Bleaching Earths

18 Ensuring coconut oil purity

Coconut oil is a value ingredient in food and oleochemical products and high quality bleaching earths and activated carbon are needed in an optimum ratio to ensure a good quality oil

24 The complete guide

The edible oil industry is the main consumer of bleaching earths. What are the main types of bleaching earths, how are they produced and utilised, what is their relationship to other adsorbents, which contaminants must they address and what are the environmental and other challenges facing producers?

Biodiesel & Biofuels

30 Global round-up of news

OFI reports on some of the latest projects, technology and company news and developments relating to biodiesel and biofuels around the world

Oleochemicals

34 Market snapshot

Growth in personal care and fatty acid derivatives are expected to be key features in the global oleochemicals market

Comment

2 Incentivising waste

Ukraine/Russia News

4 Food production at risk from dam destruction News

6 Bunge and Viterra to form $34bn agri trading giant

Biofuel News

10 Chinese resort island at centre of alleged fraud

Renewable News

12 Indian saturated fatty alcohol duty opposed

Transport News

14 Vopak expands storage for waste-based feedstocks

Biotech News

15 EPA publishes final rule on gene-edited plants

Diary of Events

16 International events listing Statistics

36 World statistical data

JUNE

EDITORIAL:

Editor: Serena Lim serenalim@quartzltd.com

+44 (0)1737 855066

Assistant Editor: Gill Langham gilllangham@quartzltd.com

+44 (0)1737 855157

SALES:

Sales Manager: Mark Winthrop-Wallace markww@quartzltd.com

+44 (0)1737 855114

Sales Consultant: Anita Revis anitarevis@quartzltd.com

+44 (0)1737 855068

PRODUCTION:

Production Editor: Carol Baird carolbaird@quartzltd.com

CORPORATE:

Managing Director: Tony Crinion tonycrinion@quartzltd.com

+44 (0)1737 855164

SUBSCRIPTIONS: Jack Homewood subscriptions@quartzltd.com

+44 (0)1737 855028

Subscriptions, Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK

© 2023, Quartz Business Media ISSN 0267-8853

WWW.OFIMAGAZINE.COM

A member of FOSFA

Oils & Fats International (USPS No: 020-747) is published eight times/year by Quartz Business Media Ltd and distributed in the USA by DSW, 75 Aberdeen Road, Emigsville PA 17318-0437. Periodicals postage paid at Emigsville, PA.

POSTMASTER: Send address changes to Oils & Fats c/o PO Box 437, Emigsville, PA 17318-0437

Published by Quartz Business Media Ltd Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK oilsandfats@quartzltd.com

+44 (0)1737 855000

European biofuel producers and organisations are increasingly concerned about a flood of Chinese biodiesel imports which they believe may be fraudulently labelled to qualify for EU green fuel incentives.

Chinese exports of biodiesel to Europe have jumped since 2022, according to Bloomberg, with EU imports of used waste oils and fats, and biodiesel produced from them (used cooking oil – UCO – methyl ester) amounting to some 500,000 tonnes since the end of 2022, the Union zur Förderung von Oel- und Proteinpflanzen (UFOP) says. The rise in Chinese exports to the EU has coincided with China importing more palm oil mill effluent (POME) from Malaysia and Indonesia, at a time when palm oil production has been stagnating.

Bloomberg reports that China may be mixing biodiesel with cheaper feedstocks like POME and exporting them to Europe, with Hainan island serving as a trans-shipment hub (see p10).

“You have a massive inflow of premium products arriving on the EU market at a very low price, probably also partly because it is not based on the real feedstock” says European Biodiesel Board secretary general Xavier Noyon. “At least that is what we strongly suspect.”

The EU has a binding target that 14% of the energy used in its transport sector must be renewable by 2030, with at least 3.5% of the target coming from advanced biofuels, which can be made from UCO as well as other waste feedstocks. Advanced biofuels can be ‘double-counted’ towards the target.

“Such virtual crediting to meet quota obligations reduces physical demand accordingly, especially for rapeseed oil-based biodiesel,” says UFOP. This has driven down EU prices for rapeseed and rapeseed oil, which have dropped some 30% in the past five months, sliding below €400/tonne at the end of May for the first time since November 2020.

The supply pressure from Chinese biodiesel imports also means some EU biofuel plants have partially or totally halted output, according to the European Waste-Based & Advanced Biofuels Association.

While it could be said that the EU has shot itself in the foot with its own incentives, demand for UCO-based renewable fuels is a global phenomena which is only set to increase as countries move away from crop to waste feedstocks.

Production volumes of UCO-based biofuels more than quadrupled from 1.48M tonnes in 2010 to 6M tonnes in 2019, according to Cornelius Claeys, a biofuels analyst with Stratas Advisors. In 2021, UCO biofuel consumption rose by another 10% compared to 2019.

While theoretical global UCO potential could be up to 28M tonnes by 2030, logistical barriers, rising collection costs, certification requirements, export restrictions and decreasing quality of marginal UCO mean this number is “purely hypothetical.” Claeys says.

Global production and demand for renewable diesel and sustainable aviation fuel is only set to rise, with UCO a favoured feedstock. The EU has, for example, just announced that starting in 2023, aircraft fuel needs to be mixed with 2% sustainable fuels, rising to 70% by 2050 (see p10).

As Vasu Vasuthewan of the International Sustainability & Carbon Certification told a May conference: “When the demand is exponential in such a way, there will be the problem not only of supply, but also the incentive for all kinds of fraud in the supply chain.”

Serena Lim, serenalim@quartzltd.com

BLACK SEA: The Black Sea Grain Initiative (BSGI) was extended for another two months – a day before it was due to end on 18 May.

The BSGI was signed on 27 July 2022 to allow agricultural food exports from Ukraine’s Black Sea ports of Odessa, Chornomorsk and Pivdennyi.

Turkish president Recep Erdoğan said the parties involved in the deal – Ukraine, Russia, Turkey and the United Nations (UN) – would continue to work to ensure all the terms of the agreement were met, AgriCensus wrote on 17 May.

While confirming the extension of the deal until 18 July, Ukraine’s infrastructure minister Oleksandr Kubrakov cautioned that the Russian side had been blocking the inspection of vessels willing to enter the Black Sea since April, which had hampered BSGI operations.

UKRAINE: Sunflowerseed production in Ukraine is forecast to increase by 14% in the 2023/24 marketing year to 12.7M tonnes, the Ukrainian Grain Association (UGA) says. This could lead to sunflowerseed exports rising to 1.2M tonnes and domestic sunflowerseed processing increasing to 11.5M tonnes, AgriCensus wrote on 1 June.

However, total potential grain and oilseeds exports in 2023/24 were forecast to drop to 43.9M tonnes.

“A sharp drop is expected due to the occupation of Ukrainian territories, mined territories, and continued hostilities, as well as the lack of funds and other resources for farmers,” the UGA said.

UGA said its forecasts would only be realistic if the Black Sea grains corridor continued to operate and was not affected by further suspensions or interruptions, AgriCensus wrote.

As well as causing a humanitarian disaster, the destruction of the Kakhovka dam in Ukraine could affect the country’s exports, with global implications for food security, Ukraine’s Agriculture ministry was quoted as saying in a report by The Guardian on 7 June.

Kiev has accused Russia of blowing up the dam and deliberately flooding the lower Dnipro River on 6 June to create a water barrier to counter a Ukrainian offensive attack.

Ukraine’s Agriculture ministry said the loss of water in the reservoir and the four canals it fed would mean an almost complete loss of irrigation systems in the Kherson region, three-quarters lost in Zaporizhzhia, and onethird lost in Dnipropetrovsk, The Guardian wrote.

“The destruction of the Kakhovskaya [dam] will mean that the fields in the south of Ukraine may turn into deserts

as early as next year,” the ministry said in a statement.

The Kherson region was one of Ukraine’s most fertile and productive areas, the BBC said on 8 June. The rich farmland either side of the Dnipro River produced a range of crops including sunflowers, soyabeans and wheat.

According to analysis on 7

June

Guardian

loss of the reservoir would reduce water to irrigate the agricultural belt in the region.

“A drop of just 1m is enough for traps to run dry. That will have a knock-on effect on food production, and on [Ukrainian] exports of corn, sunflower oil, soyabeans and wheat.”

The European Commission (EC) has extended restrictions on imports of Ukrainian grain into five member states – Bulgaria, Hungary, Poland, Romania and Slovakia – until 15 September, World Grain wrote on 6 June.

All five countries had seen a significant increase in grain imports from Ukraine since the Black Sea Grain Initiative (BSGI) was agreed between Kiev and Moscow in July 2022 to allow for commercial food and fertiliser exports from three key Ukrainian Black Sea ports – Odessa, Chornomorsk and Pivdennyi.

