costs.

At Queensland Country Bank Stadium, up to 500,000 litres of rainwater storage from roof run off is used for toilet flushing, post-game wash down and cooling tower water demand on match day. Rainfall is not the issue in the tropical North of Australia, however diverting water appropriate for non-landscape use is an important route to efficiency of operation.

Multifunctionality offers sustainability

For all the debate around the use of sustainable materials and an understandable reticence to “knock down and re build” the key to the success of any leisure facility – from community centres to mega stadia – lies in their utility and in their utilisation. The intensity with which they are used by their codes, teams, events, entertainers, governments, schools and so on is a true measure of their success and a key element to their sustainability.

Longevity is one important measure, but so is multi functional utilisation – if one venue can fulfil the role

where three or four were previously needed then this becomes a net success in the ambition of a more sus tainable future. If a venue is used 14 times a week versus the three delivered by the preceding facility, how should we then view them through the lens of longevity and sustainability?

The new Sydney Football Stadium for example houses three elite code franchises of football; Rugby Union, Rugby League and Soccer, and is also ready-made for everything from superstar concerts to community events.

Perth’s Optus stadium designed by COX in association with Hassell and HKS Architects is another successful example of multifunctionality. The multi-purpose stadium has been designed with current and future flexibility in mind and accommodates Australian Rules Football, Cricket, Rugby Union and League, and entertainment events. The 60,000seat stadium includes the widest range of hospitality op tions in any sports venue within Australia including the in novative locker room, coaches club, sky terraces, corporate suites, club lounges, a 2,000-person function room, retail and over 50 food and beverage outlets.

Community – cultural and social impacts

When looking at the carbon footprint of stadia on an an nual per capita basis, it becomes clear that attendance is key. A stadium development represents a massive invest ment – not only in monetary terms but also in terms of carbon emissions. The obvious goal is to fill the stadium with as many events and spectators throughout the year as possible.

A focus of our design ethos is the desire to enhance the civic life of our cities. Stadia are a rare and very singular oppor tunity to express this ethos to its fullest. It’s inarguable that

Ken Rosewall Arena – Photo: Martin Mischkulnigthe denizens of our cities (eight out of ten Australians in fact) see climate action as a core focus for government and climate change as an existential threat to our society. As such, a presciently designed stadium with flexibility and community at its heart can materially contribute to both objectives and deliver a more sustainable and more culturally inclusive and vibrant city. As designers, you cannot get clearer motivation than this.

We always talk about our projects, but especially our sporting venues, and their need to “give more than they take”. It is this ethos that best expresses COX’s approach to a sustainable future of stadia design.

What are the next steps?

For existing facilities, we are also seeing opera tors and management companies hard-baking a continual review of ever more sustainable prac tices as part of their periodic, and in some cases, their daily operational reviews. This is probably the biggest and most important area of progress, where there’s been a rapid shift from a “net zero” objective being ”nice to have” to one that’s both central and a “guiding operational ambition”. As this has now moved from the niche or specialist realm and into a more mainstream management enterprise, literally everything is on the table from base construction materials through to software that optimises the solar harvesting and storage and then manages to the minute how this power is deployed based on the climatic requirements of the day and the nature and needs of the event being staged.

REDUCING THE CARBON FOOTPRINT OF SPORTS AND LEISURE CENTRES EMBEDDING CARBON REDUCTION INTO THE DESIGN PROCESS

Though significant inroads have been made to reduce the energy consumption of these buildings through design, wide variations in building typology and availability of data make it difficult to identify best practices and define benchmarks.

At FaulknerBrowns, we have been working to gather some of our own data. We chose a recently completed project, the Ravelin Sports Centre in Portsmouth, UK and undertook a certified Whole Life Carbon assessment of the building. The findings are interesting but sometimes counterintuitive.

Though operational energy is still a major challenge, pro jects like Ravelin Sports Centre are successfully using passive

design to minimise primary energy demand. Form factor, performance of the building envelope, natural light, and ventilation, all provide a significant opportunity to reduce demand. Employing a Soft Landings process to first chal lenge set points and then finetune the systems and educate building operators, help to make sure that the squeeze of operational energy does not compromise the user experi ence. Figure 1 highlights the gap between the typical en ergy performance and our target. A typical pool building might consume around 750 kWh/m²/y. Best practice sug gests that this might be reduced to 350-400 kWh/m²/y and we are seeing a current generation of our own low energy pools target well below 200 kWh/m²/y.

