LIFTING INTO ORBIT

AEROSPACE & DEFENCE

Renewable Energy/Clean Tech

State Spotlight: Tasmania

FEB/MAR 2023

After introducing the World-Renowned Absolute System to Digimatic Calipers, Mitutoyo now announces a further major breakthrough in electronic Caliper Design.

The New COOLANT PROOF Caliper achieves an Ultimate Dust/Water/Coolant protection level.

The

Web: www.mtiqualos.com.au e-mail: sales@mtiqualos.com.au

QUALOS PTY. LTD. MELBOURNE

COOLANT PROOF Caliper can be used in tough workshop conditions where at present only a mechanical Vernier Caliper can be used.

M.T.I.

55 Northern Road, West Heidelberg, Vic. 3081. Phone (03) 9450 1900 Fax (03) 9458 3217

LIFTING INTO ORBIT

AEROSPACE & DEFENCE

Renewable Energy/Clean Tech

State Spotlight: Tasmania

FEB/MAR 2023

EMC, Environmental, Electrical

Accredited testing services for harsh environments

Internationally recognised testing facilities

• EMC Compliance – RF Emissions, RF Immunity, ESD, Surge, Magnetic Fields, Transients, including Automotive and Military Applications

• Product Safety – HV Insulation, Energy Efficiency, Temperature Rise, Leakage Current, Flammability etc

• Environmental Testing – Vibration, Shock & Bump, Temperature & Humidity, Ultra Violet (UV), Xenon Arc, Salt Corrosion, etc. Ingress (IP), Impact (IK), Drop

90 Indian Drive, Keysborough, Vic. 3133

RF Shielding

EMF SHIELDING for electrical substations

Compliance Engineering provide and install EMF shielding applied to electrical substations and switch rooms. For builders of retail and residential developments, or areas where a reduction in the EMF exposure levels is required.

EMC EQUIPMENT

Agents for many international EMC test equipment manufacturers. We supply items ranging from Calibrated Measuring Antennas through to High Power RF Amplifiers.

Australia’s only manufacturer of MODULAR RF SHIELDED ENCLOSURES

We specialise in a variety of RF shielding services including:

• New RF enclosure installations,

• Relocation of existing RF enclosures

• Modification Repairs and servicing of existing RF enclosures

• RF shielding effectiveness testing.

• We also stock and supply a comprehensive range of RF enclosure hardware such as RF power filters, EMC gaskets, RF waveguides, Honeycomb air vents, RF absorbing materials, etc.

info@compeng.com.au compeng.com.au Phone (03) 9763 3079

TIME TO UPGRADE YOUR VIEW AND PURCHASE THESE ITEMS ONLINE AT www.machineryhouse.com.au SHEET METAL FABRICATION AIR COMPRESSORS BAND SAWS LATHES GRINDING & LINISHING

WORKSHOP?

the world’s first desktop waterjet.

MILLING MACHINES

IDEAL FOR R&D

PRICE FROM $14,390

WAZER is the first desktop water jet that cuts any hard or soft material with digital precision. The high velocity jet uses a combination of high pressure water and abrasive particles to cut through the work piece. With WAZER, we’re bringing this advanced technology to any size workshop.

Features:

• Cuts Any Material: Metal, Stone, Glass, Ceramic, Composite, Plastic, Rubber and Foam.

• Compact size fits in any work space.

• Brings professional-grade fabrication into any workshop.

• Ideal for on demand cutting of custom parts.

• In-house capabilities reduces costly outsourcing.

WELDING EQUIPMENT

• Great for prototyping, manufacturing, fine art, and instruction.

• Simple set up. Just connect to standard electricity, water, and drain.

• Cold cutting. No heat. No fumes. No need for ventilation.

• Quickly go from design to cutting. Takes any DXF or SVG file.

• Assembled in the USA.

Now cut anything with digital precision using high-pressure water. A compact waterjet for every workshop.

AVAILABLE AT: Specifications are subject to change without notification. SYDNEY (02) 9890 9111 1/2 Windsor Rd, Northmead BRISBANE (07) 3715 2200 625 Boundary Rd, Coopers Plains MELBOURNE (03) 9212 4422 4 Abbotts Rd, Dandenong PERTH (08) 9373 9999 11 Valentine St, Kewdale AMT 070223

PRESSES

CNC MACHINES

GILMOUR SPACE TECHNOLOGIES

Australian rocket launcher manufacturer is soaring ahead in its innovative rocket production, with plans to launch its Eris orbital rocket this year and its G-class satellites from late 2024.

REGULARS

AUSTRALIAN EV COMPONENT MANUFACTURING

A wander through some Australian manufacturing companies on their projects servicing components and technology for the new worldwide EV markets.

56

ONE ON ONE: FRED FUNNELL AMT sits down with the President of the Compressed Air Association of Australia, looking into the complex future for bottled energy in Australian manufacturing.

COMPANY PROFILE

Harrop Engineering is a true Australian success story with a rich history dating back more than 65 years, and a legendary reputation in the automotive and motor sport communities.

AMT FEB/MAR 2023 006 CONTENTS

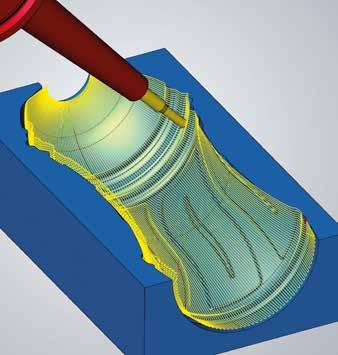

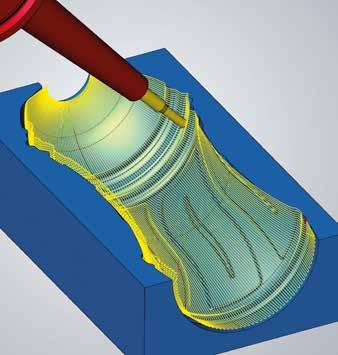

AEROSPACE & DEFENCE Gilmour Space Technologies 38 Ronson Gears 42 Raymax 44 BAE Systems 45 RENEWABLE ENERGY Australian EV components 48 Hydrogen Cressall 50 Lithium GigaFactory 51 Fossil free steel 53 COMPRESSORS & AIR TECHNOLOGY AtlasCopco 58 SMCair ACD 59 M&M Coolant 60 NystarAir 62 ADDITIVE MANUFACTURING Luyten3D concrete houses 68 Sauber Tech 69 Markforged 70 Wet blasting 72 MOTORS & DRIVES MGT 74 LAPP Cables 75 NORD drives 76 Bonfiglioli Australia 77 INDUSTRY 4.0 Sustainable Manufacturing 80 Camatic seating 82 CSIRO Quantum jobs 83 Zoomfab 84 CUTTING TOOLS EdgeTech 90 BIG KAISER 92 OKUMA 93 FORMING & FABRICATION OpenMind HyperMILL 98 Headland 99 Luna Machinery 100 ISCAR's right tool 101 MATERIALS HANDLING Eilbeck and Bonfiglioli 102 Aqualux Lighting 104 ANCA 105

FEATURES

From the Editor 8 From the CEO 10 From the Industry 12 From the Union 14 Government News 18 Industry News – Current news from the industry 20 Voicebox – Opinions from the manufacturing industry 26 Tech News 32 Product News 34 State Spotlight – Tasmania: Marinova 64 AMTIL Forums 106 AMTIL Inside – The latest news from AMTIL 110 Industry Calendar 116 Manufacturing History – A look back in time 118 Volume 23 Number 01 FEBRUARY/MARCH 2023 ISSN 1832-6080

96

48 38

PUT ALL THE PIECES TOGETHER, OKUMA JUST MAKES SENSE

Innovative technology, quality manufacturing and comprehensive service and support define the Okuma experience.

We offer the leading edge of ‘full service’ distribution and lifetime support for Okuma CNC machines. Solution focussed, our team work with our customers to provide machining realities, with exceptional results.

Our team gives you immediate access to decades of industry experience and a network of local and global machine tool experts. We partner with you from the very first meeting, guide you through project planning and support you through implementation, training and after sales care.

