PRODUCT ROUNDUPS

The 2023 outlook for the construction industry is optimistic, especially for the adoption of construction technology products.

Contractors, dealers, construction and mining company leaders and others – thank you all for being dedicated readers of Equipment Today throughout 2022, a time of great change for this publication. Whether you celebrated 2023 by setting up new projects and buttoning up 2022 invoices, watching the ball drop in Times Square, swigging champagne with friends or cozying up with loved ones, I hope the start to 2023 is a positive one. As we launch into 2023, providing our readers with what we believe are the best professional resources possible—don’t miss the Attachment Guide on pages 24 through 33—we are keeping our outlooks as optimistic and productive as we think our readers’ resolutions will be in the new year.

Speaking of optimism, if you have not listened to one of our latest Digging Deeper podcasts on ForConstructionPros.com, led by Concrete Contractor editor Jonathan Kozlowski, who interviewed Ron Stupi of Bureau Veritas, you’re in for a treat. Stupi is the senior vice president at the North American Division of Building and Infrastructure at Bureau Veritas, and the podcast looks ahead to 2023 building and infrastructure trends.

In summary, Stupi notes that society at large may not yet have flying cars, as predicted by movies like “Back to the Future” and “Bladerunner,” but we have drones and robots to make construction work easier. Specifically, inspecting bridge cables, high pole masts in parking lots or cell phone towers in agricultural fields, drones and robots—like a rebartying robot we recently featured in the pages of Equipment Today—can make the work faster and safer. Human inspections, prone to error, can be tedious and dangerous, Stupi said, and disruptive of traffic and everyday lives.

Hear more of Kozlowski and Stupi’s conversation on ForConstructionPros.com by navigating to the “Podcasts” tab, clicking on the “Digging Deeper” podcast, and hitting the “Play” button on “Construction Building and Infrastructure Trends for 2023.” Enjoy!

Investing in the right construction technology also topped the list of our recent “2023 New Year’s Resolutions for the Construction Industry” piece by content director Jessica Lombardo, proving that drones, robots, 3D paving, telematics and other construction technology (or ConTech) are vital for the industry’s advancement.

“Executing world-class performance requires contractors to continuously innovate,” Lombardo wrote in a recent article on ForConstructionPros.com, “and new technology to help construction contractors do their jobs faster and more efficiently is emerging every day."

Adding to the ConTech arsenal, IRONPROS, our powerhouse construction equipment, products, workwear and technology website and customer-centric database, now has a ConTech Solution Finder. Meet ConTech, or Connie for short, on the IronPros.com website! The little robot guides site visitors through a survey designed to pull lists of products from registered IRONPROS manufacturer profiles that best fit users’ needs, from fleet management to labor and communication needs. As tough and dirty of a job as construction can sometimes be, Connie is an awfully cute and efficient way to find the tech your company may need. Whether it is Building Information Modeling (BIM), employee time tracking or fleet and asset management software that you seek, ConTech is on a meteoric rise in 2023. The rise of ConTech is unsurprising, given the growth of connected jobsites and increased access to broadband spectrum Internet. However, where Equipment Today and our sister publications have a leg up is in the analysis of the actual usefulness of these technologies. Our technology editor, Charles Rathmann, recently noted three major ConTech predictions for 2023, including interoperability of technologies, or ease of integration with other contractors’ and vendors’ technologies: “Because construction projects are typically executed not by a single corporate entity but by several—owners, generals, subcontractors and other vendors—processes critical to success must be handed off seamlessly between different organizations,” Rathmann wrote in an article on IronPros. com. “This means requests for information, change orders, applications for payment, certificates of insurance, workin-progress (WIP) reporting, lien waivers, amendments to contract terms and more are all making the transition in many projects into multi-company digital workflows.”

Construction worksites have always been multi-company projects, as Rathmann pointed out. It is high time to make them digitally well-integrated for the best process efficiencies. Keep an eye out for more user-friendly, versatile ConTech solution recommendations in these pages into 2023 and beyond. Cheers to technology health, wealth and worksite happiness in the new year!

Read more at: https://eqtoday.co/BGJan23

Charles Rathmann crathmann@acbusinessmedia.com

Get the groundwork right with the Kubota construction lineup. Reliable, comfortable track loaders. Productivity-boosting skid steers. Powerful wheel loaders. Heavy-duty utility vehicles. All built around dependable Kubota engines. It’s equipment built the right way. So you can build your reputation. Come visit us at ConExpo Booth #W40545.

© Kubota Tractor Corporation, 2023. This material is for descriptive purposes only. Kubota disclaims all representations and warranties, express or implied, or any liability from the use of this material. For complete warranty, safety and product information, consult your local Kubota dealer. For the complete disclaimer, go to KubotaUSA.com/disclaimers and see the posted disclaimer.

Construction Lineup Durable Kubota engines Upgraded tech & featuresTo strengthen its four-axle all-terrain crane line-up, Manitowoc has unveiled the Grove GMK4070L at bauma 2022 in Munich, Germany. At its full 60 m, the crane will be able to lift 4.4 t, while at 49 m owners will be capable of picking loads of up to 8.3 t. When working at its maximum radius of 46 m, the GMK4070L will lift 1 t.

The GMK4070L will be one of the first Manitowoc cranes to offer the new Grove CONNECTTM digital platform that provides owners with real-time access to fleet data. Through Grove CONNECTTM, fleet managers can get insights into the crane’s performance with just a couple of taps on a screen.

Read More at https://eqtoday.co/GMK4070L

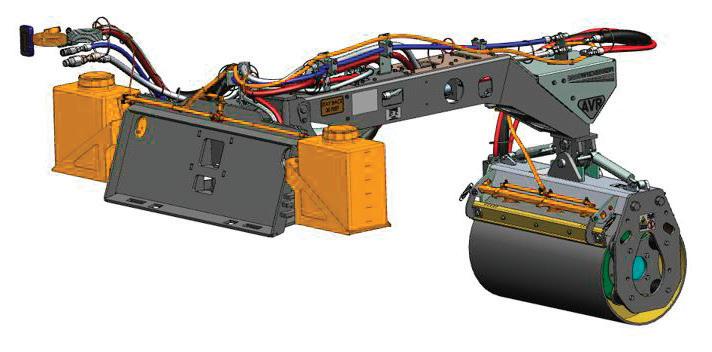

Ammann has unveiled the eARX 26-2 Light Tandem Roller for construction projects. The roller features a fully electric drive that can operate for 18 hours or longer without recharging. The absence of a combustion engine makes the eARX 26-2 quiet during operation. Sound levels reaching the operation station are 46% less compared to the diesel version. The powertrain concept eliminates almost all hydraulic components. Standard features, in addition to the electric drive, are the roller’s design, drum construction, operator platform and engine compartment.

Read More at https://eqtoday.co/eARX262

The upgraded model of the GRT8100 will be available from 2023 and offers a series of improvements over the original version. Many of the enhancements stem from a new chassis that shares commonality with the chassis from the 120 t capacity GRT8120. There’s also an updated engine and transmission package and a new, wider cab with enhanced operating features. The 100 t (100 USt) capacity GRT8100-1 features the same 360° load charts as its predecessor. It also maintains the same overall dimensions, counterweight and five-section, 12 - 47 m (39.2 to 154.3-ft.) full-power MEGAFORM boom. However, with the new chassis on the GRT8100-1 customers have the option to integrate the flexible MAXbase variable position outrigger system, which offers up to 15% capacity improvements in certain configurations.

Read More at https://eqtoday.co/GRT81001

Bobcat's E19e compact excavator offers a compact footprint, quiet operation and zero emissions. The electrical motors deliver full torque regardless of rpm, hydraulic control and multifunctioning performance with minimal power drop. Like the E10e and the E32e, the E19e offers a run time of four hours of continuous operation on its lithium-ion battery pack. It charges with a standard 120-volt outlet, requiring eight hours to fully charge. https://rnt.news/lhwj2m

Read More at https://eqtoday.co/E19e

Toro's 2500 Electric Ultra Buggy features a compact design, zero emissions, zero-turn-radius steering, full recharge in eight hours with a 120-v wall outlet and hauling capabilities of up to 2,500 lbs. of material. Featuring a narrow width of 31.5 in., the electric Ultra Buggy can fit through a 3-ft. door with a crash bar. Built to be versatile and agile, it’s equipped with a fold-up platform so operators can choose to stand on or walk behind the unit. The fold-up platform serves a second purpose, as well, allowing the unit to fit inside elevators or on trailers for easy transport. The polyethylene tub has an increased thickness of 3/8 in., allowing operators to haul more than just concrete, and a steel tub is also available for applications that require it.