E

D

C

B

A

Authors Michael Hall, FaulknerBrowns, Partner Irina Korneychuk, FaulknerBrowns, Senior Associate Graphics FaulknerBrowns Architects

65%

saving on

However, as the squeeze on operational carbon in tensifies, embodied carbon comes more sharply into focus. When considered holistically, traditionally opera tional carbon might represent above 85 % of a typical pool building’s lifecycle carbon. Figure 2 illustrates how moving to a lower energy design, with dramatically re duced operational carbon consumption, sees the share of embodied carbon increase from 15 % to nearly 40 %. Reduction of embodied carbon is therefore an urgent de sign consideration, as opportunities for operational car bon reduction diminish.

Surprisingly high impact by building services

When focusing on embodied carbon, our study showed that green roofs are accompanied by a relatively large carbon premium, due to the structure required to sup port them, additional materials used, and maintenance attracted. We found that careful specification of high-

impact materials such as concrete and refrigerants can make a tangible difference. We were surprised to see that building services can have almost as much impact on em bodied carbon as the building’s substructure. The study also suggested that offsite solutions can offer less carbon benefit than they might promise. Overall, the results show how creative we need to be to hit emerging industry tar gets that are designed to get us closer to NetZero.

We also learned of the importance of aligning the life span of individual building components to the life span of a build ing. 40 % of embodied carbon is emitted post-completion when finishes need to be refreshed, building services re placed or the layout modified to accommodate evolving sport and leisure needs. This prompted us to look at com pleted projects from further back, to see how predicted replacement cycles compare to what is really happening in terms of maintenance and refurbishment.

Photo: Ian Lawson

Photo: Ian Lawson

Refurbishment or demolition?

By reviewing around 100 of our own sports and leisure buildings over a 6-decade period, we identified common patterns of refurbishment and, in some cases, demolition. Manchester Aquatics Centre is an interesting example. The project, built for the 2002 Commonwealth Games and first opened in 2000, is now 20 years into its life and undergo ing a major refurbishment. The primary reason for refur bishment is to improve the centre’s energy performance, in line with Manchester Council’s plans to become “zero carbon” by 2038. The refurbishment also includes the re placement of the leisure pool and water rides and provid ing more space for fitness, reflecting ever-changing trends in sports and leisure. The envelope, however, will remain intact, except for the introduction of a new entrance lobby.

These changes highlight the importance of designing facil ities for flexibility and adaptation. In contrast, the building envelope must be designed to last for the whole life of the building; because of the capital and operational implica tions of replacing a building envelope, its failure is likely to trigger a conversation about demolition. Sports and lei sure are critical public services, and demolition will almost always be followed by new construction and therefore a significant further carbon impact.

Flexibility is the key

As a practice, we are increasingly involved in conversations about the future of the buildings we have delivered over the last 60 years. A large number of projects built in the 1980s and 1990s are nearing a major replacement cycle, and we are seeing some typologies weather better than others. Rapid changes in leisure trends mean that buildings with a larger proportion of leisure facilities are more likely to face the risk of demolition. Whilst sports halls and lane pools are timeless and will remain as long as the parameters of the sports they accommodate are unchanged. Inevitably, flexible buildings capable of accommodating changing technology, leisure trends and consumer habits are more likely to survive.

The ongoing energy crisis and skyrocketing costs of oper ating leisure buildings may well create the “perfect storm”, threatening not just existing buildings but the community leisure typology itself. Ever more pressing cost and climate challenges have driven us to develop a set of values for em bedding carbon reduction into our design process: r etrofit first, build less, build lean, build efficient, build to last, and build for reuse. However, more industry research is re quired. We need more data to establish meaningful targets and benchmarks and develop low-carbon solutions that will stand the test of time.

THE NEW AGE OF TIMBER CASE STUDY: ERIC TWEEDALE STADIUM

Author I vana Simkovic, dwp – design worldwide partnership, Sydney, Australia Photos dwp – design worldwide partnership, www.dwp.com

Can mass timber constructions provide a low-carbon alternative to steel and concrete structures? Based on the case study of Eric Tweedale Stadium, dwp Associate Design Director Ivana Simkovic from Sydney looks at the pros and cons in terms of procurement, handling, and performance.