CONTACT OKUMA FOR ALL YOUR CNC MACHINE REQUIREMENTS

Quality

Support

Technology

Reputation

Service Reliability

Model Range

PAUL HELLARD

Reaching for future goals

Energy companies are big and powerful enough to do what’s right for the industries and community they service. There’s nothing wrong with making profits but profiteering during an emergency is a bad look. While setting off to write this column, I wanted to write about something other than gas prices. But the continued predictable behaviour from fossil fuel companies, complaining about having their stellar profits clipped in order that society and businesses can continue to function, hastened me to just start writing. Now, history shows that fossil fuel companies are used to getting their way. The backlash worked in 2010 against Kevin Rudd, and in 2013 their lobby supported the Abbott-led Coalition’s dumping of Labor’s carbon-pricing mechanism, allowing emissions to shoot up once again. I mention this because I don’t want manufacturers to forget it. Now that Labor is back in again, the gas price caps are the only measure available to save the economy. There will still be price rises, and the opposition and lobbyists will crow about them. Watching long term trends has been a mainstay of economists and sociologists but few have seen a tougher challenge.

“A windfalls profits tax would potentially be a much more long-lasting solution to this problem,” says Alia Armistead in The Saturday Paper in December 2022. She’s a researcher for the climate and energy program at The Australia Institute. “It would be a preferable way to capture this excess profit, to ease pressure on households from being stuck with high energy prices. It could go towards fast-tracking the transition towards renewables and building out the huge amount of new generation and transmission that will be required to achieve Labor’s renewable energy target by 2030.”

The Ai Group says 2023 looks like it is still going to be ‘messy’ on the energy front, no matter what happens. There are some valid criticisms about the government’s policies. But at least these decisions are not ones made by the gas industry. Gas companies can still make profits and they’ll still be able to make their investments, but the Government needs to be allowed to protect households, businesses and jobs.

Waste

Australia generates more waste per day per capita (1.5kg) than the East Asia and Pacific region (0.6kg) and the world average (0.7kg). Almost 85% of plastics in Australia were sent to landfill in 2019, and if nothing changes, RMIT estimates that Australia’s landfill space will reach capacity by 2025. Six years ago, Xi Jinping announced bans on solid waste imports, prompting many countries including Australia to reassess their waste management strategies. The Australian Government has banned exports of waste plastics, paper, glass and tyres and set a target to reduce waste to landfill by 30% by 2030. Global energy demand declined by 5.3% in 2020, but this is expected to rebound to pre-COVID levels this year. Renewable energy sources are expected to account for 80% of the growth in global electricity demand by 2030, surpassing coal as the primary source by 2025. Australians absolutely must pull an electric rabbit out of our hats in order to get through the next couple of years. The International Energy Agency forecasts that global electricity demand will grow at twice the rate of primary energy demand out to the year 2040. Most of that demand will come from China and India. The Australian Energy Market Operator is preparing Australia’s grids to manage 100% renewable energy by 2025.

The global energy transition opens up new industry and job creation opportunities. It is estimated Australia’s abundant access to raw commodities and renewable energy, advanced agile manufacturing capabilities and concentration of relevant skilled workers yield a strong competitive advantage in emerging clean energy industries, such as green metal manufacturing. I mentioned earlier, of the multinational gas suppliers pulling massive profits out of the country and blooming gas prices, even though Australia’s local supply is abundant. By passing legislation to enable temporary gas price caps the Parliament has taken badly needed action that will help local energy users and soften the blow to Australia from events in Europe. While the uptake of agile manufacturing approaches, leveraging artificial intelligence (AI), robotics and other technologies, could also enable Australian manufacturers to dynamically respond to market changes in a cost-effective manner.

Editor Paul Hellard phellard@amtil.com.au

Contributors

Carole Goldsmith

Drew Turney Ruza Zivkusic

Sales Manager

Nicholas Raftopoulos nraftopoulos@amtil.com.au

Publications Co-ordinator

Caroline Robinson publications@amtil.com.au

Publisher Shane Infanti sinfanti@amtil.com.au

Designer

Franco Schena fschena@amtil.com.au

Prepress & Print Printgraphics Australia

AMT Magazine is printed in Australia under ISO140001

Environmental Certification using FSC® Mix certified paper sourced using sustainable tree farming practices.

Contact Details

AMT Magazine

AMTIL

Suite 10, 5 Corporate Boulevard Bayswater VIC 3153

AUSTRALIA

T 03 9800 3666

F 03 9800 3436

E info@amtil.com.au

W www.amtil.com.au

Copyright

© Australian Manufacturing Technology (AMT). All rights reserved. AMT Magazine may not be copied or reproduced in whole or part thereof without written permission from the publisher. Contained specifications and claims are those supplied by the manufacturer (contributor).

Disclaimer

The opinions expressed within AMT Magazine from editorial staff, contributors or advertisers are not necessarily those of AMTIL. The publisher reserves the right to amend the listed editorial features published in the AMT Magazine Media Kit for content or production purposes.

AMT Magazine is dedicated to Australia’s machining, tooling and sheet-metal working industries and is published bi-monthly.

Subscription to AMT Magazine (and other benefits) is available through AMTIL Associate Membership at $190.00 (ex GST) per annum. Contact AMTIL on 03 9800 3666 for further information.

AMT FEB/MAR 2023 008 FROM THE EDITOR

1697AMTFEB/MAR2023

The William Buck Hour

It could be the most profitable hour you spend on your business.

Many business owners, CEOs and Managing Directors find themselves spending a large percentage of time working on day-to-day tasks which, while critical, don't necessarily improve performance, business value or contribute towards the business strategy.

The William Buck Hour is designed to assess your current business position, realign thinking and maximise potential We'll guide you through a detailed discussion on a range of fundamentals including:

Financial management

Funding

Regulatory requirements, and Succession planning

Following the session, our advisors will use commercial insights, professional experience and best practice standards to conduct an analysis of your business and present you with a personalised written report.

Contact us today to book your complimentary William Buck Hour

Ian Cattanach Director Business Advisory

Ian Cattanach Director Business Advisory

Ph: 03 8823 6975

ian cattanach@williambuck com

Jeremy Raniti Senior Manager Business Advisory

Ph: 03 8823 6838

jeremy raniti@williambuck com

SHANE INFANTI – Chief Executive Officer AMTIL

Women in Manufacturing activities continue to grow

With the re-appointment of Brigitte Stavar as AMTIL President I thought it prudent to write about the impact that Women in Manufacturing have and the new initiatives that are encouraging more and more females into our industry.

Brigitte Stavar has been instrumental in guiding us through the past two years of her tenure. When she was first appointed to the role in December 2019, for those who can remember back then, we were in the middle of firestorms all around the country putting pressure on us as a nation to survive. Then we had the COVID-19 pandemic and the impact that had across all states, with lockdown after lockdown, the uncertainty of what the next Government regulation was and the impact these decisions would have. It has been difficult times trying to run a “services” business with member benefits almost non-existent during this time. We launched a new show, Australian Manufacturing Week, that replaced National Manufacturing Week and Austech as our premier Manufacturing show in the country, and subsequently had postponed it twice due to COVID. As President, Brigitte has worked with our team to manoeuvre through these minefields and get us back in a position focussed on providing great member benefits. She was also a driving force in getting us to invest in our own building and rebrand the organisation over recent months. I welcome Brigitte to her appointment for another term as President and look forward to working with her over the coming years.

Regarding Women in Manufacturing pathways, it is good to see a number of initiatives being developed. UNIQ You is one such initiative. Companies from around Australia are throwing their support behind this innovative new platform recently launched in Queensland, set to foster impactful conversations that will change the game for female representation in maledominated industries.

UNIQ You is a groundbreaking service and online platform that connects high school girls (and their guidance and career officers) with industry advisors drawn from sectors under-represented by women. Industry Partners, selected from industries that have less than 40% representation of women, have signed on for the program: Aurecon, BMD, Boeing, Hutchinson Builders, Origin Energy, SEQ Water, Shell’s QGC Business, Skedulo, Tesserent (VIC), Urban Utilities, and Yurika.

