Image:

VOL.

DESIGN STUDIO ERIK G L'HEUREUX (PHD) FAIA DEAN’S CHAIR ASSOCIATE PROFESSOR AR5802, AY 2022/2023 M.ARCH 1, SEMESTER 2 CHELSEA HO JIA XUAN CHEN JIAXIN CHNG YOKE MINN, ASHLEY HOU XINYAO HUGO ONG LEE YONG SOON LI PEISHAN LIU HENG MUHAMMAD ASHRAFF BIN ABDUL ALEEM SHAWN PECK WEE ANN SITI HAZIRAH BINTE HASSAN SUN JIANXIN DEPARTMENT OF ARCHITECTURE COLLEGE OF DESIGN AND ENVIRONMENT NATIONAL UNIVERSITY OF SINGAPORE

Ba Cheiu Market, Sun Jianxin HOT AIR III: DENSITY, CARBON & LABOUR

2

AR5802HOTAIRIII: DENSITY,CARBON&LABOUR

AdaptiveReuse&AdditionProjects SiteA:VictoryHotel Overall comparison of carbon & labor across projects Site Plan Ashraff & Liu Heng Ashley & Hugo Chelsea & Yong Soon 7 8 10 36 62

ADAPTIVEREUSE&ADDITION PROJECTS

6

HoChiMinhCity

SITEA:VICTORYHOTEL,DISTRICT3

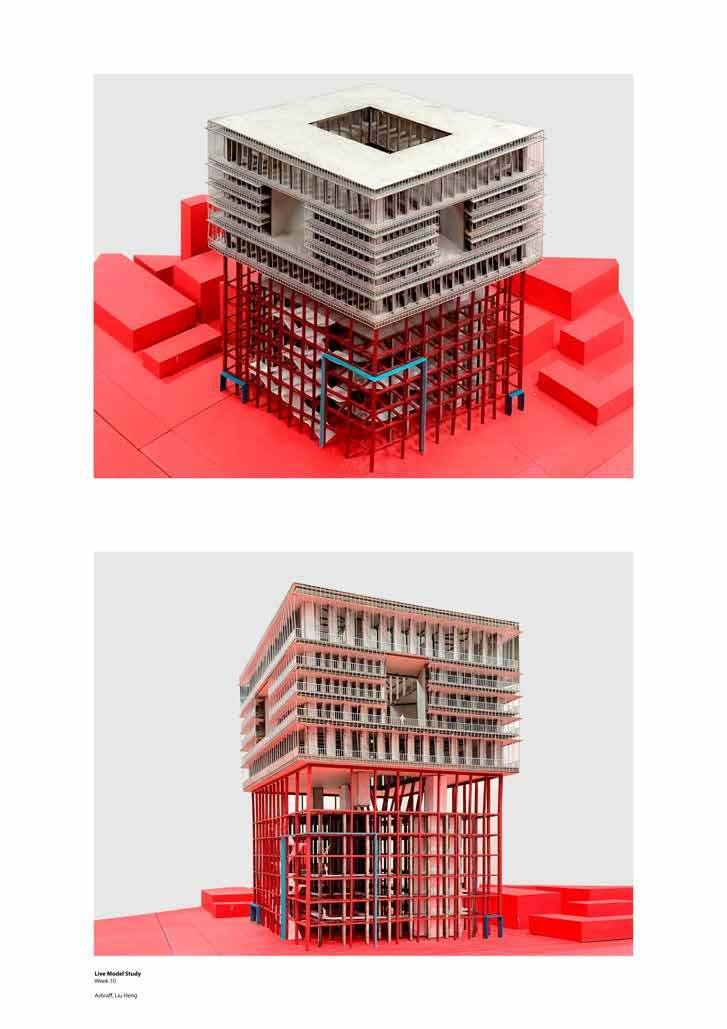

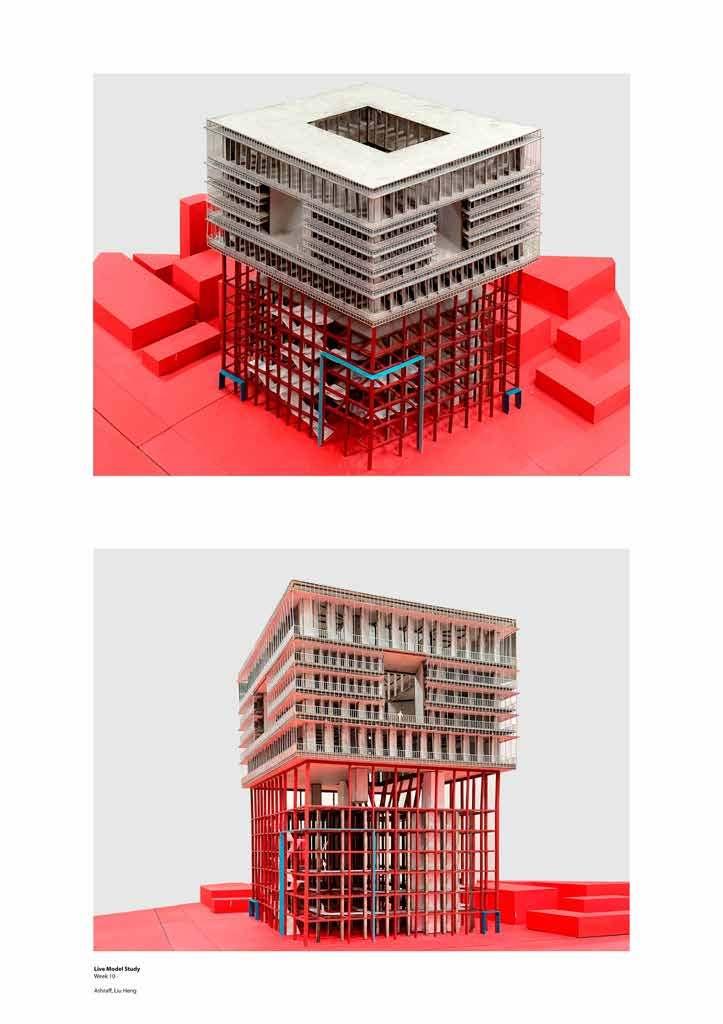

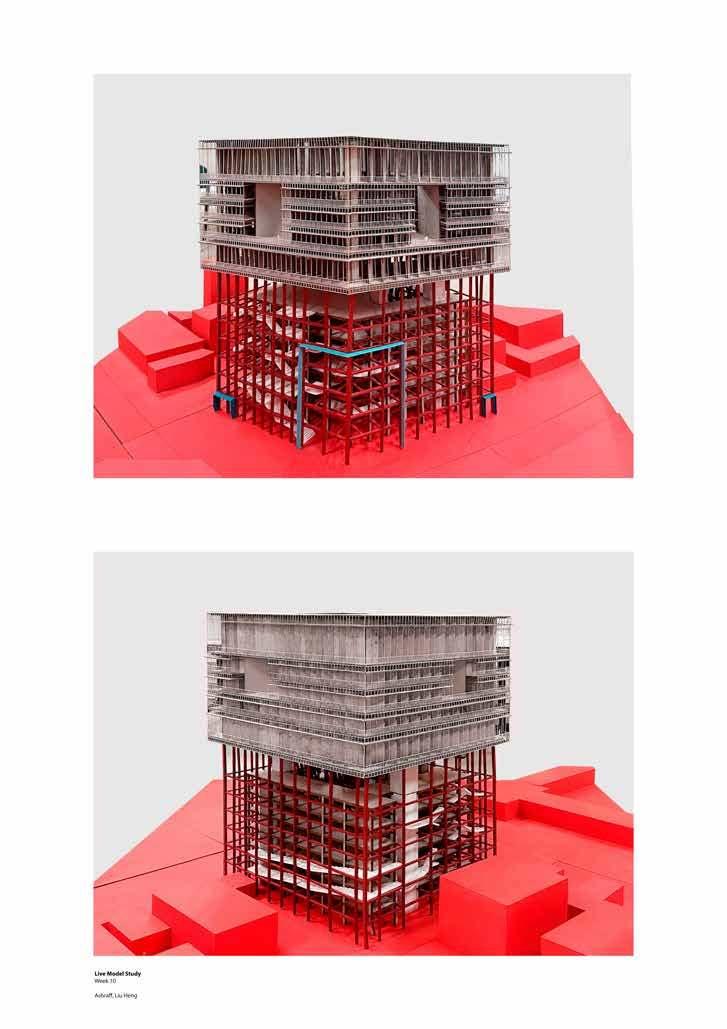

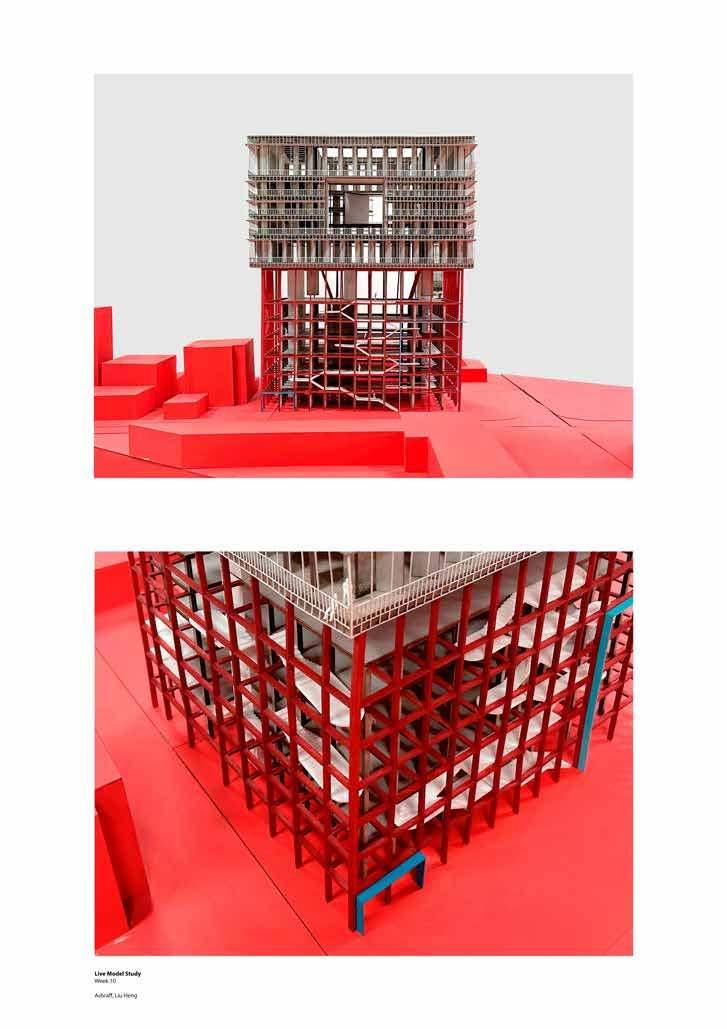

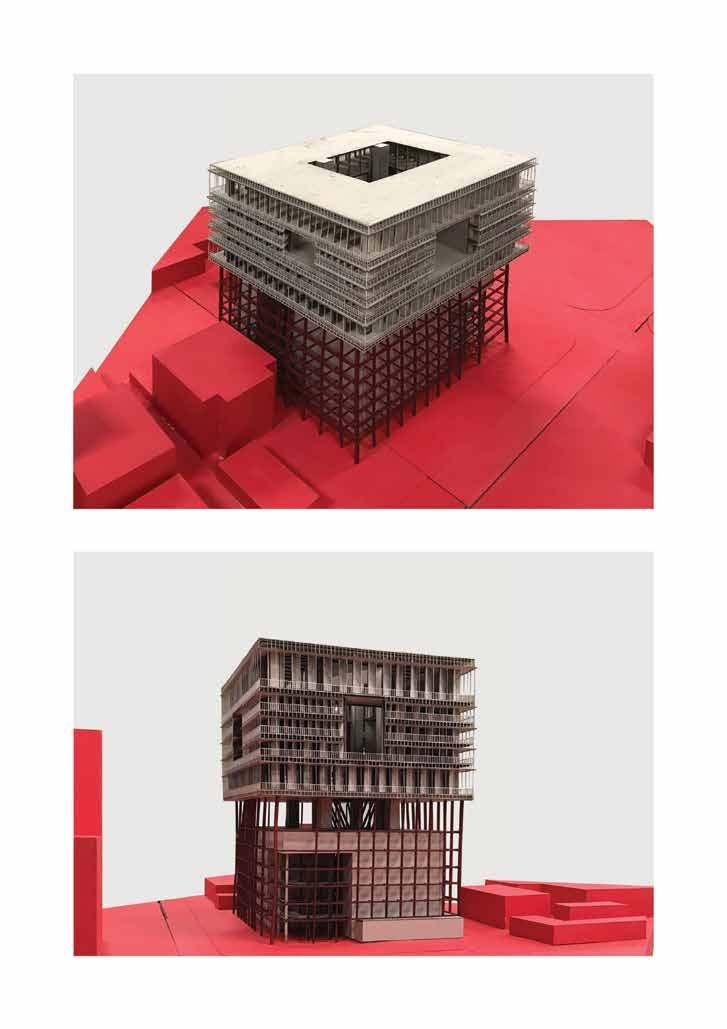

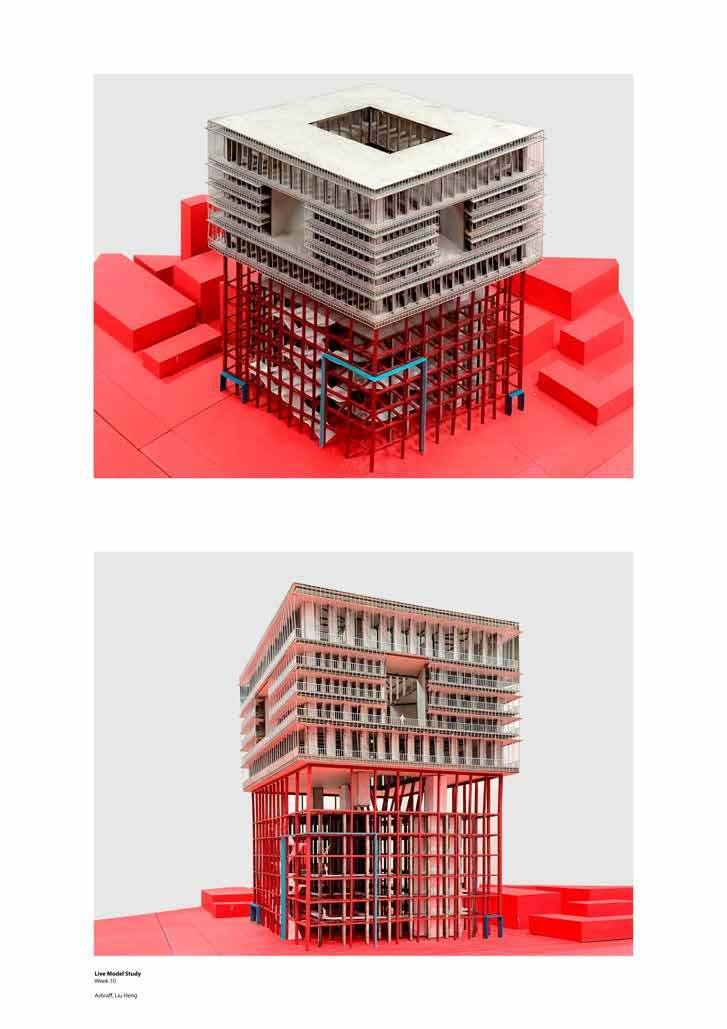

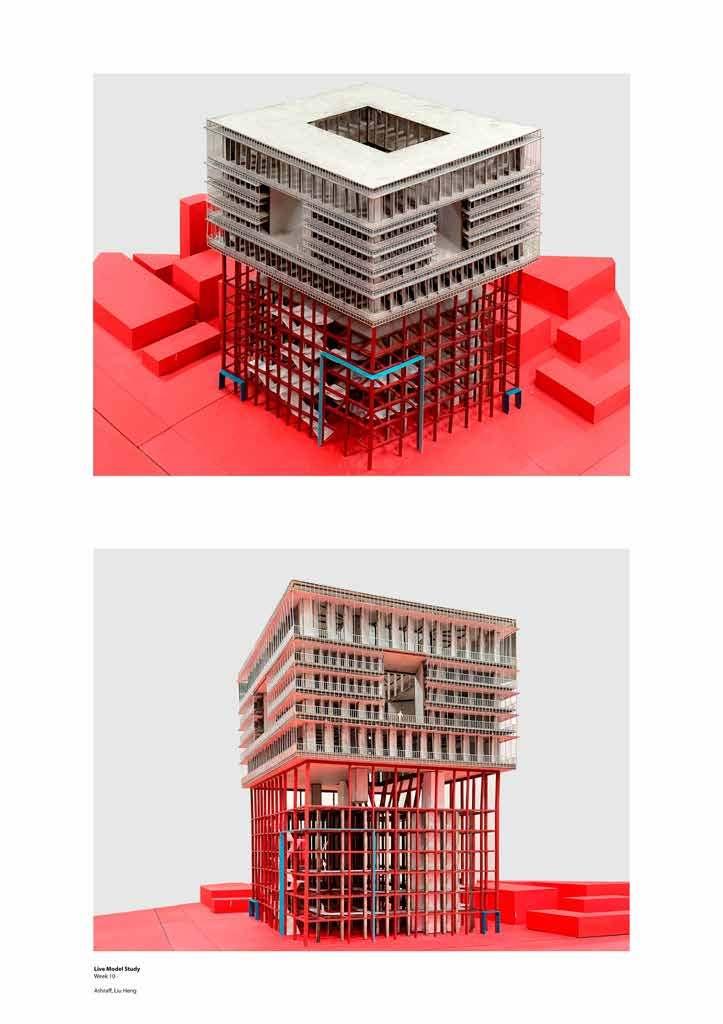

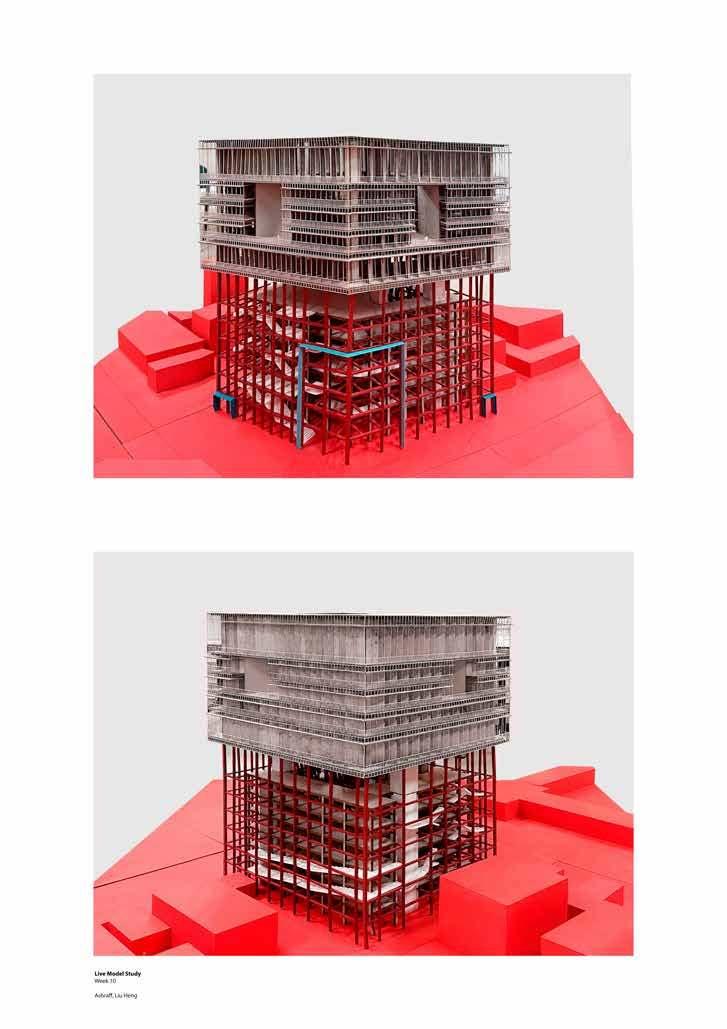

1 SKYGON -Ashraff, Liuheng

2 EMBRACE -Ashley, Hugo

3 AChanceVictoryforHCMC! -Chelsea, Yong Soon

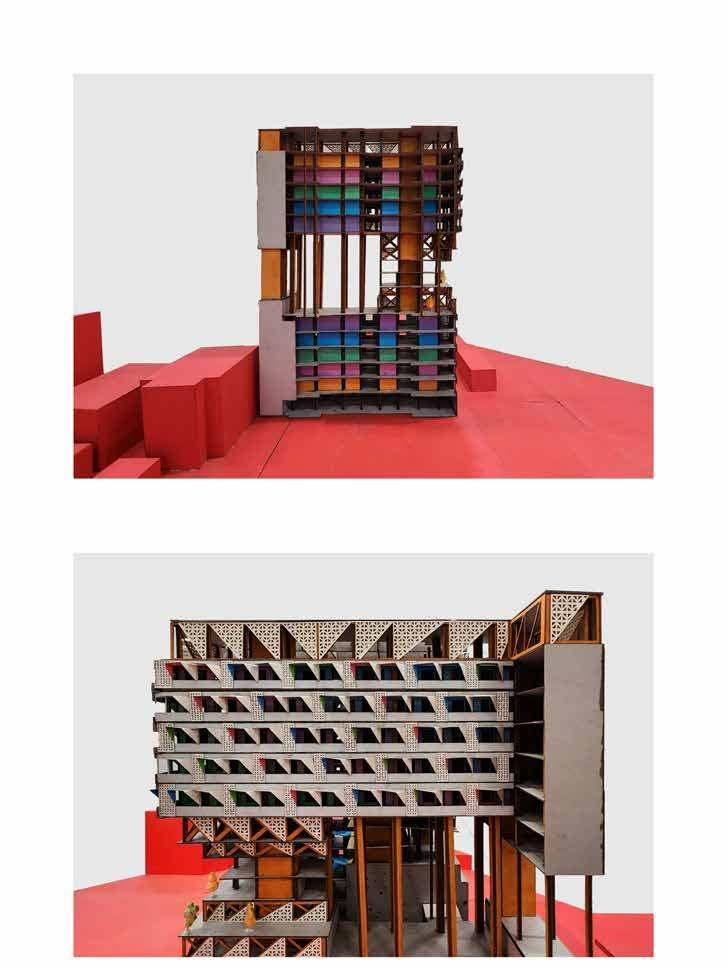

SITEB:BACHIEUMARKET,BINTANH

4 DIALOGUEBETWEENURBAN ANDBUILDING

-Jia Xin, Jian Xin

5 SAIGONCANYON -Pei Shan, Xin Yao

6 PROJECTTITLE -Hazirah, Shawn

Embodied Carbon/sqm (kgCO2e/m2) 3,546 222.9 859 267.8 Labour (hrs/week/pax) 46.65 55 50.95 Cost ($) 1,428 809 598 1,386.4 480.7 2199.30 248.37 64.9 56 47.5 2,098 2,065 800 7

