www.mwm.net/en-3016

SUCCESS FOR POWEREX

LIVE NORTH IN CHESHIRE

We review the event and feature the highlights of the GOLF DAY at The Mere Golf Club greens.

Page 15-18

BESPOKE GENSET FOR LEIGHTON BUZZARD

CPS supplied an M&E Contractor with a special AS300S 300kva genset fitted with a Scania engine.

Page 23

HOW CHP COULD BENEFIT THE UK’S FUNGI

FARMS

We examine the role of MWM’s gas engines in ensuring that farm production is both efficent and profitable.

Page 24

The British and Danish electricity grids are physically connected for the first time, following the completion of cable works on the Viking Link interconnector.

The final section of the state-of-art-high voltage subsea cable, which joins Bicker Fen in Lincolnshire with Jutland in Denmark, was completed offshore in the North Sea by Prysmian’s Cable Laying Vessel “Leonardo da Vinci” and its team.

The £1.7 billion (€2 billion) project is a joint venture between National Grid and Danish system operator Energinet.

It will be the world’s longest land and subsea interconnector – stretching for 475 miles between the two countries.

Due to be complete by the end of the year, it will enable the sharing of enough green electricity to power 1.4 million UK homes.

The complex cable joining process took place in Danish waters and took several days to complete.

It involved lifting the sections of cables out of the water and expertly joining each conductor/strand together on the Cable Laying Vessel.

Viking Link is National Grid’s

NEW VIKING LINK WILL BRING ENOUGH ENERGY TO POWER 1.4 MILLION HOMES

sixth interconnector. The company already has five operational cables joining the UK with France (IFA and IFA2), The Netherlands (BritNed), Belgium (Nemo Link) and Norway (North Sea Link).

Once in operation, Viking Link will enable fast and flexible energy to be shared between the two countries, from where it is generated to where it is needed most. Flowing at the flick of a switch, interconnectors can respond quickly to

quickly to changes in supply and demand, making them an ideal partner to intermittent renewable energy.

Rebecca Sedler, Managing Director for Interconnectors said: “This is a fantastic moment for the UK and Denmark, and a key milestone for the world record project as we join the electricity networks of our two countries for the first time. The announcement is testament to the hard work and dedication of our team and our partners.”

MWM gas generator sets of the TCG 2032 series are perfectly tailored to the challenges of a dynamic market environment. In the power range of 3,000 – 4,500 kWel reliability, flexibility, efficiency and environmental compatibility are ensured along with low life-cycle costs.

In this way, they meet the high requirements of a wide range of applications and are highly profitable.

www.mwm.net/tcg-2032-en

1

UK POWER NEWS JULY/AUGUST 2023

2023

JULY/AUGUST

CES20001_Anzeigen_MWM_TCG 3016_235x55mm_EN_2_0_RZ_sm.indd 1 21.03.22 12:53

CES20001_Anzeigen_MWM_TCG 2032 V12_95x145mm_EN_3_0_RZ_sm.indd 1 08.08.23 13:50

Publisher/Sales Director: Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager: Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu

Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

MWM, FG Wilson, NHS, CPS, mtu, Rolls-Royce, National Grid, TagEnergy, Balance Power, Prysmian Group, Kent, University of Manchester, Bruno |Group, BGG UK, GE Vernova, Ethos Energy, Mecc Alte, Bloom Energy, CTM Power, SP Energy Networks, Cadence, AMP Clean Energy, Muntons, Viridor, Teksan, Aggreko, ForePower, SES Engineering Services. Agriemach, Dallol Energy, ADE, iPowerE, ACE, DTGen, DeltaQ Technologies, Switch2, Generac, Balance Power, Cummins, Leroy Somer, NIDEC ****************

UK POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

Balance Power and TagEnergy announce first project in joint venture

Renewable energy enterprise TagEnergy and leading independent energy developer Balance Power will now build, own and operate the 30MW battery storage project Rectory Farm in Worcester. The deal is the first initiative in the pair’s joint venture struck in October last year to deliver 500MW of Bal-ance Power’s pipeline with an investment of more than £300m over four years.

This first acquisition comes after the respective teams concluded their initial due diligence. Balance Power secured planning approval for the development from Wychavon County Council earlier this year following extensive community engagement. Expected to be energised in 2024, the Rectory Farm battery project will contribute to the region’s energy security and wider netzero goals.

Phil Thompson, CEO at Balance Power, said: “Rectory Farm marks an exciting beginning to implementing our joint venture with TagEnergy, and showcases our strong working relationship to date and shared ambi-tion to accelerate the energy transition in the UK.

“It has been great to see the Balance Power and TagEnergy teams working together to deliver a robust project. He explains: “The region is already extensively supported by wind and solar PV renewable technol-ogies. Battery storage will play a critical role in balancing intermittent generation, ensuring grid stability and flexibility as the UK transitions towards net-zero carbon emissions at pace.”

Franck Woitiez, CEO of TagEnergy, said: “Gaining planning approval for this first project in our joint venture was a key step in building our pipeline. “It has triggered our agreement for TagEnergy to take majority equity in Rectory Farm.”

from wastewhether that’s electricity or heat

logical part of the move towards circular thinking

Energy from waste plants in the UK currently emit around 11 Mte CO2 per year, with proposed and under-construction energy facilities potentially adding another 9 Mte CO2 per year. Reducing these emissions would have a material impact on the UK’s low carbon energy transition.

Preliminary analysis of the potential of fitting Carbon Capture, Utilisation and Storage (CCUS) equipment to the growing number of Energy from Waste (EfW) plants in the UK as a means of CO2 reduction has therefore been undertaken.

The key conclusion from this analysis is that the cost of EfW-CCUS technology as a means of emissions abatement is competitive with other industrial abatement options.

Due to the biogenic content in waste, adding CCUS to EfW actually reduces net carbon in the system, which may be more effective than other disposal options e.g. Moving tonnes of waste to landfill. However there is conceptual tension between waste combustion with energy recovery facilities and increased recycling as options, which although carefully managed in current policy would need further consideration if EfW with CCUS is to be incentivised, requiring policies reflecting this ability to generate “negative emissions” as a consequence of using the biogenic content of part of the carbon in waste.

In the UK generating energy from waste plants (incinerators) has helped the move away from landfill and it makes sense when the alternative is power from fossil fuels. But the UK could save £6.2 billion by 2050 and avoid the need to build 20 new incinerators by achieving higher recycling rates, it is argued.

There are number of ways of generating energy from waste. These include combustion, gasification, pyrolysis, anaerobic digestion and landfill gas recovery.

Technical conclusions from the latest report suggest:

-Many EfW plants are geographically well located for CCUS, being in industrial clusters near to accessible CO2 storage locations

-A significant proportion of the UK’s EfW fleet is relatively new compared to other industrial facilities, and they therefore have a long life ahead of them in which to benefit from a CCUS retrofit investment

-CCUS significantly improves the sustainability of Energy from Waste facilities and can therefore mitigate many of the system level environmental issues that threaten the long-term sustainability of EfW in the UK

- On a lowest system transition cost basis, fitting CCUS to EfW plants could lead to 20% of all captured CO2 in the UK being derived from EfW plants by 2050, with a corresponding 20% overall increase in CO2 being captured in the same timeframe compared with the case

PowerEx Live 2023THURSDAY 7th DECEMBER,

Location: LONDON, UK

PowerEx Live 2023 at London’s Park Plaza Hotel, will be held on Thursday 7th December, 2023.

PowerEx Live 2023 aims to offer the perfect networking opportunities for international professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this event becomes a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue in December 2023.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

New - The Training & Equipment Zone

PowerEx Live 2023 will also feature a special Training & Equipment zone. This will cover four subjects presented by different companies. The object is to teach students, young people and other industry professionals about familiarisation with new equipment and key aspects of training on the job within the industry. The choice of stands is allocated on a ‘first-come-first-serve’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar for 2023. The venue is situated on London’s iconic South Bank, Park Plaza, Westminster.

2 JULY/AUGUST 2023 UK POWER NEWS NEWS NEWS www.powermediagroup.co.uk

Generating energy

- is a

Don’t miss PowerEx Live held on 7th December, 2023, London

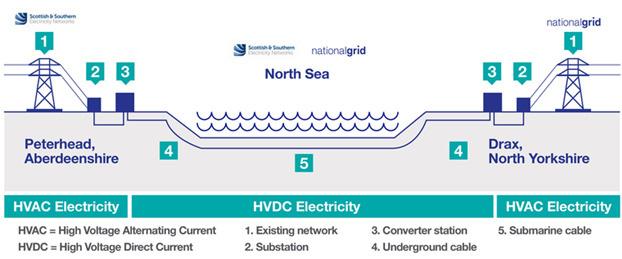

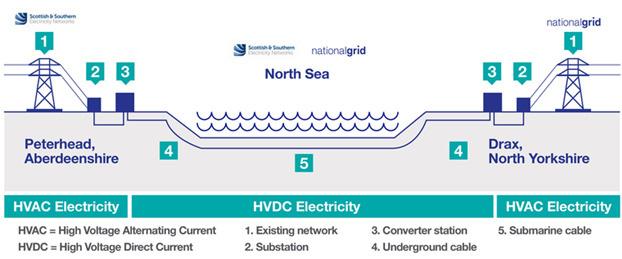

New UK-Scotland cable link

Prysmian Group has received notification from SSEN Transmission, and National Grid Electricity Transmission, Great Britain’s electricity transmission network owners, that it has been selected as the exclusive preferred bidder for the Eastern Green Link 2 (EGL2) cable connection between England and Scotland.

Prysmian Group is currently continuing the contract negotiations with the aim of concluding the contract soon.

Eastern Green Link 2 is a planned high voltage direct current submarine and underground cable link of around 500 km total length between Peterhead in Scotland and Drax in the Northeast of England. With a power transmission capacity of 2 GW the connection is expected to be one of the first cable systems in the UK to utilise 525 kV technology with extruded XLPE insulation.

