How can seals exposed to wind and weather cope with the powerful forces of multi-megawatt wind turbines with ever-larger shaft diameters? Our researchers and engineers have developed a low-friction, high performance seal that can tolerate strong shaft runout and reliably prevent leaks. This means high operational reliability, longer maintenance intervals, and signi cant cost savings. fst.com

The past few months have been dominated by ample visits to companies and exhibitions. In Stavanger and Hamburg, I had the opportunity to learn about many companies and it also allowed me to have interesting conversations with existing customers about the developments in the o shore industry. Despite the current uncertain economic situation, things look positive for our sector.

The energy transition has been put in a higher gear, and for many companies in our industry this results in various new challenges. Of course, the lack of sta is very well noticeable in our sector, however, in general terms positive sounds from the market can be heard.

While writing this column, O shore Energy Exhibition & Conference is a month away. Still, I already look forward to going to Amsterdam to meet everyone involved in our dynamic industry. Traditionally, we will have our own booth there (B119), so feel free to come by.

In order to make sure not to miss me or one of my colleagues to learn about the marketing opportunities of our magazines and online platforms, we could also make an appointment in advance, so let’s stay connected!

With kind regards,

Rob de Kerf ROB@YNFPUBLISHERS.COM

Rob de Kerf ROB@YNFPUBLISHERS.COM

NHV is the first helicopter operator to carry out a Sustainable Aviation Fuel (SAF) flight in the o shore wind industry, in collaboration with partner TotalEnergies. This project marks the beginning of a long-term collaboration between the two companies to support their commitment to the energy transition. The first helicopter flight using sustainable aviation fuel took place at NHV’s headquarters at Ostend. The NHV helicopter flew a delegation of Elia and Belgian Politicians to Elia’s Modular O shore Grid (MOG1), a platform in the North Sea that bundles cables together from o shore wind farms and connects them to the mainland.

On this flight, the use of sustainable aviation fuel produced by TotalEnergies reduced CO2 emissions by 27%. The sustainable aviation fuel is produced in Europe and made from waste and residues from the circular economy, such as used cooking oils. i. nhv.be

On 10 October at 20:00h local time, the new platform in Brazil, Peregrino C, produced its very first oil. Peregrino phase 2 will extend the Peregrino field life to 2040. Phase 2 adds 250-300 million barrels of oil, while at the same time halving expected CO2 emissions per barrel over the field remaining lifetime. Peregrino phase 2 consists of a new platform with drilling facilities and living quarters tied in to the existing Peregrino FPSO, as well as a new pipeline importing gas to the platform for power generation. The project was on schedule for planned start-up late in 2020 when COVID-19 hit the project hard, leading to cuts in the workforce several times in the crucial and normally labor-intensive hook-up phase. Still, Peregrino phase 2 is delivered within the original USD 3 billion cost estimate. In line with Equinor’s low carbon strategy, measures have been taken to reduce CO2 emissions from the Peregrino field. By switching from diesel to gas for power generation on Peregrino C, phase 2 will avoid 100,000t of CO2 emissions from the Peregrino field per year. This will also reduce costs and simplify logistics in the operational phase.

i. equinor.com

OffshoreEnergyAmsterdam,The Netherlands 29–30 November offshore-energy.biz/offshore-energy-2022

FloatingWind SolutionsHouston,USA30January–4Februaryfloatingwindsolutions.com

WindEurope Copenhagen Copenhagen,Denmark 25–27Aprilwindeurope.org/annual2023

OTCHoustonHouston,USA 1–4May2023.otcnet.org

OMCRavenna,Italy23–25Mayomc.it/en Norshipping2023 Oslo,Norway6–9Junenor-shipping.com

GROW, a consortium of leading o shore wind industry and research partners, started as a six-years innovation programme in 2016, and on 13 October, the GROW partners signed a renewed programme agreement and will continue their innovation activities to 2030. They keep working together to reduce o shore wind costs and increase the value of wind energy in the energy system and the ecosystem. Furthermore, Fugro, GBM Works, Siemens Gamesa Renewable Energy, and TotalEnergies have joined the consortium, which will further strengthen the innovative power of the programme. In the past years, GROW started nineteen projects with a value of about USD 60 million. Projects range from increasing the yield of a wind farm to improving the installation practices and technologies for the foundations of very large wind turbines. GROW creates the visibility of these projects and the partners involved by showing the innovative capacity of the Dutch o shore wind sector. GROW also represents the interest of its partners related to innovation policies and measures in o shore wind and stimulates cooperation with small and medium enterprises and higher education.

i. grow-offshorewind.nl

| Read more on o shore-industry.eu

SSC Steel Shape Cutters BV is a new, competent provider of 3D-profiling: computer-controlled machine cutting of tubes, beams, hollow sections and plate. Sub-contracting does not have to cost a lot, and it will bring substantial savings! With two state-of-the-art machines, we offer a huge range, superb accuracy, and great efficiency. Round tubes up to Ø 2,500 mm OD, with thicknesses of up to 150 mm (oxyfuel and plasma), and robot cutting of beams and sections up to 1,200 mm wide, plate up to 1,200 mm wide and 3,000 mm long. Fast, accurate, and cost effective.

>>

SSC Steel Shape Cutters BV • ‘s-Gravendeelsedijk 200 • 3316 AZ Dordrecht • The Netherlands www.steelshapecutters.nlTel: +31 (0)85 760 3226 E-mail: info@ssc.nl

Dutch heave compensation specialist Seaqualize has signed its first contract for their newly developed o shore lifting device, the Heave Chief 1100 (HC1100). DEME O shore US will deploy the HC1100 on the first commercial scale wind farm installation project in the USA, Vineyard Wind, to transfer delicate wind turbine components to and from heaving supply vessels. The HC1100 is currently the largest active heave compensator in the world. As a balanced heave compensator (BHC), it can compensate a vessel’s heave motions and safely quick-lift loads up to 1,100t, although being battery powered.

i. seaqualize.com

Ocean Energy Europe’s annual event sets sail for The Hague in 2023

Next year’s Ocean Energy Europe Conference & Exhibition (OEE2023) will take place in The Hague, the Netherlands. The Dutch Marine Energy Community, led by the Dutch Marine Energy Centre (DMEC) as platinum sponsor with local support from the Municipality of The Hague, is looking forward to hosting this exciting event in the so-called City by the Sea. OEE2023 will bring together ocean technology developers, decisionmakers, supply chain actors and researchers from around the world to share the latest news from the world of ocean energy, and to define the future direction of the sector. Since the first edition in 2013, the annual Ocean Energy Europe Conference & Exhibition has grown to be the leading European event on ocean energy.

i. oceanenergy.eu

TMC the metals company has successfully collected an initial batch of seafloor polymetallic nodules and transported them up a 4km-long riser system to the surface, in what represents the first integrated system test conducted in the Clarion Clipperton Zone of the Pacific Ocean since the 1970s.

Having successfully completed the at-sea construction of the riser system and its integration with the flexible jumper hose and pilot nodule collector vehicle, the dedicated team of 130 crew and engineers aboard Allseas’ Hidden Gem commenced initial nodule collection runs, driving the pilot collector 147m in one hour on a pre-determined path and collecting 14t of nodules. From inside the collector, nodules were channeled to the jumper hose and into the riser where they were lifted on compressed air in a twelve-minute trip from seafloor to the Hidden Gem, where the return water was sampled before being returned to the midwater column at depth. Meanwhile, aboard a dedicated monitoring vessel, expert industry contractors and independent scientists from leading research institutions from around the world are conducting a complex monitoring program to assess the environmental impacts of the collector system trials using an array of over 50 subsea sensors and monitoring stations. The assets are designed to record any changes in the marine environment that may occur during testing of the collector system.

| Read more on o shore-industry.eu

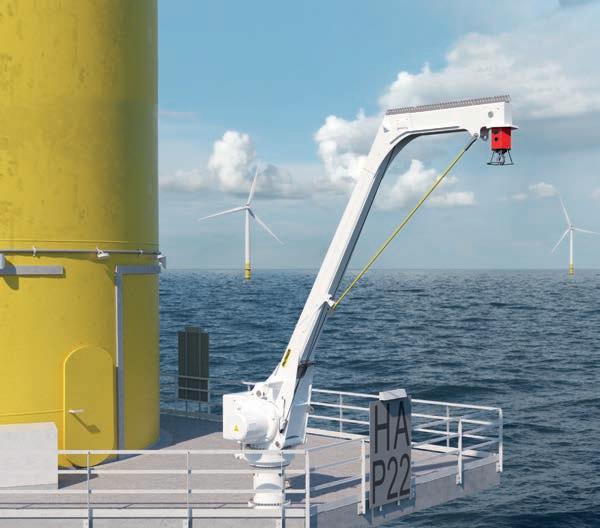

The safe transferring of people and cargo from vessels to o shore assets has taken o in recent years. One of the frontrunners in this development is SMST.

