Amazon Now Offers Supply Chain Software Industrial Companies Move Toward Open Tech Profinet: Designed for Openness and Determinism Precise Automation Required for Pick-and-Pack Machine New Product Spotlight Finance’s Role in Analytics 06 08 30 42 95 106 36 TRAINING WITH WORKFLOW AND SIMULATION SOFTWARE JANUARY 2023 / www.AutomationWorld.com

The intelligent self-contained vision sensor from Datalogic can be taught what images represent a quality product or proper object orientation. The sensor can determine a pass/fail or good/no good condition and output a discrete signal. Verifying fill level, cap orientation, and label presence as the product exits a bottling line is one example of an application these sensors are designed for. They can even make complex decisions involving the color of a product for quality assurance purposes.

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405

Machine Vision with fast and easy setup.

Smart

Datalogic Smart Vision Sensor

at

Research, price, buy at: www.automationdirect.com/vision Also Available Color Sensors Barcode Scanners RFID Devices DATALOGIC SMART VISION SENSOR PRICED AT $879.00 (959971320) • Machine learning assisted setting • Easy and Intuitive webserver GUI for maintenance and setup • No vision tools or programming experience required • 50-150 mm operating distance • Bright and highly visible red LED pointer • Powerful white polarized light illuminator • Cable exit connections can be rotated

Priced

$879.00 (959971320)

Profinet: Designed for Openness and Determinism 30

A look at Profinet’s development, from its origins in Profibus fieldbus communications to its ability to adapt to Ethernet’s ongoing evolution and provide the determinism required by many industrial users.

Training with Workflow and Simulation Software 36

As the next generation of workers comes to industry, proper training is critical to ensuring their success in complex, highly automated industrial environments. Here’s a look at how simulation and workflow software technologies are helping industrial companies more e ectively train new operators.

Precise Automation Required for Pick-and-Pack Machine

Using Mitsubishi Electric servo motors and intelligent drives enabled Hamrick Manufacturing to create a machine with a lower cost controller that reduced changeover times by nearly 98%.

EDITORIAL

David Greenfield Director of Content/Editor-in-Chief dgreenfield@automationworld.com / 678 662 3322

Stephanie Neil Senior Editor sneil@automationworld.com / 781 378 1652

Victoria Sanchez Managing Editor vsanchez@pmmimediagroup.com / 571-612-3200 x9298

Mike Prokopeak Senior Director, Content & Brand Growth James R. Koelsch, Lauren Paul, Jeanne Schweder and Beth Stackpole Contributing Writers

ART & PRODUCTION

Filippo Riello Marketing & Digital Publishing Art Director friello@pmmimediagroup.com / 312 222 1010 x1200

George Shurtle Ad Services & Production Manager gshurtleff@pmmimediagroup.com / 312 222 1010 x1170

ADVERTISING

Kurt Belisle Publisher kbelisle@pmmimediagroup.com / 815 549 1034 West Coast

Jim Powers Regional Manager jpowers@automationworld.com / 312 925 7793 Midwest, Southwest, and East Coast Kelly Greeby Senior Director, Client Success & Media Operations

AUDIENCE & DIGITAL

Elizabeth Kachoris Senior Director, Digital & Data Jen Krepelka Director, Digital Media

PMMI MEDIA GROUP

David Newcorn President, PMMI Media Group Kurt Belisle Publisher kbelisle@pmmimediagroup.com / 815 549 1034

Reed Simonsis Brand Operations Manager rsimonsis@pmmimediagroup.com / 312 205 7919

Sharon Taylor Director of Marketing staylor@pmmimediagroup.com / 312 222 1010 x1710

Amber Miller Senior Marketing Manager amiller@pmmimediagroup.com / 312 222 1010 x1130

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com / 312 222 1010 x1330

3 JANUARY 2023 |

21 |

1

VOLUME

NUMBER

AW JANUARY 2023 CONTENTS

Automation World | PMMI Media Group 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611 Phone: 312 222 1010 | Fax: 312 222 1310 www.automationworld.com PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571 612 3200 • Fax: 703 243 8556 www.pmmi.org ONLINE 4 FEATURES CASE STUDY 42 LEADERS IN AUTOMATION 44 INDUSTRY DIRECTIONS 6 NEWS 18 PERSPECTIVES 8 NEW PRODUCTS 95 KEY INSIGHTS 110 Exclusive content from AutomationWorld.com: videos, podcasts, webinars, and more Amazon Now Offers Supply Chain Software Robot Safety Awareness Aveva Outlines Its Technology Plans Robot Piece Picking Advances with Artificial Intelligence Emerson’s Plantweb Incorporates AspenTech Software to Expand Automation Capabilities Quality Assurance Using Scanning Acoustic Microscopy Industrial Companies Move Toward Open Automation Tech The Smart Sensor/Predictive Maintenance Connection How Siemens’ Amberg Factory Uses Red Hat OpenShift Does Data Need to be Standardized? Product Spotlight Industrial Collaborative Robot Product Spotlight Machine Visualization and more... All Automation World editorial is copyrighted by PMMI Media Group, Inc. including printed or electronic reproduction. Magazine and Web site editorial may not be reproduced in any form without thewritten permission of the publisher. FINANCE VIEW 106 The Case for Investing in Manufacturing Analytics By Larry White ENTERPRISE VIEW 108 How to Pivot from Vision to Value By Diane Sacra IT VIEW 107 The New MESA Smart Manufacturing Model By John Clemons

PODCAST SERIES

Determining Metrics for MES

Sam Russem with system integrator Grantek explains how MES software tracks key production metrics and how manufacturers should go about assessing their operations to figure out which metrics to track with MES software.

AUTOMATION WORLD TV

How Decoupling Hardware and Software Extends Automation

Schneider Electric’s Michael Martinez explains how decoupling devices from software allows you to extend the life of automation systems while also improving their availability, scalability, and performance.

TECHNOLOGY MATTERS

Industry Shapes the Future of Automation

Companies such as Pfizer, Shell, ExxonMobil, and Intel show the value of automation and where it’s headed through their use of specific technologies.

AUTOMATION WORLD E-BOOK

Peer-to-Peer FAQ: Cybersecurity

Learn how to protect your company against bad cyber actors.

ON-DEMAND WEBINARS

Mitigating Cyber Risks in Operational Technology (OT), Buildings, and Critical Infrastructure

In this webinar, representatives from Advantech and Veridify Security will discuss the evolving cyber threat landscape, security implications of OT/IT convergence, elements of a Zero Trust security framework, and real-time protection, device-level cybersecurity with Intel-based Dome.

New Approaches: Version Control and Device Backup for Industrial Automation

How modern version control and backup tools work and are being applied in industrial automation.

4 AW JANUARY 2023 ONLINE

^ƚƌŽŶŐ�ďƌĂŶĚƐ�ĂǀĂŝůĂďůĞ�Ăƚ�ĂƵƚŽŵĂƟŽŶ ODUC IN ST PRODUCTS EXCEPTIONAL PRICING $ PRICING $ FREEAPPLICATION SUPPORT 2 YEAR 01 0 % MONEY BACK 1 0 0 % GUARANTEE 90 DAYS GUARANTEE Y HIGH QUALIT IN S EXCEPTIONAL FREEAPPLICATION 2 YEAR % MONEY BACK 1 90 01 0 0 0 % DAYS 800-250-6772 (free) or 610-981-2900 ŵĂŝůΛĂƵƚŽŵĂƟŽŶ24.com ĂƵƚŽŵĂƟŽŶ24.com /ŶĚƵƐƚƌŝĂů�ĐŽŵƉŽŶĞŶƚƐ�fast Ăƚ�Ă�ƉƌŝĐĞ�LJŽƵ�ĐĂŶ�ĂīŽƌĚ Excellent 4.9 out of 5 See what our customers are saying: Easy ordering and super fast shipping. Will order from them again. &ĂŶƚĂƐƟĐ�ƐĞƌǀŝĐĞ�Ăůů�ĂƌŽƵŶĚ � Knowledgeable and accessible tech support, and above and beyond customer service. Easy to use website, great price, and quick FREE shipping. Ŷ 2 4 . co m ^ƚƌŽŶŐ ŽŶ�ŽƵƌ�ǁĞďƐŚŽƉ� LJŽƵ�ƉůĂĐĞ�LJŽƵƌ�ŽƌĚĞƌ ŽŶ�ŽƵƌ�ǁĞďƐŚŽƉ� LJŽƵ�ƉůĂĐĞ�LJŽƵƌ�ŽƌĚĞƌ

Amazon Now Offers Supply Chain Software

By David Greenfield

Editor-In-Chief dgreenfield@automationworld.com

It was just a matter of time before the cloud services providers began offering their own versions of the software they’ve been hosting on their platforms for years. As an example of this shift, Amazon Web Services (AWS) is now offering its AWS Supply Chain application to “help businesses increase supply chain visibility to make faster, more informed decisions that mitigate risks, save costs, and improve customer experiences.”