The restrictions, which were due to expire 5 June, applied to four agricultural products – maize, rapeseed, sunflowerseed and wheat –originating in Ukraine, World Grain wrote.

When introducing the ban on 2 May, the EC said the surge in traffic at the borders between Ukraine and the EU had had an impact on logistics costs and created bottlenecks, resulting in saturated storage capacities and logistical chains. This had hampered the economic viability of producers in those countries.

The EC said the import restrictions were part of an overall support package that it had put forward and was being complemented with fi-

nancial support for farmers in the five member states, the report said.

The measures are also facilitating the transit of Ukrainian grain exports via ‘solidarity lanes’ to other member states and third countries, according to the report. Exports via the solidarity lanes were mainly going to Romania, which had handled around 7M tonnes of Ukrainian grain, the EC said. Poland, Hungary, Slovakia and Bulgaria had taken 700,000 tonnes, 300,000 tonnes, 200,000 tonnes and less than 100,000 tonnes, respectively.

Ukraine’s government had condemned the restrictions as “categorically unacceptable”, World Grain wrote.

Against this backdrop, Ukraine’s Ministry of Renovation and Infrastructure was quoted as saying in a 2 June Reuters report that Russia was again blocking the BSGI by halting the registration of ships to all Ukrainian ports.

A UN spokesman said Russia had informed officials overseeing the initiative that Moscow would limit registrations to the port of Pivdennyi, in Ukraine’s Odessa province, until all parties agreed to unblock the transit of Russian ammonia, the report said.

WORLD: Global oilseed production in the 2023/24 marketing year is forecast to increase by 7% mainly due to soyabean output in South America and sunflowerseed production in the EU, Russia and Ukraine, according to a United States Department of Agriculture World Markets and Trade report on 12 May.

Meanwhile, global oilseed consumption was expected to rise by 4% to a new record of 672M tonnes in the current marketing year.

World rapeseed production was expected to remain almost unchanged as gains in the EU, Canada and China were offset by declines in Australia. Soyabean output was forecast to rise by 11% to nearly 411M tonnes. Brazilian soya exports were projected at a record 96.5M tonnes.

Leading US agribusiness Bunge and Glencore-backed Viterra have announced they would be merging to create an approximately US$34bn agricultural trading giant, Reuters reported.

Bringing the combined company closer in scale to leading rivals Archer Daniels Midland (ADM) and Cargill, the deal valued Bunge and Viterra at around US$17bn each and was likely to draw close regulatory scrutiny, the 13 June report said.

As Bunge would be paying for a significant percentage of the deal with cash, its shareholders would own about 70% of the combined company, Reuters wrote. Under the terms of the deal, Viterra shareholders would get about 65.6M shares of Bunge stock, with a value of around US$6.2bn, and about US$2bn in cash. Bunge would also assume US$9.8bn of Viterra’s debt.

Bunge is currently the world’s leading oilseed processor and analysts were quoted as saying the company and Viterra’s crushing businesses could face regulatory scrutiny in Canada and Argentina.

According to data from shipping agent Cargo-

nave, last year, Bunge was the largest corn and soyabean exporter from Brazil – the feedstocks for producing animal feed and biofuels. Viterra was the third-largest corn exporter and seventh largest global soyabean shipper. When combined, the companies accounted for about 23.7% of Brazilian corn exports in 2022 and 20.9% of Brazilian soyabean exports.

In the USA, Viterra’s business of buying and selling grain expanded following its acquisition of the grain and ingredients business of US oilseed and ingredients firm Gavilon last year, while the merger would enhance Bunge’s US grain exporting and oilseed processing businesses, Reuters wrote.

In early 2017, Viterra – then known as Glencore Agriculture – had approached Bunge about a friendly takeover but that had been rejected. Bunge's CEO and senior executives had since been replaced. Bunge’s management team, led by CEO Greg Heckman, would now oversee the combined Viterra/Bunge entity, Reuters wrote.

Indonesia plans to trade crude palm oil (CPO) on a local futures exchange scheduled for launch by June, Reuters reported on 4 May.

Only spot trading in the rupiah currency for direct CPO exports would be traded on the exchange initially, Didid Noordiatmoko, head of the commodity futures regulator, Bappebti, told reporters. If successful, the exchange would add CPO derivatives and future contracts later.

The country had initially planned to require overseas buyers of CPO to make their purchases via the exchange, along with exporters of refined products, Reuters wrote.

Most palm oil trades in Indonesia were currently carried out directly between producers and buyers, and auctions held by state trading

company KPB Nusantara only offered physical palm oil, and not futures, contracts.

The country does not currently have its own CPO ref-

erence price, instead referring to the Malaysia Derivatives Exchange (MDEX) in Malaysia, CIF Rotterdam prices in the Netherlands and the Indonesia Commodity and Derivatives Exchange (ICDX) in Indonesia, according to a 3 March Asia News Network report.

The selection of delivery points for cargoes continued to be an issue due to Indonesia’s size and number of ports, AgriCensus wrote on 5 May. While Dumai and Belawan were typically seen as references for exports, ports in other provinces also handled a substantial volume of export flows and prices could vary across ports, the report said.

Global agribusiness giant Cargill announced on 26 April that it would invest US$50M in Australia to upgrade and expand its oilseed crushing facilities in Newcastle, Narrabi and Footscray to meet rising global and domestic demand for canola and cottonseed oil.

As part of the investment, Cargill would upgrade and re-start its Narrabri plant,

which had been modified into a dedicated cottonseed dehulling plant. The hulls would cater to domestic feedstock markets and cottonseed would be taken to Newcastle for processing into oil and meal.

Cargill's Newcastle plant would be upgraded to crush cottonseed alongside existing canola processing capacity, significantly

increasing the plant’s total crushing capacity.

Canola crushing capacity would also increase at Cargill’s Footscray plant with upgrades to processing equipment and some modifications to improve logistics.

Cargill processes over 680,000 tonnes/ year of canola, cottonseed, sunflowerseed and soyabeans in Australia.

The Roundtable on Sustainable Palm Oil (RSPO) has issued a hot weather alert and warned of potential fires amid forecasts of drier conditions in Southeast Asia.

In the coming months, the RSPO said the region was at risk of fire and haze due to several factors, including the El Niño phase of the El Niño-Southern Oscillation (ENSO) associated with drier weather conditions in Southeast Asia; climate change causing temperatures to rise and making the region more susceptible to wildfires; and deforestation and land clearing which continued to increase the risk of fires.

“As a result of these factors, there is potential for an increase in hotspots and fire in Southeast Asia. This could pose a serious safety risk to oil palm estate workers, local communities and neighbouring areas, and also the possibility of trans-boundary haze,” the RSPO said in a 23 May statement.

The RSPO urged its members who had oil palm estates in Southeast Asia to take precautions, including familiarising workers with fire evacuation plans and reporting any suspicious activity or fires to the fire department immediately.

The RSPO said its records over the past two years showed a 39% increase in the number of hotspots between May and July, and this was projected to rise by as much as 50% this year. The average highest number of hotspot alerts took place between August-September and the hotspot trend showed El Niño mainly occurring between August-September.

According to ASEAN Meteorological Centre forecasts, El Niño conditions will develop from July and August, with a possibility of ENSO-neutral conditions in the second half of 2023.

A new animal cruelty-free oil was used to anoint King

Charles III of the United Kingdom of Great Britain and Northern Ireland during his coronation on 6 May at London's Westminster Abbey

Previous versions of the 'chrism' oil had included civet oil from the glands of small mammals, and ambergris from the intestines of whales, the BBC wrote on 3 March. However, to reflect modern animal-friendly sensitivities, the new oil did not include any ingredients from animals but included olive oil scented with a mix of essential oils – sesame, rose, jasmine, cinnamon, neroli and benzoin. The olive oil came from the Mount of Olives, a site outside Jerusalem with many biblical connections, the BBC wrote.

The coronation oil was consecrated in a religious ceremony in Jerusalem at the Church of the Holy Sepulchre, the site where Jesus was believed to have died and was buried.

BRAZIL: Brazil is expected to export at least 200,000 tonnes of soyabeans to the USA between the last weeks of May and the beginning of June, according to a 5 June AgriCensus report.

This bilateral trade was set to increase this year due to a bumper Brazilian crop and competitive pricing.

Shipping agency Williams, reported two vessels leaving Itacoatiara on 21 and 25 May, each carrying around 30,000 tonnes of soyabeans to the USA. Three other vessels were scheduled to set sail to the USA in the first week of June from the ports of Santarem and Barcarena with a joint cargo of around 120,000 tonnes of soyabeans. A sixth vessel carrying just under 30,000 tonnes of soyabeans to the USA from Baracena was reported leaving on 23 May.

