Volume 22, Number 3, 2023 THE CASE FOR A FOUR-DAY WORK WEEK >> Batteries, complexity, costs and more Bryan Leier has yet to meet a challenge he can’t manage EV REPAIR INSIGHTS PLUS CHAT GPT AND YOUR ’BIZ | AN ACCOUNT ON ADAS | NEGOTIATION TIPS & MORE! Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 8 6 John Street, Thornhill, ON L3T 1Y2 www.collisionrepairmag.com THRIVING WITH THE TIMES

Unlock more opportunities for profit at your body shop. Introducing 3M™ RepairStack™ Performance Solutions. Several body shops across the country have already successfully implemented the innovative 3M™ RepairStack™ Performance Solutions. It’s time to take your collision repair business to the next level and benefit from our new hardware and software inventory management platform. *Based on a review of body shops that used the 3M™ RepairStack™ Billables Invoicing software for at least 60 days between Oct. 1, 2021 – Jun. 30, 2022. 3M 2022. All rights reserved. 3M and RepairStack are trademarks or registered trademarks of 3M Company. All the products shown inside the 3M™ RepairStack™ Performance Solutions storage cabinet are sold separately. All products shown inside the cabinet are for illustration purposes only. The 3M™ RepairStack™ Performance Solutions storage cabinet works with both 3M and non-3M products. Unauthorized use prohibited. All other trademarks are property of their respective owners. Please recycle. Printed in USA. Keep track to be on track. Discover now at repairstack.com. “The ability to … track and, more importantly, provide an invoice and receive reporting based on that specific repair in regard to materials used is critical to the profitability of body shops.”

Anderson,

Collision

“The main reason for implementing 3M™ RepairStack™ was to become profitable with

Join the top 10% of 3M™ RepairStack™ repair facilities that recovered over $1,000 in repair materials per month* and get paid for costs you never knew were recoverable. For more information or to schedule a demo, please scan the QR code to connect with a 3M digital expert.

Mike

President and Owner of

Advice Group

my

paint material

and that happened right away. It’s cut my bill in half!” Adan Ibarra, Owner of Leading Edge Collision

ON THE COVER

Bryan Leier, this issue’s cover star, shares pearls of wisdom gained over a 30+ year career in collision repair.

Electric vehicle insights, from repair processes through to end-of-life battery usage. Plus, stats on current repair frequencies and predictions from experts.

You’ve heard of ChatGPT—but do you know how it can help ease your business operations? We share nine ways you can use ChatGPT to your advantage.

ASSETS IN ADAS

Advanced driver assistance systems are a billion-dollar market, says AutoBolt. CEO Nick Dominato breaks it down.

NO SLACK WITH ’STACK

A deep dive into the functionality of 3M’s latest collision innovation, RepairStack™.

FOUR OR FIVE?

Unpack the four-day workweek concept, in the context of the collision repair business.

PEOPLE ON THE MOVE Familiar faces swapping places.

NEWS-IN-BRIEF

The gist of industry updates.

PUBLISHER’S PAGE by Darryl Simmons

TOM’S TALES by Tom Bissonnette

LET’S GET TECHNICAL by Stefano Liessi

WHO’S DRIVING by Jay Perry

LAST WORD by Allison Rogers

ISSUE 22#3 | COLLISION REPAIR 3 CONTENTS VOLUME 22, ISSUE 3, 2023 CONTENTS THE CASE FOR A FOUR-DAY WORK WEEK >> Batteries, complexity, costs and more Bryan Leier has yet to meet a challenge he can’t manage EV REPAIR INSIGHTS PLUS CHAT GPT AND YOUR ’BIZ AN ACCOUNT ON ADAS NEGOTIATION TIPS & MORE! www.collisionrepairmag.com THRIVING WITH THE TIMES 36 38 34

FEATURES

How successful are your negotiations? We asked the Canadian collision repair industry—results on page 44. 10 51 54 66

04 48 DEPARTMENTS COLUMNS

06

HAVE YOUR SAY. SUBSCRIBE TODAY! We welcome your comments on anything you see in Collision Repair magazine. Send your feedback to editor@collisionrepairmag.com. YOUR ONLINE SOURCE Canada’s collision repair information resource. New articles and top news stories daily. For more info visit collisionrepairmag.com 22 44 40 30

THE OEM IMPACT

Automakers and insurers are no longer stange bedfellows

By DARRYL SIMMONS

With Toyota’s recent foray to provide insurance to the U.S. market, the stage seems to be quietly getting set for the ultimate behemoth of consolidation and full cradle-to-grave control by the OEM. This trend, which has been accelerated by the COVID-19 pandemic and the rise of connected cars, poses significant challenges and opportunities for collision repairers, who will have to adapt to a new landscape where OEMs have more control over the claims process and repair standards. If it works in the US, it will certainly migrate here regardless of our provincial differences of insurance models. How this will change the game is debatable, but it’s a good thing collision repair facilities are among the most adaptable repair trade out there.

Tesla is perhaps the most prominent example of an OEM that is selling its own insurance directly to its customers. The electric car maker started offering insurance in California in 2019 and has since expanded to Texas. Tesla claims that its insurance can save drivers up to 30 percent compared to traditional insurers because it uses data from its vehicles’ sensors and cameras to assess risk and reward safe driving.

One of the main drivers behind OEMs’ entry into the insurance market is customer demand. Market studies dictate that consumers are seeking a vertical car buying experience, where everything they need to get on the road is handled at the moment of sale. Automakers can access real-time data from connected cars to offer personalized and dynamic pricing based on actual usage and driving behaviour. Plus, OEMs believe they can leverage trust they build with their customers to provide an enhanced experience and convenient service.

The trend of OEMs selling insurance is not limited to one region or one type of car. Already in place in Europe and across the globe, it’s not too farfetched to think we’ll see customers buy their car and insurance in one location. The only

thing missing is recycling; oh, wait—ever heard of extended producer responsibility? OEMs are already reclaiming their “waste.” British Columbia’s extended producer responsibility action plan covers hybrid and electric vehicle batteries, which are sent back to the automaker for processing at end-of-life. Quebec’s provincial government has perused the same initiative in extended producer responsibility, believing it would ensure proper management at end-of-life. There is no doubt that these shifts will impact collision repairers, and the entire automotive aftermarket. OEMs could require or incentivize their insured customers to use only certified repair facilities or encourage—perhaps even mandate—customers to only use OEM parts in repairs; they could also charge for access to repair information, a hot-button issue and the driver of the Right to Repair movement sweeping North America.

Implementing these OEM-led initiatives is not an overnight feat. For one, a vehicle manufacturer must have a government-approved subsidiary before offering insurance in Canada. To meet this requirement, Porsche launched Porsche Insurance into the Canadian marketplace in mid-2022. Offered exclusively to Porsche vehicles owners, the auto insurance product is designed and brokered by Aon Canada. Porsche Financial Services Canada and its affiliate brands have disclosed they are not insurance companies or licensed insurance agents and are not selling or offering advice regarding insurance products.

This will shake things up. We know that already. It’s just a matter of how much. Nonetheless, Canada’s collision repairers will be here...ready to adapt, as always.

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Max Reid | max@mediamatters.ca

Kate Ng | kate@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT Wanja Mann 647.998.5677 wanjamann1@gmail.com

AUDIENCE ENGAGEMENT MANAGER

James Kerr | james@mediamatters.ca

MARKETING COORDINATOR

William Simmons | william@mediamatters.ca

CONTRIBUTORS

Tom Bissonnette, Stefano Liessi, Jay Perry

SUBSCRIPTION

Single edition $7.99 One-year $39.95 ( 6 issues) Collision Repair™ magazine is published bimonthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing in this publication have been compiled and included with the permission, though not necessarily the endorsement, of the editor, or of independent columnist contributors, and are in no way to be construed as those of the publisher, or as endorsements of them.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough, ON K9J 3R2

“We acknowledge the financial support of the Government of Canada”

Collision Repair magazine is published by Media Matters Inc., publishers of:

4 COLLISION REPAIR COLLISIONREPAIRMAG.COM PUBLISHER’S PAGE

This will shake things up. We know that already. It’s just a matter of how much.

PEOPLE ON THE MOVE

JIM SARNOVSKY | AUTOMOTIVE SYSTEMS WAREHOUSE

Jim Sarnovsky announced he has started a new position as a national accounts/ strategic market specialist for Automotive Systems Warehouse (ASW). Upon his departure from SprayMax, Sarnovsky specifically gave a shout-out to his Canadian customers, saying that the region was the no.1 market globally for SprayMax in 2022.

ZAKARI

Zakari Krieger has joined Fix Network as the vice president of Prime CarCare. Krieger brings a wealth of industry experience to the role, having previously served as director of business operations and managing director of Hamilton, Ontario’s Barton Auto Parts. Krieger will be responsible for developing brand strategies, driving transformation and spearheading growth efforts for Prime CarCare’s brands, which includes Speedy Auto Service, Minute Muffler and Brake and Novus Glass.

