Trending: Site Dumpers With Advanced Features

CHOOSING TIRES FOR BATTERY-POWERED

2023

SKID STEER SPEC GUIDE

THE SKINNY ON DOZENS OF NEW SKID STEERS

Growing Demand, Evolving Tech of Land Clearing Equipment

Trending: Site Dumpers With Advanced Features

CHOOSING TIRES FOR BATTERY-POWERED

2023

THE SKINNY ON DOZENS OF NEW SKID STEERS

Growing Demand, Evolving Tech of Land Clearing Equipment

Moving, lifting, digging or loading, Wacker Neuson vertical lift skid steers and compact track loaders are designed to handle tough applications. In addition to high hinge pin heights, these versatile machines also feature the best service accessibility in the industry and comfortable cabs with simple, intuitive operation. For lighter-duty work, as well as commercial or residential landscape projects, Wacker Neuson’s stand-on utility track loaders are the perfect fit in confined spaces.

Put your job site challenges to the test. Contact your local Wacker Neuson dealer or visit us online today.

www.wackerneuson.com

2023 Skid Steer Spec Guide

The skinny on dozens of new skid steers at your fingertips.

BREAKING GROUND

Tough Technology On the Road & Off

Hands-on experience with equipment and trucks improves my ability to understand jobsite conditions.

EQUIPMENT INTRODUCTIONS

Check Out the Latest Equipment

The latest machines from major manufacturers.

PROFIT MATTERS

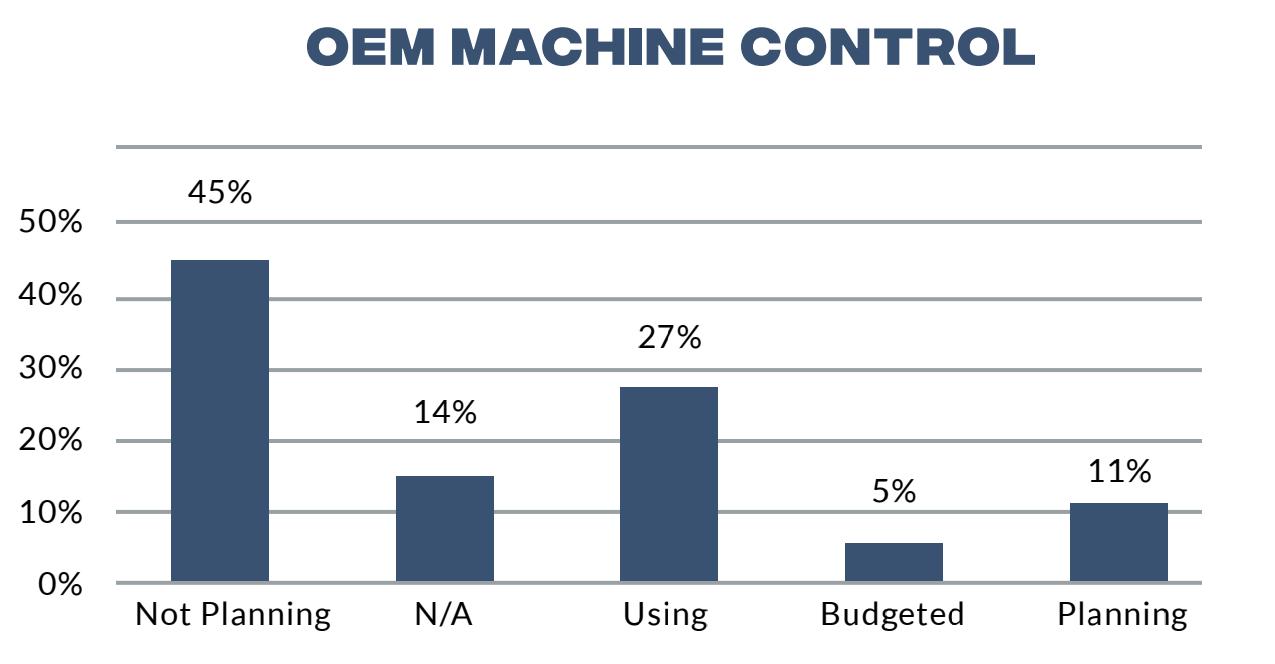

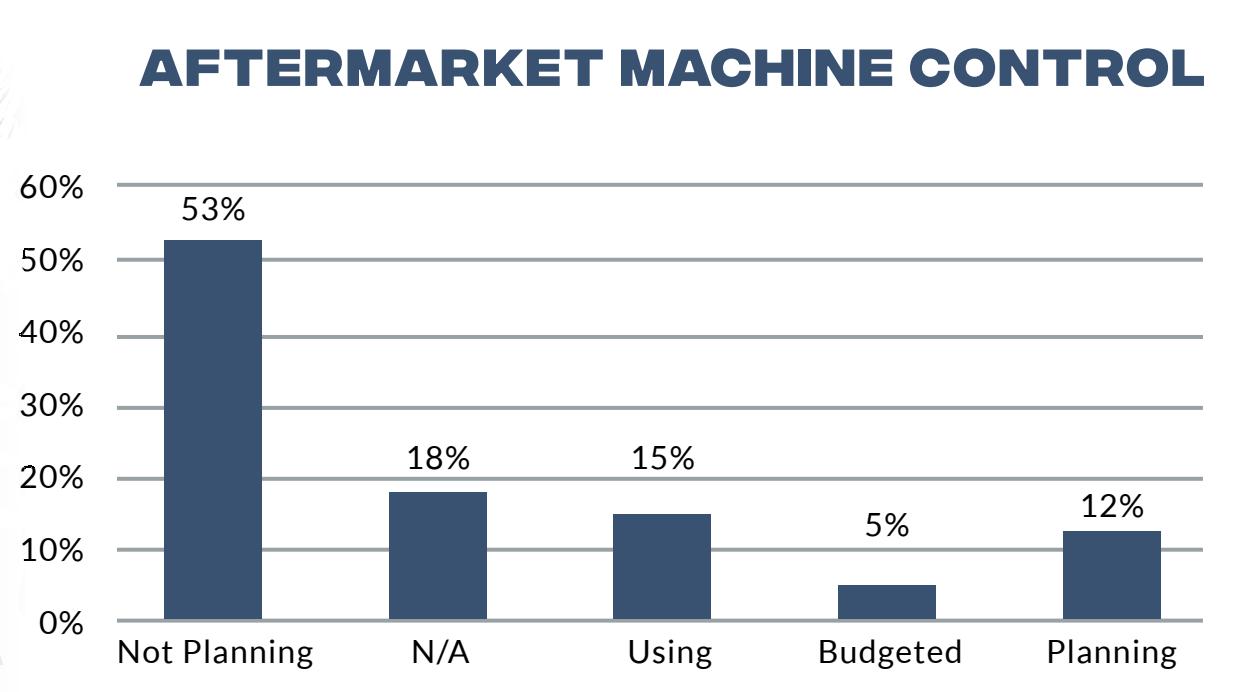

Four Crucial Trends in Construction Machine Control Off-road equipment technology is allowing fewer operators with less skill to do more.

RUNNING THE BUSINESS

Decision Time

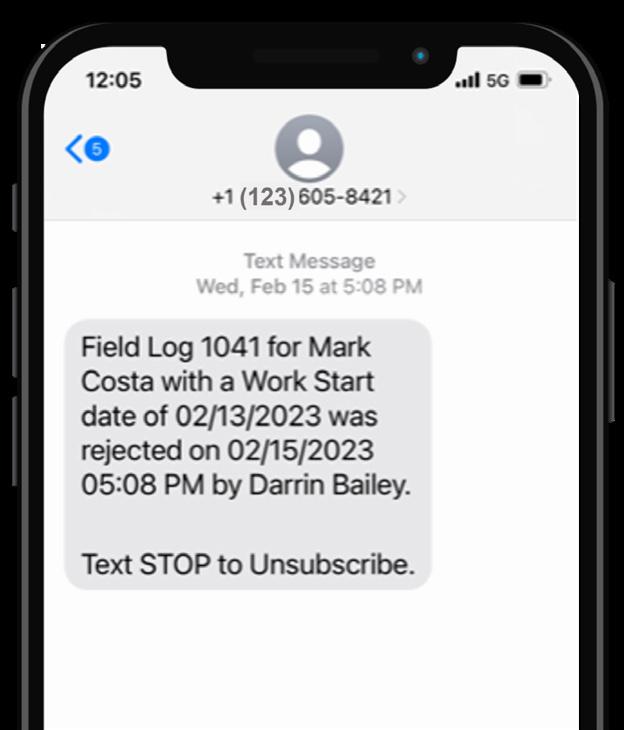

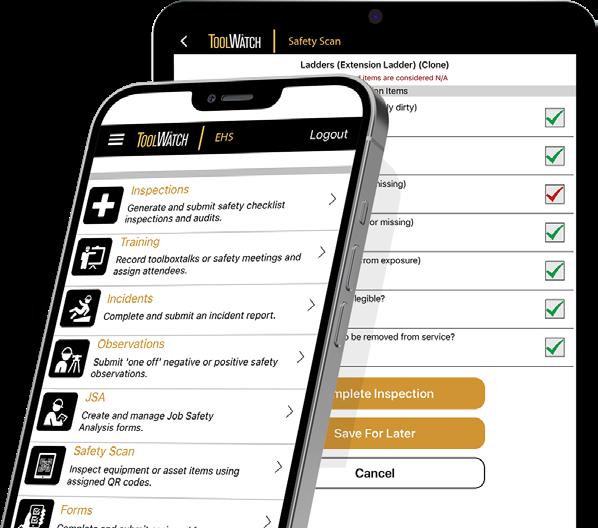

Using technology for your business improves the bottom line and decreases your time using pen and paper.

