Note: Due to the current situation caused by Covid-19, we cannot guarantee the last mile delivery of the issues. We therefore ask our readers to provide us with an email address for a digital delivery. Please contact: info@foodmultimedia.de

by

Note: Due to the current situation caused by Covid-19, we cannot guarantee the last mile delivery of the issues. We therefore ask our readers to provide us with an email address for a digital delivery. Please contact: info@foodmultimedia.de

by

You get more space and more safe. We like to call it the best combo in baking. Together, the 909A/910A create the closing line of the future for bakeries, with tamper evidence, additional safety features and a space saving compact design. Partner our updated 910A high-throughput closure machine with our 10-inch “laser stitch” 909A to ensure your product stays tamper resistant, your team stays safer, and your

Learn more at kwiklok.com

Production tasks are diverse and exciting, of that there’s no doubt: weighing out raw materials, preparing and making-up doughs, decorating and metering, producing sourdoughs and sponge doughs, operating plant and machinery. It’s a responsible job, because it involves working with foodstuffs, and also demands planning and organizing workflows.

At the same time, however, work in a production department or in sales is also challenging: shift work and/or getting up early, physical exertion, even though automation makes work easier in some areas, e.g. oven loading and unloading. There are many career opportunities nonetheless, provided the job applicant is flexible enough, e.g. even to move house.

Your commments or suggestions are always appreciated: phone: +49 40 39 90 12 28 borchfeld@foodmultimedia.de

However, the baking sector has complained about the lack of skilled specialist staff worldwide for many years. A few companies, as well as associations and guilds, have attempted to portray work in a bakery or sales department as being attractive to potential job applicants. There have been, and still are, information stands at trade fairs. Those responsible for recruitment beat advertising drums in the social media. The baking sector answers students’ questions at career days. But there is still no noticeable demand. This is also due to the fact that pay is rather poor compared to other sectors.

A tougher battle for skilled specialist staff is already being fought in other sectors, and a few bakeries are also taking action, e.g. offering trainees grants for a driving license, or including a fitness center when planning a new building, like the Ruch confectioners.

It doesn’t have to be a company fitness center, but it could be cooperation or a subsidy for the membership charge or application fee for a sports club, a supplementary health insurance including family members, a works bicycle or accepting the cost of a monthly season ticket for local public transport, an apartment, an open-ended employment contract, looking after children or assistance with family members in need of care, an old-age pension allowance, care for pets, or offers of further training and promotion opportunities – there are numerous opportunities to draw attention to oneself as an attractive employer.

The working atmosphere, corporate culture and appreciation, together with personal interaction, play an important role in retaining employee loyalty, provided the framework conditions and opportunities for personal development are right.

Thus there are companies in the baking sector that have become pioneers with their practiced values of trust, appreciation, dependability, transparency and performance strength. These companies have no difficulty in retaining their employees’ loyalty, and that pleases me.

Yours

How much does your software know about bread?

Ours knows a good deal.

Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP and MES. And best-practice standards come as part of the package.

Would you like to know exactly why industry leaders count on CSB?

06 Wolfgang Mayer: A fast, flexible response 24 Henrik Oevermann: Operations without restriction 36 Cathleen Kabashi and Michael Wippler: New ideas for iba

10 Stone Oven Bakery : Organic as an article of belief 14 Fritsch : Decoration unit for a variety of patterns 22 Sveba Dahlen : Fermentation for minimal effort 26 König : Expanding the snack area

20 Finland : New products from Fazer Bakery 28 Generation Z : Generous to itself

and Slicing 30 MKW: Redesign and facelift 32 JAC: Well positioned for the future

WP: Lye application with robotic cutting system

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk +49 40 39 60 30 61 baumfalk@foodmultimedia.de

ADVERTISING DEPT.

International sales director Dirk Dixon +44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Susanne Carstens +49 40 38 61 67 94 carstens@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide Linda Langhagen; design@landmagd.de

PRINTED BY Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department.

No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2020

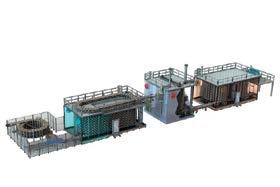

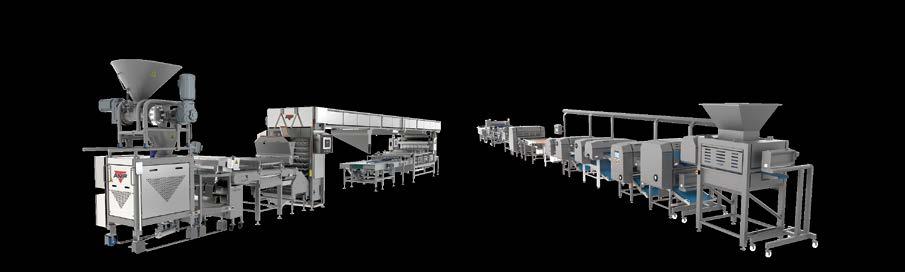

From conception to creation, ingredient to final product, our process involves full-system solutions that meet or exceed the highest industry standards. Our reliable, high-value solutions ensure years of successful operations. Designed, manufactured and installed by Shick Esteve.

• High reliability and repeatable results

• Focused on food safety

• Continuous improvement

• Solutions tailored to your needs

• Startup, training and maintenance worldwide

• Compliance with wide variety of regulations and standards

• Modular and pre-cabled equipment to minimize install time

• Easy cleaning and maintenance

Hildegard M. Keil talked to Wolfgang Mayer, a member of the Executive Board of backaldrin International The Kornspitz Company GmbH, about how the company, which supplies raw materials to bakeries around the world and operates production facilities in various countries, is experiencing and coping with the Corona Crisis.

+Keil: Mr. Mayer, backaldrin has production operations in Austria, Russia, Jordan and China. How differently is the Corona Pandemic making itself felt in these countries?

+ Mayer: The measures that have been adopted by individual countries are different, and their timings also differ. Due to official controls, our production operation in China was to close right at the start of the year, therefore our measures to safeguard production and to secure the European supply chain came into force quickly, and we are currently benefiting greatly from that.

+ Keil: Your European production facility is located at Asten near Linz; what has changed there, are you subject to government supervision, and can you export or are there any restrictions in that respect?

+ Mayer: The Austrian Ministry of the Interior had already designated backaldrin as a so-called system-critical infrastructure operation in 2019, therefore we now had corresponding crisis plans ready in the drawer. We were integrated into the information chain at a very early stage, and were able to make a fast, flexible response. Above all, that also helps our customers. Currently, we are able to export everywhere, and are doing so. A number of countries are announcing individual short-term measures, all of which we have been able to resolve up to now.

+ Keil: Austria’s bakers depend greatly on tourism, especially at the present time. What effects has that had for the sector and for its upstream suppliers?

+ Mayer: We have talked to many customers, mainly those in tourism strongholds. These really are suffering greatly in the wellknown circumstances, and in this case it is not yet possible to foresee how it will all be coped with economically. The future will also show how the chain store branch business is trending nationwide. Of course, everyone is currently struggling with problems in the areas of logistics, staff availability etc.

+ Keil: What does the situation look like for your employees in production, sales and administration – it can’t all be dealt with in a home office. Do you need special authorizations?

+ Mayer: An exit restriction is currently in force in Austria, and is really being complied with by the population. Due to our special status, backaldrin has received specific driving entitlements for employees in the production, clerking and logistics areas, who are essential to maintain security of supplies. These employees have freedom to travel for professional purposes. All the staff who can do home office working are also doing that already. But even the CEO comes to the building every day and gives his backing to the team at this time.

„Currently, we are able to export everywhere, and are doing so. “

+ Keil: Are you experiencing shifts in demand between product ranges?