VICTORY

Site Plan Victory Hotel 025m5m50m 1:500 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 8

SITE PLAN A:

HOTEL

9

1

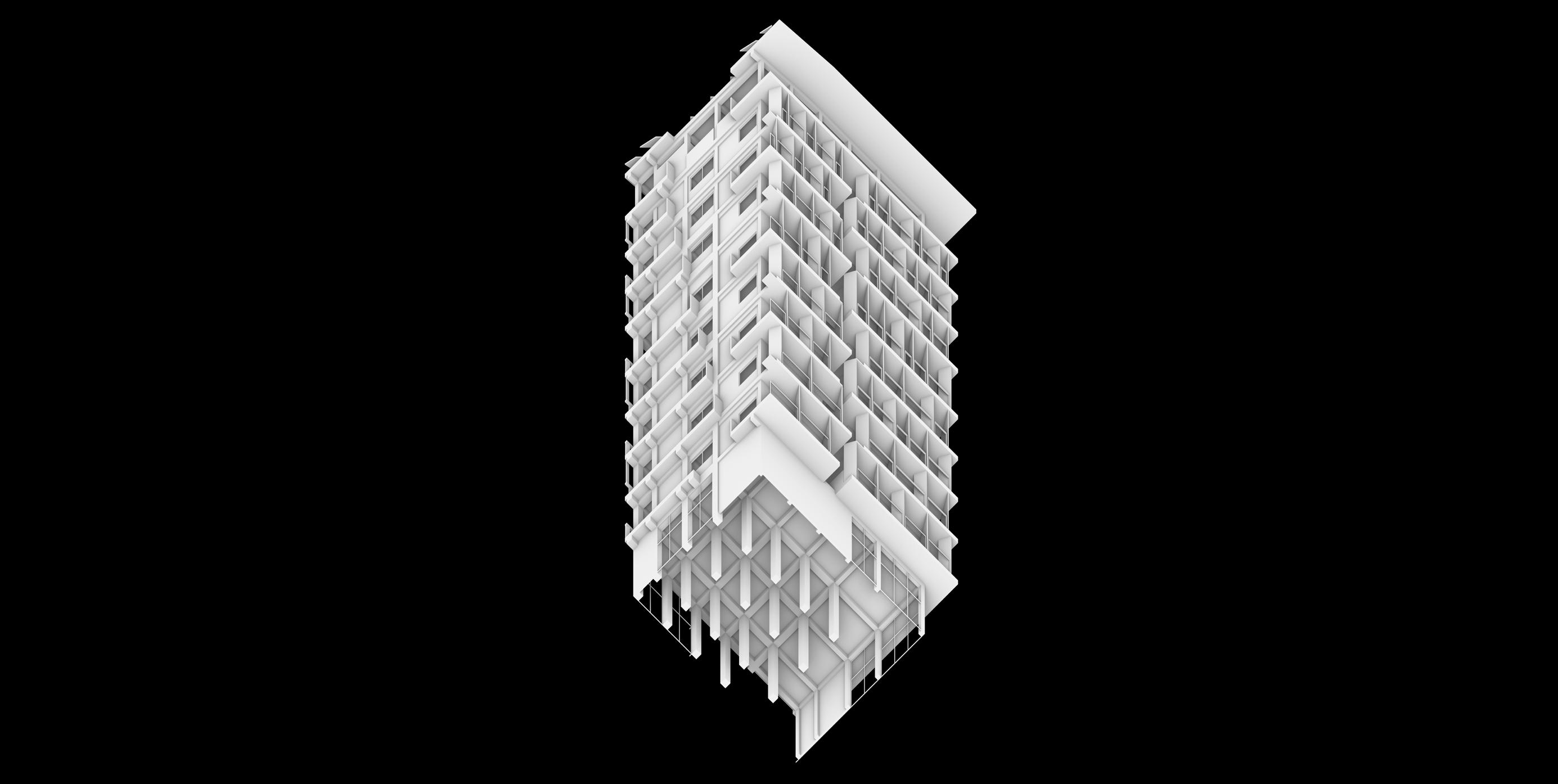

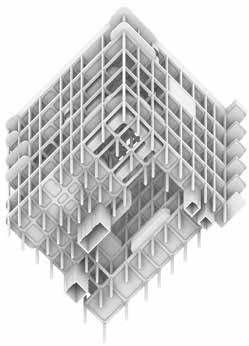

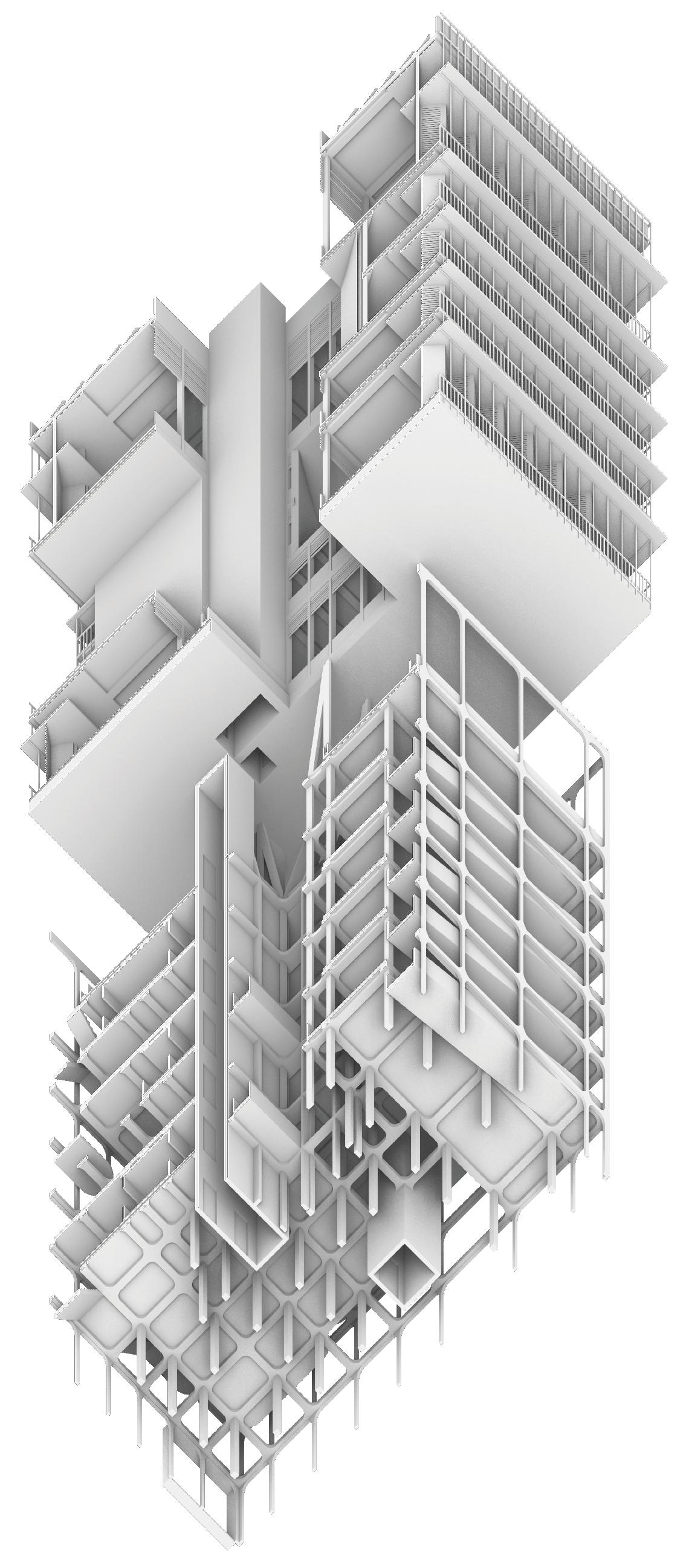

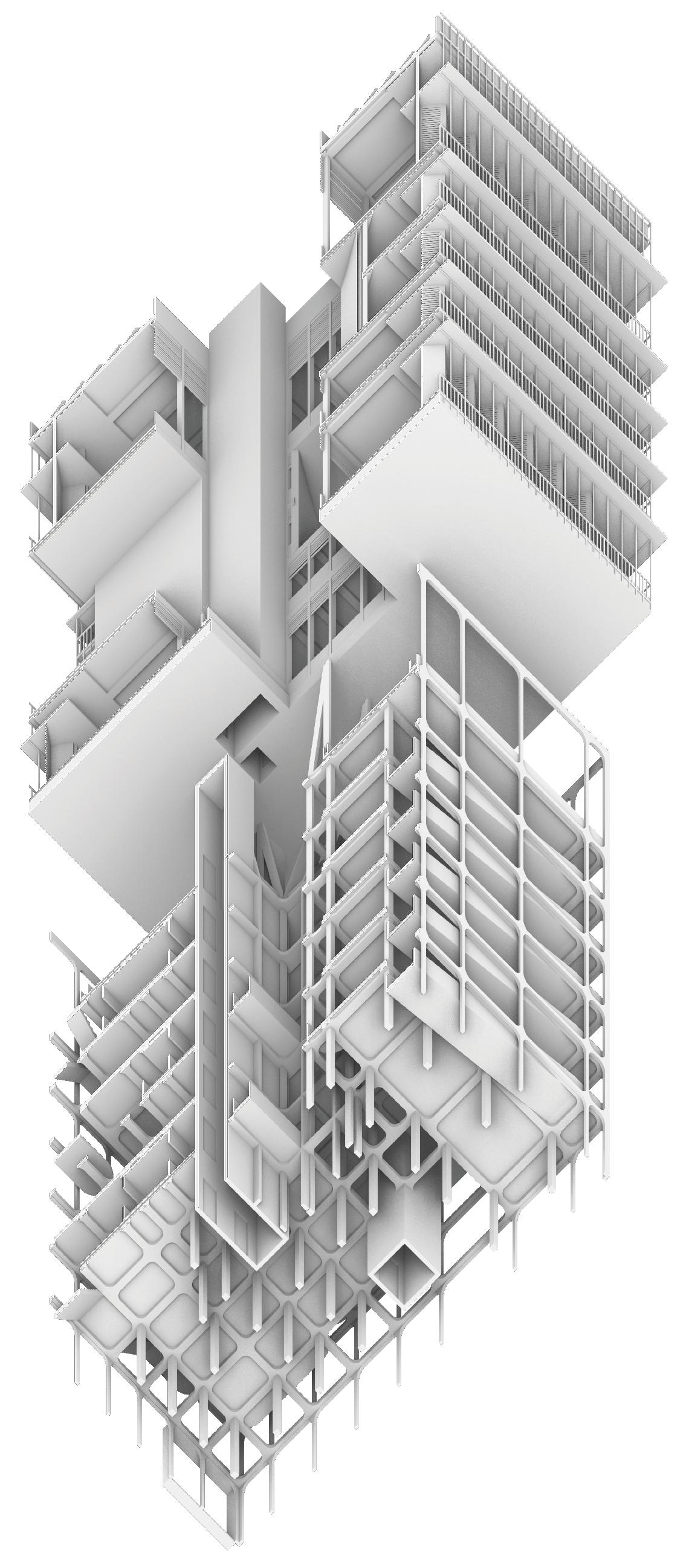

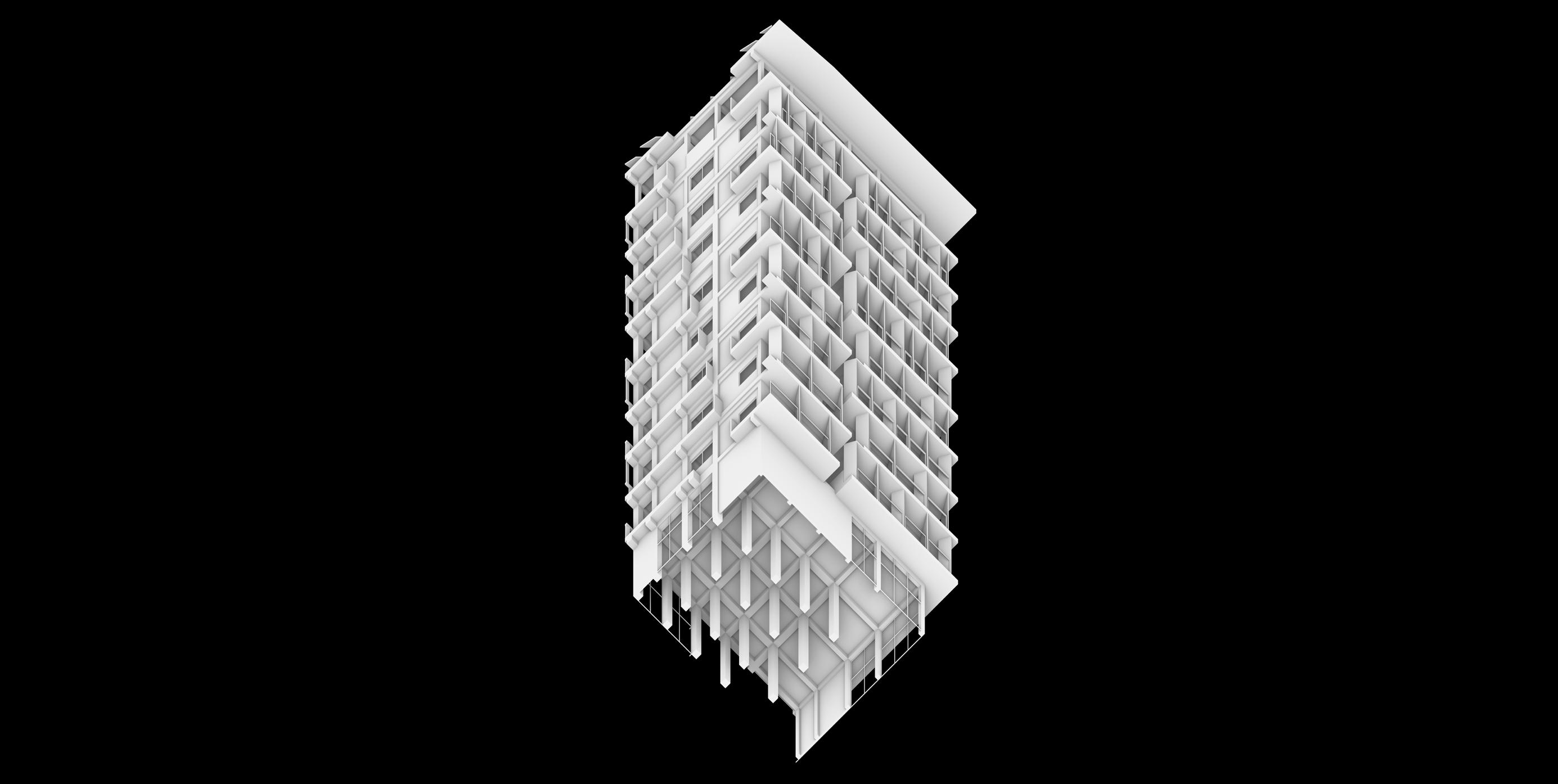

SKYGON

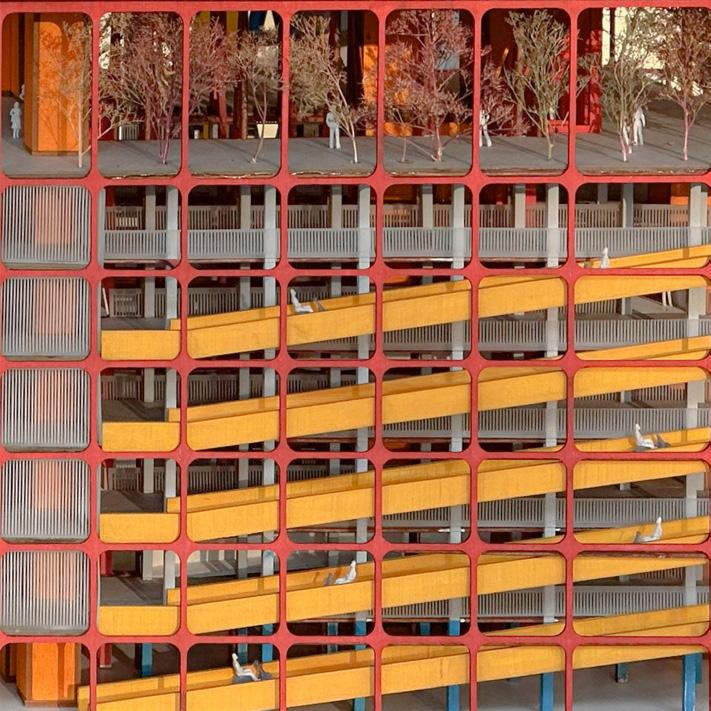

StreetsofSaigoninthesky

Victory Hotel Site A

The project is interested in investigating the unique relationship between motorcyclesandpedestriansonthepavement.Wewereintriguedbythedynamics of a fast and slow-moving objects in the same domain. This relationship mirrors the urban fabric of Ho Chi Minh City and we want to multiply and express it in a differentsetting.

Our intervention using the Victory Hotel sees it as a carbon sink and we will use its carcass to introduce a new programme of shopping and bring in pedestrian cultureintoatower.

Ashraff,LiuHeng

10

05m10m 1:150 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 11

12

NEW VS OLD INTERFACE// CLIMATIC INTEFACE 13

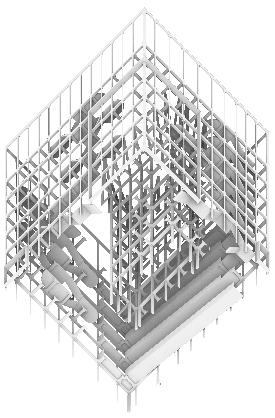

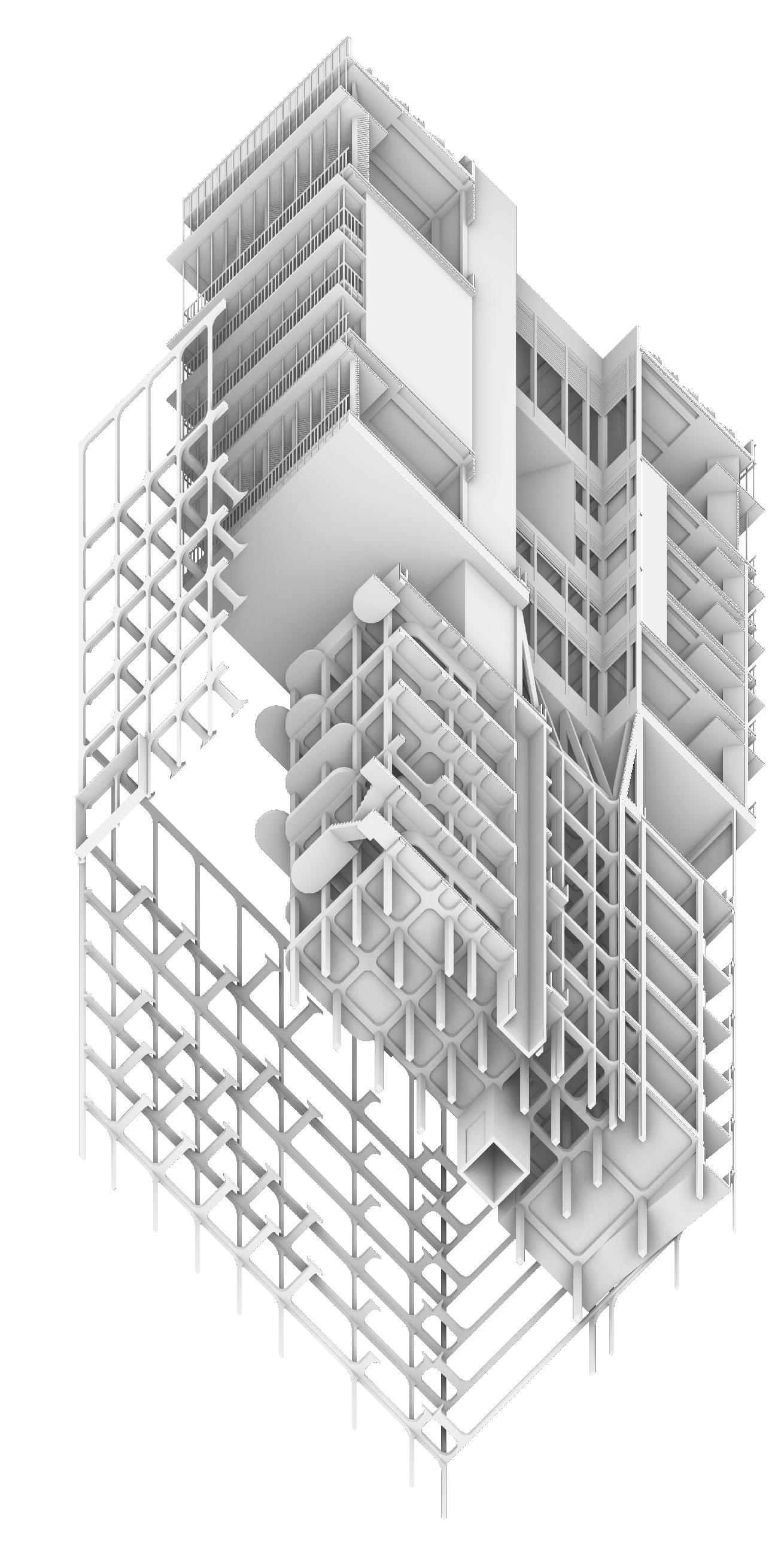

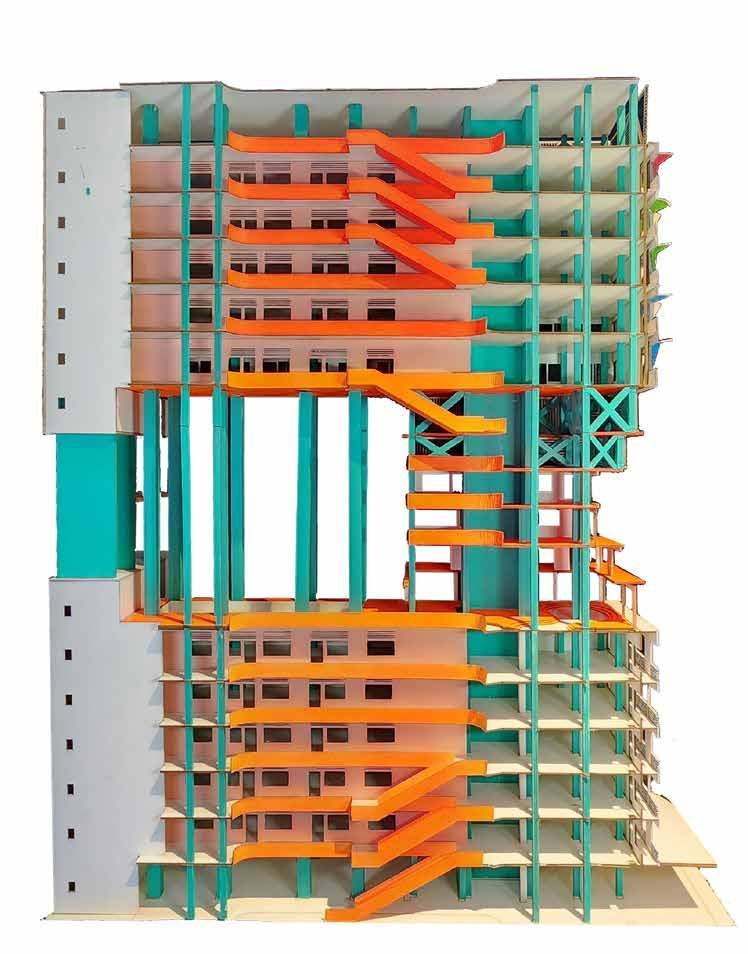

Retained Structure (Below): Reinforced Concrete Columns, Beams, Slabs & Shear Walls

