PHARMACEUTICAL 3D PRINTING

Alvaro Goyanes CEO and Co-founder, FABRX

Anna Worsley Director of Innovation, FABRX

Alvaro Goyanes CEO and Co-founder, FABRX

Anna Worsley Director of Innovation, FABRX

Gene Therapy for Cancer & Immunology

Transforming the Pharma Industry Issue 01 | 2023 | www.pharmafocusamerica.com

How AI is

www. pharmafocusamerica.com 2 TWO POWERFUL DOSES

YEAR Every issue of Pharma Focus America magazine is a powerful dose of information and knowledge – filled with original and undiluted content. Written by the best brains in pharma industry, the magazine offers timely business insights and articles on cutting-edge technologies. Subscribe now to get your doses regularly. Email: subscriptions@pharmafocusamerica.com Tel: +91 40 4961 4567 Fax +91 40 4961 4555 www.pharmafocusamerica.com

PER

Welcome & Introduction

As a publishing house there can be no other joy for us than to announce the launch of our very first issue of Pharma Focus America magazine 2023. I take this opportunity to congratulate my team, the panel of knowledgeable advisory board and all the authors who with their tenacious efforts believed in our vision of relevancy with uncompromising quality.

Backed by the team which powers Pharma Focus Asia and Pharma Focus Europe, Pharma Focus America is the newest kid in the block and strategically positioned to cater to the Pharma professionals across the American subcontinent. Fostering quality and timely delivery of trending topics relevant to the industry, Pharma Focus America magazine is committed to be its readers delight…leaving them in awe.

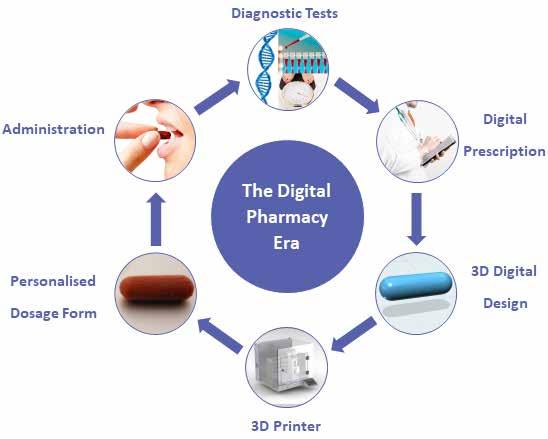

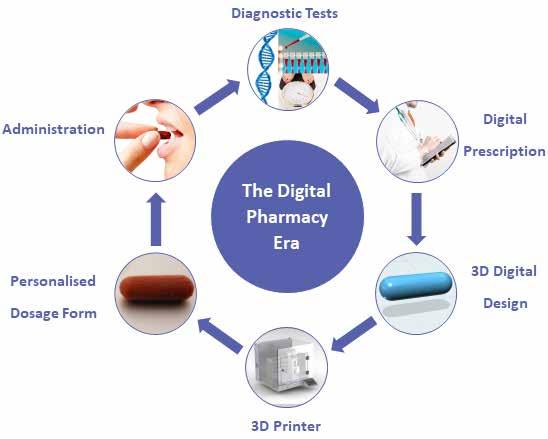

Pharmaceutical 3D Printing

Alvaro Goyanes, CEO and Co-founder at FABRX treads the path and unfolds the latest trend in 3D Printing that the Pharma sector is witnessing. Pharmaceutical 3D printing is a rapidly growing field, with more clinical studies starting every year. Able to manufacture novel dosage forms with advanced release profiles personalised to the patient, this technique is set to bring massive changes.

The pharmaceutical manufacturing industry has until now, followed a batch processing scenario to ensure that each batch was produced efficiently and effectively. Hassan Mostafa Mohamed, Chairman & CEO at ReyadaPro explains the latest trends in pharmaceutical manufacturing with the adoption of continuous processing with its impact on time taken and resources used.

Pharma industry seems to be ripe for AI transformation from drug discovery and the performance of trials, to remote patient monitoring, medication adherence tools and beyond. This article from Lydia Torne, Partner at Simmons & Simmons LLP explains some of the potential legal considerations when entering into licensing collaborations for the use of AI in drug discovery.

In the pharmaceutical industry Artificial Intelligence (AI) and Machine Learning (ML) models are being applied to improve the pharmacovigilance process. Ryanka Chauhan, Product Manager, Datafoundry – covers how these advancements have the potential to increase efficiency, accuracy, and consistency in pharmacovigilance, as well as reduce costs and delivery timelines.

Piet van der Graaf, SVP, QSP at Certara details in his article how Model Informed Drug Development (MIDD) continues to be a game changer in accelerating drug development. Quantitative Systems Pharmacology (QSP) is one such technology, which employs virtual patients in virtual clinical trials, allowing more approaches to be investigated than would be possible in the real world.

If you have any views or ideas or if you want to share your feedback with Pharma Focus America, you are more than welcome. You may also connect with us on our social media handles for exquisite stories, articles and much more.

N D Vijaya Lakshmi Editor

www. pharmafocusamerica.com 3

CONTENTS

RESEARCH & DEVELOPMENT

06 Advances in mRNA Therapeutics and Vaccines

Daniel Kavanagh, PhD RAC, Senior Scientific Advisor, Gene Therapy, Vaccines, & Biologics, WCG

13 Using Quantitative Systems Pharmacology Modelling to Accelerate Drug Development

Piet van der Graaf, Senior Vice President, Quantitative Systems Pharmacology, Certara

19 IgA-Mediated Inflammatory Disorders

Autoantigen-specific IgA, a biomarker with strong effector functions

Louis Boon, CSO & Board Member, JJP Biologics

CLINICAL TRIALS

30 Decentralization - The Future of Clinical Trials

Nicoleta Grecu, Director, Pharmacovigilance, Clinical Quality Assurance, Clover Biopharmaceuticals

39 Gene Therapy for Cancer & Immunology

Josipa Ljubicic, QA Director/Principal GCP and GVP auditor, Proqlea Ltd

MANUFACTURING

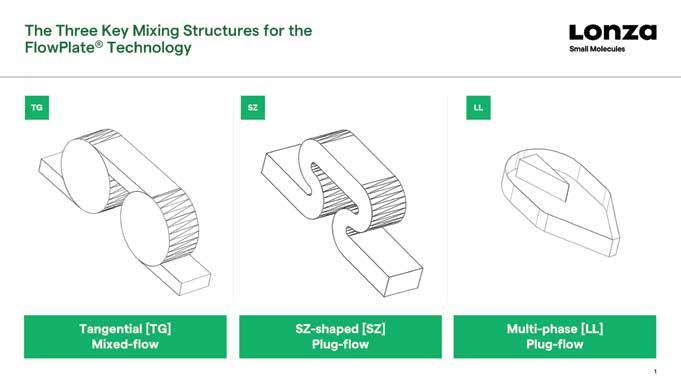

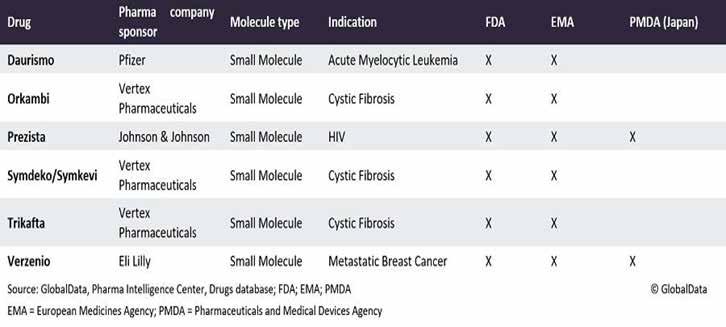

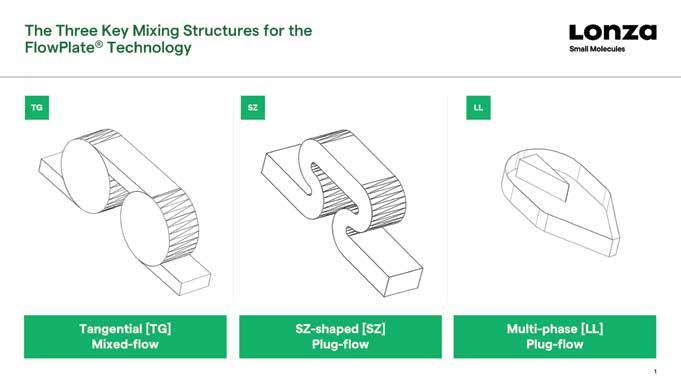

53 Choose Carefully: The Potential of Continuous Flow Chemistry in API Synthesis Charles Johnson, Senior Director, Commercial Development, Lonza

59 Viral Gene Therapy – How Can the Industry Drive Down the Cost of Goods to Better Serve the Patients?

Emmanuelle Cameau, Strategic Technology Partnership Leader - Cell and Gene Therapy, Pall Corporation

