“I am proud to have spent more than 40 years of my life manufacturing products that save lives. I am proud that my company has remained competitive against international suppliers and most of all that we have managed to create products that add value to New Zealand.”

Poignant words from the owner of award-winning high-tech manufacturing company Pertronic Industries, David Percy.

What started with one person in Ngauranga Gorge, Wellington, has turned into quite the success story for Hutt Valley manufacturer Pertronic Industries. Fast forward forty years later, the company now employs 140 people and proudly operates out of a 6,000 square metre factory site in Wingate, Lower Hutt.

Pertronic Industries manufacturing business, designs and makes fire detection systems that it sells to installation companies, who fit systems in commercial and industrial buildings such as hotels, hospitals, high-rise office blocks, schools, tunnels,

and shopping malls.

The company, founded by electrical engineer David Percy in 1982, has grown to be the largest manufacturer of fire detection systems in New Zealand. At least 50% of its business is now in Australia where it has offices in Adelaide, Melbourne, Sydney, Brisbane, and Perth. They have exciting plans in the pipeline to launch in the US market.

“We are in the process of getting a product certified for sale in the large USA market. We have a small team of people based in the US who have been working tirelessly on our first US product which has been going through R&D / Certification to

continued on Page 13

Aad

Poel: Aad@xpo.co.nz | 021 314 199 southmach.co.nz

ANALYSIS Adapt or perish. CIRCULAR ECONOMY Circular economy: so much more than recycling. DEVELOPMENTS

steel industry

new

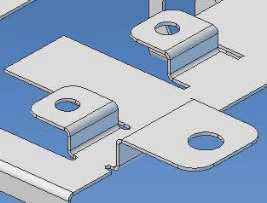

www.nzmanufacturer.co.nz March 2023 Sales and training—Aust/NZ Region enquiries@baycad.biz www.baycad.biz NZ 0274847464 AU 64274847464 Don’t delay, contact us now. Free trial available 30 Days, No Restricons NEW VERSION E P P CAD S B I O O I F 19 26 PROUDLY SUPPORTED BY 24-25 MAY 2023

Arena

about

at

and

show.

Structural

targets women with

initiative.

Christchurch

Enquire

exhibiting

the South Island’s largest engineering, manufacturing

technology trade

van der

Patrick McKibbin, Steven Mills and David Percey.

Hutt Valley manufacturer saving lives, expanding globally

7

-Rebecca Reed

2023 Media Kit www.nzmanufacturer.co.nz For a copy of the NZ Manufacturer Media Kit 2023 email publisher@xtra.co.nz All articles are published at no charge, unless promoted (advertorial) content is required. Success Through Innovation asiamanufacturingnewstoday.com ASIA M ANUFACTURING N EWS 2023 Asia’s manufacturing future. MEDIA KIT Media Kit 2023 Innovation + Dedication = Success www.australianmanufacturingnews.com TechRentals® is an IANZ endorsed Calibration Laboratory We offer both IANZ Endorsed and Traceable Calibrations of test and measurement equipment inluding: 0800 832 473 www.techrentals.co.nz

DEPARTMENTS

LEAD

Hutt Valley manufacturer saving lives, expanding globally.

BUSINESS NEWS

What recent cyber attacks have taught manufacturers.

ANALYSIS

Adapt or Perish.

SMART MANUFACTURING

Interference doesn’t stand a chance with electromagnetic compatibility cables.

WOMEN IN ENGINEERING

Caroline Su.

COMMENT

We need to secure our economic future. In praise of William White, provincial pioneer.

CIRCULAR ECONOMY

Regulated stewardship coming soon for synthetic refrigerant industry.

Circular economy: so much more than recycling!

STEM

Girl Geek Academy calls on government to increase funding for Girls in STEM.

WORKSHOP TOOLS

Cost effective automation.

Kemppi adds Pulse to welding range. Eagle Protect has high-performance disposable gloves.

DEVELOPMENTS

New business toolbox means a more sustainable supply chain.

Fabrum raises money to decarbonise the economy.

Government misses opportunities to reduce greenhouse gas emissions.

Is Chief Executive of BusinessNZ, New Zealand’s largest business advocacy body He has held a range of senior positions at Westpac and is a barrister and solicitor

Ian is a Partner, Argon & Co. NZ, a master black belt improvement specialist and global lean practitioner. He is passionate about improving productivity and helping to create world class New Zealand businesses.

thinkstep-anz

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Is Managing Director of Connection Technologies Ltd, Wellington and is passionate about industry supporting NZ based companies, which in turn builds local expertise and knowledge, and provides education and employment for future generations.

EMA chief executive Brett O’Riley has a background in technology and economic development.

Brett actually grew up with manufacturing, in the family business, Biggins & Co. He currently holds board roles with Wine Grenade and Dotterel Technologies and is also on the NZ Film Commission board.

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 4 Contents ADVISORS

Kirk Hope

Brett O’Riley

Ian Walsh

Lewis oodward

Insa Errey

Dr Barbara Nebel CEO

1 6 7 9 12 15 18

25

20 22

7 12 15

9

19 20 24

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: +64 6 870 9029

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, HERA, EMA

Business East Tamaki

Ian Walsh, Dr. Barbara Nebel, Rebecca Reed, Peter Baily, Jason Richards

ADVERTISING

T: + 64 6 870 9029

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: +64 6 870 9029

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer

ISSN 1179-4992

Vol.14 No.2 March 2023

One-person company becomes so much more

Pertonic Industries (Lead story, Page 1) have been manufacturing products that save lives for forty years.

Pretty impressive, huh?

Owner, Dave Percy, says the company has remained competitive against those from overseas and create products that add value to New Zealand.

Starting out as a one-person company, they now employ 140 people at their factory in Wingate, Lower Hutt. Half of their business is in Australia and they are looking to launch in the USA. NZ Manufacturer continues to follow their journey with interest.

There is an article in the Business News section, (Page 6) which discusses cyberattacks on manufacturing companies. Read the article, make sure your systems are up to date and call in a cyber security professional if need be.

Ian Walsh (Page 7) believes to succeed and survive in business we all need to adapt to our environment. Adapting in the business world, Ian says, is competitive advantage, a set of practices and skills which better companies embed into their “DNA.”

Elsewhere, we continue our focus on Women in Engineering, which also appears on the website www.nzmanufacturer. co.nz and on LinkedIn. This month it is Caroline Su, a quantity surveyor at Bettabuilt in Christchurch.

Insa Errey, one such focus not so long ago, is now an Advisor for the magazine. Her specialisations, leading change management within the energy, decarbonisation, and sustainability space are a welcome addition and sure to provide valuable insights for readers.

Finally, I draw your attention to two Comment articles. One is from Michael Baines, Executive Officer, Vocational Engineering Education NZ who reflects on the serious lack of skills to meet the challenges the country is currently facing (Page 15).

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

The other (Page 17) is from Dr Matthew Birchall, Research Fellow, NZ Initiative who gives the example of William White of Kaiapoi who erected the first bridge across the Waimakariri River. He was a humble hotel owner from 19th century North Canterbury.

Today’s planners can learn a thing or two from White about shepherding a project through to completion in a timely fashion!

5 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023

Success Through Innovation Editorial

What recent cyber attacks have taught manufacturers

Peter Baily, Regional Business Manager – Cyber at Kordia Group

Widespread Australasian attacks like those seen against Optus, Pinnacle Health, and Medibank saw operations grind to a halt, consumer trust erode, and sensitive data exposed. The manufacturing industry isn’t immune to these types of attacks, and my guess is that it will only be a matter of time before a prominent New Zealand manufacturer is in the same boat.

You might ask, what would a hacker gain by attacking your business?

