Welcome to the April 2023 edition of Materials Australia Magazine. For this month’s presidents message I thought it would be a great opportunity to look at the emerging topic of the use of artificial intelligence (AI) in materials science and engineering.

Artificial Intelligence (AI) is a rapidly growing field that has the potential to revolutionize many areas of research and development, including materials science and engineering. In recent years, there has been a significant increase in the use of AI in the physical sciences, with researchers utilizing AI techniques such as machine learning and neural networks to develop new materials and optimize their properties. The application of AI in materials science and engineering has opened up new avenues for research, development, and innovation, with the potential to improve existing materials

and create entirely new ones. The use of AI in materials science and engineering involves the application of machine learning algorithms and other AI techniques to large datasets of materials properties, structures, and behaviours. By using these AI algorithms, researchers can quickly analyse large datasets and identify patterns and correlations that would be difficult or impossible to detect using traditional methods. Data can be generated through a variety of sources, including experimental measurements, simulations, and theoretical calculations, and, as a result, optimization of materials and the methods through which to research them, becomes significantly more rapid. AI can also be used to improve the efficiency of manufacturing processes. For example, AI algorithms can be used to analyse the performance of different manufacturing processes and identify areas for optimization. This can lead to improvements in efficiency, reducing costs and improving the quality of the final product.

The use of AI in materials science and engineering has several benefits, including:

Accelerating Materials Discovery: The use of AI can help researchers to accelerate the discovery of new materials by predicting their properties, behaviours, and structures before they are synthesized or experimentally characterized. This can save time and resources and enable researchers to focus on the most promising candidates.

Optimizing Existing Materials: AI can also be used to optimize the properties of existing materials by predicting how they will behave under different conditions and identifying ways to improve their performance.

Reduced Experimental Costs: By using AI to generate predictive models, researchers can reduce the need for costly experimental measurements and simulations, as the models can be used to predict materials properties and behaviours accurately.

Enabling Multiscale Materials Design: AI can help researchers to design materials at different length scales, from atoms to bulk materials, and across different materials classes, from metals to polymers to ceramics.

Despite its potential benefits, the use of AI in materials science and engineering also presents several challenges, These include:

Data Quality: The accuracy and completeness of the datasets used to train AI models can have a significant impact on the predictive power of the models. Therefore, researchers must ensure that their datasets are high quality and representative of the materials they wish to study. As may be appreciated the risk of encountering data bias as the result of poor or minimal results may produce conclusions that may appear convincing, but are not necessarily correct.

Interpretability: The black-box nature of some AI models can make it challenging to interpret the predictions

they generate. This can be a significant difficulty for researchers who need to understand the underlying mechanisms driving materials properties and behaviours.

Computational Complexity: AI models can be computationally intensive and require large amounts of processing power and memory. This can limit the scalability of AI approaches and make them challenging to apply to large and complex materials systems.

Human Expertise: AI models require human expertise to design and interpret accurately. Therefore, researchers must have a deep understanding of both the AI techniques and the materials science and engineering principles they are applying them to.

The use of AI in materials science and engineering is still in its early stages, and there is significant potential for further development and innovation. Some of the key future prospects for AI in materials science and engineering include:

Incorporating Physics-Based Models: Combining AI techniques with physicsbased models can help researchers to generate more interpretable and accurate predictive models. These

MATERIALS AUSTRALIA CONFERENCE APICAM2023

21st - 23rd June 2023

The University of Sydney

hybrid models can also help to address some of the limitations of blackbox AI models, such as their lack of interpretability.

Multimodal Datasets: By combining data from different sources, such as experimental measurements and simulations, researchers can generate more comprehensive and representative datasets that can be used to train AI models more effectively.

Automated Experimentation: The use of AI can enable the development of automated experimentation platforms that can plan, execute and analyse experiments minimizing the need for manual intervention and eliminating the risk of human error. The goal of automated experimentation is to speed up the experimental process, reduce costs, and improve the accuracy and reproducibility of scientific research.

As AI continues to evolve and improve, it is likely that its use in materials science and engineering will only continue to grow. Researchers will need to work together to address the challenges and limitations of AI in this field, while also exploring new and innovative applications of this powerful technology. With continued

MATERIALS AUSTRALIA CONFERENCE LMT2023

9th -12th July 2023

RMIT University

Materials Australia National Office PO Box 19

Parkville Victoria 3052 Australia

T: +61 3 9326 7266

E: imea@materialsaustralia.com.au

W: www.materialsaustralia.com.au

NATIONAL PRESIDENT Roger Lumley

research and development, AI has the potential to transform materials science and engineering and unlock new possibilities for innovation and discovery.

I am sure many of you would already have guessed by now that the majority of this article (i.e. >95%) was generated by an artificial intelligence platform (ChatGPT). In this case I presented one or two questions to the AI and was able to generate multiple articles in under 15 seconds each, from which I chose the one I liked the best and completed final editing. The entire process of writing this presidents message took less than 20 minutes. This is an incredibly interesting topic that has implications to the way we teach, learn and prepare written information. There are many and varied ethical questions related to how scientists and engineers are using, or will use AI. As a professional community we need to begin the discussion about these kinds of topics, since they are going to enormously impact our careers and work lives over the next 10-20 years and beyond. What do you think?

Best Regards

Roger LumleyNational President Materials Australia

MATERIALS AUSTRALIA CONFERENCE MISE2023

29th - 31st October 2023

The University of Queensland

This magazine is the official journal of Materials Australia and is distributed to members and interested parties throughout Australia and internationally.

Materials Australia welcomes editorial contributions from interested parties, however it does not accept responsibility for the content of those contributions, and the views contained therein are not necessarily those of Materials Australia.

Materials Australia does not accept responsibility for any claims made by advertisers. All communication should be directed to Materials Australia.

Source: Jigneshkumar Dhimar, Branch Manager, LMATS Perth.

Jignesh Dhimar is a mechanical engineer with more than 15 years of experience working in NDT application industries. He has been actively involved in asset integrity inspection, refinery EPC projects, and pipeline corrosion mapping using conventional and advanced NDT techniques.

In NDT during manufacturing, requirements are often prescribed in specifications, codes and standards. With in-service NDT, the methods used depend on the component (e.g. structure, pipe, tube, pressure vessel, above ground storage tank), the material and the condition (e.g. surface condition, insulation, access, surface temperature). Jignesh emphasised the point that the choice of the right NDT method is crucial, and proceeded to outline recent advancements in NDT and to provide insights on their applicability in various industries.

He set the scene by reminding the audience of the main types of conventional NDT:

• Radiography – mainly internal discontinuities, sensitive to volumetric discontinuities

• Ultrasonic – mainly internal defect, sensitive to planar discontinuities

• Eddy Current – surface discontinuities, only conductive material

• Dye Penetrant – open-to-surface discontinuities

• Magnetic Particle – surface and subsurface discontinuities, only magnetic material

Advances in electronics, computing, and information and telecommunications (IT) have led to the development of advanced forms radiography, ultrasonic testing (UT) and eddy current (EC) testing techniques:

• CRT – Computed Radiographic Testing

• PAUT – Phased Array Ultrasonic Testing

• TOFD – Time Of Flight Diffraction Ultrasonic Testing

• GWT – Guided Wave Testing

• ECA – Eddy Current Array testing

• PECT – Pulsed Eddy Current Testing

• LFEC – Low frequency Eddy Current Testing

Improvements in electronics allow more sensitive data capture, for example, replacing single-use radiographic film with a reusable cassette containing a scanned phosphor plate. Greater computational power has been instrumental in allowing more complex signal processing and data analysis. Improvements in IT apply across all testing methods, notably enabling traceable, paperless results to viewed by clients anywhere in the world.