66 Adapting Containment Strategies to Futureproof the Manufacture of Sterile Drug Products

Ben Wylie, Head of Product Management & Marketing, ChargePoint Technology

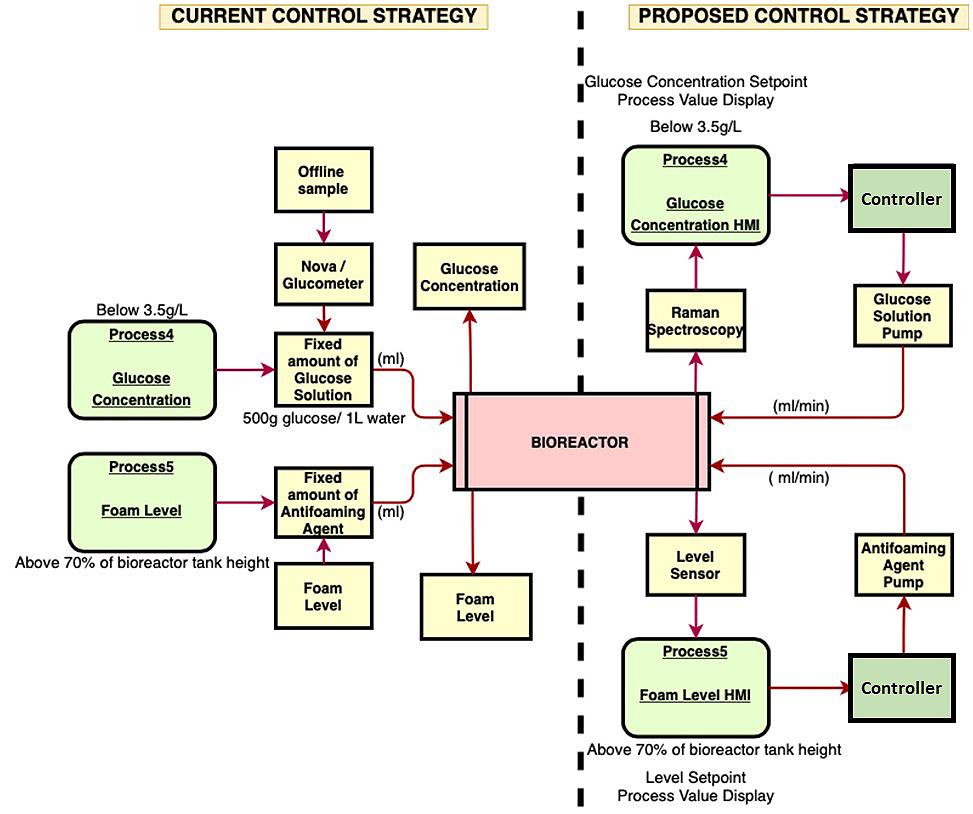

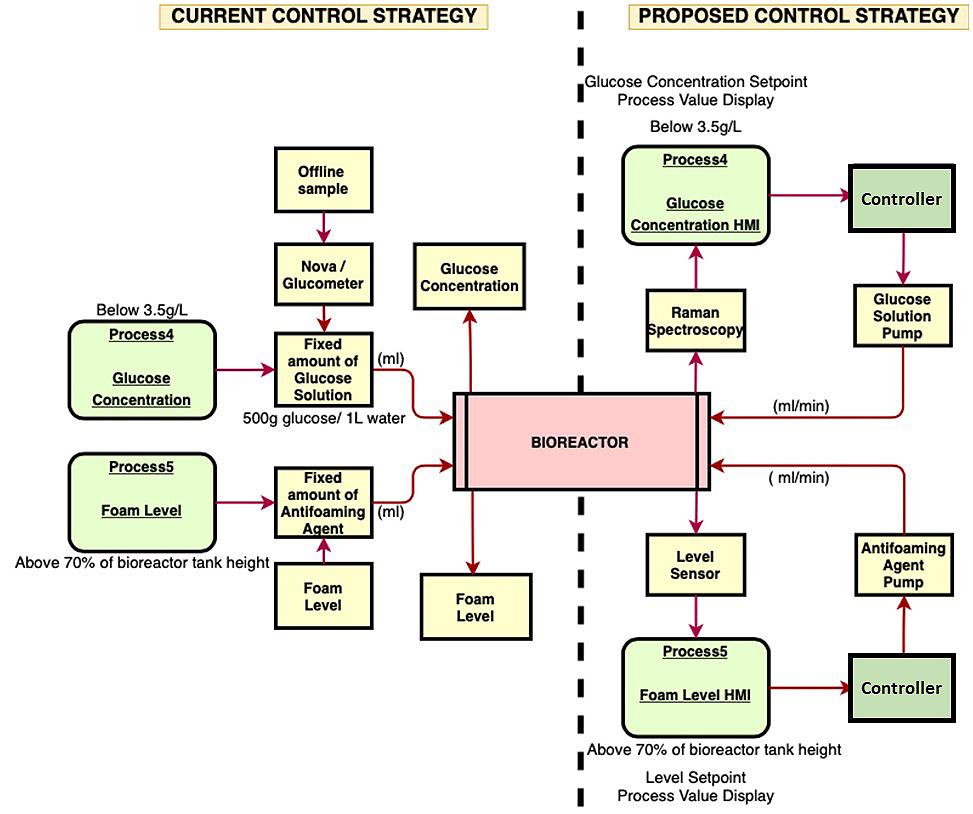

71 Advanced Model Predictive Control System of Continuous Biopharmaceutical Manufacturing Process

Ravendra Singh, C-SOPS, Department of Chemical and Biochemical Engineering, Rutgers, The State University of New Jersey

79 Continuous Vs. Batch Manufacturing

Hassan Mostafa Mohamed, Chairman & Chief Executive Officer at ReyadaPro

PHARMACEUTICAL

Alvaro Goyanes

CEO and Co-founder, FABRX

Anna Worsley

Director of Innovation, FABRX

INFORMATION TECHNOLOGY

90 How AI is Transforming the Pharma Industry

Lydia Torne, Partner, Simmons & Simmons LLP

96 Use of Artificial Intelligence in Automation of Pharmacovigilance

Ryanka Chauhan, Product Manager, Datafoundry

EXPERT TALK

104 Next Generation Sequencing - Genomics

Ravi Dashnamoorthy, Senior Scientist, Genosco

EVENT PREVIEW

112 Interphex Event

WEBINAR REVIEW

114 Developability and Immunosafety: Don’t let them threaten your drug development plans

115 Redefining Liquid Formulation Technology in Hard Capsules

4 PHARMA FOCUS AMERICA ISSUE 01 - 2023

Cover

Story

122 NEWS

116 EVENTS LIST

46 3D PRINTING

EDITOR

Vijaya Lakshmi N D

Advisory Board

Alessio Piccoli

Director & Head, Business Development

Europe, Aragen Life Sciences

Italy

Hassan Mostafa Mohamed

Chairman & Chief Executive Officer at ReyadaPro Saudi Arabia

Hector Alejandro Andonie

General Manager, Laboratorios Andifar Honduras

Hoda Gamal

Director of Regulatory and Corporate Affairs, Middle East and Africa (MEAC), Sirgio international Egypt

Joaquin Campbell

Global Director, Managed Access Services, EarlyHealth Group

Spain

Josipa Ljubicic

QA Director/Principal GCP and GVP auditor, Proqlea Ltd

Croatia

Nicoleta Grecu

Director, Pharmacovigilance, Clinical Quality Assurance, Clover Biopharmaceuticals Romania

Pinheiro Neto Joao

Chief Executive Officer, Omnimed Angola

Thitisak Kitthaweesin

Chief of Phramongkutklao Center of Academic and International Relations Administration Thailand

Eiman Shafa

Medical Director, Spine Surgery, Abbott Northwestern Hospital USA

Amine Bekkali

Director chez MEDFIELDS

United Arab Emirates

David Contorno

Founder & CEO, E Powered Benefits, USA

EDITORIAL TEAM

Sarah Richards

Debi Jones

Swetha M

Harry Callum

Supraja B R

ART DIRECTOR

M Abdul Hannan

GRAPHIC DESIGNER

Akhilesh

PRODUCT MANAGER

Jeff Kenney

SENIOR PRODUCT ASSOCIATES

Ben Johnson

David Nelson

John Milton

Peter Thomas

Sussane Vincent

PRODUCT ASSOCIATE

Veronica Wilson

CIRCULATION TEAM

Sam Smith

SUBSCRIPTIONS IN-CHARGE

Vijay Kumar Gaddam

HEAD-OPERATIONS

Sivala VNR

www.pharmafocusamerica.com

Ochre Media Group info@ochre-media.com www.ochre-media.com

©Ochre Media Private Limited. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying or otherwise, without prior permission of the publisher and copyright owner. Whilst every effort has been made to ensure the accuracy of the information in this publication, the publisher accepts no responsibility for errors or omissions.

The products and services advertised are not endorsed by or connected with the publisher or its associates. The editorial opinions expressed in this publication are those of individual authors and not necessarily those of the publisher or of its associates.

Copies of Pharma Focus America can be purchased at the indicated cover prices. For bulk order reprints minimum order required is 500 copies, POA.

Magazine Subscribe

LinkedIn

www. pharmafocusamerica.com 5

Advances in mRNA Therapeutics and Vaccines

mRNA is a type of nucleic acid molecule that plays an essential role in the natural processing of genetic information. Using modern tools of molecular biology and genetic engineering, it is now possible to design synthetic mRNA molecules capable of executing an astonishing array of therapeutic functions. Advances in nanotechnology are starting to enable safe and effective delivery of therapeutic mRNA for the treatment of acquired and inherited conditions and for prevention of infectious disease.

