BUILT TO CONNECT

Single-Source Supplier Advantage

Astec provides a significant advantage as a single-source supplier for the diverse products and services involved in building and maintaining an asphalt mixing plant. Astec liquid AC storage tanks, tank farms, and heating system controls feature high quality construction and unmatched efficiency. We offer a variety of sizes and configurations that can be fully customized. Optimize your asphalt storage tanks and hot oil heaters with the addition of the Recon® mobile monitoring system to receive status updates on a smart phone, tablet or PC.

COME VISIT BOOTH C30235

MARCH 14-18, 2023 • LAS VEGAS, NV

Scan QR code to see Astec’s full line of Tank Farm Components.

The Blaw-Knox University, now in its 58th season, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and hands-on application courses.

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

Blaw-Knox provides improved technical and problemsolving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

Blaw-Knox offers multiple dates to satisfy the demand for its popular courses.

Tax Deductions in the Ash Clouds

At press time, I couldn’t find reliable stats on the amount of methane be ing released from the alleged sabo tage of Nord Stream 1 and Nord Stream 2. Suffice it to say, the bubbling gas devastat ing marine life in the Baltic Sea was proba bly more than your properly operated, Tier IV Final wheel loader at the asphalt plant. I can’t say if the pipelines’ greenhouse gas (GHG) or particulate matter emissions ri val the collective emissions from Strom boli, Erta Ale, Nyiragongo, Piton de la Fournaise, Dukono, Ibu, Krakatau, Mera pi, Semeru, Lewotolo, Popocatepetl, San tiaguito, Fuego, Masaya, Nevado del Ruiz, Reventador, Sangay, Sabancaya, Nevados de Chillán, Mount Erebus, Kilauea, Ya sur, Shiveluch, Ebeko, Sakurajima and Su wanose-jima, considering those volcanoes currently erupt at different rates of spew.

Until our global elite focus on the big emitters of GHGs (whether naturally oc curring or based in China), it is criminal that our industry continues to be target ed, maligned and forced to comply with ever-narrowing regulations. When a state agency dictates private business owners can no longer purchase robust pieces of machinery for infrastructure construction and/or maintenance, it irks me. When an unelected agency dictates to the asphalt in dustry, which has been ratcheting down its emissions numbers and carbon footprint on its own, that we have a new, magic num ber to attain instead, it makes me wonder about the reading comprehension skills of the person at the top.

Any CEO worth his or her salt will tell you to lean on your employees’ strengths. Bring them to the table to explore attain able solutions together. Instead, the elitists have come up with random numbers, sta pled money to the clouds around the ash plumes of the above-listed volcanoes, and demanded of us, “Meet this target next.”

Before this note becomes too negative, let me say the construction industry over all has an opportunity to grab some of our country’s recently printed dollars waving above the ash plumes.

Take the tax credit bribes for purchas ing equipment with batteries comprised of Rare Earth Minerals as an example. Your electric vehicle (EV)—depending on its gross vehicle weight rating to battery ca pacity ratio—could be tax deductible.

On page 34, I’ve included another in stallment of the series on upcoming grant monies through the dubiously named In flation Reduction Act (IRA). With the Advanced Industrial Facilities Deploy ment Program, the Department of Energy (DOE) is making available $5.8 billion in rebates for facilities that can prove a 20% reduction in their GHGs with installa tion of advanced technologies. The Inter nal Revenue Service (IRS) is expanding its credits for purchases of “clean” equipment. In fact, if you look at Section 45 of the IRA, not only will you develop a migraine, but you will also get a sense that the IRS will reward you with tax incentives for pur chasing EVs and advanced technologies.

I’m not a tax advisor. Please take that whole section to your tax professional.

But examine the concept behind Sec tion 45W, where it is implied the electric off highway vehicle doesn’t have to be sourced from North America. Again, let a tax pro fessional read it more thoroughly and advise you on the specifics.

Let me finish by saying, installing ad vanced technology to lower emissions at any facility is a responsible move. If it’s possible to cut extra emissions from an operation, that’s a laudable goal. If the DOE is willing to hand you a 50% rebate for achieving the goal, that’s even better. If the IRS is willing to extend an extra tax credit to you for the business expenditure, why not take advan tage of that while it’s available?

So far, the asphalt industry has been making these strides out of a desire to be good stewards of the land and a willingness to placate homeowners who built right up to our property lines. It’s nice to think fu ture strides come with a side of rebate from Uncle Sam. What has me a little on edge is the idea that government entities and agen cies are demanding lower numbers from an industry that’s already lowered its num bers. We can’t single-handedly make up for the 26 volcanoes currently erupting around the globe. Honestly, I don’t think it’s fair to ask us to.

Have a Safe and Lovely Holiday Season, Sandy Lender

asphaltPRO

602 W. Morrison, Box 6a Fayette, MO 65248 (573) 823-6297 • www.theasphaltpro.com

GROUP PUBLISHER Chris Harrison chris@ theasphaltpro.com

PUBLISHER Sally Shoemaker sally@theasphaltpro.com (573) 823-6297

EDITOR Sandy Lender sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR Kristin Branscom

BUSINESS MANAGER Susan Campbell (660) 728-5007

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

Caltrans Investigates Work Zone Intrusion Alarms

BY SARAH REDOHL

BY SARAH REDOHL

Between 2016 and 2020, work zone fa talities increased from 782 to 857, ac cording to the American Road and Transportation Builders Association (ART BA) National Work Zone Safety Information Clearinghouse. One safety trend that aims to reduce work zone fatalities is the imple mentation of Work Zone Intrusion Alarm (WZIA) systems.

WZIAs alert workers and drivers of poten tial intrusions into the work zones through the use of alarms or alerts connected to radar-, camera-, infrared-based or other hardware and software.

The California Department of Transporta tion (Caltrans) has partnered with a research team led by Associate Professor Ghazan Khan of California State University Sacramento's Department of Civil Engineering to investi gate some of the WZIA options.

“With the availability of new systems and safety solutions on the market, there was a need to review and analyze WZIAs to see how we can supplement the best practices already in use to further improve safety,” Khan said.

What sets the research conducted by Khan’s team apart from existing research is the em phasis placed on the workers’ perspective. “How are crews going to perceive these sys tems, what issues will they identify and how will they utilize these devices—that was our goal,” Khan said.

His team identified five different WZIA systems to test in close-to-traffic conditions and trained Caltrans maintenance crews on their use prior to deployment in an ac tive work zone. The five systems selected by Khan’s team were the Traffic Guard Work er Alert System, SonoBlaster, Intellicone In cursion Prevention and Warning, Intellicone Single Sentry Beam and AWARE Sentry. Let’s take a closer look at each system.

1. Traffic Guard Worker Alert System

The Traffic Guard Worker Alert System (WAS) includes a 12-foot lightweight, portable trip hose and sensor assembly that when driven over sends a wireless signal to an alarm and flashing light. Multiple hoses can be connect

ed wirelessly to offer a larger area of coverage, Khan said. However, the team found that for long work zones, it may be difficult to main tain alarm ranges and hoses may have to be re deployed as the work zone moves forward.

His team recommended hoses be placed within 225 feet of an alarm device, compared to the manufacturer’s range of 1,000 feet. The team also recommended using three or four alarm units to enhance the warning sound in the work area, as the volume of a single alarm (60 to 70 dBA for five or six seconds) may not be sufficient.

They also discovered that the alarm units don’t perform well if placed on the ground, but that the magnet on each unit makes it easy to attach them to any metallic structure or vehicle at a height of 4 feet or higher.

Khan and his team did not measure time-delays for each device, but Khan noted that “the time involved when a device is activated and when the alarm goes off was almost imperceptible, hence we decided it was sufficient for the needs and in the context of work zone application.”

“One unique feature of WAS is the personal safety device (PSD) workers can carry in pock et or on their body to provide audible and vi

bration warnings that an incursion has oc curred and they should take evasive action,” Khan said.

Khan's team tested the WAS device in an ac tive work zone on westbound U.S. Highway 50 (65 mph speed limit). The project entailed a closure of the four-lane freeway’s shoulder so crews could repair some fencing. The crew de ployed three sensor hoses parallel to the move ment of traffic right where the closure was at the start of the work zone. “We had recom mended they place them diagonally in the clo sure, but the workers actually deployed it this way because they thought it would be more ef fective given the nature and speed of traffic at that location,” Khan said.

Setup of the four alarm units at various lo cations (two on one truck, one each on two other trucks) took only five minutes. The crew reported that deployment, operation and re trieval were easy. “A lot of them also liked the flexibility of the device and the ability to place it wherever they’d like,” Khan said.

During the operation of WAS, there were five false alarms, four of which were the result of one worker accidentally pressing a button on his PSD and one from a worker accidental ly stepping on the hose.