Manufacturers are particularly vulnerable to cyberattacks, especially ransomware. Legacy back-end operating systems that can’t be patched or updated to meet the latest cyber security standards are rife throughout manufacturing supply chains and make easy targets for opportunistic cyber criminals.

Once a hacker finds a vulnerability to exploit and gains access to your systems, they can deploy malware that will cripple your operations, demanding a ransom in exchange for restoring your data and systems.

Production line machinery has been designed to automate processes and boost productivity. Unfortunately, most of these machines come fitted with operating systems that weren’t designed to be easily updated.

This can make it nigh on impossible to remediate faults and bugs in the system, without completely rewriting the software.

Likewise, modern inventory and packing systems often rely on software and digital systems. Imagine if all the computers and servers in your network went down – could you switch to manual operations in order to move stock and manage customer orders?

Once a hacker has entered a system, it can take weeks to safely restore everything. A break in production is devastating for any business, even more so for seasonal businesses like vineyards or harvesting that rely on short production windows.

Globally, cyberattacks on manufacturing companies are all too common. Look at the ransomware attack on Bridgestone Tyres American subsidiary in March last year.

The attack shut down the computer network and factory production in Northern and Middle America for a week. As a supplier to Toyota, the attack on Bridgestone had knock-on effects that impacted the production of Toyota vehicles.

To protect yourself from cyberattacks, it’s vital that manufacturers take steps to understand and remediate the risks associated with cyber threats. A good starting place is to assess and evaluate your infrastructure – what are the key enablers for your business? What systems, technology or processes are critical for keeping your production humming?

Once you’ve determined what your most valuable systems are, your next step is to analyse these with the help of a cyber security professional. This will

help you understand what the weak points are around these systems, so you can work on a plan to remediate – or at least reduce - the risk they pose. Ensuring operating systems are sufficiently “hardened” is key to implementing a robust cyber defence strategy. This involves a regular cadence of updates and patching for operating technology and software to close off any vulnerabilities.

In cases where you can’t upgrade software, you can implement other layers of protection that will prevent malicious hackers gaining a foothold into your network.

Training your employees is also key to any business’ cyber security. Simple things like learning to spot a phishing email and enabling multi-factor authentication on employee devices are easy ways to empower your team to support your cyber security goals.

If recent events have taught us anything about cyber security, it’s that no business is immune to a significant cyberattack.

6 Business News is here to make it easier to do business; working alongside business leaders and property owners in the region on security, advocacy, development and growth. businessET.org.nz Helping build sustainable business, and sustained success.

The manufacturing industry isn’t immune to these types of attacks.

Adapt or Perish? Analysis

-Ian Walsh, Argon & Co

In these challenging times it’s useful to refer back to the lessons of the past to help navigate the future. Charles Darwin, considered to be ‘the father of evolution’, proposed the theory that a species’ survival was dependent on that species having adapted favourable traits to thrive in their natural environment. This theory is sometimes referred to as survival of the fittest.

I’d argue this theory holds true in the business world too. In order to survive you have to adapt to your environment. Those that can adapt thrive and grow. Those that cannot perish, and are replaced by competitors more suited to the environment they find themselves in.

The ability to adapt in the business world however, is not some random genetic mutation ability bestowed from the gods, but rather it is a competitive advantage: a set of practices and skills which better companies embed into their “DNA”.

The average lifespan of a Fortune 500 company has fallen by 80% in the last 80 years from 67 years to 15 years, similar statistics in the UK. Of those companies with over 100 years, there are some common charactieristics:

• Stable purpose

• Servant leaders/stewardship

• Succession planning

• Embrace change and new ideas, open to sharing

• Continuous improvement in all things they do, learn from the best always

• Teamwork and change willingness through planned disruption

• Deeply embedded systems and processes to embody their “DNA”

If you have these attributes built into your company then you should be able to adapt and survive.

At this point, it’s important to not confuse adaptation with agility. Adaptation is a response, adjusting your business and processes to meet your customer needs in a changing world. It’s strategic, systemic, and embedded into the way your business operates.

Agility is reactive, like a carpenter who usually uses a hammer and nails changing their tools for working on a different build that uses interlocking beams. It’s action-driven, and represents a solution to a problem, rather than a change in how the business works.

With this in mind, in order to be ready to adapt to your changing environment you must have systems and processes for

1. Codifying your knowledge content, to enable rapid redeployment and adjustment for rapid scaling

2. Creating internal capability, systems and processes to solve problems at all levels of the organisation

3. Creating empowered teams to make decisions

4. Developing a system of accountability and responsibility throughout the organization that ensures the deployment of required adaptations

The world is changing, with climate change, Covid, technology and many other inlfuences. The world of work has adapted, with working from home, adoption of new technology, new practices but to be ready for anything (or at least, as much as possible) we need to be able to trust that we have the systems and processes to enable the next adaptation, the one after, and the one after that.

Doing what you have always done won’t cut it. The competition can come from anywhere, and it will benefit from being ready and opportunistic. The competition won’t even necessarily come from your industry. Dairy companies are now beverage companies and vice versa!

We have to be willing to fail and learn, implement globally and scale quickly to stay ahead. Watching is not an option.

I remember working with a large multinational implementing six sigma in the 90’s. When I asked them why they were doing it, the reponse was it could be the next big thing and they could not afford to miss the boat. It’s better to fail and be on the boat than not be on board at all!

Can you afford not to be on board? Given our talent shortage, the need for training and redeployment can you afford not to have codified knowledge available? Have you got robust problem solving systems and capabilities that drive resolutions to your issues and prepare you for the future?

Have you developed the delegated systems that drive real accountability? Are you sure that when key people leave their knowledge remains?

If you were a no for any of these questions then there is no better time than now. As said historically by Rabbi Hillel the Elder and famously repeated by John F Kennedy, “if not us then who, and if not now then when?”

Want to know how to upskill your team for free? Drop me a line ian.walsh@ argonandco.com

7

ADVISORS

is an expert in the field of technology development and commercialisation. His company Design Energy Limited has completed over 100 significant projects in this vein by consulting for and partnering with some of New Zealand’s leading producers. Among Mike and his team’s strengths are industrial robotics and automated production where the company puts much of its focus.

Sean O’Sullivan

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business. She has over 20 years’ experience working with companies to boost profile and build influential connections.

Has a B Com (Hons) Otago University. In 2000 - 2001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide.

In 2001 – 2022 Founding Director Empower Workshop Productivity & Scheduling Software App. 236 manufacturing and engineering clients mainly throughout NZ and Australia, also UK and US.

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 8

Sandra Lukey

Mike Shatford

Suddenly, the robot stops: When searching for the cause, very few people think of interference caused by electromagnetic radiation. It is actually quite often the case when sloppy work is carried out while screening cable glands and connectors.

LAPP Australia has products that make it particularly easy for employees from assembly to guarantee electromagnetic compatibility.