Female advisors from these Partners across Australia will give their time to provide industry insights to grade 9 to 12 highschool girls from 30 schools through personalised one-on-one video calls. By

connecting girls with relatable female role models across a diverse spectrum of industries, it is expected that their queries and curiosity around career pathways will be answered. For more information go to www.uniqyou.com.au.

Another great initiative is the Women in Manufacturing Mentoring Program being managed by William Buck, Rigby Cooke and the Commonwealth Bank in conjunction with AMTIL. It had a formal launch at Australian Manufacturing Week in Sydney in June last year. It is being driven through the strong leadership of women in all four organisations, all making their mark on the growth of women employed in our industry.

The purpose of the Women in Manufacturing Mentoring Program is to link manufacturing consulting leaders with a manufacturing commercial leader to listen, share experiences and support development towards achieving career aspirations. The Mentoring Program aims to support, encourage and facilitate learning, development and the expansion of personal networks. Everyone’s mentoring experience will be different, reflecting

individual aspirations, preferences and motivation. The mentor relationship will provide:

• Opportunity to gain guidance and advice from a consulting leader

• The chance to discuss and reflect on development opportunities

• Development of broader relationships

• Expansion of personal networks

• Sharing of career aspirations.

The program will run over a 12 month period with mentors and mentees meeting a minimum of six times, either in person or virtually. Once the initial 12 months period ends, support will continue to be provided by way of a rolling alumni program. I encourage any females who would like to be involved in the program to contact Kim Banks at kbanks@amtil.com.au

In addition to this initiative with our Partners William Buck, Rigby Cooke and the Commonwealth Bank, AMTIL also has plans to run a number of WIM events next year, including a networking activity at Australian Manufacturing Week being held from 9-12 June at the Melbourne Convention and Exhibition Centre.

AMT FEB/MAR 2023 010 FROM THE CEO

THE HON Ed Husic MP – Minister for Industry and Science

The $15bn National Reconstruction Fund is on track

Legislation for the National Reconstruction Fund (NRF) was introduced into Federal Parliament late last year, and we’re consulting with industry and the community to make sure we get the design and implementation of the NRF right –things like its priority areas and investment mandate.

The NRF will help unlock private sector investment to create highquality, sustainable industries and well-paying jobs. It represents one of the biggest investments in Australia’s industrial capability since World War II.

Ensuring this investment flows efficiently and effectively is key to successfully diversifying Australia’s manufacturing sector. Stepping up our sovereign capability will help us avoid a repetition of the supply chain issues we experienced during the COVID pandemic. It will also give Australia another string to its economic bow by diversifying Australia’s economy helping reduce the risk of change and deliver real opportunities for people, not just in our cities, but in the vitally important regions.

It will do that by strategically investing in industries of the future. The ones that play to Australia’s natural and competitive strengths. It will back companies with good growth prospects, that help us address climate change and other major challenges.

These investment decisions will be made by the NRF Board, operating at arm’s length from Government. There won’t be a colour-coded spreadsheeting in sight. The Board will be tasked with achieving a positive rate of return on investment - a model the Clean Energy Finance Corporation successfully uses.

Since it was established by the Gillard Government in 2012, the CEFC has generated a return above the Government Bond rate, so it isn’t a drain on government funds but a net contributor to our public finances.

In that time, the CEFC has helped finance about 200 large-scale clean energy projects that put downward pressure on energy prices. Each dollar the CEFC has invested since 2012 has helped attract an additional $2.30 in private sector finance.

That’s why we’re using the CEFC as a template for the NRF.

The NRF won’t provide grants and it won’t duplicate existing Government initiatives that support early-stage research and development or commercialisation either. Instead, it will help provide loans, guarantees and equity across seven identified priority areas:

• Value-add in the agriculture, forestry and fisheries sectors;

• Value-add in resources;

• Transport;

• Medical science;

• Renewables and low-emission technologies;

• Defence capability; and

• Enabling capabilities like quantum, AI and robotics. With global capital markets tightening, it’s important our most innovative manufacturers can continue to secure financial backing to help them create new jobs and economic opportunities.

The NRF will complement other investors in the market ensuring Australian manufactures can benefit from advanced technologies and retool, refocus and re-emerge as world leaders in their sector. These are the companies that will help us expand Australia’s industrial base. We’re under no illusions about the challenges of reversing the consistent decline in investment we’ve seen over the past decade. Australia ranks last among OECD countries in manufacturing self-sufficiency.

In the 1980s, the Australian Government faced a similar predicament when large parts of our manufacturing was being shifted offshore. In response, the Hawke-Keating Government implemented industry restructuring plans and helped the manufacturing industry to modernise, innovate and find new markets. Forty years on, we need to nurture a new generation of diverse and innovative companies to broaden and transform Australia’s industrial base and create more sustainable economic growth over the longer term.

There’s also an imperative to help our manufacturing sector adapt to a low-carbon future and contribute to efforts to meet our long-term emissions reduction targets.

As part of comprehensive plan to build onshore industrial expertise, we’re also continuing to invest in the Cooperative Research Centres (CRC) Program, also started during the Hawke-Keating years. Since 1991, the program has committed $5.5bn of grant funding to support the establishment of 236 CRCs and 189 of the shorter-term CRC Projects (CRC-Ps).

With matching industry and research funding of $16.8bn, the program has enabled 35,400 commercialisation agreements and more than 140 spinoff companies. We’re committed to helping our advanced manufacturing industries in the marketplace too.

The Commonwealth spent more than $80bn on goods and services in 2021-22. Linking that procurement spending to industry development goals and economic growth outcomes will drive even more private sector investment. To make sure that the NRF delivers on its promise, I urge you to keep providing feedback to the consultation that is now open.

You can do so at:

https://consult.industry.gov.au/national-reconstruction-fund

AMT FEB/MAR 2023 012 FROM THE

MINISTRY

Fiber Lasers • Tube Lasers • Turret Punch Presses • Pressbrakes • Guillotines • Automation Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au GROW YOUR BUSINESS WITH YAWEI. THAT’S APPLIED THINKING. Precision sheetmetal processing solutions.

The workplace relations changes which passed through the Federal Parliament at the end of last year constitute the most significant suite of amendments to Australia’s Workplace Relations laws in more than a decade. The new laws have implications for all employers.

The key legislative amendments relate to major changes to our system of collective bargaining over employee entitlements, new obligations and risks around employee rights to pursue flexible working arrangements, and restriction around the use of fixed term contracts and pay secrecy clauses. There will also be new protections for employees from sexual harassment and certain forms of discrimination that will create new risks for employers and an expanded ability for employees to access the small claims jurisdiction to seek recovery of amounts up to $100,000, instead of the current $20,000 ceiling. Substantial financial penalties may be applied for non-compliance with many of the new requirements. A broader theme that employers will need to grapple with is the expanded role that the Fair Work Commission will be able to play in various workplace relations issues and disputes, as well as the significant role that unions will be empowered to play in relation to representing their members in such matters.

The most controversial IR change has been the shake-up of the rules relating to collective bargaining, including the significant expansion of union rights to require employers to engage in ‘multi-employer bargaining’ or to co-ordinate industrial action across workforces in support of it. There will also be scope for unions to obtain orders from the Fair Work Commission extending the coverage of such agreements to employers that had not been a party to negotiating it, even if the employer opposes it.

The new laws will also make it much easier for unions to force employers to renegotiate expired enterprise agreements. A particularly significant change that has received limited media attention is the creation of a pathway for unions, or employers, to seek that the Fair Work Commission ‘arbitrate’ what are described as ‘intractable’ bargaining disputes. This will see the Commission intervening to directly set conditions in a way that really hasn’t been a part of our system for decades. It will no doubt change the strategies that unions, and some employers, pursue at the bargaining table.

There are also changes to the process for making a workplace agreement that employers will need to grapple with, as well as changes to the tests that the Commission will apply when considering whether to approve an agreement. This will include changes to the way the Better Off Overall Test, commonly referred to as the ‘BOOT’, is applied by the Commission when comparing a proposed agreement to an award.