Companies already using AWS Supply Chain include Traeger Grills, Lifetime Brands (supplier of home goods by brands such as Farberware and KitchenAid), and Amazon’s own Whole Foods Market.

Features of the cloud-based software are based on nearly 30 years of Amazon.com logistics network experience, says AWS. For example, the unified data lake feature of AWS Supply Chain uses machine learning models pretrained for supply chains to understand, extract, and transform disparate data into a unified data model. AWS says the data lake can “ingest data from a variety of data sources, including existing ERP and supply chain management systems.”

Another feature of AWS Supply Chain is its Insights module for information on potential supply chain risks—such as overstock or stock outs. When risks are detected, the software automatically evaluates rebalancing options to provide recommended actions. The options provided by the software are scored by the percentage of risk resolved, the distance between facilities, and the sustainability impact, according to AWS.

The Demand Planning feature of AWS Supply Chain reportedly adjusts to market conditions and allows for collaboration across teams to avoid excess inventory costs and waste. As with the

unified data lake component, this module of AWS Supply Chain also uses machine learning. Here it is used to analyze historical sales data and realtime data, create forecasts, and adjust models to improve accuracy.

AWS offers a free trial period of 60 days, which includes 1,000 product SKU location combinations to be used for AWS Supply Chain Insights and Demand Planning and 10 GB of data storage. Following that, pricing is listed as follows:

• Data Storage and services: importing of data is free, with the first 10 GB of data priced at $0.28/hour and $0.25 per GB/month for additional storage beyond the first 10 GB.

• Insights capabilities are priced at $0.40 per product SKU for the first 100K SKUs; $0.13 per product SKU for the next 900K SKUs, and $0.065 per product SKUs over 1 million.

• Demand planning pricing is $0.30 per product SKU for the first 100K SKUs, $0.10 per product SKU for the next 900K SKUs, and $0.035 per product SKU for SKUs over 1 million.

INDUSTRY

6 AW JANUARY 2023 EDITORIAL

DIRECTIONS

en ris s are detected, the so ware automatica eva uates re a ancing o tions to rovide recommended actions e o tions rovided the so ware are scored the ercentage o ris reso ved, the distance etween aci ities, and the sustaina i it im act

Industrial Companies Move Toward Open Automation Tech

By David Greenfield Editor-in-Chief

By David Greenfield Editor-in-Chief

If there’s a holy grail in the field of automation, it’s true plug-and-play—or plug-and-produce— capability. But with decades of devices and software created to run on proprietary systems still in operation across industry, the plug-and-produce concept has faced an uphill battle against vendors’ business models until a few years ago when a few large end users began to demand easier interoperability of automation technologies more openly.

The most vocal and active among these end users was ExxonMobil with its support of the Open Process Automation Forum and its accompanying Open Process Automation Standard (O-PAS). A key aspect of ExxonMobil’s participation in the development of the O-PAS standard was its use of

nxtControl’s technology in the company’s proofof-concept testbed for the standard.

Schneider Electric acquired nxtControl in 2017 for its runtime software based on the IEC 61499 standard. IEC 61499 uses event-driven function blocks for industrial process measurement and control systems, allowing distribution of applications across multiple devices and systems, regardless of vendor.

What’s IEC 61499 got to do with it?

As Automation World contributing writer Stephanie Neil noted in her open automation coverage from the ARC Forum event in June 2022: “[IEC

61499] is not a programming language, but a system design language for distributed information.”

The standard does not define the programming language but does recommend the use of the IEC 61131-3 languages. The function blocks used in IEC 61499 act on local variables only, enabling it to be an independent and self-contained software component. The graphical nature of this function block application is familiar to automation engineers, making it easier for debugging and commissioning.

The IEC 61499 standard is core to the e orts of UniversalAutomation.org—an independent, notfor-profit association of users and vendors managing the implementation of a shared source runtime execution engine based on the IEC 61499 stan-

8 PERSPECTIVES AW JANUARY 2023

Automation Intelligence YOUR ONE-STOP SHOP FOR AUTOMATION Motion Ai is a nationwide supplier of motion control products and premier custom solutions for your automation needs. ai.motion.com

dard. UniversalAutomation.org seeks to provide the basis for “an ecosystem of portable, interoperable, plug-and-produce solutions to create an entirely new category within industrial automation,” according to the organization.

Greg Boucaud, chief marketing o cer of UniversalAutomation.org, said the organization is focused on two things: 1) Being a technology enabler with the event-driven function block use of IEC 61499 as a selfcontained software component; and 2) decoupling application software from hardware with application and device models, leading to a systems model where software components are mapped to devices. “With this, developers can write once and distribute across multiple UniversalAutomation.org-compliant devices,” he said.

Schneider Electric agrees that the IEC 61499 standard provides the groundwork for enabling “plug-and-produce” automation technology components, leading it to help develop and support UniversalAutomation.org.

John Conway, president of UniversalAutomation.org, said, no one company can deliver everything needed for industry’s interoperable digital transformation, but UniversalAutomation.org helps make this possible by delivering an implementable version of the IEC standard for integration across multivendor platforms.

Insights from ExxonMobil, Intel, and Wood PLC

At the Schneider Electric Innovation Summit 2022, David DeBari, control systems engineering associate at ExxonMobil; Brad Bonnette, technical director of applied intelligence at Wood PLC, a consulting and engineering company targeting the energy and materials markets; and Richard Kerslake, general manager of industrial control and robotics at Intel, spoke about their support for UniversalAutomation.org.

“Intel is a big believer in software-defined control systems,” said Kerslake. “Today you think of [automation in] discrete boxes, such as PLCs and HMIs. Here [with IEC 61499], we break the bonds between hardware and software, which makes the whole lifecycle easier in terms of deployment and updates. And having the flexibility to choose best-of-breed hardware is about protecting your investments.”

DeBari added that he is also a strong advocate for the hardware and software separation abilities of IEC 61499. “I’ve been using the 61499 runtime for years and it’s proven to be very capable. [At ExxonMobil] we started proof of concept tests with it back in 2017 and we’ve tortured it ever since. We want to know if we can break it.”

He noted that the state-based control model used in IEC 61499 has proven very robust and

portable. “We’re doing a rip and replace for a new open process automation system at one of our chemical plants with 2,000 instruments and hundreds of loops—and we’re using 61499 as the logic. We have no doubt this will work,” DeBari said. “We found that the features, portability, distribution, and event-driven capability of IEC 61499 takes you o the clock cycle. This is going to make enough money [for ExxonMobil] that it’ll clear accounting hurdles easily.”

Bonette added that industry should not view the runtime engine as the value of IEC 61499. “It [the runtime engine] does its job and I don’t have to think about it. The value is in using embedded intelligence in software control. It allows us to focus on high value add components, like increasing the level of intelligence applied to process control instead of having to rewrite it for every hardware platform. You shouldn’t have to think about the hardware platform when you buy a control application.”

Wood is currently working with IEC 61499 on complex control strategies like emissions. “We’re applying it to thermal oxidizer logic across multiple pieces of equipment,” Bonette said. “We can build in fault tolerance and resilience, enabling it to adapt because it is grounded in state-based control.”

Kerlsake said Intel is working with Exxon and Schneider Electric on a new generation of Distributed Control Nodes (DCNs) using IEC 61499. These DCNs are field-level edge devices capable of control functions and running applications. He added that they’re also focusing on Linux-based edge controls for industrial applications.

Beyond control applications, Bonnette believes IEC 61499 can also be used to support the next generation of cybersecurity through the development of apps that include authentication and verification principles.

Compliant hardware and software

Having the IEC 61499 runtime engine supported broadly by industry was a first step. The next step, of course, is having compliant hardware available on the market for broad implementation.

