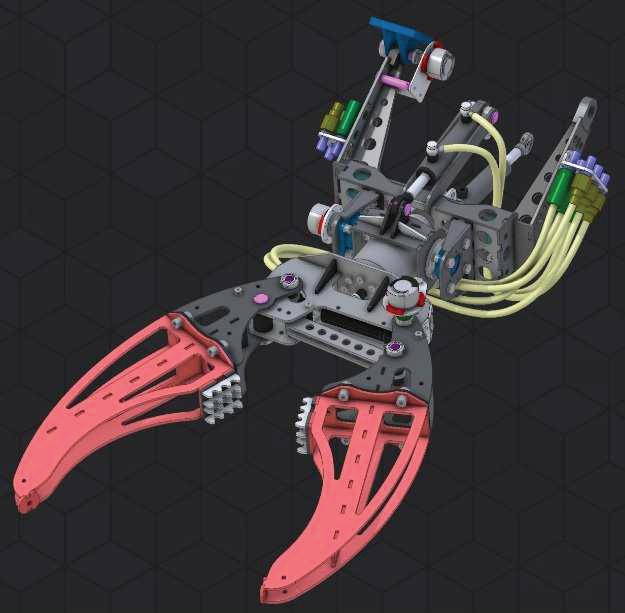

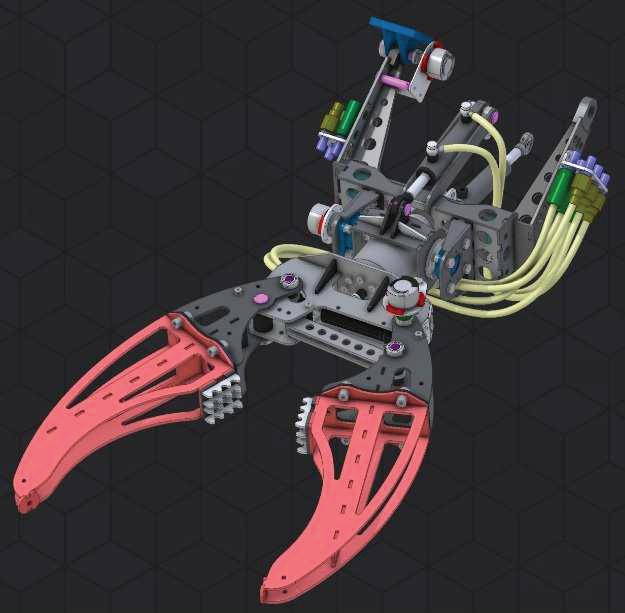

Bolstering its national reputation as a reliable supplier of high-quality steel tube, Industrial Tube commissioned its game-changing 3D Tube Laser Cutter last year – a one-of-a-kind in New Zealand that has sparked a surge in demand for its services and solidified the company’s position as a leader in the industry.

Industrial Tube general manager Ian Foster says the company is proud to have been a cornerstone of the Waikato manufacturing community for almost four decades now, catering to a wide range of industries with its broad product offering and excellent service.

“With the market demanding efficiency, versatility and extreme attention to detail, investment in automation and innovation has been a key focus for our business,” says Foster.

Known as ‘Pro-Tube services’, Industrial Tube offers 3D laser cutting, CNC Drilling, deburring, tapering, swaging and telescoping of tube, including carbon steel, pre galvanised steel and stainless steel, in addition to its extensive milled tube offering.

“Pro-Tube raises the bar in terms of what’s possible in tube processing and manufacturing. New technology like the 3D Tube Laser Cutter, coupled with the experience and knowledge of our engineers, means we can deliver more options and alternatives to New Zealand businesses that are seeking high-quality,

SMART MANUFACTURING

www.nzmanufacturer.co.nz

26 DEVELOPMENTS

Kiwi startup helps tackle carbon emissions.

Precision component production ignited with 3D Tube Laser Cutter

customised components,” he says. Since its integration into Industrial Tube’s manufacturing processes, the 3D Tube Laser Cutter has unleashed a wave of opportunities for local manufacturers. The precision, speed, and versatility offered by this cutting-edge machinery have elevated the capabilities of businesses, enabling them to create intricate components with precision and accuracy.

One client is Tony Parton, director of Smokai Limited who says the 3D Tube Laser cutter helped his product development process.

“Our product is precision engineered, and if the components are even a tenth of a millimetre out, the final product may not fit together. Industrial Tube’s 3D Laser Tube Cutting provides us with the precision components we need,” says Parton.

“One aspect we like about Industrial Tube’s laser cutter is the machine’s internal catcher, which means that the commonly used anti-splatter spray is not needed, and this results in a cleaner end product, important in our overall product presentation.”

“In all honesty, tube cutting is pretty consistent across the market, it’s the people and the care they take in the process that helps our product development.”

“It is obvious when you see the quality and care of their work that they really do take ownership of the part they each play in the production process. This seems to be reflected in the long-service nature of the team. The staff at Industrial Tube are not just ‘doing a job’, they care about their output. We really appreciate that as a client. That’s the stuff money can’t buy,” says Mr Parton.

enquiries@baycad.biz www.baycad.biz NZ 0274847464 AU 64274847464

SMART MANUFACTURING

Factory Talk Optix HMI for visionaries. July 2023

12 15

Aust/NZ Region Don’t delay,

us now. Free trial available

P CAD S N N “C” F Phone: 0800 655 465 Email: sales@acelink.co.nz Website: https://www.acelink.co.nz/mid-year-sale/

Upskilling staff faster and more cost effectively.

contact

30 Days, No Restricons Powerful, yet easy-to-use, 3D CAD Soware that’s affordable.

Industrial Tube Manufacturing, located in the Waikato, has established itself as a key player in the domestic market of carbon and stainless steel tube. Their dedication to constantly improving and expanding has enabled them to attain remarkable success in the industry.

2023 Media Kit www.nzmanufacturer.co.nz For a copy of the NZ Manufacturer Media Kit 2023 email publisher@xtra.co.nz All articles are published at no charge, unless promoted (advertorial) content is required. Success Through Innovation asiamanufacturingnewstoday.com ASIA M ANUFACTURING N EWS 2023 Asia’s manufacturing future. MEDIA KIT Media Kit 2023 Innovation + Dedication = Success www.australianmanufacturingnews.com TechRentals® is an IANZ endorsed Calibration Laboratory We offer both IANZ Endorsed and Traceable Calibrations of test and measurement equipment inluding: 0800 832 473 www.techrentals.co.nz

DEPARTMENTS

LEAD

Precision component production ignited with 3D Tube Laser Cutter.

BUSINESS NEWS

Major international summit to boost Kiwi healthcare, tech & food exports. Engineering grant grows research, outreach, media.

ANALYSIS

Mergers: The way to growth?

SMART MANUFACTURING

Zenno’s fuel-free satellite pointing system surpasses $75M sales.

HERA

What is Industry 4.0?

SMART MANUFACTURING

Factory Talk Optix HMI process visualisation for visionaries.

Top emerging technologies of 2023. Embracing smart manufacturing with futureproof technologies: Two industry experts weigh in.

Worldwide machine training system.

CASE STUDY

Pulp mill boosts plant reliability with PlantPAx DCS.

WOMEN IN BUSINESS

Karen Cook, NatureBee CEO. ANALYSIS

Becoming a data driven organisation. DEVELOPMENTS

Faster product development through machining.

WORKSHOP TOOLS

CKS2 – One key, many functions.

The rise and rise of portable welding machines.

Mastercam 2024.

BIB loader/unloader for the semiconductor industry.

Brushware for gentle cleaning.

New E4Q e-chain with extender crossbars for safe guidance of large hoses.

SUSTAINABILITY

How to select a standout sustainability team. DEVELOPMENTS

ADA NZ to open Palmerston North multi-function logistics hub.