14

New Structure (Below): Pre-cast Concrete Staircases & Ramps

New Cage Structure (below): Steel Columns & Beams

New Outer Façade (above): Partly Recycled Mild Steel Rails

New Intervention (above):

CLT Columns, Beams, Slabs

New Structural Façade (above): CLT walls

EMBODIED & OPERATIONAL CARBON ANALYSIS 15

16

New Inner Façade (above): Treated Timber Mono, Bi/tri-fold Screen Doors

PV

New Inner Façade (below): Perforated Fiberglass Panels

New Staircase Façade (below): Expanded Steel Façade Mesh

Aluminum Lift Doors

EMBODIED & OPERATIONAL CARBON ANALYSIS 17

Cells

18 Concrete 388 759 Kg 50 052 KgCO2e Steel Rebar (97% recycled content) CF 0.77 KgCO2e/Kg 847 698 Kg 652 727 KgCO2e Clay Masonry (Reclaimed) CF 0.0059 KgCO2e/Kg 588 731 Kg 3 473 KgCO2e DEMOLITION (COLUMNS, SLABS) STRUCTURE (SHEAR WALLS, EXOSKELETON) Rebar 9 575 826 Kg 27 674 139 KgCO2e

EMBODIED CARBON OF EXISTING VS ADAPTIVE REUSE

NEW ADDITION, LABOUR 19 Fiberglass CF 5.48 KgCO2e/Kg 2 193 Kg 12 017 KgCO2e Steel Mesh CF 9.27 KgCO2e/Kg 2 456 Kg 22 771 KgCO2e CLT CF 0.35 KgCO2e/Kg 2 843 988 Kg 995 395 KgCO2e Steel CF 0.62 KgCO2e/Kg 1 129 298 Kg 700 164 KgCO2e Total Embodied Carbon 4,248,463 KgCO2e Total Embodied Carbon/sqm 222.9 KgCO2e/m2 STRUCTURE (COLUMNS, BEAMS, SLAB) INFILL (WALLS,) Steel 708 Kg 2 769 KgCO2e Timber 4 011 Kg 2 126 KgCO2e Clay Masonry 379 537 Kg 91 089 KgCO2e Aluminium 3 301 Kg 54 581 KgCO2e Glass 42 074 Kg 51 331 KgCO2e Concrete 11 710 565 Kg 1 522 373 KgCO2e M 02|27 T 02|28 W 03|01 T 03|02 F 03|03 S 03|04 S 03|05 M 03|06 T 03|07 W 03|08 T 03|09 F 03|10 S 03|11 S 03|12 M 03|13 T 03|14 W 03|15 T 00|16 F 03|17 S 03|18 S 03|19 M 03|20 T 03|21 W 03|22 T 03|23 F 03|24 S 03|25 S 03|26 M 03|27 T 03|28 W 03|29 T 03|30 F 03|31 S 04|01 S 04|02 M 04|03 T 04|04 W 04|05 T 04|06 F 04|07 S 04|08 S 04|09 M 04|10 T 04|11 W 04|12 T 04|13 F 04|14 S 04|15 S 04|16 M 04|17 T 04|18 W 04|19 T 04|20 00 0.16 34.2

WITH

CARBONREPORT

EMBODIEDCARBON

Existing GFA: 8,289.3sqm

Embodied Carbon: 29,398,410 KgCO2e

Embodied Carbon/sqm: 3,546 KgCO2e/m2

Adaptivereusewithnewaddition

GFA: 19,059sqm

Discarded Embodied Carbon: 50,052 KgCO2e

Embodied Carbon of new addition: 4,198,411 KgCO2e

Total Embodied Carbon: 4,248,463 KgCO2e

BreakdownofNewaddition

OPERATIONALCARBON

Existing GFA: 8,289.3sqm

EUI: 220/ kWh/m2/yr

Operational Carbon: 1,550,100 KgCO2e

Offsets Required area of PV to offset operational carbon: 3,919.52m2

Actual area of PV: 1066.00m2

LABOUR

Adaptivereusewithnewaddition

Average working hours over 13weeks: 93.3h

Longest working hours in a week: 200h

Total cost of prints and models: $1,428.00

Alternative

20

e/m

Total Embodied Carbon/sqm: 222.9 KgCO2

2

GFA: 15,361sqm EUI: 47.3 Kg kWh/m2/yr Operational Carbon: 690,707 KgCO2e

ofImprovement 65.5%

ofOffsets

%

%

27.0%

Materials Rebar (recycled) Green Concrete Steel CLT Steel Mesh Fiberglass Mass (kg) 3,363,311 4,113,094 1,129,298 2,843,988 2,456 2,193 CarbonFactor (kgCO2e/kg) 0.77 0.13 0.62 0.35 0.56 5.48 EmbodiedCarbon (kgCO2e) 177,338 2,290,722 700,164 955,395 22,771 12,017 =4,198,411KgCO2e