EGL2 forms part of a series of planned system reinforcements required to increase the capability of the existing UK transmission network and facilitate the growth in flows of renewable generation primarily in Scotland to demand centres to the South, supporting the target of enabling 50 GW offshore wind generation by 2030 and achieving a Net Zero economy by 2050.

The full scheme consists of two 2 GW capacity submarine and underground power cables from the East coast of Scotland to northeast England. National regulator Ofgem states that “At an estimated cost of £3.4 billion for the two links, the Eastern HVDC projects would be the largest electricity transmission investment project in the recent history of Great Britain.”

In July 2022 Ofgem published its conditional decision on the Final needs case for the Eastern HVDC project, confirming its choice of two separate HVDC links, each rated at 2 GW.

The University of Manchester partnership will produce a new syngas & blue hydrogen tech

Kent, a leading engineering company in the area of oil and gas, carbon capture, utilisation and storage (CCUS), and hydrogen (H2) technologies, has partnered with The University of Manchester to produce a new syngas and blue hydrogen technology with nearly zero direct carbon-dioxide emissions.

The RECYCLE project (REthinking low Carbon hYdrogen production by Chemical Looping rEforming), a £ 5.1 million multiorganisation collaboration funded by the Department for Energy Security and Net Zero, will construct and test a fully integrated innovative hydrogen production unit at The University of Manchester.

The technology is based on chemical looping reforming using fixed bed reactors which allow modular units and cost-effective solutions for hydrogen production using different feedstocks, with inherent carbon dioxide capture and separation at high purity.

The RECYCLE process provides a flexible method for hydrogen and or syngas production, while also

showing economic potential benefits over other blue hydrogen production pathways.

RECYCLE technology could supply hydrogen to several sectors in the UK, focusing on smaller scale industrial sites, with its ability to tap into large demand sectors that require syngas to develop other lowcarbon products.

Kent will bring its engineering expertise and commercial knowhow, to complete a techno-economic study assessment of the RECYCLE technology.

Luigi Crolla, Head of Energy Transition Technologies at Kent, said: “We are delighted to be part of this cutting-edge project. It is aligned with Kent’s purpose to be a catalyst for energy transition and an exciting addition to our blue hydrogen project portfolio.”

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

UK POWER NEWS JULY/AUGUST 2023 3 NEWS NEWS

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

Becoming a supplierleadingof battery storage systems

The latest addition to the Bruno Generators Group (BGG) is the leading UPS and battery storage specialist company POWERTRONIX. Bruno is well known as one of the major world players in design, manufacturing and distribution of premium industrial generators, lighting towers and battery storage systems.

This investment in the highly respected Powertonix brand is said to fit ‘hand-in-glove’ with the Bruno group’s desire to become one of the leading suppliers of battery storage and heavy- duty truck and plant rapid charging systems.

Powertronix, headed by the Modenesi family, who have been at the helm since 1993, will seek to build on its impressive and innovative product range. The company under Luigino Modenesi has been at the forefront of development. including the introduction of the first liquid cooled UPS based on the proprietary ‘Climasystem’ technology as far back as 2005.

From the Bruno point of view this partnership has perfect synergy as it has always been very keen to be at the cutting edge of green technology, a fact reflected in the launch of its hydrogen-powered generator range at the recent Bauma show.

BGG is producing and delivering record breaking quantities of its market leading STAGE V generator RENTAL range along with the highly-engineered “Enerpack” site battery storage systems.

The Project division at Bruno will also be strengthened by having a ‘one-stop shop’ to include generator and a matching UPS package to offer to its installation customers worldwide.

For Powertronix, the Bruno group offers a highly-motivated and advanced research and technical setup. This is combined with the industrial and financial power to drive through innovative new technology and deliver new products to the market in very short lead time from conception via testing to manufacturing.

A very high priority in this new co-operation is the development of rapid charging capability for road trucks and large site equipment with the first units coming to market in November 2023.

BGG UK reports that it recently sold its 1,200th Stage V emission compliant diesel generator into the UK market. One of its most popular products is the fully-compliant FusteQ STAGE V engine gensets which features an ultra-silent compact canopy 53dBA @ 7m and has patented VSi technology continuously rated up to 55˚C ambient. All STAGE V compliant equipment is contained within the compact FUSTEQ SERIES canopies.

Bruno Power is the holding company for several major power generation and associated industry companies, including BGG UK (Bruno Generators Group), BGG Projects, BDS (Bruno Defence Solutions), Westac Power and OMC Trailers.

The group’s companies specialise in both the design and manufacture of power generation and distribution systems, supplying power generation equipment to significant civilian, industrial and military clients worldwide.

The BGG portfolio ranges from small 2kW portable petrol sets to multi Mega Watt diesel, gas and HFO (Heavy Fuel Oil) power stations. BGG is a market leading supplier of high specification RENTAL generators to most of the hire and power leasing organisations in the UK and Europe. BGG Projects specialises in the design and manufacture of bespoke power solutions, including multi-megawatt power stations and fcan build and test individual generators up to 5 MW from its UK tendering facility . BGG projects supply to a wide range of industries from military, power utilities and water authorities and offers specialists in the oil and gas sectors ATEX, Rig-Safe and Zoned equipment.

Boosting power & efficiency at the UK’s Coryton plant with two High Efficiency upgrades

Continuing to keep customers’ gas turbine fleets competitive in the UK’s energy marketplace, GE Vernova’ Gas Power business has announced an order from InterGen, one of the largest independent power producers in the UK.

The order is for two High Efficiency (HE) upgrades to modernize the Coryton Power Plant. The 800 megawatt combined cycle power plant, located 30 miles east of London on the River Thames, is powered by two GT26 gas turbines. The upgrades will be installed in 2025.

GE’s HE upgrade utilizes technology breakthroughs across gas turbine, compressor and combustor that will help Coryton Power Plant deliver approximately additional 77 MW of power output. The upgrade will also increase the units’ efficiency, and extend ongoing maintenance intervals.

In addition, the modernization is expected to result in a reduction of approximately 67,500 tonnes equivalent of carbon emissions each year, in line with the government’s goals to lower the carbon footprint in the country, by requiring less fuel to produce the same amount of power compared to the plant’s current output.

“Ar InterGen we continue to invest in the energy transition by boosting flexible generation to ensure the stability of grids as renewable generation increases, while developing advanced solutions that

keep the lights on, at a manageable cost for our customers- and we see GE as a reliable player and technological innovator to drive these goals forward,” said Jim Lightfoot, InterGen’s CEO.

“We selected GE’s HE upgrade because of its excellent part load efficiency and its fuel-flexible combustion system.

“With this innovative upgrade, we expect that our power station will benefit from improved efficiency and increased output, in line with our goals.”

Natural gas-fired power plants like Coryton are said to be the lowest emitting fossil fuel power plants, whether measured based on CO2, SOx, NOx, particulate matter, or mercury.

GE is advancing flexible, efficient and reliable gas power generation solutions, because of their fundamental role to complement renewables towards a more sustainable energy future.

GE has invested significantly in the development of this upgrade, which was introduced in 2019. This technology combines the best from both GE’s F- and H-Class fleets with additive manufactured parts and innovations in aerodynamics.

Launch of industry first CO2 asessment tool for gas turbine rotors assessment tool for gas turbine rotors

EthosEnergy, which specialises in services and solutions for rotating equipment in the energy and industrial sectors, has launched the industry’s first life cycle assessment (LCA) solution for gas turbine rotors. This enables full visibility of environmental impact and a reduction in CO2 emissions.

Developed in partnership with Politecnico di Torino and Politecnico di Milano, the new CO2 assessment tool – EcoView™ - provides comprehensive environmental insights across each phase of the rotor life cycle. These evaluations quantify the carbon and financial reductions which can be achieved from maintaining existing equipment compared with purchasing new.

Massimo Valsania of EthosEnergy told UKPN: “Having a transparent view of CO2 emissions across the entire life cycle, and how to tackle these, is a key factor in the world’s energy market and driving towards net zero carbon emissions.

“EthosEnergy’s expert team took the initiative to research and explore a pioneering solution which provides emission and maintenance insights for companies across the world to action – implementing a positive change for energy operations.

“By enabling ESG reporting and compliance, we are supporting the energy industry to achieve a fair energy transition. We play an active part in the circular economy, offering attractive solutions for our customers and the wider supply chain.”

UK POWER NEWS JULY/AUGUST 2023 5 NEWS NEWS

Eden Project North: Plans for £125m 2-dome development in Morecambe

2.5MW solid oxide fuel cells for a leading hydrocarbon company

Bloom Energy has supplied 2.5 MW of Bloom’s solid oxide fuel cells to a leading hydrocarbon company based in Dorset, UK. The company recently signed an agreement with Perenco to install 2.5 megawatts of Bloom’s solid oxide fuel cells at a key site owned by Perenco.

Perenco is a leading independent hydrocarbon company, producing 500,000 BOE of oil and gas per day from its operations in 14 partner countries.

important step as we continue to reduce our emissions wherever we work. We look forward to a successful initial deployment at Wytch Farm and to then expanding the use of the technology into other global operations sites.”

Project Morecambe, previously known as Eden Project North, has been awarded £50m in the second round of the UK Government’s Levelling Up Fund. The funding allows the project to move into its next phase and begin the process of finalising the remaining funds required from private and philanthropic sources identified as part of the bidding process.

Eden Project Morecambe is being delivered for 2026 by the team behind the first Eden Project in Cornwall, alongside local partners Lancaster University, Lancaster City Council, Lancashire County Council and the Lancashire Enterprise Partnership. It will be situated on the former site of the Bubbles leisure complex with “shell-like” domes surrounded by outdoor gardens. Two restaurants are planned, with both featuring indoor and outdoor seating, and boasting views across Morecambe Bay. News sources suggest four gensets will provide backup power for HVAC, lighting and security systems onsite.

The £125m project on Morecambe Bay’s seafront is going ahead after years of development. Once completed in 2026, the Eden Project North is predicted to attract around one million visitors a year and directly employ more than 400 people.

The original Eden Project is a visitor attraction in Cornwall, currently features two huge enclosures consisting of adjoining domes (Rainforest and Mediterranean) which house thousands of plant species and each enclosure emulates a natural biome.

