Technical information on wood from Lignum

Lignatec Climate-friendly and energy-efficient construction with wood Basic information and implementation

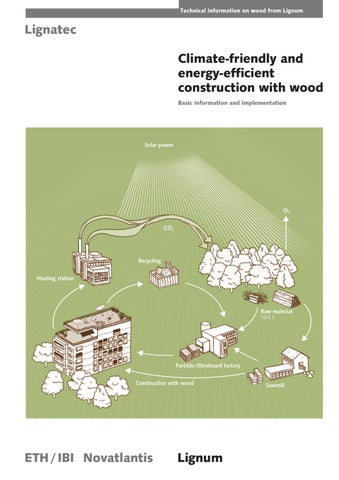

Solar power

O2 CO2

Recycling Heating station

Raw material 50 % C

Particle-/fibreboard factory Construction with wood

ETH / IBI Novatlantis

Lignum

Sawmill