The application of these improvements to UT has greatly expanded the scope of the method. In its original form, detection is limited to planar discontinuities directly under the combined source and detector. PAUT creates a steerable UT beam using interference between the ultrasound waves produced by an array of piezoelectric transducers. Steering the beam at angles either side of the through-thickness axis allows detection of non-planar defects and visualisation of data on a volumetric basis. This method has a high detection rate and is well suited to weld inspections, corrosion mapping, and monitoring and sizing defects for baseline data. TOFD, which can be used in conjunction with PAUT, detects discontinuities regardless of their orientation and is regarded the best NDT method for through wall sizing of defects. The tips of a crack that lies between a transmitter and a separate receiver (on the same surface) diffract waves that arrive at the receiver at different times, allowing the defect to be located both laterally and on the through-thickness axis.

A further extension of UT from throughthickness to axial defect detection is achieved with guided wave long-

range UT (GWUT). In this method, the ultrasonic wave travels axially, with defects located normal to the longitudinal axis being detected by the energy they reflect to the transmitter/ receiver. This allows their distance from the transmitter to be determined. This method is well suited to identifying relatively large defects, such as loss of wall thickness, in inaccessible locations, such as buried pipelines.

Eddy current testing has also advanced. Eddy Current Array (ECA) testing uses the same basic principles as simple eddy current testing. The difference is that electronics and signal processing area applied to allow a large number of exciting coils to be used simultaneously to cover a large area at once, and with greatly improved signal to noise ratio and reproducibility. This method can detect surface defects, far-surface corrosion and shallow subsurface defects. It can be implemented with flexible probes for complex shaped geometries.

Another of the improvements to eddy current testing made possible by improved signal processing is pulsed eddy current testing (PECT). In this method a step-function voltage is applied, producing a spread of

frequencies. Because the different frequencies penetrate to different depths, this allows simultaneous collection of information from a range of depths. This makes the method particularly useful for thickness measurement without removal of insulation (e.g. for corrosion under insulation), for measuring thickness of steel embedded under concrete or asphalt, and for detection corrosion of steel submerged in water.

Low frequency eddy testing (LFET) is applied to gather information deeper below the surface, though with relatively low resolution. Jignesh explained how LMATS applies this method for scanning for defects in boiler wall tubes.

Jignesh proceeded to describe factors affecting the selection of NDT methods, taking as an example inspection of heat exchanger tubes. He summarised the applicability of various methods in relation to tube material and tube form (e.g. with or without fins), and explained how the choice is further governed by the type of defect to be detected and the required sensitivity of detection. This was a comprehensive update, highlighting the range of techniques that are available locally.

Source: Dr Richard Macoun, Research Manager, Future Battery Industries CRC

Dr Richard Macoun studied physical and polymer chemistry (University of Sydney) before completing his PhD in nanotechnology and chemical engineering (UNSW). Richard also holds an MBA (UWA) and has worked in product and process innovation for over twenty years at CSIRO, BHP and BASF (Mining Solutions). He has had a long involvement in collaborative innovation efforts as Program Manager at AMIRA, and as Research Director at the Future Battery Industries CRC (FBICRC).

The FBICRC has been planned to have six-year life, “to live fast and die young”

with a mission to help develop a vibrant battery industry for Australia before the window of opportunity closes. Richard reminded the audience that while Australia possesses around half the world’s known reserves of battery materials, mining and chemical processing makes up only around 3 percent of the battery value chain.

While the centre is undertaking 15 projects across the value chain, Richard singled out one, the National Battery Testing Facility, for special mention. It is vital for providing certification for shipping lithium-ion batteries (LIBs) batteries. The point is that, unlike lead-

acid batteries, end-of-life LIBs present a significant hazard, which will soon be encountered in increasing volumes as electric vehicles (EVs) become eight to ten years old. The LIBs they contain will have to be processed somewhere, which will involve collection, storage, and transport, in addition to the processing.

The fundamental reason why LIBs are different is that they operate on flow of lithium ions between two electrodes (anode and cathode) neither of which is consumed in a chemical reaction (the way lead is consumed in a Pb-acid battery). Rather, the two electrodes

act as ‘sponges’ which can contain mobile lithium ions at differing energy states. Richard likened charging and discharging LIBs to ‘sopping up’ ions with the virtual sponge, and then ‘squeezing and wringing them out’. Extending the analogy, the basic problem is that the harder the sponges are squeezed and wrung out the greater the damage accumulated in each cycle. Unfortunately, internal failure of LBIs, particularly when being charged, can lead to runaway discharge with the potential for practically inextinguishable fires, which are now all too common.

The way LIBs work is not intuitively obvious. Indeed, the award of the 2019 Nobel chemistry Prize is an acknowledgment of their development as a triumph of materials science. The initial scientific breakthroughs, starting in the 1970s, were the discovery of materials that could accommodate lithium ions intercalated within layered crystal structures. Subsequently, the key to the development of LIBs into practical and widely used portable energy sources has been in finding electrode materials that allow higher capacity (for a given size and weight) and faster charging and discharging rates (power output), combined with adequately long life and affordable cost. The first LIBs had lives measures in hundreds of charge-discharge cycles, now they can withstand thousands, but the goal is for them to be able to withstands tens of thousands.

Currently, the most common anode material is graphite, typically ‘five nines’

purity, though graphene (single-layer graphite), lithium titanate and silicon are also options. Cathodes are mostly based on metal oxides, with several competing technologies in common use. Three of these five formulations contain cobalt, and the high cost of this element is driving the development of alternatives.

Richard outlined the production process for cathodes starting with manufacture of the cathode precursor material, which is the oxide structure that can hold the lithium ions. Lithium ions are subsequently introduced through combining the oxide with lithium carbonate and calcium, in powdered form. Details of the manufacturing processes are closely held trade secrets.

The third component of the cell is the separator and the fourth is the electrolyte, commonly lithium hexafluorophosphate. The flammability of electrolytes is a significant factor in LIB fires, which are made worse by the propensity of cells to explode and spread burning material for up to several metres, in all directions.

Richard briefly touched on manufacture of batteries, with a focus on the common small cylindrical-form cells that are the active components of most LIB packs. A rechargeable LED torch might typically have three such cells, while 18V power tool battery packs typically have five. However, battery packs for EVs contain 5000 or more of these small cells, connected electrically and structurally, together with cooling and power management modules.

The manufacture of the individual cells starts with preparing slurries of anode and cathode materials. These are used to form a three-layer sheet with a separator between the electrode layers, using processes like those in paper and film production. The spooled sheet is then rolled to form the cylindrical cells, a bit like forming a like a Swiss roll cake. The next step is to fill the cells with electrolyte and then apply a series of charge and discharge cycles to transport the lithium ions into the electrodes. Currently this final ‘formation’ process can take up to three weeks, resulting a considerable inventory of cells in production. The results of formation are not guaranteed, so cells are individually tested and graded before sale and subsequent assembly into battery packs.

Richard remarked that while EVs received the top-grade cells, the lower graded cells often end up in consumer products such as cheap scooters and power tools. It would appear no coincidence that such devices have been the cause of many house fires. Returning to his analogy, Richard’s advice was to treat an LIB like a sponge and not to wring it out too hard! He recommended keeping LIBs between 60 and 80 percent capacity, and not to leave them on-charge out of sight and out of mind.

The audience reception showed that Richard’s presentation maintained the established reputation of the Sir Frank Ledger Breakfast as a highlight of the WA Branch year.

alternative energy

palladium catalysts

glassy carbon

thin lm

screening chemicals

surface functionalized nanoparticles

zeolites

99.999% ruthenium spheres

diamond micropowder

janus particles

nickel foam

buckyballs

gold nanoparticles

III-IV semiconductors

organometallics

nanogels

metal carbenes ITO

bioactive compounds

nano ribbons

nanodispersions

3D graphene foam

osmium

MOFs

isotopes

ultralight aerospace alloys

Nd:YAG

cermet

epitaxial crystal growth

drug discovery

quantum dots

transparent ceramics

spintronics

mesoporous silica

sputtering targets

MBE

indicator dyes

macromolecules

silver nanoparticles

enantioselective catalysts

rhodium sponge

pharmacoanalysis

spectroscopy

anode excipients

superconductors

chalcogenides

rare earth metals

cryo-electron microscopy

CVD precursors

deposition slugs

laser crystals

calcium wires

platinum ink

tungsten carbide refractory metals

optical glass

graphene oxide

h-BN MOCVD

metamaterials

Fe3O4

uorescent microparticles

cisplatin

shift reagents

American Elements opens a world of possibilities so you can Now Invent!

ferro uid

dielectrics

Over 30,000 certi ed high purity laboratory chemicals, metals, & advanced materials and a state-of-the-art Research Center. Printable GHS-compliant Safety Data Sheets. Thousands of new products. And much more. All on a secure multi-language "Mobile Responsive” platform. www.americanelements.com

biosynthetics

dysprosium pellets

process synthesis

metallocenes

conjugated nanostructures

Source: Stuart Folkard

After graduating from the University of Queensland with a BSc in Metallurgy, Paul spent some time in materials consulting before joining Rio Tinto’s Wear Laboratory in Perth.