If all cargoes and volumes were confirmed, this would bring total Brazilian soyabean exports to the USA between the last weeks of May and the beginning of June to more than 200,000 tonnes. This would be in addition to 46,153 tonnes shipped to the USA between January-April.

This would amount to the largest soyabean trade between the two countries since 2014, when Brazil exported a record 1M tonnes to the USA, the report said.

Brazil is set to harvest more than 154M tonnes of soyabeans this season.

A significant rise in China’s inspections of imported soyabean cargoes is leading to costly delays, traders quoted in a 12 May Reuters report have said.

China introduced new customs procedures in April for discharging soyabeans and clearing times would now take even longer due to increased sampling of cargoes to check for pests and residues, the sources said.

“It is a double whammy. Earlier, there were delays in getting import licences and, over the last few days, there are more stringent checks on cargoes,” a Singapore-based trader at an international trading firm was quoted as saying.

China – the world’s leading buyer of soyabeans with a 60% market share of purchases

– mainly imported cargoes from Brazil and the USA.

Slow clearing times at Chinese ports were pushing up spot soyabean meal prices, which had increased by almost 14% since the beginning of April, Reuters wrote.

At the time of the report, about 30 vessels carrying about 1.8M tonnes of soyabeans were waiting at anchorage off ports in China, the Singapore trader said, leading to mounting demurrage costs.

Demurrage costs – fees paid to ship owners for failing to offload cargo at an agreed time – can be up to US$20,000/day for a Panamax vessel carrying 60,000 tonnes of soyabeans, according to the report.

fatty acids, such as omega-3s, as they create more flexible membranes that do not freeze up. At warmer temperatures, production shifts to saturated fatty acids that are stiffer and provide more structure.

Climate change could lead to a decline in omega-3 fats and higher toxin levels in ocean fish, according to a 26 May report on the Nautilus website.

The decline in omega-3 fats begins at the bottom of the food chain, as phytoplankton

synthesise two types of fatty acids to build their cell membranes, according to aquaculture nutrition specialist Stefanie Colombo of Dalhousie University. At cooler temperatures, phytoplankton tend to produce more unsaturated

Oceanic fish relied mainly on plankton to get their omega-3s, and fish was our main dietary source of docosahexaenoic acid (DHA) omega-3, which was linked to a range of health benefits including lower blood pressure, reduced inflammation and lower heart disease risks, the report said.

The global availability of DHA in fish could decline by 10%-58% by 2100, depending on global warming, according to forecasts by Colombo and her colleagues.

A deal to rescue leading global soyabean supplier Vicentin is at risk due to court delays and Argentina’s most severe drought on record, Bloomberg reported on 2 June.

The bankruptcy of Vicentin SAIC more than three years ago disrupted oilseed trading in Argentina, the leading exporter of soyabean meal and oil, the report said. Following a period of instability, which included a failed nationalisation bid, the company seemed to have secured its future

after creditors and crop suppliers agreed to restructure US$1.3bn of debt, with a consortium led by Glencore-backed Viterra and global agribusiness giant Bunge set to take over operations, Bloomberg wrote.

However, a combination of drawn-out proceedings in a provincial bankruptcy court and severe drought in the South American country had put the deal at risk, Estanislao Bougain, a Vicentin board director, was quoted as saying.

Judge Fabian Lorenzini was taking much longer than usual to approve the restructuring, according to Bougain.

If the delays continued, the company’s takeover could be at risk, according to Vicentin.

“The drought means companies are no longer bringing their grain to Vicentin,” Bougain added.

“We’re running low on work but our overheads are still there.”

EU: The EU will require aviation fuel suppliers to supply a minimum share of sustainable aviation fuel (SAF) at European airports, starting at 2% of overall fuel supply by 2025, and increasing to 70% by 2050, according to a statement on its official website on 26 April.

The mandate is part of a political agreement reached on the REFuelEU Aviation proposal requiring the use of SAF. It covers biofuels, recycled carbon fuels and synthetic aviation fuels (e-fuels). Fuels made from food and feed crops are excluded.

Once adopted by the European Parliament and the European Council, the new legislation would be published in the Official Journal of the European Union and take immediate effect.

NETHERLANDS: Glob-

al oil giant Shell is set to make the first deliveries of sustainable aviation fuel (SAF) in 2025 from its Shell Energy and Chemicals Park Rotterdam plant, S&P Global reported on 4 May.

The 820,000 tonnes/year plant used hydro-processed esters and fatty acids (HEFA) to produce biofuels by refining vegetable oils, waste oils or fats using hydrogen, S&P Global wrote.

Shell said it aimed to produce around 2M tonnes/ year of SAF by 2025 and have at least 10% of its global aviation fuel sales comprising SAF by 2030.

The Chinese resort island of Hainan may be at the centre of a green fuel fraud, where biodiesel mixed with cheap feedstocks is mislabelled and exported to the EU to qualify for green fuel incentives, Bloomberg reported on 5 May.

The island had no capacity to convert used cooking oil (UCO) – the most obviously compliant feedstock – into biodiesel, the report said. Yet Hainan-registered companies exported 498,000 tonnes of biodiesel last year, making up 28% of China’s total outbound shipments, according to customs data compiled by Bloomberg

The island’s share of biodiesel exports increased to 31% in the first quarter of this year, with volumes at 205,000 tonnes. Almost all cargoes were shipped to the Netherlands, a large consumer market and EU trans-shipment hub.

Meanwhile, Chinese imports of palm waste and palm-based biofuel from Indonesia and Malaysia had surged, with Hainan-registered

firms handling more than 60% of the country’s biodiesel imports in the first three months of this year, the report said.

China’s biodiesel production totalled 2.4bn litres last year – up by a third compared to 2021 – due to a surge in export demand, according to the US Department of Agriculture.

Germany’s Union for the Promotion of Oil and Plant Proteins (UFOP) wrote on 1 June that sharp falls in EU rapeseed prices were due to good global supply forecasts but also to imports of used waste oils and fats from China and biodiesel produced from them – used cooking oil methyl ester (UCOME) – totalling some 500,000 tonnes since the end of last year. At one point, prices fell below €400 (US$428)/tonne for the first time since November 2020, the report said.

“Doubts have been raised in industry circles about the correctness of the certifications and required proofs of raw material origin,” UFOP said.

The EU rapeseed sector is under pressure due to a huge increase in imported waste-based biodiesel, according to FEDIOL, the trade association representing the EU vegetable oil and protein meal industry.

Imports of biofuels classified as waste-based – such as hydro-treated vegetable oil (HVO) or fatty acid methyl esters (FAME) – were taking place at such scale that it had led to serious disturbances in the EU markets for rapeseed methyl ester, and consequently the rapeseed and rapeseed oil markets, FEDIOL said on 25 May.

Over the last five months, rapeseed oil prices had fallen by over 30% to €800 (US$857)/ tonne, driving down physical rapeseed prices for spot delivery from €625 (US$669)/tonne

to €410 (US$439)/tonne, FEDIOL said. “The magnitude of biodiesel imports’ growth ... raises questions on the authenticity of their ... origination from waste streams.”

Finnish renewable fuels producer Neste announced the opening of its expanded €1.6bn (US$1.72bn) sustainable aviation fuel (SAF) refinery in Singapore on 17 May, doubling its production capacity there to 2.6M tonnes/year, of which up to 1M tonnes could comprise SAF.

The project also established a SAF supply chain to Changi Airport, with Neste acquiring a stake in fuel storage and infrastructure joint venture Changi Airport

Fuel Hydrant Installation Company Pte Ltd (CAFHI) so that it could offer its blended SAF directly to airlines there.

Neste’s total SAF production capability would be 1.5M tonnes/year by the end of this year following the completion of modifications at its Rotterdam refinery, and 2.2M tonnes by the first half of 2026 following the expansion of its Rotterdam refinery, the company said.

The 1.3M tonnes/year plant would

increase Neste’s SAF capacity by up to 1M tonnes/year, in addition to a 500,000 tonnes/year project at its Rotterdam plant, Neste executive vice president Carl Nyberg told Reuters on 5 April.

The Singapore expansion and production from a new joint venture plant in California with Marathon Oil Corp would increase Neste’s biofuels capacity from 3.3M tonnes/year to 5.5M tonnes/year by the end of this year, Nyberg said.

