April 2023 www.designworldonline.com inside: page 194

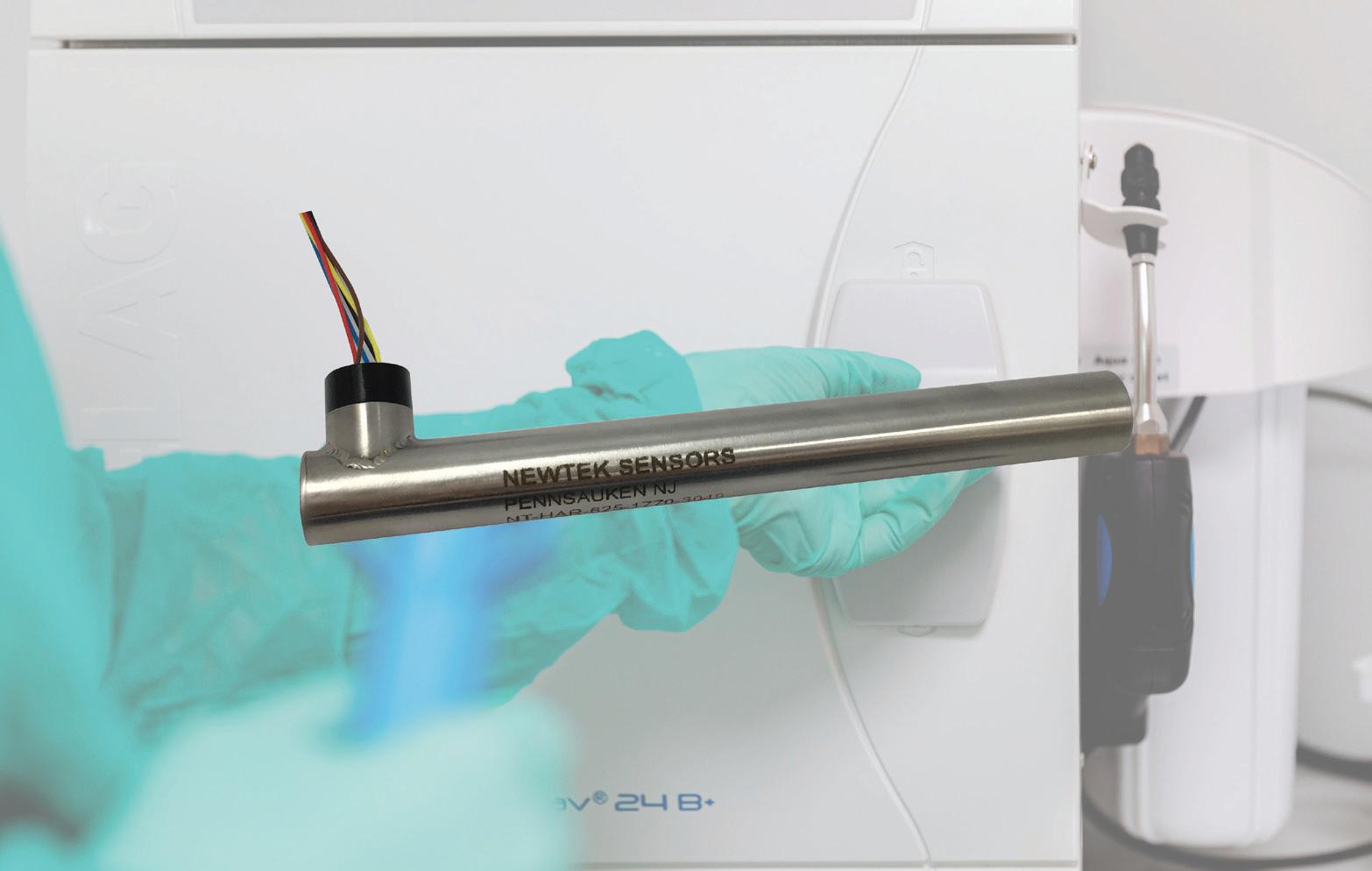

CONTROL : Lifting columns and more for medical designs p. 188

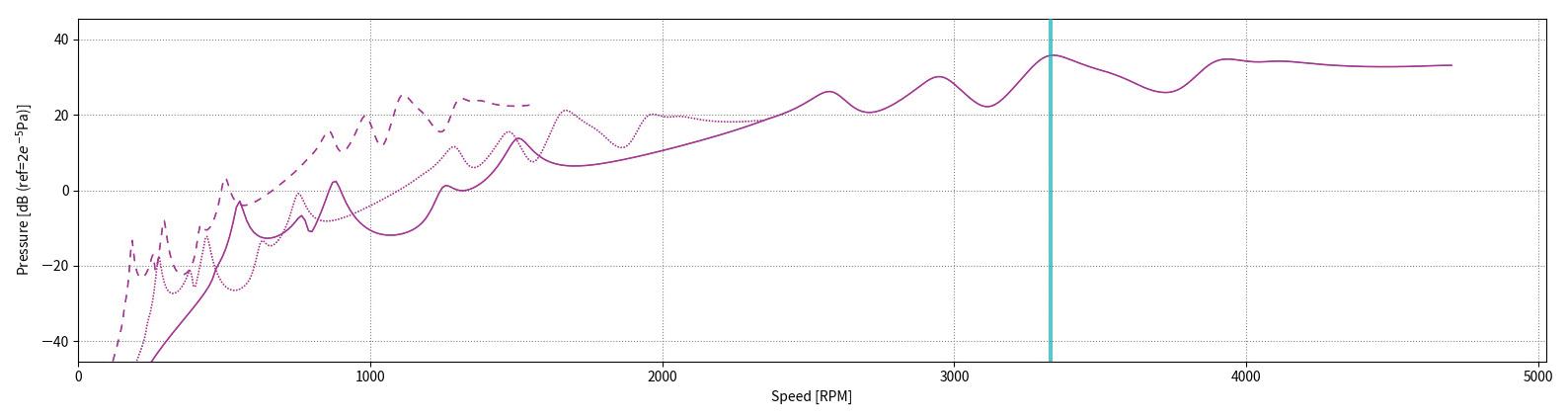

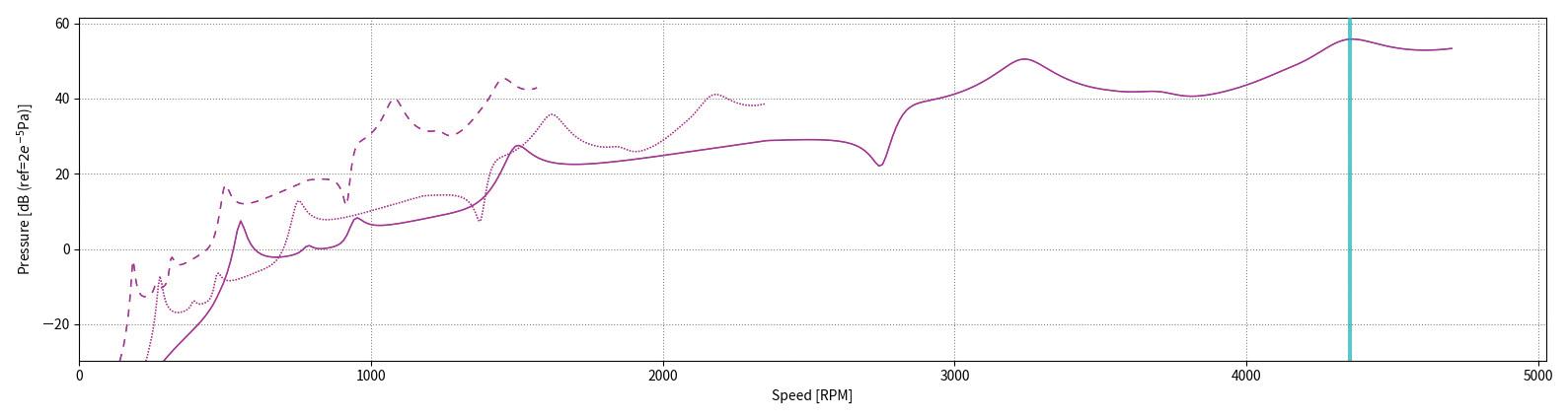

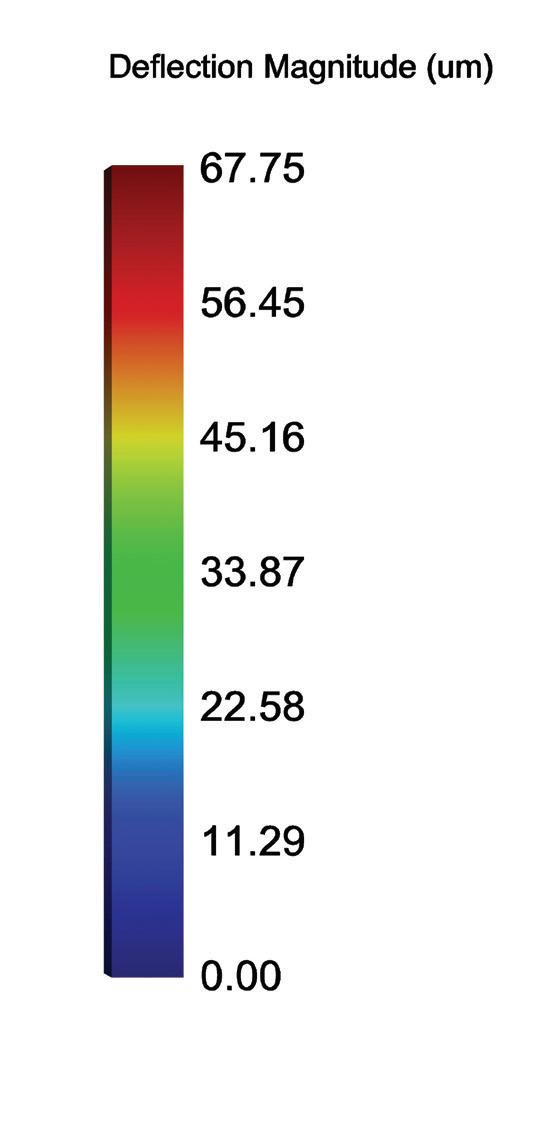

: Center distance variations influence noise in compound gearboxes p. 200 influence noise in Piezos for delicate actuation Piezo-based technologies are indispensable for micrometer and nanometer strokes. RBR 50 79-161 Innovation Awards INSIDE AEROSPACE and DEFENSE: How do the military and aerospace use MBSE? p. 64

MOTION

MECHANICAL

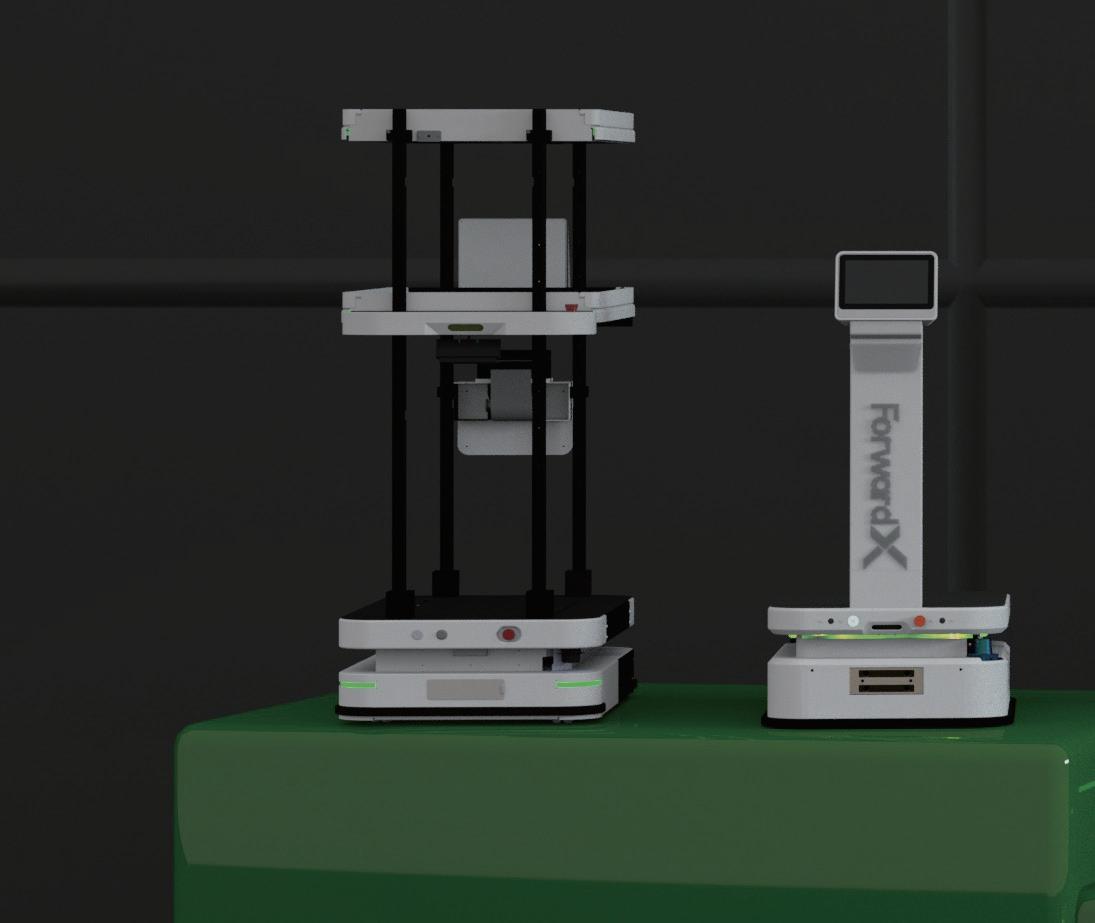

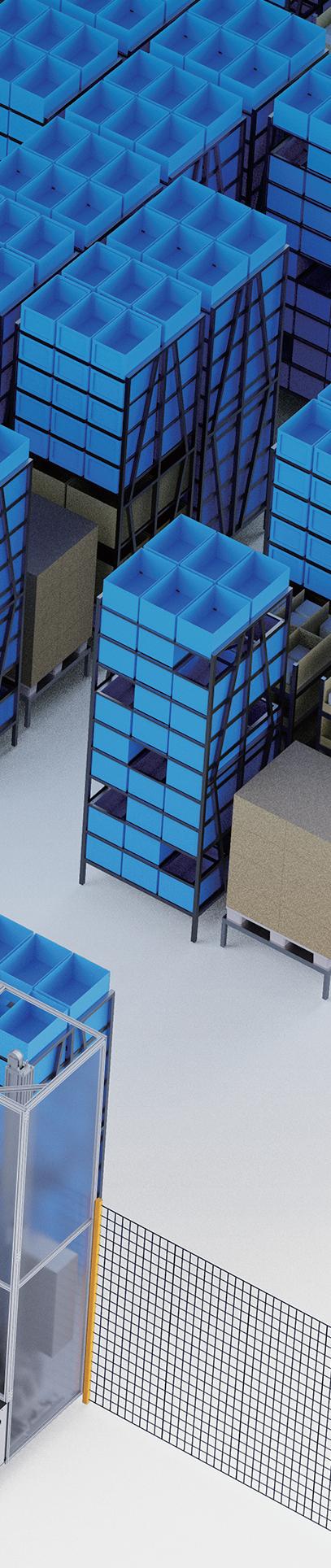

Build or buy Discover turnkey & custom automation solutions from April 2023 www.designworldonline.com

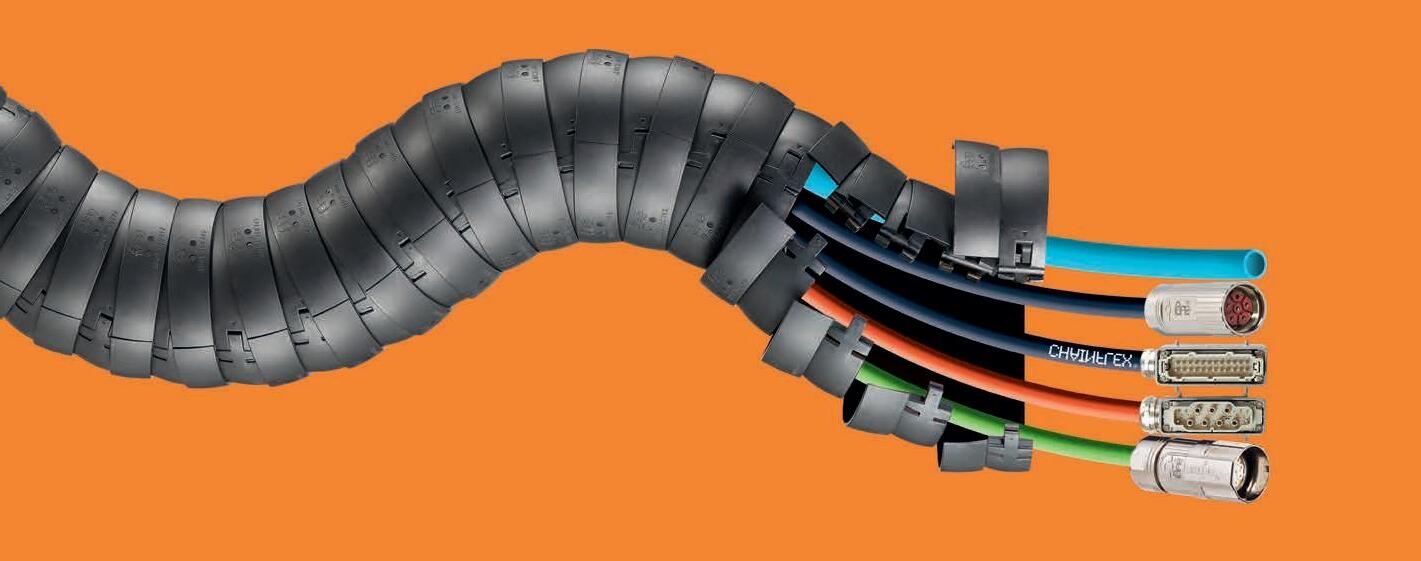

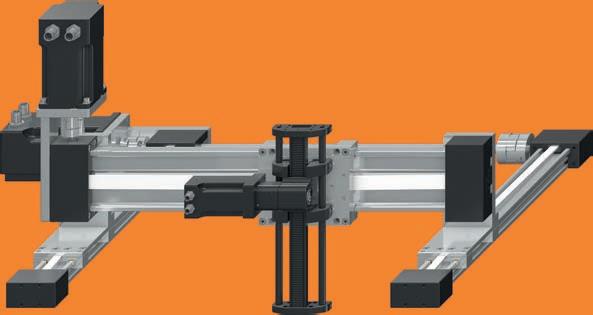

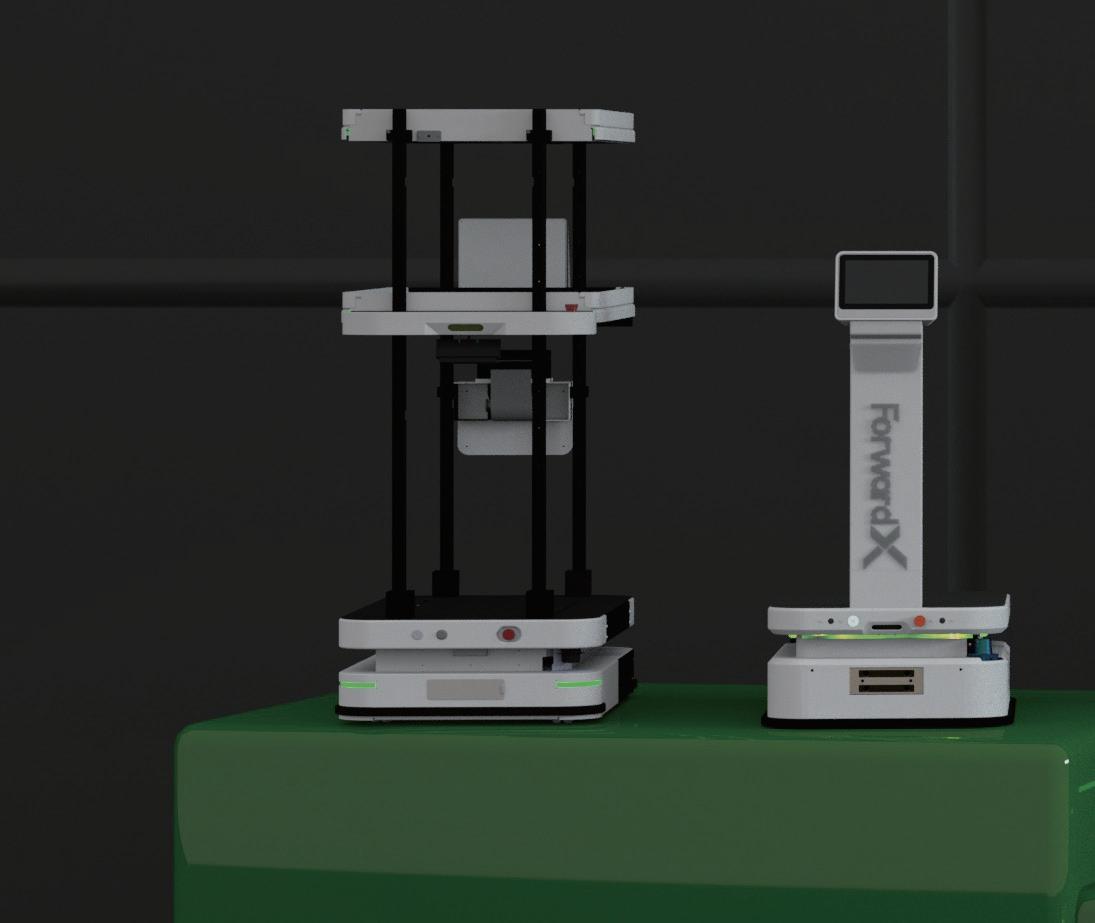

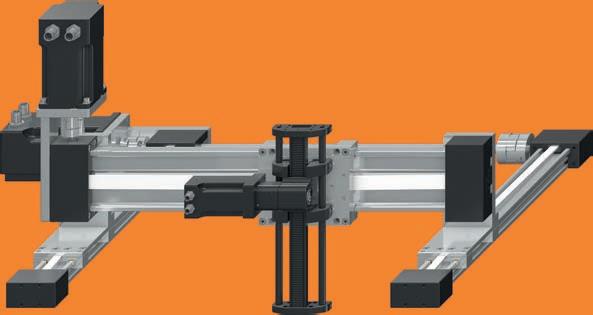

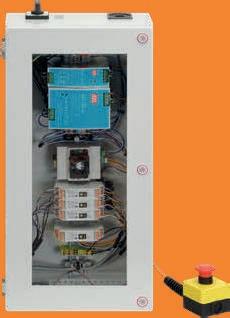

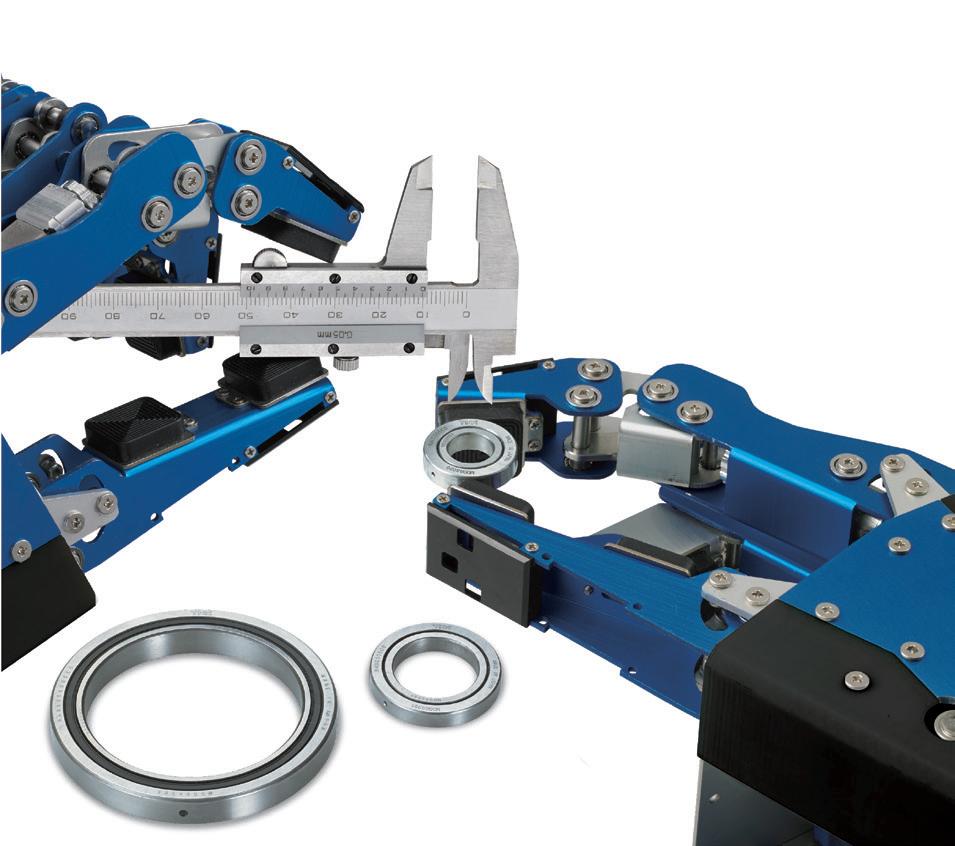

Get a firsthand look at our low-cost robots and robotic components at We’re looking forward to seeing old and new friends alike at Automate 2023! Our signature low-cost robots and robotic components will be on full display, including the latest and greatest in innovative new automation technology for all industries. We hope to see you there! Dry-running • Maintenance-free • Quiet • Lightweight • Dirt-resistant • Corrosion-resistant • Rapid return on investment • Components from various industry leaders • Free expert consultations • Guaranteed compatibility across manufacturers Need a more customized solution that’s compatible with other manufacturers? Buy Build Booth 6413 • May 22-25, 2023 • Huntington Place Convention Center • Detroit, MI

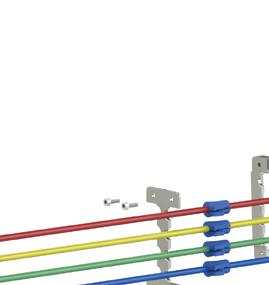

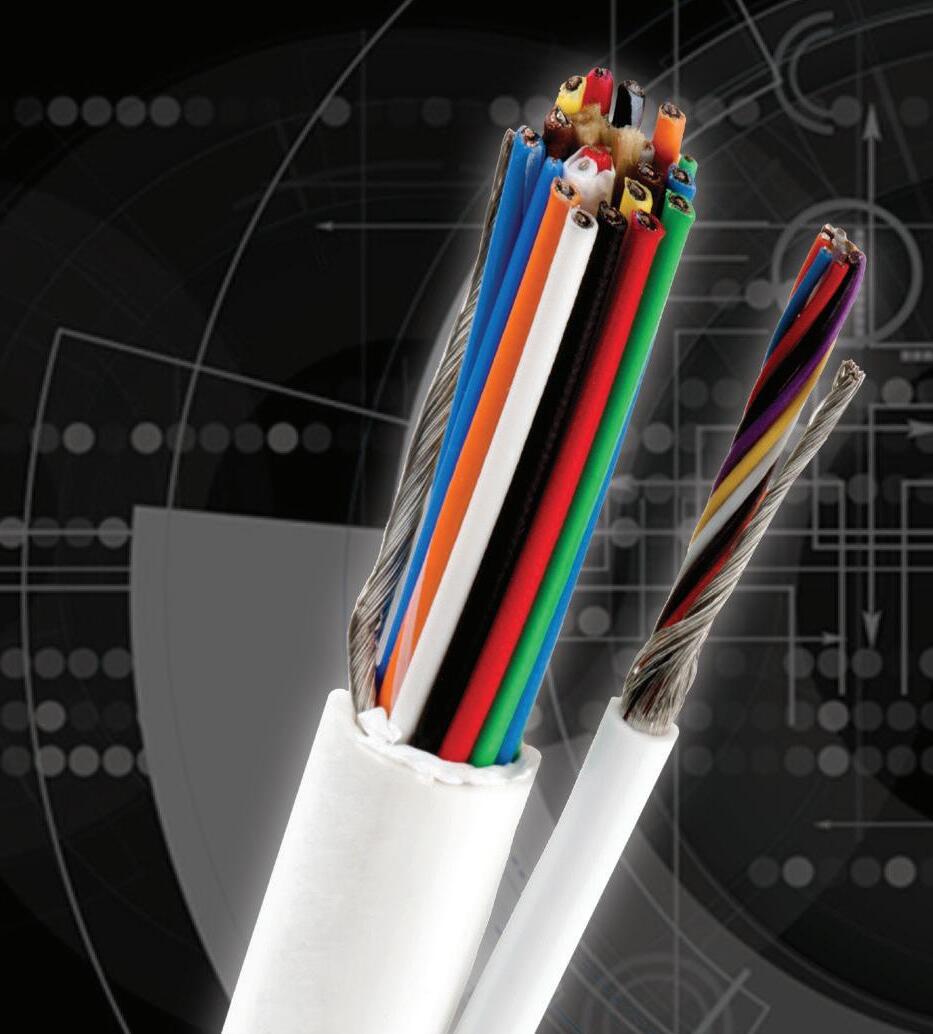

NEW! More Murrplastik Cable Entry System Options...

Murrplastik cable entry systems allow installation of non-terminated or pre-made/terminated cables through an enclosure or other bulkhead surface.

Our new additions include:

• The KDP/R series: A round one-piece frame available in two different frame sizes that can hold up to 46 non-terminated cables in a single frame.

• FDA compliant cable entry systems ideal for food, beverage, pharmaceutical, and any industry requiring sanitary components.

–KDL/H-VA-FDA series: Stainless-steel split frames, available in three sizes that can hold up to 12 pre-made or terminated cables.

–KDP series FDA Cablequick® system: A one-piece stainless-steel frame that can hold up to 56 non-terminated cables.

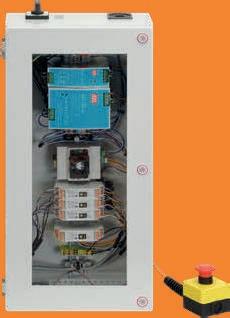

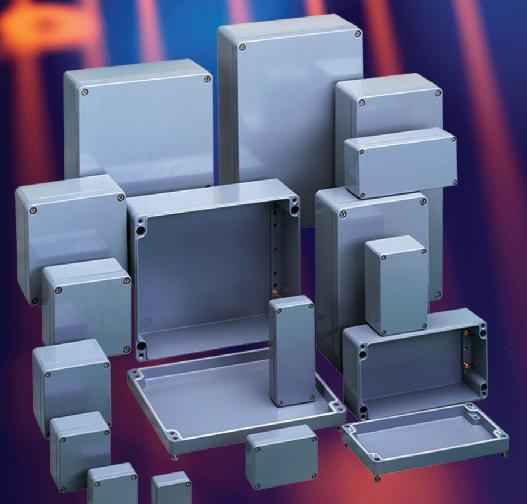

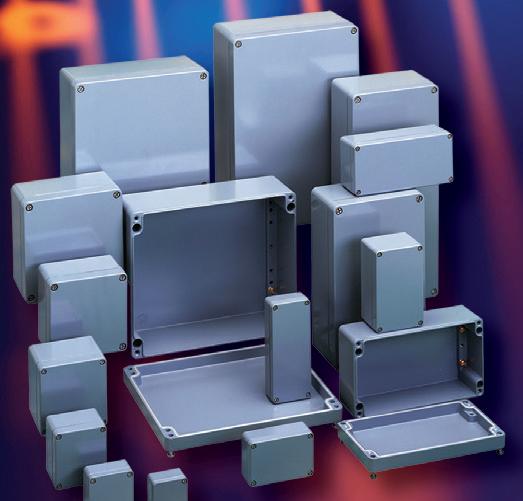

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Research, price, buy at: www.automationdirect.com/enclosures Over 7,100 top brand enclosures starting at only $7.00 • Wall-mount • Junction boxes • Pushbutton • Floor-mount • Freestanding • Desktop workstations • Various types of metallic and non-metallic constructions • And much more... • Modular Disconnect • Internal mount disconnects • Consoles and consolets • Wire troughs We o er a full line of quality enclosures from the best manufacturers in the world Plus over 5,800 low-cost accessories and wiring solutions for those all-important nishing touches!

KDP Series

Note: Mounting Hardware not included.

KDP/R Series KDP/R Series

KDL/H-VA-FDA Series

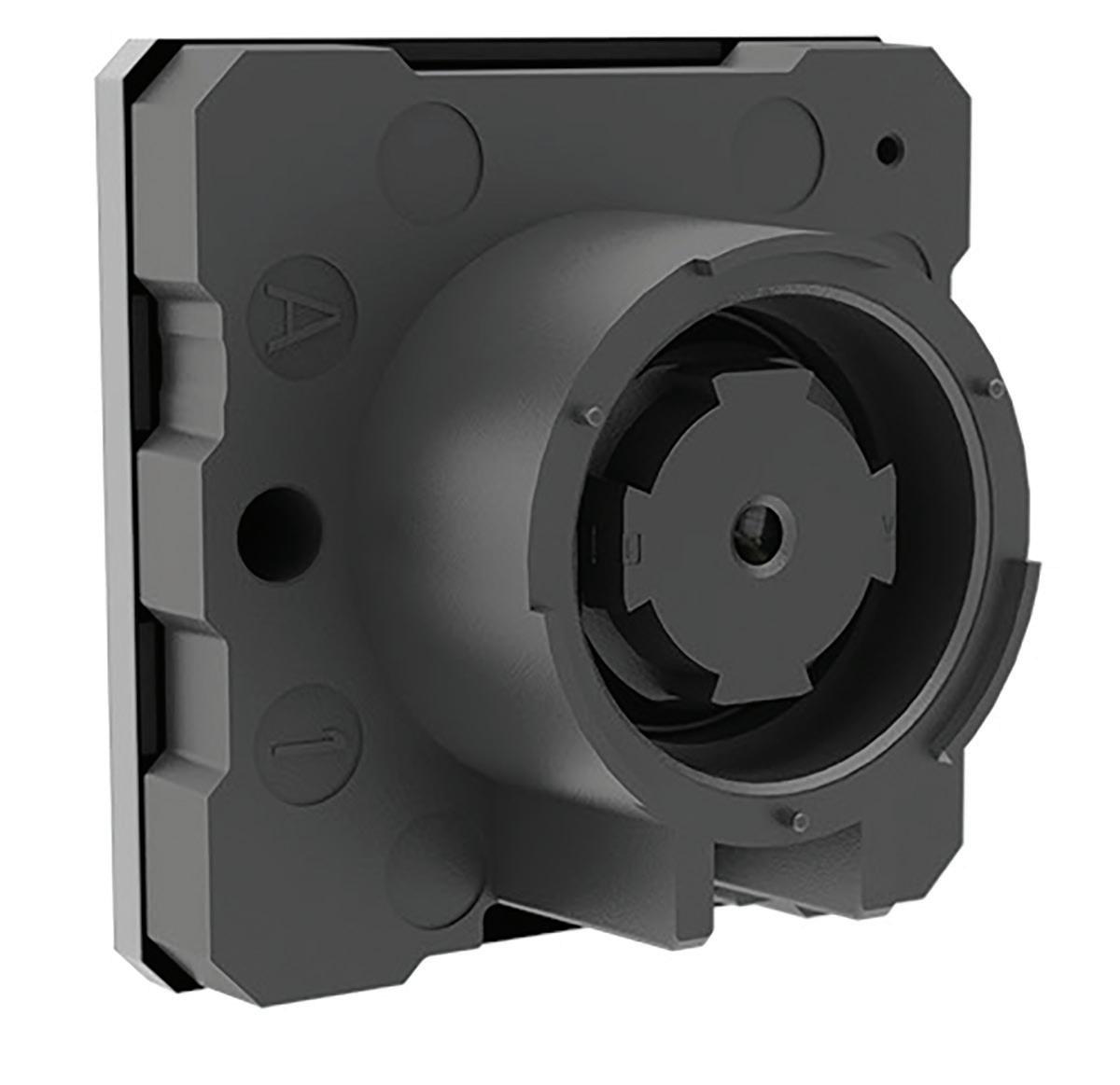

Experience the future of fan technology with AxiForce.

The AxiForce tubeaxial fan series is ideal for keeping consistent, optimized temperature in control units for automation and other highly-modern technologies. Due to its variable installation, high cooling capacity in the smallest of spaces, and interactive integration into the device logic, it has already proven to be indispensable in modern automation.

Contact s ales@us.ebmpapst.com for more info.

• Engineering Assistance / Fast Delivery www.zero-max.com 800.533.1731 PRECISE. ROBUST.AVAILABLE.

The in-person meeting returns om the brink

The COVID-19 pandemic changed so much around our jobs, from how we work to where we work. It brought Zoom into the daily vernacular of the o ce, and for many of us, that o ce now bears a striking resemblance to our living room or den, or study.

One thing that COVID-19 didn’t seem to change was the importance of meeting in person. Rather, the pandemic, in general, brought about an awful lot of hand-wringing about the future of in-person events, from conferences to trade shows to industry award celebrations. Companies like ours, and industry associations, pivoted and were often successful at digital events, if somewhat less so with hybrid events (which many people quickly decided they didn’t care for).

I’m glad to see, after the last few months of being back on the road, that these predictions of industry events’ collective demise have been proven wrong. In late November, we held a fantastic 300+ person gala celebration for the 2022 R&D 100 Awards, something I couldn’t have imagined a year prior. Our company got together in January for the first corporate meetings since the lockdown, and it was incredible to see all those faces without the aid of a computer monitor. I attended a large industry conference shortly thereafter, and it felt like nothing had changed from 2019, other than the plentiful bottles of hand sanitizer placed around the ballroom.

What’s more, I just returned home from back-to-back trade shows — the in-person events seemingly in most peril. They were on opposite coasts and in vastly di erent industries (construction and laboratory equipment), and yet both were humming with excitement, the aisle positively jammed with people.

COVID-19 may have taught us some new ways to think about things in the workplace, but it also seems to have reminded everyone how important that face-to-face human connection is to us. As Mary Gannon, the Editor-in-Chief of our sister publication Fluid Power World, remarked to me, she can’t remember ever getting so many hugs at a trade show in her life. People genuinely missed each other, and missed having that type of connection that no phone call or video chat can replace. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

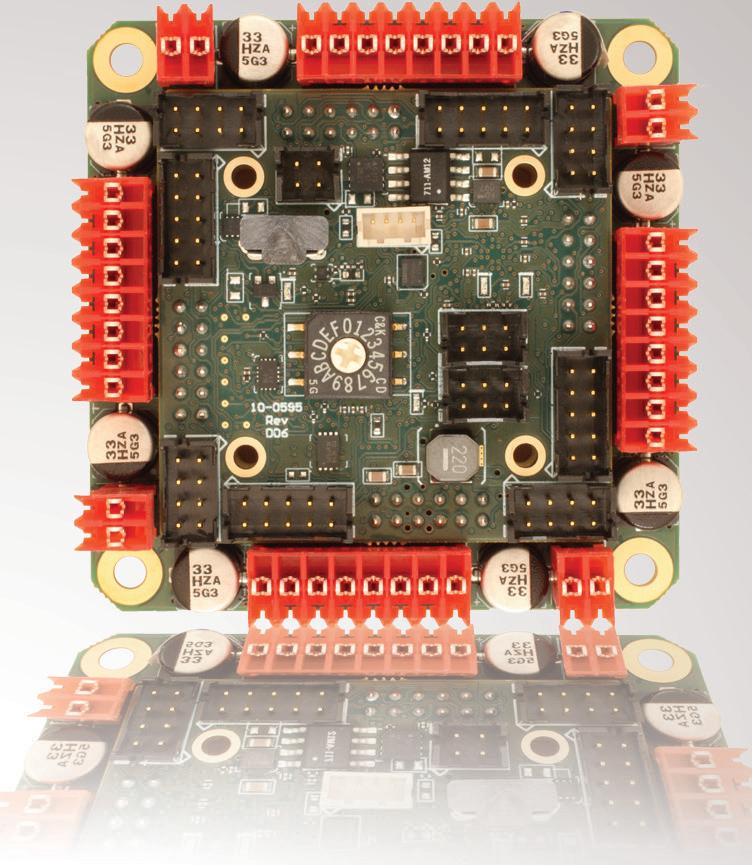

Insights 4 April 2023 www.designworldonline.com DESIGN WORLD - brushed or bldc motors - 5 amps per axis - 16 analog inputs - 16 on/off drivers - home and limit in - live tech support - made in the USA WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25” 4 AXIS SERVO from NEW!

