GLASS PRODUCTION TECHNOLOGY

ABSOLUT COMPANY PROFILE

HYDROGEN INTERVIEW

INSPECTION

A GLOBAL REVIEW OF GLASSMAKING

• Furnaces

• Conditioning

• Turn-key plants

INTERNATIONAL April 2021—Vol.44 No.4

WWW.GLASS-INTERNATIONAL.COM Glass International April 2021

Improving combustion can enable you to increase glass production, reduce fuel consumption, enhance glass quality, and reduce emissions, such as NOx, SOx, CO₂, and particulates. Let Air Products’ in-house modeling and melting experts help you get there.

For more than 70 years, we’ve delivered safe oxygen solutions, from our very first oxygen enrichment applications to our continuously evolving portfolio of low-emissions Cleanfire® oxy-fuel burners. You can count on Air Products for reliable gas supply and to help optimize your production—just like we have done for hundreds of furnaces all over the world.

Contact us to put the skills and experience of our global team to work for you. Optimal melting takes one key ingredient: Us.

tell me more airproducts.com/betterglass

© 2017 Air Products and Chemicals, Inc. U.S. +1 800 654 4567 (code 9111) Europe +44 (0) 800 389 0202 Asia 400 888 7662 +1 610 706 4730 (code 9111) +44 (0) 1270 612708 +86 21 3896 2000

To make glass better, put us in the mix.

www.glass-international.com

Editor: Greg Morris

Tel: +44 (0)1737 855132

Email: gregmorris@quartzltd.com

Assistant Editor: George Lewis

Tel: +44 (0)1737 855154

Email: georgelewis@quartzltd.com

Designer: Annie Baker

Sales Director: Ken Clark

Tel: +44 (0)1737 855117

Email: kenclark@quartzltd.com

Sales Executive: Manuel Martin Quereda

Tel: +44 (0)1737 855023

Email: manuelm@quartzltd.com

Managing Director

Tony Crinion tonycrinion@quartzltd.com

Chief Executive Officer: Steve Diprose

Chairman: Paul Michael

Subscriptions: Elizabeth Barford

Tel: +44 (0)1737 855028 Fax: +44 (0)1737 855034

Email: subscriptions@quartzltd.com

Published by Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK.

Tel: +44 (0)1737 855000. Fax: +44 (0)1737 855034.

Email: glass@quartzltd.com

Website: www.glass-international.com

Official publication of Abividrothe Brazilian Technical Association of Automatic Glass Industries

Member of British Glass Manufacturers’ Confederation

China National Association for Glass Industry

United National Council of the glass industry (Steklosouz)

Glass International annual subscription rates including Glass International Directory:

For one year: UK £185, all other countries £255.

For two years: UK £335, all other countries £460. Airmail prices on request. Single copies £50.

Printed in UK by: Pensord, Tram Road, Pontlanfraith, Blackwood, Gwent NP12 2YA, UK.

Glass International Directory 2020 edition:

UK £206, all other countries £217.

Printed in UK by: Marstan Press Ltd, Kent DA7 4BJ

Glass International (ISSN 0143-7838) (USPS No: 020-753) is published 10 times per year by Quartz Business Media Ltd, and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. POSTMASTER: send address changes to Glass International c/o PO Box 437, Emigsville, PA 17318-0437.

2 Editor’s Comment + International news

10 Company profile: Absolut Company

Bold targets secure bottle with 50% recycled glass content

15 Profile: Woman in glass

A female career in the glass industry

20 Hydrogen in glassmaking: CelSian Consortium plots industrial stage

23 Glass Futures

Planning a production and research facility

27 Company profile: Stealth Case Glass powers wireless technology

30 Comment: acquisitions

The changing face of glass business

32 Research: Bormioli Pharma

Opening of new research centre

34 Inspection: AGR

Pharma demand sparks quality management

39 Inspection: Marposs

Supporting anti-Covid vials

41 Environment: Zuccato

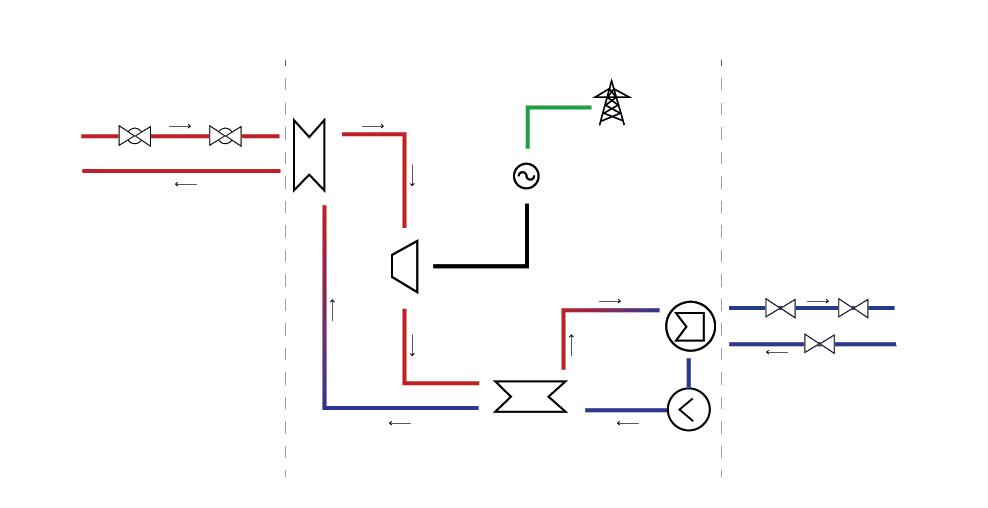

ORC technology is an ideal waste heat recovery solution

44 Swabbing: Flokontrol

Swabbing robot with automatic tool change

46 Picture spread: SGD Pharma

Celebrating Sucy-en-Brie furnace ignition

48

Decoration: Heraeus

Infrared heating system at Brewdog

51 Mould: Hexagon

Halving cycle times in mould machining

54 Event preview: Furnace Solutions

Furnace Solutions 2021 online

59 Event preview: Digital Forum

Latest solutions in glass

64

Filling: Heraeus

Automated infrared system at Mackays

65 Event preview:

Hydrogen in glassmaking

A two-day digital conference

66 History Ultraviolet transmission

Contents Glass International April 2021 www.glass-international.com 1 Plus find us on LinkedIn and Twitter. www.glass-international.com @Glass_Int April 2021 Vol.44 No 4

© Quartz Business Media Ltd, 2021 ISSN 0143-7838

10 46 15

20

FRONT COVER IMAGE: www.hornglass.com

Be first with the news! For breaking, up to date news VISIT: www.glass-international.com for daily news updates.

What is the furnace fuel of the future?

Over the past three years the glass industry has made rapid progress in its endeavours to switch to more environmentally friendly fuels.

Subjects which were only rarely spoken about have become hot topics and now feature prominently in any discussion about the glass manufacturing process.

One such topic is the use of hydrogen to help fire glass manufacturing furnaces.

In theory it looks a suitable alternative to traditional methods. One glassmaker, Steklarna Hrastnik, installed technology on its newly ignited G furnace which allows it to convert to hydrogen technology in future.

But questions remain about hydrogen’s long term suitability and its use on a mass scale, particularly when other heavy industries may demand to use it as well.

As a result several consortiums are investigating its potential use. One of those, and the largest, is interviewed within this issue about its results so far and future plans.

Steering committee member Oscar Verheijen reports that pilot tests have so far been encouraging and it already plans to progress to industrial scale testing in 2023.

Alongside the recent news of the successful Glass Futures biofuels trial in partnership with Encirc, and the already established practice of electric-powered glassmaking the sector is in a healthy place ahead of future environmental legislation which comes into place in 2030.

Heineken to trial low carbon bottles with Glass Futures

Heineken is working in partnership with Glass Futures and container glass manufacturer Encirc to produce glass bottles using up to 100% recycled glass and low carbon biofuel, replacing high carbon natural gas.