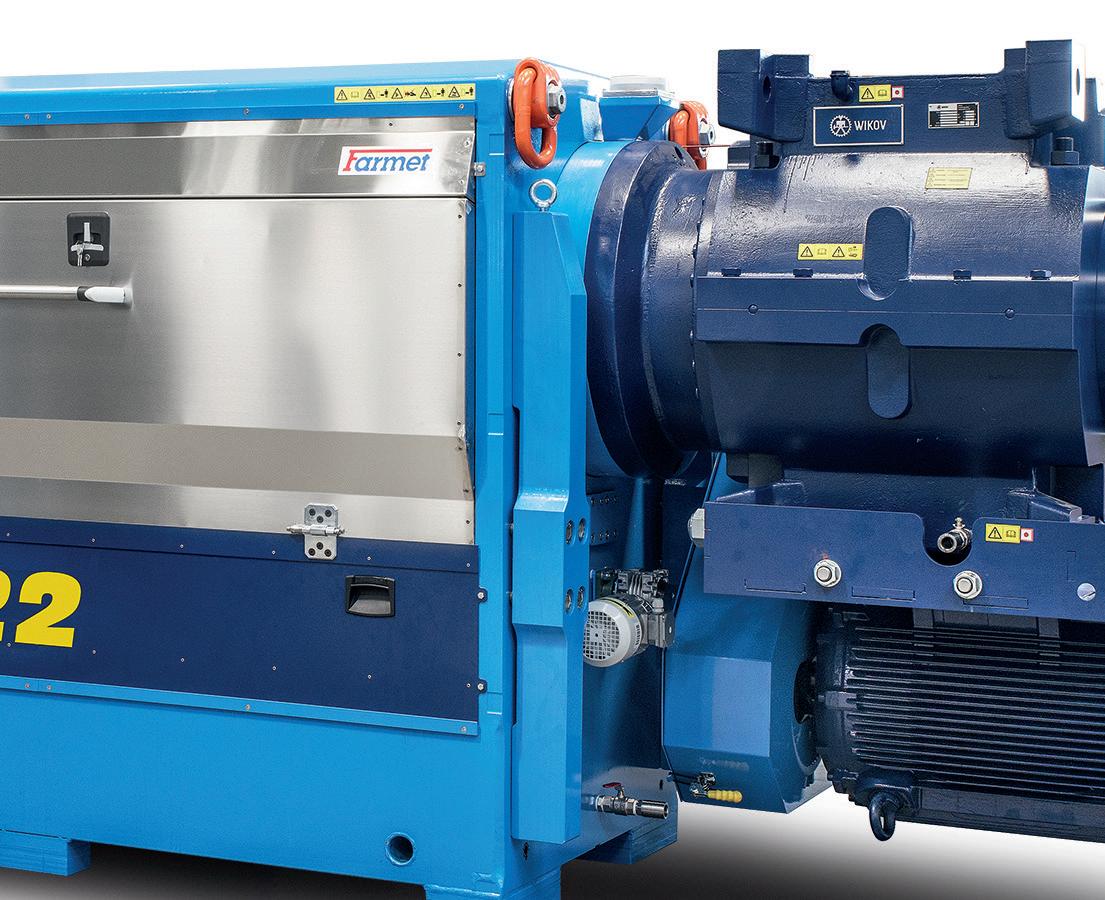

Optimized fat and meal production The high-quality product specifications you require, and the flexibility to adjust to changing demands.

Dramatically reduced downtime Unsurpassed reliability backed by the rapid response of the largest field service team and parts inventory in the industry.

Complete systems integration Every type of major rendering equipment, including new Dupps-Gratt decanters and centrifuges.

Maximize the life of your frying oil.

Our experts will work with you to optimize your frying operations and oil quality. The addition of DALSORB® oil purifier will extend the life of your frying oil and improve overall product quality.

DALSORB® keeps your food wholesome and removes undesirable compounds to keep frying oil clean from:

A proposed anti-dumping duty (ADD) on saturated fatty alcohol imports into India could raise the prices of soap, shampoos and detergents in the country, claims the Indian Surfactant Group (ISG).

In February, India’s Directorate General of Trade Remedies recommended a higher ADD rate on saturated fatty alcohol imports of chain length C12-C18 and their blends from Indonesia, Malaysia and Thailand, Argus Media wrote on 8 May.

India had originally imposed the ADD on 25 May 2018 for five years but prior to its end, Indian oleochemical producer VVF India (VVF) had requested its continu-

ance and a higher rate, claiming continued dumping and injury to itself.

However, the ISG urged India’s finance minister not to implement the new duties, saying they would significantly affect costs for producers and users of sodium lauryl sulphate (SLS) and sodium lauryl ether sulphate (SLES) used to produce detergents, shampoos and personal care products, Argus Media wrote.

The recommended rate of duties, depending on the company, would be: US$240-US$263/tonne for Indonesian imports; US$58-US$250/tonne for Malaysian imports; and US$107-US$180/tonne for

Thai imports. Indonesia’s Ecogreen Oleochemicals, Musim Mas and Energi Sejahtera Mas would be exempt, the report said.

SLS and SLES were manufactured from saturated fatty alcohols and could be imported free of any basic custom duties from ASEAN countries, making domestic production uncompetitive, the report said.

According to the Ministry of Commerce, VVF and Godrej are the only two domestic producers of SLS and SLES, and India imported 104,621 tonnes of saturated fatty alcohols from October 2020 to September 2021 while total demand is about 145,000 tonnes/year.

POLAND: Polish biofuels producer ORLEN Południe is using BASF technology to convert glycerol – a by-product of biodiesel production – into renewable propylene glycol (BioPG) at its new 30,000 tonnes/year plant in Trzebinia, BASF said on 16 May.

BioPG is used to produce polyester resins, polyurethanes, paints and de-icing solutions, solvents for the food industry, and deodorant sticks and toothpaste.

ORLEN Południe is the first Polish producer of propylene glycol and aims to meet 75% of the country’s propylene glycol needs, according to BASF, which said it also supplied the H9-66 catalyst for the facility and Air Liquide Engineering & Construction provided the licence, basic engineering, and equipment for the plant.

German chemical and biotech giant BASF said on 6 June that it would expand its production capacity for alkyl polyglucosides (APGs) at its site Cincinnati, Ohio (pictured).

Due to start in 2025, the expanded capacity would strengthen the company’s production footprint in the USA, allowing it to increase local supply points and reduce cross-regional volume flows for North American APG customers, BASF said.

APGs are commonly used in home care formulations involving skin contact, such as washing up liquids, shower gels and shampoos, as well as applications including facial cleansing, oral care and personal care. In addition, they are used in the food industry and agro-chemical sectors.

BASF’s APGs are made from fatty alcohols derived from sustainable palm kernel oil

or coconut oil, and glucose from wheat or corn – nongenetically-modified (GMO) sources – in Europe.

The company’s 100% plant-based APG range, traded as Plantacare, has been developed for the cosmetics industry.

BASF currently produces

APGs in Dusseldorf, Germany; Cincinnati, USA; and Jinshan, China. Its Cincinnati site produces a range of products for personal care, detergents and agriculture applications. BASF said the expansion of North American regional production capacity was driven by growing global demand.

US speciality chemical company Locus Fermentation Solutions (Locus FS) has secured an investment of US$117M to expand its biosurfactant business.

The loan would use Locus’s intellectual property (IP), including more than 1,300 patents, as collateral, Chemical & Engineering News (C&EN) wrote on 20 April.

Using custom microbial fermentation to produce speciality surfactants, most of Locus’ products were based on sophorolipids

– biosurfactants with hydrophilic sophorose sugar heads and a range of hydrophobic fatty acid tails, C&EN wrote.

Locus chairman and CEO Andy Lefkowitz was quoted as saying the loan would help the company triple its overall factory space to 14,000m3 at its headquarters site in Solon, Ohio, and at other locations.

Organised as a holding company with operating companies focused on different markets, Lefkowitz said the firm’s fast-

est-growing market was oil drilling and mining.

One of the companies, Locus Performance Ingredients, recently signed a pact with Veolia Water Technologies & Solutions to develop water and wastewater treatment products based on sophorolipids, C&EN wrote. Locus also has a deal under which Dow is the exclusive supplier of Locus’ sophorolipids in the home care and personal care markets.

USA: Leading US energy infrastructure company Kinder Morgan (KMI) has announced an agreement on 8 May with Finnish renewable fuels producer Neste to store feedstocks, such as used cooking oil (UCO), at its Harvey terminal in Louisiana.

The feedstocks – including UCO collected by Neste from more than 80,000 restaurants across the USA – would be used to produce renewable fuels and plastics, KMI said. Improvements had been made to rail, truck and marine infrastructure at the facility to meet the requirements of Neste’s feedstock supply chain.

USA: Global agricultural commodity company Viterra has announced plans to expand its grain and feed ingredients terminal in Etter, Texas, World Grain reported on 22 May. The expansion would increase the terminal’s storage capacity by more than 40,000 tonnes by late 2024.

“The project… will allow us to support the continuing expansion of oilseed crush and meal production across North America,” Viterra CEO of USA and Mexico Rayner Freyberg said.

Viterra has a network of agricultural storage, processing and transport operations and sources commodities such as grains, oilseeds, pulses, rice, sugar, cotton and feed ingredients.