Though UniversalAutomation.org was launched less than a year ago, several available automation hardware devices that support IEC 61499 include:

• Advantech’s UNO 430 ruggedized industrial PC;

• ESA Automation’s EW420 ruggedized industrial PC;

• Flexbridge’s IceBlock intelligent wireless dnode;

• Stahl’s IS1+ remote I/Os;

• Schneider Electric’s Modicon M251 machine PLC, Modicon M580 process PLC; and ATV variable speed drive card.

On the software side, Schneider Electric o ers its Ecostruxure Automation Expert, which uses IEC 61499 to decouple hardware and software to provide one common language to connect all systems. According to the company, Ecostruxure Automation Expert’s native IT/OT convergence via IEC 61499 helps it integrate with advanced IT applications, tools, and technologies for industrial use. And its asset-centric design with pre-developed asset models can be used to make it easier to reuse portable automation objects.

“When you start looking at this, you realize the control paradigm is going to change,” said DeBari. “You can break the 61499 into parts and run them in di erent places. We made each compute node do only one thing in a series of devices totaling 38 I/O points and 56 computers in a PID loop and it worked. And we’ve run it at 1 ms and below using general purpose compute and network capabilities. This is why we’re confident it can run our chemical plants that have highly energetic processes if not managed properly.”

10 PERSPECTIVES AW JANUARY 2023

e gra hica nature o this unction oc a ication is ami iar to automation engineers, ma ing it easier or de ugging and commissioning

C OUNTRIES WITH S ALES , SER VICE, AND MANUF A CTURING F A CILITIES 30 The quality of Yaskawa products is second to none, but Yaskawa Quality goes beyond that. It’s the total experience of purchasing Yaskawa products and working with people. 9 Global Expertise 9 Proven Quality Management 9 MTBF of up to 28 Years 9 Award Winning Customer Service 9 Product Lifetime Training 9 Free 24/7/365 Technical Support Want to have that working for you? Contact Yaskawa today. Yaskawa America, Inc. 1-800-YASKAWA Email: info@yaskawa.com | yaskawa.com 14,800+ W ORLD WIDE EMPL O YEES SINCE 19 15, Y ASKA W A HAS PRODUCED ... 18M SERVO AMPLIFIERS 500K ROBOTS RS K 30M AC DRIVES 100+ YEARS MANUFACTURING EXCELLENCE Edwards Edwards R. Deming R. Medal for Quality Northface Scoreboard Award for Excellence in Technical Support Interaction Metrics Superior Customer Experience Award action Metr t rthface f E ll FOR MORE INFORMATION: https://www.yaskawa.com $4.5B *GL OB AL S ALES * Based on 2021 reported sales. For reference only QUALITY, RELIABILITY, OPERATIONAL EXCELLENCE STRENGTH IN NUMBERS TOTAL SYSTEM SOLUTION

e mart ensor redictive aintenance onnection

By David Greenfield Editor-in-Chief

By David Greenfield Editor-in-Chief

For several years now, case studies have been showing that predictive maintenance delivers the most bang for the buck for manufacturers of all sizes. This is hardly surprising given that adding a few additional sensors and access to predictive maintenance software—much of which is cloud-based and can be purchased on a monthly or annual basis—can very quickly deliver insights into equipment health to help avoid unplanned downtime and improve scheduled maintenance activities.

The money saved here goes directly to the company’s bottom line, providing a quick return on investment on these new sensor and software technology purchases.

In fact, industry’s uptake of these sensor and software technologies can be seen in the rapid growth of the predictive maintenance technology market. Interact Analysis, an international technology research firm, expects the predictive maintenance technology market to reach a valuation of nearly $1 billion by 2024.

Understanding smart sensors

Considering the critical role smart sensors play in this growing predictive maintenance market, it helps to understand how they di er from traditional, legacy industrial sensors. According to Blake Gri n, senior analyst with Interact Analysis, “most smart sensors utilize a capacitive MEMS (micro electro-mechanical systems) technology to take readings. These sensors are placed on equipment to gather various data points, most commonly vibration and temperature measurements. Smart sensors then transmit this information wirelessly to a data collector or gateway. When analyzed, this data is particularly useful for assessing the health of equipment as the level of vibration and temperature usually increases as equipment becomes faulty.”

Gri n added that these smart sensors were first largely used in consumer electronics. Their widespread use in consumer technologies helped suppliers achieve “economies of scale in these ap-

plications, enabling the smart sensor concept [to be adapted] for industrial applications. The result is a product with a low price point which allows users to cost-e ectively expand the amount of equipment monitored in their facilities.”

The low cost and ease of implementation due to wireless communication capabilities in smart sensors make it easy for industrial companies to deploy many more sensors than has been typical with legacy wired sensor technologies. This eases the transition from condition monitoring to predictive maintenance.

How smart sensors enable predictive maintenance

Predictive maintenance requires analysis of historical data to assess if equipment is trending towards a failure. Gri n notes that machine learning (ML) algorithms are increasingly being used by analytics software providers to “enhance the understanding of the application being measured” based on the historical data produced by the smart sensor.

“This not only expands the number of applications able to be monitored beyond well understood ones, it also increases the amount of time operation managers have to resolve a piece of equipment that is trending towards failure,” he says.

While these ML algorithms are predominantly used in predictive maintenance analytic software,

Gri n says Interact Analysis is seeing some cases where these algorithms are being embedded in the smart sensor to “determine what data is relevant before transmitting that data to the software for deeper analysis.”

Gri n expects this trend of embedding ML algorithms on the sensor as an important future trend for the sensor technology market.

“Since the advent of smart sensors, major automation vendors like ABB, Siemens, WEG, and Nidec have all released their own versions,” Griffin says. “We expect this trend to continue as the product is desperately needed for manufacturers to begin generating tangible benefits from IIoT technology.”

Find out how your peers across industry are using sensor technologies and artificial intelligence to improve their operations.

12 PERSPECTIVES AW JANUARY 2023

AVAILABLE NOW Four IO-Link Ports Modbus RTU EtherNet/IP Modbus TCP ProfiNet FEATURES New IO-Link Master DXMR90-4K Compact Form Factor Rugged Design Built-in Status Indication Configurable Modbus Port

How Siemens’ Amberg Factory Uses Red Hat OpenShift

By David Greenfield Editor-in-Chief

By David Greenfield Editor-in-Chief

Among the clearest pieces of evidence that the industrial digital transformation is underway is the increasing use of tools once reserved solely for IT in operations technology (OT) applications. In many cases, automation technology suppliers are showing the way by implementing these technologies in their own production operations.

A case in point is Siemens, whose Amberg electronics plant in Germany has moved away from a legacy Oracle system it used to run operational systems such as order management. This order management system at the Amberg facility manages 350 changeover processes between di erent production lines to ensure the right tools are in place and to update system status.

To replace the legacy system, Siemens is now using Red Hat OpenShift to create a more modular, microservices-based IT/OT architecture. This move allows developers at Siemens to apply artificial intelligence-generated data insights for smaller-scope changes to avoid disrupting operations.

Red Hat OpenShift is an enterprise Kubernetes container platform deployed on premises in Siemens’ Amberg data center to create a cloud-native, modular architecture for its operational processes and systems.

According to Siemens, making changes to the previous Oracle system required planned system downtime due to the larger scope updates required by that system. Any unplanned downtime to the order management system on the Oracle system could impact the ability to meet the facility’s daily production goals for some 1,200 di erent products. Siemens Simatic products such as controllers, HMI, SCADA, and I/O are produced at the Amberg factory.

Amberg’s applicationOpenShift

With the improved data collection and analysis enabled by Red Hat OpenShift, Siemens’ developers can gain insights into current production system conditions and evaluate opportunities

for ongoing improvement. Siemens is also using Red Hat OpenShift to automate routine tasks and support code reuse, enabling operations to continuously improve the performance of its production systems.

“Using Red Hat OpenShift at our Amberg facility means our developers can be more involved and see the real-time changes that occur when applying data insights to our production operations,” said Christian Schulze, IT project manager at Siemens Amberg. “Time savings as small as tenths of a second add up in an integrated production line like ours. It generates 4.5 million requests each day, and even millisecond improvements in processing time can have a positive e ect.”

Integrated GitOps capabilities (which automate application development processes) in OpenShift enable more frequent updates and deployment of applications for uses such as predictive maintenance and quality assurance. These updates also continuously improve the prediction accuracy of OpenShift’s artificial intelligence tools used to analyze the Amberg’s factory data in the cloud.

Siemens is also using Red Hat OpenShift to address cybersecurity threats to its manufacturing systems. This is provided by Red Hat via ongoing patches and bug fixes for the entire container application stack.