YVES

Simplicity Car Care’s Soins D’Auto group in Quebec is proud to welcome Yves Pronovost, who will serve as the province’s new brand development manager. According to Simplicity, Pronovost specializes in automotive business growth and development and has experience working with Quebec dealers, bodyshops, and suppliers. “Adding Yves to our team is adding a veteran player to the roster that brings leadership and character to an already stellar line-up,” said Greg Wing, director of brand development at Simplicity.

6 COLLISION REPAIR COLLISIONREPAIRMAG.COM NEWS

PRONOVOST | SIMPLICITY CAR CARE

KRIEGER | FIX NETWORK

Call: 1-800-871-7612 | Click: simplicitycarcare.ca/franchisee Connect: contact@simplicitycarcare.ca Spend more time focusing on your customers and let us simplify the rest. Operational Efficiency Simplify your workflow to increase efficiency and profitability. Insurance Partnerships Connect with and meet the requirements of major insurers. Business Growth Use our proprietary system to service customers and help drive sales. Join One Of Canada’s Fastest Growing Collision Repair Networks

STRIVE FOR EXCELLENCE, CHOOSE FIX AUTO

Expanding as an independent auto bodyshop can come with challenges. Whether it’s growing brand recognition, training technicians or staying on the cutting edge of technology, getting to the next level can be difficult without ample support. By franchising with Fix Auto, shops circumvent a lot of the guesswork or trial and error associated with growth.

Joining Fix Auto can provide proven business resources that augment brand awareness, bolster technician training and utilize advanced technology. Franchisees have direct contact with OEMs and insurance providers, thanks to strong global relationships. They possess better buying power, which can increase profitability.

When it comes to training specifically, Fix Auto franchisees have access to

state-of-the-art facilities where technicians can improve skills, stay up to date with the latest industry trends and learn from experienced instructors. Using a training facility rather than the franchisee’s shop means technicians can learn in a controlled environment that’s free from the distractions of dayto-day business.

By offering and encouraging ongoing training for all employees, Fix Auto franchises strive for the highest level of workmanship and expertise. Staff are further provided with a clean and safe work environment that complies with the law, in addition to high standards set forth by Fix Auto.

Steady business referrals are the norm for Fix Auto franchisees. Many insurers have preferred vendor programs that refer business to franchised

auto-body shops. Owning a franchise means a higher likelihood of being included in these programs, which drives more business and fosters relationships with insurance companies.

Sometimes the goal is not just more work, but instead more profitable outcomes. Fix Auto franchisees have access to a suite of services from Performance Groups to dedicated field coaches who work to maximize everyone’s efforts.

Another great benefit of franchising is the consistent exposure and periodic evaluation of best practices. These best practices are informed by a global network’s worth of auto bodyshop experience. Knowledge is shared and tested regularly, successes and room for improvements are assessed, and standards are determined to help fran-

ADVERTORIAL

chisees maximize efficiency on their quest for excellence.

Choosing a Fix Auto franchise means joining a group of business owners who share the same values and goals, as well as prioritize quality, ethics and performance. It’s the opportunity to interact with other franchise owners to share ideas, collaborate and offer support.

For customers, Fix Auto franchises provide clear and accurate estimates. They strive for professionalism and objectivity in all evaluations, insisting only on proper repairs. They adhere to written estimates and to those of insurance companies with the goal of executing all repairs correctly the first time.

Fix Auto franchises obtain approval from customers and insurance com-

panies prior to proceeding with any additional repair work not previously authorized. They use only the most suitable parts and materials, obtained from reputable suppliers.

Peace of mind for franchisees, customers and employees alike is of paramount importance for Fix Auto and all brands in its network. Adhering to applicable legislation is fundamental and prioritizing company integrity is taken seriously.

Fix Auto franchisees have access to the latest marketing tools, including branded content, regional marketing support and access to global social media platforms, to name just a few. Available are all marketing tools necessary to help promote increased visibility in the market. Advertising campaigns and other resources raise the profile

for each Fix Auto location and attract new customers.

Choosing a Fix Auto franchise means owning your own business, while having the power of a global network supporting you.

Ready to join a global brand on a path to excellence? Visit Fixauto.com and choose your region at the top of the page. From there, click on ‘Join the Network’. You will be prompted to complete a form that will be sent to the appropriate Fix Network regional vice president.

ADVERTORIAL

REFINISHING REPARATIONS

Mike Anderson’s most recent “Who Pays for What” report has been released; this time with its sights set on the use of invoicing systems for material costs. This latest report from the CEO of Collision Advice builds off findings from a 2021 survey that found that about half of bodyshops used a flat hourly rate model to bill for the cost of materials during refinishing work, while only about 19 percent used a materials calculator or invoicing system. According to Anderson, the portion of shops using these systems has remained largely unchanged, however, more than 40 percent of shops now report using a mix of flat rates and materials calculating, up from 32 percent in 2021. “I think the large change is due to the multiple increases in paint prices virtually all shops experienced since we last did this survey in January of 2022,” he said. Results from this most recent survey showed that the most significant change was to payment for two-tone work, which experienced a 5.9 percent drop to a total of 75 percent of shops who report “always” or “most of the time” being compensated for such work. “It would be interesting to know if [the compensation decline] is because shops previously included this under ‘second colour set-up’ and now they separate it out, or if there is insurance pressure as part of virtual reinspections,” Anderson speculated. “All of the paint manufacturers have bulletins on the need to denib or finish sand or buff, often noting (as the AkzoNobel statement reads) that, ‘It is not likely that a repair can be made that is completely free of surface defects,’ and that it is (as the Axalta statement reads) ‘a normal and necessary operation for both OEM manufacturers and collision repair shops.’

10 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY NEWS

OPEN 8 AM - 5 PM MONDAY - FRIDAY Go to www.carcone.com | Call Toll Free 800.263.2022 Or visit us at 1030 Bloomington Road, Aurora, Ontario L4G 0L7 CARCONE’S CARCONE’S AUTO RECYCLING & WHEEL REFINISHING Our state of the art equipment and quality craftsmanship makes us the industry leader in Wheel Refinishing and OEM aftermarket wheels. Your trusted source since 1978 for recycled OEM Parts. Providing quality wheel refinishing for 29 years. Your source for quality recycled OEM parts on all makes and models with 1 million parts guaranteed in stock. We have new products arriving daily. WHEEL REFINISHING RECYCLED PARTS WE SHIP CANADA WIDE. 24-48 hour deliveries to many of the surrounding areas including: Toronto | Mississauga | Scarborough | Port Hope | Brampton | Barrie | Orillia | Cookstown | Alliston | Tottenham C M Y CM MY CY CMY K ai1673372384116_Carcones_COLL_AR_HalfPage_7125x475_FIN copy.pdf 1 2023-01-10 12:39 PM

“Some automakers, like Toyota, Lexus, Nissan, and INFINITI, also have statements that processes (such as denibbing, finish sanding or buffing) are necessary even at the manufacturing plant as well as at body shops,” noted Anderson.

AFTERMARKET STRONG

DesRosiers Automotive Consultants (DAC) has released its latest Automotive Aftermarket scorecard, reporting increased repair costs 2022 and expectations for “strong [aftermarket] growth” in 2023. With parts shortages “widespread throughout the year,” writes DAC, the customer price index for passenger vehicle maintenance and repair services (as of December 2022) increased 5.6 percent compared to December 2021. Passenger vehicle parts, accessories and supplies consumer price indexes were up 8.6 percent in December 2022 over December 2021. The report also states that gasoline consumption (in place of vehicle usage data) remained “fairly steady” in 2022, with just a 1.9 percent decrease overall, which DAC says is “unsurprising given the improved efficiencies of the fleet.”

“All expectations point to another strong year for the Canadian aftermarket in 2023, barring severe wider economic uncertainty,” concludes DAC’s report.

ISSUE 22#3 | COLLISION REPAIR 11 INDUSTRY NEWS

WEB: AUTEL.COM | SUPPORT: 1.855.288.3587 EMAIL: USSUPPORT@AUTEL.COM FOLLOW US @AUTELTOOLS SUBLET TO YOURSELF DIAGNOSTICS + DIGITAL INSPECTION + ALIGNMENT + ADAS CALIBRATION IA9OOWA At the Cost of a Typical Alignment System MAXIMIZE WITH A SINGLE SYSTEM & WORKFLOW PROFITABILITY & EFFICIENCY 3 ALIGNMENT 3D Wheel Alignment with Any Electronic Component Reset. 2 DIGITAL INSPECTION Text or Email All Customized Reports Instantly to Your Customer. DIAGNOSTICS 1 All Systems and Module Health Check Including Steering and Suspension. 4 ADAS CALIBRATION Step-by-Step Illustrated Instructions with Automatic Vehicle Height Tracking. RECOUP YOUR INVESTMENT IN AS LITTLE AS 30 DAYS CALCULATE YOUR REVENUE POTENTIAL *Return on investment varies by service volume.