Global tank storage company Vopak has expanded its storage capacity for waste-based feedstocks at Rotterdam port with the launch of 16 new tanks.

The new tanks at Vopak’s Vlaardingen terminal had a combined capacity of 64,000m³ and were designed to store waste-based feedstocks for the production of biodiesel and sustainable aviation fuel (SAF), the company said on 10 May.

The terminal had extensive experience in storing these types of products and was well-connected for logistics via vessels, barges, trucks, and trains, Vopak said.

It also had a long-term commercial agreement with

global oil giant Shell to store feedstocks for Shell’s new biorefinery in Rotterdam, which was set to be one of Europe’s largest SAF production facilities, producing SAF and renewable diesel from waste

materials such as used cooking oil (UCO), waste animal fat and other residual products.

Vopak stores and handles a range of products including biofuels, vegetable oils, chemicals, gases and crude oil.

German chemical giant BASF and Stolt Tankers have launched a a new inland tanker to navigate low water levels on the Rhine River.

The Stolt Ludwigshafen was launched at BASF’s Ludwigshafen site on 26 May.

“Following the extreme low water levels on the Rhine in 2018, we initiated an extensive programme to improve climate resilience at Ludwigshafen,” said Uwe Liebelt, BASF president, European Verbund sites.

Built between 2021-2023, the inland tanker had been operational since the end of April and featured a lightweight and hydro-dynamically optimised hull and a special propulsion system adapted for extreme low-water conditions.

To achieve a high load-bearing capacity, the ship’s dimensions were 135m by 17.5m, con-

siderably larger than conventional tankers on the Rhine, BASF said.

These features allowed the ship to pass the critical point on the Rhine River near Kaub, with a cargo payload of 800 tonnes even at a gauge level of 30cm (corresponding to a water depth of 1.6m).

At moderately low water levels, the tanker’s loading capacity of around 2,300 tonnes would be double compared to conventional inland vessels, BASF said. Overall, the Stolt Ludwigshafen featured a maximum loading capacity of 5,100 tonnes.

Stolt Tankers operates a fleet of more than 160 parcel tankers, providing global transportation services for bulk liquid chemicals, edible oils, acids and clean petroleum products.

Against a backdrop of falling petroleum prices, the cost of marine fuel has dropped to 2021 levels, Freight Waves writes.

“Oil prices have been on the decline over the past few weeks, falling further this week on weak manufacturing data out of China,” Deutsche Bank shipping analyst Chris Robertson was quoted as saying in the 2 May report.

Most commercial ships burn fuel with 0.5% sulphur known as very low sulphur fuel oil (VLSFO), according to the report.

Following the introduction of the IMO 2020 environmental regulations on 1 January 2020, the use of VLSFO or other low-sulphur fuels has been required. The only exception is for ships with exhaust gas scrubbers, which can continue to burn cheaper 3.5% sulphur fuel known as high sulphur fuel oil (HSFO), according to Freight Waves

The price of VLSFO had fallen more steeply, in line with the drop in Brent crude oil prices, while the price of HSFO had

held up better, significantly narrowing the VLSFO-HSFO spread, the report said.

The average price of VLSFO at the world’s top 20 refuelling hubs had dropped to US$593.50/tonne on 1 May – on par with December 2021 prices, according to Ship&Bunker data.

Meanwhile, the price of HSFO at the world’s top 20 hubs was US$496.50/ tonne on 1 May, a drop of 35% from the peak in May 2022 and back to levels seen in September 2021.

The US Environmental Protection Agency (EPA) has published a final rule on gene-edited (GE) plants exempting them from an in-depth review process if the change could have been achieved with conventional breeding, Science website reported on 2 June.

However, to ensure safety for humans and wildlife, the EPA said it would require developers to submit data to show plants that had been gene-edited to resist pests – for example by producing more of a naturally-occurring toxic protein – would not harm other components of the plant’s eco-system or people.

The EPA’s ruling followed a decision made last year by the United States Department of Agriculture (USDA) which exempted specific GE changes to plants. Developers, for example, were not required to ask for approval if they had

given a crop a trait that already existed naturally in a sexually compatible plant, the report said. The EPA said on 25 May that it would use the conventional breeding exemption for many GE crops, although – unlike the USDA – it would require companies to submit confirmatory safety data, such as evidence that the changes did not increase pesticide levels beyond those found in food from conventional crops, Science wrote.

According to the EPA, regulatory review would be faster and cheaper for GE crops – in which existing genes are altered – against genetically modified crops where foreign genes are used.

Biotechnology expert Jennifer Kuzma of North Carolina State University said the EPA had struck a reasonable balance to ensure industry was thinking about risks to non-target organisms and humans when it came to pesticidal compounds.

Canada’s Minister of Agriculture and Agri-Food Marie-Claude Bibeau announced on 3 May that Canadian Food Inspection Agency (CFIA) seed guidelines would now allow for some modified plants.

The updated rules would allow for seeds created through genetic engineering (GE) that were not spliced with foreign DNA or altered to make them pesticide-resistant, a 10 May CBC News report said.

These seeds would be approved without an independent safety assessment by the government as they were already considered safe.

Canada also announced an industry-managed database to make it clear which seeds were and were not organic.

However, organic farmers

WORLD: The adoption rate of gene-edited (GE) crop seeds is expected to increase significantly in the next five to 10 years, according to a 9 May Rabobank report.

Factors driving increased adoption included enhanced crop productivity, drought tolerance, improved crop quality, reduced environmental impact, increased sustainability, addressing consumer needs, and new market opportunities.

Although the timeline for the adoption of GE seeds was hard to estimate, Rabobank said it expected adoption rates would surpass 50% within five to 10 years.

Rabobank farm inputs analyst Chia-Kai Kang said there were at least five factors that would determine if a GE crop could achieve a high adoption rate: product performance such as quality, yield, and consistency; possible long-term risks such as allergic and toxic reactions; disruption to trade flows due to export bans on GE crops; the marketing power, selling strategy and distribution network of the input company; and access to technology.

GE seeds not spliced with foreign DNA or made to be pesticide resistant will not need an independent safety assessment in Canada

Calyxt says seedless hemp offered improved yields and quality

have called for a mandatory registry of organic producers, saying the updated guidelines put their produce at risk, while

consumers would not know which food contained GE ingredients due to the lack of labelling requirements.

The USA was the frontrunner in GE applications, with 169 applications made from 2011-2020 including plants for human consumption, feed, industrial uses, and some micro-organisms for industry, with some of these applications due for commercial application.

The Chinese government has approved the safety of a gene-edited (GE) soyabean with increased levels of oleic acid, Reuters reported on 4 May.

Developed by privately-owned Shandong Shunfeng Biotechnology, the soyabean had two modified genes, significantly raising the level of oleic acid in the plant.

According to a document published at

the end of April by the country’s Ministry of Agriculture and Rural Affairs, the approval was for five years from 21 April.

Unlike genetic modification (GM), which introduces foreign genes into a plant, gene editing technology alters existing genes.

China published rules on GE last year and Shunfeng claimed to be the first company in China seeking to commercial-

ise GE crops, Reuters wrote. The company was researching around 20 other GE crops, including higher yield corn, rice and wheat, herbicide-resistant rice and soyabeans, and vitamin C-rich lettuce.

Additional steps were needed before Chinese farmers could plant GE soyabeans, including approvals of seed varieties, Reuters wrote.

9-12 July 2023

10th European Symposium on Plant Lipids Amsterdam, the Netherlands

https://eurofedlipid.org/10th-europeansymposium-on-plant-lipids/

19-21 July 2023

20th Global Oleochem Summit 2023 Xiamen, China https://webshow.ienmore. com/?activityId=1804&languageType=1

9-10 August 2023

Malaysian Palm Oil Workshop Series for Professionals

Ho Chi Minh City, Vietnam https://mpoc.org.my/mmd-programmecalendar-2023/

17-18 August 2023

Palmex Thailand 2023 Suratthani, Thailand www.thaipalmoil.com/

29-30 August 2023

North American SAF Conference & Expo Minneapolis Convention Center, Minnesota, USA

https://saf.bbiconferences.com/ema/ DisplayPage.aspx?pageId=Home

3-8 September 2023

FOSFA Introductory Course + FOSFA Advanced Course University of Greenwich London, UK www.fosfa.org/education

11-13 September 2023

Argus North American Biofuels, LCFS & Carbon Markets Summit Monterey, California, USA (+ Online) www.argusmedia.com/en/conferencesevents-listing/biofuels-and-lcfs-markets

17-20 September 2023

Euro Fed Lipid Congress & Expo Poznań Congress Centre

Poland

https://veranstaltungen.gdch.de/tms/ frontend/index.cfm?l=11215&sp_id=2

19 September 2023

Techno Economic Marketing for Palm Oil (TEMPO) Series #3 2023 (China)

