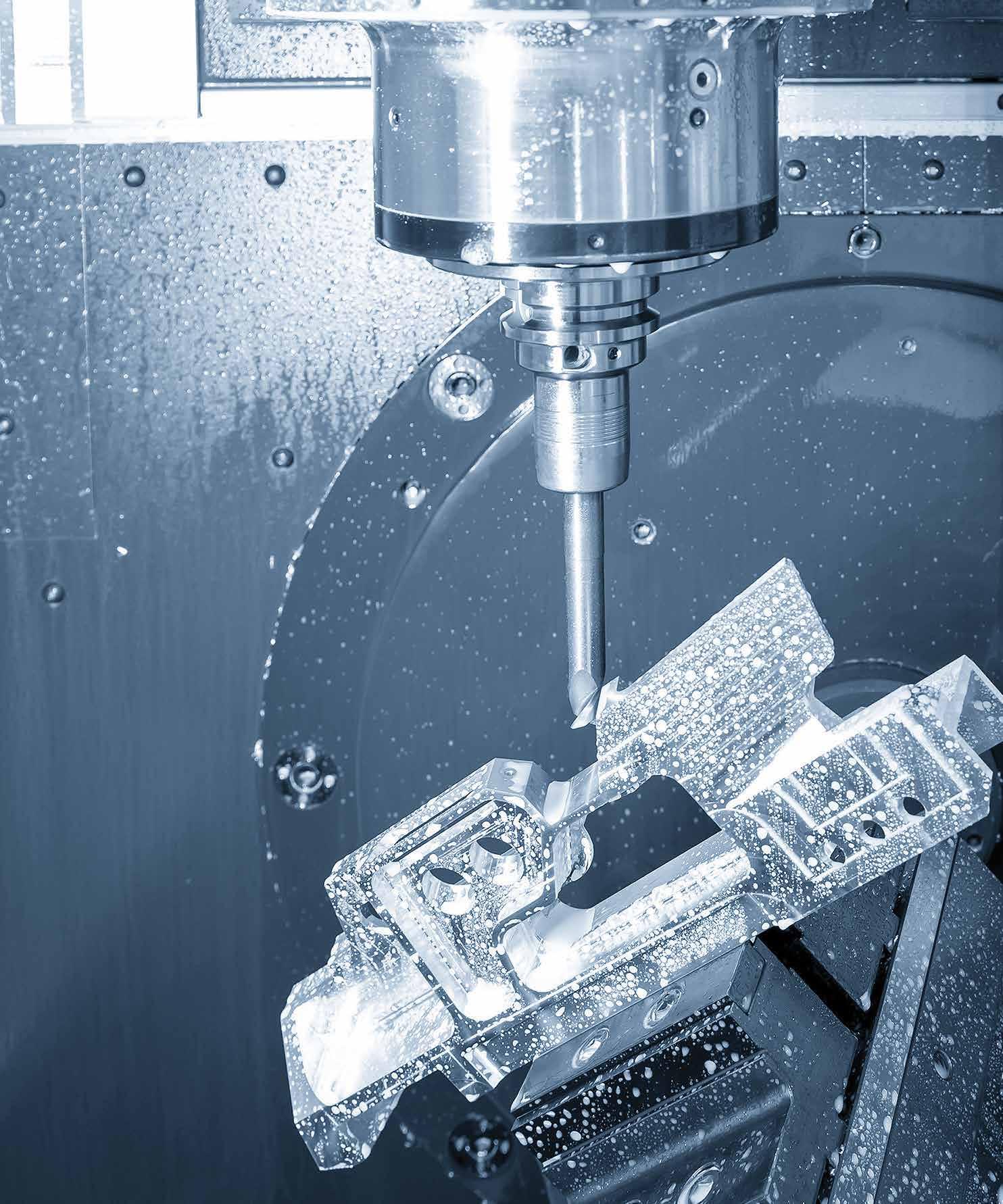

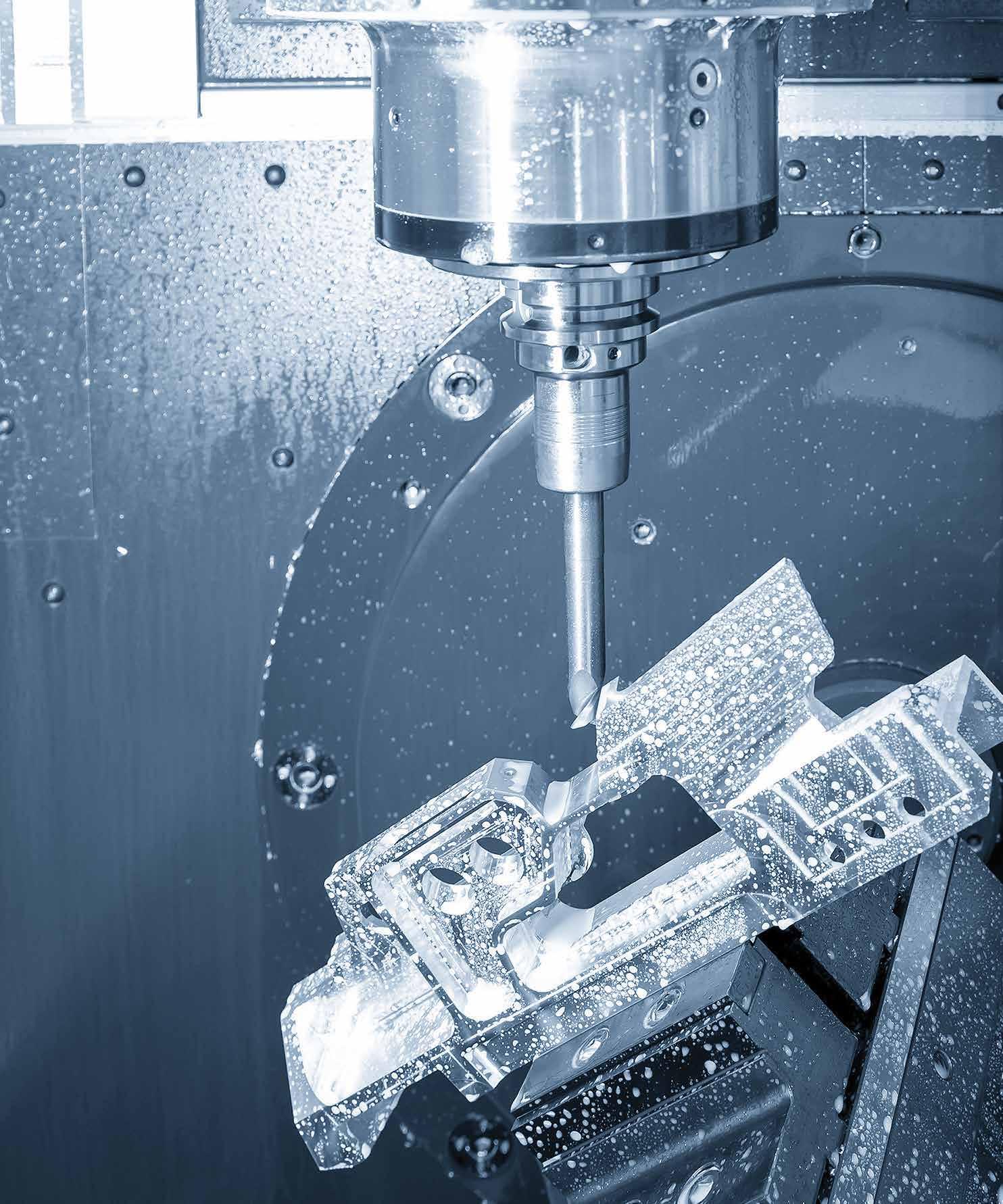

Okuma Australia’s stand at AMW 2023 will showcase the future of manufacturing, demonstrating the latest lathes, machining centres, multitasking machines and automation plus IOT Connectivity Solutions with the Okuma Connect Plan.

Okuma machines on Stand Number MT940 will be cutting metal with several Okuma specialists on hand to demonstrate the cutting power of the Okuma machines as well as Okuma Connect Plan, new Okuma OSP Suite and 5-axis Auto Tuning systems.

Highlighting the Okuma exhibit will be the all-new Okuma ARMROID with built-in robot packaged within the Okuma LB3000EXII. ARMROID functionality includes part loading and unloading, chatter suppression, chip removal, and in-machine cleaning, ensuring that your Okuma machine is consistently operating at its highest efficiency.

MELBOURNE: INTELLIGENT MANUFACTURING

AMW PREVIEW

Construction & Infrastructure

State Spotlight: South Australia

33 Brodie Street, Rydalmere NSW 2116

Ref. Mr. Heino Windhorst

T. +61 (02) 96389600

E. heino@mafosyd.com.au

The next best compact panel bender.