“Security has become an increasing concern, given the value of our data, the complexity of our operations, and the potential cost of disruption,” said Schulze. “Even though our central IT team is only 80 km away in Munich, we cannot have any interruption in connectivity that would slow a production line in our manufacturing facility. Red Hat OpenShift allows us to complete patches on a rolling schedule with no disruption to daily production.”

14 PERSPECTIVES AW JANUARY 2023

When assembling printed circuit boards at the Amberg facility, AI provides insights into the probability of errors in the printed circuit boards. Source: Siemens

Imagine the benefits of motor feedback and position measurement from a single compact rotary encoder installable on all robot axes. Look no further than the new KCI 120 Dplus dual encoder from HEIDENHAIN. It lets you master the inaccuracies

that plague dynamic, highly articulated robots, such as gearbox backlash and forces induced by the application at the end effector. The KCI 120 Dplus turns a conventional articulated robot into a high-accuracy production system and a dependable cobot.

HEIDENHAIN CORPORATION www.heidenhain.us

The KCI 120 Dplus dual encoder High-accuracy robot motion Advanced robotics solutions www.heidenhain.us/industries/robotics

Does Data Need to be Standardized?

By David Greenfield Editor-in-Chief

By David Greenfield Editor-in-Chief

No matter where you’re at in your digital transformation process, the core requirement of connecting automated machines or systems for any kind of Industry 4.0 or Internet of Things integration or analyses requires data standardization. The reason for this is that data from these various systems is created in many ways. Therefore, to make each system’s data understandable, transferable, and digestible in real time by any other system, standardization of the originating system’s data is a must.

That’s why you’re hearing so much about UNS (unified namespace). As described by Will Aja of systems integrator Panacea Technologies, “UNS allows for a central location to be the source of data for your plant’s assets. This central repository then allows connections to edge devices as well as other platforms and databases, thereby decreasing the number of separate connections that must be maintained.”

Aja adds that “UNS is not only here to stay but is becoming the default deployment option. The majority of our projects in the past several years have included partial or complete utilization of a UNS.”

While a UNS serves as the critical data connector, it is just an architecture designed to be used in this manner. How the data within it is handled can be done in several di erent ways depending on how the UNS is built.

John Harrington, co-founder and chief product o cer at HighByte, the supplier of Intelligence Hub (software designed for industrial data modeling, delivery, and governance), says industrial companies have three options to building a UNS when using Intelligence Hub.

MQTT broker

Over the past several years now, MQTT has become a preferred method for making plant floor data accessible to multiple sources in a way that does not impact the performance of the plant’s equipment. According to Harrington, the most frequently deployed UNS architecture involves building it in an MQTT broker. In this manner, data from multiple systems is published to the UNS via a topic structure in the MQTT broker. This basic structure usually follows the broad ISA-95 outline of company, site, area, line, work cell, and asset.

These steps alone, however, do not address all the data management challenges involved. The topic namespace with relevant data payloads still needs to be logically structured and MQTT requires further support for publishing and subscribing applications. Harrington says this is where Intelligence Hub can help.

“The Intelligence Hub can consume data from multiple sources, assemble the data into logical payloads that follow the ISA-95 structure or other standards, and publish the payload to the UNS,” he says. “The Intelligence Hub can also be used to subscribe to data in the UNS and then publish it to systems via MQTT or through REST APIs, SQL databases, or OPC namespaces for those systems that don’t communicate over MQTT.”

Data lakes

Rather than adjust existing system integrations, some companies prefer to send their data to a cloud-based data lake for use by analytics or dashboard visualization applications. Even here, data standardization and contextualization are still required due to the varied origins of the data as noted above. Here, Intelligence Hub can serve as a UNS gateway.

“Models in the Intelligence Hub consolidate and standardize data into contextualized information objects, while flows in the Intelligence Hub target data to the specific location in the data lake or cloud broker where they are needed,” explains Harrington.

Integration hub

This is type of UNS implementation referenced above by Aja. Here the focus is not on creating a central broker, but on integration—which helps explains the interest from system integrators—as it standardizes data for transfer among systems.

Harrington explains that, in this hub-and-spoke architecture, Intelligence Hub serves as the UNS integration hub. “The Intelligence Hub makes connections to source systems, ingests the data, and standardizes and contextualizes the data into information objects specifically designed for the consuming application,” he says. “By providing a

code-free user interface, Intelligence Hub eliminates the need for custom-coded integrations or additional data transformations and reduces integration maintenance.”

To further clarify why this hub-and-spoke approach is preferred to other methods of data centralization and transference for integration projects, Aja says, “Data historians, for example, often involve a complex series of drivers and connectors to roll the data up into the centralized storage, whereas the UNS model allows for a single connection to the UNS to collect all the data. The reporting platform can then query the UNS, which knows to query the data historian (and other databases if required) to return the desired data. This helps eliminate the complexity, points of failure, and maintenance costs required to keep vast amounts of connectors updated and operable.”

16 PERSPECTIVES AW JANUARY 2023

Learn more about HighByte’s DataOps software for data standardization.

See why MQTT is such a popular industrial communications method.

We develop the best automation solutions. Together. With you. Today for tomorrow. Innovation needs Dialogue. We look forward to a conversation with you. Contact or visit us at www.lenze.com See us at:

West 2023 – Booth #4183 | February 7-9 | Anaheim, CA

2023 – Booth #S437 | March 20-23 | Chicago, IL

ATX

ProMat

Robot Safety Awareness

By David Greenfield Editor-in-Chief

When it comes to automation technologies, robots always draw the most interest and attention. This happens for two reasons: 1) robots are fascinating to watch in action; 2) robots are helping to address realworld labor issues that are, in some cases, crippling production operations.

Amid this fascination with robot kinetics and the labor issues they’re helping to resolve, one issue that isn’t always adequately addressed is robot safety. Even with ever-safer robot technologies emerging via the growth of collaborative robots and technologies that can make industrial robots more collaborative, robots are still moving equipment that require safety assessments the same as any other automated machinery.

To raise awareness of this issue, Festo Didactic and Sick have created a safety awareness training package that focuses on robot risk assessments and related safety implementations. This package includes a Festo Didactic Manufacturing Production system and a simulated smart factory featuring a six-axis robot, Sick area scanners, a safety PLC, and a safety relay.

Though this safety awareness training package has been established in several community colleges and universities across the country, its use is not limited to students. Workers in industry can also sign up for the safety awareness course to upskill their robotics knowledge.

Beyond helping students and workers understand the importance of risk assessments, the training course is also helping them understand what to do with the digital data captured in the process. The curriculum features a six-step method around robotics and automation equip-

ment safety to ensure students understand risk assessments, safe design, technical protective measures, administrative information about residual risks, and machine validation and deployment.

Festo and Sick designed the curriculum to be robot agnostic so that it can be used by all robot manufacturers.

Listen to this podcast on machine risk assessments.

18 NEWS AW JANUARY 2023

Moxa Inc. www.moxa.com • Industry-leading Network Security: IEC 62443-4-2 certified • Unprecedented Performance: 90 W PoE and 2.5 GbE connectivity • Multiple Industrial Certifications: NEMA TS2, EN 50121-4, IEC 61850-3/IEEE 1613, DNV*, ATEX Zone 2**, Class I Division 2** • Advanced Usability: Intuitive Web GUI and rotatable power module * Only available for the LV and PoE models ** Only available for the LV models Networking Evolved, Strengthened Resilience Networking Evolved Moxa's EDS-4000/G4000 Industrial Managed Switches Visit www.moxa.com/ EDS-4000-G4000 to learn more

Aveva Outlines Its Technology Plans

By David Greenfield Editor-in-Chief

With the recent acquisition of Aveva by Schneider Electric (which already owned a sizable stake in the company), many current and perspective users may be wondering about the future direction of the company. Aveva executives sought to clarify this at the Aveva World 2022 event in San Francisco.

Peter Herweck, CEO of Aveva, said Aveva will continue to operate as a separate company under the Schneider Electric umbrella. “Aveva will become a private operation in a large, publicly listed company.” He added that Schneider Electric is Aveva’s “largest client today” and most of Aveva’s software is already part of Schneider Electric’s technology offerings.