The trial, which is in its early stages, will see 1.4 million bottles of Heineken produced

with the intent of hitting supermarket shelves in the UK with this glass in early 2021.

If successful, the trial could set the path for a reduction in the use of carbon in glass manufacturing.

The concept is currently being tested in the UK in a joint project with Encirc, utilising Glass Futures’ technology

funded by the UK Government’s Department for Business, Energy and Industrial Strategy (BEIS).

Made from waste organic materials, biofuels are a renewable and more sustainable fuel source than those traditionally used, and can reduce the production carbon footprint of each bottle by up to 90%.

O-I in $75 million Zipaquirá, Colombia glass

O-I will invest approximately $75 million in an expansion at its Zipaquirá, Colombia facility.

The investment will include the addition of a fourth furnace at the site.

The Zipaquirá facility will be one of O-I’s largest facilities and the most cost-effective in

expansion

its network.

Upon completion by the end of 2022, the project is expected to add nearly 2% of capacity to the company’s Americas segment and produce about 500 million bottles annually.

Andres Lopez, O-I CEO, said strong market growth and af-

finity for glass was fueling demand for glass packaging in the Andean market.

He aid: “Working with our customers, we aim to enable profitable growth in attractive markets such as this new furnace at Zipaquirá and last year’s expansion at Gironcourt, France.

International News

MORRIS, EDITOR

GREG

www.glass-international.com 2

Glass International April 2021

AGI glaspac appoints Horn Glass for 154t/day furnace

Recresco starts Ellesmere investment

UK glass recycling company Recresco is undertaking a number of changes at the Ellesmere Port site it purchased in a multi-millionpound deal last year.

The company, headquartered in Nottingham and operates a second site in Cwmbran, Wales, has started improvements and facility upgrades. A 1100m2 covered structure has been constructed on the site to accommodate increasing material storage demands.

Indian container glass manufacturer AGI glaspac, has appointed Horn Glass Industries, Germany to build a new furnace at its Bhongir plant in Telangana.

The technology will cost INR 55 crores. It is a part of the recent investment raised by AGI glaspac from its parent company HSIL Limited, amounting to INR 220 crores.

The facility will comprise end-fired furnaces with six forehearths for production. With the set up of this new furnace. It means the Bhongir plant will be able to produce 154 tonnes of premium flint and other different colours.

The speciality glass produced will cater to industries such as carbonated water, sparkling wine, pharmaceu-

SGD Pharma for sale?

French pharmaceutical glass manufacturer SGD Pharma could be up for sale for more than €1 billion.

A Reuters news report states the glass manufacturer’s owner, China Jianyin Investment (JIC), has asked Bank of America to look for a potential buy-

er of the business, which has core earnings of about €100 million and could be valued at 10-12 times that.

An SGD Pharma spokesman said: “As of today, we are not aware of any decision taken by our actual shareholder China Jianyin Investment Co (JIC) or

NSG Pilkington begins

ticals, including vials and in cosmetics, such as beauty products, perfumery, nail polish and others.

Horn’s scope of supply includes the planning of the refractory, the combustion equipment, measuring and control, boosting, a new HVR 400 batch charger for the furnace, distributor, and forehearth.

The company has seen a surge in tonnage going through the site which is thought to be as a result of increased kerbside recycling from homes under lockdown.

Piramal Glass success

A Credit Suisse report has named container glass manufacturer Piramal Glass as one of 100 unicorn startups from India.

The research report reveals that the nation has 100 unicorn companies with a combined market capitalisation of $240 billion.

A unicorn company, or unicorn start up, is a private company with a valuation over $1 billion. As of March 2021, there were more than 600 unicorns around the world.

eventual wishes to sell.

“It is quite common for a shareholder to regularly consider strategic options for his investments.

“We remain fully engaged to produce the highest quality pharmaceutical packaging for our customers.”

Laurinburg, USA furnace rebuild

NSG Pilkington has begun rebuilding one of its furnaces at its float glass plant in Laurinburg, North Carolina.

The project started on 10th March 2021 and is expected

to be completed in late June 2021.

“The investment is part of our ongoing commitment to our customers and the Laurinburg community,” said Chris

Miller, Manufacturing Operations Director.

The Laurinburg plant manufactures float glass for the commercial architectural and export markets.

Furnace Solutions 2021 to take place online

Furnace Solutions conference organiser the Society of Glass Technology (SGT) will host this year’s event online.

The two day programme will include six speakers who will discuss the latest trends and topics about furnaces in glass manufacturing.

The SGT said the conference would take place on the afternoons of June 9th and 10th starting at 13.30pm.

SGT President Stuart Hakes said: “We have chosen this timing so that we have the opportunity to link-in easily with our European contingent, as well as hopefully attract interest from the Indian subcontinent and early risers in the USA.”

International News Glass International April 2021 NEWS IN BRIEF www.glass-international.com 3

Cleanfire®

ThruPorte™ Burner

A prescription for aging regenerators

Undergoing regenerator repairs or having difficulty maintaining full production in an aging furnace? Turn to Air Products’ Cleanfire ThruPorte oxy-fuel burner for a quick, costeffective heating solution to avoid downtime or extend your furnace life. This patented and commercially-proven technology, installed from the underside of your port, allows you to add heat where and when it’s needed.

Key features:

• Tandem water-cooled oxy-fuel burner and oxygen staging lance assembly

• Proven durable design; easily installed in an existing port while furnace is running

• Adjustable flame length and angle for optimal heat distribution and surface coverage

• Remote, wireless and continuous online monitoring of burner performance

• Available for rapid deployment

To make glass better, put Air Products in the mix.

FEVE’s F4F Project elected for Stage 2 of EU funding

The Furnace for the Future (F4F) has been selected out of 311 projects to progress to the second phase of the EU Innovation Fund, one of the world’s largest funding programmes for the demonstration of low-carbon technologies.

The F4F project is a breakthrough technology,

which will enable the industry to switch to renewable electricity and cut CO2 emissions by up to 60% in the furnace (50% for the whole factory).

Michel Giannuzzi , FEVE President, said: “We’re honoured to be among the 70 projects considered by the European Commission as

AGI Group announces European expansion

Japanese glass processing equipment manufacturer AGI Group has announced an expansion of its AGI Glassplant brand in Europe.

The AGI Group currently operates seven glassware manufacturing and ser-

vicing companies in Japan and, over the past decade, has built on more than 70 years of expertise and experience in the field through a series of acquisitions in Europe and the USA.

Yasuyuki Ikeda, CEO of AGI Group, said: “We see

strategic to a climate-neutral Circular Economy.

“The Furnace for the Future represents a key step towards a sustainable future for glass packaging. With this project we will address the priorities of our customers and strengthen our relationship with them.”

strong potential for our glass technologies in the EMEA region and, as we see increased adoption of our products and solutions, we want to reaffirm our commitment to this important market by strengthening our presence.”

British Glass hosts first UK Recycling Summit

British Glass has held its first UK Glass Recycling Summit with attendance from right across the glass supply chain.

The event saw the UK glass packaging industry launch its commitment to achieving a 90% collected

for recycling rate by 2030.

The summit saw attendees agreeing to collaborate with British Glass on their journey to achieving a 90% glass collected for recycling target by 2030.

Dave Dalton, CEO, British Glass said: “We hope

to build on the discussions from today by starting the right conversations and formulate a plan of action for the next 12 months. So, when we gather in a year’s time, we can demonstrate and celebrate achievements towards our goal.”

© Air Products and Chemicals, Inc., 2019 (42615) tell me more airproducts.com/thruport 800-654-4567, code 9091

International News Glass International April 2021

Tomorrow ,s Technology Today www.fic-uk.com +44 (0) 1736 366 962 Come to FIC for superboosting and large all-electric fur naces – we have the answers to reduce carbon footprint Are you interested in CO2 reduction? GLASS SERVICE A Division of Glass Service The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate Penzance, Cornwall TR20 8HX United Kingdom

Pilkington develops bird protection coating

Pilkington UK has developed AviSafe - a glass with a coating designed to help prevent birds from colliding with the windows and facades of buildings.