+ Mayer: Basically, we hear from the marketplace that there is again an increased demand for classical breads. There was a slight downturn in sweet baked products during the stocking-up period. Initially, the public was stockpiling, but it has now become clearly visible that supplies are guaranteed, and the situation is relaxing again.

+ Keil: How is the logistics area operating now – are there any bottlenecks?

+ Mayer: Currently running very well; we have our own distribution network in Austria and Germany, and employees are also aware that they are playing their part in securing supplies for the public. They are doing magnificent work, and we are very grateful to our employees, who are now bearing an even greater burden than they otherwise would.

+ Keil: How are you responding in giving advice about the Corona Crisis; what are you offering to bakeries, can they obtain advice by telephone or E-mail, and are there any special tips?

+ Mayer: Many customers are addressing inquiries to us, and we are glad to help. We have prepared summaries of the hygiene regulations for them, and we have incorporated graphical suggestions from the health authorities and have processed them in such a way that customers can also make further use of them.

Basic advice applicable to all is to maintain a separation distance, wash your hands frequently and properly, and simply be even more disciplined than otherwise. Our sector is very hygienic in any case, and what is needed now is simply to pay a little more careful attention to it. We are optimistic that everything will go well for our customers! We are also keeping various product ideas in readiness, which bakeries can use to design more variety into their product range, and serving suggestions they can pass on as recommendations to their customers, for example to make the evening meal exciting, which is important especially for children.

AMF Bakery Systems (AMF) announced that Guillaume Joly, previously Global Business Development Manager, will transition to the role of Director of Sales for U.S. and Canada focusing on artisan bread and rolls, pizza and flatbreads, cakes and pies, as well as pastries and croissants. As the Company’s expertise in developing innovative production solutions for artisan breads and specialty baked goods continues to grow throughout North America, Guillaume Joly will lead the sales team focused on offering complete mixing through packaging solutions, including AMF Tromp sheeting and laminating as well as AMF Den Boer baking system technologies throughout the region. He will continue to work closely with AMF’s Director of Sales, U.S. and Canada, for the soft bread and bun segment, Blake Millard, as the duo aim to expand AMF’s reach across the complete range of best-in-class technologies from mixer to marketplace. “This is a natural transition for Guillaume,” mentioned Jason Ward, President of AMF. “His expertise in artisan bread and laminated product formulation, bakery process, and best-in-class equipment will continue to be influential in driving our market strategy for the artisan bread and specialty segments.” Guillaume Joly joined AMF Bakery Systems in October 2019 with over 25 years in the baking industry. +++

Since 1 February 2020 Marc Dagnelie has been strengthening Kempf GmbH as Key Account Manager International. He will be responsible for "Key Accounts" in the French speaking countries and in Central Europe. In this function he will report directly to the management. Marc Dagnelie has many years of professional experience in international sales and international market opening, the company says, including leading positions in companies in France, Belgium and Luxembourg. Marc Dagnelie's last position was with Panelaux S.A. as head of purchasing. +++

AMF Bakery Systems (AMF) announced that Eric Tellier has joined the Company as Regional Account Manager for the United Kingdom. Eric Tellier is a true bakery market specialist, who has worked in this industry of baking machinery and solutions for nearly his entire career. For over 13 years, he has grown his network of industry professionals, knowledge and successes in various suppliers in the industrial baking industry. “The UK is a key market for AMF Bakery Systems, with over 60 million residents, who love to consume their

daily bread and snacks. Brexit will certainly have its effect on the import of consumer goods, so local producers, large bakeries and also the local bakeries will have their hands full supplying the market, that is where AMF comes in to support and develop their capacity and efficiency”, noted Eric Tellier. +++

Gilbert Bundy, CEO Bundy Baking Solutions, recently announced the appointment of Jason Bowman as President of European and MENA Operations. Bowman has been with Bundy Baking Solutions for over 10 years and has been instrumental in the international growth of American Pan. He was most recently Senior VP for European Sales significantly increasing the company’s sales in that region. In his new role, Bowman will set the strategic direction and provide oversight of sales, engineering, production, finance, and human capital development for the four American Pan European entities.

Bundy Baking Solutions, headquartered in Urbana, OH USA, provides baking pans and equipment to the global baking industry with locations worldwide including two facilities in the UK, one in Spain and one in Romania. The family owned group of companies includes American Pan®, Chicago Metallic, DuraShield ® , Pan Glo ® , RTB, Shaffer and Synova. +++

++ Dennis Wendlinger is new Co-Managing Director at Anneliese Backtechnik

Anneliese Backtechnik, Eschweiler/ Germany, has expanded its management team. Together with the managing director Helmut Leuver, Dennis Wendlinger has led the company's business since 1 March 2020. Wendlinger began his training as industrial sales representative in 2011 at Anneliese Backtechnik and passed through all areas of the company before he took over the management and leadership two and a half years ago. In this position, Dennis Wendlinger was largely responsible for production and quality optimization.

Puratos, an ingredient manufacturer for bakers and confectioners based in Groot-Bijgaarden, Belgium, celebrates its 100th birthday this year. In its anniversary year, the company plans to open three new innovation centres on three continents. In January, two new joint ventures were also signed in Kenya and Ethiopia. The Group has around 9,500 employees in 70 countries. Puratos estimates its annual turnover at EUR 2 billion. +++

KEEP CUSTOMERS COMING BACK WITH A VARIETY OF BAKED SNACKS ON ONE FLEXIBLE SYSTEM.

With innovation as the key ingredient, RBS can help take the future of your snack operation to a healthy new level. Our advanced baking technology offers you the flexibility to make different types of healthy baked snacks all on one line. Change shapes. Swap ingredients. Give your customers the variety of healthier snack options they’re looking for. To find out more about adding a Multi-Crisp Snack System to your production lines, call (01) 610-693-5816 or visit readingbakery.com for more information.

A Markel Food Group Company

A Markel Food Group Company

J. Friedrich Dieter, Managing Partner of the Stone Oven Bakery and the Doppelkorn organic bakery, is an experienced, well-networked industry expert. He attaches great value to artisan skill and high-quality organic raw materials.

+According to its Managing Director J. Friedrich Dieter, the Stone Oven Bakery is one of Germany’s Top 5 organic bakeries. In recent years, the Ibbenbüren company has increased its sales revenues from EUR 5 million (2011) to EUR 7.5 million (2018). Around 90 employees working a two-shift system in a bakery measuring approx. 2,200 m 2 produce around 50 different types of bread, 25 kinds of bread rolls, 20 different long-life baked goods and approx. 15 spicy foods every day. At the same time, the Stone Oven Bakery operates its one and only sales outlet directly alongside the production unit. However, the branch is more like an organic supermarket with its own café and a large area where baked products are sold. According to Dieter: “On the one hand, we serve the local demand here, and on the other I also regard the business as a reference project vis-à-vis the business-to-business customers we supply in the specialist organic retail trade.” The bakery was founded in 1984, and after J. Friedrich Dieter took it over in 2011, the businessman focused on B2B business and withdrew from direct end

customer business. Its eleven existing sales outlets were handed over to the retail, and have since been supplied directly. Only one location at the company’s headquarters is still operated under its own management.

J. Friedrich Dieter gained a Business Studies degree and worked in the food industry with Kamps and Schöller for many years. Under his leadership, the organic bakery has steadily increased its sales revenues. Its main business nowadays is in supplying fresh baked products and snacks to the specialist organic retail trade. Dieter says “We see ourselves as a partner of the organic food retail, and market both directly and in cooperation with our partners SuperBioMarkt AG and the organic wholesaler Weiling.” SuperBioMarkt AG is an organic supermarket chain in North Rhine-Westphalia and operates 26 branches in North Rhine-Westphalia and Lower Saxony. Weiling is the Number 2 organic wholesaler, and supplies the Stone Oven Baker’s baked products to the specialist organic retail throughout the whole of Germany.