Timber is one of the world’s oldest building materials and has been valued for its raw beauty, versatility, and strength since ancient times. Today, it remains one of the most popular materials for architects and designers, used for everything from cladding to structural framing. Over the past three decades, however, advancements in new types of innovative engineered timber products have revo lutionized the way we use wood in construction.

Mass timber products, such as cross-laminated timber (CLT) and glued laminated timber (glulam), offer an ex ceptionally strong, low-carbon alternative to concrete and steel structures. They can be used for everything from simple load-bearing systems to major timber-frame struc tures and complete wood structure solutions, enabling architects to build bigger and higher with timber.

Around the world, timber towers – often dubbed „ply scrapers“ – are rising in our cities, challenging the conven tional notion of cities as concrete and steel jungles. The world’s tallest is the 85-metre-tall Mjøstårnet tower in the Norwegian town of Brumunddal; while the HoHo Vienna in Austria stretches 84 metres into the sky; in Vancouver, Pritzker Prize-winning architect Shigeru Ban has recently designed a “hybrid” tower that combines steel and con crete with a timber frame; and by 2024, Japan’s Sumitomo

Group hopes to use CLT to build a 70-storey wood sky scraper in Tokyo.

Compared to what is happening in the rest of the world, Australia is just at the beginning of its journey with tim ber construction. Part of the issue is that Australian timber is still more expensive than timber imported from Europe, even when shipping is included in the cost; and the first cross-laminated timber (CLT) plant in Australia only opened in 2017.

Eric Tweedale Stadium in Sydney by dwp, however, offers an exciting example of Antipodean timber engineering. dwp has a real focus on innovative sustainability, and tim ber engineering is one of those sustainability initiatives. The use of mass timber construction for the stadium is the first use of glulam timber for this type of facility in Australia and it represents an impressive achievement in timber engineering.

The stadium is constructed almost entirely from glulam timber and features a 760-seat grandstand and first-floor function space enclosed by a soaring cantilevered roof. A key part of the brief was to incorporate sustainability initia tives where possible, and the client was supportive of the use of a timber structure.

CASE STUDY: ERIC TWEEDALE STADIUM

Concept & connection to site

The design of the Eric Tweedale Stadium in Granville, Syd ney, is driven by the facility’s connection to its local en vironment and the history of the Cumberland Plains. The area was once home to several clans of the indigenous Darug people and was widely forested. The construction of the Sydney-Parramatta railway in the 1850s, however, brought large-scale deforestation and much of the usable timber had disappeared by the following decade. The tim ber construction of the stadium not only celebrates this heritage but creates a connection with the enormous grey and red gum trees to the west of the site today.

Massing & materiality

The architectural form of the stadium takes inspiration from the modest nature of “aboriginal architecture”, which was a product of highly complex relationships between the physical and social environment. The materiality is also a response to the heritage of the site, with a distinctive glu lam timber construction that responds to the history of the site and its current surroundings. The glulam timber has a warm, earthy glow that softens the interior palette and makes the space welcoming to the wider community.

Timber roof

Together with engineering firm Northrop, dwp explored two different options for the timber roof of the Eric

Tweedale Stadium. One option featured a continuous tim ber bean and less heavy fabricated steel. It was preferred by the structural engineer, but as it was disconnected with the planning of level one, it wasn’t dwp’s preferred option. The second option had a simpler structure and worked well with the planning of level one but had a considerable amount of fabricated steel at the cantilever connections –which highlights some of the structural constraints encoun tered when working with a timber construction.

Prefabricated timber structure

One of the benefits of a timber structure is the ability to prefabricate off-site and install in sections. Timber con struction specialists Rubner split the construction of the Eric Tweedale Stadium into three distinct phases, which were informed by production and shipping constraints as well as installation procedure. The circular penetrations in the roof purlin for the siphonic system were also done in the off-site plant, simplifying the on-site construction process.

There was a huge amount of customisation in the project –from ensuring the bracing fit inside the wall thicknesses to the precast concrete lift shaft. Rubner and Northrop were keen to keep the design intent without any changes to the appearance of the timber, however, allowing dwp to realize the project’s vision. Prefabricating the structure off-site was essential to this.

