FOR MANUFACTURERS ABOUT SUBCONTRACTORSJanuary 2023 MACHINED COMPONENTS | CASTINGS | SOUTHERN MANUFACTURING www.engineeringcapacity.com

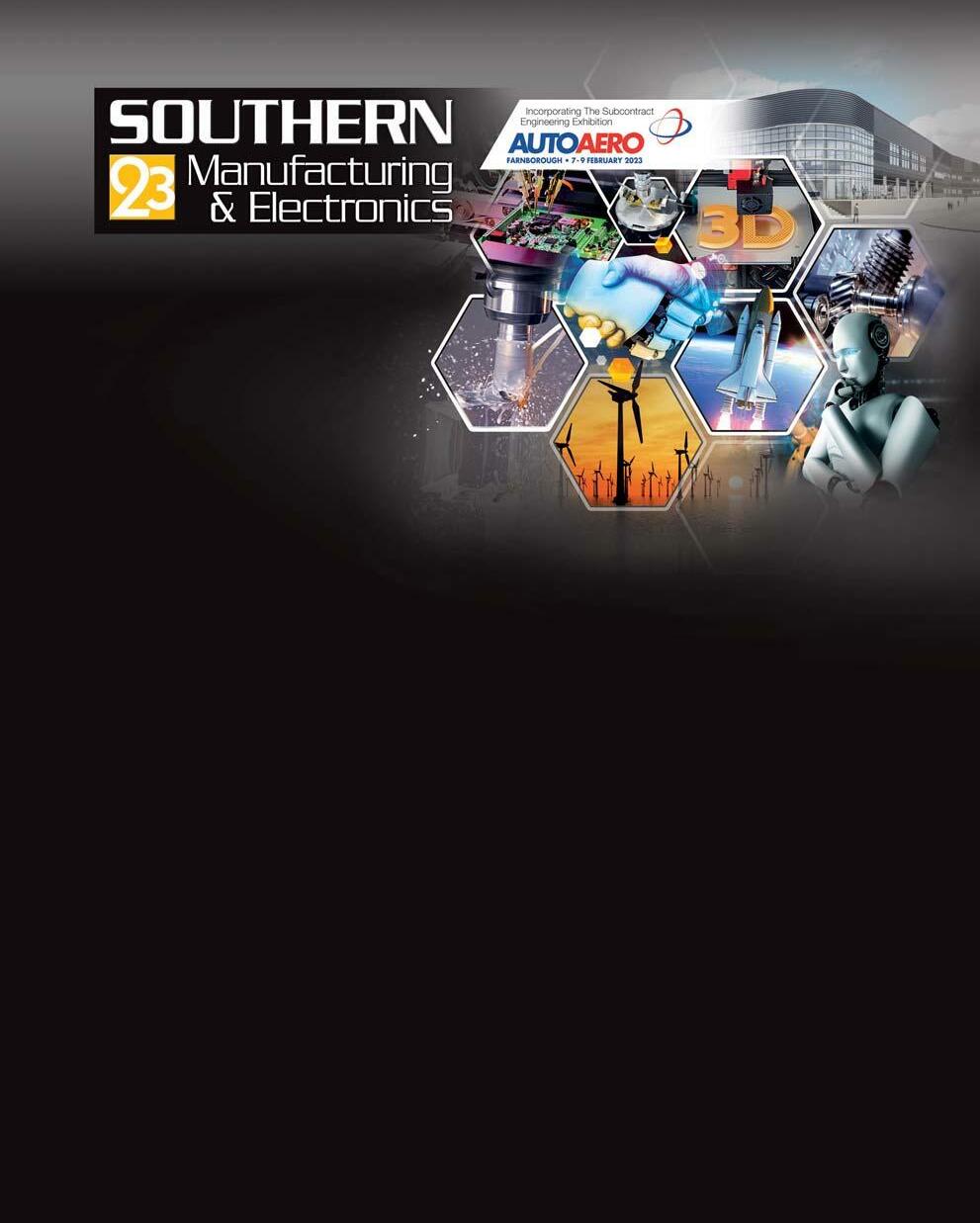

7th | 8th | 9th FEBRUARY FARNBOROUGH | Hants | GU14 6TQ 9.30am - 4.30pm (3.30pm close Thurs) FREE SEMINARS FREE PARKING AUTOMATION DEFENCE ELECTRONICS AUTOSPORT MARINE AEROSPACE TRANSPORTATION PACKAGING ELECTRICAL & MECHANICAL ENGINEERING ADDITIVE MANUFACTURING LOGISTICS FOOD & DRINK ENERGY SMART MANUFACTURING SPACE ENGINEERING R&D MEDICAL COMPOSITES CONSTRUCTION

Industry and Innovation converge Over 600 national and international suppliers come together to exhibit at Farnborough International Exhibition and Conference Centre this February for Southern Manufacturing and Electronics (inc AutoAero) 2023. Meet the power behind UK manufacturing industry and see live demonstrations and new product launches of machine tools & tooling, electronics, factory & process automation, packaging & handling, labelling & marking, 3D print technology, test & measurement, materials, composites & adhesives, rapid prototyping, ICT, drives & controls and laboratory equipment. Free industry seminar programme online @ www.industrysouth.co.uk The exhibition is free to attend, free to park and easy to get to. Doors open at 9.30am on Tuesday 7th February. PRE-REGISTER TODAY for your Fast Track Entry Badge, Preview Magazine and Event Catalogue at www.industrysouth.co.uk SOUTHERN MANUFACTURING & ELECTRONICS is an ETES event organised by European Trade & Exhibition Services Ltd Tel 01784 880890 · email philv@etes.co.uk

Where

FOR BUYERS OF CONTRACT MANUFACTURING SERVICES

Visit our online edition for breaking news, jobs, events, features and searchable directory. www.engineeringcapacity.com

Editor: Andy Sandford editor@engineeringcapacity.com

Commercial Director: Arfan Qureshi sales@engineeringcapacity.com Tel: 0208 013 5752

Graphic Design: Dave Blake blakey@djbdesign.co.uk

Printer: Holbrooks Printers Limited Norway Road, Portsmouth PO3 5HX

Engineering Capacity is published six times a year in January, March, May, July, September and November

SUBSCRIPTIONS

Engineering Capacity is available free of charge to UK buyers and suppliers of subcontract manufacturing services.

For non-qualifying readers, annual subscription rates are as follows for 6 issues posted to addresses in: UK £60.00; Europe £80; Rest of the World £100

You can request your copy and sign up to our free weekly email newsletter on our website or contact us via subscriptions@engineeringcapacity.com www.engineeringcapacity.com Tel: 01737 270 648

Published by: Engineering Capacity Ltd Abbey House, 25 Clarendon Road Redhill, Surrey, RH1 1QZ United Kingdom Registered in England company no. 10567217 ISSN 0306-0179

COMING UP IN OUR MARCH 2023 ISSUE

Turned Parts, Forming & Fabrication, Aerospace & Defence, Heat & Surface Treatments, Heavy Engineering, Automotive, Casting & Forging

Please send editorial for consideration to editor@engineeringcapacity.com

There is no charge or cost involved with having your editorial included in the magazine or on our website

Editor’s View

Happy New Year. Well let’s hope it is anyway. So what has changed? Well for one thing fuel costs and inflation have come off the boil –although if you are using a lot of electricity it will still be pushing down on profitability. Some of the supply chain issues seem to have eased a bit, and there are signs of healthy activity in areas such as aerospace, the energy sector and medical.

In fact, there even seems to be a shortage of 5-axis subcontract capacity at the moment – see article on Yamazaki Mazak on page 16. That article came after a visit to Mazak’s impressive manufacturing facility in Worcester.

One theme that came up on the visit, and seems to be a constant, is the problem of recruiting skilled staff. As ever there are basically three ways of addressing this: grow your own, use somebody else’s or make the most of what you’ve got.

Companies like Mazak already put a lot of effort into ‘growing their own’ skilled workers of the future – and there are opportunities to make your own effort here by embracing and engaging with the new T Level qualifications – see article on page 30.

The second approach, using somebody else’s skills, is what subcontracting is all about, and why the market is relatively healthy at the moment.

The final route, making the most of what you’ve got, implies using automation to take the drudgework off your team so they can get on with more value adding activities, and using smart technology, such as Artificial Intelligence (AI), to digitally upskill your operators.

Apparently the latest thing in AI is something called ChatGPT which can write intelligent articles based on a few simple inputs. Let me know when you spot the difference.