The Commission will also obtain new powers to amend a proposed agreement to address any concern over whether it passes the BOOT. In short, the Commission will be able to change or ‘re-write’ terms of an agreement that is lodged with it even if the employer doesn’t agree to the alteration. This will be a concerning risk that employers will need to weigh when engaging in bargaining.

Among other changes, the National Employment Standards have been amended to provide significantly strengthened provisions affording certain cohorts of workers a right to request ‘flexible work arrangements’. Under the new provisions, employers will need to follow prescriptive rules dictating how they respond to requests and

will only be able to refuse them on reasonable business grounds. Crucially, if employers don’t agree to such requests, they will face the prospect of the matter being pursued by the employee or their representative through the Fair Work Commission, which will be empowered to ‘arbitrate’ any disagreement. They will also be exposed to significant financial penalties for non-compliance if their refusal wasn’t properly justified.

As mentioned, the other big theme underpinning the legislative changes is the expanded role and powers of the Fair Work Commission and unions.

The Commission will be empowered to intervene in a whole range of workplace relations issues in a more substantial way than is presently the case. This ranges from dealing with disputes over bargaining, through to dealing with complaints over sexual harassment and to powers to resolve disputes concerning employee requests for access to flexible working arrangements.

Unions will similarly be given a raft of new or expanded rights in relation to bargaining and representation of employees. The changes will encourage employers to engage in bargaining, rather than relying upon awards. Coverage by an individual enterprise agreement will provide the surest protection against being unwittingly drawn into the multi-employer agreement that doesn’t suit their enterprise.

Employers should consider whether they have appropriate strategies in place to deal with the new bargaining environment. This should include a proactive assessment of their potential exposure to multiemployer bargaining and what options they have to avoid being a part of it if they don’t want to be.

Ai Group is helping members navigate the new laws and will be consulting closely with the government as it develops its next round of workplace relations changes expected later in the year. aigroup.com.au

AMT FEB/MAR 2023 014 FROM THE INDUSTRY

INNES WILLOX – Chief Executive Australian Industry Group

Employers could expect changes in casual employment, labour hire arrangements and the introduction of criminal penalties in relation to what is termed ‘wage theft’.

MOVIGEAR ® with the times

Be the energy-saving company you’re expected to be

As sustainability becomes a more dominant topic in today’s industry, it is now a more measurable focus in the present social, economic and environmental arenas. With MOVIGEAR®, you can achieve energy savings of up to 50% in comparison to a traditional drive system.

Your Benefits:

Compact - Up to 50% lighter than conventional drive solutions.

• Universal - The number of variants is reduced thanks to optimal dimensional based on a large speed range and impressive overload capacity.

Efficient - Motor energy efficiency class IE5 resulting in energy savings of up to 50% in comparison to a traditional drive solution.

• Low noise - Some 75% quieter than typical AC motors and hygienic convection cooling without fan.

www.sew-eurodrive.com.au

Driving the world

Trusting our shipbuilders is the first step to ensure sovereign defence capability

The Federal Minister for Defence Richard Marles will reveal the biggest decision of his tenure so far in March: how to fill the looming defence capability gap left by Scott Morrison’s bizarre and costly decision to pull out of the $90bn submarine deal with France.

Under the AUKUS pact signed in 2021, the United States and the United Kingdom will help Australia build a fleet of nuclearpowered subs domestically – a process that will take decades. The US and the UK took 36 and 30 years, respectively, to transition from conventional to nuclear submarine fleets.

With our current fleet of conventional Collinsclass submarines due to be completely retired by 2038, the Navy is faced with the very real prospect of having no deploymentready submarines at all, perhaps for years.

Opposition leader Peter Dutton has suggested Australia could plug this capability gap by buying two Virginia-class nuclear subs from the General Dynamics shipyard in Connecticut. This is an impossibility – something everyone besides Dutton has already figured out. Senior members of Congress and the US defence establishment have repeatedly said that America’s shipyards simply don’t have the industrial capacity to meet their own needs, let alone Australia’s.

In July, the Australian Shipbuilding Federation of Unions – made up of the AMWU, the ETU, the AWU, the CEPU and Professionals Australia – recommended that the new Albanese Government commission up to six domestically-built conventional submarines.

Not only would this fill the gap between the retirement of the Collins class and the eventual arrival of the next-gen nuclear subs – it would revitalise the domestic shipbuilding industry, create thousands of jobs, and form the defence manufacturing base of skills, training, and knowledge Australia will need in the future.

For too long, governments have treated defence manufacturing – and domestic manufacturing more broadly – as an expense to be trimmed rather than an investment that brings in returns, monetary and otherwise. Instead of putting in the work and building up local industry over generations, governments have bought defence builds off-the-shelf and allowed local jobs and knowhow to wither.

This has led us, in large part, to our current predicament. We are increasingly reliant on other governments and foreign suppliers for

our defence needs – including repairs and maintenance of our ships and submarines. The pandemic showed how quickly global supply chains can snap, leaving those dependent on them at the mercy of forces beyond their control. As the geopolitical climate grows increasingly volatile, there is a profound need for Australia to maintain and grow our sovereign capability for defence manufacturing, production and maintenance.

There is also the security aspect to consider. Defence builds that are designed, built and maintained domestically would be much less vulnerable to the leaks that have jeopardised major defence builds overseas. As malicious cyber-attacks get more sophisticated and ambitious, keeping sensitive institutional knowledge as closely guarded as possible makes sense.

Despite decades of neglect, Australian shipbuilding still employs more than 30,000 workers across the country. Our great historic shipbuilding centres like Osborne and Henderson are still home to thousands of workers who know what Australian ships and submarines need. These workers are experienced, knowledgeable, and eager to help build the next generation of Australian defence materiel.

Nuclear subs don’t maintain themselves. They will need a highly skilled domestic workforce. You can’t buy that experience and knowledge off the shelf – you need to grow it, invest in it, and nurture it over

many years. Building and maintaining a new generation of conventional submarines would be the perfect way to grow that workforce, laying the foundation it will need to build and maintain the ones that come after.

That will require significant investment – not just in committing to domestic builds, but in skills development and maintenance, workforce retention, establishing and improving career paths, better using workers’ competence, and rates of pay. Any investment in building workers’ skills and capacities will not only deliver a superior product – it will have flow-on effects for our sovereign defence capability and the wider manufacturing sector.

All of this is possible if we have the vision and will to make it happen. When it comes to shipbuilding, we need governments to think in decades, not in three-year election cycles. We can’t maintain our sovereign defence capability if we allow our industrial base to fall into the “valley of death” every ten years and have to start from scratch every time a generation of ships or subs ages out.

If the government puts its trust in shipbuilding workers, they will repay that faith tenfold. A new generation of conventional subs will put Australia back on the path to sovereign capability, and ensure local defence manufacturing has a bright future.

amwu.org.au

AMT FEB/MAR 2023 016 FROM THE UNION

STEVE MURPHY – National Secretary Australian Manufacturing Workers Union

+ Punching, laser cutting, marking, forming, and tapping in one machine + Complete range of modular automation that grows with your business + Up to 30 tonnes of servo-electric punching force - no hydraulics + Up to 384 tools in the turret at any time = less down time + Industry-leading support in Australia and New Zealand from IMTS Machinery www.imts.com.au sales@imts com au 03 9314 9888 Combi Genius Technical Excellence, Innovative Products Discover more about the range of industry leading machinery from IMTS by scanning the QR Code above

Hydrogen fuel cell research facility

Works begin at Australia’s first hydrogen fuel cell research and development facility.

Works have begun at Australia’s first hydrogen fuel cell research and development facility at Deakin University’s Warrnambool campus, with construction expected to be completed in late 2023.

Minister for Training and Skills and Higher Education Gayle Tierney turned the first sod of earth at Deakin’s Warrnambool campus to begin works on the Hycel Technology Hub, a cornerstone facility within Deakin’s $23m hydrogen research and innovation program, including co-funding by the Victorian Government ($9m) and Deakin University ($5m).