Interference doesn’t stand a chance with electromagnetic compatibility cables

Tiny hairs provide a tight seal

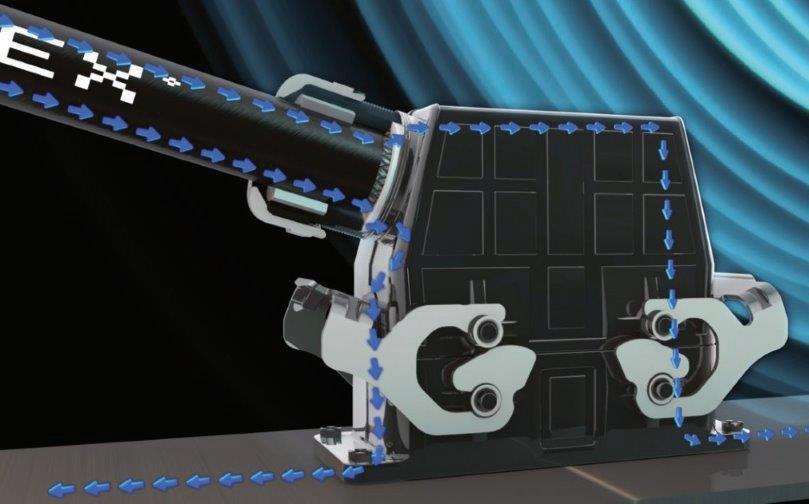

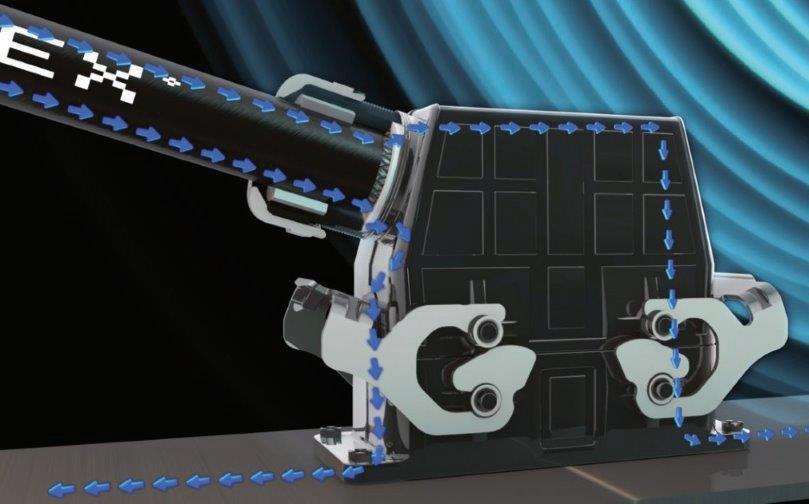

The EPIC ULTRA rectangular connector shows how it works. Its metal housing is nickel-plated, the seal is on the inside so that the two metallic housing parts have a large contact area. The SKINTOP MS-M BRUSH cable gland goes perfectly with this, as a well-screened overall system also needs the transition from the connector to the cable to provide a tight seal.

Industrial connector EPIC® ULTRA from LAPP: Due to the conductive nickel layer on the connector surface, the connector housing acts like a Faraday cage.

Older people will remember the annoying humming from the radio when the neighbours switched on their drill. Thanks to digitalisation, such problems with electromagnetic compatibility (EMC) are thought to be a thing of the past. But are they really?

Unfortunately not, as the boom in digital communication via various wireless standards and cables means that EMC problems are highly topical again. Particularly in industry, where automation and therefore electrification are progressing even faster. There has been little change in the causes of this type of interference. Poorly shielded connections, particularly for cable glands or connectors, are frequent gateways.

This can be avoided by means of the largest possible contact area between the braided shield and the connector housing. The cable shield should be positioned closely around the transition from the cable gland to the connector without any gaps.

Only then can the connector housing act as a Faraday cage and keep external interfering signals at bay. It is also important that this optimum screen contact takes place on both ends of the cable and is connected to the ground potential as it is the weakest link that determines how effective the screening is.

The screen is secured by thousands of little brush hairs arranged in a ring. The cable is centred, attached, strain relieved and hermetically sealed in a single operation. Currents that are induced through interfering signals from outside are efficiently diverted by the highly conductive 360° brush screen. This is especially important for the transmission of sensitive signals. The EMC Institute has confirmed that screening is much better than conventional solutions.

If power cables with high currents run directly next to this, the strong electromagnetic pulses may disperse into the poorly shielded cable and even lead to a machine failure.

“This explains why sometimes a robot suddenly stops for no apparent reason and everyone searches desperately for the fault until someone finds the unprofessional installation”, says Lisa Schlingmann, product manager at LAPP.

With the SKINTOP MS-M BRUSH, the large contact area always provides complete screening, even in the case of moving applications, for example on a robot arm, where several power and data cables run in the smallest space.

Patches for screening

However, you can never be completely certain. If a cut is made too deep when stripping during assembly and the shielding is damaged, the shielding effect suffers. This can happen in the event of a window cut.

SKINTOP® MS-M BRUSH, above, and ÖLFLEX® CONNECT SERVO – Core Line with 360-degree screen contact for optimum screening, below

Watch out for kinks

EMC problems can also be found where they are least expected: in control cabinets. For example, if there are no ground straps on the doors, the screening suffers. Or if it is cramped in the control cabinet and cables are kinked behind the cable outlet.

For certain connection types, only a narrow hole is cut in the sheath to expose the shielding underneath rather than the whole cable end being stripped. If something goes wrong here, the cable must be cut off and reworked if there is still enough length remaining. In the event of minor damage to the shielding, however, the damaged area can be repaired using a conductive and self-adhesive screening tape so that the cable is intact again.

9 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023

SMART FACTORY SHOWCASE

Featuring

The Smart Factory Showcase

Your chance to experience the future of advanced manufacturing by immersing yourself in the Smart Factory Showcase.

Transform your business

Understand how Industry 4.0 can transform a business and see first-hand what a high level of maturity in Industry 4.0 technologies looks like, based on a real ‘smart factory’ in New Zealand.

The sessions

Feature a digital twin of Nautech Electronics’ Auckland facility which enables us to deliver real content and stories directly to you. The interactive session examines how Nautech integrated smart technology to enhance efficiency, connectivity, and processes. They also highlight how you can engage and improve employee experiences and enhance manufacturing agility.

Questions or feedback? Please contact - manufacturing@ema.co.nz

Get started www.industry4.govt.nz/UpcomingEvents

Our aim is that you will leave the showcase feeling inspired by the solutions offered and armed with the knowledge needed to kick-start your own Industry 4.0 journey

text title NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 10

DELIVERY PARTNER PROGRAMME PARTNERS POWERED BY Register here

NETWORK SITE VISITS

The Network Site Visits is a programme to encourage sharing of Industry 4.0 knowledge across the sector. Whether you are well into your Industry 4.0 journey or just starting out, the programme provides a range of opportunities to expand your understanding of Industry 4.0 technologies and learn from others who have already embarked on their Industry 4.0 journey. Join us for events, undertake an assessment or expand your knowledge through resources and case studies.

eadiness Assessment

Companies can apply for a fully funded Smart Industry Readiness Index (SIRI) Assessment process to help accelerate their own journey towards Industry 4.0, the result of which will be a benchmark against other companies in their sector and a high level prioritisation roadmap.

Apply for the assessment

Factory Tour

The tours provide an opportunity to see first-hand what businesses have implemented as a result of the SIRI Assessment. They will showcase developments, specific technologies and learnings on their Industry 4.0 journey. Targeted at local manufacturers, these events are delivered across New Zealand and are a great way to network and connect with others in the region.

Upcoming events

Webinars

The webinar series is an opportunity to hear stories from all stages of the Industry 4.0 journey, focusing on the benefits of implementing these technologies, what challenges you may need to overcome along the journey and specific examples of Industry 4.0 technologies, all based on the experience of New Zealand companies.

Upcoming events

Case Studies

Documented as part of the SIRI Assessment, the case studies provide an opportunity to understand a specific example of how Industry 4.0 technology has been implemented in a manufacturing environment. They will provide you with key learnings to take away and inform your own journey.

Resources

11 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023

DELIVERY PARTNER PROGRAMME PARTNERS POWERED BY

Women in Engineering

Caroline Su

Share what you actually do?