On Twitter

@wtwh_paulheney

Steel, Stainless Steel, and Aluminum Shafting cut to length and optimized for use with LEE Linear bearings.

LEE Linear has the ability to manufacture custom shafting to required standards in a short amount of time, eliminating downtime and increasing profits for our customers.

Special machining capabilities include threading, diameter reduction, flats, keyways, plating, and more.

Roller Pillow Blocks are well suited for heavy loads and long travels.

Large cam follower design delivers superior contamination resistance and excels in applications requiring joined shafts or rail assemblies.

Simplified installation and alignment makes for lower system costs.

Request a FREE Sample at 6402 E. Rockton Rd. Roscoe, Illinois USA +1.800.221.0811 sales@leelinear.com leelinear.com Flexibility to

Meet Your Needs

bit.ly/DW-LEE2023

Chips (semiconductor) chips, I dream of you

“Chips chips da ti du di du … I dream of you …” skats Italian jazz musician Paolo Conte in his 1981 masterpiece Via con me. This is the manufacturing community’s refrain as international borders threaten to harden into chokepoints for semiconductorrelated commerce.

In fact, the chip industry is widely considered the hardest hit by the supply-chain issues of the COVID-19 pandemic and its container ships waiting weeks for cargo unloading; purchase-quantity limits; and backordered parts and subcomponents. But every modern vehicle, industrial component, smart device, consumer gadget, and appliance is peppered over with semiconductors imparting the processing power of electronic products most valued today.

The issue laid bare by COVID is how the cosmopolitan yet nondiversified nature of the semiconductor industry currently renders it vulnerable to disparate global issues. In many cases, a small handful of companies execute chip processing in Europe; chip-processing machine building in California and Japan; chip testing in Southeast Asia; and assembly into the final product (where applicable) in China.

Of most concern now is how more than half of all semiconductors and more than 90% of all advanced semiconductors are made in Taiwan. Fabrication plants there supply more than half of all the world’s semiconductors and nearly all advanced semiconductor chips having

extremely miniaturized features. However, the looming possibility of China’s claim of Taiwan as a province could threaten this industry. Heightening tensions are Trump-era sanctions restricting Chinese telecomm-unications and electronics giant Huawei from employing U.S. software or technology and Biden-era sanctions as well as the 2022 Creating Helpful Incentives to Produce Semiconductors (CHIPS) and Science Act. The latter designates $280B for coordinated spending over the next decade on U.S. including semiconductor R&D and commercialization; manufacturing and workforce development; and chip production tax credits. Many times over the years, I’ve heard industry-savvy folks at tradeshows and various other industry events declare the U.S. semiconductor industry e ectively dead and beyond revival. Perhaps (as Miracle Max from Princess Bride might say) it’s only mostly dead.

For the 2023 Design World Trends issue (readable via the QR code above) many industry experts we surveyed indicated cautious optimism about this CHIPS program … although there’s almost universal concern about the many years it will take to develop and expand the industry. Most are delightfully bullish.

The U.S. CHIPS act is similar to the CHIPS Act o cially adopted by the European Council of the European Union in December 2022. Beyond the supply-chain arrangements these acts will prompt, it will be fascinating to see what new chip technologies they yield. DW

AdobeStock.com On Twitter @dw_LisaEitel

Forward 6 April 2023 www.designworldonline.com DESIGN WORLD

Technology

®

Engineering

Lisa Eitel • Senior Editor

Digital-transformation sustainability: Waste minimization and energy savings

Nearly two thirds of all energy created globally for commercial, transportation, industrial, and residential use is lost to ine ciency and waste. For operations aiming to achieve carbon-neutral status (or just higher profitability through energy conservation) preventing the loss of energy is at once immediately possible and commendable. After all, Energy Information Administration analysis indicates that industrial operations consume a quarter of the nearly 100 quadrillion BTUs produced in the U.S. every year (not counting the energy expenditures associated with logistics and outer transportation activity) but half of that is wasted.

Though rendered impossible by current national and global politics, it’s still technically feasible for humanity to restrict coming decades’ climate change to within 1.5° C — the U.N. Intergovernmental Panel on Climate Change target for avoiding the absolute worst

8 April 2023 www.designworldonline.com DESIGN WORLD

e ciency and

Sustainable

Predictive maintenance routines can maximize energy

throughput.

| Suwin Puengsamrong

e ects of climate change — in part by minimizing energy waste. But it’s nearly certain climate change in coming decades will in fact exceed 1.5° C, so in the U.S. will vastly increase deadly heat events, droughts, wildfires, and farming catastrophes in Texas, Oklahoma, Kansas, Nebraska, Iowa, and the Dakotas. It will also bring coastal flooding and devastating storms to Texas, Louisiana, Florida, South Carolina, New York, Hawaii, and California as well as the death, destruction, and extinction of both terrestrial and marine species, habitats, and ecosystems (including 70% to 90% of the world coral reefs). NASA imaging confirms that in less than 20 years, Antarctica and Greenland ice has already melted the volume of Lake Michigan … and despite a half century of advancements in agricultural approaches, global farming productivity is 21% lower than it could’ve been sans climate change.

For manufacturers and automated facilities who acknowledge that climate inaction is costlier than action, a top goal is achieving net-zero greenhouse gas emissions. These e orts prioritize the reduction of CO2 and to a lesser extent methane, nitrous oxide, and fluorinated gases. If urgent warnings are to be heeded, manufacturers should cut their emissions by half within the next 10 years.

Of course, many industrial operations — including those involving heating and cooling processes, machining, and any physical transport of raw materials and workpieces — are inherently energy intense. That said, the application of digital-transformation (DX) systems such as energy analysis software, realtime energy tracking, and digital energy management can handily trim an industrial operation’s energy waste by 10% or more. These DX technologies measure and (in some cases) continually monitor energy flows

Shown here is a Sankey representing sources, uses, and wastes of energy in the U.S. Values are based on data from March 2022 via the Energy Information Administration. Distributed electricity here includes retail electricity sales and none self-generated. Electricity production e ciencies here is the total delivered electricity divided by the primary energy input. End-use e ciency is about 65% for residential, 65% for commercial, 21% for transportation, and 49% for industrial (with the latter reflecting DOE analysis of manufacturing). Source: Lawrence Livermore National Laboratory • Department of Energy.

If urgent warnings are to be heeded, manufacturers should cut their emissions by half within the next 10 years.

Numbers are expressed in quads — short-scale quadrillion 1015 BTU (1.055×1018 J). SOLAR • 1.5 NUCLEAR • 8.13 HYDRO • 2.28 WIND • 3.33 GEOTHERMAL • 0.206 NATURAL GAS • 31.3 COAL • 10.5 BIOMASS • 4.83 PETROLEUM • 35.1

DESIGN WORLD www.designworldonline.com April 2023 9

Sustainable Engineering

DX initiatives can help operations identify where in a plant or operation the most dramatic e ciency gains can be had. For larger operations, such programs can save millions of dollars in energy per year.

through a facility to profile and target areas of potential improvement.

Key is the reduction of waste heat and emissions from electric utility power plants and transmission systems (purchased power) as well as the power distribution elements, motors, drives, engines, compressors, lights, mechanical components, and other elements under an operator’s control in the plant itself.

The EMIS solution

In many cases, DX software for the improvement of energy e ciency takes the form of energy management information systems or EMISs. EMIS software is complemented by sensors (wired and wireless), data systems, and employee as well as organization programs to review and apply EMIS data collected from energyperformance tracking. Comprehensive deployments can even aggregate the data across a whole plant (or multiple company locations) to optimize energy use. In contrast with legacy approaches (in which operations may have only reviewed energy consumption trends every month or year over year) today’s EMIS-based systems often use sensor-

generated data collected every day, hour, or minute (or in realtime) to detect or profile even slight issues rather quickly.

EMIS digital twins can also inform future designs without impacting immediate facility operations. These designs often include component and subsystem purchases such as the procurement of automation subassemblies right-sized for a given application; smart controls to optimize machine routines; regenerative drives; electric motors with NEMA-certified e ciencies; actuators in place of fluidpower technologies; LED lighting; and predictive-maintenance peripherals to identify irregular or degraded system performance before resulting ine ciencies linger or compound energy and production losses.

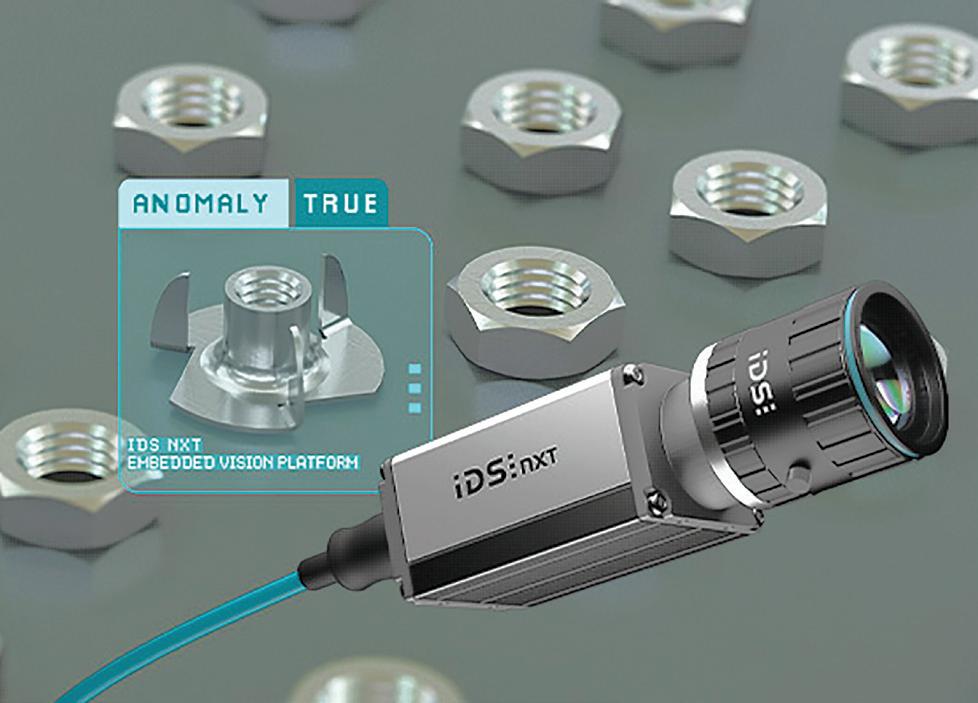

Edge devices key to reducing waste Sustainability-related programs leveraging edge computing are seeing increased adoption for two main reasons. First of all, edge computing supports green-engineering e orts through its processing of vast data streams to improve monitored operations’ sustainability profile.

Correlating process functions to energy use, raw material consumption, and emissions generation via sensors can yield information about specific operations that can be standardized on one data set. Filters on this locally processed data then remove all irrelevant or invalid data to output actionable information. Edge computing in such arrangements also helps industrial operations keep massive amounts of raw data (the production of which has only grown exponentially over recent decades) o remote servers that globally consume more than 200 trillion Watt-hours every year.

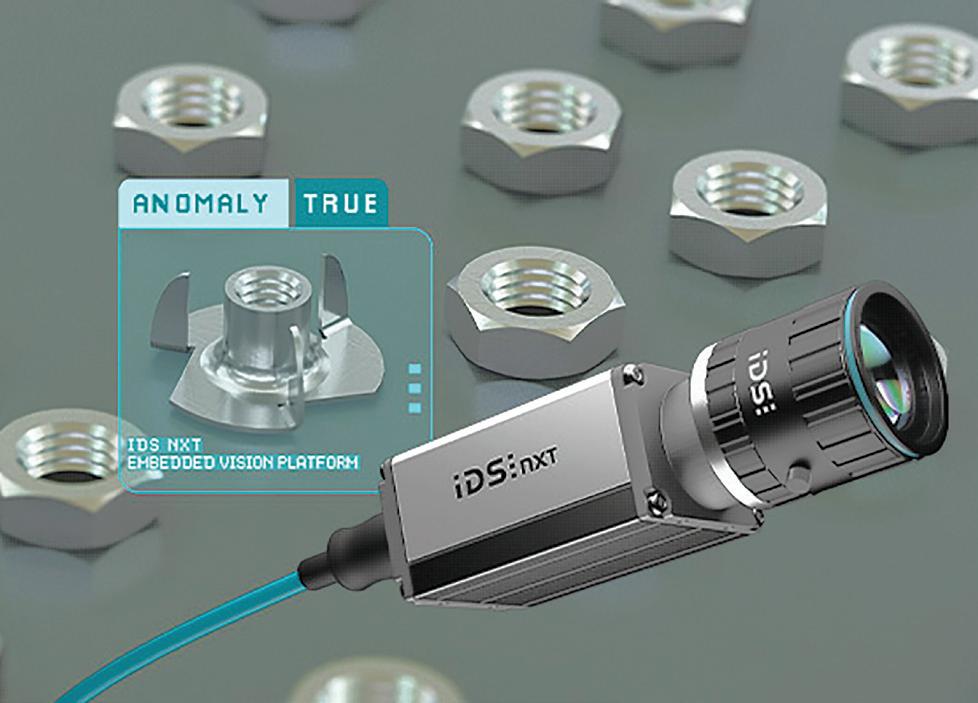

In addition, edge computing supports green-engineering e orts by minimizing scrap and defective output products. Because solid industrial waste is nearly twentyfold that generated by municipalities worldwide, all conservation e orts here are worthwhile. Sensor arrays used in this way prevent overproduction of a given ingredient or subcomponent while concurrently preventing the output of defective items destined for scrapping. Continuous machine monitoring quickly identifies value anomalies and malfunctions; these can then trigger warnings, a temporary halt to operation if possible, and [ideally predefined] troubleshooting and corrective measures. Upon completion of machine rebooting or repairs, operations are resumed — and all the collected, filtered, and standardized machine data of the downtime event can be used to yield deeper insights into a given machine’s profile and prevent similar issues in the future … or optimize upgraded or next-generation versions of the equipment. DW

10 April 2023 www.designworldonline.com DESIGN WORLD

| Armmy Picca

We make it easy to take your design further with a custom ring or spring. • Economical Prototyping (No-Tooling-Charges™) • Quick Lead Time • Diameters from .118” to 120” in 40+ Materials • Industry-Specialized Design Support Custom Retaining Rings and Wave Springs YOUROPTIMIZEDESIGN Request Free Samples at 847-719-5900 or smalley.com Visit us at Hannover Messe in Hall 3, Stand L43

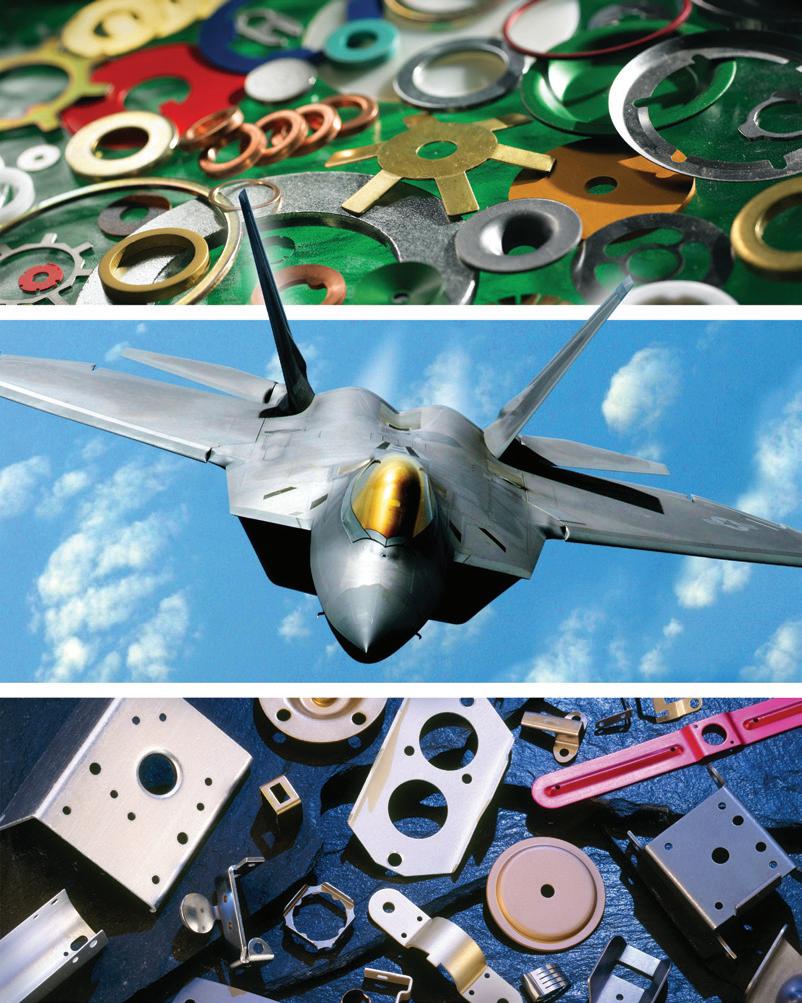

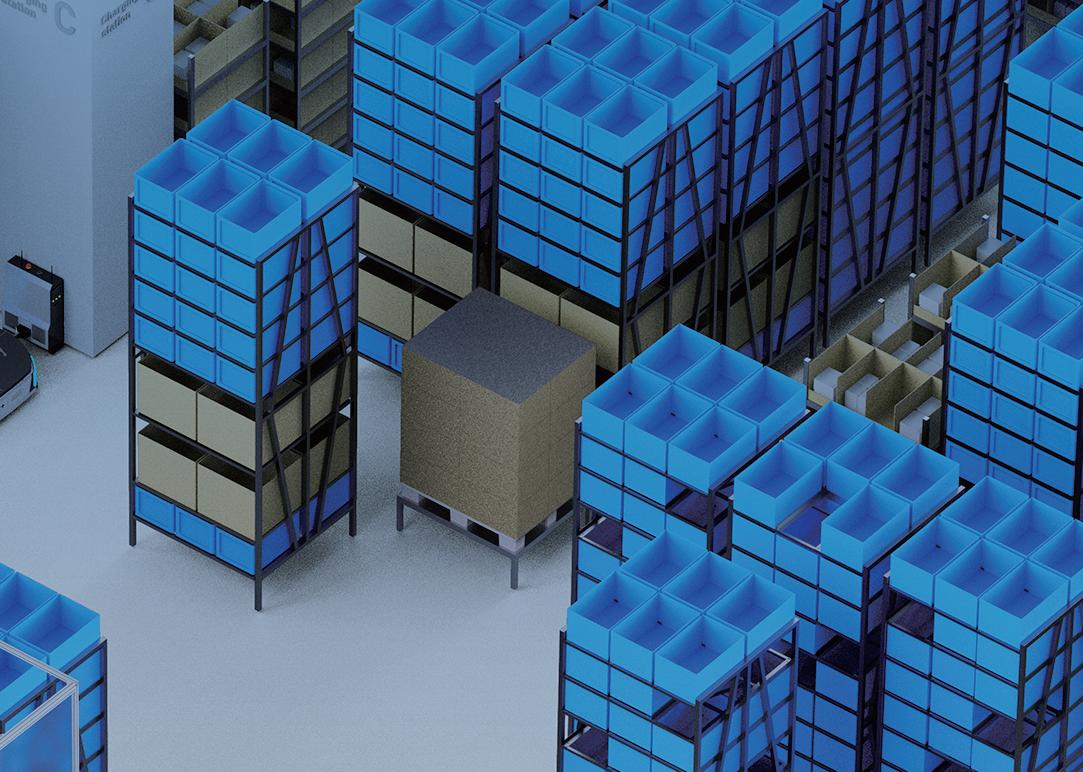

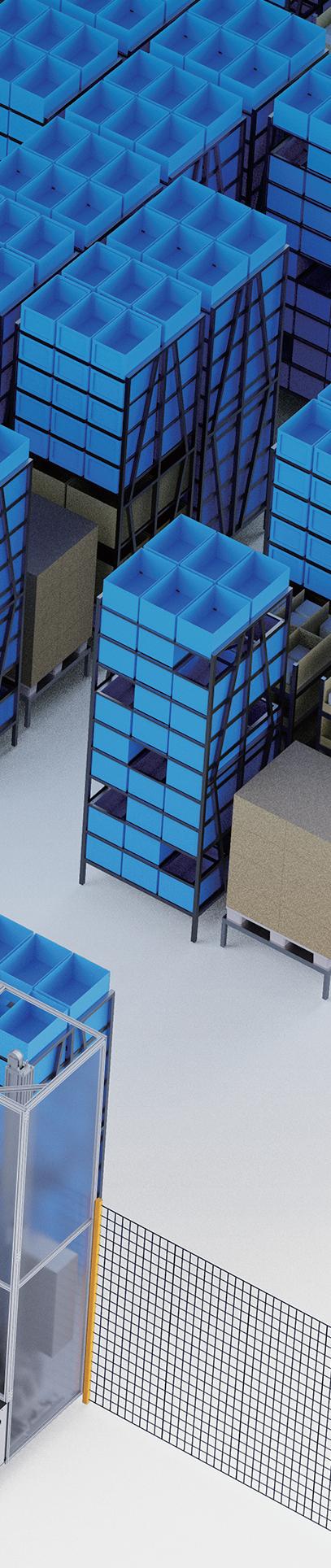

Contents 4 • 2023 • vol 18 no 4 • designworldonline.com asbpe.org SILVER REGIONAL AWARD 2022 asbpe.org GOLD REGIONAL AWARD 2022 asbpe.org BRONZE REGIONAL AWARD 2022 12 April 2023 www.designworldonline.com DESIGN WORLD asbpe rg BRONZE NATIONAL AWARD 2022 asbpe.org GOLD NATIONAL AWARD 2022 ON THE COVER Piezo elements are at the core of many transducers and sensors; those piezo-based components are perhaps the best known by engineers. | Dreamstime | AdobeStock.com 163-187 www.therobotreport.com 188 MOTION CONTROL Motion for medical A bevy of new motion control components are tailor-made for medical equipment applications. 200 200 MECHANICAL Center distance variations influence noise in compound gearboxes Although gearboxes are a well-understood technology, they don’t always operate as designed. To provide a framework for creating a more optimal gearbox design, we recently simulated how center distance variation influences noise. 79-161 Design equipment faster, smarter, and under budget with TiPS from leading suppliers. April 2023 59-78 A supplement of Design World April 2023 Inside: Fastener Fair 2023 is headed to Music City USA 166 Lightweight heavyweights: How self-adhesive die cuts are leveraging the bond Digitalizing inventory: How automation can save time & money 194 LINEAR MOTION Piezos for delicate actuation Piezo-based technologies are indispensable for micrometer and nanometer strokes. RBR 50 79-161 Innovation Awards INSIDE

4.23 • contents 14 April 2023 www.designworldonline.com DESIGN WORLD departments 04 Insights 06 Technology Forward 08 Sustainable Engineering 18 Design For Industry 30 Design Notes 42 3DP AM 50 CAE Solutions 56 Sensor Notes 207 Ad Index 208 Technical Thinking THIN ENOUGH? BXR Brakes · Up to 480 in-lbs static · Up to a 1.125'' bore · 19 watts or less · Produced for over 10 years Our Innovative design features a very thin profile, reducing weight and space. For more information: Call: 800.533.1731 www.mikipulley-us.com

Follow

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor

Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor

Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor

Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Services

Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director

Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer

Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Bruce

bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Francesca Barrett fbarrett@wtwhmedia.com

Webinar Coordinator

Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator Dan Santarelli dsantarelli@wtwhmedia.com

EVENTS

Events Manager

Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Videographer

Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer

Kara Singleton ksingleton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist

Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production

Elise Ondak eondak@wtwhmedia.com

FINANCE

Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

TOP WORK PLACES 2022 DESIGN WORLD www.designworldonline.com April 2023 15

WORLD Medical Design & OUTSOURCING

the whole team on twitter @DesignWorld DESIGN

Specialist

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph: 888.543.2447 2011 - 2020 2013 - 2017, 2021 2014 - 2016

Audience Development

Director,

Sprague

Design for Industry

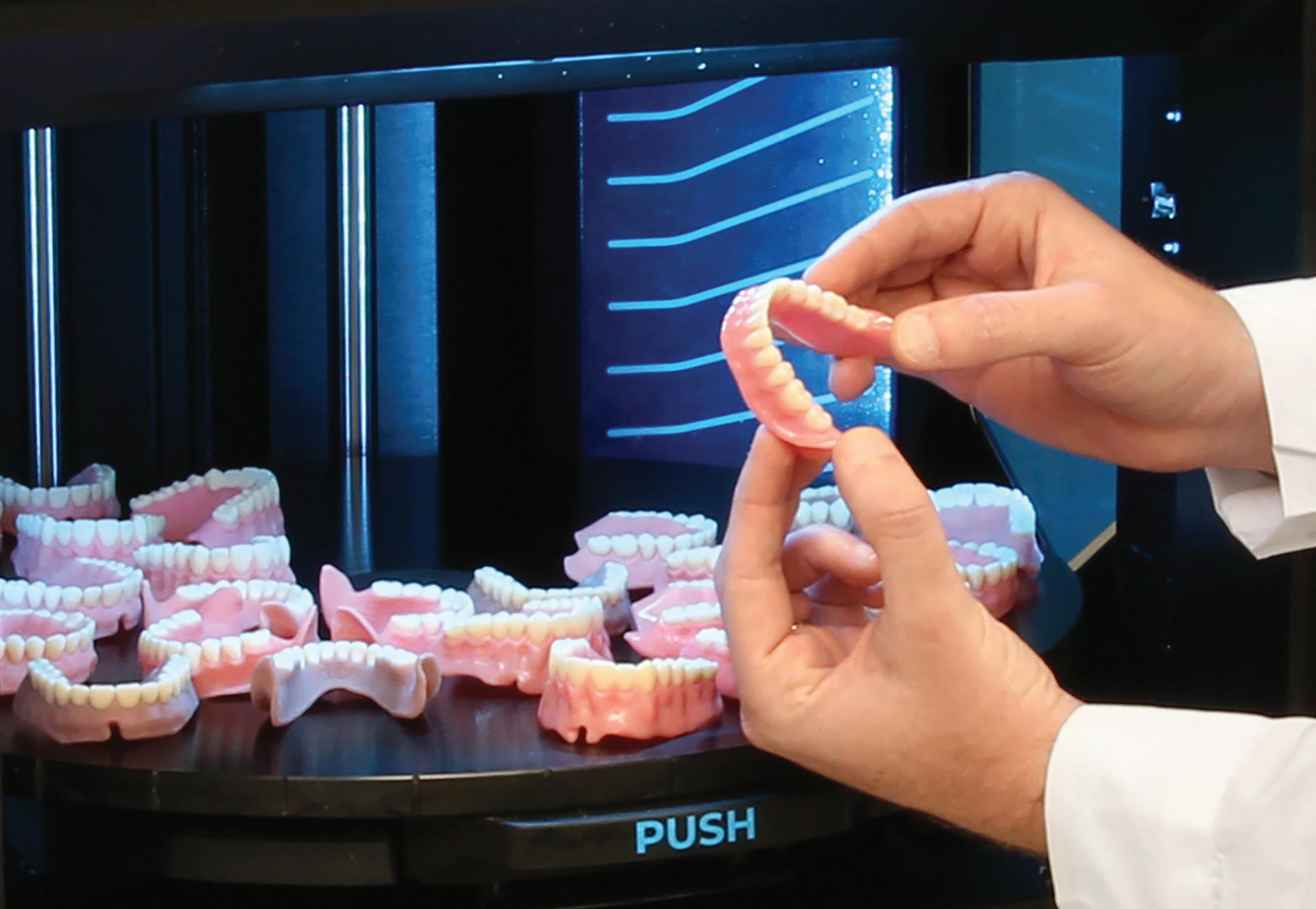

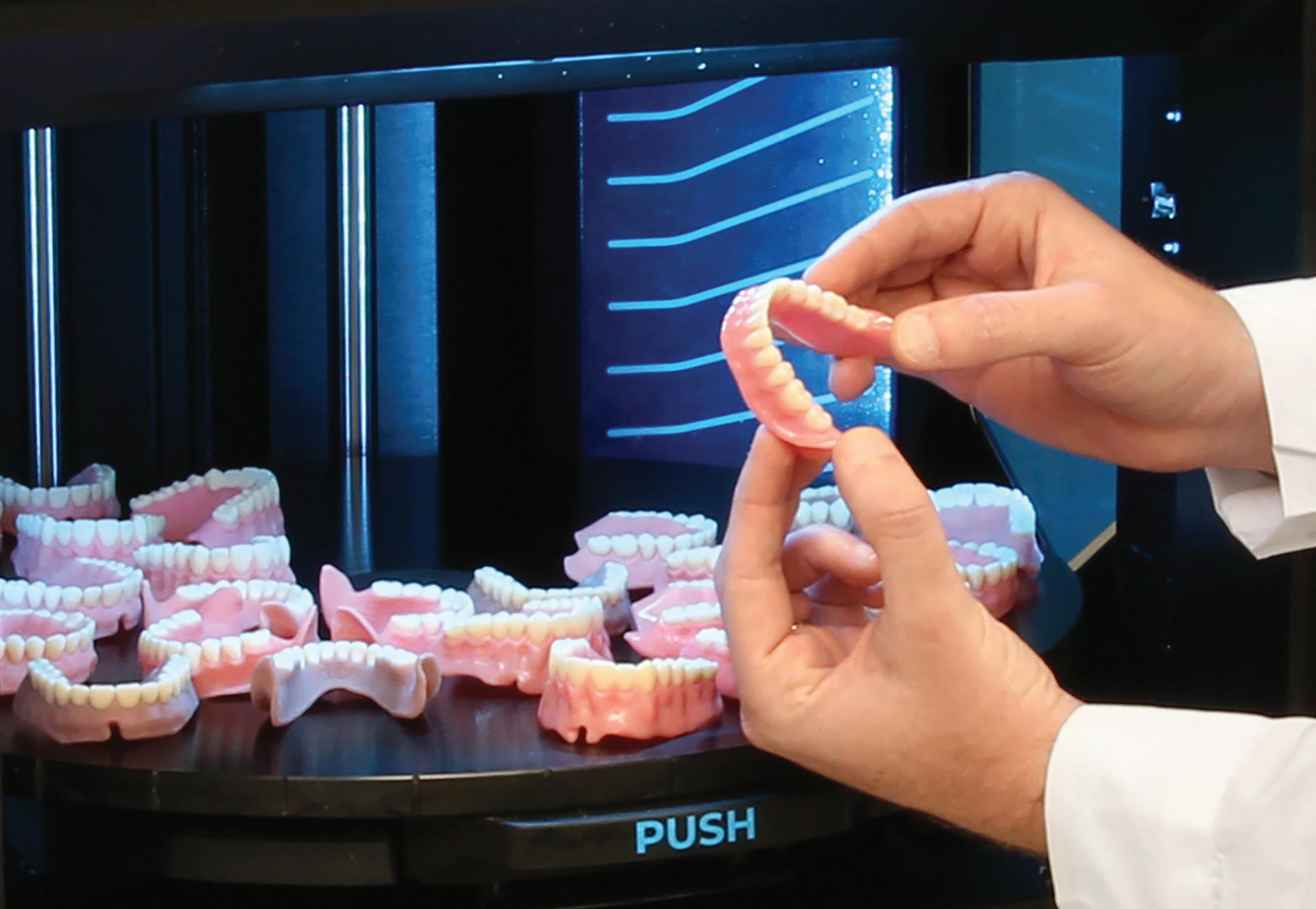

New resin creates high-fidelity polychromatic dental appliances

Stratasys recently introduced TrueDent, the first monolithic, full-color 3D-printed permanent dentures solution. In one continuous print, labs can create permanent, natural-looking gums with accurate tooth structure, shade, and translucency.

“Until now, printed dentures and appliances had to be designed and manufactured in multiple parts and bonded together,” said Frank Acosta, owner of AA Dental Design. “The TrueDent solution, utilizing Stratasys’ systems and software, takes a lot of that stress out. It simplifies the process, lowers the costs, and allows for dentures and temporaries to be produced much faster, achieving incredible aesthetics. We can now expand our prosthetic service printing multi-colored personalized appliances at scale.”

TrueDent is an FDA-cleared (Class II) dental resin explicitly made to fabricate dental appliances, including removable dentures. The resin is patent-pending, currently available only in the U.S., and exclusively compatible

18 April 2023 www.designworldonline.com DESIGN WORLD Medical

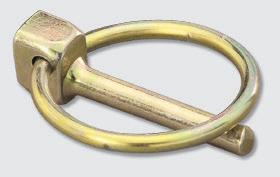

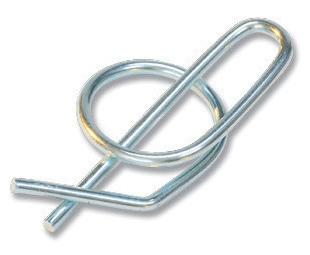

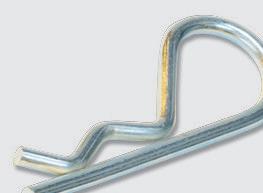

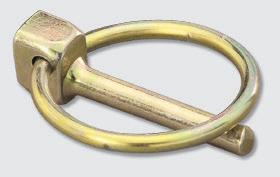

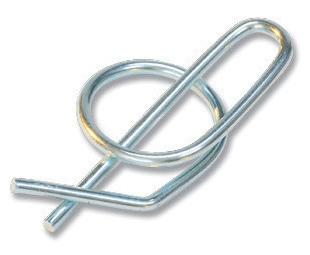

POWER TRANSMISSION

RETAINING DEVICES & maintenance & assembly tools

with the Stratasys J5 DentaJet 3D printer and GrabCAD Print software platform. Dental labs can scale denture manufacturing by simplifying workflow and reducing processing time while achieving a personalized, highly aesthetic dental appliance.

The solution is designed to eliminate barriers and address concerns for patients and laboratories, including:

• Potential chair-time reduction for o ce visits, measurements, fittings, and adjustments.

• High-fidelity matching of the scan, design, and fit.

• Scalable, repeatable digital solutions that provide consistent production of accurate, well-fitting dentures.

• Increased e ciency through streamlined workflows with less time between scan and delivery.

The global dentures market, which Stratasys estimates at $5.5 billion, has a shortage of skilled dental laboratory technicians and is challenged to meet the rising demand for dentures and appliances through conventional methods. According to iData research, in 2021, more than 4.2 million full dentures were created in the U.S., and 18 million full dentures were sold worldwide. Of that total, an estimated 5% were made through a 3D-printed solution.

“This new solution will be transformative for the dental industry, and we believe it will help our customers significantly reduce the time and cost of producing dentures and temporaries,” said Ronen Lebi, vice president of dental at Stratasys. “Stratasys continues to push the boundaries of digital dentistry, leveraging our portfolio of advanced 3D printing technologies, including hardware, resins, and software, to deliver disruptive solutions that make a di erence.” DW

Stratasys

www.stratasys.com

WHAT DO YOU THINK?

