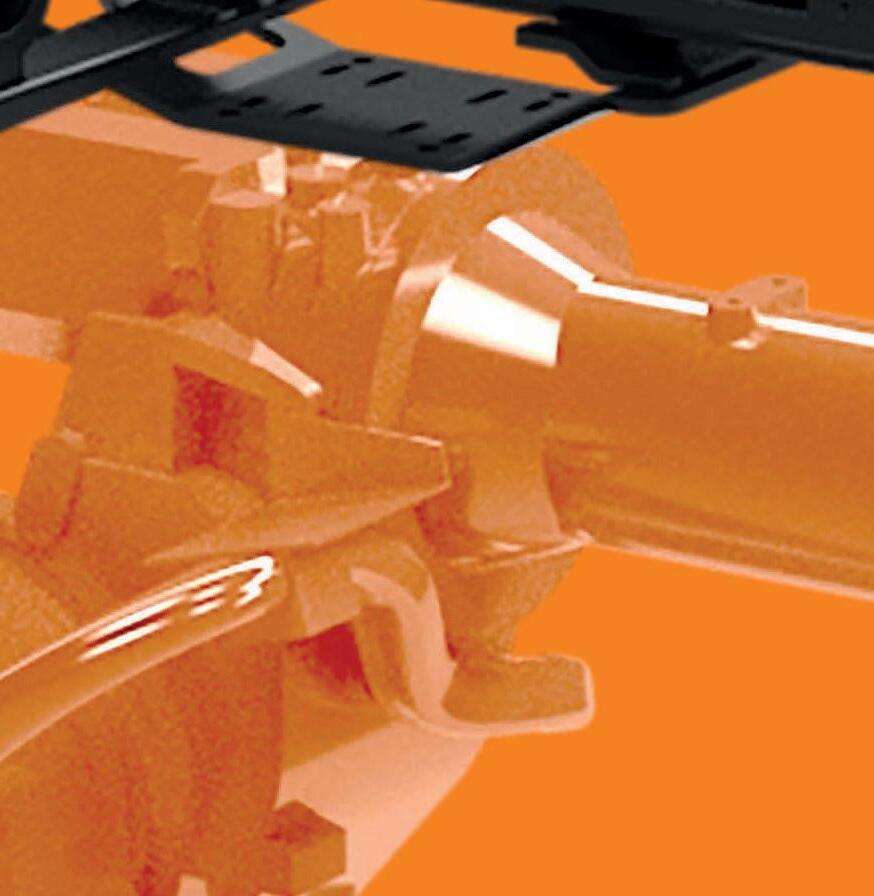

THK is committed to meeting the worldwide demand for linear motion products. We manufacture, assemble, and ship across North America from our location in Hebron, Ohio. We’ve also ramped up our automating processes at existing facilities, including our U.S. manufacturing plant, where over 70% of THK Robotics Components are manufactured. Automated processes at this state-of-the-art facility enable increased production while maintaining the high standard of precision associated with THK products.

To learn more, call us at 1-800-763-5459 or visit www.thk.com.

See us at: Rapid + TCT, Chicago IL, May 2-4 Booth #1634

See us at ATX West, Anaheim CA, Feb. 7 - 9, Booth #4254

Robotics Summit & Expo. Boston MA, May 10-11, Booth #332

Automate, Detroit MI, May 22-25, Booth #5610

THK Manufacturing in Hebron, Ohio

1–2 Week Delivery of Select LM Guides and Actuators

AutomationDirect carries a full line of almost 4,000 sensors from photoelectric to limit switches, proximity, and ultrasonic. Our sensors have the best pricing available with fast FREE shipping on orders over $49*. When it comes to buying sensors, it makes sense to choose AutomationDirect.

NEW! Schmersal Compact Limit Switches

Starting at $37.00 (PS116Z11-L200S200)

Schmersal compact limit switches provide an affordable solution for a range of object detection applications. They are available in a variety of actuator types, and their small size allows easy installation in confined spaces.

• Zinc die-cast switch in a thermoplastic housing

• 2-meter cable or M12 quick disconnect

• Connection exit from bottom or right

• 1 N.O. and 1 N.C. contact on all units

Contrinex Specialty

Inductive Proximity Sensors

Starting at $105.00 (DW-AS-711-M12-967)

• Models for high-temperature applications up to 230°C [446°F]

• Models for high-pressure applications up to 500 bar [7251 psi]

• Models with metal chip immunity eliminate the risk of false switching due to metal debris

• Models DNV-GL certified for maritime use

• IO-Link v1.1 on select models

• Protecting ratings up to IP69K

Photoelectric Sensors

Starting at $76.00 (OPT2133)

• Diffuse with background suppression, retroreflective, retroreflective for transparent objects, and through-beam models

• LO/DO, NO/NC outputs

• IO-Link compatibility

• Visible light spot allows easy target set-up

• IP67/IP68 rated

Linear Transducers

IP69K Rated Photoelectric Sensors

Ultrasonic Sensors

• Snap-action and slow-make/ slow-break contacts

• 45-degree adjustable head

• IP66/67 protection rating

ProSense RW Series

Mini Rectangular

Photoelectric Sensors

Starting at $44.00 (RWRT-LP-0A)

• Small footprint - rectangular

14 x 8 x 28mm

• Diffuse with background suppression, diffuse reflective, retroreflective, through-beam models

• Sensing distances up to 3m

• Axial cable or M8 quick-disconnect models

• Complete overload protection

• IP65/67 protection rating

Limit Switches

Starting at $14.50 (ZS-236-02Z)

• Available in 30mm and 40mm body widths

• Zinc alloy, aluminum or glass-fiber thermoplastic bodies

• 90-degree adjustable head, with levers adjustable to any angle

• Snap-action contacts in a variety of NO/NC configurations

www.automationdirect.com/sensors

At the recent IFPE and CONEXPO shows in Las Vegas, there was plenty to see for fans of mobile hydraulic technology. Hydraulics has long been the technology of choice for many o -highway vehicles thanks to its excellent power density. In the past decade, it’s been increasingly married to electronic controls, and these shows confirmed that trend.

On the machinery side, it was particularly interesting to hear how CASE Construction Equipment and CNH Industrial have been doing — in 2022, they grew an incredible 20% year over year. CASE has been electrifying more product lines to try and build a quieter, more satisfying workplace while also reducing emissions and lowering ownership and operating costs. They unveiled a host of new products at the show, including mini excavators, small articulated loaders, mini track loaders, wheeled excavators, and compact wheel loaders.

In addition, CASE is introducing five new backhoe models, so they now have models from entry-level machines to something being used as a utility workhorse (and ideal primary machines for owner-operators). Backhoes are seeing a huge resurgence in construction these days. That’s actually being driven by the ongoing labor shortages since these small, nimble machines provide plenty of job site flexibility and functionality for customers.

I asked Brad Stemper, CASE Construction’s Director of Product Management, how the company sees the future of hydraulics with the continued move toward electrification.

Stemper told me he thinks there absolutely is a convergence of electric and hydraulic technologies, and that we’ll continue to see a meld of electric, hydraulic, and mechanical components on their machinery. He explained that it really is something that’s a cost/value justification. It comes down to their engineers asking, “Are we able to provide a solution that allows the machine to do the work for a justified cost?”

One of the things that they’re most concerned and involved with now, is the control of the machine. Their focus is managing how much energy is being used by the hydraulic and electrical systems to really maximize how much work can be accomplished. To me, this is a great illustration of what engineers do best — combine older and newer technologies in innovative ways — to increase e ciency and create an exciting new generation of machines. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

On Twitter @wtwh_paulheney

Before attending the 2023 AMUG Conference, I was told exciting tales of networking lunches, themed evening parties, friendly competitions, and hands-on workshops. This one-of-akind event was filled with enthusiasm, camaraderie, and a commitment to advancing the additive manufacturing industry.

A common discussion point was that additive technology isn’t here to take over or magically solve all manufacturing problems. It’s an innovative solution for creating parts, next to machining and injection molding, that has advantages and drawbacks and lends itself well to specific applications.

Lightweight components with complex geometries are AM’s breadand-butter. Aerospace, defense, and medical are still the top sectors willing to adopt 3D printing and gain the most value. But collaboration across industries is where innovation really takes o .

Keynote speakers Rob Ducey, technical supervisor at LAIKA Studios, and Nicholas Jacobson, MDes, clinical research faculty at CU Anschutz Medical Campus, showed how an unlikely pair of AM enthusiasts could swap stories

and solve problems together. Their “Collaboration Between an Animator, an Architect, and a Surgeon” discussion demonstrated the vast use cases for 3D printing and how leveraging the right technology can save lives.

In industry, most manufacturers’ current challenges are volume and scale. 3D printing has been traditionally used for prototyping and low-volume production, but there’s a push to integrate AM into highervolume applications. However, experts caution against viewing additive technology as the holy grail or buying 3D printers without thinking it through. As Diana Kalisz, vice president of materials for 3D Systems, explained on stage, there must be a reason and value for 3D printing.

“One of the biggest challenges to moving 3D printing into manufacturing is that you’ve got to have a champion on the customer side willing to stick their neck out and who knows what they need,” said Kalisz.

Customers often approach AM experts with a list of unnecessary

attributes and desires that prompts engineers to go back to the drawing board and understand the problem better.

“Many people have no idea how hard it is to make anything,” said Kalisz.