I am currently a quantity surveyor at Bettabuilt, which is part of the Brosnan Construction Group of companies. I am working closely with the project team and key project stakeholders managing the carpentry contract from project commencement through to completion.

My duties and responsibilities include, but are not limited to, assessing payment claims and variations, enforcing adherence to contractual terms and risk management.

I also manage relationships with clients, main contractors, and key project stakeholders, along with the project team to ensure all financial deliverable and outcomes are achieved.

What drew you to your profession?

I came to NZ just after the 2011 Christchurch Earthquake. The first time I went to the town centre I saw lots of damaged buildings and containers, hoardings and safety nets everywhere. Which potentially brought my interest in construction and thoughts of rebuilding Christchurch.

Is this a field many other women are working in?

There were not many, but now there are more! I remember when I first became an intern I was asked if I minded being the only female in the office. That was in 2017-ish. Now, in my office, we have nearly half females and the percentage is increasing!

How do you enjoy your work?

My day to day work is not just using the construction knowledge that I have learned, we also have a lot happening on site every minute. I enjoy problem solving every day, which brings the joy of success. Is there a specific project you have enjoyed doing?

I am quietly enjoying my current project: UC Psychology Staff Building Refurbishment. How do you deal with issues like climate change… and what needs to be considered for the future?

For construction, the climate change will possible affect the programme delay and materials shortages. We now have more & more eco/environment friendly materials, e.g site hoarding 100% made by rubbish etc.

Who has been the biggest influence in choosing your career?

My parents, they fully supported me when I wanted to study construction.

If not this career, what other one would you consider?

I would probably be doing accounting or a financial job.

Favourite book?

The Three-Body Problem, a science fiction novel written by the Chinese writer Liu Cixin. The title refers to the three-body problem in orbital

mechanics. This book also has an English version. Highly recommended. How do you relax?

I enjoy hiking and exploring the wildness in NZ.

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 12

DEUTSCH HD30 & HDP20 CONNECTOR SERIES Designed specifically for the truck, bus, and off-highway industry, heavy duty, environmentally sealed, multipin circular connectors. contact sizes 4 through 20. Tel: 04 566 5345 Email: sales@connectors.co.nz Web: www.connectors.co.nz

continued from Page 1

Hutt Valley manufacturer saving lives, expanding globally

meet the local requirements. The opportunities in the US market are significant. With our recent investment in new technology and ongoing R&D, we are setting ourselves up for growth in the US market.”

Investing in R&D and new technology

With an eye to the future, David says the company has invested heavily in R&D so they can continue to manufacture high quality competitive products.

Pertronic’s Production Manager Stephen Mills says if it wasn’t for David and his willingness to reinvest the profits of the company back into R&D, the business wouldn’t be the leading manufacturer for fire protection in NZ and they certainly wouldn’t be entering the US market.

“The investment in R&D and new equipment has enabled us to get through Covid-19 and be positioned for continued growth. The R&D component of this company, with 30 people in the team, is unbelievable in terms of the investment spent so that’s why this is so successful - it has enabled us to create better products and keep Pertronic at the leading edge of our industry.”

The company also understands the importance of continuing to develop high quality products that stand out amongst its competitors. To keep up with productivity demands it recently invested $1 million in new technology which will increase their printed circuit board manufacturing capacity by 50%.

The new Surface Mount Technology Europlacer, purchased from France, can be configured to run up to 30,000 components per hour and most importantly reduces the set-up time on production from 2.5 hours to 7 minutes.

“The growth we have been experiencing has meant we needed to add capacity and increase productivity, and the Europlacer met all of our requirements. For a number of years, we have used older technology machines which have given us good service, but technology has moved on considerably, so we needed to think about our future growth and demands.”

Growth in the wake of challenges

Despite challenges relating to the global pandemic, Pertronic Industries achieved a record 30% growth last year, which David puts down to several factors.

“Like many other high tech manufacturing businesses, we haven’t been immune to the challenges faced because of Covid-19 such as supply chain disruptions, hyperinflation and staff shortages. However, our growth is a result of a combination of reasons including our excellent relationship with our suppliers, being a NZ based manufacturer of fire detection products, our investment in R&D, and our team.”

David says a clear advantage of being a NZ based manufacturer is they are able to stay very close to their customers and offer a degree of customisation that suits each project, which suppliers with imported products struggle to meet. He says a major fire detection system installed in the Waterview Tunnel in Auckland is an example of this.

“One of the key requirements to win the business for Waterview tunnel was to be able to fix any programming problems, or be there in the event of any equipment being damaged during the installation or commissioning process. This would not be so easy to achieve if the products were imported - because we manufacture locally, we are able to offer far more support than our competitors.”

David says although they use local suppliers such as metal working firms Metco in Seaview and RH Freemans in Grenada North, they also have to rely on imported products such as semiconductor components of which there is a worldwide shortage.

“The whole supply chain disruption over the last couple of years has been challenging and Stephen Mills, our Production Manager, has managed to put a lot of time and effort into ensuring we have the shipments.

“Unfortunately, due to demand and hyperinflation, we have had to pay prices for the products up to 15 times higher than what we normally pay. It does put us in a difficult position, and we have had to put some price increases through although we have absorbed some of those price increases to assist our customers.”

Investing in future generations

As Pertronic Industries continues to grow it is looking to invest in its future workforce. It has been involved in the Gateway programme offered through High Schools and offers selected secondary school pupils work experience during the school holidays.

“We have had some great students who have worked for us through the school holidays. One has decided to study Electrical Engineering at Canterbury University and every holiday he comes back to work for us. Having enthusiastic hard working young people work for us is of great benefit because older staff are keen to pass knowledge on, and simple projects that usually sit on the backburner are worked on by these people who are exposed to an industry they might want to consider in the future.”

Hutt based opportunities

Pertronic have been based in Lower Hutt for 30 years and have made four major expansions over that time, including a $5 million building extension just before Covid lockdown.

David says the Hutt has been an ideal location to run a manufacturing business.

-Rebecca Reed

“Lower Hutt is a great place to run a business, there is a lot of manufacturing history out here and a good workforce. There’s also a lot of growth in the region and it’s an attractive place to work and live. Accessibility is excellent with proximity to the ports, airport, and transport links. Collaboration in the Hutt Valley manufacturing community is also strong with many beneficial relationships.”

David is also positive when it comes to the support they receive from local agencies such as the Hutt Valley Chamber of Commerce.

“Patrick McKibbin and the Chamber have been really supportive when it comes to manufacturing in our region. They acknowledge the important role we play economically.”

He says one of the things we can do better as a country is to empower and support the manufacturing sector which will in turn generate the income required to transform this economy and lead the world to a social and sustainable future.

“We don’t want New Zealand to decline into becoming a low skilled country. We need to remain at the forefront and be competitive against imported products so that’s why high-tech manufacturing needs to be taken seriously and be at the front of the government’s thinking. Support, especially when it comes to R&D, is vital because if we don’t do this then we can’t develop enough innovative products to stay ahead of our international competitors.”

Patrick McKibbin, CEO of the Hutt Valley Chamber of Commerce agrees.

“Manufacturing and technology in the Hutt Valley are pivotal to the Hutt Valley and the Wellington region’s future, providing high paid employment, generating revenue, and stimulating economic growth. In fact, the manufacturing and technology sectors in the Hutt Valley contribute in excess of $1 billion of GDP to the country’s economy. We need to support and champion these sectors because the Hutt Valley is a major centre of manufacturing, technology of innovation excellence.”

Patrick says the region is home to several research and development centres and innovation hubs that support the development of new products, processes, and technologies.

“We have a responsibility to support the sector because they are pivotal to our economy and our future, they are important employers in our communities, and they need our support.”

