Some of the most valuable things in life are invisible.

Port and transshipment solutions

EDITORIAL

featuring...

TRADE & COMMODITIES

Restraints on dry bulk trade growth

Russian coal ban kicks in

SALES

ADMINISTRATIVE OFFICE

Business

MARKETS

SHIPPING & TRANSPORT

Water lubricated propeller shaft bearings found to reduce fuel consumption

Reederei Gerdes orders second Damen Combi Freighter 3850

BOAT

PORTS, TERMINALS & LOGISTICS

Port of Ipswich number one for agri-products exports for 17 years in a row

Resumption of grain shipments from Ukraine to Euro-Silo at North Sea Port

Gdynia and Riga Freeport sign memorandum on coal

ENGINEERING & EQUIPMENT

New CRS Maxebeam transforms reach stackers into dedicated Rotainer handlers

BULK HANDLING

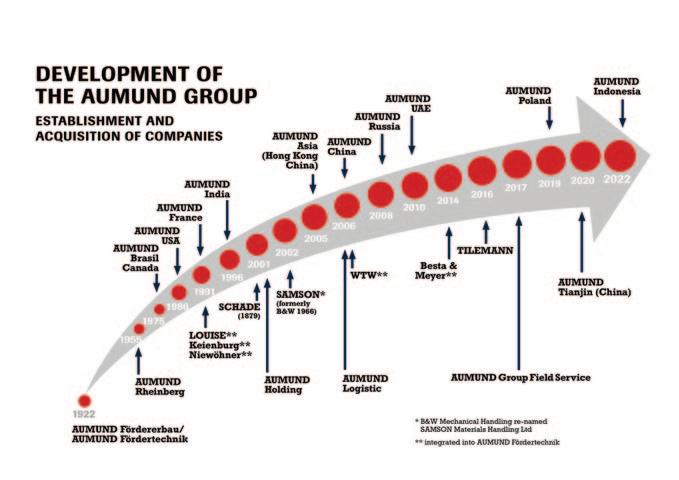

YEARS OF AUMUND:

CARGO:

WITH

HEAD OFFICE

Trade

GRAIN:

COVER

HELP FROM TENOVA’S HIGH TECH SYSTEMS

INTERNATIONAL TECHNOLOGY

AND WHY IT IS SO IMPORTANT

CONVEYORS,

HANDLING

BREAKBULK & BAGGING

& TECHNOLOGIES

EASIER WITH THE

Restraints on dry bulk trade growth

During recent months signs of restraints on commodity trade imports into numerous countries have multiplied. As a result, earlier expectations of significant albeit modest growth in global seaborne dry bulk trade in 2022, compared with last year, have diminished and a flat outcome now looks more likely.

Adverse effects arising from severe inflationary pressures around the world, China’s slowdown and the war in Ukraine are inhibiting the world economy’s performance. The IMF’s latest assessment emphasized that risks are “biased to the downside”, hinting that further downgrading of economic growth forecasts beyond those already made could materialize. Unfavourable consequences for dry bulk trade are implied.

GRAIN & SOYA

Global grain trade, comprising wheat plus corn and other coarse grains, is expected to reflect lower import demand and restricted export supplies within the 2022/23 crop year ending June 2023.

According to the International Grains Council’s mid-August estimates, world total trade could fall by 15mt (million tonnes) or 4% from the previous year’s 424mt volume, to 409mt

The biggest change envisaged among major buyers is a decline of 8mt in China’s grain imports, from exceptionally high volumes in the past two crop years (61mt in 2020/21 and 54mt in 2021/22), to 45.5mt in the

current period. Elsewhere imports into the Middle East region and a range of other smaller importing countries seem likely to be lower. However there is more evidence of a reduced grain harvest in Europe this summer, possibly resulting in additional foreign purchases.

COAL

Increased coal imports into the European Union, India, Japan and a few other countries this year are envisaged by some analysts. But there is uncertainty about whether these rises will be sufficient to fully or more than offset weakness in China and elsewhere, enabling the world seaborne coal trade total to remain flat or even rise slightly.

Amid tight energy supplies in Europe, especially natural gas, an emphasis on fuel sources immediately available which can be used to offset shortfalls has intensified, especially in the approach to the winter season. Coal is seen as a contributor. One example of changes envisaged is a recent estimate by Germany’s coal importers association, suggesting that the country’s steam coal imports could increase by almost a fifth in 2022 from last year’s 27mt volume, reaching 32mt.

IRON ORE

Weaker import demand in China looks set to prevent any growth in world seaborne iron ore trade during 2022, even though some positive changes may occur among other buyers. The unfolding deterioration in many nations’

MAJOR GRAIN EXPORTING AREAS (MILLION TONNES)

economic activity, with direct effects on steel consumption and production in iron ore importing countries, is becoming more apparent.

Although there is still uncertainty about events in the remainder of the year, China’s annual iron ore imports are expected to decrease. Downwards pressure on economic activity and steel production has been prominent and prospects for a pickup in the months ahead are unclear. In the first seven months of 2022, China’s crude steel output was 6% lower, while iron ore imports declined by over 3% to 627mt.

MINOR BULKS

Among the many and varied elements of the minor bulk commodity trade segment, growth prospects this year seem limited. A large proportion (steel and forest products for example) is associated with manufacturing output and construction work, much of which is becoming more restricted by economic activity headwinds.

BULK CARRIER FLEET

Slower expansion of the world bulk carrier fleet is evolving, as shown in table 2. In 2022 another large fall in newbuilding deliveries is likely to be a feature, but earlier expectations of substantially higher scrapping now seem unlikely to be fulfilled. Fleet deadweight tonnes capacity growth could decelerate to well below 3%, from 3 4% annually in the past few years.

TABLE 2: WORLD BULK CARRIER FLEET (MILLION DEADWEIGHT TONNES)

EU Russian coal ban kicks in

As of 10 August, the European Union placed a total embargo on all coal imports from Russia. This formed part of an earlier sanctions package first announced in April. The delay is explained by a buffer period, in which European countries could either negotiate with new coal source providers or increase their own domestic production. Alternatively, they could also use the time to bring forward plans to use alternative energy generators, such as renewables.

The EU had relied heavily on Russian thermal coal, which accounted for 70% of thermal coal imports for electricity production. Poland and Germany were significantly locked into this source of

supply. With Europe also switching away from Russian gas to generate electricity, EU countries were also expected to import more thermal coal to replace this.

Australia, Colombia and the United States are all now exporting more coal to Europe than previously.

In June, for example, countries in Europe imported 7.9mt (million tonnes) of thermal coal, which was at least double the same amount in June 2021. Despite this, overall reliance on coal is diminishing since this figure was 2mt less than in both April and May.

Colombia is particularly benefiting, exporting 1.2mt to Europe in June, which compares with around 287,000 tonnes in

the same month in the previous year. However, Australian thermal coal imports of 1.1mt in June are its most ever, despite the long distance involved. The United States also reports that its coal exports to Europe were up 28% in June.

This trend is expected to continue as EU countries continue to retain sanctions against Russia because of its invasion of Ukraine. Indeed, with Russian oil imports due to be phased out in the longer term, more coal will be needed to replace them. Maritime oil imports from Russia will cease in their entirety in December and petroleum products in February 2023. In the meantime, pipeline imports remain unchanged. Barry Cross

Strike action from Ukrainian coal miners

Workers at a state-owned coal mine in Ukraine have decided to strike, despite martial law and a ban on all protests.

Striking workers at Mine No. 9 in Novovolynsk, who include miners as well as management, voted to strike over what they say is an attempt to seize control of the mine.

Long-standing corruption is cited as

the reason for the strike, with the miners recently prevening a new director from taking over because of his links to embezzlement at another mine.

Workers believe that the director was appointed by the local ‘smotriashchiy’ — corrupt unofficial overseers of Ukrainian coal mining. The miners have gone on strike to protect

their jobs and working conditions.

Early in Volodymyr Zelensky's admin istration, the Ukrainian president vowed to stamp out corruption in the coal sector. Workers at Mine No. 9 link recent appointments to the possible return of corrupt practices. The strike is not the only protest in the western Ukrainian coal fields since Russia’s invasion.

SGS Secured Document – protecting the commodity industry against document fraud

Fraudulent documents are a major concern across the commodity industry due to the large quantities of commodities being moved, strict regulations that must be adhered to, and the multimillion-dollar contracts involved, writes Frederico Stewart, Head of Business Solutions and Market Intelligence at SGS

This situation is made even more challenging by complex supply chains that often span several nations, as well as the endless number of parties and contractors involved in every transaction.

Sophisticated malware software has made validating the authenticity of documents increasingly challenging. As personal signatures can no longer be relied upon to safeguard against falsification, how can we guarantee the authenticity of reports and certificates that testify to the integrity and quality of commodities?