Most birds collide with glass when they confuse what’s visible in its reflection for the real thing, such as trees or an open sky.

Pilkington AviSafe features a UV enhanced pattern that’s more visible to birds than it is to humans, which helps to prevent these collisions and ensures maximum transparency, while maintaining the aesthetical appeal of glass in architecture.

SGD Pharma offers Type I moulded glass vials

Pharmaceutical glass manufacturer SGD Pharma, has become the first company to offer Type I moulded glass vials.

SGD Pharma has organised its Type I moulded glass offer into three tailored value propositions – AXess, AXecure and AXpert.

Schott reaches Covid vaccine milestone

Pharmaceutical glass manufacturer Schott has delivered enough of its glass vials to provide more than one billion doses of Covid-19 vaccines.

The company says it remains well on track to deliver vials for more than two billion vaccine doses throughout 2021.

The vials were delivered to projects around the world, with a focus on the US, Europe, and China. Approximately 90% of approved vaccines rely on Schott vials.

“The reaction of the pharmaceutical community to Covid-19 is a testament to the power of scientific progress,” said Dr. Frank Heinricht, CEO of Schott.

“In just under a year, all previous records for vaccine development have been shattered by not just one, but several research groups.”

Top 10 stories in the news

Our most popular news over the past month, as determined by our website traffic. All full stories can be found on our website.

� 1. O-I $75 million Zipaquira expansion

� 2. Stoelzle acquires Anchor Hocking site

� 3. Verallia invests into Jacutinga, Brazil site

� 4. Hydrogen in Glass Manufacturing conference in June

� 5. India’s Sunrise Glass installs furnace

� 6. Verallia starts Villa Pom, Italy furnace

� 7. Steklarna Hrastnik inaugurates furnace

� 8. Heineken trials low carbon bottles

� 9. Solvay to exit glass business?

� 10. Verescence acquires South Korea’s Pacific Glass

For the latest Industry News scan the QR CODE using your iOS or Android device

AGC Europe develops anti-Covid glass coating

AGC Glass Europe has produced a coating for glass to help protect against Covid-19 contamination.

Respiratory droplets and aerosols contaminated with SARS-CoV-2 viral particles represent a risk of indirect transmission of Covid-19.

Infectious droplets on sur-

faces see their viral infectiousness decreasing with time, depending on the type of material and temperature.

A study published in the Coatings Journal with support from AGC was done on different materials ranging from metallic materials to float glass, acrylic glass and coated

Vidrala awarded for UK investment effort

Container glass manufacturer Vidrala has been awarded in the category ‘Growth in the UK’ at the Trade and Investment Awards, organised by the British Embassy’s Department of International Trade in Spain.

The award recognised Vidrala’s investment efforts in the

UK since the acquisition of Encirc in 2015.

Since then, the company has provided over £150 million worth of investment for projects in the UK.

Carlos Delclaux, President of Vidrala said: “I’m thrilled to receive this award and would like to give special thanks to

glass (Planibel Easy) rench. The result showed the time taken for the number of infectious viral particles to decrease, and demonstrates that SARS-CoV-2 viral particles stay active for a shorter time on Planibel Easy coated glass previously exposed to daylight (photocatalytic effect).

the great work carried out by Encirc in the UK, which really adds value to Vidrala.

“Due to its great potential, the UK is one our most relevant markets.

“Even during the tough times of Brexit and COVID-19, it has shown great strength and growth potential.”

www.glass-international.com 6 Glass International April 2021 NEWS IN BRIEF

International News

Come to FIC for superboosting and large all-electric fur naces – we have the answers to reduce carbon footprint Tomorrow ,s Technology Today Are you interested in CO2 reduction? www.fic-uk.com +44 (0) 1736 366 962 GLASS SERVICE A Division of Glass Service The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate Penzance, Cornwall TR20 8HX United Kingdom

Encirc appointment

Encirc, part of the Vidrala Group, has appointed Paul Williams as its new 360 Development Director, with Mark Holmes taking over Paul’s previous role as Beverages General Manager.

The pair will work together to bolster the company’s filling and supply chain offering following a period of growth and investment.

Gerresheimer sets sustainability targets

Ambitious targets will direct Gerresheimer’s sustainability strategy in the coming years.

Among other things, the company wants to cut its CO2 emissions by half by 2030.

The number of occupational accidents is to be significantly reduced by 2028. By 2023, ecodesign criteria are to become a fixed component of product development at Gerresheimer.

Covid hits Vetropack 2020 finances

Swiss container glass manufacturer Vetropack Group has released its financial figures for 2020, where its earnings margin of 11.5% was slightly down from 2019 in part due to the Covid-19 pandemic.

Consolidated net sales stood at CHF 662.6 million ($714 million), compared to 2019 net sales which were CHF 714.9 million ($770 million).

At the end of the year, the group acquired a S.A. glassworks in Moldova, in a takeover which was financed by the Group’s own funds, costing CHF 42.8 million ($46 million).

With this acquisition, the Group is growing in a region where it has been successfully manufacturing and selling glass packaging for almost three decades.

The Moldovan subsidiary was fully consolidated for the first time as of 30 November 2020. A new glassworks planned by Vetropack in Boffalora sopra Ticino, Italy, remains the group’s central strategic project in 2021.

Horn Glass Industries acquires JSJ Jodeit

Horn Glass Industries has acquired the Melting Technology Division of JSJ Jodeit with effect from April 1, 2021.

JSJ Jodeit has been a supplier of technology and equipment for the production of speciality glasses since its foundation in 1991.

Horn said that with the

know-how gained, it is expanding its competences in the field of electrically heated and gas-oxygen heated melting plants for technical and speciality glasses.

Sales will be handled jointly by Horn while production of components will take place in Plößberg, Germany. The busi-

ness units of JSJ Jodeit that were not sold, such as special and small melting units, melting technology services, heat treatment plants, glass tube production lines as well as plants for the chemical strengthening of glass, will continue to be managed by Dr Harald Jodeit.

RHI Magnesita to invest €23 million in its Urmitz, Germany plant

Refractory products and solutions provider RHI Magnesita is to invest €23 million over the next two years in the digitalisation and modernisation of its Urmitz, Germany plant.

This investment, the company’s largest in Germany,

will be used to expand and upgrade the traditional plant as a hub for non-basic refractory products in the steel, glass, cement, lime, energy and chemical industries.

The modernisation will increase the plant’s production

volume while boosting energy efficiency by ten percent.

In addition, investments made in its recycling methods will allow RHI Magnesita to increase the share of secondary raw materials.

Piramal Glass successfully uses blockchain technology

Piramal Glass has successfully kicked off its first cross-border trade digitisation programme using blockchain.

The Indian container glass manufacturer is prioritising the technology in 2021 as a means of unlocking hid-

den margins and efficiency through digital automation.

The team partnered with the enterprise blockchain platform, #dltledgers, a fintech operating out of Singapore and India.

The Piramal Glass project

will now progress into its next phase. The objective will be to streamline supply chain processes throughout the company’s global manufacturing operations and to build out the company’s private, digital network of suppliers and buyers.

NEWS IN BRIEF www.glass-international.com 8

Glass International April 2021 International News

ENDLESS PERFORMANCES IN GLASS

MORE THAN 1000 INSTALLATIONS IN THE WORLD

SINCE 1946 MACHINERIES • SYSTEMS • SOLUTIONS

Bold target sees Absolut develop bottle with 50% recycled content

In February 2021, the Absolut Company announced that it had reached the target of using 50% recycled material in its clear glass vodka bottle in collaboration with manufacturer Ardagh Group, four years ahead of schedule.

But the company isn’t stopping there and through its ambitious internal goals, it aims to have a carbon neutral product by 2030 at the latest.

Tina Robertsson, who heads up the Sustainability Performance team at the Absolut Company, based in Åhus, Sweden said the company decided to increase its recycled content in 2016 by 10% from 36%. The goal was to increase by 1% at a time.