The flexible bending centre solution.

Made-to-measure modularity.

Custom solutions to widen versatility.

kit and batch-one production.

More autonomy and smaller batch sizes management.

Manage your factory, in real time.

Programming, quick and easy.

The METAMASTER Syncro series has been specifically developed to provide reliable & advanced bending features at an affordable price. With a range of machines from 40T to over 200T we have a machine to suit your needs.

5 CNC CONTROLLED AXIS (Y1, Y2, X, R, V) AS STANDARD

ALL MACHINES ARE FITTED WITH THE SWISS DESIGNED CYBELEC TOUCH 12

CNC CONTROLLER WITH INTUITIVE 2D GRAPHICAL TOUCH DRAW PART PROFILE PROGRAMMING AND STANDARD WITH AUTO BEND SEQUENCING

ITALIAN MADE LASERS & MONITORED SAFETY SYSTEM COMPLETE THE MACHINE WITH QUALITY COMPONENTS

Australia's most popular CNC plasma, With Swiftcut tables made in the UK & Hypertherm Plasma units made in the USA there is no compromise on quality.

Four Machine Sizes

UP TO 25MM CUTTING CAPACITY DEPENDING ON THE HYPERTHERM UNIT SELECTED DXF & JPEG PHOTO IMPORT FOR CREATION OF CUTTING FILES

SOFT SENSE DIGITAL TORCH-HEIGHT CONTROL (DTHC) QUICK RESPONSE FOR IMPROVED CUT QUALITY AND IMPROVED CONSUMABLE LIFE.

METALMASTER ClearAir mobile welding fume bench is a compact all in one downdraft table with 1120 x 825mm work area (with fume shroud closed)

HEPA H13 filtration ensures a safe & comfortable work environment

Our Euro Pressbrakes are fully featured with the latest premium technology from 5 axis to 9 axis machines we stock a huge range.

FEATURING THE LATEST DELEM DA66T (2D) OR DA69T (3D) CNC CONTROLS

GERMAN AKAS LASER GUARDING ENSURES ULTIMATE PRODUCTIVITY WITH UTMOST SAFETY

5 AXIS / 7 AXIS - 3 METER OR 4 METER WE STOCK A HUGE RANGE

Operator Control

METALMASTER ClearAir mobile welding fume extractors come in single arm & dual arm configurations. With HEPA H13 filtration Mig, Tig & Arc welding fumes are safely removed and filtered from the work area.

LYNX 2600SY - Doosan Fanuc I Series (0iPlus) CNC Controller

3 JAW HYDRAULIC POWER CHUCKS

The Metalmaster Deburr1380 manual deburring machine is the ultimate cost-saving solution for deburring, grinding, edge rounding and finishing of metal parts.

GREASE CARTRIDGE AUTO LUBRICATION SYSTEM SLAG REMOVAL PRE-GRINDING & DEBURRING

EPPINGER ROTARY TOOL HOLDERS WITH PRECIFLEX ADAPTER SET

A range of different types of pads and brushes for deburring, edge rounding, finishing, laser oxide removal and heavy slag removal are available.

1300 X 800MM TABLE WITH VACUUM AREA TO SECURE SMALL PARTS IN PLACE

GRINDING HEAD WITH MULTIPLE STATIONS AND ALLOWS FOR THE INTEGRATED EXECUTION OF DIFFERENT PROCESSES

VARIABLE SPEED ALLOWS FOR EASY SPEED ADJUSTMENT TO SUIT THE TOOL AND PROCESS

IF YOU CAN DRAW IT, DOWNLOAD IT, TRACE IT OR IMAGINE IT, YOU CAN CUT IT

Any table is a plasma table with ArcDroid™.

Portable powerful and easy to use. ArcDroid™ brings CNC plasma to your garage or workshop. ArcDroid™ combined with our custom operating system with Simple Trace™ can accurately reproduce your designs delivering fast, accurate and repeatable parts from your plasma cutter.

AUSTRALIAN MANUFACTURING WEEK 2023

- The Journey to Intelligent Manufacturing

Melbourne is ready for the return of the largest manufacturing showcase when AMW 2023 takes over the MCEC. Here's a preview of some exhibitors.

ONE ON ONE AMT speaks Natalie O'Brien, CEO of the MCEC, and Romilly Madew, the CEO of Engineers Australia.

PROFILE: SEVAAN

114

RED EARTH ENERGY STORAGE

flight to

Chris Winter is the brains behind RedEarth Energy Storage systems (BESS) and LFP Troppo batteries.

We offer the leading edge of ‘full service’ distribution and lifetime support for Okuma CNC machines. Solution focussed, our team work with our customers to provide machining realities, with exceptional results.

Our team gives you immediate access to decades of industry experience and a network of local and global machine tool experts. We partner with you from the very first meeting, guide you through project planning and support you through implementation, training and after sales care.

Technology

Reputation

AMTIL’s Australian Manufacturing Week is proof positive local manufacturers are up to the task of producing materials and products that are high-quality, ready-for-market, and fit for purpose.

Sheet metal manufacturing has never been busier. Businesses involved in CNC cutting, forming and fabrication, have not been busier in years. The feeling sensed in the crowd of manufacturers at the latest AMTIL industry event showed there was huge momentum in orders, and many had exceeded their capacity in forward orders due to the unavailability of raw materials. Juggling can be hard and full of risk if you don’t know where the balls are falling.

And the reason for that is that economically, the international picture is very cloudy. As KPMG’s Partner In Charge of Manufacturing and Life Sciences, Toni Jones, says in a recently released report on the world economy, divisions in the world economy were growing, well before war broke out in Ukraine or before COVID tightened its grip. Since then, these worldly tensions have caused companies to rethink their international strategies. Around 85% have discontinued working in Russia in particular, in response to the Kremlin’s moves on Ukraine, but globalisation is not necessarly retreating, it is more likely just changing shape.

Jones’ companion Stephane Souchet, the Global Head of Industrial Manufacturing at KPMG, cites an uncertain future for businesses, characterised by the disrupted patterns of global trade, geopolitical tensions and a growing investment drive into defence. The move into defence is a signal of changing shapes in our economy, not a retreat, as such. Jones adds that, “we have to not only focus on re-evaluating our sourcing locations, supply chain dependencies but also [to] foster nearshore and onshore capacity.”

Labour shortages here in Australia, increased costs for inputs, supply delays, wet weather and flooding were constraining factors in November. Interest rate rises have reduced demand from construction customers with builders delaying or cancelling orders. Import competition has increased. Despite all of this, surprisingly, new orders and stock deliveries were all positive in that month.

COVID-19 has also highlighted many risk and resiliency gaps. In another recent KPMG study citing global supply chain issues, 67% of CEOs indicated they would increase investment in disruption detection and innovation processes to reduce the impacts of disruption.

Government and industry leaders are also looking to build domestic capabilities to reduce their reliance on global supply chains. Of course, organisations must review their sectors’ supply chain flows and consider local inventory capabilities to reduce risk. Spreading the load of third parties to rely on for supply will ensure access to their stock. Relying on this ecosystem of vendors and having a wide-ranging strategic partnership within the domestic industry will keep parts coming in, and your knowledgebase up to date to future conditions. You should know everyone in your local network will want you to succeed as well. AMTIL knows the value of local networking during times like this, and it pays to stay connected.

The KPMG report confirmed the volatility of the Australian construction industry, with complexity becoming the new normal. As manufacturing is so much a part of the maze of construction and infrastructure ecosystems in Australia, learning to transform these projects into manageable business is paramount. Juggle as you stay on top of what you manufacture but keep all your balls in sight at all time.

Editor Paul Hellard phellard@amtil.com.au

Contributors

Drew Turney

Sales Manager Nicholas Raftopoulos nraftopoulos@amtil.com.au

Publications Co-ordinator

Caroline Robinson publications@amtil.com.au

Publisher Shane Infanti sinfanti@amtil.com.au

Designer Franco Schena fschena@amtil.com.au

Prepress & Print Printgraphics Australia

AMT Magazine is printed in Australia under ISO140001

Environmental Certification using FSC® Mix certified paper sourced using sustainable tree farming practices.

Contact Details

AMT Magazine

AMTIL Suite 10, 5 Corporate Boulevard Bayswater VIC 3153 AUSTRALIA

T 03 9800 3666

F 03 9800 3436

E info@amtil.com.au

W www.amtil.com.au

Copyright

© Australian Manufacturing Technology (AMT). All rights reserved. AMT Magazine may not be copied or reproduced in whole or part thereof without written permission from the publisher. Contained specifications and claims are those supplied by the manufacturer (contributor).