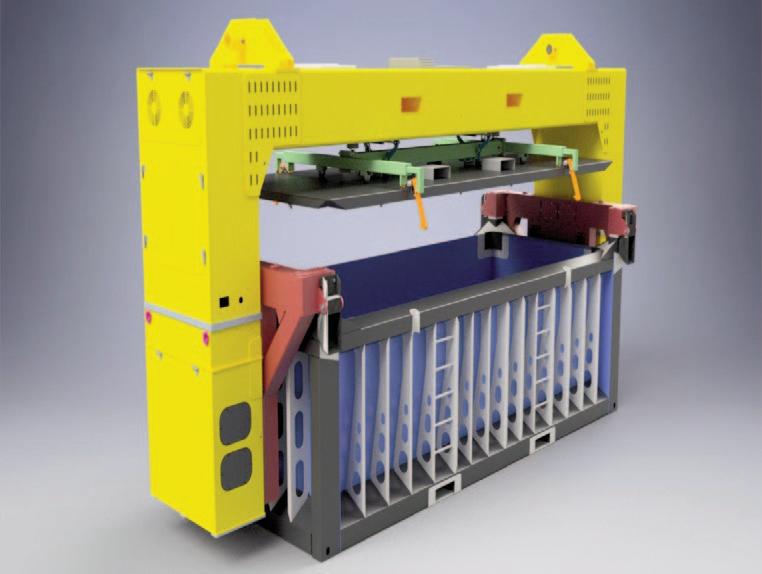

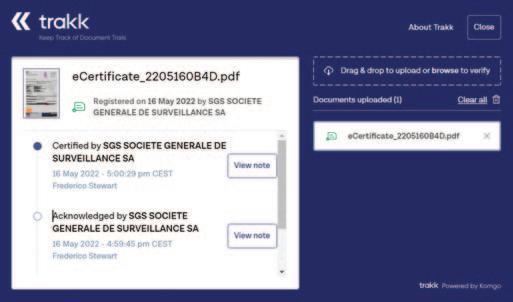

As a solution, SGS has launched SGS Secured Document — a blockchain-based registration system that gives users secure access to a document’s history, enabling the verification and authentication of its origin.

SGS Secured Document is powered by Trakk, a tool developed by Komgo that

provides a secure network to register, trace and authenticate digital documents. Tried and tested in the global banking and trading ecosystem, Trakk makes it easier to identify fraud by building a unique and immutable audit trial behind every document.

BLOCKCHAIN — HOW SGS SECURED DOCUMENT GUARANTEES AUTHENTICITY

The SGS Secured Document process utilizes blockchain technology to generate an accurate audit trail for a document. Blockchain technology is most well known for recording digital transactions; however, the secure nature of the technology also makes it ideal for validating and authenticating the origin of e-documents. In short, a blockchain acts as a digital ledger of transactions that is duplicated and distributed across the entire network of computer systems on the blockchain.

Using blockchain to track a document creates a unique, time-stamped and encrypted transaction record that enables users to see a document’s origin and its subsequent pathway. Once an SGS expert signs a document, their activities are registered in real time on the SGS Secured Document platform.

While the underlying technology of our solution may sound complex, its everyday use couldn’t be easier. Documents can be verified simply by dragging and dropping the PDF file into a widget on the SGS website, or directly in your email inbox via the Trakk plug-in feature.

REDUCED OPERATIONAL RISK

All stages of the supply chain are at risk of document fraud, including commodity inspection and testing certificates. Using a blockchain-based system like SGS Secured Document enables companies to reduce operational risk by protecting against fraud, increasing the efficiency of the audit process and building trust amongst customers. SGS guarantees that documents can be trusted, as the blockchain ensures documents cannot be duplicated, altered or falsified.

Additionally, the Trakk software provides an all-in-one tool that raises alerts and detects potential fraud sooner in the process. Crucially for the end customer, secure documentation builds trust as the supply chain can be validated. As technology and cyber threats become more advanced, it’s more important than ever to protect documentation against falsification, shielding our customers throughout the supply chain.

global outlook

Feed markets on edge, volatility high

grains & oilseeds trades

deteriorated

throughout 2022 amid high inflation, aggressive monetary tightening, the uncertainty caused by the war in Ukraine and the lingering Covid-19 pandemic. *Soaring food and energy prices

eroding real incomes, triggering a global

crisis,

vulnerable groups. Growth in the

exacerbating fiscal and balance of

in many developing

three largest

EU

with

US, China

spill-over to other countries. At

same time, rising government

large capital

The United Nations (UN)

substantial downward revision

the global economy, projected to grow between

and 2.8% in 2022.

markets

susceptible to bouts of extreme volatility. The unprovoked Russian war in Ukraine continues to exacerbate the global food security crisis, with high and volatile energy, food, feed and fertilizer prices, restrictive trade policies and supply chain disruptions. The partial re-opening of Ukraine's Black Sea ports backed by the UN relieved pressure from global food markets by providing a corridor for grain exports from Ukraine. Rising tensions could sharply escalate the war and disrupt Black Sea shipments again. Persistent drought in some northern hemisphere countriesincluding the US, EU and China, adversely affected yields for wheat and coarse grains, expected to tighten global corn supplies. Looking ahead, geopolitics, weather and southern hemisphere crops, critical to bolster global food and feed supplies. The Food and Agricultural Organization (FAO) preliminary forecast for wheat and coarse grains pegged global output at 2.25bn/t in 2022/23.

WAR AND DROUGHT CUT FEED SUPPLIES IN 2022/23

Global wheat output at 784mt (million tonnes) is marginally increased due to better wheat crops for Russia recovery in Canada, the US and in some other countries, partially offset by a drought-reduced EU wheat crop. Following Russia’s invasion of Ukraine, wheat and coarse grain output has been significantly reduced. Global coarse grains are forecast lower at 1.46bn/t, due to exceptional dry conditions that mostly affected corn output in the US and in the EU. High soybean prices supported by demand for food, feed and renewable biofuels and soaring fertilizer prices encouraged many farmers to favour less-fertilizer-intensive crops, such as soybeans in 2022/23. Soybean acreage in the US and South America increased, with the global oilseed crop pegged at a record 645mt.

FEED USE OF OIL MEALS EXPECTED TO RISE IN 2022/23

Overall global consumption of wheat and coarse grains is forecast to fall by 21mt to 2.26bn/t. Wheat for feed use is forecast lower at 155mt, more feed wheat use in Russia, Ukraine, offset by less feed wheat in the EU and a sharp fall in

China by 5mt to 30mt, Covid-19 restrictions/lockdowns impacted demand, while higher wheat prices encouraged a switch to other feed ingredients. For coarse grains feed use is expected to fall by 6mt to 906mt with more corn and barley fed and less sorghum this year. With increased oilseed supplies anticipated, feed use of oil meals is expected to rise to a record 351mt in 2022/23.

TRADE IN OILSEEDS EXPECTED TO INCREASE IN 2022/23

Global trade in wheat and coarse grains is projected to fall by 8mt to 435mt in 2022/23 due to slow demand and higher prices. A small increase in trade for wheat 208mt offset by an 11mt cut in coarse grains to 227mt, with combined global stocks of wheat and coarse grains expected to fall to 599mt. Tight stocks, especially for corn are anticipated to support prices for the remainder of the season. Trade in oilseeds is anticipated to rise by 19mt to 197mt with global stocks increased to 119mt.

GLOBAL WHEAT HARVEST FORECAST AT 784MT

Global wheat harvest in 2022/23 is

EU

Other Europe

CIS Baltic’s

GLOBAL WHEAT

2018/19 2019/20 2020/21 2021/22 2022/23

139 127 138 132

16 10 15 15

4 4 4

129 139 134 139

N & C America

S America

N East Asia

F East Asia

Oceanic

Total

Source:

Sources:

89 88 70 87

29 28 34 32

43 43 35 37

272 277 283 277

26 25 30 27

15 33 37 34

780

GLOBAL WHEAT SUPPLY & DEMAND 2018-2022/2 (MT)

2018/19

provisionally forecast at 784mt, though likely to be revised higher. Recovery in wheat output mainly in Canada 35mt, Russia 91mt (revised c.95 99mt) and the US 49mt bolstered output, while searing drought affected several countries in the EU that led to a smaller wheat crop of 132mt — France is expected to increase acreage in the new season by relaxing rules on crop rotation and mandatory fallow. By contrast floods cut India’s crop by 7mt to 103mt. The Russian invasion reduced Ukraine’s wheat crop from 33mt to 21mt as farmers could only harvest 4.6m/ha compared to 6.7m/ha in the previous year. Ukraine’s Agrarian Council (UAC) believes farmers may shrink the winter grain area from 6m/ha to 3.8m/ha due to a rising costs of seeds and fuel combined with low selling prices. Longer term, the pace of recovery of Ukraine’s agriculture influenced by, the increase in hostilities, extent of the destruction to infrastructure, labour disruption and the ability to harvest, store and export grain.

DRY CONDITIONS LIKELY TO AFFECT ARGENTINE WHEAT

Argentina’s main grain producing areas are facing the driest conditions not seen for thirty years. Lack of rain and continued dry conditions impacted wheat plantings and its early development. The Rosario Grains Exchange, estimates the planted area for

wheat at 6.1m/ha and confirmed some planted areas have been abandoned — reports indicate that 42% of the crop is in a poor condition. Wheat output has been revised lower to c.16.5 17.5mt with harvest expected to begin in late October/November.

UPBEAT FORECAST FOR AUSTRALIA’S WHEAT

The wheat crops have excellent yield potential heading into spring following a strong start in most cropping regions and above-average winter rainfall, particularly in eastern states. Abares forecast wheat production at 32.2mt in 2022/23, the second-highest wheat harvest on record. Heavy rainfall in Queensland and large parts of New South Wales caused waterlogging issues in some regions experiencing ongoing wet conditions, delaying the planting of winter crops. The possibility of a wet spring could interrupt harvest and negatively impact grain quality in some regions.

REDUCED ACCESS SUPPORTS HIGHER GLOBAL WHEAT PRICES

Since July, the agreement referred to as the ‘Black Sea Initiative’ brokered by the UN, made it possible to ship Ukraine’s exports of cereals, coarse grains, oilseeds-meals and oils, via a designated corridor to Black Sea ports. According to the UN this is working

with close to 5mt being shipped having either arrived at their destinations or enroute. The agreement is in place until November, but rising tensions suggest there may be limited scope for it to be renewed. Ukraine’s continued logistical challenges (access to farmland, grain storage capacity, freight insurance and the availability of farm inputs and labour) is expected to limit the availability of their wheat on the world market, leading to higher wheat prices. The uncertainties regarding production and exports from Ukraine, may continue to be a source of volatility in the short-term.