When the 40% target was reached in 2019, she said the whole company was ‘really proud’ and to commemorate this milestone, created the ‘Absolut Comeback’ bottle, a bottle using actual pieces of

broken, recycled glass which was also designed to look like it was made of recycled material.

Absolut hoped that this bottle’s design would enhance the image of using recycled glass in the bottle and was a collaboration between design agency Drama Queen Communications, Absolut bottle manufacturer Ardagh and Absolut.

But Absolut did not stop at 40% and when Pernod Ricard, which owns the Absolut brand, set its target of 50% to 2025 for its coloured and clear glass, Mrs Robertsson said Absolut took this on as its own goal as well.

Absolut did feel it would be a tough goal to reach as it may reduce the clarity of glass. But after its teams got together and realised there was no reduction in clarity and quality, the company became more ambitious.

Company profile: The Absolut Company Glass International April 2021 www.glass-international.com 10

The Absolut Company has created its glass vodka bottle using 50% recycled material four years ahead of its schedule. George Lewis spoke to Tina Robertsson* about how it was achieved and hear more about the company’s other sustainability goals.

� Tina Robertsson is the head of the sustainable performance team and has been at Absolut since 2004.

�The Absolut ‘Comeback’ bottle was manufactured to look like it was made from pieces of broken, recycled glass, reflecting the recycled glass that goes into every bottle.

Sweden is known to be one of, if not the best in the world at collecting and recycling glass which results in high quality recycled glass that lets Absolut continue to recycle above 50%.

Mrs Robertsson said: “We were quite surprised it was so easy (to reach 50%). We have already taken the decision to increase by 3%.” This campaign to reach 53% will start sometime in spring of 2021.

“We’ve decided, what’s the worst that can happen? We will continue for as long as we can. We know there will be a limit at some point, we’re just not sure where that is yet.”

“To achieve what we want to achieve, to reduce climate impact overall, we must collaborate with suppliers, manufacturers, societies/associations, everything, it is crucial,” she added.

It is not only in the manufacturing process that Absolut are looking to improve on. It also wants to have a target of having a climate neutral distillery without offsetting by 2025, using other solutions rather than using the liquified petroleum gas (LPG) it currently uses.

Mrs Robertsson said that once this has been offset, alongside production there are three other topics Absolut wishes to improve on – wheat cultivation, packaging and distribution, which will all be worked on in parallel.

“We want to have zero output and we think it can happen. We are going to have a climate neutral product by 2030”, she stated.

Absolut has been looking at making its distillery more sustainable since back in 2004 when it first installed energy efficient equipment. Throughout the following years it has been able to do things like recompress the steam generated for reuse, meaning energy use is minimised.

Mrs Robertsson said that for every 1kwh of new energy applied, the equivalent of 5kwh of steam is generated, meaning it is extremely efficient.

Since 2013, it has bought renewable electricity for the distillery and has been near to being climate neutral since then, with only a small amount of fossil fuel offset, something it wishes to eradicate completely by 2025.

Absolut has a longstanding relationship with the Ardagh Group, which has manufactured its glass bottles in one place since 1979 in Limmared, Sweden. The bottles that are created are then distributed to 120 markets around the world.

Mrs Robertsson explained: “We work very closely with our supplier in Limmared within the Ardagh Group. It’s a really great collaboration which we’ve had since day one.”

Due to this relationship that has lasted over 40 years, the two companies are able to ‘challenge’ each other in order to collaborate on other sustainability goals.

Mrs Robertsson said: “If they are going to provide us with good quality (glass bottles), then we must design the bottles in a way that is possible

Company profile: The Absolut Company Glass International April 2021 www.glass-international.com 11 Continued>>

to be recycled well (using Sweden’s high quality recycling scheme). It’s so important to have the close connection and possibility to change things.”

Absolut has had recycled materials in its production since the Swedish recycling scheme started in 1984 which has been increasing year-onyear.

Absolut uses a third of all the country’s clear recycled glass and all of this cullet is reused in Ardagh’s Limmared glass plant.

Within this relationship, Absolut and Limmared have made a climate roadmap which includes a cold furnace rebuild in either 2025 or 2026.

Ardagh has the ambition to use the Best Available Technology (BAT) when making the cold repair in Limmared in 2025/26.

This furnace repair will coincide with the European Container Glass Federation (FEVE’s) ‘Furnace for the Future’ (F4F) project, which is hoped will cut direct furnace CO2 emissions, and replace a major part of the natural gas with renewable electricity.

The potential CO2 reduction of this innovation is potentially even higher if it can be subsequently combined with other sources of energy such as hydrogen or biogas.

Ardagh Group has volunteered to lead a coalition of 19 independent companies representing over 90% of the total glass container production in Europe (more than 80 billion containers yearly). Ardagh Group will build the F4F furnace and run it in Obernkirchen, Lower Saxony, Germany.

Glass packaging stands for around a third of Absolut’s footprint and it hopes that cutting CO2 emissions from the furnace will be a big step forward in its roadmap to reach zero impact.

Mrs Robertsson also believes that using BAT in the renovation of the furnace, and using renewable fuels, along with increasing the proportion of recycled glass and other measures will be an important part of its roadmap.

She explained that Pernod Ricard has included in its commitments to 2030 that it ‘will be part of schemes to increase recycling rates in our 10 largest markets’.

She said that Pernod Ricard are pushing for change just like Absolut and is constantly look at ways to make changes such as using less raw materials and more cullet.

But along with Pernod Ricard aiming for a more sustainable future, these goals also come from the Ardagh Group, with it very much a prominent part

of the F4F project.

Why glass?

When asked why Absolut is always in glass, Mrs Robertsson explained that because glass is inert, it doesn’t affect the vodka and its taste. She said that ‘glass is an excellent material – but you need to recycle it’ and understands the need to work on its carbon footprint and energy efficiency within its manufacturing.

The future

Mrs Robertsson said the company is well aware of the environmental aspects of its bottle and believes that ‘if you don’t work with sustainability as a topic of great importance you may not survive, you need to be on top of it’.

“We believe that to enjoy things is also good to be sustainable as well”, she added.

Pernod Ricard hopes to have piloted five new circular ways of distributing its wine & spirits by 2030 and wants to help increase recycling rates in the top 10 largest markets with low recycling levels.

It has set up or joined various programmes worldwide to improve recycling or reuse packaging, including in Europe where it has contributed approximately €8 million to national schemes designed to improve the collection and recycling of domestic packaging, including glass.

Both Absolut and Pernod Ricard have also joined the US’s Glass Recycling Coalition to ‘foster efficient and economically viable recycling channels by involving all players in the chain’, including glass manufacturers, bottlers, recycling service providers, and in Brazil, Pernod Ricard has joined the “Glass is Good” project, whose purpose is to increase the glass recycling rate by involving all sectorial players.

“The important message is - recycle! And that everyone understands recycling, including glass manufacturers, politicians, people, everyone”, Mrs Robertsson explained.

She believes that some customers don’t have a full understanding of the need to be more sustainable yet but thinks through Absolut, Pernod Ricard and the Ardagh Group it can positively affect them and hopes external campaigns and providing ambitious goals can really make a difference. �

*Director

The

of Sustainable Performance

Absolut Company, Åhus, Sweden

https://www.theabsolutcompany.com/

Glass International April 2021 www.glass-international.com 12

“The important message isrecycle!”

HORN® RAPID ADJUST BRACKET H-RAB

The burner angle is a very important parameter, as it can have a strong influence on the melting process, furnace life and emission values. It further facilitates lower energy consumption. Therefore an accurate and rapid adjustment of the burner angle after burner replacement or cleaning is of utmost importance.

The HORN® Rapid Adjust Bracket H-RAB offers a simplified adjustment of the correct burner angle to get replicable values. With two adjusting wheels the operator can easily adjust both the horizontal and vertical angle. The centre point of rotation is the nozzle tip itself. Thanks to an integrated scale, the angle can be read off easily.