The ‘energy-friendly’ Eden Project is said to have contributed over £1 billion to the Cornish economy and had over 1 million visitors in 2019. The complex also uses Green Tariff Electricity – the energy comes from one of the many wind turbines in Cornwall, which were among the first in Europe - and now has its own geothermal energy source for its eventual electrical power and heating.

Multi-million pound project to refurbish overhead electricity lines is underway

A multi-million project to refurbish miles of overhead electricity lines is now up and running across Wrexham, Whitchurch and Crewe thanks to SP Energy Networks.

The £5.5 million project – covering a distance that’s equivalent to the length of a marathon – will modernise the network circuit between Legacy in Wrexham, Marchwiel through to Whitchurch and Crewe.

It will enhance the resilience and capability of the network in the region, ensuring it’s ready for the continued uptake of green energy solutions like electric vehicles and heat pumps.

SP Energy Networks serves more than 50,000 homes and businesses across the area, who will all benefit from this investment and the cleaner and greener choices it will allow them to make, while ensuring a resilient and reliable power supply.

The works are the first in a wider five-year investment programme, which will see SP Energy Networks invest £200 million in its 132kV network in England and Wales,and have been planned carefully with customers in mind to keep power flowing while the works are underway.

Mark Sobczak, 132kV General Manager at SP Energy Networks said: “It’s great to be out of the starting blocks and getting to work on this exciting project.”

The Bloom Energy Server® platform, to be delivered in late 2023, will be installed at Wytch Farm in Dorset, the largest onshore oil field in western Europe, where it will be used to support Perenco’s baseload requirements.

The agreement marks the first deployment of Bloom fuel cell technology in the UK.

“This is an important step that will demonstrate how our solid oxide fuel cell technology supports the resilience and sustainability goals of our energy-intensive clients,” Tim Schweikert, Senior Managing Director of International Business Development at Bloom Energy, told UKPN.

“Perenco has always been a pioneer in innovation and long-term investment in the countries where we operate,” comments Benoit de la Fouchardiere, Perenco CEO.

“This announcement is another

The third generation of fuel cells includes the solid oxide fuel cell (also known as SOFC), an all-solidstate device that efficiently and sustainably transforms chemical energy stored in fuel and oxidant into electrical energy at medium and high temperatures.

Similar to the proton exchange membrane fuel cell, solid oxide fuel cells are typically thought to be fuel cells which will be widely employed in the future.

A solid oxide fuel cell (SOFC) is an electrochemical device that uses the inclination of oxygen and hydrogen to react to transform the chemical energy in fuels into electrical energy. The solid oxide fuel cell runs on air and a gaseous fuel like natural gas or biogas. They are unique in that they produce heat and electricity with a high level of efficiency while emitting no harmful emissions.

Gensets provided for a key South London hospital

CTM Power Ltd, part of the CTM group, was involved in the supply design and commissioning of three 1.5MVA generator sets for a South London hospital. Also supplied was a generator control panel integrated to facilitate starting, paralleling and connection via LV switchgear.

Because the need for low nooise levels in the hospital envrions, noise attenuation measures were applied to the built environment.

The fuel supply system for the three backup power gensets included double-skin day tanks, all pipework, control panel and transfer pumps for the transfer of fuel from bulk tanks to over 150-metres away. CTM specialises in the supply of

standardised & bespoke diesel and gas generating sets, UPS Systems, as well as weather, sound and blastproof containers and low, medium & high voltage containerised substations.

6 JULY/AUGUST 2023 UK POWER NEWS NEWS NEWS

The Electromechanical Specialists CERTIFIED QUALITY SYSTEM Call: 01572 755 168 Email: info@cabeluk.com www.cabeluk.com We go further Essential electromechanical repair and rewind for alternators, pumps, motors and so much more. Designed to assist your business and extend the life of your equipment. WINDING REWINDING SERVICE &REPAIR SUPPLY 24/7 ALL BRANDS

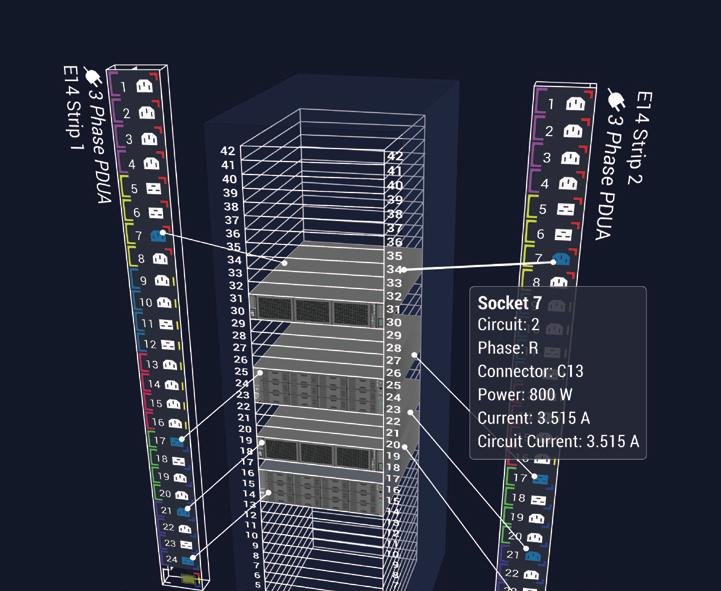

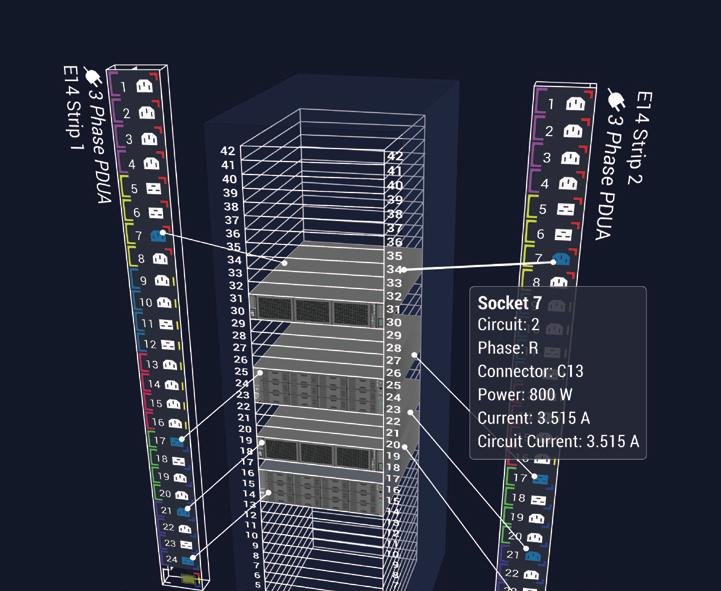

Revolutionising Data Centre Power with Management with Digital Twins

New Energy Centre and biomass boiler will be installed at a Stowmarket site

Power is undoubtedly the lifeblood that keeps the digital infrastructure in data centres running. The servers, storage systems, and networking equipment all require a constant and reliable power supply. Maintaining this is the number one priority for data centre engineers, as well as having to juggle considerations such as cooling and space limitations, explains Dave King, Senior Product Marketing Manager, Cadence. However, a power fault will not only prevent the data centre from operating but also carries inherent risk and a need for precision. As such, it’s no surprise that it’s a top concern and can be a daunting task to manage without the right tools. Luckily there is technology available to support power management.

One of the main challenges in power planning is acquiring a comprehensive understanding of available power capacity. For instance, if a manager only has knowledge of measured data, such as historical power drawn from a particular panel or breaker, that does not offer a definitive answer about the power already assigned to that piece of infrastructure. This could leave them unaware of the potential impact if and when they make a change.

The manager will know an additional server will use more power, but the amount it consumes will vary dependent on its workload, and how much it varies will be determined by the work it’s doing. For example, a machine that runs periodic jobs that are resource intensive might spike consumption up, while equipment that’s part of a disaster recovery system might usually run idle, waiting for failover from another center. This makes it challenging to understand how much power is being consumed within a facility holistically.

The traditional approach of relying on spreadsheets to understand and manage power capacity often falls short in providing accurate, granular insights and enabling effective planning, particularly for future power demands. This is because spreadsheets, by their nature, are prone to error. They are built on complex calculations that are hard to get right, and when ownership is passed from one individual to the next, mistakes can easily creep in. Digital twin technology - a 3D replica of the physical data centre - offers a powerful alternative, giving complete visibility over the power system in a way spreadsheets never could and working equally effectively from one owner to the next.

Digital twins enable managers to make confident decisions on changes to power systems. They can show what the power draw would look like if equipment was running at maximum load over a month or six-month period, illustrate if the breakers would be overloaded if more equipment was installed, or establish how to balance three-phase power to prevent inefficiencies and loss of capacity due to uneven loads. Engineers can run scenarios, with the software doing all the math, to visualize their options and make an informed decision. As such, digital twins reduce risk.

Digital twins can also deliver cost savings in a couple of different ways. Firstly, as we’ve seen, they put information at managers’ fingertips, so confident decisions can be made quickly. This reduces time spent on each project and, therefore, costs. They also offer cost savings through improving resilience. According to Uptime, power-related outages account for 43% of significant outages. Using a digital twin, managers can achieve better visibility over power loads and simulate failure, which is a powerful tool for preventing expensive outages.

Additionally, costs can be controlled by preventing stranded capacity. This has long been a challenge in data center power management, resulting in wasted physical and financial resources. For example, if power delivery and cooling delivery are mismatched, the facility could end up with either stranded power or cooling. This is because the manager either can’t deploy enough equipment to make use of the cooling or they run out of cooling before all the power that’s been distributed to that rack has been used up. Visualizing how these two things are distributed within a data centre digital twin allows the manager to start matching the utilization of both power and cooling to avoid stranding either.

The benefits of digital twins are clear, but what are the considerations for implementing them?

A top consideration is the managers’ level of understanding of power connectivity; they should have a firm grasp on this and the capacities of each component in the chain so that the digital twin can be deployed effectively.