With Aveva’s stated goal of bringing together its technologies into one end-to-end, artificial intelligence-infused software for engineering and

20 NEWS AW JANUARY 2023 PROComSol Process Communications Solutions ProComSol, Ltd is a leader in the design and manufacture of advanced, cost-effective, and reliable HART communication products for the Process Control marketplace. +1 216 221 1550 sales@procomsol.com Convert your mobile device into a full featured HART communicator. A modern replacement for expensive hand-helds Hazardous area options available for Windows and Android! procomsol.com DEVICE CONFIGURATIONS Cloud features!

Aveva's Rob McGreevy explaining the company's technology vision at Aveva World San Francisco 2022.

Aveva CEO Peter Herweck.

: Agile machines with adaptive automation

Flying 2D product transport with up to 6 degrees of freedom

XPlanar enables new dimensions of freedom in product and material handling: Levitating planar movers fly over flexibly arranged planar tiles accommodating nearly any track layout and path planning.

Individual 2D transport at up to 2 m/s

Processing with up to 6 degrees of freedom

Transport and processing in one system

Wear-free, hygienic and easy to clean

Free arrangement of planar tiles enabling totally customized machine and process layouts

Multi-mover control enables parallel and individual product handling

Fully integrated into the powerful and standardized PC-based Beckhoff control system (TwinCAT, PLC IEC 61131, Motion, Measurement, Machine Learning, Vision, Communication, HMI)

For use across all industries: assembly, packaging, food/bev, pharma, laboratory, entertainment, …

AT11-20USA

Individual product transport Free system layout 6D motion Scalable payload kg Levitating planar movers Velocities up to 2 m/s

Scan to experience XPlanar in action

operations, all accessible via one pane of glass, the task lies in achieving this broad-based integration.

Rob McGreevy, chief product officer at Aveva, explained the work ongoing at Aveva to achieve this vision.

“We will continue to offer a modular, not monolithic, approach with the intent to create an open, vendor neutral environment to deliver an industrial software platform,” he said, explaining that 30-40% of that data that comes into Aveva’s engineering and operations software comes “from other company’s products. The PI System (acquired by Aveva from OSIsoft in 2020) was a leader in this. And it’s the same with Wonderware InTouch HMI/SCADA (acquired by Aveva in 2018 via the merger with Schneider Electric, which had owned Wonderware since 2014 with its acquisition of Invensys).”

McGreevy said Aveva is essentially blending different user interfaces to connect systems from the edge to the enterprise. Based on this approach, Aveva plans to release the “first-ever coordinated HMI/SCADA release in 2023 via the integration of the Aveva Historian and PI systems to the cloud-based Aveva Data Hub,” McGreevy said. “This takes the HMI concept and applies it to the enterprise.”

To optimize both equipment assets and operational processes, McGreevy said the combined

forthcoming system will be able to schedule work based on data-driven performance plans and asset maintenance predictions. This will involve the integration of Aveva artificial-intelligence-powered analytics and the PI system to connect operational processes and analytics.

As an example of what will be possible for industrial companies with these combined technologies, McGreevy noted Thai petrochemical company SCG now saves 40% on maintenance costs after digitalizing its equipment and processes data through application of the PI system. “SCG achieved a 9x return on investment (ROI) in 6 months using predictive analytics, mobile operator technology, Unified Operations Center, and the PI system,” he said.

He added that Aveva’s vision is to create a connected community where users still own all their data but can securely share it with equipment vendors, suppliers, and customers. “Digitizing this value chain—from design to operations—helps identify and minimize costs,” said McGreevy.

The ability to access a digital twin of assets, processes, and sites gives users information needed to improve operations and maintenance as well as training. With digital twins built on this coordinated data, engineering efficiencies can be increased by 30%, McGreevy added. “It’s more than linking documents for access,

its’s about delivering additional information to a worker as it’s presented; for example: Do you need a ladder to access the equipment [to perform the required maintenance]?”

22 NEWS

AW JANUARY 2023

Learn more about the trend toward HMI/SCADA becoming core to enterprise-level software.

How Pfizer, Shell, and others are digitally transforming their operations.

others

SCG Chemicals plant in Thailand. Source: SCG Chemicals Business

�ƵƚŽŵĂƟŽŶ �ŽŶƚƌŽůƐ WƌŽĐĞƐƐ 60&�LV�SURYLGLQJ�WKH�SRLQW�WR�SRLQW�GLJLWDO�FRQQHFWLRQV�WR�PHHW�\RXU� FRPPXQLFDWLRQV�SURWRFRO�UHTXLUHPHQWV� +LJK�3UHFLVLRQ� 'LJLWDO�3UHVVXUH� � 9DFXXP�6ZLWFKHV +LJK�3UHFLVLRQ�'LJLWDO� 3UHVVXUH��6ZLWFKHV� IRU�DLU��DQG�IOXLGV 'LJLWDO�)ORZ� 6ZLWFKHV�IRU�ZDWHU $FWXDWRU�6WURNH� 3RVLWLRQ�6HQVRU )LHOGEXV�6,�8QLW�IRU� &RQWURO�9DOYHV (OHFWUR - 3QHXPDWLF� 5HJXODWRU 6WHS�PRWRU�&RQWUROOHU� IRU�(OHFWULF�$FWXDWRUV 3URYLGLQJ�6XVWDLQDEOH��(QHUJ\�(IILFLHQW�DQG�&2 ��5HGXFLQJ�&RPSRQHQWV�IRU�,QGXVWULDO�$XWRPDWLRQ 60&�&RUSRUDWLRQ�RI�$PHULFD ���-���-���� ���������ZZZ�VPFXVD�FRP 60&�$XWRPDWLRQ�&DQDGD�/WG� ���-���-���� ����������ZZZ�VPFDXWRPDWLRQ�FD (PDLO��VDOHV#VPFXVD�FRP ,2 - /LQN�%DVH�IRU� (;����6,�8QLW�IRU� &RQWURO�9DOYHV

Robot Piece Picking Advances with Artificial Intelligence

By David Greenfield Editor-in-Chief

Artificial intelligence applications have been growing rapidly in a variety of industrial technologies, ranging from data analytics and quality inspections to autonomous mobile robots. Now the technology is being applied to robotic grasping applications to enable accurate picking and placing of random objects in unstructured and changing environments.

Siemens says it is working to “democratize artificial intelligence (AI)-enabled robotics by encapsulating systems for complex problems in easy-to-use software.” To this end, the company is developing an as-yet-to-be-named software technology designed for use by system integrators and OEMs to create cost-effective, advanced AI-driven piece-picking systems that can “reliably pick and place objects that are unknown to the system at runtime.”

Differentiating factors

Traditional automated pick-and-place systems follow fixed, pre-programmed routines in a structured environment. Applying AI enables robotics to perform generic tasks in unstructured and dynamically changing environments.

Go sustainability.

Emerson’s

Learn more at Emerson.com/Sustainable-Automation

Explaining how the technology Siemens is developing differs from the use of 3D vision to enable robots to pick and place random objects, Dr. Eugen Solowjow, head of the Robotics & AI Research Group at Siemens, said, “picking and placing unknown objects is still relatively new. It has existed for, at most, two years in the market and, up until now, has not been very commonly distributed. These systems rely on AI—more precisely Deep Neural Network technology—to pick objects that are unknown to the system during setup and/or engineering.”

Thus, the key differentiator with the developing Siemens technology is its ability to pick unknown objects.

According to Siemens, this new software will enable users to move from using robotic systems with static pick points to an AI-driven piece picking robot in less than an hour. Setup for the system is accomplished in four steps: set the robot arm and related end-of-arm tooling to move safely to static pick-and-place points; mount the 3D camera; install the Siemens software for piece picking on the target runtime hardware of choice; follow the guided setup via the user interface for calibration.

With these steps implemented, calculated pick points are then continuously provided to the robot motion program, enabling the robot to grasp any object.

“The set up takes only 30 minutes through an easy and straightforward calibration process,” said Solowjow. “The user interface is very simple and clear.”

Target applications for this technology include order fulfillment operations with a high number of SKUs requiring 500-1,200 picks per hour, such as goods-to-person tote picking, conveyor induction and sortation in e-commerce, e-grocery warehouse automation, and food and beverage packaging.

24

IIoT solutions and analytics software detect compressed air leaks saving manufacturers over 20% in energy costs.

