Leading UK materials handling supplier Impact is stepping up its support for warehouse operations, thanks to nonstop product development at Cat® Lift Trucks.

“The rate at which new Cat® products, innovations and upgrades are being introduced is outstanding,” says Steve Shakespeare Impact Handling’s CEO. “We are now better placed than ever to meet every need with our comprehensive Cat warehouse equipment range. What’s more, each truck comes with all the advanced technology, quality, and dependability our customers have come to expect from Cat forklifts.”

One of many technological breakthroughs in the last two years is ProRide+, as seen on Cat NPV/NPF platform power pallets. This system solves the age-old problem of how to combine effective traction, damping and stability.

Its uniquely designed floating drive unit works with extra friction force from the hydraulic system. By maximising drive wheel pressure and traction, it prevents wheelspin on slippery surfaces and optimises braking performance.

The ProRide+ system also features a unique castor wheel design. It uses variable damping to minimise shocks and vibration, however rough the floor or ground. Meanwhile, the castor wheel’s locking function maintains strong stability when cornering, with or without a load.

Another industry first on these trucks is the option of electrically adjustable damping on fixed platform versions. At the touch of a button, its setting can be adapted to each operator’s weight and preference.

As well as improving the ergonomics, performance, productivity and costeffectiveness of their products, Cat warehouse truck designers have expanded customer choice. For example, there are now 26 reach truck models to choose from, including light, standard, high-performance, four-way and multiway ranges. The ideal model can then be matched perfectly to specific applications through programming and a wide selection of options.

For the highly specialised world of VNA (very narrow aisle) warehousing, two

new product categories have extended the Cat portfolio. One is a man-down VNA truck range, combining in-aisle storage-maximising efficiency with out-of-aisle mobility. It can be used to transport goods to and from the racking, as well as stacking and retrieving within it. This means there is no need for feeder trucks or P&D (pick-up and deposit) stations at aisle ends.

More specialised still is the Cat man-up turret truck range, designed for ultraefficient stacking and order picking in high VNA racking. Each truck is custombuilt, following a detailed site and operation study by a VNA consultant, to fit its application precisely. Modular construction allows almost infinite variation in cabin size, design and furnishing, truck width, mast and fork specifications, and other equipment.

The Cat range covers all common conventional warehouse truck types, along with some more unusual choices. Impact urges customers to be openminded. “If you’re currently operating

pedestrian or platform trucks, for instance, take a look at our ‘stand-in’ concept,” says Steve. “This is an area in which the trucks’ designers have been building on their long-established world leadership.”

He continues: “Our stand-in stackers and stand-in pallet trucks allow you to make fuller use of your valuable warehouse space. They also speed up every process. Compared to platform models, they have a more compact footprint and are more manoeuvrable, so you can make your aisles narrower. The stackers also have superior lifting abilities, so you can increase your racking height and store heavier loads at each level.”

Steve concludes: “The latest developments have strengthened an already comprehensive Cat warehouse line-up – and there are many more to come. We will be very happy to find you the right solution and back it with firstclass, nationwide service and support.”

For further information, visit https://impact-handling.com/

The Cat range covers all common conventional warehouse truck types, along with some more unusual choices.

High-speed interior doors are an integral part of manufacturing environments. But as operations run faster and smarter, more is demanded of these doors – from efficiency and speed through to hygiene and safety.

Designed with the food and beverage sector in mind, the HS9120G and HS9120GHY from ASSA ABLOY Entrance Systems perfectly balance these requirements and equip manufacturers with the solutions they need to boost performance and protection.

By accelerating the flow of people and goods, the high-speed industrial doors can dramatically improve operational efficiency. Designed for fast-paced, high-cycle environments, the systems are highly durable, meeting the demands placed on them – even in round-the-clock manufacturing facilities. The addition of ASSA ABLOY’s new door curtain also helps to reduce noise levels and improve energy efficiency.

Expertly designed to enhance performance, the high-speed door systems contribute to reduced downtime in environments where every moment matters. Supporting this, ASSA ABLOY’s maintenance service ensures reliable service and longevity.

Where safety is concerned, high-speed doors from ASSA ABLOY come into their own. The inclusion of LED traffic lights, a safety light curtain, soft bottom profile and a break-away system make them the perfect solutions for busy environments. By effectively separating

areas, the doors can also help to maintain more comfortable climates, creating suitable manufacturing environments while enhancing the comfort and wellbeing of staff.

The HS9120GHY is designed specifically for applications with stringent hygiene demands – even those where humid and corrosive environments are commonplace. This protection is made possible with a stainless-steel side frame and toproll cover, together with a slanted

stainless-steel enclosure for the door’s control unit, preventing corrosion and contamination.

To meet the specific requirements of different manufacturers, each of ASSA ABLOY’s high-speed door systems can be customised, with 11 curtain colours and the option of a touchless opening system available.

To maximise performance and protection in your manufacturing environments, visit www.assaabloyentrance.com/uk

The new ASSA ABLOY HS9120GHY is designed to operate in humid and corrosive environments by meeting the most stringent hygiene demands possible. With its fast speeds, integrated safety features and range of customizable add-ons, you simply get a high-safety, high-efficiency, high-speed interior door you can always count on.

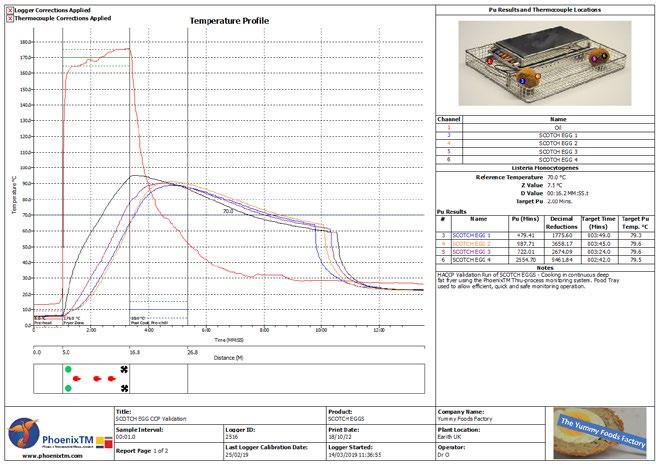

As part of any Food processors HACCP program, validation of cook and chill processes is a critical and significant task taking time, effort, and resources.

PhoenixTM have developed a thruprocess temperature monitoring technology specifically for this task designed to meet the numerous cook challenges of the food processing market. Ideal for the validation process for any new cook regime, new product, or annual process certification.

An important innovative system in the PhoenixTM range is that designed specifically to handle the challenging monitoring demands of continuous deep fat fryers. The monitoring system has been designed specifically to travel safely through the oil bath, navigating drops and inclines and provide protection from oil impregnation, heat of the oil and allow accurate and repeatable measurement of the food core being cooked.

At the heart of the system the data logger provides multiple thermocouples (choice of 6 or 10 channels). The PhoenixTM NT data logger range has been designed specifically for the challenges of monitoring food processing applications with an IP67 case design protecting from moisture/oil. Type K or Type T data logger options allow accurate measurement of both cook and chill processes (Type T measurement range -200 °C to 400 °C). The data logger itself can operate between -40 °C to 80 °C with a data logger accuracy of ±0.3 °C operating below +50 °C. Data logger and thermocouple correction factors can be further applied to the recorded data logger data to maximise measurement accuracy. The data logger is protected from submersion in oil by the TS14-0502 thermal barrier. The barrier is low height (50 mm) so fits safely through the low height clearance of the fryer line (Top / bottom belts) but provide

impressive protection of 25 mins @ 200 °C (Oil) or 50 mins (Air). The face plate design of the barrier allows easy access to the data logger and quick efficient exchange of thermocouple cables.

A critical component of the system is the unique food tray which not only contains the thermal barrier but allows fixed positioning of thermocouples within the product samples being measured. Probing of the product can be done away from the processing line with care and no need to rush.

Custom designed thermocouples allow accurate / repeatable measurement at the core (cold spot) of the product. The customized thermocouple positions are fixed so that probe or product movement during the run is minimized. Test conditions are maintained also from run to run across the fryer width.