Another key consideration is how the facility tracks which socket rack equipment is plugged into. Managers may know that equipment is connected to a certain power strip or could have insight into specific socket connections.

Working in conjunction with AMP Clean Energy, Muntons, the Stowmarket-based malt and malted ingredient manufacturer, has signed an agreement to install a new Energy Centre at its site in Stowmarket.

The new energy centre will be located in the North-West corner of their site and will include a Biomass boiler, a gas-powered combined heat and power generator and two, back-up, gas-powered boilers.

This new facility will provide virtually all of their site’s future steam, heat and electricity requirements, whilst also significantly reducing their carbon footprint.

Mark Tyldesley, Muntons Group Managing Director, commented: “We have recently installed a Biomass heat and energy plant at our maltings in Bridlington in Yorkshire, and have already seen significant benefits, including a dramatic reduction in our carbon footprint. “So much so, that with our new plant at Stowmarket this will bring us in line with our science-based target of reducing greenhouse gas emissions by 45%, based on 2010 levels by 2025.”

He continued: “We are delighted to

be able to celebrate another major milestone in the history of the site at Stowmarket and look forward to a bright future of sustainable energy supply of which we can all be proud.”

Work on the new facility will begin shortly and it is anticipated that the new biomass plant will begin generating heat and electricity for Muntons from early spring next year.

Muntons’ new facility will include a biomass boiler, a gas-powered combined heat and power generator and two back-up gas-powered boilers – on the north-west corner of its factory site.

Maltster’s AD plant powers equivalent of 2,000 homes a year.

AMP Clean Energy says the project will provide virtually all of the site’s future steam, heat and electricity requirements, while significantly reducing its carbon footprint.

A previous biomass plant at the Bridlington plant came online during 2020, using waste woodchip from forestry activities. This reduced GHG emissions from the heating of the kiln by up to 90%. The site’s energy management system continues to be verified to ISO50001. A project appraisal system has evaluated capital projects for like this for reduced GHG emissions.

Waste facility now heats the equivalent of 8,000 homes

VIRIDOR’S Glasgow Recycling and Renewable Energy Centre is situated in the south side of Glasgow City at Polmadie. Producing enough energy to power the equivalent of 26,496 households and heat the equivalent of some 8,000 homes, it delivers a saving to Glasgow of 90,000 tonnes of CO² every year.

The Glasgow Recycling and Renewable Energy Centre Handles 222,000 tonnes of residual waste every year.

Of the vast tonnage of household waste that is collected annually by Glasgow City Council, the vast majority, 72%, was sent to landfill in 2016. With annual hikes in landfill tax and ambitious Scottish

Government zero waste targets focusing on waste reduction, re-use, enhanced recycling and recovering renewable energy from what remains, the council has been working towards great change.

Glasgow has now changed gear with a state-of-the-art recycling and sustainable waste management facility at its long established waste treatment plant at Polmadie, radically overhauling the way the city’s household waste is managed, reports the city council..

8 JULY/AUGUST 2023 UK POWER NEWS NEWS NEWS

THE POWER TO DELIVER

Whether it’s our flawless 9-series, 13-series or V8 16-series of engines, Scania Power Solutions will make sure you get it right. Our team have all the experience and sheer depth of knowledge to match the perfect engine to your power generator needs, every time. And because Scania Power Solutions lead the way in Stage V compliance, you can be sure that you’re choosing from a range of engines – from 202kW to 566 kW – that is not only super-efficient, reliable and economical, but sustainable, too. When it has to work, it has to be Scania.

SPEAK TO OUR SCANIA POWER SOLUTIONS

TEAM TODAY – CALL 0845 034 3034

scania.co.uk/powersolutions

NHS hospital facility in Cheshire installs a 1,650kVA diesel generator set to provide critical power onsite

Temporary energy supplier for the 44th Ryder Cup will be teeing off in September 2023

Now delivered , off loaded & positioned, another Teksan™ UK 1650 kVA containerised diesel generator solution is providing critical power for the NHS supply chain in Cheshire.

The Teksan TJ165BD 150kVA diesel generator offers reliability and economy thanks to the robust Baudouin 4M06G165/5 engine. The Overhead Valve (OHV) 1500rpm engine produces a dependable 150 kVA / 120 kW of prime power and has been designed to be quiet, rugged, and durable, reports the manufacturer.

The Teksan TJ165BD features a close-fitting acoustic canopy, long run bunded fuel tank and copes well with tough environments and a range of high and low temperatures.

It has a prime power rating of 150 kVA / 120 kW and standby power rating of 165 kVA / 132 KW. This canopied diesel generator is extremely compact and robust, so can be stored with ease with minimum effort. With a generous bunded fuel tank of 400 L, the Teksan TJ165BD diesel generator is perfect for your next project. With an easy-to-use configuration this diesel generator gives you a fantastic balance between performance and price.

Simply press the button and up it starts. The button start makes starting straightforward and easy. The Baudouin 4M06 is currently one of the most powerful engines from the 4M06 range, and in fact the highest powered to run at 50 Hz. The 6 cylinder, 2.3L engine has a turbocharger and is air to air after cooled. It is currently produced in France and China.

Genset details are as follows:

-Prime Power 150 kVA / 120 kW

-Baudouin Engine (4M06G165/5)

-Deep Sea Electronics 7320 control module

-Leroy Somer alternator

-3 Phase / Voltage 400V

Teksan generator sets comply with ISO 8528, ISO 3046, BS 5514, DIN 6271 standards, are being used. These engines with low fuel consumption, provide accurate speed setting and order, mount to the fuel pump, also have mechanic or electronic type governors.

All alternators pass the necessary test process and are appropriate according to EC 60034-1; CEI EN 60034-1; BS 4999-5000; VDE 0530, NF 51- 100,111; OVE M-10, NEMA MG 1.22. standards, have bearing system that do not need maintenance, with electronic type voltage regulator providing voltage setting.

The Control Panel ensures comfortable and safe usage. All measured and statistical parameters, operating modes, notice and alarms and condition of generator, are monitored easily from the control panel.

On the front of the panel’s metal body has electronic control module and the emergency stop button and the panel’s metal body is made of steel sheet and is painted with electrostatic powder paint. The chassis is manufactured from steel - thanks to its rigid structural design and anti-vibration mounts, it reduces vibration level to minimum. All chassis contain lifting lugs.

Apart from gensets with less than 1600 kVA power, the fuel tank is manufactured integrated to the chassis. In more than 1600 kVA power generator sets, a rectangular type fuel tank is provided with generator set separately. All types of fuel tank on offer from the company have fuel level and indicators.

The genset’s Cooling System System consists of quality industrial - type radiator, expansion tank and cooler fan, designed to keep the temperature of generator set equipment constant at a proper level. For more information visit: teksanuk.com

UK-based Aggreko will be the official temporary energy supplier for the 44th Ryder Cup teeing off in September.

Aggreko will provide power and HVAC across the event from all hospitality to both the opening and closing ceremonies. The Ryder Cup is one of the most iconic tournaments in golf and attracts tens-of-thousands of fans from all over the globe. This will be our fifth time supporting the European leg of the competition having previously supplied energy to the 2006, 2010, 2014, and 2018 editions.

It will be the first time ever power for the Ryder Cup will be supplied by a combination of resilient temporary generators and two solar arrays to further improve energy efficiency

“We are proud to continue our ongoing support of the Ryder Cup working with Ryder Cup Europe and the PGA of America for the event that’s on every golf fan’s calendar,” said Jono Rose, General Manager - Aggreko Event Services. “Every

global sporting occasion presents its own set of unique challenges. Aggreko not only has the tools to solve these complex situations, but to do so in a way that continues to reduce carbon footprint and implement a flawless Ryder Cup event. Our team will be on the ground months ahead of the event to ensure we can meet every demand asked of us, so that the organisers can deliver yet another unforgettable Ryder Cup.”

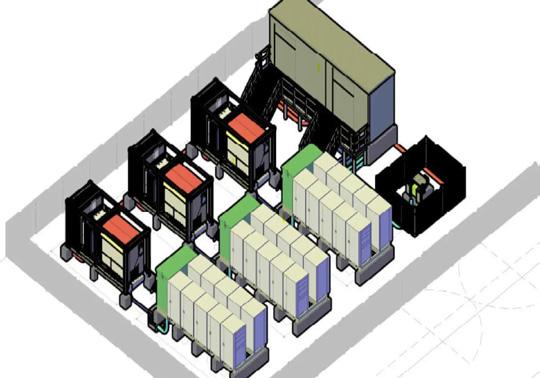

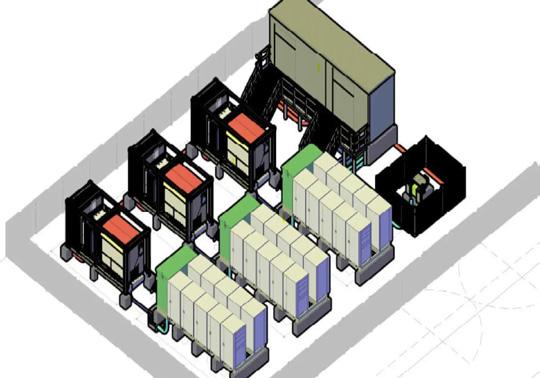

ForePower invests in a 10MW battery energy storage system for South Yorkshire

In 2022 UK infrastructure projects developer ForePower ordered a 10MW battery energy storage system (BESS) project for its engineered, system-integrated turnkey solution.

ForePower invested in a systemintegrated BESS solution. to provide the National Grid with the ability to stabilise the electricity network via a portfolio of assets.

Funded by Nash Business Capital Ltd, the 10MW 1-hour duration BESS project is based in South Yorkshire, UK, where it will provide a range of balancing services to the electricity grid to ensure power security, system flexibility

and accelerate renewable energy integration.

The modular outdoor battery energy storage solution is fully integrated and prefabricated with lithium iron phosphate (LFP) battery cell chemistry, liquid-cooled thermal management system and skidmounted inverter systems.

10 JULY/AUGUST 2023 UK POWER NEWS NEWS NEWS

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

An innovative £10m district energy centre, situated in the heart of Helix - a landmark mixed-use development in Newcastle City centre, and one of the largest urban regeneration projects of its kind celebartes its third anniversary.