DRIVE YOURSELF

In a move that diverges from the path of fellow legacy automakers, Ford announced in late March that it has withdrawn its petition to the National Highway Traffic Safety Administration (NHTSA) to develop Level 4 autonomous driving systems. This decision coincides with the shuttering of Argo AI, a joint Ford-Volkswagen AV development firm, in October. “As evidenced by the planned shutdown of our autonomous driving system (ADS) partner Argo AI, we believe the road to fully autonomous vehicles, at scale, with a profitable business model, will be a long one,” Ford wrote in its February 13 letter to the NHTSA. Prior to this decision, Ford was seeking approval to deploy up to 2,500 autonomous vehicles annually.

SENSOR CENSUS

Some deeper analysis into Tesla’s October decision to cut ultrasonic sensors from its production lines seems to show that the cost-cutting measure from the leading EV brand is not as foolhardy as initially perceived. Tesla’s decision to put its faith into its proprietary computer vision software, Tesla Vision, instead of the industry standard combination of LiDAR, radar and cameras made it an outlier. Recent evaluations of the technology, however, including a 2019 research paper from Cornell University, show that the stereo cameras that Tesla uses in place of other systems “could be capable of generating a 3-D map of nearly equivalent quality to that of a LiDAR system.” From a cost perspective, Tesla figures it can get essentially the same result with a $5 as with a $7,500 LiDAR system, so the decision becomes pretty clear.

BRAIN CUSHION

An engineer at Honda has been honoured with the U.S. Government Award for Safety Engineering Excellence for his work on creating a “groundbreaking” passenger air bag system with proven life-saving capabilities. Eric Heitkamp, alongside eight others, was recognized at the National Highway Traffic Safety Administration’s (NHTSA) Enhanced Safety of Vehicles conference, held in Yokohama, Japan in early April. Heitkamp’s design, which Honda describes as functioning similar to a catcher’s mitt, was directly aimed at mitigating brain injuries caused by traffic accidents. Where a conventional side airbag may see a passenger’s head rotate and slide off, Heitkamp’s system effectively catches, cradles and protects the head, according to Honda.

12 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY NEWS

A PROCESS YOU CAN TRUST. Catalytic Converters • ECUs • Hybrid Batteries UNITED CATALYST CORPORATION UNITED CATALYST CORPORATION • PGM prices DIRECT to your phone twice daily - It’s Free! • Get market prices for Platinum, Palladium, and Rhodium twice each business day. PGM DAILY DOUBLE Subscribe Today! Text “DAILY” to: 844.713.PGMS (7467) www.UnitedCatalystCorporation.com 100 Industrial Blvd. | Fountain Inn, SC 29644 | 864.834.2003 YEAR ANNIVERSARY YEAR ANNIVERSARY

GOING GLOBAL

Collision Builders is expanding and is currently in discussion with multiple franchised collision repair businesses across the United States. According to a press release on the company’s LinkedIn profile, the team currently advises a twostore franchised collision repair business in California and is looking to provide collision repair business advice to more shops. Collision Builders provides a feebased advisory service for owners who want to sell their business, increase its value or acquire additional auto repair shop locations.

CHECKS AND BALANCES

Uni-Select and LKQ say they are pleased to announce they have gotten the green light from the Canadian Competition Bureau to go forward with LKQ’s acquisition of Uni-Select, first announced in February. According to Uni-Select’s press release, the arrangement remains subject to certain closing conditions, including the receipt of other applicable regulatory approvals, consisting of approval under the Investment Canada Act and clearance by the U.K. Competition and Markets Authority. The companies expect the arrangement to be concluded by the second half of 2023.

14 COLLISION REPAIR COLLISIONREPAIRMAG.COM BUSINESS NEWS

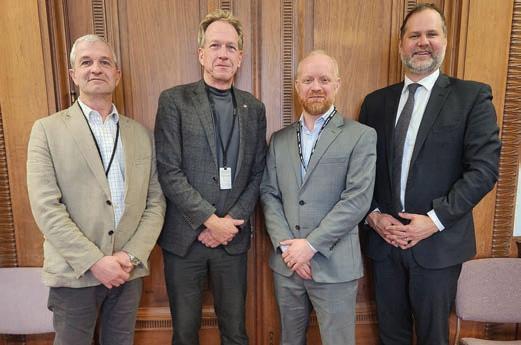

Collision Builders is led by (left to right): Larry Jefferies, former v-p and co-founder of CARSTAR Canada, Bing Wong, former colleague and understudy to Jefferies, and Jeff Keddies, a business coach with more than seven years of experience in the automotive collision industry.

FORD’S FINANCES

Ford does not expect its electric vehicle (EV) unit to be profitable until 2026, Known as Model e, Ford’s EV unit lost US$2.1 billion in 2022 and could lose as much as US$3 billion in 2023. Ford’s Model e business also reported US$900 million losses in 2021. The automaker says it sold approximately 96,000 EVs in 2022, representing US$5.3 billion in revenue. On EBIT, Ford Model e worked with a profit margin of negative 40 percent in 2022. The automaker said the unit is targeting an eight percent operating profit margin, and profitability, by 2026. For comparison, Tesla reported a 22 percent profit margin for Q4 2022.

ISSUE 22#3 | COLLISION REPAIR 15 BUSINESS NEWS

accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575 ACCUVISION-3D IS RECOGNIZED BY CERTIFICATION PROGRAMS - Honda QUICKEST, SIMPLEST AND MOST ACCURATE 3D MEASURING SYSTEM IN THE WORLD NEW NOW INCLUDES WHEEL ALIGNMENT DIAGNOSTICS SOFTWARE ACCUVISION-3D® IS RECOGNIZED BY CERTIFICATION PROGRAMS - Certi ed Collision Care - CCIAP - Honda - ICBC Made in Canada “ICBC” Recognized - NO Moving Parts, NO Lasers, NO Targets, - NO Adaptors, NO Magnets, NO Arms, NO Extensions, - NO Wires, NO Wi-Fi, NO Bluetooth - NO Calibration Needed, MITCHELL chassis data

Nonetheless, Ford CFO John Lawler remains confident. “We’re already seeing green shoots of the improvements in the profitability of Model e. We expect Model e to break even at the end of this year, and, in 2024, we believe our first-generation products can be EBIT margin positive.”

MIX ‘N’ MATCH

Ford’s engineering department is working towards what could be a significant cost-cutting measure for the automaker, as a recent patent filing dug up by Ford Authority shows a design for a one-size-fits-all configurable frame for use on future vehicles. The patent design, which was filed in November 2022 and published in March, illustrates a single vehicle frame where individual components, such as batteries, motors, suspension, and wheels could be swapped out and rearranged to suit the requirements of various Ford models and trims. The common consensus among Ford observers is that this sort of modular frame design will, if effective, offer the company significant savings in assembly, as well as potentially contribute to the streamlining of repairability for future Ford vehicles.

PAINT PROBS

Hyundai Elantra owners in Quebec have filed a lawsuit against the OEM seeking compensation for paint degradation damages. The class action was filed May 1 by Lambert Avocats, on behalf of Michel Allard and other drivers who purchased or leased a white or pearl-white Hyundai Elantra on a long-term basis and experienced paint degradation issues. Allard had purchased a “perfect condition” white 2017 Elantra in June 2019. Three months after purchase, Allard noticed peeling paint on the hood of the vehicle. He approached the dealer, who covered the repair—but the same problem occurred in the summer of 2022, this time on the left front fender and the roof of the vehicle. This time, Allard’s dealer said he would not cover the repairs because the warranty was expired. Repairs for Allard’s Elantra were estimated at $4,581.52. The presence of rust was also noted. While his vehicle was being estimated, Allard rented the exact same car, a white 2017 Hyundai Elantra, which he claims “also had paint degradation issues, particularly on the front hood of the vehicle.” Then, Allard learned of a Facebook group of more than 300 Elantra owners facing the same issues.

16 COLLISION REPAIR COLLISIONREPAIRMAG.COM OEM NEWS

The “configurable vehicle frames and associated methods” patent is currently filed in the U.S. under serial number 0088224.

IN

DISTRIBUTION Providing Refinish Solutions Since 1968! www.pbedistributors.com

At PBE we continually strive to build customer relationships based on integrity, an industry leading product assortment, and two-way communication. We take pride in bringing new and innovative products to the market by working closely with manufacturers and their representatives. With 5 warehouses across Canada, we will provide you with what you need, when you need it.

