ANTIFRAGILE GLASS

edited by Maria Antonia Barucco, Elti Cattaruzza, Rosa ChiesaANTIFRAGILE GLASS

supported by

Antifragile Glass edited by Maria Antonia Barucco, Elti Cattaruzza, Rosa Chiesa

Printed version ISBN 979-12-5953-034-9 Digital version ISBN 979-12-5953-096-7

This publication is an Open Access Gold book. The publication file is freely downloadable from the Anteferma Open Books platform (https://www.anteferma.it/aob/index.php/antefermaopenbooks/index)

Anteferma Open Books is the platform for publishing research volumes, respecting ethical and qualitative standards and the provision of open access content.

Book design Margherita Ferrari

Editorial board Emilio Antoniol, Rosaria Revellini

Publisher Anteferma Edizioni Srl via Asolo 12, Conegliano, TV edizioni@anteferma.it

First Edition November 2022

Copyright

This book is published under a Creative Commons license Attribution - Non Commercial - Share Alike 4.0 International

ANTIFRAGILE GLASS

This volume collects proceedings from the ANTIFRAGILE GLASS Conference - Venice November 18th, 2022

PROMOTED BY Università Iuav di Venezia, Università Ca’ Foscari Venezia, MUVE Fondazione Musei Civici Venezia

SUPPORTED BY Fondazione Universitaria Iuav, Regione Veneto, OFFICINA*, Anteferma, Rehub

PARTNERSHIPS

SITdA Società Italiana della Tecnologia dell’Architettura, International Year of Glass 2022, Promovetro Murano, Future Cities Research Hub, CoReVe, Consorzio Nazionale Imballaggi, Confindustria Venezia Area Metropolitana di Venezia e Rovigo

SCIENTIFIC COMMITTEE

Michele Back Università Ca’ Foscari Venezia; Laura Badalucco Università Iuav di Venezia; Adolfo Francesco Lucio Baratta Università degli Studi Roma Tre; MariaAntonia Barucco (chair) Università Iuav di Venezia; Paola Boarin University of Auckland; Laura Calcagnini Università degli Studi Roma Tre; Andrea Campioli Politecnico di Milano; Elti Cattaruzza (chair) Università Ca’ Foscari Venezia; Cristiana Cellucci Università Iuav di Venezia; Rosa Chiesa (chair) Università Iuav di Venezia; Massimiliano Condotta Università Iuav di Venezia; Alessio Franconi Brunel University London; Elena Giacomello Università Iuav di Venezia; Francesco Gonella Università Ca’ Foscari Venezia; Monica Lavagna Politecnico di Milano; Ligia Moretto Università Ca’ Foscari Venezia; Giovanni Mucelli Università Iuav di Venezia; Serena Panighello Stevanato Group Lab Analytics; Augusto Panini Fondazione Musei Civici di Venezia; Barbara Pasa Università Iuav di Venezia; Alberto Quaranta Università di Trento; Raimonda Riccini Università Iuav di Venezia; Massimo Rossetti Università Iuav di Venezia; Chiara Squarcina (chair) Fondazione Musei Civici di Venezia; Setsuhisa Tanabe Kyoto University; Valeria Tatano Università Iuav di Venezia; Maria Chiara Tosi Università Iuav di Venezia; Dario Trabucco Università Iuav di Venezia; Enrico Trave Università Ca’ Foscari Venezia; Arianna Traviglia Centre for Cultural Heritage Technology dell’Istituto Italiano di Tecnologia.

ORGANIZING COMMITTEE

Emilio Antoniol Anteferma Edizioni, Università Iuav di Venezia; Margherita Ferrari Anteferma Edizioni, Università Iuav di Venezia; Pietroluigi Genovesi MUVE; Rosaria Revellini Università Iuav di Venezia; Matteo Silverio Rehub.

ORGANIZING SECRETARIAT

Letizia Goretti BnF Parigi; Marta Possiedi Università Iuav di Venezia; Daniela Fontana Fondazione Universitaria Iuav; Chiara Pagani Fondazione Universitaria Iuav.

ANTIFRAGILE GLASS

MARIA ANTONIA BARUCCO, ELTI CATTARUZZA, ROSA CHIESAThe year 2022 is the International Year of Glass, established by the United Nations with Resolution 75/279. Università Iuav di Venezia, Università Ca’ Foscari Venezia and the Fondazione dei Musei Civici Veneziani are celebrating 2022 with ANTIFRAGILE GLASS: a conference, an exhibition and a publication, but also, and most of all, a celebration of a material, an ancient art form and an industry in constant evolution.

The objective of the UN is to highlight glass technologies and their potential contribution to addressing the challenges of sustainable development and inclusive societies. With this in mind, ANTIFRAGILE GLASS examines the past and future of glass, so that those who work and study this material can continue to ensure that crises are, to all intents and purposes, new starting points for bold innovations.

For many years, Università Iuav di Venezia, Università Ca’ Foscari Venezia and the Fondazione dei Musei Civici Veneziani have been involved in training, research and promotion of the history and innovation of glass. The year 2022 was therefore chosen as the ideal time to establish potential partnerships, to structure the dialogue between the region and academia with new guidelines, to challenge young people to imagine the future, to learn from the past and to describe the current state of the art.

The ANTIFRAGILE GLASS programme was designed to promote opportunities for exchange, interaction and discussion. Developed during a period between the initial resumption of collective life and the outbreak of the war in Ukraine, it is therefore a proudly optimistic, broad and challenging programme. ANTIFRAGILE GLASS is an opportunity for discussion, to envision the future of glass, to meet and discuss the need to respond to crises and work on new projects. ANTIFRAGILE GLASS is an opportunity to reaffirm the interest in continuing, renewing or reinventing the aptitude for innovation that craftspeople, manufacturers and researchers share.

Even the title, ANTIFRAGILE GLASS, affirms these objectives. Nassim Nicholas Taleb has proposed using the adjective “antifragile” to describe a new worldview; indeed, this very adjective is the title of his acclaimed book, published in 2012, in which he emphasises the difference between resilience and antifragility. Those who are resilient stand the test of time and retain their structure, their choices and their goals. Those who are antifragile change over time and with time grow, transform, evolve or regress in alternating phases; this renders them consistent with the present day and often innovative. Research, culture, and glass are antifragile. Antifragile is the property of remaining strong during the fluctuations between authority and checks and balances. Antifragile is the ability to develop new ways of thinking and new products in the constantly changing human, economic, and political environment. Antifragile has a stubborn, challenging and revolutionary character. Antifragile is an attitude that becomes stronger in adversity. The city of Venice must also, now more than ever, persists in becoming fully antifragile.

ANTIFRAGILE GLASS enters into a dialogue with this definition and provides evidence that, throughout history, glass has faced challenges, crises, and innovations by transforming technologies, processes, production methods, shapes and designs, while continuing to enhance the characteristics of the material. Glassmakers, innovators, scientists, artists, entrepreneurs and designers have studied and worked with this material; one that has accompanied mankind in the development of new products since the very dawn of civilisation. The material, its design and its technologies are transformed by fulfilling different functions, affirming some of its characteristics and modifying others, adapting to changing contexts and demonstrating a capacity for innovation.

The history of Murano glass is such an example of antifragility. Many crises have affected this art form; they have exhausted and renewed it, put it to the test, overcome and strengthened it. Antique glass more than a thousand years old is very different to the glass that is created in the kilns of Murano today, but between these two manifestations there exists a strong historical and cultural bond. An antifragile, stubborn, and tenacious culture, in as much as it is willing to rise to the challenge of learning the new and from the new. The characteristics that can be observed in a small but highly-valued geographical area – the island of Murano – are also recognisable in academic research, in science, in art-historical and archival research, in design skills, in business culture, and in the skills of the artists and designers who work with glass. It is for this very reason that glass is antifragile.

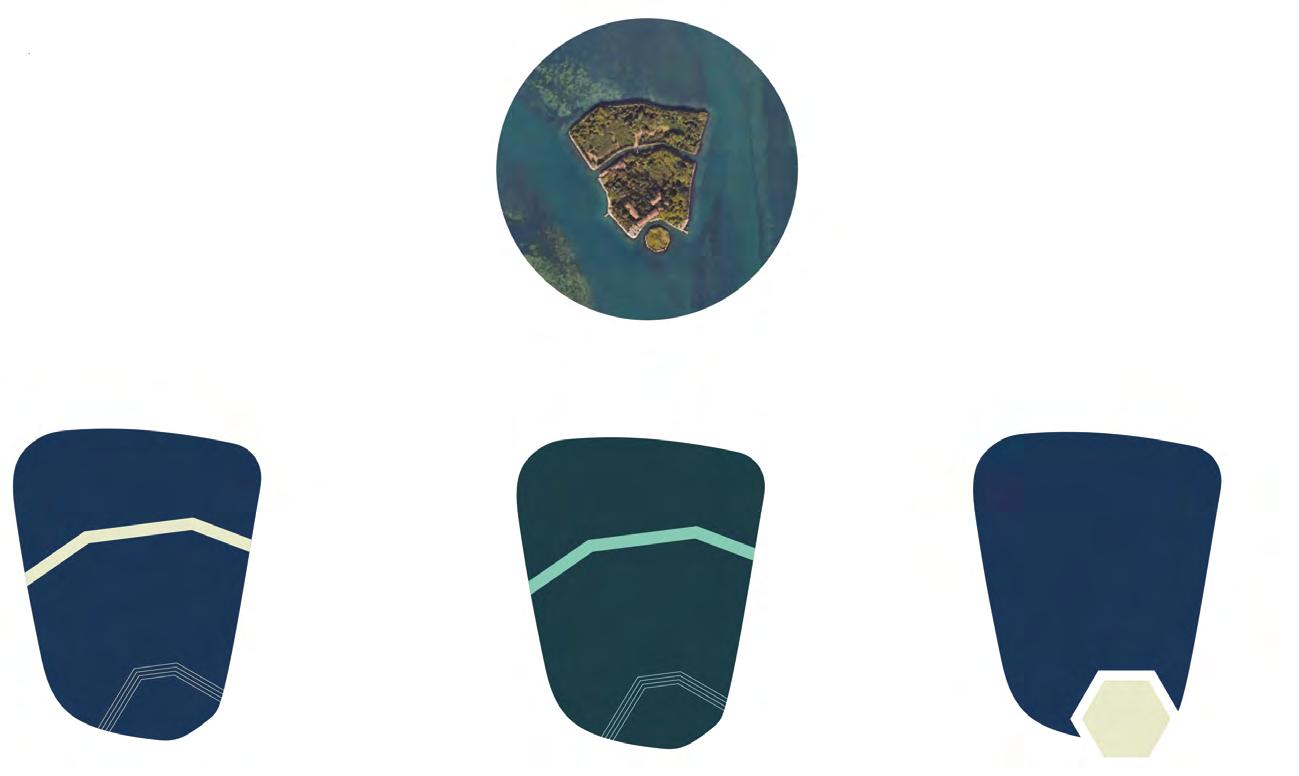

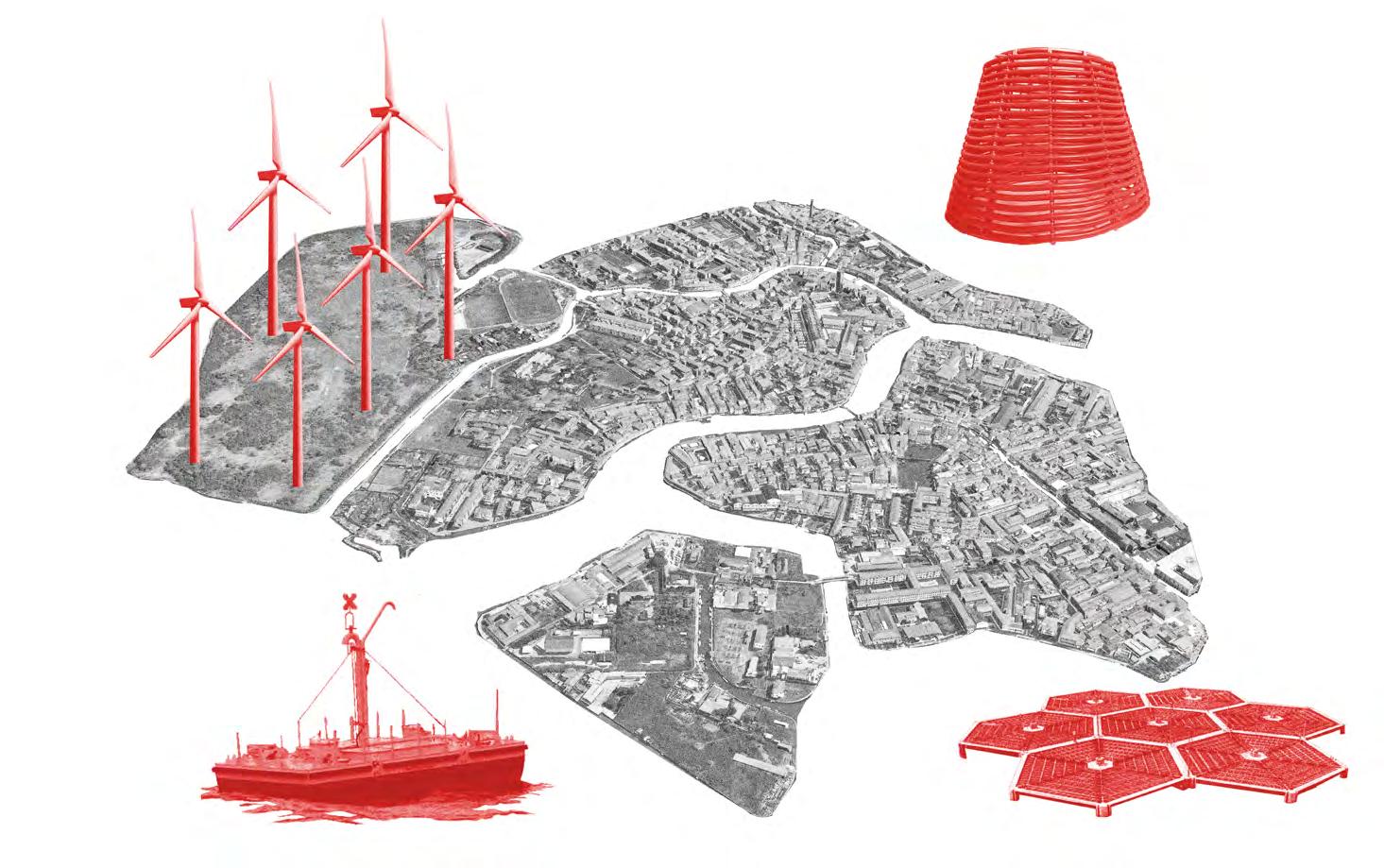

And to draw the attention of young people to these issues, to invite them to describe their vision for the future of glass and to emphasise the value of shared work, we organised a residential interdisciplinary workshop entitled VETRO FUTURO, which took the form of a hackathon. Strongly endorsed by Università Ca’ Foscari Venezia and organised by Università Iuav di Venezia, VETRO FUTURO was included in the programme of The Italian Glass Weeks 2022. This volume of proceedings presents the outcomes in the form of three posters, material produced by twelve master’s degree students from the two Venetian universities. What clearly emerges from these papers is the extraordinary ability of these students to reframe the issues we face as starting points for recognising that these problems represent opportunities and new challenges. With this approach, everything can be reevaluated. With muraNEWABLE, the energy supply issue that is affecting Murano becomes an opportunity to rethink energy sources for sustaining a large territory, while poroVE suggests the recycling of waste glass to exploit its chemical and physical characteristics in order to address the complex problems of drinking water pollution and microplastics; finally, wearGLASS proposes the technology transfer of innovations to the fashion industry, which could enable even the most underused waste (such as discarded plate glass from buildings) to be exploited. In this context, Murano and Venice serve as a laboratory of ideas and a hotbed of experimentation, land and culture: ingenuity and willingness to work together are the qualities that the students lend to the universities they attend and to the proposed outreach to local companies. The

editors of this volume aim to seize this momentum in order to work on glass with an increasingly international, collaborative and inclusive outlook.