Chengdu, China

https://mpoc.org.my/mmd-programmecalendar-2023/

20-22 September 2023

Argus Sustainable Marine Fuels Conference

Houston, Texas, USA

www.argusmedia.com/en/conferencesevents-listing/sustainable-marine-fuelsconference

24-27 September 2023

16th International Rapeseed Congress

Sydney, Australia

www.irc2023sydney.com

28-30 September 2023

Globoil India 2023

Westin Mumbai Powai Lake, Mumbai, India

https://globoilindia.com/

2-4 October 2023

Sustainable Aviation Futures North America Congress

Houston, Texas, USA

www.safcongressna.com

4-6 October 2023

13th Palmex Indonesia 2023

Santika Premiere Dyandra Hotel & Convention Centre Medan, Indonesia http://palmoilexpo.com/

9-11 October 2023

Algae Biomass Summit Madison, Wisconsin, USA

www.eaba-association.org/en/events/ algae-biomass-summit-2023

11-13 October 2023

Argus Biofuels Europe Conference London, UK (+ Online)

www.argusmedia.com/en/conferencesevents-listing/biofuels

17-18 October 2023

American Fats and Oils Association (AFOA) Annual Meeting

Grand Hyatt, Nashville, USA

https://fatsandoils.org/future-annualmeeting-dates-and-locations/

23-24 October 2023

The Future of Oilseeds: Prospects for Plant-Based Proteins?

Frankfurt, Germany

www.dgfett.de/meetings/aktuell

23-25 October 2023

International Fish Meal and Fish Oil Organisation (IFFO) Annual Conference

Cape Town, South Africa www.iffo.com/annual-conference-2023

24-25 October 2023

Future of Biofuels 2023

Copenhagen, Denmark https://fortesmedia.com/future-ofbiofuels-2023,4,en,2,1,27.html

24-27 October 2023

North American Renderers Association Annual Convention Ritz Carlton, Naples, Florida, USA https://nara.org/about-us/events

7-9 November 2023

International Palm Oil Congress & Exhibition (PIPOC) 2023

Kuala Lumpur Convention Centre, Malaysia http://pipoc.mpob.gov.my/

13-15 November 2023

AAOCS Lipid Conference Australia

Newcastle, NSW, Australia

https://aaocs2023.wordpress.com/

20-22 November 2023

Roundtable on Responsible Palm Oil (RSPO) Annual Roundtable Conference on Sustainable Palm Oil (RT2023)

Hotel Mulia Senayan Jakarta, Indonesia https://rspo.org/event/save-thedate-rt2023-in-jakarta-20-22november-2023/

5-9 December 2023

Palm Oil Internet Seminar 2023 (POINTERS) (Virtual)

https://mpoc.org.my/mmd-programmecalendar-2023/

12-14 February 2024

4th International Symposium on Microbial Lipids

Graz, Austria

www.dgfett.de/meetings/aktuell

28 April-1 May 2024

2024 AOCS Annual Meeting & Expo + Sustainable Protein Forum

Montreal, Québec, Canada www.aocs.org/attend-meeting

For a full events list, visit: www.ofimagazine.com Information subject to change

Coconut oil is a value ingredient in food and oleochemical products and high quality bleaching earths and activated carbon are needed in an optimum ratio to ensure a good quality oil

The coconut tree (Cocos nucifera) is a tropical plant which has been used as a source of cooking oil for centuries and, more recently, for producing food, cosmetics, medicines and various other products.

Coconut oil is made from coconut meat which is sun-dried or heat-treated to produce copra.

Oil is extracted from copra by means of mechanical pressing or solvent extraction, which is then refined through physical or chemical treatment.

In the case of virgin coconut oil, only fresh mature coconut meat is used, which is wet or dried for extraction through mechanical pressing, without further refinement to maintain the unique fresh aroma of coconut oil.

Currently, the main producers of coconut oil include India, Indonesia, the Philippines and Vietnam, while the top importers are the European Union (EU) and the USA.

Coconut oil is extensively used in commercial food processing and in the oleochemical industry, as it offers advantageous chemical properties such as a high lauric acid content that is otherwise only found in palm kernel oil. That makes it unique among edible oils.

Despite the potential impact of coconut oil on cardiovascular health due to its high saturated fat content, it is high in medium chain triglycerides (MCTs) and therefore easier to digest than other types of edible oils.

Marla Ruby QuintinePhoto: Adobe Stock

P

Recommended values for neutralised oil

Recommended values for bleached oil Recommended values for degummed oil

Moreover, it is very stable at elevated temperatures (for example, when deep frying) and it is a good source of energy.

Coconut oil is solid below room temperature and liquid above it, with a melting point range of 23.8-28.3ºC.

It has a low iodine value, high saponification value and high saturated fatty acid content, and mostly consists of short chain fatty acids.

As a result, coconut oil is highly resistant to oxidation and is commonly used in applications where a long shelf life is desired. Its low viscosity imparts a less greasy mouthfeel when compared to other edible oils.

All natural fats contain fatty acid glycerides (see Table 1, left) as well as minor quantities of other substances. The saponified content of coconut oil mostly consists of sterols while the unsaponifiable component includes a small number of tocopherols and phytosterols.

The quality of refined coconut oil is subject to the quality of the copra used in oil extraction, while the quality of the copra is mostly dependent on its production process and the maturity of the coconut meat.

Copra is made by first removing the husk from the coconut, breaking the shell, and then dehydrating the meat by sundrying, oven-drying or direct smoking.

The drying process greatly influences the quality of the oil. For example, when the meat is smoked directly using fuel, the shell may be contaminated by polycyclic aromatic hydrocarbons (PAHs), leading to a lower quality crude oil.

After dehydration, the copra undergoes solvent extraction or mechanical pressing to obtain unrefined (crude) oil which is then refined using a chemical or physical process to remove impurities (see Figure 1, left).

This is to ensure that the oil meets recommended standards (see Figure 2, left).

Generally, food specifications are defined by national standards and industry requirements. There are specific criteria for edible oils and oleochemicals.

=

Specifications for refined coconut oil follow the internationally recognised Codex Alimentarius standard (see Table 2, following page).

Besides Codex specifications, there are additional regulations applied by authorities, such as the EU, regarding

Colour

Relative density at 400C/200C

Refractive index at 400C

Moisture & other volatiles at 1050C

Free fatty acids, calculated as lauric acid % by mass (maximum)

Peroxide value (millequivalents of active oxygen per kg)

Iodine value

Saponification value

Unsaponifiables, % by mass, maxiumum g/kg

Reichert value

Polenske value

contaminants in coconut oil products intended for direct human consumption, or for use as an ingredient in food.

For example, EU regulation No 835/2011 addresses PAH content in coconut oil intended for direct human consumption or for use as an ingredient in food and it defines the maximum limits as: 2.0 mcg/kg for benzo(a)pyrene; and 20.0 mcg/kg for total benzo(a)pyrene, benz(a)anthracene, benzo(b)fluoranthene and chrysene (PAH4).

Polycyclic aromatic hydrocarbons (PAHs) are chemical compounds comprised of carbon and hydrogen molecules in a cyclic arrangement. PAHs are associated with risks to human health, especially carcinogenesis. Contamination with PAHs can be caused by:

• Environmental pollution of the vegetable raw material

• Unfavourable seed drying (particularly through combustion gases)

• Extraction with solvents

• Burning of soil

• Packaging material

• Mineral oil residues

• Contact with contaminated water or soil

Impurity removal

Each step in the refining process of coconut oil is intended to remove specific impurities. During neutralisation, most impurities are reduced, hence the load for subsequent steps is lighter. Next, degumming removes phospholipids (gums), while the bleaching stage removes most of the residual

Figure 3: Efficiency of bleaching earth and activated carbon compositions & dosages Source: Clariant internal testing Figure 4: Vacuum bleaching coconut oil using Tonsil Optimum 231S + activated carboncontaminants to safe levels. The final deodorisation step eliminates any remaining volatile impurities and odours.

The bleaching process plays an important role in “perfecting” impurity removal following these refinement steps. In this stage, bleaching earth is used to remove colour bodies, peroxides, soap, remaining gums, chlorophyll, carotene, water and other impurities, such as PAH compounds.

Typically, activated carbon is also added during the bleaching process to remove PAHs – particularly heavy PAHs, such as benzo(a)pyrene – and to improve the colour of refined coconut oil.

However, it is important that the interplay between bleaching earth and activated carbon are optimised to ensure efficient impurity removal and colour enhancement (see Figure 3, left, previous page) while optimising the total cost of ownership.

With bleaching earth and activated carbon, quality is particularly critical. Not only does it impact the physiochemical properties of the refined coconut oil, but also its appearance, which is usually measured against the Lovibond colour scale.