Yet customers propel the industry every time they speak up about their problems and hint at desired solutions. AM experts who learn from customers build technology around what matters most. Customers keep the conversation going and are encouraged to share more so that the industry and technology can continuously advance.

“Don’t hide your problems,” said Kalisz. “We need to get more knowledge out there so the technology and industry can improve.”

The same can be said for any industry. Instead of shying away or viewing every problem as something that needs to be fixed, we can take a few steps back and learn to embrace failure as a starting point for something new and improved.

DW Rachael Pasini rpasini@wtwhmedia.com

The world’s first wireless IoT sensor node based on Wiegand technology. Left: The two Wiegand Harvesters between the bar magnets (inside the white enclosure) and the transmitter board with microcontroller, temperature sensor, and UWB transmitter module. Right: The receiver station located 60 m away, collecting the data by radio.

UBITO, a member of the FRABA family of technology companies, has announced a development of Wiegand technology as an energy source for smart sensors. After more than two years of e ort at FRABA’s R&D center in Aachen, Germany, a research team has demonstrated a prototype of a wireless sensor powered by Wiegand technology that could support Internet of Things (IoT) networks. The project involved the development of a new Wiegand Harvester capable of capturing enough energy to power the sensor’s electronics package, including a high-e ciency ultra-wide-band radio transmitter.

This achievement (a world first) helps to position Wiegand technology (which collects energy from movements of an external magnetic field) beside established energy harvesting techniques such as solar, piezo, or thermo-electrics as an energy source for sensor nodes in the emerging industrial IoT (also called Industry 4.0).

“Wiegand sensors have been a core component of our encoder products for over 15 years,” said Tobias Best, global head of the UBITO startup. “While this technology has provided a highly reliable way of detecting and recording rotations in flow meters

and multiturn encoders, we have always been looking forward to its wider potential, especially for energy harvesting.”

With this goal in mind, FRABA undertook a development project aimed at improving the energy output from Wiegand devices and demonstrating the possibility of self-powered sensors that could detect events and transmit data wirelessly to an IoT network. The R&D project was conducted by specialists from FRABA and Aachen’s University for Applied Science, with financial support from the German Ministry of Education and Technology. The project team succeeded in producing a new Wiegand Harvester — a device that could generate more than fifty times more energy than commercial Wiegand sensors.

“This level of output makes it possible to dream of energy selfsu cient sensors that can communicate data wirelessly over a significant distance,” said Best.

The team chose a window sensor system for a practical demonstration of an IoT sensor node powered by Wiegand-harvested energy. Two Wiegand harvesters and their associated electronics were mounted on the window, with bar magnets mounted on the frame. The harvesters, made up of a 21 mm long pieces of Wiegand wire surrounded by a copper coil, are the size of an AAA battery (d=7.5 mm). Whenever the window is opened or closed, the harvesters pass the magnets, triggering abrupt magnetic polarity changes in the Wiegand wires. The amount of energy delivered is largely independent of how quickly or slowly the window is moved … a key benefit of Wiegand technology.

The current pulses induced by these polarity reversals generate about 10

microjoules of energy. A key goal had been achieved: the amount of energy captured was su cient to activate a microcontroller and collect a reading from a temperature sensor built into the system. The team added an ultrawide-band (UWB) transmitter module that could transmit 134 bytes of data to a receiving station 60 m away. This lab demonstration, which marks a milestone towards self-su cient Wiegand-based IoT sensor nodes, was presented in April at EnerHarv 2022 in the U.S.

“This is a lab demonstration, not a commercial product. However, by showing the capabilities of a system made up of Wiegand devices and othe-shelf electronic components, we hope to spark interest in the wonderful potential for this technology. With the Industrial IoT projected to grow by a factor of three over the next decade, the future is very exciting,” said Best. DW

UBITO | www.ubito.com

“Wiegand sensors have been a core component of our encoder products for over 15 years,” said Tobias Best, global head of the UBITO startup.

Part two: Scalar and vector VFD control methods

In the first of this two-article series, we considered VFD operation types to satisfy process and motion-control applications. Here we delve deeper into two advanced types of operation.

14 experts on

For the annual Design World Trends issue, we asked industry experts to share their insights into linear-motion trends.

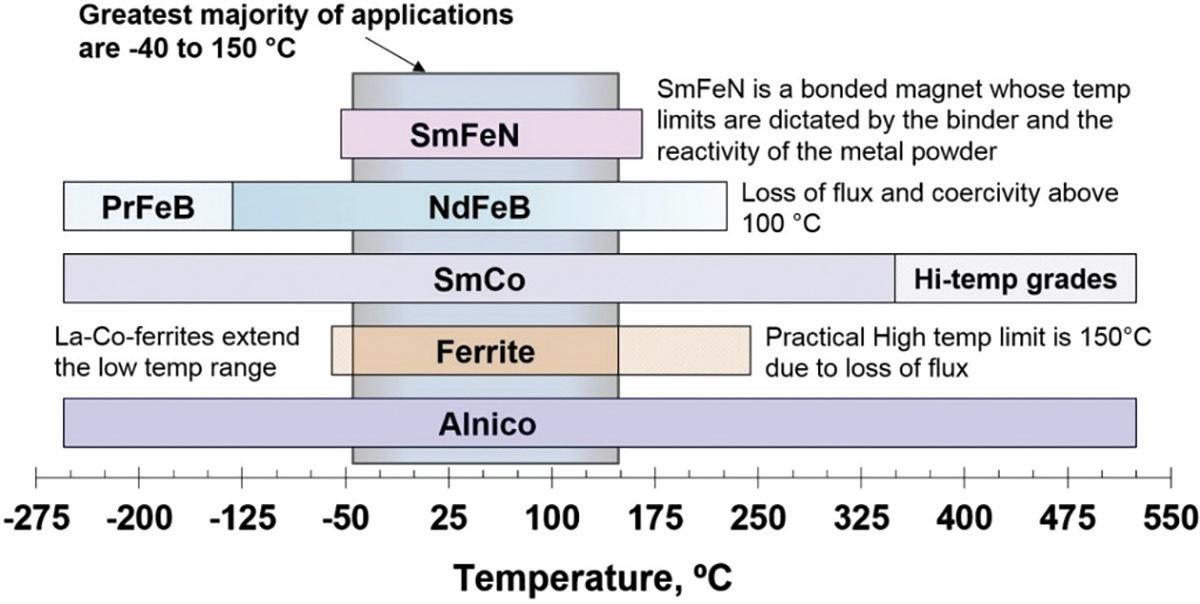

What types of magnets contribute to sustainability?

E orts are underway to develop new magnetic materials that improve sustainability and maintain performance in industrial applications.

SAM increases electro-mechanical sensor reliability

Scanning Acoustic Microscopy testing ensures that oilfield and optical sensors are built without essential material defects.

Follow the whole team on twitter @DesignWorld

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor

Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Art Director Allison Washko awashko@wtwhmedia.com @wtwh_allison

Senior Graphic Designer

Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Meagan Konvalin mkonvalin@wtwhmedia.com

Digital Marketing Coordinator

Francesca Barrett fbarrett@wtwhmedia.com

Webinar Coordinator Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator Dan Santarelli dsantarelli@wtwhmedia.com

FINANCE Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

EVENTS

Events Manager

Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist

Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Videographer Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer

Kara Singleton ksingleton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative

Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager

Samantha King sking@wtwhmedia.com

Marketing Graphic Designer

Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

With lingering supply chain challenges and uncertain futures, manufacturers and design engineers seek flexible solutions that check all the boxes for harsh environments, compact areas, digital transformation, and built-in safety.

Siemens’ new Sinamics G115D is a compact drive system specifically designed for motor-mounted and wall-mounted horizontal motion control conveyor applications. The drive system includes the motor, drive, and gearbox in one unit with power ranges from 0.5 to 10 hp (0.37 to 7.5 kW) for wall-mount applications and 0.5 to 5 hp (0.37 to 4 kW) for motor-mounted applications.

The drive system is characterized by a high IP protection class (up to IP66/ UL Type 4X) and is suitable for harsh environments and confined areas. It can be operated over a wide temperature range of -22 to 131° F (-30 to 55° C), enabling operation in deep freezing applications. It is also suitable for applications in intralogistics, airports, automotive, and food and beverage industries.

The drive system integrates with the Totally Integrated Automation (TIA) portal, including Startdrive commissioning software or the Sinamics Smart Access Module (SAM) web server for WiFi setup and diagnostics. To prepare for digital transformation and enable cloud-based analysis, it is also integrated into the entire MindConnect portfolio and compatible with MindSphere applications, such as Analyze MyDrives.

Safety is integrated with Profisafe in the form of STO (Safe Torque O ) SIL2, which standardizes and facilitates the certification process. The solution is also equipped with a plug-in connector and flexible connection possibilities. The device is particularly suitable for interaction with Simatic controllers, such as the S7-1200 or ET200, for motion control. DW

Siemens | www.siemens.com

A new laser-based system continuously monitors the surface of flat fabric or steel cord conveyor belts in industrial and mining applications. The system automatically and constantly scans for damage to the belt to reduce the risk of catastrophic belt failure and minimize downtime. It evaluates the belt for cuts, gouges, or large impact damage events and surface adhesion issues. The data is continually analyzed and reported, alerting operators to the exact position and size of any damage, even for di cult-to-access conveyors.