A call for papers, an exhibition, a workshop and a publication, but, above all, a place for dialogue: all this serves as an important reminder that we cannot be antifragile alone. Antifragility is a quality that can only be developed through a network of connections and bonds that, although in constant flux, recognise the value of antifragility, and support and benefit from it. When one node or connection in the network fails, others make up for this and develop new skills and aptitudes. Every failure, as well as being the actualisation of a crisis, is an impetus for fresh growth. ANTIFRAGILE GLASS is the result of a working method based on collaboration between many people.

For the support given to this work, sincere and grateful thanks are due to the organisations that supported it: Fondazione Iuav, Anteferma Edizioni, the OFFICINA* cultural association and the Regione del Veneto. Without these partners, ANTIFRAGILE GLASS would not be antifragile at all and would lack courage, perseverance and substance. Furthermore, we should not forget the sponsoring bodies, who believed in the value of a wide-ranging and complex project and encouraged its dissemination:

• Italian Committee of IYOG2022 – International Year Of Glass 2022

• CONAI – National Packaging Consortium

• Confindustria Venezia – Metropolitan Area of Venice and Rovigo

• Consorzio Promovetro di Murano

• COREVE – Consorzio Recupero Vetro

• Future Cities Research Hub, School of Architecture and Planning, Waipapa Taumata Rau – University of Auckland

• SITdA – Italian Society of Architectural Technology

The visual identity and, in particular, the logo of ANTIFRAGILE GLASS expresses this variety and diversity in its network of stakeholders: the atoms that make up the tetrahedron structure of silica draw a pattern and constitute the main “ingredients” in the “recipes” of the ordinary glass that is all around us. Silica atoms and three backgrounds, to highlight the three lenses through which we have chosen to investigate glass: science, architecture and design. These are just three among many other potential approaches, questions, perspectives and insights – the first three, and not the only three, points of view that Università Iuav di Venezia, Università Ca’ Foscari Venezia and the Fondazione dei Musei Civici Veneziani want to address.

ANTIFRAGILE GLASS is a set of research, teaching and third mission activities that has actively involved teachers and students in a dialogue with the historical, industrial and artistic activity of Venice, the glass capital of yesterday and tomorrow. Both the title and the logo representing the event express the hope that this opportunity for work, discussion and meetings will enable a varied and complex series of activities to be launched to support and enhance the present and possible future of a material that is as innovative as it is ancient.

TABLE OF CONTENTS

13. Glass and Science

ELTI CATTARUZZA

17. Glass and Architecture MARIA ANTONIA BARUCCO

21. Glass and Design

ROSA CHIESA

24. How the technological advancement of glazing changes cities’ identity: the example of Dubai CHIARA SCANAGATTA

34. Systemic reuse models for sustainable glass packaging design and innovation CRISTINA MARINO, PAOLO M. TAMBORRINI, LAURA MIOTTO, GIULIA FERRONATO

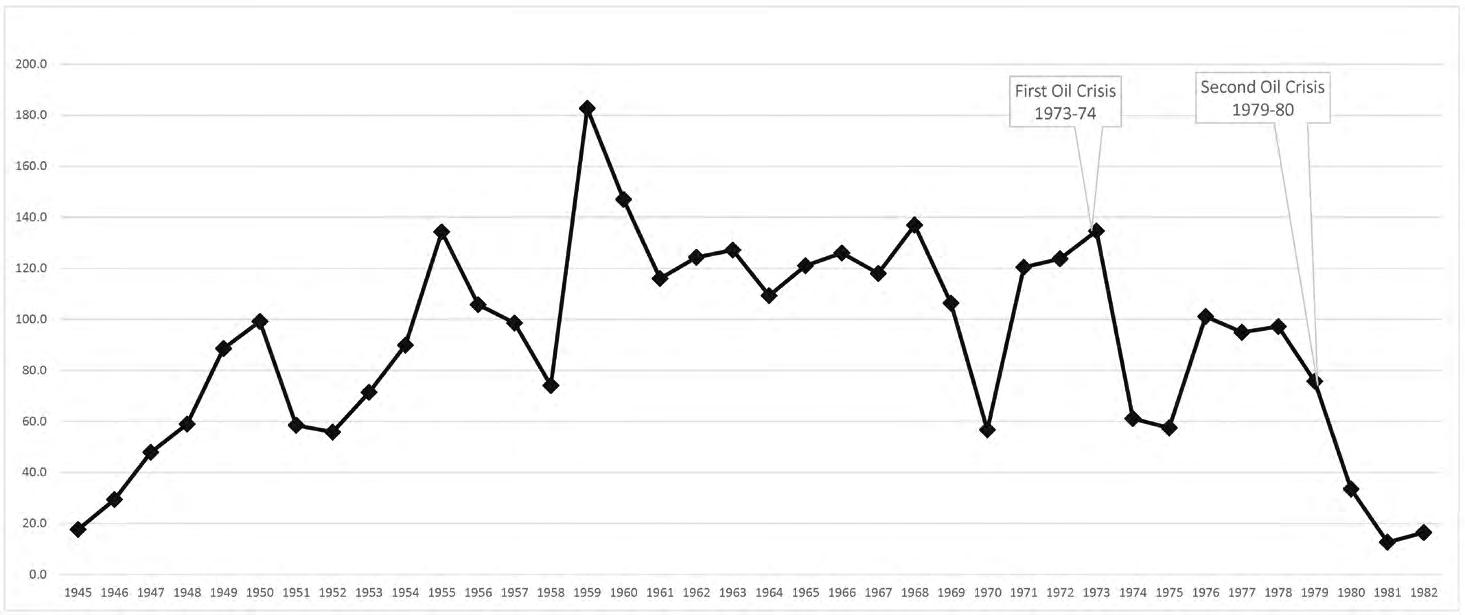

44. Fragile Business: Libbey-Owens-Ford and the impact of the 1970s energy crisis on the american glass industry GIORGIO MARFELLA

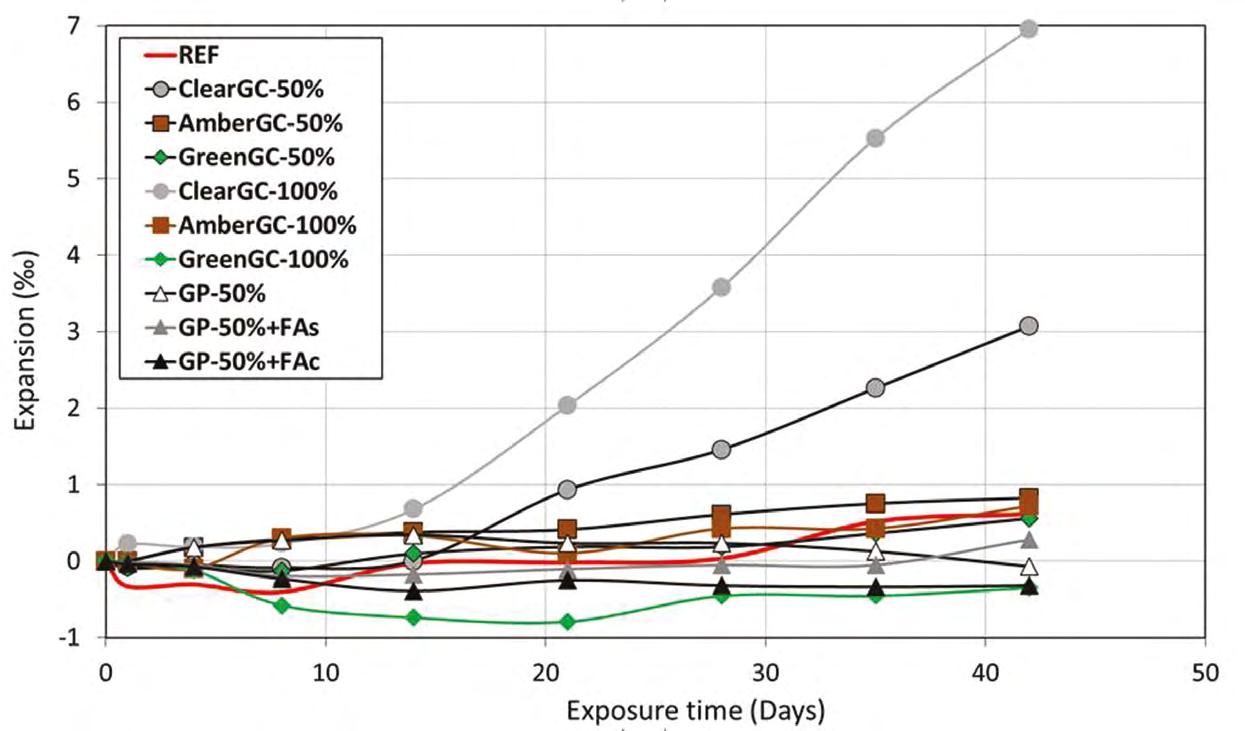

54. POSTER Use of waste glass as aggregate for cementitious mortars

JACOPO DONNINI, ANGELO MONTENERO, L. DAVID PYE, VALERIA CORINALDESI

56. Glass on stage. The woman of fire Marietta Barovier MASSIMILIANO CIAMMAICHELLA

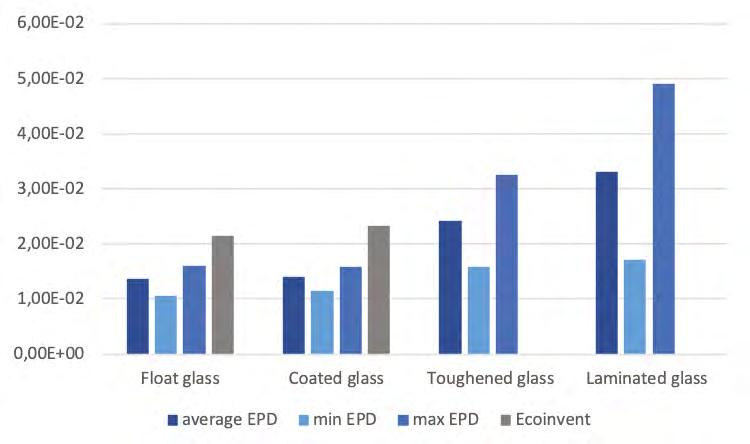

66. Insights into LCA and EPD environmental impacts data related to glass products for windows

ANNA DALLA VALLE, MONICA LAVAGNA, ANDREA CAMPIOLI

76. The “beautiful scraps” a precious resource ERIKA COCCATO, LAURA BADALUCCO

86. POSTER Ancient glass alteration and advancement in active conservation strategies

GIULIA FRANCESCHIN, ROBERTA ZANINI, STEFANO CENTENARO

88. Authorship in Glass Design in Portugal- Four Cycles: from 50´s to Contemporaneity

CLÁUDIA PEDRO SANTOS

98. MURANO PIXEL. An experimental and shared research

MARIA ANTONIA BARUCCO, ELTI CATTARUZZA, MATTEO SILVERIO

108. From industrial float glass to collectible design: the functional light sculptures Baracche, project by artist Paolo Gonzato

BEATRICE BIANCO, MARINELLA FERRARA

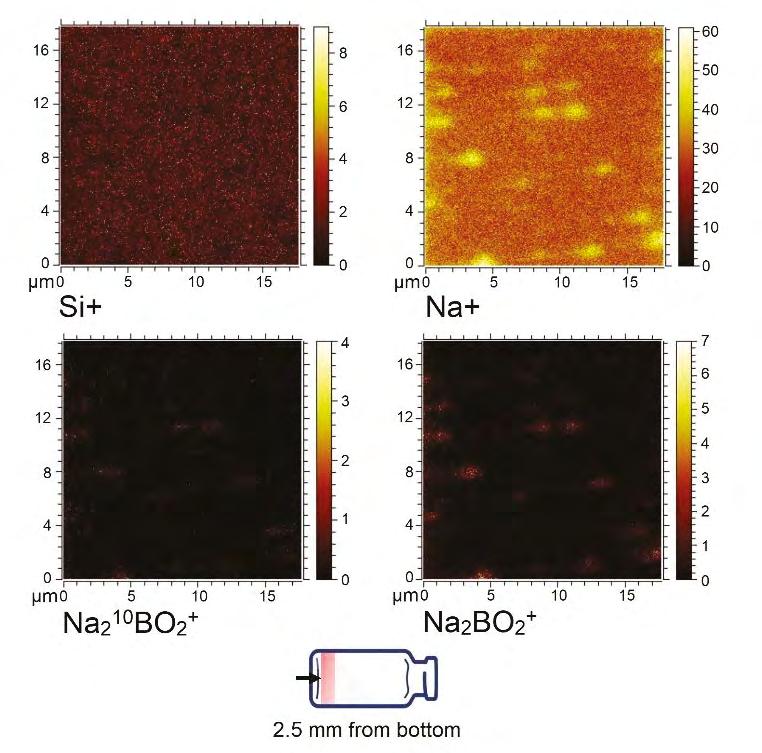

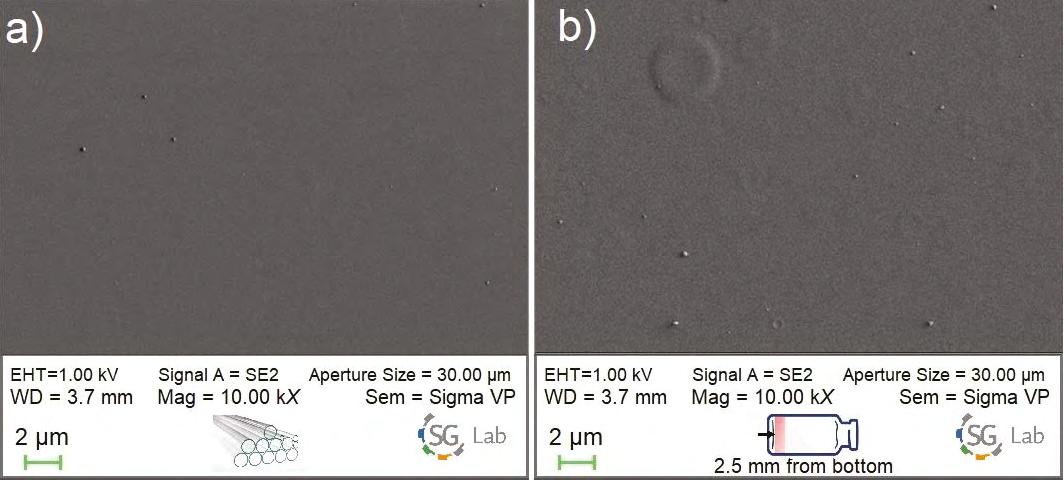

118. POSTER Physico-chemical and morphological characterization of inner surfaces of glass pharmaceutical vials

GIOVANNA PINTORI, SERENA PANIGHELLO

120. (E)merging layers in Venice. The potential of one landscape and single raw material