Employing the tray principle, the whole monitoring system can be placed on the fryer line by a single operative safely and efficiently during a production run. Thermocouple cables are retained in the tray so tangling risks are eliminated. The unique saw tooth guide rails fitted to the tray allow efficient true transfer (no rotation) through the whole process. Both entrance decline and demanding exit incline can be negotiated without slipping/stalling which could leave the system stuck/stranded in process. The same system can further pass through any chill process to complete the monitoring task.

Employing the thru-process temperature monitoring principle provides the food technologist with a complete temperature profile of the cook process from start to finish. This information is like the Cook DNA giving full details of the product and or process temperature which is invaluable to allowing validation of the Cook CCP.

From a temperature profile it is possible to accurately quantify product safety (pasteurisation) knowing

both the temperature, and time at temperature, of the product.

From the profile graph you can see instantaneously the variation in product temperature at any point in the process either at different locations on the product or different product positions within the fryer.

The PhoenixTM Thermal View Food Software provides a comprehensive suite of analysis tools to convert the raw profile temperature data into useful process information. The analysis tools include the ability to calculate Fo/Pu values for the process against target micro-organisms.

For most typical cooks Listeria Monocytogenes is often used as the target micro-organism to quantify lethality. The Fo/Pu parameters

(Tref 70 °C, Dt 16.2 s and Z value 7.5 °C) can be input to calculate for each monitoring point the number of decimal reductions of the pathogen achieved during cook to meet CCP limits.

The information gathered, further to process validation, can be used to allow informed process problem solving and optimisation to maximise product quality, yield, process productivity and efficiency.

Contact PhoenixTM to help Find, Fix and Forget your Food Cook Problems!

Further Information www.phoenixtm.com

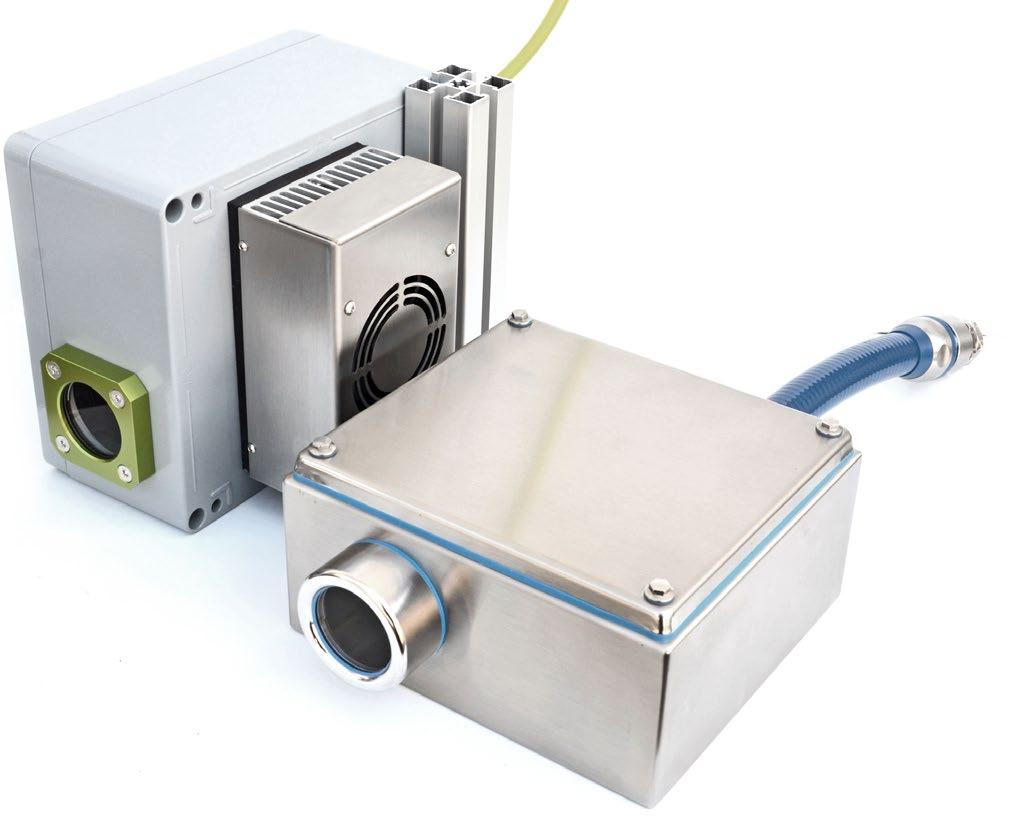

autoVimation supplies temperature-controlled and hygienic protective enclosures for Specim FX10 and FX17 hyperspectral cameras.

autoVimation expands its protective enclosure range for Specim FX10 and FX17 hyperspectral cameras by two new models. In addition to the standard enclosure for Specim cameras featuring protection class IP66/IP67, a stainlesssteel version in hygienic design and a temperature-controlled version are now also available.

Specim hyperspectral cameras are mainly used for foreign object detection, plastics sorting and drug concentration analysis in food and pharmaceutical processes. However, until now, no suitable, hygienically designed protective enclosures were available that could be safely installed above the production lines. autoVimation now closes this gap,

In addition to the standard enclosure for Specim cameras featuring protection class IP66/IP67, a stainless-steel version in hygienic design and a temperature-controlled version are now also available.

launching the new camera enclosures made of AISI 316L (V4A) stainless steel, which withstand wet cleaning with aggressive cleaning agents. Gap-

free enclosure surfaces and hygienic cable glands minimize the risk of contamination.

The second innovation for Specim cameras, thermoelectrically temperature-controlled protective enclosures allow cameras with a permissible temperature range of 5 °C to 40 °C to be used in ambient temperatures up to -20 °C to 70 °C. The system provides camera cooling by up to 25 K below the ambient temperature. The enclosures can also be used to stabilize camera temperatures to increase measuring accuracy in critical applications.

www.autovimation.com

Versatility, hygiene and precision are all key to food and drink production. The effective management of fluids is central to this, which is why a series of highly engineered stainless steel and transparent pressure vessels from UK manufacturer SR-TEK are taking the industry by storm. SR-TEK founder, Loris Medart, outlines the key challenges his firm is helping manufacturers and packaging producers overcome.

One of the biggest and most overlooked challenges with any form of fluid production, and particularly in the food and packaging industry, is process. When things aren’t going to plan, all too often, the focus is on a piece of equipment in isolation. Understanding the whole process and knowing how fluid is managed and stored on the production line will quickly pay dividends.

Three of the quickest inter-related wins are:

1. Size of the vessel – In the past it was typical to have large vat like vessels no

more technical than a paint pot. This approach is not only dated but highly wasteful. The majority of the vessels we supply to the food and packaging industry are sized from 0.5 to 2 litres, with the option for going as high as 25L in the steel ST Series and 5L in the transparent CT Series.

2. Top to bottom effect –The top to bottom effect explains why there is a reduction in the flow rate as fluid levels decrease and air levels increase. This becomes more pronounced the bigger the differential between a full and near empty vessel, meaning a tank sized to the production needs will ensure a more consistent result.

3. Production time – The nature of fluids is that they can change over time. We tend to recommend limiting fluid use in a pressure vessel to one or two productions cycles to reduce variation.

For certain fluids performance and quality will be influenced by movement. Fortunately, both the ST steel and CT transparent series can be designed with agitation. The right level of agitation or mixing ensures fluids aren’t damaged and helps with consistent delivery on the production line.

As an independent manufacturer we provide full traceability for all parts used in the production of our pressure vessels. Manufactured from 304 or 316 grade stainless steel, all SR-TEK vessels can be supplied with FDA approved wetted parts, including seals. For food and drink applications there is also the option of specifying a high-grade mirror finish to meet standards and requirements.

To find out more about SR-TEK steel ST-Series and transparent CTSeries pressure vessels visit: www. smartreservoirs.com. To download SRTEK’s free to access whitepaper on fluid management visit: www.bit.ly/fluidmanagement.

Pneumatic cylinders are an efficient, reliable and clean solution for moving loads in a linear direction (back and forth or up and down), with good levels of force and speed.

Cylinders are often the most important component of a linear motion system. If the cylinder fails, the linear motion system is unable to function. In a harsh environment where contaminants are heavily present, standard cylinders are going to fail all the more frequently, resulting in greater downtime. Cylinders can be contaminated internally from the air supply or externally from the operating environment.