In 2020 Newcastle District Energy Centre scooped a prestigious RICS Social Impact North East’s ‘Infrastructure’ Award for the development.

SES Engineering Services (SES) was a key contributor to the successful delivery of the scheme in a ground-breaking joint venture between Newcastle City Council and ENGIE Urban Energy formed to create a 40-year partnership. The aim of the project was to tackle a city wide climate change challenge by implementing energy solutions across the city, the energy centre being the first development.

Today Newcastle Helix is a 24-acre landmark sustainable development on the site of the old Newcastle Brewery, and is one of the largest urban regeneration projects of its kind.

Designed to bring together industry leaders, businesses and top researchers, by creating a new innovation community, it is an exemplar of sustainable urban development, comprising prestigious commercial and residential space with first class research and education facilities, in the heart of a flourishing city.

At its heart is Newcastle District Energy Centre delivering heating, cooling and electricity through a distribution network to 10 buildings and approximately 500 future homes on the site. It has been calculated that the scheme is providing a carbon-emission saving of 30,650 tonnes over 40 years. Critically, the CHP energy centre is a key component of the city’s energy masterplan and is a significant contributor to achieving Newcastle City Council’s (NCC) ambitious green credentials and net zero carbon emissions target by 2030.

The project’s overarching value delivers at every stage and stands out because it both generates and supplies sustainable low-cost energy, provides significant emission savings until 2060 and beyondand sets the stage for the future development and the construction of further energy centres around the UK.

The energy system of Newcastle Helix includes the following infrastructure:

-11kV smart grid throughout the site

-Combined heat and power (CHP) district heating

-Electric vehicle (EV) fuelling station

-Low carbon heating

-Building-mounted solar photovoltaic

-Solar thermal photovoltaic (PVT), producing power and hot water

-The first University teaching building on site is Urban Sciences Building (USB). This is key to ongoing research at Newcastle Helix and is home to CESI HQ.

In the CESI & UNEW energy Lab, researchers are demonstrating projects developing exciting technologies, most of which will offer more efficient energy solutions to create a greener, lower carbon future. Recently, work in the lab has involved testing the rapid EV charger in a hybrid system of PV and BESS which is capable of charging an electric vehicle in around 30 minutes and has been developed for the Smart Hubs project.

The District Energy Centre provides affordable heating to all businesses and homes on Newcastle Helix via a network of underground pipes. Non-residential properties on the site also benefit from a cooling system and a bespoke electricity supply.

It is integrated with the smart electricity grid, smart meters and onsite electrical energy storage to allow the generation, distribution and consumption of heat and power to be closely monitored and managed. The Newcastle Helix development is in the vanguard of UK ‘Smart’ developments, providing a significant opportunity to showcase Newcastle Helix as a demonstration project which exemplifies the benefits of smart energy systems.

Keeping it clean at Glastonbury music festival 2023 with a new fuel filtration system for the generators

UK-based Agriemach provided a key service to one of the biggest music festivals in the world last month by ensuring site fuel supplies remained pure. Before the event began Agriemach supplied a vital Agriepure™ Fuel Filtration System is onsite to keep diesel fuel clean for onsite generator systems

Agriemach’s maintenance team supplied Worthy Farm with an Agriepure™ Fuel Filtration System before the event, making sure their Fuel was always clean and ready to use.

The Agriepure™ Filtration system is also HVO Compatible and is programmed to run every day ensuring the fuel is free of any Water & Particulates.

The Agriepure System has been developed to filter 25 litres of diesel per minute.

This system is generally used on small machinery, generators and tanks with small access points. It can be used for filtering any type of diesel in any type of tank.

System 1 uses 16mm hose on the suction and delivery sides, meaning that it is ideal for the smaller applications but while still producing 25 litres per minute of filtration.

The filter chamber holds a Racor Aquablock filter element which is coated with a resin. This filter will not allow any water past it. These filters also filter out particulates with the option of 2, 10 or 30 Micron.

Agriemach also offers reuseable MESH elements for applications with heavy particulate content.

At the bottom of each filter chamber is a system which uses centrifugal force. This system gets the diesel spinning and enables the larger contaminants to be pushed down into the clear bowl.

With the clear bowl being fitted, this allows you to see immediately; what type of contamination is in the tank. This also allows you to see which areas of the tank are most contaminated with sludge and rubbish, making the cleaning process more effective.

Bunnahabhain Distillery gets top sustainability award

Developed, built and operated by Dallol Energy in Scotland, the Bunnahabhain Distillery’s energy centre offers the first Net Zero distillation process on Islay.

The CHP system, finished in 2022, is fuelled with a mix of spent process malt (draff) and local woody biomass.

The Bunnahabhain clean burn biomass boiler is said to be one of the cleanest systems in Europe and whisky’s first example of three zoned biomass combustion coupled with NOx reduction technology.

According to the site managers

It saves 5500 tonnes of carbon emissions a year, representing a reduction of 95% over oil.

The biomass development has

created a new forest economy and employment on the island.

The need for woody biomass fuel provides a local market for low value biomass which helps to finance the export of premium sawlogs, a largely uneconomic prospect up to now.

The project has also improved biodiversity and wildlife habitats through replanting.

12 JULY/AUGUST 2023 UK POWER NEWS NEWS NEWS

Newcastle District Energy Centre is the hub of all things to do with CHP

Compact. Smart. Efficient.

With our MWM container solutions, you have everything under one roof – precisely aligned with your needs. Benefit from our assistance in planning, configuring and installing comprehensive plant concepts. Thanks to digital possibilities such as a highly developed, secure data analysis, these steps can be tailored to maximize your profit.

www.mwm.net/en

UFR1001E G99/98 compliant Loss of Mains Relay

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

• Presetting per G99/98, values as per the standard pre programmed

• Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt) Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

• Supports the mains synchronisation when using generators

• Measurement 3 phase 3 or 4 wire systems or single phase

Self-test

• Third Part Independently tested Compliant to G99/98 by Bureau Veritas

Tel: +44 (0) 1206 575755

Email: sales@tvri.co.uk www.tvri.co.uk

TVR Instruments Limited 143 Butt Road, Colchester CO3 3DP Essex, United Kingdom

UK’s leading independent producer of

Urea Solutions 32.5% & 40% for NOx abatement

Production Cost effectively manufactured in the UK Solutions 32.5% & 40% Urea solutions for NOx abatement

Delivery National bulk delivery directly into storage tanks Packed goods available

Quality Produced to ISO22241 & ISO18611 quality standards

For further information contact us: Telephone: 0161 205 4454 Email: info@greenoxsolution.co.uk

Tennants Distribution Ltd, Manchester, England, M8 0GR www.greenoxsolution.co.uk

ENGINE GENERATOR CONTROLS AIR & HYDRAULIC STARTERS

& Gas Markets Tacho & Speed Switch Products Hazardous Area Certifications ATEX, IECEx, UL/cUL & CSA Pressure Relief & Safety Valves Tel: +44 (0)161 476 4606 sales@precisioncontrols.co.uk

is a

trademark of the Verband der Automobilindustrie eV (VDA) is a licensed trademark of Tennants Distribution in the UK and Ireland