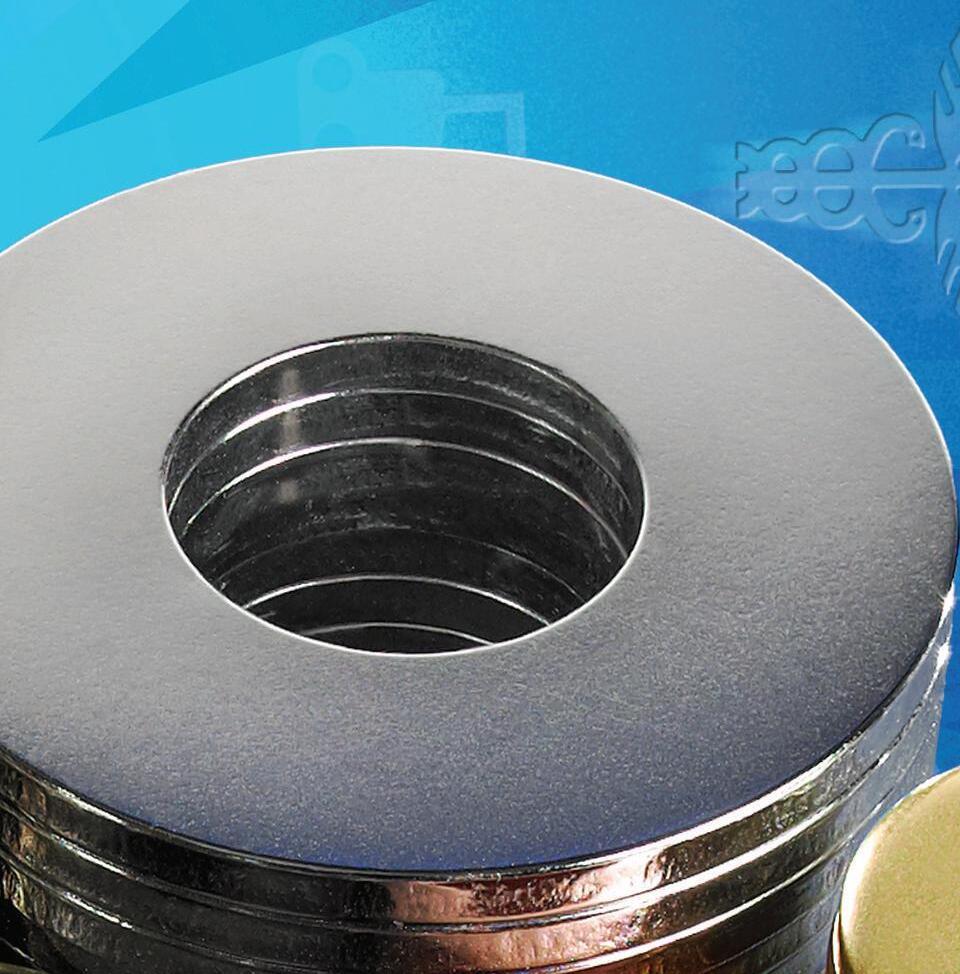

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

DESIGN WORLD April 2023 19

Connect and discuss this and other engineering design issues with thousands of professionals online

33 Higginson Avenue, Central Falls, Rhode Island 02863 Telephone: (401) 728-0700 • FAX: (401) 728-0703 E-mail: info@whittet-higgins.com Web: www.whittet-higgins.com

WHITTET-HIGGINS USA

BEARLOK SHOELOK BEARLOK Shrink Disc

PRECISION

ADAPTER

NUTS

INCH

LEFT

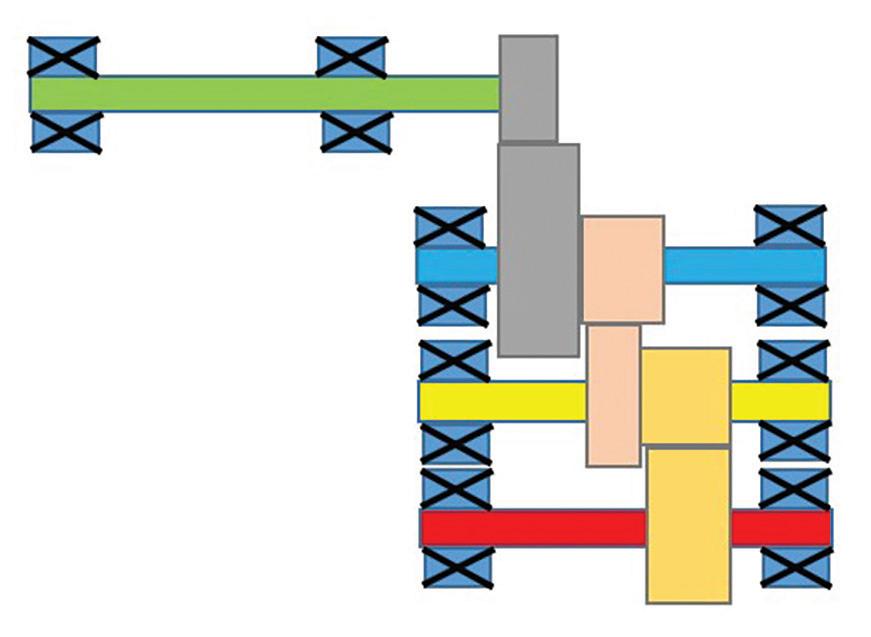

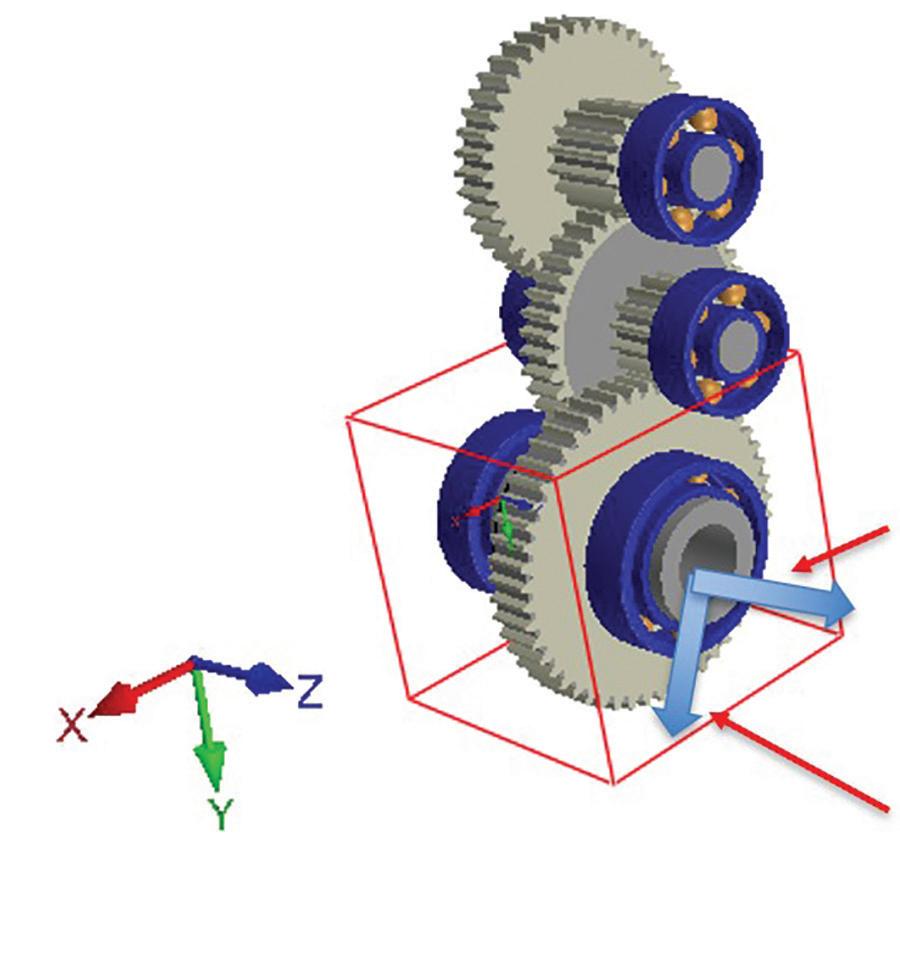

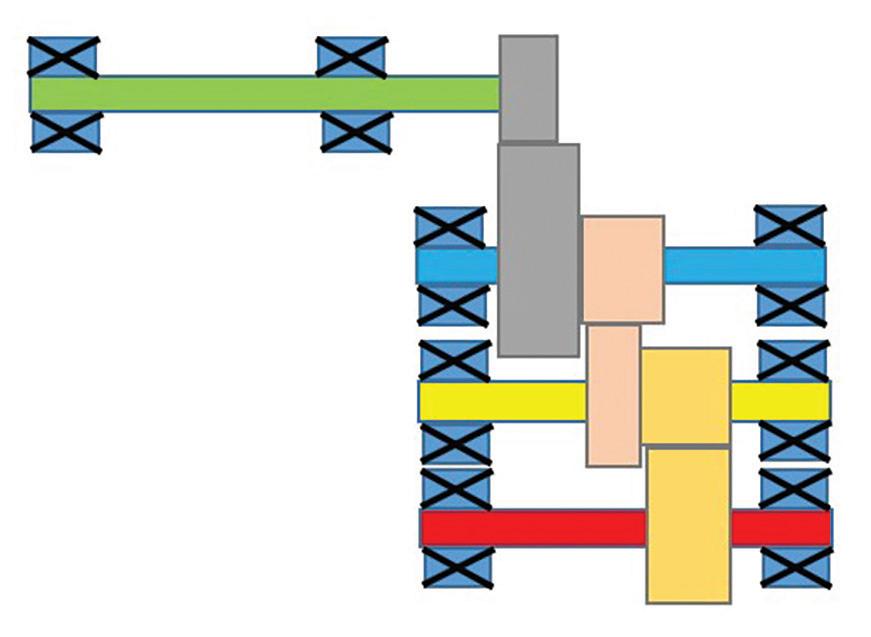

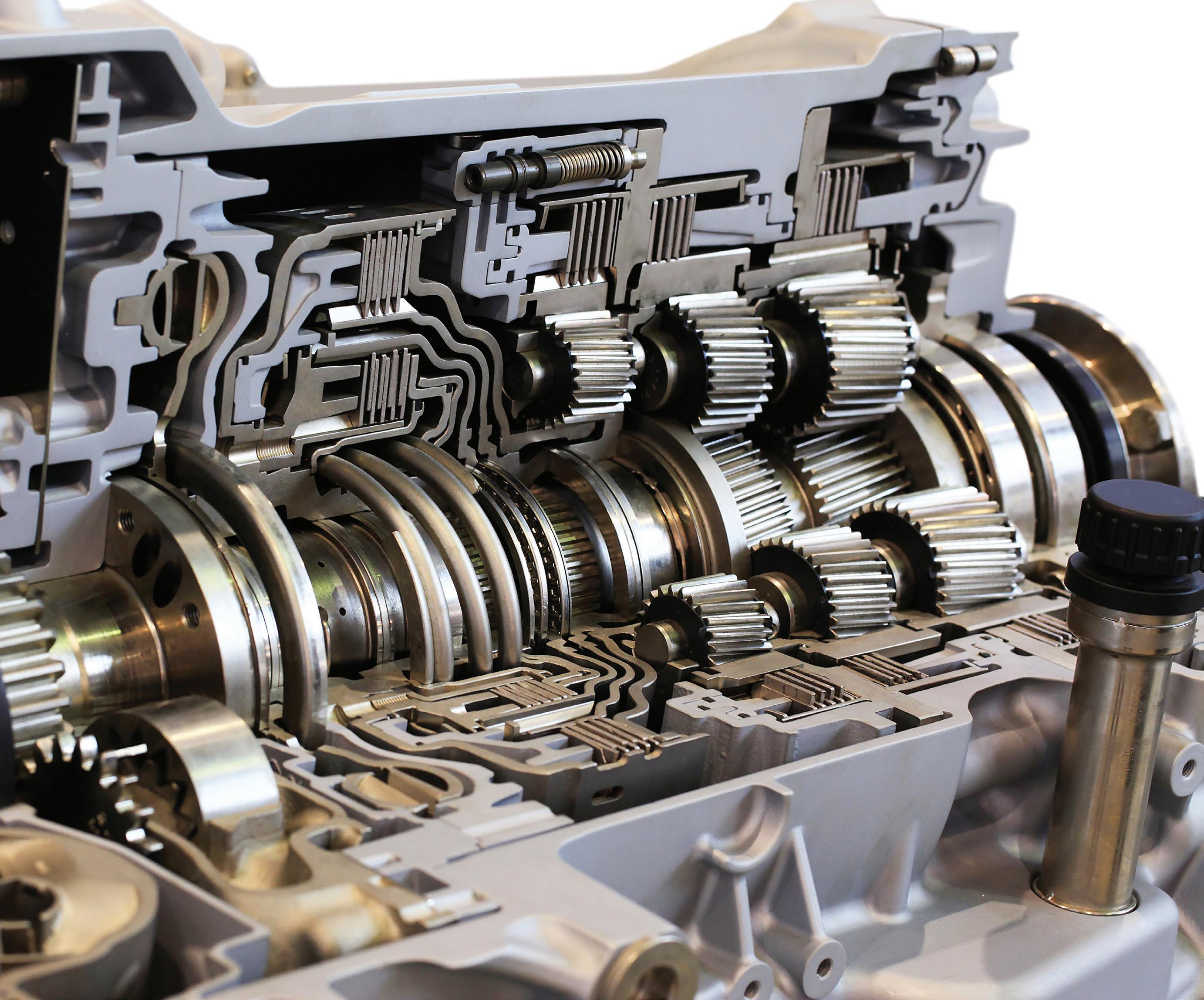

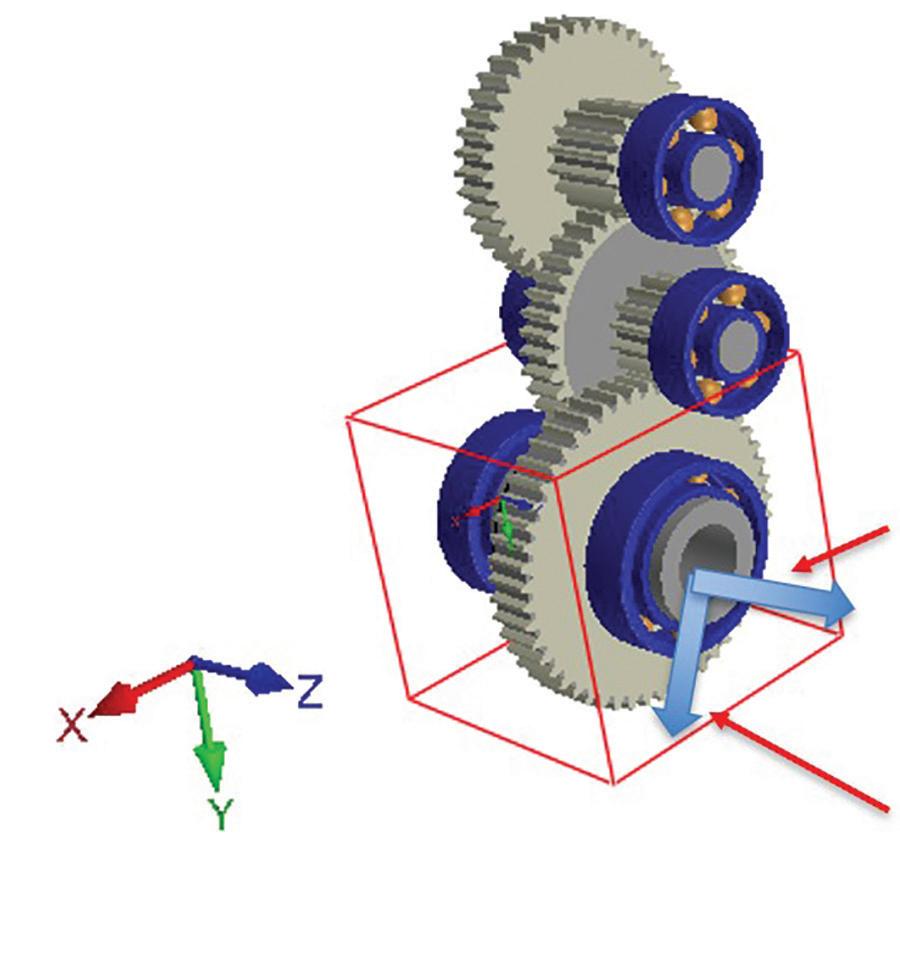

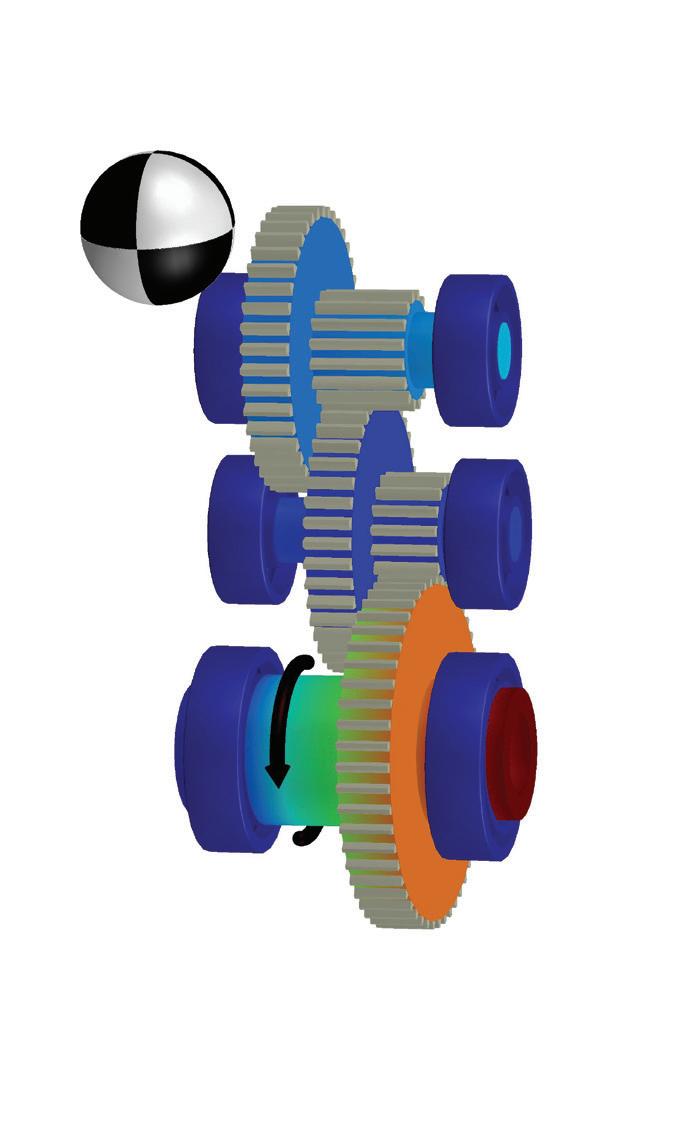

-HANDED

BEARHUG CLAMPNUT TANGENTLOK

NUTS & WASHERS

SLEEVE ASSEMBLIES

& WASHERS HARDENED TONGUE WASHERS SPLIT COLLAR RETHREADING DIES ADJUSTABLE SPANNER WRENCH BEARING ASSEMBLY SOCKET

and METRIC THREADS

HANDED as well as RIGHT

Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS

Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

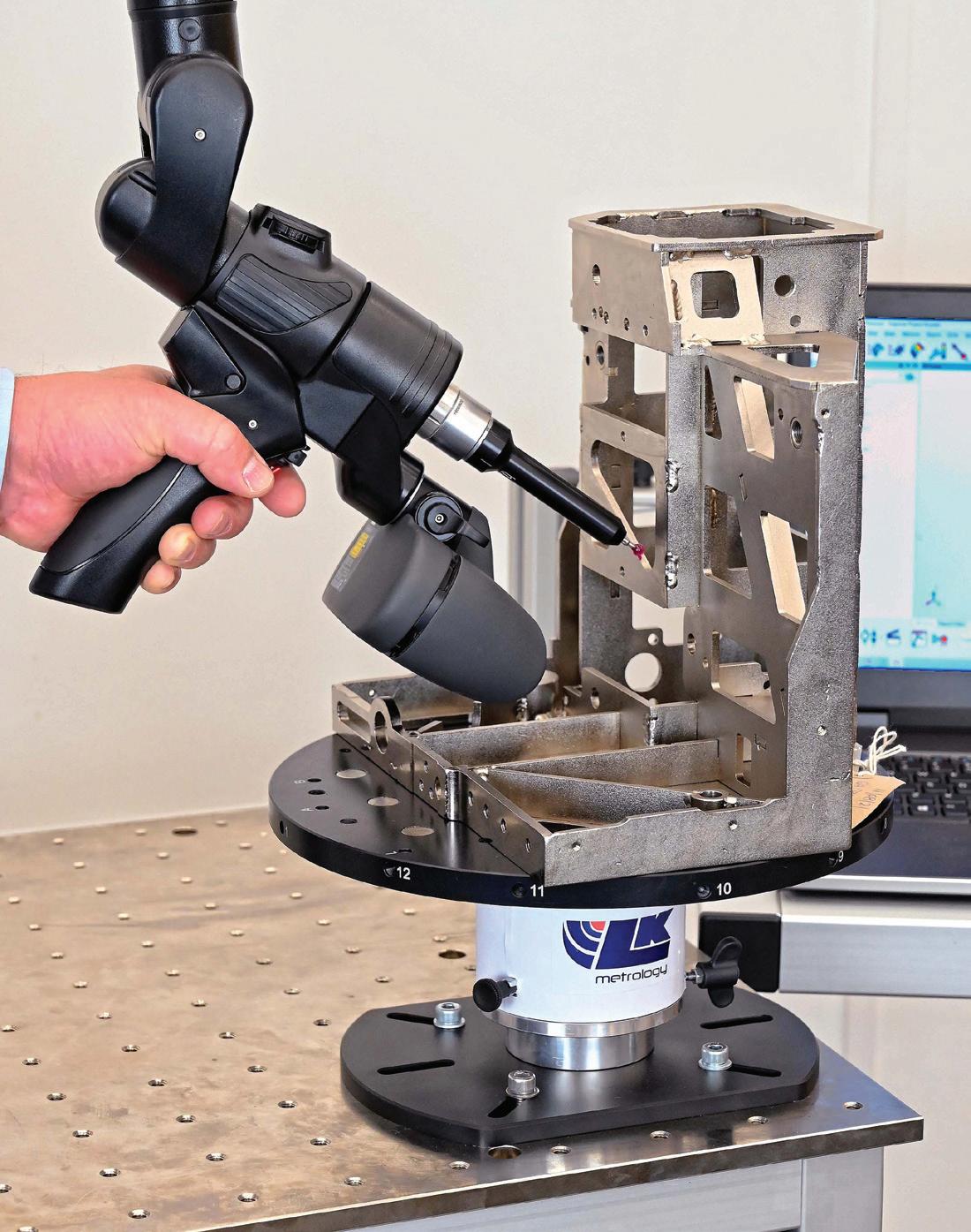

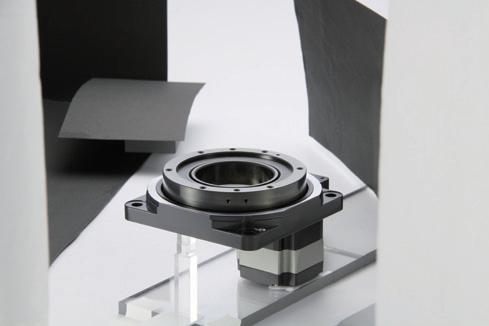

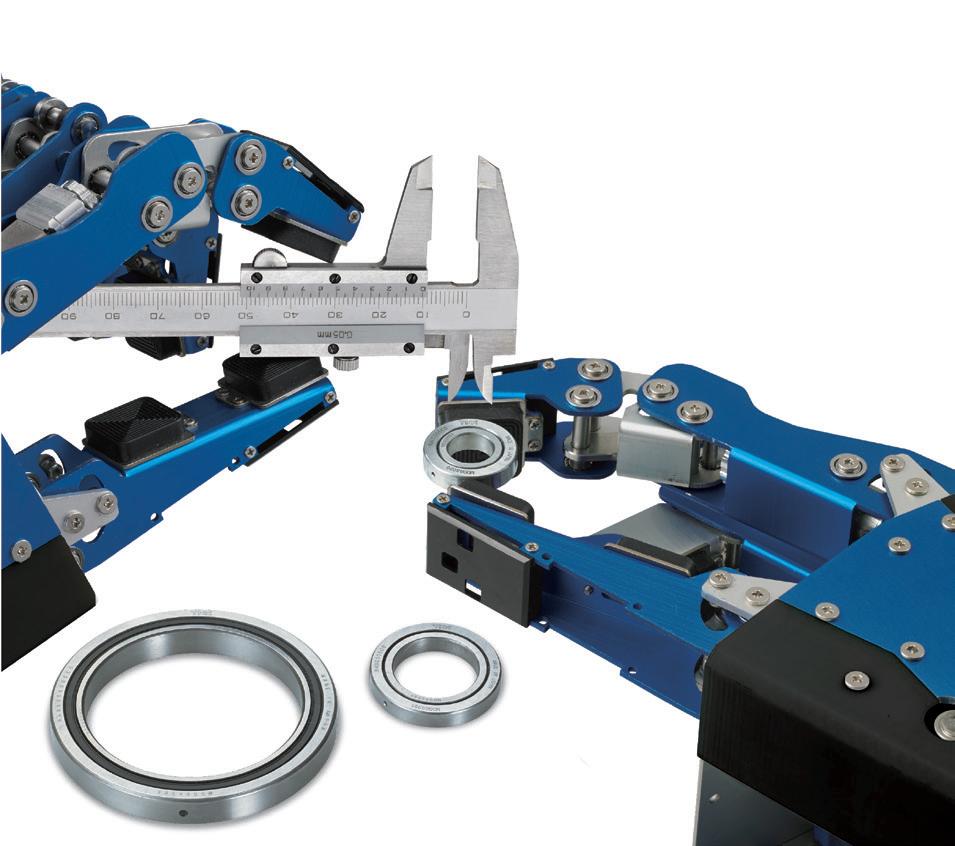

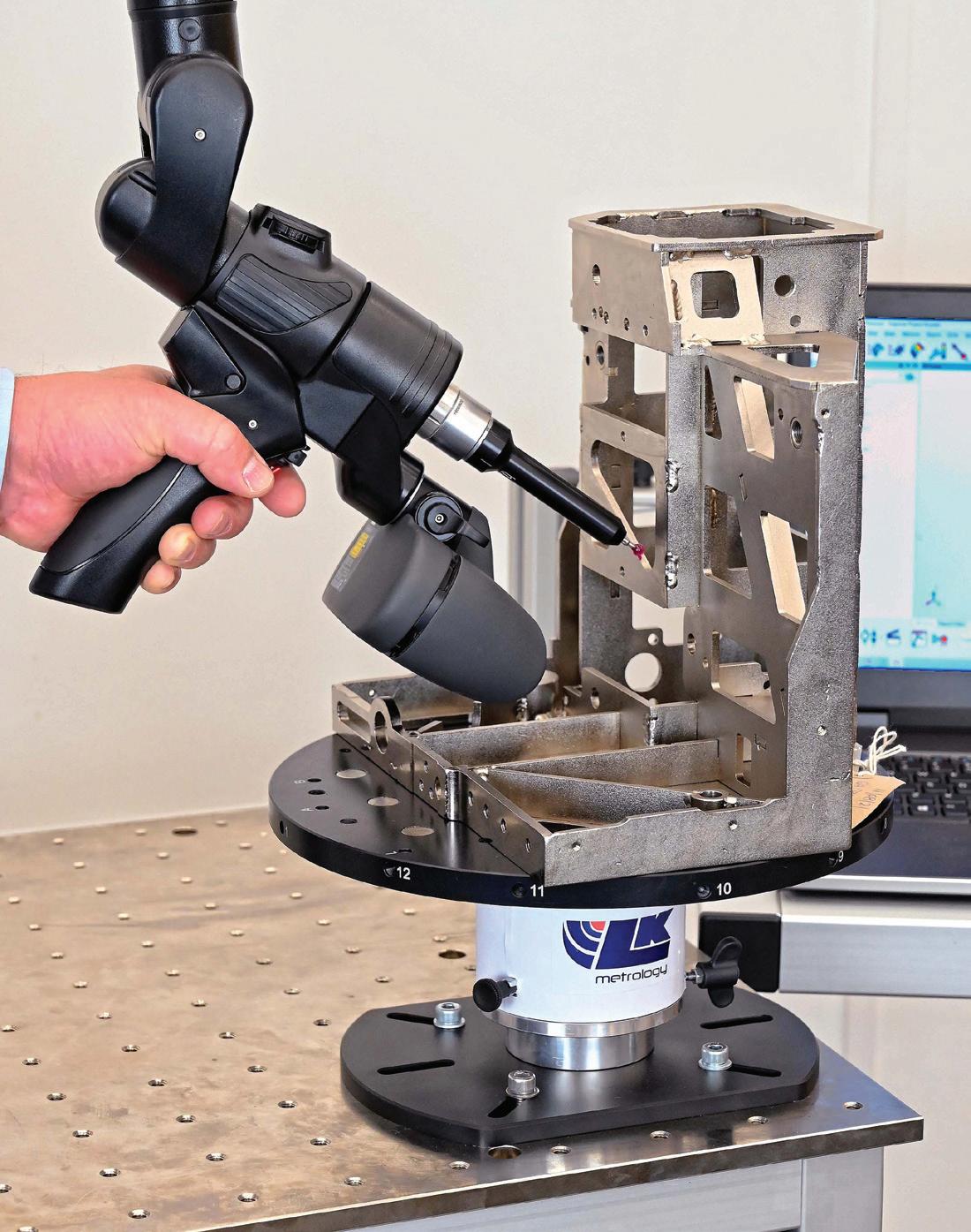

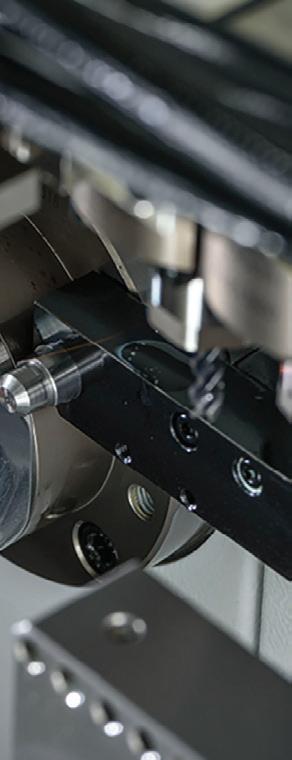

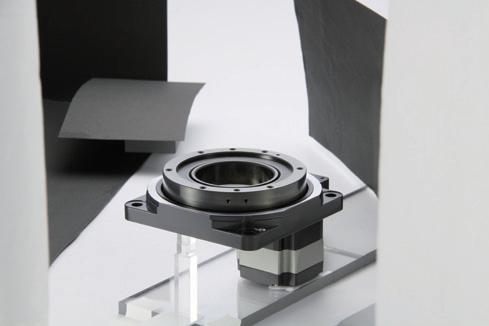

Rotary index table improves portable arm metrology

LK Metrology’s new Freedom Index Table aims to increase component inspection speed when using portable, multi-axis measuring arms. The table’s portability can increase e ciency and, in some cases, e ective measuring volume by using smaller, less expensive arms to access all component areas.

Static tables require operators to relocate the arm to access the back of a part, which can lengthen the measuring cycle and introduce inaccuracies. However, the ergonomic rotary index table enables su cient access and prevents operator fatigue from repeatedly reaching around the component, which can weigh up to 220 lb (100 kg).

Requiring no cables, the portable, manually operated, metrology-grade index table is compatible with any portable measuring arm, including LK’s six- and seven-axis Freedom Arm models. Operators can quickly set up the 11.8 in. (300 mm) or optional 19.6 in. (500 mm) diameter table on a work surface and secure a component with the pre-drilled, threaded fixing holes or integral clamping magnets.

Initial calibration of the start position is also quickly performed by inputting the table’s location in InnovMetric’s PolyWorks Inspector software. Randomly placed, alphanumerically labeled, fiducial dimples are machined into the top of the table and around its periphery. When the measuring arm probes three or more reference dimples, the software recognizes the irregular pattern and automatically detects the orientation. Operators then select the software’s on-screen Freedom Index Table macro to update the coordinate system and continue the part inspection.

When operators need to access the far side of the part, the table rotates 180° (or any intermediate angle), and the arm probes three or more reference dimples to update the software with the new position and continues measuring. The software automatically aligns both sets of inspection data. The PolyWorks 3D dimensional analysis and quality control software also performs geometrical feature measurements, surface evaluation using advanced point cloud analysis, part-to-CAD comparison, and complete reporting. DW

LK Metrology www.lkmetrology.com

20 April 2023 www.designworldonline.com DESIGN WORLD Design

Medical

for Industry

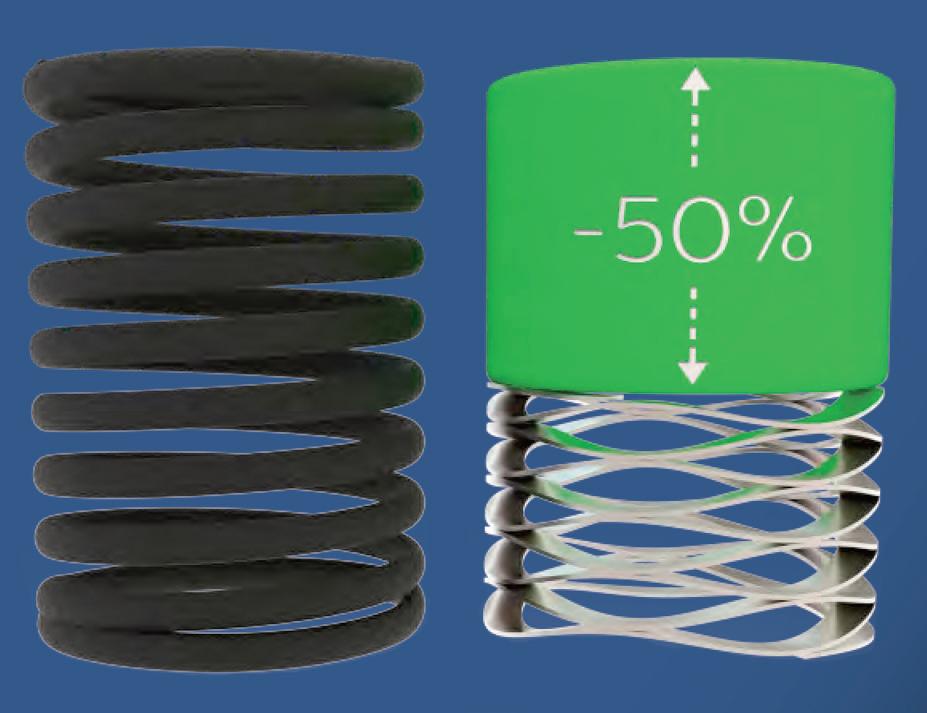

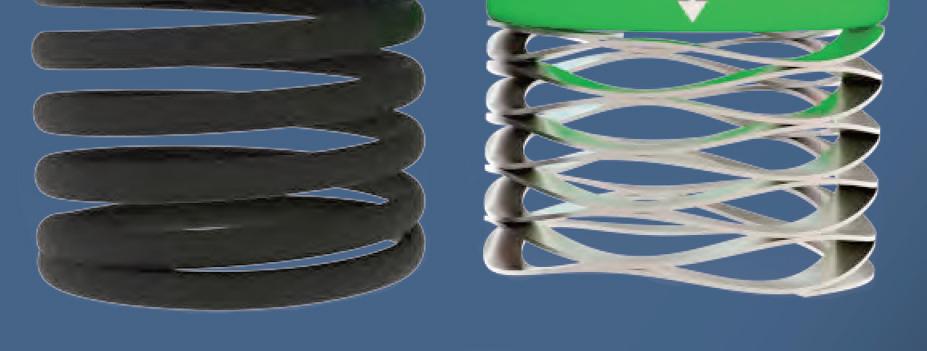

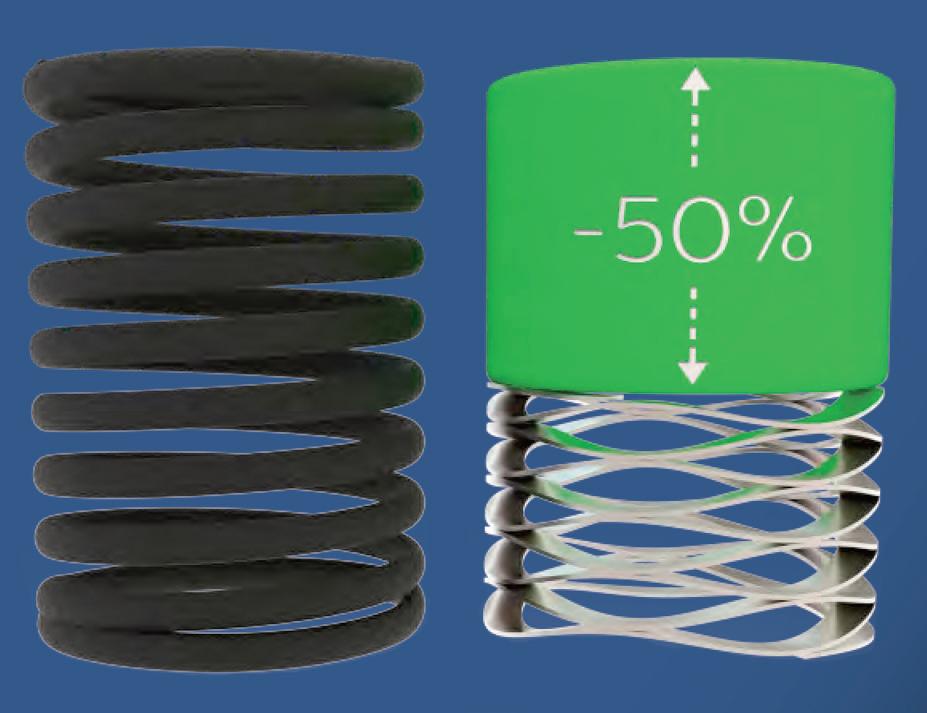

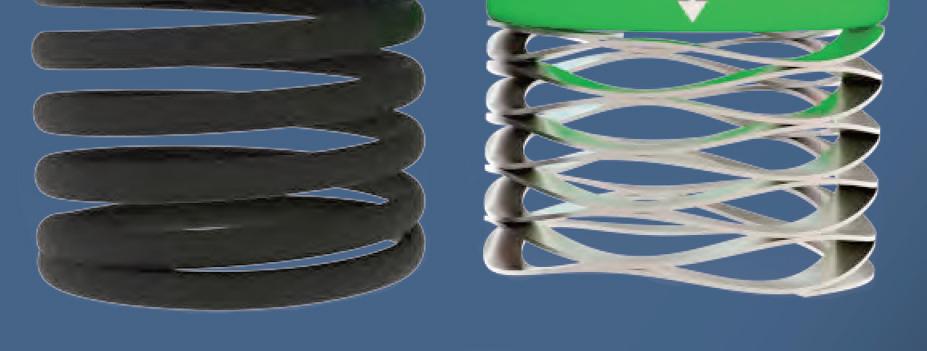

Application Driven Solutions™ Request Samples rotorclip.com Product Focused, Support Driven Reduce Operating Heights By Up To 50% Free Engineering Support: info@rotorclip.com • +1.732.469.7333 Thousands of applications supported Diameters from .100" to 140" Stainless steel & exotic alloys readily available Custom engineered capabilities

Design for Industry

Compact electromagnets meet holding force and duty cycle requirements

Electromagnets are used in various medical testing, monitoring, and point-of-care devices. And like every industry, medical OEMs continuously seek smaller, more e cient components that spare cost and space.

Magnetic Sensor Systems (MSS) recently released the E-05-125 Series of Tubular Low-Profile Electromagnets for various applications. This compact series measures 1.25 in. in diameter and 0.50 in. in length and features 18 di erent windings based on the application duty cycle and holding force requirements. They can supply 12 to 40 lbs. of holding force, and duty cycles can range from 100% (continuously on) to 10%.

The new electromagnets are low-cost and immediately available o -the-shelf in sample quantities. Larger OEM quantities for just-in-time deliveries can be shipped within four weeks.

This series is ideal for use in medical equipment, relays, valves, games, o ce equipment, door controls (hold open, hold close), lifting gantries, material handling, sensors and detectors, magnetic locks and switches, magnetic separation, toys, games, security systems, fuel injectors, research equipment, and fail-safe brakes.

All MSS electromagnets use materials that quickly lose residual magnetism when the current is removed. For easy integration into new and existing applications, the E-05-125 Series have a centered 6-32 UNC-2B threaded hole in the backside.

For applications that need a more compact electromagnet or an electromagnet with greater holding force or duty cycle, customers can contact MSS for help. DW

Sensor Systems

Magnetic

www.magneticsensorsystems.com

22 April 2023 www.designworldonline.com DESIGN WORLD Medical

Connect and discuss this and other engineering design issues with thousands of professionals online

DO

WHAT

YOU THINK?