Daniel Kavanagh PhD RAC, Senior Scientific Advisor, Gene Therapy, Vaccines, & Biologics, WCG

Prophylactic Vaccines

In the field of infectious disease, a prophylactic vaccine is a product that prevents disease by inducing an immune response against an infectious agent or pathogen. Prophylactic vaccines have played a critical role in the public health response to diseases such as smallpox, polio, measles, and many others – most recently COVID-19. The coordinated response by government, academic, and commercial research teams to the COVID-19 epidemic raised public awareness of the potential for mRNA vaccines to play a significant role in public health and resulted in the

RESEARCH & DEVELOPMENT

first two FDA approvals for mRNA products. These results helped to reinvigorate ongoing efforts to develop prophylactic mRNA vaccines for a broad variety of infectious diseases. In the coming years, mRNA vaccines will play an important and complementary role alongside other approaches, such as those involving recombinant proteins, live attenuated viruses, and engineered viral vectors in protecting public health.

For pathogens that cause cancer, such as human papilloma virus (HPV), a vaccine against that infectious agent can also contribute to protection against cancer. HPV prophylactic vaccination programs have provided significant public health benefits by reducing the occurrence of cervical cancer.

The molecular target of an induced immune response is called an antigen. Many investigators are interested in developing prophylactic vaccines that may prime an immune response directly against a cancer antigen rather than an infectious agent; however, development of such prophylactic cancer vaccines is still in early stages.

Therapeutic vaccines

Building on the science of prophylactic vaccines, much recent effort has focused on therapeutic vaccines. A therapeutic vaccine is intended to treat an existing disease by inducing an immune response against a disease-associated antigen. Some of this effort involves infectious disease, but most of the research is focused on treatment of cancer.

A defining feature of both prophylactic and therapeutic vaccines is the targeted induction of an immune response against one or more antigens associated with the disease. Most therapeutic drug products are not vaccines. However, modern gene transfer techniques provide shared platforms that are being used to develop (i) prophylactic vaccines, (ii) therapeutic vaccines and (iii) non-vaccine therapies across a broad range of therapeutic areas.

Gene transfer research

Gene transfer research constitutes a rapidly growing sector of drug/biologic product development and encompasses the closely related fields of cell and gene therapy (CGT), gene editing, molecular medicine, genetic medicines, and advanced therapy medicinal products.

In every nucleated cell, genetic information is stored as DNA in chromosomes in the nucleus, where that information is transcribed into RNA, which then exits the nucleus and passes into the cytoplasm. In the cytoplasm, information from this RNA is translated into proteins, which act as essential structural and enzymatic components of cells. RNA performing this function of carrying the message encoding instructions for the protein sequence from the nucleus to the cytoplasm is called messenger RNA (mRNA). Molecular interventions that add or alter genetic information in DNA or mRNA have the potential to affect almost any biological

www. pharmafocusamerica.com 7

RESEARCH & DEVELOPMENT

process controlling human health and disease. The key challenges are making the correct genetic changes and targeting them to the correct cells.

Transient nature of mRNA

As part of the natural process of gene expression, individual mRNA molecules are generally short-lived in the cytoplasm. The transient nature of mRNA is an essential aspect of dynamic gene regulation. For some applications utilizing engineered mRNA, highly transient expression is desirable. For other applications, investigators have developed modifications to the basic mRNA design that result in mRNA persistence and prolonged translational activity. Some such modifications are based on naturally occurring sequence variations that signal the cell to protect and preserve the mRNA molecule. Other approaches use chemical modifications of the building blocks of mRNA not found in nature to protect the mRNA product from rapid degradation. Discovery, testing, and implementation of these modifications to basic mRNA chemistry have been critical steps in enhancing the efficacy of mRNA products destined for commercialization and clinical use.

Introducing genetic information into a cell

One way to deliver new genetic information to a cell is by adding genetically modified DNA. For most systems, the engineered DNA must cross both the outer plasma membrane of the cell and

the nuclear membrane to reach the nucleus, where the genetic information can be expressed. Often the engineered DNA is delivered by means of a viral vector—a biological construct derived from a wildtype virus that has been extensively modified to carry recombinant genetic material and not cause disease. Viral vectors are the key components in successful products including both prophylactic vaccines and gene therapies for cancer and other diseases. Many different families of wild viruses serve as the basis for engineered viral vectors in clinical and preclinical development. Various FDA-approved products utilize viral vectors based on adenoviruses, adeno-associated viruses (AAV), and herpes simplex viruses. Compared to most small molecules and many biologic products, viral vector products involve complex and resource-intensive efforts for design, testing, manufacturing, and quality control.

Rather than directing DNA to the nucleus, another way to deliver genetic information to a cell is to introduce synthetic mRNA into the cytoplasm. In contrast to most DNA-based approaches, genetic information encoded in synthetic mRNA can be expressed immediately upon entering the cell and does not need to cross the nuclear membrane to enter the nucleus, be transcribed, and then exit the nucleus to reach the cytoplasm as a translatable message. Thus, functional gene delivery by synthetic mRNA is simpler than that required for DNA in significant ways. Rather than viral vectors, many approaches

8 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

to mRNA delivery utilize nanoparticles. The simplest nanoparticles for gene transfer use lipid or lipidoid compounds to form selfassembling nanoscale spheres around mRNA cargo. These particles serve the dual function of protecting mRNA from destructive enzymes in the environment and allowing the mRNA to cross the plasma membrane and enter the cell.

The DNA in our chromosomes is chemically very stable, with information stored in two complementary strands assembled as a double-helix (double-stranded DNA). mRNA

is a single stranded molecule, inherently less stable and suitable for transient functions in the cell. Partly as a mechanism for protection against dangerous viruses, our bodies produce an excess of RNA-degrading enzymes, called RNAses. For these reasons, in the past, mRNA molecules were often regarded as too unstable to be very useful for drug development. Recent experience has shown that RNA prepared under strict RNAse-free conditions and packaged appropriately, as with lipid nanoparticles, is quite stable and very much suitable for use as a drug substance in many applications.

Manufacturing biological products

Non-biologic drugs such as small molecules can often be manufactured via an easily routinized process that reliably yields a product with predictable CMC (Chemistry, Manufacturing, and Control) output. In contrast, biological products in the CGT category often pose severe challenges for design, testing, and CMC, due to the complexity of products comprised of nucleic acids, proteins, lipid membranes, and in some cases living cells. With synthetic mRNA, manufacturing considerations are largely independent of the sequence of the genetic code, meaning that an established manufacturing process for one mRNA

product can often be implemented broadly in many different applications. In this way, the production of mRNA drug products is more like non-biologic chemical drugs than most CGT products. Using advanced sequencing and bioinformatics techniques, it is possible to acquire genetic sequences from biological samples and generate new mRNA products within a very short timeframe – within days of sample acquisition for preclinical research. This allows mRNA products to be incorporated into rapid-response plans for public health emergencies for example. This flexibility also makes mRNA approaches suitable for personalized therapeutic cancer vaccines.

www. pharmafocusamerica.com 9

RESEARCH & DEVELOPMENT

Commercialization Challenges

As discussed above, DNA-based gene transfer approaches usually rely on a viral vector for gene delivery. One of the most popular platforms uses AAVs as vectors for DNA transfer. An important issue with these vectors is that for any natural AAV serotype, a significant percent of the population will have circulating antibodies that neutralize the respective AAV vector. Seronegative individuals usually seroconvert after a single dose of AAV gene therapy, and thereby become ineligible for future treatment with the

same AAV serotype. As a result, most AAV products are designed to be one-and-done treatments, intended to provide lifelong therapeutic effects without the possibility of re-dosing. The one-time nature of AAV dosing poses significant challenges for dose-finding studies, as well as for longterm follow up to assess safety and efficacy. This treatment approach is also a challenge for commercialization strategies given that payment models in many therapeutic areas are built around the assumption that the same drug will be administered in multiple doses over time.

Advantages for clinical applications and commercialization

In contrast to AAVs, mRNA lipid nanoparticles currently in use do not induce an immune response to the particle that interferes with redosing. Furthermore, as explained above, after administration, synthetic mRNA products are usually short-lived in the cell and result in transient protein expression. In combination, these factors make it easier to optimize dosefinding approaches with mRNA compared to AAVs. The ability to apply repeated doses allows for serial boosting in vaccination regimens. As a therapeutic approach for chronic disease, mRNA treatment plans would potentially allow continuous administration of the therapeutic in multiple doses for as long as clinically necessary; they would also allow for rapid

cessation of treatment in case of unwanted side effects and adverse events. It is likely that commercialization plans for mRNA-based therapies would also be more compatible with standard reimbursement plans for the cost of drugs. While AAVs and other vectorbased approaches will certainly be the basis for many valuable new therapies for the indefinite future, mRNA presents an opportunity to develop complementary modalities in many therapeutic areas.