The Hycel Technology Hub will see the development, assembly, testing, and demonstration of hydrogen fuel cells, with a focus on developing fuel cells for heavy vehicles, starting with heavy haulage trucks, and potentially progressing to other larger scale uses including trains or boats.

Hydrogen fuel cells convert hydrogen into electricity that can then be used to power vehicles and similarly in stationary applications to power or heat homes, businesses, and industry.

“The Hycel Technology Hub is an important driver in the research and application of hydrogen as a fuel source and we expect the benefits of this research to be far reaching both in Australia and internationally,” said Minister for Training and Skills, Gayle Tierney.

“Deakin’s focus on hydrogen fuel applications will also have a direct benefit to the people of Warrnambool as Deakin aims to transition its Warrnambool campus from gas to hydrogen and support conversion of the Warrnambool Bus Lines fleet to clean energy.”

The project includes the construction of a new 2,200sqm facility at the Warrnambool campus with specialised fuel cell assembly and testing equipment and a heavy vehicle integration bay, along with training facilities and a multi-functional space for education and demonstration activities.

The Victorian Government’s contribution supports construction and development of hydrogen and future energy education programs. With the funding, Deakin is creating new hydrogen curriculum for primary and high schools, hydrogen short courses for professional

engineers and is also seeking to develop a hydrogen bus training package in collaboration with vocational and industry partners. The facility will form part of a broader hydrogen precinct on the campus which currently includes the existing Hydrogen Test Beds, where researchers from Deakin’s Institute of Frontier Materials are testing the efficacy of plastic piping to understand if Australia’s gas network can safely transport 100% hydrogen in the future.

Other proposed hydrogen projects within the precinct include a hydrogen boiler demonstration using 100% hydrogen fuel for domestic hot water and hydronic heating, as well as potentially supporting Warrnambool Bus Line’s new hydrogen bus refuelling station and depot as they convert their fleet from diesel to hydrogen fuel cell buses, making it the first public bus deployment of its kind in Australia.

"Deakin is combining its expertise in science, technology and education to meet the needs of Australia’s emerging hydrogen industry,” added Deakin University Vice-Chancellor Professor Iain Martin. “Our Warrnambool Campus will be a hydrogen precinct of research, innovation, and training. We are thrilled to collaborate with local and national industry partners to focus on advancing hydrogen as a fuel in transport and pipelines.”

The Hycel Technology Hub is being built by southwest Victorian group Fairbrother Construction, with construction expected to be completed in late 2023. It will support up to 200 jobs over the life of the project, including around 50 construction jobs and 16 in the energy sector.

Victorian Government funding is part of the $350m investment in local universities through the Victorian Higher Education State Investment Fund. The fund supports universities with capital works, applied research and research infrastructure to support jobs and the state’s economic rebound from the coronavirus crisis.

The project has also secured significant Federal Government support and funding. deakin.edu.au

National Rail Manufacturing Plan

Government appointing an advocate for National Rail Manufacturing Plan.

The Australian Government hopes an advocate will help grow local manufacturing of safe, fast and sustainable rail.

Assistant Minister for Manufacturing Tim Ayres said the Rail Supplier Advocate and the Office of National Rail Industry Coordination (ONRIC) will advise the Government on the Australian rail industry and the most effective strategies to back Australian manufacturing.

“Australia’s railways have been a core part of our national story since Federation, and they employ more than 50,000 people today,” Assistant Minister Ayres said. “High quality Australian rail manufacturing should be part of our vision to reduce emissions, secure supply chains and put Australian research and

innovation to work. “The Rail Supplier Advocate will be an important part of the National Rail Manufacturing Plan – the plan will support skilled manufacturing jobs and support more trains being built here in Australia. The Advocate will support small to medium sized enterprises and manufacturers to seize export opportunities, market their products to government and champion sectoral initiatives to improve competitiveness.”

Assistant Minister Ayres said the recruitment process will commence in the coming days.

“I want the very best person for this role to back the rail industry and help it grow,” Assistant Minister Ayres said. industry.gov.au

AMT FEB/MAR 2023 018 GOVERNMENT NEWS

Schools harness solar power

TBox remote telemetry units (RTU) from Ovarro support CO2 reductions in Australian schools.

The Australian Government has introduced new measures to educate the nation’s students about green initiatives. By providing schools with grants for photovoltaic (PV) systems, solar hot water systems and rainwater storage, the government hopes to make environmental responsibility a key part of education and early years’ learning. Here, Matthew Hawkridge, chief technology officer at Ovarro, explains how this initiative is helping Australia deliver 300,000 tonnes of CO2 abatement and why remote telemetry units (RTUs) are crucial to making it happen. The government’s Solar for Schools programme is funding the installation of solar panels in schools primarily for education purposes. The solar systems are connected to each school’s main grid, to provide green power and reduce the building’s carbon footprint for a positive effect on the environment. In addition, the systems will be connected to a cloud-based monitoring system. This means data from the solar panels can be accessed by students and local communities. Remote telemetry units (RTUs) will play a crucial role here because they are flexible and are designed to collect data from multiple sources and share that data with several recipients.

The Solar for Schools programme has various requirements for the data. First, it will be used by students to help learn how solar panels supply their energy needs. Second, there will be the option for local communities to engage in the learning experience too and discover the effectiveness of solar panels. Third, the schools need

to monitor the continual safe operation of the equipment. Lastly, the government will use the data to track the resulting CO2 reductions. To satisfy all these demands, TBox RTUs from Ovarro were chosen to gather the data. The TBox is a complete supervisory control and data acquisition (SCADA) system in a single site controller. It is ideal for collating data from many sources, analysing the available information and reporting results to various recipients in multiple formats.

The ability of TBox RTUs to satisfy different end users is a key reason why it was chosen for the Solar for Schools project. Users of the system will require different data sets, and for these to be presented in different ways.

The TBox also offers ease-of-use. Novice users can securely access data relating to the real-time monitoring and control of the schools’ solar systems. Meanwhile, stakeholders can use the RTUs for logging, communication, alarming inputs/outputs (I/Os) and presenting the data to others. So far, Ovarro’s TBox RTUs have been installed at 200 sites as approved data collection devices for the Solar for Schools programme.

By using the technology, students can immerse themselves in the power of green technologies including solar. The Australian Government, meanwhile, can ensure environmental responsibility stays at the heart of its curriculum.

ovarro.com/en/australia--new-zealand/home/

AMT FEB/MAR 2023 019 GOVERNMENT NEWS

The Ecoefficiency Group

A Queensland State Government subsidy is helping Queensland manufacturers boost sustainability and cut costs when it comes to reducing energy, water and waste.

Queensland Minister for Regional Development and Manufacturing

Glenn Butcher said lots of manufacturing businesses want to streamline resource use and shrink their carbon footprint, but they don’t know where to start.

“We know these measures will help cut costs as well as help the environment, but auditing these processes within the business has been challenging – until now,” he said. “Manufacturing contributes $20bn a year to the state’s economy, so when businesses can be as efficient as possible, it means more good jobs and better services for Queenslanders.”

The Palaszczuk Government is offering a subsidy for businesses who want to benchmark their sustainability processes and target waste to improve efficiencies. Sunstate Timbers in Deception Bay and All Industries Group in Yeppoon were the first businesses in Queensland to be part of the program.

“My department is working with The Ecoefficiency Group (TEG), who will come into each business and identify areas where improvements can be made in the use of energy, water or other resources. They will create a report that identifies areas for improvement and measures the business against industry best practice,” he said. “To assist Queensland manufacturers further, we will subsidise up to 75% of the cost for the first 40 businesses to sign up,” he said. “Businesses who apply after that will be eligible for up to 50 per cent subsidised costs of the audit,” Mr Butcher said.

Healthy food nutrition

TEG Director Penny Prasad said: “Making sure the manufacturing sector is as efficient as possible means less water and energy is wasted and less waste is generated and this benefits the environment and our society as a whole,” she said. “Also, it improves the bottom line for the business – it’s a win-win all around.”