2. SonoBlaster

According to Khan, SonoBlaster is essentially a pressure horn activated by a CO2 cartridge that can be mounted on traffic cones, drums, delineators, a-frames and other barricades. “When the cartridge is punctured, such as

when a vehicle hits a cone that SonoBlast er is installed on, it releases a pressurized gas, which blows the horn to warn work ers,” he said. The audio alarm sounds at 125 dBA, by far the loudest of the devices Khan’s team tested, for anywhere between 15 and 90 seconds depending on how the cartridge is punctured.

“There’s no need for batteries or charging, but the coverage is limited to cones on which SonoBlasters are installed,” Khan said, add ing that installation takes some time. Once the Caltrans maintenance crew Khan’s team taught to install the devices had gotten fa miliar with the process, each device installa tion averaged 10 to 12 minutes. When Khan’s team conducted trials with the device, 16 were successful and four failed as a result of improper seating of the CO2 cartridge. Furthermore, it’s also possible to trigger the alarm when deploying or clearing cones. “There’s a switch that has to be turned on to arm the unit and once turned on, if the cone tilts, this can trigger the alarm unit.”

The researchers also discovered that cones equipped with SonoBlasters could not be transported in two rows at the back of a cone body truck, though the cones can still stack on top of one another for deployment from the front of a truck.

SonoBlaster was deployed on a live work zone along eastbound U.S. Highway 50. It was intended to be deployed in the ramp closure area of the project, but when the project supervisor decided the ramp didn’t need to close down on the day of testing, the crew deployed SonoBlasters along the lane closure portion of the project but stopped after only arming three units.

“Very quickly the workers decided it was not a good idea because of exposure to traf fic,” Khan said. Ultimately, Khan’s team found that SonoBlasters may only be suit able for specific types of work zones, such as ramp closures.

3. Intellicone Incursion Prevention and Warning

The Intellicone Incursion Prevention and Warning (Intellicone) system consists of a Portable Site Alarm (PSA) and lamps in stalled on the tops of traffic cones. “When a cone is hit and the cone lamp is dislodged, it triggers the alarm, which can warn the workers,” Khan said. This results in a visu al alarm (rotating lights on the cone lamp) as well as a three-tone audio alarm of 70 to 90 dBA for 30 seconds. “We found that to

be sufficiently loud, especially if you utilize multiple alarm units,” Khan said.

The cone lamps connect wirelessly with each other and the alarm units at a range of up to 100 feet, “so you can provide as much cover age as you would like as long as you ensure the maximum distance between two units is not more than 100 feet,” Khan said. He also not ed the ability for two alarm units to connect to each other via the cellular network at an un limited range, “but obviously that depends on the availability of cell phone coverage.”

The Intellicone system also offers broader work zone management features such as an online management dashboard and mobile alerts.

Ten Intellicone lamps were deployed in a work zone on westbound U.S. Highway 50. “Some workers shared concerns about expo sure while deploying the cone lamps,” Khan said, adding that the team is discussing best practices for safe deployment. However, they considered deployment and utilization of the system easy, and the PSA setup and con nection took about two minutes.

4. Intellicone Single Sentry Beam

The Intellicone Single Sentry Beam porta ble laser (Intellicone Laser) is a device that shoots a laser beam at various distances (set by the user) between 35 and 110 feet. Any disruption of the laser beam triggers the same PSA unit used in the Intellicone In cursion Prevention and Warning system.

Although the Intellicone Laser provides more continuous coverage than the other Intellicone system, Khan said, the range of 35 to 110 feet is limiting, especially if laser deployment is desired parallel to the mov ing traffic, and considering that multiple lasers cannot be connected to extend cov erage. However, the limited range makes sense; “That’s to prevent any accidental ac tivations if you want to deploy it on a sin gle lane or limited space,” Khan said.

The Intellicone Laser has a battery life of 120 hours.

The research team observed that the la ser should be within 175 feet of the PSA,

SAFETY SPOTLIGHT

which is less than the manufacturer’s range of 250 feet. Khan said a single laser/alarm pair might not be sufficient for high speed or longer work zones and that multiple pairs might be required to provide ade quate coverage and warning.

Despite the crew’s concerns that the system might not provide ample warn ing, they did find the system easy to de ploy, operate and retrieve. During the live work zone test on eastbound Highway 50, the crew placed the laser perpendicular to oncoming traffic after initial setup/range configuration and the PSA on a truck in the work area.

5. AWARE Sentry

The AWARE (Advanced Warning and Risk Evasion) Sentry is a radar-based system with a 15-hour battery life that monitors nearby traffic speed within a range of 600 feet to predict potential incursions. “If it assumes a high probability of an incursion, it triggers an alarm that warns workers and drivers,” he said. The alarm includes an audio alarm that sounds somewhat like a police siren and a visual alarm of flashing white and amber lights.

If a vehicle is traveling slightly above the speed threshold (set manually by the oper ator), AWARE will alert the driver to slow down. If a vehicle is traveling significant ly faster than the speed threshold, AWARE will alert both the driver and workers.

“This cuts down on any false alarms which might make the workers immune to these alerts,” Khan said. “Not only does [the sys tem] warn workers and drivers, but it’s also the only system that doesn’t have to wait for an incursion to occur.”

LEARN MORE

These devices are sold at a variety of traffic control suppliers. Contact your local or regional safety device distributor and ask for the system by name. Let them know you saw the product detailed in AsphaltPro Magazine. This article will appear on theasphaltpro.com under the Safety Spotlight department for easy reference.

BUILT TO CONNECT

Efficiency and Productivity

Designed with safety and operator comfort in mind, the SB-3000 Shuttle Buggy ® material transfer vehicle features adaptive cruise control, bright LED lighting, four-wheel steering for easy transport and ground-level maintenance access for added convenience. Operators can rely on clear sightlines and the ground operator is safely protected inside the structure of the machine. The Roadtec SB-3000 is the perfect blend of traditional craftsmanship and modern technology.

Scan to learn more about the SB-3000.

AWARE Sentry also comes with a personal safety device workers can carry to provide an audio and vibration alarm if an intrusion occurs. Furthermore, the system can record a short video anytime the alarm is triggered for later review.

The speed threshold is set by the user via a mobile app. Khan said the crews would have preferred the option of configuring the Sentry directly from the device. Setting the right speed threshold is particularly im portant to the system’s effectiveness to min imize false alerts.

When AWARE Sentry was deployed in an active work zone, a flagging operation on the two-lane Highway 16 (55 mph speed limit), the initial speed threshold of 35 mph was too low. “We were having a lot of triggers because so many cars were traveling faster than that,” Khan said. “Anytime this system is deployed, it’s critical to make sure the system is set up

properly for the traffic flow and speed.” Prior speed information would be useful in appro priately setting the thresholds.

THE BOTTOM LINE

According to a survey Khan’s team conduct ed after the crew training but before the ac tive work zone deployment, the crew rat ed the WAS, Intellicone and Intellicone La ser as the most effective in mitigating work zone crashes. However, the crews generally reported that they thought all devices would increase work zone safety. “This was reflect ed in discussions with them also, that any device or system that can provide a warn ing to workers or drivers would be beneficial given the safety issues they face every day in these work zones,” Khan said.

Ultimately, Khan’s team uncovered several key takeaways. For example, the importance of designating a supervisor or lead worker to take responsibility to make sure the system is deployed and used correctly.

Another key takeaway was that certain systems are best suited for certain locations.

For example, they found the AWARE Sen try is ideal for flagging operations and slow moving traffic. “Detailed information about the active work zones where the systems are to be deployed is critical to ensure the right devices are utilized at the right location,” Khan said.

Khan’s team tested these five WZIA sys tems in active work zones with high-speed traffic, but in the future plans to test them in work zones with lower traffic speeds to eval uate their performance in various types of traffic and work zone conditions. Khan said some concerns with deployment and ex posure in the initial active work zone tests might not be an issue at sites with relatively lower speed limits, “as such the results may vary in the future with further tests.”

Next, Khan and his team plan to perform additional testing in active work zones, con duct further surveys with Caltrans crews who have used the systems, coordinate with manufacturers on the team’s recommenda tions, and investigate new devices such as Guardian Cone.

ON THE ROAD TO NET ZERO EMISSIONS, WE CAN HELP YOU FIND YOUR WAY.

Are you exploring NAPA’s climate challenge, but unsure of your navigation? We can help you take at least one step forward — by replacing your tank heaters, hot oil heaters, fuel oil preheaters, and distributor truck heaters with our zero-emission, 100% efficient, Lo-Density® drywell-style electric heat.

Check out our new operating cost calculator at processheating.com!

www.processheating.com

PaveScan® RDM 2.0

PaveScan RDM 2.0 is ideal for uncovering inconsistencies that occur during the paving process, helping to avoid premature failures such as road raveling, cracking and deterioration along joints.