Targeting neoantigens

One area where mRNA therapeutics show particular promise is the development of personalized vaccines. An essential challenge in cancer immunology comes from the fact that cancer cells originate from the patient’s

10 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

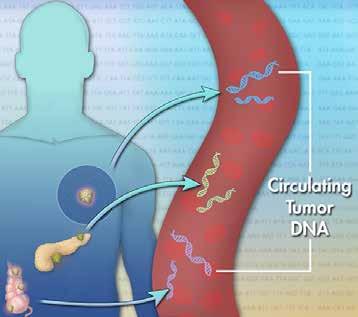

own tissue. This means that most potential antigens found in tumor cells are shared with normal healthy tissue and cannot be the basis of a useful immune response. Over the course of oncogenesis, tumors usually undergo extensive mutations in tumor cell chromosomal DNA. Many of these changes encode proteins that contain altered, tumorspecific antigens, also known as neoantigens. A key feature of neoantigens is that they are sufficiently distinct from antigens in normal tissue to serve as targets for an immune response. For certain cancer types, immune responses directed against neoantigens have been shown to provide significant clinical benefits in preclinical and clinical testing. For most tumor types, the majority of neoantigens detected from a biopsy are “private” and specific to the respective individual patient.

Creating personalized cancer vaccines

As noted above, new mRNA products can be rapidly designed and manufactured from any genetic sequence. This makes mRNA a promising platform for personalized cancer vaccines. To create a personalized vaccine, investigators sequence genetic content of a tumor biopsy and use bioinformatic methods to identify potential neoantigen targets –representing protein sequences present in the tumor but not in healthy tissue. mRNA encoding those neoantigen targets can then be rapidly synthesized and administered to the originating patient in an immunogenic

formulation to induce a protective immune response against the tumor.

As with any new treatment approach, development of neoantigen vaccines involves challenges and potential pitfalls. If the identified neoantigens are too similar to native host proteins, then the immune system may fail to see the neoantigens as “non-self,” and thus may fail to mount an effective response. Alternatively, if the neoantigens are too similar to native host proteins, an aggressive immune response could be primed against both the tumor antigen and normal healthy tissue, resulting in potentially serious autoimmune disease. Another potential issue is that neoantigens are often the result of extreme genetic instability of tumors. Therefore, as effective immune responses start to suppress the tumor, the tumor may rapidly evolve to cease expression of the most effective neoantigen targets. This process is called

www. pharmafocusamerica.com 11

RESEARCH & DEVELOPMENT

antigenic escape. One approach to minimize antigenic escape is to vaccinate with many neoepitopes at once. At the time of this writing, news reports indicate very promising results in a Phase 2b clinical trial of a personalized mRNA vaccine in combination with an anti-PD-1 immunotherapy, in participants with Stage III/IV melanoma.

To date, the majority of clinical trials of mRNA products have been for prophylactic vaccines for infectious disease. Most of the remaining trials are for the development of therapeutic cancer vaccines. Nevertheless, there are many preclinical and clinical efforts to apply mRNA in the area of nonvaccine therapeutics. One promising approach is a gene replacement therapy for inherited rare disease.

Rare disease applications

There are more than 7,000 rare diseases recognized, with a large percentage being congenital conditions affecting individuals that received two defective versions of the same gene, one from each parent (i.e., through autosomal recessive inheritance). In theory, each of these conditions should be treatable via molecular gene replacement therapy. Gene replacement refers to a variety of therapeutic approaches whereby the missing function of the defective gene is restored by delivering a corrected gene to some key tissue in the body. To date, most gene replacement therapy approaches have utilized AAV, an approach with great potential and significant drawbacks as described above. Some of those drawbacks

may be avoided with mRNA-based gene replacement, and ongoing efforts in this area include clinical trials in cystic fibrosis and a variety of inborn errors of metabolism.

Aside from gene replacement, mRNA can potentially be utilized for the delivery of a next generation of products developed with synthetic biology. Synthetic biology uses systematic modular engineering approaches to create novel biomolecules, some of which perform new functions distinct from any natural molecules. Some products of synthetic biology may enable white blood cells to recognize and attack tumor cells. Some are designed to detect and correct hormonal imbalances in vivo in real time. For clinical purposes, the underlying genetic constructs may be delivered by a variety of gene transfer techniques, including mRNA. Thus, we can expect mRNA to be an important part of the drug development landscape in the coming decades.

12 PHARMA FOCUS AMERICA ISSUE 01 - 2023 AUTHOR BIO

Daniel Kavanagh, PhD RAC, Senior Scientific Advisor, Gene Therapy, Vaccines, & Biologics, WCG, where he engages with sponsors, CROs, and research institutions on topics related to human gene transfer research. He was previously an Assistant Professor of Medicine at Harvard Medical School, and a member of the Executive Committee of the Harvard Center for AIDS Research.

RESEARCH & DEVELOPMENT

Using Quantitative Systems Pharmacology Modelling to Accelerate Drug Development

Model informed drug development (in silico modelling) continues to be a game changer in accelerating drug development. Quantitative Systems Pharmacology (QSP) is one such technology, which employs virtual patients in virtual clinical trials, allowing more approaches to be investigated than would be possible in the real world. Examples described here demonstrate the impact on some of today’s most urgent medical needs, including evaluating a potential treatment for Alzheimer’s disease, paediatric dosing for a COVID-19 vaccine, and evaluation of novel therapies for irritable bowel disease.

Piet van der Graaf

Senior Vice President, Quantitative Systems Pharmacology, Certara

Quantitative systems pharmacology (QSP) combines computational modelling and experimental methods to explore the relationship between a drug, human biology, and the disease

process. QSP modelling leverages large quantities of biological and pharmacological data to increase scientific knowledge of disease pathophysiology and facilitate the investigation of different therapeutic

RESEARCH & DEVELOPMENT

approaches in virtual patients in virtual clinical trials. As virtual patients are used instead of real people, QSP modelling saves time and money and allows more drug doses and drug combinations to be investigated than could be practically and ethically evaluated in real life.

QSP modelling can help to identify a new drug target or biomarker, select the optimal drug dose for a vulnerable patient population or an individual patient, repurpose an existing on-market drug for a different indication or develop a new combination therapy.

QSP is a relatively new discipline, but it is already having a profound impact on decision making at many stages along the drug development continuum. In a CPT:

Treating Alzheimer’s Disease

Eisai and Biogen Inc. announced positive results from their large, global, Phase 3 confirmatory Clarity AD clinical study of lecanemab on November 29, 2022. Lecanemab is an investigational antiamyloid beta (Aβ) protofibril antibody for the treatment of mild cognitive impairment due to early Alzheimer's disease (AD) with confirmed presence of amyloid pathology in the brain. Clinical results were presented at the 2022 Clinical Trials on Alzheimer's Disease conference, in San Francisco, California.

Pharmacometrics & Systems Pharmacology paper published in November 2022, U.S. Food and Drug Administration (FDA) staff reported that there has been a notable increase in the number of regulatory submissions that contain QSP, including Investigational New Drug Applications (INDs), New Drug Applications (NDAs), and Biologics License Applications (BLAs) during the past several years. Their report concluded that QSP is increasingly applied to model and simulate both drug effectiveness and safety throughout the drug development process across disease areas.

The following case studies illustrate what all the excitement is about and demonstrate QSP’s potential to advance drug development.

Lecanemab treatment showed 31% lower risk of converting to next stage of disease by Global CDR assessment (Hazard Ratio: 0.69). A slope analysis using CDR-SB based on observed data and extrapolation to 30 months showed that lecanemab takes 25.5 months to reach same level as placebo at 18 months, indicating a 7.5 month slowing of progression.

The Certara team had started to work with Eisai about two years before these results were announced and developed a QSP model to predict and help interpret the outcomes of the trial. In fact, Certara’s

14 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

Studying Amyloid Aggregation

AD pathogenesis is widely believed to be driven by the production and deposition of the Aβ peptide. Amyloid aggregates are classified as monomers, oligomers, protofibrils and fibrils based on their size and solubility. As antiamyloid monoclonal antibodies have different affinities for these species, it could lead to different levels of standardized uptake value ratio (SUVr) reduction, and potentially different clinical outcomes.

Certara created an amyloid QSP model to study lecanemab. The model included all known features of the Aβ aggregation process, together with the mechanisms of action employed by drug candidates endeavouring to treat Alzheimer’s disease by modifying Aβ pathology.

The model was validated by demonstrating that it could accurately replicate the clinical pharmacokinetic/pharmacodynamic (PK/ PD) data for several monoclonal antibodies – lecanemab, gantenerumab, solanezumab, bapineuzumab, and crenezumab. The model was then used to investigate 18 months of treatment with those antibodies, followed by 2.5 years of observation. The platform revealed significant differences in oligomer, protofibril, and plaque reduction between the monoclonal antibodies. At clinical doses, lecanemab produced pronounced reductions in protofibrils and the SUVr, which served as encouraging precursors to its phase 3 clinical results.

Other examples of using QSP modelling to predict clinical outcomes are included below.

COVID-19 Pediatric Vaccine Dosing

QSP model predicted the positive outcome of this trial about one year early, as presented at the AD PD Annual Meeting in March 2022.

At the start of the COVID-19 pandemic, Certara quickly realized that the QSP model of the human immune system that it had developed to predict immunogenicity with protein-based therapeutics, such as antibodies, could be repurposed as a vaccine model.

Immunogenicity, or the tendency to trigger an unwanted immune response, is a major problem with biological therapies because it can lower the patient’s exposure to the medicine and reduce its efficacy. Immunogenicity can also cause immune-related adverse events. While the goal of the original model was to identify drugs that generated low levels of immunogenicity, the goal of the new model was

www. pharmafocusamerica.com 15

RESEARCH & DEVELOPMENT

the opposite, to find vaccines that produced high levels of immune response to provide protection against the SARS-CoV-2 virus. Part of the COVID-19 virus sequence was input into the new vaccine model to demonstrate that it would generate an immune response. Then, the model was calibrated using the structure of actual COVID-19 vaccines and validated by replicating their published clinical data. The resulting COVID-19 vaccine simulator was able to predict with a virtual trial the outcomes of actual clinical trials using those vaccines.