ALL PHOTOS COURTESY OF SMST.Since the company started to develop a range of motion compensated gangway systems, SMST has continuously looked for further improvement. Recently, a unique height adjustment system was added to their modular rental gangway fleet.

According to Menno de Jong, Sales Manager at SMST, business is going well

for SMST in both sales and rentals. “Five years ago, we started our rental business, and since then our gangway fleet has been expanded to eleven systems”, he says. “And, currently, the expansion is continuing. We have four new systems under construction for the o shore support vessel market. For many shipowners our track record with leading companies is proof of our excellent Walk-to-Work solution.”

More and more shipowners choose the SMST products, also for floating wind operations. Ingmar Otter, Commercial Manager of SMST, states, “We have recently successfully deployed our gangway at a floating wind farm. This operation has shown that even for this type of wind farms, despite the combination of turbines moving on the waves and height-changes caused by

tide, our modular gangway setup is an excellent solution to cross fast, safe, and flexible.”

The modular design of the gangways is one of the factors of SMST’s success. Mr Otter explains, “We can o er high flexibility with our modular telescopic access bridge (TAB). The gangway system consists of building blocks that enables setting up a TAB that meets all projectspecific requirements and makes it suitable for every possible operational condition. Both for the transfer of people and for handling cargo up to an impressive 1,000kg for our rental gangways.” Recently, SMST added a unique height adjustment system as a setup option for their gangways. “With our TAB, working on various heights has always been possible by means of stacking modules, and now we have introduced a height adjustment system that raises the flexibility even further”, Mr Otter states.

“The new height adjustment system ensures comfortable crossing and maximum workability at every level of an o shore platform”, Mr De Jong adds. “By means of a rail system attached to the stacking modules, the height of the TAB can be easily adjusted vertically up to 17m. This enables safe and easy connections with a large window of landing heights. The gangways are therefore suitable for deployment in all existing wind farms worldwide and for a wide variety of vessels and operational situations.”

“The height adjustment system is an addition to the modular TAB system in which we already have a lot of knowledge and experience”, Mr De Jong continues. “This means that this system is an innovation based on proven technology, so in fact it is just a matter of plug and play, making it a reliable product that can be installed without extensive preparations. A few of our partners have already experienced this and are pleasantly surprised with the fast mobilisation time. Due to the building blocks, the entire gangway system can be installed in just one day.” Apart from this, the modular gangway systems have more advantages, such as a small deck space footprint and avery low energy consumption.

“When looking more in detail to the low energy consumption”, Mr De Jong explains, “this is realised by making the gangway self-balancing, for which no additional energy is needed. This results in a gangway that has the lowest energy consumption and the lowest installed power in the market. This is important from a sustainability perspective, and also because it enables our systems to be installed on smaller vessels that often don’t have enough capacity available on board for powering additional tools such as gangways.”

At sea, all equipment has to deal with harsh and demanding circumstances. Data collection and data analysis are important tools for SMST to keep control over the operability of their fleet of gangways. “We stay in touch with our equipment 24/7 by collecting data we retrieve from the various sensors on our gangways. Analysing this data helps us to optimise the operations of the gangways”, Mr Otter elaborates. “For us, the data-driven decision-making process is very valuable. It supports us in taking steps for, for example, preventive maintenance, and in further improving our systems. We want to keep our systems at the forefront of autonomy and intelligence. The next step we are aiming for, is integrating our gangway systems with the DP, communication, and propulsion systems of the vessels. In the end, this could result in autonomous operating systems.”

With their innovative and flexible gangway systems, SMST is at the front row of the market. In addition to the gangways, SMST also o ers a range of 3D motion compensated cranes, Access & Cargo Towers, and cargo handling equipment. “End of November, we will be exhibiting at O shore Energy Exhibition and Conference in RAI Amsterdam. Of course, we look forward to meeting you there, and to show and tell you all about our range of products”, Mr Otter concludes.

i. smstequipment.com

plays a pivotal role. The o shore

sector is in the middle of all

Canan Acar, Assistant Professor of Thermal Engineering at the University of Twente.

Session: The Roadmap of Hydrogen

Arnoud Kuis, Managing Director O shore Wind at Van Oord.

Session: Opportunities in O shore Wind

The content program of O shore Energy Exhibition & Conference 2022 (OEEC) gives an overview on what is going on and singles out important drivers of change. This year hydrogen, floating wind and CCS will be in the spotlight. O shore renewables like wind, wave and solar take the stage, together with the maritime industry and fossil energy.

Harry Brekelmans, plc’s Projects & Technology Director at Shell.

Session: The Executive Outlook

Barend Jenje, Commercial Director Floating Wind at GustoMSC

Session: Floating O shore Wind

In an inspiring setting, thought leaders and industry experts come together to share knowledge and discuss the latest trends. From specific presentations on game changing developments to translating global trends to the o shore sector, the OEEC conference program gives you the opportunity to increase your industry knowledge.

their invention, new product, process, or services.

Tuesday 29 November | 10:00 – 11:00

The event at RAI Amsterdam is considered one of Europe’s leading events for the entire o shore energy industry. Around 9,000 visitors and exhibitors will be present, and therefore the event o ers an excellent opportunity to reach business leaders, highly qualified experts, and professionals across global markets.

When it comes to hydrogen, the ambitions are sky high. But how does the society transform into a hydrogen economy? Panel discussion and presentations are going to tell the story on how hydrogen is going to be integrated in our lives.

Tuesday 29 November | 11:30 – 12:30

Floating o shore wind turbines make renewable energy accessible to other parts of the world. Is it the game changer the energy transition is waiting for? The focus of this session will be on the opportunities this innovation brings to the supply chain, and the new regions where floating wind can be a solution to create renewable energy.

wave, and solar will take the stage, together with the maritime industry and fossil energy.

Tuesday 29 November | 13:30 – 14:45

Wednesday 30 November | 10:00 – 11:15

Governments around the globe commit to o shore wind. This is generating a lot of business opportunities for the supply chain. High demand also creates challenges, from aligning the supply chains to grid capacity and the need for qualified personnel to create future wind parks.

Energy is grabbing the headlines daily. When it comes to fighting climate change or from the viewpoint of foreign dependency, energy plays a pivotal role. The o shore energy sector is in the middle of all these developments and the content program of OEEC 2022 gives an overview on what is going on and singles out important drivers of change. At the event, di erent markets meet under one roof to foster business opportunities and to learn from each other. This year, hydrogen, floating wind, and CCS will be in the spotlight. Apart from this, o shore renewables like wind,

The Executive Outlook

Wednesday 30 November | 13:30 – 14:45

The world is changing fast. What does it entail to lead a company in these turbulent times, where it is not business as usual? Expect insight information from business leaders that represent the di erent markets that together form the o shore energy sector. Because market collaboration is key when it comes to solving today’s problems.

By exhibiting at OEEC 2022 companies make themselves visible at the heart of the o shore energy industry. It gives the opportunity to present products and services, to expand networks, and to connect with experts and professionals across global markets. Companies that are operating in the hydrogen industry and are looking for opportunities and collaborations within the o shore energy sector can join the dedicated Hydrogen Area and the Startup Zone is the place for companies to showcase

Waters around us can create a supply of unlimited energy. So, what is going on when it comes to marine energy? Expect an update of the latest developments and insights from the industry and the broad perspective and outlooks when it comes to marine energy. Companies and policy makers share their knowledge. This session is powered by DMEC.

Wednesday 30 November | 15:30 – 16: 30

The future starts now. How do you make decisions in a fast-changing world? Because the challenges are there. How are we going to move to a net zero supply chain? How important is it for your company to become more sustainable? With the reality that we need fossil energy too, to make the transition to renewables. How necessary is energy independency in a world that is becoming more unstable?