Interior

The interior of the Eric Tweedale Stadium is a celebration of material honesty. Timber rafters and columns are exposed in the function space, and are complemented by the raw, polished block walls on the ground level. As the raw timber structural columns are a part of the interior scheme, great attention was paid to the design of the columns’ steel base during the prefabrication process. It is a very simple and restrained interior palette. Warmth and brightness are cre ated by leaving the wood and other raw materials exposed.

Carbon footprint

Sustainable design was an important objective of the pro ject, and the timber construction was key to achieving this. The goal was to demonstrate that this scale of building can be a highly sustainable development that is low carbon, low waste and highly energy efficient. Beyond the low carbon footprint of the timber structure, the stadium has an eastwest orientation to allow for natural cross-ventilation, pas sive solar shading, a rainwater tank for irrigation and toilets, and there is a provision for photovoltaics and metering to monitor and reduce wastage.

According to a study by Rubner, thanks to the net storage effect, Eric Tweedale Stadium provides an active contribu tion to climate protection of around 130 t CO2. This storage effect corresponds to the greenhouse gas emissions of the combustion of 268 barrels of oil, or truck transport over 119,878 ton-kilometres.

THE BENEFITS AND CHALLENGES OF BUILDING WITH TIMBER

Sustainability

Timber sourced from ecologically managed forests has ex cellent sustainability and environmental credentials. It is a renewable, recyclable, and re-usable resource that is able to act as a carbon sink, absorbing and storing carbon diox ide from the atmosphere – while concrete is widely recog nized as the construction industry‘s primary contributor to greenhouse gas emissions. According to a 2014 study in the Journal of Sustainable Forestry, up to 31 % of global carbon dioxide emissions could be avoided using timber structures instead of steel and concrete.

Engineering properties

A mass timber structure has a high load-bearing capacity yet is lightweight – and outperforms even steel when it comes to breaking length. These properties not only allow for an impressive material efficiency, but also for speed of construction and easy handling on site. CLT and glulam can be prefabricated off-site to almost any dimension and shape and can theoretically span any length – yet will re main more lightweight than comparable concrete and steel structures. Timber has also proven to be less vulnerable to collapse in fires than steel structures. Burning speed and retention of load-bearing capacity can be calculated.

Quality

Mass timber constructions lend themselves to off-site fabrication – and a higher quality can be achieved when building in a factory than the less-controlled conditions of a construction site. Timber elements can be measured ac curately and produced to very millimetre, then equipped for assembly to ensure ease of construction on-site.

Aesthetic appeal

Timber has a natural warmth and brightness that creates a desirable aesthetic appearance in both interior and exterior use. There are a wide range of timbers available in different hues and timber grain offers a pleasing visual tactility. Tim ber has also been proven to regulate humidity and surface temperature to create a comfortable interior environment; and has impressive acoustic qualities that make it particu larly suited for workplace and hospitality interiors.

Challenges

Of course, there are also challenges specific to building with timber. In Australia – as on the Eric Tweedale Stadium project – it is common to work with an overseas supplier and engineer through the shop drawing process, which can be challenging and time consuming. It is also necessary to account for the exact size and location of all penetrations in the timber at the outset due to the time needed to replace elements that are incorrect. When pre-fabrication is done overseas, it can also raise challenges around certification.

During the shop drawings process for the Eric Tweedale Stadium, for example, certification of the structure was done in EuroCode to Australian standards.

The future of timber at dwp

As the Eric Tweedale Stadium shows, timber engineering not only allows for the creation of aesthetically beautiful constructions but is essential for greening our cities. By of fering a viable low-carbon alternative to steel and concrete, we can continue to push the boundaries of possibility in terms of architectural expression with less of an impact on our planet. Creating greener cities is one of the driving mo tivations at dwp. Based on the success of the Eric Tweedale Stadium, we will consider timber for future projects first and foremost for its many sustainability credentials – but also for its impressive structural potential and its unparalleled natural beauty.

SUSTAINABILITY BY PRESERVATION AND ENHANCED FAN EXPERIENCE

CLIMATE PLEDGE ARENA IN SEATTLE, WA

Populous was engaged as architect of record by Oak View Group and the City of Seattle to design this 68,750 m² arena with three goals: to create the most sustainable arena in the world, to responsibly revitalize a historic landmark, and to cultivate the ultimate fan experience. As the region’s largest indoor venue, Climate Pledge Arena will host the NHL’s newest team, the Seattle Kraken, the WNBA’s Seattle Storm, and numerous concerts and other events.

