Wolmanized'

Effective protection with less chemical

. Limited Lifetime Warranty

.

Patented co-biocide

Respected brand with over 75 years of wood preserving experience

. Has eamed the Good Housekeeping Seal

Produced with dissolved and/or disperced coPper

Juxn 2OO9 Bannnre Pnooacrs DIGEST @ tlbod TEtcd Rig.f qffiB8R ,4.*d\ Ir{ousSKEEPlNGl \{$/ Join the winning team

CA-C PressurdTreated Wood has

that

give confidence to purchasert and reflect well on

it.

features

ensure effective performance,

the dealers who stock it and the people who specify

OUTDOOR'WOOD Wolmanized" Outdoor" Wood protected by the revolutionary CA-C preservative. www.wolmanizedwood.com

WOLMAN IZED'

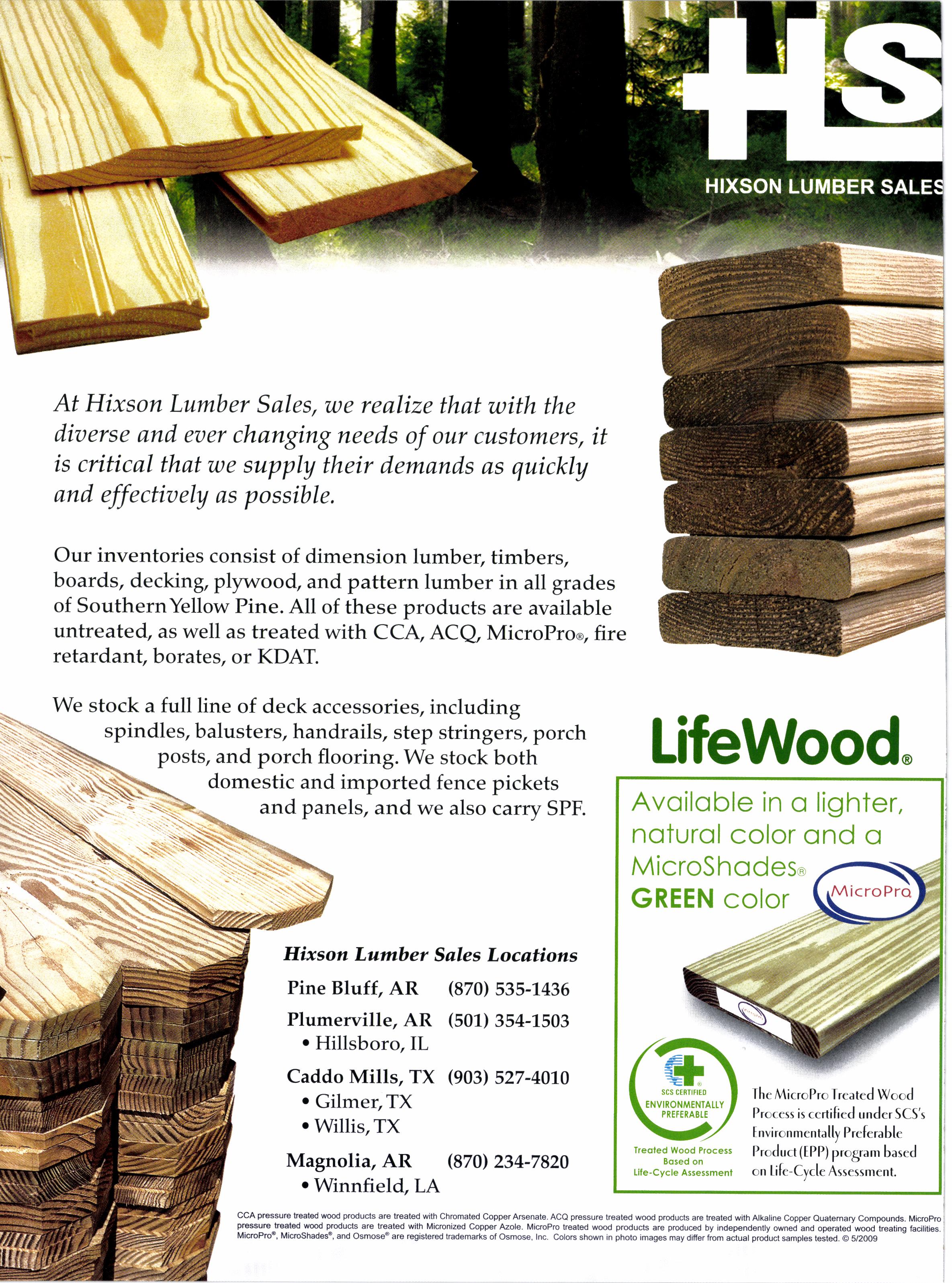

At Hixson Lumber Sales, we realize that with the diaerse and eaer changing needs of our customers, it is critical that we supply their demands as quickly and effectiaely as possible,

Our inventories consist of dimension lumber, timbers, boards, decking, plywood and pattern lumber in all grades of SouthernYellow Pine. All of these products are available untreated, as well as treated with CCA, ACQ, MicroPro., fire retardant, borates, or KDAT.

We stock a full line of deck accessories, including

spindles, balusters, handrails, step stringers, porch

posts, and porch flooring. We stock both

domestic and imoorted fence nickr

omestic imported pickets

and panels, and we also carry SPF.

$

\.\\ r.,,*"\

--'- 'i -\r '--,:.'-\

. -", ^\r$\

i.$\t

\ .:::\a .... = = _Y =_

Hixson Lumber Sales Locations LifeWood. Pine Bluff, AR Plumerville, AR . Hillsboro,IL Caddo Mills, TX . Gilmer, TX Willis, TX Magnolia, AR o Winnfield, LA (870) 535-1436 (s01) 3s4-1s03 (9031s27-40r0 (8701234-7820 CCA pressu€ beatod wood products are treated with Chrcmatod CopperAronato. ACQ pressu.e lreated wood p@ducts are Ireated with Alkaline Copper euatemar Compounds. Micrpro pGsUFtoat€dw@dprductsar€tr€atedwithMicroniz6dcopperAzo|e.MidoProtreat6dwoodproductsareprdu@dbyindependent|yownedandoporatedwoodlreatin9faci|ies. Mi@Prc', MicrcShadeso, and Osmosoo are registered trademarks of osmose, Inc- Cdore shown in photo images may difier frcm actuat produd samptes tested. G) 5/2009 Avoiloble in o lighfer, noturol color ond o MicroShodes,. GREEN color \(licroPro Treoled Wood Process Bosed on l-ife-Cycle Assessmenf The MicroPro Treated Wood Process is ccrtified underSCS's I nvi ron m en ta lly Prefera b[e Product (tPP) proganr based on Iife-Cycle Assessment.

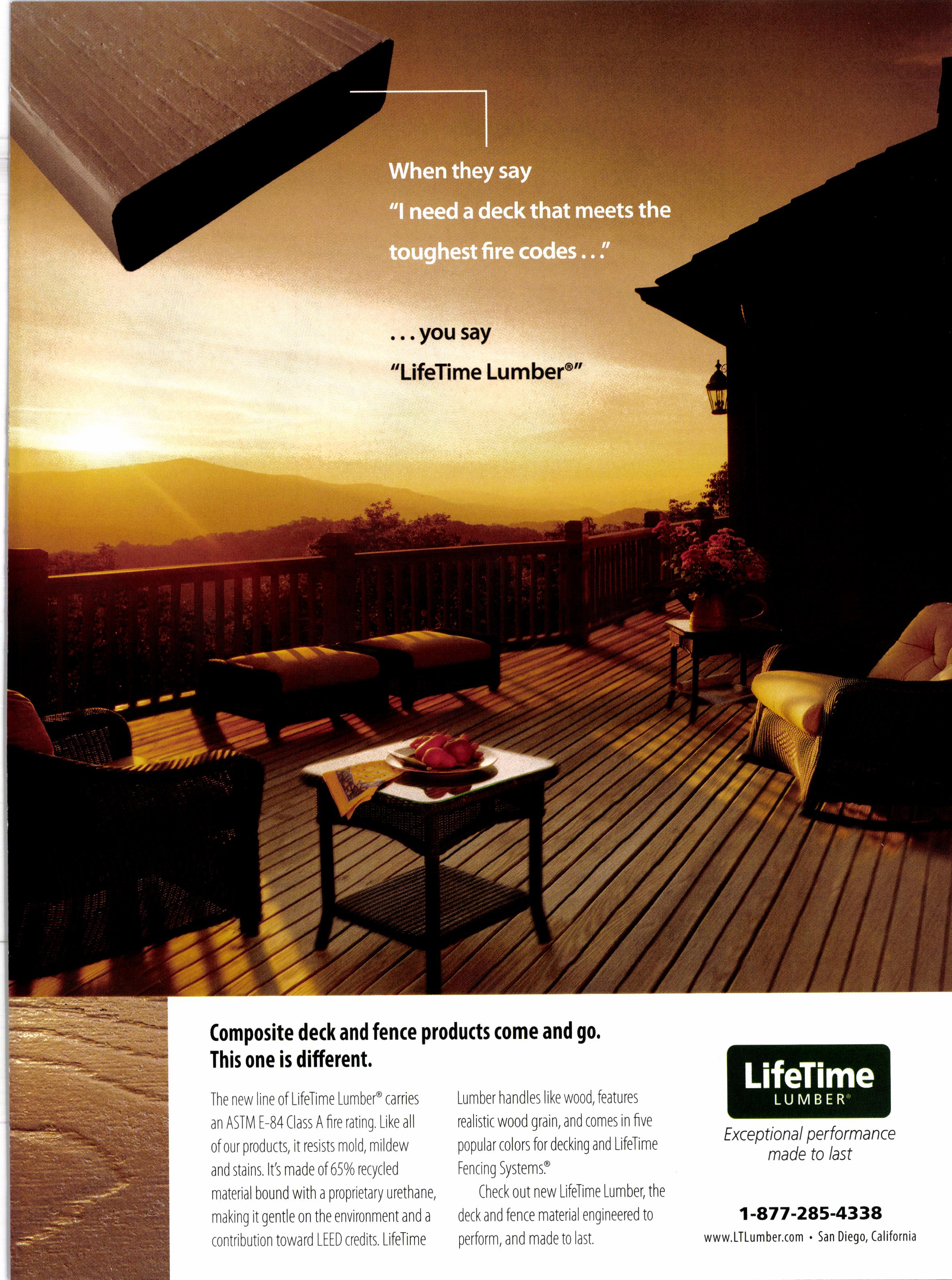

"LifeTime Lumber@" Composite deck and fence products come and go. This one is different. The new line of LifeTime Lumber'canies an ASTM E-84 Class A fire rating. Like all of our products, rt resists mold, mildew and stains.lt's made of 65% recycled material bound wrth a proprietary urethane, making it gentle on the environment and a contribution toward LEED credits. LifeTime Lumber handles like wood, features realistic wood grain, and comes in frve popular colon for decking and LifeTime Fencinq SystemsP [heck out new LifeTime Lumber, the deck and fence material engineered to perform, and made to last. Exceptional performance made to last ta77-285-4338 www.LTLumber.com . San Diego, California