Mr Butcher congratulated Sunstate Timbers and AIG for stepping up to help create change and encouraged others to follow suit. “We’re keen to really get businesses engaged and invested in this project,” he said. “It will deliver a range of benefits and the more businesses that we get to do it, the greater those benefits to the environment and to the community will be.” qld.gov.au

Queensland headquartered wellness company experiences significant global growth by nutritionally supercharging amateur and professional athletes alike.

Queensland based health and wellness company Fixx Nutrition are finishing 2022 at an all-time high, having undergone significant annual growth due to unprecedented consumer demand for their premium nutritional supplements.

Founded in 2017 by passionate athletes Michelle and Jan Buchegger, Fixx Nutrition provides a natural, healthy alternative to sugar-laden energy drinks for people to rehydrate and prevent and relieve cramping during exercise activities.

The Fixx Nutrition strategy over the past year has incorporated the successful implementation of its worldwide expansion plans, with its products now being sold in 15 countries across Australia, Asia and the US.

Calendar year growth is 33% for the company due to local market increased distribution through sports retailers and direct online sales. “2022 has certainly been an incredible year for us on many levels and we are grateful that our nutritional supplements are the number one choice for athletes from world-class sporting teams such as the Wallabies, UK Cricket & Football, and the Springboks, to local grassroots teams and athletes alike,” Fixx Nutrition co-founder Jan Buchegger said.

“We attribute our success to only using nature’s finest ingredients to fuel our customers and we are so proud that the world’s top athletes entrust us to power their sporting and recovery efforts on and off the field,” Ms Buchegger said.

2023 will see further increased growth as the company expands their manufacturing facility in Burleigh, Heads, Queensland. The additional space will allow more space for storage of raw materials, packaging and finished goods plus improved warehousing and logistics for their online sales division.

This larger space will see their manufacturing capacity increase by at least 100%, allowing them to increase their batch sizes and focus on exporting internationally, particularly to US and Korean markets. Early 2023 will see Fixx Nutrition launching two new product ranges that complement their existing sports endurance nutrition range. This new machinery will enable Fixx Nutrition to broaden their packaging options along with improving existing packaging with the CrampFix range.

“We’re super proud to offer an Australian Made brand that is not made by subcontractors like most other nutrition products. We have complete control over ingredients, quality and processing, eliminating contamination risks and allowing flexibility,” Ms Buchegger said. Fixx Nutrition has a loyal following domestically, with exclusive Australia-wide distribution for its products with Woolworths Supermarkets. Their retail presence sits at over 1000 stores nationally to date.

“A major growth driver this year was the market acceptance of our new endurance nutrition brand - reviews and feedback have been overwhelmingly positive bringing repeat customers which is so rewarding. We love seeing the amazing sports our customers undertake and the goals they achieve while using our productsfrom 100km ultra runs to Ironman to four day adventure racing,” Ms Buchegger said.

This year, they were once again the official sports nutrition partner for one of Australia’s largest marathons, the 2022 Village Roadshow Theme Parks Gold Coast Marathon and they will once again continue this partnership next year. fixxnutrition.com

AMT FEB/MAR 2023 020 INDUSTRY NEWS

Inyarrimanha Ilgari Bundara

CSIRO gives Wajarri Yamaji traditional name to its radio astronomy observatory.

Australia’s national science agency, CSIRO, has welcomed a new Wajarri Yamaji traditional name for its radio astronomy observatory in mid-west Western Australia.

The name Inyarrimanha Ilgari Bundara means ‘sharing sky and stars’ in the Wajarri language. The traditional name is part a new Indigenous Land Use Agreement, or ILUA, with the Wajarri Yamaji. CSIRO, along with Australian and Western Australian Governments, has signed the new ILUA with the Wajarri Yamaji People, the Traditional Owners and native title holders of the land on which the observatory sits.

This observatory in the heart of Wajarri Country in remote Western Australia is home to the ASKAP radio telescope as well as other international radio astronomy projects. The Curtin University-led Murchison Widefield Array (MWA) and Arizona State University's Experiment to Detect the Global Epoch of Reionisation Signature (EDGES) instrument is also currently hosted.

The site is also being prepared for one of the two SKA telescopes. The SKA telescopes will be the largest and most capable radio telescopes in the world and promise to answer some of the biggest questions about our universe.

Radio telescopes at the observatory detect radio waves at similar frequencies to digital TV broadcasts and 4G mobile networks. This means that the telescopes must be located a long way from human settlements, so that terrestrial signals don’t interfere with the weaker signals coming from natural sources in space, which is why the site is one of the best places in the world for radio astronomy.

The agreement enables expansion of CSIRO’s radio astronomy observatory site to allow for construction of the international SKALow telescope, part of the global SKA Observatory, alongside existing instruments including CSIRO’s ASKAP radio telescope.

The traditional name was suggested by Wajarri woman Shakira Whitehurst for a competition run by the Wajarri Yamaji Aboriginal Corporation (WYAC) and selected by members of the Wajarri Minangu Land Committee, the Traditional Owners of the observatory area on Wajarri Country. The Wajarri name will be one part of a new dual, official name for the site: Inyarrimanha Ilgari Bundara, the CSIRO Murchison Radio-astronomy Observatory.

“We look at the sky every day, and we now have the opportunity to share our skies with the rest of the world,” said Jennylyn Hamlett, WYAC Chairperson and Minangu Land Committee member. “This Wajarri name connects our culture and language to what our Country is being used for,” Hamlett said.

Dwayne Mallard, member of the Minangu Land Committee, said that the observatory has a light footprint on the land and is combining ancient culture with modern science to create mutual benefit. “We are born into the responsibility and obligation to preserve, protect and maintain dignity of our land, culture and people,” Mallard said.

“My good friend Shane Howard sings 'you look into the heart of the land, and you have to choose whether the wealth we gain is worth the wealth we lose'. I don't think we've lost anything here, and that's very important.”

“Providing a means for the Wajarri Yamaji to share their culture and language with Australians and researchers around the world is a privilege,” Dr Marshall said.

“Protecting heritage and Country are critical elements of the ILUA, and CSIRO is proud to be partnering with the Wajarri Yamaji in the land management and cultural heritage protection of the observatory site, ensuring that we leave our footprints carefully in the sands of time as we walk side by side into a better future together.”

Through its Reconciliation Action Plan, CSIRO is committed to building genuine partnerships with Aboriginal and Torres Strait Islander peoples through education, science, innovation and research.

The new ILUA with the Wajarri Yamaji People demonstrates this commitment by fostering a culture that respects and honours the rich history of the nation.

Construction of the SKA-Low telescope at Inyarrimanha Ilgari Bundara, the CSIRO Murchison Radio-astronomy Observatory, is expected to begin later this year.

The SKA-Low telescope, alongside its counterpart SKA-Mid in South Africa, will explore the Universe in more detail than ever before, transforming our understanding of the cosmos and benefitting society through global collaboration and innovation. csiro.au

AMT FEB/MAR 2023 021 INDUSTRY NEWS

CSIRO Chief Executive Larry Marshall said he was humbled the Wajarri Yamaji had chosen a name connecting the rich heritage of the region’s first astronomers and their connection to Country with the modern scientific instruments on the site.

SMaRT Trailblazer

UNSW recycling and clean energy initiative secures Trailblazer funding.

A combined SMaRT Centre-led recycling and UNSW/University of Newcastle-led clean energy initiative has been awarded $50m under the Australian Trailblazer Universities Program.

Headed by UNSW in partnership with the University of Newcastle, the new $277m Australian Trailblazer Recycling and Clean Energy (ATRaCE) initiative will lead research commercialisation initiatives that will help Australia and the world transition to sustainable recycling and clean energy solutions and systems.

Federal Government funding of $50m has been matched by $50m cash and $47m in-kind from UNSW and the University of Newcastle for the recycling and clean energy initiative. Over 20 industry partners have expressed support for the initiative and have committed more than $130m in cash and in-kind contributions.

UNSW Vice-Chancellor and President, Professor Attila Brungs, said that UNSW was proud and honoured to be leading Australia’s efforts in research commercialisation to support the nation’s manufacturing priorities.