With panel discussions, presentations, and after talks, experts and industry leaders focus on the changing o shore energy landscape. The conference program is titled ‘The Future of O shore Energy’. It includes, among other things, conference sessions, The Stage, masterclass sessions, and a matchmaking program. During the conference sessions thought leaders and industry experts come together to share knowledge and discuss the latest trends. From specific presentations on game changing developments to translating global trends to the o shore sector, the OEEC conference program gives you the opportunity to increase your industry knowledge. At The Stage, an open stage on the exhibition floor, di erent aspects of the o shore energy sector are placed into the spotlight. You can visit The Stage for market insights, interviews, and views

The event at RAI Amsterdam is considered one of Europe’s leading events for the entire offshore energy industry.

conference@o shore-energy.biz.

O shore Energy Exhibition & Conference at a glance

Date: 29 and 30 November 2022

Opening hours:

from the next generation. The OEEC reporter is present to share interviews from the exhibition floor. All items are instantly available for the participants to share. The Dutch Government hosts a program during OEEC 2022 with exclusive masterclass sessions on

o shore wind and hydrogen. The matchmaking program is available to all visitors, exhibitors, and participants of the event.

• Tuesday 29 November 2022: 09:30h – 18:00h

• Wednesday 30 November 2022: 09:30h – 18:00h

Get in touch with ±450 exhibitors from the o shore wind, oil and gas and marine energy sector at the exhibition floor. Make sure to check out the Hydrogen Area - this year’s new feature - the Start Up Zone, and the country / regional pavilions. Make sure to make use of the matchmaking tool which is available for all event visitors to connect up to the event to enable one-on-one meetings and round table sessions during OEEC 2022.

i. offshore-energy.biz

Venue: RAI Amsterdam Convention Centre, Europaplein 24, 1078 GZ Amsterdam, the Netherlands.

All carbon-neutral options are needed in the future fuel mix to meet existing and accelerated targets to decarbonise shipping. This creates a big challenge for deciding what fuel production, distribution and bunkering infrastructure to invest in, and which on-board technologies to choose.

DNV’s sixth Maritime Forecast to 2050 presents the findings of an enhanced GHG Pathway Model running 24 updated fuel scenarios to generate insights for decision-making processes to achieve more robust and future-proof emissions-reduction solutions for shipping.

The Maritime Forecast to 2050 report uses an enhanced version of the GHG Pathway Model to build and run an updated portfolio of scenarios to explore the fuel transition ahead. The modelling shows that the future fuel mix is highly

dependent on underlying assumptions, notably regarding fuel prices and policy ambitions. Vessel owners therefore need transition plans that reflect the uncertain future, and flexible fuel solutions that provide robustness and reduce carbon risk.

The model updates DNV’s portfolio of decarbonisation scenarios for investigating what will determine the future fuel mix and uptake of carbonneutral fuels. The scenarios are applied to assess fuel costs by region. The report also illustrates what impacts regional fuel production and infrastructure will have on the fuel mix. The results highlight key factors for achieving specified decarbonisation pathways. Using scenarios can assist strategic decisions on newbuilding and onshore fuel infrastructure for an industry that needs to be flexible and resilient to a range of possible regulatory and technology futures.

DNV explored twelve scenarios (Figure 1) in each of two decarbonisation pathways: IMO Ambitions, in which shipping achieves the ambitions in the current IMO GHG Strategy to halve total GHG emissions by 2050 compared with in 2008, and full Decarbonisation by 2050. Six ‘fuel family’ variations, simulate the availability of sustainable biomass to produce biofuels (for example bio-MGO), renewable electricity to produce electrofuels (for example e-MGO), and fossil fuels with CCS (so called blue fuels). For each of these three fuel families, ‘High’ or ‘Very high’ fuel-price advantage are assigned to one fuel family over the others on a basis described in the report. Three cost variations are explored for specific fuel types, in which changes in the relative cost di erences between fuels within each family are explored (as described fully in the report).

Figure 2 shows the energy mix in midcentury for each of the 24 numbered scenarios in Figure 1. The report describes the 24 energy mixes in fuller detail, but illustrative highlights include: IMO ambitions scenarios (scenarios 1-12): fossil fuels have a 53% to 63% share in the total energy consumption of the fuel mix. The share of carbon-neutral fuels (not including electricity from grid) is 30% to 40%. Decarbonisation by 2050 scenarios (scenario 13-24): fossil fuels are eliminated. All scenarios: around 3.5% of total energy is from grid electricity, mainly from shore power, but also from battery-driven ships.

Figure 2: The uptake in 2050 for each fuel type, expressed by the range from minimum to maximum across all scenarios within the pathways IMO ambitions and Decarbonisation by 2050.

According to DNV in most of the scenarios, around 5% of the energy use in 2030 is from carbon-neutral fuels. Under IMO ambitions, this grows to around 20% in 2040, depending on the scenario. In Decarbonisation by 2050, the share of carbon-neutral fuels

reaches 40% to 50% in 2040. Some carbon-neutral fuels dominate the 2050 energy mix in at least one scenario, namely bio-MGO and e-MGO, bio-LNG, blue ammonia and e-ammonia, and bio-methanol. Among carbon-neutral fuels, the share of carbon-neutral dropin fuels (bio-MGO, e-MGO, bio-LNG, e-LNG) is greater in IMO ambitions

scenarios than in Decarbonisation by 2050 scenarios.

DNV’s survey shows that the narrow range of fuel families that will contribute to the 2050 energy mix for shipping reflects how policy decisions are the main influencers of uptake of carbonneutral fuels. According to the company it is only in the ‘Very Low bio’ and ‘Very Low electro’ scenarios that one can see a slightly lower fossil share, and this is attributed to biofuels and electrofuels being cost-competitive with fossil in some regions. Biofuels dominate the carbon-neutral fuels’ share in scenarios where the bio price is advantageous (‘Low bio’ or ‘Very Low bio’). Where electrofuels have the price advantage (‘Low electro’ or ‘Very Low electro’) they can outcompete bio-alternatives.

In the IMO ambitions scenarios (Figure3), the bio- and electrofuel families include drop-in fuels compatible with conventional fossil fuel technology: namely bio-LNG or e-LNG for LNG, and bio-MGO or e-MGO for MGO/LSFO. The blue fuel family lacks drop-in options, and bio-alternatives therefore also dominate in the IMO ambitions scenarios where blue fuels are assigned price preference (‘Low blue’ or ‘Very Low blue’). In these, fossil fuel prices are also low. Consequently, drop-in solutions in which either cheap fossil fuel or expensive biofuel can be used outcompete those that need more expensive on-board fuel technology and storage.

All fossil fuels are removed by policy requirements when it comes to the Decarbonisation by 2050 scenarios (Figure 4). In these scenarios, biofuels dominate the mix when the bio- price is advantageous (‘Low bio’ and ‘Very Low bio’) but are also much in evidence when blue fuels are given preference (‘Low blue’ and ‘Very Low blue’). Blue fuels attain only a 58% share even under the most advantageous conditions. Where they have the price advantage (‘Low electro’ and ‘Very Low electro’), electrofuels can outcompete the bioalternatives.

In general, the share of drop-in fuels among carbon-neutral fuels is less in Decarbonisation by 2050 scenarios than in IMO ambitions. This is because the decarbonisation regulations require all ships to be fully carbon-neutral when 2050 is approaching (and newbuilds from 2040). Hence, more ships tend to invest in ammonia or methanol technology instead of fulfilling the requirements with carbon-neutral dropin fuel. Aside from newbuild and retrofit costs for vessels, shipowners contemplating the energy transition are likely to factor in fuel availability and decisions by other stakeholders. The availability of carbon-neutral fuels and relevant technologies will be critical to achieving either the IMO ambitions or Decarbonisation by 2050 pathways. The modelling varies fuel prices to simulate fuel-supply constraints. For example, if there is insu cient sustainable biomass to meet demand, its consequently high price will lead to either the ‘Low electro’ or ‘Low blue’ scenarios in which lowerpriced electro or blue fuels, respectively, will replace biofuels.