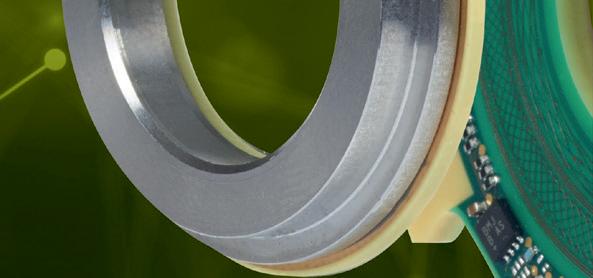

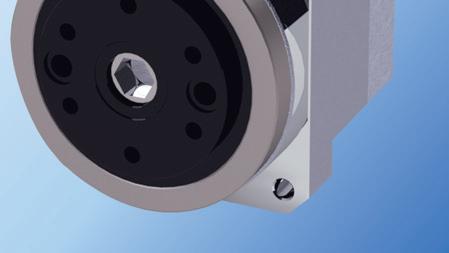

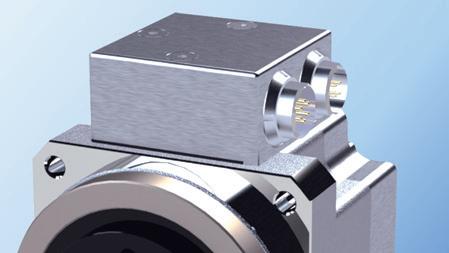

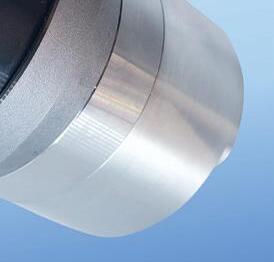

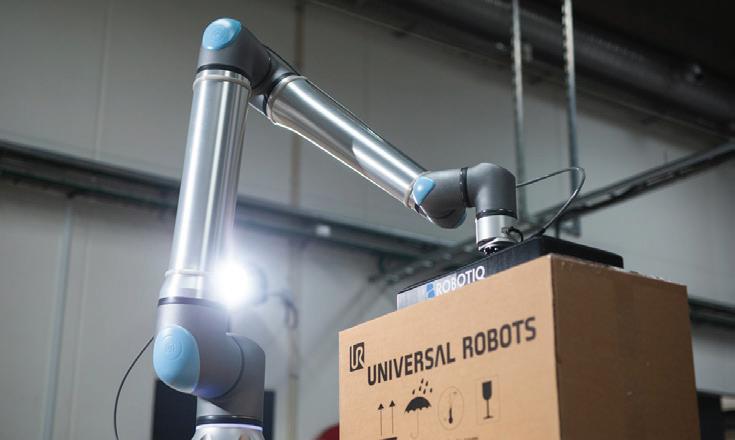

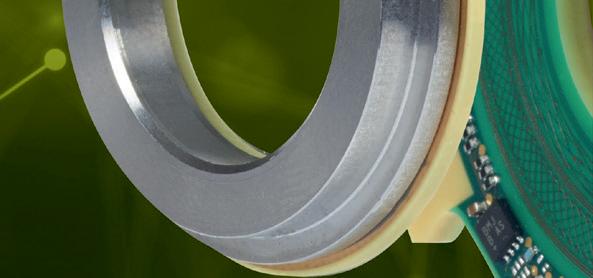

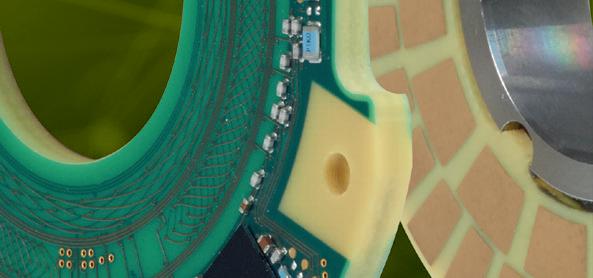

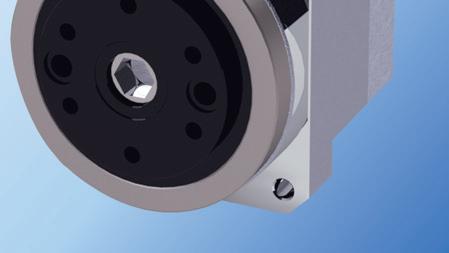

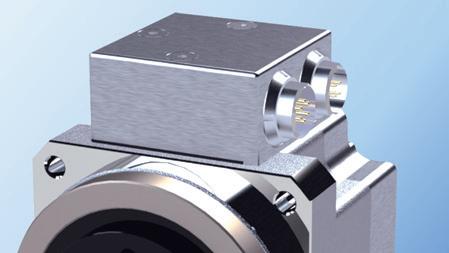

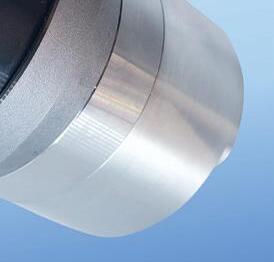

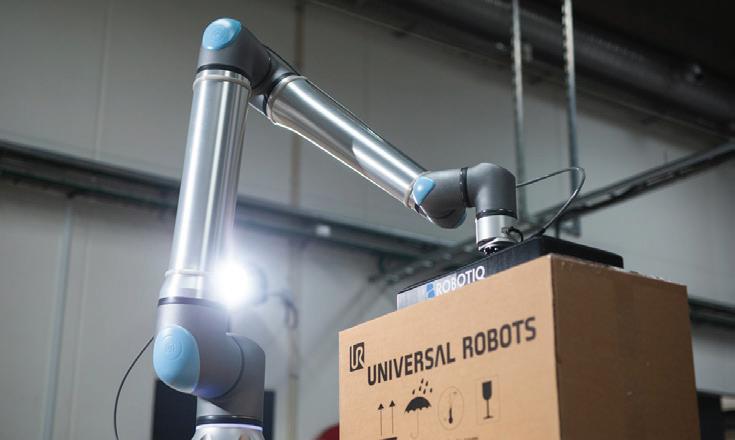

The KCI 120 Dplus dual encoder High-accuracy robot motion Visit us at Robotics Summit Booth #130 www.heidenhain.us/industries/robotics HEIDENHAIN CORPORATION www.heidenhain.us Imagine the benefits of motor feedback and position measurement from a single compact rotary encoder installable on all robot axes. Look no further than the new KCI 120 Dplus dual encoder from HEIDENHAIN. It lets you master the inaccuracies that plague dynamic, highly articulated robots, such as gearbox backlash and forces induced by the application at the end effector. The KCI 120 Dplus turns a conventional articulated robot into a high-accuracy production system and a dependable cobot.

Design for Industry

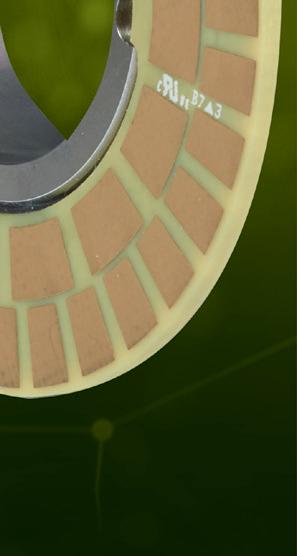

So very clean: new slewing ring bearing for food contact

igus announced a new hygienically designed slewing ring bearing that enables quick, residue-free cleaning during use. The new slewing ring bearing can remain permanently installed in an application with food contact, saving the user the e ort of developing a suitable cover.

Manufacturers of special machinery for clean areas in the food, medical, and pharmaceutical industries are familiar with the problem: the market has hardly any hygienically designed slewing ring bearings for rotating components in applications such as bottle-filling plants. Traditional components o er bacteria plenty of target areas and usually cannot be cleaned thoroughly enough. Hence, additional development work for a hygienic cover is typically necessary, involving more time and money.

“We want to o er a simpler solution, so we developed a hygienic version of our iglide PRT slewing ring bearing,” said Fabian Wieking, product manager of PRT slewing ring bearings at igus. “It is made of stainless steel and FDA-compliant plastics, and its design allows users to clean it without any residue left behind and without removing it from the machine. This eliminates the need for an additional cover.”

Food/beverage 24 April 2023 www.designworldonline.com DESIGN WORLD

When designing the new slewing ring bearing, igus engineers followed the guidelines of the European Hygienic Engineering and Design Group, an association of research institutes, public-health institutions, food processors, and food production equipment suppliers. The primary goal was to give bacteria as few target areas as possible. The new slewing ring bearings are designed with rounded components. There are no 90° corners, weld seams, or edges. All surfaces have a slope of at least three degrees so that water drains o completely. FDA-compliant seals are used wherever metal meets metal. This prevents dead spaces, for example, in screw connections.

“These special design features allow clean-in-place processes,” said Wieking. “No disassembly is necessary for cleaning. Users can simply rinse the bearing with cleaning agents, reliably removing all residue.”

igus manufactures new slewing ring bearings on request as special components.

“We see that the food and packaging industry is developing rapidly and that there is greater demand for special machinery,” said Wieking. “However, in most cases, manufacturers require special components. For that reason, we are o ering them the possibility to have the new hygienically designed slewing ring bearing manufactured according to their individual requirements.”

Users also benefit from the usual advantages of igus products: the stainless-steel rings move on sliding elements made of iglide, a high-performance plastic into which solid lubricants are integrated. They allow low-friction dry operation, protecting the environment. The slewing ring bearings are delivered ready to install, and the self-lubrication e ect keeps them working for years without maintenance. DW igus www.igus.com

DESIGN WORLD April 2023 25 Connect and discuss this and other engineering design issues with thousands of professionals online

WHAT DO YOU THINK?

Design for Industry

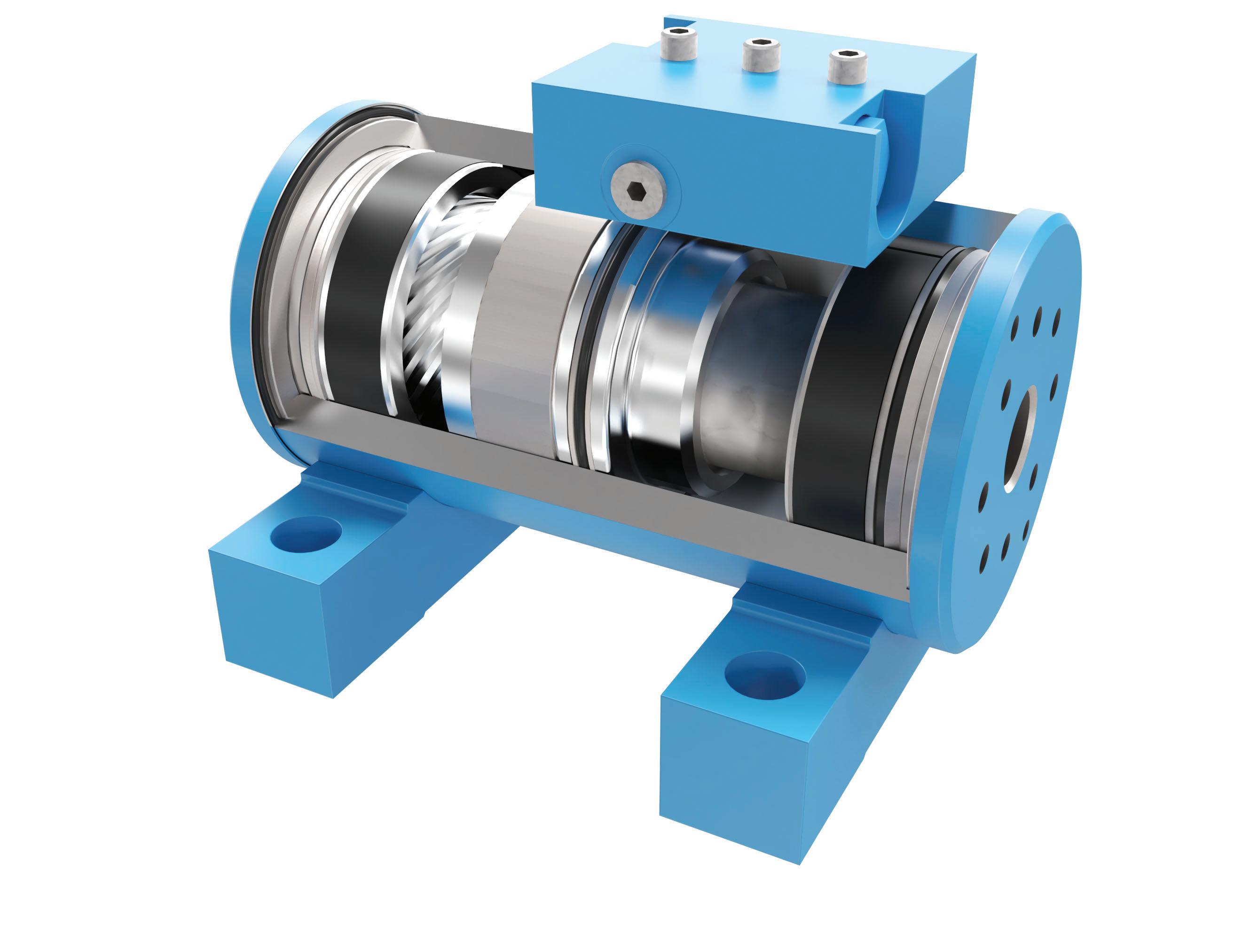

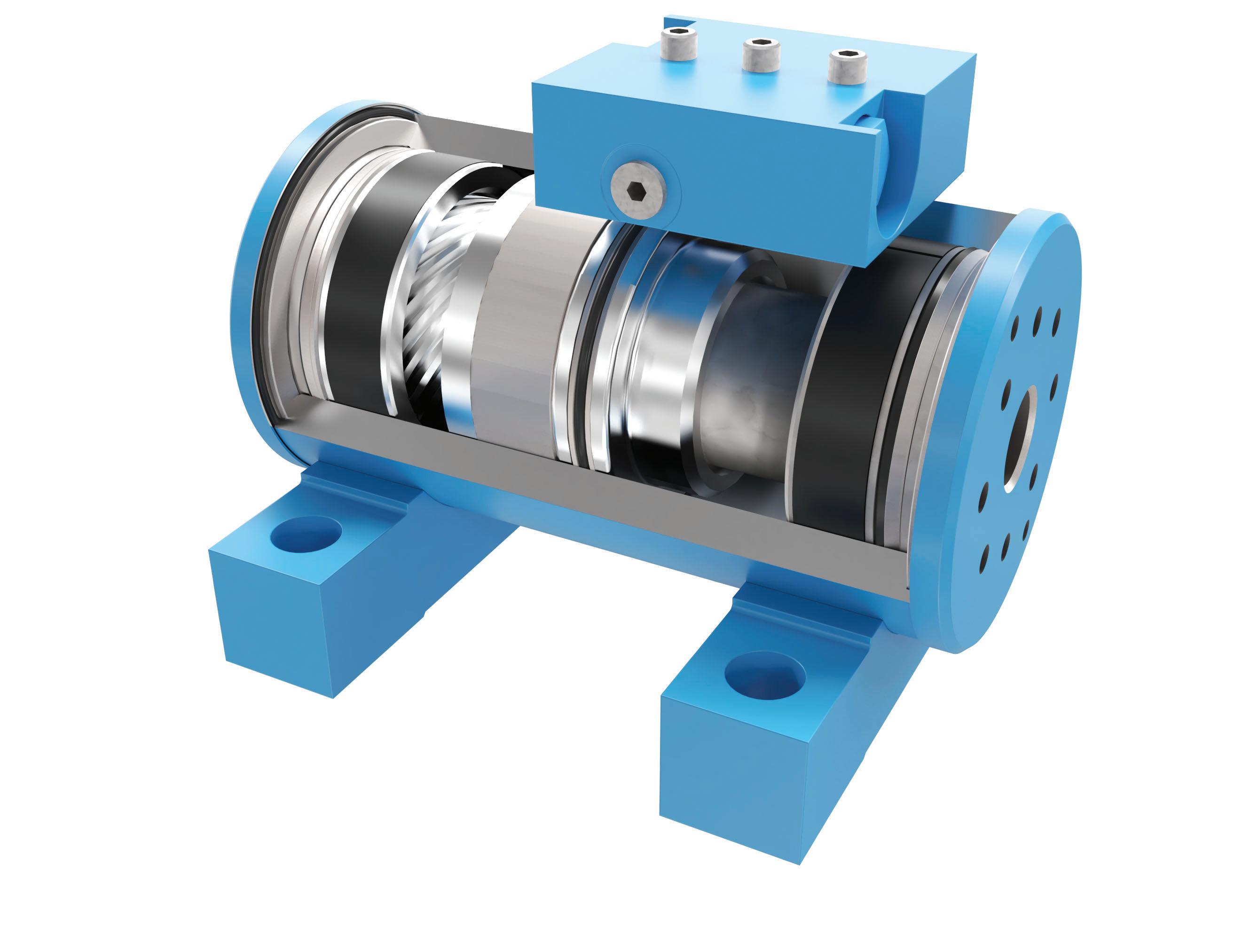

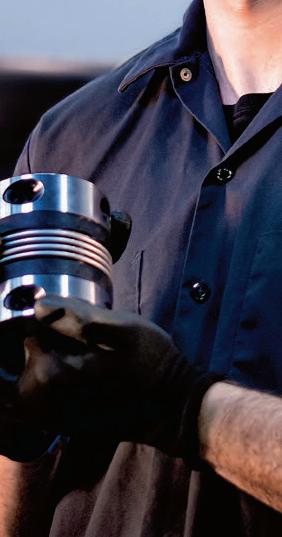

Hydraulic rotators let harvesters revolve eely

Forest machine manufacturer Ponsse is launching the new HH360 rotator, which lets the harvester head freely rotate 360° without limitations. The harvester head speeds up wood processing, makes the operator’s job easier, and reduces hose failures.

The product was developed in close cooperation with hydraulic motor and rotator manufacturer Black Bruin, and Ponsse has exclusive rights to the product for forest machine use.

“The HH360 is a combination of the well-known and durable radial piston technology of Black Bruin’s harvester rotators and Ponsse’s innovation,” said Tero Ylä-Mononen, Black Bruin’s R&D manager. “Thanks to the structure, the torquetransmitting components are wear-proof, and the rotator maintains a firm grip throughout the machine’s service life. The rotator is extremely accurate in use and responds precisely and consistently to the user’s actions.”

Due to the radial piston rotator’s high e ciency, just 20 lpm of oil flow su ces to operate. Operating costs are low, and the rotator is easy to service if needed. This means that service life can be extended far into the future.

The powerful and exceptionally energy-e cient HH360 rotator is available for multiple Ponsse harvester heads when mounted as a loose-head installation.

The most important factor in choosing a rotator product is the application’s load capacity requirements. Black Bruin’s harvester rotator design is made for heavy-duty use and is based on its radial piston motor, giving the same highly e cient power as the motors. Black Bruin harvester rotators are rotary housing, which means the rotator shaft (cylinder block) remains in place while the rotator is running.

The rotation of the motor is achieved by feeding pressurized hydraulic fluid through the rotator distribution head to the distribution valve. The distribution valve directs the flow through the cylinder block to the pistons, which are on a power stroke. The pressure pushes the pistons, and the cams roll outwards against the cam ring on the housing (distribution head). The waveform of the cam ring transforms the force into torque. When the pistons reach the end of the power stroke, the distribution valve closes the flow to the pistons and switches the pistons to a return stroke. The cam ring pushes the pistons back into the cylinder block, preparing them for the next outward power stroke.

Harvester rotators are used for cut-tolength and full-tree wheeled and tracked harvesters, while grapple rotators are for forwarders, timber trucks, and bulk material handling. Unlike harvester rotators, the radial piston grapple rotator housing remains in place, and the shaft (cylinder block) rotates.

A rotator connects to a boom or crane tip with a link and pin kit, and brakes can be installed to dampen the harvester head or grapple swinging. In harvester rotators, links enable the use of up to four brake kits, while links in grapple rotators enable up to two brake kits. Both rotators can also be used without brakes. DW Black Bruin |

Off-highway 26 April 2023 www.designworldonline.com DESIGN WORLD

www.blackbruin.com

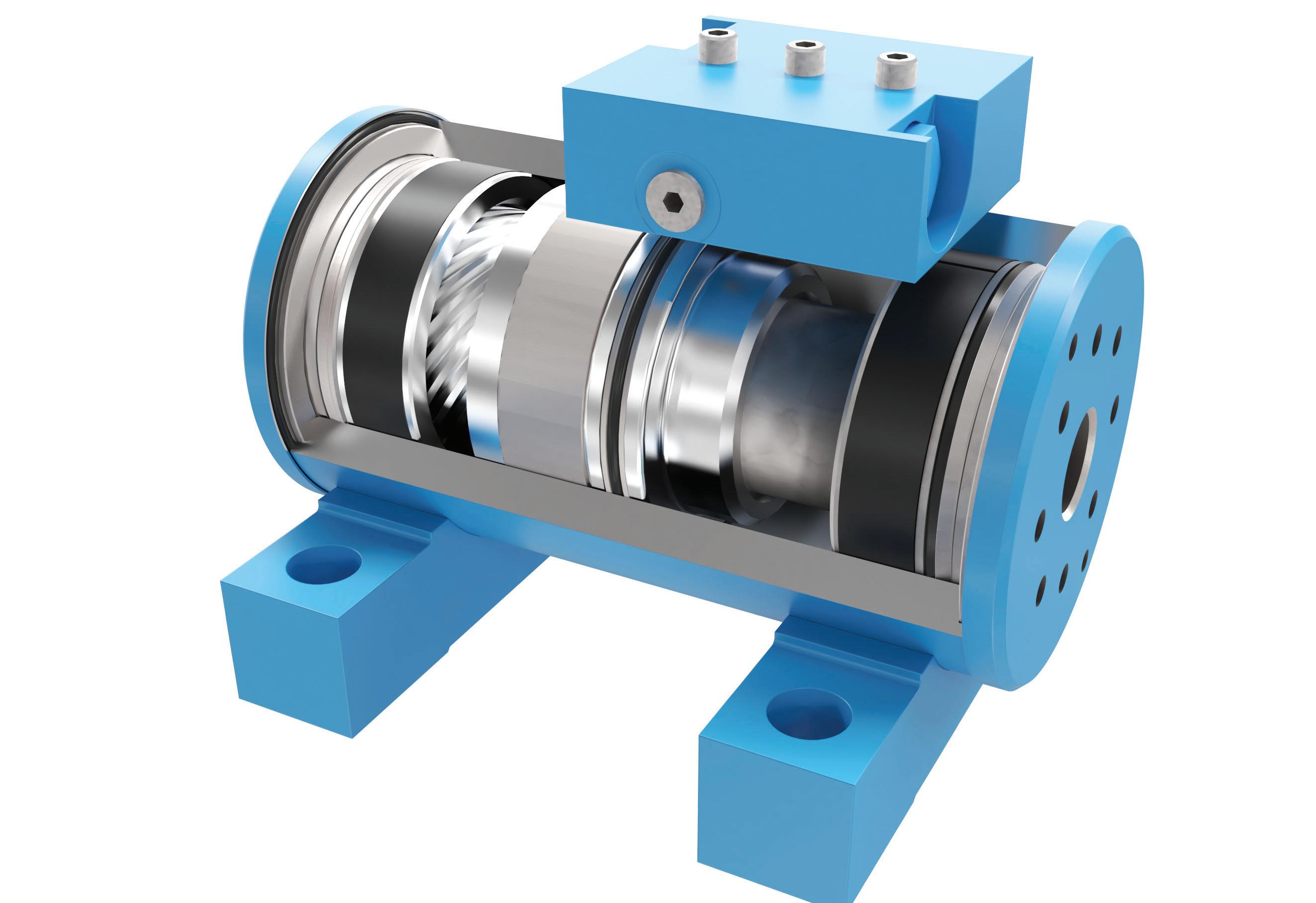

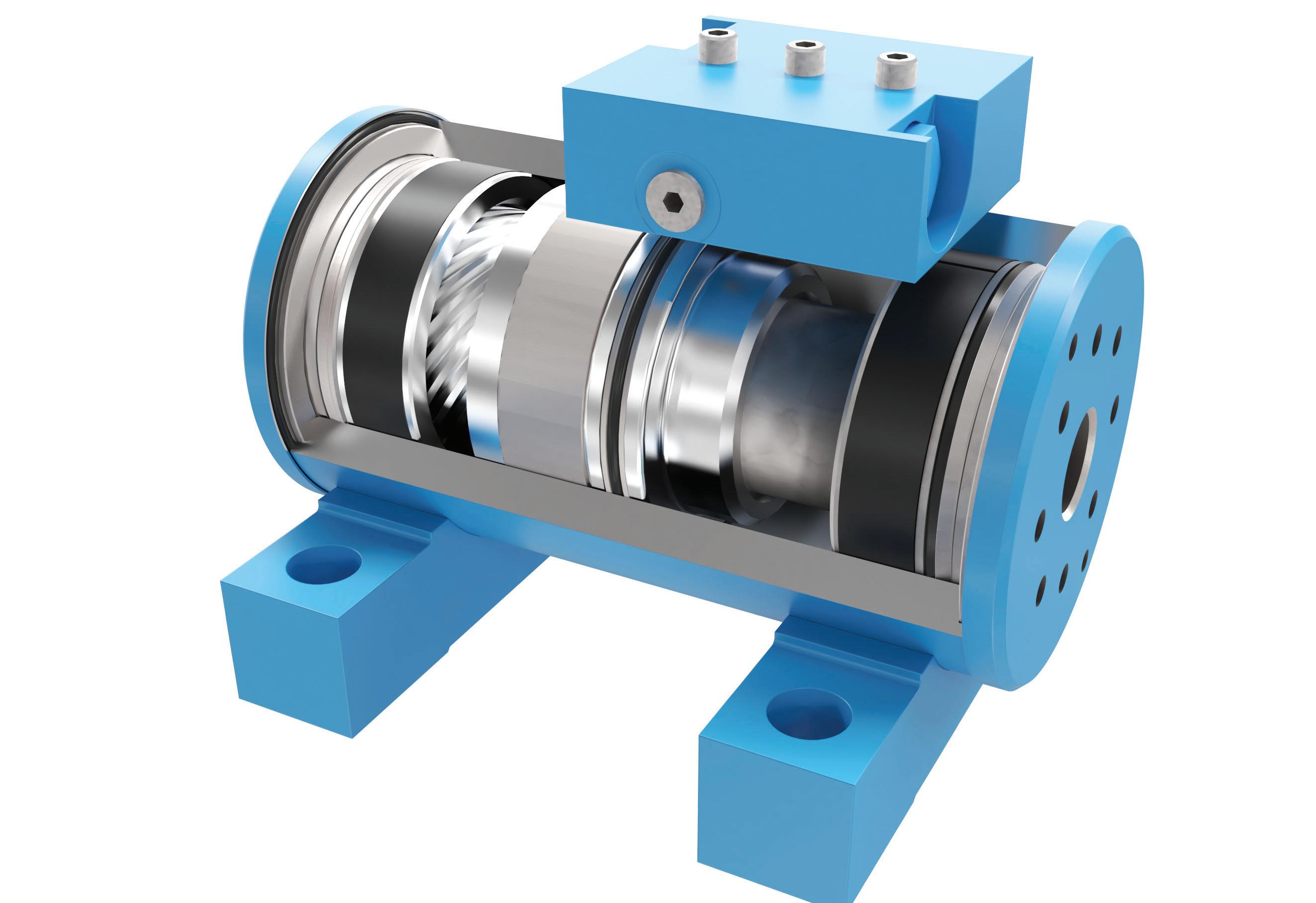

Oilgear drop-in helical rotary actuators for mobile machinery

Oilgear’s helical rotary actuators for mobile machinery are designed to replace multiple components and function as an all-in-one rotating device, mounting structure, and bearing. They o er high power density with high drive and holding torque capabilities in a small, compact space claim. For leak and drift-free operation, load-holding counterbalance valves provide high-holding torque to resist external loads. Exclusion sealing and regular greasing ensure contamination resistance.

Drop-in-ready installation is easy on existing or new applications. The SM82 and SM45 feature up to 180 rotations with drive torque of 8,200 and 4,500 in.-lb., respectively. They feature adaptable grounding to many applications, including:

• Construction

• Agriculture

• Material handling

• Mining

• Marine

• Energy

• Truck/trailer

These new components are produced on a new production line in Fremont, Nebraska, which is pivotal for Oilgear’s future growth.

“It’s already making an impact. Honestly, it did from the first day the leadership team selected Fremont to manufacture the new rotary product lines,” said Alan Circo, general manager of Oilgear’s Fremont location. “Impactful to the people working here, those supporting our e orts, the future of the company, the contribution to the community at large.”

This production line stretches Fremont into more diversified manufacturing, embracing new manufacturing technologies, providing, and securing employment for future generations.

“It’s very exciting to see our company energized through the development of new core product o erings … just like the rich legacy Oilgear was founded on over 100 years ago,” said Circo. DW

Oilgear | www.oilgear.com

WHAT DO YOU THINK?

DESIGN WORLD www.designworldonline.com April 2023 27

Connect and discuss this and other engineering design issues with thousands of professionals online