NEWS AW JANUARY 2023

Camera and robot agnostic

A key aspect of Siemens’ piece picking software technology is that OEMs and integrators can use any robot, gripper, or vision system. The software supports multiple RGB-D 3D camera manufacturers, allows for the robot arm to be chosen based on the application, and is modularly designed with robot system designers in mind. The runtime platform can be integrated into a Siemens Simatic S7-1500 TM (Technology Module) MFP (multifunctional platform) PLC or any industrial PC to operate independently of any robot/vision system.

To enable the software to be robot hardware agnostic, Solowjow said, “We use the Siemens Simatic Robot Integrator and Library, which act as an abstraction layer and enable universal communication between the PLC and various robots of different makes.”

As for robot grippers, Solowjow said grippers “usually support generic communication protocols such as Profinet. Gripper specifics—such as their geometry or suction cup diameter—can be addressed through calibration.

Software capabilities

Inputs to the Siemens pre-trained, AI-powered

vision software in the PLC come from the 3D camera’s point cloud, with the output being the grasp pose for any object at runtime. A Siemens HMI is used to interface with the PLC and software; and Siemens TIA Portal can be used to program the entire system—Siemens PLC and HMI as well as the robots, vision system, and gripper.

Solowjow noted that the software requires the PLC to have Siemens’ TM MFP, which allows for edge computing applications on Simatic controllers. The TM MFP is designed for integrating various independent applications, he explained, and will be extended to other platforms such as Siemens Industrial Edge, industrial PCs, and cloud platforms.

The Siemens AI-driven piece picking system also provides for collision avoidance for all actions in the robot workspace, enables robots to master challenges such as handling tightly packed boxes using low-cost 3D cameras, and reduces errors through features such as automatic bin detection.

“We pretrain the AI skill for grasping using simulation,” said Solowjow. “Similar to a human, the AI learns how to grasp in general—as opposed to specific objects—so that grasping of unknown or previously unseen objects is possible.”

The Siemens AI picking software is robot and end-of-arm tooling agnostic. In its exhibit at PACK EXPO 2022, Siemens used a KUKA Agilus KR3 robot and a Robotiq EPick vacuum gripper to demonstrate the technology.

This engineer just set up several ultrasonic sensors for a new machine line. Despite the varying ranges he had to set, he used a single software application. He set the distances. He adjusted gain. He filtered out anomalies. And those settings will remain for future replacement sensors.

25 NEWS

That was “Simply easy!”

...Flexible... www.tesensors.com/XXSonic ...and SMART! AW JANUARY 2023

Programmable...

Emerson’s Plantweb Incorporates AspenTech Software to Expand Automation Capabilities

By David Greenfield Editor-in-Chief

By David Greenfield Editor-in-Chief

Automation trends are not as rare as they once were. Today we can easily see new trends around robots-as-a-service, innovative new methods of material handling, and remote monitoring, just to name a few. But one of the early trends in automation that’s clearly still going strong is the shift toward the importance of software.

That’s not to imply that automation hardware isn’t critical. It’s just that many hardware features and functions have become commoditized to a large degree, leading companies to differentiate and innovate through the capabilities of specific software packages.

This trend has become important as the worlds of IT and operations technology (OT) converge across industry.

The most recent example of this trend can be seen in Emerson’s announcement that it is incorporating AspenTech’s portfolio of asset optimization software into its Plantweb digital ecosystem. This combina-

22_004416_Automation_World_JAN Mod: November 23, 2022 3:48 PM Print: 12/12/22 4:28:52 PM page 1 v7

tion of technologies is a result of Emerson’s transaction with AspenTech in May 2022. That transaction involved Emerson contributing $6 billion to AspenTech in exchange for a 55% stake in the company.

Prior to the addition of Aspentech’s software, key features of Plantweb have been its Optics Analytics, Insight, and digital twin software to optimize plant-wide systems performance via insights into plant assets and their operating condition; pervasive sensing technologies for non-intrusive measurement of process and asset variables; and data management technologies to ease the process of data identification, contextualization, security and governance.

Emerson says AspenTech’s software leverages the information provided by Plantweb’s other components to “enable companies to optimize the business and sustainability performance of their plants and enterprise through advanced asset and business optimization software.”

Mark Bulanda, executive president of Emerson’s Automation Solutions business, said, “Our Plantweb digital ecosystem, combined with the asset optimization leadership of AspenTech, gives organizations the ability to see, decide, act, and optimize every aspect of their operations to drive exceptional returns on automation investment in productivity, safety, and sustainability.”

Here’s how Emerson explains the “see, decide, act, and optimize” capabilities of the newly expanded Plantweb with AspenTech:

• The ability to “see” is provided via Emerson’s sensing and measurement technologies, via capabilities such as leak and corrosion detection, tank, safety and equipment monitoring, personnel awareness, process measurements, and liquid and gas analysis.

• Automation systems and software, such as batch and advanced control, SCADA, PLCs, safety systems, asset and alarm management, remote monitoring, artificial intelligence and digital twins, enable the “decide” capability through analytics and improved visibility. Emerson says its software drives better decisions through on-demand access to expertise, while auto-

NEWS 26 AW JANUARY 2023

THE RIGHT TOOLS FOR THE JOB ORDER B M FOR SAME DA HIPPING π SHIPPING SUPPL SPECIALISTS COMPLETE CATALOG 1-800-295-5510 uline.com

mated workflows empower personnel to focus on high-value activities rather than low-value tasks.

• Emerson technologies such as digital valve control, process isolation, pressure regulation, motion control, and air handling provide the “act” capabilities to protect people, equipment, and the environment.

• The ability to “optimize” has expanded with AspenTech’s software via the ability to perform capital estimation, facility modeling, economic analysis, reservoir modeling, planning and scheduling, process and dynamic simulation, process knowledge management, supply chain management, process and energy analytics, management execution, electricity grid management, and operations and asset performance management.

Boundless automation

Following on this trend around the centrality of software to industrial automation, Peter Zornio, chief technology officer for Emerson, said, “Plantweb has remained a platform for continuous innovation in the industry since its introduction in 1997, including the world’s first integrated digital safety loop, machinery health monitoring, and the pervasive deployment of wireless technologies. Now Plantweb sets the software foundation for the future of ‘boundless automation,’ where the intelligent field, edge, and cloud become a seamless architecture for world-class responsiveness and performance.”

The core of this “boundless automation” vision is the ability to more easily manage, connect, and deliver both OT and IT data across the enterprise— from the field to the cloud.

Bulanda noted that the historical automation architectures we’re all familiar with were purposebuilt, with operational data isolated from hardware and software systems. These architectures, by design, created layers of automation, across which data could not easily be shared. But as industrial businesses move toward decentralized

operating models and self-optimizing plants, there has been a growing demand for a unified software environment that allows for data to stream across the enterprise when and where it’s needed.

Zornio added, “The shift to a software-defined architecture across the cloud, edge, and intelligent field will eliminate functional and architectural

silos” to create this “boundless automation” platform. “Such a platform is required to truly enable all the benefits promised by digital transformation applications and programs,” he said.

Responsive Experts p p

Read about Plantweb’s use of augmented reality for asset management.

27 NEWS AW JANUARY 2023

1-800-366-5412 · encoder.com

Yo

IN MOTION

EPC encoders provide motion feedback designed for printing, marking, & product inspection, and are manufactured in Idaho, USA. Contac

TO LEARN MORE ed in Idah C R E

Your

CONTROL

t EP

The Power of Vision

Murrelektronik has developed efficient and economical system solutions for integrating industrial image processing systems. The advantages include minimal installation effort as a result of decentralized, pluggable modules that can be mounted directly on the machine.

This achieves the goal of maximum performance with minimum wiring effort. The compact, powerful module is located right where it is needed. All in all, this saves installation time and reduces installation efforts while offering maximum availability enhanced by LED diagnostics each module. As a result, control cabinet components for connecting camera systems are replaced by a decentralized installation systems.

Quality Assurance Using Scanning Acoustic Microscopy

By David Greenfield Editor-in-Chief

Most automated quality inspection technologies involve machine vision systems and aspects of artificial intelligence-powered software to speed the identification of part defects. But visionbased quality inspection is not the only quality inspection technology available. Another option is scanning acoustic microscopy (SAM).

Also known as ultrasonic non-destructive testing, SAM can identify small defects during manufacturing and analyze the specific root cause of a failure when a device fails in the field.

Hari Polu, president of Okos, a supplier of industrial SAM systems, says the SAM technology makes it possible for manufacturers to move to a higher level of failure analysis because of SAM’s ability to detect defects at a 50-micron level. “With this type of testing, we can inspect materials and discover flaws that were previously undetected,” Polu says.