Disclaimer

The opinions expressed within AMT Magazine from editorial staff, contributors or advertisers are not necessarily those of AMTIL. The publisher reserves the right to amend the listed editorial features published in the AMT Magazine Media Kit for content or production purposes.

AMT Magazine is dedicated to Australia’s machining, tooling and sheet-metal working industries and is published bi-monthly. Subscription to AMT Magazine (and other benefits) is available through AMTIL Associate Membership at $190.00 (ex GST) per annum. Contact AMTIL on 03 9800 3666 for further information.

SHANE INFANTI – Chief Executive Officer AMTIL

SHANE INFANTI – Chief Executive Officer AMTIL

I have been banging on about Government procurement for a long time now. The need for a whole of government approach to their own procurement policies has supposedly been on the agenda for a number of years. However, we still have the situation where some industry sectors are left with significant roadblocks to overcome when dealing with state and territory governments on an individual basis. This is certainly the case with rail.

The Australasian Railway Association (ARA) has called for a national approach to rollingstock procurement in response to a new report that found governments missed out on $1.85bn in cost savings over the last decade due to inefficient local content policies in place across Australia. ARA Chair Danny Broad said state-based local content policies made operating in different states akin to operating in different countries. This led to the duplication of facilities and inconsistency between states, and made it too hard for some organisations to bid for key contracts.

“It is unfortunate to see cost savings on such a huge scale being left on the table at a time when demands on government budgets have never been higher,” Broad said. “State-based policies make it harder for industry to gain scale, drive innovation and adopt greater efficiency and productivity across their operations.

“This hampers their competitiveness over time and puts local jobs at risk in the long term.

“Australia has fantastic capability in rollingstock manufacturing, but its effectiveness is hampered by inefficient state-based local content policies that make it difficult for organisations to work across state lines to build economies of scale.

“These lost savings could have contributed to funding the huge infrastructure pipeline currently underway, or supported 1500 health and education jobs over the ten-year period.”

The report, authored by BIS Oxford Economics and the Hadron Group, identified foregone procurement cost savings from the last decade included:

• $717m of savings from increased scale

• $811m of savings from reduced complexity in planning and design

• $318m of savings from major componentry harmonisation

Assistant Minister for Manufacturing and Trade Tim Ayres welcomed the report’s findings.

“We know the different approaches by the states and territories to rail procurement and manufacturing leads to capabilities being

duplicated,” Assistant Minister Ayres said ahead of today’s launch. “This pushes up costs, exacerbates skills shortages, and constrains investment. “By working together to build and maintain modern passenger trains, Australia can reduce procurement costs while boosting manufacturing capability and creating high-skilled jobs in regional and outer suburban Australia.”

States and territories use different procurement policies for purchasing rail assets such as rollingstock, including state-based local content requirements. The report found that while this approach supported local jobs in the short term, it undermines the long-term sustainability of the rollingstock manufacturing industry. A national approach to rollingstock procurement would allow both governments and industry to achieve improved outcomes, realising the cost savings outlined in the report.

A national approach would also support the growth and competitiveness of the industry, supporting further jobs growth in this essential market. The rail manufacturing and supply sector generates $2.4bn in revenue per year and supports more than 4000 jobs, many of which are in regional areas.

Assistant Minister Ayres said the Albanese Government has committed to delivering the National Rail Manufacturing Plan, aimed squarely at coordinating a national approach to support and grow the Australian rail manufacturing sector. “The Australian Government wants Australia to be a smart nation that makes high-value products for the country, the region, and the world,” Assistant Minister Ayres said. The National Rail Manufacturing Plan's development is being led by the Office of National Rail Industry Coordination (ONRIC) in the Department of Industry, Science and Resources.

As part of the Plan, the government will shortly appoint a National Rail Advocate and Rail Industry Innovation Council to support and drive change in the rail manufacturing industry.

So it is now over to the Federal Government for action. Having recognised that this is indeed an issue which costs significant dollars, wastes resources and stymies investment, it will be interesting to see how they manage any change.

Australia is a wealthy, advanced nation. Where do you think we rank globally for 'economic complexity'? You might have guessed top 10 or 20. You would be wrong.

Australia languishes in 91st place, well down from countries with which we really like to compare ourselves. What about ‘manufacturing self-sufficiency’? Well, we rank dead last among OECD countries. And why does this matter? I will come to that later.

WA has always been a pioneer in manufacturing and innovation. From the Western Australian Boot Manufacturing Company, established in 1907, which produced over 100,000 pairs of boots a year, right through to the vast Kwinana Industrial Area which turbocharged WA's manufacturing sector and has supported tens of thousands of jobs since the 1950s.

And WA still leads the charge. Just two weeks ago I was in Perth seeing it first-hand. I visited ChemX and the Future Battery Industries Cooperative Research Centre who are both making headway to help Australia become a key player in battery industries.

I visited BGC’s concrete manufacturing operation which is looking at greener ways to produce building materials.

I also saw how Murdoch University is nurturing the next generation of innovators through its new robotics mentoring program for high school students. Sadly, for too long, Liberal governments have talked big on manufacturing but delivered little beyond glitzy advertising or election slush funds.

The idea of making things at home was an abhorrent idea for the Liberals. It’s resulted in jobs, skills and investment going offshore at an alarming rate. Those rankings I mentioned earlier. They point to a country that relies on others. One that doesn’t make enough anymore. That’s problematic for a range of reasons, but as we learned most recently at the peak of the COVID pandemic when we went looking for the things we needed, we didn’t have them.

In many cases – like in critical minerals – Australia exports resources, waits for the value to be added somewhere else and then imports them back at higher prices.

And as the Prime Minister recently said, "one of the lessons of the pandemic is that we need to be more self-reliant, we need to be

more resilient, we can’t just sit back and allow ourselves to be at the end of global supply chains." In short, we want Australia to be a country that makes things. And a country that makes things creates good, secure, fulltime work. WA has all the ingredients to be a manufacturing powerhouse.

Smart people using their know-how to build strong businesses, showing the rest of the country how to get things done. You have an abundance of raw materials, a strong R&D investment and longstanding trade relationships. And the state is thinking long term about its economy and jobs. Australia has a rich and diverse endowment of critical minerals that are crucial to the wires, batteries, magnets, and semiconductors that power clean energy technologies for the world.

That’s why I say if we mine it here, then we should make it here. It’s why we’re developing a National Battery Strategy. We’re building the National Reconstruction Fund. At $15bn, it’s one of the biggest investments in Australian manufacturing in living memory.

It will invest in businesses that want to grow and stay onshore. It will be managed by a board of people drawn from industry and investment circles. It will make decisions in the national interest instead of politicians’ interests.

There are several priority areas that have unique benefit to WA. We want to use this fund to boost medical manufacturing and enabling capabilities such as critical technologies and advanced manufacturing. The fund will also target projects which value-add in resources, agriculture, forestry, fisheries, food and fibre.

WA is at the forefront of production when it comes to many of these industries - which means WA and its businesses stands to benefit from the opportunities presented by the NRF.

It’s time to back Australian know how so we can grow our economy, create new jobs, and make sure that happens across the country including right here in WA.

And I know plenty in WA will be ready to step up and make that happen.

After two years of pandemic-induced interruptions, 2022 was a more stable and successful year for Australian business. While Australian business leaders are cautiously optimistic for 2023, they are readying plans to adjust to the challenges expected in the coming year.

Now in its tenth year, Ai Group’s annual Australian CEO Survey provides critical insights into business experiences over the past year, and how business leaders expect the coming year to evolve.

Our 2023 CEO Survey has revealed that businesses consolidated the post-pandemic recovery in 2022. Business conditions, turnover, employment and investment all improved as the dislocations of the COVID era gradually abated.

However, business leaders also contended with a new set of ‘supplyside’ challenges, as rampant inflation, chronic labour shortages and supply chain disruptions weighed heavily on performance. Business leaders have reported declining margins due to these supply-side pressures.

It is a testament to the resilience, flexibility and innovation of Australian business that we successfully navigated the challenges of post-COVID recovery in 2022.

There is, as always, a wide range of views about how 2023 will play out. But our Australian CEO Survey reveals several common themes that Australian business leaders largely agree on.

On balance, employers go into 2023 with cautious optimism. They expect business conditions and performance to improve again on the strong results of 2022. Despite the headwinds facing the Australian economy, business leaders are undertaking ambitious investment plans to adjust to the new market realities of the postpandemic era.