The vaccine simulator was initially used to determine the optimal timing between COVID19 vaccine doses and whether vaccines could be combined during a shortage. Daiichi Sankyo employed Certara’s vaccine model to optimize the phase 1 study design for its COVID-19 vaccine and to predict immune responses in specific populations, such as Japanese people and older adults.

The focus later shifted to paediatrics where the simulator was used to guide dose selection in young children. That is one of the biggest challenges in vaccine development. When working with vulnerable populations, such as the elderly, young children, or babies, it is even more imperative to use exactly the right dose and not a little too much or too little. It is a delicate balancing act, selecting a dose that is high enough to be sufficiently efficacious but low enough to produce minimal side effects. The situation is more complex in children because their physiology, enzyme and transporter levels change as they mature. One

of the many advantages of QSP modelling is that it allows vaccine doses and other variables to be adjusted and the results observed virtually without the need to conduct clinical trials.

Pfizer-BioNTech’s rollout of its COVID19 vaccine was extremely successful. But even Pfizer-BioNTech had to redo its first paediatric COVID-19 vaccine trial and change the dosing regimen because two 3 µg doses of its vaccine did not produce a sufficiently protective immune response in children aged two to four years. They ultimately added a third 3 µg vaccine dose, administered at least two months after the second dose, for that population.

Certara’s COVID-19 vaccine simulator, which now includes 32 clinical datasets, three vaccines, eight dosing regimens, and 10 biomarkers, predicted that response. Its QSP model confirmed that two 30 µg doses of Pfizer-BioNTech’s COVID-19 vaccine would be effective in children aged 16 to 25 years (the same as an adult), two 10 µg doses (one-third the adult dose) would be effective in children aged 5 to 11 years, but two 3 µg doses (one-tenth the adult dose) would be ineffective in children aged 2 to 4 years and they would require a third 3 µg dose.

Inflammatory Bowel Disease

Inflammatory bowel disease (IBD) refers to two conditions, Crohn’s disease (CD), and ulcerative colitis (UC), which are characterized by chronic inflammation of the gastrointestinal (GI) tract. Prolonged inflammation results in damage to

16 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

the GI tract. IBD symptoms include persistent diarrhoea, abdominal pain, rectal bleeding/ bloody stools, weight loss, and fatigue.

In 2015, an estimated 1.3% of US adults (three million) reported having received a diagnosis of IBD. The prevalence of IBD varies based on a person’s age, race/ethnicity, education level, employment status, nativity, poverty status, and urbanicity. IBD occurs more often in non-Hispanic White persons than in other racial/ethnic groups.

The impact of medication on IBD symptoms has traditionally been hard to measure. When a patient with IBD meets with their clinician, they are often asked to rate how they are feeling on a scale of 1 to 5 with five representing the worst/most severe symptoms. But how do you rate “not great”? How do you represent biology on a questionnaire?

Further compounding the complexity of the situation, different hospitals use different disease activity scores to measure

disease severity and therapeutic outcomes. For example, the Mayo Clinic developed the Mayo Score/Disease Activity Index for Ulcerative Colitis to assess the initial disease severity, change in activity over time, and response to treatment. This scoring system factored in four elements: rectal bleeding, stool frequency, physician assessment, and endoscopic appearance. Each element was rated from 0 to 3, giving a maximum total score of 12. The higher the score, the more severe the ulcerative colitis.

But the FDA is now accepting a modified Mayo Score, which no longer includes mucosal friability in the endoscopic score or the physician’s global assessment in the composite index, and has a maximum total score of 9.

Clinicians prefer to use these scores rather than levels of biomarkers, such as fecal protectin (FCP) or serum c-reactive protein (CRP), when evaluating a patient’s progress because they also factor in clinical observations such as intestinal bleeding and ulceration.

The primary challenge in this field is how to link biological mechanisms to these subjective endpoints, which are the actual clinical development scores that clinicians use.

To achieve that goal, Certara combined QSP with model-based meta-analysis (MBMA), another in-silico technology, to create QSP models which can predict those subjective clinical endpoints in IBD. Essentially, the team used artificial intelligence and machine learning to link mechanistic QSP to clinical endpoint scores.

www. pharmafocusamerica.com 17

RESEARCH & DEVELOPMENT

QSP combines computational modelling and experimental methods to explore the relationship between a drug, human biology, and the disease process

QSP can model the biological effects of drugs up to the biomarker level, i.e., it can determine whether cytokine levels are going up or down. Then, MBMA uses data reported from clinical trials and in the scientific literature to correlate the tissue biomarker measurements from the QSP model with disease activity scores for UC and CD. It determines in a purely statistical manner what cytokine levels correlate with specific scores on the Mayo Scale.

The Certara team included inflammatory cytokines and therapeutic antibodies in a mechanistic, multistate QSP model. Then they added published baseline and patient Mayo Score, Crohn’s Disease Active Index (CDAI), CRP, and FCP data to enable correlation between the biomarker levels and clinical measurements. A virtual patient population was created with tissue cytokine, cell density, and gut measurements to match an existing clinical patient population. The tissue biomarkers used were Treg, TNFα, neutrophil, and Th17. An algorithm then assigned the appropriate clinical score to the virtual patients based on their Mayo, CDAI score distribution in relation to FCP or CRP. The resulting virtual population helped to train a multinomial logistic regression model which was able to successfully predict clinical response and remission rates for patients prescribed anti-TNFα (adalimumab), anti-IL-23 (mirikizumab) or a combination of the two drugs in clinical trials.

The resulting predictive model can now be used to guide dose selection for IBD drug candidates in Phase I/II clinical trials.

Prior to this breakthrough, most QSP model predictions ended at the biomarker level with no quantitative linkage to actual patient outcome.

Conclusion

QSP modelling is a powerful tool that can be applied throughout the drug development continuum from identifying a new drug target in the earliest stages through to predicting clinical outcomes. These advances all serve to accelerate the drug development process safely and efficiently.

Professor Piet van der Graaf is Senior Vice President, Quantitative Systems Pharmacology at Certara and Professor of Systems Pharmacology at Leiden University in the Netherlands. Before joining Certara, he was the Director of Research (CSO) of the Leiden Academic Centre for Drug Research and held various research leadership positions at Pfizer across discovery and clinical development.

18 PHARMA FOCUS AMERICA ISSUE 01 - 2023

AUTHOR BIO

RESEARCH & DEVELOPMENT

IgA-Mediated Inflammatory Disorders

Autoantigen-specific IgA, a biomarker with strong effector functions

Autoantigen-specific IgA autoantibodies closely correlate with symptoms severity in a subgroup of patients in multiple autoimmune diseases. High autoantigen-specific IgA serum levels will be used as companion diagnostic to stratify patients for personalized treatment with JJP-1212. Interfering with the IgA/ CD89 axis by JJP-1212, resolves IgA/ autoantigen-induced inflammation and tissue damage in autoimmune diseases.

Louis Boon

CSO & Board Member, JJP Biologics

In current drug development, we are educated and trained to follow identical development strategies that have been proven to be successful in the past and assume a guaranteed success for the future. However, as we see with the stock market, past successes do not guarantee anything for the future and a case-by-case customized approach is essential.

For example, consider the biology around IgA-IgA receptor (CD89 or FcαR1) interaction in which there are significant differences in species. Ample information has been published over the last 3 decades to show that levels and appearance of autoantigen specific IgA antibodies correlate very well with disease severity in over a dozen of different clinical

www. pharmafocusamerica.com 19

RESEARCH & DEVELOPMENT

autoimmune indications in humans. For this reason, it is difficult to understand why absolutely no therapeutic development efforts have been initiated to target the interaction between IgA and CD89. It becomes even more surprising when one considers the significant body of data that proves the functionality of the IgA-CD89 biology using human patient cells in in vitro experiments. It becomes even further surprising when you realize that auto-antigen IgA responses are already measured in a clinical setting and reported to for over thirty years to correlate with disease severity. The auto-antigen IgA antibody response, measured as antigen-specific IgA antibodies in patient serum, is a ready-made companion diagnostic (CDx) that provides the opportunity to stratify patients for interference of IgA-CD89. The question remains why in spite of all the evidence no development to target this pathway has been initiated? In the case of CD89, this is most probably due to the fact that the CD89 receptor is completely absent in murine models and therefore impossible to perform preclinical in vivo studies in mice or rat disease models, a presumed essential part of current drug development. Apparently, this has been viewed as a major roadblock, because the supportive human in vitro data has not resulted in the development of a specific drug for these patients with high IgA autoantibodies. Blindly follow the identical route without considering a detour may end up at a roadblock, like with geese that colliding with the wind turbines and are dying because

the always follow the identical route. In my view, not a major issue, since geese that fly into a stationary wind turbine can be categorized into the group of “stupid geese” because they always follow the same route, and ultimately we can let natural selection take care of it since there is a group of “smart geese” that exist, which are fast, flexible, creative and adapt easily to new situations that will escape a tragic death following a collision with a wind turbine. For the development of a drug like anti-CD89 a detour around the roadblock of preclinical in vivo evidence is needed and behavior like a fast, flexible and creative smart goose is needed. We have faced many examples where accumulating evidence proceeds protective action. With age, we can become more nostalgic, how many of us have heard elderly parents lament the current state of society and refer to the GOOD OLD DAYS when life was so much better or so it seemed. Wouldn’t it be interesting to go back in time and be a fly on the wall during the so called GOOD OLD DAYS to witness what was so good. For those of us of a certain age, we can recall jumping into a car without seatbelts, flying through the streets on motorbikes without a helmet and not a care in the world. The tobacco industry

20 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

was able to convince people of the benefits of smoking, and whether you were convinced by that or not, you were subjected to other people’s smoke in close confinement such as aircraft cabins or entertainment venues. Alcohol was seen as a tonic, in particular doctors would encourage pregnant ladies to take a Guinness a day and excessive consumption was seen as a virtue. There was no understanding of the link between LDL cholesterol and heart disease, the so called benefits of fatty foods outweighed any negative impacts. Many of the chemicals that we came into contact with on a day to day basis were deemed to be safe and useful, asbestos, in particular, had a place in many homes across Europe.