The Conti SurfaceProtect system from Continental provides an early warning when belt maintenance or replacement will be required. This

allows for planned, orderly belt service, which is faster and less costly than repairing belts after a catastrophic failure.

“With the Conti SurfaceProtect system, industrial and mining belt conveying applications can be monitored on a constant basis, reducing the need for manual reviews of the belt condition,” said Anthony DiGiacobbe, communications manager for North America at Continental. “The belt profile information can be used to determine the remaining life of the belt and identify the exact location and severity of wear and damage. The system is especially useful in applications where conveyor belts are di cult to access or

inspect, allowing for remote examinations of the belt condition. By monitoring over the entire belt life cycle, operators can maximize belt life.”

The top cover monitoring unit projects a laser line on the running conveyor belt surface. An optical sensor records the shape and position of the laser line to create a digital map of the belt cover surface topography. This digital profile is analyzed in real time with user-defined thresholds for damage detection. The software reports on large impact defects, slits, cuts, gouge events, edge damage, misalignment, splice surface control, and abnormal abrasion.

The bottom cover monitoring unit provides overall belt shape monitoring and optical monitoring for longitudinal belt rips without the need for rip detection inserts in the belt. The bottom unit includes automatic alarm and belt stop functions. DW

Lead frames are used in the semiconductor assembly process. They are essentially thin layers of metal that connect the wiring from tiny electrical terminals on the semiconductor surface to the large-scale circuitry on electrical devices and circuit boards. In lead frame design, one size does not always fit all, and very often, demand is for customized features, designs that enhance electrical and thermal properties, and specific cycle times.

The micrometal Group has developed a next-generation photo-chemical etching (PCE) process well-suited for lead frame production. The process allows manufacturers to make innovatively designed lead frames with tight tolerances repeatably and accurately concerning miniaturization and weight-saving trends.

“We etch simple or sometimes more complex lead frames from metal and alloys that demonstrate a very low expansion

rate at room temperature. These low thermal expansion alloys have found use in modern applications which require joining metal to glass or ceramics and preventing associated problems within the joint area,” said Jochen Kern, head of sales and marketing at the micrometal Etching Group.

Lead frames can be highly complex and fragile. In many instances, geometric complexity, exacting tolerances, and precision requirements limit the technology capable of producing certain lead frames. When stamping lead frames, complex designs often require complex mold tools, which increases costs and lead times.

PCE is agnostic to the geometry and tool complexity. It can produce lead frames with tighter tolerances and finer detail than stamping, minimal to no metal degradation and deformation, and little to no likelihood of burrs or defects. Failure rates are minute, and unlike stamping, every lead

frame produced is absolutely flat, which is a vital prerequisite.

“micrometal’s unique process can achieve dimensional tolerances as low as ±0.005 mm, small feature sizes of 25 microns, a minimum hole diameter of 80% of the material thickness, and single-digit micron tolerances repeatably. Compare this with traditional chemical etching, which can only achieve the smallest feature size of 100 microns, and the smallest hole diameter is a factor of 1 to 2 when compared to material thickness. Our PCE process opens up numerous impossible design opportunities when manufacturing lead frames,” said Kern.

micrometal’s tight tolerance manufacturing processes are appropriate for numerous lead frame applications and ideally suited to high lead/pin count and ultra-fine pitch lead frame manufacture in high volumes DW

Micrometal | www.micrometal.de

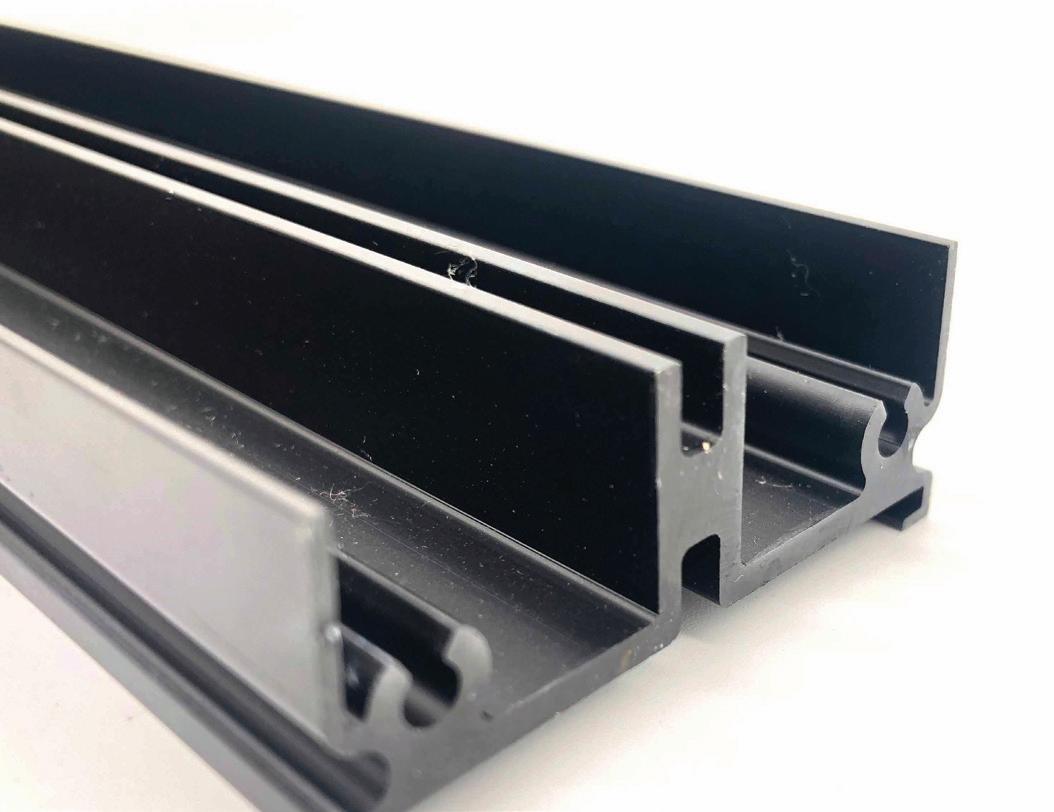

New ultra-compact linear modules position small masses accurately and economically, thus paving the way to electrification.

Bosch Rexroth has a portfolio of small-handling linear axes and recently added new Small Modules Screw Driven (SMS) linear modules with an ultra-compact range and ball screw assembly. These linear axes are suitable for handling cost-sensitive small parts and are an alternative to complex pneumatic solutions. They can position small masses in a wide range of applications with low to medium dynamics, including the consumer goods and packaging industry, semiconductor and battery production, 3D printing, automotive, and medical technology.

The low-profile and light linear modules allow economical electrification with high repeatability of up to ± 0.005 mm. Design engineers can select from five predefined sizes from 30 to 120 mm and optional attachment sets for motors and drive controllers from various manufacturers.

The electromechanical axes have a compact, low-profile aluminum design with integrated precision guideways. A magnetically fixed steel cover strip protects the components inside. The product range includes five tailored module sizes from 30 to 120 mm for travel ranges up to 1,200 mm. DW

Bosch Rexrothwww.boschrexroth.com

The proportional pressure regulator VPPM controls the air volume on the input side of the DPP piston pump.

A critical step in folding box manufacturing is the highly precise gluing of the box blanks. Folding-gluing machines process box blanks from a die cutter by folding and gluing them into finished folding boxes. Afterward, the folding boxes are assembled and filled by automatic packing machines. Many boxes must be folded in and across the machine’s direction of movement before the glue is applied to ensure that the boxes can be put together e ortlessly later.

“Applying the right amount of glue in the right place is no easy task,” said Marco Ahler, technical director at Baumer hhs, a German manufacturer of industrial adhesive application systems.

Gluing machines achieve speeds of more than 700 meters per minute and can glue well more than 40,000 folding boxes per hour, depending on the packaging size. Baumer hhs builds systems that apply glue with millimeter accuracy and without contacting the blank, even at high production speeds. Its modular systems include a high-pressure adhesive supply, fast-switching electromagnetic application valves, and a control unit.

The centerpiece of this gluing process is the DPP-8 doublepiston pump, which must provide a specific fluid pressure to apply the adhesive accurately. Each piston takes in compressed air on the upward stroke and displaces liquid from the glue cylinder on the downward stroke.

“You could call it a two-cylinder engine with the performance of an eight-cylinder,” said Ahler.

The DPP-8 piston pump regulates the air input pressure to set the required adhesive fluid pressure. The precise proportional pressure regulator VPPM from Festo controls the air volume on the input side. The VPPM has a linear pressure regulation range between 0.06 and 6 bar. For a delivery pump with a transmission ratio of 8:1, this means a reliable fluid pressure regulation range of 8 to 40 bar. The regulation starts with small increments to the control quality at 2 bar.

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

The advantage of regulating the input pressure instead of fluid pressure on the output side is that only the amount of compressed air required for the actual operating conditions is consumed. Compressed air consumption is proportional to the material pressure, so operational costs can be reduced if the maximum delivery pressure is rarely required.

The air pressure on the input side is converted into a largely fluctuation-free fluid pressure in accordance with the transmission ratio of the delivery pump. This enables the delivery volume to be quickly regulated and adjusted. A pressure sensor in the pump measures the fluid pressure on the output side. A closed-loop pump control circuit ensures the pressure is automatically

adjusted if the actual pressure deviates from the target pressure. This is particularly advantageous when the fluid is delivered intermittently. Tests show that when a delivery valve is opened, the spontaneous drop in the pump is 25 to 50% less than with a pump with a downstream material pressure regulator, while the drop is intercepted much faster and more reliably by the closed-loop control. In addition, critical fluids are subjected to less stress and largely retain their original consistency. DW

Festo

www.festo.com

Lightweight mobile robots improve production speed and e ciency by reducing energy consumption and recharging time. The nimble maneuverability of lightweight robots is also a huge advantage for tasks that require frequent turning or have limited space.