However, they also identify three challenges which will define their priorities in 2023:

1. Historically tight labour markets, which have exacerbated chronic staff shortages, particularly for skilled roles.

For the first time in the history of our CEO survey, staff training is the top investment priority. 90% of CEOs expect to be affected by staff shortages in 2023. They intend to invest in staff training and development to grow their in-house skills base.

In contrast, more conventional types of investment such as physical CAPEX — buildings and equipment — or research and development ranked very lowly for 2023.

This illustrates one of the hidden costs of the skills crisis in Australia today. As businesses are redirecting their investment plans to workforce, there's not much left over for growing industry or doing R&D. Given Australia ranks fairly poorly on international league tables for R&D, this could have significant implications for our future competitiveness in five to ten years’ time.

Perhaps unsurprisingly, given the national and global inflationary context, in 2022 business leaders reported the fastest rises in industry prices ever seen in the history of the Ai Group CEO survey. And businesses are expecting inflationary pressures of the past two years to continue, particularly for energy.

Investment in process improvements and technology are already underway to manage the effects of cost pressures on the balance

sheet: in terms of investment priorities, improving business processes was ranked second, while ICT investments were ranked third. While not strictly workforce, these investment priorities are in fact also very much related to skills shortages. Process improvement and ICT allow for a more effective deployment of a business’s current workforce and help adjust to conditions in which labour supply will remain constrained.

Business leaders have elevated supply chain resilience to be a top priority and nearly 90 per cent of CEOs plan to make a supply chain investment this year, looking to improve their logistics practices, cultivate new suppliers, and adjust their product offerings to manage this ongoing challenge.

Just under 20% of businesses say they plan to find new suppliers while a quarter of businesses say their only strategy is to increase their prices to recoup supply chain costs — effectively passing them on to customers.

A quarter of businesses might sound like a lot, but it is actually a worryingly low number. Given 79% of businesses say they're currently affected by supply chain problems, it tells us that most businesses don't expect they can recover those additional costs via pricing. The balance sheet is going to have to wear the difference. Our survey demonstrates that it will clearly be another challenging year for many businesses and the need for a relentless focus on productivity across the broader policy agenda has become even more important.

The strategies businesses deploy and their investment priorities are critical for Australia to achieve the economic resilience needed for prosperity in a time of global economic uncertainty.

The Federal Government in particular will also need to put productivity and flexibility at the forefront, especially when considering the further changes to workplace relations it plans to introduce later this year. We need to catch up on years of below-par productivity growth and we need to gear ourselves for at least a return to 1990s level growth. aigroup.com.au

Rather than planning for the future, too many politicians and governments have neglected the hard but necessary work of imagining what Australia’s built environment will need 50 years from now. Huge changes in industry, technology and housing have left enormous sections of our national infrastructure scrambling to keep up – or just falling further and further behind.

There are several reasons why this has happened. Privatisation and the rise of “consultancy culture” has hollowed out the public service and its institutional knowledge, and left governments captured by vested interests. For-profit companies are unlikely to consider any aspect of the projects they undertake other than profitability. And offshoring has sidelined the knowledge and experience of local workers who understand – and care about – the context and environment in which they work.

The results of this neglect are all around us. Investment in electric vehicle (EV) infrastructure like charging stations, especially outside the major cities, hasn’t kept pace with the rising demand for EVs. Cars banked up in regional towns along the Pacific Highway during the summer holidays as people waited to recharge. An important part of the energy transition is being held back by a simple lack of planning.

The same is true of our energy infrastructure. The number of largescale solar projects in the pipeline is bottoming out because our ageing grid is struggling to cope with the influx of renewables. Large amounts of energy generated by solar farms like Molong are going to waste – as is much of the electricity coming from millions of rooftop solar panel installations.

A lack of decent city planning is also letting people down. Property developers have been given free rein to build thousands of uninsulated, dark-roofed houses that rely entirely on air conditioning to keep cool. The suburbs these houses stand in are often built at the absolute limit of the urban fringe, with no access to decent public transport or basic amenities like parks, footpaths or shops. Many have only one access road in and out, creating enormous traffic snarls and presenting a risk in the case of natural disaster – which many of these suburbs are especially vulnerable to, being built in fire- or flood-prone areas. And areas that experience scorching temperatures have been completely cleared of trees, turning houses and tarmac into outdoor ovens and forcing people inside to their air con.

From the $50bn debacle that was the Turnbull government’s “mixedtechnology model” for the NBN to the ongoing failures on NSW’s public transport system, treating the complex and interlocking demands of our society as opportunities to make money has resulted in spectacular policy failures over and over again. The only people who benefit are a handful of investors and shareholders, who leave everyone else to deal with the consequences and clean up their mess. If we don’t urgently change this mindset, we could end up like the United States, with its crumbling roads, bridges and water infrastructure.

The Federal Government’s $15bn National Reconstruction Fund (NRF) is a welcome opportunity to start addressing this. After nearly a decade of inaction from the previous government, a big, ambitious plan to re-establish domestic manufacturing and build some badly needed national infrastructure is a refreshing change of pace. But throwing money at new projects won’t magically solve the underlying problems. If big businesses are given blank cheques without any conditions, they’ll do what they’ve always done –

spend taxpayer money on enormous white elephants that worsen the problems they’re supposed to fix.

That's why the NRF board needs the perspectives of workers when deciding where to spend its money. This can’t be through some box-ticking consultation process either. Workers must be in the room where these decisions are being made.

The idea that executives and public servants know more about manufacturing, infrastructure or construction than working people do isn’t just insulting – it's been disproven repeatedly by their own failures. Worker representation on boards is why industry superannuation funds consistently outperform commercial funds. Having worker representation on the board of the NRF would help ensure that $15bn doesn’t go to waste.

Because they’ll be trusted with public money, businesses that receive NRF funding should also demonstrate a willingness to consider the social, human and environmental effects of the projects they undertake. Requiring those businesses to have a collective bargaining agreement with their workers would help weed out those that see the NRF as an opportunity to put more money in executives’ pockets.

The NRF is a massive opportunity to fix our built environment – but if workers are empowered through its processes, it can become an opportunity to fix our policymaking as well.

amwu.org.au

VISIT US AS AMW 2023! - STAND MP350

Industry 4 0, digital processes & information all in one central location

Achieve unparalleled digitisation

Facilitates industrial operations across all sectors

Floor, wall & desk-mounted options

43” Touchscreen

Wirelessly connected

Ruggedised, powdercoated steel enclosure

Touchscreen or touchless

ip54 rated kiosk (for dust protection)

Email: integratransform@integrasystems.com.au

Website: www.integratransform.com.au

Phone: +61 3 9359 3133

Fully customisable

Australian-made

Dimensions: 700W x 2006H x 120T mm

Flip out keyboard & storage drawers

B0200 Ardcam camera & K5mic lav microphone

Intel Z8300 Quad Core 1 8GHz or equivalent

Operating systems - Windows 10/Linux/Ubuntu

Scan here to find out more

The

and environmental benefits generated by portfolio, with over $4.2bn in new revenue growth, 6,000+ jobs and $2bn investment in future R&D by 2030.

After seven years successfully supporting the transformation of Australian manufacturing, the Innovative Manufacturing Cooperative Research Centre (IMCRC) has concluded its operations.

Over its lifetime, IMCRC purposefully invested $40m of Commonwealth funding into industry-led R&D to grow Australia’s manufacturing capability and capacity and drive real-world commercial outcomes. IMCRC’s Achievements and Outcomes Report has just been published, summarising the substantial impact and legacy IMCRC leaves for Australian manufacturing.

From its initial pool of funding, IMCRC catalysed a $254m project portfolio comprising 71 collaborations between 78 industry partners, 13 universities and the CSIRO.

Backed by a transparent governance structure and clear framework for commercialisation, IMCRC facilitated collaborations that leveraged Industry 4.0 technologies to explore new ideas, business models, products, processes, services and platforms.

Many of these projects are already delivering substantial commercial outcomes that will shape the future of Australian manufacturing, including new revenues, business growth, high-value jobs and global exports. In 2022, these outcomes were quantified by leading advisory firm ACIL Allen in an independent impact evaluation report, “The Impact of IMCRC”. ACIL Allen found IMCRC’s business model had delivered ‘significant positive impacts for the Australian manufacturing industry’, including economic benefits of more than $4.2bn by 2030.

Further benefits include the creation of 6,000+ ongoing full-time jobs, 224 collaborations and new partnerships, planned investment of $2 billion in future R&D and a 3.3m tonne CO2 reduction in greenhouse gas emissions.

“What set IMCRC apart was its commitment to operating with strong commercial principals, and in a timeframe that met industry’s needs,” IMCRC’s Chair, the Hon Ian Macfarlane said. “This approach enabled IMCRC’s partners to realise significant return on investment, including through the ownership of intellectual property and commercialistaion of technology.