MOROCCO, TURKEY AND INDONESIA INCREASE WHEAT IMPORTS

Increased imports into Morocco 7.5mt due to prolonged and widespread drought, Indonesia 11.2mt for food and feed, the EU 5.5mt due to drought and in some other countries, increased global trade to 208mt. With demand for wheat outpacing supply, wheat stocks are drawn lower to 269mt (world 125mt, China 144mt), stocks in key major exporting countries to fall to 57mt.

RUSSIAN WHEAT TRADES BELOW COMPETITORS

Wheat prices expected to remain strong given the uncertain outlook for the agreement to keep open the three Ukraine ports for exports. Demand for wheat in

price-sensitive markets in Africa, the Middle East and South-East Asia has been strong. Despite finance restrictions and higher freight costs Russian wheat has been trading below key competitors' since harvest-with exports pegged at 42mt. Exports from Canada have recovered to 26mt, US 23mt, EU 33.5mt and Ukraine11mt in 2022/23. Chicago wheat futures fell on strong supply soft demand and a surging US dollar CBOT Wheat SRW Contract Dec ‘22 closed-$8.60/bu ($315.96/t-16 Sept ’22). EU FOB Rouen ($340/t -16 Sept ’22); UK Feed Wheat Futures Contract Nov ’22 closed ($297.66/t-8 Sept ’22).

ARGENTINE CORN REVISED LOWER

Buenos Aires grain exchange cut its forecast for Argentina’s corn crop to 50mt (previously 55mt), with provisional estimates for exports at 41mt.

The revised output for corn is due to the third consecutive year of the La Niña weather pattern that limits precipitation and reduces yields. The World Meteorological Office (WMO) predicts the current La Niña event — capable of exacerbating drought and flooding in different parts of the world — is drawing to the end of a three-year-cycle in February ’23; until then, there is a 70% per cent chance of occurring between SeptemberNovember ‘22, gradually decreasing to 55% percent between December February

2022/23.

Conab forecasts Brazilian farmers will produce a record 126mt corn crop due to a larger planted area. Producer margins for corn are said to remain positive, despite the rise in input costs. Brazil’s exports are forecast at 46.5mt in 2022/23, given large available supplies, favourable exchange rates and robust demand.

DROUGHT CURBS COARSE GRAINS PROSPECTS

Global coarse grain output is forecast to fall by 43mt to 1.46bn/t in 2022/23. Mostly due to reduced output in the US Midwest, where hot, dry weather curbed yield prospects for corn. Severe drought also affected EU countries, reducing coarse grain output to 139mt. While in Ukraine, the war severely cut coarse grain output by 15mt to 39mt.

COARSE GRAIN DEMAND TO FALL IN 2022/23

For the first time in ten years, global feed, food/industry use of coarse grains, is set to fall by almost 17mt to 1.47bn/t in 2022/23. This includes a 11mt cut mainly in food/industry use to 577mt with feed use reduced by 6mt to 906mt.

GLOBAL DEMAND FOR FEED LOWER IN 2022/23

Global corn output on a reduced corn area of 204m/ha is forecast to fall by 47mt to

1.17bn/t, and reflects a switch to planting oilseeds soybean and sunflower due to higher prices and lower fertilizer requirements. Hot, dry weather conditions in the US and EU contributed to drought stress for corn crops, decreasing yields, with output lower in the US 354mt, EU 59mt and in Ukraine 31.5mt, partially offset by a better crop in China of 274mt. Global demand is cut by 4mt to 743mt. Feed use expected to increase in China 214mt, Brazil 66.5mt, Mexico 26.3mt and Ukraine 11.5mt.

TIGHT CORN STOCKS DRIVE CORN PRICES

HIGHER

Global corn stocks have fallen to 305mt in 2022/23 (China 207mt World 98mt), with major exporters stocks 52mt. Since August major exporters’ quotes increased — Argentina Feed (Up River) $299/t (Sept 8 ’22); Brazil Feed (Paranagua) $290/t (Sept 8 ’22); US 3YC (Gulf) $324/t (Sept 8 ’22).

MODEST EXPANSION FOR MEAT TRADE IN 2022/23

Despite the challenging environmentwidespread animal diseases, conflicts and rising input costs. Only a modest expansion in world trade in meat and meat products is anticipated in 2022/23, reflecting limited export availabilities from exporters and a likely decline in China’s pig meat imports.

Higher beef prices-incentivized major

producers in the US to cull animals, resulting in a high level of exports at competitive prices; improved rainfall led Australian producers to retain more heifers for breeding. Production growth in Brazil, Canada and Mexico offset a reduction in Australia. China’s beef production to rise to 7.4mt with imports lower at 2.5mt; low domestic prices, weaker economy, to impact imports of high value beef. Despite inflationary pressures and logistical issues global beef demand is expected to remain strong, helped by some countries lifting Covid-19 restrictions.

With a decline in pork production in the EU and Brazil-global pork production is forecast at 110.7mt in 2022/23 — upward revision for China 52mt (below pre-African Swine Fever (ASF) levels) offset by lower output in the EU 22.6mt, Brazil 4.3mt slow exports weigh on prices. Pork exports revised lower to 10.6mt 2022/23, due to a cut in China’s exports to 1.85mt, despite increases for South Korea, Mexico, Japan and the Philippines.

Rise in Ukraine’s chicken meat outputincreased global production to 101mt, largely offsetting weak domestic demand in Brazil. While, the EU continues to grapple with elevated feed prices and the highly pathogenic avian influenza. Chicken meat exports are slightly higher to countries, other than China and expected to fall as domestic pork production rebounds and eases demand for other animal proteins.

IMPROVED PROSPECTS FOR BARLEY

Despite a smaller global area, production of barley is forecast at 148mt in 2022/23.

GLOBAL COARSE GRAIN SUPPLY & DEMAND 2018-2022/23 (MT)

2018/19

2020/21 2021/22 2022/23

Production 1,403 1,420 1,441 1,506 1,463

Consumption 1,424 1,434 1,456 1,490 1,473

Trade

Stocks

which China:

Key Exporters*

235 238 227

323 339 330

207 211 208

Source: IGC/USDA * US, Argentina, Brazil, Russia, Ukraine, EU, Australia, Canada

GLOBAL CORN SUPPLY & DEMAND 2017-2022/23 (MT)

2018/19

Production

Stocks

which China:

Exporters*

Source: IGC/USDA * Argentina, Brazil, Ukraine, US

Good yields improved output in Russia 21mt, Canada 10mt and Turkey 7.4mt partially offset by smaller crops in the EU 50mt, Ukraine 6.4mt and Australia 12.2mt. Feed use is forecast at 101.2mt with increases for Canada and Russia. Barley exports increased to China 9.5mt, Thailand 0.5mt, Vietnam 0.7mt, Saudi Arabia 4.7mt, Iran 2.5mt and in some other countries-a small increase in global trade to almost 30mt. International prices for barley remain firm — Jordan bought 120,000/t of feed barley $328/mt CFR for delivery Jan Feb 2023. Feed Barley FOB Rouen $299/t (8 Sept’22) and FOB Argentine (up-

river) $320/t (8 Sept’22).

SORGHUM OUTPUT IN 2022/23

Global sorghum output has increased in several countries, but a much reduced US crop of 6.4mt cut global output to 60mt in 2022/23. Sorghum exports are forecast at 9.7mt. China is the largest market importing 8mt to support feed demand mainly for pig and poultry and the production of Baijiu (a national spirit beverage) made by fermenting cooked sorghum or other grains. Major sorghum exporters include the US, Argentina and Australia. Sorghum values, like other coarse grains have increased FOB Texas $361.59/t (8 Sept ’22).

SIGNIFICANT RISE IN SOUTH AMERICAN SOYBEAN ACREAGE IN 2022/23

In the southern hemisphere Brazil is primed to plant a much larger soybean area, rising by 4m/acres to nearly 106m/acres — with a crop estimated at 149mt. The Argentine crop is pegged at 48mt (USDA 51mt) and Paraguay 10mt. This crop year meteorologists predict that Brazil and Argentina may experience the re-emergence of La Niña-type precipitation to be limited in the South of the country but adequate in the North. This type of weather pattern last year was responsible for cutting Brazilian soybean production by over 20mt.

RECORD GLOBAL OILSEED OUTPUT DRIVEN BY SOYBEANS IN 2022/23

USDA’s latest forecast for global oilseed crops predicts a rise of some 43mt to

645mt in 2022/23, driven by a record output anticipated for soybeans of 390mt — this includes a downgrade to the US crop by 4mt to 119mt with yields of 50.5bu/acre, due to hot and dry weather in western growing areas.

There were also gains for rapeseed 82mt following a recovery in Canada, cottonseed 43mt, palm kernel 21mt, with groundnuts 50mt and copra 6mt unchanged. Lower output for sunflower seed 52mt, mainly due to the war that reduced Ukraine’s sunflower seed crop from 17.5mt to 9.5mt.

GLOBAL DEMAND FOR OILSEED MEALS FORECAST AT 357MT

Global demand for oilseeds is expected to increase in 2022/23 though oilseed prices are expected to ease as potential rising supply offsets rising demand for its three major uses — meal fed to animals, oil used for cooking (food) and for fuel. Trade in oilseeds is forecast to rise by 19mt to 197mt in 2022/23, with increased imports into China, EU, Mexico, Argentina, Egypt, Turkey, Thailand, Pakistan and in many other countries.

SLOWDOWN IN CHINA REDUCES DEMAND FOR SOYBEANS IN 2022/23

China's slowing economy and zero tolerance-Covid-related restrictions and widespread lockdowns weakened demand for oil meals for swine and poultry rations and vegetable oil for food use. USDA

Sorghum cargoes.