New Kiwi startup to tackle carbon emissions. Preventing a workplace safety crisis in NZ.

THE LAST WORD

We could need six times more of the minerals used for renewables and batteries.

ADVISORS

Kirk Hope

Is Chief Executive of BusinessNZ, New Zealand’s largest business advocacy body He has held a range of senior positions at Westpac and is a barrister and solicitor

Ian is a Partner, Argon & Co. NZ, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

EMA chief executive Brett O’Riley has a background in technology and economic development. Brett actually grew up with manufacturing, in the family business, Biggins & Co. He currently holds board roles with Wine Grenade and Dotterel Technologies and is also on the NZ Film Commission board.

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 4 Contents 1 6 7 9 11 12 16 18 19 20 22 24 25 27

6 9 12 14 16 18 20 27

Brett O’Riley

Ian Walsh

Lewis oodward

Insa Errey

Dr Barbara Nebel CEO thinkstep-anz

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: +64 6 870 9029

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, EMA, Business East Tamaki, Ian Walsh, Dr. Barbara Nebel, Rob Veal, Keren Cook, Adam Sharman, Rusty Langdon

Elsa Dominish

ADVERTISING

T: + 64 6 870 9029

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: +64 6 870 9029

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer ISSN 1179-4992

Vol.14 No.6 July 2023

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

Will the election matter?

YES, if the party you want to get in, gets in.

How about the rest of it – what will the victor do to work closely with the business community? What will the victor do to keep business moving forward, to stabilise the economy and bring about greater equality?

We are in the ‘silly season’, the time before an election that allows lots to be written and outcomes suggested, not based on knowledge, grandstanding to be seen to be part of the decision-making process. Businesses always has a plea – for solutions to help them to be more competitive in the marketplace.

This means having the financial tools to invest in the technology required to do so, engaging with Industry 4.0 and keeping an eye on AI and what that will mean soon. Dealing with climate change. Confidence to invest in innovative technology, because it is a risk, especially if there is no guarantee of contract manufacturing on a financially viable level. Greater access and identification on world markets for our products, creating business opportunities, engaging with some of the excellent innovators in the country, who take financial risks by putting their ‘stake in the ground’ to become be a success story.

Innovators with bonafide credentials are what we are talking about. Those from such companies as Buckley Systems, The Gallagher Group, Fisher & Paykel, Fonterra, Stabicraft who have the expert knowledge required.

A new government will take time to settle in. A year of consolidation of processes and getting to know each other.

NZ businesses punch above their weight. Within our small population are lots of people who develop great products. A Minister of Manufacturing could help them to succeed.

Back to the beginning…will the election matter? Not really, because business usually does it all itself.

Doug Green

Publisher

5 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

Success Through Innovation Editorial

Major international summit to boost Kiwi healthcare, tech & food exports

A major international healthcare summit to be hosted in New Zealand is set to boost export access for Kiwi health, tech and food product manufacturers into over 10 nations with a combined GDP of US$33 trillion.

A number of foreign dignitaries will be among the projected 10,000+ international and domestic attendees at the event, which is also expected to benefit the tourism sector and the local economy. Guests include health policy specialists from United Arab Emirates, China, Indonesia and Singapore. Government and industry representatives from Vietnam, Japan, Malaysia, Thailand, Egypt, UK, Germany and Kazakhstan are also expected to attend.

A number of the country’s healthcare organisations and largest food exporters including St Johns, Fonterra and Zespri have also confirmed they will use the event to promote their products to buyers from countries with a population of over 2 billion.

In addition, buyers from China’s largest e-commerce platforms including Alibaba, JD.com, Meituan and Kuaishou are also set to attend - as they look to grow the number of their New Zealand suppliers.

Tony Browne, former New Zealand ambassador to China and chairman of the Council of Next Federation, the event organisers, says the High 5 “Post Pandemic” summit, will include a series

of seminars, forums, workshops and exhibitions focusing on economic recovery, mental health, telemedicine, ageing wellness, PPE and education.

“The event will provide attendees with the opportunity to engage with industry leaders as they share industry policy research and market insights dealing with challenges facing the health industry.

“We will also provide a centralised procurement platform for exhibitors to connect with international buyers and health experts.

“While New Zealand has established trading relationships for food and beverages there is an increasing opportunity for us to look at growing health supplements and health tech exports.

“The event will enable participants to identify target customers, build industry relationships, and promote new products and unique brands,” says Browne.

William Zhao, Next Federation executive chairperson, says while primarily focused on healthcare, the event will also help boost export access for New Zealand’s technology and food firms.

Zhao has more than 30 years of international business management experience in food production and played a critical role in the investment and establishment of China’s first milk powder production factory in New Zealand.

“The High 5 summit was created in essence to enable participants to seek and share health insights and

developments in a post-pandemic world.

“New Zealand’s food and technology sectors have an increasingly important role to play in global healthcare and the objective of the expo is to help facilitate this through greater collaboration across industries,” he says.

Zhao says the event will be supported by a wide range of international organisations and Government agencies including the China Chamber of Commerce of Foodstuffs and Native Produce (CFNA), the Indonesian Artificial Intelligence Association, the Singapore Economics and Management Institute and the Chinese Ageing Well Association.

The High 5 New Zealand International Health Industry Expo will be held in Auckland on 25-26 November 2023 at the Due Drop Event Centre, Manukau City.

6 Business News

businessET.org.nz

is here to make it easier to do business; working alongside business leaders and property owners in the region on security, advocacy, development and growth.

Helping build sustainable business, and sustained success.

Tony Browne

Mergers: The way to growth?

With inflation at a high, the cost of capital has now caused the deferral of many projects, or to make the cost of any investment more palatable, the restructuring of them. In addition, many senior leaders, having navigated COVID and the associated supply chain disruptions, have already invested in additional storage and now find interest rates sky rocketing.

In this environment many business owners (and baby boomers especially) are choosing to retire or find themselves needing to sell due to cash constraints, the interest rates, and difficult trading conditions. This, of course presents opportunities for growth-minded companies to acquire businesses and associated capital.

The challenge is how to do this well. It is one thing to write a cheque, it is another to acquire and integrate a high performing asset quickly to realise the merger benefits.

Unfortunately, I have seen many businesses do the former and struggle for years to achieve the benefit, if ever. In fact, only 6% of capital projects deliver target objectives in the first two months.

But the prospect of merging can be enticing; an established footprint, brand, proven capability, established supply lines, existing capital, complimentary capability and so on.

So, why do so few do this well?

In my experience, it is a function of a number of things;

• The leaders of the purchasing business overestimate their understanding of the new business, and do not engage or retain adequate support.

• They do not create an integration team to manage all the aspects of the integration, and as they are inexperienced in mergers and integrations (it is not their core business) they do not know the pitfalls, heading blindly forward without a sherpa.

• If they do create a team, the brief is narrow, failing to consider all the elements of strategy, people, process and technology which would ensure a multi-dimensional integration. The result ensures the pain points keep coming up over time.

• Even when all the elements are considered, there is little thought given to the additional resource required, and so timelines become unachievable with existing burn-out of key people.

-Ian

Walsh, Partner, Argon & Co

• There is no clear vision, measurable objectives, timeline, or ‘tone’ for the integration, viz. merging two companies (or more) is ultimately about people and culture and how it is done is often more important that what is done.

• There is no change management, and so the process of addressing issues as they arise is reactive and sub optimal. Ultimately good people are lost and the process is extended.

• Any initial due diligence is financially focussed, and typically does not adequately cover the operational complexities of the existing businesses. There are many more...

World class mergers are designed to achieve a vertical start-up. They identify, the true process potential of both organisations and consider a number of elements;

• What is the true capacity of both organisations without further capital spend to avoid overspending or unnecessary spending?

• What further capacity could be realised with what spend?

• What are the process bottlenecks?