“I would like to thank the Board for their tireless dedication to the success of the IMCRC, and CEO and Managing Director, David Chuter, and his team for their incredible work supporting participants on their innovation journeys. Their efforts have made IMCRC arguably Australia’s most successful CRC.”

“IMCRC has been one of the best ever Cooperative Research Centres,” added IMCRC Director, Professor Mary O’Kane AC. “Thanks to the hard work and vision of the team and partners, IMCRC leaves behind a considerable legacy.” IMCRC has been an independent and for-impact cooperative research centre with a successful, proven and scalable model for catalysing research and business partnerships that drove transformative commercial outcomes for participating Australian manufacturers. Over its lifetime, IMCRC successfully co-invested in 71 R&D projects, catalysing $254m in transformative manufacturing research. imcrc.org

Supporting Australia’s battery manufacturing industry to charge ahead.

Minister for Industry and Science Ed Husic formally launched consultations for the country’s first National Battery Strategy at a visit to Energy Renaissance, an Australian lithium-ion battery technology and manufacturing company, at Tomago in the New South Wales Hunter Valley.

Developing the Strategy will be integral to help Australia transition to a decarbonised economy, hit our ambitious emissions targets, foster Australian innovation and support Australian industry.

Minister Husic said domestic battery industries will be buoyed by Australian know-how and domestic access to minerals to help power the move to clean energy here and around the world.

“Our general approach should be one where if we mine it here, we should make it here,” Minister Husic said.

“Large scale uptake and manufacture of batteries will be vital transitioning to net-zero. New battery capacity will help support grid scale capacity, power our homes, and electrify our transport sector.

“We know there is huge demand for energy storage to support the widespread uptake of solar generation by households, business and industry.

“Global demand for existing and next-generation batteries is forecast to increase nine to 10-fold over the next decade.

“That’s why it is important that we harness the opportunity to become a key player in battery manufacturing and export on the world stage.

“Australia has globally significant deposits of essential battery materials and strong local innovation and research capabilities. By drawing on these strengths, Australia can take its place in the profitable global battery supply chain.”

Globally, Bloomberg New Energy Finance estimates that 387 gigawatts of new energy storage will be added by 2030, providing an excellent opportunity for Australian battery industries.

Bolstering Australia’s battery manufacturing capability presents an opportunity to integrate and diversify global battery supply chains. A joined-up national approach to battery technology will also work to support Australia’s National Electric Vehicle Strategy.

“The National Battery Strategy will complement the development of Australia’s new Critical Minerals Strategy to articulate a clear pathway for integrated, end-to-end onshore battery minerals supply chains,” Minister Husic said. “A coherent, national approach to the development and uptake of emerging technologies won’t just deliver economic growth and jobs, but also help safeguard our national wellbeing,” Minister Husic said.

The Albanese Government will work closely with states and territories, and consult widely with industry, community and experts to shape the strategy and help grow globally competitive domestic battery industries.

Engagement on the Strategy will help inform other elements under the Australian Made Battery Plan including:

• creating a Battery Manufacturing Precinct, in partnership with the Queensland Government;

• establishing a Powering Australia Industry Growth Centre to support industry translation of research into local jobs and investment; and

• supporting 10,000 New Energy Apprenticeships.

The discussion paper can be found at: consult.industry.gov.au/national-battery-strategy-issues-paper

To mark International Women’s Day, Weld Australia is calling on the Federal Government to implement a proactive, targeted approach that: engages and recruits women into the trades; implements innovative trade training programs designed specifically for women; and sets measurable gender diversity targets on governmentfunded projects.

“Australia will have a shortfall of at least 70,000 welders by 2030,” said Weld Australia CEO, Geoff Crittenden. “Industry is already at capacity. Weld Australia’s members are currently operating at 50% to 70% capacity, and turning away work because they cannot find enough welders.” “Increasing diversity in the trades is one of the best ways to alleviate the looming skills shortage, and every effort needs to be made to encourage women to become welders,” said Crittenden.

“There are significant economic benefits for women in welding, from increased choice and availability of jobs, through to improved job security, higher than average pay and ample opportunities for progression and promotion. A career in welding is safe and secure—once you’re qualified, you can walk into a job tomorrow. Welding is in-demand because it is essential to the success of so many industries,” said Crittenden.

The five-year pipeline of major federally-funded infrastructure projects is valued at $237bn. On top of this, a veritable army of skilled welders will need to be assembled to build and install the wind and transmission towers, solar farms and other power generation assets needed to achieve the Federal Government’s 43% emissions reductions target by 2030 and net zero by 2050. Plus, there are countless projects in Defence, state government

funded projects, and other private developments. With all these government-funded projects in play, measurable gender diversity targets on government-funded projects would have a huge impact. In effect since 1 January 2022, the Victorian Government’s Building Equality Policy (BEP) is an Australian first and aims to disrupt gender stereotypes in the country’s most male-dominated industry. The BEP applies to new government projects, and mandates female representation in at least 3% of each trade role, 7% of each non-trade position and 35% of management, supervisor and specialist labour roles. It also mandates that 4% of labour hours for apprentices and trainees are performed by women.

“The Advanced Manufacturing Outreach Program is unique because it actually engages kids. It is hands-on, fun and educational. It is not just about studying more maths and physics textbooks. The Program uses Seaberry’s Soldamatic augmented reality welding simulators to gamify the learning experience. Anyone can try their hand at the welding simulators and be a star. A lot of these kids have never passed a test in their lives—the light in the kids’ eyes when the simulators gives them the all-clear is really something to see,” said Crittenden.

“Industry research demonstrates that investing in well-paid, secure jobs, expanding the Commonwealth Paid Parental Leave scheme, making early childhood education more affordable and accessible, and making workplaces safe from sexual harassment were key to getting women into work. All these measures must be implemented by both our governments and private industry,” said Crittenden. weldaustralia.com.au

Smart and robust modular units offer designers the opportunity to tailor projects to meet unique needs at low cost.

Lifgo

When fast, precise and synchronised linear motion is required, our Lifgo rack and pinion gear units have proven to be reliable in many industry sectors around the world.

A collaborative research centre of excellence will develop ultraprecise measuring devices that could enable high-speed internet, better medical screening technologies and carbon emissions monitoring.

RMIT University will lead a consortium of universities and industry partners in the new $72m ARC Centre of Excellence in Optical Microcombs for Breakthrough Science (COMBS), announced recently by the Australian Research Council.

They will focus on bringing optical frequency comb technology –which translates electronic signals into light waves for high precision measurement – out of the lab and into a wide range of real-world applications.

Centre Director, RMIT Distinguished Professor Arnan Mitchell, said it was a major milestone in the growing momentum of optical frequency comb technology.

“A photonic chip industry has finally emerged and the unique technology it produces will transform many fields of science,” Professor Mitchell said. “After so much hard work by so many people, the stars are finally aligning.”

The multi-disciplinary COMBS team includes world-leading experts from eight Australian universities (ANU, Monash, Swinburne, UTS, UniSA, Adelaide and Sydney) and 23 global partner organisations including The Garvan Institute, Advanced Navigation and the National Measurement Institute.

This investment in the Centre will develop a trained, versatile and diverse researcher workforce engaging collaboratively across fundamental science and technology, translation, enabling advances in multiple application areas.

Mitchell said the team spanning various career stages and disciplines had strength in diversity and a strong conviction to lead change in the Australian research community.

“We are passionate about improving equity, building Australian capability, educating the next generation and translating our research so that it really does achieve global impact,” he said.

RMIT Deputy Vice-Chancellor Research and Innovation and VicePresident, Professor Calum Drummond, said COMBS was perfectly aligned with RMIT’s mission to drive research with impact.

“The power of real-time information delivered by microcomb technologies is truly transformative. Microcombs will transform the way we measure everything around us, and in doing so change how we communicate, travel and live our lives,” Drummond said. “The high-impact applications we will see coming out of this new centre will catapult Australian research and industry into new domains."

Story: Michael Quin and Rachael Vorwerk rmit.edu.au scienceinpublic.com.au

Adelaide-based space industry-research centre SmartSat CRC and NASA team up to collaborate on astronaut emergency communications.

SmartSat Cooperative Research Centre, has announced a project agreement to further develop new Search and Rescue (SAR) beacon technologies with partner NASA.

Australia and the USA have a long history of cooperation in Search and Rescue. In 2020 NASA and SmartSat announced a collaboration to advance satellite-based emergency communications and Search and Rescue, combining communications and navigation technology. This new project deepens the strategic collaboration in this important field.