The design enables Climate Pledge Arena to employ numerous sustainable practices and op erations. The arena relies solely on renewable en ergy sources – including on-site solar energy de signed on the atrium roof – to power the facility. The fully-integrated transportation plan subsi dizes mass transit for fans. The site design pro vides space for electric vehicle charging s tations and bike valet servic es, while also building s trong con

nections with the monorail. The arena supports water conservation systems – such as harvesting rainwater from the roof and zero waste initiatives.

Historic revitalization of original design

This multifunctional venue in the heart of Seattle Center harkens back to its original arena, which was built for the 1962 World’s Fair. The design was centered around revitalizing the landmark arena and honouring its original design intent while activating and enhancing a pedestrian-fo cused plan. The former arena was a flat-floor, column-free pavilion with an entirely glass facade allowing visitors

Location Seattle, USA

Client / operator Oak View Group, Seattle Kraken Hockey and Seattle Center

Architects

Populous US – 64112 Kansas City, MO www.populous.com

Author Populous Photos

Climate Pledge Arena Populous

Official opening October 2021

Construction costs USD 1.15 billion (EUR 1.17 billion)

to see inside. Populous’ design preserves many of these character-defining features and draws from the firm’s vast experience of creating meaningful spaces for people to gather.

The idea was to maintain the preservation of the 59-yearold historic roof designed by Paul Thiry, the father of archi tectural modernism in the Pacific Northwest. The new con struction required the 20,000-tons roof to be suspended above the site while the new arena was built underneath.

To increase the size of the arena to 68,750 m² – approxi mately twice the size of the former venue – and give the venue 360-degree pedestrian access, it was necessary to dig 5 m deeper than the previous 1995 renovation that bot tomed out at 11,5 m below ground level, and significantly

expand the below-grade building footprint in all directions. In addition, a historic glass curtain wall was preserved in the new arena’s north end, presenting visitors with a view to the plaza.

The Plaza: All-seasons open space in the Emerald City

The expansive and universally accessible outdoor plaza sur rounds the arena, providing year-round open and green space within the Seattle Center campus. With 360 degrees of landscaped plazas surrounding the venue, effectively placing the arena within a picturesque, landscaped park – a first for an urban professional arena in the United States –

Climate Pledge Arena is more accessible to all, links local neighbourhoods, and restores the original relationship be tween surrounding plazas and the building.

The world’s first dual suspended scoreboards Unlike any other arena video display, Populous designed the industry’s first dual suspended arena scoreboards – a signa ture element of Climate Pledge Arena. Behind this new de sign lies a thorough analysis of on-ice and on-court action for hockey and basketball, spectator and athlete sightlines, and flexibility for shows and concerts. The result is a pair of distinctly shaped video displays that place digital content in an ideal location for spectators, improving the atmosphere and connection between fans on opposite sides of the seating bowl.

Colourful wayfinding from top to lower level

Each level of Climate Pledge Arena has a different colour of wayfinding signage, which harkens to natural features as the

levels go deeper underground – from the light blue on the top level to mimic the atmosphere, to a muted orange to reflect the earth on the main concourse level, to a dark grey for the lower level.

The arena boasts 2,620 m² of digital signage, the most in the world for a sports and entertainment venue. The immersive LED experience throughout the user journey displays way finding, events and partner promotion, and atmospheric im agery that is customizable for each event. The Climate Pledge brand is further strengthened through a 61-m living wall with live plants and LED activations on the main concourse creat ing social media-friendly content opportunities. Egress tunnels and other LED displays throughout the arena blur the lines between the structure and the outdoors with graphic imagery.

AUSTRALIA’S FIRST HIGHEST RATED SPORTS BUILDING IN DESIGN AND SUSTAINABILITY

LA TROBE UNIVERSITY SPORTS STADIUM IN MELBOURNE

The La Trobe University Sports Stadium has been designed by Warren and Mahoney in association with MJMA Toronto and is an Australian-first. Generating more energy on site than it uses – making it net positive – it is the first sports building in Australia to be awarded the highest rating for both the design and build by the Green Building Council of Australia. This was achieved through an integrated strategy covering building m aterial performance, natural ventilation, sustainable energy generation, water storage and reuse, and building management and operational strategies.