IMPROVE QUALITY Quickly assess the quality of pavement during the paving process. Finally, you can fix low density issues related to cold mix, paver stops and breakdowns.

IMPROVE LIFE SPAN Detect problems to help avoid such premature failures as road raveling, cracking and deterioration along longitudinal joints.

IMPROVE SAFETY Reduce the need to core and expose fewer workers to the dangers of work zones.

THE POWER

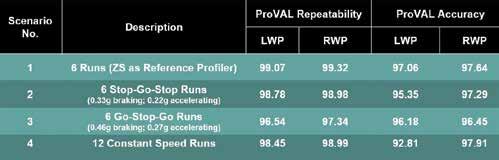

Zero-Speed System Fits Reference Device Category

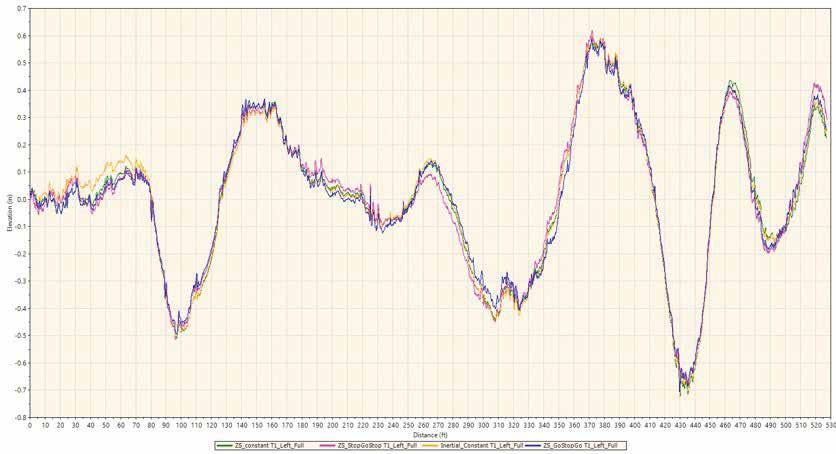

Surface Systems and Instruments Inc. (SSI), Larkspur, California, col lected profile data under multiple conditions to replicate acceleration, decel eration and stopping during a data collec tion rodeo for the National Cooperative Highway Research Program (NCHRP). The scenarios selected tested the accuracy and repeatability of the Zero-Speed Iner tial Profiler under various conditions.

The SSI Zero-Speed inertial profiler uses multiple sensors to collect data over a range of 0-100 miles per hour (mph). This eliminates the collection speed floor and speed dropouts, which can introduce Interntional Roughness Index (IRI) error for project and network level roads. The Zero-Speed Inertial Profiler is designed to eliminate the noise of accelerometer drift over time while collecting an accu rate profile at any speed, even through stoppages.

NCHRP 10-106 testing was created to learn more about the AASHTO r56 equip ment certification. SSI took this opportu

nity to collect three stop-and-go scenar ios plus additional constant speed runs with traditional inertial profilers. All runs were analyzed for repeatability and accu racy against well-known walking-speed inertial profile reference data. The three scenarios—plus constant-speed collec tions—were:

Six low speed runs at 10 mph for ana lyzing the Zero-Speed system as a refer ence device;

Six Stop-Go-Stop runs (with no run up or run out, accelerate to 30 mph during collection);

Six Go-Stop-Go runs (start collection at 50 mph, stop in middle of track, accelerate to 30 mph to end); and

Twelve constant speed traditional iner tial profiler collections (six at 50 mph, six at 30 mph).

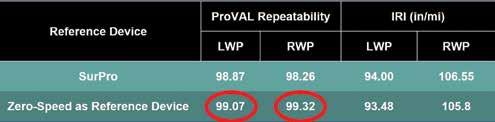

The requirements for an inertial profiler to be compliant with American Associa tion of State Highway Transporation Offi cials (AASHTO) r56 are 92% repeatabili ty and 90% accuracy. The Zero-Speed de vice achieved a passing certification score under AASHTO r56 for each of the above scenarios (see Table 1 for data).

Table 1. MS NCHRP 10-106 Repeatability and Accuracy Data

The fourth, constant-speed scenario was collected in the left wheel path (LWP) on the second day of testing; the walking pro filer reference data was collected on the first day. The inertial profilers and the Ze ro-Speed had IRI values of around 90 inch es per mile where the walking profiler had a reference IRI of 94 inches per mile. The sur face may have changed, which may explain the discrepancy between the LWP accura cy and the first-day, right wheel path (RWP)

Runs

accuracy of almost 98%. This may highlight the importance of collecting reference data at the same time or as close to the time of the certification as possible.

REFERENCE DEVICE LABEL

For a device to be considered a “refer ence device,” the system must have three runs that are at least 98% repeatable against itself. Most department of trans portation (DOT) certification tracks will

make multiple runs in each wheel path with their walking reference device and compare them for repeatability to con firm the runs are similar to each other. Repeatability in the Profile Viewing and Analysis (ProVAL) app is a function of profile amplitude and trends. It consid ers more than the ride value number so that the elevation profile is the driving comparison metric.

A 4 - day training and technical conference

Join us for Hotmix University in Louisville, Kentucky. During the intense exchange sessions, participants enjoy a combination of lectures, and hands on workshops on actual equipment.

PLANT MANAGERS are interested in making their plants run better while maitaining maximium profitably. Other topics include:

Industry changes and trends which require Plant Response/Modifications.

Tuning Plant Asphalt Automation to achieve 100% End Results and Project Bonus Pay.

Importance of Combustion and Air Systems to Achieve Production Rates.

Benchmarking and Measuring Plant Performance.

PLANT OPERATORS will invest half of their course time at our manufacturing facilities. The other half of the course time will be invested in learning via classroom-style presentations. Topics include:

Specifies where the Hot Mix Asphalt Plant fits into the entire business operation including the management of aggregates, liquid A.C., paving, and quality control.

Dr ying Systems: Alignments, lighting, and troubleshooting.

Slat s & Silo System monitoring and wear-reduction.

Plant Automation and Multiple Liquid Blending.

Scenario 1. Plot vs Speed: Zero-Speed Reference Profiler Collection

Scenario 2. Plot vs Speed: Stop-Go-Stop Collection (No Run Up or Run Out)

Scenario 3. Plot vs Speed: Go-Stop-Go Collection

Scenario 4. Plot vs Speed: Constant Speed Zero-Speed System Collection

Table 2. Reference Device Repeatability Data

The Profile Viewing and Analysis (ProVAL) engineering software application is a product sponsored by the U.S. Department of Transportation’s Federal Highway Administration (FHWA) and Long-Term Pavement Performance Program (LTPP). It’s designed to let users view and perform analyses including, but not limited to: ride statistics, profilograph simulation, profiler certification, smoothness assurance modeling (SAM), and so on.

The SSI Zero-Speed device achieved ref erence level repeatability and introduced a concept of using the Zero-Speed device as a faster way to collect baseline reference pro files for certification tracks. More data is re

quired to progress this methodology, but the data for the Zero-Speed as a reference device was proven on the Mississippi track with the NCHRP 10-106 project.

The benefit of using the Zero-Speed system as a reference is the speed of collection; it may reduce reference collection time by an order of 15. The Zero-Speed data was collected at 10 mph (15 feet per second) compared to a walking profiler, which usually collects under 2 feet per second. The SSI Zero-Speed system also cancels vehicle motion and dynamics,

lessening the susceptibility of the system to operator-induced error.

This testing shows the SSI Zero-Speed In ertial Profiler is a compliant method of collec tion data throughout the speed range of 0-100 mph and through stoppages. The Zero-Speed system can also be used to collect data with out run up or run out distance; a highlight for tightly constrained projects such as airfield paving.

For more information, visit https://www. smoothroad.com.

Let’s grow the future of asphalt.

At Colorbiotics, our soybean-based science is changing the asphalt industry just as much as it changes the molecules inside recycled asphalt. But having the best science in the business only makes a difference if we have the best people, too.

We are looking for sales people to join our team — so let’s talk about your future and get to growing together.

Give us a call: 888-663-6980 | Apply today: invigorateasphalt.com

Colorbiotics is a registered trademark of MBCC Group. © 2022 MBCC Group. All Rights Reserved.

Scenic Mountain Road Gains Smoothness with CIR

BY SARAH REDOHL

BY SARAH REDOHL

Prior to 2022, the 43-mile section of Colorado’s State Highway 149 between Creede and Lake City had not seen any pavement surface treatments in more than 20 years, and up to 40 years in some sections.

After passing through the historic mining town of Creede, CO-149 winds through the San Juan Mountains before passing through Spring Creek Pass (elevation 10,901 feet), Gunnison National Forest and Slumgullion Pass (elevation 11,361 feet) and descending into the town of Lake City.