registered

www.precisioncontrols.co.uk

Oil

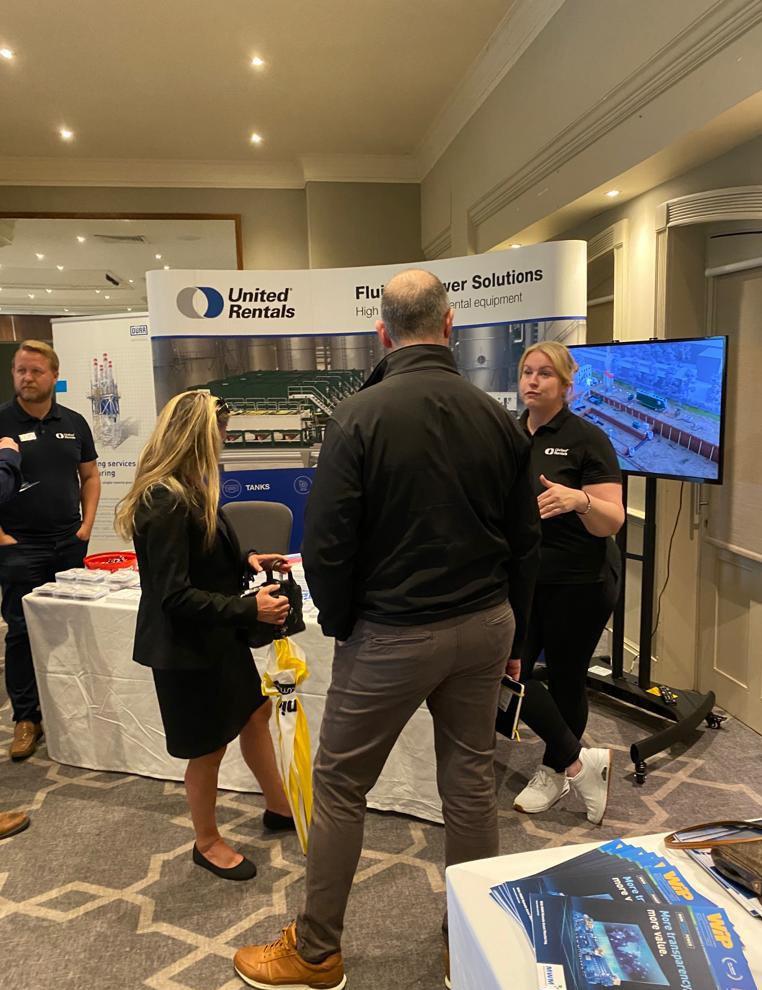

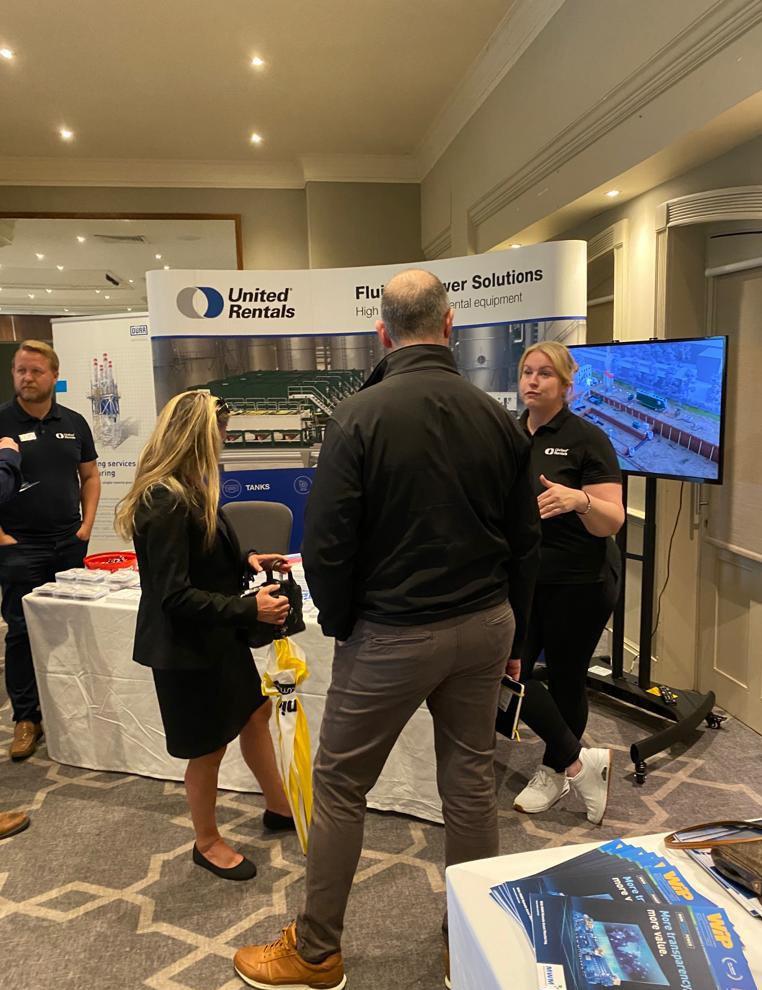

POWEREX LIVE NORTH -

27TH JUNE 2023 - A FIRST FORAY UP NORTH PROVES SUCCESFUL

The Mere Golf & Spa Club, Knutsford, Cheshire, UK, was the unique setting for the Power Media International Group’s first PowerEx Live North, a regional conference & exhibition event designed to give enhanced access for the power generation sector to companies with a primary focus on the north of England. Over 120+ delegates and exhibition personnel were registered.

Conference organiser Richard Teasdale commented: “PowerEx Live North 2023 offered a wide spectrum of UK professionals the perfect networking opportunities for meeting their counterparts in CHP, Genset, Data Centre, Statistics, Noise and Energy Systems and Consultancy markets based in the north.” Amongst the speakers at the Conference, the ever-popular Romain Mocaer of Powergen Statistics spoke on the 2023-2024 European Generator Market: Impact of the gas crisis and Ukrainian conflict on the generator market.

Paul Smethurst gave his key perspective on DATA CENTRES - “Powering improved Data centre operation and efficiency”. He provided the audience with insights into why gensets are key to operating the IT load and more importantly how to prevent losing the critical load being a total Data Centre disaster.

Clinton Noble, Senior Sales Manager –Finning – spoke about Large Electric Power Sustainability in the power generation industry. He examined the varying options there are to combat the market’s restraints, demand and growth. He also explained about alternative fuels, what’s possible now and about the likely options in the future.

A much-appreciated complimentary PowerEx

Live Lunch was followed by a key speaker for the afternoon: John Kerr – Durr Universal – provided an introduction to acoustics on stationary power generation applications. He discussed issues such as: what we hear and how sound is measured; The acoustical characteristics of the sound and how they relate to the applications; Topography and the effects on sound; How silencers work and how they are sized.

Harry Douthwaite – ide Systems Ltd – followed this lecture with his own key presentation on Energy Management and Control Tools. Sponsorship partners for this highlysuccessful event were WIP magazine, the Power Media International Group, UK Power News, and also Euro Power News magazine.

One attendee, Adam Thomas, CTO, had this to say about the event: “Thanks for running the event, it was a good place to network with other people in the generator industry.

“The talks were informative and helped to give a good summary of the issues and opportunities in the market.”

Marc Cooper, Sales Manager, MEMS Power Generation, commented: “Great day last week, thanks for organising and inviting me.”

Don’t miss the next PowerEx Live event on December 7th, 2023

PowerEx Live 2023 is once again being held for one day only at London’s Park Plaza Hotel, on Thursday, 7th December, 2023, Westminster Bridge, London. PowerEx Live has enjoyed a growing reputation as a venue offers the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With 24 conference speakers at the top of their respective fields, alongside premier display space in a worldclass venue, this event has become a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue on one special day on December 7th, 2023.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run in parallel with prime exhibitor space available in adjoining rooms. This represents a not-to-be-missed chance for companies to take their products to their customers in an environment which fosters opportunities for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets. The reach of products and Topics involved is not just pan-Europe but global too: Training, Engines, Controls, Alternators & Generators.

New - The Training & Equipment Zone PowerEx Live 2023 will also feature a special Training & Equipment zone This will cover four subjects presented by different companies. The object is to teach students, young people and other industry professionals about familiarisation with new equipment and aspects of training on the job within the industry.

One of the top speakers at PowerEx Live 2023 will be Ian Bitterlin, presenting papers on Data Centres and Energy Storage. Ian is a Chartered Engineer with more than 52 years in engineering including 32 years’ experience in data-centre power and cooling.

, He is a former CTO for Emerson Network Power in EMEA and Visiting Professor to the University of Leeds.

UK POWER NEWS JULY/AUGUST 2023 15 POWEREX LIVE NORTH

“Thanks for running the event, it was a good place to network with other people in the generator industry. The talks were informative and helped to give a good summary of the issues and opportunities in the market.”

- Adam Thomas, CTO, on the PowerEx Live North event in Cheshire.

16 JULY/AUGUST 2023 UK POWER NEWS

LIVE

POWEREX

NORTH

UK POWER NEWS JULY/AUGUST 2023 17

DAY

POWEREX LIVE NORTH - GOLF

THE POWEREX LIVE NORTH GOLF DAY

Participants at PowerEx North also enjoyed an active GOLF DAY held for those people staying on. Staged a day after the PowerEx Live North this was generally regarded as the perfect opportunity for “unwinding and combining business with sport,” as one golfer put it. The PowerEx Live golfers were able to enjoy an impressive 18-hole, 6,882 -yard, par-71 course at The Mere. This was designed by James Braid and was created out of 150-acres of Cheshire parkland in 1934 - and has been enjoyed by golfers ever since, reports UKPN. The Championship course holds a well-deserved

Organiser Richard Teasdale.commented:

“The PowerEx Live North GOLF DAY proved an epic and thoroughly-enjoyable event for everyone taking part.

“It was hugely entertaining display of individual skill, determination and good humour. We were blessed by good weather and players of all competency levels were able to enjoy a whole day of pure, uninterrupted golf in the sunshine at a truly wonderful venue.

“It is impressive how competitive people can get at the prospect of winning fancy prizes - and we had plenty of those to match just about every category. We look forward to repeating this success at another golf event to be announced in 2024.”

The Championship course at the Mere, Cheshire, holds a well-deserved reputation as one of the best-maintained and highest-quality golf courses in the North of England.

Surrounded by mature trees, flowering banks and with stunning views over the Mere Lake, the course offers the charm of the Cheshire countryside, coupled with a range of challenging features to test the precision and driving skills of every golfer.

Water, ravines and thick vegetation have been incorporated into the landscape. The course has a reputation for demanding care and challenging accuracy from players whilst navigating the greens.

The results of the PowerEx Live North Golf Tournament were as follows:

Golf Day Prizes

Teams:

Winning Team - 94 points

Industrial & Marine Silencers Ltd

Chris Patterson, Danny Buttar, Glyn Rennocks and Richard Hughes.

Second place Team- 91 points

Jeremias UK – Chimney Systems

Andy Harper, Joe Murphy, Peter Law and Shaun McDonnell.

Individual Prizes:

1st Place- 42 points

Chris Patterson

Industrial & Marine Silencers

2nd Place- 41 points

Lyn Burns PMIG

3rd Place- 39 Points Tom Rossiter

Hamilton Court FX

Putting Conpetition Winner - Kevin Jackson

United Rentals

Longest Drive:

Hole 7 - Lee Carey

United Rentals

Hole 15 - Anthony Wenden

Mems Power Generation

Nearest to Pin:

Hole 3 - Daniel Bradbury

The Jockey Club

Hole 8- Glyn Rennocks

Industrial & Marine Silencers Ltd

Hole 12 - Clint Noble

Finning (UK)

Hole 14 - Steve Davies

United Rentals

Nearest to Pin in 3:

Hole 1 - Steve Davies

United Rentals

Hole 18 - Nick Tvedt

Hamilton Court FX

18 JULY/AUGUST 2023 UK POWER NEWS POWEREX LIVE NORTH - GOLF DAY

TOTAL CONTROL FROM EVERY PERSPECTIVE

Anyone who knows gensets, knows that Mecc Alte is unrivalled for our knowledge and expertise worldwide. From alternators and controllers to an integrated generator system, we are the Power from Within. From prime power to standby power, data centre, renewables, telecoms and more, Mecc Alte delivers complete intelligent systems with digital AVR to identify fuel efficiencies and every component working perfectly together. All backed up by the support and unbiased advice you only get from the world’s leading independent alternator specialists. Take 360° control. Talk to Mecc Alte.