BPD

Bvtr,ome Pnooucrs DrcEsr

(Sbtor publication Building Products qigast soves the West)

PUBLISHER Alan Oakes (aioakes@aol.com)

PUBIISHER EMERITUS David Cutler

EDIT0R David Koenig (dkoenig@building-products.com)

ASS0GIATE EDIT0R Karen Debats (kdebats@building-products.com)

COI{TRIBUTII{G EDITORS Carla Waldemar, James 0lsen

ADVERTISII{G SATES MAIIAGER Chuck Casey (ccasey@building-products.com)

ADlrlll{lSTRAT|0ll DIRECT0R/ SECRETARY Marie Oakes (mfpoakes@aol.com)

ClBCULATl0ll Heather Kelly (hkelly@building-products.com)

How toAdvertise

Gonlacl our adyeilising olfices for rales:

S0UTH, MIDWEST & WEST: Chuck Casey, 4500 Campus Dr. #480, Newport Beach, Ca. 92660. Phone (949) 852.1990 Fax 949-8520231 Email ccasey@building-products.c0m

I{ORTHEAST: Paul Mummolo, 404 Princeton Ave., Brick, N.J.08724. Phone (732) 899-8102 Fu732-899-27 58 mummolop@comcast.net

lllTERl{ET ADS: Alan Oakes, www.buildingproducts.com. Phone (949) 852-1S90 Fax 949-852-0231 Emailajoakes@aol.com.

How to Subscribe

Call Heather al (949) 852-1990 or send a check for the following amount to Building Products Digest,4500 Campus Drive, Suite 480, Newport Beach, Ca.92660-1872: U.S.A.: One year (12 issues), 924

Two years, $39

Three years, $54

FORElGll (Per year paid in advance in US funds):

Surface-Canada or Mexico. $49

Other countries, $65

Air rates also available.

Single copies, $4 + shipping

Back issues (when avaitabte), $5 + shipping WWW. B Ul LDlllc-PR0DU CTS. C0trl

About the Cover

The front cover is a paid advefiisement, this month sponsored by CA-C pressure treated wood developed by Arch Wood Protection,

Iloioln bchnology helpr 13ff1deolen run norc efllclently New softwore improves stoff efficiency, streomlines inventory monogement, ond lowen fleet costs. l0 f il fime to rcdeelgn yourwebrlb? How to updote your site to drow more online visilors ond convert more soles. 12 tnergyrovlngs keyb selllng sldlng rcoflng ond Insutotlon l{ tohng the nef rbp: Cellulor hlC Trlm 2.0 16 pol your prcffr wiilr Strucurul Inruloted Poneb 23 Sourtrern Forccf Prcdudr Speclolsecflon Twelve-poge guide to helping deolers sell more southern lumber. @ilil

Jdn tha winnir€ team Hgl1:i'::*: .b---*==-----Tn:a::i:

Seruing lumber & bullding products retallers Et, wholesale dtstrlbutors I 3\ ? 3 o' F

5 Editoriol l8 News Briefs 20 colendor 22 Regioncl Associction News 35 Personols 38 Competitive Intelligence /O on scles 44 New Produds 46 Green Retoiling 47 Obituories 48 Clossified Morketploce 49 Buyers'Guide 50 Advertisers tndex 50 FAXResponse Form EUltDll{G PR0DUCTS DIGEST is published monthty at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buitding-products.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East ol the Rockies. Copyrigh@2009 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must n0t be reproduced in any manner without written permission. All Rights Reserved. Building Products Digest reserves the right to accept or reject any editorial or advertising matter, ano assumes no liability lor materials furnished to it. 4 Burr,orxc Pnouucrs Drcrsr Jurue 2009

Extra! Extra! Read

Newspapers are no longer important to Americans, Warren Buffet remarked recently. In many cities you soon may not be able to read all about it. Or, if you can, your choice of newspaper may be seriously changed. All we see and hear today is that the newspaper industry is going away.

That assessment may be over-blown, but there's no doubt that a shift is taking place. Today, there are about 1,400 dailies in circulation (and that may be the root cause of the issue). Slightly less than half of all adults read a newspaper every day.

I would be the first to say that the advance of technology is wonderful. In fact, I spend at least half of each day on my computer, much of it online. But it's not where I want to read my news in any volume. I want it all in one place where I can choose what I wish to read about without searching through hundreds of pages or having to load multiple pages to read one story. I will no longer read many stories that in the newspaper would have caught my eye, but now won't because I'm shown only a headline. Is this progress? It is time to stand up for print before we succumb to this supposed progress gone awry.

I must admit that at times I have been as harsh a critic of our press as anyone, but I cannot imagine not reading a newspaper at some time in the day. During the work week, I arrive at the office and read the business journal (which I also have loaded on my Blackberry and find absolutely frustrating). At lunch, I read a large non-local newspaper. At home in the evening, I read the regional. Getting up on a Saturday and Sunday morning

all about it... or not

and reading the paper cover to cover with my cup of tea (yes, as a Brit, the habit has never changed) is one of the pleasures of the week. In fact, when I am out of the country traveling, by the third day I'm trying desperately to buy a U.S. paper at an exorbitant price. CNN doesn't do it for me. And yet, we are some time soon going to see newspaper after newspaper go the way of the dinosaur. And for what? We will miss hundreds of news items if this happens.

There is a place on the Internet for news. I read all the fun stuff there. I follow what Britney and Lindsay are doing (like them, I too must have too much time on my hands). I enjoy reading instant headlines of late-breaking news items or seeing up-to-date market news. But I don't just want to read about the top l0 pieces of news. I want to read about hundreds of pieces of newslocal, regional and national.

More importantly, I want to read good journalism and what is behind those headlines-and that is what will be most missed if we allow this to happen. Online is not where I want to read or will even find serious stuff that matters. For the most part, it is plain vanilla written by low-cost journalism students, due to the fact that the Net has always been seen as a way to cut costs. Most of the cost and hence most of the quality will be taken out to produce these e-versions. As real journalism fades away, will we really know the origin of much of the news in the blogosphere?

When reading on the screen, I tend to skim more (and these flip books are useless). I get fed up with crashes and wair ing for pages to load. When newspapers

go away, it will not be the same experience. Where will I read easily in one place about the sports scores, the local sale at Macy's, the church event, the time of the movie, as well as what really is in that state budget? Where will I see dozens of conflicting articles on what the Fed should be doing, or why we should be in Afghanistan with a higher troop count? It will be the biggest hassle I can imagine.

There is no vehicle that I have seen as of now that suggests we would be better off not having newspapers. We are being told it is better, but it isn't.

Now we know that our newspapers are heavily sponsored by advertising, and that is the real issue. Advertising has gone down because readership has gone down, and that is what they must solve. I have personally listened to investment bankers who espouse that everything has to move to the Internet. For those MBA's, the model shows that getting rid of paper, mailing and other growing distribution costs will make businesses very profitable. What they do not understand is that advertisers are unwilling to pay the same price for advertising on the Net. Indeed they want to pay much less, and long-term it will make media companies less profitable, as revenue shrinks drastically. And like so-called progress in everything else, quality standards will continue to decline.

So the question is who is not buying newspapers today? Clearly, much of that lies in our youth no longer reading the paper. Maybe the situation was brought about by how our children are being educated and how we have allowed them to spend all their time surfing the Net. We have become a nation of headlines, not of investigation of real issues. We are samplers of sound-bites in arenas where personality and celebrity override common sense. We must view journalism and newspapers as absolutely essential to our communities. For good or bad, there is a power of the press that will be lost if this movement continues.

Now some will argue there will be other ways to get the good stuff published. I doubt it. I may be classified as old school, but it will be a tragic day when we see the end of our daily read.

v StpECtrp V Hiddcn Dcck lrasrcncrs : E-4GEEEE aoooo f Anilable in brom, black or grcy colors. * l00o/o

r Achlqc

no

* No

r ComPatible

&

* Availablc

phone (864)-9O2-88I8 toll frce l-866-427 -2547 Burr,orNc Pnooucrs Drcnsr Juue 2009 www.IpeClip.com

maintooefre festening system.

flawls bauty with

visiblc fatencts.

worrying about nail popa on the decking surfaa.

with hadwood

composite decking.

with a sinle ced in*n molded inside for added strength.

Get *Lat y'u need, *h.. you need it.

INTEX provides a component based Pergola System, engineered to allow the contractor the ability to customize the size based on construction requirements. Everything from INTEX is pre-engineered to enable a quick and efficient installation. Our engineered aluminum reinforced carrying beams and rafters are designed to be field trimmed. A bracket system is also included for easy assembly. The INTEX Pergola System can accomondate clear post spans up to 14 feet. For more information, visit our web site. www.intexmillwork.com

where you will find a complete listing

o{ all our Finely Crafted PVC Millwork.

Call us at 609-567-5900 -- Fax 609-567-5901.

I.] ,, ,. ,'; ii t' ,,' , i' i ; ...,i ; *.l: l: ",,r ir {

FHRE$

il# $ Yl,l v, g !|! |l (l Jr r I ql Jq I I q tr ri i qt J

IFindovr **d Doo, Sorroond* - No*eb *rrd e*lo*tt .W'r.e; if ,il L: ro r,ji,;,,,,,,,.]lt ri..,.itrlJj ;;',,tt' .'. ( ill! I M NTEX ILLWtrRK 5OLUTItrN5

tf ,ila

Latest technologu helps dealers run more efficientlg

TTTECHNOLOGY solutions for

I LBM dealers have undergone an interesting transformation in recent years. Computerized business management systems first entered the market years ago to help dealers keep up with large sales volumes. Overwhelmed with all the paperwork and administration costs involved in selling building materials and maintaining proper stock levels, dealers turned to these computer-based systems to help them stay ahead ofthe curve.