BRIDGING THE GAP

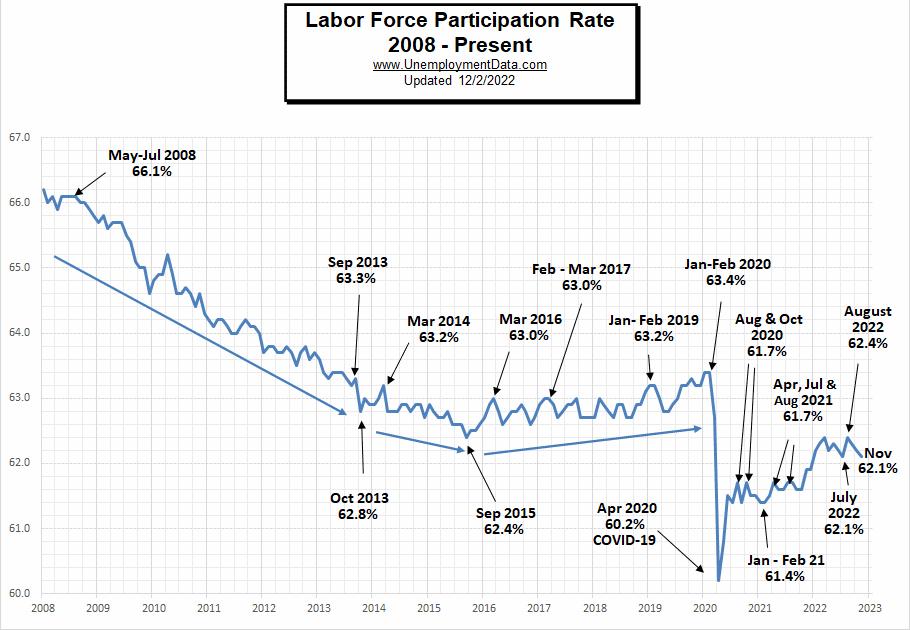

Diversifying Construction Labor Pools With Intention Being intentional about posting positions marketing to different talent pools is key to refreshing your old recruitment routine.

EARTHMOVING TRENDS

Evolving Tech of Brush & Land Clearing Equipment

Mulchers and mulcher attachments are evolving, offering new benefits for land clearing, including a cleaner finish.

EARTHMOVING TRENDS

Use of Site Dumpers Increasing in North America

There are many factors that make site dumpers so popular overseas, such as advanced safety features.

EARTHMOVING TRENDS

Three Factors Driving the Trend for Full-Size Stand-on Skid Steers

A step up from a traditional compact skid steer, these machines have a smaller footprint.

FLEET MANAGEMENT

Tire Technology Isn’t Static

Digital solutions, new tread patterns and proper maintenance improve fleet uptime and efficiency.

FLEET MANAGEMENT

Navigating the Shift to Electric

With sustainability at the forefront, manufacturers are providing electric options for contractors.

FLEET MANAGEMENT

Demolition Manufacturers Draw Engineer Electric Models

The real challenge is optimizing performance, especially in heavy duty applications.

TECHNOLOGY

Lighting Sites in New Ways

Battery, solar and drone systems are changing how operators see the jobsite.

TECHNOLOGY

Why Managing Edge IT Is Critical For Construction Companies

IT asset management plays a role in the success of construction companies, as more assets are deployed in unmanned, remote sites.

TECHNOLOGY

The Road Less Traveled Can Offer Greater Screening Productivity Departing from traditional screening systems to advanced technologies improves productivity and profits.

TECHNOLOGY

ChatGPT: The Next Frontier of Construction Contracts

Whether you find generative AI exciting or scary (or maybe a bit of both), AI has already optimized construction contracts.

TECHNOLOGY

Advances in Machine Control

Advancements in machine control are bringing improved safety and efficiency to work truck operations.

EARTHMOVING TRENDS

Heavy equipment for earthmoving.

FLEET MANAGEMENT

The latest in tires and fleet management products.

TECHNOLOGY PRODUCTS

The latest construction technology.

VIDEO NETWORK https://eqtoday.co/k2p285

DIGGING DEEPER PODCAST https://eqtoday.co/s7sfkm

CONTENT https://eqtoday.co/9pd73s

lditoro@ACBusinessmedia.com

Last month, I talked about my first time driving a wheel loader with the Mecalac team. This month, I’ve driven another exciting vehicle. Ford hosted media professionals in June to drive and learn more about the new 2023 F-Series Super Duty pickup.

We didn’t just drive these flexible, powerful vehicles on the road, which was a pleasant, smooth experience. We drove them off-road, including through twist ditches and muddy tracks and up a rock hill (check out the QR code below for a video of a fellow driver on the course tackling this obstacle).

We also had the opportunity to drive a truck fully loaded through different road conditions, including up and down hills.

The 2023 Super Duty, according to presentations at the event, is more efficient and simplified. I jumped right in and drove just like my passenger car at home, so I agree with the idea of simplification.

Comfort is also a priority, including while driving offroad, which I’d never done before. Imagine my surprise to spray mud all over the truck and drive through branches and leaves to stay on the trail.

Even with this toughness, the interior includes modern amenities. Each truck features fleet management software, telematics and a 5G modem for connectivity.

In addition, the XL model includes an 8-inch display, while the Lariat and higher trim models have a 12-inch display. The interior also features four USB power ports and an available wireless charging pad and a center console slot that holds a tablet upright to make using it easier when parked.

More to come later about this truck, which can perform tasks on the jobsite and off-road.

This issue also features equipment that performs on the jobsite and to prep the jobsite. First, check out the Skid Steer Spec Guide on page 8 to see the latest technology in this category. For more on skid steers, see the latest trends on page 18.

Some other industry trends include diverse jobsite lighting options (see page 32) and site dumpers (page 16). Also, don’t miss the article about how ChatGPT can help you on page 38.

As always, let us know what you’d like us to cover and discuss in upcoming issues by emailing me at lditoro@acbusinessmedia.com. We always love hearing from you!

Watch the video: https://eqtoday.co/rockclimb.

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Kimberly Fleming kfleming@acbusinessmedia.com

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

E @EquipmentToday

D @EquipmentToday

C @equipment-today-magazine-official

Q @equipmenttoday

To get the best performance available for Bobcat® compact track loaders, it’s important to look at where the rubber meets the road … and the soil, and the concrete, or anywhere that your tracks will take you. Bobcat rubber tracks are made using a blend of natural and synthetic rubbers to minimize wear, providing strength and durability for the most demanding conditions.

Bobcat tracks also bring the traction needed to pull out your loader’s full capabilities. Wider and thicker roller path areas maximize your traction and reduce vibration. They also distribute the machine’s weight over a larger surface area, naturally improving your ride.

An investment in genuine Bobcat quality can pay off in longer tread wear and fewer track replacements. When tested against numerous aftermarket track brands, Bobcat comes out on top in terms of durability, superior performance and longer track life.

Compared to tested aftermarket tracks, Bobcat tracks’ tread life is up to 30% greater.

Choosing the right set of tracks will ensure more comfort, better production and longer tread wear.

That’s why Bobcat offers a range of tracks for different applications, so you can choose the best track based on your hours of use and application.

Here are a couple of highlights:

Compared to tested aftermarket tracks, Bobcat tracks tread life is up to 30% greater.

Don’t settle for second best when it comes to your compact track loader. Invest in Bobcat tracks and get superior performance and durability with longer life doing tough jobs. You can purchase Bobcat tracks online at Shop.Bobcat.com/Rubber-Tracks or by contacting your local dealer.

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Takeuchi expanded its TB300 Series excavator product line with the new TB350R short tail swing compact excavator, the first short tail swing model in the manufacturer’s 5-ton class. The TB350R has a rear swing overhang of just 2.95 in., helping minimize rear-swing impacts.

The TB350R weighs 10,980 lbs. in canopy configuration and 11,235 lbs. when equipped with a cab. It is powered by a Kubota V2607-CR-E5B diesel engine that is U.S.

EPA Tier 4 Final compliant and delivers 41.7 net hp (ISO 9249 and SAE1349) and more than 130.2 ft-lbs. of torque.

A four-pump hydraulic system delivers smooth, harmonized control of the work equipment. The TB350R provides a bucket breakout force of 10,431 lbs., a traction force of 12,320 lbs. and a maximum dig depth of 11 ft., 8.8 in.