Airborne particles in the form of dust and grit are the most obvious threat to cylinders. If this penetrates a nose seal, it builds up and sits in seals and bearings with a similar effect to sandpaper. In a normal environment, with regular preventative maintenance, standard cylinders can cope well with basic levels of dust, but where these contaminants are prevalent, such as flour mills, a more robust cylinder must be considered.

Water may not be deemed a contaminant in the usual sense, but when it comes to pneumatic cylinders it is very much a problem as where there is compressed air, there is water vapour. Furthermore, in the food industry where washdowns are conducted regularly and very thoroughly, the water collects within system components where it can block the flow of air through orifices, dilute or adulterate lubricants, corrode the barrel or rod finish and, of course, freeze in cold weather.

Water may not be deemed a contaminant in the usual sense, but when it comes to pneumatic cylinders it is very much a problem as where there is compressed air, there is water vapour.

Contamination from synthetic oils used to lubricate the air compressor can have a similar impact on cylinders to water. In harsh environments, greater quantities of lubricant are often used, which makes the contamination situation worst.

In applications where extreme heat is used, the piston rod and rod-seal are prone to damage.

So, these are the problems, but what are the solutions?

Selecting a cylinder for harsh applications

For harsh environments you will need to look to a more customised cylinder, but most of these are relatively straightforward and represent a good ROI.

Let’s start with the cylinder seals, these being one of the most important means of preventing the ingress of dirt and water. Standard seals can be replaced with specialist versions to meet the needs of your specific application. Viton™ - a fluoropolymer elastomer and synthetic rubber compound - seals, for example, have been designed for use in some of the harshest environments, where temperature extremes are common. These can readily be used in Matara’s standard rod type pneumatic cylinders and rodless pneumatic cylinders.

Moving further into the cylinder construction, with rod type pneumatic

cylinders a rod seal/wiper can be incorporated to both stop contaminants from entering the inner body of the cylinder, with the wiper removing larger particulates from the rod. For added protection the rod can be fitted with a rod bellow/gaiter which keeps contaminants away from piston rods.

For corrosive environments, including those where regular washdowns are conducted, the choice of rod material may need to be reconsidered. Standard rods are mostly manufactured from chrome, but swapping to stainlessexercised steel rods and fasteners, or even a stainless-steel rod, will provide extra protection against corrosion. This will impact the cost, usually by an additional 10% of the overall cost of the cylinder. For complete corrosive protection, Matara offers a range of 100% stainless steel pneumatic cylinders.

The other option is to stick with existing materials but use specialist coatings or epoxy paints. There are a good range of options here, including Armoloy TDC® coating, which we use on our linear rail and ballscrews for maximum longevity in demanding applications and locations. Armoloy TDC® is a hard (78Rc), thin, dense chromium coating with a micronodular surface texture which provides corrosion protection equal to 440 series stainless steel.

Having selected the right cylinder type for your environment, it’s important to

conduct basic preventative maintenance to a regular schedule. This should include the regular cleaning of external parts of the system so that visual inspection of seals and other parts is straightforward; inspection for wear and tear; draining of air line filters and checking that the water traps are operating as they should; lubrication of the cylinder, rod seal, piston seals

and surfaces; checking for air leaks and resealing where required; and last, but not least, replacement of air filters.

Harsh environments make for difficult operating conditions, but by selecting quality pneumatic cylinders customised to your specific site, you can costeffectively prolong the service life of a cylinder and reduce costly downtime.

Matara designs and manufactures pneumatic and linear automation products, which are available from stock or can be custom built to order.

www.matara.com sales@matarauk.co.uk

Cool a 250m2 area for the same cost as boiling a kettle

With the rapid increase of energy costs, businesses are looking at reducing their electricity usage while maintaining comfortable and compliant conditions within their facilities. EcoCooling offers a cost-effective cooling solution for food storage and processing facilities. With blanket or spot cooling options available, evaporative cooling offers a flexible approach to process or people cooling that can be easily retrofitted to the majority of buildings.

Evaporative cooling is extremely beneficial in a bakery environment. The humidity levels keep the bread fresh and don’t dry it out, unlike traditional air conditioning which is extremely dry and can often shorten the lifecycle of fresh produce, so it is highly effective for bakery cooling.

Premier foods were looking for a costeffective bakery cooling strategy for their Barnsley site. Evaporative cooling can guarantee cool supply air of below 25°C all year round in the UK, making it the perfect solution for those wanting to reduce temperatures in their bakeries. 12 down discharge EcoCoolers were supplied and fitted to 12 existing Air Handling Units (AHU’s) on the roof of Manor Bakeries, Barnsley to provide cooling for the bakery. The existing refrigeration based cooling system has been decommissioned and the packaging area is now solely cooled using the EcoCooling Evaporative cooling system.

Following commissioning the system was tested and monitored, the following performance figures were recorded for the facility:

EXTERNAL AMBIENT = 23°C (WARM SUNNY CLEAR DAY)

AIR

AIR VOLUME THROUGH COOLER = 4.47M3/S

PRESENT COOLING CAPACITY = 34KW PER COOLER

TOTAL SYSTEM CAPACITY = 12 COOLERS X 34KW = 408 KW

The Subway at the Beehive Shopping Centre in Cambridge was designated by the management as a test site to trial the provision of the most environmentally friendly retail site possible.

EcoCooling was invited to look at the cooling of the unit.

Subway stores bake bread three to four times each day so the EcoCooling system was designed to capture the surplus heat generated by both the ovens and the walk-in fridges to provide heating for the whole shop and not just specific hot spots. This was done by redirecting the hot air into the shop to provide heating in the winter months. Evaporative cooling is then used to cool the store during the summer when the hot air from the ovens is extracted to the outside of the building.

The Beehive site is now using 75% less power than the equivalent site and is being held up as a flagship example of green technology for the whole of the Subway chain. The Cambridge franchisee installed power usage monitors at both this site and a similar site.

OFF COOLER = 16.6°C

Please contact us on 01284 810586 / sales@ecocooling.co.uk or visit our web site: www.ecocooling.co.uk

The launch of a brand-new range of multihead weighers will form the centrepiece of the Ishida Europe stand at this year’s Gulfood Manufacturing exhibition in Dubai.

Full details will be released at the show, but Ishida says the new range, the company’s 11th generation multihead weigher, will deliver unsurpassed levels of speed and accuracy, particularly in the handling of more challenging products.

The stand will also highlight some of Ishida’s other latest developments in weighing, packing and quality control solutions. With global markets facing

challenges such as labour shortages and fast-rising raw material and energy prices, Ishida will demonstrate how its equipment can help packing lines become leaner and more efficient, increasing yields, throughput and energy-efficiency while meeting the strictest quality standards of the retail sector. These benefits will help manufacturers maximise opportunities and respond to the latest market trends in fast-moving and competitive food markets.

Highlights include the world’s first and only single-source fully integrated snacks packing system; an entry-level

Ishida IX-G2-F

multihead weigher, emphasising the breadth of Ishida’s offering in this sector; and two X-ray inspection systems from its extensive quality control solutions portfolio.

The Inspira iTPS combines the company’s top-of-the range RV multihead weigher with its high-performance Inspira rotary bagmaker. The system delivers almost zero giveaway and greater than 99% efficiency at speeds of up to 200 bags per minute (bpm) for extruded snacks and up to 150 bpm for potato chips. Advanced software and servo-controlled variable seal time, jaw temperature and jaw pressure enable the bagmaker to handle a variety of films, including standard, metallised, recyclable and biodegradable, as well as gusseted and block bottom bags, with minimal change parts.

The Inspira comes equipped with Ishida’s proven iTPS™ software which facilitates full integration with other Ishida weighing and inspection systems. It is being shown with an integrated Ishida TSC sealtester and force balance checkweigher to offer a high-speed solution for leak detection, fill level monitoring and pack weight control. In addition, the TSC sealtester is specified with AAF (Auto Air-Fill) feedback software that automatically monitors and adjusts the pack inflation level on the bagmaker.

Inspira rotary back of machine

Ishida’s CHW-214 multihead weigher offers an entry level option that is ideal for growing food businesses who are looking to expand their capacity and harness automation for the first time. It delivers excellent value and a fast return on investment, typically achieving payback within one year. The weigher can handle dry, free flowing products such as snacks, cereals, biscuits, confectionery and pasta, at speeds of up to 90 packs per minute.