2018/19 2019/20 2020/21 2021/22 2022/23

Production 601 581 607 602 645 of which (soybeans) 362 340 368 353 390 Crush 489 508 508 512 532

Consumption* 328 340 344 345 357

Trade Meals* 95 96 97 96 98

Trade Seeds 172 191 192 178 197

Stocks 134 112 116 109 119 of which (soybeans) 91 65 65 60 67 key exporters**

Source: USDA/*Meals cons/trade-excl. fishmeal. **Argentina, Brazil, US

forecast China will import 96.5mt of soybeans this season, 1.5mt lower than previously forecast.

HOG PRICES BEGIN TO IMPROVE

Following months of lacklustre soybean imports and negative crush margins, soybean meal prices on the Dalian exchange picked-up at the end of August, on firm demand from hog farmers-who fatten their herd during this period to meet seasonally higher demand for pork products in winter. With hog prices beginning to recover, improved profits for pig producers while increasing the demand for soybean meal, helping to drive-up soybean meal prices.

SHORT TERM SHORTAGE OF SOYBEAN MEAL

While China is expected to meet increased soybean demand by producing and

importing more soybeans — a short-term soybean meal shortage developed, with prices soaring in some provinces in September ahead of the Chinese National Day holidays. Spot prices of soybean meal rose in some of the main processing hubs of Guangdong and Shandong according to data from Shanghai JC Intelligence Co. and reflected in rising soybean meal prices on the Dalian Exchange for November delivery-4,525yuan/t ($635.89/t-15 Sept ‘22). Soymeal stocks fell to 493,000/t in mid-September well below the five-year average of 845,000/t. Chinese importers have stepped-up soybean purchases in recent weeks, notably from Argentina and with the US harvest under way likely to ease supply tightness in the coming monthsthe Mysteel Group predict China to import 6.8mt of soybeans in September, 5mt in October and 8.8mt in November.

Water lubricated propeller shaft bearings found to reduce fuel consumption

Peer-reviewed research by Thordon Bearings into the hydrodynamic lubrication efficiency of a ship’s propeller shaft bearing has found that the use of seawaterlubricated elastomeric polymer bearings reduces fuel consumption.

The environmental and financial benefits of adopting a seawater-lubricated propeller shaft system are well documented, but this is the first indication that the arrangement reduces hydrodynamic resistance enough to improve fuel consumption, compared to a conventional oil-lubricated bearing arrangement.

The groundbreaking research is based on new methodology for calculating the performance of seawater-lubricated bearings, which, until now, has been based on decades-old theory developed for oillubricated propeller shaft bearings.

“Classic rigid surface bearing theory is valid and commonly used for oil-lubricated metal bearings. However, two major factors of seawater-lubricated bearings, namely low lubricant viscosity and deformability [of the polymer bearing surface], make the application of rigid surface bearing calculations

susceptible,” Thordon Bearings’ Chief Research Engineer, Dr. Gary Ren, says in his peer-reviewed paper published in the July edition of the Elsevier journal Tribology International

“We believe Dr Ren’s method is more accurate, because it takes into account the characteristics of seawater as a lubricant, the polymer materials used, bearing pressures, viscosity, friction and so on,” said Elena Corin, Senior Manager, Special Marine Projects, Thordon Bearings. “This is the first time anyone has investigated whether there are differences in friction coefficient between the two types of bearings. And there are!”

Corin furthered that the new methodology provides “strong evidence” to quantitatively support the benefits of a Thordon COMPAC system. “By applying the results, we were able to determine the minimum required shaft speed for hydrodynamic lubrication efficiency, the coefficient of friction as well as the water film thickness at any given load and shaft speed,” she said.

“Test results confirmed that fuel losses due to the friction coefficient

[hydrodynamic resistance] of an oillubricated propeller shaft bearing system can be reduced by as much as 85% by using seawater-lubricated polymer bearings.”

Thordon Bearings used the methodology to compare the fuel consumption of a Panamax containership and an Aframax tanker operating a 640mm (25.2in) diameter oil-lubricated propeller shaft bearing versus the same ships operating an open COMPAC seawaterlubricated bearing system.

Each vessel was assumed to run on VLSFO (very low sulphur fuel oil) at a global average price of US$890/mt, operating for 70% of the time.

“The results confirmed that fuel losses due to the friction coefficient (hydrodynamic resistance) of an oillubricated propeller shaft bearing system can be reduced by as much as 85%.

“Fuel costs will depend on the operational profile of the vessel, but we conservatively estimate annual savings of at least US$10,000 per vessel,” said Corin. “This is in addition to the other life cycle cost savings associated with a Thordon seawater-lubricated bearing system.”

Reederei Gerdes orders second Damen Combi Freighter 3850

EFFICIENT SHORT SEA GENERAL CARGO VESSEL

German short sea shipping specialist ship owner company Reederei Gerdes signed the order for Damen Cargo Vessels to build a second Combi Freighter 3850, following delivery of the Benabell G in September last year. The new vessel of the same type will be named the Kalli G. This addition to the fleet will increase overall efficiency.

Impressive performance of the Damen CF 3850 that was taken into service end of 2021, convinced Reederei Gerdes to order the next vessel of this type. Now that European short sea shipping is experiencing a period of growing demand, fleet renewal is key to be prepared for future operations. Tightening environmental regulations require fleet upgrades. The CF 3850 performs well within the requirements from IMO and port states, making it a future-proof vessel. Additional benefit for the ship operator is of course the low fuel consumption at high deadweight.

“It is important for us to utilize the resources available in a responsible manner,” states Nicole Gerdes, managing partner at the ship owner company. “We focus on longevity and sustainability to retain our competitive advantage in coming years.”

Kalli G can sail at over ten knots carrying full cargo load, with less installed propulsion power. Optimized design of the hull reduces water resistance and enables substantial fuel savings. The 89.70-metre length over all, 12.50-metre beam vessel has a 1,104kW main engine. The relatively small power source is enough to maintain her 11.8 knot design speed even in

rough conditions. The vessel carries 3,830 tonnes of load. Cargo hold tanktop strength is reinforced to carry 15 tonnes per square metre. The CF 3850 takes 172 containers: 108 in the hold and 64 on deck.

Gerdes, with its associated chartering company over-C GmbH & Co. intends to employ the ship in the European coastal trade. Dennis Clavier, Director at over-C states: “The size, in combination with its ‘NAABSA notation’ make the CF3850 a good vessel for calling smaller tidal ports for example in the UK. The movable bulkheads which can be used as partial tween-decks offer flexibility to carry grain, animal feed, fertilizer, steel but also project cargoes from time-totime.”

Damen Cargo Vessels, located in Drachten, the Netherlands, serves ship owners in the short sea trading with standardized designs for combi freighters, tankers and container feeders, building in stock and where needed to client specification.

By 2021, four vessels of the CF 3850 design were available ready built, all of them have been taken into service in the

last year and 13 more contracts have been signed for vessels of the same design.

DAMEN SHIPYARDS GROUP —OCEANS OF POSSIBILITIES

Damen Shipyards Group has been in operation for over 90 years and offers maritime solutions worldwide, through design, construction, conversion and repair of ships and ship components. By integrating systems, Damen creates innovative, high quality platforms, which provide its customers with maximum added value.

The company’s core values are fellowship, craftsmanship, entrepreneurship and stewardship. Its goal is to become the world’s most sustainable shipbuilder, via digitalization, standardization and serial construction of its vessels.

Damen operates 35 shipyards and 20 other companies in 20 countries, supported by a worldwide sales and service network.

Damen Shipyards Group offers direct employment to more than 12,000 people.

MCTC celebrates 10 years of supporting vessels and their crews improve seafarers’ health with nutritious meals

Leading maritime catering management provider MCTC is celebrating its first decade of improving catering standards onboard ships by focussing on healthy and nutritious meals.

MCTC has been celebrating its milestone year with a special anniversary party and events throughout the year.

The company launched in 2012 with the aim of improving catering standards in the galley, serving healthy and nutritious meals and improving crews’ overall health, while reducing dietrelated illnesses in crew members that are caused through consumption of fatty and high-calories foods.

MCTC started with offering training courses in catering and health and nutrition, with its flagship programme being the Catering Competency Development Programme. This offered the full training programme, as well as access to an experienced team of consultants, regular vessel visits, trade tests and weekly practical evaluations.

Over the years, the company evolved to offer full catering management services along with its training packages, taking care of the full spectrum of a vessels’ needs from budget planning, creating recipes and ordering supplies. MCTC is now on target to soon have 1,000 vessels under its service.

CEO of MCTC, Christian Ioannou said: “We are delighted to have reached our tenth anniversary and have enjoyed celebrating with numerous events throughout this year. The business has evolved significantly over the last decade and we are immensely proud to have gone from offering training to now offering a full scope of catering management services, along with our training programmes. “MCTC started with the aim and vision to improve standards in the galley and there has certainly been a big shift in vessel managers and owners’ mindsets when it comes to health and nutrition over the last few years, particularly following the Covid pandemic. The new generation of seafarers are heavily invested in their physical and mental health and it is important that as an industry we are ensuring we are meeting this new set of needs.”

Alongside its training and catering management packages, MCTC has a team of experts who are on hand 24/7 with advice and support. All galley staff under its management has access to a fully interactive digital platform where they can receive nutrition advice, recipe ideas, communicate with the team, or access any of their training modules. It also places focus on keeping fit and promoting a positive mindset to ensure seafarers are looking after both their physical and mental health.

ABOUT MCTC

MCTC offers a full Catering Management Programme covering the vessel’s entire catering management needs such as ordering supplies, recipe planning, menu management, and health and nutrition. It also provides a Catering Competency Development Programme designed to increase standards in the galley through a safe food handling and nutrition course; onshore upgrading culinary course; trade tests, briefings, on board visits and also crew conferences.