The project is studying a new search and rescue system for future human exploration on the surface of the moon, known as LunaSAR. Astronaut safety is paramount and the ability to reliably communicate an emergency incident must be maintained, even if other services are not available. Similar to distress beacons on Earth, this system will provide miniature low power radio beacons mounted on space suits and lunar rover vehicles. The technology will support SOS and two-way messaging over a lunar orbiting satellite constellation. It will also allow the beacon location to be accurately determined, in the absence of GPS. This information will be provided securely and quickly to both the mission control centre on Earth and the response team on the moon who are able to take immediate action.

Under the agreement, NASA’s Search and Rescue Laboratory (SARLab) at the agency’s Goddard Space Flight Center in Greenbelt, Maryland will bring experts to the project to help guide and review the technical direction. The research team will design a new specialised beacon for extra-terrestrial environments based on a new waveform. As well as direct Artemis applications, they will also investigate the

potential for enhanced services to extend beyond SAR to broader emergency management such as natural disaster warning systems.

Visiting Adelaide recently, the NASA Search and Rescue office Chief, Dr. Lisa Mazzuca gave this insight. “NASA is delighted to advance technology in this field, which will allow our astronauts exploring the Moon to do so knowing they have a system focused solely on their safety,” she said. “This is pioneering work that takes such a dedicated international partnership to get to fruition.”

Dr. Mazzuca’s SAR team also has the full support and sponsorship of the Space Communications and Navigation (SCaN) Program at NASA Headquarters in Washington, through Mr. James J. Miller, Deputy Director for Policy & Strategic Communications within SCaN.

“Australia is a unique location with many skilled and talented technologists who are fully capable as a full international partner of making major contributions to safeguard astronauts. We are proud to work with such like-minded experts to ensure the safety of our future astronaut corps.”

“This agreement is not just a fantastic development for Safety from Space’s low-power, high-efficiency safety technology, it signals that Australia’s space sector is developing globally important technologies,” SmartSat CEO Andy Koronios commented. “NASA has been instrumental in the development journey for this essential safety technology – and while it is early stages, we now have the further potential of this Australian-developed tech playing an important role in Lunar and Martian exploration missions under the Artemis program.” smartsatcrc.com

The managing partner of the Kübler Group was on site recently to open the brand new Kübler Australia distribution centre in Melbourne.

The Kübler Group is a leading global specialist producing position and motion sensors (including encoders), slip rings and transmission technology, counters and other process devices. The company is flagged as one of the 100 most innovative medium-sized companies in Germany for the fourth time running, in 2022. At the newly opened facility in Melbourne, Lothar Kübler noted the company’s year-onyear increase in revenue of just under 20% recently, and added that the most important element is their manpower. For the size of the company, with a good 500 employees worldwide, the strongly developed international sales and application network, as well as a high R&D share, are very important competitive advantages in the international business. In addition, at the end of 2021, Kübler set up an incubator team focused on digitalisation and Industry 4.0 solutions.

Kübler Group is a leading global specialist for position and motion sensors (including encoders), slip rings and transmission technology, as well as for counters and process devices. The company also supplies products and solutions for industries such as elevator technology, drive technology, wind power, mobile automation as well as intralogistics and mechanical engineering.

Kübler supplies products and solutions for industries such as elevator technology, drive technology, wind power, mobile automation as well as intralogistics and mechanical engineering. “We always want to understand exactly the application and future trends of our customers in their segments. This enables us to create the right product solutions,” says Lothar Kübler.

The new Australian team recognised that the pillar for Kübler’s success was the close customer dialogue, keeping them happy.

“Developing new ideas together and ‘continuously improving the existing’ is the motto,” said Australian Managing Director Jason Bouyer. “No less important is the manpower behind it. With the active R&D network at Kübler, a new portfolio of measuring wheel systems and bearingless encoders with IIOT functions are coming onto the market.”

kuebler.com/en/company/about-kuebler

Hetech teams up with EcoJoule to manufacture the PCB boards for the EcoVAR building products ready for distribution.

EcoJoule’s EcoVAR is improving and innovating electricity supply through smart grid technology.

The influx of solar on homes and businesses changes the way the local grid operates. EcoVAR technology helps improve voltages and increases the ability of solar to export clean energy.

The EcoVar is not only improving the quality of electricity in these areas, but it is also helping grid businesses like Ausgrid work towards a net-zero future.

With the rapid uptake of solar PV, the low voltage residential electricity network is being required to perform in ways it was never designed to perform. The main problem being experienced is worsening voltage regulation. The solar PV systems are generating at their maximum during the middle of the day when residential consumption is typically low, this then causes voltage rises on the low voltage networks causing solar inverters to trip, reducing the ability of solar panels to export clean energy. This sustained delivery of excess voltage levels is also diminishing reliability, reducing appliance lifetime and reducing appliance efficiency.

Hetech has teamed up with EcoJoule to manufacture the PCB boards for the EcoVar and they build the products ready for distribution. With many installations complete and delivering results in multiple states currently, the EcoVar is predicted to continue to roll out nationally over the coming months.

The EcoVAR technology helps improve voltages and increases the ability of solar to export clean energy to the grid. The benefits of this product are felt throughout the whole solar energy supply chain, with households benefiting from better energy utilisation, higher solar export volumes and lower bills.

Ausgrid has installed a three phase EcoVAR unit from EcoJoule Energy at Nords Wharf, which has successfully reduced the voltage fluctuation to consumers, also preventing the potential tripping of solar systems and delivering reliable outcomes in the delivery of power.

In the area where the EcoVAR unit has been installed there is a significant increase in the amount of solar energy that can be exported into the grid, virtually eliminating constraints on existing solar customers.

Not only is the EcoVar improving the quality of electricity in these areas, but it is also helping businesses like Ausgrid work towards a net-zero future.

“Ausgrid has a diverse and complex network and we are looking to use innovative technology to improve service quality for all of our communities,” Ausgrid’s Executive General Manager of Asset Management Junayd Hollis said. “That’s why we commenced these trials with the EcoVAR units, to improve customer voltage and quality of electricity supply. This is an integral part of our actions to increase hosting capacity for rooftop solar as well as other Distributed Energy Resources (DER), and reduce costs on our network. In turn this helps de-carbonise the grid and work towards a net-zero future.” hetech.com.au

Digital technologies for construction industry will improve safety and efficiency.

Victoria University researchers have developed state-of-the-art technology that will take outdated aspects of Australia’s construction industry into a modern digital age.

Professor Zora Vrcelj (Head of VU’s Built Environment) and Professor Yuan Miao (Head of VU’s Information Technology) and their teams have combined high-tech tools with engineering and architecture to improve safety training in the construction profession – which has one of the highest rates of preventable accidents and deaths of any sector in Australia.

With the help of a construction simulator (COSI) with virtual reality (VR) at VU’s Werribee Campus, the researchers want to reduce workplace injuries and deaths. COSI’s fully-immersive VR experience allows trainees to use high-tech goggles and equipment to enter and explore a detailed simulation of a construction site to learn about safety – a big change from learning it through an instruction booklet or computer modules.

The simulator lets users learn to climb ladders, move equipment, work in a confined space, or walk along narrow scaffolding, without any real risk. Already city councils, construction giants like Simonds Homes, and even the Victorian Building Authority – the state’s chief industry regulator –have expressed interest. Professor Vrcelj said the project would help modernise the construction industry, which is currently among the least digitised industries in Australia, leading to high rates of worksite injuries, a lack of quality control and inefficiencies.

Andrew Shea, CEO of the Builders Academy Australia, Simonds Group, said training workers via simulated experiences would make a real difference to a worker’s learning and have a, “genuinely positive impact.”

The VU researchers have developed a cloud-based platform where photographs and 360-degree scans of the building are uploaded, and can be accessed remotely in real time from a smartphone or iPad. VU.edu.au

New Touch Industries (NTI) is a progressive company with locations in Bayswater and Clayton South.

Our dynamic, rapidly expanding business provides high quality services in metal laser cutting, bending/ folding, welding and fabrication, delivering customers with precise streamlined project management with minimal margin for error.

This is achieved by our philosophy regarding the importance of teamwork and investing in staff. We pride ourselves on offering ‘pay for schooling’ and ‘promote from within’ policies, providing our staff with an environment to thrive. We are continuously striving to better serve our staff and become an employer of choice

Come and join a company where we believe happy staff are great staff!

Learn more at newtouchind.com.au, or contact us today.

How manufacturers can empower smart decisions that optimise operational efficiencies, increase productivity and minimise costs.

By Jaco Maritz, CEO at SYSPRO.

By Jaco Maritz, CEO at SYSPRO.