With regard to Industry 4.0 the holder is prepared for later installation of servo drives. With the input of additional information coming from NIR camera systems or other sensors the HORN® Rapid Adjust Bracket H-RAB bears the possibility of remote control.

HORN ® GLASS INDUSTRIES AG

BERGSTRASSE 2

D-95703 PLÖSSBERG/GERMANY

LET ‘ S GO FULL CIRCLE. WWW.HORNGLASS.COM

Multi-spectral imaging for defect detection like no other.

Color Imaging. Powerful. Proven.

appliedvision.com ANTARES VISION GROUP

Dr. Diane Nicklas worked in the glass industry for 20 years as a global commercial leader. She is one of the few women on the front line of the industry. Diane describes her view on the necessity to revamp the image of the glass industry as an employer and attract and retain the next generation of young leaders.

A female career in the global glass industry

How long have you worked in the glass industry? What was your first job and subsequent roles since then?

I discovered the Glass Industry in 2001 by joining Saint-Gobain Sekurit, an automotive glass producer. And in the six years that followed I headed the global team of Saint-Gobain Solar Glass and engaged into an exciting journey of this booming market. Those were breathtaking years when I did spend probably more nights in planes and airports than in my own bed.

Eight years ago, I took over the responsibility as the global commercial Director for SEFPRO, a wellknown refractory producer, based in Avignon, south of France. On top of my experience in flat glass production, this job allowed me to deeply experience and understand the needs and challenges of each individual customer of the entire glass Industry, from container-, flat and fiberglass to those industries focusing on special glasses such as pharmaceutical or display glasses.

What was your major achievement in your last job?

It was the successful transition from an ‘old-style’ product-focused commercial approach into a completely revamped, dynamic and customer centred style, and all the inclusions that it takes.

In short words, how did you do this transition?

When joining, I quickly identified the indispensable need of changing and transferring SEFPRO into a much more customer focused

business. I guided my global team to new paths of customer relations and we have put the customer into the centre of our activity, starting by listening and understanding their needs.

And thanks to our new commercial approach we could install trustful and long-term oriented collaborations with our clients. And of course, this has been also very beneficial for the results.

Also, I had the autonomy to deploy long term commercial strategies and one of them was to accompany our customers in times when the entire glass industry undergoes enormous changes. This strategic part of my job has formed the commercial foundation for the company’s future. And of course, all of this is only possible with a great team.

Whom you seem to be quite proud of!

Definitely! I enjoyed immensely to shape and to lead a large global and diverse team. They all have great personalities and were always passionate to walk the extra-mile for their clients, what is essential if you want to provide an outstanding customer experience.

What is it about the glass industry that you enjoy?

Beside the fascinating and evolving technology, it is about the people.

In this rather small cosmos of glass producers of any type of glass and their related suppliers I discovered a tight network of people with an outstanding level of expertise and passion for their

Profile: Woman in glassmaking Glass International April 2021 www.glass-international.com 15

Continued>>

� Phoenix award 2019.

industry. Representing my company, I experienced at a global level stimulating discussions on eyelevel with my business partners, all following the strong mission to add value and move things dynamically forward.

In other words, to me it is the combination of ‘technology’ and ‘people’ which makes this industry special.

You’re also a member of the Phoenix Committeewhat benefits has this brought by being a member?

The networking! In the Phoenix Committee I humbly enjoy being part of a community of suppliers for the glass industry that all share common values and passions: being excellent in products and services, committed that the best is not enough and that people make a real difference to the business. And the informal communication as well as the solidarity in this community is priceless to me.

I participated in three ceremonies, the award to

Mr. Surasak Decharin, to Mr. Oliver Wiegand and to Professor Alicia Durán. Each award recipient is an impressive personality, from whom we all can learn from.

You’re one of the relatively few women in industry. Why do you think there are fewer women than men in the industry?

Well, you definitely are right by saying there are ‘relatively few’ women. Indeed, our industry clearly lacks of gender diversity. During my university time we were only a handful of female students and consequently today in my generation you do not find many women in leadership functions. What concerns me is that even nowadays you don’t find many women in junior positions either, which means that the problem of diversity will continue to exist.

So, what can be done to encourage more women to join the industry?

Encouraging young women won’t be enough, I fear. In front of us we do have the challenge to attract an entire new generation. At first glance, nowadays no heavy industry is really appealing to the young generation. We are neither exciting, nor techy, nor cool in their eyes.

I observe and hear what they care for: environment, sustainability, networking & culture, innovation, digitalisation, high-end technology, and working for purpose-oriented organisations.

And aren’t those notions the very same important challenges, if not opportunities, that the entire glass industry faces for the upcoming decades? Hence, I believe we can be an attractive industry to the young generation, men and also women, provided we address some of those topics in a determined and consequent way.

Profile: Woman in glassmaking Glass International April 2021 www.glass-international.com 16

Continued>>

� Glasstec 2018.

� With colleagues in the plant 2020

�With Sefpro Asia commercial team

Do you have concrete ideas?

It all starts with a ‘good and meaningful purpose’!

In SEFPRO I hired and onboarded several young talents, out of which more than 50% were female, and they all had one thing in common: they needed a vision, a mission, you might want to call it a ‘good purpose’ to embrace, to identify with, and to engage for.

So, I shaped my company’s image or profile to the outside, allowing to become a relevant, authentic and responsible employer, and consequently attract new talent and skills. This effort paid out; the junior talents are today valuable pillars of the team.

Could you share with us your experience of shaping a company’s profile?

Working on your future profile and purpose is a challenge for industrial companies. It took me some years to profoundly change the appearance and attractiveness of my past company on the market. There is an initial work to be done that starts with a definition of a ‘vision’. Then the defined intents need to be translated into real actions. And finally, you must communicate your actual progress and achievements, allowing you to position your company – if not the glass industry as a whole – in a more attractive way.

I am convinced that our industry has so many good elements to highlight. I think about the sustainability of container glasses, the growing role of the pharmaceutical glass products, the infrastructural projects that need fiber glasses, antibacterial display glasses and so many more. Are we really communicating enough the many benefits that glass contributes to society? The upcoming Year of Glass 2022 is in my eyes a great moment to do so.

And, once the young people are in the glass industry, how can they be encouraged to stay and develop their careers?

Trusting them and providing them with a career path. This upcoming generation of young managers is eager to act and get empowered. Furthermore, they need to understand what the company can offer them in terms of personal development, which is important to retain them.

Giving them autonomy to explore their individual way and accompany them with trustful support from senior management is my leadership

style. I believe that this is easier in smaller or midsize companies, where an entrepreneurial talent is earlier identified and higher valued.

Do you think women can bring different skills to the sector? How do these skills benefit the industry?

It is all about the right mix. Of course, women bring in a very natural way other skills than those you would find in a team composed exclusively of men. Like it would be once you bring men into a team that is composed only out of women. Diversity has proven to be an essential key success factor for teams and companies. I see further benefits for our glass industry if an additional dimension of diversity would be included, namely the ‘cultural diversity’.

This is even more important if the glass company serves customers at an international, if not global level. My experience has shown me that both, gender and cultural diversity, can and will help any company going through a transition, if not a transformational phase.

How and where do you see yourself in the coming years in our industry?

Well, I’ve been active in the glass industry now for 20 years and almost half of this time as a global refractory supplier for the glass industry. I believe that I deeply understand what moves the different glass markets and their suppliers. Then I experienced how to successfully shape the profile of a company in a transition period, how to take true leadership and responsibility for a global team, and how to identify and develop young talents. I am a deeply passionate commercial leader that has experienced and knows how to gain market share by growing revenues profitably and sustainably, and how to create long term relations with customers. With all those assets I would like to continue working for the glass industry. In this sense, I am excited to further explore upcoming opportunities, which the glass industry certainly has, considering the current dynamic market environment.

And should the reader be interested to contact you, how can they do so?