Read More at https://eqtoday.co/e2500buggy

The Volvo offers the EC200E 20-ton excavator for large-scale building and land projects. Designed for light- to medium-duty digging, its maximum digging reach is 32-ft. 9-in. with a maximum digging depth of 22-ft. 3-in. The excavator has a lifting capacity of 16,138-lbs. It also supports a variety of attachments and is equipped for quick couplers. Its size, versatility and price point make the Volvo EC200E excavator ideal for rental.

Read More at https://eqtoday.co/EC200E

The Felling Trailers’ Utility Cable Reel “R” series model lines have been modified to increase operator safety and ease of use. An update to the model design is the auto-locking reel bar system. The auto-locking reel bar system eliminates the use of pins and brackets; it now utilizes a locking plate system. The R series product line offers payload capacities ranging from 1,740 pounds to 13,520 pounds. All models have the capability to load up to a 120-in. diameter reel. The auto-locking reel bar system's locking plates automatically open when lowering the reel to the ground for unloading. As the reel is loaded and raised, the locking plates automatically close to contain the reel bar. Once the reel is raised to transport position, spring-loaded pins automatically lock the slides into place. When the pins lock, they provide visual validation to the operator that the reel is properly locked for transport.

Read More at https://eqtoday.co/RSeries

Streamlight has launched several new portable lighting solutions, which are wireless and enable mobility while conducting a wide range of tasks, including inspections, equipment installations, work in industrial shops and operating heavy machinery.

The Dualie 3AA Color Rite is an intrinsically safe work light that provides the option of bright, white light to illuminate large areas.

The Syclone Jr. Streamlight’s smallest multi-function work light.

The ProTac 2.0 and the ProTac 2.0 Headlamp are rechargeable lights powered by Streamlight’s SL-B50 USB Li-Ion battery pack that charges via USB-C cord inside or outside of the light. Both are dust tight and water resistant.

Read More at https://eqtoday.co/streamlightlamps

has expanded its truck body line-up with the introduction of the new Contractor Body. Designed with today’s contractors in mind, the Contractor Body reflects Reading Truck’s commitment to innovation, manufacturing and customer needs. Reading Truck’s new Contractor body comes equipped with many features, including A60 steel construction, e-coat primer and powder coat finish. Available in 10 ft. and 12 ft. lengths, the Contractor Body is built upon Reading’s heavy-duty platform body and includes standard features like a fork truck loadable material rack, 12 gauge hot-rolled deck plate, moveable tailboard for different space configurations with 17 in. fold-down rails and signature tool boxes (among others). The Contractor Body also addresses the safety of operators with LED lighting.

Read More at https://eqtoday.co/readingcontractor

The DiamaPro Systems DX26-P is a gear-driven, propane-powered concrete floor grinder engineered with the operator in mind. It is user-friendly and can handle the most demanding grinding jobs. The DX26-P is the perfect grinder for prep, removal, and concrete polishing.

Heavy duty gearbox Easy folding weights with secure locks Foldable handle for easy, compact transportation LED Lighting Transportation wheel Magnetic tool plates Velcro tool holders

Read More at https://eqtoday.co/DX26P

Doosan DX140W-7, DX190W-7 and DX210W-7

Doosan has introduced its next-generation, 7-series wheel excavators: the Doosan DX140W-7, DX190W-7 and DX210W-7. The “dash 7” excavators replace the “dash 5” models in the Doosan excavator lineup.

DOOSAN 7-SERIES

DX140W-7

Horsepower: 137-hp (102 kW) at 2000 rpm

Maximum digging depth: 14-ft. 8-in. (4.5 m) DX190W-7

Horsepower: 159.6-hp (119 kW) at 1900 rpm

Maximum digging depth: 18-ft. 9-in. (6 m) DX210W-7

Horsepower: 171.2-hp (127.7 kW) at 1900 rpm

Maximum digging depth: 19-ft. 4-in. (5.9 m)

Read More at https://eqtoday.co/Doosan7Series

Vermeer has introduced a redesigned version of the HG4000 horizontal grinder. This new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production. It’s equipped with a 536-hp (399.7 kW) CAT C13B T4F Stage V diesel engine, a Series III duplex drum, an infeed to accommodate a variety of materials and many performance and durability features. It has a working sound level of 112 decibels. The HG4000 has a feed table capacity of 4.6-cu. yd. (3.5 m3).

Read More at https://eqtoday.co/HG4000

Roads are so intrinsic to the American way of life that our vernacular comprises thousands of road-referencing phrases, idioms, musical lyrics and jokes:

“Every day is a winding road.” –Sheryl Crowe

“The road to hell is paved with good intentions.”

And one of my personal favorites:

“Take the high road.”

Roads, streets, paths, trails and tracks all evoke a sense of progress, and that forward movement can be wandering or purposeful. Whether emphasizing the journey of life or a path toward a noble goal or inevitable downfall, roads are a vital part of both the American infrastructure and vocabulary. It’s no wonder the need for roadbuilding and connectivity go hand in hand. However, since we’re reflecting on word choice and vocabulary, the word “connectivity” begs further inquiry.

The term “connectivity” can refer to broadband Internet and its vital importance to the infrastructure of the United States, as well as connected construction jobsites via the aforementioned broadband Internet, smart roads with LiDAR cameras, roadbuilding equipment with updated sensors to determine and guide proper compaction pressure and techniques, and machine manufacturing processes that reduce carbon footprints for maximum efficiency and productivity. These are all key pieces of the puzzle that add up to an overarching, desirable image—a well-connected map of maintained roads and transportation solutions throughout the country.

With advancements in AI and 5G network connectivity, smart-road infrastructure technology offers the promise of being added to many different roads, bridges and other transit systems across the U.S., in hopes of improving real-time traffic analytics and tackling the most challenging road safety and traffic management problems, Georges Auode, CEO and co-founder of Derq, recently wrote in an expert column that appeared in the August 2022 issue of Equipment Today Road connectivity extends to the machinery used to build it, as well. All integrations and equipment — from wireless to wired to steel — must work together to make roads the best they can be in the coming years. There is no royal road to learning.

Connectivity a Top Trend for the Construction Industry’s Future AI and connectivity, along with renewable energy and alternative fuels, will dramatically impact the construction jobsite in the next 10 years, according to a recent whitepaper published by the Association of Equipment Manufacturers (AEM).

As jobsites become more connected, contractors and construction companies gather thousands of data points for later use. These data points could be monetized and shared with others outside the industry for even greater good and connectivity, according to AEM. From weather mapping with cloud-based systems to wearables detecting when people take falls, the bright future of construction site technology that AEM details in its latest whitepaper suggests more than just contractors and operators can benefit from data collection and interconnectivity.

Simply put, due to more advanced 5G networks and cloud systems, connectivity on the jobsite will improve significantly in the next decade, according to AEM’s data and projections. Better

While drivers are well-versed in traffic signals and signs alerting them to when they should or should not drive their vehicle, AVs need different alerts in the form of radio or cellular network signals.

equipment tracking will allow real-time visibility into productivity and maintenance on a jobsite, so operators and contractors can make sure they queue properly and have the most efficient job flow they can, said Ray Gallant, Volvo vice president of product management and productivity region, at an AEM webinar in September 2022.

This increased connectivity has significant implications for the future of roadbuilding, from possible, monetizable data point collection to vigilant planning of safer roads. Let’s get this show on the road.

A significant part of President Joe Biden's infrastructure plan, the Infrastructure Investment and Jobs Act (IIJA), deals with evolving transportation and roadways with smart infrastructure, which includes Vision Zero. Vision Zero is one of the newer strategies looking to eliminate deaths and severe injuries due to road traffic and unsafe infrastructure. First successfully implemented in parts of Europe, the strategy recently gained traction in North American cities.

Collaborations are integral between traffic planners, engineers, and policy makers alike in the Vision Zero strategy. Committing to Vision Zero means unlearning old ways of the roads and making room for new strategies to better the transportation infrastructure, according to Auode. This means that system designers and policy makers are expected to improve the roadway environment and policies in addition to other related systems in order to dramatically lessen the severity of crashes.

Advanced technologies including video analytics solutions use artificial intelligence (AI) and machine learning approaches to analyze large quantities of video streams in realtime to then provide actionable insights on complex traffic situations including road hazards, congestion and traffic collisions. For example, companies like Waycare, Derq and Applied Information provide software that analyzes behavioral patterns of vehicles, pedestrians and traffic flows from existing traffic infrastructure in real-time to identify and predict potential road incidents. These advanced video analytics can then activate a pedestrian blinking sign to alert a distracted driver from colliding with a pedestrian. They can also alert a city operator so emergency responders can be dispatched to the location of the incident if a collision is detected. Furthermore, real-time AI analytics provide additional context in the form of incident identification, near-miss heatmaps and accurate traffic counts to traffic engineers and operators, allowing them to better understand traffic patterns and proactively improve the safety of roads.