Off-highway

Design for Industry

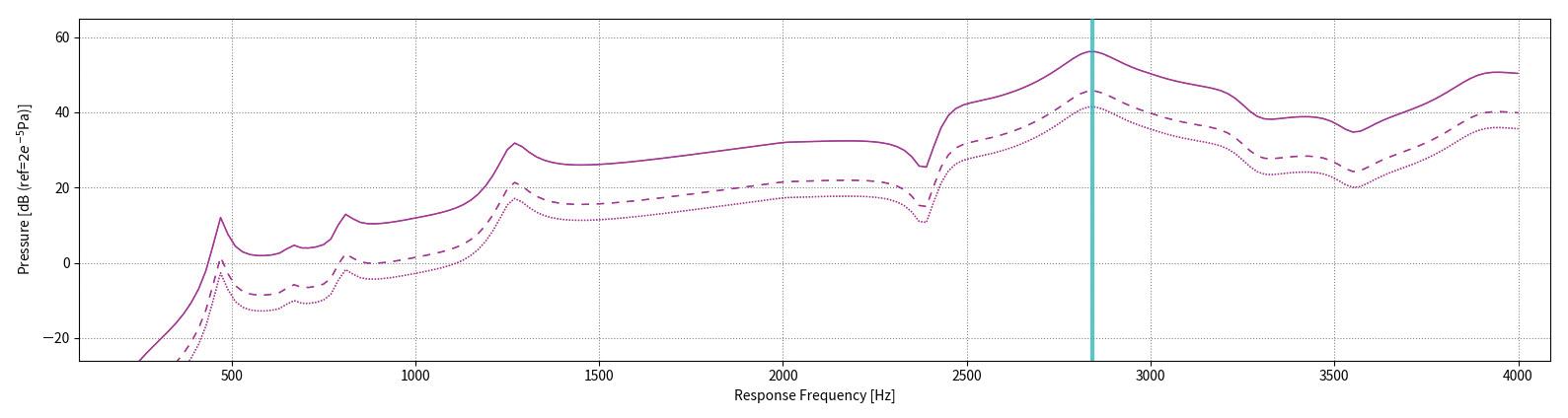

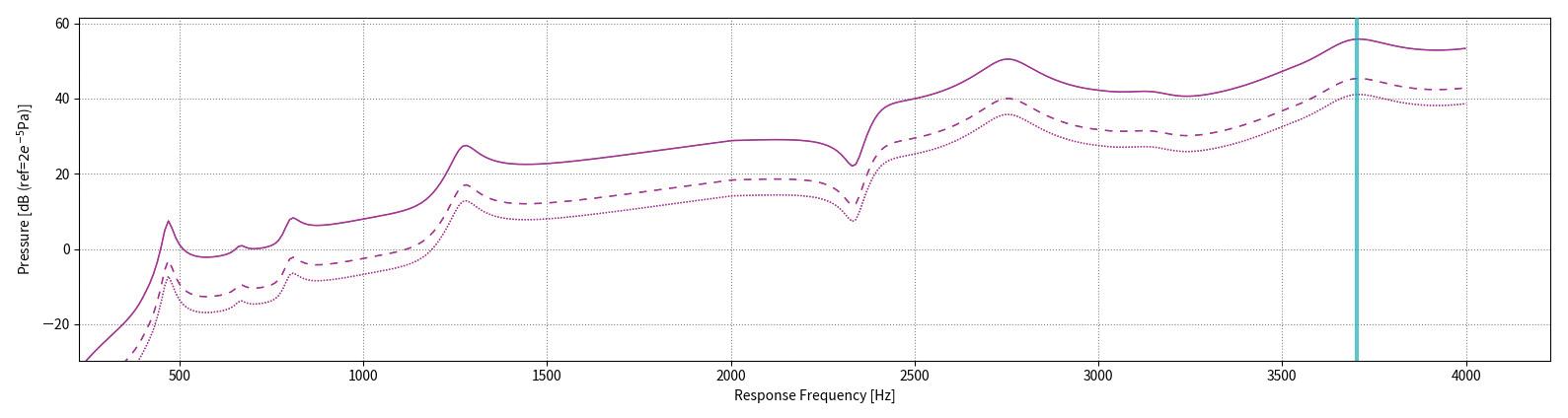

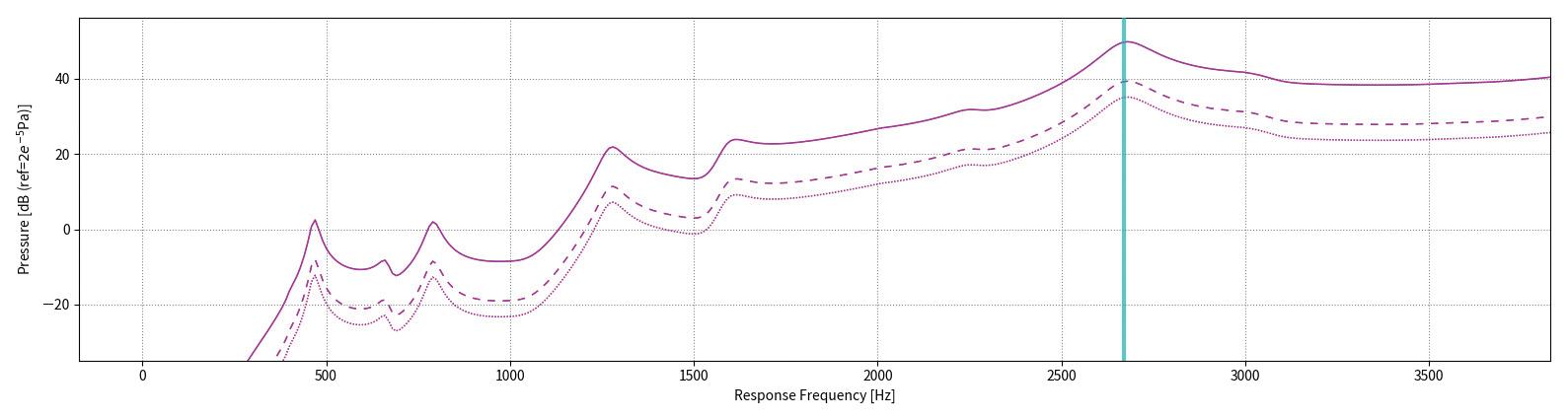

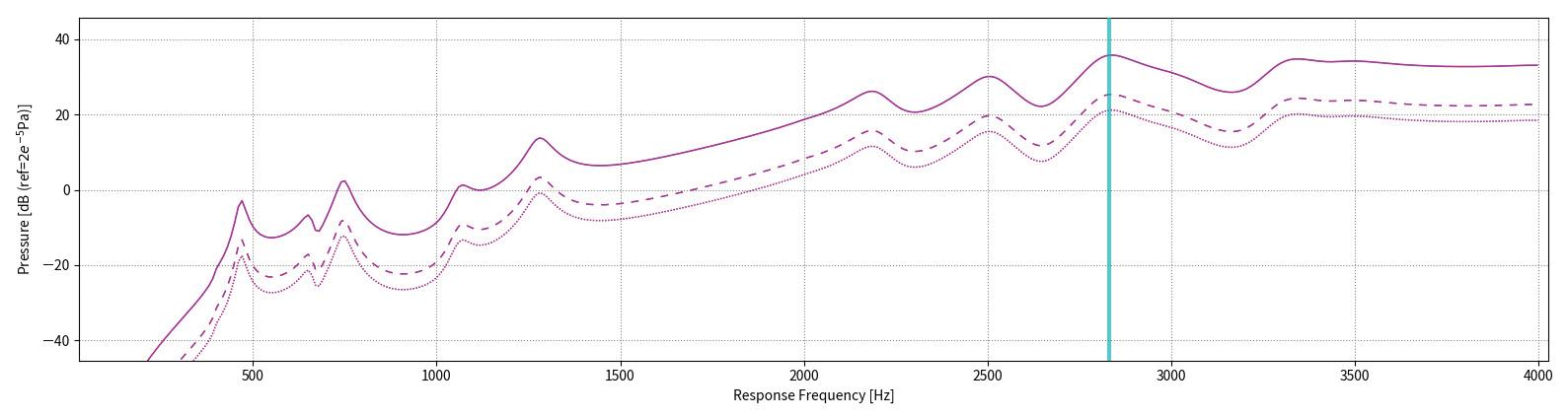

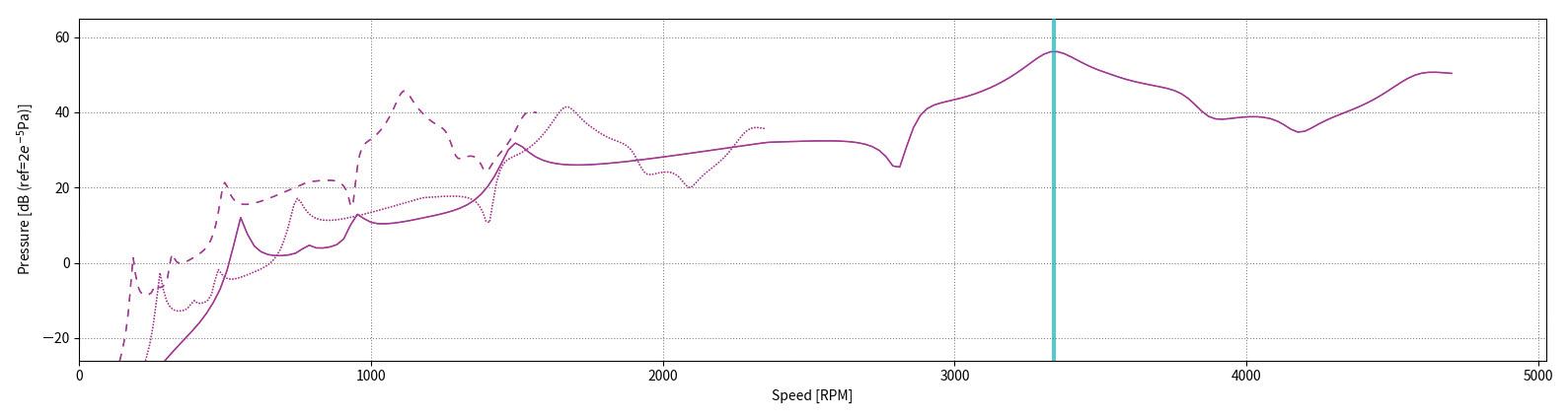

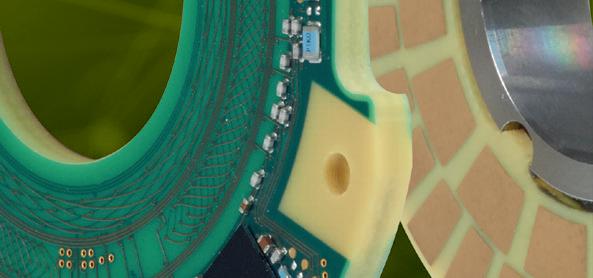

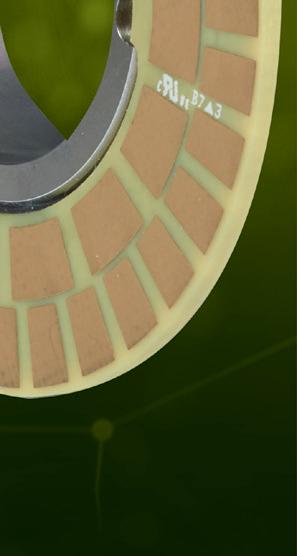

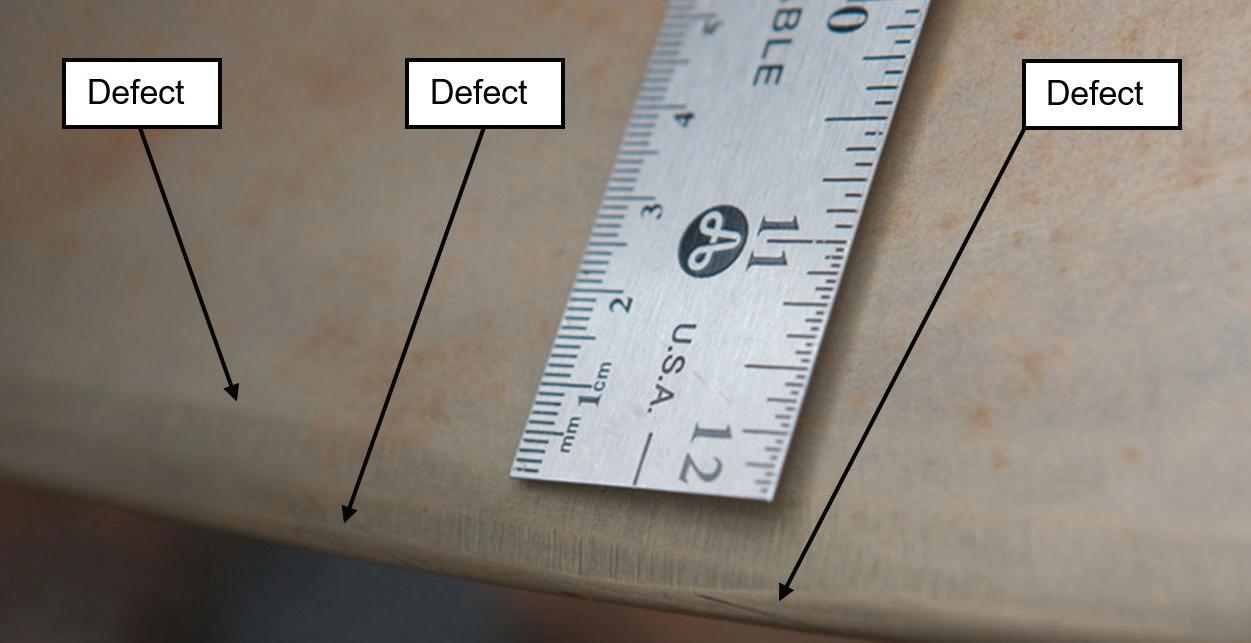

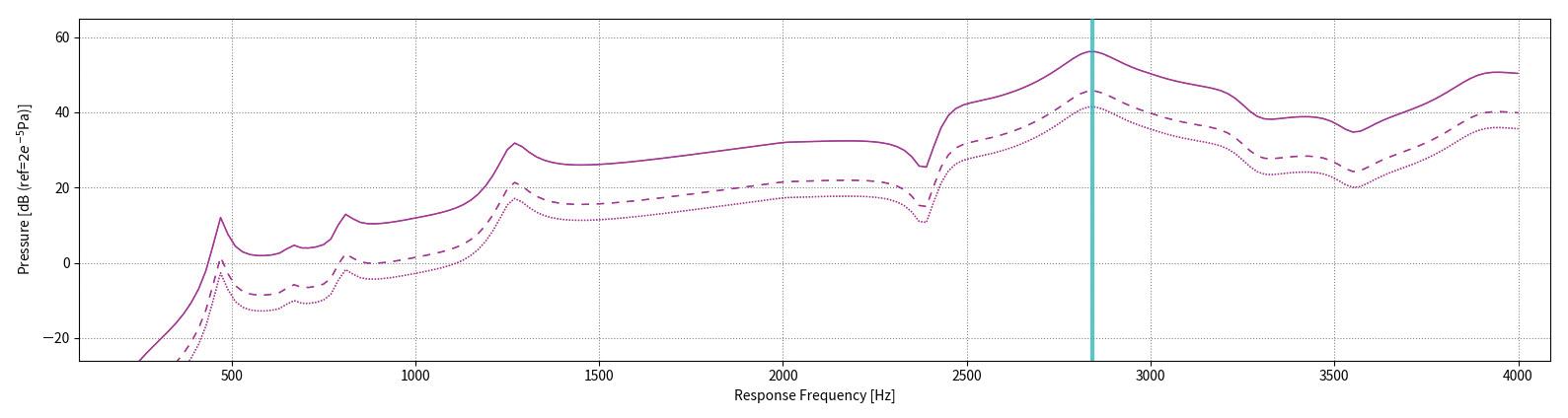

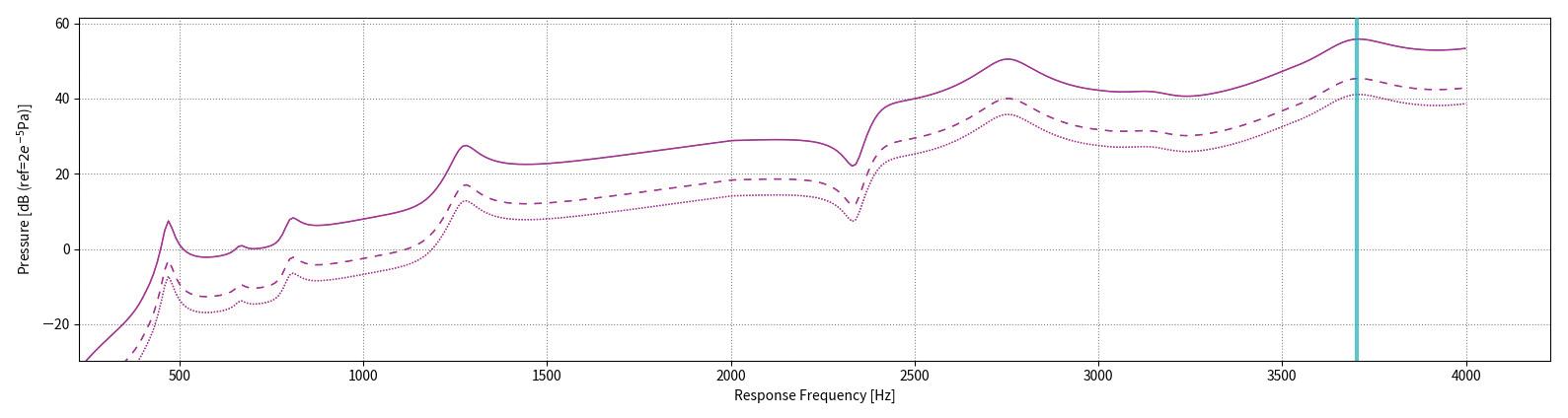

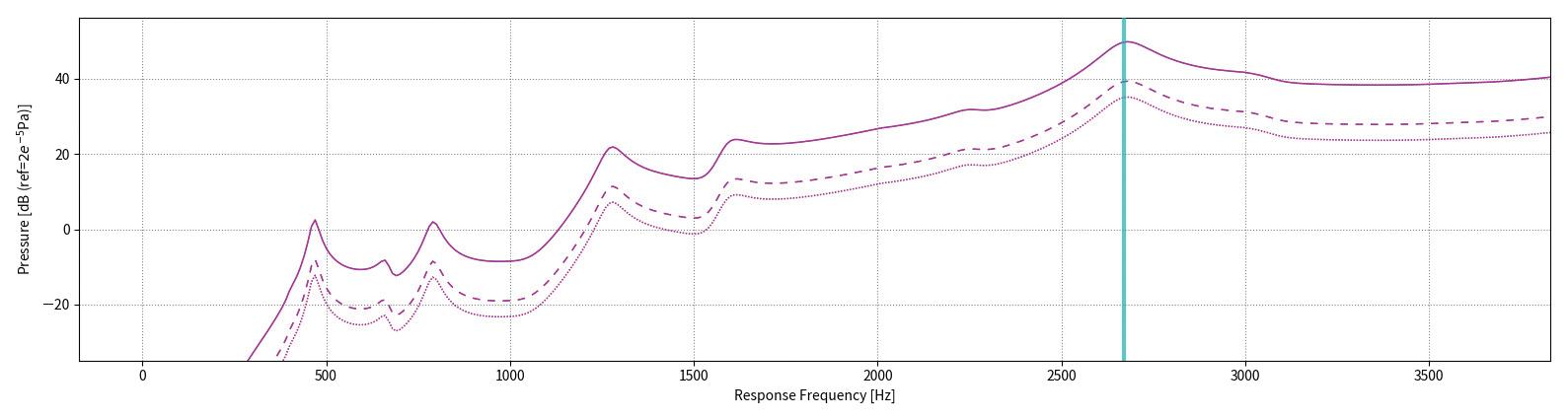

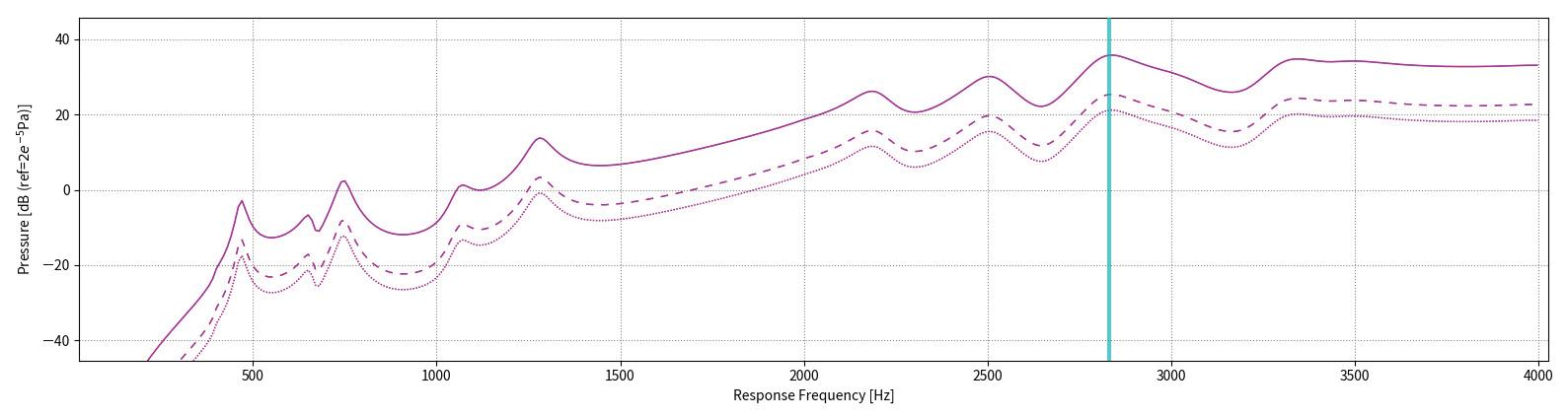

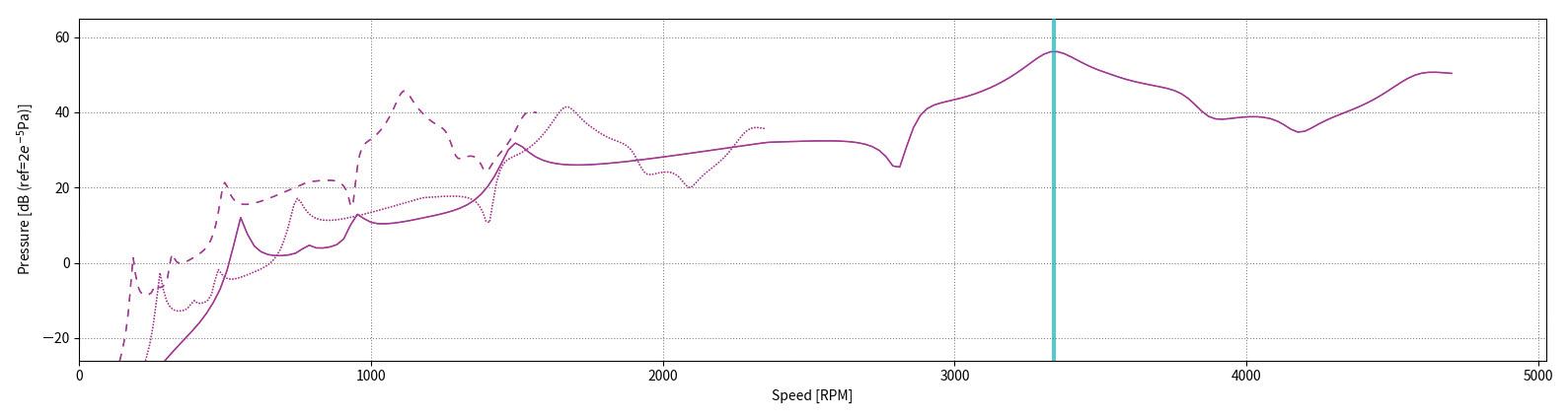

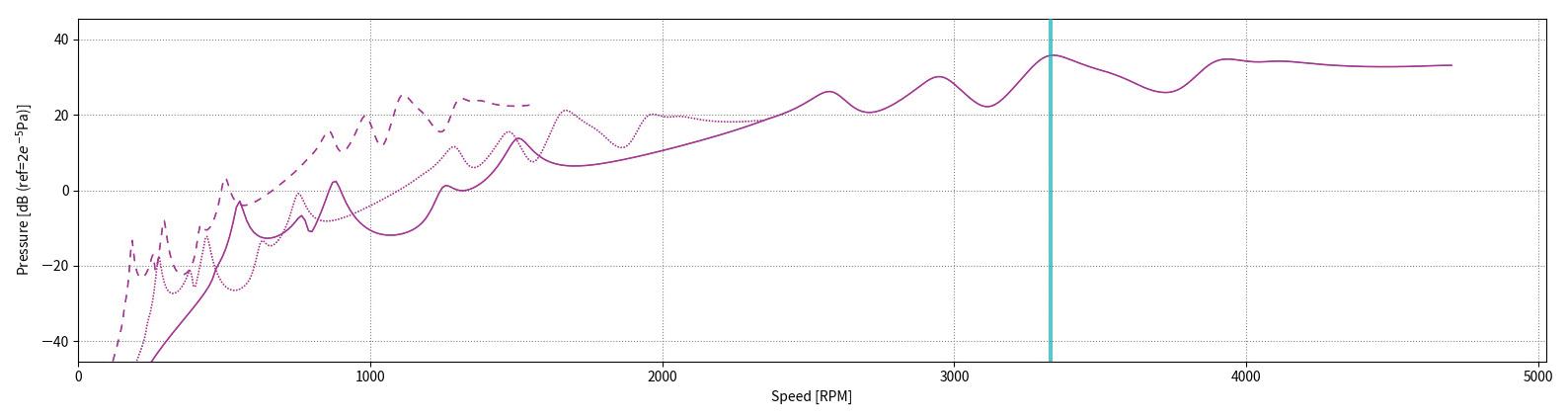

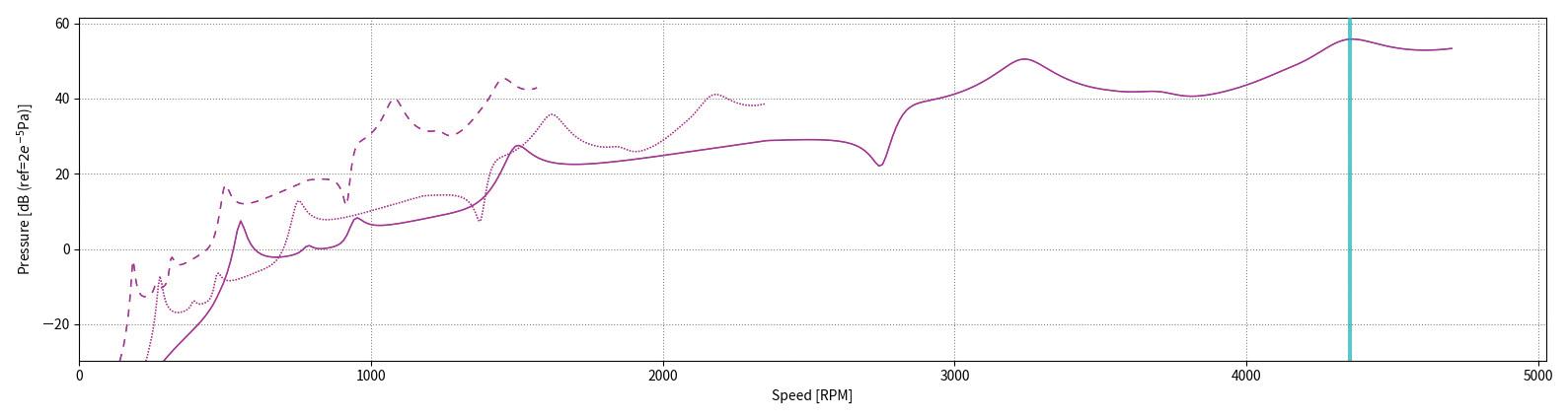

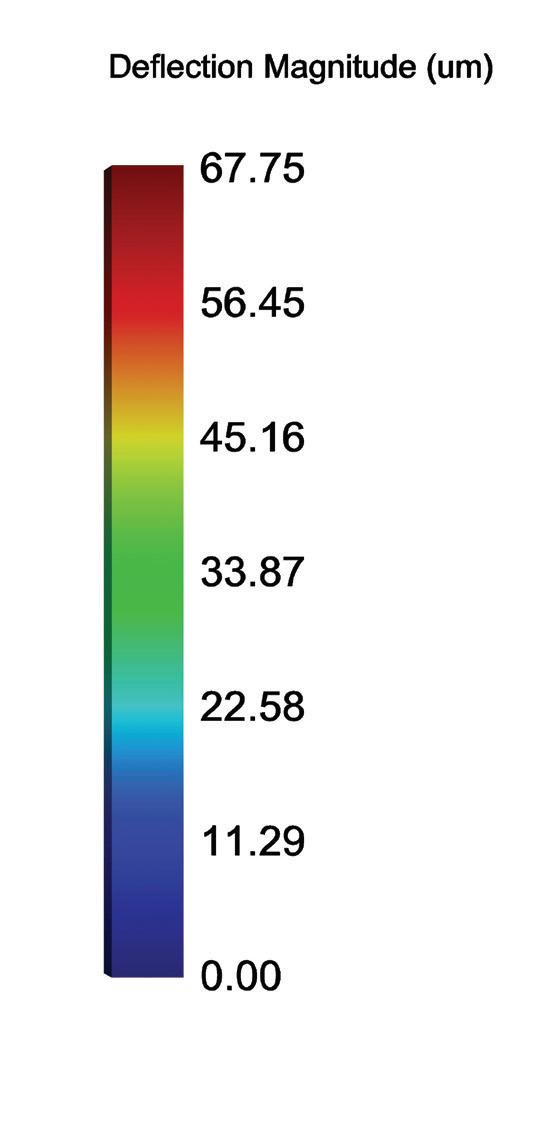

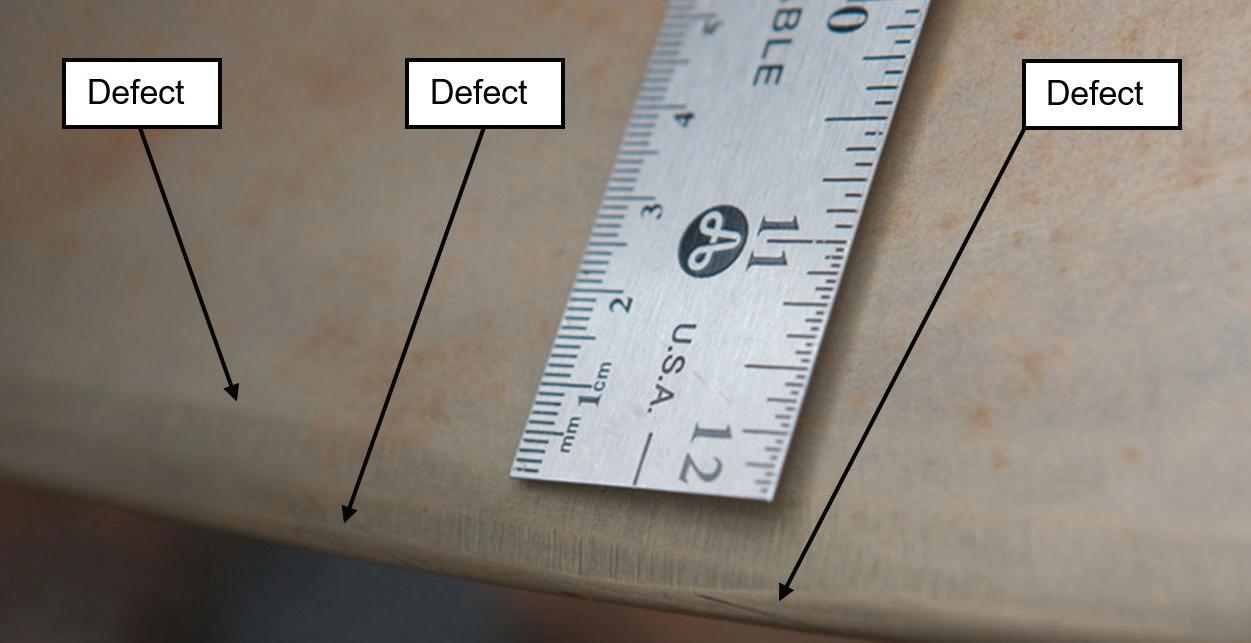

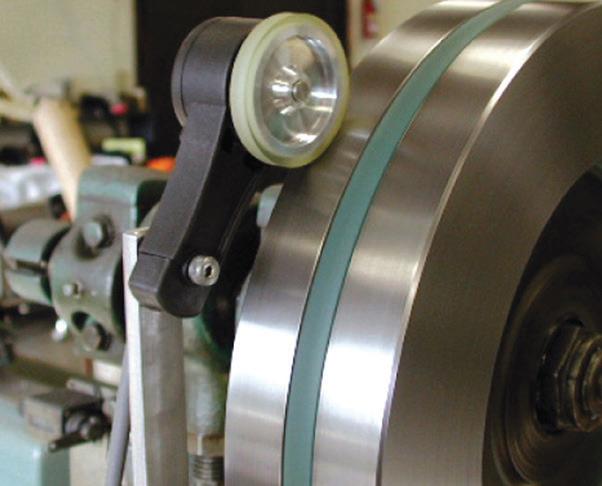

Small propeller defects can make a big noise

The slightest deviation in the machining, polishing, and finishing of ships’ propeller blades could result in underwater radiated noise and cavitation, even if defects are within the maximum tolerance allowed by classification societies and the ISO 484-1 standard.

A Canada Transport-funded study on the impact of manufacturing tolerances on propeller performance (by the Memorial University of Newfoundland, DRDC Atlantic Research Centre, and propeller manufacturer Dominis Engineering) found the slightest change in propeller geometry resulted in “significant” cavitation much earlier than previously thought.

The behavior of a propeller blade section with leading edge defects of 94 µm, 250 µm, and 500 µm was studied using Computational Fluid Dynamics (CFD) at the DRDC Atlantic Research Centre and the Memorial University of Newfoundland in a three-year project that concluded last year.

“Experimental results show that current widely accepted propeller manufacturing tolerances as stated in the ISO standard need to be thoroughly evaluated and investigated further,” said Bodo Gospodnetic, project lead and president of Dominis Engineering.

The current tolerance for a defect to the leading edge of a propeller blade is 500 µm (0.5 mm).

Ship propellers are manufactured according to ISO 484-1, with most propellers made from castings rough machined on CNC (computer numerically controlled) mills and then finished using robotic and manual grinding. However, robotic and manual grinding of propeller surfaces introduces inaccuracies and deviations from the approved design, which can lead to cavitation, erosion, noise, vibration, and loss of propeller e ciency.

“The leading edge is a very challenging area to manufacture accurately, yet it has a strong influence on sheet, streak, and vortex cavitation,” said Gospodnetic.

Researchers found that a ship with a “defective” propeller must travel at a given percentage slower than a vessel with a “correct” propeller to operate below the cavitation inception speed and remain quiet. For example, a ship with a propeller

defect of 0.5 mm would have to sail at 45% of the speed of a defect-free propeller to avoid cavitation noise. The smaller the defect, the less speed reduction is required to remain quiet.

“The 0.5-mm defect tested is one of the tightest ISO 484-1 propeller manufacturing tolerances, yet it has been demonstrated that it a ects cavitation inception significantly and detrimentally. The rules need tightening up,” said Gospodnetic.

ISO 484-1:2015 has been a standard for propellers since 1982, and although the standard was reviewed in 2015 and 2022, the allowable tolerance and geometry remain unchanged.

“We know that 80% of underwater radiated noise comes from the propeller, but if ships are legislated to be quiet in sensitive habitats such as the Juan de Fuca Strait, then they will have to limit their speed to below the cavitation inception speed,” said Gospodnetic.

While initial CFD studies show how very small defects can influence cavitation inception, research partners seek funding to continue their investigation in second-phase model tests in a cavitation tunnel. DW

28 April 2023 www.designworldonline.com DESIGN WORLD Offshore

Dominis Engineering www.dominis.ca

Custom Synchronous Drives Precise. Reliable. Trusted. American Engineering | American Made © 2017 Custom Machine & Tool Co., Inc. Manufacturer of Power Transmission and Motion Control Components You’ve created a unique design. Now relax. We’ll take it from here. Custom precision manufacturing.