Manufacturers are now realising that digitalisation has the potential to fundamentally change their businesses. To ensure that Australia’s manufacturing capability is at the forefront of change and innovation in the Asia Pacific region, all manufacturing decision-makers should be moving towards Smart Manufacturing.

A Smart Manufacturing enabled organisation has all the information about the entire manufacturing process available in real-time, when and where it is needed and in the correct format to empower smart decisions.

Data analytics technologies and techniques provide a means of analysing data sets and drawing conclusions about them to empower smart decisions. Big data analytics applications integrated with an enterprise resource planning (ERP) system can enable manufacturers to analyse growing volumes of structured transaction information, plus other forms of data that are often left untapped by conventional business intelligence (BI) and analytics programs.

This encompasses a mix of semi-structured and unstructured data, for example, information from customer emails and survey responses, mobile phone records and machine analytics captured by sensors connected to the Internet of Things (IoT).

A smart ERP system provides embedded analytics that manage, analyse and process big data and provides manufacturers access to relevant and critical information from anywhere for better decisionmaking. However, to have full visibility of the whole business requires the business to be fully digitalised and interconnected.

Manufacturers must respond to demanding schedules while constantly seeking ways to lower costs, better manage inventory and streamline their processes. Add to that a constant need to innovate, as well as forecasting challenges and the ongoing pressures of supply and demand and this results in rising complexity in all areas of a manufacturing business.

For manufacturers that make-to-stock, make-to-order, engineerto-order, or employ project-centric, job shop, batch, or repetitive manufacturing approaches, they need a comprehensive ERP system to manage the entire manufacturing business that also provides them with a 360˚ view of their production.

Currently, many manufacturers are automating simple jobs and relying on people to manage the remaining processes, and this often places a heavy demand on their employees. As an alternative, a sophisticated system like Manufacturing Operations Management (MOM), implemented within an ERP solution, can help manufacturers to take control of their end-to-end manufacturing operations, without the risk of human error.

To provide more control of manufacturing operations, frontline managers need 360˚ visibility of the shop floor to prevent problems such as overruns, bottlenecks, downtime, poor employee or machine performance and excessive waste. MOM offers a unique level of delivery, cost and quality control of manufacturing operations for job shop, batch production, production line and mixed-mode environments.

With MOM, manufacturers have a single source of data and in turn, full visibility of production. Besides providing equipment status, employee performance and job status, data is digital and can be analysed to provide a predictive function to improve factory

performance. Once it is adopted, manufacturers will see how quickly their manufacturing operations gain efficiency and become more streamlined, with improved quality and increased profitability.

One of the simplest ways to improve operational efficiency is to leverage automation, one of the key components of Industry 4.0. Whilst employees still need to oversee and manage production, automation can eliminate the human errors that decrease efficiency; and Artificial Intelligence (AI) and machine learning can take a manufacturing business to the next level including basic, process, advanced, and “intelligent” automation.

The key to implementing automation effectively is ensuring the free flow of data and analytics. This will encourage manufacturers to finally give up on using spreadsheets and moving to systems that automatically allow the collection, organisation, analysis and distribution of data to all departments in a business. This level of data automation allows managers to make decisions based on current information without having to worry that the latest spreadsheet is updated and correct.

When configured and used to the best of its capabilities, automation can help businesses make better quality products, improve profitability, keep workers safe and increase overall operational efficiency to help meet and exceed business goals.

By pragmatically taking these steps and regularly iterating and improving operational efficiency does not need to be an allconsuming process. It's something that can be achieved gradually and is better-done step by step than when the business is forced to do it as a matter of urgency.

Getting buy-in from all levels of the organisation and making it everyone's job is one way to delegate responsibility during a technology transition. Keeping lines of communication open and rewarding transparency can reduce any potential problems. Once completed it will result in an improvement in product quality, increased productivity and reduced costs, which will all help businesses to retain their highly trained talent.

au.syspro.com

Sustainability is widely considered across industry. However, it is critical to purposefully understand what sustainability means for asset-intensive industries, including how to manage and comply with emerging sustainability standards. Opinion

by Mike Brooks, Global Director, APM Solutions, Aspen Technology, Inc.

by Mike Brooks, Global Director, APM Solutions, Aspen Technology, Inc.

Sustainability is defined in several ways including Oxford Languages (via Google) expressing it as the ability to be maintained at a certain rate or level; including avoidance of the depletion of natural resources in order to maintain an ecological balance. The Cambridge dictionary defines sustainability as the quality of being able to continue over a period of time; with the follow on, the quality of causing little or no damage to the environment and therefore able to continue for a long time. Finally, the American Heritage dictionary explains sustainability as being capable of being sustained; followed by capable of being continued with minimal long-term effect on the environment.

The initial statements in Google and Cambridge each represent maintaining a process, wherein American heritage is a little more ambiguous. Each follow on item in all definitions reflects minimal disturbances on the environment including depletion of natural resources. However, there are insufficient definitions to apply the appropriate context for industry sustainability.

In industry we dig a little deeper and expand the context of sustainability by defining at least three core pillars of sustainability, namely “economic, environmental, and social — also known informally as the: profits, planet, and people” – the three Ps. This brings in a third concept not mentioned in the foregoing dictionary definitions –the idea of not introducing social harm to people inside and outside of the company. Furthermore, some companies include a fourth sustainability pillar to track compliance with government regulations. In summary, we want to maintain the manufacturing process to make the profits, while not breaking the law, and supporting the continuing health of people and the environment. Consequently, we see manufacturing businesses implementing initiatives to actively reduce their environmental footprint, often described as green initiatives, while increasing their social responsibilities by eliminating practices that may disturb or harm people and to be sensitive to compliance issues.

Managing sustainability is hard. You can track relevant indicators such as energy consumption, waste, emissions in air and water releases, even labor standards, and safety records, build KPIs, place them in a dashboard to check how well you are performing.

As Peter Drucker, management consultant said, “If you can’t measure it, you can’t improve it.” A good first step, but you run the danger of all dashboards and few improvement activities. After all, the results are only lagging indicators and contain nothing proactive to control and manage sustainability. It’s a fallacy to believe that automated management and control of sustainability can come from computer applications. Sure, computer applications can watch and optimise energy usage but how about emissions, safety performance, and social behaviour?

Sustainability management and improvement is all about fashioning people’s behaviour to engage in activities and work processes likely to improve practices. And to do so people need to buy into the idea that sustainability has a major impact on corporate reputation, branding, and shareholder value in order to shape their behaviour in their day-to-day work processes. So, in the spirit of this article this begs a question.

We are not aware of tools that directly manage anything but the rate of production and perhaps energy consumption. You cannot use an application to reduce environmental impact or improve impact on people’s welfare. In one respect, sustainability effectiveness in APM applications is most often driven by recognition of and avoidance of the conditions and events that can cause disturbances in profits, the environment, and people safety.

The idea is that the application recognises an errant condition that can affect sustainability and issues alerts and potentially prescriptive advice for people to take action to avoid the issue. Alternatively, applications can simulate alternative operating scenarios to enable decisions to adjust conditions in design and operation for better performance. In all cases, it’s shaping the workers’ behaviour that is key.

For example, in recent years there has been a transformation in condition-based monitoring applications using new technologies of pattern recognition using machine learning. Such applications are capable of recognising patterns of behaviour that are abnormal and destructive well in advance of impending degradation and potentially disastrous situations; those conditions that can cause unexpected breakdowns, environmental emissions, and harm to people. Sudden emergency shutdowns often induce rushed and illconsidered decisions and actions that present unwanted danger and environmental releases. The APM application’s early alert capability provides the heads up to stimulate action to avoid the emergency unexpected shutdown. For example, in a chemical processing facility a 40-day warning of an imminent failure of a compressor allows the staff the time to plan and prepare to convert to a safe, orderly, managed shutdown that is unlikely to lift flare valves or safety valves, prevent release of toxins, and assure safe procedures avoiding harm to workers. All supporting sustainability improvements.

In summary, given the economic, environmental, compliance, and social pillars of sustainability in industry, APM applications provide insights into causes and guidance on what to do and what work processes to engage in order to support and improve sustainability. aspentech.com/en

Understanding Quality Management Systems (QMS) for commercial success in MedTech/Biotech.

The medical technology, biotechnology, pharmaceutical and digital health (MTP) sector is critical to Australia’s economy, the health outcomes of the population and the innovation ecosystem. In 2019 there were nearly 1,300 companies in the MTP sector that employed approximately 68,000 workers and contributed $5.2bn to the economy. The MTP sector added an additional 5,000 jobs across 2020 and 2021 and contributed around $5.5bn to the economy, respectively. The market capitalisation of MTP companies continued to grow strongly at 20% p.a. and MTP companies raised nearly $3.4bn in capital through 2020/21, as markets realised how resilient and vital the sector was to the broader economy.