He thereafter joined Warman International where he provided specialist support to all of Alcoa WA operations (including field testing of leading-edge materials). During his four years at Austral Technologies in Perth, Paul led the introduction of high deposition PTA into the Australian market. Paul then joined Hardchrome Engineering in Melbourne where he was involved in providing leading edge surface engineering technologies (including laser cladding) to the mining and manufacturing industries.

Paul joined Gerard Daniels in 2005 and today is a Partner in the firm.

Paul has had a long-standing relationship with Materials

Australia:

During his time in Queensland, and Victoria he served on the local Branch Councils often leading the technical and training programs. Today, he is a current serving member on the WA Branch Council where is also a past Branch President. He is actively involved in organizing seminars and was instrumental in launching the Material Innovation in Surface Engineering series of seminars, which have been running since 2011. Over the last 10 or more years Paul has been the convenor of, and indeed seeing to the success of, this annual Sir Frank Ledger Breakfast (which is now mentioned in the Who’s Who Directory entry for Frank Ledger).

Paul is a director and member on the National Executive

Hitachi’s range of materials analyzers support the end-to-end metals production process from incoming inspection to final product assembly and finished goods testing to ensure product reliability, safety and regulatory compliance.

See the full range at: hhtas.net/read-the-metal Complete

Committee of Materials Australia where he is the Honorary Treasurer. In 2011/2012, the Institute went through a very difficult financial period and Paul was instrumental in developing fiscal strategies that saw MA pull through. We are in a much stronger financial position thanks to his contribution and we look forward to a bright future ahead.

The Distinguished Service Medal is presented to Paul Howard in recognition of the tireless support and enthusiasm given to Materials Australia.

21st - 23rd June 2023

The University of Sydney

The 3rd Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industrial application focused conference of 2023.

The 5th Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industry conference of 2023. APICAM was created to provide an opportunity for industry professionals and thinkers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

APICAM was created to provide an opportunity for industry professionals and academic researchers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

Some of the leading minds in the industry will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as 3D printing and additive manufacturing in the automotive, biomedical, defence and aerospace industries will be covered by experts from each respective field.

Some of the leading minds in the field of additive manufacturing will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as applications of additive manufacturing in the, biomedical, defence and aerospace industries will be covered by experts from each respective field.

The event is being curated by Materials Australia, the peak Australian materials technology body, which has drawn on its considerable pull in the industry to create a world-class event that is a must-attend for anyone involved in the additive materials industry.

The purpose of this conference is to provide a focused forum for the presentation of advanced research and improved understanding of various aspects of additive manufacturing.

Abstracts are able to be submitted in the following areas:

Additive Manufacturing of Metals

Additive Manufacturing of Polymers

Additive Manufacturing of Concretes

Advanced Characterisation Techniques and Feedstocks

Computational Modelling of Thermal Processes for Metallic Parts

The APICAM2023 organizing committee is seeking abstracts for either an oral or poster presentation.

The main features of APICAM 2023 will include presentations by experts as well as workshops that will help attendees sharpen their skills and then be able to pass on this knowledge to other industry professionals. The event has been designed to allow for ample networking time so that important knowledge-transfer can take place and partnerships can be created that will enrich the industry.

Enquiries:

Tanya Smith | Materials Australia

+61 3 9326 7266 | imea@materialsaustralia.com.au

Part Design for Additive Manufacturing

Failure Mechanisms and Analysis

Mechanical Properties of Additively Manufactured Materials

New Frontiers in Additive Manufacturing

Process Parameter and Defect Control

Process-Microstructure-Property Relationships

Enquiries:

www.apicam2023.com.au

Tanya Smith | Materials Australia

+61 3 9326 7266 | imea@materialsaustralia.com.au

Testing and Qualification in Additive Manufacturing

Source: Rachel White

The NSW branch committee has released its event list for 2023. We are in the process of planning these events and firm dates will appear on the Materials Australia website as we book dates. A list of these events is below. We will shortly be releasing our branch newsletter.

June – Careers event with Australian Ceramic Society. This is an online event with a panel of people working in different areas and roles in materials

science speaking about their careers and answering questions from attendees. The event is aimed at people undertaking studies and those in their early career to learn more about career paths.

August – our Metallurgy course will be running again this year. This course is well suited to people working in materials science who wish to refresh their skills or learn about metallurgy in more depth.

Lastek proudly introduced precision measurement instruments from the Helmut Fischer Group. Helmut Fischer is an innovative leader in supplying high-value products in industrial, process and laboratory measurement technology. Our products include instruments for measuring coating thickness, microhardness as well as material analysis and testing.

Handheld Instruments: Portable instruments for onsite measurements with interchangeable probes. Measure coating thickness on metals, electrical conductivity of metals, ferrite content in welded products, sealants on anodic coatings on aluminium, finding pores and defects on enamel, paint, rubber, bitumen and plastics.

September – Certified Materials Professionals (CMatP) Mini-Conference. Come along and hear from our newest CMatPs. This event will be online.

November – our popular Student Presentation Event will be run in-person and we will have a hybrid option if possible. Students present talks and posters on their research. Generous prizes are provided by our sponsors for this each year.

FUNDAMENTALS OF TITANIUM

CONTINUING EDUCATION WORKSHOP

The ITA is offering the Fundamentals of Titanium / Titanium the Ultimate Choice workshops in an in person format.

This comprehensive workshop will provide attendees with detailed information on the types, uses, and properties of common titanium alloys. Attendees will leave with an understanding of applied titanium metallurgy fundamentals.

Objectives & Content

Fundamentals of Titanium will prepare you to work effectively with job related functions that involve titanium. You will receive a complete overview of the titanium industry and a thorough grounding in its metallurgy, characteristics, properties and uses.

This workshop is brought to you by LMT2023 (Light Metals Technology 10-12 July 2023) www.lmt2023.com.au and sponsored by DMTC Ltd.

SESSION 1

• History

• Titanium from Ore to Metal

• Titanium Alloys and Heat Treatment

• Titanium Characteristics

• Corrosion

• Forming

SESSION 2

• Joining

• Finishing

• Properties & Design

• Comparisons with other Metals

• Applications

• Safety

• Recent Technology Advances

Donald E. Larsen

Donald E. Larsen is currently President of KineTic Engineering a consulting firm that provides expertise across the Titanium industry. Prior to this he spent over 30 years at Howmet Aerospace/Arconic retiring in 2018 as Vice President, R&D, General Manager Advanced Manufacturing for Arconic. In this role, he was responsible for leading R&D and production teams working on priority titanium technology projects, including 3D printing and advanced manufacturing activities. He also served as a liaison to the Arconic Technical Center (ATC) and Arconic’s Whitehall Technology Center. Don retired in Q3 of 2018 and temporarily took on the role of Interim Plant Manager Ti-Ingot Operation and Director of Special Projects.

Don joined Howmet Aerospace in 1988 and served in a number of roles focused on the research, development and production of titanium products. He has also held operational and sales and marketing roles with the company. Don has a master’s degree in metallurgical engineering from The Ohio State University, and is the holder of 11 U.S. patents. He has published more than 30 technical articles in the field of titanium.