In Miami-Dade County, the autonomous vehicle research team at Ford is exploring how emerging technology from smart infrastructure can provide additional information to an autonomous vehicle (AV) before it even arrives at an intersection, Auode wrote in a 2021 ForConstructionPros. com column. While many cities have different types of traffic signals — horizontal, vertical, posted in the corner of the intersection as opposed to in the middle of the intersection — AI algorithms unite smart infrastructure with AVs, which enable the launch of these vehicles in new locations much faster. In Las Vegas, Motional’s driverless vehicles are partnering with Derq to test how driverless technology reacts when given an even broader perspective than it already has. The collaboration has created a bird’s-eye view for the AVs at some of the most highlytrafficked intersections in the city.

The focus on technology should not be isolated to the car itself, but also in upgrading the actual road infrastructure, according to Auode. State-of-the-art artificial intelligence (AI) to advance smart infrastructure will not only help driverless vehicles understand the roads better, but also improve overall road safety as AVs are not equipped to see around corners or other impediments. With smart infrastructure now being introduced by AI startup companies such as Derq, having those “eyes” outside of the vehicle also allows for greater visibility overall — making the ride not only safer, but more comfortable and with even better performance. This will also result in less-congested roads. For an average U.S. citizen, congestion costs 99 hours

of their time and $1,377 each year, according to a Global Traffic Scorecard report published by INRIX in 2019. Smart infrastructure can prevent traffic backups by adjusting traffic signals when needed.

While some self-driving companies currently don’t rely on smart infrastructure, the AV industry is realizing that it’s an important piece of the puzzle when it comes to accelerating the ability to deploy more AV routes in different cities and countries. In addition, transportation systems can’t achieve safety without smart infrastructure. The need for innovative technology on the roads is growing. Autonomous vehicles have become an increasingly popular topic among transportation committees and vehicle experts on a federal level. U.S. Secretary of Transportation Pete Buttigieg has even stressed the importance of building better infrastructure, as well as technology, for self-driving cars.

The incorporation of AI and video analytics in smart roads will further the development of the technology of driverless vehicles. These innovations will also revolutionize the safety, comfort and performance of not only the autonomous vehicles, but also the overall transportation ecosystem. Now, where the rubber meets the road—ensuring the roads themselves get built safely and efficiently with high-tech equipment and connected jobsites.

Smarter Equipment and Jobsites

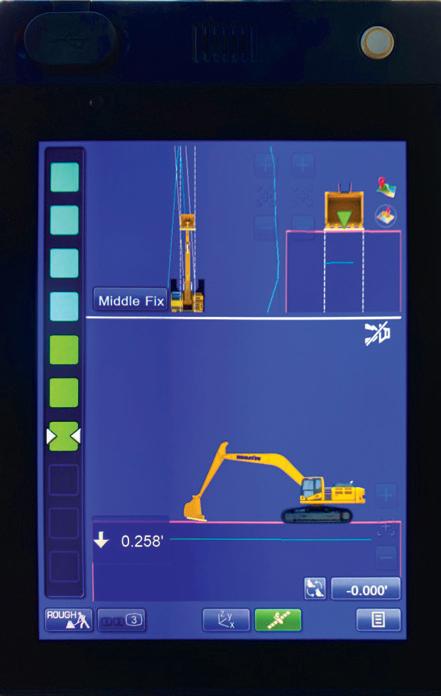

In North America, competitive bidding of projects is becoming increasingly dependent on being able to guarantee a road surface meets stringent specifications for smoothness or compaction, and contractors are further incentivized by bonuses for meeting these specs — and doing so in as little time as possible. In this way, the market itself is pushing the adoption of technologies like intelligent compaction, digital jobsites and networked equipment and employees.

Another market pressure is the labor shortage. Contractors are attempting to meet these specs and earn these bonuses with a smaller available workforce to pick from. For some crews these digital efficiencies become the difference between being able to get a job done or not.

And though some North American contractors are not eager to adopt electric machines yet, fuel consumption is still top of mind. There is no better illustration of the adage, “Time is money,” than a roller having to do more passes than is necessary.

Making fewer roller passes is not the only way to save fuel, and BOMAG is aware of this fact. After all, the company does have two small batteryelectric rollers in the lineup and offers the BW 174 hybrid roller. When you

become more efficient in your process, you use less fuel; there is much efficiency to be gained.

In fact, BOMAG pavers vice president and current North American head Marco Faulhaber said he has seen a trend of compactor operators who over-compact out of fear of not compacting the surface enough. For some contractors, the rate of overcompaction could be as high as 50%.

“Imagine if I could cut my fuel consumption on a compactor by 50% just by making sure that my operator knows exactly when to stop,” Faulhaber said.

In that way, Faulhaber said the machine and the efficiencies BOMAG has created on the machine itself is a bridge to finding more efficiencies through jobsite connectivity and broader networking throughout the operation. Implementing technology to make road construction work more efficiently and accurately is nothing new to BOMAG. The company introduced its intelligent compaction solution Asphalt Manager all the way back in 2001.

“So far this work has been focused mostly on the machine. The next step, of course, is to start linking machines and make sure that the total outcome is what you need,” Faulhaber said. “Those digital solutions, when you start linking the jobsite together, improves the overall efficiency of the jobsite, the quality of the job that is being built and improves the efficiency greatly.”

When machine control technology is paired with a digital jobsite and a networking of all the processes, “I control my quality throughout the job,” Faulhaber said. That line of thinking is fueling the questions and problems

the company is trying to answer and solve with the networking technology it is currently developing. Faulhaber asked rhetorically, “So, how do you create this level of confidence, so that the contractor knows that his crew is up for any job, no matter what happens? What kind of support can the machine manufacturer provide the machine application experts with, beyond the digital job tools we have and easy-to-operate machines, so that at the end, you get the best out of the road that you possibly can?”

Building upon the company’s machine control offerings is the chosen path. The company is exploring autonomous roller technology and has displayed cabless rollers at a few trade shows. But at bauma 2022 the real focus was on networking people and machines.

At its booth in Munich, BOMAG had a entire room dedicated to the digital road jobsite of the nearfuture, complete with scale models and several displays. In that room, the company brought in scores of customers to discuss what they are seeing on their jobsites and to see how BOMAG’s vision for connected jobsites matches up.

BOMAG’s vision of connectivity includes ensuring that the key jobsite data is dispersed throughout the jobsite. Rather than one supervisor managing a dashboard of all the various digital touch points, BOMAG wants to equip every operator, driver and employee with that dashboard

Central Hall -- C5176

Las Vegas Convention Center January 17-19, 2023

Central Hall -- C30280

Las Vegas Convention Center March 14-18, 2023

via a tablet, smartphone or their in-cab display. The idea is that if you arm each and every individual with the information they need to do the best job they can, the strength and efficiency of the jobsite as a whole will increase. In short, the sum will be greater than its parts, but a sum dependent on those parts nonetheless.

If the road, street or adjacent sidewalk is made out of concrete rather than asphalt, connected jobsites and equipment also exist to aid in the efficient and safe production of concrete pathways.

Soracom, Inc., a global provider of advanced IoT connectivity, has partnered with EXACT Technology Corp., a concrete monitoring technology company, to help build future infrastructure projects.

The first seven days of the concrete curing process are critical. The temperature of the concrete needs to be maintained consistently throughout the weeklong period, otherwise it has the potential to crack, letting in salt and water, and compromising the longevity of the concrete. EXACT’s technology checks for temperature fluctuations in real time, collecting data and alerting project managers via Soracom’s connectivity solutions.

Access to this real-time data allows project managers to adjust accordingly by heating or cooling sections

of the concrete as needed. Properly managing the curing process means infrastructure projects can last up to 125 years without remediation, while projects not properly cured may last only half that time.

On the equipment side, all GOMACO pavers have the most up to date G+ control system and GOMACO Remote Diagnostics (GRD), both of which allow GOMACO to communicate with pavers remotely. The GOMACO Navigator software consolidates all the G+ paver accessories, allowing pavers to communicate with each other while on the same jobsite.

Additionally, sensors on the jobsite, from safety backup sensors for rollers and equipment to wearables that help detect worker jolts and falls, will proliferate in the next decade, according to AEM.