MAXIMILIANO ROMERO, ANNA LORENS

130. Air, light, and liquid in motion: blurred transparency of the Glass pavilion in Toledo

AKI ISHIDA

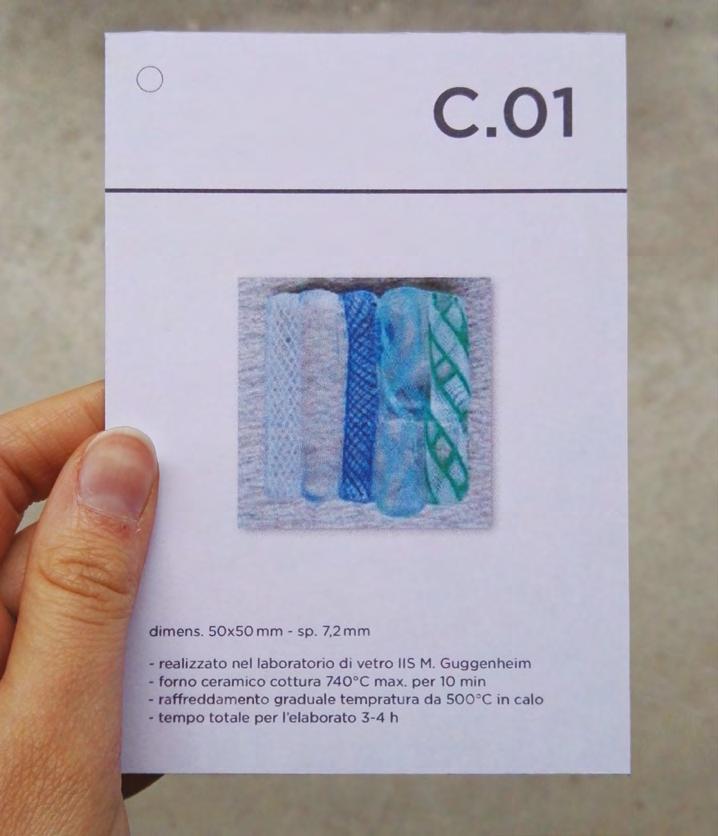

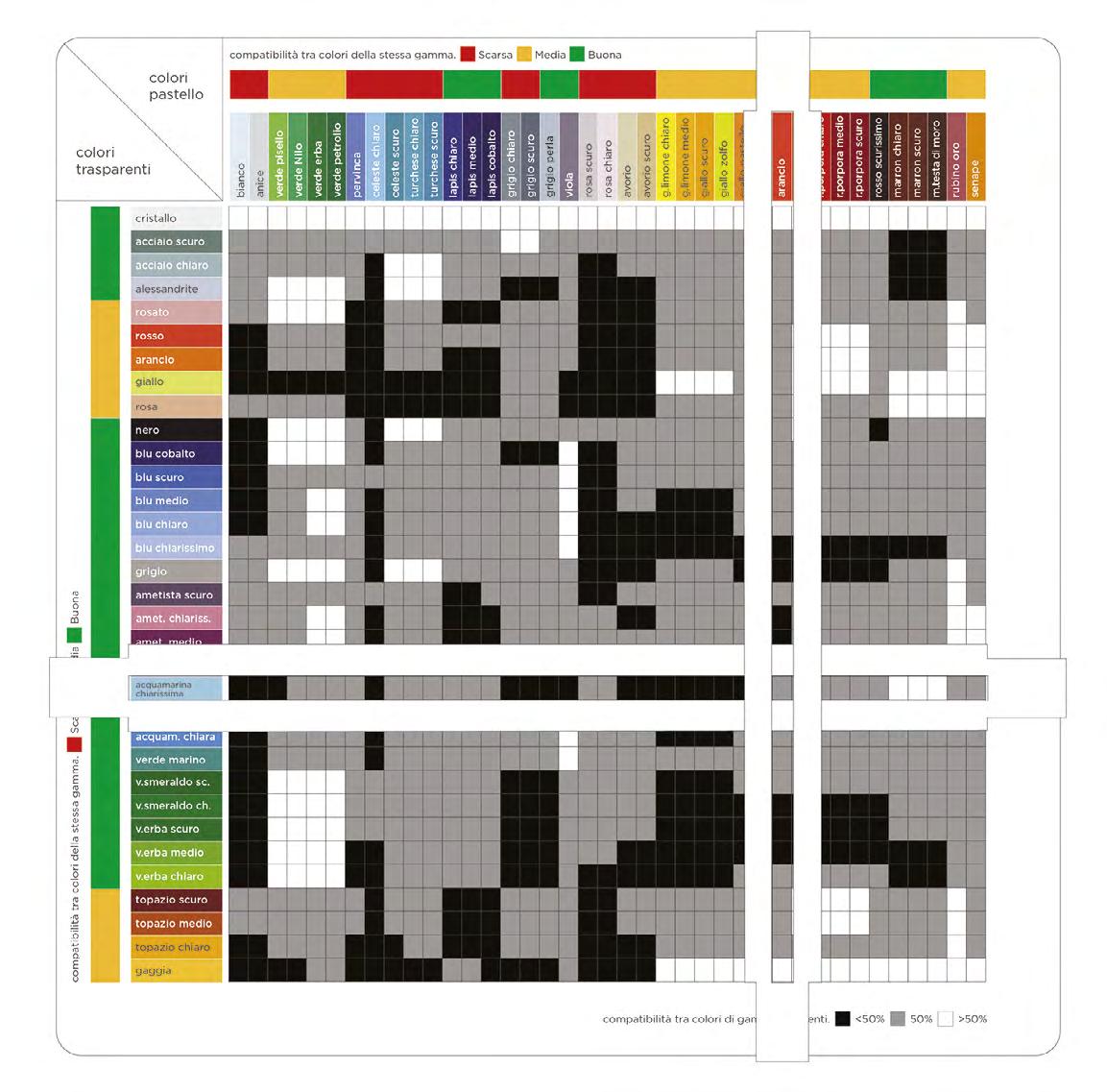

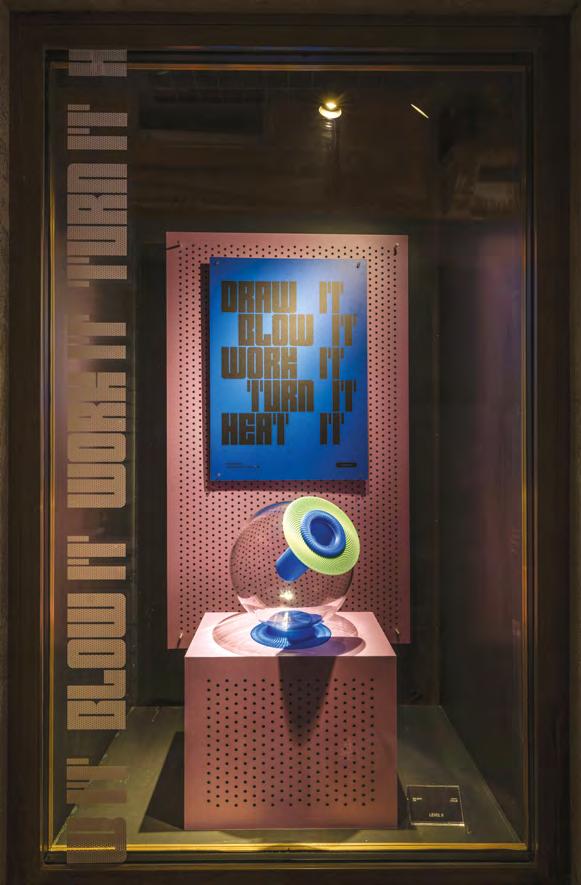

140. POSTER Glass-making workshop: fostering new design practices

SOFIA CRETAIO, CRISTINA MARINO, JOSEAN GARCIA DIAZ, PAOLO TAMBORRINI

142. Glass Future Lab. Murano glass production and digital manufacturing: possible relationships in a future scenario

ROSA CHIESA, RICCARDO BERRONE, LUCA COPPOLA

150. Innovation scenarios in the glass industry in Europe

LUCA TRULLI

160. POSTER XPS characterization of plasma-activated surfaces. A possible benefit for glass bonding

ANNE TALNEAU, CHRISTOPHE CARDINAUD

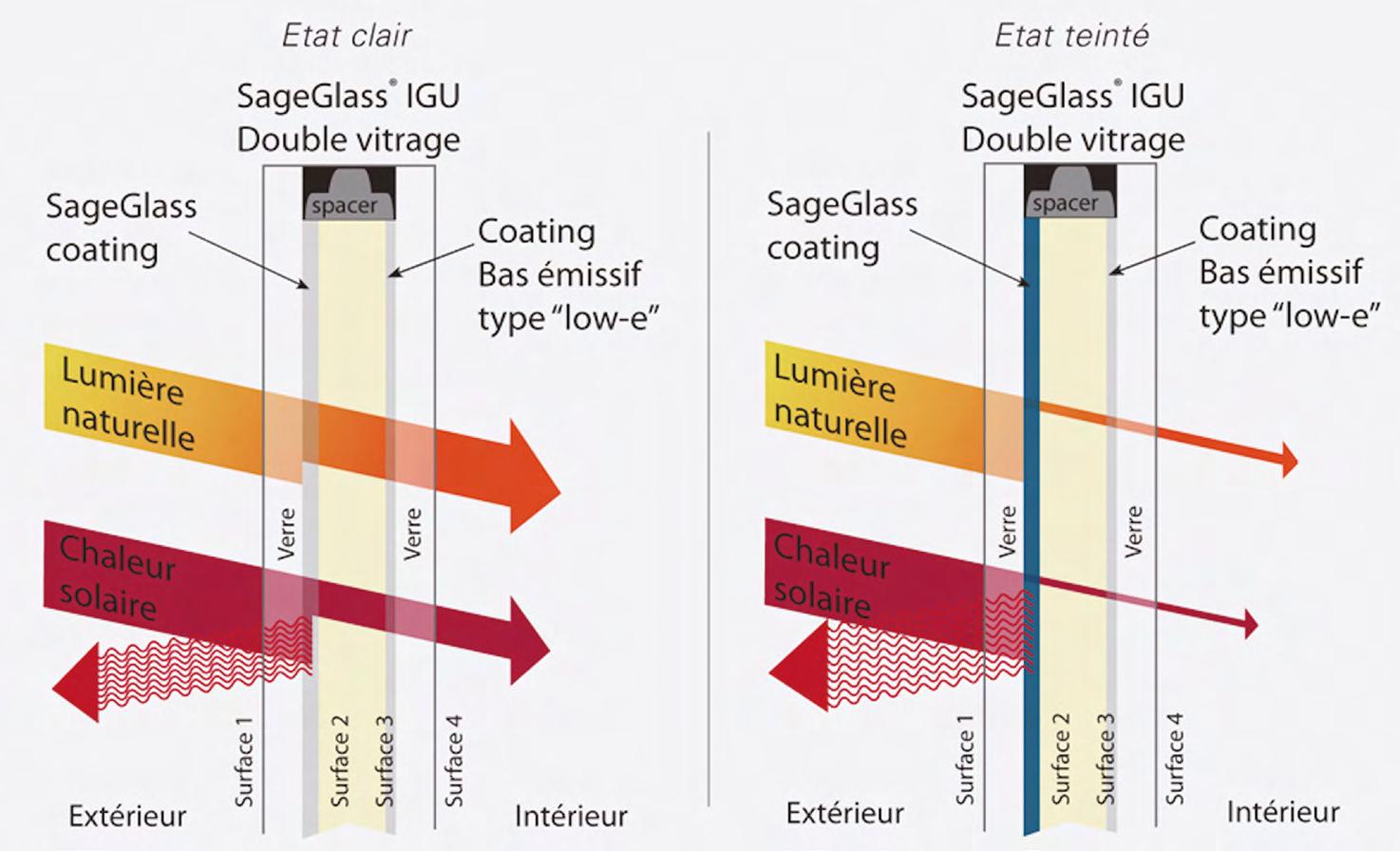

162. Technology hybridization for multi-performance variable glazing

CRISTIANA CELLUCCI, BENEDETTA MARRADI

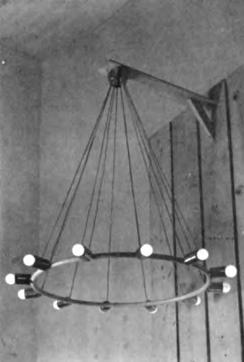

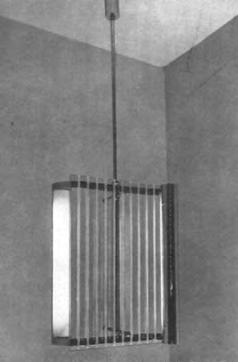

172. Glass and light. Suspension lamp design in Italy between 1930 and 1969 in the magazines

FEDERICA DAL FALCO, RAISSA D’UFFIZI

184. POSTER Guaranteeing the authenticity of VENINI Murano glass

ELENA TESSER, FABRIZIO ANTONELLI

186. Apparent divide. An observation of the handmade and the machine-made through the work of Laura de Santillana LAURA PANCHAUD

196. Digital manufacturing for Murano glass OMRI REVESZ

206. POSTER VETRO FUTURO muraNEWABLE: from the needs of glass comes a new energetic opportunity GIULIA CAZZADOR, GIANMARCO GNOATO, DANIELE VENDRAME, SOFIA ZANANDREA

208. POSTER VETRO FUTURO poroVE: the fluid value of the waste CHIARA GHIDINI, SARA LABIDI, IRENE MARTIN, ILENIA PESSOTTO

210. POSTER VETRO FUTURO wearGLASS: from waste to resource for wearable GIULIA DA PIAN, SERENA DE CONTI,NICOLA MASSIMI, MICHELE MESCOLIN

GLASS AND SCIENCE

ELTI CATTARUZZA

Glass is an extraordinarily distinctive material. Its uniqueness is recognised by ordinary people, who value its colour and luminosity in everyday objects such as glassware and in the most sought-after items such as glass beads (included on the UNESCO List of the Intangible Cultural Heritage of Humanity since 2020), but also by scientists who understand and explore its innermost patterns of behaviour, discovering that it flouts the usual rules that other common materials, such as metals, follow. Glass is in the transparent cup we can use to drink a fantastic vintage red wine, capable of making us fly over Mount Parnassus... but that cup is made of a material with devilish properties. A material considered fragile? This is just a small aspect of its existence. That same material can make our daily lives better, thanks to its features explored in smart windows, in optical fibres, in the flexible glass of some now commonly used devices, and in bioglass, which are bioactive glass materials that are capable of stimulating bone regeneration... This is why we prefer to think of it – in a way that is more inclusive of all its distinctive features – as an antifragile, enduring material that persists, undaunted, in remaining mysterious, complex, multifaceted, elusive and perennial. Its properties are never hic et nunc, because they depend on its history, on the chronology of the thermal processes that led it to become an object, on the atmospheres it went through in its creative labour. And will the form it has now taken really be the final one, for a material that can always prove to be as divine as it is infernal? Or is it just our desire as humans to demand it to be eternal, static, as if it were a cornerstone of our ability to conquer matter? Glass can often provide answers, but above all it raises endless questions that transcend science by meeting art, that go beyond mere utility by enchanting and rousing the senses. It is no coincidence that the poet Wisłava Szymborska, winner of the Nobel Prize for Literature in 1996, once wrote about a man who “built himself a glass violin because he wanted to see the music”.