Read More at https://eqtoday.co/kd71w57

Hitachi added the ZX190LC-7 excavator for construction projects to its portfolio of heavy-duty machines. This 43,652-lb. (19,800kg) excavator offers a 23-ft., 2-in. (7.07-m) maximum digging depth and 28,551-lb. (127-kN) bucket breakout force. The HIOS IV hydraulic system minimizes hydraulic loss while supporting performance. The HIOS IV hydraulic system features a responsive boom, arm and bucket with intuitive control. On the ZX190LC-7, the system produces a maximum flow rating of 100 gpm (380 lpm). Attachment, arm and swing priority can be adjusted on the monitor to match the attachment or the operator’s preference. A Yanmar engine puts out 132 hp (98.6 kW). The Yanmar power system features economy, power and high-power modes to match available power to the working conditions. An auto idle system with auto shutdown control prevents wasted fuel.

Read More at https://eqtoday.co/2qwkqf

The new D10 is powered by the Cat C27 engine, which offers aftertreatment solutions to meet U.S. EPA Tier 4 Final/EU Stage V as well as Tier 2 equivalent emissions standards for meeting the needs of the global market. Maximizing material moved per liter of fuel, the C27 switches power settings based on travel direction to deliver power in reverse. The new D10 offers up to a 4% fuel consumption advantage over the D10T2 and up to 10% over the D10T. The dozer’s new torque converter design with stator clutch automatically frees up the stator when torque multiplication is not required. During high-load and retarding conditions, the stator clutch locks without the need for operator input.

Read More at https://eqtoday.co/43m660

The CX42D delivers a high level of feature standardization with excellent options to further improve performance. A standard two-way blade with float improves backfilling and grading operations, while an optional six-way blade seriously beefs up those capabilities. While the zero tailswing design provides excellent access to tight sites, additional counterweights can be added for further balance and confidence. Standard two-speed travel with automatic shift down improves performance when tracking/carrying up hill. Standard multifunction (1-way/2-way) hydraulics and standard 2nd auxiliary (2-way) circuit make these new D Series machines attachment beasts, while an optional 3rd auxiliary circuit delivers even more versatility. Each machine comes standard with a thumb bracket and can be ordered from the factory with an optional thumb.

Read More at https://eqtoday.co/p89jyw

The Movex Track-O Cross-Country serves as an all-terrain truck for transporting equipment, materials and heavy items on rugged jobsites. This product is designed for outside work and makes it possible to reach hard-to-access places, such as mountains and backyards even in conditions that include snow, water, mud and sand. It has a clearance of nearly 9 in. (23 cm) that enables it to negotiate obstacles or bumps such as stones, tree stumps, etc. The all-terrain truck Track-O Cross-Country can climb 40-degree slopes. This model can be adapted to the customer’s needs by adding a crane attachment or other accessories. The runtime is nearly 2.5 hours and can be extended by adding another battery. With an operating voltage of 24 VDC, the battery recharge time is approximately eight and a half hours.

Read More at https://eqtoday.co/nvhenx

HEVI offers the GEL-5000 all-electric wheel loader for loading, transporting and material handling on construction sites. With its electric motor and battery system, the GEL-5000 offers performance, while minimizing emissions in outdoor environments. With a 5-ton load capacity, the GEL-5000 is for contractors, landscapers and other professionals who need a reliable and highperforming wheel loader. The work vehicle includes a 282-kWh battery, a base charger (220 V, with an optional 480-V upgrade) and a 3.9-cu.-yd. bucket. Capable of delivering 9 hours of operating time on a full charge, the GEL-5000 is compatible with a range of Electric Vehicle Supply Equipment (EVSE) brands, such as Blink Charging and Siemen’s eMobility.

DEWALT expanded its TOUGHSYSTEM 2.0 storage portfolio with three new products: Adaptor, Deep Compact Toolbox and Three-Drawer Toolbox. The new TOUGHSYSTEM 2.0 Adaptor (DWST08017) allows users to build a versatile and customized storage solution through expanded compatibility. The TOUGHSYSTEM 2.0 Deep Compact Toolbox (DWST08035) is built for durability in tough working environments. The IP65 water resistant toolbox offers abundant storage with a volume capacity of up to 5.3 gallons or 20 liters and up to a 77-lb. load capacity. The TOUGHSYSTEM 2.0 Three-Drawer Toolbox (DWST08330) has three shallow drawers with a load capacity of up to 43.5 lbs./19.8 kg total or 14.5 lbs./6.6 kg per drawer to store and transport small tools and accessories.

Read More at https://eqtoday.co/xfkvzz

Read More at https://eqtoday.co/lth5oe

AUSA launched the D151AEG electric dumper, which can be paired with a mini-excavator. The D151AEG, which has a 3,300lb. and 1.18-cu.-yd. payload on its swing skip, allows operators to offload earth, rubble or other materials at an angle using a joystick. Because of its compact size, this machine is designed for work in tight spaces. The D151AEG dumper is equipped with a liion battery power unit. In the case of this dumper, it features a pack with a 9.3-kWh capacity, enough for at least one full day of work. Its 7.6-kW batteries and peaks of up to 17.3 kW are managed electronically to offer power and all-terrain capabilities.

Read More at https://eqtoday.co/slxcbp

To address the needs of customers looking for compact solutions on the jobsite, John Deere expanded its Performance Tiering offerings with the shift from L-Series to P-Tier for the 244, 324 and 344 Compact Wheel Loader models. The new P-Tier compact wheel loaders will carry over all L-Series capabilities and will introduce new features, including standard ride control in base models and optional factory-installed features, including an auto-reversing fan option. Additional optional features include attachment assist controls, which include integrated electrical (three-pin) controls for attachments and combined creep control and throttle lock. The upgraded combined creep control and throttle lock found within the attachment assist controls package allows customers to run their machines with higher rpms and lower ground speeds with overall fewer manual inputs when using attachments. Pause and resume functions can be used for reactivating the feature after a change in direction or switch to neutral.

Read More at https://eqtoday.co/52w2hg

Equipped with a powerful 250-hp CAT C7.1 Tier 4 Final engine, the Morooka MST110CR is emissions compliant and reliable. With an upgraded final drive, it can reach a top speed of 8.7 mph, an increase of 18% over the previous model. The Morooka MST110CR also features a rugged HARDOX steel dump bed, resistant to impacts and wear. The Morooka E-Hydro Control, or M-EHC, system, provides electronic monitoring of systems, while the single joystick control enables operators to maneuver the machine. This machine offers auto deceleration and a ROPS cabin. Side and rear cameras provide a clear view of the surrounding area.

Read More at https://eqtoday.co/cwnrx4

Mulchers are evolving, offering new benefits for land clearing, while mulcher attachments have become smaller, lighter and, consequently, more efficient, so they can be used on smaller, mid-frame machines.

As the construction industry continues to flourish, site preparation and land clearing work are steadily becoming more popular. In response, numerous manufacturers are offering a wider range of equipment that enables professionals and contractors to clear land and brush as they prepare for new construction opportunities.

For example, Caterpillar has the Cat BR320 brush cutter. It can remove thick brush and saplings, allowing operators improved access to properties, which is the “first step in a land clearing job,” said Brock Bahr, senior sales support specialist, Caterpillar. For a clear path and to have as clean of a finish as possible, Bahr advises operators to pair the BR320, which can cut a tree of up to 3 inches in diameter, with a D3 Series skid steer or compact track loader (CTL).

After clearing smaller, thick brush, operators can focus on more significant obstacles. Bahr believes they should use an industrial brush cutter or mulchers, whichever option is the most ideal for them, according to their particular property’s terrain and accessibility.

“The Cat BRX318 industrial brush cutter can do everything the BR series can and more, as it was designed for land management, small trees and dense vegetation,” Bahr stressed. “With its four blades, reinforced push bar and open-face design, the BRX can get close to large debris, such as trees that are up to 8 inches in diameter, as it cuts them close to the ground.”

He added, “It pairs well with skid steers, CTLs and compact wheel loaders, too. Although the BR series leaves a much cleaner finish, if operators want to remove everything and the final finish isn’t an issue, they should consider using the Cat BRX318.”

To remove large trees, operators can also use a mulcher. Caterpillar currently provides nine different

models, along with two different drum styles. The manufacturer’s most common drum style is its standard or open drum mulcher, with either carbide teeth (such as the HM316 and the HM418) or reversible chisel teeth (like the HM112 and the HM215).

According to Bahr, the mulchers’ standard or open drums don’t limit tooth engagement, resulting in a significant bite and, in turn, higher productivity. If operators are working on sites that have rough and rocky terrain, Bahr thinks carbide teeth are the most ideal option. After all, they’re highly durable and more forgiving than chisel teeth. And they require less maintenance than chisel teeth because they’re less prone to damage.

In addition, the manufacturer provides depth control or bite limiter drums on its HM316, HM416 and HM418 offerings.

Each of these drums have chisel teeth and depth control rings that decrease bite size and offer operators a helical tooth pattern. Consequently, the HM316, HM416 and HM418 can cut faster, burn less fuel and provide operators a cleaner finish when compared to other mulchers on the market, Bahr said.

“Each Cat mulcher comes standard with a heavy-duty, adjustable push bar, as well, which directs 8-inch trees away from operators as they cut,” Bahr said. “Furthermore, every Cat mulcher has adjustable, replaceable skid shoes, a two-speed hydraulic motor and a color-coded pressure gauge, which offers operators feedback, leading to higher productivity.”

Prior to purchasing a Caterpillar industrial brush cutter or mulcher, operators should keep in mind how much space they have to operate. The machines require some space for maneuverability to be as close to the tree bases as possible.