For any existing or new business partner and colleague, I remain reachable via: dr.d.nicklas@ gmail.com �

Profile: Woman in glassmaking Glass International April 2021 www.glass-international.com 18

”

“In front of us we do have the challenge to attract an entire new generation. At first glance, nowadays no heavy industry is really appealing to the young generation. We are neither exciting, nor techy, nor cool in their eyes.

To ensure your data does not get lost in translation, our technologies speak the same language.

Data is power. However, only our industry leading machines can communicate with each other, automatically collecting and sharing data throughout the hot end and cold end to influence the entire process. And with plans to develop the first fully automated lines, Emhart Glass is the only supplier worth talking to. Start the conversation at emhartglass.com

Hydrogen consortium plots industrial stage

Aproject to investigate the use of hydrogen in the glass manufacturing process has made progress this year and aims to apply for industrial scale funding.

The consortium, headed by Dutch energy group DNV and which includes a number of glass manufacturers and technology suppliers, has continued its pilot phase and even increased its number of participants.

Oscar Verheijen, Project Manager from CelSian and a member of the consortium’s Steering Committee, said there were now 34 members of the hydrogen group, with the majority from the glass industry but other members from other sectors such as steel.

“It is an interesting consortium made up of companies from different

geographies as well as diverse industries, such as steel and energy.”

The aim of the pilot phase has been to test the performance of different airand oxy-fuel burner types combusting mixtures of CH4 and H¬2, and consider the implications of switching to hydrogen by for example determining the changes in the radiative heat transfer and NOx emission. It is hoped to develop a burner type that will allow the gradual transition from natural gas to hydrogen.

He added: “The results so far have been encouraging. At this stage we’re still gathering more knowledge, developing NOx mitigating strategies, testing the burners and control systems which is ongoing. At the same time we have had more participants join, despite the fact we have already been running for a year.

Hydrogen in glassmaking Glass International April 2021 0 20 www.glass-international.com

A consortium which was formed last year to investigate the potential of hydrogen in the glass manufacturing process has continued to make progress despite the challenges of the pandemic. Greg Morris spoke to steering committee member

Oscar Verheijen about its aims.

We are very pleased with the increased engagement from the glass industry.”

Some of CelSian’s work within the project includes working with laser sensor to monitor the convection process, look at how the flame shape is developing and the combustion process. A simulation is then carried out to quantify and describe the heat transfer, which might be critical for any future furnace and process design based on hydrogen.

While the pandemic did halt some of the operational parts of the project, such as ensuring everything ran at a scheduled time, the technical and management side continued unabated.

The pilot phase of the project is due to come to an end on 2022 but there are already plans to extend it to an industrial phase. This will depend on receiving

appropriate economic support from the funding authorities.

Mr Verheijen hopes that the project will eventually be able to demonstrate there are no technical hurdles to implement hydrogen combustion in the glass industry. This could either be the use of 100% hydrogen or the use of blends such as natural gas.

Mr Verheijen said: “If you can use blends and can easily control the combustion process based on the mixture and do not see impact on glass quality then it opens the way for the introduction of hydrogen combustion, whether it is full scale, or 50% or 30%.”

Mr Verheijen is hopeful that some glass manufacturers would consider introducing hydrogen on a small scale in order to reduce their CO2 emissions rather than waiting for a full furnace rebuild, which could be several years for some glass producers.

“They do not have to wait until the moment they do a rebuild before completely switching over to hydrogen, and that creates a flexibility for the availability of hydrogen. Although we have to acknowledge there will be local challenges based on the necessary infrastructure of hydrogen.”

Members

The number of participant companies within the consortium has increased to 34 in the past year, and approximately 40% of participants are from the glass sector.

These include container manufacturers O-I, Ardagh Glass, Bormioli Rocco, and Verallia, flat glass makers AGC, Cardinal, Saint-Gobain and Vitro Architectural Glass, specialist glass manufacturers Corning, Schott, and Nippon Electric Glass, fiber glass producer Owens Corning, pharmaceutical manufacturer SGD Pharma, tableware specialist Arc International, as well as furnace supplier Tecoglass and technology supplier Stara Glass.

Mr Verheijen said: “A lot of companies see they will have to do something in

the future and use this project to get knowledge and to define their roadmap. It’s difficult to define whether it will be electric firing or a hydrogen hybrid, it is about collecting know how at this stage.”

He added: “One of the biggest challenges is always to find a good consortium of companies who work well together. We do have a good group and it has snowballed. Other companies look towards it and say they should be part of that otherwise they might miss some information. So the size of the group automatically increases.”

The subject of sustainability and of the environment has become a hot topic within the glass industry in recent years. Mr Verheijen has been impressed by how rapidly manufacturers have investigated new technologies that could reduce glass production emissions.

The GlassTrend organisation, of which Mr Verheijen is chairman, has seen increased interest in the subject in recent meetings, not just from European and Asian companies but from North America as well.

“The US re-signing up to the Paris climate agreement will further support the development of sustainable technologies from which hydrogen might be a solution for the future. Therefore, USbased companies are keen to participate in this project.

“They are aware of investing in glass resources and even looking at carbon capture followed by storage and/or utilisation, which I would not have expected to have happened two years ago. So there is more traction in the market on this topic.”

A unique aspect about the project is that a specific facility has been constructed at DNV’s site near Groningen, The Netherlands where the testing has taken place. DNV has a strong background in the development and testing of combustion technologies within their R&D facilities. The facility includes a furnace with a water cooled bottom, which extracts heat from the furnace.

The consortium aims to deliver the proposal for the next phase of the project next year with the intention to start work on the second phase in early 2023.

For this follow-up phase it is envisioned to include batch melting in the pilot facility to assess also the impact of H2rich combustion on glass quality. �

Hydrogen in glassmaking Glass International April 2021 www.glass-international.com 21

CelSian, Eindhoven, The Netherlands www.celsian.nl

� Oscar Verheijen.

The three different companies forming the SORG Group combine to offer a unique, all-in-one solution for glass manufacturers. Our market-leading melting and conditioning technologies range from the supply and storage of raw materials through to conditioned glass and cullet return systems.

THE POWER OF THREE3

BATCH & CULLET TREATMENT EQUIPMENT MAINTENANCE FURNACES SERVICES eme.de sorg.de sks.net

Planning a glass production facility, for the unimaginable

Detailed planning for the Glass Futures research and development (R&D) and training facility is underway, with input from a variety of professionals from various glass manufacturing sectors. Peter Firth* discusses the challenges of designing a facility that is both a research project and a glass melting facility.

OOnly a year ago, a Pilot Plant with the sole purpose of being a ‘playground’ for glass industry development work may have seemed unimaginable. Now that concept has come to reality in the form of the Glass Futures’ Global Centre of Excellence in St Helens, UK. Furthermore, this is a project jointly supported by UK national and local governments, for the benefit of the international glass industry.

Maybe even the concept of Glass Futures (GF) as a not-for-profit research and technology organisation seems unimaginable to some people. The clue is in the name of the company of course, ‘Glass Futures’. This is a company dedicated to securing the future of all types of glass products. Fundamentally, that is GF’s raison d’être. As such, it exists to serve the glass industry as a partner in addressing all the challenges and opportunities it faces.

In doing so, it aims to bring the various sectors of the glass industry together on common ground. That is as well as also

supporting company-specific initiatives, all the while creating a pre-competitive collaborative environment.

If you then think about bringing such an R&D Glass Plant into reality, it won’t get any easier to imagine either. I am presently working on this as a Production Consultant, together with a large team of other global glass specialists. The other experts on GF’s Pilot Plant team consists of a mixture of GF employees and memberorganisation employees. Currently, the technical design group memberorganisations include O-I, Vidrala, Encirc, Guardian Glass, NSG Group and Siemens.

As a facility design group, we have to constantly remind ourselves to ‘take our production hat off’. By doing so, we can think more about the R&D and testing needs of the industry, rather than focusing on the glass production itself.