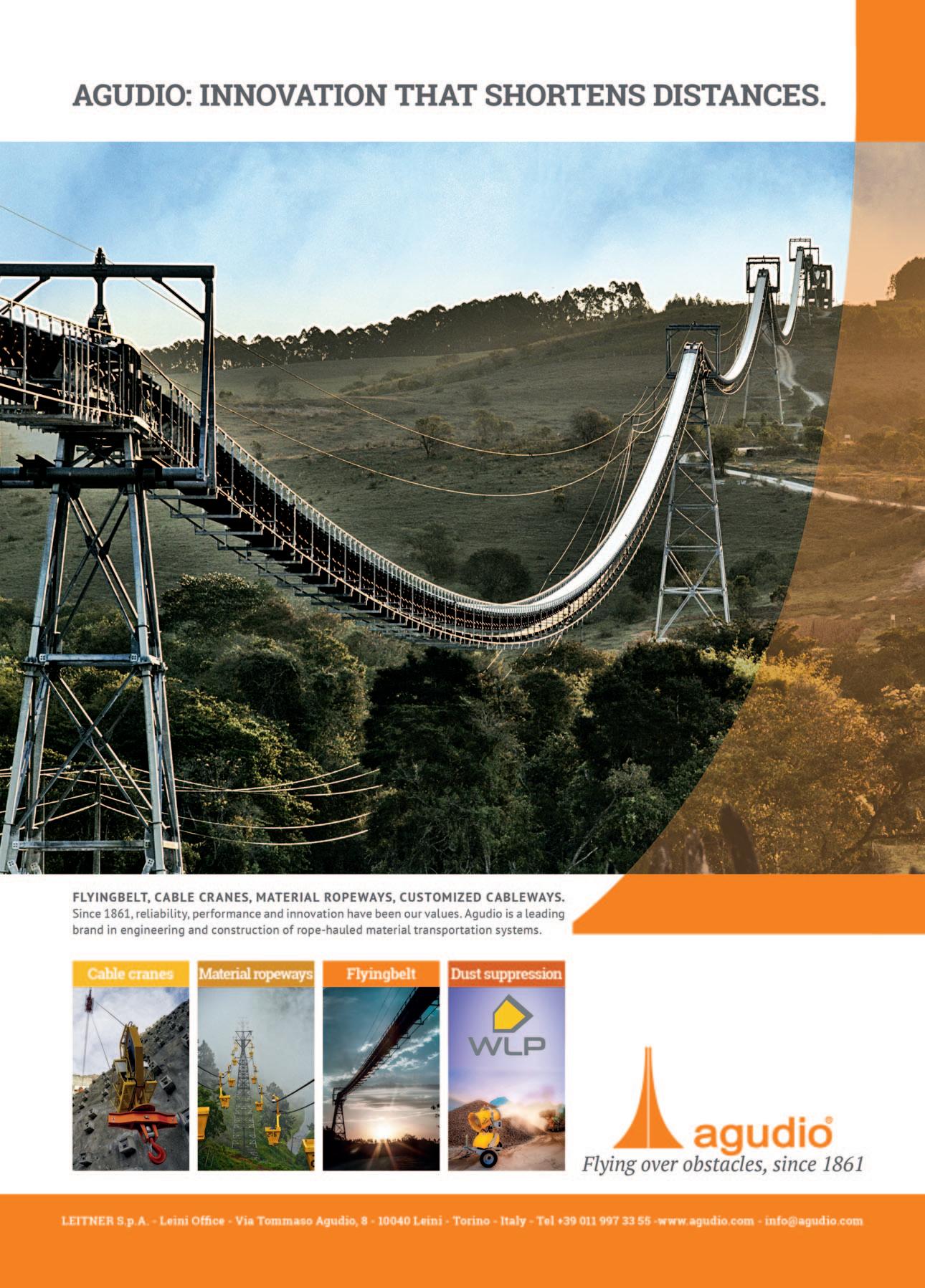

THINK THAT RAW MATERIALS TRANSPORT REQUIRES TRUCKING. WE THINK DIFFERENT.

Keeping the boat afloat bulker services, safety & maintenance

Hempel coats 3000 ships with flagship hull coating, Hempaguard

Coatings company, Hempel A/S, has passed a landmark number of ships coated with Hempaguard. Alexander Enström, Executive Vice President of Marine at Hempel, explains why passing this milestone is so impactful. “Our customers are looking for technologies that can support them on their sustainability journey. Three thousand applications of Hempaguard is equal to removing 27 million tonnes of CO2, corresponding with 8.6 million tonnes of fuel saved by having a smoother hull.”

“The adoption of Hempaguard is growing exponentially. This year alone, we have seen sales of Hempaguard systems grow by 82%,” continues Enström. “The antifriction properties of Hempaguard help shipowners and charterers save on fuel usage and thereby emissions, so it’s the obvious choice for our customers.”

With stricter regulations related to decarbonization coming into force in 2023, Hempel is seeing a widening range of clients seeking its advice, including an increasing number of bulker, tanker, containership and cruise operators and owners all keen to keep their vessels in

operation come next year.

The new regulations being introduced by the International Maritime Organization are the Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI). Hempel’s data suggests that about 80 per cent of the world fleet will be required to take action to secure a good CII rating while reaching the required EEXI. Vessels will be forced out of the market if their owners and operators do not identify and adopt a comprehensive emissions’ reduction pathway.

CALCULATION METHOD

The savings related to the 3,000 vessel applications have been calculated by estimating the fuel savings of each Hempaguard application against a market average coating, based on market average numbers from the Fourth IMO GHG Study.

For Hempaguard applications, the consumption, activity, duration until next dry dock and relative savings from the IMO GHG Study are estimated and the impact from the full DD cycle is summarized in the year of Hempaguard application, where

the coating choice and thus fuel savings decision is taken.

ABOUT HEMPEL

As a supplier of trusted coating solutions, Hempel is a global company with strong values, working with customers in the decorative, marine, infrastructure and energy industries. Hempel factories, R&D centres and stock points are established in every region.

Across the globe, Hempel’s paints and coatings can be found in almost every country of the world. They protect and beautify buildings, infrastructure and other assets, and play an essential role in our customers’ businesses. They help minimize maintenance costs, improve aesthetics and increase energy efficiency.

At Hempel, the company’s purpose is to shape a brighter future with sustainable coating solutions. It firmly believes that it will succeed as a business only if it places sustainability at its heart. Not only is this the right thing to do, it will also strengthen the company’s competitive position, make it more resilient and reduce its risk.

Polish Register of Shipping classification services on the way to assure bulk carriers safety in sea trade

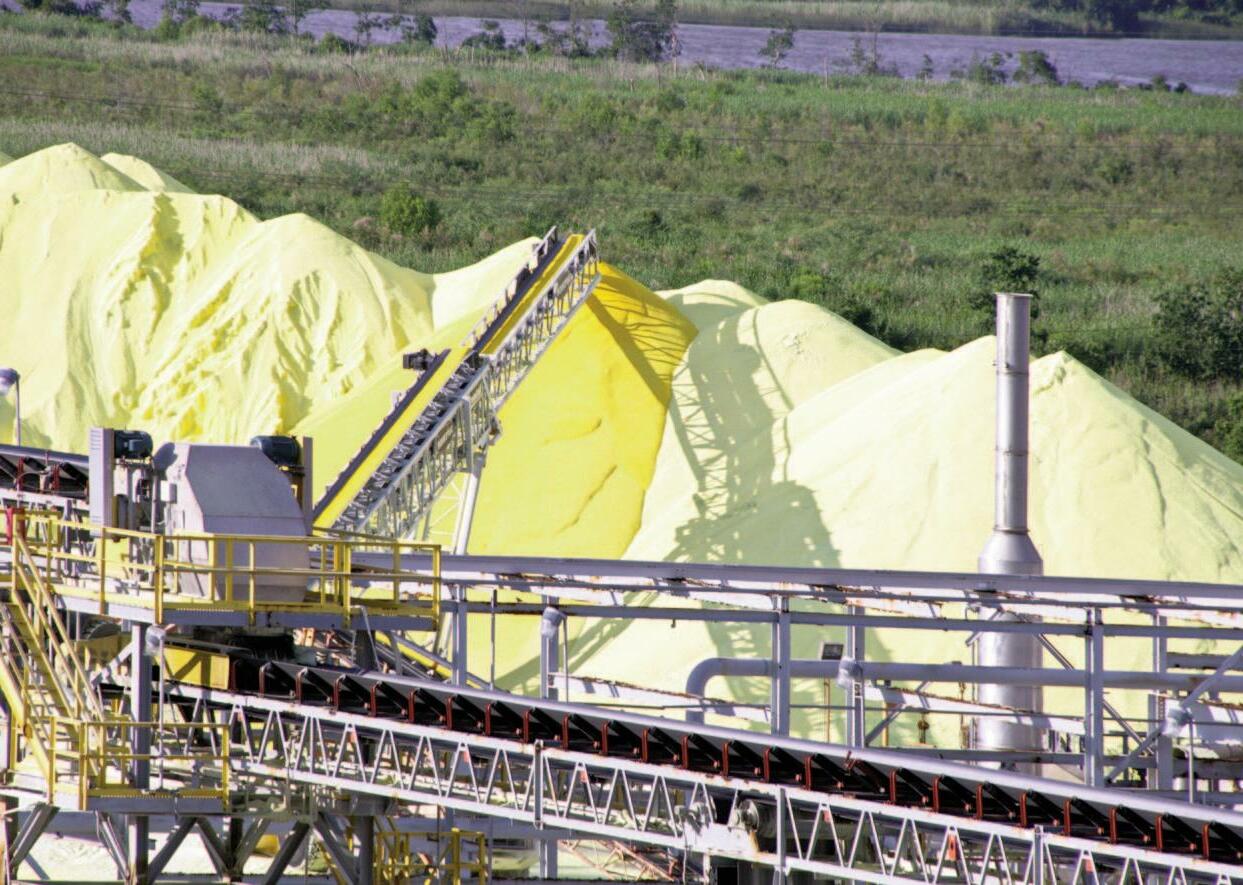

Bulk carriers play a major role in the global economy. Dry bulk cargoes cover a wide range of products, writes Marek Narewski, Rules Development Department, Polish Register of Shipping (PRS).