The bakery itself has four transporters of its own for deliveries to direct customers in the region.

As a business management graduate, J. Friedrich Dieter attaches great importance to artisan skill and good raw materials in the production operation. He knows that people who buy organic products are also willing to pay more for high quality. The best-selling bread roll, a Kamut Khorasan roll, is also the most expensive. Consumers pay EUR 1.29 for each bread roll. According to the Managing Director: “The flavor and trustworthiness of organic products are the decisive factors, not their price.” The quality of the raw materials and the way they are processed in turn determine the price. Dieter therefore also places great value on being a fair partner for everyone, and on promoting and preserving regional structures. In this respect, the bakery team also plays a large role. Thus J. Friedrich Dieter finds it self-evident that his employees act independently and on their own responsibility. According to the Managing Director: “I want everyone to be involved with their heart and soul, and for us to live on the basis of trust.”

As well as its headquarters in Ibbenbüren, the company has also operated a bakery in Essingen near Aalen since 2011,

where it produces mainly breads. The Doppelkorn bakery at Laatzen is an additional location supplying branches in Hanover. The main production site is in Ibbenbüren, where on the one hand the Stone Oven Bakery has invested in automating the production operation, e.g. in a new Rheon dough divider, and on the other it has also invested in new chiller and freezer areas. Thus a new cold-storage warehouse costing around EUR 500,000 is currently under construction directly alongside the production unit. J. Friedrich Dieter sees further opportunities for growth, especially in the frozen rolls area,

rather special

and intends to expand the product range. The company continues to offer cakes and breads as fresh products.

Otherwise, the Stone Oven Baker’s production still looks exactly the same as before it focused on B2B business. Raw materials come into the bakery through silos and as bagged

The Stone Oven Bakery’s Managing Director, J. Friedrich Dieter, heard of the financial difficulties of the Doppelkorn organic bakery in Hanover by chance. That was in 2017. When an insolvency administrator had been appointed, Dieter asked for a meeting. The entrepreneur saw prospects for the organic bakery, and took it over. Customer numbers and sales revenues have remained stable since then. Dieter sees growth opportunities for the bakery, and wants to open up new business areas and win new customers. He attributes the Doppelkorn company’s insolvency to management errors. After several months of chaos, seven of the Hanover organic baker’s branches were re-opened. According to Dieter, the intention is for Doppelkorn to remain a quality bakery using artisan methods to work transparently with high-quality organic raw materials. The new owner wants to give the bakery a more modern, fresher, more open design. Dieter also plans to simplify its structures. The kitchen in one branch has already been closed, and products such as quiches, soups and vegetarian rissoles now come from the Ibbenbüren stone oven baker. In future, the plan also includes producing part of the bread rolls by the stone oven baker at the Ibbenbüren site. Bread rolls will then be baked off in the sales outlets. The Doppelkorn production unit in Laatzen will be retained. +++

rolls – every baked product should be unique

goods. Sourdough and sponge dough are prepared and stored in stainless steel tanks. As Dieter explains: “Each type of bread has its own flavor profile, and the baked products have a shelf life of up to seven days.” Most of the rolls have a rather compact structure compared to conventional bread rolls. Here again, the process basically takes place using sponge doughs. The company also attaches importance to the fact that confectionery products should offer the customer something rather special. According to J. Friedrich Dieter: “Cakes and cake slices provide the customer with an experience and enjoyment.”

In addition to appropriate raw materials, producing highquality baked goods also involves allowing doughs plenty of time to develop. In-depth specialist knowledge of the production process is also needed. According to Dieter: “That’s why our dough preparation teams must have a great understanding of their artisan skill.” However, this also makes recruiting good specialist staff difficult. Therefore, the bakery also emphasizes the exchange of specialist knowledge between the individual Hanover, Ibbenbüren and Essingen locations. To stand out from competitors, J. Friedrich Dieter stresses that artisan production is possible even on the scale of size of a stone oven bakery. However, continuity of customer and supplier relations is also significant. For example, the bakery has obtained its flour from the Eiling organic mill in Warstein for many years. As Dieter explains: “Due to our long-standing business relationship, we have never had any supply shortages, e.g. when spelt became scarce.

The Managing Director wants to expand cooperation with his customers in the future. Major consumers such as hotels or suppliers to community caterers could become additional customers in the future. What is important, however, is that customers remain convinced by the product range and the “organic” attitude. +++

Fritsch’s Product Decoration Unit (PDU) allows the gentle, precise molding of patterns on a variety of dough pieces, and does so regardless of their shape and weight.

Usually, the FRITSCH plant constructor’s developers thought, solutions that function well in one area are also a good starting point in another area. That’s true, for example, for the croissant-bending robot, whose functioning principle is now also used, in a modified form, on the IMPRESSA bread, FRITSCH’s industrial bread line. It now makes the modular plant even more flexible with regard to the products it can make because the company developed an entirely new solution: the PDU decoration unit (“Product Decoration Unit”), based on the robotic engineering of the

CBD croissant bending system. This allows patterns to be pressed or cut into the surface of products on the bread line, regardless of their shape and weight. Whether they are classical Kaiser rolls, rye rolls or products with individually customized anniversary or football patterns – creativity has scarcely any limits here.

In conjunction with the new PDU decoration unit, product quality represents an important characteristic feature of

the IMPRESSA bread line. FRITSCH’s SoftProcessing technology enables the fully automatic production of large volumes of bread rolls. Gentle dough sheeting subjects the dough to only the most minimal stresses during the entire manufacturing process, to preserve its sensitive structures. As a result, doughs with a high dough hydration can be processed. According to the company, it can even process gluten-free dough types or rye doughs. Dough sheet preparation and processing before decoration need no proofer for intermediate dough piece relaxation, which not only increases the quality of the products and their hygienic standard, but also considerably reduces the space requirement.

Moreover, the decoration unit offers maximum flexibility regarding dough piece shape and weight. The new equipment can emboss decorations not only on round-molded products, but also on long-molded ones. As well as molded bread rolls, the dough pieces can also be punched out or cut, then given a pattern. The system’s possibilities are also almost unlimited with regard to product weight. The position of the products is recorded by a camera system, and the embossing or cutting tool is aligned at right angles to the conveyor belt’s direction of travel. The PDU

decoration unit then travels to the position of the product, so as to apply the required pattern exactly in the center. As already happened with the croissant bender, the camera on the PDU ensures maximum operating precision. Furthermore, the decoration system acts as an autonomous unit, which not only reduces interfaces and thus synchronization difficulties, but even avoids them altogether, because due to the camera system, the machine works independently of the cycling of upstream components, thus minimizing rejects. However, the system also inspires confidence through its high capacity, because decorations can be pressed and/ or cut into the surface of the product at up to 60 cycles/ minute. With big lines, this allows the production of approx. 50,000 bread rolls per hour. +++

• Constant production capacity

• Constant product quality

• Labor saving

• Cost saving

• Hygienic and safe

• Available with RedCase®

2018. In addition to his significant commercial experience in bakery, Chris Plüss has deep food industry experience having worked in Unilever, Haco Group and Fressnapf/ Maxizoo prior to joining ARYZTA. Chris is a Swiss national and holds an MBA from the University of Berne, Switzerland. Rob O’Boyle, COO APMEA will be leaving ARYZTA at the end of May, 2020 after 14 years with the business to take up another position. +++

Integrated and transversal solutions that become complete lines for all the different food processing. Tecnopool TP Food Group, an according to the company new world leader in the food processing equipment sector, was created with this objective, that can be summed up with the acronym “Tp”. Tp also stands for Tecnopool, a Padua company (Italy) whose lines for all processing food treatments can be found all over the world. It was Tecnopool, in fact, that grouped together Gostol, Tecnofryer, Logiudice Forni, Mimac Italia and Mecateck Group, companies with a strong international mission to guarantee that customers receive complete, integrated and customized solutions.