High tech manufacturing companies like Pertronic Industries are doing Hutt Valley and NZ Inc proud and the future is looking incredibly bright for a business that was started by one passionate electrical engineer 40 years ago.

13 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023 Lead (continued)

The leading supplier of high quality components and products to industrial markets

Treotham Automation is the exclusive distributor for many world class international product lines. As a leader in automation control, Treotham have a broad capacity to provide systems and custom-built solutions using a diverse range of products and components. Contact our technical engineers for more information.

text title NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 14

Auckland & Hamilton | 0800 847 200 | www.treotham.co.nz | info@treotham.co.nz CHECK OUT OUR NEW WEBSITE www.treotham.co.nz

Cables Measuring Systems

Conduits Chainflex Cables Energy Chains

Accessories

boxes Bearings

Units

Connectors Safety Products

Flexible

Flexible

Cable

Gear

Linear

Sensors

We need to secure our economic future

Michael Baines, Executive Officer, Vocational Engineering Education New Zealand (VEE NZ)

We currently need to repair, replace and future-proof our infrastructure. Civil, Mechanical and Electrical engineering needs to be undertaken right across New Zealand, but the issues we have sustained with climate damage, nationally, in the last 18 months, has focused our attention on skills we are sorely lacking.

In 2010 the National Engineering Education Programme (NEEP) identified that we needed, then, between 2,000 to 2750 level 6, 7 and 8 graduates to keep the “status quo”. It also identified that our percentage of engineering graduates was 50% of the average of all other OECD countries.

In 2016 we had 1818 graduates, at all levels, and that included foreign students! That was then and this is now. Post covid we have seen a dramatic fall in enrolments and graduates; we don’t have the skill base to even make a dent in the issues we face. NEEP also stated we needed a ratio of about 4.5 technicians and technologists to every graduate; in

2016 we achieved .541 to every graduate. If we don’t start to treat this as a strategic issue requiring a long term cohesive plan, we won’t be able to deal with our current issues, let alone achieve our economic goals.

We can no longer rely on immigration to fill the void; we need to have our own programmes to fill our needs. We have in the New Zealand Diploma of Engineering (NZDE) and Bachelor of Engineering Technology (BengTech) an integrated set of qualifications taught collaboratively across New Zealand.

These courses are administered by a group consisting of an equal partnership of industry and providers. They ensure that the content is current and required, can be collaboratively and effectively taught to meet the economic needs of the New Zealand.

Definitions

An engineering technologist, or technologist, is a professional who physically builds what an engineer

designs. They use parts and products to construct, maintain and repair systems and equipment an engineer develops. Some technologists also help implement existing technology to solve a problem. An engineering technician is primarily trained in the skills and techniques related to a specific branch of engineering, with a practical understanding of the relevant engineering concepts.

Engineering technicians often assist engineers and technologists in projects relating to research and development or focus on post-development activities like implementation or operation.

Greater exchange of information and collaboration needed to tackle current manufacturing challenges

A greater exchange of information and collaboration is needed to tackle current global challenges in manufacturing, such as the increase of information density in products and the increasing interconnectedness of the manufacturing process, according to research from Vlerick Business School, Georgetown University and Singapore Management University.

The researchers state that these two challenges raise a number of key questions for manufacturers, who are searching for answers on how to deal with them. Standard manufacturing strategies are no longer enough to overcome these challenges, say the researchers, who have also highlighted five capabilities that are needed if manufacturers are to respond to these challenges in their factories. This research was conducted by Ann Vereecke, Professor of Operations Management at Vlerick Business School, Professor Kasra Ferdows, Georgetown University, USA and Professor Arnoud De Meyer, Singapore Management University, who wanted to understand the key challenges currently facing manufacturers, and how they can be overcome.

To do so they created a framework based on the implications of these two recent trends. By using this framework, the researchers were able to identify specific approaches for manufacturers to overcome these key challenges.

The five capabilities that companies can utilise for manufacturing to give them a competitive edge are:

Expanding your view

Companies need to look beyond the traditional walls of manufacturing and integrate better into their immediate surroundings, connecting to larger numbers of their stakeholders to reduce potential adverse environmental, social, and regulatory effects.

Final assembly plants may also need to be located close to consumption to be in sync with the customers and to enhance responsiveness and reduce transportation.

Utilising new technologies

Companies need to deploy new processes and technologies as quickly as possible if they are to get one step ahead. In order to implement these seamlessly and efficiently, companies need to be more open than usual to internal or external partners.

Selling solutions not products

There needs to be a greater focus on developing new capabilities to support, help, or even lead the shift from providing mere “products” to providing “solutions”. Many customers are shifting from buying the product to buying the experience of using the product.

Leveraging intracompany networks

Organisations must leverage their own global manufacturing network to mitigate adverse effects of disruptions. A network of factories can cope with sudden changes in demands, disruptions in supplies, and other unforeseen events much better than the same set of factories when they are run independently.

It also offers more opportunities for learning and knowledge transfer.

Building effective ecosystems

Companies must look to work effectively in intercompany networks and ecosystems. A shift to solutions, not products, demands more collaborations with the ecosystem partners, not only in the daily operations but also when innovating and creating new value for the customer.

However, the researchers say that it is not possible to excel in all five of these capabilities. Focusing on a small number of them is enough to create a competitive advantage in comparison to companies who are simply using more traditional methods of boosting production.

Professor Ann Vereecke says, “While manufacturers cannot ignore development

of any of these capabilities, trying to excel in all of them would spread their resources and attention too thinly, reducing their chances of developing distinctive superiority in any one of them. While some of these capabilities partly support and reinforce each other, a company benefits from clarifying which of these capabilities must be developed or deepened further to turn its manufacturing into a competitive weapon.”

The researchers say that these findings have important implications for manufacturing executives, who can no longer have an purely internal view when it comes to manufacturing. These managers need to hone their skills in understanding what consumers want, and communicate this with senior management.

They also need to improve their knowledge of technology and how to utilise the abundance of data available to them, if they want to become the leader of the pack, and not just part of the peloton.

15 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023 Comment

They also need to improve their knowledge of technology and how to utilise the abundance of data available to them.

DO YOU HAVE A DIGITAL TWIN?

There is no doubt that the manufacturing industry is seeing the biggest change in how goods are produced in decades, and it is all driven by data, or the access, storage, and analysis capabilities we now have to make use of this data, coupled with the ability to interconnect everything in the manufacturing process.

Enabling technologies of Industry 4, such as IIoT edge gateways, advanced analytical software, or scalable control platforms, are all contributing to this change and to the creation of what has been coined the Digital Twin of a physical process or asset. This enables visibility into all stages of

production, quickly contextualize process and quality data, improve batch consistency and identify deviations, collaborate to create and share process knowledge. Does your manufacturing process have a Digital Twin yet?

NZ controls, a leading industrial automation solution provider believes that the best approach is to consider the industry 4 technologies as a set of tools and concepts to enable faster insights that drive asset availability, consistent product quality, higher yields, increased water and energy efficiency, and cost containment.

“We want to add value. It’s our responsibility to be informed and

ready to help guide our customers into the world of Industry 4. We work hard to battle the hype and drill down into real and practical applications with measurable returns,” says NZ Controls director, Nikk King. NZ Controls operations manager, Dave Lee says: “Controlling and monitoring of processes and operation is key to a secure and sustainable manufacturing business. Automation of processes is vital and can result in significant direct cost reductions but also importantly ensure repeatable and high-quality products are produced.”

These automation solutions rely on

the data that can now be utilized from industry 4 technology.

Before you create a digital twin for assets or processes, first you need a digital twin automation partner for your business.