The world’s largest independent producer of alternators 1 – 5,000kVA

FOR

INFORMATION VISIT WWW.MECCALTE.COM

FURTHER

www.megsa.org MEGSA FOUNDER MEMBERS: MEGA CONNECTIONS Get In Touch: sales@megsa.org sales@megsa.org | www.megsa.org | Middle East Gen-Set Association | Copyright © 2023 MIDDLE EAST GEN-SET ASSOCIATION

NEW 2,750 KVA DIESEL GENERATOR PACKAGE FOR A MAJOR NHS HOSPITAL

The Shenton Group was recently involved in the specification, supppy and installation of a new HV 2750kVA mtu unit - this is now providing a key role in supplying backup power at a major UK NHS hospital.

The contract included providing a bulk underground fuel tank, fuel transfer system, and bespoke 70@1 attenuation.

The mtu 16V4000 DS2750 380V – 11 kV/50 Hz/ standby power/fuel consumption optimised 16V4000G94F/water charge air cooling diesel generator set has a Power rating - System ratings: 2800 kVA - 2860 kVA, accepts rated load in one step per NFPA 110.

The generator set complies to G3 according to ISO 8528-5 and the set exceeds load steps according to ISO 8528-5 Benefitds of the new genset include:

* Low fuel consumption

* Optimised system integration ability

GENSETS

*High reliability

*High availability of power

*Long maintenance intervals

The engine generator set is designed and manufactured in facilities certified to standards ISO 2008:9001 and ISO 2004:14001. The generator set complies with ISO 8528 And meets NEMA MG1, BS5000, ISO, DIN EN and IEC standards - NFPA 110.

In terms of power rating the system ratings is 2600 kVA. It has been designed to accept rated load in one step per NFPA 110. The generator set complies to G3 according to ISO 8528-5. The generator set exceeds load steps according to ISO 8528-5.

It comes with a performance assurance certification (PAC) showing that the enginegenerator set has been tested to ISO 8528-5 for transient response with an 85% load factor. This is a verified product design, quality and

performance integrity. All engine systems are prototype and factory tested. In terms of emissions this is a Tier 2 optimised engine and an NEA (ORDE) optimised engine as well.

A complete range of accessories is accesssories is available with this model. These include: control panel; power panel; circuit breaker/power distribution; a fuel system; fuel connections with shut-off valve mounted to baseframe.

Also available is a starting/charging system; an exhaust system; mechanical and electrical driven radiators; and medium and an oversized voltage alternators.

www.mtu-solutions.com

www.rolls-royce.com

UK POWER NEWS JULY/AUGUST 2023 21

A new HV 2750kVA mtu unit is now providing backup power at a major UK NHS hospital. The installation - by the Shenton Group - includes a bulk underground fuel tank, fuel transfer system, and bespoke 70@1 attenuation.

“ The Shenton Group has over 35 years of experience and expertise in Standby Power, Uninterruptible Power Supplies and Combined Heat and Power Supplies, delivering lifesaving power solutions to the healthcare sector.”

4,000+ visitors from energy, environment, sustainability and climate action space

69% of visitors are budget holders or influencers

+£1m annual spend on Energy Efficiency, Management & NetZero projects confirmed by a ¼ of visitors

82% of exhibitors rated the quality of visitors as excellent

BY

The Net Zero & Energy Management Expo 22-23 November 2023 • ExCeL London Contact: Ray Green, Sales Manager, EMEX London M: 07764438075 / 07881803480 BOOK YOUR STAND TODAY www.emexlondon.com

SPONSORED

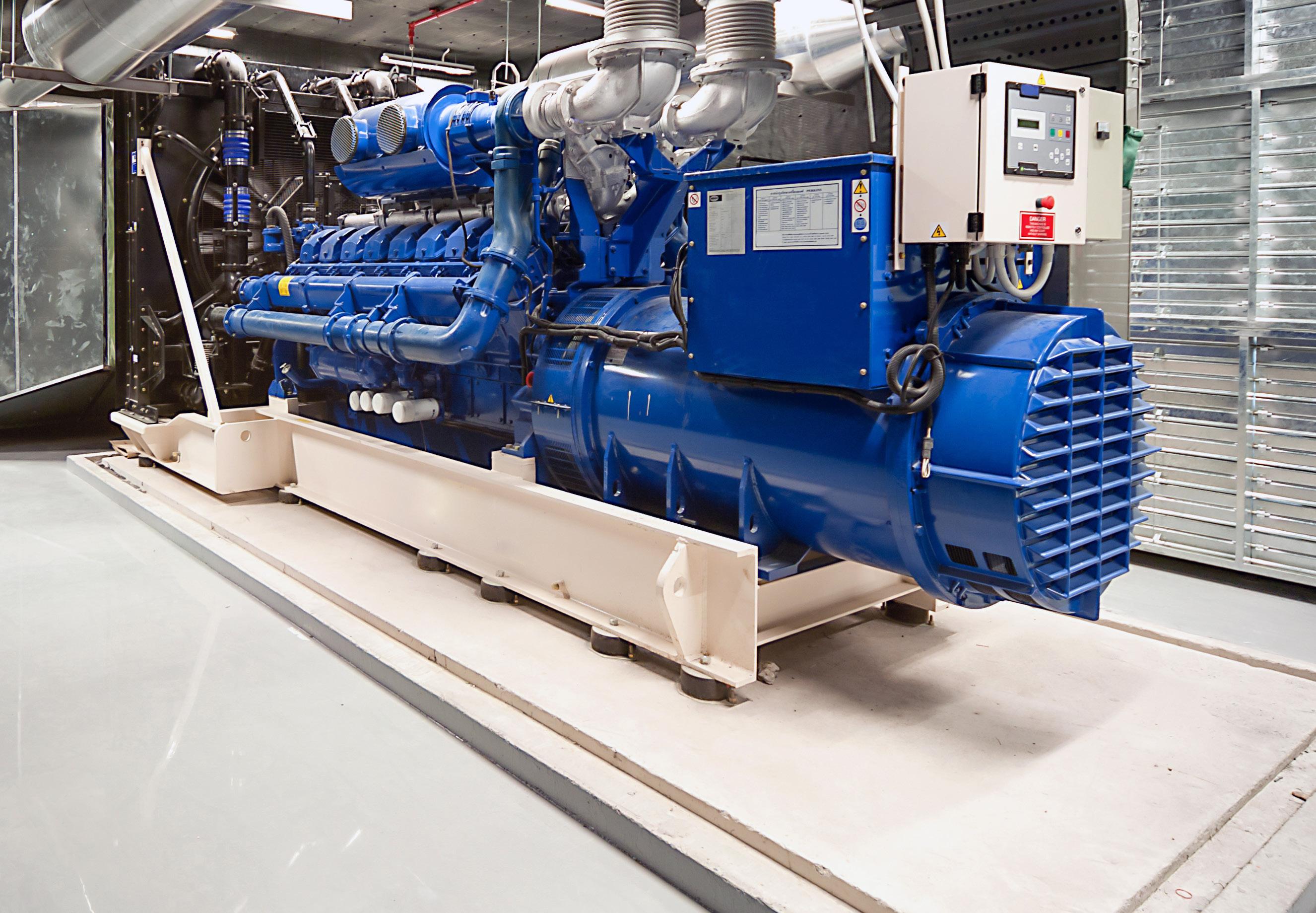

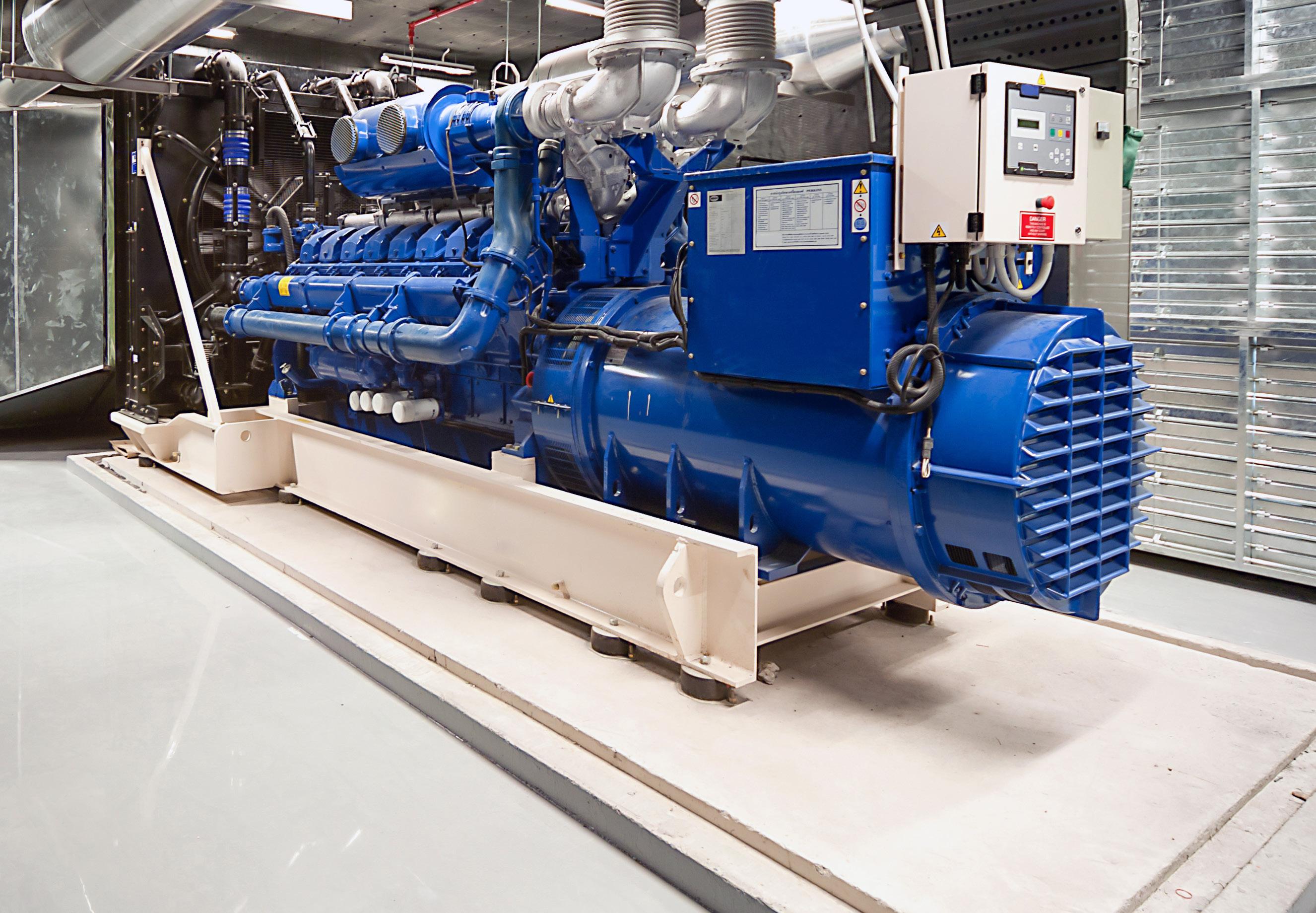

A BESPOKE GENSET FOR A CARE HOME IN LEIGHTON

home

B

ack in 2021 CPS was contacted by an M&E Contractor regarding a specification they had received from a design consultant. The specification was for a bespoke diesel generator system for a care home in Leighton Buzzard. The design consultancy had been contracted by a company which was about to begin construction of a care home for the elderly. The company approached CPS hoping its technical experts would work with them to manufacture a bespoke power supply system. CPS reports that this project was set in motion with a nearly two- year lead time. This was to

ensure that the power system was ready in time for the care home’s grand opening.