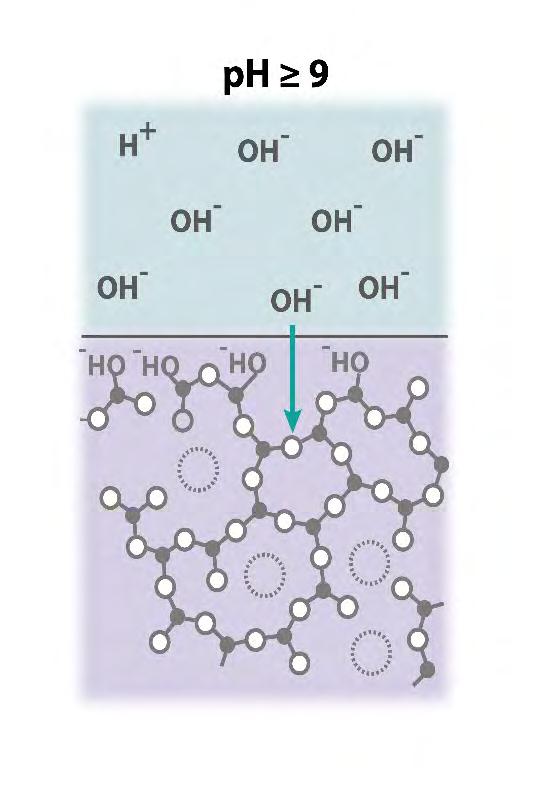

The history of glass is a continuous crossing of boundaries between magic and science, utility and art, transparency and colour. In a famous scientific article published in 2016, entitled Welcome to the Glass Age, two famous researchers floated the idea of declaring the current century the Age of Glass. We can hardly blame them, if we consider that in recent years some 7,000 scientific articles containing the word glass are published every year, and more than 25,000 a year on the topic of glass. Moreover, it is not surprising that the United Nations decided to celebrate this material by declaring 2022 the International Year of Glass. And just to recall a historical fact, it was right here in Venice that the great scientist Galileo Galilei was invited on 25 August 1609 to present to the Doge and the Venetian aristocrats a new instrument that he had perfected as no one had ever been able to do before. It was an instrument containing glass lenses whose creation he himself had patiently and skilfully overseen at every stage, from the search for optimal transparency of the material to the perfection of the curvature of the surfaces, which he polished with his own hands, cooperating on all these aspects with the master glassmakers of the island of Murano. We are talking about the telescope – an ancient example of how glass allows us to “see far”. Staying on the subject of devilishness, the great Wolfgang Pauli, Nobel Prize winner for Physics in 1945, once said that “the surfaces were invented by the devil”. Thinking about the surface of a solid, the atoms that compose it are the boundary between one world and another, a door to be passed through to access new possibilities, the development of physical and chemical rules that are amplified in the ambiguity of the boundary atoms. Similarly in the case of glass, such as the most widely used type of glass (sodium-calciumsilicate glass), which is used in a variety of applications such as materials for screens, pharmaceutical containers, photovoltaic systems and so on, it is important to have investigation techniques that enable the study and analysis of its surface, allowing light to be shed on highly complex phenomena relating to the reactivity between its surface atoms and those of the surrounding environment. These interactions can lead to alterations in surface chemistry and structure, internal structural connectivity, the ratio of bridging and non-bridging oxygen, corrosion resistance, leaching of modifier elements, adsorption, wetting and hydrophobicity. The use of appropriate analysis techniques, capable of investigating the boundary atoms between the solid and the surrounding environment (techniques with sampling depths that can vary from a few atomic layers up to several microns), allows us to understand the condition of the glass surface, thus making it possible to plan conservation or protective treatments and to verify their actual effectiveness over time. This applies, for example, to artistic glass for the purpose of studying and preventing/slowing down its degradation, or to glass that comes into contact with liquid solutions (such as in the pharmaceutical field, food industry, etc.) with regard to the potential release of atoms into the solution.

Glass has countless lives, because it is a highly recyclable and reusable material. Europe is aiming to reach a glass recycling rate of 75% by 2030. Italy has already surpassed this target ahead of schedule, reaching a glass recycling rate of 79% in 2020. But the many facets of glass – its antifragility –enable it to be easily and almost directly reused even as an additive material in many areas of the building industry, or even to become the centrepiece of objects of design if the scraps come from highly distinctive and unique manufacturers, such as the Murano glassworks. Here, even scraps – not remelted but transformed into new objects – retain the history and beauty of the places and artefacts from which they originate, transmit the poetry and wisdom of centuries of craftsmanship and knowledge handed down through the generations. These distinctive features should not be lost, neither on the scraps nor on the originals, but rather safeguarded and protected. Recycling, repurposing, reusing: these words should have increasing resonance in the case of glass too, given that the manufacture of an object from scratch –i.e. produced from the usual raw materials, including silica sand – requires approximately three times as much energy as that produced by recycling glass fragments and powder. The simple initial melting of silica sand, due to the high temperature required, consumes about 25% more energy than the melting of preformed glass... It is needless yet self-evident to emphasise today, in the current geopolitical situation, the importance of energy savings in the various stages of the production of a material. In 2017, so quite some time ago now, a scientific article entitled “Venice artistic glass: Linking art, chemistry and environment – A comprehensive emergy analysis”, which featured an “emergy” analysis of the annual production of artistic glass by an averagesized Murano glassworks (an analysis that quantitatively considers and evaluates both the economic and environmental aspects of the entire process of making the glass artefact), highlighted how dangerously dependent its overall economy was on traditional energy sources, for which economic and social factors are extremely critical and cannot be controlled from within the system. Ipse dixit? Unfortunately, reality. Even for glass, therefore, we need education geared towards fully enhancing and understanding it in a broader sense, so as to embrace the concept of synergy between aesthetic possibilities and functional opportunities. Cross-pollinating, reinterpreting, experimenting: glass science and industrial technology that confronts and merges with the manual art of those who know how to make unique artefacts, with a view to innovation that must not disregard the preservation of ancient craftsmanship, making each approach increasingly sustainable and suited to a society in a constant state of flux. This, perhaps, is the new paradigm of glass.

GLASS AND ARCHITECTURE

MARIA ANTONIA BARUCCO

The cultural aspects of the project cross fields and touch upon different areas, and the work of the innovators transforms what is experimental research into practical and valuable innovation. The contributions presented here describe glass technology and its connections with various fields and take stock of the relationship between business, experimentation and research; processes and products useful for the near future; and projects and products that have marked the development of glass technology.

The papers describe a form of architectural design that is closely linked to materials and is shaped by the history and culture of people, territories and companies: the balance between history and innovation; the cultural references and the character that a technology can help to anchor in the design of places; the strong connection between production and economies, between designs and needs, between thought and technique. At the same time, the nexus between the study of a material and architectural design is technology.

The entire call for papers of ANTIFRAGILE GLASS is strongly linked to the themes of science and technology, but there are profound and manifold cross-references to the humanities, history and environmental awareness, which affects every field of research as well as representing a real and pressing shared need.

ANTIFRAGILE GLASS has its roots in the Venetian lagoon and the factories of Murano: places where the boundary between art, myth, technology and production becomes so blurred that it loses its meaning. Art and technology blend like glass in furnaces and become unique objects in the hands of master glassmakers. And the production of glass that is both industrial and artisanal is in itself mythical, known the world over for its alternating fortunes, discoveries and innovations as well as for the unique beauty of its creations.

Thus, the ANTIFRAGILE GLASS call for papers is open to the framework in which technology is the dominant element, which makes explicit the aim of

keeping the industry running. ANTIFRAGILE GLASS also addresses the myth – everything that glass has conveyed since the dawn of time, and which has nothing to do with the mechanisms and supply chains to which it belongs or to which it is accountable for its choices.

Reading the papers reveals how technology connects these two opposing visions. Architectural design is the field of application and articulation of the historical, scientific, cultural and experimental analyses; the conference, the exhibition and this publication offer those who responded to the call for papers a useful forum for discussion.

Writing a preface to these papers means emphasising different points of view and shared roots. It also means interpreting a discourse and helping to recognise the considerable interest there is in working in the context of boundaries, between technology and myth of glass in the past, the present and the near future.

This future is certainly influenced by the issue of energy, which will drive major choices in both the design of glass products and the design of glass production processes.

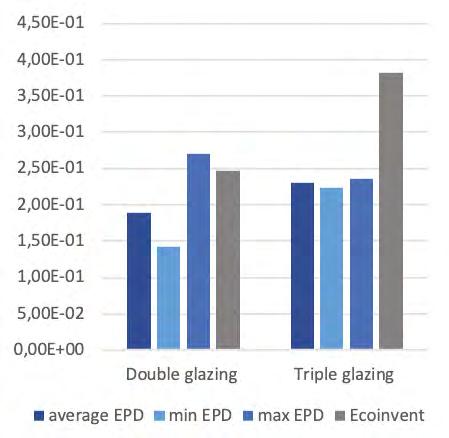

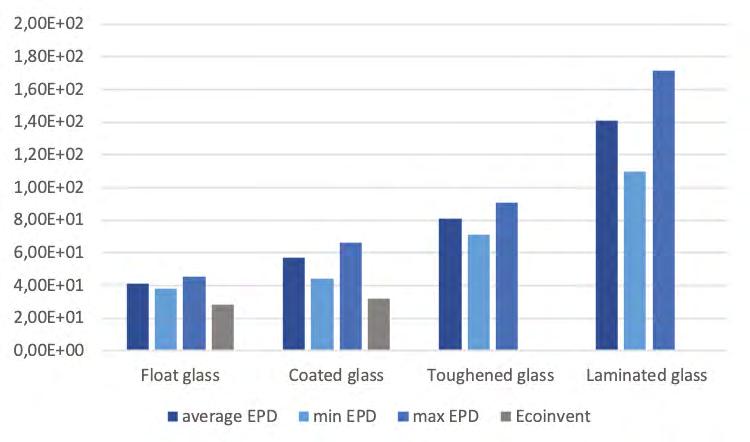

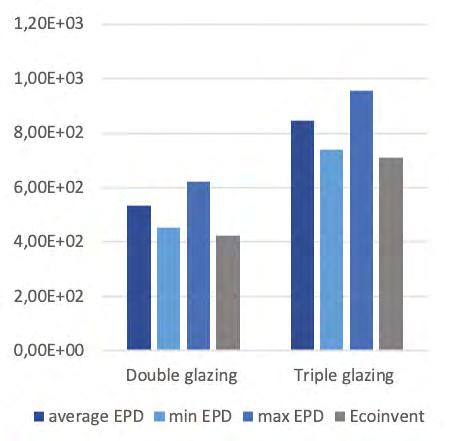

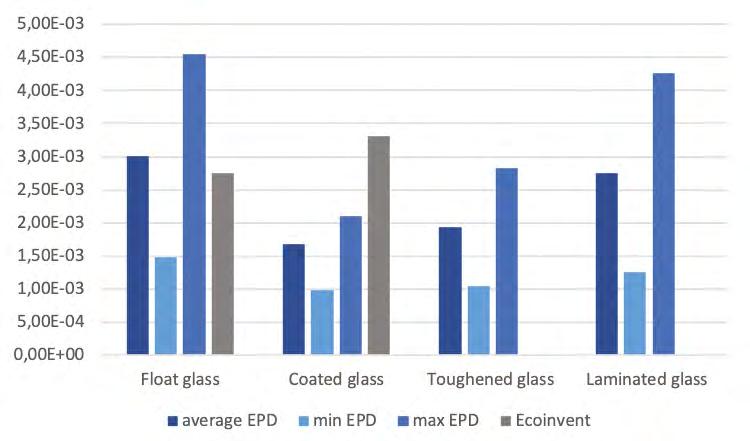

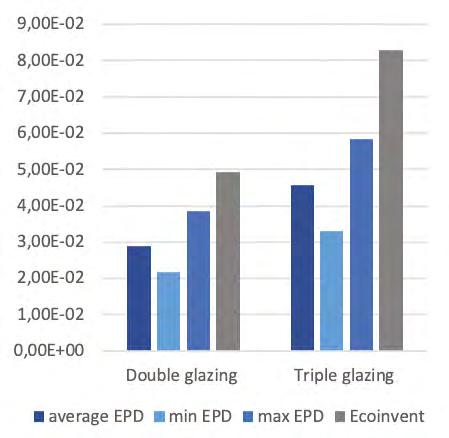

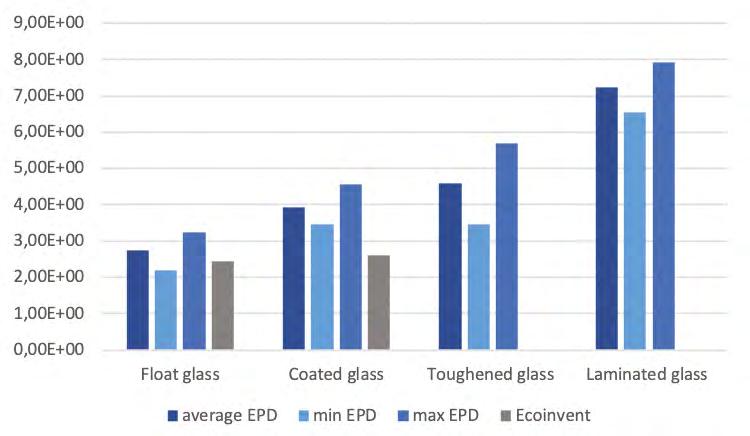

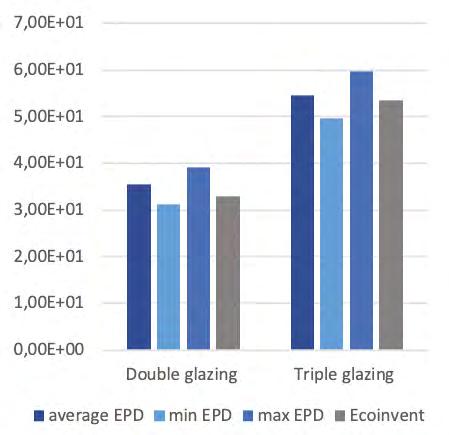

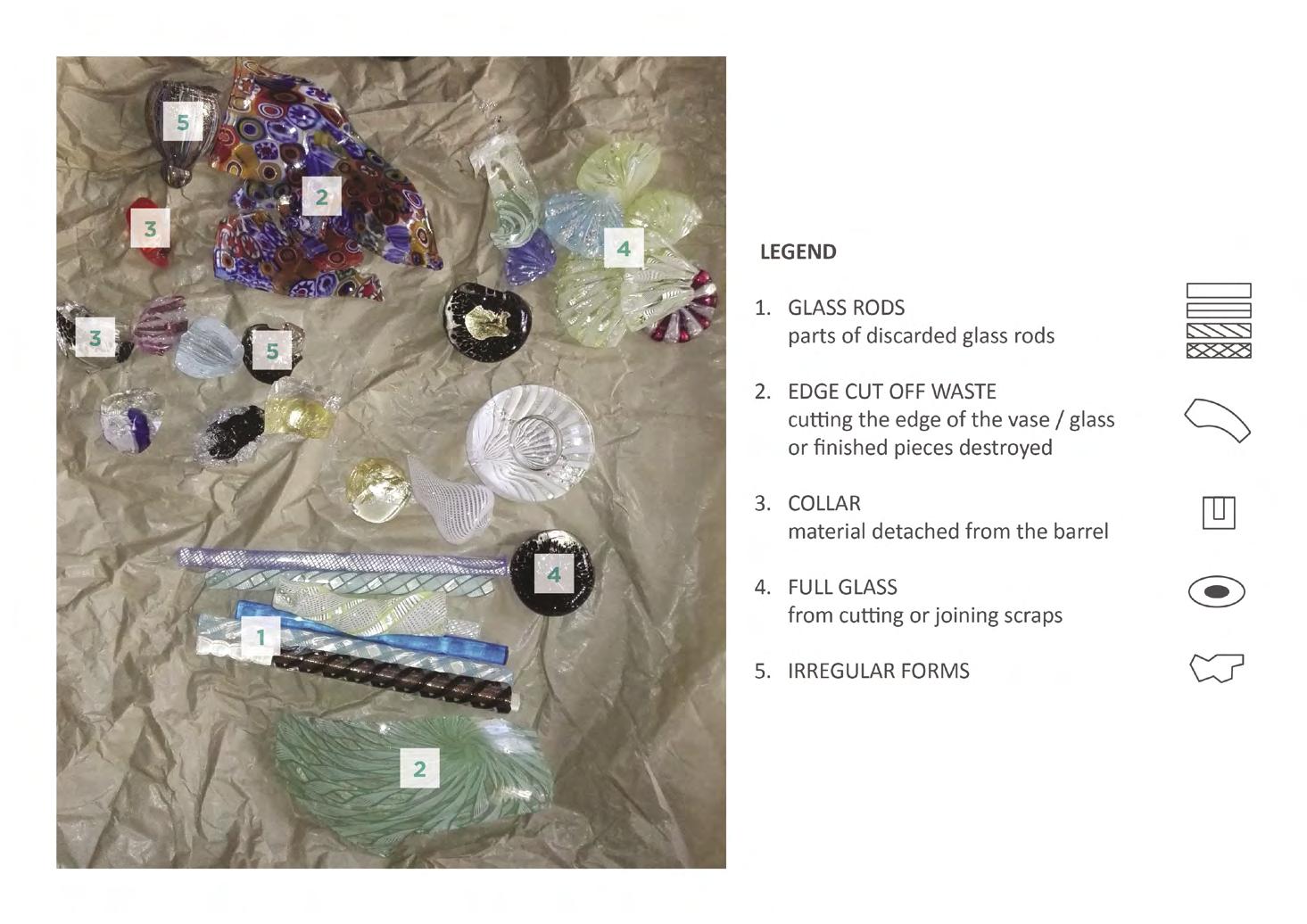

On the first aspect, which is almost completely unexplored, Campioli, Dalla Valle and Lavagna focus on research that is both promising in terms of its findings and highly relevant to the construction sector: they offer an analysis of LCA and EPD environmental impact data related to glass products for windows. The paper defines a number of principles that are fundamental to the development of research on these issues: “identifying reference values, verifying any differences between the internationally recognised datasets and the data of producers, and disclosing the percentage increase that results from the various types of glass processing”. The issue of embodied energy and waste reduction in production are themes that also recur in different contexts: Barucco, Cattaruzza and Silverio analyse production and waste in Murano glassworks through the lens of the circular economy. And it is to this research and the provocative nature of the proposed theme that we effectively owe the triggering of a series of interests and dialogues that have taken shape in the organisation of ANTIFRAGILE GLASS.