Different realities are united by the awareness that the best innovations come only from uniting skill and intuition, that in today’s increasingly more global market the most ambitious challenges can only be overcome together. The pillars are the same ones that characterised the growth of each company over the past decades: flexibility, reliability and efficiency, innovation, listening to and paying attention to customers. The numbers – an overall turnover of more than 100 million Euros, eight production units in four countries and more than 500 employees – are the accelerator for Tecnopool TP Food Group’s continual global development, as is proven by the success of the Group at the main international trade shows.

This success is headed by Tecnopool, which is obtaining approval from different sectors: in addition to the traditional bakery sector, it is answering the growing demand for meat and vegetable processing technology. This is because its in-house patents can be adapted to suit all food processing systems, guaranteeing maximum productivity, quality of the product, lower energy costs and easy maintenance. +++

ARYZTA announced the appointment of Chris Plüss as COO APMEA commencing early June 2020. Chris Plüss is currently ARYZTA’s Regional Managing Director for Southern Europe (Switzerland, France and Hungary). He joined ARYZTA in 2014 as MD of Switzerland and was promoted to MD for Southern Europe (Switzerland, France, Hungary) in March

++ Yvon Guérin takes over as CEO of Vandemoortele Vandemoortele, Ghent/Belgium, announces a change at the top of the company. CEO Jules Noten is leaving the company after eight years with Vandemoortele. Noten will in future devote himself to various supervisory board mandates. As of 1 July 2020, Yvon Guérin, the current Managing Director of the Bakery Products division, will succeed Noten. With regard to the 2019 financial year, the Vandemoortele Group has recorded strong results: Adjusted EBITDA rose to EUR 152 million, an increase of 17% compared to 2018. +++

The Eurogerm group announced the appointment of Jean-Charles Hamelin to the position of Group CSR Manager. Set at the heart of the company’s global strategy, the new CSR Manager’s mission takes in two key activities in terms of economic, social and environmental issues: Deployment of the CSR policies across the whole EUROGERM group and implementing and managing the CSR action plan by involving all the stakeholders, suppliers, partners, customers, colleagues etc. +++

Syntegon Technology, a globally leading supplier of processing and packaging technology, appoints Dr Michael Grosse as new Chief Executive Officer (CEO). Most recently, Michael Grosse was a member of the Management Board of Tetra Pak. He will succeed Dr Stefan Koenig, who spent a total of 24 years working for the Bosch Group, ten of which at Syntegon Technology, or Bosch Packaging respectively. Since 2017, he has been leading the company as CEO. In 2019, he was in charge of the company’s spin-off from Robert Bosch GmbH and its subsequent sale. +++

Packaging machine manufacturer Gerhard Schubert GmbH once again looks back on a very successful business year. The Schubert Group achieved a 5.3 per cent increase in total operating revenue to 289 million euros in fiscal 2019. +++

The international food group Mondelez is introducing block chain traceability for its biscuit brand "Real Petit Beurre de Lu" in July this year. Consumers scan the QR code on the package by smartphone and receive information about the raw materials. They can find out, for example, where the wheat grown according to the rules of the Mondelez concept Harmony was harvested, who grew it, where the mill is located and when they ground the wheat into flour and where and when the biscuits were baked. The information is linked via the batch number in a block chain, which makes any subsequent change impossible, they say. This block chain allows the consumer to provide proof of local supply of Harmony wheat, a flagship of this program, which aims to grow wheat to exact specifications. Mondelez has chosen Connecting Food's food transparency platform as its partner for the block chain.

Since 2016, Mondelēz International has developed the automation of reporting on local agricultural practices to calculate and monitor 12 economic and agri-environmental performance indicators based on the benchmarks recognised among them: the global nitrogen balance, greenhouse gas emissions, water eutrophication or the index of treatment frequency and evaluation of the added value of the practices of the Harmony Charter compared to conventional wheat. For example, the Harmony Charter encourages farmers to include legumes in crop rotation, as they contribute to the reduction of greenhouse gas emissions by, among other things, reducing the need for fertilisers for wheat. In 2018, 9% of Harmony wheat areas in France were preceded by legumes (compared to an average of 5% in France). In addition, data collection shows that fields farmed under the Harmony Charter are generally treated with 20% less pesticides. +++

+NOWEL, a leading producer of frozen bakery goods in Poland, has launched a state-of-the-art Research and Development Centre that will help optimize current processes and allow the application of innovative production methods. The value of the investment reached a total of PLN 24 million, with PLN 5.5 million funded under the Intelligent Development Operational Program 2-14-2020.

NOWEL continues to invest in production technologies in their factory in Legionowo near Warsaw. The bakery covers 18,000 m² and is one of the most innovative premises of that kind, not only in Poland but in Europe as well. Since 2013, the company has invested almost PLN 200 million in developing machinery, with two cutting-edge production lines launched only in 2017. Currently, NOWEL uses one semi-automatic and five fully automatic production lines. The factory operates around the clock, seven days a week, producing 270 tons of bread every day. 30% of its production is sold on the global market, not just in Europe but also in the United States and South Korea. The laboratory launched in October 2019 constitutes yet another crucial step in the company’s development.

“The construction of the Research and Development Centre is our investment in the advancement of both our bakery and our products. Nowadays, not only do consumers expect their baked goods to be tasty and high-quality, but also they pay attention to the ingredients and the nutritional characteristics of the products they put into their shopping carts and, eventually, on their family’s plates. Ultimately, the laboratory will also be a research unit investigating up-to-date production methods as well as a platform for cooperation with the scientific community in Poland”, said Michal Zajezierski, Vice President of the Board, NOWEL sp. z o.o. [Ltd.].

Within the framework of the Research and Development Centre, NOWEL bakery has established cooperation with two higher education institutions. NOWEL will be conducting research and technological tests in collaboration with the University of Life Sciences in Lublin and the Lodz University of Technology.

The NOWEL bakery is a family company with a tradition of almost 100 years, and one of the leading manufacturers of bake-off products. The company’s history dates back to 1925, when the grandfather of the current owner of the company, Elzbieta Zajezierska, opened a small, artisanal bakery in the suburbs of Warsaw. Today, NOWEL baked goods produced in Legionowo near Warsaw are distributed to the biggest retail chains in Poland and in Europe as well as to non-European markets such as the United States and South Korea. +++

A thinner type of dark portion bread is becoming more popular in Finland. This is why Fazer`s rye bread Oululainen Jälkiuuni Täysjyväruis is following the trend and is now thinner than before. The bread is baked for a long time at a low temperature. This process results in a crisp, rustic crust and firm, but easy to chew middle. Made with 100% wholegrain rye from Finland. The packaging is easy to recycle: the bag as plastic waste and the clip band as metal waste. Recycling instructions are found on the packaging.

Oat is an increasingly interesting ingredient for Finnish consumers and many are aware of its positive health effects. Now oat is boosting the traditional market of rice pasties: Fazer Kaurainen Riisipiirakka has a mild taste and a new, lighter crust consisting of 70% oat and 30% wheat. The pasties are filled with rice porridge as before. Fazer rice pasties are made at the Lappeenranta bakery.

White bread and flatbread are becoming more popular in Finland. White flatbread is particularly popular among families with children and consumers of white portion bread. This is why the Fazer Lemppari product family is growing with a new oaty, soft and round product. It`s low in salt (0.7%).