However, the existing pavement of the scenic highway had reached the end of its useful life. According to Colorado Department of Trans portation (CDOT) Region 5 Materials Engineer Tim Webb, the pave ment consistently contained at least ¼-inch wide and 4- to 5-inch deep cracks (primarily transverse) throughout the 43-mile span between Lake City and Creede.

“The driveability life of this stretch of highway was zero to one year,” Webb said, based on a condition-based index system within CDOT’s statewide pavement asset management approach of quantifying sever al surface distress criteria. “The resulting existing ride was not smooth and there was no useful life remaining in the existing surface.”

When CDOT received special senate bill funding for rural roads, Webb’s Region 5 teamed up with neighboring Region 3 to pool funds to repair a large section of CO-149 across the border of the two regions.

“We don’t always have such funds for a rural road like this, but that enabled us to cover a significant number of miles on this one project,” Webb said. With a fairly short paving season and the harsh winter con ditions in Colorado, Webb said CDOT prefers to complete projects in one construction season, “especially in mountain passes like where this project is.”

With such a large project and limited time, CDOT opted to perform cold in-place recycling (CIR) on this job. “A faster construction method like CIR helped us achieve that goal because it allowed us to resurface 40 plus miles in a single construction season,” Webb said.

CIR is a process that cold mills and recycles the top 2 to 5 inches of asphalt using a continuous train operation. According to the Pavement Preservation & Recycling Alliance (PPRA), CIR reduces construction times by anywhere between 20 and 40% compared to conventional re construction methods.

Furthermore, the conditions of the existing pavement were a perfect fit for CIR as a treatment. “When you have older pavement that has cracks that are primarily top-down but are pretty severe, that’s a perfect candi date for CIR,” Webb said. The CIR on CO-149 recycled the top 4 inch es of the existing pavement, “basically eliminating all of those cracks,” Webb said.

The sustainability aspect of CIR was another selling point to CDOT, as the process reuses 100% of existing materials and can reduce greenhouse gas emissions by up to 90%, according to PPRA.

Discover the strength of the most versatile, durable, and reliable crushing equipment on the market today. Take on even the toughest applications with confidence. Experience unparalleled parts and service support, 24/7. Let Eagle Crusher keep you up and crushing, year in and year out.

TRUST THE STRENGTH OF EAGLE CRUSHER

“We strive to use recycling methods when it fits the existing road way conditions,” Webb said. Webb shared that using the existing ma terials in place negated the environmental impact of a project that would transport new materials to the site from a remote location.

ABOUT THE PROJECT

The two sections of the project included 22 miles between the town of Lake City and the north side of Slumgullion Pass and 19 miles south of the pass to the town of Creede, for a total of 82 lane miles. The project was divided in two sections because the section of the road passing through Slumgullion Pass had received a more recent resurfacing treatment.

United Companies, Grand Junction, Colorado, a subsidiary of CRH North America and the midwestern extension of Staker Parson in Utah, was the prime contractor on the project.

“The majority of CIR bids on the western slope are installed by my crew,” said United Paving Foreman Ramon Chavez. When United won a bid on its first CIR project eight years ago, Chavez’s crew was the one tasked with the new challenge. “At that time, we thought we drew the short straw, but it turned out to be the long straw.”

To date, his crew has performed six CIR projects in the last eight years. “My crew is probably the most experienced crew in western Colorado with this process.”

United subcontracted the recycling portion of the project to Cough lin Company Inc., St. George, Utah. The 101-year-old company has been milling asphalt since 1992 and expanded into asphalt recycling in 2006. Today, Coughlin has 23 roto-mills and three recycling trains that trav el throughout the western United States, including Arizona, California, Colorado, Idaho, Nebraska, New Mexico, Nevada, Oregon, Washington, Wyoming and Utah.

Coughlin frequently works with United, said Coughlin Safety Manag er Stephen Steed. “They’re a great outfit to work with,” he said. “We can’t compliment them enough.”

Recycling on the project began in May and the new asphalt overlay was completed in October. Coughlin milled to a depth of 4 inches at a full-lane width of 12 feet, 6 inches wide with a production rate of 23 to 25 feet per minute with its Astec (Roadtec) RX 900e. “We have quite a few of those,” Steed said. “They’re very powerful, dependable machines.”

In total, Coughlin recycled approximately 86,000 tons of material.

Coughlin injected a lime slurry into the cutting drum of its roto mill at 1.5% based on weight of dry recycle. “We put lime slurry in there as well to help with the conditioning of that asphalt to be like new again when it’s laid that back down,” Webb said.

Next came Coughlin’s recycle unit, an Astec (Roadtec) RT-500. The impact crusher within the 100% enclosed unit crushed the recycle to size, 1 inch minus, before running it up through the machine’s weighbridge. The material is then dropped into the pugmill where the rejuvenating agent (AC emulsion) is introduced and mixed before it’s dropped out of the pugmill into a windrow where it can be picked up by the paver on the other end of the recycling train.

The RT-500’s onboard computer helps determine the amount of emul sion based on specifications. For the CO-149 job, Coughlin operated in the 3.2 to 3.4% emulsion content range.

“To be successful with the recycling portion of the project requires you to go in and calibrate all the different components to make sure you’re putting the specified amount of emulsion, lime or other addi tives on the job,” Steed said. “You can’t meet the specification if you don’t get the calibration done right.”

Steed said the most unique aspect of the job to him is its location. “It’s beautiful country out there,” he said, adding that the crew even saw a moose on the side of the road. “The scenery is just unbelievable. You just can’t ask for a better place to work.”

LOCATION-RELATED CHALLENGES

According to Webb, CDOT doesn’t perform many CIR projects, but the lion’s share of CIR jobs in Colorado take place on the state’s western slope due to its remoteness.

“The project took a lot of coordination and logistics to get the material out there,” Steed said, adding that teamwork is key to the company’s success on the project. Although using CIR reduced the number of trucks needed to get the required materials to the job site, Steed said “it can still be a challenge when you have to move even the amount of material we did need (emulsion, lime, etc.) at that distance.”

Coughlin located unused gravel pits midway through both ends of the project to use as its staging areas. It set up a couple tanks of emulsion at those sites that could be brought to the recycling train with transfer trailers. Lime slurry was mixed at the staging area and transported to the recycle train by supply tankers.

The remote job also spanned a number of challenging road condi tions, including portions that are narrow, winding and steep. Steed said the south end of the project was fairly easy because it was rel

atively straight and flat without a lot of sharp turns. However, the northern side had many narrow areas where Coughlin had to stop traffic entirely to give the train enough room to maneuver.

“There wasn’t much room for traffic on those mountain roads alongside that CIR train,” said United QC Manager David Fife. “The traffic going through some of the canyons was a challenge.”

At one point, the road became so narrow, the recycle train result ed in a one-hour delay to the traveling public. Although it was un fortunate for the traveling public in the short term, Coughlin was assured of the importance of the project to local residents when the recycle train pulled into Lake City.

“You don’t see a recycling train going through the main street of a town very often,” Steed said. “We had shop owners coming out tell ing us how excited they were to see the road getting fixed and how much it means to them.”

COMPACTING COLD IN-PLACE

Because the material changes throughout the project as it’s milled up, the rolling pattern must also change, Chavez said. “With a tradi tional HMA job, you can fine tune everything on the test strip,” he added. “With CIR, it’s like the mix design is changing throughout the entire project.”

Results from the modified Proctor tests performed on material from the project ranged from 110 to 130 pounds per cubic foot. “It’s easy to get density on 130 pounds, but it’s harder to get density on 110 pounds,” Chavez said. “It seems counter-intuitive, but if you’re not able to get heavy densities with the hammer, it tells you that ma terial doesn’t compact well.”

The modified Proctor test is a CIR mix design method (in accordance with AASHTO T 180, Method D) where loose material is put in a cylinder and struck a preset number of times with a 10-pound weight to determine optimum moisture content (OMC) at peak dry density of the material.

To compact the rejuvenated asphalt behind the recycle train the crew started with a breakdown roller (Volvo DD140) running two full passes on the edges and one in the middle, followed by two rubber tire pneu matic rollers (Bomag BW27RHs) until the breakdown roller finished the next section. “That might result in 15 or 16 passes,” Chavez said. Then, United’s Volvo DD120 finish roller passed through to achieve final den sity, which must be 100% of lab compacted density in accordance with Colorado Procedure 53 (CP-53).

“There was a bit of a learning curve early on, but once we got going the process went pretty well,” Fife said. “With CIR, you shoot for different densities based on where you are on the project, so we were monitoring densities behind the rollers with a nuclear gauge to make sure we were compacting to the appropriate percentages.”

This is where the unexpected weather the crews faced became particu larly challenging. Although the weather was often good for the first twothirds of the day, it would get overcast, humid and cool most afternoons and frequently rain, shutting down that day’s production, Chavez said.