CANADA’S LEADER

JOBBER

Meet Patrick, a Delivery Driver at our Lévis, Québec, Canada location. Patrick is one of the more than 45,000 men and women of LKQ who shares the passion for providing the best possible parts and service for our customers. This year, as LKQ celebrates 25 years of providing choice in vehicle repair, we honor those, like Patrick, and all our employees, for the passion they bring to their job, every day. Feel the passion and find your next replacement part at www.LKQcorp.com Call Us : 866-LKQ-CORP Visit Us Online : www.LKQCorp.com New Aftermarket | Recycled OE | Remanufactured Engines & Transmissions | Paint Products The Passionate Parts People Patrick | 23+ Years of Service Delivery Driver | Lévis, Québec, Canada Join Our TeamVisit our Website

TESLA’S PRICE TAG

Tesla has plans to use cheaper, iron-based batteries in electric semi-light trucks, the OEM announced in April via its Master Plan Part 3 paper. Tesla currently uses nickel-based batteries in its EVs. Lithium iron phosphate batteries are generally cheaper than nickel and cobalt-based lithium-ion batteries, which analysts expect will help the OEM cut down on manufacturing costs while simultaneously addressing supply issues related to nickel and cobalt. Lithium iron phosphate batteries are also considered less likely to catch fire compared to their nickel and cobalt-based counterparts. They are, however, larger, heavier and hold less energy than nickelbased batteries. The proposed lithium iron phosphate batteries, intended for use in “short range” heavy electric trucks Tesla calls the “Semi Light,” will hold a capacity of 53 kWh. The Model Y and Model 3 batteries tout a 75 kWh capacity. Tesla intends to use lithium iron phosphate batteries in the Model Y and Model 3 eventually, though it has not provided a timeline.

DEAD BATTERIES

With the current state of insurance, an EV might be written off completely if its battery is dented, warped or slightly scratched, according to an article first published by the Times Live. The article says this stems from a general inability to assess or repair battery packs after accidents, resulting in write-offs even if the vehicles have been barely used. Consequently, this has (reportedly) resulted in battery packs piling up in scrap yards, further worsened by the units costing half the price of an EV–meaning you get more value from buying a new EV than replacing a damaged battery. While several OEMs including Ford and General Motors have promised repairable EV battery packs, many are assembled in a way that makes repairs significantly tougher, with Tesla Model Ys gluing these battery packs into the car’s structure. The decision by OEMs to refuse to disclose diagnostic data has resulted in insurers writing off vehicles as a precaution, according to Peter Gruber, owner of Gruber Motor Co. “An insurance company is not going to take that risk because they’re facing a lawsuit later on if something happens with that vehicle and they did not total it,” he said.

OEM ORIGINS

Tesla is selling Chinese-made Model 3 and Model Y units in the Canadian market, confirming suspicions that the EV maker had shipped vehicles from its Shanghai factory to the North American market. As of May 23, Tesla’s website had Model Y vehicles and long-range, all-wheel-drive Model 3s available for immediate delivery in British Columbia, which bore codes indicating they were manufactured at Tesla’s Shanghai Gigafactory. Fans of the brand had suspected the recent reduction to the Model Y’s range performance—from 488 kilometres on a single charge to 455 kilometres—indicated that Tesla was selling China-made cars in Canada. Tesla models built at the Shanghai factory have VINs beginning with ‘LRW’, Reuters reported.

MISPLACED PRIORITIES

A PC Insurance commissioned survey found that safe driving discounts are the prime factor for most Canadians, with collision and liability coverage ironically considered the second and third most important factors in an auto insurance policy. The survey polled 1,500 Canadians, asking which factors they considered important, along with the most common misconceptions about auto insurance. Safe driving discounts topped the list, with 50 percent considering it the most important factor. This was followed by collision coverage at 42 percent, liability coverage at 38 percent, bundles with home insurance at 38 percent, and multi-car discounts at 25 percent.

18 COLLISION REPAIR COLLISIONREPAIRMAG.COM OEM NEWS

INSURANCE NEWS

According to the Times Live’s article, battery units cost half the price of an EV–meaning you get more value from buying a new EV than replacing a damaged battery.

Pictured: Iron phosphate powder. CEO Elon Musk is reportedly all for lithium iron phosphate battery technology, and Reuters said he was quoted to say “the vast majority of heavy lifting for electrification will be iron-based cells” this past March.

NOTE: Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards.

NOTE: Eligible parts only. Wheels are excluded from CAPA certification but are subject to strict SAE standards.

CAPA Certified.

An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation. PLATINUM GOLD STANDARD IS LIMITED LIFETIME WARRANTY All Keystone Platinum Plus products offer the highest standards and Industry-leading Limited Lifetime Warranty. CAPA CERTIFIED Over 90% of Keystone Platinum Plus aftermarket collision repair products are CAPA Certified.

ABSORBERS • BUMPERS • BUMPER BRACKETS • BUMPER REINFORCEMENTS • DOORS FENDERS • GRILLES • HOODS • LIGHTING • MIRRORS • STEP BUMPER ASSEMBLIES • WHEELS An LKQ Company ® Call Today! (866) LKQ-CORP | (866) 557-2677 or Order Online at LKQCanada.ca/en/ ©2021 LKQ Corporation.

CAN IT STEER?

Ever wondered if a roll of toilet paper could steer a car? What about a Panasonic flat-screen? Or a bottle of water? Instagram user @dejonsvids has made it his mission to answer those oftenasked questions, with a whole portfolio of videos where the steering wheel is replaced by, well, anything but. He’s confirmed that a roll of TP can steer a car—as can a freshly-sharpened kitchen knife, a plastic clothes hanger, a box of tissue and much, much more.

WE ARE INFINITE

Sometimes it’s not enough to simply crack a window—you’ve got to stick your whole body out the sunroof to truly satisfy the urge for fresh air. Whether you relate or not, someone does, as Ontario police caught a woman cruising at 100 kilometres per hour with her entire body sticking out the sunroof. She stays in the position for the entirety of a 30-second clip posted to Twitter…so we know she wasn’t sneaking a quick fix. All in all, she was charged with not wearing a seatbelt.

STICKY SALESMAN

Back in November 2022, a Brampton, Ontario driver was pulled over in a barely-driveable BMW that appeared to be held together by duct tape and determination. When police questioned why the driver—who had a suspended license, no insurance and six other violations on record—he said he was simply en route to sell his car, so no problems here.

WHEELY BIG

You know what would make a Tesla a whole lot better? 10-foot wagon wheels. The members of YouTube channel WhistlinDiesel clearly felt the same, ‘cause the crew posted a video of a Tesla Model 3 outfitted with 10-foot wagon wheels back in mid-March. The overarching goal of the project was to flip the Tesla completely upside down while maintaining drivability—a feat achieved in the full 13-minute video.

20 COLLISION REPAIR COLLISIONREPAIRMAG.COM CAN YOU BELIEVE THIS?!

Seriously, there’s so much more on the @dejonsvids Instagram page.

We wonder how many flies she caught. (PHOTO: OPP Highway Safety Division)

We hear he’s selling…any takers? (PHOTO: OPP Highway Safety Division) The final stunt of the video features the car rolling downhill at full speed.

UNCOVERING HIDDEN DAMAGE

If you’re not looking for something, will you find it anyway?

Sometimes. Maybe.

More likely, maybe not. When it comes to collision repair, that’s a problem. For the customer, and for the repair shop. Missing things that could or should have been caught results in inconvenience, extra cost and a very annoyed customer.

To uncover hidden problems, you’ve got to know where they might be hiding. The Collision Alignment System from Hunter Engineering shows technicians where to look.

This is often necessary, because what’s appropriate for a typical maintenance wheel alignment won’t always be enough for a collision scenario. Primary measurements, such as toe, camber and caster, only get you halfway to where you need to be. Possible hidden damage remains hidden.

The Collision Alignment System helps techs finish the job, thanks to specific collision workflow procedures to ensure they take essential in-depth measurements to uncover damage right away – rather than as a surprise during the alignment at the end of the repair process. Or worse: missing it altogether.

The five collision-specific diagnostic measurements are:

• Toe out on turn

• Maximum steer

• Ride height

• S uspension body dimension audit (SBDA)

• Symmetry and setback

Frequently, a vehicle can check out fine with the usual primary measurements. What the tech would not find without looking would be things like a damaged subframe or unibody, damaged lower control arms, shifted axles, bent spindles or other affected components that would slip under the radar.

Not only will the system provide a more complete blueprint of the necessary work, but it also makes the tech’s life easier by walking him or her through the process. Instead of hunting and pecking all over to find additional measurements, Hunter’s award-winning WinAlign® software guides the tech through the procedures step by step with minimal interaction.

Easily decipherable documentation also clearly communicates the nature of the work to be performed.

By finding hidden problems at the start of the process instead of the end, a complete estimate can be written that will require no later adjusting.

This means no extra cycle time and cost, saving time and money for both the customer and the collision shop. Not to mention missed items remaining dormant until they rear their heads months and many miles later, possibly in an unsafe manner.