The most commonly shipped dry bulk materials are for example: coal, cement, grain, sulphur, fertilizers, iron ore and sugar. These products are generally transported in large quantities in bulk in the typical holds arranged in the construction of the specialized ship — bulk carrier. The portfolio of safety-related services for bulk carriers involved in international trade is provided by class societies associated in IACS, and one of its members is the Polish Register of Shipping (PRS).

Currently designed and constructed bulk carriers and implemented survey procedures present high engineering quality necessary to ensure cost-effective, safe and reliable operation. Based on experience gained from the past, the safety of the current world fleet of bulk carriers is much better, as can be seen in EMSA (European Maritime Safety Agency) or IMO statistics. The progress in safety assurance is the result of parallel class societies efforts and flag states activities related to verification of compliance with international and national regulations. This is particularly important in the case of aged ships that require compliance with business standards requested by shipowners and ship operators to keep required level of competitiveness.

IACS class societies play a vital role in and are committed to the safety of existing and future bulk carrier fleet. According to EQUASIS 2019 the fleet of ships over 500 GT is dominated by ships classed by IACS members (56% by number and 78% by tonnage). In the case of bulk carriers, IACS societies are classing over 83% of the total world bulk carrier fleet. We can expect that the number of IACS classed ships will be on a steady increase both in numbers and in GT. The high rate of IACS classed bulk carries means that the majority of the world bulk carrier fleet has a major impact on the safety of commodities trade.

Some studies conducted recently touched subjects of prediction of commercial fleet future structure and certain ship types development as well as the rate of new-buildings and scrapping old ships. One of the studies is forecasting that the number of bulk carriers will remain almost constant within the coming three

decades. Considering the maritime safety aspect, EMSA reports contain some statistical data on ship accidents and incidents rates, and these statistics show that the figures for new ships are much better than in the case of old ships.

The ship classification is a special type of business activity where specific and wide expert knowledge and safety consider ations are of utmost importance. The basis for classification societies activities are their rules dedicated mainly to shipping industry as well as to specific parts of the oil & gas industry, energy generation, rail & road transport or aviation. PRS as a classification society offers portfolio of services focused mainly on safety assurance. The set of PRS Rules has been developed based upon the society’s own experience and is continuously amended by inclusion of own R&D work results, e.g. IMO and IACS requirements as well as other applicable international technical and safety standards.

At present, PRS has over 500 seagoing ships classed and bulk carriers constitute about 16% of all classed ships. The substantial number of classed bulk carriers is of the medium age. PRS experience gained when dealing with older ships enabled the society to elaborate effective and high quality survey services. The last two years PRS was on the list of high performance classification societies of the Paris Memorandum of Understanding on Port State Control. Only classification societies that have a low ratio of detentions by PSC can get on the list of recognized organizations with the high performance result, what underlines the quality of their work and at the same time is one of the determinants allowing a vessel to be the Low Risk Ship. Being high on the performance list of Paris MoU shows PRS’ commitment to keeping a high level of services.

Over the years class societies took several steps to enhance the safety of bulk carriers. These have included the introduction of the corrosion protection requirements for ballast spaces, minimum thickness requirements for side shell web frames in cargo areas, tough regime of Enhanced Surveys and most notably the introduction of Common Structural Rules for Bulk Carriers (CSR) in 2005 followed by Common Structural Rules for Bulk Carriers and Oil Tankers (CSR BC & OT) in 2015. PRS implemented CSR Rules into its own

activity and developed a set of related PRSCSR software for verification of the bulk carrier strength. The software has been assessed and positively verified according to IACS procedures.

Another important aspect of bulk carriers safety assurance is related to winter navigation in ice-infested waters. Like other class societies, PRS has implemented rules dedicated for seagoing ships that must have a sufficient strength of hull and machinery during navigation where increased risk of damage by brash ice blocks to the propulsion system exists. PRS’ practical experience in that area covers also special surveys and repair of damages caused by ice during ship operation.

An example is a serious ice damage that happened a few months ago when a fully loaded bulk carrier suffered failure to propeller blades. Due to circumstances, the only solution to the problem was to conduct repairs underwater at the nearest harbour. The repair was done after detailed underwater inspection, carried out under supervision of a classifier. Damaged blades were cut and straightened by the professional diving and underwater service provider company. Underwater repairs completed fully underwater has been surveyed by PRS and allowed to release the ship to sail fully loaded across the Atlantic.

PRS provides a specially tailored expert service dedicated to ships involved in commodities trade called Condition Assessment Program (CAP). CAP service is already well established within the tanker industry, but is also implemented as vetting practice in case of bulk carriers as a proved method leading to improvement bulk carriers risk assessment. It is an important voluntary service that provides independent evaluation of the technical condition of a bulk carrier. Based upon CAP process results, third parties can assess the suitability of the ship to be chartered and its current condition in relation to its age.

CAP assessment provides a charterer with a technical evaluation of the condition and maintenance of a vessel above standard requirements for a class. It is applicable to bulk carriers of 15 years of age and above. The CAP programme scope covers a detailed survey of the hull structure including verification of gauging as well as extensive testing of ship

machinery, equipment and cargo systems. Gathered information, combined with a strength and fatigue engineering analysis, is transferred into a numeric rating to be assigned to the verified ship — from 1 (Very Good) to 4 (Unsatisfactory).

A specific class activity is related to evaluation of novel technical solutions for implementation in ship technology. Newly developed designs and equipment prototypes are being verified by class societies to be implemented on board of ships using marine engineering practice. Completion of certification process allows for legal introduction of new solutions on ships and is a proof of the compliance with existing sound marine engineering and new

safety and environmental standards as required by law.

Class societies are here to assure that ship technology developments are compliant with the mandatory requirements for technical and operational safety of bulk carriers as well as other ships involved in international trade.

ABOUT PRS

Polish Register of Shipping (PRS) is an independent expert institution acting on the international market, whose business is conducted for the benefit of the community. Through the formulation of the requirements, survey and issue of the appropriate documents, PRS assists State

Progress report: Black Sea Grain Initiative

The Joint Coordination Centre (JCC) was inaugurated in Istanbul on 27 July following the Black Sea Grain Initiative launched by Russian Federation, Türkiye, Ukraine and the United Nations.

From 1 to 15 August, the JCC has authorized a total of 36 movements of vessels (21 outbound and 15 inbound) through the maritime humanitarian corridor in the Black Sea to facilitate the safe exports of grain, foodstuffs and fertilizer, including ammonia, from Ukrainian ports.

During this period, 21 vessels have been authorized to move from the Ukrainian ports of Odesa (11), Chornomorsk (6) and Yuzhny/Pivdennyi (4) under the Initiative. Those vessels are carrying a total of 563,317 metric tonnes of grain and other foodstuffs.

BREAKDOWN:

451,481 tonnes of corn 50,300 tonnes of sunflower meal 41,622 tonnes of wheat 11,000 tonnes of soya beans 6,000 tonnes of sunflower oil 2,914 tonnes of sunflower seed

According to information provided to the JCC, the preliminary destinations of Ukrainian food exports so far include:

Turkey: 26%v

Iran: 22%v

Republic of Korea: 22%v

China: 8%v

Ireland: 6%v

Italy: 5%v

Djibouti: 4%v

Romania: 2%v

To be determined: 5%v

Routes of commercial vessels and cargo

ownership are determined through commercial activity and they may change en route. The food en route to Djibouti is 23,000 tonnes of wheat purchased by the World Food Programme (WFP) to contribute to the drought response in Ethiopia as part of the WFP’s humanitarian operations.

From 1 15 August, the JCC has conducted a total of 27 inspections through its joint inspection teams on inbound and outbound vessels. All ships inspected so far were cleared.

As part of its responsibilities, the JCC has been closely monitoring the inbound and outbound movement of vessels through the maritime humanitarian corridor in the Black Sea. It has so far observed on two occasions vessels deviating from the corridor and it has responded appropriately by contacting captains and advising them to follow the co ordinates.

The JCC is also providing pre-transit briefs to inbound masters during the inspection process in Istanbul. The JCC continues to assess and review the procedures put in place to ensure the safe passage of vessels through the maritime humanitarian corridor.

Administrations, Underwriters and the Society’s clients in ensuring the safety of people, floating objects, land undertakings, the safety of carried cargo and that of the natural environment. PRS is IACS member and acts also as RO upon over 40 authorizations of Flag States.

ABOUT THE AUTHOR

Marek Narewski is a specialist and expert in PRS R&D Division with wide experience resulting from involvement in number of various marine and offshore R&D projects, novel technologies implementation in ship design and construction including marine application of composites and alternative fuels.

The Black Sea Grain Initiative aims to respond to high food price inflation and to global food insecurity which is at record levels with tens of millions of people at risk of famine. According to the UN’s Food and Agriculture Organization, Ukraine contributes about 10.3% and 12.6% of global exports of wheat and maize respectively. Its share for sunflower products (seeds and oil) is 48.2%. Restarting exports will free up storage space in Ukraine and avoid wastage. It will also ensure a supply chain of food for this and subsequent harvests.

The deal aims to improve global food supply and calm markets. Prices across different food commodities are volatile and can be subject to a range of economic and climatic influences that go beyond Ukrainian exports.