Achieving each scenario will require substantial investment in on-board technologies for vessels to use new fuels, and in onshore infrastructure for producing and distributing carbonneutral fuels. Fuel infrastructure investments outpace on-board investments in almost all our scenarios. Decarbonisation by 2050 would need about 150% more investment than IMO ambitions. About USD 28 billion to 90 billion per year will be required to scale up onshore production, fuel distribution and bunkering infrastructure to supply 100% carbon-neutral fuels by mid-century. The largest onshore investment needs are for renewable electricity production and electrolysis plants. These occur in scenarios with ‘Low electro’ and ‘Very Low electro’ prices and high uptake.

In DNV’s modelling, carbon-neutral fuels, disadvantaged by their higher cost, make a limited contribution to emission reduction before 2030. Until then, requirements are met mainly by LNG’s

increasing share in the mix, energye ciency measures, logistics improvements and speed reduction. Beyond 2030, carbon-neutral fuel use grows to become the dominant measure for reducing CO2 emissions beyond the year 2040. Nevertheless, multiple stakeholders are already considering what advantages there might be for first movers initiating projects making carbon-neutral fuels available at volume in specific regions. These players include vessel and cargo owners, finance, fuel providers, energy majors, governments and ports, including some involved or interested in green shipping corridors. To demonstrate how modelling can inform decision-making for this purpose, DNV has run Decarbonisation by 2050 scenario 19 with increased (‘High’) initial availability of ammonia in Europe and South East Asia. The results show significant short- and long-term increases in uptake with higher initial availability. Uptake of ammonia also increases in other regions, such as Middle East and North Africa), and globally (Figure 5).

The initial availability in selected regions has ripple e ects beyond their borders, and they have seen this pattern before in the uptake of LNG and batteries in shipping. DNV expects similar e ects for other carbon-neutral fuels assigned favourable conditions in the scenario design. Driven by procurement requirements from governments, uptake of LNG and batteries was assisted by infrastructure first being developed locally, then nationally, then regionally and globally. It illustrates that the public sector can be an important enabler for phasing in new low-emission technology in shipping. The challenges and opportunities illustrated in DNV’s modelling can only be solved by strong alliances among the sector’s stakeholders and with other industries competing for carbon-neutral fuels.

i.dnv.comMultiple stakeholders are already considering what advantages there might be for first movers initiating projects making carbon-neutral fuels available at volume in specific regions.

“

This year has flown by for Rometal. According to Martijn van Manen, Director Project & Sales, the company can look back at a successful period.

Looking back on the period behind us, we can only be happy and grateful that we have been able to carry out beautiful projects for our clients again”, Mr Van Manen says. He continues, “The most important thing is

that all the Rometal employees, who are actually the ones that ultimately matter, both in the Netherlands and in Romania, and at various locations on board, were able to execute our projects safely and successfully.”

This year has not been without disputes and the upcoming years will ask a lot from the industry. “The biggest challenge for now and in the future,” Mr van Manen says, “ is to find enough qualified

personnel to carry out the projects safely and according to all requirements. In addition, due to the terrible war in Ukraine, managing the current raw material prices is a major challenge which the entire steel processing market is facing. Despite these challenges, currently there is a high demand for carrying out medium- and long-term projects.”

Due to the current market developments and the expected strong demand for the future, Rometal is currently busy with adapting and strengthening its organisation at its two locations and preparing them for the future. “Obviously, we want to keep ourselves in a position in which we are able to continue to serve our clients in the future and this asks for a strong and fit organisation”, Mr Van Manen explains.

Besides the Dutch government, other, mainly Western European, countries also

have big plans to become energy independent in the future. Mr Van Manen states, “Since more than 80% of our order portfolio comes directly or indirectly from the o shore wind energy sector, we look forward to the future with confidence and we are convinced that, with our services, we can contribute to the

Rometal will be exhibiting at the O shore Energy Exhibition and Conference that will take place on 29 and 30 november in Amsterdam. “We are excited to be present in Amsterdam again, where we can meet our customers and partners and discuss the opportunities and possibilities in the market with each other face to face. For the o shore wind sector, O shore Energy is a worldwide well-known event and therefore important for us to participate in”, Mr Van Manen concludes.

i. rometal.com

energy transition of many countries.”

“Looking back on the period behind us, we can only be happy and grateful that we have been able to carry out beautiful projects for our clients again.”Martijn van Manen – Director Projects & Sales of Rometal. Load-out of a piling template. More than 80% of Rometal’s portfolio comes directly from offshore wind.

With its many advantages, 3D-printing is becoming more and more popular in technical solutions. Royal3D (part of Royal Roos) is your partner for 100% recyclable 3D-printed special transport and storage cradles and supports for transport over sea, road, or by air.

3D-printing allows full freedom of form, ensuring a perfectly fitted cradle or support. Material is lightweight but strong and special shock absorbing layers can be incorporated in the print. Regardless of the size of the products, the company can make any kind of perfectly fitting customised support.

The additional use of customised packing inserts for boxed products helps prevent shifting that could potentially harm the goods. This is especially interesting for sensitive and valuable

goods during transportation and storage. After usage, all 3D-printed items can either be reused or Royal3D can take back the parts to shred and recycle them into new 3D-print material, o ering a fully circular sustainable approach towards waste-free transportation and storage packaging.

Royal3D can o er complete printing solutions ranging from engineering services such as AM on demand, design and digital tools, and research and prototyping. Thanks to a combination of technical engineering knowledge and

3D fabrication power, the company is able to provide scalable solutions from concepts to product. The company has a centrally located quay side and a storage and packing facility of over 1,500m2 in the Merwehaven in the port of Rotterdam. The facility is powered via 1,500m2 of solar panels. With their facilities the company has full control over specia l product transports while investing in the future of green shipping in the meantime.

i. royal3d.nl

The Dutch government recently announced its revised plans for the further growth of o shore wind until 2050 to accelerate sustainability of industry and society.

In these plans, o shore wind should provide 50GW of power in 2040 and 70GW in 2050. For realising its sustainability goals, o shore wind at sea should grow faster after 2030 than expected, which is why now is aimed at the maximum of what was thought to be necessary. Currently, goals are set at

21GW in 2030, which is around 75% of the currently used amount of electricity in the Netherlands.

Next to the o shore generation of electricity, the Dutch government also aims for large scale hydrogenproduction

at the North Sea. This way, a large part of the industry will be able to switch from natural gas to green hydrogen. As of 2030, o shore wind will be generated at more North Sea areas, hundreds of kilometers of the coast. Therefore, energy hubs must be realised at sea. Apart from using the hubs as connecting

0,75 Borssele, kavels I en II

Implemented in 2016 2020 Operational

0,75 Borssele, kavels III, IV en V Implemented in 2016 2020 Operational 0,76 Hollandse Kust (zuid), Sites I and IIImplemented in 2017 (2022-2023) Under construction 0,76 Hollandse Kust (zuid), Sites III and IVImplemented in 2019 (2022-2023) Under construction 0,76 Hollandse Kust (noord), Site VImplemented in 2020 (2023) Under construction approx. 0,7Hollandse Kust (west), Site VI Implemented in 2022 (2025-2026) Planned approx. 0,7Hollandse Kust (west), Site VII (2025-2026) Planned approx. 1,0IJmuiden Ver, Site III

Fourth Quarter of 2023

(2028) Planned approx. 1,0IJmuiden Ver, Site IV (2028) Planned approx. 1,0IJmuiden Ver, Site I (2029) Planned approx. 1,0IJmuiden Ver, Site II (2029) Planned approx. 1,0IJmuiden Ver (noord), Site V

Second Quarter of 2025 (2029) Planned approx. 1,0IJmuiden Ver (noord), Site VI (2029) Planned approx. 2,0Nederwiek (zuid), Site I (2030) Planned approx. 2,0Nederwiek (noord), Site II 2026* (2030) Planned approx. 2,0Nederwiek (noord), Site III (2031) Planned approx. 0,7Hollandse Kust (west), Site VIII2026/2027**

TBD ** Planned approx. 0,7Ten noorden van de Waddeneilanden, Site I 2026/2027* (2031) Planned approx. 2,0Doordewind, Site I 2027* (2031) Planned approx. 2,0Doordewind, Site II 2027* (2031) Planned

Table courtesy of Netherlands Enterprise Agency.