The recipes and packaging of Fazer Juuresleipä bread are updated in January 2020 – at the same time their packaging will start carrying the Fazer Brainhow and Vegan labels. The Fazer Brainhow label indicates the product’s high nutritional quality and brain-friendly nutrient content. The Vegan label is given to vegan, fully plant-based products that are suitable for an environmentally-friendly diet. All Juuresleipä packaging has at least 25% less plastic than before. +++

Sveba Dahlen is launching a new series of proofers. Smart functions are given high priority to simplify and streamline everyday workflows at the bakery.

+The F-Series proofer concept from Sveba Dahlen belongs to a new generation of proofers jointly developed with bakers from all over the world. Smart functions are given high priority to simplify and streamline everyday workflows at the bakery. The proofers not only give complete control of the entire fermentation process, they are also designed to meet the baker’s need for easy handling and feature well thought-out options for the control panel and for easy cleaning, energy efficiency and long service life.

The F100 is the solution for those who have the possibility to convert a room in their premises into a proofer. Maximum volume is a steam capacity up to 40 m 3 which is achieved by connecting four separate F100 units. The moisturizer is of a very high standard and can be placed anywhere in the space. The location of the digital panel is also flexible and it can be beneficial to have it outside the fermentation space.

F200 – flexible, freestanding and energy-efficient proofer with great capacity and a small footprint. Performance out of

the ordinary with modern technology in the form of ultrasound vaporizers that generate an even flow of moisture for an optimal fermentation process, without the risk of drying out the dough. The proofer’s sleek design means that it suits all environments – from the small in-store bakery to larger supermarkets. It also comes in two colors: stainless steel and black. The proofer’s digital touch panel is easy to use and is placed at an ergonomic height next to the window, which also provides a clear view of the process thanks to LED lighting. The flexible design of the guides means that the proofer can be quickly adapted for different sized trays. The F200 is available as both a retarder-proofer and as a standalone proofer.

“We are delighted to launch the proofer of the future,” says Åsa Ericsson, Head of Marketing at Sveba Dahlen. “This means that we have an extremely enticing offer for our customers who currently choose to buy a rotating mini rack over, for example, the S-Series, from us. They can now achieve even greater volume in their baking using the F200 retarder-proofer as a complement to the oven, at a very reasonable cost. The F200 also serves as an complement to our deck oven, the D-Series,” continues Åsa.

F500 – simply put, our top-class model of freezer-proofer, retarder-proofer and proofer for performing both traditional fermentation and dough-on-demand. Functions as an outstanding complement to our larger rack ovens. Equipped with the latest technology to facilitate the daily work at the bakery. It treats the dough with great care – no more dried-out or over-fermented doughs. The design is well-conceived and adapted to the everyday work of a baker, with features like a user-friendly touch panel, optimized lighting with a daylight effect, and a reliable “oversleep function”. And all 8 models in the series are of course easy to keep clean. “We’ve focused our product development process on optimizing the utility value for bakers; the cabinet must be flexible and quick to clean, and its fermentation, dough retarding and freezing settings must be easily adjustable,” says Ion Folea, R&D Manager, Sveba Dahlen.

The F500 is made of sturdy materials, tried-and-tested components guarantee the cabinet’s performance and long service life. Stainless-steel baking trays and a sustainable plastic drain valve will withstand the stress and strain of bakery production time and time again. +++

Customers demand the highest quality bakery products delivered on time and at the right price. Rademaker understands these challenges. We provide efficient bakery equipment for every possible production environment, based on your specific dough processes and product requirements. Resulting in the lowest cost of ownership in the market yielding maximal results in terms of product quality and return on investment.

We offer equipment for the production of:

• Dough bread / roll lines for bread rolls, Mediterranean breads and flatbreads.

• Dough strip toaster for premium quality toast and sandwich loaves.

• Laminating and processing lines for puff pastry and croissants.

• Dough roll-out lines for yeast doughs, shortcrust pastry, cake, Berliner and donuts.

• Pressing and punching machines for cakes, pies, quiches and tortelettes.

• Pizza bottom and topping machines, application specific dispensers and strewing.

Specialists in food processing equipmentInterview with Henrik Oevermann , CEO DIOSNA Dierks & Söhne GmbH, Osnabrück, Germany, about the consequences of the current crisis.

+bbi: What are the consequences of the current crisis on DIOSNA Dierks & Söhne GmbH in the short and medium term?

+ Oevermann: Since there are new announcements and measures almost every hour to keep the infection curve as flat as possible, meaningful forecasts are currently almost impossible. Like every manufacturing company in Germany, we also see the uncertainty of our customers and our employees. Fortunately, we can rely on Diosna’s “Made in Germany” for 135 years. This enables us to continue our day-to-day production operations almost without restriction. With our high-quality mixing machines and systems, for bakery products, we serve a market for one of the most important staple foods. In this crisis, we are seeing a significant increase in industrially manufactured and packaged products. Our task is to make sure that we do everything we can to meet this need. Whether we can do this in the short and medium term depends on many factors.

+ bbi: Which measures are DIOSNA taking internally and in relation with customers?

+ Oevermann: Our goal is of course to do everything to protect our employees and customers. Our production facilities are so spacious that the work areas are separated from one another. Great importance has always been attached to the topic of hygiene, however, all employees were also informed and quiet a lot are able to work from home, if the situation demands it. Internally and with our customers and partners we meet online, if possible. So far, everyone has responded to the changed behavioural measures with understanding, especially since we can be reached by phone, by customers, both at home and abroad.

+ bbi: What about the ability to deliver, is production at risk?

+ Oevermann: Our customers can rely on us one hundred percent, because our in-house workshops are well organized. Orders that have already been confirmed will of course be processed and delivered. If there are any delays due to illness or from our sub-suppliers, we will inform our customers in good time. Reliable processes have been developed to keep the information up to date. Provided that the production chains work, we can continue to deliver on time. Restrictions naturally result from restricted freedom of travel. This primarily affects our experts, who work closely with the customers, these are our salesmen, technical fitters, technologists, programmers and commissioning engineers. The DIOSNA Group has a large network consisting of its own competent sales and service employees, as well as reliable partners. Depending

on availability, the relevant specialist personnel or partners on site will act quickly. We can therefore cover a very large market and continue to offer a well-structured customer service.

+ bbi: What measures are you taking to compensate for the trade fair cancellations? Are there any options for interested customers to get an idea of the company's performance?

+ Oevermann: As the market leader, we always strive to offer our customers something special. We are currently testing how we can use social media and tools such as 3D scans to interact with our customers. Since it is not possible for every customer to get detailed information from us in Osnabrück, we use digitalization as an opportunity to develop new ways to keep our customers up to date. You can be amazed to see what new ideas we come up with.

+ bbi: What do you generally advise your customers in this uncertain situation?

+ Oevermann: The eagerness of the Germans to organize and regulate was laughed at in many other countries, but situations like this one desperately require these skills. My advice is therefore to keep calm, regionally, e.g. shop at the local bakery and grocer and actively contribute to slow down the increasing of the number of infections as much as possible in order to keep the respective health system functioning.