Andy Sandford, Editor

3 JANUARY 2023 www.engineeringcapacity.com

Member of the Engineering Industries Association

4 www.engineeringcapacity.com JANUARY 2023 06 More 5-axis at NTG 06 First machine into new facility 07 Automated 3D inspection 06 Faster throughput on PCBs 08 Smarter plastic production 06 Industry 4.0 implementation at Westley 09 £2m robot plating line first 06 Eectoless nickel automated at CBE+ 10 Moulding for 60 years 06 Celebrations at OGM 11 Precision toolmaking academy 06 £1m skills partnership 12 Machined Components 06 Turn-milling cuts lead time 5-axis opportunities 18 Laser Processing 06 Dental tools tracked 20 Sustainability 06 Aerospace net-zero opportunity; Responsible sourcing excellence 22 Additive Manufacturing 06 Emmerdale in 3D 25 Castings 06 Cast of winners at CMF Awards North Star offers direction 30 T levels 33 Southern Manufacturing Show 39 BTMA Directory Features Contents January 2023 16 MACHINED COMPONENTS News 24 ADDITIVE MANUFACTURING 29 CASTING

Made in Britain and the British Design Fund have launched a joint initiative to champion manufacturing innovation, collaboration and growth in 2023.

The initiative will kick off in January 2023 with the launch of a series of joint webinars for Made in Britain members.

The British Design Fund (BDF) is the only fund in the UK that invests exclusively in early-stage product design and manufacturing businesses. With a mission to boost homegrown enterprise and innovation, the BDF works with these British start-ups – providing a range of support, including mentorship –to scale their products, accelerate growth and build long term value for both investors and business owners.

Made in Britain brings together British SME manufacturers united by the licensed use of the Made in Britain registered, collective mark. Additionally, member companies receive support across exports, sales, marketing and PR; feature in a public, searchable product directory showcasing British-made goods; and enjoy access to the organisation’s Green Growth sustainability programme.

The UK manufacturing sector has an annual output of £183 billion and employs 2.5 million people – while the design economy is growing at twice the UK average, contributing £97.4bn in GVA to the UK economy and providing employment to 1.97 million people.

British design and manufacture

Made in Britain CEO John Pearce said: “In the tenth year of the Made in Britain initiative, I’m delighted to announce a new collaboration with the British Design Fund. This partnership will enable us to play a greater role in connecting innovative, young British companies with a wide spectrum of experienced manufacturers within our community to help turn their ideas and IP into a reality.”

British Design Fund CEO Damon Bonser said: “At the British Design Fund, we celebrate and support the design and innovation skills which drive so much of our growth in Britain - so

we are delighted to be partnering with Made in Britain to support more of the great ideas produced in the UK being manufactured in this country too.”

The two organisations are jointly launching a series of webinars that will be held during the first half of 2023. The first webinar will take place in January 2023 to introduce the British Design Fund to Made in Britain’s community of manufacturing companies – with a focus on how the BDF selects investments, supports and mentors some of the UK’s brightest entrepreneurs. 8 madeinbritain.org britishdesignfund.co.uk

Engineering Capacity | INDUSTRY NEWS 5 JANUARY 2023 www.engineeringcapacity.com

NTG has put its first machine into a new facility in Gateshead and at the same time has increased its 5-axis machining capacity.

The subcontract manufacturer remains on the Team Valley Trading Estate in Gateshead, but has massively increased the size of its premises, up to 45,000 sq ft, from 18,000 sq ft.

The first machine into the new facility was a new state-of-the-art Mazak VARIAXIS i-800 NEO, a move that is designed to both increase NTG’s 5-axis machining capacity and enable the company to enter new markets.

Mike Hutchinson, Group Managing Director at NTG Holdings, said the investment in both the new facility and the new machining technology opens up opportunities for his company.

“Our 5-axis capability has become a bottleneck due to demand from customers for this type of complex work. The new machine will enable us to offer shorter lead times by reducing the restrictions around our 5-axis work.”

The VARIAXIS i-800 NEO is a 5axis vertical machining center that delivers advanced high-speed multiple-surface machining in an exceptionally large machining area that enables the production of larger diameter parts.

The VARIAXIS becomes the first machine into NTG’s new facility and will be followed by another 50 machines that will be transferred to the new facility in the coming weeks, including Mazak turning centres, INTEGREX

More 5-axis at NTG

multi-tasking machines and vertical machining centres.

Mr Hutchinson said the new facility offers further growth opportunities for NTG. “We’ve increasingly diversified the business from its roots as predominantly a tooling and oil and gas focused supplier. We now operate across defence, food production, energy, subsea, electric vehicles and renewables. The new facility will give us the footprint to be able to continue to grow and service all our sectors, whilst also giving us the footprint to introduce more capacity and new technologies in the future.”

Mazak has been a long-time partner for NTG helping the company make the move into

complex 5-axis work more than a decade ago. “When we purchased our first 5-axis machine, the INTEGREX, it was because we wanted to be an early adopter of the latest production technology to maintain the highest levels of quality and productivity for customers.”

He continued: “Bringing in the new VARIAXIS allows us to take that capability to the next stage, opening up the potential for us to machine larger and more complex components. We are operating in a number of sectors, including defence and electronics, where we can now offer another level of capability and quote for work that was previously beyond our existing technology.”

8 ntg-ltd.co.uk

INDUSTRY NEWS | Engineering Capacity 6 www.engineeringcapacity.com JANUARY 2023

Contract electronics manufacturer Sellectronics, which specialises in quick turnaround prototype assembly and low volume/high mix production, has recently invested in Koh Young’s 3D AOI (Automated Optical Inspection) equipment to enhance its production.

Focused on innovative, highquality PCB assembly, Sellectronics continually invests in leading-edge technology to provide assembly excellence. Looking for the equipment that would enable precise inspection, and best performance to price ratio to increase quality further and improve production times, the company approached Altus for guidance.

Jason O’Connell, Sellectronics Technical Director, said: “As the business grows, the company makes many investments in the latest equipment to improve processes and ensure we are capable of providing the most intricate PCB assembly service with the best possible accuracy.”

To help increase inspection precision, Altus recommended the Zenith Alpha HS+ from Koh Young. As a true 3D AOI solution, it is powered by artificial intelligence and machine learning, combining the best optomechatronics and vision technologies to deliver outstanding performance without sacrificing accuracy.

Suitable for demanding production lines like those in Sellectronics, Zenith Alpha HS+ greatly improves process yields by removing the need for manual

Automated 3D inspection

inspection. In addition, the technology incorporates AI to deliver the accuracy required for ultra-fine pitch and solder joint interreflection challenges to enhance production. It also features KSMART, a measurement-based process analysis solution that allows for Industry 4.0 implementation with reliable full 3D measurement data. Graham Tonkin, Sellectronics Director of Sales and Marketing, said: “Due to the

precise and quantifiable measurement of the Koh Young platform, and by exploiting KSMART statistical process capability, our engineering process improvement and quality teams can aggregate real time production information. This not only removes the chances of an escape, but also to study our production processes in detail to improve our yields and drive our quality standards ever higher.” 8 sellectronics.co.uk