“Achieving compaction in such a constantly changing climate was the biggest challenge we faced,” he said, adding that CIR is dependent on

temperature. “It’s difficult to get good densities in the types of weath er we were working in.” Chavez said his crew’s expertise was critical to overcome these weather-related challenges.

“When it comes to traditional HMA jobs, you have this trigger telling you have a certain window to achieve density,” he said. “But with CIR, there’s no set amount of time. So much depends on the weather. You have to understand how the material works to know how and when to roll it. Most of my guys know based on the color of the mat and the feel of it from the rollers if it’s the right time. And that’s what my guys did, and they were able to get compaction throughout the project.”

“We thought the weather might give us problems with raveling, but in actuality, we had very little raveling despite the rain,” Steed said. He attributes a large portion of this to the performance of the AC emulsion used on the project.

“The emulsion we used was an awesome emulsion,” Steed said. “At the end of the day, we could put traffic on that road and it looked like a regu lar hot mix paved asphalt road even though it was recycled.”

EMULSION MASTERS

To determine the chemistry of the emulsion, cores were taken from the road to develop a mix design for the project. Arkema-Road Science, Tul sa, Oklahoma, provided the surfactant, ArrTekk 800 series High Perfor mance chemistry, to make the engineered emulsion used on this project.

During the design phase, several high performance specialty tests outlined in the specification were conducted to establish predictability of the mix for long term performance. The tests included Lottman test CPL 5109 on freeze/thaw, Marshall stabilities, indirect tensile strength for crack resistance and raveling tests to indicate cure time of the emul sion itself. “Ultimately, these tests determine what emulsion content and chemistry is appropriate for the climate conditions of the project,” said Arkema-Road Science Account Manager Jeff Weitzel.

“The raveling test is very important,” Weitzel said. “The raveling test (ASTM D 71 96) is a short-term strength test that must result in less than 2% raveling. This indicates if the material will cure fast enough to allow traffic rolling on it without raveling. You don’t want to build a road out in the middle of nowhere that you can’t put traffic on for a week. You want to put traffic on it that same day the CIR was done.”

Weitzel said Arkema-Road Science recommended that CSS spe cial asphalt emulsion be used on CO-149 based on the emulsion’s early strength build and cure. “This chemistry enables maximum emulsion dispersion throughout the mix itself and provides heavy film thickness, while lowering void content, delivering better rut resistance and better thermal and fatigue cracking resistance,” Weitzel said. “Even with all the thunderstorms and varying temperatures in this mountain region, we still had no raveling or rutting issues.”

The cure time following the CIR portion of the project was a min imum of 10 days, however, poor weather struck again. “We generally like to be paving on it within a couple weeks, but a ton of bad weather up here held us up,” Fife said. However, he added, the CIR still held up really well. “Instead of paving on top of a crumbly old road, CIR gave us a really nice product to pave on top of that I think will be a really nice road for years to come.”

Even without the wearing course, Fife said the CIR alone dras tically improved the smoothness of the road. The Coughlin crew agreed. “The level of smoothness we were able to achieve with the CIR left a much easier job for the paving crew to come back through and pave,” Steed said.

As soon as the weather allowed, United’s paving crew returned to the jobsite to place the asphalt overlay with its Cat 1055F paver. The overlay consisted of a 1-inch leveling course on the Creede side, an ST mix with PG58-28 and a ⅜-inch nominal maximum aggregate. On both sides, the crew placed a 1.5-inch wearing course, an SX mix with PG58-34 and a ½-inch nominal maximum aggregate. The Lake City side contained 30% RAP coming out of United’s pit in Gunnison, Colorado. “On the Creede side, we didn’t have RAP available to us, so that’s a virgin mix,” Fife said.

In total, the project required 64,000 tons of the SX HMA.

SMOOTH & SCENIC

Ultimately, both companies and CDOT are pleased with the results of the project. “We were able to remove the severe cracking in the roadway, place a recycled pavement surface without cracks, top it with two lifts of fresh HMA, and give the traveling public a very smooth ride,” Webb said.

By eliminating those cracks, the CIR will not only improve ride ability but also the longevity of the roadway by preventing water from infiltrating the pavement, Webb added. PPRA estimates CIR adds 15 to 20 years of life to that pavement. “They’ve gained quite a few years by putting down CIR under the asphalt overlay,” Fife said. “The CIR and overlay combined should result in a nice road that should last a long time.”

“The job turned out really well,” Steed said. “It’s definitely a big improvement on ride quality.” The average IRI for the north seg ment of the project was 185 before construction began, and now has an average IRI of 65.

In addition to the success of the project, this may be the one of the largest, if not the largest, CIR project in the western United States. “I’ve been doing this for 30 years, and it’s definitely the largest I’ve ever seen in this region,” Weitzel said.

“I’ve always taken pride in my crew’s expertise with CIR,” Chavez said. “To know we’ve been involved in such a history-making proj ect fills me with gratitude.” Steed agreed: “It’s an honor to be able to have been involved in a project of this size, and it’s a very successful project to boot.”

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to success for contractors across North America. Weiler’s material transfer vehicles, commercial pavers, road wideners, windrow elevators, static compactors, soil stabilizers, rock drills, tack distributors and front mount screeds are engineered with innovative features to increase productivity while reducing operating costs.

Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America.

GMI Maximizes Trucks, Fuel, Labor

GMI Asphalt has invested in a new drag, silo and flop chute from ALmix to improve haul truck cycle times and reduce fuel and labor costs.

BY SARAH REDOHL

BY SARAH REDOHL

Every five or so years, GMI Asphalt, Belmont, New Hampshire, has made at least one major investment in the growth of the company. From buying oth er construction companies and acquiring its quarry and sand pit in Boscawen, to pur chasing its 6-ton Barber Greene batch plant in Franklin, the company only seems to know one way to go: forward.

“We bought the plant to be more compet itive in our market and to take the next step in GMI’s growth,” said Neil Arruda, gener al manager of GMI Asphalt’s materials divi sion. “With our quarry, sand pit and asphalt plant, we now control the whole process and are able to price ourselves accordingly.”

Through each investment, GMI Asphalt has kept the end goal in mind regardless of the challenges they may face—and they have faced their share of challenges.

“When GMI bought the plant, it had only made 40,000 tons of mix total,” Arruda said. “I can’t even begin to describe the problems we faced in order to get the plant up to state spec and capable of producing 200,000 tons of consistent mix a year.”

For example, GMI invested in a fugitive dust fan to manage high dust content in the mix, as well as a blower and airlock to fur ther control dust content, and a reclaimed asphalt pavement (RAP) system. “It’s been a continuous process of improvements,” Ar ruda said.

Having its own plant has enabled GMI to compete for state work, which was particularly important during the height of the COVID-19 pandemic when the municipal and private work that makes up the majority of GMI’s work was delayed or canceled.

Arruda estimated that 15% of GMI’s book of work in 2022 has been for the New Hampshire DOT.

Then, in October 2021, GMI made perhaps the most significant investment in its plant: a

GMI Asphalt's new drag, silo and flop chute from ALmix enable the company to distribute mix from two points, at the batch plant tower drive-through and the silo. And, for the first time, the plant can store mix as needed.

300-ton silo, 500 TPH drag conveyor and cus tom flop chute from ALmix, Fort Wayne, Indi ana. “We made those investments so we could produce more mix at the plant and also in crease our production and trucking efficien cies,” Arruda said.

BIG SILO, BIG BENEFITS

Having the silo allows GMI to distribute mix from two points, at the batch plant tower drive-through and the silo. And, for the first time, the plant can store mix as needed.

“The silo allows the plant to run contin uously and enables us to fill the silo in the morning or the night before,” Arruda said. He’s also noticed a number of cost savings re lated to GMI’s latest investments. First and foremost, in terms of trucking.

“We went from an average time for a truck in the yard of 35 minutes to less than 10 min utes,” Arruda said. “Just loading the truck used to take 7 minutes from the batch plant. With the silo, we’re at 1 minute, 5 seconds to fully load a truck. That has been particularly

beneficial during the current truck shortage because it enables us to run with fewer trucks. A line at the plant to get loaded is just wast ed money.”

Arruda has also noticed savings related to labor costs as having the silo has enabled the operators to make what they need for the day, store it in the silo, and start shutting down the plant a bit earlier than before.

He also estimates that GMI has saved 5% on its total fuel and electric bills by reduc ing startups and shutdowns. “Being able to continue to produce mix even if there’s not a truck in the yard also allows us to produce a more consistent mix.”

Around the same time that GMI installed the new drag, slat and chute, the company also installed a Libra Self Service Kiosk from Command Alkon so truck drivers don’t have to get out of their cabs to grab their tickets. “That was planned in conjunction with the silo because we needed to get the final location of the silo to see how traffic was going to flow before we could build the building and stand in which the printer sits,” he said. “That’s also reduced our truck times by a few minutes.”