*The tender dates for these offshore wind farm sites are indicative. A final decision on the planning is expected in 2024, based on the results of the research programme –Programme for Offshore Wind Energy Landfall – Eemshaven (PAWOZ - Eemshaven) for Ten noorden van de Waddeneilanden and Doordewind, and the research into landfall for Nederwiek Site III.

**The tender date for this Wind Farm Site is indicative. Pending clarity on Tata Steel’s plans currently under development to make the energy supply and production process more sustainable, further decisions will be made with regard to this matter. The decisions regarding the landfall of the relevant section of the offshore grid will be related to this.

Borssele 1

Site V Two Towers, 19 MW

Site III and IV Blauwwind, 731,5 MW

Site I and II Ørsted, 752 MW

Hollandse Kust (zuid) 2

Luchterduinen 129 MW

Site III and IV Va enfall, 760 MW Site I and II Va enfall, 760 MW

3

Hollandse Kust (noord) Egmond aan Zee 108 MW

Site V CrossWind, 759 MW

Prinses Amalia 120 MW

Hollandse Kust (west) 2.100 MW tender sites VI and VII: 2022 tender site VIII: to be determined

Ten noorden van de Waddeneilanden 700 MW tender to be determined

IJmuiden Ver 6.000 MW tender(s) sites I to IV: 2023 tender(s) sites V and VI: 2025

Nederwiek 6.000 MW tender site I: 2025 tender(s) sites II and III: 2026 (indicative)

7 Doordewind 4.000 MW tender(s) sites I and II: 2027 (indicative)

points for the various wind farms, they will also be used for the production of green hydrogen. The energy produced o shore can be transported partly as electricity and partly as hydrogen to the shore which will save money and

reduces the need for onshore space. Through the hubs, connections with other North Sea countries will be realised too, which contributes to a higher supply security.

A few days before the Dutch

As of 2030, o shore wind will be generated at more North Sea areas, hundreds of kilometers of the coast.

Liftal Vlissingen

Groenlandweg 4 Havennummer 4056 4455 SN Nieuwdorp (Vlissingen-Oost)

Tel: +31 (0) 118 - 488 450 Email: vlissingen@liftal.com

Liftal Rilland De Poort 15 4411 PB Rilland

Tel: +31 (0) 113 - 571 523 Email: rilland@liftal.com

Liftal Rotterdam p/a Admiraal de Ruyterstraat 24 3115 HB Schiedam

Tel: +31 (0)10 - 60 036 60 Email: rotterdam@liftal.com

Liftal Belgium Duitslandstraat 4 9140 Temse

Tel: +32 (0)3 710 11 82 Email: temse@liftal.com

The growth of wind energy at sea must be realised while taking other interests at the North Sea, such as fishery and nature, into account.

announcement, nine European North Sea countries, that are united in the North Sea Energy Cooperation, agreed to jointly develop 260GW of wind power at the North Sea until 2050. Earlier this year, it was also agreed that Belgium, Denmark, Germany, and the Netherlands will work more closely together at the North Sea. The planned energy hubs of these countries will be interconnected. This will lead to a more robust energy systems for all countries.

The growth of wind energy at sea must be realised while taking other interests at the North Sea, such as fishery and nature, into account. More o shore wind farms will lead to more ecological e ects that will be monitored very carefully. Also, enough space must be left for other activities at the North Sea, such as food production and shipping. The Dutch government targets at research to map all possible e ects of o shore wind farms. In the Programme North Sea, the Dutch government investigates how all interests can go together in a proper manner. For this, the government also talks with all parties involved in the so-called North Sea consultation. Apart from this, o shore wind farms will be constructed in a natureinclusive way so that they could also have positive e ects on the underwater nature. Rob Jetten, Dutch Minister of Climate and Energy, says, “Earlier this year, we have already set firm plans for 2030 and now we present an ambitious plan for 2050. 70GW is very challenging and in the upcoming years we will investigate how much of GW will be exactly needed. This enables us to sustainably electrify a large part of the Netherlands and produce green hydrogen, for example for the industry. In doing so, we will work carefully with a good eye for nature above and under water, as well as for other interests at the North Sea, such as the production of food, the shipping sector, defense, and coastal protection.” i. government.nl

Corinth Pipeworks has been awarded a contract for the development of a 28km long o shore and onshore natural gas pipeline by Gastrade.

The pipeline will connect the Alexandroupolis Floating Storage and Regasification Unit (FSRU) to the National Natural Gas Transmission System of Greece for the transportation of gasified LNG to Northeastern Europe, with the prospect of also supplying Ukraine.

The Alexandroupolis FSRU is a floating LNG terminal that will provide 5.5m3 billions of natural gas annually when completed to the markets of Greece, Bulgaria, Serbia, and North Macedonia. It will be permanently moored at a fixed point and at a distance of 17.6km SW from the port of Alexandroupolis and 10km from the nearest coast of Makri.

Corinth Pipeworks’ proposal was evaluated by contractor Saipem as the most advantageous, providing a both technically and economically feasible solution. The o er consists of 28km of 30” SAWL steel pipes, which also includes anti-corrosion coating and concrete weight coating. The entire quantity of pipes will be manufactured and externally coated at the company’s plant in Thisvi, Viotia, Greece. Deliveries are scheduled to begin in 2023.

The development of the pipeline plays a decisive role in the energy security of Greece and Southeastern Europe and contributes decisively to the smooth energy transition and heterogeneity of

supply to this extremely sensitive region. The pipeline’s construction and operation will also strengthen the strategic role of Greece as an energy hub for the wider region and will o er alternative sources and routes of natural gas supply, strengthening security of supply and energy autonomy, in a challenging period. The new infrastructure is tied to other interconnection projects, such as the Gas Interconnector Greece-Bulgaria (IGB) that will be operational from September 2022, but also the important gas links between Bulgaria, North Macedonia, and Serbia. Through these recent and new projects, these countries will be able to reduce their dependency on Russian natural gas by diversifying their routes and sources of supply.

The pipeline is part of the Alexandroupolis Independent Natural Gas System project of Greece company Gastrade. The Final Investment Decision (FID) for the construction of the Alexandroupolis INGS project was taken in January by the shareholders of this company. Alexandroupolis INGS is included and financed by the Operational Program of the NSRF ‘Competitiveness, Entrepreneurship and Innovation 2014-2020’ (EPAnEK), with an amount of public spending of EUR 166.7 million. The floating terminal is expected to operate by the end of 2023, with the contracted regasification capacity already reaching up to 50% of its technical capacity of 5.5m2 per year.

i. gastrade.gr i. cpw.gr

With assets growing in weight and size, much is asked of the lifting and hoisting tools used in the o shore industry. To meet this development, Safe Lifting Europe is constantly working on keeping its portfolio of rental equipment up to date.

Oshore professionals use Safe Lifting Europe to source lifting and rigging equipment for short- or long-term rental. Being specialised in serving the dynamic and demanding heavy lifting sector, the company works with the lifting industry’s top manufacturers to deliver solutions up to any capacity.

Throughout the years, Safe Lifting has been providing lifting and hoisting

equipment to many well-known internationally operating customers.

Jacques Vroegop, Operational Manager at Safe Lifting Europe, explains, “When considering the costs associated with purchasing lifting equipment, the rental solutions o ered by Safe Lifting often are more favourable. In addition to initial purchase price, equipment owners must also budget for maintenance, periodic re-certification, storage, and more.”

Apart from this cost advantage, renting lifting and rigging gear at Safe Lifting

also adds value and e ciency in other ways. “We not just supply a tool,” Mr Vroegop adds, “as from start to finish we can supply everything for a project, including drawings, engineering, people, and planning.”

A look at Safe Lifting’s rental portfolio shows a comprehensive list of equipment. It includes a huge range of lifting, testing, site operations, marine operations, ROV, and hydraulic equipment. Mr Vroegop continues, “We started our business as a reply to market demands, and today we serve clients around the globe by providing high quality equipment. Clients reach out to us for single items, but also for all the equipment they need for an entire project. They know us as a company that delivers only world-class equipment. Whether it is a force measurement device, a spreader beam, a shackle, or any other below-the-hook tool, all our products are supplied with the high safety standards of the o shore industry in mind.”