Engineering Capacity | INDUSTRY NEWS 7 JANUARY 2023 www.engineeringcapacity.com

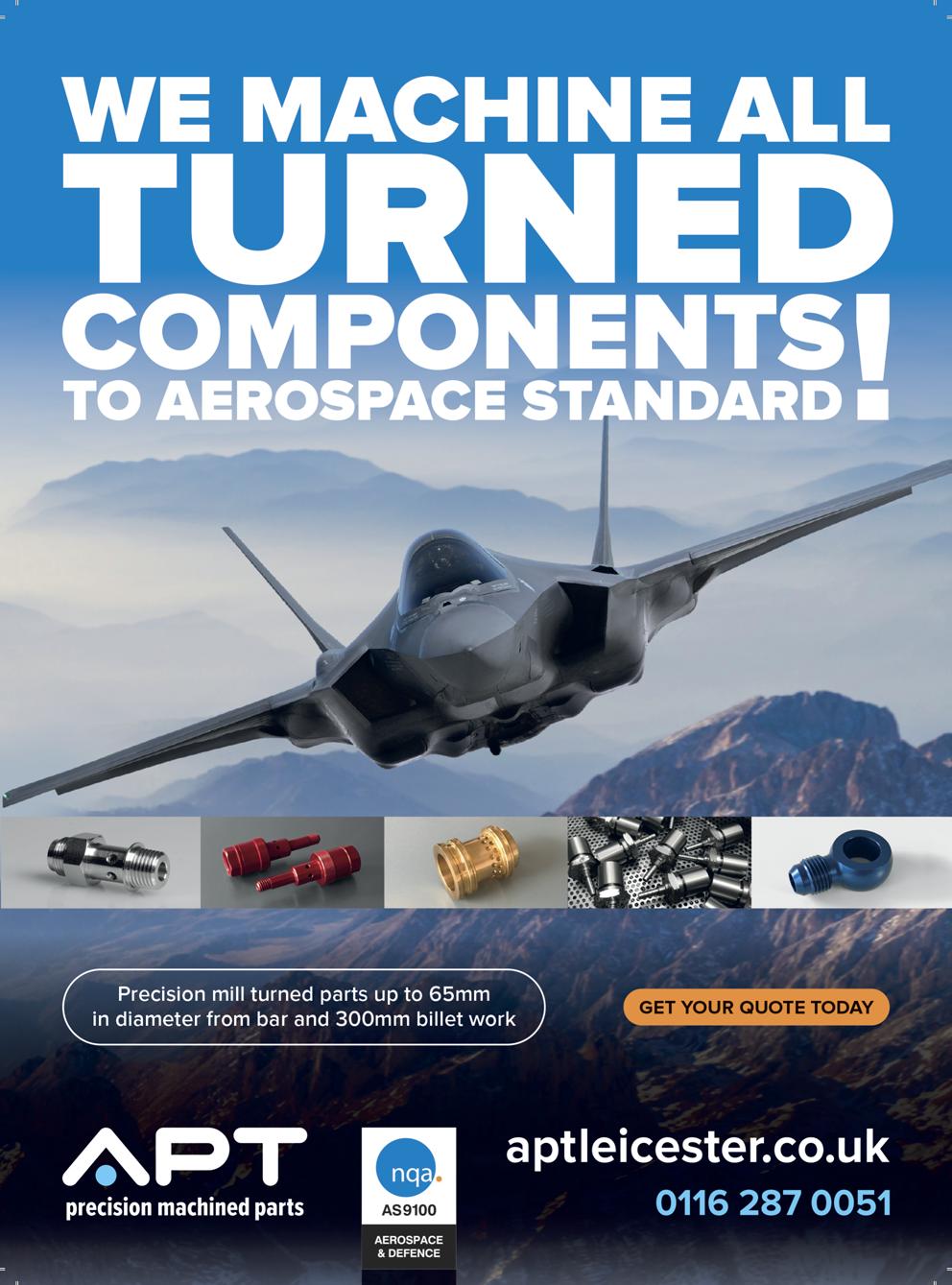

High quality cost effective CNC subcontracting. Produced on state of the art machines EN 9100:2018 ISO 9001: 2015 Approved Telephone: 01905 779783 Email: sales@lmsprecision.co.uk

High Quality Subcontract Machining LMS Precision Engineering

www.lmsprecision.co.uk

Industry 4.0 machine monitoring software from FourJaw is helping Westley Plastics improve its production efficiency.

The company, which specialises in cast-nylon and plastic components, has improved cycle times and achieved more consistent and efficient 24/7 production after adopting the smart technology, which has given the company greater visibility of its manufacturing process.

Westley Plastics is a family-run business that specialises in taking engineering plastic products from concept and design to final manufacture, utilising its on-site design, casting and CNC machining facilities. It works across several heavy industrial sectors including construction, defence, automotive, rail and steel.

The company operates 24 hours a day, but it wasn’t evident whether machine utilisation and productivity were consistent throughout any 24-hour period. It was agreed that greater visibility of the shop floor through machine monitoring would enable it to identify capacity and cycle times and help to focus the workforce on the processes that required and benefited most from their skills.

FourJaw’s manufacturing analytics platform, which works on machines of all types and ages, enabled the business to identify machine downtimes and understand the reasons behind the stoppages. Machine monitoring has also identified and improved cycle times. The team had previously discussed running

Smarter plastic production

two machines at the same time but didn’t think it could be done. However, the data from FourJaw revealed which machines could be run together – improving efficiency, productivity and job profitability.

Tom Westley, Operations Director said: “The information that the FourJaw platform provides has resulted in some very positive changes for the business, including the introduction of new production processes, improvements to the factory layout, and improved cycle times by creating new jigs, reducing onjob operations of big jobs by 50%.

“We now have a clear and informed picture of the factory floor including accurate cycle times and utilisation by shift. The factory is now more efficient and productive with its resources which is evidenced by the increased utilisation of machines running 24 hours during the week, which has improved so

much that fewer shifts need to run over the weekend, saving the business money on staffing, energy and other operating costs.”

Westley Plastics’ smart factory strategy will include installing FourJaw machine monitoring to every machine that it adds to its manufacturing operations as it grows.

Oliver Pogmore, Head of Business Development at FourJaw, said: “Our MachineLink IIoT device can be easily and quickly selfinstalled on any manufacturing machine, regardless of brand, type or age, which makes it perfect for small and medium-sized businesses who’d prefer a low-cost, no-fuss ‘plug-and-play’ solution. By monitoring and analysing machine data, FourJaw enables manufacturers to make machines run productively and profitably. This is certainly the case for Westley Plastics.” 8 plasticsuk.com fourjaw.com

INDUSTRY NEWS | Engineering Capacity 8 www.engineeringcapacity.com JANUARY 2023

Engineering supply chain provider CBE+ is installing the first 6+1 robotic Electroless Nickel Plating (ENP) line in the UK and Europe at its Chesterfield manufacturing facility.

Representing a £2 million investment, the automated plating line will allow the company to undertake a range of innovative projects, including the processing of small, precisionengineered components in high volumes and the ability to deliver high-quality parts at a consistently high standard.

The automated line from Sidasa Engineering will also facilitate a highly repeatable surface treatment process, reducing the time taken to complete and send large orders to customers and significantly increasing CBE+’s Electroless Nickel production capacity.

Chief Executive Officer, Marie Cooper (pictured), said, “This is a significant investment for CBE+ and one that will bring many benefits to the business and our customers. The new plating line reduces the scope for human error by automating dosing control and deposition monitoring and measuring. This results in a consistently high-quality finish on the products we process.

“Automating these tasks means we can redeploy skilled employees to projects that require higher levels of expertise. As well as freeing up time from the plating line, we are also automating parts of the jigging process in partnership with the Manufacturing Technology

£2m robot plating line first

Centre (MTC). This will enable the team to use their skills and expertise on projects that will interest and challenge them, as well as helping to drive the business forward.”

This investment continues CBE+’s commitment to sustainability and innovation, the new nickel-plating line will be linked with the newly commissioned effluent water treatment plant and combined

heat and power (CHP) system. The CHP system captures heat generated as a by-product of electrical power generation which is then used to provide heat energy for the surface treatment processes. The effluent plant filters and neutralises all waste chemistry on-site and allows for environmentally safe disposal and recycling.

8 cbeplus.com

Engineering Capacity | INDUSTRY NEWS 9 JANUARY 2023 www.engineeringcapacity.com BRITISH MANUFACTURER OF PRECISION MACHINED COMPONENTS SUPPLYING ALL QUALITY DRIVEN INDUSTRIES SINCE 1965 Dawson Precision Components Ltd Tel: +44 (0)1706 842311 Web: dpc.co.uk Defence & Aerospace Motorsport & Leisure Communications Transport Scientific Instrumentation Medical Subsea Environmental & Energy ISO9001:2015 Certified • BTMA Member • Bespoke Engineering Solutions

Vacuum brazing plant upgraded

Wall Colmonoy Limited (UK) has upgraded its capabilities with the acquisition of an Ipsen Vacuum Braze furnace.

The new furnace will be comparable to the largest braze furnaces at Wall Colmonoy, with dimensions of 1400mm x 1270mm x 1015mm and an improved vacuum level of 5x10-6 mbar. Due to the larger hot zone, the investment will enable the brazing of next generation heat exchangers and other larger components.

With a maximum temperature of 1315°C, the new furnace investment was focused on improving capabilities for higher temperature brazing projects. The furnace provides an ultraclean environment suitable for complex geometries.

Business Development Manager, Dr Lewis Berry, said: “This upgrade allows us to meet the needs of a growing number of customers who are looking for improved throughput for complex next generation brazed assemblies in materials that require a clean environment to vacuum braze.”

As the inventor of hightemperature nickel brazing, Wall Colmonoy continues to invest in its brazing capabilities to ensure it remains at the forefront of this technology.

8 wallcolmonoy.co.uk

Moulding for 60 years

Plastic injection moulding company OGM (Owen Greenings and Mumford Ltd) is celebrating an impressive milestone having achieved its 60th anniversary.

OGM was founded in Oxford in 1962 with one plastic injection moulding machine used to produce plastic door handles and a range of plastic tableware. Over the next 30 years, however, OGM grew rapidly as a trade moulding company, moving to larger premises a number of times to satisfy demand. In the 1990’s, OGM took a decision to specialise in plastic injection moulding for the electronics, medical and general industry sectors.

Paul Wightman, group managing director of Owen Greenings & Mumford (Holdings) said: “We have a strong heritage that underpins our company culture, values and how we do business. We’ve grown through a reputation for quality and reliability, technical excellence and flexibility but key to it all has

been the forging of long lasting customer relationships.

“We’ve always been an innovative business since my dad, Bev Wightman, founded the company with his three business partners 60 years ago. Recently, through expansion, acquisition and from having a great team across all of our sites, we’ve expanded to offer full-service solutions to both local and global businesses.”

Over the last 10 years, a new factory at Yarnton, in Oxfordshire, with a state-of-theart cleanroom, a purpose built toolroom, a team of skilled engineers and experienced and dedicated workforce has helped OGM become one of the UK’s most innovative plastic injection moulding businesses. The company now offers product design, consultancy, prototyping, toolmaking, injection moulding, assembly and distribution of hundreds of millions of components every year.