However, with the recent slowdown, dealers have shifted their focus and are looking for ways to trim overhead and run more efficiently. Technology providers have followed suit with a number of new products to help companies accomplish more with fewer resources. These technologies help dealers get the most out of their three key assets: employees, inventory and equipment.

lmproue 0ffice Staff tfficiencu

By and large, the LBM business is still based on good, old-fashioned paper. Most dealers have a number of people charged with tracking the many different types of invoices, contracts, forms, receipts and orders that are generated every day.

Recent advancements in document management technologies are making the paperless office a reality. Document management technology allows customers to reduce the amount of paper they must store while increasing customer service and overall business management. It gives dealers the ability to easily store customer signatures with receipts and invoices, and deliver electronic billing statements that incorporate this information. Dealers can realize a quick and substantial return on investment by eliminating stamps, envelopes and storage space, and by eliminating the hours they spend daily researching old invoices or stuffing envelopes.

Optical character recognition technology automates the data entrY process by allowing users to scan in all the accounts payable invoices. The software analyzes each invoice, matches it with its corresponding vendor, and places the file for the scanned invoice in the correct vendor folder. The result is a smooth transformation from paper-based invoices to actionable accounts payable records.

Streamline Inuentorg lllanagement

In today's economic climate, dealers need to maintain a careful inventory balance. Good inventory management means carrying enough products to meet customer demand while eliminating unnecessary excess that negatively affects cash flow. The first and most important step to achieving effective inventory management is establishing and maintaining accurate inventory counts.

A wireless warehouse management system allows LBM dealers to know exactlv what thev have in stock and

By Steve Bieszczat Activant Solutions

precisely where everything is. Greater accuracy and visibility mean less need for safety stock, allowing dealers to reduce inventory by up to 10Vo.

WMS solutions track items as they enter and exit the warehouse, using handheld wireless terminals equipped with barcode scanners. These devices guide warehouse staff exactly where to find and store each item. The system also automatically directs warehouse staff to perform cycle counts and automatically adjusts quantity in the company's ERP system.

Studies indicate that dealers who adopt and fully implement WMS technology can improve shipping to approximately 99.9Vo accuracy and boost warehouse productivity by as much as 20-307o.

Lotuer fleet Equipment Costs

Recent spikes in gas prices were a grim reminder of the importance of keeping an eye on fuel costs and vehi(Please turn to page 4I )

ii*:;

{1O

@ ttt$l i.st: ll .r!!i r.n.i

SlO

Bivry Vdw % by Lud IW hrill.u.til,a,tlhorr(2.ot a)

Odvry vdu€ by Stda

MIO Odivry

Jurur 2009 BurlorNc PRoDUcrs Drcrsr

DISPATCH & DELIVERY from Activant allows dealers to map out deliveries to save time, cut fuel costs, avoid unnecessary wear on vehicles, and make better use of people and resources.

V6[&

by Odvry E Trud lyp

ls it time to redesien your website? \.'

A STAGNANT website is like a .CLfaded, yellowing sign in your store window-it may deliver some useful information, but probably does more harm than good. It tells your customers that your business may be falling behind and doesn't thinking putting on its best face is worth its time or effort.

But, LBM industry tech experts argue, even modern-looking websites should be regularly updated and periodically redesigned to keep the clicks coming.

ordered a top-to-bottom overhaul ofits site less than two years after its initial launch. The motivation was that entering its primary product line, "poplar + bark + siding," into Google, Yahoo or the other top search engines directed searchers first to its dreaded rival. Parton's site showed up four pages and dozens of matches later.

Even though Parton was happy with the look of its old site, a small local design firm, Zurv, recommended starting from scratch. The designer, said Andy Parlon, "wanted to write the code himself, to redo the website from

the ground up, to become 'search engine optimized."'

"Websites should be search-engine fiiendly so that potential customers who use the main search tools on the Web can find them," agreed Kimberly Brandner, Brandner Communications, Federal Way, Wa., which has redone websites for a host of major LBM manufacturers. "It's important to identify key terms or phrases a company wants to be associated with-and that a user would identify the product type withand to clearly use those throughout the website."

Within a month of its relaunch, Parton's site skyrocketed to between #3 and #5 on all major search engines.

"If we keep working with it, tweaking it, (our designer) thinks he can get us up higher. We want to be #1," said Parton. In the meantime, "there'll be small changes, we'll add news releases, change pictures. The website will continue to grow as far as page numbers and-hopefully- site rankings."

Search engine optimization, or SEO, was also a primary goal for redesigning Custom-Bilt Metals' site, according to Andrew Rogers, Purdie Rogers, Seattle, Wa.

IIAIN {:,UTTER 5Y$TE&i5

)/c0lltI(itlf,r:iirrsilr*s!rj|:ie! daL:9r!,jria:_i:j'i!nlj:rr.11fr cli,,t.jrr:t[1

iCrrLtrilLni llto O, ii$rjr!{!j:o' atI::r{ri::a: ititar ,rjiatrJtcr It:asE tidd!i!r: .i,rj ;liil'ldl)lf} ir j i:irrn1!iI 5lir*l jfiJ ictpeJ r:lalilrra;ill{s.Prrlrliliri}riigl,llt?!tir,al6iilrrPrirfla!li,-r,i ltrslfi,:.ir,J :i9,ri'!ris Il;{,nti lhrlic4r h a;e fn:rlt,N.f! ,:tB i! *::1i r[...] e! .lir

kn. I Sorl U. | $h lialp I Csnt*t Ui I tdv.c, tutky

Redesign: www.custombiltmetals.com

Client: Custom-Bilt Metals

Desioner: Purdie Rooers

Goaii Segment the siie's tratfic by audience

ASOUI

RAN

RAN

COFER UIX GUITTRT uN GUrT:t nacxnGs coLoRs {ArutrNut} coLons {srt€Ll NOOUCT IITEUTURE waRutn txFoRuanoN

Changes: The company's full line of products is presented in detail, including expanded coverage of its green'cool roof" technology. Visitors can learn how it can cbntribute to Energy Star points and LEED credits. Additional pages round out the company's background and current achievements, and point visitorstoward local Custom-Bilt branches when they're ready to begin their projects.

He explains that factors contributing to optimal rankings include your website structure, authority site status, historic activity, relevance, depth of content, and key word density. In addition, inbound and outbound links from other authority sites, directories, associations, press releases, blogs and social media venues can dramatically improve organic search rankings. Activity breeds attention.

"Web users search hundreds of times a day, and it's important that your prospective customers can locate you easily," Rogers said.

He also recommends paid advertising on search engine results pages, with the cost typically based on the number of clicks, leads or impres-

Parton Lumber, Rutherford, N.C.,

st|sl,lhgh6 i$clS'ltrg|$ Al6le lgr.ts Carnr!.t d PHfr ndn 6{tbrt Wil r 8ofrt Prmlt $&AMLA:;S

xoMEoFrGi I aRcRtt€cf I comaaclot

RAIN 6UTTIA5

OU'TIR PNODUCTS

CUTIf,R PROFIEA

10 BurlrrNc Pnolucrs Drcpsr Jurur 2009

sions. "strategically engaging in SEM (search engine marketing) drives qualified traffic to a site," he noted. "It's highly measurable and typically has a good ROI."

The redesign boosted traffic to Custom-Bilt's site by 25Vo in six weeks and significantly increased qualified leads.

A new redesign of distributor Bluelinx's website aimed to make it easier for visitors to find the products and literature they need. Visitors can search for product lines-and the dealers that stock them in their area-by branch. The site also provides a foundation for future product catalogs and online ordering capabilities.

To keep visitors coming back, the site will post sales specials-updated every two weeks-tailored to each market and searchable by zip code.

"Increased access to our products and service offering will enable our customers to take advantage of our expanding portfolio," says Bluelink c.e.o. George Judd.

Similarly, A.E.R.T. simply wanted a better, hard-working site to promote its MoistureShield composite decking. "The main goals of our website redesign were to focus more on our target market (trade professionals), provide access to more tools and product information, and make it more interactive and user-friendly," said Brent Gwatney, v.p. of sales & marketing for MoistureShield.

A.E.R.T. worked with Brandner to make the website easier to navigate, while adding plenty of new features, including deck design and color visualization tools, more product details, a contractor corner of resources, and a dealer locator.

"A website should provide a clear path to purchasing the product," said Kimberly Brandner. "This could be through a dealer locator, a form for a visitor to request more information, or even purchase on the site itself. Without a purchase path, the site is an interactive billboard."

She advises clients to overhaul their sites about every two years, "depending on the performance of the site, new technology, and new design trends."

Ongoing updates, according to Rogers, can include new "product information, case studies, white papers, tutorials, installation instructions, industry domains, and customer reviews."

He added, "Another valuable feature of a company's online presence is a blog. They're quick and easy to update, and encourage two-way communication. If you blog, use Facebook or Twitter. Having RSS feeds from those sites on your company website integrates your online efforts and enhances online search visibility."

The key is keeping it fresh, to be constantly looking for ways to improve and add content to your site. "A website presence should be viewed as an ongoing process, not a project," Rogers advised. "Build a Web presence, not a website."

Redesign: www.bluelinxco.com

Client: BlueLinx

Designer: AtlantaSky

Goal: lmprove customer service by better connecting visitors to oroducts and info thev need

Chdnges: New features jnclude detailed listings of branch product offerings, sales specials customized by market, a com' orehensive-liierature librarv, and a nationwi-de search tool for iocatinq stockinq dealers.-Customers can more easily track order s-latus and invoices online, access MSDS sheeits and details on green product certifications, discover supplier inlormation-through direct links, and download daily news feeds and the company's FASTSuite software for EWP

Redesign: www.partonbarksid i ng.com

Client: Parton Lumber

Designer: Zurv

Goal: Showcase and draw traffic to primary product, premium poplar bark siding

Chinges: The hom-e page immediately grabs the attention of viewers with llash animation featuring a home covered in bark cladding, Other new features: a user'friendly interface, a portfolio of bark-sided homes and stuctures, a fascinating discussion on the historical aspects of bark siding, an exten' sive Frequently Asked Questions (FAa) page, and a quick, convenient Free Sample Request button.