The two advanced Ishida X-ray inspection systems offer food manufacturers powerful quality control and food safety solutions. The IX-G2-F Dual Energy can reliably detect low-density wish, rib and fan bones in unpacked chicken fillets at up to 400 per minute. The machine can also carry out detection in uneven and overlapping products, reducing product waste by minimising false detection.

The Ishida IX-GN-4044-S provides best-in-class foreign body detection and quality control for a wide range of packed and unpacked products, ensuring unrivalled food safety and brand protection. The machine can identify a large variety of foreign bodies such as aluminium, tin, glass, stone, hard rubber, dense plastic, Teflon, PVC, bones and shells at high inspection speeds, while Ishida’s Genetic Algorithm (GA) technology enables operators to optimise the X-ray system for greater sensitivity to specific foreign bodies.

Other quality control functions available on the machine include counting components, weight estimation, and spotting missing or broken items, product voids and deformations.

Both X-ray systems come with Ishida’s comprehensive service package, that delivers a guaranteed Total Cost of Ownership of less than 3% per annum over a five-year period.

www.ishidaeurope.com

The stand will also highlight some of Ishida’s other latest developments in weighing, packing and quality control solutions.Inspira ITPS with QC

From locally grown cocoa beans, Singapore-listed JB Cocoa manufactures and markets cocoa butter, cocoa powder and cocoa mass. Located 30 km from the port of Surabaya in the province of East Java, Indonesia, JB Cocoa’s facility can process 50,000 tonnes of cocoa beans annually.

The beans are cleaned, roasted and winnowed to separate the cocoa nibs, which are treated to enhance flavour and colour. The nibs are then ground into cocoa liquor, which is squeezed by a “butter press” to yield cocoa butter used in making chocolate, and crumbled cocoa “presscake” that is pulverised into cocoa powder.

A portion of the presscake is shipped directly to customers in 1 tonne bulk bags, but most is processed into cocoa powder and packaged in handheld sacks.

To increase efficiency of the cocoa powder line, the plant installed a Flexicon BULKOUT® BFC-C-X bulk bag discharger to handle loose cocoa presscake being put in storage before being reduced to powder and packaged for customers

The discharger is configured with an electric hoist and trolley that ride on a cantilevered I-beam, allowing bulk bags to be loaded into the frame without the need for a forklift.

To connect a bag, the operator slips the

bag straps into four Z-Clip™ strap holders of a bag lifting frame, and uses a pendant to hoist the bag into the discharger frame. A Tele-Tube™ telescoping tube pneumatically raises a Spout-Lock™ clamp ring, allowing an operator to make a highintegrity sealed connection between the clean side of the bag spout and the clean side of the equipment.

With the bag spout secured, the operator pulls its drawstring, allowing presscake to discharge into the surge hopper.

Releasing the telescoping tube’s air pressure allows the clamp ring to maintain constant downward tension by gravity as the bag empties and elongates to promote material flow. Additional flow promotion is provided by Flow-Flexer™ bag activators that raise and lower opposite sides of the bag bottom to promote complete discharge through the bag spout.

The 226 l capacity surge hopper with top-mounted enclosure is vented to a side-mounted Bag-Vac™ dust collector that creates negative pressure within the sealed system to prevent displaced air and dust from escaping into the plant environment.

The enclosure also serves to contain spillage that might otherwise escape through seams in the bag and folds in the spout, and is equipped with a hinged access door and folding bag shelf, allowing manual dumping of under-filled sacks.

A rotary valve at the hopper outlet metres the presscake into a pneumatic conveying line that moves it to a storage silo. From there, it is mixed and milled into six different recipes of cocoa powder and packed into 25 kg bags.

Constructed of stainless steel finished to sanitary standards, the discharger is certified for operation in food-grade environments. “The use of the Flexicon bulk bag discharger provides a safe and hygienic way to unload cocoa cake from bulk bags.” said JB Cocoa’s Redi Koerniawan. “It ensures efficient unloading with little to no dust released into the processing environment.”

The beans are cleaned, roasted and winnowed to separate the cocoa nibs, which are treated to enhance flavour and colour.

Engineers and technicians working in the food and drink processing and packaging industries are well aware of the possible consequences of tools going missing. Foreign object damage (FOD) is a threat in any manufacturing or line maintenance workplace, especially those where food or drinks are being produced.

Keeping track of every tool and item of equipment presents a major challenge, making professional tool storage and management more important than ever.

Snap-on Industrial’s Level 5™ automated tool management system constantly tracks every tool, advising with voice announcements which tools have been removed or when they are returned, ensuring greater protection against FOD.

It also enables engineers and technicians to find every tool they need quickly, saving time and easing stress.

Major benefits of the system include:

• No individual tool scanning required;

• No RFID tags to install or replace;

• No limitations on tool size: from ¼” screwdriver bit upwards;

• Intuitive interface, via touchscreen;

• Audible voice confirmation of tool removal and replacement;

• Automatic locking for maximum security;

• Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snap-on’s automated system takes tool management to an entirely new level. The ability to monitor several boxes from one central computer offers managers a huge time saving advantage.”

For more information visit: www.snapon-industrial.co.uk; call (01536) 413904 or e-mail: industrialuk@snapon.com

A UK Pet food Manufacturer contacted us requiring 4 easy clean high viscosity transfer pumps for the transfer of tallow in a pilot plant being used in a new blend of pet food. Tallow – an animal fat from Beef or Mutton which has had its moisture removed extending its shelf life, has a dry waxy texture, is solid at room temperature and is rich in vitamins and flavour.

Pilot plants are a smaller scale version of a newly designed production facility which are built for the testing of methods, procedures, ensuring the intended design produces the outcome or recipe they require and for proof of concept for investors before a much larger design is produced requiring heavy investment.

As the customer was trialing several recipes of pet food, they wanted to guarantee batch results, accelerate the speed of cleaning between differing blends as well ensure bacterial contamination was not incurred.

Pet food is subject food safety standards with requirements for producers to identify Risks, perform Hazard Analysis and ensure Critical Control Points known has HACCP are adhered to. Producers are required to undertake bacteriological sampling frequently as well as have a safety management system.

Typically in such plants, industrial stainless steel pumps are used which are constructed in standard stainless steel which are not easily cleanable.

The customer wanted a variable flow pump where flow could be reduced by up to two thirds, yet pressures remain consistent at up to 6 Bar. They also wanted a pump which was easily cleanable when mounted on a skid frame forming part of the plant design.

Nominal

Standard BS 1449 Pt.

3B

4

5

7

pump for manual intervention.

North Ridge specified and supplied 4 Hygienic Progressing Cavity Pumps for this pilot plant with well-polished internal parts to ensure parts could be cleaned and sanitized effectively in minimal time frames.

As the customer wanted to automate cleaning, ensure plant uptime was maximised and fully disinfect pumps between batches, the pump was manufactured from AISI316L then Polished to Ra1.6-3.2um (a micron polishing level).

Various polishing levels are available to buff pump internal parts with some of the most common standards listed above:

Polishing a pumps internal stainless steel parts enables internal parts to be easily sanitized, and ensure that pumped media is easily removed from the body or moving parts. It also ensures the pumps internal hygiene can be maintained via Cleaning in Place (CIP) or Sterilisation in Place (SIP) without dismantling of the

Furthermore a hygienic Open pin joint ensures superior sanitation, with lubrication of this joint is provided by the pumped product, preventing the introduction of cross contamination from lubricants. It can be quickly maintained, assembled and dismantled without the need for tools.

This is important as pet food is subject to similar controls to that of feed for livestock in particular with additives, animal origin and bacteria levels to reduce the risk to public and animal health.

The unit was coupled to a geared motor as progressive cavity pumps require high starting torque, . this design of motor multiplies the output torque without increasing the power consumption of the motor.

The pumps were assembled on AISI304L baseplates, supplied and delivered within 6 weeks from order.

Whether you’re dealing with clogging, separation, downtime, or other issueit’s costly. Time wasted troubleshooting and lower production mean missed targets and less profit. A sanitary pump is the solution but choosing the right one feels like stepping into a minefield. You know what you need it to do but with so many options, it’s difficult to know which is best for your process and parameters.