A TALL ORDER

Although the investments have brought big benefits, GMI’s plant location and its tim

ing goals brought on additional challenges. This included difficulties with the layout of the plant, limited space between the batch plant’s legs for the flop chute, and a short timeline to complete the installation.

In fact, Arruda said GMI had signed a contract with another OEM who ended up backing out of the project when it couldn’t figure out how to make the flop chute work. “Then we talked to ALmix, and they were willing to find a way to make it work while offering a competitive price and delivering within our time constraints,” he added.

“We wanted a 300-ton silo because it’s the only one we were installing,” Arruda said, adding that the silo itself is 85 feet. But GMI also wanted a weigh batcher on the bottom of the silo because the layout of the plant made it impractical to install a truck scale.

“That left us with two ways to approach the problem,” said Ryder Harman, ALmix’s sales and marketing manager. “Either we could put the whole silo on load cells or we could build a weigh batcher into the silo.”

Ultimately, GMI opted for the weigh batch silo, and ALmix designed an 8-ton, fully lined weigh pod built on top of three load cells beneath the silo. As the silo dis charges mix into the weigh pod, the pod weighs it and then discharges it into the truck below while safeguarding against mix segregation. It was the more economical option, but it added an additional 8 feet of height to the silo.

The total height of the silo (91 feet, 6 inch es) called for a 36-inch by 116-foot drag con veyor. “We’re no stranger to drags this large,” Harman said, adding that although the con

veyor wasn’t the largest the company has ever made, it is among the largest in recent years. The drag conveyor is powered by a 150-horsepower drive system, allowing it to feed the 300-ton silo at top production rates.

Instead of being supported by stiff legs lo cated midway up the conveyor, this drag con veyor is constructed using cambered bridge beams. “The drag expands and contracts due to the changes in temperature depending on if the plant is running or not, and when you have those legs attached, they don’t allow the drag the range of motion it needs,” Harman said. That’s why ALmix opts for cambered bridge beams on drags of this size. “They're a more expensive approach to constructing drag conveyors, but the strength and cam bering of the beams allows for the conveyor to be quite long and not sag over time with out the need for stiff legs.”

The strength of the silo is derived from structural steel legs, and the 1/4-inch, 100% double welded silo tube is housed within the frame supports. The silo walls are insulat ed and covered with pre-painted aluminum sheeting to keep heat loss at a minimum. Silo top decks are insulated with 10 inches of high-density insulation and covered with diamond decking, toe kicks and OSHA ap proved handrails. A caged ladder is provid ed to access the bird’s nest on the main drag. ALmix also built the silo with 6-foot railings at the top, which is standard for the compa ny’s silos.

GMI's plan to install additional silos in the future meant that even more height was added to the new silo setup. To account for the future addition, ALmix included a chute where a future transverse conveyor can be installed, allowing mix to be diverted to the new outboard silo, making the future instal lation an easier process for GMI.

“When it comes to adding silos and drags to batch plants not originally designed for them, we have a lot of experience with these projects,” Harman said. “We also manufac ture a complete line of batch mix plants, so we are quite familiar with engineering

“WE WENT FROM AN AVERAGE TIME FOR A TRUCK IN THE YARD OF 35 MINUTES TO LESS THAN 10 MINUTES.”—NEIL ARRUDA

LEFT: In early spring, GMI took advantage of rainy days and scheduled any work installing the new equipment that

have otherwise shut down the plant for those days, and as the season progressed, on nights and weekends. MIDDLE: Throughout

process,

plant, average time for a truck in the yard went from 35 minutes to less than 10 minutes, with loadout dropping from 7 minutes to 1 minute, 5 seconds.

plant only had to be shut down for one day, the day the flop chute was installed. RIGHT: With the latest additions

around them. We’ve faced enough challeng es in the past that we knew our tenured staff of engineers would be able to solve these problems, with enough information from Neil and enough elbow grease.”

Around 90% of the mix GMI produces is for its own projects.

A FOLDABLE FLOP CHUTE

GMI wanted to continue to use its batch plant after adding the silo so it would have dual loadout ability. This was particularly chal lenging to achieve, given the drag conveyor’s width of 36 inches and the 40-inch clearance between the batch plant’s legs. GMI was also looking to limit any modifications to the orig inal plant, including the tower legs where the drag would need to be positioned.

“We could see right away why other com panies might have been scared off by the flop chute in particular,” Harman said. However, ALmix’s engineers were up to the task, land ing on a flop chute design with two folding functions.

First, the flop chute folds out from be tween the batch plant’s legs. Then, the chute extends using pneumatic cylinders allowing the chute’s opening to expand up to the dis charge gates of the batch tower to catch the

mix. The flop chute can fold up and into the side of the drive-thru area, allowing trucks to load out from the batch tower when the chute is not in use.

“Being a larger batch plant, the discharge opening is quite a bit larger and you have to of course cover that whole opening,” Arruda said. “They also had to make sure the chute could take the larger drops that come out of a 6-ton batch plant and funnel it down into a 30-inch opening.”

With the photos and measurements Ar ruda provided, “everything ended up fitting perfectly without any modifications to the ex isting plant,” Arruda said.

“[Arruda] was a champ,” Harman said. “He got us every single measurement we needed and helped us every step of the way to ensure that our designs would meet GMI's needs and that everything would fit perfectly.”

Arruda has worked at GMI for 15 years. “I started as a truck driver and have grown my way through the company since then.”

A TIGHT TIMELINE

In early spring, GMI took advantage of rainy days and scheduled any work installing the new equipment that might have otherwise

shut down the plant for those days, and as the season progressed, on nights and weekends.

It was also a struggle to find subcontractors to perform some of the work related to the installation of the silo. “In the end, we end ed up self-performing a lot more than we had originally intended,” Arruda said. This in cluded the concrete work, dirt work, plumb ing, and erecting the silo and drag. “We had a tight timeline and didn’t want to wait for la bor to become available once we got our per mits in place. Doing that work ourselves gave us more control.”

Once all was said and done, the batch plant had only been shut down for one day, the day the flop chute was installed. “Other than that, the plant was running the whole time the silo and drag were being erected,” Arruda said.

“This was a fun project for us to be a part of,” Harman said. “We like to be involved in the decision making process, see the chal lenges they’re facing, and build custom solu tions. Being able to design and build bespoke asphalt equipment and facilities is what we’ve become known for.”

As GMI continues to grow, Arruda and the rest of the leadership team is equipped to tackle whatever challenges that may present. “Our owners, Warren Colby and Mark Bour geois, are very driven and focused on year over year growth. I don’t see that changing anytime soon. Our hope for the future is that we continue to grow.”