Moreover, the dosages of activated carbon and bleaching earth should be in an optimum ratio to achieve the desired performance.

An optimum blend ratio is implemented in premium-grade bleaching earths, such as Clariant’s Tonsil Optimum 231S, where the correct dosage ratio of activated carbon relative to bleaching earth has a

considerable impact on coconut oil colour. It should be noted that increased activated carbon content is not necessarily better (see Figure 4, below left, previous page).

Coconut oil is a highly valuable ingredient in the food and oleochemical industries, thanks to its unique physiochemical properties and lipid profile.

However, refining coconut oil can be challenging and is greatly influenced by how the crude oil is sourced.

To fulfil all safety and specification requirements for refined coconut oil, high-

quality bleaching agents are needed for an effective and efficient bleaching process. The most common bleaching agents used to refine coconut oil are bleaching earth and activated carbon.

High-quality activated carbon is critical for removing PAH impurities, while oil colour can be significantly enhanced and lightened using the right bleaching earth and process. Furthermore, the bleaching agents should be combined in an optimum ratio in order to achieve the desired oil profile. ●

Bleaching earths and clays are vital for the edible oil industry. Oil producers use these crucial minerals to “bleach” or purify vegetable oils by allowing the bleaching clays to soak up impurities from the processed oil. Without them, our vegetable oils would simply not be fit for consumption.

Yet, despite their immense significance, bleaching earths can be poorly understood within the edible oils industry beyond their basic purpose. That is not due to any failure on industry professionals’ part. Bleaching earth mining, processing, and distribution are complex topics, but knowing how these allimportant minerals make their way from the ground into the oil vat can help edible oil producers improve their processes.

Multiple types of bleaching earth are utilised across various industries but the oils and fats sector is the largest user, and will continue to lead as population growth drives further consumption.

The three basic types of bleaching earth – bentonite, attapulgite and sepiolite –can be used as natural products but they are more commonly refined further for specific industries and uses.

Bleaching earths are clay minerals that –when added to vegetable, animal or fish oil – have the ability to bind and absorb unwanted impurities and contaminants, such as trace metals, oxidation products, chlorophyll and carotenoids. Once the

The edible oil industry is the main consumer of bleaching earths worldwide. What are the main types of bleaching clays, how are they produced and utilised, what is their relationship to other adsorbents, which contaminants must they address and what are the environmental and other challenges facing producers?

Ile Kauppilaminerals are removed from the oil, they take the contaminants with them, thus cleaning or “bleaching” it.

All bleaching earths and clays are able to bind contaminants due to their specific physical properties, such as large surface area, porosity and particle size. However, different types of bleaching earths possess distinct characteristics that affect their overall performance, making them more or less suitable for different oils or processes. In general, three different clay minerals are used as bleaching earths: bentonite, attapulgite and sepiolite.

Jorge Bello, technical support manager at US Silica, says that each of these clays belongs to a group called 2:1 clays.

These clays get their name from their internal structures, which consist of one octahedral sheet sandwiched between two tetrahedral sheets, in the case of bentonite (also called montmorillonite). Attapulgite and sepiolite also have similar structures, but their internal “windows” or areas between the sheets are larger.

“Bentonite is a phyllosilicate, with layers

like a pack of cards,” Pat Howes, technical and marketing director at Malaysia’s Natural Bleach Sdn Bhd, explains. “The space between the layers can be accessed from all four faces of the edges of the stacked layers.”

Bentonite removes impurities by absorbing them between the “cards” or mineral layers through capillary action. Due to the wider absorptive area, Howes notes that bentonite’s capillary effects are weaker than those of attapulgite or sepiolite.

“Attapulgite and sepiolite have a needlelike morphology. Their structures resemble a bundle of straws and, like straws, their interior absorptive area can only be accessed via either of the two ends.” The straw-like structure also gives attapulgite and sepiolite stronger capillary action.

It could be assumed that higher capillary attraction would make attapulgite and sepiolite more effective at removing impurities, but the situation is actually the opposite. In addition to impurities, attapulgite and sepiolite absorb large

amounts of the oil product, which is naturally undesirable for edible oil producers.

“Bentonites result in about 15-20% oil loss, whereas attapulgites and sepiolites cause about 30-35% oil loss. That oil loss is a very important contributor to the total cost of vegetable oil refining,” says Howes.

Attapulgite and sepiolite can also pose a potential health hazard to oil refinery staff. If a worker were to inhale airborne powdered attapulgite or sepiolite, their needle-like fibrous structure could cause fine material particles to become trapped in the lungs – not unlike asbestos fibres.

Prolonged exposure to the powdered clays may result in lung damage, medical conditions such as chronic bronchitis or tuberculosis, and potentially even cancer, according to research by Purdue University. “Inhalation of these materials must be avoided,” Howes stresses.

Due to the lower oil loss and health risks associated with bentonite, these minerals are more popular as bleaching earths. However, attapulgite and sepiolite also have their uses, as long as correct safety precautions are followed.

Bleaching clays are naturally-occurring minerals that are found in huge deposits all around the world where ancient volcanoes were once active.

“Wherever there was volcanic activity, there is a potential to find a bleaching clay deposit of any type,” says Bello. “Volcanic ashes are the parent materials. The ashes have experienced rearrangement and evolution in their structure to become clay. Deposits are all over the world but ‘good’ clay deposits are only located in specific areas of the globe.”

One example of such deposits is the Deccan Plateau in India, which arose around 66-60M years ago. According to Howes, the super volcanic activity at the time deposited roughly 200,000 to 1M km3 of ash in the area. “We can compare that to the eruption from Mount St Helen’s in 1980, which was estimated at 4km3. Bentonites, attapulgites, other closely related minerals and intergrowth materials can be found in the Deccan Plateau,” Howes adds.

Similarly, there is a significant bleaching clay deposit in Europe, running from the area of Redhill, UK, across the English Channel, all the way to France, Spain and northern Africa. Other major deposits are found in Australia, Brazil, China, Iran, Nigeria and South Africa, with bleaching earths being mined from each of them.

However, certain bleaching earths are concentrated in specific areas. According

to the British Geological Survey, China is the world’s top producer of bentonite, being responsible for roughly a quarter of all production. This is followed by the USA, where sodium bentonite is found in the western parts of the country, while calcium bentonite deposits are located in the south. Germany, Greece, India, and Turkey are also significant bentonite producers due to natural deposits.

Attapulgite is found in abundance in southeastern USA (with the mineral getting its name from the town of Attapulgus, Georgia). Other significant deposits can be found in China, Spain and Turkey. Most commercial sepiolite on

the market comes from Turkey, although less abundant deposits also exist and are exploited in Greece and central and southern Africa.

Thanks to the enormous global supplies, the edible oil industry does not have to worry about dwindling reserves. The global consumption of bleaching clays stands at a few million tonnes/year. As such, both Howes and Bello agree that it is unlikely there will be any shortages of the material for decades to come. Governments choosing to restrict the development of mines for ecological or other reasons stand as the only foreseeable limitation on bleaching earths’ availability.

Due to bleaching clays’ plentiful supplies around the world, bleaching earth producers often operate multiple mines in various regions. Clariant, for example, operates 60 bentonite mines.

“Prior to any mining activity, a core drilling campaign has to be performed on the mine deposit. This information will map out the usable layer configuration across the whole area and will facilitate selective mining activities. After the mineral is extracted, it is formed into big stockpiles to guarantee the homogeneity of the raw clay,” Bello says.

Once their quality is verified, the clays go to a processing facility. After reinspection, the bleaching clays become either natural or activated bleaching earth.

Natural bleaching earths, also called Fuller’s earth, undergo minimal processing after mining. Impurities such as stones are removed and the material is dried and milled to a specific particle size, depending on the product. Natural bleaching earth has been used for a long time and its production is a very low-cost process.

Activated bleaching earths, on the other hand, are subjected to an acid-activation process, also called acid-leaching or acid-washing. The process increases their acidity, as well as their absorptive capabilities. Acid activation can be carried out using either the slurry method or the granular method. Each method is suitable only for certain types of clays.

The slurry method involves submerging the raw, milled bleaching clay in water (called mother liquor), and the two are mixed into a slurry. Producers add sulphuric acid to the water and heat it to either up to

105°C for atmospheric digestion or up to 160°C for pressure digestion.

After the required period of activation, the slurry is quenched with water. The acid-activated clay is separated from the mother liquor and washed to remove excess acid and acidic salts by filtering it with plate-and-frame filter presses or by sedimentation, followed by filtration.

“The acid-activated filter cake is then sent to the drying and milling system to produce a free-flowing powder of the required moisture content – usually lower than 15%. The mother liquor may be sent to an effluent treatment plant or utilised to manufacture by-products,” Howes explains.