Start creating sustainable product designs

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

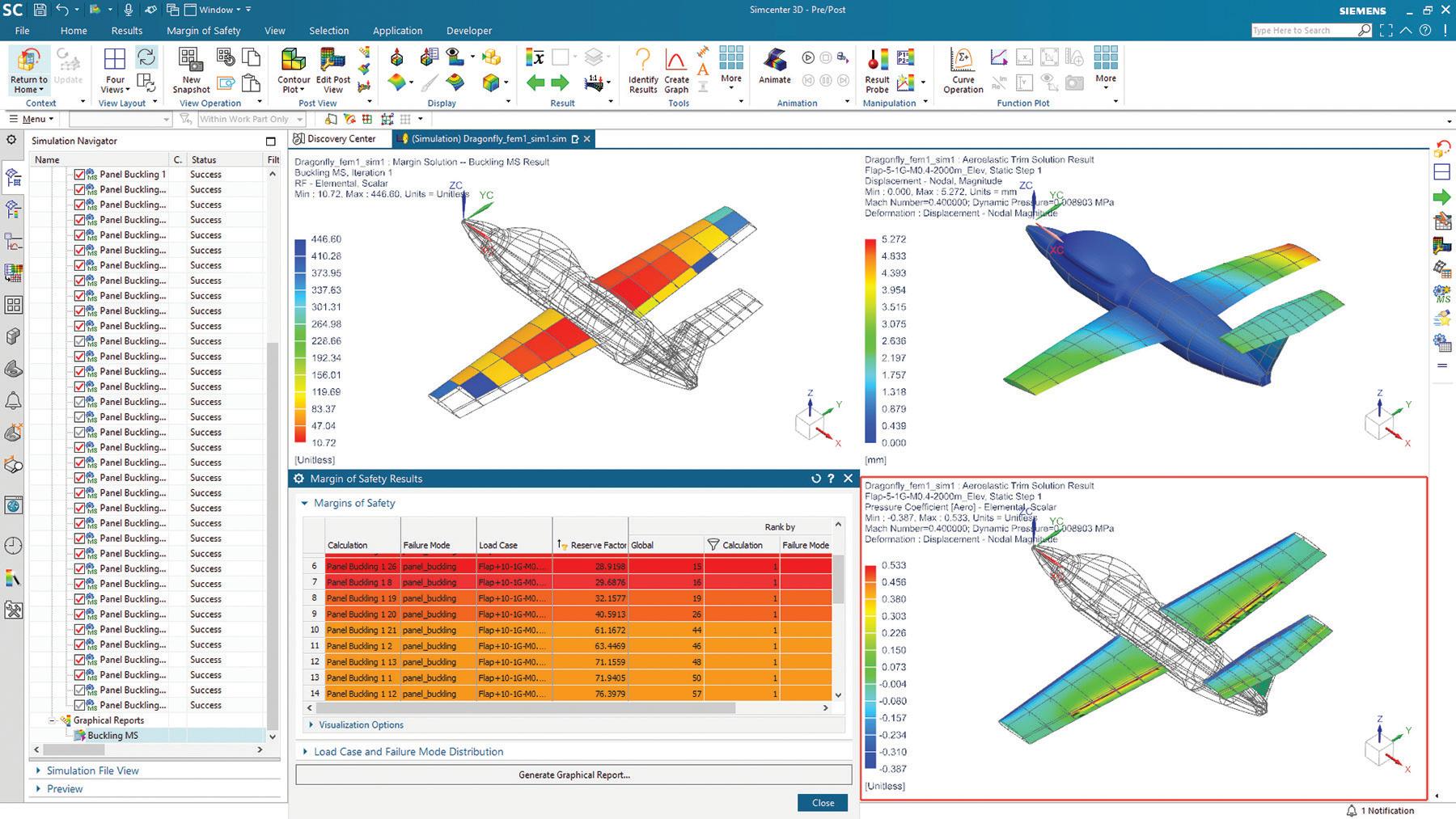

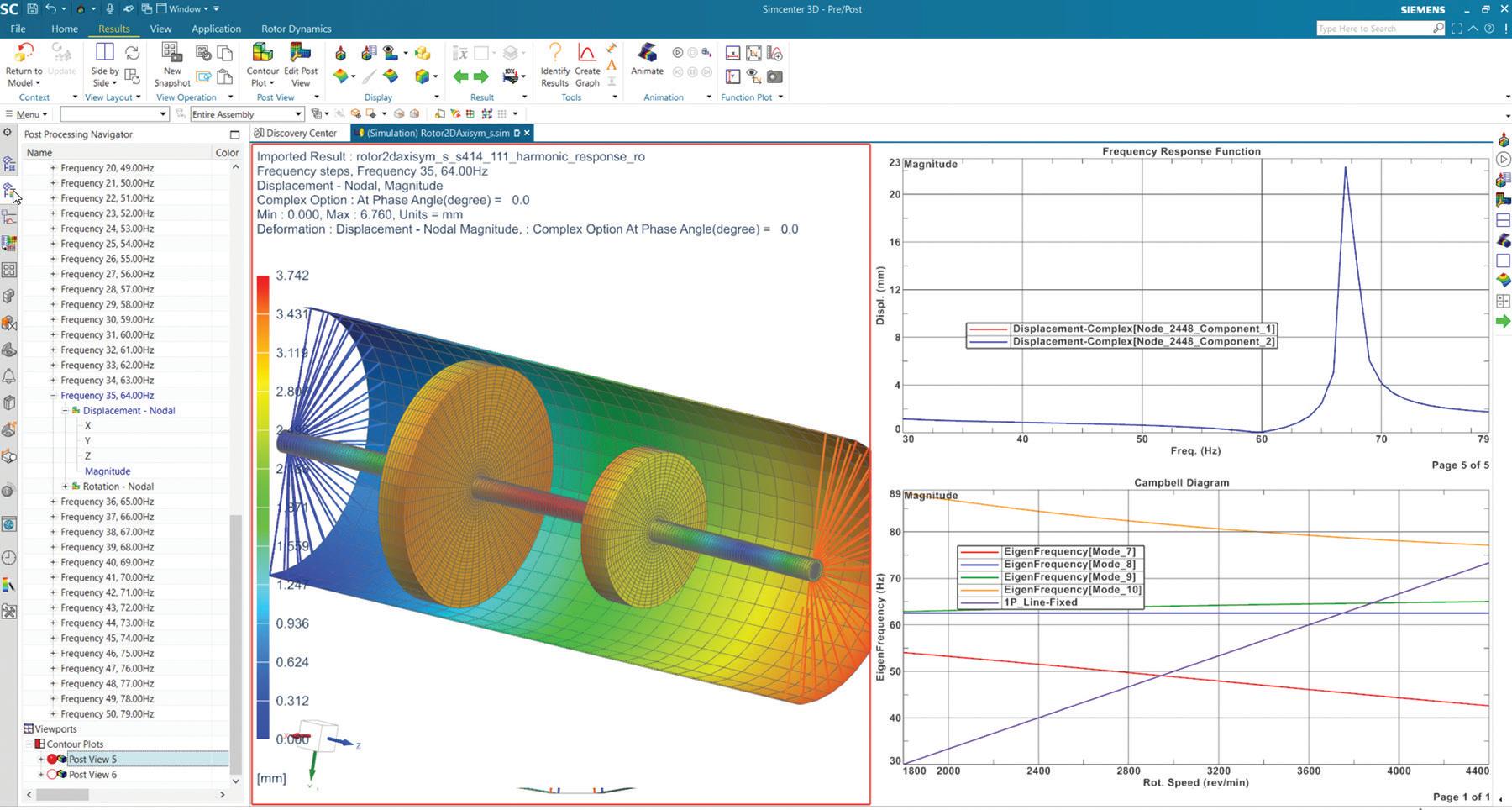

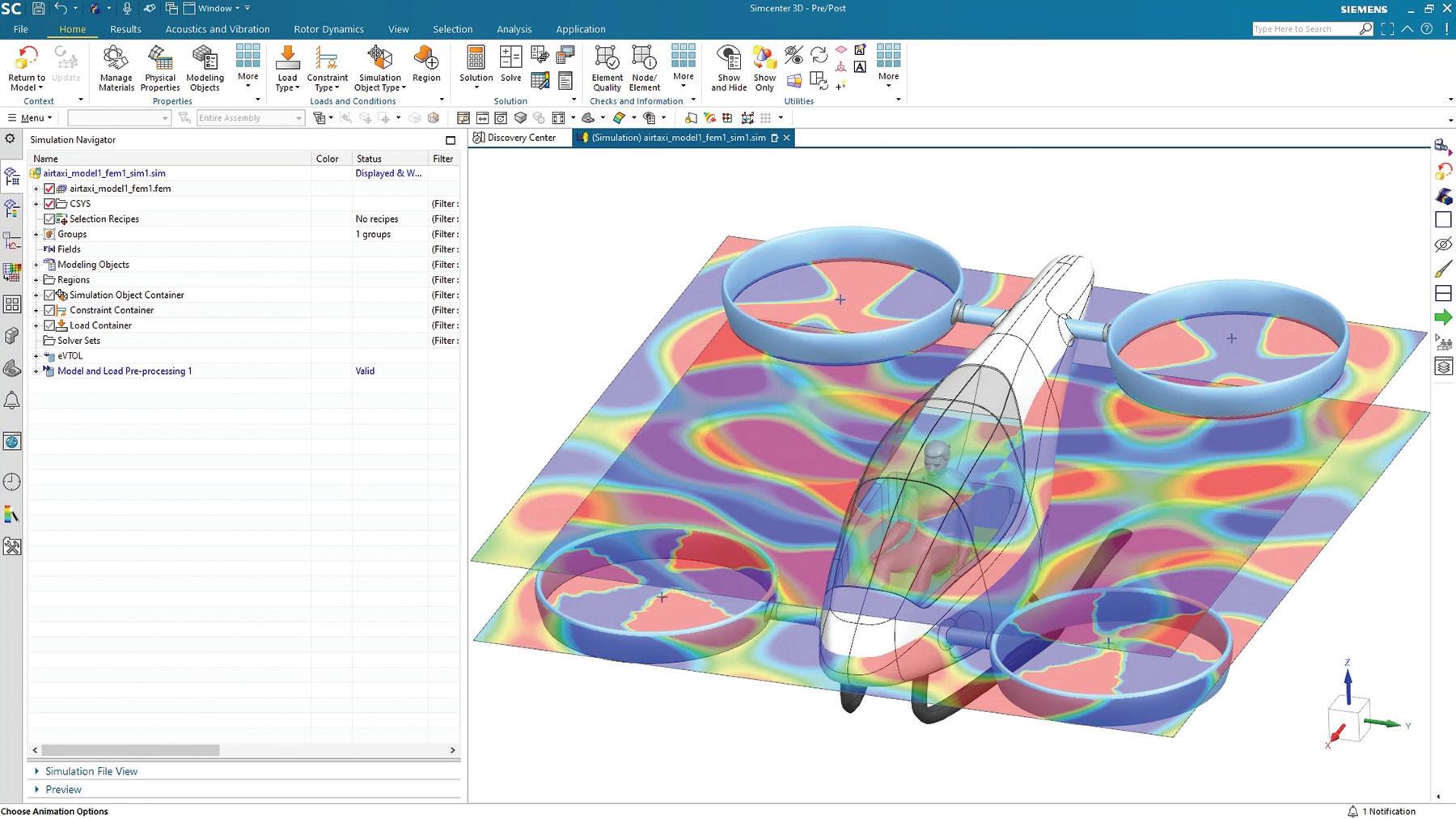

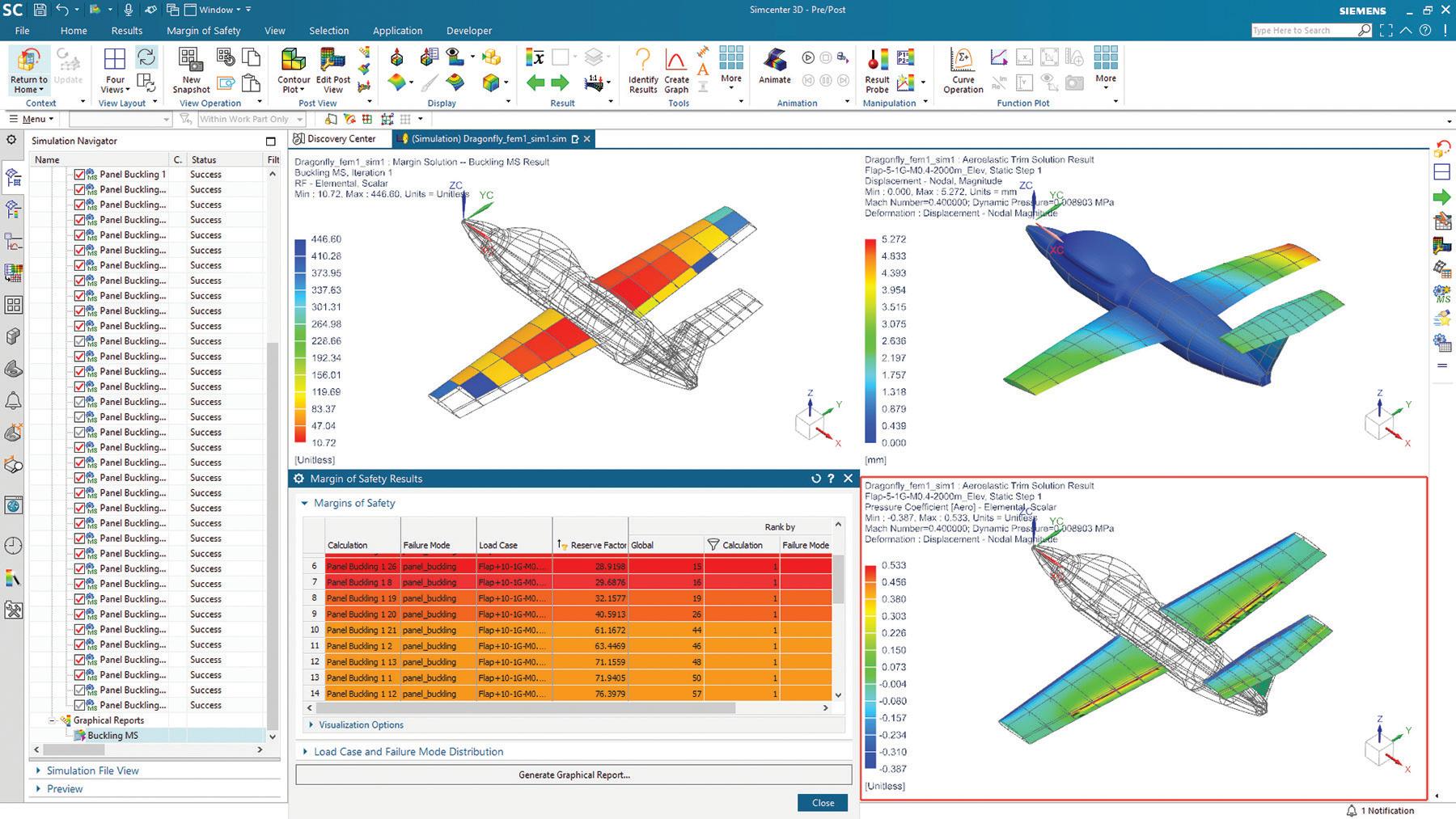

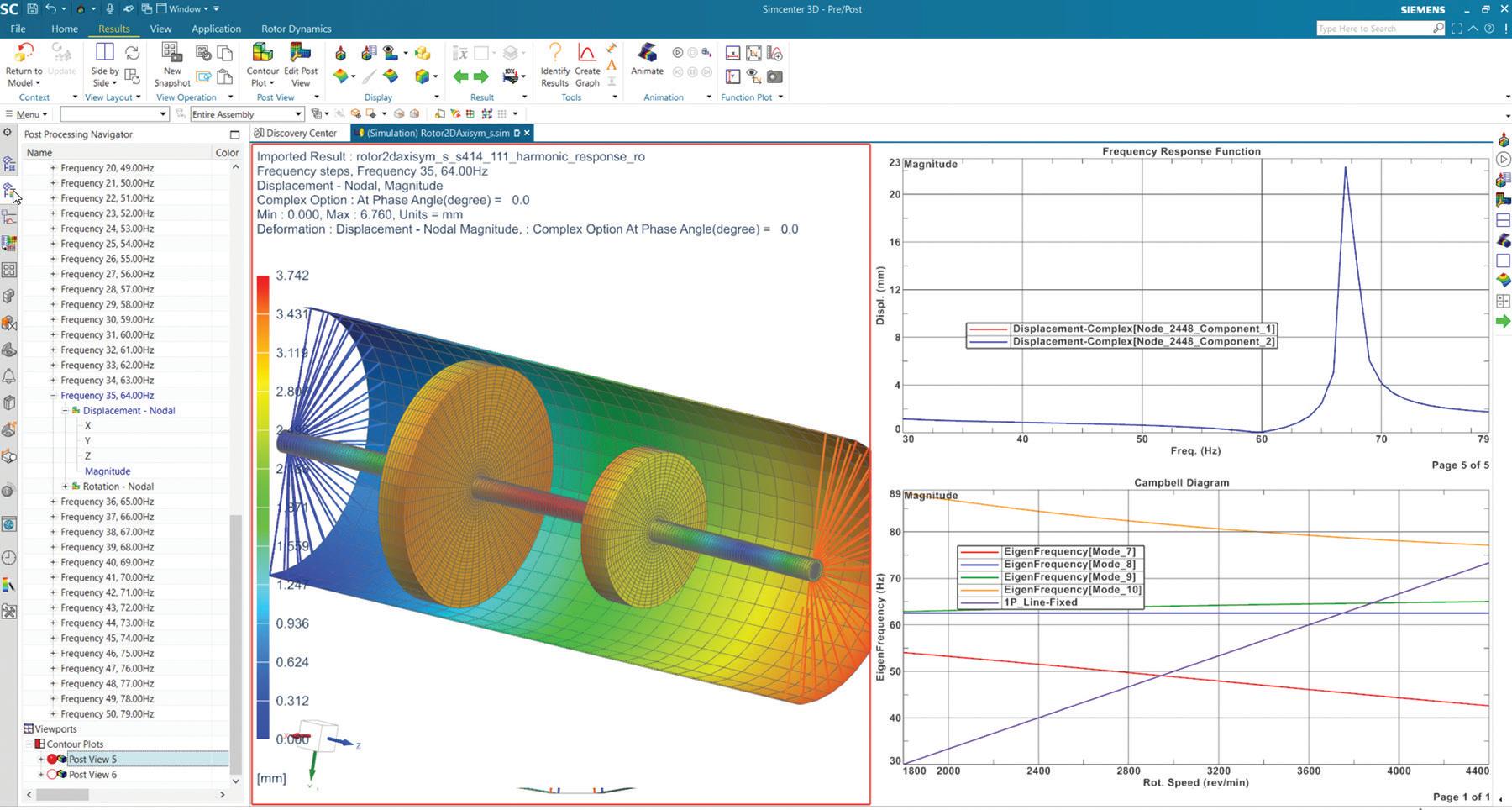

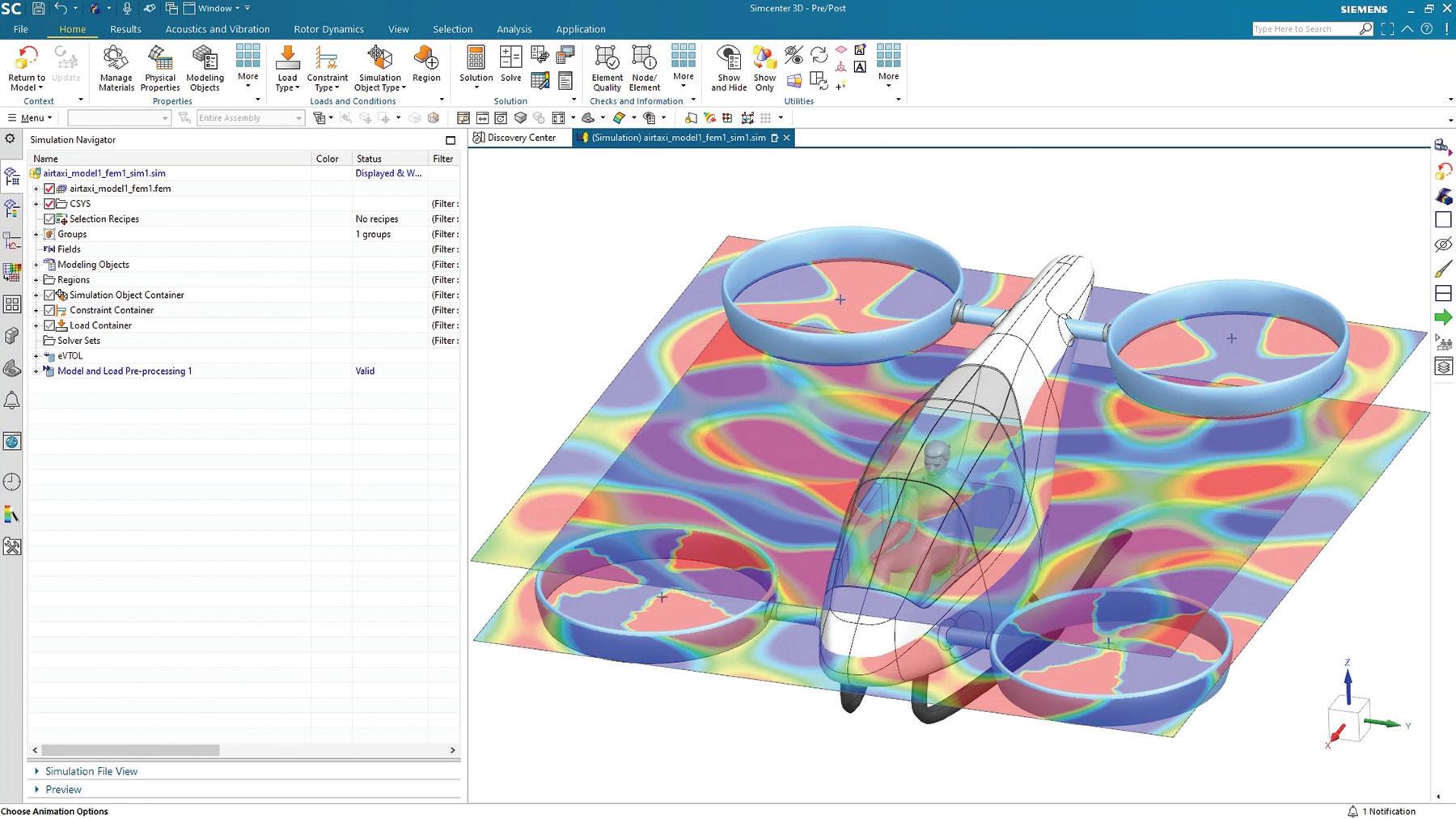

Design has always been a balance of performance, cost, and quality. But these metrics do not take the full, lifetime environmental impact of a product into account. Sustainability must be added to ensure that every impact of a product is addressed in even the most complex systems. The only e ective solution starts at the beginning, as nearly 80% of a product’s lifetime environmental impact is determined during the design phase — what materials are used, how it’s manufactured, energy e ciency, and what comes of it after its usefulness ends. The solution to these problems is to deploy sustainability as an additional business metric and use digitalization to get there faster than the competition.

Designing sustainable products requires an understanding of environmental impacts early, including insight into the product’s material and energy use, the manufacturing process’ environmental impacts, and its expected resource consumption. The designer must account for suppliers, distributors, and logistics providers while balancing sustainability, profitability, performance, and quality goals. Data and digitalization are key in a holistic approach to design, leveraging the Collective Intelligence of the Digital Enterprise. Achieving this requires reimagining product design to be built on a system of systems approach, connected industrial ecosystems, and holistic sustainability indicators.

30 April 2023 www.designworldonline.com DESIGN WORLD

Start with systems of systems design

A system can be as specific as a feature of the integrated circuit in an electronic device or as extensive as the environment that product will occupy. Most modern products cannot be described as a single system because of the many engineering disciplines required for development. Instead, these products are considered a system of systems. Coordinating diverse disciplines when working on a project requires simulation early and often to optimize individual systems and then balance how they interact.

This robust simulation is enabled by the comprehensive digital twin of the product, first and foremost.

There is also value in simulating production to gain insight into how the product is produced, logistics costs, usable lifetime, and how it fits into circular economies. Early exploration provides a more intelligently defined design space and binds it to what is viable, profitable, and sustainable for the business. Requirements and assessments must be seamlessly woven in from the beginning to make informed decisions. One material may be selected over another due to a superior strength to weight ratio for product performance. A material may be avoided due to the estimated CO2 emission cost of extraction over the recyclability of yet another material, and components might be designed for a specific manufacturing process like 3D printing to minimize waste.

Making the right sustainability decisions during the design phase requires access to the most accurate and broad collection of data to create a truly comprehensive digital twin, that includes the extended network of suppliers, logistics operations, and energy infrastructure. Such an approach delivers the collective intelligence needed to make better decisions, and as your digital twin is informed with data collected from simulation, manufacturing, and the value chain, it becomes an increasingly accurate representation.

The communications ecosystem must cover the entire value chain and be

Supplier decisions can have dramatic impacts on the sustainability of a product. One supplier might be able to employ renewable electricity because of their proximity to wind, solar, or other sustainable energy sources.

established early — coordinating actions and data exchange with the suppliers, distributors, and other partners. This gives designers direct access to sourcing information on materials and contracted sub-systems. Simultaneously, a robust product lifecycle management system built on digitalization, weaves all engineering work together to create today’s complex products while still considering the available resources of the enterprise. Integrating these siloed processes helps bring a better and more sustainable product to market faster.

A well-connected industrial design ecosystem also provides feedback loops between design and the value chain. The mechanical designers may have requested and designed a product around one aluminum alloy in initial design iterations, but the supplier discovers a slightly di erent alloy with comparable properties but better print viability within the existing infrastructure. Whether the business decision is to change the alloy or contract a di erent manufacturing supplier that can reliably print in the initial alloy, this new data point is added to the collective intelligence for future iterations.

Supplier decisions can have dramatic impacts on the sustainability of a product. One supplier could employ renewable electricity because of their proximity to wind, solar, or

DESIGN WORLD www.designworldonline.com April 2023 31

Design Notes

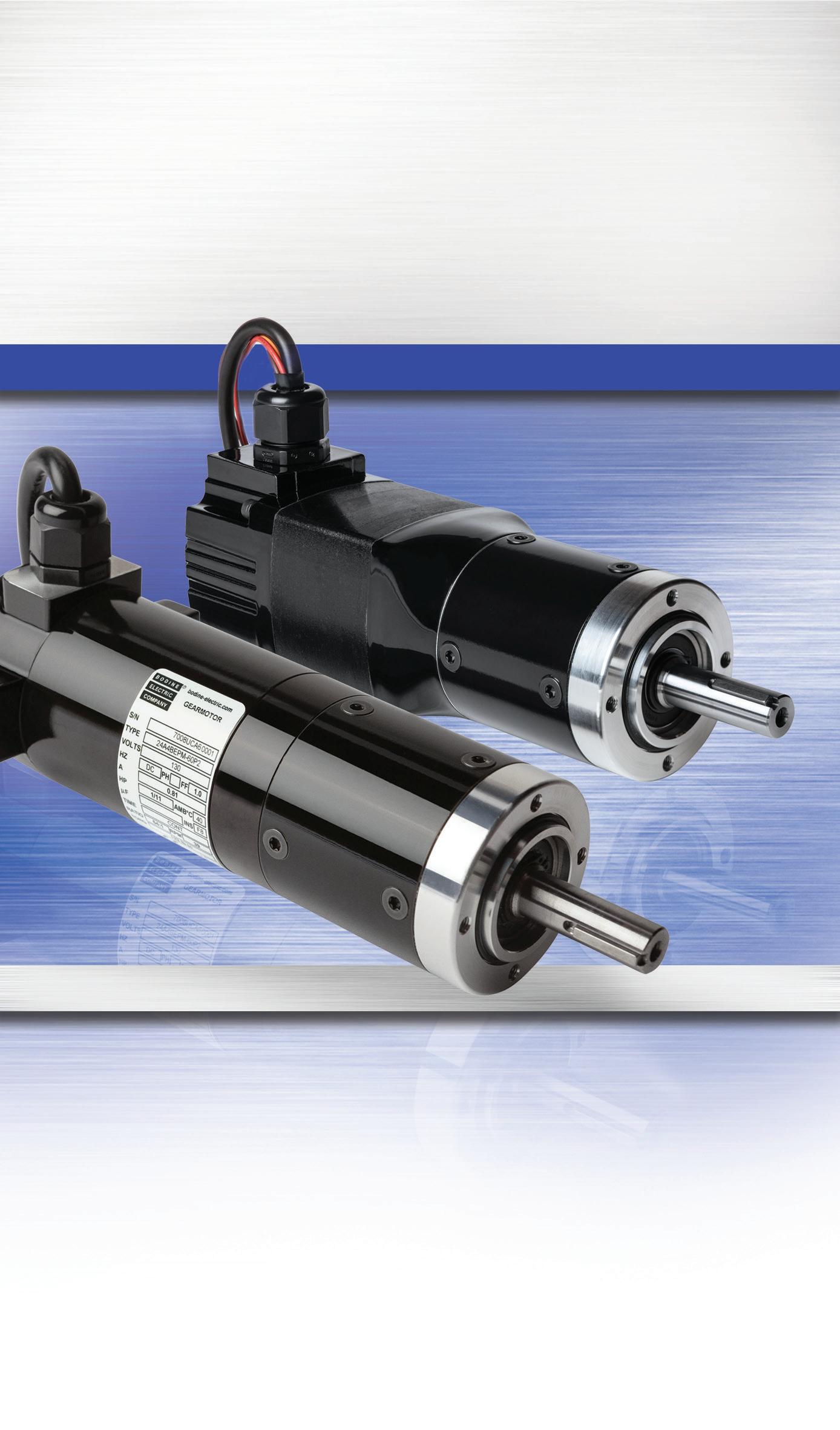

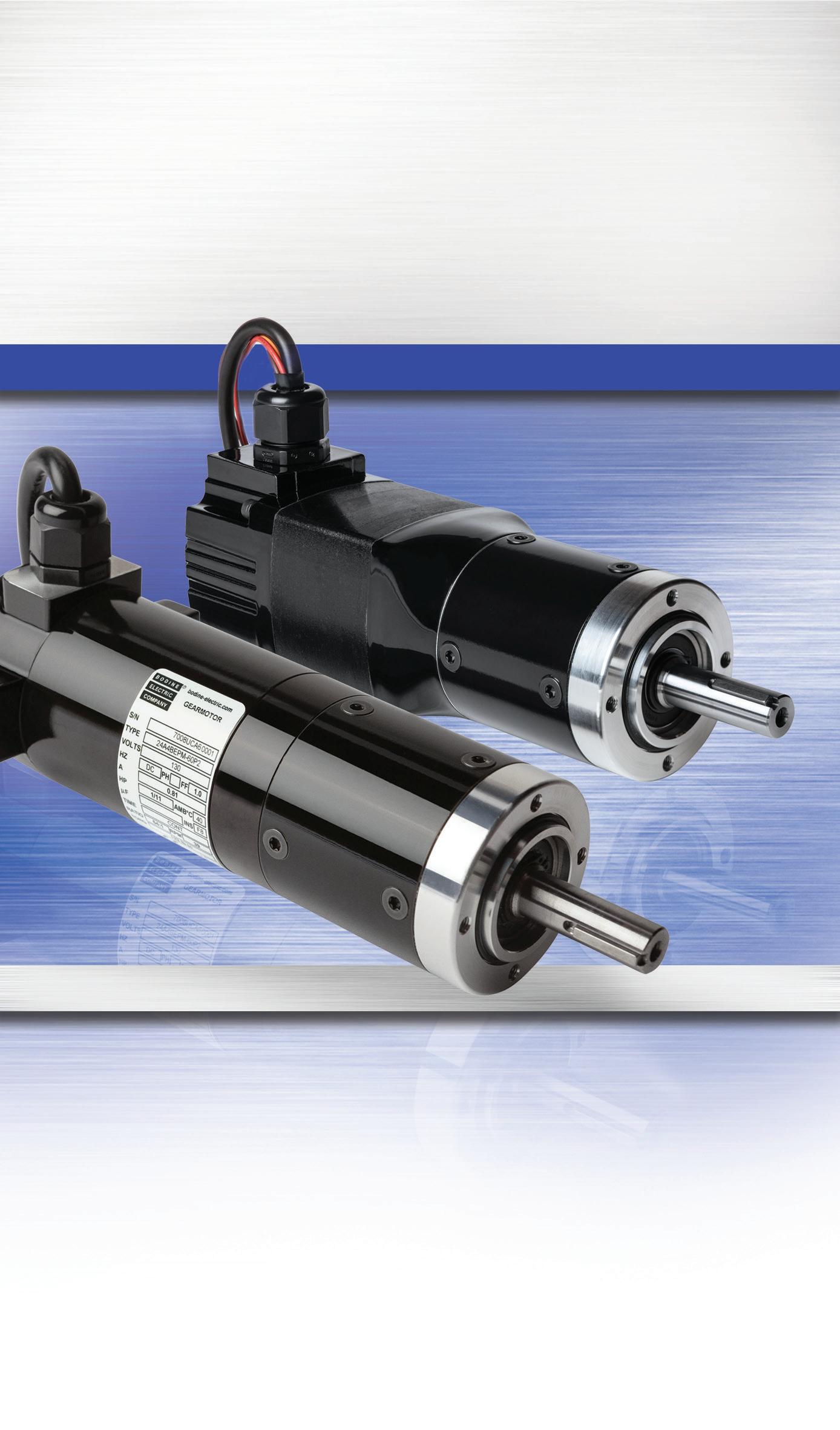

PLANETARY BLDC and PMDC GEARMOTORS

other sustainable energy sources. Another might be closer, geographically, to the rest of manufacturing which limits the emissions due to transportation and logistics. These types of metrics are critical in making products more sustainable across the entire value chain.

Collaborations can extend further into the value chain to a product’s end-of-life, working towards circularity. Choosing a stronger material means it could be re-used. A more robust component may also be more di cult to manufacture, requiring more energy-intensive processes. The volume and variability of these decisions are why digitalization and simulation are so important to sustainable design — simpler decisions can be automated, and complex ones are infused with greater intelligence.

Further optimize design with holistic sustainability indicators

Finally, it is important to revisit and evaluate the decisions at every stage of the product lifecycle. Holistic sustainability indicators must be integrated into the digital twin from the beginning for ongoing visibility of sustainability goals in concert with other requirements. This may require the design to include physical sensors that collect diagnostic and environmental conditions through manufacturing, delivery, and usage as well as carbon footprints and material costs. With a larger dataset, it is even possible to include virtual sensors that rely on the models created in the digital twin.

Physical sensors feed the simulation models, providing a clearer understanding of decisions early in design, while virtual sensors and models interpolate and extrapolate sustainability indicators from complex systems. These indicators enable closed-loop optimization between design, manufacturing, and usage. DW

These 60 mm gearmotors are available from stock and with many custom options. PMDC models are rated up to IP-66. Low-voltage 12 & 24 VDC models are ideal for solar or battery powered applications.

Visit our website at: bodine-electric.com info@bodine-electric.com

32 April 2023 DESIGN WORLD

Siemens www.siemens.com/global/en.html

RATED SPEEDTORQUE GEAR RATIOSVOLTAGES 11 to 658 rpm5 to 226 lb-in.4:1 to 162:190/130, 24, 12 VDC

•

High Torque. Compact Design.

773.478.3515 (USA)

Long Life.

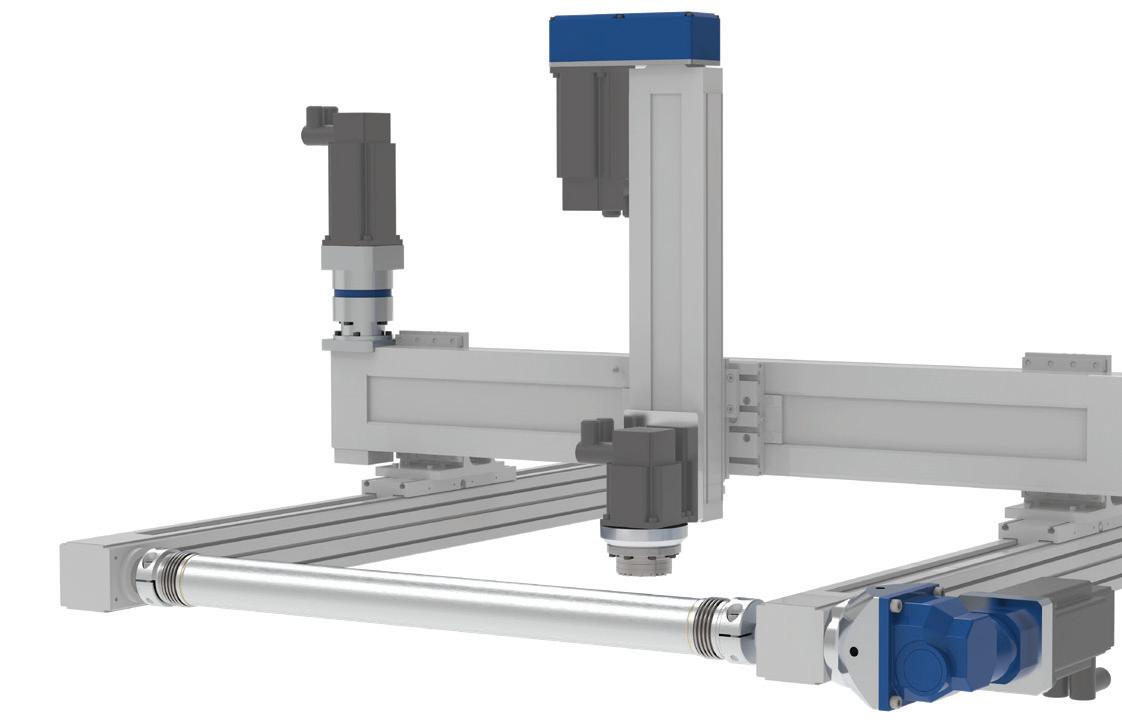

Articulated

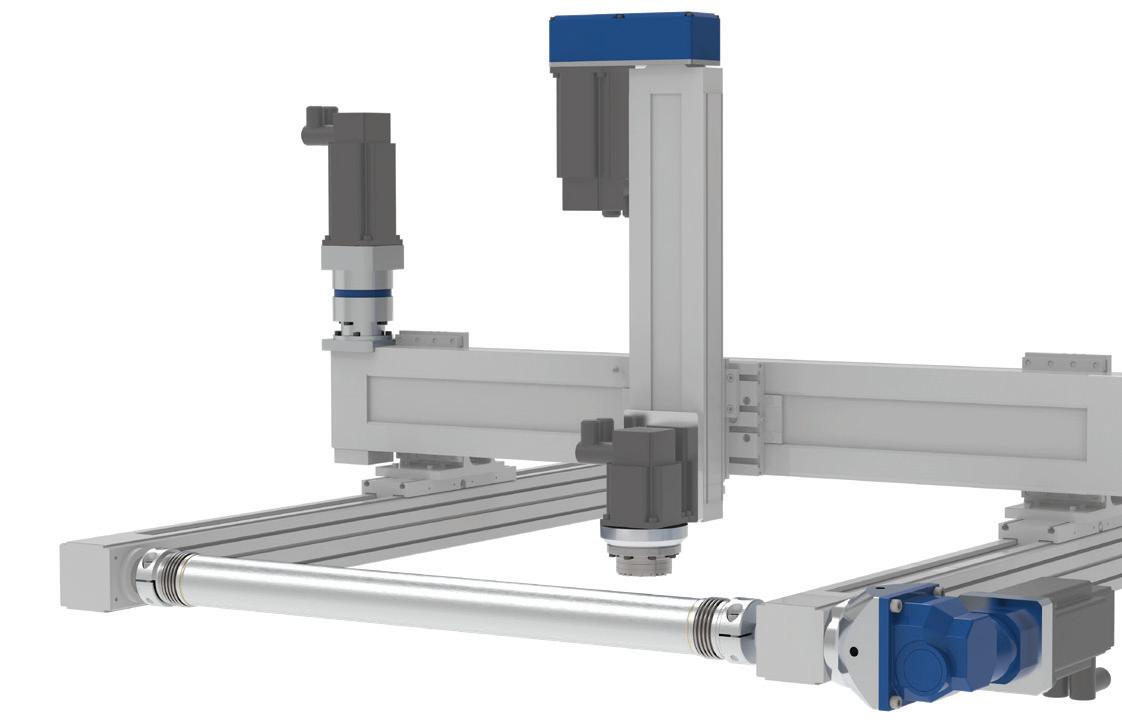

Cartesian

GAM offers a full range of robotic and servo gearboxes, along with rack & pinion, couplings, and linear mount products for motion control and robotic applications.

With our broad product offerings in the gearbox market, as well as the in-house engineering design experts and manufacturing capabilities to develop customized solutions, we can help with your application.

RACK & PINION FOR PRECISION

& ROBOTIC APPLICATIONS

GEARBOXES | COUPLINGS |

MOTION CONTROL

Robot

and 7th Axis

Robotic Flange Gearboxes and Helical Rack and Pinion

application

Axis/Robot Transfer: Dyna Series + Helical Rack & Pinion Designed for optimal system performance GCL Cycloidal withstands shock loads of 5x nominal torque GSL Strain Wave with harmonic gearing for precise motion

Joints

Zero-Backlash

Systems, customized to your

7th

System

GSL Strain Wave Theta/Wrist Axis Distance Coupling Connect actuators without additional external bearings PMK Space-saving Parallel Mount Kit Hollow Output Gearboxes Inline or Right Angle, include custom adapter to mount to any linear actuator

Build your own with Linear Mount Products designed to simplify the process of designing and building a cartesian system. Everything Between the Motor and the Actuator

GAM Can. www.gamweb.com | info@gamweb.com | 888.GAM.7117 AMR/AGV Wheel Drive Standard or Custom gearboxes for precise positioning GSL Strain Wave Zero-blacklash gearbox with a compact design GML-F Coaxial Wheel Drive Planetary gearing inline design. Includes mount designed for your motor