If operators don’t have enough space, they can consider buying a mini excavator. A mini excavator can be parked in one location since it

can reach out to cut several trees and brush without having to be moved.

Once operators have removed trees, whether they choose to use an industrial brush cutter, a mulcher or a mini excavator, they must eliminate stumps, too. To do so, operators can attach Caterpillar’s 46-inch stump bucket, which can be used for small stumps and roots. Offering a long, narrow design with serrated edges, the stump bucket allows operators to dig closely around and underneath stumps’ root balls.

Operators can consider using Caterpillar’s SG36 stump grinder, as well. Featuring a 22-inch cutting wheel with 32 carbide teeth, the SG36 is known for its rapid stump removal.

“To ensure they quickly and efficiently remove whichever stumps they need to, operators can extend the SG36’s head up to 11 inches and swing it 60 inches to the right and left, if necessary,” Bahr added. “Not to mention, while grinding stumps (up to 20.5 inches below the ground),

operators will never have to leave the comfort of their cabs, either.”

In the past, site preparation was completed by pushing vegetation over with dozers and excavators. Unfortunately, this process led to a considerable mess of brush and branches, which would generally need to be burned. Brush cutters and mulchers allow for a cleaner option that allows contractors to remove vegetation in a mechanized fashion instead.

In addition to offering a cleaner finish, these mechanized options are

evolving, said Matt Nelson, director of development at Diamond Mowers. For instance, mulching attachments are becoming more efficient regarding the ways in which they cut and mulch because they’re leveraging enhancements in components such as hydraulic motors and cutting tooth technology.

Moreover, mulcher attachments, which were previously suitable for large-frame and high-flow skid steers and CTLs, have become smaller, lighter and, consequently, more efficient because they can be used on smaller, mid-frame machines. Therefore, contractors no longer have to purchase machines dedicated only to land clearing. Instead, they can use the loader they already have and choose an attachment that fits, resulting in cost savings.

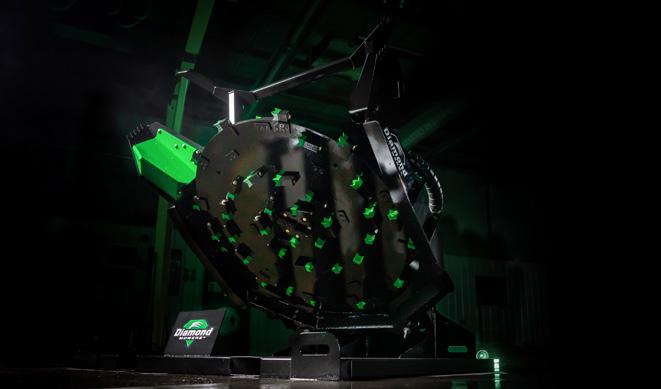

In preparation for the future of mulching, Diamond Movers recently announced its Belt Drive Disc Mulcher, which features a patented driveline that leverages a two-speed hydraulic motor that runs through a gear-reduction belt system. Due to its design, it increases operators’ production by 20% to 40%, in comparison to traditional disc mulcher designs. And, of equal importance, it also diminishes hydraulic oil temperatures.

“We believe the mulcher will positively impact the contractor market, as its ability to enhance productivity will ensure [that] it’s a clear choice for those who are paid according to output,” Nelson said.

In the meantime, Diamond Mowers has released the Drum Mulcher OD (open drum) Pro X as well, which provides a hybrid design that integrates the features of depth control and open drum mulchers into one attachment. Created to enable heavy ground engagement, the product has an infeed system that leads to a smaller, more uniform and aesthetically-pleasing end product once operators have finished their first pass.

“It has not only allowed contractors and landowners to realize an improved finished product, but it has also reduced their operating costs and boosted their profits,” Nelson emphasized.

With regard to brush cutters, Diamond Mowers presently has two options, the Brush Cutter Pro and the Brush Cutter Pro X. Each of these attachments are compatible with skid steer carriers or CTLs, as they feature hydraulic motors that are properly sized for enhanced blade performance and safe handling at every flow level.

Offering high durability and multifaceted cutting capabilities, the Brush Cutter Pro can be used for a wide array of applications and carriers. After all, it has two steel blades that can maintain a 72-inch cutting width, while cutting through branches, brush, grass and small trees that are up to 5 inches wide. Featuring a lower push bar, the Brush Cutter Pro can reach under fences, too.

Meanwhile, the powerful and versatile Brush Cutter Pro X provides three cutting widths: 60 inches, 72 inches and 84 inches. Utilizing three steel blades, it also has a Tr-Hex cutting disc that can slice through different materials, including those that have diameters of up to 10 inches.

Once operators have used the Belt Drive Disc Mulcher, the Drum Mulcher OD Pro X, the Brush Cutter Pro or the Brush Cutter Pro X, Nelson advises them to use one of Diamond Mowers’ two stump grinders, the Reflex Stump Grinder or the Miller Stump Grinder. Particularly ideal for land clearing and rural grinding applications, the Reflex Stump Grinder uses a skid steer’s lift arm to position its wheel in a stump prior to driving it through the wood with its wheels or tracks.

“Easy to operate, the Reflex Stump Grinder is equipped with a patented cushioning device that protects the wheel from too much pressure, alleviating overload by flexing and keeping the wheel out of harm’s way,” Nelson said. “Grinding wheels are available in 24-inch or 26-inch cutting widths and are paired with an appropriately sized motor to match the machine’s hydraulic flow.”

Meanwhile, the Miller Stump Grinder can cut stumps up to 36 inches in diameter without moving the carrier. Using a 26-inch, six-way grinding wheel that features swing, lift and telescoping functions, the stump grinder enables operators to process a stump with the loader in one position.

“Therefore, the risk of soil and turf damage declines,” Nelson added. “With this in mind, it is especially

ideal for settings in which aesthetics are important.”

Although construction projects are diverse regarding their types and locations, contractors all strive for one common goal—a clean, suitable jobsite.

To achieve this in the most effective way, they should utilize mulching equipment, particularly drum mulcher attachments, according to Ryan Bricker, product manager at Fecon. Attachments, after all, are not only efficient, but convenient, too, as they can be effortlessly paired with equipment found on most jobsites.

To provide operators efficient and convenient mulching equipment, Fecon has several attachments they can choose from, including models that have been optimized for standardflow and high-flow skid steers and excavators.

One attachment that has recently been added to the manufacturer’s mulcher attachment lineup is the BULL HOG RK6015 skid steer drum mulcher. A standard flow mulcher attachment developed especially for landscape construction and lighter vegetation management, it can mulch brush and trees that are up to 5 inches in diameter.

“It’s ideal for right-of-way maintenance for road construction, as well as clearing of smaller lots for building projects,” Bricker noted. “In addition, it’s optimized for 50-horsepower (hp) to 75-hp skid steers, which can be found on virtually any construction jobsite.”

Furthermore, contractors can use the manufacturer’s FMX28 mulcher, which has been created for 3.5-ton to 8-ton standard-flow excavator models. It can clear trees and brush alongside creeks, ravines, riverbanks, roads and other areas that are difficult to reach.

Also a draw for rental centers, in particular, the mulcher offers contractors an attachment option that’s effortless to rent, use for a project and return once the project has been completed.

“Because of excavators’ unique operations, the mulcher opens the door to the usage of compact excavators in mulching applications, specifically for selective or precision mulching,” Bricker explained. “It’s especially suitable for clearing small pads for tower construction or removing invasive species.”

Finally, contractors can use the BLACKHAWK BK6218, a mulcher that’s been designed to quickly process the fibrous, stringy vegetation that’s typically found in the Southeast.

“Utilizing a DCR rotor, a shear bar, a wear liner and a body geometry that enables it to tackle trees that have fallen or are standing, the mulcher

To ensure land and brush clearing is more effortless for operators, John Deere Construction and Forestry offers specialized attachments like the ME36 mulchers.John Deere John Deere

Because of its four blades, reinforced push bar and open-face design, Caterpillar’s Cat BRX318 can get close to large debris, such as trees that are up to 8 inches in diameter, and it cuts them close to the ground.

can clear any jobsite,” Bricker added. “And, due to its rear throat, it can process debris during back dragging, without ever leaving any unprocessed materials behind.”

Without question, contractors have a wide array of options to clear land at jobsites. Sometimes the job calls for equipment with specific functions.

Other times, equipment is chosen based on the types of brush and land that operators need to clear. With this in mind, John Deere Construction & Forestry has a variety of equipment for operators to choose from.

“We provide drum-style mulchers that can process material into smaller pieces, along with disc-style cutters that cut, knock down and process the larger pieces,” said Doug Laufenberg, solutions marketing manager, attachments at Deere.

“If timeliness is critical, disc-style cutters may be the more suitable option, as they’ll likely cover more ground faster, since they aren’t processing material into smaller pieces.”

Deere also offers grapples and root rakes with which operators can knock down the growth and then gather material with a grapple or a rake to dispose of in another way, he added.

Recently, Deere added drum and disc mulchers to its compact excavator lineup. Furthermore, the manufacturer has introduced a depth control rotor on its skid/CTL mulcher.

As a result of the rotor, operators can minimize “the bite that the drum (of each drum mulcher) can take on trees,” according to Laufenberg. It also allows operators to work with thinner, twiggy wood more efficiently, whenever they need to cut and process brush and trees.