The highly energy-intensive glass manufacturing industries are a key focus of attention in the energy cost debate that has dominated discussions in recent months. However, for some time now, these industries have been committed to understanding how they can innovate and evolve production systems that use energy from fossil fuels. Trulli offers a historical reading of the manufacturing processes and innovations developed in Europe, but with a global outlook. Marfella presents an accurate and compelling analysis of a business that he defines as “fragile” and describes the Impact of the 1970s Energy Crisis on the American Glass Industry. Marfella illustrates “the vital relationship of the glass industry with the global economics of energy and its business repercussions for the development of architectural products with better environmental performance”.

But glass is more than just production, energy and industry: the boundary between magic and concreteness that characterises working and designing with glass is aptly described by Ishida. Her paper highlights meticulously crafted details of the Glass Pavilion built in Toledo (the American city of glass) by SANAA: “When glass is experienced in motion under changing light, the perception of it is not simply as transparent but is a specific kind of transparency that can be called blurred. A mix of mechanical and structural engineering, light design and sensibility make magic the architecture described and its description”.

And undoubtedly the values of glass in architecture and its meanings profoundly influence design choices: Scannagatta describes “how the technological advancement of glazing changes cities’ identity”. The example of Dubai is certainly one of the most stunning in the world and the contribution published here “analyses how the technical advancement of glass façades can change the skyline of cities through the example of Dubai”. Cellucci and Marradi cast their gaze towards an even more distant horizon: “technology hybridisation should aim at multi-performance variable glazing. The authors describe the trend in which sheets of glass become a variable multi-performance system with the aim of creating highly usable and accessible products. The cross-pollination of creative forms, adaptive façades and new uses of glass are stressed in this paper”.

In this context, Venice is once again an example. It was an example at the beginning of this discussion on glass technology, when the energy, technical and analytical aspects of environmental sustainability assessments were addressed. It was also (and perhaps above all) an example in its conclusion, in developing a linguistic experiment that allows architectural design to appropriate what is usually considered waste but which can become the material that enhances an object, a space and a place. The projects described by Romero and Lorens have the merit of transforming an emergency into cultural signs capable of enhancing places that are in themselves emblematic, enriching them with a range of profound meanings and renewed environmental awareness. This is thanks to the ability that a design workshop develops in designing and offering products that translate contemporary values into designs, forms and objects that determine the architecture of places. The set of papers presented in this section proves that talking about glass using Venice as a catalyst for ideas around the future means creating a short circuit between technology and myth. Working on ANTIFRAGILE GLASS meant placing ourselves in this context, accepting and welcoming new ways of thinking. Venice is a place that may also be difficult but is certainly unique (as well as magnificent). A place to develop new ideas, stimulate supply chains and nurture myths: ancient and recent, of history, innovation and development. A place that is not a territorial boundary but an amplifier of similarities and different ideas; a place where new approaches to technology can be developed and goals to aspire to can be set, including having the courage to propose visions that are as extraordinary and revolutionary as the myths of its past.

GLASS AND DESIGN

ROSA CHIESA

The design and culture of the project, understood in its most inclusive sense, is of course also based on our relationship with materials, as Laura Tripaldi (2020) reminds us: “because the materials we use are not passive objects, but, on the contrary, are determined by our socio-cultural life and in turn determine our relationship with the world, forming what is usually called material culture: a culture that is structured around the invention, production and use of the materials that surround us”.

How, then, can we not reflect on our relationship with a material as ancient and enduring as glass? But above all, how can we ignore its intrinsic capacity to be antifragile, to reshape its configurations according to its state (liquid, solid) and, at the same time, metaphorically reconfigure itself to cope with moments of crisis?

The highly interdisciplinary approach of the ANTIFRAGILE GLASS call for papers thus represents a meeting place between the project themes –investigated through architecture and design – those more appropriately pertaining to science and technology, and the “humanities”, understood here as wide-ranging historical disciplines that push the boundaries of reflection on the future, starting from the past.

Talking about glass as a “cultural” material, with which our history has been built through the design of artistic and architectural artefacts and utilitarian objects, without forgetting the field of science, therefore means dwelling in those places of intersection between liminal areas, which share both the use of a material – glass – and its ability to shape the technologies we use to mould it. This is how historical analysis, scientific research and experiments into processes and applications take on new cultural significance – in dialogue between history and design, and between technologies, innovation, successes and failures.

The design of glass artefacts (artistic and industrial) as well as the modernisation of glass production processes will, in the future (and even now), have to deal with changes in the energy supply and the unavoidable steps towards a transition to more sustainable systems.

The meeting points and cross-disciplinary sharing thus help to map out a structural network of tense relationships between history and innovation, which – as is the case with materials subject to hysteresis phenomena, i.e. those that change their behaviour to a stimulus on the basis of their previous history (Tripaldi, 2020) – will prove to be fundamental in renewing the entire glass industry.

To simplify reading – but without wishing in any way to detract from the originality of each contribution – the papers have been grouped thematically in the following summary.

The “magic” of glass, a simple and constantly evolving material, especially that associated with blown glass and the island of Murano, is recognised around the world. An initial founding contribution by Massimiliano Ciammaichella, Glass on Stage. The Woman of Fire Marietta Barovier, helps to define the historical frame of reference of the themes progressively proposed, highlighting precisely the narrative linked to the events surrounding the manufacture of glass beads, but at the same time emphasising a highly topical theme, that of female entrepreneurship in 15th century Murano through the pioneering figure of Marietta Barovier. What emerges is a compelling dialogue between the past and the future, which uses theatre as the vehicle to convey a contemporary story.

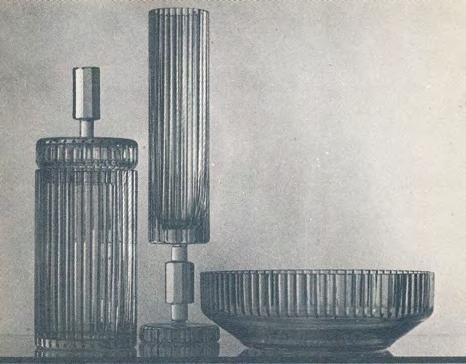

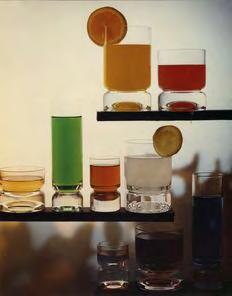

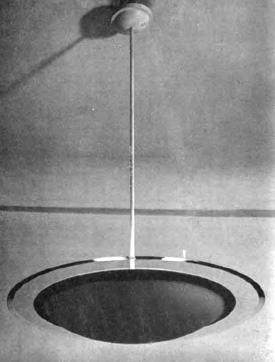

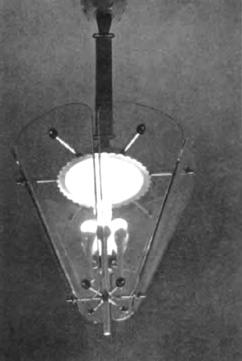

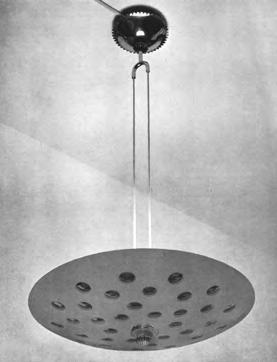

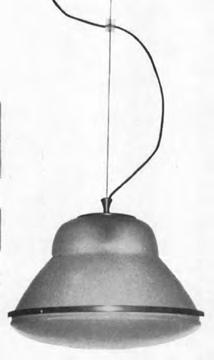

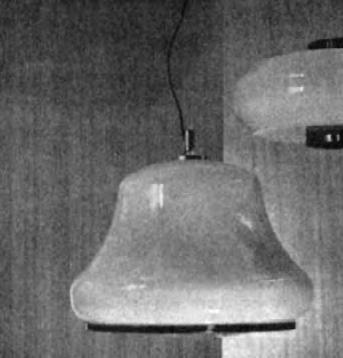

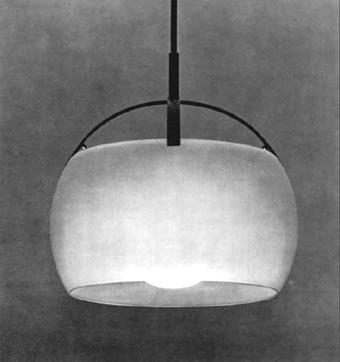

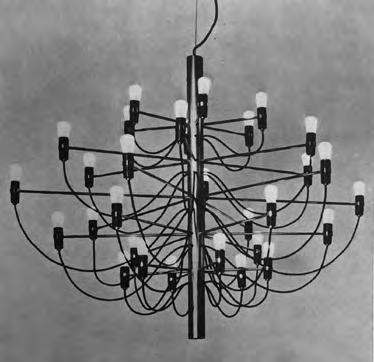

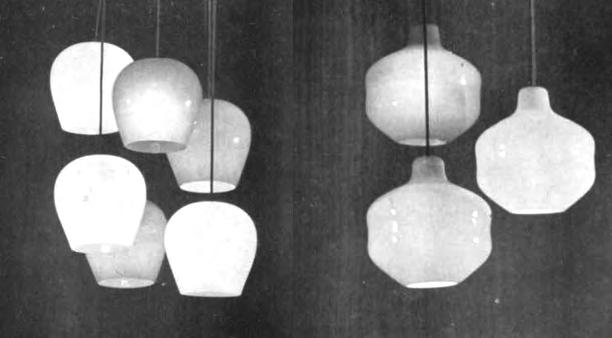

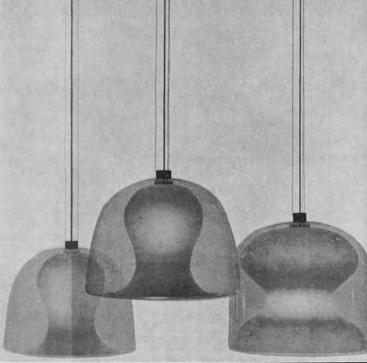

Resilience, understood as “balance between tradition and innovation, to the transformations in various contexts under the banner of the craftsmanship and elegance of glass design”, is the key theme of the historical overview presented by Federica Dal Falco and Raissa D’Uffizi in Glass and light. Suspension lamp design in Italy between 1930 and 1969 in the magazines, recounts the evolution of glass light fittings between the early 1930s and the mid-1960s, focusing in particular on pendant lamps. The rigorous methodology of historical investigation, conducted through the analysis of magazines, highlights the implications, not only in terms of form, that glass had with the technological evolution of other materials.

The systematisation of historical knowledge about the authorial production of Portuguese glass, in the period from 1950 to the present day, is the main focus of the paper proposed by Claudia Pedro, Authorship in Glass Design in Portugal –Four Cycles: from the ‘50s to the Present. The complex theme of the relationship between art and design emerges between the lines of the contribution that addresses the issue of glass design authorship, investigated in the Marinha Grande cluster in Portugal.

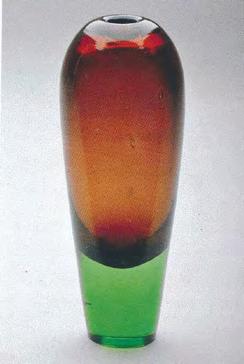

By contrast, it is the innovative work of artist/designer Laura de Santillana that serves as an opportunity for Laura Panchaud, in her paper Apparent divide –An observation of the handmade and the machine-made through the work of Laura de Santillana, to focus on the apparent opposition between the “handmade” and the “machine-made” within the Murano and international glassmaking tradition. Exploring a new production process, “slumping” glass, and its many possible applications, the discussion leads into broader considerations on training and the often “crystallised” roles in the traditional glassmaking process.

Another important theme – that of the relationship between design and craftsmanship – is addressed by the essay From industrial float glass to collectible

design light sculpture: the case of Baracche project by artist Paolo Gonzato by Maria Rita Ferrara and Beatrice Bianco. The central focus is “the intersection of the industrial and standardised material of float glass, and artist Paolo Gonzato’s creative approach to this material in creating unique lightweight glass sculptures” in a novel use of the material, commonly used for construction purposes, that is becoming “promising in the perspective of the development of creative industries and economies in Italy”.

In Systemic reuse models for sustainable glass packaging design and innovation, Marino, Tamborrini, Miotto and Ferronato take stock of the Italian glass packaging industry, a strategic sector for Italy. Indicating some possible strategies that could be implemented to initiate a sustainable transition and reduce environmental impact, the contribution focuses on the topic of reuse and, ultimately, the search for innovative solutions aimed at creating a “systemic business”. Again, the theme of the potential of waste and the role of the designer as a promoter of innovation on a systemic level is the focus of The “beautiful scraps” a precious resource, curated by Erika Coccato and Laura Badalucco.

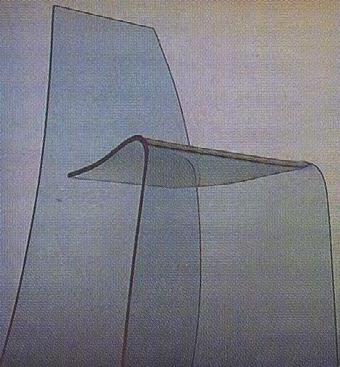

Finally, two contributions share a pursuit of integrating digital technologies with the traditional production process of glass artefacts.