As a centralised facility, the Sports Park offers high ball sports courts, high performance assessment and testing laboratories, teaching spaces and sports management tenancies. Breaking down barriers between industry and the student experi ence, the stadium provides facilities for grass root community sport and in return creates a pathway to connect the community and university life.

The Sports Park Stadium project allows student sport and sport related clubs to increase student participation; actively engaging the local com munity and schools through the use of enhanced sporting facilities and sport services at La Trobe; leveraging sports facilities to encourage all mem bers of the university to improve their health and fi tness; securing long-term, meaningful institu

tional influence within the sport industry in Victoria and Aus tralia; and developing links between high performance sport and the teaching and research capacity of the university.

Passive design and a photovoltaic roof

The facility was designed as a Net Zero emissions building. This was achieved through application of the energy hierarchy-op timised passive design which includes natural and mixed mode ventilation, a highly efficient facade well over BCA minimums, highly efficient all-electric building systems and maximisation of PV on the extensive roof. The mixed mode provided chal lenges in terms of thermal separation and performance be tween the naturally ventilated and conditioned spaces.

The stadium is equipped with a vast high-spec photovoltaic array on the roof that amounts to over 519 kW and generates around 724,000 kWh per year. This is more than enough to meet the stadium’s electrical demand, so surplus renewable energy is fed back into the rest of the campus. The first major piece of La Trobe’s bold “University City of the Future” plan, the stadium and surrounding park will help it achieve its Net Zero strategy for a net positive operation.

The building makes use of the stack effect to enable an ef fective natural ventilation to the sports courts. High level windows also facilitate this, providing daylight into all spaces in line with best practice levels. The building has considered

PHASE2PHASE1

The project was designed to accommodate a third fieldhouse expansion. Each fieldhouse uses natural ventilation with base louver walls allowing fresh air to enter low and exhaust high through banks of upper clerestory louvers located between each fieldhouse. The rooftop houses a full PV array with interspersed linear skylights to power the building and provide daylight autonomy to the fieldhouses throughout the day.

The project was designed to accommodate a third fieldhouse expansion. Each fieldhouse uses natural ventilation with base louver walls allowing fresh air to enter low and exhaust banks of upper clerestory louvers located between each field house. The rooftop houses a full PV array with interspersed linear skylights to power the building and provide daylight to the fieldhouses throughout the day.

climate change adaptation and resilience – future climate change scenarios were assessed and building design re sponses implemented to address identified risks. These in clude the provision of plant space for additional services and others.

Procurement, cost allocations and environmental performance

Operable louvres were implemented with the wall construc tion and structural systems to achieve a high level of natural ventilation to the 3-court event hall and community halls. There were some challenges experienced, including the set ting of pre-set modes responding to the building weather s tation and overrides for the operational staff to control air movement on high wind days.

Naturally ventilated cells (courts) were created to separate the naturally ventilated courts from the high thermal insu lation education, commercial and front of house areas. The

wall separating the conditioned space from the naturally ven tilated space was treated thermally as an external wall.

The skylight design was modified using a combination of off the shelf products to ensure that the skylights perform ther mally similar to the adjacent roof insulated panels, incorpo rating a top material to match the roof profile of the selected roof and a bottom layer to create an air gap and internal appearance to match the perforated acoustic metal lining to the interior.

The structural design of the long span roof drew from ar chitectural elements, such as the striking cantilevered cano py over the main entrance and the trussed columns in the southern hall, to find an efficient form. By using these features as key structural elements, a reduction in the overall amount of structural steel – a highly carbon intensive material. Re duced by 21.1 tonnes, it resulted in a 5 % decrease across the whole building.

exhaust high through daylight autonomy

Sustainable performance over entire lifespan

Provision has been made for the modification of the Event Stadium and Show Court, so that it transitions from a ventilat ed three court sports hall to being a thermally sealed condi tioned space to address patron comfort for the 2,500 patrons that will be accommodated by retractable seats on both sides of the main show court.

There is also provision in the design to accommodate more teaching spaces and an additional three courts to the south of the site to increase the capacity of the facility to meet the requirements of the local community and add to the university campus experience. Consideration of future expansion and provision for that expansion is a critical piece of addressing the sustainable performance of the building.

Exceeding the Green Building Council of Australia’s criteria

The stadium achieved innovation points for sustainable sourc ing, use and disposal of materials, material reduction and

efficient material use, with 16 % of the building area fit out with locally procured sustainable products.