To ensure land and brush clearing is more effortless for operators, the manufacturer offers specialized attachments like the ME36 and ME50 mulchers, which are equipped with knife-style cutting teeth on a split ring motor.

“The mulchers’ spiral, double helix tool patterns, along with their tool shapes, enable operators to quickly and efficiently cut mulch that’s up to 5 inches in diameter,” Laufenberg said.

Deere provides brush cutters like the RE40 and the RE50 that offer more versatility for excavators. Especially ideal for embankment and ditch management, over-fence brush management and rail right-of-way maintenance, the brush cutters can be used for other areas that are difficult to reach, as well.

“Each of these attachment offerings allow operators to tackle land clearing and brush cutting tasks with the equipment they likely already own,” Laufenberg stressed.

“However, since they’re made specifically for brush cutting and land clearing, operators can achieve these tasks more efficiently than they previously did.”

As evidenced by the wide assortment of product offerings on the market, from brush cutters, to mulchers and stump grinders, land and brush clearance is a complicated undertaking. Clearing jobsites is only becoming more complicated as the construction industry continues to evolve.

The bottom line? Operators’ equipment use must evolve, as well, to ensure their land and brush clearance processes are as effective and straightforward as possible.

“As roads and utility infrastructures expand and alternative energy sources grow, the need for brush and land clearing will only continue to grow, too,” Fecon’s Bricker said. “Evolution will be the name of the game, as manufacturers continue to respond to this growth through continuous changes.

“[Because of] these evolutions in products and the demand for them, the future is certainly bright for brush and land clearing equipment manufacturers — and each of the professionals and contractors that utilize their offerings.”

Read more at: https://eqtoday.co/mulcher

To clear brush and land that’s difficult to remove, operators can use specialized attachments and tools.

Whenever Fecon launches a new product, the manufacturer is inspired by direct feedback and requests from customers. For example, after hearing customers in the Southeast express how difficult stringy, fibrous wood is to remove, the manufacturer developed its BLACKHAWK mulcher attachment

Because of its durable, heavy-duty design, the attachment can process and mulch this type of wood, ultimately resulting in a clean jobsite that’s fully prepared for future construction work.

Meanwhile, as a result of customers’ demands, it also developed its STUMPEX attachment, a safer alternative to traditional wheeled stump grinders.

“Operating with a low rpm (19 rpm to 41 rpm), as well as high torque (up to 33,000 foot-pounds), the attachment processes stumps—both above and below ground—with easy cleanup and no flying debris,” stressed Ryan Bricker, product manager at Fecon.

Aside from these two attachments, operators, whether they’re professionals or contractors, can use disc or drum mulchers, too, as they strive to clear brush and land that’s challenging to remove. While doing so, Matt Nelson, director of development at Diamond Mowers, advises them to install whichever teeth are the most suitable for their particular jobsites.

Carbide hammer-style teeth: Because of its durability, this type of teeth can be used in areas that are difficult to clear. However, they often bludgeon wood apart rather than cutting or slicing it, leading to a decline in productivity, an issue operators must bear in mind.

Steel teeth: Very sharp because they can be sharpened throughout their lifespans, steel teeth can effortlessly cut and slice through wood. Yet, they can also become dull rather easily, particularly whenever they hit rocks or contact with the ground.

A combination of both: Since Diamond Mowers’ cutting tools weigh the same, operators can mix and match teeth on their drums without impacting balance, according to Nelson.

“As operators encounter brush and land that’s difficult to clear, they’ll regularly install sharp steel teeth towards the middle of each of their drums, where larger materials are naturally processed, and carbide teeth towards the outside of their drums,” Nelson said. “This combination will enhance productivity and minimize operating costs, regardless of how challenging a jobsite is to clear.”

You’re less likely to see a site dumper in North America than in the U.K., where you may see an entire fleet on a jobsite. However, contractors looking for compact equipment solutions that offer more for their investment are starting to take notice of the factors that make the equipment popular overseas.

With advanced safety features and a compact footprint, site dumpers offer outstanding efficiency and safety on all jobsites—especially those where space is at a premium.

While contractors in Europe that are accustomed to compact jobsites have long appreciated the benefits of the site dumper in industries ranging from construction to agriculture, North America’s wide-open spaces invited and allowed larger equipment. Now, as urban sprawl continues and jobsites become smaller with heightened safety concerns, contractors across multiple industries are reconsidering the site dumper.

Site dumpers first gained acceptance in North America in the

concrete market. With numerous jobs requiring the delivery of concrete in tight areas that won’t accommodate a mixer truck or pump truck, site dumpers paired with an optional concrete chute accessory offer a viable solution.

The chute provides the added benefit of precisely dumping the concrete where it’s needed without splashing, effectively minimizing any cleanup.

The popularity of the site dumper is growing beyond the concrete industry into landscaping applications. With the ability to move much more material than a skid steer without tearing up turf, the site dumpers offer an ideal solution for not only hardscaping applications but also mulching and maintenance.

Along with landscaping, golf course developers purchase site dumpers to aid in the construction of new golf courses and find them a versatile tool for not only construction but also overall maintenance.

Cemeteries are perhaps one of the most often overlooked areas of growth for site dumpers. While few people like to spend much time reflecting

on cemetery management, those in charge of managing large cemeteries recognize the challenges of tight spaces, sensitive turf and even more delicate emotions. With so much on the line, it’s important to take extra precautions to be as careful, efficient and meticulous as possible. Many cemeteries find that by using a site dumper, they can quickly maneuver an excavator to dig a grave and load the soil directly into the site dumper, leaving no mess or tarps for the family to navigate. Then as soon as the burial is complete, the site dumper backs up and easily and quickly unloads all the material directly into the grave quickly and cleanly, finishing the burial. High flotation, low-impact turf tires provide additional benefits in all

As the array of site dumper benefits — including capacity, efficiency, safety and reduced diesel maintenance — become more apparent in North America, the growth of the site dumper market will undoubtedly increase.

these applications by limiting ground disruption.

But as jobsites continue to get tighter, construction challenges are driving up demand in general construction applications.

The enhanced efficiency the machines offer over traditional equipment solutions is perhaps at the heart of expanding interest in site dumpers in North America. Some manufacturers offer 3-ton site dumper models with capacities of 1.3 cubic yards for liquid material such as concrete, 1.7 cubic yards for struck material such as aggregate and 2.5 cubic yards for heaped material like mulch. Though skid steers were once the standard on any jobsite for moving a variety of materials, contractors are finding that replacing a skid with a skip (site dumper) and mini excavator duo often results in three to four times the material handling capacity. In addition, site dumpers increase efficiency because material can be loaded directly into the skip—or bucket—and left until maneuvered wherever needed, and dumped, instead of multiple material moves with a skid steer.

A more compact design and tighter operating footprint further enhances efficiency. The forward and swivel tipping mechanisms of site dumpers allow contractors to maintain a small jobsite footprint and improve safety.

Unlike skid steers, most site dumpers swivel and tip material out of the bucket without the need to reposition the entire machine. This allows operation in tighter spaces and minimizes additional maneuvering around an already tight jobsite.

To realize the benefits of the site dumper, it is paramount that contractors not just choose any brand or model, but a high-quality one from a trusted manufacturer.

Many features, though subtle to the eye, greatly affect safety, ease of operation and performance.

As sites get smaller and pressures increase to get more done, a keen focus on safety protects not only the operator but the entire jobsite and the company as a whole. Site dumpers designed with precise attention to detail, ensuring perfectly symmetrical wheels equal distance from the center articulation post of the machine, maximize safety and stability even while driving through heavily rutted areas in mud or other unstable terrain. This reduces the risk of tipping and provides a smooth ride, as the back wheels follow the same path as the front at all times.

With current skilled labor shortages, ease of use and intuitive controls present another key

consideration. Contractors gravitate toward models with controls that are easy to learn and use, benefiting safety, and allowing for a lower barrier to entry for operators at any experience level.

Finally, some manufacturers produce site dumpers with engines rated under 75 horsepower. This helps

avoid diesel exhaust fluid (DEF) and diesel particulate filter (DPF) related maintenance.

As the array of site dumper benefits—including capacity, efficiency, safety and reduced diesel maintenance—become more apparent in North America, the growth of the

site

With a load capacity from 2,200 to 22,000 lb and 0.74 to 5.1 cu yd skip capacity, the AUSA dumper collection will become your most valuable piece of equipment for your construction jobs. Designed to increase your profitability by being able to remove dirt faster than other equipment options, especially when combined with a mini excavator. Safety is also an increased highlight with visibility provided by the operator’s position located on top of the machine.

Visit www.ausa.com for more information

In today’s competitive construction industry, contractors are always looking for ways to make their work more efficient. New technologies and tools are constantly being introduced to increase productivity and safety on the jobsite. One tool that has become increasingly popular is the stand-on skid steer. These machines—which are a step up from a traditional compact skid steer but have a smaller footprint than other compact track loaders— offer several benefits that make them an attractive option.

In an industry where time is money, here are a few of the key reasons contractors are reaching for full-size stand-on skid steers.

If you’re having trouble finding crew members for your jobs, you’re not alone. According to the Deloitte 2022 Engineering and Construction Industry Outlook report, more than half of construction executives indicated that they are facing a severe labor and talent shortage on the jobsite. And these shortages are expected to continue.