8 ogm.uk.com

INDUSTRY NEWS | Engineering Capacity 10 www.engineeringcapacity.com JANUARY 2023

Precision toolmaking academy

The UK’s first Precision Tooling Academy has been launched in a partnership between InComm Training and Brandauer.

Over £1m has been invested by the two strategic partners to create a commercial toolroom in the training provider’s facility in Aldridge, which will produce complex tooling, as well as acting as a professional training ground for the toolmakers and designers of the future.

The sector is being held back by a severe lack of toolmakers and the very real possibility of losing these essential skills forever as older workers choose to retire.

The Precision Tooling Academy aims to reverse this trend by offering companies access to professional toolmaking courses, upskilling opportunities for qualified engineers looking to diversify their skills and a Level 6

Tool Process Design

Apprenticeship to develop the next generation of talent.

Training will be unlike anything currently on the market, with up to 35 individuals in the first twelve months able to learn on live tooling projects that will be producing hundreds of thousands of parts every week and will give Brandauer and other tooling

experts the opportunity to reshore more manufacturing projects from Asia, the EU and the US.

A car manufacturer has agreed to be the first company to put their engineers through the toolmaking course and has contributed to the actual development of the curriculum. 8 in-comm.co.uk

11 JANUARY2023 www.engineeringcapacity.com Engineering Capacity | INDUSTRY NEWS

Turn-milling cuts lead time

Subcontracting firm Mintdale Engineering, Chesterfield, is run by four members of the Toyne family, managing director Chris, his wife and company secretary Christine and two other directors - their son Jason and his wife Julie.

The company specialises in CNC turning of bar, tube and billet as well as CNC milling on five vertical machining centres (VMCs). It operates twice as many machines for rotational parts production as for prismatic, although the borderline between the two is increasingly blurred these days.

Take for example an aluminium gas regulator base produced on the company's latest turning centre, an Italian-built Biglia B465 T2 Y2 twin-spindle, twin Yaxis turret model supplied in spring 2022 by UK and Ireland sales and service agent Whitehouse Machine Tools. The 1.25 inch high cuboid part is machined from 2 inch square bar fed by an LNS Quick Load Servo 80 S2 short bar magazine.

The component, which Mintdale Engineering has been producing for 22 years, was latterly machined 20 at a time on a twin-pallet-change VMC. Op 1 involved machining three sides, milling a circular pocket, drilling various holes and then tapping them, while Op 2 after pallet change completed similar features. Floor-to-floor time per base was two minutes.

On the Biglia, the part is produced in one hit and requires only a small amount of face turning and parting off, the remainder of the cycle being prismatic machining. Both live turrets are deployed at the main spindle for some of the time, followed by simultaneous machining at both spindles using the two tool carriers. Although cycle time is three minutes, i.e. 50% longer per part than before, the big advantage is that production is unattended, unlike on the VMC. The finish-machined components pass through the counter spindle onto a conveyor feeding a Hydrafeed Rota-Rack parts accumulator.

The lathe continues producing throughout the day shift, after which 100 parts can be added by running the machine lights-out until the bar is used up. The only special items needed to realise this application, which represents a good balance between main and counter spindle operations, were a spindle liner and a bar feed attachment for the square stock.

Another component produced more efficiently on the B465 T2 Y2, this time from 3 inch diameter round brass bar, is a conversion body for legacy gas delivery systems used in hospitals. The so-called Mark III component formerly required

MACHINED COMPONENTS | Engineering Capacity 12 www.engineeringcapacity.com JANUARY 2023

four operations: milling on a VMC and turning on a single-turret lathe, followed by two further separate visits to different VMCs for more prismatic operations and engraving.

The part is now turned, milled and drilled complete in the Biglia in a five-minute cycle. That is quicker than just one of the previous VMC operations.

Moreover no special workholding is needed, which would add expense and cause

unnecessary delay to the delivery of the first batch of parts.

A third part that has been transferred to the Italian lathe is a Mark IV version of the gas delivery conversion body, turnmilled from the same brass bar. It used to be produced in two

operations on a chucking lathe on which a special jig was made for holding the irregularly shaped Op1-machined billet to enable Op 2 to be carried out.

The extended floor-to-floor time for producing batches of the components is eliminated by the Biglia's ability to machine the component in one hit from bar in a five-minute cycle. Again, the cost of making a fixture and of work-in-progress is avoided.

8 mintdale.com

Engineering Capacity | MACHINED COMPONENTS 13 JANUARY 2023 www.engineeringcapacity.com

BS EN ISO 9001:2008. Approved by BSI since 1991. Subcontract Capacity Wealdpark Limited Company Contact Details Phil Smith, Director, Wealdpark Limited Sutton Road, St. Helens, Merseyside, WA9 3DJ Tel. 01744 22567 / 732083 Fax. 01744 451339 E: sales@wealdpark.co.uk www.wealdpark.co.uk

Two new 51mm capacity lathes are being put through their paces on parts for JCB at JTB Pressings in Wolverhampton.

The company had formerly subcontracted out turning and this move was made to help the company increase the range of manufacturing services it provides to existing customers, as well as spearheading a drive to secure new business from different sectors. It now offers a one-stop-shop, vertically integrated, manufacturing service that also includes laser cutting, welding and fabrication, powder coating and assembly services.

The DN Solutions (formerly Doosan) machines, a 6” chuck/ 51mm bar capacity Lynx 2100LYSA and, a similarly sized Lynx 2100, were installed at one of the company’s (three) production facilities in Willenhall, Wolverhampton.

Since their arrival both lathes have been machining, almost exclusively, a range of small, precision turned parts for the construction and agricultural equipment manufacturer JCB.

These parts, with their short cycle times and machined in high volumes, include six individual components (i.e., washers, bolts, bushes etc.), made from a range of materials that include steel, bronze, Nylon 6 etc., for a specific JCB Telehandler model’s door catch system which, after being machined, are then finished, powder-coated and assembled in-house by JTB.

Over 600 of these fullyassembled door catches are

Turning on new service

manufactured every week by JTB: a majority being dispatched immediately to the customer’s production line and the remainder, including the assembly’s individual components, retained for spares and stock.

Explains Ivan Evans, JTB’s managing director, said: “We are always looking to improve, diversify and grow.

“As such, we regularly invest in advanced manufacturing technologies to increase our productivity, manufacturing flexibilities and overall competitiveness.”

A recent example of JTB’s investment strategy in action saw the company, in 2018, acquire a state-of-the-art, large-capacity Nukon Eco 315 (2kW) laser cutting machine.

“This machine has added another string to our bow”, says Ivan Evans. “It has helped us grow the business enabling us to acquire a number of new

customers looking for highquality laser cut parts.”

To protect and strengthen its supply chain position with customers, help it increase productivity, improve process efficiencies, and control operational costs, JTB made the decision, back in 2021, to further expand the range of services it offered to customers, by developing its machine shop at its Willenhall facility.

Steve Lounds, JTB’s general manager said: “We knew from experience, and from talking to customers and prospects, that there was a demand we could meet for machining high-quality, competitively priced turned parts.

“We made the decision to meet this demand by creating a world-class, in-house subcontract machining resource, focused on producing complex, high-precision small turned parts for customers.”

8 jtb-pressings.co.uk

MACHINED COMPONENTS | Engineering Capacity 14 www.engineeringcapacity.com JANUARY 2023

Mill and turn for repeatability

Irish subcontract machining company Shannon Precision Engineering Ltd has recently invested in new mill-turn centres for aerospace and automotive contracts.

The two Nakamura-Tome machines, a WT150II and an SC100X2 , were supplied by the Engineering Technology Group (ETG).

Located in Shannon, the 80 employee manufacturer is AS: 9100 and ISO: 9001 certified, and it frequently works on highprofile projects for Airbus, Lear, Bombardier, Collins Aerospace, Liebherr, Safran, Spirit and many other leading names in the aerospace, automotive, offshore, rail and power generation sectors.

Machining everything from inconel, titanium, Hastelloy, duplex and Nitronic 40 and 60 as well as hardened steels, the stability and performance of its machine tools are of paramount importance. With the company winning a significant automotive order as well as major opportunities in the aerospace sector, SPE needed a new strategy in its mill/turn department.

Managing director Dominic Murphy said: “On some projects, we have been struggling with repeatability when machining particularly difficult materials. We won a contract to machine electro-mechanical connections for the aerospace industry from Nitronic 40 and titanium, and we

needed to be very responsive with our changeovers and lead times. With regular batches from 200 to 500 and up to 20 different part families in the series, the project has some very ambitious cycle time targets. With tolerances of +/-5 and +/-10μm on many features, we didn’t want to be chasing repeatability – we needed a more robust process than we had.”

The County Clare company

investigated the mill/turn market and it was the Nakamura WT150II that won the day with cycle times more than 20% faster than its rivals. “We gave ETG and other vendors a series of components as a prove-out. ETG built a machine set up around the family of components and they delivered a turnkey solution to our facility that was best suited to our requirements. We already have a lot of mill/turn centres onsite, so the Nakamura-Tome WT150II wasn’t just about cycle times. We needed a turnkey solution that could meet our ambitious cycle times and tight tolerances with relentless repeatability for long batch production – the NakamuraTome WT150II certainly delivered on that.”