+ bbi: Thank you for the Interview +++

++ From the smallest handcraft mixers to industrial fully automated large-scale plants –DIOSNA offers solutions for various ways of preparing dough

Palsgaard, supplier of emulsifiers from Denmark, has taken over the Turkish food supplier Teknaroma. Palsgaard acquired 90 % of the company shares, 10 % remain with the previous owners. Teknaroma has been selling Palsgaard products on the Turkish market since 1997. +++

The Sustainable Brand Index (SBI) – the most comprehensive independent brand survey in Europe focused on sustainability – has now released the results of its B2C/businessto-consumer survey for 2020. Lantmännen continues to rank high, in second place among food brands and sixth overall. What’s more, Lantmännen also ranked number one brand on the Swedish market in the B2B/businessto-business survey for 2019, which was published earlier this year. The SBI survey has been performed annually since 2011. For the 2020 survey, 58,000 respondents were interviewed in Sweden, Finland, Norway, Denmark, The Netherlands, Estonia, Latvia and Lithuania. +++

In view of the global spread of COVID-19 (coronavirus) and after close communication with exhibitors and partners, the trade fair company will postpone Bakery China 2020 (originally scheduled on May 6-9, 2020 at Shanghai New International Expo Centre) to July 21-24, 2020 at National Exhibition and Convention Center (Shanghai). +++

A number of bakery chains in the UK have closed numerous locations for the time being in response to the increasing number of corona-infected people and the increasingly strict codes of conduct for consumers and suppliers of goods. Market leader Greggs, for example, closed all 2050 stores. The Sayers bakery in Bolten, which operates almost 150 stores under the name Poundbakery, has also closed down. Birds Bakery from Derby has also closed its 65 stores. Others such as Cooplands from Scarborough (around 150 stores) or Warrens Bakery, one of the most traditional bakeries in Cornwall, have withdrawn from the delivery service. +++

The British confectionery chain Patisserie Valerie, with almost 100 branches, was one of the fixed addresses in the London food service sector. When the parent company had to file for insolvency last year, Patisserie Valerie went to the Causeway financial group. This group reduced the number of locations to 75 and has now merged with its existing chain Bakers+Baristas. Together they manage more than 125 locations in the UK and Ireland. The new director of the joint venture, which will operate under the Bakers & Barista flag, is James Fleming, who was previously head of Euphorium Bakery and UK head of the French chain Paul. +++

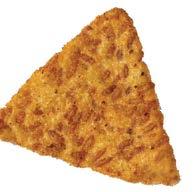

Mexican cuisine is also becoming increasingly popular in Central Europe. Burritos, wraps, tortilla chips and quesadillas are popular snacks, and are based on thin Mexican tortilla flatbreads.

+Whereas its own Tortilla Industry Association has already existed in the USA for a long time, tortillas are also becoming increasingly popular in this country. Traditionally made from corn flour (maize flour), in Europa they are usually wheat tortillas.

The Austrian machine constructor König has already recognized this trend. Manuel Hobacher, the manager of König’s Customer Demonstration Center, says: “We see a trend towards the production of flatbreads such as pita, naan or tortillas, because there is a big demand among consumers for these types of bread. Bakeries can use them to considerably enlarge their product range, especially in the snack area.”

Out-of-house consumption is steadily increasing and is leading to consumers expecting to find snacks available at a wide variety of sales outlets, so Street Food is booming like never before. Expanding the range of snacks by adding tuna wraps, chicken tacos or avocado burritos can mean increased turnover for bakeries.

Processing tortilla doughs can be implemented very well by using suitable technical equipment. König’s Manuel Hobacher explains: “Tortilla doughs are easy to process on dough sheeting lines. The challenge lies in making the dough pieces uniformly thin and circular. The key to this is gentle, stress-free processing of the dough sheet.”

König offers a system, the Menes-H dough sheeter, to allow the production of tortillas as well as bread rolls and breads on a single line.

The Menes-H high capacity plant can process up to 5,000 kg/hour of dough, and is expandable by adding various modules (e.g. a molding station, poppy strewer, punching and cutting tools, proofer). As well as pita and tortillas, the Menes-H offers a wide variety of products including breads, baguettes, bread rolls, ciabatta, toast-bread, pizza, hot-dogs, donuts, cakes, croissants and strudels.

Forming and shaping a thin, stress-free dough sheet is important for thin products such as tortillas. Stresses in the dough sheet cause tortillas to lose their typical circular shape and become oval. Therefore, gentle dough sheet forming from the very start is essential.

The heart of the dough sheeter are plug-in rollers with various surface textures which, according to the company, can process both firm and soft doughs. The company also says the dough sheeter is equally suitable for coarsely-pored ciabatta doughs with a long bowl resting period and a TA (dough hydration) of 185, and for finely porous lye roll doughs with a TA of 150.

Between the specially designed rollers, the dough sheeter creates a uniform, continuous dough sheet with a continuously adjustable dough sheet thickness. The rollers are specially arranged in such a way that the shaped dough sheet adheres to the rollers and is supported by the rollers to prevent it undergoing uncontrolled flow under its own weight. The pneumatic scraper separates the dough sheet from the rotating roller and deposits it onto a conveyor belt for further processing in the plant. As a result, the dough sheet is shaped very gently and free from stresses.

Due to the quick-change system with different widths, the various rollers can be used to set dough sheet widths from 240 to 600 mm. As a result of the accurate adjustment depending on product and weight, scrap dough can be reduced to a minimum.

The Twin Sat double satellite head is an essential component of every Menes plant – it gently reduces the dough thickness to produce a practically stress-free dough sheet. The double satellite head uses two satellite roller heads arranged one above the other to decrease the large mechanical loading. In

Humidity in a thermal process interacts with the product. The moisture in the environment often comes from the product itself and represents a delicate balance affecting finished product quality in many ways. Product throughput can also be affected by when and how much moisture builds in a process. Moisture laden environments reduce baking efficiency, thereby reducing product throughput.

Reading Thermal recently developed the SCORPION® 2 Digital Humidity Sensor to measure humidity in your thermal process. This breakthrough design provides a more accurate and reliable way to measure the absolute moisture content. The sensor contains a proprietary humidity sampling system with patent pending Anti-Saturation Technology™ that allows measurements in high temperature and high dew point processes.

• The amount of moisture in a product can determine its shelf life.

• Reduced evaporation can keep the surface of a product moist, allowing it to stretch, preventing cracks.

• Low humidity in a cracker oven can cause blisters leading to undesirable dark spots and excessive breakage.

• The lack of humidity in a cookie oven can cause case hardening, which prevents internal moisture from escaping and leads to checking.

• High humidity in bread ovens produces the desirable glossy crust on many bread products. For this reason steam injection is often used.

• High humidity will assist with the killing of pathogens, like salmonella, potentially found in surface toppings.

The above graph displays the shape of the humidity profile, the peak moisture value obtained, and where it occurs in your oven. Profiles identify problem areas and allow you to fine tune your process for optimum results.

For details, e-mail us at info@readingthermal.com or call 610-678-5890 ext. 2.

this process, instead of being rolled when trans ported through the machine, the dough is brought to size by a high-speed striking movement.

To manufacture thin flatbreads such as tortillas, König recommends positioning two Twin Sat components one behind the other, to shape the dough gently to the required thinness, thus not allowing any stresses to arise.

Various cutting and stamping tools can be used to punch tortillas with any desired shapes and sizes from the dough. Interchangeable plastic rollers enable fast product changeover. Scrap dough is formed when tortillas are cut from the dough sheet. There are simple options to use 100% of this scrap dough. A conveyor belt designed specifically for the purpose gently and safety lifts it and feeds it, via a transverse belt, to the mixer or a scrap dough portioner, and thus to the dough sheeter.

The entire Menes-H is designed in hygiene construction type “H”. All mechanical drive components, e.g. in the dough

area, are encapsulated, and the use of sealed bearings makes the plant, including the dough sheeter, capable of being washed down. For cleaning and maintenance, the entire dough sheeter can be driven out on its own frame. In addition, the rollers and side-shields can be simply removed and washed separately.

Baking thin tortillas succeeds best when using a tunnel oven, which enables short baking times at high temperatures. König has also offered tunnel ovens for some years. According to the company, the SDD EOS oven is especially suitable for products such as tortillas.