For collision shops interested in doing ADAS work instead of subletting it, the system integrates with Hunter’s ADASLink® diagnostic scan tool, capable of guiding the technician through ADAS calibrations for millions of vehicles.

When you don’t know what you don’t know, it’s like walking around in the dark. The Collision Alignment System sheds light and allows you to retain your customers by maintaining your usual standard of quick and accurate service.

ADVERTORIAL

The time to look for issues is before alignment, not during

FROM PROCESS TO PROFIT

Story by MAX REID

Sometimes it takes a leap of faith to find out where your true passions lay. Here at Collision Repair, we have heard stories from numerous industry professionals who found themselves swinging a hammer or spraying a panel through some combination of good luck and pure coincidence. Those first forays into the world of autobody repair can sometimes plant the seed for what could ultimately become a prolific, productive and progressive career in this industry.

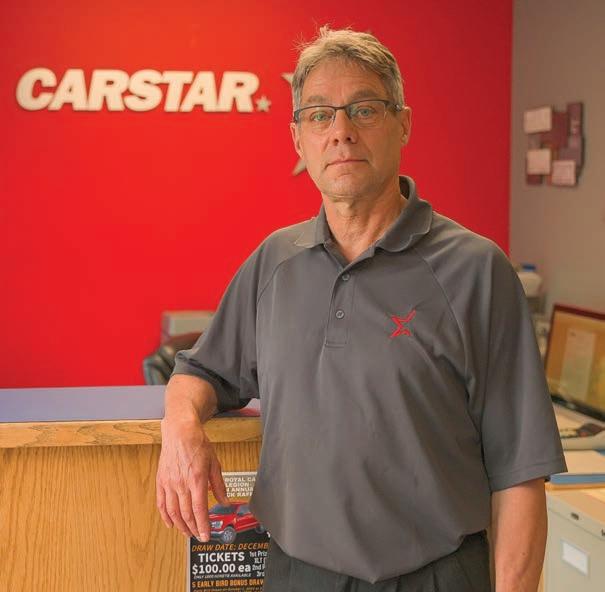

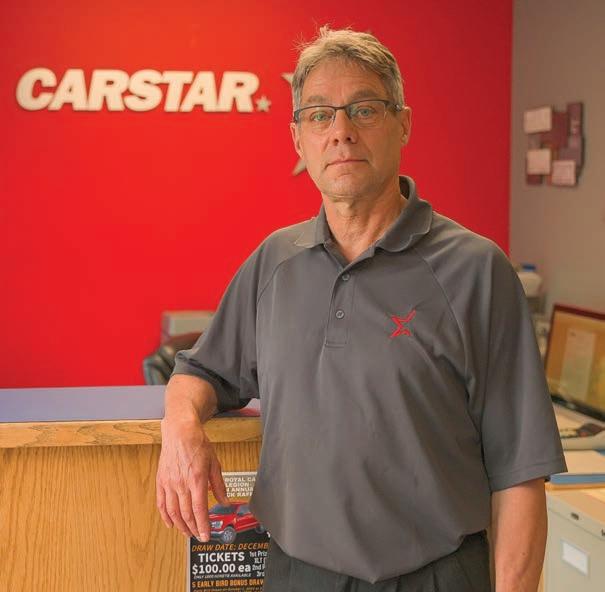

For Bryan Leier of Bennett Dunlop Ford in Regina, this was exactly the case.

It’s the late 70s and Bryan is in university studying engineering, while spending his summers working part-time at a bodyshop.

Before long, his passion for academics was being overtaken by a new passion for autobody repair, citing his understanding of metals and keen eye for detail as what set him apart early on.

“I worked there part-time while I was going to university, and it turned out I was pretty good at it,” Bryan said over the phone with Collision Repair

“When the fall semester came around, I quit university and started working full-time—I was about 18 or 19 at the time.”

Bryan took to his new vocation like a moth to flame, and seeing the financial peril of his current employer on the horizon, elected to make a go of things on his own at the tender young age of 20 years old.

“I was 20 years old and had just bought a building in Sedley, Saskatchewan; it was an old GM dealership back in the 50s and 60s,” said Bryan.

“I borrowed some money from my grandpa, and my dad kicked in some cash to buy the building. I paid like $7,000 for this 4,000 square-foot dealership building.”

Bryan says he fondly recalls the era where his shop was lined with Firebirds on one side and Camaros on the other; and never with a shortage of custom work to do.

“I remember the first car I painted: it was a 1969 Camaro and I painted it in silver enamel.

“I was one of the first shops in Saskatchewan to use acrylic enamel paint products,” Bryan said proudly.

ON THE COVER

Regina’s Bryan Leier on the systems of success

22 COLLISION REPAIR COLLISIONREPAIRMAG.COM

As an entirely self-taught, one-man collision repair machine, Bryan says he rode a steep learning curve, not just in proving his individual skills by challenging and passing the journeyman exam, but in learning how to manage an entire collision centre on his own.

“When I started my business, the interest rate on my line of credit was about 17 percent, so to say it was difficult to survive would be an understatement,” he said,

“When you’re starting out, you need to buy equipment, buy parts and keep getting work out the door while you have interest rates that are just unbelievable.”

Being out in Sedley, a town of a little more than 300 residents, Bryan knew that to survive, he would have to take whatever work he could get.

“We did everything from collision repair to restoration, and being that we were out in the country, we also did a lot of stuff for farmers.

“It would not be unusual to have someone pull up in their tractor and want you to weld their hitch for them. We also did a lot of grain trucks.”

It took a few years of growing pains, but Bryan took these struggles in stride and used them as opportunities to expand his understanding of the collision industry’s inner workings.

Throughout the 90s, Bryan always had one foot in his shop and the other in a SaskPolytech classroom (SIAST, at the time), taking a position as a part-time instructor—a position that he says became a great source for new staff later on.

ISSUE 22#3 | COLLISION REPAIR 23 ON THE COVER

Bryan Leier turned his passion for autobody to an incredibly healthy business—and now he brings his expertise to the bustling bodyshop at Bennett Dunlop Ford in Regina, Saskatchewan.

“I was one of the first shops in Saskatchewan to use acrylic enamel paint products!”

—Bryan Leier, manager, Bennett Dunlop Ford

After a successful 27 year run in Sedley, Bryan elected to sell his shop and start a new chapter of his career.

“I sold my shop in ’02, and about nine or ten months later I started with Bennett Dunlop Ford as an estimator,” said Bryan, recalling his start in the collision centre of a Regina Ford dealership.

“In a few months, I became the manager, and I have been the manager ever since.”

Bryan attributes the relatively quick progression through the collision repair industry, in large part, to the many connections he maintains with representatives of various industry stakeholder groups throughout Saskatchewan.

As a member of the Saskatchewan Trade and Apprenticeship board, the Sask Polytech board of directors, and rep to the SGI committee on behalf of the Saskatchewan Auto Dealers Association, Bryan’s appetite for the growth of his business is well sated.

Working with these groups has built for Bryan a reciprocal relationship in which he can advocate directly on behalf of collision shops just like his, while serving as a star example of all the latest advancements in skills training and education.

24 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

Thanks to a great team, Bryan says he rarely wakes up worried about what’s happening at the collision centre.

Let’s play a game: count the I-CAR certs.

“We were an I-CAR Gold shop way before anyone else. We had platinum technicians way before anyone else—we had scanners. A lot of the things other shops were farming out, we were doing in-house,” said Bryan.

“You start to look at how to maximize your square-footage, how to maximize your strong points and the qualities of your technicians so that you are getting better, faster repairs from qualified techs.”

Bryan says that one of the biggest lessons he learned along his journey had almost nothing to do with repairs themselves, but with the almighty “P-word”—process.

“When you look at repairing a car, it all comes down to process: how to process paperwork, even after the repair is done, so that it is done properly for the insurance companies.

“I ran a small shop for over 25 years. It was not a big deal to come in on a Saturday to fix a door so that you could paint it on Monday—that doesn’t work anymore. The process on repairing things, getting things out the door, scheduling and having parts arrive on time, is a nightmare.”

ISSUE 22#3 | COLLISION REPAIR 25 ON THE COVER

“I ran a small shop for over 25 years. It was not a big deal to come in on a Saturday to fix a door so that you could paint it on Monday—that doesn’t work anymore.”

—Bryan Leier, manager, Bennett Dunlop Ford

From the Archives: Bryan’s pics from the Sedley Automotive days.

Despite all his many connections and experiences, Bryan and Bennett Dunlop Ford are by no means immune to the pressures currently being faced by bodyshops across the country. The difference for Bryan, however, is that he has a plan.

Bennett Dunlop Ford is planning to launch a new initiative soon, where customers can skip the often-lengthy wait to have their vehicle towed to, and appraised at an SGI commercial claims appraisal site.