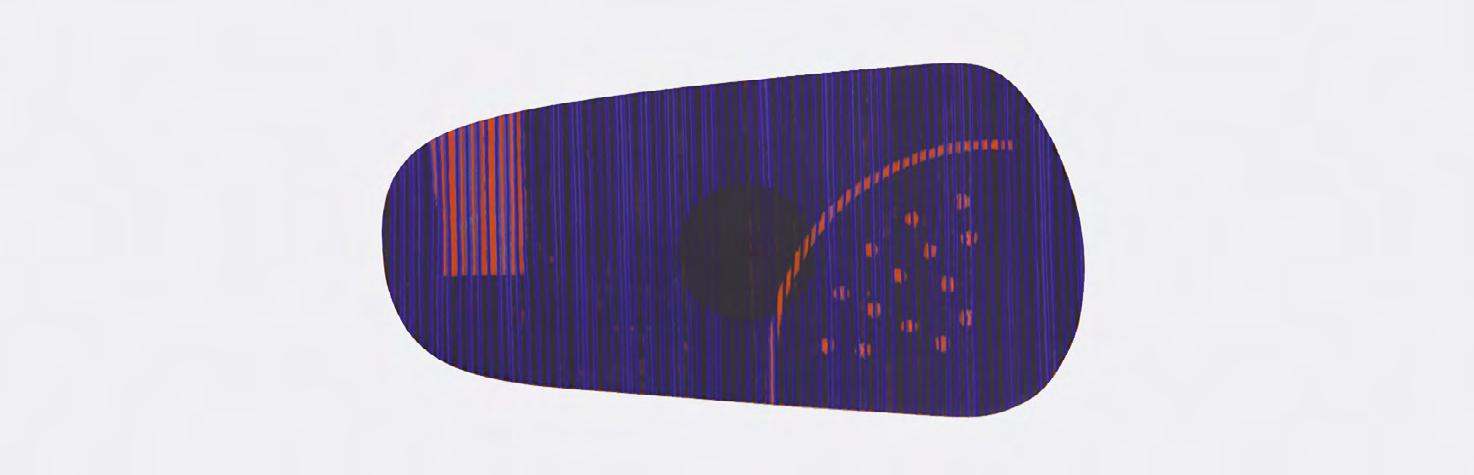

In Digital manufacturing for Murano glass, Omri Revesz focuses on an experiment – Islands – which reveals original and expressive results on the use of traditional murrine through the development of an innovative production technique, giving rise to a kind of digital craftsmanship under the banner of the fruitful combination of digital and manual.

Glass Future Lab. Murano glass production and digital manufacturing: possible relationships in a future scenario by Chiesa, Berrone and Coppola, proposes a reflection on the topic of the possibilities of integrating digital fabrication into the traditional process of producing glass artefacts. Imagining new ways of hybridising production processes, once again, certainly means solving or facilitating certain technical aspects and producing new aesthetic results, but at the same time, it means envisioning a future for the glass industry that stems from continuity with its valuable historical heritage.

Albeit with some simplifications, what emerges from the papers presented in the design section yields a wealth of stimulating nuances for research around the theme of glass investigated from a design perspective. From history – an essential discipline that always plays an active role in foreshadowing future scenarios – to thematic nodes such as the redefinition of glass production, long disputed between art, craftsmanship and design, and that perhaps the prospect of encountering new technologies may help to resolve, by opening up new paths instead of building increasingly insurmountable barriers.

Finally, the issue of the transition to a sustainable structure – inseparable from digital – is key to supporting all research that looks to the future of the industry and will be fundamental in providing, as always, new lifeblood to the glass industry, which even today is challenging the economic crisis with its eternal antifragility.

How the technological advancement of glazing changes cities’ identity: the example of Dubai

CHIARA SCANAGATTAAGlazing technological advancements changed the language used in architecture all over the world, and they defined the development of some cities. The present contribution wants to analyze how the technical advancement of glass façades can change the skyline of cities through the example of Dubai. The first part of the paper studies the scenario and the state of the art of architectural glass, by considering how its use as an architectural element changes buildings’ aesthetics. The second part focuses on the development of Dubai from the 1990s through the analysis of iconic buildings such as the Burj Al Arab and the Burj Khalifa. Conclusions then comment on how technological advancements of glazing changed the way buildings are designed, and how that influences cities’ heterogeneity.

KEYWORDS: ARCHITECTURAL GLASS AESTHETIC, DUBAI’S SKYLINE, GLAZING TECHNOLOGICAL ADVANCEMENTS

Introduction

In recent decades glass has increasingly become a major player in architecture, moving from its traditional use on windows to its use as a structural component in iconic buildings such as New York’s Apple Store on the 5th Ave. This change in how architects use glass was possible due to important technological advancements that allowed to improve its strength.

The opportunities given by new glazing technologies such as curtain walls allowed architects to have greater freedom in terms of architectural language, making it possible to split structural boundaries from exterior appearances. But this was not the only aspect that allowed a wider spread of glass with different applications in architecture.

Due to climatic changes, more focus is put on energy-saving solutions, and all building sectors have focused on the goal of having better materials and construction systems to reduce energy consumption. In the glass sector, new advancements in terms of glass coating permitted to reach higher levels of UV radiation blocking and of heating control. These new coated glasses allowed to make extensive use of glass in areas with important climate fluctuations and with extreme temperatures, where traditionally glass was not used due to its low insulation performance. On the other hand, the possibility of having curtain wall façades even in climatically adverse areas, completely changed the design process of new buildings, to the point of erasing traditional construction techniques that characterized the different areas.

An impressive example of this evolution of the architectural language based on the wider use of glass is desertic areas, where climate fluctuations are extreme throughout the whole year and architecture saw a complete change of stylistic language. The most known example is that of Dubai with its change from traditional Arabic architecture to curtain walls skyscrapers that sometimes have no link to tradition.

This paper, based on these preliminary remarks, wants to investigate how glazing’s technological advancements modified and modify buildings’ architectural language, and how this influences cities’ identity. To analyze such changes the city of Dubai is used as case study, since its new development took place in the past thirty years, and it followed different architectural trends creating a unique city in the Arab world.

Literature review

Glazing technological advancements

The development of what we nowadays know as architectural glass started in the 1950s with the introduction of the float glass production process, which allowed the mass production of a flat, high-quality, and transparent material (Savić et al., 2013). After the development of the float process,

technological advancement for glazing was aimed at maximizing three characteristics: the ability to transmit light, the capacity to block heat, and safety issues. Indeed, apart from esthetic criteria, contemporary structures – and the materials used for their building – must meet several criteria. As Savić et al. (2013, p. 35) remember, “regardless of it being used for windows, façade or interior partitions, glass connects the space, improves the quality of space, transmits sufficient light, and the contemporary types of glass may contribute to energy saving [since] it is known that energy saving is one of the most important architectonic challenges of our age”.

Due to the energy savings needs, that represented a hot topic in the past decades, the development of glazing allowed the transition from monolithic glasses to multi-cavity insulating glass units, that can be integrated with different treatments and interlayered films which contribute to energy saving and indoor comfort. Parallel to this, efforts were also made to develop the aesthetic aspects of glazing, moving from treatments that varied the coloring of the glass to colorless glass with outstanding performance.

Modern architectural glazing usually combines laminated glasses and multi-cavity insulating glass units, allowing for improved performance. By doing so, it is possible to choose which characteristics are needed. Glass plies can be thermally toughened, annealed, heat-strengthened, or different types of glass can be combined in a single laminated glass, and the number of glass plies and the requirements for the interlayer depend on the application of the glass component (Musgraves et al., 2019). The presence of polymeric interlayers also allows to contain the thickness compared to monolithic glasses. The clarity characteristic was gone lost in the initial advancements aimed at improving glass’ energy-saving characteristics, but modern processes also allowed the optimization of transparent façades, curtainwalls, and commercial windows, by improving the visible light transmittance1 .

As abovementioned numerous processes and technologies can be applied to float glass today to meet different needs, and this allows for glass to now play an important role in architecture. Indeed, as Wiederhorn and Clarke (2022, p. 561) said, “recent decades have seen growing and widespread adoption of glass as an architectural material that can be used not only in window panes [since] glass has enabled architects to expand their visions of buildings, using light and space to create wonderful new designs”. Such achievement was possible thanks to many advancements in glazing technologies and to a better understanding of how glass works when applied for uses other than windows.

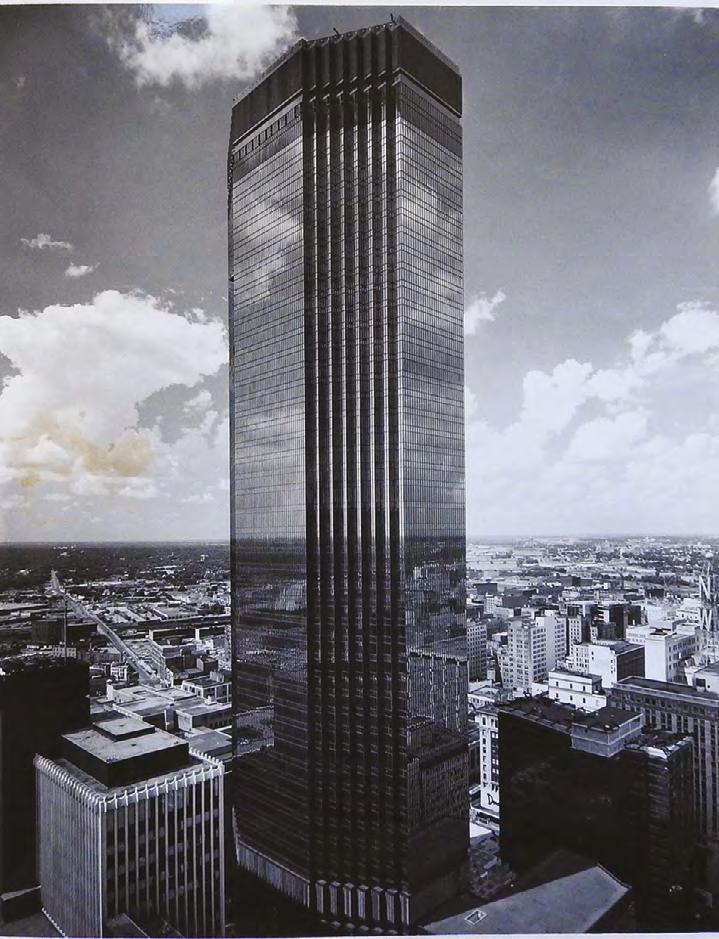

Architectural glass’ language

Glass became a predominant material in the definition of architectural language since the beginning of the twentieth Century with the spread of skyscrapers. An example is that of Mies van der Rohe’s skyscrapers in Chicago, with their recognizable dark skins. Later, over the last two decades of the twentieth Century, architects emphasized the tall building’s form and façade, by stressing the height aspect and mixing materials. Starting from the twenty-first Century, glass is becoming almost the only visible material on tall buildings’ façades, defining new languages by using its different treatments and characteristics. As Al-Kodmany (2013, p. 26) announced nearly ten years ago “these tall buildings are notable for their shape, lightness, transparency, and reflectivity”. There is then a return to the idea of skyscrapers from the 1960s, but the language proposed by new ones becomes completely different due to the lighter and reflective surfaces that are now proposed, which express lightness in opposition to the dark solid surface of the 1960s ones (Al-Kodmany, 2013).

1 Vitro Architectural Glass, Starphire® Glass for Exteriors. More information at: https://www.vitroglazings. com/products/low-iron-glass/starphire-ultra-clear-glass/exterior-starphire-glass/ (last accessed July 2022).

The use of color becomes important for glass skins as well since now it is possible to choose façade finishings freely from the technical characteristics that are required from glass. Since color has an important role in the visual perception of buildings’ exteriors, architects can choose how to use it to further define a building. By doing so, it is possible to add an aesthetical effect to glass architectural façades. Color then gains two uses: symbolic and functional. The first is to get the impression that the color gives about the form of the building, and the second allows to reach the best integration between form and structure based on the used color (Osman Bakr, 2019), and this is particularly important for glass façades since they can be no more linked to the structure’s shape.

At the same time, the lightness and luminosity of new skyscrapers are reshaping most cities’ skylines, as they define the city’s identity at urban scale. In this sense, the technological evolution of glazing that led to curtain wall cladding, allowed architects to stretch the rules applied to tall buildings in the past, moving to the idea that such iconic buildings can become sculptures with their skin detached from the structural form (Al-Kodmany, 2013).

Open questions on glass aesthetic and its environmental contribution

The evolution of the architectural language of glass has always been linked with its technological advancements because, even if it was mostly appreciated for its aesthetics, environmental concerns have been a hot topic in past decades (Ritchie, 2004). This means that glazing technological advancement towards energy-saving solutions was mandatory, otherwise it wouldn’t be able to meet current regulations.

But questions arise on future implementations of glass in architecture both from an aesthetical and a technical point of view. Based on what was studied in the past, it is important to understand how glazing’s technological advancements will modify the architectural language of buildings and cities, given the enormous changes that have already been triggered. And considering the big push there is toward issues related to sustainability, how can glass façades be implemented to face the demand for nearly-zeroenergy buildings in areas with adverse climatic conditions.

Dubai is the perfect example of how a city skyline changed following the trends and advancements of glass, and where adverse climate conditions call for always updated energy-saving solutions to reduce cooling demands. Starting from the analysis of the development of modern Dubai, some considerations on how architectural glass will further change cities will be made.

Dubai’s identity evolution through its façades

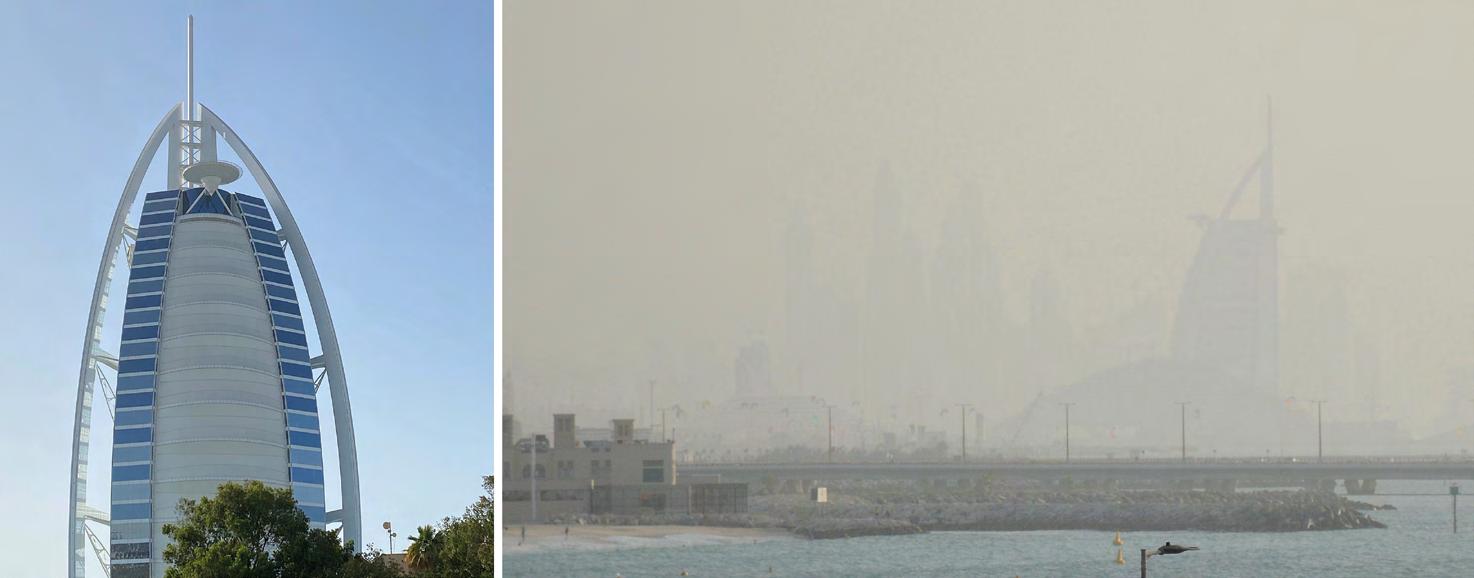

Modern Dubai is completely different from both its historic area and its first phase of development in the 1990s. Traditional buildings’ architectural features were aimed at facing the desertic climate and included few façade openings, windcatchers for natural ventilation and cooling of the interiors, and façade colors that recalled the environment (Figure 1). Today none of these characteristics are visible in new constructions since modern buildings make great use of glass façades and HVAC systems.