The SDD EOS directly-heated, single deck tunnel oven is a special solution for baking flatbread. Baking takes place using radiant gas burners installed above and below the conveyor belt. Heat transfer to the product takes place mainly via infrared radiation, but also through contact and of course circulating air. This oven can achieve high temperatures (500°C), but can also be regulated down to 150°C. +++

The FoodService Instituut in the Netherlands has looked at out-of-home consumption by the Millennials Generation and by Generation Z. Generation Z includes those born between 2000 and 2015, and thus the successor generation to the Millennials, whose birthdays are from 1980 to 1999. (The dividing line between the generations varies considerably depending on the market observers.) In the Netherlands, the two generations combined include around 4.7 million adults and young adults respectively.

Today, the Millennials Generation in the Netherlands already spends more on out-of-home eating than all the older generations added together. Collectively, according to the FoodService Instituut, in ten years’ time the Millennials Generation and the Generation Z are expected to account for 65% of spending on out-of-home eating. Generation Z is the first real out-of-home generation. Accordingly, they eat outside their own four walls more often than the Millennials. The main factor in this respect is enjoyment, and meeting together for a meal with friends is in second place. In a survey, 84% of the Millennials questioned said they had eaten out-of-home in the past month, and this proportion was significantly

higher among the representatives of Generation Z: 92%. However, the amount of money available among Generation Z is still scarce, which is one reason why they play safe when choosing places to eat, and prefer known formats, discount concepts and all-you-can-eat offers. Although Generation Z is health-conscious and interested in sustainability, it definitely allows itself small escapes into the fast-food world. Among the so-called Digital Natives, young women in particular browse the Net beforehand to see what the choice, prices and discounts look like in the restaurant they have in mind.

Generation Z no longer think in terms of big weekly shopping trips for their household. They buy for the next few hours at most. The shopping destination is chosen depending on whether a shopping trip there is enjoyable and convenient. Consuming large amounts of meat is regarded as old-fashioned, but only 5% of Generation Z see themselves as vegetarians, while 20% say they are flexitarians. Generation Z expects mainly the state and food suppliers to take care to ensure healthy, sustainable food and its production. In Generation Z, as in all the generations, it is the women who consider a healthy diet to be important. +++

The Wave SSP 800 introduces the latest innovation in our high speed extrusion bun divider, providing the ultimate in lane control. Scaling is done via a Servo Sine Pump per each lane. Our large diameter polymer double screws rotate slowly, and prevent dough from sticking. The result is higher quality product, truly round dough balls, with lower shear and substantially lower pressure than our competitors.

•Servo Sine Pump per each line provides unparalleled scaling accuracy.

•High speed, up to 150 cuts per minute

•Output center lines of manifold can be customized to fit existing equipment

•Hygienic divider design and easy access to all assemblies

•Lower formula cost (scaling weight & dough conditioners)

•Tool-less design reduces time for clean up & changeover

•Lower maintenance cost

•Visually inspectable product path

•Available in 6 & 8 lanes

MKW GmbH, Wuppertal, has further optimized the 3000 X slicing machine and re-engineered the plant’s design.

MKW GmbH, Wuppertal/Germany, reports that in addition to a visual facelift, further optimizations were undertaken when redesigning the Rotec 3000 X slicing machine.

This is how the plant operates: first of all, the required product is selected on the controller. The machine then adjusts itself to pre-specified values, e.g. slice thickness, number of slices, product height etc. The operator now positions loaves of bread by hand on the bread feeder table. The loaves are then transferred individually to the feeder belt, thus cycling them into the slicing machine. In the Rotec 3000 X, bread is fed forward via two servo drives: the upper and lower chains. Optical sensors determine the beginning and end of a loaf. If required, these are cut off into the residual scrap. Residual scrap is carried out of the slicing area on two belts and a Z-conveyor.

The slicing machine is also equipped with volumetric bread strand measurement at the bread infeed. The data are used to adjust the slice thickness. After slicing, a portioner accepts the slices and places them pack-wise onto the finger web. The portioner is designed for pack heights from 5 to 20 mm.

The first belt after the finger web is the weighing belt. Combined with volume information, the weighing data are used to regulate the slice thickness. Finally, an outfeed belt carries the bread packages out of the slicing machine and readies them for the downstream periphery.

a. Bread feed table with upstream feeder belt

+ Bread feed table dimensions: 1,500 x 1,500 mm (width x depth)

+ Frequency-controlled drives

b. ROTEC 3000 X circular knife slicing machine

+ Single-channel model

+ According to the patterns, the slicing area is designed for 150 x 150 mm (width x height)

+ 10-slice sections at front and back for strand bread with a length of 1,000 – 1,500 mm

+ Continuously adjustable knife rotation and cutting speed

+ The Rotec has a nominal output capacity of 150 stacks/ minute (at 2 slices/stack) and a gap-closing overload of 200 stacks per minute (with 2 slices/stack)

+ The machine is designed for a rotation speed of up to 550 rpm. However, the actually usable speed is product-dependent

+ The circular knife is oiled by an oiling system (adjustable via the recipe)

The control cabinet is made of stainless steel and arranged above the machines. A Beckhoff Industrial PC is used, programmed in TC3. Remote servicing is also possible. The plant is operated via a 12" multitouch control panel of closed construction and with integrated operating elements mounted at the machine exit point. A product scanner is also offered. According to MKW, this is located upstream of the slicing process and is used to ensure weight-optimized slicing. +++

JAC, a manufacturer of bread cutting/slicing machines and dough processing plants, invested several million Euro in a new production facility in Lüttich, Belgium, in 2019. Productivity grew as a result of the investment, and the family-owned company wants to grow further worldwide.

+The Belgian company JAC can be described as a successful family business. The brand has existed since 1946. Production of the first cutting/slicing machine followed in 1949 – a manually operated model that was to be found in most Belgian bakeries in the nineteen-fifties. JAC’s activities have developed continuously since then – initially in 2000 through the takeover of the Marie/Prodec company, followed by the opening of JAC/USA. JAC also took over the Matfour brand in France, which rounded out the product range of dough production machines. Another member of the JAC family of companies is the traditional German company WABÄMA. JAC took over this bread cutting/slicing machine specialist in early 2018. The Belgian group also acquired the Dutch company ABO in the Netherlands. Bread slicers are now produced in Lüttich.

The research & development teams develop new plants both in Lüttich and in Langres, and the company employs around

150 staff. For example, auto-mode without a start button is an innovation on self-service bread slicing machines. The company also presented the Swift model, which is designed for a high hourly capacity and different types of bread. Another new development is the Bagobag, a plant specifically for cutting / slicing baguettes. After being cut/sliced, the individual slices automatically drop into a bag, which the customer can then take away with them. But JAC can also provide further help when it’s a question of sourdough plants, for example. Thus the company offers the Tradilevain to prepare and conserve liquid sourdough. The machine is available in three sizes (Tradilevain TL40, TL105 and TL220). Mixing takes place using a stirrer in the sourdough, thus guaranteeing homogeneous stirring. There is no need to clean the stirrer device because it is situated at the bottom of the trough. The container has a large, hermetically sealable cover that can be fully opened to allow it to be easily filled with flour and warm water (45°C). The plant is entirely made from stainless steel, and the cooling unit allows control of the temperature in the different production cycles.