+ Accelerated stator wear

Clogging + Changes to fluid consistency + Clean-in-place and sterilise-in-place hygiene issues + Crushing of sensitive products

Inconsistency in finished product

Inaccurate transfer of flavourings or ingredients

We’ve been engineering sanitary pumps for sectors such as distilling, brewing, food manufacturing/processing, and more, for 20+ years. We understand industry-specific processes and know what it takes to optimise performance through better-suited pump design - giving you complete peace of mind.

EXPERT GUIDANCE: Our expert engineers understand your process and guide you through the options, so you can confidently select the most suitable sanitary pump.

Fish & meat

Fruits eg. cooked apples, plums, berries, grapes

Grains & seeds

Pastes & purees

Syrups, juices & alcohols

Vegetables & peelings + Waste eg. trimmings, packaging & offcuts + Sheer sensitive liquids + Solid laden or viscous mixtures

Replacing ambient air in Modified Atmosphere Packaging (MAP) with a mix mainly consisting of nitrogen can save the food industry a lot of headache. With the ever increasing cost of carbon dioxide coupled with various supply chain issues, switching to on-site nitrogen generation seems like a great alternative to traditional ways of packaging.

During the packaging process, nitrogen is often picked above other inert gases such as carbon dioxide and argon, as it is colourless and odourless.

With on-site gas generation, food and beverage processing plants can benefit from increased production efficiency and lower manufacturing costs as compared to bottled or liquid gas solutions.

Using Pneumatech nitrogen gas generators provides food and beverage manufacturers with many benefits such as:

• Lower cost - The costs of a cubic meter of on-site generated nitrogen is significantly lower than that of bottled or liquid gas.

• Independence and price certainty –On-site nitrogen production can be easily calculated, with no need for entering into long-term supply chain contracts with fluctuating supply prices.

• Increased quality - On-site gas generation allows you to select the right gas purity for your application. Delivered bottled nitrogen is only available in a very high purity that most users do not need.

• Sustainability - Bottled or liquid gas deliveries come with significant transport emissions. Pneumatech’s on-site generators further reduce your carbon footprint by minimising the need for deliveries and helping you to monitor your energy consumption.

• Supply chain control - Buying your oxygen or nitrogen means you are dependent on third parties. On-site generation gives you complete control and a continuous, reliable supply of your mission-critical industrial gas.

• Simplified logistics - The purchase of bottled nitrogen poses various logistical challenges. Everything from ordering and receiving the bottles to storing and replacing them requires time, space and labour. And that is if everything goes smoothly. On-site gas generation removes all of these challenges.

• Scalability - Are you planning to grow your business? An on-site gas generator offers the required flexibility.

Pneumatech have a wide range of nitrogen generators available and ready to suit your business needs, typically seeing payback within two to three years of your initial investment.

For smaller users, Pneumatech offers the PMNG HE, a highly efficient generator using membrane technology.

PMNG HE is a simple and easy to run small nitrogen generator with great reliability and potential huge cost savings.

You can learn more about our PMNG HE here: https://www.pneumatech. com/en-uk/gas-generators/ membrane-nitrogen-generators/ pmng-membrane-nitrogengenerators-4-40-he

For the larger users, Pneumatech offers PPNG series, premium on-site nitrogen generators for high to low flows. PPNG is Pneumatech’s most efficient nitrogen generator with the lowest life cycle cost - perfect to keep your production running smoothly.

If you want to find out more information about the PPNG series click here: https://www.pneumatech. com/en-uk/gas-generators/psanitrogen-generators

To view the full range of Pneumatech nitrogen generators visit www.pneumatech.com/en-uk/gasgenerators.

Removing harmful contaminants and excess moisture is of vital importance for food industry manufacturers. Pneumatech air treatment products have been designed to deliver quality air standard that is required for their needs. With food grade filters and dryers compatible with compressed air quality standard ISO 8573-1:2010 food manufacturers can now take control of their air quality and tackle the risks of cross-contamination.

Contaminants are bound to creep in and develop in any compressed air system used for food production. Air contamination can develop at various stages during the manufacturing cycle:

• The atmosphere: The ambient air that is pulled in by the compressor contains particulate matter, water and oil vapour or micro-organisms.

• Air compressor: The compression process can add its own contaminants, notably oil vapour, oil aerosols, and liquid oil.

• Air receiver and piping: The accumulated contaminants from the earlier stages inevitably end up in the

receiver as well as the distribution piping. This can lead to the growth of micro-organisms; the resulting chemical reactions can cause pipe scale and rust.

Pneumatech has developed a series of air filters to ensure the quality of compressed air used in food production including:

• Coalescing filters screening out oil aerosols and wet particulates

• Dust removal filters removing dry particulate

• Adsorption activated carbon filters removing oil vapour

Creating clean, dry, and high-quality air is of paramount importance in the food industry. Compressed air is used anywhere from the packaging systems, mixing, cutting, and drying of ingredients, to transportation and propulsion of food.

All these operations bring compressed air into contact with the product either directly or indirectly and must adhere to strict quality standards.

Pneumatech has developed a series of ISO 8573-1:2010 certified air treatment solutions for food manufacturers to tackle these challenges and help them improve the quality and crosscontamination issues.

Leading safety guidelines concur on the need to remove moisture wherever possible. This typically means maintaining a pressure dew point of at least -26° C/-15°F (to limit microbial growth). Filtration with a minimum DOP efficiency of 99.999% should be set up at every point where the air might affect the product.

When removing water and moisture from the air, Pneumatech offers a variety of adsorption dryers that to suit various sizes of food production businesses.

Pneumatech products can ensure the Compressed Air System is fully compliant with the HACCP Process to Achieve Food & Beverage Grade Compressed Air.

For smaller users the PH 45-690 HE is perfect raising the bar in efficiency, reliability, low maintenance and versatility. Thanks to its ground breaking structured desiccant, Pneumatech’s PH 45-690 HE adsorption dryer offers unprecedented benefits and the lowest cost of ownership. It is the most efficient dryer available on the market today with an optimal, even air flow and low pressure drop.

Because structured desiccant decays at a much slower rate than desiccant beads, the PH HE’s service intervals are 40% longer. The desiccant blocks also make maintenance much faster and easier.

For larger users the PB 210-635 HE is a great choice using its heated blower purge to remove moisture from the desiccant material.

To view the full range of Pneumatech adsorption dryers and air filters visit https://www.pneumatech.com/en-uk .

Pneumatech have a wide range of nitrogen generators available and ready to suit your business needs, typically seeing payback within two to three years of your initial investment.

The Apollo Root Cause Analysis Methodology is a new way of thinking that goes far beyond the traditional root cause analysis problem solving processes It facilitates the creation of a common reality, using input from all stakeholders to produce an evidence based understanding of the problem and ensures your solutions address proven causes and prevents recurrence

The Apollo Root Cause Analysis Methodology is a new way of thinking that goes far beyond the traditional root cause analysis problem solving processes It facilitates the creation of a common reality, using input from all stakeholders to produce an evidence based understanding of the problem and ensures your solutions address proven causes and prevents recurrence

The Apollo Root Cause Analysis Methodology is a 4 step process which facilitates a thorough incident investigation It makes problem solving easy and gives those who have been trained the skills to solve real world problems faster, more efficiently and effectively every time.

The Apollo Root Cause Analysis Methodology is a 4 step process which facilitates a thorough incident investigation It makes problem solving easy and gives those who have been trained the skills to solve real world problems faster, more efficiently and effectively every time.

Create a common reality and gain buy in from all stakeholders

Eliminate recurring problems through identifying all the solutions Get a definite result know when a problem is solved

Create a common reality and gain buy in from all stakeholders Eliminate recurring problems through identifying all the solutions Get a definite result know when a problem is solved

Students learn by doing with interactive training courses

Students learn by doing with interactive training courses

RealityCharting Software to make documentation and reporting easier

RealityCharting Software to make documentation and reporting easier

Helping you to solve real world problems faster, more efficiently and effectively every time.

Helping

to solve real world problems faster, more efficiently and effectively every time.