“We are delighted to be able to work with the University of Newcastle and our innovative industry partners on transformative research projects that deliver real world outcomes. The Trailblazer program will undoubtedly strengthen university-industry collaboration to support the start-up and growth of Australian businesses. The Recycling and Clean Energy Trailblazer will create a step change in Australian environmental sustainability transition.

“UNSW has a proud track record of commercialising research such as solar panels, energy storage, Green Steel and various

MICROfactorie technologies led by 2022 NSW Australian of the Year, ARC Laureate Professor, Veena Sahajwalla. We look forward to working with our partners on the Trailblazer program to deliver further change in the recycling and clean energy innovation landscape.”

The UNSW – UoN partnership is the third Trailblazer to receive funding through the Trailblazer program which is designed to focus Australia’s considerable research power on Australia’s National Manufacturing Priorities.

“This partnership between University of Newcastle and UNSW will combine the strengths of our two universities to give us the power to accelerate Australia’s clean energy and recycling industries and bring more, greener technologies to Australians,” said University of Newcastle Vice-Chancellor Professor Alex Zelinsky AO. “This program will transform the way technology readiness, commercialisation and industry-led research are prioritised, taught and rewarded in our universities with targeted opportunities for university staff and students to succeed.”

Professor Nicholas Fisk, UNSW Deputy Vice Chancellor, Research and Enterprise said the Australian Trailblazer for Recycling and Clean Energy is targeting the commercialisation of at least 63 new products which will contribute to the achievement of net zero emissions by 2050, delivering critical new skills for a high value manufacturing workforce, and enabling cultural change and workplace reform in our universities. smart.unsw.edu.au

Local manufacturers big supporters of STEM

Sutton Tools and Nichol Industries were the major prize sponsors of the Vernier Foundation’s ‘Inter-schools STEM Competition’, held at Kooyong Tennis Club in Melbourne recently.

Teams from Dandenong High School and St Margaret’s Berwick battled it out in a competitive but light-hearted challenge, with St. Margaret’s taking the trophy in the end by just one point! The Vernier Foundation has been proud supporters of the STEM programs in both schools for some years now. Dandenong High School has run its STEM initiative for six years now, with a high percentage of immigrant and refugee students. The STEM support program at St. Margaret’s is still in its infancy but keen to attract more girls towards a career in engineering and manufacturing.

The audience were also entertained in a musical interlude by students from both schools, demonstrating that the A for arts should not be forgotten in the focus on STEM. The overall event was sponsored by the Foundation’s originator, the Vernier Society and several of their member manufacturers were in the audience. Andrews Engineering, Balcombe Engineering, Dimac Tooling, Ace Wire and Okuma must all be looking forward to the future prospect of attracting such bright students into their organisations.

While the Foundation hopes the new government will put much more funding into STEM programs in secondary schools, they also believe strongly that the manufacturing industry itself needs to do much more to support community schools in STEM. The Foundation clearly aims to play a part through their members donations and support for their big plans in 2023, including a planned ‘industry/ school visit’ program; the provision of specialists from industry supporting STEM teaching in schools, the introduction of more schools into their funding program and the exciting prospect of an ‘education’ involvement at AMTIL’s Manufacturing Week in Melbourne in May!

The Foundation believes this inaugural challenge was a big success and hopes to expand it to more schools in the coming years. Anyone who has a passion for manufacturing and believes our education system needs all the support it can get, should contact the Foundation through their website, which is also going to be upgraded in 2023. vernier.org.au

AMT FEB/MAR 2023 022 INDUSTRY NEWS

Textor textiles

Key to success in manufacturing is differentiation through innovation in textiles.

CSIRO and Textor have co-invested to conduct research into the surface treatments of textiles using plasma; understanding moisture transport via capillary action; odour reduction; and new composite web structures.

Textor Technologies, a Victorian family-owned company, produces an array of technical textiles used in health care, personal hygiene and industrial products.

These technical textiles that make up incontinence products in particular, focus on moisture management through permeable barrier materials. The competitive technical advantage in this product sector, comes from material with advanced fluid absorption. Textor's goal was to enter the international market by demonstrating a significant technical advantage over competitive products, many of which are produced in low labour cost countries.

This research has culminated in the invention of a novel threedimensional fabric that is employed as a next-to-skin component of predominantly infant diapers. The fabric is highly effective in facilitating moisture movement away from the 'point of insult' and into the absorbent layer of the diaper whilst maintaining a sense of dryness, and hence comfort, to the wearer.

CSIRO's commercial engagement with Textor resulted in a new product development, in turn increasing annual gross turnover. The new material has been incorporated into the millions of nappies produced around the world by global company Kimberly-Clark.

Australian manufacturing constantly faces pressure from increasing production costs and mounting global competition. To increase market share our manufacturing businesses need to grow through competitive advantage, and improved profitability.

Entering and expanding into international markets is vital for the longevity of Australia's manufacturing industry. It is important that Small and Medium Enterprises (SMEs) receive the research and development resources and capabilities which allow them to maintain competitiveness in the global market.

CSIRO and Textor co-invested, initially through the then Commonwealth Department of Industry, Innovation and Science and ‘Researcher in Business’ Program, and later via sequential bilateral arrangements, to conduct research into:

• surface treatments of textiles using plasma

• understanding moisture transport via capillary action

• odour reduction; and new composite web structures.

Ultimately, the research culminated in the invention of a novel threedimensional fabric that is employed as a next-to-skin component of predominantly infant diapers.

The fabric, produced via hydroentanglement, is highly effective in facilitating moisture movement away from the 'point of insult' and into the absorbent layer of the diaper whilst maintaining a sense of dryness, and hence comfort, to the wearer. csiro.au

AMT FEB/MAR 2023 023 INDUSTRY NEWS 600 Machine Tools is now Colchester Machine Tool Solutions Colchester Machine Tool Solutions has a world-class reputation in the manufacture and distribution of high-quality machine tools. Customer support and service is the number one priority to ensure a machine tool is best suited to your exact needs. Call | (02) 9674 4738 Email | sales@colchestermachines.au Visit | colchestermachines.au World-renowned Alpha CNC Lathe

ACS Australia hits 30

Advanced Composite Structures Australia: 30 years of transforming design

For over 30 years, the team at Advanced Composite Structures Australia (ACS Australia) has been delivering high-value engineering and manufacturing solutions of unique composite materials related products for clients based around the world. Originally under the constellation of a Cooperative Research Centre (CRC), and later as a private entity, ACS Australia is headquartered in Port Melbourne and is celebrating 30 years of operation.

ACS Australia has expanded into series manufacture and assembly of high-value, composite products and has made strategic investments into advanced manufacturing equipment including automated machining and additive manufacturing. Recently, ACS Australia was awarded a Defence Global Competitiveness Grant to support the development of Australia’s sovereign capability in Ultra-High Temperature Composites for hypersonic aerospace structures. While Defence and aerospace clients are among their largest customers, ACS Australia is also contributing to three major renewable energy and aquaculture projects as a proud partner of the Blue Economy Cooperative Research.

Their long-standing commitment to composites technology development has enabled ACS Australia’s team members to develop products in almost every industry sector including transportation, mining, energy and civil infrastructure. It has been their mission to advance composites technology and deliver worldleading engineering services, which has seen an impressive 30 years of contribution from hundreds of people.

It was in 1990 that the seeds were sewn for what is now ACS Australia. This was when the then Chief Scientist of Australia –Ralph Slatyer, AC, proposed to the Commonwealth Government that Australia needed a Cooperative Research Centres program to better facilitate industry-focused research and innovation.

The leaders in the aerospace structures design and manufacturing industry and their research and development partners in universities and government quickly came together and formulated a successful proposal for the Cooperative Research Centre for Aerospace Structures (CRC-AS) – one of the first 15 formally established in 1991.