As such, Techman Robot released a new lightweight high-payload AI cobot, the TM20 robotic arm. At only 32.8 kg, the cobot carries up to 20 kg and can reach up to 1,300 mm with six rotation joints. Despite being light, the cobot’s high payload capacity makes it suitable for heavy-duty AMR applications. It can also be used for automotive, semiconductors, and secondary packaging for food, plastics, or machine tools.

The built-in smart vision compensates for positioning errors and ensures precision in fast pick-and-place tasks without additional visual or positional monitoring. This reduces integration time and costs. Moreover, Techman’s exclusive TM Landmark capability allows real-time updating of the relative position of the arm and key points in the environment, keeping the robot safely oriented in 3D space regardless of its position.

This robot’s versatility is suitable for high-volume packaging and palletizing, massive pick-and-place jobs, material handling, and heavy machine tending. Specific applications where the TM20 excels include semiconductor backend processes that require a large amount of manual loading, unloading, lifting of wafer boxes weighing more than 10 kg, and the retrieval and transfer of medical equipment and drugs.

DW Techman Robot www.tm-robot.comWHAT DO YOU THINK?

In the world of cobots, the spectrum of human-motion sequences poses a safety challenge. A robot’s power and power-limited mode is usually designed for the permissible force values of arms and hands. The robot must also avoid contact with sensitive body regions, such as the face, skull, and forehead, and therefore must stop near personnel.

safeVisionary2, a new 3D time-of-flight (ToF) camera with Performance Level c (PL c) from Sick, detects a person’s upper body and upper limbs so that safety distances can be reduced around the cobot. The sensor enables extended protection of the robot work area at human-head height such that a robot standstill is only necessary when a person’s head moves into the work area.

The compact 3D camera helps increase productivity and provides precise 3D measurement data to enhance automation. In addition to human safety, it can detect empty pallets for object localization and measurement, and it is especially e ective for AMRs for autonomous and intelligent navigation.

With safeVisionary2, obstacles above the scanning field level of a safety laser scanner are also reliably detected in the direction of travel, preventing collisions. In contrast to 2D anticollision solutions, safeVisionary2 can automatically restart in many cases.

Side protection safety is also increased during turning and pivoting maneuvers after loading and unloading. The 3D environmental information can also be used in mobile applications for precise localization and navigation via Gigabit Ethernet.

Mobile service robots used in unstructured environments require careful risk assessments. Obstacles such as stairs or ramps can pose potential crash risks for the robot. In addition to track protection, safeVisionary2 also enables cli detection and contour-based navigation. DW

GuardLink 2.0 from Rockwell Automation is a serially connected safety input solution designed to reduce downtime and installation costs. GuardLink 2.0 o ers advanced diagnostics through the new Allen-Bradley 432ES GuardLink EtherNet/IP On-Machine Interface or a combination of Rockwell Automation’s Dual GuardLink Relay and EtherNet/IP Interface. GuardLink 2.0 protocol also enables safety-rated control device status reporting and automatic diagnostic reporting to an HMI using CIP Safety over EtherNet/IP.

The new 432ES GuardLink EtherNet/IP interface allows design engineers to connect up to 96 safety devices via three independent safety channels. The interface can cascade power to additional interfaces and keep track of the timing and frequency of events to improve maintenance and create process e ciencies. The 432ES supports linear, star, and Device Level Ring (DLR) topologies while meeting the highest safety ratings up to SIL 3, Cat 4 PLe. DW

Rockwell Automation

www.rockwellautomation.com

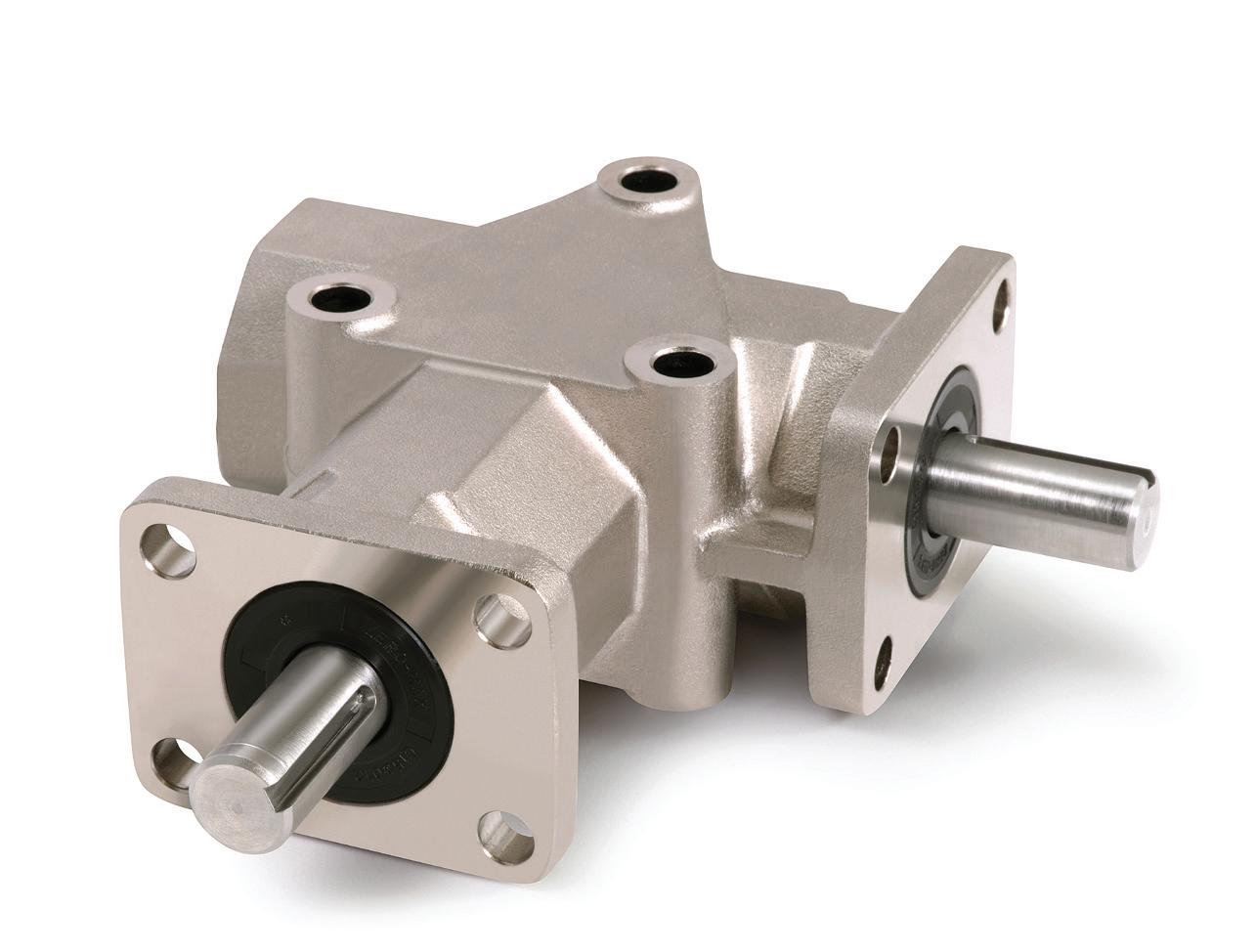

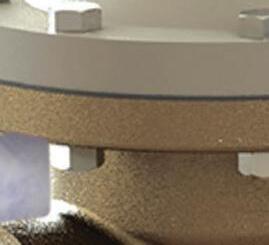

The recently released Zero-Max IP65-Rated Crown Gear Drives are used in the OpenAire Vertical Opening Glass Wall System for a swimming pool enclosure on a Cruise Ship. This retractable Wall System provides a naturally ventilated, healthy, safe, and energy-e cient environment made possible with a mechanical drive system using the IP65-Rated Crown Right Angle Gear Drives.

OpenAire is a designer, manufacturer, and installer of custom glass wall panels, retractable roof structures, and operable skylights. There are many di erent applications for this OpenAire window system, including use as a retractable enclosure for patio restaurants.

Retractable vertical opening glass wall systems promote the extensive use of daylight and natural ventilation. Not only do they give access to an outdoor experience, but these systems also save significant energy. As a result, these glass wall systems

Providing this level of performance is assured with the high precision gears, quality materials, and construction of the IP65-Rated Crown Gear Drive. These drives feature spiral bevel gears, having curved teeth that always maintain tooth contact, which are designed to reduce vibration and noise during operation.

The Zero-Max IP65 Right Angle Gear Drive is ideal for the OpenAire retractable glass wall system application. Connected to the mechanical system lead screws, the Right Angle Gear Drives handle the torque and shaft speed requirements of the application.

OpenAire Vertical Glass Wall System in a swimming pool enclosure on a Cruise Ship uses Zero-Max IP65-Rated Crown Gear Drives ensuring smooth open and closure operation.

may be operated frequently and must provide e cient, trouble-free operation.