The SC1002 was able to produce an extremely complex automotive part in one hit. It previously required a 4-axis horizontal machining centre and two lathes.

8 spe.ie

Visit our website or contact us for a quote or advice

Engineering Capacity | MACHINED COMPONENTS 15 JANUARY 2023 www.engineeringcapacity.com

Yamazaki Mazak’s Discovery Week in December featured live cutting demonstrations on 20 machines, presentations by senior managers on the state of the market and the business’ goal of cutting its carbon footprint by 50%, and the use of AI to bridge the skills gap.

From the point of view of the subcontract manufacturing market, Alan Mucklow, Managing Director UK, Eire and National Distributors at Yamazaki Mazak, said that the UK market is remarkably resilient and there are big opportunities for subcontractors that invest in 5-axis machining.

“There have been many challenges over the last few years – the pandemic, an economic crisis and a skills crisis that we are living through now. But the impact of recessions is neither universal nor uniform. Some sectors will do better than others and some companies will thrive.”

He added that the key way to use these challenges to grow a business is to focus on taking those challenges on board and maximising the opportunities they present.

He noted that aerospace was really starting to get on track and growing, the effects of the war in Ukraine were creating opportunities in the energy market, the medical sector continues to be strong and has grown significantly. Automotive has struggled with shortages of microprocessors, but the transition away from traditional combustion engines was

5-axis opportunities

presenting opportunities – and Mazak had certainly seen growth in those areas.

“Our customers are still telling us they are very busy … I think most companies remain fairly confident.”

And companies are confident that investing in manufacturing technology will help them to grow.

“I think that the more technologically advanced you are in your machining operations the more positive the outlook. Anecdotally there is a shortage of 5-axis capability in the marketplace. OEMs and Tier One suppliers are struggling to find subcontract capability for 5-axis machining.”

“It is key that subcontractors are forward thinking in their investment plans to take the opportunity and really grasp the benefits that will accrue to them.”

He stressed that Mazak has made a real effort to focus on bringing 5-axis machines to a wider market.

“The CV5-500 that we developed here in the UK – and we are very proud of that fact –has really enabled us to target and achieve penetration in the marketplace and that has enabled smaller companies to invest in the transition away from 3-axis or to supplement their 3axis with 5-axis machining.”

Presentations to the press at the event also set out Mazak’s Go Green initiative that aims to significantly reduce the environmental impact of the manufacture and use of its machines.

The goal is to halve its carbon footprint by 2030 compared to 2010 and to achieve four times higher environmental efficiency in the same time frame. For example, using a range of approaches such as replacing pneumatic and hydraulic systems with electrical ones, the carbon footprint of the latest VARIAXIS NEO has been reduced by 22%.

The presentations also looked

MACHINED COMPONENTS | Engineering Capacity 16 www.engineeringcapacity.com JANUARY 2023

at approaches to addressing the skills crisis. These included the greater use of automation –freeing up operators to carry out more value added tasks – and the use of Artificial Intelligence to refine some of the processes that previously required a high degree of skill. Examples include Solid MAZATROL, which can create a machining programme from a 3D file in a matter of minutes on the machine, and SMOOTH AI spindle, which uses machine learning to set the optimum parameters to minimise vibration and tool chatter.

Machines on display at Discovery Week included Mazak’s latest vertical machining centre, the VCN-700, which is designed and manufactured in the UK specifically for machine users requiring highperformance machining. The VCN range has been developed to significantly improve productivity rates for manufacturers undertaking everything from heavy-duty cutting through to high-speed machining.

The event featured live demonstrations with the VCN700, along with the VARIAXIS i300 AWC that offers an expandable high-capacity tool magazine for high-mix, lowvolume applications. In addition, the UK-designed and built CV5500 was displayed with an MA robot for increased productivity, including lights-out and unmanned machining.

Laser users were able to see in live cutting action the OPTIPLEX

3015 FIBER III 10. kW laser processing machine, equipped with a TEKMAG automated sheet metal loading system. Specifically, the ultra-high-speed cutting of medium thickness material and the ability to cut the finest widths and most difficult reflective materials. The 10.0 kW 3015 FIBER III model that was displayed at Discovery Week can also process workpieces up to 1525 mm x 3000 mm.

Discovery Week also served as a showcase for Mazak iCONNECT, the latest remote servicing solution that allows users to monitor their machine

operations, perform remote diagnoses, access part order history and more through the company’s secure cloud service –ultimately delivering improved productivity and machine performance.

Mazak’s European Manufacturing Plant in Worcester is responsible for the production of an extensive range of UKdesigned and built machines, including the highly popular entrylevel CV5-500 5-axis machining centre as well as the VCN-700 and VCE-600 next generation vertical machining centres.

8 mazakeu.co.uk

Engineering Capacity | MACHINED COMPONENTS 17 JANUARY 2023 www.engineeringcapacity.com

Aerospace Oil & Gas Nuclear Defence PRECISION ENGINEERING www.thomas-brown-engineering.co.uk Automotive Electronics Hi Fi Industrial & High Volume Machining Tel: 01484 548903

ES Precision has helped an Oxfordshire dental practice to keep track of dental tools without the need for label application or hard-to-read serial numbers. The laser marks are permanent, clear and withstand repeated autoclaving.

Deddington Dental is a 4-surgery dental practice with around 40 fast and slow dental handpieces that are used by 7 dentists and looked after by 8 nurses. Each dental handpiece costs £400-700 so it is important to keep track and account for each one. Each surgery has its own allocation of handpieces, and they are taken to a different decontamination room and processed several times each day.

Akhil Gupta, Principal Dentist, explained: “Previously, we relied on using the tiny serial numbers marked on the handpieces or using a coloured tape on each one to identify which surgery

Dental tools tracked

they belonged to. The method of using the serial number was very time consuming and hard to read. The tapes would regularly come off when the handpieces were autoclaved.”

The handpieces are made out

of titanium or stainless steel and some are coated by physical vapour deposition (PVD), so Deddington Dental needed a permanent marking solution that would be compatible with each of these materials and also their regular cleaning processes.

Dr Gupta continued: “After researching, we decided on laser marking with a local company, ES Precision. We were able to mark each handpiece with S1, 2, 3 or 4 (for surgery 1-4). These marks were clear and large enough and were cost-effective to do. Now, our nurses can easily identify each handpiece and we can account for each one at the beginning and end of the day as part of our daily checklists. The feedback from my nurses has been that the process saves a lot of time and looks a lot neater than using a coloured tape.” 8 esprecision.co.uk

LASER PROCESSING | Engineering Capacity 18 www.engineeringcapacity.com JANUARY 2023

From design, sampling and technical support to manufacture, Simpson Springs & Pressings Ltd provide the complete service. Tel: 0118 978 6573 Email: sales@simpsonsprings.co.uk

Cutting architectural metalwork

Dunstable-based Steel & Glass Solutions has taken delivery of a new Nukon Rex 315 6 kW 2D fibre laser cutting machine from Nukon Lasers UK. The machine was ordered at the UK’s MACH 2022 machine tool exhibition, with installation postponed until Steel & Glass Solutions moved into purposebuilt new premises.

Steel & Glass Solutions produces architectural metalwork for some of the UK’s most iconic building projects. Earlier this year, with a growing order book, the business decided it was time to invest in its own flat sheet metal laser cutting capability.

“Traditionally, we have relied on outsourcing the laser cutting of the high-end polished steel fabrications and steel cladding panels used in our designs,” said production director, Warren Few. “However, these would sometimes arrive with imperfections, meaning they would have to be sent back. Additionally, outsourcing laser cutting meant we couldn’t always react quite as quickly as we would like to customer needs. We were also aware that having our own fibre laser cutting capability on site would help us to remain as competitive as possible in these times of high energy prices.”

Steel & Glass Solutions chose the Nukon Rex 2D fibre laser machine for its ability to cut intricate shapes and pieces with

speed and precision, supported by fast, easy programming –essential for a business dealing with short product runs and complex, different projects. A Nukon machine can accommodate sheet dimensions of 3050 mm x 1530 mm and is equipped with a 6 kW nLIGHT fibre laser, with cutline beam shaping technology for a superior edge finish.

“We appreciate that the Nukon Rex is a very fast machine. But for us, the real benefit has been the quality of the parts produced and the ease of programming. The Nukon Lasers UK team helped immeasurably in getting our laser cutting capability up and running. Perhaps what’s most impressive

is that if they don’t have an immediate answer to a cutting challenge, they don’t blag it, they solve it. For example, a nesting issue for a particularly complex design was resolved with a quick call to Lantek, who linked up with our PC in under 15 seconds.”

Steel & Glass Solutions has over 20 years’ experience in architectural metalwork. Projects include the design and manufacture of complex, intricate metalwork for the Whitechapel and Bond Street Elizabeth Line stations, as well as exquisite balustrades, framework and metalwork for many highend, bespoke residences and office buildings in London and the South of the UK.