All of this flies in the face of what we currently understand, and it is only through a scientific endeavour that enabled a change in public health. Let’s remember, the pioneering epidemiologists, Doll and Hill first published a series of ground breaking papers on the impact of environmental and lifestyle factors on health in 1954, yet a complete change in perception of these practices was not fully accomplished until the 1990s, and in some nations, the dated perceptions linger.

The historical resemblance of the involvement of IgA-autoantibodies in autoimmune disease, especially in rheumatoid arthritis (RA) and the serum levels of IgA autoantibodies (e.g., IgA-rheumatoid factor (IgA-RF)), is remarkable. It is curious to note that the link between high serum levels of anti-RF IgA antibodies and the severity

of RA was established over 30 years ago, and yet no one has really exploited this in delivering therapeutic interventions. Strong neutrophil-driven and CD89-mediated effector functions of IgA antibodies have been reported. The activation of neutrophils through IgA autoantibody-CD89, resulting in an excessive innate immunity response and has pathological consequences in autoimmunity. This justifies antagonizing the potent damaging and pathogenic effector functions of autoantigen specific IgA antibodies in autoimmunity by an antagonist anti-CD89.

RA is the most common autoimmune disease, affecting 0.5 to 1.0% of the world population, it is characterized by chronic inflammation in the symmetric joints and by the appearance of autoantibodies and infiltration of inflammatory cells. Blocking TNFα in RA patients has remarkably improved treatment outcomes for RA patients. Still, about 25-30% of anti-TNFα treated RA patients, do not effectively respond to treatment and for this non-responsive group, RA is a highly personalized disease with regard to its flare ups and periods of remission. Each patient's unique disease pathology requires a high level of personalization in terms of treatment, which can be achieved by stratifying patients according to biomarker profiles through the use a CDx. Precision medicine treatments are rapidly shifting the treatment of many diseases from a ‘one-size-fits-all’ to a ‘targeted testing and treatment’ approach. Since the determination of various isotypes

www. pharmafocusamerica.com 21

RESEARCH & DEVELOPMENT

of autoantibodies (e.g., IgM-RF, IgG-RF and sometimes IgA-RF) in RA patients is included in current standard diagnostic practice, potential effector cells and mechanisms responding to autoantibody complexes can be predicted and novel therapeutics developed. Local autoantibody complexes provide a highavidity matrix for homing of cells expressing the corresponding Fc-receptor. These cells subsequently locally get activated inducing collateral tissue damage and aggravating and broadening the inflammatory response. Interestingly, high pre-treatment levels of IgA RF are associated with a poor clinical response to TNFα inhibitors. Whereas patients with low IgA-RF and those with negative IgA-RF had a good response rate, patients with high positive IgA-RF were poor responders to anti-TNF treatments. This perfectly shows how already available CDx (anti-RF IgA) and clinical unresponsiveness to current treatment can enable a personalized medicine approach for patients receiving JJP-1212. The absence of IgA autoantibodies renders JJP-1212 into a non-relevant treatment in these specific IgA negative patients. By excluding these IgA negative patients, potential adverse events of the negative group will be excluded and potential adverse events are limited to the IgA positive patients in which JJP-1212 can have its clinical efficacy. Such a personalized medicine approach, supported by the failure to respond to a current treatment and a relevant CDx, provides a strategy that optimizes clinical development with respect to efficacy, risk and

costs. For note in the realm of personalized medicine, costs are associated with failure to effectively treat patients such that the symptoms of a chronic disease have to be continually treated palliatively, additionally giving a targeted treatment to a biologically irrelevant individual in which a CDx does not support its use, can cause more damage than simply administering a placebo. The massive and impressive amount of data which associates IgA autoantibodies to severity of disease in RA, makes it hard to understand why no therapeutic interventions were designed to antagonize this pathway. The considerable species differences in the IgA-CD89 axis may have contributed to this, since in vivo evidence is hard to obtain when biology is completely different between species. So despite having evidence of the causal link between IgA autoantibodies and disease severity for many years, little has been done with this data to address and treat the progression of disease in this cohort of patients. It seems therefore inevitable to subdivide high titre IgA autoantibody RA patients in a new clinical indication: IgA-mediated RA and subsequently customized their treatment protocol to their disease specifically supporting a personalized medicine approach.

With all these positive points it is incomprehensible why targeting this pathway has been completely ignored. The answer to this lies in the fact that there is considerable species difference in the biology and that mice do not have CD89. Hence it becomes difficult to get in vivo proof of concept data for this pathway in

22 PHARMA FOCUS AMERICA ISSUE 01 - 2023

RESEARCH & DEVELOPMENT

mouse models. Since both venture capital funds and large pharma due diligence teams stipulate that in vivo proof of concept is essential to support their investment analysis, the absence of animal models to support IgA-CD89 as a target has been drowned by development dogma. Targeting the CD89 receptor needs an unconventional approach in which animal experiments can only be done using transgenic animals delivering limited information, and therefore a custom approach is obligatory that needs fast and flexible adaptation and creativity in development.

The parallel between the situation with our bad habits from the GOOD OLD DAYS, for which healthcare professionals were able to initiate changes in public health with massive and impressive amounts of data which conclusively demonstrated causal links, is remarkable. They succeeded to discourage and reduce smoking, reduce consumption of alcohol and junk food and obliged the use of safety belts and helmets over time. Improvements in current diagnosis, application of RF-IgA as CDx and treatment in RA using JJP-1212 in the future will make us smile retrospectively and make us conclude that the GOOD OLD DAYS when anti-TNFα therapies and small molecule treatments prevailed in the treatment of severe RA and were not always that good.

By following a standard, so called tried and tested drug development route, new therapies with significant potential such a targeted antagonist anti-CD89 antibody are at risk of being lost. The IgA-CD89 example

shows that drug developers that blindly follow the same established pathway without adapting diverting onto an alternative route are consigning themselves to the same fate of as the “stupid goose” that is found lying dead under a turbine. It’s up to you to decide which category of geese you would like to belong! Unevidentely, this will result in joining and supporting the “SMART GOOSE” community.

www. pharmafocusamerica.com 23

AUTHOR BIO

RESEARCH & DEVELOPMENT

Louis is CSO and Management Board Member of JJP Biologics, an innovative Polish Company backed by the Starak family. JJP Biologics develops novel personalized medicine and companion diagnostics. Louis is an author of over 350 publications and an inventor at more than 20 patent applications.

Recombinant Antibody Production in Drug Discovery

Therapeutic antibodies are one of the best-selling drug classes in the pharmaceutical market, and the advent of antibody engineering and recombinant production dramatically improved the arsenal of therapeutics against acute and chronic diseases.

Li Na, Technical Account Manager, Sino Biological

Antibody engineering and production are essential tools in drug discovery, providing powerful and specific therapeutics and diagnostic or prognostic materials for various diseases. Antibodies are proteins produced by the immune system in response to foreign invaders,

Antigen

such as bacteria or viruses. They can bind specifically to these invaders, neutralizing them and preventing them from causing harm. Over the last few decades, scientists have developed methods for engineering and producing antibodies that can be used as drugs.

Myeloma cells

Mouse

B cells

24 PHARMA FOCUS AMERICA ISSUE 01 - 2023

Monoclonal antibody Hybridoma

Figure 1. Hybridoma technology

This article will provide an overview of the process of antibody engineering and production as well as their applications in drug discovery.

History

The history of antibody engineering and production in drug discovery can be traced back to the 1970s and 1980s, when scientists first began to explore the potential of using antibodies as therapeutics. The first-generation antibodies were derived from natural sources, such as animal blood, and were used primarily as diagnostic reagents.

One of the key early milestones in the history of antibody engineering was the development of hybridoma technology in 1975 by César Milstein and Georges Köhler. This allowed for the production of monoclonal antibodies (mAbs) by fusing a B cell, which produces a single antibody type, with a myeloma cell that can divide indefinitely (Figure 1). This made it possible to produce large quantities of specific antibodies. However, the production of early mAbs was limited by the availability of suitable myeloma cell lines (usually mouse or rat) and the fact that hybridomas can be low-yielding or genetically unstable. (Figure 1)

In the 1980s, scientists began to develop methods to produce recombinant antibodies, which are made using genetic engineering techniques. These methods allowed scientists to produce large quantities of pure and consistent antibodies in a controlled environment. This was a significant

step forward, as it made it possible to manufacture antibodies on a large scale for use in preclinical and clinical trials.