To ensure this, OpenAire uses a well-planned mechanical system incorporating IP65-Rated Zero-Max Crown Right Angle Gear Drives. These drives deliver dependable and economical transfer of speed and power in an e cient and compact design with quiet operation. In congregate settings, quiet and smooth operating mechanical features are crucial.

The IP65-Rated Crown Gear Drive has a nickel-plated aluminum housing, stainless-steel shafts, and purpose-built shaft seals. It provides an added level of protection to withstand conditions such as frequent washdowns, corrosive elements, and outdoor installations that can include temperature extremes, sunlight, rain, humidity, and condensation. This fully enclosed design prevents contamination from water, chemicals, and debris, allowing it to hold up to harsher operating environments.

of as water,

Another important feature is that the IP65-Rated Crown Gear Drives are pre-lubricated, making them a “Lubedfor-Life” design o ering maintenancefree operation for the life of the product. Most importantly, these Zero-Max Crown Gear Drives have been tested by an independent laboratory to obtain the IP65 Certification for ingress protection against dirt and water.

One particular OpenAire project for a patio restaurant consists of 17 Vertical-Opening Glass Wall Systems

incorporating the IP65 Crown Gear Drives. Each system has three, two-inch thick panels and measures 12-ft high by 15-ft wide. In addition, retractable roof panels are incorporated into this OpenAire patio design. The overall system makes for a true open-air patio restaurant, providing the maximum “open air” experience, which can be quickly closed up tight at the touch of a button during cooler or rainy days.

Panels

The bottom window panel is stationary. The upper window panel is directly connected to the lead screws on either side of it. The window panels stack side-by-side next to the stationary panel as the upper window panels are lowered, forming a railing when the windows are opened. When the top panel is lowered, the middle panel is also lowered until it comes to rest alongside the bottom stationary panel. Once the middle panel comes to rest, the upper panel is lowered further, sliding alongside the middle panel until it reaches its fully lowered position. The

three windows, when stacked sided-by-side, only require 6 inches of total thickness.

For each glass window system, two IP65-Rated Crown Right Angle Gear Drives are enclosed in a header beam above the window mechanism. A Crown Gear Drive is positioned on each side of the window system, with both Crown Gear Drives interconnected by an intermediate shaft, allowing one motor to drive the system. Included are vertical lead screws on both sides of the window system, which are connected to the output shafts of the Crown Gears to run the windows up and down.

The intermediate shaft connecting the pair of Crown Gear Drives synchronizes the assembly so that each side of the window panel lifts at an even rate, providing a smooth vertical lifting and lowering of the window panels. The framework has all the mechanical and electrical components concealed within the framework, making for a very clean, contemporary exterior design. DW

Emulate3D can integrate virtual reality (VR) features so that detailed safety checks or danger predictions can be completed in virtual environments in addition to checking on machines running PLC programs.

Hirata Corporation is an OEM machine builder based in Kumamoto, Japan. It is active in automotive and semi-conductor industries and end-toend machine supply from design and engineering through commissioning.

2019: Hirata’s challenge

It seemed that everything was on track, but program debugging and position education had been a headache at Hirata for a long time. The program itself can be checked even before machines are built, but debugging can be done only after machines are built and running the program. Then the teaching follows. Typically, teaching is done through HMI — inputting the position of each axis of the robots. It must be done with a great deal of care to ensure precise position input. Therefore, it was only natural for Hirata

to think, “What if we can start the debug process without waiting for the machine to be built?” At the same time, commissioning is another challenge for Hirata. Especially when it comes to overseas projects, people at the site had to wait several weeks (or even months, depending on the destination) before machines arrived at a site. They then wondered if there was anything they could do during shipping and freight time.

Hirata then encountered Emulate3D software from Rockwell Automation. Hirata and

Rockwell Automation had a business relationship in component supply with programmable logic controllers (PLC) or servo products, especially for machines shipped to the United States. In January 2019, Rockwell Automation acquired Emulate3D for its expanding digital engineering capabilities and started the sales promotion of the digital tool. At that time, o ine teaching through simulation software was becoming popular, but simulation could not test the program, so debugging could not be done with simulation tools. Emulation allows engineers to run the program on the virtual environment with the 3D computer-aided design (CAD) objects so engineers can start to debug the program without waiting for the machine to be built. Hirata was impressed by the first demo done by technical consultants from Rockwell Automation Japan.

It was June 2019 when the Rockwell Automation Japan team conducted an Emulate3D demo in front of Hirata engineers. The Hirata team

was impressed by the presentation and demo but felt the need for technical verification as well. Then the collaborative proof-of-concept journey started. Hirata gave some technical information to Rockwell Automation consultants to let them set up a more tailored demo. Rockwell Automation consultants returned to Hirata with a tailored demo and gave Hirata additional inputs for more rounds of setup.

After the rounds of communication back and forth for several months, Hirata engineers became more confident in the tool and turned to management for budget approval. Mr. Shimizu in the #2 Kumamoto Business Division, #2 Business Unit, referenced that moment by saying, “We’ve encountered multiple simulation solutions that resulted in a smallscale deployment. But Emulate3D was di erent. Once we obtained the demo program developed by Rockwell Automation with our real 3D CAD data, we were impressed by its quality and could feel the potential in various use cases.”

After the budget was approved, dedicated engineers were assigned in January 2020, and intensive hands-on training began by Rockwell Automation technical consultants. Months of training enabled dedicated engineers to fully use the emulation tool and resulted in strong outcomes within some actual projects. This success led to the new “Digital Engineering team” under Mr. Kusuguchi, general manager’s division, including four new engineers. The next year in April 2021, #3 Business Unit, the next business unit to Mr. Kusuguchi’s organization, established the “3D Design Promotion team” which included four engineers. Now, Emulate3D has been expanded with a 30% reduction in engineering time and a 70% increase in e ciency and debugging work.

Hirata Corporation is an OEM machine builder based in Kumamoto, Japan. Founded in 1951, Hirata strives to have a wide ranging customer base in more than 40 countries by leveraging its own developed modules.

Emulate3D can integrate virtual reality (VR) features so that detailed safety checks or danger predictions can be completed in virtual environments in addition to checking on machines running PLC programs. This can also be used for virtual commissioning, which enables Hirata to reduce the needed engineer dispatch and commissioning time. Additionally, troubleshooting or factory acceptance testing (FAT) can be done with virtual emulating machine operations. In fact, according to Hirata, due to the global pandemic, more and more remote FAT/troubleshooting requests are being received. It is a huge benefit, not only for Hirata, but also for end users to change their business behaviors from real/in-person to remote. Furthermore, combining Emulate3D with VR can help realize the virtual training environments so that site workers can complete operation training while waiting for oceanic transportation. This virtual training is also applicable for newly hired employees seeking training. DW

Rockwell Automation rockwellautomation.com

can

Since Greg Kordalski founded KES Machine LLC, the business has been helping engineering and manufacturing companies maximize productivity and minimize downtime with its accredited calibration and repair services. KES Machine LLC’s technicians help machinists solve geometry errors, lead screw errors, and repeatability concerns.

While the company initially focused on CNC service work, in 2008, it invested in its first Renishaw ML10 laser system and began developing its calibration services. In 2019, KES opened a Polish subsidiary to support manufacturers there. “Since I was

• Managing Editor

“Renishaw o ers a range of calibration solutions for improved machine performance, increased machine up-time, and preventative maintenance schedules,” explained Je rey Seliga, Marketing Manager at Renishaw Inc.

born in Poland, I visit quite frequently, so this is why I chose Poland as the first country on the European continent,” explained Kordalski. In 2016, KES obtained ISO 17025 certification and became a fully capable calibration service company.

“ISO 17025 accreditation demonstrates our capabilities to our customers,” said Kordalski. “Showing that we follow industry requirements for testing and calibration enables us to provide a value-added service to engineers and ensures all our equipment is up-to-date and our technicians o er the best service to customers.”

Component quality is dependent on machine performance. Without understanding a machine’s error profile, it is impossible to have confidence that components will fall within specifications during manufacture. KES works with highprecision industries, such as aerospace, defense, and medical. This led KES to investigate volumetric machine tool compensation and explore the systems available on the market.

“In the past few years, we have seen manufacturers invest in more automated machining systems,” said Kordalski. “Probes and calibration are key to the success of these systems, so we’ve seen a growing interest in the annual calibration of equipment and machines using probing systems.”

Krzysztor Siergiejczyk, Head of KES Machine in Poland, explained, “After having a good experience working with Renishaw in the USA, when opening the Polish subsidiary, we quickly established contact with Renishaw Poland. We were the first company in Poland to adopt Renishaw’s XM-60 and we have a big ambition to take care of customers within the European market over the upcoming years.”

With over 1,400 standard products to choose from, you can count on the engineers at Bodine to help you find a gearmotor with the right torque, power and speed for your application. We’ll get your design moving. Contact us today!

vertical straightness at the same time it takes to collect a single measurement using conventional techniques.”

When he founded KES, Kordalski purchased his first ML10 laser and QC10 ballbar from Renishaw. Since then, KES has purchased a range of Renishaw equipment, including XL-80 laser systems, XR20 rotary calibrators, o -axis rotary software, and QC20 ballbar systems (pictured here).

Renishaw has had a long-standing relationship with KES. As Kordalski explained: “When Renishaw comes out with a new product, it sparks our interest. As a result, we’ve worked with Renishaw for many years.”