8 steelandglasssolutions.com

Engineering Capacity | LASER PROCESSING 19 JANUARY 2023 www.engineeringcapacity.com

Aerospace net-zero opportunity

Net Zero is the single driving force behind aerospace plans and the biggest technological challenge since the dawn of the jet age, according to the keynote speaker at the Farnborough Aerospace Consortium’s annual conference.

The conference was addressed by Sir Michael Ryan CBE who said net-zero was a huge opportunity. Sir Michael is VicePresident, European Space and Defence, Government Affairs, and Chairman of Spirit AeroSystems UK.

He spoke to almost 100 delegates at the Elvetham Hotel near Hook in Hampshire and said ‘net-zero’ is the ‘single driving force behind aerospace plans’.

He added that this was ‘the biggest technological challenge since the dawn of the jet-age’ but that it was a ‘generational opportunity’.

To achieve net-zero, Sir

Kloeckner Metals UK has achieved the BES 6001 ‘Excellent’ rating for its Leeds, Westok, Thurrock and Dudley sites. Assessed by BSI, the BES 6001 certification allows Kloeckner Metals to demonstrate that its products are made with constituent materials that have been responsibly sourced.

Kloeckner says the rating is an endorsement of its dedication to continuous

Michael said, ‘means we have to work better together; all sectors, supply chains and academia’.

Afterwards he said: “It was great to be in an area of historical importance in aviation and aerospace, both in capability and innovation, and to be part of a dynamic regional association body.”

The event heard from a dozen speakers in a packed day titled ‘Destination Net Zero’, and there were lively question and answer sessions.

Speakers included Paul

Griffiths, head of AerospaceHub, BEIS, Oriel Petry, Senior VP of Airbus and Steve Gillard, UK Sustainability Director and International Defence Sustainability Leader.

Alan Fisher, chief executive of FAC, said: “Net-zero was seen as a huge opportunity in aerospace – a way of keeping the UK in its position as world leaders in the sector.

“It’s not to say that difficulties weren’t addressed – particularly lack of skills and a difficult recruitment landscape – but solutions were put forward.

“Our keynote speakers are some of the most influential thought leaders in the country and provided great insights, market intelligence and statistics.

“The message of collaboration was delivered by many speakers who said it was the key to achieving net-zero.” 8 fac.org.uk

Responsible sourcing excellence

improvement of management processes and environmental and social impact. This achievement puts Kloeckner in the elite group of 8.33% of UK Steel product companies that have successfully managed to raise their responsible sourcing procedures to the highest possible standard.

Kloeckner Metals was previously awarded a ‘Good’ rating In July 2021. Since

then it has implemented ambitious initiatives and rigorous assessments which allowed it to achieve significant improvements in the areas of: Greenhouse Gas Emissions, Energy Use, Waste Prevention, Waste Management, Employment, and Skills, working with Local Communities.

8 kloecknermetalsuk.com

SUSTAINABILITY | Engineering Capacity 20 www.engineeringcapacity.com JANUARY 2023

A new carbon footprint calculator for metal polishing has been created thanks to a collaboration between industry and academia.

Professional Polishing Services (PPS), which has created three new jobs in the last twelve months, has tapped into funding and advice from the University of Birmingham’s ATETA programme to develop a digital process that will help it identify thousands of pounds of savings on energy costs.

The project has involved mapping out the manufacturing flow and installing high-end data logging sensors in key places to monitor real-time power consumption of industrial equipment.

Several variables, including type of material and speed of job, are factored into the equation to provide robust calculations that work out PPS’ carbon footprint and identify where savings can be made.

The West Bromwich-based company is not looking to keep this IP to itself, instead it is planning to roll-out the calculator to the rest of the finishing sector in a bid to help industry move towards Net-Zero.

Kirsty Davies-Chinnock, Managing Director of Professional Polishing Services, commented:

“Our bespoke stainless steel and non-ferrous polishing services are energy intensive, so it made perfect sense for us to look at how we could monitor costs – especially with prices going through the roof.

Tracking polishing footprint

“As a SME, it’s sometimes difficult to make the time or spare the money for non-core activities. That’s why tapping into the ATETA programme and all the academic expertise that came with it was a no-brainer and has resulted in such impressive progress.”

She continued: “We now have a carbon calculator that can instantly work out the footprint of each of the jobs we put on our lines, and this is fantastic information to have. It gives our production team the opportunity to look at how we save energy, making us more competitive in the process.

“The next step will be to roll this out to the rest of our sector and we’re already talking to the University and our competitors to see exactly how we do this.”

Kirsty Davies-Chinnock concluded: “The carbon footprint calculator is for specific industries/processes and takes a much deeper dive into the data and, importantly, how manufacturers can offset some of the findings. It’s a very powerful weapon in the fight against emissions.”

8 professionalpolishing.co.uk

Engineering Capacity | SUSTAINABILITY 21 JANUARY 2023 www.engineeringcapacity.com

EDM parts off additive parts

CA Models is using two wire-erosion machines from Sodi-Tech EDM to optimise the process of removing 3D-printed parts from their build platforms.

The company specialises in high-quality, fast-turnaround metal and plastic additive manufacturing. With sectors such as Formula One currently in development for next year’s cars, the new Sodick machines are making a real difference to operational efficiency.

Established in 1983, CA Models has five different additive manufacturing departments, including metal laser sintering. This process allows components to be 3D printed from powdered metal that includes aluminium, titanium and steel. The 35-

employee company can provide printing, finishing and optional post-machining, all in-house.

“We had two Sodick wire EDM machines that were still running well but getting on in years,” said founder and Managing Director Clark Campbell. “I felt it was the right time to bring in some new technology for the next decade. The new Sodick machines are even more accurate and faster. At CA Models we are in the ‘quick’ business, where just about every client wants their parts yesterday. That’s why we need an in-house resource when it comes to wire erosion. Every time we have a really complex, accurate part to produce, the clock is ticking.”

Installed in September 2022, the new Sodick ALC600G and

ALC800G wire EDM machines are already busy.

“For example, take a titanium build platform with 14 motorsport parts on the base,” said Mr Campbell. “When the printing process is complete, the entire platform goes into our furnace for heat treatment for 24 hours, after which we wire-off all the components from base plate using our Sodick technology. As the wire cuts so finely we do not lose any dimensional accuracy in the parts. Furthermore, the machines wire so quickly that we get a head start in finishing the components. Although this process is the underlying reason behind our investment, we also get many subcontract CNC machining projects, some of which lend

ADDITIVE MANUFACTURING | Engineering Capacity 22 www.engineeringcapacity.com JANUARY 2023

themselves to wire EDM. It’s great to have that flexibility, particularly for complex, intricate parts required by sectors such as Formula One.”

The Sodick ALC800G wire EDM which provides 800 x 600 x 500mm (Z-axis option of 800mm).

“As far as wire EDM is concerned it’s always nice to have a big machine because we sometimes get large or unusual requests,” explains Mr Campbell. “I think we’re the only company in the UK to have the ALC800G model.”

Without the Sodick wire EDMs,

CA Models would have to remove additively manufactured parts from base plates using its large bandsaw, which is far from ideal.

“It’s something we’ve done before, but it always feels a little unsafe and not exactly bestpractice in my opinion,” said Mr Campbell. “Wire EDM is far more practical, efficient and effective. Furthermore, once finished, the support plate looks brand new and ready to use again, which is really helpful.”

Although CA Models serves clients across a host of industries that include aerospace, defence,

medical and energy, among the busiest sectors at present is motorsport, particularly Formula One, where teams are designing and manufacturing parts for next year’s cars.

“I think we could be particularly busy this time around as Formula One currently has one dominant team, so the others are very keen to make up ground,” said Mr Campbell. “We received a nice order last week from a team towards the back of the grid, who should really be towards the front. ” 8 camodels.co.uk

Engineering Capacity | ADDITIVE MANUFACTURING 23 JANUARY 2023 www.engineeringcapacity.com

A 3D printed model of Emmerdale featured in a trailer for the show’s 50th anniversary climax.

When ITV’s Emmerdale soap opera reached its milestone 50th birthday, the show’s producers marked the occasion with a series of stories that came to a head in a gripping special episode. Weaving the show's past with the present, an all-action climax saw a deadly storm hit the village and, in the run-up, viewers were treated to a powerful trailer, that featured starring cast members recreated as full colour 3D printed models.

ITV contacted Cheshire-based 3D scanning and printing specialist Europac3D to establish the possibility of 3D scanning and colour printing for the project and, as the company’s Operations Manager Danielle Kenny said: “We visited ITV at their offices in Leeds and scanned the cast members using the Artec Leo scanner,” she continues. “We had a full day on site with the team and scheduled the actors to attend specific timeslots, during which they were scanned in costume, holding poses to match the requirements of the animated trailer.

“Once the scanning was complete, we processed the files back at Europac3D to prepare them for print, with every model edited to enable two different sized versions of each to be produced.”