While the industry works to find a solution, an easy and immediate step to compensate for a lack of workers is to maximize equipment. Contractors are looking for full-size, stand-on skid steers to fill in the gaps for lack of skilled labor. Increased horsepower on full-size stand-on skid steers means they have the ability to connect with larger attachments, in return being able to lift and move larger loads in fewer trips. This added power can fill the workforce gaps by lifting loads that would otherwise require three or four workers.

Additionally, storing and

transporting equipment can be a daily, yet headache-inducing task for contractors. To help eliminate the downtime associated with this task, it is crucial that you bring machinery onto the jobsite that is designed to be quickly stored at the end of the workday and easily transported from one project to the next. Stand-on skid steers are compact enough to fit on a trailer, yet large enough to make a difference in filling the gap for laborers.

In addition to added power and workforce support, contractors are reaching for full-size stand-on skid steers for their versatility. Rather than hauling multiple smaller, specialized machines to a jobsite, a larger standon skid steer can be outfitted to complete a wide variety of tasks. Fullsize, stand-on skid steers have the capability to be outfitted with power attachments like a microtrencher for fiber installation projects. A fullsize, stand-on skid steer can go from trenching for a utility installation to hauling gravel in a matter of minutes.

In fact, the versatility has made the tree care industry a major driver larger stand-on skid steer trend. Being able to move bigger logs means tree care professionals are spending less time making cuts before hauling away. Attachments like tree grapples and bucket grapples are being used to help improve efficiency in treecare jobs like debris removal. The compact size—compared to cabbed machines of the same operating capacity—also make it ideal for tree care professionals who need to seamlessly maneuver through yards and residential areas.

With smaller crews and high

demand, many contractors are taking on two or three different jobs in a day, so having a machine in the fleet with more power and versatility to stay efficient and cost-effective is key.

With the wide variety of attachments, a stand-on skid steer can be rented year-round for tasks like digging, hauling, grading and snow removal. This versatility means that the machine can be rented to a wide range of customers with different needs, making it a profitable addition to any rental fleet.

Compared to their cabbed counterparts, stand-on skid steers are a simpler, less intimidating option for inexperienced renters working on residential projects. The compact design of a stand-on skid steer allows it to fit navigate around obstacles, making it perfect for use in backyards or other confined jobsites.

Stand-on skid steers are designed to be easy to use, even for novice operators. The simple controls and intuitive design make it easy to get

started with the machine, and their reliability gives renters reassurance they’ll be able to complete projects with minimal maintenance. With a stand-on platform, operators receive a 360-degree view. This increase in jobsite visibility and comfort helps operators see what is happening around the machine, boosting jobsite safety.

With so many options on the market, there’s a reason contractors and renters are driving the trend for full-size stand-on skid steers. The powerful, versatile machines are a valuable asset to any rental lot or contractor’s fleet. They’re powerful enough to fill the gap where the workforce is short, yet simple enough for renters to hop on safely and get to work in their backyards. The range of attachments and easy-to-operate design makes full-size, stand-on skid steers a great option for those looking to get the best bang for their buck on the jobsite.

Read more at: https://eqtoday.co/c16gqw

The Canycom CMX1402 Ride-on Brush Cutter features four-wheel drive and large tires for added traction on slopes and wet ground.

• Hydrostatic drive system for smooth and seamless operation

• Shaft-driven cutter deck requires no belts or pulleys

• Adjustable cutter deck for trimming from 0 in. to 6 in.

• 389-cc Honda gas engine with a rated output of 14 hp

Grapple LIne

Ignite Attachment’s grapple lineup offers powerful, versatile tools that allow equipment operators to pick up and move heavy objects, such as logs, rocks, roots and debris, without sacrificing heavyduty performance capability. The Ignite grapple attachment is designed to fit a selection of machines and can be used in construction, demolition or landscaping projects. You will be able to find the root, rock and bucket grapples in 82-in., 74-in., 68-in. and 62-in. models. Ignite Attachment’s grapple line is capable of picking up and moving objects of various shapes and sizes. Its powerful jaws can grip objects securely, preventing slips or falls during transport.

The Compact Stumpex is a slow-speed, high-torque, auger-style stump grinder designed specifically for compact utility loaders.

• Slow auger speed ensures a safer work environment with no flying debris and faster cleanup

• High torque eradicates stumps of any species from 4 in. to 11 in. in diameter in a single plunge

• Powerful, robust drive generates up to 4,000 lbs. of torque

• Features hardened auger cone that ensure positive draw into stump and stepped blades made of 1/2-in.-thick durable AR500 material

• Suited for compact utility loaders with 10 gpm to 20 gpm of hydraulic flow and 2,000 psi to 3,000 psi

The heavy-duty Battle Ax horizontal drum mulcher is offered in 61-in. and 71-in. cutting widths for skid steers with 50 hydralic hp to 120 hydraulic hp.

• 17-in.-diameter rotor features built-in depth gauges to prevent attachment from engaging too much material at one time

Two-stage cutting chamber allows material to be cut twice by the rotor and helps produce smaller particle sizes

• Primary shear bar adjustable for customizing particle size

• Adjustable skid shoes (0.5 in. to 1.5 in.) enable below-grade mulching

• Fixed-displacement gear or variabledisplacement piston motor

The M60-S and M60-C forestry mulchers have a 60-in. cut width and are powered by a 160-cc variable piston hydraulic motor controlled by E-TECH Smartdrive.

• ECU-controlled power management system adapts and controls motor displacement to produce instant torque and optimal mulching performance

• Can be tuned to any machine in seconds using Bluetooth and a smartphone app or with the in-cab monitor

• Direct drivetrain puts all available power to the rotor

• Head on the M60-S produces up 780 ft.-lbs. of torque with a maximum rotor speed of 2,500 rpm

M60-C includes a hydraulically controlled dual-mode cutting chamber that offers fingertip control of mulch size and degree of broadcasting desired

The 915E FM is a professional forestry excavator designed for logging, collecting and transporting wood under harsh working conditions, such as forests, wetlands and more. This machine is equipped with a Cummins engine and a coordinated hydraulic system for output and movement. The 915E FM uses specific protection for forestry and a 960-mm-wide single-grouser track. The minimum ground clearance is up to 600 mm for safety and low grounding pressure for travelling in the forest.

The ME36 and ME50 are suited for right-of-way maintenance and fire/fuel reduction as well as clearing standing or felled trees and brush along fence rows, roadsides, waterways and other hard to reach places.

• Knife-style cutting teeth on a split ring rotor

• Spiral double helix tool pattern and tool shape allow for efficient cutting of up to 5-in. material

• Controlled and metered cutting depth allows the operator to maintain high rpms and a productive mulching rate

• Teeth may be sharpened and flipped

• Tested and optimized to work with the company’s excavators and compatible with many competitive 5-ton to 10-ton models

The Grubber slices roots and extracts brush in one easy motion and is available in models to fit most excavator sizes and classes including minis.

Constructed with a heavy-duty upper channel, AR400 steel cutting edges and triple pass welds on the high-stress areas

• Available with a replaceable bolt-on edge V-edge or straight edge

• Suited for select extraction of brush and nuisance vegetation

• Minimize ground disturbance, reduce erosion and promote grass growth

Powered by the 104-hp Cat C3.6 Tier 4 Final/Stage V-compliant diesel engine, the D1 Mulcher includes closed-loop hydraulics and upgraded screening that optimize performance while clearing a mix of small- to medium-diameter materials in a 72-in.-wide strip with each pass. The unit is design-matched with the rugged HM518 mulcher, which has a drum speed range of 2,150 to 2,450 rpm and comes with 38 fixed teeth featuring a single-bolt carbide tooth retention design. Its pressurized, heated and air conditioned cab includes mulcher controls mounted on the air suspension seat, a 10-in. color touchscreen monitor with standard reversing camera display and an in-cab drum indicator for monitoring drum speed and direction at a glance.

The 135VRT has a 4,150-lb. rated operating capacity with integrated counterweight or hydraulic winch kit, and is powered by a 132-hp Cummins 3.8L Tier 4 Final engine. A 50-gpm auxiliary attachment flow provides 119 hp to the VM602SS Bull Hog Forestry Mulcher or other attachments; a 16-gpm reserve allows full machine control without loss of attachment performance. A bite-limiting rotor is fitted with 30 carbide or doublesided tools and maintains rotor rpms to easily mulch material up to 8 in. in diameter. An improved loader arm design enhances attachment visibility. The full forestry spec cab includes 1/2-in. polycarbonate side windows, a Level 2 FOPS and a complete guarding package, while the more spacious, comfortable operator station includes an 8-in. color display.

Danuser’s EP Auger System for backhoes, mini skid steers and excavators feature a planetary gear drive that is up to 42% stronger than the competition with greater torque for drilling through hardcompacted surfaces. It is available in a wide array of models, ranging from 6 to 35 gpm and from 1,500 psi to 3,500 psi.