When he founded KES, Kordalski purchased his first ML10 laser and QC10 ballbar from Renishaw. Since then, KES has purchased a range of Renishaw equipment, including XL-80 laser systems, XR20 rotary calibrators, o -axis rotary software, and QC20 ballbar systems. The company is also an advocate of Renishaw’s machine tool probes, tool setters, and broken tool detection systems, and is a full-service representative of Renishaw products.

KES Machine LLC ultimately selected Renishaw’s XM-60 and XM-600 multi-axis calibrators. KES can use the equipment on both CNC machine tools and CMMs to perform volumetric compensation. This laser measurement system can measure errors in six degrees of freedom along a linear axis,

simultaneously from a single setup. It provides a powerful diagnostic tool to measure all geometric errors in the axis from a single capture.

Additionally, the XM-600 multiaxis calibrator is designed with extra functionality, enabling it to communicate directly with Renishaw’s UCC controllers and is compatible with Renishaw’s CARTO software suite. These features make it a good calibration solution for manufacturing facilities using both machine tools and CMMs, such as KES.

“Renishaw o ers a range of calibration solutions for improved machine performance, increased machine up-time, and preventative maintenance schedules,” explained Je rey Seliga, Marketing Manager at Renishaw Inc. “By using the XM-60, the KES team can collect a range of measurements, including the pitch, yaw, roll, linear positioning, horizontal, and

“I would say that about 80% of our equipment is now Renishaw,” explained Kordalski. “Although we still investigate other brand systems, ultimately, we are looking for the best technology, and Renishaw typically wins. For example, we recently invested in the XK10 alignment laser system. While it’s still a new product for us, we’ve already seen its benefits when testing spindle direction or when installing machines, to help adjust straightness and squareness.”

KES Machine used the XM600 to implement CNC volumetric compensation and will soon o er CMM calibration to its customers and support for Renishaw CMM hardware, as the XM-600 directly interfaces with Renishaw UCC controllers. For years, before the release of the XM60 and XM-600, KES typically used multiple pieces of di erent equipment to measure linear positioning, pitch, yaw, and roll. The XM-60 manages this process with one pass and will include horizontal and vertical straightness over the completed travel. Measurements that used to take two to four hours are now reduced to under 30 minutes, depending on the length of the machine axis.

The equipment can also be used to diagnose machine errors. KES uses CARTO software, along with its own custom software, to simplify its processes. The KES team uses the “cut and paste” feature in CARTO software to help the compensation process and saves time using the report builder feature. DW Renishaw |

FLOW-3D AM simulates powder-based DED process parameters, such as powder feed rate, laser power, and scan speed.

| Courtesy of Flow Science

Melt pool flow dynamics is a critical and often overlooked aspect of the metal 3D printing process. Changes in heat input, powder, and alloy properties directly impact the melt pool evolution, a ecting a part’s quality and mechanical properties. Since the melting process occurs at the microscale in space and time, it is quite di cult to do in-situ measurement and characterization.

Computational fluid dynamics (CFD) simulation provides a detailed view of the physical phenomena during 3D printing. It directly models the melt pool fluid dynamics as the laser interacts with the metal powder. CFD software provides a level of control and accuracy that cannot be replicated by measurement or lower-fidelity models.

More than 40 years ago, C.W. Hirt, the founder of Flow Science, established a computational technique for tracking the evolution of an interface between two fluids with drastically di erent densities — such as the free surface between air and water. This technique, called the Volume of Fluid (VOF) method, is the foundation of Hirt’s commercial CFD software, FLOW-3D. Since its original development, FLOW-3D and the VOF method have been used in research and design processes for a range of applications, such as dam spillways, high-pressure die castings, and inkjet microfluidics.

In the last decade, Flow Science engineers applied the VOF method to melt pool dynamics in the metal AM industry. The result was FLOW-3D AM, which combines the fluid solver in FLOW-3D with laser physics and powder dynamics to model the full process of powder settling,

FLOW-3D AM simulates powder settling and spreading on an LPBF build plate, accounting for particle collisions, powder size distribution, and geometry e ects of the blade or roller.

| Courtesy of Flow Science

spreading, melting, and solidification in laser powder bed fusion (LPBF) and directed energy deposition (DED), along with the dynamics of non-laser-based AM processes, such as binder jetting and material extrusion.

In LPBF, metal powder is spread over a build plate and subsequently melted by a laser beam into a specific pattern. The process is repeated hundreds or thousands of times to build a part layer by layer. Using the discrete element method (DEM), engineers can simulate the powder settling and spreading process in detail by accounting for the particle collisions, powder size distribution, and geometry e ects of the blade or roller that spreads and packs the powder layer.

Once the powder bed is generated, a CFD simulation models the lasermaterial interaction during the melting process. To do this accurately, engineers must account for the large body of relevant physics, including the viscosity of molten metal, surface tension, heat transfer, laser reflection and absorption, phase change, recoil pressure, and solidification, among others. Clearly, there is a lot going on.

The norm in metal additive manufacturing is to use thermomechanical simulations to predict part-scale stresses and distortions. While useful, these models are lower fidelity in nature and cannot accurately predict track geometry and defects, such as keyholing, balling, porosity, and lack of fusion, which are all related to the evolution of the melt pool. Process parameters must be

optimized to reduce the formation of defects and provide a low scrap rate for additively manufactured parts to compete in the industry.

By adjusting the process input parameters, such as laser power and speed, scan path, beam shape, and powder size distribution, in the software, researchers and engineers receive deeper insights into the physical phenomena at play behind the process issues, which can then drive the development of process parameter windows.

Keep in mind that high-fidelity modeling is limited by its high computational cost. The large number of physics being solved for is computationally intensive, meaning that simulations are limited to the mesoscale — track lengths on the order of millimeters and singledigit layers. The software also does not directly solve for stress and microstructure formation, although information can be gained about both using the accurate thermal data from a simulation in other models.

Despite these limitations, the value of the information obtained using high-fidelity modeling tools like CFD is an order of magnitude higher than that gained from lower-fidelity, partscale tools. But since the AM process involves multiple scales, process design must rely on multiple tools. As of now, there is no modeling tool that

can do everything engineers need, so integration is key. Each company or university uses di erent measurement, simulation, and in-situ process tools, and it is imperative that these tools can communicate with each other.

“The overwhelming number of process parameters in AM calls for automated optimization tools based on physics-driven simulations,” said Marcin Serdeczny, Ph.D., CFD engineer at Flow Science. “To drastically reduce the cost and time of new developments, we can no longer rely on a trial-anderror experimental approach. Tools like FLOW-3D AM are exactly a step in that direction.”

As the metal 3D printing industry advances, high-fidelity simulation tools will play an even greater role in manufacturing. With continued advancements in computing power, material science, and machine learning, the accuracy and capabilities of these simulation tools will only improve. DW

FLOW-3D www.flow3d.com

Over the past decade, industrial digital transformation has enabled organizations to leverage the growth of data and connectivity to improve operations and engineering. Connecting Industrial Internet of Things (IIoT) devices and embedding tools, such as digital twins, across the IT/OT infrastructure allows deep data to be gathered, analyzed and contextualized to add meaning and value, providing complete and early visibility across an enterprise.

Having this visibility empowers engineers to make informed decisions that can help lower operational risks, respond faster to changes, and operate more e ciently. It can also reduce the time and e ort needed to deploy engineering solutions by creating new means to execute activities virtually.

As designers and customers are aware, time is costly when dealing with the construction and commissioning of equipment. Often, much of the investment comes directly from facility commissioning. Technologies leveraging digital twins can save organizations up to 40% in time compared to conventional methods

through the application of a practice called virtual commissioning. While virtual commissioning is not a new capability, we are seeing a wider adoption of it in recent years.

Before diving deeper into virtual commissioning, it’s important to first understand digital twins and their industry adoption. A digital twin is a superior, virtual representation of a physical entity or system across its lifecycle using comprehensive data, analytics, simulation,

and emulations. They can help virtualize physical designs, products, and processes, resulting in faster prototypes, more agile processes through simulations, and the ability to spot design issues early in the cycle, minimizing rework and accelerating cycle time. This means systems or processes can be tested and validated, and potential failures identified, before they even exist in the real world. Digital twin has many di erent applications in industrial manufacturing, including virtual commissioning.

The global digital twin market value is set to surpass $53.5 billion by 2028, exhibiting a CAGR of 42.1% during the forecast period 2022-2028. Therefore, it comes as no surprise that many organizations, from mining and manufacturing to healthcare, are adopting digital twin strategies as part of their digital transformation roadmaps. The application of digital twin spans the value chain and can be used for design, system simulation, integration, monitoring, training, and maintenance across industries.

While virtual modeling has commonly been used for product design in industries like aerospace and

auto, the wider adoption of modeling in operations used for the testing of engineering equipment is relatively new.

Applied to industrial enterprises, digital twins enable engineering teams to virtually perform activities that have conventionally been done through empirical calculations or physical work. This includes design validation, throughput analysis, and equipment testing. Doing this work manually can be labor intensive and often inaccurate.

There are considerable investments being made in digital twin technology to improve operations throughout the lifecycle of a facility. This is where virtual commissioning comes in. It can bridge traditional and virtual development by leveraging the technology to model and emulate real equipment and engineering systems.