Redesign : wwut. moistureshield.com

Client: A.E.R.T.

Desioner: Brandner Communications

Goali Provide a more interactive, user-friendly experience

Changes: The upgraded site leatures deck design and color visualization tools, a dealer locator, more product info, and tips and resources for building professionals.

6n6srgr\rg' €. € "m- HQ -l'.lll..,"..,......".!ry re BARK

heu6lCdim

Jurue 2009 BuIlltNc PnolucrsDlcnsr 11

s@le$sidirg, roofing & insulation

pBy Mike Loughery CertainTeed Corp.

ANT to give a lift to your sales of siding, roofing and insulation? Consider addins a wider varietv of products to your inventory as the demand for greater energy efficiency continues to grow. Today's homeowners want to reinvest in the American Dream without breaking the bank, and builder owners want to watch their bottom line. Communicating energy- and cost-saving benefits will likely lead to increased sales for you and your pro customers.

Improving a home or building's energy efficiency reduces energy consumption and greenhouse gas emissions to help preserve the environment for the generations of the future. The nobility of such a goal may resonate with a large number of people; however, even more will be drawn to the cause for a more energy-efficient America by one concrete detail: it will save them money.

Homeowners are beginning to realize that certain energy-efficient home improvements help the environment and can also lower their monthly utility bills-a powerful selling point today. Plus, with the American Recovery and Reinvestment Act of 2009, homeowners could recoup 307o of the cost, up to $1,500, of such home improvements as insulation, solar reflective asphalt shingles, and more efficient windows and doors. According to a recent National Association of Homebuilders survey, many homeowners are willing to make the investment-Sl7o of them said they would invest $5,000 to $10,999 in their homes if energy costs could be reduced by roughly $ I ,000 a year

With these factors in place, congressional economists are forecasting that there will be an estimated $6 billion in

new remodeling work by the end of 2010.

To meet the needs of an increasingly energy-conscious public and building industry, LBM dealers should become better acquainted with the concept of energy efficiency and how it can benefit them and their customers.

There are many ways to make a home more energy-efficient. Homeowners can upgrade to ENsRcy Sran-qualified appliances, caulk and seal leaks in the structure, and install ENsncy Sran-qualified building products that place less demand on heating and cooling systems. In addition to doors and windows, other primary building components that effectively contribute to increased energy efficiency are insulation, insulated siding, and solar-reflectant roofing.

Insulation

A well sealed and insulated home will keep a home either warmer or cooler, depending on the season, and create less work for the heating and cooling systems. Homeowners need to find out the recommended insulation thermal resistance level, or R-value, for their region and work to at least match that level. If an area of the home's insulation R-value doesn't meet or exceed the DOE's recommended level, more insulation should be installed to raise the R-value to the desired amount.

Prepare for increased demand for a variety of insulation products, such as fiberglass batt and blow-in fiberglass insulation. In addition, a newer material-spray foam insulation-is also attracting attention for its excellent performance attributes.

$ U \ o

12 BurlorNc Pnotucrs Drcrsr JuNE 2009

Polyurethane spray foam insulation is sprayed into an open building cavity and quickly adheres and expands filling all voids. This creates an effective air seal and provides the insulating power that can be used in whole house and building applications or in combination with fiberglass insulation. It is particularly useful in hard to reach areas such as cathedral ceilings, knee walls, and roof decks. Spray foam insulation minimizes hot and cold spots and provides outstanding comfort and indoor air quality by impeding the penetration of moisture and outdoor allergens.

Fiberglass HVAC duct board, duct liner, or duct wrap is another option for increasing energy efficiency with insulation, as they each do a superior job of maintaining the desired temperature of conditioned air throughout the ductwork until it is delivered to its destination.

Insulated Siding

According to ENsncv Srnn statistics, up to 4OVo of energy lost through a traditionally insulated wood-framed wall is through wood studs, which comprise up to 257o of a home's exterior. Think of each stud as a "thermal bridge," which, depending on the season, allows warm or cool air to pass through the wall. To stop this drain on a home's heating and cooling system, you must break the thermal bridge. One of the newest and best ways to accomplish this task is with insulated vinyl siding.

Insulated vinyl siding products consist of rigid foam insulation behind the exterior surface of a vinyl siding panel. The insulation is precision-cut and contoured to fill the gap between the siding and home, so it insulates continuously across a home's framing, breaking the thermal bridge. The foam insulation backing allows the siding to deliver an average R-value that is more than triple that of most exterior cladding materials.

Solar-Refleetive Roofing

With today's roofing technology, there are now cool roofing products available both in roofing membranes and shingles. New roofing shingle products use reflective surface colors and granules to repel the sun's rays and lower roof surface temperature. This prevents absorption of

excessive roof heat into the structure, which decreases the demand on heating and cooling systems. Now that cool roofing products are available in a wider variety of colors and styles, more homeowners are likely to request them for their next roofing job. Point out that choosing solar reflective roofing can also earn homeowners federal tax credits. Selling insulative roofing, siding and insulation benefits both you and your customers.

Campia llol

I I 1 l I

SIDING with a foam insulation backing can triple exterior cladding's energy efficiency.

COOL ROOFS are easier to market with the introduction of new colors and styles.

- Mike Inughery is director of corporate marketing communications .for CertainTeed Corp. He can be reached at (800) 27485 30 or mike.b.loughery@ saint- gobain.com.

WE CHALLENGE YOU TO FIND A "GREENER" DECKING MATERIAL! Junr 2009 ButlolNc Pnonucrs Dlcnsr 13

Tilking the next step Cellular PVC Thim 2.0

By Brian Kincaid Azx Building Products

trim has gained recognition and market share as a wood replacement product, dealers have begun to fill their marketing arsenal with even more profiles and product styles. Likewise, contractors continue to find new benefits and discover additional areas where cellular PVC wins out over wood. Sales of cellular PVC continue to be impacted by new manufacturing technologies such as improvements that have enabled the production of trim boards up to 16" wide and solid sheets up to 48" wide by 20 ft.longlarge, wide boards that will remain stable over time.

SfNCE the introduction of cellular LTPVC trim a decade ago. the category has provided increased growth opportunities for building material dealers.

The product offered obvious advantages from the beginning: cellular PVC was shown to be impervious to moisture, could be left unpainted but has excellent paint adhesion. is easy ro handle and install, and offers low maintenance with sustainable great looks. These early, identifiable bene-

fits resonated with the market almost immediately and offered the greatest differentiation from wood trim.

In addition to the many product features and benefits, LBM dealers were also educated about the importance of cellular PVC trim products having ICC building code listings so their customers could be secure in knowing the products would peform as designed and there would be no hassle with inspections.

Through the years, as cellular PVC

A wide, solid wooden trim board or sheet is virtually unheard of for obvious reasons-the boards' negative reactions to the moisture cycle. With cellular PVC, covering larger, wider areas is now easy to do - and easy to maintain. For example, cellular PVC sheets are a perfect solution that can be cut into just about any shape or size. And, not only is cellular PVC easily workable, but most products carry up to a 25-year warranty against cupping. warping or cracks. so contractors can rest easy that cellular PVC will reduce their callbacks. Overall, the variety of profiles, made from a sustainable material, have clearly helped to foster the return of more trim and more elaborate trim in housing designs and renovations.

F

14 Burr.ulxc Pnonucrs Drcpsr Jur.re 2009

TRIM USES include detailed dentil mouldings and attractive, nearly invisible coordinating gutters.

In our own focus group studies, we have discovered that there is a significant price elasticity for cellular PVC trim products, which means contractors and consumers are unlikely to be negatively influenced by price when they understand the product benefits. This underscores the dealer's need for product knowledge to ease the selling process by being prepared to overcome pricing objections. Successful dealers have recognized, and been able to properly communicate to their customers, that the initial product cost is more than justified by the long-term benefits of cellular PVC trim products. This remains the number one reason that product training is so important.

Once cellular PVC products are in the hands of contractors/installers, then the real ingenuity kicks in. These folks are the genesis of many real-life product innovations and solutions to challenges that come up on the jobsite. For example, cellular PVC trim became a no-brainer for one-steppers and subcontractors who once went through the intensive labor of wrapping wood trim with aluminum coil wrap. By simply replacing the twostep process of installing wood and then coil wrap with a one-time installation of cellular PVC, the labor time was virtually cut in half-and no more wavy coil wrap. In addition, groundcontact applications that are prohibitive for wood, such as garage door jambs, are a great use of cellular PVC trim profiles.

Other breakthroughs driven by dealer and contractor feedback include on-the-job performance issues such as improved width tolerances and smooth, sealed edges on trim. Typical specs for wood and other trim prod-

ucts allow a width variation of plus or minus l/16". In response, Azer can now make trim profiles with 1/64" tolerance instead of the allowable l/16" width variations.

At the same time, Azex began producing boards with smooth, sealed edges designed to stay cleaner in the dealer yard and on the jobsite. And, if they do get dirty, the edges are easier to clean. In addition to regular exterior trim, these S4S "surfaced four sides" boards can also be used as deck trimor a variety of other uses that contractors will surely identify. The other benefit of the smooth edge boards with tight width tolerances is that boards can be installed tightly side to side or end to end. With no moisture cycle to cause swelling or warping, you can rest assured the boards will stav that wav.

Current market conditions represent an opportunity for dealers to offer real value to their customers. It is also a time when reputations are critical, so it's more important than ever that dealers align their companies with trusted, branded products. A dealer should expect a branded product to offer the commitment of code listing, proven track record, on-going product development, manulacturing experience, production capacity, field sales support, marketing leadership, and advertising/brand building in order to drive business to their location.

A manufacturer's pull-through efforts can be some of a dealer's best opportunities to weather the current economic environment, so be prepared to take full advantage of leads, training, sales support, and the like. Also, keep in mind that innovative trim products can be a true workhorse for your business. Unlike other products, trim is a year round business and is not seasonally driven. As a year-round revenue generator, you can target different types of contractors regardless of the weather.

In the ever-evolving cellular PVC trim category, the importance of code listings, manufacturing precision, and product enhancements are the latest recognized advantages. It's no longer simply a discussion of low-maintenance, no splitting, and no rottingwhen the product clearly offers many more rewards.