Planetary maintains lifetime zero-backlash

Cycloidal with integrated pre-stage

GPL

GCR

Design Notes

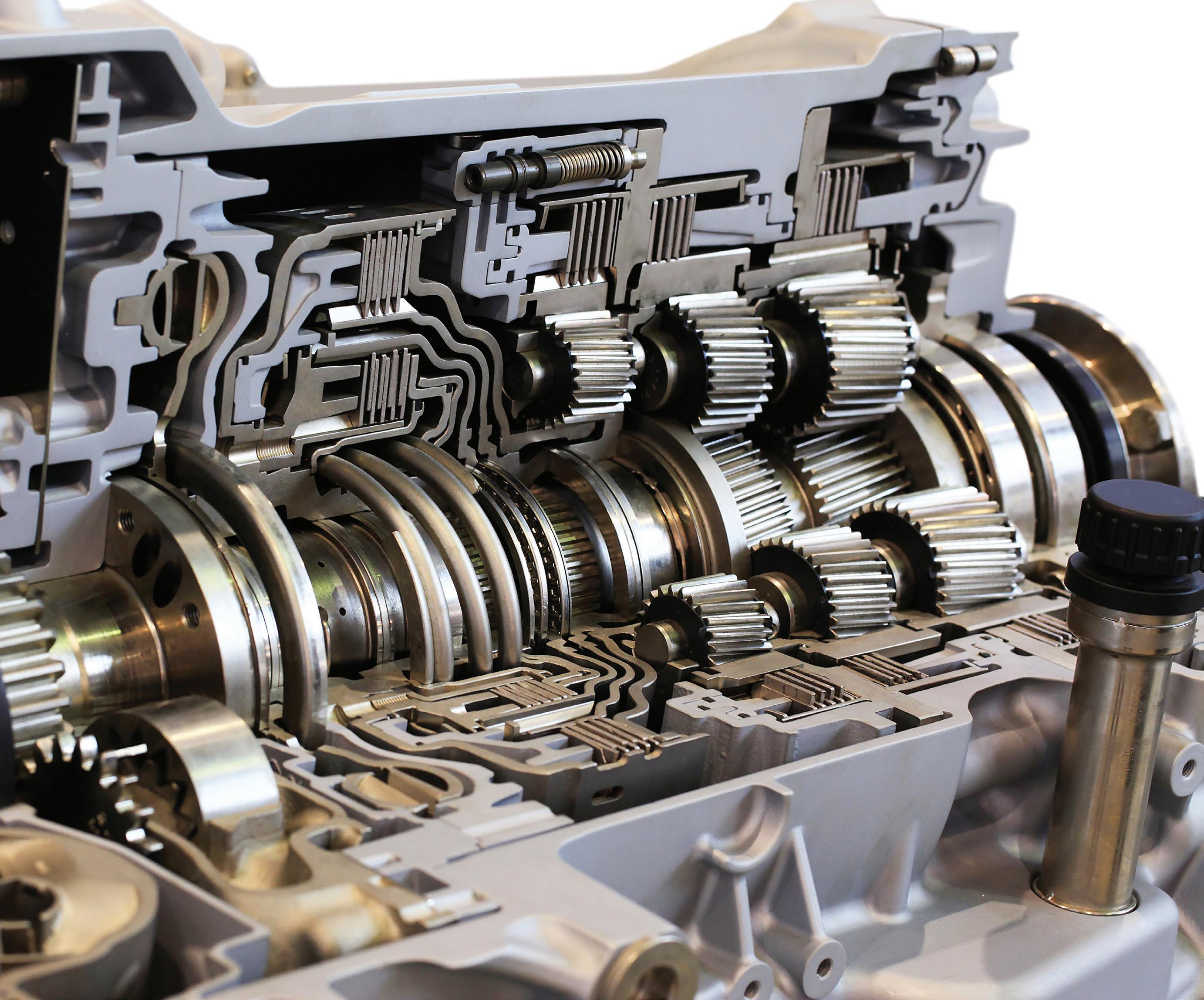

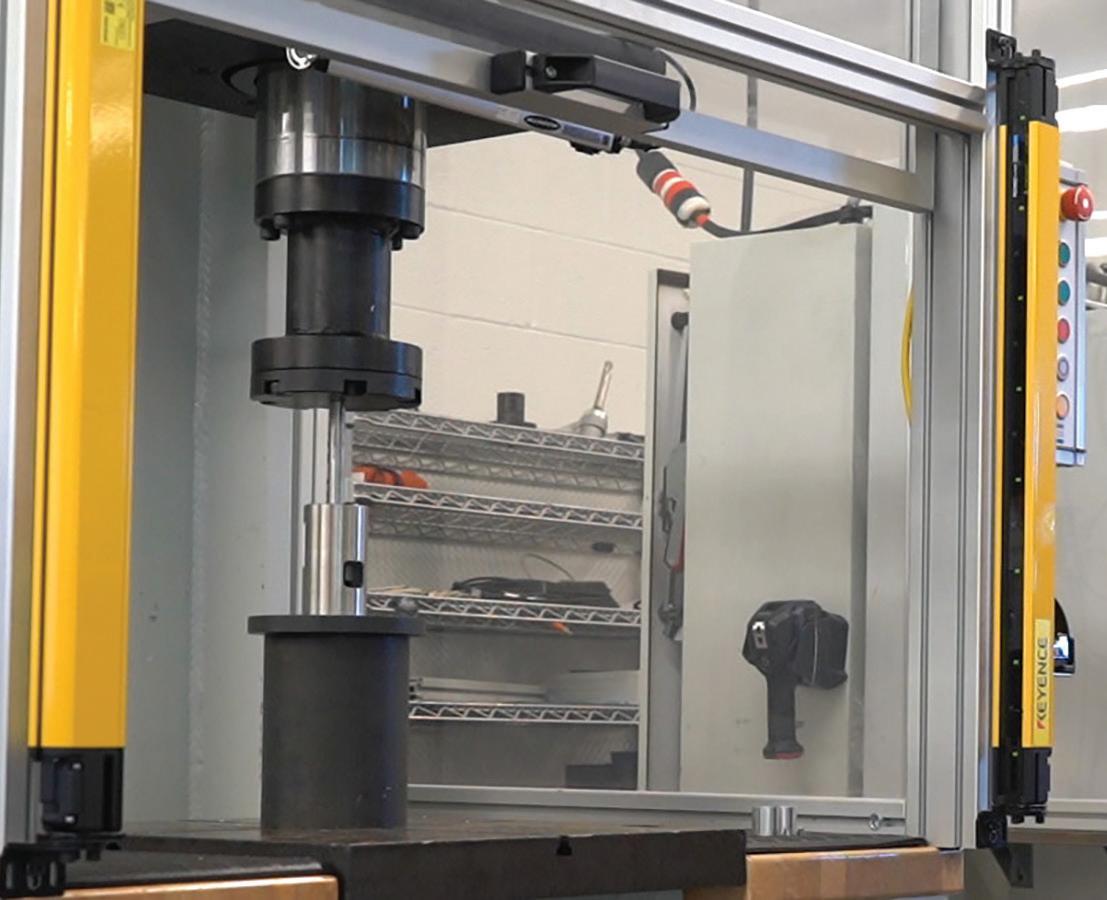

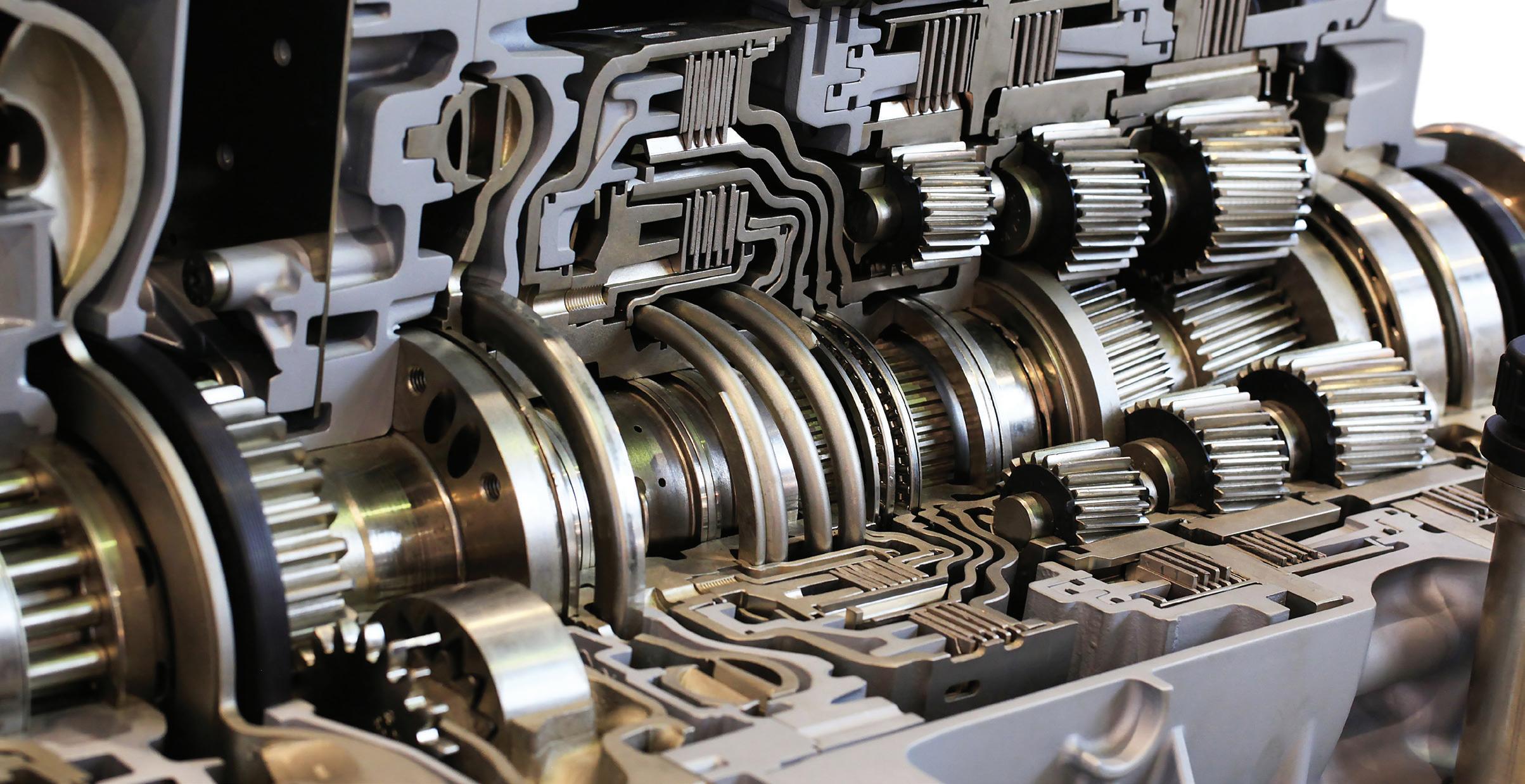

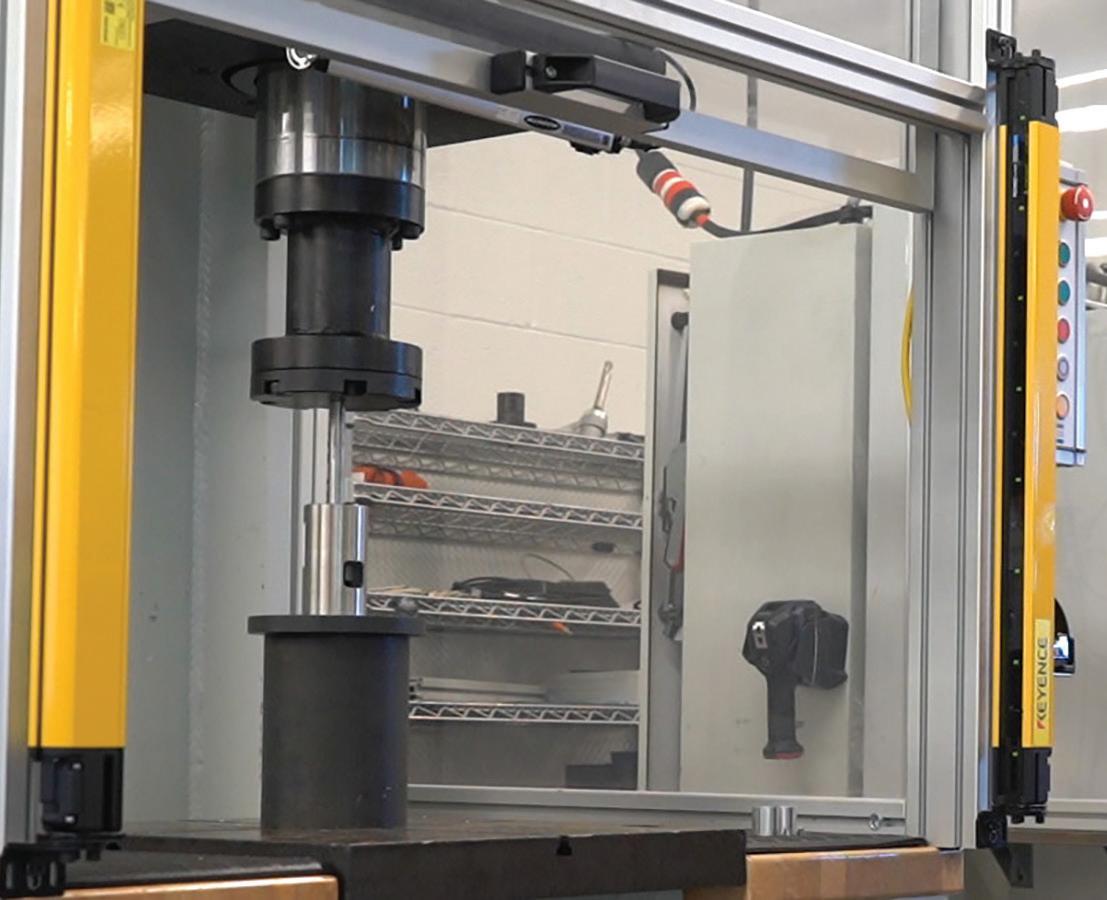

Making transmission manufacturing automatic

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

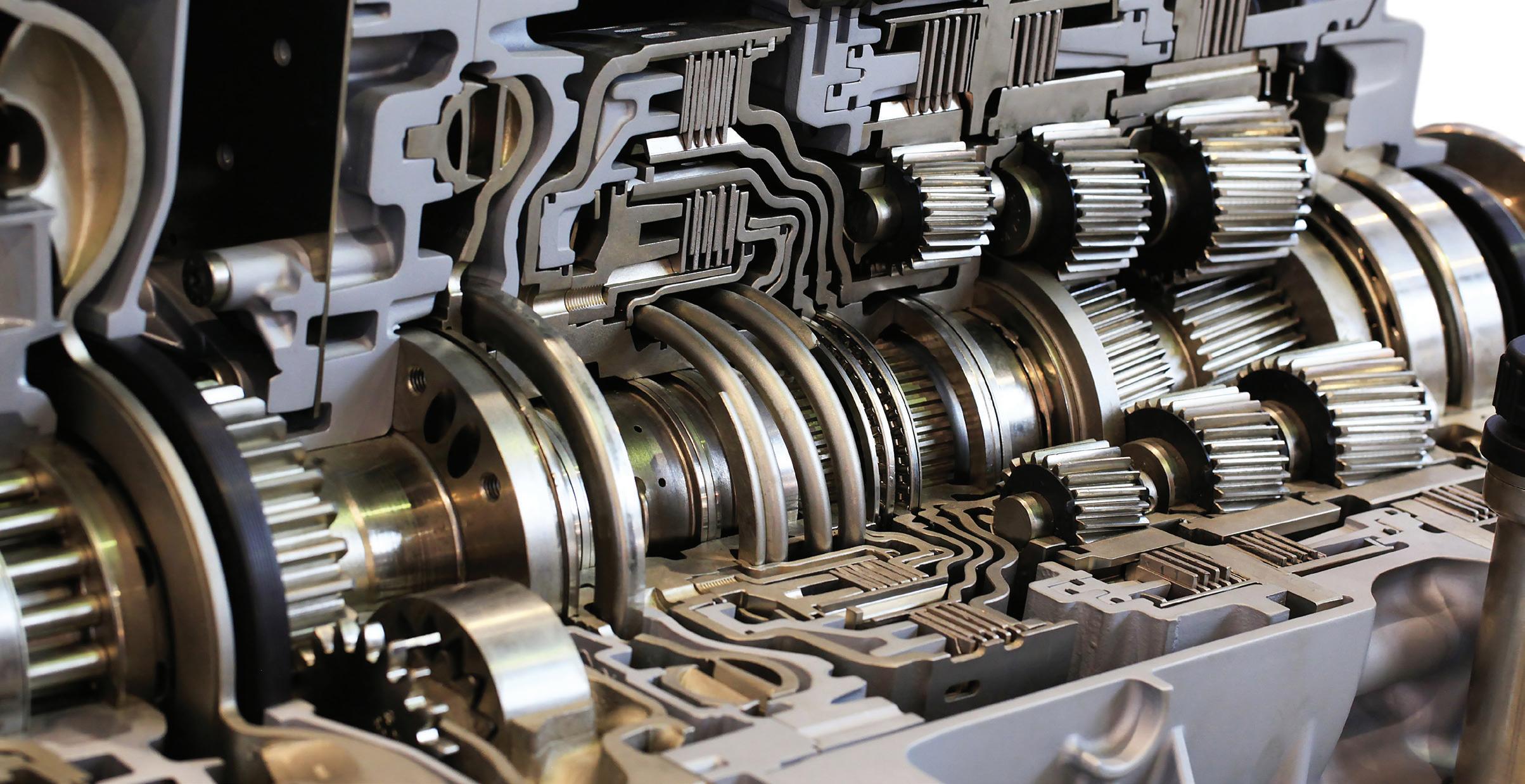

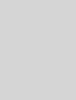

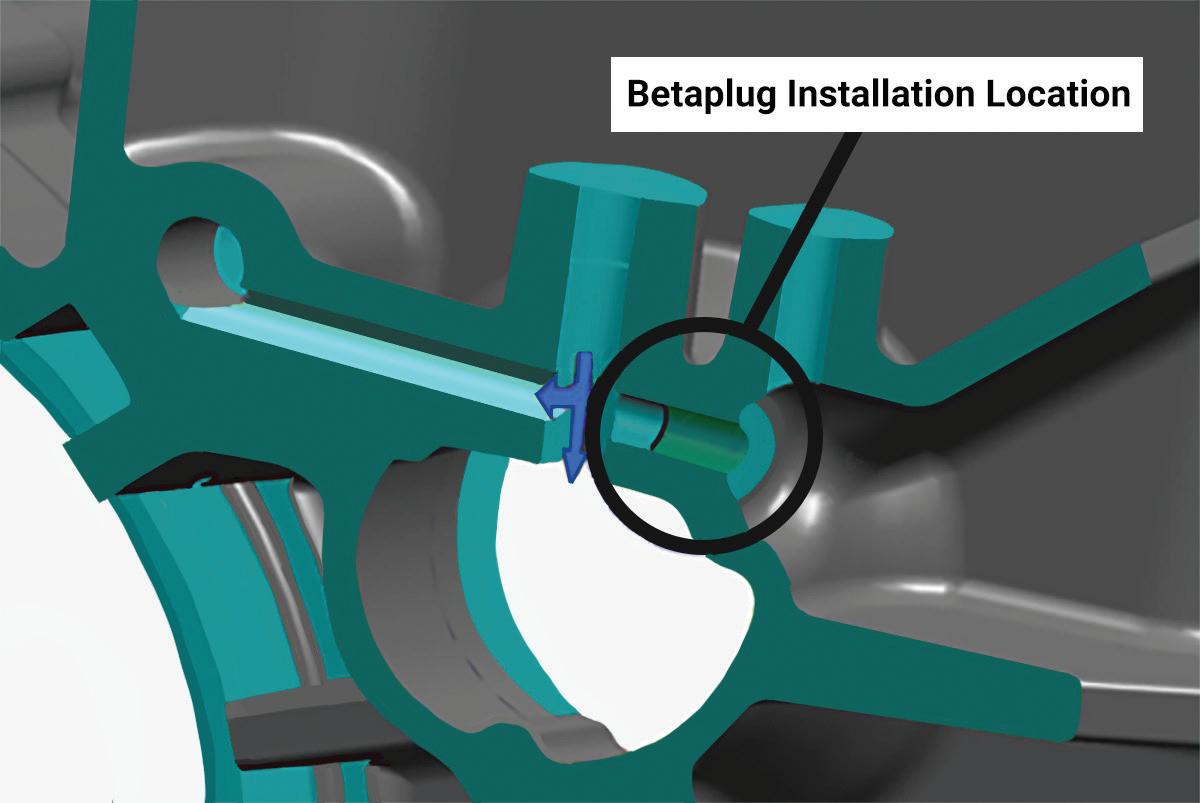

An automobile’s automatic transmission case is a complex casting with a sophisticated valve body with many channels and passages. These features must be precisely connected to perform the necessary control functions. However, it’s not always possible to cast all interconnections. Some case features necessitate drilling through the casting’s outer shell (and one or more internal channel walls) using cross drilling. Such drilling leaves a hole in the outer shell requiring sealing to prevent fluid loss.

are

34

www.designworldonline.com DESIGN

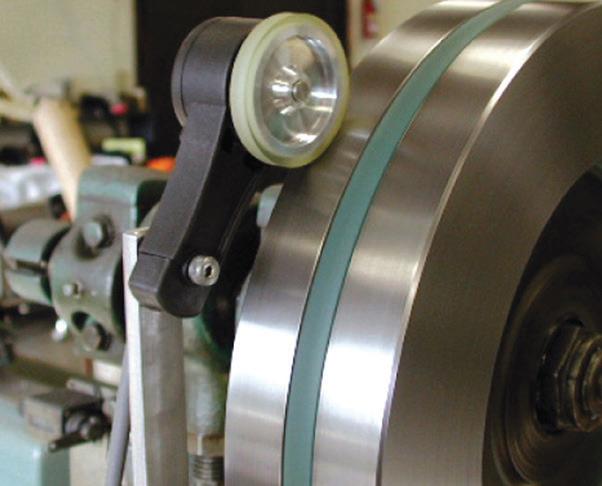

Precision press feedback ensures engineered plugs

correctly installed.

April 2023

WORLD

More controllable cross-drill sealing method

One automotive manufacturer — a longtime customer of monitoringsystems supplier Promess — employed a Promess Electro-Mechanical Assembly Press (EMAP) to press steel ball bearings into cross-drilled holes to seal the holes. While this sealing method worked in previous applications, it failed for a new thin-walled transmission case, causing housing cracks, unacceptable leakage rates, and warranty issues.

The EMAP is an electric servo press instrumented to monitor and precisely control peak force and final position. However, the user had programmed

the ball-pressing application to stop at a specific distance, so only distance was controlled. Neither the dimensions of the ball nor the diameter and surface finish of the hole were held to tight tolerances. As a result, the same level of force could leave the ball in a broad range of positions within the hole. This variability was the root cause of the leaks and cracks.

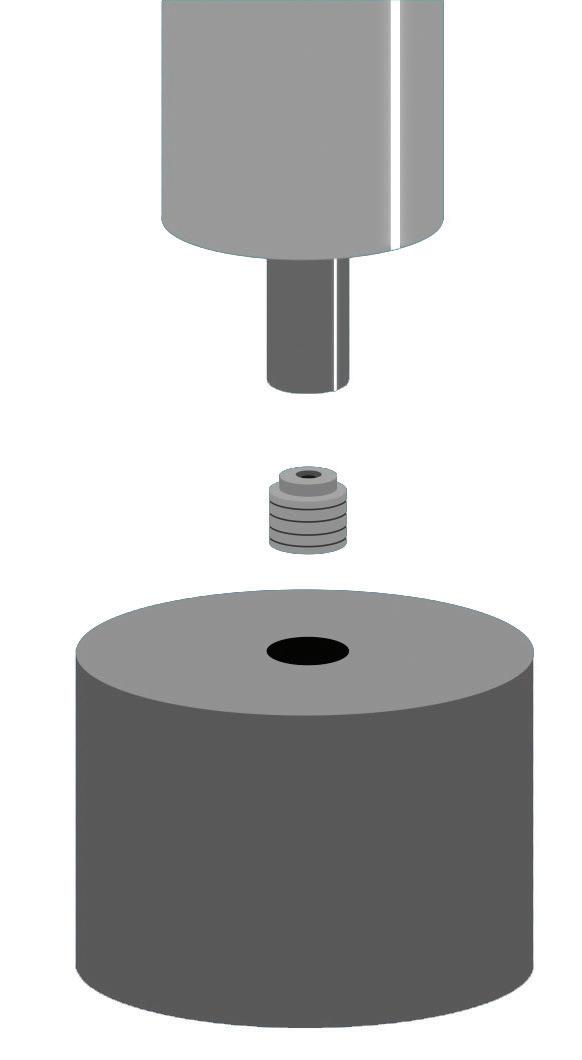

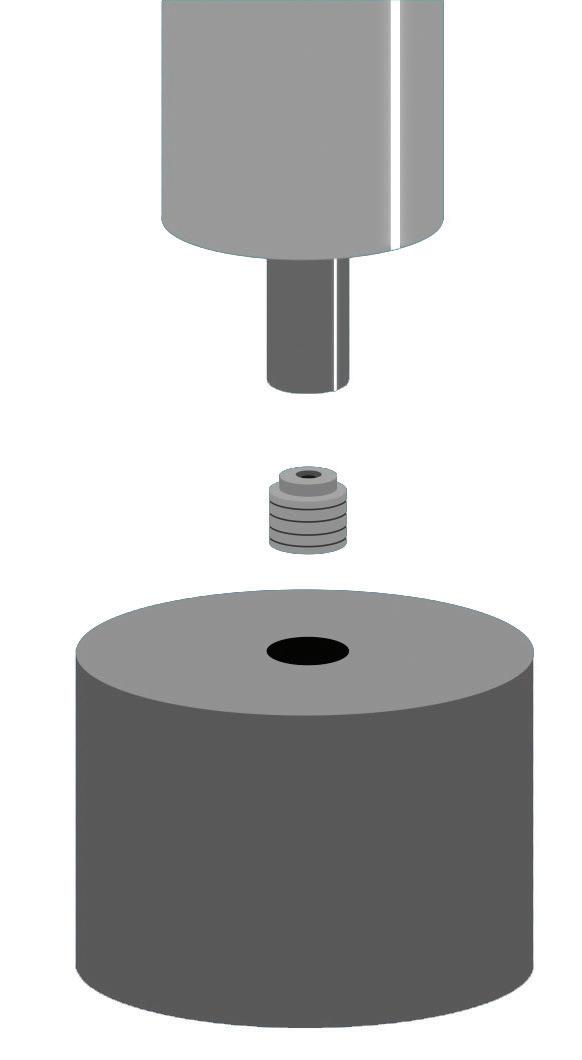

To address these unacceptable yield issues, the manufacturer replaced the steel ball with a Betaplug expansion plug produced by The Lee Company. This preassembled, two-piece tapered expansion plug has an inner pin and an outer plug body with lands and grooves

The Betaplug product includes a body and an inner pin that causes expansion for tight seals.

Betaplug is a trademark of The Lee Company.

Design Notes

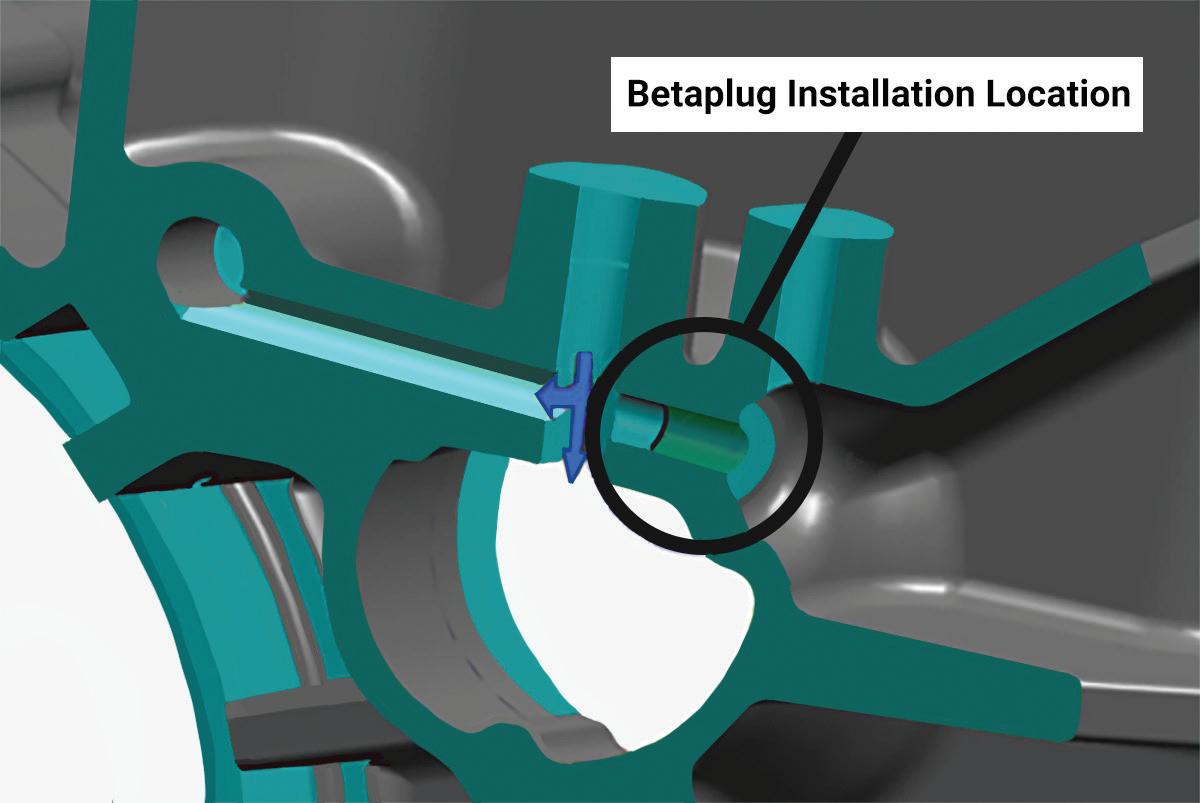

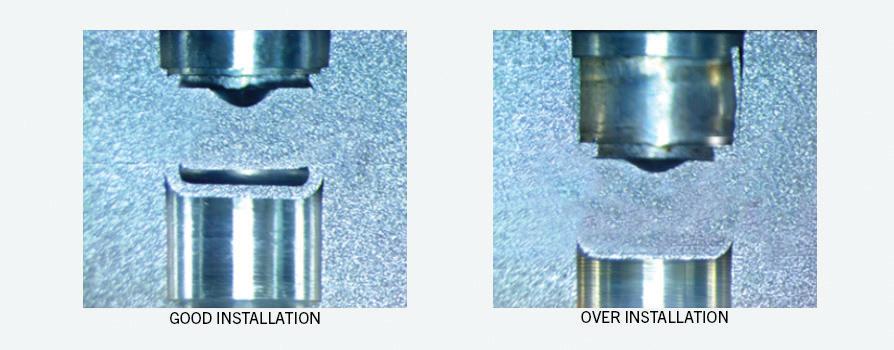

Fine-tuning the case-plugging process

With proper installation, the pin is installed 0.5 to 0.8 mm below flush of the plug body, and all stake marks are present. With overinstallation, the pin is over-driven so far that it contacts the plug body. This overpressing causes the plug body to extrude up the installation hole wall — resulting in a pin that’s greater than 0.8 mm below flush of the plug body.

that bite into the housing during installation. More specifically, the Betaplug product is designed to install in a matching tapered bore that creates a suitable fit. It reduces unnecessary expansion and has a predictable boss stress suitable for brittle materials or thin wall conditions.

An installation tool is designed to install the inner pin below flush while staking over the plug body’s back edge.

Using the Betaplug expansion plug eliminated the cracked housing and production yield issues. However, the manufacturer carried over an improper installation specification that created new manufacturing issues — namely, an unacceptable scrap rate, yield issues, and fixturing damage. So, the manufacturer contacted Promess and The Lee Company. Both companies were asked to examine the complete installation and assembly process and suggest a solution to the high scrap rate.

The Lee Company engineers determined that the Betaplug products were being overpressed; this produced excessive radial force when the pin moved to expand the plug body and extrude the plug in the installation bore. The manufacturer was reluctant to change the distance-based programming because successfully installed plugs weren’t failing in the field.

New sealing component requires new sealing approach

Force starts to increase here when the cup moves through the bore. 2) The cup stops, and the pin begins moving into the cup. 3) The inflection point is when the system begins staking the part. 4) Final inflection is when staking has been finished and the rate of change completes.

A proper installation for a Betaplug product should be terminated when the staking is complete, regardless of where the unit is located within the bore. The manufacturer’s engineers wanted to install the plug at a fixed point within the bore regardless of the optimum staking location; that was where the steel ball plug had performed best. However, in a tight bore, it generated the excessive installation force that extruded the Betaplug expansion plug.

Promess engineers recommended that the manufacturer change the programming to measure more than

36 April 2023 www.designworldonline.com DESIGN WORLD

Shown here is where the automotive manufacturer employs the Betaplug on the cross-drilled transmission case casting.

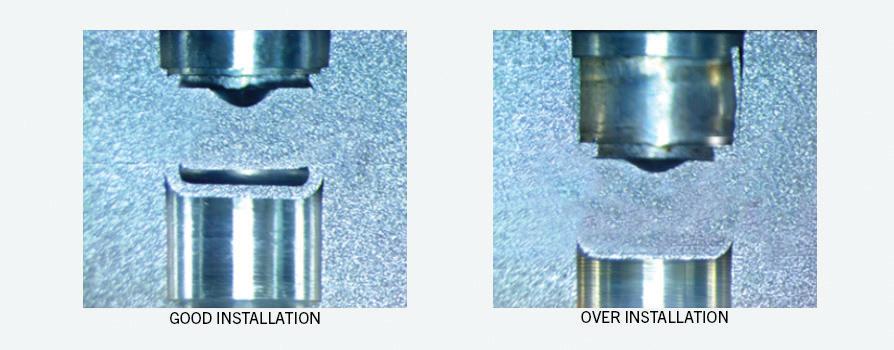

Shown here is Promess’ Electric Servo Press used to install the Betaplug product.

a simple force level or distance. The engineers highlighted the benefit of combining EMAP instrumentation with the sophisticated data-processing capabilities of the Promess Motion Controller. The result is the ability to measure and control absolute force, distance, and more complex relationships, such as the rate-

of-change between those measurements.

During installation, the Betaplug product initially moves as a unit until it lands on the outer plug body and begins to dig into the bore. When adequate resistance is achieved, the plug body stops moving, but the inner pin continues moving, generating the expansion force that creates leaktight seals and ensures retention. When the pin is 0.5 to 0.8 mm below flush, the installation tool stakes over the top edge of the plug body.

This transition produces a readily detectable inflection point in the rate of change relationship between press

force and distance. After it’s detected, it’s a simple matter to stop the press when the pin is appropriately inserted into the plug body. The result is a properly staked installation that avoids harmful pin over-insertion. As an added benefit, the programming can also detect parts that are upside down, sideways, or missing a pin/component.

Promess engineers and their Lee counterparts performed extensive laboratory testing to validate the new programming. This was done prior to installing the upgraded application in the manufacturer’s plant, where more trials were performed. The new rate of change-based application was put into production after all the needed tests were completed. DW

Lee Company | www.theleeco.com

DESIGN WORLD www.designworldonline.com April 2023 37

PUSHBUTTONS JOYSTICKS ROCKERS GRIPS TOGGLES HALL EFFECT SOLUTIONS CONTROLS www.otto-controls.com @OTTO.Controls

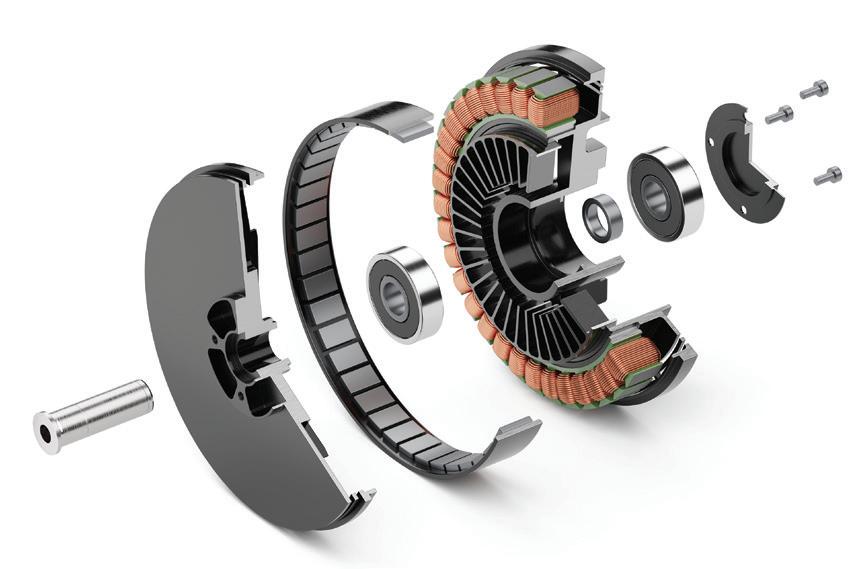

Bearings take heart in ergometer application

By Thomas Renner

By Thomas Renner

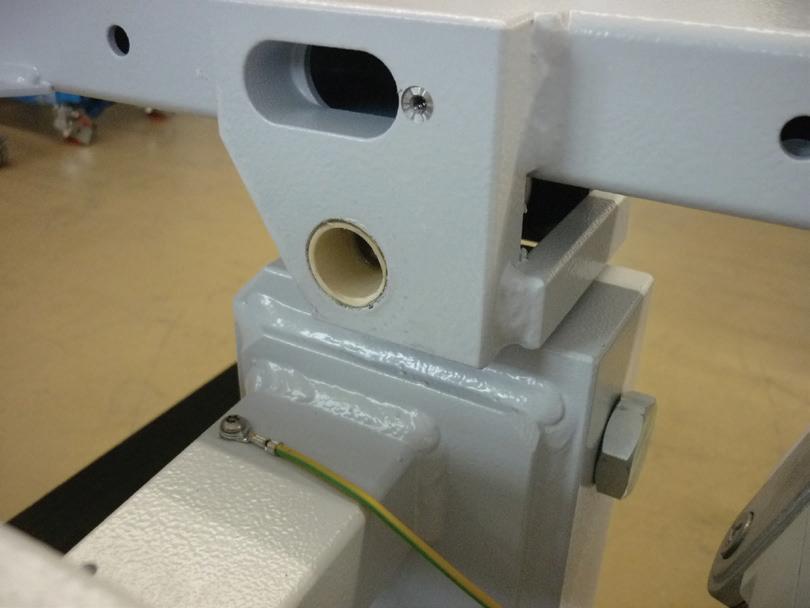

In today’s fast-paced manufacturing climate, businesses must react swiftly to quick-moving economic markets. Supply chain shortages and shipping delays forced the hand of many companies during the pandemic, driving innovation and identifying new pathways to adapt to the changing conditions.

That’s where ergoline GmbH found itself with the production of its ergometers. The products are used in exercise and for diagnosing heart diseases. The company needed wear-resistant and lubrication-free bearings in a custom dimension so that the company could start production of its new series of ergometers.

Shaft modifications in the product’s design resulted in too much clearance from items that had been selected from a catalog. “Since

production was about to begin, we initially decided to turn a small number of the parts from barstock,’’ said Dominik Huber, Head of Design at ergoline GmbH. Volume production, however, required an even faster solution.

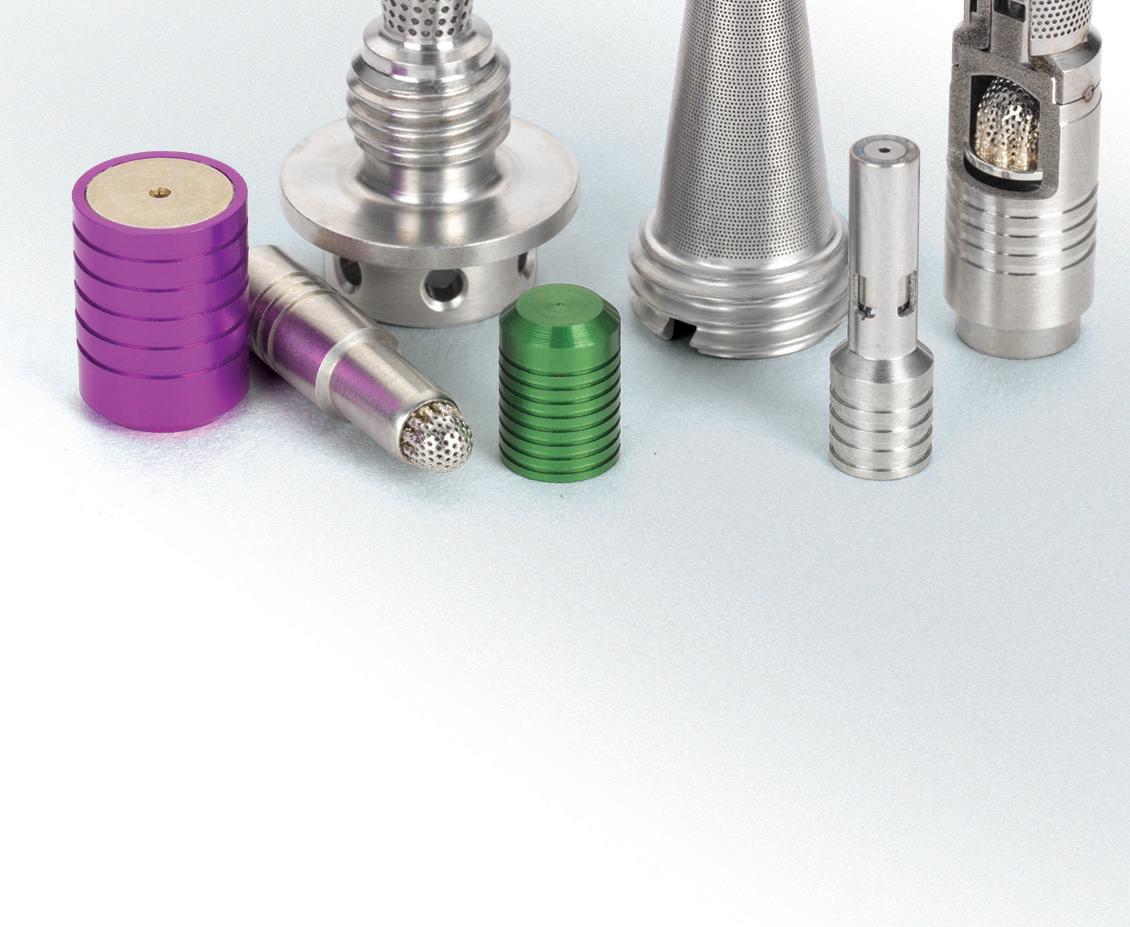

Making parts from barstock required six weeks and was too time-consuming and expensive. Igus, a German manufacturer of motion plastic components, o ered ergoline the capability to produce components with its FastLine Service. The new resource features modern computerized numerical control (CNC)

38 April 2023 www.designworldonline.com DESIGN WORLD

The ergoselect 1200 recumbent ergometer has been developed for cardiac diagnostics.

Source: ergoline GmbH

technology. The time from order to delivery was four days.

“By investing in our tool shop with its own production line for round parts that features modern CNC technology, we were able to produce specially shaped plain bearings for ergoline within a very short time,’’ said Benjamin Haupt, Technical Sales Consultant at igus GmbH.

The company’s ergoselect 1200 model is a reclining ergometer developed for dynamic stress echocardiography. The procedure evaluates cardiac structure and function during physical exercise or the pharmacologic simulation of exercise by measuring increased heart rate, cardiac output, and myocardial oxygen demand. The procedure allows for echocardiographic images to be obtained anywhere along the continuum from rest to peak physiologic stress.

Huber sought a plain bearing to support the adjustment mechanism for height and tilt. The company selected igus’ iglide P210 bearing, which works well in pivoting movements on various shaft materials.

The bearing, like all of igus’ components, requires no external lubrication and thus meets the stringent demands of the medical field. It is also extremely durable.

The issue with parts working together properly after shaft modifications required ergoline to use igus’ FastLine service.

In CNC, computer instructions guide mills and lathes that control the precision of the instruments. The process enables the development of parts and components that would usually be impossible to create manually. The fourday turnaround time and coste ective price surprised Huber. “We had expected to pay three times as much,’’ he said. “Of course, we were very pleased. It gives us the possibility to work flexibly in design.”

Customers such as ergoline are interested in more expedient turnaround time for select components, according to Tom Krause, head of 3D Printing at igus.

DESIGN WORLD www.designworldonline.com April 2023 39

The tilting function of the ergometer also allows the heart to be examined with ultrasound.

Source: ergoline GmbH

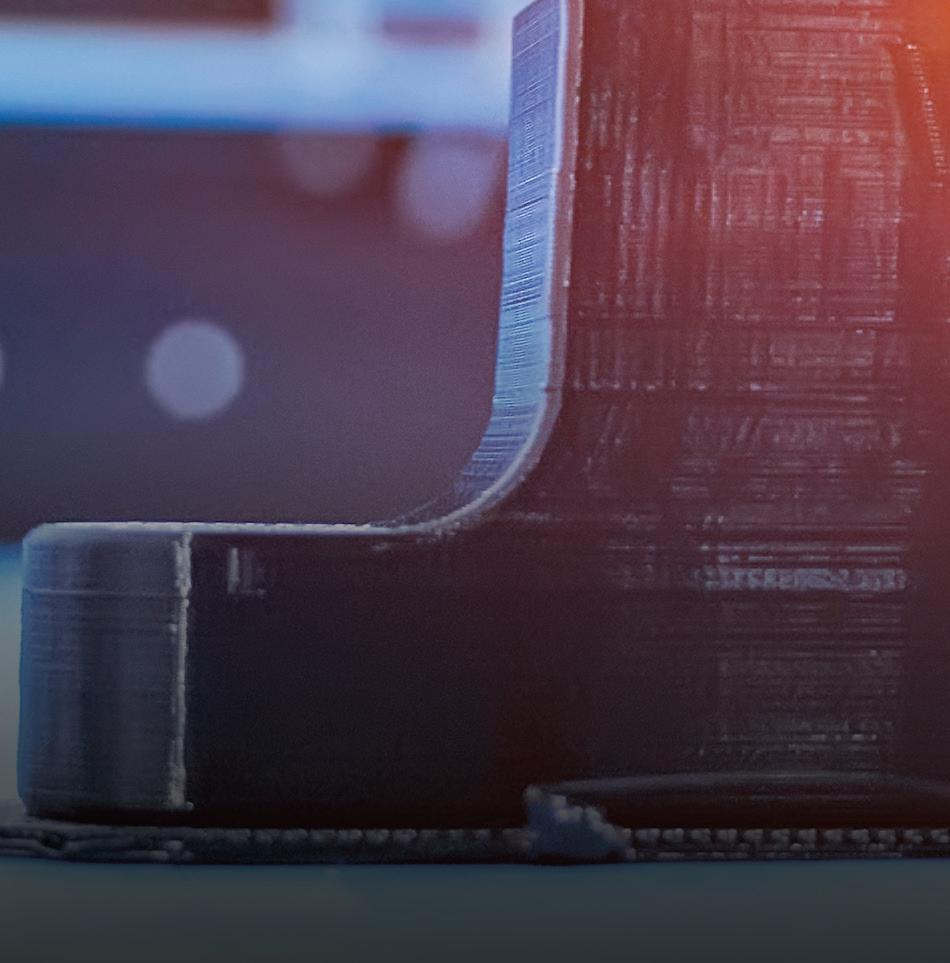

The iglidur P210 plain bearings from igus ensure a safe lubrication-free height and tilt adjustment.

Source: ergoline GmbH

Design Notes

(Source: ergoline GmbH)

Our new U.S.-based production facility integrates the best of both worlds – the pride of American manufacturing and the precision of German technology.

With advanced equipment and cutting edge processes, our factory ensures incomparable efficiency and quick delivery times.

Join us in our commitment to excellence and benefit from our expertise. Contact us now to be a part of our success story.

“There are di erent reasons,’’ he said. “A common one is that part of a machine is broken down and needs to be replaced, so it’s imperative to get the machine running again. Other reasons are sourcing methods failed or an expectation of getting individual parts in a few days.”

Igus’ focus on speedy delivery did not begin with FastLine. It previously manufactured molds from aluminum for time-critical developments and later added in print2mold (3D printing). “The advantage of FastLine is that we have a mold that is 100 percent suitable for series production and is not limited in the number of shots in injection molding,’’ Krause said.

In 2014, igus introduced its first 3D-printing filaments, which are made especially for moving applications because of the solid lubricants, Krause said. In 2016, it introduced its first SLS material, iglide i3, and started with its SLS 3D print service. “Since then, our customer interest was constantly growing so that we now have 10 SLS machines worldwide,’’ he said. “We are able to produce special wear parts very quickly in Boston, Shanghai, and Cologne. Last year, we made more than 200,000 special wear parts by 3D printing.”

Igus’ FastLine service was created to meet the needs of manufacturers with high product demand, such as ergoline. Customized parts, such as plain bearings in unique shapes, must be delivered without complications. Injection molding can require several weeks.

“By investing in our toolmaking department with its own production line for round parts with modern CNC technology, we are now able to respond even faster to our customers’ needs,’’ said Stefan Loockmann-Rittich, Business Unit Manager of iglide at igus GmbH. “In addition to our large catalog range of polymer plain bearings, which are available from stock, we can produce customized parts cost-e ectively in just a few days using the appropriate injection molding tool.” DW

igus | igus.com 40 April 2023 DESIGN WORLD

The plain bearings in special sizes are pressed into the bearing location, enabling a reliable and secure adjustment of the ergometer.