“It starts with understanding what’s going on, on the site and that’s where sensors really came into it. There already are a number of Internetconnected devices — sensors on the machines that are feeding information all the time,” Gallant said. “Our problem has not been getting the information. It’s been how we use it, how to consolidate it and how we use it smartly. And that’s, I think, the next big frontier here…We get better and better at controlling the sites and helping the operators be better, more efficient, more sustainable operators.”

Better insight into jobsite safety will ensure proper construction, according to Gallant and AEM, keeping the future of roads on the right track.

As Faulhaber put it during a discussion at bauma in Munich, Germany, the path to more sustainable road construction does not pass through the engine — or battery — compartment. While much of the focus around sustainability and construction focuses on the emissions of construction equipment, the majority of roadbuilding’s carbon footprint lies in the production and transportation of asphalt and concrete.

The company believes that type of digital optimization can be effectively expanded beyond the roller and surface to not only the jobsite as a whole, but to every step of the roadbuilding process, including production and transport. Ultimately, these greater efficiencies won’t just reduce the industry’s carbon footprint but will also ease the difficulty contractors face in finding enough skilled workers.

The company envisions fully networked and connected jobsites for the roads of the future and is dedicated to pushing the industry forward through the promotion of these connected jobsites and networking tools.

But beyond the need for solutions to decrease carbon emissions that are

optimized and designed specifically road building, BOMAG tempers this work with feedback from customers. And those conversations differ greatly depending on where in the world the feedback is coming from.

In Europe Faulhaber says they do hear from more contractors who name reducing carbon footprint as a core goal of their business. That sentiment isn’t held nearly as widely among contractors in North America, where Faulhaber suspects legislation will be the key driver in the industry’s move toward more sustainable fuels such as electric- or hydrogen-powered equipment.

Which points us right back to why optimizing the production and transportation of materials, and making the actual installation of the asphalt or concrete surface more efficient is the best focus for BOMAG and its peers in the industry. While there is little global agreement on the viability of zero-emissions equipment with the current state of charging infrastructure, battery technology and hydrogen fuel technology in general, process optimizations are hard for anyone to argue with.

Read more at: https://eqtoday.co/roadconnectivity

“Eyes” outside the vehicle allow for greater visibility overall, making the ride not only safer, but more comfortable and better performing.

Our distributors are authorized to put a new Gorman-Rupp engine-driven contractor’s pump alongside any other pump of the same size, type and horsepower, anytime, anywhere. Our pumps will work harder, faster and smarter, ensuring optimal uptime. If within 30 days of purchase, it isn’t the best all-around pump, our distributor will accept the return of the Gorman-Rupp pump and offer a full refund. Guaranteed.

Hitachi's Tier 4 Final excavator line, which includes the ZX250LC-6, ZX350LC-6 and ZX380LC-6, is designed for work in cold weather operations with its fuel recirculation system, which prevents fuel from gelling in the main filter by circulating warm return fuel back to the main fuel filter, rather than to the fuel tank.

• Isuzu engine with cooled exhaust gas recirculation (EGR), a diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR)

• ZX250LC-6 offers 177 hp; ZX350LC-6 and ZX380LC-6 offer 271 hp

• DEF lines encapsulated by lines filled with engine coolant to defrost DEF

• Grade reference ready option - Topcon, Trimble or Leica

• Programmable attachment modes, including thumb

• Standard upper-structure handrails for added safety and accessibility

Simplified daily and periodic maintenance thanks to features like single-side groundlevel filters and a battery disconnect switch

• ZXLink system provides access to fleet location, functions, hours, fuel consumption, alerts and other essential machine data

The battery-powered 9VXB electric miniexcavator comes standard with all the features found on the diesel excavator models. It combines a no-emission motor with other standard features such as the spanner function (27.5- to 37.5-in. variable width) and auxiliary hydraulic piping to the front of the unit.

• 8-hour run time on full charge

• 360° house swing with independent 140° boom swing

• 4-gpm hydraulic flow

• 5-ft. 2-in. dig depth

• 2,375-lb. operating weight

• Two-speed travel

Volvo Construction Equipment has upgraded its zero-emissions, lownoise L20 and L25 Electric compact wheel loaders by increasing the maximum speed to 12.4 mph (20 km/h), adding the option to fit a parallel linkage that delivers high breakout torque in various applications, additional operator features and improving charging. Operators in colder climates will appreciate the new programmable cab heater option, which allows them to easily choose the times and days of the week when they would like to arrive in a prewarmed and defrosted cab. Operator comfort is also upgraded thanks to a more ergonomic joystick with the latest design on the market. A new electric parking brake supports uptime with hill-hold functionality: a convenient automatic feature for operators working on inclines or rough terrain. And because the disc brake in the former model is now replaced by a spring-applied and hydraulic-released wet-disc brake, related maintenance requirements are removed. The time it takes to achieve a full charge from zero is only six hours with the 6 kW on-board charger if used with a 240V socket or Level 2 public charging station. Speedier charging is available with optional off-board DC fast chargers at 11.5 kW or 17.3 kW

The 100-ton EC950F features improved hydraulics to deliver constant high pressures across each phase of the digging and lifting cycle.

• 603-hp Volvo D16 Tier 4 Final engine with ECO mode

• Electrohydraulic system controls on-demand flow and reduces internal losses in the hydraulic circuit Boom-swing priority valve adjusts priority of hydraulic flow between boom-up and swing

• Integrated work mode allows operators to select from Idle, Fine, General and Heavy modes

• Attachment management system can store settings for up to 20 attachments

• Includes a retractable undercarriage, Dig Assist and rear view camera

Komatsu has launched XT-5 tracked harvesters for forestry applications. With this machine, operators can harvest close to the carrier and maneuver around the site thanks to a low center of gravity and off-set boom.

Made to perform in demanding conditions, Komatsu’s XT-5 closed loop tracked harvesters enable operators to simultaneously travel, cut, delimb, harvest and swing timber. Engineered with hydraulic lines for each function, operators can use tracks, boom, arm and tools concurrently.

• Heavy-duty lift capacity

• 10% more horsepower

• 16% more torque

5% lower fuel consumption

• Supports uptime and serviceability

The short-tail swing of Komatsu’s 331 hp harvesters lets operators work through dense forests and clear-cutting environments. The set-back boom allows cutting close to the undercarriage and tracks, while the swing torque excels in demanding applications. With balance between boom lift and arm holding capacity, the XT-5 harvesters can be equipped with a wide selection of harvesting saw heads.

With the XT-5 harvesters, you can save on maintenance costs because the hydraulic tank system design requires 55% less hydraulic oil. Pumps are equipped with hydro-nucleation to help prevent pump cavitation and are 17% larger to help extend component life by operating 500 rpms slower. The engine gull-wing and wide swing-out doors on the XT-5 harvesters offer access to all engine service points and all key components.

The 78,709-lbs. Link-Belt 355 X4S minimum swing radius excavator has a maximum digging depth of 22 ft. 10 in., maximum reach at ground level of 34 ft. 8 in. and a bucket digging force of 39,340 lbf. An Isuzu AQ-6HK1X 6-cyl., Tier 4 engine produces 205 net hp at 1,800 rpm. Four work modes offer varying levels of selectable rpm settings. The new Eco mode maximizes fuel economy and the new Lifting mode ensures power boost is always on during lower rpm crane tasks. The fullsize cab offers more room and comfort, a high-back air suspension seat, improved cab layout and a 10-in. LCD monitor. Two high-resolution cameras are standard with the optional WAVES camera system providing a 270° view around the machine.

Whether they’re loved or hated by the industry, electric excavator offerings continue to progress rapidly as manufacturers strive to drastically decrease emissions.

in the quest for reduced

JCB is committed to exploring and manufacturing hydrogen-powered excavators and other equipment emissions and quieter jobsites.

One of the hottest online topics lately regarding the construction industry is whether electric excavators are worth the time, money and commitment to change. Battery charging times may slow down a day's work, some argue. Others proclaim that a small electric excavator would not run for eight continuous hours on a jobsite anyway, as a construction project typically requires multiple pieces of equipment for different parts of the work. For example, as operators run dozers or wheel loaders, their small electric excavator battery packs could

charge. Despite wide-ranging opinions, more manufacturers are focused on achieving two primary goals as they release new electric excavators: sustainability and fuel efficiency. Whether they're loved or hated by the industry, excavator engineering and product development, which prioritize electric and alternative fuels, are progressing rapidly on the road toward drastically lowered emissions.

Although JCB produces roughly 400 diesel engines every day for its agricultural and construction machinery, the company is currently considering alternative ways to power its machines.