1

- Brian Kincaid is vice president of marketing for Azex Building Products, Scranton, Pa. He can be reached via www.azek.com.

CELLULAR PVC trim can cover large areas, such as these routed raised panels, or be heatformed to create curved window arches.

Jurue

Butlorxc Pnooucrs Drcosr 15

CELLULAR PVC can be heat-formed in two ways. Custom window arches can be curved with heat blankets. For larger production lobs, propane-heated duct work lunnels make sense.

2009

Insulate profi ts with

By James Hodgson Premier Buildins Svstems

IIJHILE North American design

Y Y professionals and builders have used structural insulated panels (SIPs) in place of stick-built construction for several decades, many contractors are still unfamiliar with them. However, as requirements for energy efficient buildings become more stringent, building material dealers and distributors can anticipate more customer inquiries about SIPs.

"The word is out on SIPs," said Scott Bergford,2009 Energy Value Housing Awards Builder of the Year by the National Association of Home Builders. "Customers are coming to me and requesting SIPs so much that I had to increase my staff just to keep up with demand, and I still have more jobs than I can handle."

SIPs are pre-manufactured wall, roof or floor components delivered to the jobsite ready to install. Designers can use them in wall, roof and floor systems in place of other structural elements such as wall studs and joists.

They are typically made with oriented strand board "skins" that are laminated and pressure cured to a rigid insulating foam core. The OSB and foam work together as both a structural system and for insulation.

SIPs are very strong and in most applications are structurally self-sufficient. Builders can incorporate SIPs into typical exterior walls, as well as shear walls to resist earthquakes and high winds. Extensive testing has proven that SIPs are appropriate for use in high-risk earthquake areas, including seismic zones D, E and F.

In roofs, SIPs can be used without an engineered truss system and can span long distances-up to 20 ft.

based on design parameters. As a result, they can help create open interior spaces by reducing the need for intermediate structural supports.

SIPs also work well in floors, typically in applications where an insulated floor system is required. This includes over crawl spaces, in threeseason porches, or above an unheated garage.

A key advantage SIPs provideespecially in the current building market of razor-thin margins-is their ability to dramatically reduce dry-in time. The large, single-piece panels (up to 8 ft.by 24 ft. long) enable contractors to install entire wall, roof and floor sections at one time. They eliminate the need for separate framing, insulating and sheathing work on site,

16 Burr,orNc Pnouucrs DrcBsr Jur.rg 2009

STRUCTURAL INSULATED PANELS-or SlPs-are increasingly being requested by builders.

and enable subs to start and finish work faster since walls, roofs and floors are plumb and square.

In addition, SIPs manufacturers pre-cut window and door openings, including curves, arches and complex shapes. Depending on an opening's dimensions, subcontractors don't need to spend time installing separate headers. The panels also come with pre-cut electrical chases, eliminating the need to drill through studs for wiring.

The design and construction process for a SIPs building is straightforward. The architect provides construction documents to a SIP manufacturer or dealer, who converts them into shop drawings that give each panel's specific dimensions. After review by all applicable parties, the manufacturer or dealer finalizes the shop drawings, makes the panels, and delivers them to the jobsite.

SIPs play an important role in ensuring quality interior finishes. Because they are made in a controlled setting and come in large sections, they allow for straighter walls than is possible with stick-built framing.

Straight engineered walls do not bow or warp like stick framed construction can, and they allow for faster, easier and higher quality installation of doors, windows, cabinets, millwork and other finishes. They also are important for homeowner and building owner satisfaction, especially in cases where artwork displays, intricate lighting designs and other architectural highlights could expose underlying wall flaws.

Building with SIPs results in fewer gaps than stick-built construction, creating a tight building envelope. This is a critical benefit for high energy efficiency and indoor air quality. "A SIP house has fewer joints, less complicated interfaces between conditioned and unconditioned spaces, and it is dramatically easier to make it tight,"

according to Sam Rashkin, national director of the EPA's Energy Star for Homes Program

Contractors can use SIPs to earn points for their projects under the LEED Green Building Rating System-up to 36 or more points in homes and up to 23 points in commercial construction. SIPs also integrate well with the NAHB's National Green Building Standard.

SIPs provide exceptional energy efficiency compared to stick-built construction for both cold and hot climates. The insulating foam is continu-

ous across the panel, unlike fiberglass batts that come in narrow sections and typically leave gaps near framing members.

The R-Value of a SIP panel offers a greater energy efficiency rating than higher R-value fiberglass insulation.

The U.S. Department of Energy's Oak Ridge National Laboratory found that a R-14 whole-wall value 4.5" SIP wall outperformed a2"x6" wall with R-19 fiberglass insulation. The lab also concluded that SIPs can help reduce a building's annual energy costs by 50Vo to 6OVo compared to more common framing methods.

"It only costs an average of $200 to $300 a year to heat one of my SIP homes," said Scott Bergford. "That's anywhere from one-fifth to one-sixth the typical costs for this region (western Washington State), so the savings are pretty significant."

Stick-built construction also generates large waste volumes as builders cut stock boards to length. Framing a structure can generate thousands of pounds of scrap wood. By comparison, SIPs are manufactured in a controlled setting that allows for more careful material management than is possible on a jobsite. As a result, contractors can reduce waste by up to

two-thirds.

Many SIPs are l00%o recyclable, as well as have rigid foam cores made from a specified amount of recycled content. In addition, the OSB skins come from fast-growing, renewable trees. OSB manufacturing uses a high percentage of each log, making efficient use of natural resources.

SIPs can also play a significant role in improving indoor air quality. They provide a tighter building envelope than other framing methods, which helps reduce infiltration of common pollutants such as radon, molds, pollen, volatile organic compounds (VOCs),lead dust, and asbestos. Some manufacturers' SIPs also do not contain chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs) or formaldehyde.

As more contractors look to use SIPs in their projects, dealers can serve as a valued information resource. Becoming a SIPs distributor can help tap into a growing, advanced building technology that many in the industry view as the future of framing.

- James Hodgson is general manaSer for Premier Building Systems, Fift, Wa. He can be reached at (800) 275-7086 or via www pbssips.com.

17 Proudly grown and manatactured by the Calville lndian Tribe nd ri$iials fiom-Omak, \llla. sf6-tf .CoLvtLLE INDIAI! Producerc of high qaali$ Plyw6od & Dfy V6fieef'-"'' 'from'Om8k;Wa. Een 6aq 422:75',A '''Fax 389r{2?7&n ' '"''""JuNe 2009 Burr-orNc Pnooucrs Drcrsr

l:tm:ns

Grffith Lumber Co., Manhattan, Ks., has reopened after suffering $900,000 in damage from an April 24 fire that claimed two warehouses and extensive inventory ...

National Lurnber has relocated its Kitchen Views showroom in Newton, Ma., to its nearby yard and has added a new showroom in Mansfield,Ma....

Carolina Millwork & Building Supply, Hickory, N.C., has added a 2,000-sq. ft. design center and transitioned to SpruceWare.NET software

Vitlas Lumber Yard, Lower Township, N.J., was extensively damaged by a fire April 24weeks after new owners took over the business

Building Materials Reuse Warehouse has opened in Houston, Tx., specializing in lumber and other donated construction materials

Schappell Hardware, Topton, Pa., is closing after 99 years due to big-box competition

Hardware Hank, Onawa, Ia., closed May 30 after 4l years ...

MC Supply relocated its Berlin, Ct., branch May 16 to a more convenient location offering over 67,000 sq. ft. of showroom and warehouse space Send

Have your recent expansion, promotions or other company changes published in the next issue of BPD.

Just Fax your news to 949.852-0231 or send by email to kdebals@buildingDroducts.com.

h frce sevice)

Tzeland Ace Hardware opened a second branch May 13, a 11,400sq. west-side store managed by Nick Visser to complement its smaller store in downtown Zeeland,Mi....

Menards opened a 162,000-sq. ft. home center April 14 in Sandusky, Oh.

Lowe's opened new stores May 29 in Jonesborough, Tn.; trday 22 in Middleburg, Fl.; Weaverville, N.C., and Indian Land, S.C., and May I in New Albany, Ms., and Clarkstown. N.Y. ...

Lowe 's expects a 4th quarter 2009 opening in Moberly, Mo.

Home Depot opened a 115,000sq. ft. store April 23 in S. Bronx, N.Y. (Stanley Pierre, store mgr.)* one of only five Depots set to open in the U.S. this year

Ace Hardware,Peoria, I1., was robbed Apnl29 by a l5-year-old who used a fake gun and was arrested less than 10 minutes after committing the crime

Wrorrslrrrs/lhrurlcrurrrs

Hietala Lumber Co., Avrora, Mn., was destroyed by a $500,000 flre April 30

Mountain View Lumber, Motgantown, W.V., lost its 35-year-old sawmill in anApril2Sblaze

Sutton Brothers Lumber, Crandall, Ga., will rebuild its 21O00sq. ft. sawmill destroyed by an Apnl2 fire caused by lightning

As sociated Materials, Cuyahoga Falls, Oh., is phasing out use of the warehouse next to its downsized vinyl siding plant in Ennis, Tx.

DiPrizio Pine Sales, Middleton, N.H., received the Northeastern Lo g gers' As sociation's Outstanding Sawmill OperatorAward

MeadWestvaco Corp. sold 25,000 acres of South Carolina timberland for $49 million to investment funds Keystone Forest Investments and Sustainable Growth LLC ...

Huttig Building Products' Columbus, Oh., DC is now carrying Fiber Composites 'Fiberon composite decking and railing, expanding Fiberon's availability in Ohio, northern Kentucky, West Virginia, and eastern Indiana ...

BW Creative Wood Industries is showcasing its line of interior stair railing products on a new website, www.stairsimple,com ..

Railing Dynamics Inc., Egg Harbor Township, N.J., is celebrating its 20th anniversary by offering dealer and consumer rebates on its posts and railing kits ...

Lo ui siana - P ac ific, Nashville, Tn.,launched a voluntary recall of Veranda, WeatherBest and ABTco brand composite decking produced from 2005 to mid-2008

Ainsworth has launched a free online seminar about using its concrete-forming panels

Fasco America, Muscle Shoals, Al.. has been selected to exhibit its Scrail collated fasteners in the Smart Solutions section of PCBC June 17-19 at the Moscone Center. San Francisco, Ca. ...