• What are the network and supply chain opportunities? Can these be simplified to avoid future costs, optimise existing facilities, reduce logistics costs, in terms of last mile, inventory holding, and realising procurement opportunities?

• What is the critical internal knowledge and how is this captured?

• How to plan, manage and optimise the two entities?

• What is the structure and how can this be moved from the current to the future structures?

• Who are the steering team and guiding coalition to the new state?

• How will new people be trained into the merged entity when organisational knowledge is a critical intangible asset and typically missed as a vital element?

• How do we onboard, engage, motivate and inspire the acquired entity?

I have seen this done well in a range of businesses, especially in Japan and the USA utilising best practice models and a defined 100-day plan/vertical start-up approach. There are also some great examples, although fewer, in NZ.

The keys to success are;

• Engage a dedicated project manager who has been there before (you don’t want someone who didn’t make it to the top)

• Engage subject matter experts to provide;

o operational expertise

o supply chain capability

o change and transformation management

o knowledge management deploy

o and other specialist skills as needed

• Engage experts early to ensure there is enough time to implement the key opportunities. Yes, it will cost more up front, but all studies show it is significantly cheaper in the long run.

• Allocate your internal resources from both organisations to the project for a fixed timeframe and back-fill.

• Set challenging, but achievable and measurable goals, and create a war room with regular updates (a week is a long time during that first three months)

Over the last thirty years I have seen a number of acquisitions and subsequent ‘vertical start-ups.’ The worst are what I would call ‘horizontal start-ups’ failing withing the first couple of years, with business value destroyed. The best achieved the business objectives within a month or two and are now industry leaders.

Unfortunately, the best practice approach to mergers is also the most expensive up front, and in difficult business climates, hardest to justify versus traditional cost avoidance/reduction and corner cutting. The good news, however, is the cost of doing this well can be capitalised in many cases overcoming some of the hurdles.

It is time most business wanting growth and considering a merger takes the road less travelled… the road to world class…

If you want to discuss this further, please give me a call.

Analysis

7

Engineering grant grows research, outreach, media

Engineering New Zealand Foundation Grant Programme.

The Foundation were seeking well-defined projects that would benefit or advance the engineering profession with the potential to enhance diversity and inclusion, acknowledge and reflect Te Tiriti o Waitangi, and raise the profile of engineering in Aotearoa.

The recipients

Alyce Lysaght, a Graduate Water Engineer at WSP in the office of Te Whanganui a Tara, received $9,620 towards the hosting and production for another year of her popular podcast, Māori in Engineering.

The Trustees commended Lysaght’s application for its plan to continue and develop a proven and successful project that was seen as having influence, community reach, and providing a positive portrayal of the engineering profession through storytelling.

Marie McCarthy (Ngāti Porou (Whanau-a- Ruataupare), Ngāti Whakaue, Ngāti Whitikaupeka, Ngāti Tama (Mokai Patea)), an environmental social scientist, received $40,500 for her He Rau Aroha –Response to Cyclone Gabrielle proposal. He Rau Aroha will kickstart a process of bringing together Māori working broadly in the infrastructure sector, to engage in pro bono work to assist iwi and their communities in Tairāwhiti region, Te Wairoa, Napier/Hawkes Bay and Northland impacted by Cyclone Gabrielle. It will be supported by Tonkin +Taylor with pro-bono time from participating consultancies Beca, WSP New Zealand (WSP), Stantec, Pattle Delamore Partners (PDP) and Mott MacDonald.

Felicia Indrawidjaja, a fifth-year mechanical engineering and English student at the University of Auckland, received $34,000 to produce ENGGEN 101, a scripted mockumentary web series highlighting the presence of women in

the engineering community, increasing the visibility of role models and informing the general public about engineering in a fun and entertaining way.

Felicia has been involved with the Women in Engineering Network (WEN) club at the University of Auckland since her first year. She started with running events to support first year WEN students and went on to create social media content which inspired her project.

Esther Blain, a fourth-year Mechatronics Engineering student and president of the Women in Engineering club at the University of Canterbury | Te Whare Wānanga o Waitaha, received $5,000 for her Women in Engineering High School Outreach programme.

The goal of the Outreach programme is to encourage more female high school students to consider engineering as a career option and is specifically aimed at female students that are underrepresented in the current engineering cohort at the university. This includes Māori and Pasifika students, and female students attending co-ed schools.

Elizabeth Stewart, who has a MSc in Industrial and Organisational Psychology from the University of Canterbury | Te Whare Wānanga o Waitaha received $12,000 over three years for her project Career Trajectories in the Engineering Profession. This initiative will be integrated into her PhD, which will focus on data from the BeLongEng Project led by the project’s other applicant, Enda Crossin, who runs the Engineering Management programmes at the university.

The BeLongEng project is the first prospective longitudinal study of practicing engineers and is the biggest ever study of its type globally, including about 350 engineers who reside in Aotearoa New Zealand.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 8

Five projects that support a thriving engineering profession have been funded from a pool of $100,000 in the inaugural round of the

Business News

Tricentis launches engineering community ShiftSync

New community to serve as destination hub for professionals, passionate about the development of high-quality, high-performing, and highly secure software.

Tricentis, a global leader in continuous testing and quality engineering, has launched ShiftSync, a new online community dedicated to quality engineering and open to all industry professionals interested in applying quality engineering best practices throughout the software development lifecycle.

ShiftSync is designed to foster a dynamic and engaging learning space for developers, testers, executives, and industry leaders, driving collaboration and lowering the quality engineering barrier to entry for the software development community.

Members can ask questions, share ideas, learn new techniques, and connect with other quality champions and industry experts across industries and from around the world.

“At Tricentis, we know improving software quality is a growing priority for organisations,” said Darren Beck, Chief Marketing Officer, Tricentis. “We

want this community to be a resource for quality champions around the globe to enhance their overall software development lifecycle, including building high-functioning development teams, optimizing code writing, improving performance, and delivering secure and high-quality software.”

Offering more than just content, the community invites members to earn points and badges by participating in challenges and missions led by industry experts to track their learning progress.

Members can connect with peers via user groups and roundtables to build personal connections and knowledge. They can also be front row to hear Tricentis experts speak on latest innovations and best practices.

Bas Dijkstra, Independent Test Automation Consultant and Trainer on OnTestAutomation, a contributor to the ShiftSync community, said, “ShiftSync is a place where quality advocates can gather and share their viewpoints and learnings on testing, automation and quality engineering in a collaborative space. I can’t wait to see what’s in store

for the future for ShiftSync and will keep a close eye on the exclusive resources that will be published in time.”

Tricentis is a global leader in continuous testing and quality engineering. The Tricentis AI-based, continuous testing portfolio of products provide a new and fundamentally different way to perform software testing.

An approach that’s totally automated, fully codeless, and intelligently driven by AI. It addresses both agile development and complex enterprise apps, enabling enterprises to accelerate their digital transformation by dramatically increasing software release speed, reducing costs, and improving software quality. Widely credited for reinventing software testing for DevOps, cloud, and enterprise applications, Tricentis has been recognised as a leader by all major industry analysts, including Forrester, Gartner, and IDC. Tricentis has more than 2,500 customers, including the largest brands in the world, such as McKesson, Accenture, Allianz, Telstra, Dolby, and Vodafone.

Zenno’s fuel-free satellite pointing system surpasses $75M sales

New Zealand headquartered space-flight systems company Zenno Astronautics (Zenno) has surpassed $75M in product sales (USD 48M) for its world-first superconducting magnetorquer for spacecraft attitude control, the Z01.

Built on Zenno’s proprietary superconducting magnet technology, Z01 is a fuel-free satellite pointing system designed to significantly increases the range of capabilities for attitude control in space, including fully autonomous satellite positioning and extended satellite orbit time.