It was in early 1992 that work started in earnest under the leadership of Gordon Long as Technical Director from the then Aeronautical Research Laboratories (ARL), now the Defence Science and Technology Group (DSTG). Key directors on the new board came from Hawker de Havilland (HdH) and AeroSpace Technologies of Australia (ASTA), both now Boeing Aerostructures Australia (BAA).

The CRC-AS expanded in 1997 and focussed on advanced composite materials and became the CRC for Advanced Composite Structures (CRC-ACS), with the leadership passing to Ian Mair as CEO and new members joining the group, including Australian Defence Industries (ADI), now Thales Australia.

In 2003, Murray Scott took over as CEO and led the well-established CRC-ACS team into its third term, and subsequent expansion in 2007 to include helicopter structures

and manufacturing ideas into reality.

and then the final fourth term from 2010 to 2015, when Airbus in Australia and Europe, and also Petronas in Malaysia, became members. Some major milestones were achieved over this twelveyear period, some of which were returns on investments made years earlier.

The team received several major awards with the highlight being the recognition for developing, maturing and implementing key technologies for the Boeing 787 wing trailing edge moveables program. The key composites technologies that were successfully transitioned into the industrial environment were liquid resin infusion, double-diaphragm forming, component co-curing, postbuckling design, bird-strike simulation and optimum repair design. The continuing success of the manufacturing activities at Boeing’s Port Melbourne facility is testament to the impact of this initial work. It was in 2008 that the rapidly growing commercial activities were formalised by the establishment of the original spin-out company, Advanced Composite Structures Australia – a wholly-owned subsidiary of CRC-ACS, with Murray Scott as Managing Director, who is still currently Chairman and has been involved from the very beginning. This entity was restructured in 2010, with Tony Carolan as Chairman and Bill Schofield as Deputy Chairman (2010 - present) together with Tony Carolan as Chairman (2010 – 2016), to formally position it as the successor to CRC-ACS when it concluded its mission after 24 years. As part of this process, the ownership was passed in 2014 to the then directors and employees of ACS Australia, who were charged with leading the company into a fully commercial future. This responsibility is now being carried by Paul Falzon in the lead role of General Manager, together with Rodney Thomson as Engineering Manager, Andre Duarte as Business Development Manager, and Tess Kirkpatrick as Administration Manager.

The team is now celebrating three decades of incredible achievement in advanced composites research and translation of new technologies and capabilities to innovative industry partners. At the core of the unique organisation are some of the key people who kicked it all off over 30 years ago working alongside a young talented team still engaging in cutting-edge research and practical implementation in products and services. acs-aus.com

AMT FEB/MAR 2023 024 INDUSTRY NEWS

Blade solution needed now

End-of-life plan needed for tens of thousands of wind turbine blades

A new study led by The University of South Australia indicates tens of thousands of wind turbine blades will end up in landfill by the end of the decade unless end-of-life programs are established soon.

The study, led by Professor Peter Majewski, highlights the challenges of recycling wind turbine blades, which are made of either carbon-fibre or glass-fibre composite material, both of which are expensive to break down, with the recovered materials having minimal market value.

“The same features that make these blades cost-effective and reliable for use in commercial wind turbines make them very difficult to recycle in a cost-effective fashion,” Prof Majewski says.

“As it is so expensive to recycle them, and the recovered materials are worth so little, it is not realistic to expect a market-based recycling solution to emerge, so policymakers need to step in now and plan what we’re going to do with all these blades that will come offline in the next few years.”

In many parts of the world, wind turbine blades are currently dumped in landfill, but this practice has been banned in some European countries, and with estimates suggesting there will be more than 40 million tons of blade waste worldwide by 2050, alternative solutions are urgently being sought.

Prof Majewski says that, while there is some very limited potential for reuse of blades in niche construction settings and a small market for some of the reclaimed materials, it is likely the costs of disposing of the blades in a sustainable fashion will need to be factored into their production and running costs.

“Our research indicates the most likely viable option is a product stewardship or extended producer responsibility approach, where the cost of recycling the blades is factored into either the cost of their manufacture or the cost of their operation.

“So, drawing on the experience of similar programs for other products, either the manufacturer must take responsibility for what needs to be done with the blades at the end of their useful life, or the wind farm operators must provide end-of-life solutions as part of the planning approval process for their business operations.”

While self-regulation may offer one solution, Prof Majewski believes the long lifespan and high cost of blades means official frameworks are required to ensure transition of responsibility where necessary. “If manufacturers disappear, or wind farms go broke, we need to ensure processes are still in place for the turbine blades to be disposed of properly,” he says.

Prof Majewski says it is likely consumers will ultimately bear some of the end-of-life cost through energy tariffs, but he believes market competition between energy producers should help to minimise the impact of that on the public.

“There will be some cost to this for everyone involved, but we have to accept that as part of the cost of producing energy in this way,” Prof Majewski says. “Without such solutions, energy options like wind and solar may prove to be no more sustainable than the old technologies they are aiming to replace.” unisa.edu.au

AMT FEB/MAR 2023 025 INDUSTRY NEWS

The benefits of optimising manufacturing inventory

Five ways for manufacturers to benefit from optimising inventory management systems. Rob Stummer is the Asia Pacific CEO of SYSPRO.

The rationale for inventory management is that it saves manufacturers money and allows them to fulfil customers' needs, enabling them to successfully control the cost of their operations. Therefore knowing what stock they have, what is in their warehouse and how to manage the supply chain effectively is the backbone of any manufacturing business’s operations.

Inventory management provides manufacturers with greater accuracy and visibility to inventory information throughout their business and will deliver the following four key benefits:

1. Managing the replenishment of stock

Effective replenishment is dependent on there being sufficient stock to cover demand. The inventory manager’s role is to ensure the right inventory items are ordered, in the right quantity, at the right time and to the right location.

Maintaining an appropriate inventory level is critical for both customer service and profitability. An oversupply of stock, or obsolete stock, increases business costs, and a lack of stock means customer demands will not be met.

The inventory replenishment process varies depending on the type of manufacturing business and its circumstances. Using an Enterprise Resource Planning (ERP) system to manage inventory will provide many of the necessary standard processes and rules for inventory replenishment.

2. Managing suppliers

As part of the supply chain, inventory management includes several aspects, such as controlling and overseeing supplier purchases. One of the key ways to manage this process is through the approved suppliers’ list.

Purchasing modules in an ERP system allows approved suppliers rules to be set and specific suppliers to be approved, which is a very important way to mitigate supply chain risk. The organisation knows these suppliers are compliant and will adhere to the regulations. An increased level of trust and reliability means a manufacturer can benefit in other ways, such as keeping inventory levels low. A manufacturer may have to manage many suppliers, meaning controlling spending, negotiating the best deals and mitigating risk can be time-consuming and complicated. Maintaining a preferred supplier list will help make this process efficient and straightforward.

3. Support for product traceability

There are countless examples of manufacturing businesses hitting the headlines because of problems with contamination, product malfunction and sometimes industrial sabotage.

There has never been more demand for transparency in every part of the supply chain, and increasingly it is seen as an opportunity to differentiate and grow a manufacturing business. However, having an effective traceability process takes more than updating an audit trail. Traceability is about trust, reputation, efficiency, safety, innovation, quality, staff morale and risk management. And regardless of the type of manufacturing business, effective batch traceability is cost-effective and reassuring to the wider supply chain.

A product traceability functionality enables an item to be tracked through the manufacturing process, from purchasing raw materials to manufacturing, assembly, inspection and stocking to the final dispatch stages. In the event of a recall, the organisation can identify what finished item the lot went into and who bought the

items. Having traceability in place enables the manufacturer to keep track of the item being manufactured for compliance and quality assurance purposes or to view what materials were used in the production process.

4. Stock availability

Anyone who has ever shopped for a product and found it was out of stock has experienced the challenges of stock availability. For the suppliers, managing stock availability can be equally frustrating. Stock availability is a straightforward concept: It's the degree to which a business has enough inventory of each item to meet customer demand. Managing stock availability, however, is not so clear-cut. Suppliers must balance the need to fulfil orders and keep customers happy with the cost of buying and storing inventory. In addition, they must do this whilst being prepared for unexpected changes in demand and supply.