Anniversaries: Sacft Lumber, Aurora, Ne., 110th lackson's True Value Hardware, Kittery, Me., 100th ... Umber's Do It Best Hardware,Waynedale, In., 65th ...

Housing starts in April dropped 12.8Vo to a seasonally adjusted annual rate of 458.000 units single-family starts rcse 2.8Vo to 368,000, while multi-family units plunged 46.IVo to 90,000 permits fell 3.3Vo to a record-low pace of494O00.

briefs

us your news!

18 Burr,orNc Pnooucrs Drcrsr Jute 2009

_k= ,'11 .ll:l;;:.i:iiil: -r:. -,, ].', ri i l I{ave Your Custorners Choose Any Color For Their Siding. Let Us Do The Rest. Cabot Factory Finish'Fade-Resistant, Nature Inspired Colors . Saves Time and Eliminates Weather Delays Applied in Factory-Controlled Conditions Available with S-year, 1 S-year or 25-Year Warranty To Learn More, visit CabotFactoryFinish.com orcall 1-8OO-US-STAIN Oun PERFORMANCE IS LEGENDARY.."

& Cornprwror Patt:

-Fumpa

-3oor Ga**atr for S'lo 1O diemeter doors. We carry thasc gmkeb fur kth bolted and quick opening doors

-Tram Car Parts sudl as whe€ls, bearings, axles, end lumber straps

Listings are often submitted months in advance. Always verifi dates and locations with sponsor before making plans to anend.-'

luru

Southern Forest Products Association - June 9-13, mid-year meeting & expo, New Orleans, La.; (504) 443-4464.

Forest Products Machinery & Equipment Expo - June ll-13, Morial Convention Center, New Orleans, La.; (608) 231-1361

Eastern New York Lumber Dealers Assn. - June 12, golf, Eagle Crest Country Club, Clifton Park, N.Y.; (800) 292-6752.

Mid-America Lumbermens Association - June 12, Kansas Sunflower Shootout golf tourney, Salina, Ks.; (800) 7 4j -6529.

Central New York Retail Lumber Dealers Association - June 15, golf outing, Pompey Country Club, Pompey, N.y.; (800) 292-6'752.

Twin Cities Hoo-Hoo Club - June 15, golf & picnic, Highland National Golf Course, St. Paul, Mn.; (612) 490-8583.

National Retail Federation - June 15-17, loss prevention conference & expo, Los Angeles, Ca; (202) 783-7971.

Construct 2009 - June 16-19, Indianapolis, In.; (301) 670-0604.

National Lawn & Garden Show - June 16-19, Hyatt Regency, Atlanta, Ga.; (888) 316-0226.

Forest Products Society - June 21-23, convention, Boise, Id.; (608) 231-1361.

Midwest Hardware Association - June 22-23, annual convention, Wisconsin Dells, Wi.; (800) 888-1817.

Western New York Lumber Dealers Association - June 23, golf outing, Canandaigua, N.Y.; (800) 292-6752.

Temperate Forest Foundation - June 23-26, teachers tour, Duluth, Mn.; (503) 445-9472.

House-Hasson Hardware Co, - June 25-27, market, Gaylord Opryland Resort, Nashville, Tn.; (865) 525-04j1.

Missouri Forest Products Association - June 26-27. show. Show Me Center, Cape Girardau, Mo.; (573) 634-3252.

furY

Rhode Island Lumber & Building Material Dealers Associ. ation - July 8, annual golf tourney/clambake, Green Valley Country Club, Portsmouth, R.I.; (8OO) 292-6152.

Illinois Lumber & Material Dealers Assn. - July 9, golf tournament, Tamarack Golf Course, Naperville, Il.; (800) 252-8641.

Construction Suppliers' Association - July 9-12, summer management conference, The Ridges Resort & Club, Hiawassee, Ga.;(800) 351-2255.

Mississippi Lumber Manufacturers Association - July 9-12, convention/show, Beau Rivage, Biloxi, Ms.; (601) 982-l'l3l

Oklahoma Lumbermen's Association - July 10-L1, convention, Tanglewood Resort, Pottsboro, Tx.; (800) 444-1771.

North American Retail Hardware Association - July 13-15, Marriott Rivercenter, San Anronio, Tx.; (317) 290-0338.

Western Red Cedar Lumber Association - Juty 16-18, cedar summit, Victoria, B.C.; (604) 891-1231.

Whether you are looking to increase your wood treating plant's production, build a new treating plant, or just need a part for a exisitng one, call us. We're here to helpl

Tank Fab Inc.

Call 1-800-67 5-9007 or 910-675-8999 or visit our website: www.TankFab.com

e-mail: JUppincott@TankFab. com

Eastern New York Lumber Dealers Assn. - July 20, summer outing, Wiley Bros., Schaghticoke, N.Y.; (800) 292-6752.

New Jersey Building Materials Dealers Association - July 20, annual golf outing, Battleground Country Club, Manalapan, N.J.: (800) 269-9603.

Northeast Window & Door Assn. - July 20-21, summer meeting, Marriott Seaview Resort, Galloway, N.J.; (609) 799-4900.

Southeastern Lumber Manufacturers Association - July 2325, annual conference, Ritz Carlton, Amelia Island, Fl.; (404) 36t-1445.

Southern Building Material Association - Juty 30-Aug.2, summer conference & leaders meeting, Wyndham Oceanfront Resort, Virginia Beach, Va.; (704) 376-1503.

20 Burr,lrNc Pnolucrs Drcesr Jur.re 2009

GatorGuard" treated lumber I always delivers. Canfor operates two treating plants in Camden

a nd Conway, South Ca rolina.

aotn are equipped with new

state-of-the-art control systems

,o ensure consistent quality.

TOUGH... RESILIENT... EXPERIENCED!

,, having control over our fiber

resources and lumber treatment,

nf rt delivery by Canfor trucks,

guard the entire process.

www.eAroR-cuARD.coM

M BER

4r- GATOR r?-s=,e GUARD TREATED LU

I

|

I |

1

I

I

I

| *"

| ,.*

--l | ;;;;;-*r-r.r,

J

I

f / '""-:=::j=-"=FcncKUdu' tll '-l trAt\FOR

M.RE rNFoRMArroN,

oR vrsrr

,

Florida Building Material has formed the Florida Rebar Fabricators Council, which includes association membership.

The association will kick off its 89th annual convention and trade show Aug. 19 with the Tom Snead Golf Classic. The next two days will include a kick-off breakfast with ESPN analyst Lee Corso, WoodSource seminars, and the Gulf Atlantic Building Products Expo. New this year is space for heavy equipment.

Mid South Building Material Dealers Association will hold its midyear meeting Aug. 14-15 at Hampton Inn & Suites. Natchez. Ms.

Vermont Retail Lumber Dealers Association plans its annual meeting and golf outing for Aug. 19 at the Killington Grand Resort, Killington, vt.

Rhode Island Lumber & Building Material Dealers Association hosts its annual golf tourney and clambake July 8 at Green Valley Country Club, Portsmouth.

New Jersey Building Materials Dealers Association's annual golf outing tees up July 20 at Battleground Country Club, Manalapan.

Southern Building Material Association's annual summer conference & leaders' meeting is July 30Aug. 2 at Wyndham Resort, Virginia Beach, Va.

Economist Dr. Ed Seifried will discuss why a healthy construction industry is right around the corner.

Indiana Lumber & Builders Supply Association's 15th annual Sycamore Scramble is Aug. 6 at the Oak Tree Golf Course, Plainfield, In.

Michigan Lumber & Building Materials Association hosts its 12th annual golf outing Aug. 6 at Hawk Hollow Golf Course, Bath, Mi.

Southeastern Lumber Manufacturers Association has booked political analyst Dick Monis to keynote its annual conference Jily 22-25 at the Ritz Carlton, Amelia Island, Fl. Issues forums and education sessions are also featured, as well as low country boil/oyster roast, fishing, golf, volleyball, and chairman's gala.

Mississippi Lumber Manufacturers Association has set its mid-year convention and trade show for July 912 atBeat Rivage, Biloxi, Ms.

Appalachian Hardwoods Manufacturers will hold its annual summer conference Aug. l-4 at The Homestead, Hot Springs, Va.