$450+GST MA MEMBER

$500+GST NON MEMBER

$250+GST STUDENT

NOW

Enquiries: Tanya Smith Materials Australia +61 3 9326 7266

imea@materialsaustralia.com.au

Orthopaedics project, and that led to Hannah being employed by SEAM as a postdoc for the industrial companies of D&T Hydraulics and Engineering, Titomic, and King’s Flair.

While all the projects are rooted in materials engineering, each project has its own specialty. The D&T Hydraulics and Engineering project uses laser cladding to repair and refurbish worn and damaged mechanical parts, the Titomic project is developing machine learning models for optimisation of their cold spray additive manufacturing process, and the King’s Flair project is developing bioactive coatings. Hannah works mainly in project management, and collaborates with fellow ECRs and colleagues like Dr Samuel Pinches (another SEAM postdoc) to lead the D&T and Titomic projects. There are currently 6 active PhD candidates working industriously with SEAM ‘s industry partners to solve critical materials science problems. The feedback from the industry partners has been energising, with the universitybased R&D solutions being applied to commercial real world products. The work done by Hannah and the team at SEAM keeps young Australian researchers at the frontier of national and international STEM innovation.

Hannah King is a Postdoctoral Fellow with the Australian Research Council (ARC) Industrial Transformation Training Centre on Surface Engineering for Advanced Materials (SEAM) at Swinburne.

Hannah is an analytical chemist by training, with a PhD in chemistry (2020) from James Cook University in Queensland. Like many young researchers, Hannah was faced with a plethora of unknowns and opportunities once her PhD was completed; Was it best to continue blue sky research? Was it time to move from academia to industry and face real world technical problems? Was research and development (R&D) a viable career option in Australia? Then, lightning struck -literally. Hannah was offered an R&D postdoctoral position working with a wholly Australian

owned company called Lightning Protection International (LPI) on the next generation of lightning strike protection devices (i.e. lighting rods). Funded through the Innovative Manufacturing CRC (IMCRC), Hannah begun a postdoc career with the SEAM ARC training centre.

This was the best of all worlds; creative R&D work grounded in a real world problem. Hannah was able to apply her existing chemistry knowledge of materials characterisation to the project, but had to learn quickly the industrial-scale engineering systems which would be used to manufacture the lighting rod prototypes. The LPI project completed in 2022, but Hannah had her foot-in-the-door for real world R&D at SEAM: The LPI project led to another SEAM affiliated Allegra

Hannah appreciates that as a woman in science and engineering, she is given a greater opportunity to promote her work and have her story told. She understands that there is a unique power in being seen as a woman at the forefront of innovation by both young girls who inspire to a career in STEM, and fellow material scientist/engineers who understand the importance of closing the gender gap. The ARC and SEAM are thanked for providing equal opportunities to women of merit, such as Hannah, and are praised for their strong vision for diversity and inclusion.

For more information about SEAM, please visit www.arcseam.com.au/ or email seam@swinburne.edu.au.

10 TH INTERNATIONAL LIGHT METALS TECHNOLOGY CONFERENCE

9-12 JULY 2023 RMIT UNIVERSITY, MELBOURNE, AUSTRALIA

The Light Metals Technology (LMT) Conference is a biennial event that focuses on recent advances in science and technologies associated with the development and manufacture of aluminium, magnesium and titanium alloys and their translation into commercial products. The conference presents an opportunity for academic researchers, students and industry to discuss cutting edge developments and to facilitate new collaborations.

You are invited to submit abstracts on topics within the themes of Net Shape Manufacturing, Solid State Transformations and Mechanical Performance, and Translation to Applications. For example, but not limited to:

Opportunities for sponsorships and exhibitions are available, see below for contact details.

▶ Alloy development

▶ Solidification and casting

▶ Thermomechanical processing and forming

▶ Machining and subtractive processes

▶ Mechanical behaviour of light metal alloys

▶ Corrosion and surface modification

▶ Advanced characterisation techniques

▶ Joining

▶ Applications in bio-medical, automotive, aerospace, and energy industries

▶ Simulation and modelling

▶ Integrated computational materials engineering

The following members of Materials Australia have been certified by the Certification Panel of Materials Australia as Certified Materials Professionals.

They can now use the post nominal ‘CMatP‘ after their name. These individuals have demonstrated the required level of qualification and experience to obtain this status. They are also required to regularly maintain their professional standing through ongoing education and commitment to the materials community.

We now have nearly 200 Certified Materials Professionals, who are being called upon to lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

A/Prof Alexey Glushenkov ACT

Dr Syed Islam ACT

Prof Yun Liu ACT

Dr Karthika Prasad ACT

Dr Takuya Tsuzuki ACT

Dr Olga Zinovieva ACT

Prof Klaus-Dieter Liss CHINA

Mr Debdutta Mallik MALAYSIA

Prof Valerie Linton NEW ZEALAND

Prof. Jamie Quinton NEW ZEALAND

Dr Rumana Akhter

Anna Paradowska

Elena Pereloma

Miss Ana Celine Del Rosario VIC

Dr Yvonne Durandet VIC

Dr Mark Easton VIC

Dr Rajiv Edavan VIC

Dr Peter Ford VIC

Mr Bruce Ham VIC

Ms Edith Hamilton VIC

Dr Shu Huang VIC

Mr Long Huynh VIC

Mr. Daniel Lim VIC

Dr Amita Iyer VIC

Mr Robert Le Hunt VIC

Dr Michael Lo VIC

Dr Thomas Ludwig VIC

Dr Roger Lumley VIC

Mr Michael Mansfield VIC

Dr Gary Martin VIC

Dr Siao Ming (Andrew) Ang VIC

Dr Eustathios Petinakis VIC

Dr Leon Prentice VIC

Dr Dong Qiu VIC

Mr John Rea VIC

Miss Reyhaneh Sahraeian VIC

Dr Christine Scala VIC

Mr Khan Sharp VIC

Dr Vadim Shterner VIC

Dr Antonella Sola VIC

Mr Mark Stephens VIC

Dr Graham Sussex VIC

Dr Kishore Venkatesan VIC

Mr Pranay Wadyalkar VIC

Dr Wei Xu VIC

Dr Ramdayal Yadav VIC

Dr Jayantha Epaarachchi

Dr Jeff Gates

Mr Payam Ghafoori

David Harrison

Dr Damon Kent

Miss Mozhgan Kermajani

Mr Jeezreel Malacad

Dr Jason Nairn

Mr Sadiq Nawaz

Mr Bhavin Panchal

Mr Bob Samuels

Dr Mathias Aakyiir

Mr Ashley Bell

Ms Ingrid Brundin

Mr Neville Cornish

A/Prof Colin Hall

Mr Nikolas Hildebrand

Mr Mikael Johansson SA

Mr Rahim Kurji SA

Mr Andrew Sales SA

Dr Thomas Schläfer SA

Dr Christiane Schulz SA

Prof Nikki Stanford

Prof Youhong Tang

Mr Kok Toong Leong SINGAPORE

Mr Madhusudhanan Jambunathan UK

Mr Devadoss Suresh Kumar UAE

Dr Shahabuddin Ahmmad VIC

Dr Ossama Badr VIC

Dr Qi Chao VIC

Dr Ivan Cole VIC

Dr John Cookson VIC

Dr Sam Yang VIC

Dr. Matthew Young VIC

Mr. Mohsen Sabbagh Alvani WA

Mr Graeme Brown WA

Mr Graham Carlisle WA

Mr John Carroll WA

Mr Sridharan Chandran WA

Mr Conrad Classen WA

Mr Chris Cobain WA

Ms Jessica Down WA

Mr Adam Dunning WA

Mr Jeff Dunning WA

Dr Olubayode Ero-Phillips WA

Mr Stuart Folkard WA

Mr Toby Garrod WA

Prof Vladimir Golovanevskiy WA

Mr Chris Grant WA

Mr Paul Howard WA

Dr Paul Huggett WA

Mr Ivo Kalcic WA

Mr Ehsan Karaji WA

Mr Biju Kurian Pottayil WA

Mr Mathieu Lancien WA

Mr Michael Lison-Pick WA

Dr Evelyn Ng WA

Mr Deny Nugraha WA

Mrs Mary Louise Petrick WA

Mr Johann Petrick WA

Mr Stephen Rennie WA

Dr Mobin Salasi WA

Mr James Travers WA

Source: Materials Australia

Accreditation as a Certified Materials Professional (CMatP) gives you recognition, not only amongst your peers, but within the materials engineering industry at large. You will be recognised as a materials scientist who maintains professional integrity, keeps up to date with developments in technology, and strives for continued personal development.