As industrial organizations consider expanding facilities or constructing new ones, it’s critical that every step in the design and deployment of these projects is executed smoothly, e ciently, and cost-e ectively to ensure operations begin and ROI is achieved

Scheduled orders allow customers to lock in a price and have their North American and international cord sets shipped whenever they need them year-round. Scheduled orders allow customers to set predetermined schedules, such as ordering 1,000 cords and having 250 delivered quarterly or monthly—how many you need when you need them.

Our cord sets ship straight from the factory. Want the cords hanked, coiled, tied, bagged and boxed? Need 1-D or QR barcodes for easier warehousing? Customize lengths and colors for countryspecific cords.

A pathway to 40% time reduction through virtual commissioning.

as quickly as possible. Delays must be minimized or, ideally, eliminated completely.

The digital replica of the physical entity allows engineers to design, test, and virtually validate their work. This requires considerably less manual e ort and, in turn, less time. Organizations have also seen benefits such as increased safety, enhanced agility, and lower cost of design changes compared to legacy physical commissioning.

By using digital twins, engineering teams are able to test any number of system elements, including Programable Logic Controller (PLC) logic and code, software integration, and user interfaces.

Creating digital twins requires that aspects of the engineering system be accurately and virtually replicated. Typically, this involves the modeling of mechatronics systems, including elements such as motors, actuators, and conveyors, all connected to a controller (usually a PLC). The digital twin for system engineering replication includes two aspects:

• System modeling using CAD

• Controller code

During program testing, the virtual system is integrated with either a physical or simulated controller. It’s at this stage that the benefits of virtual commissioning are realized. The ability to test the integration of controller code with the physical system in a virtual environment enables an organization to test various code configurations, create and analyze various failure modes, and conduct comprehensive throughput analysis. ‘What if’ scenarios can be run, and potential program issues or bugs can be identified and triaged before expensive equipment fabrication and physical testing is started. Engineers can also make improvements to the products at this stage, based on the simulated interaction between the product and the equipment.

This kind of virtual testing leads to a valuable reduction in physical testing time, risk, and uncertainty by converting a sizable

portion of that physical testing to be finished virtually, prior to the fabrication of equipment. It is traditionally executed on the shop floor. At this point however, making design changes is significantly restricted and significantly more expensive.

With the increase in model fidelity, more processes and critical elements can be factored in within virtual testing. Typically, an organization will move towards a convergence of five di erent types of digital twins to accelerate the commissioning of new equipment and processes.

1. Geometric Design: Digital representation of physical assets (3D model of a product cell or line)

2. Physical Dynamics: Digital representation of physical processes and dynamics (details around how equipment physically moves, where the constraints are, and the interaction of di erent mechanical components)

3. Programmed Behavior: Digital emulations of logic and animations of physical processes (incorporating physical kinematics of the equipment with software control)

4. Human Interface: Digital representation of the interface between human and equipment (virtual version of an equipment HMI or enhanced methods of interacting with the equipment such as using VR)

5. Analytical Insights: Digital characterization of data, measurements, sensor readings, and telematics of assets or processes (utilizing sensor data to monitor equipment condition and to predict failures)

The development of industrial engineering systems goes through three generalized phases:

1. Planning and Concept: In this initial phase, the work, functions, business

requirements, and selection criteria are defined. Front-end engineering studies are conducted, options are narrowed down, and the first conceptual designs generated.

2. Engineering and Construction: Moving from conceptual to tangible, all the functional and technical requirements are laid out. This phase includes elements such as safety, mechanical, electrical, software, and instrumentation specification, as well as the selection and fabrication of systems and equipment based on the previously defined specifications.

3. Installing and Commissioning: The final stage is the installation and testing of systems against design specifications and pre-defined acceptance criteria to identify any gaps. This phase also includes work done to resolve any issues. This step leads to the performance of site acceptance and final equipment commissioning.

All three phases require the engagement of multiple stakeholders, such as general contractors, subcontractors, and equipment suppliers. Any undiscovered design or development issues in phases one or two can cause substantial problems downstream during the installation and commissioning phases of engineering systems.

After the first two phases, the cost of resolving issues grows exponentially and can be between 200 and 800 times more costly compared to issues addressed in early phases. Running scenarios to troubleshoot software and hardware in the early phases also allows engineers to generate feedback and plan accordingly to avoid these costs later down the road.

Crucially, digital twins can shorten physical testing time during the Installation and Commissioning phase.

By creating a virtual commissioning phase prior to physical testing, teams can perform actual acceptance tests and resolve issues encountered within the specified equipment in short order and with minimal disruption.

We’ve seen first-hand that enterprises that deployed virtual commissioning were able to reduce time to steady-state operations by up to 40% compared to using conventional methods.

By using digital twins to capture the design, engineering, construction, and commissioning elements of a facility expansion, organizations can reduce risk and enable faster ramp up.

Digital twins are one of the technologies at the heart of digital transformation, powered by the digital thread that unifies data across an organization, removing legacy silos and creating a truly connected enterprise. It enables the integration of the internet of things (IoT), artificial intelligence and software analytics to enhance outputs, evolve, and scale with organizational needs. Over time, the digital twin can be leveraged to help realize significant breakthroughs, including generating PLC code or even removing the PLC programming step of the commissioning process entirely.

Virtual commissioning can be leveraged alongside other capabilities of this technology, such as facility layout planning, capacity planning, and operator training. It can even be combined with AI and other forms of advanced technology to perform dynamic system optimization, AI-enabled control, and intelligent model training. As merely one application of digital twin technology, virtual commissioning’s benefits include decreased commissioning times, reduced risk, increased reliability, and lowered costs throughout the manufacturing operations commissioning process. As the technology continues to evolve and incorporate more capabilities, organizations will have to adapt their strategies or risk missing out. DW

Bringing your supply chain back home? Let Interpower worry about manufacturing your cords and cord sets while locking in your price—have your North American and international cord sets delivered on your schedule year-round!

Our cord sets and accessory power systems ship straight from the factory. Want the cords hanked, coiled, tied, bagged and boxed? Need 1-D or QR barcodes for easier warehousing? Customize cord lengths and colors for countryspecific cords configured and ready to use right out of the box!

In recent years, smart mechatronics applications have become increasingly common in various industries. Smart mechatronics refer to the combination of mechanical engineering, electrical engineering, and computer science to create intelligent systems that can interact with the environment and make decisions based on real-time data. This technology has proven to be e ective in improving the e ciency and e ectiveness of many industrial processes. Here’s a look at five applications where smart mechatronics make sense.

Smart mechatronics technology is being applied in a variety of industries, where the benefits include increased efficiency, improved accuracy, and enhanced productivity.

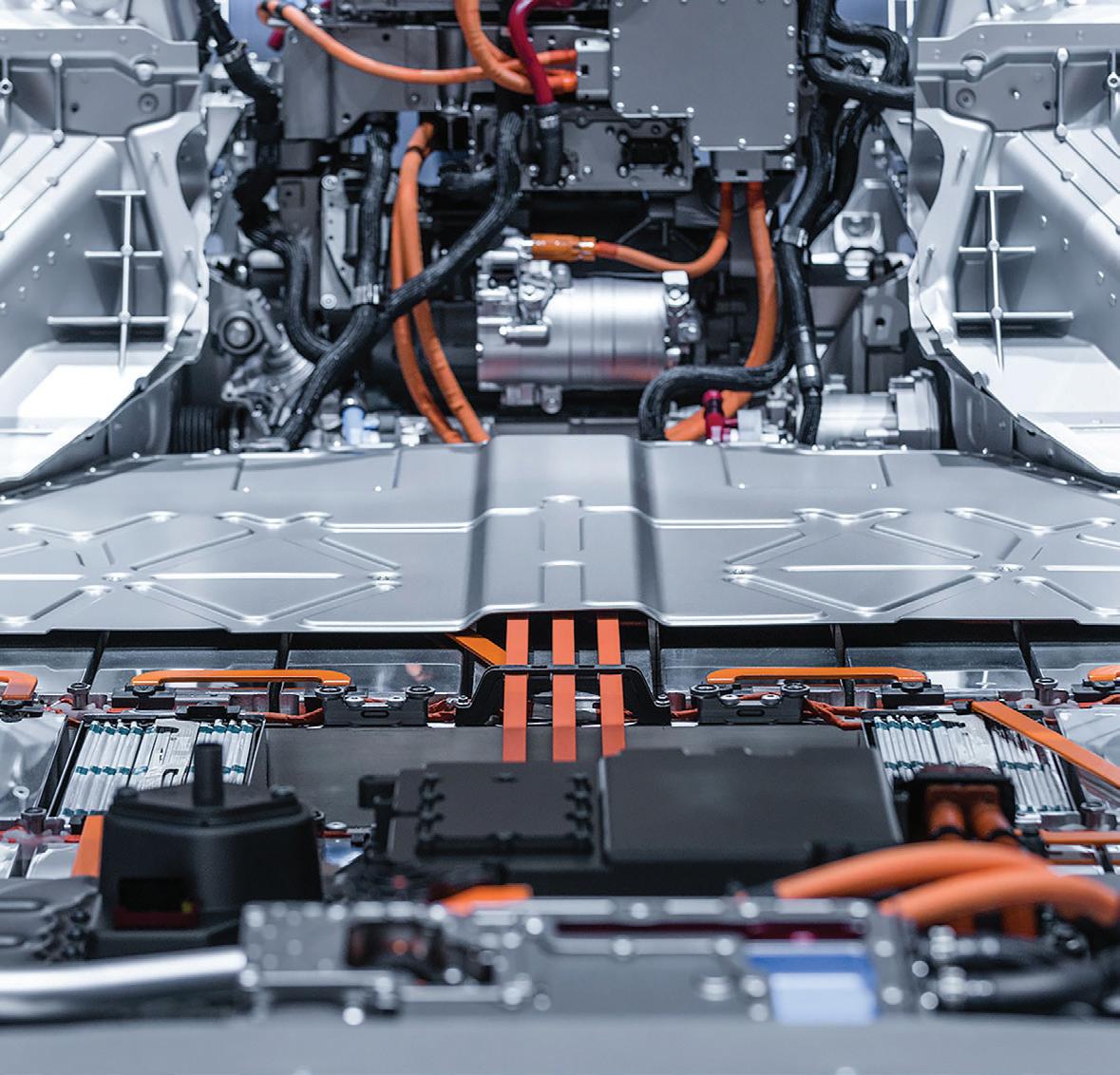

The increasing demand for electric vehicles (EVs) has led to a surge in research and development of smart mechatronics in the battery and EV industry. Smart mechatronics technology is being used to improve

the performance and reliability of battery packs, which is critical for the widespread adoption of EVs. There are a multitude of use cases within battery and EV manufacturing where smart mechatronics are necessary.