Coded electronic safety systems, like the CES-C14 from machinery safety specialist Euchner, are modern, type-4 (in accordance with BS EN ISO 14119:2013) interlocking devices designed for the protection of people, machines and processes. Their non-contact transponder technology consists of a coded actuator, read head and evaluation electronics which, in the case of the CES-C14, forms a self-contained unit featuring the read head and evaluation electronics to produce a safety switch.

The CES-C14 is ideal for use on safety guards and for the reliable position detection in machine and plant construction. Thanks to its fullyencapsulated design it is, for example, perfect for use in food processing applications where, to combat on-going complications caused by lactose and dairy products damaging exposed equipment in these arduous environments, they can significantly outlast conventional IPrated safety-switches, which increases productivity through reduced downtime and straightforward installation.

The encapsulated, ingress-proof design of Euchner’s unique CES-C14 safety switches comprises a two-part epoxy resin outer shell that has been extensively tested for material resistance, including alkaline and acidic cleaning agents and disinfectants in accordance with ECOLAB specifications. It is supplied with a 20M specially prepared PUR cable sheath that, in addition to a very tough outer shell, offers a high degree of ingress protection including IP67/IP69K for the most arduous of environments, including high-pressure chemical washdowns.

The interlocks are designed with a high level of integrity and can be used in systems up to and including CAT4/PLe (EN

ISO 13849-1). With two semiconductor safety-outputs these switches can easily be integrated into most safetyrelated control systems, including where the replacement of existing, less reliable switches is required. For more complex installations CES-C14 interlocks are available with ‘series connection’ connectivity, allowing a chain of compatible interlocks to be wired in series while still achieving up to PLe.

To ensure dependable operation, the CES-C14 switches have a high tolerance to misalignment and can be provided in both Unicode and Multicode versions. Unicode units create a ‘matched pair’ of switch and actuator, to provide a high level of protection against tampering by

preventing personnel from manipulating the safety system with a spare actuator. This helps the facility meet the requirements of the safety standards relating to interlocking devices, including BS EN ISO 14119:2013.

To ensure easy diagnosis of misaligned safety gates, the CES-C14 switches have two wide-angle LEDs, which are easily visible through the transparent sleeve and provide straightforward information about the status of each switch.

For further information on the CES-C14 transponder-coded safety switch, email sales@euchner.co.uk or call the Safety Technology Centre on +44 (0)114 256 0123.

www.euchner.co.uk

Instant, prioritised information, giving you end of end visibility of your production processes, can help you to reduce your transformation costs and improve your net profit

Manufacturers of packaged goods everywhere are facing the same dilemma of rising input prices; raw materials, energy prices, increased labour rates, with little or no opportunity to pass on these rising costs to their supermarket customers, who are themselves fighting a price war with other supermarkets.

Even if you are fortunate enough to be increasing your sales turnover, with this exponential rise in transformation costs (cost of sales), your bottom-line profit must be under constant attack.

With no opportunity to pass on these rising transformation costs, the only place for manufacturers to look is internally, to reduce their own cost of sales by reducing wastage, improving efficiencies and increasing ‘right first

time’ production procedures. In order to achieve this, it becomes essential to examine production processes, from goods-in to dispatch, so as to identify areas of added and lost value, to streamline these processes and reduce costs at every opportunity.

Did you know that by reducing your ‘end to end transformation costs’ by a mere 1% could double or triple your net profit?

Harford Control have spent the past 40 years listening to their clients and developing an MES system which helps them do exactly that.

You might be very clear on what you

want to achieve during the coming year, but do you have total visibility of production operations, in real time? You might personally be blessed with 20:20 vision, but unless you can see precisely what is happening right now, within your production operations, then it is hard to see how you can expect to achieve your objectives.

The well-worn phrase ‘You cannot improve what you don’t measure’ could also include ‘You can’t improve what you can’t see’

Real time visibility of factory floor operations has now become an essential performance improvement enabler on the road to Operational Excellence.

Fortunately, the use of the Harford MES system throughout the continuous improvement process, makes stagnation

becoming instantly aware of this from their PC, computer tablet or mobile phone, wherever they are. They can find out instantly the current performance status of all their local and remote production lines, timely enough to take action before it’s too late, and ensuring

Real-time information, instantly displayed across integrated networks and also constantly displayed upon large TV screens in the production area, means that the whole operational team, from top floor to shop floor, see the same information and have the same opportunity to make improvements in real time - no more guess work.

As there is, for many companies, such a significant level of wastage contained within the conversion process, to implement a paperless system with such visibility should provide rapid and cost-effective improvements, such that no new money is required. The right system for the right application would be financed from the existing cost of

Systemisation is therefore absolutely essential for any company seriously intent upon minimisation of risk and wastage and maximisation of Right First Time, at lowest manufactured cost.

Harford MES helps factories eliminate risk, reduce wastage and improve efficiency by turning data into instantly actionable information.

Find out how by contacting us today: www.harfordcontrol.com +44(0)1225 764461

The well-worn phrase ‘You cannot improve what you don’t measure’ could also include ‘You can’t improve what you can’t see’

The BCMPA was proud to announce Staci UK as this year’s ‘Co-Pack & Fulfilment Company of the Year’ at the UK Packaging Awards 2022, with Granby Marketing Services being Highly Commended.

The awards recognise the extraordinary support that contract packing and fulfilment firms provide to the brand owners and the wider retail sector, services which have become increasingly vital in the current uncertain and turbulent world of commerce.

The prestigious black-tie event held at London’s Grosvenor House on Park Lane saw the BCMPA, the Association for Contract Manufacturing, Packing, Fulfilment & Logistics, as proud sponsors of ‘Co-Pack & Fulfilment Company of the Year’ one of 27 categories at the 2022 UK Packaging Awards.

The five finalists in this hotly contested category – Complete Co-Packing Services, Expac, Granby Marketing Services, Staci UK, and Worldwide Logistics – were all represented and enjoyed the event along with 600 guests from across the packaging industry.

Emma Verkaik, Membership & Marketing

Emma Verkaik, Membership & Marketing

Director of the BCMPA, was delighted to present the winners with their awards. In congratulating Staci UK on their win, Emma commented; “We are thrilled and honoured to be sponsors of the Co-Pack & Fulfilment Company of the Year Award at this year’s UK Packaging Awards. It

is particularly rewarding to be able to shine a light on the huge and growing contribution that the co-packing and logistics sector makes in supporting businesses running efficiently and effectively in such challenging times.”

Overall winners, Staci UK, are one of Europe’s leading fulfilment and logistics specialists, with 56 fulfilment centres across 8 countries. Also highly commended at the event were BCMPA members Granby Marketing Services.

Emma added; “The amazing quality of all the finalists this year demonstrates the fundamental importance and relevance of contract packing & fulfilment in the packaging industry, and the increased collaboration between brands and their third-party partners has now become a necessity for many. With the multiple challenges ahead, I have no doubt that this collaboration will continue to strengthen in 2023.

“Congratulations to all our 200 members for their commitment and sterling efforts this year, and in particular our winners and finalists at this year’s UK Packaging Awards.”

www.bcmpa.org.uk

The amazing quality of all the finalists this year demonstrates the fundamental importance and relevance of contract packing & fulfilment in the packaging industry

1. There is no visible sign of a PHE defect

Probably the most regularly encountered and significant issue with PHEs is that they often show no outward sign of defect. Rather than obvious external leaks, generally the corrosion and expansion/ contraction defects occur inside the PHE meaning contamination sites happen unseen. The Gappscan uses software to detect minute pressure changes within the PHE which allows for a more effective maintenance programme that is proactive rather than reactive.

2. Downtime associated with testing can be a headache

PHE testing, when units need to be dismantled, decontaminated, and reassembled takes PHEs out of use for long periods, obviously affecting production time. The Gappscan doesn’t require dismantling of the PHE for full testing to be conducted, nor does it need to use any invasive chemicals. This results in testing that is very quick, meaning the PHE can be back in productive operation fast, and

multiple PHEs can be completed in one visit, improving the ROI drastically on traditional testing methods.

3. Testing is labour intensive and takes time to produce results

The Gappscan only requires the PHE to be disconnected not dismantled and the testing can be carried out by one person in less than 5 minutes, with the results available immediately.