The high quality of the machines is important to the family. For example, as CEO Adrien Craeninckx explains, the bread slicer chassis are welded, not bolted or riveted. Chief Sales Officer Volker Gross adds: “It takes around an hour per chassis just to carefully manually grind and polish smooth of the weld seams.” Investment in the new factory doubled production capacity for bread slicing machines. The fabrication unit’s equipment now includes two laser cutting machines, six welding cabins and an automated paint line. As CEO Adrien Craeninckx also explains: “Due to extensive vertical integration, JAC has the process fully under its control, and can respond flexibly to changing requirements.” The

warehouse logistics, now integrated into the production process, saves space and shortens walking distances at the same time. In future, moreover, the intention is to enable spare parts to be delivered ex works within 24 hours. Volker Gross explains: “By pre-producing carcasses, i.e. the supporting frameworks, the aim is to reduce the delivery time for bread slicing machines to only one week after an order is received.” When the customer has selected his color of choice, all that is then necessary is final assembly of the machine, and it is ready for delivery. As a result of the investment, the company now considers itself to be well positioned for the future. +++

As it says itself, JAC possesses a network of 400 approved marketing partners in 80 countries. The familyowned company’s headquarters is located in Lüttich, Belgium, where the company has built up specialist knowledge in the cutting and slicing machines area since its foundation in 1946. The site has its own research & development department. Together with the new building in 2019, the company also invested in new fabrication lines to manufacture bread slicing machines. The site at Langres in France is the second production facility, where manufacture specializes in dough preparation plants, sourdough fermenters, dough dividers and long rollers. This factory also has its own research & development department. JAC has also operated a subsidiary in Boston, USA, since 2006, with a business, technology and logistics unit that looks after customers in North America. In addition, a subsidiary has existed in Moscow, Russia, since 2018. Its customers are various bakeries – from small artisan businesses and medium-sized companies to industrial operations – but also the food retail throughout the whole world. +++

We set our focus on your product!

WE PLAN AND REALISE TAILOR-MADE SOLUTIONS FOR YOUR ENTIRE BAKERY

Koenig is your specialist for planning and equipping your entire production:

MIXING & LIFTING

DOUGH PROCESSING

PROOFING SYSTEMS

BAKING

COOLING

PACKING

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.

+Under the WP Robot brand, WP Riehle presents the first robotic module connected to the COMJET automatic lye application unit. It says the automation increases efficiency when manufacturing lye products, and ensures highly precise cuts in the dough pieces. The new, modular robotic module is used directly after lye application. Lye-dipped dough pieces move automatically into the robot cell, which is equipped with camera technology that uses a laser-3D triangulation method with up to 78 cameras to visually record the dough pieces. Robots then make precise cuts exactly as specified.

The cutting plant is offered with various different cutting techniques. There is a choice between ultrasound, water jet, a rotating knife and fixed blades. The ultrasound knives are available in titanium alloys with various cut widths. The mechanical knives are available with regular cutting blades, rotating circular knives or serrated blades. The water cutting technique generates a fine jet of water that can cut into and through the individual products.

The robotic cutter complies with the high clean design requirements of the meat industry, including fully-encapsulated motors. The entire module can be cleaned quickly and easily with a high-pressure jet cleaner. The company also says the

motors and mechanical parts of the cutter robot are very robust. Consequently, it can run for more than 100,000,000 cycles without maintenance.

The COMJET automatic lye applicator is also characterized by minimum personnel effort with maximum production volume. Due to the fully automatic lye application process, only a single employee is needed to operate the plant to apply lye to up to 300 trays/hour. Feeding can be by a proofed dough roll-off device – and now, as an innovation, with peelboards. The loading trolley is automatically docked onto the loading system, and all subsequent process steps run fully automatically. Dough pieces are accepted at the loading station and fed into the lye application machine, where the lye shower with two additional lye curtains ensures the most intensive lye application and thus high speed. In addition, the belt speed can be regulated to match individual products. After this process, the dough pieces are deposited directly onto a baking tray or transferred to a cutting plant. The COMJET has a 180-liter lye tank, with lye tank heating on request. The electronics offers an abundance of evaluation options via a touchscreen. Special customer-specific models can be fabricated to link directly to downstream processing machines – e.g. tunnel ovens or shock-freezers. +++

Smooth-running: The experience, knowledge and skill of the baker’s trade shows in every step of each process performed by our IMPRESSA croissant systems. Effortless punching and turning, precise coiling along with fully automated bending of filled or unfilled croissants. The entire spectrum of coiled pastries – perfection and volume production combined. Find out more www.fritsch-group.com

is when it all comes together.

bbi: You announced in June 2019 that iba 2021 would be reduced to five days. According to your justification at that time, this was based on a survey of exhibitors and visitors during the trade fair in 2018. But both of these groups are very heterogenous – Mrs. Kabashi, could you please explain to us in rather more detail which groups of exhibitors expressed a wish for a shortening, and who on the other hand were against it?

An interview with Cathleen Kabashi, Exhibition Director of iba, and Michael Wippler, President of the German Bakers’ Confederation, Owner of iba, about planning ideas, Hall layout and the sensitive topic of duration. ©GHM

+ Kabashi: The survey of exhibitors and visitors, together with personal feedback during the 2018 trade fair, motivated us to critically examine the question of duration. After a sixmonth interval, as a result of which it was also possible for follow-up business after the trade fair to be taken into account in the considerations and in the assessment of iba among exhibitors, the entire sector of industry, national and international exhibitors, and stakeholders of the visitors, were questioned about their wishes. The number of participants was larger than average, especially in view of the fact that the survey took place in a non-iba year, which shows on the one hand the great importance of iba in the sector of industry, and on the other how highly sensitive the specific subject of duration is.

The heterogeneity of iba is beyond doubt. This characteristic is also an essential point that makes iba what it is. Therefore, we considered it important that we obtained an objective result for each group of suppliers and providers, which is why exhibitors were given an opportunity, within the survey questionnaire, to classify themselves into one of the following clusters: Production technology, Raw materials and ingredients, Packaging technology, Logistics, Cleaning and hygiene, Shop fittings and furnishings. Thus, the survey yielded not only a good cross-section with respect to the sector as such, but also with regard to different stand sizes. The evaluation gave a clear statement: a shortening of iba duration from six to five days is the majority wish of the entire sector, not just of individual groups of exhibitors.

+ bbi: In the course of recent years, there has been a steady retreat of raw materials suppliers, and with them has also vanished the small-talk between Artisan bakers and their suppliers in the absence of an order pad, which is so important for customer relations. Have you received any signals from the ranks of the raw materials suppliers that their interest in participation would be reawakened by a shortened duration?

+ Kabashi: iba is the biggest networking platform for the bakery sector worldwide, and the only trade fair in which visitors ranging from shopfitters and machine manufacturers to raw materials suppliers can find everything from all around the world gathered together in one place. With the shortened duration, iba will also become attractive again for those raw materials suppliers who no longer had any active participation in the trade fair in past years, as has also already been reflected to us in direct conversations with manufacturers. According to the visitor survey, the truth is that the raw materials area is in the topmost position with regard to visitor interest. Furthermore, we record growth in the numbers of international raw materials producers, which keeps the portfolio of iba comprehensive and attractive. Because an optimum duration is not the only reason for a decision to participate (again) in the trade fair, we are currently making other fine-tuning adjustments in the form of contentdriven formats, to keep iba attractive for raw materials producers, and to expand its attractiveness. Something to look forward to!

+ bbi: Artisans and the industry both want to see new developments at iba, and exhibitors want to present them. As a visitor, I must trudge through all 12 Halls and visit every stand to find out if something really exciting is there, or whether it’s just all talk and a lot of empty words. Is it possible that you might separate the wheat from the chaff at the forthcoming iba, and really provide an opportunity for information and knowledge transfer – either in a special exhibition on the site or digitally via the Internet?

+ Kabashi: Your question has struck a planning chord that will take concrete form in the coming months.

+ bbi: Three years is a long time in today’s business world, and structures have also changed, companies have vanished, others have been bought up and new company groups have come into existence among the suppliers to the baked products sector. What effect is that having on your previous Hall layout? Will there be specialized Halls? Will you continue to keep at least one major corporate group as an anchor exhibitor in each Hall? Will the partly traditional Hall communities continue to exist?