• Accessible check and fill plugs

• Swings from a knuckle to allow left to right, forward to back leveling

Most vehicles with 72-in. or greater hinge pin height may use standard 4-ft. length augers. Hinge pin heights of 71 in. or shorter require 3-ft. length augers maximum

• The output spindle is manufactured as a single piece, allowing Danuser to offer a lifetime warranty covering output spindle pullout

Vermeer has introduced a redesigned version of the HG4000 horizontal grinder. This new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production. It’s equipped with a 536-hp (399.7-kW) CAT C13B T4F Stage V diesel engine, a Series III duplex drum, an infeed to accommodate a variety of materials and many performance and durability features. It has a working sound level of 112 decibels. The HG4000 has a feed table capacity of 4.6 cu. yd. (3.5 m3). It features the cutting performance of the Vermeer patented Series III duplex drum with reversible hammers and tips for reliable wear life, compared to singlesided designs, while offering bolt in replacement parts. The hard-faced anvil on the HG4000 delivers cutting action with the drum and a redesigned anvil-mount structure minimizes the hard-faced wear edge replacement process.

Purpose-built for processing applications, the 197-hp PC230F-11 has a rugged design, high and wide undercarriage, a powerful swing motor and is designed to withstand high-debris conditions. The wide-fin radiator is covered by heavy-duty forestry screens, and a variable pitch reversing fan helps promote airflow. With a powerful swing system and a large swing circle, trees can be moved with the PC230F-11. Its reach of up to 29.3 ft. (8,951 mm) and maneuverability help support operations. This machine features a Komatsu SAA6D107E-3 Tier 4 Final engine. Operators can adjust to a sudden change in load weight with the Auto Power Max feature. It automatically senses the difference and reacts with an 8.5-second burst of additional horsepower to help pull the trees through during the delimbing process.

SEPPI has launched its latest mulching equipment: the MAX 50 le, a mulcher than can be operated by remote control, the MICROFORST cl compact mulcher for skid steers or compact track loaders and the MINISOIL cl that crushes stones and mulches wood. The MAX 50 le can be operated from a safe distance by using a remote control that displays key machine data like fuel, rpm and speed. The MICROFORST cl is a compact mulcher that can attach to any compact track loader or skid steer loader that delivers between 13 gpm and 27 gpm of hydraulic flow. The MINISOIL cl takes the power of a PTO stone crusher and mulcher and brings it down to size for skid steers, compact track loaders and hydraulic tractors that deliver at least 28 gpm to 66 gpm of hydraulic flow.

IronCraft redesigned its Forestry Disc Mulcher, which is capable of eradicating 6-in. to 14-in. diameter materials and standing or felled trees. A 60-in. fully machined disc includes 44 beaver teeth located on the top, bottom and perimeter of the disc, with five additional beaver teeth located on the inside of the deck for mulching capacity. An angled throat design guides material into the mulching chamber to support the shredding of brush. This mulcher is available with either 150-cc motor that requires 32 gpm to 44 gpm of hydraulic flow or 200-cc motor that requires 45 gpm to 60 gpm of hydraulic flow. All models feature a 1-in. hinged deflector and 0.375-in. thick deck with reinforced sides.

Diamond Mowers offers the Belt Drive Disc Mulcher for contractors and mulching professionals. The attachment features reliable torque and promotes low hydraulic temperatures for uptime and carrier life. Forward visibility for contractors minimizes the possibility of hitting obstacles and enables positioning vegetation for performance. Featuring a 60-in. cutting width, this attachment slices through trees and brush up to 14 in. in diameter, shreds material up to 6 in. in diameter and attaches to most skid steers and compact track loaders. While Four-Point Hardened Steel Teeth come standard, users can swap them for Twin Maul Carbide Teeth to absorb impact and apply the right bite for various applications.

The Mini Skid Steer Quick Attach Frame for Mini Track Loaders includes a Common Industry Interface (CII) loader quick attach, enabling use with a variety of brands of mini loaders, including Bobcat, Boxer, Ditch Witch, Kanga, Ramrod, Toro and more.

• Designed for a maximum load of 3,000 lbs. at an 18-in. load center, depending on fork tine capacity

• Frames can be used with the company’s pallet forks, grapples, stump buckets, hydraulic plow and more

Built using high-strength steel with MIGwelded construction

• Baked-on powder coat augmented by a proprietary graphite coating on the fork rails for easier sliding of forks

• Includes a built-in 2-in. receiver

Mecalac’s new product line of compact loaders to the North American market is comprised of six models, including the MCL2, MCL4, MCL4+, MCL6, MCL6+ and MCL8. The series offers performance for industries ranging from agriculture to landscape, forestry, snow removal, utility and construction. The M-Drive and speed control features allow the loader to function as a tool carrier, providing control of rpm by hand throttle and speed via a foot pedal. This enables controlled operation of a wide variety of hydraulic attachments. Each MCL in the series has an option for auxiliary hydraulic lines on the boom and at the rear of the machine, as well as 12-volt three-pole plugs, allowing the ability to use hydraulic attachments on either end of the machine. The MCL series maximizes attachment possibilities with 7.9 gpm flow on the MCL2 and MCL4 models and 15.9-gpm flow on the MCL6 and MCL8 models. Each machine has a 45-degree articulation that keeps the front wheels traveling in the same path as the rear wheels while driving. A 10-degree oscillation allows a stong follow up and maximum traction wherever the machine might travel, including on uneven ground. Each machine in the MCL series offers transportability between jobsites with low transport weight, which ranges between 3,836 lbs. and 6,283 lbs.

The overall importance of having the right tires on jobsite equipment and maintaining them properly cannot be overstated. Maximizing uptime and increasing efficiency is always top of mind for construction fleets, and both factors are directly impacted by a fleet’s tires, noted Robby Hamby, Bridgestone America’s director of commercial product strategy.

“These tires are asked to navigate challenging surfaces and conditions, making the equipment vital for operations,” Hamby added.

Bridgestone has invested heavily to advance tire technology and digital solutions to help fleets get the most out of their equipment and to arm operators with data to help them make informed decisions, Hamby pointed out, adding “keeping a vehicle’s tires healthy and at max performance allows jobsites to move forward.”

“Most jobsites today cover large areas, meaning it is crucial for the crews to be able to maneuver around the site safely and efficiently,” noted Cory Trombley, NHT North America regional sales director for Nokian Tyres. “Wheeled machines allow job crews to do just this.”

“Tires play a crucial role in ensuring the safe and efficient operation of construction equipment,” noted Scott Holub, BKT manager, offthe-road (OTR) technical services. “Properly functioning tires can stabilize heavy machines and prevent accidents from occurring on jobsites.

“Tires that are well-maintained and replaced when necessary can help reduce downtime by preventing breakdowns,” Holub added. “Additionally, with the correct tire, contractors can impact fuel consumption, operating costs and overall productivity.”

“Having the right tires will ensure that the application has the best performance to do the job,” said Molly Chen, MAXAM Tire North America spokesperson. “Tires should be maintained along with the equipment itself as they provide support for the application.”

Tire options abound in the marketplace. Bridgestone offers a wide variety of tires for construction fleets, all of which are designed to help drive uptime, Hamby said. Bridgestone’s portfolio of construction tires includes the Bridgestone VMT and the

Firestone Duraforce MH, two products designed with enhanced tread patterns for traction and high performance in construction.

The company recently announced its new 25-inch VZT construction tire at 2023 CONEXPO-CON/AGG. Used for loader and grader applications, the VZT is designed to enhance key performance attributes to help maximize productivity and provide traction while improving on its smooth, comfortable ride, Hamby said.

Nokian Tyres offers premium block-pattern and flotation tires for the construction industry.

“Our tires are designed to offer end users long working hours and high-load capacities as well as a more comfortable ride when moving around the jobsite,” Trombley said.

MAXAM Tire manufactures tires for a variety of construction applications, including skid steers,

backhoes, telehandlers and pavers.

Chen noted that the tires are designed with high-quality materials and engineered to provide the lowest cost per hour.

BKT offers tires for a wide range of construction equipment including excavators, bulldozers, loaders, graders, dump trucks, and more.

Tires for Electric Equipment

More electric vehicles (EVs) are coming on the scene. As states such as California set the stage for carbon emissions reduction, some tire companies are answering the call for EV-appropriate tires.

Hamby noted Bridgestone’s line of premium construction tires and integrated technologies are EV-compatible.

“Our team of engineers is continually looking for ways to innovate and develop new products with EV technology in mind for commercial fleets,” he said. “It’s important to note that tires for electric fleets can exhibit different wear and replacement cycles, but with the proper settings and the latest technology, that wear cycle can be controlled.”

BKT recently introduced its first E-READY tire line, the Agrimax Factor, in response to a growing trend toward EVs in the construction industry.

The Agrimax Factor is designed for tractors and features reinforced side walls, a stronger bead package and an updated tread compound.

“In the future, BKT will look into expanding the E-READY tire line to additional applications,” Holub said.

Tires for electric vehicles must be different from traditional ones because EVs weigh more since their batteries may add up to 30% extra weight, which

can affect tire performance, according to Piero Torassa, BKT field engineer manager at BKT Europe.

Tires also must withstand higher drive torque, especially at the start, Torassa noted, adding it is necessary to revisit the tire’s bead structure to ensure better grip on the rim, especially during acceleration. The tread also be optimized in design and compound.

Tires mounted on an EV that are inadequate can cause significant energy losses, since rolling resistance can contribute as much as 20% of the vehicle’s energy consumption, according to Torassa.