Instead, the shop will accept tow-ins and carry out 100 percent teardowns of customer vehicles so that proper damage appraisal and parts ordering can be done within the week the vehicle is received.

“The problem with [an SGI claims appraisal] is that the car is going to get, at best, a partial estimate. So now if the vehicle isn’t a write-off, you need to figure out how much extra damage there is, and then that

vehicle sits at my place until I can schedule it in because we have a lot of vehicles here. Now I take it apart and find out that there is an extra 10 or $15,000 worth of damage on it,” said Bryan.

“Instead of waiting weeks or months to find out if their car is a write-off or whether it is repairable, they’re going to get it done in a very short period of time.”

Bryan says the calibration equipment he is planning on purchasing for the shop will also do wonders for keeping Bennett Dunlop’s many services under one roof.

Further to that, the shop proudly uses a combination of Car-o-Liner and ProSpot welders, in addition to a Car-o-Liner frame machine and a full suite of Sherwin-Williams paint products, according to Bryan.

It takes a special kind of leader to remain steady at the helm over the course of a 47 year career, but Bryan has uncovered the

science of his operations and knows exactly what formulas will deliver him to the solution he needs.

Many of the staff members at Bennett Dunlop have been working with Bryan for at least a decade; this is a fact evident in both the excellent work done on the production floor, as well as through the cohesion and hard-work of his front-end staff.

One aspect of this system that cannot be quantified, however, is the personal difference it makes to Bryan on a day-to-day basis.

“I have always worked with amazing people. People have come and people have gone, but for the most part, I have an amazing crew of people that I work with that are dedicated and resourceful,” said Bryan.

“I rarely wake up in the morning worrying about what might be happening in my collision centre.”

26 COLLISION REPAIR COLLISIONREPAIRMAG.COM ON THE COVER

I have an amazing crew of people that I work with that are dedicated and resourceful.”

—Bryan Leier, manager, Bennett Dunlop Ford

AN ODE TO OARA

Ontario Automotive Recyclers Association hosts annual convention

Story by ALLISON ROGERS

On March 31 and April 1, the Ontario Automotive Recyclers Association (OARA) hosted its annual Convention and Trade Show, where representatives from across the aftermarket gathered for two days of learning, networking and good times.

While the previous day’s discussion centred around electric vehicles at the Automotive Recyclers of Canada’s EV Roundtable, OARA focused on other pressing topics in the auto recycling industry.

“We’d love to talk about EVs [at OARA]—there are just too many other things on our plates!” said OARA executive director, Steve Fletcher.

Topics of conversation largely included staffing, the consumer perception of the industry, trends in the auto recycling and insurance sectors, the future of auto recycling, sales, e-commerce and more.

Check out our photo album from the event!

EVENTS/ OARA

Gloria Mann; Daryll O'Keefe, Fix Network; Steve Fletcher, ARC and OARA; and J.F. Champagne, AIA Canada.

IAA had its crew out in full force.

Allison Rogers and Kirk Monger of Solera | Hollander.

Paula Carcone Baldali, Michael Carcone of Carcone's Auto Recycling with Ian Ticknor of Standard Auto Wreckers.

Karan Raina and Harshit Singh, Lacero Solutions.

Left, Andrew MacDonald, Maritime Auto Parts.

ISSUE 22#3 | COLLISION REPAIR 29 OARA /EVENTS

David Gold of Standard Auto Wreckers and Jeff Haltrecht, Call2Recycle.

Josh Stark and Jared Stark of Stark Auto Sales with Gloria Mann.

Kristen Alexander and Amanda Morrisson, URG, with Allison Rogers, Media Matters.

Troy Edwards and Vinesh Mistry of IAA Inc.

If you want this hat, you'll have to contact Steve Fletcher, OARA's executive director and managing director of the Automotive Recyclers of Canada.

Paul Prochilo, Simplicity Car Care; Flavio Battilana, CSN Collision Centres.

The Future of Recycling panellists: David Gold, Standard Auto Wreckers; Dalber Livingstone, Island Auto Supply; Ryan Mandell, Mitchell International; Shan Lathem, Automotive Recyclers Association; Rob Rainwater, Profit Team Consulting.

The crew from LKQ.

The ladies of United Catalyst Corp. Becky Beruke and Erika Warner.

Bruce Woodbeck, Woodbeck Auto Parts, and Wanja Mann, Media Matters.

Carly Masters and Dom Vetere, Dom's Auto Parts.

Gloria Mann, Media Matters and Michael Demik, Supershear.

Marty Hollingshead, ARA and Northlake Auto Recyclers, with Roger Schroder of Car-Part.com.

Trenton Cameron and Darin Baker from Glencoe Auto Recyclers.

EV RUNDOWN

Electric vehicles add 2.5 days cycle time, six hours labour; rate of repair drops 10 percent, and more insights from ARC’s EV Roundtable

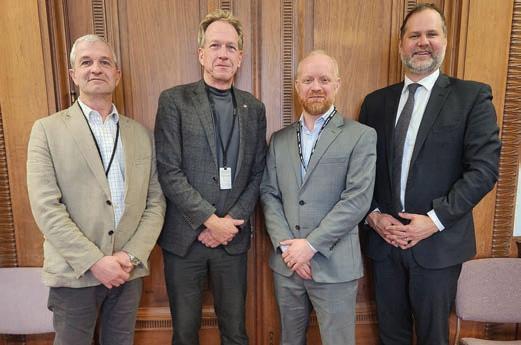

On March 30, the Automotive Recyclers of Canada hosted more than 80 members of the Canadian automotive aftermarket for an in-depth discussion on electric vehicles and how electrification will impact the auto recycling, collision repair and other automotive industries.

The event was separated into four parts: Steve Fletcher, managing director of the ARC, welcomed attendees before environmental consultant Maria Kelleher; battery whiz Jeff Haltrecht of Call2Recycle and Ryan Mandell of Mitchell International each detailed a respective part of the electrification process and its effects.

“No one is really looking into the end-oflife side of electrification,” explained Fletcher in his welcome address. “Yet 40 percent of ARC members are processing end-of-life EVs, according to a 2022 survey.”

A GENERAL OVERVIEW: HOW MANY BATTERIES AND WHAT CAN WE DO WITH THEM?

By 2035, the Canadian government wants 100 percent of new vehicle sales to be electric, which translates to approximately two million units sold in all.

To get there, the federal government aims for 20 percent of new vehicle sales to be electric by 2026—which equals approximately 395,000 units sold—and for EVs to comprise at least 60 percent of new vehicles come 2030 (with about 1.2 million EVs sold, total).

national Energy Agency (IEA), there will be a significant spike in the number of EOL EV

batteries between 2030 and 2040. Contrary to public perception, electric vehicle batteries are outliving the EVs they’re housed in.

“When an EV battery is no good for the vehicle itself, it still holds between 70 percent and 80 percent of that charge,” explained Kelleher. “It’s no good to run a vehicle, but it works for energy storage and other applications.”

EV battery life can be extended by up to ten years via reuse, said Kelleher; up to 15 years, according to a Toyota study, she added.

There are a few different ways to repurpose a battery, she explained. The first, and often consider the most ideal option, is to refurbish and reuse the battery secondhand in an EV. Alternatively, EV battery packs can either be combined with others to create energy storage systems or backup power sources; or separated into smaller units for reuse in smaller applications—like in wheelchairs or golf carts.

If the IEA’s predictions pan out by 2030, battery recycling efforts will only supply 12 percent of demand.

“Recycling won’t solve the supply problem, but it will help.”

Kelleher elaborated that EV batteries contain a multitude of different components, including copper wiring, circuit boards, a variety of chemistries (i.e. nickel cobalt aluminum; nickel manganese cobalt; lithium

30 ELECTRIC INSIGHTS

“Significant dismantling is required [to reach the valuable materials],” which, to recyclers, would be cobalt, nickel and copper.”

— Maria Kelleher, Kelleher EnvironmentaL

THE PATH MOST TRAVELLED: WHAT DO WE DO WITH USED EV BATTERIES?

According to Haltrecht, one of five things can be done to an EOL EV battery: repair or remanufacture the unit; resell the battery as-is; repurpose the battery or recycle it all together.

“There are five different pathways the battery can hop to, depending on a number of factors: the health or geographic location of the battery; which damage stream activity is closest [geographically] to the battery; who has a contract on that battery and so on,” he explained.

Currently, the majority of EOL EV batteries are handled by dealers, said Haltrecht. He explained that dealerships may have unique access to shipping containers through the connection to OEMs, whereas recyclers may have to find a logistics partner for their own shipping container access.

“And it’s still too early to tell how long these shipping containers will last,” he added.

Haltrecht acknowledged that there are plenty of other questions about handling EV batteries as a repairer or recycler.

“Sharing what works and what doesn’t work is probably of the single best things we can do today.”