Zenno CEO and co-founder Max Arshavsky says achieving the sales milestone for Z01 in under a year demonstrates that the global space industry is embracing innovative technology that solves a real problem.

The Zenno invention enables higher performance in satellite design and function, offering benefits well beyond the constraints of existing technologies. Alarming in its simplicity, the Z01’s pointing capabilities unlock new opportunities and new services in orbit by enabling better imagery and communications and offering the benefit of more time in space.

“Z01 is the world’s most advanced spacecraft pointing technology and operates ‘like a sustainable magnetic sail or electric vehicle in space’ - addressing

the challenges of moving objects in space while reducing the impact on the planet. Z01 radically enhances sustainability, reliability, and accuracy – as it is fuel-free, harnessing magnetic forces and solar for spacecraft control,” says Arshavsky.

Zenno is planning to launch its first full-scale Z01 attitude control system in late 2023. The innovation is the first of several the six-year-old company is bringing to market to support its mission to build life in space.

Pointing and turning objects in space without fuel

Getting an ever-increasing number of satellites into orbit is only one half of the equation; satellites require persistent shifts to ensure their antenna, sensors, solar panels, and more are facing the correct directions.

Zenno’s breakthrough Z01 super torquer consumes electricity only and does not require on-satellite fuel consumption for satellite control in orbit. In contrast, existing propulsion systems that enable these movements require fuel until a satellite’s mission ends.

Powered by solar panels, Zenno’s Z01 on-satellite hardware uses cryogenically cooled high-temperature superconductors to generate strong magnetic fields, which interact with the Earth’s geomagnetic field, allowing the satellite to rotate and shift.

Attitude control systems are one of the largest and heaviest subsystems on a satellite. Z01 is significantly smaller and lighter than existing attitude control technologies.

9 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

Zenno CEO and co-founder Max Arshavsky

What is Industry 4.0?

Industry 4.0 refers to the fourth industrial revolution taking place right now. This revolution is driven by the convergence of digital technologies such as the Internet of Things (IoT), robotics, artificial intelligence (AI), augmented and virtual reality, 3D printing and more. Adopting these technologies is enabling manufacturers to enhance their performance, output, monitoring, quality and control on a global scale.

The Industry 4.0 Demonstration Network

The challenge for New Zealand businesses starting out on their Industry 4.0 journey is knowing when, how and what technologies to adopt to improve efficiency, quality, documentation, business intelligence and sustainability.

Where do I start?

This Government initiative enables Kiwi manufacturers to experience Industry 4.0 technologies first-hand via nationwide showcase events, manufacturing site visits, interacting with and learning from industry leaders.

THE FUTURE OF MANUFACTURING IS HERE

THE SMART FACTORY SHOWCASE

The Smart Factory Showcase is a free, interactive session designed to demystify and break down Industry 4.0 with a world leading NZ example. The session will highlight how incorporating smart technologies improves efficiencies, productivity, connectivity, solves common manufacturing issues and streamlines systems and processes. The Showcase provides an ideal introduction to kick-start or progress your own Industry 4.0 journey.

Who should attend

This event is designed for CEO’s, Digital Technology Managers, Operations Managers, Design Engineers and Managers seeking an in-depth understanding of the latest available technologies for businesses. It is a valuable forum to get buy-in from stakeholders and the events are relevant across all sectors. Teams are encouraged to attend together.

What to expect

The Smart Factory Showcase highlights Nautech Electronics’ Auckland facility and what the future of advanced manufacturing looks like – You will be inspired, gain powerful insights to enhance your manufacturing agility and be armed with the knowledge to join the Industry 4.0 revolution.

View all Showcases

It can really help by providing concrete examples of how you can actually apply this stuff and get value from it, and network with others to find out what they’re doing to implement Industry 4.0

Mitchell Sanson, Engineering Manager, Hansa Products

Featuring

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 10

“ “

What is Industry 4.0?

Industry 4.0 is our fourth industrial revolution, driven by converging digital technologies including the Internet of Things (IoT), robotics, AI, augmented and virtual reality, and 3D printing. With Industry 4.0 technologies, manufacturers can enhance performance, monitoring, quality and control on a global scale.

THE INDUSTRY 4.0 PROGRAMME

Join us for events, apply for a readiness assessment to see how you compare to others in your sector or simply expand your knowledge through the resources and case studies.

THE SMART FACTORY SHOWCASE:

The Smart Factory Showcase is a free, interactive session designed to demystify and break down Industry 4.0 with a world-leading NZ example. The session will highlight how incorporating smart technologies improves efficiencies, productivity, connectivity, solves common manufacturing issues and streamlines systems and processes. The Showcase provides an ideal introduction to kick-start or progress your own Industry 4.0 journey.

WHAT TO EXPECT:

The Smart Factory Showcase highlights Nautech Electronics’ Auckland facility and what the future of advanced manufacturing looks like – you will be inspired, gain powerful insights to enhance your manufacturing agility and be armed with the knowledge to join the Industry 4.0 revolution.

Thursday 20th July

Wednesday

Wednesday 9th August

Wednesday 16th August

Wednesday

11 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

events FACTORY TOURS Ȱ Wellington Petone Engineering

Register for upcoming

19th July 10:00AM - 12:00PM SMART FACTORY SHOWCASES Ȱ Auckland

3:00PM

- 6:00PM

7:30AM

26th July

- 10:30AM

7:30AM

- 10:30AM

9:00AM

PROGRAMME PARTNERS POWERED BY Register � Register � Register � Register � Register � View all Showcases �

- 12:00PM

Factory Talk Optix HMI process visualisation for visionaries

The world’s largest company dedicated to industrial automation and digital transformation, Rockwell Automation, has begun rolling out its cloud-enabled human-machine interface (HMI) platform, FactoryTalk® Optix™, throughout Australia and New Zealand.

FactoryTalk Optix, enhances the capabilities of the FactoryTalk software suite. This suite is used globally to support advanced industrial applications, such as IoT, creating a robust ecosystem.

“FactoryTalk Optix enables users to design, test, and deploy applications directly from a web browser, allowing them to achieve new levels of collaboration, scalability, and interoperability in optimising automation and IoT systems,” says Anthony Wong regional director, South Pacific, for Rockwell Automation.

One of the new software’s first showings in Australasia will take place at ROKLive September 5-7, 2023, on the Gold Coast, Queensland, an event which showcases the future of manufacturing by bringing together hundreds of operations, maintenance, engineering, and technology leaders to connect and learn about the industry’s latest innovations and solutions.

FactoryTalk Optix is one of the five core solutions in FactoryTalk Design Hub™, which helps industrial organisations transform their automation design capabilities with a more simplified, productive way to work.

FactoryTalk Remote Access, along with FactoryTalk Optix, allows users to access machines, controllers, or HMI from almost anywhere with a Virtual Private Network (VPN) that uses industry standards for cybersecurity.

Remote access is an enabler for on-demand remote assistance, installation, programming, updates, troubleshooting, and maintenance of remote systems and applications.

The result is increased design productivity, faster time to market, and systems that cost less to build and maintain.

“I’m calling this release ‘Visualisation for Visionaries’, because FactoryTalk Optix unlocks unprecedented collaboration and innovation through cloud-based engineering workflows. The result is visually stunning, data-driven, scalable solutions with seamless connectivity, which are faster to create and easier to maintain, to better support our customer’s smart manufacturing efforts,” said Adrian Giecco director, software and control, Rockwell Automation Asia Pacific.

FactoryTalk Optix is designed to help improve processes and efficiency. Among its features and benefits are:

• Design options: Design and test projects in a modern object-oriented programming environment.

Top 10 Emerging Technologies of 2023

1. Flexible Batteries

Standard rigid batteries may soon be a thing of the past as thin, flexible batteries – made of lightweight materials that can be twisted, bent and stretched –reach the market.