Subsequently, it is necessary to adapt the tread compound, tread pattern and sidewall structure. Tires used for EVs should have different tread patterns and compound compositions, both natural and synthetic. Size also significantly contributes to a tire’s quietness, Torassa pointed out.

Selecting the Ideal Tire for an Application

An equipment operator should consider many factors when choosing a tire for construction site work. Focus on understanding the job conditions in which the equipment will operate when selecting a tire for construction site work, Chen said.

“For example, will the equipment be on soft underfoot conditions in mud? Or will it be operated on icy roads? What is more important to the contractor?” Chen added.

“If it is off-roading, consider the load-carrying capacity. Does the

contractor prefer radial or bias? Does the contractor worry about puncture? Many variables come into play other than size and pricing. One must consider the condition the equipment operates in and choose the right tires accordingly.”

Trombley echoed the point that the biggest key when choosing a tire is making sure to select the right tire for the application, adding that it is important to make sure the tires are rated for the type of environment in which they will be used.

Equipment operators should choose a tire that offers excellent traction, stability and durability, Holub said. “With that being said, it is important

Nokian Tyres TRI 2 excels in a wide variety of tasks from job sites to highways, from snowy winters to hot tarmac. Its durability, economy and comfortable driving response make it a reliable choice for versatile contracting work.

nokiantyres.com/heavy

Tires play a crucial role in ensuring the safe and efficient operation of construction equipment.

to keep in mind many factors, like application, type of equipment, load and speed, before making a final decision,” Holub added.

Hamby said that it is important to understand the site conditions in which the equipment in the fleet will operate when deciding. Bridgestone’s network of 2,500 authorized dealers helps evaluate this information

and recommend tires based on the conditions, he added.

Asset management capabilities are also worth considering, said Hamby, adding that Bridgestone offers solutions and technologies designed to enhance the ability of an equipment operator to properly monitor tires on a construction fleet.

“Our tires are manufactured to seamlessly connect with digital

health-monitoring solutions like IntelliTire that monitor a tire’s attributes in real-time,” he said. “By pairing tire monitoring solutions with premium tires, equipment operators can detect and avoid tire issues before they happen, maximizing their investment by extending the life of the tire.”

Hamby pointed out that “increasingly, forward-looking fleet operators are looking at tires not simply as a cost to be managed but as an investment to be maximized, realizing that tires are integral to an optimally safe and efficient fleet.

“By pairing … Bridgestone tires with data-driven insights, our Bridgestone end users are seeing how the right tires and data can drive significant, bottom-line efficiencies as well as sustainability in their daily operations.”

Today’s Tire Technology Tire companies are now offering technology enabling equipment for operators to identify tire problems before they develop. The best way to maintain tires is to prevent downtime before it happens with health

Routine maintenance is not only vital to the health of tires but also to overall fleet efficiency, said Bridgestone America’s Hamby. “Tire-related downtime can result in significant financial and operational costs, so it is important to maximize the investment and get the most out of the tires,” he added.

Basic tips for maintaining tires:

˜ Regular tire inspections should be performed to look for any damage (cuts, embedded materials, torn lugs, bulges and cracking) that could impair the equipment operation.

˜ For radial tires, always check the air pressure to ensure that it is at its optimal pressure according to the manufacturer, said MAXAM Tire North America’s Chen. “Air pressure for each application is determined by many different factors, and just as we all know, a tire cannot perform without air,” she said.

˜ BKT’s Holub added, “In addition to looking for damage during the inspection, contractors should check air pressures weekly, as improper air pressure by as little as 5 pounds can reduce the performance and life of a tire.”

˜ “Proper pressure maintenance is crucial and must be done regularly,” said NHT North America’s Trombley. “Overloading is one of the main causes of early failures in tires, so as an industry we need to do everything we can to educate end-users on the importance of checking air pressures regularly.”

˜ Cold inflation checks are the best and most accurate. A cold tire is generally defined as one that has been sitting idle and not used for a minimum of 24 hours, said Chen, adding from this point, the pressure can be monitored more accurately.

˜ “Hot inflation checks in most cases are the norm since many operations are 24/7,” she said. “Therefore, knowing the cold inflation pressure of the tire will help track the rise in pressure in a working tire. This will then help to set the correct standards for warm inflation checks.”

˜ For certain tires and applications, rotating the tires may be required to maximize life, noted Holub.

˜ Use a tire gauge if needed.

monitoring solutions like IntelliTire, said Hamby.

The digital solution is a remote health monitoring system that uses internal or external stem-mounted sensors to provide critical real-time data such as tire inflation pressure and temperature to continually monitor the health of each tire throughout its life cycle, he added.

“The data gathered by this tool help fleets reduce downtime by scheduling maintenance when needed, optimize total cost of ownership, and maximize productivity,” Hamby said.

BKT has developed a device called SPOTech (Satellite Performance Optimization Technology). SPOTech uses GPS, accelerometers, video cameras and data loggers during site visits to record distances, cycle times and speed. BKT combines that information with the customer’s production data to calculate which tires will perform best. This helps optimize a customer’s operation and reduce maintenance issues, said Holub.

Nokian Tyres recently launched its own tire monitoring system called Nokian Tyres Intuitu.

“Our goal with this program is to offer our customers ‘Smart Tires,’ giving them the ability to track the performance of their tires right from their phone,” Trombley said.

Tire Maintenance

MAXAM Tire has a series of technical bulletin articles to help end users maintain their tires and understand how to choose the right tire. The company advocates daily maintenance checks on tires, making the point that it’s important for construction companies to do so to derive optimal productivity and life from them. Basic inspection points include the tire’s external appearance, rims and valves, and inflation pressure.

Additional signs of damage include punctures and cuts. Small, hard objects can penetrate the tread, casing and inner liner, resulting in loss of air and casing strength. If the damage is caught early enough, the tire can be repaired. If the cut is too deep, the tire should be scrapped.

Separation of the tread from the belt or casing ply is another sign of damage. It is caused by normal shear forces in a working tire after being cut. Small cuts can transform into separation over time, resulting in heat build-up and subsequent increases in the size of the separation. If caught early, the tire can be repaired. If not, it must be scrapped.

Heat separation is caused by excessive brake heat and loads, causing tread or bead area separation, with the rubber giving off a burnt smell. Operators should stay within ton-mile/hour requirements and monitor loads.

Turn-up separation is caused by excessive shear and/or bending force in the bead area, resulting in excess load and causing the tire to bend over the top of the flange.

The result is heat buildup and subsequent separation, although it may also be a manufacturer issue. The issue can be addressed through proper and evenly distributed loading of the

vehicle. The tire should be removed once the steel is showing.

Impact breaks are caused by excessive impact energy loading beyond breaking the strength of the casing. It results in immediate air loss—blow out—or damaged cords, causing separation. The tire should be scrapped, and the operation should

focus on improving clean-up and proper operation.

Read more at: https://eqtoday.co/ykg6jh

No matter how challenging your needs, EARTHMAX SR 41 is your best ally when it comes to operations that require extraordinary traction. Thanks to its All Steel radial structure and the special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort.

EARTHMAX SR 41 is BKT’s response to withstand the toughest operating conditions in haulage, loading and dozing applications.

Vehicle electrification remains a hot topic. In his annual letter to stakeholders, BlackRock’s CEO Larry Fink asserted, “The next 1,000 unicorns won’t be search engines or social media companies. They’ll be sustainable, scalable innovators who help the world decarbonize and make the energy transition affordable.”

Off-highway electric vehicles (EVs) are witnessing high adoption across industries globally as governments aim to reduce carbon emissions and offer rebates and tax incentives to deploy these types of vehicles on jobsites

They are reaping some of its benefits: fewer fumes, noise, emissions, and decreased energy costs and operating costs. While electrification in construction equipment is expected to grow globally, barriers remain.

Many incumbent vehicle manufacturers and component suppliers are grappling with how they can best respond to an increased demand for EVs in the construction industry, disrupting their traditional product offers and business models in the pursuit of maintaining market share in this market shift.

While the path forward is necessarily different for every company, construction equipment

manufacturers that focus on these three key areas — customer value creation, product and technology planning and development, and financial performance and potential— will do the best at speaking to a growing segment of contractors looking to electrify jobsites.

Many fleets have made bold sustainability commitments and goals—and at the same time remain committed to improving total cost of ownership, end-customer satisfaction, and their own employees’ satisfaction. To deliver against all these goals, much will have to change.

No one player has “cracked the case” on an end-to-end electrification solution—but those who focus on first becoming experts in their customers’

end-to-end production processes are the likely winners.

Partnering with customers to understand priorities and to define jointly how their processes can evolve for electrified vehicles will be key to achieving market adoption. For example: How will electricity be generated and transmitted (for example, at the depot or the jobsite)? How will EV drivetrains impact vehicle uptime and duty-cycle performance, and what compromises may need to be made?

This range of issues spanning customers’ processes and how manufacturers and suppliers will address these needs can be tackled with a master plan that clarifies a wide range of issues. Distinct vocations with disparate dutycycle requirements—for example, mining and construction equipment—necessitate offering a portfolio of solutions to address customer segment needs.

Investors recognize the imperative to shift to electrified vehicles and are also beginning to recognize what manufacturers and suppliers have known for years: there is no one-toone conversion of profit pools.