After all, governments globally are striving to end the use of diesel and gas in passenger cars and light goods

vehicles. However, JCB has encountered one significant issue: batteries aren’t usually a viable power option for the agricultural and construction industries, as heavy machinery requires massive batteries. And batteries wouldn’t be charged in an easy manner, as machines are often used in remote areas.

With zero-emission technology as its ultimate goal, JCB doesn’t provide hybrid-diesel electric technology as a solution either. Nonetheless, in July 2020, JCB engineers began to design an engine for a backhoe that runs completely on hydrogen. Six months later, the first working prototype was

tested, as the engineers successfully developed a high-performance, purpose-engineered, zero-carbon-dioxide, hydrogen fuel engine.

“Hydrogen engines solve all of the problems that are associated with battery charging on busy, remote sites, as OEMs work on the internal

Maximize productivity on your job sites with advanced automation technology. Komastu’s intelligent Machine Control (iMC) can help you get the most from your machines, crew and carefully designed plans.

• Get new operators up to speed quickly

• Go from mass excavating to finished grading faster than ever

• Helps eliminate potential damage to design surface

• Empower operators to work efficiently, pass after pass komatsu.com/imc

combustion principle,” said Chris Giorgianni, vice president of government and defense, product and marketing, JCB. “They’ll feel familiar to anyone who is used to diesel or gas engines.”

Of equal importance, the costs of using hydrogen-powered excavators are roughly the same as utilizing excavators that are powered by traditional engines, which run on fossil fuels. Furthermore, unlike batteries, hydrogen engines aren’t inflationary. And, above all else, hydrogen engines don’t release any carbon dioxide into the atmosphere, as they’re completely carbon neutral.

“Now that hydrogen-powered excavators are here and proven, global governments need to be encouraged to adopt hydrogen engines and incentivize investment in hydrogen energy infrastructure,” Giorgianni emphasized. “While the benefits of hydrogen power are hopefully clear for everyone to see, it is still a relatively new technology. So, it is crucial that we start to take the lead in getting the message out.”

To help ensure that hydrogen power begins to be viewed as a genuinely viable alternative to electric and battery-powered machinery within the construction industry, JCB is investing $130 million to create super-efficient hydrogen engines for a wide array of machines — from backhoe loaders and telescopic handlers, to larger, heavier equipment.

In addition, the company strives to offer its first hydrogen-powered excavators to customers as soon as possible.

“This commitment reinforces our conviction — as a company — that hydrogen power will be a key part of the solution, in response to climate change’s ongoing threat,” said

Giorgianni. “As a result, JCB is looking forward to being firmly at the forefront of the hydrogen revolution.”

On the other hand, KATO-CES has two models of battery-electric miniexcavators: the 9VXB, which has a 5-foot, 2-inch digging depth, along with a bucket force of 2,360 pounds, and the 17VXB, which has a 7-foot digging depth, as well as a bucket force of 3,687 pounds. Since they each utilize a standard hydraulic system, users can run the same attachments with them as the diesel versions that the company has previously released.

“There is definitely a growing demand and a market for these mini-excavators,” said Bart DeHaven, director of sales, North America, KATO-CES. “Electric units are a little heavier than the diesel units, but they still have the same dig depth. The only drawback is run time, as the diesel mini-excavators can be filled at any time, yet the battery-electric miniexcavators need to be charged eight to 12 hours to ensure they’ll run for eight hours.”

Additionally, the battery-electric mini-excavators release fewer emissions, are less noisy and have less vibrations than diesel mini-excavators, thereby improving operators’ comfort, while also reducing their fatigue.

Completely maintenance-free, the mini-excavators’ lithium-ion batteries and electric motors have lifespans that are just as long as a diesel engine’s lifetime, if not longer.

“Battery-electric mini-excavators do have higher purchase prices than their diesel equivalents, but the total cost

excavators can be fully recharged overnight. The E10e and the E19e have standard 120-volt outlets, whereas the E32e has a 240-volt outlet.

of product management, excavators, Bobcat Company.

Furthermore, the battery-electric excavators support environmentally-

of ownership should be considered when evaluating them, too,” DeHaven added. “This total cost of ownership includes the fuel savings and extended component life of not having an engine, which decreases users’ overall maintenance costs, as well.”

Focused on minimizing its environ mental impacts, while also helping its customers achieve the same goals, Bobcat Company is currently lever aging technology to become more productive and utilize resources more efficiently. As an example, the com pany is now using alternative-energy products that aren’t only environ mentally conscious, but also ensure customers can continue their business operations as government mandates are steadily established regarding zero emissions and clean energy.

So far, the company has advanced its commitment to environmental sustainability through the launch of the T7X, which is the world’s first-ever all-electric compact track loader. And it’s also producing a range of batteryelectric excavators, as well as a variety of electric products that offer users viable alternatives to diesel-powered equipment.

“While significantly reducing their carbon footprints and producing much less noise than diesel-powered offerings, the battery-electric excavators will also expand users’ jobsite versatility,” said Joel Honeyman, vice president of global innovation, Bobcat Company. “Producing no emissions, the batteryelectric excavators can tackle tough jobs — outdoors and indoors — as they also require less maintenance than their diesel counterparts.”

During bauma 2022, Bobcat Company revealed its latest electric excavator, the E19e compact excavator, which joins the E10e and the E32e as the product lineup’s third member. Each of the battery-electric excavators have compact footprints, quiet operations and zero emissions. In addition, their electrical motors deliver full torque, regardless of rpm, leading to high productivity, on-demand, multifunctioning performance (without any noticeable decline in power) and smooth hydraulic control.

Providing users a run time of roughly four hours of continuous operation on its lithium-ion battery pack, each of the battery-electric

Say hello to the KATO 35V5 mini excavator. The 35V5 is the ultimate in utility and flexibility with is standard expandable track feature and optional Extend-a-Hoe Side Arm helping take power and stability to a whole new level. To top it all off the this 23hp beast boasts a Yanmar engine, digging depth of 10’11”, and operating weight of 8082 lbs. The 35V5 Mini Excavator has a zero tail swing, increased digging force is increased by 10%, and the 4-pump system is quick to respond, making this the ultimate mini excavator.Comfortable and easyto-use, the 35V5 mini excavators are also fuel efficient and easy to maintain. With an auto-parking brake and a neutral engine-start, the 35V5 mini excavator is proactive in error-prevention. Contact KATO CES today for more information.

leading to an improvement in jobsite communication, as they can also be used in sound-sensitive areas.

“With the introduction of our allelectric compact track loader, the Bobcat T7X, as well as our battery-electric excavator lineup, which is, again, comprised of the E10e, E19e and E32e, we’re reaffirming our commitment to offering more environmentally sustainable products,” Honeyman said.

He added, “We have many customers who have their own Environmental, Social and Governance (ESG) goals, and our battery-electric excavators support environmentally-conscious customers, while still delivering diesel-equivalent machines’ performance and power, too.”

Earlier this year, Takeuchi announced that the first 100 units of its TB20e, an electric compact excavator, will be available at some United Rentals locations. Built by Takeuchi, the battery-powered machine is the first to be released in the company’s anticipated lineup of electric products, created to meet its ESG goals.

“United Rentals and Takeuchi have a long history together, [so] we’re pleased to be the first to offer the environmentally-friendly TB20e excavator,” said TJ Mahoney, vice president, supply chain, United Rentals. “Not only does [the excavator] provide our customers a more sustainable equipment option, it’s also more cost efficient to operate.”

“The product and market development for the TB20e took place in North America, so it made sense to debut the machine here,” added Clay Eubanks, director of global sales, Takeuchi. “We’re excited to see how [United Rentals’] customers react to this new environmentally-friendly excavator.”

Meanwhile, Caterpillar — which has been dedicated to working on electrification for the last 30 years — is focused on increasing the power of some of its high-volume loader and excavator product lines. As an example of this dedication, in October, the company showcased a variety of fullyelectric prototype machines at bauma.

From a sustainability standpoint, one excavator especially stood out: the Cat 301.9 electric mini-excavator. Providing users a Cat 48V, 32kWh bat-

commercially-available electric excavator offering.

At the same time, Caterpillar has issued seven sustainability goals that it is striving to achieve by 2030. The goals range from reducing absolute greenhouse gas emissions from its operations by 30%, to decreasing its landfill intensity by 50%.

“We have set a goal to have 100% of the new products that are released through 2030 be more sustainable than the previous generation,” stressed Jason Conklin, senior vice president, global construction and infrastructure, Caterpillar. “To achieve this goal, we will collaborate with customers, decrease waste, enhance the design for rebuilding and remanufacturing, lower emissions and improve our efficiency.”