In the granular method, the natural bleaching clay is milled into small pellets, often around 6mm in diameter. These granules are placed in an open reactor with a porous lower membrane. This membrane allows the mother liquor to pass through while keeping the pellets in place. While submerged in the liquor, the producer adds acid into the reactor, which is recycled externally and heated to roughly 85°C. Howes notes that the granular process requires a longer activation period than the slurry method.

After activation is complete, the mother liquor is drained through the membrane and the clay undergoes washing, either with water or diluted acid.

The reactor is then drained for the final time and the clay granules are removed through a small hatch or door at the lower part of the reactor. Removing the clay from the reactor often requires additional labour as all the granules rarely flow out freely. After the clay has been removed,

the holes of the bottom membrane require piercing to ensure they are not clogged for the next processing batch. As such, the granular method is more workintensive than the slurry process. Finally, the activated clay granules are dried and milled for distribution.

Natural and acid-activated bleaching earths not only differ in their production methods, but in their mode of action as well.

Natural bleaching earth removes impurities by absorbing them wholly physically, without altering the edible oil or other products, Howes says. The only exception to this is the natural bleaching earths’ greater ion exchange capacity, which allows them to remove iron and other undesirable metals.

Natural bleaching earths have a lower absorptive capacity than activated ones, although their lower acidity makes them more suitable for certain applications. All in all, however, natural bleaching earth makes up a single-digit percentage of global consumption, notes Bello.

Surface-modified acid-activated bleaching earth has a structure that is very similar to natural bleaching earth. However, the acid activation process increases their surface area, giving them higher absorptive ability. This is partially due to new silica surfaces that form during activation. At the same time, however, their ion exchange capacity falls as the sites causing the charge in the clay layer are removed during the bleaching process.

Additionally, the activation process turns the clays into solid acid catalysts, which enables them to crack and otherwise alter the structure of various pigments, making them invisible to the human eye.

“This bleaching earth will also easily convert primary oxidation products, such as hydroperoxides measured by peroxide value (PV), to secondary oxidation products, like aldehydes and ketones measured by anisidine value (AV),” explains Howes. “The PV will fall as far as zero, but the AV will increase. Consequently, the odour of the oil will become worse due to the formation of aldehydes and ketones. These odours need to be removed by deodorisation or steam refining under high vacuum.”

The activation process also causes other undesirable modifications. Activated bleaching earth can cause cis- to transisomerisation — in other words, the formation of trans acids. Not only are trans isomers harmful to health, they also make the oil look cloudy and less appealing.

Another catalytic reaction that activated

bleaching earths may cause is the double bond shift. This reaction may, for example, turn anti-inflammatory omega-3 oil into pro-inflammatory omega-6 oil.

“In nature, an oil that has three double bonds will have them separated by two single bonds. But when placed over a solid acid catalyst – such as acidactivated bleaching earth – the bonds will conjugate so that there is only one single bond between each double bond. This conjugation adversely affects the stability of the oil. An oil that would naturally take 25 days to go rancid could turn rancid in only one day,” says Howes.

So, although activated bleaching earths have a generally higher ability to absorb impurities, they are not a silver bullet for the edible oil industry. Due to their capacity to cause negative changes in oils, natural bleaching earths still have their place.

In edible oil refining, bleaching earth can be used in two ways.

In the dry bleaching process – more common in Europe and Asia – the oil is heated by injecting steam into it and mixed with a bleaching clay under a vacuum to prevent oxidation. Following bleaching, the clay is removed from the oil with pressure leaf filters and gathered for post-processing.

In the wet bleaching method, water (in the form of a citric acid solution) is added to the oil after heating and before adding the bleaching earth. The added water makes it easier for the minerals to absorb metals and remove residual soaps, reducing bleaching earth consumption and oil loss. Despite its increased efficiency, wet bleaching has much higher initial costs, which limits its applicability.

In addition to vegetable oils and animal fats, bleaching earth is used to purify a wide range of other oil and fuel products.

Biodiesel and green diesel production is the second largest consumer of bleaching earths, and Bello sees this segment continuing to grow in the next five years. Biodiesel producers use bleaching earth to purify their feedstocks, which often contain phosphorous and metal contaminants.

“Bleaching earths are used to purify used cooking oil (UCO), sludge oils, acid oils and other waste oils that are utilised in the manufacture of biodiesel and renewable diesel. Thus, bleaching earth plays a part in the control of greenhouse gases,” says Howes.

Bleaching clays are also used in the final purification steps of petroleum oil refining, for products such as kerosene and jet

fuel. Howes notes that they can also help recycle petroleum products. “Bleaching earths are used to recycle synthetic and mineral oils, such as engine oil. After bleaching earth treatment, the recycled oil can have a better quality than the original base oil. Many leading brands such as Mercedes and Aston Martin have approved the utilisation of recycled engine oils.” Bleaching earths are also used in many other industries including as:

• An animal feed additive to reduce the amount of fungal mycotoxins

• A moulding sand additive to increase the accuracy of metal casting in foundries

• A drilling additive in civil engineering projects

• A formation additive in paper production

• Stabilisers and aromatic removers in plastics production

• Purifiers for wastewater treatment

• Surfactants in detergent and soap production

Once bleach clays have been used in edible oil bleaching, they are known as spent bleaching earths (SBEs).

The global edible oil industry produces around 2.5M tonnes/year of SBE, according to the report ‘Effect of activating solution modulus on the synthesis of sustainable geopolymer binders using spent oil bleaching earths as precursor’. SBE poses various problems for industry.

According to the American Oil Chemists’ Society (AOCS), SBE can contain 30-50% of entrained oil by weight. Due to the high oil content, SBE is susceptible to spontaneous combustion as the thin film of oil spread across the clay’s high surface area oxidises rapidly, generating heat. This makes handling, transporting and reusing them a significant challenge.

The oil trapped in SBE is also a source of environmental regulatory concerns. SBE decomposes slowly, so it cannot be disposed of in landfill. Due to the risk of combustion and environmental issues, SBE is classified as hazardous waste in the EU. Yet, there is a strong incentive for oil producers to do something with SBE to mitigate some of the oil loss associated with bleaching earth use.

Sabah M. Abdelbasir et al describe some uses for SBE in their 2023 review, ‘Spent bleaching earth; recycling and utilization techniques’. SBE can be recovered and recycled by removing the entrapped oil through various methods, including pyrolysis, chemical treatments (particularly acid), solvent extraction, or a combination method. However, many of these methods are labour-intensive and not economically viable. To date, solvent extraction with methanol, acetone and hexane is the most commercially sensible method.

After SBE recovery, there are various uses for both the separated oil and bleaching clay. Neste, for example, uses oils recovered from SBE as a raw material for its NEXBTL renewable diesel. SBE can be composted with palm oil milling and other agricultural residues to create a fertiliser that can positively impact soil

quality. The de-oiled SBE may also be suitable for re-use in processes such as wastewater purification.

AOCS has experimented with a process to add salt to SBE to eliminate the risk of spontaneous combustion. A salt content as low as 35% can reduce the risk, but for optimal results, a salt content of 45% is recommended. The salt/SBE mixture can then be compressed into a salt-lick brick for cattle and other livestock.

Other experimental uses for SBE include compressing it into bricks for construction utilising polymerisation under high heat. The polymerised oil remnants form bonds that hold the bricks together. It should be noted, however, that many such theoretical SBE applications have not been applied commercially and may not be economically viable.

Bleaching earths are popular adsorbents in edible oil refining and other industries, but they are not the only options refiners have available to them. Many alternatives exist, although Bello highlights that these products are not rivals.

“Porous materials like synthetic hydrogels, activated carbon, activated cellulose and other products do not compete against bleaching earths but they complement their application. These mesoporous and microporous materials are effective on certain types of impurities but, in the end, bleaching earths are the adsorbents to remove 90% of the contaminants,” he says.

Silica, or silicon dioxide, is one product that works in conjunction with bleaching clays. In fact, acid-activated bleaching earths form silica structures on their surfaces. “Acid-activation of bentonites removes a part of the octahedral alumina layer, leaving the two silica layers in place.

This enriches the silica species that are beneficial to the absorption of certain impurities,” Howes explains.

In addition to naturally-occurring silicas, there are synthetic silicas, such as silica hydrogel mentioned by Bello. This material is produced by allowing a sodium silicate solution – also called water glass – to react with an acid, according to the AOCS Lipid Library.

The acid destabilises the water glass and forces the silicate polymers to form colloidal silica particles known as silica hydrosol. The product is then washed to remove excess acid and salt by-products and left to age so it develops the required pore structure.

After milling, the silica hydrogel is ready for use in edible oil or chemical refining, biodiesel production and the oleochemical industry. Silica hydrogel can have triple the surface area and pore volume of bleaching clays, which can make it an extremely efficient adsorbent.