“With our background”, Mr Vroegop elaborates, “we are familiar with deadlines, SHEQ requirements, and high standards. Each order involves thorough consultation. This way the products supplied are designed specifically for the application in hand. Our experts carry out quality assurance (QA) checks before

any lifting and rigging gear leaves the facility and upon its return from site. Of course, we advise our customers on using the equipment, but on request we can also o er our own trained and qualified personnel to do the lifting operations. In terms of products, we have everything from A to Z, but having our own specialist personnel means that we are a true one-stop-shop.”

Based in Vlaardingen, in the heart of the Port of Rotterdam, the company started business with a focus on the o shore oil & gas industry, however, the company’s services are also highly suitable for sectors outside of the oil & gas realm. “Today, we have clients from sectors as diverse as onshore construction and engineering, and inland shipping”, Mr Vroegop states. “We are of course still involved with o shore clients, where the energy transition is significant. As wind turbine components become bigger and heavier, the relevance of safe lifting operations becomes even more important. For our customers, Safe Lifting is a trusted brand. It is this confidence that puts the ‘safe’ into Safe Lifting’s name. In a complex lift with multiple components, it is imperative to know exactly how each element will behave. And because we know all the ins and outs of all our products, we can call ourselves Safe Lifting.”

i. safelifting.eu

“In terms of products, we have everything from A to Z, but having our own specialist personnel means that we are atrue one-stop-shop.”Jacques Vroegop – Operational Manager at Safe Lifting. Being specialised in serving the dynamic and demanding heavy lifting sector, Safe Lifting works with the lifting industry’s top manufacturers to deliver solutions up to any capacity. Whether it is a force measurement device, a spreader beam, a shackle, or any other below-the-hook tool, all products are supplied with the high safety standards of the offshore industry in mind.

In the o shore industry, a lot of attention is paid to technical innovations and production improvements. However, the human factor cannot not be overlooked as o shore projects highly depend on people’s hands, skills, and knowledge, too. In O shore Industry Insights, we introduce individuals that made their bones in our market.

Lex de Groot has over 30 years of experience in the upstream oil & gas sector in various roles, focusing mainly on the Dutch continental shelf. He has been Managing Director Netherlands of Neptune Energy since September 2018. He is a graduate of the Delft University of Technology (TUD) where he obtained a degree in Mining Engineering.

Mr De Groot, you have been working in our industry for over 30 years. How did this happen?

Mr De Groot: “Indeed, I have always worked for oil & gas projects in the Dutch North Sea area, with only a short switch to Qatar. I started my career in 1988 as Reservoir Engineer at Placid International Oil, the current Occidental Oil. Since this first job, I have >>

enjoyed various functions at di erent companies. In February 2018, I was Head of Reservoir Management at Engie when Neptune took over their gas fields and assets in the Dutch North Sea. In September of the same year, Neptune appointed me Managing Director. Of course, in times when the industry is at a low, one sometimes thinks about other careers, but, in the end, I always decided to stay, and without any regrets, as I love the relevance and dynamics of the sector.”

How did you get involved in the O&G industry?

Mr De Groot, “When I had to decide which study to pursue, I first thought of Aerospace Engineering. When I visited an open day of the study Mining Engineering at TUD, today this is called Applied Earth Sciences, Iwas pleasantly surprised and decided to go for this study. It happened to be very attractive with many di erent angles. Next to the obvious technical aspect there is also the combination with geology for instance. A large part of the course was about petroleum engineering. I graduated at the end of the eighties, which was quite a challenging time for the oil& gas industry. Still, I was able to start at Placid Oil, and the rest is history.”

What exactly do you like about our industry?

Mr De Groot, “First of all, the oil & gas industry is very relevant in our society. Look at today’s situation

It was always very excited to be o shore and to be witness of the first results of an exploratory drilling campaign.

caused by the war in Ukraine, and you know how important energy and therewith our industry is. What I also like is the way how projects in our sector are set up and realised. And for me it has always been fascinating to work on something seemingly invisible. I mean, you start drilling a well, without exactly knowing what you will find. It was always very excited to be o shore and to be witness of the first results of an exploratory drilling campaign. And, even after finding oil or gas, it is not exactly known how much awell contains. One should realise that a drilling hole only has a diameter of around 15cm, and through this small hole the connection with a huge field is made with volumes that can only be predicted. So sometimes you are lucky and sometimes you are not. Apart from this, as soon as a discovery is made and the decision taken to start exploiting, an extensive process must be started which asks a lot from many people in a broad range of companies. For me, all these things make our industry very exciting and challenging.”

So far, what do you remember the most of your career?

Mr De Groot, “The basis of our industry has not changed much throughout the years. Simply said, you drill a hole and collect the oil and gas that flows through it. The way of drilling and collecting data of course has changed a lot over the years to make production more e cient, and also more sustainable. In my career one of the things I mostly remember are situations that were safety related. O&G can be a dangerous industry and in the past decades I have dealt with various accidents with and without persons involved. These accidents always have a high impact on everyone, including myself. Today, it is good to see that a lot has been improved. To give a small example, in the past I stepped into a helicopter wearing just my ordinary clothes, whereas today, everyone stepping into a helicopter to go o shore must wear a survival suit. There is no question that a lot of measures, rules, and regulations have raised the level of safety at sea. Apart from this, I think that the increased safety awareness certainly has contributed to my own personal development as well, so in this way has been a positive development too.”

O&G is one of the industries that is often blamed for a negative impact on the environment. What are your thoughts about this?

Mr De Groot, “Of course I understand the public opinion about fossil fuels and the urge of governments to promote the transition from fossil fuels to renewables. Still, we will all be depending on oil and gas for many decades to come. Not only as a fuel but also as a raw material for many products. I think the energy transition is an inevitable necessity. However, the current situation caused by the war in Ukraine shows that we should take good care of not going too fast in saying goodbye to the good things we cannot do without in the short term. What will be important for the upcoming years is to aim for producing close to where the demand is. For the Netherlands and other European countries, the North Sea already plays and will play an important role in this. Even when I started my professional life everyone was sure of the fact that the volumes of oil and gas in the Dutch North Sea would only last for another ten years. Still, now more than 30 years later, we are here producing oil and gas to meet internal demand. The problem is that when we keep saying that the production of oil and gas will stop, it might have an eroding e ect on companies. As they do not exactly know what will happen, they might be hesitant in investing in their assets. It is obvious that this does not help in keeping the sector healthy and up to date.”

Mr De Groot: “Looking at myself, I hope to be able to continue at Neptune Energy and build our business activities with a culture where safety is top priority. Safety not only from a physical point of view, but also

“I love the relevance and dynamics of the sector.”

mentally, as everyone working at our company, no matter who they are, what they are, and where they are from, must feel safe under all circumstances. Also, when looking ahead, I see Neptune Energy as a company that, next to continuing our E&P activities, will soon have a solid position in CCS, going beyond net zero by 2030, and possibly also in o shore green hydrogen production. In contrast to, for example o shore wind, these are typically things close to our current expertise and know-how that can help reduce global emission of CO2. Looking at the industry as a whole, it will be important for us to keep on searching for the best way to keep producing oil and gas safely and meanwhile trying to phase them out as e ciently as possible for realising a proper energy transition. Also, with the growing activities at the North Sea, for example o shore wind and aquaculture, it will be important to stay connected with all other North Sea users and stakeholders. There should be room for every sector, of course with a keen eye on the ecological e ects of everyone’s activities. And as good neighbours we all should keep each other informed about what we intend to do and how this might a ect each other’s presence at sea.”

i. neptuneenergy.com

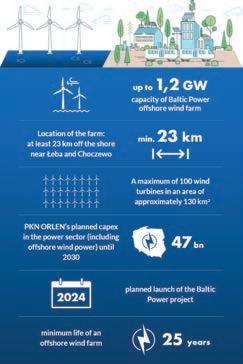

Vestas will provide 76 V23615.0MW turbines for the project which is located 23km o the coast of the Polish Baltic Sea shoreline, near Łeba. Once completed, this will be the largest wind project in Poland. With a swept area exceeding 43,000m2, the V236-15.0MW delivers industry-leading performance and moves the boundaries of wind energy production to up to 80GWh/year, enough to power around 20,000 European households and displace more than 38,000t of CO2, which is the equivalent of removing 25,000 passenger cars from the road every year. The Baltic Power wind farm, with a capacity of up to 1.2GW will be located about 23km from the coast at

Choczewa and Łeba. Once it achieves its expected commercial operations in 2026, it will be able to supply more than 1.5 million households with clean energy. “We are very proud to collaborate with PKN ORLEN and Northland Power on this landmark project for Poland, which has progressed thanks to all involved actors, including the Polish authorities. We aim to leverage our extensive experience and market leadership in the Polish wind energy sector, where Vestas has installed more than 3.9GW of onshore wind turbines”, says Nils de Baar, President of Vestas Northern & Central Europe. “The Baltic Power O shore Wind Project underlines Vestas’ leading role in

supporting countries on their path towards greener and safer economies.”