As Ray Gallant, vice president, product management and productivity, Volvo Construction Equipment, looks ahead to the evolution of zero-emission heavy construction equipment, he said the response to electrification or sustainable power isn’t just a single technical solution, but a variety of solutions that manufacturers will need to develop and then “bring into play.”

“Volvo Construction Equipment is working with technologies such as battery-electric, hybrid, hydrogen fuel cells and alternate fuels like hydrogen combustion, as a result,” Gallant said. “We’re interested in any energy source that can provide the energy we need in a sustainable process.”

these systems in the future,” he said. “And we’re considering cable electric excavators that can connect directly to the grid and draw power while they’re being used, which are especially excellent options if customers have stationary excavators or applications.”

If customers are using larger excavators that require 200 kilowatts of power or more, they will need to purchase equipment that utilizes exotic fuels like gaseous or liquid hydrogen. As an example, they could obtain a hydrogen-powered direct combustion engine (a modification of a standard diesel block) or they could acquire electric energy from a fuel cell, which would power each of their excavators through a battery pack. Both options can be used for very high power ranges, especially those that are required in mining or quarry sites.

“One of the considerations for all power ranges and different technologies is that we’ll need to be much more efficient as OEMs, in order to recapture as much of this energy as possible while the excavators are being used,” Gallant said. “Customers can’t afford to waste or lose power through an inefficient system if they have a battery pack with limited capacity.”

He continued, “That’s why, as manufacturers, we need to be more efficient in how we use the power, recover it in the non-work cycles and ensure the excavators and battery packs last as long as possible.”

Offering the same performance that Takeuchi’s diesel-powered TB216 compact excavator does, the TB20e is 100% battery powered, enabling it to provide lower noise and vibration levels than the dieselpowered compact excavator, while also emitting no exhaust emissions. And when it’s completely charged, the TB20e provides a continuous working time, which ranges from four to eight hours, fully dependent on the application and environment in which it’s utilized in.

In addition to offering an operating weight of 4,255 pounds, the electric compact excavator has a bucket capacity of 1.34 cubic feet, along with a primary auxiliary flow of 9.0 gpm. Furthermore, it has a reach of up to 13 feet and 4 inches, as well as a digging depth of 7 feet and 10 inches, at most. To ensure its operators remain comfortable, the TB20e also has a spacious station that features a high-definition, multi-informational color display.

tery, the excavator has a run time of up to eight hours on one charge; this run time declines to five hours during continuous trenching, though.

Additionally, the company has created the Cat 320 electric excavator, which also has a run time of up to eight hours on one charge. However, it uses a different battery than the Cat 301.9 electric mini-excavator does, as it features a Cat 600V, 320kWh battery instead.

“Each machine will also include an onboard AC charger, which will enable it to be charged overnight,” said Corne Timmermans, vice president, sales and marketing, Europe, Africa and the Middle East, Caterpillar. “We’re also planning on providing DC fast-charging options that customers can utilize during their break times.”

Both of the excavators are anticipated to be available for customers in Europe and North America within the coming years, as the Cat 301.9 electric miniexcavator is expected to be the first

For instance, small excavators are great fits for battery-electric drives. So, Volvo CE has placed a 48-volt battery pack in each of its compact excavators. The battery pack can store enough energy for the excavators to conduct their daily work tasks on a general-duty cycle basis. And, in order to recharge them, the company offers an assortment of charging solutions.

“Even heavier machines that use up to 120 kilowatts can be powered with a battery pack,” he added. “The difference is that the battery pack goes up to a much higher voltage (600 volts for our excavators, in fact), so that we not only have faster recharge times, but also acquire the power we need—all with a reasonable weight and power balance.”

Once manufacturers’ customers require 120 to 150 kilowatts of power, along with longer duty cycles, they’ll need to consider other types of technologies, as well. The primary reasons? For these types of requirements, excavators’ batteries are too heavy to supply the power that such customers need, especially if they have applications where excavators are utilized continuously for 24 hours. And very large battery packs tend to have very long recharge times.

“Therefore, we’re looking at different technologies like hybrids and alternative fuels that can power

With these goals in mind, Volvo CE, which offers two compact electric excavators, is preparing to develop other options, as well. The company is expanding electromobility to larger excavators, such as the mid-size EC230E Electric, a prototype that will be available in North America in 2023 for customer pilot projects.

As it prepares for the future of hydrogen fuel, the company has recently introduced a prototype fuel cell hauler, too. Using a hydrogen fuel cell test lab in Sweden, which tests complete fuel cell units, the company is continuing to invest in partnerships that will help it develop more sustainable equipment and initiatives.

“Volvo Construction Equipment was the first construction equipment manufacturer to commit to an electric future for its compact machine range, as we stopped the development of new diesel engines for mini-excavator models globally—from the EC15 to the EC27—as well as compact front end loaders, from the L20 to L28,” Gallant added. “That’s a bold decision, made in step with a challenge from our president, Melker Jernberg, to stir the market by providing compact, zero exhaust emission excavators.”

Read more at: https://eqtoday.co/elecexcavators

Selecting the proper roller for the application, and using it correctly, will ensure optimal surface compaction on your construction projects.

There are many different types and styles of rollers available for compaction, but not every roller is right for every job.

Factors that you should consider when choosing the right roller for your job include:

˜ Type of material that will be compacted (dirt, sand, gravel, asphalt, etc.)

˜ Budget

˜ Size of area

˜ Site layout (open area or confined areas)

˜ Transportation to and from the jobsite

Take a look at the types of rollers available and decide when, where and how to use them on your projects.

When a new road or structure is being built, the foundation will need to be compacted before final construction can begin. The new surface is often loose and unstable and needs to be compacted before structures are built upon it.

There are a few main types of soil compactors to accomplish this task:

These rollers consist of large, smooth steel drums that use a combination of impact, vibration and static pressure to compact materials such as sand, ballast and gravel. They are the most effective in compacting silty or sandy soils with the fewest passes.

This style of rollers have many raised lugs called "feet" on the roller drum. The feet provide a tamping action and change the surface area of the roller drum, which enables the roller drum to apply more pressure per square inche.

The roller operator can increase the pressure on the feet as needed by filling the drum with wet sand and other materials. Typically sheepsfoot rollers are used with silty or heavy clay or cohesive soil surfaces.

Soil compaction rollers can either be tandem (double drum) or single (threewheeled) depending on the project needs.

Tandem rollers have drums in the front and the back for additional

power and faster compaction times. However, the lack of tires results in less stability and traction than single drum versions.

Three-wheeled or single drum rollers have a drum in the front and specialized tires in the back, allowing them to roll over almost any surface.

Many times, asphalt roadways are put down over soil and there are many specialized rollers to use during different phases of asphalt compaction. These can come in single drum configurations, but you usually see tandem rollers operating during asphalt compaction.

These styles of roller are most commonly used for asphalt compaction but have varying styles and technologies that make them more suited for different applications.

Static rollers are used to compact many different types of material, but are used on some jobsites for asphalt compaction. Static rollers are sometimes seen as the final roller in the paving train, used for finish rolling. The primary purpose of finish rolling is to obtain the last little bit of density and to remove the marks, if any, left by the first and second rollers. When needed, finish rolling should be accomplished with mix surface temperatures above 175° F.

Vibratory rollers are almost identical to smooth wheel rollers except they feature a specialized vibrating component. As the roller compacts and flattens the surface, it will vibrate and increase the compactive effort. Double drum vibratory rollers operate close behind the paver to obtain the initial compactive effort while the mix is still hot.

This “breakdown” rolling, completed with a vibratory roller, should be completed before the surface temperature of the mix falls below 240º F. The breakdown roller should be operated at the highest possible frequency level available for the particular make and model of roller and at an amplitude setting that is dependent on the thickness of the asphalt concrete mat being placed.

Intermediate rolling is usually done with a vibratory roller, as well, and must be accomplished immediately after the initial rolling is completed.

Oscillation is a technology developed to help increase compactive effort even further. With these vibe systems, the drum stays in constant contact with the material, allowing the roller to deliver dynamic compaction energy to the asphalt layer as an alternative to traditional vibration. Instead of vibrating the pavement up and down,

Consider the material being compacted when choosing a roller, whether asphalt, sand or gravel.

oscillating rollers stay in contact with the surface, and there are no repeated impacts to the surface for compaction.

This provides more compaction force than static rolling, but less force than traditional vibration. Tandem rollers with one oscillation drum and one vibrating drum achieve at least the same degree of compaction as double vibrating drum rollers, but with fewer passes.