The CMatP, like a Certified Practicing Accountant or CPA, is promoted globally as the recognised standard for professionals working in the field of materials science.

There are now well over one hundred CMatPs who lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Benefits of Becoming a CMatP

• A Certificate of Membership, often presented by the State Chapter, together with a unique Materials Australia badge.

• Access to exclusive CMatP resources and website content.

• The opportunity to attend CMatP only

networking meetings.

• Promotion through Materials Australia magazine, website, social media and other public channels.

• A Certified Materials Professional can use the post nominal CMatP.

• Materials Australia will actively promote the CMatP status to the community and employers and internationally, through our partner organisations.

• A CMatP may be requested to represent Materials Australia throughout Australia and overseas, with Government, media and other important activities.

• A CMatP may be offered an opportunity as a mentor for student members.

• Networking directly with other CMatPs who have recognised levels of qualifications and experience.

• The opportunity to assume leadership roles in Special Interest Networks, to assist in the facilitation of new knowledge amongst peers and members.

What is a Certified Materials Professional?

A Certified Materials Professional is a person to whom Materials Australia has issued a certificate declaring they have attained all required professional

standards. They are recognised as demonstrating excellence, and possessing special knowledge in the practice of materials science and engineering, through their profession or workplace. A CMatP is prepared to share their knowledge and skills in the interest of others, and promote excellence and innovation in all their professional endeavours.

The criteria for recognition as a CMatP are structured around the applicant demonstrating substantial and sustained practice in a field of materials science and engineering. The criteria are measured by qualifications, years of employment and relevant experience, as evidenced by the applicant’s CV or submitted documentation.

Certification will be retained as long as there is evidence of continuing professional development and adherence to the Code of Ethics and Professional behaviour.

Contact Materials Australia today: on +61 3 9326 7266 or imea@materialsaustralia.com.au or visit our website: www.materialsaustralia.com.au

Source: ATA Scientific Pty Ltd

Source: ATA Scientific Pty Ltd

Regardless of whether you are working with lithium-ion (Li-ion) batteries, alkaline batteries, lead-acid batteries, fuel cells, MOFs, or any other energy storage device; there are critical component properties that must be characterised for performance and safety considerations. A high energy density, high power density and long cycle life has driven the adoption of Li-ion batteries toward renewable solutions in applications like automotive, grid energy storage and consumer electronics With demand expected to continue to grow, developing domestic battery supply chains, including battery manufacturing capacity is becoming increasingly important.

Micromeritics technologies offer analytical solutions for every step in the Li-ion battery manufacturing process, from precursor consistency to the electrode slurry preparation, coating, drying, and calendaring, and final cell electrolyte filling. Understanding the porosity of the electrodes and separators is important to guarantee the right ion accessibility and safety performance while BET surface area helps to optimise battery capacity and charging. Here we discuss pore structure and surface area determination using two proven techniques, namely mercury intrusion porosimetry and gas physisorption.

The AutoPore V uses mercury porosimetry with intuitive software to characterise Li-ion battery separators and electrodes. This uniquely valuable technique delivers a wide pore measurement range plus speed and accuracy critical to battery safety, energy density, and longer cycle life.

Separators are an important component that mechanically separates the anode and cathode while allowing maximum ionic conductivity of the Li-ion containing electrolyte. Its design and performance directly affect the capacity, cycle life, and safety performance of the battery. The separator must have sufficient porosity to hold liquid electrolyte, but excessive porosity hinders the ability of the pores to close which shuts down an overheated battery. The pore size must be smaller than the particle size of the electrode components, be uniformly distributed, while also having

a tortuous structure. This ensures a uniform current distribution helping to suppress the growth of lithium dendrites on the anode – a neural-like network of metallic growth that can form during charging that can short circuit the battery and cause the battery to catch fire.

The porosity of a separator or diaphragm is commonly measured directly by the mercury intrusion method, and the porosity result is generally about 40%-60%. Separators are thin films, less than 100 μm thick and to improve the statistical reliability of the measurement, a test sample consists of several pieces, sized to fit within the sample holder, or penetrometer. However during the test, mercury will be intruded into gaps at low pressure between these

sample test pieces and appear to indicate the filling of very large pores that are not characteristic of the material. As the pressure is increased, smaller and smaller sized pores are filled. The Autopore method identifies and eliminates the contribution of the interstitial filling to the porosity analysis of the separator thereby correcting the apparent pore volume distribution, which can be a critical property for the safety and reliability of li-ion batteries. Figures 2a and 2b show the cumulative intrusion and log differential intrusion as a function of applied pressure and pore diameter, respectively, for the separator. This example shows the wide dynamic range of pore volume measurement available, with most at sizes larger than 10,000 nm, due to the filling of interstitial space.

Electrode microstructure resulting from the manufacturing process has a direct influence on energy density, power, lifetime, and reliability of the lithium-ion cell, therefore understanding surface topology is critical. Increasing the surface area of the electrode will facilitate the ion exchange, however it does have limitations due to the degradation interaction of the electrolyte at the surface and resultant capacity loss along with thermal stability. While nanoparticles hold much promise to increase surface area without capacity loss, lower surface area materials are better suited for improved cycling performance of the cell resulting in longer battery life.

Micromeritics offers several physisorption systems like the 3Flex, for the development of cathode and anode materials that impact power and energy density as well as thermal/ chemical stability and enhance battery life and charge cycling.

DFT surface energy reveals surface topology and the level of interactions with an adsorptive gas present on the sample surface. The method uses an experimental isotherm based on the library of model isotherms of non-porous surfaces with different surface energies. The incremental surface area is plotted against the adsorptive potential energy which relates to the isosteric heat of adsorption. The colder the temperature the fewer interactions between the surface and the adsorptive gas and visa-versa. Adsorption

potentials ranging 50-60K represent basal planes; below 50K are prismatic surfaces; above 60K are defects, and those near 20K and 100K represent nitrogen condensation and presence of micropores, respectively, so they are unrelated to the surface energy of the material. The DFT surface energy distribution in Figure 3 shows graphene had stronger interactions with nitrogen than the graphite anode sample and graphene oxide exhibited the strongest interactions with the most surface area and defects.

Contact us for more information today!

ATA Scientific Pty Ltd

+61 2 9541 3500

enquiries@atascientific.com.au www.atascientific.com.au

Reference:

1. Micromeritics.com/lithium-ion/. CHARACTERIZING LI-ION BATTERY SEPARATORS. [online] Available at: https://www.micromeritics.com/ wp-content/uploads/12.08.21-AutoPore-APP-Note.pdf [Accessed 27 March 2023].

2. Micromeritics.com/lithium-ion/. CHARACTERIZING ADVANCED BATTERY ANODES WITH GAS ADSORPTION BET SURFACE AREA AND DFT SURFACE ENERGY. [online] Available at: https://www. micromeritics.com/Repository/Files/AppNote-202-Anode.pdf [Accessed 27 March 2023].

Monash University researchers recently demonstrated a counterintuitive way to protect atomically-thin electronics by adding vibrations.

Researchers squeezed a thin droplet of liquid gallium, and then painted graphene devices with a protective coating of glass, gallium-oxide. This oxide was remarkably thin and covered centimetre-wide scales, which made it potentially applicable for industrial large-scale fabrication.

“The oxide not only enhances and protects our devices when we first transfer it, but also later, during subsequent processing and fabrication,” said co-author Semonti Bhattacharyya.