King says: “From NZ Controls perspective we must provide measurable value. We seek to collaborate on developing a measurable business case, delivering industry 4 technology solutions, and becoming the digital twin automation partner to our customers on their journey to a digitalised future. Return on investment is key and can be achieved quicker than ever before.”

- Peter Drucker

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 16 FTR845 Drive productivity with data

Measure to gain control • Repeatable production • Traceability • Track costs and outcomes • Manage efficiency • Drive continuous improvement

“You

can’t

manage what you don’t measure”

PROCESSING

In Praise of William White (1824–1899), Provincial Pioneer

Dr Matthew Birchall, Research Fellow, NZ Initiative

But it was not always so difficult.

The story of William White of Kaiapoi shows what can be accomplished when Kiwis are able to simply get to work and build.

Even though he did not have a background in engineering, White took the initiative and erected the first bridge across the Waimakariri River. That is quite an achievement for a humble hotel owner in 19th century North Canterbury.

While you would not want the local manager of Quest to design you a bridge today, there is something appealing about a good project being able to progress without being bogged down by excessive rules and regulations.

And here is the kicker.

White personally paid for the construction of the bridge. As compensation, he was given permission to collect a toll fee for seven years.

If he failed to deliver, the people of Kaiapoi would not have been any worse off. But if he pulled through, everyone stood to gain.

As it transpired, the bridge was a rip-roaring success. He certainly did not mess around.

White signed a contract with the provincial government in August 1862 and completed the

project the following year.

Financial incentives have a way of concentrating the mind.

If nothing else, today’s planners could learn a thing or two from White about shepherding a project through to completion in a timely fashion.

Locals were enthralled. Before this, the only way to cross the great rivers of Canterbury was by ferry or by fording, which sometimes resulted in the tragic loss of life.

White’s timber construction was also a fillip to growth in a region that lacked basic transport infrastructure.

The bridge enabled local industry to thrive, such as the valuable timber trade. People and goods could now move efficiently between different parts of the town.

And it helped with flooding, too.

When the water level was high, the bridge could be raised to prevent water from flowing over it and into the town.

Despite his obscurity, White serves as a shining example of the determination and drive to create a brighter future. His bridge across the Waimakariri is an example we would do well to take inspiration from.

HRS Heat Exchangers operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide, focusing on managing energy efficiently

17 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023 Comment

Getting things done in New Zealand can be a challenge. Even a simple deck extension can prove a hurdle.

Food Environmental Industrial Pharmaceutical Heating Cooling Evaporation Crystallisation HRS Heat Exchangers info@anz.hrs-he.com | AU +61 3 9489 1866 | NZ +64 9 889 6045 www.hrs-heatexchangers.com/anz MANAGING ENERGY

EFFICIENTLY

If nothing else, today’s planners could learn a thing or two from White about shepherding a project through to completion in a timely fashion

Regulated stewardship coming soon for synthetic refrigerant industry

By Jason Richards – National Programme Manager -

Synthetic greenhouse gases, such as synthetic refrigerants (sometimes called F-gases), are used in everything from vehicle air conditioning to heat pumps, supermarket and corner store fridges, and industrial-scale cooling and freezing.

While they only account for 2% of New Zealand’s emissions their potency means, globally, properly managing them is one of the most effective ways to tackle climate change.

In July 2020 Government declared synthetic refrigerant gases, and the equipment that contains them, from consumer equipment like heat pumps and car air conditioning units to retail and industrial refrigeration systems, as a priority product. This means a regulated product stewardship scheme will have to be established, encompassing all of industry to manage the gases.

Product stewardship manages the collection of products at the end of life so they can be reused, recycled or properly disposed of. In the case of synthetic refrigerants, proper disposal through high-heat incineration is currently the best pathway.

SF6 is included

Also included in the stewardship will be SF6 (sulphur hexafluoride) gas, which is found in equipment used to distribute electricity. It is the most potent greenhouse gas known to man, being over 20,000 time more effective than carbon dioxide at trapping heat.

What is the current situation?

New Zealand has had a voluntary stewardship scheme for synthetic refrigerants since 1993 operated by The Trust for the Destruction of Synthetic Refrigerants (RECOVERY). Between then and October 2022 it has prevented 1,236,000 tonnes of CO2eq greenhouse gas emissions, in addition to 36,000 tonnes of avoided ozone depletion to our atmosphere.

Following a scheme design phase, which was facilitated by 3R Group, the Trust has applied to Government to be the product stewardship organisation (PSO) for a regulated stewardship scheme.

RECOVERY, now known as Cool-Safe continues to be managed by the Trust and operates the country’s only voluntary scheme for synthetic refrigerants. It works with industry to collect and properly destroy the gases, as well as works with industry to promote installation, maintenance and decommissioning aligned to industry best practice to avoid leaks.

The Trust and Cool-Safe’s Chief Executive Janine Brinsdon says they’re on a mission to inspire,

support and reward the refrigerants industry for protecting the atmosphere from the harm of released refrigerants:

“Refrigerants play a really important role in our day-to-day lives, along with making a huge contribution to our economy both directly and indirectly.

Our first priority is to make sure we are all doing all we can to protect the environment from the synthetic refrigerant harm, while also recognising the innovation and new technology industry has already adopted with the switch to lower GWP refrigerant, and rewarding those organisations and technicians who are doing the right thing.

It’s a win-win for both the environment and the valuable role refrigerants play in our communities.”

In October 2022 Cool-Safe launched a Buy-Back Programme for synthetic refrigerants and is developing and streamlining the recovery process for technicians across our network of collection sites. The Trust is also in the process of leading the development of a multi-million-dollar, state-of-art destruction facility in the Bay of Plenty, so the gases can be dealt with onshore. This facility will use plasma arc technology to break the gases down on a molecular level. Any toxins are neutralised and the resulting by-product can be safely disposed of in landfill.

The facility, which should be operational by 2024, is key to creating an onshore solution and will mean collected gases don’t need to be shipped overseas to be destroyed – lowering the scheme’s operating emissions.

Why regulated stewardship?

While voluntary product stewardship has been effective at keeping some synthetic refrigerants from the atmosphere it’s limited by data, resources and free riders who don’t contribute but whose products are still stewarded.

Regulated stewardship creates a level playing field, the scheme is better resourced, and data is greatly improved. Well designed and run regulated schemes are almost always more effective.

Will this affect me?

If your business or organisation uses refrigeration, imports the gases, or imports or manufactures the equipment they go in, then you will be affected. Regulated stewardship requires everyone from importers to retailers to be part of the scheme and contribute to the collection and safe destruction of the synthetic refrigerants.

Users of the gases and equipment will

need to make sure they are dealing with registered scheme participants or certified technicians. The scheme will also be heavily focused on ensuring industry best practice is followed when installing, maintaining, and decommissioning machinery which uses synthetic refrigerants.

Cool-Safe will award accreditation to those handling synthetic refrigerants who can demonstrate they are compliant with best practice.

Refrigerant technicians will also be able to apply for Cool-Safe certification after completing industry-recognised training and quality-control assessments. The overall aim is to create a consistent and high standard which will keep refrigerants from leaking and adding to climate change.

When will this happen?

According to Cool-Safe it expects that by 2024 the recovery and disposal of synthetic refrigerants will be controlled, with a government-accredited, regulated scheme in place. This regulated scheme will be run by a PSO for the priority product, which the Trust for the Destruction of Synthetic Refrigerants is currently working to become.