Dubai’s development as skyscrapers’ capital began in the early 1990s, and it started with the construction that were influenced by Chinese skyscrapers. These buildings presented external claddings made of stones resembling desert tones and glazing with a specific gradation of blue that was due to the polymeric interlayers added to glasses to block UV radiations and heating. Architectural choices were thus extremely constrained by the technical properties of glass, which was mainly used to add the necessary glazing since polymeric interlayers for solar radiation and heat control were not that performing. Furthermore, when possible, the glazing was placed in a rearward position, or even inside loggias to reduce direct radiation.

With further improvements in glass treatments and coatings, it was then possible to change the used architectural language by using wider glazing and less stone or similar claddings. But this change in the used language,

combined with an absence of regulation on the typological characters to be used, led to a skyline development based on the research of the most iconic building (Figure 2).

The game-changer for Dubai’s skyscraper development was the Burj Al-Arab (Figure 3) since it is notable for several complex engineering and construction features that were firstly applied at the time. The building has a V-shaped floor plan, with two façades completely glazed, and one that is covered with two layers of architectural fabric (a PTFE-coated glass fiber fabric), separated by 60 cm to filter out excessive heat and sunlight (Design Buildings, 2022).

The membranous façade covers the 18-stories hall and filters UV radiations, and it appears as opposed to the other glass façades of the building where the different glass tones are used to define the aesthetic of the building itself. The use of different glass colors – obtained with polymeric interlayer that ensures solar and heat control – contrast with the plain white of the steel structures and atrium membrane, creating a specific language that characterizes the building and that was a novelty for the skyline when it was built. Moreover, the color choice for the glasses emphasizes the height and “sailing” shape of the building itself.

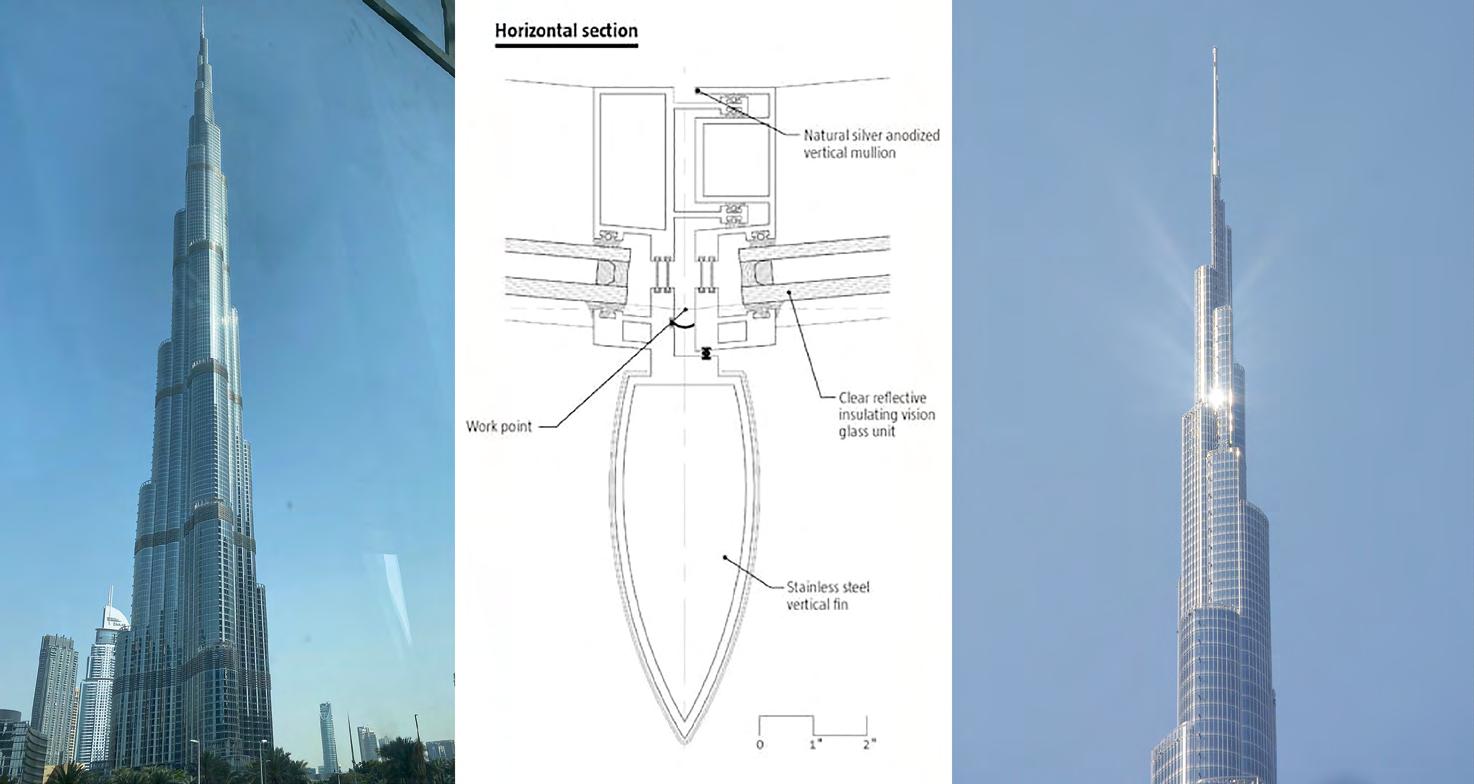

As plenty of building sites begins in Dubai, it is possible to see how recent skyscrapers now are more influenced by European and North American architectures rather than Chinese and Asian ones, since Dubai has commercial exchanges shifted to the West (Figure 4). This results in a preference for curtain wall façades (e.g., Burj Khalifa) and wider neutral color windows (e.g., Etihad Museum). The extensive use of glazing then raises the abovementioned technical issues of maintenance and climate control, which can be analyzed through the example of the most “extreme” skyscraper: the Burj Khalifa.

Burj Khalifa’s curtain wall is the quintessential evolution of skyscrapers and glass façades in Dubai, and various technological gimmicks were used to allow its realization. Hereby the façade aspects are considered to explain why technological advancements in glazing were essential for its development.

The Burj Khalifa’s design was inspired by the form of the Spider Lily, a regional desert flower, that was used in the definition of the building’s outline. Due to the shape of floor plans, and the extreme wanted height, technical issues concerning winds, solar exposure, and climate control arose.

The height development of the building was therefore shaped to counteract wind thrusts, but a great deal of technical work was done on the façades as the aim was of creating a curtain wall cladding that emphasized the verticality of the building while keeping high-security standards to avoid glass panels detaching due to the extreme wind. Furthermore, architects and engineers needed to study solutions to control solar gain and the amount of heat coming from this broad glass façade surface. The solution adopted to help disperse sunlight was that of a curved curtain wall (Al-Kodmany, 2013; Fink Shapiro, 2010) but, since curved glass was cost-intensive, the rounded effect was achieved with flat panels with angled joints hidden behind the aluminum vertical fins (Figure 6). To emphasize the building’s verticality, and to reduce the possible amount of sand deposited on horizontal elements, structural silicone glazing technology was used to seal the superimposed glasses (Weismantle et al., 2007). This technique has made it possible to have a fully glassed façade, without any other framing visible from the exterior.

The used glasses are coated and have specific characteristics of high selectivity for solar protection2 and with a reflective appearance3. In addition, a neutral-looking finish was chosen to have an unfiltered view of the outdoor environment, and this colorless characteristic of the glasses from the indoor was quite a novelty at the time of building.

2 Guardian Glass, SunGuard® SuperNeutral SN 50 T. More information at: https://www.guardianglass.com/ ap/en/our-glass/sunguard-superneutral/sn-50-t (last accessed May 2022).

3 Guardian Glass, SunGuard® High Durable Silver 20. More informatio at: https://www.guardianglass.com/eu/ en/our-glass/sunguard-high-durable/silver-20 (last accessed May 2022).

Conclusions

Dubai’s example shows how technological advancements in architectural glass enhance infinite possibilities for architects, that can choose freely how to design tall buildings.

This improvement of glazing characteristics also allows to better face the requests for indoor comfort considering the restraints given by the need to reduce energy consumption. This is possible because coated glasses used for curtain walls can now contribute by reducing solar radiations while keeping a clearer view from the inside, and by having higher heat control capacities, with a consequent reduction of HVAC systems use. However, there are also some downsides. Despite having higher indoor comfort performances with less aesthetic boundaries, maintenance requests and costs raised (e.g., cleaning all Burj Khalifa’s façades requires up to 4 months of manual work), and now almost breaks even with the benefits of reduced energy demand.

Despite this, tall buildings are now considered sustainable from an energysaving point of view (this is possible if the construction phase, with its use of non-renewable materials, e.g., sand used for construction is of marine origin, it is not considered when evaluating the environmental impact of buildings).

Besides, architectural glass has a higher impact on changing cities’ identity if compared with other materials. In this sense, Dubai is an example of how glass can change a city, as it changed and was defined starting from “small” glass buildings and recently it has been defined by its megastructures (Figure 5).

Cities are losing more and more of their traditional language, arriving at the extreme where some European buildings look more “Arabic” (e.g., Jean

Nouvel’s Arabic World Institute in Paris) than the ones built in Dubai. This results in an absence of a distinctive architectural language, that creates a crowded skyline where the watchword is: the bigger the better.

Glass is then just an example of how even small technological advancements can change the way buildings are designed and how the identity of cities is perceived.

References

Al-Kodmany, K. (2013). The Visual Integration of Tall Buildings: New Technologies and the City Skyline. Journal of Urban Tech nology, n. 20 (2). London: Routledge, pp. 25-44.

Design Buildings (2022). Burj al-Arab, Dubai (online). In https://www.designingbuildings.co.uk/wiki/Burj_al_Arab,_Dubai (last accessed August 2022).

Fink Shapiro, G. (2010). Detail: Burj Khalifa Curtain Wall (online). In https://www.architectmagazine.com/technology/architec tural-detail/detail-burj-khalifa-curtain-wall_o (last accessed June 2022).

Musgraves, J. D., Hu, J., Calvez, L. (2019). Springer Handbook of Glass. Cham: Springer Nature Switzerland.

Osman Bakr, A. (2019). The Aesthetics of Color in Architecture Glass Facade. Journal of Applied Art and Science. Damietta: Damietta University, pp. 1-16.

Ritchie, I. (2004). Aesthetics in Glass Structures. Structural Engineering International, n. 14 (2). London: Taylor & Francis, pp.73-75. Savić, J., Durić-Mijović, D., Bogdanović, V. (2013). Architectural Glass: Types, Performance and Legislation. Facta Universitatis –series: Architecture and Civil Engineering, n. 11 (1). Niš: University of Niš, pp. 35-45.

Weismantle, P. A., Smith, G. L., Sheriff, M. (2007). Burj Dubai: an Architectural Technical Design Case Study. The Structural De sign of Tall and Special Buildings, n. 16(4). New York City: John Wiley & Sons, Inc, pp. 335-360.

Wiederhorn, S. M., Clarke, D. R. (2022). Architectural Glass. Annual Review of Materials Research, n. 52 (1). San Mateo: Annual Reviews, pp. 561-592.

Systemic reuse models for sustainable glass packaging design and innovation

CRISTINA MARINOA, PAOLO M. TAMBORRINIA,B, LAURA MIOTTOC, GIULIA FERRONATOCThe Italian glass packaging industry is in first place in Europe with 21.3% of production value. It has 14 companies with 39 factories, 7,800 employees and a growing annual turnover of 2.4 billion euros. This trend of production preserves, on the one hand, a good synergy concerning the recycling process, but at the same time, it needs to reduce environmental impacts through reuse practices.

This research and analysis work was carried out in collaboration with a company that designs and produces glass packaging, focusing on and evaluating the current reuse and returnable-empty models, outlining the opportunities for a transition towards systemic business that stimulates innovation in new sectors. Subsequently, through a researchthrough-design approach, a second concept phase defines which guidelines to design packaging within returnable vacuum systems in new sectors and which strategies are feasible to start a transition.

A Department of Architecture and Design, Politecnico di Torino, Italy.

B Department of Engineering and Architecture, University of Parma, Italy.

C Marketing and Communication, Verallia, Italy.

KEYWORDS: PACKAGING DESIGN, SYSTEMIC APPROACH, REUSE MODEL

Introduction

The Italian glass packaging industry is today in first place in Europe with 21.3% of production value. It has 14 companies with 39 factories, 7,800 employees and an annual turnover of 2.4 billion euros. The growing trend reported by sector association studies (Feve and Weber Shandwick, 2020) predicts an increase of over 500 jobs between 2020 and 2024, with a production of 500,000 tonnes of glass packaging. This continuously increasing production as early as 2019 indicates virtuous glass-environment ‘synergies’. Indeed, data published by the Close the Glass Loop platform (Feve, 2019) confirm that glass collection and recycling increased in 2019 to an average rate of 78%, up 2% from the previous year’s results. These figures, encouraging for the multi-stakeholder platform that has set itself the goal of achieving a 90% post-consumer glass container collection target by 2030, ensure that a large proportion of packaging glass is correctly recycled in the glass production cycle.

This industry overview shows how, over the years, the environmental footprint of this material has been increasingly reduced, so much so that 85% of Italian consumers consider it the best packaging (Feve, 2019). Compared to 40 years ago, producing bottles and jars has reduced energy requirements by 50% and emissions by 70%. The recycling rate for glass reached 76.3% in 2018 (+6.6% compared to the previous year). Thanks to recycling in 2018, 3,395,000 tons of virgin raw materials, 320,000 tons of energy, and 2,082,000 tons of CO2 were saved. In 2018, 85.9% of households sorted glass (10 years earlier, it was just over 50%). Bottles and jars then underwent a drastic ‘slimming down’: a bottle of sparkling wine since the 1990s, for example, has decreased in weight by 18%, a jar of baby food by 13% and an oil bottle by 12.2%.

Glass is the only material that meets the definition of a ‘permanent’ (Larsen et al., 2009). This is because:

• it maintains its chemical and physical features unaltered over time;

• collection systems are centralized for an effective recycling, treatment and reuse strategy; and

• reuse is permitted an infinite number of times.

This virtuous process thus saves energy for production from virgin materials, reduces the impact of glass on the environment and creates new entrepreneurship (Cocking, 2003).

Nonetheless, although the glass industry, and the glass packaging industry in particular, already applies circular economy principles (e.g. with water and minor with beer packaging), not all product categories are currently in these processes, and the circular economy approach is sometimes limiting concerning the urge to close the process on itself.

In particular, the circular economy applied to glass is strictly linked to the manufacture of products and the concept of the life cycle of industrial

processes (Verallia, 2022). Instead, this research uses Systemic Design as a methodological approach (Barbero and Tamborrini, 2015). An innovative design practice developed to apply design knowledge to systemic problems with the aims of co-designing products, systems, and policies for better and sustainable services (Jones, 2014).

Systemic design methods and principles enable the human-centred design of complex, multi-system and multi-stakeholder services and programmes by connecting different cycles and creating open systems sustained by relationships and connections between local realities.