The protective gallium-oxide delivered surprising results, as it reduced the electrical resistance in graphene, which is caused by thermal vibrations due to heat in the surrounding materials.

Lead author Matthew Gebert said gallium-oxide encapsulation is a mechanical transfer technique, which makes it different from other deposition methods. “That’s surprising because in effect we are actually adding extra vibrations, to reduce total vibrations.”

The study was the first time such a strategy to reduce the resistance due to thermal vibrations has been demonstrated in a graphene device.

The Monash team from the ARC Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET) used a novel liquid-metal printing technique to create galliumoxide (Ga2O3) glass. The glass film that formed on the surface of droplets of liquid gallium metal is more than 5,000 times thinner than a human hair.

However, it can be reliably ‘printed’ from the surface of the liquid metal to form uniform continuous layers over centimetre-sized areas.

The liquid-metal method offers two advantages to protect

devices. Firstly, the layer-printing prevents growth damage, while the transferred layer is a good barrier for further processing.

Gallium-oxide encapsulation not only offers protection, but can also enhances performance because of its High-K dielectric qualities.

it is fundamentally different to alternative deposition methods, such as atomic layer deposition, evaporation, sputtering and vapor deposition, which have undesirable attributes such as high temperature requirements. Because gallium metal is liquid close to room temperature (30 0 C), this process has a lot of advantages for industrial adoption.

The vibrations of materials due to heat, which cause electrical resistance in materials, are called phonons. These vibrations cause the atoms in a solid to oscillate, and flowing electrons bounce off these oscillations and change their direction, which leads to electrical resistance.

The thermal vibrations of the carbon atoms in graphene itself cause remarkably little resistance, which is one reason why graphene is such a useful material for electronics.

However, the thin nature of graphene means that thermal vibrations in surrounding materials can have a large effect on electrons in graphene, and these are the predominant cause of electrical resistance in graphene at room temperature.

“You can think of this scenario as a fence. The fence (the 2D graphene) is affected by the actions of neighbours on both sides (the insulating materials on either side of graphene). One neighbour might have a clean environment on their side of the fence (a good insulator, with few phonons) but the other neighbour might have an overgrown garden that damages the fence,” Gebert said.

An automated, three-station, BET surface area and porosity analyser that delivers excellent repeatability and speed of analysis . Krypton option, allows measurements in the very low surface area range, as low as 0.001 m2/g.

MICROMERITICS TRISTAR II

MALVERN MASTERSIZER 3000

Market-leading laser diffraction particle size analyser (10nm to 3.5mm) to consistently deliver the accurate and reliable data for both wet and dry sample analysis. Intuitive software with built-in expertise informs critical decision-making throughout R&D and manufacturing processes.

Fully integrated desktop Scanning Electron Microscope (SEM) provides an easy-to-use interface with full-screen images in <40sec from sample loading. Ideal for large samples up to 100mm x 100mm. Live element ID using integrated X-Ray (EDS) detector.

PHENOM XL DESKTOP SEM

MICROMERITICS ACCUPYC

Non-destructive gas displacement pycnometry system provides high-speed, high-precision measurements of true density of powders, solids, and slurries. Monitoring true density of the electrode material ensures stability of the slurry coating and drying process. DENSITY

Universal powder tester for measuring the rheological properties of powders, pastes and semi-solids. Determine a powder’s Specific Energy, an indicator of inter-particular friction to reduce agglomerates in the electrode slurry.

Laser Metal Deposition (LMD), also known as laser cladding, is an innovative additive manufacturing (AM) technique that injects metal powder into a laser beam to create a new, strongly-bonded layer on top of a substrate. This technology has gained significant attention recently as a cost-effective and time-efficient repair method that can sometimes enhance material properties in the repaired area.

However, LMD can result in residual stresses and intricate microstructures that may negatively affect the performance of repairs. To tackle these challenges, the Australian Nuclear Science and Technology Organisation (ANSTO) has partnered with leading institutions, including the Royal Melbourne Institute of Technology (RMIT), Swinburne University of Technology (Swinburne), Defence Science and Technology Group (DSTG), and Rosebank Engineering, under

the auspices of the Defence Materials Technology Centre (DMTC), to develop advanced numerical models that capture the development of residual stresses and microstructure during the LMD process. These high-fidelity multi-physics numerical models can significantly enhance the optimisation of the LMD process and thus ensure the fatigue life of repaired components.

ANSTO's previous research on stainless steel and nickel alloys showed that thermo-mechanical models could predict welding-induced residual stresses accurately. However, modelling residual stress development in lowalloyed steels requires accounting for metallurgical and transformationinduced plasticity strains and heat treatment (tempering) of the material during the deposition process. To address these challenges, ANSTO has developed a high-fidelity thermometallurgical-mechanical numerical model for predicting the microstructure and residual stresses associated with a multi-pass (14-pass), single-layer LMD repair.

ANSTO’s numerical model, developed using the SYSWELD finite element package, takes into account the kinetics of solidstate phase transformations (SSPTs) and tempering (heat treatment) that occur during the

low-alloyed steel powder deposition on a matching low-alloyed steel substrate. The validity of the developed numerical methodology was assessed by comparing numerical predictions with experimental measurements. Microstructure predictions were indirectly validated through hardness measurements (Figure 1), while residual stress predictions were directly validated using X-ray measurements (Figure 2).

The comparison between hardness predictions and experimental measurements depicted in Figure 1 shows a good agreement, confirming the numerical model's accuracy in capturing the resulting microstructure consisting of bainite, martensite, and their tempered equivalents. The model correctly predicts the initial formation of martensite in the fusion zone (FZ) and its softening in the earlier LMD passes (P1 – P4) due to tempering from heating during subsequent material deposition. Later passes (P5 – P12) show higher hardness, suggesting a limited amount of tempered martensite, while in the absence of further deposition, the final two passes (P13, P14) remain in the as-formed (untempered) martensite condition.

When it comes to the prediction of residual stresses, the numerical model reveals a relationship between residual stresses and the formed microstructure. Regions with higher hardness containing more significant amounts of untempered martensite experience compressive residual stresses (P5 – P14), while softer regions with higher amounts of tempered martensite are under tensile residual stresses (P1 – P4). Similarly, the heataffected zone (HAZ) containing large

Figure 1: The developed model predicts the formation of complex microstructure containing martensite, bainite, and their tempered equivalents. The accuracy of the microstructure predictions is performed indirectly through hardness measurements. The excellent agreement between the predicted and measured hardness values validates the applied methodology, confirming the model's accuracy in predicting the resulting microstructure in an LMD repair.

amounts of soft tempered bainite is under tensile residual stresses. The modelling results demonstrate that martensite formation is associated with the development of compressive residual stresses, which is a result of the volumetric expansion of the crystal lattice upon cooling during the austenite-to-martensite (AtM) SSPT. The AtM SSPT counteracts the formation of tensile stresses, which is a common residual stress inducing mechanism in materials without AtM SSPTs. The model also shows that subsequent tempering of the formed martensite leads to the relief of compressive residual stresses, leaving tempered martensite regions under tensile residual stresses. The presence of residual stresses in components can significantly impact their life under operating conditions, as these stresses may either enhance or diminish the component's overall resistance to crack nucleation and propagation. Tensile residual stresses at the surface of the deposited layer can initiate crack nucleation and accelerate its propagation, potentially undermining the performance of LMD repair in realworld operating conditions. The current fatigue crack growth analysis indicates that cracks originating in regions of high tensile stresses of earlier passes (P1 – P4) grow considerably faster and deeper than those that form in regions of compressive stresses (P12 – P14). However, it is important to note that although the compressive residual stresses are often preferred, the presence of untempered martensite in the material can result in brittle characteristics that may not be desirable for all applications. It is, therefore, crucial to consider the benefits and drawbacks when optimising the LMD process for specific repair applications.