Traditionally labour-intensive testing methods using substances whether dye, chemical or gas can be time consuming as each PHE must be dismantled for these penetrants to be applied and be allowed time to penetrate each section for results to be reviewed for defects.

4. Environmental accountability: “I have to dispose of chemicals/dyes/gases and ensure the PHEs are thoroughly clear of any residues before reintroducing the PHE to production”

The Gappscan test uses water under pressure... that is all. Traditional testing

methods employing dye penetrants and other substances/ gases, need disposing safely and responsibly once all tests are complete. Additionally, thorough cleaning protocols need to be carried out before the PHE can be brought back into service. By using water under pressure, Gappscan not only gets your PHEs back into productive use quickly, it does so safely with low environmental impact.

5. “Tests that only produce pass or fail results, mean I can’t plan maintenance or replacements”

The Gappscan testing method can identify and report numerous cracks and defects in a PHE using varying levels of pressure, and detect defects as small as a few microns, so the reporting is more granular and each test is saved securely to monitor changes in PHE behaviour and performance over time, allowing effective of preventative maintenance.

For further information on Gappscan™ G2, please get in touch or visit www.eit-international.com

In a hygiene-sensitive manufacturing environment stainless steel components are true all-rounders: easy cleaning, no adhesion of dirt, germs or detergents, permanent cleanliness. They are also corrosion-resistant, durable, temperatureresistant, low-maintenance, hygienic and economical. Find these products in our full range with more than 70,000 parts in THE BIG GREEN BOOK 2022

The combination of intense competition in the meat industry, rising input costs and increasingly stringent retailer and consumer quality requirements means pig processors need to maximise the yield from every carcase.

According to food and drink IT specialist CSB-System, this has resulted in strong demand for its Image-Meater® industrial vision device, which automates pig carcase grading. The company says the system delivers an objective result which can be used to accurately calculate the market value.

Offering a grading speed of up to 1,300 pig carcases per hour, the CSB ImageMeater® uses proprietary software to identify and measure key muscle and fat cross sections from a photographic image and calculate the grading results according to a verified formula. Image-Meater® displays and records the SEUROP grade, lean meat percentage (LMP) of the carcase - and the weight, percentage and LMP of key primals within the carcase.

As well as providing an accurate assessment of the grade and market value of carcases at the abattoir, the Image-Meater® can also be used downstream for sorting carcases to optimise yields. According to CSB, this has delivered gains of around two Euros per pig.

“In competitive markets, maximising yields while maintaining quality is vital,” said Mathew Simpson of CSB-System. “ImageMeater’s software driven solution delivers highly consistent results, as the error prone job of accurate probe placement is eliminated – along with the risk of repetitive strain injuries. And manual data recording can be removed so the results are more reliable as well as more accurate.”

All of the information from the classification process is automatically archived and can be reproduced in customisable reports. This includes the photograph, lean meat content, grade, date, grader code, slaughter line

number and date of slaughter. This gives both farmer and processor end-to-end traceability and transparency.

The Image-Meater’s compact dimensions mean it can easily be integrated into most slaughter lines. It’s non-invasive measurement process ensures maximum hygiene, and the low-maintenance system means near-zero downtime. CSB says return on investment for carcase sorting and cutting optimisation projects can be less than one year.

The Image-Meater® has been installed in factories across Europe and beyond, including Belgium, China, France, Italy, Portugal, Spain and the UK.

As well as providing an accurate assessment of the grade and market value of carcases at the abattoir, the ImageMeater® can also be used downstream for sorting carcases to optimise yields.

Innovia Films is launching Rayoface™ CSA46, a clear, one-side gloss coated BOPP film, perfect for use in Food and Beverage or Household and Personal Care applications. This 46 micron film is approximately 10 percent thinner than most facestock films, giving this a higher yield and an improved carbon footprint.

Rayoface™ CSA is a high clarity and low haze film which gives enhanced product visibility and the “no-label look” appearance. The material has a very wide print window and is suitable for printing with flexo, gravure, screen offset and

letter press. Also with UV, low-migration, and water-based inks.

Alasdair McEwen, Product Manager, Labels explains “the performance of CSA46, means it has excellent cold foil

adhesion and appearance, allowing eye-catching graphics and label designs for your product. Whilst reducing carbon impact versus thicker coated facestock films”

McEwen adds “CSA46 provides balanced orientation for enhanced die-cutting and die lifetime and importantly also has EU food contact compliance”.

To find out more contact your local Innovia Films Sales Manager or email labels@innoviafilms.com

www.innoviafilms.com

The performance of CSA46, means it has excellent cold foil adhesion and appearance, allowing eye-catching graphics and label designs for your product.Rayoface™ CSA46 clear film allows for eye-catching label designs for Food and Beverage or Home and Personal Care applications

The new fork sensors of the GS 04B and GS 08B series from Leuze detect even the smallest objects with absolute reliability. They are ideal for reliable detection in high speed applications

Even the smallest objects can be reliably detected - as proven by the new Leuze GS 04B and GS 08B series fork sensors. They detect objects as small as 0.05 mm in diameter. Due to their high switching frequency of up to 10,000 HZ, they are well suited for use in fast automation processes. Users benefit from a wide choice of different variants: the sensors of the GS 04B series are available in 14 different fork widths from 5 to 220 mm. The GS(L) 08B series offers four fork widths from 30 to 120 mm. This makes them suitable for a variety of industriesfor example in the packaging sector or in assembly and handling technology.

The new GS 04B series fork photoelectric sensors with red light LED are also available with extra-wide fork widths of 170 or 220 millimeters. Using these, applications with larger components can also be solved with fork sensors

The compact fork shape of the sensors combines the transmitter and receiver in one device. This enables simple and quick mounting without the need for alignment and offers a high level of operational reliability. Due to their very compact design, Leuze fork photoelectric sensors can also be integrated into areas where space is limited. The extrawide fork widths of 170 or 220 mm, also allow larger objects to be detected.

The cleanroom-compatible V4A stainless steel housing of the GS(L) 08B series is ECOLAB-certified and therefore ideal for industries with high demands on hygiene and resistance to cleaning agents

The sensors of the GS 04B and GS 08B

Even the smallest objects can be reliably detected - as proven by the new Leuze GS 04B and GS 08B series fork sensors.

series can be configured either via IOLink or manually via a potentiometer. Sensitivity adjustment and light/dark switching ensure maximum reliability. When it comes to high demands on hygiene and resistance to cleaning agents: the GS(L) 08B series offers a robust, resistant, and cleanroomcompatible V4A stainless steel housing. It is ECOLAB-certified and meets the high standards of protection class IP67.

www.leuze.co.uk

Interbake Limited have been the sole UK agent for the Krumbein Rationell manufacturing company who are based in Tabarz, Germany for over 20 years .

This innovative company specialise in producing probably the most comprehensive range of cutting and slicing machines that are available for baked products and also include bespoke sandwich make up lines.

Ensuring that the portioning of cakes is accurate, is the key to success for profitability and uniformity. In most circumstances a pair of laser cut stainless steel blades reciprocate against each other to slice through fresh product and this method permits the blades to sharpen themselves in the course of their movement, hence the cut is self maintained to be both sharp and efficient.

Fermented goods such as bagels, hot dog rolls, teacakes, etc. can either be full cut or hinge cut together with traybake cakes or round cakes cut into segmented portions.

Additionally, horizontal slicers are available to cut oblong cakes into multiple layers.

The employment of these machines reduces labour costs dramatically with the total concept representing high standards of health and safety together with hygienic design features.

For further details contact Interbake Limited.

Tel: 01706 825596 email: info@interbake.co.uk

After a long break, NORD DRIVESYSTEMS will be presenting its innovative drive solutions for intelligent production from 8 to 10 November at sps smart production solutions in Nuremberg. The drive experts look forward to meeting you in person again at their Stand 451 in Hall 3A that can be reached by shuttle bus via a separate entry.

One of NORD’s exhibition highlights is the new LogiDrive solution space: As well as previous LogiDrive system solutions from the company’s modular system, such as an IE4 synchronous motor –integrated into a two-stage helical bevel gear unit – products like the DuoDrive, NORDAC ON (+) and the manufacturer’s IE5+ motors are now included. For the post & parcel, airport and warehouse application areas, basic and advanced designs are available that are optimised

in terms of energy efficiency, version reduction or Total Cost of Ownership (TCO).