This new generation of battery technology – expected to hit a market value of $240 million by 2027 – has applications across medical wearables, biomedical sensors, flexible displays and smart watches.

2. Generative Artificial Intelligence

This year’s list would not be complete without mentioning generative AI – a new type of AI capable of generating new and original content by learning from large datasets that was catapulted into public dialogue at the end of 2022 with the public release of ChatGPT.

Evolving rapidly, generative AI is set to disrupt multiple industries, with applications in education, research and beyond.

3. Sustainable Aviation Fuel

With 2%-3% of annual global CO2 emissions coming from aviation, and no sign of long-haul electric flights, sustainable aviation fuel produced from biological (e.g. biomass) and non-biological (e.g. CO2) sources could be

the answer to decarbonize the aviation industry in the short to medium term.

4. Designer Phages

Phages are viruses that selectively infect specific types of bacteria. Equipped with increasingly sophisticated genetic engineering tools, scientists can now reprogramme phages to infect the bacteria of their choosing, allowing them to target one type of bacteria in a complex community of co-existing types of bacteria such as in plant, animal and human microbiomes.

Though many of the near-term applications will be in research, there are signs these “designer” phages could eventually be used to treat microbiome-associated diseases or eliminate dangerous bacteria in

• Reduce design time with:

o Multi-user collaboration

o Simplified standardisation through libraries of reusable content, custom templates, and style sheets

o Responsive graphics, easy wizard-based workflows

• Improve Development and deployment flexibility: Create an application once and deploy it to any device.

• Reduce Risk: better manage changes to applications and libraries through cloud-based storage with version control.

• Drive Standardisation with Graphic options: Style graphics to support a global audience.

• Reduce costs.

o Pay-for-what-you-need runtime licensing model based on application features used.

o Scale hardware requirements based on application complexity.

• Extensible options: Achieve openness and interoperability through machine-to-machine and machine-to-cloud communications enabled by Open Platform Communications (OPC), Unified Architecture (UA), Message Queuing Telemetry Transport (MQTT), Internet of Things (IOT) native connectivity and an open C# interface.

• Standardise HMI platform regardless of controller selection. Connect with any controller or device with built-in 3rd party drivers.

food supply chains.

5. Metaverse for Mental Health

Responding to the growing mental health crisis, product developers are starting to build shared virtual spaces to improve mental health. Video games are already being used to treat depression and anxiety and VR-enabled meditation is on the rise.

Combined with next-generation wearables that allow the user to feel touch and or respond to the user’s emotional state, the future metaverse could be ripe for improving mental health.

6. Wearable Plant Sensors

Drones and satellites have been a game changer in monitoring large-scale farms that traditionally relied on manual soil testing and visual observations. Now we have a new generation of plant sensors – small, non-invasive devices that can be “worn” by individual plants for continuous monitoring of temperature, humidity, moisture and nutrient levels.

Assuming they can overcome scaling costs, wearable plant sensors could improve plant health and increase yields.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 12

7. Spatial Omics

By combining advanced imaging techniques with the specificity of DNA sequencing, spatial omics allows scientists to “see” biological processes at the molecular level inside cells.

By revealing previously unobservable biological structures and events, this powerful new technology is poised to speed up our understanding of biology and help researchers develop new treatments for complex diseases.

8. Flexible Neural Electronics

Brain machine interfaces allow direct communication between the brain and external computers. They have potentially life-changing applications in

medicine and neuroscience such as the treatment of epilepsy, depression or paralysis. So far, the technology has been based on rigid electronics and limited by the mechanical and geometrical mismatch with brain tissue.

But breakthroughs in flexible electronics and more biocompatible materials mean a less invasive and uncomfortable experience for patients. The $1.74 billion market for this technology is expected to grow to $6.18 billion by the end of the decade.

9. Sustainable Computing

Data centres consume approximately 1% of the electricity produced globally. Multiple technologies are intersecting to make the dream of net zero-energy data centres an achievable reality.

Bucketed together as “sustainable computing” technologies, they include liquid cooling systems, AI analytics and modular data centres that can be co-located with existing energy sources such as methane flares.

10. AI-Facilitated Healthcare

From diagnostics to drug design, AI has been widely reported as an enabler of better healthcare. The application pulled out in this report goes one step higher and focuses on the role of AI to support the entire healthcare system – from monitoring pandemic outbreaks to reducing hospital wait times by optimizing resource allocation.

Embracing smart manufacturing With futureproof technologies: Two industry experts weigh in

As flexibility, efficiency, resilience, and sustainability take centre stage in the post-pandemic world, many industry leaders now believe the era of smart manufacturing will arrive sooner rather than later.

Indeed, new technologies and standards, such as Open Platform Communications Unified Architecture Field Exchange (OPC UA FX), time-sensitive networking (TSN), Wi-Fi 6/7, 5G, and Single-pair Ethernet (SPE)/ Ethernet-APL, are increasingly adopted to enable Industrial Internet of Things (IIoT) networks for smart manufacturing.

Two seasoned experts in the field of IIoT have decided to share their insights on the future of smart manufacturing and how we can get there. Stefan Schönegger, Vice President of Product Management Control Systems, Machine Vision and Networks at B&R Industrial Automation (a member of ABB Group), joins Jack Lin, Product Manager of Industrial Networking Infrastructure at Moxa, in answering five important questions many industries face as they plan and implement industrial networking solutions for intelligent manufacturing.

1. What makes the key technologies enabling smart manufacturing so important and how do they interact?

Stefan: Smart manufacturing is a technological concept that uses machines networked via the Internet to seamlessly monitor the entire production process. The devices in smart manufacturing continuously collect and analyse data from a variety of sources, including real-time data, to enable a new level of adaptability and rapid design changes through digital information technologies. In addition, data scientists can use the data to simulate manufacturing processes and figure out how to do certain things more efficiently.

It is therefore crucial that all this data can be extracted and analysed, which will allow knowledge and insights to be gained from it. Seamless and

secure interoperability is a mandatory prerequisite for this, which is exactly what OPC UA does.

In addition, OPC UA

• supports a wide range of applications from the cloud to the field level, such as OPC UA FX (Field eXchange)

• complements TSN, which enables different IT and OT protocols to coexist in a common network infrastructure by supporting IEC/IEEE 60802 profiles

Moreover, the OPC Foundation cooperates with the organisations behind

• new 5G and Wi-Fi 6/7 technologies

• the Advanced Physical Layer (APL) project group, which defines the requirements of the process industry

continued on Page 14

13 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

title

Thus, OPC UA is becoming universal for many applications in both factory automation and process industries.

Jack: Since OPC UA FX, TSN, 5G, Wi-Fi 6/7, and Single-pair Ethernet (SPE)/Ethernet-APL share the same packet switching and Ethernet foundations. They easily connect with each other and align with comprehensive efforts from all industrial partners involved with most standards bodies and communities, such as IEEE 802.1, TSN TG, 802.3, 802.11 TGbe, IETF, 5G-ACIA, and IEC/IEEE 60802 joint projects.

In a nutshell, these technologies have a high level of effective interactions with each other in a variety of industrial applications.

Stefan: Machine learning and artificial intelligence (AI) require high quality data inputs for highly likely predictions. My thoughts on this are twofold:

1. Thanks to advances in chip technology and new single-pair Ethernet connectivity, there will soon be even smaller intelligent sensors with Ethernet connections that can communicate over OPC UA. Real-time requirements for smart manufacturing can be achieved via copper with TSN or via new wireless signals with 5G/Wi-Fi 6/7. These next-generation sensors will also become new sources of data and insights.

2. These new data sources will also provide high-quality inputs for machine learning and artificial intelligence through the comprehensive data semantics of OPC UA.

As such, operational technology (OT) will adopt many proven productivity advances from information technology (IT). IT will find its way into machines and factories, albeit in a modified form.