Within the EV manufacturing process, assembling battery covers and

windshields requires accurate dispensing of sealants and thermal materials which is done e ciently with a smart dispensing system. Using precise dispensing technology, manufacturers can control the flow rate through the dispensing head along with the cartesian motion profile to create an accurate, repeatable process.

Smart handling or pressing systems can simplify battery production by automating precise steps in production such as picking up battery cells, press fitting the caps on cylindrical cells, or pressing the casing onto the packs themselves, all while providing a continuous feedback loop. In sorting and cell testing, a smart mechatronic handling system is beneficial because it automates the process and provides real-time feedback. Easy commissioning and intuitive programming commands allow users to generate complex pickand-place cycles in minutes. Recent innovations such as the Bosch Rexroth Smart Flex E ector can provide increased precision to battery automation processes with pouch, cylindrical, and prismatic type battery cells. The e ector can also be used to

guide collaborative robots in welding or cabling applications by providing the robot controller with continuous positional deviation commands to maintain accurate motion paths. By measuring the position deviation of the gripping device in relation to the workpiece in six degrees of freedom, the robot can adjust its position to ensure accurate placement. Smart mechatronics technology improves precision and increases the overall e ciency of battery and electric vehicle manufacturing processes.

Consumer packaged goods (CPG) manufacturers are always looking for ways to increase their flexibility, maximize the use of space, and minimize the time and e ort required to modify or add new production tools. Plug-and-produce smart mechatronics systems are designed to meet these needs by combining established linear motion components with smart controls and easy-to-use engineering tools. By using these systems, CPG manufacturers can benefit from accelerated engineering, commissioning, and faster time to market for their products. These systems also provide more transparent, e cient, and reliable production processes. Smart mechatronics systems o er high operating performance and sustainability through permanent updates, ensuring that manufacturers always have access to the latest technology and capabilities. Handling systems, such as the Smart Function Kit for Handling, are an example of how smart mechatronics technology can improve the accuracy of packaging, create a repeatable process, and increase production speeds in palletizing operations. These systems can also monitor the quality of products in real-time, allowing manufacturers to identify and address any issues quickly. Open interfaces allow software engineers the ability to customize the operator interface and collect system

Smart mechatronics systems can automate material handling, sorting, and transporting processes, reducing the need for manual labor, and increasing the speed of operations.Consumer packaged goods is one industry benefitting from smart mechatronics systems. | Bosch Rexroth

data to increase throughput and e ciency of the operation.

One of the largest challenges in CPG operations is e cient product changeover. Most manufacturers o er multiple sizes of a single product, each with their own packaging designed for that specific size. To switch production from a 12-in. package to a 6-in. package, traditionally a manufacturer would have to pause production and reset the line to accommodate the new handling requirements of the smaller package. Advances in smart mechatronics are helping to tackle this challenge head on with sensor-based innovations that can sense the size of a bag and automatically adjust the handling system for the exact product it needs to grab.

Smart mechatronics also play a critical role in improving ease of use for factory operations. For example, a simple Galaxy Note touchpad or an iPad can program smart mechatronics. This plug-andplay mentality eliminates the need for operators to receive specialized training, so manufacturers do not have to hire somebody with a robotics programming background to run the line. As an added benefit, the plug-and-play mentality also saves space in the production line, because a large electrical control cabinet is no longer needed to manage the robotics.

Smart mechatronics is playing an increasingly significant role in the semiconductor industry. Within semiconductor manufacturing, even the slightest vibration when wafers are in motion can compromise chip quality — requiring precise and accurate automated manufacturing processes. Smart mechatronics technology can help achieve this. These smart systems are being used to improve the accuracy and precision of semiconductor manufacturing equipment, reducing defects, and improving product quality.

Specifically, sensor-based compensation units, like the Smart Flex

Sensor-based compensation units, like the Smart Flex Effector from Bosch Rexroth, are used in wafer production in the semiconductor industry. They ensure accuracy of linear motion devices with high-resolution sensors, which are then translated into active correction movements.

Effector, ensure accuracy of linear motion devices with high-resolution sensors, which are then translated into active correction movements. This tactile sensor can enhance the accuracy of automation systems used for wafer handling and processing, while also providing a digital twin throughout the process. This smart device can also incorporate in-process metrology to robotic applications, enhancing currently existing equipment used throughout the industry. Incorporating smart mechatronics systems is critical to meeting the ever-increasing demand for precision in the semiconductor industry, enabling greater productivity and quality control.

Intralogistics is the process of managing and optimizing the internal flow of goods in a warehouse or distribution center. Smart mechatronics technology is being used in intralogistics to improve the efficiency of these processes. Smart mechatronics systems can automate material handling, sorting, and transporting processes, reducing the need for manual labor, and increasing the speed of operations. Specific smart technology such as the Smart Flex

Effector can be used with collaborative robots to increase accuracy of linear motion devices and pick-and-place operations. Smart handling systems can be commissioned and monitored easily and can provide greater efficiency in palletizing operations. These systems can also help digitalize the value stream through software-based commissioning and monitoring, and even creating digital twins for a streamlined process, allowing for better management of the supply chain.

Smart mechatronics has been playing an increasing role in the medical device industry, especially in areas such as cartesian pick-and-place operations and sorting operations. One notable application of smart mechatronics in this industry is the use of pick-and-place robots and cartesian systems for sorting test tubes. In medical laboratories, pick-and-place robots equipped with cameras and sensors are used to sort test tubes based on specific criteria such as sample type, patient ID, or test required. These robots can quickly and accurately sort large quantities of test tubes, reducing errors and minimizing the risk of contamination. Overall, smart

mechatronics is a rapidly advancing field that is revolutionizing the way designers approach medical device design and manufacturing. DW

Bosch Rexroth www.boschrexroth-us.com

In the first of this two-article series, we considered VFD operation types to satisfy process and motion-control applications. Here we delve deeper into two advanced types of operation.

Lisa Eitel | Executive editorBrushless AC (BLAC) motors are driven with sinusoidal AC currents and (due to skewed magnets and sinusoidally distributed windings in their stators) also produce sinusoidal back EMF. Sinusoidal commutation is a common way to control BLAC motors, as it provides a very consistent torque output with little torque ripple. But at high speeds, sinusoidal commutation begins to sacrifice motor e ciency.

Another method called field-oriented control (FOC) or flux-vector control also generates sinusoidal waveforms and produces consistent torque … and it yields better motor e ciency, especially at high speeds.

Precise vectorbased modes of VFD operation are often useful in advanced conveyor applications.

| Itsanan Sampuntarat

| Itsanan Sampuntarat

Shown here is a block diagram of field-oriented control with space vector pulse width modulation. The goal of FOC is to align the stator current vector to be orthogonal (90°) to the rotor flux.

Kirchho ’s current law states that at any junction in an electrical circuit, the sum of currents flowing into the junction is equal to the sum of currents flowing out. In the case of a three-phase motor, Ia + Ib + Ic = 0. So if two currents are measured, the third must be the negative sum of the first two to maintain a zero sum of the three.

Sinusoidal motor commutation

Torque output in any motor is maximized when the stator and rotor magnetic fields are orthogonal at 90° to each other. Sinusoidal commutation works to generate a rotating current vector with a constant magnitude and direction that is orthogonal to the rotor. Recall that vectors have both magnitude and direction.

To achieve this, two of three stator phase currents are generated 120° phase-shifted from each other based on rotor position, which is provided by an encoder. The third is determined using Kirchho ’s current law. The result is a smoothly rotating current vector with constant magnitude that is always orthogonal to the rotor.

Sinusoidal commutation provides smooth motion with very little torque ripple. But as motor speed increases, e ciency deteriorates. This is because with increasing speed, the frequency of the sinusoidal current command signals also increases, making it di cult for the current loop controllers to track the command signals. In addition, as speed increases, motor back EMF increases in frequency and amplitude. The result is phase lag between the stator and the rotor, taking the current vector out of the optimal 90° alignment with the rotor flux. This reduces the torque produced for a given current and decreases the motor’s e ciency.

Where sinusoidal commutation is based on a three-phase system that is dependent on time and speed, field-oriented control transforms this