One of Poland’s first ”The construction of Baltic Power represents one of Poland’s first o shore wind farms and is currently one of the most important projects implemented by the ORLEN Group. Commercial operations are expected to begin in 2026 and will strengthen the energy security of the Polish economy. We want to use the knowledge and experience gained in the Baltic Power project to implement further investments in the Baltic Sea. When selecting cooperation partners, we pay attention to how their involvement will translate, not only into

our project but also into building a local value chain for the entire o shore wind energy sector”, stresses Daniel Obajtek, President of the PKN ORLEN Management Board. “Today’s announcement reflects an important milestone in the development process as the project works towards the start of construction in 2024. By signing the contract, we have created the foundation for realising the Baltic Power Wind Farm jointly with PKN ORLEN. We are very proud to partner with PKN ORLEN and the broader dedicated team to progress the project forward. Once complete, Baltic Power will represent a cornerstone of Poland’s energy transition”, states Mike Crawley, Northland’s President and Chief Executive O cer.

Baltic Power also secured a reservation contract for the design, manufacturing and installation of the inter-array, o shore, and onshore export cables. In total, there will be approximately 355km of cables in the Baltic Power farm area, of which approximately 130km will be inter-array cables picking up power from the turbines and delivering it to o shore substations. The remaining cables will be used to export energy on an approximate 39km long connection route from the o shore to the onshore substation. NKT, one of the most experienced power cable suppliers, will

be responsible for the design and manufacturing of the o shore export cables. The inter-array cables and the onshore section of the export cables will be supplied by TELE-FONIKA Kable together with JDR Cable Systems. TELEFONIKA Kable will also be responsible for the transport and installation of the cables on the onshore section. The transport and installation of all cables o shore will be handled by DEME.

Baltic Power is a fast-developing project in the Polish part of the Baltic Sea. In May, it was announced that the port in Łeba will be used to service the o shore wind farm for at least 25 years. The company has signed an agreement to lease a site on which a base will be built for service operation vessels to be used

for maintenance of the wind turbines. The service base is expected to permanently operate at least two CTVs, each capable of taking on board up to 24 technicians with the necessary equipment. In June, JV was the first to complete geotechnical surveys of the seabed in the area of the farm. In July, JV signed a reservation contract with Cadeler for the transport and installation of the turbines. The monopile foundations will be supplied by Steelwind Nordenham. Smulders will be responsible for supplying the transition pieces. The o shore transportation and installation of the foundation components has been entrusted to Van Oord.

i. balticpower.pl

Hydrogen is a key factor in the decarbonisation of energy-intensive sectors – both the production and application of hydrogen are possible without emissions. Which is one of the reasons why green hydrogen has an important role in achieving climate neutrality.

The possibilities of green hydrogen are currently being researched all over the world. This is also the case in the Netherlands. The Dutch project H2opZee aims to build 300 to 500MW electrolyser capacity far out in the North Sea in order to produce green hydrogen, powered by a dedicated o shore wind park. The hydrogen will then be transported to land via pipeline. The pipeline has a capacity of 10 to 12GW and is already suitable for the further roll-out of green hydrogen production to gigawatt scale in the North Sea.

Recently, the H2opZee consortium comprising RWE and Neptune Energy announced a series of technical feasibility study contract awards to wind turbine manufacturer Siemens Gamesa, and engineering contractors H2SEA and Enersea. The technical feasibility studies support the concept engineering work as part of the o shore green hydrogen project’s feasibility phase. The consortium aims to develop the project in the North Sea before 2030. The H2opZee project was announced in February this year and the consortium continues to progress its development plans.

The project is an initiative of TKI Wind op Zee that, supported by the Dutch government, brings people, knowledge and financing together to realise the

o shore energy transition in the North Sea. The project is the first of its kind and scale. The project builds upon the AquaVentus and PosHYdon pilots, leveraging key learnings to help de-risk large scale roll-out of o shore green Hydrogen generation.

A joint feasibility study began in June 2022, which is planned to run until the beginning of summer 2023. The study forms part of the first phase of H2opZee in which various technical concepts and potential development locations are

The project is the first of its kind and scale.

being evaluated to assess the optimal solution to generate green hydrogen o shore. Transportation to shore of this green hydrogen will be via pipeline. In the second phase, the project will be implemented. For that phase, a tender methodology has yet to be defined.

The work scopes that have been announced include o shore platform concept design and engineering, awarded to H2SEA, pipeline concept design awarded to Enersea, and wind turbine generator systems concept work awarded to Siemens Gamesa. The remainder of the technical work will be

Demonstration: 300-500 MW wind farm Large-scale implementation 10-12 GW

supported by in-house engineering by RWE and Neptune Energy. The consortium is also working closely with o shore infrastructure owners to evaluate various export options via the existing pipeline network to shore. Thenew contracts are e ective as of August 2022.

Neptune Energy’s Managing Director in the Netherlands, Lex de Groot, says, “Following the very successful roll-out of wind farms producing green electricity in the Dutch North Sea, o shore green hydrogen is the next step in the energy transition and crucial for our domestic future energy supply. It can be produced right here in the North Sea, giving the

Part

Natural gas-hydrogen mixture

Netherlands a leading role in providing green energy to Northwestern Europe, reducing the need for imports. By reusing existing gas infrastructure, the energy transition can be faster, cheaper, and cleaner. This infrastructure is technically suitable and already in place, including landing and possible international connections with other countries, such as Norway, Denmark, Germany and the UK. Lessons learned through Neptune’s support for the PosHYdon o shore hydrogen pilot will be applied to H2opZee. The faster we can scale up green hydrogen at sea, the faster industries such as chemical and steel production can become more sustainable. With H2opZee, the Netherlands is becoming a world leader

in this area. That is why we, together with RWE, are excited about H2opZee and what it has to o er the Netherlands.”

Sven Utermöhlen, CEO O shore Wind at RWE Renewables, adds, “It’s good that we are taking the next step with the H2opZee consortium to advance the project. Large-scale production of green hydrogen based on o shore wind is a key solution to decarbonising the industry. A demonstration project such as H2opZee helps us to better understand how this could be put into practice. Thanks to our cooperation with partners such as Neptune Energy, Siemens Gamesa, H2SEA, and Enersea, we are getting closer to achieving the Dutch climate goals.”

i. neptuneenergy.com

“Following the very successful roll-out of wind farms producing green electricity in the Dutch North Sea, o shore green hydrogen is the next step in the energy transition and crucial for our domestic future energy supply.”Lex de Groot – Managing Director of Neptune Energy Netherlands. procurement by the industry procurement by the industry Hydrogen storage farm of o shore wind farm can produce hydrogen in base of turbine Natural gas extraction on electrified platform Separation system (optional)

The last remaining piece of the Tyra II puzzle was lifted by heavy lift vessel Sleipnir into its final position. Recently, the 85.4m long bridge was set down between the new Tyra II processing platform and the accommodation platform.

With 35,000t of steel located 54m above the seabed, Tyra II is Denmark’s new high-tech hub for natural gas production in the Danish North Sea. The design, construction, and installation of the Tyra II platforms, when completed in the winter season 2023/24, have taken a

total of more than ten years. Tyra II will be one of the world’s most advanced gas fields, developed for the energy production of the future, which at the same time reduces CO2 emissions from natural gas production by as much as 30%.

Now, all dots of Tyra II are connected and the lifting of the final four Tyra II pieces – the process module, two bridges and a flare tower – came to a successful end. After this operation, the last welding work takes place to ensure that the new modules can resist many

years of rough North Sea weather. Finally, the hook up and commissioning team will focus on completing and powering up the installed platforms and reconnecting them to the existing North Sea infrastructure. That will be the last phase before delivering the first gas from Tyra II in the winter season 2023/24.