These types of rollers are suited for compacting thin lifts, tender mixes, joints, bridge decks or when working near structures. Oscillation is also useful for joint compaction, as most asphalt contractors have to deal with hot and cold lanes when they pave.

Pneumatic Rollers:

Pneumatic rollers use smooth pneumatic-tired wheels that overlap, instead of steel drums for compaction. Pneumatic rollers use static pressure in both vertical and horizontal directions to reduce air voids in material which creates compaction. This is often referred to as kneading or manipulations and helps bring compaction to materials differently than traditional static rollers or vibratory rollers.

These compactors are mainly used as one of the last steps for compacting both soil for road work and asphalt for sealing purposes.

When a pneumatic tire roller is used as an intermediate roller, it is necessary to keep the tires at the same temperature as the mat being compacted — otherwise the rubber tires will pick up some of the mix from the mat. So when using a pneumatic roller, don’t allow the roller to sit and wait for long periods of time, as the tires will cool.

Road rollers aren’t the only construction tools used for compaction work. Other types of compactor equipment include the rammer and the vibratory plate.

Rammers are handheld and are best used for small jobs in tight areas. Due to their comparatively lightweight, they can be hand or machine operated, which allows deep vibratory compaction.

Vibratory plate compactors are used to increase the density of a variety of soils and fill any voids. Because they are walk-behind compactors and are smaller in size, these compactors are best used for tight spaces where large equipment can’t reach.

Trench rollers, also called multipurpose compactors, perform well in cohesive soil types that can be very difficult to compact (such as clay).

Trench rollers can compact high moisture content in clays by utilizing powerful compaction energy and the kneading effect from their padfoot drums.

Trench rollers get their name because they are often used to

compact the soil in trenches. Trench rollers are popular because they are maneuvered by using a remote control — the operator does not stand or sit on the machine while it moves.

Compaction is an important part of any project. Understanding the benefits of each roller can make choosing

the right one for your project more efficient. Be sure to always properly train your operators, to ensure they are making the most of their work and compacting each surface efficiently to ensure density. Under-compaction can cause decreased strength, reduced fatigue life, accelerated aging/

decreased durability, rutting, raveling and moisture damage, while over-compaction can affect the integrity of the material and damage the roller.

Read more at: https://eqtoday.co/whatroller

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.

BKT USA Inc.

202 Montrose West Ave. Suite 240 Copley, Ohio 44321

Toll free: (+1) 888-660-0662 - Office: (+1) 330-836-1090 Fax: (+1) 330-836-1091

•

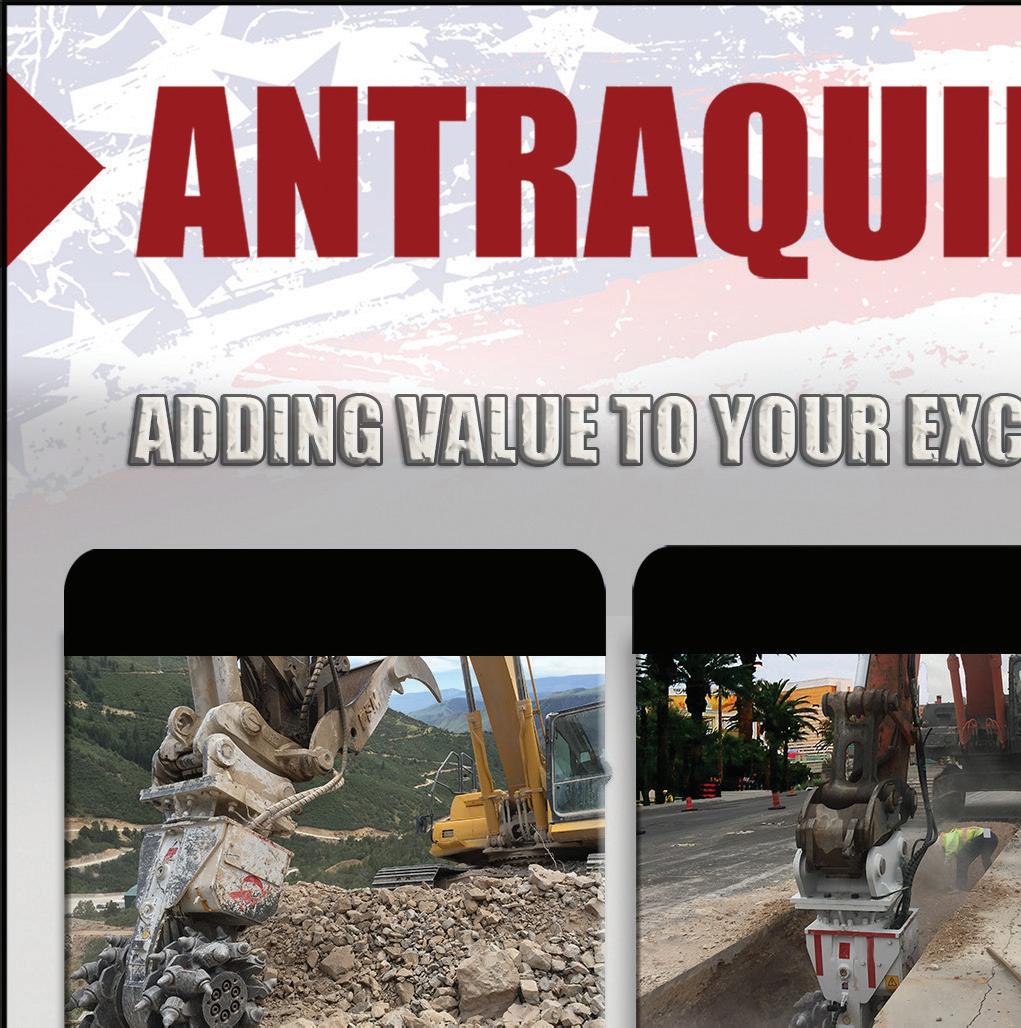

The TRS10, TRS14, TRS18 and TRS23 models for tracked excavators seamlessly integrate to the machine, contribute up to 13% more productivity and offer easy operation.

• Available for machines from 11 to 30 metric tons (24,250 to 66,140 lbs.)

• 360° bidirectional rotation and 40° left and right tilt allow work from many different angles with less machine repositioning

• Machine controls allow for simultaneous tilt, rotation and machine movement

• Pin-on or S-type coupler top interfaces or S-type coupler bottom interfaces

• Optional grapple module allows operator to move materials out of the way, such as large rocks, without switching attachments

The Mini Skid-Steer Quick Attach Frame for Mini Track Loaders by Artillian Tractors includes a common industry interface loader quick attach, enabling use with a variety of manufacturers' mini loaders. Highlights include:

• Designed for a maximum load of 3,000 lbs. at an 18-in. load center, depending on fork tine capacity

• Frames can be used with the company's pallet forks, grapples, stump buckets, hydraulic plow and more

• Built using high-strength steel with MIGwelded construction

• Baked-on powder coat augmented by a proprietary graphite coating on the fork rails for easier sliding of forks

• Includes a built-in 2-in. receiver

The SQ90 fully automatic coupler system is targeted toward excavators up to 70 tons in the demolition industry.

• Provides increased safety and the ability to change hydraulic powered work tools in seconds without leaving the cab

• Compliant with the Open-S standard

• Upgraded Front Pin Lock safety solution offers mechanical lock of the front shaft to limit the risk of an unintended drop of heavy demolition tools

• Hydraulic couplings with Qplus technology enable higher hydraulic flows with less pressure drops

The Hydra-clamp bucket features a builtin rotary actuated thumb that maintains consistent clamping force on the load through the entire rotation for improved flexibility and precision.

• Helical actuator provides up to 54,000 ft.-lbs of torque at 3,000 psi

• Provides consistent clamping force throughout the 120° range of motion

• Serrated side plates help secure debris while moving and are available in various sizes to match machines capacities

• Tapered side plates reduce wear on bucket sides and allow easier dumping

• Various tooth options or bolt-on cutting edge available

The compact productivity package includes a Heavy-Duty Excavator Bucket, a Main Pin Hydraulic Thumb and D-Lock Coupler, providing added versatility and production for excavators from 5,000 to 25,000 lbs.

• Combination allows users to dig into virgin soil, move rocks, logs, debris and other materials, demolish structures, and more

• Standard buckets range from 10 to 42 in. and feature T-1 steel in all critical or high wear components, heavy-duty horizontal wear straps and tapered side plates and a dual taper radius

• Thumb comes in two-, three- and four-tine versions, offers roughly 120° of thumb rotation and can be left on the machine during normal excavation

• D-Lock Coupler includes an automatic front lock, multi-pin centers and multi-pin diameters and only two hydraulic lines required for installation

The 100% hydraulic-fired V-series breakers modulate their impact force and frequency with up to 16 working positions to match to most applications. Compatible with the PC210 up to the PC490 excavators. Energy-saving recovery valve recuperates energy to drive efficiency. Automatically select best piston stroke length and speed based on material hardness. Shock-dampening upper and lower suspensions help reduce risk of cracking booms and breaker housings.