The care home at Leighton Buzzard was looking for a back-up power system to kick into action and power the site in the case of a main grid failure.

This system was required to power basic appliances in their resident accommodation, such as lights, kitchen appliances and security systems.

The vital medical equipment used onsite was one of the reasons why the generator was needed in time for the opening.

for a back-up power system to kick into action and power the site in the case of main grid failure. This system was for powering appliances in their resident accommodation, such as lights, kitchen appliances and security systems.”

A 100% reliable power supply was needed for equipment such as artificial ventilators and nebulisers.

The care home authorities felt this was an absolute necessity for their complex to ensure the comfort, safety and well-being of the residents.

Stephen Lucas (a CPS sales manager) was in charge of this project and as the care home neared completion, the generator was prepared.

A company spokesman comments: “During this project we remained flexible as there was no set time frame. Stephen adapted well throughout and continued to work with the M&E contractors to ensure all the clients needs were met.”

Standby generator details

The diesel denerator was an AS300S 300kva genset with a Scania engine. An Automatic Transfer Switch was incorporated into the genset to allow for instant power connection transfer in the case of mains failure.

CPS added a Water Jacket Heater to aid in engine start-up during cold conditions. The system was housed into a super silent canopy to reduce the noise level from 82dba to 65dba to avoid any disruptions it might cause while running for employees and residents.

Also added was a fuel tank upgrade to hold 24-hrs’ worth of fuel at 100% – this allows for of 24-hrs of uninterrupted operation at one time from the larger fuel storage capacity.

To ensure the success of this project the customer chose to include CPS Diesel Generator Commissioning to ensure that the generator will always be properly functioning onsite.

The comissioning process includes a generator load bank test, protective function checks as well as full visual checks.

Finally, to ensure the longevity and continual efficiency and smooth-running of their bespoke genset, the care home management opted for CPS Diesel Generator Servicing, with one minor and one major service per year.

A CPS spokesman comments: “We highly recommend conducting Generator Servicing for the proper maintenance of a genset, especially for emergency generators as it is vital they are ron stand-by at all times.

“This client selected Constant Power Solutions as they required a bespoke, UK-manufactured genset.”

www.cps-generators.com

UK POWER NEWS JULY/AUGUST 2023 23

Constant Power Solutions supplied an M&E Contractor with an AS300S 300kva genset powered by a Scania engine. The contract, involving a care home, included a generator load bank test, protective function checks as well as full visual checks and - finally - a CPS Diesel Generator Servicing agreement with one minor and one major service for the standby genset per year, reports UKPN.

GENSETS

“The care

was looking

OPTIMAL MUSHROOM GROWTH THANKS TO CHP

ACHP plant with an MWM gas genset ensures high mushroom yields all year round at moderate energy costs for the mushroom producer, the Hajduk Group Sp.z o.o. in Poland. Polygeneration makes it possible.

Poland is the world’s leading exporter of mushrooms and truffles, ahead of China (Statista 2022), and the market leader in European mushroom production.

One of Poland’s leading mushroom and mushroom substrate producers is the Hajduk Group Sp.z o.o. The Hajduk Group produces around 160 tonnes of mushrooms per week in four cultivation plants.

As mushrooms are energy-intensive in production, the company already invested in a CHP plant in 2018. The cogeneration plant with an MWM TCG 2020 V16 gas genset was supplied by the official MWM distributor in Poland, Centrum Elektroniki Stosowanej CES Sp. z o.o..

Using polygeneration, the plant produces electricity and heat but also cooling and steam for mushroom cultivation.

Best conditions for mushroom cultivation

For a year-round harvest, mushrooms need stable growing conditions with the proper humidity and temperature.

Typically, this means cooling in summer and heating in winter with the help of air conditioning. Mushrooms are energy-intensive to produce.

The energy costs of the production facilities, therefore, significantly affect the mushrooms’ final price.

To keep these costs as low as possible, the polygeneration plant supplied by Centrum Elektroniki Stosowanej CES Sp. z o.o. is based on CHP. Liquefied natural gas is used as fuel.

Agricultural production plants far from conurbations and large cities often have limited connection options to the natural gas grid. To operate a CHP plant, Hajduk Group relies on LNG for its CHP plant with a capacity of over 1.5 MWe. With this solution, polygeneration plants can be installed almost anywhere.

Engine exhaust heat for cooling

Thanks to the additional equipment, the CHP plant generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset to generate cooling for the halls.

The absorption chiller has a capacity of 720 kW. Steam is used to sterilise the refrigeration halls between production cycles.

For this purpose, the high-temperature heat of the exhaust gases is used in the steam generator, which supplies 1,060 kg/h of steam at nine bar

to the additional equipment, the CHP plant generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

pressure. The hot water is also used for washing and other technical purposes. CHP plant enables independent and flexible energy supply

In typical operation, the CHP plant with the MWM gas genset covers the entire demand for heating, cooling, steam, and electricity of the production facility at Hajduk Group.

Part of the electrical energy is used on hot summer days for additional cooling. In winter, the halls can, in turn, be heated with heat from the CHP plant.

The polygeneration system offers flexibly controllable energy generation with a heat and cooling supply. This allows Hajduk Group to maintain optimal production conditions for the popular edible mushrooms all year round while saving energy costs through the combined production of the different media.

The MWM TCG 2020 V16 gas gensets offer the highest ratings in ecology and economy:

- Output range from 1,000 to 1,560 kWel

- Best electrical and thermal efficiency in its output class

- Runs on all gas types: natural gas, biogas, landfill gas, sewage gas, mine gas, etc.

- Low operating costs.

The TCG 2020 is mainly used for CHP plants in Europe and for biogas worldwide.

The MWM gas gensets of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment.

The models in the output range of 1,000 – 1,560 kWel are said to meet the high requirements of a broad range of applications and offer efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability. www.mwm.net

24 JULY/AUGUST 2023 UK POWER NEWS CHP

Producing and exporting mushrooms & truffles represents a major business concern in Europe today. Here, MWM looks at how one major grower is relying on energy from MWM gas gensets & CHP.

“Thanks

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset.”

PIONEERING ZERO CARBON HEAT SOURCE FOR THE CITY OF LONDON

“Tackling the environmental impact of heating, especially in densely populated areas, will be key to meeting the UK’s 2050 net zero targets. Part of that challenge means re-imagining how energy is provided to homes, businesses and cities. In taking the next step and installing heat pump and geothermal technology at Citigen we’ve made a powerful statement of what can be done to reduce carbon usage on a large scale. “The Citigen building itself has a long and storied history, and our £4m investment in a zero carbon heating and cooling system gives it an exciting new chapter and makes sure it’s fit to support the capital’s cleaner future.“

E.ON has completed a £4 million project to install one of the UK’s largest zero carbon heating and cooling systems, beneath the streets of London.

The heat pump installed at E.ON’s Citigen energy centre in the heart of London’s square mile draws from the natural warmth of the earth as well as recycling waste heat from power generation which would otherwise vent into the atmosphere.

This energy can be stored in three boreholes extending 200 metres below the capital and provide zero carbon heating and cooling for buildings.

The 4MW of extra heating capacity is equivalent to the demand of 2,300 average UK homes and is complemented by a further 2.8MW of new cooling capacity to customers across the financial district.

The new technology adds to Citigen’s existing combined heat and power engines which already produce enough electricity and heating for the equivalent of more than 11,000 homes.

To celebrate the installation of the heating and cooling system, E.ON even unveiled an ice sculpture in Charterhouse Square taller than a London bus, showcasing iconic landmarks and E.ON’s heat network that lies beneath the city’s streets.

The innovative heat pump and borehole solution cuts the carbon emissions associated with heating and cooling by up to 50% and will help to improve local air quality by reducing nitrogen oxide emissions.

The project is now an important part of the city’s wider efforts to meet net zero targets and contributes to London’s climate emergency plans.

Michael Lewis, E.ON UK Chief Executive, said:

Energy Minister Lord Callanan, said: “Heating in buildings forms a significant part of the UK’s carbon footprint, so changing how we warm and cool our homes and workspaces is a vital part of eradicating our contribution to climate change by 2050.

“Heat networks offer an effective way of reducing carbon emissions while bringing down costs to consumers.

E.ON’s project is a commercial vote of confidence in heat networks and heat pumps, meaning homes and businesses across the City of London will benefit from clean heat and is another great example of how the pace of rolling out cuttingedge low-carbon technologies is being accelerated across the UK.”

Catherine McGuinness, the City of London Corporation’s Policy Chair, said: “This scheme offers a really creative solution to helping meet our energy needs and tackle climate change, by tapping into the earth as a sustainable energy source.

“Innovative projects like this will play a hugely important role in helping us meet the ambitious goals set out in our Climate Action Strategy of achieving net zero carbon status for our operations by 2027 and for the Square Mile as a whole by 2040.”