Europac3D called upon UK and Ireland Mimaki distributor, Hybrid Services to create the

Emmerdale in 3D

Once the scanning was complete, we processed the files back at Europac3D to prepare them for print, with every model edited to enable two different sized versions of each to be produced

final models, printing them on the high-end Mimaki 3DUJ-553 full colour 3D printer. “The Mimaki was the only solution available to us to complete the job,” cites Kenny. “We needed full colour output that would stand up to close scrutiny on the nation’s TV screens, and with its ability to print up to 10,000,000 colours, the Mimaki fit the bill perfectly.”

Aired in the weeks prior to the landmark episode, the trailer is a

1-minute animated scene, depicting the explosive impact of a huge storm on the fictional village. Key characters are shown in emotive poses, suspended in time as the storm wheels around them, and as the camera pulls back, it becomes apparent that they’re actually portrayed as decorations, set amidst a vast cake situated in the village pub.

“The finished trailer is a really dramatic watch, and the 3D printed models were really put to the test during the filming,” concluded Dannielle Kenny. “The producers were delighted with the results of the scanning and printing – and It was a privilege to be able to contribute to a memorable bit of TV history.”

8 europac3d.com

ADDITIVE MANUFACTURING | Engineering Capacity 24 www.engineeringcapacity.com JANUARY 2023

‘‘

Company of the year at the UK Cast Metals Industry Awards was MRT Castings, which tripled the size of its business in weeks to support the Covid-19 effort.

The Andover-based company impressed judges with the way it scaled up rapidly to supply cast aluminium components to one of the world’s largest producers of critical care ventilators.

The firm invested over £3.5m in two additional diecasting cells, seven additional CNC machines and recruited 45 staff to meet huge increases in volumes that saw it grow from £7.8m to £20.8m in a matter of months.

Organised by the Cast Metals Federation, the Awards also saw major accolades going to Sarginsons Industries’ digital twin activities (Innovation) and Atkinson Vos who, working in partnership with The Boro Foundry, ADI Treatments, Partline and Lancaster University, claimed the ‘Component of the Year’ title.

The award-winning part is a 3-point linkage power lift arm for Unimog, which produces a range of multi-purpose tractors, trucks and lorries used in agriculture, forestry and rail sectors.

Initially a steel fabrication, consisting of 9 laser-cut parts, the component was inelegant and prone to distortion and failure.

By converting it from a fabrication to a casting in Austempered Ductile Iron (ADI), the new cast design is four times stronger in the critical areas, whilst being lighter due to the inherent stiffness of the ADI

Cast of winners at CMF awards

compared with the steel equivalent.

CMF Chairman and CEO of Castings PLC Adam Vicary opened the celebration dinner at the Drayton Manor Resort: “Despite the gloomy economic predictions, the majority of our foundries are doing well, and this is typified by the quality and innovation of our finalists.

“We can clearly see a commitment to innovation and problem solving, working with customers and embracing new technology from all our winners, not to mention a willingness to collaborate, develop workforces and push forward with sustainability.”

He continued: “The castings and foundry industry can be part of the solution to growth for the

UK. And let’s remember, our sector makes all the components a modern economy depends upon, and metals recycle forever.”

The UK Cast Metals Industry Awards, which attracted nearly 200 guests, focused on the great castings being manufactured in metal by UK foundries, and their huge achievements in innovation, growth and component performance.

Co-presented by Dr Pam Murrell of the Cast Metals Federation (CMF) and comedian Patrick Monahan, the evening clearly showcased the successes of the sector and its evolving impact on UK manufacturing.

This was typified by the Innovation winner, with Sarginsons Industries recognised for the way it has embraced the

Engineering Capacity | CASTINGS 25 JANUARY 2023 www.engineeringcapacity.com

latest 4.0 digital platforms.

Based in Torrington Avenue in Coventry, the company took the strategic decision to invest in a series of digital twin activities that was fundamental in developing business strategy and improving supply chain management.

The new enhanced ‘design for manufacture’ not only includes the traditional aspects of design and simulation, but also now features property simulation, data mapping to client’s computer-aided engineering software and integrated optimised topography – all conducted before tooling manufacture.

Importantly, judges were really

impressed with the way the automotive supplier has worked with leading UK universities and involved many of its apprentices, interns and graduates.

Anthony Evans, Chairman at Sarginsons Industries, said: “Our customers are now able to make informed decisions on design suitability, leading to significant lightweighting, through reduced safety factors, and critical reductions in development

timescales. In fact, one of our clients has described this development as ‘the most exciting innovative concept in aluminium casting in the last 30 years’!”

The final element of the evening was a presentation from William Cook Cast Products on its work in making ‘Shiny Sheff’ –a memorial to commemorate the 40th anniversary of the sinking of the HMS Sheffield during the Falklands conflict with the loss of 20 personnel.

Both the base and the crests were cast by the company in stainless streel and the memorial is now located at the National Memorial Arboretum in Staffordshire. 8 castmetalsfederation.com

CASTINGS | Engineering Capacity 26 www.engineeringcapacity.com JANUARY 2023

The latest companies to join the Cast Metals Federation include a supplier, a service provider and a historic foundry company.

Supplier Ultraseal International Group Ltd is a global specialist in porosity sealing technology, whilst also offering a wide breadth of subcontract post casting treatments, such as powder coating, wet painting, chromating, pressure testing and shotblasting.

Gareth Ridge, Operations Manager, said “We pride ourselves on being a trusted partner to foundries to help achieve superior casting quality, cosmetic enhancement and ultimately delivering added value to our customers products, and by joining the Federation we can demonstrate our continued commitment to the castings industry in the UK.

Asset Disposal Services Ltd has joined the Cast Metals Federation to enhance its support of the UK foundry and castings industry. “We have been supporting the Federation and its members in the industry for many years but are keen to formalise this relationship by becoming a supplier member,” explains ADS Director Phil Stokes. “We have one simple objective, and that is to maximise the return generated for our clients from their surplus assets, whether that means single items or full production lines, without adding to their workload.”

Paralloy Ltd with its two divisions, Paralloy and Firth

Membership grows at CMF

Vickers, is the latest foundry group to join the Cast Metals Federation. The company has its origins in the UK’s steel industry, and Paralloy & Firth Vickers (comprising FVC & FVE) manufacture centrifugally cast, as well as static cast, products and solutions in a wide range of alloys, including high nickel alloys, for the petrochemical, industrial gas turbine and aerospace sectors.

Robert McGowan, CEO for the group company Paralloy Ltd said: “Our group supplies the highly engineered components for sectors where exceptional quality and reliability are demanded, and we take pride in serving some of the words most challenging industries from power generation and transportation to manufacturing and critical chemical industries. We are

pleased to be part of the Federation at a time when there is a growing recognition of the importance of manufacturing to the UK economy and look forward to playing an active role though our membership.”

CMF CEO Pam Murrell commented: “It is really important that we work together as a sector in the UK – there are some clear challenges for UK manufacturing, but also some great opportunities as we look to re-power the UK economy. Our sector has a role to play in providing the engineering solutions for the UK and also contributing to net zero, to the circular economy for metals and to levelling up. It is fantastic to have companies like Paralloy Ltd joining with us at this time.”

8 castmetalsfederation.com

CASTINGS | Engineering Capacity 28 www.engineeringcapacity.com JANUARY 2023

More than 650 school children between the ages of 11 and 14, attended North Star 2022 in November and had a go at casting as part of the Science Summer School Programme.

United Cast Bar Group were one of the main sponsors and hosted an activity zone featuring sand casting and additive manufacturing, and supported by staff from Weir Minerals and using several ‘Foundry in a Box’ kits from the Cast Metals Federation, CMF.

During the day, which was organised by The Work-wise Foundation, hundreds of the children were able to have a go at moulding and then casting a star in a low melting point tin alloy which they could then take home with them. The activities were led by UCB’s own apprentices and graduate metallurgists who were able to discuss the role of the casting and foundry industry in making engineered components for all sectors of the UK economy, using recycled metal as the raw material.

The team from Weir Minerals also featured in the programme of talks in the main theatre with foundry patternmaker CharlieAmber Tattersall and machinist Rosie McQuillan both speaking about their careers and the opportunities being offered to them in manufacturing by Weir Minerals.

Leonie Greenwood, HR Coordinator for Weir Minerals Europe Limited, said, “It was great for some of our young team to be able to share their passion

North Star offers direction

for the metals sector with all these young children. Hopefully we shall have encouraged some of them to consider taking science subjects when selecting their options. And for our young technicians to be on a programme which also featured Professor Brian Cox CBE was particularly inspiring.

“Seeing all the other activities on offer from companies like CBE+, Forged Solutions and the UK Atomic Energy companies has also given us some ideas of how we can increase our own engagement with some local schools which will help with our own future apprentice recruitment.”

James Brand, Managing Director of United Cast Bar Group, agreed saying, “It is important that we, as businesses, take an active role in initiatives like this. We can’t expect school staff and parents to know about

the career opportunities available in UK engineering and manufacturing, and if we are to attract future talent then we all need to spread the word.