MTPConnect is an independent, not-for-profit Growth Centre established to drive connectivity, innovation, productivity and competitiveness in Australia’s MTP sector.

In May 2020, MTPConnect was contracted by the Australian Federal Government to operate the Researcher Exchange and Development within Industry (REDI) program. This four-year initiative is backed by $32m in funding from the Medical Research Future Fund (MRFF) that aims to build an industry-ready workforce with the skills and capacity to keep pace with the demands of a rapidly changing sector – for now and the future – deploying an integrated three-pillar plan as per the figure below.

Within Pillar Two, REDI delivered a forward-looking 'root and branch' analysis of the MTP workforce to provide a deep understanding of current and future skills gaps. The November 2020 Interim Report identified skills gaps that need to be addressed across the sector in the near-term following assessment against four key metrics:

1. Alignment of the skills gaps with sector priorities

2. Alignment of the skills gaps with global megatrends

3. Breadth of impact across the MTP value chain

4. Depth of impact and estimated value from addressing the gap

The top three priority skills gaps were identified as those that can unlock significant value for the MTP sector if addressed, impact a broad cross-section of the MTP sector value chain, are not currently addressed by existing REDI programs and can be reasonably addressed within a short timeframe.

Priority Skills Gap One was identified as “Understanding of Quality Management Systems (QMS) and protocols” within the “Advanced manufacturing & supply chain” theme.

Overview

The MTP sector is highly regulated with manufacturers needing to be verified by government regulators (e.g. TGA in Australia and FDA in the USA) as meeting relevant quality standards before they are eligible to market products. Applicable international Quality Management System (QMS) Standards for manufacturers of MTP products include ISO 9001 (generic Quality Management), ISO 13485 (medical device Quality Management), ISO 17025 (competence of testing and calibration laboratories) and Good Laboratory Practice (GLP - quality control for non-clinical health, safety and environmental studies).

Stakeholder consultations highlighted that universities, start-ups and Subject Matter Experts within the MTP sector often lack the following skills related to quality management:

• Understanding of the importance of adopting and maintaining appropriate quality management systems among business leaders; and

• Lack of staff members with sufficient training in quality management systems to:

- Define best-practice quality management principles and protocols that are aligned to relevant industry standards;

- Design and implement a path for achieving greater alignment to industry accreditation; and

- Maintain quality procedures and quality systems to ensure high standard facilities

Although it is a core capability for commercial success in the MTP sector, adoption of QMS processes and maintaining informal alignment or formal certification to standards can be considered too time consuming and difficult.

Large and established companies tend have sufficient in-house capabilities due to their scale and deep knowledge of the regulatory requirements of the MTP sector. However, the QMS skills gap is particularly evident within start-ups and SMEs noting the emergence of more MedTech, Biotech and digital health businesses.

Broader adoption of Quality Management Systems and standards by start-ups and SMEs will drive greater commercialisation success, as companies will be better positioned for investor / partnering discussions, regulatory submissions and becoming preferred suppliers in a global market.

Developing greater quality management at the basic research level will also drive greater commercialisation outcomes long-term. Researchers will gain greater credibility among big MTP companies and increase the likelihood of obtaining licensing deals if the assets and data have been processed in compliance with international quality standards. There were instances highlighted in interviews where research was required to be repeated under GLP processes, slowing commercialisation.

Furthermore, the COVID-19 pandemic highlighted the value of appropriate quality certifications when responding to global supply chain disruptions. A number of potential domestic manufacturers of medical equipment and supplies were unable to effectively pivot their operations and contribute to the pandemic response because they didn’t have ISO 13485 certification.

SeerPharma, a consulting and training organisation servicing life science industries, was selected by MTPConnect as the REDI Partner to deliver a range of QMS training courses across Australia addressing ISO 9001, ISO 13485, ISO 17025 and GLP. To date, over 700 Australians have undertaken the free online and ondemand QMS Primer while over 300 people have undertaken a three or four-day deep-dive workshop learning the requirements of ISO 9001, ISO 13485 and GLP QMS Standards as well as how to meet them.

seerpharma.com/REDI

Talent retention and the rise of environmental, social and governance top issues for project management profession.

Australian Institute of Project Management (AIPM), identifies the pressure points among the profession, launching the 2022 ‘The State of Project Management in Australia’ report. With over 73% of respondents claiming projects experienced staff shortages, 52% reporting delays due to sourcing key skills and 62% expecting ESG requirements to influence their projects and programs in the future, AIPM representatives are calling for greater investment in attracting new talent, fostering career development and upskilling from leaders in the profession to improve business outcomes and stay relevant within today's market.

AIPM’s newly released annual report, based on a survey of the profession conducted with KPMG Australia, on the ‘State of Project Management in Australia’ aims to help identify and elevate the key issues within the project management workforce. The fifth instalment of the report brings to light the increasing pressure facing project management professionals including an ageing workforce, supply chain issues, digital transformation projects and the emerging influence of Environmental, Social and Governance (ESG).

“The broad effect of skills shortages and supply chain disruptions places immense pressure on the project management profession. These report findings raise the need for innovative and inclusive ways to bring more people into the profession and to retain and upskill the existing talent.”

“The C-suite critical leaders and decision-makers should consider attracting emerging talent, and mentoring and professional development are key focuses for their organisations. With 65% of respondents directly working on high-value projects in the past 12 months, it is crucial for the shortages not to hamper project success.”

The survey of project management professionals highlights trends and factors around the quality of project delivery. Topic areas also include:

Experienced project managers are approaching retirement with over 40% of respondents having 20+ years of experience. Organisations must focus on attracting and developing emerging talent to prepare for the looming skills exodus. Yet, 42% of respondents said their organisation wasn’t doing anything (or they didn’t know what they were doing) to attract and encourage emerging project professionals.

On-time project delivery has slipped in the past two years (32% compared to 42% in 2020), likely due to de-prioritisation, rise of complex projects, skills shortages, supply chain disruptions and other economic constraints. Delivery of most projects in line with business goals is steady (50% compared to 51% in 2020), demonstrating resilience and perseverance in challenging times. Concerningly, 48% of respondents claimed stakeholder satisfaction and only 36% of projects were delivered on-budget most of the time.

The report clearly calls for Australian organisations to deploy innovative and inclusive ways to attract people into the profession and to retain the experienced and qualified professionals already in place. 39% of respondents said team stress and burnout were increasing with a further 28% saying their own stress and burnout were increasing.

Several factors pointed to the under-valuing of project management as a profession. These factors included weakness in recruiting and appointing suitably skilled project managers and a need for greater investment in continuing professional development. Many respondents indicated that their organisations did not offer a professional development path and career opportunities and almost 30% indicated that their organisation committed none or less than one day of professional development per year.

Australian organisations have accepted the need for action on ESG issues, driving an increase in transformation projects. Organisations must recognise the need to put Project Management Offices at the helm to get the best ESG outcomes. Similarly, project professionals must upskill to lead these projects to success.

The report respondents clearly already understand the need for upskilling as organisations continue to incorporate ESG matters into business operations and strategy. The profession is already seeing the impact: ESG specific roles are already growing in demand, with hundreds of open positions in Australia alone.

Supply chain disruption

Supply chain constraints, resource scarcity and rising costs are some of the biggest disruptors facing the project profession. 44% of respondents had projects affected by supply chain disruption and 51% faced rising costs of materials and/or staff.

The report calls for supply chains to be reimagined to help organisations build resilience and avoid material shortages and spiralling costs to better navigate future volatility. Cultivating resilience through technology investment and strategic partnerships will help organisations better anticipate and respond to the unexpected.

Highlighting the need for evolution of project methods to keep pace with the complexity and agility of modern workplaces and projects, 57% of respondents believe that project complexity has increased with the use of artificial intelligence software increasing from 10% to 29% this year.

Artificial intelligence will help to absorb more transactional project tasks, addressing and improving support for project professionals and executives. 74% of organisations said its digital transformation projects are business-driven to improve customer experience, cost reduction and maintain competitive action.

AIPM is committed to continue to monitor new ways of working for impacts on its certifications, members and the profession as a whole. Its certifications are always aligned with best practices and ensure individuals can demonstrate their capabilities to drive project management excellence so they can meet strategic objectives for businesses in a dynamic environment.

aipm.com.au

Researchers from Basel and Tel Aviv discovered that friction varies with speed in specific graphene structures on platinum surfaces, defying Coulomb’s law which states that friction is speedindependent in the macro world.