Terminology:

Outbound: merchant vessels departing the ports of Odesa, Chornomorsk and Yuzhny (Pivdennyi) heading to Istanbul

Inbound: merchant vessels departing from Istanbul heading to the ports of Odesa, Chornomorsk and Yuzhny (Pivdennyi)

A perfect storm for the dry cargo sector

INTERVIEW: KOSTAS GKONIS, SECRETARY GENERAL INTERCARGO

The time frame required to change the direction of a bulker is frequently quoted in management speak, and many of the issues faced by the dry bulk shipping sector could be said to follow the same pattern. The dry cargo industry is used to making decisions for the long term and dealing with complex issues that have a lengthy lifespan and wide implications.

Today however, dry bulk operators are facing a perfect storm of circumstances to deal with.

Kostas Gkonis, Secretary General of INTERCARGO explains: “Following the turbulent pandemic years, the industry now finds itself dealing with the situation in Ukraine, the legacy of Covid and of course the incorporation of IMO’s greenhouse gas (GHG) reduction targets into everyday operations. Yet these issues are coupled with the safety, security environmental and regulatory challenges that the dry bulk industry has always faced.”

Gkonis explains that progress is being seen in some areas, but other issues are not so transparent.

“Our Association welcomed the Black Sea Grain initiative to resume grain shipments from Ukraine,” he says. “But amid the very public discussions regarding insurance and chartering, it must be stressed that the safety and security of the vessels, and their crews, must be at the heart of the debate.

“Practically, this means that there must be continued assurances at berths and anchorages in Ukrainian ports as to the safety of vessels and their crews, the security of cargoes, and that shipping in the area is free from attack. The creation of a mine-free sea corridor protected by naval escort is essential.”

The issue of Covid is now rarely in the news, but INTERCARGO members have advised of continuing difficulties. “The shipping industry is facing its own version of ‘long Covid’,” says Gkonis. “Seafarers worldwide continue to face major issues with crew change, port entry and changing vaccination requirements. New waves of infection persist at ports, and once again we are seeing local authorities creating

their own interpretation of the rules.” He also explains that in a number of ports globally seafarers are finding access to shore leave restricted, and in some cases are finding it difficult to access nonemergency medical assistance.

Liquefaction too remains on the agenda, and industry partners could still do more to ensure the safety of crews, says Gkonis. INTERCARGO recently submitted its latest Bulk Carrier Casualty Report to IMO where it warned that not only were IMSBC Code requirements not being followed, especially in relation to testing and certification of cargo condition, but that there was also lack of adequate assessment and monitoring of the condition of cargoes being loaded in the cargo holds by representatives of all interests.

“Despite high levels of awareness from shipowners themselves of the dangers of improperly loaded cargo, the Report identified that liquefaction continues to be the greatest contributor to loss of life in the bulk sector,” says Gkonis.

“Between the years 2012 to 2021, 27 bulk carriers over 10,000dwt have been identified as total losses and 92 seafarers lost their lives. Liquefaction accounted for about 19% of the total vessel casualties in the past ten years yet was the cause of 76% of the total loss of life, as a result of five related bulk carrier casualties, four carrying nickel ore and one carrying bauxite.”

Ship operators are well aware of the risks to their crews and their vessels caused by carrying cargoes prone to liquefaction and make every effort they can to mitigate those risks, he says. “It is the lack of consolidated effort and commitment from many stakeholders to resolve the problem that is evident. These can include shippers, receivers and port state authorities at loading and discharging ports. We need action from those our industry relies upon for its safety — the IMO, legislators, and suppliers to ensure that the minimum obligations under the IMSBC Code are properly fulfilled. The industry is simply talking to itself if we cannot force action from our other stakeholder groups.”

Of course, all this is taking place against the backdrop of an industry striving to

Kostas Gkonis, Secretary General, INTERCARGO.

achieve IMO’s target of zero emission shipping by 2050, and facing a confusing array of MARPOL amendments, circulars, resolutions and guidelines, as they work to achieve this ambition. “You cannot place responsibility for meeting IMO’s zero emission shipping targets fully on the shoulders of shipowners,” warns Gkonis.

“It must be remembered that the commercial development of these solutions is within the control of a spectrum of stakeholders. Such a target requires a drastic and urgently needed acceleration in the commercial development of the required technologies, fuels, propulsion systems and related infrastructure.

“The net-zero target will only be plausible if governments take the necessary action to achieve this at IMO.”

Returning to the Bulk Carrier Casualty Report, INTERCARGO is pleased to also report good news, with statistics of ship losses and consequential seafarer fatalities suggesting that the safety performance of the bulk carrier industry is showing a clear trend of improvement.

“We note positively that these figures continue to head in the right direction,” says Gkonis. “However, there is no room for complacency and we at INTERCARGO will continue to seek further improvement by re-evaluating and implementing enhanced measures to address cargo safety and safe navigation.”

Oldendorff inks a contract with Blue Water for voyage optimization and fleet decarbonization by implementing BOSS after a year-long trial

The largest German bulk carrier company, Oldendorff Carriers, and Indiaheadquartered maritime technology company, Blue Water, announced the official signing of their contract to implement Blue Water’s “BOSS Voyage Optimisation Suite” for Oldendorff’s Cape & Baby Cape fleet of owned and time chartered vessels.

The BOSS Suite will propel Oldendorff’s continuous efforts towards a greener maritime trade by reducing emissions through intelligent voyage optimization, weather routing, vessel performance analysis and efficient fleet management.

Capt. Dexter Jeremiah, Managing Director Operations at Oldendorff, said: “After one year of successful trials, we chose the BOSS Suite for our Cape & Baby Cape Fleet since it met our needs for optimizing voyage operations, whilst enabling us to see real-time CII analytics for the vessels in one platform. The level of customization and development of advance voyage monitoring tools in the BOSS ecosystem with a quick turnaround has been second to none.”

Adding to the announcement, Capt. Kumaresh Gupta, Managing Director at BlueWater, said: “We are elated to have Oldendorff’s Cape & Baby Cape fleet in

BOSS. Throughout the trials, we were presented with challenges to develop certain customized solutions for operational excellence and performance analysis, and the BOSS team turned them into opportunities to further showcase the platform’s customizability, scalability, and an eagerness to make significant changes to suit Oldendorff’s needs.”

About Oldendorff Carriers: since its establishment in 1921, Oldendorff Carriers has grown into one of the world’s leading

dry bulk owners and operators, operating about 700 vessels around the world.

About Blue Water: the company provides a host of Software as Service for voyage optimization including its pioneer cargo heating management for tankers. Blue Water employs 100+ personnel in its Dehradun office and currently optimizes over 700 vessels of various type for maritime industry leaders, and provides quantifiable savings through a verifiable benchmarking system.

Barnacle-laden bulkers: bad for business, bad for CII ratings

For as long as people, products and raw materials have been traversing the oceans, ship hulls have acted as attractive structures for marine life. Biofouling, whether by shell-forming creatures or soft organisms such as slimes and algae, significantly increase the amount of frictional resistance across a ship’s hull when it moves through the water.

Increased frictional resistance requires a ship to burn more fuel to maintain a set speed, or if operating on fixed shaft power or fuel consumption, then speed losses will occur. A 2007-published study by Michael. P. Schultz proclaimed that a vessel with 10% barnacle coverage would need a 36% shaft power increase to maintain the same speed. Put simply, the greater the barnacle fouling coverage, the greater the fuel demand. These are creatures that you do not want on your ship when profit margins are tight.

In June 2020, the results of a study commissioned by I-Tech AB and carried

out by global marine consultants, Safinah revealed the true scale of highly impactful hard biofouling present across the global shipping fleet. A 249-ship sample was surveyed at drydock with their underwater hull condition inspected. The sample spanned all major ship types coated with biocidal and foul release coatings of different grades and generations, covering a wide range of activity and trading routes.

Following the analysis of the hull condition inspection data, it was found that

every vessel surveyed had some level of hard fouling. Troublingly, 44% of vessels surveyed had more than 10% of underwater hard fouling coverage. When looking at the breakdown of fouling by vessel type, it was found that across vessels with relatively lower activity, the frequency of barnacle fouling was greater. On lower activity vessels it was found that 45% of vessels had barnacle fouling coverage greater than 10% compared to just 27% observed across higher activity vessels.

When factoring in data from another Schultz study, published in 2011 that investigated the performance penalty of biofouling, we can assume that levels of barnacle fouling across >10% of the hull surface is present on just under half the global shipping fleet. This means that the global shipping fleet is producing an excess of least 110 million tonnes of carbon emissions per year due to barnacle fouling alone. Furthermore, barnacle fouling on the hulls of ships is estimated to account for an additional US$6 billion spent on fuel per year for the global commercial fleet. The true figure is likely to be even higher, as this is a conservative calculation based fuel prices in 2020 and only assumes a 10% coverage of hard fouling on the fleet.

Since the underwater hull plays a huge role in ship performance, coatings play an equally huge role for a vessel to achieve good Carbon Intensity Indicator (CII) rating. Biofouled hulls, particulary those with any hard fouling, will negate important gains made by installing fuel efficiency enhancing technologies or using cleaner fuels.

The bad news is that the issue of biofouling will only worsen. As we sail further into the future, a greater number of ships will face a higher risk of biofouling creatures and barnacle infestations on the hull and bulk carriers are not immune to this. Any bulk carriers sitting at anchor for a period of a few days, or more are at a great risk of biofouling accumulation. The majority of antifouling coatings rely on a vessel moving through water to function

effectively. So, what happens when a vessel stops? Usually that means that barnacles can attach and accumulate at a rate of knots.

The greatest concentration of biofouling creatures are found in the warmer waters of the tropics and subtropics. Since the 1990s, a shift in global trade has resulted in ships visiting ports in tropical and sub-tropical waters. Furthermore, vessels are spending significant periods of idle time in these ports either loading or unloading or queuing in increasingly congested waiting zones. During this time, they face a high risk of picking up hard fouling organisms.