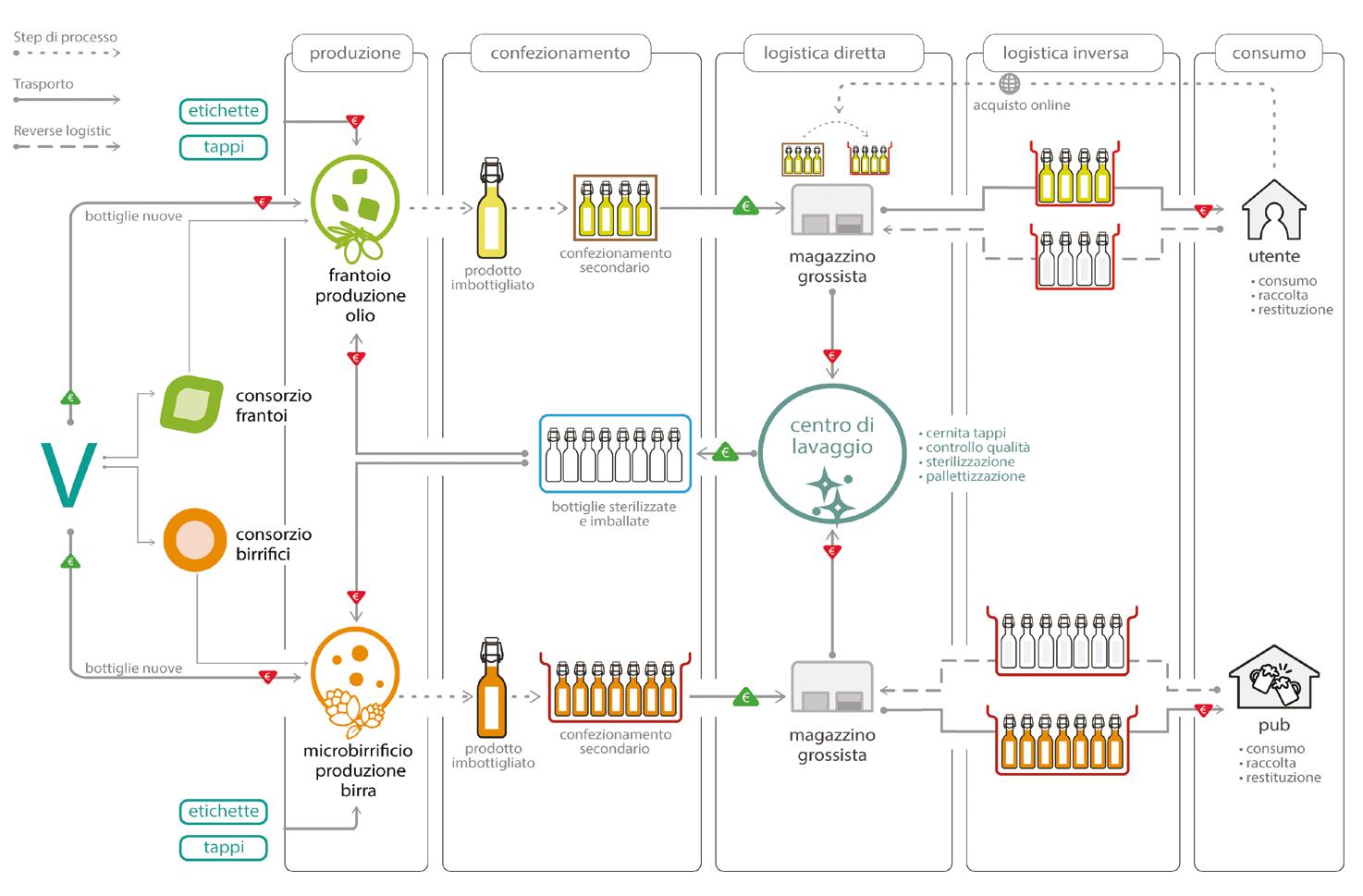

With this approach, the main aim of this research and analysis work carried out in collaboration with a company that designs and produces glass packaging is to focus on and evaluate the current reuse and returnableempty models, outlining the opportunities for a transition towards systemic business that stimulate innovation in new sectors1. Subsequently, through a research-through-design approach, a second development phase defines which guidelines to design packaging within returnable vacuum systems in new sectors and which strategies are feasible to start a transition.

Methodology

For future sustainability, it is necessary to understand the different and complex challenges surrounding glass reuse: from changing consumer behaviour to product design trends, from logistics for glass collection and cleaning to the development of new business models within the different political contexts of the target markets. This investigation, thus guided by a two-track approach, on the one hand, systematises research for means to reduce emissions through alternative business models and, on the other, identifies the most compelling features and practices to reuse glass packaging.

The broad inquiry subject, including different product categories and production formats, underwent the first skimming through selecting some product categories. The selection was made by taking into consideration both qualitative aspects for which product categories not yet involved in returnable vacuum systems were preferred, and quantitative aspects that, concerning the identified category, considered the possible collection volumes and a balance between revenues and investments about the business model, at first linear, then systemic.

The theoretical framework, considering the complexity of the topic, is based

1 This research work was conducted within the Design 1 laboratory of the Master Eco Packaging Design – Systemic Innovation Design for the packaging project of the Politecnico di Torino in collaboration with Verallia. The Master is a one-year training course that deals in an interdisciplinary way with the strategic and project aspects of design, communication and sustainability for the packaging project in collaboration with Fondazione Carta Etica. The students involved in the research were: Marta Caruso, Marika Baresi, Anna Rita Asaro, Irene Rubino, Ginevra Grisotto, Margherita Viràg Sartori, Natalia Cito, Andrea Guidi, Ruben Faraci, Elisabetta Sechi, Maria Chiara Tortia.

FERRONATOon a “mixed” approach. It proposes the use in the first instance of an analysis of current models and, in the second phase, a research-through-design approach aimed at defining design guidelines for reusing glass packaging.

In order to explore a business model for reuse, it was necessary to know in-depth the challenges and characteristics of the main stakeholders in the supply chain. Therefore, the basic research integrated concepts, experiences, and interventions not only from the glass packaging design field but also from the business sector, whose models are examined in the analysis. For this reason, we involved several brands that accompanied the research project and returned a helpful transdisciplinary approach to thinking in terms of open systems. Specifically, the stakeholders that have been involved were: an online shopping brand, a food delivery service, a mineral water brand, a producer of food packaging caps, an organic supermarket chain and a producer of food packaging labels.

This transversal involvement of several realities was fundamental to treating the individual production systems as complex ones with complementary and symbiotic activities rather than disconnected entities. In this way, the research process could benefit from sharing resources, knowhow and technological skills.

The second part, dedicated to applied research where concept

Fig. 01 Example of the linear model analysis of the wine q-commerce system. Courtesy of the authors

development took place, was supported, and verified by the glass packaging company, which provided feedback on the prototypes’ suitability concerning innovative business models.

Therefore, the research methods involved the analysis of several case studies divided into the following categories: large-scale retail purchasing models, large-scale retail distribution platforms, traditional e-commerce and quick commerce, and proximity commerce.

Then, four innovative business models were developed, each assuming a specific product category. Bottles of oil, beer, wine, fruit juices and jars for jam and ready-to-eat products were analyzed. A user with different needs was traced back to each product category to define better the aesthetic-functional characteristics of both the model and the product under consideration. Following the validation phases by the experts, the data collected were synthesized into some guidelines for the design of glass packaging capable of adapting to the returnable vacuum models.

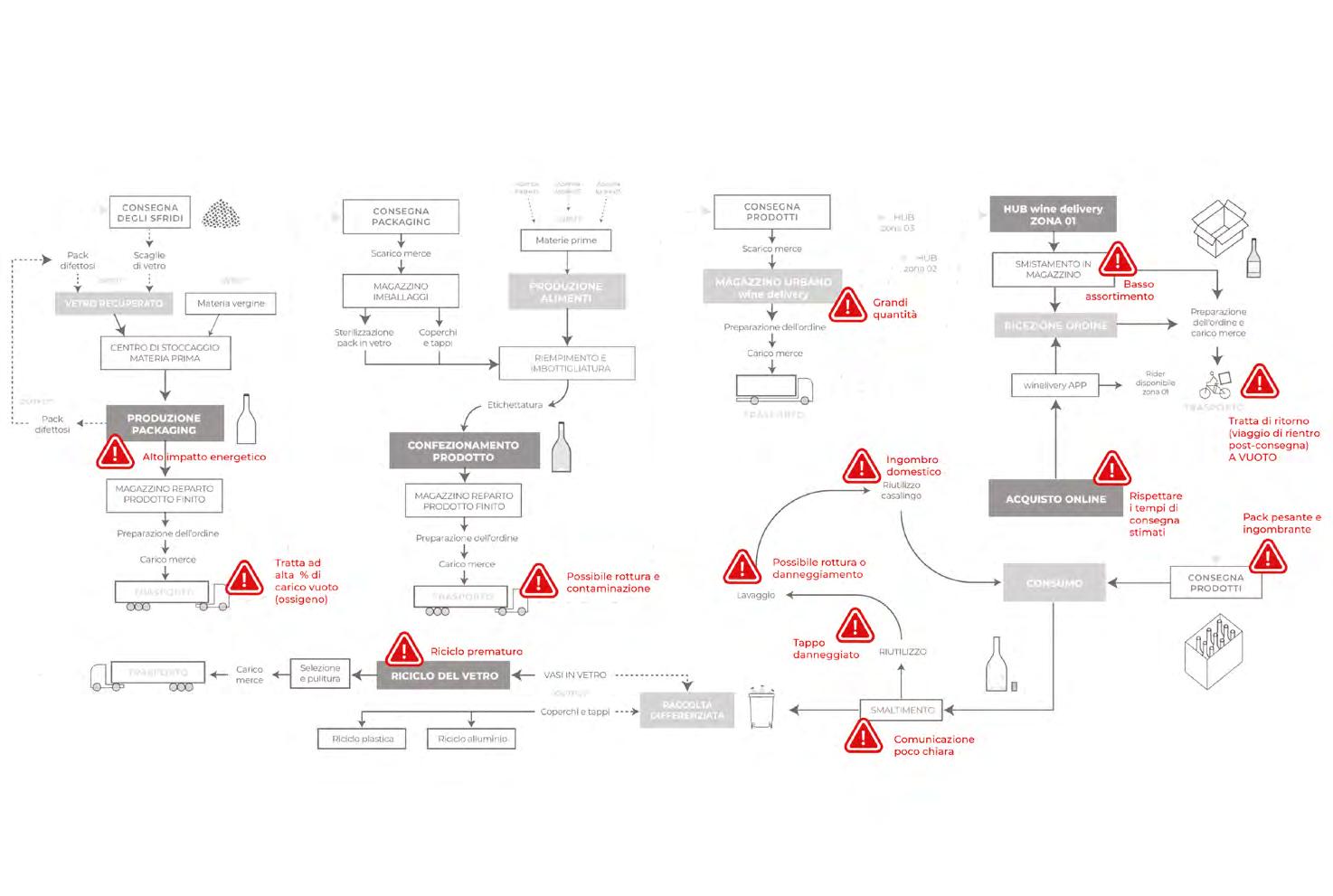

Analysis of existing business models

The first part of the research provides a basic description of the functioning of the different models and distinguishing implementation issues. The models analysed fall within the following categories: retail purchasing models, retail distribution platforms, traditional e-commerce, quick commerce and proximity commerce (Barbero and Pereno, 2020).

The analysis summarised in Table 1 shows that each model has peculiarities concerning timing and supply. The transport systems and logistics platforms differ mainly in the distribution over the territory and the size of the warehouses. If storage and timing are two factors that specifically impact the user experience, transport systems, handling dynamics, and the need for large or small warehouses are critical points for the design of returnable collection systems.

Figure 1 exemplifies a scheme for analysing the linear system of a quick commerce model, highlighting critical points. All the other models were investigated using the same method; the results of the comparative analysis are summarized in Table 2.

Recurring criticalities include the premature disposal of glass packaging, often still intact, and the over-packaging of the product for further protection. On the other hand, opportunities enclose leveraging local relationships, exploiting empty trips by riders, warehouses and points of sale throughout the territory to facilitate collection operations on the one hand, and container storage on the other.

However, a gap in the analysis was found in the lack or reduced availability of external washing and sterilisation services. The latter would represent a costly investment for companies to start an internal returnable vacuum cycle but also a pivotal point to establish new entrepreneurship around reusing glass packaging.

FERRONATOTraditional Commerce E-commerce Quick commerce Proximity commerce

Time to shop Self-service 2-3 day delivery Less than 1h delivery Reservation of grocery

Offer Wide offer Limited offer Small offer Small offer

Transport Private vehicles Road transport Bike transport Private vehicles

Support platform Superstore Mega warehouses Warehouse / local stores Local stores

Tab. 01 Business Model Analysis categories.

Designing innovative business models for glass packaging reuse

The second part focuses on packaging reuse solutions in business-toconsumer (B2C) and business-to-business (B2B) applications. Both design directions have been retained because, although there are many opportunities for reuse in business-to-business (B2B) applications, the latter are generally better understood and adopted at scale. Therefore, part of the research aimed to identify sectors that do not currently adopt reuse models, which could also open up to reuse models, especially to consumers.

For this reason, before conceptualising a functional reuse model for the glass packaging industry, a case study review was interposed on currently advantageous reuse models, both environmentally and economically. Such models, classified in the Ellen MacArthur Foundation’s Reuse report (2019), can be categorised as:

• Refill at home: where users refill their reusable packaging at home;

• Refill on the go: where users refill their reusable containers away from home (e.g.at, an in-store dispensing system);

• Return from home: packaging is picked up from home by a pick-up service (e.g. by a logistics company);

• Return on the go: users return the packaging at a store or drop-off point (e.g. in a deposit return machine or mailbox).

Based on the analysis of the case studies, some of the strategies identified appear to be ill-suited to the world of glass packaging, so it was decided to opt for door-to-door and out-of-home return models. A door-to-door collection is an option that, although it can overcome certain limitations, as far as recycling is concerned, from a system perspective, is more costly due to the weight of the product itself and the emissions generated during transport. However, it becomes disadvantageous if collection volumes are not high and the consumption of specific product categories infrequent.

The analysis, therefore, led to the exclusion of product categories with sporadic consumption and instead to a preference for local productions, with low volumes but high networking potential in the local area, and categories that cannot do without glass packaging at present.

An example of a new business model which comes from the intuition to systematise similar packaging is the ‘Elis’ project, which is based precisely on the creation of added value through the collaboration of existing and geographically close players. The project proposes the development of a new range of hybrid bottles. Also, it connects oil mills and microbreweries that, despite being realities of limited size and production scale, are born with the concrete intention of being sustainable and therefore need suitable containers to communicate their mission.

The design of this model is aimed at both B2C and B2B users. This way, the system can optimise the delivery trip for vacuum collection by consumers and companies by fitting both consumption times and collection volumes.

Similar projects also targeted small local producers in the concept phase by leveraging proximity commerce as a collection point. Other projects, referring to wine or ready-to-eat products, have optimised the reduced volumes of collected packaging by redistributing it to micro and mediumsized enterprises that do not need large orders and can quickly source from third parties.

Finally, some reflections concerning the conceptualisation of new models emerge about the colouring of glass packaging produced mainly in three colours: clear, green and amber. Undoubtedly, although mixed scrap can only be used for the production of green glass, the production of clear or flint glass and, to a lesser extent, amber glass requires a scrap of the same colour. Therefore, mixed colours can lead to overcapacity for green glass furnaces (Testa et. al, 2017), and the collection of the products should take place in a differentiated manner. This point, in particular, meant that colour was a characteristic feature of packaging explicitly designed for inclusion in unique returnable vacuum models at the expense of clear glass.

Logistics Criticalities User Criticalities

Commerce Lack of door-to-door pick-up; packaging management delegated to the municipality

Autonomous time and vehicles for grocery shopping, fatigue; storage space needs

Opportunities

In-store collection possibilities, user incentives, warehouse space, suppliers network

E-commerce Excessive consumption during transport Delivery/collection booking Multiple productions/ systems connection on territory

Q-commerce Rider’s empty trips Unclear disposal process Take advantage of empty trips and warehouse points