sources ofcarbonoffsets Hydrogen fuel cellsl %ofImprovement 93.7%

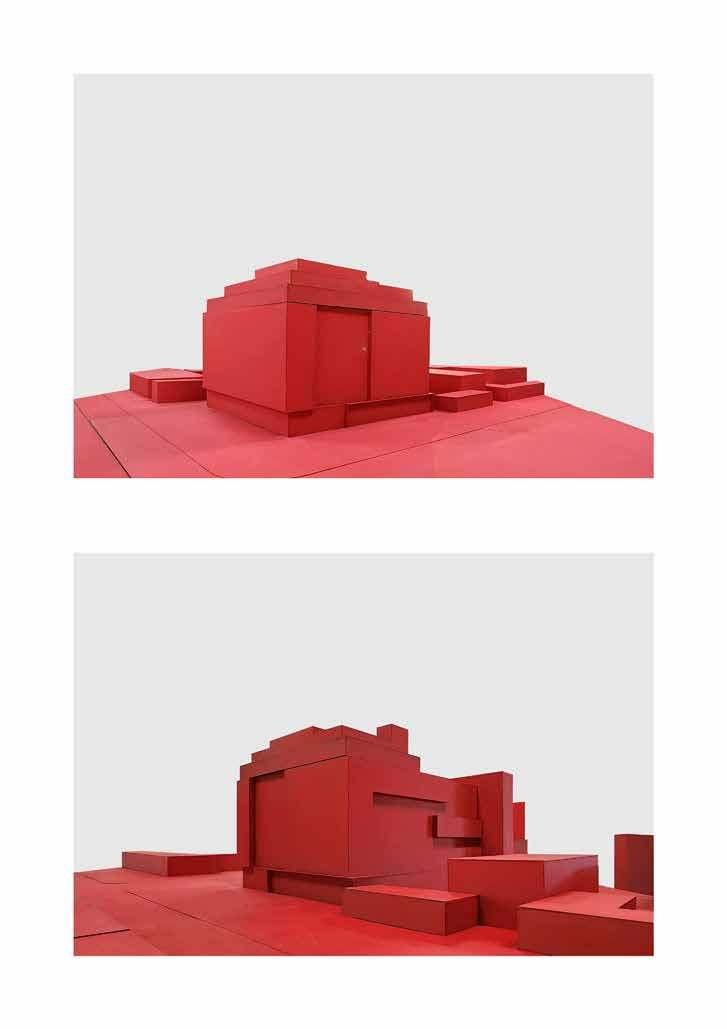

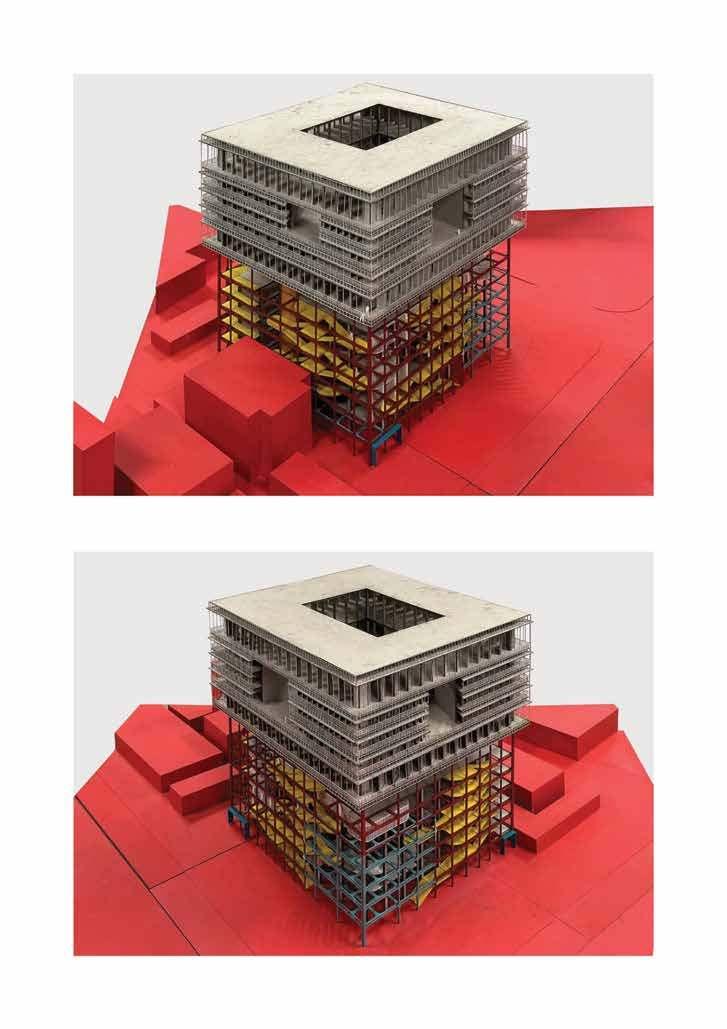

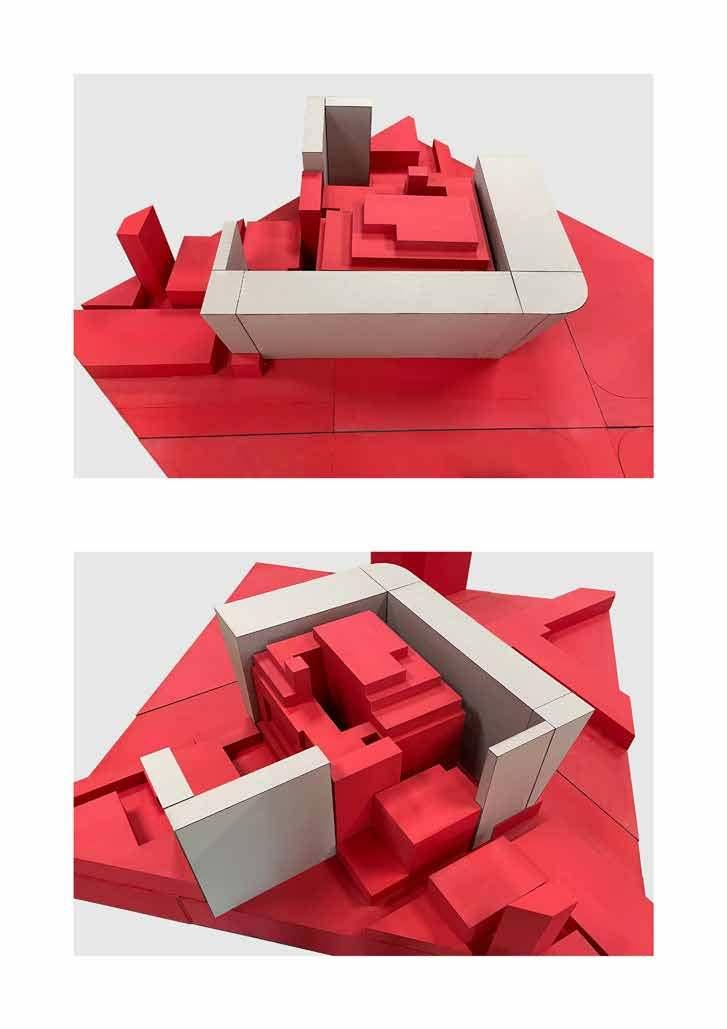

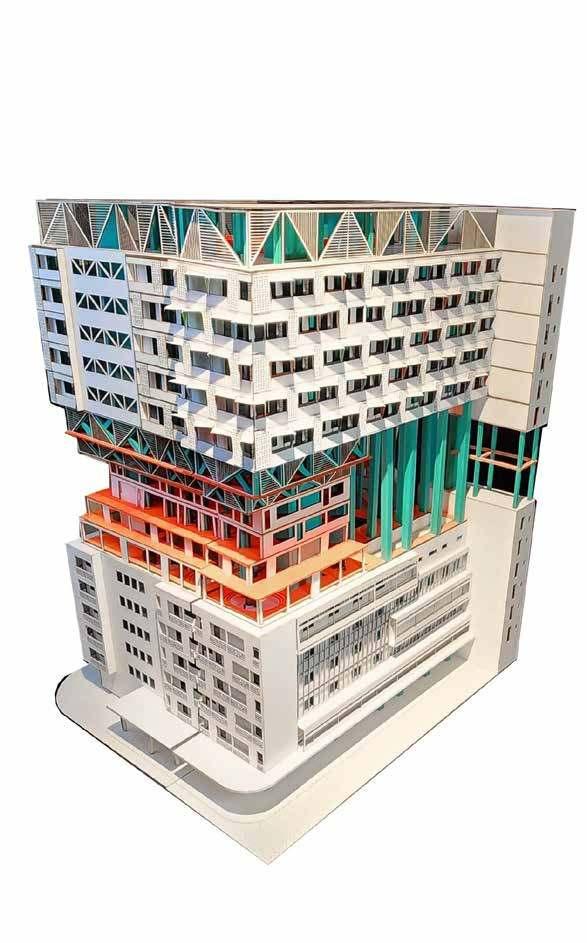

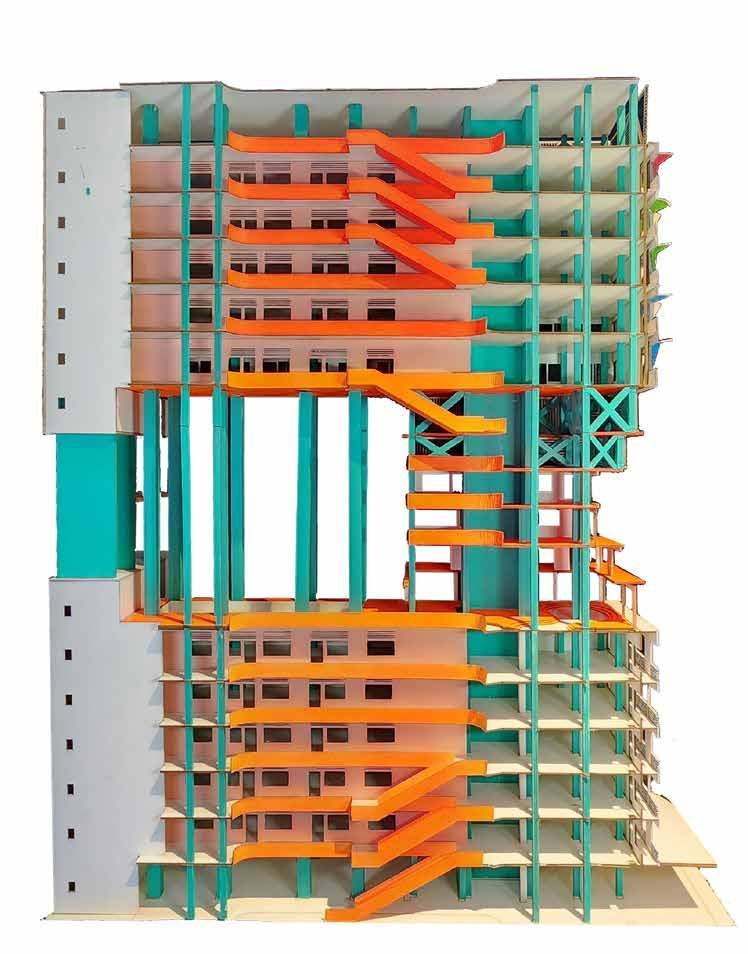

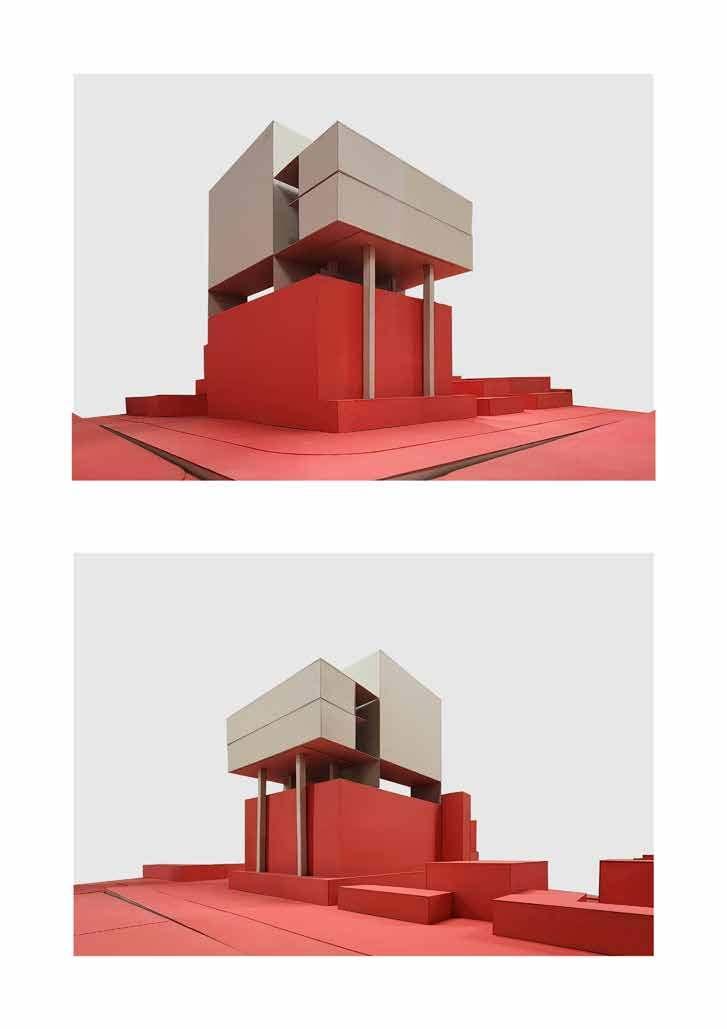

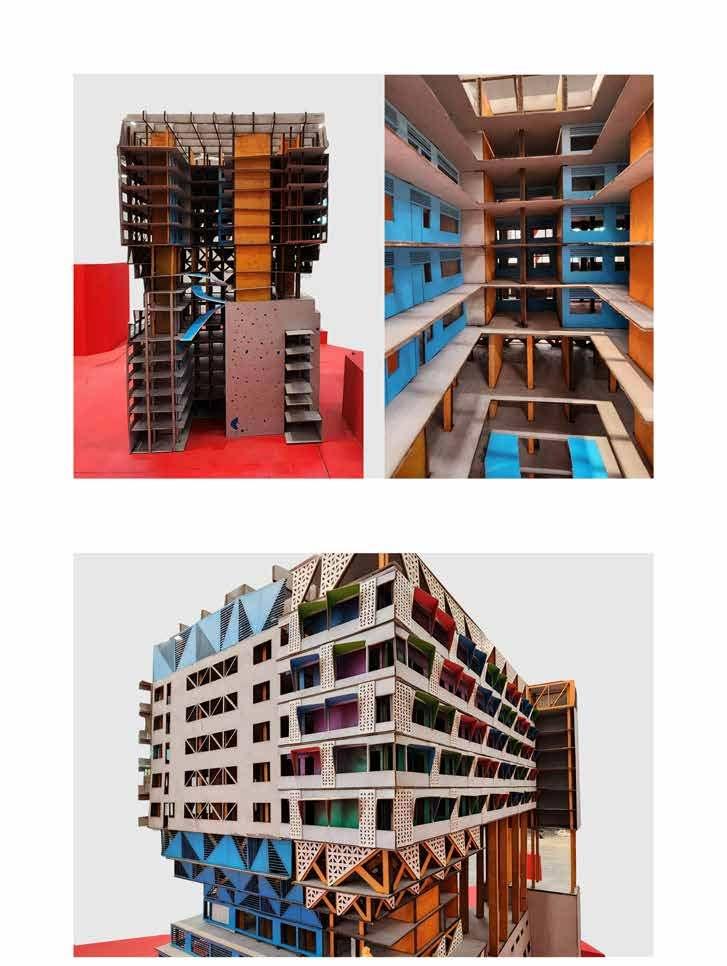

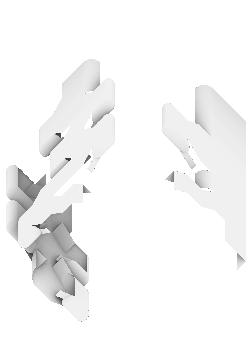

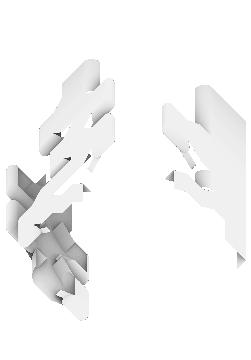

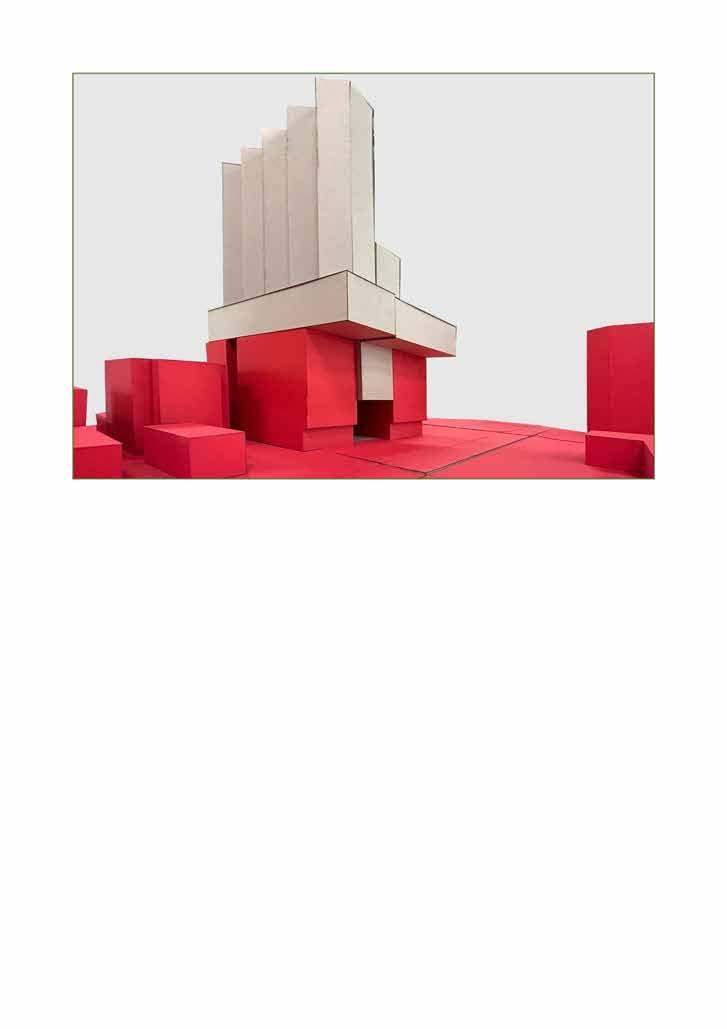

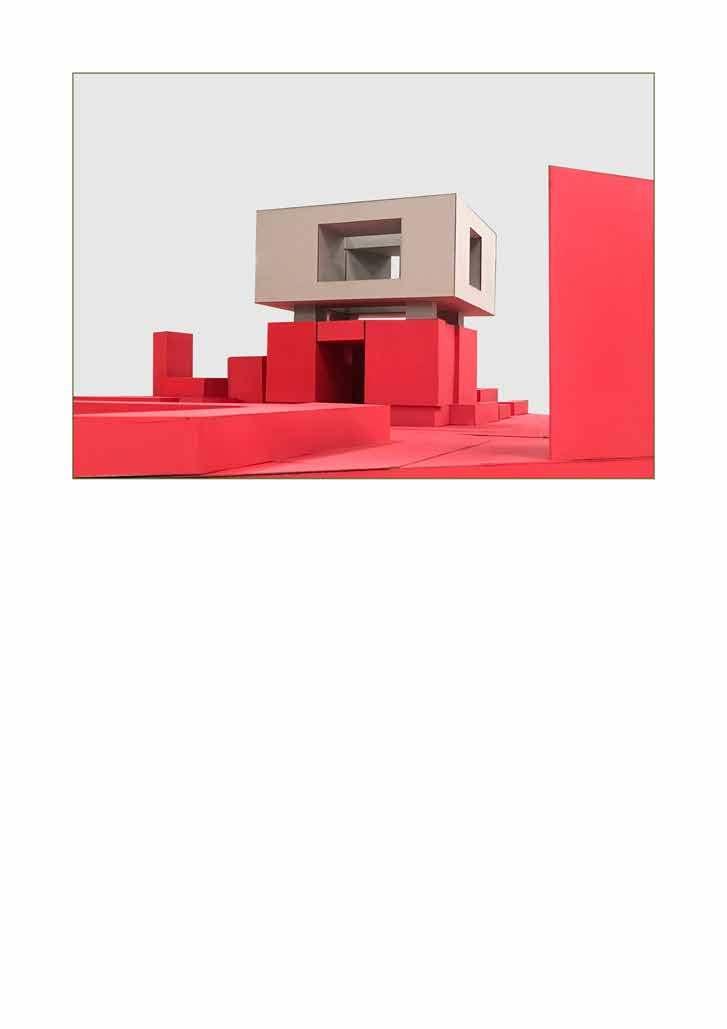

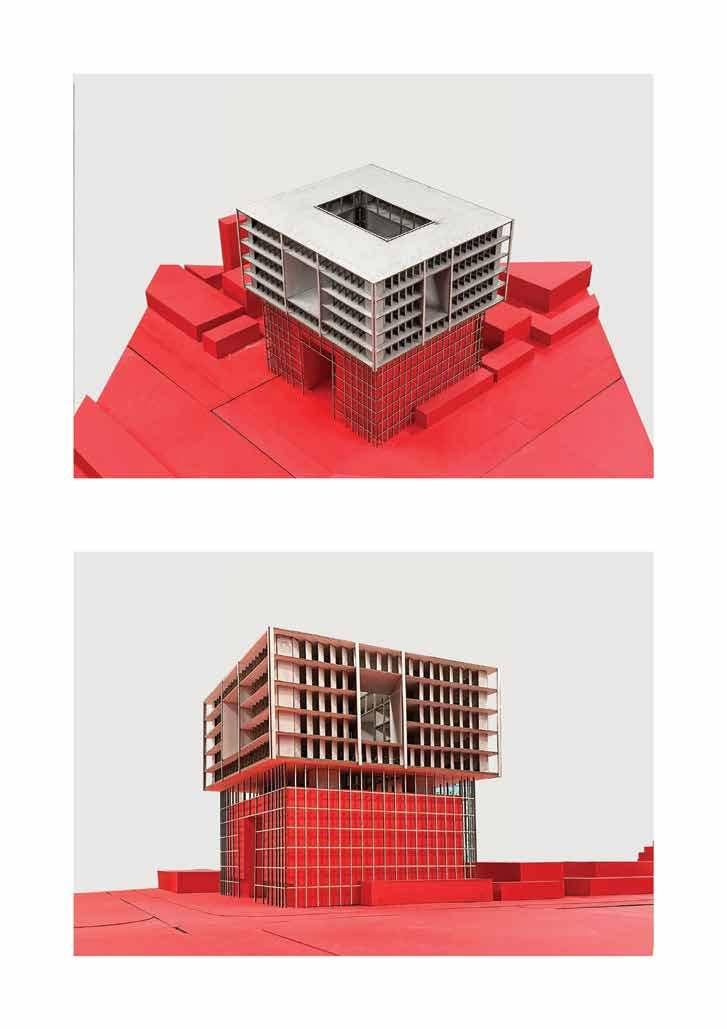

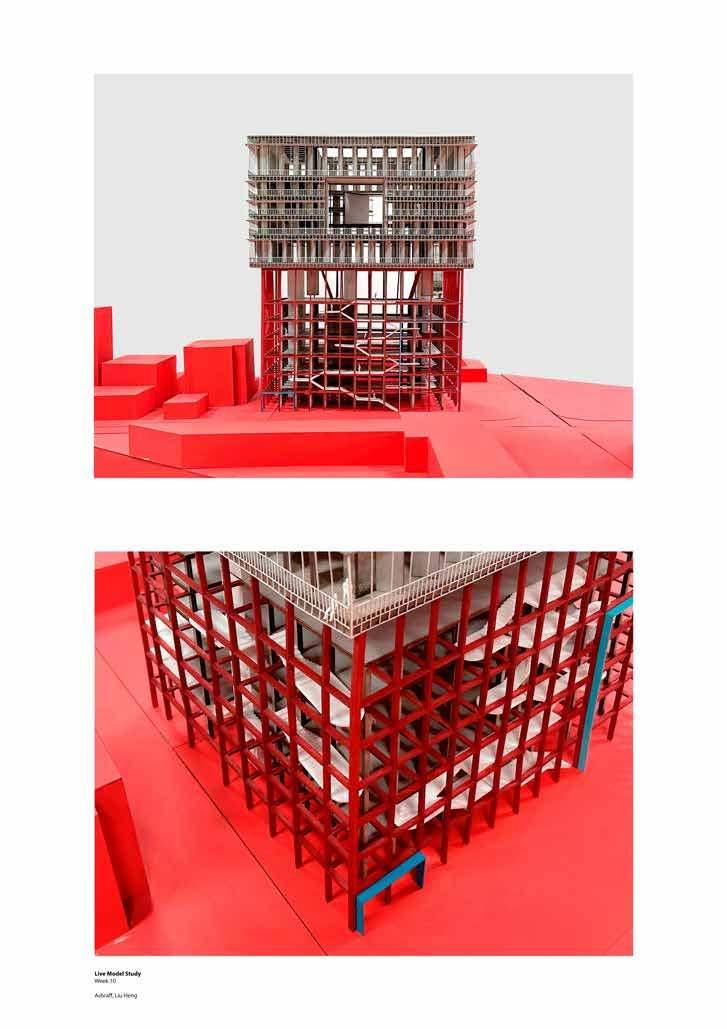

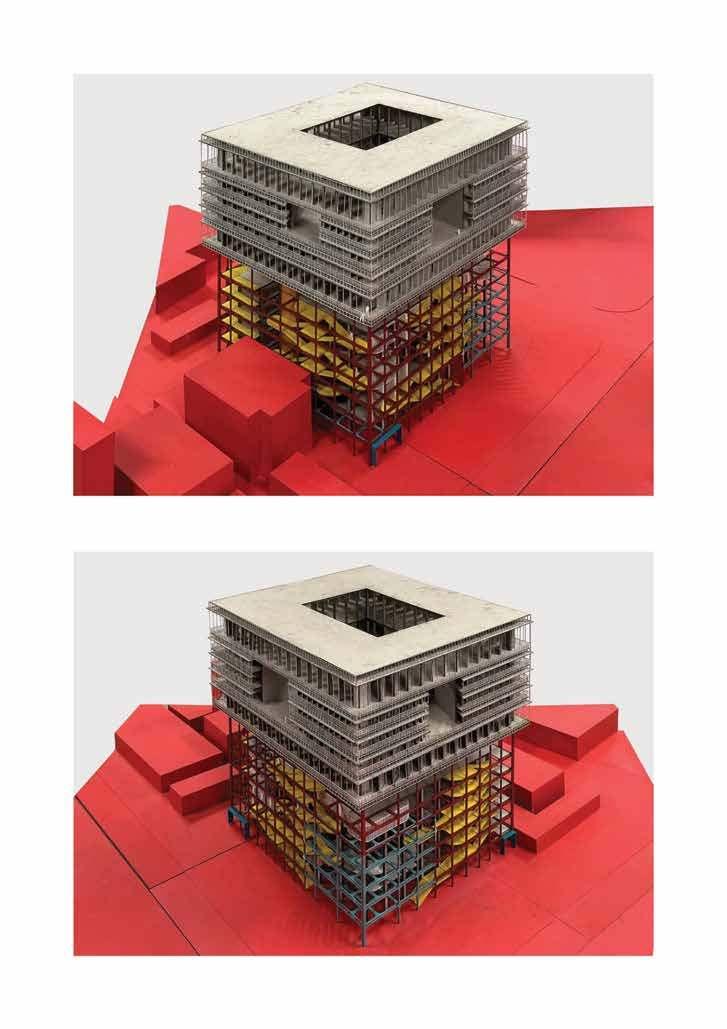

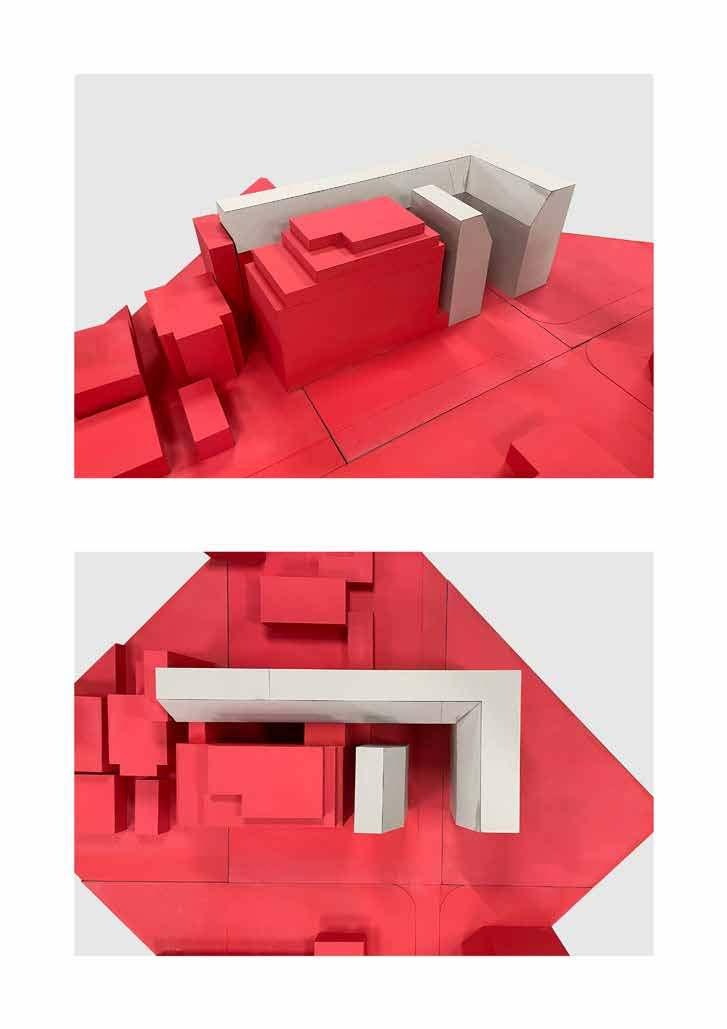

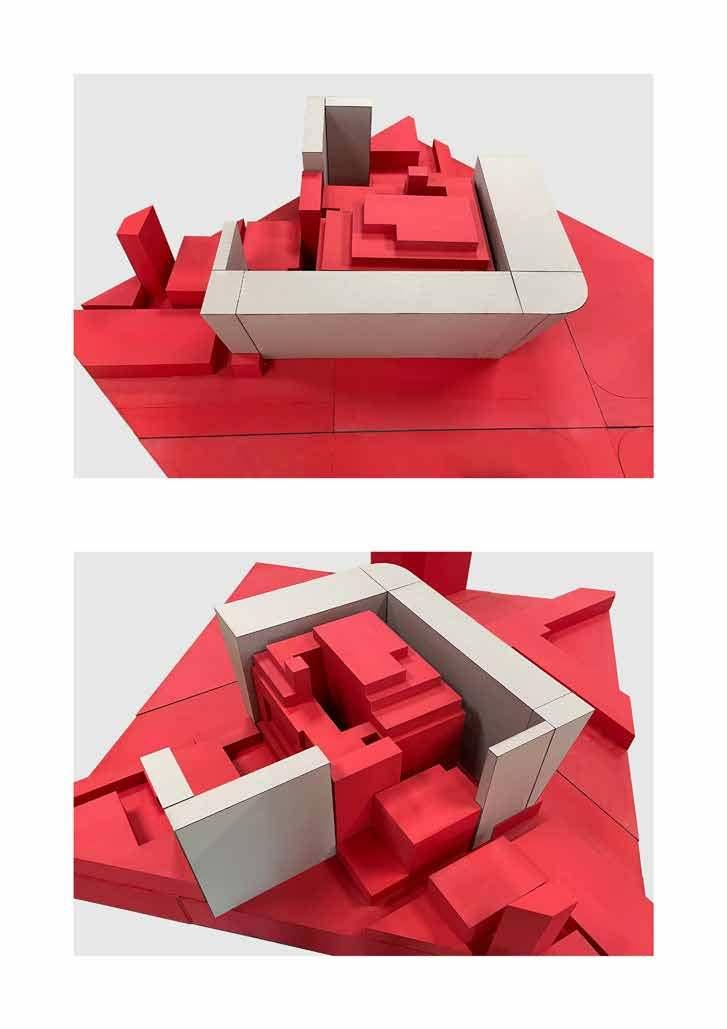

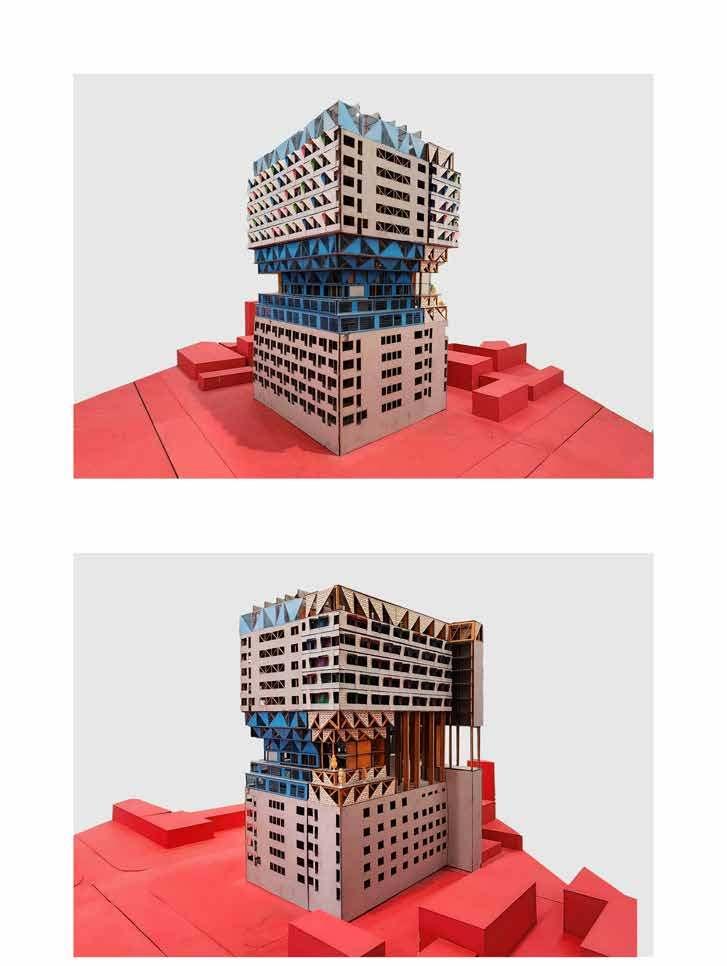

FINALMODELS

22

23

24

25

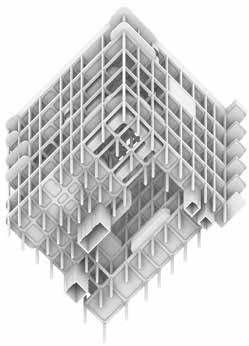

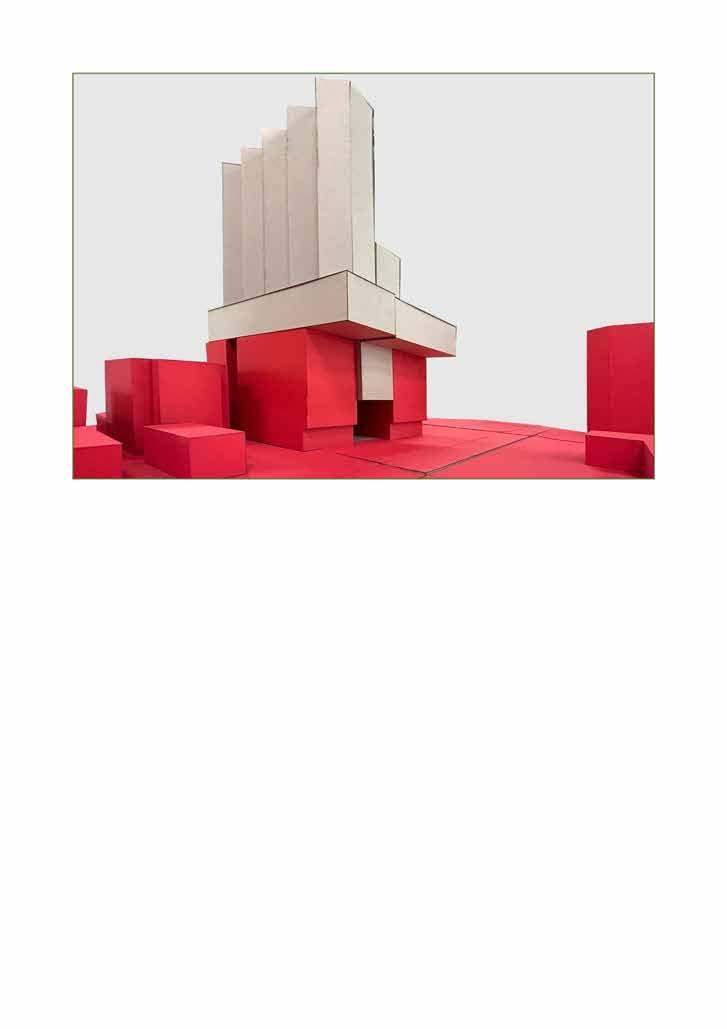

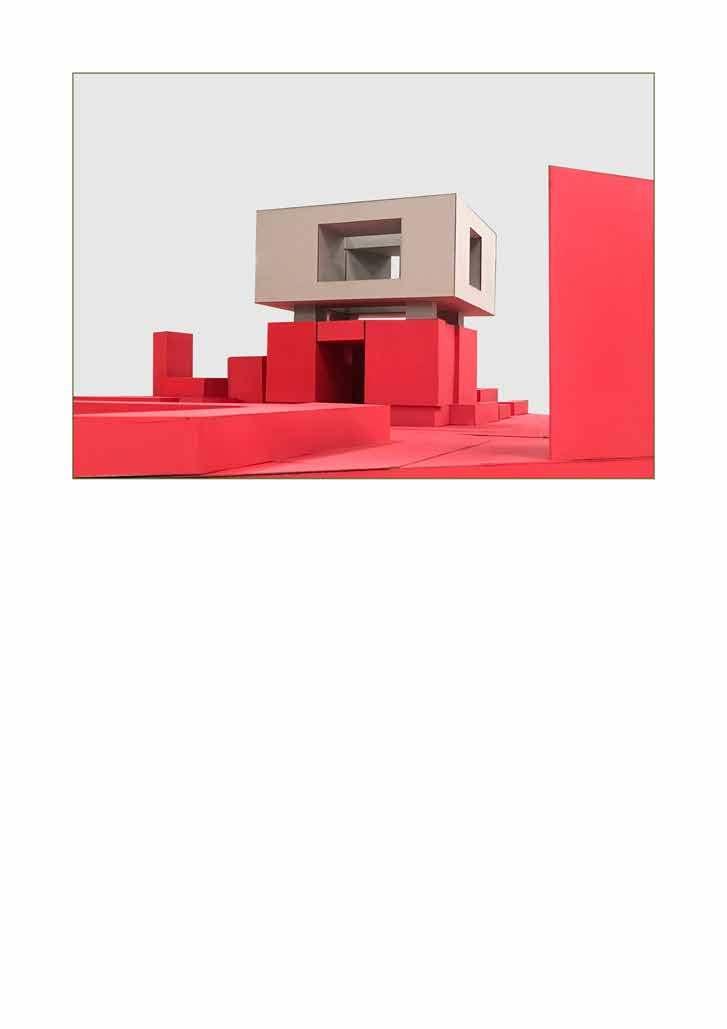

WEEK 05 // MASSING 26

WEEK 06 INTERIM// LIUHENG, ASHRAFF WEEK 06 // MASSING 27

WEEK 07 // MASSING 28

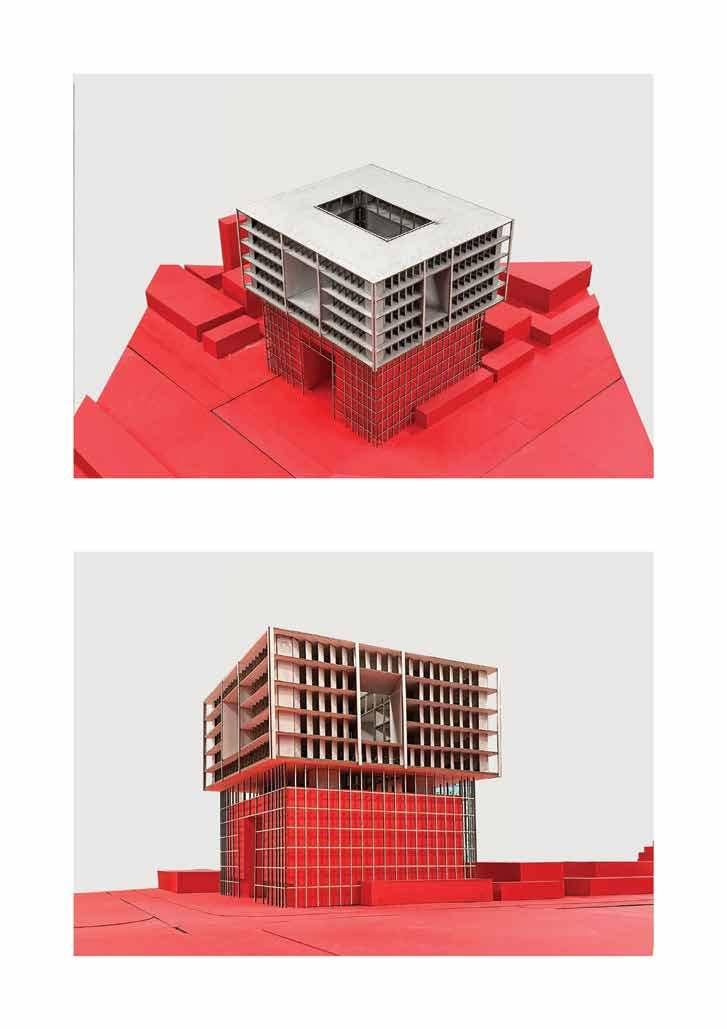

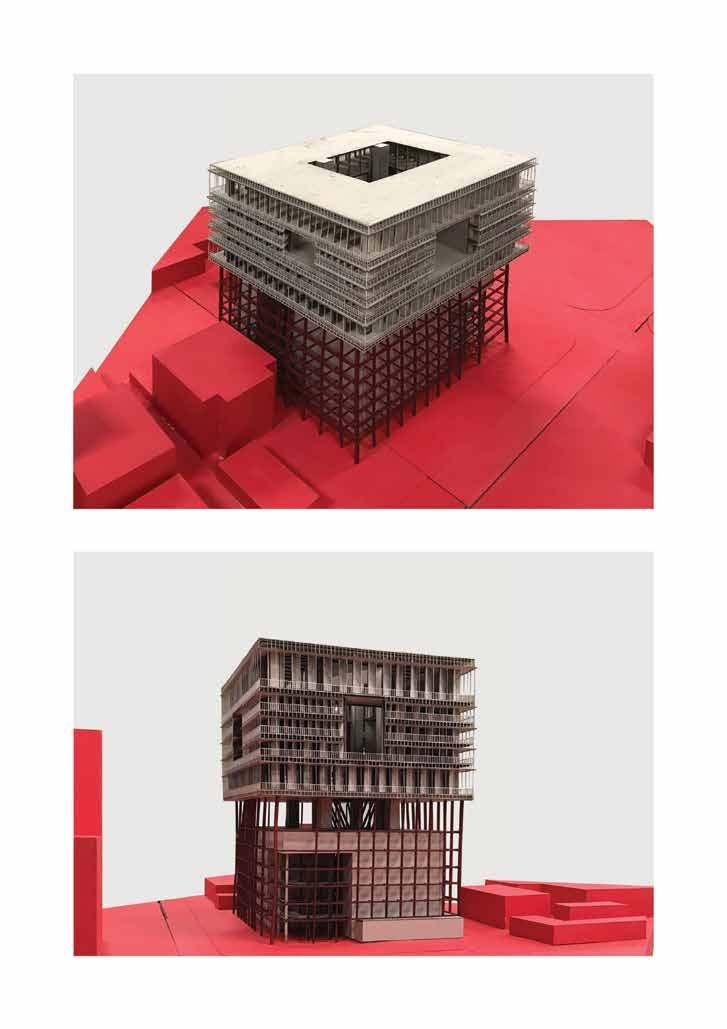

WEEK 08 // STRUCTURE 29

WEEK 09 // STRUCTURE, ENVELOPE, COLOR 30

WEEK 10 // ENVELOPE, COLOR, PROGRAM 31

WEEK 10 // ENVELOPE, COLOR, PROGRAM 32

WEEK 10 // ENVELOPE, COLOR, PROGRAM 33

WEEK 10 // ENVELOPE, COLOR, PROGRAM 34

WEEK 11 // ENVELOPE, COLOR, PROGRAM 35

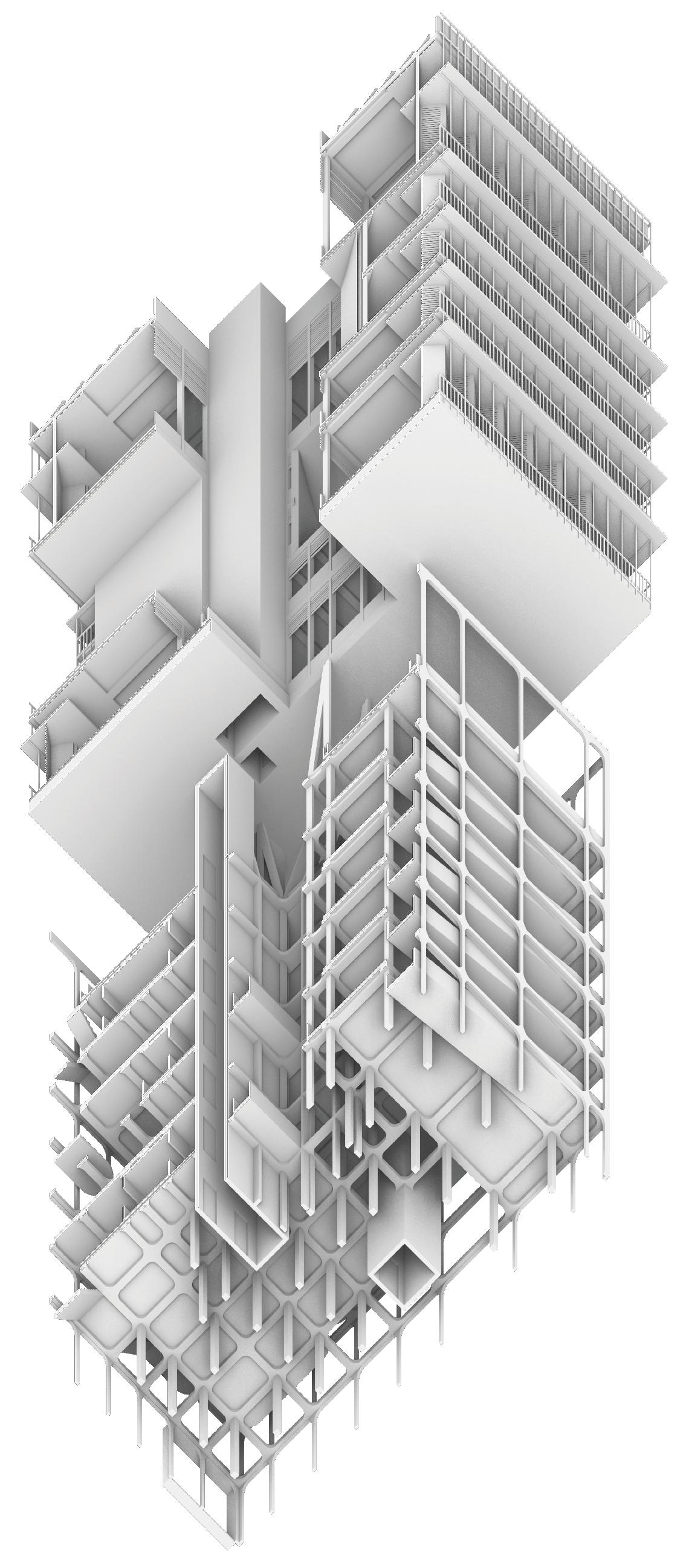

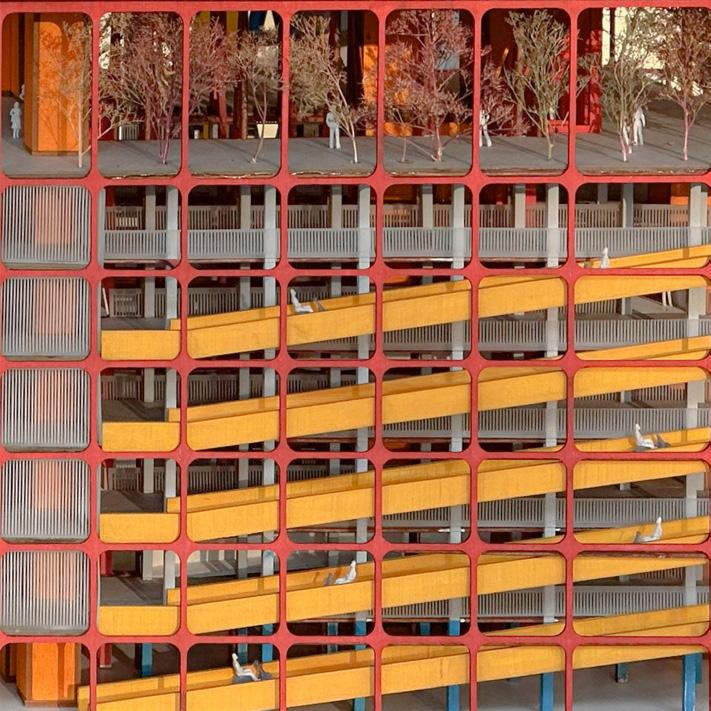

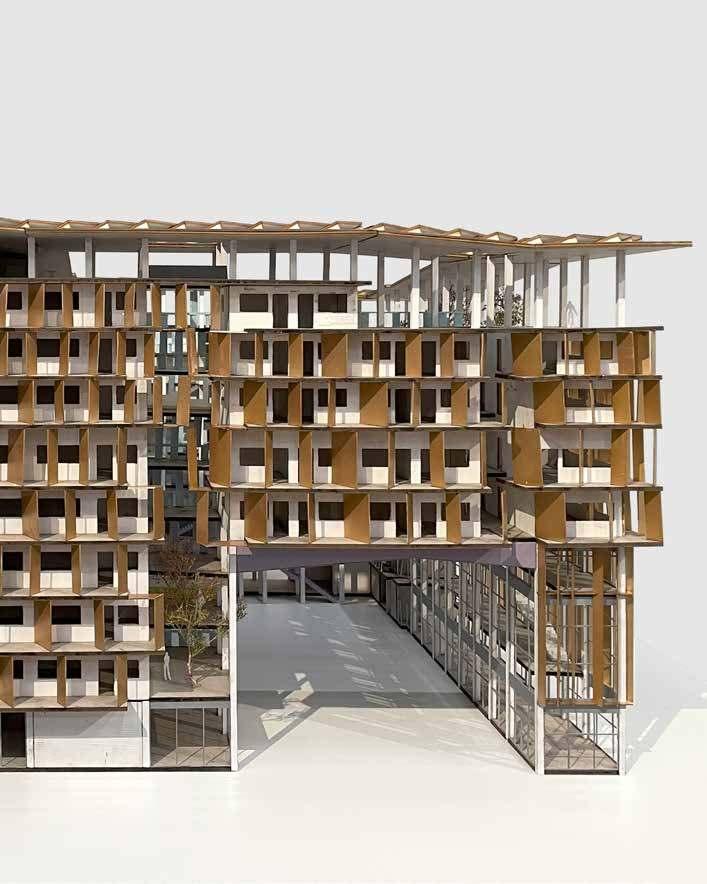

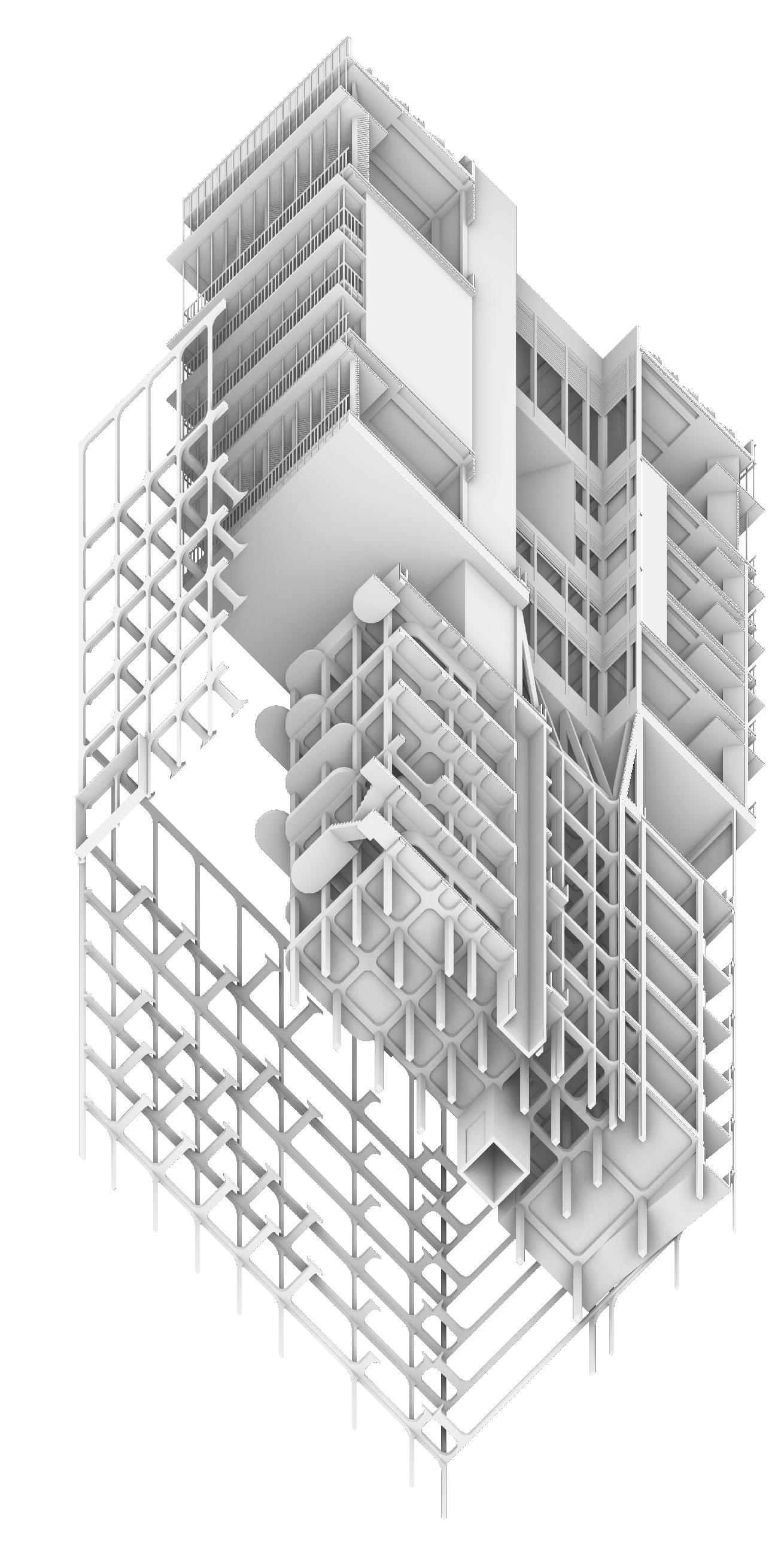

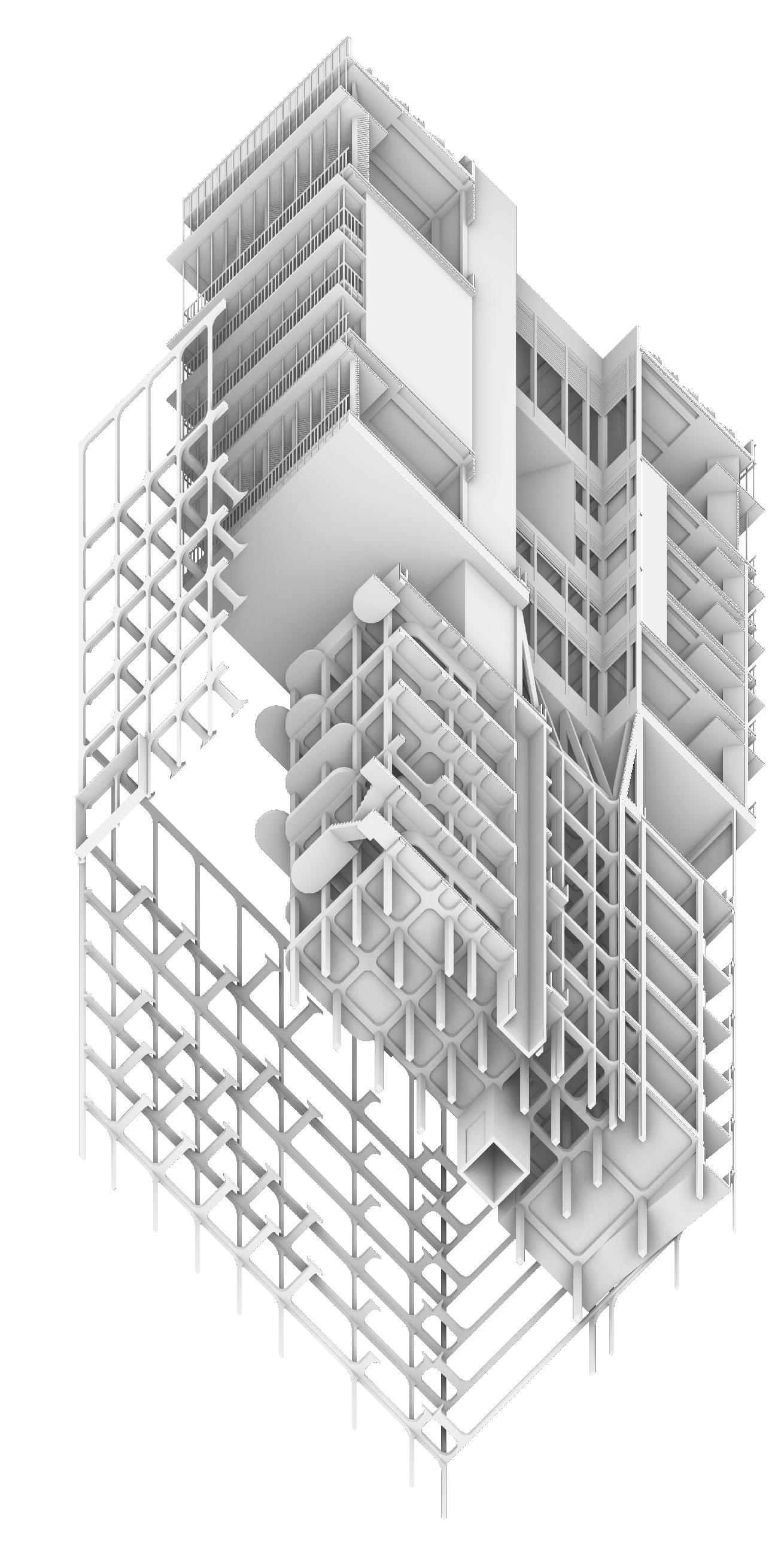

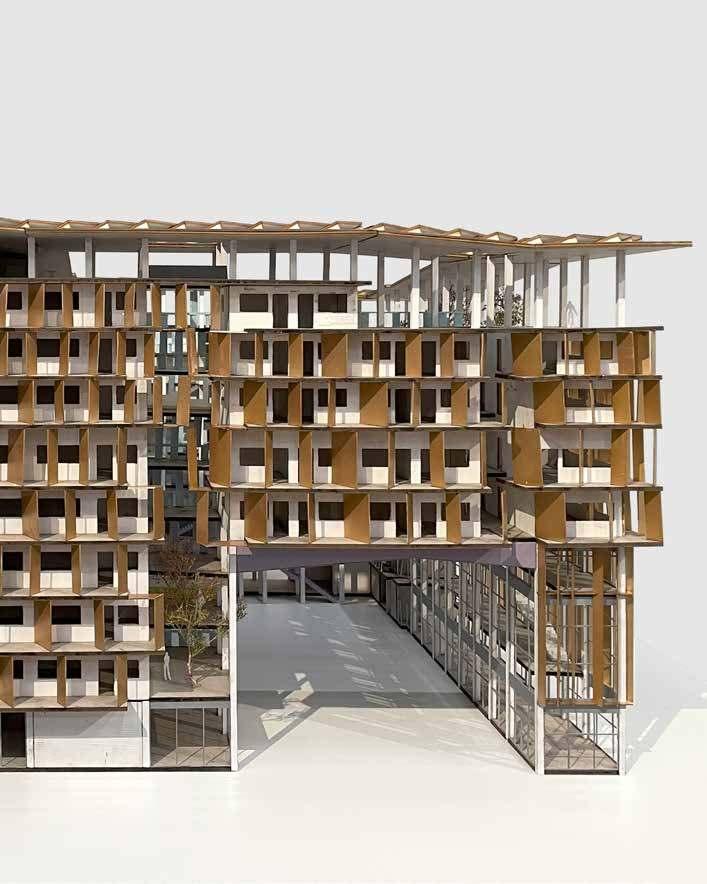

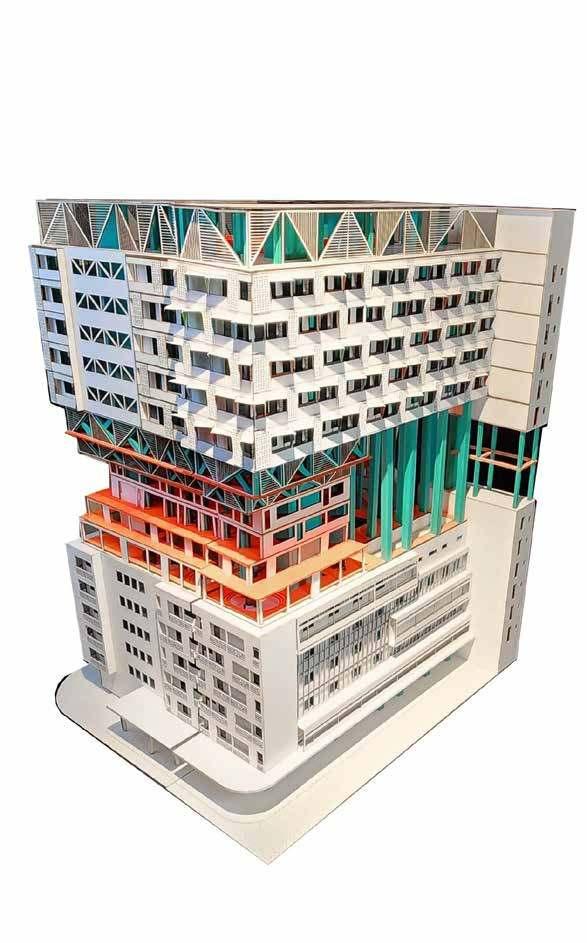

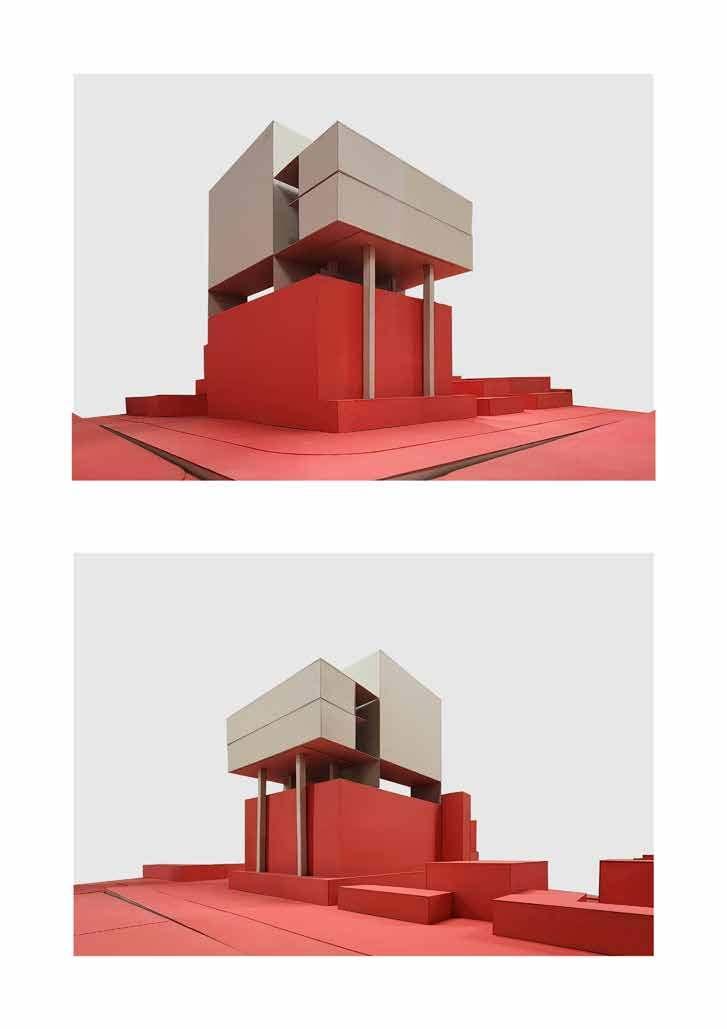

EMBRACE Victory Hotel Site A

Ourprojectembracespracticesacrossmanyfieldsofourresearchduringthesite study and design development process. We extracted a fundamental principle from a precedent study – that many architects in Vietnam took approaches to formallyandspatiallyreconcilewiththeurbanfabricdespiteconsistentlypushing for varied original design. As an adaptive reuse, our project challenges the view that Victory Hotel should be read as a stand-alone building, separated from the urban block. Hence, our vision adopts an urban strategy of sleaving to allow the Victory Hotel to reconcile with the urban fabric of Ho Chi Minh City. Challenging the belief of complete preservation, our project intends to improve the climatic responseofVictoryHotel,whilebuildingontheexistingculturalfabricofthecity byintroducingasustainablewayofliving.