R+W Coupling Technology 845 W Hawthorne Lane West Chicago, IL 60185 +1 630 521 9911 info@rw-america.com www.rw-america.com

PRECISION COUPLINGS INDUSTRIAL COUPLINGS SENSOR TECHNOLOGY

MAY 2-4, 2023 McCormick Place - West Building | Chicago North America’s largest and most influential Additive Manufacturing event. KEEP PACE WITH THE 3D-PRINTING REVOLUTION REGISTISTER TODAY FREE Expo Pass and 20% Off Conference Passes when you register with code RP23PA4 Join us in Chicago for the RAPID + TCT conference! Learn how additive technologies can transform your manufacturing with freeform design, reduced tooling time, and lighter parts. • 8 AM-Specific Tracks • 84 Conference Hours • 169 Individual Presentations • 229 Dynamic Presenters rapid3devent.com

Design for 3D printing and Additive Manufacturing

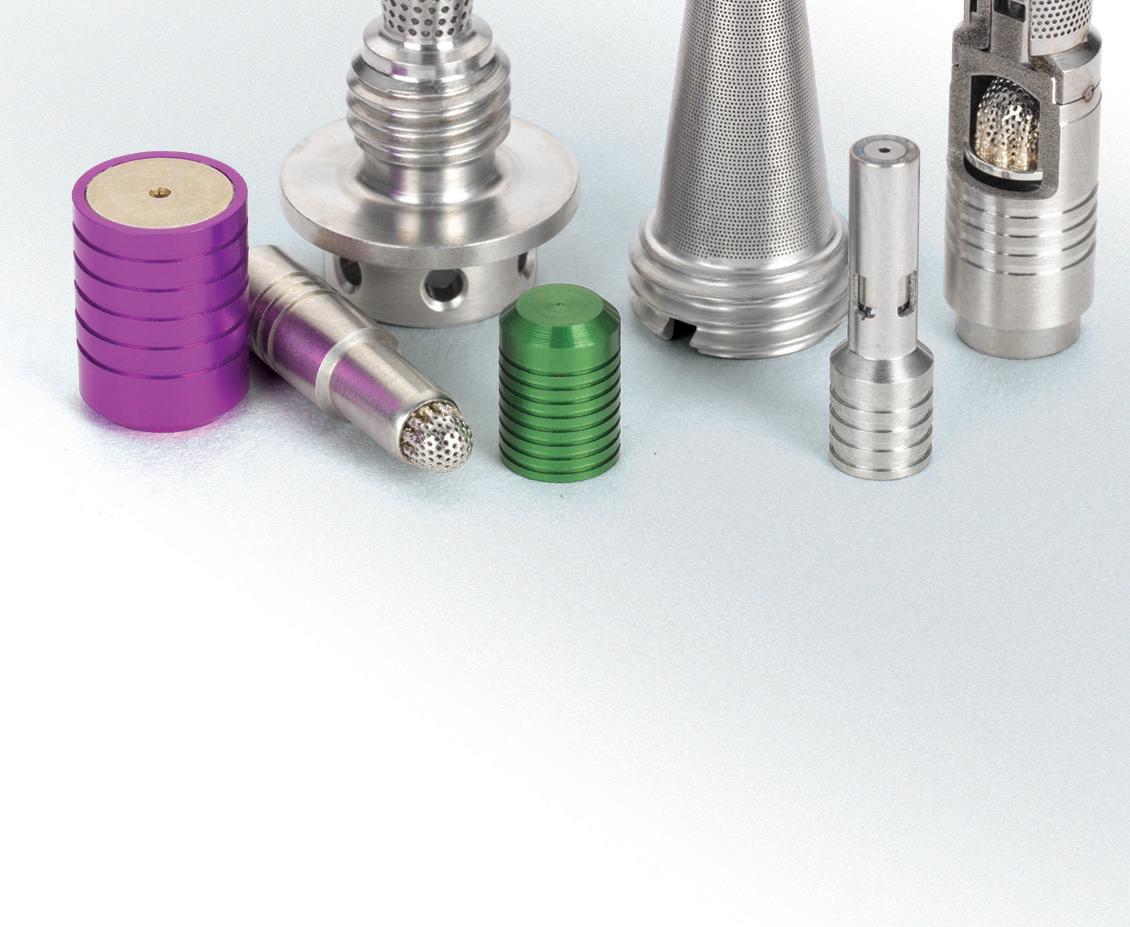

Micro AM is changing the economics of manufacturing

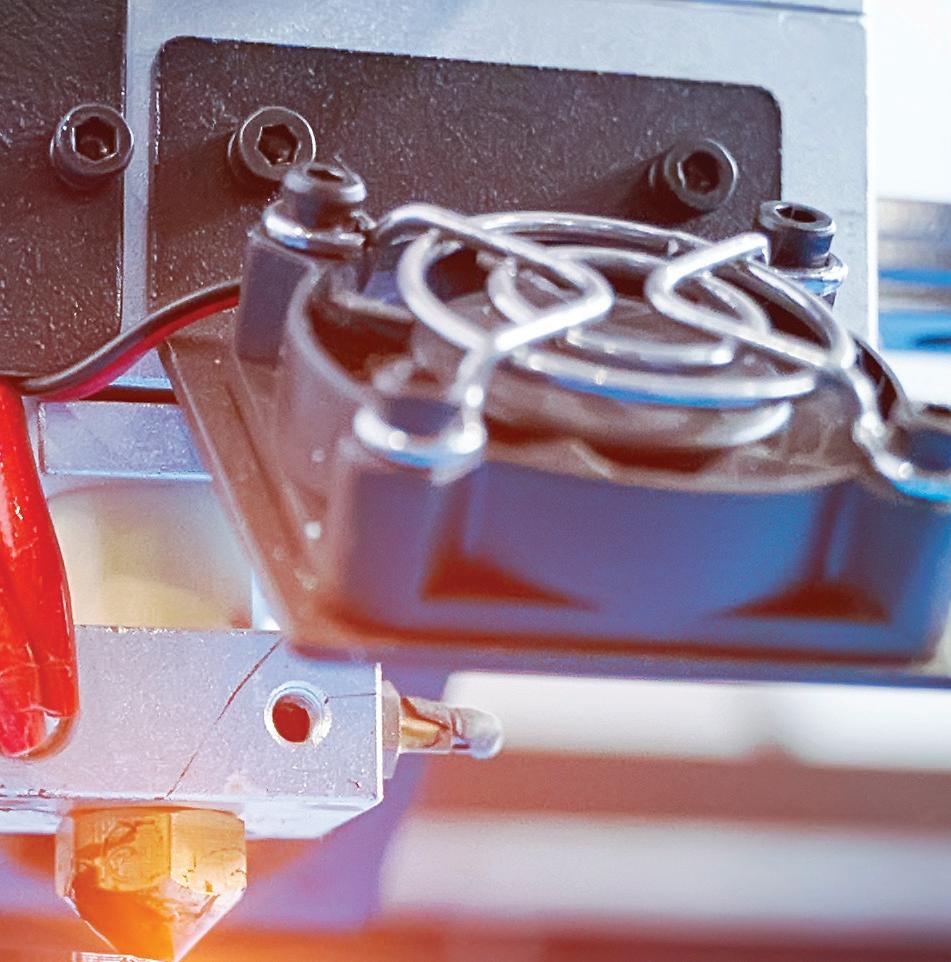

3D microprinting is a versatile technology appropriate for prototyping, small batches, and potentially mass manufacturing.

| courtesy of Accumold

Micro additive manufacturing (AM) appeals to an array of customers unable to fulfill design intent cost-e ectively or e ciently with traditional manufacturing processes. As micro AM is agnostic to part complexity, it allows for the manufacturing of hollow structures, holes, complicated interior details, and atypical shapes — and it’s promoting innovation as an enabling technology. Accumold, an Iowa-based company that specializes in micro molding, continues investing in its micro AM capability with the purchase of a second Fabrica 2.0 machine from Nano Dimension.

“The Fabrica 2.0 will make the prototype stage of the product development process more flexible and quicker for our customers. In time, it will move towards small- to medium-sized production runs and also promote creative geometric complexity and mass customization,” said Aaron Johnson, vice president of marketing and customer strategy at Accumold.

The Fabrica 2.0 can cater to volume applications — multiple thousands of small parts and components fitting easily in the machine’s 50 x 50 x 100 mm

42 April 2023 www.designworldonline.com DESIGN WORLD

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

build envelope — so OEMs can reduce reliance on economies of scale. Micro AM technology makes possible low- to medium-volume production runs that were previously uneconomical due to high tooling and setup costs associated with traditional manufacturing alternatives.

“In general terms, success through the use of the Fabrica 2.0 is measured in microns and hours. Micron-level detail can be achieved without the need to fabricate tools, and this means that you can have intricate and geometrically complex prototypes in a matter of hours,” said Johnson.

With traditional micro tooling, increased complexity means increased cost, so part complexity is limited. However, with micro AM technology, the absence of physical tools enables design engineers to think outside the box and attain design goals previously unimaginable. This design freedom, coupled with AM’s inherent manufacturing agility, a ords reassessments of all aspects of the product development process.

“Through the use of Fabrica 2.0, you can also optimize workflow, the technology producing less scrap and fewer tools than

The Fabrica 2.0 system 3D prints micron-level resolution parts for aerospace, electronics, automotive, medical, optics, and R&D applications.

| courtesy of Nano Dimension

conventional manufacturing processes,” said Johnson. “It also promotes the reduction of iterative process, assembly, and inventory. This means that significant operational cost benefits are now attainable at the micro manufacturing level for our customers.”

The Fabrica 2.0 system enables the drive toward miniaturization for high precision for high-performance applications. This includes micronlevel resolution of medical devices, micro-optics, semiconductors, microelectronics, micro-electro-mechanical systems (MEMS), and microfluidics. The Digital Light Processing (DLP) based system enables the critical advantages of additive manufacturing, including rapid prototyping, high-mix-low-volume production, IP security, and a minimal environmental footprint. DW

Accumold | www.accu-mold.com

Nano Dimension

www.nano-di.com

DESIGN WORLD www.designworldonline.com April 2023 43

Design for 3D printing and Additive Manufacturing

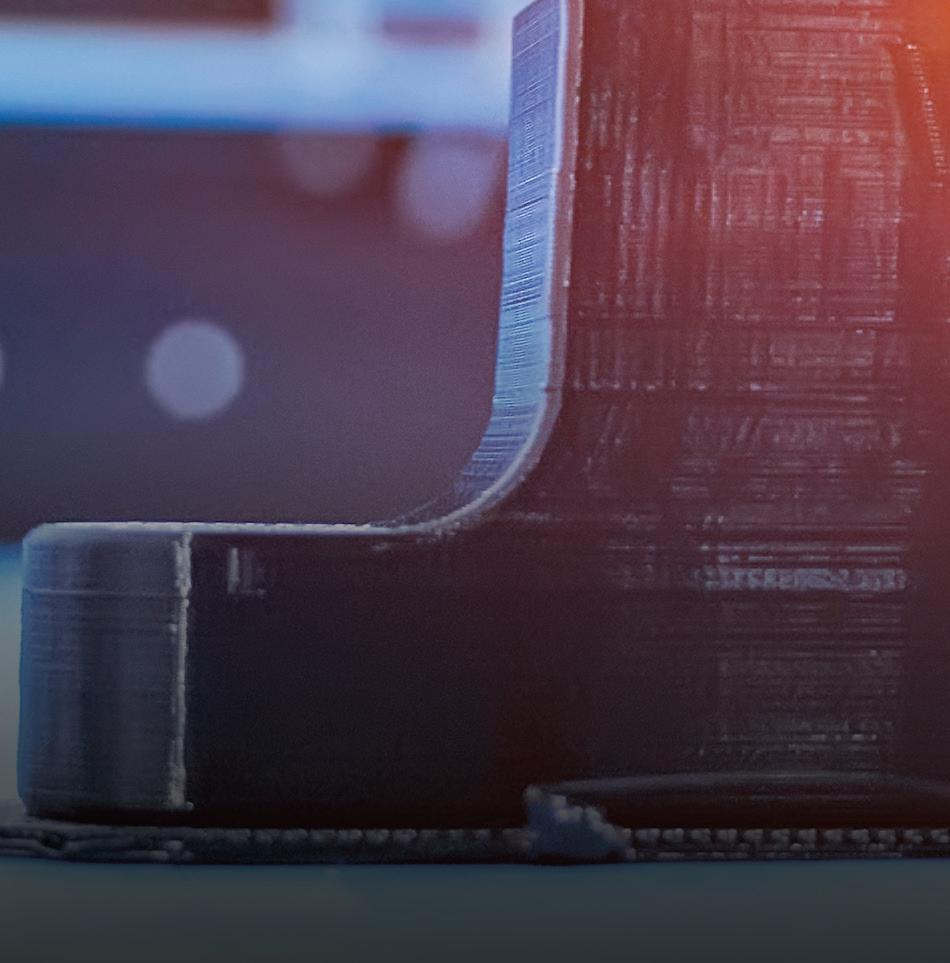

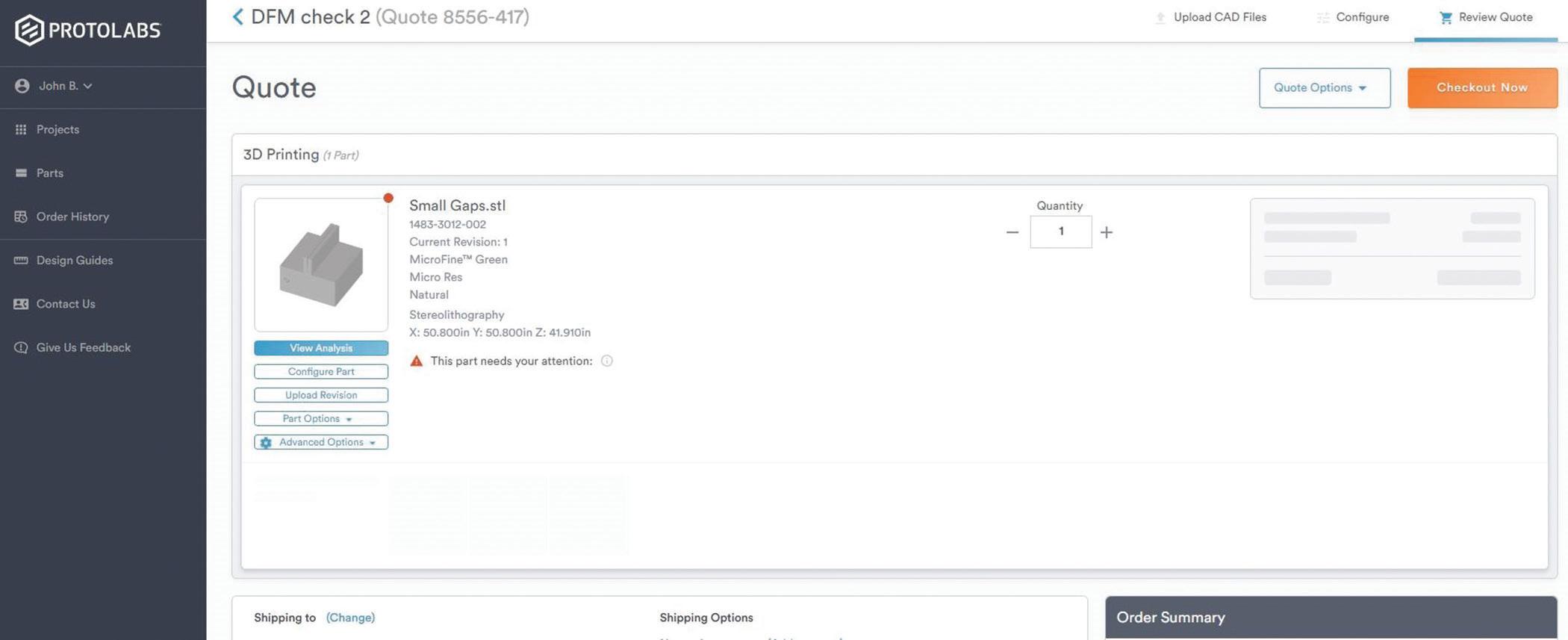

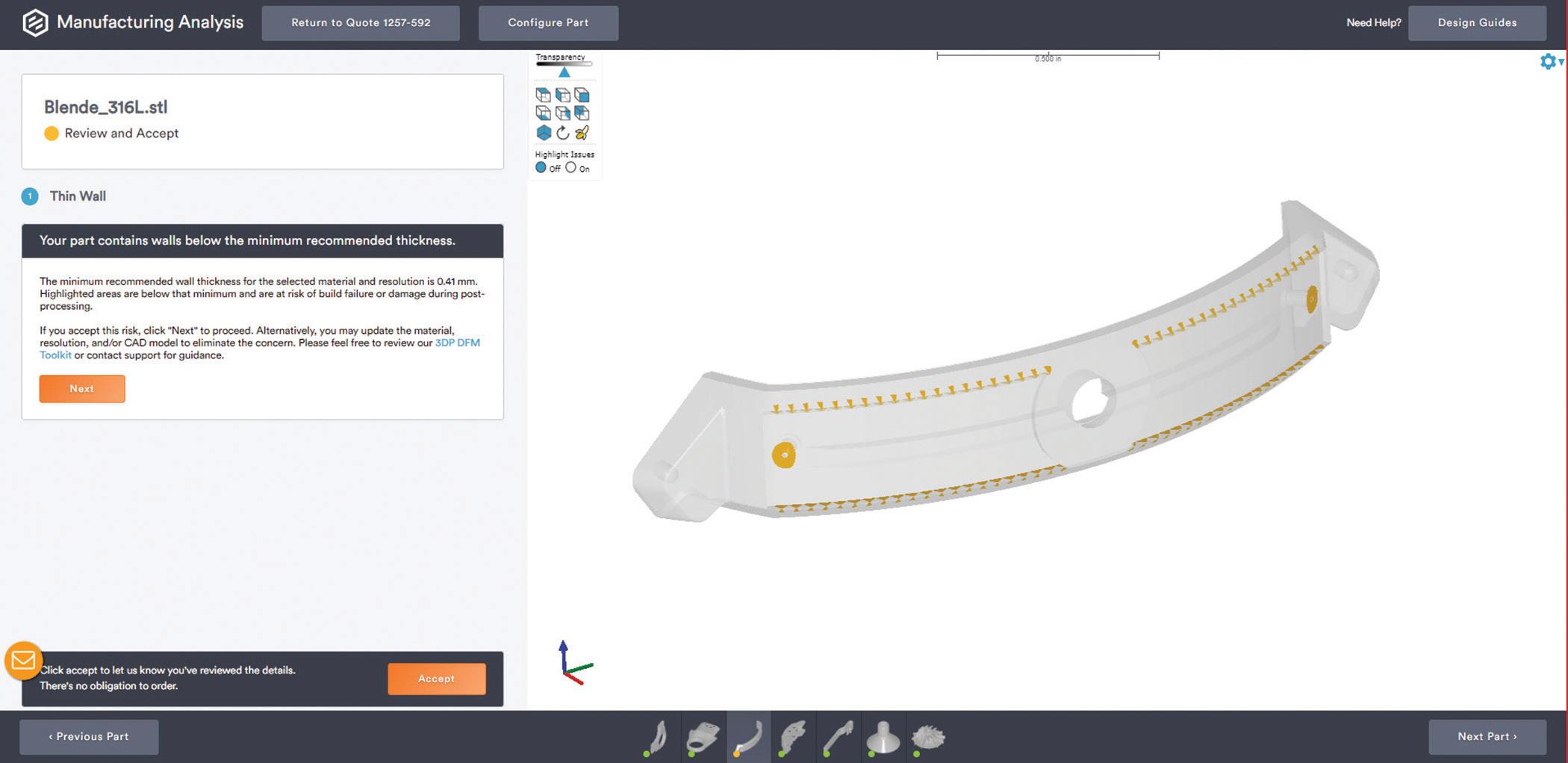

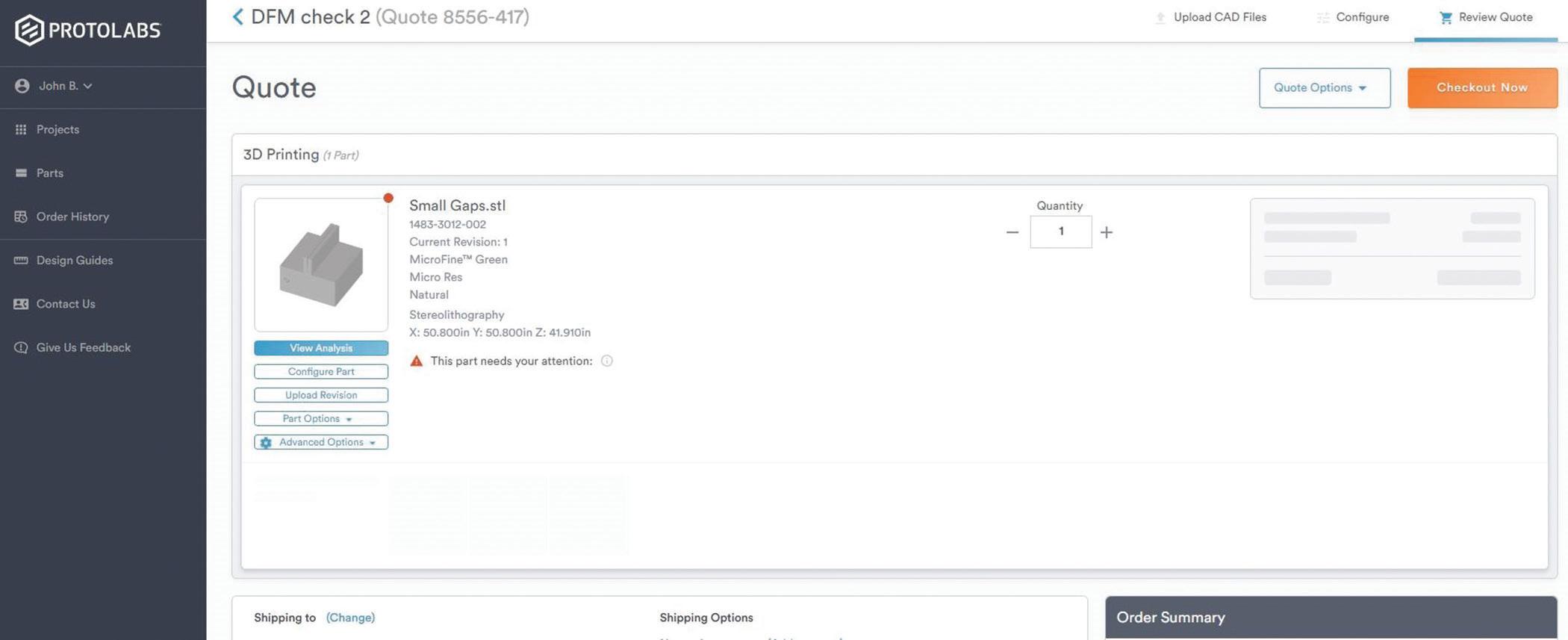

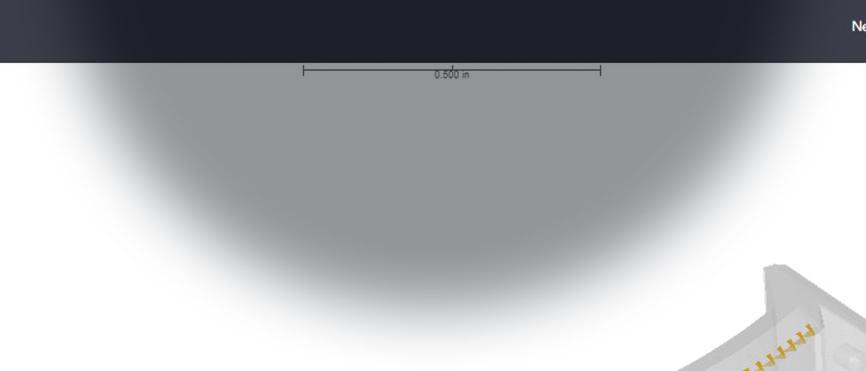

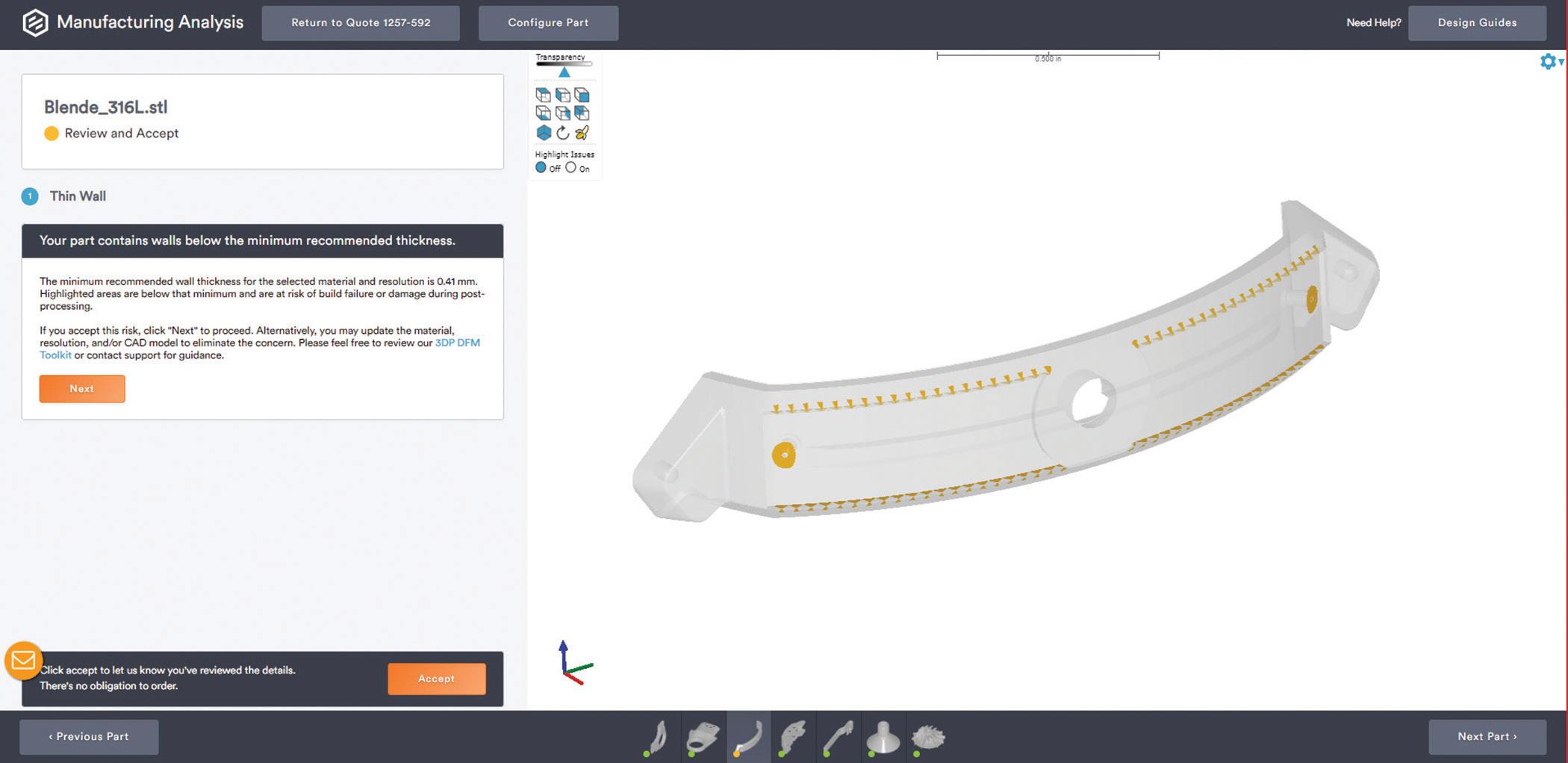

Design for manufacturability analysis prevents 3DP disasters

Additive manufacturing is a brilliant technology, but there are a few limitations that engineers must consider. A design for manufacturability analysis provides guidance and highlights critical issues, such as parts that are too large to be produced, or non-critical issues, such as dimensions that are close to thresholds and may not form completely.

Protolabs o ers manufacturers peace of mind with its online design for manufacturability (DFM) analysis for 3D-printed parts. In a matter of seconds, the service assures that parts are suitable for manufacturing before committing to production.

The automated feedback enables product developers and engineers to optimize additive designs before parts are printed, which helps accelerate product development and avoid unnecessary production costs by making design adjustments early.

“We understand the importance of speed, but ensuring that parts are correct, high quality, and delivered rapidly is critical. Instant analysis means you can have all the advantages of additive manufacturing with even more

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

44 April 2023 www.designworldonline.com DESIGN WORLD Protolabs’ online DFM analysis provides quick feedback on whether parts are suitable for production.

| courtesy Protolabs

The automated DFM analysis warns users of any issues before order submission.

| courtesy Protolabs

| courtesy Protolabs

certainty without sacrificing speed,” said Andrea Landoni, 3D printing product manager at Protolabs EMEA.

The DFM analysis is available globally on parts uploaded to Protolabs’ website for any of the company’s plastic and metal 3D printing technologies. When users receive their quotes, the analysis immediately highlights potential manufacturability advisories concerning thin walls, small gaps, and parts that exceed maximum size restrictions. This eliminates lost-time incidents for most common issues, preventing engineers from proceeding with orders only to discover issues hours later. While most problems are solved, there are circumstances where the user may still require further support.

“Protolabs understands that specific projects require technical consultancy to solve complex issues. In these circumstances, our Application Engineers are still on hand to overcome these challenges and accelerate the process,” said Landoni.

The company has also recently broadened its additive material and finishing options. Product developers and engineers can now choose 3D-printed silicone in multiple levels of shore-A hardness. The material is 100% pure silicone, which is biocompatible

and functional at various temperatures. Earlier this year, vapor smoothing was launched for select materials, providing enhanced finishes that eliminate rough surfaces and leave a glossy, aesthetic appearance on 3D-printed parts. DW

Protolabs

www.protolabs.com

The online manufacturability analysis provides design guidance so that engineers can correct and reevaluate parts quickly.

| courtesy Protolabs

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

DESIGN WORLD www.designworldonline.com April 2023 45

Design for 3D printing and Additive Manufacturing

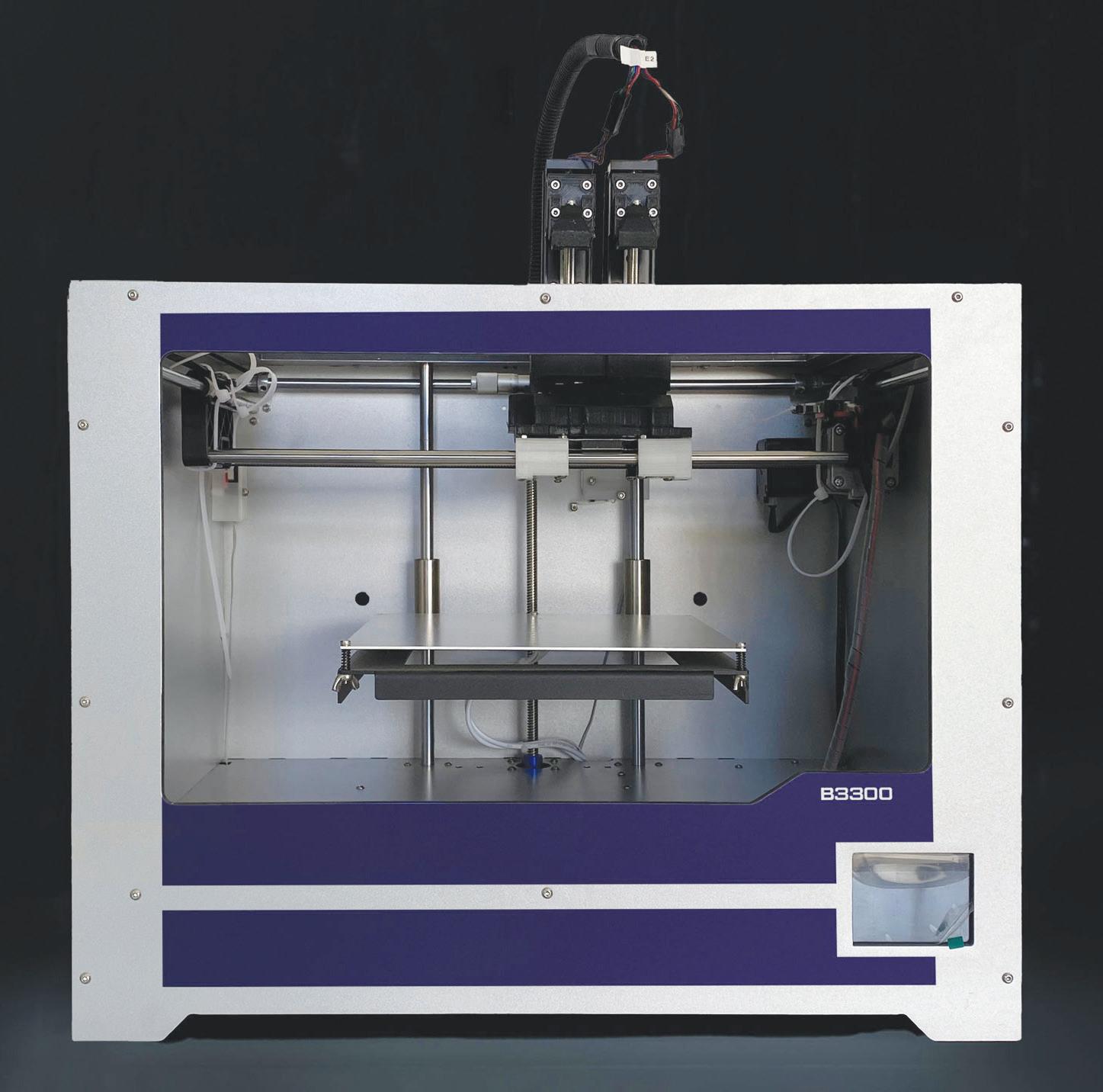

Orthopaedic surgery lab builds sensor-embedded smart casts for children

Modern 3D-printed casts are lightweight and customizable. The Billi Research Lab is advancing 3D-printed smart casts by embedding sensors that monitor the healing process.

The Billi Research Lab, supported by the Luskin Orthopaedic Institute for Children (LuskinOIC) at UCLA, aims to improve patient quality of life by developing breakthrough technologies and solutions to address unmet clinical needs.

nano3Dprint has entered a collaboration with the lab so that Dr. Fabrizio Billi and his team can build integrated microcontroller systems for sensor-embedded devices for children. Devices currently under development include scoliosis braces, smart casts, and Ponseti braces, which are used to treat clubfoot.

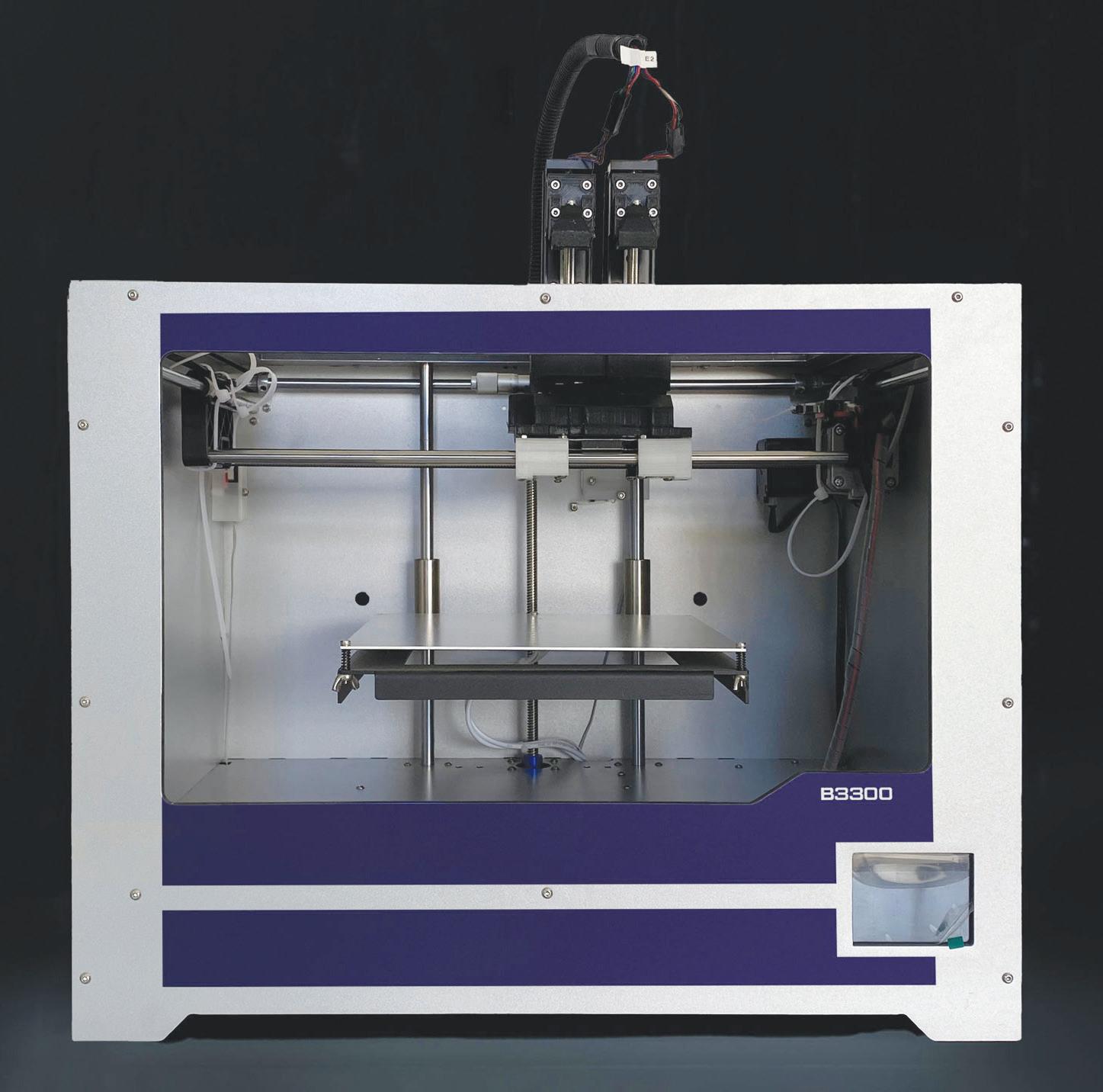

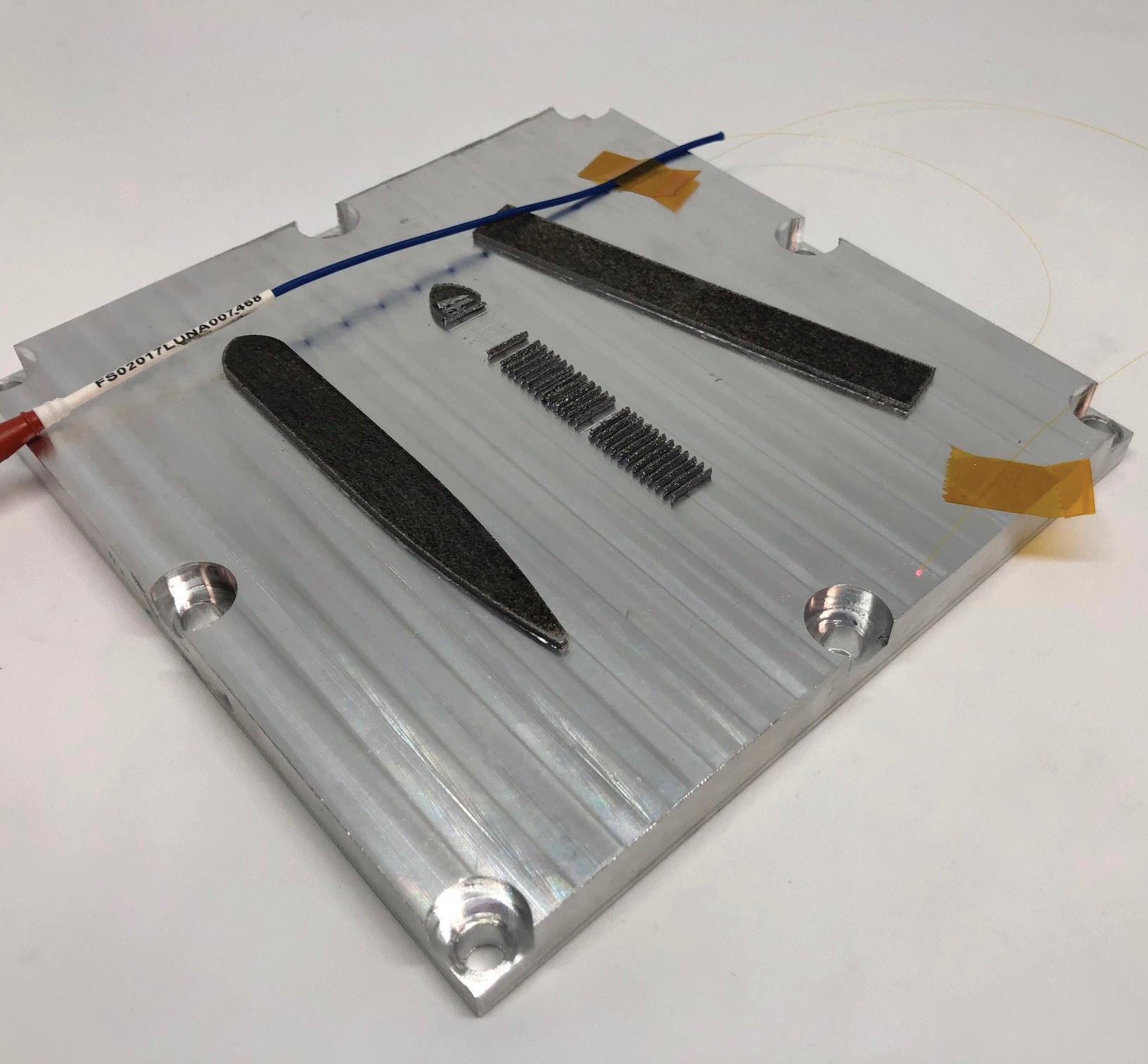

“We’re looking forward to utilizing nano3Dprint’s B3300 Dual-Dispensing 3D Printer to further our research and development of wearables, fusion sensors, and smart textiles. Current additive technologies are not versatile enough to allow us to build the complex, multifunctional devices required to provide modern and truly disruptive healthcare,” said Dr. Billi, director of the musculoskeletal devices and technologies development group.

The Billi Research Lab’s smart cast project will deliver real-time details about the fracture healing process, providing early warning of compartment syndrome. In this dangerous condition, swelling inside the cast limits blood flow to the limb, causing tissue necrosis.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 46 April 2023 www.designworldonline.com DESIGN WORLD

| courtesy of Tom Claes

Dr. Billi and his team intend to use nano3Dprint’s B3300

Dual-Dispensing 3D Printer to research and develop wearables, fusion sensors, and smart textiles.