Then, about a decade later, the development of display technologies, such as phage display, yeast display, and ribosome display, made it possible to screen large libraries of antibodies for specific binding properties. This quickened the process of identifying antibodies that bind to specific antigens. This also made it possible to optimize the structure of antibodies to improve their binding properties using mutant libraries. Such display technologies, particularly phage display, are a major driving force in the discovery of numerous antibodies that can be engineered, optimized, and recombinantly produced. Phage display antibody library technology involves multiple steps, including the construction of phage display antibody libraries, panning, mAb identification, and recombinant expression of positive clones (Figure 2). Sino Biological is specialized in recombinant protein production and antibody development. Based on its expertise in the construction and screening of phage display antibody libraries, Sino Biological provides efficient antibody discovery services. (Figure 2)

The first licensed mAb drug was muromonab-CD3 (1986), a hybridom-derived antibody that was used for immunosuppression during organ transplantation. Rituximab (Rituxan), approved by the FDA in 1997, targeted the CD20 protein in B-cell non-Hodgkin’s lymphoma. It marked a significant milestone in the

www. pharmafocusamerica.com 25

RNA isolation Tissues VL/VH scFv Cloning Phagemid Electro-transformation Phage Library Sequencing Phage Amplification Hits Expression Clones Analysis Phage Elution Washing Panning 2~4 Rounds Target Binding Phage Library Amplification Flexible screening strategies Supernatant screening Multiple screening methods 1 2 3 4 5 6

Figure 2. Technical route of phage display library construction and screening

field of antibody engineering and production as it was the first antibody drug made with recombinant technology. Rituximab was also the first monoclonal antibody approved for cancer treatment, followed by a number of other mAbs in the following years. Since then, approximately 170 antibodies and antibody-based therapeutics (including antibodydrug conjugates) have been approved by authorities worldwide.

Antibody optimization

Besides the ability to produce large quantities of antibodies with a controlled quality, benefits of recombinant antibody production include: through antibody engineering, allowing for the generation of different antibody structures and derivatives (Figure 3), such as bispecific antibodies (bsAbs) and Fc-fusion proteins; and enabling the optimization of antibody structure, which can be done by introducing mutations into antibody genes, in order to improve the clinical effectiveness of antibodies. (Figure 3)

BsAbs, which are designed to bind two different antigens or epitopes at the same time, have a wide range of applications, including redirecting specific immune effector cells to tumour cells and blocking two different pathways. Fc-fusion proteins, composed of the Fc region of an IgG antibody and a desired linked protein, such as receptor extracellular domains, enzymes, cytokines, and active peptides, have additional beneficial biological and pharmacological properties. The primary reason for fusing a biologically active protein of interest with Fc is that the Fc domain contributes to plasma half-life extension. Sino Biological has extensive experience in producing recombinant antibodies in diverse formats

and provides a variety of service packages to meet different research and drug discovery needs.

Antibody humanization is one of the key antibody optimization technologies. Humanized antibodies represent a major type of antibody drug. The clinical application of mouse mAbs is limited by the human anti-mouse antibody (HAMA) response, which not only neutralizes these therapeutic antibodies but also leads to an allergic response in patients. Humanization of mouse mAbs by genetic engineering can minimize the heterologous nature of mouse mAbs while maintaining their specificity and affinity. Humanized antibodies also improve the safety and therapeutic efficacy of mAbs in clinical applications. Sino Biological provides high-quality mAb humanization services using complementaritydetermining region (CDR) grafting technology and computer-aided molecular modeling (Figure 4).

More optimization methods are evolving as the field of antibody engineering and production continues to expand. For instance, scientists can optimize the way an antibody binds to its antigen using techniques such as artificial intelligence (AI)-driven affinity maturation performed in silico instead of relying on in vivo affinity maturation that requires animal use. Sino Biological provides an AI-driven affinity maturation service, which is a computational and experimental service aimed at improving the affinity and specificity of mAbs using machine learning algorithms to predict the effect of mutations on antibody-antigen binding and then validating the predictions in a wet lab (Figure 5). This service is useful for researchers who are developing mAbs for therapeutic or diagnostic applications, making their candidate antibodies more effective. (Figure 5)

26 PHARMA FOCUS AMERICA ISSUE 01 - 2023 VL CL CH1 VH CH2 CH3 Fab Fc IgG Nanobody Bispecific scFv Bispecific F(ab)2 Fc-fusion Protein ScFv Fab

Figure 3. Examples of recombinant antibody formats

Process

Production method

Once the desired antibody sequences are obtained, they must be produced in large quantities for use in drug development. This is typically done by growing large numbers of cells, such as Human Embryonic Kidney 293 (HEK293) cells or Chinese hamster ovary (CHO) cells, which have been genetically modified to produce the desired antibodies. CHO and HEK293 cells are advantageous over other host cells, such

as E. coli and yeasts, due to their high capacity for post-translational modifications, which are important for the proper folding and activity of antibodies. The cells are grown in large bioreactors and are given the nutrients and growth factors they require. Then, the antibodies are purified from the culture media with various available purification techniques and are ready for use in in vitro, preclinical,

clinical studies.

www. pharmafocusamerica.com 27

and

FR1 CDR1 CDR2 CDR3 FR2 FR3 FR4 FR1 CDR1 CDR2 CDR3 FR2 FR3 FR4 FR1 CDR1 CDR2 CDR3 FR2 FR3 FR4 CDR Identification & 3D Structural Modeling CDR Grafting Mouse Antibody Human Framework Region Humanized Antibody Back Mutations

Figure 4 depicts the antibody humanization and CDR grafting technology processes

Antibody

Chimeric Antibody Humanized Antibody Mouse Antibody CDR Grafting Technology

of

Humanization

Lead Time 4 weeks 103 increase High Affinity 15% Hit Rate Screen up to 1010 sequence space Direct access to sequence No animal use Cost effective Can be combined with “humanization” module Higher hit rate will be achieved on subsequent computation by incorporating wet-lab data

Figure 5. AI-powered affinity maturation platform advantages

Future perspectives

Antibodies have become one of the most successful classes of therapeutics used to treat various diseases, including cancer, autoimmune diseases, and infectious diseases. They are also essential tools for biomarker detection in the process of drug discovery.

Researchers are still working on improving the manufacturing process and developing new ways of engineering and high-throughput (HTP) procedures to produce antibodies that can be used during drug discovery. Sino Biological is continually working on developing new workflows and methods to improve the efficiency and reduce the cost of antibody production. Sino Biological currently offers HTP recombinant antibody production services, providing the most cost-effective solution for the rapid production of a large number of antibodies. In response to the rapidly increasing therapeutic needs, Sino Biological combines its expertise in gene synthesis, vector design, and transient antibody expression technology to produce highly efficient antibodies in HEK293 and CHO cells in as little as 2 weeks (Figure 6).

The future of recombinant antibody production is expected to be driven by several factors, including the development of new technologies, increased demand for therapeutics, and the need for more affordable and efficient production methods. The field is likely to continue to evolve and expand, providing new opportunities for the development of more effective and accessible therapeutics.

1. Marks L. The birth pangs of monoclonal antibody therapeutics: the failure and legacy of Centoxin. MAbs. 2012;4(3):403-412. doi:10.4161/mabs.19909

2. Liu JK. The history of monoclonal antibody developmentProgress, remaining challenges and future innovations. Ann Med Surg (Lond). 2014;3(4):113-116. Published 2014 Sep 11.

doi:10.1016/j.amsu.2014.09.001

3. Geyer CR, McCafferty J, Dübel S, Bradbury AR, Sidhu SS. Recombinant antibodies and in vitro selection technologies. Methods Mol Biol. 2012;901:11-32. doi:10.1007/978-1-61779931-0_2

4. Wang SS, Yan YS, Ho K. US FDA-approved therapeutic antibodies with high-concentration formulation: summaries and perspectives. Antib Ther. 2021;4(4):262-272. Published 2021 Nov 18. doi:10.1093/abt/tbab027

5. The Antibody Society. Therapeutic monoclonal antibodies approved or in regulatory review. (Accessed on January 10, 2023); www.antibodysociety.org/antibody-therapeutics-product-data

Na Li (Lina), Ph.D., QIHCCM, is a technical account manager at Sino Biological. She has completed her Ph.D. research at the Singapore-MIT Alliance for Research and Technology. She has multiple years of experience as an antibody-based assay development scientist and has led pre-clinical projects involving multiple research areas, including cancer therapy, toxicology, and infectious diseases. Lina joined Sino Biological in 2022 as a technical account manager, helping clients from various biotechs, academic research groups, and pharmaceutical companies with protein and antibody development.