The high-fidelity, multi-physics numerical model of the LMD process developed by ANSTO can effectively capture the evolution of microstructure and residual stresses during the material deposition process. Hence, validated numerical simulations have the potential to revolutionise the LMD process by providing a faster method of testing a wide range of processing parameters with the aim of obtaining an optimal microstructure and residual stress distribution within a repaired component. As a result, the numerical simulations can reduce costs, shorten turnaround times,

and improve material properties in repaired regions, making LMD repairs an increasingly attractive option for industries seeking cost-effective and reliable repair technologies.

With the ongoing advancements in numerical modelling and additive manufacturing technologies, the future of LMD repairs is poised to become even more promising and transformative for the manufacturing and repair sectors. As research and development efforts continue to push the boundaries of LMD technology, industry stakeholders can expect further improvements in the efficiency, reliability, and performance of LMD repairs. By harnessing the power of high-fidelity numerical simulations, the collaborative efforts of ANSTO and its partners are paving the way for a new era of advanced repair solutions that cater to the diverse needs of various industries.

As LMD technology becomes more prevalent, industries worldwide will continue to benefit from the advancements driven by ANSTO and its collaborating partners. The high-fidelity numerical simulations developed through this collaboration have the potential to leave a lasting impact on the way repairs are conducted, leading to more efficient and reliable solutions for a broad array of applications. By continuing to refine and enhance the high-fidelity, multiphysics simulations, researchers and

engineers will unlock new possibilities for the LMD process, ultimately resulting in a more sustainable and innovative manufacturing landscape for years to come.

In summary, the collaborative research undertaken by ANSTO, RMIT, Swinburne, DSTG, and Rosebank Engineering has yielded valuable insights into the complex interplay of factors that influence LMD repair performance. This work has shown that by leveraging high-fidelity multi-physics numerical simulations, researchers and engineers can better understand these factors and develop more efficient and reliable repair techniques tailored to specific applications, ultimately benefiting a wide range of industries, from aerospace and automotive to energy and infrastructure.

Source: Sally Wood

Engineers in Melbourne recently used sound waves to boost production of green hydrogen by 14 times, through electrolysis to split water.

The team believe their invention offers a promising way to tap into a plentiful supply of cheap hydrogen fuel for transportation and other sectors, which could radically reduce carbon emissions and help fight climate change.

By using high-frequency vibrations to divide and conquer individual water molecules during electrolysis, the team managed to split the water molecules to release 14 times more hydrogen.

Electrolysis involves electricity running through water with two electrodes to split water molecules into oxygen and hydrogen gases, which appear as bubbles.

This process produces green hydrogen, which represents just a small fraction of hydrogen production globally due to the high energy required. Most hydrogen is produced from splitting natural gas, known as blue hydrogen, which emits greenhouse gases into the atmosphere.

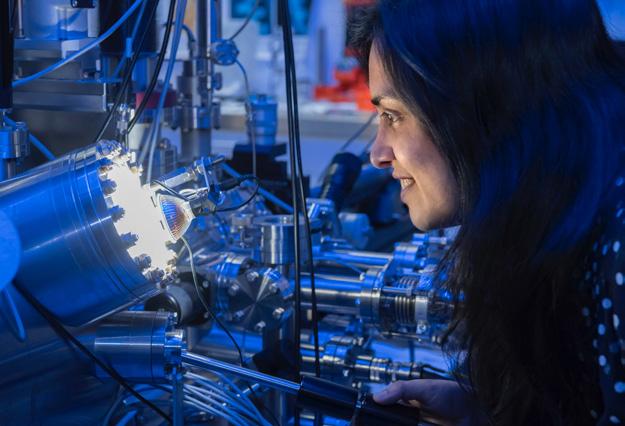

Associate Professor Amgad Rezk

from RMIT University said the team’s innovation tackles big challenges for green hydrogen production.

“One of the main challenges of electrolysis is the high cost of electrode materials used, such as platinum or iridium.”

“With sound waves making it much easier to extract hydrogen from water, it eliminates the need to use corrosive electrolytes and expensive electrodes such as platinum or iridium. As water is not a corrosive electrolyte, we can use much cheaper electrode materials such as silver,” Rezk said.

The ability to use low-cost electrode materials and avoid the use of highly corrosive electrolytes are gamechangers for lowering the costs of producing green hydrogen.

The team recently secured an Australian provisional patent application to protect the new technology.

First author Yemima Ehrnst said the sound waves also prevented the buildup of hydrogen and oxygen bubbles on the electrodes, which greatly improved its conductivity and stability.

“Electrode materials used in electrolysis suffer from hydrogen and oxygen gas build-up, forming a gas

layer that minimises the electrodes’ activity and significantly reduces its performance,” said Ehrnst, who is also a PhD researcher at RMIT’s School of Engineering.

As part of their experiments, the team measured the amount of hydrogen produced through electrolysis with and without sound waves from the electrical output.

“The electrical output of the electrolysis with sound waves was about 14 times greater than electrolysis without them, for a given input voltage. This was equivalent to the amount of hydrogen produced,” Ehrnst said.

The Potential Applications of The Team’s Work

Distinguished Professor Leslie Yeo, who was one of the lead senior researchers, said the team’s breakthrough opened the door to using the acoustic platform for other applications.

“Our ability to suppress bubble buildup on the electrodes and rapidly remove them through high-frequency vibrations represents a major advance for electrode conductivity and stability,” said Yeo.

“With our method, we can potentially improve the conversion efficiency leading to a net-positive energy saving of 27 per cent.”

While the innovation is promising, the team hopes to overcome challenges with integrating the sound-wave innovation through existing electrolysers to scale up the work.

The fifth International Materials Innovations in Surface Engineering (MISE) conference will be convened in Brisbane, Australia. The conference will be located at the state-of-the-art St Lucia Campus of the University of Queensland: twenty minutes from the centre of Brisbane.

MISE2023 features eminent academic and industrial plenary, keynote and invited speakers who encompass the engineering modification of a material’s surface to improve its performance.

The conference will cover topics such as:

> Coatings and Thin Films for Extreme Industrial Environments

> Surface Modification for Industrial Applications

> Surface Modification for Biomedical Applications

> Modelling and Simulation related to Surface Engineering

> Vacuum Deposition Coatings and Technologies: PVD and CVD

> Thermal Spray Coatings and Technologies

> Weld Overlays and Technologies

> Laser Processing and Technologies

> Characterisation of Surfaces, Coatings and Films

> New Horizons in Coatings and Thin Films

> Educational and Training of Early Career Researchers in Surface Engineering

> Case Histories for Surface Engineering, including Failure Analysis

> Corrosion, Bio-corrosion and Coatings for Corrosion Protection

> Wear of Materials

> Surface modification for Wear and Corrosion Resistance

Abstracts

Abstracts open 1 December 2022 and can be submitted online through the MISE website - www.mise2023.com.au

• Guidelines and an abstract template can be downloaded

Sponsorship and Sponsorship and Industry Displays

A number of limited sponsorship packages will be available. There will also be opportunities for sponsors to reserve space to exhibit their products and technologies. Please see the MISE2023 website for details.

Why should you participate in MISE?

Enquiries

Tanya Smith

Materials Australia

+61 3 9326 7266

imea@materialsaustralia.com.au

• Networking opportunities to kick-off and maintain your research profile

• Interacting with leading, global industrialists to promote future activities

Contribute to your Continuing Professional Development (CPD) portfolio

Learn of the emerging manufacturing technologies that are on the near-term horizon

• A post-conference intense workshop

Source: Sally Wood

When thinking of renewable energy sources, it is often solar or wind that spring to mind first. But what about ocean energy?

The ocean covers more than 70 per cent of the earth’s surface, which provides enormous potential for renewable and clean energy. Institute for Frontier Materials (IFM) researchers hope to unlock this potential.

In a paper published in the Journal of the American Chemical Society, IFM researchers have demonstrated how new advanced two-dimensional (2D) nanomaterial membrane technology can improve blue energy harvesting processes. Blue energy harvesting is a renewable energy that uses the salt content difference between river water and seawater to generate electricity.