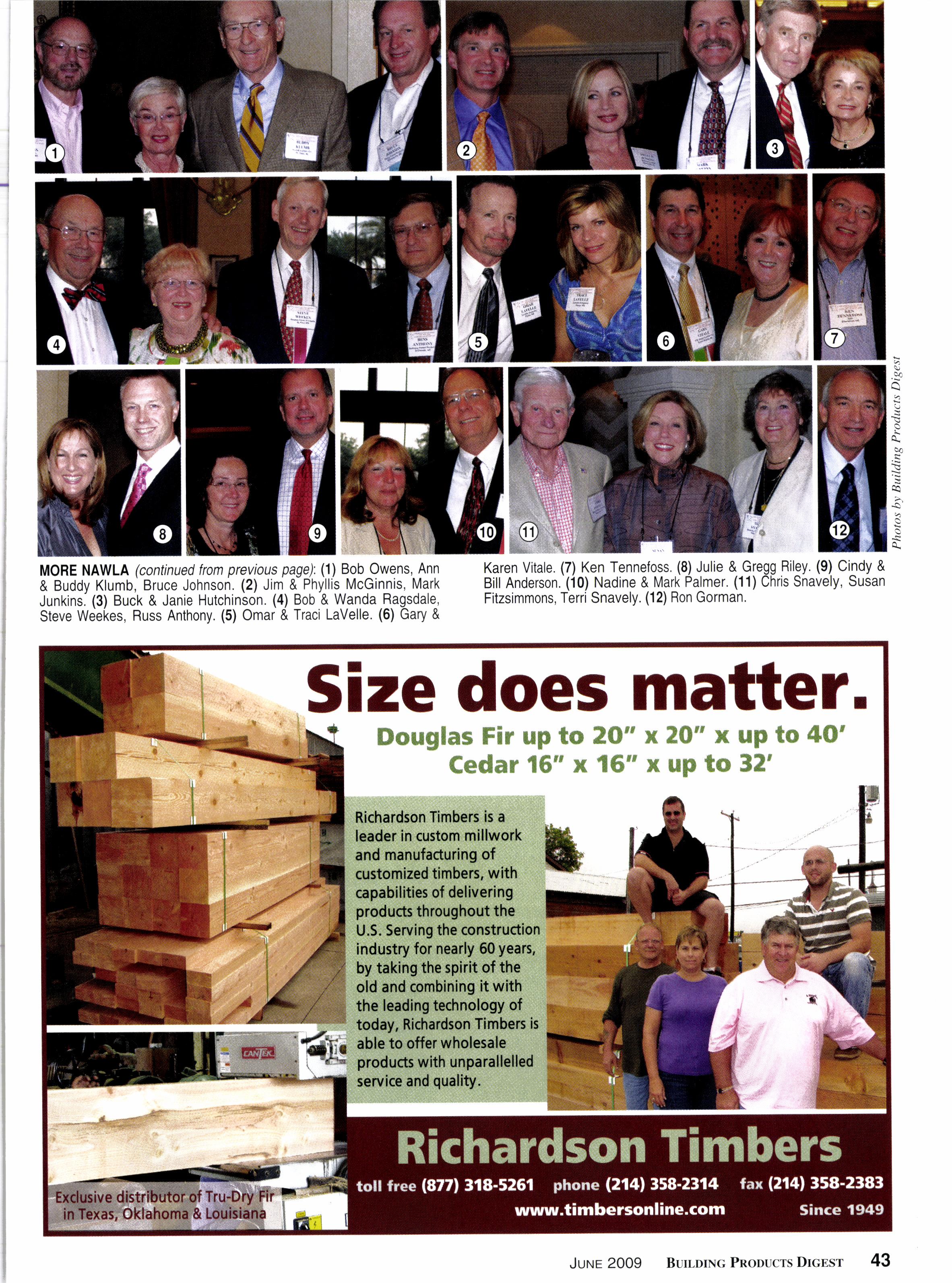

North American Wholesale Lumber Association honored Aubra H. Anthony Jr., president and c.e.o. of Anthony Forest Products, El Dorado, Ar., with the 2009 Mulrooney Award during its recent annual meeting (see photos, p. 42-43.)

At PLM, we understand that you need an insurance company with property and casualty insurance products and services that you can trust.

For over IOO years, our experts have been providing quality claims and risk management services to the lumber, woodworking and building material industries. Remember, "you get what you pay tor." We understand wood. We know your business... because it's our business too.

lf you're looking for quality and value from your insurance provider, please contact the PLM Marketing Department at 800.752.1895 or log onto www.plmins.com.

Yesterday, Today, Tomorrow... grow knowing you're covered.

on

PrrurusyLVANtA /r{.5uRA LuvtgrRMENS Murua,l NCf COMPANY I'ennsvlvania Lurlbcrnrcns \'lutual I nsur,irrtcc Oornl;ar11. ()nc ( lomrlcrt:e Sclua rc 2{)05 i\larket Strcct, Suite 12(X) l'hiladclplril, lA I I IO:t wood is all we do. Serving Continental United States

r^ _ru* Sniil i,lllffil,ll, :;,:,'r,".utive orricer 22 BuTLDTNG Pnolucrs Drcosr Jurrrr 2009

Southern forest products industry ready for rebound

IESPITE a global recession, southLf ern forest products manufacturers are hanging tough and bracing for the eventual rebound.

The companies have found strength in numbers, joining two primary trade groups, the Southern Forest Products Association and the Southeastern Lumber Manufacturers Association.

SLMA consists of independently owned and operated manufacturers of 4.8 billion bd. ft. of softwood and hardwood products. Most are third or fourth generation family-owned, which means they have demonstrated their strength and resiliency by weathering many storms before.

Since 1961, SLMA has helped strengthen its membership by providing value-added programs and services including marketing, federal lobbying on legislative and regulatory affairs and member networking and educational opportunities. While many of SLMA's 120 member companies are considered small companies, their involvement in the association enables them to band together with other members to create a large voice for the

independent manufacturers.

"Our members have carved out a great niche for themselves," said SLMA president Debbie Brady. "By focusing on quality products and outstanding customer service, they have withstood many economic downturns. While this current downturn has pushed both prices and production to historic lows, our members have continued to invest in their mills, products and services so that they will be standing stronger than ever once things turn around."

Likewise, since 1915, SFPA has represented southern pine lumber manufacturers, promoting members' products for a wide variety of residential, light commercial, and industrial applications and helping them weather a depression and several recessions.

"Our industry has faced downturns before, but the current demise of homebuilding activity across the country has put a squeeze on lumber markets unlike any previous period," noted SFPA president Digges Morgan. "Consequently, SFPA is taking aggressive steps that allow our indus-

try to undertake the best possible promotional strategy for these challenging months ahead."

A major step forward came with the formation of the Southern Pine Council in 1988. A joint markering effort by SFPA and SLMA, SPC works to promote ways to sell more lumber. Working with dealers is a key component of its campaigns.

SLMA's Brady said that SPC has been a key driver in encouraging the use of more southem pine products in new construction by promoting raised floor foundations. The council has also developed an extensive product library on subjects ranging from span tables to treated wood safety, all of which are available for free download at www.southernpine.com.

To complement SPC's trade efforts, SLMA launched the Southern Pine Awareness Network in 2005 to promote southern pine products directly to consumers. While SPAN promotes the full gamut of interior and exterior southern pine products, more opportunities have evolved throughout the years to promote pressure treated southern pine. SPAN has successfully garnered coverage of southern pine products and applications in newspapers and magazines, on television and radio, and online. Dealers can refer customers to www.spanpine.com for product info, southern pine's green attributes, free project plans, and more.

Dealers should keep in mind that the best products are not necessarily the newest, according to SFPA's Morgan. The inherent features that made southern pine a key player in our nation's colonial days continue to make it a wise choice today.

The current recession is approaching two years, creating the roughest downturn for construction markets ever recorded. Until a recovery is in sight, resourceful lumber dealers are finding the means to stay ahead even in such a depressed market, and SPC and SPAN are here to help.

FONEST PNODUCTS SPECIAI, SECTIOT

24 Burlornc Pnolucrs Drcesr Jur're 2009

THROUGHOUT the year, SPC conducts educational seminars for building professionals across the Southeast.

$u* PO Box l1l0 I Alexandria. LA 71309 n'l;',ffi lfi ::::1'j:;;::",::,'j:lii'"1;:;.To*. J- J l5( lradema'k c l9i6 | ore5l Slewdrdsnrp Coun.rl A.(. -=-pq mark ol 'p5PoFsrble furestry 5W (OL 000695. FSC sw ( or oooLec, sw r M/coc'ooor86. W

Raised wood floors open the door to lumber sales

the base flood elevations of many areas, SPC's efforts are convincing builders and homeowners alike that a raised floor home is the best option over a mound of expensive fill for meeting stricter federal and municipal guidelines. The homeowner realizes lower flood insurance rates. The builder can market a home with added curb appeal, front and rear porches and decks, plus many other features. The lumber dealer is successful. too. moving more lumber to make it all happen.

fN COASTAL and flood-prone Iareas, a raised floor home makes sense. Sites that experience soil subsidence, even simple room additions and remodeling projects are other examples where a raised floor system can offer long-term benefits. When the job calls for a raised wood floor, lumber dealers can add up to a third more lumber to the typical framing package order.

Southern Pine Council has devoted vast resources toward educating building professionals and consumers about the advantages of incorporating a raised wood floor system in a new home rather than a concrete slab. Alliances have been established with APA, universities and other industry organizations. Since its launch in 2000, the campaign has grown to include demonstration homes, seminars and research.

On a regular basis, SPC teams up with industry allies. delivering presentations to groups of homebuilders,

floodplain managers, and code officials. Ongoing research is addressing common questions and concerns, including cost comparisons with slab construction, moisture control, and foundation design options.

Consumers are getting the raised floor message, too. For the fourth consecutive year, SPC is undertaking tv advertising in key markets stretching from Houston to the Florida panhandle, encouraging homeowners to demand raised floor construction, using locally sourced, renewable southern pine materials. Later this summer, the 2009 campaign will be launched, hopefully coinciding with some recovery in home construction activity. Audience surveys have documented proven effectiveness in delivering messages to help turn the tide toward raised wood floor systems. The tv campaign is supplemented with online advertising, too, triggered by popular search engines.

As FEMA and local agencies raise

SPC and APA publish a free monthly newsletter recapping the campaign's progress and listing information about demonstration homes, plus research and training opportunities for dealers and building professionals. Lumber dealers can subscribe by sending their name and email address to mail@sfpa.org. Complete information about raised floors and the television ads can also be found at www.raisedfl oorliving.com.

FONEST PNODUCTS SPECIAI, SESNON

t! .':'l r

26

SFPA's Richard Kleiner (ight) explains how more lumber is used in the typical framing package of a raised floor home to Jonathon Bachrack, president of Wolfe Lumber & Supply, Ponchatoula, La.

Burr,nrxc PRoDUCTs Drcnsr JuNe 2009

MATERIALS needed to build raised floors can add a third more lumber to a framing package.

ffiffiwffiffi wwffiwffiffiwffiffi ffituwtueffiu* ffiffituffiww% ffiffiffiw% eMffi ,,l 't:'t'': ,!q& 'i.rirr.r.'riii.r,i*i i.:i 'y1ij11t,::.: 1.. il!;t:ll,t' '' r.l,:l. l.,i qt. "f t .,.: lli' ...,. f:,, if' @#''' ,f i [[ FH TRI * sl rt 6;& i-l L:i | [-] .t i{ Wr I .lt,

Are you a woodaholic?

homeowners prefer the look of real wood over composite products," explains Kim Drew, SPAN's public relations counsel. "If you combine those two findings and add in the growing focus on outdoor living spaces, you have a great case for the Real Outdoor Living campaign. The timing is perfect for this type of promotion, and we have a really unique and exciting campaign under way."

you a

That is the .CLq uestion the Southern Pine Awareness Network asks in its new advertising and public relations campaign. Titled "Real Outdoor Living," the campaign launched in late April. SPAN is banking on consumers'

love of real wood for the campaign, which focuses on outdoor wood applications including decks, pergolas, raised garden beds, and any other outdoor project d-i-yers can dream up.

Historical data shows that during recessionary times, consumer spending on remodeling and repairs rises. And, according to home and garden experts, today's homeowners are more apt to "grow where they are planted" and make their existing houses an oasis for their families. To capitalize on this trend, SPAN decided to seize the opportunity to promote the use of treated wood as a means of expanding and enhancing the outdoor living area.