The DuoDrive geared motor in its hygienic wash-down design covers powers of up to 3 kW and integrates an IE5+ synchronous motor into a singlestage helical gear unit. Calculated across the system, the compact geared motor achieves up to 92 percent efficiency –one of the highest on the market in this power class – and is characterised by high energy efficiency.

With the NORDAC PRO product family, the company’s range includes compact frequency inverters with an integrated

multi-protocol Ethernet interface for different power classes (0.25 to 22 kW) : The NORDAC PRO SK 500P basic version is exceptionally versatile. It offers high-quality connection and functional features such as a CANopen interface, brake chopper, PLC function and POSICON positioning control. Plugin control and option modules ensure maximum flexibility.

With its electronic drive technology product portfolio, NORD supports drive-based functional safety for control cabinet and decentralised inverters. The integration of the drives is carried out fail-safe via Ethernet and via discrete inputs and outputs. www.nord.com

Green Rock Group, the UK’s leading provider of fully recyclable paper cups and lids, has opened new manufacturing facilities on the Whitegate Industrial Estate. The seven-figure investment will help meet the demand for fully sustainable, UK manufactured paper cups as well as allow the business to extend its product range to include all food to go paper packaging products.

The new facilities are to be officially opened by Wrexham Member of the Senedd, Lesley Griffiths, who is also the Minister for Rural Affairs and North Wales and Trefnydd, in the Welsh Government.

The opening means the company will have six manufacturing facilities based in Wrexham spanning more than 100,000 sq ft. The company has already created 50 jobs in the past three months and has plans to grow the number of employees to more than 100 by the end of the year.

The company’s innovative paper cups are manufactured using aqueous coated materials, eliminating the need for polyethylene (PE) or polylactic acid (PLA) linings, which means the products can be composted or recycled. Being manufactured in the UK also means they have a lower carbon footprint compared to cups manufactured overseas.

The significant investment in its Wrexham facilities allows the business to meet the demand for its products as well as increase the company’s capacity and capabilities. The site will grow from 70 machines dedicated to the manufacture of paper cups and two dedicated to paper lids, to more than 84 high speed machines in total.

Steve Granville, managing director of Green Rock Group, comments: “The exponential growth and demand for our sustainable paper products has

“This is a significant milestone for the business and allows us to meet the strong demand there is for our UK made products. We’re excited about the year ahead as we look to building on this growth and lead the sector in terms of innovation, capability and growth.”

Lesley Griffiths MS, adds: “This investment in the company’s manufacturing capacity and capabilities is a testament to the businesses’ success, as well as the people and city of Wrexham that help make Green Rock Group the success it is today.”

The new facilities will expand the manufacturing capacity to produce paper cups for hot and cold drinks as well as paper lids. The new facilities will also allow the business to produce all food to go paper packaging products including bags, napkins and food trays. The company also has a manufacturing capability for paper straws.

From October 2022 the company launch their new espresso cup and also their

Green Rock work with strategic partners across the whole supply chain, Just Peel who manage sales, Mcarthy Distribution on Logistics, Herbert Walker and the Graphics factory on Print and Design, and Denmaur / Delipac on supply.

By not using traditional PE or PLA linings, the company’s products are easily recyclable and compostable. The Delipac paperboard follows years of innovative ground-breaking research and development. The product is specifically designed for use in food and drink packaging where full sustainability is required. The fully compliant products can be used from freezer to oven and are EU and FCA approved for direct food and drink contact.

The Green Rock Group’s products are fully recyclable in any paper waste stream, compostable, and fully biodegradable. The products are Flustix certified as plastic free and are legally compliant with the EU single use plastic regulation.

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a push button operated electrical actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

Mettler-Toledo Product Inspection is running a live webinar on 17th November (09.00 and 14.00 GMT) designed to explain how smart product inspection solutions can support food producers to tackle rising manufacturing costs.

The free webinar – titled “5 Ways to Combat Rising Food Manufacturing Costs with Product Inspection Technologies” –will be presented by Robert Rogers, Senior Advisor for Food Safety & Regulation at Mettler-Toledo. With more than 26 years’ industry experience, Robert Rogers is a key expert at Mettler-Toledo, consulting with manufacturers to help them protect their products, prepare for food safety

digital maturity and compliance, and how to future-proof their business.

A recording of the webinar will also be available on-demand from the MettlerToledo website for those unable to join on the day.

In the webinar Robert will highlight five key cost-related challenges faced by food manufacturers today, and the ways that these challenges manifest themselves from day to day:

• Challenge #1: Reducing Material and Energy Costs – including incorrect fill levels, using machinery with poor energy

efficiency, wasted materials through not identifying contaminants until late in the process, and the issue of false rejects.

• Challenge #2: Optimising Human Resources – such as inefficient manual processes that slow production and demotivate staff, continued reliance on employees for tasks that could be better handled by automation, and protecting employee safety.

• Challenge #3: Avoiding Unnecessary Waste – covering issues such as false rejects which cause unnecessary waste, poorly maintained machinery not correctly identifying issues, product

Live event scheduled for 17th November 2022 will discuss cost-related challenges faced by food manufacturers and illustrate how product inspection systems can help save money and improve efficiency.

giveaway due to poor fill level control, and time-consuming sample checks.

• Challenge #4: Modernising Data Management – this involves the transition from manual record-keeping to automated processes, improving connectivity between systems to enable data sharing, getting ready for food safety digitalization, and enabling transparency of food manufacturing throughout the supply chain.

• Challenge #5: Minimising Downtime – this section will cover product changeovers, overcoming system breakdowns, reducing cleaning time, and preventive maintenance.

During the webinar, Robert will outline

the key role that smart product inspection solutions, i.e. checkweighing, metal detection, x-ray and vision inspection, can play in helping to meet these key challenges and reduce manufacturing costs. Alongside cost factors, additional benefits that accrue from using relevant product inspection systems will also be put forward for each scenario. In addition, customer stories will demonstrate the impact that product inspection can make.

“We will give food manufacturers a number of concrete takeaways that will benefit their businesses’ profitability and efficiency,” says Robert. “Rising food

manufacturing costs can be tackled with smart product inspection solutions, with reduced waste, better product quality and more transparent supply chains being among further benefits that manufacturers can look to gain. This will be an informative session, packed with practical solutions to the challenges that many food manufacturers are faced with today.”

To register for the webinar: www.mt.com/pi-combatcosts

For more information, please visit: www.mt.com/pi-pr

This will be an informative session, packed with practical solutions to the challenges that many food manufacturers are faced with today.”

CBV, in partnership with motor and drive manufacturer WEG, has contributed to developing a self-sustaining waste to energy (WTE) island for Hong Kong’s residual waste. It is estimated the island will save 440,000 tonnes of carbon emissions per year, the equivalent of the yearly carbon emissions produced by 2.2 million gas-based cars.

In response to the Paris Agreement, the Government of Hong Kong’s Climate Action Plan set a target of reducing the country’s carbon intensity by 65 to 70 per cent, compared to 2005, by 2030. The country is progressing steadily in meeting this ambitious goal. In 2019, it had already reduced its carbon emissions by 35 per cent.

The new WTE facility will represent another step in the right direction. The facility will consist of six lines supplying mainland Hong Kong with two GWh of electricity per day, thanks to a highly efficient WTE process. This is complemented by a state-of-the-art flue gas cleaning system that complies with strict emissions standards.

Waste heat, which is generated as a byproduct of working machines, will be used to dry the waste going to mechanical sorting for material recovery. Part of the heat will also be used to power the cooling system of the buildings on the island. A wastewater treatment plant will ensure that no water needs to be disposed of, while solar panels will guarantee that the power requirements of people working on the island are met. Moreover, the facility will produce 40 m³

of desalinated water per hour, which will be used for processes, building services, and irrigation of the green spaces covering the entire island, including the facades of the WTE facility. The project will also prevent the landfilling of 1,2 million tonnes of residual waste, generated by one-third of the citizens of Hong Kong, which is unsuitable for recycling.

The WTE plant is composed of three process modules, each consisting of two incineration lines. Each line needs one induced draught (ID) fan and one secondary fan, both of which require motors.