“Ocean energy is made up of five forms—tidal, water waves, ocean currents, temperature gradients and salinity gradient energy, offering a potential alternative, limitless energy resource,” said Associate Professor Weiwei Lei, who is leading the sustainable energy generation project at IFM.

“Therefore, harvesting ocean energy through artificial devices has attracted tremendous interest. Salinity gradient energy, also called “osmotic energy” or “blue energy”, provides significant promise for the development of renewable energy.”

Associate Professor Lei and his team members introduced a strategy to optimise the nanochannels within the 2D nanomaterial membranes, which harvest more energy through higher volumes of water.

Researchers constructed nanochannels from graphene oxide nanosheets. The sheets were chemically exfoliated, which altered loose reactive nanosheet fragments called oxidative fragments, which then became charged in alkaline conditions. The negatively charged channels attracted positive ions in sea water. The osmotic pressure can then ‘push’ the ions through the channels

to create a net current that can be harvested.

“However, the energy harvesting efficiency of these membranes is still too low to meet the demands of practical applications due to their high internal resistance and low selectivity of ions.”

“New advanced 2D nanomaterial membranes with novel and robust properties will solve this problem, which is in high demand now,” Associate Professor Lei said.

Through this approach, the membrane overcame the trade-off between permeability and selectivity.

Together, it ensured Associate Professor Lei’s membrane received a boost in energy generation compared to graphene oxide membranes that have not been treated to include negatively charged nanosheet fragments.

“This means we can harvest more energy through high volumes of water. This boosted energy generation is due to the enlarged nanochannels together

with the enhanced local charge density of the detached oxidative fragments,” he said.

The new strategy provides an alternative and facile approach for many applications that can exploit the ionic charges.

While the research is still limited to laboratory-sized equipment, researchers are planning to purchase a large facility to fabricate large membranes and other devices for large-scale applications.

“In the real-world we think that membranes could be installed in river mouths or at exit points for wastewater from industry,” Associate Professor Lei said.

“We are now looking for industry partners who are interesting in the development of new membrane technology for renewable energy generation.”

This work was supported by the Australian Research Council Discovery Program and the Australian Research Council Future Fellowship.

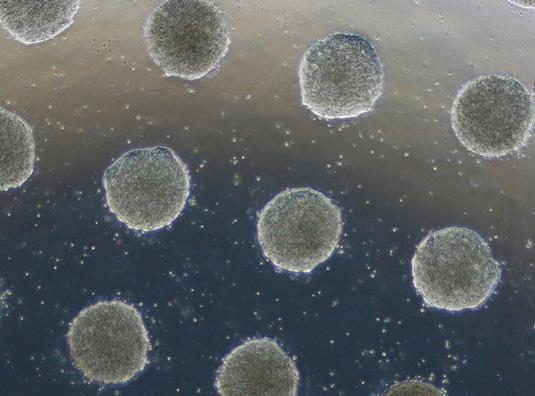

A serendipitous discovery has the potential to revolutionise embryo models and targeted drug therapies.

Materials scientists at UNSW Sydney recently showed that human pluripotent stem cells in a lab can initiate a process resembling the gastrulation phase. This involved cells differentiating into new cell types much earlier than what typically occurs in mother nature.

For an embryo developing in the womb, gastrulation occurs at day 14. But in a lab at UNSW’s Kensington campus, Associate Professor Kris Kilian oversaw an experiment where a gastrulation-like event was triggered within two days of culturing human stem cells in a unique biomaterial.

“Gastrulation is the key step that leads to the human body plan.”

“It is the start of the process where a simple sheet of cells transforms to make up all the tissues of the body—nerves, cardiovascular and blood tissue and structural tissue like muscle and bone,” said Kilian.

“So it’s really exciting that we were able to see this happening in vitro.”

The achievement was recently reported in the journal Advanced Science, and offers new treatments in medicine including cell therapy, targeted drug development and CRISPR gene-editing technologies.

Gastrulation is the key event in an embryo’s development when a mass of undifferentiated cells begin the first steps of a long journey in the womb towards formation of a human being.

This is one of the reasons that work on embryos left over from IVF is forbidden beyond 14 days, when gastrulation occurs.

Associate Professor Kilian said that up until now, it has been difficult to study this process in humans.

“Controlling gastrulation using materials alone will provide an

entirely new way for studying human development.”

“We currently can’t do this because embryo research beyond 14 days is often viewed as unethical, and it’s currently impossible in vivo because you’d need to observe an embryo in a pregnant human mother,” said Kilian. While there are animal models to study, and other researchers have induced gastrulation-like events in the lab using chemicals, this is the first time culture conditions alone have initiated gastrulation outside of a human body.

“Our method could lead to a new approach to mimic human embryogenesis outside of a person,” said Kilian.

As with most great discoveries in science, serendipity played a role.

In fact, the research team were not actively looking to bring on gastrulation when they dropped some stem cells onto the hydrogel substrate.

Lead author Dr Pallavi Srivastava was surprised by what she observed.

“Initially I was trying to get stem cells to attach to our hydrogels and planned to differentiate them in the conventional way.”

“The difference between cells cultured on glass and those on our gels was very striking. I remember thinking, ‘wow, something is going on here. I need to investigate.’ This led to a big shift in my project, and ultimately this exciting discovery,” said Srivastava.

The researchers believe they can continue exploring the benefits of their discovery by understanding how materials can guide embryogenesis and beyond.

In order increase IVF success rates and reduce stress on embryos, Fertilis, the Australian medtech startup, has developed and patented a unique environment for the critical life phase between fertilisation and implantation of the embryo. This was done by more closely mimicking the human body than other products currently on the market. The first-of-its-kind 3D-printed micro-device incorporates features 0.05 mm in diameter, allowing embryologists to precisely monitor and control the culturing process of the fertilised egg, eliminating the need for IVF-practitioners to move cells between petri-dishes, a process that is fraught with risk.

It is exactly those minuscule features –channels with a diameter smaller than a human hair – that proved challenging in the production of the device – especially with material and printers from other manufacturers. UpNano GmbH (Austria) achieved this by choosing specific base resins for a new material - UpFlow, a photopolymerising material – by keeping the viscosity of the material low until a final UV-exposure hardens the material and makes it ready to use. Additional advantages of the material include a high optical transparency –

making it ideally suited for microscopic inspections of the incubated embryos –and a very low autofluorescence.

Fertilis uses the brand new UpFlow resin, which was specifically developed for microfluidics, together with UpNano’s NanoOne 2PP 3Dprinter delivered last year to the Australian National Fabrication Facility (ANFF) at the University of South Australia. The NanoOne is an ultra-high-res 3D

printer that can print features down to 0.2µm and structures all the way up to 40x40x40mm. The 3D printer not only improves the quality of the 3D-printed micro-device for incubating embryos, but also the speed of production could be decreased from a full fortnight to only 4h by using a new feature called adaptive resolution. This enables the user to specify a combination of highquality areas and structural parts with less critical requirements.

The new procedure allows for a 30 –40% reduction of implantation cycles as commonly required to get pregnant, thus saving patients’ emotional and financial pain.

UpNano 3D printers and inks are distributed in Australia by AXT PTY LTD who offer a range of 3D printing and bioprinting solutions and related products.

By Dr. Cameron Chai and Peter Airey, AXT PTY LTD

By Dr. Cameron Chai and Peter Airey, AXT PTY LTD

This year marks the 50th since Rigaku pioneered the benchtop XRD. At the time, the concept was revolutionary with the system being significantly smaller and more affordable than anything before it. As such, it made XRD so much more accessible, bringing it out of highend research and into smaller labs and industry and is now referenced in more than 43,000 papers and patents.

Rigaku have continued to innovate to ensure they maintained a leadership position and the MiniFlex has registered several firsts:

• 1995 - First benchtop XRD to run on a Windows PC

• 2005 - First to benefit from a fast 1D detector

• 2010 - First to be powered by a powerful 600W X-ray generator

• 2017 - First to be compatible with a 2D detector