Throughout our design process, we worked at the intersection of this principle alongwithotherkeytenetsofparamountsignificance–reconcilingtheadaptive reuse with embodied factors of the climate, the carbon arithmetic, the social backgrounds of Ho Chi Minh city, and a larger thesis to extend the design envelope of the adaptive reuse process in architecture for a more sustainable future. The final outcome showcases iterations of this reconciliation attempts, summating at its ultimatum with the title ‘Embrace’, a dignified design stance that warmly includes the grounds for many environmental, practical, and socioculturalconstructsthatallactasdriversinthisexploration.

Ashley,Hugo

2 36

37

01m5m 2m 1:50 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 30°C 55°C 24°C 30°C Surface Temperature Ambient Temperature 38

01m5m 2m 1:50 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 30°C 55°C 24°C 30°C Surface Temperature Ambient Temperature NEW VS OLD INTERFACE// CLIMATIC INTEFACE 39

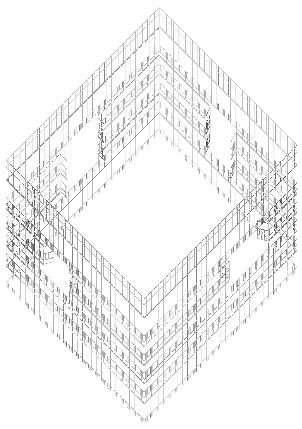

Existing Victory Hotel Reinforced Concrete Structure Masonry Infill 40

Adaptive Reuse Glulam Columns & Beams CLT Walls & Floor Slab Adaptive Reuse Recycled Plastic Internal & External Facade EMBODIED & OPERATIONAL CARBON ANALYSIS 41

42 Adaptive Reuse Aluminium Window Frames Steel Railings

EMBODIED & OPERATIONAL CARBON ANALYSIS 43 Adaptive Reuse Glass PV Panels

44 PARTIAL DEMOLITION ADAPTIVE REUSE OF EXISTING BUILDING EMBODIED CARBON SAVED = 26 210 844 KgCO2 FULL DEMOLITION COMPLETE REBUILD OF NEW DESIGN EXISTING EMBODIED CARBON = 31 810 153 KgCO2 Concrete 7 876 872 Kg 1 023 993 KgCO Rebar 8 587 978 Kg 24 819 258 KgCO Masonry Brick 812 872 Kg 195 089 KgCO Steel 753 Kg 2 946 KgCO Aluminium 13 392 Kg 221 369 KgCO Glass 525 Kg 860 KgCO Timber 5 152 Kg 23 363 KgCO Concrete 12 457 680 Kg 619 498 KgCO e Rebar 10 186 748 Kg 29 439 704 KgCO e Masonry Brick 2 289 705 Kg 549 529 KgCO e Steel 18 055 Kg 70 595 KgCO e Aluminium 5 194 Kg 85 870 KgCO e Glass 28 500 Kg 34 770 KgCO e Timber 19 220 Kg 10 186 KgCO e

EMBODIED CARBON