Therefore, an insurance policy against hard fouling is needed. Since idle periods can hinder the efficacy of biocidal and foul release coatings, most coatings can only offer 14 21 idle days performance guarantees. The development of antifouling coatings that better protect vessels which may sit idle or longer than standard idling

guarantee offered by coatings manufacturers during a three or five year service period is essential, if not vital.

Yesterday’s solution will not work for tomorrow’s problems. This has catalyzed great innovation in the marine coating sector. An increasing number of ship owners are demanding 30-day plus guarantees and for antifouling coating manufacturers, one way that this can be achieved is through the inclusion of the active agent, Selektope®

Selektope® is an organic, non-metal active paint ingredient that is relatively unique compared to traditional biocides currently found in many marine paints. Through natural receptor stimulation, Selektope® activates hyper-mobile behaviour in barnacle larvae, which prevents them from attaching themselves to the hull and niche areas. The effect is temporary while they are in close proximity to the coated surface and ultimately leaves them unharmed. When used in antifouling paints, all ship types can remain idle or at low speeds for extended periods of time, even in extreme barnacle fouling conditions.

Out of the top six marine coatings manufacturers, three of them have commercialized products containing Selektope® in the past five years: Chugoku Marine Paints, Hempel and Jotun. The technology is also being used in many outfitting coating products following demand from shipyards located in South Korea who were facing the issue of barnacle fouling during long fitting out periods.

The use of Selektope® also presents a significant advantage over a reliance on hull-cleaning technologies for hard fouling removal and reduces the risk of coating damage after cleaning. Also, as opposed to the need to constantly monitor hull condition, antifouling coatings with Selektope® confer relative peace of mind to bulker operators that their ship hulls will remain barnacle-free.

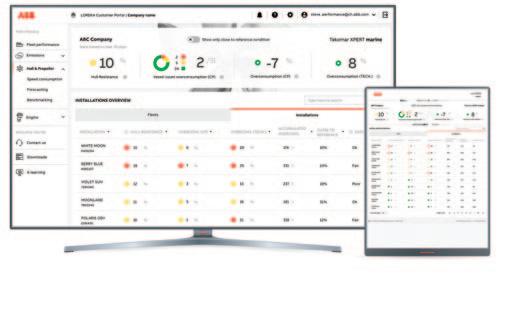

Making vessel operations future ready: Blue Water rolls out BOSS CII Estimator

Blue Water being cognizant of the recent CII developments, has introduced a smart and practical CII Estimator, that allows vessel owners and operators to assess future operational impact on their fleets, and gives them estimates to improve efficiency, optimize CII ratings and help with their decarbonization targets.

Serving as an intrinsic feature of Blue Water’s BOSS Voyage Optimization Suite, the BOSS CII Estimator readily calculates the yearly CII based on multiple parameters using BOSS’ extensive AI & ML assisted vessel digital twins.

HOW BOSS CII ESTIMATOR WORKS

The BOSS CII Estimator simulates hundreds of trading patterns at a flick of button to estimate how the operational parameters will impact the vessels’ CII rating. Further, it answers the following most commonly sought questions by vessel owners and operators:

What is the vessel’s current CIIv rating?

What will be the impact of CO2v emissions on the current CII rating due to the future trade pattern? How to identify the most suitablev trading pattern for better CII ratings? How to determine the optimumv speed instructions for a vessel for a certain trade route?

BOSS CII ESTIMATOR FEATURES

2,000 Simulations at an Instant:v Considering 100 Cape Vessels in a fleet, simulating all Baltic route combinations for eco and full speed at both laden and ballast conditions would have taken 2000 simulations. BOSS CII Estimator dramatically cuts this down to one click & one second.

Supports Vessel Specific Balticv Routes: Computes vessel class specific Baltic Routes at a click of button, and generates the estimated CO2 emissions and corresponding CII rating.

Estimations basis Vessel’sv Performance: Uses vessel’s past data or sensor data to generate a digital twin and provide realistic estimations. Estimations basis Vessel’s SnC datav Draft and Load Condition Specificv Simulations

Dynamic Sea Margin: The estimatorv does not only consider a standard sea margin for simulation, but also provides an option to use historical weather data to calculate sea margin.

Vessel Specific Retardation Factors:v Apart from Sea Margin, the BOSS CII estimator also takes in vessel class specific weather and sea retardation factors to compute speed and emissions details, giving a much

transparent and practical estimates.

Determine Optimum Speed &v Trading Pattern: On simulating the different trading routes, BOSS CII estimator suggests optimum speed and trading pattern to optimize CII rating of vessels.

Fuel Specific Calculations:v Calculates CO2 emissions based on fuel type usage.

Interactive UI: Removes the need forv both tedious excel sheets and evaluating results on multiple routes. Instead, an interactive interface provides a much simpler way to conduct route and speed comparisons.

Share Simulation Reports: BOSS CIIv estimator lets the user easily export and share simulation details with anyone.

ABOUT BLUE WATER

The company provides a host of Software as Service for voyage optimization including its pioneer cargo heating management for tankers. Blue Water employs 100+ personnel in its Dehradun office and currently optimizes over 700 vessels of various type for maritime industry leaders, and provides quantifiable savings through a verifiable benchmarking system.

ABB and shipping company Wallenius Marine have introduced OVERSEA — the maritime industry’s first digital offering and fleet support center available as a service. The two companies have developed OVERSEA to help ship owners, operators and managers enhance the efficiency and sustainability of vessel operations.

OVERSEA leverages ABB’s extensive expertise in ship technologies and the ABB Ability™ Genix Industrial Analytics and AI suite, combined with fleet management knowledge from Wallenius Marine, to enable measurable performance improvements for vessels, leading to decreased fuel consumption and reduced emissions.

OVERSEA helps address such aspects of vessel performance as hull and machinery, speed and route planning, as well as emissions and carbon intensity reporting. With deeper insights into vessel’s

operational data, backed by advanced analytics, OVERSEA centre experts will be able to recommend concrete actions to shipping companies to help them improve energy efficiency, safety and reliability of operations.

OVERSEA is scalable to meet the various and ever-changing needs of shipping companies. With OVERSEA digital solution, shipping companies with in-house fleet support centres can collaborate on the same data with vessels and onshore office to get insights, provide recommendations and manage improve ment actions. In addition, shipping companies in need of further support can rely on the assistance of OVERSEA center experts for daily advice, periodic performance reviews and reporting, and on-demand performance consulting.

“We talk a lot about innovations that will make us more sustainable in the future,

and OVERSEA makes a real difference already today. From our experience, we know that the operation of a vessel has a deep impact on released emissions and fuel consumption,” said Johan Mattsson, CEO, Wallenius Marine. “With clear recom mendations to the crew, based on datadriven analysis, vessel owners and operators are able to significantly reduce both their environmental footprint and fuel cost.

“ABB is committed to driving shipping decarbonization, and OVERSEA has been developed to further support this target,” said Jyri Jusslin, Head of Service, ABB Marine & Ports. “OVERSEA allows turning insights into actions that can significantly improve the efficiency and sustainability of vessel operations. We are confident that this pioneering innovation will serve as a new standard in fleet and vessel performance optimization.”

ABB and Wallenius Marine introduce pioneering digital offering driving efficiency gains for ships

Rivertrace launches SMART VISCO sensor for Main Engines

Rivertrace, an ISO9001 Quality-Assured Company and market leader with over 30 years of experience developing environmental monitoring solutions for the marine market, launched its innovative SMART VISCO sensor at the SMM Maritime Fair, which was held in early September in Hamburg, Germany.

The SMART VISCO sensor is designed to measure the viscosity and temperature of fuel oil before injection into the main engines of large ships. The monitor then reports this data via both analogue and digital outputs, with volt-free relay contacts.

The SMART VISCO sensor measures all grades of HFO using ultrasonic guided wave technology. Due to the high frequency and speed of ultrasound, ambient vibration and flow speed have no impact on the measurements. The monitor incorporates an LCD display that visually indicates all parameters. The viscosity and temperature data can also be easily retrieved using RS485 or a USB stick.

The fuel oil’s viscosity provides a direct indication of its impact on engine performance and efficiency. The availability of this information aid in the prevention of engine damage, reduces maintenance costs, and helps to minimize greenhouse gas emissions.

This SMART VISCO, with its digital capabilities can be integrated with the RIVERTRACE CONNECTED service to collect and share the data with ship management to monitor and analyse trends in fuel performance at both a vessel and fleet level.

The RIVERTRACE CONNECTED service initiative provides calibration compliance and equipment performance data. It can either be viewed on a cloud platform or shared through an API to the vessel/fleet management systems. The digital service is designed to support customers seeking simplified, continuous monitoring and efficient operations.

Martin Saunders, Managing Director of Rivertrace, says: “Monitoring environ

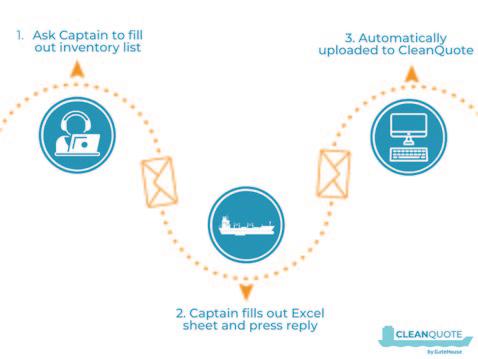

Stellium and Voyager Portal announce partnership

DIGITAL TRANSFORMATION, PARTNERSHIPS, SUPPLY CHAIN, VOYAGER

Stellium and Voyager Portal have announced a first of its kind partnership to bring a fully integrated SAP TM and Bulk shipping operations platform to global markets.

Until now, Transportation Management solutions have struggled to handle the nuances and complexities of global bulk commodity shipping. Instead, TM solutions have been focused on helping businesses manage rail, truck and container freight operations.