If you are in doubt about how you fit into this picture, I encourage you to visit the Cool-Safe website and make contact. www.coolsafe.org.nz

3R accelerate the circular economy through the design, implementation and management of product stewardship schemes and other sustainability services. They facilitated the design of the scheme for synthetic refrigerants and supported RECOVERY in their accreditation application. Find out more at www.3r.co.nz

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 18

Circular Economy

Chemicals, 3R Group

In the race to combat climate change a lot of emphasis is put on CO2, and with good reason, but there is another widely used group of gases which are thousands of times more potent at warming the planet.

Jason Richards is the National Programme Manager ChemCollect at 3R Group

Article: Part one

Circular economy: so much more than recycling!

Dr Barbara Nebel, CEO thinkstep-anz

The circle has been an important symbol since early times. To many ancient Eastern and Western civilisations, it represented unity, balance and stability. Fast forward to 2023 and the circle is the most talked about shape in sustainability. Why? Because it’s time to get serious about the circular economy and the business, environmental and social benefits it offers.

What is ‘circular economy’?

Circular economy (CE) is an economic system that can help your manufacturing business reduce risks and costs, become more resilient and build your brand. It can also help you identify new income streams.

CE decouples using resources from economic growth. It recognises that the ‘linear’ economic system we use to produce and consume goods and services –‘take-make-dispose’ – cannot go on forever.

As manufacturers, you know that the resources you use are finite (‘take’). You may be facing shortages or skyrocketing prices, particularly with critical materials like lithium. Many of you will be looking for a more sustainable way to manufacture your product (‘make’). You may be concerned about what happens when consumers dispose of your product (‘dispose’). Are you contributing to landfilled waste?

Could you be liable?

Enter circular economy and solutions to these problems.

Circular economy is based on three principles

Principle 1: keep products and materials in use

Circulating products and materials means keeping them in use at their highest value. It avoids the costs of extracting and creating materials, and of disposing of waste.

A circular product is one that consumers can use for as long as possible (e.g. it is easy to repair). When the product wears out, its parts can be reused, or the product remanufactured (remade). At the end of the product’s life, its raw materials can be fully recycled.

Principle 2: design out waste and pollution

CE sees waste as a design flaw that causes us to use more resources than we need. Overusing resources results in volatile prices, shortages, and ecological damage. By designing out waste, CE lets businesses create value without using up finite resources.

Principle 3: regenerate natural systems

A circular economy supports natural processes and lets nature flourish. CE encourages regenerative systems as well as economic gains. Positive side effects include regenerating soil, well-managed water resources and thriving biodiversity.

Circular manufacturing processes (and why recycling is the last resort)

There are several circular manufacturing processes. They involve making products from material that is safe, renewable, and already in use, and designing

them to be shared, repaired, reused, and recycled. Every circular manufacturing process achieves one or more of the three principles above. However, some are more circular than others.

Highly circular: sharing products, ‘building to last’, reusing products

• Sharing. The ‘sharing economy’ (one product, many users) is ‘gold star’ CE. It moves economies from ‘owning’ products to ‘accessing’ the services those products provide. For a business, sharing achieves the same economic outcomes with fewer resources and generates many streams of income. Examples include car-sharing schemes.

• Building to last and repairing. Blunt™ Umbrellas designs its product to withstand extreme weather. The company offers replacement parts for simple fixes plus repair centres across New Zealand. This strategy helps Blunt build a premium product and continue to engage with its customers over time.

• Reusing. Medsalv collects medical devices that health providers would otherwise discard after one use. It cleans, inspects, and repackages them and sells them back to hospitals. This strategy helps Medsalv reduce the cost of its materials and keeps high-value materials in use. (In practice, reuse involves some ‘losses’ from the circular system. For example, some medical devices will be damaged before Medsalv can reuse them. This makes ‘reusing’ a little less circular than ‘building to last’.)

Moderately circular: remanufacturing products and materials

• Remanufacturing. AB Industries remanufactures, repairs, and maintains mechanical equipment like

diesel engines and compressors. This strategy helps the company keep high-value components in use without incurring the full costs of manufacturing.

Slightly circular: recycling products and materials

Yes, recycling features low on the list. This is because a recycled product is much less valuable than the original product. The value of intangible assets like a product’s branding and warranties is often far greater than the value recovered from recycling materials. (Think of the effort that goes into building your product’s brand!) Remanufacture your product and you retain much of this value.

Recycling begins at a product’s end-of-life. CE focuses on the beginning of life: it prevents waste from being created in the first place. About 80% of the environmental impact of a product is locked in when it is designed. Creating circular products involves changing the way we choose materials and design, produce, and distribute products.

Recycling still matters: it lets us reuse materials. Product stewardship goes further: it makes manufacturers, importers, and retailers responsible for what happens with products, rather than the products’ users. Tyrewise is New Zealand’s first regulated product stewardship scheme for recycling tyres. It will keep used tyres away from landfill and reduce stockpiling and illegal dumping. In next month’s issue, we’ll look more closely at the business benefits of CE and show you how to get started.

www.thinkstep-anz.com

19 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023

Circular Economy

Many valuable materials inside batteries can be reused. Photo credit: Journey by Story.

Women in STEM

Girls in STEM is a Trans-Tasman initiative.

“With ‘Women in STEM’ programs under review for most of this year, we currently don’t anticipate any new funding commitments until 2024. The government’s third year in office is far too late to wait, we need action now,” said Girl Geek Academy co-founder, Sarah Moran.

“While we are supportive of the review of ‘Women in STEM’ programs and hope it eventuates in more funding made available in the long term, we cannot ignore the short term fact that women and girls are falling behind.

Ahead of the UN International Day of Women and Girls in Science (11 February), the United Nations highlights in cutting edge fields such as artificial intelligence, only one in five professionals (22%) is a woman.

Girl Geek Academy trained over 1000 high school girls in A.I. in virtual classes without government support and had been hopeful that a change of government would bring about fresh funding to support the growth of similar programs.

“There has been a drought of these type of programs as most organisations, typically run by women, have not survived the impacts of the pandemic. Girl Geek Academy lost 99.9% of our cash flow overnight when COVID hit and the only reason we still exist is because I went and got a day job to keep us alive.

“The government must act as we know women and

STEM.

girls have already slipped too far behind. We’re calling for a solid investment in programs for the May budget to secure much needed support for women in industry to “lift as we climb” - we desperately need to bring young girls through the pipeline.

The Australian October 2022 budget committed $5.8 million over five years towards the Women in STEM and Entrepreneurship program. But on the flip side, $3.9 million over two years was removed from the Supporting Women’s Mid-Career Transition into the Tech Workforce component of the 2022–23 March Budget measure titled Digital Economy Strategy.

“We are looking at industry shortages across the board in tech, A.I. and cybersecurity, we have to invest in one of our most underutilised resources: women and girls.”

According to the United Nations, despite a shortage of skills in most of the technological fields driving the Fourth Industrial Revolution, women still account for only 28% of engineering graduates and 40% of graduates in computer science and informatics.

“Girl Geek Academy were successful recipients of the inaugural Women in STEM and Entrepreneurship grants in 2016. We used this funding to build the successful #MissMakesCode program and teaching 1000 teachers to teach coding in the classroom. Over the past 7 years, there have only been four rounds of this funding deployed. That’s simply not enough.

In less than one month, businesses will be gathering

around Australia to discuss action for International Women’s Day on March 8.

IWD 2023 Theme: “Cracking the Code: Innovation for a gender equal future”

Based on the priority theme for the United Nations 67th Commission on the Status of Women – Cracking the Code highlights the role that bold, transformative ideas, inclusive technologies, and accessible education can play in combatting discrimination and the marginalisation of women globally.

“We need more than words and cupcakes this year, we need the government to have our back so we can all ‘Crack The Code’ on gender equality together.”