28 PHARMA FOCUS AMERICA ISSUE 01 - 2023 AUTHOR BIO

References

Sequence Synthesis Vector Transient Expression Purification & QC Fast Delivery Framework & Sequence Check Codon Optimization Multiple Isotypes & Species Available HEK293/CHO Cells Optimized Culture Conditions to Increase Yield Guaranteed 100% Success Rate Flexible Scales Guaranteed Purity >90% or Higher SDS-PAGE, Endotoxin Additional Characterization Tools (ELISA, Octet, FC, Biacore, SEC, etc.) High-copy Expression Vector

Figure 6. Technical workflow of Sino Biological’s high-throughput recombinant production platform

“Digital Transformation is the way forward”

Highly accountable marketing campaigns. Every dollar counts. Digitally powered marketing campaigns may be cheaper than you thought... Ask us how?

Use our guaranteed ROI programs for reposition, penetrate or launch of your new products or services.

Grow your audience with increased reach, impact and user-friendliness

Rise above geographical boundaries

Generate new business

Gain the strong web presence differentiating yourself from competitors

Connect and engage with your target audience

Give more exposure to industry specific people

Increase your brand profile and share your capabilities with leading industry professionals

pharmafocusamerica.com 29

Let the true “Digital Transformation” be the base of all your marketing campaigns

UPGRADE YOUR MARKETING STRATEGY

Email : advertise@pharmafocusamerica.com Website : www.pharmafocusamerica.com Our recent successful partnerships:

Decentralization - The Future of Clinical Trials

Nicoleta Grecu Director, Pharmacovigilance, Clinical Quality Assurance, Clover Biopharmaceuticals

Nicoleta Grecu Director, Pharmacovigilance, Clinical Quality Assurance, Clover Biopharmaceuticals

The COVID-19 pandemic made the regulatory authorities recognize that there is a need for change in the conduct of clinical trials. Clinical trial management guidelines were released to adjust to the hindrances that this pandemic brought but also to support pharmaceutical innovation, especially for COVID19 vaccines and treatments. These changes led to decentralized clinical trials. Currently, the regulatory authorities are working to strengthen the system and the regulatory framework for decentralization. The first steps in this direction were taken, but more changes are about to come.

Decentralization was a necessity for the conduct of the clinical trials during the Coronavirus Disease 2019 (COVID-19) pandemic. This new way of managing clinical trials became a more recognized concept during the past few years that needs further development and a regulatory framework.

The decentralized clinical trial (DCT) is defined by the Food and Drug Administration (FDA) as "a clinical investigation where some or all of the trial-related activities occur at a location separate from

30 PHARMA FOCUS AMERICA ISSUE 01 - 2023

CLINICAL TRIALS

the investigator’s location." DCTs are divided into two categories based on the degree of decentralization, which can range from fully decentralized to partially decentralize. In the case of a fully DCT approach, all trial procedures are conducted remotely through digital means and supply delivery with no in-person visits required to the trial site, whereas a hybrid approach may include some decentralized trial activities combined with traditional trial procedures such as in-person visits via mobile clinicians or alternative sites.

Clinical trials are essential for drug development and improving the health of patients. The remote DCT approach was recommended for adoption during the pandemic, with the scope to facilitate participation in trials by offering maximum flexibility and convenience. Nevertheless, the DCT approach has been recognised to bring benefits, and there is an increased demand for conducting clinical trials remotely. Some of the benefits DCTs provide are presented in Image 1.

Hereinafter, the background of clinical trial decentralization, the current knowledge, and the future of DCTs will be described.

The desire to conduct fully or partially remote clinical trials has been supported by continuous technological advances despite the lack of a regulatory framework on this topic. The industry’s limited experience and the absence of corresponding infrastructure and regulatory guidelines slowed down DCT adoption.

Industry recommendations and best practices

The benefits of conducting remote clinical trials have been recognized over the last few years, especially during the COVID-19 pandemic. However, the challenges of implementing this approach compelled pharmaceutical companies, clinical research organizations, investigators, and technology companies to collaborate in order to accelerate the development of tools and methods for working with DCTs.

The first to issue relevant recommendations on DCTs is an organization that was co-founded by Duke University and the FDA, the Clinical Trials Transformation Initiative (CTTI). CTTI sought to develop and drive adoption of DCT practices by releasing their recommendations in 2018. These recommendations covered DCT approaches and protocol design in brief, as well as telemedicine state licensing issues, drug supply chain, mobile healthcare providers,

www. pharmafocusamerica.com 31

Participants Investigators Stakeholders Easier access to Clinical Trials Faster recruitment Less burdensome trial participation Better retention and engagement Potential for real-time feedback Less manual data entry Cost-effective Sense of ownership Real-time safety and monitoring Faster access to trial outcomes Trial data generated in real-world settings Agile and resilient trials Increased diversity of trial populations Greater geographical reach CLINICAL TRIALS

Image 1. Benefits of clinical trial decentralization

investigator delegation and oversight, and safety monitoring.

The opportunities brought by DCTs were further explored by a multi-stakeholder consortium supported by EU/EFPIA Innovative Medicines Initiatives (IMI), namely Trials@ Home, which had as common goal the development of in-depth recommendations and pilot tools supporting widespread acceptance and use of remote DCTs in Europe. Trials@Home issued their first deliverables in 2020, and since then they have completed several reports that are spread throughout six work packages, each of which focused on investigating solutions and developing practical recommendations for the adoption of DCTs on the following six topics: (1) best practices in DCTs; (2) technologies—barriers, enablers, and data management; (3) a pan-EU remote DCT pilot; (4) ethical, regulatory, good clinical practices (GCP), and legal aspects; (5) communication, dissemination, and stakeholder engagement; and finally, (6) project management and synthesis.

The Association of Clinical Research Organizations (ACRO) is another organization dedicated to promoting clinical trial innovation and efficiency. It brings together CROs and technology companies to support optimization and development of new methodologies affecting DCTs. In 2020, ACRO developed a DCT toolkit in order to support and advance the adoption of decentralized trials, which includes five resources: (1) a detailed Quality by Design (QbD) manual for DCTs; (2) an

accessible, quick-reference QbD manual; (3) a risk assessment considerations template; (4) DCT data flow maps; and (5) a change management question-and-answer (Q&A) resource. In addition to the DCT Toolkit, ACRO’s White Paper provides an overview of key issues in the decentralization of clinical trials and includes case studies from ACRO members.

One last organization worth mentioning is the Digital Medicine Society (DiMe), which tackles digital medicine involving the different fields of medicine, healthcare, and technology by generating best practices and guiding principles for accelerating clinical research and enhancing clinical care. They promote the use of digital medicine through the development of tools for measurement and intervention to support the practice of medicine broadly. Their library includes a large number

32 PHARMA FOCUS AMERICA ISSUE 01 - 2023

CLINICAL TRIALS

Decentralization has been used in a few trials because of the difficulties in making the quick transition from on-site to remote trial activities

of projects and resources categorized by four topics: digital measures; health care and public health; regulatory science; and publications.

DiMe’s Playbook of Digital Clinical Measures addressed the processes for digital clinical measures and technologies used for remote monitoring in clinical trials, clinical care, and in public health settings.

Regulatory framework

The existing legal framework on clinical trials with medicinal products and associated guidelines do not prohibit the conduct of decentralized trials in general, but few of them provide advice on the use of specific decentralized elements (e.g., remote recruitment, digital endpoint selection) and trial-related interventions outside the trial site (e.g., digital consent, electronic data collection systems, electronic consultations).

The first regulations to provide recommendations for performing remote activities during the conduct of a clinical trial were issued during the COVID-19 pandemic. In March 2020, the World Health Organization (WHO) declared a COVID-19 pandemic for which no specific treatment existed at that time. COVID-19 had a large impact on the performance of traditional clinical trials due to quarantine measures, travel restrictions, and supply chain interruptions that led to patient trial participation discontinuation or withdrawal, unavailability of the clinical trial staff, site closures, and shortages of investigational medicinal products (IMPs).

The degree of impact was different between the countries and regions, as this was depended on the implementation of the pandemic prevention measures at the national level as a response to the public health emergency. Thus, the decentralization of clinical trials started to gain attention and needed to be adopted within the regulatory framework. Given the impact of COVID-19 on traditional clinical trials, as well as the critical need for developing new COVID-19 treatments, regulatory agencies were forced to issue guidelines on clinical trial management during this time period.

Under these circumstances, the European Medicines Agency (EMA) released the Guidance on the Management of Clinical Trials during the COVID-19 (coronavirus) Pandemic to limit the disruption of clinical research during COVID19 in the European region, which supported a harmonized approach among European (EU) Member States (MS) even though the local or national requirements prevailed in case of conflicting requirements. DCT-related elements introduced by this guideline were: conversion of trial participants’ physical visits into phone or video visits; contacting the trial participants via phone or video calls; obtaining written consent or approvals by email or mail; direct distribution of IMP to trial participants’ homes; transfer of trial participants to another trial site closer to their homes; trial participants testing in local laboratories; remote centralized and site monitoring activities; remote source data verification; and remote audits. The FDA also issued guidance for the conduct

www. pharmafocusamerica.com 33

CLINICAL TRIALS

of clinical trials of medical products during the COVID-19 Public Health Emergency, with recommendations similar to the EMA guidance and additional details such as practice examples and Q&A that provide readers with more clarity.

The COVID-19-related guidelines and the specific exemptions granted during this pandemic are effective until the COVID-19 outbreak has passed. Moreover, EMA advised sponsors managing clinical trials impacted by the war in Ukraine to use the experience gained during the COVID-19 pandemic and apply the approaches and flexibilities agreed in this context.