"We have a good bit of data to support the stability of the R&R market and research which suggests that

1907-Is That Sustainabk Enough For You?

Lumber Company

For starters, consumers have a great new resource for outdoor building projects at www.realoutdoorliving.com. One of the first things visitors to the site will notice is the interactive "Are You a Woodaholic?" diagnostic. The tongue-in-cheek quiz builds on consumers' affinity for real wood by asking them to identify what they see in different wood grains. The end result: depending on their answers, test-takers are either real woodaholics or fakes.

"When we did our initial research, we found a whole community of d-iyers who actually refer to themselves as woodaholics," says Drew. "We're taking that identity to a whole new level by giving it legs so that it can build a true loyal following."

Site visitors also have access to a wide variety of outdoor project plans, including tree benches, bird houses, arbors and dog houses. Most plans are offered as PDF downloads, but SPAN will add a total of 12 video plans to the site by the end of the year. The first video, plans for an Adirondack chair, has already generated a lot of views. Each video features SPAN spokesman Brad Staggs, of HGTV and DIY Network fame, building a series of simple projects. Staggs reviews safety precautions, materials

FORES PNODUCTS SPECIAL SECTIOIY

magazine

all

SPAN's

new five-project brochure is advertised in Southern

Living

as well as

SPAN Dress release6.

A

RE

woodaholic?

McShan

205.31 5.62'7'r- 800. 882. 37 I 2 mcshan @ mcshan lumber.com www.mcshan I umber. com Producing Quality Southern Pine Lumber from Our Sustainable Southern Forest Since 1907 414. 5/4. 8/4 Southern Pine Rough or Dressed 5l4xl2 Stepping, Pattern Stock Pattern Stock Highlights: . We use only our own stock . Restrictive Grading Standards We control the entire process from log to finished product . Carefully Steam Dried to proper moisture content for interior applications ' SFI O Certified for fiber sourcing standards M:,SUAN 28 BurllrNc Pnooucrs Drcnsr Jurue 2009

NEW WEBSITE separates the wood proponenls from the oretenders.

Since

and tools needed. and an estimate as to how long the project will take.

To expand the reach of project plans, SPAN teamed up with Southern Living magazine for several projects. On most of the video projects and on SPAN's downloadable five-project brochure, plans were designed by Southern Llvrng stall and were previously only available for purchase directly from the magazine.

"Adding Southern Living's name to these project plans is a win-win for both parties," explains Drew. "They get more publicity for their plans, and we get thc recognition and trust that come with the Southern Livint! brand."

Teamwork between Real Outdoor Living and Southern Living, does not stop with project plans. ROL is a special contributor for both of the magazine's 2009 Idea Houses, providing treated southern pine for an outdoor kitchen and a wrap-around deck. As a special contributor, ROL will receive coverage in the August issue of the magazine, along with a table-top display at each of the show homes, driving traffic to realor-rtdoorliving.com.

To further promote the website (and thus treated wood), ROL banner ads will run on popular consumer websites from May through August. ROL extends its online reach with a Facebook page (www.facebook.comp ages/wood/707878591 35) and a Twitter account (twitter.com/woodaholics).

Later this year, ROL will hit the road with "Woodaholics Give Back." The series of community service events will see two well-deserving charities receive free outdoor building projects, courtesy of the woodaholics.

ROL has plans to not only drive more foot traffic to retailers, but also to make it easier on retail employees to sell pressure treated wood to d-i-yers with a host of tools and training.

"All of our consumer research ranks retail stores as one of the most popular sources of information for d-iyers looking to build a project," says Drew. "Whether they are going into

the stores and talking to sales associates or visiting the stores' websites, oonsumers really trust retailers as building experts."

- For mora infirmatbn about tha ROL, visit www.raaloutdoorliving,.com.. To sub' scribe tu SPAN'.r .free monthlv nawsletter tracking the campaign's sut:tess, email info@slnrunrg. For more inlo ttn SPAN, visit www.spanpine.com.

RAY WHITE LUMBER COMPANY Sparkman, Arkansas Phone: (870) 226'6850 . (870) 678-2277 ' Fax: (870) 678'2522 The White Family * Serving the Lumber lndustry for Four Generations High Quality Arkansas Southern Yellow Pine Boards' Pattern Stock and 5/4 Square Edge, Flooring, Beaded Geiling' 105, 1 16, 117r 1 19, 1221 131, 139, 514x12 Nosing. Jut'tE 2009 Burr.orNr; Pncluucrs Dtcssr 29

Treated lumber material

TJ1HANKS to progress in wood I preservation technology. new "earth-friendly" formulations are now available for pressure treatment of southern pine, addressing green building concerns.

Some 857o of all pressure treated wood produced in the U.S. is southern pine. Treated southern pine is popular for outdoor living applications like decks and gazebos, plus marine applications such as fishing piers, bridges and walkways. And, of course, it's perfect for framing homes and other structures in areas where decay and

PRESSURE TREATED southern oine lramino offers value-added protection frorh decav and termites to the entire home.

SOUTHERN FOREST PRODUCTS SPECIAL SECTION

30 BultorNc Pnooucrs DIcosr Juue 2009

tcrnr ites creatc prolrlen'ts.

Fivc ncrv code-approvccl prescn lttives inclucle u rrcu' fixatcd boratc firrnrulation. a ncw "carbott-based" t.tottcoppcl' prcservativc firr above-grouttd use outcloors. ancl thrcc nticronizccl (or di spcrscd) copper firnnulations. u'l-tich recluce irnpact on acluatic or terrestrial enr ilonrnettts ancl ittc lcss ctturrstve ttl f'astencrs.

To h.'lp dcalcrs scll rtrore trcated sonthcrn pine. SPC ofl'crs a trunrbcl of technical !ruicles about choosing ancl nsing this rersatilc oLttdoor bLrilcling nraterial. ,\r iriluble as l 1'rec PDF tlclrvn loatl at \\ \\ \\ .southcrnpine .cttt'tt. these helpful hooklcts includc rccentll relcased upclatcd vcrsions ol' SPC's sl.rccit'ication guidc-"Pressurc

Treatcd Southeru Pinc"ancl "Aquatic and Wetlancl Structures."

Thc spccil'ication -guidc fcatures a complchensivc tablc with the cornnrercial tradc narnc unclcr u'hich cach prcscr\ltive is rtiarkctecl and lt corresponding procluct u'cbsitc lot' tl'tose rr lrtl rilrrtI lrrltlitionrrl ittlottttlrliott.

Follou in-t an explanation ol' itvltilable southern pinc glades and sizcs. the uquatic guide providcs clctailcd spccif ications lur tre atecl lr-rnrbcr uscd in salt and ll'csh taler. Dcckin-r.r. sltecification s. l'astcncr reconrtlenclltti tttt s. lrntl rlree ill Ltlttle r I'ot ntltritt.' \ct \ ir'r arc also incluclccl.

In a green world. wood wins. Many alternative products make a claim to be the "greenest," but wood still stands on t0p.

America has some of the best-managed public and privately owned forests rn the world. Trees are renewable, and studies have shown that wood outperforms other materials when compared over a complete life cycle. Wood is reusable, recyclable and biodegradable. Inorganic materials not orry reouire excesstve energy to produce. but also to recycle or dispose of when their service life has been exhausted. And. of course, the proper use o{ wood bL,ilding nrodrrctq nart.nilrarlv n"eSS-re t'eated southern pine when warranted. helps ensure that structures built with wood enJoy an exlremely long service l'{e, reducing demands on our valuable forest resources.

According to McGraw-Hill Construction's "Green Outlook 2009," the value nf nropn-hrrildi^n nnnstrUCtiOn StartS rose from $10 billion in 2005 to $36-$a9 billion in 2008 and could reach 596$140 billion by 2013.

r, i :: i.1 i ,t ll it ..1-' .' .'

!,,4 :1 :.,,

': , ''. ,

":, ', ,, t .''

oi

Junr 2009 Ilt ru-nlrt; PR(llrt t L s Dtt;Es l' 31

Let the wood grain show!

AS NEW home construction continues to languish, -fl,remodeling projects are becoming popular options for many homeowners. Interior applications for southern pine patterns offer several options for dramatic improvements: flooring, paneling and ceilings.

Dealers can grow sales of southern pine flooring with instore displays showing the various grades and finishes available. The southern pine grade of C&Btr. includes mostly clear material suited for formal living and dining areas. The grade of No. 2 is becoming a favorite item for a more rustic appearance-the knotty pine look ideal for vacation homes. Add a clear polyurethane finish and watch the distinctive southern pine grain show through. Selection between flat and vertical grain material, available in several widths and lengths, offers even more appearance options.

Complete information on product selection, installation and maintenance is available in SPC's "Guide to Southem Pine Flooring," available as a free PDF download at www.southernpine.com. Dealers can order a free single copy to keep at their counter as a ready reference.

Walls and ceilings are easily enhanced using an array of patterns. Double-beaded ceiling material installed as wainscoting dresses up bedrooms, kitchens and baths. It also adds warmth as the ceiling of a porch or patio area. Paneling on an accent wall of any room can be installed vertically, horizontally, even diagonally to create dramatic interior spaces. Design options are virtually unlimited.

As with southern pine flooring, dealers can promote sales of stains and other finishes with pattern orders.

SPC's pictorial "Guide to Southern Pine Patterns" is offered as a free PDF download at www.southernpine.com. A copy at the counter includes many photos to share with customers to demonstrate the possibilities.

FORDST PROT}UCTTI srDcnf sEctIoN

Inside

A ^-r,tll HOOD INDUSTRIES to

satisfaction" Phone 6o't -264-2sss Qir,ifg,m- Fax607-296-4740 www.h o o dindu stri e s. co m 32 BunorNc Pnooucrs Drcrsr Jurue 2009

WITH THEIR distinctive grain, southern pine flooring, paneling and ceiling patterns are all value-added sales opportunities for dealers.

great lengths to ensurc your

Aesthetic Timber Barrier Systems

TimBarrier'' Aesthetic Timber Barrier is a sysfem of three barriers designed to fulfill the needs of architects and deuelopers who require a safe, economical, and most imp ortantlg, ae sthetic g uar drail.

StreetGuard'" - Intended for use along low speed roadways in parks, private developments and subdivisions.