Sarah Moran will be giving the keynote at the Brisbane UN Women International Women’s Day event where she plans to discuss these issues further. ✨ Girl Geek Academy ✨ is a movement to bring one million women and girls into technology careers by 2030.

Established in 2014, Girl Geek Academy has worked with more than 1000 teachers in delivering the National Digital Technologies Curriculum, ran the world’s first hackathon for women, hosted a games career incubator for women in games, built a community of more than 2000 high school girls learning A.I. and has sold over 30,000 copies of “Girl Geeks” - a series of middle-grade fiction books with Penguin Random House about girls exploring the world of STEM.

NZ Manufacturer March 2023 / www.nzmanufacturer.co.nz 20

The Australian federal Minister for Industry and Science, Ed Husic says the “Pathway to Diversity in STEM Review” won’t be complete until the end of this year and Girl Geek Academy says that is too long to wait for funding new programs to increase the number of women and girls in

STEM

The Interview

Doppelmayr sustainable transport solutions across New Zealand

Garreth Hayman, CEO Doppelmayr New Zealand

To meet our 2030 and 2050 climate targets, Aotearoa must think differently about how to move its growing population.

Doppelmayr’s urban ropeway technology offers innovative, affordable and sustainable solutions that can keep our cities moving. With the ability to transport 12,000 people per hour, ropeways enhance a city’s liveability, connect harder to reach communities, integrate with existing transport infrastructure, relieve congestion and attract more people to use public transport.

Do you have examples as to where your company has done this before?

Doppelmayr has designed and delivered several public transport systems using ropeway technology, including in London, Mexico City, Luxemburg and Portland. We are currently underway with the first-ever public transit gondola for Paris which will be completed in 2025.

Our largest urban ropeway ‘Mi Teleférico’ in La Paz, Bolivia, consists of ten lines with an overall length of more than 30 kilometres. Mi Teleférico transports about 300,000 people every day as a means for getting to work and school, whilst providing access to community hubs and leisure-time activities. With more than 300 million passengers transported to date, commuters continue to benefit from significant time savings and escape from daily road congestion. What do you mean by an integrated transport solution?

Doppelmayr’s urban ropeway solutions can be

integrated into existing and future transport networks, to complement train, bus and ferry services. This includes integrated stations for easy transfers between modes and the integration with existing payment methods, such as Auckland Transport’s HOP system or the new National ticketing system. Do you see this integration across large cities or rurally?

Most of our existing urban ropeway solutions have focused on connecting cities where high density and geographical barriers have prevented other transport expansion to take place. However, this doesn’t mean that integration isn’t possible in rural communities.

With the rise of new housing developments on the fringe of New Zealand cities – T maki Makaurau Auckland in particular – we believe there is an opportunity to provide links between rural communities with their connecting cities. This is something Doppelmayr is actively pursuing.

How will this assist in emission reduction?

Over 40 per cent of Auckland’s emissions are from transport. Ropeway systems could drastically reduce this, generating less than a quarter of the greenhouse gases compared to other transport options. If used with renewable energies, ropeway operations can even be entirely carbon neutral.

How are you finding current business conditions?

Like most businesses, we have experienced the impact of rapidly rising costs over the last year and

ongoing labour constraints. It’s heartening to see confidence returning to the tourism industry, which we anticipate will rebound to full strength again in the next two years. Doppelmayr will continue to support our customers over this period and ensure we have capacity to respond once they are ready to make investments.

Staff retention – difficult?

We are lucky to have a dedicated core team in New Zealand, our focus is to ensure we can retain them and provide opportunities for the future.

How hard is it to find the right staff?

While we are fortunate to attract interest from people in our industry, it can be difficult to find people with all the skills and qualifications we are looking for. We are working with key industry members to develop a qualification that will upskill and attract new people to our workforce.

Areas of growth for your company?

As mentioned above, we see public transport as a key area of growth for Doppelmayr in New Zealand. Our vision is to support the country’s sustainability targets, whilst offering affordability, liveability and creating sustained employment opportunities.

The role of ERP in ESG performance reporting

Jaco Maritz, Chief Executive Officer, SYSPRO

In a manufacturing business, measuring ESG standards comes down to tracking internal and external Environmental, Social and Corporate Governance standards.

ESG has become a determining factor in access to capital and in the decisions made by consumers and B2B customers.

So, it’s not surprising that leaders are taking ESG seriously. EY’s 2022 CEO Outlook indicates that 97 per cent of CEOs say their company has a sustainability strategy. What’s more, 28 per cent believe they will gain valuable competitive advantage by becoming leaders in sustainability.

However, before CIOs, CFOs and boards consider technology investment, they should be fully aware of the growing role of ESG in reporting and in boosting corporate performance. As corporate strategy rapidly incorporates ESG, digital strategies must align accordingly.

For example, a manufacturing company may commit to improvements in water usage in production processes, carbon emissions, the proportion of its products that are recyclable, and wages and working conditions of employees and contractors.

Without a technology strategy that supports the collection of high-quality data along the entire value chain, companies will not be able to report data or demonstrate progress against these commitments.

ESG in the supply chain

Supply chain sustainability shifts the focus from short-term financial considerations to long-term value creation as well as managing the ESG performance of suppliers.

By taking these factors into account, sustainable supply chain management not only benefits the environment but also reduces risks, mitigates impacts and realises reputational and financial benefits such as cost savings, brand goodwill and customer loyalty. Companies with strong ESG performance typically have robust governance frameworks, manage social and environmental risks well and have stronger relationships with suppliers.

Prioritising supply chain sustainability can reduce general risks for corporations, including minimising operational disruptions caused by environmental and regulatory risks as well as reducing reputational risks posed by labour issues.

Weak ESG performance, on the other hand, can translate into a financial or environmental cost, harmful social or reputational exposure and financial damage to the bottom line and, ultimately, the shareholders.

Getting to grips with ESG reporting

The time and effort needed to produce an annual sustainability report have increased dramatically. Internal and external demands for ESG data continue to rise, compelling companies to do more than put a spreadsheet together once a year.

Instead, they need to embark on a journey that will involve evaluating the data needed to track ESG performance, identifying how and where to source it from, understanding local and global compliance requirements and implementing systems to enable existing, amended and new processes.

The role of ERP in ESG reporting ERP has a critical role to play. Without a centralised ERP system, compliance and visibility can be manual, tedious and costly, even resulting in penalties. Supply chain visibility has many advantages for today’s global and agile businesses. It allows them to reduce complexity, improve communication throughout the organisation, stay nimble and keep up with a complex regulatory landscape regarding ethically and sustainably sourced goods.

By providing organisations with visibility into relevant data across the business, ERP enables the insights required to comply with regulations, meet stakeholder and customer expectations, cut costs, optimise processes and improve overall efficiencies to meet ESG standards.

21 www.nzmanufacturer.co.nz / NZ Manufacturer March 2023

Workshop Tools

Cost effective automation

Low Cost Automation reduces the barriers to getting started with automation and gives special assistance to small and medium-sized companies in increasing their competitiveness. To this end, motion plastics specialist igus has built up a broad network of 55 robotics providers and 40 integrators over the past three years - and new partners are constantly being added.

As a result of continuous developments and product innovations, affordable robotics has become especially interesting for small and medium-sized companies. And the number of offers on the market is increasing. For instance, igus Low Cost Automation represents a broad portfolio of articulated arm, linear, delta and SCARA robots.

Product modularity means that single components or individual complete solutions can be assembled according to the build-or-buy principle. The focus is always on a low entry-level price and quick payback. This is where igus high-performance plastics play to their strengths.

They are tribologically optimised and especially durable, lightweight, lubrication-free and maintenance-free, and cost-effective to produce.

The most cost-effective solution that works