45 ADAPTIVE REUSE DESIGN ADDED EMBODIED CARBON = 3 638 036 KgCO2e TOTAL = 29 848 880 KgCO e NEW BUILD DESIGN NEW EMBODIED CARBON = 11 057 123 KgCO2e TOTAL = 42 867 276 KgCO e Green Concrete CF: 0.09 1 123 348 Kg 101 101 KgCO Rebar (97% Recycled) CF: 0.77 1 096 802 Kg 844 537 KgCO CLT CF: 0.35 3 007 870 Kg 1 052 754 KgCO Glulam CF: 0.29 689 422 Kg 199 932 KgCO Reclaimed Brick CF: 0.01 81 559 Kg 815 KgCO Steel 112 412 Kg 439 530 KgCO Recycled Aluminium 5 192 Kg 109 034 KgCO 19 150 Kg 23 363 KgCO Timber 42 327 Kg 22 433 KgCO Recycled Plastic CF: 0.56 1 096 802 Kg 844 537 KgCO Green Concrete CF: 0.09 9 919 189 Kg 892 727 KgCO e Rebar (97% Recycled) CF: 0.77 9 684 780 Kg 7 457 280 KgCO e CLT CF: 0.35 3 007 870 Kg 1 052 754 KgCO Glulam CF: 0.29 689 422 Kg 199 932 KgCO Reclaimed Brick CF: 0.01 894 432 Kg 8 944 KgCO Steel 113 197 Kg 442 600 KgCO Recycled Aluminium 6 531 Kg 107 962 KgCO e Glass 20 675 Kg 25 223 KgCO e Timber 47 479 Kg 25 164 KgCO Recycled Plastic CF: 0.56 1 096 802 Kg 844 537 KgCO 050m100m 200m 1:2000 02|27 02|28 03|01 03|02 03|03 03|04 03|05 02|23 02|24 02|25 02|26 03|06 03|07 03|08 03|09 02|20 02|21 02|22 02|16 02|17 02|18 02|19 02|13 02|14 02|15 02|09 02|10 02|11 02|12 02|06 02|07 02|08 02|02 02|03 02|04 02|05 01|30 01|31 02|01 01|26 01|27 01|28 01|29 01|23 01|24 01|25 01|19 01|20 01|21 01|22 01|16 01|17 01|18 01|12 01|13 01|14 01|15 03|10 03|11 03|12 03|13 03|14 03|15 00|16 03|17 03|18 03|19 03|20 03|21 03|22 03|23 03|24 03|25 03|26 03|27 03|28 03|29 03|30 03|31 04|01 04|02 04|03 04|04 04|05 04|06 04|07 04|08 04|09 04|10 04|11 04|12 04|13 04|14 04|15 04|16 04|17 04|18 04|19 04|20 Group: Chelsea Ho Jia Xuan Lee Yong Soon

OF EXISTING VS ADAPTIVE REUSE WITH NEW ADDITION, LABOUR

EMBODIED CARBON

Existing GFA: 8,289.3sqm

Embodied Carbon: 31,810,153 KgCO2e

Embodied Carbon/sqm: 3,837 KgCO2e/m2

Adaptive reuse with new addition GFA: 16,354.3sqm

Discarded Embodied Carbon: 10,412,581 KgCO2e

Embodied Carbon of new addition: 3,638,036 KgCO2e

Total Embodied Carbon: 14,050,617

Total Embodied Carbon/sqm: 859 KgCO2e/m2

OPERATIONAL CARBON

Existing GFA: 8,289.3sqm

EUI: 220/ kWh/m2/yr

Operational Carbon: 1,550,100 KgCO2e

Offsets

Required area of PV to offset operational carbon: 4,163.80m2

Actual area of PV: 2,060.68m2

LABOUR

Adaptive reuse with new addition

Average working hours over 13weeks: 101.9h

Longest working hours in a week: 251h

Total cost of prints and models: $598.00

46

GFA: 16,354.3sqm EUI:

KgCO2e % of Improvement 43.0% % of Offsets 49.5% % of Improvement 77.6% Materials Rebar (recycled) Green Concrete Glulam CLT Recycled Plastic (HDPE) Mass (kg) 1,096,802 1,123,348 689,422 3,007,870 1,096,802 Carbon Factor (kgCO2e/kg) 0.77 0.09 0.29 0.35 0.56 Embodied Carbon (kgCO2e) 844,537 101,101 199,932 1,052,754 844,537 =3,638,036 KgCO2e