This means we need to plan on potentially rejecting a lot of production and internally recycling it. This is diametrically opposed to what most of us on the team are ‘programmed’ for, which

is to achieve highly-efficient, high-quality glass production. In fact, at the very heart of the funding agreement as an R&D facility, is that the plant cannot produce any scale of commercial products. ‘Taking our product hat off’ is therefore a change in mindset that we have had to go through, carefully cultivating it together as team.

Having said all that, it is still necessary to end up with a Glass Plant that looks, feels and acts like a production facility, not just a series of fragmented glass testing facilities. This is what will make Glass Futures different to other glass testing facilities currently available to the industry. This is not to say that GF is looking to replace those services, but rather augment and compliment them, in fact welcoming them as potential partners with GF too.

Detailed planning for this facility is now well under way. However, this does not mean it cannot still be altered in

Glass Futures Glass International April 2021 www.glass-international.com 23 Continued>>

response to the input and comments from the wider industry. Such input is now being welcomed in a series of Open Design Sessions held by regular webinars and open to all.

On a recent such webinar, I presented the current thinking behind the proposal for the production line(s), from the working-end to the packer. That thinking behind each of the three production areas of the hot end, the lehr, and the cold end was presented. Questions were invited in order to take on board any comments from those attending the webinar and some great challenges were raised, which allows us to develop our thinking even further.

Please look out for the webinars on Glass Futures’ social media channels and join future events to give us your input. This is your chance to help shape the development of this revolutionary new R&D Glass Plant.

In the area of the hot end, I discussed how we are planning to feed a single I.S. Machine for hollow-ware container production. The current layout drawings I presented showed the largest envisaged production equipment so that we can easily accommodate future plant development. In addition to the one forehearth feeding the I.S. Machine, there is proposed to be a second forehearth. This will have an outlet that can be used for drawing off a ribbon of flat glass.

The proposed extent of flat glass production equipment at the end of this second forehearth is currently quite vague and needs further consideration. However, as far as flat glass compositional development needs go, any testing in changes to glass compositions can be tested from samples of hollow glass taken at the I.S. Machine. This second forehearth will also enable good glassflow to be maintained through the furnace throat, specifically for when glass flow may need to be stopped or restricted at the I.S. Machine.

On both of these forehearths, there is intended to be a colourant section with a traditional frit introduction mechanism, followed by at least three rows of stirrers. The specification of this feature is still under consideration. However, in addition to introducing new colours, there will be the opportunity to make late-stage compositional changes to the glass and therefore support a further basis of experimentation.

There is a third forehearth and forming machine that have been considered, but

this is just for future planning purposes. This is mostly for shopfloor design loadings calculations. Any future forming machine in that location may well not be another I.S. Machine, but, in any case, it would be lighter than the large forming machine shown on the layout drawing.

The single I.S. Machine currently proposed is a 10-Section bed with 6 installed sections. This will allow for development sections at either side of the operational 6 sections. Forming sections of different widths to the standard 21” section could be tested, with good access space being maintained for any such live development work or testing.

A further consideration for the I.S. Machine that has been built into the overall plant specification is the glass metal line height. This has been designed to be six metres to provide plenty of space between the shears and the gob distributor. There will therefore be ample space to facilitate future gob monitoring and control equipment, not always available in traditional glass plants.

Another area of deliberate space creation is on the machine conveyor extension. This will allow for easier access to possible future glass hot-end coatings development work, or hot end inspection development. In itself, the longer machine conveyor will present its own challenge because of the relatively low production tonnage combined with the length of the conveyor.

This naturally leads us to considering the specification for the lehr. The glass entering the lehr is likely to have cooled down much more than in a normal production situation with a more appropriately sized conveyor extension. As a result, it will need more heating in the first zone or two than would normally be required. This will be necessary to get the glass back up to the annealing temperature, before starting the slow cooling phase of annealing.

The challenge regarding the available space for the lehr was also raised during the presentation. The point I made was that a compromise on lehr width might be necessary to allow for the additional heating zone(s). This may mean longer lehr times for the product than would otherwise be more ideal in a production context. But this is a current area of focus and there might be other more satisfactory solutions available.

Attention then came on to the area of cold end inspection. The current layout proposal has two inspection legs.

However, the output of the I.S. Machine will only need one inspection leg. Nevertheless, as a development facility, a second inspection leg is being proposed to be installed. Removable conveyor sections will allow for production to be recirculated at the cold end for inspection testing.

In fact, the inner inspection loop can be operating on recirculation mode, while the outer leg takes production to the packaging machine. It could also be configured so there are two inspection loops in recirculation mode and both with different products. This can be used to test either individual items of inspection equipment, or entire inspection legs.

The linking of the cold end data back to the hot end is of course also another area of focus. The involvement of Seimens as a key partner in the project will be a significant part of this, as well as for data management for the whole plant. In addition, there will be ample laboratory space available for off-line testing of glass production. This information will of course also be included in the ‘big data’ set being generated for the production and testing work being carried out.

On a wider point about the plant in general, a previous webinar had already covered the batch plant and furnace proposals. These proposals are focused on testing composition changes, validating the modelling of the melting process, refractory testing, furnace design and alternative fuels development for net-zero carbon production for the future.

If you feel the St Helens R&D plant project may be of interest to your company, please make contact and we will be happy to discuss this with you. There are many levels at which you can get involved, we can discuss what would be right for you. Or if you simply have any general points or suggestions to make, we would welcome your input. �

*Peter Firth, Private Consultant (Glass Container Production), Working with Glass Futures Ltd on the GFL St Helens Project

Contact: Via LinkedIn Profile (search ‘Peter J Firth’) or email peterjfirth@gmail.com

Glass Futures, https://www.glass-futures.org/

To find out more please contact Alanna Halsall, Media and Communications: alanna.halsall@glass-futures.org

Glass Futures Glass International April 2021 0 24 www.glass-international.com

We build your furnace. You enjoy peace of mind. Glass Industry Division +81-3-5442-9177 Mita NN Building Floor 6, 4-1-23, Shiba, Minato-ku, Tokyo 1080014, Japan https://www.agcc.jp/en/core/glass/tabid/160/Default.aspx

www.parkinson-spencer.co.uk WHEN QUALITY MATTERS

Glass powers wireless technology

Stealth Case won the Innovation of the Year category at the recent British Glass Focus awards. Mika Partanen*

describes the award-winning technology, which is installed in glass and improves indoor wireless connectivity.

Congratulations on your innovation of the year award at the recent British Glass Focus awards.

1 Can you tell us more about the device?

Thanks! Our new generation glass antenna dramatically improves indoor wireless connectivity – in other words, it enables faster download and upload speeds and better call quality for the people inside buildings. It can be added to window glass at fabrication stage and does not require power, maintenance or special installation to function. Importantly, it is virtually undetectable to human eye and does not compromise window’s thermal performance.

2 What gave you the idea for this technological innovation?

A few years ago, our founder & CTO Juha moved to a newly completed apartment building in Tampere, Finland only to realise he could barely get a connection on his mobile phone. He realised this was caused by the attenuation of the building materials. Building on his experience in antenna design, Juha came to view windows as a natural

entry place for mobile signals (along with light) into buildings. In hindsight, we think he was right!

3 Where does it work? What type of location is it more suited for?

Our glass antenna works by reversing the attenuation of building materials – window glass in this instance. It brings the mobile network signal strength you would find outside the building, into the building. That means the antenna works wherever there is mobile coverage outdoors. It benefits especially low-E windows since they tend to attenuate wireless signals heavily. As for building types, especially the ones with concrete, brick, stone or metal exteriors stand to benefit from windows with glass antennas.

4 How does it work (specifically in glass)?

Our technology uses a laser to print a twodimensional pattern on window glass at the fabrication stage. The laser removes extremely thin traces of the metal coating on the glass to create a

Company profile: Stealth case Glass International April 2021 www.glass-international.com 27

Continued>>

� In a residential setting, one antenna window per room is typically recommended to achieve the best results.