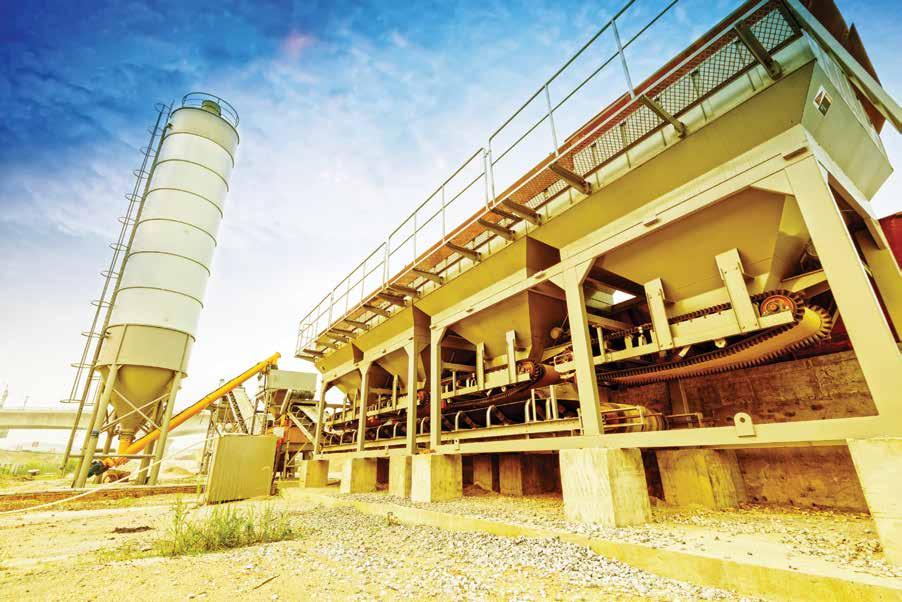

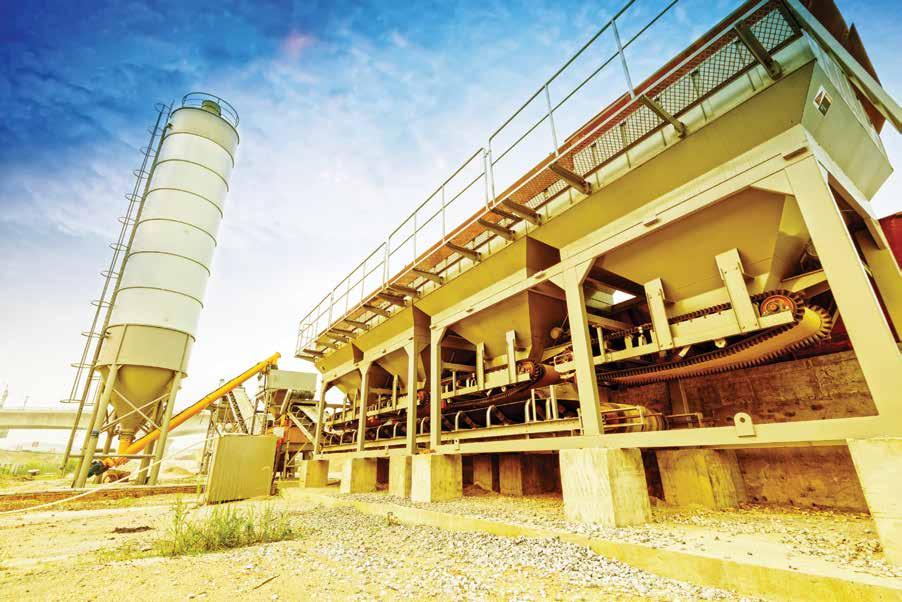

It takes a road to get there.

And a world of experience to build that road. As the global leader in road construction and minerals processing technology, we‘ve seen just about everything there is to see. In every climate, every condition, every twist, turn and terrain. And we put that world of experience in your hands, so you can experience exceptional performance and results at every phase of the road construction cycle.

OOwners of hot-mix asphalt (HMA) sites and quarries have the oppor tunity to not only upgrade existing facilities for best environmental per formance, but also to receive government funding for a portion of the cost, according to information from a recent National Asphalt Pavement Association (NAPA) update. During a Sept. 8, 2022, member briefing, Jay Hansen, executive vice president—advocacy for NAPA, shared infor mation about the $5.8 billion available through the Advanced Industrial Facilities Deployment Program, through which facilities owners can re ceive rebates of up to 50% of the cost to design and install advanced tech nology at their plants.

This is merely one piece of the overall $369 billion pie that is supposed to drive down greenhouse gas (GHG) emissions to achieve a 40% re duction below 2005 levels by the year 2030. The program is run through

the Department of Energy (DOE), and that is the entity to which an as phalt company owner will apply to receive a grant to upgrade or replace the plant.

Identifying and installing appropriate technology while applying for a government-embroiled grant to receive half the cost back may sound like a lot of effort to the average reader. The payoff is a more efficient op eration that could more reliably hit your sustainability goals than current equipment, with money back. And, as Hansen stated during the Sept. 8 briefing, “If you’re not doing this, you can bet your competitors are.”

What is “this” that leaders among the asphalt industry should be look ing into? We shared some grant-writing resources with the introductory article “Learn How to Write a Grant” for the plant product gallery de partment of the November 2022 edition of AsphaltPro. Next month, the January 2023 edition will look specifically at upgrading and updating the HMA plant with various advanced technologies. Right now, let’s dig a lit

tle deeper into the concept for which the DOE had yet to provide specifics at press time, and for which the Internal Revenue Service (IRS) seemed to be seeking clarity during the month of October.

Oct. 7, the Department of the Treasury (Treasury Department) issued a “Request for Comments on Energy Security Tax Credits for Manufacturing Under Sections 48C and 45X.” Notice 2022-47's purpose, as explained in Section 1 of the official document, was to receive general and specific comments of questions the Treasury Department had prior to developing guidance for implementing and administering the two codes, which are part of the Inflation Reduction Act (IRA).

Keep in mind, the IRS request is looking at how to provide tax credits on qualifying technologies; the DOE will award grants based on its own set of qualifying technologies. The two will not necessarily be identical, although industry would be short-sight ed to think they will not overlap. When speaking with NAPA’s Hansen, it became clear our industry has an opportunity to guide the categories of what is logically considered an advanced energy property designed to reduce GHGs, but our focus should be on partnering and avoiding a prescriptive list in any paradigm.

Hansen shared that the comments NAPA submits, on behalf of the asphalt industry, ahead of the Treasury Department’s Nov. 4 deadline, will reflect that the association supports the tax credit goal of re-equipping plants to achieve a 20% reduction in GHG emissions. “We don’t think listing out specific technologies is the way to go,” Hansen explained. “Rather, set the goal and let the manufacturers of asphalt mix deploy current technologies and de velop future innovations to achieve the reduction. No one technol ogy will get you there. It will require multiple combined technolo gies and some that have not yet been developed.”

Innovation is a hallmark of the asphalt industry, after all. Whether providing tax-reference guidance, grants or otherwise, the industry has a chance to work hand in hand with agencies that have yet to release any specifics.

“This is an opportunity for a new partnership,” Hansen said. “We don’t know what’s eligible for grant money yet. Will man ufacturers of asphalt mix be able to apply for grants to reim burse installation of electric or solar charging stations? We don’t know yet.”

The Energy Security Tax Credits for Manufacturers was ex tended and expanded under the IRA. Specifically, Section 48C of the Internal Revenue Code, known as the “qualifying advanced energy project, provides a 30% investment tax credit on qualify ing projects,” Hansen explained. “IRA was expanded to include a project that re-equips an industrial facility such as an asphalt plant with equipment that is designed to reduce GHG emissions by at least 20%. The IRS is seeking comments from the asphalt industry on how the credit should be applied.”

The request for comments offered an intriguing sense of lat itude for asphalt plant owners who will write their future grant applications. The request referenced the IRA’s Section 48C(c)(1) (A)(ii), stating it adds to the list of eligible projects any project which installs low- or zero-carbon process heat systems, carbon capture, energy efficiency and any other technology designed to reduce GHG emissions.

The IRS sought guidance to define terms in that paragraph, of course, but also for how a qualifying advanced energy project would substantiate its eligibility for tax credits. In other words, how will the equipment, technology or advanced energy project prove its worth? That’s where cooperation among industry pro fessionals must come in.

WINTER MAINTENANCE

WE’RE ALL IN THIS TOGETHER

“The federal government is the largest purchaser of construction materi als,” Hansen said. “We’re on the cusp of innovation and we have to part ner with the federal government, state transportation agencies and oth ers to make it happen.”

We also must partner with one another. The top-of-mind example of industry working together is in the verified environmental prod uct declaration (EPD) tool industry professionals and stakeholders as sembled over years of data-mining, in conformance with ISO 14025 and EN 15804. NAPA’s website states these standards systems “estab lish principles and procedures for developing a Type III environmental declaration program and describing the potential environmental im pacts of a product.”

EPDs for Idiots from 2019 = https://theasphaltpro.com/ label-asphalt-sustainable/ Eco-Emerald Label information with video = https:// www.asphaltpavement.org/programs/napa-programs/ emerald-eco-label

Another obvious example incorporates OEMs, their customers, and the vital collection and exchange of data—telematics.

Consider the use of training directors, heavy equipment distributors, and fleet operations managers who teach wheel loader operators best loading, stockpile management, cold feed delivery, and other practices. As Cat.com points out, fuel represents 50% of the cost to operate a ma chine; thus, you obviously want operators learning best practices to keep fuel use optimized.

The learned wheel loader operator lowers the environmental cost of operating the machine with best practices, with optimum routes through the yard, with perfected bucket loading for least trips to and from stock piles and cold feeds, with adequate lift to fill the right bins between bum pers, and so on. The fuel economy is the amount of work he accomplish es per unit of fuel burned. To get good fuel economy is to save money, yes, but it’s also a way to lessen fuel expenditures and emissions.

The company owner isn’t just saving money by training wheel loader operators on best practices, but he’s also introducing good environmen tal practices to the operation in the yard. Is that training something he can put a dollar figure on? Is it something he can write into a grant or En ergy Star Program application?

Where synergy and cooperation come into the fuel economy dis cussion starts with telematics. Copious fleet management software companies flood the AsphaltPro email inbox with article pitches to tell readers of their latest iteration to track equipment movement, fuel use, idle time, and so on. If your fleet is large enough, you might be saving enough on fuel use—through good tracking and best operator practices, thus tailpipe emissions—to warrant putting that on a grant application. You won’t know until you track it; the telematics provid er is there to help.