63.65 Kg kWh/m2/yr Operational Carbon: 884,808

CARBON REPORT

Breakdown of New addition

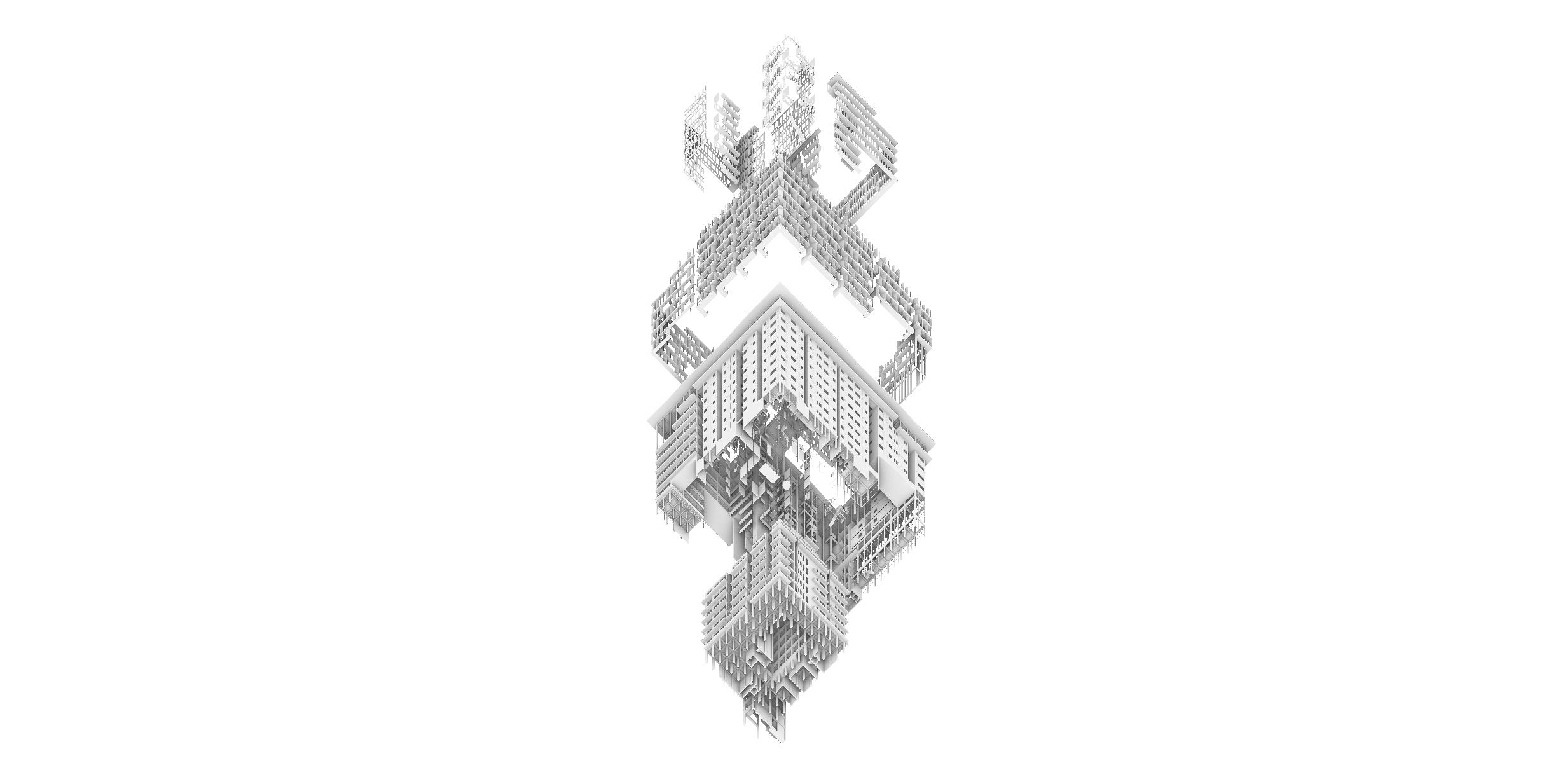

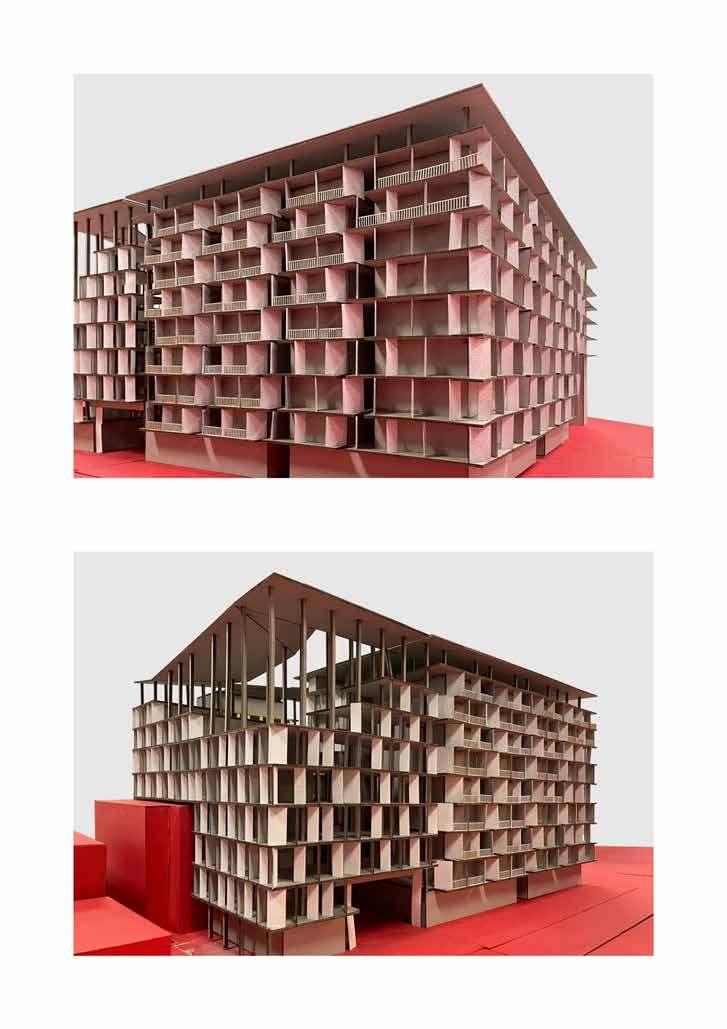

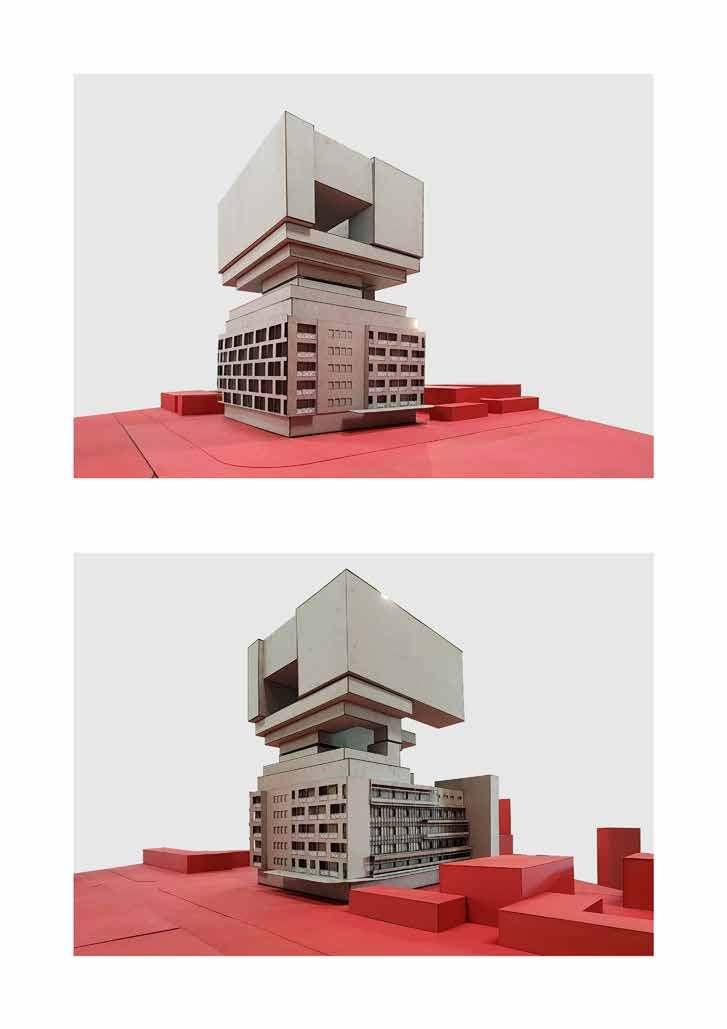

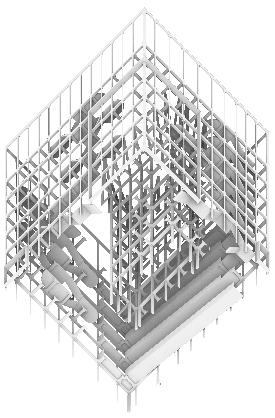

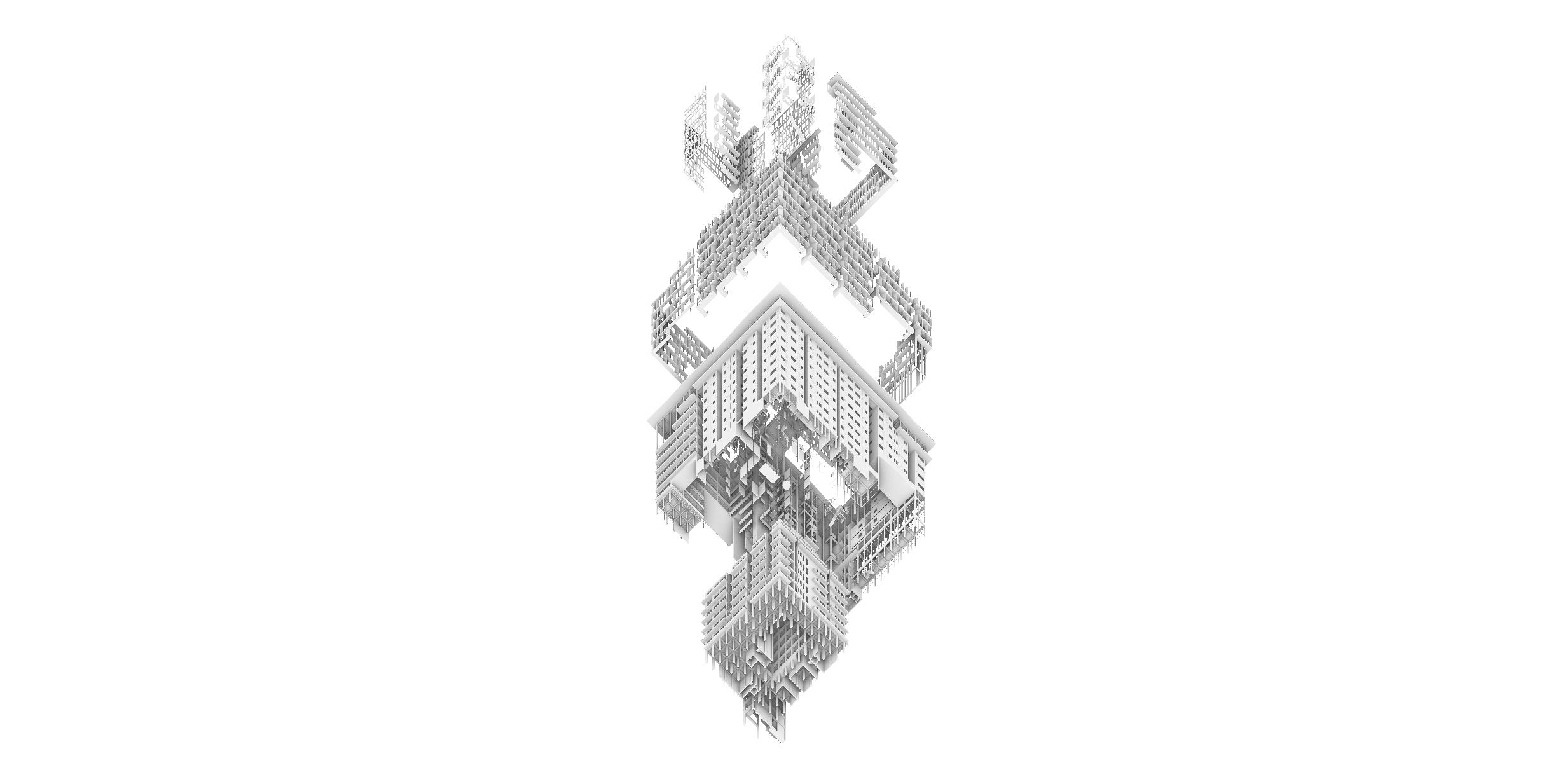

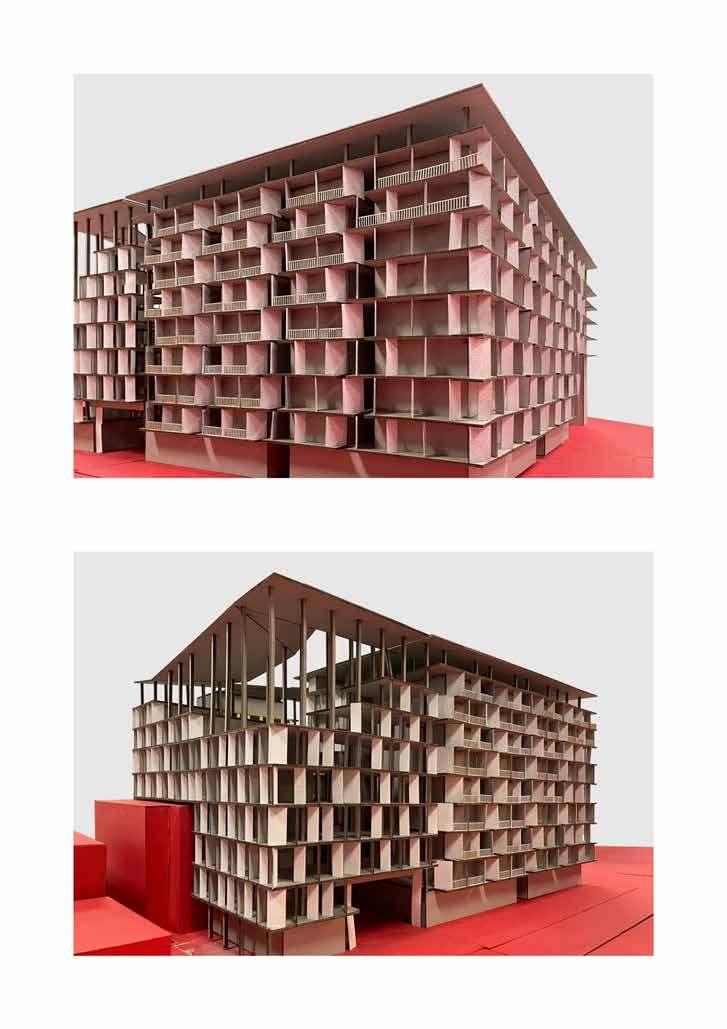

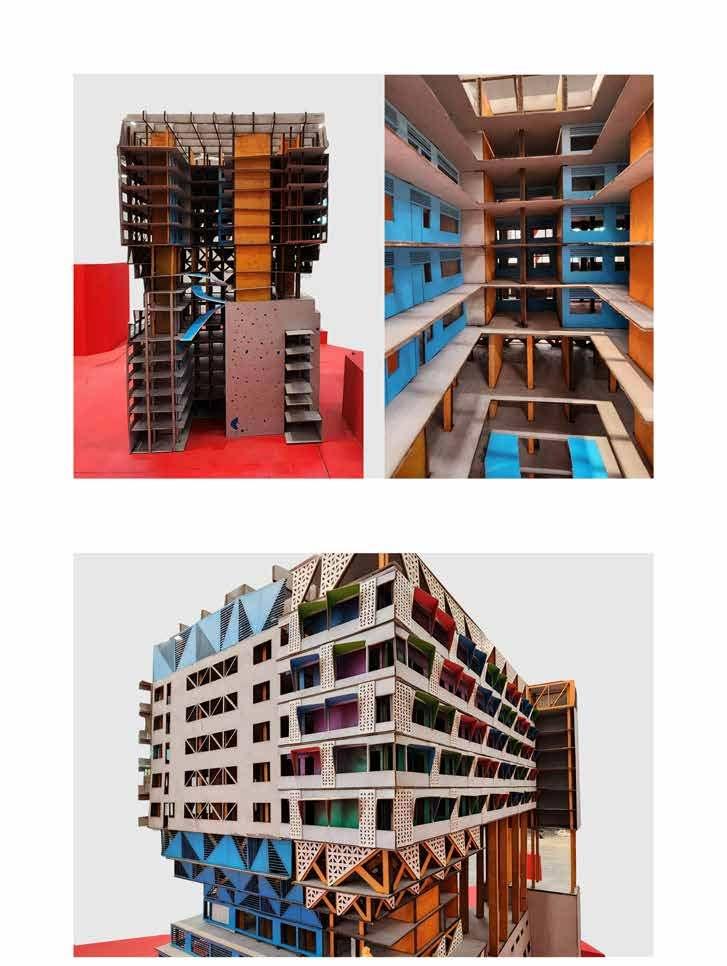

FINALMODELS

48

49

50

51

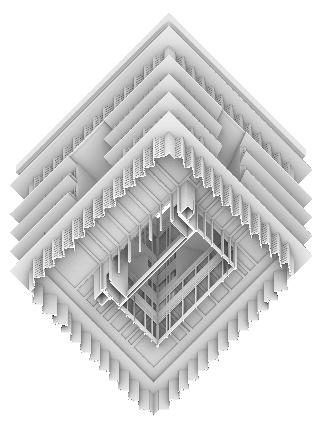

WEEK 05 // MASSING 52

WEEK 06 INTERIM WEEK 06 INTERIM// HUGO, ASHLEY WEEK 06 // MASSING 53

WEEK 07 // MASSING 54

WEEK 08 // STRUCTURE 55

WEEK 09 // STRUCTURE, ENVELOPE, COLOR 57

Desi·gnDeveoPment - Facade Week 10 Ashley, Hugo 58

Design Development - C o ur t yard s Facad e Week 10 Ashley, Hugo WEEK 11 // ENVELOPE, COLOR, PROGRAM 59

60

WEEK 11 // ENVELOPE, COLOR, PROGRAM 61

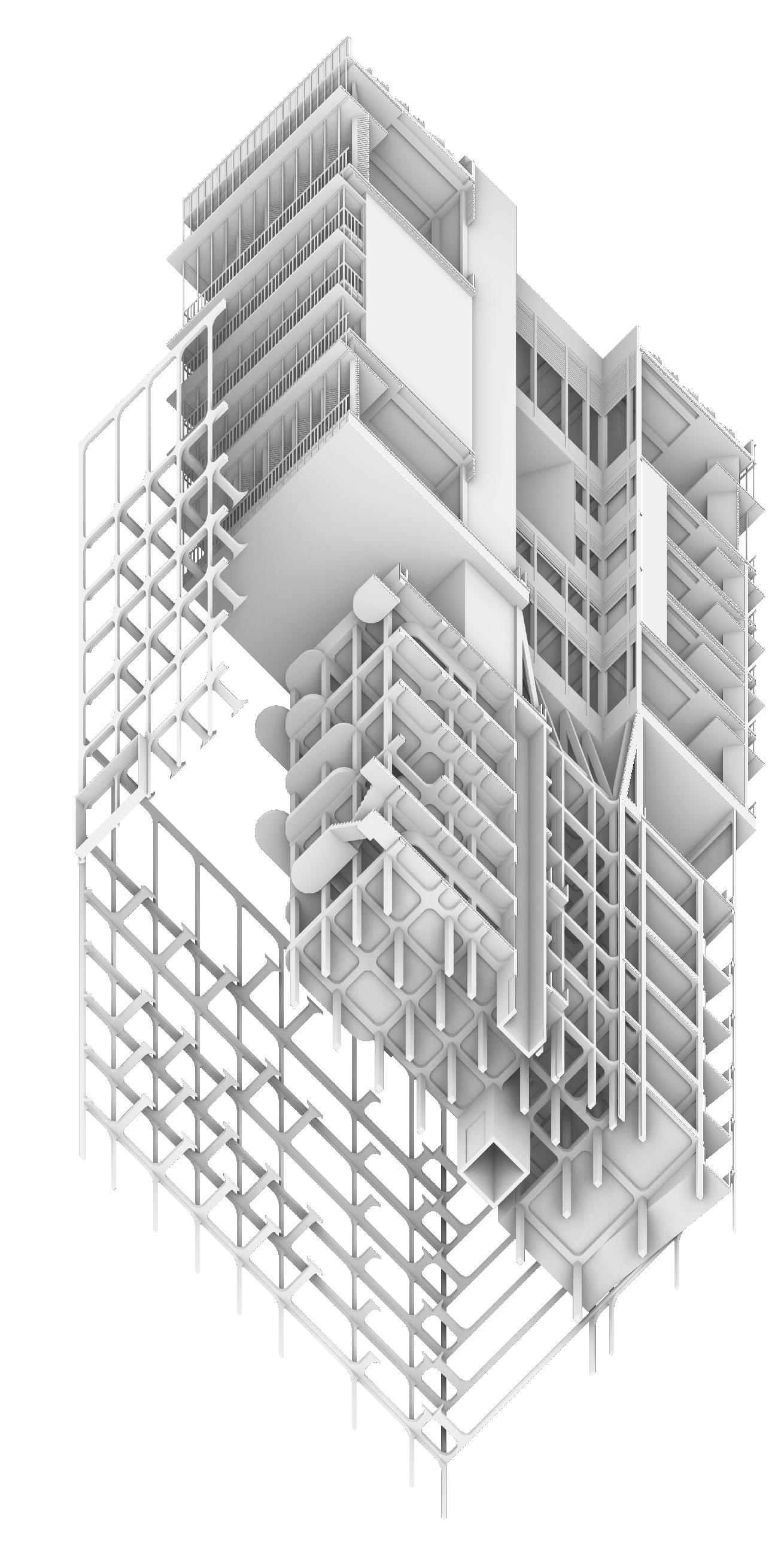

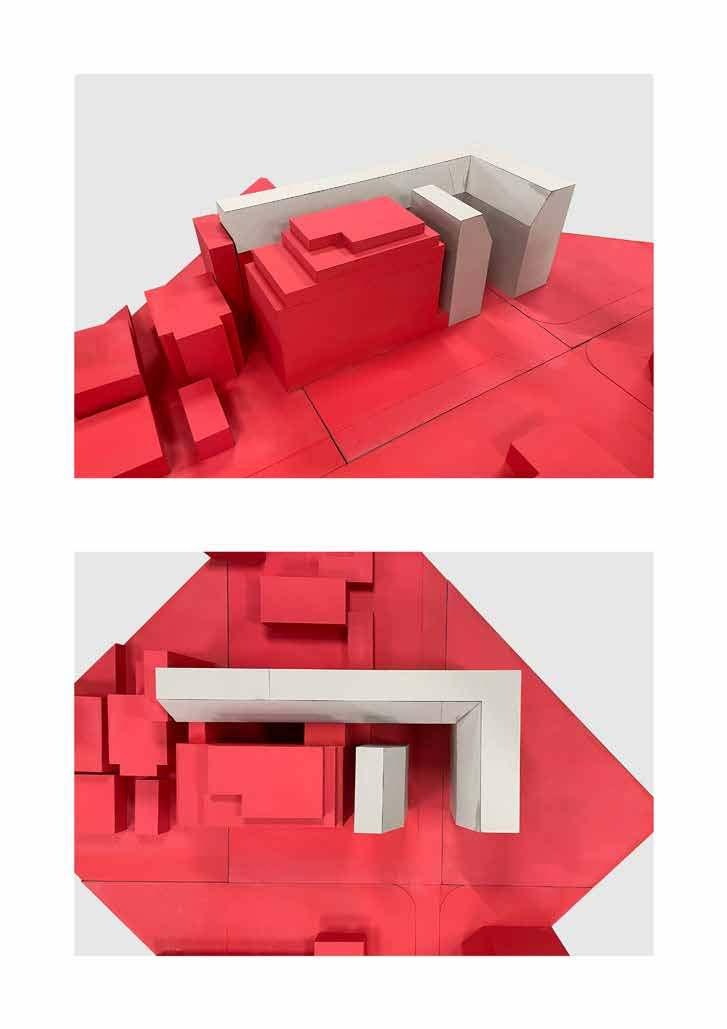

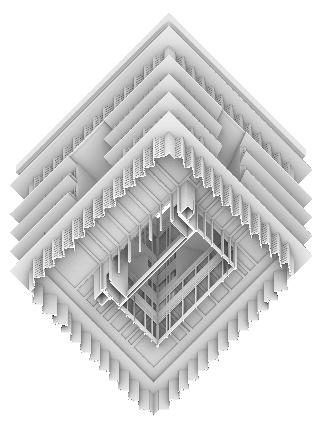

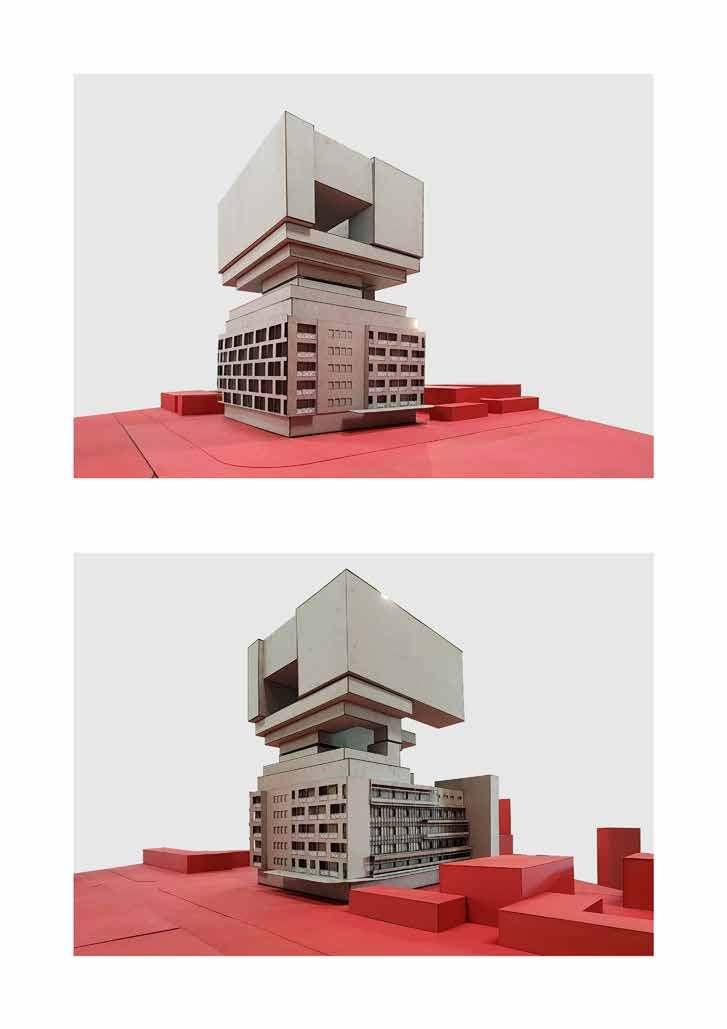

AChanceVictoryforHCMC! Victory Hotel

Site A

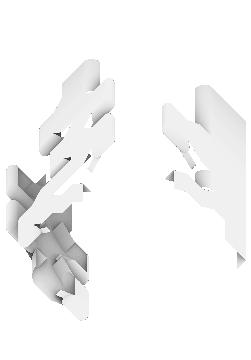

The new addition is an playful inversion of the existing victory hotel, which was formerlyusedastemporaryhousingquartersfortheCIAinthe70s;Anoutlierset backfromDistrict3’shighlystructuredfrenchcolonialcityplan.Colorfullouvres climatically orientated to the sun’s path don the facade of the new addition in livelycontrasttothemodernistexisting.

Theinversionwasconceivedbyembracingchanceandentertaininganirrational thoughtofhavingthehotel,literallyturnedonitshead,withtheintentofflipping itintoanopenandaccessiblebuildingforall.

Intheprocess,theresultofthechanceoperationcreatedmultipletiersofpublic spaces. The multi tiered urban belt serves as a vertical extension Ho Chi Minh City’svibranturbanstreetlifeamidsttheintenselydensifyingurbanlandscape.

A series of inversions were carried out in the adaptive reuse of victory hotel, transforming the once deep private spaces of the double loaded hotel keys into singleloadedresidentialapartmentswithanexpandedcourtyard,maximisingday lightingandnaturalventilationinthebuilding.Acentralstaircasethatenvelopes the courtyard enables vertical connectivity between the once disconnected floorslabsandthegroundflooropensuptothestreet,allowingforaporousflow ofcirculationbetweenstreetandbuilding.

Structurally, the existing building was not built with the capacity to withstand double its load. Thus, an inversed column grid offsetted from the existing building’s was adopted to carry its new additon. Infill walls between hotel keys were also emptied out, converting them into 2 bedrooms apartments to further offsetmoreloadontheexistingstructure.

Nonetheless, the removed brick walls were recycled into a brick pavings on the ground floor restoring the new building to the boundary line of the district 3 urbanblock.