More than 260 people executed the lifting of the process module, two bridges, and one flare onboard Sleipnir in October 2022. On 4 October 2022, the biggest and final Tyra II topside was safely installed at the Tyra field. The lift of the 17,000t heavy process module

broke a world record as the heaviest crane lift ever undertaken at sea. Thebridge that connects the accommo dation and process platforms was the final Tyra II module that was lifted into position. It is 85.4m long and weighs 370t. “It’s exciting to be able to see the complete shape of Tyra II as all eight platforms, six bridges, two jackets, and one flare are now in their final position. I’m very proud of our installation team and our skilled partner Heerema Marine Contractors who once again executed textbook lifting operations. Nevertheless, there is still a lot of work o shore to complete to get Tyra II ready for first gas in the winter season 2023/24”, says LarsBo Christiansen, Deputy Project Director for TotalEnergies EP Denmark.

TotalEnergies is the operator of the Tyra field on behalf of Danish Underground Consortium (DUC) – a partnership between TotalEnergies (43.2%), Noreco (36.8%) and Nordsøfonden (20%). Tyra is Denmark’s largest natural gas field and has been a center for processing and exporting more than 90% of the natural gas produced in the

Danish North Sea before its redevelopment.

The redevelopment of the Tyra field is necessary due to the field’s natural subsidence of the chalk reservoir after many years of production. As a result, the platforms have sunk nearly five meters over the past 35 years. This has reduced the distance between the sea and the platforms’ decks.

The redevelopment of the Tyra field includes three main elements: decommissioning and recycling of the old Tyra platforms, extending the current platform legs on six of the platforms with 13m, which now also has new topsides, a completely new process module, and a new accommodation platform.

Once the modernised Tyra II is back on stream, it is expected to deliver 2.8m3 billion gas per year which amounts to 80% of the forecasted Danish gas production. Tyra II will secure continued production of natural gas with 30% less CO2 emissions and contributing to energy security of Denmark and Europe.

Sleipnir is the world’s largest crane vessel owned by TotalEnergies’ EPC contractor Heerema Marine Contractors. Sleipnir’s two huge cranes can lift a weight of up

to 20,000t. The vessel is 220m long and 102m wide – a size equivalent to approximately three football fields. Sleipnir has been part of the Tyra removal campaign and also helped to install the new jackets in September 2020 as well as the remaining new

Tyra II modules including the accommodation module, six well head and riser modules, and four bridges in September 2021, and in April 2022.

i. tyra2.dk

More

October 2022.

Dr Jörg Stratmann has been appointed as CEO of Rolls-Royce Power Systems. Separately, Dr Andreas Strecker will join Power Systems as Chief Financial O cer.

Mr Stratmann, who holds a doctorate in industrial engineering, was most recently CEO and chairman of the executive board of the automotive supplier Mahle.

In this role, he significantly expanded the business outside the area of combustion engines towards customised solutions for e-mobility and successfully developed new business opportunities based on sustainable

EnerMech has bolstered its senior management team with the promotion of Alison Hazell into the newly created position of Marketing and Communications Director. In the quest for accelerating the company’s growth, Ms Hazell will implement a new group-wide marketing plan to underpin its ongoing ambitions. Having joined EnerMech in 2017, she combines business knowledge with over 20 years of industry experience. Previously, she held senior client service positions at various companies and more recently founded and directed her own marketing agency.

Fulkrum has announced the appointment of Wilson Chettiar as the new Country Manager for India. With over a decade of experience working in the Oil & Gas industry Mr Chettiar brings a wealth of business development, strategic recruitment and market intelligence expertise to Fulkrum. He joins Fulkrum with extensive knowledge of the Middle East and APAC regions as well as a strong track record in the execution of technical sta ng, global mobility and strategic project planning, reinforcing the existing regional teams.

Lisa Edvardsen Haugan is appointed as the new President of Kongsberg Maritime.

Ms Edvardsen Haugan has long and extensive experience from both the defence and civil business area in Kongsberg Gruppen including having been EVP Finance at Kongsberg Maritime and Finance Director at Kongsberg Protech Systems. She currently heads the Deck Machinery & Motion Control division.

In the past she played a significant role in the integration and restructuring of Commercial Marine, a business area acquired from RollsRoyce in2019.

technologies for global markets. Previously, he held various international positions for Siemens AG.

Mr Strecker has extensive experience in the financial management of international corporations, primarily in the automotive and industrial sectors. Most recently, he was President Europe &Asia at Accuride Wheels. Prior to that he was CFO of Deutz, and CEO of Solaris Bus & Coach.

Rovco has its sights set on supporting the energy transition in the US market with the strategic appointment of Mitchell (Mitch) Johnson as the company’s new Director – Americas. Mr Johnson joins Rovco at an exciting time as the company seeks to expand its international o ering, bringing operational excellence, learning and expertise from its extensive portfolio of o shore wind projects across the UK and Europe. He brings significant experience to the new role. His previous role saw him head up Oceaneering’s global subsea inspection business unit.

Aquaterra Energy has appointed Anne Haase as Renewables Director to drive the o shore renewable energy arm of the business – significantly accelerating market growth. She will focus on delivering a defined growth strategy that predominantly targets the global o shore wind and green hydrogen markets.

MsHaase brings over 25 years of energy industry experience gained from roles within engineering and industrial organisations, such as Petrofac and Bilfinger – as well as supporting major developers and operators across key stages of wind and hydrogen projects.

Asset Guardian Solutions has appointed Stephanie Calder to the position of Chief Commercial O cer. In her new role she will oversee all commercial aspects of the company, from marketing and lead generation, through business development and sales, to contract negotiations and awards.

Originally from Aberdeen, Scotland, MsCalder has sixteen years of experience in sales, as well as ten years of softwarerelated experience, focusing on inspection, training, and the renewable industries.

ANCOFERWALDRAM STEELPLATES B.V.

P.O. Box 190

4900 AD Oosterhout

The Netherlands

T +31 (0)162 491 500

F +31 (0)162 429 806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V. (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profiled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profiled parts The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated profiling plant that gives AWS a decisive lead in experience, product range and customer service.

EMIGREEN B.V.

Noordeinde 19 3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector.

Emigreen also provides services including design, specification, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, flow dynamics, thermodynamics and noise and vibration control. Emigreen develops and tests components including catalytic converters, particulate filters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot filter system has set the standard for others to beat. All Emigreen solutions are highly efficient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market

DELTA SUBSEA

550 Club Dr, Suite 345 Montgomery, Texas 77316, USA

T +1936-582-7237

I www.deltasubsea-rov.com Delta SubSea (DSS) is a leading integrated independent provider of ROV Services and Solutions. Delta SubSea’s ROV fleet is focused on solutions for customers in the inspection, repair and maintenance, construction, drilling and decommissioning market segments. In addition to ROV Services, DSS also provides Subsea Project Management, Subsea Project Support Services, Subject Matter Experts and Client Representation for Diving/ROV/Subsea Construction.

HUBEL MARINE B.V.

Karel Doormanweg 5, 2nd Floor 3115 JD Schiedam P.O. Box 3219 3003 AE Rotterdam

The Netherlands

T +31 (0)10 458 7338 F +31 (0)10 458 7662 E info@hubelmarine.com I www.hubelmarine.com Twitter: HubelMarine

Contact: Mr Erik A. de Koning M +31 (0)6 53724457

Hubel Marine is a full-service firm for advice regarding Vessel Registration, Mortgage Registration, Seafarer Endorsements and Technical Flag State matters. We represent the flags of Panama, Belize and St.Kitts & Nevis.

We are fully authorised to perform Safety Surveys and issue Statutory & Class Certification including ISM, ISPS and MLC audits. We provide services for any type or tonnage of vessel worldwide.

HEINEN & HOPMAN

Produktieweg 12 3751 LN Spakenburg The Netherlands

BREMAN MACHINERY B.V. Sasdijk 20, 8281 BM Genemuiden, The Netherlands P.O.Box 135, 8280 AC Genemuiden, The Netherlands

T +31 (0)88-27 36 200

E info@breman-machinery.nl

I www.breman-machinery.nl