To this end, OPC UA allows cross-platform, cross-industry, and cross-country industrial communication to take place. The devices of the future will be smart devices capable of performing updates remotely for cybersecurity with extended functions and features. It is important that devices can communicate with one another and with the cloud using the same set of standards.

Therefore, OPC UA, TSN, 5G, Wi-Fi 6/7, and Single-pair Ethernet (SPE)/Ethernet-APL will all continue to play key roles into the future.

Jack: If Industry 3.0 is characterised by independent, pre-programmed loops and processes, then Industry 4.0 will see the development of a collaborative, fast-response and harmonised single loop.

All resources, whether they are people, machines, data, or networks, tie in together harmoniously so that the right resource is mobilised and made available in the right place and at the right time to achieve production objectives.

5. What obstacles are keeping us from realising the future of smart manufacturing?

2. Are the new technologies for smart manufacturing only reserved for greenfield applications? What about brownfield applications?

Stefan: It must be remembered that customers have invested in existing technologies and cannot change everything overnight. Therefore, there must be a harmonious transition from good to better. The extensions made to OPC UA technology, called OPC UA FX, support this transition by allowing different established communication protocols to coexist in a common network infrastructure. This supports the migration from traditional fieldbus and real-time Ethernet protocols to a unified communication solution, which is exactly the right approach to evolve existing industrial operations into smart factories in a practical way.

Jack: When looking to adopt these new technologies, we’re not just looking at greenfield applications but also brownfield applications too. Let’s take IEEE 802.1 TSN TG as an example.

Those features are considered “TSN related” and are based on technologies that have been established for more than 40 years. We’ve been developing those features on top of a solid foundation, which means they are both backward and forward compatible.

3. How are technologies contributing to machine learning and artificial intelligence?

Complete information about values, their units and thresholds, together with an absolute timestamp, means that the prediction quality of algorithms will become qualitatively better and better. It is a dream of every data scientist come true.

Jack: Good data always needs to be abstracted from large amounts of information, but the space and speed for information to be shared is restricted due to physical limitations. That is where TSN and ultra-reliable wireless technology such as 5G come in. TSN provides 10 to 100 times more bandwidth over proven industrial Ethernet networks, whereas 5G provides 10 times the capacity of previous cellular technologies.

With determinism and ultra-low bounded latency, these technologies are capable of deterministically transmitting more precise and higher quality information, such as high-resolution images or video streaming. Furthermore, with the Single-pair Ethernet (SPE) and Ethernet-APL technologies, data access has been seamlessly extended to devices on the very edge as well as sensors within applications, so a holistic view can then be obtained.

4. What will smart manufacturing look like in 10 years?

Stefan: People will still be indispensable in the factories of the future, but they will need to cooperate more with robots and intelligent machines to achieve safer, more efficient, and hopefully carbon-neutral manufacturing.

Stefan: The silos separating information technology and operational technology need to be broken down so that IT and OT can continue to converge. Promoting a culture of openness and cooperation across disciplines can help IT and OT stakeholders exchange and transfer knowledge to achieve synergies and carbon neutrality.

Jack: We have discussed many positive aspects of these key technologies. However, there are still realities to be considered such as business initiatives and investment ROIs.

Sometimes we see our customers struggling to reach a balance between satisfying current market demands and investing for the future. In fact, investing for the future is sometimes delayed due to current market demands.

I suggest that organisations take steps to identify variables, mitigate risks, overcome unforeseen obstacles, and provide leadership for businesses to evolve.

Conclusion

As Stefan and Jack noted, the future of smart manufacturing is a journey built on a foundation of interoperable standards including OPC UA, TSN, 5G, W-Fi 6/7, and Single-pair Ethernet (SPE)/Ethernet-APL across many sectors. To learn more about the road to smart manufacturing and TSN, please visit our TSN microsite.

Moxa Inc ( www.moxa.com )

Acelink ( www.acelink.co.nz ) is the representative of Moxa in NZ.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 14

Worldwide machine training system helps manufacturers bridge skills gaps

specialists. to use valuable shop-floor equipment.

By combining hardware that realistically replicates machines with manufacturing simulation and operator’s software tools, it helps trainees gain practical experience without risking damage to expensive business-critical equipment, wasting materials, or tying up valuable production resources.

HxGN Machine Trainer was developed by Hexagon to help companies and educational institutions attract and train the next generation of machine workers – something that is vitally important with the industry facing a skills and labour shortage. In the US, for example, job openings are hovering near all-time highs at 800,000 with 55% of roles unfilled 1, while almost three in 10 manufacturing firms in Europe reported production constraints in the second quarter of 2022 due to a lack of workers 2.

The skills shortage is compounded by the fact that training people to use CNC machines, and similar tools, is expensive, slow and potentially dangerous. By training machine operators using an accurate and interactive physical simulator, manufacturers can onboard and upskill their staff faster and more cost effectively than ever before.

Hexagon’s new hardware simulator bridges the manufacturing skills gap by making it easier to prepare inexperienced staff for the demands of the factory. It is versatile because a digital twin can be created for the specific machine brand, type and configuration they will use. Once trained, workers can easily move from HxGN Machine Trainer to real machines, because the simulator is designed to be as realistic as possible – with hardware that replicates the look and feel of a real machine and a 43-inch screen that displays accurate simulations of a large variety of machine and cutting tools.

A light tower, physical CNC hand wheel and CMM

joystick completes the experience by enabling trainees to respond to issues and control machine movements exactly as they would on the shop floor. The agile training system also offers a range of digital twins for coordinate measuring machines (CMMs) to provide practical experience.

Each trainer unit can be equipped with up to three CNC controllers — including those by Fanuc, Heidenhain, and Siemens — on a single training console. The machine trainer utilises the latest version of Hexagon’s NCSIMUL CNC simulation software to simulate 3-axis, 5-axis, and mill-turn machine tools; and I++ Simulator software to simulate complete metrology processes.

“Crashing a machine tool because of incorrect setup is a nightmare for both the new machinist and management concerned that a piece of machinery worth millions could be permanently damaged,” said Alexander Freund, director of product management at Hexagon, “Crashing a virtual machine tool or CMM is safer for staff and equipment and provides a realistic experience to trainees while ensuring that valuable resources remain up and running.”

Staff training to be machine-tool operators, machinists and, ultimately, CNC programmers, can use any of the three controllers to learn how to use its associated conversational programming language. Accompanying student exercises include instruction sheets that mimic typical manufacturing workflows and job specifications.

These instructions list virtual cutting tools to be assigned to jobs and the CNC program to be loaded to the trainer unit. In addition to troubleshooting and learning how to switch between manual and automatic run modes as needed, students learn how to set machine-tool origins and tool parameters, and

to determine cutting tool compensation.

HxGN Machine Trainer is available globally now, supporting 3-5 axis CNC machine tools, mill-turn machining and CMM training, with support for up to 3 CNC controllers on a single unit. It comes with a library of machine digital twins for Hermle, DMG and Fanuc machines. CMMs support includes the Hexagon TIGO SF, with support for other CMMs through the I++ Simulator, paired with either QUINDOS or PC DMIS metrology software. Customers can request a digital twin of any other machine.

Sources:

1. Deloitte 2023 Manufacturing Outlook

2. World Economic Forum, Future of Jobs Report, 2023.

15 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

New training technology now available globally from Hexagon’s Manufacturing Intelligence division. leverages the power of its digital twins to help manufacturers train machinists and metrology

By training machine operators using an accurate and interactive physical simulator, manufacturers can onboard and upskill their staff faster and more cost effectively than ever before.

Case Study

Pulp mill boosts plant reliability with PlantPAx DCS

A leading New Zealand pulp mill has upgraded its Distributed Control System (DCS) to Rockwell Automation’s PlantPAx. Winstone Pulp International Ltd (WPI) produces a range of timber and pulp products derived from renewable plantations of Radiata pine for both New Zealand and international markets.