He adds that a growing number of manufacturers are equipping their R&D and quality assurance labs with SAM, as well as integrating it into production lines for inspection. According to Polu, SAM testing is already the industry standard for inspection of semiconductor components to identify defects such as voids, cracks, and the delamination of different layers within microelectronic devices.

How SAM works

Using SAM, sound is directed from a transducer toward a small point on a target object. To produce an image for quality analyses based on the sound pulses, scans are produced. These scans range from single to multiple layers, which can include up to 50 independent layers. These multi-layer scans allow for “depth-specific information to be extracted and applied to create two-and three-dimensional images without the need for time-consuming tomographic scan procedures or X-ray equipment,” says Polu.

These images are then analyzed by software to detect and characterize flaws such as cracks and voids.

Polu says advanced, phased array SAM systems can detect minute flaws in specialty metals and alloys.

SAM at scale

Even though small manufacturers can use a tabletop SAM system for scan envelopes of more than 300mm with a scan velocity up to 500 mm/s and accuracy and repeatability of +/- 5.0 micron, larger manufacturers typically require higher speed inspection capabilities.

Performing such high-speed inspections with 100% accuracy, as typically required by semiconductor manufacturers, requires automated equipment that can simultaneously inspect several layers, often on multiple channels.

“When high throughput is required for 100% inspection, ultra-fast single or dual gantry scanning systems are utilized along with 128 sensors for phased array scanning,” says Polu. “Multiple transducers can also be used to simultaneously scan for higher throughput.”

Polu noted that an advanced phased array with up to 128 sensors and accompanying software can enable inspection times of five minutes for granular detection of small impurities or defects, compared to the 45-minute inspection time required for a 5 MHz sensor to inspect an 8–10-in. square or disc alloy.

The Okos software designed to accompany the physical and mechanical SAM scans enable A, B, and C scans, contour following, off-line analysis, and virtual rescanning for composites, metals, and alloys. Polu says this results in highly accurate internal and external inspection for defects and thickness measurement via the inspection software.

“Various software modes can be simple and user friendly, advanced for detailed analysis, or automated for production scanning,” says Polu. “An off-line analysis mode is also available for virtual scanning.”

Okos’s software-driven SAM model enables the company to reduce the costs of SAM testing while still delivering high quality inspection results, thus putting SAM technology “well within reach of even modest testing labs,” Polu says.

28

murrinc.com

Xelity Hybrid Switch Master Breakout Box

Injection Box NEC Class 2 Splitter

NEWS AW JANUARY 2023

Innovate today for a new tomorrow

Realize your vision with Festo‘s approach to smart automation. Partner with Festo today.

www www.festo.us

Indu Industry Leadership

Supe Superior Quality Products Glob Global Training & Support

PROFINET:

Designed for Openness and Determinism

A look at Profinet’s development, from its Profibus fieldbus origins to its adpatability amid industrial Ethernet’s evolution, and how it provides the determinism required by many industrial users.

By James R. Koelsch, contributing writer

By James R. Koelsch, contributing writer

30 AW JANUARY 2023

INDUSTRIAL

MAKING SENSE OF

NETWORKS

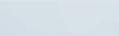

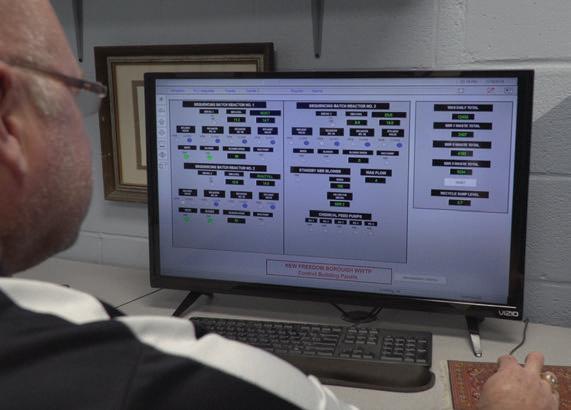

John Smith, director of the New Freedom wastewater treatment plant, monitors remote data via Profinet communications. Photo Courtesy: Phoenix Contact

When your factory runs only three months a year, you’re always investing in ways to increase the yield from your equipment. That’s why Joey Scarborough, general manager of the cotton gin facility owned by the Mildstead Farm Group in Shorter, Ala., chose Profinet for its industrial Ethernet communications to pass data between controllers and automation devices.

Part of Milstead Farm’s operating strategy is to be proactive at continuously maintaining and improving the gin’s equipment and process controls. A combination of proper maintenance and new equipment has been largely responsible for a gradual, but steady increase in the gin’s productivity over the years. Production topped 50 bales per hour in 2018, double the initial 25 bales an hour that the gin could process when operations began in 1998.

Scarborough believes Milstead Farm’s program of continuous improvement will be easier to perpetuate with Profinet as the backbone protocol of its control network. This open protocol defines both cyclic and acyclic communications among the Profinet components connected to standard Ethernet cables. With the protocol, the network can accommodate any Profinet product developed by

MAKING SENSE OF INDUSTRIAL NETWORKS

At the New Freedom wastewater plant, a fiber-optic ring connects these redundant RFC 460R controllers and the Profinet Media Redundancy Protocol provides millisecond fault recovery time. Photo:

hundreds of automation vendors. This includes programmable logic controllers (PLCs), programmable automation controllers (PACs), drives, robots, input-output devices (I/Os), and diagnostic tools.

At Milstead Farm, Profinet was initially installed as part of an upgrade project aimed at fine-tuning the company’s process controls and adding some new moisture-control equipment to help the humidifier keep pace with rising production levels. The company was already using Profibus for its plant floor fieldbus communications. The upgrade included replacing an obsolete PLC with a more powerful one and changing a local I/O rack at the end of the 2017 ginning season. At the end of the following season, Profinet was installed to network the two controllers in the plant.

Profinet also prepares Milstead Farm’s gin for the future. Although the existing Profibus network was still performing quite well, it was approaching its design limits in terms of node counts and cable distance, according to David Adams, the systems integrator at Design Automated Controls who performed the upgrade.

Besides extending these limits, Profinet also increased data transfer rates and integrated easily with the company’s existing Profibus network. The

new central processing unit (CPU) has Profibus and Profinet onboard, so it permits the machinery still using the Profibus protocol to communicate seamlessly with the control system.

Perhaps just as important is the path that Profinet opens for future upgrades. Among the first upgrades Milstead Farms has planned are the new Ethernet-based human-machine interfaces (HMIs) to replace the five aging HMIs on the Profibus network. The new HMIs will provide Milstead Farms with more—and better— troubleshooting tools.

Building on the past to create the future

In a way, the migration toward Profinet at Milstead Farm reflects the lessons learned from its predecessor, the Profibus fieldbus. “The experiences gained from building Profibus during the 1990s helped immensely when the time came to introduce Profinet in the early 2000s,” explains Michael Bowne, executive director, Profibus and Profinet International (PI) North America.

His reasoning is that a fully functional fieldbus does more than simply transfer bits and bytes among devices on the factory floor. It also

31 AW JANUARY 2023

Courtesy Phoenix Contact

MAKING SENSE OF INDUSTRIAL NETWORKS

facilitates such things as diagnostics, configuration, redundancy, vertical integration, functional safety, and energy management. “Many of these capabilities in Profibus are baked into Profinet,” says Bowne.

The big di erence between the two, of course, lies in the physical layer. Whereas Profibus relies on RS-485, Profinet uses Ethernet. “This opens a world of possibilities,” observes Bowne. “Ethernet speeds are orders of magnitude greater.” Profinet’s telegram size is also larger, and Ethernet’s full-duplex nature allows Profinet to send and receive data simultaneously.

Besides handling larger amounts of bi-directional data, the Ethernet-based backbone also permits open communications. “Other protocols—such as OPC UA or HTTP—can coexist on a Profinet network,” says Bowne, indicating that “the network is now an infrastructure.”

These attributes have enabled Profinet to

grow beyond its historic uses in industrial automation networking.

“The very first iteration of Profinet was developed for machine-to-machine integration,” notes Bowne. At the time, it was believed that “serial-based fieldbuses like Profibus would be used at the field level and that horizontal integration at the controller level would be achieved via Ethernet-based Profinet.”

Almost immediately, however, the automation industry found that Profinet would also work at the field level. Consequently, Profinet has progressed over the two decades since to include features for motion control, process automation, functional safety, and energy management.