These drum cutter attachments are suited for detailed excavation applications such as contouring and trenching.

• BDC 40 and RT 15-40 offer 15.2- and 4.7-in. cutting widths and are suited for the Brokk 70 demolition machine

• BDC 50 pairs with the Brokk 110, 120DII and 170 to provide a cutting depth of up to 1.2 in. at a width of 18.9 in.

• BDC 100 for the company's larger demolition machines (200, 300, 500, 520D and 900R) is 24 in. wide with a cutting depth of up to 2.6 in.

• BDC 250 pairs with the Brokk 500, 520D and 900, is 26.8 in. wide and offers up to a 3.1-in. cutting depth

Takeuchi has added seven sound-suppressed hydraulic hammer models to the Takeuchi Attachment Program, helping compact track loader and compact excavator owners accomplish their goals on construction sites. Takeuchi’s new hydraulic hammer line includes seven models with reliable power-to-weight ratios for a variety of applications. Providing noise and vibration insulation, the sound-suppressed design of every Takeuchi hammer also protects it from dust and debris. Constant blow energy, or “CBE” allows for a wide range of oil flow settings and protects the hammer against high back pressure. An integrated, membrane-type hydraulic accumulator eliminates nitrogen leakage and the need to recharge for lower operating costs and consistent impact energy.

The H190 S and H215S fit in the 13,000and 18,000-ft.-lb. impact energy class and deliver 370 to 530 and 300 to 520 bpm, respectively.

• Switchable power mode from high frequency/low power to low frequency/ high power to fine tune power to the material being broken

• Buffering material dampens vibration feedback to the carrier

• H190 S sized for use on 349 through 374 excavators and the larger H215 S is designed for the 374 and 395

• Auto Stop instantly terminates hammering when tool breaks through material, preventing damage

The G40 is suited for excavators from 20 to 50 tons and generates a maximum cutting force of 30,300 lbs.

• Cutting drum speed of 45 to 75 rpm

• Max cutting head torque of 34,100 ft.lbs.

• Cutting width of 33 in. with demo drums

• 190-hp input power (continuous) with a max operating pressure of 5,800 psi

• Required flow rate of 50 to 110 gpm

Mazio XL breakers are designed for carriers from 1 ton to 140 tons of operating weight — including mini excavators, skid steer loaders, backhoe loaders and excavators. Mazio hammers feature a closed case built from 100% Hardox steel to protect the body from wear and impact. The breakers feature anti-blank fire technology, which minimizes wear, an energy recovery system that reduces the required oil flow and a double-damping system for reduced vibration. Variable impact speed and power can be manually tuned using an Allen tool. A lower breaker speed provides greater power, while higher speed reduces the power, depending on the application's needs.

Tool choices for Mazio XL hydraulic breakers include:

• Cone-shaped tool for universal use in concrete and rock

• Chisel tool for rock breaking, concrete demolition and asphalt breaking

• Cylinder tool for drilling and concrete demolition

• Moil point for universal use in concrete and asphalt

• Blunt tool for demolition

Pavement Removal Buckets are designed to easily wedge under pavement, increasing the force of the excavator to quickly and easily remove pavement slabs.

• C-type profile and inclined sides aid the prying action and expedite removal of broken concrete and pavement slabs

• Standard sizes from 18 to 54 in. to fit all classes and sizes of backhoes and excavators

• Special designs and capacities available upon request

• T-1 steel used in all critical or highwear components, bottom wear straps provide extra protection and ribbing on inside bottom prevents denting and reduces wear

Toro's vacuum excavation attachment is available for use with the robust Toro Dingo compact utility loader product line. The Vacuworx PS 1 portable vacuum lifting system is ideal for concrete removal projects and is designed for both interior and exterior applications. The PS 1 delivers productivity for concrete removal jobs sacrificing runtime. The unit is powered by a 12-volt rechargeable battery and depending on the application at hand, operators can expect a run time up to eight hours between charges. The vacuum lifting system is engineered to lift a variety of hard-to-transport materials including concrete, marble, granite, thick plastic materials and most types of metal. The PS 1 vacuum lifting attachment is compact and simple to operate. With dimensions of 14.25 in. high, 6.5 in. tall and 11.5 in. wide, maneuverability is simple, regardless of the restrictions of the jobsite. The unit weighs only 25 lbs. and includes an 8-ft. standard vacuum hose and a standard pad. Available size options for the pad are: 8 in. x 12 in., 12 in. x 16 in. and 16 in. x 16 in.

The MB-HDS523 is compatible with excavators ranging from 30- to 45-ton operating weights and features five shafts positioned to ensure a greater production rate and processing speed.

• “V Shaft System" design creates a simultaneous dual screening effect

• Concealed comb allows material to enter and flow through rotors without jamming

• Powered by two motors for consistent and quick performance

• Shafts can be easily switched out and replaced on site in minutes

• Rotors can be easily extracted and repositioned

Danuser’s EP Auger System for backhoes, mini skid steers and excavators is compatible with Danuser’s Stump Auger, a standard 2-in. hex auger attachment that planes away stumps without requiring large, specialized equipment. A threaded, hardened steel pilot digs into the stump and large cutting blades then shave the stump away. The large cutting blades are reversible for more cutting life.

The stump auger is available in 10-in. and 16-in. diameters. The 10-in. model can run on auger units with 1,700 ft.-lbs. or more of torque and the 16-in. model can run on auger units with 3,000 ft.-lbs. or more of torque. Complete stump removal is achieved by overlapping planning locations.

Carbide and diamond saw rockwheel attachments are available for excavators of all sizes and various applications.

• Carbide rockwheels offer a cutting solution for soft to medium hard rock and concrete cutting applications with a minimum width of roughly 2 in.

• Diamond saw rock wheels (AQD Series) cut the hardest rock including granite, basalt, etc., as well as reinforced concrete

These new buckets feature T1 and AR400 steel in critical wear areas for strength and durability, with weight saving features and is designed for use with John Deere 470P, PC490LC-11, Cat 349 and other 50-metric ton excavators. With 20% more capacity than a standard 5-yard bucket, the new heavy-duty highcapacity bucket can load a 30-yard haul truck in five passes. An effective dig angle allows the bucket to tear through virgin ground and materials. In addition, tapered side plates are engineered to reduce wear and allow for smoother dumping. The bucket can be equipped with a wide selection of industry standard ground engaging tools for durability.

With its V-shaped design, the latest drum cutter from Epiroc sets a new standard in trenching and quarrying. A seemingly simple solution with an extraordinary effectiveness, enabling energy savings of up to 40%. Thanks to the V-shaped design, that enables a cut with a flat base, no material is left untouched between the drums. Where a regular drum cutter must move side to side to create an even trench, an approach that causes extra wear on the carrier arm, the VC 2000 can reach the same result by just going straight. The distinguishing features of the classic Epiroc drum cutters, like the spur gears, adoptable high torque gear motor and the QuickSnap retaining system for fast and easy pick changing, are all to be found in the new VC 2000.

ASV offers smooth turf tracks for minimized damage to soft, delicate surfaces. With a combination of more ground surface area and the performance of ASV’s Posi-Track undercarriage, the turf tracks can achieve equal or better traction than treaded tracks on dry surfaces. This product minimizes damage to topsoil and root systems, allowing for faster job completion in landscape, hardscape and golf course applications. ASV’s green turf tracks have a smooth design and are manufactured from a specialized blend that resists cracking, provides traction and maximizes overall life. The rubber tracks eliminate rusting and corrosion because they contain no steel cords.

Werk-Brau's Nox tiltrotators for excavators. The attachment provides 360° of endless rotation with a tilt angle of 2 x 50°, allowing versatility with a wide range of attachments. These tools transform excavators into multi-functional carriers that work in deep trenches, under or between existing pipes and tubes and in other confined space applications. Designed for use with fork tines, grabs, grippers, buckets and more, this technology allows operators to complete projects without repositioning the carrier. A range of Werk-Brau NOX tiltrotators are available for excavators in various classes and categories, from 3-25 tons. With integrated hydraulics and no components protruding from the compact design, the risk of damaging hydraulic cylinders, hoses or other components is reduced on the jobsite. The product has minimal wear parts and only two fittings that require grease.