Chelsea,YongSoon

3 62

05m10m 1:150 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h

01m5m 2m 1:50 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 30°C 55°C 24°C 30°C Surface Temperature Ambient Temperature 64

01m5m 2m 1:50 3-11km/h 11-24km/h 24-35km/h Average speed: 11.2km/h 30°C 55°C 24°C 30°C Surface Temperature Ambient Temperature NEW VS OLD INTERFACE// CLIMATIC INTEFACE 65

66

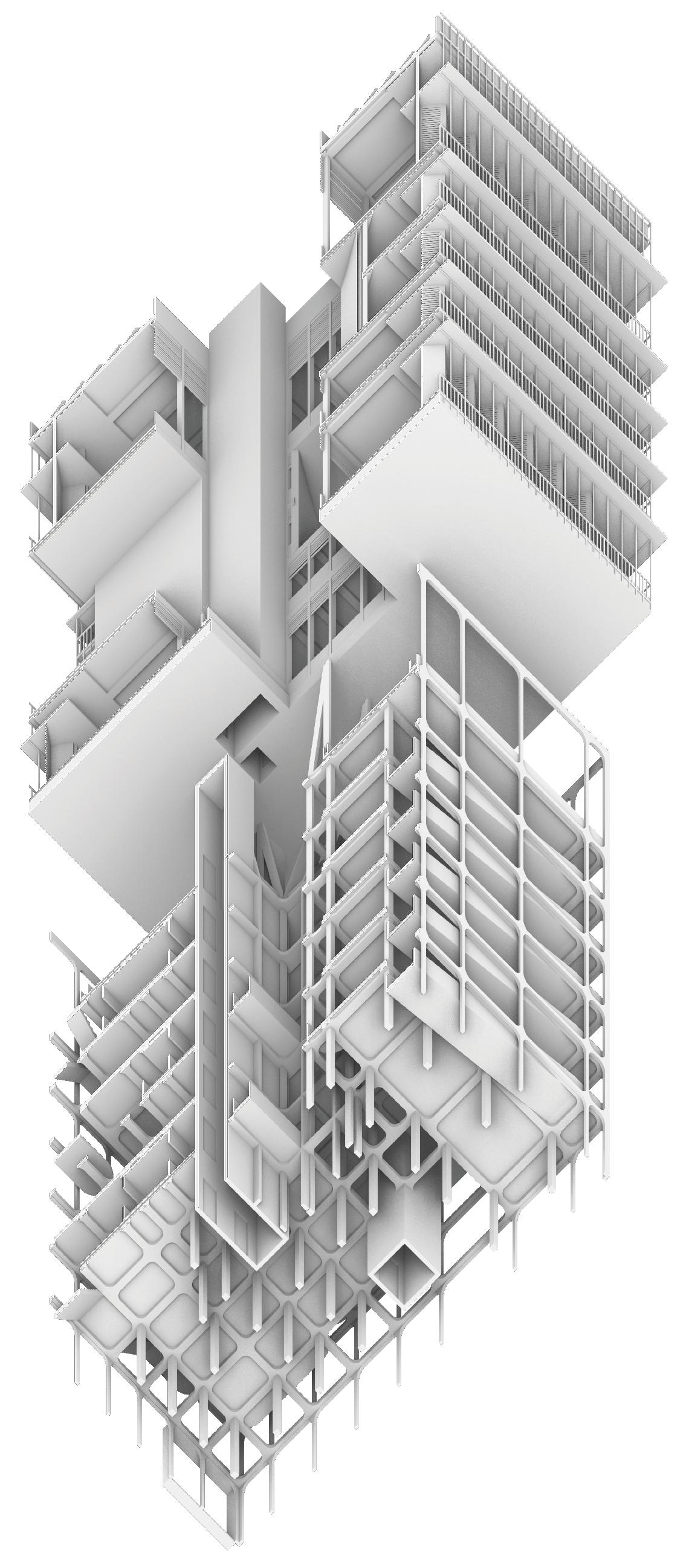

DEMOLITION (MANSORY INFILL, COLUMNS, SLABS)

STRUCTURE

WALLS, TRUSSES) GREEN CONCRETE AND 100% RECYCLED REBAR GLULAM

(SHEAR

EMBODIED & OPERATIONAL CARBON ANALYSIS 67

STRUCTURE (COLUMNS, BEAMS, SLAB)

CROSS LAMINATED TIMBER 68

INFILL (WALLS, PARAPET, STAIRCASE) (PERFORATED

RECYLED HDPE PLASTIC PV CELLS AND HYDROGEN FUEL CELLS OPERATIONAL ENERGY & CARBON OFFETS ENVELOPE (PERFORATED PANELS, WINDOW HOODS, RAILINGS) 05m10m 1:150 EMBODIED & OPERATIONAL CARBON ANALYSIS 69

GLULAM CF:0.35 2 097 995 Kg 734 298 KgCO e CLT CF:0.35 1 003 895 Kg 351 363. KgCO2e Green Concrete CF: 0.07 5 074 872 Kg 659 733 KgCO2e Steel Rebar (97% recycled content) CF: 0.77 KgCO2e/kg 4 149 765 Kg 3 195 319 KgCO2e Recycled CF: 0.77 KgCO2e/kg 189 106 124 EXISTING EMBODIED VICTORY =29 398 Rebar 9 575 826 Kg 27 674 139 KgCO2 Concrete 11 710 565 Kg 1 522 373 KgCO2 EMBODIED NEW =3, 904, Clay Masonry 379 537 Kg 91 089 KgCO2 Aluminium 3 301 Kg 54 581 KgCO Glass 42 074 Kg 51 331 KgCO e Steel 708 Kg 2 769 KgCO e 2 M 01|30 T 01|31 01|26 F 01|27 01|28 S 01|29 M 01|23 01|24 W 01|25 01|19 F 01|20 01|21 S 01|22 M 01|16 01|17 W 01|18 01|12 F 01|13 01|14 01|15 70

Recycled HDPE Plastic KgCO2e/kg 508 Kg KgCO2e EMBODIED CARBON OF VICTORY HOTEL 398 410 KgCO2e EMBODIED CARBON OF NEW ADDITION 904, 221 KgCO2e TOTAL EMBODIED CARBON (NEW ADDITION + DISCARDED CARBON) =4, 114, 091 KgCO2e OPERATIONAL CARBON OF ADAPTIVE REUSE & ADDITION =690, 707 KgCO2e OPERATIONAL CARBON OFFSET BY PV (31%) =214, 119 KgCO2e DISCARDED EMBODIED CARBON OF VICTORY HOTEL FROM DEMOLITION =209 870 KgCO2e RECYCLED EMBODIED CARBON =51,465 KgCO2e EXISTING OPERATIONALCARBON/ YEAR = 1 550 110 KgCO2e Clay Masonry 214,438 Kg 51,465 KgCO e (56.5%) Clay Masonry 214,438 Kg 51,465 KgCO e (56.5%) Rebar 252 973 Kg 194 789 KgCO e Concrete 116 013 Kg 15 081 KgCO e Timber 4 011 Kg 126 KgCO2 050m100m 200m 1:2000 M 02|27 02|28 W 03|01 03|02 F 03|03 03|04 S 03|05 02|23 02|24 S 02|25 02|26 M 03|06 03|07 W 03|08 03|09 M 02|20 02|21 W 02|22 02|16 02|17 S 02|18 02|19 M 02|13 02|14 W 02|15 T 02|09 02|10 S 02|11 02|12 M 02|06 T 02|07 W 02|08 02|02 02|03 02|04 S 02|05 01|31 W 02|01 F 03|10 03|11 S 03|12 M 03|13 03|14 W 03|15 00|16 F 03|17 03|18 S 03|19 M 03|20 T 03|21 W 03|22 T 03|23 03|24 S 03|25 03|26 M 03|27 03|28 W 03|29 T 03|30 03|31 S 04|01 04|02 M 04|03 04|04 W 04|05 04|06 04|07 S 04|08 04|09 M 04|10 04|11 W 04|12 04|13 04|14 04|15 04|16 M 04|17 04|18 W 04|19 04|20 Average working hours over 13weeks: 50.95h Longest working hours in a week: 125.5h Total Costs of prints and models: $598.00 Group: Chelsea Ho Jia Xuan Lee Yong Soon EMBODIED CARBON OF EXISTING VS ADAPTIVE REUSE WITH NEW ADDITION, LABOUR 71

EMBODIEDCARBON

Existing GFA: 8,289.3sqm

Embodied Carbon: 29,398,410 KgCO2e

Embodied Carbon/sqm: 3,546 KgCO2e/m2

Adaptivereusewithnewaddition

GFA: 15,361sqm

Discarded Embodied Carbon: 209,870KgCO2e

Embodied Carbon of new addition: 3,904,221 KgCO2e

Total Embodied Carbon: 4,114,091

OPERATIONALCARBON

Existing GFA: 8,289.3sqm

EUI: 220/ kWh/m2/yr

Operational Carbon: 1,550,100 KgCO2e

Offsets Required area of PV to offset operational carbon: 3042.30m2

Actual area of PV: 945.30m2

LABOUR

Adaptivereusewithnewaddition

Average working hours over 13weeks: 50.95h

Longest working hours in a week: 125.5h

Total cost of prints and models: $598.00

Alternativesources ofcarbonoffsets Hydrogen fuel cellsl

Total Embodied Carbon/sqm: 267.8 KgCO2e/m2

GFA: 15,361sqm EUI: 52.9 Kg kWh/m2/yr Operational Carbon: 690,707 KgCO2e %ofImprovement 55.4% %ofOffsets 31.0%

%ofImprovement

Materials Rebar (recycled) Green Concrete Glulam CLT Recycled Plastic (HDPE) Mass (kg) 3,363,311 4,113,094 1,441,649 483,047 189,508 CarbonFactor (kgCO2e/kg) 0.77 0.13 0.35 0.35 0.56 EmbodiedCarbon (kgCO2e) 3,435,888 189,050 188,460 30,795 14,425 =3,904,221KgCO2e

92.0%

CARBONREPORT

72

BreakdownofNewaddition

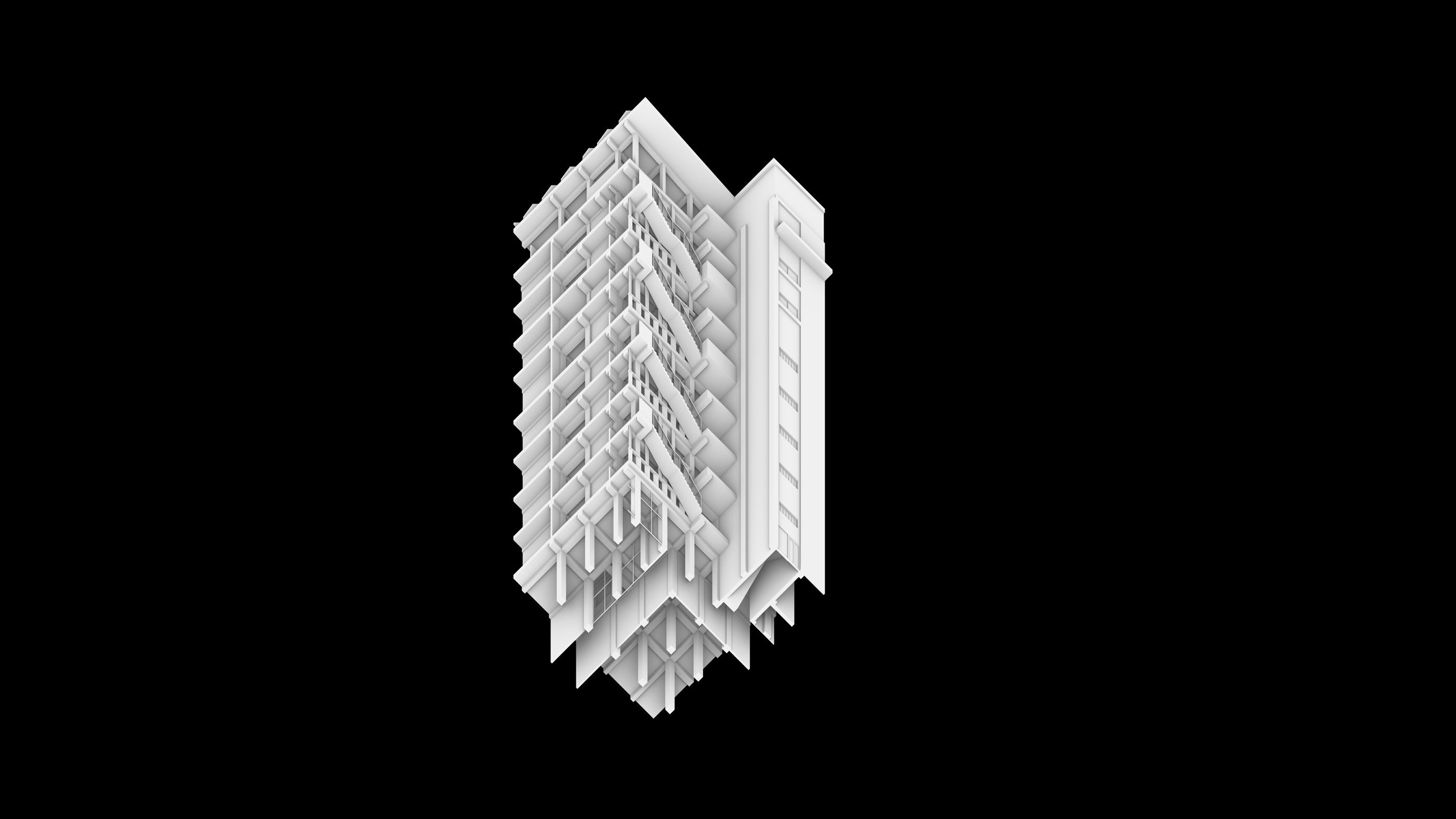

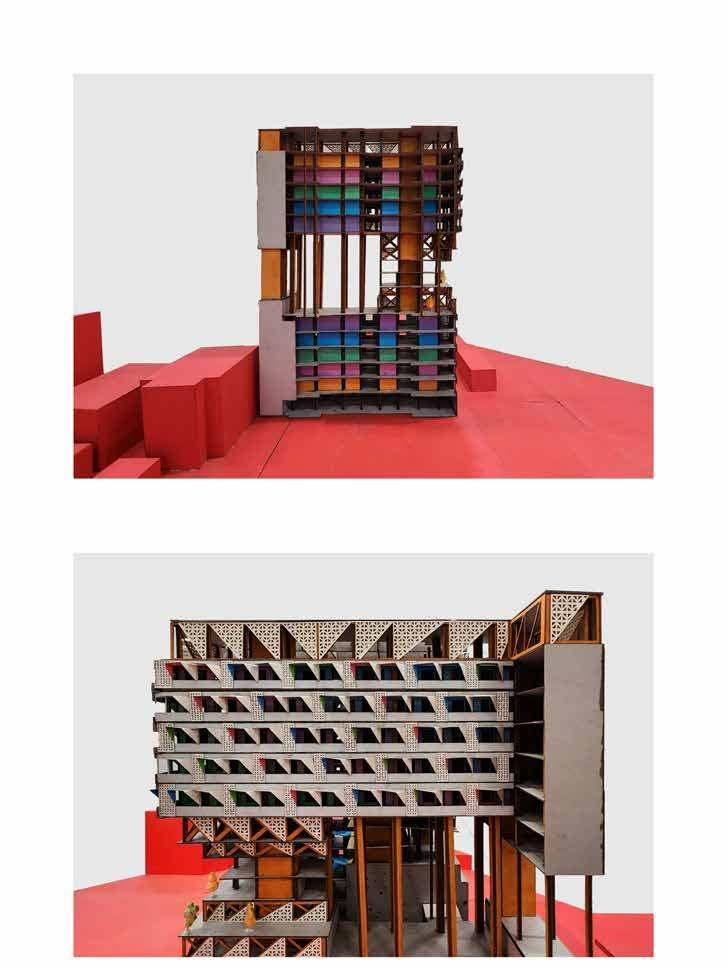

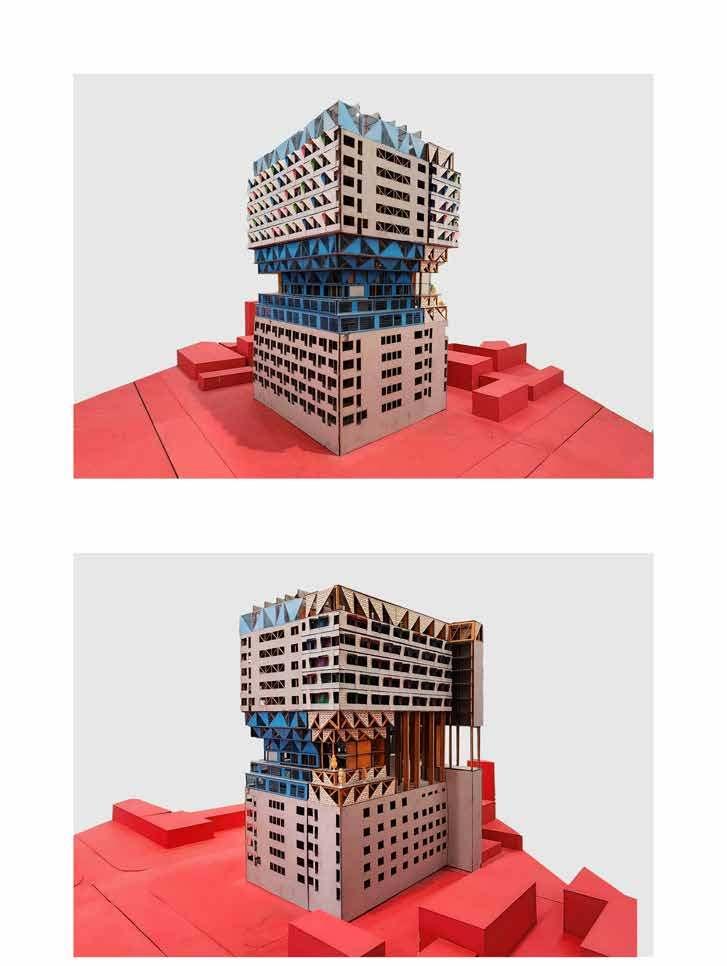

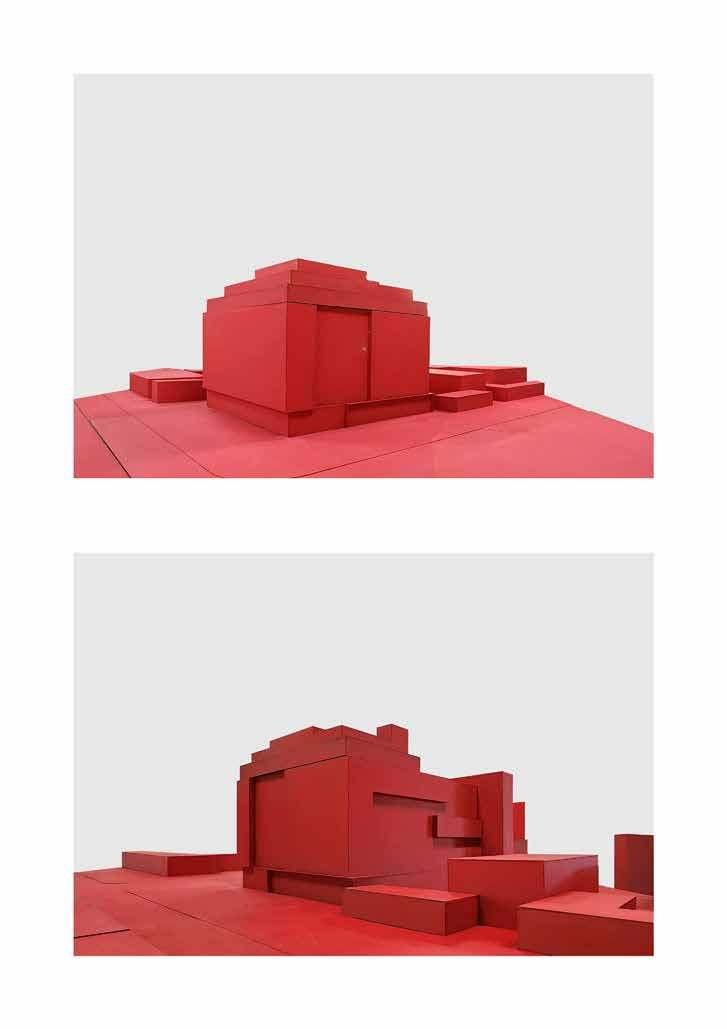

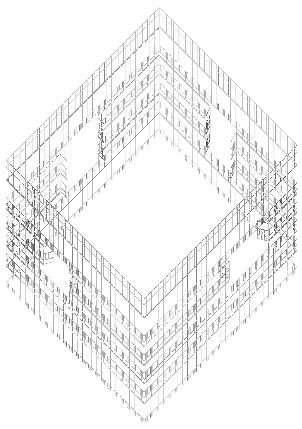

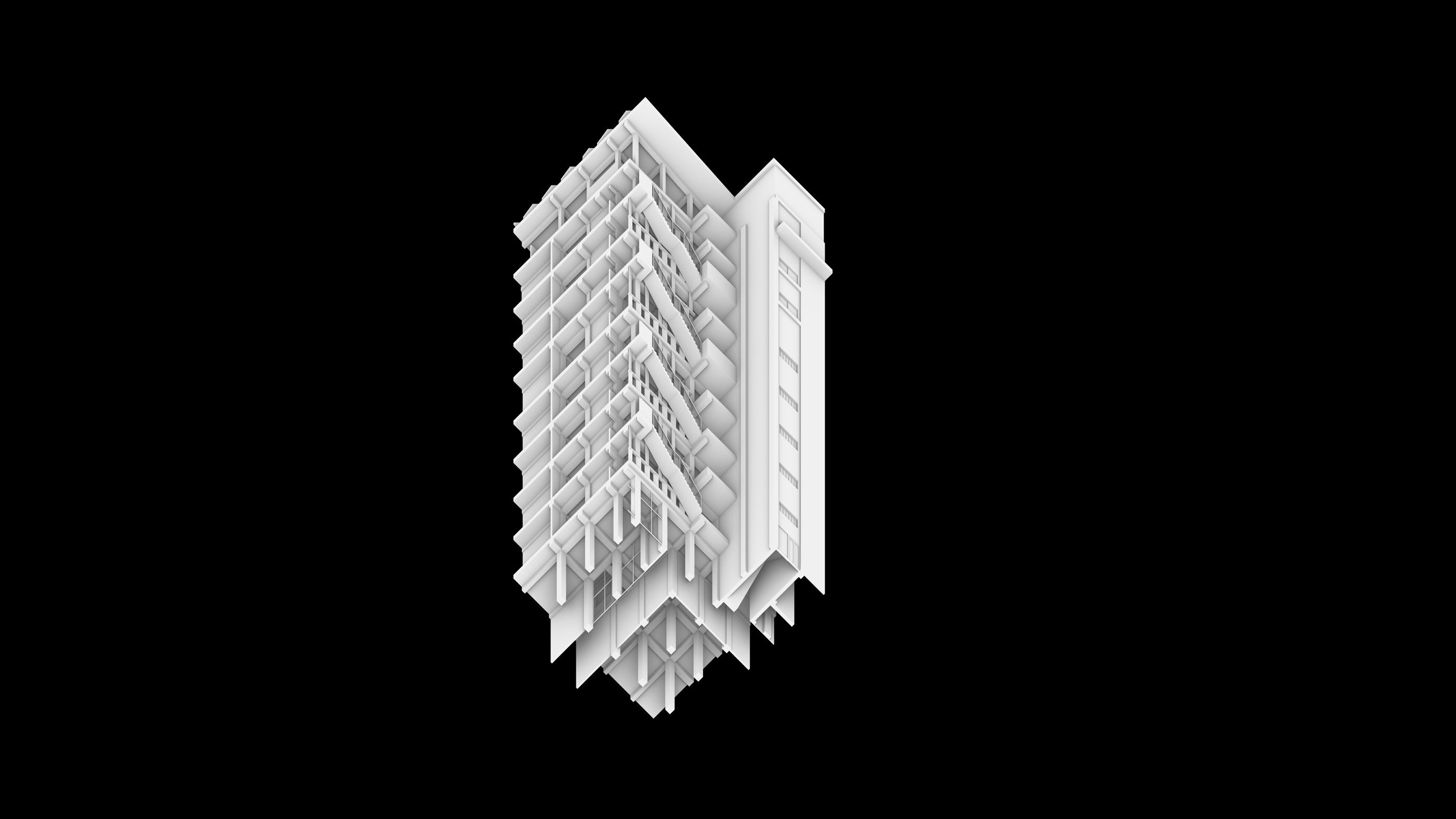

FINALMODELS

74

75

76

77

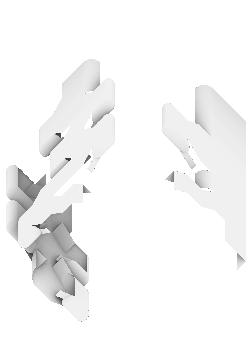

WEEK 05 // MASSING 78

WEEK 06 INTERIM// YONGSOON, CHELSEA WEEK 06 // MASSING 79

WEEK 07 // MASSING 80

WEEK 08 // STRUCTURE 81

WEEK 09 // STRUCTURE, ENVELOPE, COLOR 83

84

WEEK 10 // ENVELOPE, COLOR, PROGRAM 85

WEEK 11 // ENVELOPE, COLOR, PROGRAM

HOT AIR III M. ARCH 1 SEM 02 ERIK L’HEUREUX DEPARTMENT OF ARCHITECTURE COLLEGE OF DESIGN AND ENVIRONMENT