Another benefit of Profinet is its determinism, which is not a native characteristic of Ethernet. Profinet can bring determinism to the factory floor by skipping the TCP/UDP and IP layers of the ISO/OSI Model and going directly

from the data link layer (Layer 2) to the application layer (Layer 7) of the OSI model. This means that applications requiring synchronized, high-speed motion can use Profinet IRT (isochronous real-time) to provide sub-millisecond cycle times.

Bowne points out that many of the mechanisms in Profinet IRT are also found in the Time-Sensitive Networking (TSN) standard being developed by the Institute of Electrical and Electronics Engineers (IEEE). “From this perspective, Profinet is ready for TSN,” he says. “It’s already written into our spec.” He expects the first Profinet over TSN devices to be released in a year or two.

Further Ethernet developments promise to extend the reach of Profinet. One of these is Ethernet-APL (advanced physical layer), a technology that brings Ethernet to field devices in hazardous areas.

is an intrinsically safe version of IEEE

32 AW JANUARY 2023

“It

These switches from Phoenix Contact are among the products that members of PI design for Profinet.

MAKING SENSE OF INDUSTRIAL NETWORKS

WASTEWATER APPLICATION

The New Freedom wastewater treatment plant in southern Pennsylvania needed to upgrade its control system as the existing controls—based on a DOS binary system—had become obsolete. Finding replacement parts and programmers for the system became increasingly di cult and there was a growing potential for prolonged failures that could be disastrous to both water quality and the surrounding environment.

John Smith, plant director at New Freedom, wanted to avoid these problems while executing the upgrade with minimal disruption to the plant’s biological and chemical treatment processes. He also wanted to replace the obsolete controls with a network of reliable, redundant PLCs capable of taking the plant’s sequential batch reactor process into the future.

For these reasons, he and his staff settled on a plant-wide, fiber-optic ring connecting redundant RFC 460R controllers from Phoenix Contact. The controllers use the Profinet Media Redundancy Protocol (MRP) to provide fault recovery within milliseconds and which can connect remote I/O stations on the ring.

The migration plan—designed to minimize any interruption in the plant’s processes—was to install the new controls while the older ones continued to operate. Then, once the new controls were tested, the old controls would be removed and the new ones would go into operation as the plant’s primary controls.

The resilience provided by this architecture proved itself from the very beginning. When a fatal error rendered the old PLC inoperable during the site acceptance test, Phoenix Contact’s engineering services team was able to bring the new control system online quickly without significant interruption in the treatment process.

Besides enhancing the network’s resiliency, the Profinet protocol on the new PLCs also expands the universe of peripheral systems that New Freedom can add to the control network. For example, single-purpose displays have already been replaced with touch-screen HMIs. New Freedom can also now explore the implementation of industrial Internet of things (IIoT) and artificial intelligence technologies for predictive maintenance and energy management.

34 AW JANUARY 2023

2-wire Ethernet (10BASE-T1L) that brings both power and communication to instruments at 10 Mbit/s over cables as long as 1 km,” explains Bowne. “The richness and transparency of Ethernet can now be utilized down to the field level in process automation.”

Open by design

The ability of Profinet to accommodate a mix of devices from diverse suppliers has been a leading factor driving the protocol’s proliferation across industry.

“Building a factory today requires a diverse mix of devices,” explains Bowne. “With Profinet, users are free to select best-of-breed solutions from their vendors of choice and can rest assured that these products will communicate properly.”

Vendor agnosticism was part of the plan from the beginning, even though Profinet was originally conceived as the industrial communications protocol for Siemens products.

“Siemens understands that users don’t want to be tied to one specific vendor or a proprietary technology,” says Torsten Paulsen, general manager of the Profi Interface Center, Siemens Industry Inc.

For this reason, the company chose not to pursue what Paulsen describes as the easy route when industrial Ethernet emerged in the early 2000s. Rather than mapping its well-established Profibus protocol into existing Ethernet protocols like TCP/IP and UDP/IP, Siemens instead decided to develop the protocol as an open and vendor-independent technology.

It did so by founding Profibus and Profinet International, a consortium that manages the technology and its evolution. “After the original patents were written and finalized, the intellectual property rights were handed over to PI,” reports Bowne. “Any company that joins PI as a member, anywhere in the world, is granted rights to these patents.” PI is now governed by a board of directors composed of representatives of the member companies.

These member companies joined and supported this and similar consortia for the same reasons that Siemens organized PI. Phoenix Contact, for example, joined PI in 2004 to develop a migration path to an Ethernet platform for its own InterBus fieldbus. “The choice of going it alone with our own Ethernet-based platform made no sense,” says Arnold O ner, strategic marketing manager, automation infrastructure at Phoenix Contact.

Like other member companies, Phoenix Contact allocates resources to support PI. This includes selecting employees to sit on the governing board of directors and participating on various technical committees and working groups. “Our employees are still working at the Phoenix Contact o ces,” explains O ner. “They do in-house testing to verify

MAKING SENSE OF INDUSTRIAL NETWORKS

what other members are uncovering, build up designs, and verify that these designs will work with our own products.”

As a member, Siemens also has employees performing many similar functions as Phoenic Contact. Siemens also “supports and sta s several PI testing labs, training centers, and competence

centers around the globe,” says Paulsen. An example is the Profi Interface Center he manages. This combined competence center, training center, and testing lab has been certified and accredited by PI to support the PI community in North America.

The supercomputer for automation and IoT

In the most advanced digital production lines or the highest performance machines, more and more functionality must be implemented with even shorter cycle times, requiring more powerful centralized control systems. With the C6670 industrial server, Beckhoff offers a paradigm-shifting machine controller offering up to 40 processor cores for the pinnacle of high-performance automation. This immense computing power can be fully harnessed via the TwinCAT 3 automation platform, which is designed to maximize the potential of each individual core in many-core control systems.

Scan to experience the full potential of the C6670 and many-core control

35 AW JANUARY 2023

PC11-46USA |

|

Beckhoff many-core control offers up to 40 processor cores

TRAINING WITH WORKFLOW AND SIMULATION SOFTWARE

As the next generation of workers comes to industry, proper training is critical to ensuring their success in complex, highly automated industrial environments. Here’s a look at how simulation and workflow software technologies are helping industrial companies more effectively train new operators.

By Mat Dirjish, contributing writer

Even in the early days of computing, businesses were looking at computers as tools for setting up complex simulations. Some credit Keith Douglas Tocher for developing the first discrete-event simulation program in 1960. Dubbed the General Simulation Program, his program used a common structure to execute a range of simulations.

Today, computers can simulate any industrial application for use in training or for control and analysis of specific automation operations. And when it comes to training industrial workers in their tasks, the confluence of simulation and workflow management are growing closer together.

Workflow guidance

When it comes to the benefits of workflow software for operator training, Allen Hackman, head of manufacturing at ServiceNow (a supplier of workflow software), explains that workflows aren’t simply a software checklist, they are a true driver of digital transformation. His reasoning for this is that workflow software integrates with existing software systems to unify the underlying insights and connect siloed teams, data, processes, and systems to drive action and get work done as required.

“For example, a digital workflow for a machine setup process will provide the steps to take in addition to knowledge that gives the employee instructions on

how to complete a task,” he said. “If there is an issue with a step or the employee has a question, he or she can trigger a request that automatically gets routed, assigned, and actioned by a support team.”

Allen noted that, despite the similarities among industrial companies when it comes to their interest in workflow software, “we’re seeing di erent industries use workflows in di erent ways to solve challenges. Organizations with large complex supply chains are prioritizing workflows that improve communication and collaboration. Companies with a large population of front-line factory workers are using workflows to improve overall equipment effectiveness and productivity. And those with ma-

36 AW JANUARY 2023 AUTOMATION TRENDS

AUTOMATION TRENDS

jor technology investments are using workflows to identify and reduce cyber risk.”

According to Allen, companies such as Jabil, Siemens, and Owens-Illinois are just a few of the hundreds of companies that ServiceNow has helped in the industrial sector.

Training simulations

The line between digital twins and simulations can blur a bit when it comes to training applications. The principal difference is that digital twins are connected to their real-world counterparts and reflect their operations in real-time—often including the ability to control them remotely. Simulations, on the other hand, are not typically connected in a live fashion with the physical equipment they represent. As such, simulation software replicates the actions of real-world equipment offline, providing a safe space for trainees to interact with the equipment.