Its pulp mill in Karioi, Ohakune was experiencing usability challenges with its DCS, and WPI saw risks for the future of the business.

“Our existing DCS was coming to the end of its lifecycle. It required highly specialised knowledge and was not easy to modify if our needs changed. It was not a cost-efficient or optimised way of running the pulp mill,” said Lindsay Rowe, project manager, WPI.

WPI already had Rockwell Automation’s PlantPAx DCS running in some areas of the plant, where it was operating reliably and efficiently, so the decision was made to convert the rest of the plant to PlantPAx, to create a unified DCS.

“We wanted a true DCS to be implemented plant-wide – something that was user-friendly, with standard template that could easily be modified as our needs change in the future. Importantly, we wanted a DCS that was simple to learn and to operate, to minimise the risk of an experienced maintenance technician retiring and leaving a knowledge gap in the company, for example,” added Rowe.

The Karioi pulp mill – which produces wood pulp that is used for folding boxboard manufacture – has more than doubled its production capacity since it began in 1978, by implementing new plant, processes, and technology. WPI’s latest investment follows this trend of utilising proven technology to drive reliability and efficiency benefits.

Feed study optimises outcomes

Prior to Rockwell Automation’s involvement, spare parts were more difficult to come by, and the legacy system lacked newer functionalities, which presented further risks in a major shutdown scenario.

“We conducted a feed study for WPI, to provide a complete understanding of processes right from the outset. This helped shape our planned migration to PlantPAx, and optimised the outcomes for WPI,” explained Lin Han Thwe, account manager, Rockwell Automation New Zealand.

The feed study and documentation process involved interviews with engineers and operations personnel, to gain a complete picture of WPI’s operations, and of their customers’ needs.

Resourceful and creative measures to overcome pandemic-related challenges

The PlantPAx migration project commenced in 2020, when New Zealand was experiencing its strictest lockdowns and significant Covid-19 outbreak in the community.

To navigate these challenges, Rockwell Automation conducted remote tests, and employed careful contingency planning and assignment of resources. The team was able to commission around plant shutdowns to minimise any disruptions to WPI’s operations.

“Upgrading so many areas of a plant within a short duration is challenging enough, and that’s before adding the pandemic restrictions on top of it. But the commitment, technical prowess, and resourcefulness of the team shone through to deliver a satisfactory outcome for our customer,” said Bernard Ooi, project manager, Rockwell Automation New Zealand.

PlantPAx delivers user-friendly, connected, and efficient DCS

WPI has now converted the entire pulp production area to Rockwell Automation’s PlantPAx DCS, where it can now take advantage of a standardised DCS that is simple to update, modify, and train new staff to use.

“Having one vendor, and one solution, makes our lives a lot easier,” said Rowe. “We no longer have to engage different system integrators each time we need to update our processes. Further, we can easily train new operators to use the PlantPAx DCS, so we’re never at risk of losing that knowledge if an employee leaves the company,” she added.

In addition to supplying the latest PlantPAx DCS technology, Rockwell Automation is also providing ongoing service and maintenance to WPI, to keep everything running at optimal levels, so that WPI can maximise the return on their investment.

“Service is faster and simpler with Rockwell Automation, which is a big downtime saver. Additionally, we often have complex requirements, and Rockwell Automation is always there to help us with problem solving. This support is a major asset to us, as we look to continue building on the growth we’ve experienced over more than 40 years,” said Rowe.

PlantPAx benefits

The PlantPAx system is based on four core principles:

• Plant-wide Control and Optimisation: The PlantPAx system uses a common automation platform for seamless integration between critical areas of a plant. Benefits include common platforms, seamless information flow, ease of management, and lower total cost of ownership.

• Scalable and Modular Architecture: A wide range of architecture options for increased flexibility are provided with the PlantPAx system. This means easy integration without replicating data, faster time to market, and scalable system capabilities such as HMI, batch management and data collection.

• Open, Information-enabled, and Secure: The PlantPAx system is based on open communication standards leveraging Ethernet/IP as its backbone. As a result, secure real-time information is readily available throughout the enterprise for better business decision-making.

• Flexible Delivery and Support Network: Users can select the optimal implementation and support team based on their needs with a PlantPAx system, with the long-term confidence that the investment is protected with support from Rockwell Automation.

“PlantPAx is what we like to refer to as a ‘full-blown’ DCS. It has everything from cybersecurity, streamlined workflows, and drives consistency, through to intelligent analytics and a reduced footprint. For operations looking for outstanding reliability, it’s a powerful solution,” concluded Lin Han.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 16

WPI has converted its entire pulp production area to Rockwell Automation’s PlantPAx DCS, where it can now take advantage of a standardised DCS that is simple to update, modify, and train new staff to use.

The leading supplier of high quality components and products to industrial markets

Treotham Automation is the exclusive distributor for many world class international product lines. As a leader in automation control, Treotham have a broad capacity to provide systems and custom-built solutions using a diverse range of products and components. Contact our technical engineers for more information.

text title 17 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023

Auckland & Hamilton | 0800 847 200 | www.treotham.co.nz | info@treotham.co.nz CHECK OUT OUR NEW WEBSITE www.treotham.co.nz

Cables Measuring Systems

Conduits Chainflex Cables

Chains

Accessories

Units

Connectors Safety Products

Flexible

Flexible

Energy

Cable

Gear boxes Bearings Linear

Sensors

Women in Business

Q&A Keren Cook, Naturebee Ceo and Global Consumer Advocate

Q: How are you finding current business conditions?

A: Continued talk of a recession and the rising cost of living is reducing consumers’ discretionary spending, which naturally makes sales growth tougher. For us, this means working harder to position our product in a crowded marketplace where price is king for many.

Q: Where do you see future growth opportunities for your company?

A: We see some positive future growth opportunities offshore presently, specifically with a focus on the United States and United Kingdom markets.

Q: Business success – what’s it all about?

A: For us, business success is about customer-centric thinking and actions; having products that people both need and want. The key is to continually adapt and find ways in which to communicate the key benefits of our products and the drivers that really cut through a noisy marketplace.

Q: How do you measure success –money or satisfaction for the task at hand?

A: At NatureBee success is about having happy customers, which leads to business growth and customer retention! As such, success is measured by the lifetime value of our customers. We currently have over 29,000 loyal, returning customers and over 55,000 customers who we communicate with regularly, and we are always growing.

Q: How are you finding staff retention in the current environment? Is it hard to keep them?

A: Because of the way we’re set up as a business, the staff retention issues others are facing aren’t an issue for us at NatureBee. We tend to work alongside our long-term partners in a contract capacity and are fortunate that this creates consistency as well as flexibility.

Q: What one thing would make business easier for you?

A: Great question. I think finding the magic button for Amazon would be it for me! We have been working on Amazon in the United States for a while. There are several barriers which inhibit us from having the same level of growth in the US market that we’ve had in New Zealand and Australia. We are currently looking to open up in the United Kingdom as a next step.

Q: Who is your inspiration?

A: The President of Ukraine, Volodymyr Zelensky.

Q: What’s your favourite book?

A: Not Spare by Prince Harry, which I gave away! I need to get off my phone and find something else, fast.

Q: Do you have a favourite quote?

A: “Life is really simple, but we insist on making it complicated.” ~ Confucius

Q: What is the best business advice you have ever received?

A: “Change before change catches up with you.” ~ aka Who Moved my Cheese? by Dr Spencer Johnson.

Q: What does your computer mean to you – why not live without it?

A: I’m not particularly attached to my computer; I work mostly remotely!

About Keren Cook

Keren Cook, NatureBee CEO and Global Consumer Advocate, is motivated by the opportunity to help people feel better in themselves.

As host of the At Source podcast, Keren likes combining her experience and inquisitive nature in conversations with the guests.