� Mika Partanen, LeadStealthCase International Business Development.

passive antenna pattern in the desired area (e.g., close to the window edge; there is no need to cover a substantial area). Using beam forming technology commonly found in radars, this antenna pattern then “grabs” the signals arriving from the serving base station(s) outside and spreads them indoors through the window.

5 Do you have to work with glass manufacturers to incorporate the technology into a glazing?

Yes we do – our expertise lies in antenna design, signal strength modelling and measurement. We partner with glass fabricators and work closely with them to incorporate our technology into their products. In the Finnish market, Pihla whose Antenna Glass window incorporates our technology, has been an important strategic partner for us. It is worth noting that we optimise our antennas by partner and product line, to maximise the benefits and ensure good fit with the production line setup.

6 Can you tell us about the testing process? How did you test it and what were the results like?

We carry out both field trials and extensive lab testing in a controlled environment. We always start the testing procedure in our anechoic chamber (in lab conditions) where we can measure passive frequency responses of the windows under test, as well as to investigate the angular dependency of different designs at each frequency. Our field tests, on the other hand, aim to provide “real-life” results; a typical test would be a “beforeafter” setup inside a building where we replace a traditional window sash with a glass antenna sash, or alternatively suppress the operation of an already installed glass antenna sash with a microwave absorbing panel to block the signal. We then measure the indoor signal strength with a portable spectrum analyser to observe the improvement. To make the test as realistic as possible, we also use mobile phones to track the changes in the signal strength.

Across our field tests we have typically observed signal strength improvements ranging from nearly 10 decibels to as high as over 20 decibels in very

optimal conditions. For reference, a 10-decibel improvement means ten-fold increase in the signal strength and 20 decibels a hundred-fold increase. This can make quite a difference e.g., for 5G network download speeds!

7 What has feedback from potential customers been like so far?

Based on the positive anecdotal customer feedback and the steadily increasing sales figures, we view the market reception as very positive! An exciting trend we have noticed recently is that construction companies (the largest customers) are starting to consider the glass antenna as a standard (rather than exception) feature for the windows they install on buildings. Since we aim for mass adoption, this is an encouraging development.

8 Do you have any background in glass before you launched this innovation? If so what? If not, what gave you the inspiration to work with glass?

Our background was outside the glass industry, mainly in antenna design. The inspiration to work with glass came from the simple realisation that windows represent a natural entry point for wireless signals, along with natural light. We also discovered that adding our antennas to a window could be done as part of the fabrication process without disrupting the production line. This further reinforced our belief that window glass is great application area for our technology.

9 Does the technology work with all wireless providers or is it more suited to specific providers?

Our technology works across the different operators since their mobile networks operate in the frequency band that our antennas are designed for. It is also worth mentioning that although we often discuss 5G in our test examples (it is the future, after all), our antennas benefit also the older mobile communication generations and types (3G and 4G) as well as first responder networks. �

Glass International April 2021 www.glass-international.com 28

*Business Development, North America, Stealth Case, Finland http://www.stealthcase.fi

� The glass antenna reverses the window’s signal attenuation, enabling faster data speeds and better call quality indoors.

Tiama Xlab – the revolutionary 3D sampling solution

Turn virtual reality into reality with the new Tiama Xlab.

This highly flexible laboratory module can be installed at the hot end, the cold end or in the laboratory. It loads the container automatically and makes a 3D scan, generating an image composed of millions of facets.

The 3D image can be rotated and “dissected” on all sides. Virtual volume, capacity, and vacuity can be measured as well as glass distribution fully mapped. You can also analyse engraving, embossing and much more. Practically all container types and shapes can be inspected and it’s non-destructive because the image (and not the container itself) is “cut” virtually.

For an online presentation of the Tiama Xlab please contact us at marketing@tiama.com.

Data – the deciding factor

www.growth-group.com

Don’t just look at it, look into it.

The changing face of glass makers

David Harbcraner discusses what impact the recent wave of investments in the glass manufacturing industry will have.

Recently there have been a number of successful transactions which have seen container glass plants around the world changing hands. In itself, this should be regarded as positive. There are investors with money who see the glass industry as an attractive investment. Of course, for every buyer there is a seller. These sellers see it as time to cash out and exit from the industry.

Overall, are these new investors a positive and healthy wave for the industry? Investors will be looking to grow investments and maximise their returns. This could mean that there will be a flood of capex spent creating a step change in technology and productivity which are positive forces that could drive the industry forward. On the other hand, the step in investment could simply be filling in the hole created by years of under investment by the previous owners. This is also a positive force. We all hope that the new owners don’t simply squeeze all juice out of their newly acquired assets, leaving them in a perilous state after a couple of years. Time will tell if these transactions create a step change or result in an short term exploitation and digging a hole of under investment.

The new owners of these recent transactions have different profiles, with a range of differing approaches. They include private equity, glassmakers, diversified packaging companies, fillers and entrepreneurs each with

differing time horizons and investment approaches. Which type of investor is best for the industry in the long term?

The big money from Private Equity

Private equity firm, Blackstone, was successful in acquiring Piramal Glass recently for a reported $1bn. Serious money by any measure.

Private equity firms are normally in it primarily for the money. They will push like crazy to extract the maximum and increase the valuation, so that they can exit and count their profits after a few years. Their time horizons are normally five to seven years, which is relatively short, when compared with the glass industry, where time horizons are measured in multiple furnace campaigns of 12 to 15 years.

PE firms’ conventional approach often involves ruthless reductions in expenditure and cost control, minimising capex, sweating the assets and leveraging the balance sheet to the max. Some may conclude this being detrimental in the long term.

On the other hand, PE companies have a large war chest of money. They could bet that a significant investment in technology will dramatically increase capability, capacity and efficiency. This drives extraordinary value creation for them on their exit. No doubt a positive for the industry.

Upstream investment and divestiture by brand owners

AB InBev has been actively investing and divesting in the glass business. It is the largest brewer, and arguably the biggest buyer of glass in the world. Last year it invested into Nampak Glass now Isanti Glass, with promises of continued investment and expansions which certainly sounds positive.

Contrasting this in February, it announced the sale of the Longhorn glass plant in the USA to Ardagh. One can debate the real reasons that drove these upstream investments and divestitures and their timing. However, one thing is clear, making and selling beer is usually more profitable than selling glass.

The buyer, Ardagh, is the second largest glass maker in the world and announced last year a four-year capital investment programme of $1.8bn, of which 15% was earmarked for its glass business.

With positive speak of large investments in capex, a takeover of a glass plant by Ardagh sounds like a long term positive. For the Longhorn plant, do the new owners bring increased investment in technology compared with the previous owners?

Regional consolidation

There have been many examples where smaller local glass manufacturers have benefited by being incorporated into larger glass makers. Potentially this

Acquisitions Glass International April 2021 0 30 www.glass-international.com

unlocks synergies and opportunities for expansion and economies of scale and skills, which is again a positive.

Good examples of these include Vetropack’s acquisitions in Moldova, BA taking over Yioula; Altair acquiring Frigo Dubai; Consol buying Glass Force and Central Glass, O-I acquiring Vical and Vitro, Ardagh buying Anchor, Vidrala securing Encirc, to name a few.

New entrants

O-I sold its Australian and New Zealand operations in 2020. This is part of a strategic and tactical divestiture programme aligned with its ‘Portfolio Optimisation’ strategy. These transactions

have generated some much needed cash which has helped OI get its debt burden under control – a positive for O-I.

The new owners in Australia, Visy, a diversified packaging company, with ambitions to enter a new packaging substrate, have legacy of investing in technology and a long term view – in all, it appears very positive for the industry.

Entrepreneurs see value in glass

A number of entrepreneurs are investing lots of money into new glass plantsArglass in the US, Embalvidro in Angola and Glass Pack in Lebanon. New entrants see the opportunity and use technology

to get ahead of the market – a positive wave for the industry.

Investors will come and go

There is no shortage of investors seeking their fortunes in what many consider a mature industry.

An industry renowned for is long term cycle’s, relatively predictable custom, and strong cash generation. This is very positive for the industry.