“I am grateful to my colleague David Beet for all his hard work in organising our area and for the additional support from our partners, Weir Minerals and the Cast Metals Federation. We will all be back again next year.”

The North Star programme aims to promote and applaud innovation and provide the opportunity to inspire the next generation to consider careers in STEAM (science, technology, engineering, arts and mathematics) subjects, backing a vision for the UK to become the best place in the world to practice these subjects through establishing sustainable partnerships between businesses with local schools. 8 work-wise.co.uk

Engineering Capacity | CASTINGS 29 JANUARY 2023 www.engineeringcapacity.com

A strong start with T Levels

Sue Lovelock, Director Professional and Technical Education at the Department for Education, explains how T Levels promise a strong start for students everywhere.

Since their creation in 2020, T Levels have offered a new way for engineering businesses to address skills shortages within their workforce and invest in future talent. The first cohort of just over 1,000 students completed their courses last summer, with a fantastic overall pass rate of 92%. Now, just over two years into offering T Levels, we have around 170 education providers across England offering

the qualifications, with 16 different subject areas available.

One T Level is roughly equivalent in size to three A levels and they offer a new choice for young people after their GCSEs. The 16 T Level subjects currently on offer range from engineering and manufacturing and construction to childcare and science, and by September 2025, the total will increase to 24.

T Levels involve a unique blend of academic and technical education, thanks to the industry placement embedded into the programme. Each student spends around 20% of their qualification (45 days minimum) working with

an employer to develop the practical and technical skills required for the profession or trade that they are studying. This not only gives students a chance to delve into an industry they’re passionate about, but also allows employers to grow their talent pipeline.

Positive student experiences

For many years, statistics have shown that students entering the world of work do so feeling unprepared. Research from the Chartered Management Institute shows nearly 80% of employers believe that current graduates do not arrive fully equipped with the

T LEVELS | Engineering Capacity 30 www.engineeringcapacity.com JANUARY 2023

skills they need to be ready for work. T Levels help to address this issue at its root, through the industry placement element of the qualification, which introduces young people to a work environment and gives them a chance to build those skills early on.

Alex Long chose to study a T level in Design, Surveying and Planning for Construction and for her placement spent time working at multi-billion-pound railway project Transpennine Route Upgrade (TRU) Alliance. It was an obvious choice for her, as someone who had always had an interest in this area and even had a shared family background within engineering. Reflecting on her experience, she agrees that the industry placement was definitely one of the highlights. She said: “I was able to see all aspects of the project and I realised that I liked planning as well as quantity surveying and I liked the civil engineering work. This is important for me to know moving forwards as I make further decisions in my career, for example whether I want to specialise in a certain area.” For her, it was the hands-on research she was able to do during her industry placement that made it all the more beneficial.

Alex is now studying for a degree apprenticeship in civil engineering at Teesside University, an opportunity offered to her through her T Level placement employer. Thinking about her future she said, “I am hugely excited and eternally grateful.”

Alex is one of thousands of students who have had doors open for them during or upon completing their T Level. As the first cohort finished their qualification last summer and are now establishing their career ambitions, she is one of many success stories that demonstrates how T Levels are enabling young people to kickstart their careers.

A helping hand for employers Students are not the only people who benefit from the T Level experience – employers do too.

Karen Vigar, Education Engagement Manager at global dynamic construction specialist, ISG, helps to manage the business’s Early Careers Programme. She said: “We actively invest in technical education because we recognise there is an ever-present skills challenge in our industry. Taking positive action and investing in programmes and initiatives that will close this skills gap and inspire individuals to look at construction through a new lens will prepare our workforce for the future – and that’s the right

thing to do for our industry.”

Hosting T Levels students on industry placement is a way for employers to be proactive and promote the skillset they would like to see in applicants who enter their recruitment pipeline. Karen advises that the key to making it a smooth process is a solid relationship with the education providers with which the T Level student is studying. Speaking of ISG, Karen says, “We have forged a strong relationship with Barnsley College through our industry placement programme, proactively unlocking funding pathways and learning together on ways to improve the experience for each student.”

A beneficial investment

Overall, the benefits for all parties mean that T Levels make good business sense. For students, T Levels can lead to skilled employment, higher technical education, apprenticeships or university – helping to kick-start their careers. For employers, T Levels offer an opportunity to bring in young talent and fresh ideas. With three different T Levels on offer across the Engineering and Manufacturing skills area, and three T Levels in the Construction area, the engineering industry has much to gain from this new qualification.

If you are interested in finding out more about T Levels and hosting a student in your organisation, as well as the benefits it can bring to your business, please visit: 8 http://bit.ly/3We0ov6

Engineering Capacity | T LEVELS 31 JANUARY 2023 www.engineeringcapacity.com

This year, European Springs & Pressings have been reaping the rewards of working collaboratively with their sister companies. Making their mutual platform of products and services more accessible enables them to deliver a wider range of manufacturing capability and products to their customers than ever before.

Working more closely with our UK manufacturing partners Metrol Springs and Lesjöfors Heavy Springs UK has brought significant benefits for the respective companies, as well as allowing the group to offer an unrivalled portfolio of springs, stampings and industrial hardware.

Shared attendance at exhibitions, pooling experience at cross-company strategy meetings and developing a mutual knowledge of each other’s products and specialisms has broadened the shared capability they can offer and increased the company’s sales reach considerably.

This support brings tangible benefits to clients as well. European Springs’ commitment to providing the coiling and pressing expertise customer’s need to find custom-made solutions for their manufacturing processes remains unchanged, with the added assurance that when they claim to have the required capability in the UK to design and produce the optimal component at the most competitive price, they make good on that promise.

Group Dynamic

This culture of collaboration has been fostered by their parent company, Lesjöfors Springs & Pressings. Although not a household name in the UK, since its conception 150 years ago Lesjöfors has patiently and practically built from its manufacturing base by acquiring a broad network of companies with specialist capabilities and strengths.

Lesjöfors is now the biggest spring manufacturer in the Nordic region, the third largest in Europe, and has a strong and growing presence in the US and Asia.

Lesjöfors’ culture of supporting innovation, and developing capability is why European Springs & Pressings Ltd. joined the group in 2007.

Their dedication to investment, both in people and technology, mirrors ESP’s, and has allowed them to develop as a business, as well as recruit and retain the talent, and acquire the machinery required to continually provide the high quality manufacturing that clients’ demand.

The culture of collaboration developed within European Springs’ UK manufacturing family, alongside the market-leading portfolio of products and services across the Lesjöfors group, means that customers can continue to rely on the ESP promise - to provide innovative design solutions, reliable service and custommade, quality components.

8 Europeansprings.com

EUROPEAN SPRINGS SPONSORED FEATURE | Engineering Capacity 32 www.engineeringcapacity.com JANUARY 2023

All set for Southern Manufacturing

The worlds of mechanical engineering and electronics will converge once more from 7 to 9 February at the Farnborough International Exhibition and Conference Centre.

Southern Manufacturing & Electronics 2023 is the ideal venue for firms looking to find new business opportunities. Undeniably one of the most important engineering shows in the UK calendar, it has been running virtually continuously since 1998, so this year marks its 25th anniversary.

The event has grown from a small, regional gathering of entrepreneurial companies to one of international importance. A large proportion of participants have supported the show since the beginning and the percentage of returning firms is high. Many regular participants have booked stands for 2023 and the show is set to be a sell-out again.

Having in one place the best of mechanical engineering and electronic products and services in approximately equal measure exhibited by companies from around the world gives the event a unique character. It is the go-to place to address multiple sourcing requirements efficiently. An interesting facet of the show is that although the technologies and industries covered are

enormously diverse, there are no physical barriers between the areas, allowing easy cross-over between the various engineering disciplines.

Many hundreds of firms will highlight a vast array of mechanical, electrical, electronic, optoelectronic, electromechanical, hydraulic and pneumatic components and assemblies, PCBs, cables and connectors, as well as sensors, drives, encoders, fasteners, pressings, wireforms, springs, plastic and rubber mouldings, gaskets and more.

As usual, there will be suppliers of machine tools and tooling, workholding systems, metrology equipment, test and inspection systems, finishing machines, laser cutting and marking equipment, additive manufacturing machines and consumables, production and planning aids, and engineering and business software. Industry

4.0 solutions will be in evidence alongside controls, displays, HMIs, data acquisition systems, augmented, mixed, and virtual reality, robot and cobot machine tending and other automation solutions.

Additional diverse and no less essential products and services on offer will encompass oil and coolant supply, workshop equipment, dust and fume extraction, humidity control, workplace storage systems, bespoke case and foam manufacture, plastic packaging and injection moulding, hand tools, adhesives, industrial flooring, waste removal and recycling, training, freight services and business consultancy.

The event is also an important destination for subcontractors working in the production / mechanical engineering and electrical / electronic sectors to take stands and explain the scope

Engineering Capacity | SOUTHERN MANUFACTURING 33 JANUARY 2023 www.engineeringcapacity.com