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 18

Join us and scores of other Kiwi organisations that have galvanised around one common goal: 20% more women engineers by 2021. www.diversityagenda.org

Only 14% of all our engineers are women. We want to change that.

Becoming a data-driven organisation to optimise performance

-Adam Sharmer, senior partner, Dsifer

-Adam Sharmer, senior partner, Dsifer

Whilst the collection and analysis of data to inform operational decision-making is not a new concept, advances in connectivity of technology, AI and machine learning as well as ERP and MES solutions have driven exponential gains in the availability, quality, and integration of data in manufacturing organisations.

Spend a few moments on LinkedIn and its easy to become overwhelmed by the level technology available and the visions of possible futures available through its adoption. However, whilst there is no doubt that Industry 4.0 technologies represent a potential step-change in manufacturing performance, the reality is that the CAPEX required for investments in, for example, lights-out warehousing or production automation, is beyond the reach of a lot of organisations.

As a result, the journey from current state to the Industry 4.0 utopia can seem like an insurmountable one.

The good news is that, whilst strategic adoption of technology should be on the business plan for all organisations if they are to remain competitive, there is a lot of value that can be unlocked with the current context or with low levels of investment.

In our experience, most organisations have increased their maturity in the collection and storage of data in all or most organisational processes. However, the true value of this data is not yet being realised.

A deliberate focus on process, system, analytics and cultural dimensions to become a data-driven organisation, can unlock the latent value in current

systems and data and build the foundation from which to optimise I4 technology.

From our experience, data-driven organisations share the following characteristics:

1. They collect data from robust operational processes

Manufacturing companies typically generate large amounts of data from various sources, such as production processes, supply chain, quality control, customer interactions, and people system. However, the quality, integrity and relevance of this data is often lacking due to low maturity when it comes to operational discipline. Getting the foundations of operation processes such as daily management systems, production and efficiency targets and continuous improvement processes, as well as strong data capture and reporting disciplines are essential if the data collected if going to be useful.

2. They build a decision ecosystem through data analytics

Once data is collected and integrated, data-driven organisations use a combination of descriptive, predictive, and prescriptive analytics, to identify trends, predict conditions such as maintenance needs, optimise production processes, identify underlying cause of issues. The most successful data-driven organisations recognise that data and decisions are intrinsically connected across the organisation. For example, there is often a connection between overtime worked and absenteeism which in turn can

lead to productivity impacts.

Data-driven organisations consider these connections in terms of a decision ecosystem and use data analytics to identify their impact across all aspects of the organisation to optimise performance and identify false economies.

3. They foster a data-driven culture

Creating a data-driven organisation goes beyond technology and processes; it requires fostering a culture that values and promotes data-driven decision-making. Data-driven organisations encourage and incentivise employees at all levels to embrace data and analytics by providing training and resources to enhance data literacy, and recognising data-driven thinking that aligns to the organisation’s strategic goals.

The most successful organisations go one step further, encouraging cross-functional collaboration and empowering employees to explore and experiment with data to find innovative solutions to challenges. Over this series, we will explore the most common challenges we observe in manufacturing organisations and how a practical, data-driven approach can support their mitigation and resolution to maximise performance.

www.Dsifer.com

Visualisation for Visionaries

19 www.nzmanufacturer.co.nz / NZ Manufacturer July 2023 Analysis

As the pace of digital innovation accelerates, and organisations look to exploit the financial and strategic advantages of digital technology, automation and AI, data is increasingly becoming the lifeblood of organisational decision ecosystems.

Design, test, and deploy applications directly from a web browser

Developments

Faster product development through machining

~ New Y-axis method makes it possible to machine several features with just one tool ~

“We should not prioritise on the basis of project profitability,” wrote the best-selling product development author Donald G. Reinertsen, “but rather on how this profitability is affected by delay.” Manufacturers are expected to accelerate product development cycles to meet rapidly-changing market demands — yet they are also losing hundreds of production hours to equipment downtime and unnecessary tool changes.

Here,

Staffan Lundström, product manager and application specialist for turning at the cutting tool specialist Sandvik Coromant,

explains how innovative Y-axis turning can overcome delays

The demands on manufacturers can be summed up as: ‘produce innovative and higher quality products, more quickly and in less time.’ Add sustainability initiatives into the mix, and it becomes clear that manufacturers in all sectors must apply comprehensive strategies to overcome these obstacles while staying ahead of the competition.

But what does a ‘comprehensive strategy’ entail on the machine shop floor? Antidotes to the rising energy and commodity prices, suggested in PwC’s Achieving excellence in production and supply report, include that companies should monitor and optimise their processes to make them as efficient as possible.

This also means that manufacturers should

and support faster production.

accelerate their product development cycles to meet rapidly-changing high-performance and safety standards. One approach to this is through on-demand manufacturing, where manufacturers deliver precisely what a customer wants in certain quantity and to particular manufacturing specification.

On-demand manufacturing is made possible by the latest additive manufacturing (AM) technologies, like 3D printing, which speeds-up manufacturing and prototyping. Elsewhere, manufacturers are use artificial intelligence (AI) and Industry 4.0 concepts to optimise their processes.

These technologies have clear advantages. However, manufacturers mustn’t overlook the latest

cutting-edge developments in CNC machining. Manufacturing concepts that, at first glance, are decades-old also have the potential to greatly improve product development cycles. Modifications can made to the angle at which the workpiece is cut by an insert, how the itself tool moves — faster directional changes for example — and the performance characteristics of tools designed with greater wear resistance, or to support improved process security. Suddenly, what appeared as a decades-old concept is far more sophisticated than first perceived.

These approaches go hand-in-hand with the continued evolution of computer aided manufacturing (CAM) software. With them, manufacturers can realise more

NZ Manufacturer July 2023 / www.nzmanufacturer.co.nz 20

Looking for a marketing edge?

70% of licence holders say signing on has positively affected sales.

complex and innovative designs without sacrificing product quality — for faster product development cycles overall. Let’s examine how in more detail.

Generating toolpaths

CAM software is capable of telling a machine how to make a product by generating toolpaths. For example, a factor that is integral to more efficient machining is the entering angle at which the cutting tool interacts with the workpiece — too high an angle results in a weak cutting edge and breakages. Too small an angle might cause the tool to rub at high feed rates, creating rapid heat build-up and tool failures.

With CAM software, it’s possible to program the cutting tool to engage with the workpiece at the best possible entering angle, and maintain this consistent for greatly improved chip control. Software can optimise when the tool either cuts into, or retracts from, the workpiece, before moving quickly and safely to the next point and repeating the process.

However, CAM software alone cannot satisfy manufacturers’ needs to produce more complex and innovative shapes. Requirements expressed by Sandvik Coromant’s own customers — machine shops in automotive, aerospace, general engineering and more — include the need for higher metal cutting efficiency and improved predictability in their machining processes. Put simply, they wanted to increase their production output without sacrificing component quality.

Another major requirement is increased machine utilisation. According to Forbes, the average manufacturer experiences 800 hours of equipment downtime per year, which is more than 15 hours per week — unacceptable against today’s rapidly-changing market requirements. Tool changes also waste time — did you know that it can take up to 20 seconds to change a cutting tool?

These are the reasons why Sandvik Coromant’s specialists sought to develop a solution that would make it possible to machine several features with just one tool. It was decided these methods should ensure cutting forces are directed into the tool holder, for higher process stability, with a constant, fixed entering angle for drastically improved chip control. The result was Y-axis turning.

Intricate shapes

So how does Y-axis turning work? As the name implies, the new method makes use of the Y-axis, and all three axes are used simultaneously when machining. The tool rotates around its own centre, the insert is placed for machining in the Y-Z plane and the milling spindle axis interpolates during turning. This way, intricate shapes can be machined with a single tool.