Now let’s talk about the obvious GHG reduction zone of “heat,” and what cooperative effort is available to producers there. Even members of the Treasury Department can recognize the burner at the asphalt plant is an area where industry has made strides in reducing emissions in re cent years. From implementing warm-mix asphalts (WMAs) that lower production temperatures—which should be worth grant money—to in stalling Lo-NOx and Ultra Lo-NOx burner technologies to manipulate combustion gases and burner flame, asphalt producers have already been finding ways to turn down the heat at the drum.

OEMs are willing to partner with customers to show how to reduce heat and emissions all around the tank farm and yard. Ron Herman,

business development manager of Enerquip Thermal Solutions, Med ford, Wisconsin, spoke of helping a customer find ways to reduce ener gy use for its U.S. Environmental Protection Agency’s (EPA) ENERGY STAR® industrial program goals.

“I’ll do the math for them,” Herman said. While his company doesn’t sell or install insulation packages for existing liquid asphalt tanks, he was willing to work on the equation to show a company how the 100,000 BTU/hour heating load increased by 25 times without insulation, mak ing the “expense” of insulating a tank well worth its investment. “The sav ings on the utility bill alone pays for that in a season,” he said.

The researchers at Heatec Inc. (now Astec Industries) prepared Tech nical Paper T-140 “Heating and Storing Asphalt at HMA Plants,” which not only looked at the cost-per-unit of energy to heat liquid asphalt (and emulsions) but also discussed a heater’s thermal efficiency. The bottom line is a heater’s efficiency can change over its lifetime and that change in efficiency can influence how much energy is required to maintain tem peratures.

The team at Process Heating Company (PHCo), Seattle, has more than 70 years of experience in manufacturing its Lo-Density® low-watt-den sity, drywell-style electric heating systems designed to spread heat over large surface areas. The researchers at PHCo state: “An electric-powered asphalt tank heater or hot oil heater...operates at 100% efficiency; there is no heat or emissions exhausted into the air. And over the lifetime of the heater, that efficiency never drops.” To help customers prove this, PHCo performed a fuel cost comparison of maintaining 30,000 gallons of liq

LEARN MORE

States Get Started with Initiative Funds

The White House released a fact sheet Oct. 20 regarding a convening at the White House for “Buy Clean” commitments. The federal Buy Clean Initiative “leverages the Federal Government’s power as the largest purchaser in the world to advance low-carbon construction materials across its procurement and funded infrastructure projects,” according to the sheet.

Through the Initiative, the Department of Transportation announced that 25 states are receiving the first Federal Highway Administration (FHWA) Climate Challenge grants—to the tune of $7.1 million— to support sustainable pavements. The Department of Energy will coordinate Inflation Reduction Act funds for an Advanced Industrial Facilities Deployment Program. This will help industrial facilities retrofit, upgrade, or install industrial technologies and produce lowcarbon materials. More information can be read at the WhiteHouse.gov briefing room documents.

Those first 25 entities are Alabama DOT, Arizona DOT, Caltrans (three projects), Colorado DOT, State of Delaware DOT, State of Hawaii DOT, Illinois DOT, Indiana DOT, Iowa DOT, Louisiana DOT & Development, Maryland DOT and MD Port Administration, Minnesota DOT, Mississippi DOT, New Jersey DOT (two projects), New York State DOT, North Dakota DOT, Oklahoma DOT, State of Oregon DOT, Puerto Rico Highway and Transportation Authority, Rhode Island DOT, Texas DOT, Virginia DOT, West Virginia DOT Division of Highways, Washington DOT. Four local agency projects in the City of Seattle and in the Port of Authority of New York and New Jersey will receive technical assistance only.

uid AC at 300°F for 24 hours with natural gas, LP propane, No. 2 oil, No. 6 oil and electric at a heater’s “year 1” and at its pro jected year 8.

Check out PHCo’s “By the Numbers—Electric is Better” comparison chart at the company’s home page at processheating.com. There are dynamic fields where you can input your utility costs to calculate results.

Armed with actual figures, a company can plug everything from simple to complex technology into any number of green energy rating system program proposals such as an ENERGY STAR program or Institute for Sustainable Infrastructure (ISI) Envision® application. And the CFO can plug those numbers into a DOE Advanced Industrial Facilities Deployment Program grant proposal as well.

Enerquip’s Ron Herman had a host of ideas we’ll be sharing in the January equipment and technology installment of this article series, but here are basic “hot spots” he recommended customers look at for energy and money savings.

• Replacing tank fire tubes with bottommounted tank coils, which removes an emissions source at each tank on the site

• Addressing tank insulation, whether that’s repairing or installing

• Repairing or replacing old hot oil heaters with new technology

• Replacing boilers with hot oil heaters and steam generators

• Going Lo-NOx or Ultra Lo-NOx on burners

Maybe the OEM you approach can share its scope 3 emissions to improve the upstream numbers you’re compiling. For example, the team at Honeywell, headquartered in Houston, has unveiled its ECOMAX® LE burner. The team developed it for furnace OEMs that need to meet tightening global nitrogen oxide emissions re quirements and end users who want to increase fuel gas savings. The ECOMAX LE offers both flame and flameless operation, switching into flameless when a set temperature is reached, to de liver an average of 30% fuel gas savings compared to a typical cold air burner, according to the manufacturer.

With IRS seeking guidance and industry stakeholders willing to strategize alongside asphalt producers, it seems the asphalt in dustry is poised to take advantage of its innovative charge on The Road Forward. As Hansen pointed out, the DOE guidance on grants will be different from the guidance that ultimately comes from the Treasury Department, but our industry can hope that both offer guidance that sets a goal and is not prescriptive.

“The one difference may be that while the IRS tax credit is for re-equipping plants, the DOE grants might make plant replace ment eligible,” Hansen said. When you consider the number of older facilities that have been replacing components or updating one aspect of the plant at a time, the idea of having $5.8 billion in grant money available to replace an entire plant with something exceedingly more efficient is mind-boggling. “This could be a big deal for the asphalt industry,” Hansen said.

Crestview Bypass Project Innovates Through Supply Chain Issues

BY SARAH REDOHLTThe town of Crestview, Florida, is located along Florida State Road 85, U.S. Route 90 and just north of Interstate 10. It’s a major route for tourists making their way south to Florida’s many beaches and Eglin Air Force Base 20 miles south of town.

“A large population travels from Crestview down to Eglin or the Gulf Coast to support the military and tourism industry,” said Jason Autrey, director of Okaloosa County Public Works. Pair that with the city’s population increasing by 30% between 2010 and 2020, ac cording to the U.S. Census Bureau, and Okaloosa County faced “a classic case of a community growing and the need to find a better way for the people of Crestview to get around town.”

That’s why Okaloosa County began work on the Southwest Crest view Bypass more than 15 years ago, the first four phases of which included the widening of P.J. Adams Parkway connecting I-10 and SR-85 from a two-lane roadway to a four-lane roadway. In Septem

ber 2021, Anderson Columbia Co. Inc., Marianna, Florida, began the largest phase of the Southwest Crestview Bypass.

Anderson Columbia is performing both the Phase Five Corridor, which includes 3.1 miles of a four-lane roadway, as well as the EastWest Connector, 2.2 miles of two-lane roadway. “Phase Five is the missing link to complete the Bypass,” said Kevin Buchanan, project manager and estimator for Anderson Columbia.

“We’re confident the work on Phase Five will have a huge impact on our local area,” Autrey said. “The community really needs this new route. Once Phase Five opens up, it’s sure to be heavily utilized and appreciated.”

Anderson Columbia is also performing the work on a related Florida Department of Transportation (FDOT) project, a new in terchange on I-10 near P.J. Adams Parkway in Crestview. “We won that job about 8 months after we won the bid on Phase Five and the East-West Connector,” Buchanan said, adding that construction be gan in the summer of 2022.

The interchange will be known as Exit 53 and is the first new FDOT interchange in 30 years, Autrey said. “That will also have a dynamic impact on the way traffic moves through Okaloosa County.”

“Our big goal, which is still many years out, is to create a loop road around Crestview,” Autrey said, adding that the county is actively working on a Project Development and En vironment Studies (PD&E) timeline for the northwest quad rant of the eventual loop road. “We’re constantly thinking about how to improve traffic flow in the future.”

ONTO PHASE 5

When Anderson Columbia won the bid for Phase Five and the East-West Connector, it seemed like an ideal project for the company. “This type of project is right in our wheelhouse,” Bu chanan said. “Plus we had an asphalt plant just 5 miles from the project and local crews available, so the timing was perfect.”

Anderson Columbia was started by Joe Anderson Jr. in 1958 as Anderson Contracting. When the company later bought out an asphalt company called Columbia Paving, Anderson Columbia was born.

Now, the company has around 1,250 employees and per forms heavy highway and bridge construction, mostly for state departments of transportation, in Florida, Texas, North Carolina, South Carolina, Georgia and Alabama.