Anyone working on or planning to handle EVs or their components in their facility should have a thermal sensor/thermal imaging gun, a four-gas meter (that detects different gases given off by EV batteries), a fire blanket and heat-sensitive gloves onsite, Haltrecht told the audience.

“That’s the absolute minimum for safety equipment you should have on-site,” he said.

In terms of developments on detecting the health of and potential pathways for EV batteries, Haltrecht said he “can see where this is going.”

“We’ll have a highly robust algorithm app on our phones, with a special cable that connects to the vehicle [to read battery diagnostics]. At certain sites, like a dismantler’s, you’ll be able to get a [battery health] reading. We’re just not quite there yet.”

The most common reasons for battery degradation are typically factors like temperature, altitude, number of charge cycles and the type of load; fast chargers will degrade a battery faster than a normal charger, added Haltrecht.

He ended his portion on the mic with

several policy suggestions for lawmakers.

“We are a North American industry— cars and parts travel across the borders to be built. The batteries will also move around. We need one policy to standardize everything.

“If we don’t, car prices will [be] drive[n] up due to batteries being stranded, simply because it’s too cumbersome to deal with them.”

Haltrecht also said that any policies around EV batteries should support the entire useful life of the battery; not just the time it’s working in a vehicle.

“Don’t force an early retirement on a battery when you’re talking about policy.”

Current regulations should be reviewed and amended, said Haltrecht, specifically to allow EV batteries destined for recycling to cross the border without permits, just as those being remanufactured are permitted, and shipping container requirements should be aligned with U.S. DOT.

Finally, standards and/or safety requirements are EV battery recycling should be developed as soon as possible.

“[The lack of safety standards] is the weakest link—and the weakest link can bring down an industry.”

ISSUE 22#3 | COLLISION REPAIR 31 ELECTRIC INSIGHTS accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575 AUTOMATIC, INVERTER RESISTANCE SPOT WELDERS 3664 & 3680 Smart Spot welder Automatic setting of parameters Water cooled for hi productivity 22 ft. long cable, No EMF emissions Output 14,000 Amps, 450 daN or 700 daN Input 50 Amps, 208-240V, 3 Phase Approved by OEMs 3680 model wi-Fi, enabled for factory Updates and diagnostics #60-TM736 ACCUWELD® SINGLE TORCH PULSE MIG WELDER #60-TM742 ACCUWELD® 2 TORCH PULSE MIG WELDER #60-TM750 ACCUWELD® ARC DENT PULLER SYSTEM #60-TM743 ACCUWELD®3 TORCH PULSE MIG WELDER

TIME TO STRATEGIZE: EV REPAIR COMPLEXITY AND COST

New vehicle sales fell eight percent in 2022, but new sales of EVs grew by a whopping 65 percent in the same period.

According to statistics from Mitchell International, 2.5 percent of repairable claims processed through the Mitchell platform in 2022 were EVs. The data collected on these claims demonstrated the increased complexity of EV repairs, Mandell told audiences at the EV Roundtable. In fact, the average EV repair takes an extra 2.5 days of cycle time and six additional labour hours.

This results in a “pretty significant” difference in the cost of repair between an ICE vehicle and an EV.

“If EV adoption continues to maintain its growth pace, the average repair could cost about $8,000 by 2035. Today, it’s about $4,600.”

There are nearly twice as many semiconductors in an EV, compared to an ICE vehicle, said Mandell. ICE vehicles have

about 1,000 semiconductors, where EVs contain about 2,000.

Mitchell’s scans also showed increased complexity with EV repairs—a 2018 ICE vehicle had 31 codes, while a 2018 EV threw 40 codes.

Lightweight substrates only add to the complexity.

“You simply just don’t have the same opportunity to repair aluminum, carbon fibre or composites that you do with steel. Steel has a memory. It likes to go back to its original shape. Those other materials do not.

“The rate of repair [with lightweight materials] drops about ten percent,” added Mandell. “That will give recyclers a lot of opportunity.”

32 COLLISION REPAIR COLLISIONREPAIRMAG.COM ELECTRIC INSIGHTS

Jeff Haltrecht called on the Canadian government to reconsider and develop different layers of policy around EV batteries to allow for more fluid movement and accessibility.

Maria Kelleher told the audience that EV battery life can be extended by up to ten years via reuse—up to 15 years, according to a Toyota study, she added.

Steve Fletcher is the managing director of the Automotive Recyclers of Canada. He said that, according to a 2022 ARC study, 40 percent of members were already processing electric vehicles.

Ryan Mandell delivered insights from Mitchell International’s database, revealing that EV repairable claims have 2.5 extra days of cycle time and six additional labour hours, when compared to the average ICE repairable claim.

““If EV adoption continues to maintain its growth pace, the average repair could cost about $8,000 by 2035. Today, it’s about $4,600.”

View a recording of the entire EV Roundtable by scanning the QR code.

—Ryan Mandell, Mitchell International

Are you ready to embrace change for a secure future? PROCOLOR IS YOUR ANSWER Operational field support Exclusive territory –adds equity to your business Proven experience in winning Insurance work National supply arrangements Full branding and marketing support The power of a global brand Contact Daryll O’Keefe at dokeefe@fixnetwork.com or visit procolor.com/franchise to find out more.

COUNTING CALIBRATIONS

ADAS calibrations are a billion-dollar business, says AutoBolt report

Story by ALLISON ROGERS

It's time the industry gets a clear look at the sheer size of the ADAS calibration for auto glass market—and AutoBolt's done the math for you. According to the company's calculations in a recent report, there should have been 3.8 million ADAS calibrations on auto glass in 2022. Based on that data, the total addressable market for ADAS calibrations in the auto glass industry in the United States in 2022 was, in U.S. dollars, $959 million.

"[The report] shows that ADAS calibrations on auto glass is already a billion-dollar business," explained Nick Dominato, CEO of AutoBolt.

The company analyzed more than 10,000 windshield lookups with AutoBolt, where a VIN-verified result was provided, to determine how prevalent calibrations are in the auto industry, and to “identify new ADAS systems and the growth of non-ADAS technology.” Based on the collected data, there should have been 3.8 million ADAS calibrations in the auto glass industry in 2022, translating to a total addressable market of US$959 million.

“For the vast majority of automakers, a windshield replacement on a newer vehicle (i.e. model year 2020) all but guarantees a calibration will be required,” elaborates the report.

The company says 89 percent of 2023 model year vehicles include windshields requiring calibration.

"We noticed a sharp up stick in windshields with ADAS requiring calibration starting in 2016. This coincides with a voluntary agreement by 20 automakers in 2015/16 to make automatic emergency braking standard on all light-duty cards and trucks with a gross vehicle weight of 8,000 lbs. or less, no later than September 1, 2022.”

While Asian and luxury automakers produce more than 95 percent of their models with forward-facing cameras (on average), domestic OEMs have been "laggards in ADAS adoption across the board," says AutoBolt.

Some of this can be attributed to higher sales of pickup trucks or Jeeps—which have a gross vehicle weight rating exceeding the terms of the AEB voluntary agreement—but, even after filtering those out, AutoBolt says domestic automakers remain slower to adopt ADAS than Asian and European automakers.

When it comes to static versus dynamic calibration, there's no clear winner. Both are equally as common and have negatives and positives, notes AutoBolt, with the steep learning curve and space requirements that come with static calibrations and the fact that some dynamic calibrations can be impossible to perform under certain climate conditions.

One marked trend, however, has been the increase in vehicles allowing for a choice of static or dynamic calibrations—the best-case scenario, says Dominato.

This won't mark the end of growth in the ADAS calibration on auto glass market; automakers will continue to push the technological envelope, says AutoBolt—especially as head-up displays gain popularity.

It's already a billion-dollar business, and it's only set to grow.

34 COLLISION REPAIR COLLISIONREPAIRMAG.COM INDUSTRY INSIGHTS

Vehicles requiring calibration, by model year.

Nick Dominato, CEO of AutoBolt.

download the full AutoBolt Auto Glass ADAS and Technology Report 2023, visit myautobolt.ca/ knowledge-center.

To

Impact Auto Auctions is Now IAA CA.IAAI.com © 2022 IAA, Inc. All rights reserved. BID. BUY. REPAIR.

STACKED TEAM

Story by ALLISON ROGERS

When you look at your ducks, would you consider them to be in a row?

Anyone in this industry is more than aware of the many moving parts that come with running a collision centre; a bodyshop’s gears run consistently, and even the slightest slowdown sends a ripple of interruptions throughout the process, at the cost of patience and precious dollars.

We’ve all heard, in this day and age, tales of how technology can streamline operations and optimize efficiency across the board —but how often are we privy to information on how a business has integrated technologies to do so?

3M™RepairStack™Performance Solutions, officially unveiled last year at the SEMA Show, is a three-pronged hardware and software system that offers bodyshops high-tech inventory management, integrated invoicing capabilities and up-to-the-moment performance analytics, all under one umbrella.

The product has generated buzz around the industry for its ability to offload and automate inventory management as well as

its capabilities in collecting detailed data to help in-the-know shop owners make key business decisions.

Collision Repair magazine recently spoke to Andy Boyd, digital platform leader of connected bodyshops for 3M Automotive Aftermarket.

One of RepairStack ™ ’s most attractive features is automated inventory management with automatic ordering and inventory tracking for both 3M and non-3M materials.

“RepairStack™is designed to transform storage,” said Boyd. “It’s for the shop owner who is looking to add bottom line improvements and use technology to aid in managing inventory across the shop.”

RepairStack™shops stock their cabinets with the materials of their choice, and each material has a barcode associated with it. The user scans the barcode via the provided scanning tool—an iPod Touch with an attached scanner—and selects the quantity of material used and removes the material for use. The cabinet is unlocked via Bluetooth—you can even see which of your staff pulled the materials.

Users set minimum and maximum inventory levels. When product hits the minimum level, it automatically sends an order to your distributor.

The second of the RepairStack™pillars— integrated invoicing.

The program is designed to streamline blueprinting and billing by automating scanning and invoicing via two-way integration with your bodyshop management system. The inventory management system captures inventory usage and helps to assure all procedures and materials are precisely documented to their respective ROs, says 3M.

“That’s huge for material reimbursement,” explained Boyd.

There were 90 Canadian customers on the RepairStack™platform when Collision Repair magazine spoke to Boyd at the end of March. In the States, there were more than 2,500 users on the platform. Top-performing users have seen significant results when recovering material costs—in fact, Boyd said that, in the U.S., users on the platform have the potential to recover over $1,500 per month.

RepairStack™integrates with CCC, Axalta

36 COLLISION REPAIR COLLISIONREPAIRMAG.COM TECHNOLOGY

Organization on a whole new level with 3M’s latest innovation

ProfitNet, and Body Shop Connect (Canada) today. 3M is pursuing ongoing integrations with leading body shop management software, distributor and paint company order portals, and more.

Compare month-to-month spending; view invoice records according to RepairStack™’s precise inventory tracking; monitor material usage by tech—there are boundless opportunities.

Boyd says the ideal user is a shop owner dedicated to working on their business: someone who keeps a keen eye on the bottom lines, follows standardized operating procedures and is consistently driven toward better results.

“The ideal [RepairStack™] user wants to

be better. It’s like a gym membership—you have to want results.”

While that tends to be heavy-lifters or multi-shop operators, Boyd maintains that there are no restrictions to who can use the highly customizable platform.

Not only are there ample on-demand training modules to teach staff the ins and outs of RepairStack™ itself—there are plans to integrate the 3M Academy Training platform with RepairStack™, offering both paid and free courses on collision repair practices.

“At 3M, we’ve been creating automotive products since the dawn of the automobile. We’re simply looking to provide continued, dedicated support for the connected bodyshop.”

Q: What if I buy from more than one jobber?

3M says RepairStack™ allows for flexibility to fit your shop demands.

When supplies are removed from the cabinet, the user simply scans the barcode and RepairStack™ keeps track of your material supply levels. Materials are automatically reordered when they hit the user’s designated minimum level, customizable to your shop’s needs.

ISSUE 22#3 | COLLISION REPAIR 37 TECHNOLOGY

“The ideal [RepairStack] user wants to be better. It’s like a gym membership—you have to want results.”

— Andy Boyd,Digital Platform Leader, Connected Bodyshop, 3M Automotive Aftermarket Division

FROM NINE-TO-FIVE TO THE FOUR-DAY JIVE

The

Story by MAX REID

Story by MAX REID

The last 20 years or so has seen significant transformations in the work lives of people all across the world.

For many of us, when we think of these transformations our minds flash images of the offices of young tech startups, furnished with beanbag chairs and ping pong tables—often more evocative of a McDonalds play-place than the cubical farms that we are more familiar with.

It’s easy to perceive these amenities as frivolous comforts for an already comfortable generation of young workers, however, more and more research is beginning to show that employers who actively invest in the wellbeing of their staff, even after they have clocked out for the day, are able to both earn more and increase productivity.

One of the most common of these worker-supportive initiatives, currently under consideration for businesses across many industries, is the four-day work week.

The four-day work week is a concept that tends to raise the guard of business owners, especially those who have “been around the block a few times.”

The idea that “if you give an inch, they take a mile” does not exist for no reason and it is often owners who stand to be burned the worst when they take a shot on doing a nice thing.

However, as years have passed and terms like “The Great Resignation” enter the common lexicon, additional thought and research has been devoted to concepts like the four-day work week in the effort of making work—to put it bluntly—slightly less dreadful.

A 2022 trial conducted by labour research firm, 4 Day Week Global, and led by Boston College economist and sociology professor, Juliet Schor, found that a four-day, 32-hour work week led to an average 8.14 percent increase in revenue among the 33 companies studied over a six month period.

Additionally, revenue was seen to grow by 37.55 percent when compared to the same six-month period of the previous year.

In terms of productivity, 95 percent of the companies involved recorded either stable or improved levels of productivity among employees during the trial period.

In a recent TED Talk related to the report’s findings, Schor explained that “A key part of the model is that in return for the ‘gift’ of a day off, people will squeeze all of their productivity into four days. While they may be spending less time at work, they are not necessarily doing less work.

“The ‘secret sauce’ is work reorganization–cutting out the least productive activities,” she said, citing superfluous meetings as often

38 COLLISION REPAIR COLLISIONREPAIRMAG.COM HUMAN NATURE

Jolene Watson, a Saskatchewan-based professional speaker and trainer, and founder of Clarity Coaching & Development, has been working with businesses across Canada to help them implement practices geared around employee wellness.

benefits of a four-day work week

being the first item on the chopping block.

The report also sought clarity in the issue of engagement versus disengagement among workers of various schedules. More plainly, it compared feelings of enthusiasm and apathy among employees who work four-day, fiveday and six-day work weeks.

Among U.S. employees who work at least 35 hours per week, it was found that those who work traditional five-day weeks report the highest levels of engagement, 32 percent, as compared to 28 and 30 percent for four-day and six-day workers respectively.

What is of note, however, is that levels of disengagement—or as Schor put it, the feeling of “I hate my job”—are lowest among workers with a four-day schedule.

By comparison, five-day and six-day-aweek workers reported disengagement of 17 and 21 percent respectively.

This points to the fact that while a four-day model is not a one-way ticket to the hearts of your employees, but again—a reduction in overall workplace dread is not a bad place to start.

Jolene Watson, a Saskatchewan-based professional speaker and trainer, and founder of Clarity Coaching and Development, has been working with businesses in her province to help them implement practices geared around employee wellness.

She recently made news for helping a Regina mechanic shop carry out a four-day work week trial period, while being a fierce advocate for the practice, acknowledges that there specific considerations businesses need to make before launching blindly into a reduced schedule.

As many reading have probably mumbled to themselves already, collision repair is typically an hours-based industry, as opposed to flat rate pay, and the thought of surrendering a full day of production is borderline sacrilege for owners and technicians alike.

That is why Watson recommends an approach to the four-day week that properly accounts for both the operational necessities of the business and the responsibilities of individual staff members.

“With Kinetic, what [the owner] did was not cut their hours—they are still giving her a 40-hour work week…it’s just that now they get that full extra day off to spend time with their family,” she said.

Kinetic’s owner, Erin Vaughan, wanted to be able to give her staff Mondays off, but realized that customers would still expect to be able to pick up their vehicles on that day.

It was decided that shifts would be staggered and a manager would come in on Mondays to hold down the fort and deliver keys to customers.

“Another school of thought on that might be that everyone gets to choose which day they have off. That way, you do not have to close for a day because that's not always possible, logistically speaking.”

Watson says that by opening up this one avenue of flexibility, business owners may actually find themselves more likely to explore other mutually beneficial offerings to potential employees.

For example, a bodyshop on a shortened or staggered work schedule may be able to benefit from the presence of more part-time employees, particularly in the business’ front-end.

Lower stakes or temporary work can then be offered to those who want it, while the business can reap the savings that come from fewer benefits to provide.

Further to that, the previously mentioned report cited a study conducted in Sweden, in which nurses at a hospital saw their shifts reduced to six hours, with additional staff hired to fill in the missing hours.

At the end of the trial, it was found that the money saved from unused sick days and unemployment benefits was able to support the wages of those additional staff without any reduction in pay to the original nurses.

For collision repair centres who may be seriously considering offering a four-day week to their staff, Watson suggests you follow the example of a former boss of hers.

“In my past, I had a boss who would incorporate something called ‘stay interviews’ and he would encompass that within my performance review.

“He would do that every three months, and would ask questions, such as ‘What are you passionate about? Are we actually using your talents, interests and skills to their full ability? What professional opportunities are you excited about?’”